High-performance silicon-based conductive rubber and preparation method thereof

A conductive rubber, high-performance technology, applied in the field of high-performance silicon-based conductive rubber and its preparation, can solve the problems of low conductivity and easy aging, achieve good oxidation resistance and high and low temperature resistance, easy processing and molding, excellent The effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing high-performance silicon-based conductive rubber includes the following steps:

[0047] (I) Drying of conductive powder

[0048] Bake the conductive powder in a blast drying oven for 60 to 80 hours to remove moisture;

[0049] (Ⅱ) The particle size of conductive powder is extremely matched

[0050] The particle size of the conductive powder is extremely matched, and the larger and smaller conductive powders are taken according to the weight ratio of 10:1, and premixed in a mixer to make the two conductive powders with different particle sizes preliminary mixing;

[0051] (Ⅲ) Conductive powder coating

[0052] Surface treatment of the powder obtained in step (ii) using a wet method to obtain a conductive powder coated with a layer of silane coupling agent;

[0053] (Ⅳ) Mixed

[0054] The conductive powder obtained in step (iii) is mixed with silicone rubber, flame retardant, vulcanizing agent, etc. in an internal mixer for 10-20 minutes to ...

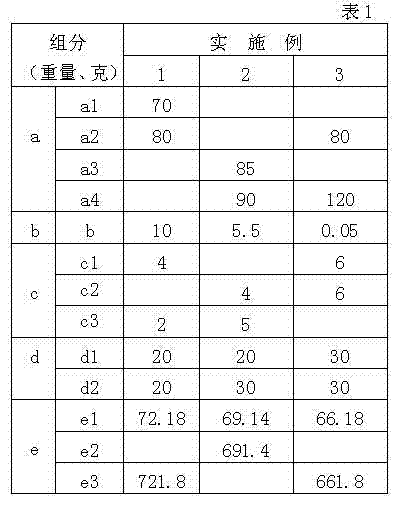

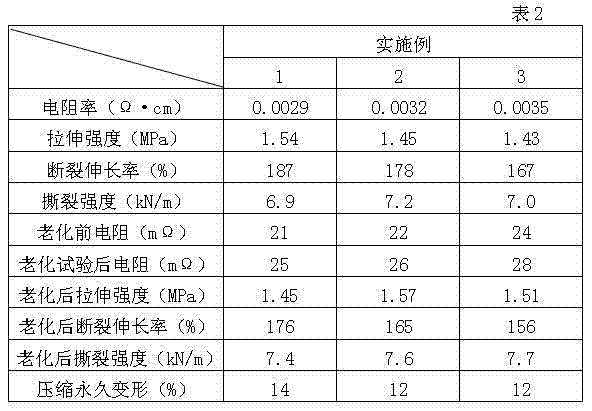

Embodiment 1~3

[0056] (1) Prepare raw materials

[0057] a Silicone rubber

[0058] Among them: a1 methyl silicone rubber

[0059] a2 Methyl vinyl silicone rubber

[0060] a3. Methyl phenyl vinyl silicone rubber

[0061] a4. Methyl vinyl trifluoropropyl silicone rubber

[0062] b Silane coupling agent A-172

[0063] c Curing agent

[0064] Among them: c1 DCBP c2 DCP c3 DBPMH

[0065] d Flame retardant

[0066] Among them: d1 magnesium hydroxide d2 aluminum hydroxide

[0067] e Conductive powder

[0068] Among them: e1 pure silver conductive powder (average particle size 35μm)

[0069] e2 Silver-coated aluminum conductive powder (average particle size 70μm)

[0070] e3 Silver-coated copper conductive powder (average particle size 70μm)

[0071] The above-mentioned powders were polarized according to the ratio shown in Table 1, and then the surface of the polarized powders was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com