Patents

Literature

7201 results about "Niobium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium, formerly known as columbium, is a chemical element with the symbol Nb (formerly Cb) and atomic number 41. Niobium is a light grey, crystalline, and ductile transition metal. Pure niobium has a hardness similar to that of pure titanium, and it has similar ductility to iron. Niobium oxidizes in the earth's atmosphere very slowly, hence its application in jewelry as a hypoallergenic alternative to nickel. Niobium is often found in the minerals pyrochlore and columbite, hence the former name "columbium". Its name comes from Greek mythology, specifically Niobe, who was the daughter of Tantalus, the namesake of tantalum. The name reflects the great similarity between the two elements in their physical and chemical properties, making them difficult to distinguish.

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

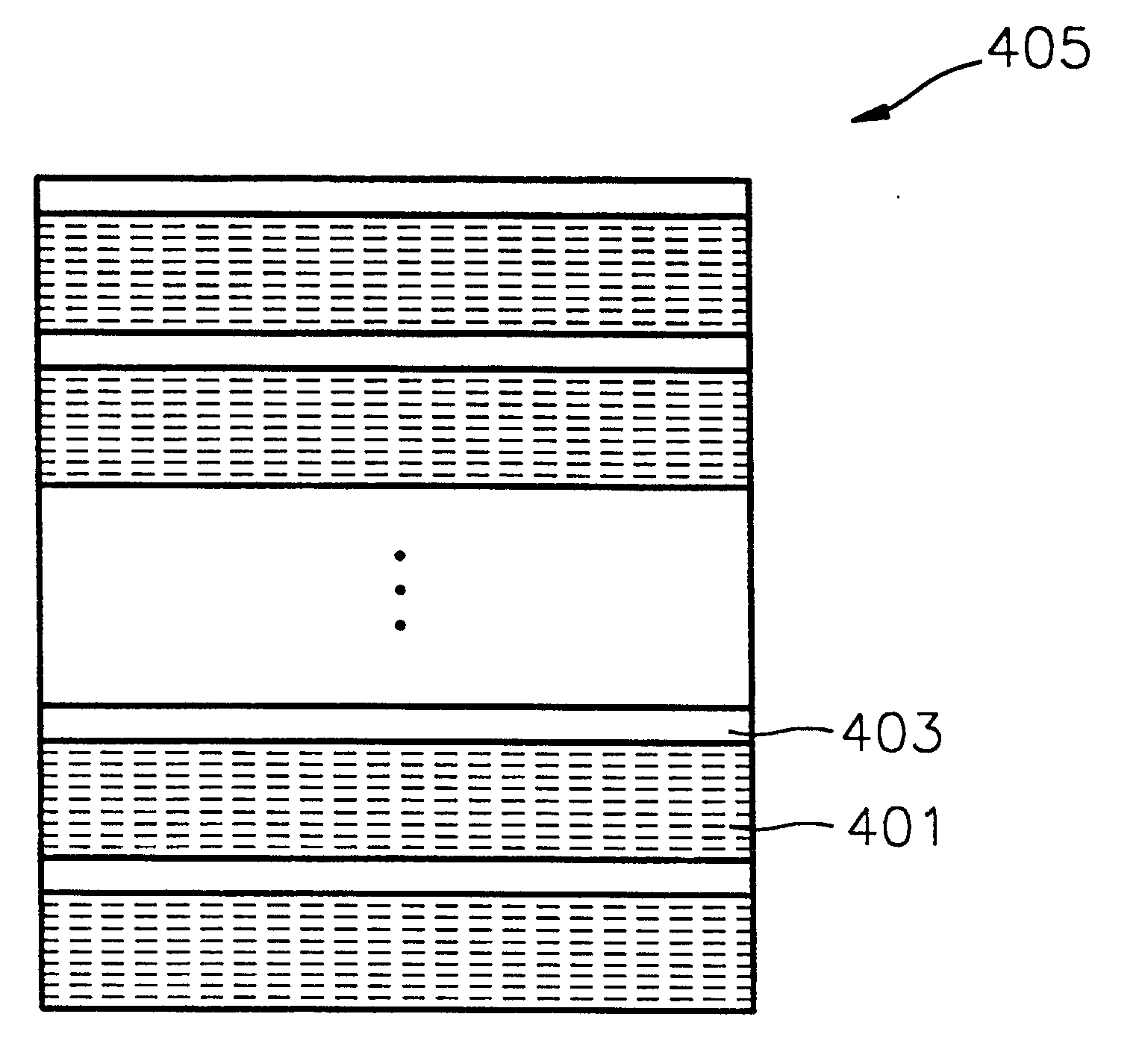

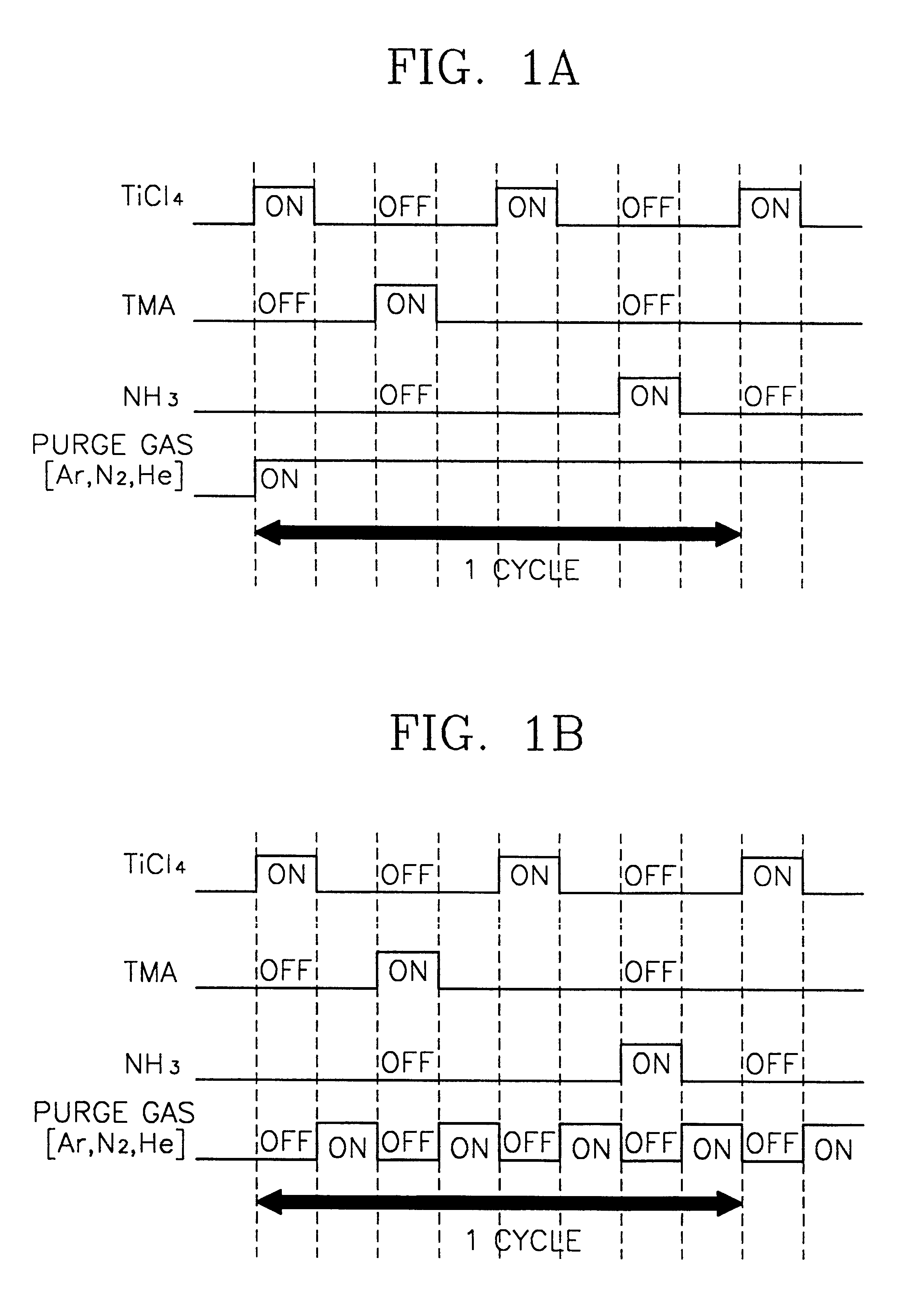

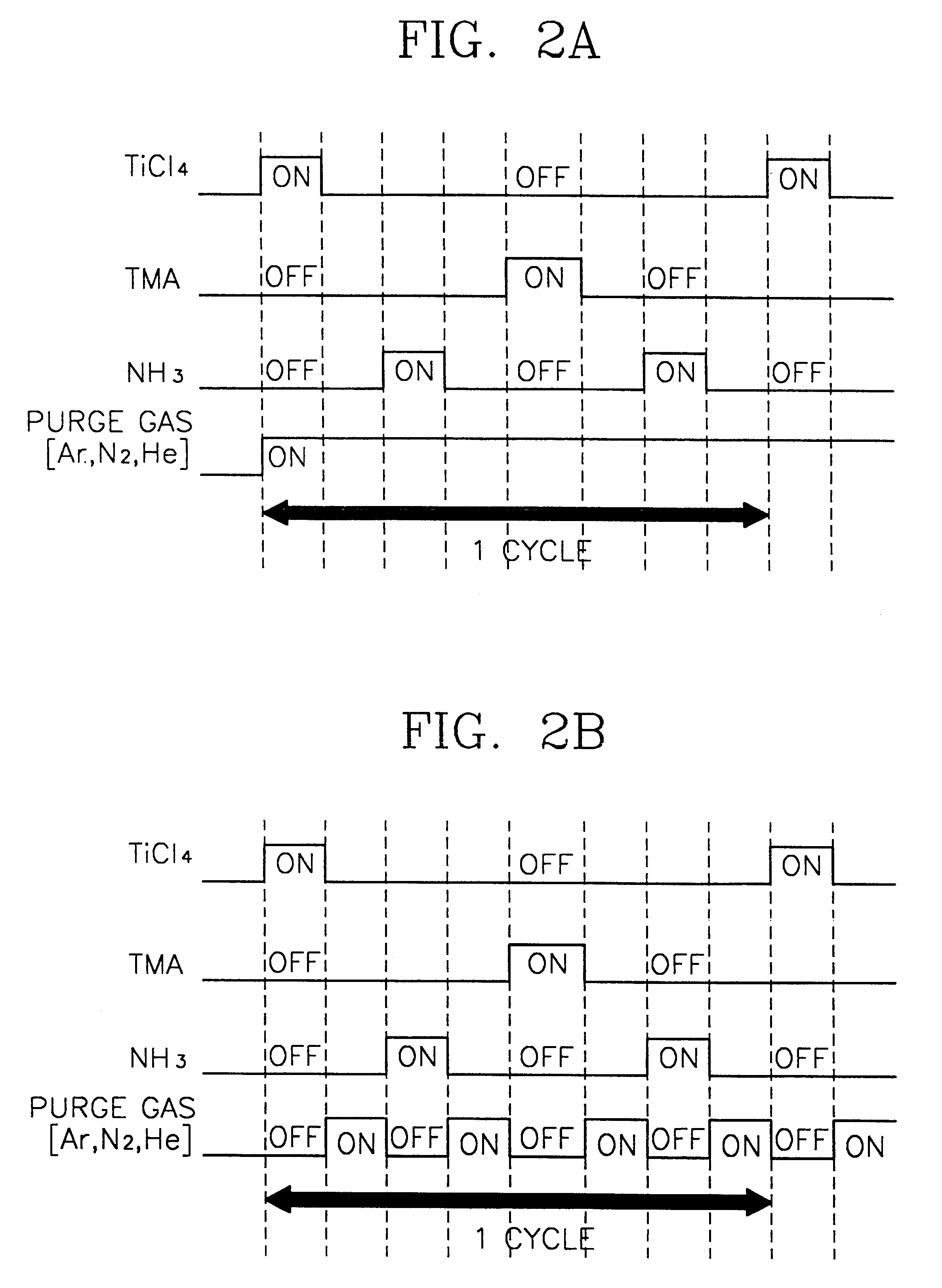

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

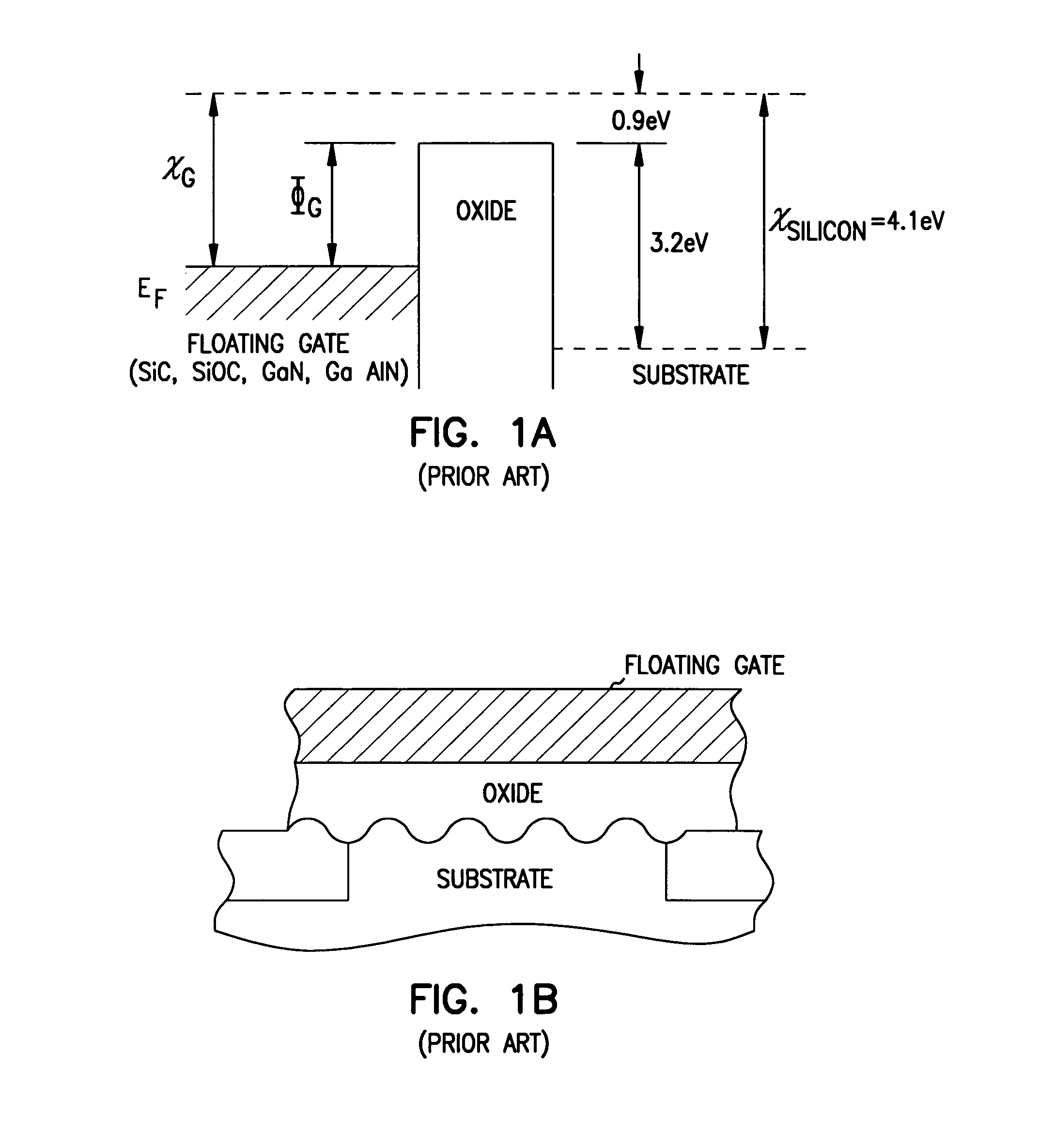

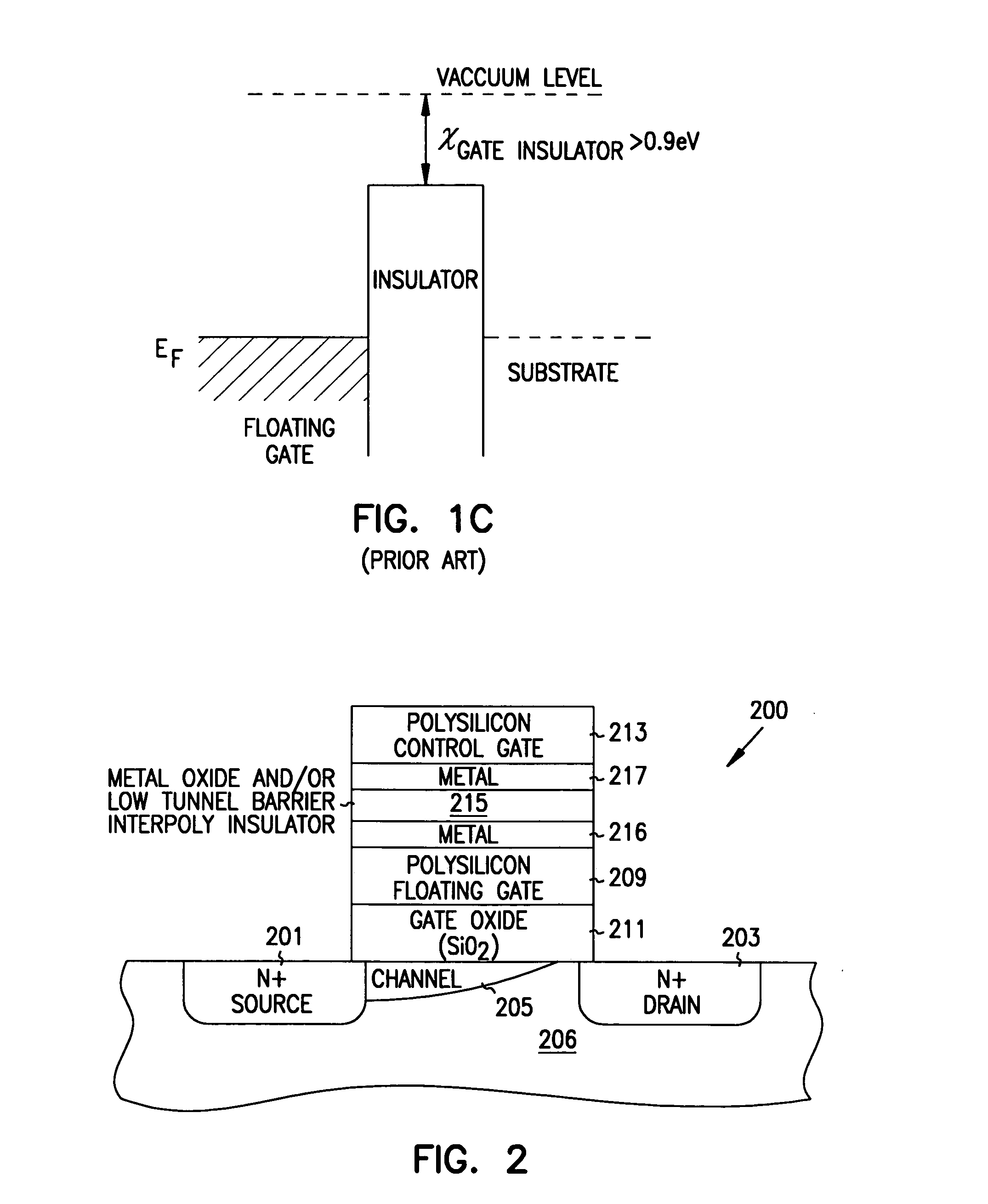

Atomic layer deposition of metal oxide and/or low asymmetrical tunnel barrier interpoly insulators

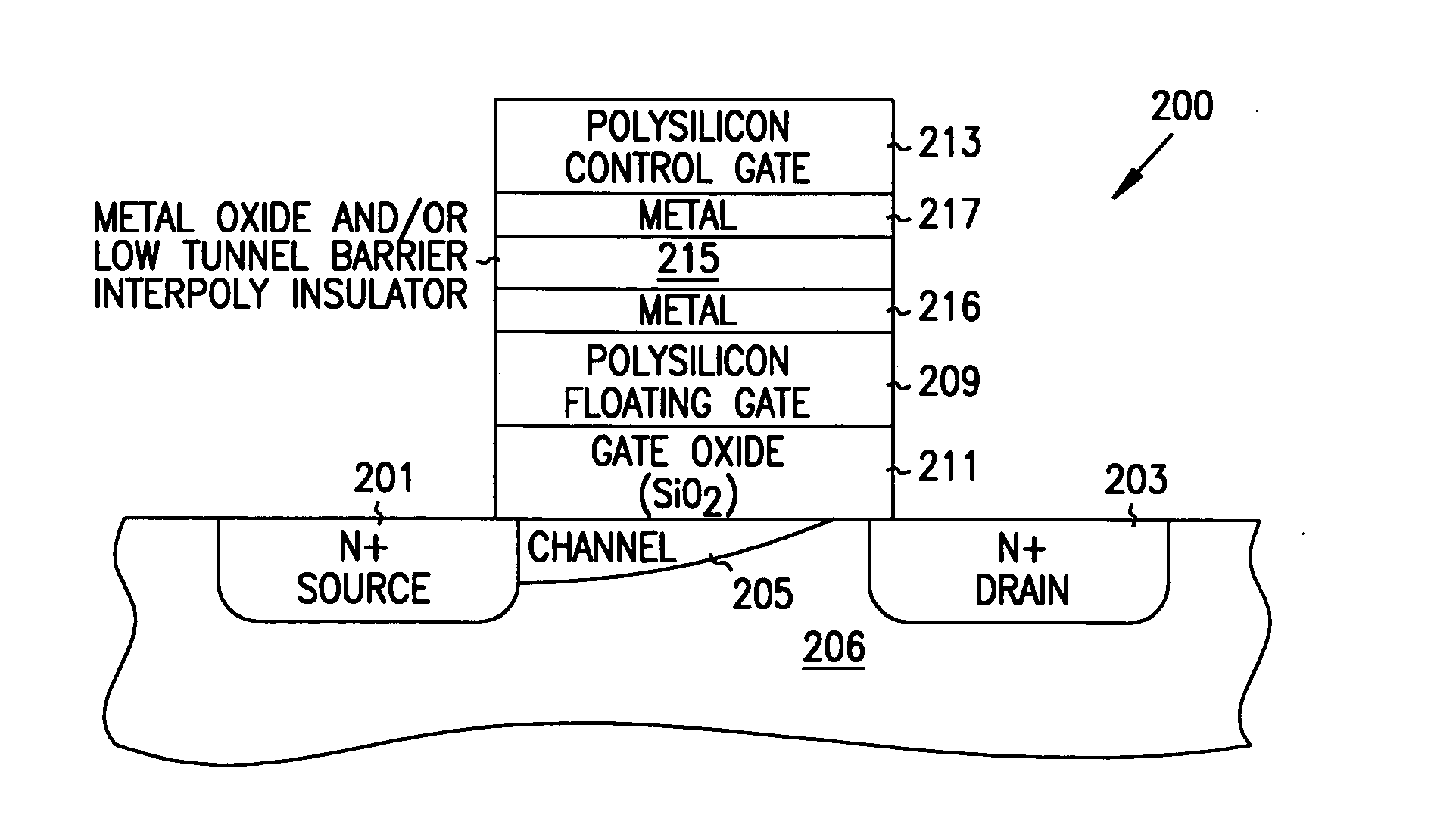

Structures and methods for programmable array type logic and / or memory devices with asymmetrical low tunnel barrier intergate insulators are provided. The programmable array type logic and / or memory devices include non-volatile memory which has a first source / drain region and a second source / drain region separated by a channel region in a substrate. A floating gate opposing the channel region and is separated therefrom by a gate oxide. A control gate opposes the floating gate. The control gate is separated from the floating gate by an asymmetrical low tunnel barrier intergate insulator formed by atomic layer deposition. The asymmetrical low tunnel barrier intergate insulator includes a metal oxide insulator selected from the group consisting of Al2O3, Ta2O5, TiO2, ZrO2, Nb2O5, SrBi2Ta2O3, SrTiO3, PbTiO3, and PbZrO3.

Owner:MICRON TECH INC

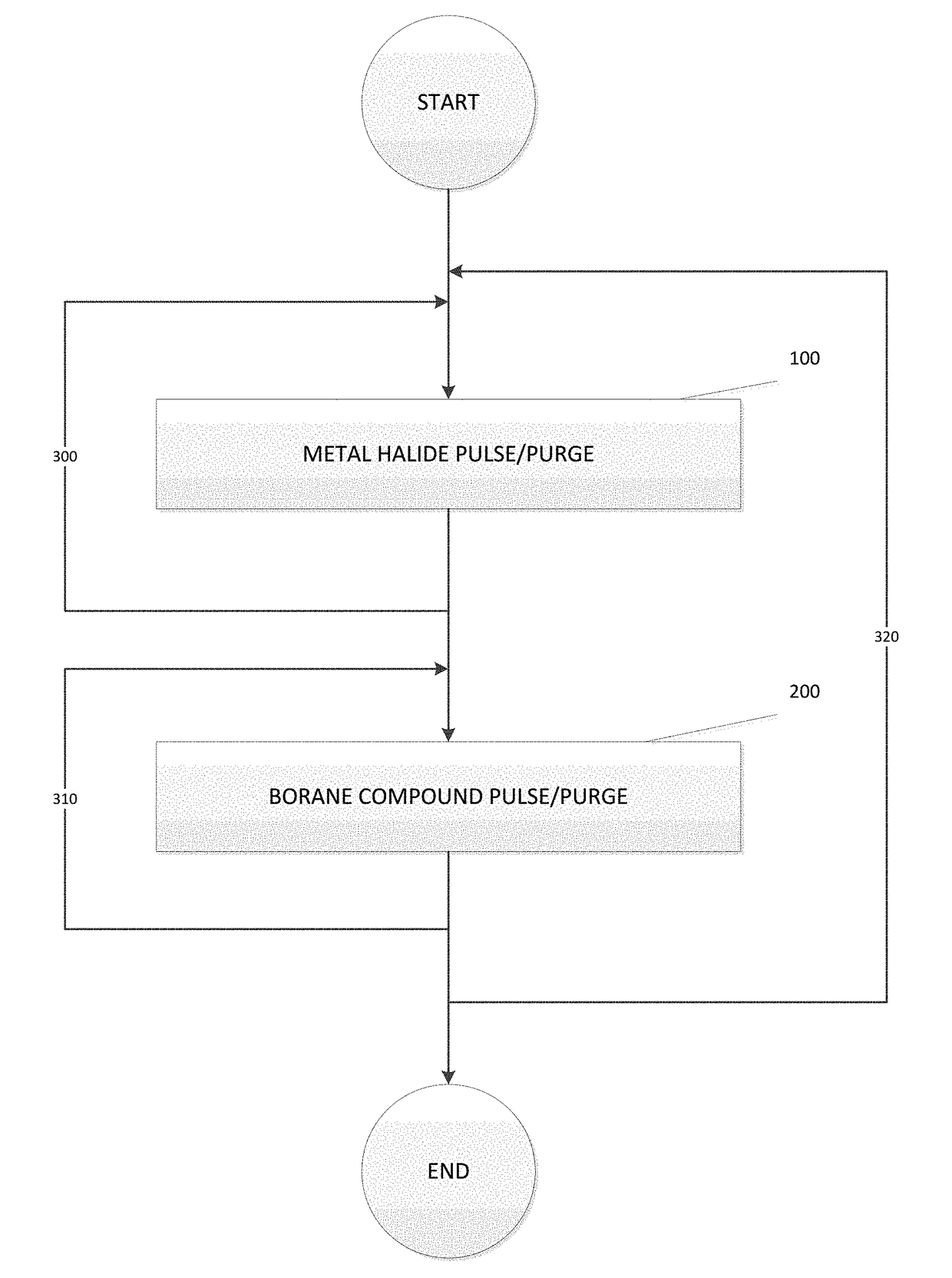

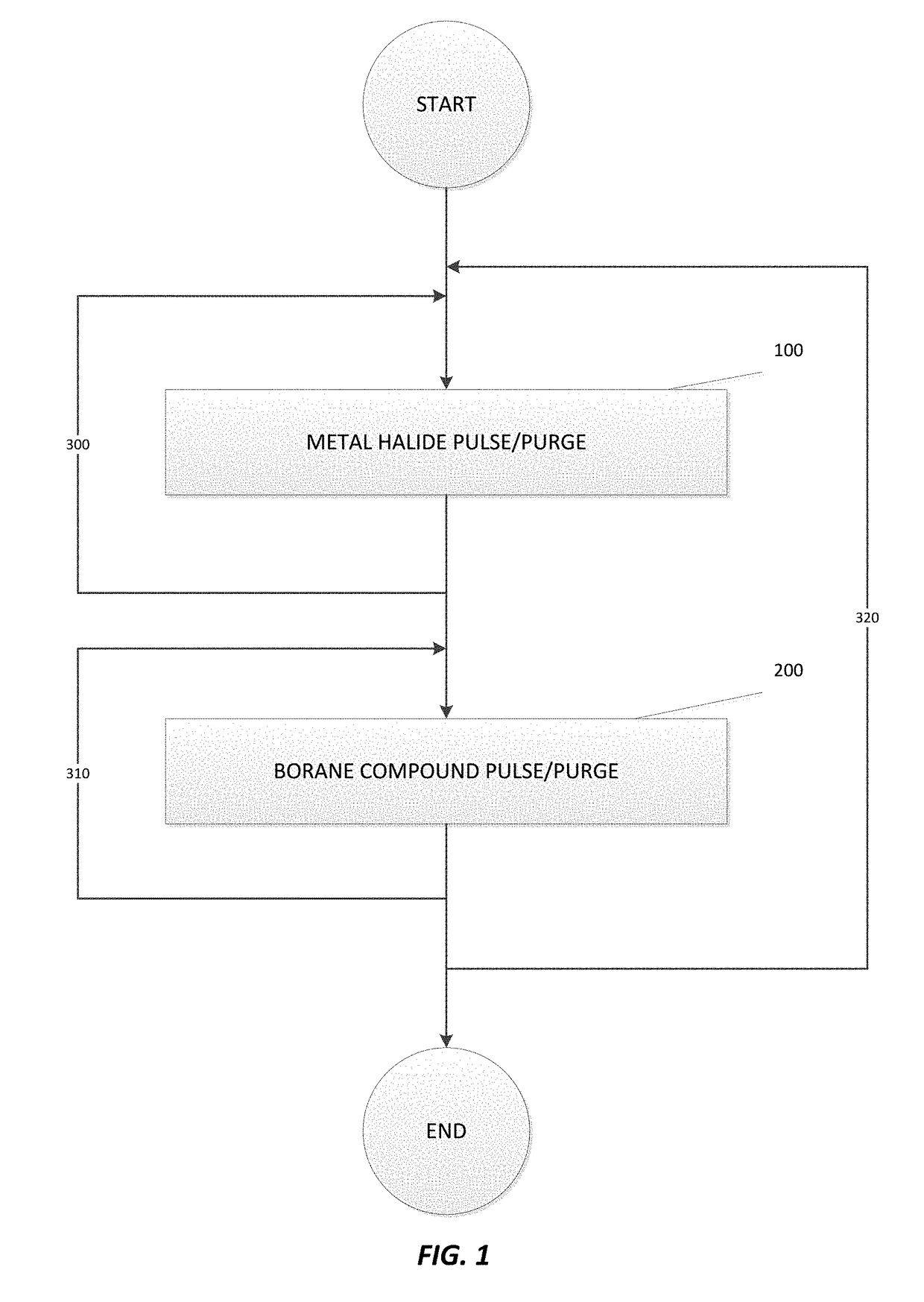

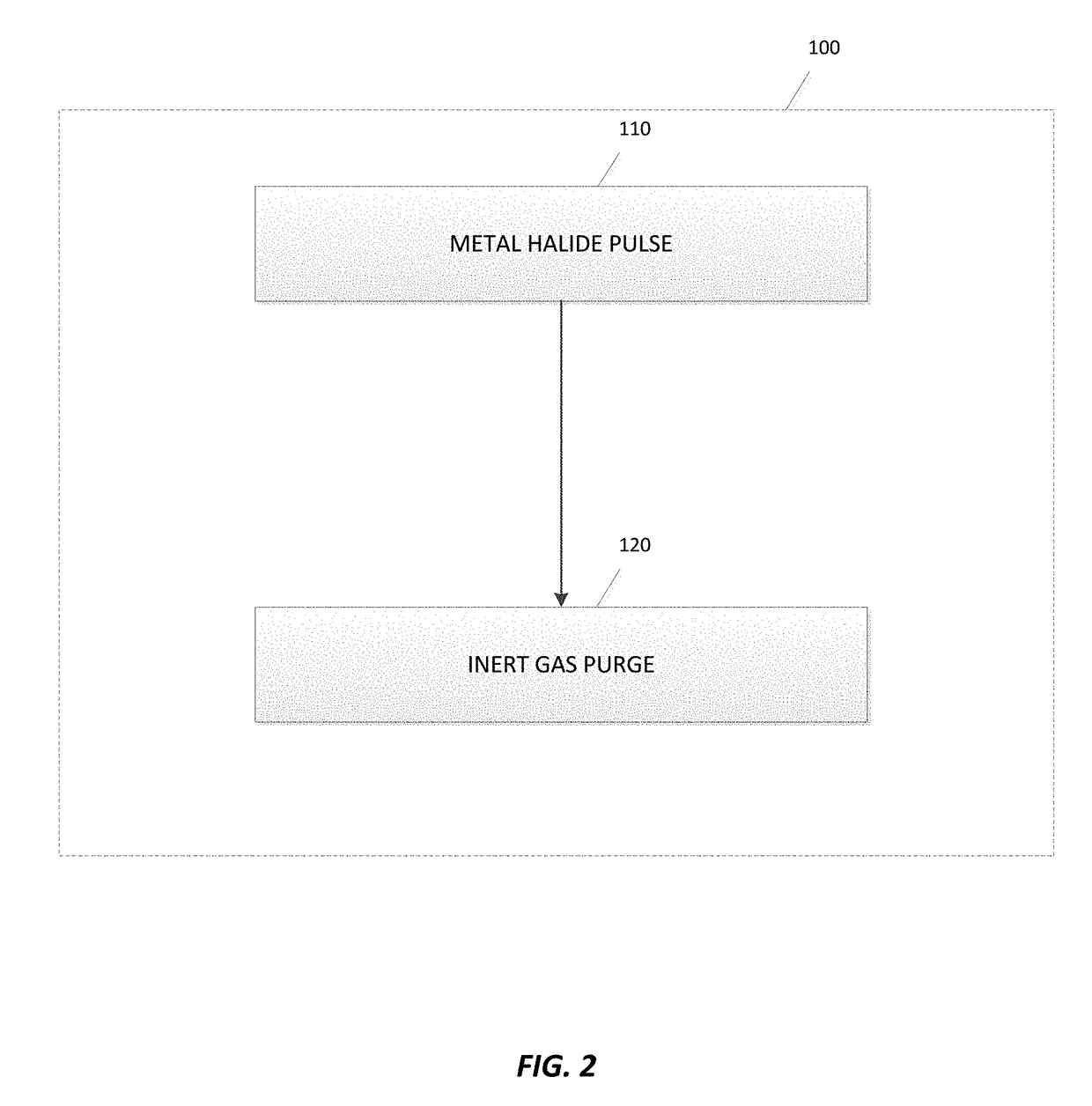

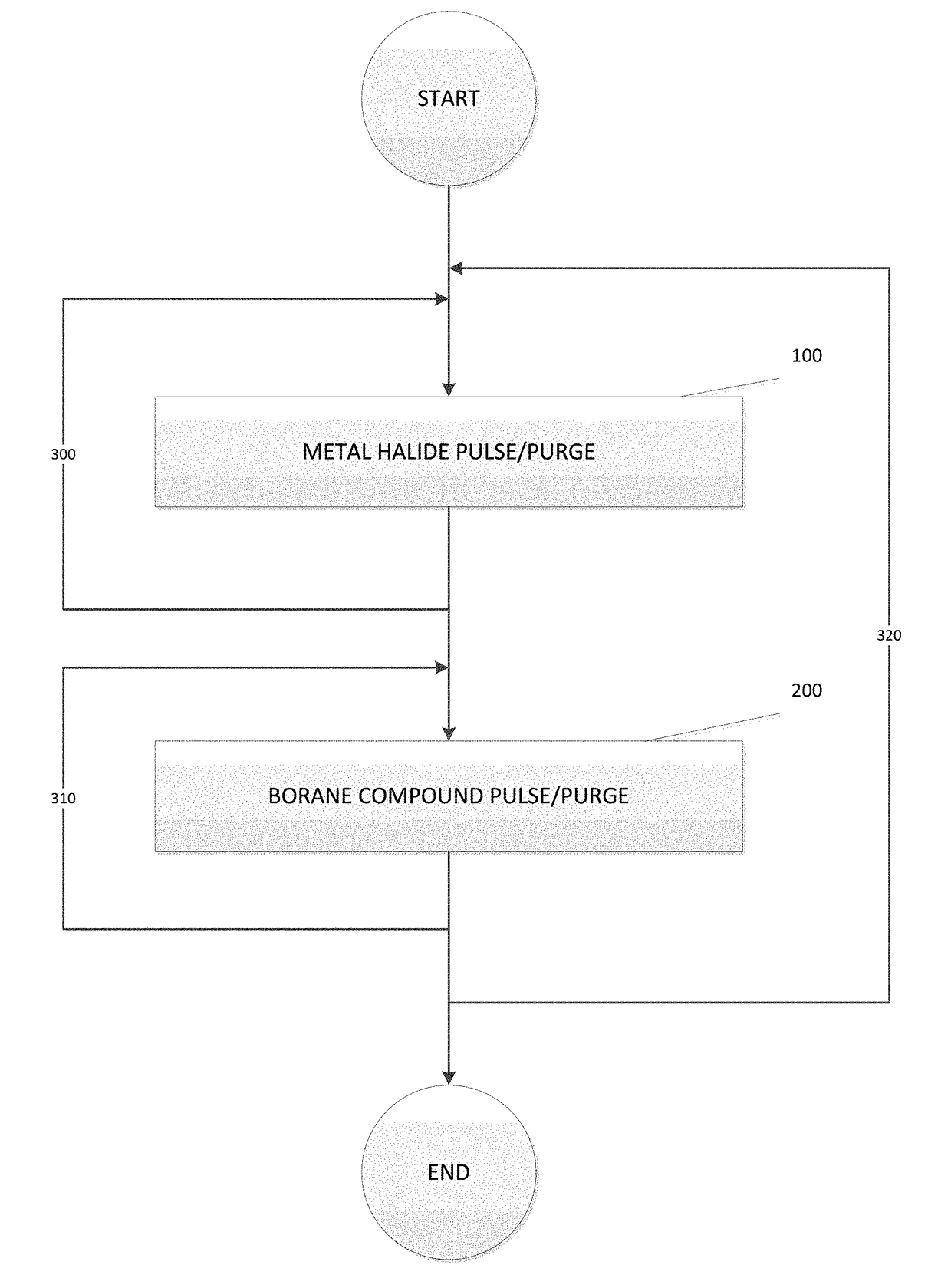

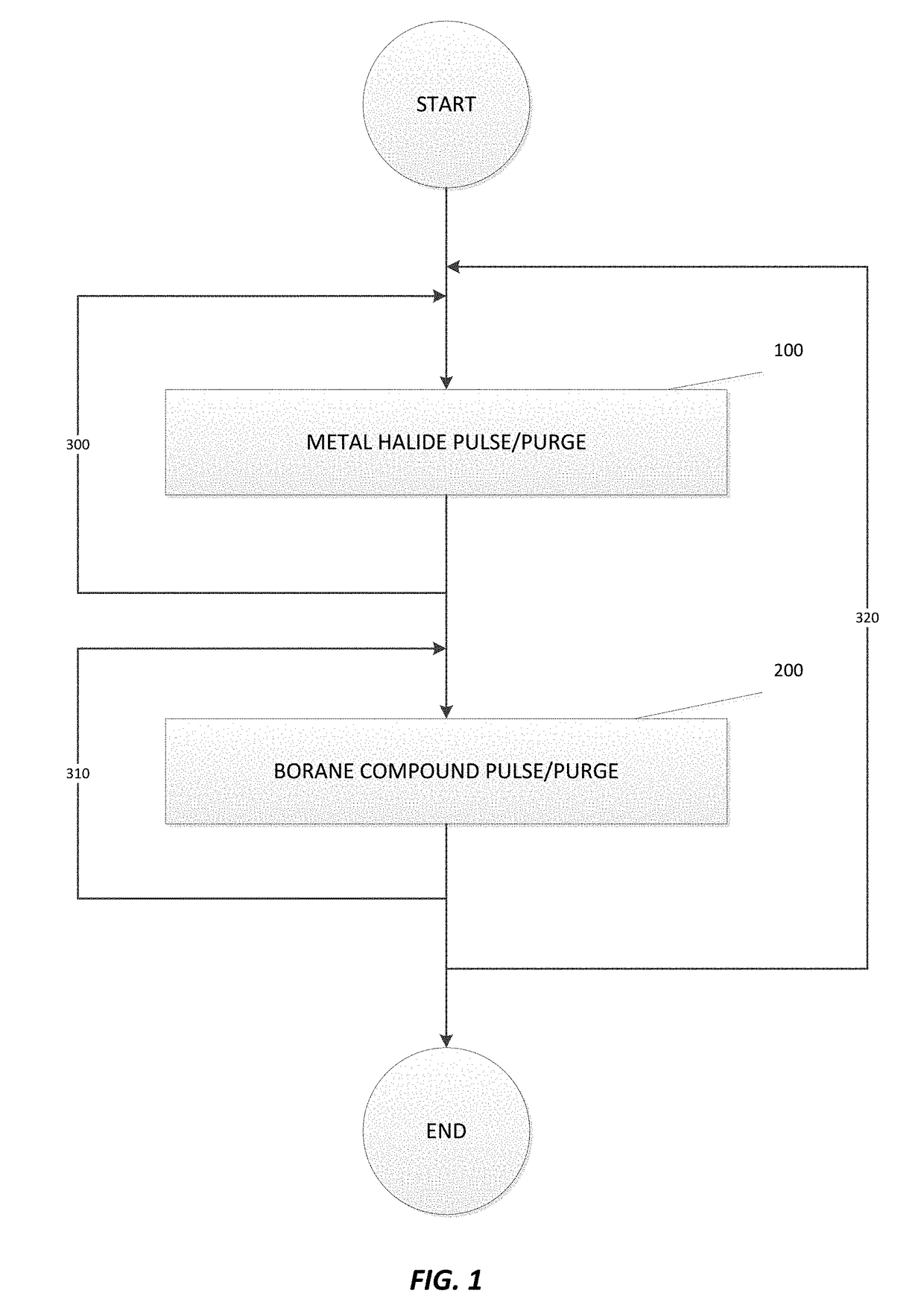

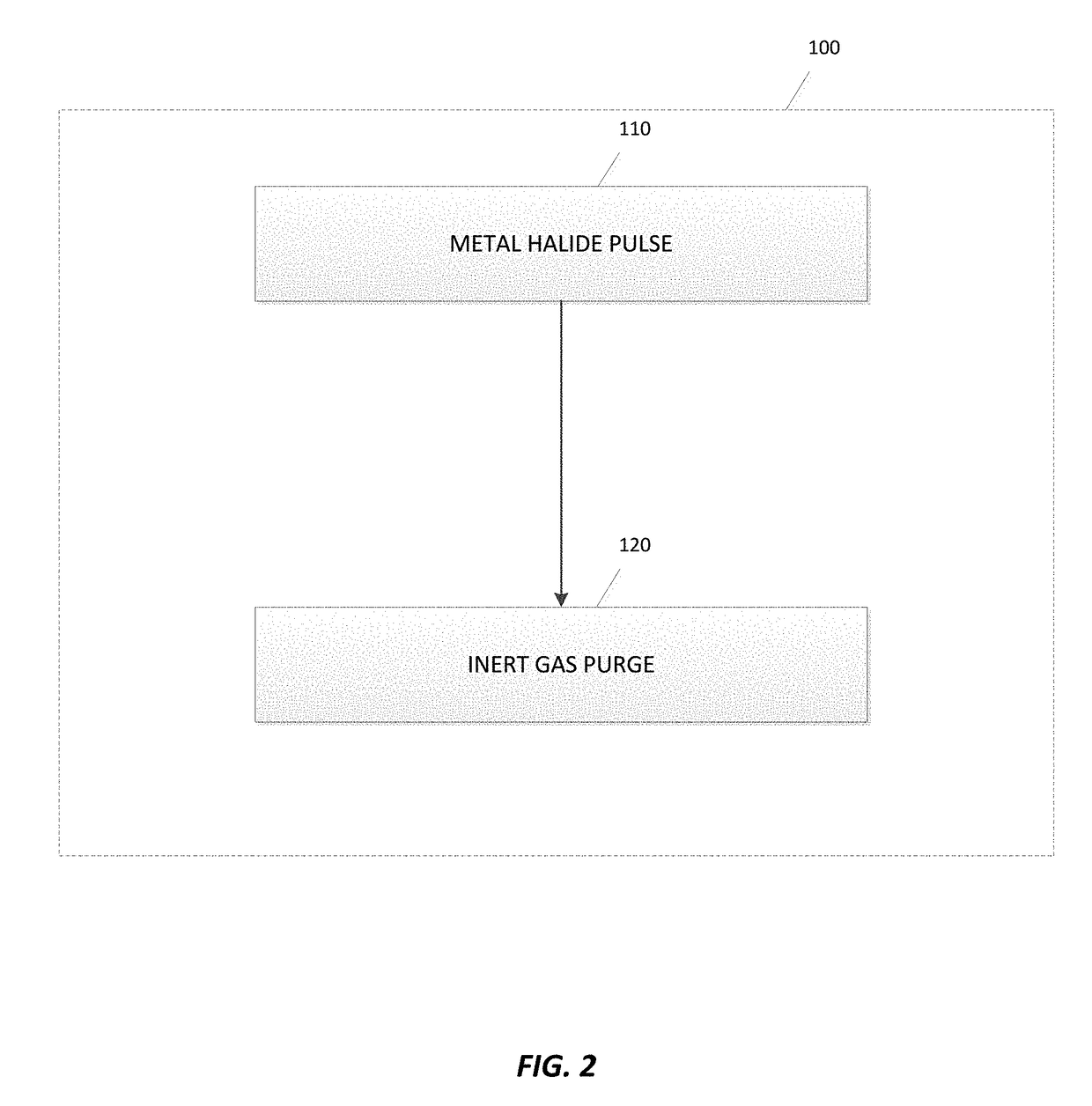

Deposition of metal borides

A method for depositing a metal boride film onto a substrate is disclosed. In particular, the method comprises pulsing a metal halide precursor onto the substrate and pulsing a boron compound precursor onto the substrate. A reaction between the metal halide precursor and the boron compound precursor forms a metal boride film. Specifically, the method discloses forming a tantalum boride (TaB2) or a niobium boride (NbB2) film.

Owner:ASM IP HLDG BV

Deposition of metal borides

A method for depositing a metal boride film onto a substrate is disclosed. In particular, the method comprises pulsing a metal halide precursor onto the substrate and pulsing a boron compound precursor onto the substrate. A reaction between the metal halide precursor and the boron compound precursor forms a metal boride film. Specifically, the method discloses forming a tantalum boride (TaB2) or a niobium boride (NbB2) film.

Owner:ASM IP HLDG BV

Process for producing niobium suboxide

ActiveUS20050019581A1Increase capacityIncrease volumeLiquid electrolytic capacitorsTantalum compoundsHydrogenNiobium

A method is described for preparing a niobium suboxide represented by the formula, NbOx, in which 0.7<x<1.3. The method involves reacting NbOy (in which y<1.8<2.1) with a stoichiometric amount of niobium metal, in the presence of hydrogen. The niobium suboxide produced by such method may be used to fabricate anodes for solid electrolyte capacitors.

Owner:TANIOBIS GMBH

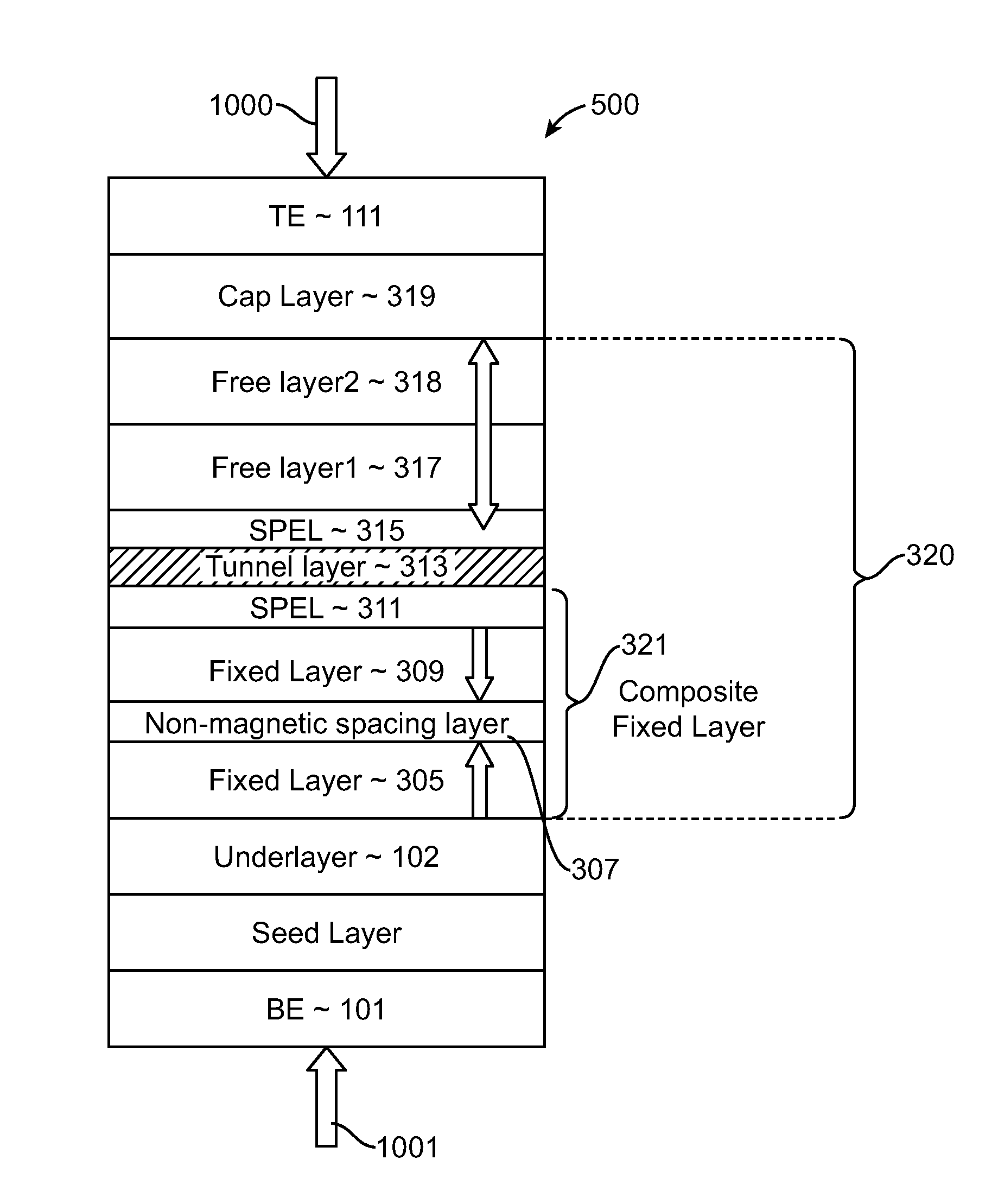

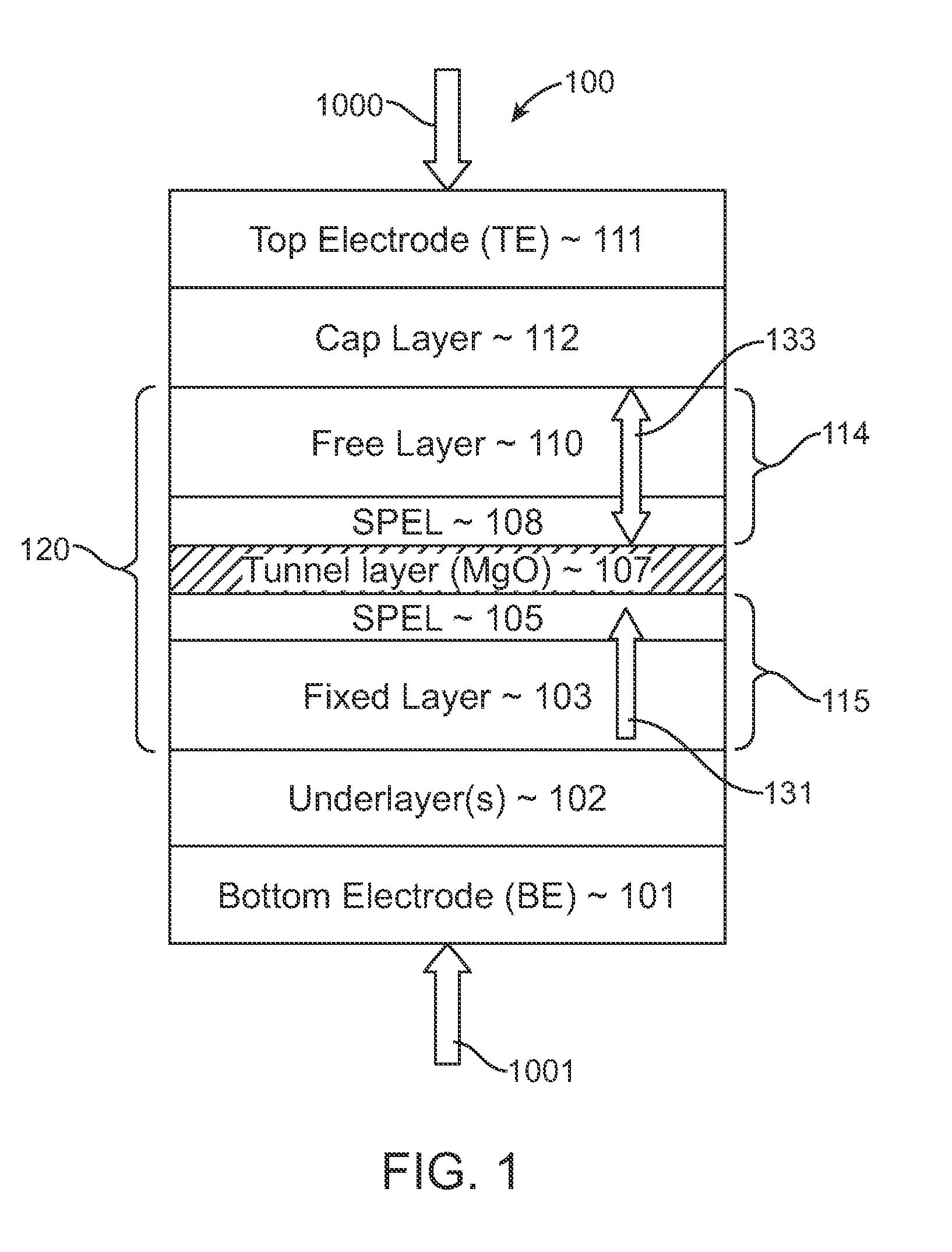

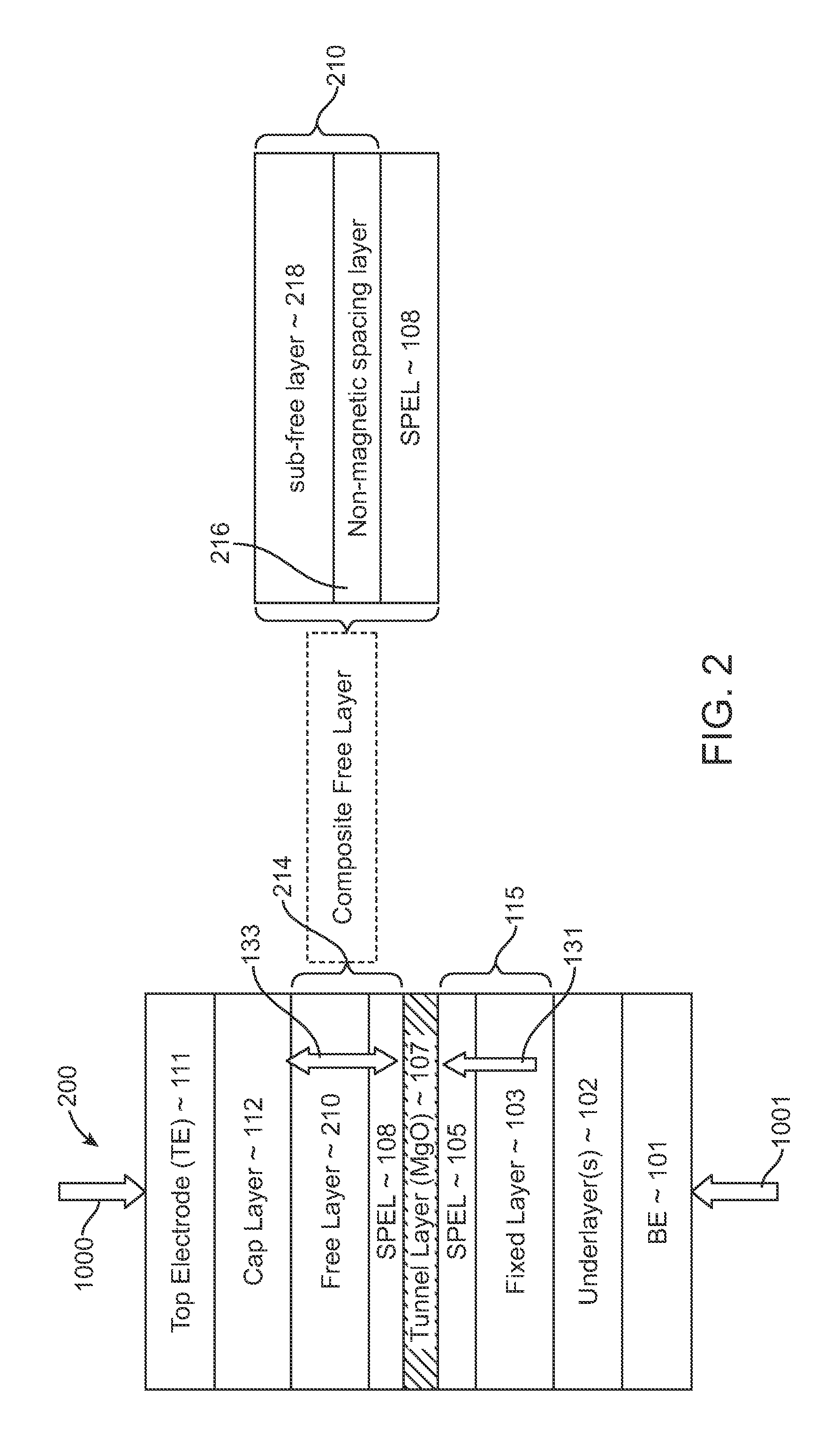

Spin-transfer torque magnetic random access memory having magnetic tunnel junction with perpendicular magnetic anisotropy

A spin-torque transfer memory random access memory (STTMRAM) element includes a fixed layer formed on top of a substrate and a a tunnel layer formed upon the fixed layer and a composite free layer formed upon the tunnel barrier layer and made of an iron platinum alloy with at least one of X or Y material, X being from a group consisting of: boron (B), phosphorous (P), carbon (C), and nitride (N) and Y being from a group consisting of: tantalum (Ta), titanium (Ti), niobium (Nb), zirconium (Zr), tungsten (W), silicon (Si), copper (Cu), silver (Ag), aluminum (Al), chromium (Cr), tin (Sn), lead (Pb), antimony (Sb), hafnium (Hf) and bismuth (Bi), molybdenum (Mo) or rhodium (Ru), the magnetization direction of each of the composite free layer and fixed layer being substantially perpendicular to the plane of the substrate.

Owner:AVALANCHE TECH

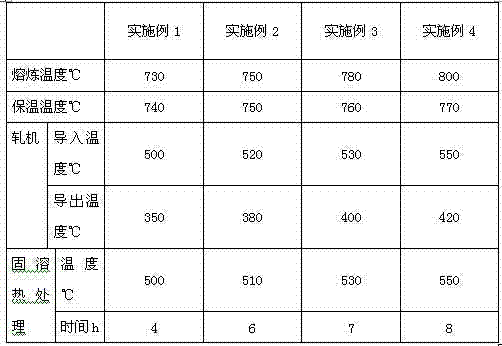

A kind of aluminum alloy material and preparation method thereof

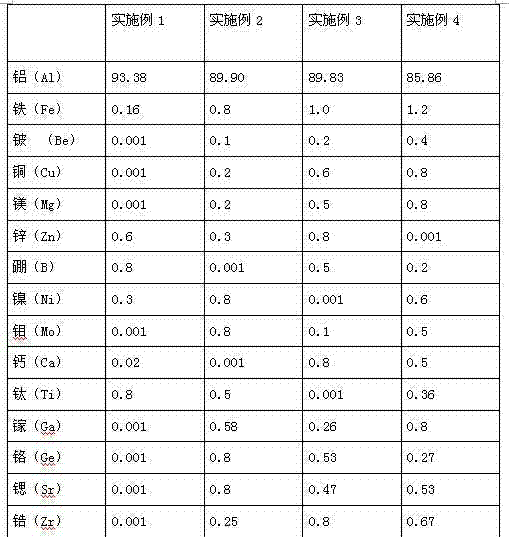

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

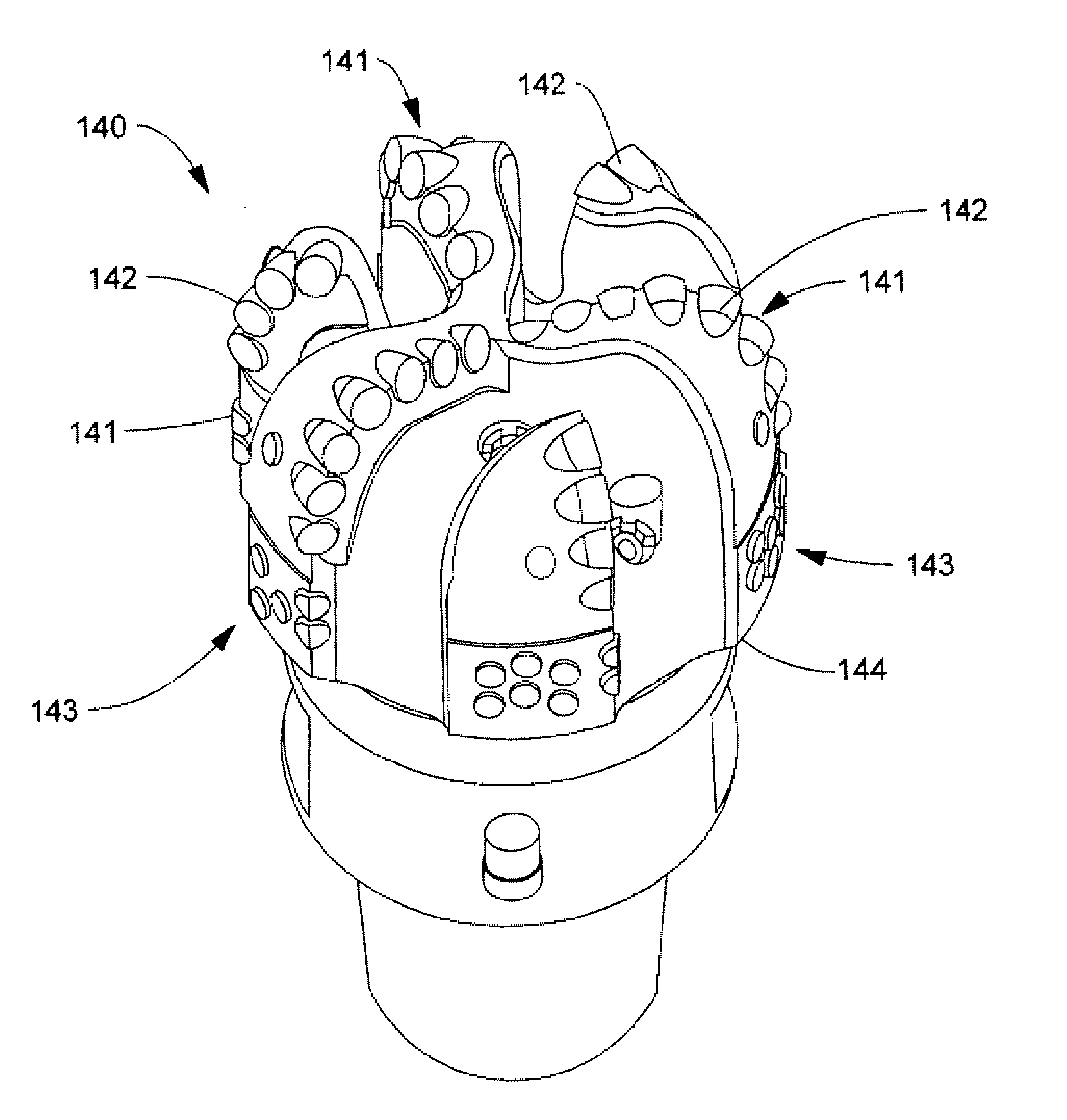

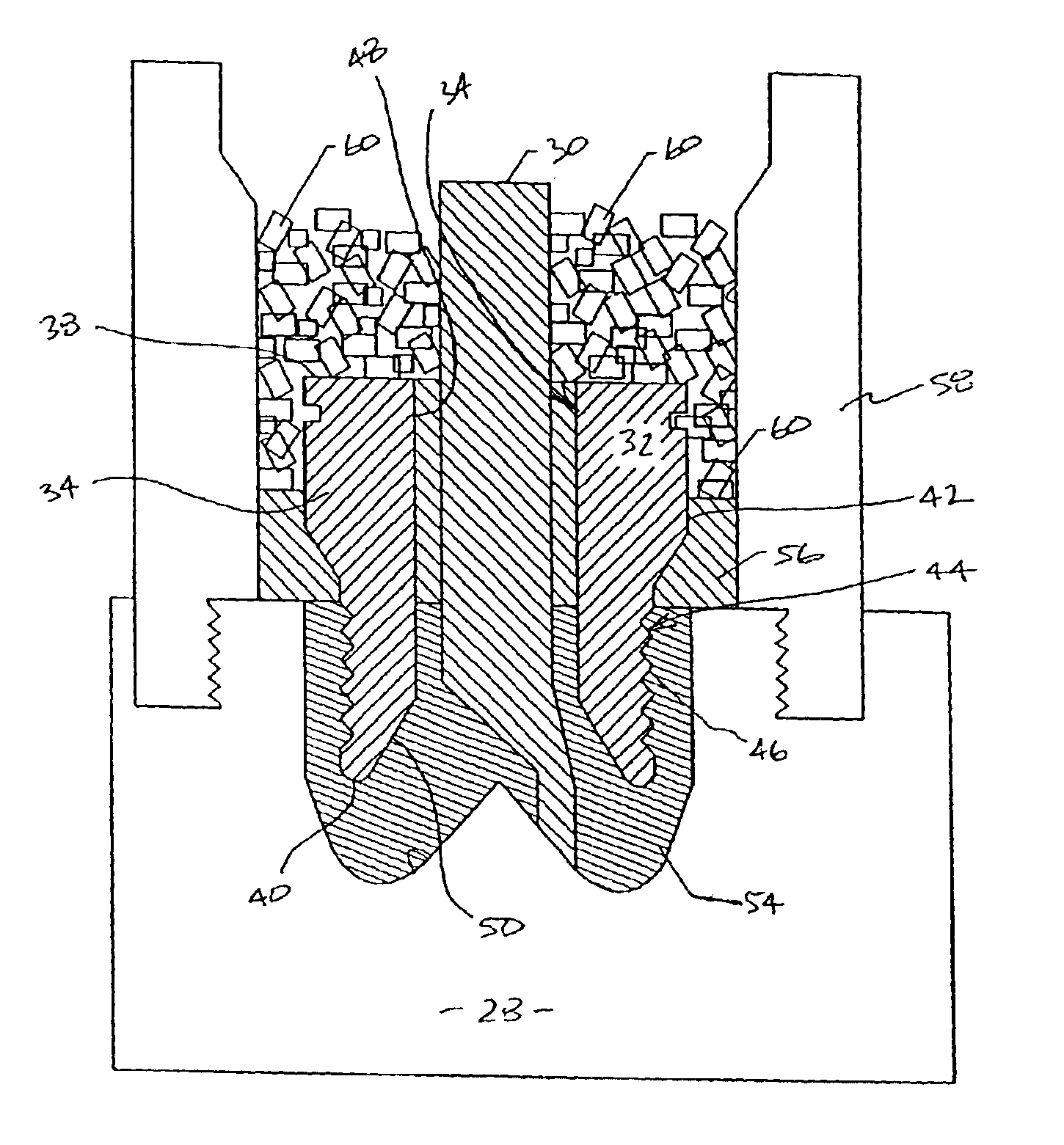

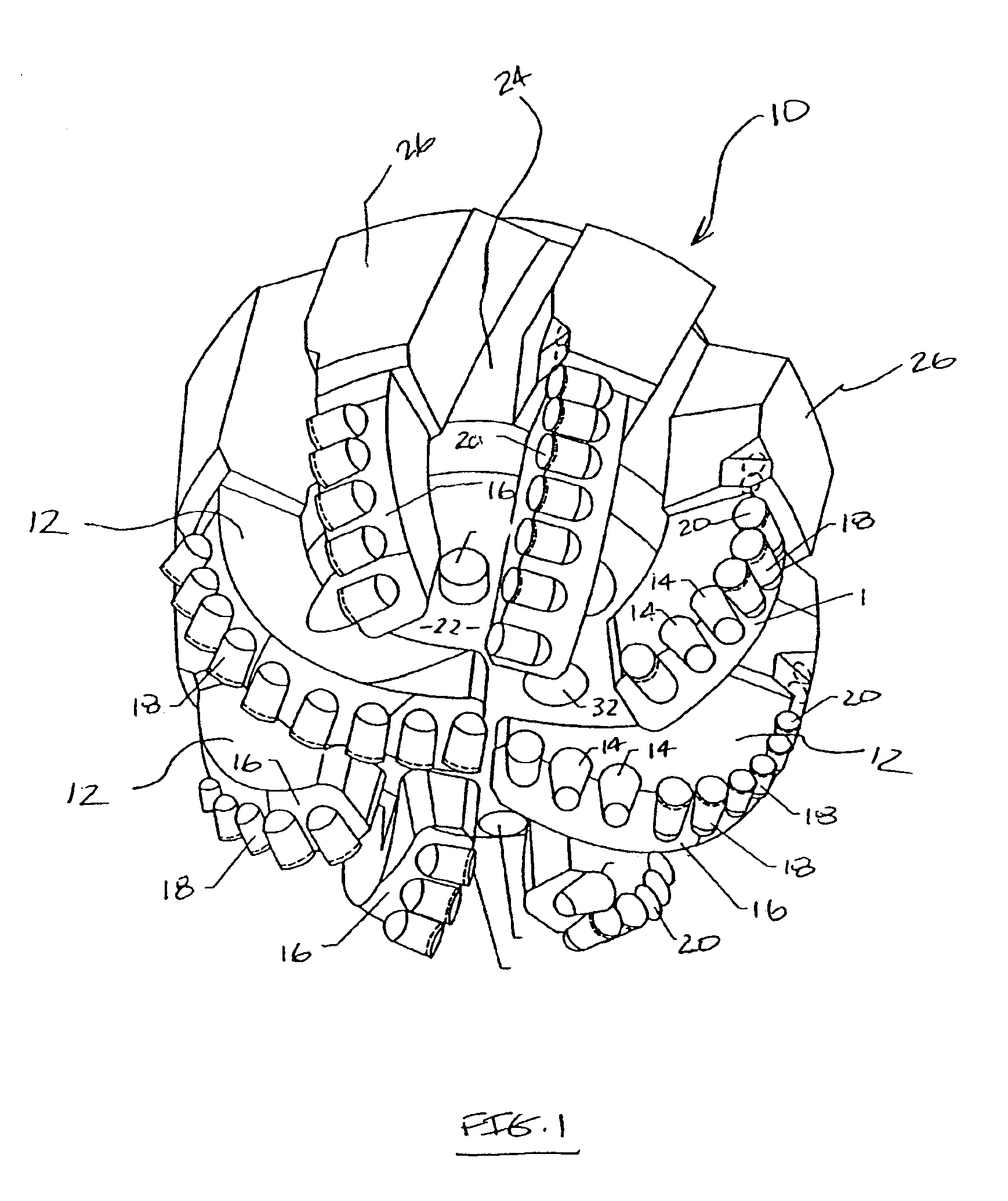

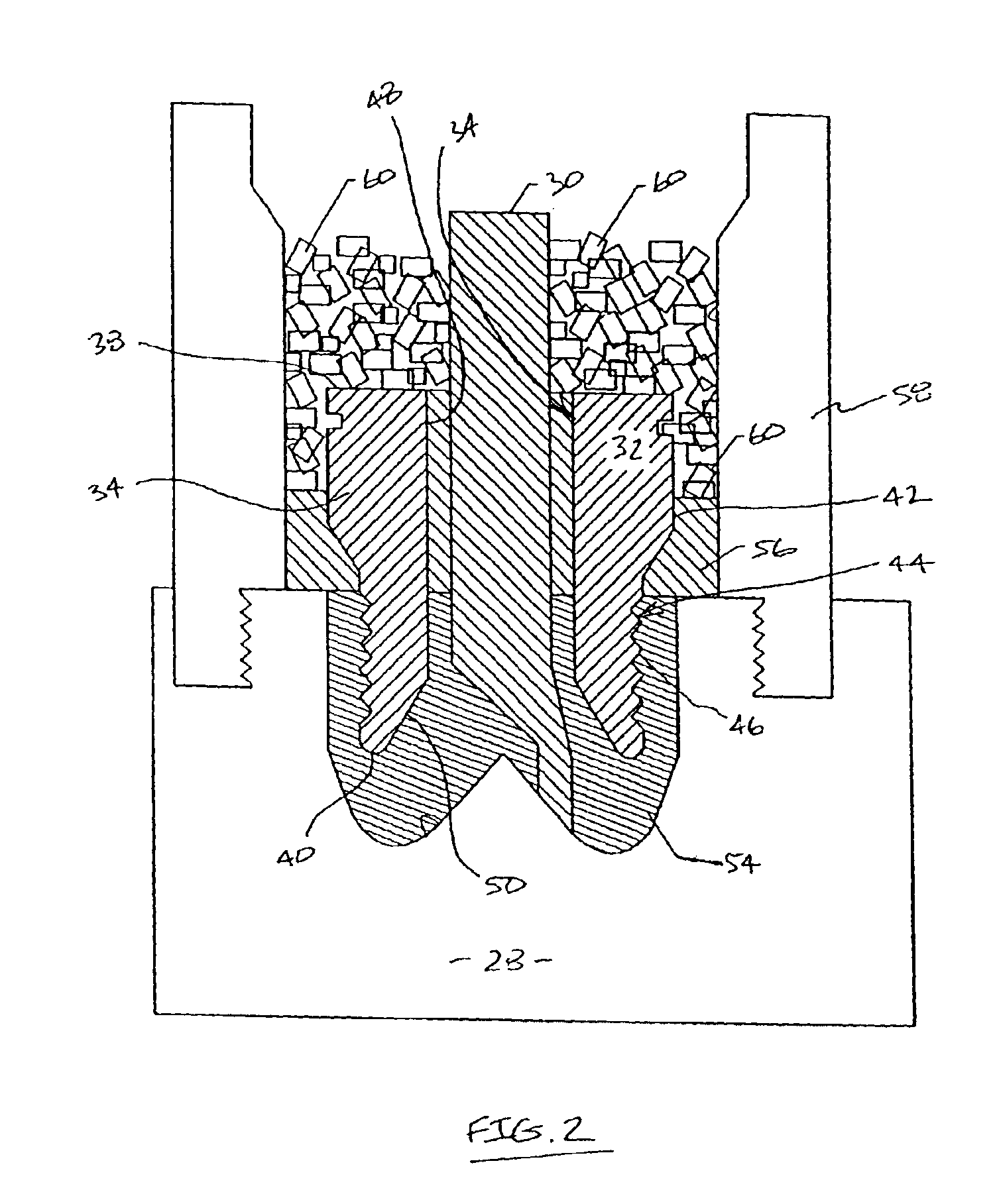

Earth-boring bits

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

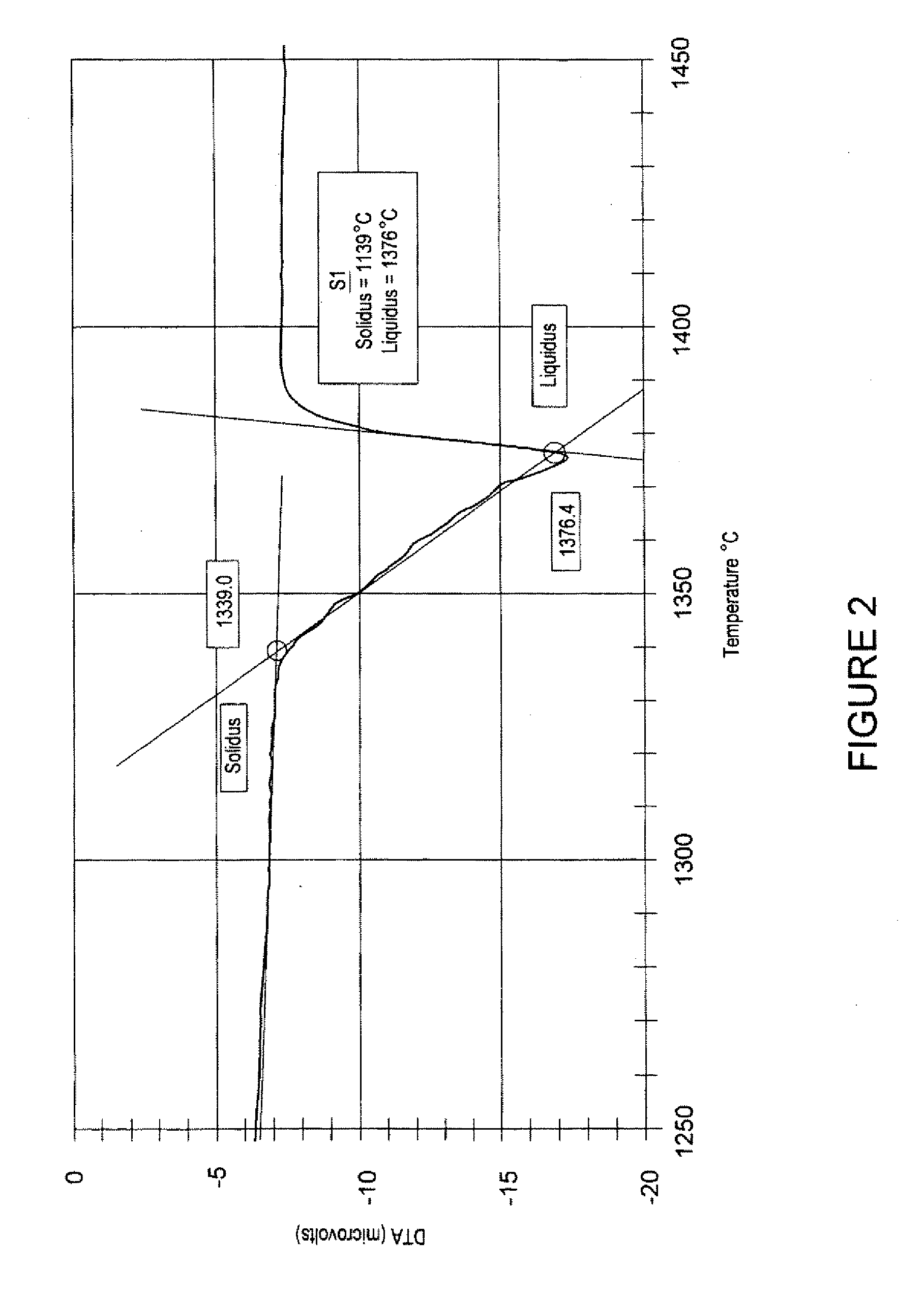

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

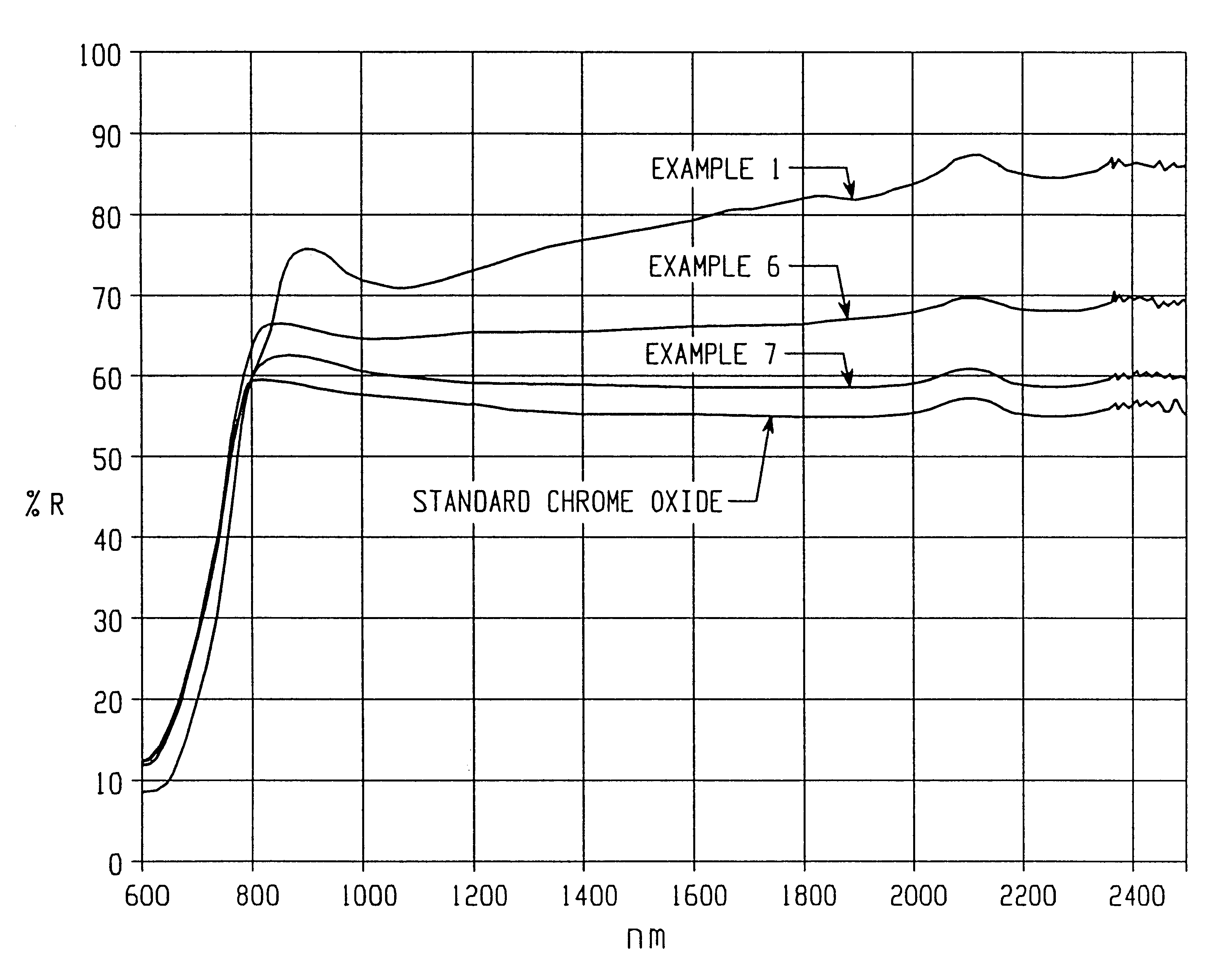

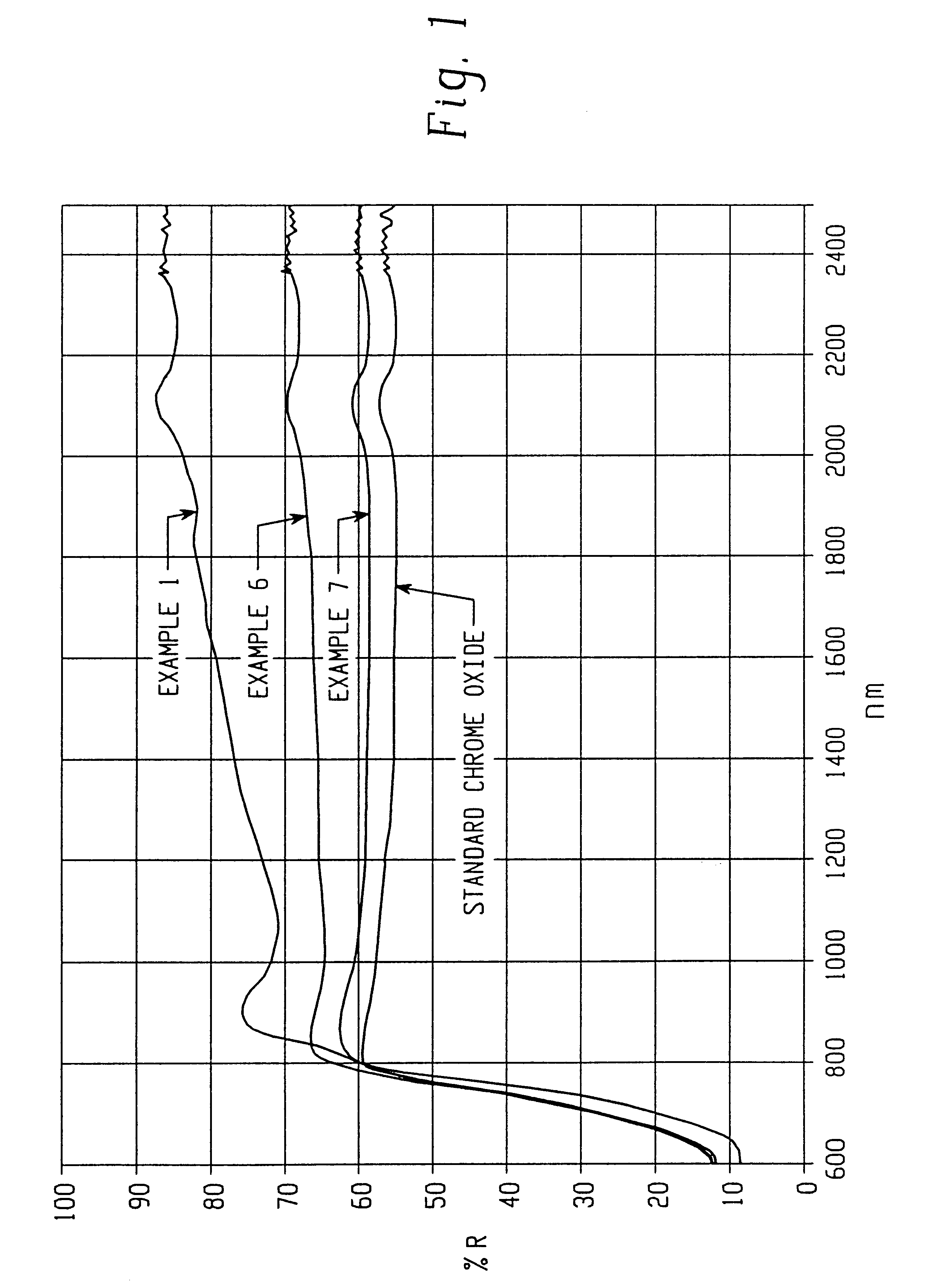

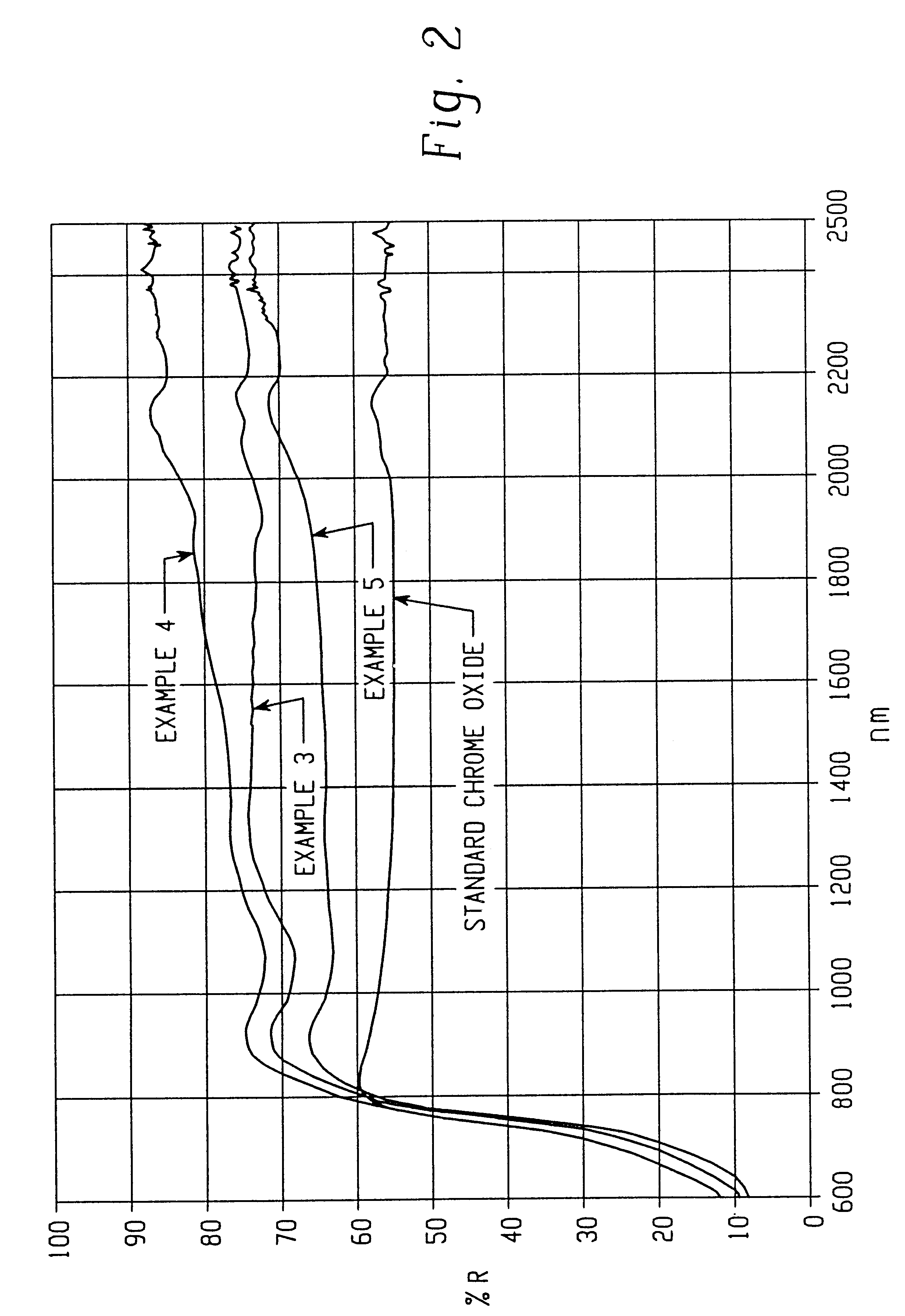

Infrared reflective color pigment

InactiveUS6454848B2Reduce heat buildupReduce energy costsInorganic pigment treatmentCoatingsIndiumCobalt

The present invention provides new solid solutions having a corundum-hematite crystalline structure which are useful as inorganic color pigments. Solid solutions according to the present invention include a host component having a corundum-hematite crystalline structure which contains as guest components one or more elements from the group consisting of aluminum, antimony, bismuth, boron, chrome, cobalt, gallium, indium, iron, lanthanum, lithium, magnesium, manganese, molybdenum, neodymium, nickel, niobium, silicon, tin, titanium, vanadium, and zinc. Solid solutions according to the present invention are formed by thoroughly mixing compounds, usually metal oxides or precursors thereof, which contain the host and guest components and then calcining the compounds to form the solid solutions having the corundum-hematite crystalline structure. Some of the new solid solutions according to the present invention exhibit relatively low Y CIE tri-stimulus values and relatively high near infrared reflectance.

Owner:FERRO CORP

Polymer nanocomposite implants with enhanced transparency and mechanical properties for administration within humans or animals

Polymer nanocomposite implants with nanofillers and additives are described. The nanofillers described can be any composition with the preferred composition being those composing barium, bismuth, cerium, dysprosium, europium, gadolinium, hafnium, indium, lanthanum, neodymium, niobium, praseodymium, strontium, tantalum, tin, tungsten, ytterbium, yttrium, zinc, and zirconium. The additives can be of any composition with the preferred form being inorganic nanopowders comprising aluminum, calcium, gallium, iron, lithium, magnesium, silicon, sodium, strontium, titanium. Such nanocomposites are particularly useful as materials for biological use in applications such as drug delivery, biomed devices, bone or dental implants.

Owner:PPG IND OHIO INC

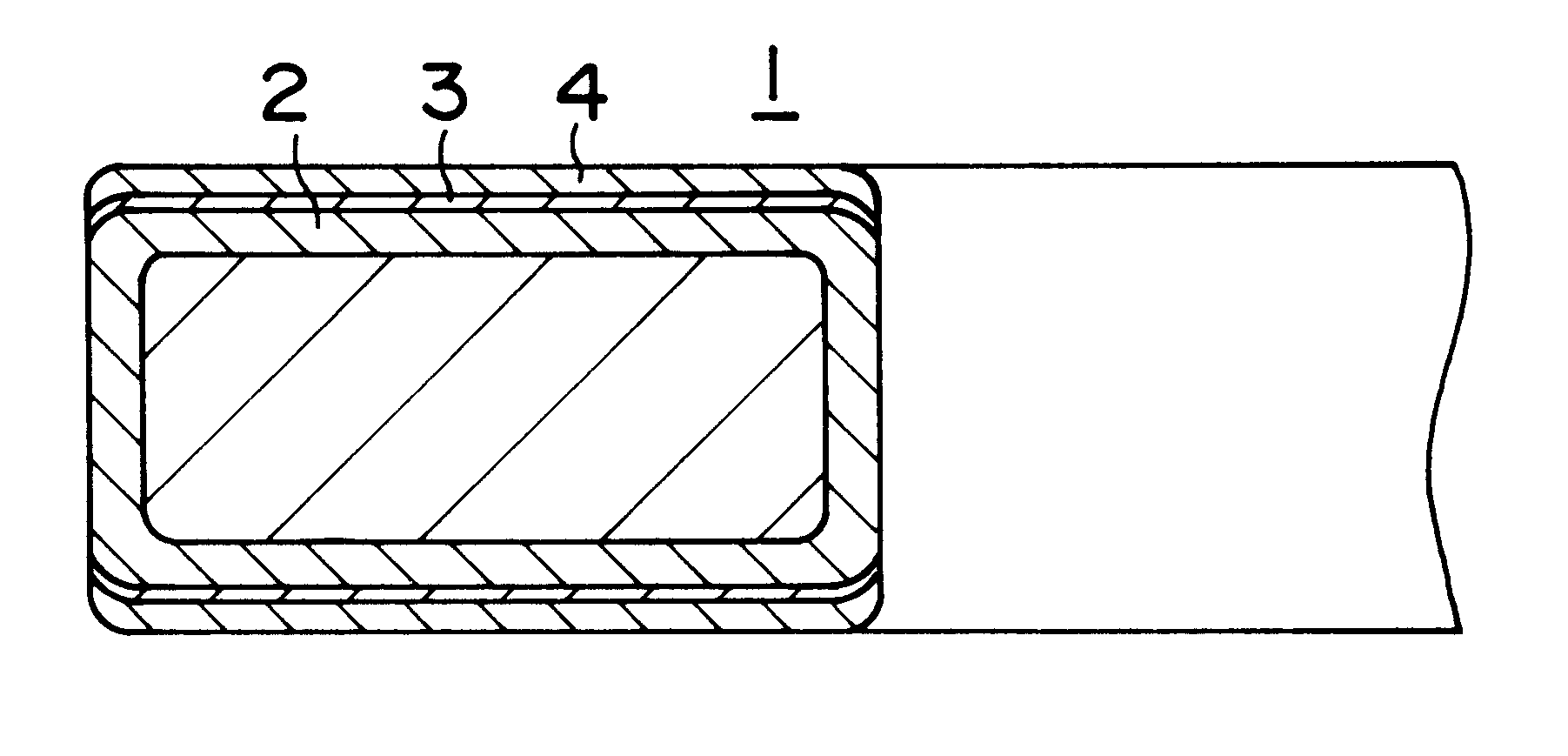

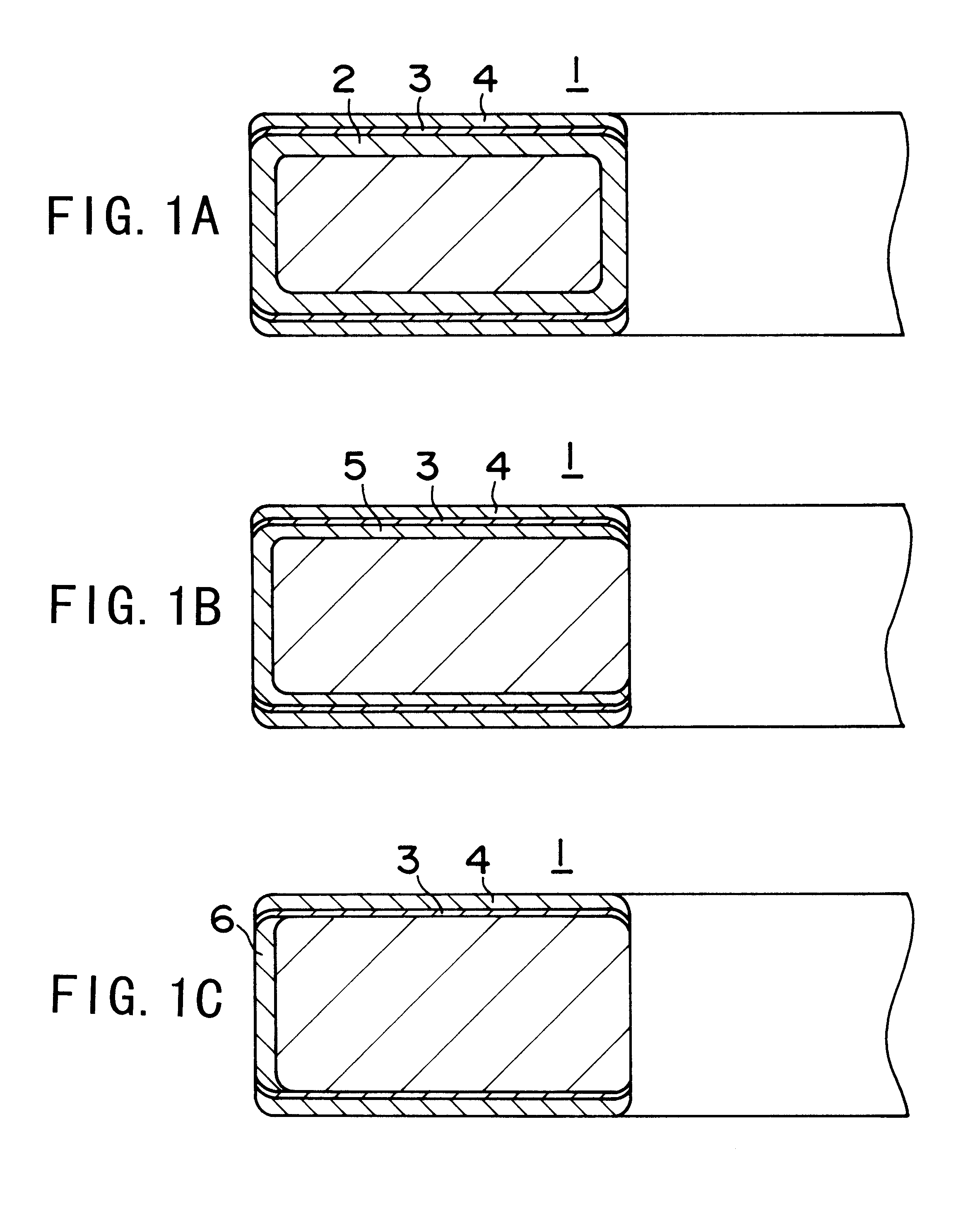

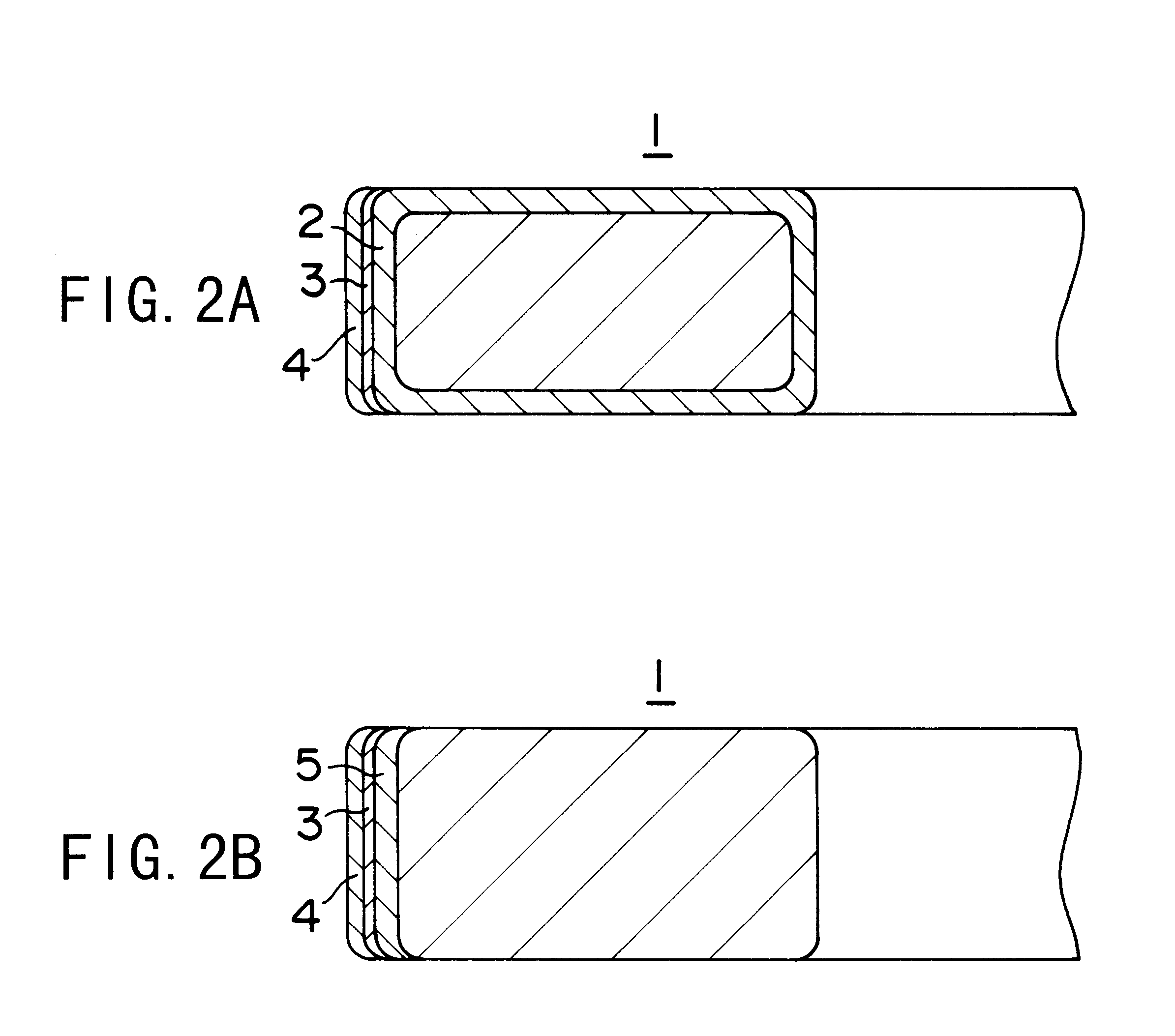

Piston ring

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

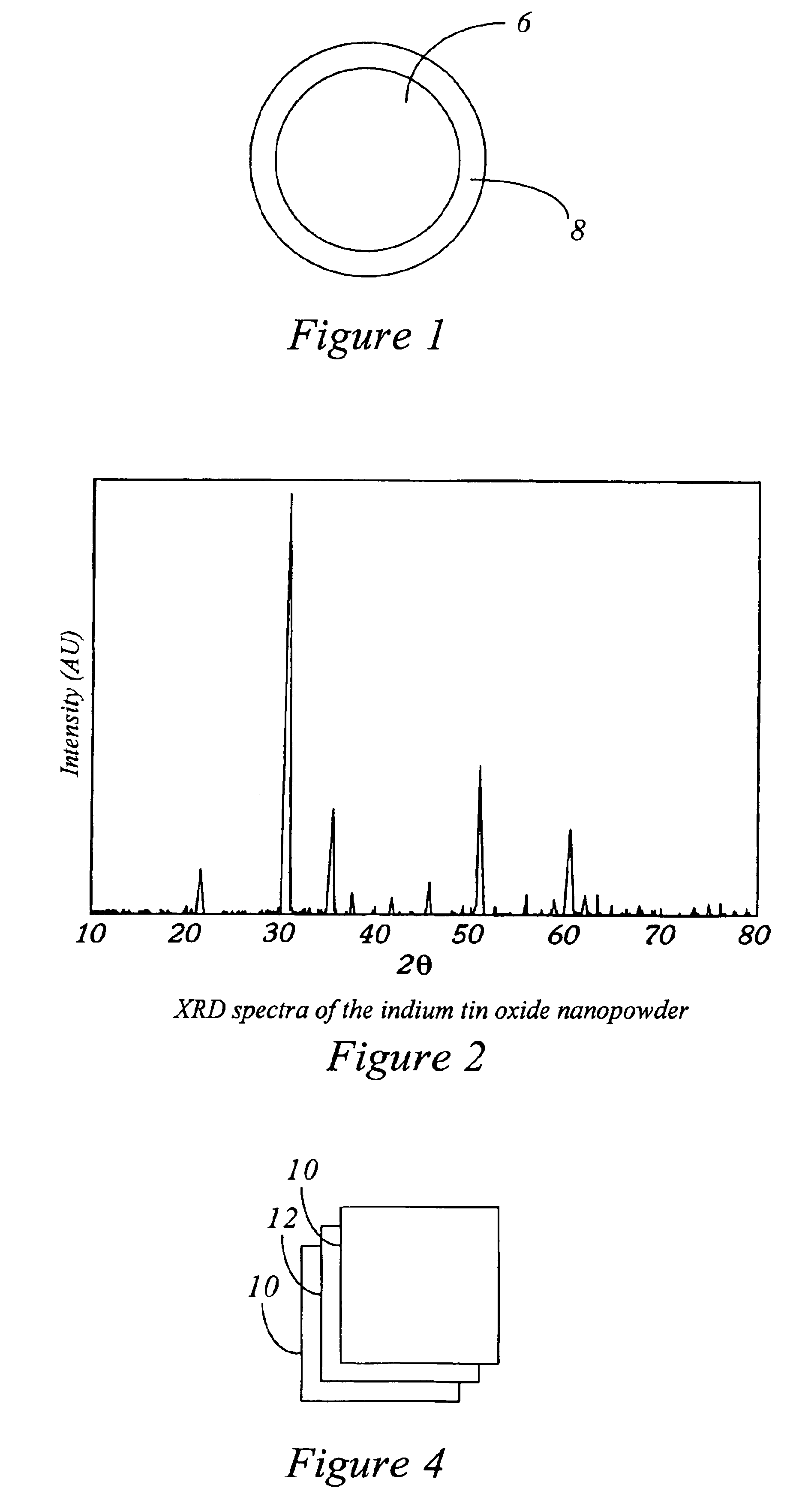

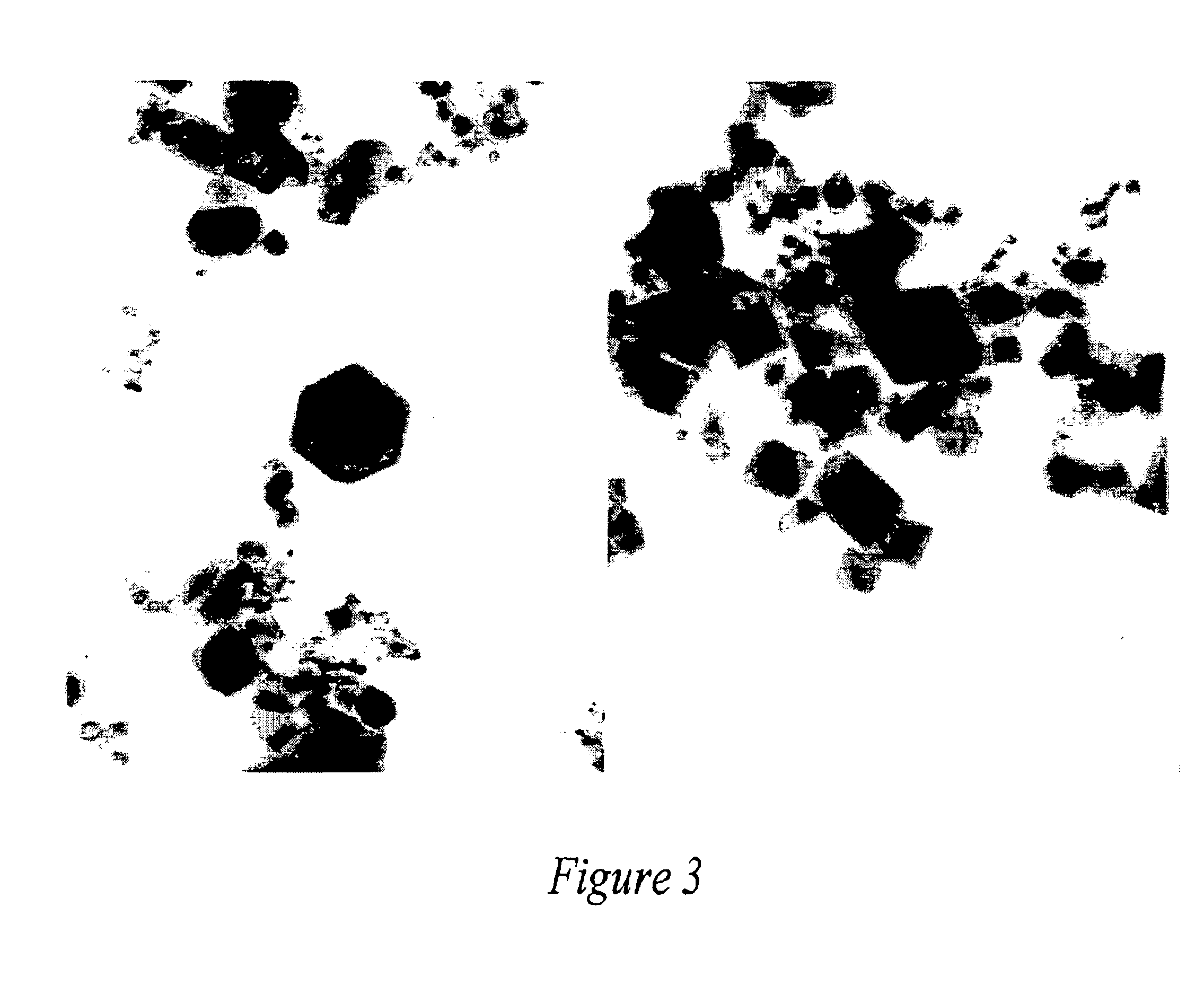

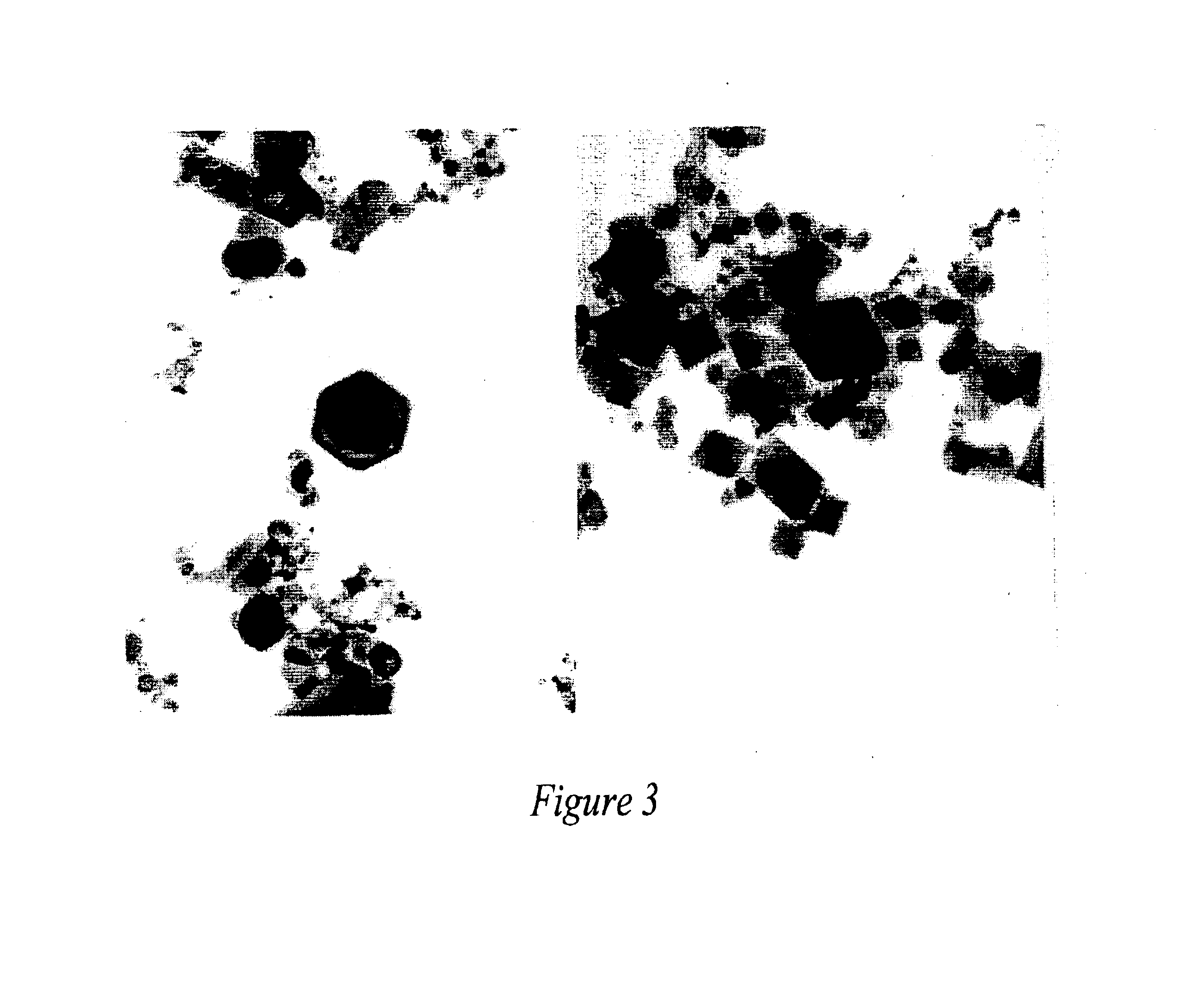

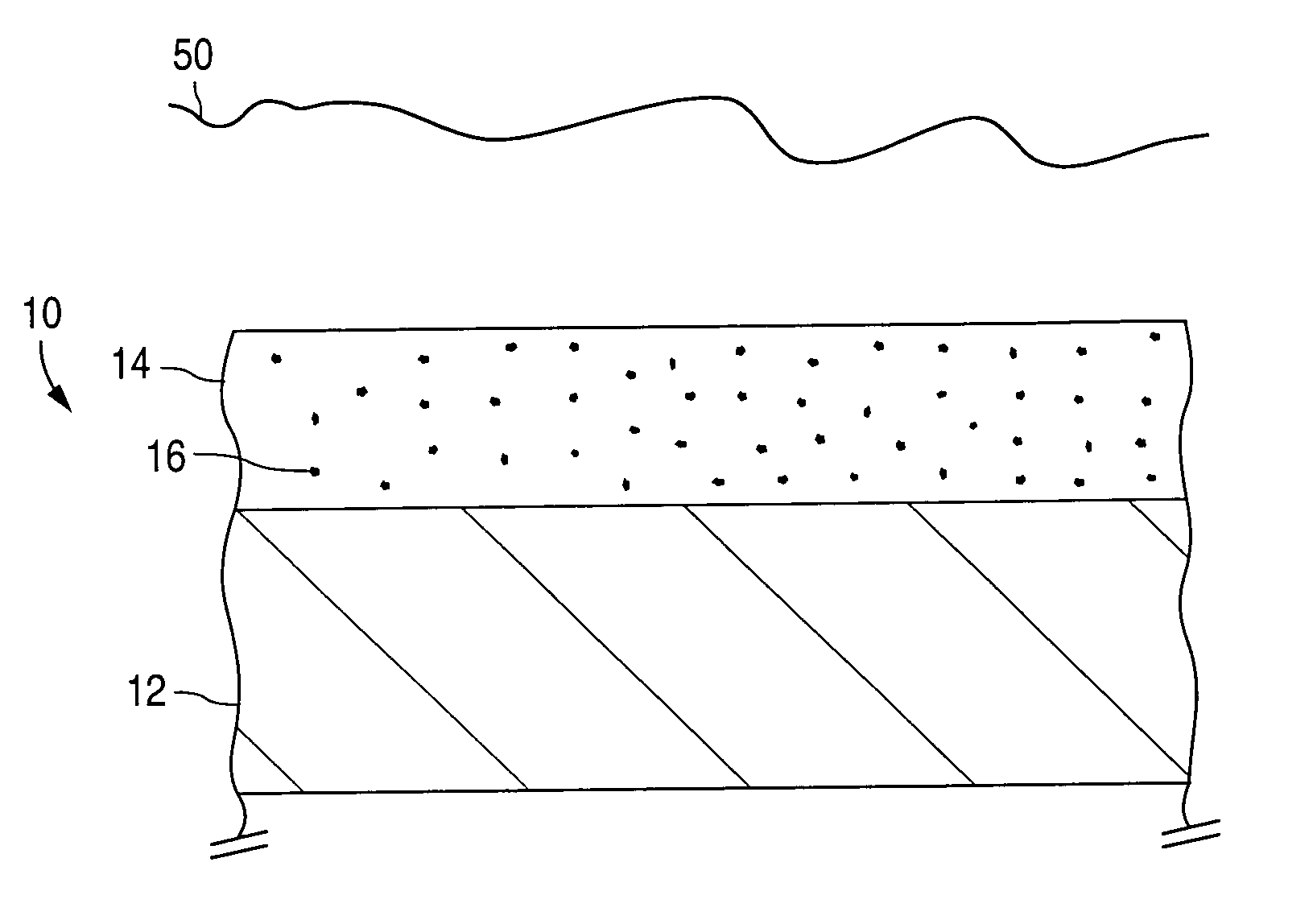

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

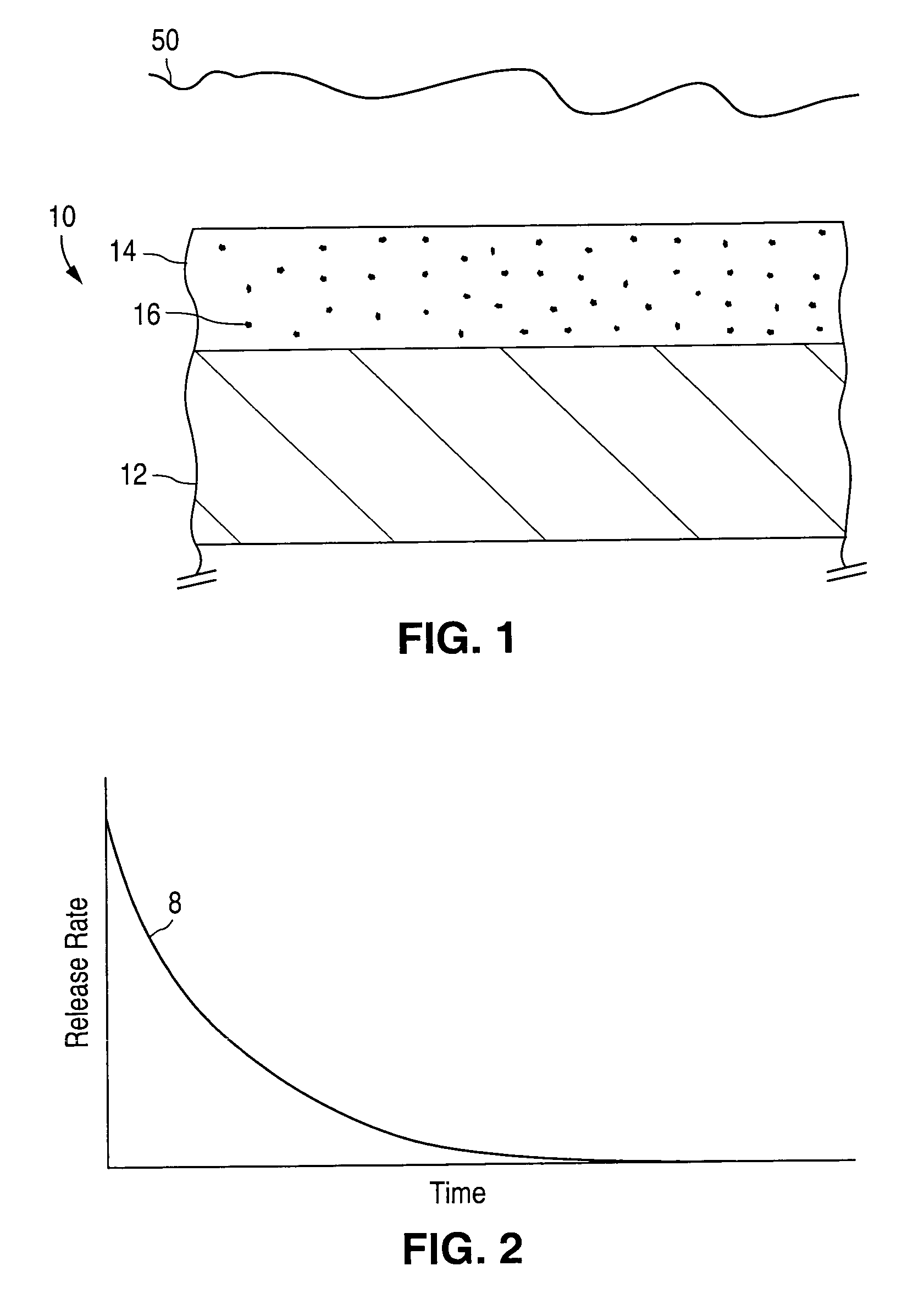

Barriers for polymer-coated implantable medical devices and methods for making the same

InactiveUS6953560B1Reduce and prevent and inflammationReduce and prevent proliferationStentsSurgeryHafniumPt element

An implantable medical device and methods for making the implantable medical device are disclosed. The implantable medical device includes a substrate. At least a portion of the substrate is coated with a first layer including a polymer containing a drug. A barrier overlies the first layer. The barrier significantly reduces the rate of release of the drug from the polymer, thereby sustaining release of the drug from the medical device for a longer time.The barrier may be a homogeneous layer overlying the first layer, or a number of discrete deposits over the first layer. Alternatively, the barrier may be intermixed with an outer portion of the first layer. The barrier material is biocompatible, and typically has a thickness ranging from about 50 angstroms to about 20,000 microns. Suitable materials for the barrier include, but are not limited to, inorganic compounds, such as inorganic silicides, oxides, nitrides, carbides, as well as pure metals such as aluminum, chromium, gold, hafnium, iridium, niobium, palladium, platinum, tantalum, titanium, tungsten, zirconium, and alloys of these metals. The barriers disclosed may be applied to the first layer by several techniques, depending on the material being applied. Exemplary deposition techniques include physical vapor deposition, alkoxide hydrolysis, and electroless plating.The implantable device may be a stent or a graft, among other possibilities.

Owner:ABBOTT CARDIOVASCULAR

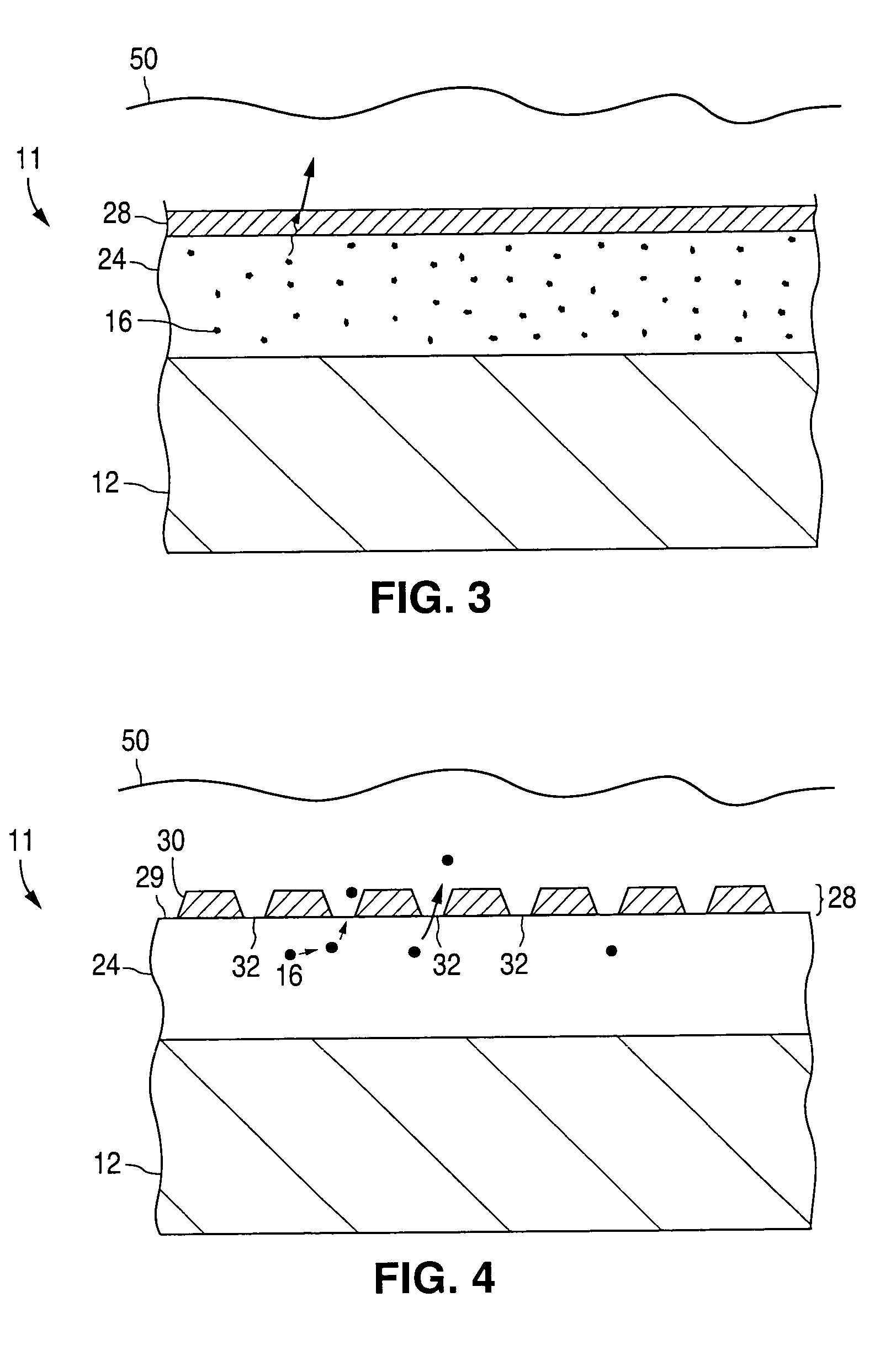

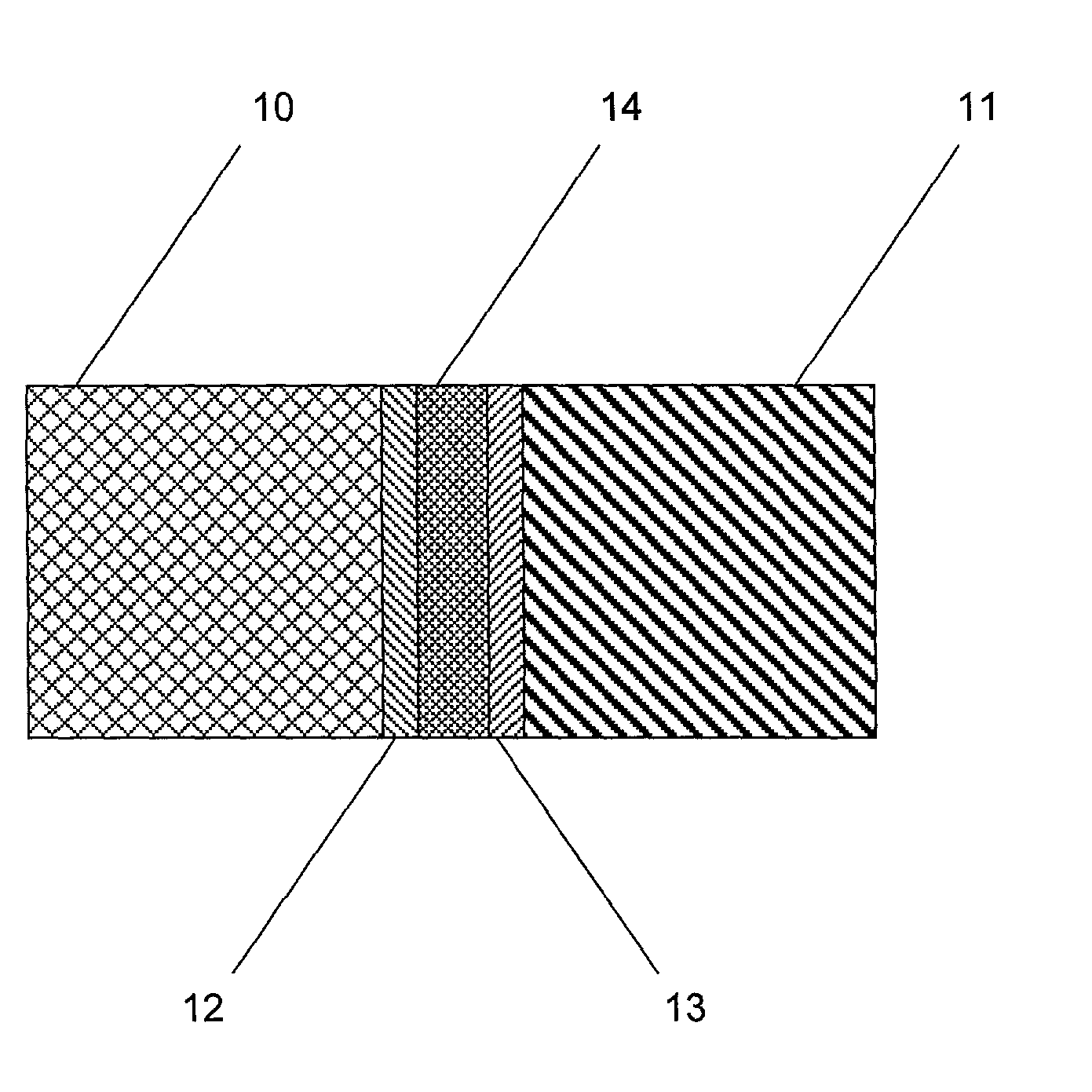

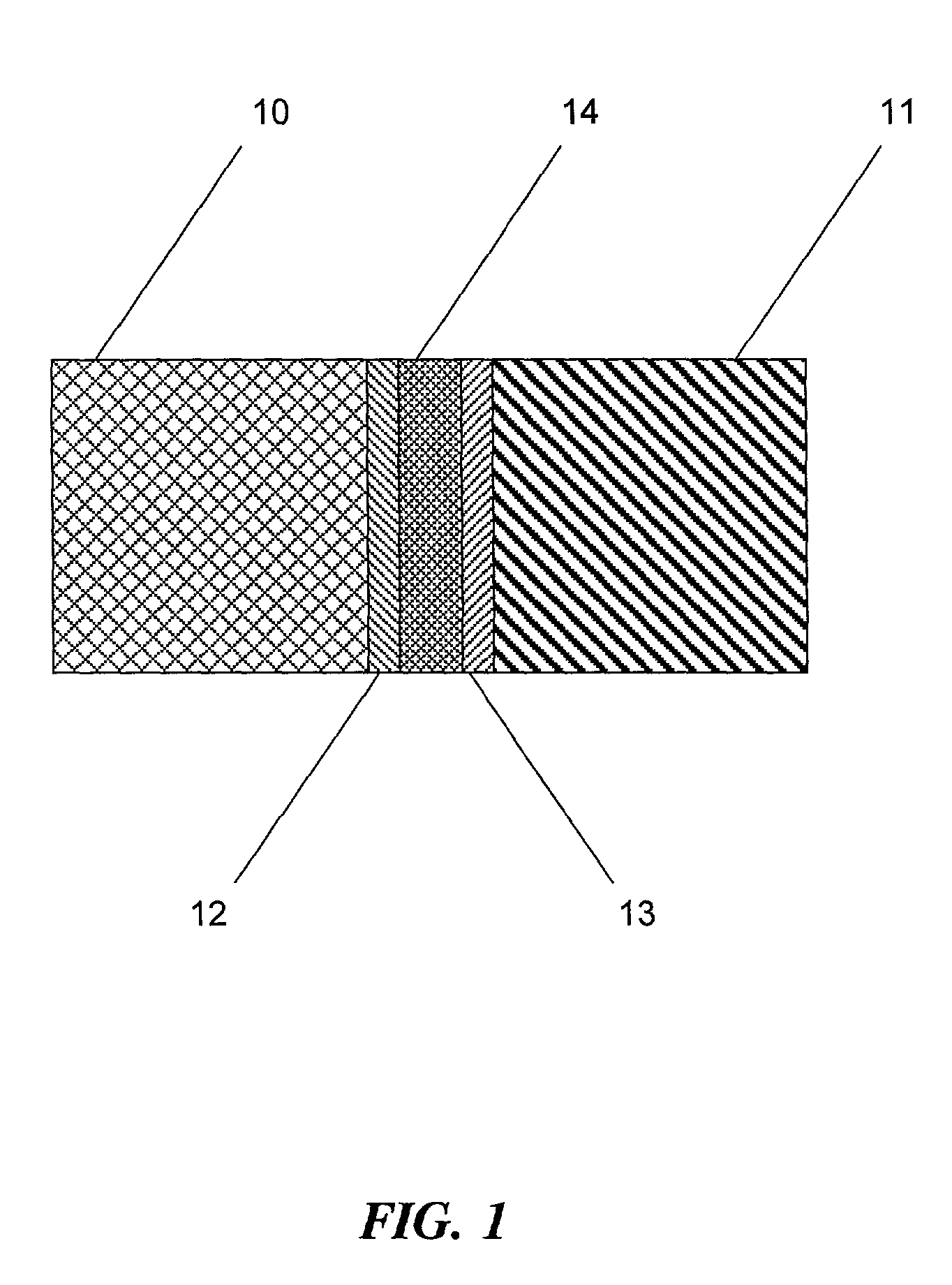

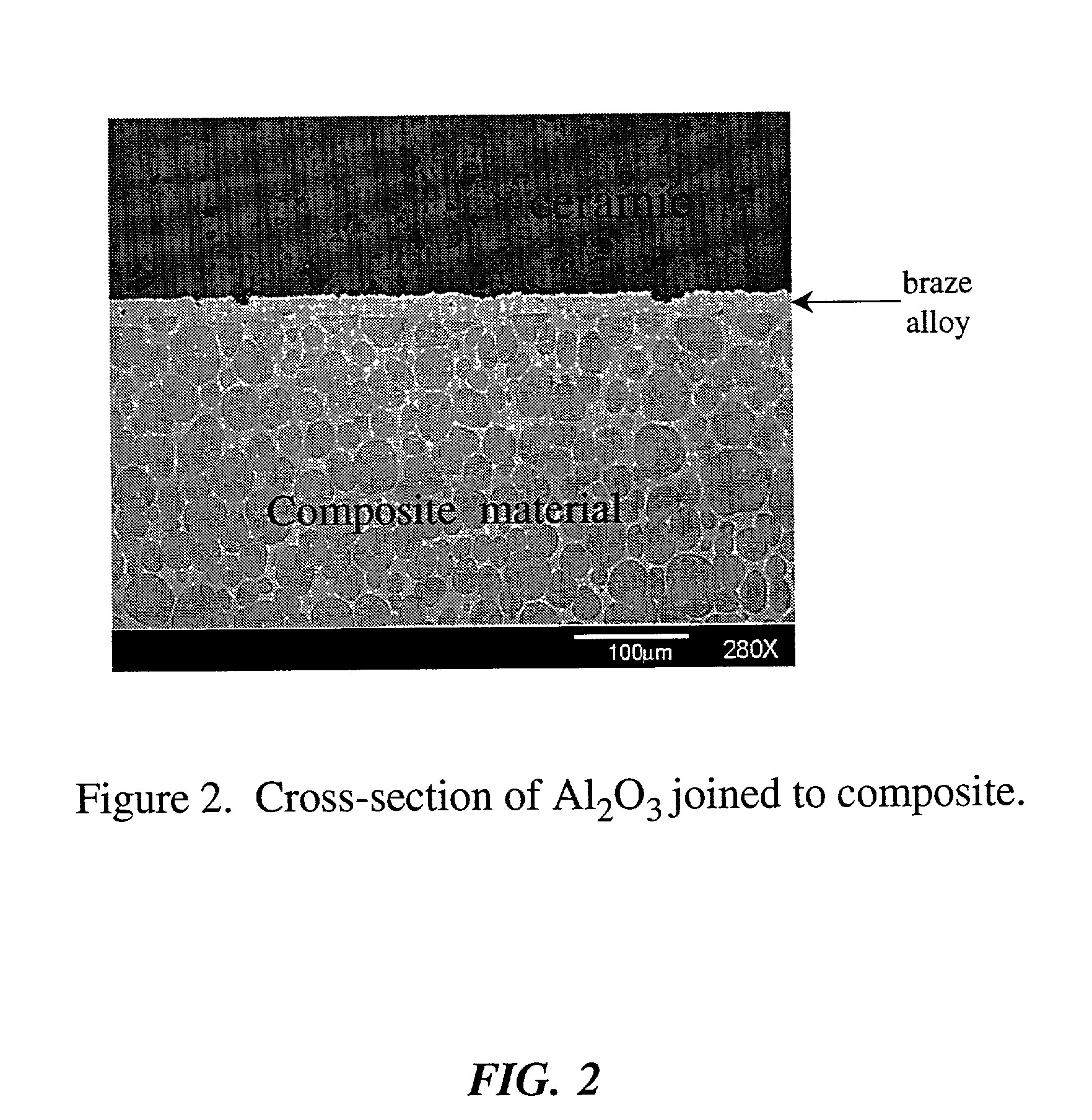

Braze system and method for reducing strain in a braze joint

A system for joining a pair of structural members having widely differing coefficients of thermal expansion is disclosed. A mechanically "thick" foil is made by dispersing a refractory metal powder, such as molybdenum, niobium, tantalum, or tungsten into a quantity of a liquid, high expansion metal such as copper, silver, or gold, casting an ingot of the mixture, and then cutting sections of the ingot about 1 mm thick to provide the foil member. These foil members are shaped, and assembled between surfaces of structural members for joining, together with a layer of a braze alloy on either side of the foil member capable of wetting both the surfaces of the structural members and the foil. The assembled body is then heated to melt the braze alloy and join the assembled structure. The foil member subsequently absorbs the mechanical strain generated by the differential contraction of the cooling members that results from the difference in the coefficients of thermal expansion of the members.

Owner:SANDIA NAT LAB

Metal alloy for medical devices and implants

InactiveUS20080312740A1Maintain good propertiesImprove uniformityStentsHeart valvesNiobiumBiocompatibility Testing

Owner:ABBOTT IRELAND

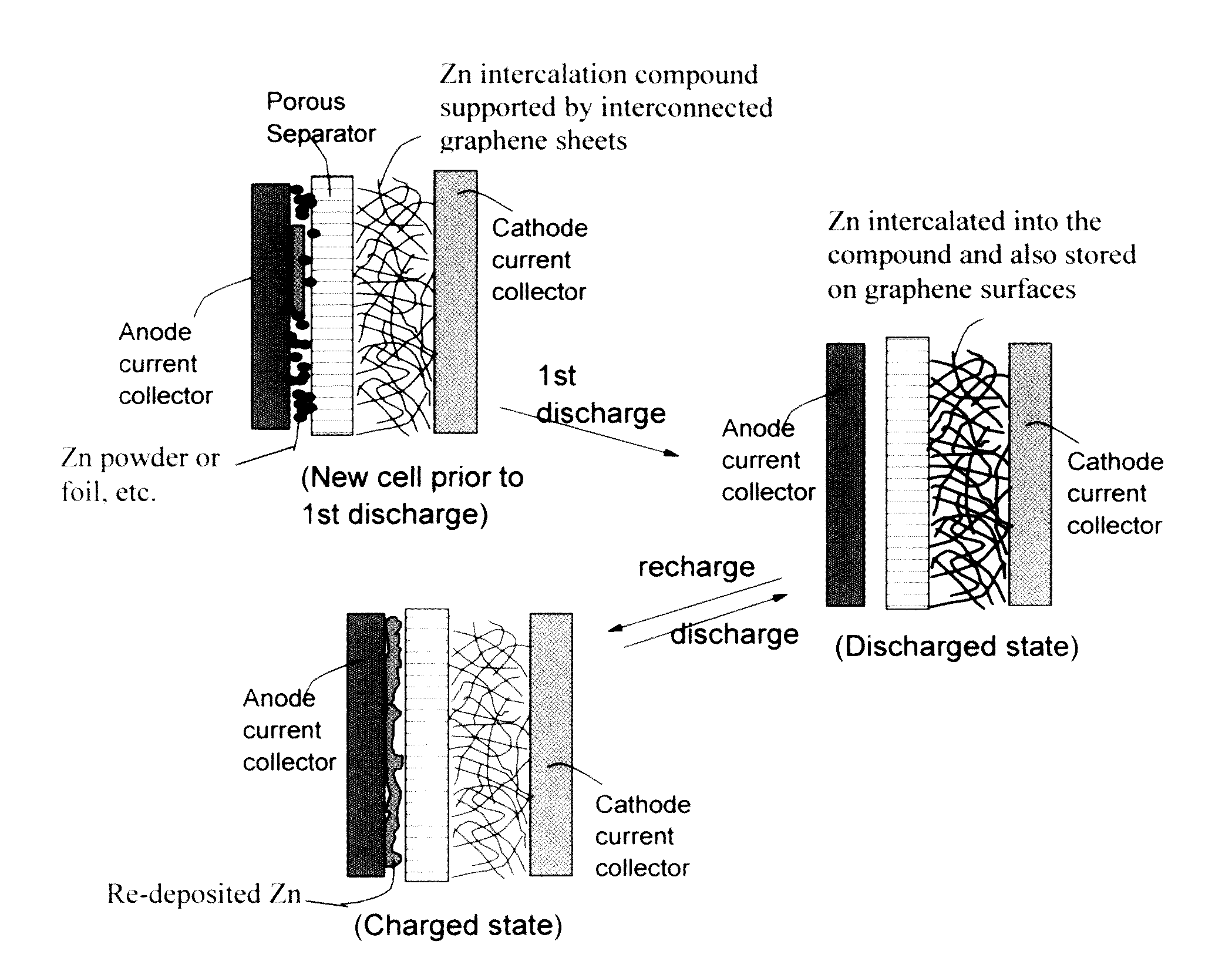

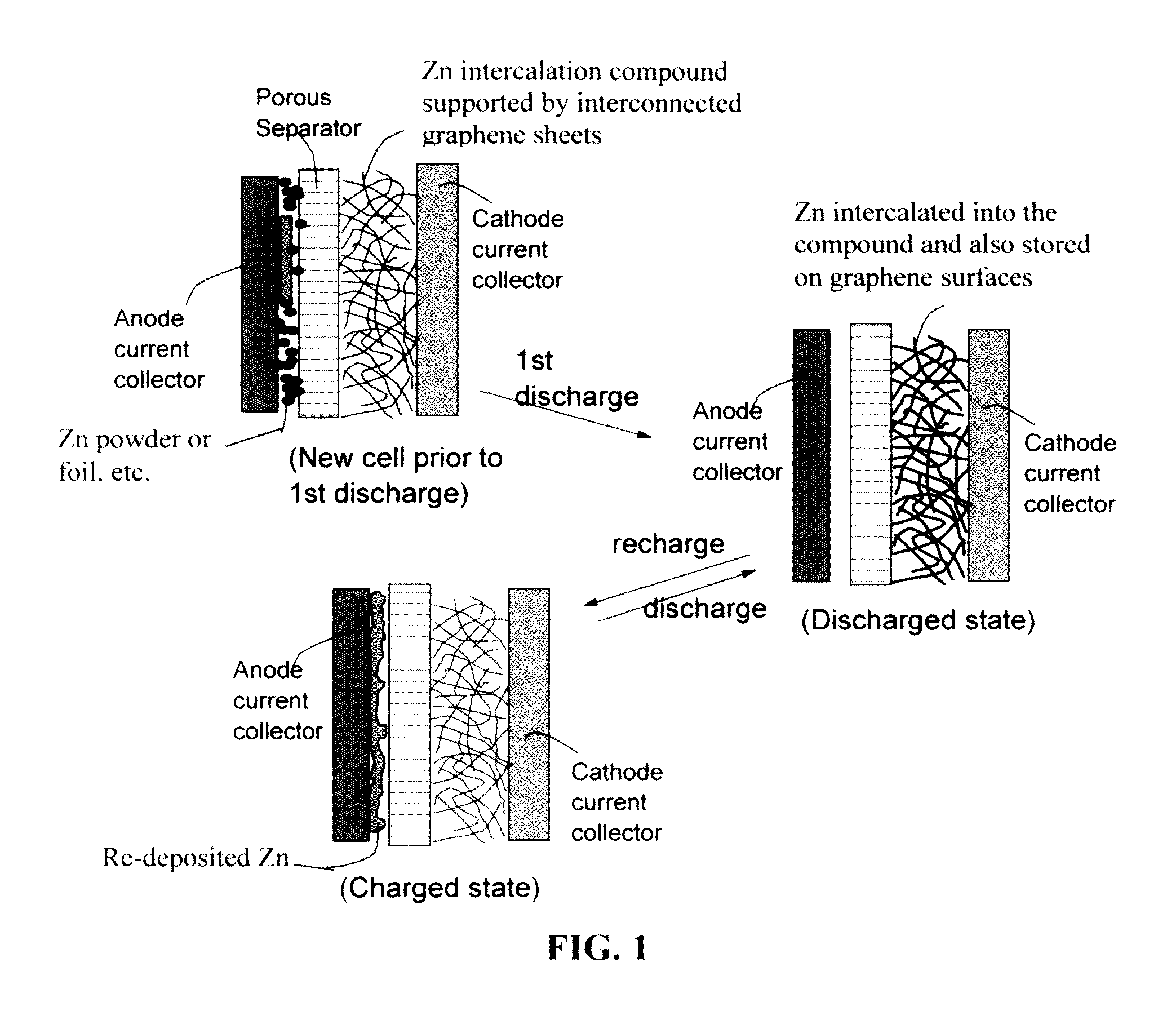

Zinc Ion-Exchanging Energy Storage Device

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

Medical implant or device

The present invention relates to a medical device or implant made at least in part of a high strength, low modulus metal alloy comprising Niobium, Tantalum, and at least one element selected from the group consisting of Zirconium, Tungsten and Molybdenum. The medical devices according to the present invention provide superior characteristics with regard to biocompatibility, radio-opacity and MRI compatibility.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

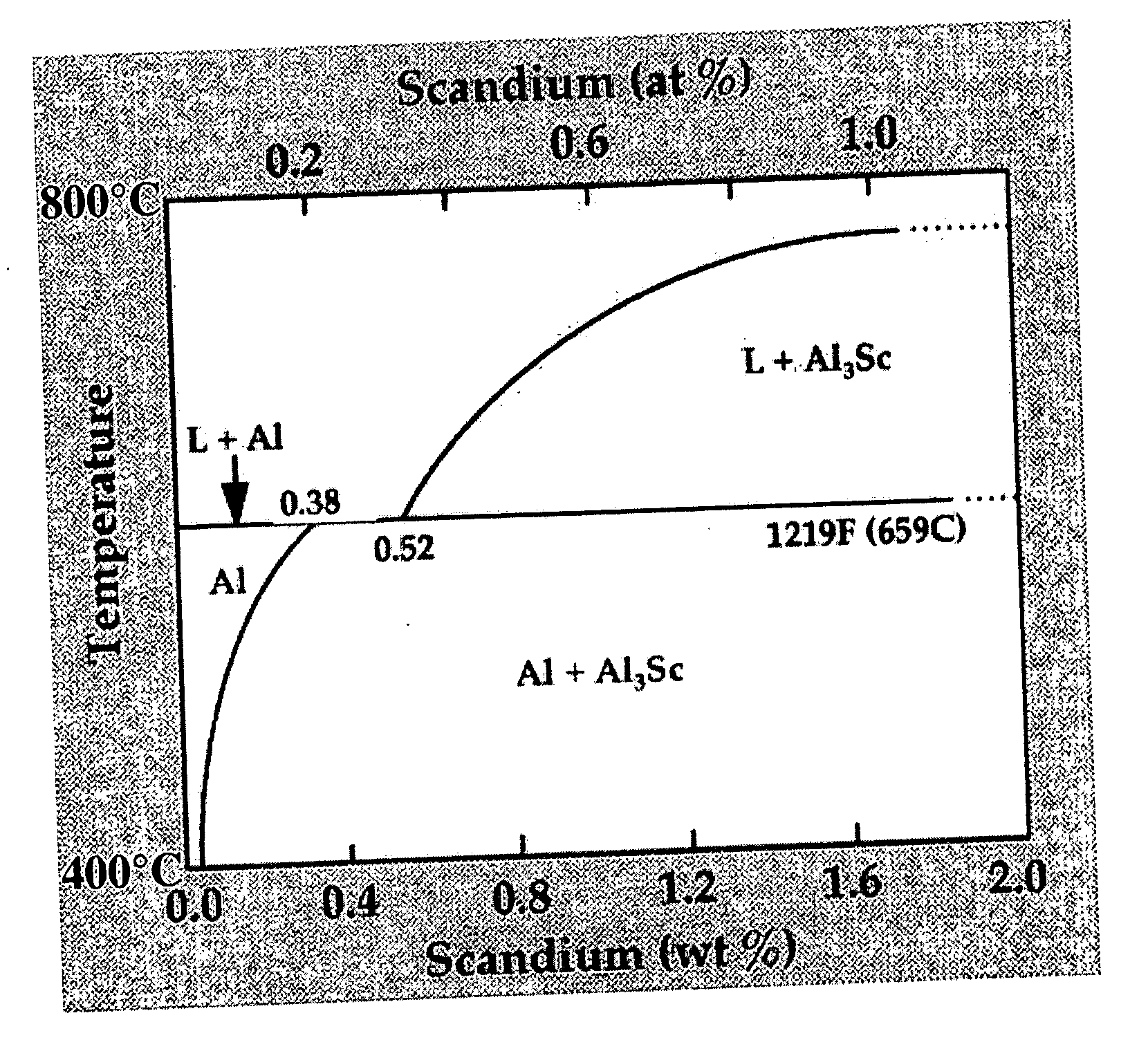

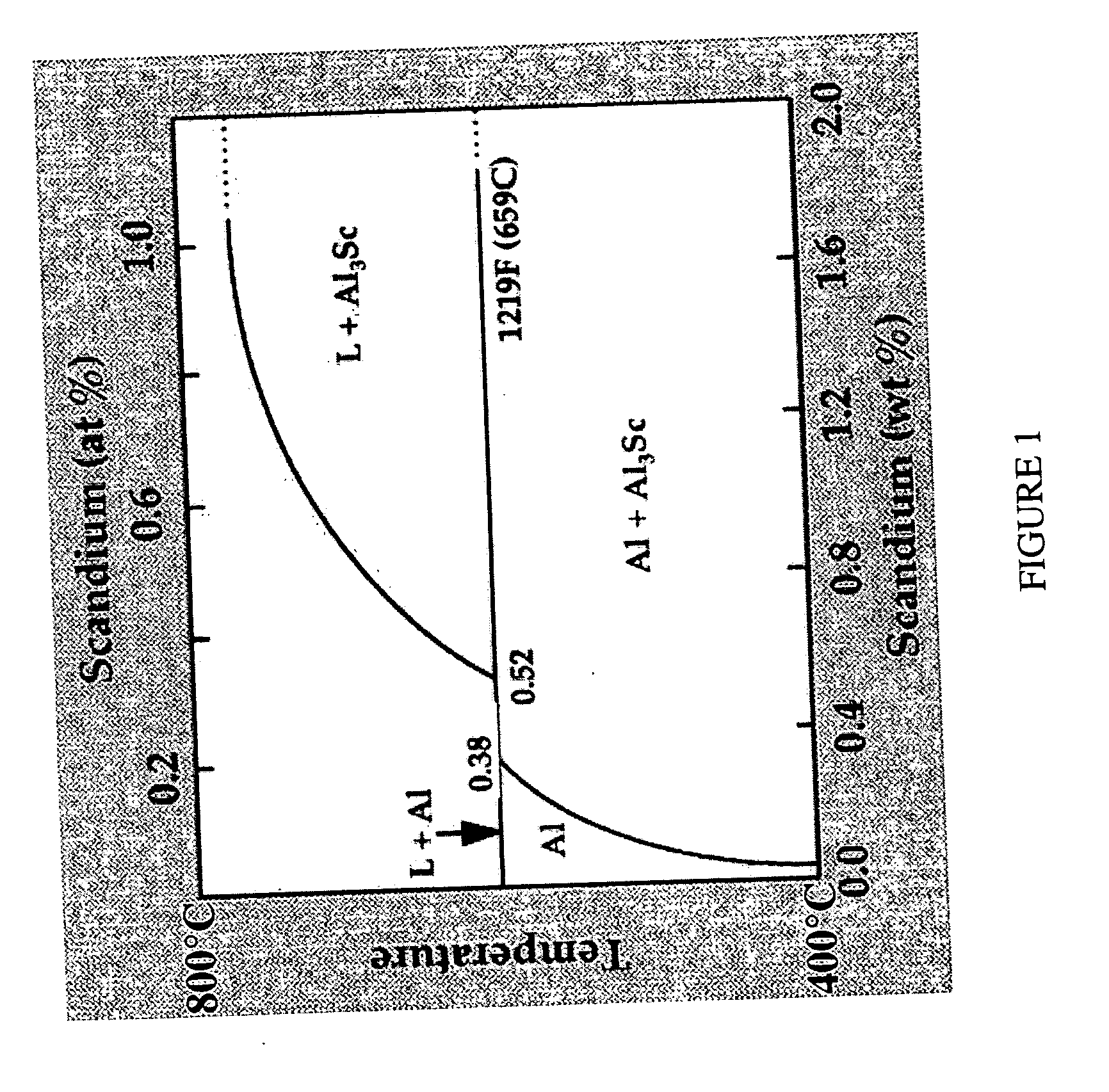

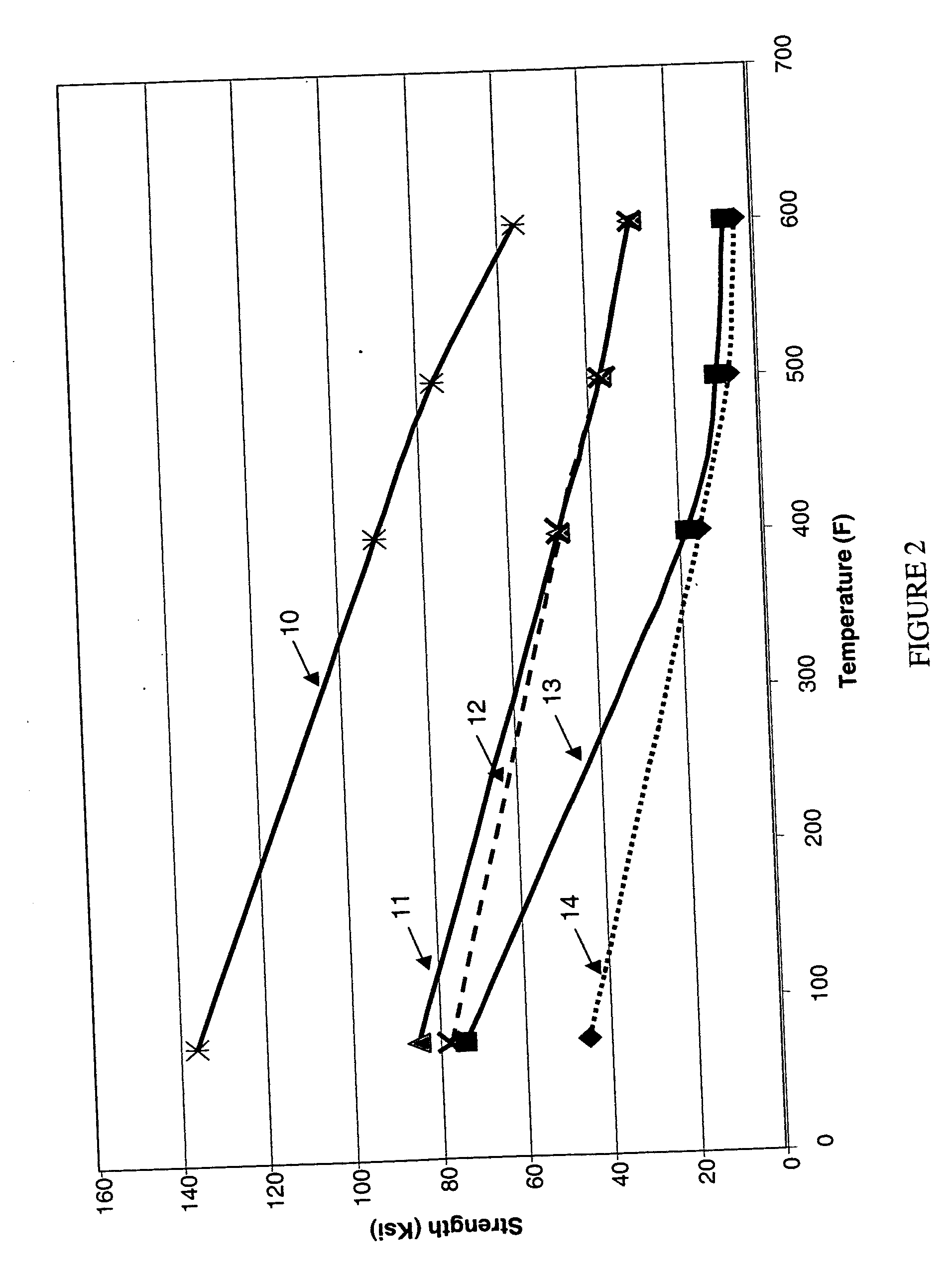

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

Process for producing niobium suboxide

ActiveUS7341705B2Increase capacityLiquid electrolytic capacitorsTantalum compoundsNiobiumPhysical chemistry

A method is described for preparing a niobium suboxide represented by the formula, NbOx, in which 0.7<x<1.3. The method involves reacting NbOy (in which y<1.8<2.1) with a stoichiometric amount of niobium metal, in the presence of hydrogen. The niobium suboxide produced by such method may be used to fabricate anodes for solid electrolyte capacitors.

Owner:TANIOBIS GMBH

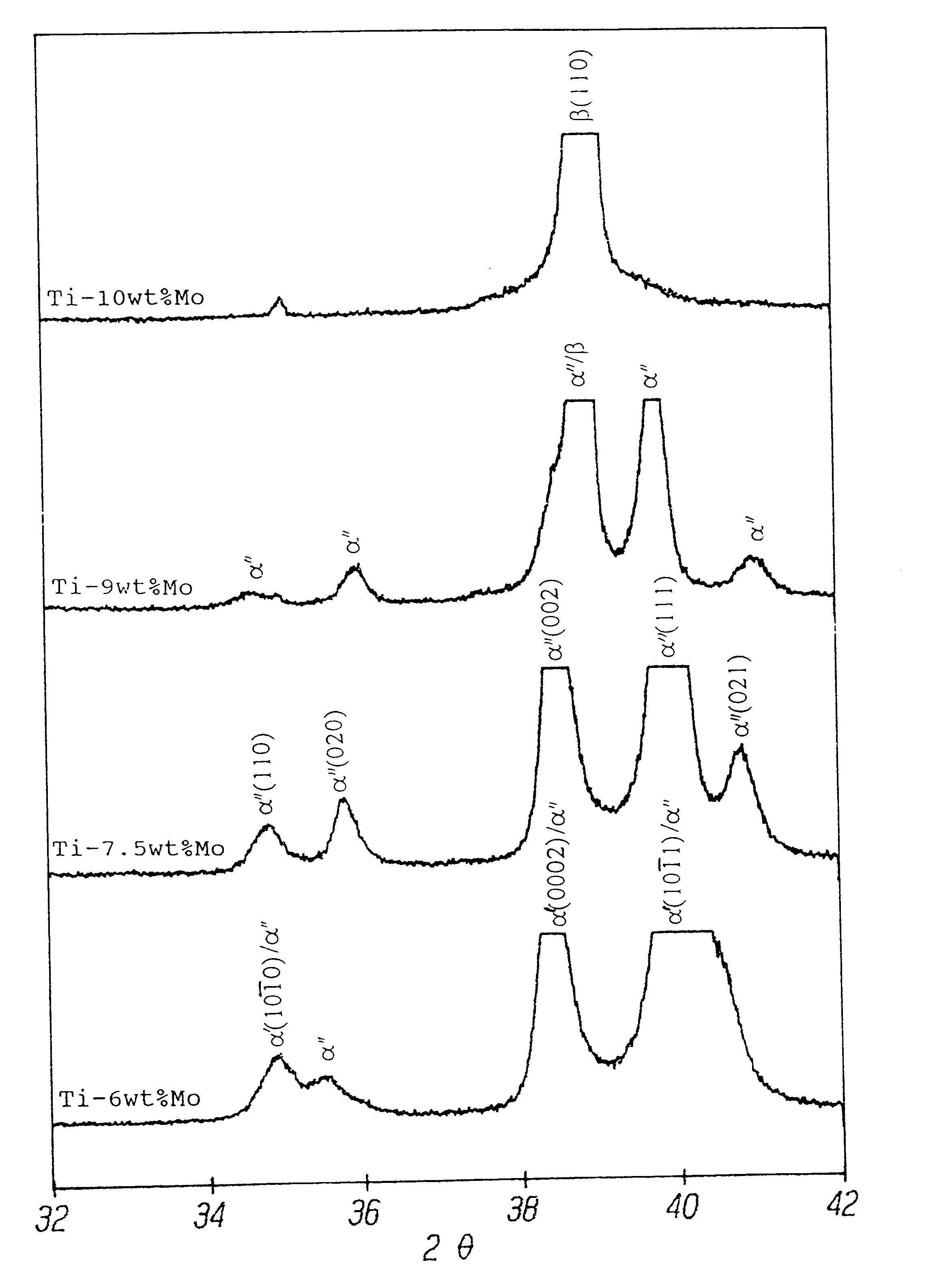

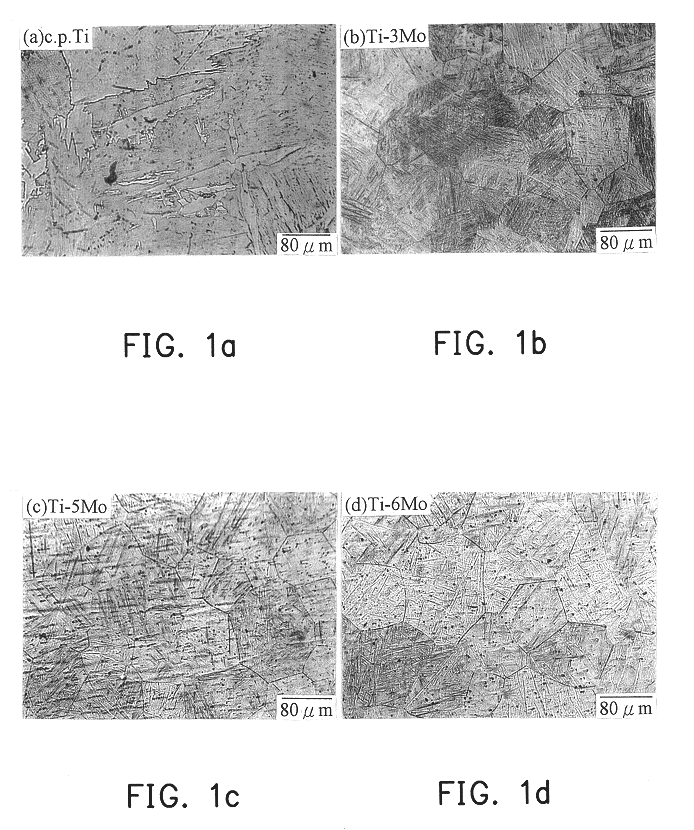

Biocompatible low modulus titanium alloy for medical implant

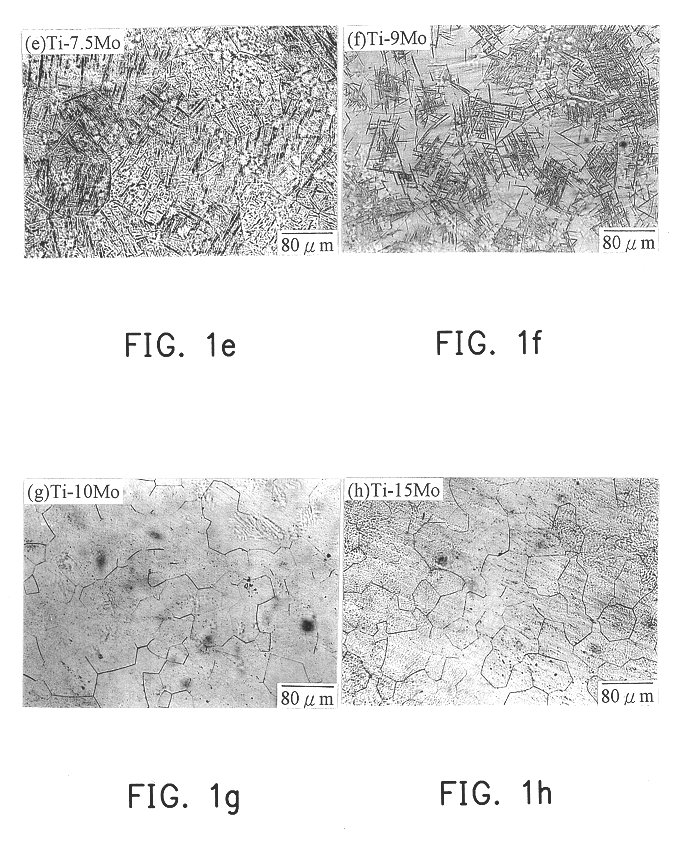

A biocompatible titanium alloy with low modulus comprising alpha'' phase as a major phase and containing from about 6 to about 9 wt % of molybdenum, from 0 to about 1 wt % of an alloying element and the balance titanium. The alloying element is niobium and / or zirconium. The biocompatible titanium alloy is suitable for use as a material for a medical prosthetic implant.

Owner:NAT CHENG KUNG UNIV +1

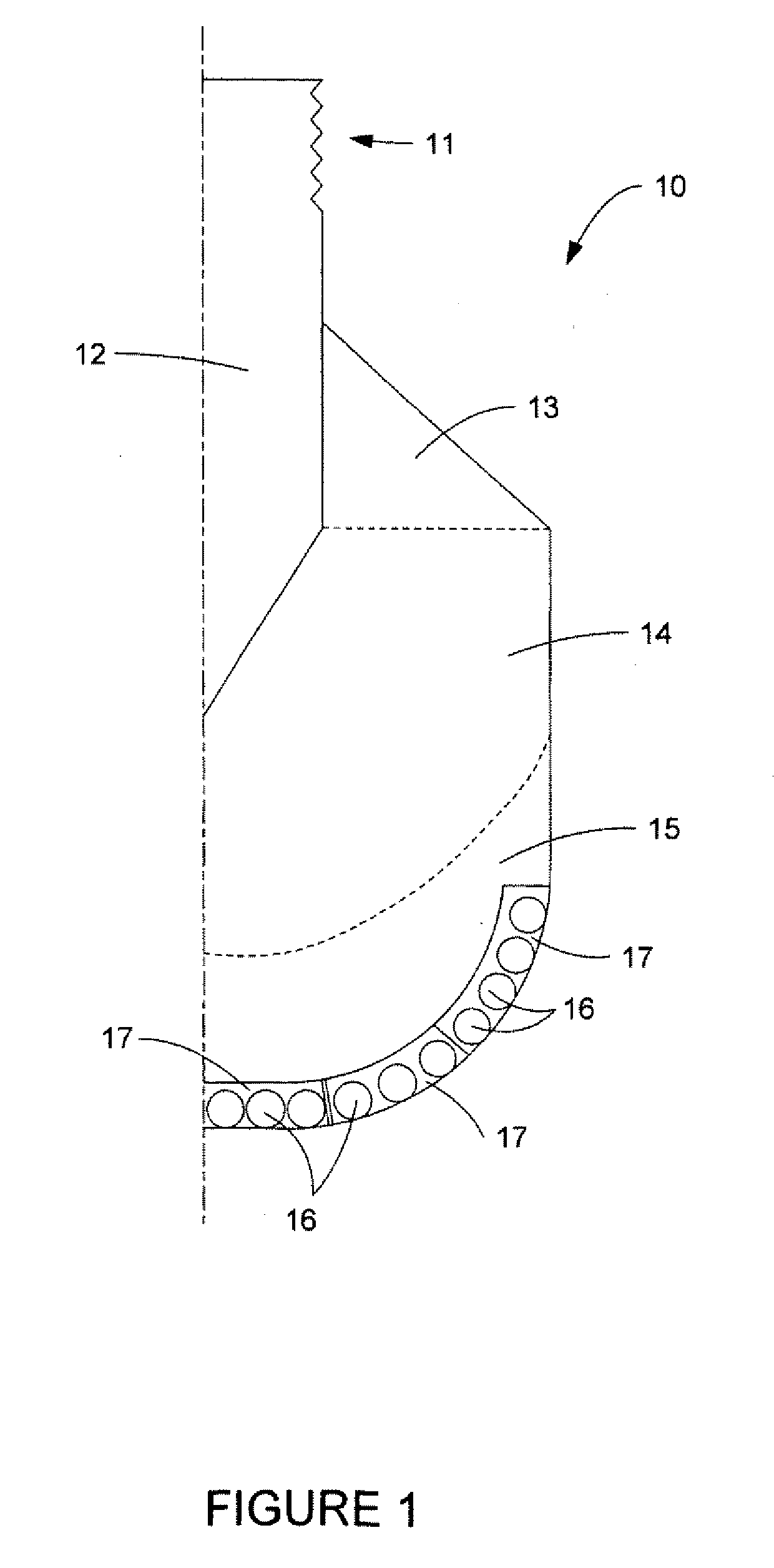

Sintered bodies for earth-boring rotary drill bits and methods of forming the same

InactiveUS20080101977A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:EASON JIMMY W +2

High-strength/high-toughness alloy steel drill bit blank

Drill bit reinforcing members or blanks of this invention are formed from high-strength steels having a carbon content less than about 0.3 percent by weight, a yield strength of at least 55,000 psi, a tensile strength of at least 80,000 psi, a toughness of at least 40 CVN-L, Ft-lb, and a rate of expansion percentage change less than about 0.0025% / ° F. during austenitic to ferritic phase transformation. In one embodiment, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.5 to 1.5 percent by weight manganese, up to about 0.8 percent by weight chromium, 0.05 to 4 percent by weight nickel, and 0.02 to 0.8 percent by weight molybdenum. In another example, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.9 to 1.5 percent by weight manganese, 0.1 to 0.5 percent by weight silicon, and one or more microalloying element selected from the group consisting of vanadium, niobium, titanium, zirconium, aluminum and mixtures thereof.

Owner:SMITH INT INC

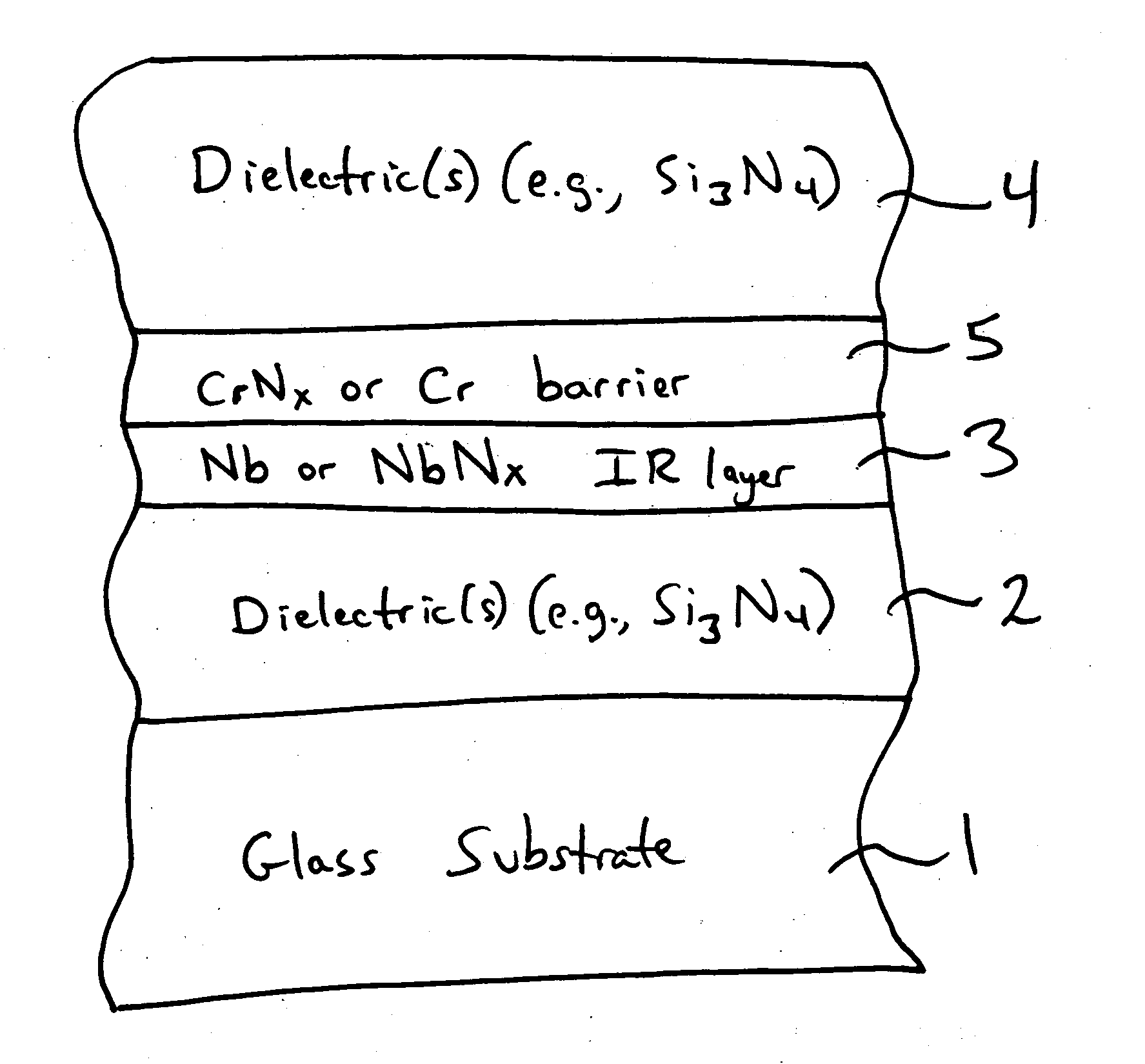

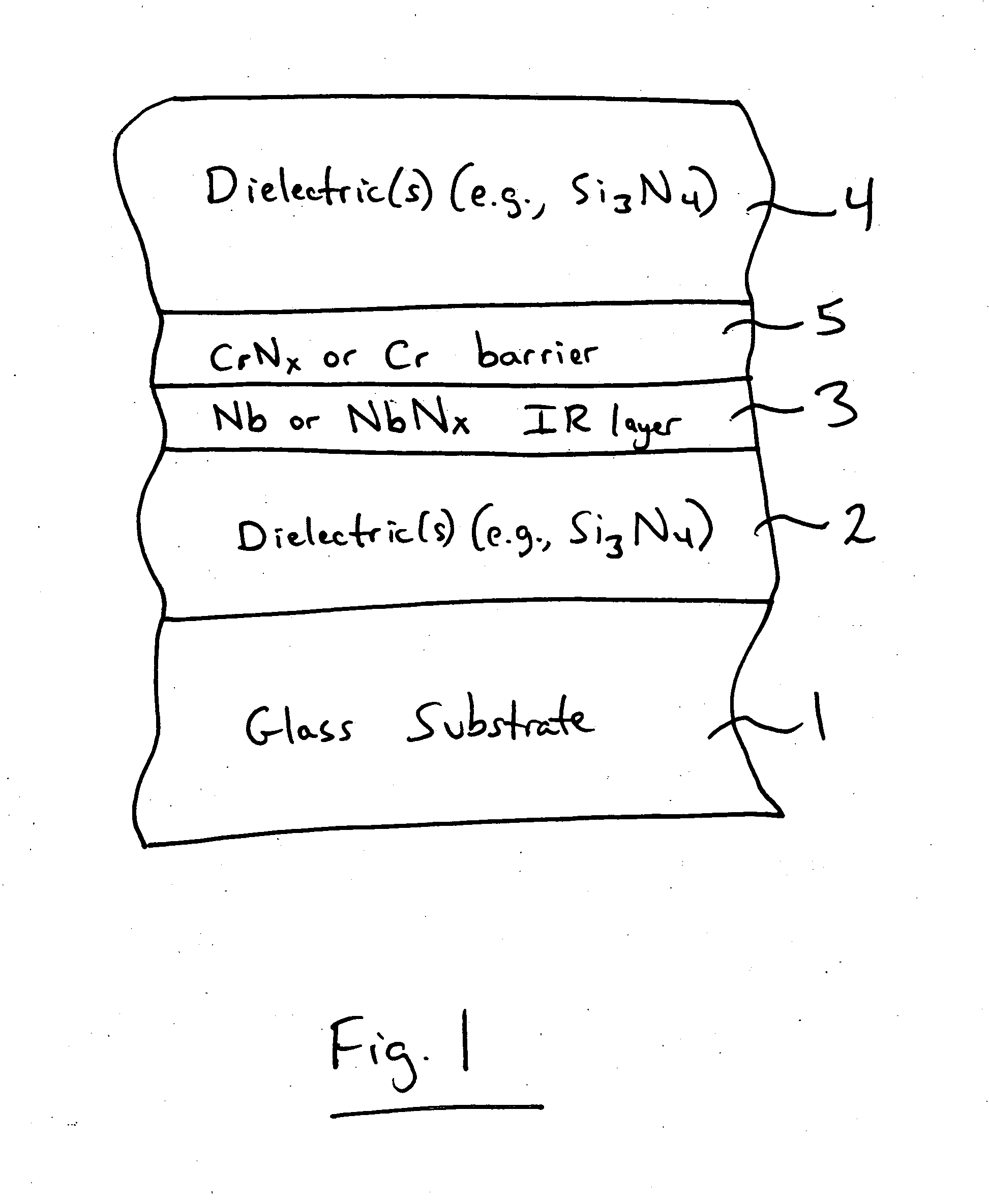

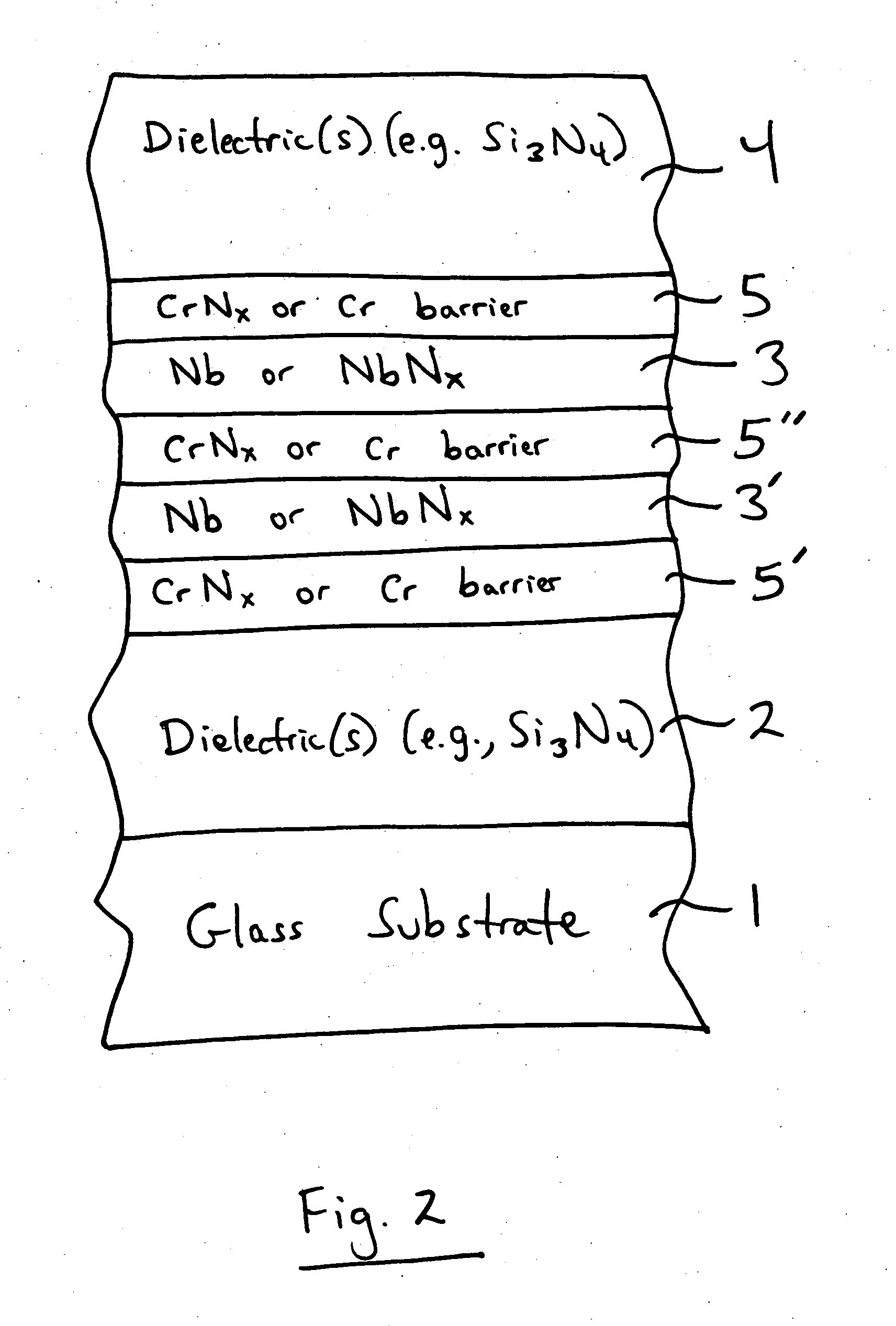

Heat treatable coated article and method of making same

ActiveUS20050079369A1More durableImproved color stabilityGlass/slag layered productsCoatingsNiobiumReflective layer

A coated article or layer system is provided which includes at least one infrared (IR) reflecting layer including niobium (Nb) sandwiched between at least a pair of dielectric layers. In certain embodiments, a Cr inclusive barrier layer is provided to protect the Nb inclusive IR reflecting layer, for chemical durability purposes. In other example embodiments, a protective overcoat including a zirconium oxide inclusive layer may be provided to protect the Nb inclusive IR reflecting layer for durability purposes.

Owner:GUARDIAN GLASS LLC

Sintered bodies based on niobium suboxide

Disclosed are sintered bodies that include: (a) 30 to 100 mol % of NbOx, wherein 0.5<x<1.5; and (b) 0 to 70 mol % of MgO. The sintered bodies may be used as inert apparatuses in the production of niobium suboxide powder or niobium suboxide anodes, or as chemically resistant components in chemical apparatuses.

Owner:H C STARCK GMBH

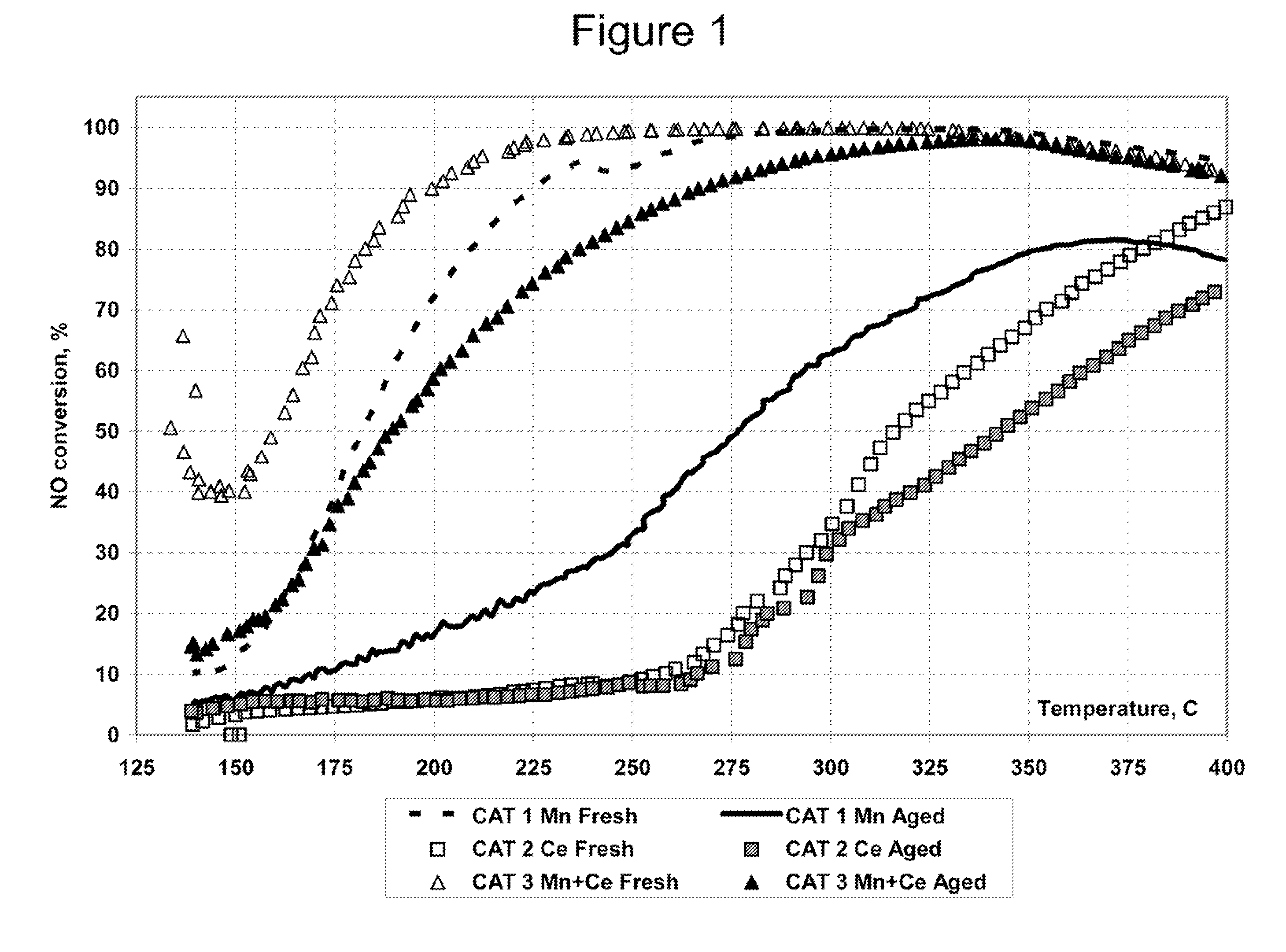

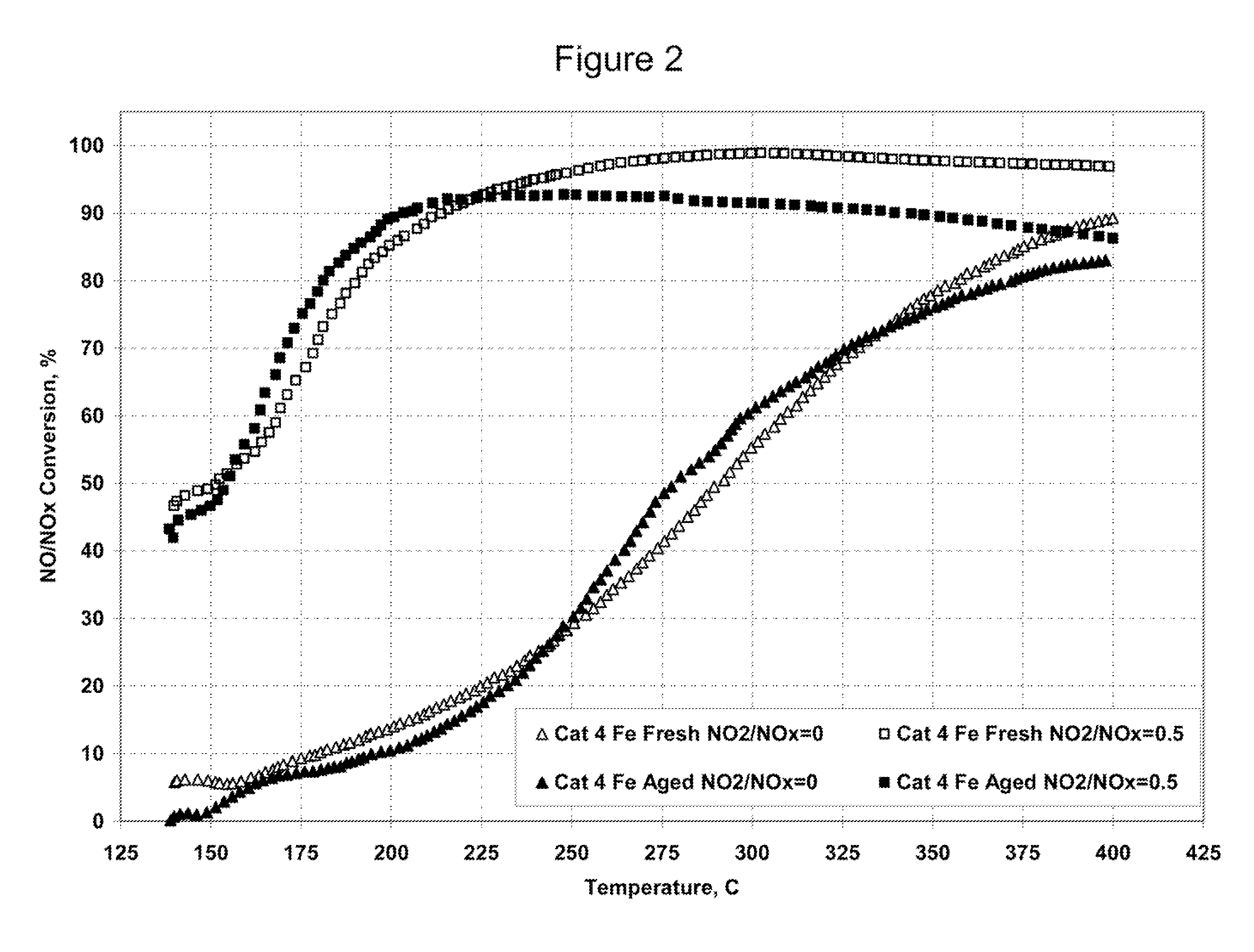

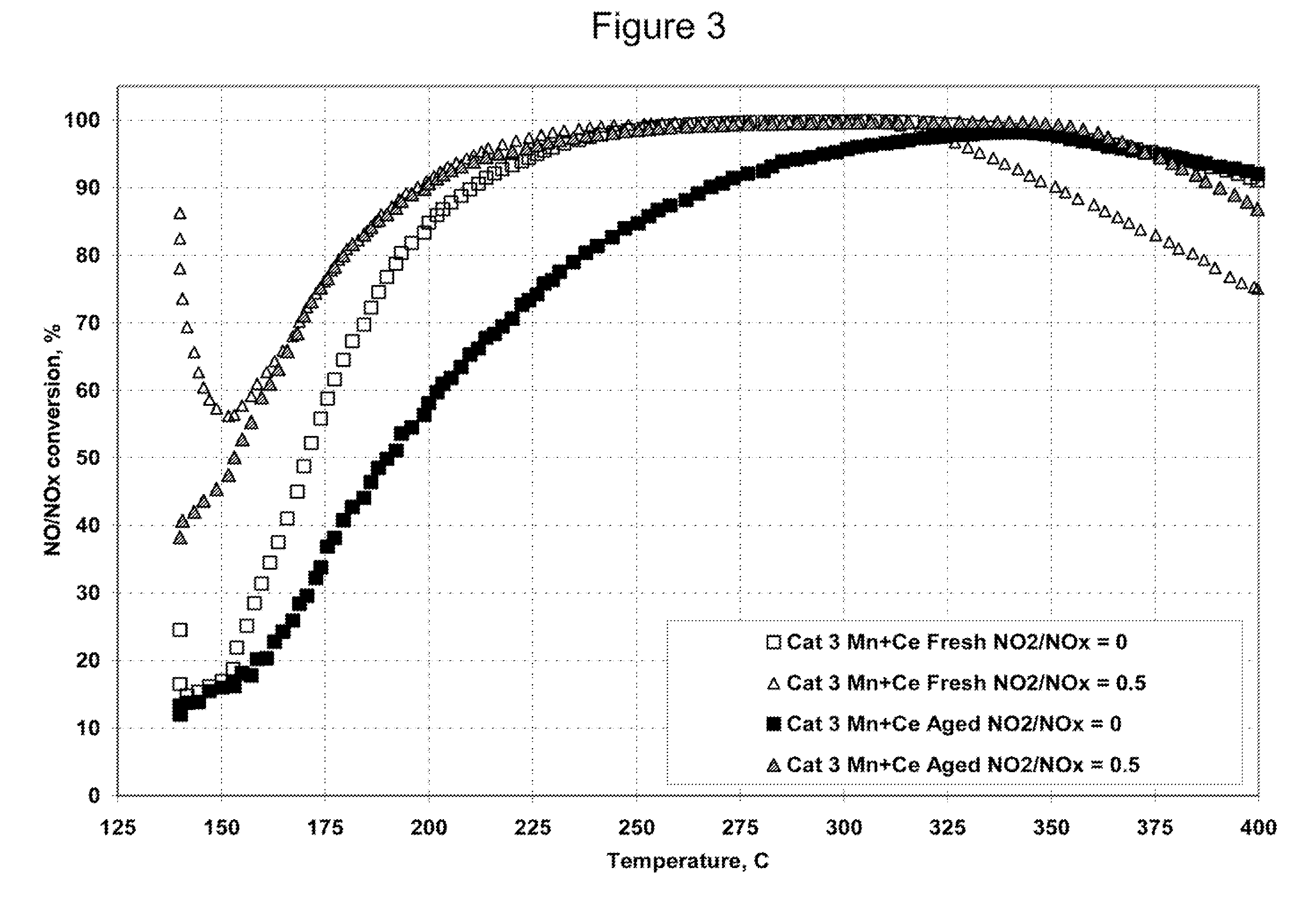

Ammonia scr catalyst and method of using the catalyst

ActiveUS20090304566A1Enhanced Surface AcidityCombination devicesOrganic chemistryParticulatesNiobium

A DPF with an SCR catalyst and a method for selectively reducing nitrogen oxides with ammonia, filtering particulates, and reducing the ignition temperature of soot on a DPF are provided. The catalyst includes a first component of copper, chromium, cobalt, nickel, manganese, iron, niobium, or mixtures thereof, a second component of cerium, a lanthanide, a mixture of lanthanides, or mixtures thereof, and a component characterized by increased surface acidity. The catalyst may also include strontium as an additional second component. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia and oxidizes soot at low temperatures. The catalyst has high hydrothermal stability.

Owner:CATALYTIC SOLUTIONS INC

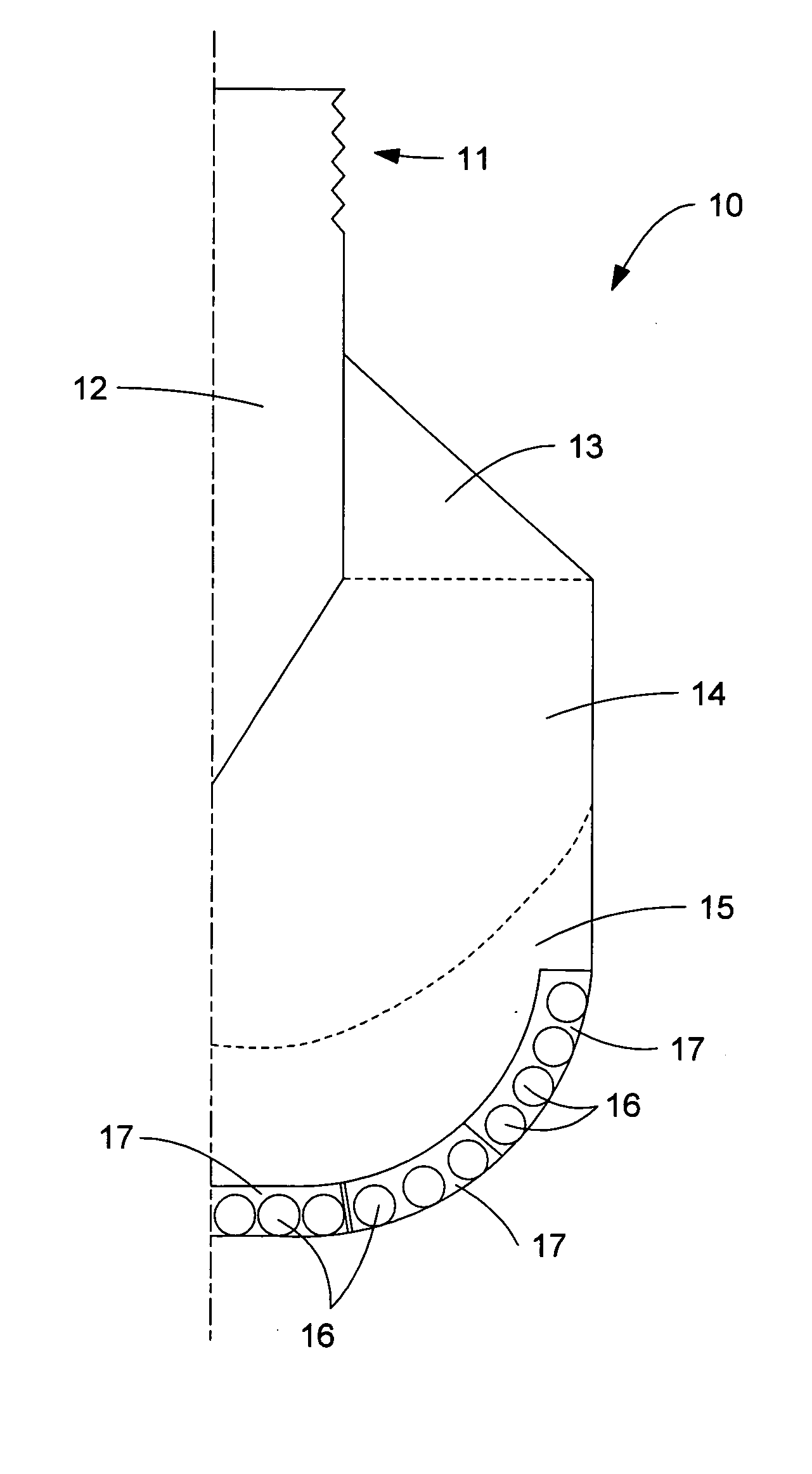

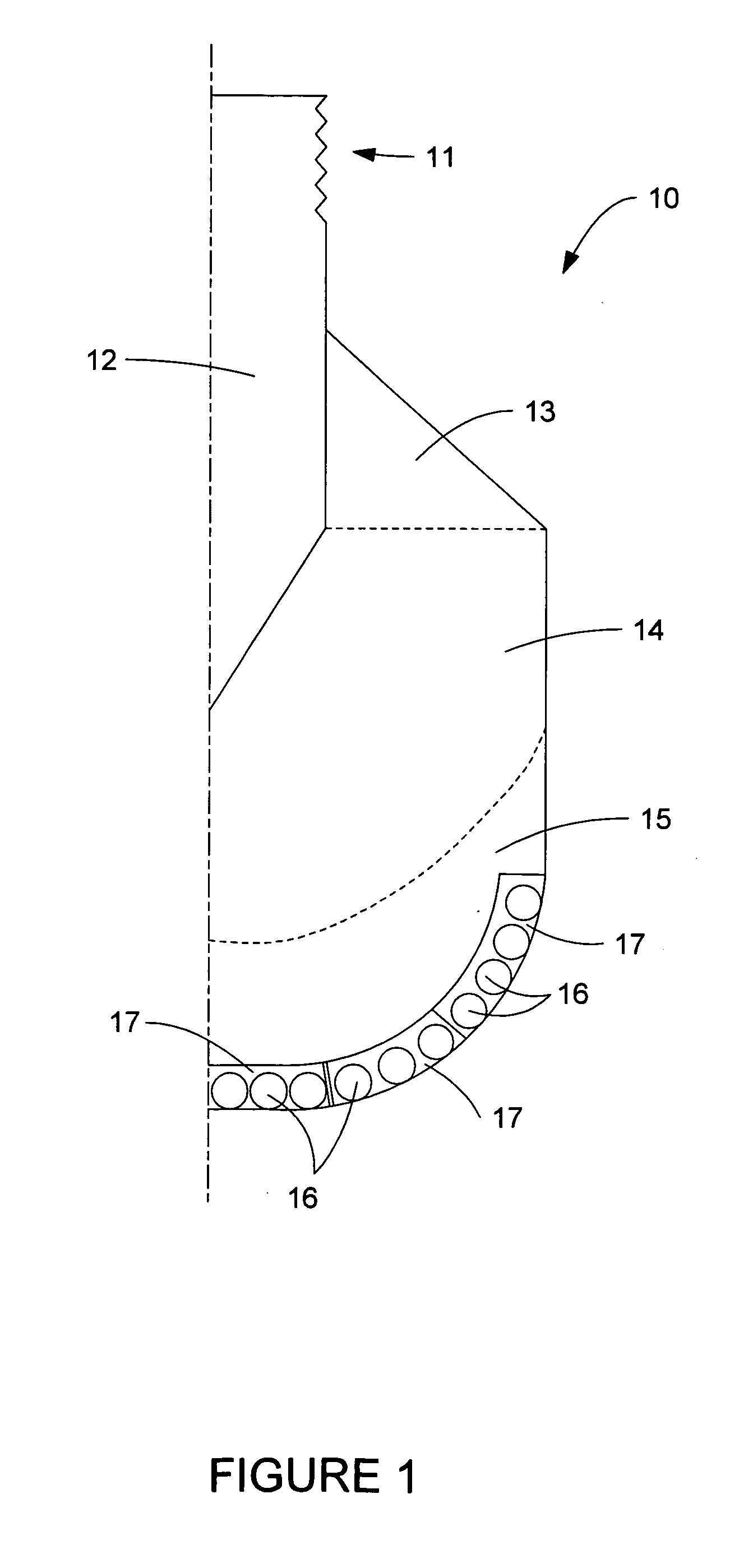

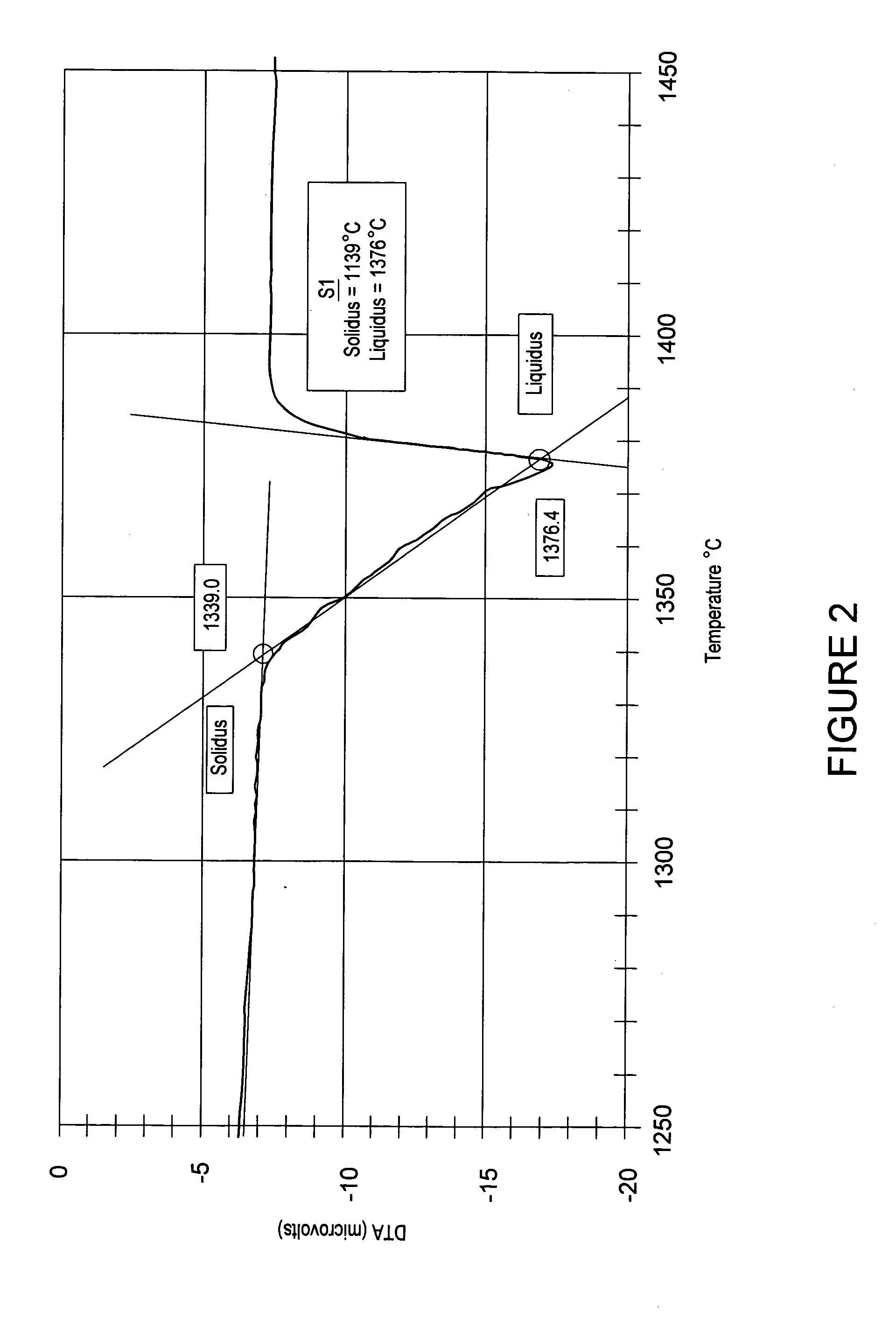

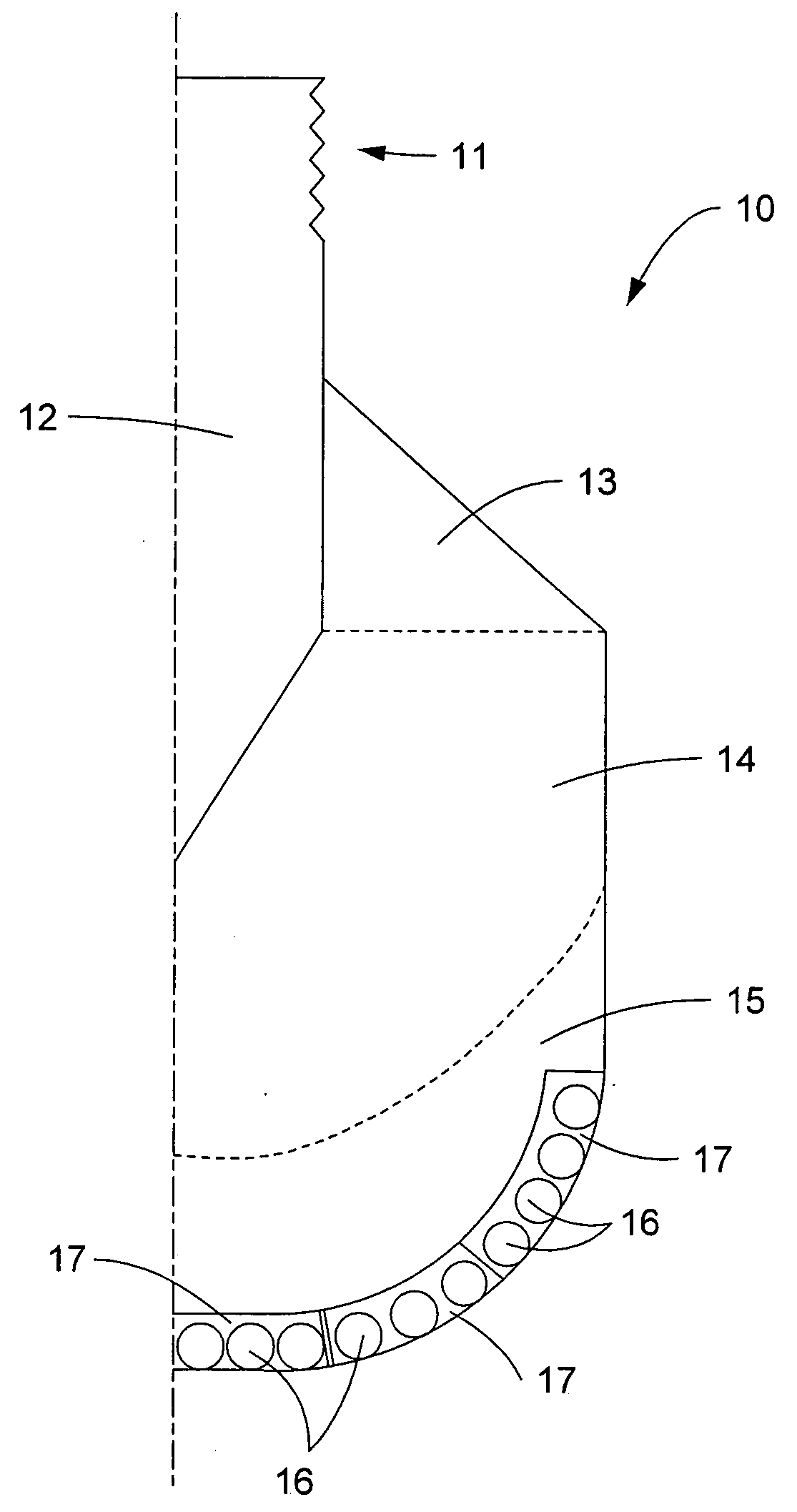

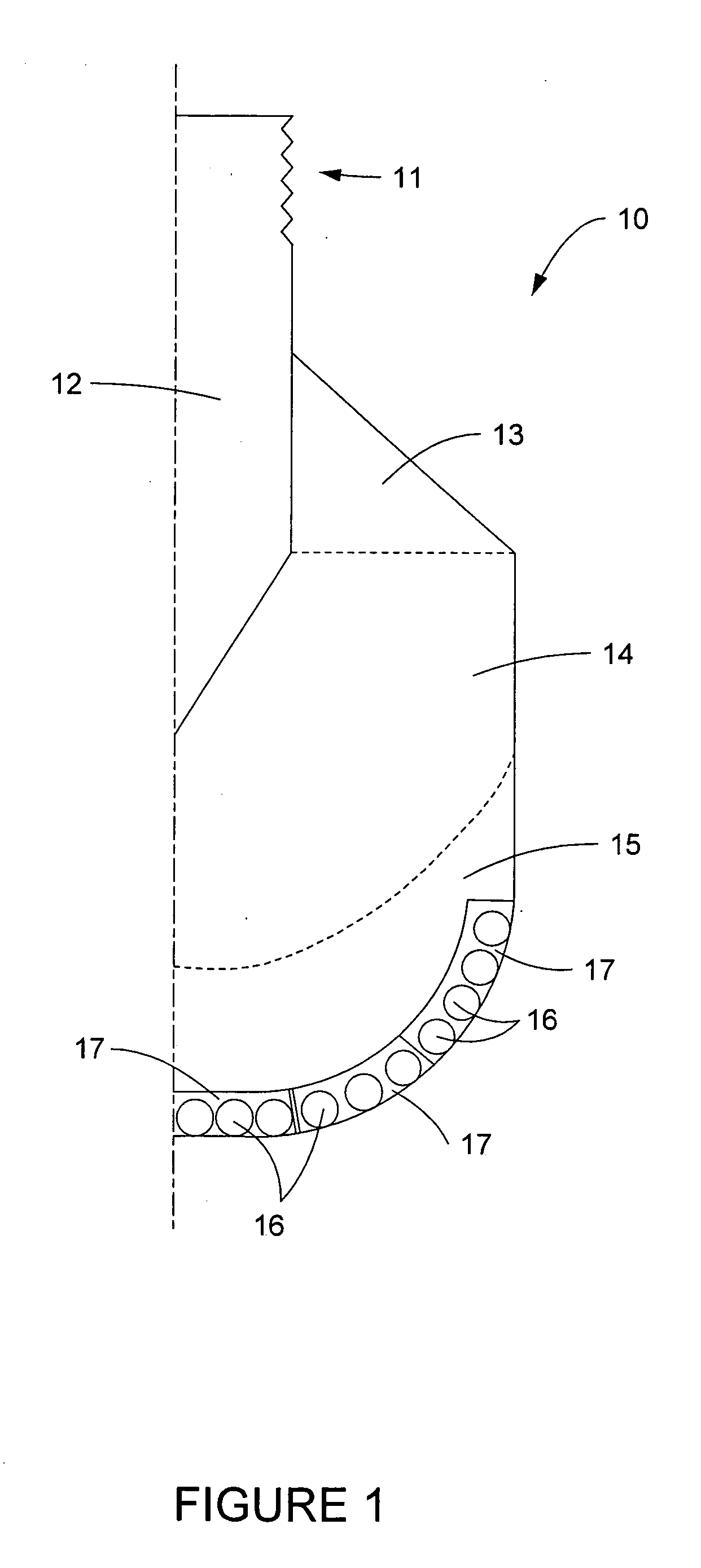

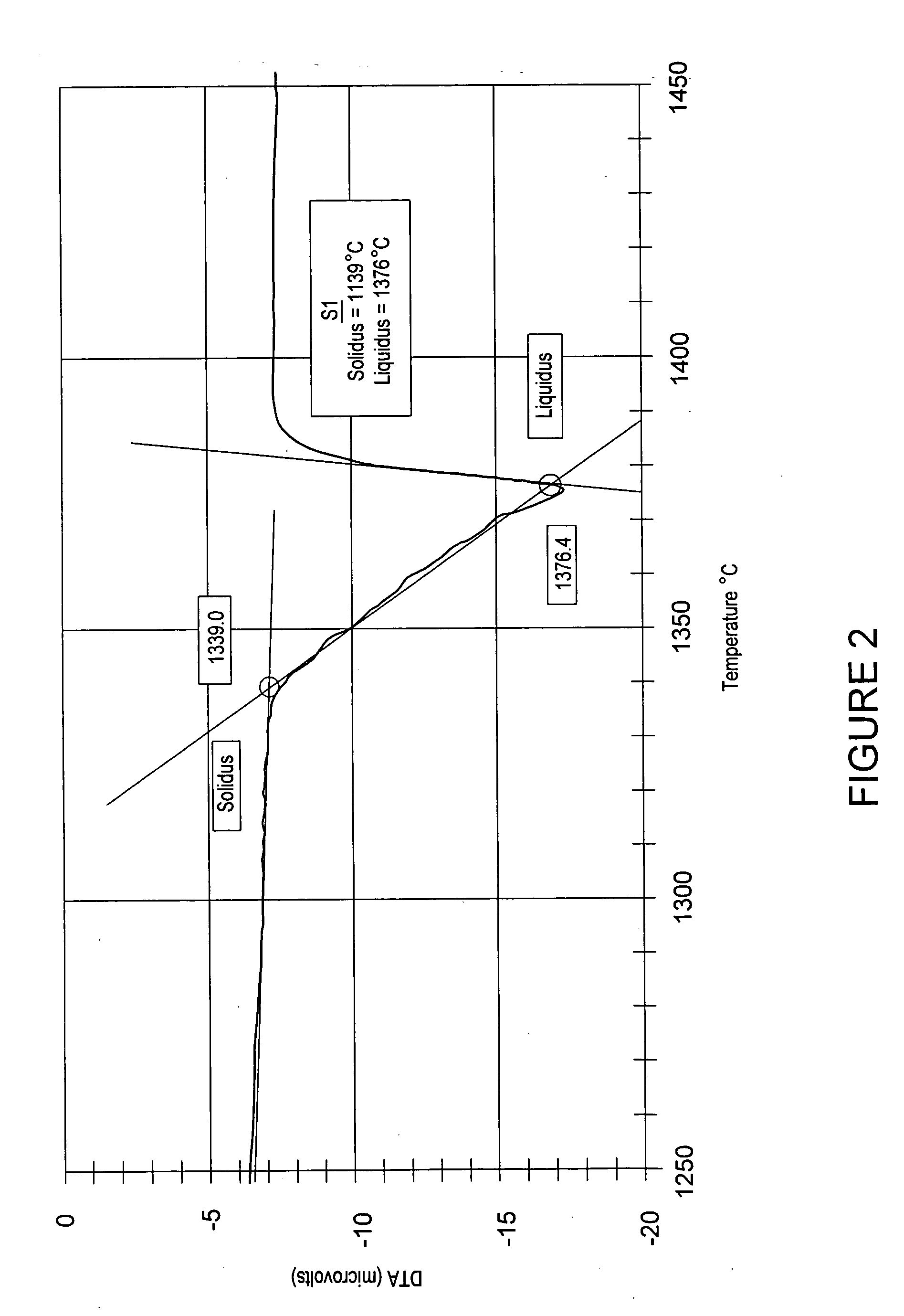

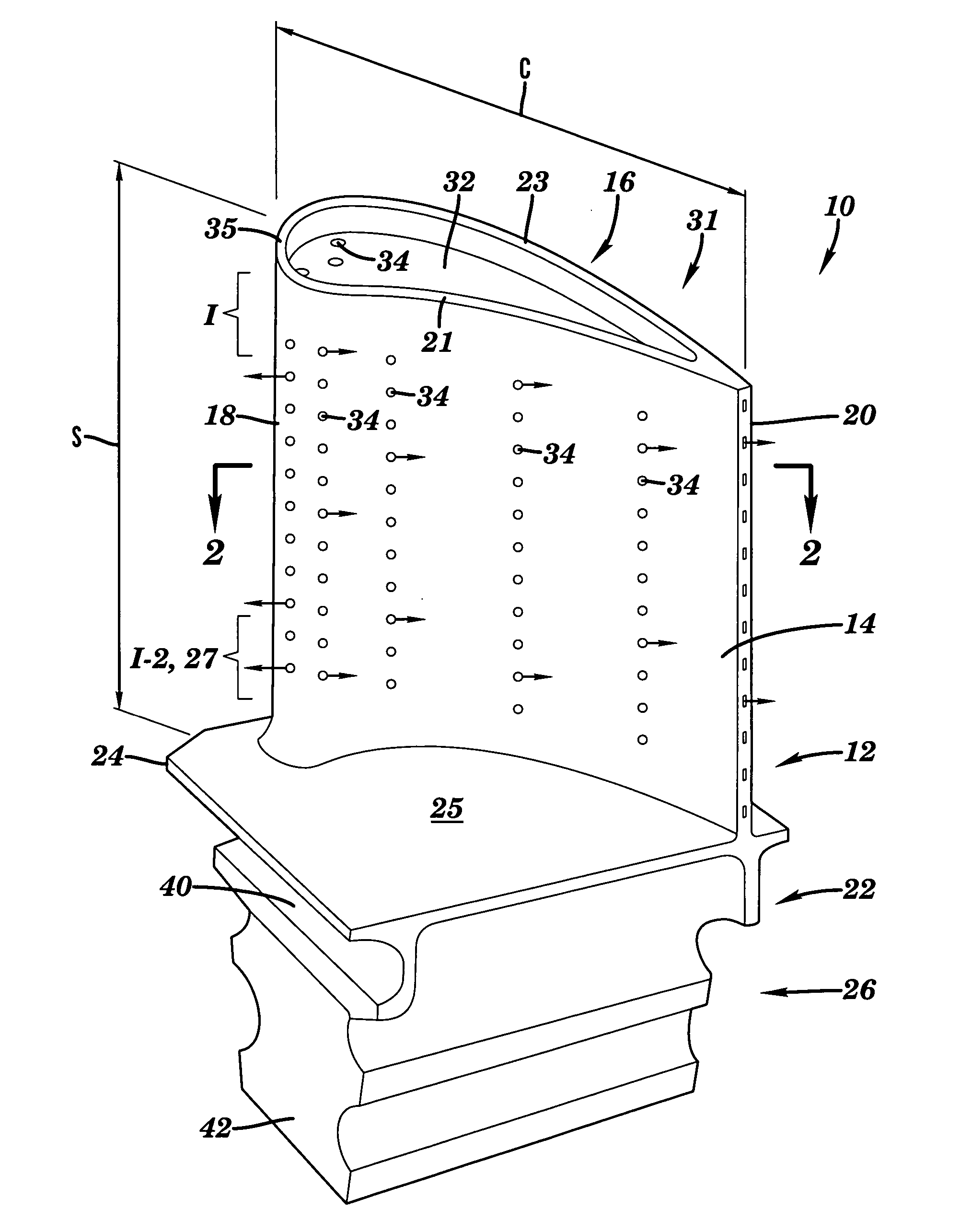

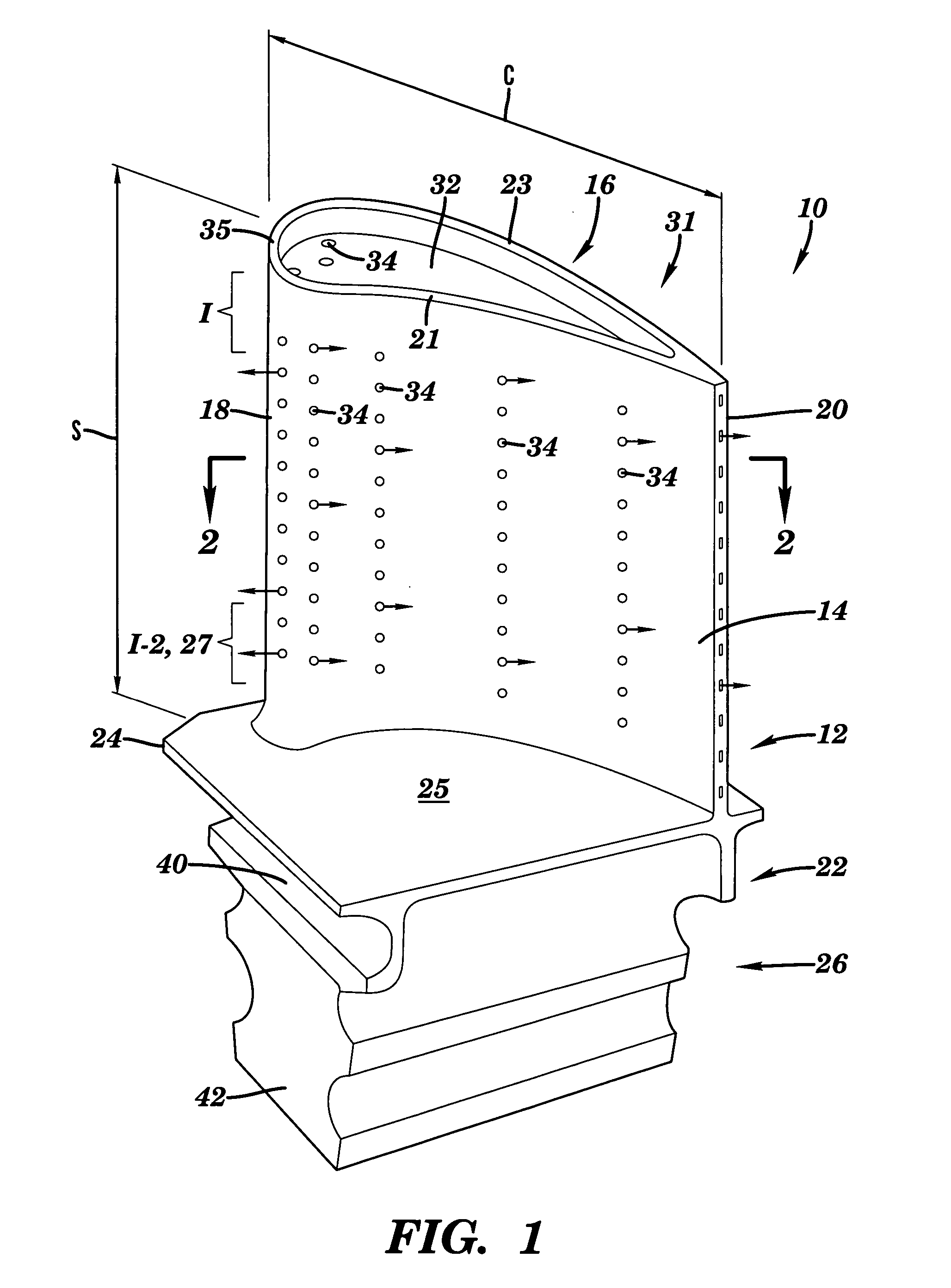

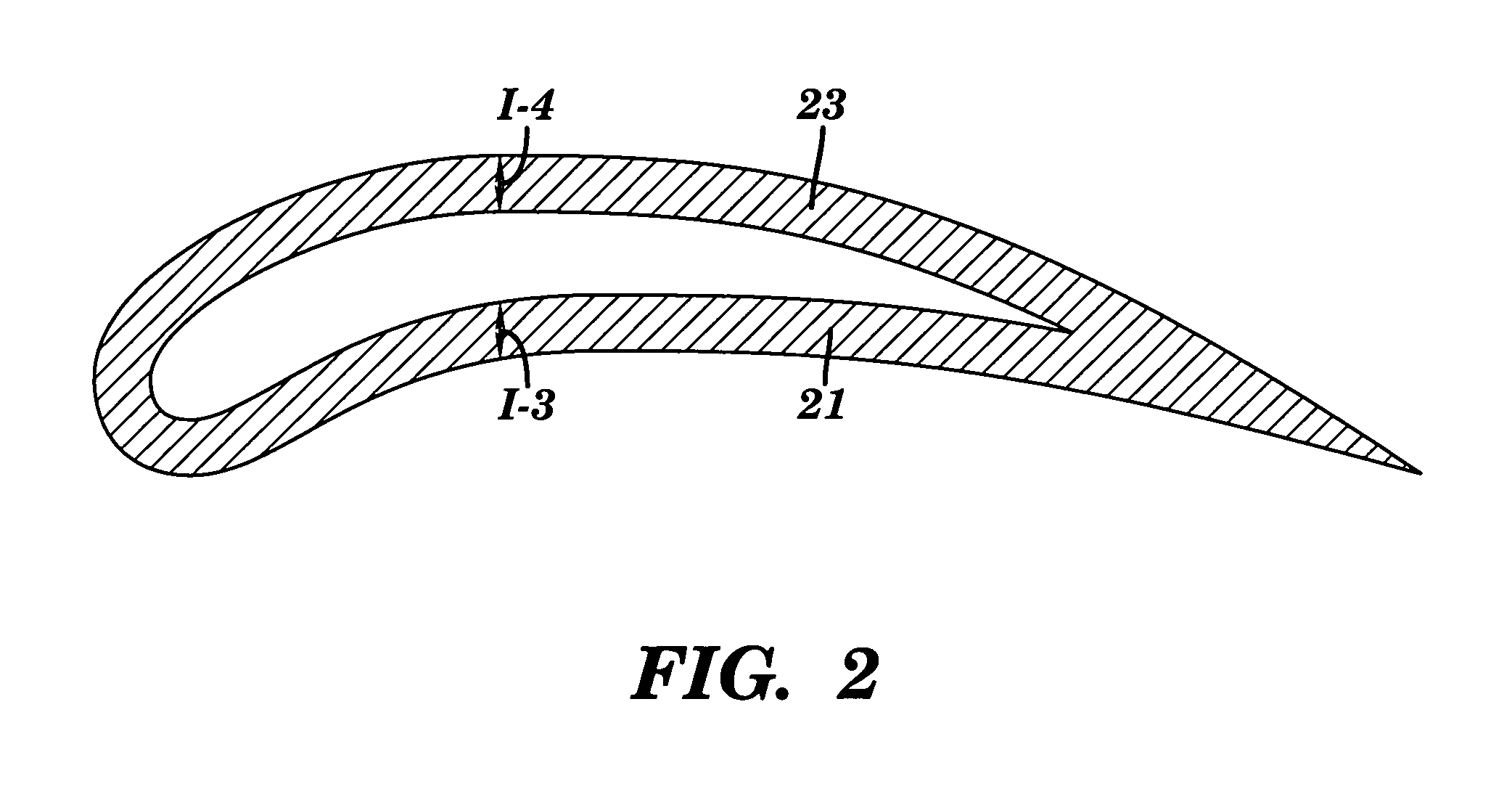

Niobium silicide-based turbine components, and related methods for laser deposition

A turbine component formed from a niobium silicide-based composition is described. The component can be compositionally-graded through at least a portion of its structure. A turbine blade formed from a composition which includes a niobium silicide alloy is also described. The blade includes an airfoil; an airfoil tip region; a platform on which the airfoil is mounted; and a dovetail root attached to an underside of the platform. The niobium silicide alloy in at least one portion of the turbine blade is compositionally different from the niobium silicide alloy in another portion of the blade. Processes for fabricating a niobium silicide-based turbine article are also described, using laser cladding techniques. Repair methods are also set forth in the application.

Owner:GENERAL ELECTRIC CO

High manganese containing steels for oil, gas and petrochemical applications

Provided are high manganese containing ferrous based components and their use in oil, gas and / or petrochemical applications. In one form, the components include 5 to 40 wt % manganese, 0.01 to 3.0 wt % carbon and the balance iron. The components may optionally include one or more alloying elements chosen from chromium, nickel, cobalt, molybdenum, niobium, copper, titanium, vanadium, nitrogen, boron and combinations thereof.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com