Patents

Literature

57 results about "Tantalum boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum borides are compounds of tantalum and boron most remarkable for their extreme hardness.

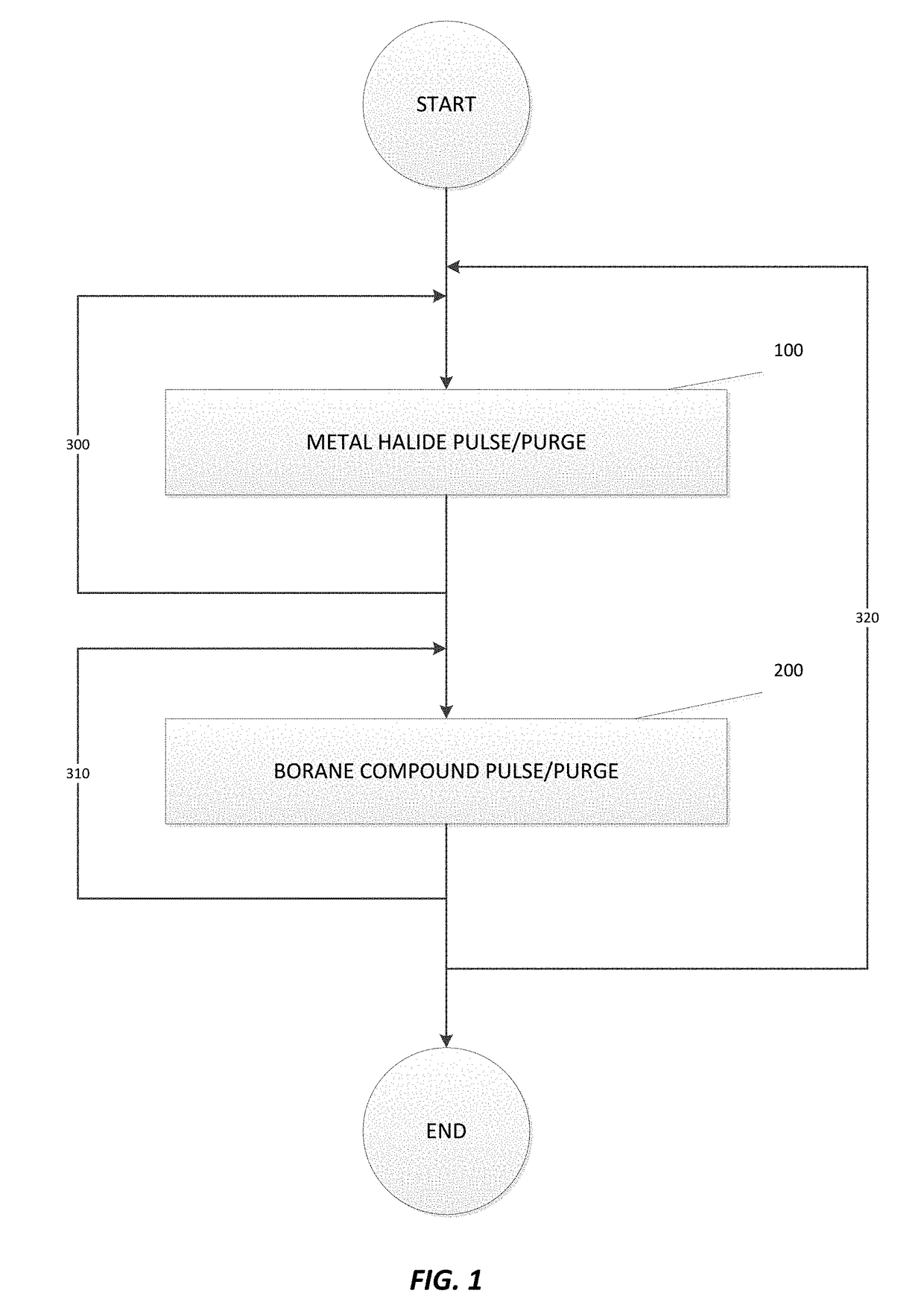

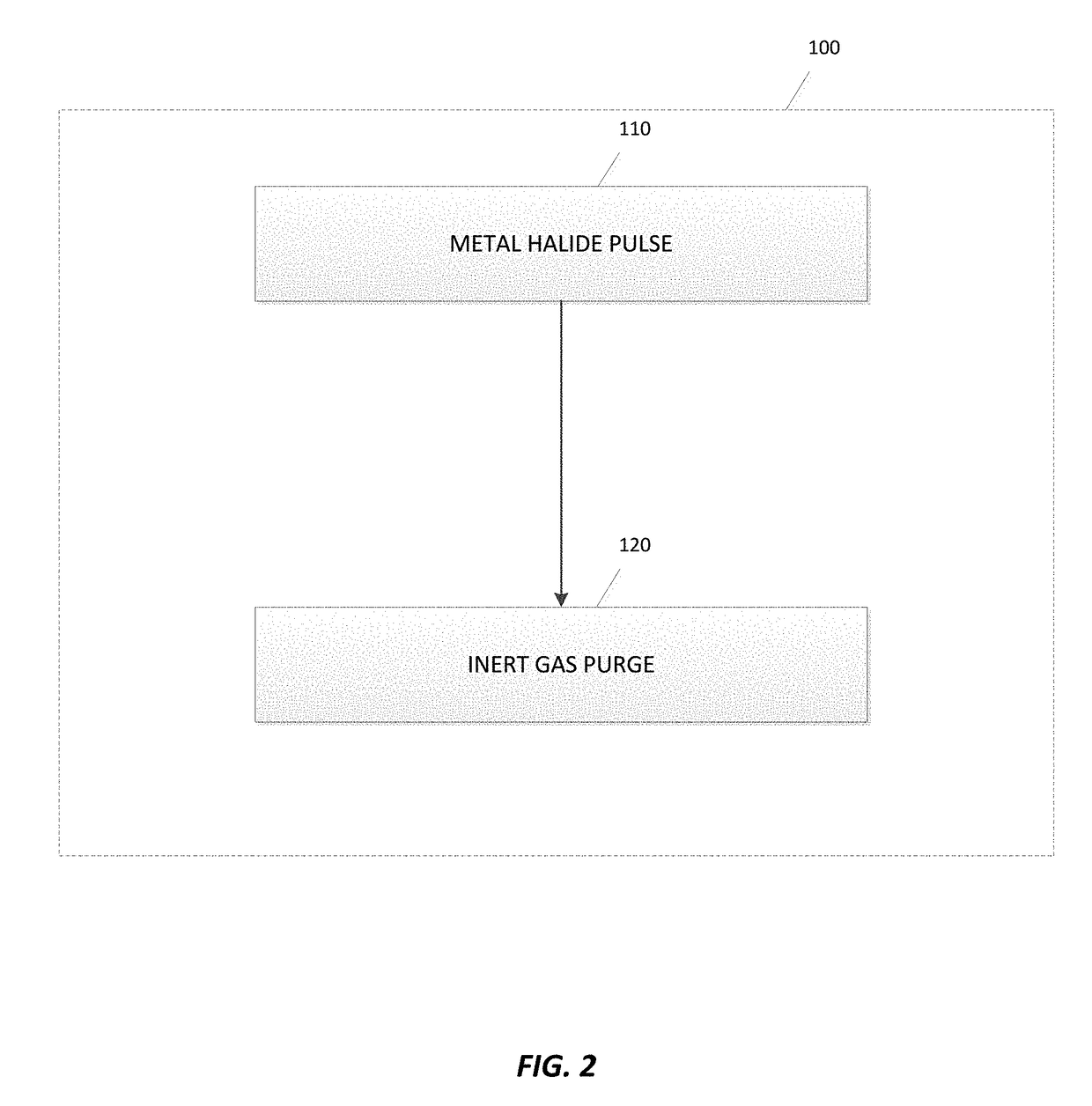

Deposition of metal borides

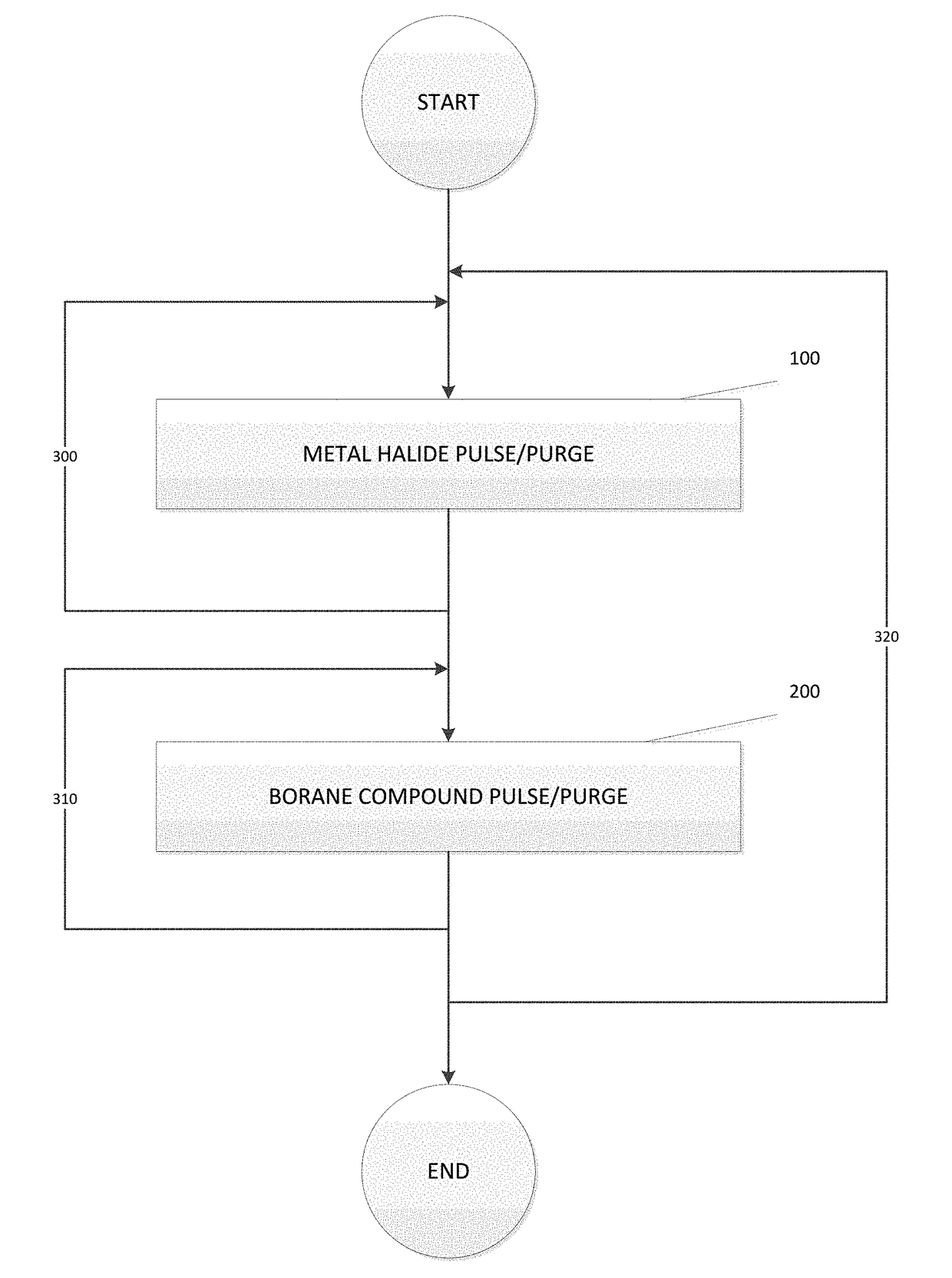

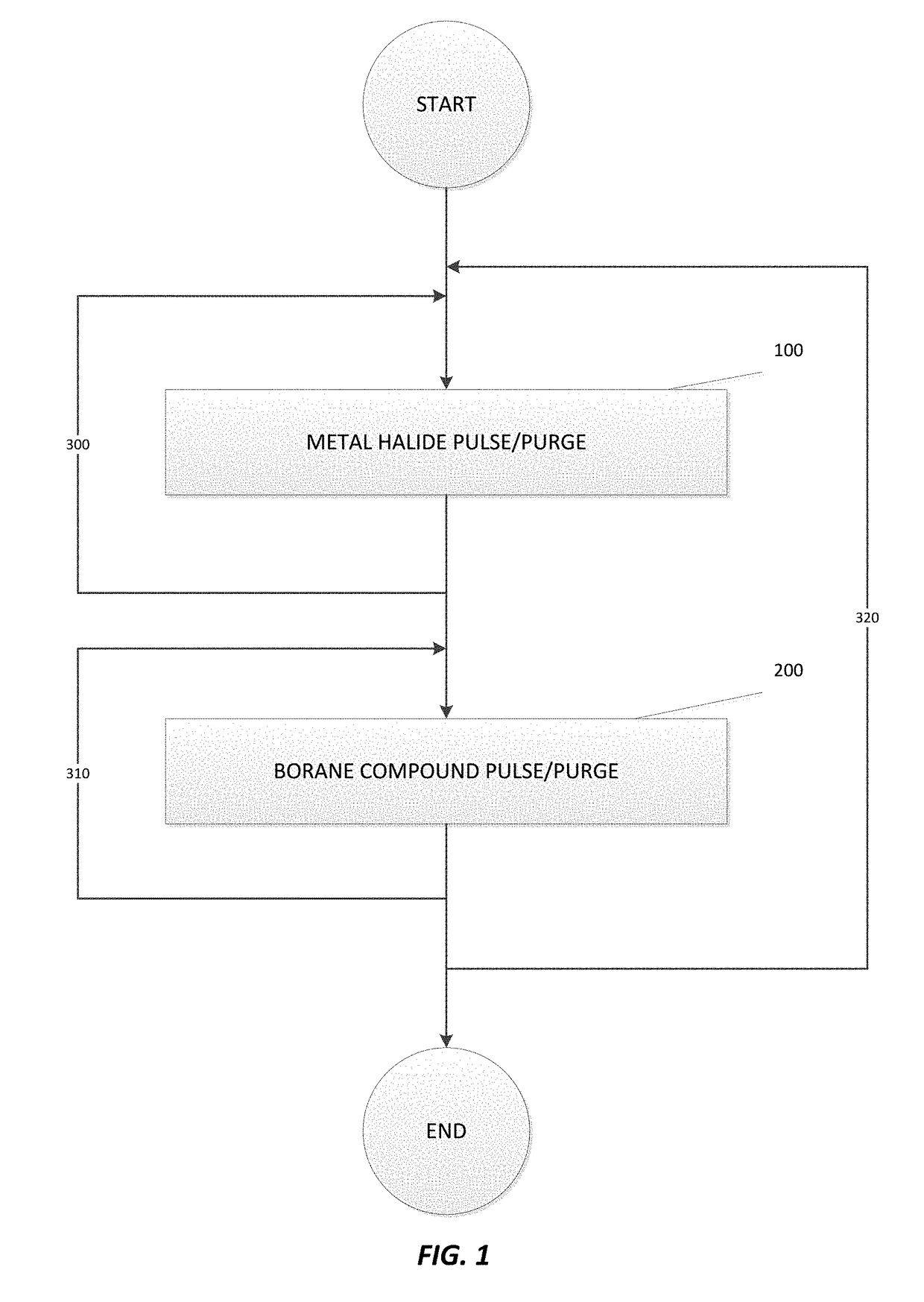

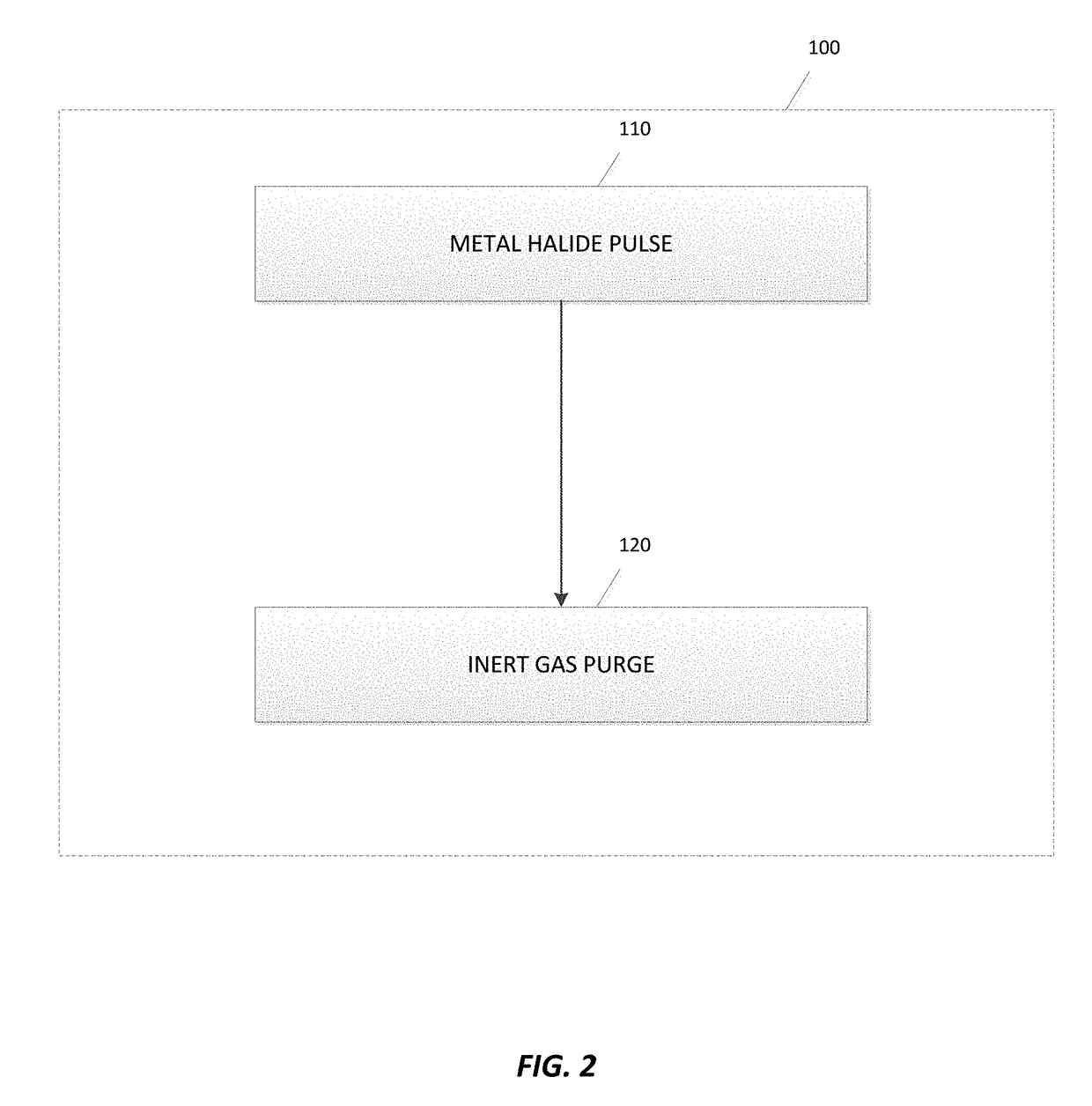

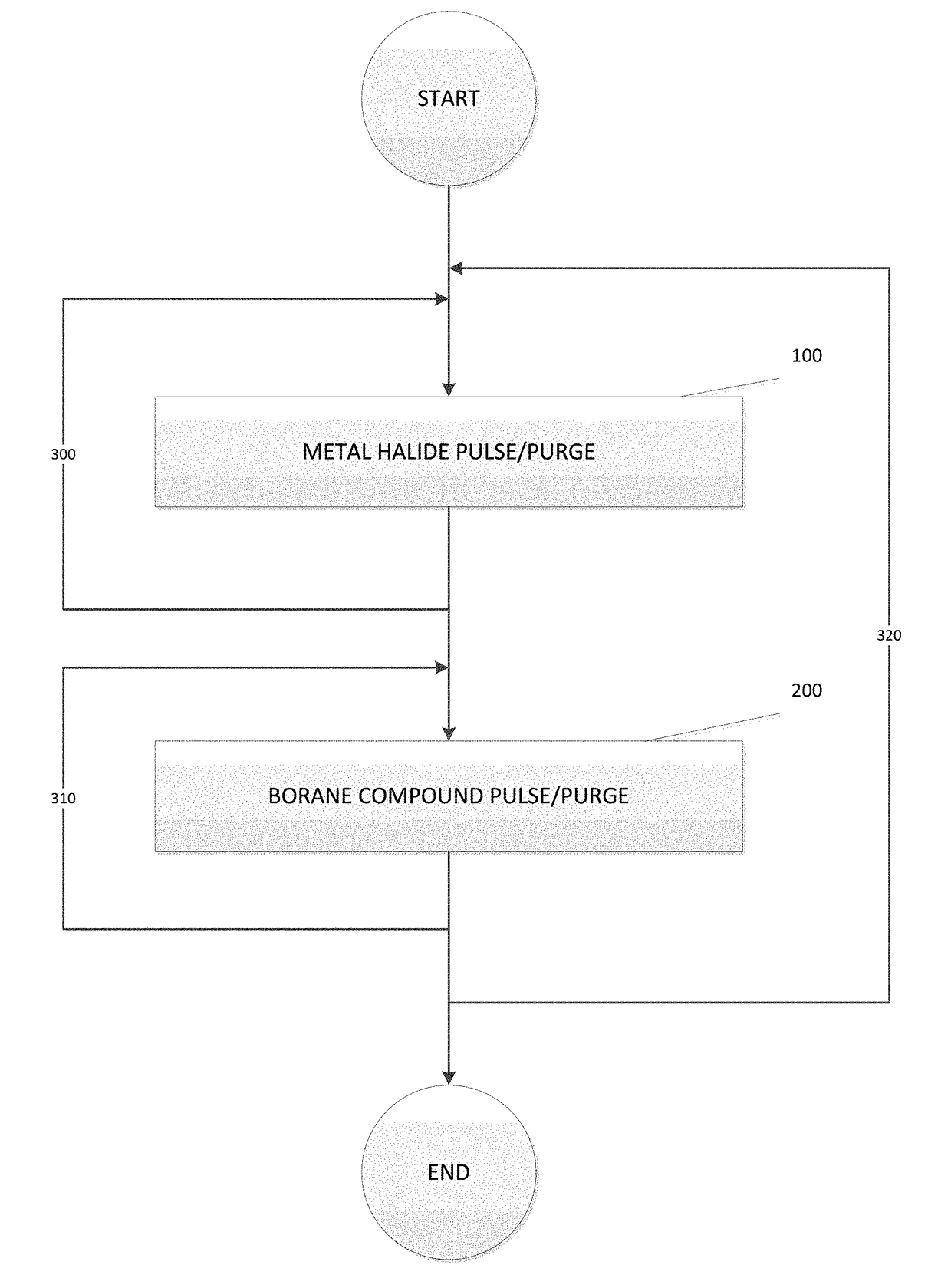

A method for depositing a metal boride film onto a substrate is disclosed. In particular, the method comprises pulsing a metal halide precursor onto the substrate and pulsing a boron compound precursor onto the substrate. A reaction between the metal halide precursor and the boron compound precursor forms a metal boride film. Specifically, the method discloses forming a tantalum boride (TaB2) or a niobium boride (NbB2) film.

Owner:ASM IP HLDG BV

Deposition of metal borides

A method for depositing a metal boride film onto a substrate is disclosed. In particular, the method comprises pulsing a metal halide precursor onto the substrate and pulsing a boron compound precursor onto the substrate. A reaction between the metal halide precursor and the boron compound precursor forms a metal boride film. Specifically, the method discloses forming a tantalum boride (TaB2) or a niobium boride (NbB2) film.

Owner:ASM IP HLDG BV

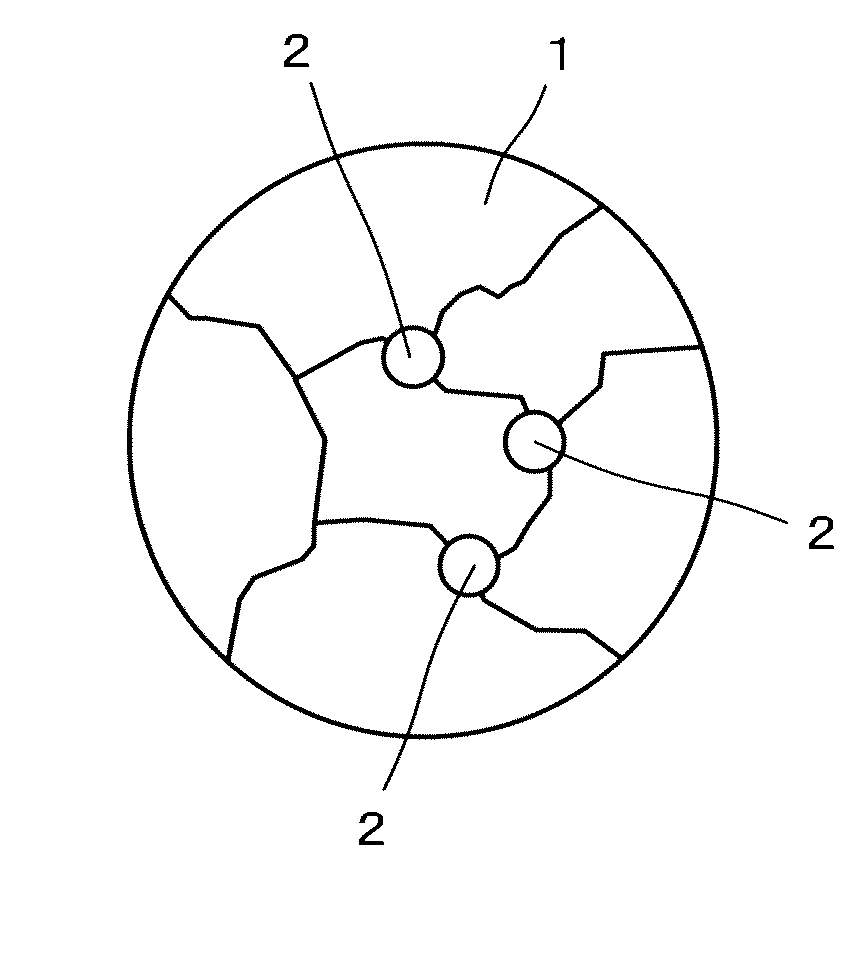

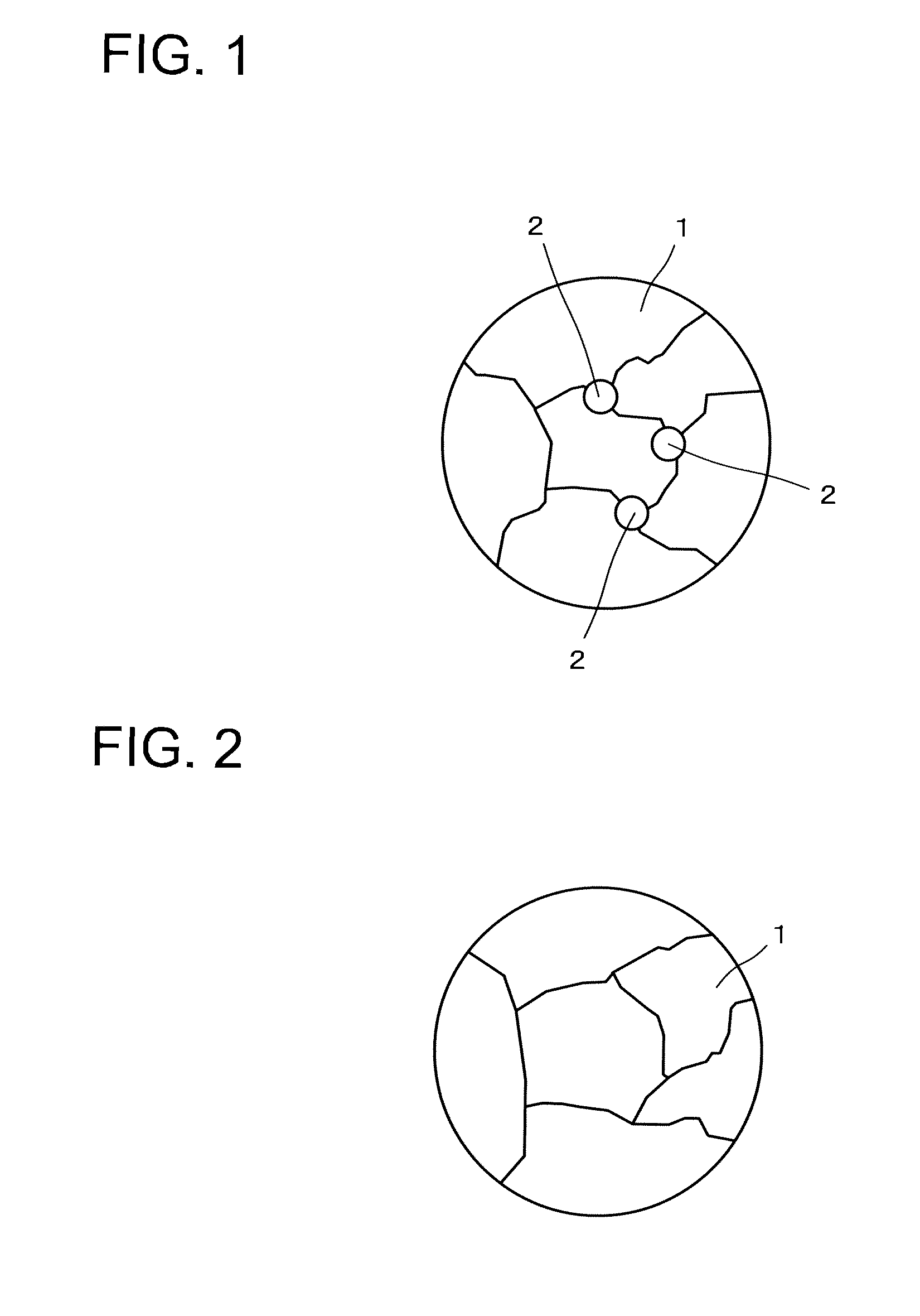

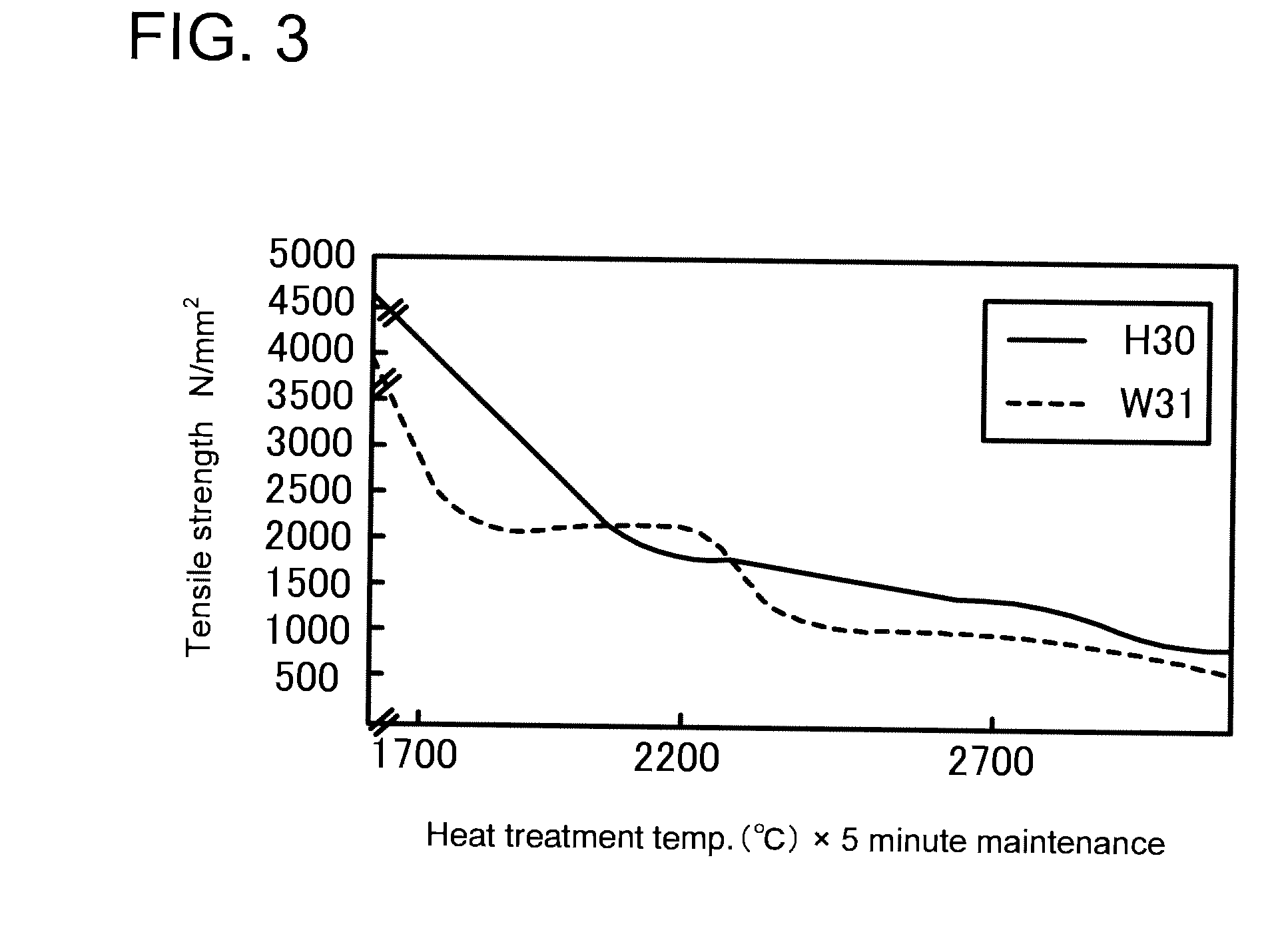

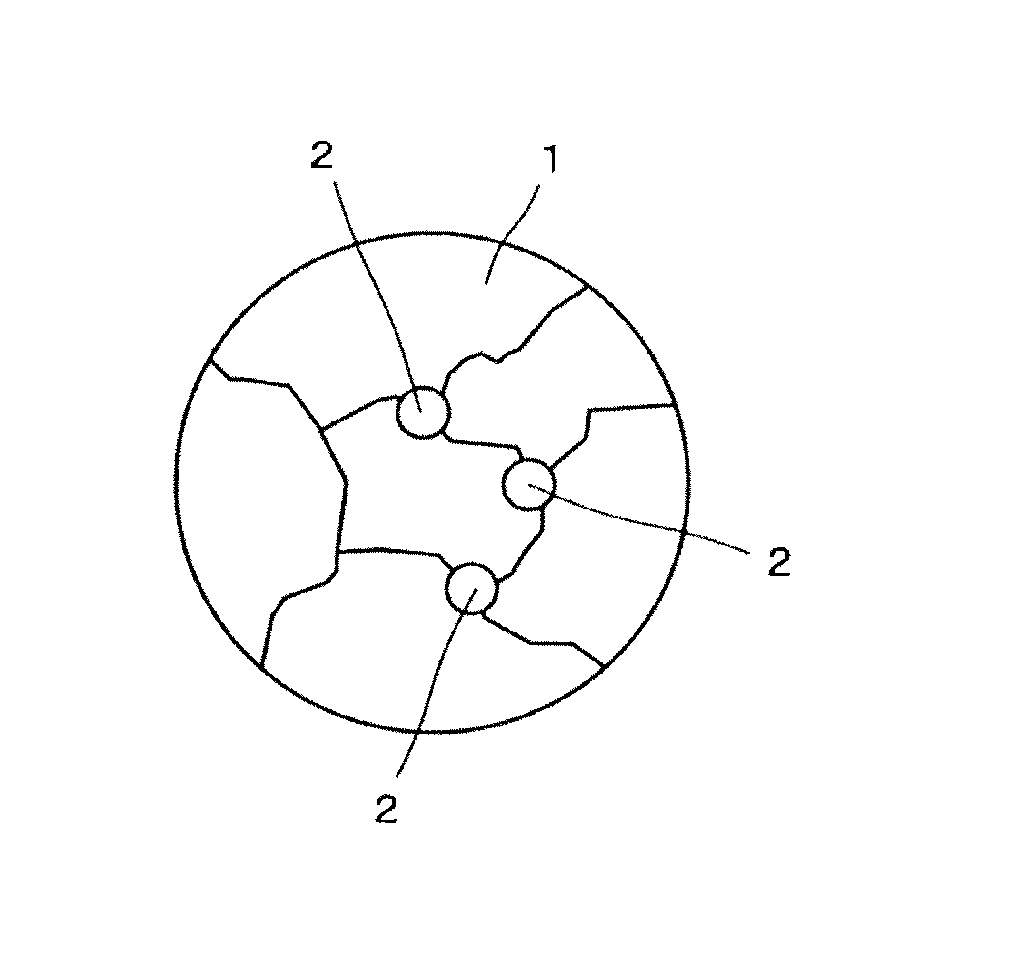

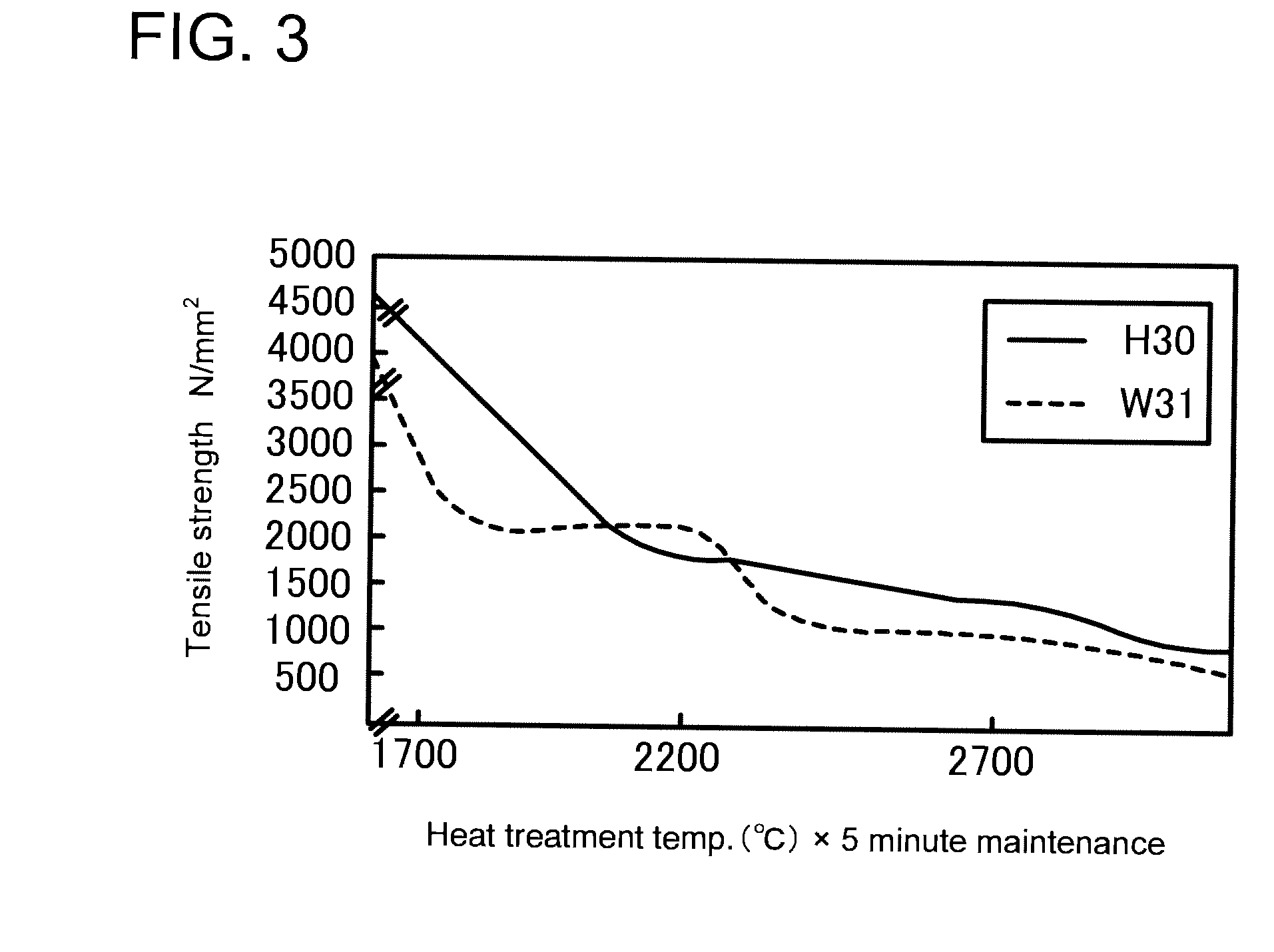

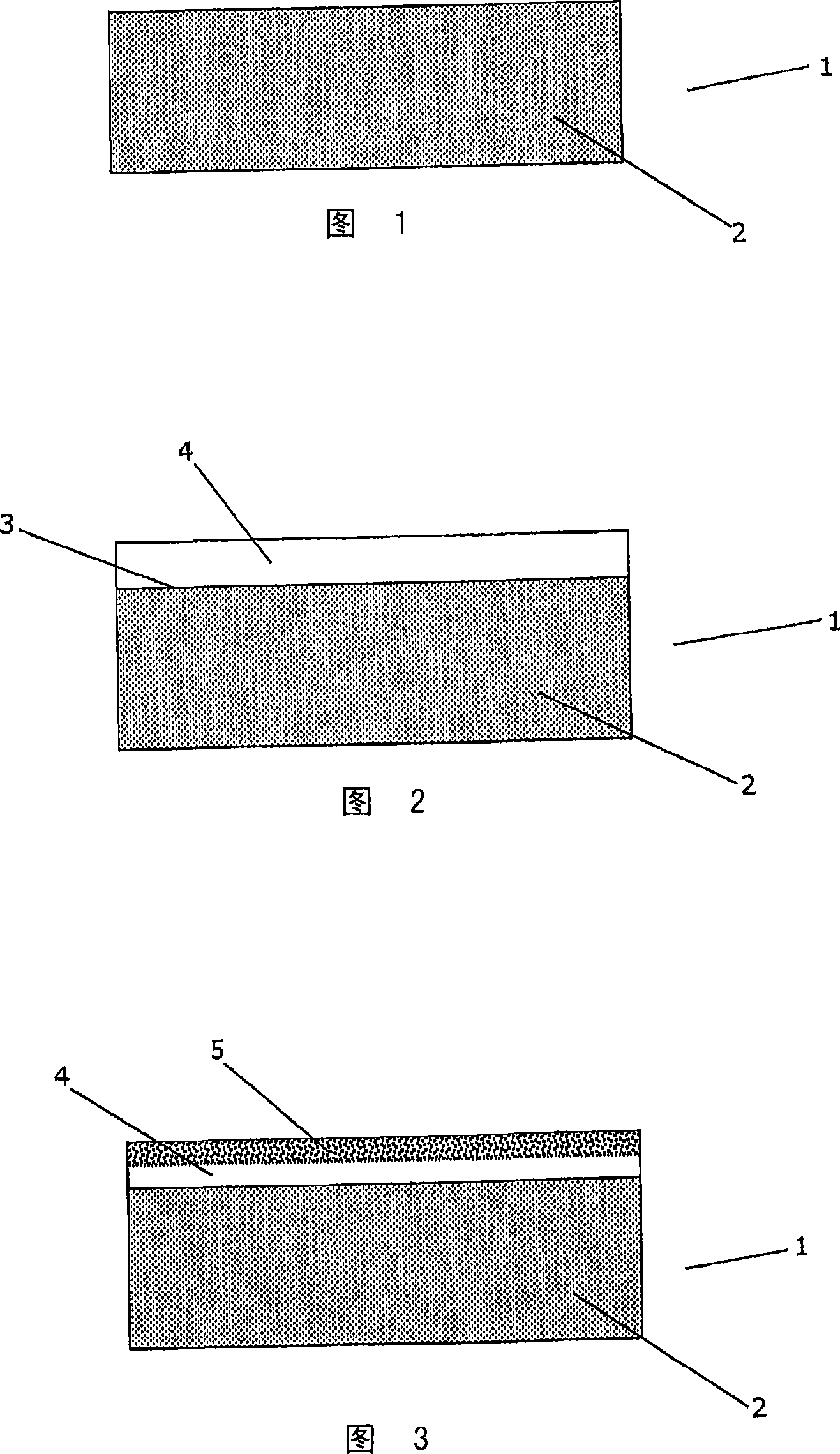

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

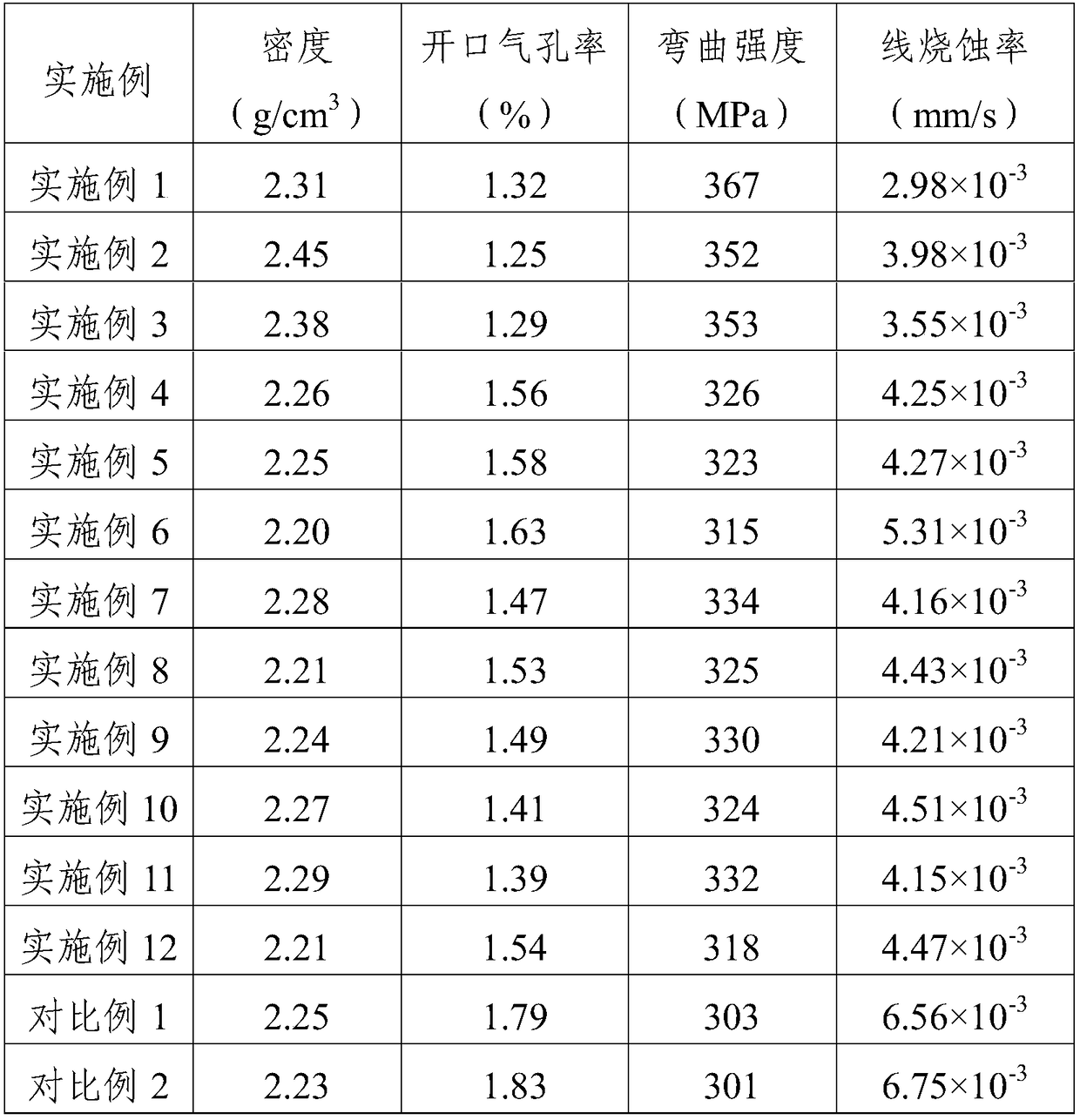

Carbon fiber enhanced hafnium boride-tantalum boride-carbon ceramic-based composite material and preparation method thereof

The invention relates to a carbon fiber enhanced hafnium boride-tantalum boride-carbon ceramic-based composite material and a preparation method thereof. The method comprises the following steps: (1)soaking carbon fiber prefabricated bodies into a tantalum hafnium precursor solution containing a tantalum hafnium precursor copolymer, a boron source precursor, a carbon source precursor and an organic solvent; then, sequentially curing and cracking the soaked carbon fiber prefabricated bodies; (2) repeating the steps (1) for many times to prepare the carbon fiber enhanced hafnium boride-tantalumboride-carbon ceramic-based composite material. The preparation method has the advantages that the process is simple; the addition of additives is not needed; the preparation temperature is low; thepreparation period is short; the industrial implementation is easy, and the like. The prepared carbon fiber enhanced hafnium boride-tantalum boride-carbon ceramic-based composite material has the advantages of high toughness, super-high-temperature resistance, excellent anti-oxidization performance, excellent ablation resistance performance and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

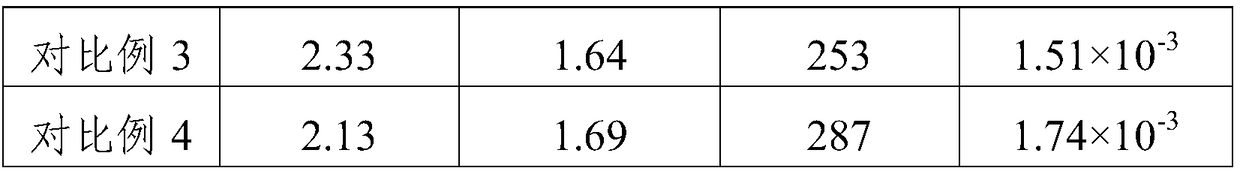

High-flame-retardant, low-smoke and halogen-free cable material and preparation method thereof

InactiveCN103351508AHigh Material Oxygen IndexImprove flame retardant performanceInsulated cablesInsulated conductorsLow-density polyethyleneBenzoic acid

The invention provides a high-flame-retardant, low-smoke and halogen-free cable material and a preparation method thereof. The material is prepared from the following raw material by weight parts: 60-67 parts of low-density polyethylene, 3-4 parts of magnesium hydroxide, 25-28 parts of montmorillonite, 2-3 parts of zinc borate, 3-4 parts of a silane coupling agent KH 550, 1-2 parts of ferriferrous oxide, 3-4 parts of tantalum boride, 1-2 parts of tantalum diboride, 1-2 parts of tert-butyl benzoic acid, 2-3 parts of triphenyl phosphate, 2-3 parts of ferrocene, 2-3 parts of gamma-methacryloxy propyl trimethoxy silane, 4-6 parts of polyvinyl acetate, 2-3 parts of dibutyltin dilaurate, 1-2 parts of cyanuric acid zinc, 1-2 parts of zinc oxide, 3-4 parts of soybean oil, 16-18 parts of aluminium hydroxide, 25-29 parts of attapulgite, 1-2 parts of a promoter DTDM, 1-2 parts of a antioxidant MB, 1-2 parts of an anti-scorching agent CTP, 12-14 parts of carbon black N220, 8-10 parts of carbon black N 660 and 6-8 parts of modified diatomite. According to the invention, the zinc borate and the aluminium hydroxide are combined as the flame retardant, thereby improving performances of flame retardation. The method is simple in technology and convenient to produce; the produced cable materials are high in oxygen index, that is, being higher than 40, and excellent in fire resistance. A vertical flame class experiment of the material reaches a supreme grade, that is, FV-0 grade, and a smoke density of the material is lower than that of other similar products.

Owner:ANHUI CABLE

Environmentally friendly inflaming retarding type PVC cable material and preparation method thereof

InactiveCN103724871AHigh tensile strengthImprove heat resistancePlastic/resin/waxes insulatorsEnvironmental resistanceMicrocrystalline wax

The invention discloses an environmentally friendly inflaming retarding type PVC cable material which is characterized by comprising the following raw materials in parts by weight: 34-38 parts of PVC, 5-9 parts of chlorcosane, 4-6 parts of epoxidized soybean oil, 5-8 parts of antimonous oxide, 12-15 parts of aluminium hydroxide, 4-5 parts of zinc borate, 12-14 parts of polyphenylenesulfide, 4-6 parts of poly(4-methyl-1-pentene),12-16 parts of bentonite, 3-4 parts of tantalum boride, 1-2 parts of 4-tert-Butylbenzoic acid, 10-15 parts of magnesium oxide, 5-8 parts of microcrystalline wax, 1-2 parts of an antioxygen 1010 and 6-8 parts of an addition agent. The environmentally friendly inflaming retarding type PVC cable material is high in tensile strength, has favorable heat resistance, ageing resistance and fire resistance, does not produce toxic gas in case of fire, and is low in production cost.

Owner:WUHU JIACHENG ELECTRONICS TECH

Methods of repairing a substrate

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium boride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

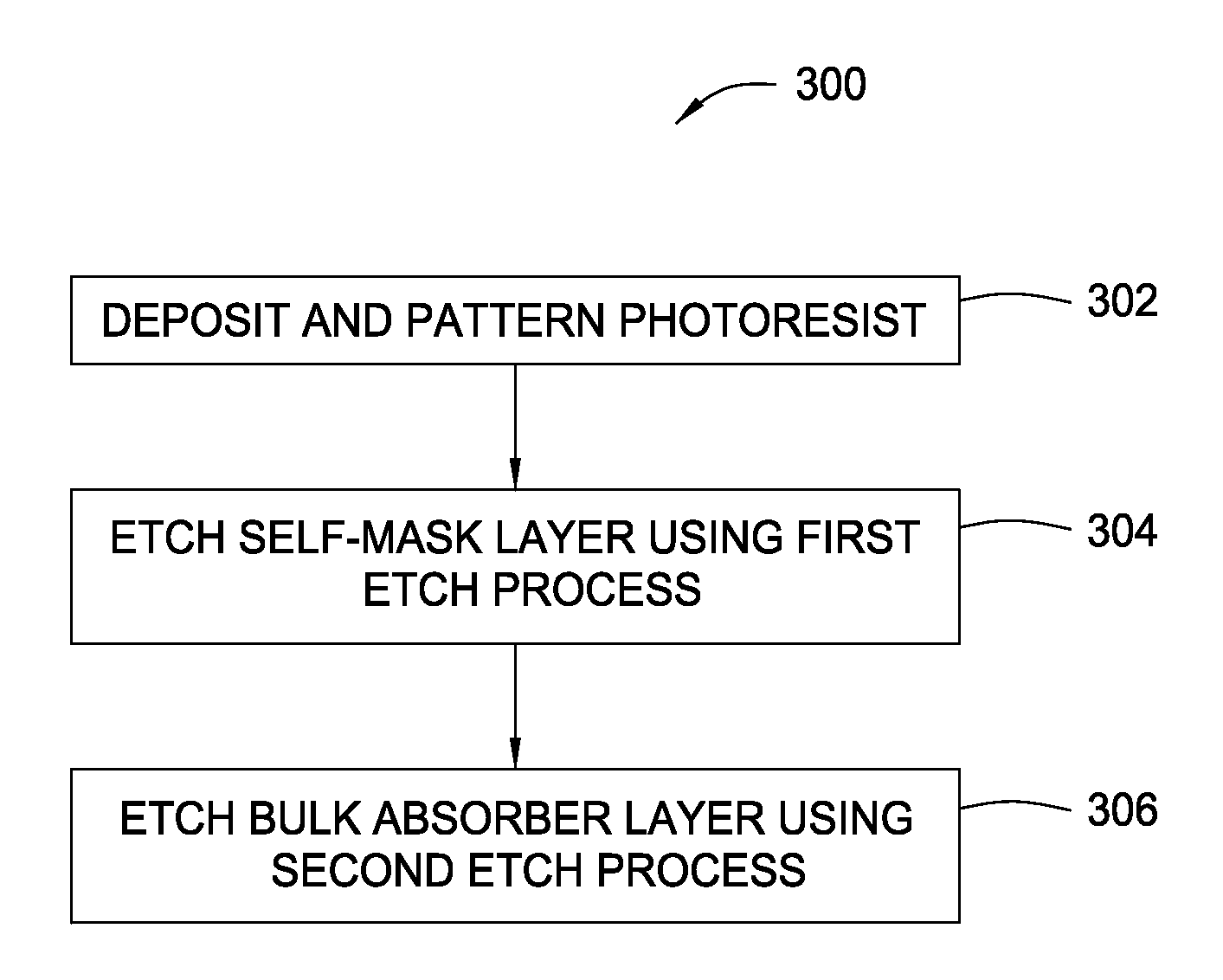

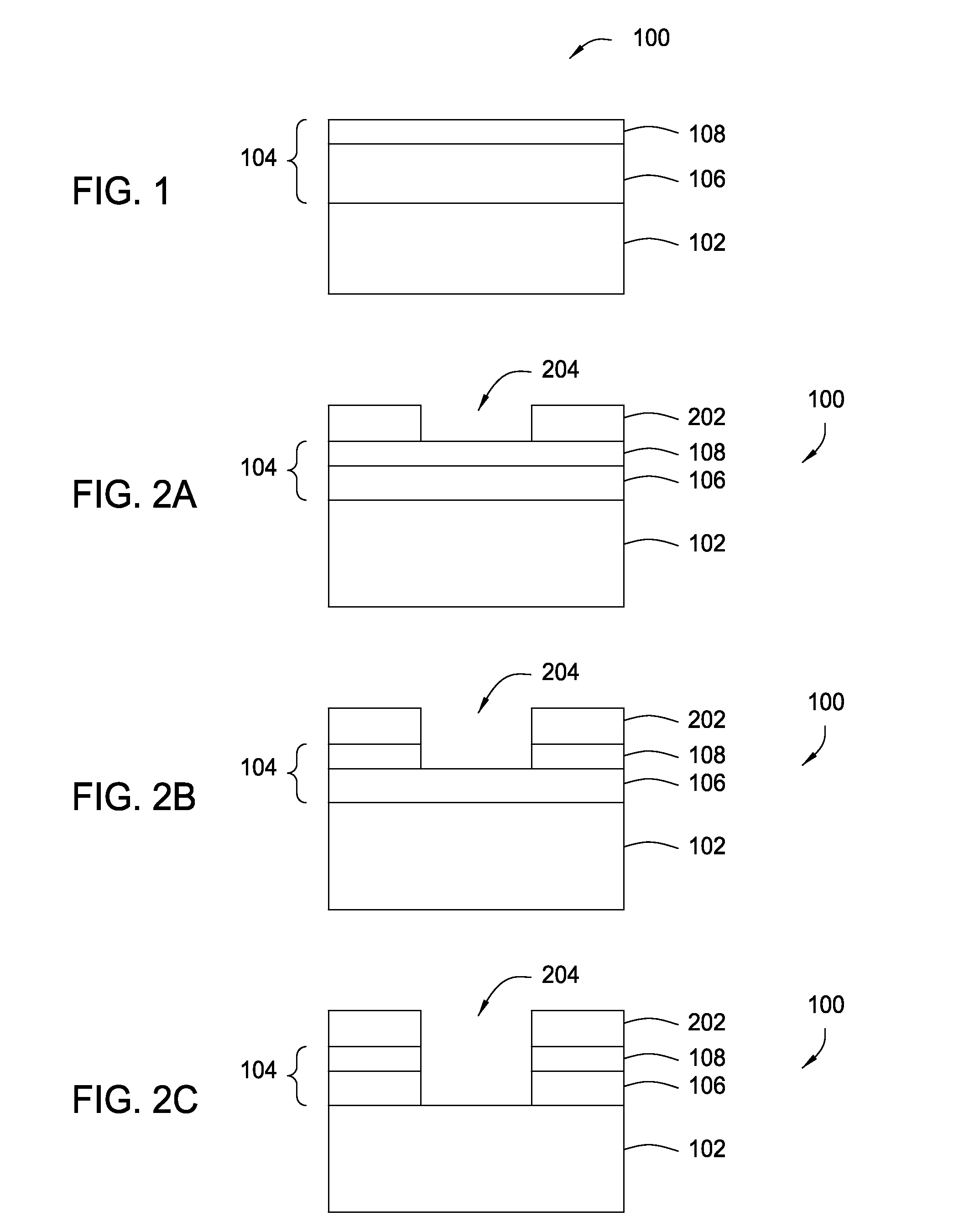

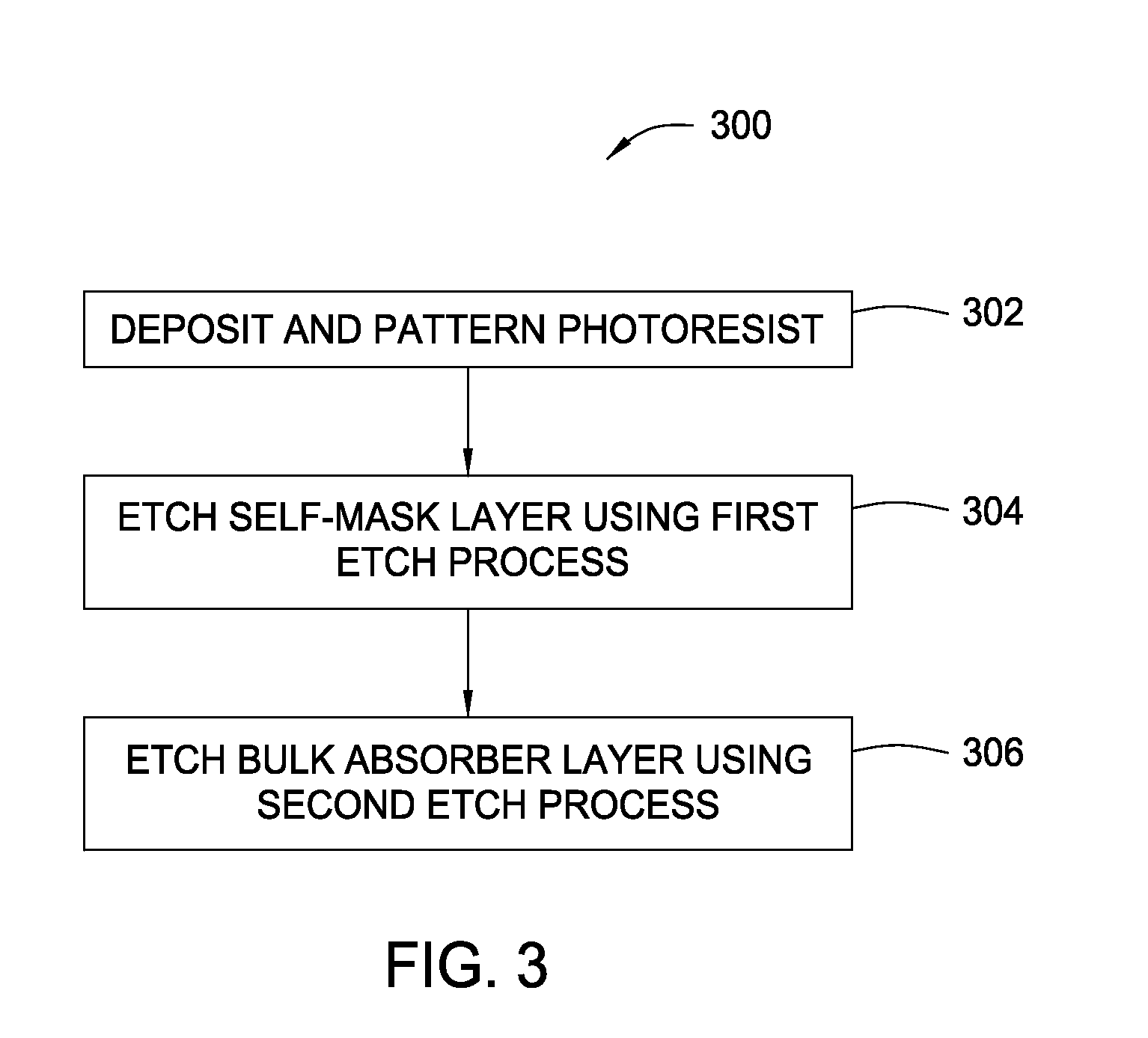

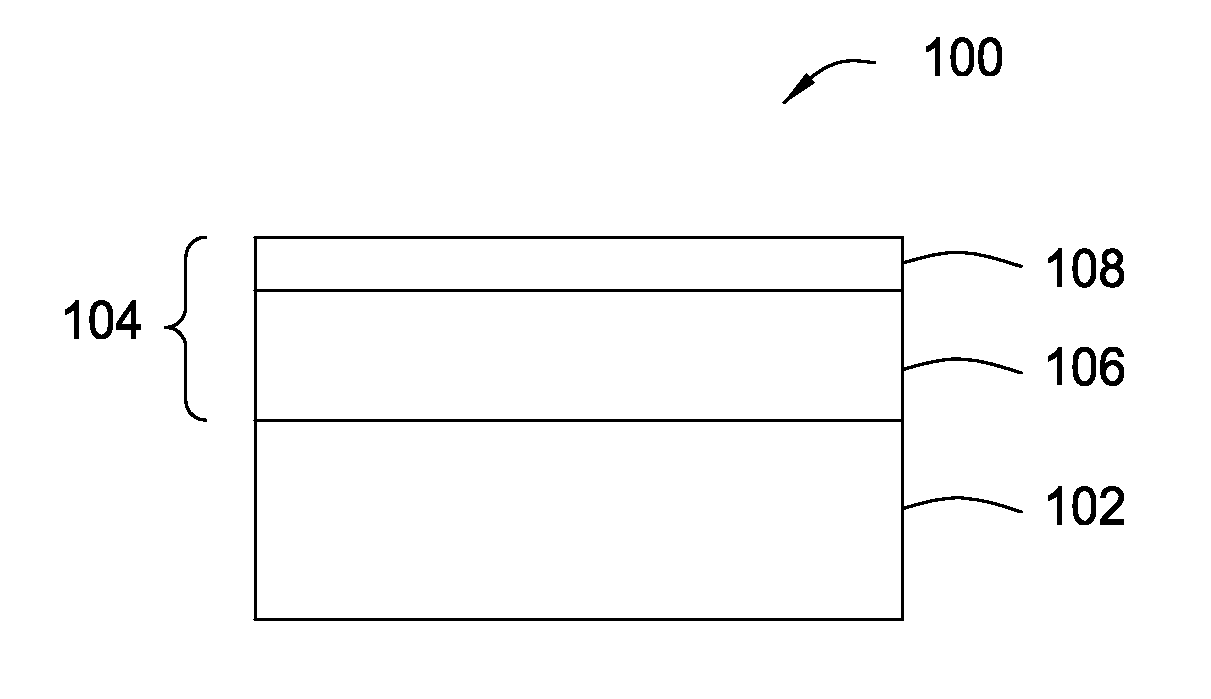

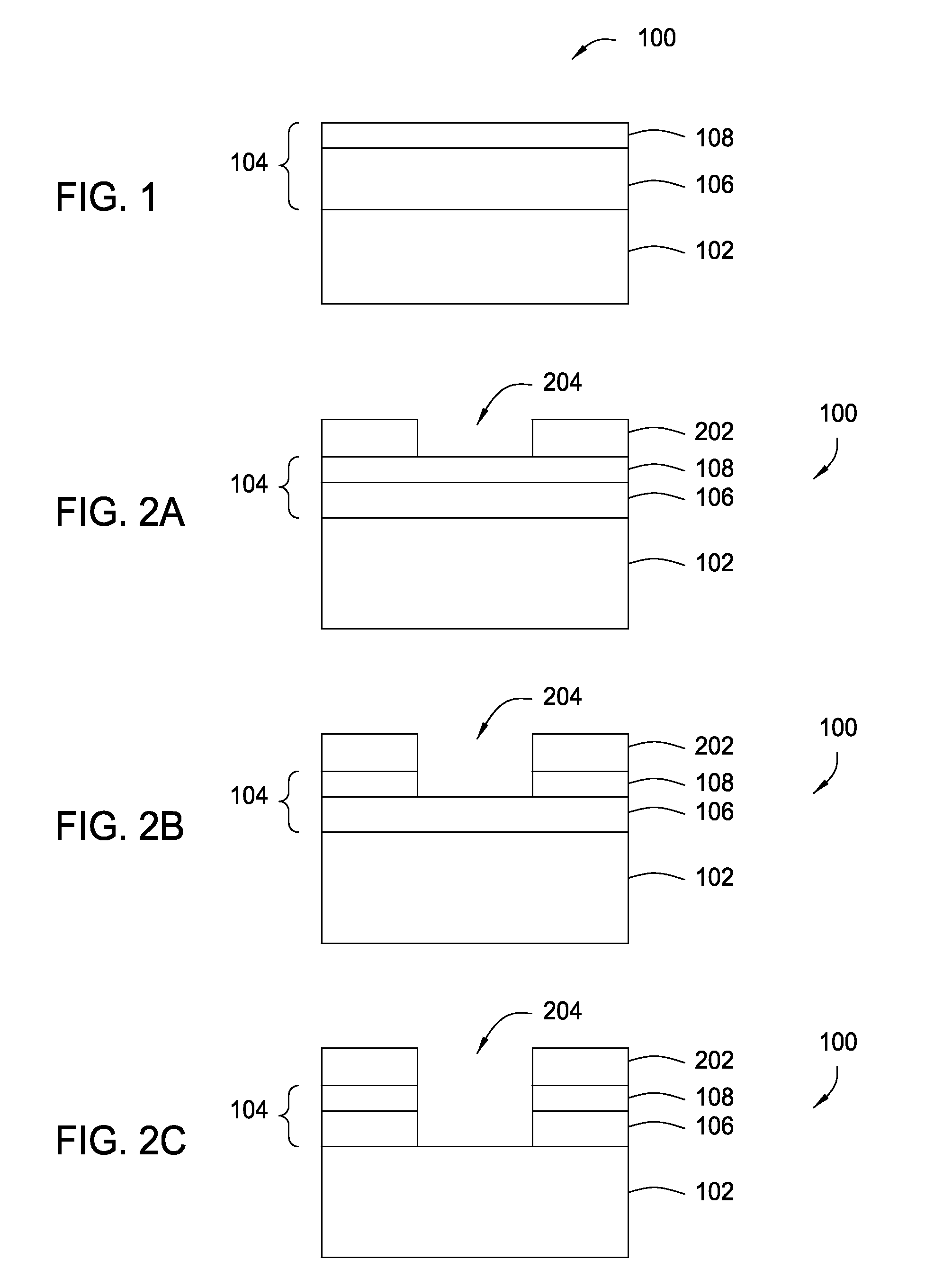

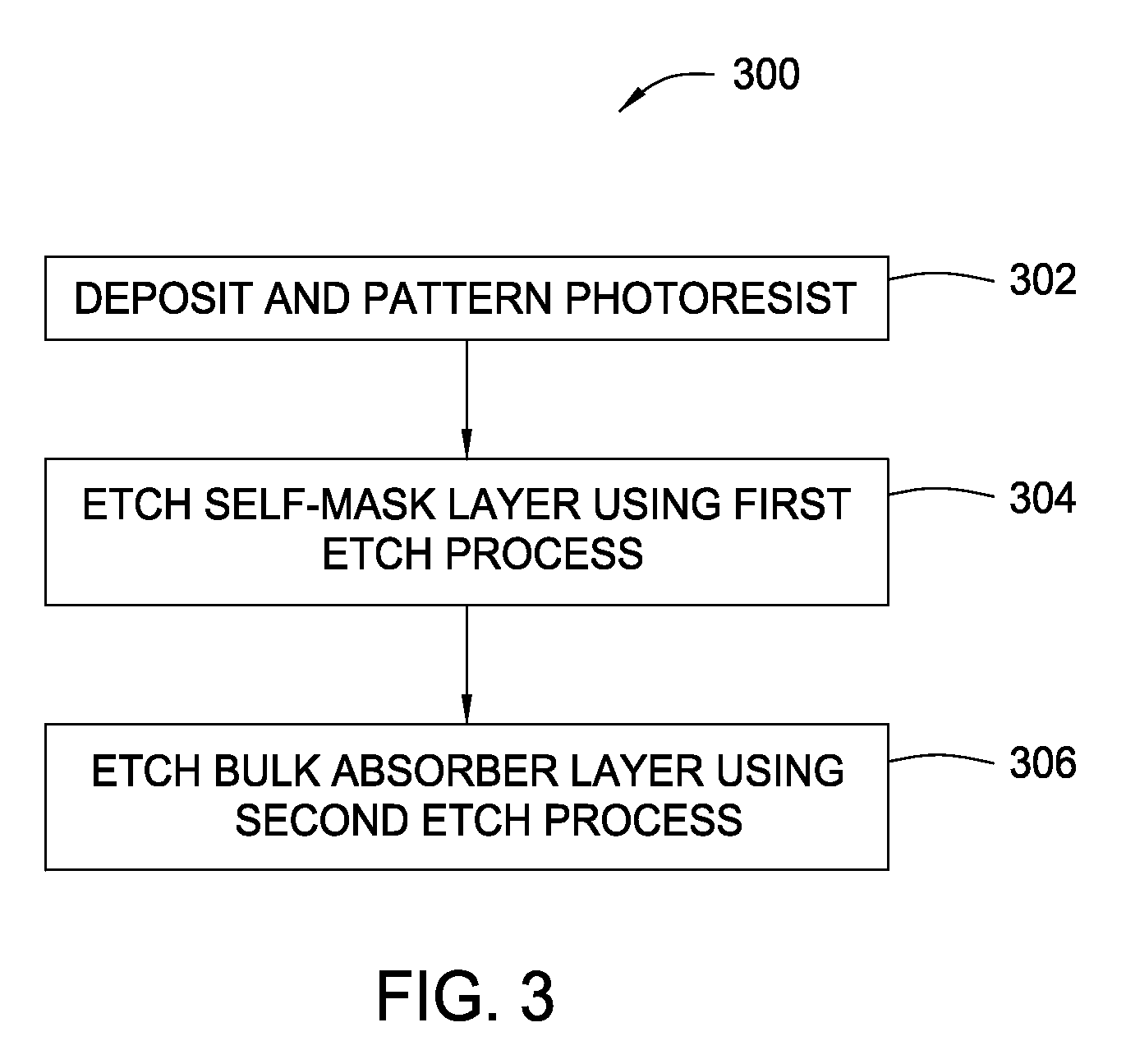

Photomask having self-masking layer and methods of etching same

ActiveUS20080070127A1Photomechanical apparatusSemiconductor/solid-state device manufacturingTantalum nitrideTantalum boride

A photomask structure and method of etching is provided herein. In one embodiment, a photomask includes a translucent substrate and an opaque multi-layer absorber layer disposed over the substrate. The opaque multi-layer absorber layer comprises a self-mask layer disposed over a bulk absorber layer. The self-mask layer comprises one of nitrogenized tantalum and silicon-based materials (TaSiON), tantalum boron oxide-based materials (TaBO), or oxidized and nitrogenized tantalum-based materials (TaON). The bulk absorber layer comprises on of tantalum silicide-based materials (TaSi), nitrogenized tantalum boride-based materials (TaBN), or tantalum nitride-based materials (TaN). The self-mask layer has a low etch rate during the bulk absorber layer etch step, thereby acting as a hard mask.

Owner:APPLIED MATERIALS INC

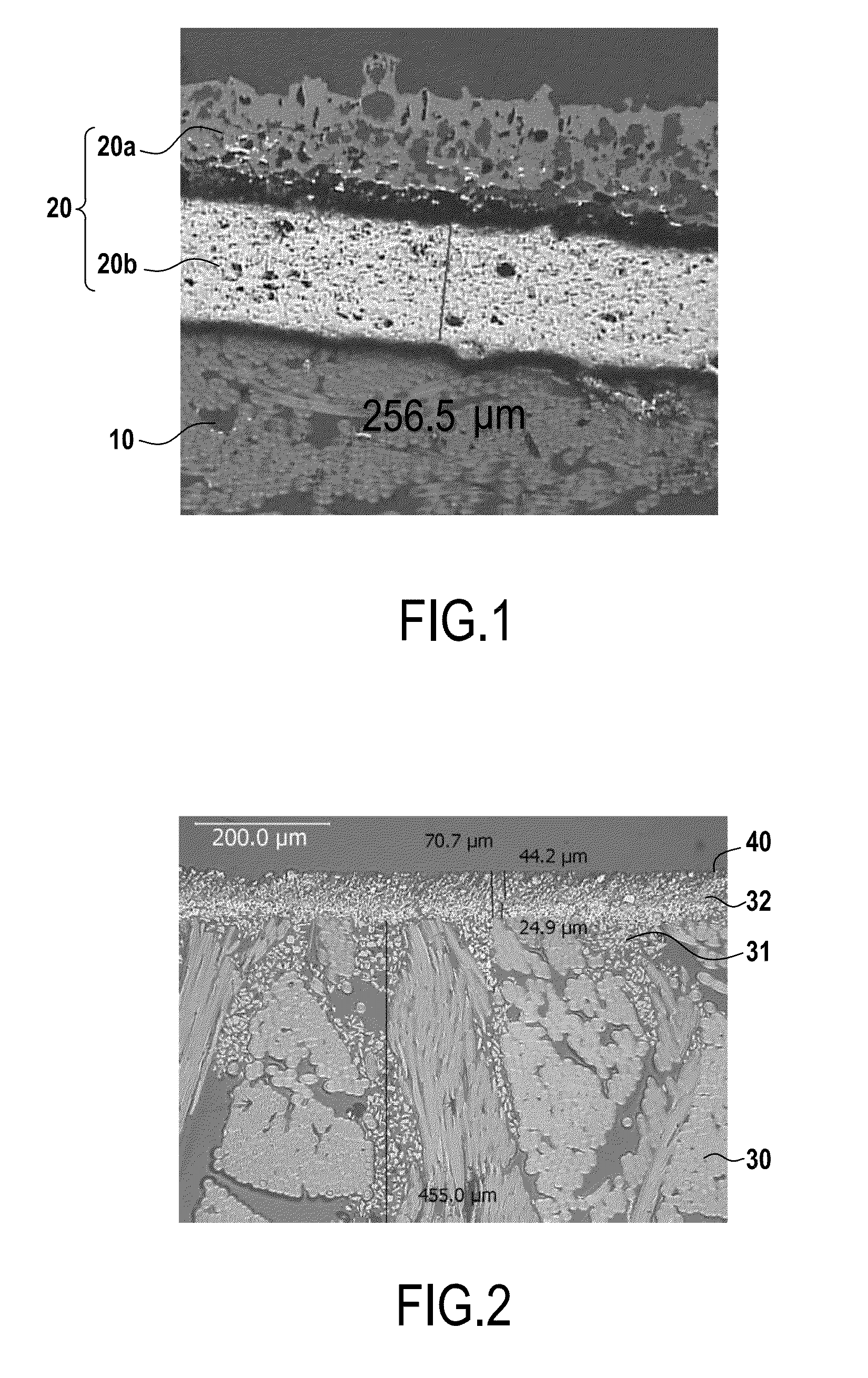

Ultra-Refractory Material that is Stable in a Wet Environment, and Process for Manufacturing Same

InactiveUS20150175487A1Reduce riskIncrease utlrarefractory naturePretreated surfacesCeramic shaping apparatusRefractoryHafnium

A refractory material withstanding high temperatures in an oxidizing medium contains at least hafnium boride and tantalum boride, hafnium and tantalum being present in the refractory material exclusively in compound form.

Owner:ARIANEGRP SAS

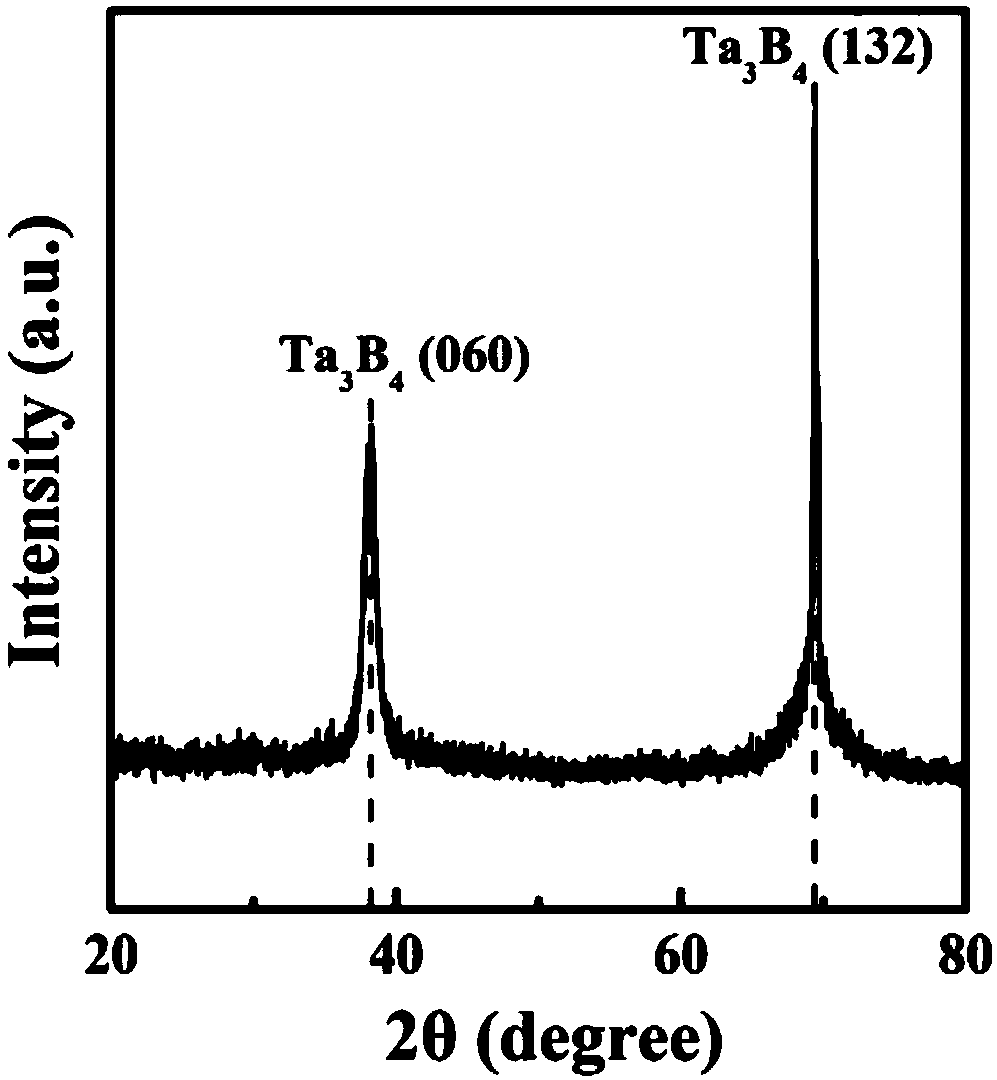

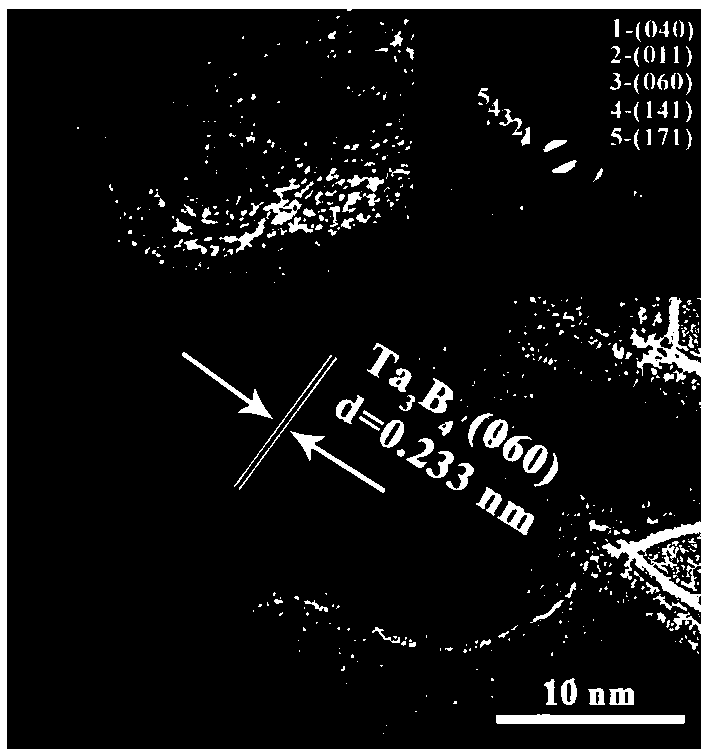

Tantalum boride bio-coating, and production method and application thereof

ActiveCN107583107AImprove tribological performanceImprove wear resistanceVacuum evaporation coatingSputtering coatingHigh resistanceBiocompatibility Testing

The invention belongs to the technical field of high bioactive film materials on the surfaces of biomedical implant materials, and concretely relates to a controllable production method of a boron-rich structure tantalum boride film. A new-generation medical implant material is adopted as a substrate, a metal tantalum target and a boron target are selected in a vacuum chamber, argon is used as a discharge gas, different radiofrequency powers are applied to the metal tantalum target and the boron target in the deposition process, and the phase structure of the film is regulated and controlled by controlling the working gas pressure and the substrate bias in order to finally obtain the tantalum boride coating having a dense and large-area boron-rich structure. The coating is nontoxic, hasgood biocompatibility, good osteoinductivity and high resistance to body fluid corrosion, and can effectively prevent the precipitation and diffusion of toxic ions in the medical implant material. Theproduction method of the coating has the advantages of simplicity, high efficiency, low cost and simple process, so the coating can be used as a surface modification coating for novel medical implantmaterials.

Owner:JILIN UNIV

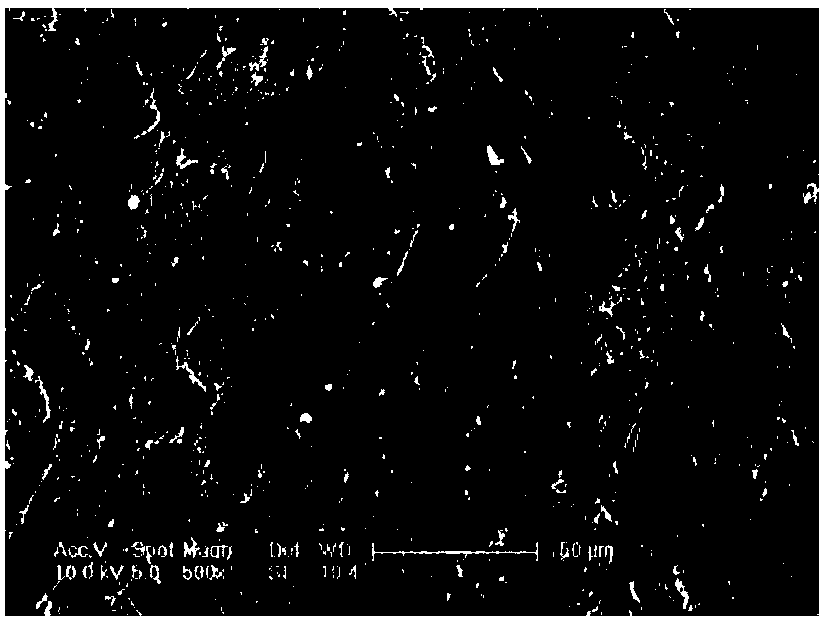

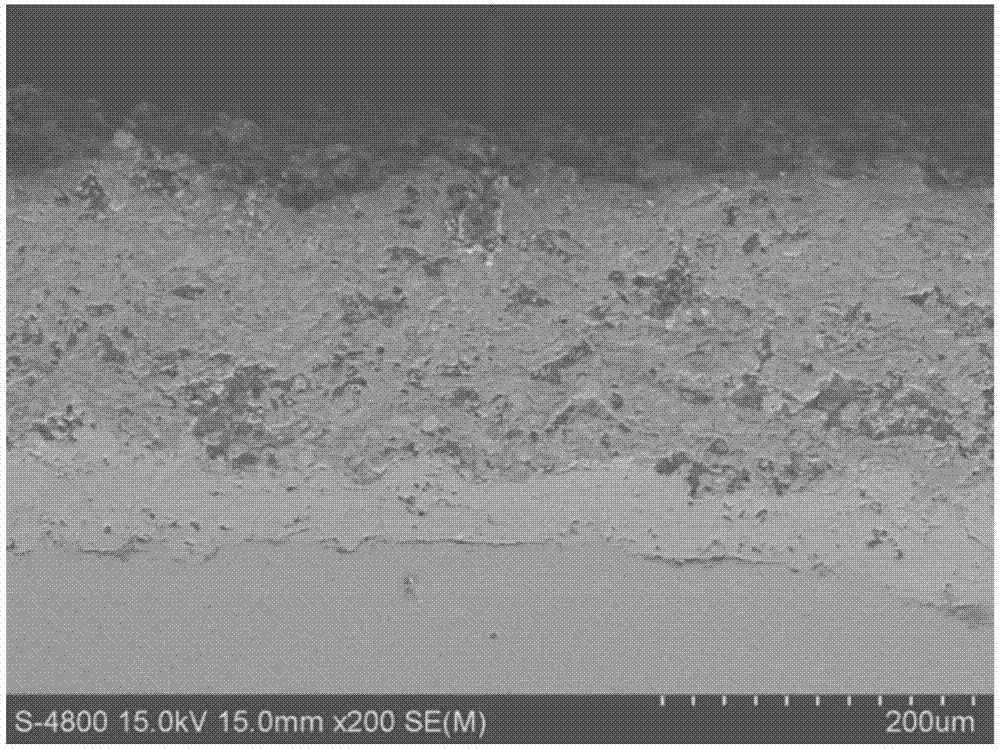

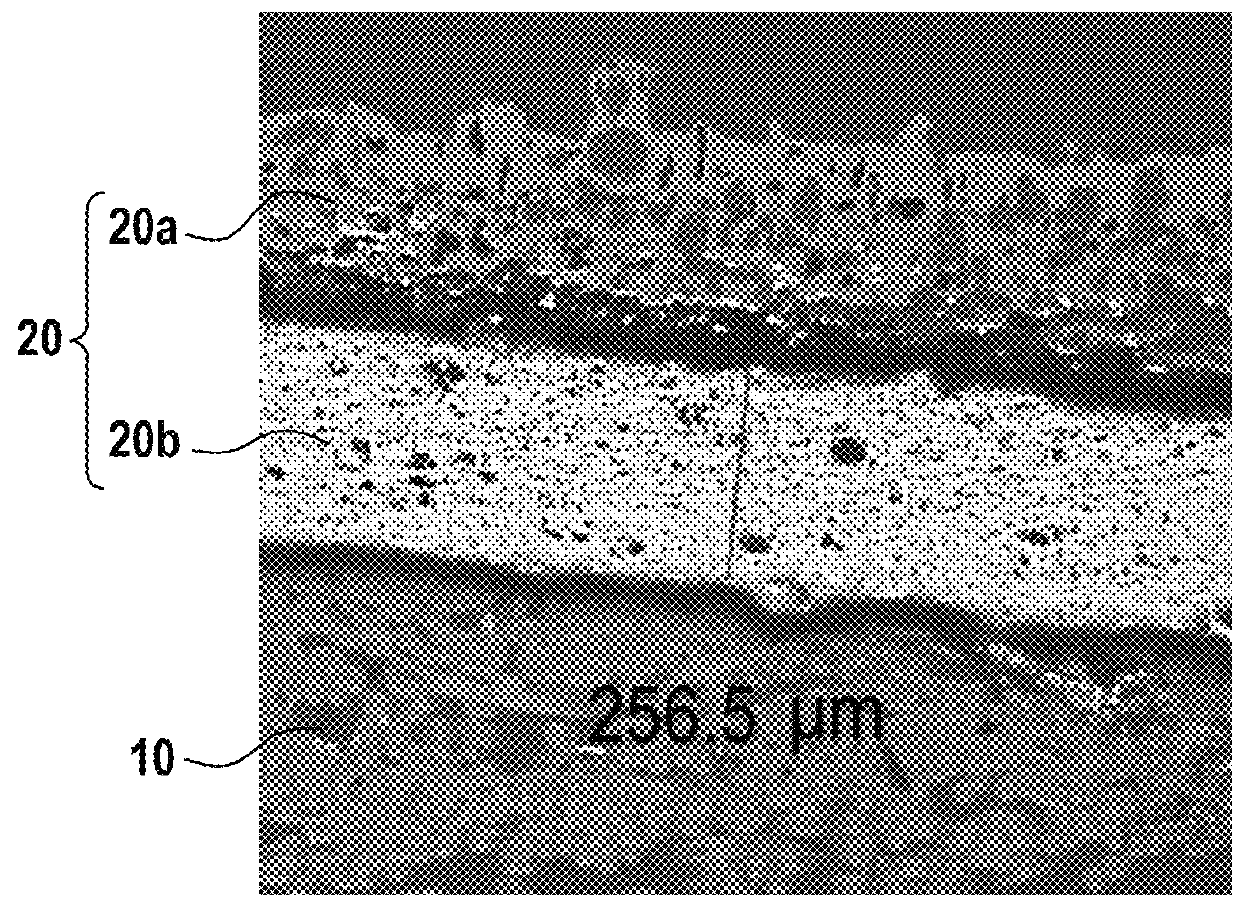

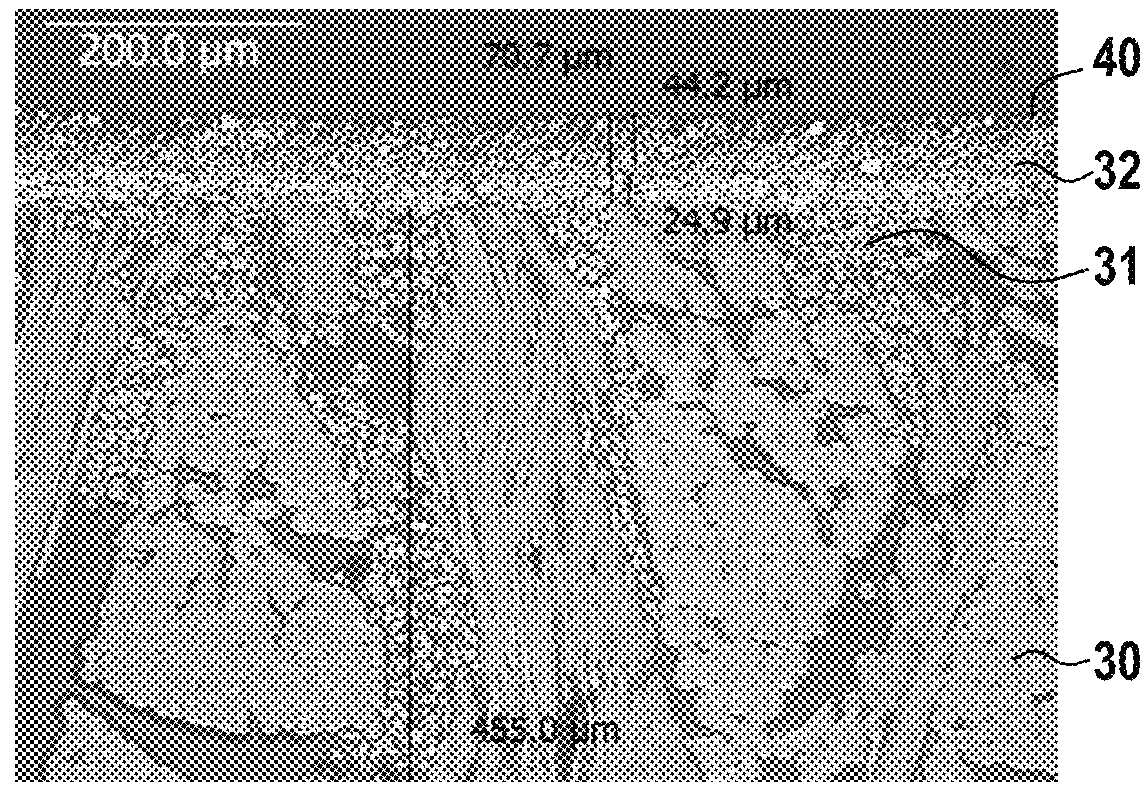

Preparation method of tantalum boride composite coating

InactiveCN107287547AHighlight substantive featuresHigh densityMolten spray coatingThermal sprayingBoron carbide

The invention discloses a preparation method of a tantalum boride composite coating, and relates to coating of boride to metal materials. The tantalum boride composite coating is obtained through the thermal spraying in-situ reaction in a synthesis manner. The preparation method comprises the steps of preparing tantalum oxide / boron carbide / aluminum composite powder for thermal spraying, carrying out pretreatment on the surface of a matrix material needing the coating and preparing the tantalum boride composite coating. According to the preparation method, the defects that a tantalum boride composite coating prepared in the prior art is complex in preparation process, high in cost, large in pollution, low in deposition efficiency, small in coating thickness, small in coating density, poor in uniformity, low in toughness, poor in coating and matrix binding force, prone to cracking and not suitable for being applied to large-scale industrial production are overcome.

Owner:HEBEI UNIV OF TECH

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS8324918B2Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

Photomask having self-masking layer and methods of etching same

ActiveUS7771894B2Photomechanical apparatusSemiconductor/solid-state device manufacturingTantalum nitrideTantalum boride

A photomask structure and method of etching is provided herein. In one embodiment, a photomask includes a translucent substrate and an opaque multi-layer absorber layer disposed over the substrate. The opaque multi-layer absorber layer comprises a self-mask layer disposed over a bulk absorber layer. The self-mask layer comprises one of nitrogenized tantalum and silicon-based materials (TaSiON), tantalum boron oxide-based materials (TaBO), or oxidized and nitrogenized tantalum-based materials (TaON). The bulk absorber layer comprises on of tantalum silicide-based materials (TaSi), nitrogenized tantalum boride-based materials (TaBN), or tantalum nitride-based materials (TaN). The self-mask layer has a low etch rate during the bulk absorber layer etch step, thereby acting as a hard mask.

Owner:APPLIED MATERIALS INC

Special packing for wear-resistant and corrosion-resistant high-pressure rubber pipe and preparation method of special packing

The invention discloses special packing for a wear-resistant and corrosion-resistant high-pressure rubber pipe. The special packing is prepared from the following raw materials in parts by weight: 3-5 parts of ferroferric oxide, 1-2 parts of tantalum boride, 7-9 parts of spodumene, 1-2 parts of tantalum diboride, 2-3 parts of p-tert-butylbenzoic acid, 8-10 parts of magnesium aluminate spinel, 3-4 parts of niobium boride, 3-5 parts of butylated hydroxytoluene, 2-5 parts of composite lead stabilizer, 1.3-1.8 parts of zinc stearate, 1-2 parts of calcium stearate, 50-55 parts of coal ash, a proper quantity of 4-6% hydrochloric acid, a proper quantity of water and 15-20 parts of auxiliary. Due to the addition of ferroferric oxide and the magnesium aluminate spinel in the packing, the wear resistance and heat resistance of the rubber pipe are improved; due to the addition of p-tert-butylbenzoic acid, the rubber pipe has favorable chemical corrosion resistance and soapy water resistance and is suitable for conveying chemicals; due to the adoption of the coal ash, the cost is reduced, and the reinforcing property of the packing is good; due to the adoption of the auxiliary, the dispersibility and reinforcing property of the packing can be improved, the strength and impact toughness of the high-pressure rubber pipe can be improved, and the high-pressure rubber pipe is not easy to bubble and deform.

Owner:HEFEI HEAN MACHINERY MFG

Antiflaming shock resistant modified PVC cable sheath material

ActiveCN103881268AImprove performanceGood chemical stabilityPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneTantalum boride

The invention relates to a cable material, and particularly relates to an antiflaming shock resistant modified PVC cable sheath material. The material is prepared from the following raw materials in parts by weight: 24-28 parts of PVC resin, 21-23 parts of poly 1-butene, 12-14 parts of low density polyethylene, 14-15 parts of dioctyl adipate, 13-14 parts of epoxidized soybean oil, 23-25 parts of calcined kaolin, 6-9 parts of aluminum hydroxide, 4-5 parts of zinc borate, 2-3 parts of barium stearate, 2-3 parts of silane coupling agent KH550, 3-4 parts of sodium tripolyphosphate, 1-2 parts of tantalum boride, 1-2 parts of accelerator DM, 2-3 parts of zinc oxide, 4-5 parts of dimethyl phosphite, 1.3-1.5 parts of accelerator D, and 14-16 parts of additive. The insulating material combines advantages of the raw materials like PVC resin, poly 1-butene and the like, is flexible and impact resistant, has good chemical stability, is antiflaming, resists weather ageing cracking, is safe and reliable in use, can be widely used for preparing various cable sheath insulating materials, and has broad market demand prospect.

Owner:ANHUI EFARAD ELECTRIC POWER TECH

Perlite filter element and preparation method thereof

ActiveCN103521001AUniform stressUniform cellsFiltration separationTemperature resistanceTantalum boride

The invention discloses a perlite filter element and a preparation method thereof. The perlite filter element is characterized by being prepared from the following raw materials in parts by weight: 12-14 parts of perlite, 20-22 parts of bauxite, 4-6 parts of aluminium nitride, 4-6 parts of sodium hydrogen carbonate, 3-4 parts of medical stone powder, 2-3 parts of nano carbon, 5-6 parts of colleseed oil, 24-26 parts of clay, 3-4 parts of sodium tripolyphosphate, 4-6 parts of propylene glycol, 2-3 parts of ethylene glycol, 1-2 parts of tantalum boride, 2-3 parts of ammonium chloride, 30-35 parts of modified attapulgite clay and a proper amount of water. The stress in the filter element is uniform through regional sintering, and the phenomena of breakage and the like are avoided; bubble holes are uniform; the perlite filter element has excellent high-temperature resistance and corrosion resistance and has the outstanding advantages of high purification efficiency, high-temperature resistance, low pressure loss, corrosion resistance, long service life, capability of removing micro dust from air and the like.

Owner:安徽雄伟阀门制造有限公司

Composite high-strength zirconia ceramic material and preparation method thereof

The invention discloses a composite high-strength zirconia ceramic material and a preparation method thereof.The ceramic material comprises 20-40 parts of zirconium oxide, 5-12 parts of silicon carbide, 4-10 parts of tungsten carbide, 3-7 parts of boron nitride, 3-7 parts of zirconium boride, 2-7 parts of molybdenum boride, 2-6 parts of tungsten silicide, 2-6 parts of barium silicide, 2-4 parts of vanadium silicide and 3-6 parts of tantalum boride.The preparation method includes the following steps that 1, all ingredients are subjected to mechanical milling in a ball mill; 2, after ball milling is conducted, the ceramic material is subjected to high-temperature sintering in a sintering furnace, the temperature raising rate is 30-70 DDG C / min, the temperature is raised to 900-950 DEG C in the first place, the temperature is maintained unchanged for 2 hours, then the temperature is raised to 1250-1350 DEG C, the temperature is maintained unchanged for 3 hours and then lowered to the room temperature, and the composite high-strength zirconia ceramic material is prepared.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Preparation method of tantalum boride powder

Owner:SHANDONG UNIV OF TECH

A corrosion resistant object having an outer layer of a ceramic material

Owner:坦塔莱恩化学气相沉积控股有限公司

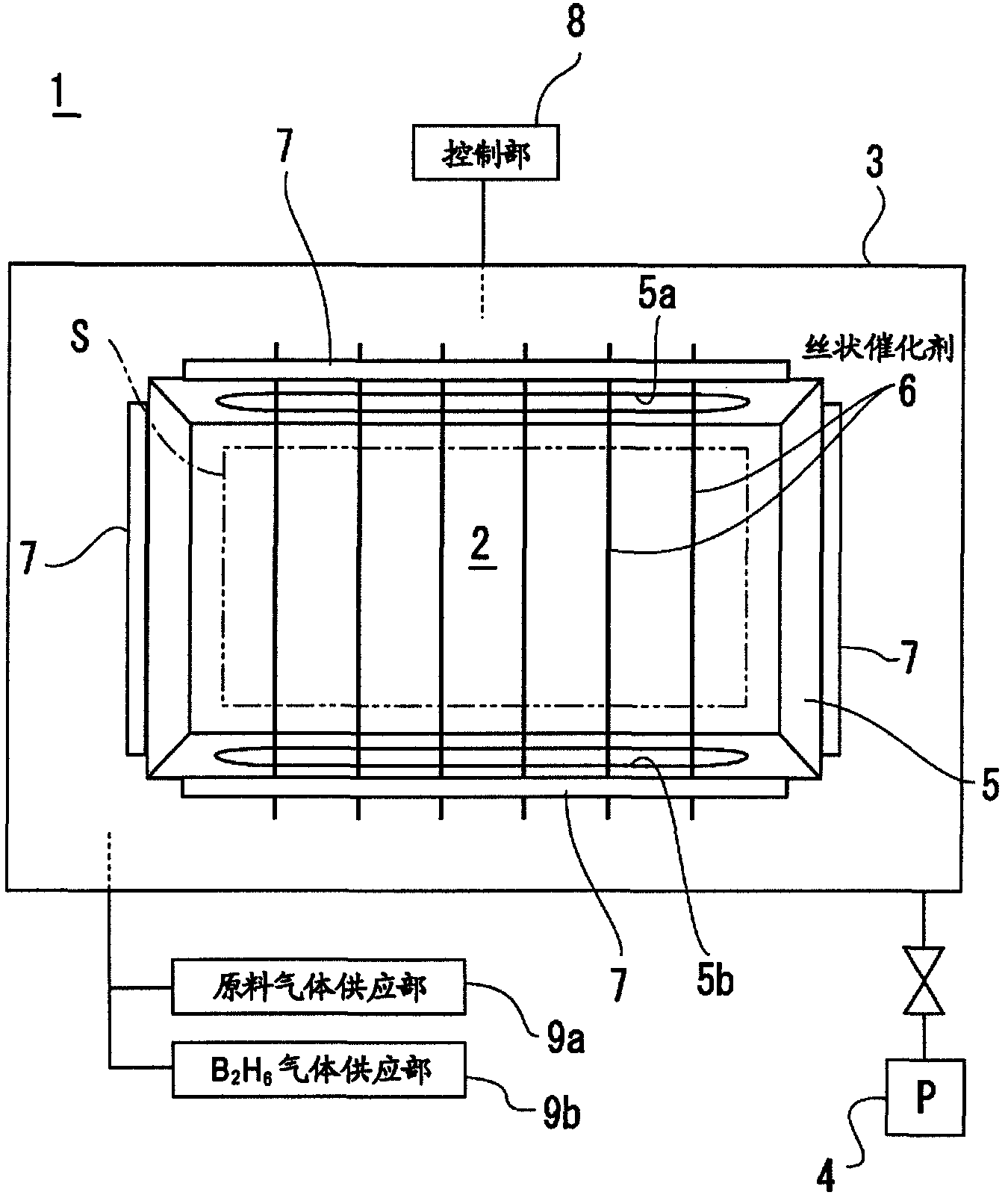

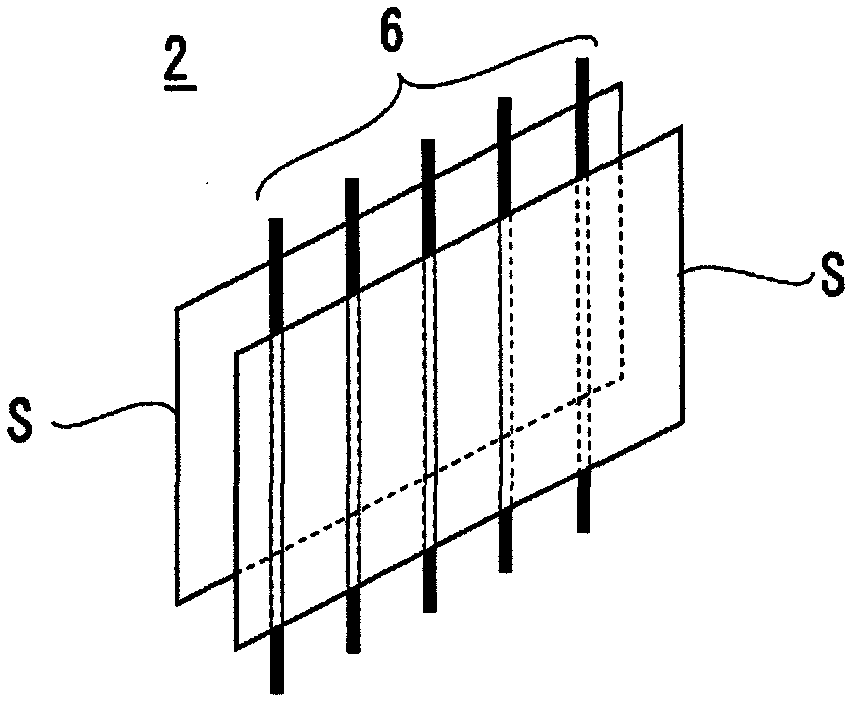

Catalyst chemical vapor deposition apparatus

ActiveCN102245803AExtended service lifePhysical/chemical process catalystsSemiconductor/solid-state device manufacturingGas phaseThermal expansion

The invention provides a catalyst chemical vapor deposition apparatus which can prolong the service life of a catalyst wire. A catalyst chemical vapor deposition apparatus (1) comprising a catalyst wire (6), the catalyst wire (6) comprising a tantalum wire and a layer of tantalum boride provided on the surface of the tantalum wire. The boride of the metallic tantalum (tantalum boride) has a larger hardness than the metallic tantalum. Accordingly, the use of the tantalum wire, with the boride layer formed on the surface thereof, as a catalyst wire can reduce thermal expansion of the catalyst wire, can improve the mechanical strength, and can prolong the service life. When electric heating of the catalyst wire (6) is performed by continuous energization, further prolongation of the service life of the catalyst wire (6) can be realized.

Owner:ULVAC INC

Method for preparing ethyl alcohol dispersion tantalum boride silicon carbide-carbon fiber friction material

A method for preparing an ethyl alcohol dispersion tantalum boride silicon carbide-carbon fiber friction material is characterized in that carbonization is conducted on a graphited carbon fiber blanket with the density of 0.1-1.8 g / cm3, then ethyl alcohol dispersion tantalum boride filling, silicon carbide deposition and submerged siliconizing are conducted in sequence, and finally nitriding is conducted in the nitrogen atmosphere to generate the ethyl alcohol dispersion tantalum boride silicon carbide-carbon fiber friction material. The friction material is prepared through carburization, tantalum boride filling, silicon carbide deposition, submerged siliconizing and nitriding of the graphited carbon fiber blanket, has high strength, tenacity and friction performance, and is adaptable to various weather conditions.

Owner:SHANDONG UNIV OF TECH

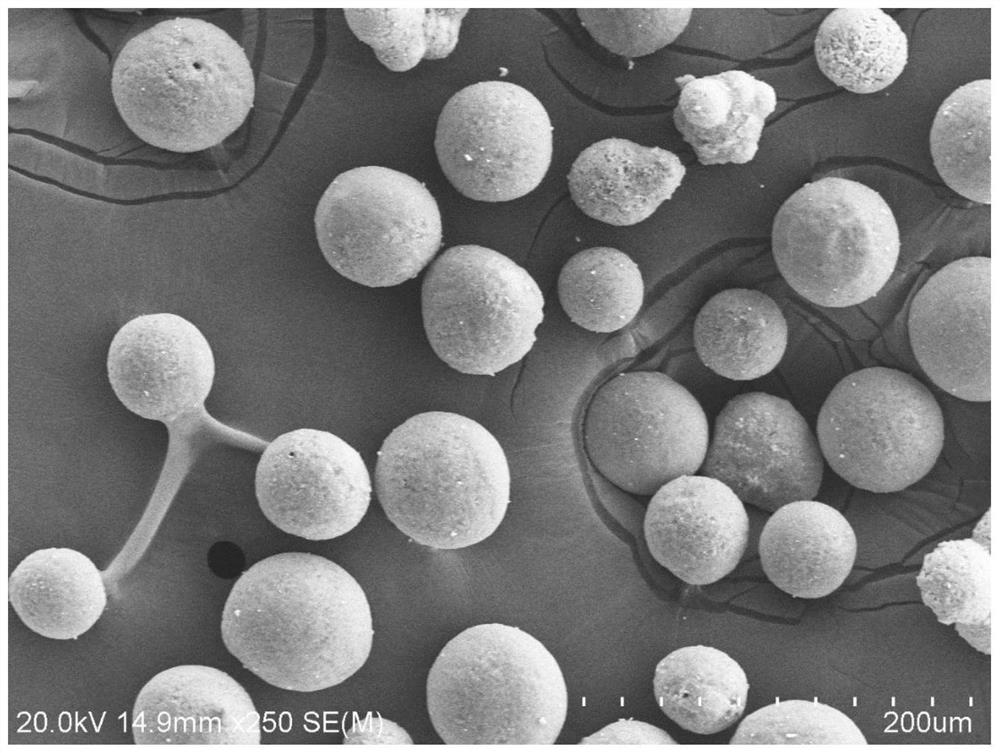

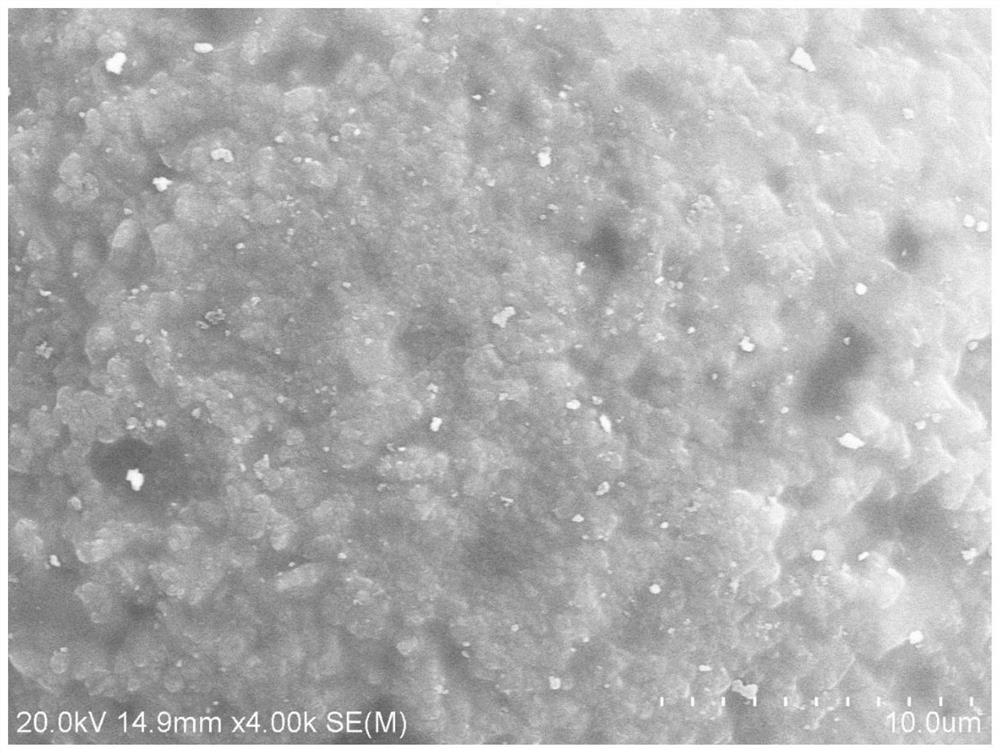

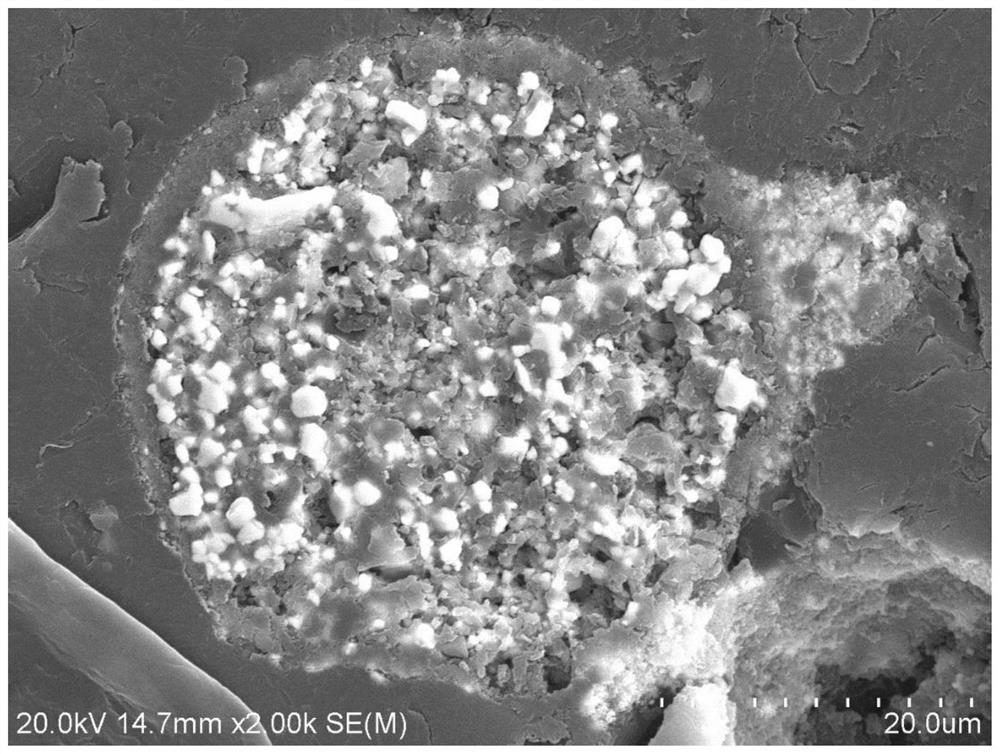

Molybdenum disilicide coated tantalum boride-hafnium carbide spherical powder and preparation method thereof

The invention relates to the technical field of composite powder materials, and provides a molybdenum disilicide coated tantalum boride-hafnium carbide spherical powder and a preparation method thereof. A tantalum boride-hafnium carbide agglomerated powder is prepared through ball milling and spray drying granulation, then the agglomerated powder is subjected to induction plasma spheroidizing treatment, sintering densification of the powder is achieved, and then the surface of the obtained tantalum boride-hafnium carbide spherical powder is coated with a molybdenum disilicide coating layer to obtain the molybdenum disilicide coated tantalum boride-hafnium carbide spherical powder with the core-shell structure. The prepared molybdenum disilicide coated tantalum boride-hafnium carbide spherical powder is high in density and cohesion, high in sphericity degree and good in fluidity and meets the requirement of plasma spraying for powder, the melting point of molybdenum disilicide is lower than that of tantalum boride, in the plasma spraying process, melting can be more sufficient, the compactness of a coating is improved, the molybdenum disilicide coating layer can also inhibit volatilization of hafnium carbide in the plasma spraying process, and the loss of hafnium carbide is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Ultra-refractory material that is stable in a wet environment, and process for manufacturing same

InactiveUS9340460B2Increase utlrarefractory natureImprove natureThin material handlingRefractoryHafnium

A refractory material withstanding high temperatures in an oxidizing medium contains at least hafnium boride and tantalum boride, hafnium and tantalum being present in the refractory material exclusively in compound form.

Owner:ARIANEGRP SAS

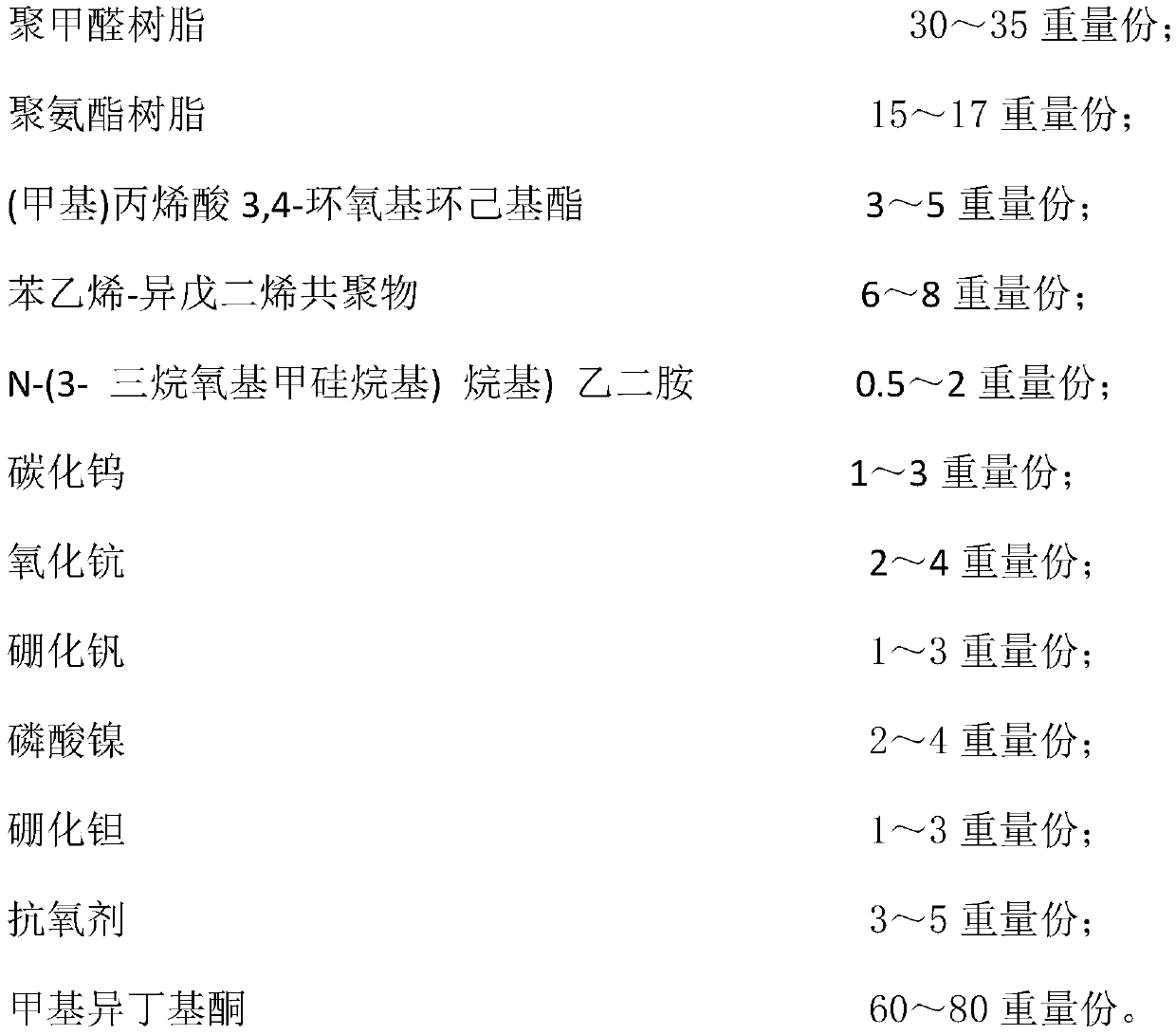

Pipeline for LNG gasification pressure regulating measuring skid-mount package

InactiveCN111174000AGood anti agingImprove high temperature resistanceCorrosion preventionPipe protection against corrosion/incrustationNickel phosphateMeth-

The invention discloses a pipeline for an LNG gasification pressure regulating measuring skid-mount package. The pipeline comprises a steel pipe and an anti-corrosion layer arranged on the steel pipe.The anti-corrosion layer comprises the following components 30-35 parts by weight of polyoxymethylene resin, 15-17 parts by weight of polyurethane resin, 3-5 parts by weight of (methyl) acrylic 3, 4-epoxycyclohexyl ester, 6-8 parts by weight of styrene-isoprene copolymer, 0.5-2 parts by weight of N-(3-trialkoxysilyl) alkyl) ethylenediamine, 1-3 parts by weight of tungsten carbide, 2-4 parts by weight of scandium oxide, 1-3 parts by weight of vanadium boride, 2-4 parts by weight of nickel phosphate, 1-3 parts by weight of tantalum boride, 3-5 parts by weight of an antioxidant, and 60-80 partsby weight of methyl isobutyl ketone. The pipeline for the LNG gasification pressure regulating measuring skid-mount package has excellent ageing resistance, high temperature resistance, low temperature resistance and corrosion resistance.

Owner:无锡爱尔拓燃气技术设备有限公司

Ni-Zn soft magnetic ferrite material for transformer iron core

InactiveCN106380191AEnhanced mass transferPromote sinteringInorganic material magnetismTransformerManganese oxide

The invention discloses a Ni-Zn soft magnetic ferrite material for transformer iron core. Raw materials of the Ni-Zn soft magnetic ferrite material contain main materials, auxiliary materials and modified wood pulp. The main materials contain, by molar weight, 40-50 parts of iron oxide, 30-40 parts of manganese oxide, 20-30 parts of zinc oxide and 15-25 parts of nickel oxide. With total mass of the main materials as the reference, the auxiliary materials contain 500-700 ppm of silica, 300-500 ppm of tantalum boride, 220-280 ppm of molybdenum trioxide, 300-360 ppm of cobalt oxide, 200-220 ppm of bismuth oxide, 300-380 ppm of vanadic anhydride, 240-360 ppm of tantalum oxide, 200-260 ppm of calcium oxide, 200-280 ppm of niobium oxide, 160-240 ppm of calcium carbonate, 200-300 ppm of manganese carbonate and 200-280 ppm of barium carbonate. Weight ratio of the main materials to the modified wood pulp is 100: 5-7.

Owner:ANHUI HUALIN MAGNETIC TECH

High-strength and wear-resisting boride-based cermet bearing and production method thereof

The invention discloses a high-strength and wear-resisting boride-based cermet bearing and a production method thereof. The high-strength and wear-resisting boride-based cermet bearing is prepared from the following raw materials in parts by weight: 10 to 20 parts of titanium boride, 40 to 50 parts of tantalum boride, 2 to 8 parts of tin powder, 4 to 9 parts of iron powder, 13 to 20 parts of realgar powder, 10 to 20 parts of dickite powder, 10 to 15 parts of wolframite powder, 3 to 8 parts of graphene, 2 to 6 parts of ferric citrate, 10 to 15 parts of glass fibers and 11 to 15 parts of paraffin. Compared with a traditional cermet bearing, the high-strength and wear-resisting boride-based cermet bearing produced by the production method disclosed by the invention has the advantages of better strength, wear resistance and heat resistance; the bearing does not deform under the condition of high temperature, and is not easy to wear; in addition, a preparation technique is simple, the processing cost is low, parameters are easy to control, and the production process is safe and environmentally-friendly; and the high-strength and wear-resisting boride-based cermet bearing and the production method therefor are suitable for large-scale industrial production.

Owner:王莹

Conductive ceramic and method for preparing conductive ceramic from silicon carbide

The invention provides a conductive ceramic and a method for preparing the conductive ceramic by using silicon carbide. The conductive ceramic comprises silicon carbide, tantalum diboride, yttrium oxide, titanium carbide and auxiliaries, is stable in performance, can meet various performance requirements of the conductive ceramic, and enriches market requirements. The method for preparing the conductive ceramic by using the silicon carbide is high in yield, and the production cost can be effectively reduced.

Owner:宁夏北伏科技有限公司

Preparation method of ethanol-dispersed tantalum boride silicon carbide-carbon fiber friction material

A method for preparing an ethyl alcohol dispersion tantalum boride silicon carbide-carbon fiber friction material is characterized in that carbonization is conducted on a graphited carbon fiber blanket with the density of 0.1-1.8 g / cm3, then ethyl alcohol dispersion tantalum boride filling, silicon carbide deposition and submerged siliconizing are conducted in sequence, and finally nitriding is conducted in the nitrogen atmosphere to generate the ethyl alcohol dispersion tantalum boride silicon carbide-carbon fiber friction material. The friction material is prepared through carburization, tantalum boride filling, silicon carbide deposition, submerged siliconizing and nitriding of the graphited carbon fiber blanket, has high strength, tenacity and friction performance, and is adaptable to various weather conditions.

Owner:SHANDONG UNIV OF TECH

Preparing method of synthetic-fat dispersion tantalum boride and boron carbide-carbon fiber friction material

The invention discloses a preparing method of a synthetic-fat dispersion tantalum boride and boron carbide-carbon fiber friction material. The preparing method is characterized by including the steps that a graphitized carbon fiber blanket with the density of 0.1-1.8 g / cm<3> is subjected to boron carbide deposition after being subjected to carburization; synthetic-fat dispersion tantalum boride filling is carried out, then embedding boronizing is carried out, nitridation is carried out in nitrogen atmosphere, and the synthetic-fat dispersion tantalum boride and boron carbide-carbon fiber friction material is prepared. According to the preparing method, the friction material is prepared from the graphitized carbon fiber blanket through the steps of carburization, boron carbide deposition, tantalum boride filling, embedding boronizing, nitridation and the like; the prepared friction material is high in strength, tenacity and friction performance, and is a friction material adapting to various climate conditions.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com