Preparation method of tantalum boride composite coating

A composite coating, tantalum boride technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of complex preparation process, low toughness, high cost, etc., and achieve simple preparation process and high density , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

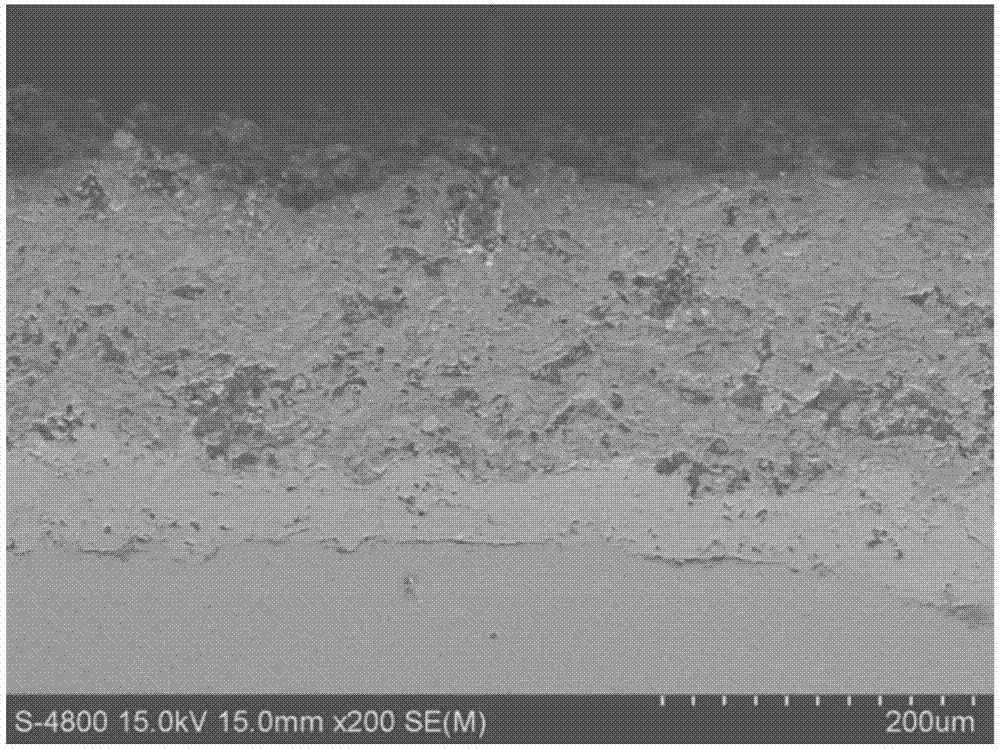

Image

Examples

Embodiment 1

[0040] The first step is to formulate tantalum oxide / boron carbide / aluminum composite powder for thermal spraying:

[0041] Mix aluminum powder with a particle size range of 0.1 micron to 10 microns, tantalum oxide powder with a particle size range of 0.001 micron to 10 microns, and boron carbide powder with a particle size range of 0.001 micron to 10 microns to form a composite powder. Wherein, boron carbide powder accounts for 5% by weight of the total mass of the three raw material powders, aluminum powder and tantalum oxide powder account for 95% by weight of the total mass of the three raw material powders, and the weight percentage between the tantalum oxide powder and the aluminum powder The weight ratio is then 60: 40, and then evenly mixes into the binder polyvinyl alcohol, the binder polyvinyl alcohol consumption is, and the weight ratio is the above-mentioned composite powder: polyvinyl alcohol=100: 0.1, thus being formulated for use in Thermally sprayed tantalum ox...

Embodiment 2

[0047] The first step is to formulate tantalum oxide / boron carbide / aluminum composite powder for thermal spraying:

[0048] Mix aluminum powder with a particle size range of 0.1 micron to 10 microns, tantalum oxide powder with a particle size range of 0.001 micron to 10 microns, and boron carbide powder with a particle size range of 0.001 micron to 10 microns to form a composite powder. Wherein, boron carbide powder accounts for 10% by weight of the total mass of these three raw material powders, aluminum powder and tantalum oxide powder account for 90% by weight of the total mass of these three raw material powders, and the weight percentage between tantalum oxide powder and aluminum powder The weight ratio is then 85: 15, and then uniformly mixes into the binder polyvinyl alcohol, and the binder polyvinyl alcohol consumption is, and the weight ratio is the above-mentioned composite powder: polyvinyl alcohol=100: 1, thus being formulated for use in Thermally sprayed tantalum ...

Embodiment 3

[0055] The first step is to formulate tantalum oxide / boron carbide / aluminum composite powder for thermal spraying:

[0056] Mix aluminum powder with a particle size range of 0.1 micron to 10 microns, tantalum oxide powder with a particle size range of 0.001 micron to 10 microns, and boron carbide powder with a particle size range of 0.001 micron to 10 microns to form a composite powder. Wherein, boron carbide powder accounts for 30% by weight of the total mass of these three raw material powders, aluminum powder and tantalum oxide powder account for 70% by weight of the total mass of these three raw material powders, and the weight percentage between tantalum oxide powder and aluminum powder The weight ratio is then 90: 10, then uniformly mixed into the binder methyl cellulose, the amount of the binder methyl cellulose is, the weight ratio is the above-mentioned composite powder: methyl cellulose=100: 2, thus preparing into tantalum oxide / boron carbide / aluminum composite powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com