Patents

Literature

1561 results about "Laser etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

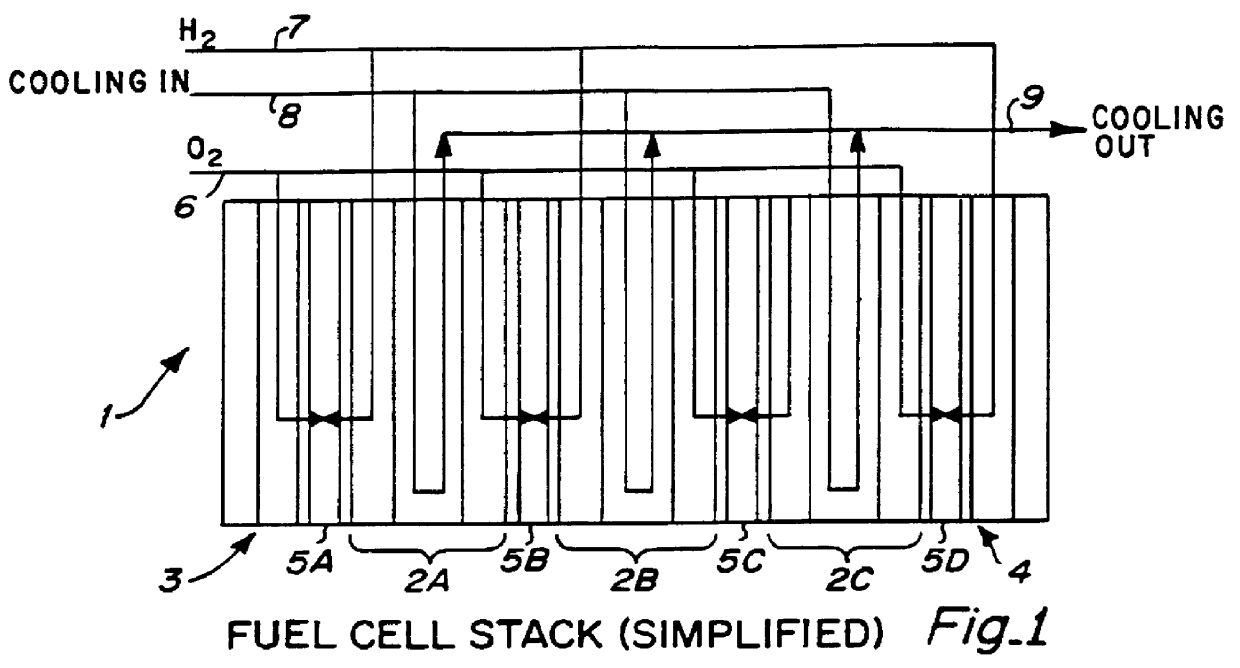

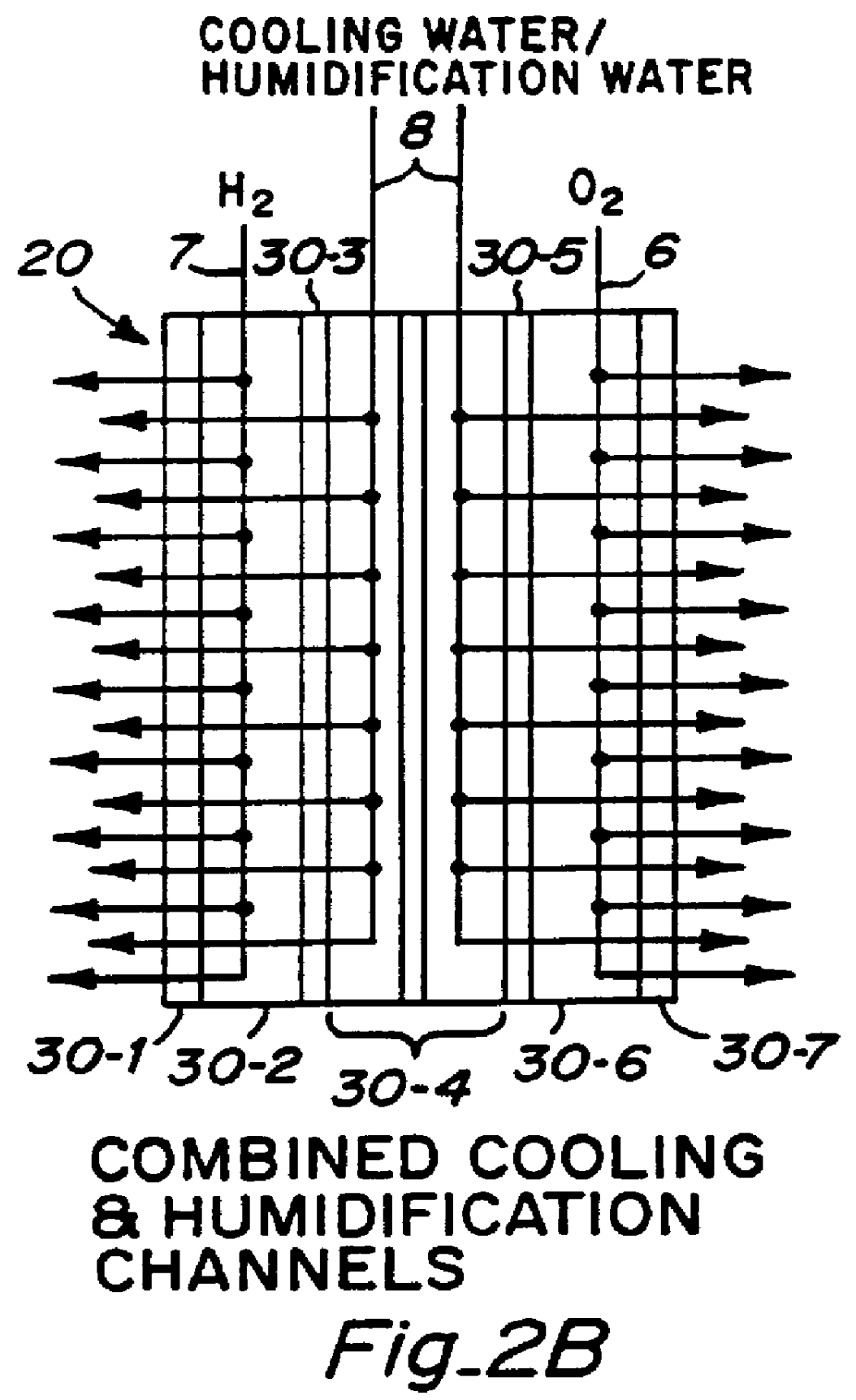

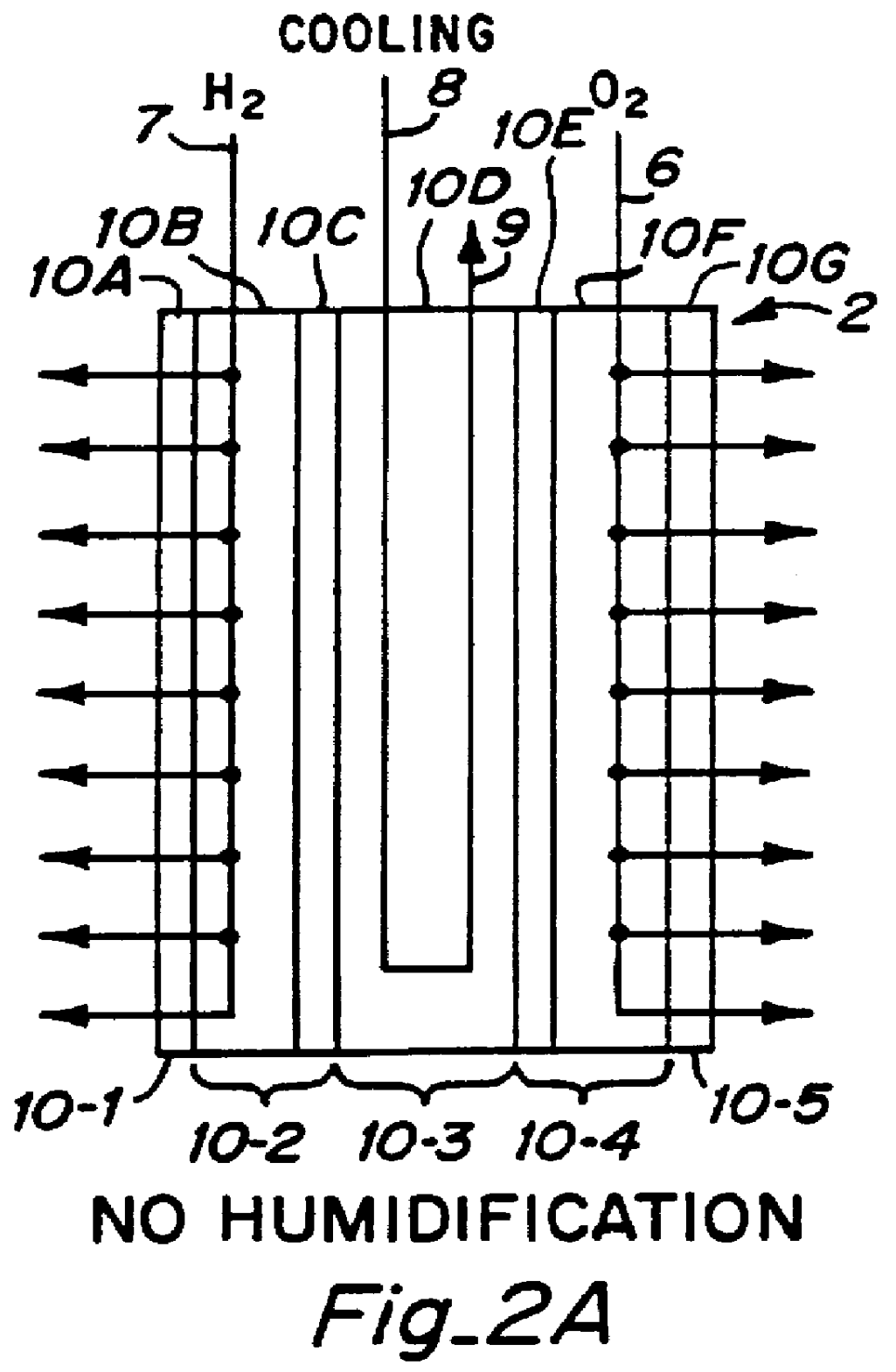

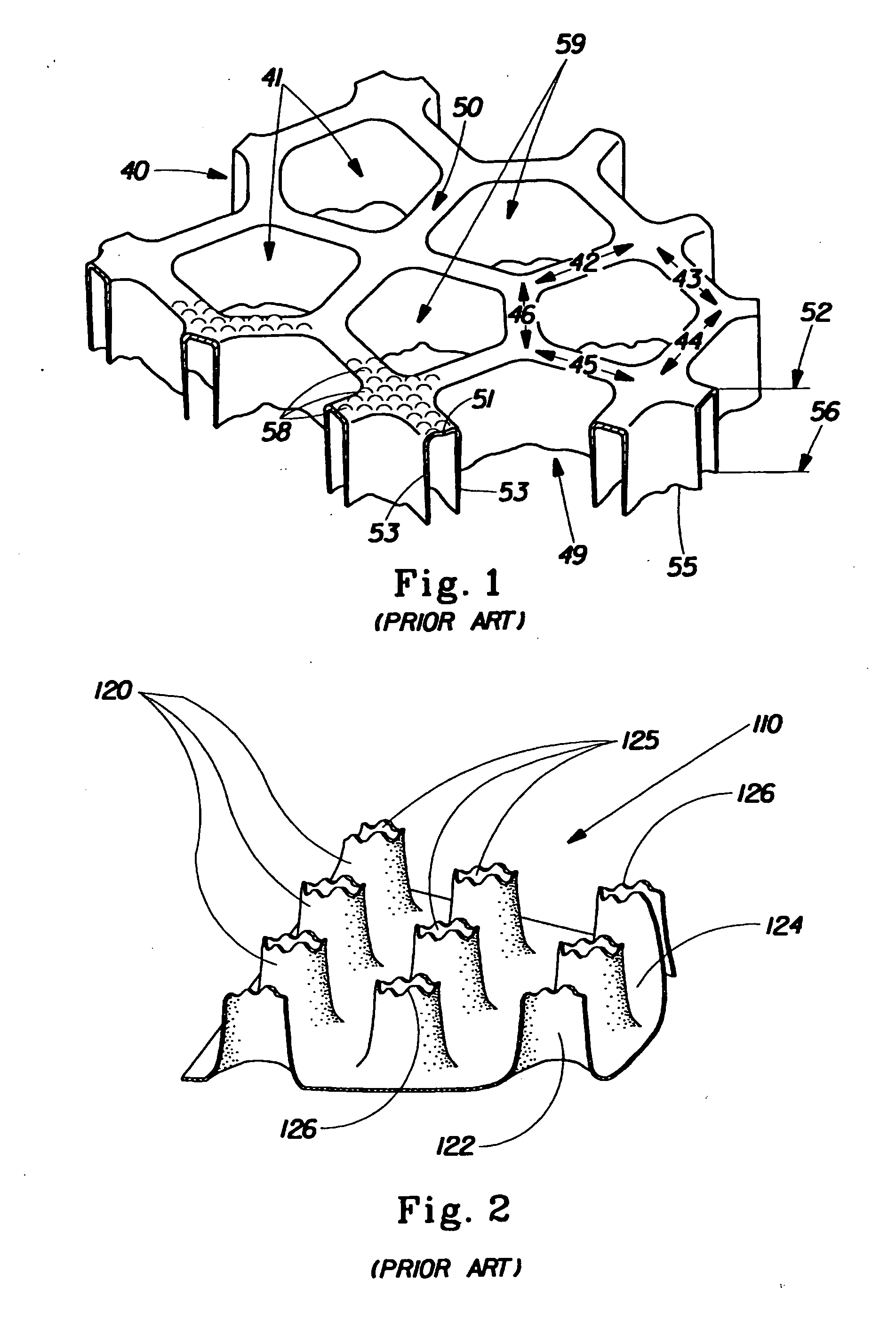

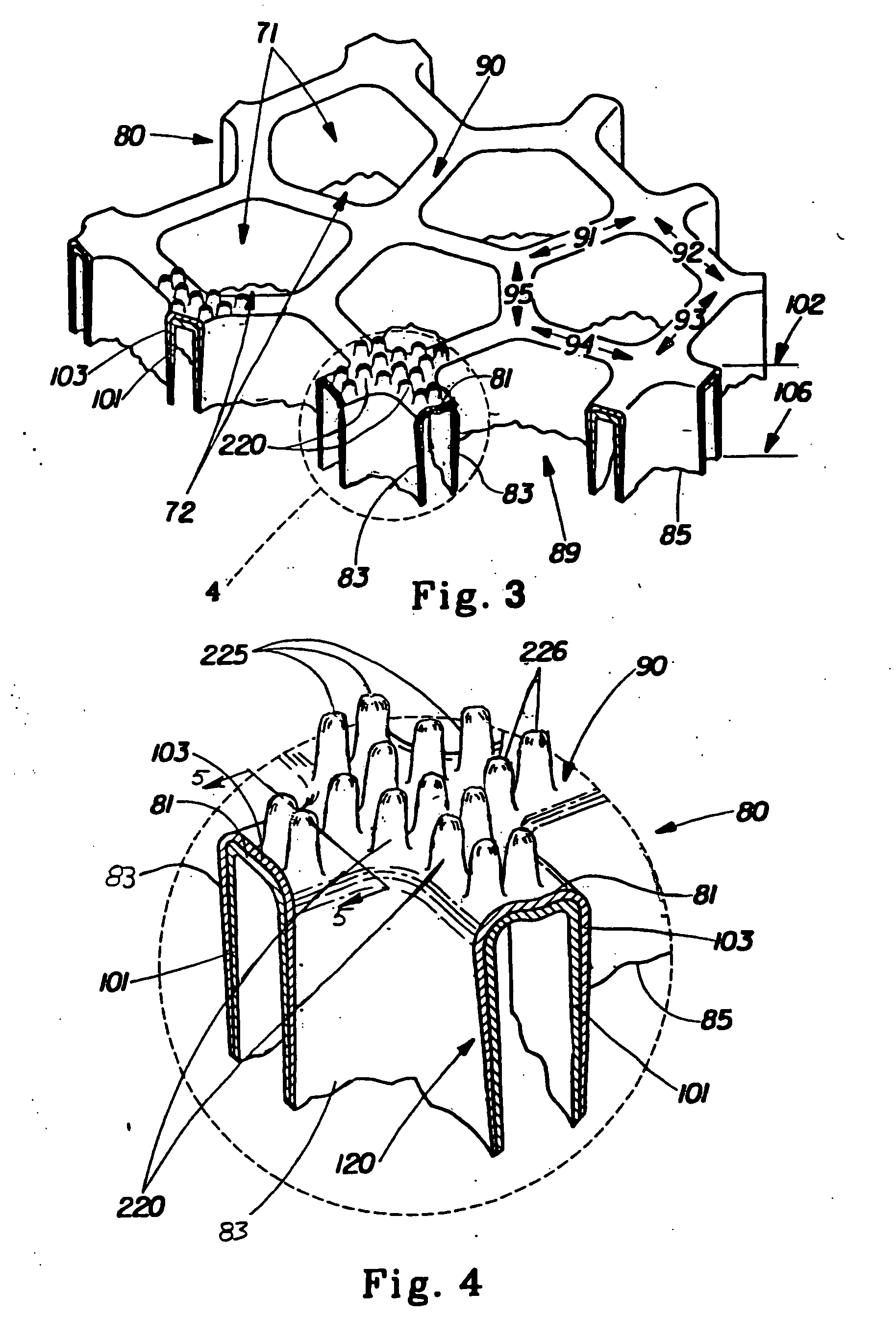

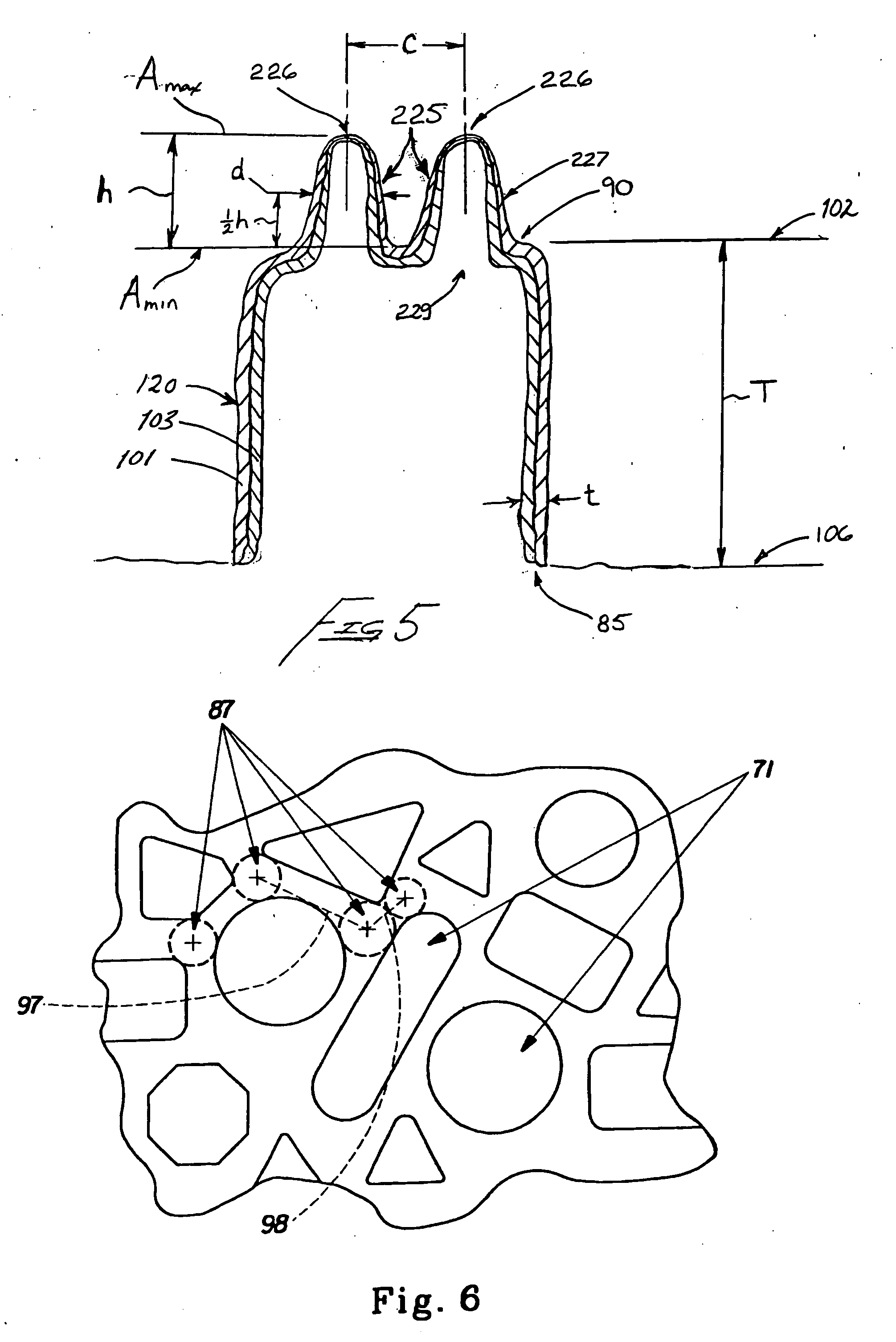

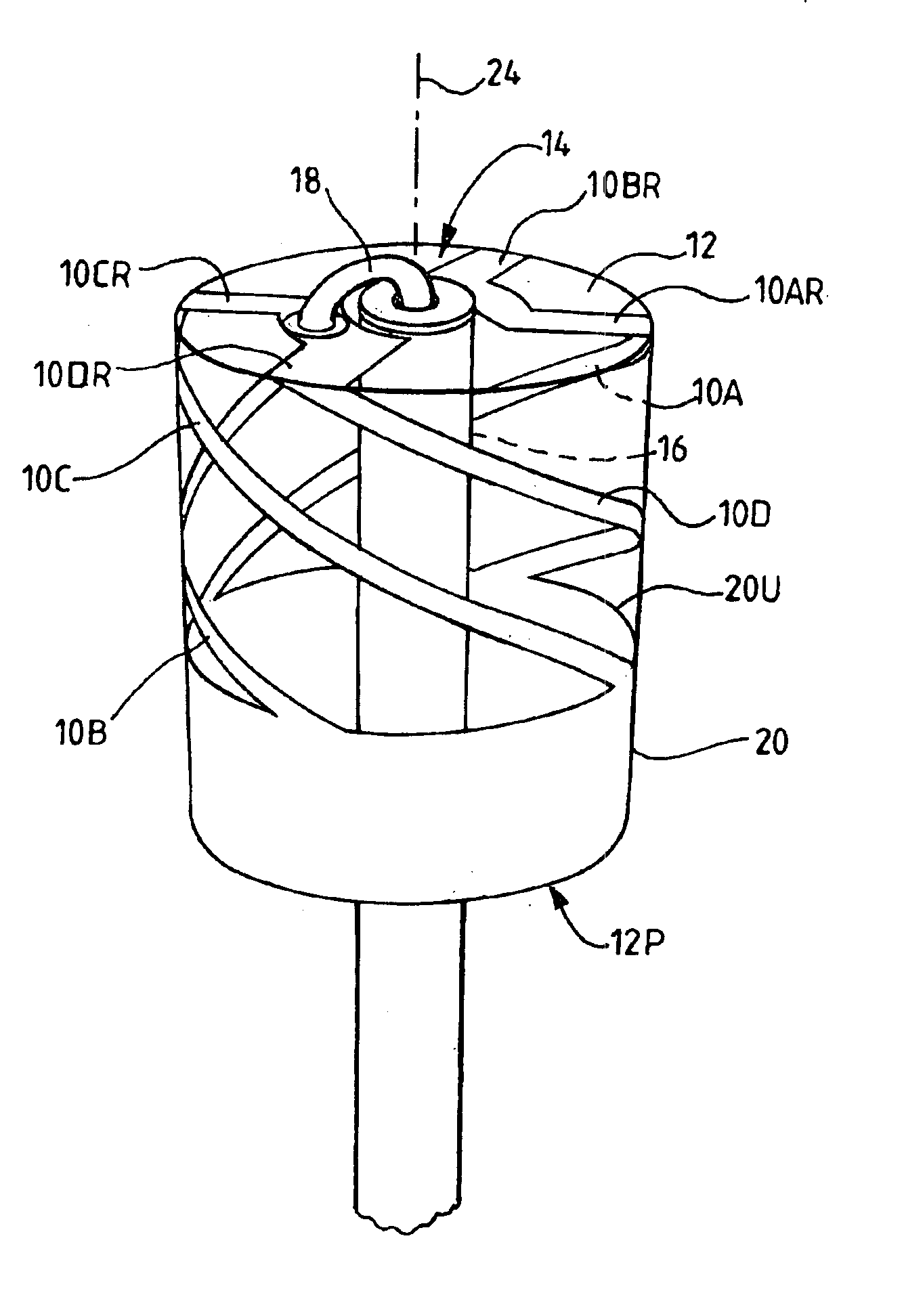

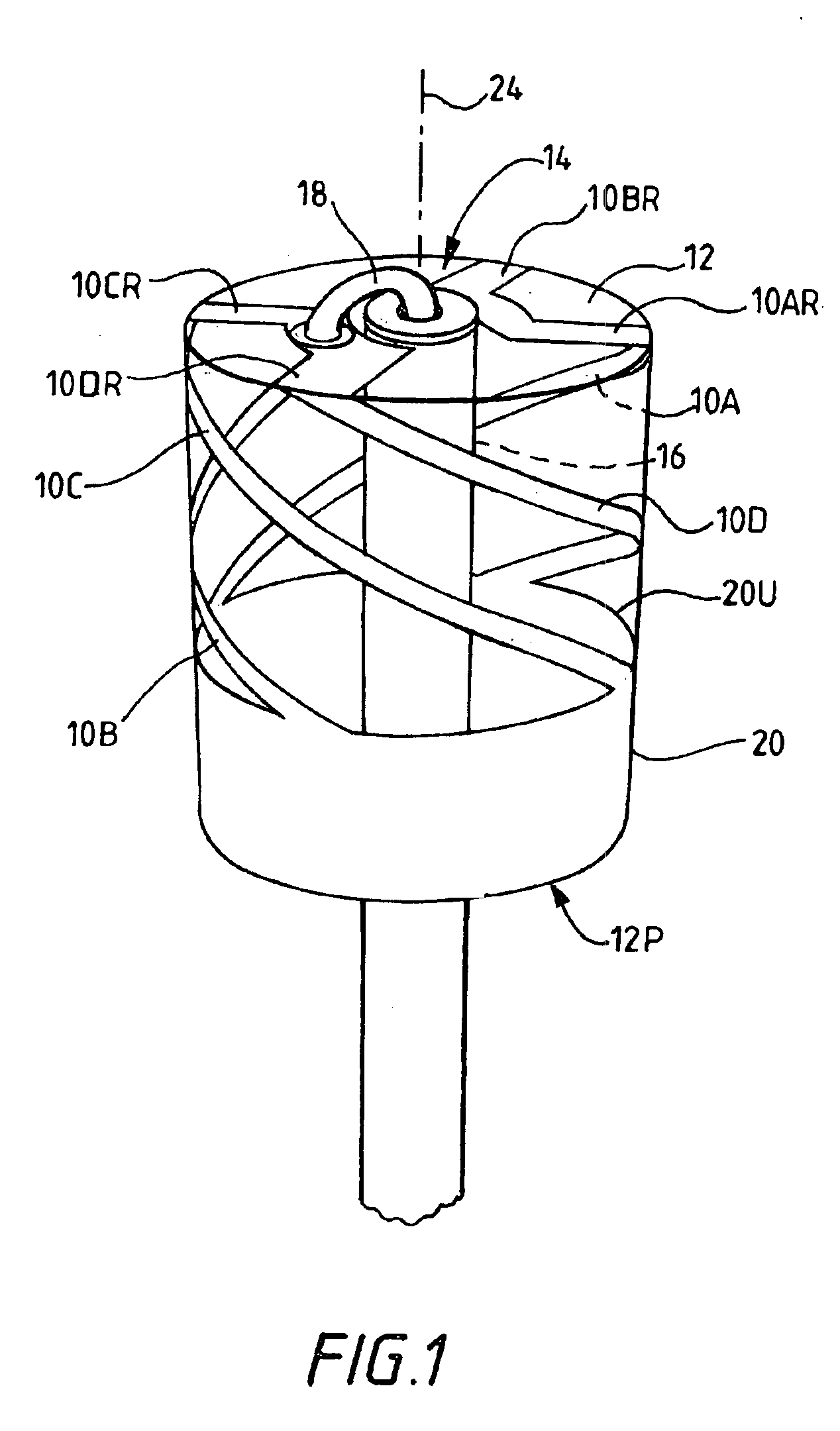

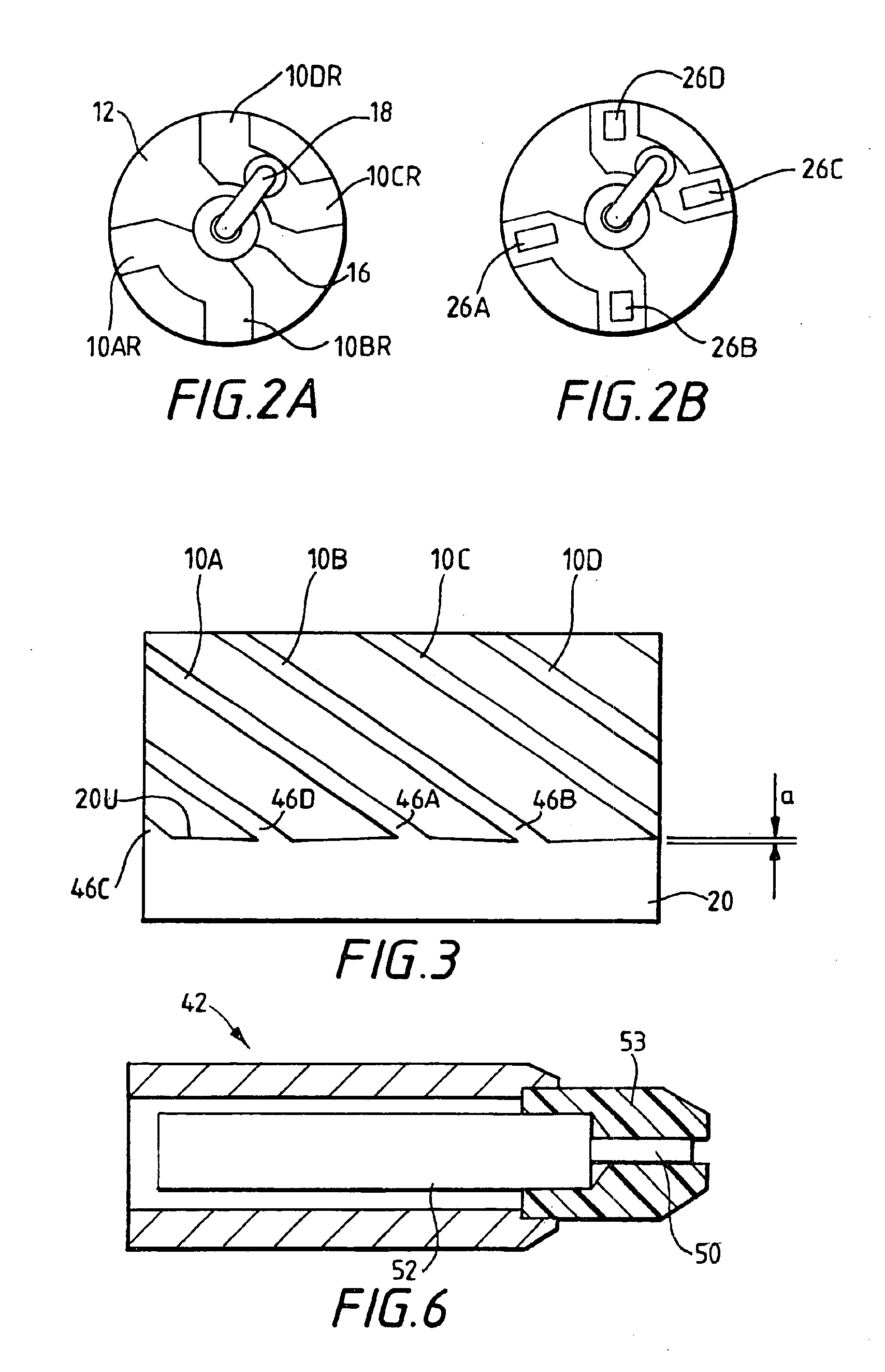

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

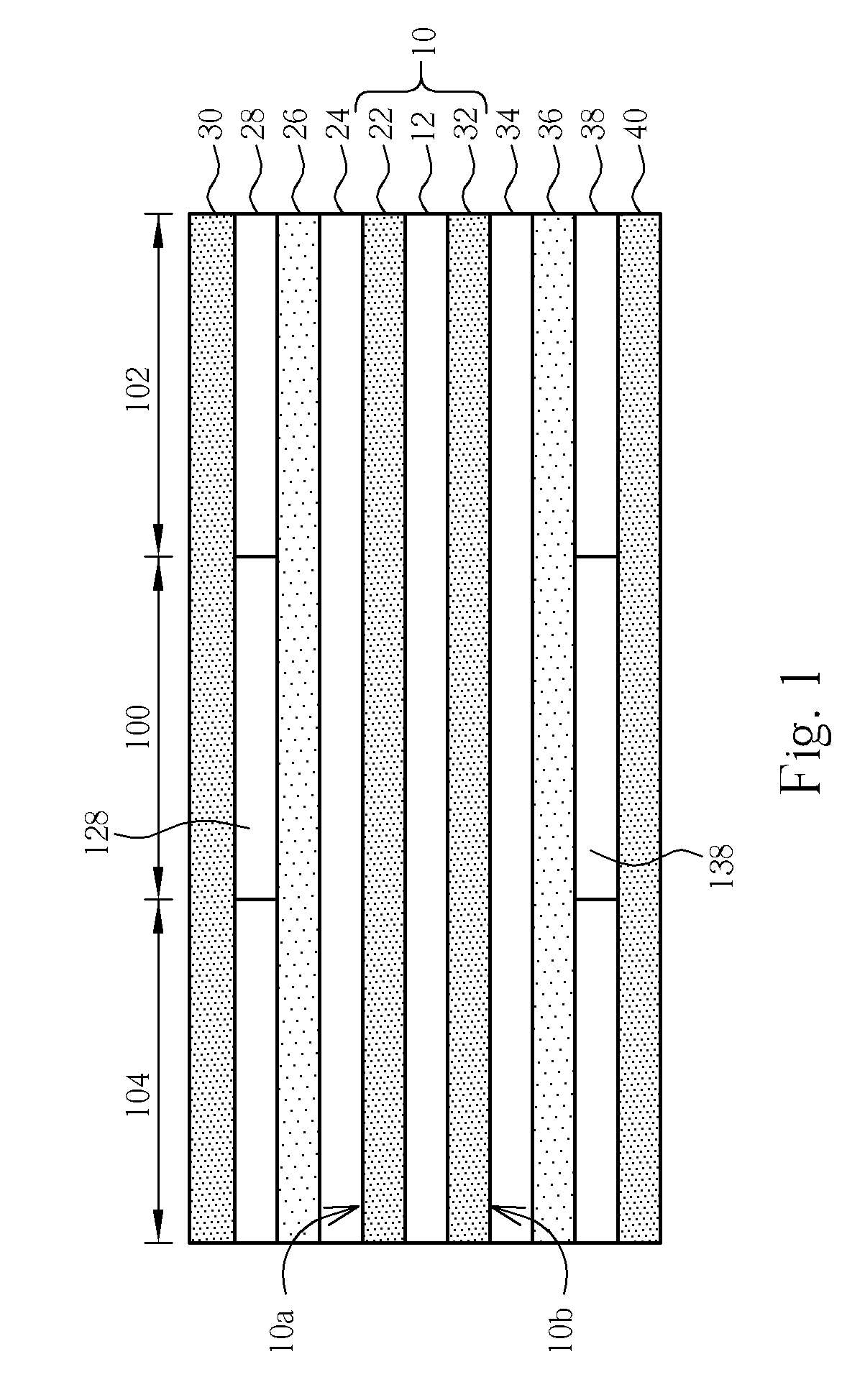

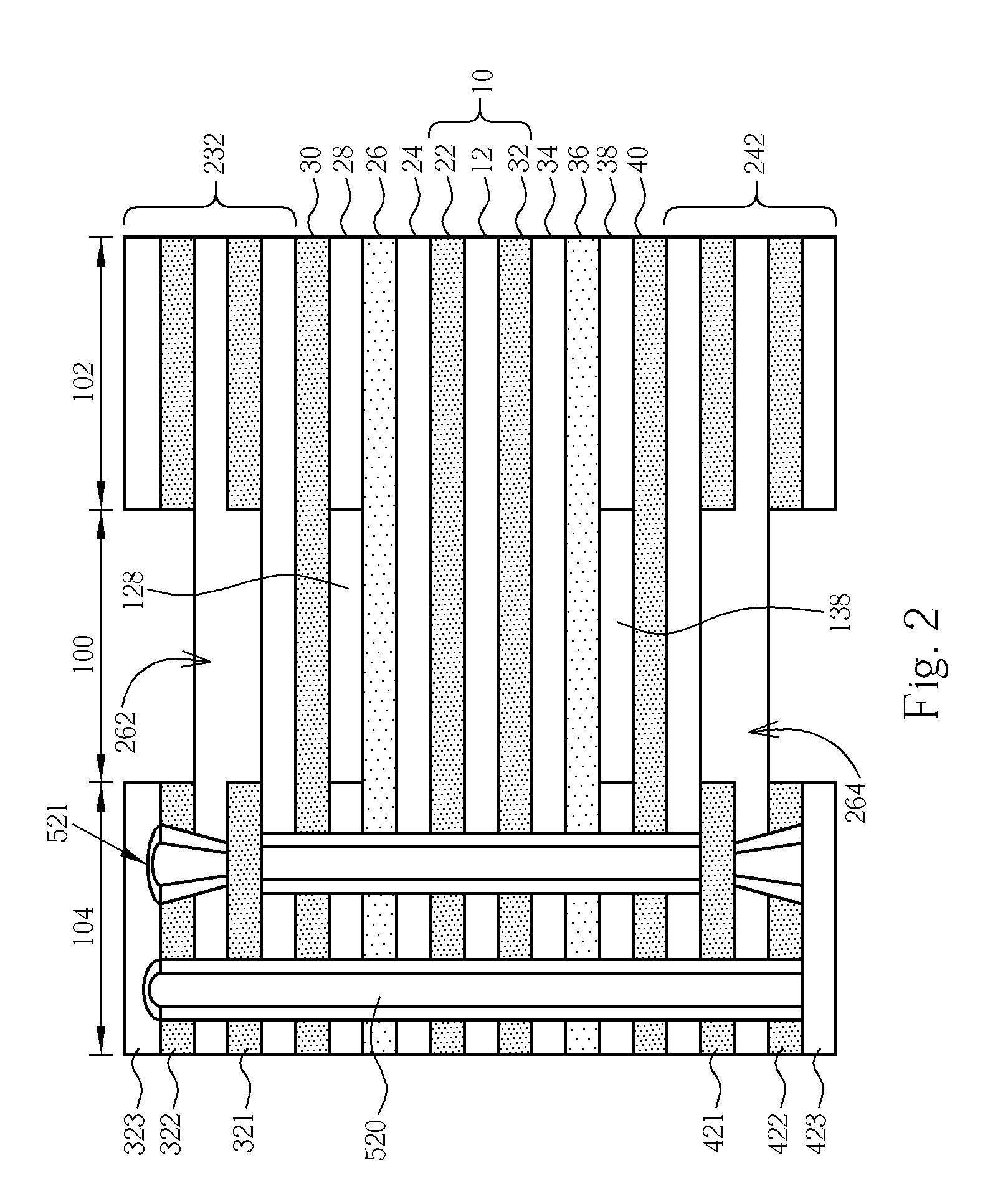

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

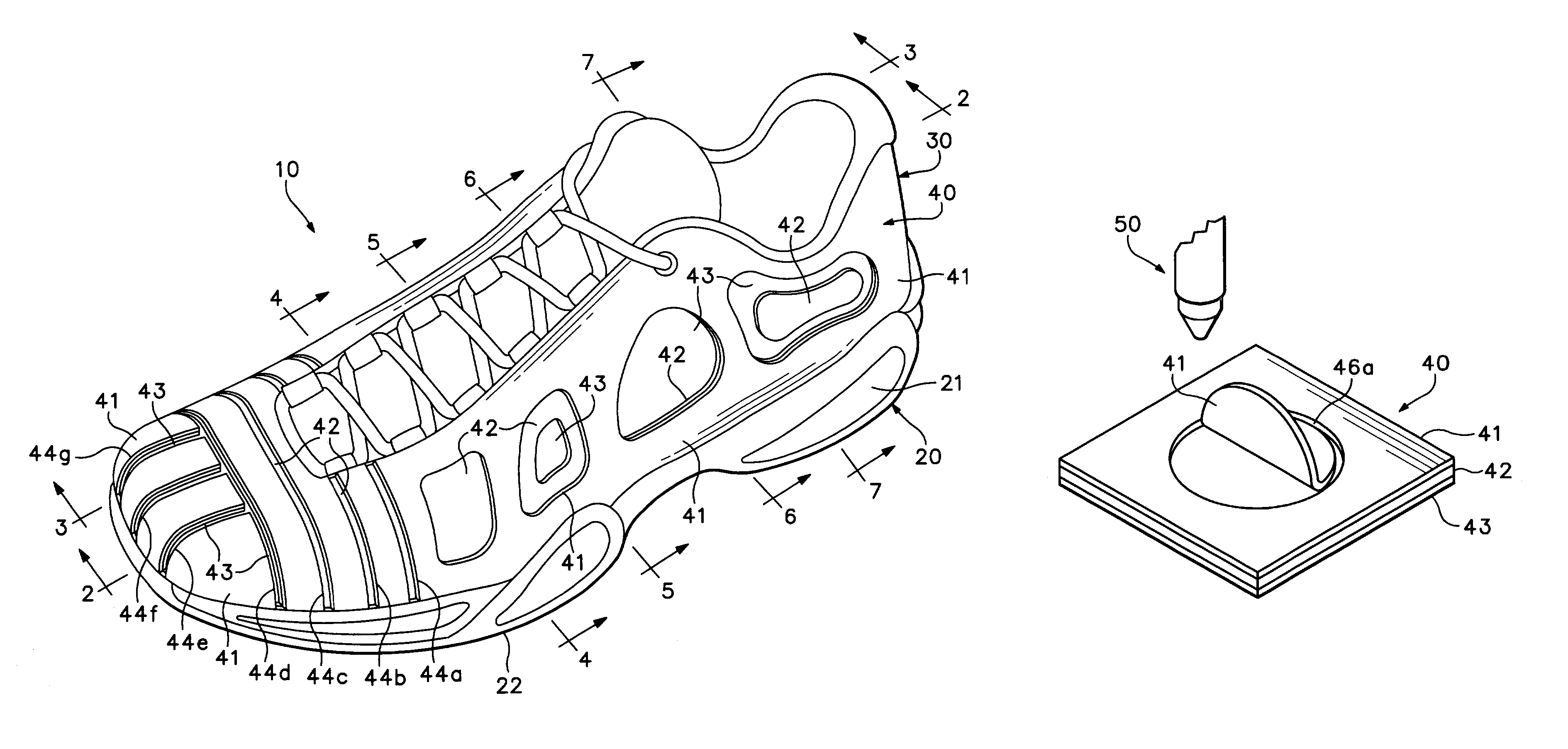

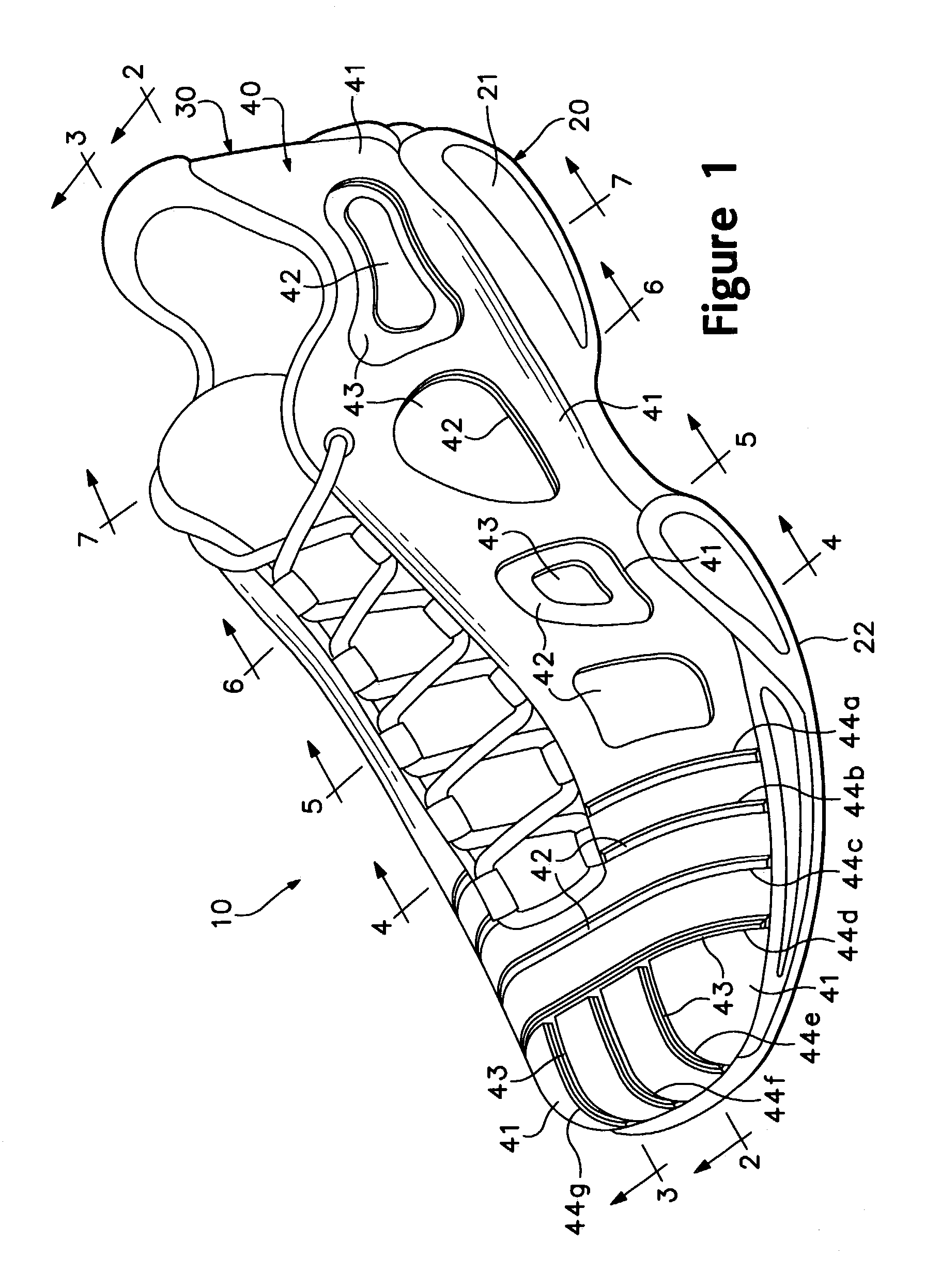

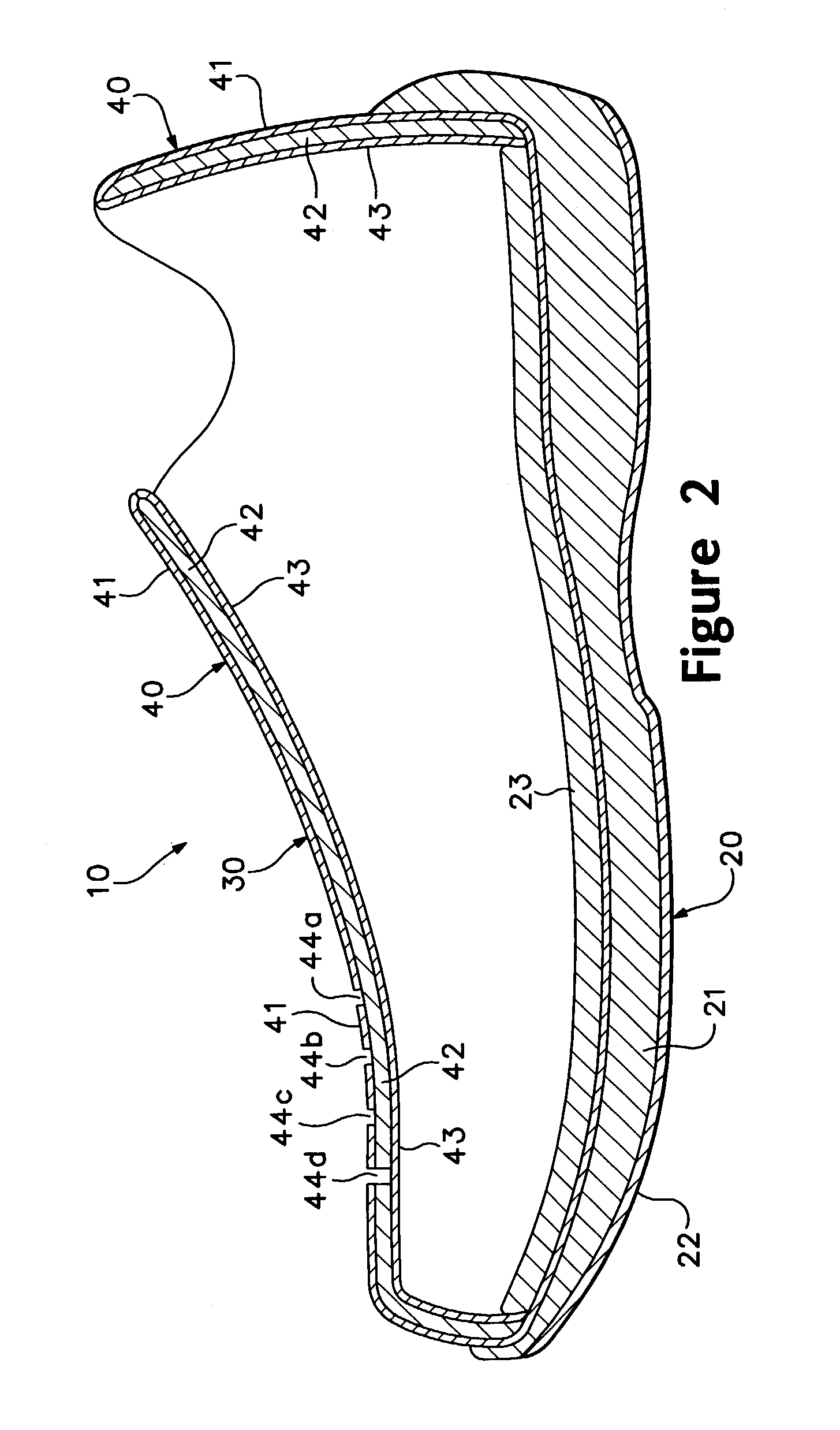

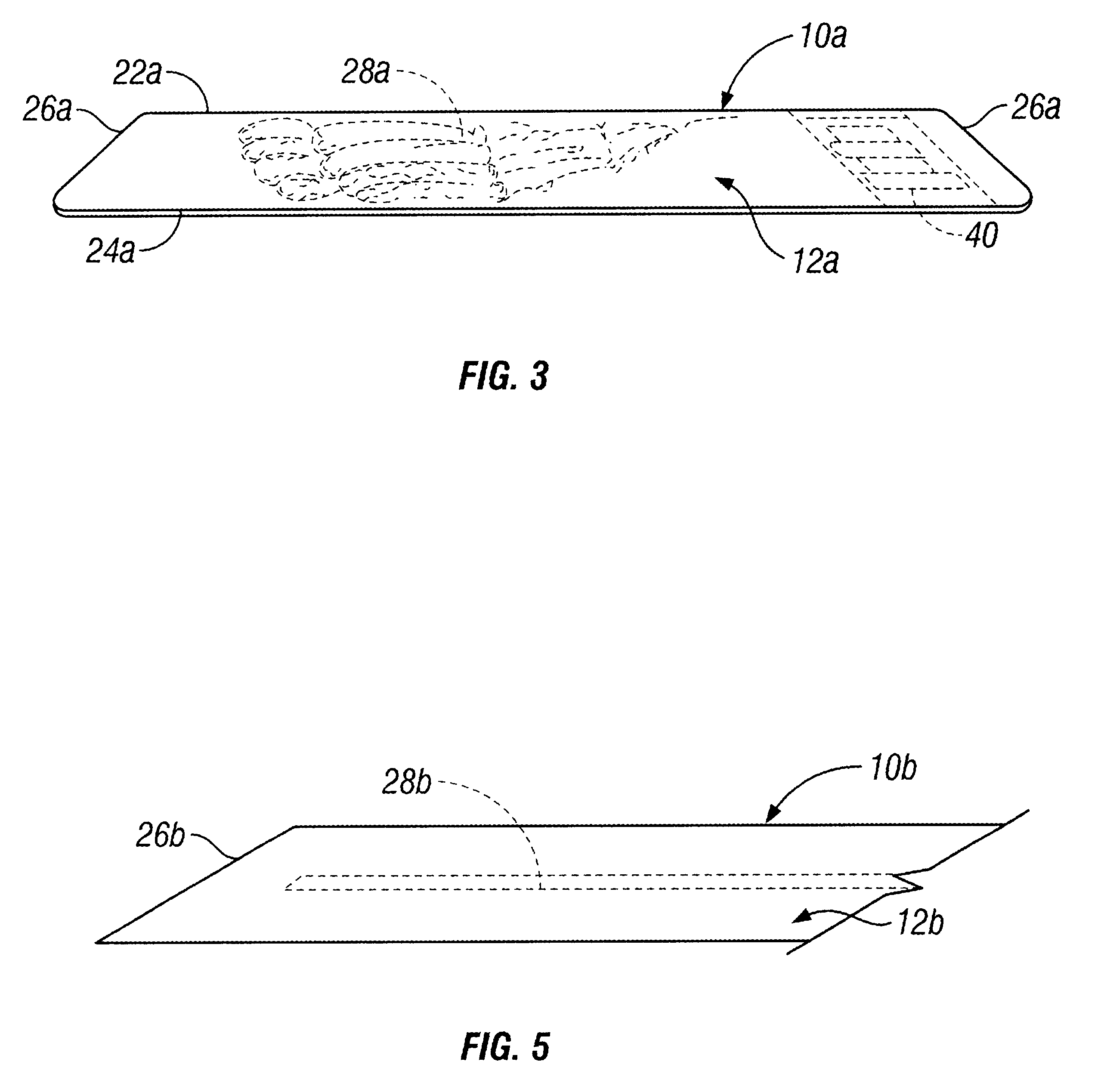

Article and method for laser-etching stratified materials

A method for utilizing a laser to etch a stratified material is disclosed. The method includes providing a stratified material having at least two layers that are secured together, the layers including a first layer and a second layer. An incision is then formed in the stratified material with a laser, the incision extending through the first layer to expose the second layer. The stratified material may then be incorporated into an upper of the article of footwear, for example. By exposing portions of the second layer, properties of the second layer may be exposed in the area of the removed first layer.

Owner:NIKE INC

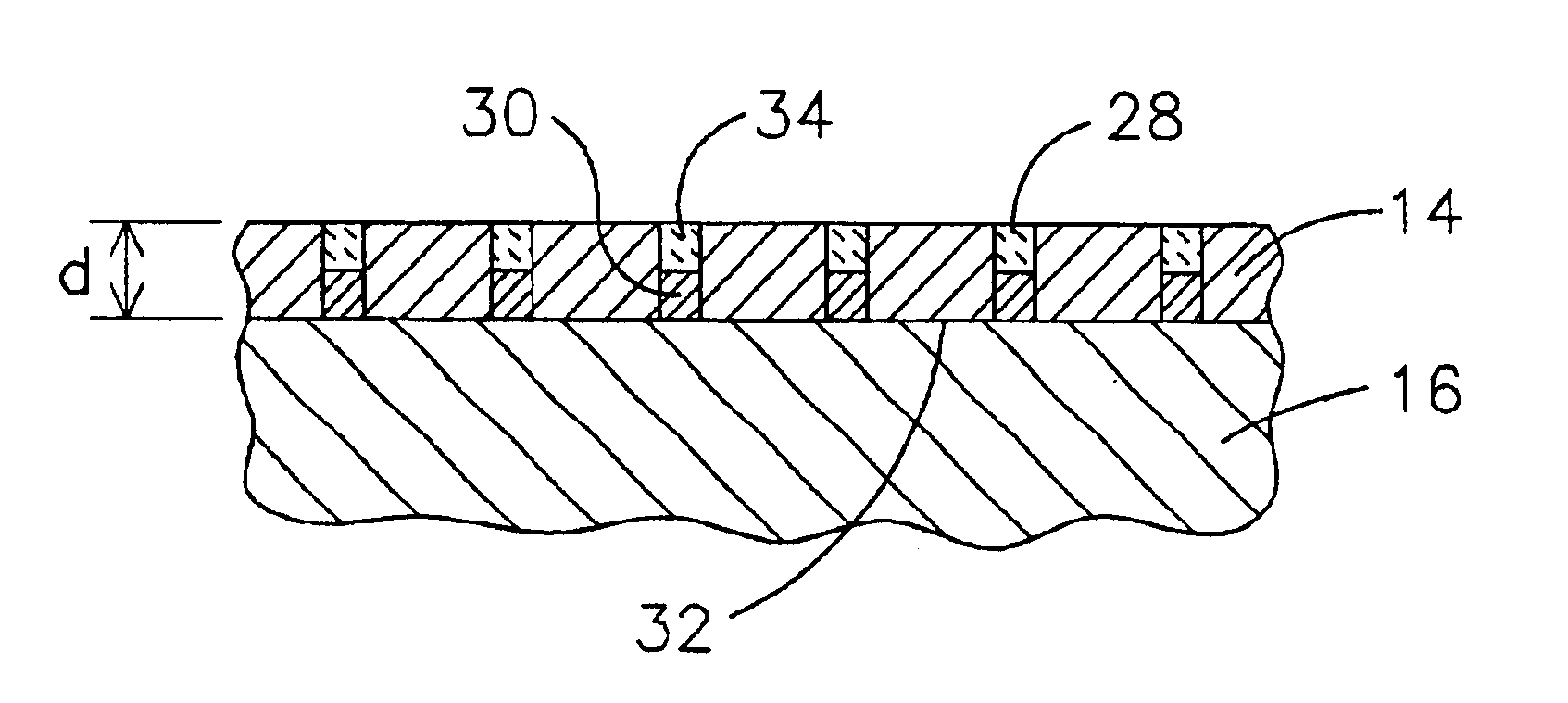

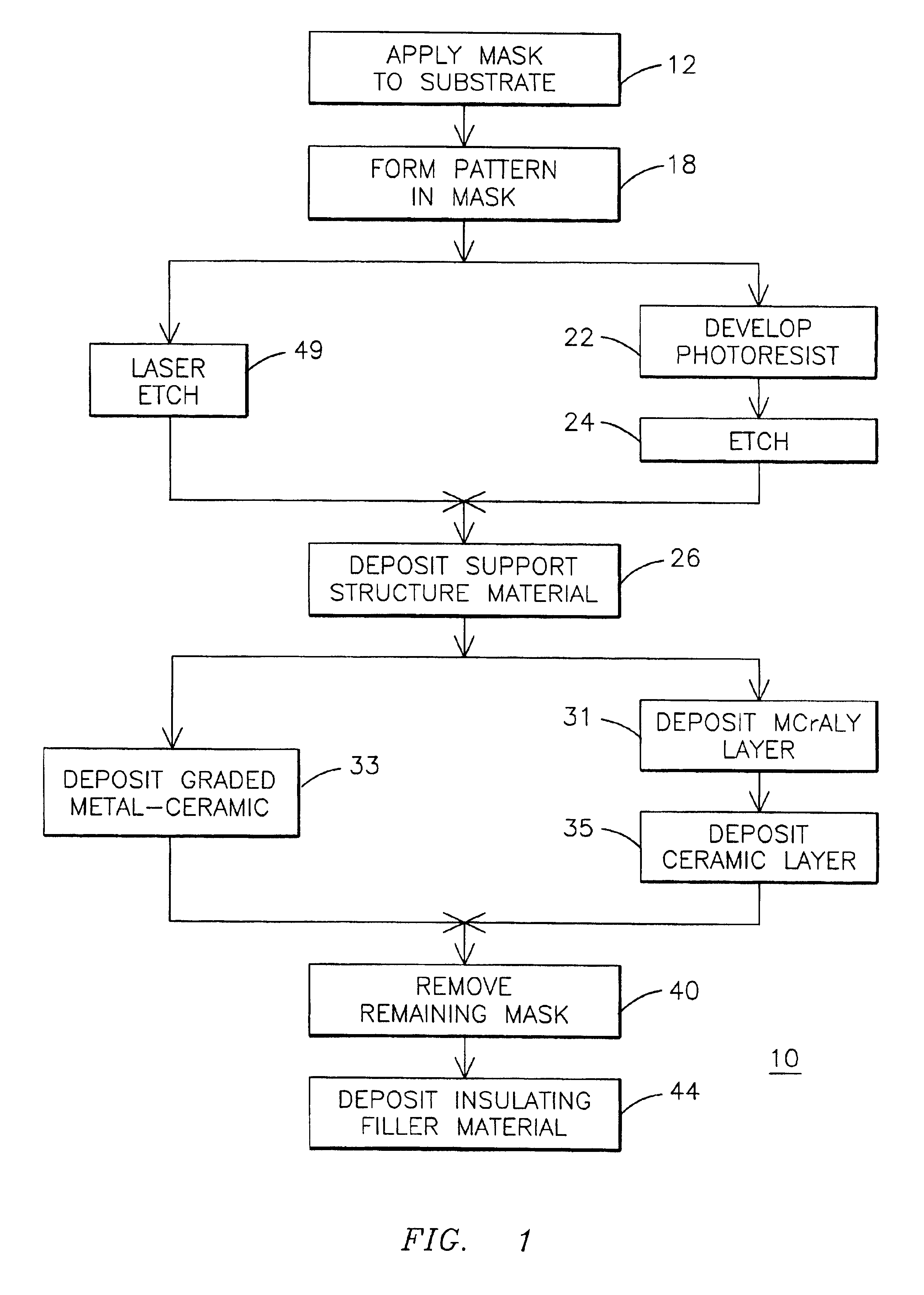

Honeycomb structure thermal barrier coating

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

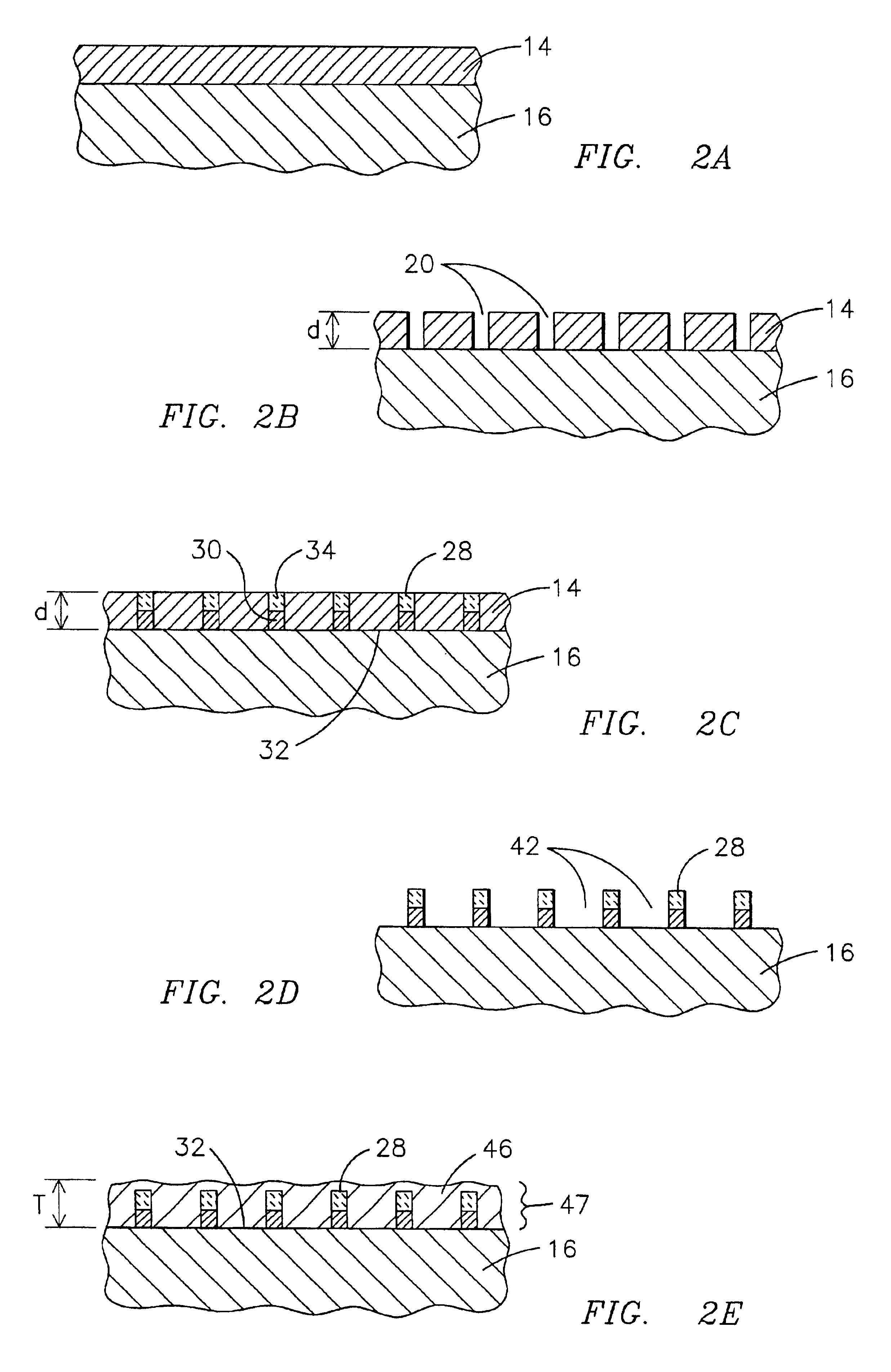

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

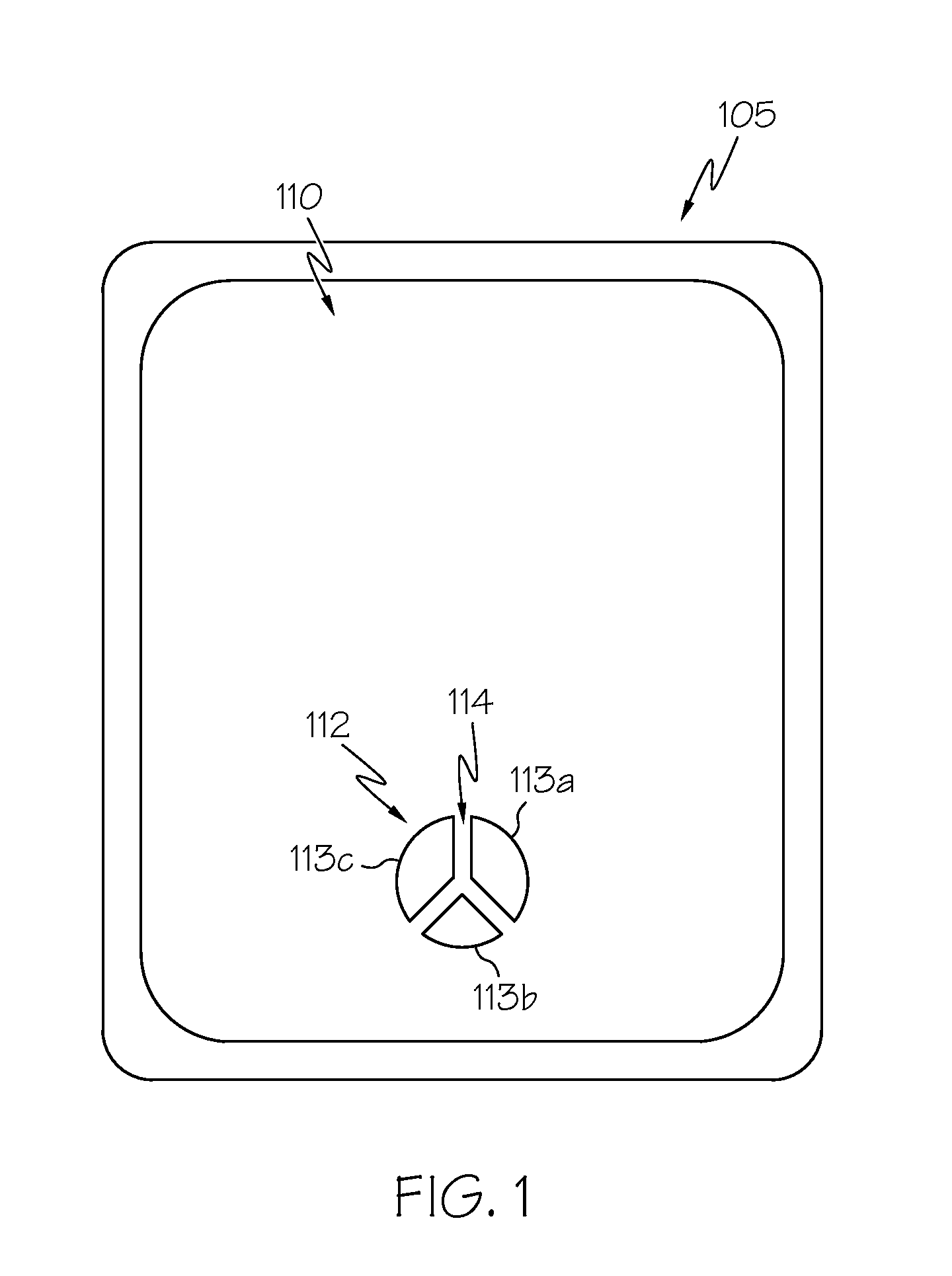

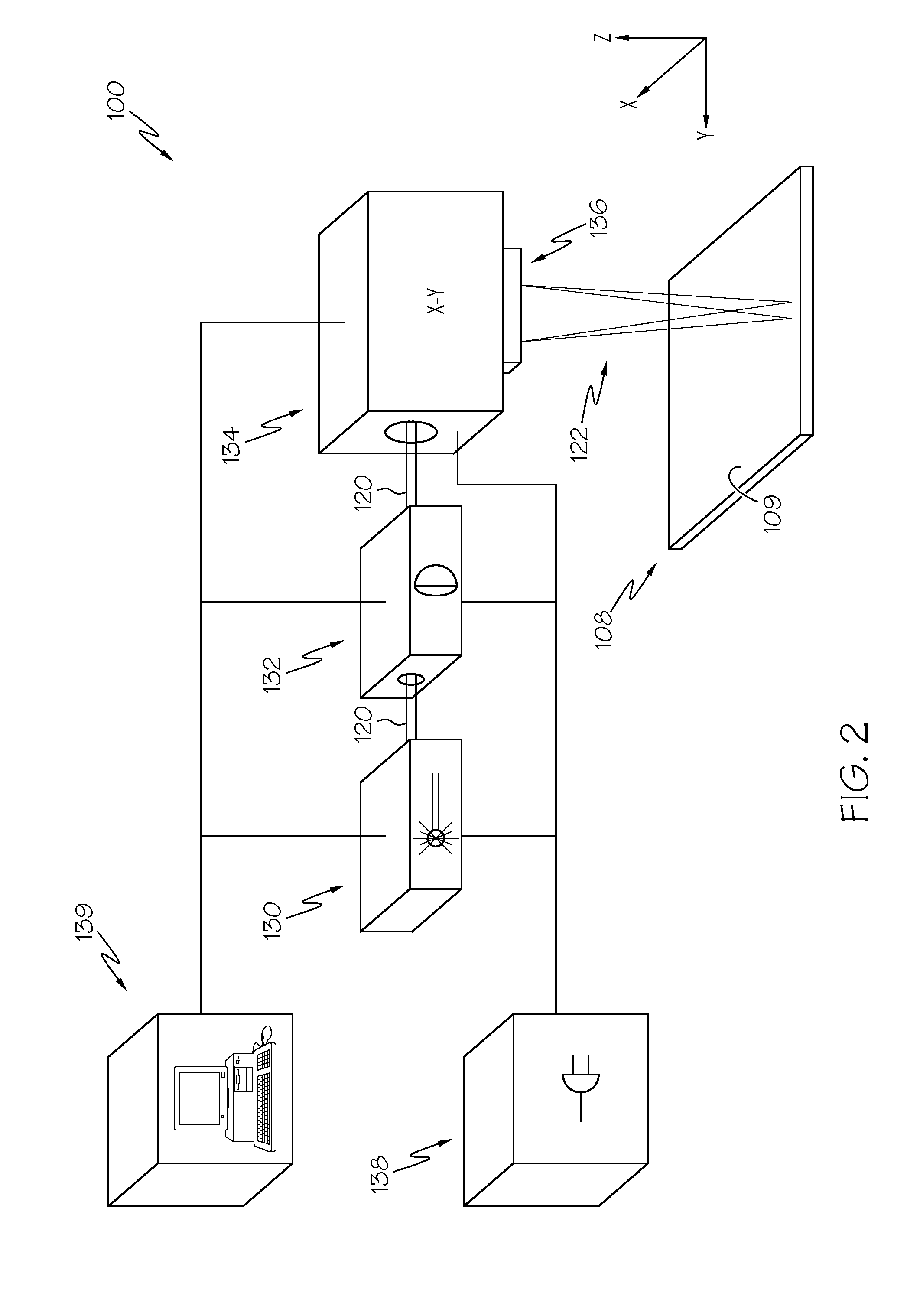

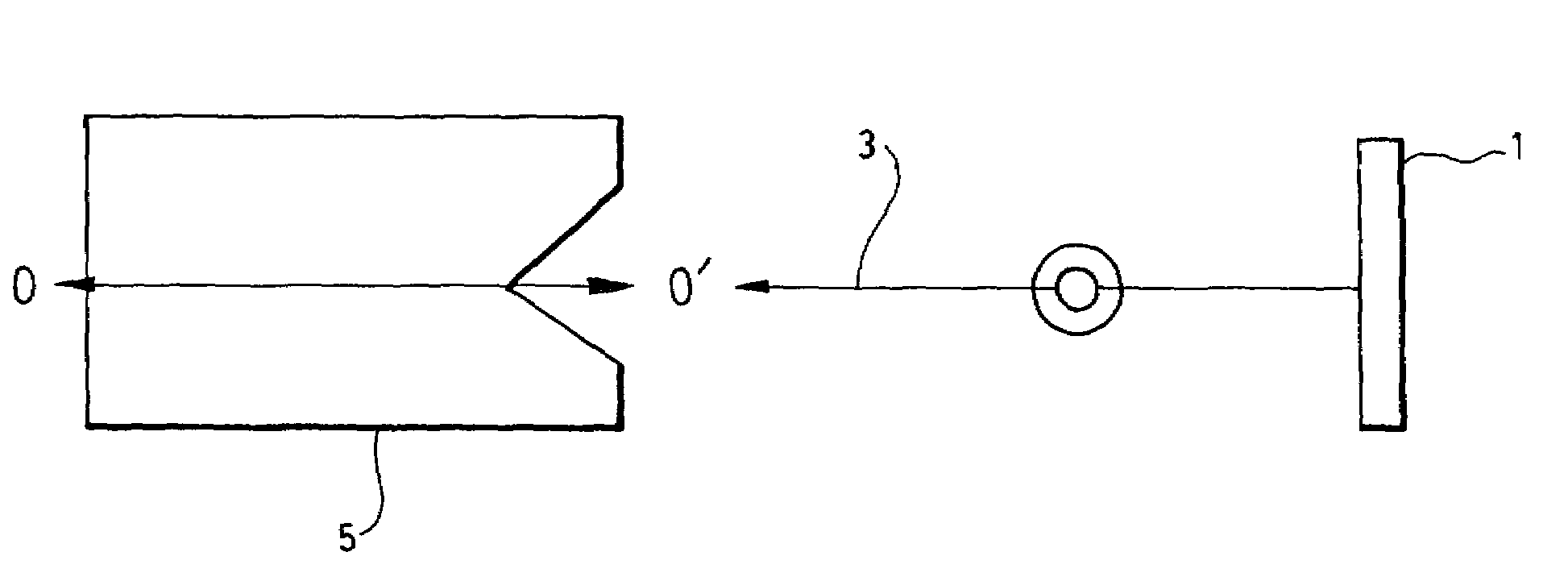

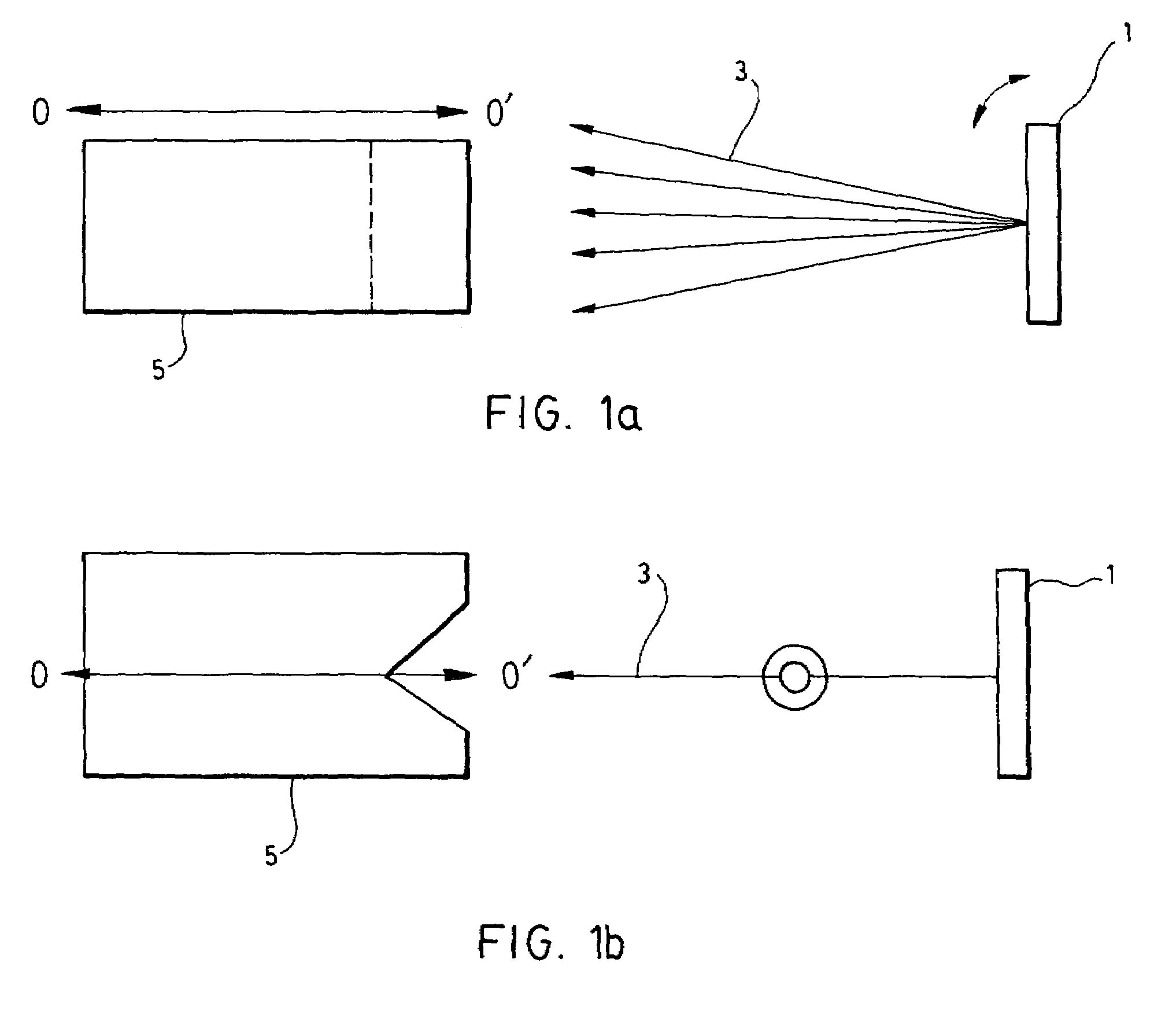

Beam steering optical arrangement using Risley prisms with surface contours for aberration correction

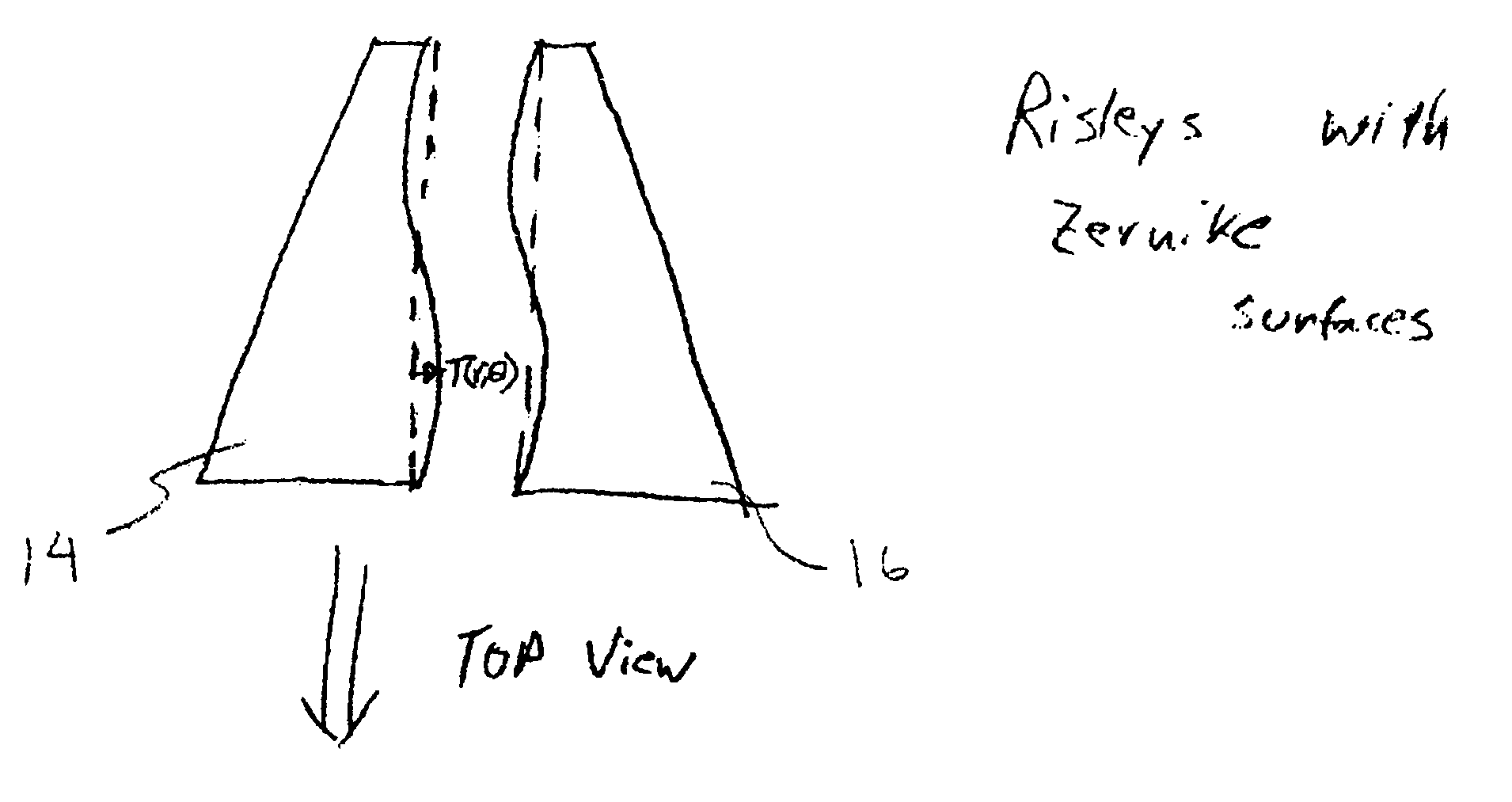

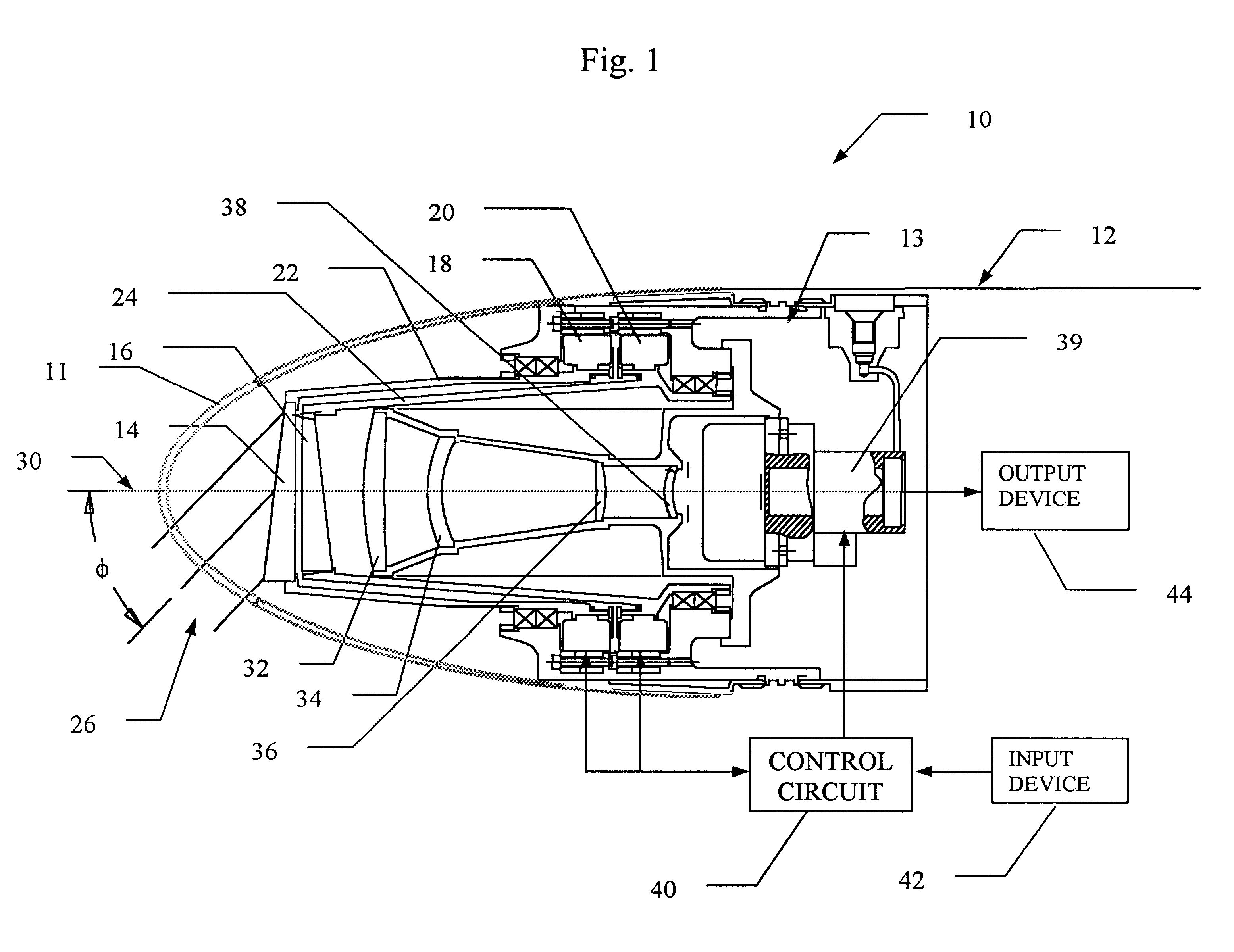

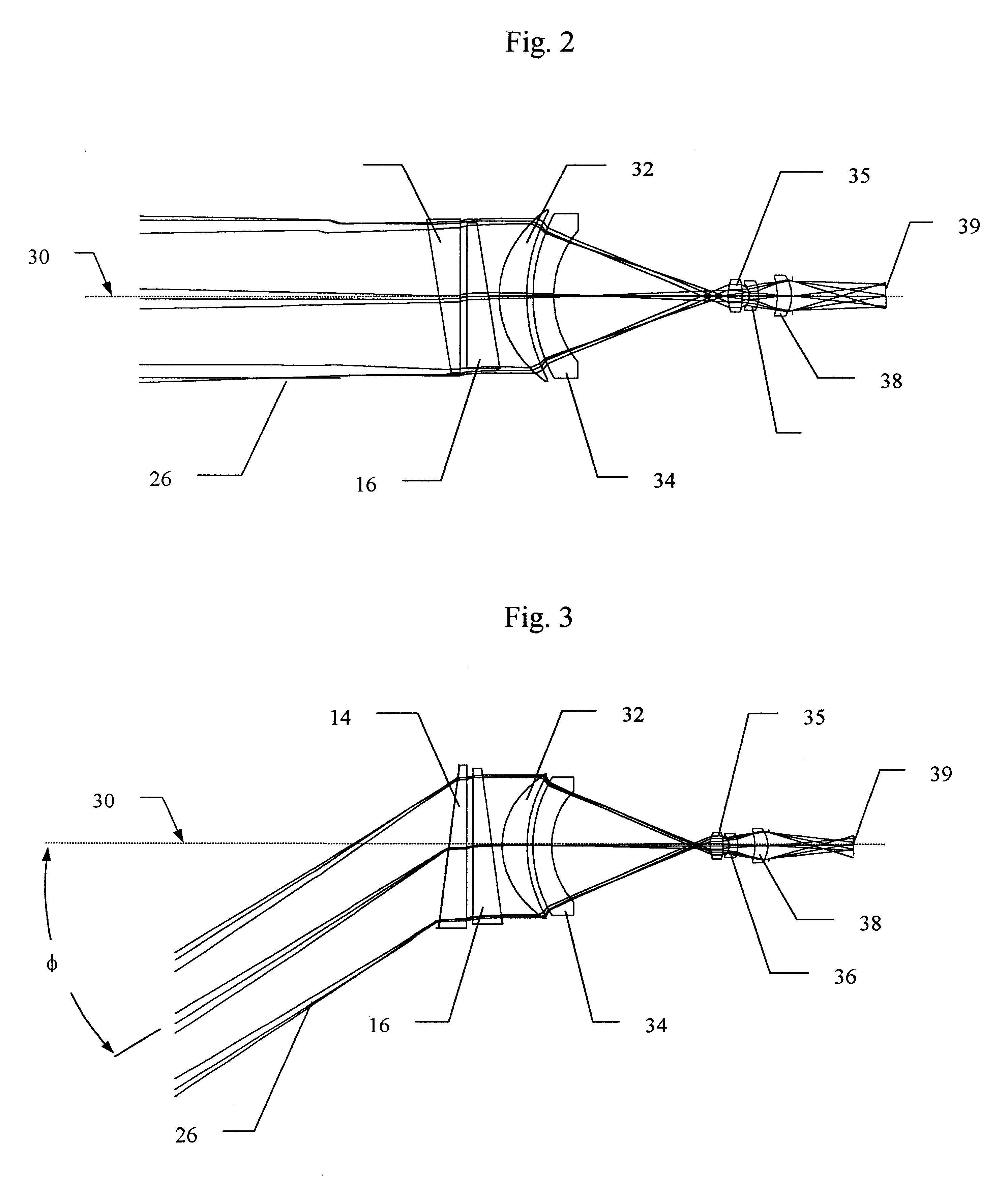

A steerable optical arrangement. The inventive arrangement includes a first prism mounted for rotation about an optical axis and a second prism mounted for rotation about the optical axis. In accordance with the inventive teachings, the first prism and / or the second prism have at least one surface contoured to correct for optical aberration. In the illustrative embodiment, the first and second prisms are Risley prisms. In addition, the illustrative implementation includes a first motor arrangement for rotating the first prism about the optical axis and a second motor arrangement for rotating the second prism about the optical axis. A controller is provided for activating the first and second motors to steer the beam at an angle phi and nod the beam at an angle theta. At least two surfaces at least one prism is contoured to correct for astigmatism, coma, trefoil and other non-rotationally symmetric aberration. The contour is effected by laser etching, micro-machining or optical thin-film coating of the prisms in the manner disclosed herein.

Owner:RAYTHEON CO

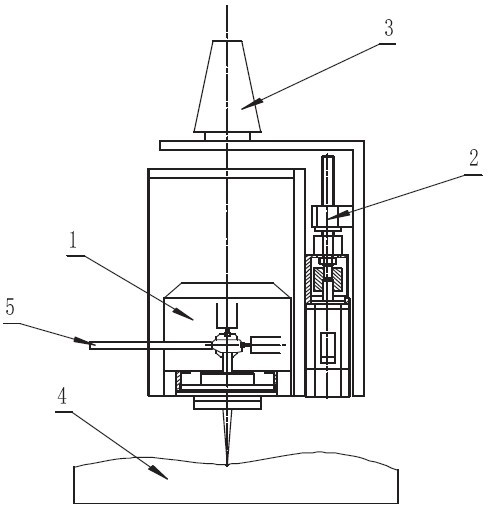

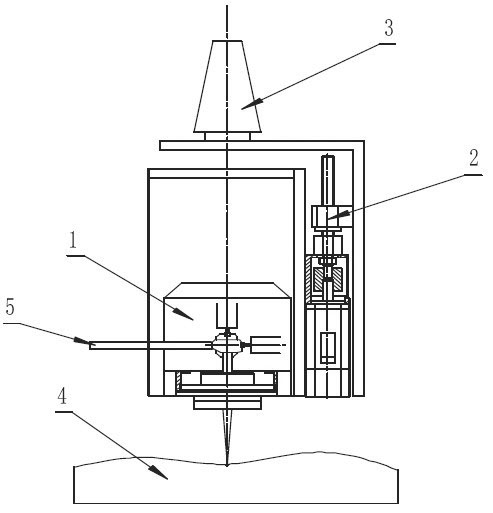

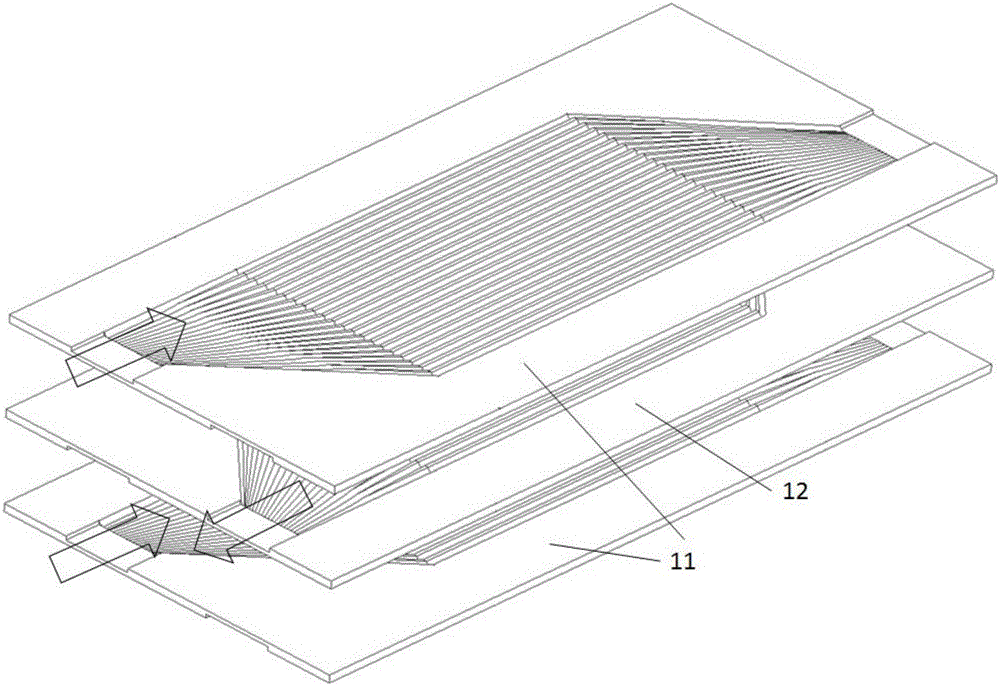

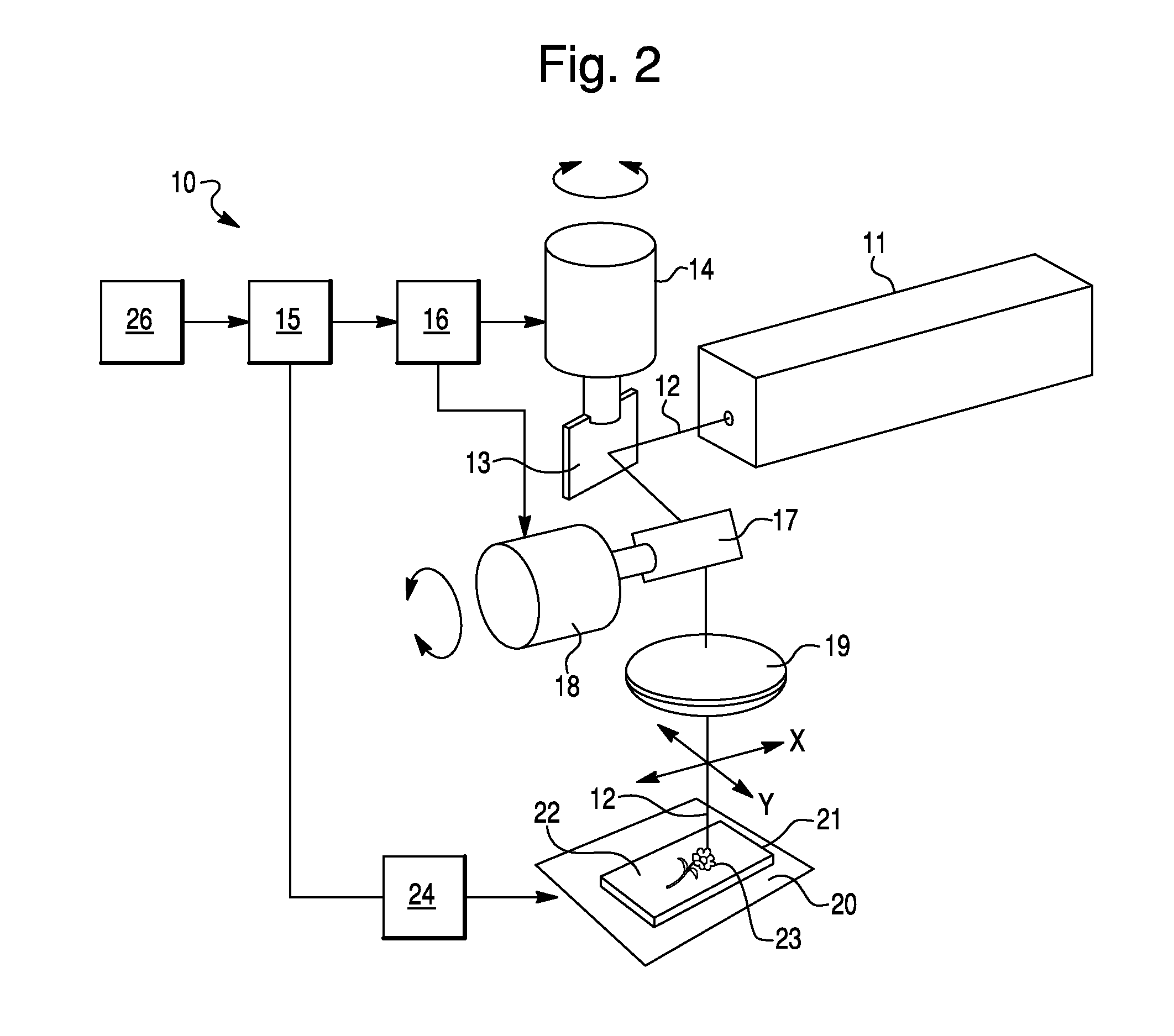

Laser machining method and device applicable for complicated curved surface

ActiveCN102151984AReduce the overall heightImprove energy consumptionLaser beam welding apparatusLaser etchingLaser processing

The invention provides a laser machining method applicable for a complicated curved surface. By adopting processing steps of dividing the complicated curved surface into curved surface sheets and establishing a coordinate system of each curved surface sheet, the subsequent processing steps of dividing sub blocks and machining pattern parallel projection can be implemented according to the coordinates of the curved surface sheets respectively, so the limit that a machining molded surface backing to a laser incident direction or a steep surface parallel to an optical axis direction cannot be machined because only one coordinate system is adopted to perform whole injection in the prior art can be overcome, the machining efficiency is improved and the machining applicable range is extended. The invention also provides a laser machining device. The laser machining device has a three-axis laser machining head structure provided with a two-axis laser polarization mirror and a Z-axis mobile mechanism, so the problem that the conventional system depends on a three-axis lathe is solved; therefore, a machining unit is independent and compact, and is easy to assemble and disassemble; the conventional five-axis linkage milling machine can be changed into a laser-etching machining lathe so that the functions are compatible; and the laser machining device has a significant practical value.

Owner:武汉飞能达激光技术有限公司

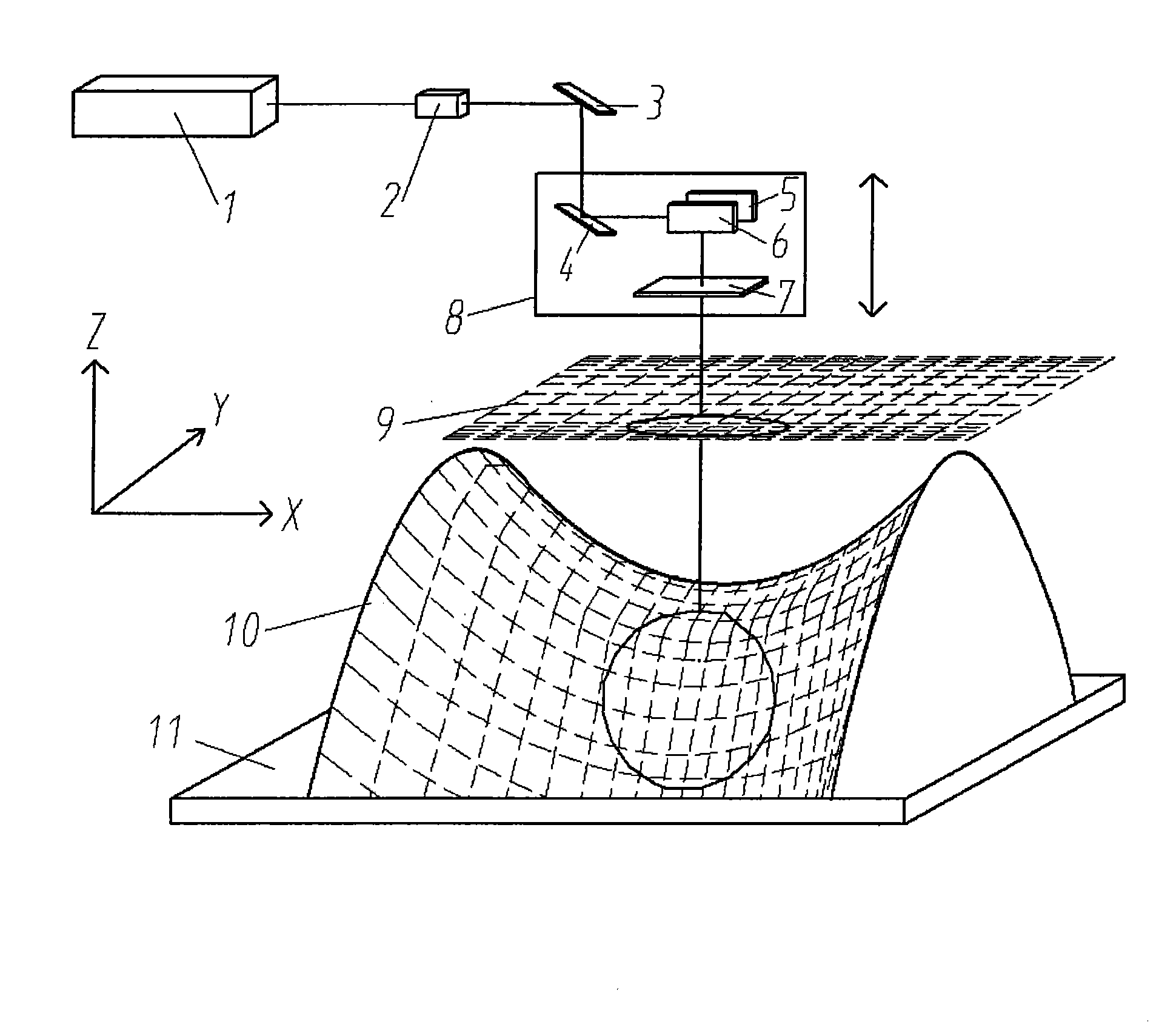

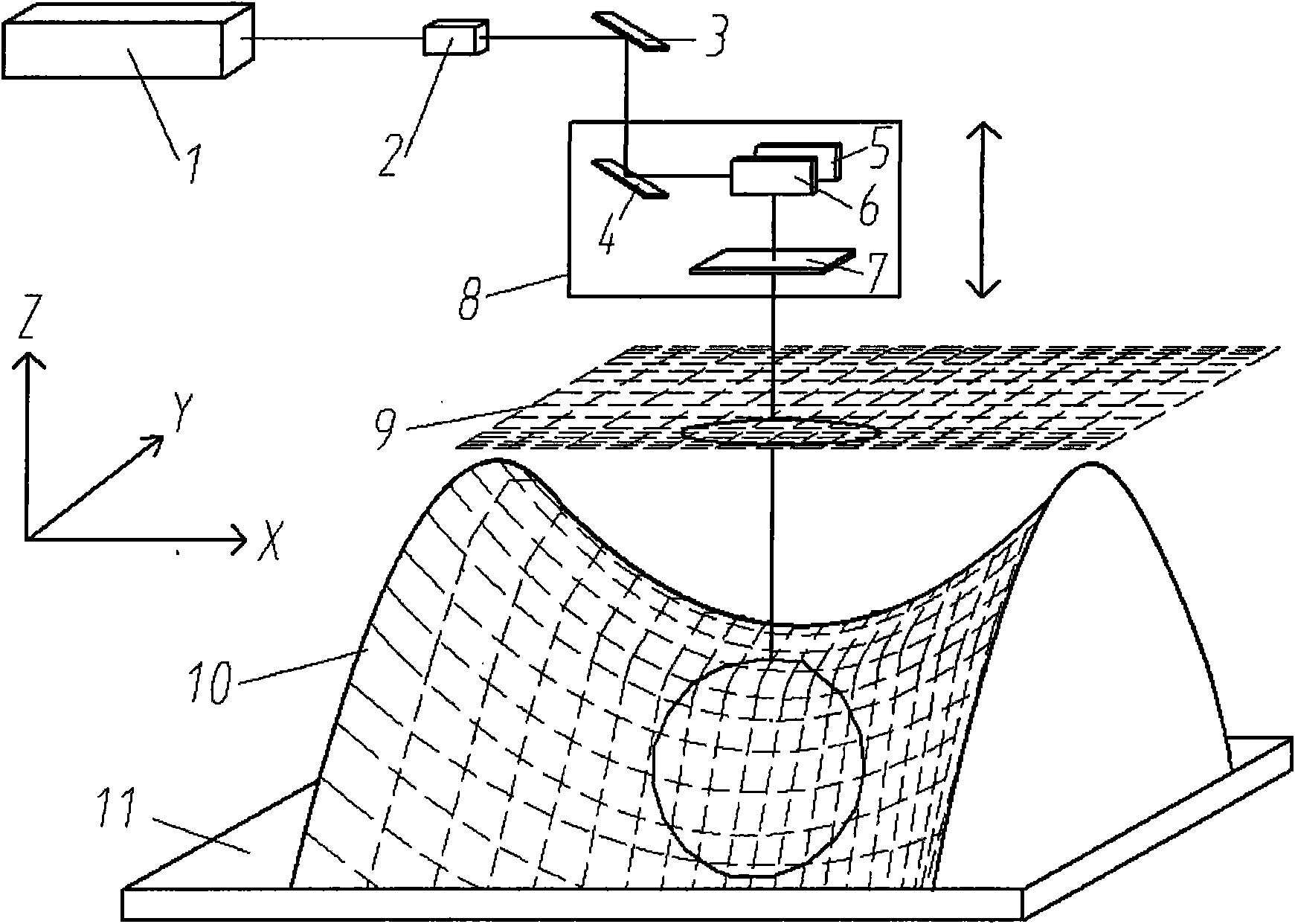

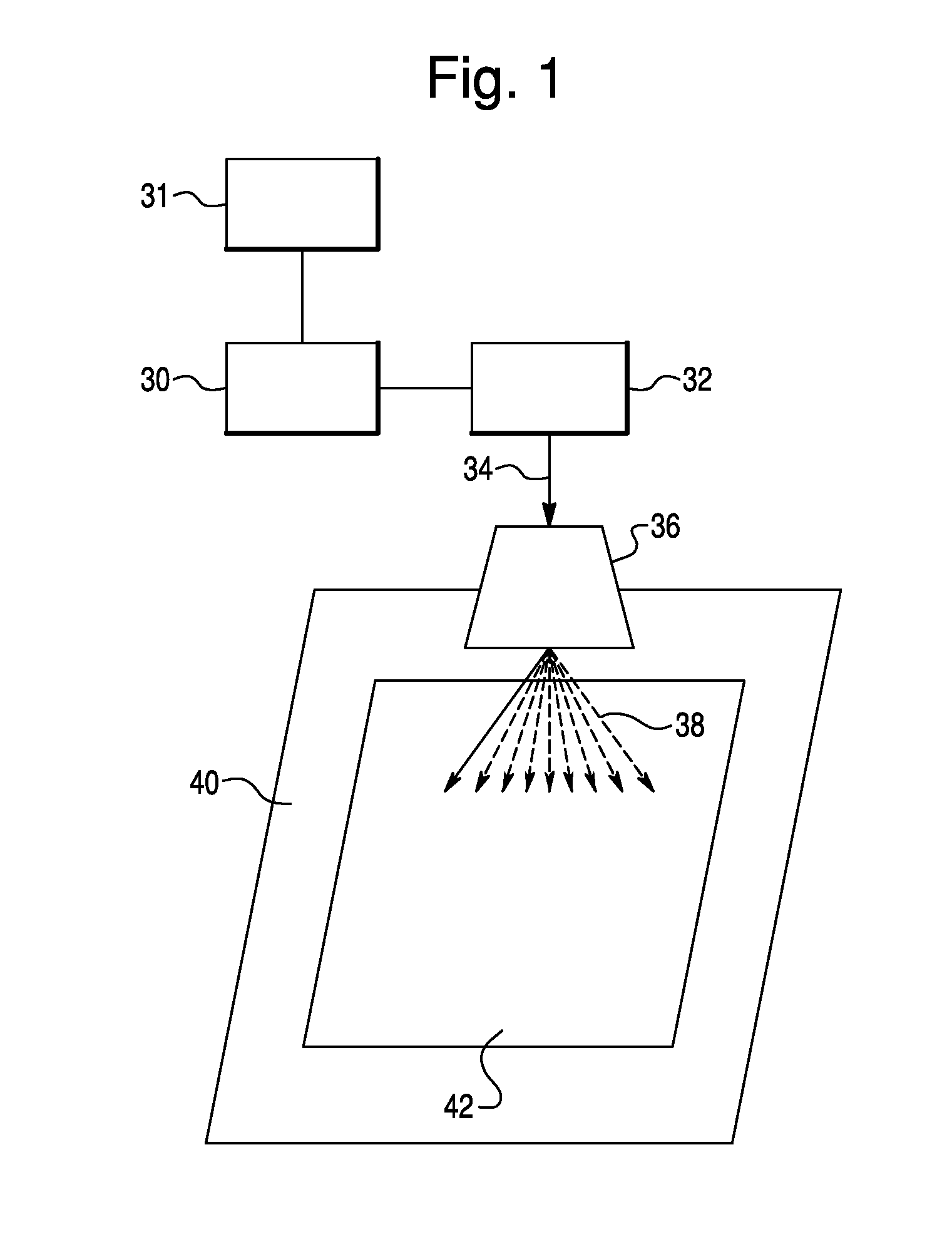

Method for projection-type laser etching on free curved surface

ActiveCN101786200AImprove efficiencySimple processLaser beam welding apparatusLaser etchingLaser processing

The invention discloses a method for projection-type laser etching on a free curved surface. By combining a laser galvanometer as well as a triaxial coordinate positioning technology and adopting the principles of partitioned parallel projection as well as height mapping, the invention directly conducts precise surface laser etching on the basis of a discrete point cloud model of a free curved surface part. The method has the characteristic that the laser etching properties such as the shape and size of a spot and the energy distribution remain unchanged within the focal depth range of a focusing lens, so that the free curved surface is converted into a plurality of plane subblocks for processing, and the high-precision processing efficiency of the free curved surface can be improved even by adopting the existing laser etching technology. The diameter of the focusing spot of a laser beam can reach tens of microns and is much smaller than the size of the part processed by a traditional knife tool; and the processing precision of nearly 10 microns can be realized by controlling the laser energy property. Under the premise of meeting the demands for high precision and high efficiency of pattern etching on the free curved surface, the method can realize high reliability and high flexibility in the processing of the free curved surface.

Owner:武汉飞能达激光技术有限公司

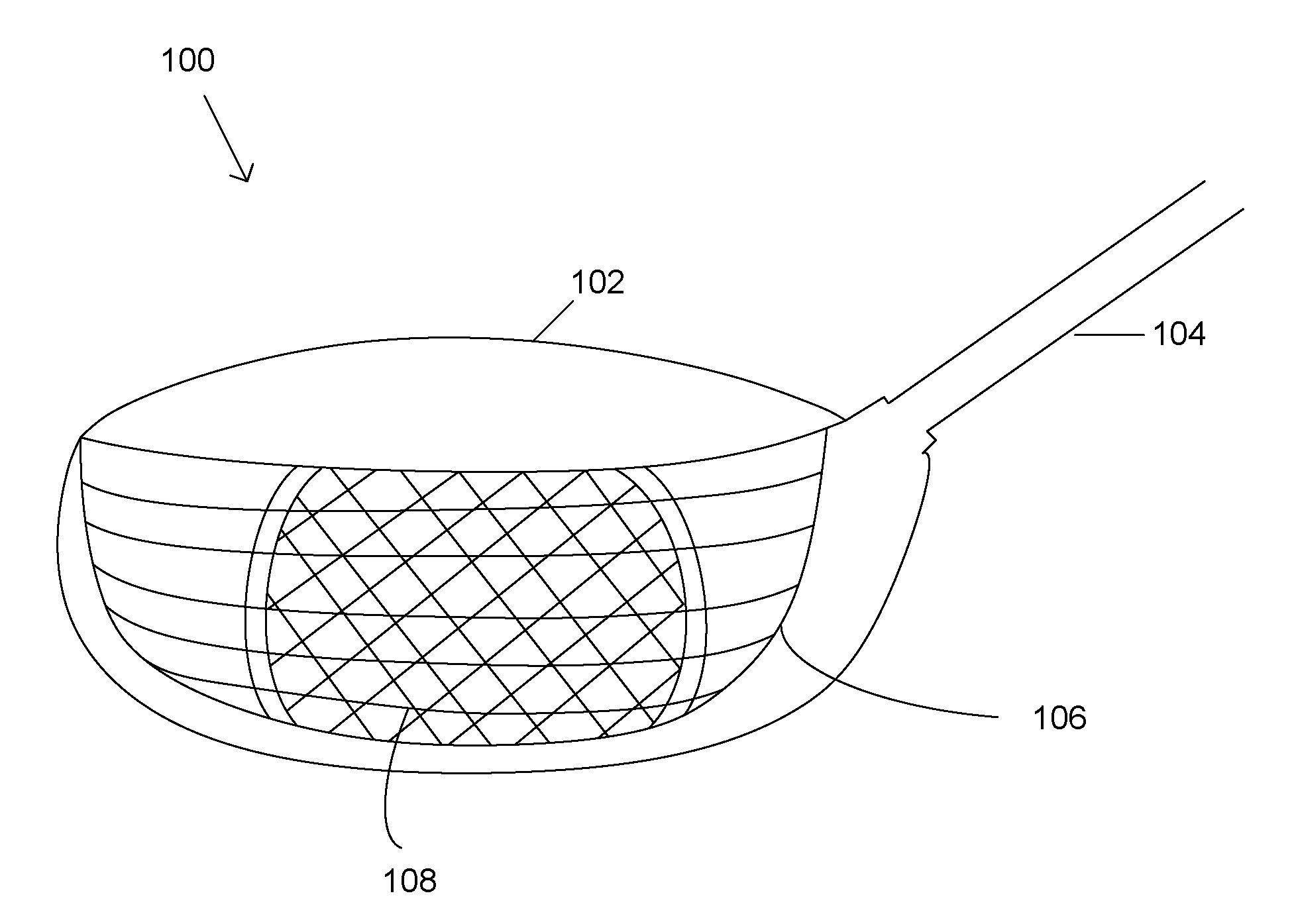

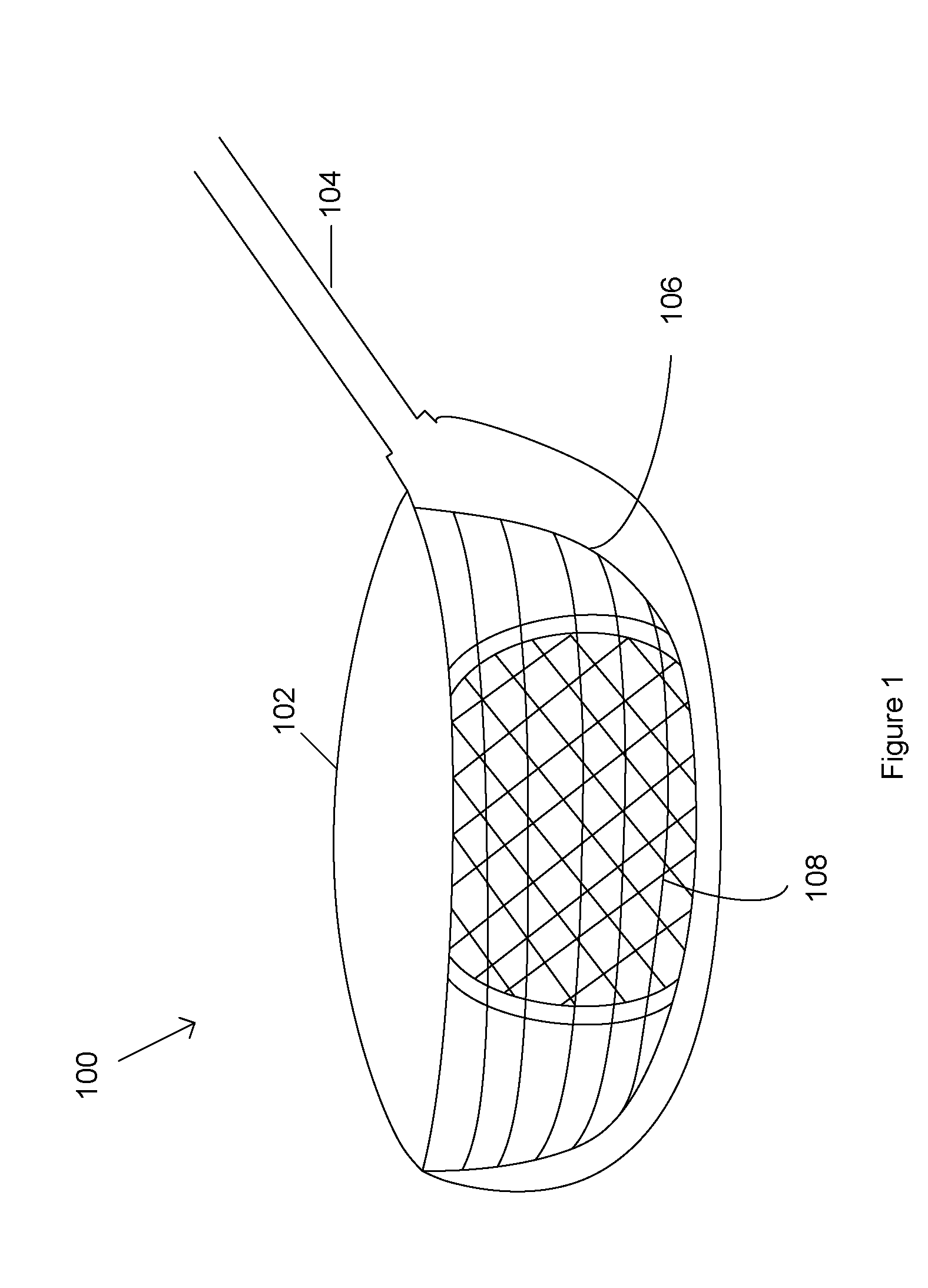

Treatment for the hitting surface of a golf club and a method for applying the same

InactiveUS20080051212A1Prevent slidingGood lookingGolf clubsRacket sportsLaser etchingDiamond cutting

A treatment that can be applied to the face of a golf club head complies with USGA regulations but imparts certain advantageous characteristics. The treatment can comprise a certain pattern and can be imparted to the club head via laser etching, diamond cutting, chemical etching or any other process that will achieve the desired result. In accordance with USGA rules, the treatment must cover the intended area of impact on the golf club face.

Owner:MAX OUT GOLF

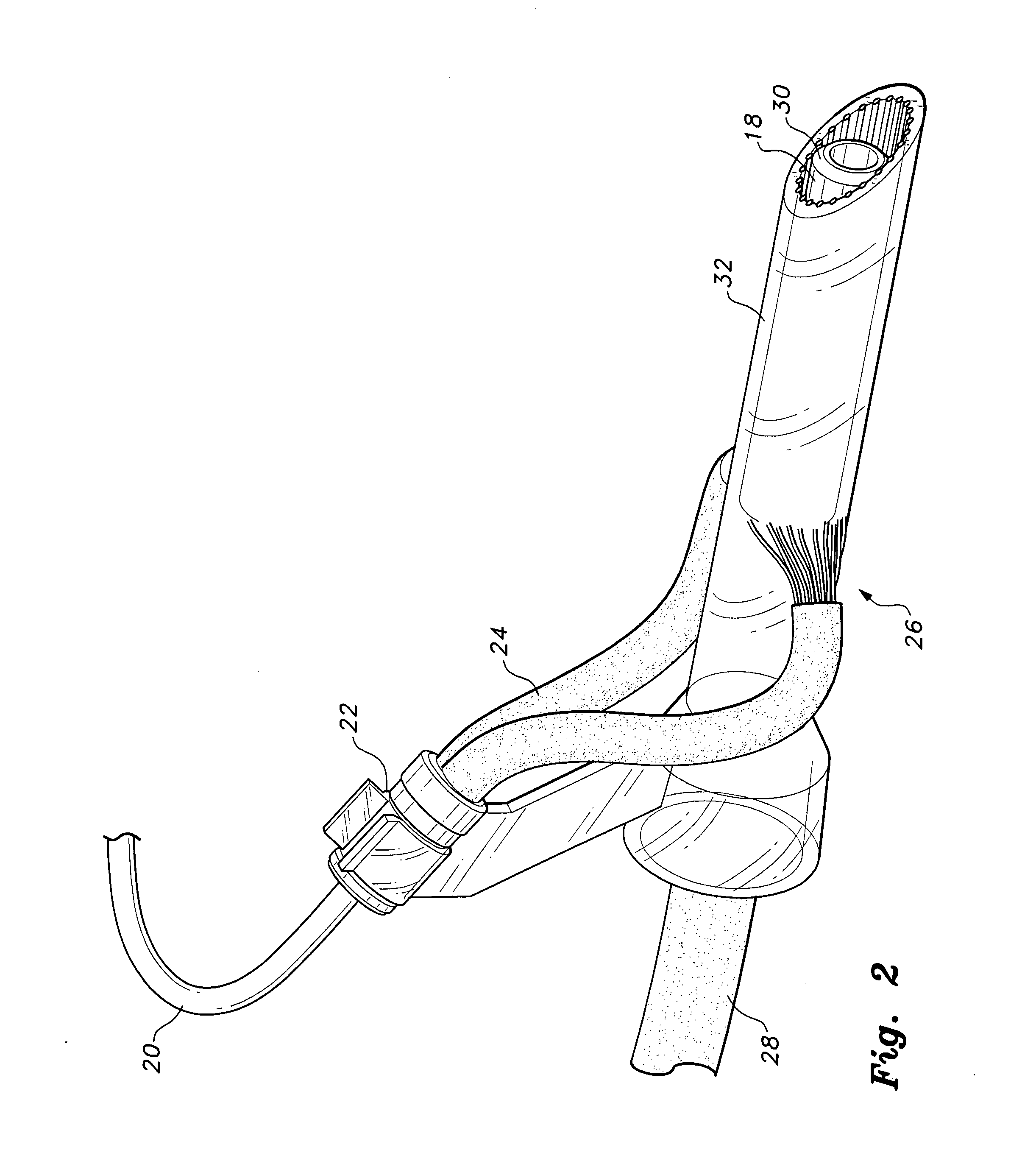

Self-cleaning and sterilizing endotracheal and tracheostomy tube

ActiveUS20080257355A1Trend downMaintain airwayTracheal tubesPhysical/chemical process catalystsEndotracheal tubeGuide tube

The self-cleaning and sterilizing endotracheal and tracheostomy tube may include a combination of an endotracheal tube or a tracheostomy tube and a suction catheter that decreases the tendency of mucus and bacteria to adhere to the inner surfaces of the thereof. The endotracheal tube and the catheter may have a hydrophobic surface exhibiting the lotus effect, which may be formed either by femtosecond laser etching or by a coating of ploy (ethylene oxide). Alternatively, the endotracheal tube and the catheter may have a lumen coated with a photocatalyst. The endotracheal tube may also have a light source and a fiberoptic bundle mounted thereon, the optical fibers extending into the lumen to illuminate the photocatalyst.

Owner:RAO CHAMKURKISHTIAH P

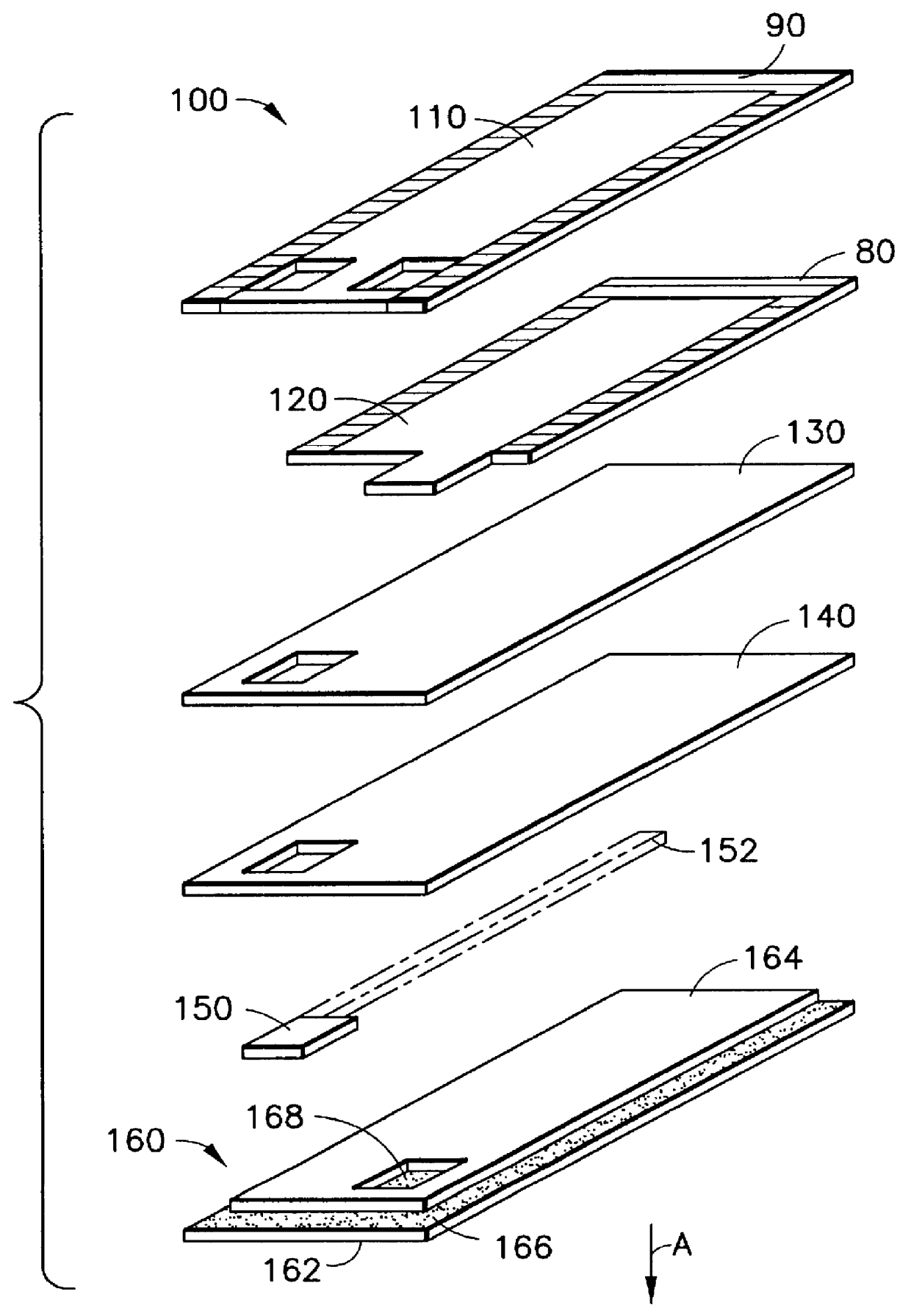

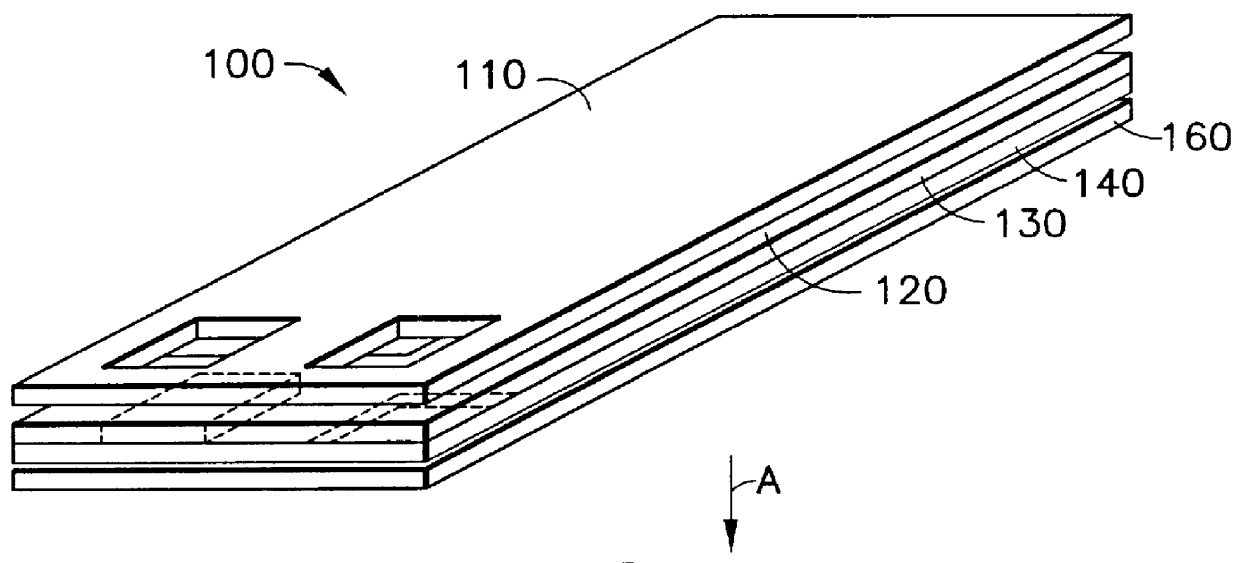

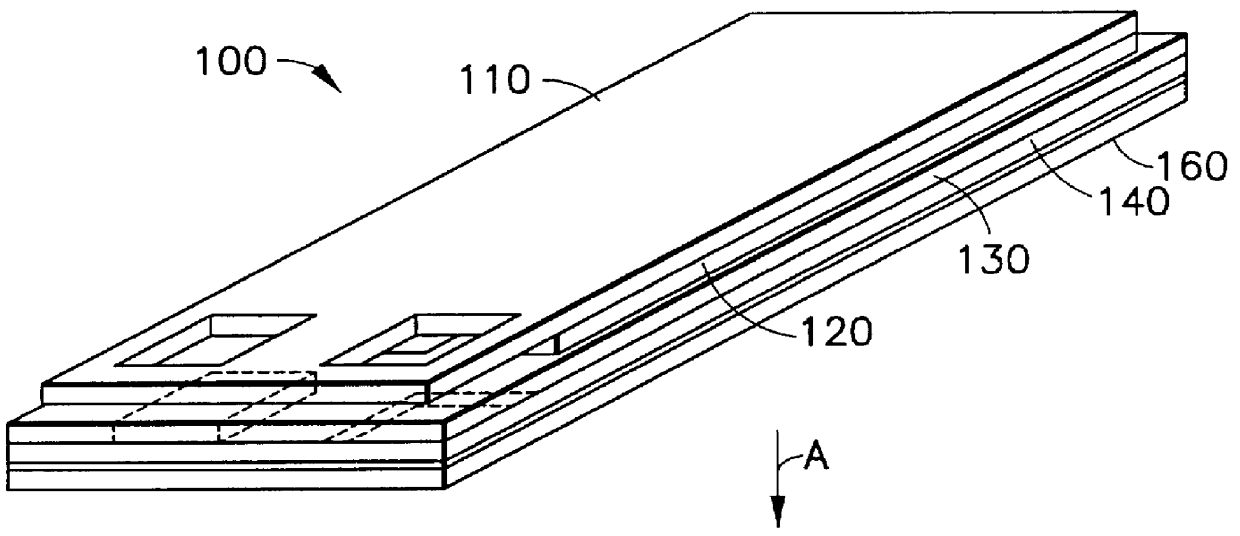

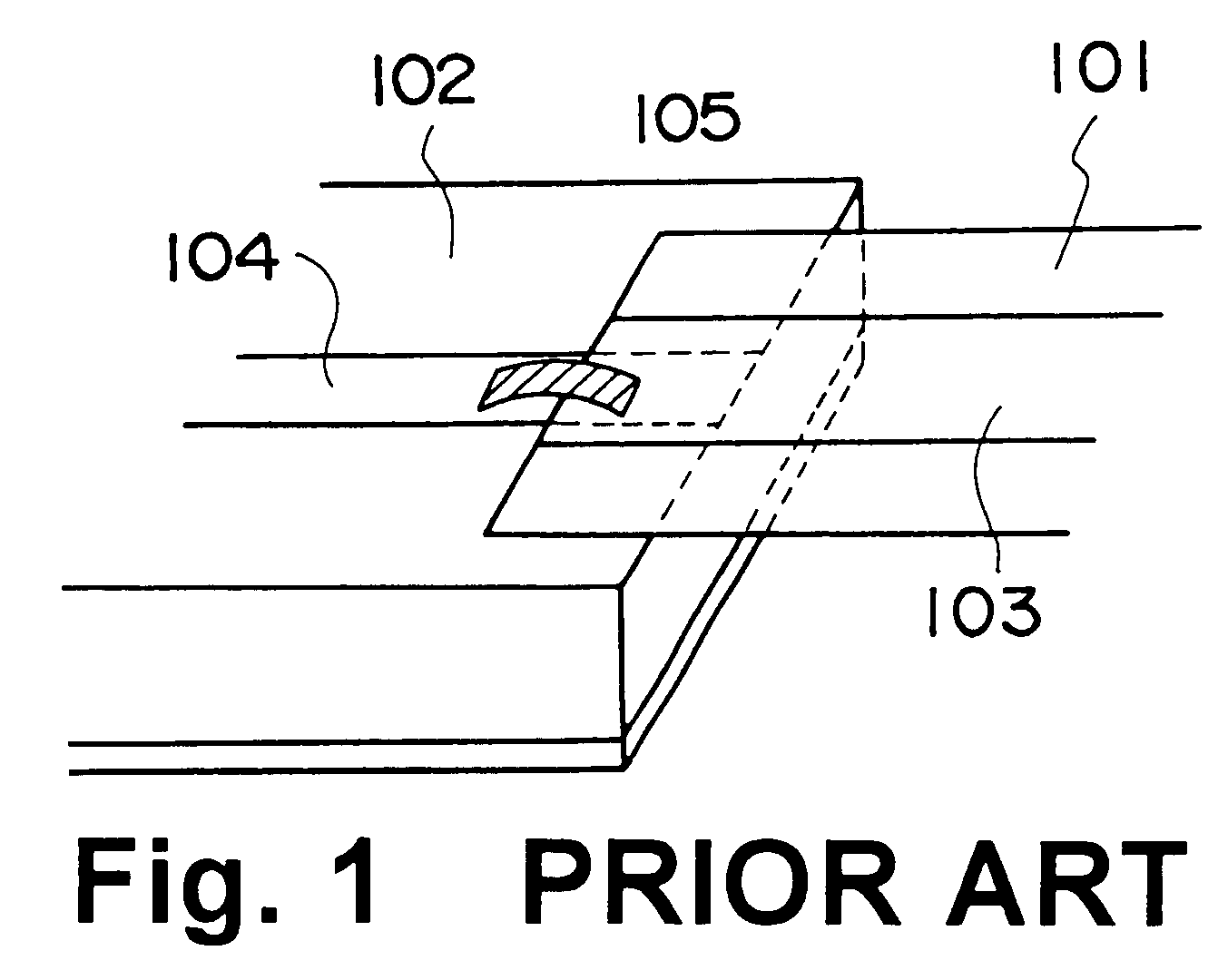

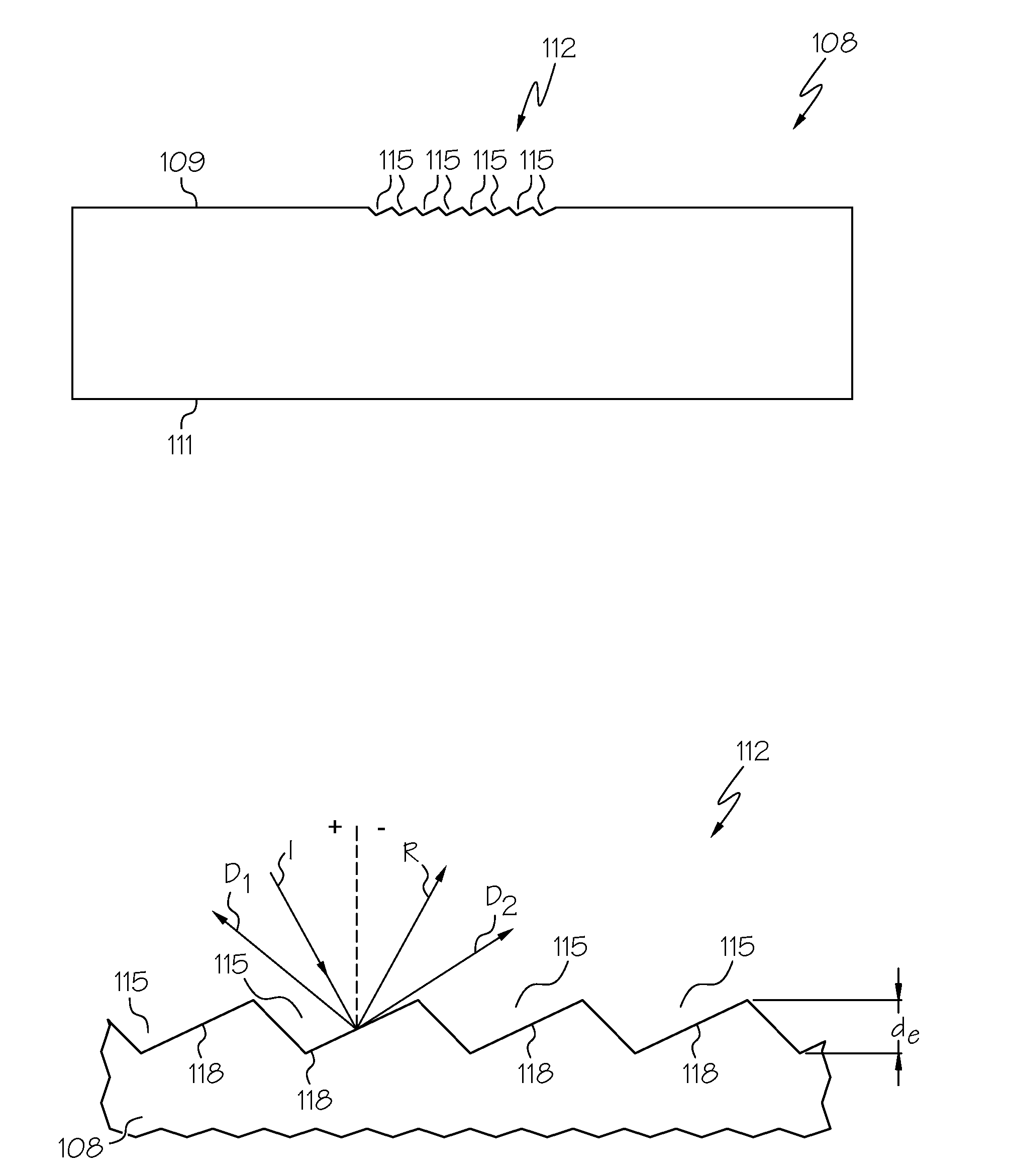

Laser etching of electroluminescent lamp electrode structures, and electroluminescent lamps produced thereby

InactiveUS6066830ADischarge tube luminescnet screensElectroluminescent light sourcesLaser etchingElectrical conductor

A process for manufacturing electroluminescent lamps using a laser beam to remove a material layer of a multi-layer material structure, in which the laser beam has a first energy level directed at a first material layer, e.g., a conductor, laid over a second material layer, e.g., an insulator / substrate. The laser beam is moved in an overlapping fashion such as spiral pattern motion across the first material layer. A part of the first material layer is sublimed exposing a region of the second material under the area where the spiral pattern was applied. Additionally, a second laser beam having a second energy level, e.g., higher than the first energy level, is moved along a path over the exposed second material layer subliming the remaining underlying layers to form the final lamp shape.

Owner:ASTRONICS

Plastic composition and surface selective metallization process thereof

ActiveCN101654564AImprove bindingHigh precisionCatalyst activation/preparationLiquid/solution decomposition chemical coatingLaser etchingChemical plating

The invention provides a plastic composition and a surface selective metallization process thereof. The plastic composition comprises a high molecular polymer and a photocatalyst, wherein the mass ratio of the polymer to the photocatalyst is 1 to 100. The surface selective metallization process of the plastic composition comprises the following steps: performing laser etching on the surface of theplastic composition; putting the plastic composition after the laser etching into an aqueous solution containing a metal ion salt and a cavity sacrificial agent to perform photocatalysis reduction reaction so as to obtain a plastic composition with nanometer metal particles on the surface; and finally performing metal chemical plating. By adopting the plastic composition and the surface selectivemetallization process of the plastic composition, the bonding force of a plating layer and the chemical plating precision are very high.

Owner:BYD CO LTD

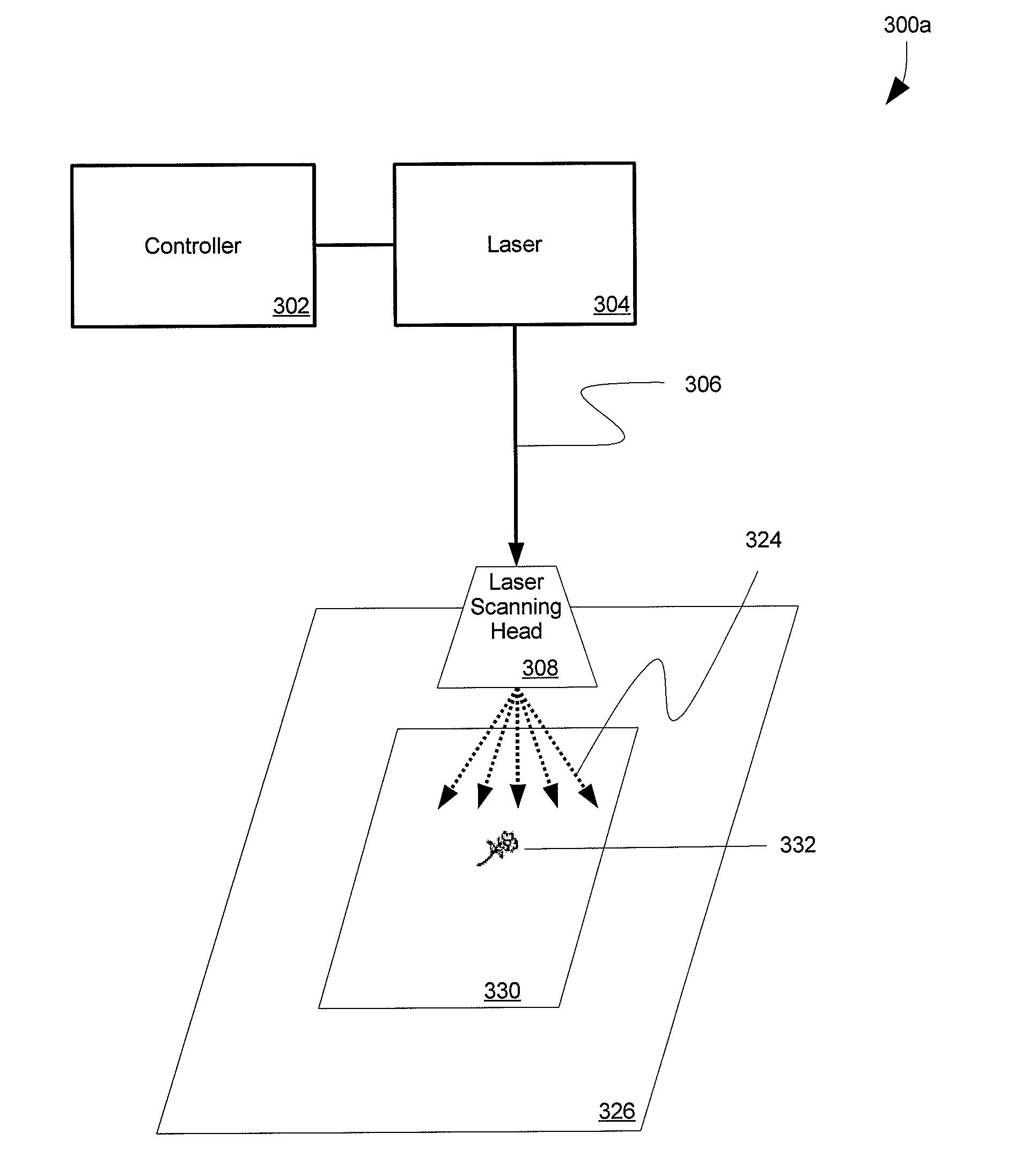

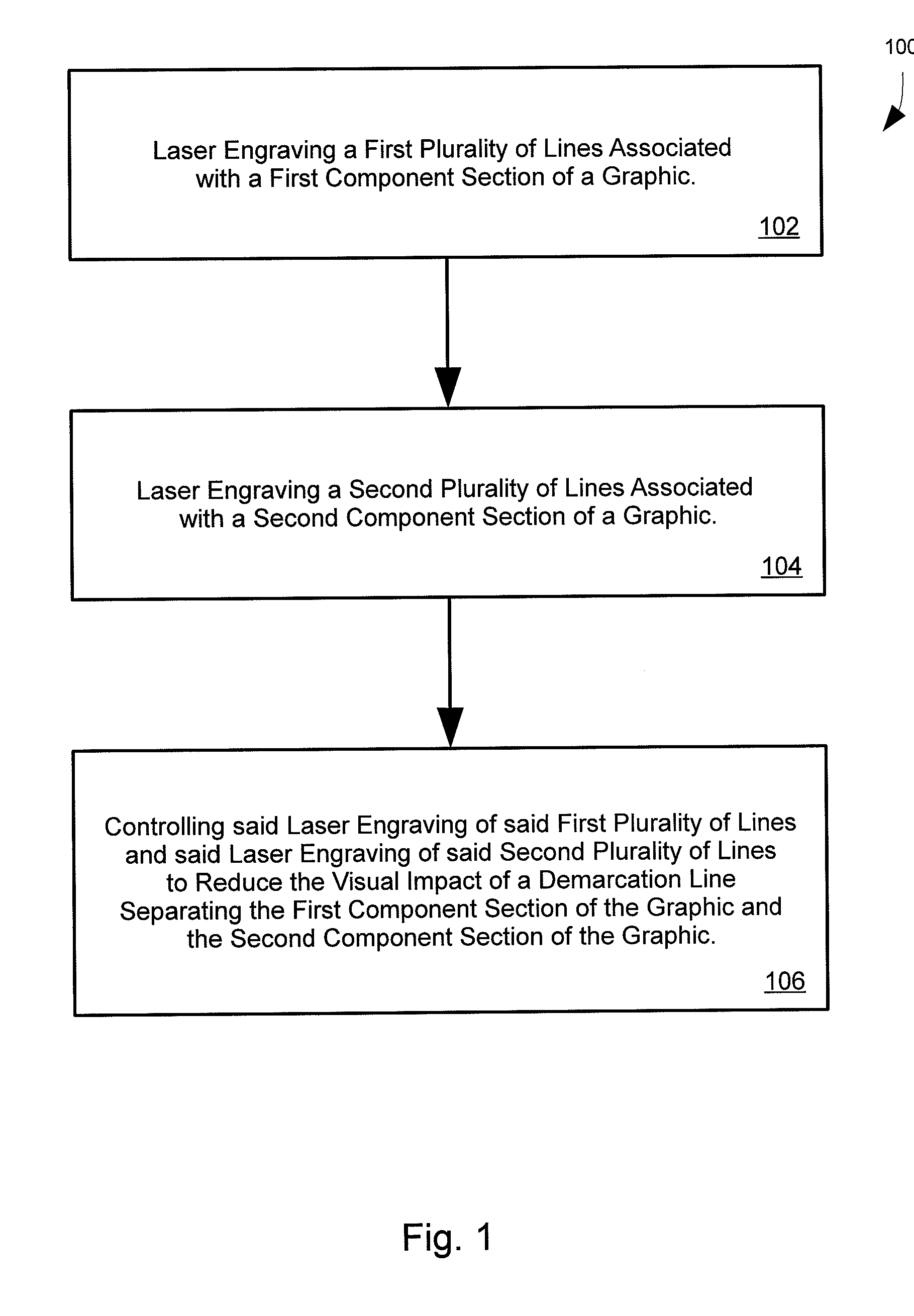

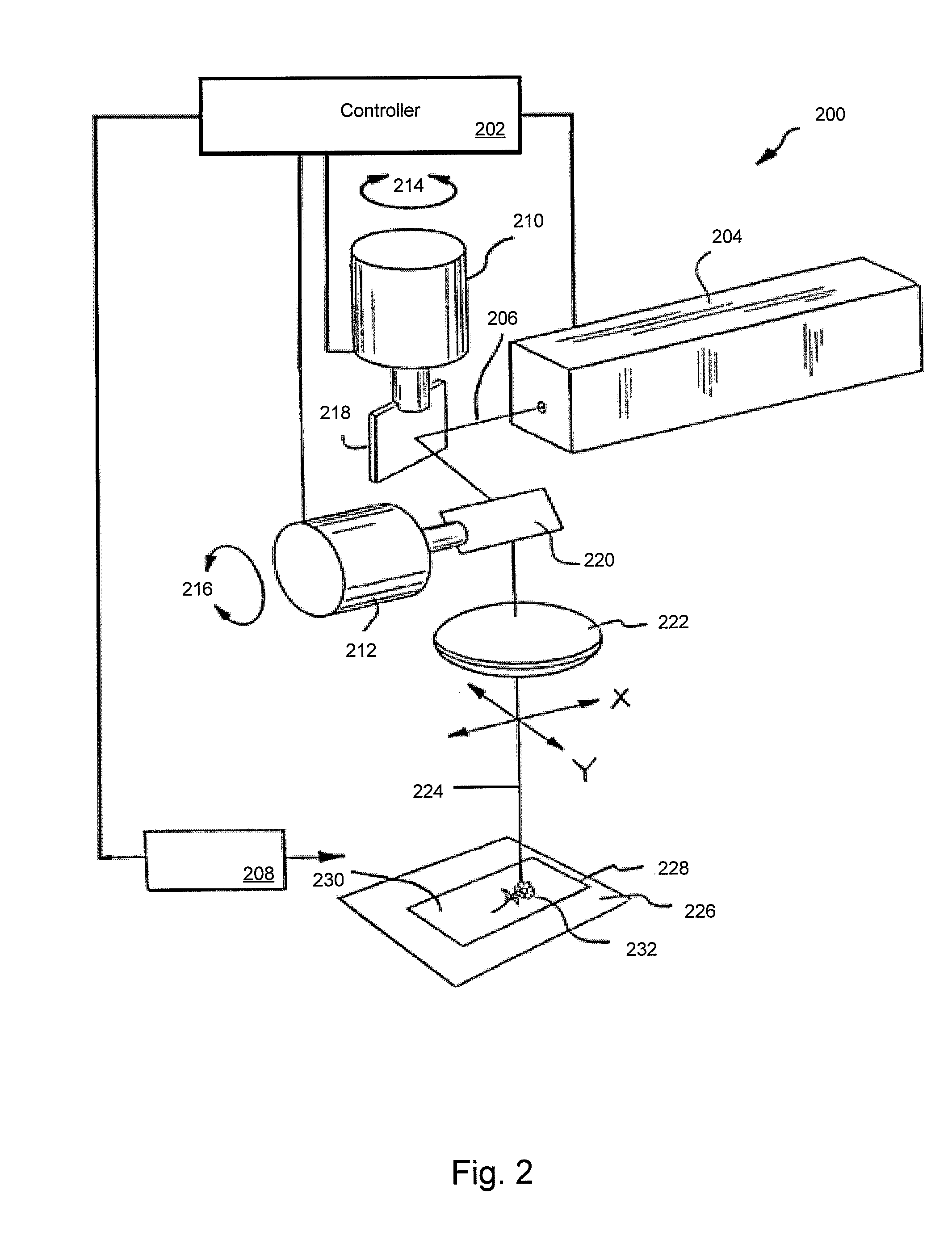

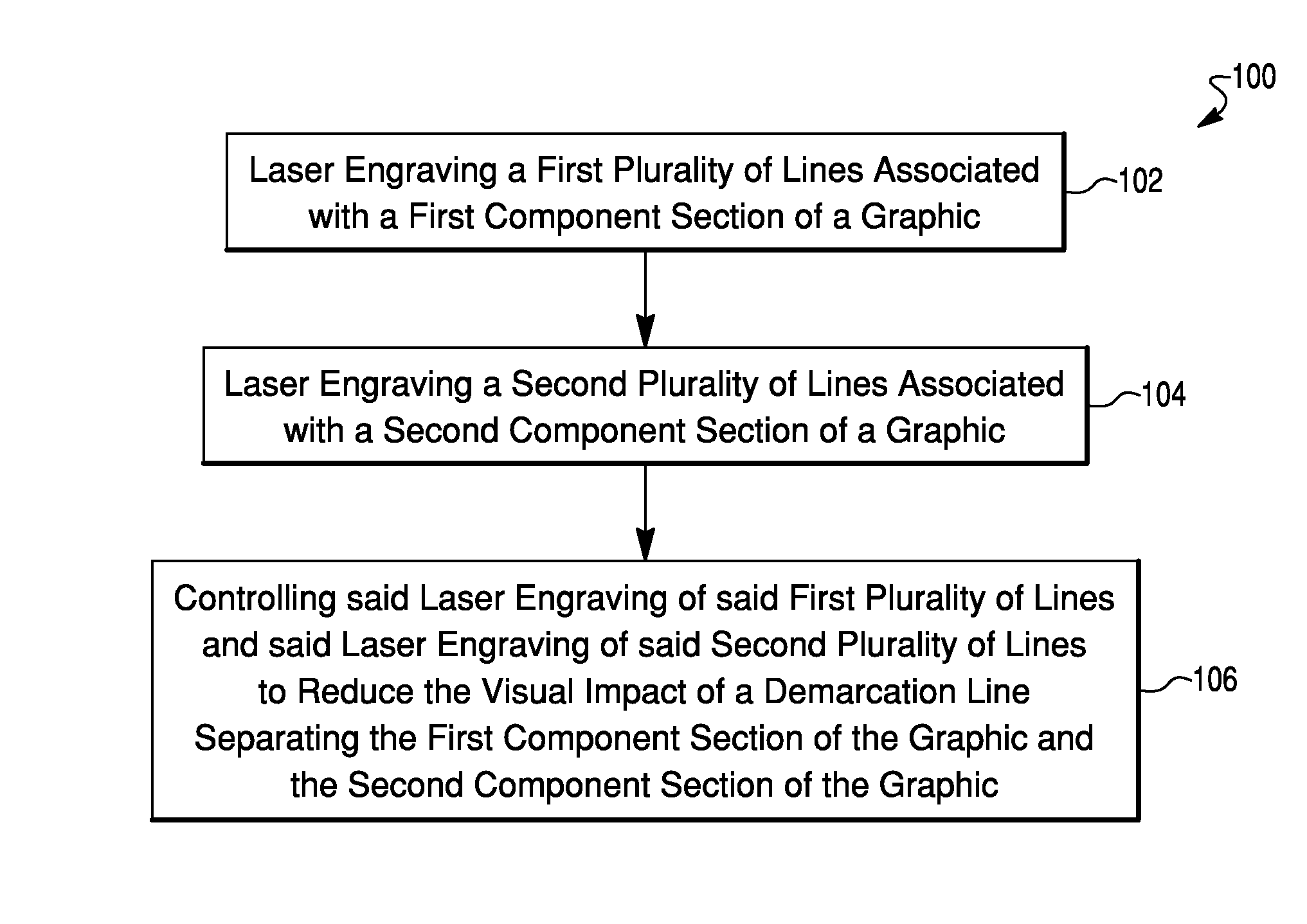

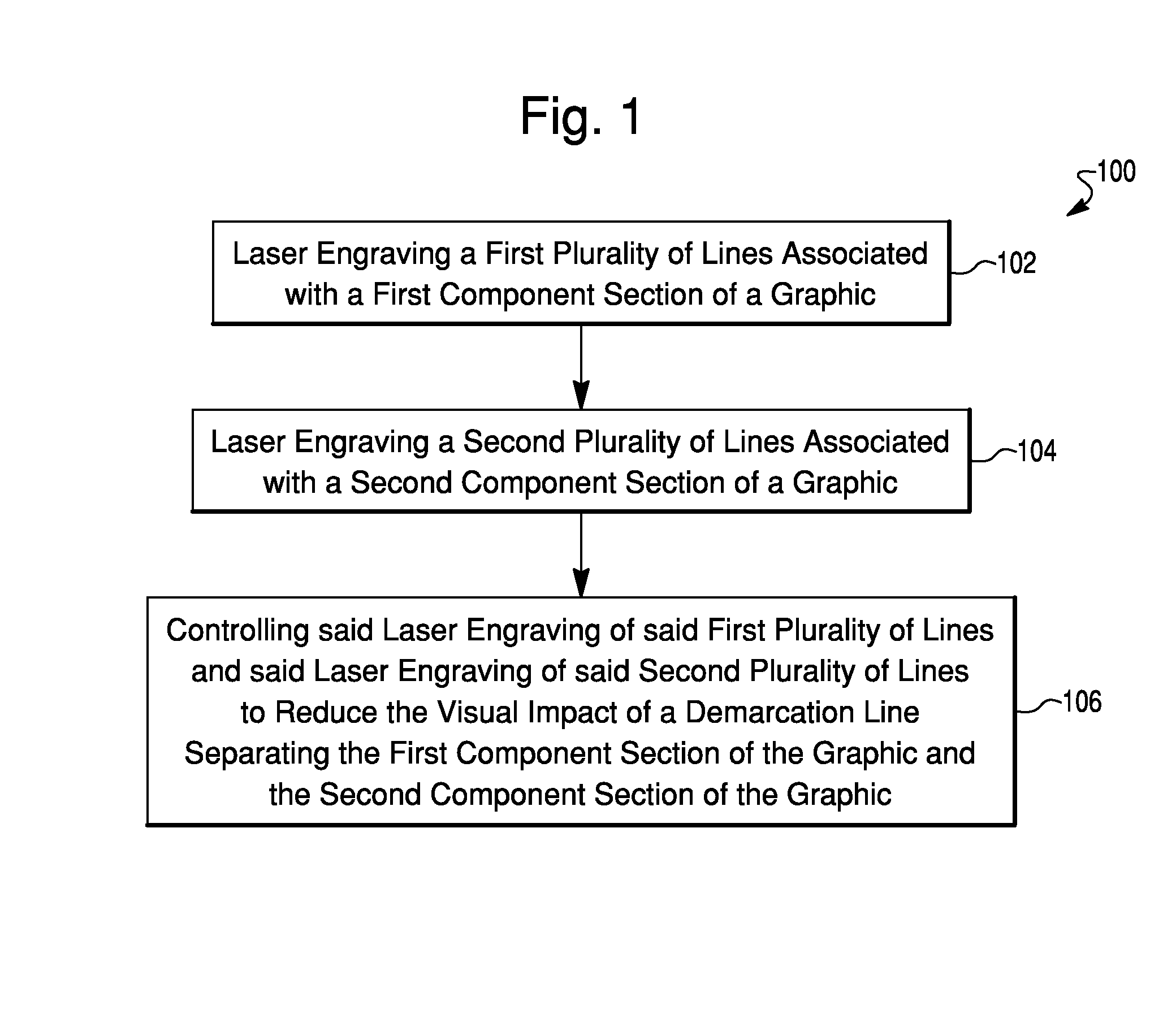

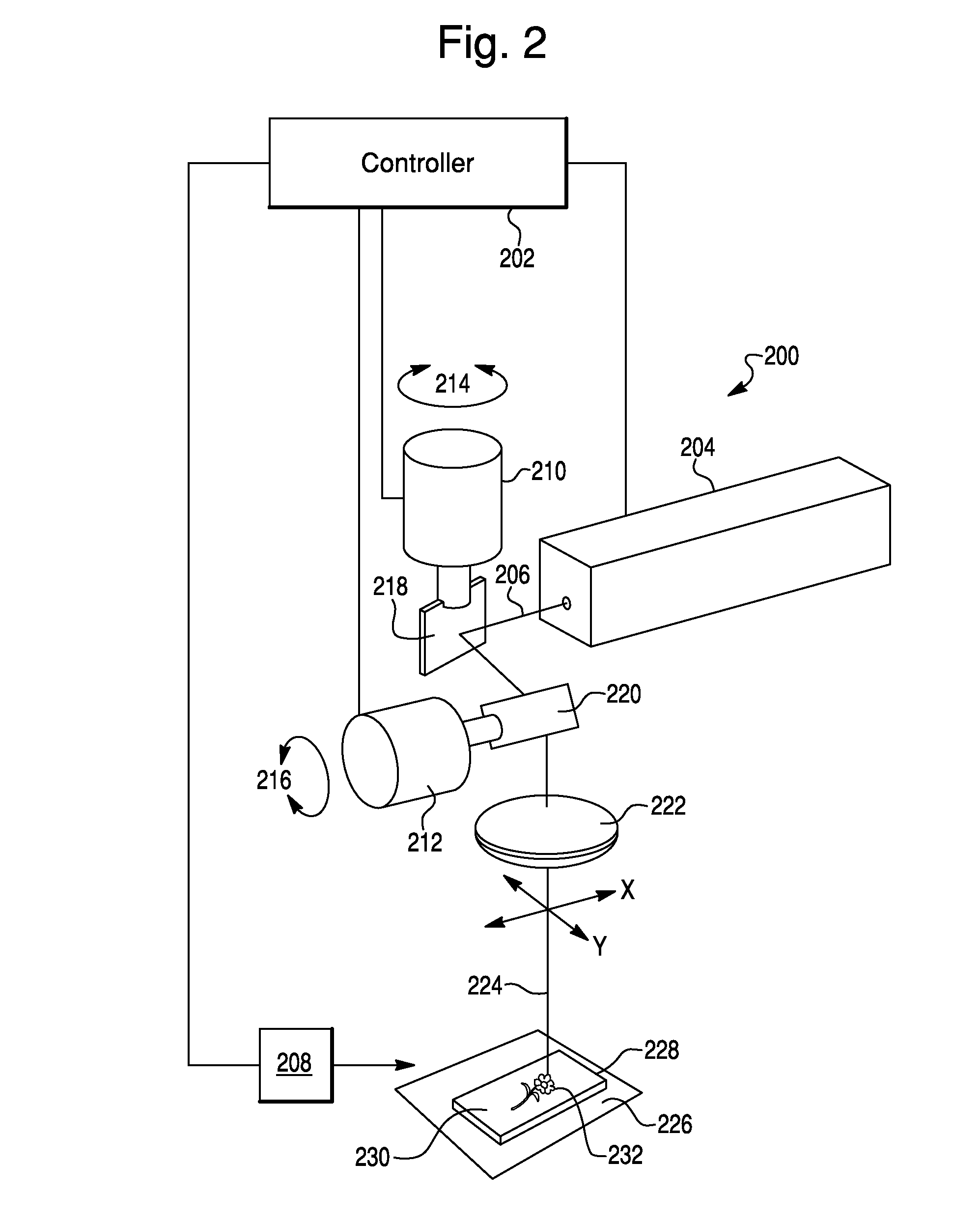

Staggered laser-etch line graphic system, method and articles of manufacture

InactiveUS20100272961A1Reduce visual impactReduce the impactVacuum gauge using ionisation effectsDecorative surface effectsGraphicsLaser etching

A staggered laser-etch line graphic system, method, and articles of manufacture are provided. One described method includes the steps of laser engraving a first plurality of lines associated with a first component section of a graphic on a surface of an article; laser engraving a second plurality of lines associated with a second component section of the graphic on the surface of the article; and controlling said laser engraving of the first plurality of lines and said laser engraving of second plurality of lines to reduce the visual impact of a demarcation line separating the first component section of the graphic and the second component section of the graphic.

Owner:REVOLAZE LLC

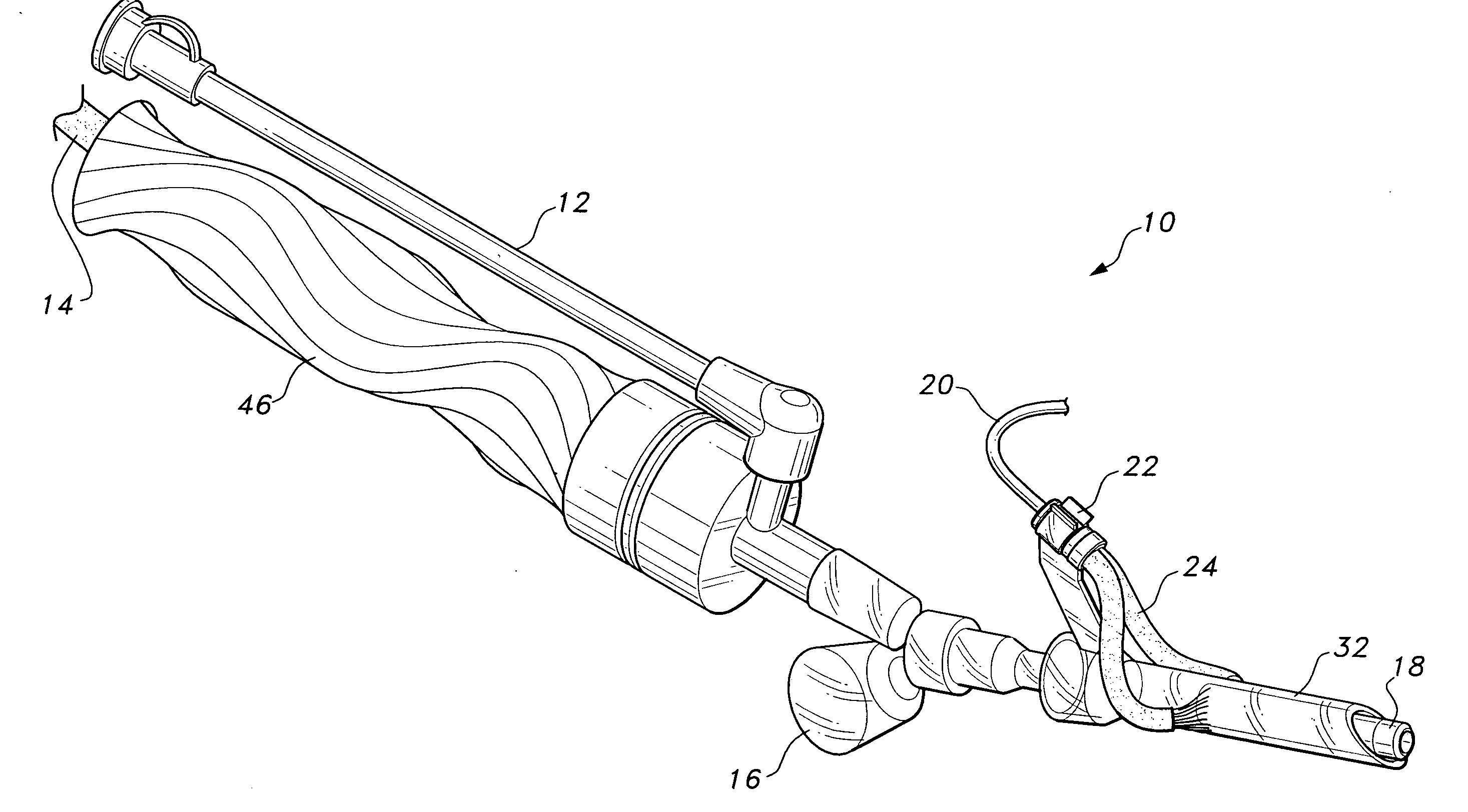

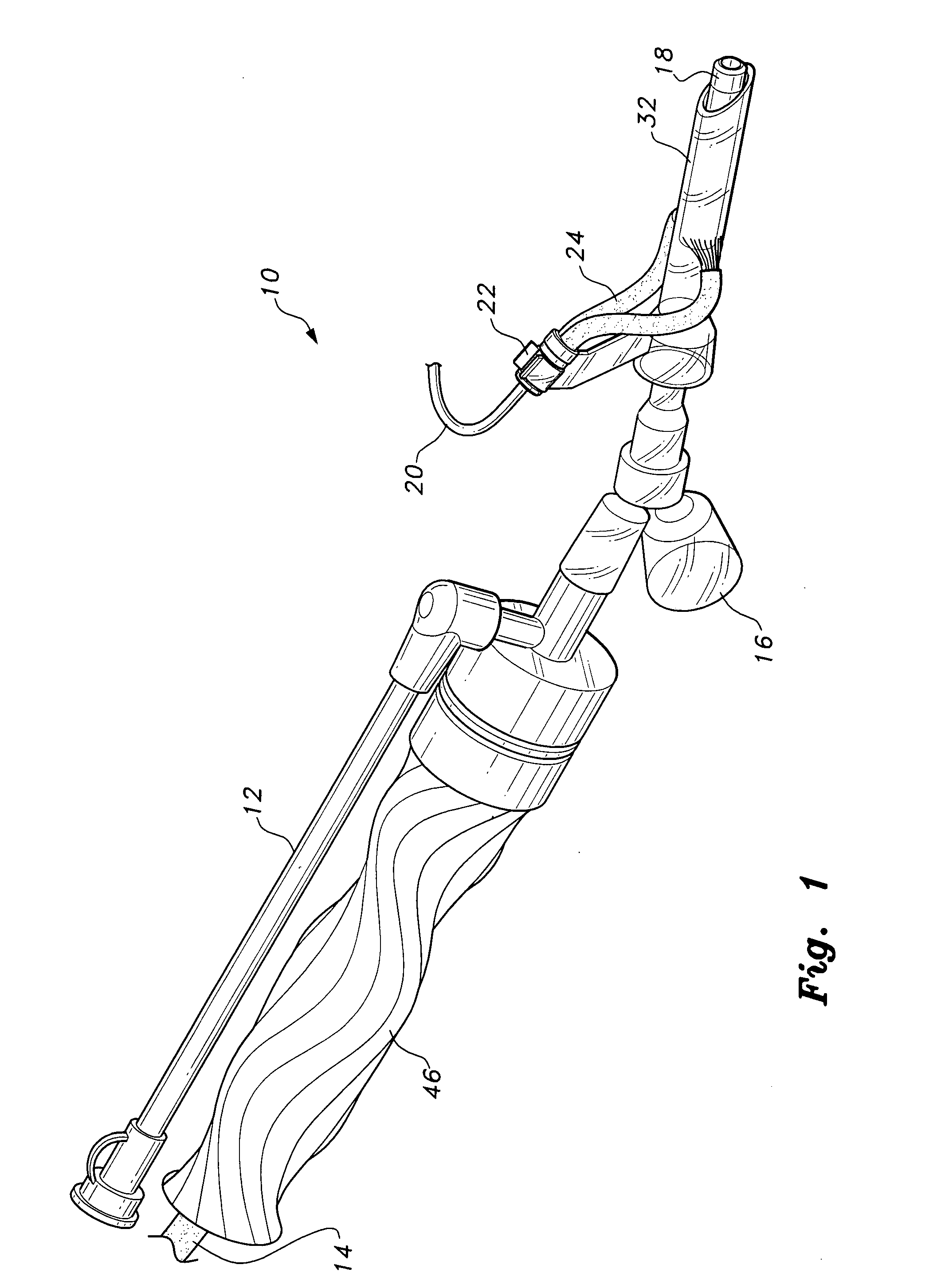

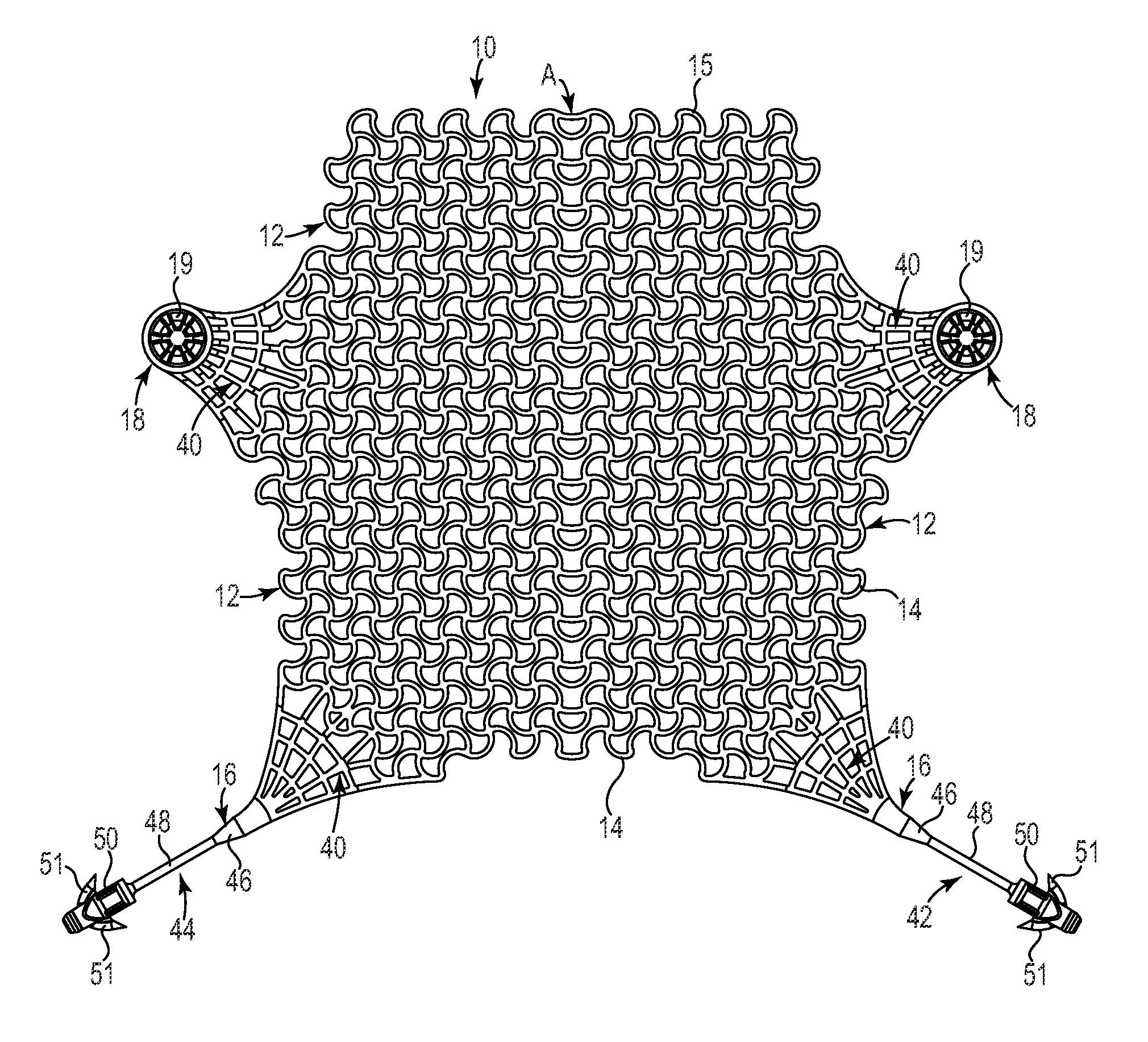

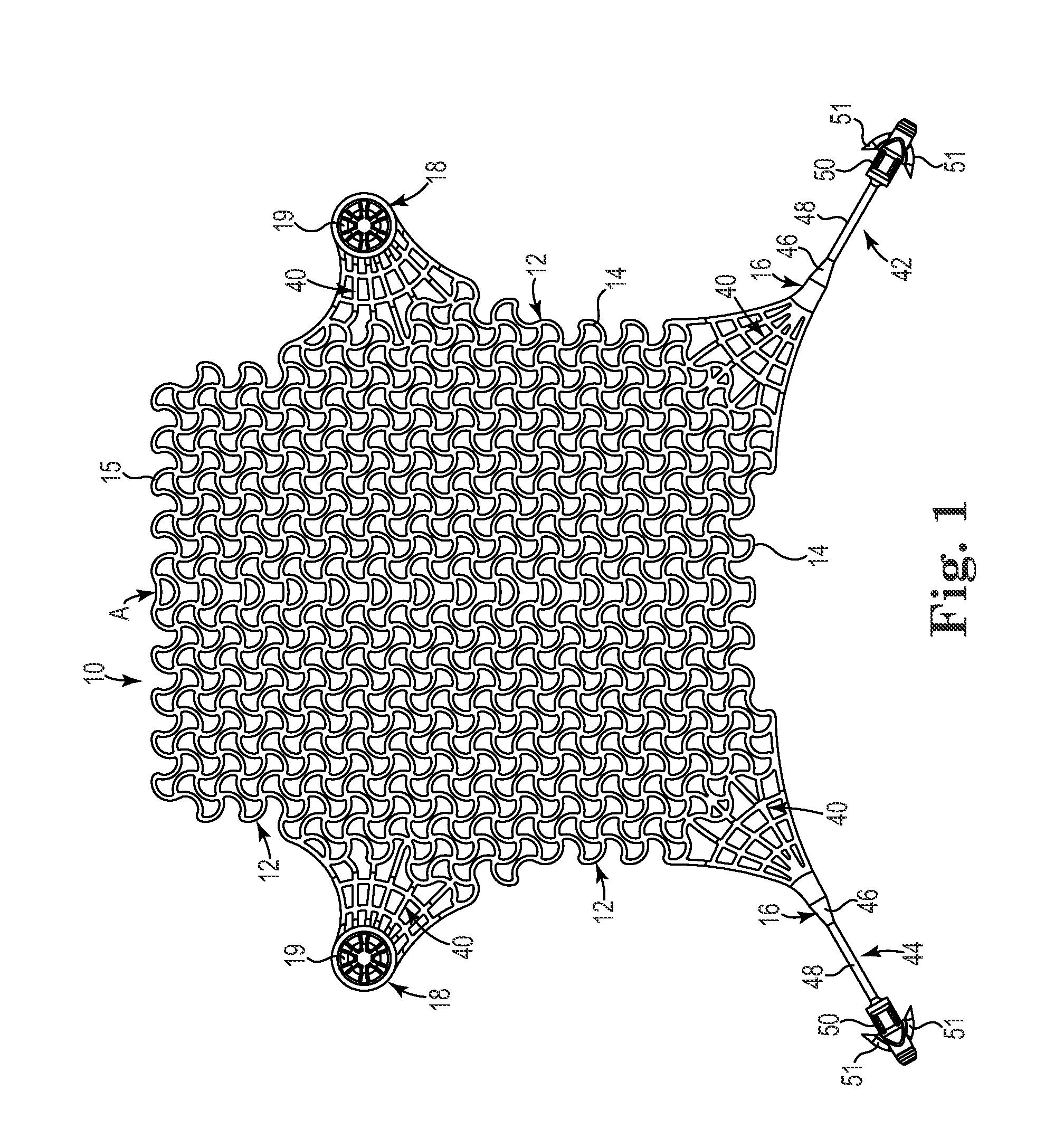

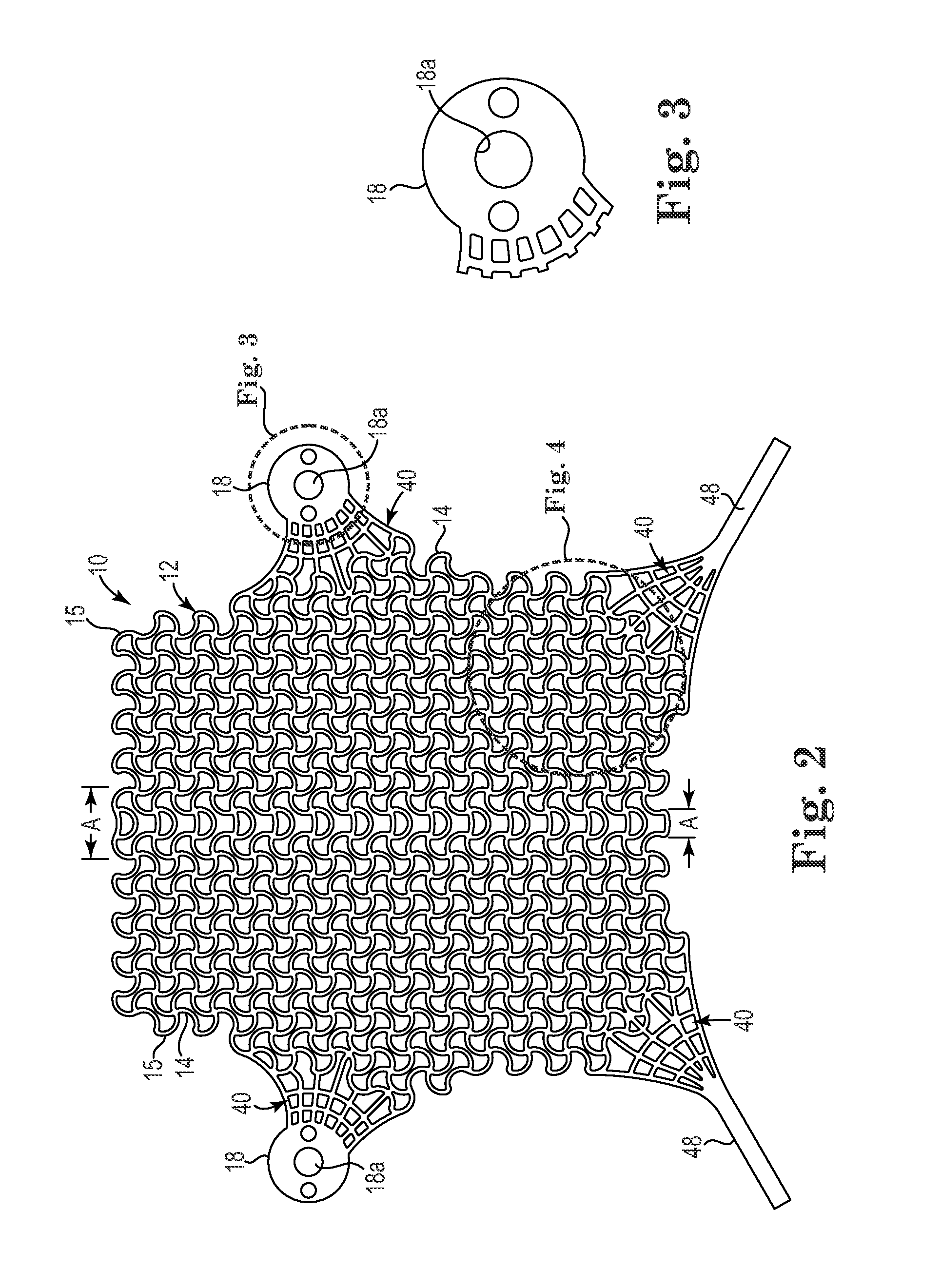

Patterned Implant and Method

InactiveUS20110144417A1Optimize and increase tissue in-growthIncreased load-bearing capacityAnti-incontinence devicesLigamentsLaser etchingDie casting

A unitary or homogeneous patterned implant is provided. The implant is constructed of patterned cells formed by way of a molding, die casting, laser etching, laser cutting, extruding, and the like. Portions of the implant can be formed into sinusoid or other waveform strut members to control and promote elongation, expansion or contraction along single or multiple axes. As such, controlled and designated stress, tension and compression distribution is promoted across specific or localized areas of the implant.

Owner:BOSTON SCI SCIMED INC

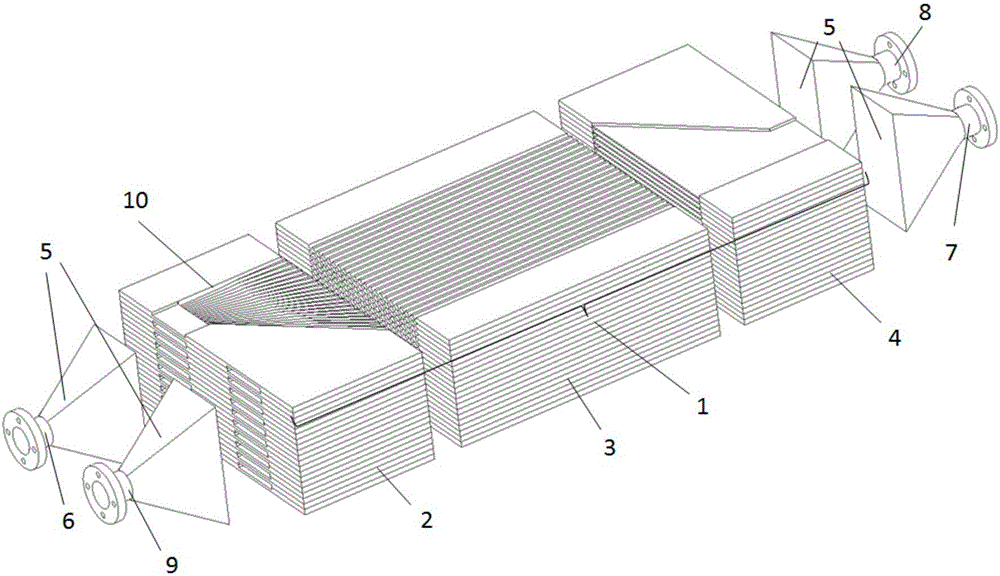

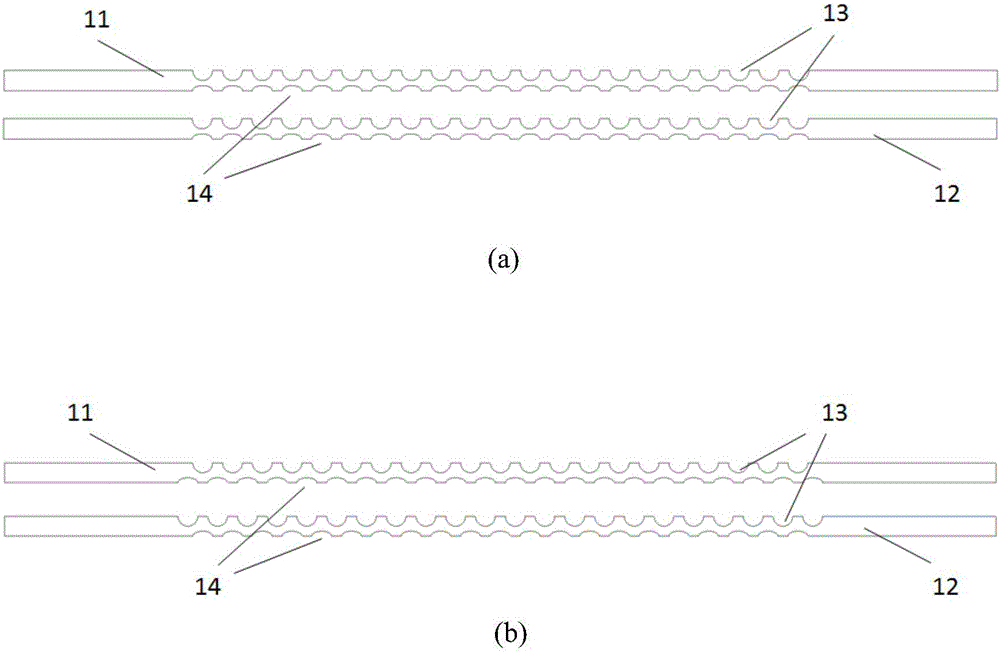

Double-side etching high-temperature and high-pressure printed circuit board heat exchanger

InactiveCN105043144AReduce thermal stressAvoid plastic deformationLaminated elementsStationary plate conduit assembliesStress distributionStress concentration

The invention relates to a double-side etching high-temperature and high-pressure printed circuit board heat exchanger. The double-side etching high-temperature and high-pressure printed circuit board heat exchanger is composed of a heat exchanging core, a flow equalizing section, a hot fluid inlet and outlet port and a cold fluid inlet and outlet port. The core is divided into an inlet section, a core heat exchanging section and an outlet section. According to the heat exchanger, runners are machined in the double sides of heat exchanging plates with a certain thickness in a photochemistry manner, a laser etching manner, a machining manner and the like. The first heat exchanging plate and the second heat exchanging plate are arranged in a spaced manner. A fusion type channel novel structure is adopted in an inlet distribution section, and fluid in the heat exchanger can be easily distributed more evenly. The heat exchanging efficiency of the heat exchanger can be improved, the thermal stress damage at an existing channel sharp corner is effectively avoided, the circulation section area of the heat exchanger is increased, and the compactness of the heat exchanger is improved; thermal stress distribution at the sharp corner is improved, plastic deformation caused by stress concentration is avoided, and the even distribution of fluid in the heat exchanger is improved; and the safety performance of the heat exchanger is improved, and the service life of the heat exchanger is prolonged.

Owner:XI AN JIAOTONG UNIV

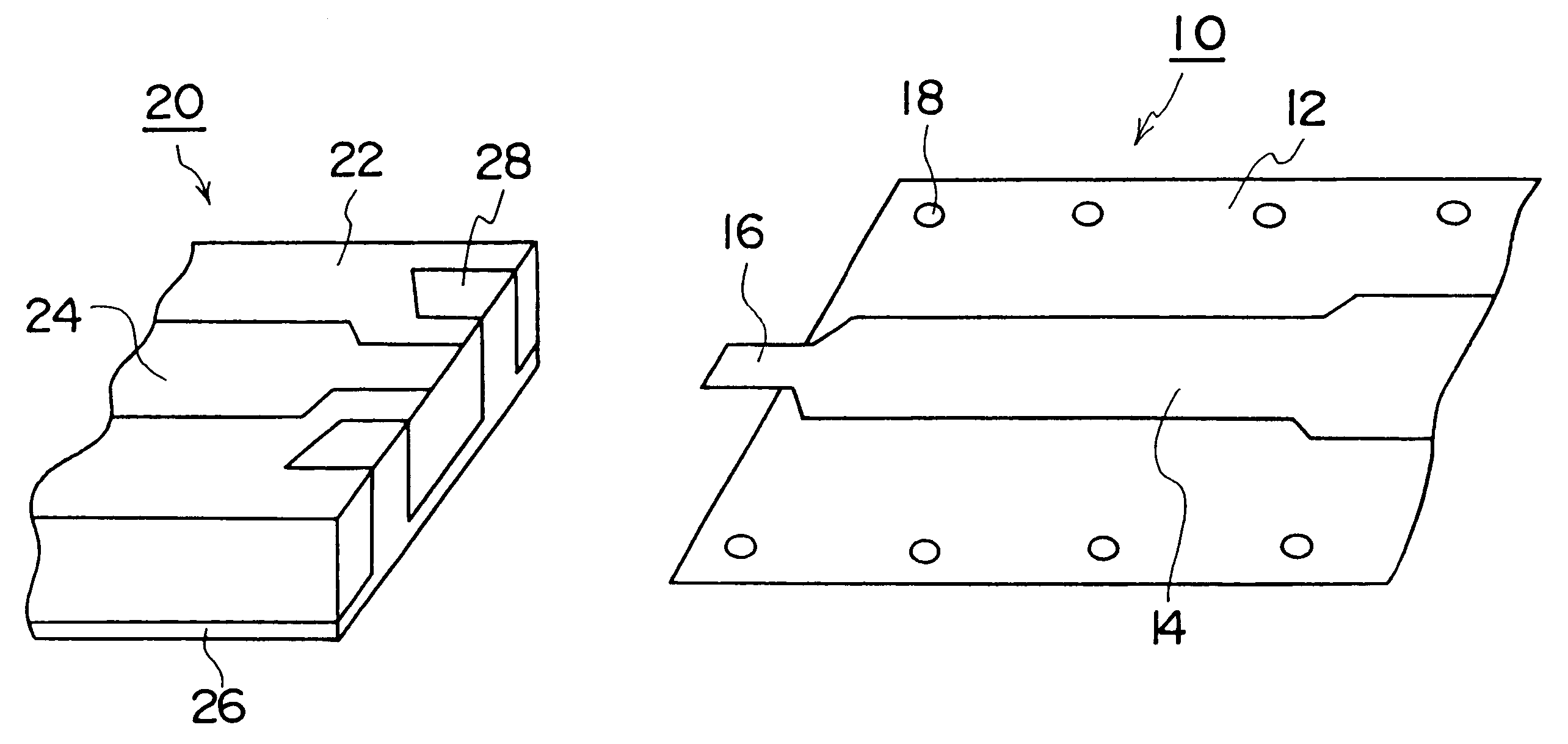

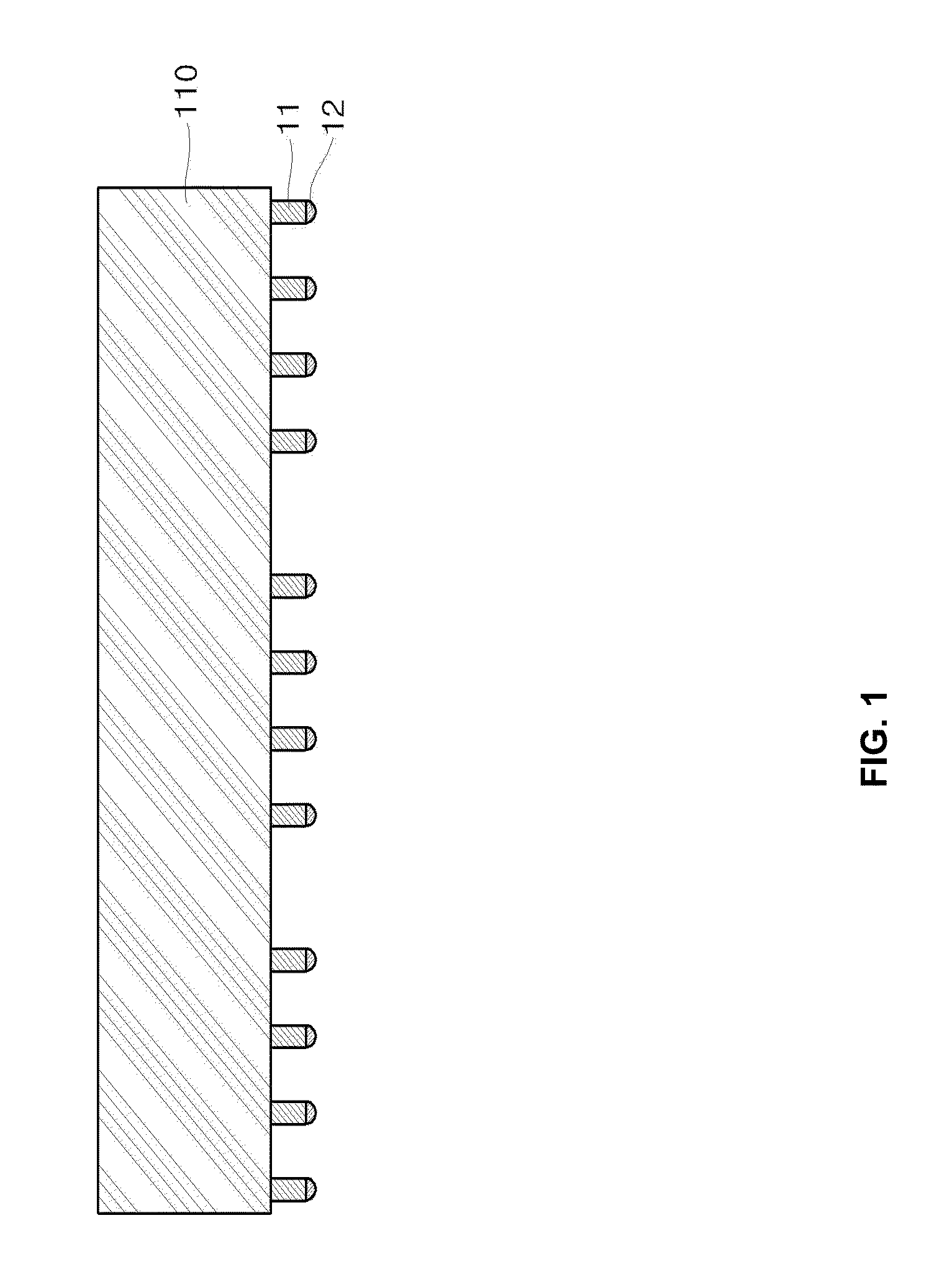

Producing method of a film-type transmission line and method of connecting to an existing line

InactiveUS6241143B1Lower impedanceThe connection is tight and firmPrinted circuit assemblingHigh frequency circuit adaptationsLaser etchingDielectric substrate

An exposed connecting portion is formed by partially removing a film substrate by such laser etching while leaving a transmission line pattern. A film-type transmission line is placed in such a manner as to overlap the exposed connecting portion and a transmission line pattern on a side to be connected. Bonding, for example thermo compression bonding, is applied to the two overlapped line patterns. Since a gold ribbon is not used and overlapping of a high-dielectric substrate and the film substrate is unnecessary, impedance irregularity is reduced. This makes it possible to carry out bonding without the medium of the film substrate and a connection with high reliability may be achieved.

Owner:TOYOTA JIDOSHA KK

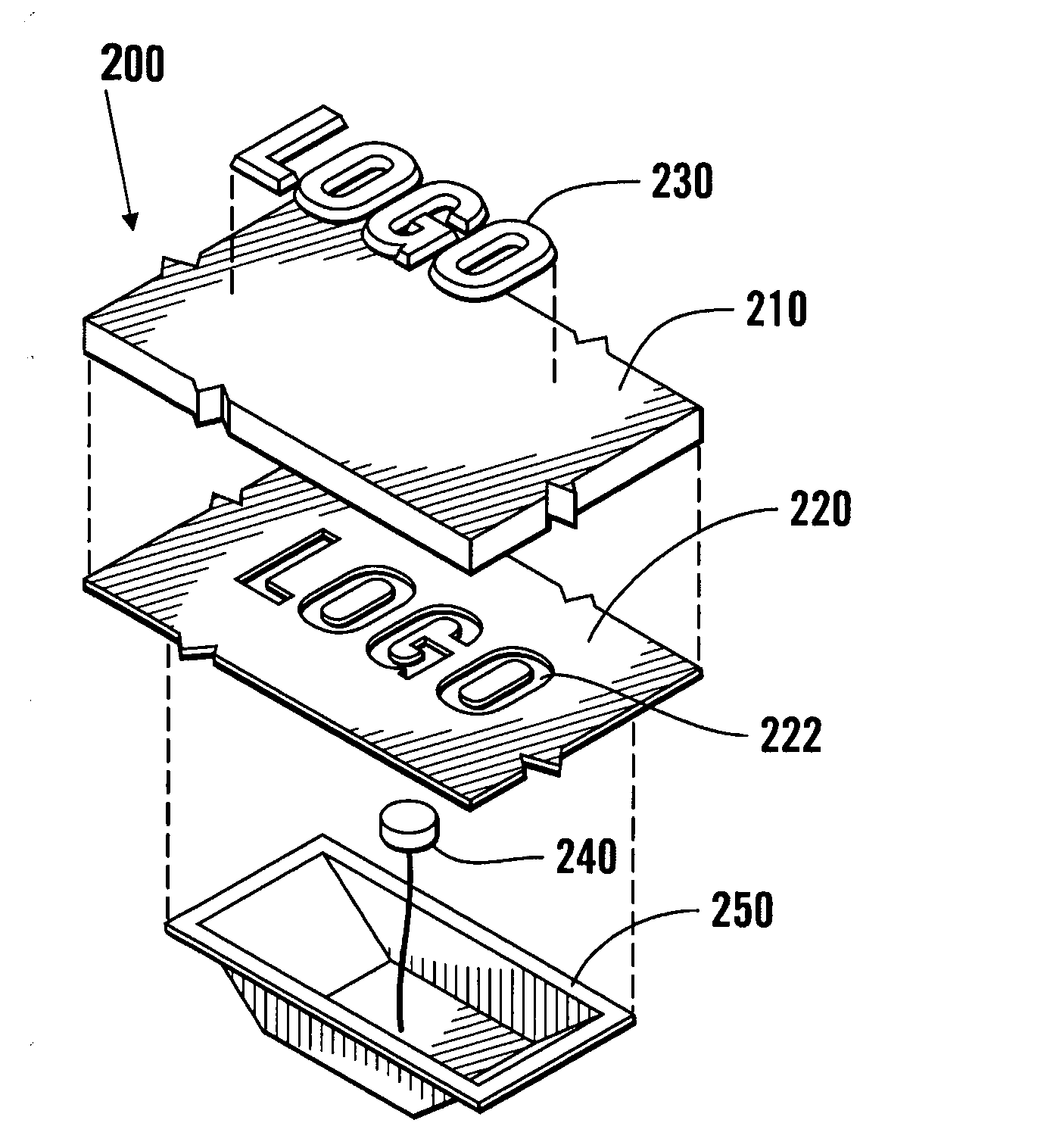

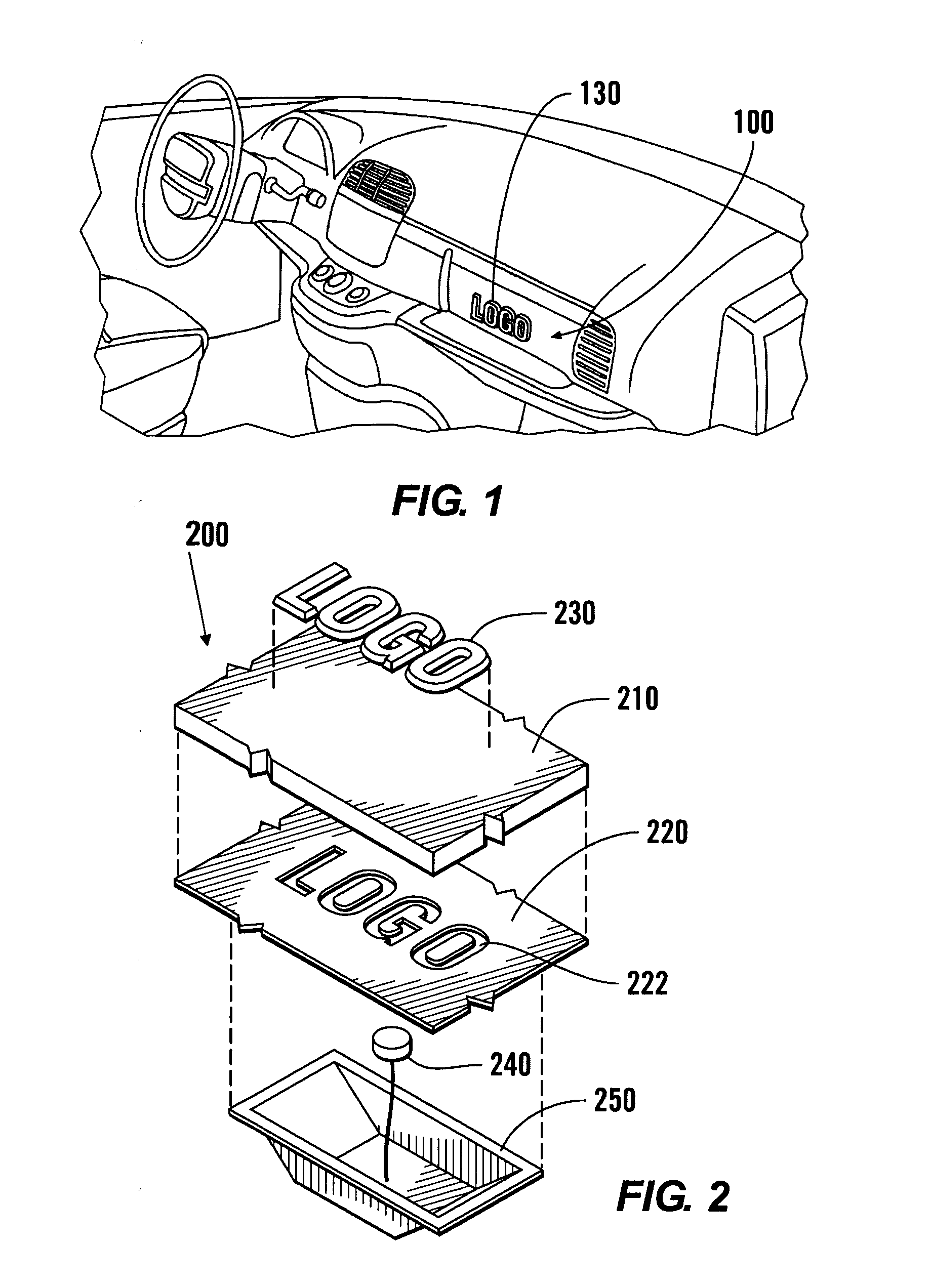

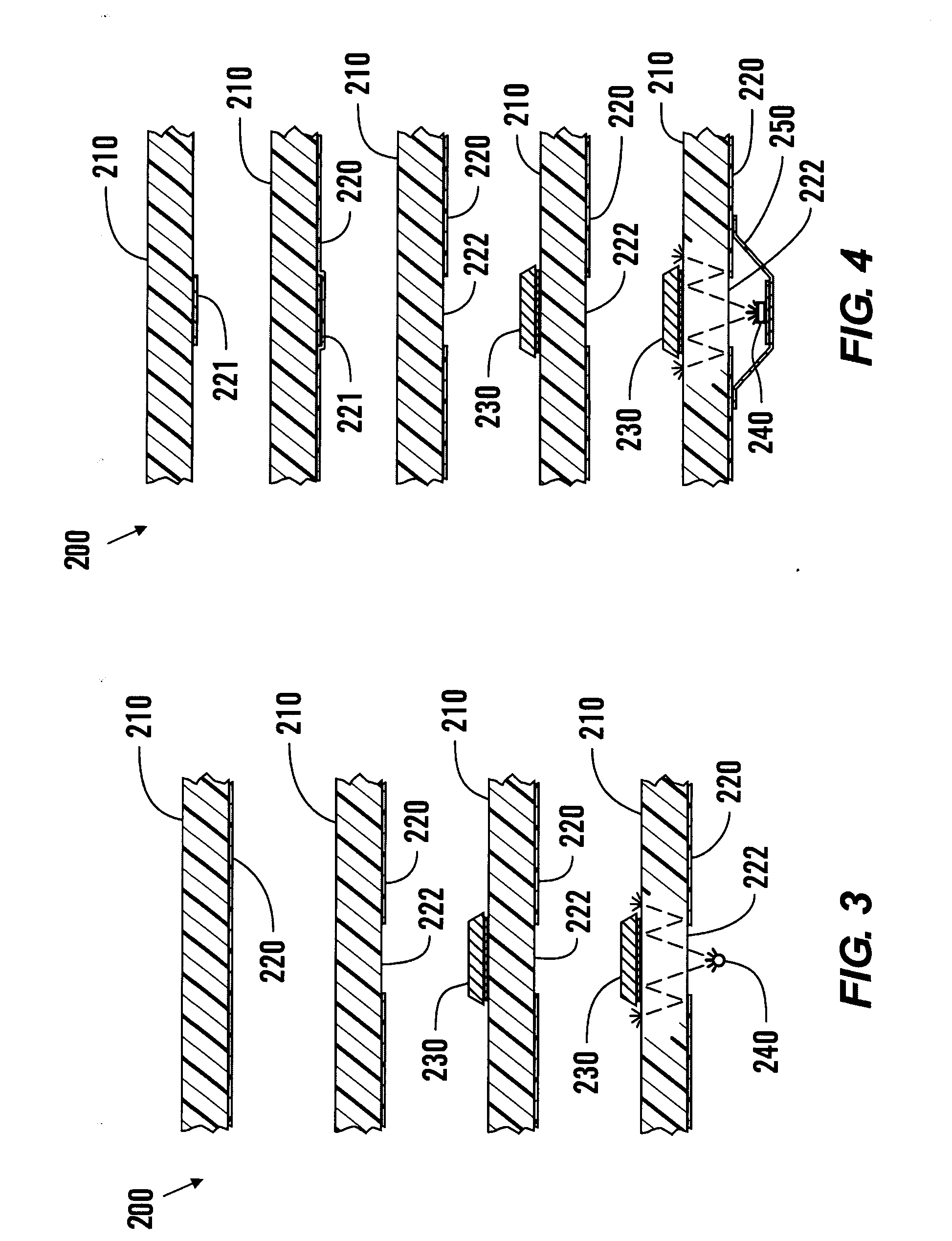

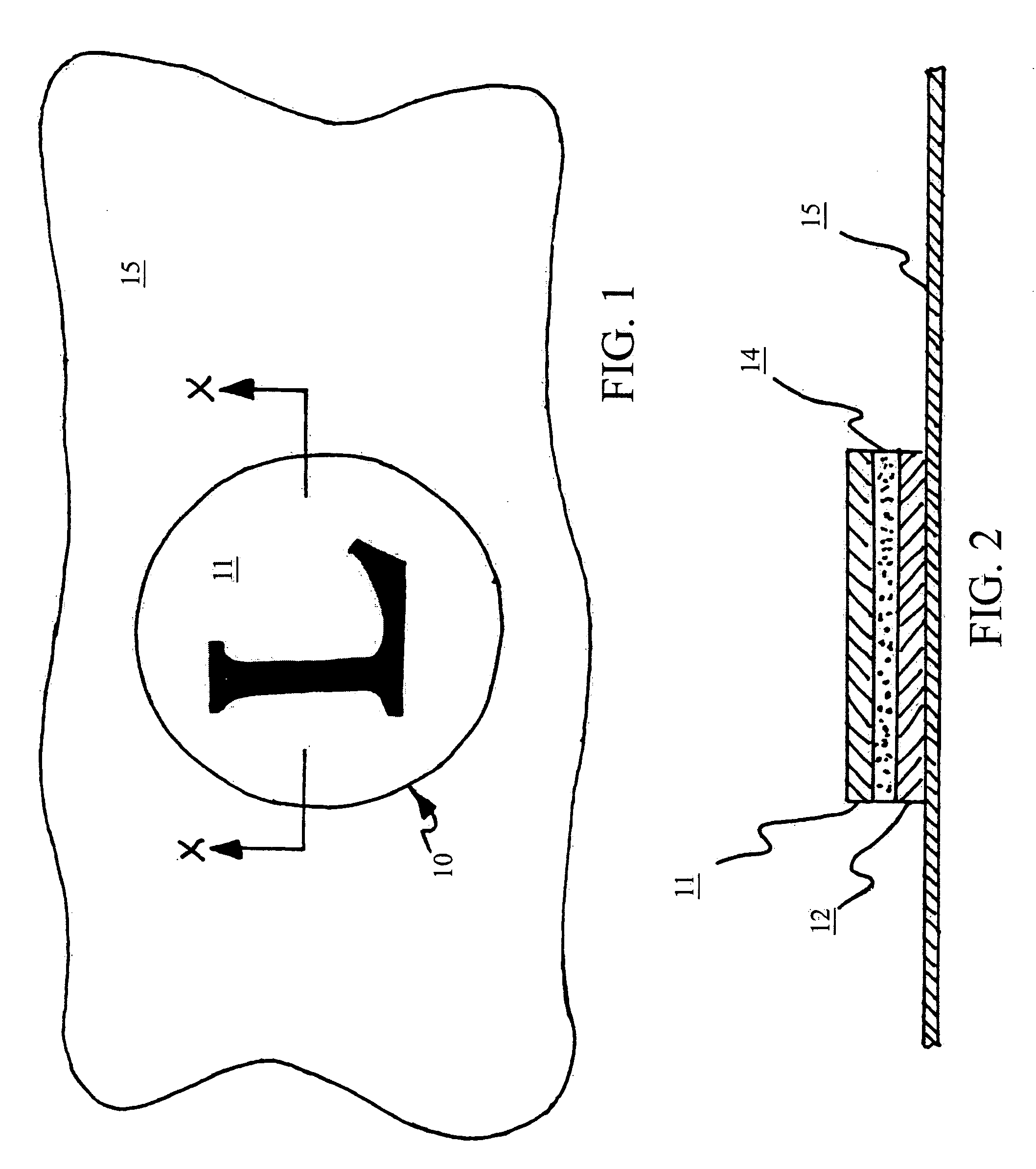

Illuminated trim panels

A vehicle trim panel is illuminated from behind to create an illuminated design (e.g., logo and / or lettering) includes a transparent layer and an opaque layer with an opening(s) in the shape of the design. An opaque or partially opaque design piece may be placed over the opening(s) in the opaque layer and be lit around its edges. The vehicle trim panel may be formed by forming a panel with a transparent layer and an opaque layer. An opening in the opaque layer may be formed by removing opaque material (e.g., by machining or laser etching) or by masking (the mask is placed between the opaque layer and transparent layer and removed taking a portion of the opaque layer with it). A design piece may be placed over the location of the opening in the opaque layer.

Owner:YANFENG CZECHIA AUTOMOTIVE INTERIOR SYST SRO +1

Strengthened glass articles having etched features and methods of forming the same

ActiveUS20130273324A1Reduce surface roughnessRadiation applicationsLayered productsSurface layerSurface roughness

Strengthened glass articles having laser etched features, electronic devices, and methods of fabricating etched features in strengthened glass articles are disclosed. In one embodiment, a strengthened glass article includes a first strengthened surface layer and a second strengthened surface layer under a compressive stress and extending from a first surface and a second surface, respectively, of the strengthened glass article to a depth of layer, and a central region between the first strengthened surface layer and the second strengthened surface layer that is under tensile stress. The strengthened glass article further includes at least one etched feature formed by laser ablation within the first surface or the second surface having a depth that is less than the depth of layer and a surface roughness that is greater than a surface roughness of the first surface or second surface outside of the at least one etched feature.

Owner:CORNING INC

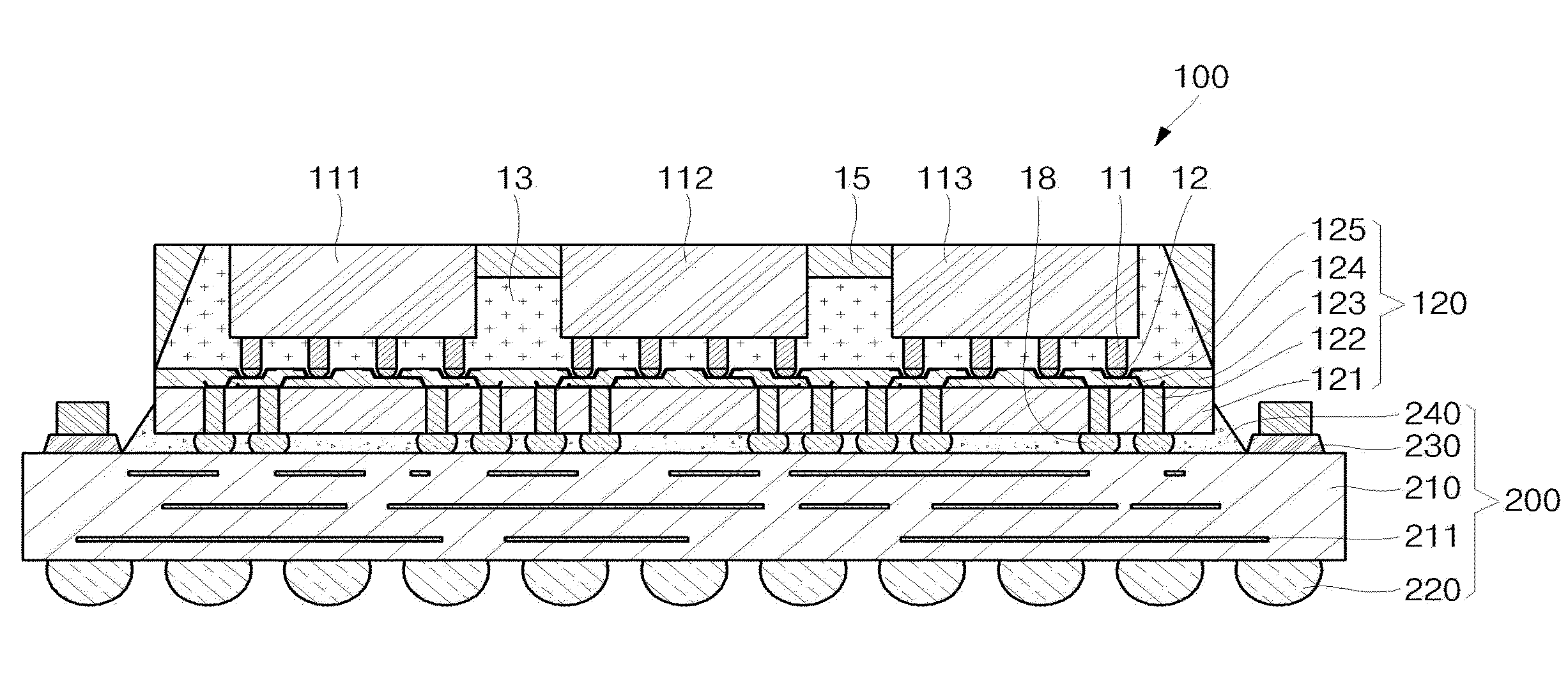

Semiconductor device with reduced warpage

InactiveUS20150255426A1Semiconductor/solid-state device detailsSolid-state devicesLaser etchingEngineering

A semiconductor device with reduced warpage is disclosed and may, for example, include bonding at least two semiconductor die to a substrate, forming underfill material between the at least two semiconductor die and the substrate and between the at least two semiconductor die, and removing a portion of the underfill material between the at least two semiconductor die, thereby forming a groove. The at least two semiconductor die and the underfill material may, for example, be encapsulating utilizing an encapsulant. The groove may, for example, be filled using the encapsulant. The underfill material between the at least two semiconductor die may, for example, be removed utilizing laser etching. The underfill material between the at least two semiconductor die may, for example, be removed to a depth of 60-70% of a thickness of the at least two semiconductor die.

Owner:AMKOR TECH INC

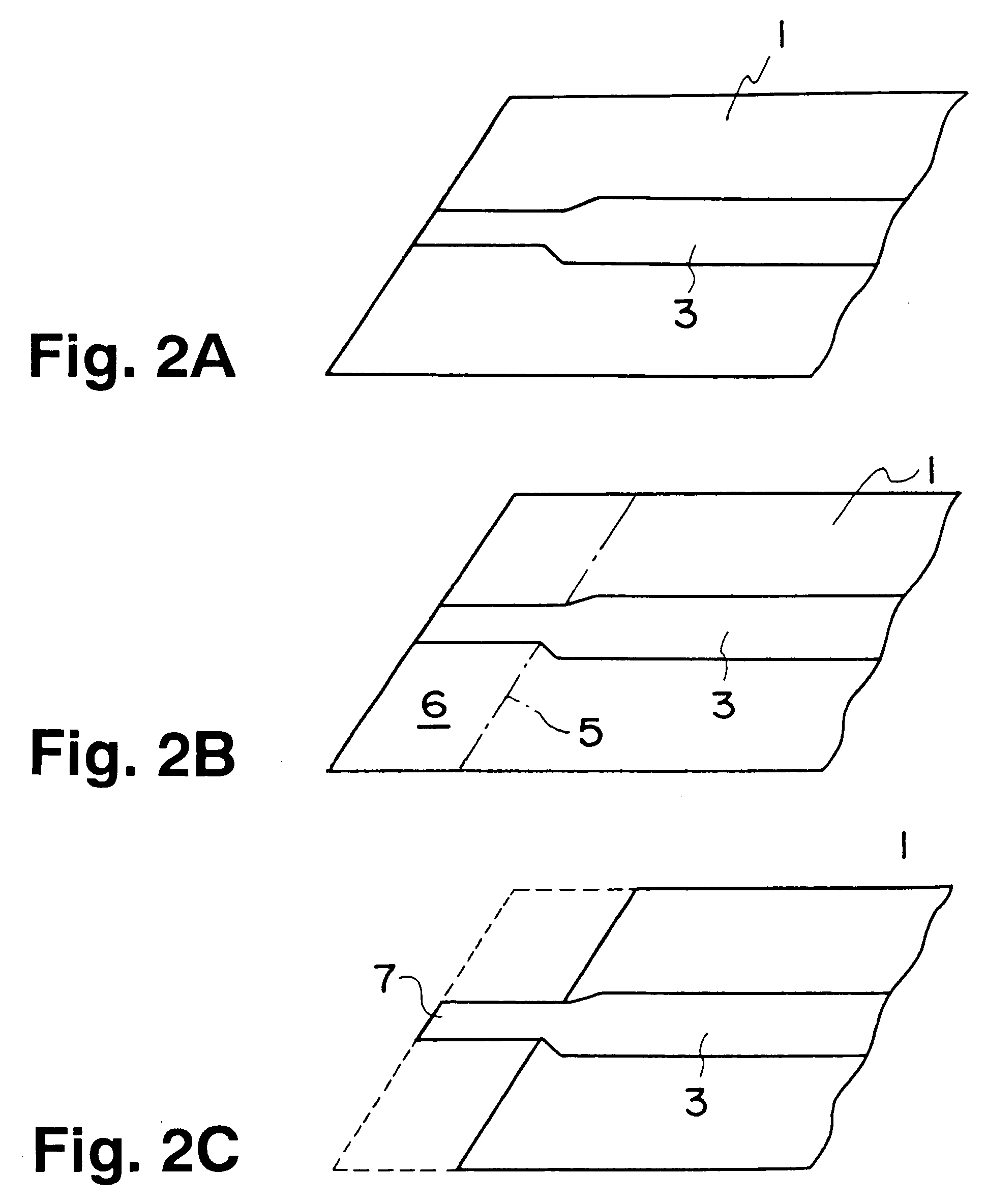

Method for manufacturing a rigid-flex circuit board

InactiveUS20090026168A1Printed circuit aspectsConductive material chemical/electrolytical removalLaser etchingEngineering

A method for manufacturing a rigid-flex board is disclosed. After the formation of each layer of the rigid-flex board, a laser-etched groove is formed at the interface between a rigid part and a bending area of the rigid-flex board. After the laser etching process, a circuit-board routing process is performed to remove materials along the sideward perimeter of the bending area. The exposed copper layer is then removed from inside the laser-etched groove. Thereafter, a redundancy rigid structure within the bending area is readily removed to expose the flex board within the bending area.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

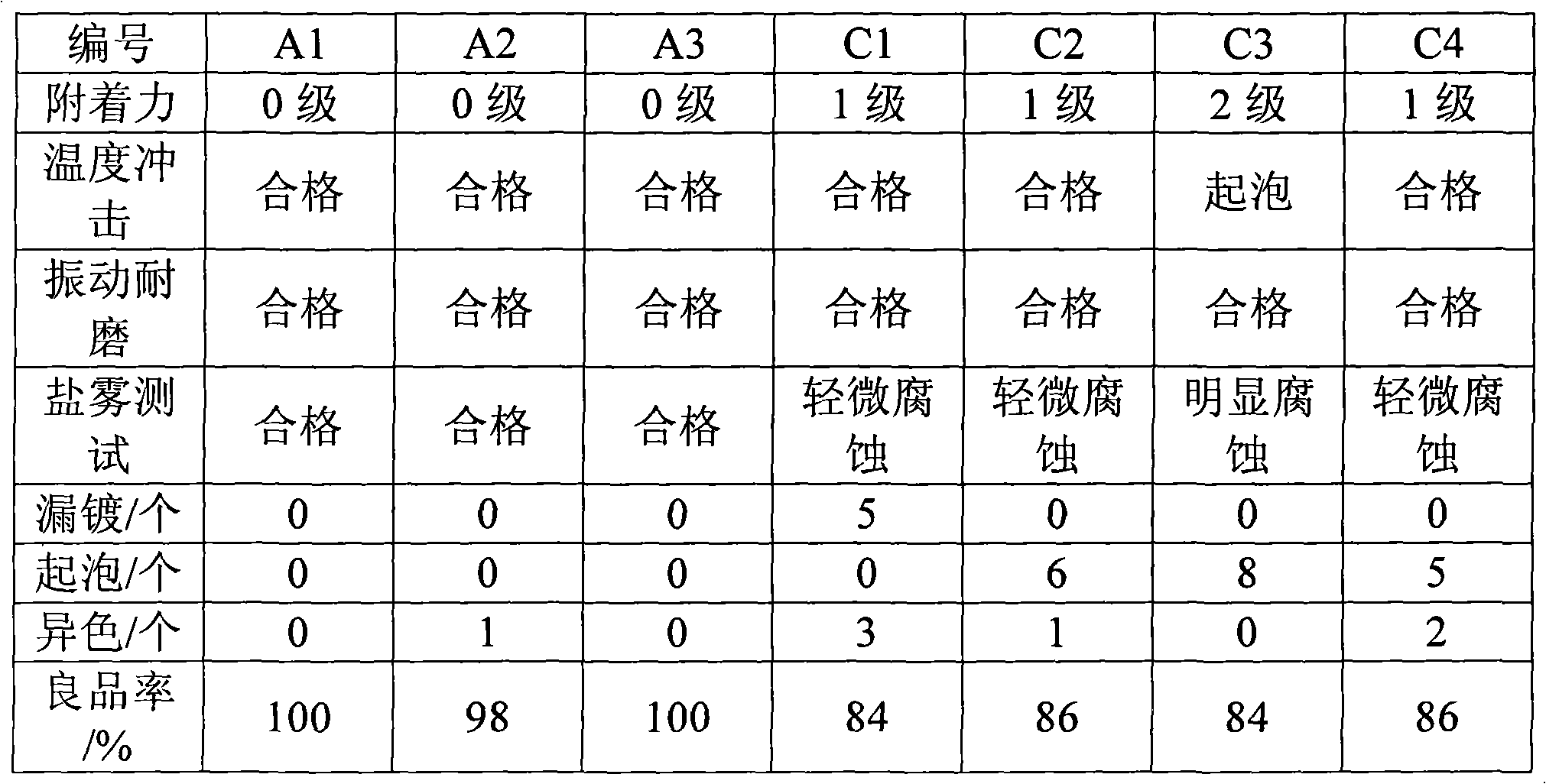

Aluminum alloy surface treatment method

InactiveCN101922010ALess prone to missing platingNot prone to foamingHot-dipping/immersion processesAnodisationAcid etchingLaser etching

The invention provides an aluminum alloy surface treatment method which comprises the steps of sequentially carrying out pretreatment, chemical plating and electroplating on an aluminum alloy matrix, wherein the pretreatment comprises the steps of sequentially carrying out anode oxidation, laser etching, erosion and acid etching on the aluminum alloy matrix. By using the method for forming electroplating texture on the surface of an aluminum alloy, the obtained product has natural texture, is not subject to skip plating, bubbling and discoloration phenomena and has a good decorative effect. Besides, the method has the advantage of simple operation, realizes the unshaded treatment and the convenient maintenance by using the technology of anode oxidation plus electroplating, and facilitates the mass production.

Owner:BYD CO LTD

Apparatus and method for making a forming structure

InactiveUS20050191496A1Set is reduced and preventedPattern makingLayered productsLaser etchingWavelength

A method for making a forming structure having columnar protrusions extending therefrom comprising the steps of exposing a liquid photosensitive resin to light having an activating wavelength thereby inducing partial curing of the photosensitive resin to form a monolithic slab of partially-cured photosensitive resin; and, including the step of inducing partial curing of a plurality of protrusions on the monolithic slab such that they are joined to and integral with the monolithic slab. The method can further comprise the step of laser etching a plurality of apertures through the forming structure.

Owner:THE PROCTER & GAMBLE COMPANY

Staggered laser-etch line graphic system, method and articles of manufacture

InactiveUS8460566B2Reduce visual impactReduce impactVacuum gauge using ionisation effectsDecorative surface effectsLaser etchingGraphics

A staggered laser-etch line graphic system, method, and articles of manufacture are provided. One described method includes the steps of laser engraving a first plurality of lines associated with a first component section of a graphic on a surface of an article; laser engraving a second plurality of lines associated with a second component section of the graphic on the surface of the article; and controlling said laser engraving of the first plurality of lines and said laser engraving of second plurality of lines to reduce the visual impact of a demarcation line separating the first component section of the graphic and the second component section of the graphic.

Owner:REVOLAZE LLC

Method of producing an antenna

InactiveUS6886237B2Increase inductanceImprove circularly polarised radiation patternLogperiodic antennasElectronic circuit testingCapacitanceLaser etching

In a method of producing a quadrifilar antenna for circularly polarised radiation at frequencies above 200 MHz, the antenna is tuned by coupling it to a test source, measuring the relative phases and amplitudes of currents at predetermined positions in the individual elements of the antenna by means of probes capacitively coupled to the elements, and laser etching apertures in the elements to increase their inductance, the sizes of the apertures being computed according to the deviation of the measured relative phases from predetermined values.

Owner:SARANTEL LTD

Method for engraving materials using laser etched V-grooves

Disclosed is a method for engraving materials such as fused silica or ceramic by continuously actuating a laser producing a Gaussian beam, directing the beam towards the surface of the substrate and moving the beam relative to the surface of the substrate so that a V-groove is obtained by laser ablation of the substrate. The depth of the groove, the angle of the top of the groove, can be controlled by the relative speed between the laser beam and the substrate, the power density and the width of the laser beam, the polarization of the laser beam and the incident angle of the laser beam with respect to the surface. A method for treating an optical fiber connector is also disclosed.

Owner:INSTITUT NATIONAL D'OPTIQUE

Preparation method of anti-creeping and anti-corrosive titanium or titanium alloy material

ActiveCN102051615AMaintain superamphiphobic propertiesImprove corrosion resistanceSurface reaction electrolytic coatingChemical vapor deposition coatingTemperature resistanceTitanium alloy

The invention discloses a preparation method of an anti-creeping and anti-corrosive titanium or titanium alloy material with a super-hydrophobic and super-oleophobic surface. The preparation method comprises the following steps: microprocessing the surface of metal titanium or titanium alloy through laser etching to obtain a roughened surface with a micron structure; then, forming a layer of titanium dioxide nanotube array film on the surface of the micron structure through anodic oxidation treatment; and finally, modifying by perfluorosilane or perfluorosiloxane to obtain the super-hydrophobic and super-oleophobic surface. The microstructure on the surface of the prepared metal titanium and titanium alloy is very stable and has good high temperature resistance; and after the chemical modification, the surface has super-hydrophobic (acid, base and salt solution) and super-oleophobic property, namely the contact angles to most of organic liquids and aqueous solutions are more than 150 degrees.

Owner:甘肃中安瑞科科技有限公司

Heat activated applique with upper stretch fabric layer

ActiveUS20090280290A1Excellent heat activated appliquéEasy to cutDecorative surface effectsSynthetic resin layered productsYarnPolyester

The heat activated appliqué for providing in particular decorative elements providing contrast in texture or color including graphical images, logos, numbers and letters for apparel and other textile products, specifically but not limited to those made out of stretch fabrics (typically knit or woven fabrics) comprised of synthetic or natural fiber yarns constructed with spandex fibers and yarns. The appliqué includes an upper stretchable fabric layer bonded to a substrate by a thermoplastic adhesive. Preferably, the stretchable fabric layer is a knit or woven fabric comprised of at least 3% and preferably between 3% to 33% spandex and polyester or nylon threads and the thermoplastic adhesive is a urethane-based thermoplastic adhesive with suitable stretch and recovery characteristics. The appliqué can be layered to provide three-dimensional characteristics. The stretchable fabric layer can be embossed to provide surface characteristics to the heat activated appliqué, either prior to or during application. This is also suitable for applying additional indicia in the form of direct printing or sublimation dye heat transferred into the stretchable fabric layer.The above appliqué may bear a combination of digitally-printed elements such as letters, logo graphics and numbers or other indicia, and may include a simulated embroidery-stitched appearance from either said printing or laser-etching or some combination of both, all in a form that is easily heat-sealed to a garment or other textile.

Owner:LION BROS CO INC

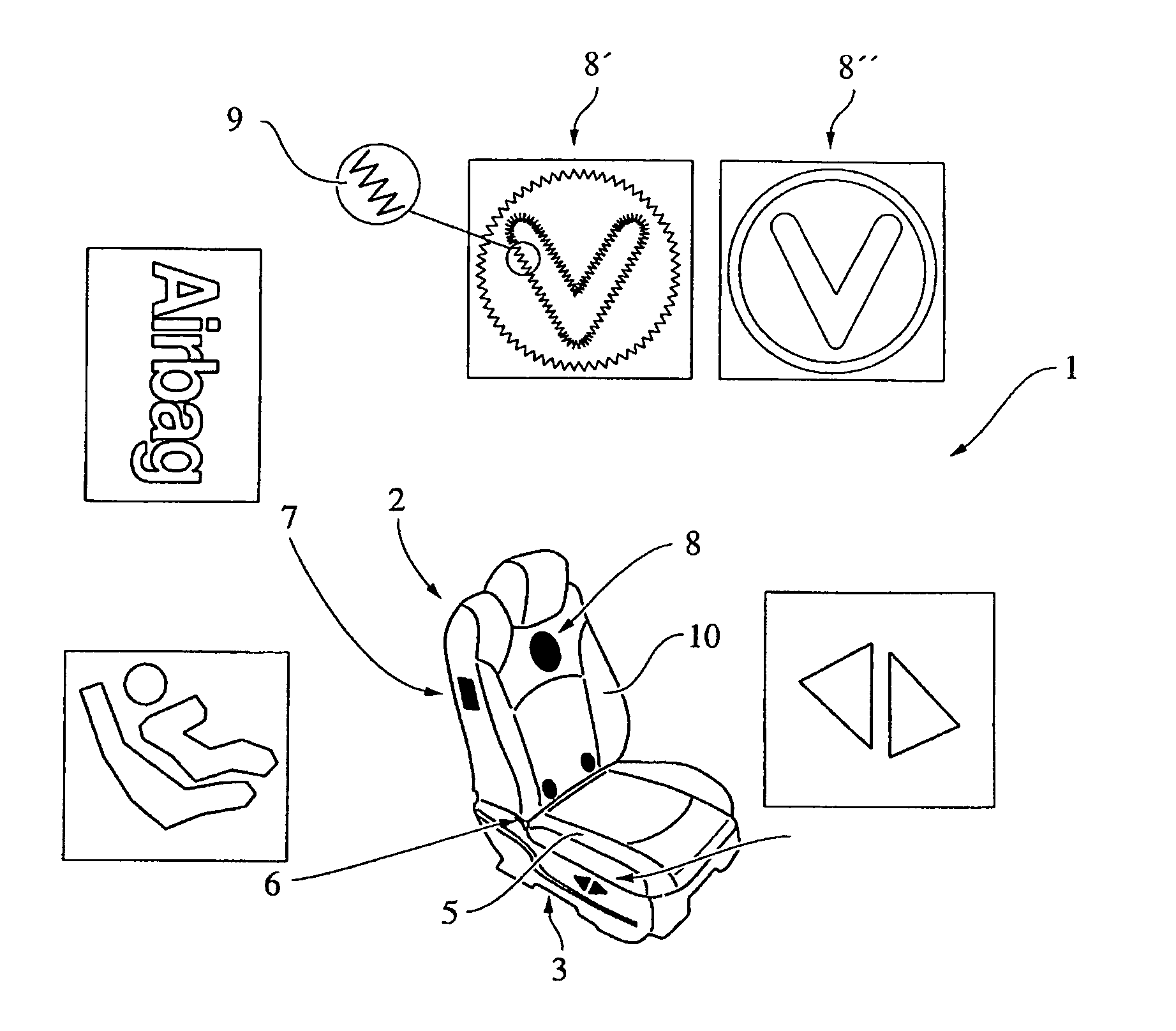

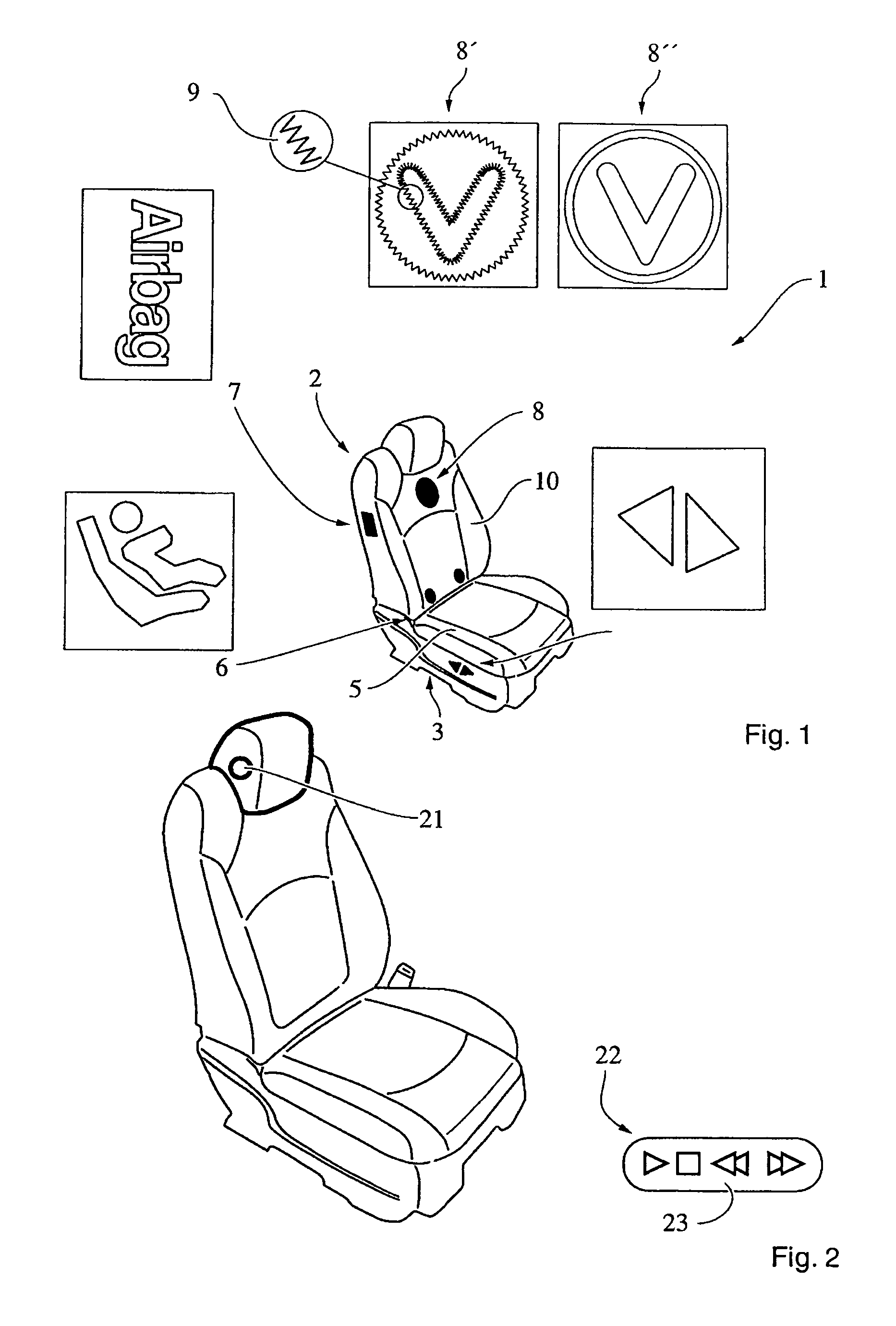

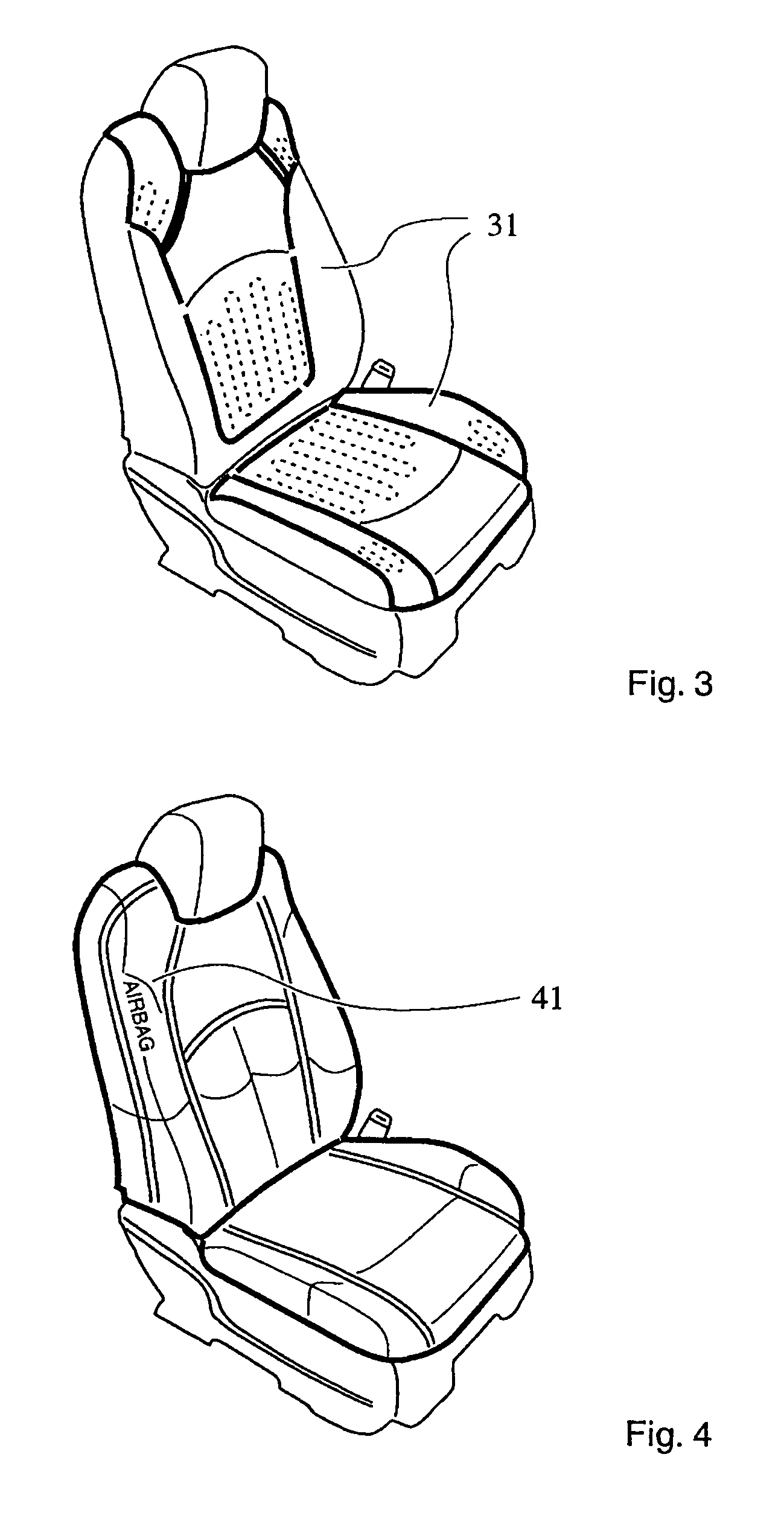

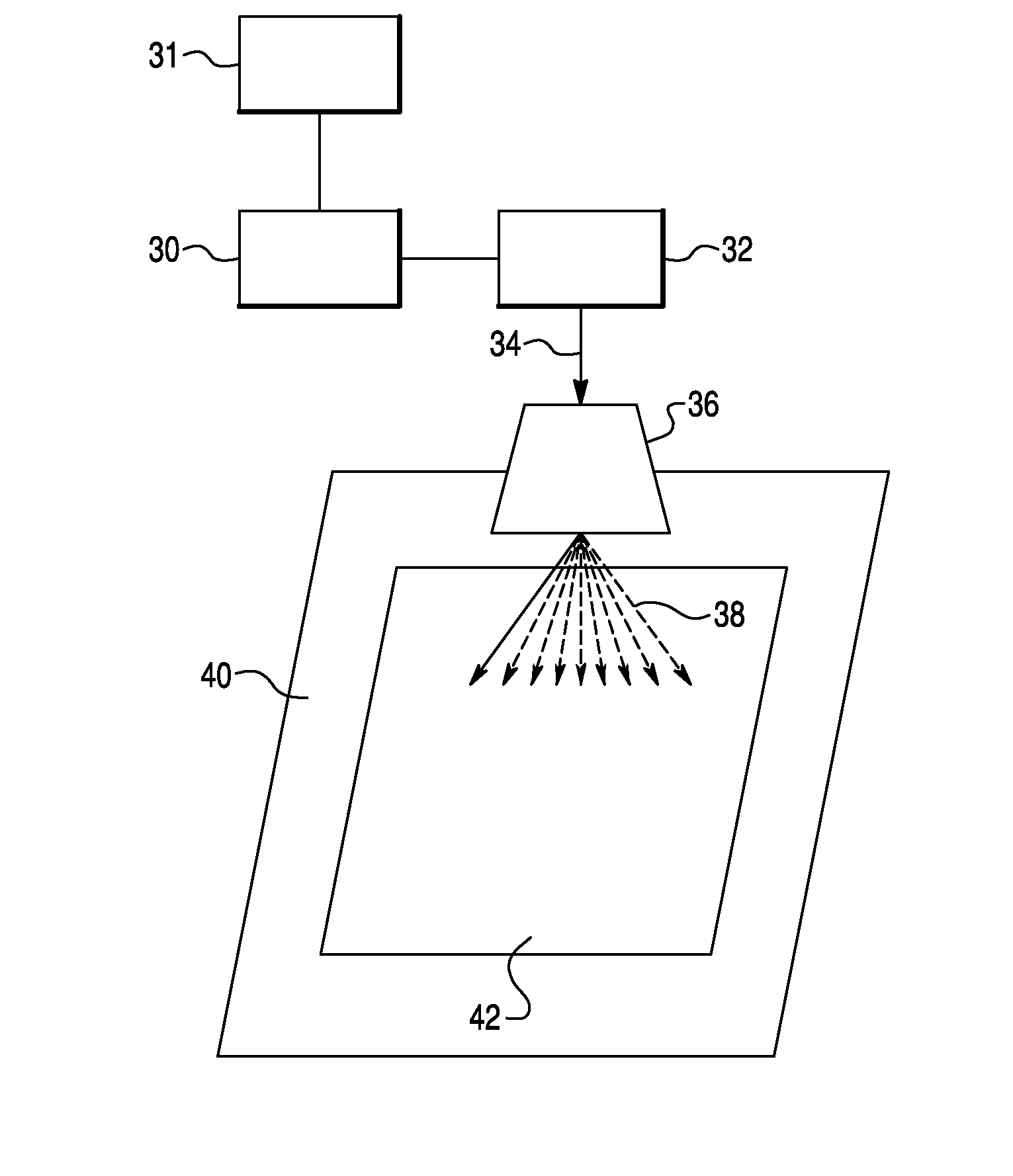

Laser etched trim

Owner:ADIENT LUXEMBOURG HLDG SARL

Laser etching of an acrylic and polyvinylchloride composition, and laser etched article

InactiveUS20110261141A1Reduce visual impactQuality improvementAblative recordingLaser etchingGrating

A laser-markable acrylic and PVC composition (commonly known as Kydex®) is lased using a CO2 laser to differentiate a laser etched graphic or pattern from the base material. A discoloration may be controlled to improve an appearance of the graphic or pattern. An embodiment uses a 500 to 2,500 watt CO2 laser to provide a raster or vector graphic pattern on the Kydex® finished part. Yet another embodiment is to use a 500 to 2,500 watt CO2 laser to provide a seamless raster or vector graphic pattern on a large piece of Kydex® which can then be cut and divided into multiple finished parts. In this case, an embodiment would include providing the necessary software and process controls to insure that the seams between individual parts that make up a larger part are without lines of demarcation.

Owner:REVOLAZE LLC

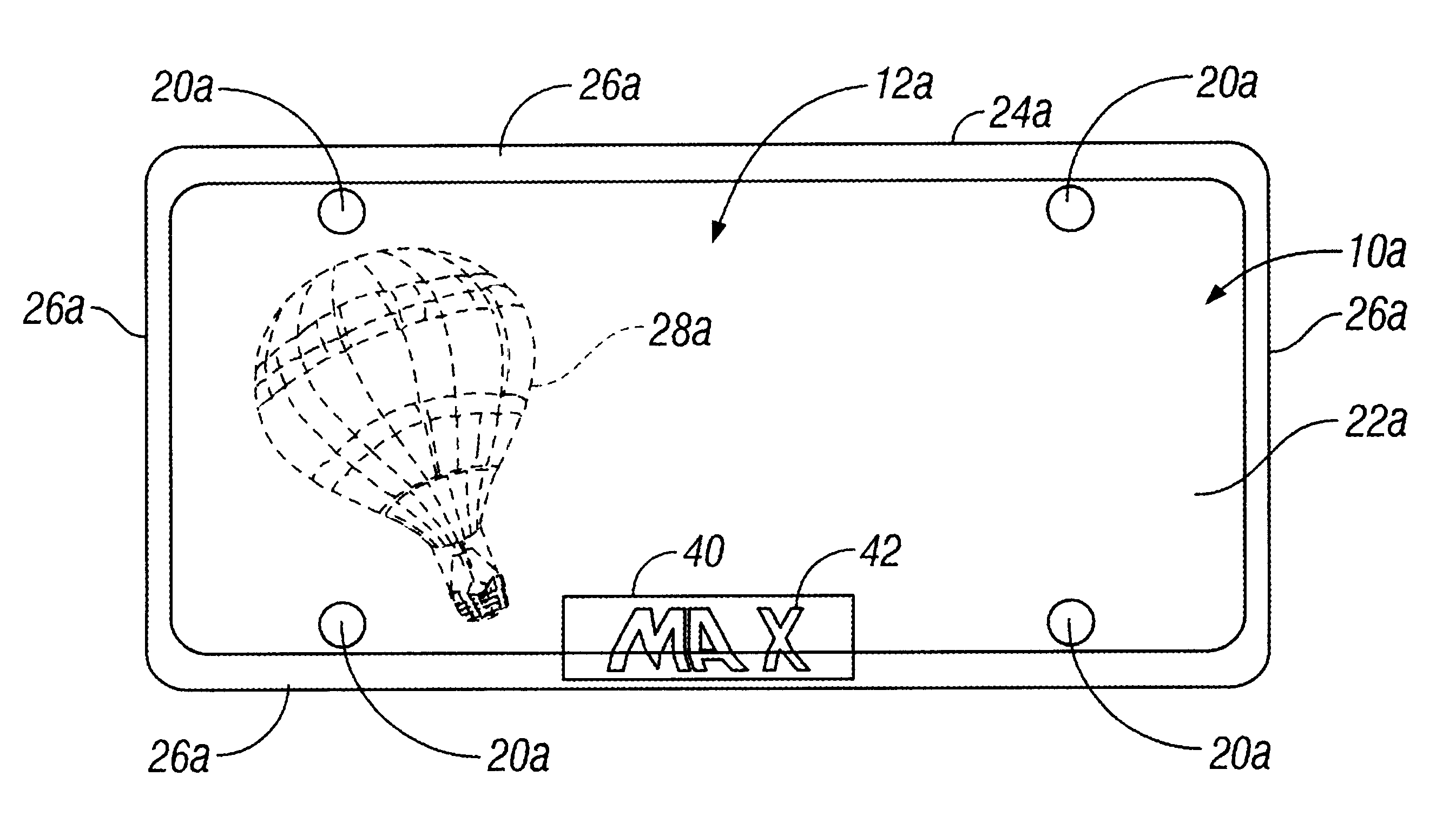

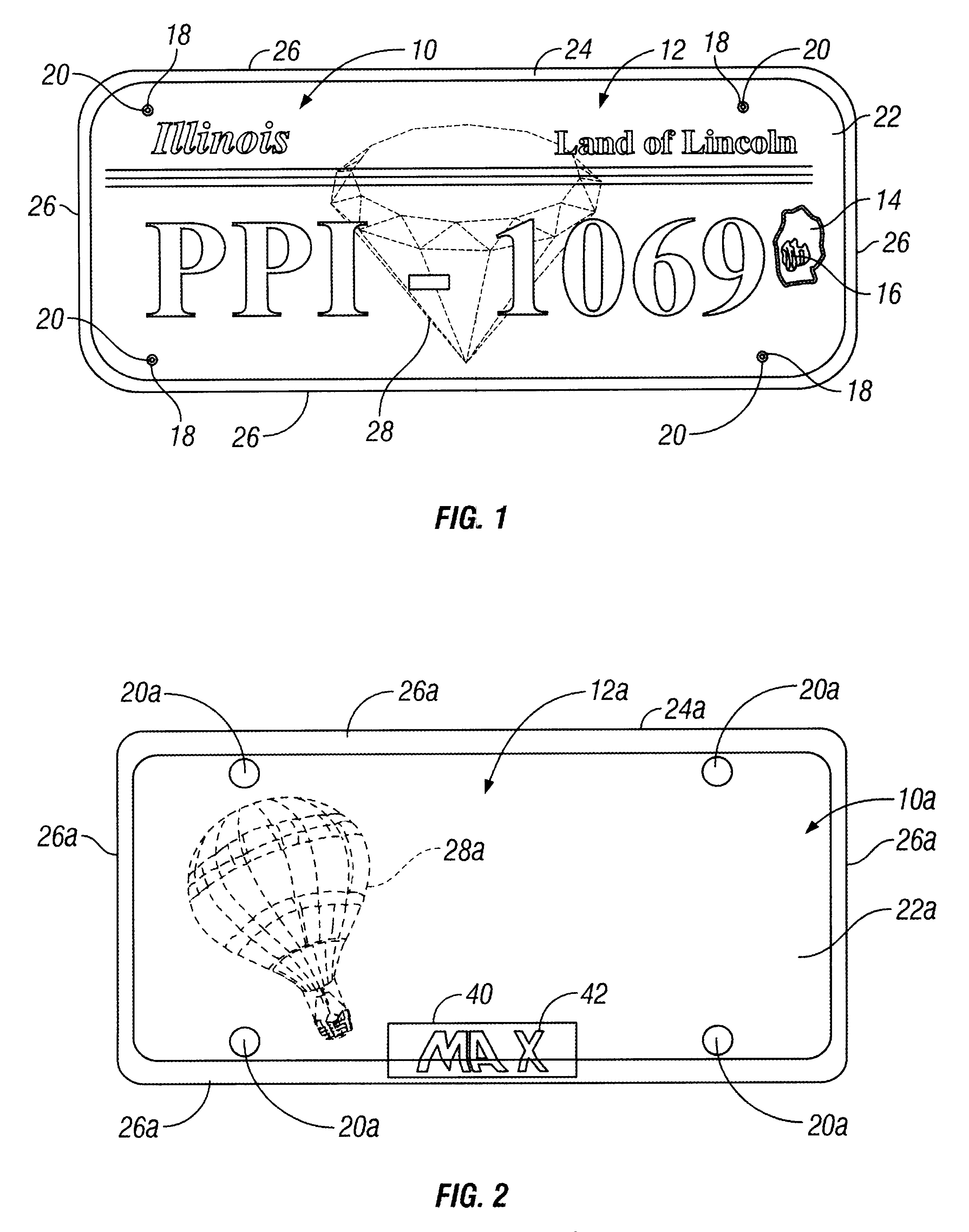

Vehicle license plate cover

A decorative and durable vehicle license plate cover is a flat, rigid, relatively thick, mar-resistant plate of optically transparent stable plastic, such as acrylic plastic. The plate has a solid body, with a front surface, a rear surface and sides interconnecting the front and rear surfaces. At least one and preferably all of the sides slope at about 30-60 degrees forwardly from the larger area rear surface to the smaller area front surface. The sloped sides are smooth and light reflective to enhance the appearance of the cover. Spaced holes are drilled or otherwise formed in the perimeter of the front surface and extend to the rear surface for attaching the cover to a vehicle license plate. The plate includes at least one of laser etching or engraving and printed indicia. The laser etching is disposed on the front and / or rear surface and / or interior of the plate.

Owner:PRECISION PLATES INT

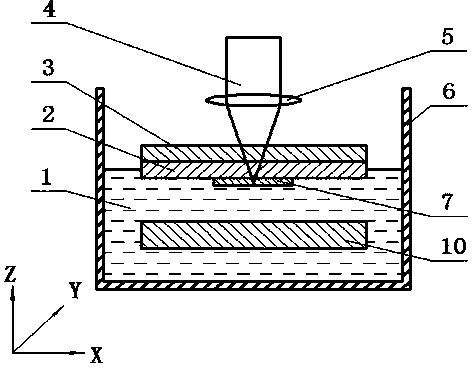

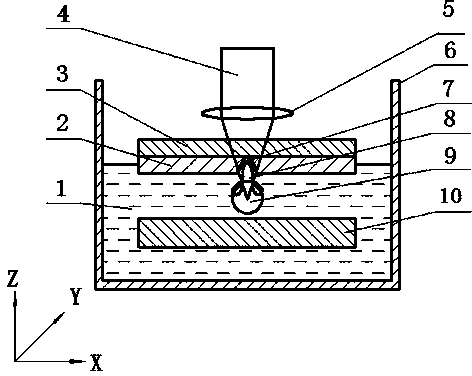

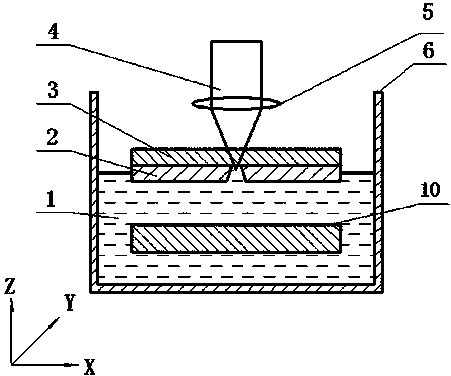

Machining device and machining method for enhancing sapphire laser back wet etching rate

ActiveCN103418912AEnhanced laser etch rateRealize the microstructureLaser beam welding apparatusSemiconductor devicesMicro structureLaser etching

The invention relates to a machining device and a machining method for enhancing a sapphire laser back wet etching rate. The machining device comprises a protection device, a laser beam, a lens assembly, a container and a limit layer, operating fluid is filled in a hollow cavity formed in the container, a workpiece is placed on the surface of the operating fluid and contacts with the operating fluid, the protection device is mounted at the top of the workpiece, the limit layer is mounted below the workpiece, and the laser beam irradiates the back of the workpiece through the lens assembly. The machining device has a high material removing rate under the condition of ensuring fine surface machining quality of sapphires. According to the machining method, chippings are easily taken away by the fluid, the heat effect of laser ablation is small, a regelation layer in a machining area is omitted, machining quality is fine, a laser-induced cavitation effect leads to a micro-jet enhancement effect, the laser etching rate of transparent materials such as the sapphires is enhanced, and micro-structures and shape cutting of material surfaces can be realized. The machining method is simple to operate, convenient, practical and high in machining speed.

Owner:GUANGDONG UNIV OF TECH

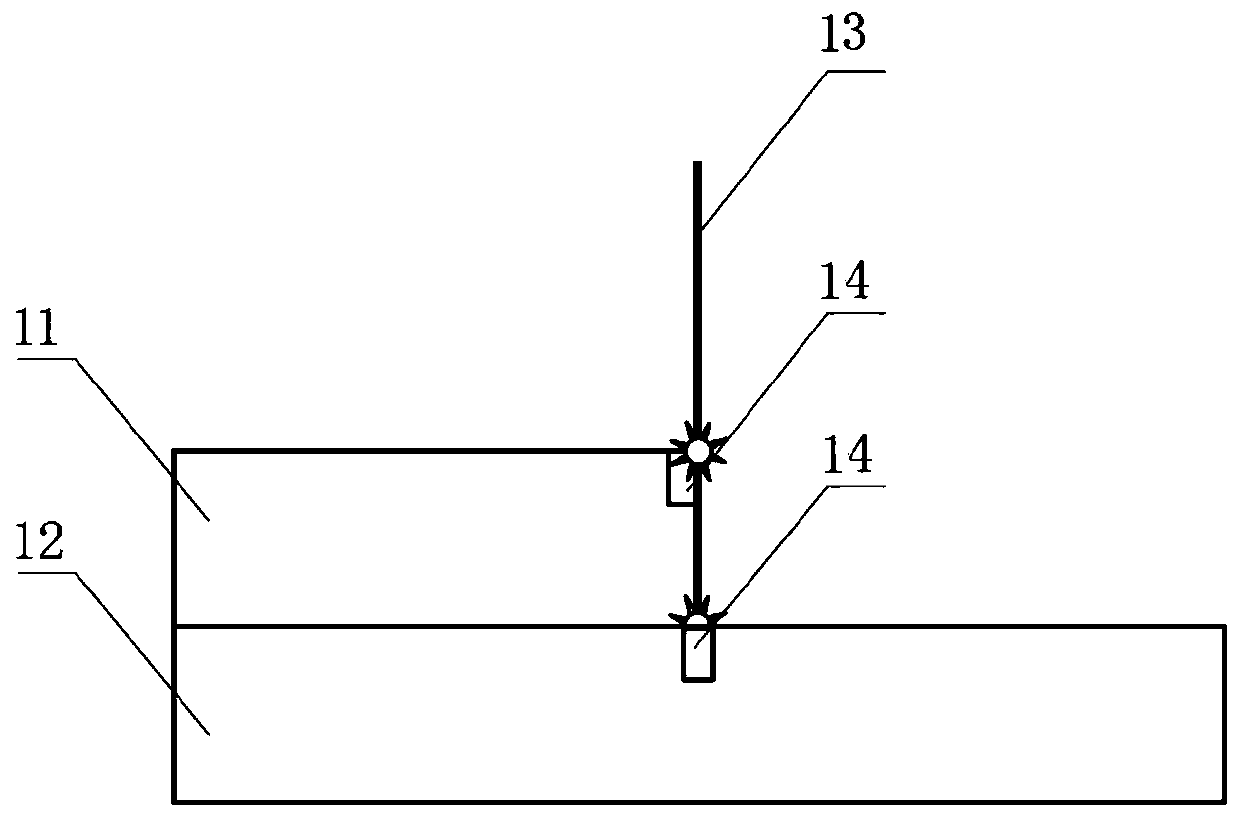

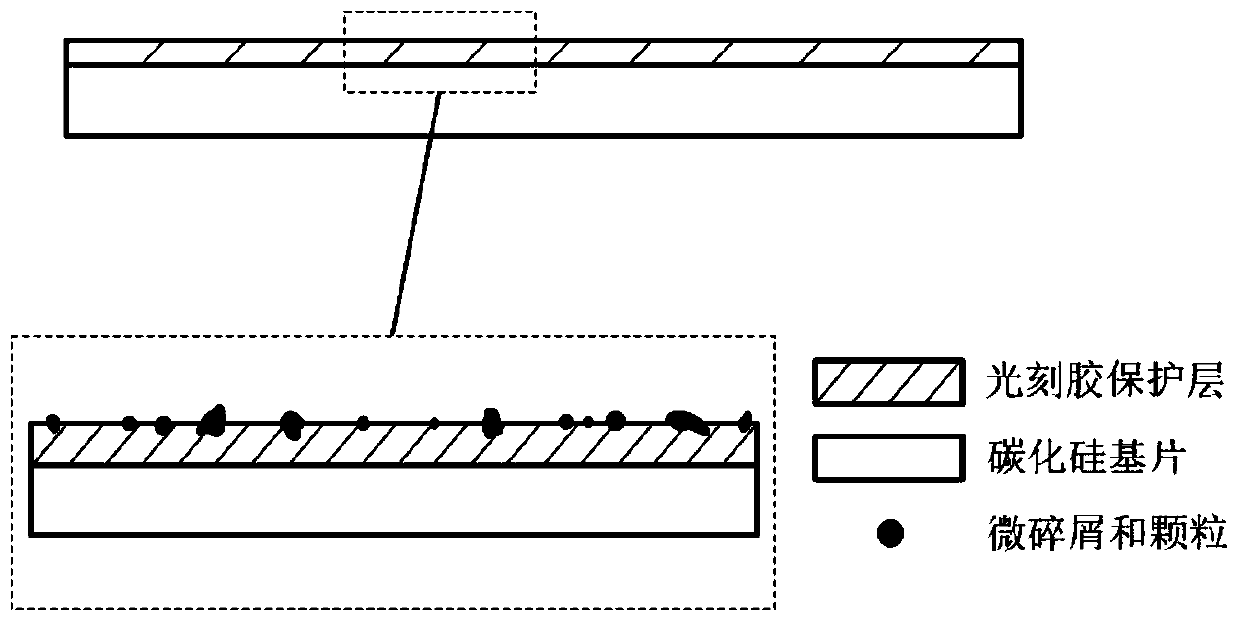

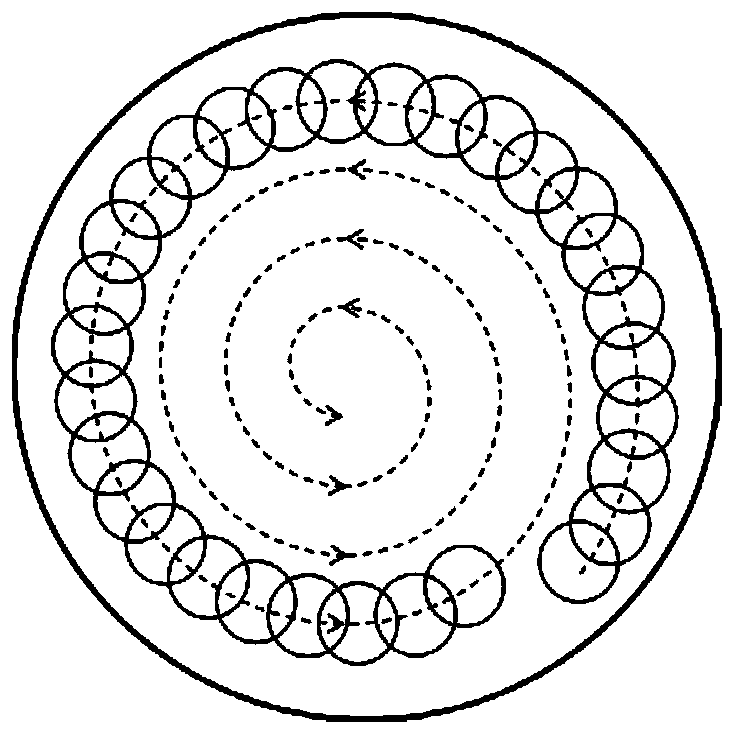

Femtosecond laser processing device and method for rapid deep etching of silicon carbide

ActiveCN110385521AFast etch qualityImprove etch qualityLaser beam welding apparatusLaser etchingLaser processing

The invention discloses a femtosecond laser processing device and method for rapid deep etching of silicon carbide. The femtosecond laser processing device mainly comprises a laser source module, a laser motion module, a shaping and focusing module, an auxiliary gas module and a laser etching module. According to the device and method, a focal plane is calibrated, a protection layer is prepared, an etching path is planned, layer-by-layer scanning etching is carried out according to parameter groups, and micro-chips are removed, so that deep etching of silicon carbide is realized. According tothe method, due to the fact that a femtosecond laser is used for processing silicon carbide, factors influencing the etching quality are controlled, namely, the laser energy density, the light spot overlapping rate and the line overlapping rate, and therefore silicon carbide is subjected to rapid and high-quality deep etching in a layer-by-layer scanning manner and a continuous feeding processingmanner according to the planned etching path.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com