Method for projection-type laser etching on free curved surface

A laser etching method and free technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of inability to perform secondary processing, and achieve the effect of low equipment cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

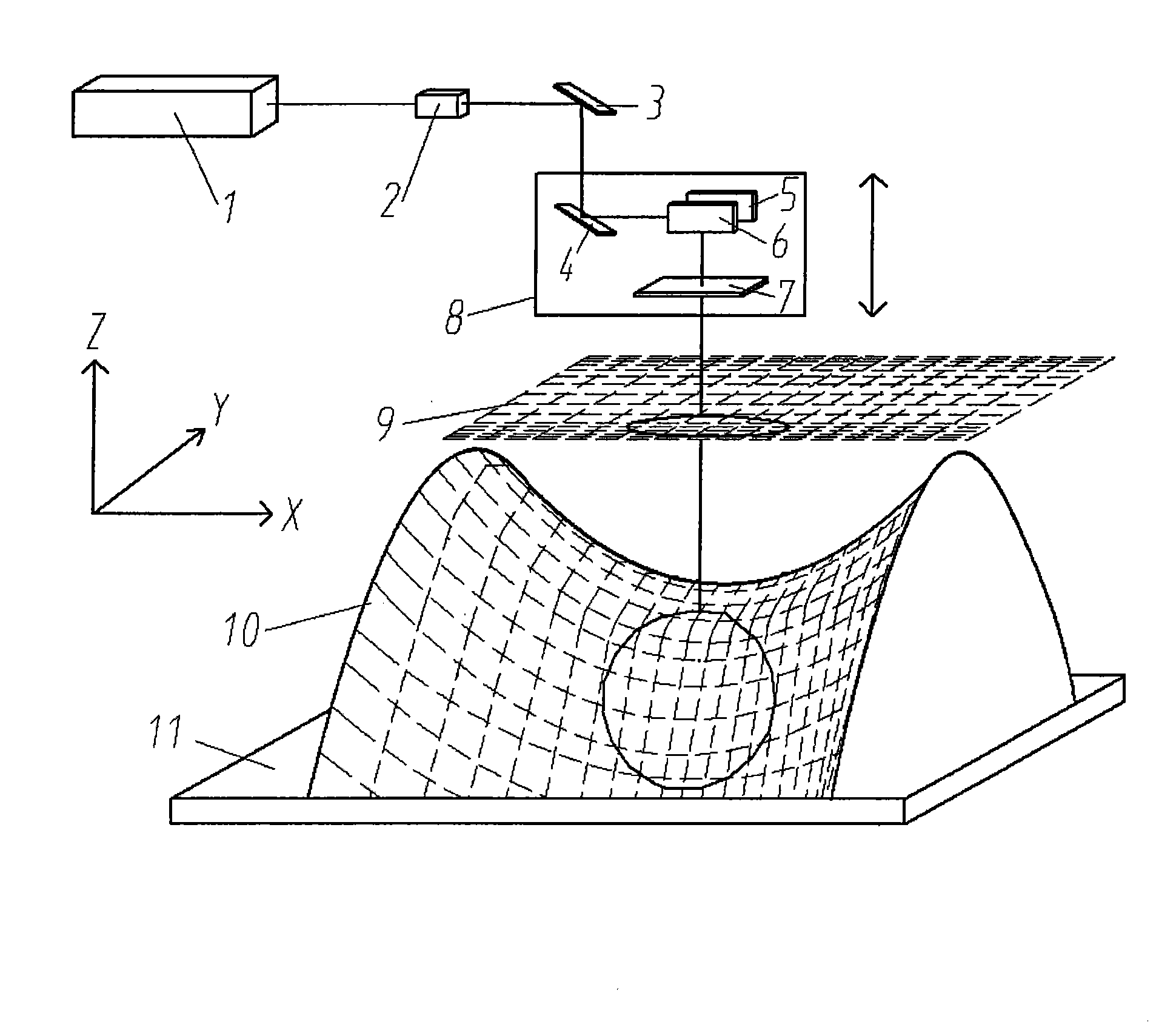

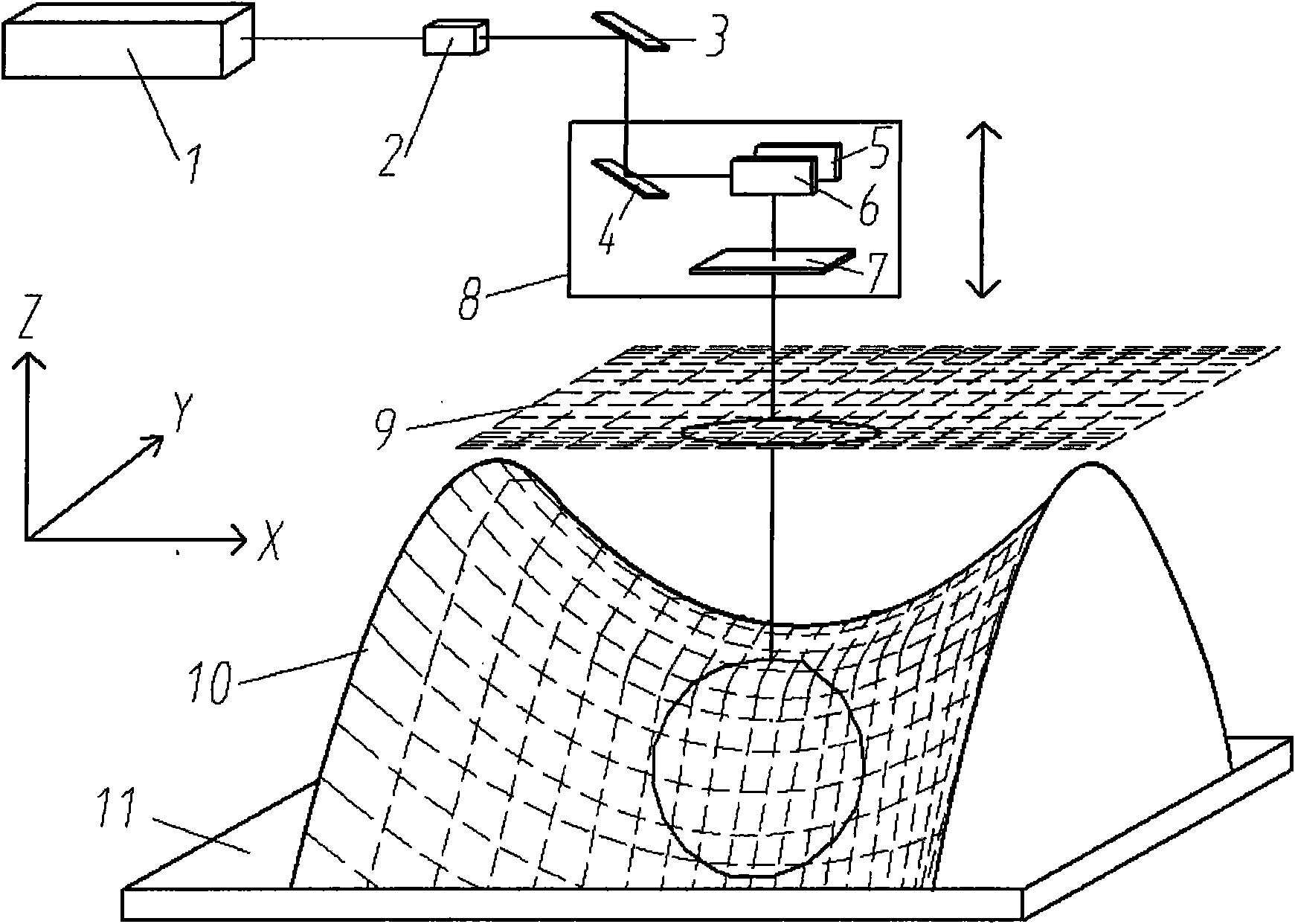

[0020] The projection-type laser etching method on the free-form surface provided by the present invention adopts a general-purpose "3+2" axis CNC laser processing machine tool, and the machine tool includes an XYZ three-axis motion positioning mechanism and a two-axis laser galvanometer scanning device. The sub-block positioning is realized through the XY two axes, and the Z-axis moving mechanism cooperates with the laser vibrating mirror to perform sub-block projection processing. The method includes the following steps:

[0021] (1) Establish a discrete point cloud model of the free-form surface part surface in the XYZ rectangular coordinate system. The point cloud data either directly comes from converting the 3D solid model of the computer-aided design (CAD) free-form surface part into a point cloud data type, or from Point cloud data obtained by reverse engineering measurement of existing free-form surface parts;

[0022] (2) Divide the graphics or patterns to be etched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com