Patents

Literature

575results about How to "Avoid plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

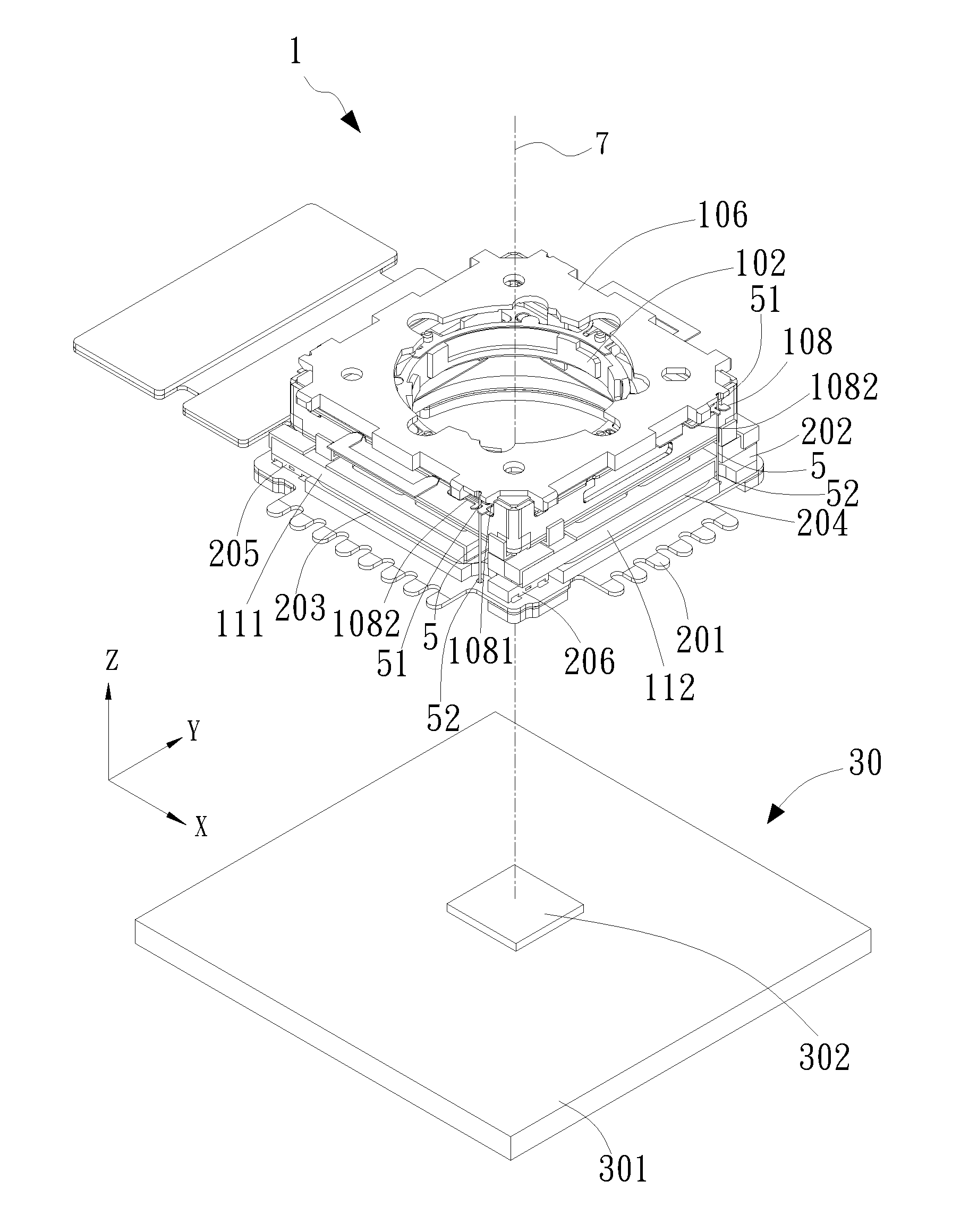

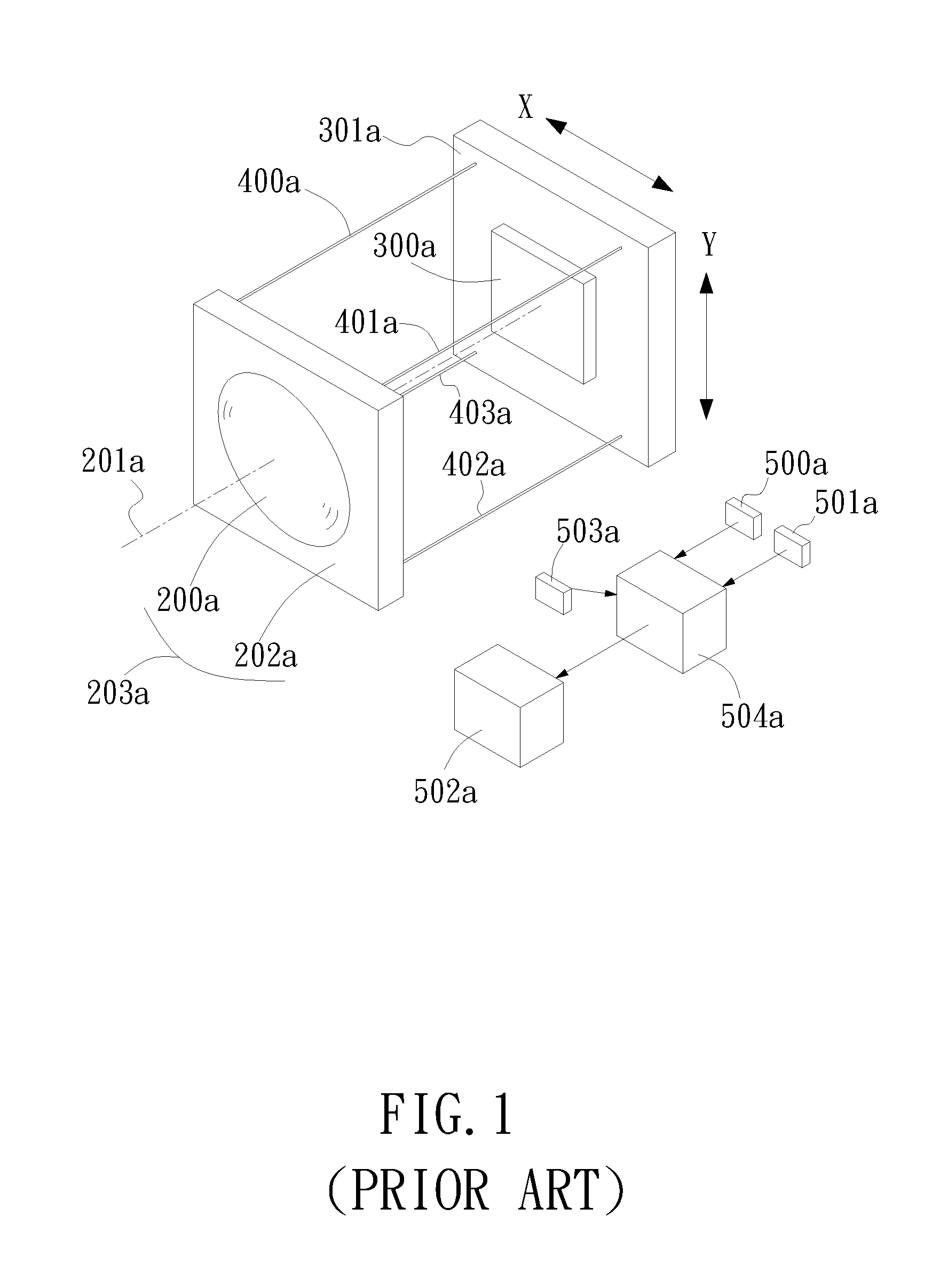

Elastic supporting structure and optical image stabilizer having the elastic supporting structure

An elastic supporting structure for an optical image stabilizer is provided. The optical image stabilizer includes a movable portion, a compensation module, and a plurality of suspension wires. The movable portion is provided therein with a lens. The compensation module corresponds to the movable portion, and both are located on the same image-capturing optical axis. Each suspension wire has two ends respectively connected to the movable portion and the compensation module. The movable portion is provided with an upper spring plate. One end of each suspension wire is connected to a length-increased outer line element and at least one additional auxiliary line element of the upper spring plate, and the other end of each suspension wire is connected to the compensation module, such that the movable portion corresponds to the compensation module and is spaced therefrom by a predetermined distance. Also, anti-shake function performs well with suspension wires.

Owner:TDK TAIWAN

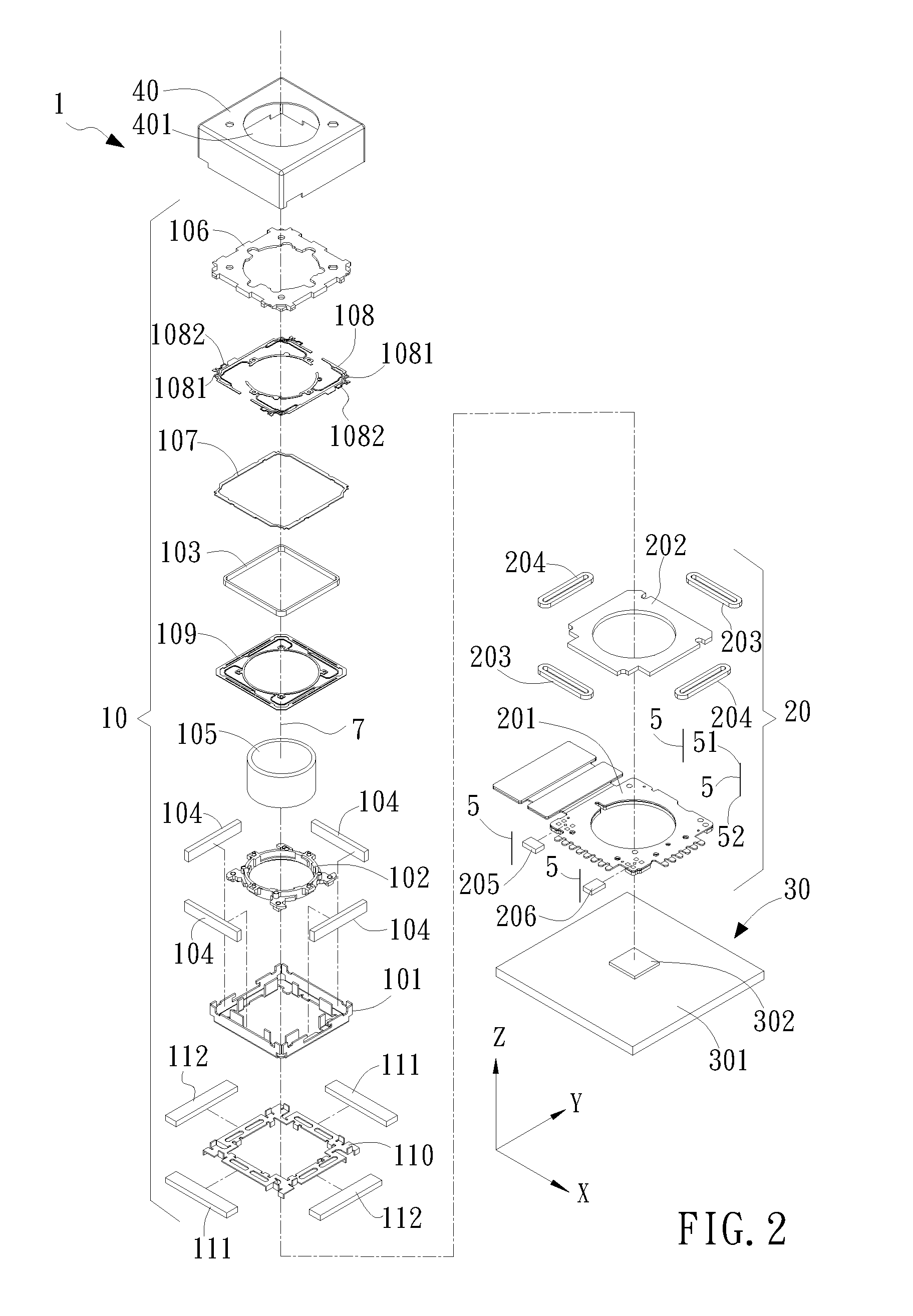

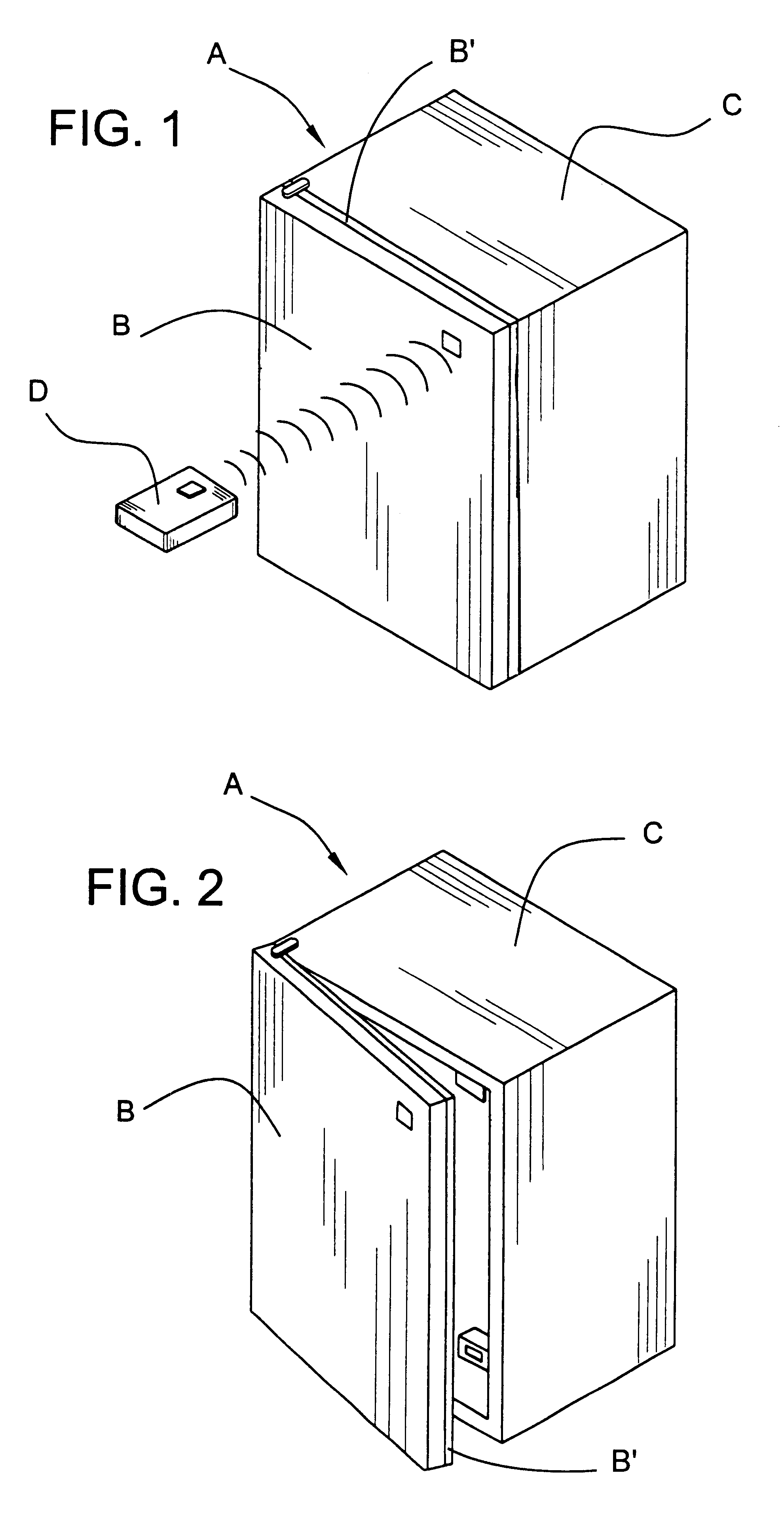

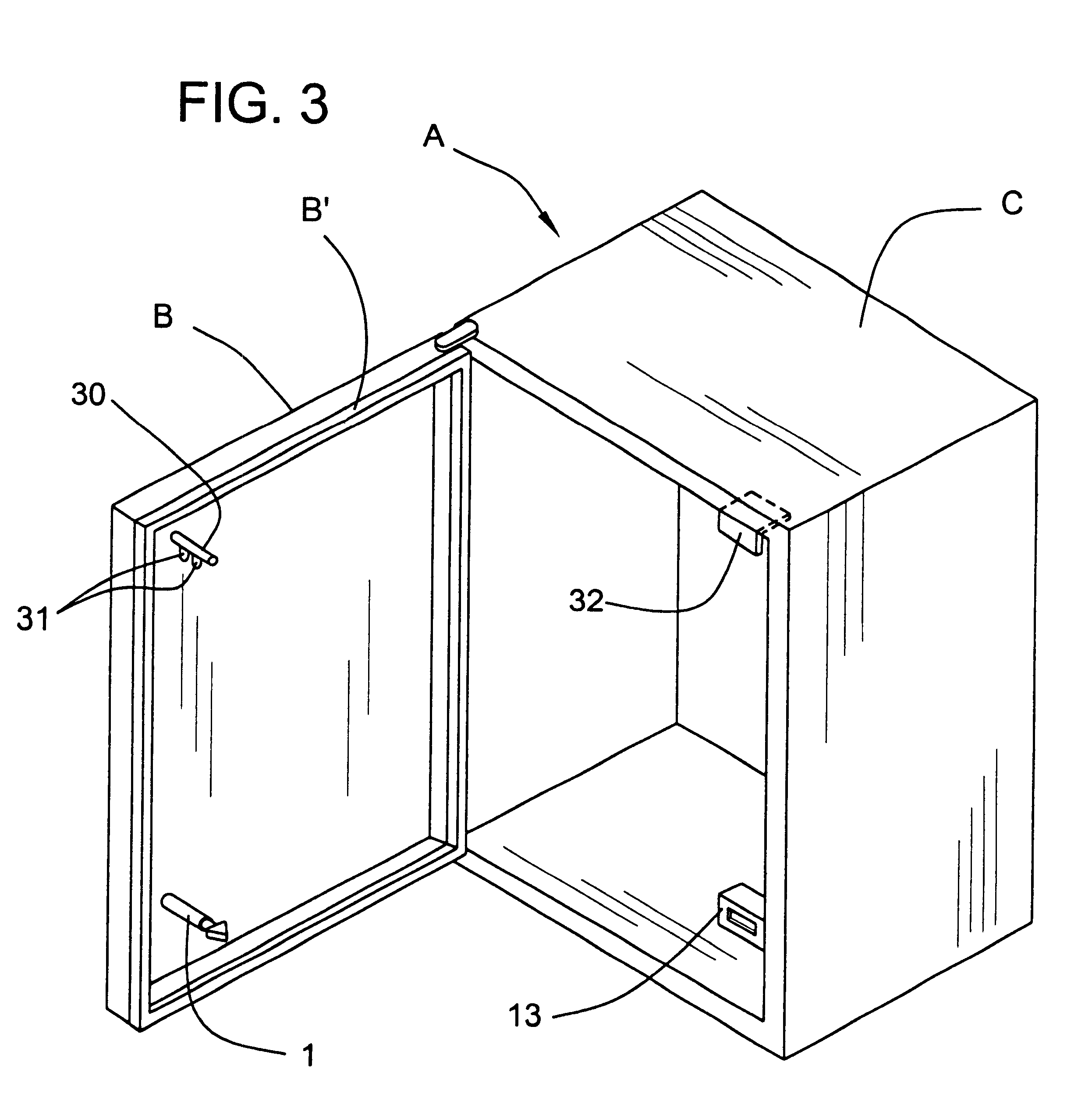

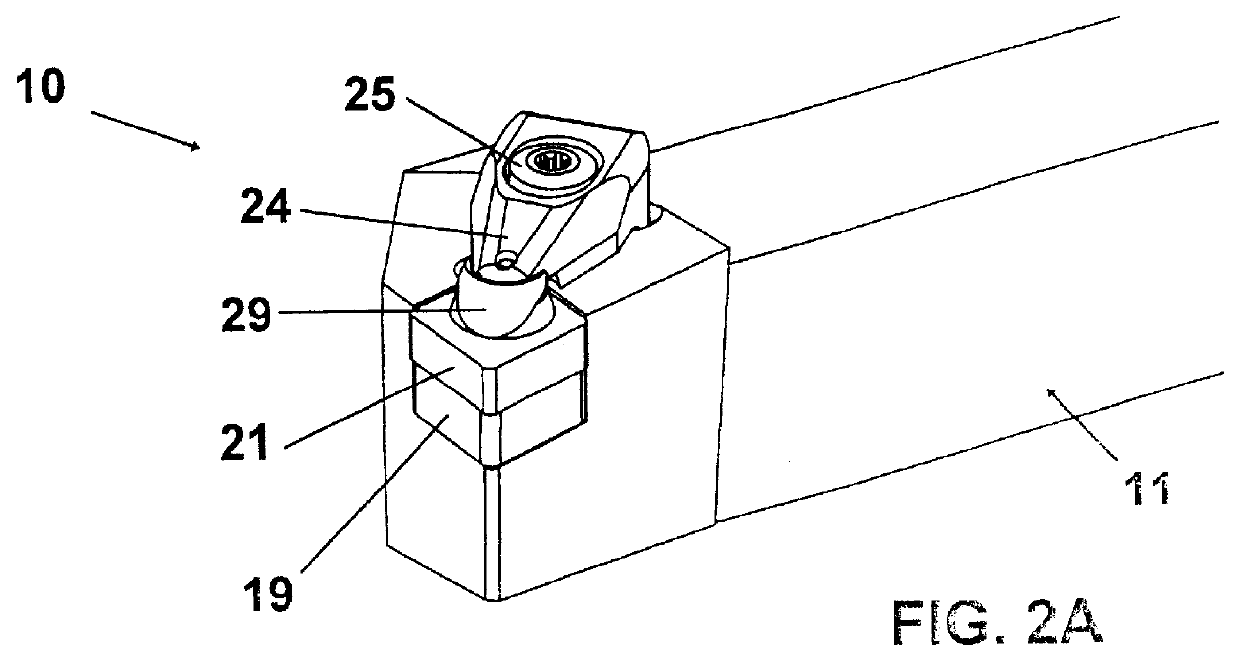

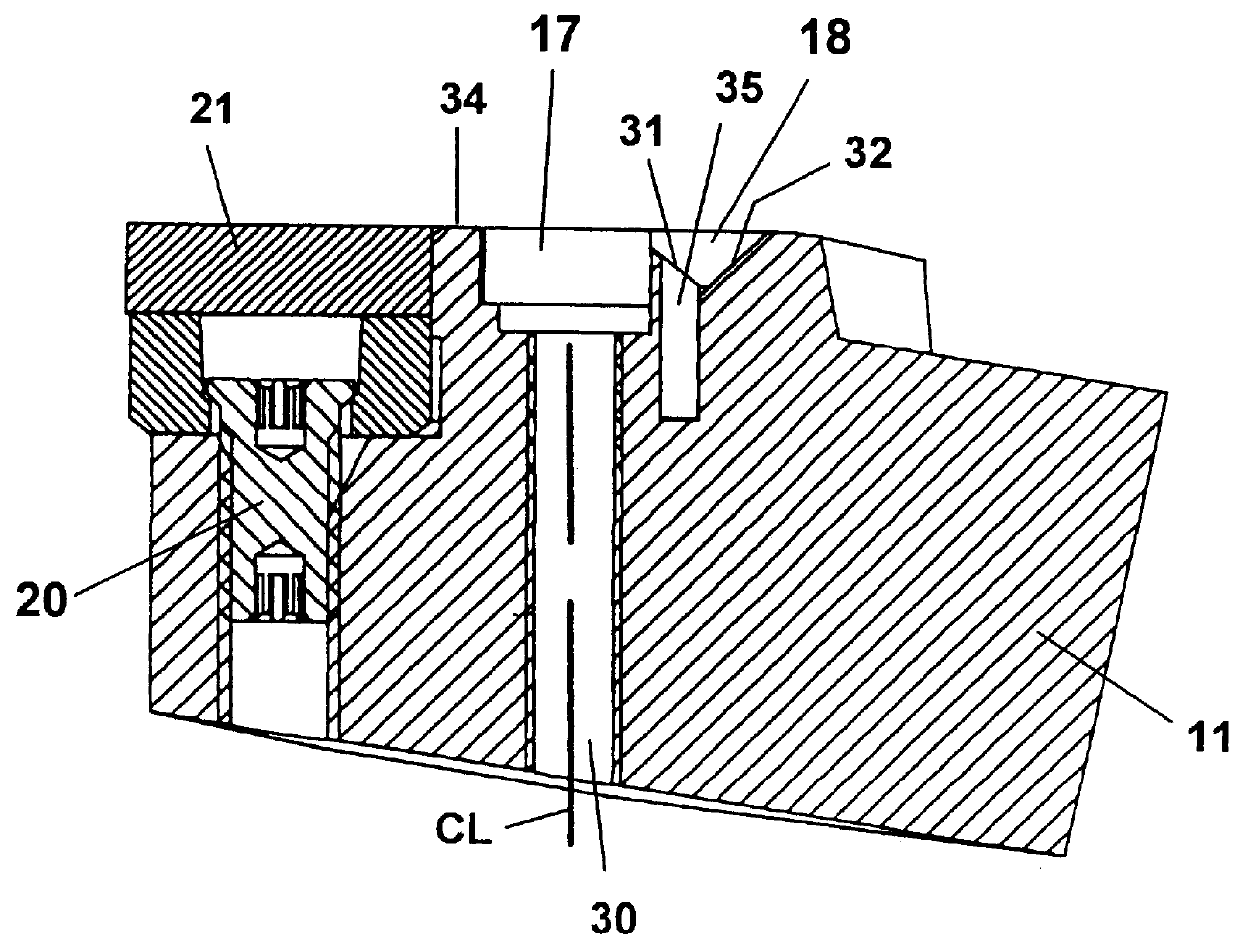

Bayonet locking system and method for vending machines and the like

InactiveUS6581986B2Avoid plastic deformationAnti-theft cycle devicesAnti-theft devicesMotor driveEngineering

A bayonet locking system for vending machines is provided to lock and unlock the machine preferably with a remotely controlled electronic operating unit. It includes at least one motor driven axially and rotationally movable bayonet with an enlarged shaped head being mounted preferably on a gasketed door and at least one receptacle receiving device disposed within the machine interior positioned for engagement by the bayonet when the door is moved to an intermediate position. The bayonet advances into the receptacle and rotates to capture it in the receptacle and then axially retracts to pull the door into the closed position wherein a gasket disposed between the door and the machine is substantially uniformly compressed and sealed around its periphery. An axially rotatable pin with fins may be used with a bracket on either the door or machine to prevent prying of the door at opposite corners.

Owner:TRITEQ LOCK & SECURITY L L C

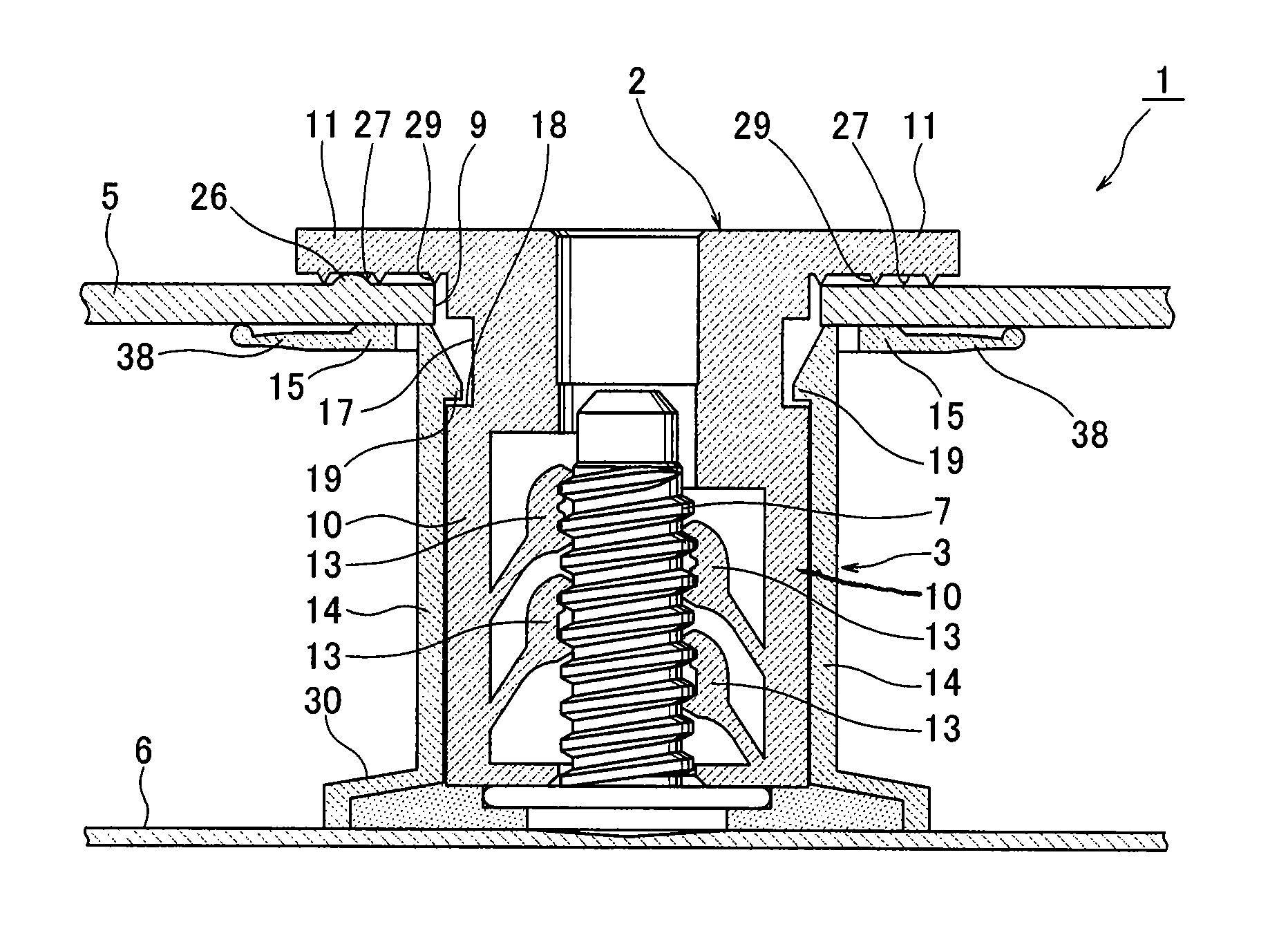

Fasteners for clamping sheet-form members, and apparatus and method using such fasteners to attach undercover onto underside of vehicle floor panel

ActiveUS7891151B2Facilitate intentional turningAvoid plastic deformationVehicle seatsCeilingsEngineeringFlange

Owner:NEWFREY

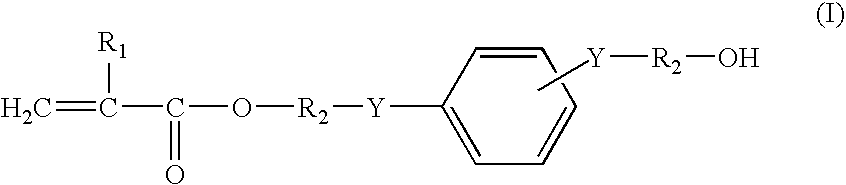

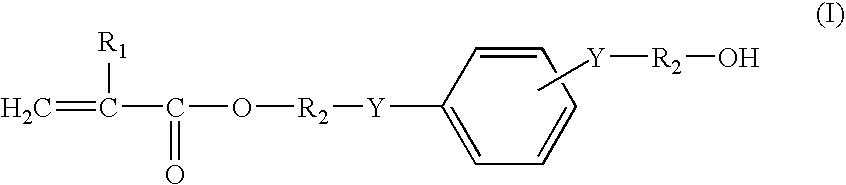

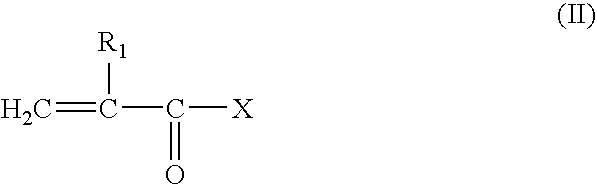

(Meth)Acrylate Compound and Process For the Production Thereof, (Meth)Acrylate Copolymer and Process For the Production of (Meth)Acrylate Copolymer, and Soft Intraocular Lens

ActiveUS20080139769A1High refractive indexAvoid it happening againOrganic compound preparationCarboxylic acid esters preparationMeth-Hydrogen atom

A (meth)acrylate copolymer obtained by copolymerization of a monomer mixture containing a monomer (A) of the general formula (I),wherein R1 is a hydrogen atom or methyl, R2 is a linear or branched alkylene group having 1 to 8 carbon atoms and Y is a single bond or an oxygen atom, a monomer (B) copolymerizable with the monomer (A) and a crosslinking monomer (C).

Owner:HOYA CORP

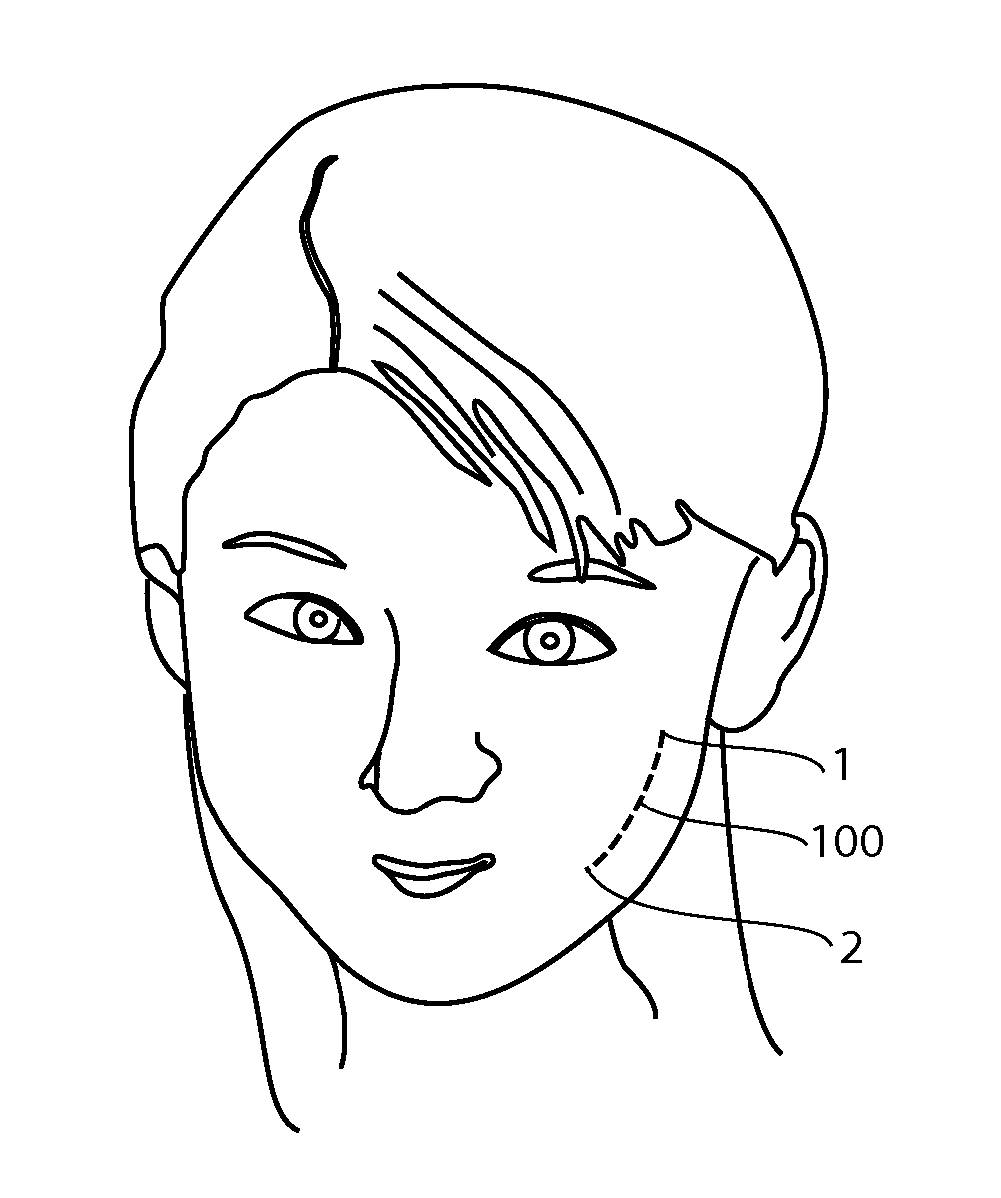

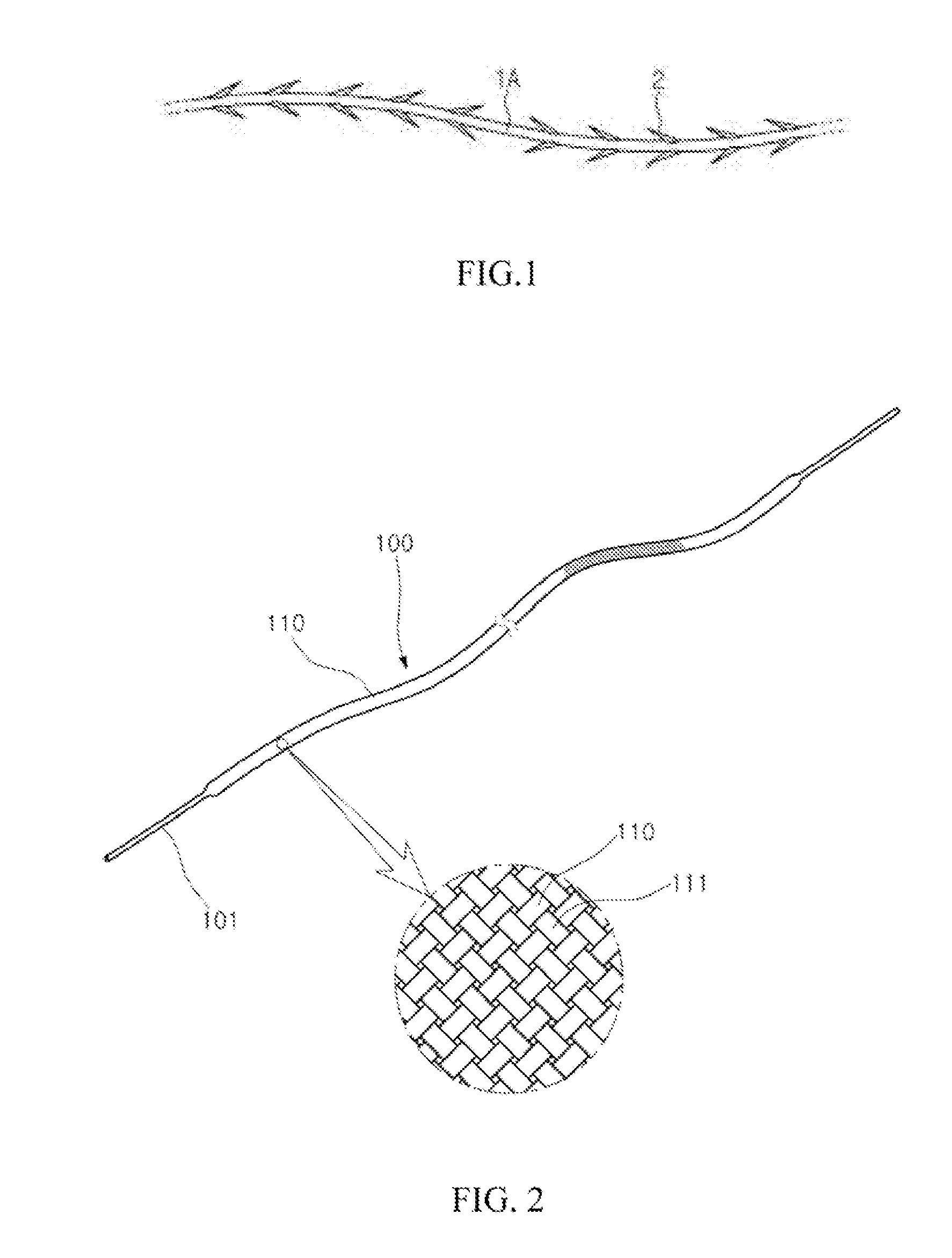

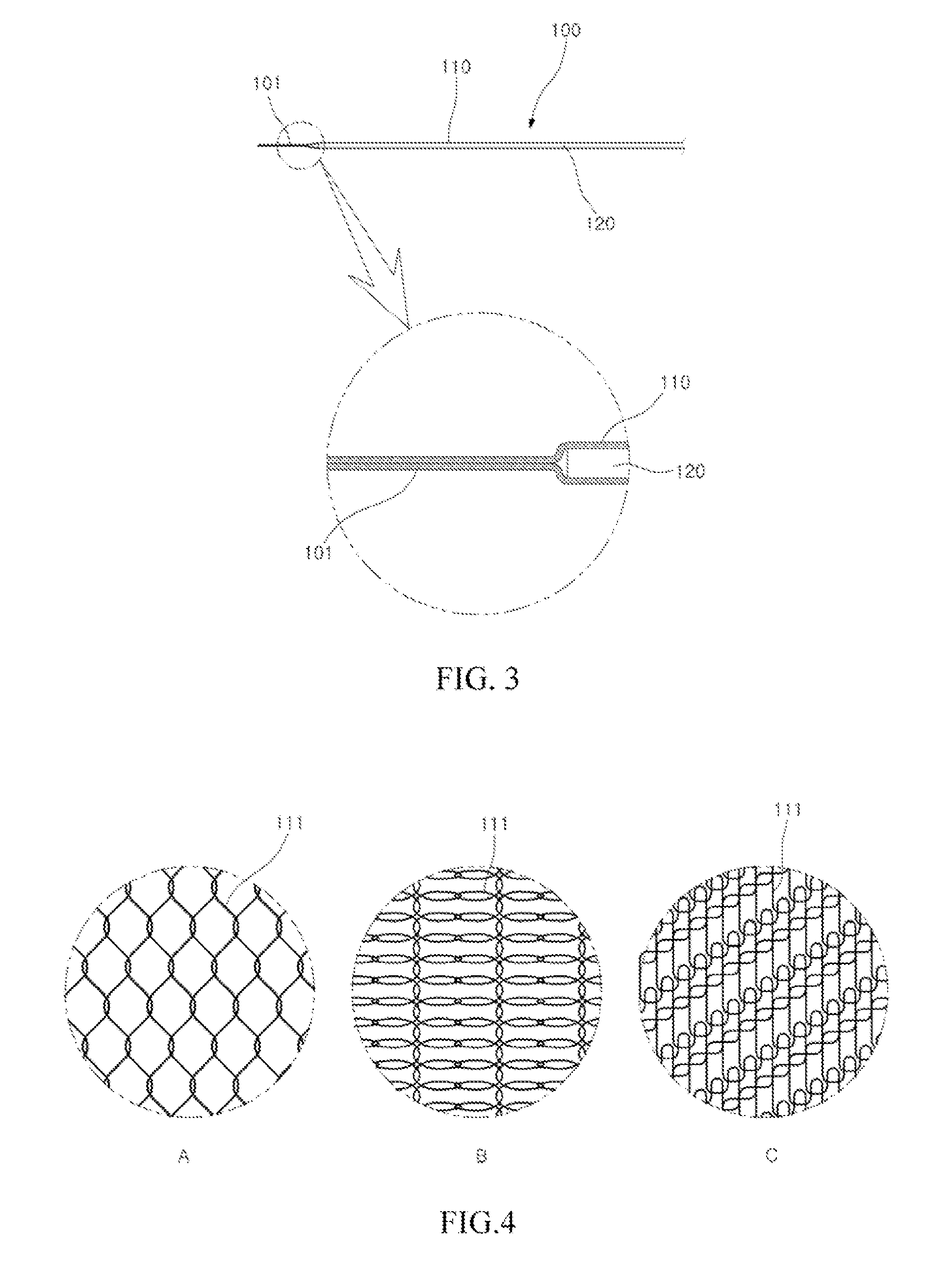

Linear tension material for plastic surgery

InactiveUS20080046094A1High strengthAvoid fatigueSuture equipmentsCosmetic implantsWrinkle skinFiber

The present invention relates to a linear tension material for surgery used to pull skin tissue. An object of the present invention is to provide a linear tension material for plastic surgery which prevents permanent deformation due to excessive elongation and fatigue and of which a portion besides united portions is uniformly and properly united with body tissue. According to an aspect of the present invention, there is provided a linear tension material for plastic surgery which is provided to pull a predetermined site inside skin tissue of the body in a state of tensile load so as to smooth out wrinkles and pull the tissue to tighten a saggy portion, the linear tension material including: a core material in a code shape, which is made of a flexible resin including polyorganosiloxane; and a covering material which covers an outside of the core material to be united with the core material, shrinks together with the core material, and has a fiber textile structure formed by weaving a number of fiber threads.

Owner:HAN KWANG HEE +1

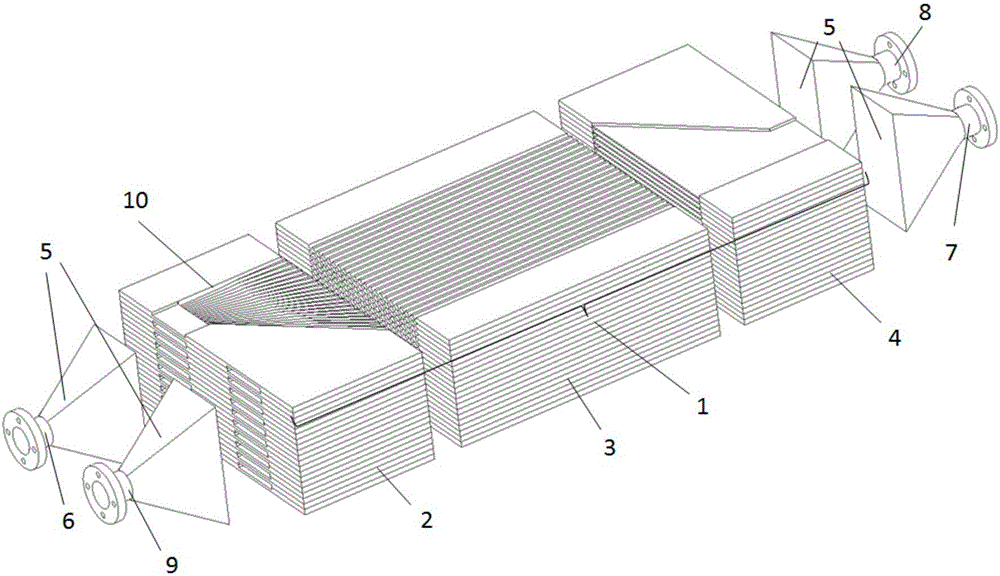

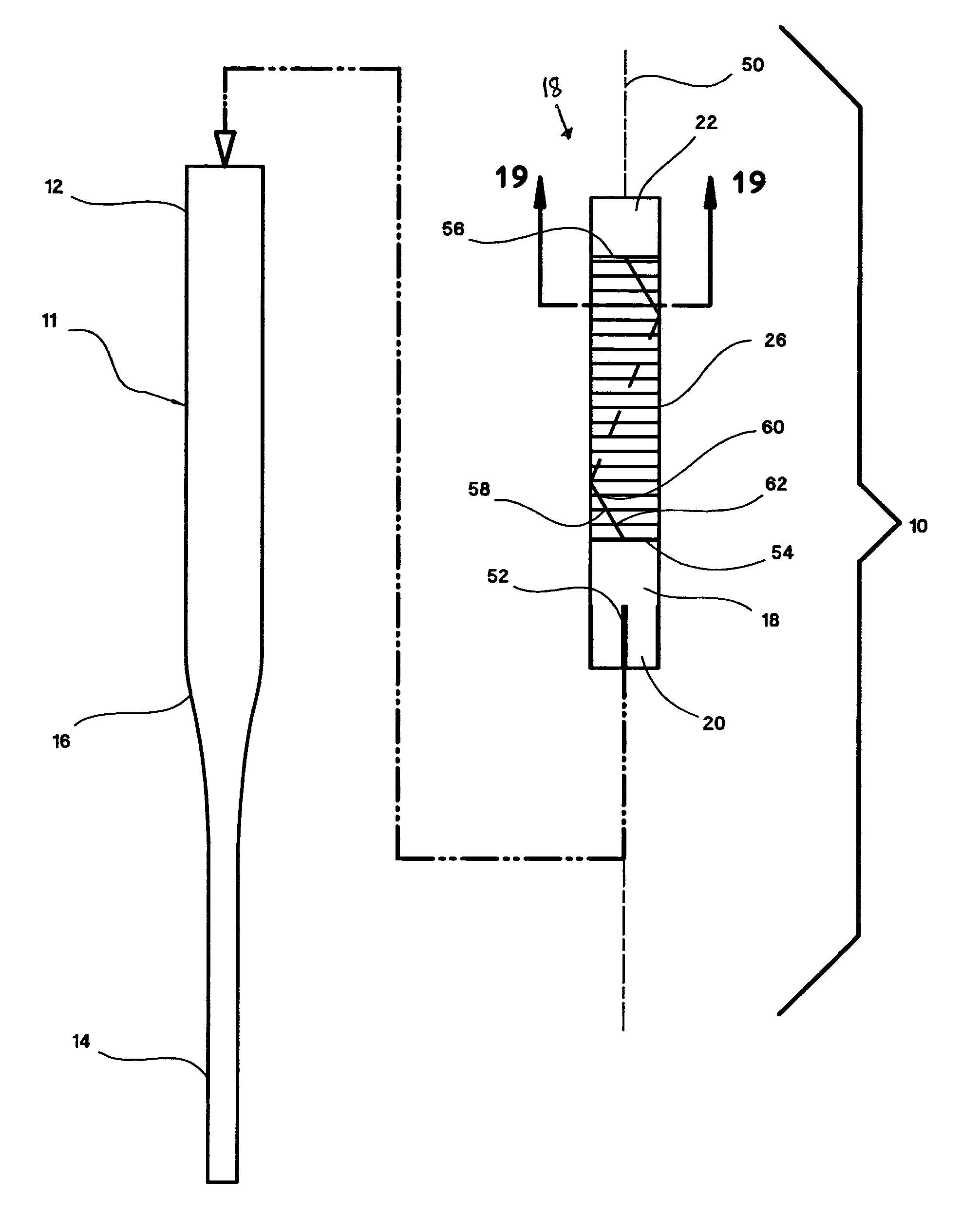

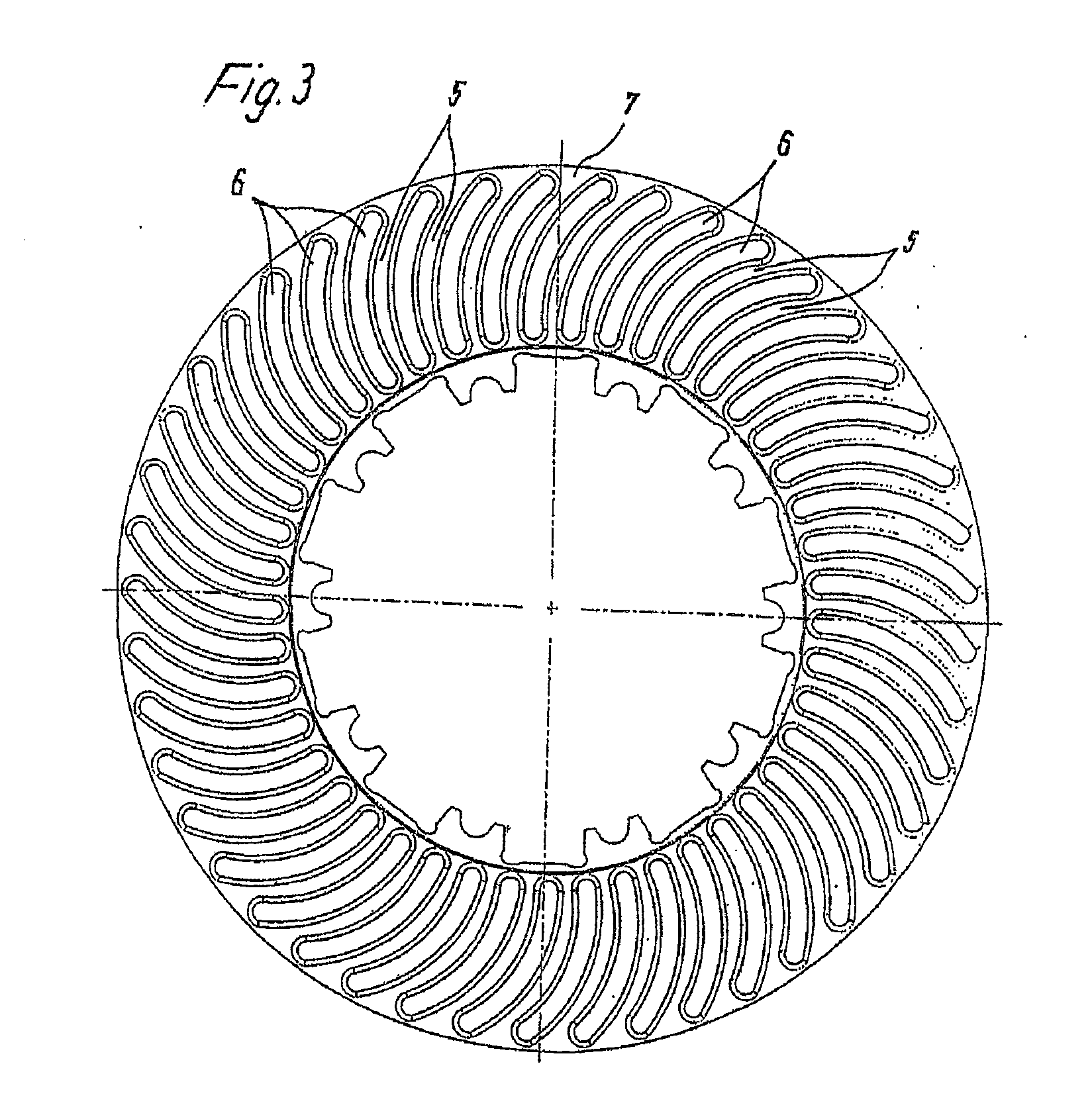

Double-side etching high-temperature and high-pressure printed circuit board heat exchanger

InactiveCN105043144AReduce thermal stressAvoid plastic deformationLaminated elementsStationary plate conduit assembliesStress distributionStress concentration

The invention relates to a double-side etching high-temperature and high-pressure printed circuit board heat exchanger. The double-side etching high-temperature and high-pressure printed circuit board heat exchanger is composed of a heat exchanging core, a flow equalizing section, a hot fluid inlet and outlet port and a cold fluid inlet and outlet port. The core is divided into an inlet section, a core heat exchanging section and an outlet section. According to the heat exchanger, runners are machined in the double sides of heat exchanging plates with a certain thickness in a photochemistry manner, a laser etching manner, a machining manner and the like. The first heat exchanging plate and the second heat exchanging plate are arranged in a spaced manner. A fusion type channel novel structure is adopted in an inlet distribution section, and fluid in the heat exchanger can be easily distributed more evenly. The heat exchanging efficiency of the heat exchanger can be improved, the thermal stress damage at an existing channel sharp corner is effectively avoided, the circulation section area of the heat exchanger is increased, and the compactness of the heat exchanger is improved; thermal stress distribution at the sharp corner is improved, plastic deformation caused by stress concentration is avoided, and the even distribution of fluid in the heat exchanger is improved; and the safety performance of the heat exchanger is improved, and the service life of the heat exchanger is prolonged.

Owner:XI AN JIAOTONG UNIV

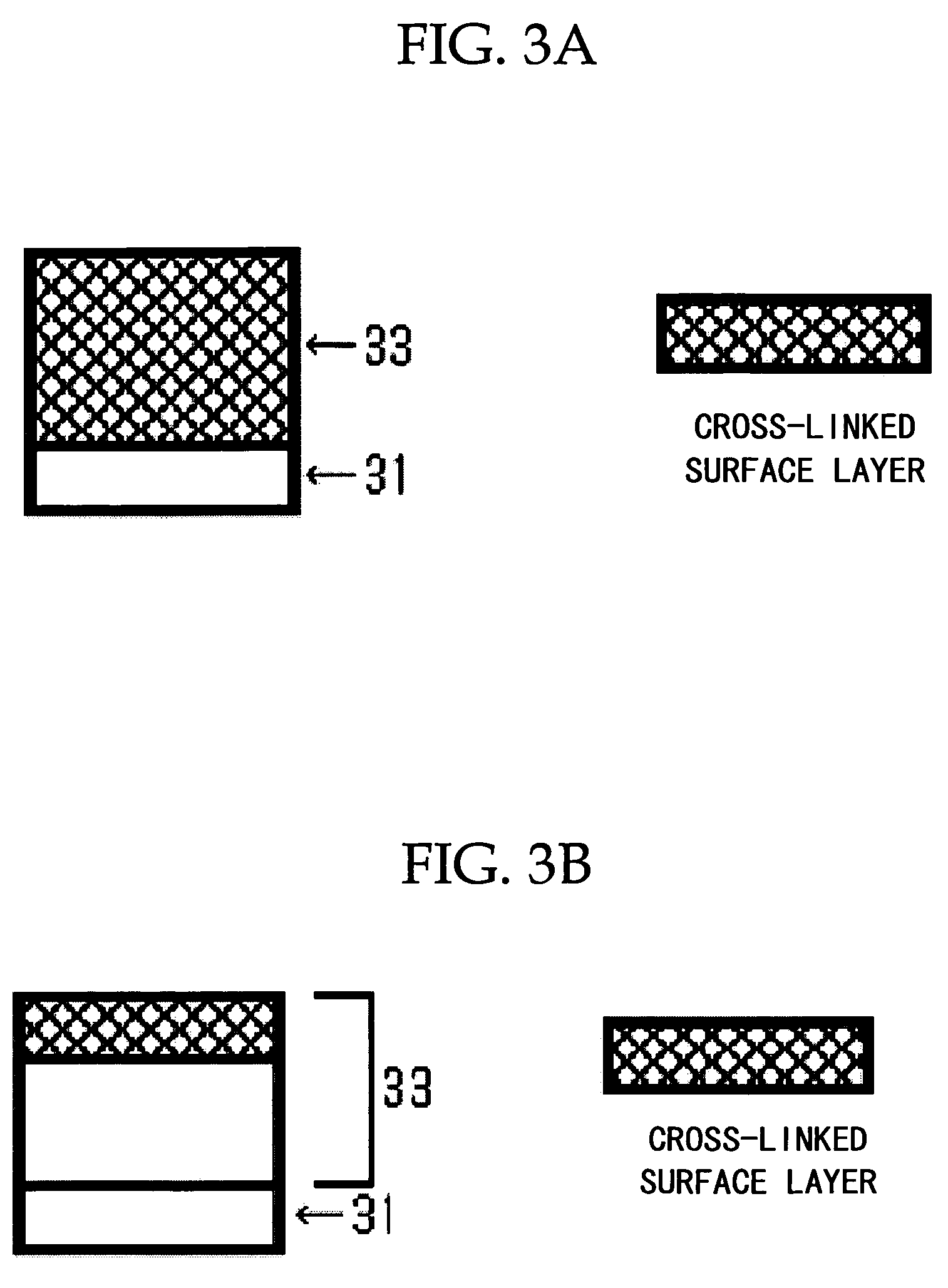

Electrophotographic photoconductor, and image forming process, image forming apparatus and process cartridge for an image forming apparatus using the same

ActiveUS7175957B2Increase resistanceMaintain good propertiesElectrographic process apparatusElectrographic processes using charge patternElectrical conductorSurface layer

Disclosed is an electrophotographic photoconductor including at least a photoconductive layer on a conductive substrate, wherein the surface layer of the photoconductive layer contains at least a surface crosslinked layer formed by curing a tri- or more-functional radical polymerizable monomer without having a charge transporting structure and a mono-functional radical polymerizable compound having a charge transporting structure and the surface crosslinked layer has a surface roughness Rz of 1.3 μm or less.

Owner:RICOH KK

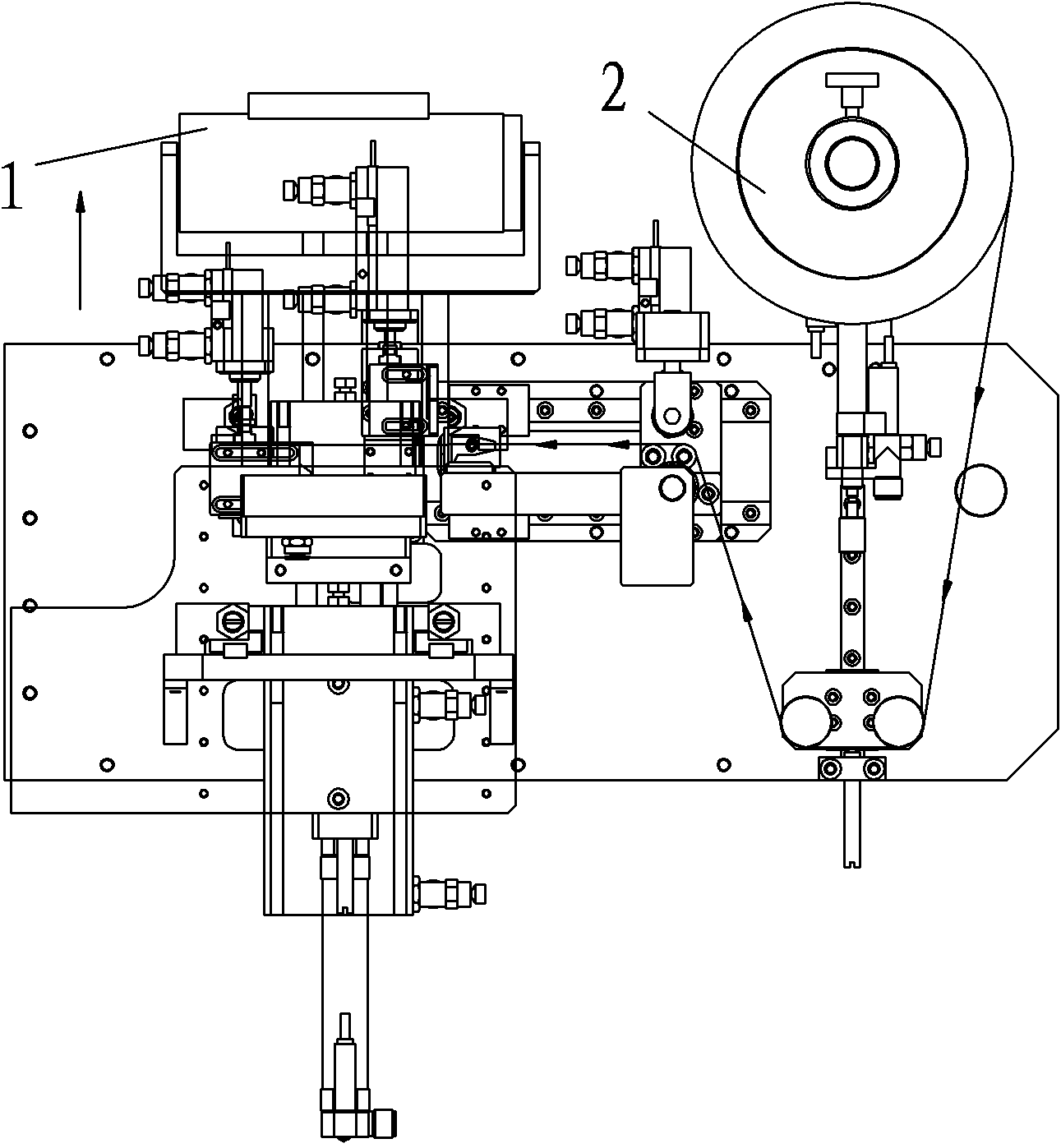

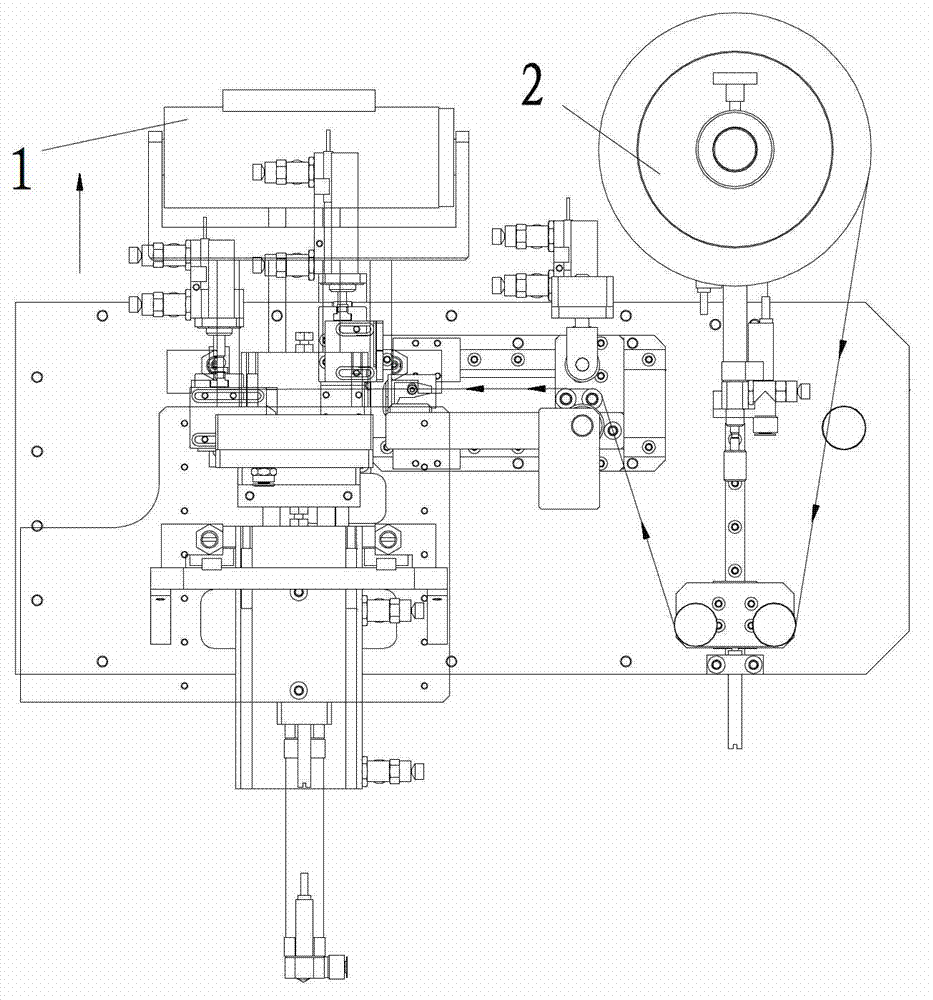

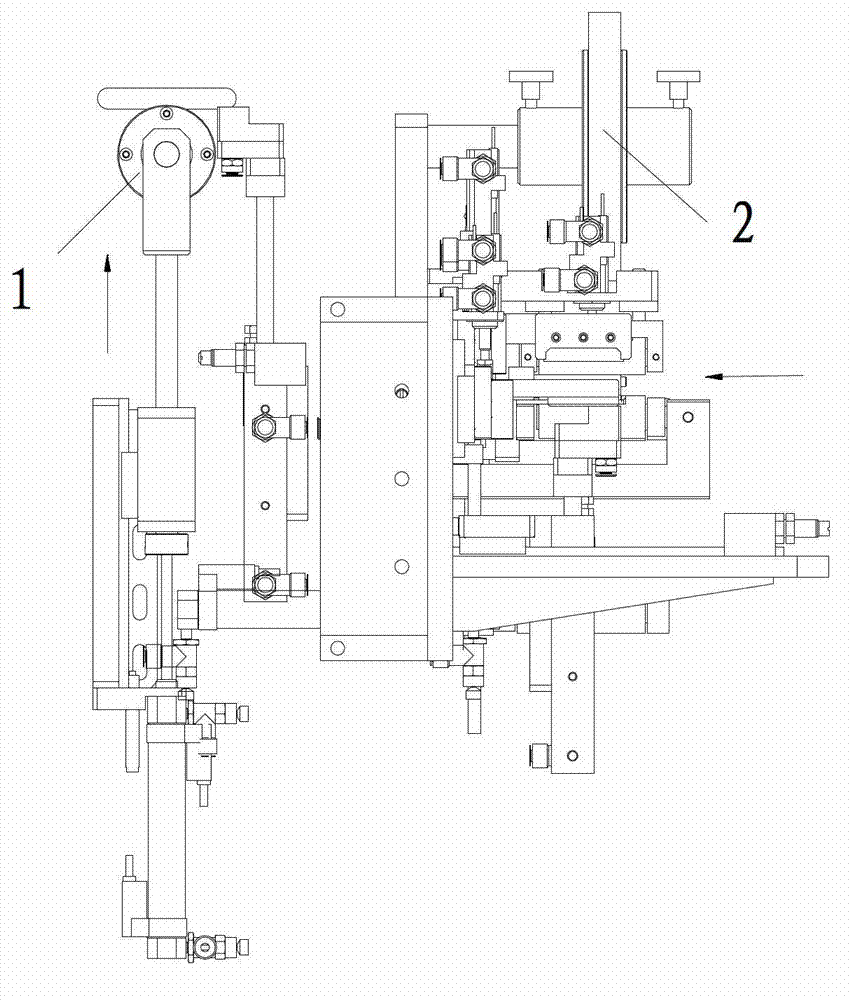

Fully automatic tape pasting mechanism

InactiveCN101966942ANot easy to stretch relative to external forceAvoid plastic deformationFinal product manufactureElectrolyte accumulators manufactureLinear motionEngineering

The invention relates to a fully automatic tape pasting mechanism which is used in the preparation device of the lithium ion battery core, wherein the preparation device comprises a frame. The mechanism of the invention comprises a tape roller, a plurality of roll wheels, a tape-pasting wheel, a first driving device, a second driving device, a tape-pressing component, a tape-clamping component and a tape-cutting component, wherein the tape roller is arranged on the frame and can rotate to release the tape; the roll wheels are arranged on the frame and used to convey the tape; the tape-pasting wheel is used to wind up the tape and convey the cut tapes to the tape-pasting pressing positions of the battery cores to be pasted with the tapes, the tape-pasting angle and direction of the tape-pasting wheel can be adjusted; the first driving device drives the tape-pasting wheel to perform linear motion; the second driving device drives the tape-pasting wheel to rotate at a certain angle; the tape-pressing component is arranged above the tape-pasting wheel and rotates with the tape-pasting wheel; the tape-clamping component is used to clamp the tape and prevent the tape from turning backwards and disconnecting; the tape-cutting component is used to cut the tape on the tape-pasting wheel which is fixed and compressed by the tape-clamping component and the tape-pressing component; and the axial directions of the tape-pasting wheel, the roll wheels and the tape roller are the same and are perpendicular to the same plane.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

Dicing die bond film and method of manufacturing semiconductor device

InactiveUS20130330910A1Reduce frictionSuitable for downsizingLayered productsSemiconductor/solid-state device detailsEngineeringWafer bonding

The present invention provides a dicing die bond film in which yielding and breaking of the dicing film are prevented and in which the die bond film can be suitably broken with a tensile force. In the dicing die bond film of the present invention, the tensile strength of the contact part in which the outer circumference of the push-up jig contacts the dicing film at 25° C. is 15 N or more and 80 N or less and the yield point elongation is 80% or more, the tensile strength of the wafer bonding part of the dicing film at 25° C. is 10 N or more and 70 N or less and the yield point elongation is 30% or more, [(the tensile strength of the contact part)−(the tensile strength of the wafer bonding part)] is 0 N or more and 60 N or less, and the breaking elongation rate of the die bond film at 25° C. is more than 40% and 500% or less.

Owner:NITTO DENKO CORP

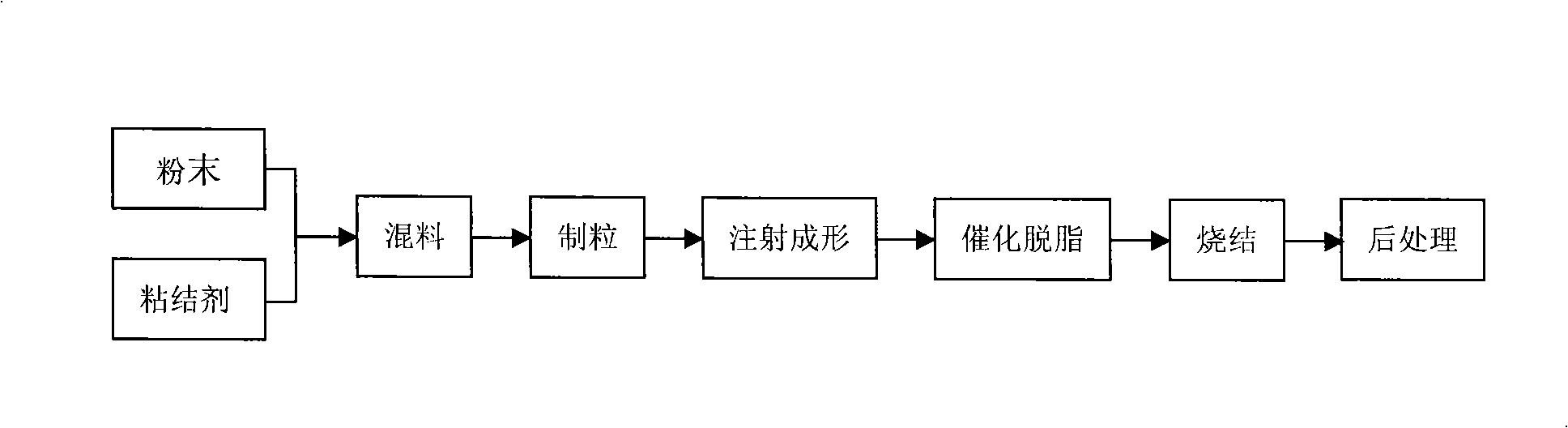

Catalysis degreasing type adhesive for powder injection moulding and preparation of material feeding thereof

The invention discloses a catalytic degreasing type binder used for powder injection molding and feedstock preparation method; the catalytic degreasing type binder used for powder injection molding consists of polyoxymethylene homopolymer, high-density polyethylene and paraffin wax, as well as compatibilizer, plasticizer, and surfactant, with the volume percentage thereof as follows: 85 to 95 percent of polyoxymethylene homopolymer, 4 to 9 percent of high-density polyethylene, 3 to 6 percent of paraffin wax, 0.5 to 1 percent of compatibilizer, 1 to 2 percent of plasticizer, and 0.5 to 1 percent of surfactant. According to the binder ratio and a certain powder load, the binder and the powder are added into an internal mixer so as to undertake mixing and prepare catalytic degreasing type feedstock. The catalytic degreasing type binder used for powder injection molding and feedstock preparation method overcome the shortage that only the imported catalytic degreasing type feedstock can be applied in the current PIM industrial production and thus causing the production cost to be expensive, thereby reducing the cost of using the catalytic degreasing technology and promoting the extensive application thereof in the PIM industrial production.

Owner:CENT SOUTH UNIV

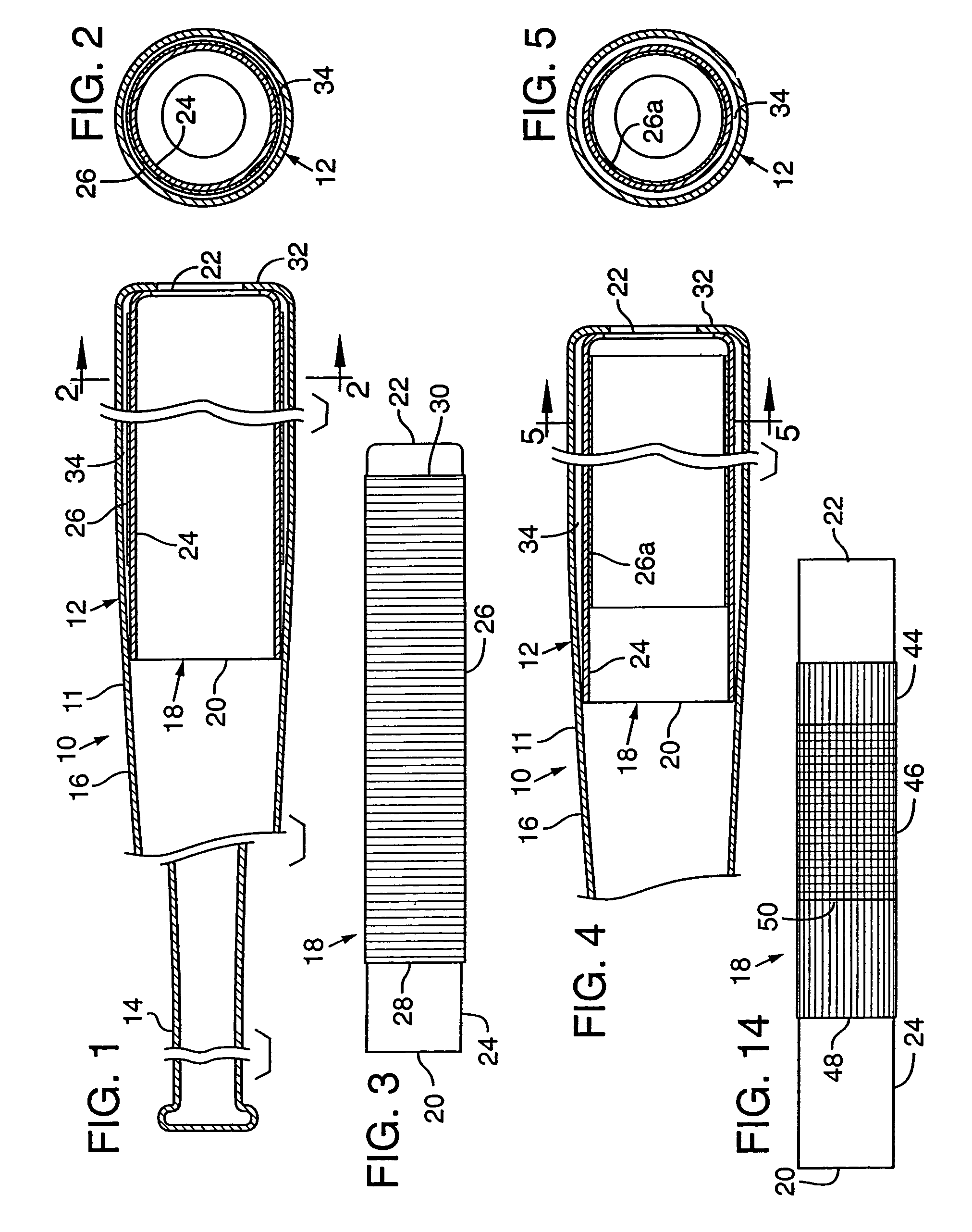

Insert for a bat having an improved seam orientation

InactiveUS7011588B2Increased durabilityLittle and no reduction in bat performanceRacket sportsEngineeringMechanical engineering

A bat includes a substantially tubular frame, a substantially tubular body and at least one sheet. The frame extends along a longitudinal axis. The frame has a handle portion and a primary hitting portion. The body is coaxially aligned with the hitting portion of the frame. The sheet has a proximal edge, a distal edge, and first and second side edges. The sheet is coupled to at least a portion of one of the hitting portion of the frame and the body such that the first and second edges each extend from the proximal edge to the distal edge along a path that is substantially non-parallel with the longitudinal axis.

Owner:WILSON SPORTING GOODS

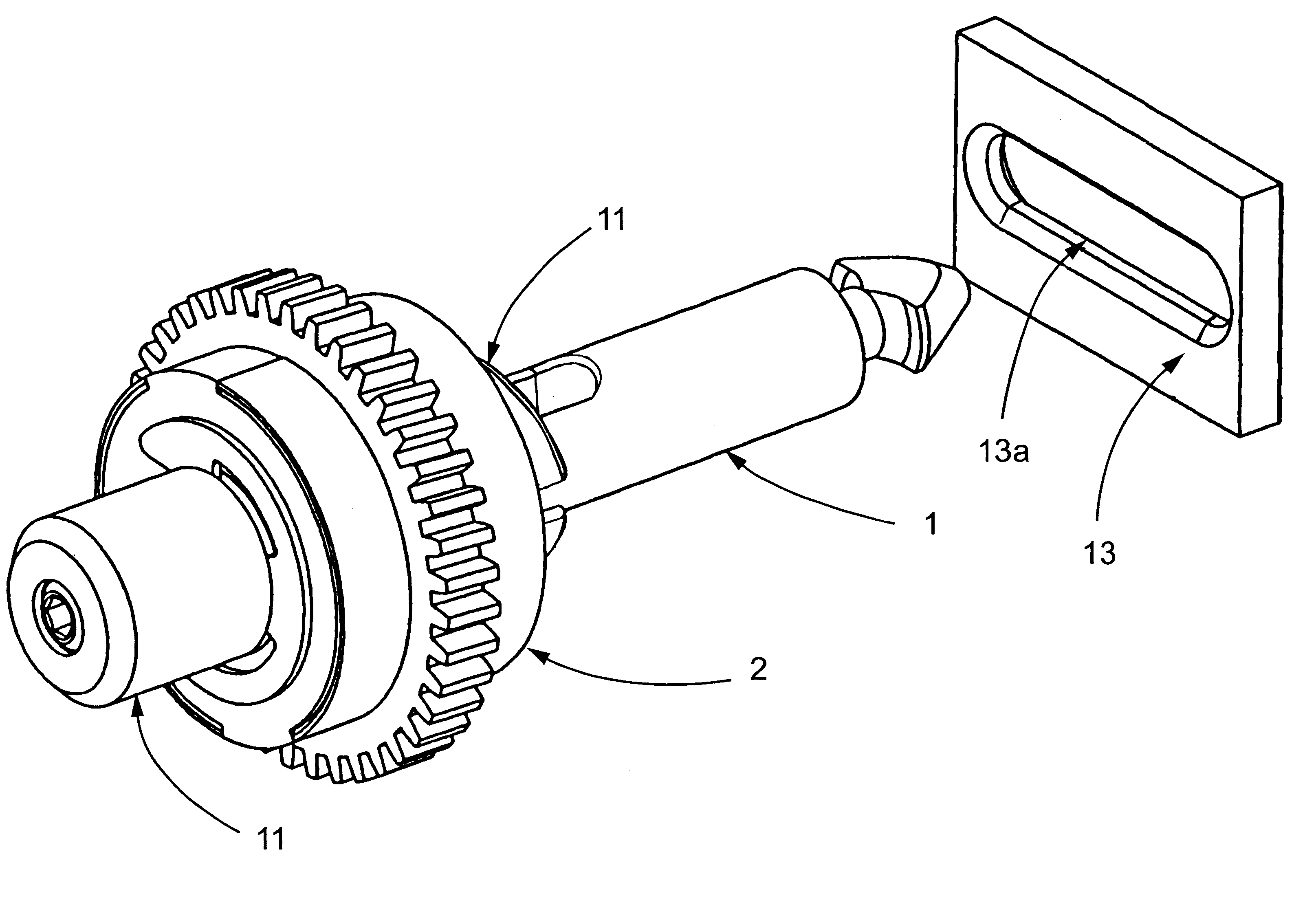

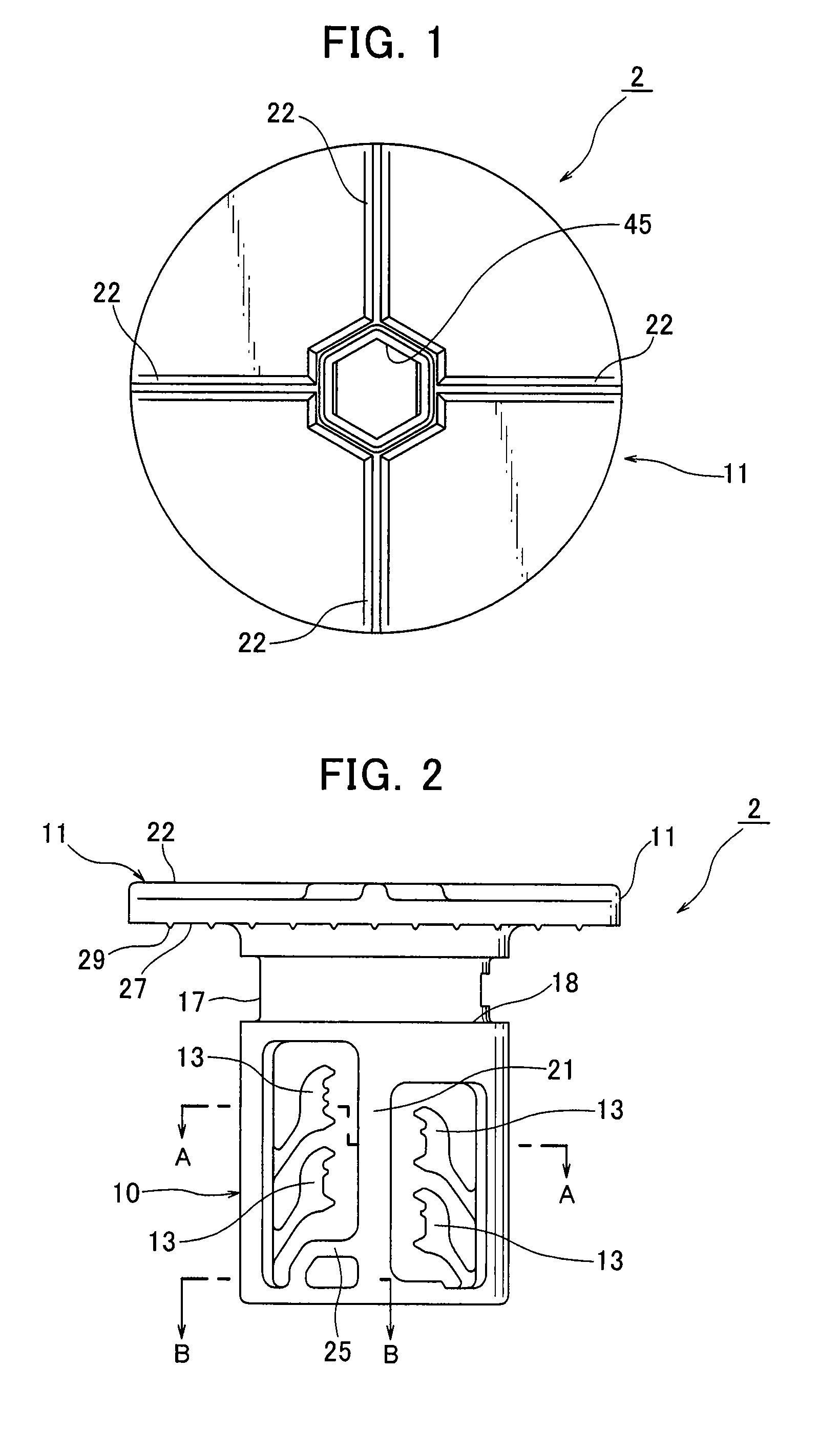

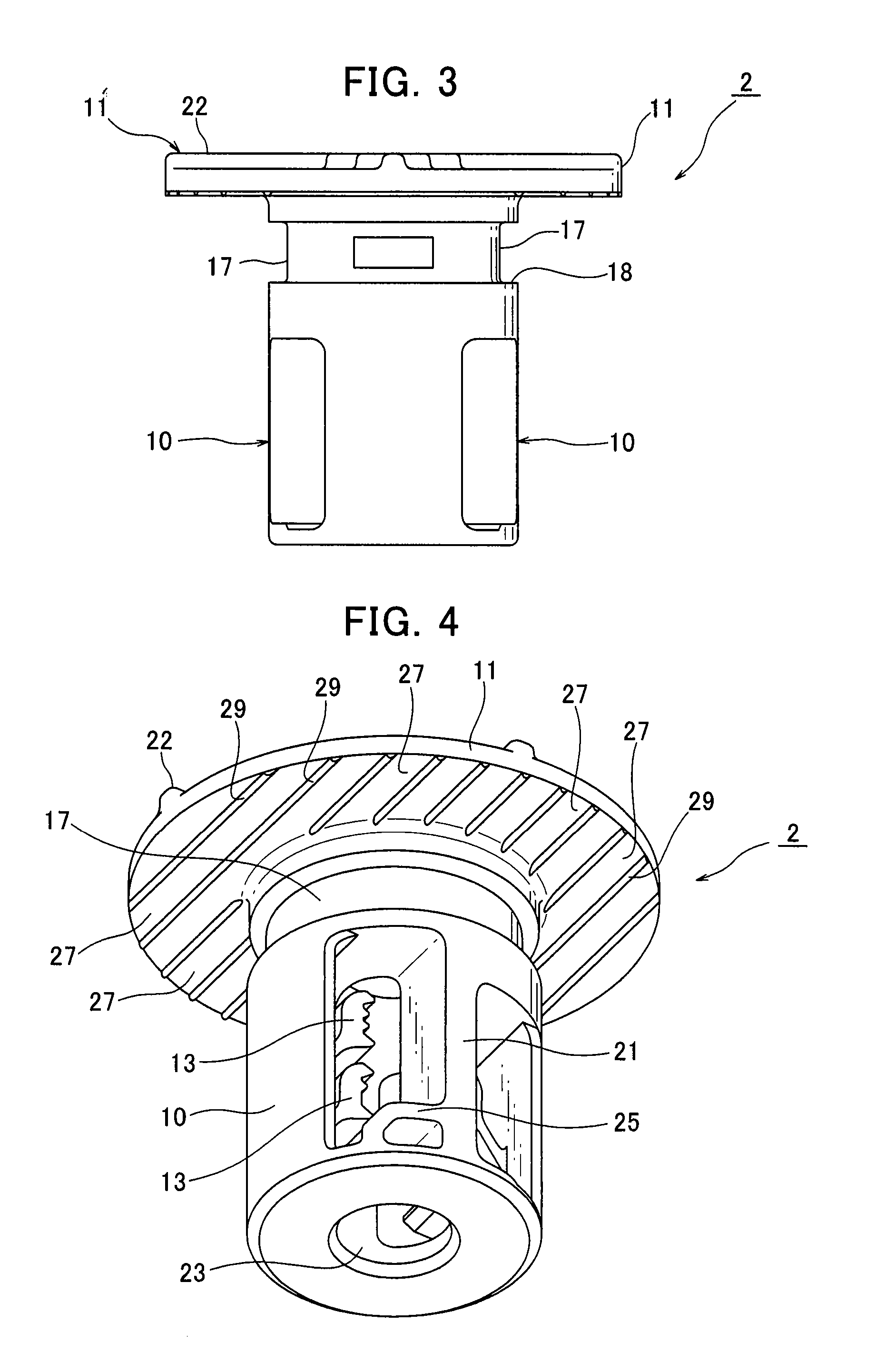

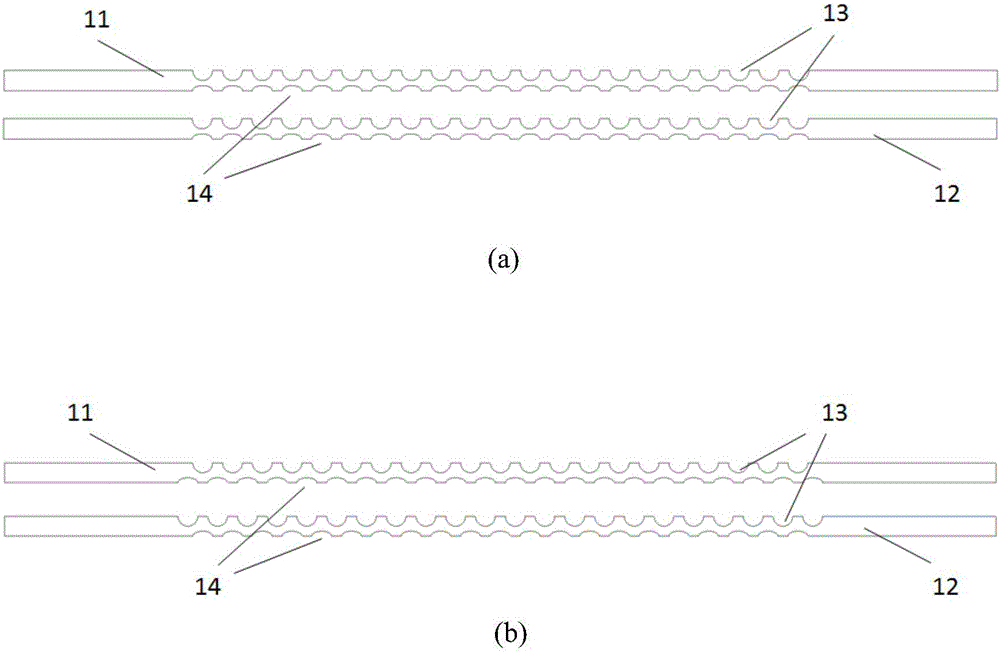

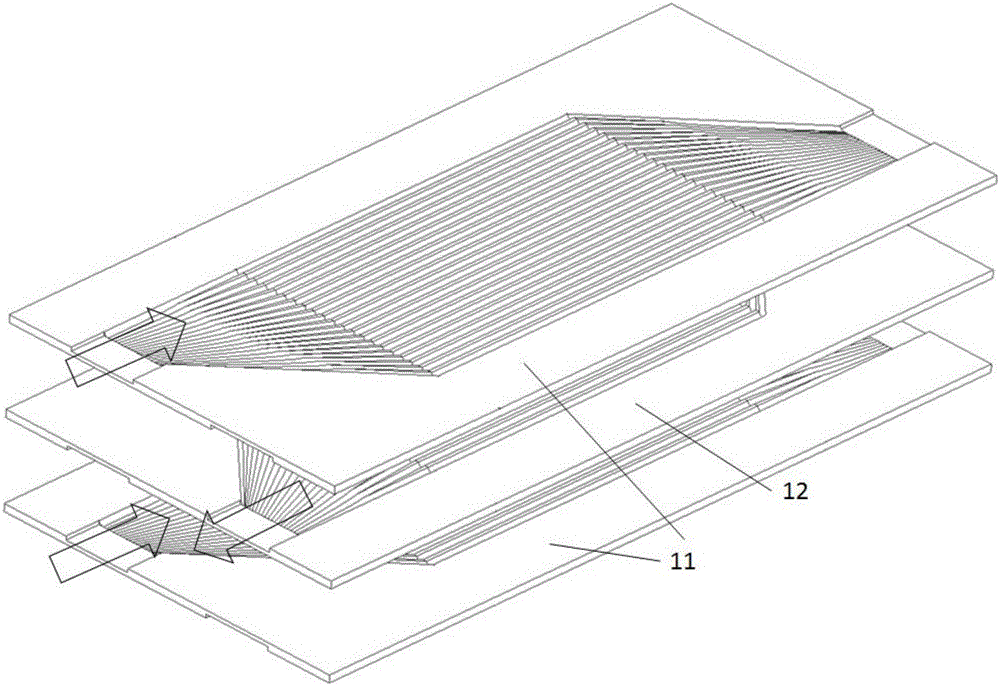

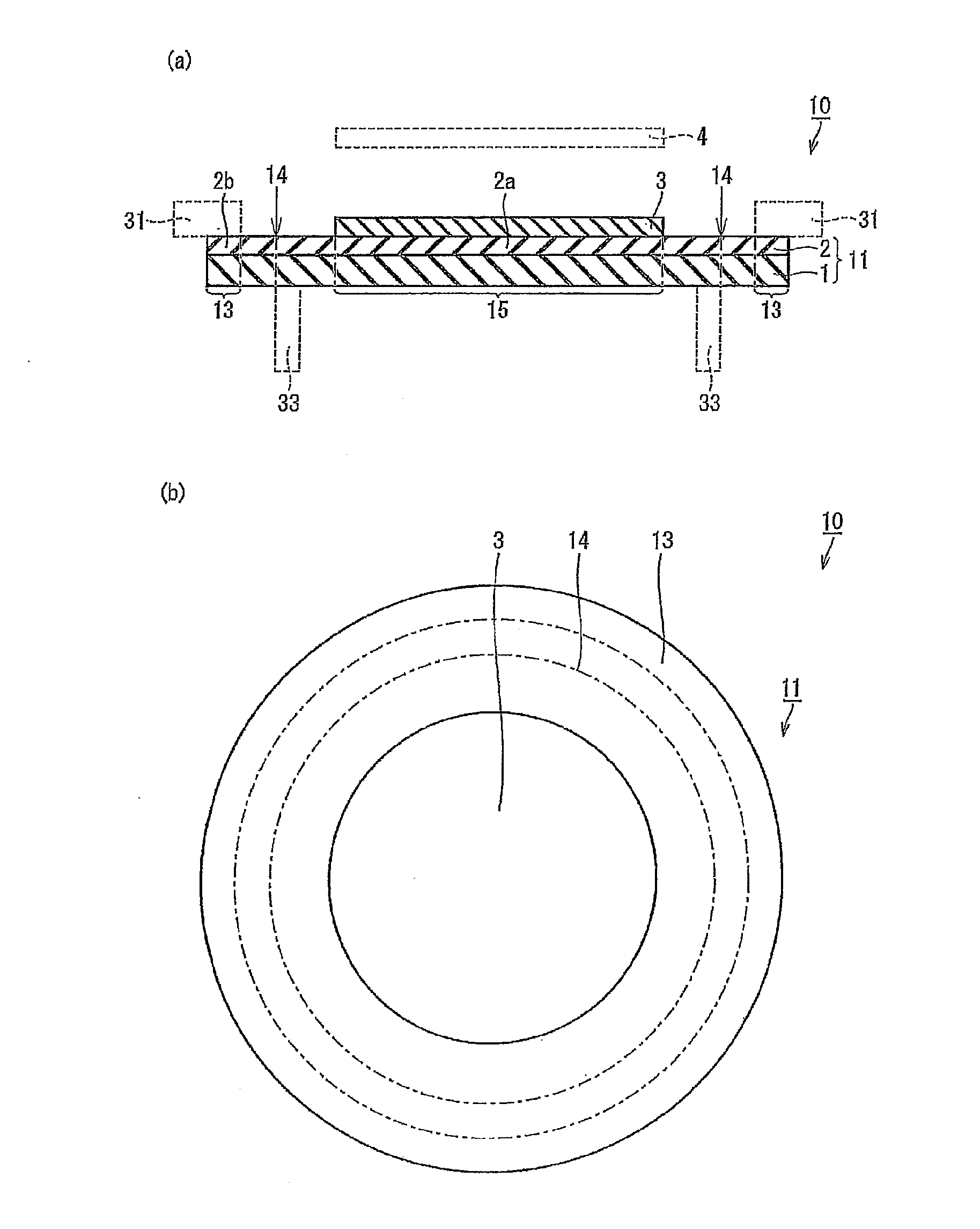

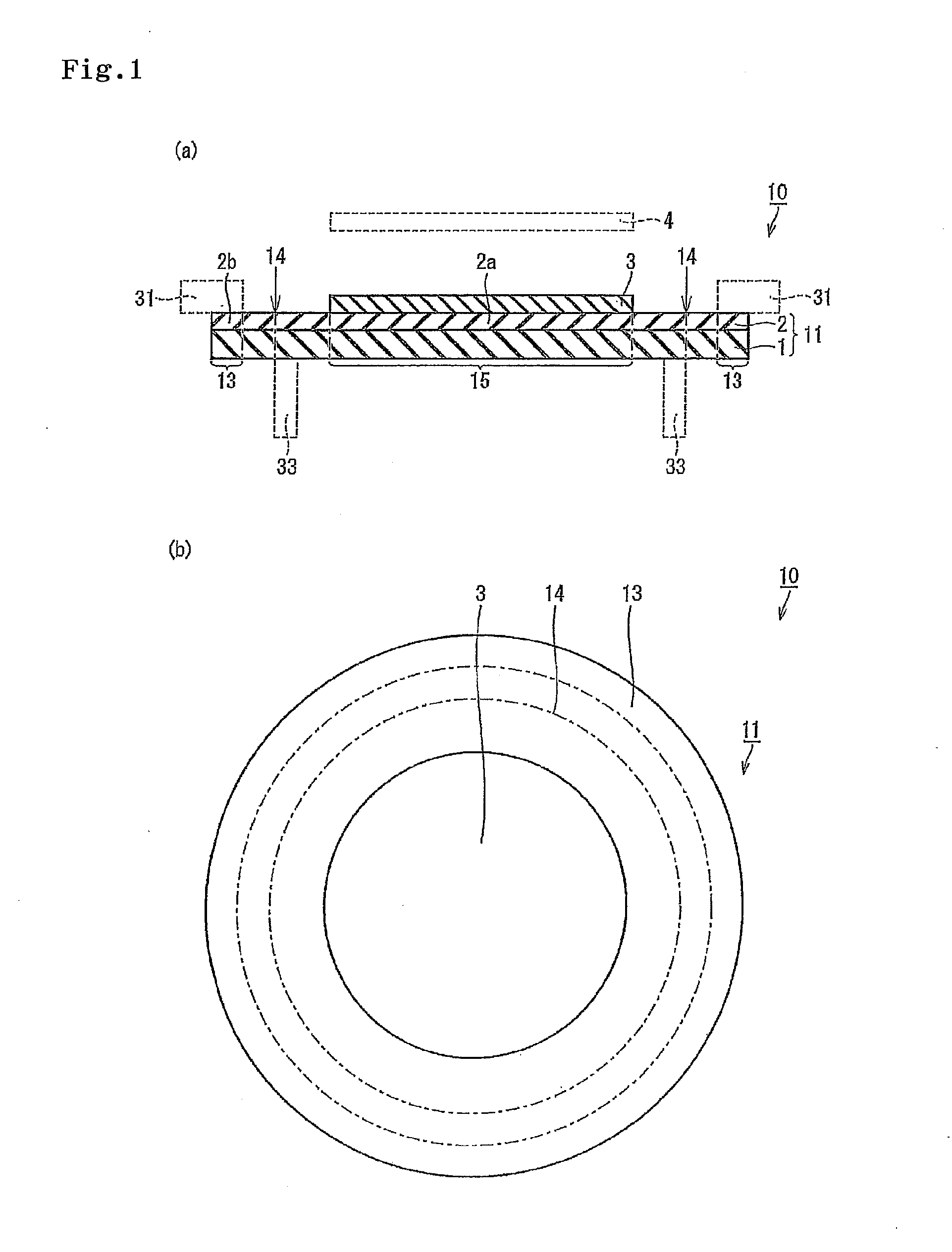

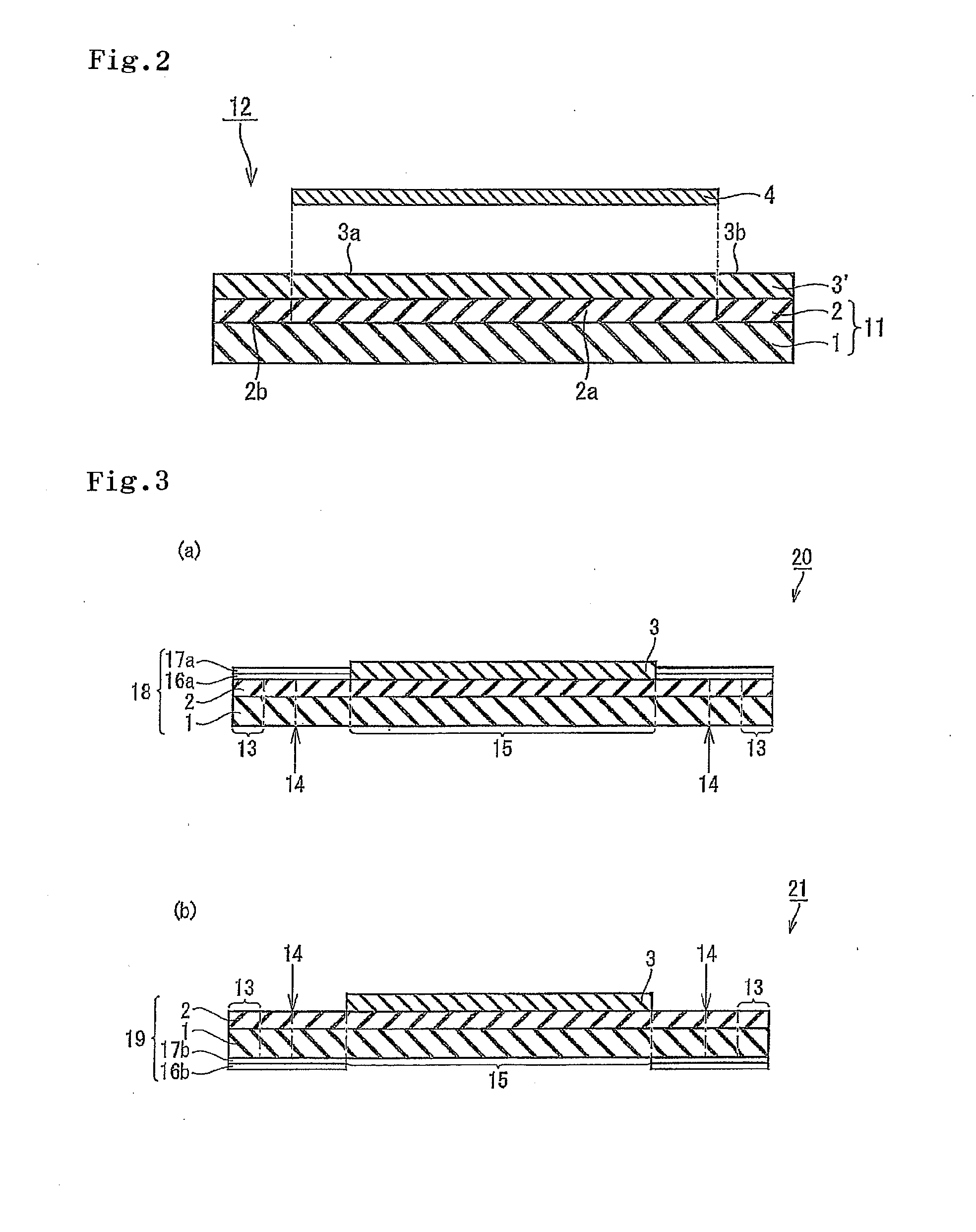

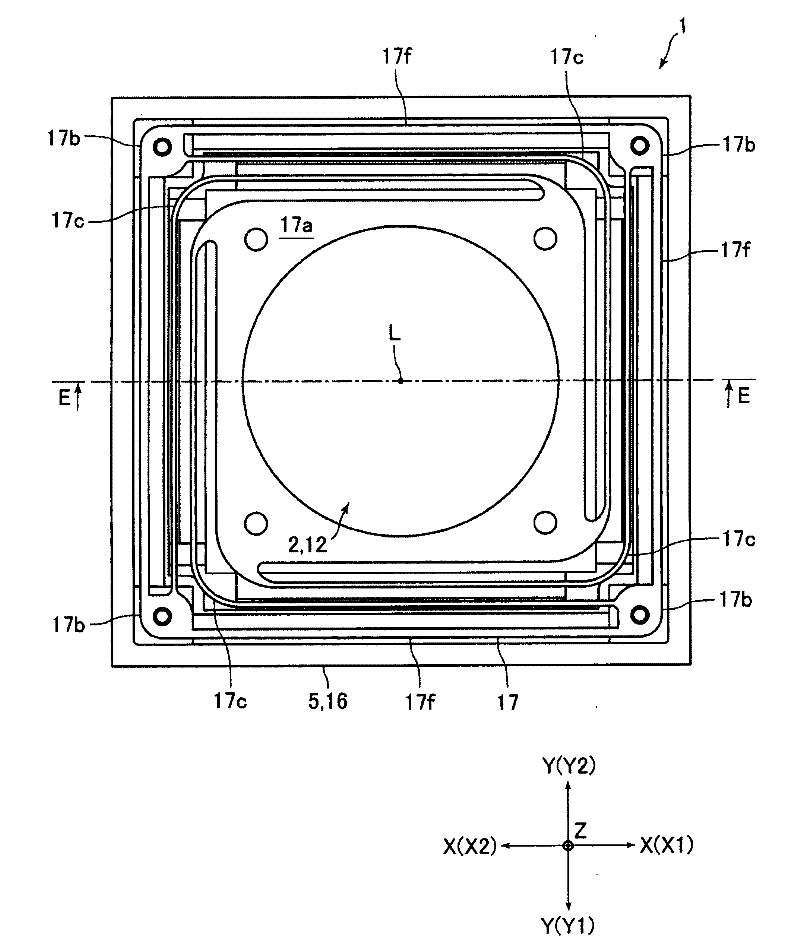

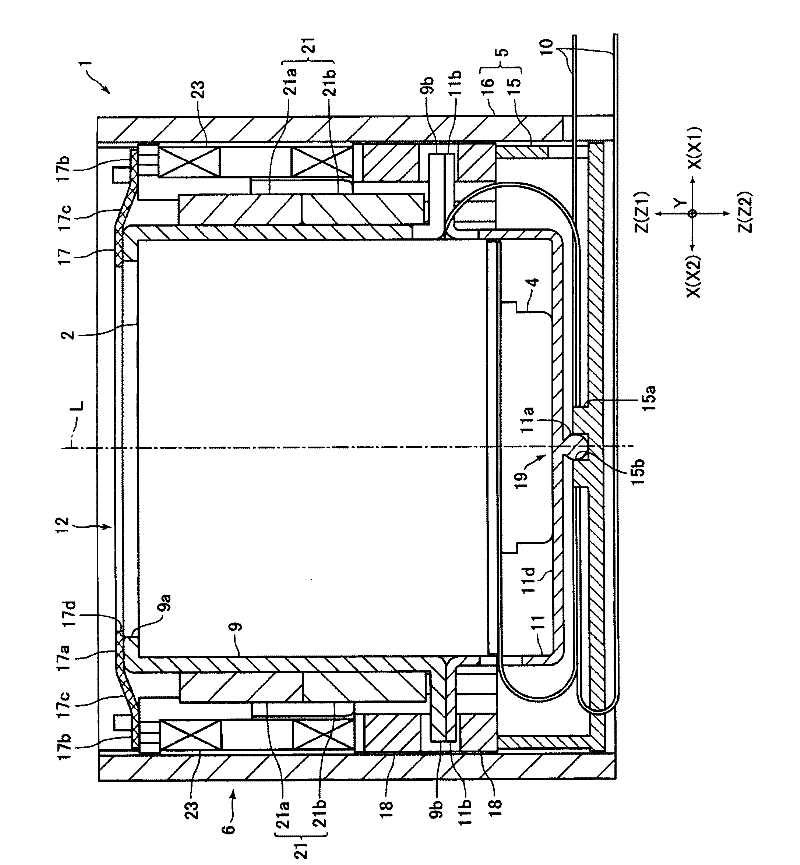

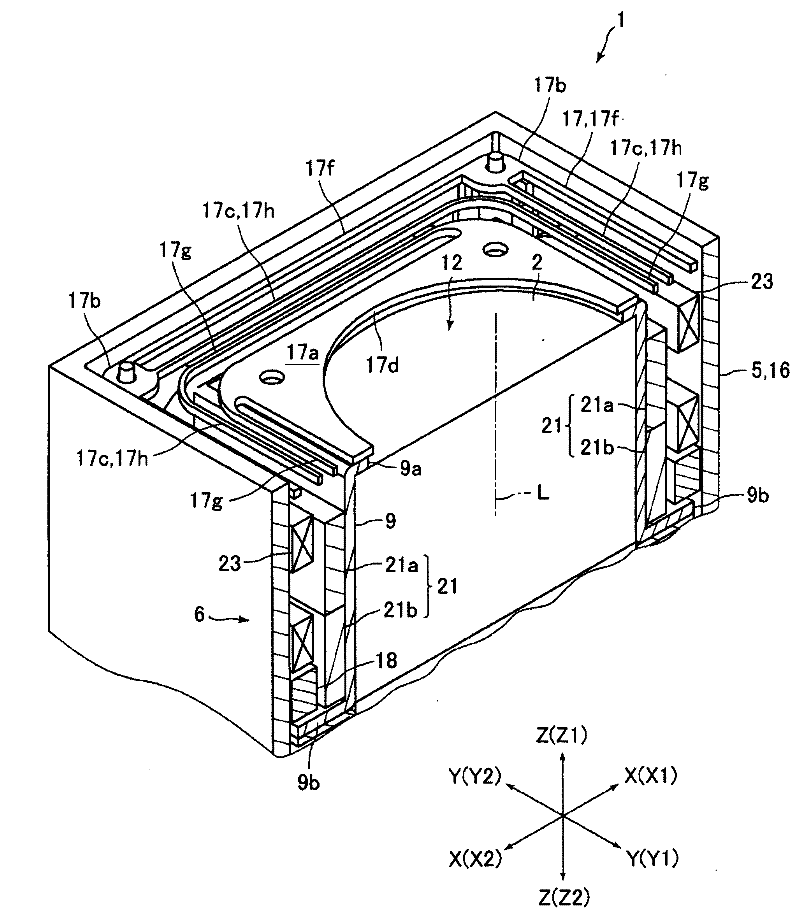

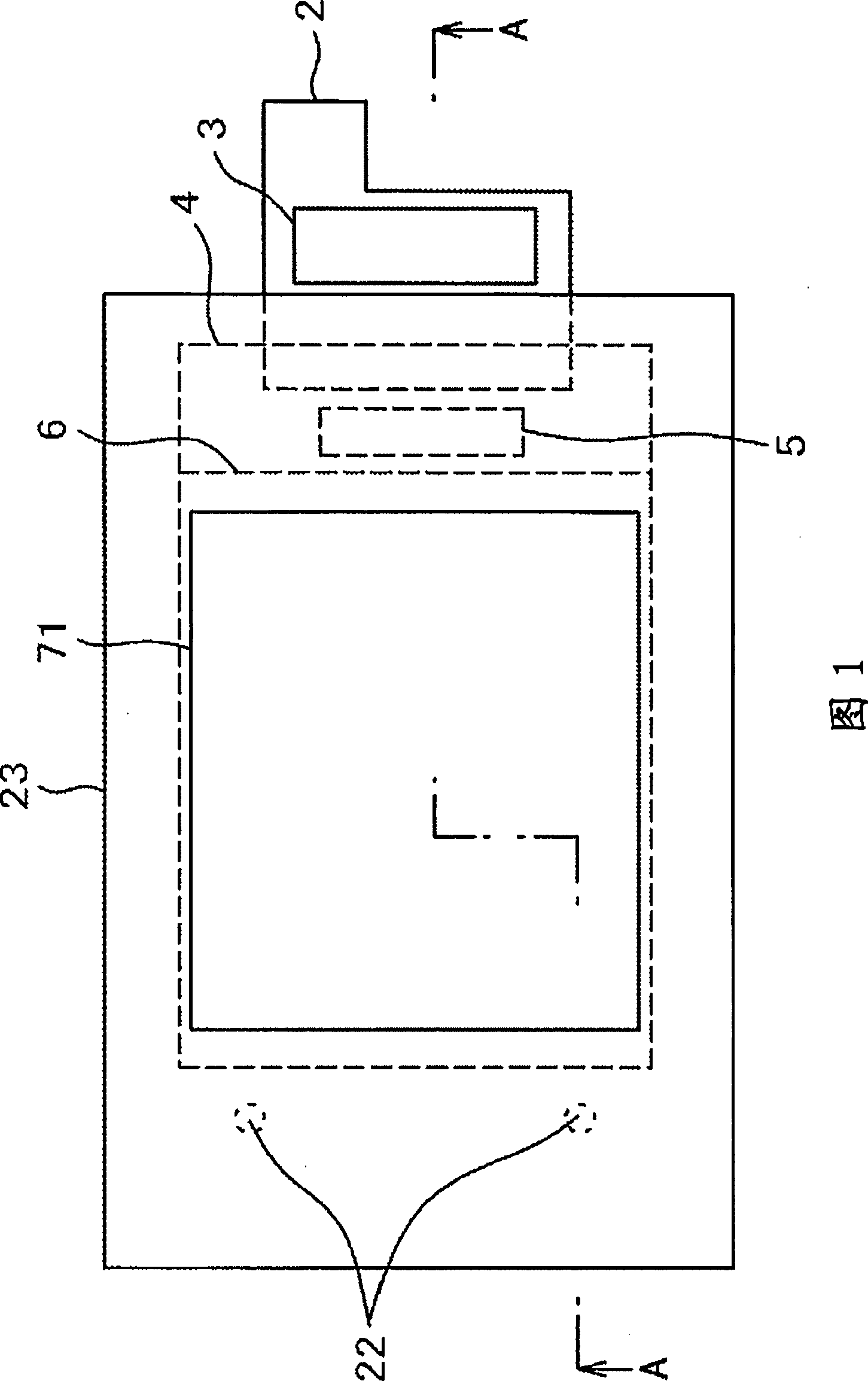

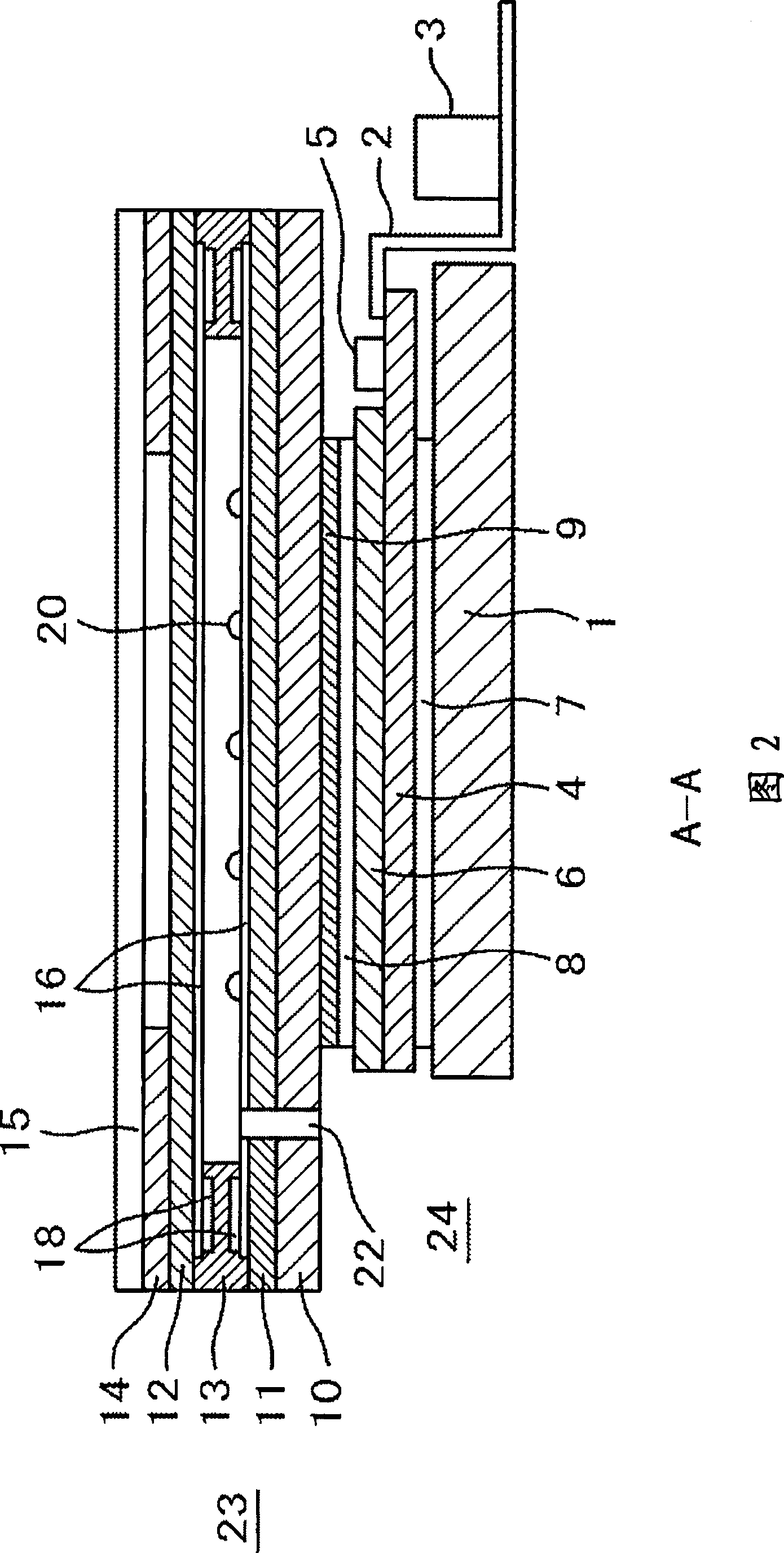

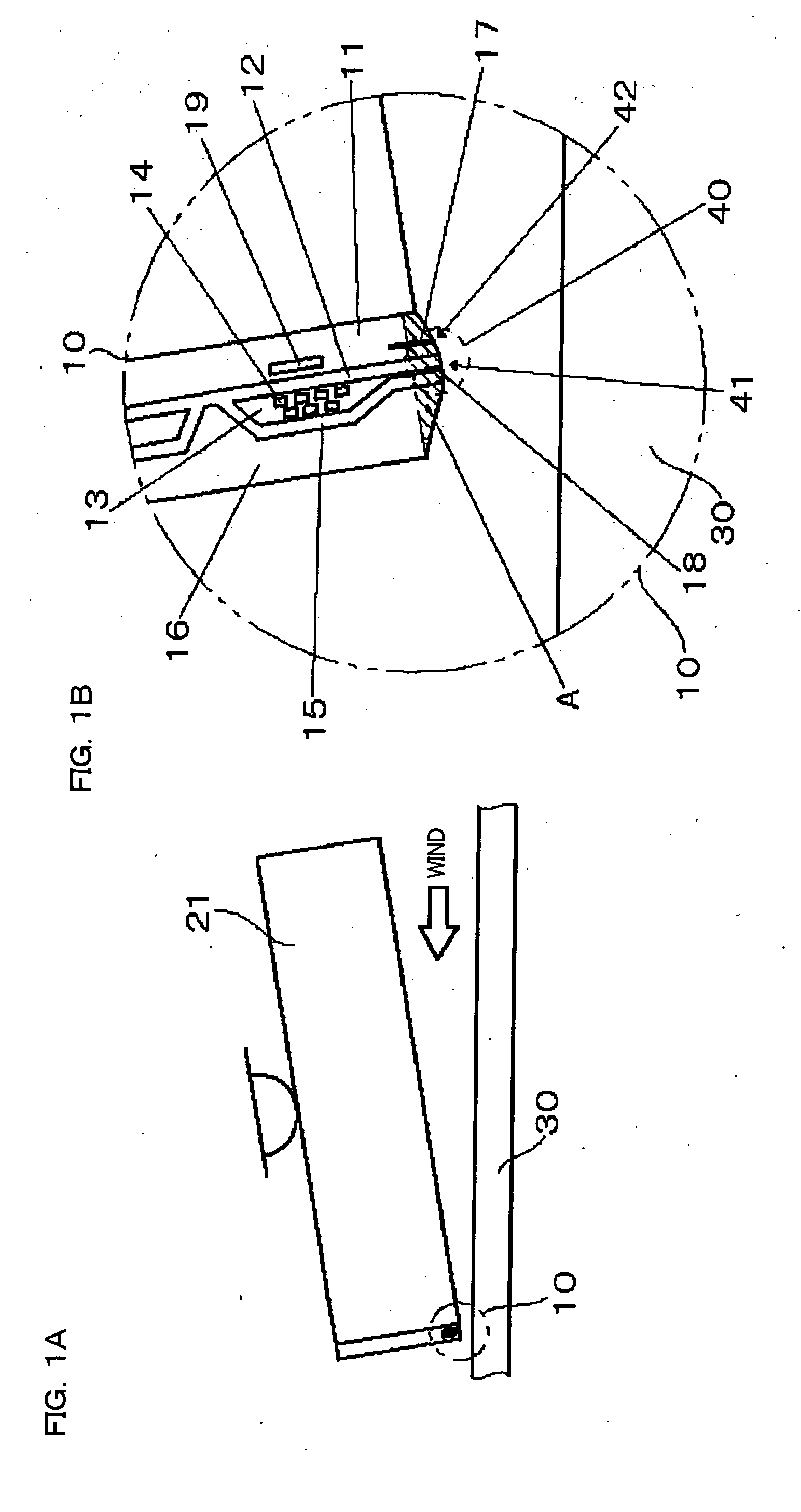

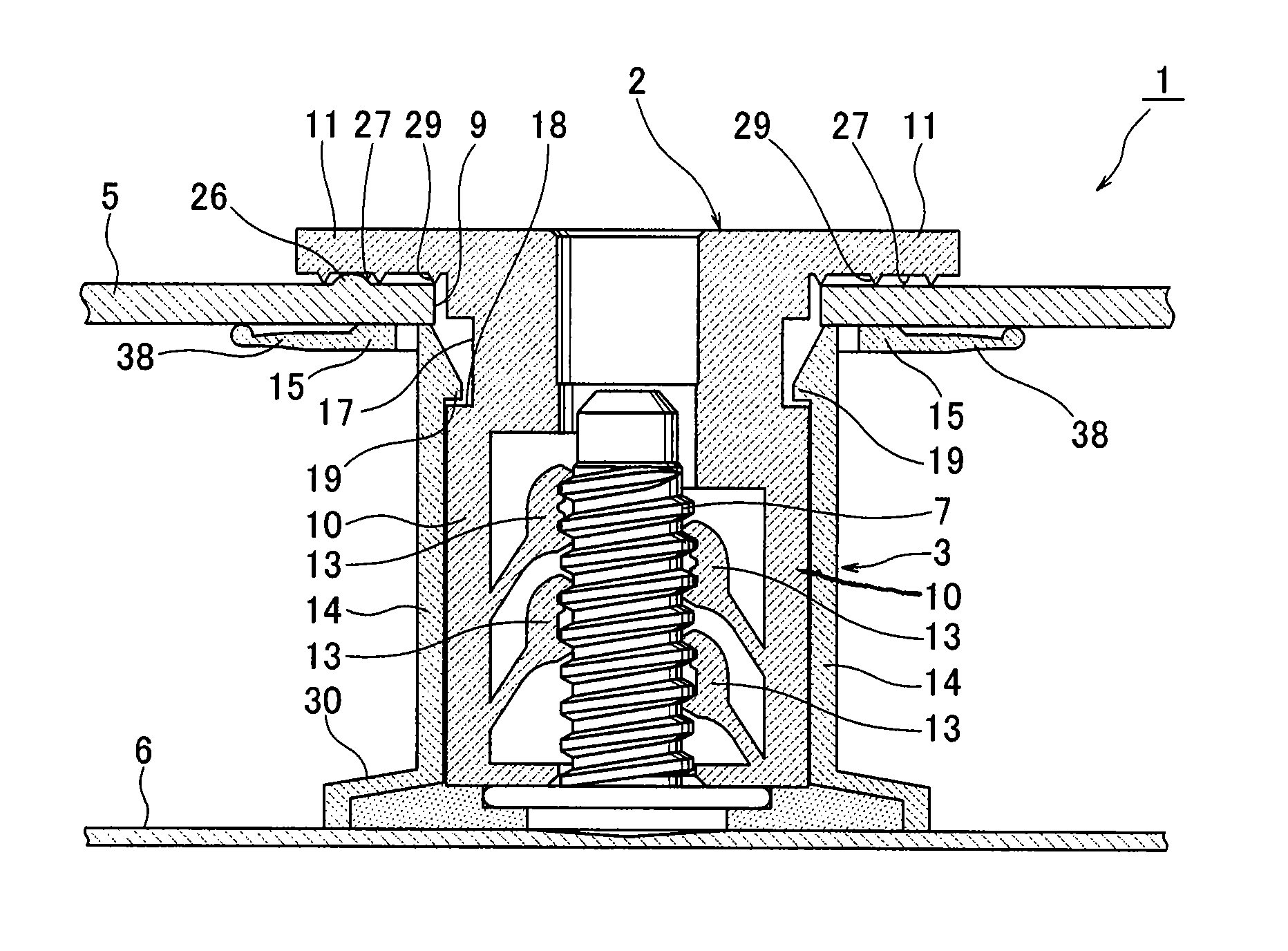

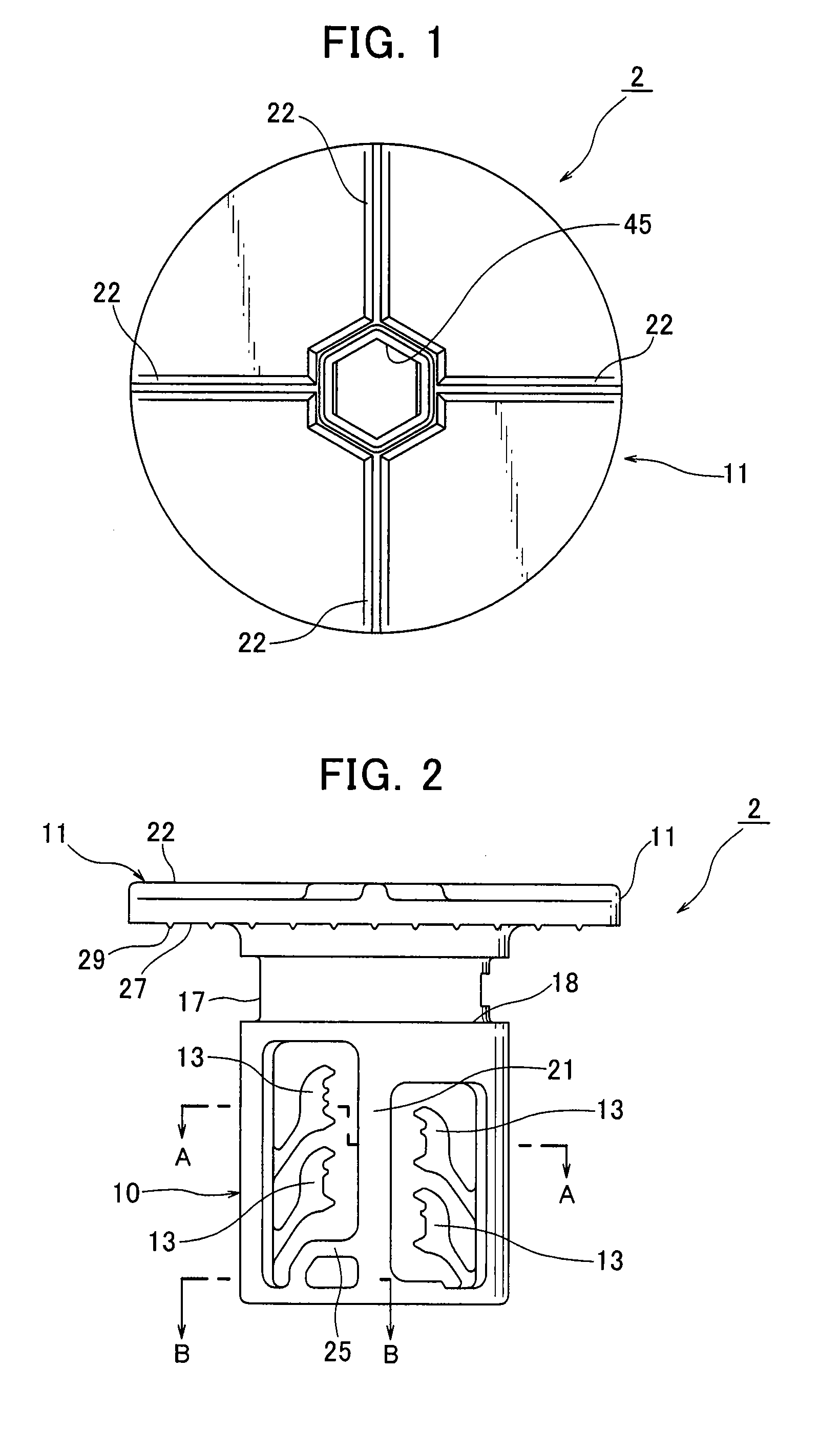

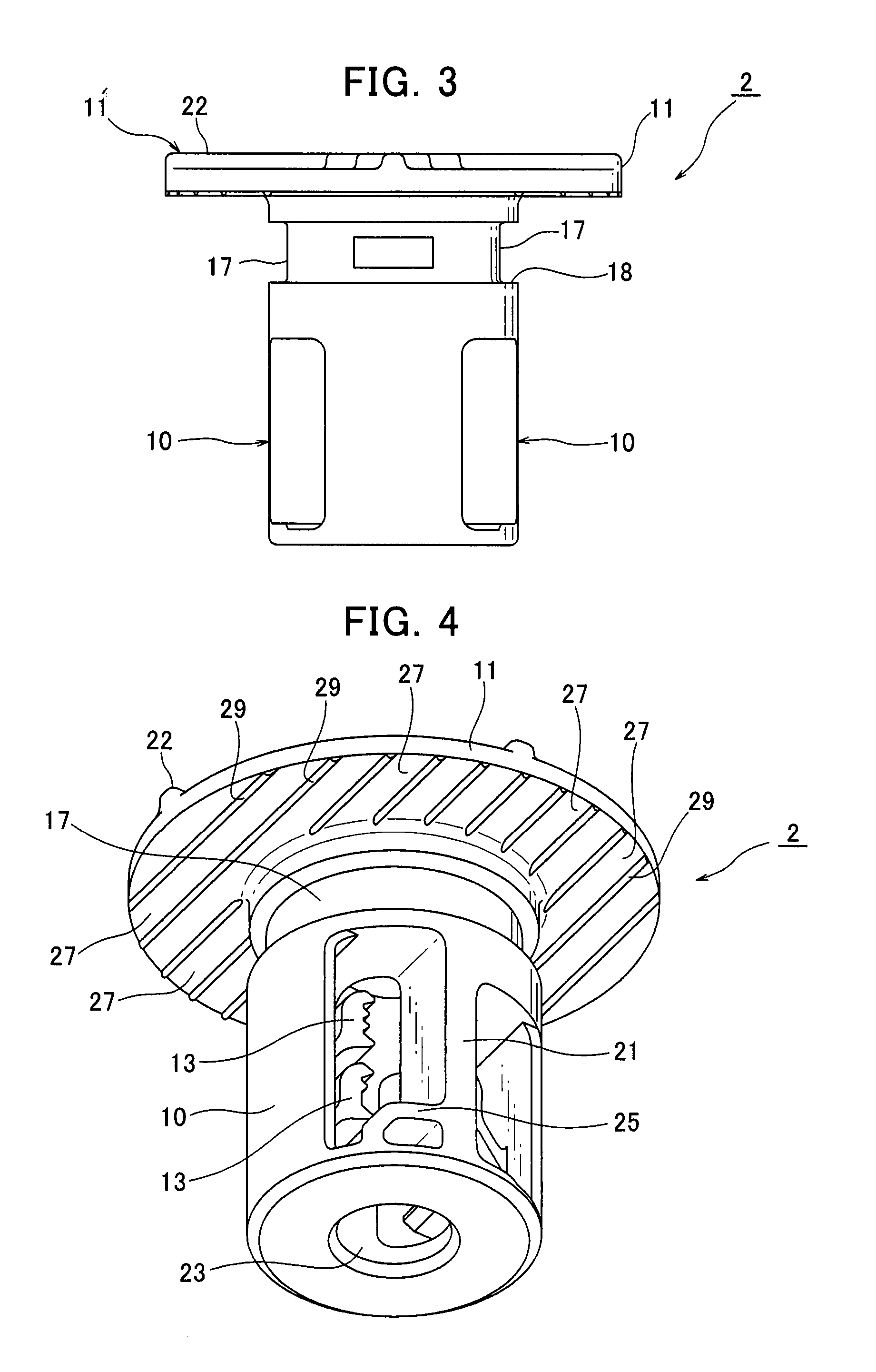

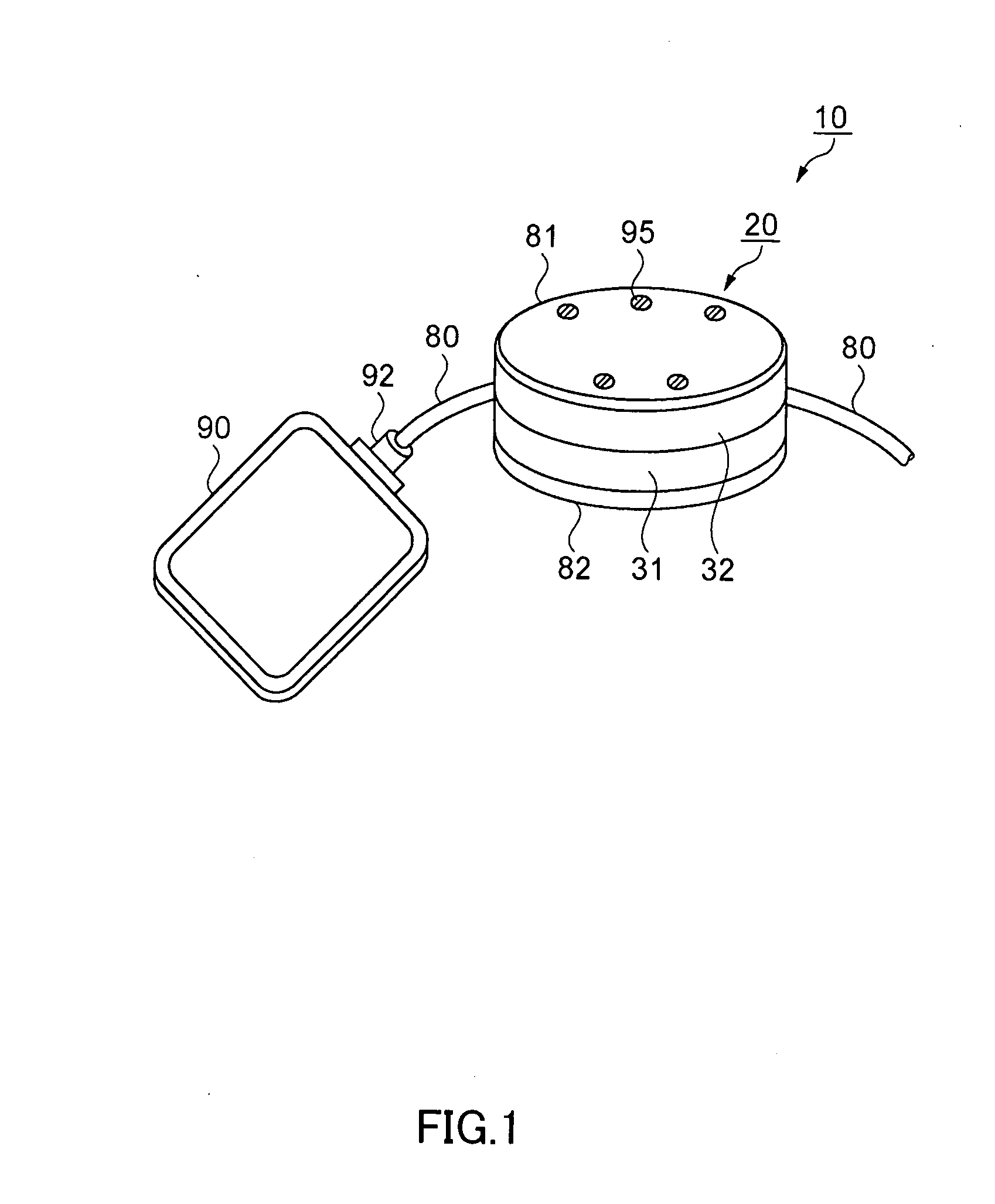

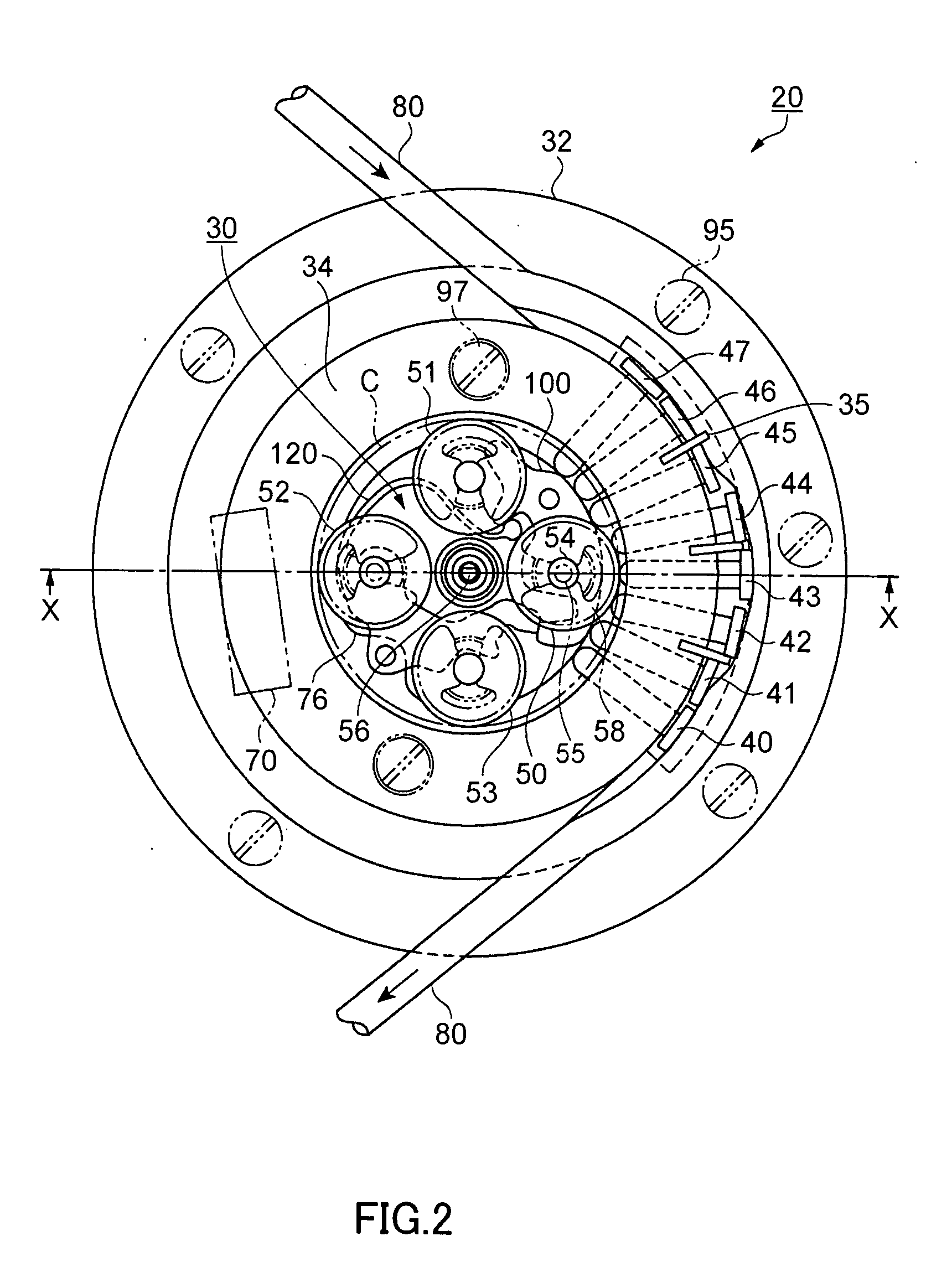

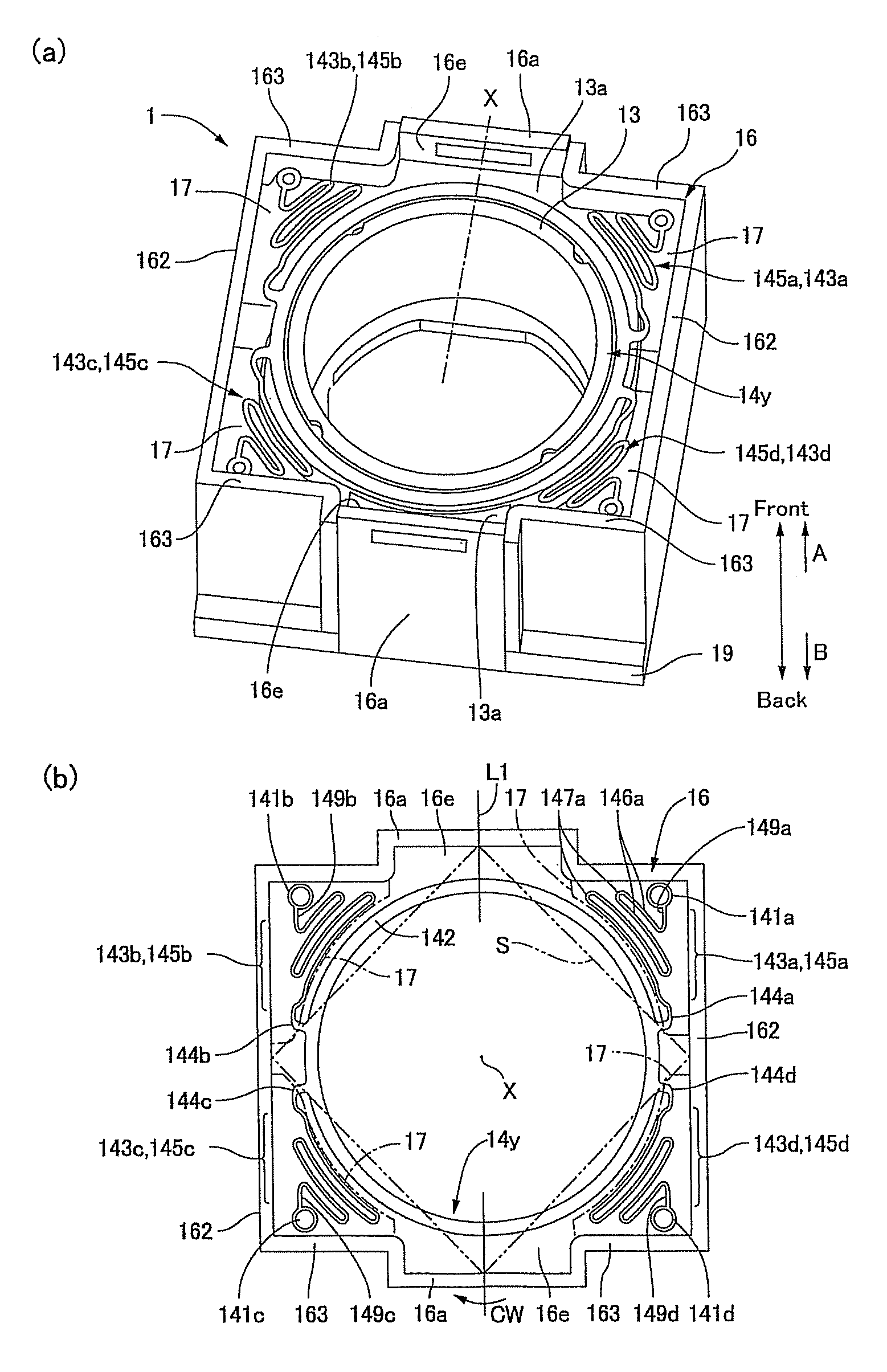

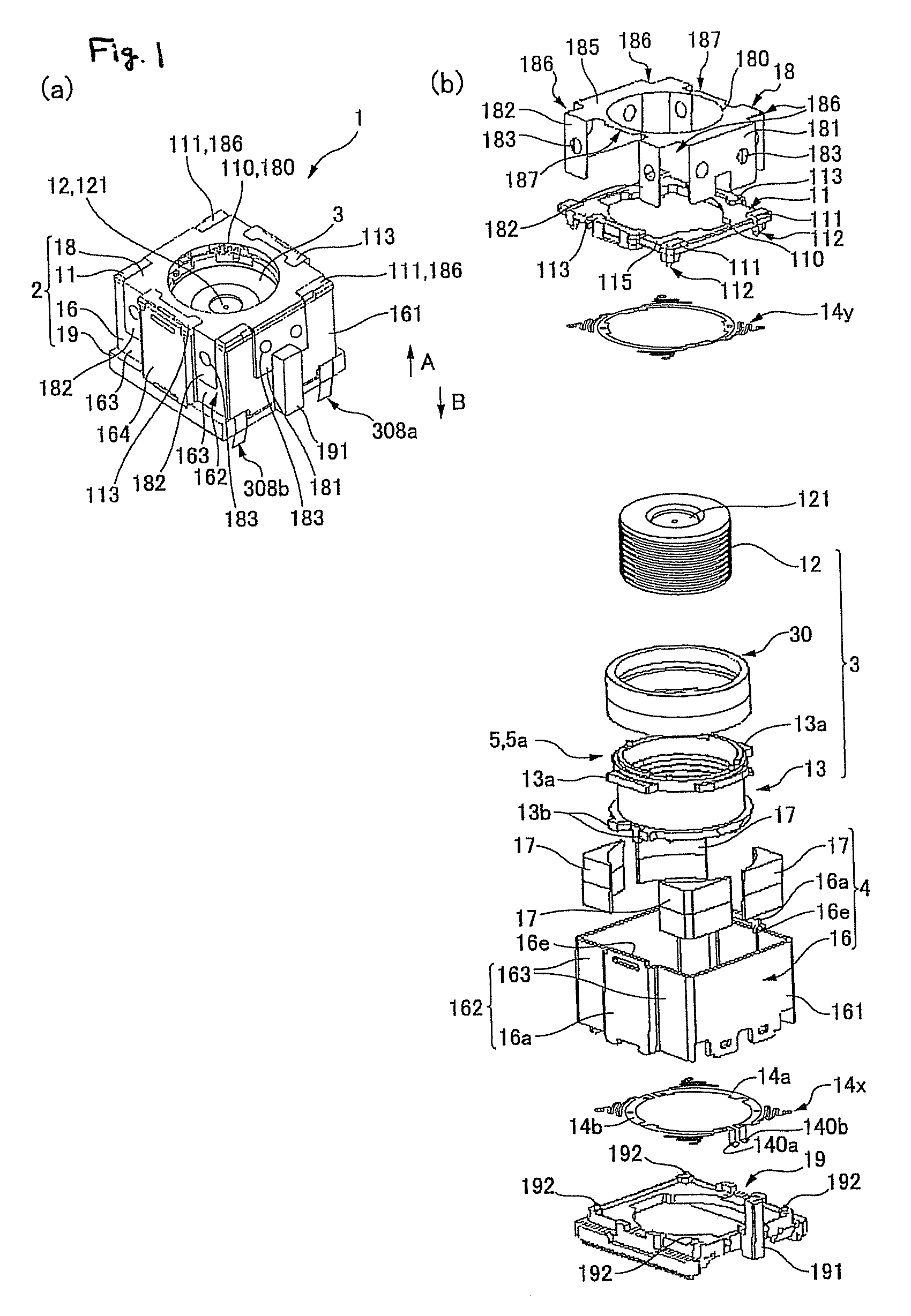

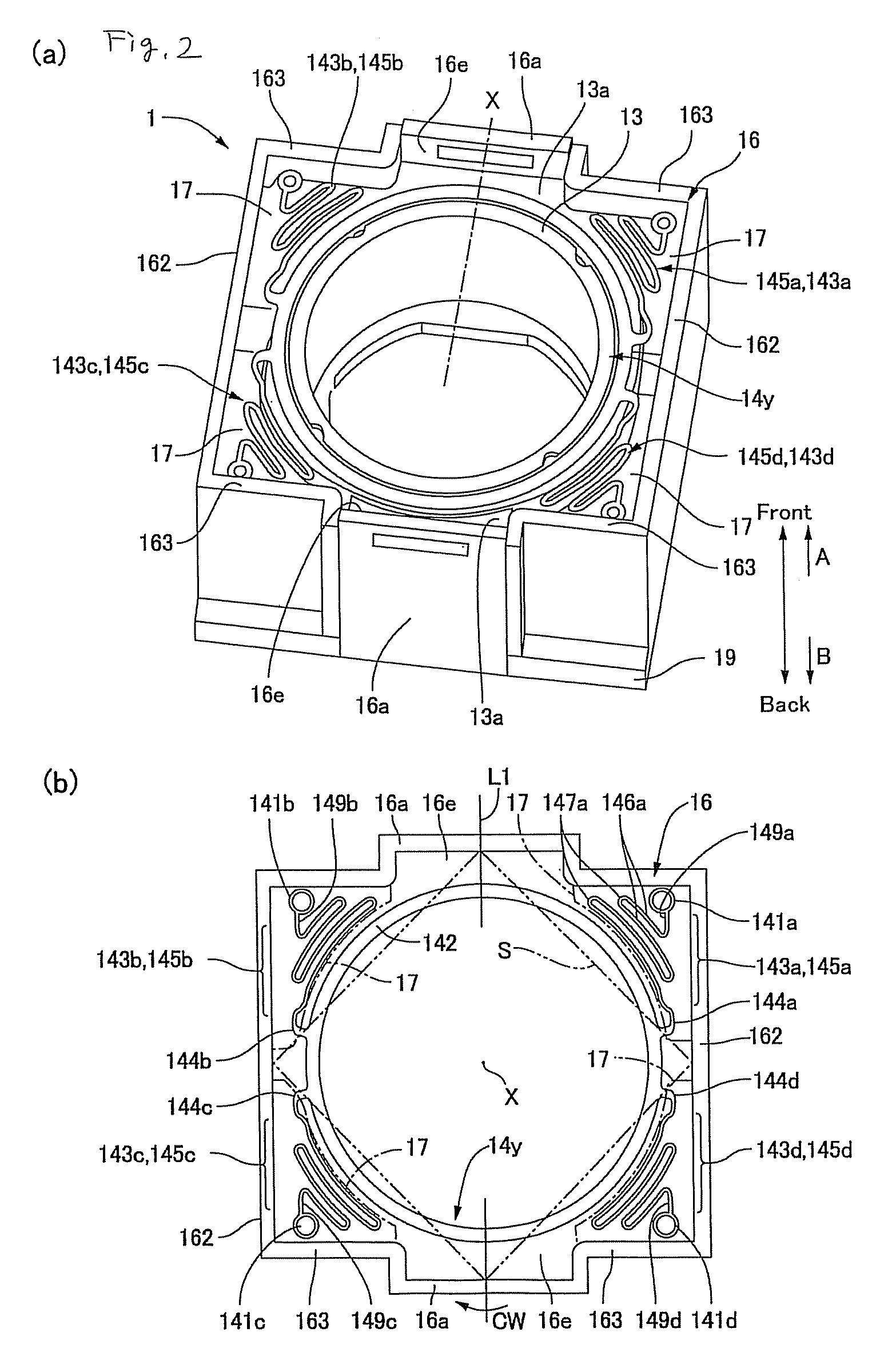

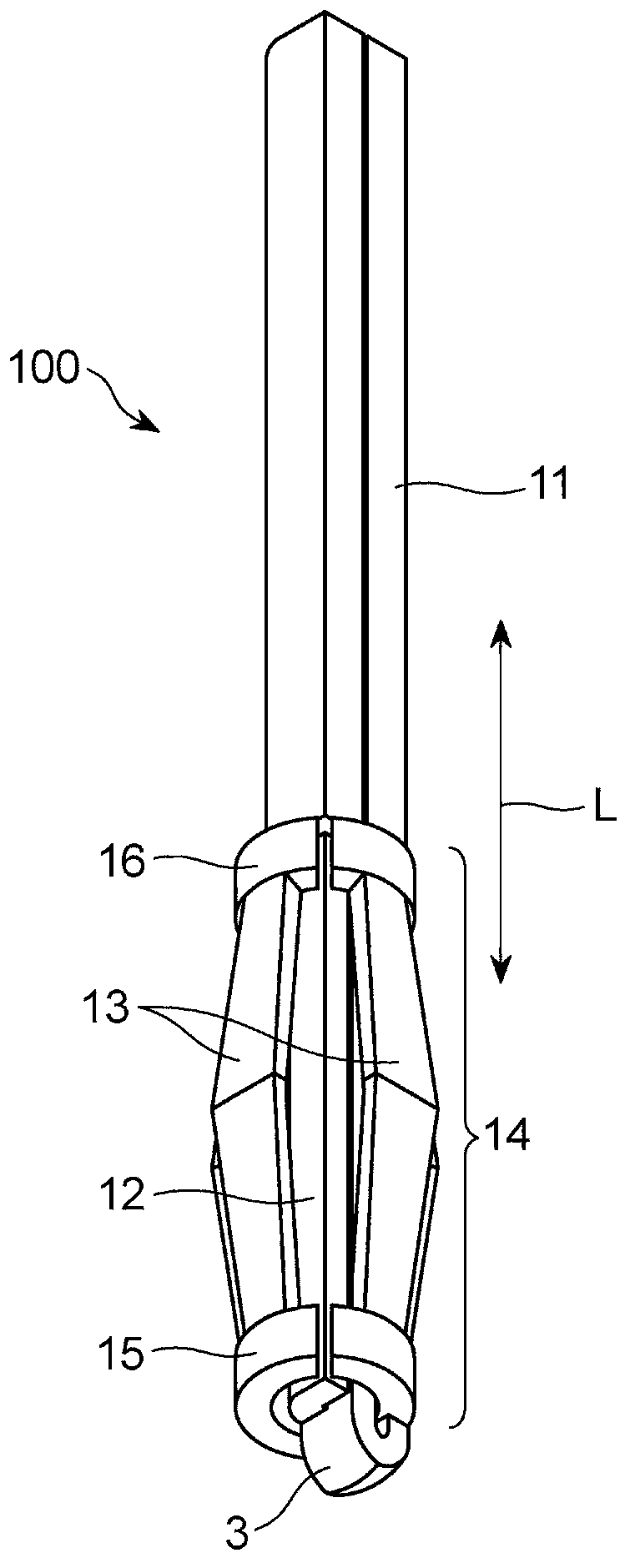

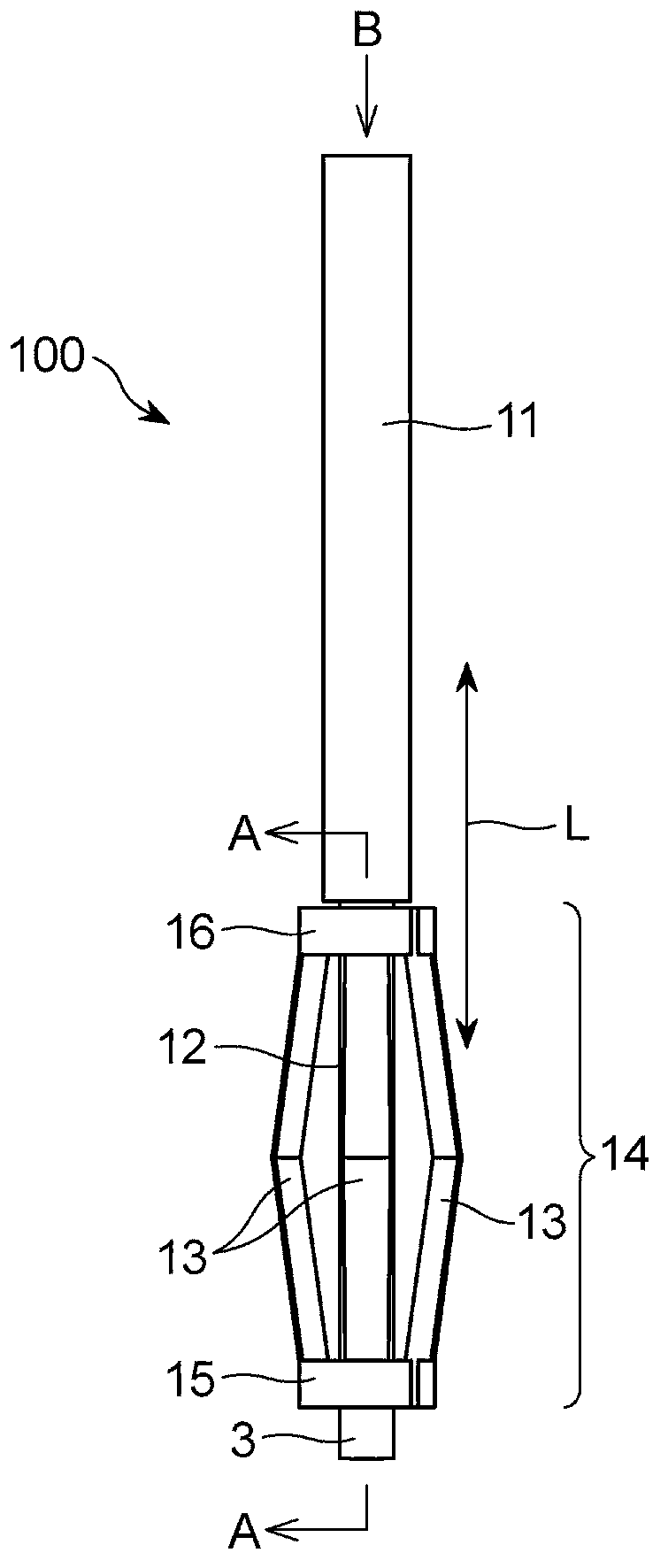

Imaging optical device

InactiveCN102177465ASmooth swingSmall spring constantTelevision system detailsPrintersOptical axisElectrical and Electronics engineering

An imaging optical device configured such that shaking can be appropriately corrected by smoothly rocking a lens drive device on which a lens and an imaging element are mounted. An imaging optical device (1) comprises: a movable module (12) having a lens drive device (2) on which a lens and an imaging element are mounted; a support body (5) for supporting the movable module (12); a rocking drive mechanism for rocking the movable module (12); and a plate spring (17) for rockably supporting the movable module (12). The plate spring (17) is provided with a holding section (17a) for holding the movable module (12), a fixed section (17b) fixed to the support body (5), and a spring section (17c) for connecting the holding section (17a) and the fixed section (17b) to each other. The spring section (17c) can deform in the direction perpendicular to the optical axis (L) and in the direction of the optical axis.

Owner:SANKYO SEIKI MFG CO LTD

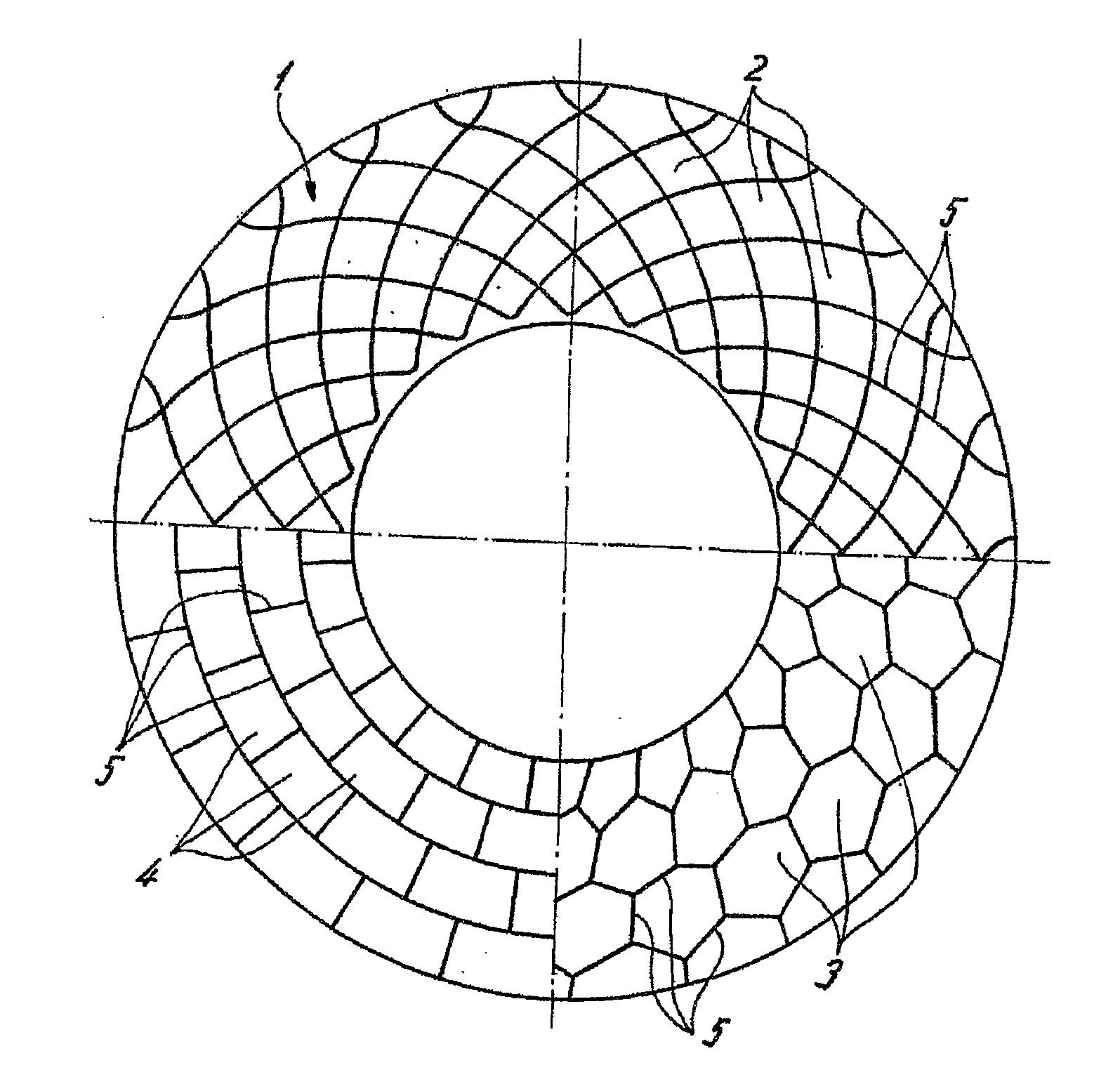

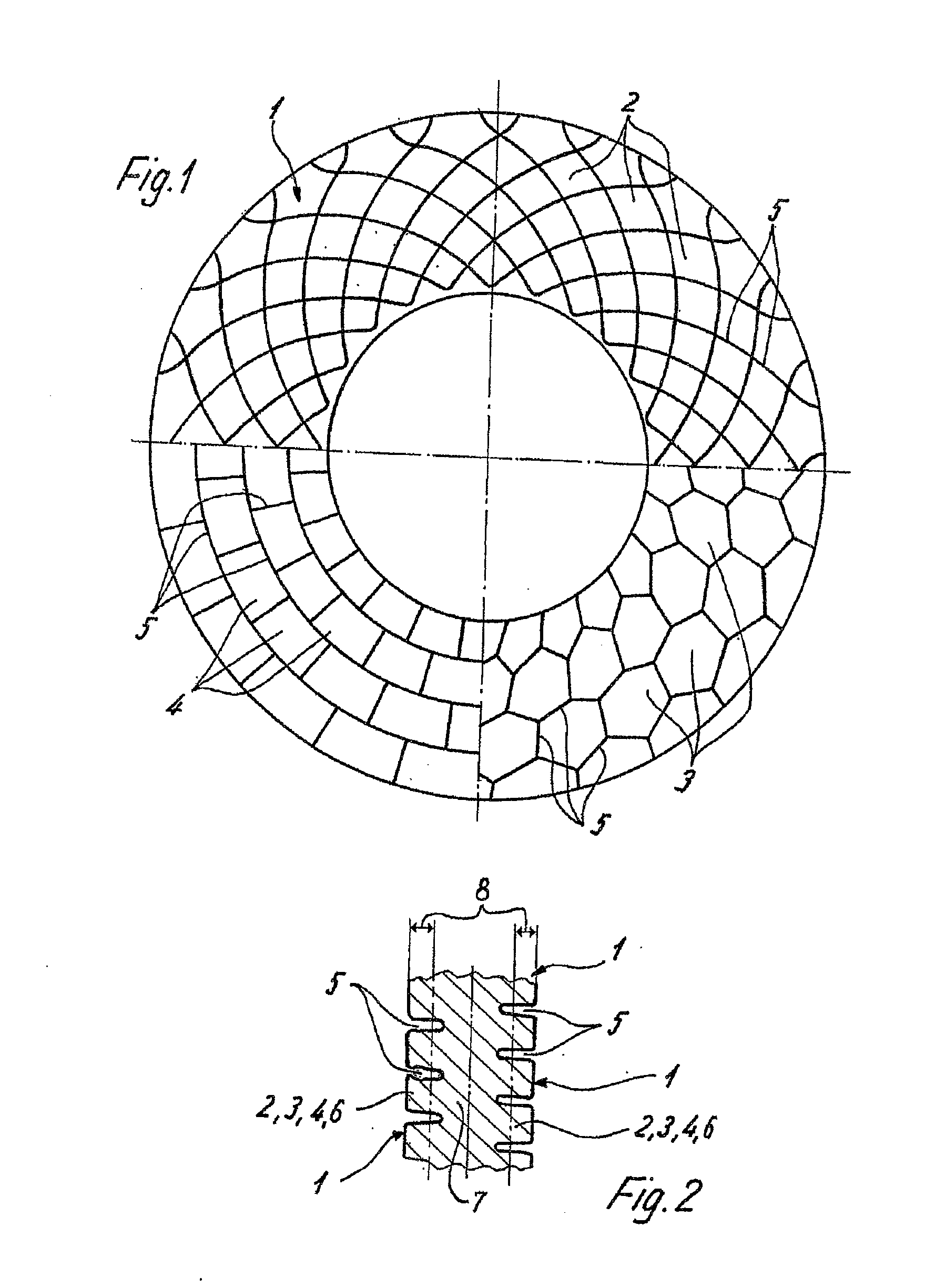

Brake Disk, In Particlular for a Vehicle

InactiveUS20080041675A1Reduce widthEasy to wearBraking discsFriction liningEngineeringExpansion joint

A brake disc for a vehicle has at least one annular friction surface provided on at least one outer face of the disc to which a brake pad can be applied for braking purposes. The friction surface has a large number of subsegments, at least some of which are physically separated from one another by expansion joints. The brake disc is configured in such a way that the depth of the expansion joints is greater than the permissible rate of wear of the friction surface.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

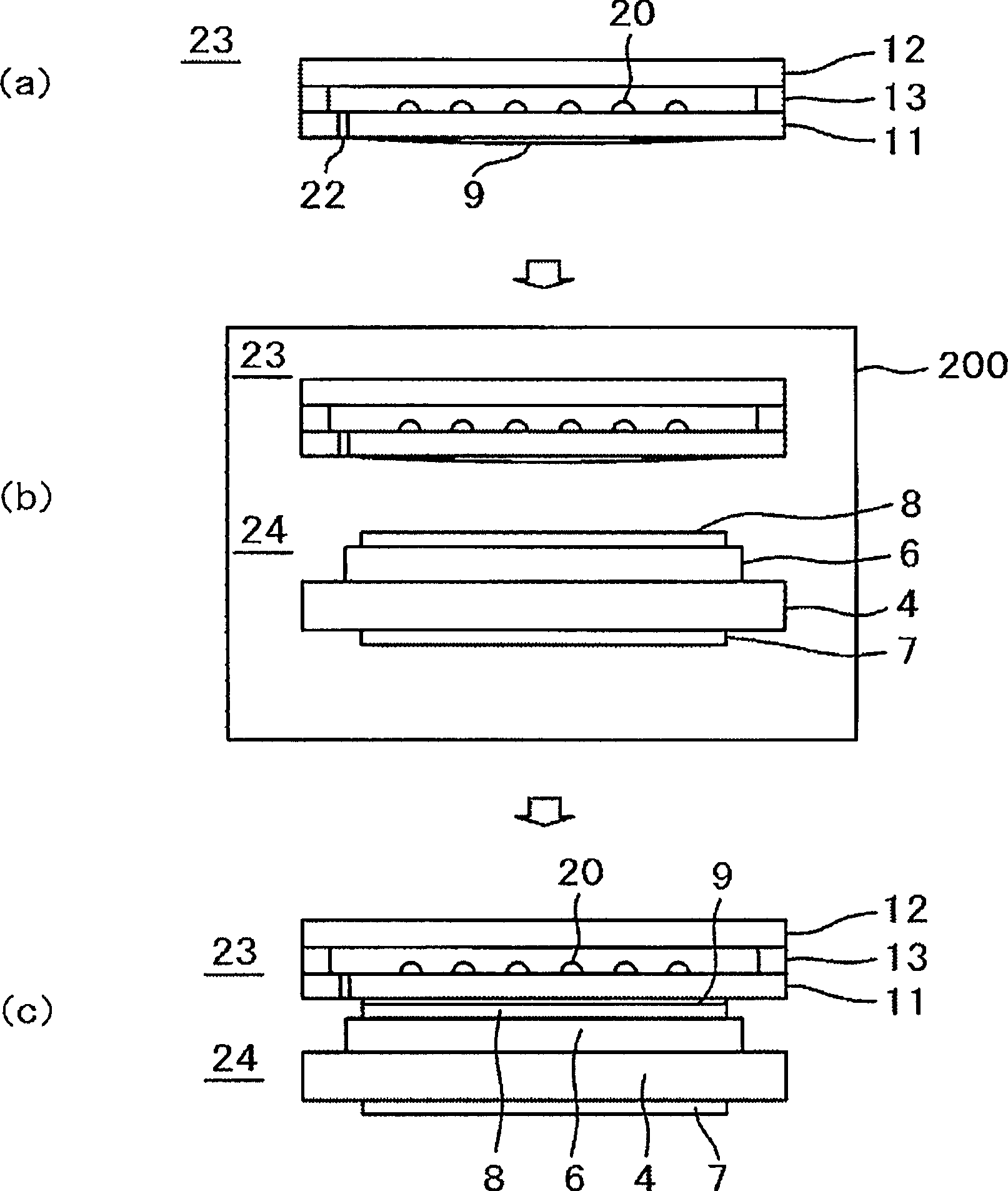

Display device

ActiveCN101398555AAvoid reflectionsAvoid plastic deformationStatic indicating devicesNon-linear opticsUV curingDisplay device

In a display device having a touch panel, it is possible to prevent the generation of a screen defect caused by the intrusion of air bubbles into a UV curing resin formed between a touch panel and a display panel. The touch panel is constituted of an upper transparent-electrode-attached film 12 and a lower transparent-electrode-attached film 11, and an air hole 22 is formed in the lower transparent-electrode-attached film 11. Due to such constitution, in adhering the touch panel and the display panel to each other in a vacuum using a UV curing resin 9, air in the touch panel is also discharged and hence, there is no possibility that the touch panel swells. Accordingly, it is possible to prevent warping of the lower transparent-electrode-attached film 11 and hence, in curing the UV curing resin 9 for adhering the touch panel and the display panel to each other, it is possible to prevent the entanglement of air into the UV curing resin. Accordingly, a touch-panel attached display device free from a screen defect attributed to air bubbles can be manufactured.

Owner:JAPAN DISPLAY INC +1

Rubber composition containing cross linkable polyethylene

The present invention provides a rubber composition in which the coexistence of low heat build-up, heat resistance and high hardness can be achieved without damaging failure characteristics. According to the present invention, a rubber composition comprising a 100 parts by weight of matrix rubber and a 2-75 parts by weight of a polyethylene composition which contains 0-80% by weight of polyethylene and 20% by weight or more of a composite comprising a polyethylene component and a rubber component previously bonded via a coupling agent to the polyethylene component, said rubber component is crosslinked with the matrix rubber. At least at one of the kneading stages before the final stage, the compound is kneaded so that the maximum temperature of the compound of the kneading of that stage is higher than the melting point of the polyethylene component mixed, preferably, by 10 DEG C. or more.

Owner:BRIDGESTONE CORP

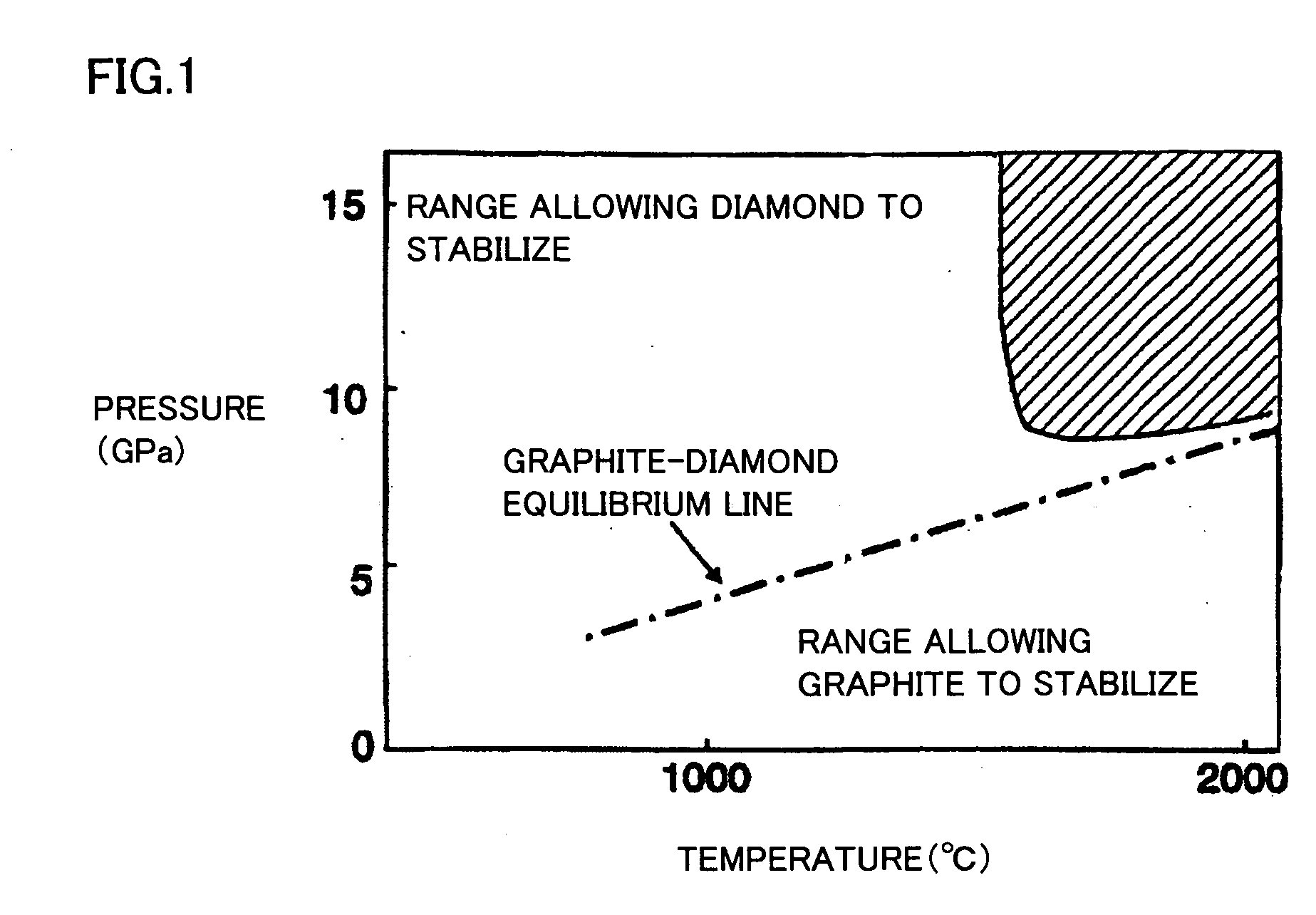

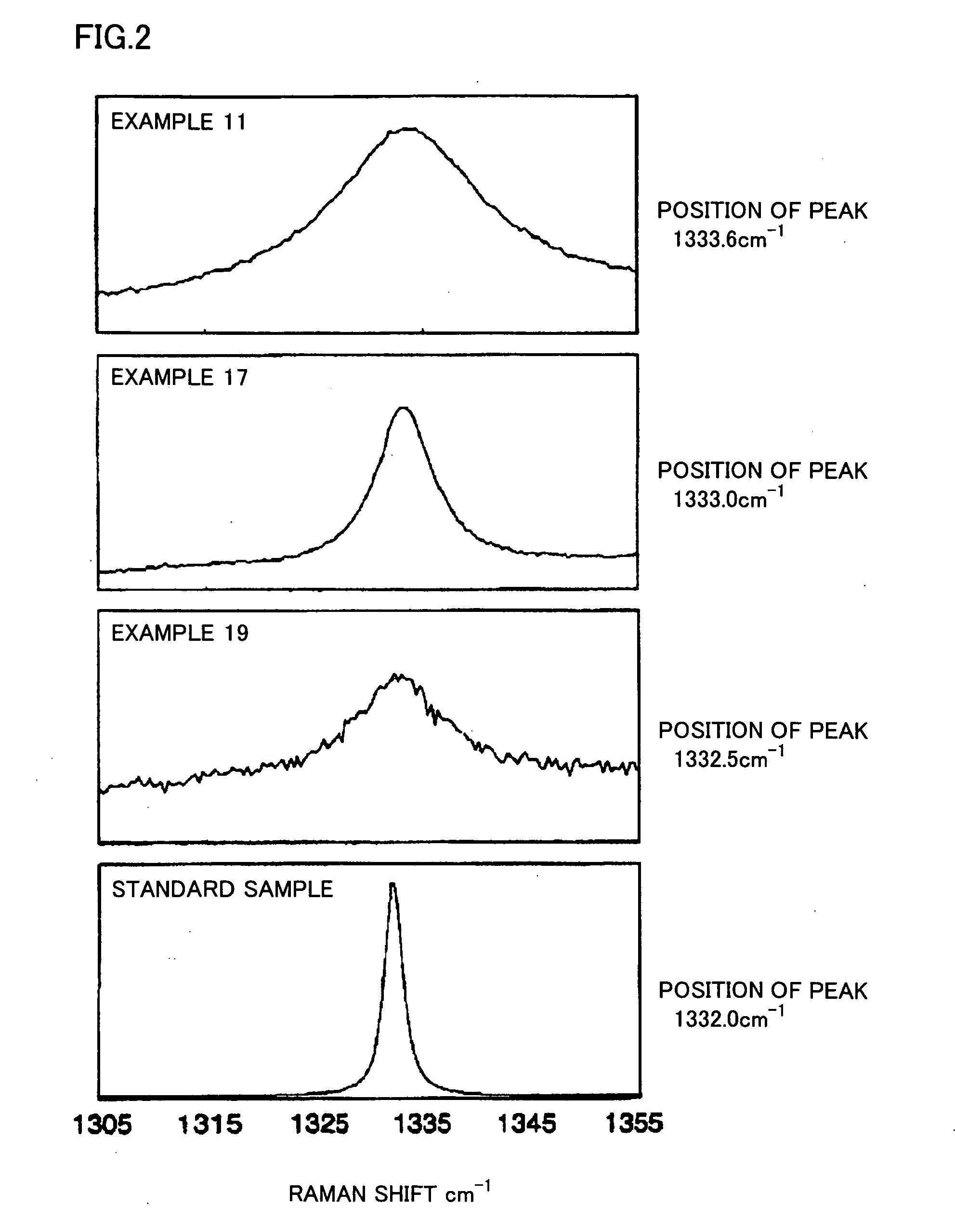

High-hardness polycrystalline diamond and method of preparing the same

ActiveUS20090305039A1Inexpensive and reliableImprove mechanical propertiesMaterial nanotechnologyUltra-high pressure processesUltra high pressurePolycrystalline diamond

There are provided sufficiently strong, hard, and heat resistant, dense and homogenous polycrystalline diamond applicable to cutting tools, dressers, dies and other working tools and excavation bits and the like, and a cutting tool having a cutting edge of the polycrystalline diamond. The polycrystalline diamond is formed substantially only of diamond formed using a composition of material containing a non diamond type carbon material, the composition of material being converted directly into diamond and sintered at ultra high pressure and ultra high temperature without aid of a sintering aid or a catalyst, and has a mixed microstructure having a fine crystal grain of diamond having a maximal grain size of at most 100 nm and an average grain size of at most 50 nm and a coarse crystal grain of diamond in the form of one of a platelet and a granule having a grain size of at least 50 nm and at most 10,000 nm.

Owner:SUMITOMO ELECTRIC IND LTD

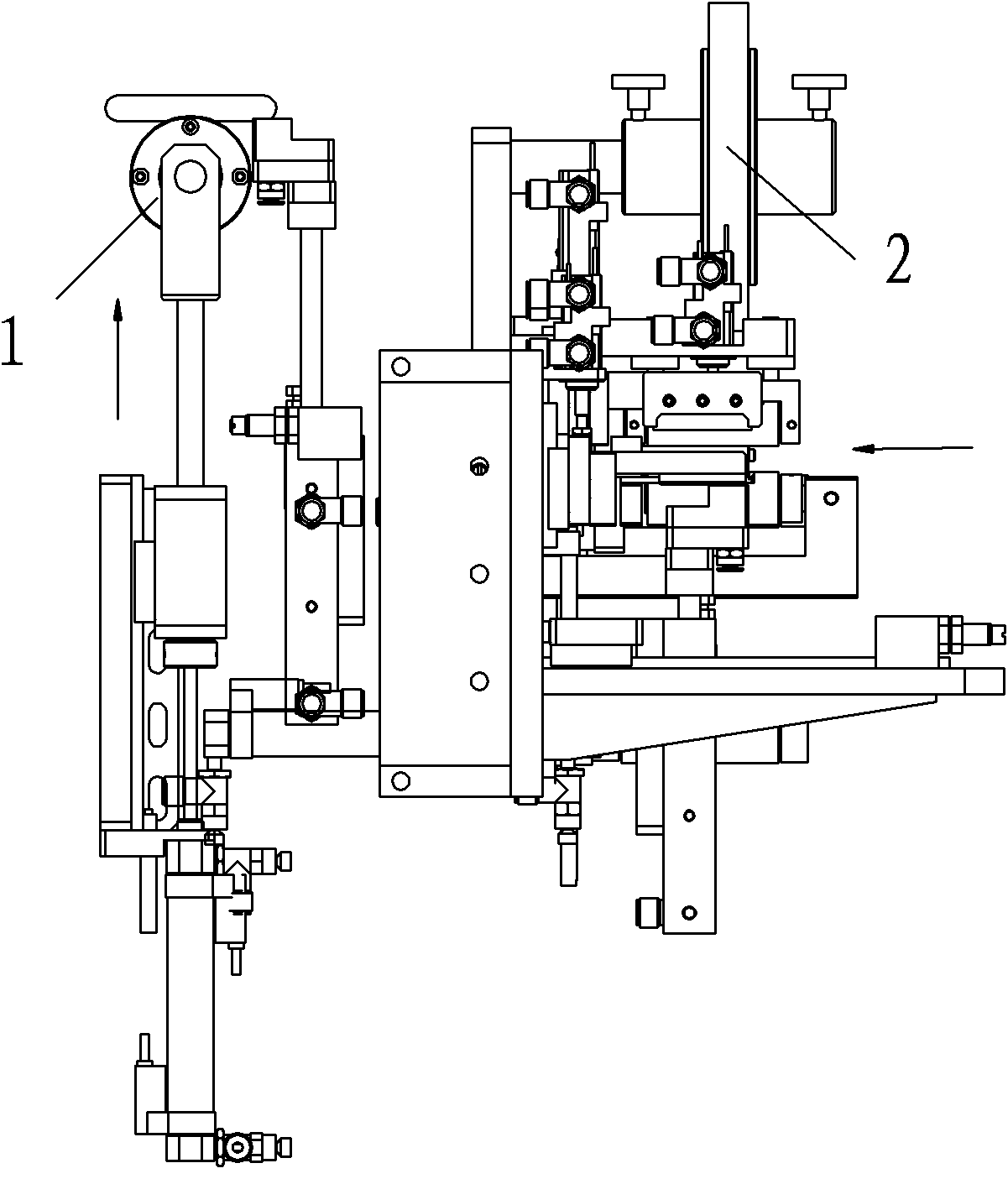

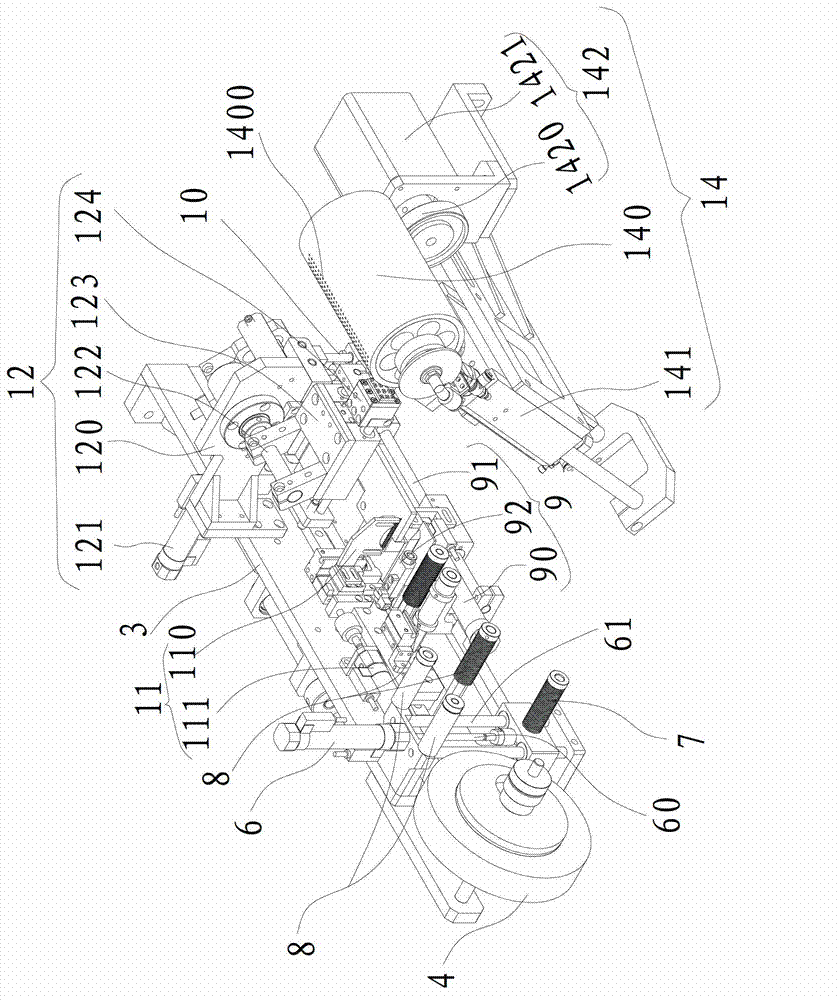

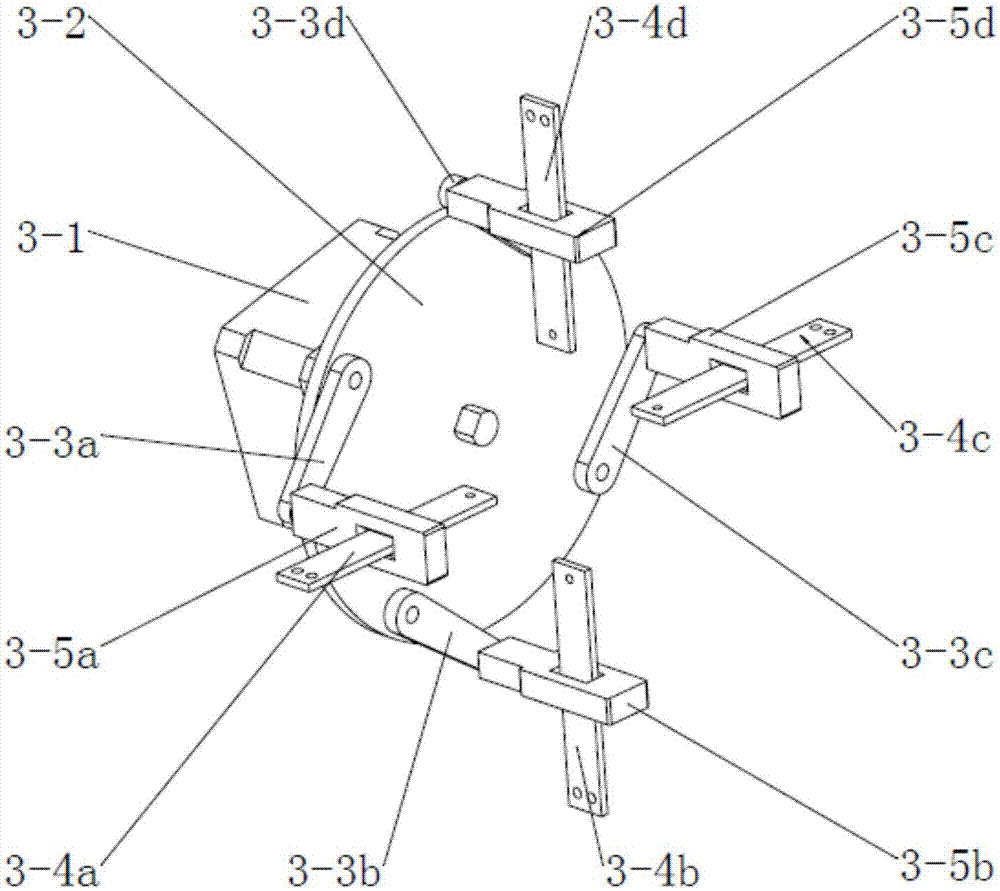

Lithium battery winding and sticking mechanism

ActiveCN103050737AAvoid plastic deformationEasy to adjustFinal product manufactureSecondary cellsLithium-ion batteryMechanical engineering

The invention relates to a lithium battery winding and sticking mechanism which is applied to lithium ion battery cell manufacturing equipment. The winding and sticking mechanism comprises a machine frame; an adhesive tape roller capable of rotatablely releasing an adhesive tape is mounted at the initial end of the machine frame; an adhesive tap starting cylinder and an adhesive tap roller, which are used for controlling the unwinding of an adhesive tape spool on the adhesive tape roller, are mounted near the adhesive tap roller on the machine frame; a plurality of rollers for transporting adhesive tapes is mounted on the machine frame; an adhesive tap preparing component is mounted at the middle part of the machine frame; an adhesive tap holding component which is used for withholding the adhesive tape drew by the adhesive tap preparing component to prevent the adhesive tape from turning and being detached is mounted at the tail end of the machine frame; an adhesive tape cutting component for cutting the adhesive tape drew and withheld is mounted behind the adhesive tap preparing component on the machine frame; an absorbing and overturning component for turning over the cut adhesive tape is mounted above the adhesive tape drew from the rear part of the adhesive tape cutting component, on the machine frame; and a sticking device for delivering the cut adhesive tape to a battery cell to be sticked is mounted on one side of the absorbing and overturning component and on the machine frame.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

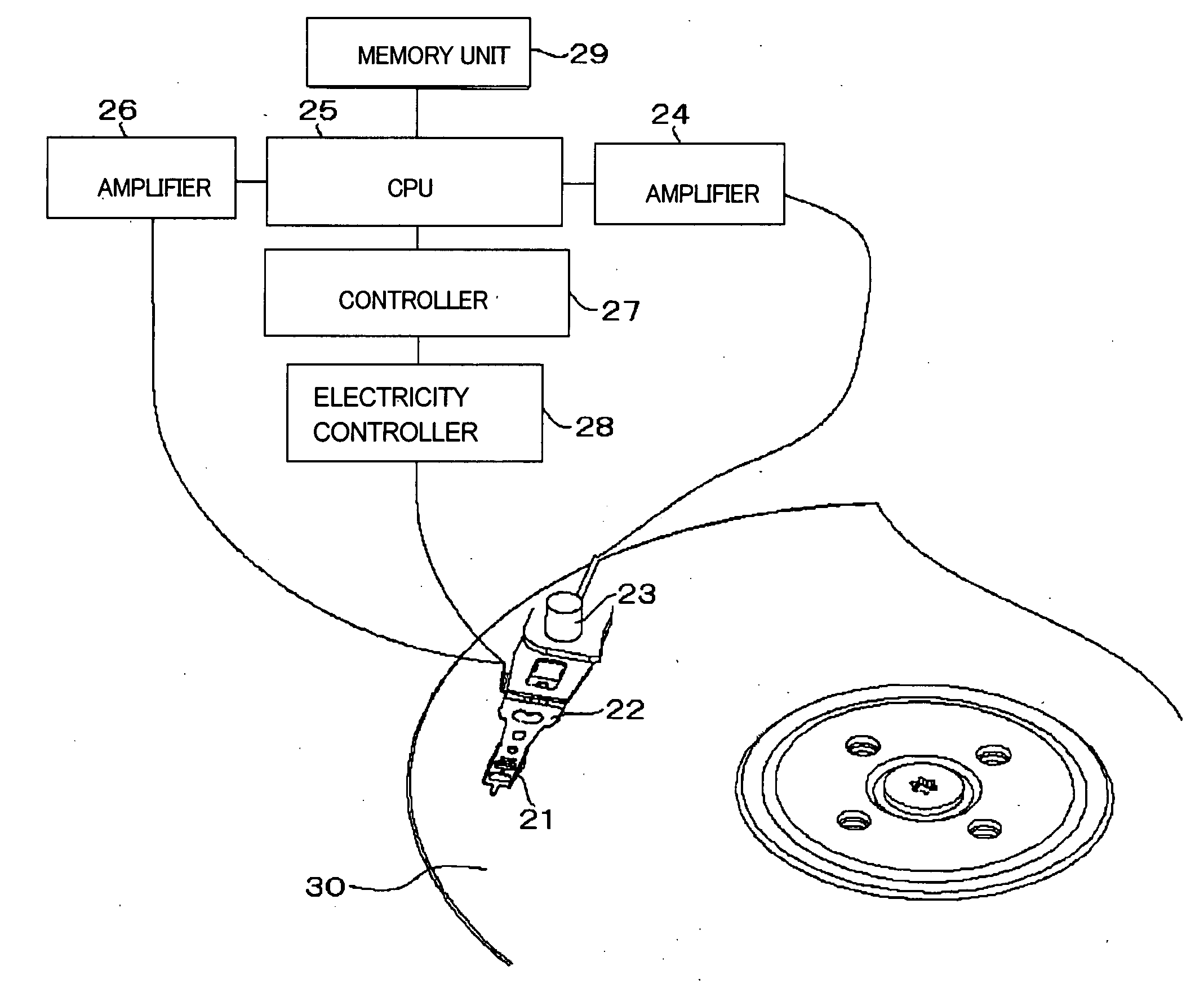

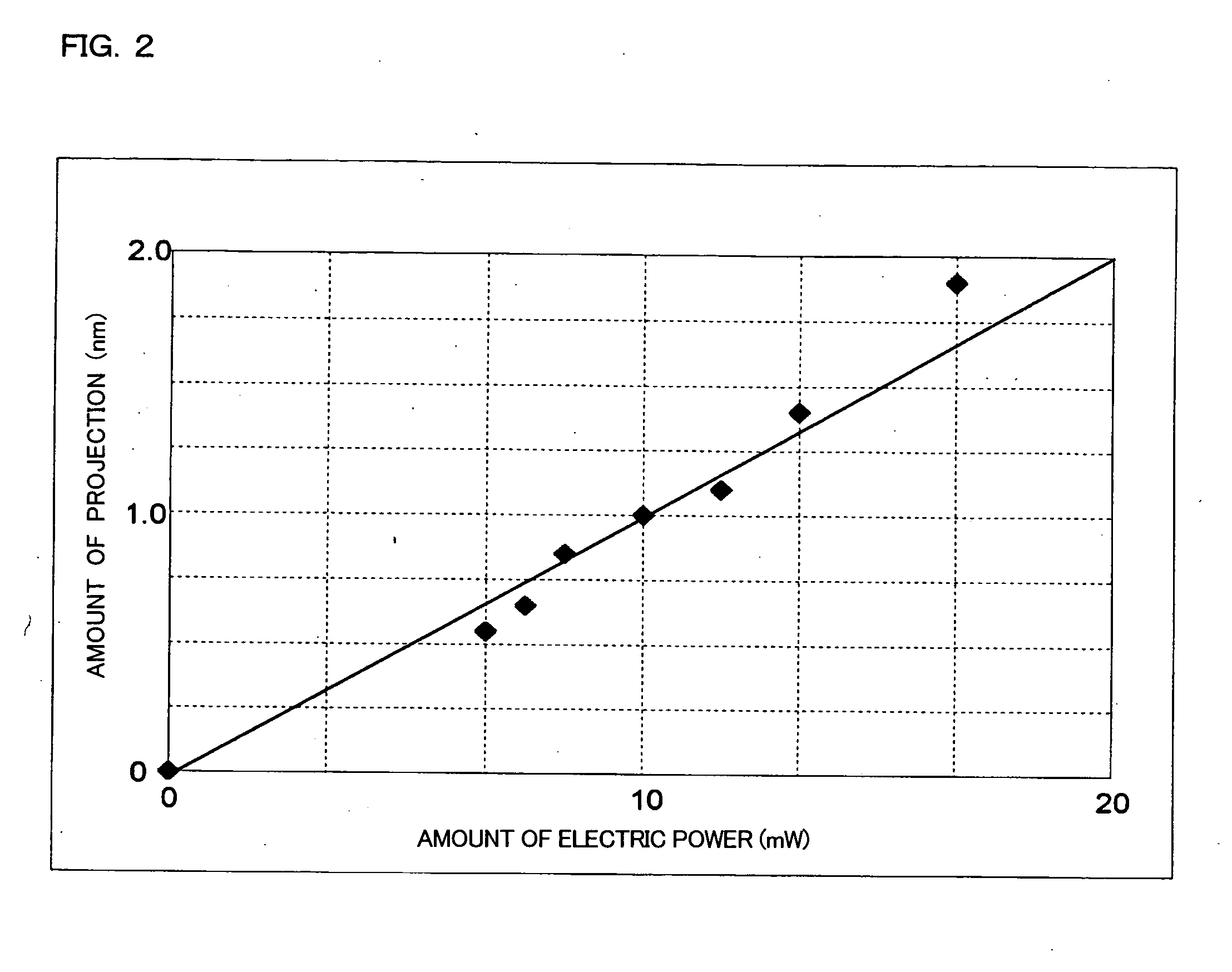

Information storage apparatus

InactiveUS20070133118A1Quick calibrationShort timeDriving/moving recording headsRecord information storageMagnetic polesEngineering

An information storage apparatus includes a magnetic head having a magnetic pole end that is controllable so as to project, a recording medium for recording and / or reproducing data, a protrusion provided on a surface of the recording medium, the protrusion being used for measuring a flying height of the magnetic head, and a flying-height adjustment controller that adjusts the flying height of the magnetic head by controlling the amount of projection of the magnetic pole end of the magnetic head on the basis of the amount of projection obtained when the magnetic pole end of the magnetic head comes into contact with the protrusion.

Owner:FUJITSU LTD

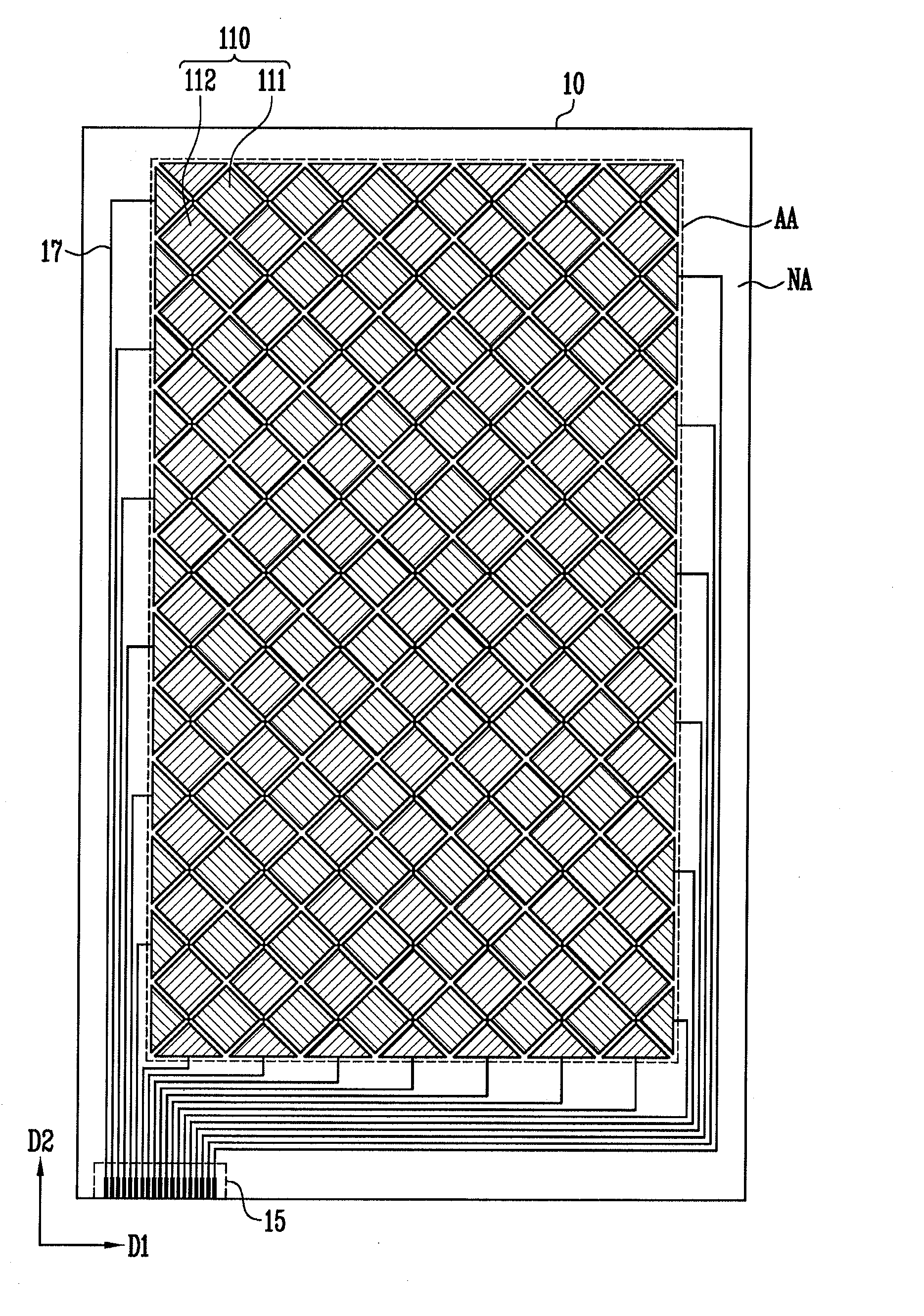

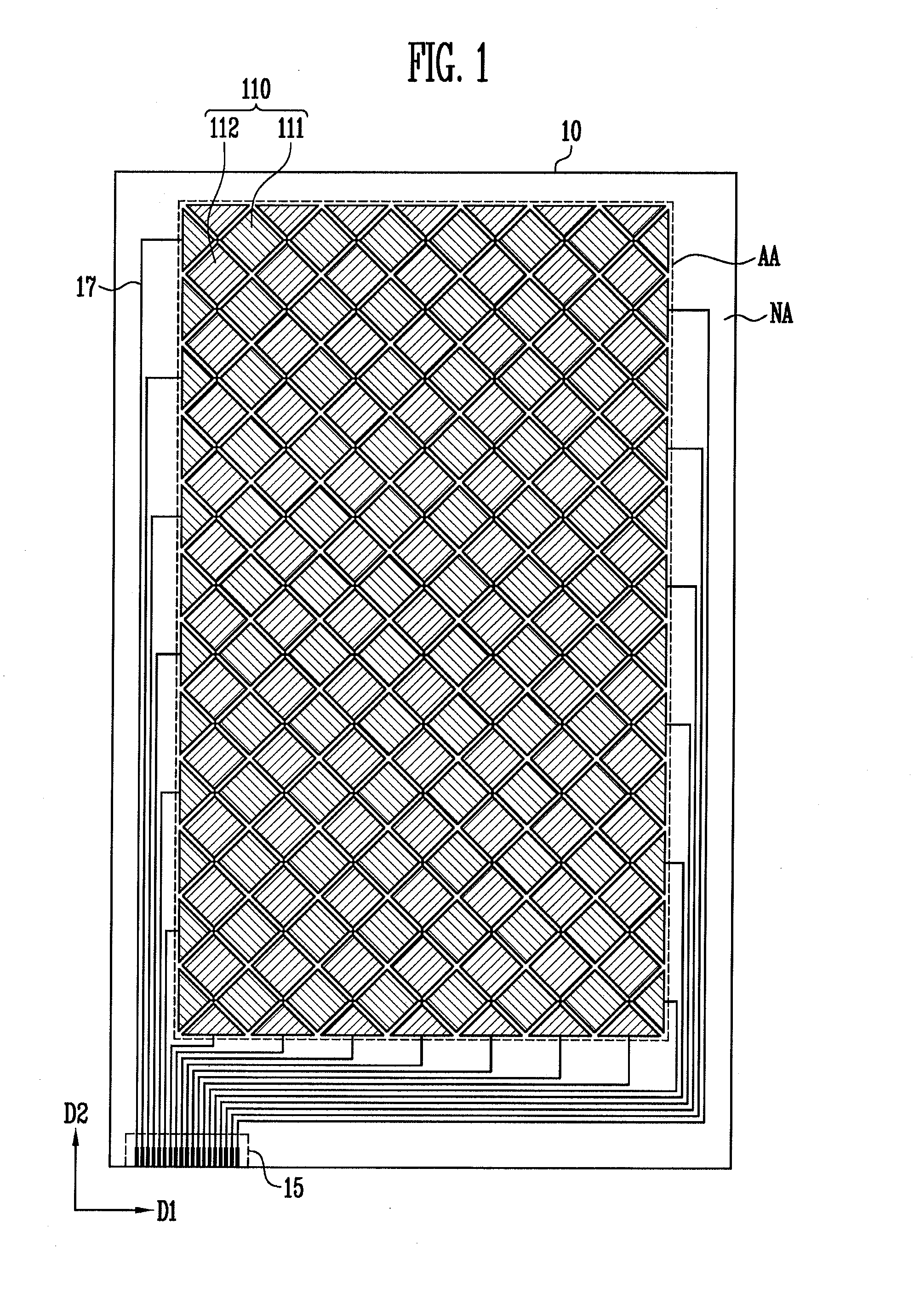

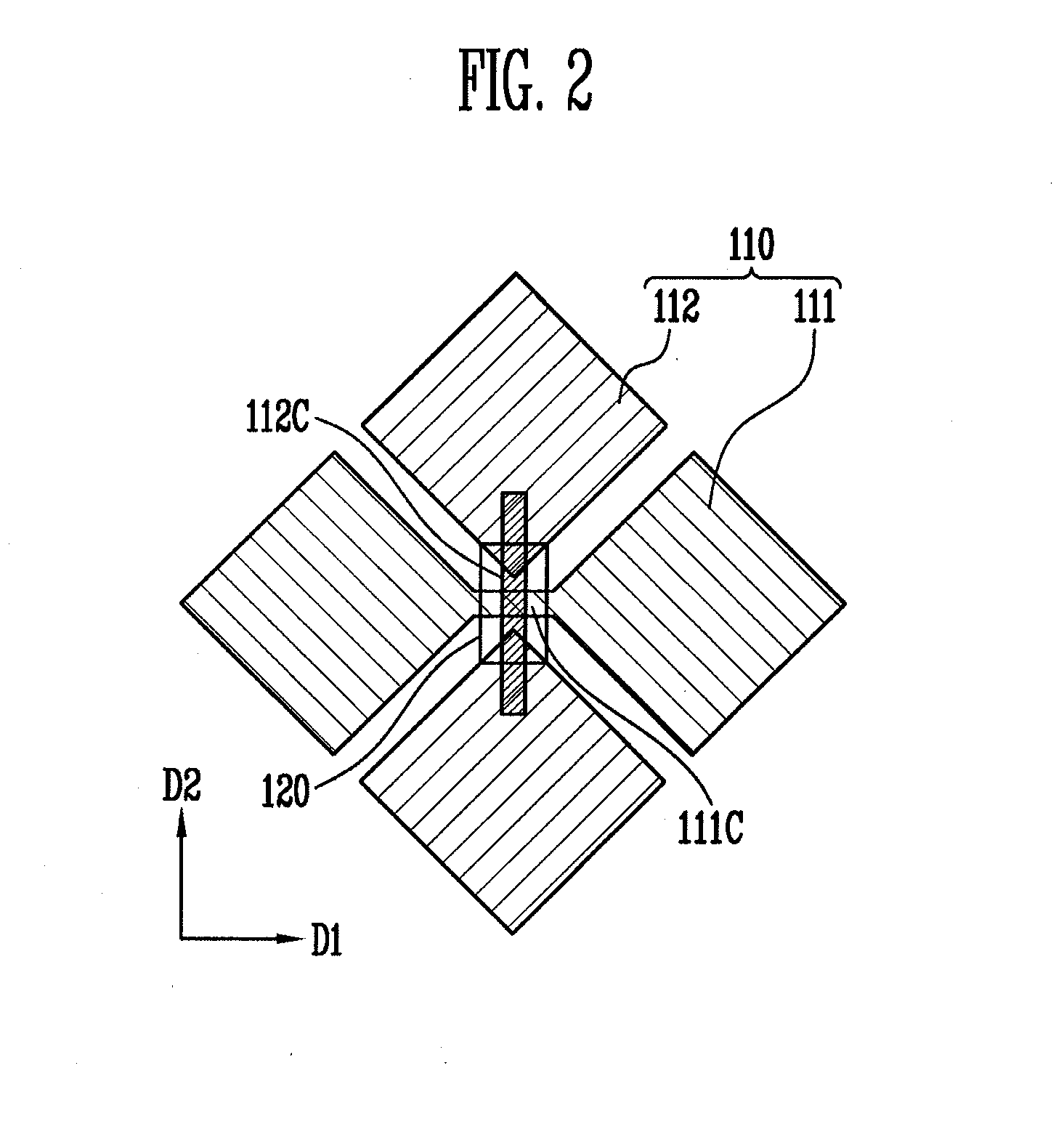

Flexible touch screen panel

ActiveUS20140218630A1Easy to bendAvoid plastic deformationDetails for portable computersNon-linear opticsEngineeringTouchscreen

A flexible touch screen panel includes a substrate, first and second sensing electrodes and conductive lines. The substrate includes an active area and a non-active area positioned at the outside of the active area when viewed in a thickness direction thereof. The substrate further includes a first surface and a second surface. The first and second sensing electrodes are formed over the active area of the substrate. The first sensing electrodes are formed to be connected along a first direction, and second sensing electrodes are formed to be connected along a second direction intersecting the first direction. The conductive lines are formed over the non-active area of the substrate, and electrically connect the first and second sensing electrodes to an external driving circuit. In the flexible touch screen panel, one or more concavo-convex patterns are formed on one or both of the first and second surfaces.

Owner:SAMSUNG DISPLAY CO LTD

Fasteners for clamping sheet-form members, and apparatus and method using such fasteners to attach undercover onto underside of vehicle floor panel

ActiveUS20070248436A1Facilitate intentional turningAvoid plastic deformationVehicle seatsNutsEngineeringFlange

Owner:NEWFREY

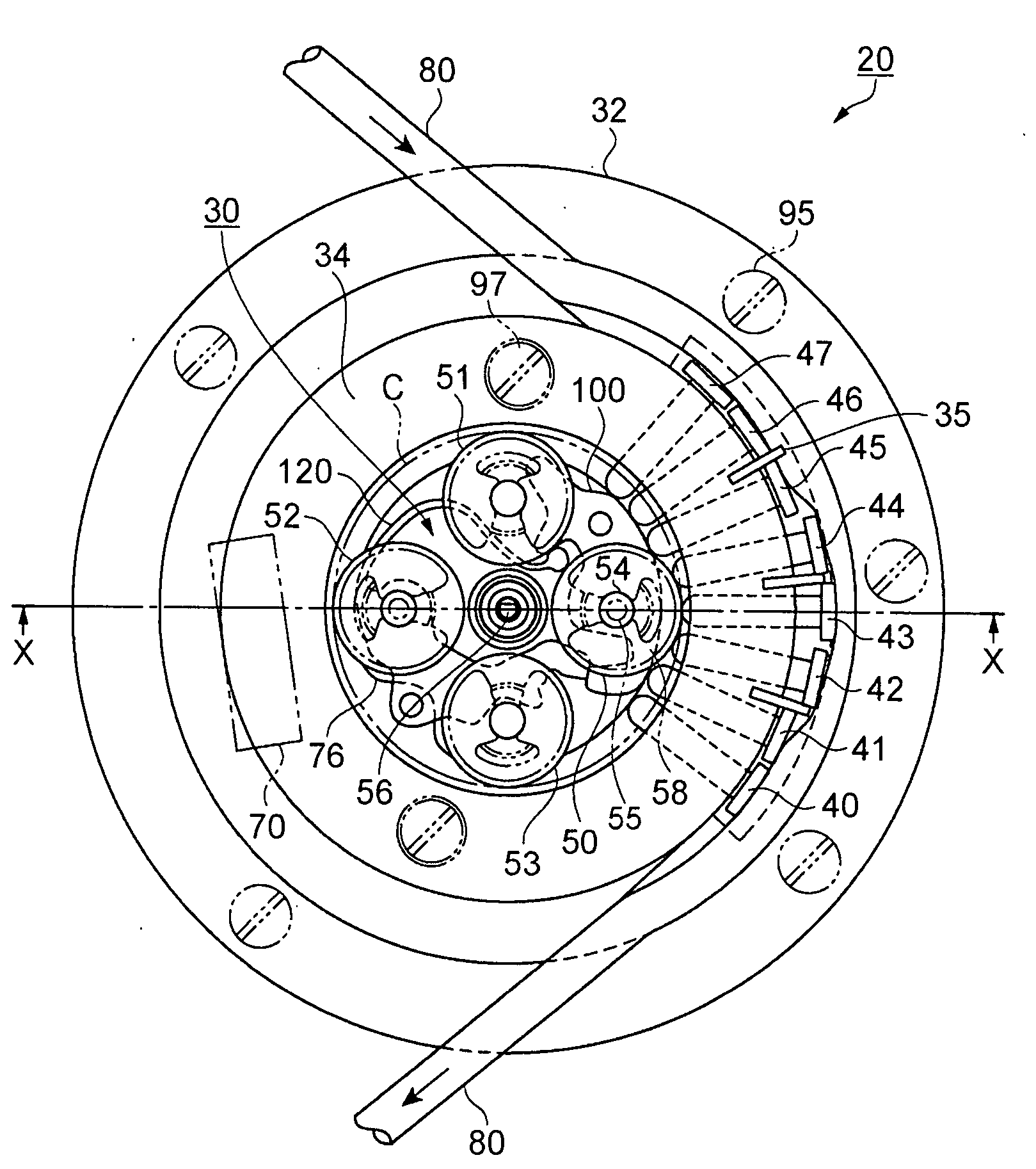

Fluid Transporting Device, and Fluid Transporter

InactiveUS20080138222A1Easy to replaceEasy to handleFlexible member pumpsPositive-displacement liquid enginesFluid transportEngineering

A fluid transporting device comprises a tube frame having a tube guide wall for arranging a tube having an elasticity in an arcuate shape, and a rotary pressure mechanism having a plurality of rollers. The rotary pressure mechanism is arranged, when the tube is arranged in the tube frame, on the side opposite to the guide wall side of the tube, such that its center of rotation is aligned with the center of the arc of the tube guide wall. A plurality of push pins are interposed between the tube and the rotary pressure mechanism and are arranged radially of the center of rotation of the rotary pressure mechanism. A switching mechanism moves at least one of the rollers to a position for the push pins to release the tube and a position for the push pins to press the tube.

Owner:SEIKO EPSON CORP

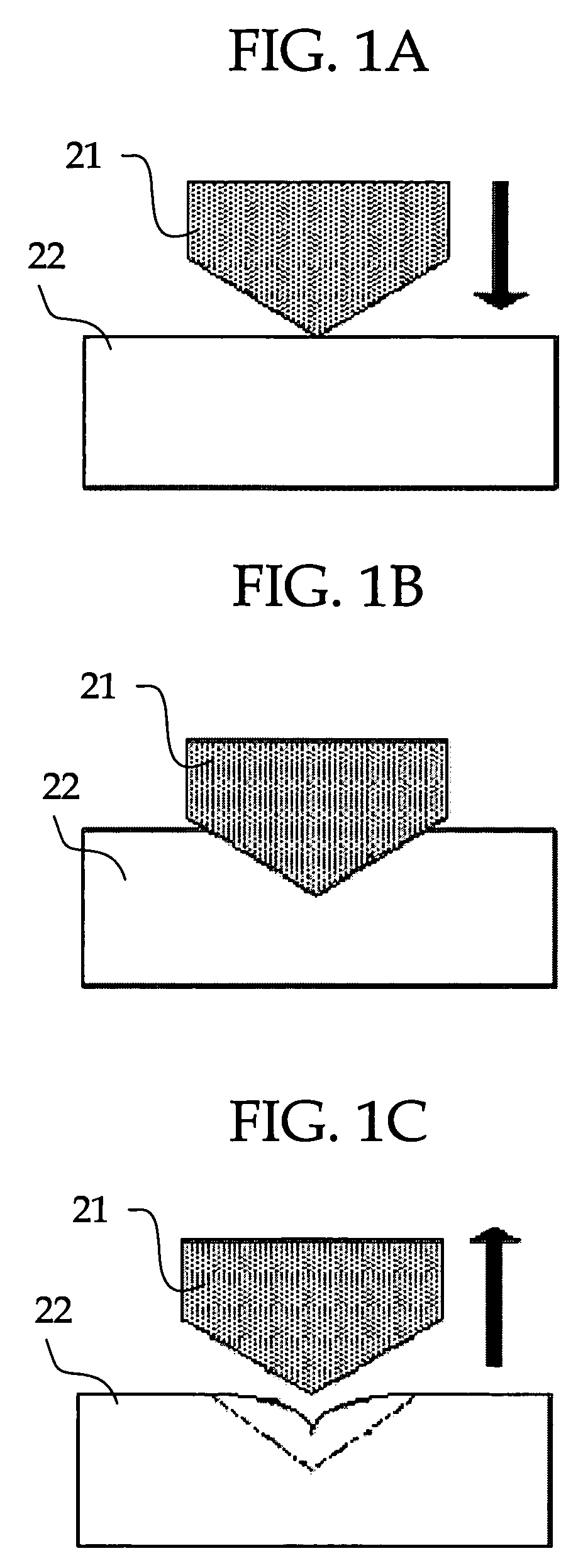

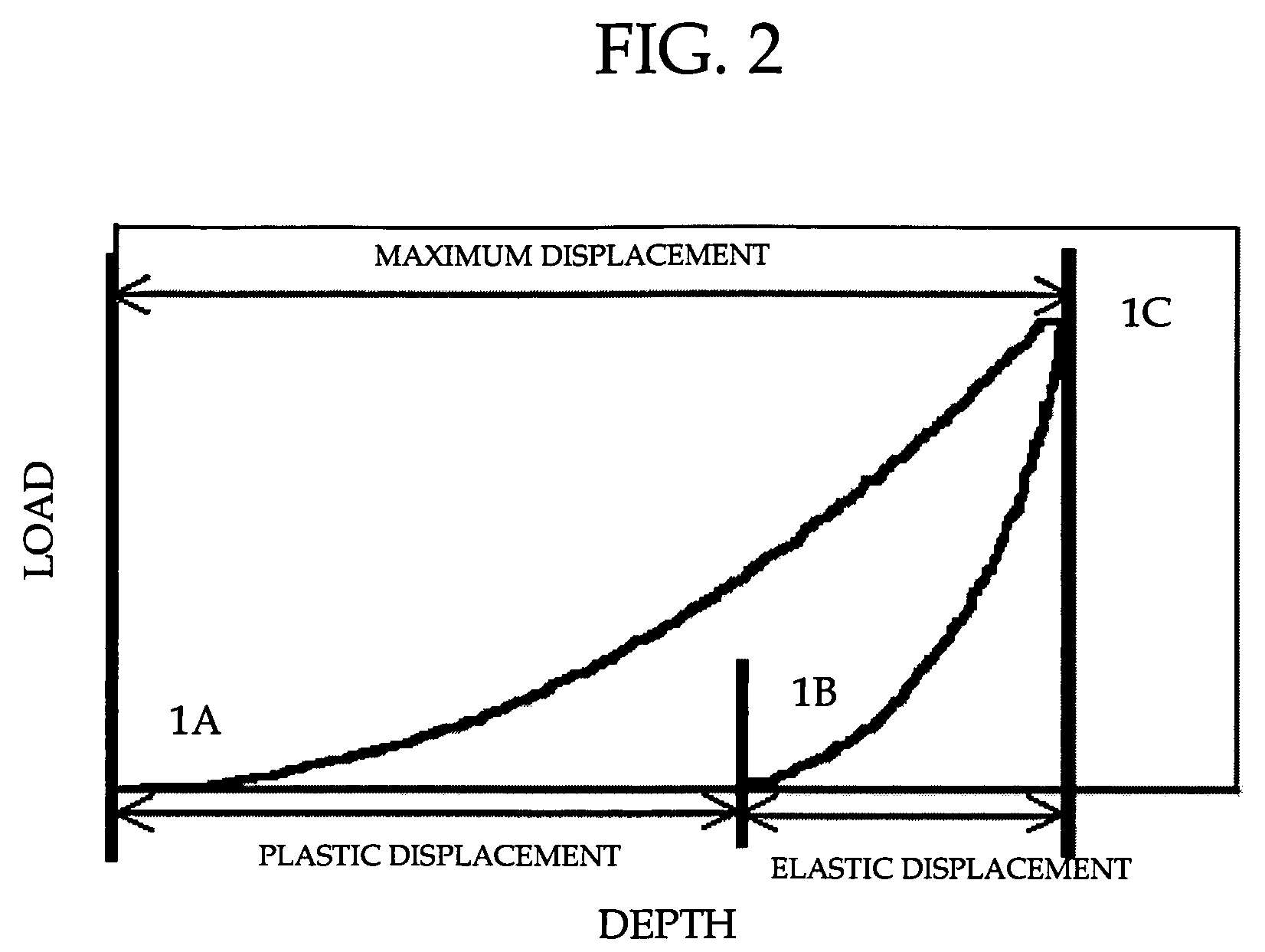

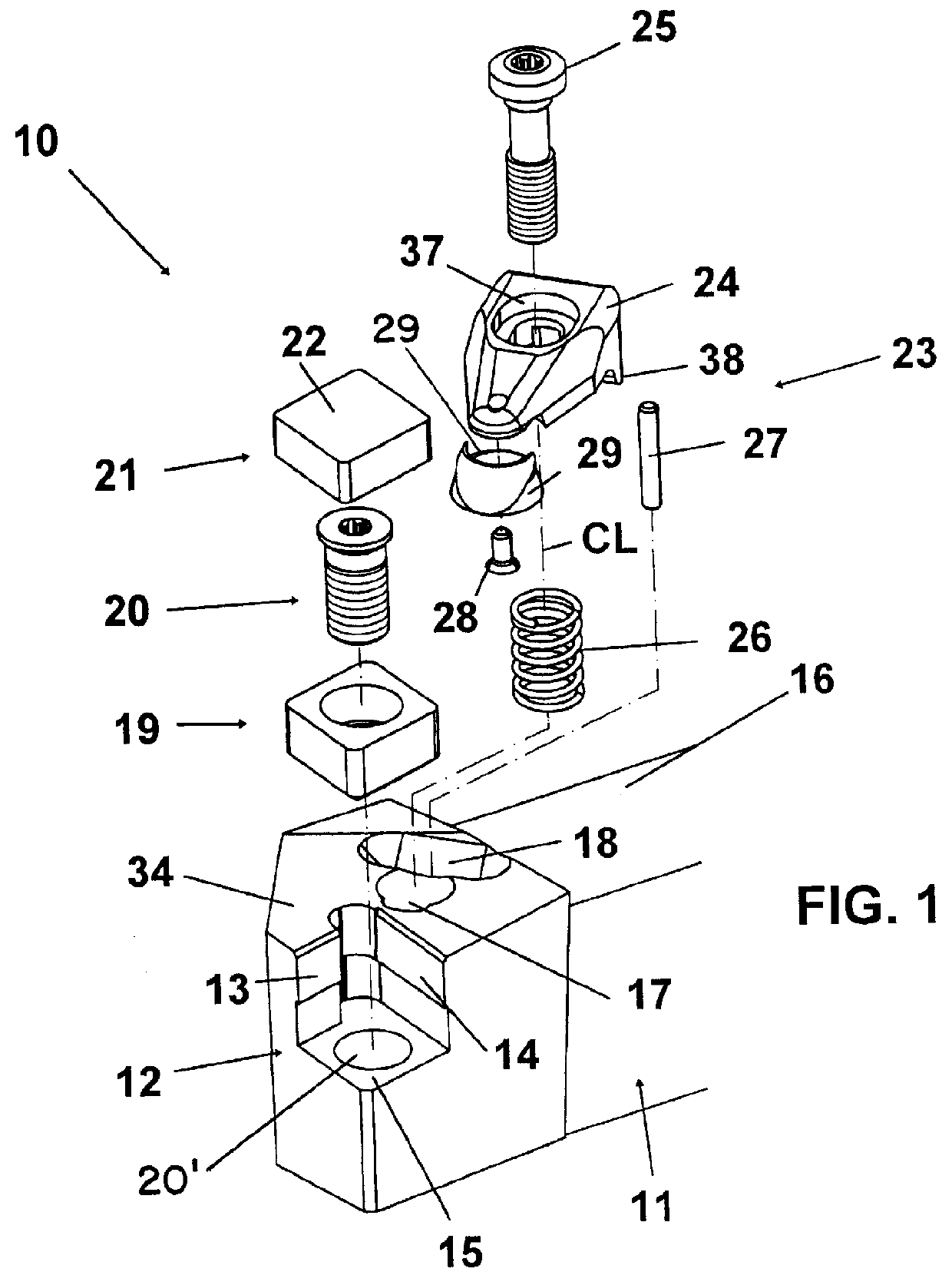

Tool and clamp for chip removing machining

A tool for chip removing metal machining includes a holder, a solid cutting insert mounted in a pocket of the holder, and a clamp for securing the insert. The clamp includes a clamping surface frictionally engaging a planar upper surface portion of the insert. The clamp is attached to the holder by a screw causing a downward projection of the clamp to slide along a sloping surface of the holder in order to displace the clamp and the insert rearwardly until the insert abuts an upstanding support surface of the holder. As the clamp is being tightened-down by the screw, an elastic lip of the clamp is elastically deformed by a surface of the holder to tilt the clamp in a direction causing the clamping surface to bear more firmly against the insert. A stop arrangement terminates the tightening down of the clamp before the clamp is plastically deformed.

Owner:SECO TOOLS AB

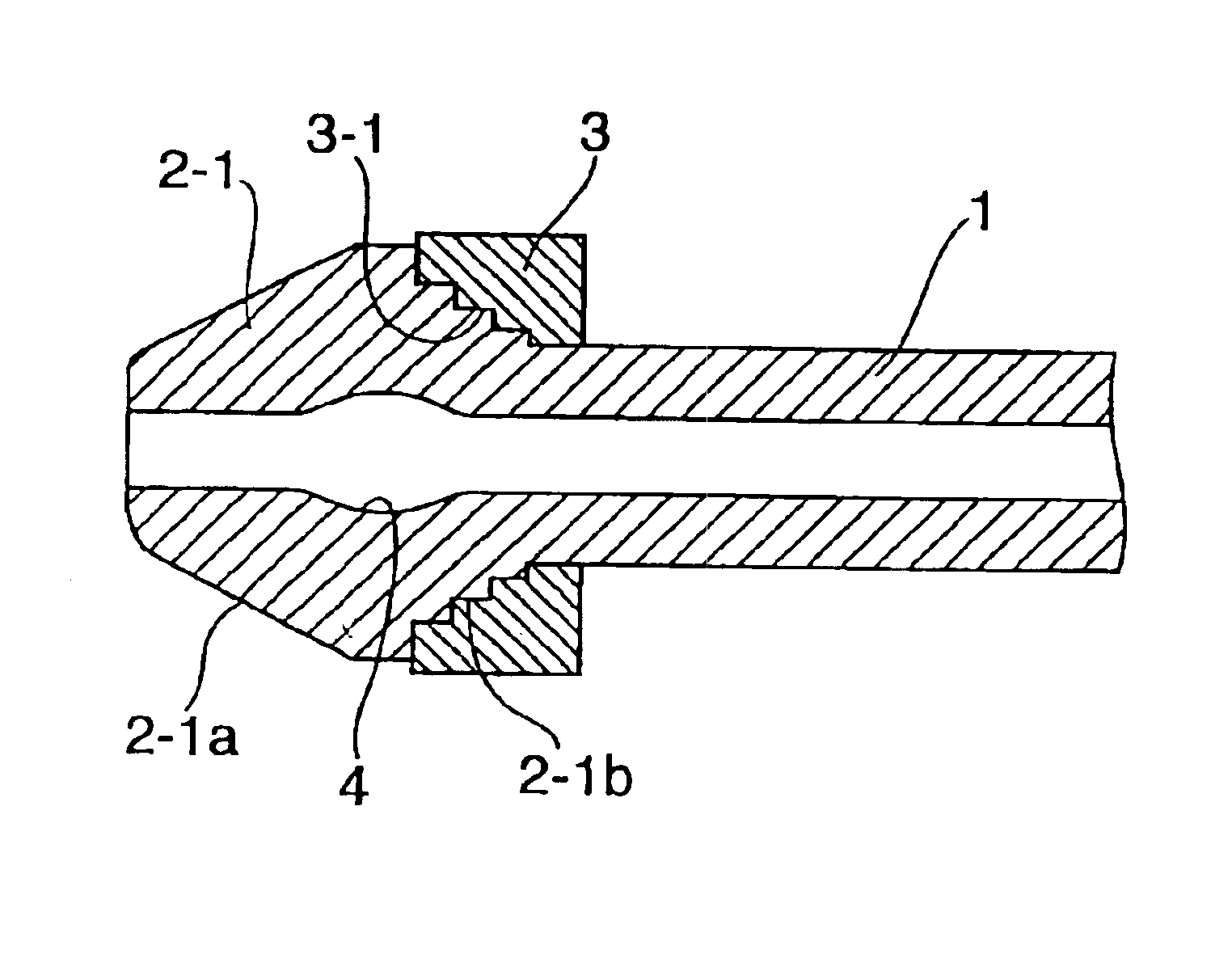

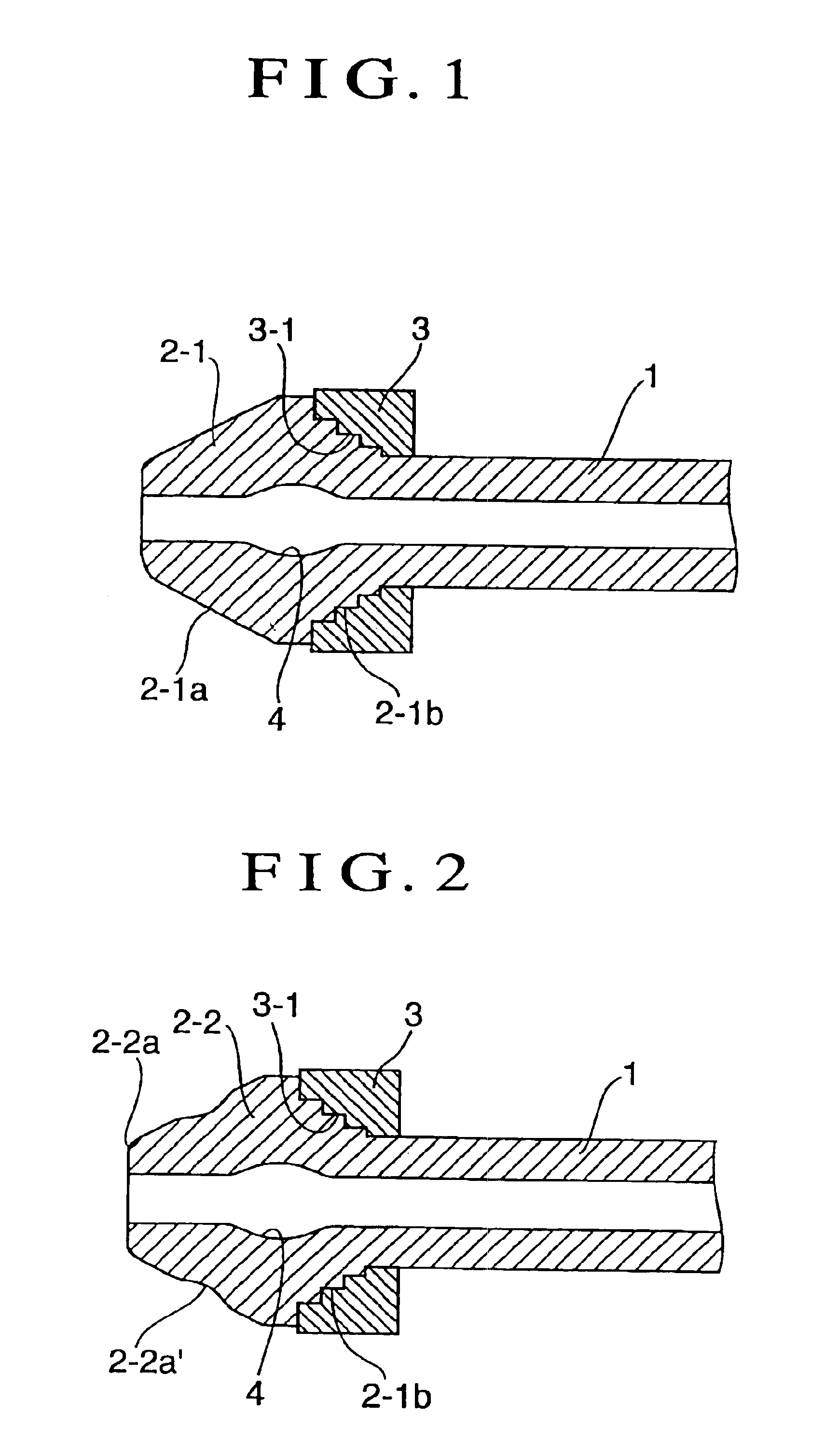

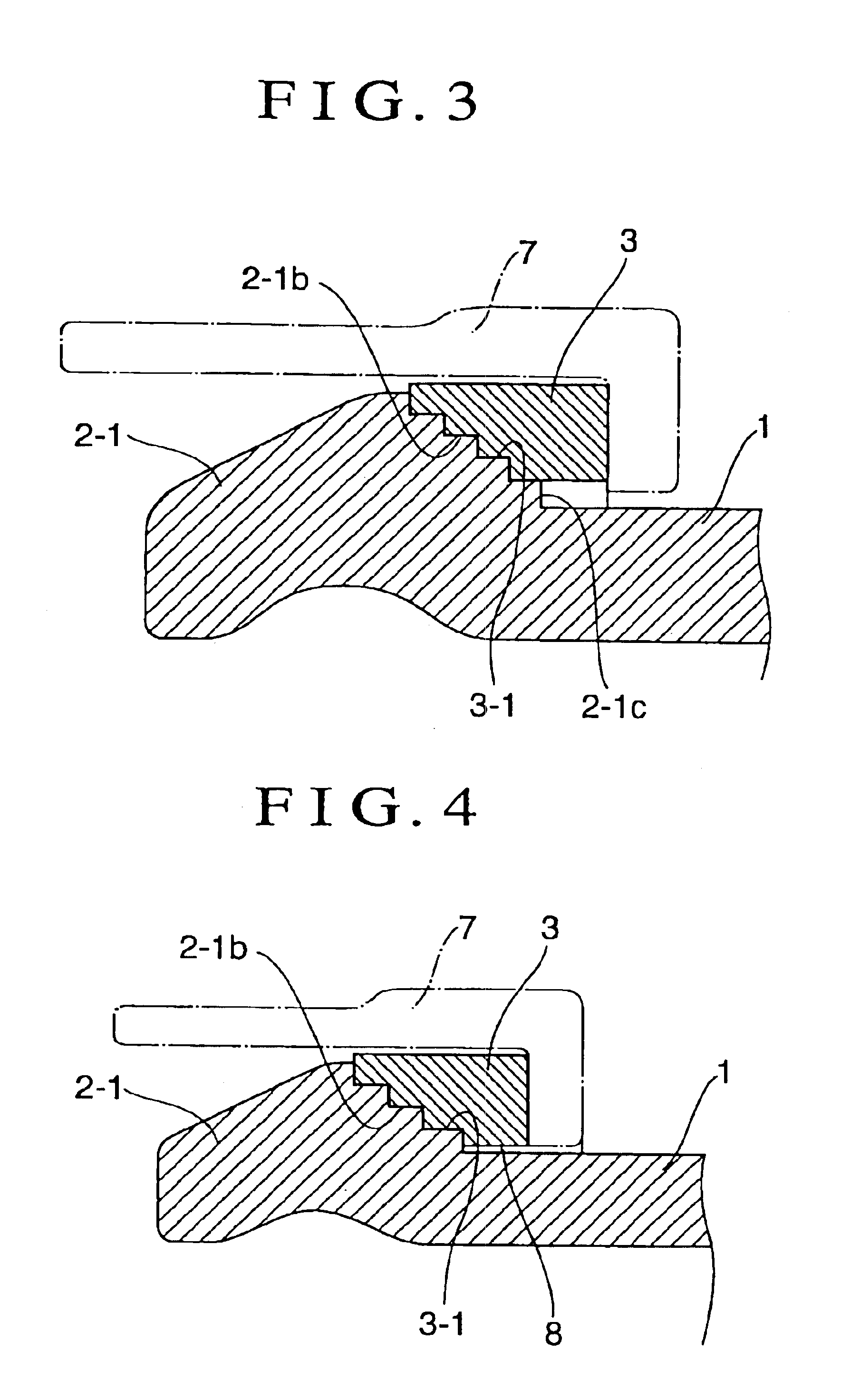

High-pressure fuel injection pipe having connecting head

InactiveUS6935377B2Reduce the possibilityWell formedFlanged jointsFluid pressure sealed jointsHigh pressureFuel injection

A high-pressure fuel injection pipe has a connecting head with an outer circumference formed for a mating seat portion. A shallow annular groove is formed in the inner side of the connecting head while shaping the head. A connecting washer is fit on the outer circumference of the lower neck of the connecting head. The injection pipe is characterized in that the lower neck of the connecting head is provided with an at least two-stepped portion having no slope, and in that the connecting washer is provided with a stepped portion corresponding at least partially to the stepped portion of the connecting head, so that the stepped portions may abut against each other.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

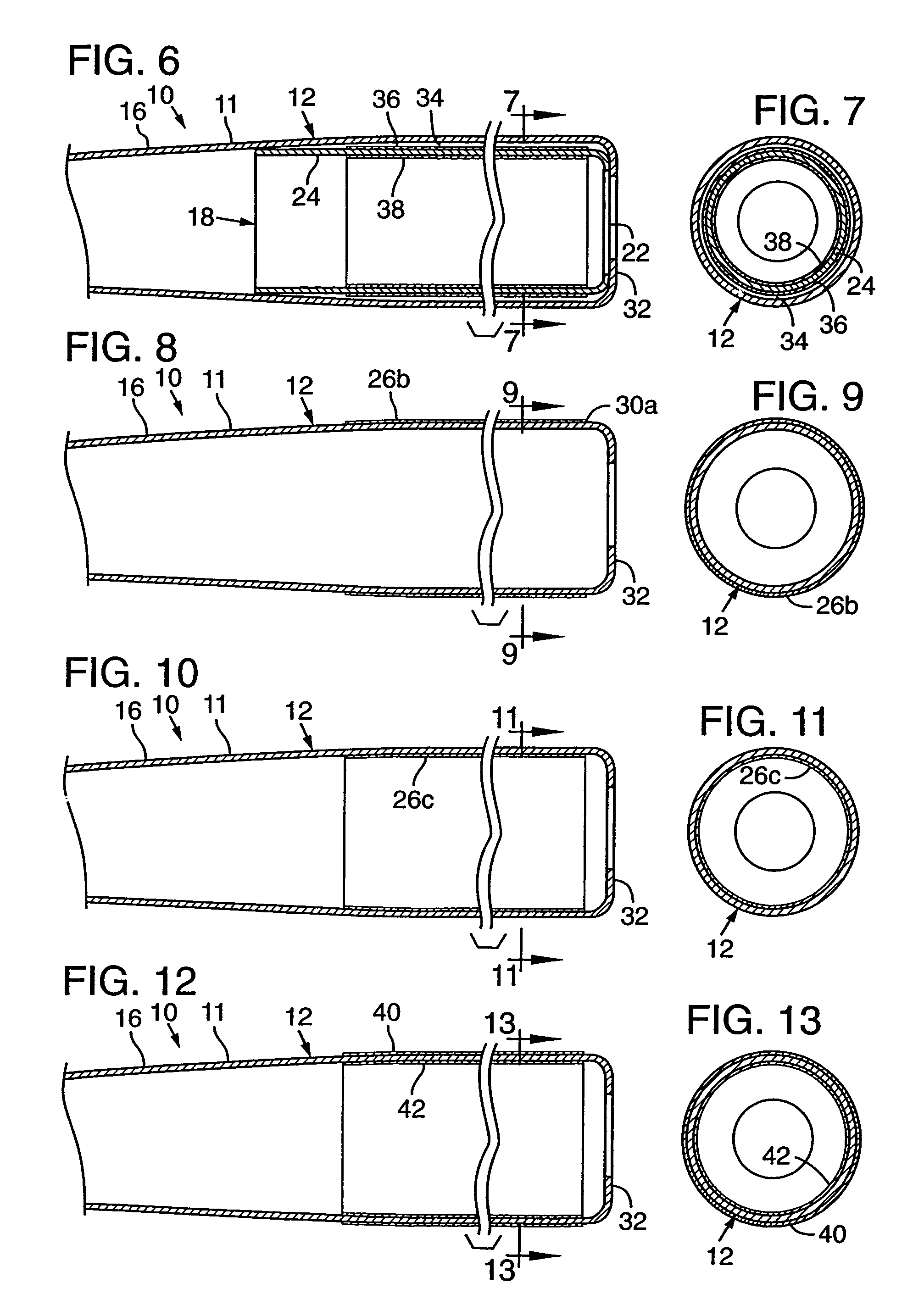

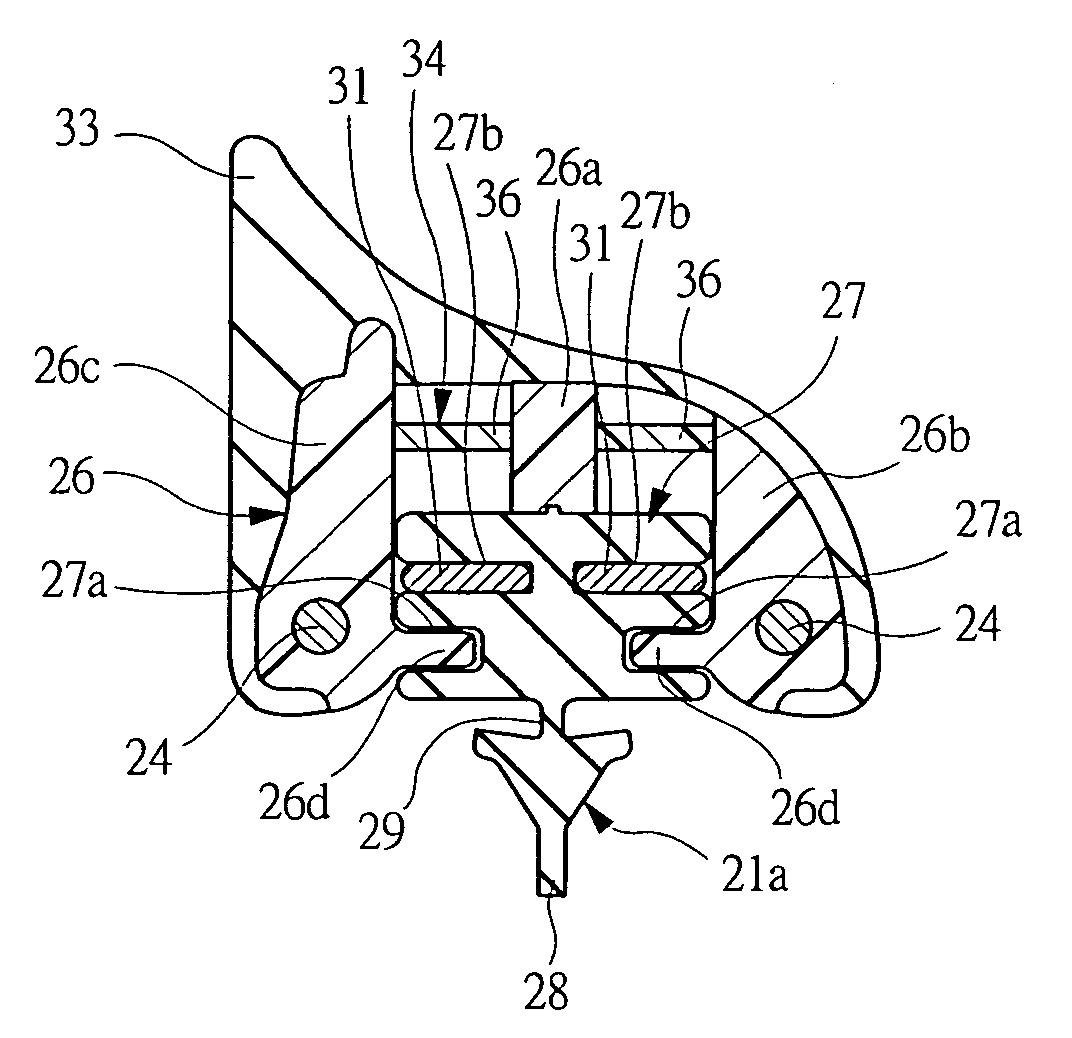

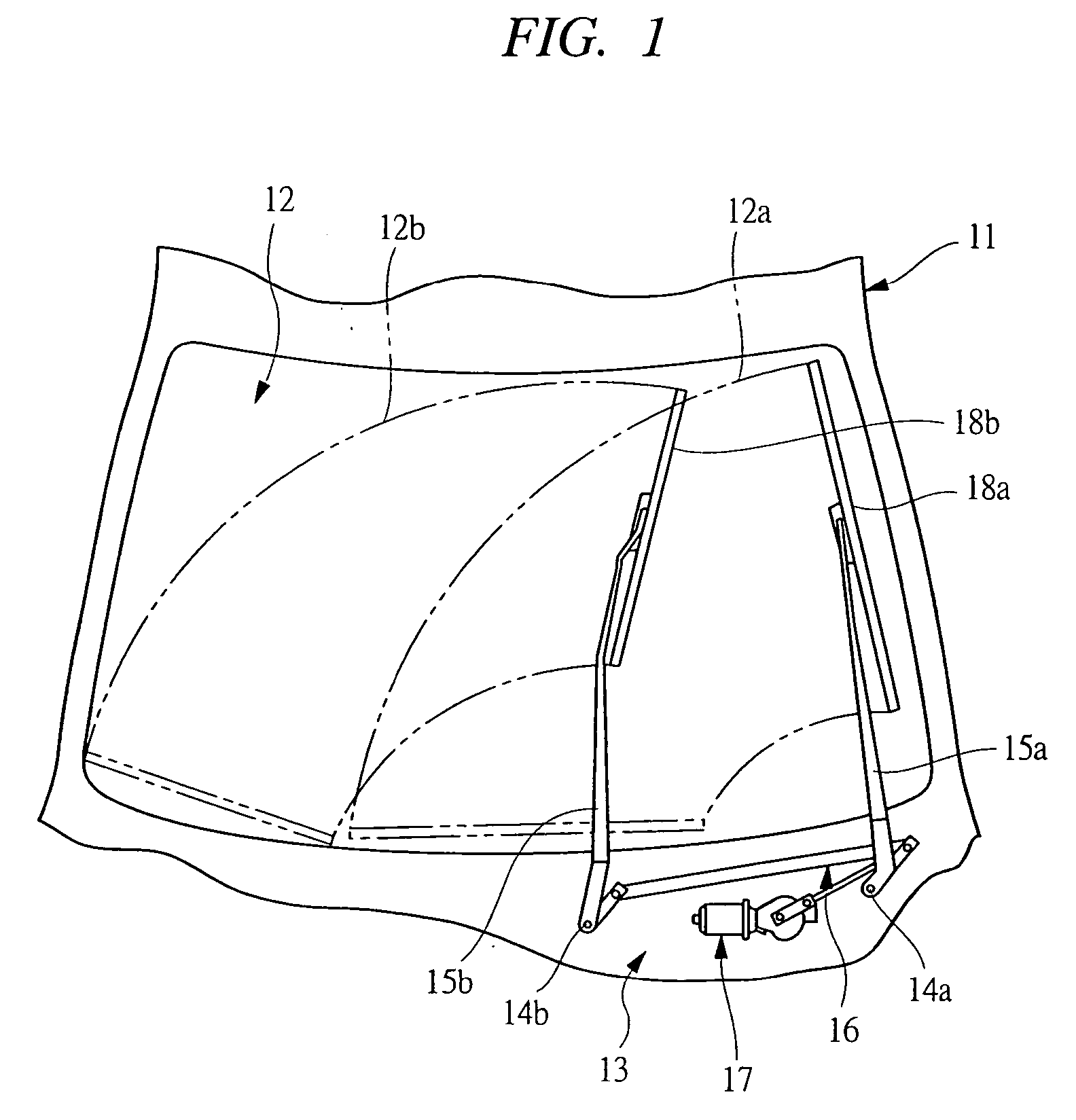

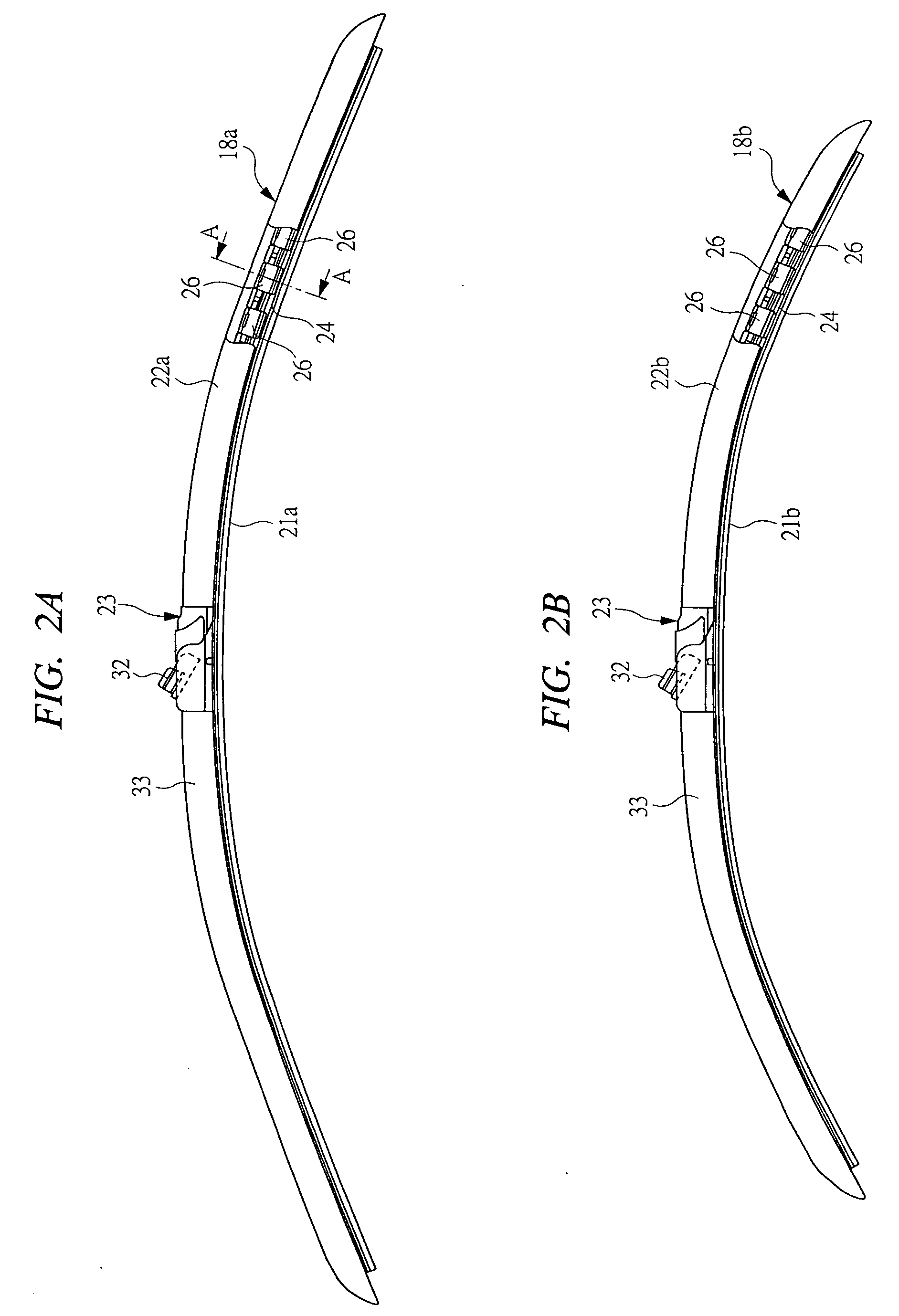

Wiper blade

InactiveUS20060090282A1Prevent permanent deformationIncreased durabilityWindow cleanersVehicle cleaningEngineeringBending force

A rubber holder on the DR side (22a) having rod-shaped spring members fixed to holding blocks and a plurality of holding bridges (26) fixed to these rod-shaped members at specified intervals is provided on a wiper blade on the DR side, and a stopper (34) is attached to the rubber holder on the DR side (22a). The stopper (34) has a plurality of deformation restricting blocks (35) disposed between engaging portions (37) formed on the holding bridges (26) and linking strip portions (36) for linking the deformation restricting blocks (35). When excessive bending force is applied to the wiper blade on the DR side, the deformation restricting blocks (35) interfere with the engaging portions (37), or the linking strip portions (36) restrict the increase of the distance between the deformation restricting blocks (35), thereby restricting the deformation of the rubber holder on the DR side (22a) within the range of elastic deformation of the rod-shaped spring members.

Owner:MITSUBA CORP

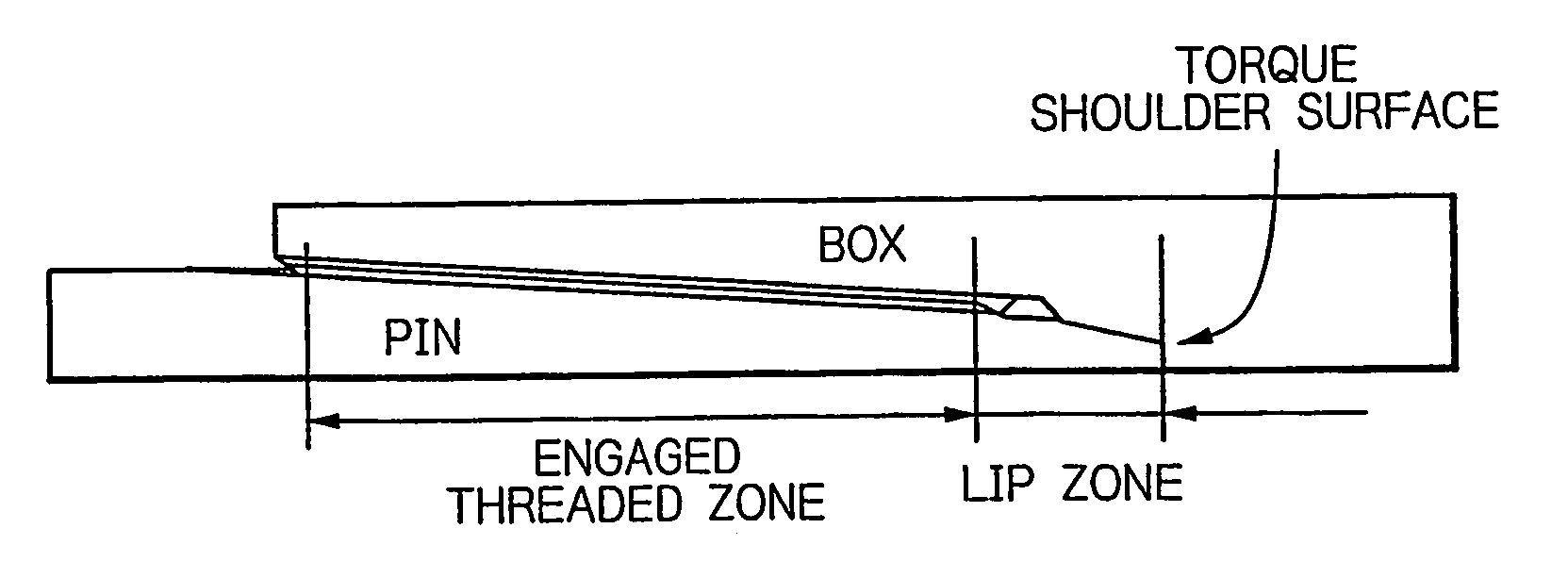

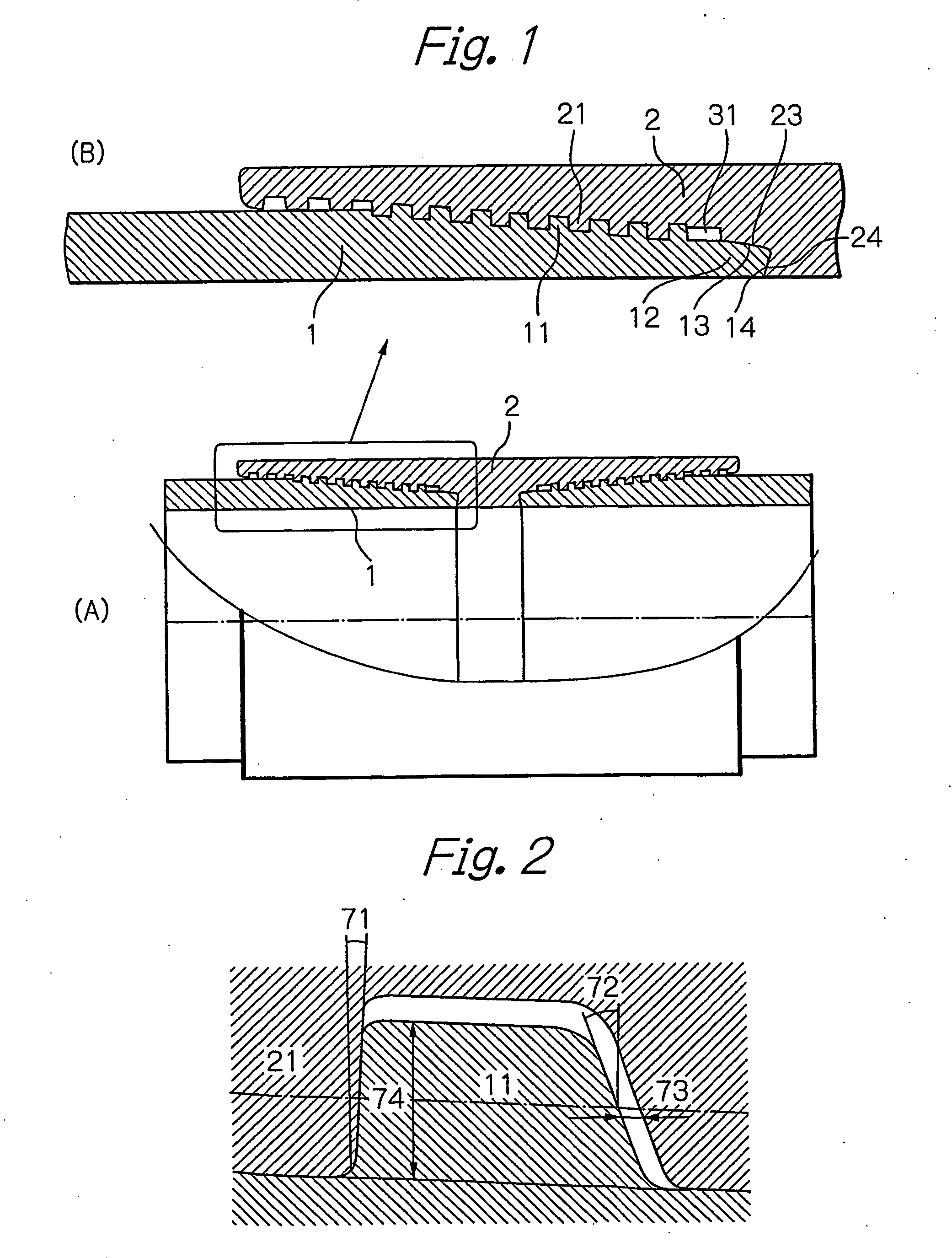

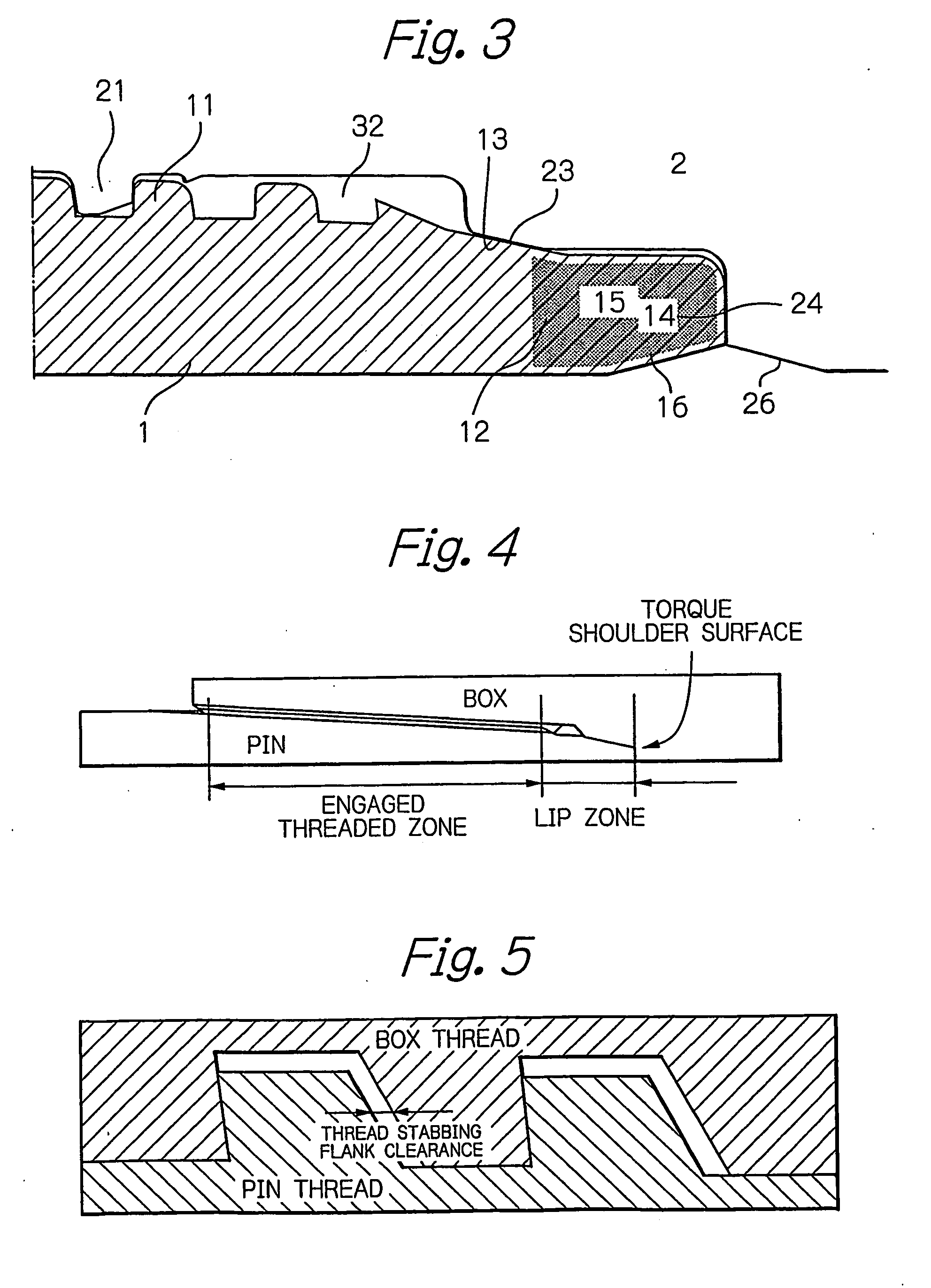

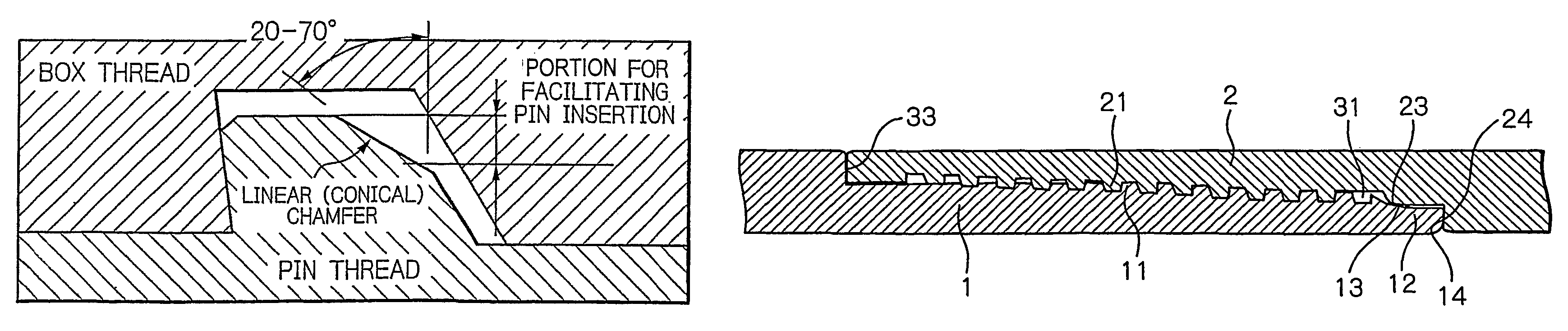

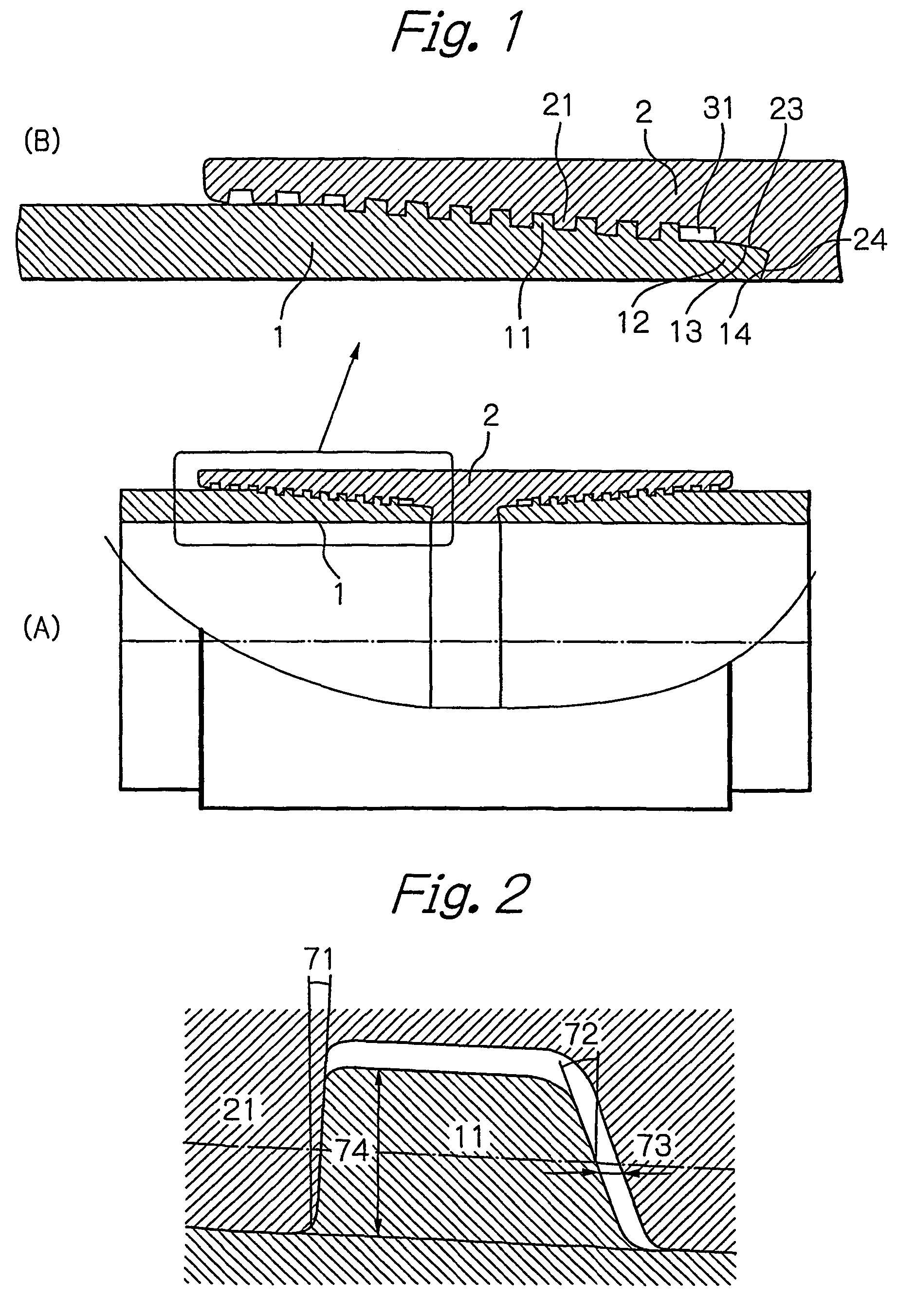

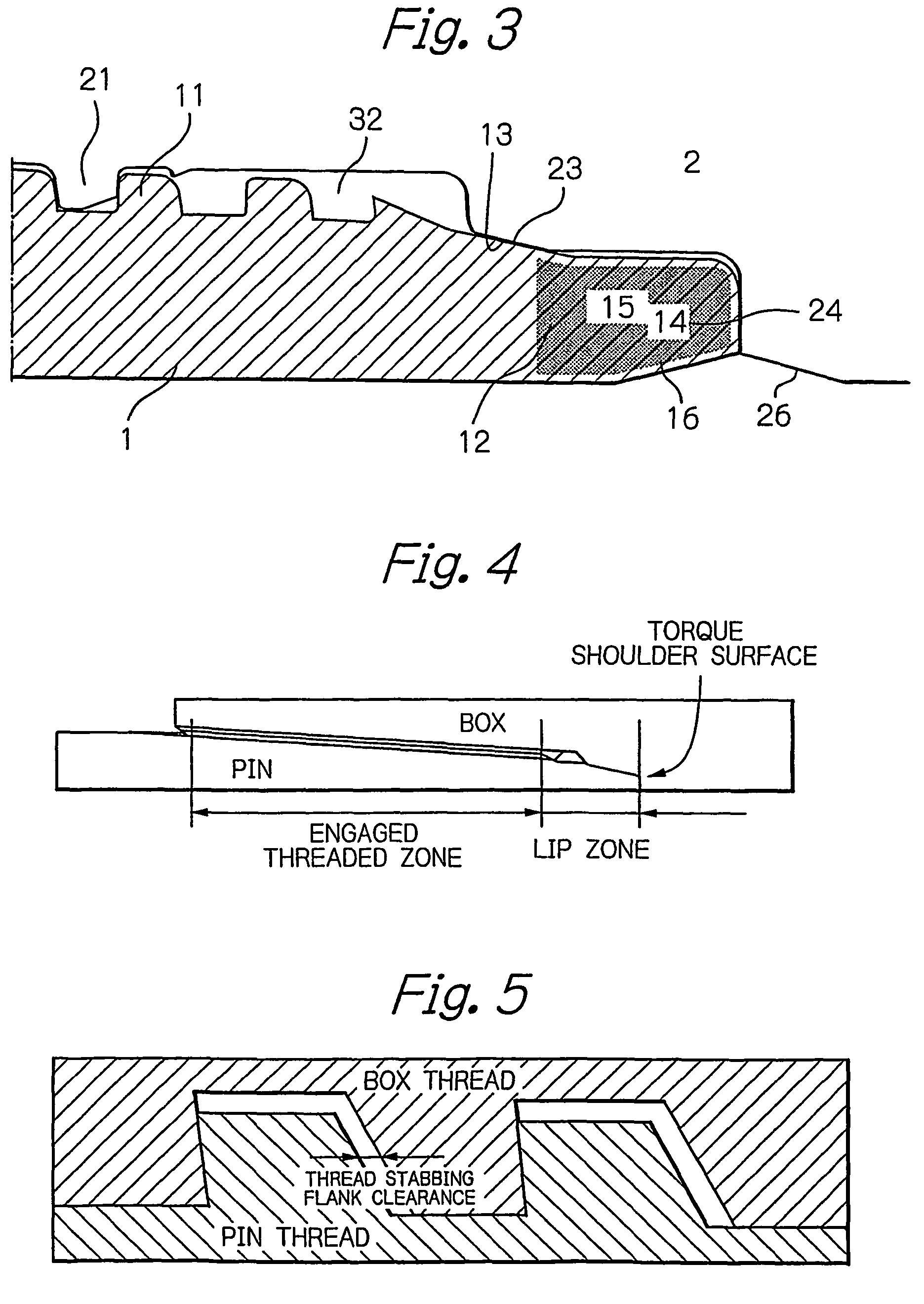

Tubular threaded joint

ActiveUS20090200798A1Reduce variationEasy to operateDrilling rodsHose connectionsEngineeringScrew thread

A tubular threaded joint which has excellent resistance to compression and which permits easy tightening operation in the field in a vertical state comprises a pin having a male threaded zone and a box having a female threaded zone. The pin or the box has an end shoulder surface on its end, and the other member has a shoulder surface which abuts against the end shoulder surface. The screw threads of the male threaded zone and the female threaded zone are trapezoidal threads having a crest, a load flank, and a stabbing flank. The lip length, which is the distance in the axial direction of a member having an end shoulder surface between the end shoulder surface and the closest engaged thread to that surface, is at least 140 times the stabbing flank clearance, which is the distance in the axial direction between the stabbing flanks of the male thread and the female thread when the load flanks of the male and female threads contact each other. The stabbing flank of the male thread is preferably chamfered.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Tubular threaded joint

ActiveUS7823931B2Improve stress resistanceIncrease contactDrilling rodsHose connectionsEngineeringScrew thread

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

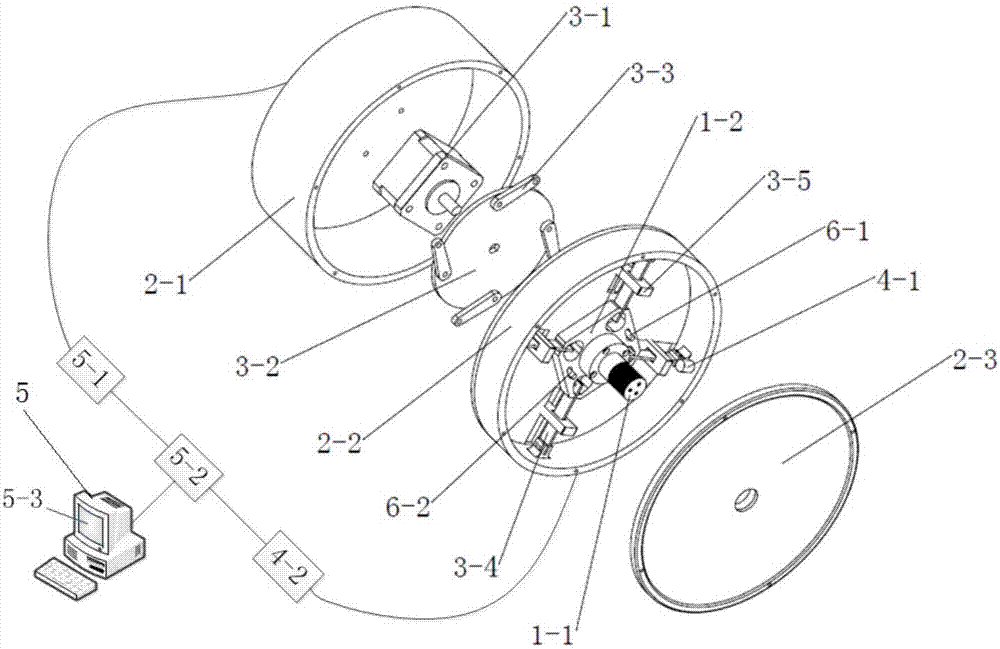

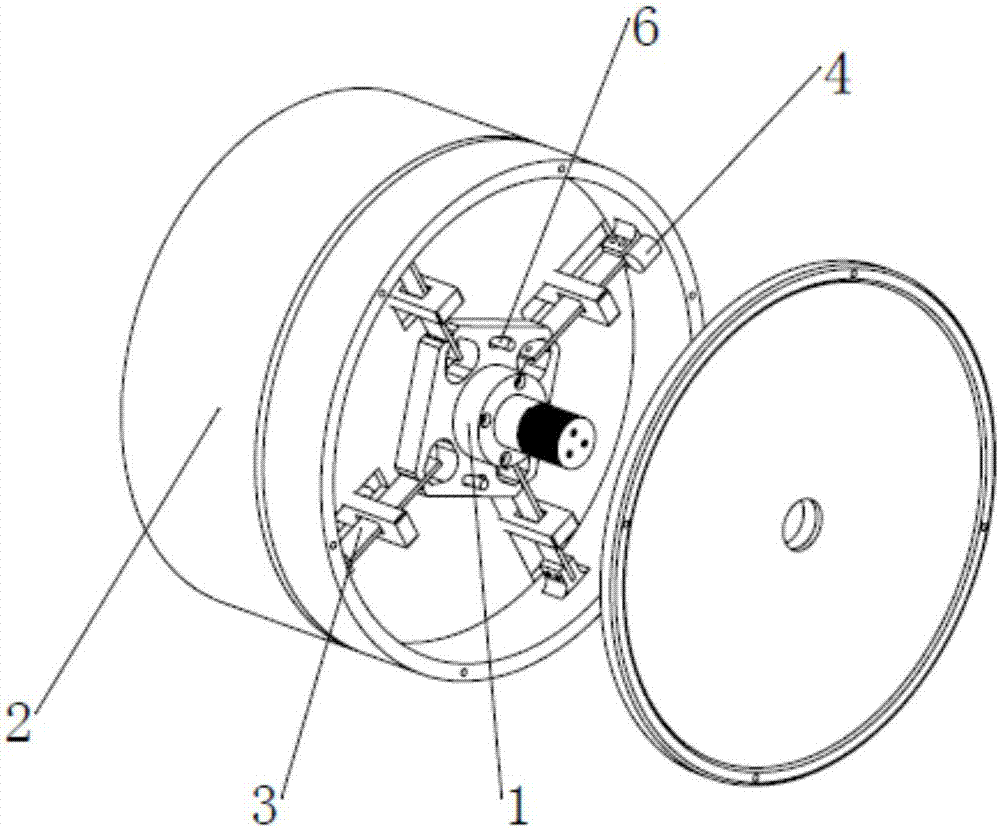

Variable-rigidity flexible joint based on leaf springs and control method of variable-rigidity flexible joint

ActiveCN108000554AAchieve self-protectionControl the amount of bendingProgramme-controlled manipulatorJointsVariable stiffnessControl system

The invention discloses a variable-rigidity flexible joint based on leaf springs. The variable-rigidity flexible joint based on the leaf springs comprises an input shaft, an output shaft, a rigidity adjustment mechanism, a displacement detection system and a control system. The input shaft comprises a first input shaft body and a second input shaft body. The output shaft comprises a first output shaft body, a second output shaft body and an output end cover. The rigidity adjustment mechanism comprises a control motor, an indexing disc, a connecting rod set, a leaf spring set and a sliding block set. The input shaft and the output shaft are matched through a revolute pair and are fixed in the revolute pair. The rigidity adjustment mechanism is installed on the output shaft. The control motor of the rigidity adjustment mechanism is fixed to the bottom of the first output shaft body. The leaf spring set is fixed to the inner side of the second output shaft body. The sliding block set is installed in sliding grooves of the second output shaft body. The variable-rigidity flexible joint based on the leaf springs is simple in structure, can be made small and is easy to control; and meanwhile, the rigidity can be adjusted linearly, the adjustment precision is high, errors are small, and the application range is wide.

Owner:CHINA UNIV OF MINING & TECH

Lens driving apparatus

ActiveUS7880982B2Low costShorten the timeProjector focusing arrangementCamera focusing arrangementCamera lensOptical axis

A lens driving apparatus may include a movable body holding lenses; a support body for supporting said movable body to move in the optical axis direction of said lenses; and a drive mechanism for driving said movable body in the optical axis direction; wherein said movable body is provided with an extension portion that is extended toward the outer periphery, and a moving path and a movement-stopping portion are formed to at least a member of said drive mechanism mounted on the support body or to said support body, said moving path allowing said extension portion to move in the optical axis direction when said movable body is moved in the optical axis direction and said movement-stopping portion regulating the moving range of said movable body as said extension portion makes contact with said movement-stopping portion.

Owner:SANKYO SEIKI MFG CO LTD

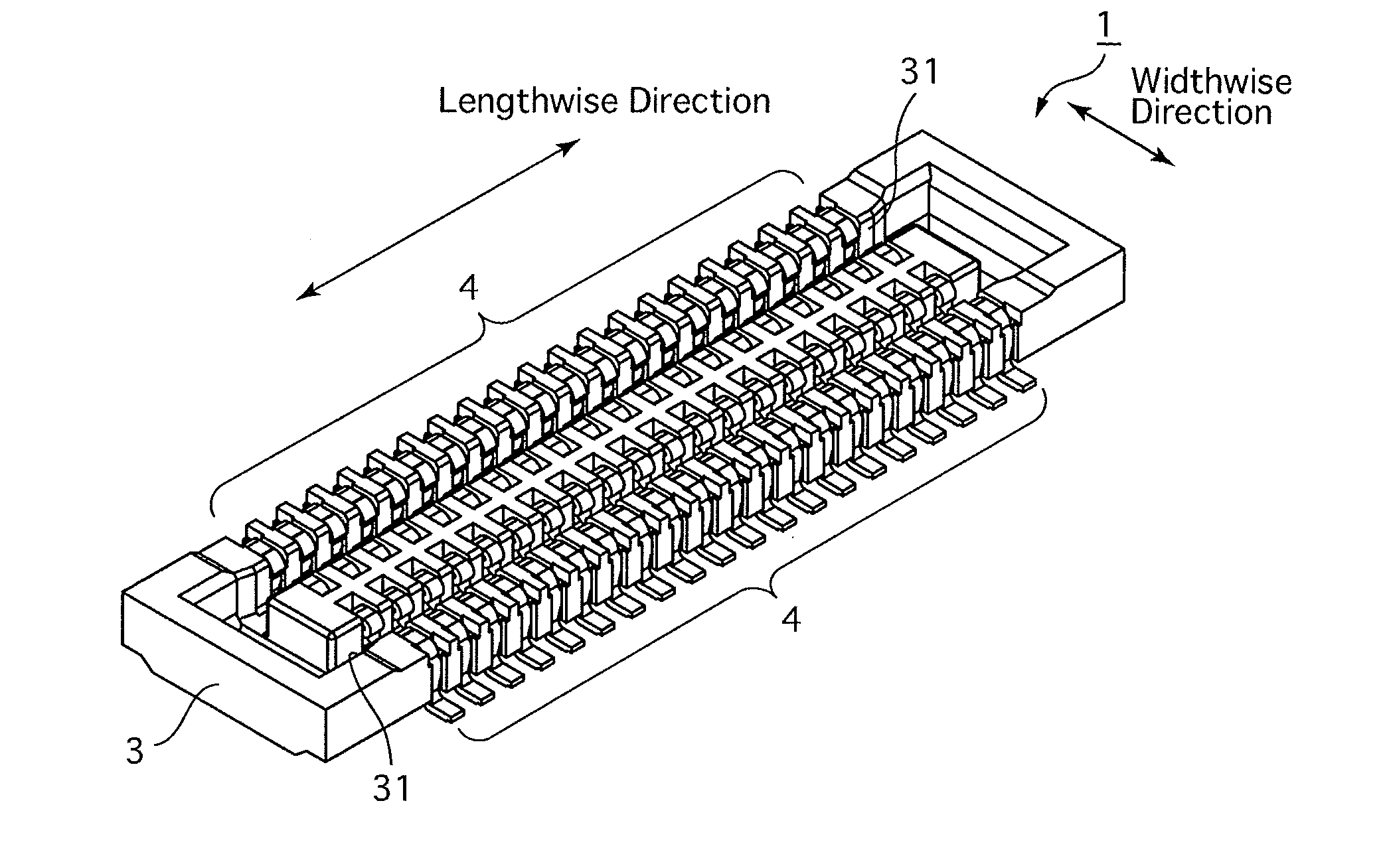

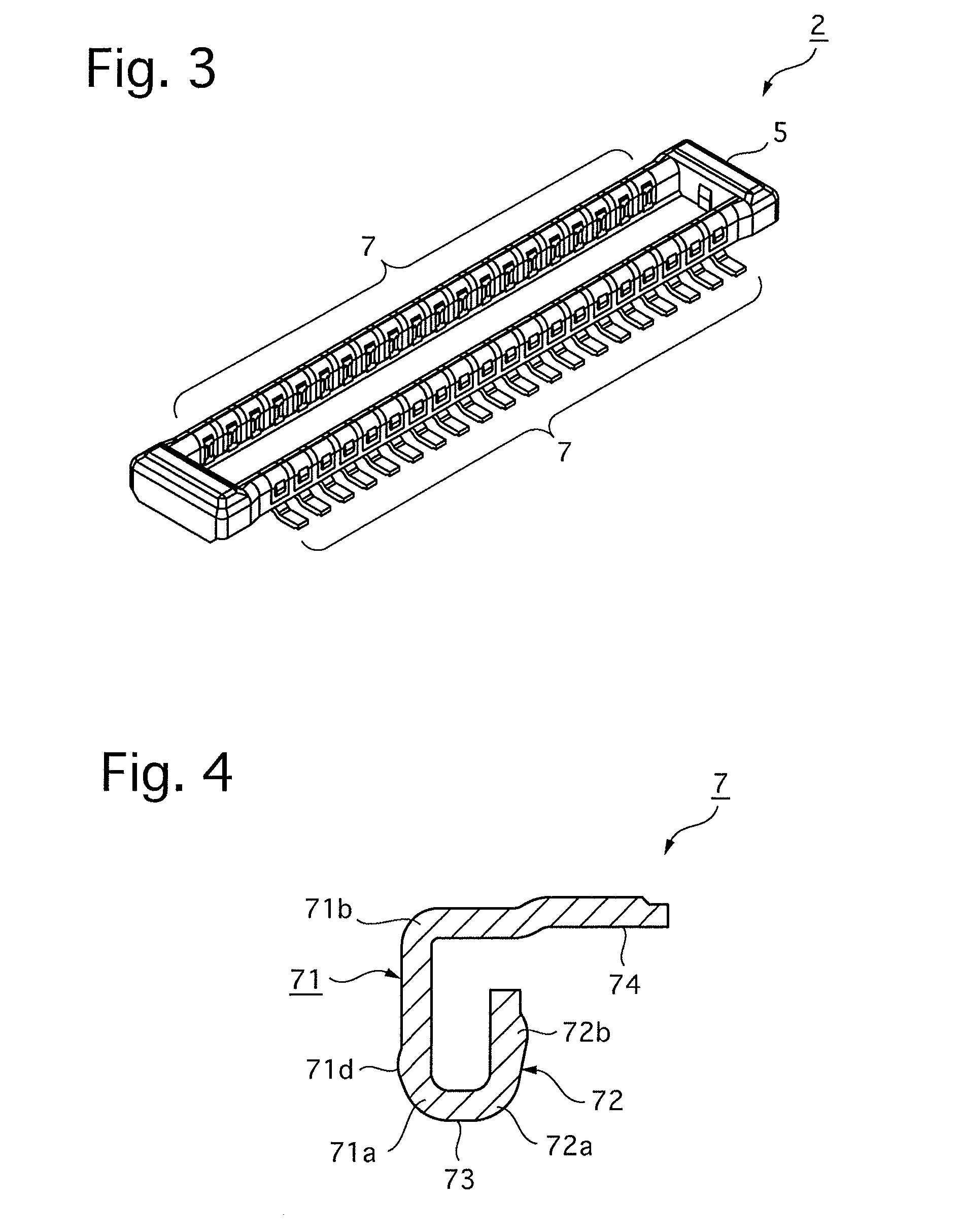

Connector, and portable terminal equipment including the connector

InactiveUS20070264854A1Improve retentionReduce the overall heightCoupling contact membersPrinted circuitsTerminal equipmentEngineering

A connector includes a plug including a plug body made of an insulating material and a plug contact; a receptacle including a receptacle body made of an insulating material and a receptacle contact, wherein the receptacle contact contacts the plug contact to be electrically connected with the plug contact when the plug is inserted into the receptacle; a plug-contact contacting portion formed on the receptacle contact for contacting the plug contact when the plug is inserted into the receptacle; an inner-wall-contacting portion extending from an end of the plug-contact contacting portion toward an inner wall of the receptacle body; and a contacting portion formed on the plug contact extending in a plug insertion / extraction direction. The first contacting portion slides on the plug-contact contacting portion and the inner-wall-contacting portion contacts the inner wall of the receptacle body when the plug is inserted in / extracted from the receptacle.

Owner:KYOCERA CORP

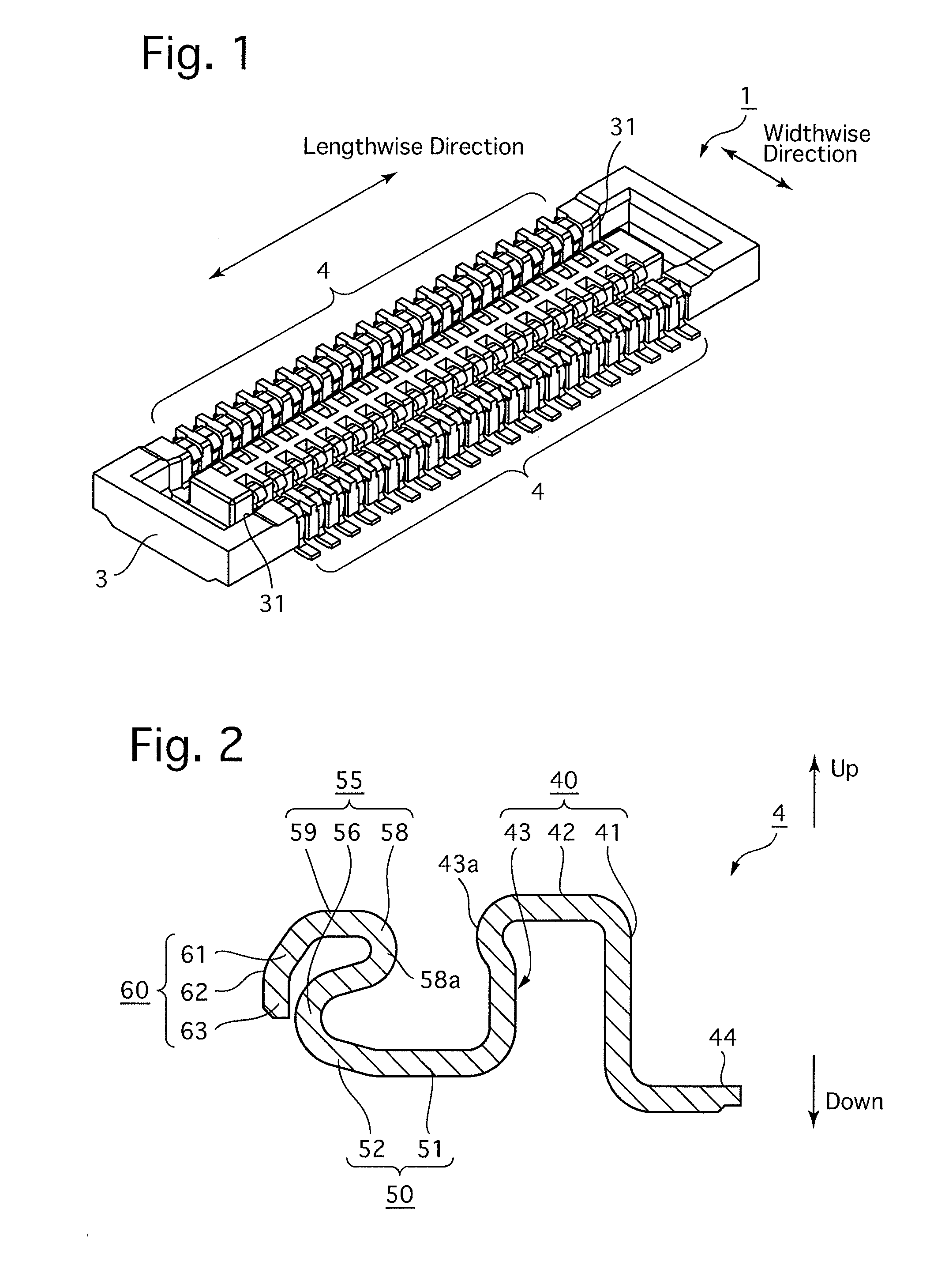

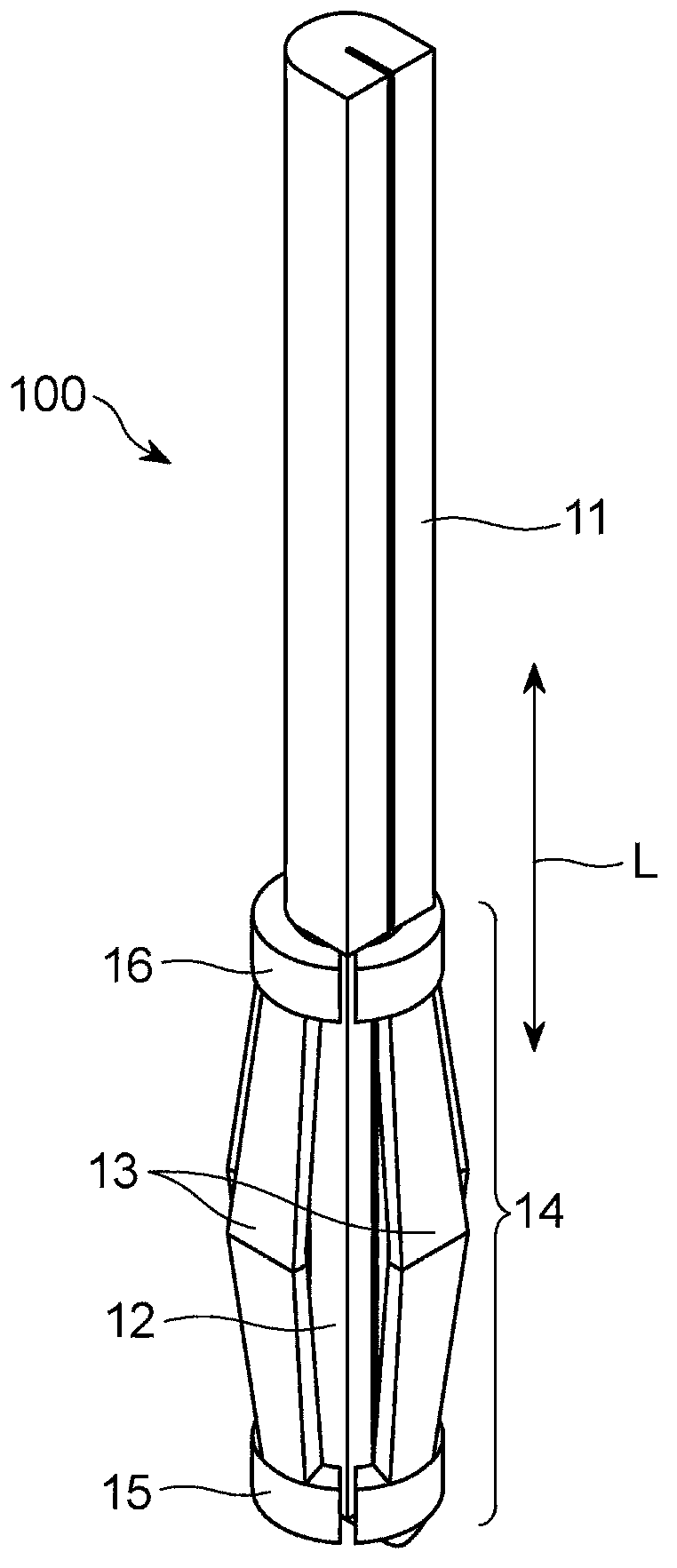

Press-fit type connector terminal

ActiveCN103311708AHigh yield strengthGood repeatabilityContact member manufacturingCoupling contact membersMechanical engineering

The press-fit type connector terminal includes a pin section having a U-shaped or quadrangular cross-section, and a contact section situated at a front end of the pin section. The contact section includes a contact piece surrounding an imaginary center line parallel to a longitudinal axis of the pin section, and a slit formed at a part of the contact piece and extending substantially parallel to the imaginary center line. The connector terminal is comprised of a single bent metal plate having elasticity.

Owner:DAIICHI SEIKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com