Patents

Literature

221results about How to "Prevent permanent deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

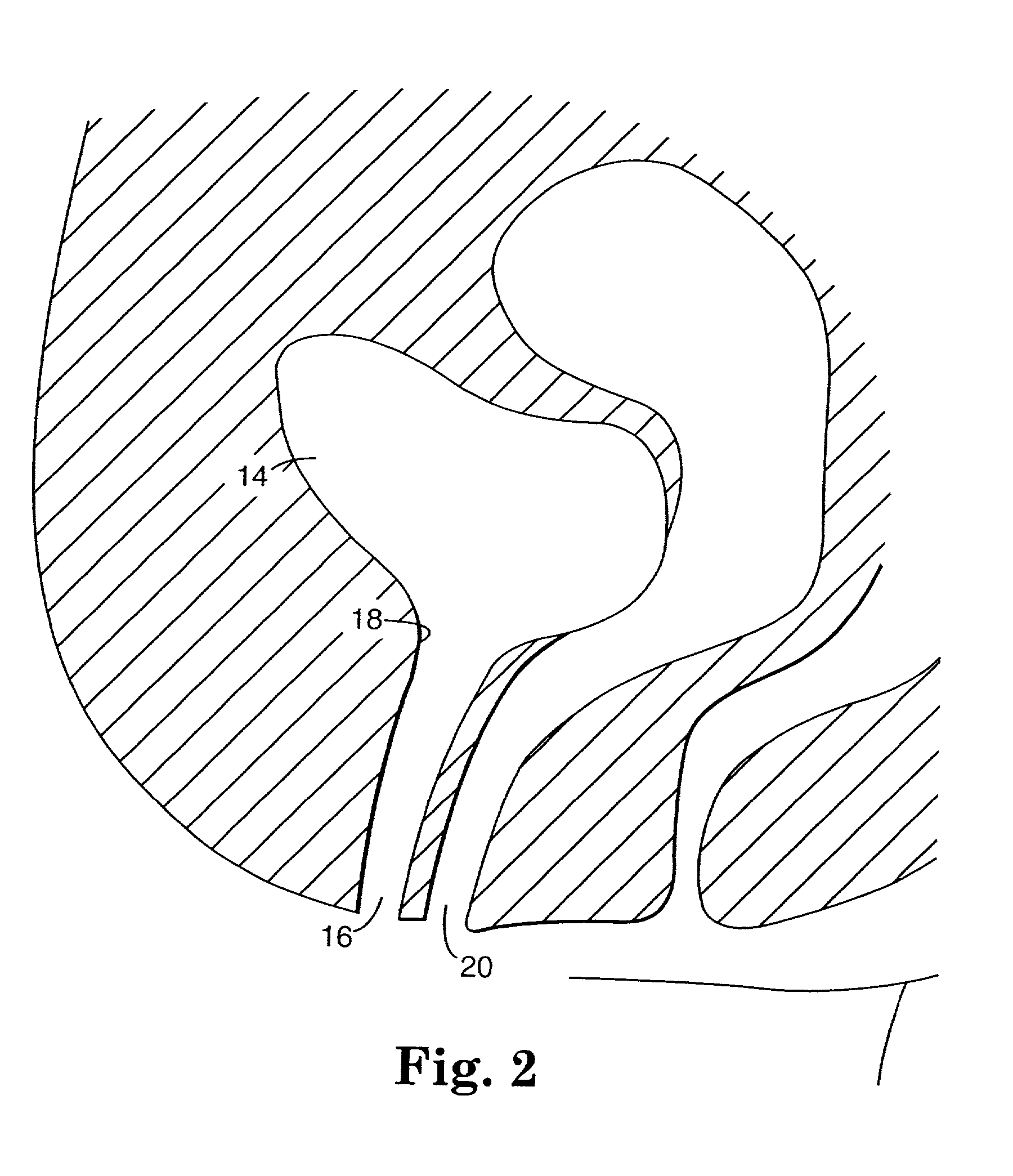

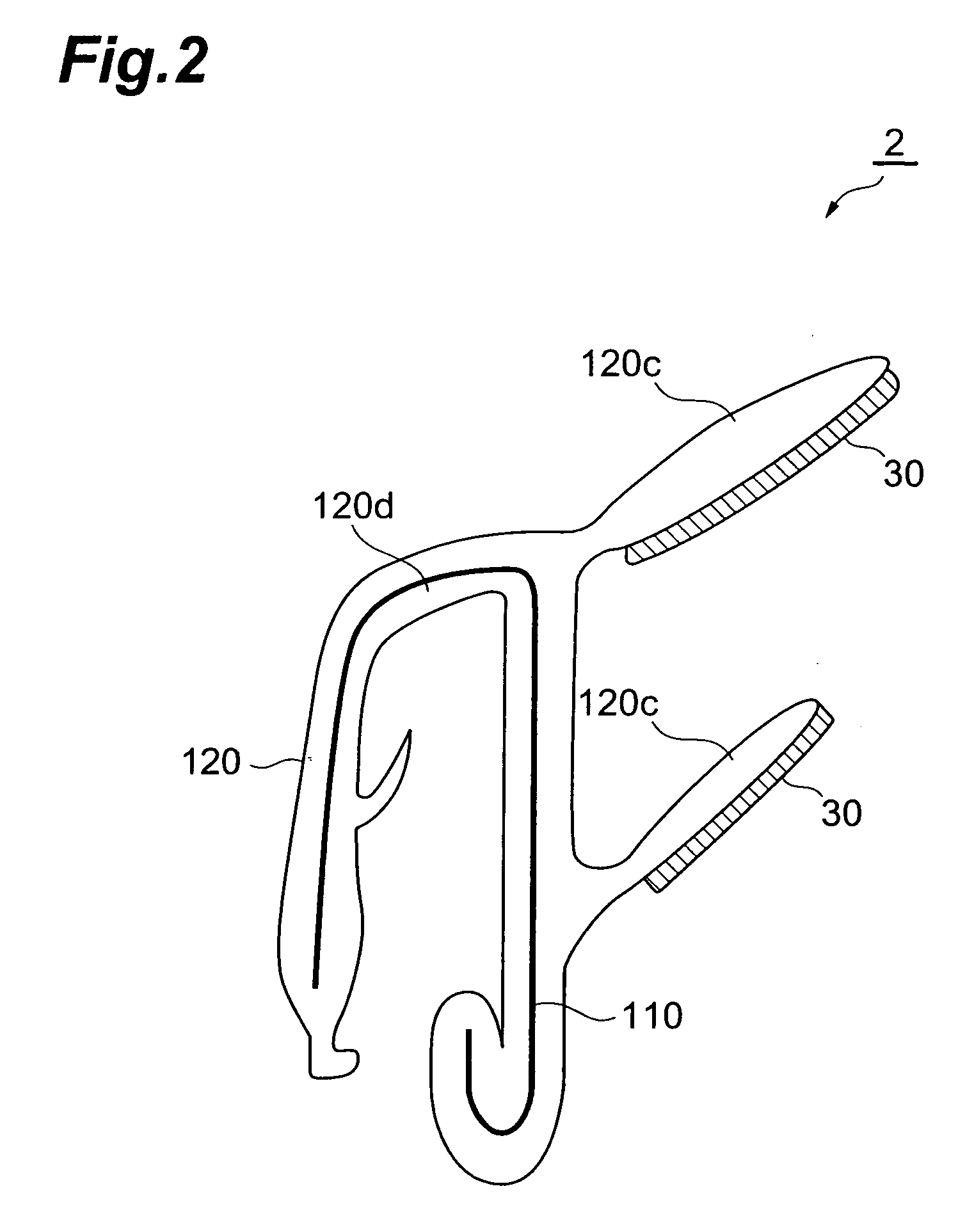

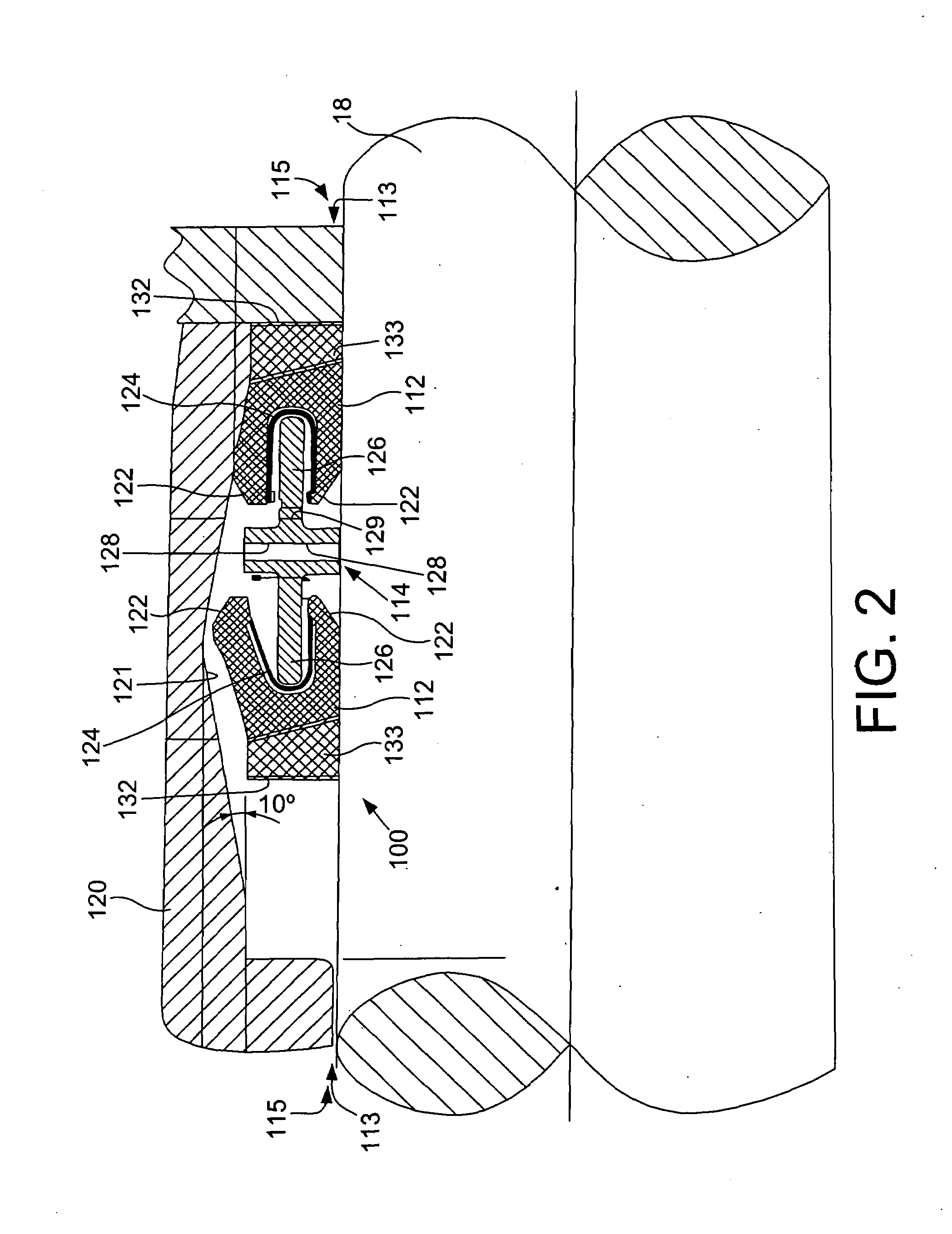

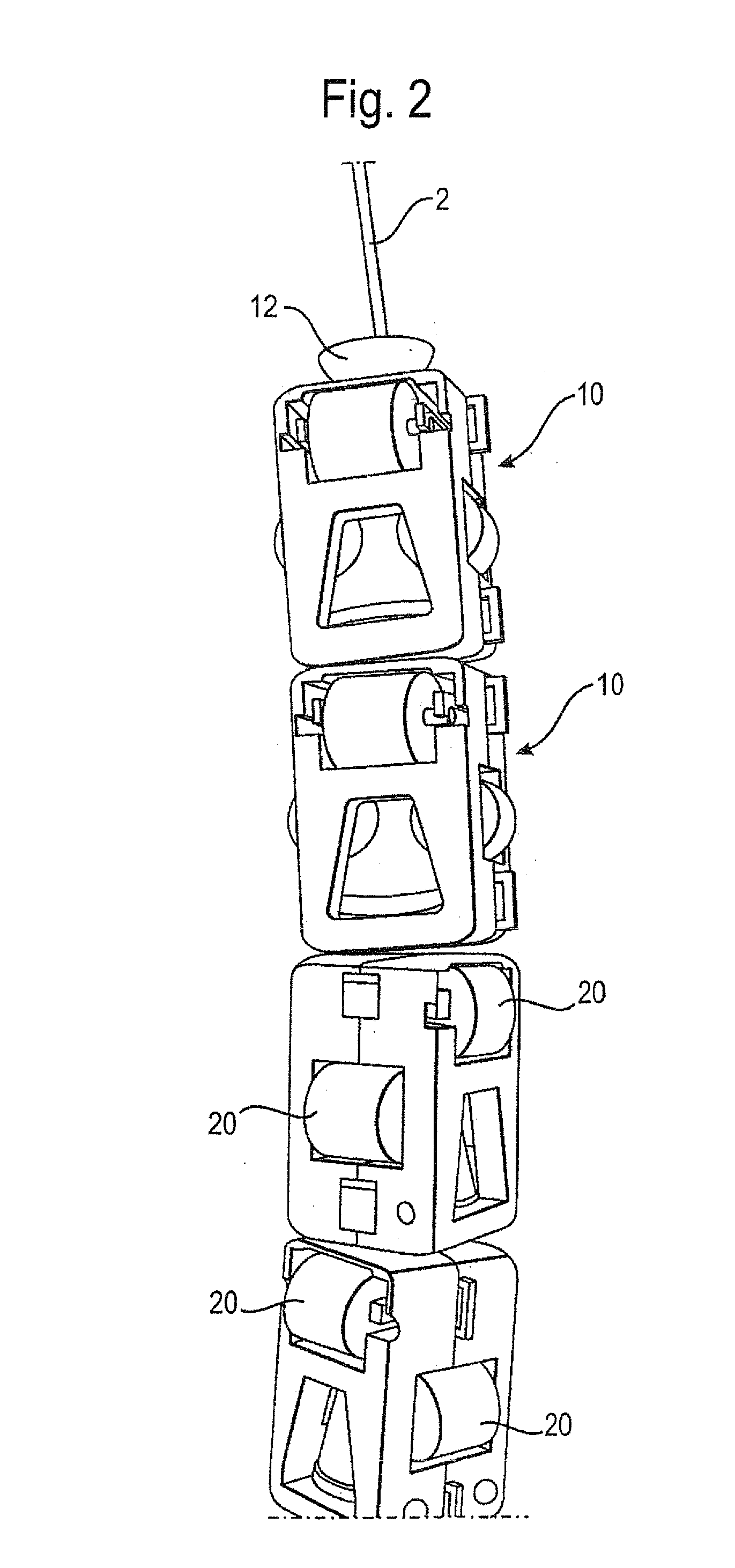

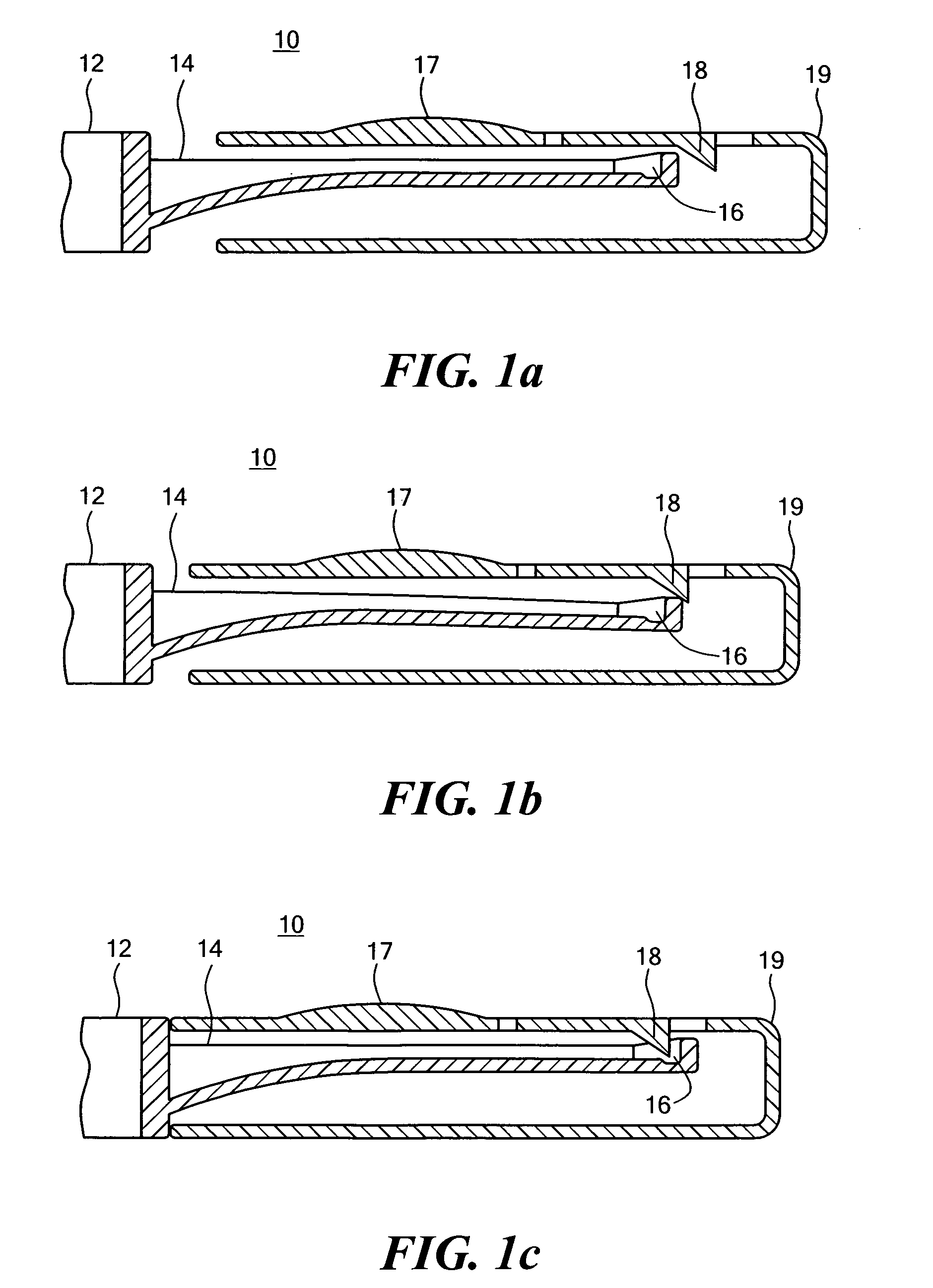

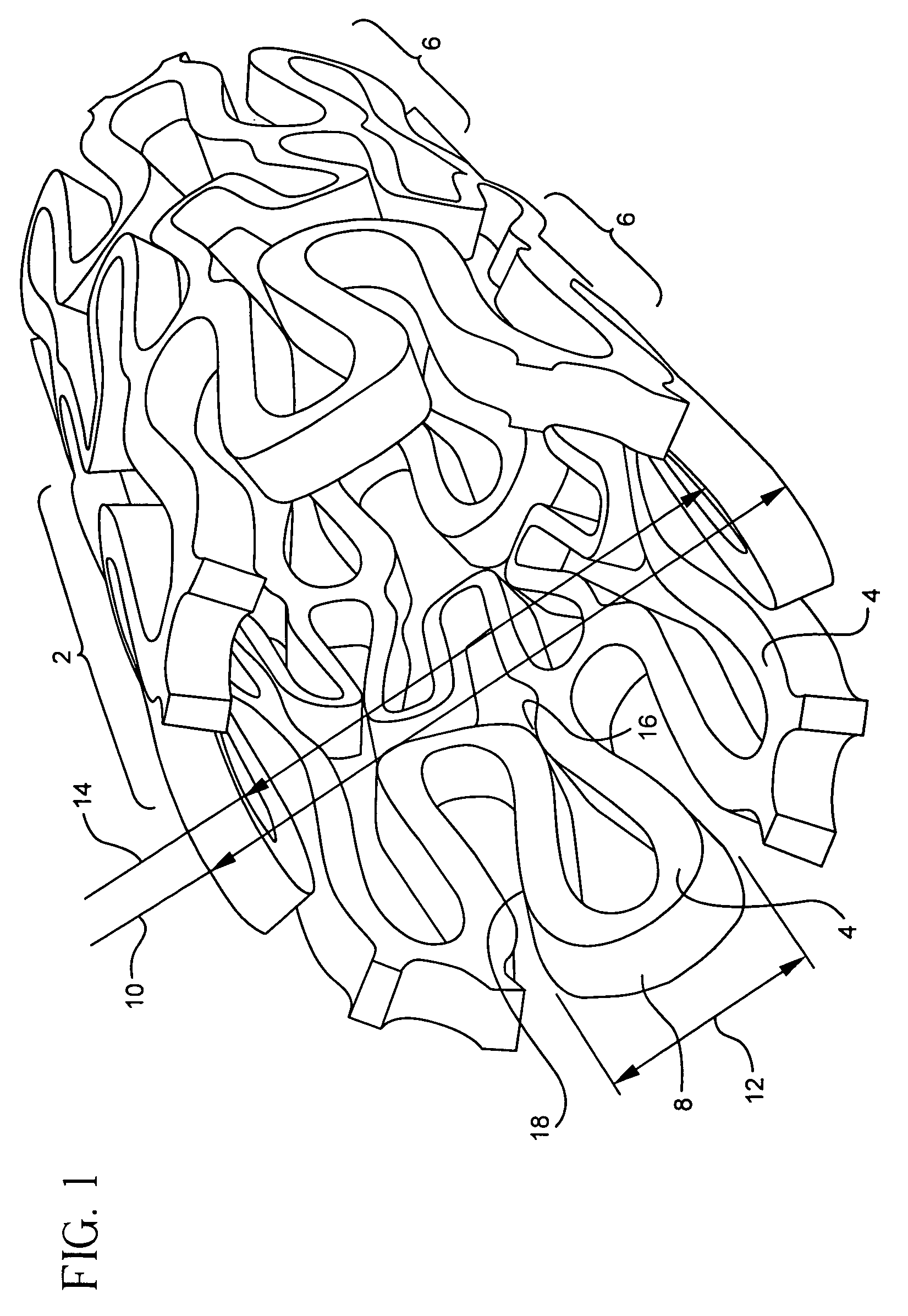

Implantable article and method for treating urinary incontinence using means for repositioning the implantable article

InactiveUS6652450B2Adversely therapeutic effectPrevent permanent deformationSuture equipmentsIncision instrumentsDiseaseUrological Disorders

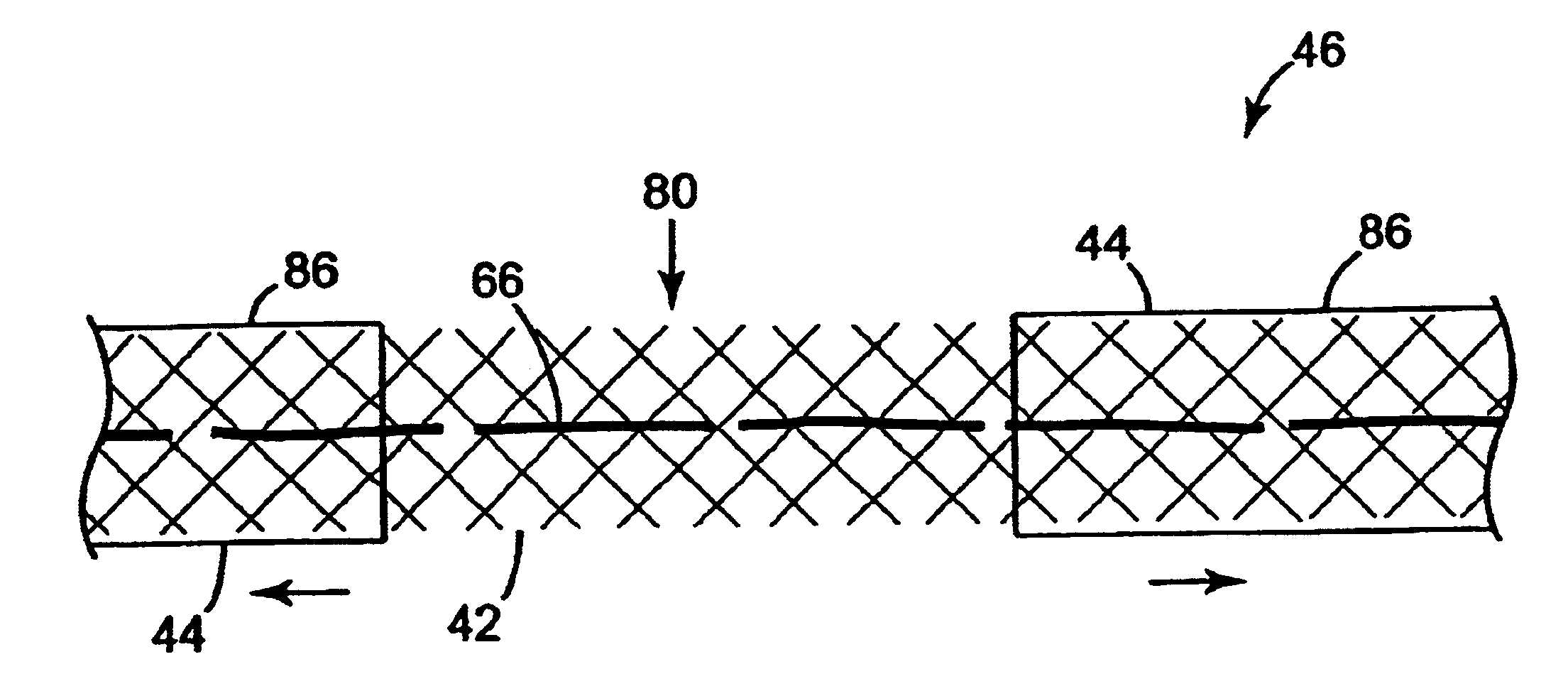

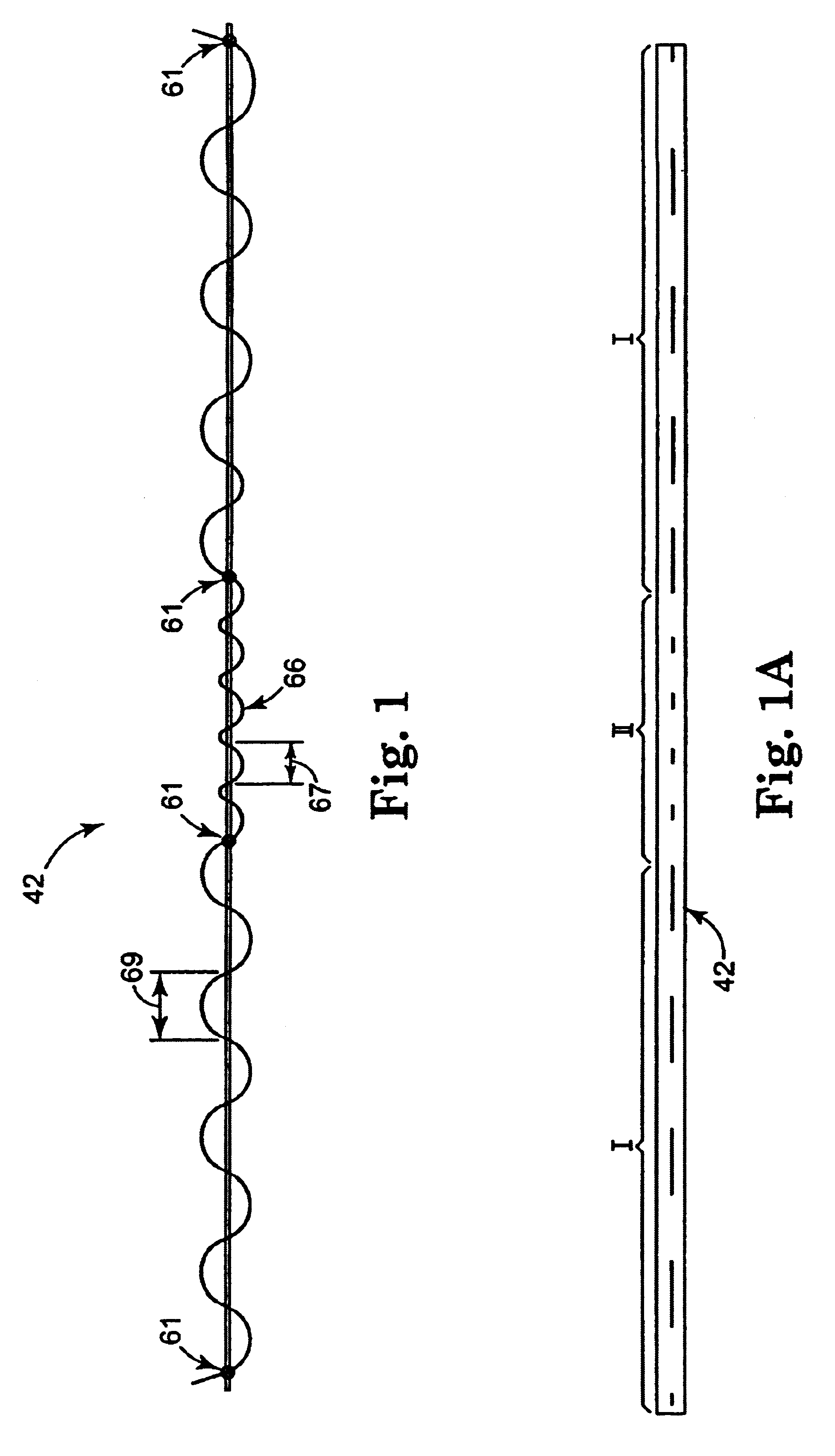

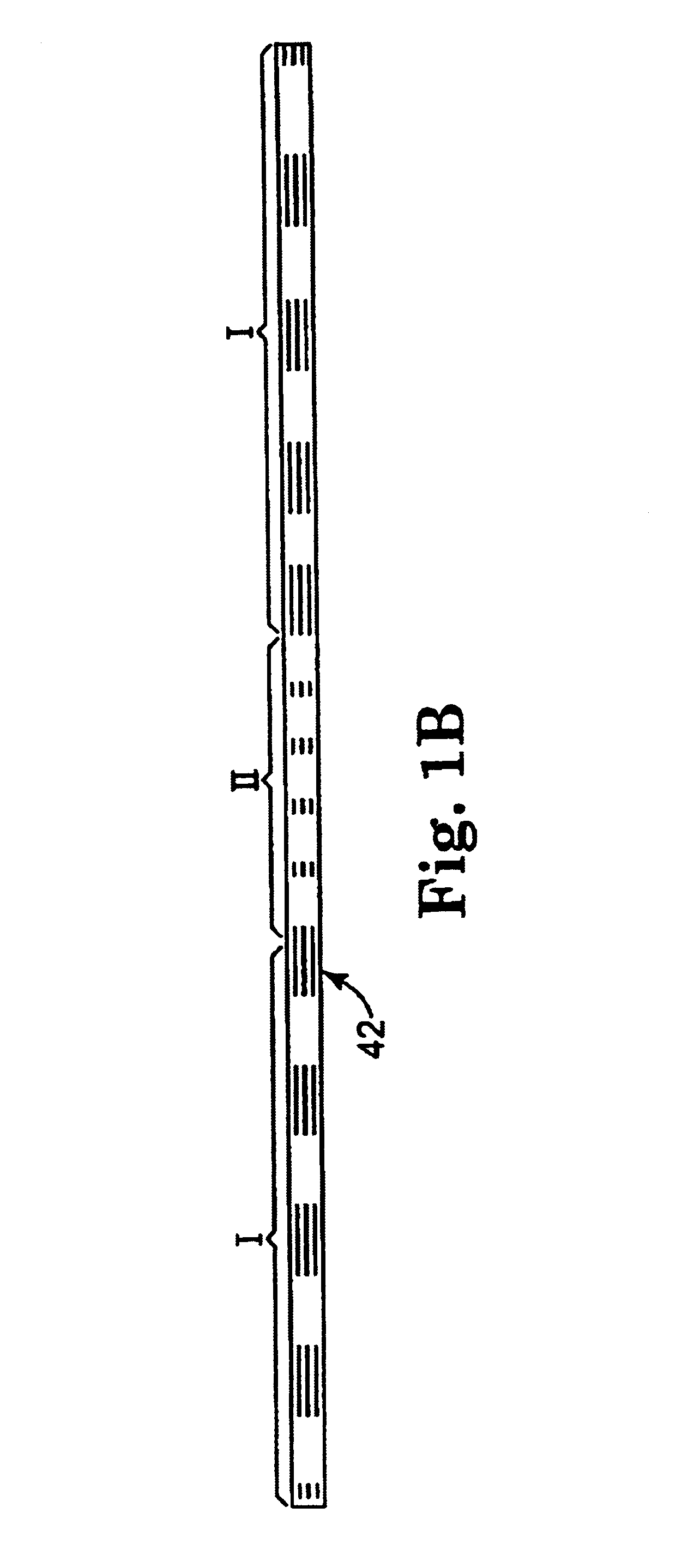

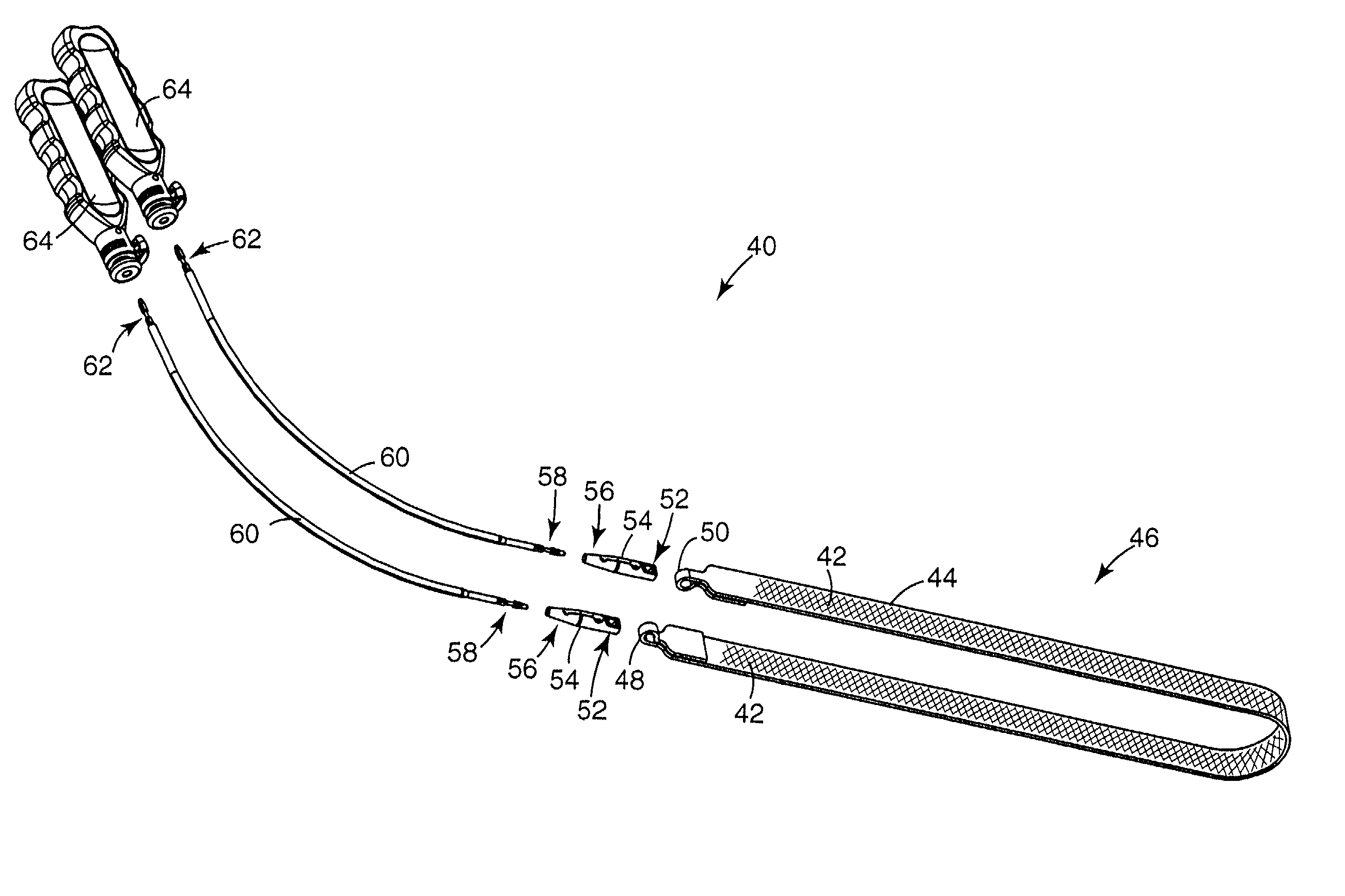

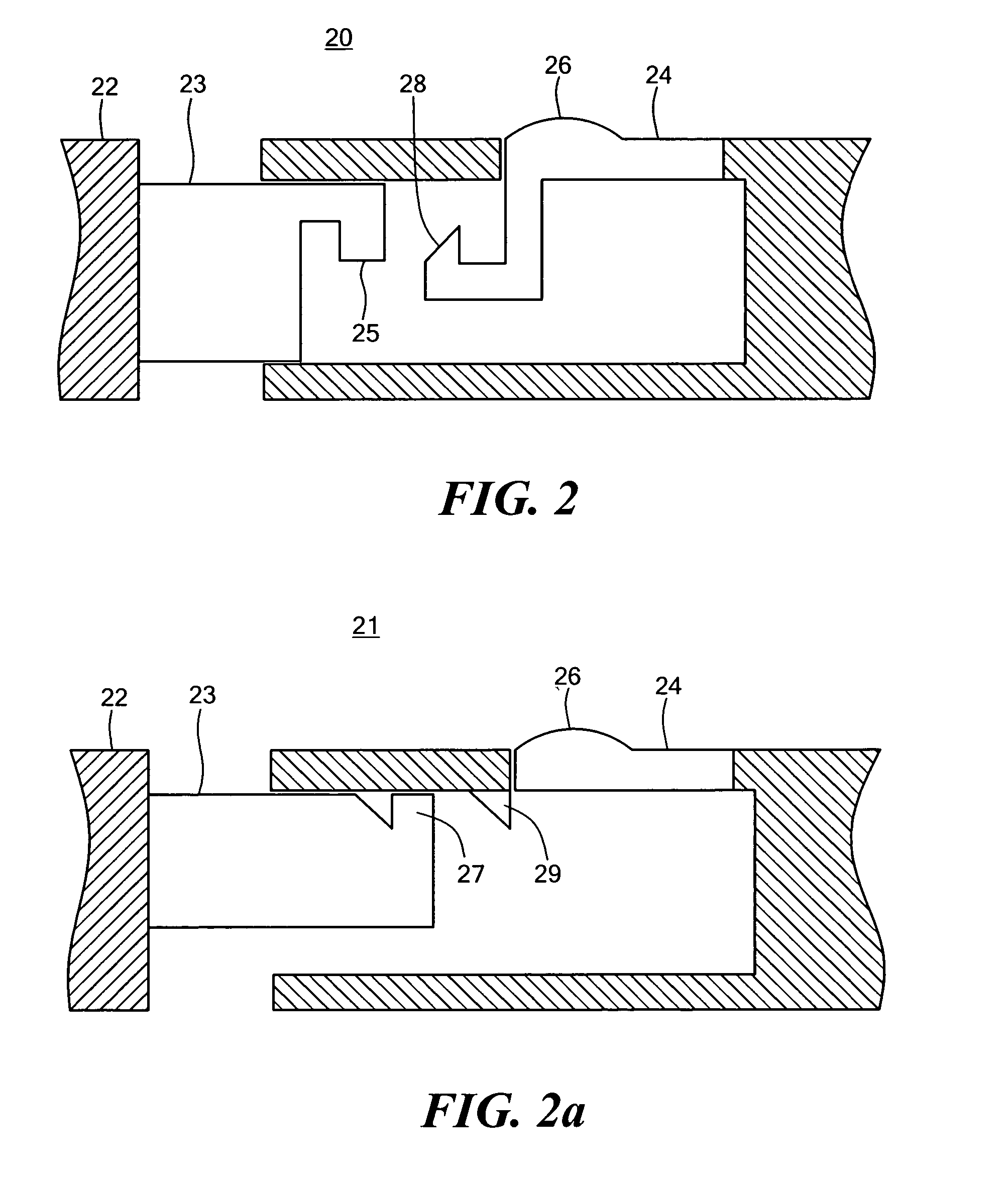

An implantable article and method of use are disclosed to treat urological disorders. The biocompatible device includes a sling assembly configured to be minimally invasive and provide sufficient support to the target site. In addition, the configuration of the sling assembly also allows the position of the sling to be permanently changed during and / or after implantation.

Owner:STASKIN DAVID MD DR

Implantable article and method

InactiveUS20020107430A1Adversely therapeutic effectPrevent permanent deformationSuture equipmentsIncision instrumentsEngineeringUrological Disorders

An implantable article and method of use are disclosed to treat urological disorders. The biocompatible device includes a sling assembly configured to be minimally invasive and provide sufficient support to the target site. In addition, the configuration of the sling assembly also allows the position of the sling to be permanently changed during and / or after implantation.

Owner:STASKIN DAVID MD DR

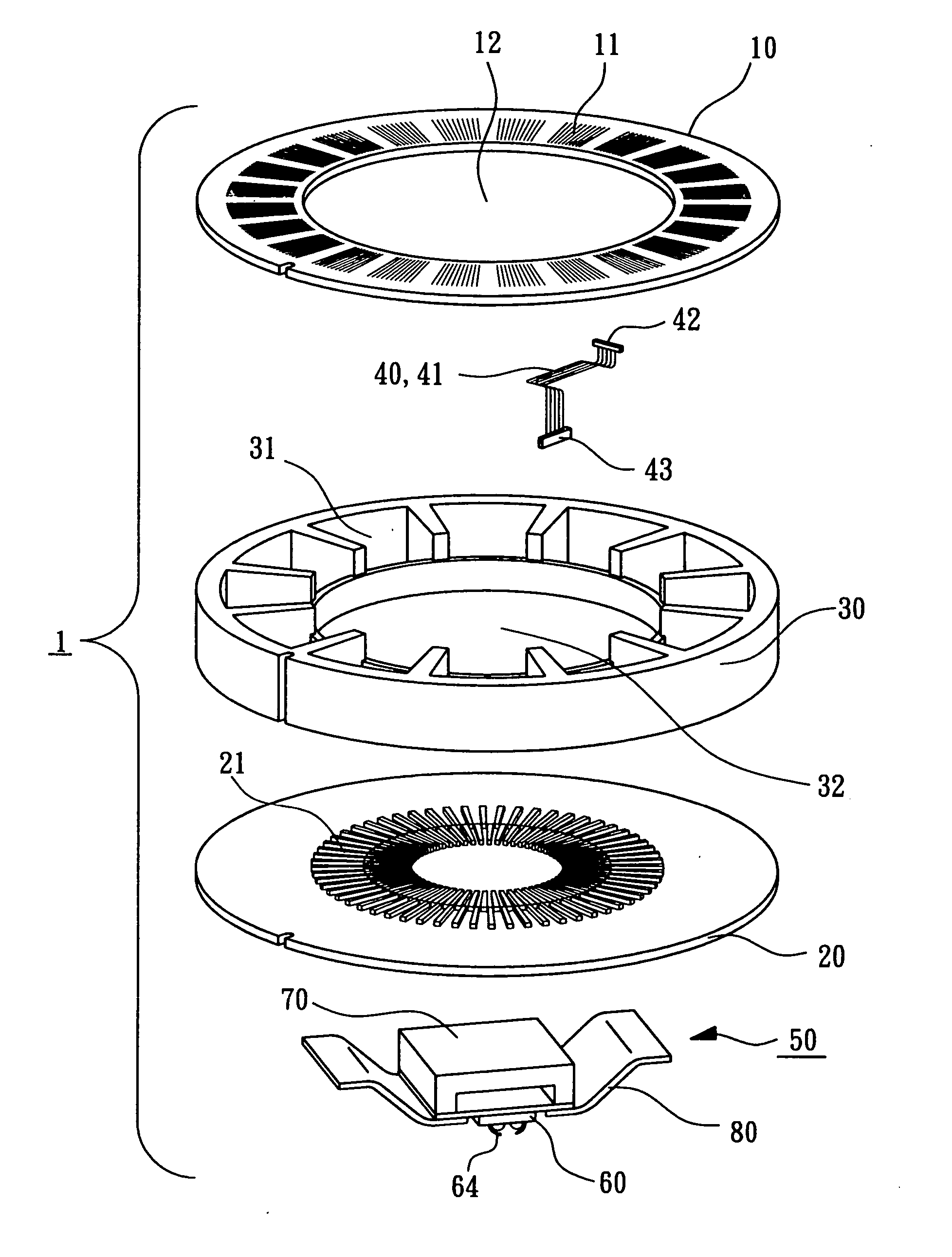

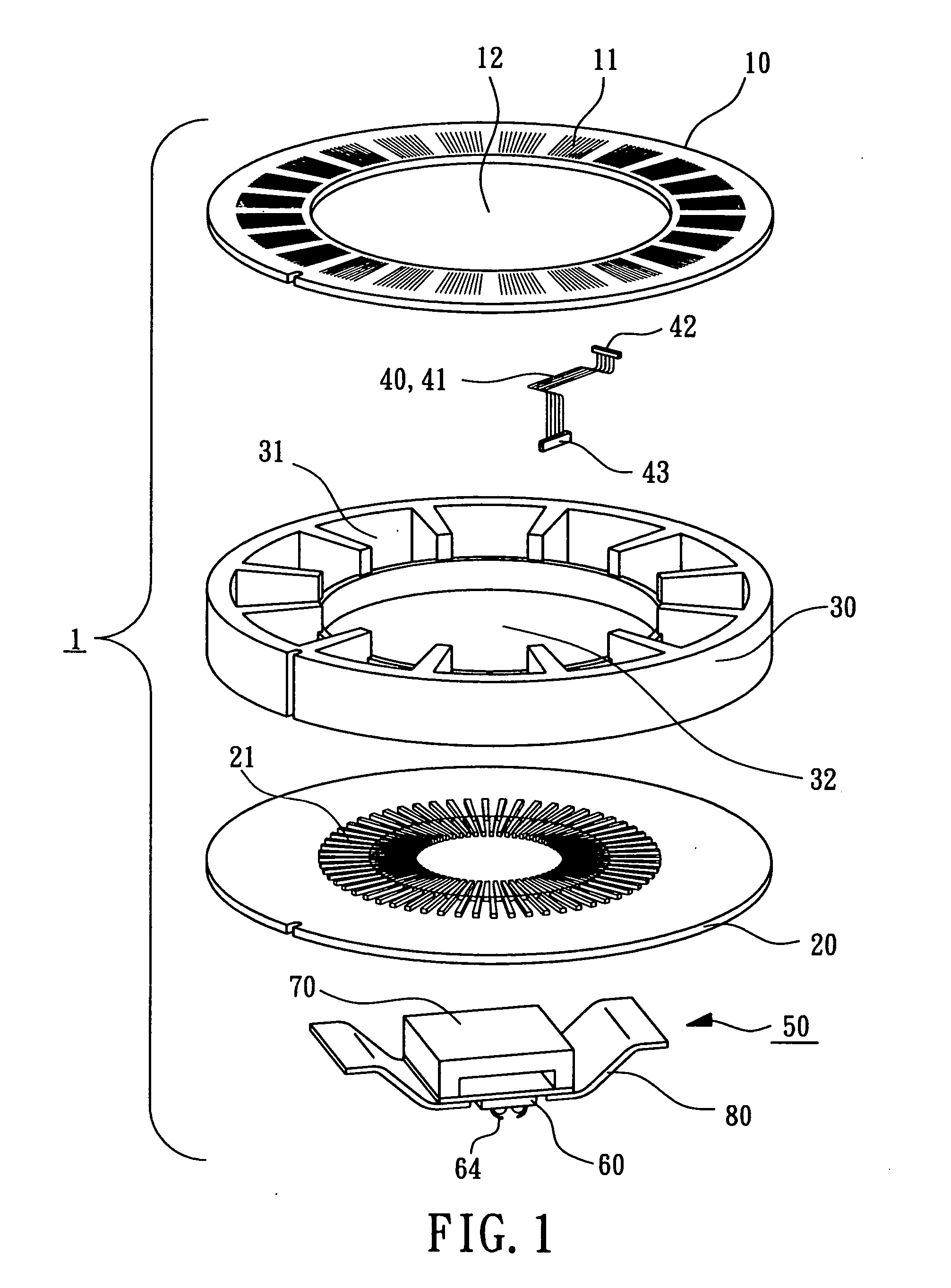

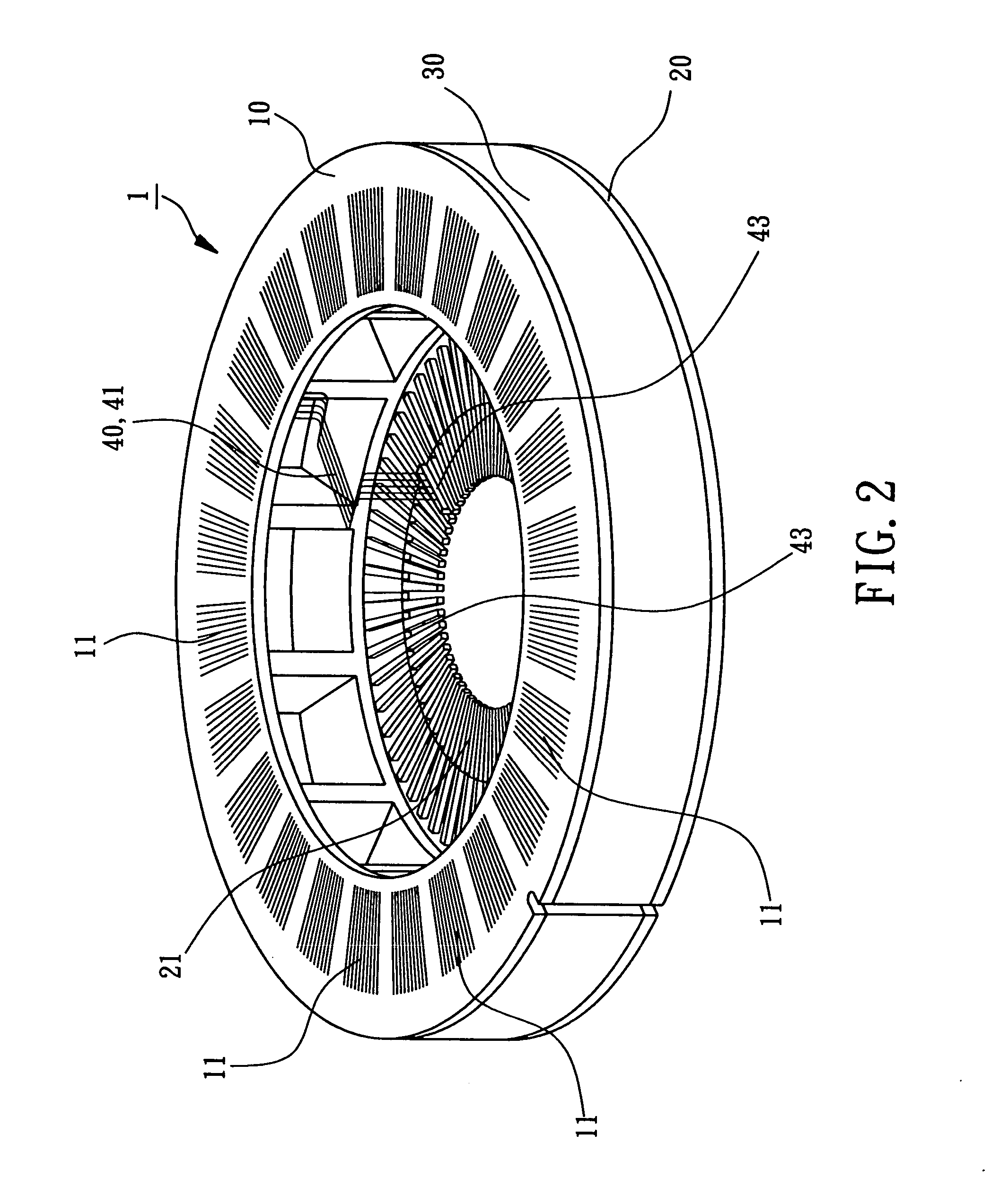

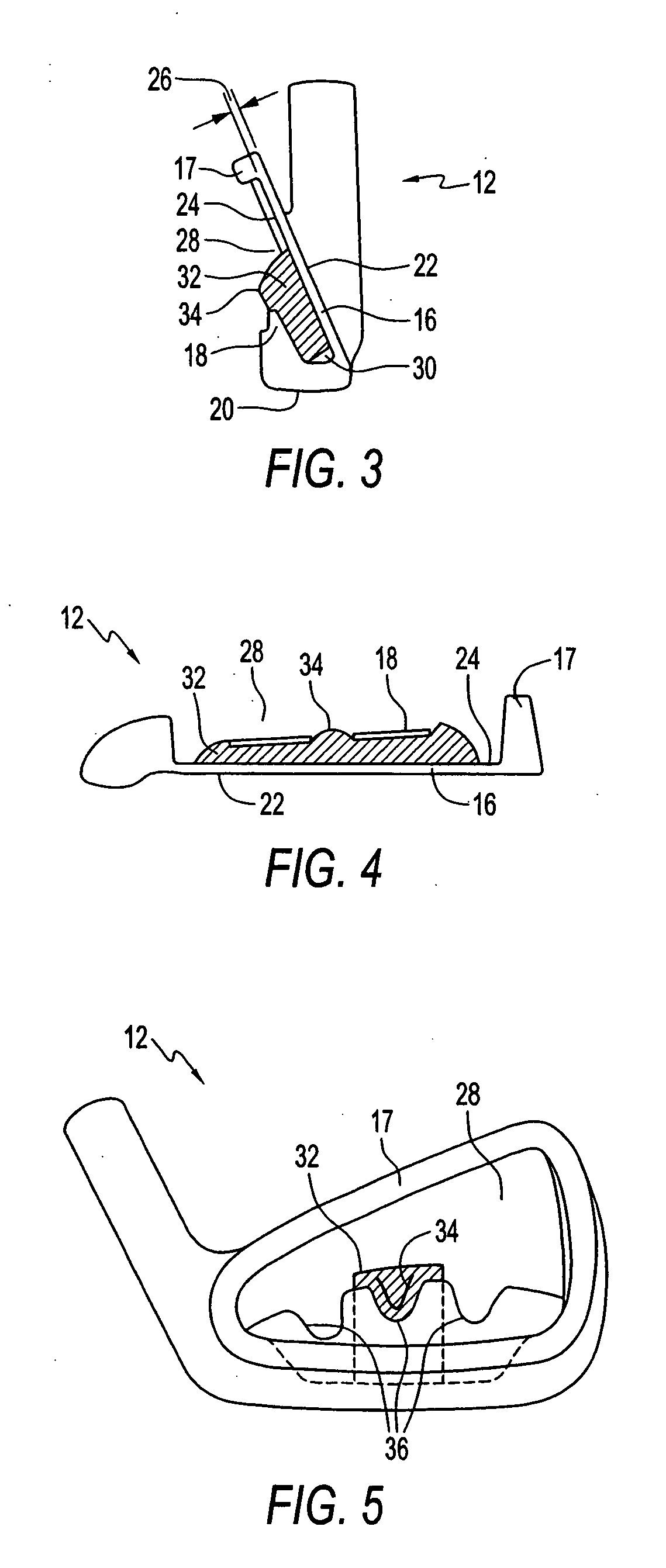

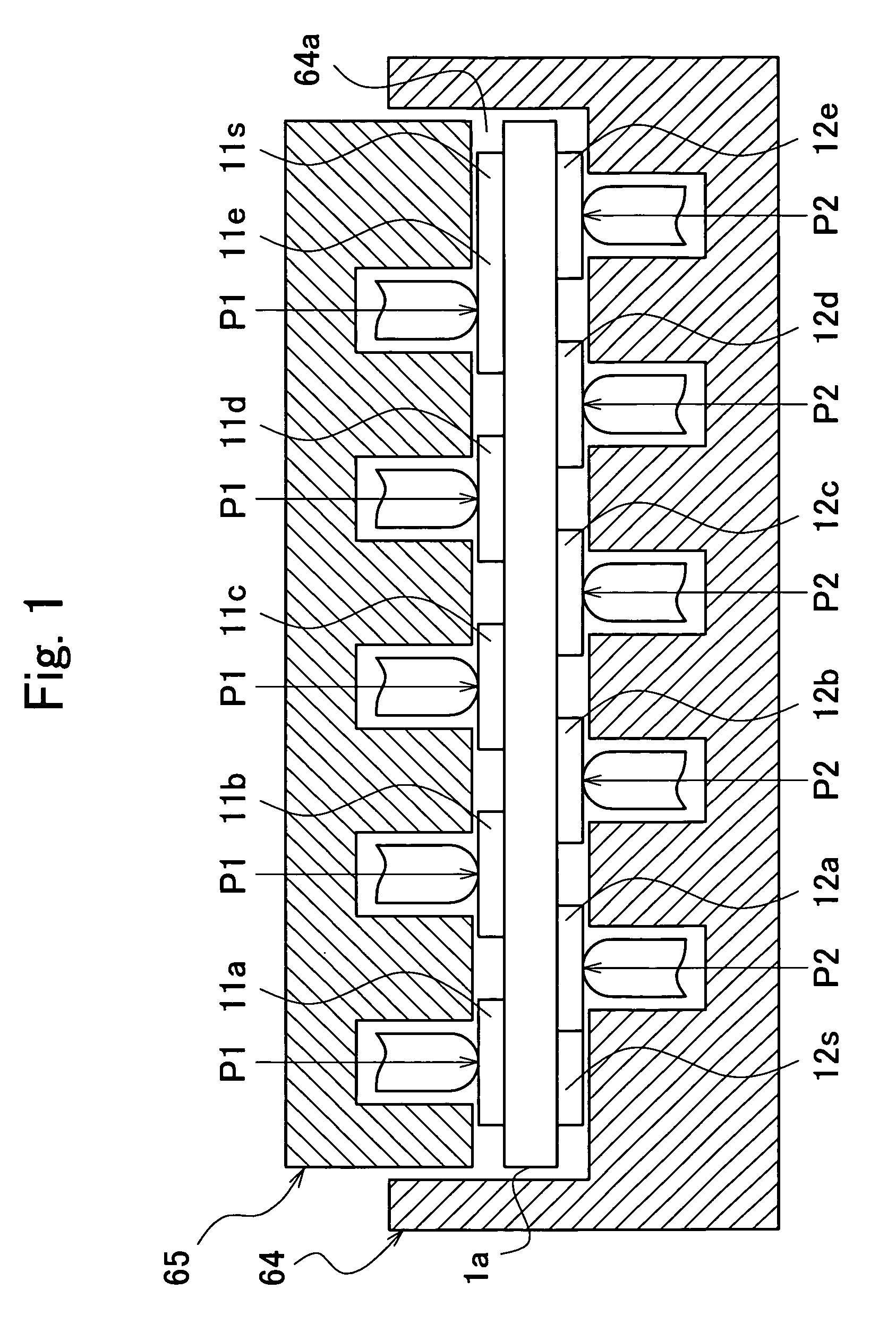

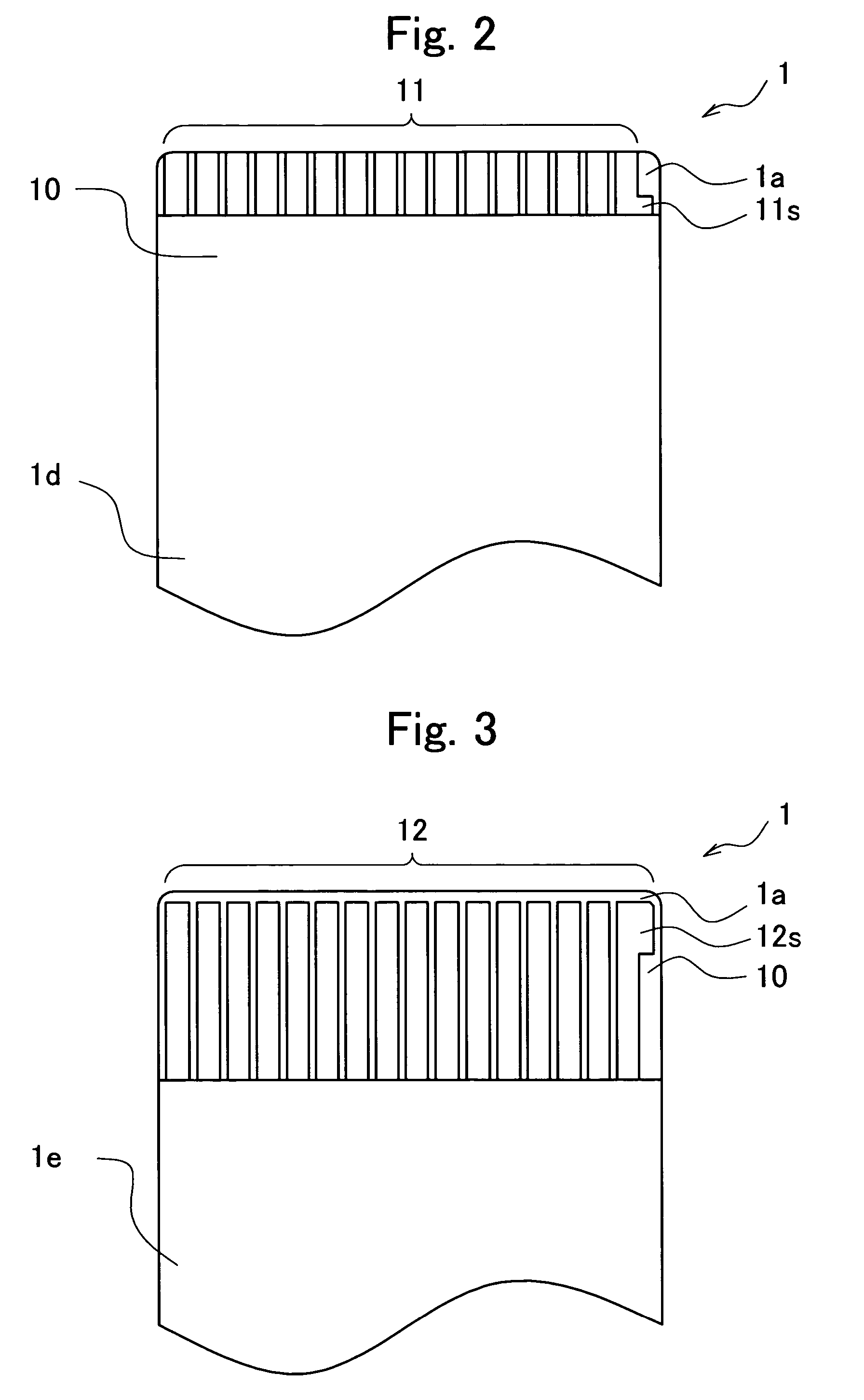

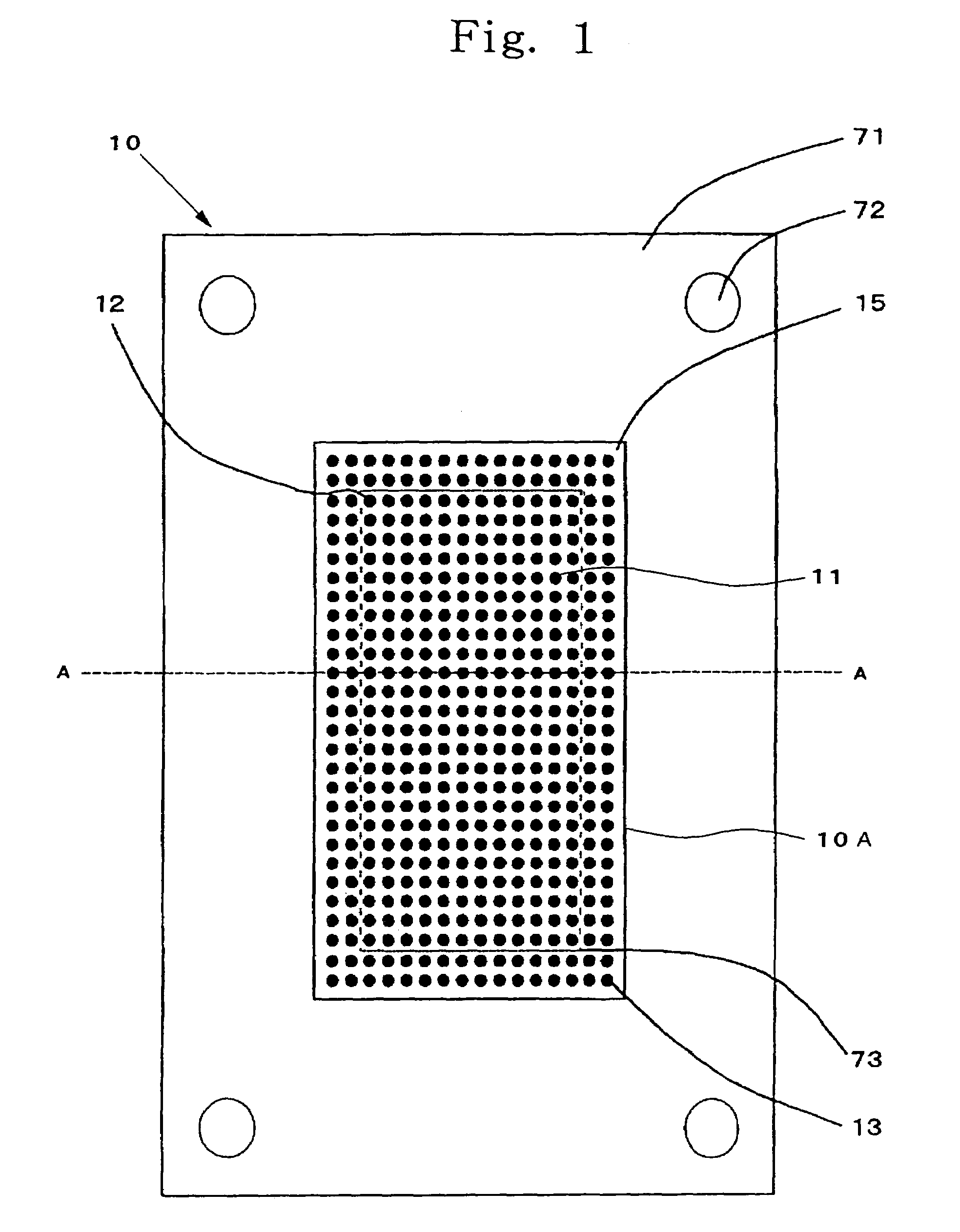

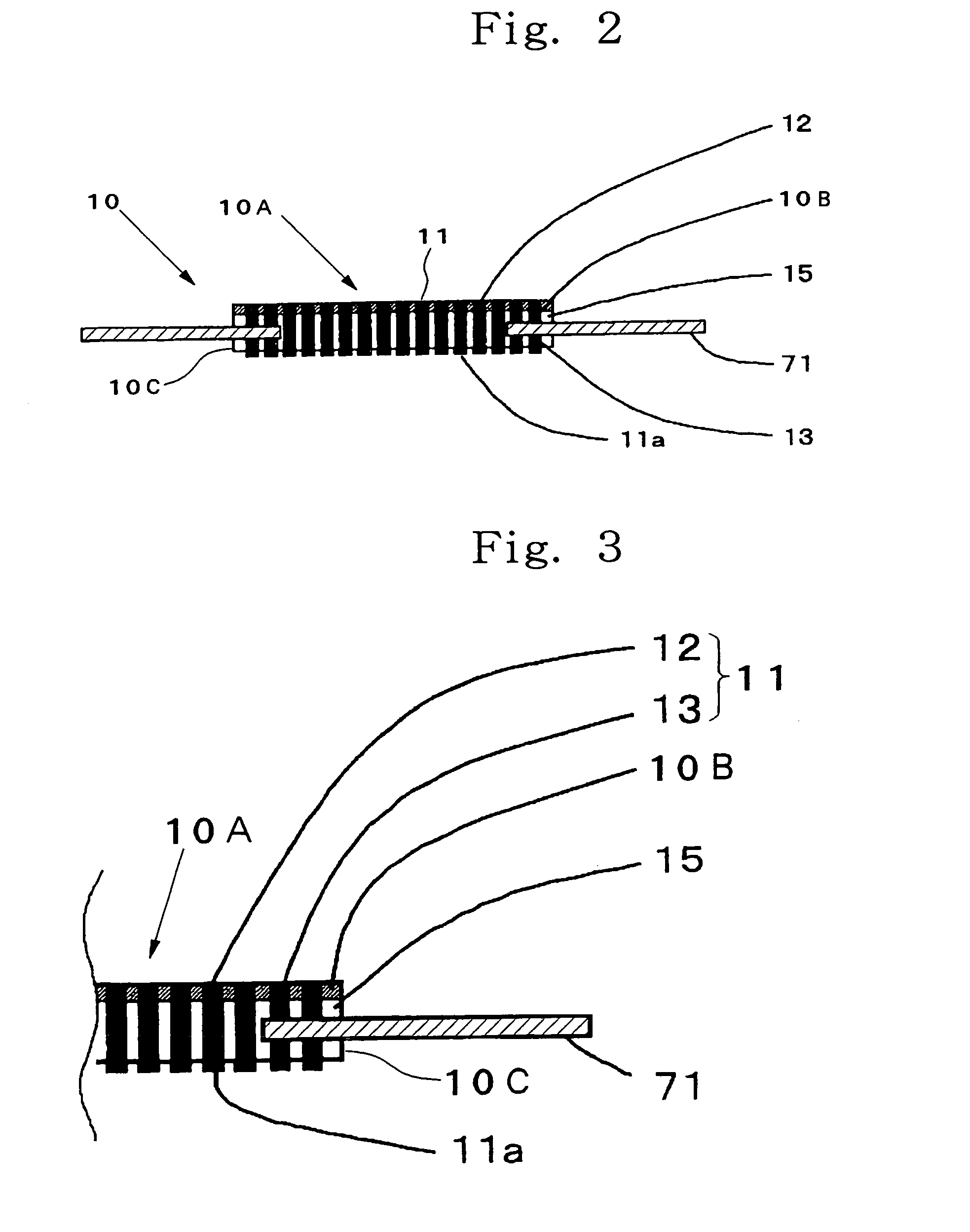

Probe card assembly

InactiveUS20050012513A1Reduce electrical interferenceReduce high-frequency cross talkElectronic circuit testingInstrument screening arrangementsProbe cardEngineering

A probe card assembly is disclosed. The probe card assembly comprises a stiffener ring combining respectively with an upper printed circuit board and a lower printed circuit board. A plurality of coaxial transmitters are installed in the stiffener ring, and connect to the upper and lower printed circuit boards by cable connectors. The lower printed circuit board is assembled with a detachable probe head which comprises a silicon substrate with probing points and a probe head carrier. A downset is formed at the center of the probe head carrier. The standardized coaxial transmitters, printed circuit boards and probe heads are then assembled as a probe card assembly for testing all sorts of IC products.

Owner:CHIPMOS TECH INC

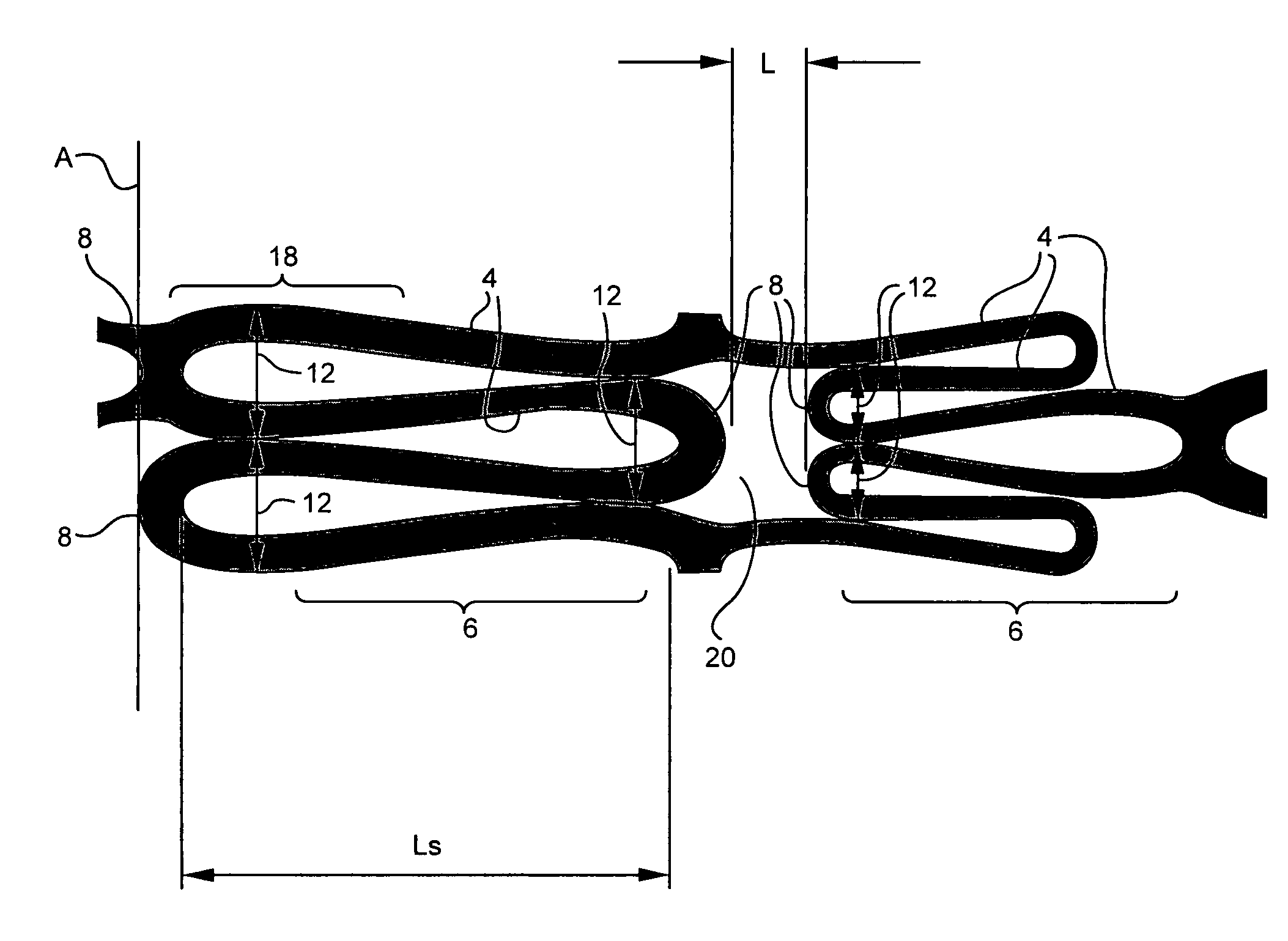

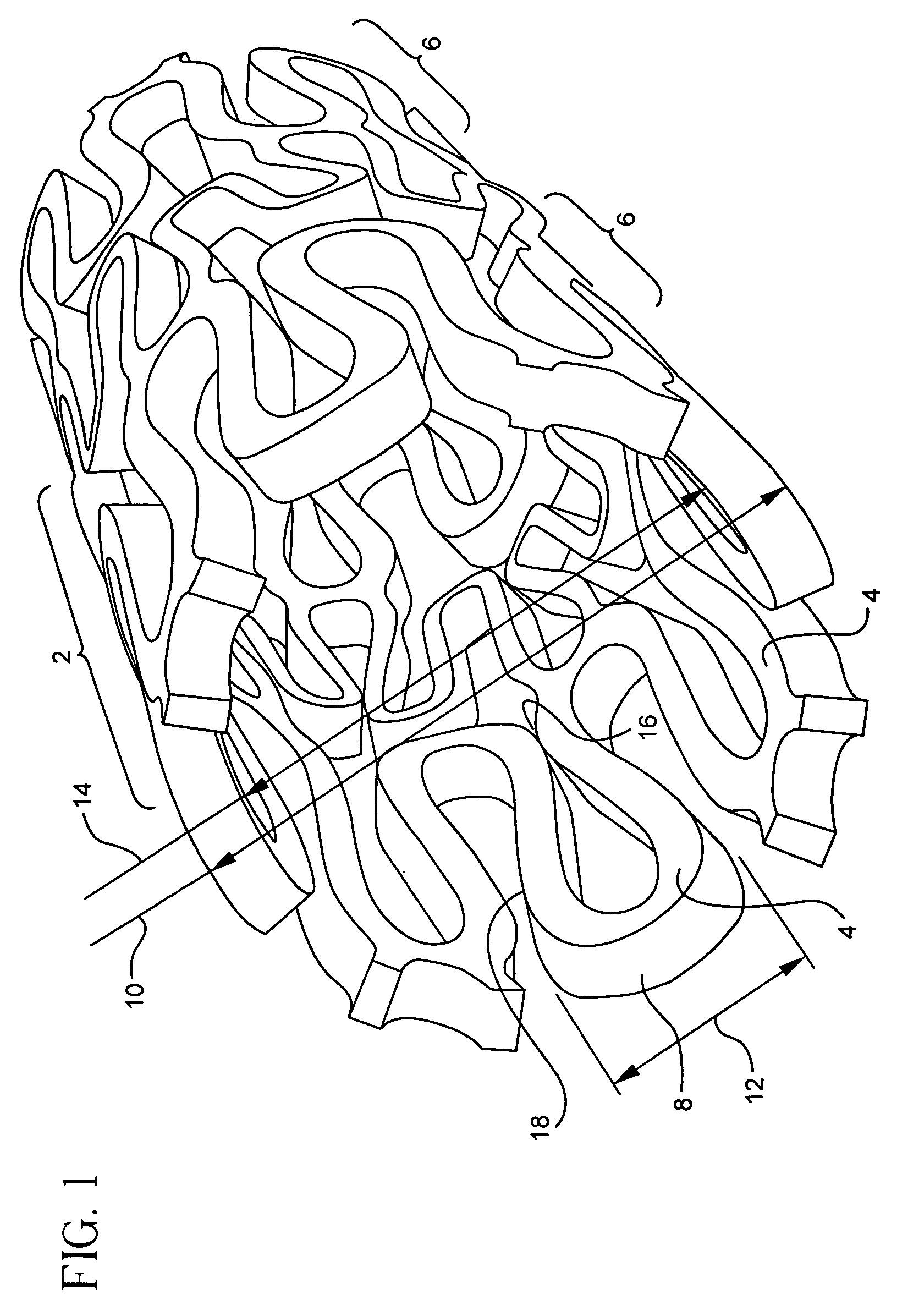

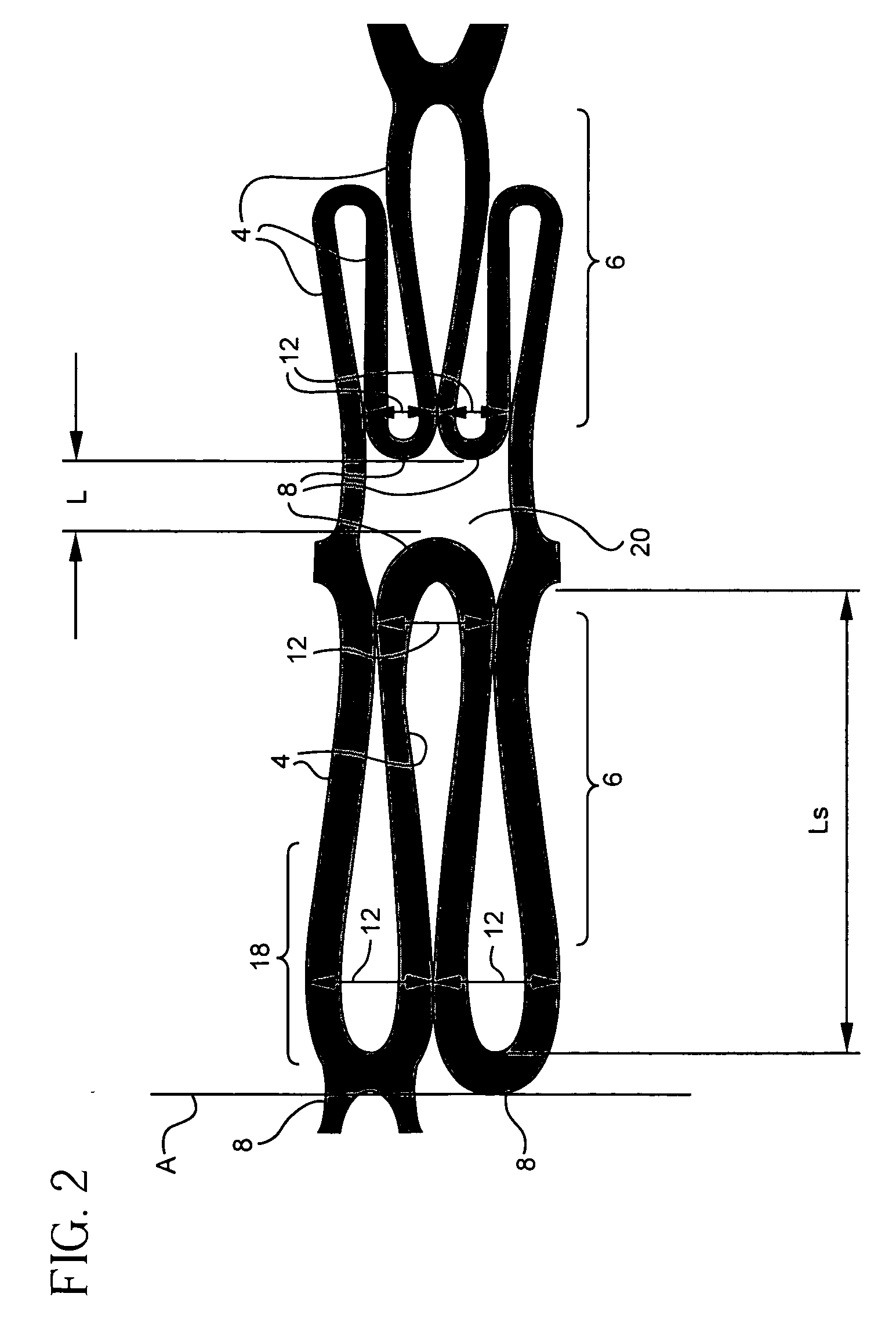

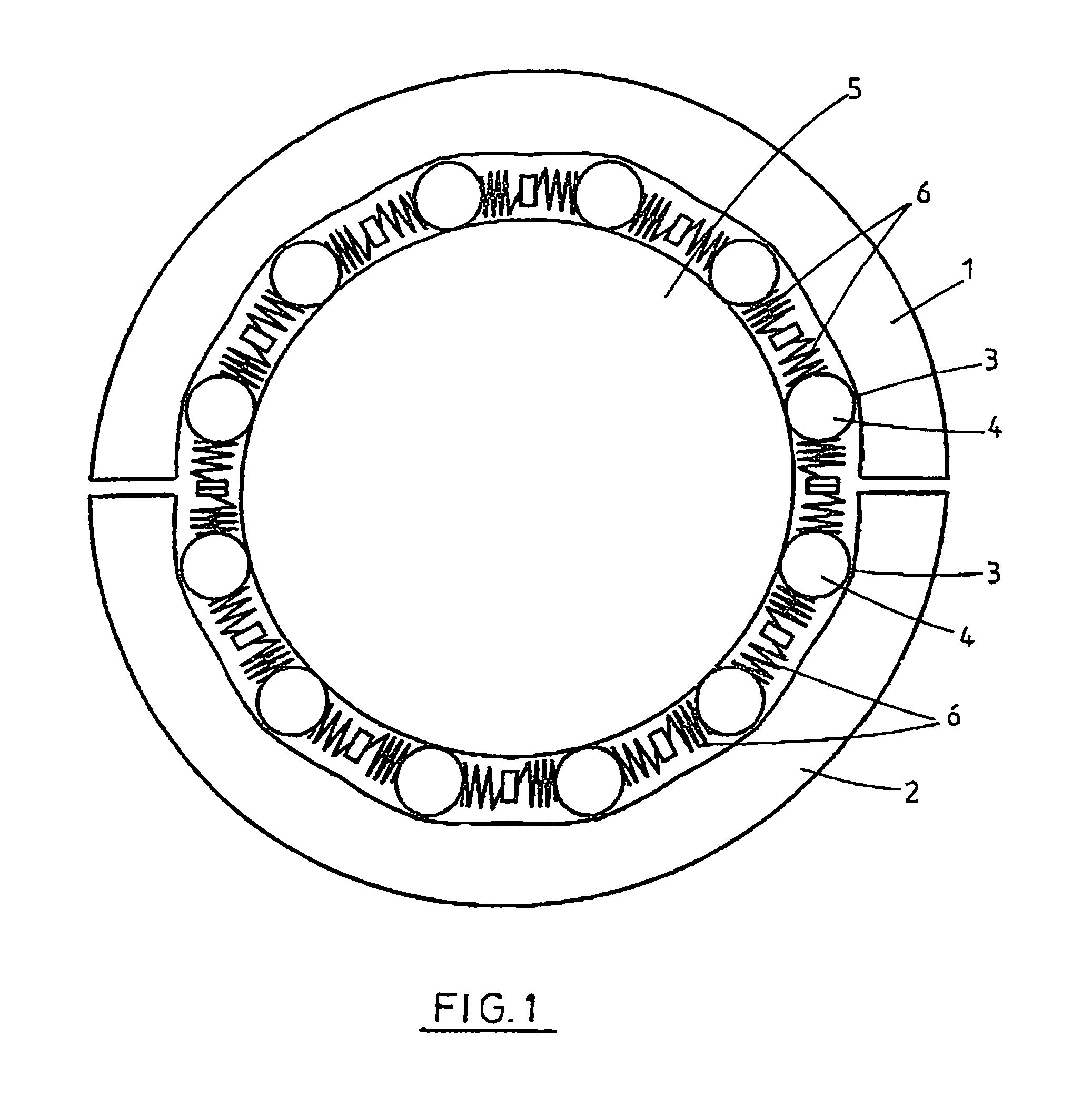

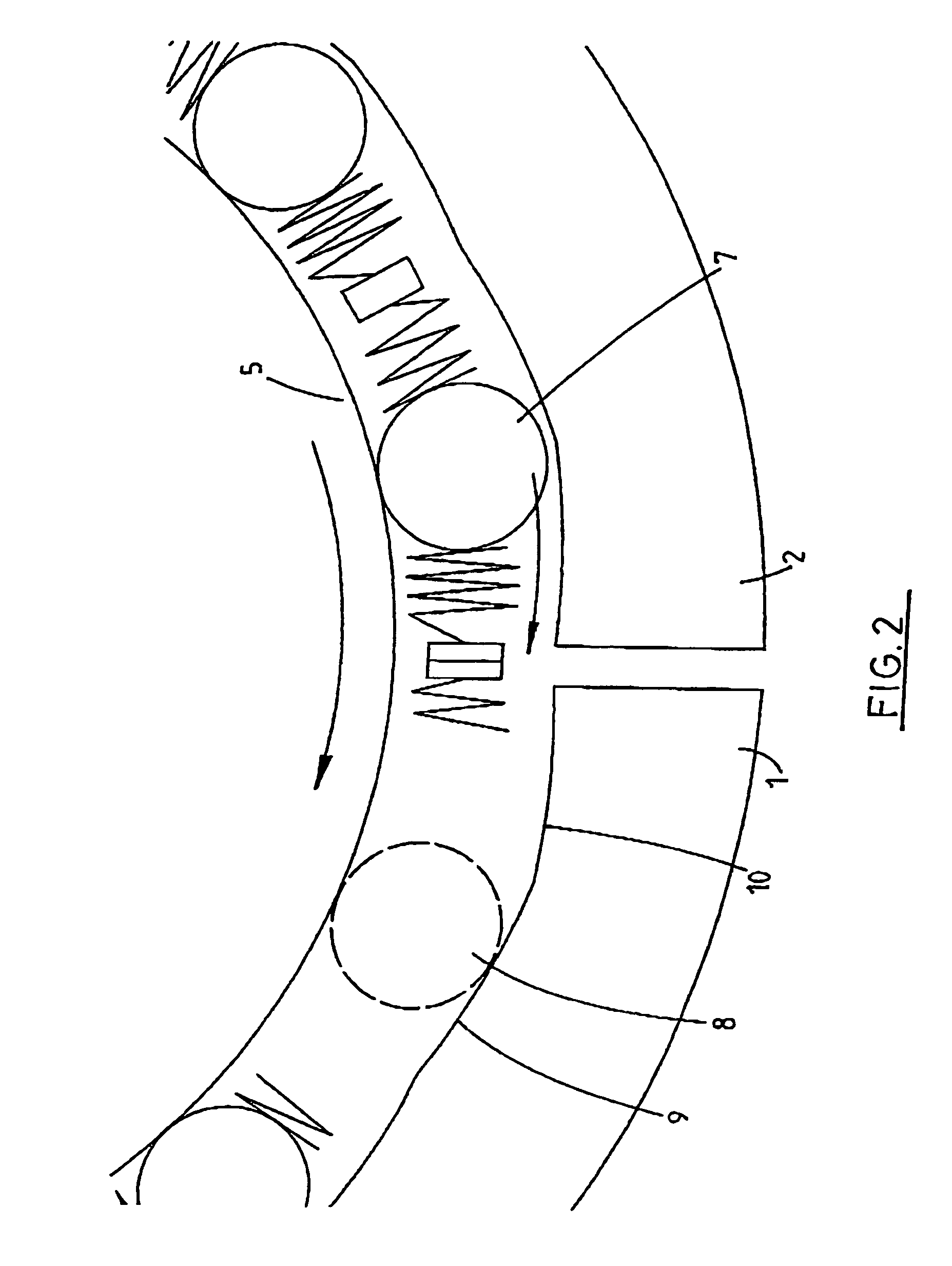

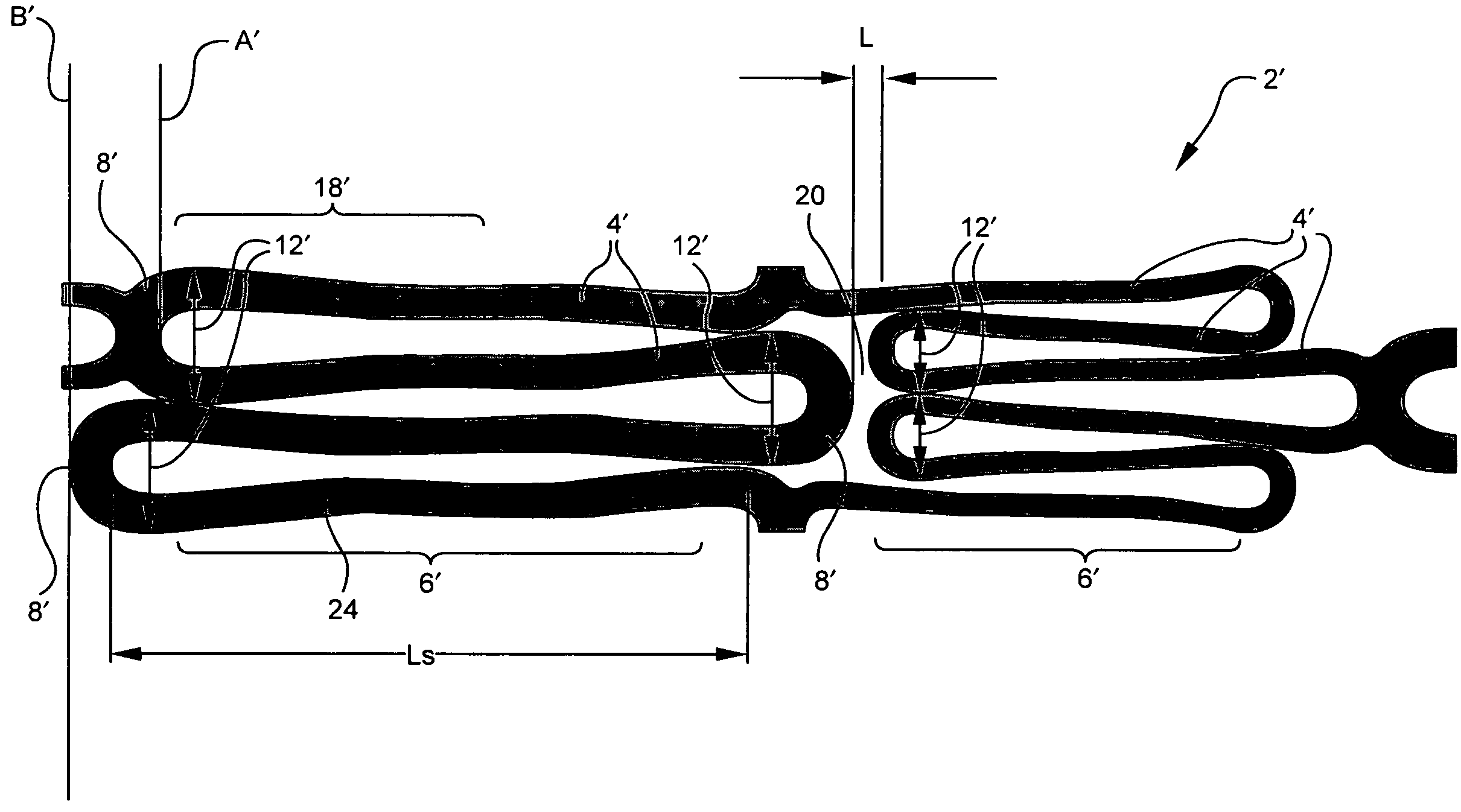

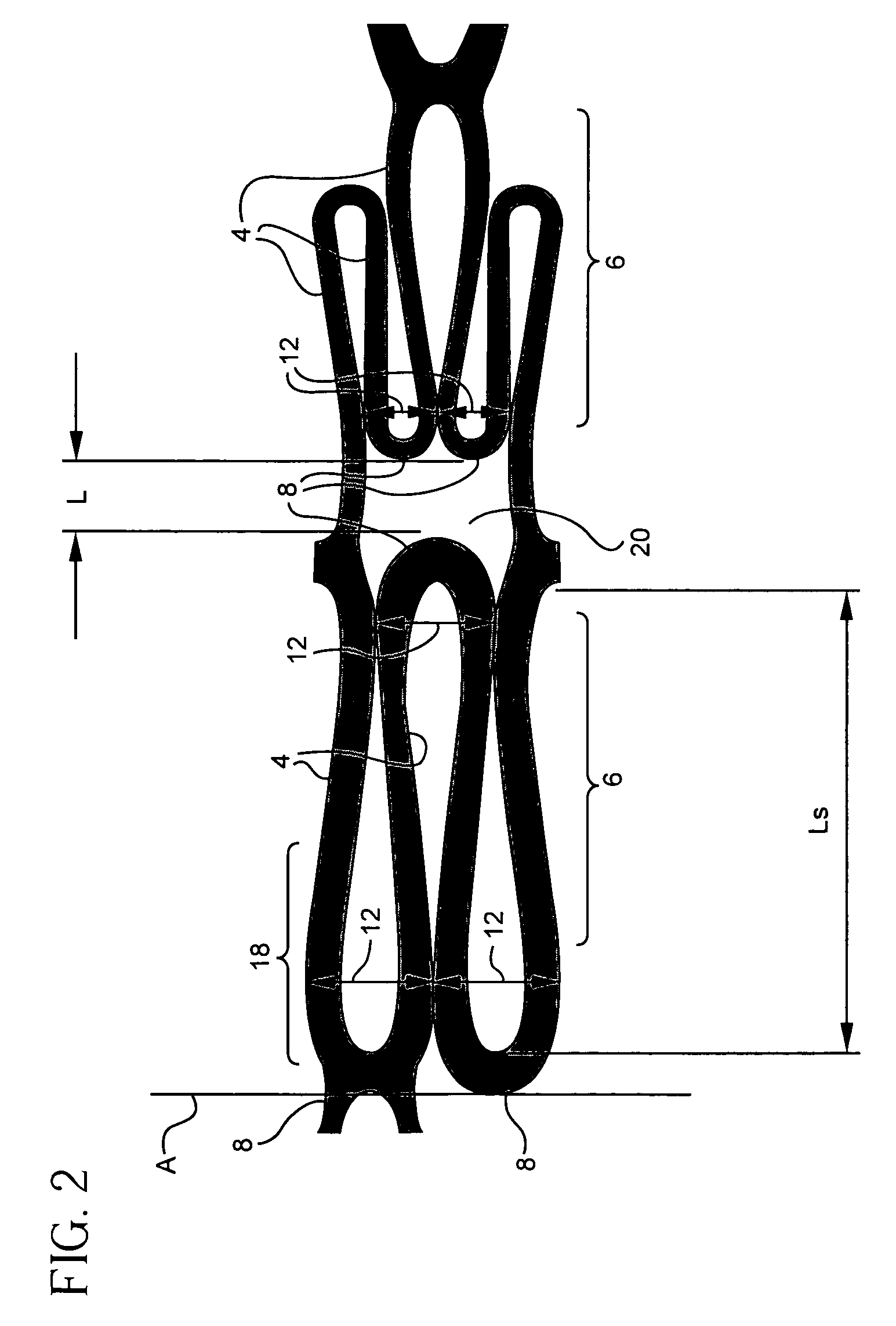

Stent having struts with reverse direction curvature

ActiveUS20050273157A1Increased expansion to compression ratioIncrease ratioStentsBlood vesselsDiameter ratioStent design

Disclosed is a stent having struts with reverse direction curvature for providing a reduced compressed profile and an increased expanded profile. The strut configuration comprises a plurality of arcuate sections facing in opposite convex and a concave orientation. The strut width may be gradually decreased from its ends towards the strut's mid-section to redistribute maximal strains away from portions of the stent more susceptible to permanent deformation, such as the loop portions. Varying strut lengths to offset the maximum circumferential widths of adjacent portions of the stent may further reduce the compressed stent profile. The varied stent lengths may also contribute to an increased expanded stent profile. Stents with the reverse direction curvature strut design can obtain an expanded to compressed stent diameter ratio of about 7:1 compared to conventional stents that have a ratio of up to about 5:1. The curved strut can be utilized with any stent design.

Owner:MEDINOL LTD

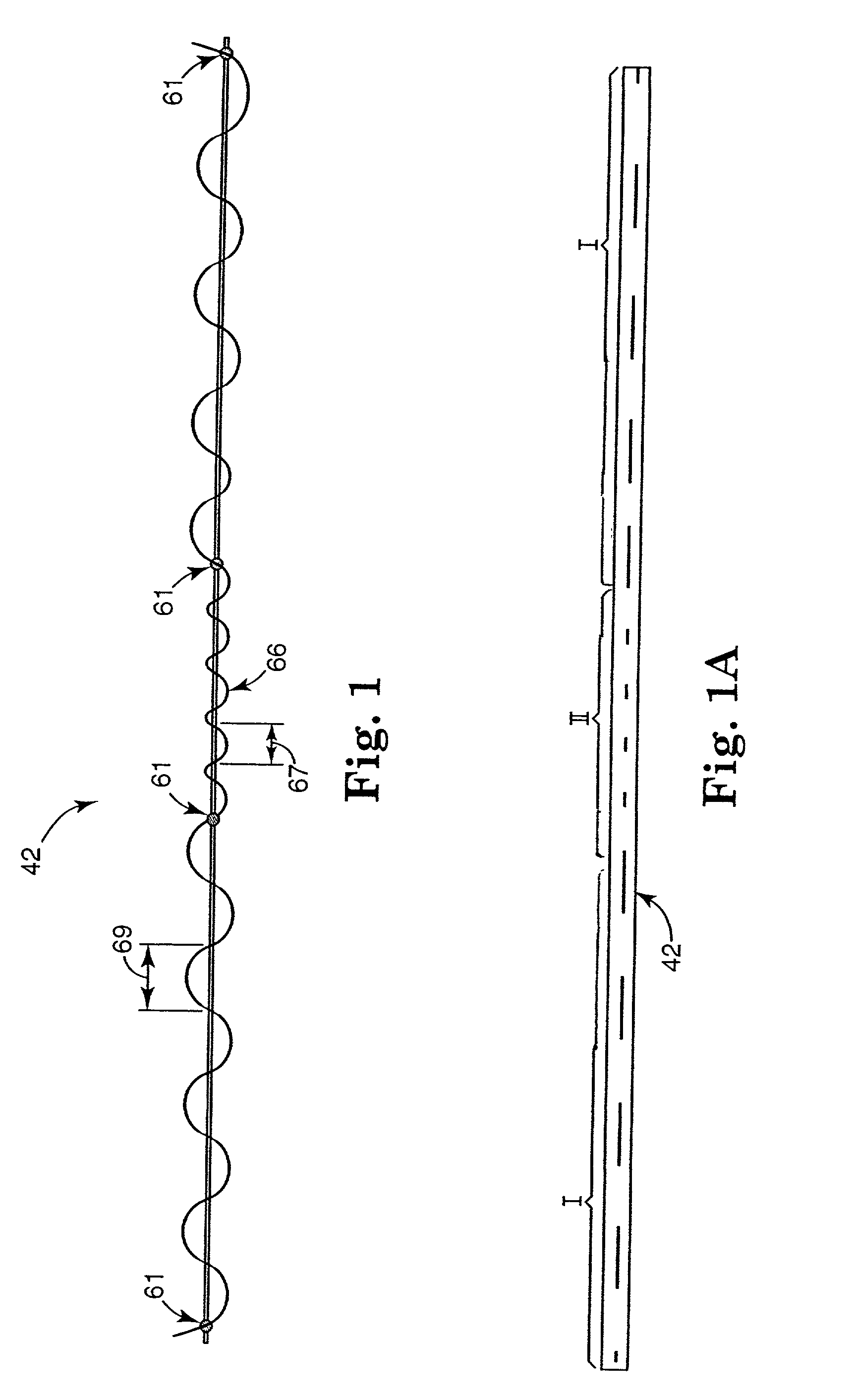

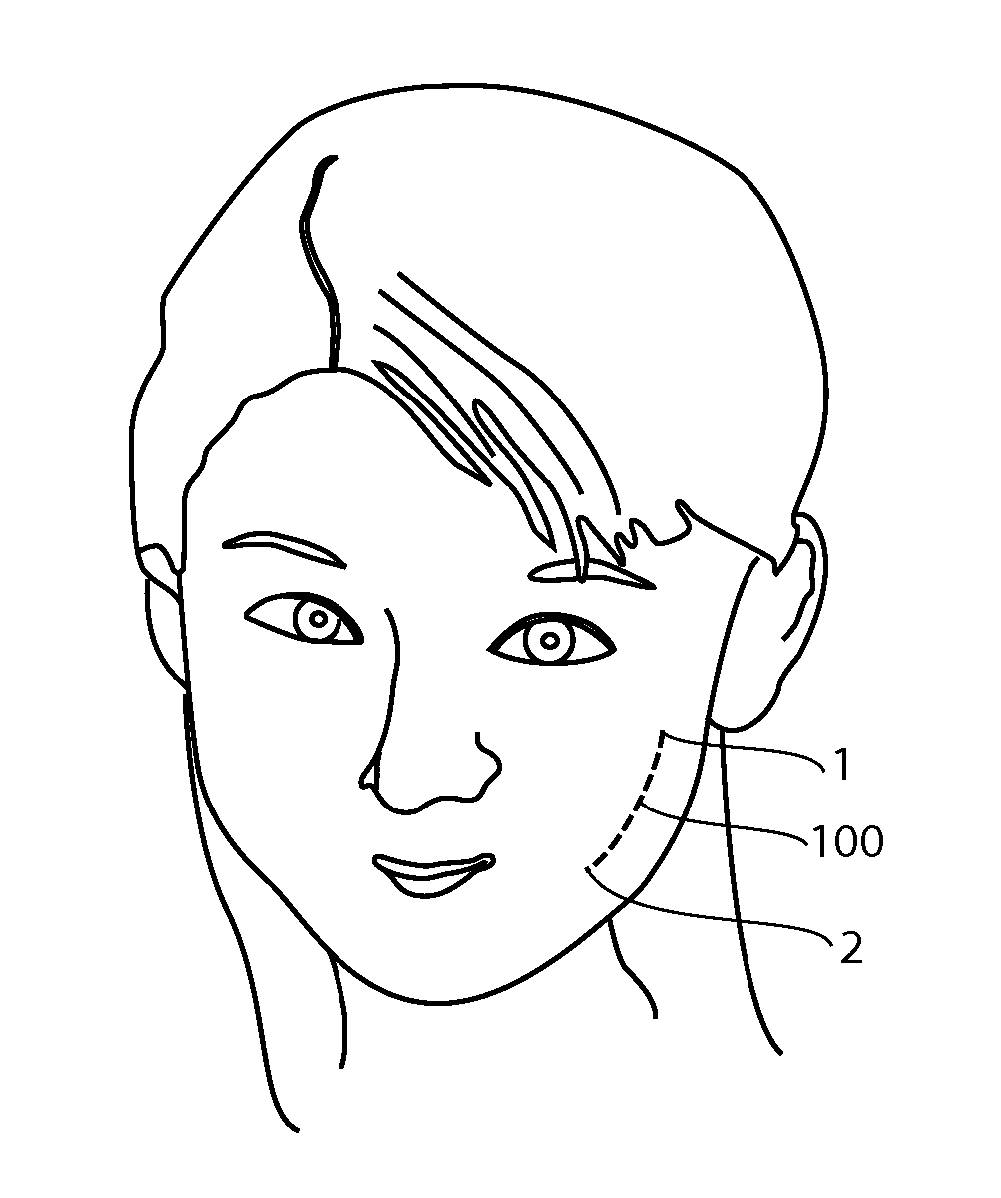

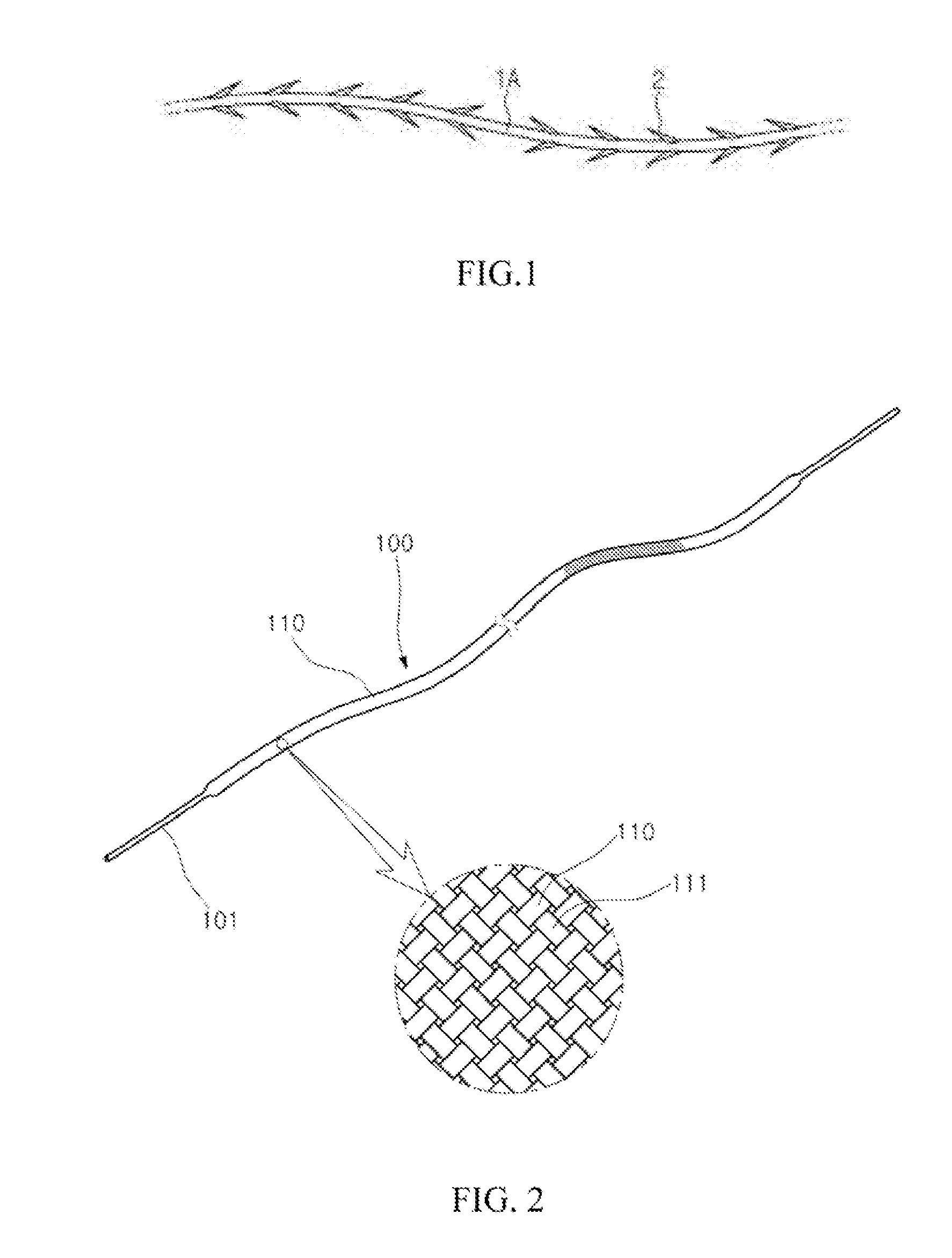

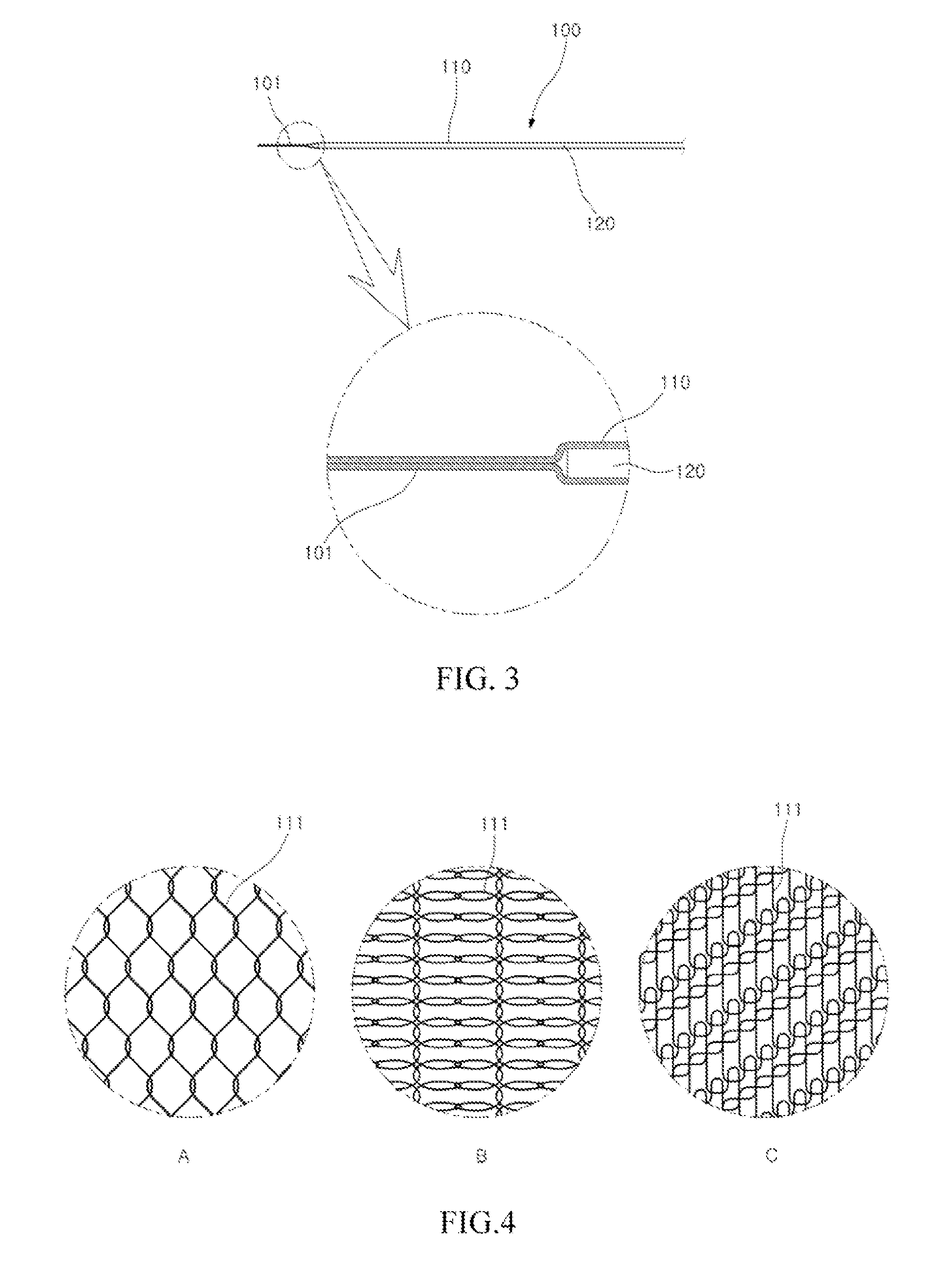

Linear tension material for plastic surgery

InactiveUS20080046094A1High strengthAvoid fatigueSuture equipmentsCosmetic implantsWrinkle skinFiber

The present invention relates to a linear tension material for surgery used to pull skin tissue. An object of the present invention is to provide a linear tension material for plastic surgery which prevents permanent deformation due to excessive elongation and fatigue and of which a portion besides united portions is uniformly and properly united with body tissue. According to an aspect of the present invention, there is provided a linear tension material for plastic surgery which is provided to pull a predetermined site inside skin tissue of the body in a state of tensile load so as to smooth out wrinkles and pull the tissue to tighten a saggy portion, the linear tension material including: a core material in a code shape, which is made of a flexible resin including polyorganosiloxane; and a covering material which covers an outside of the core material to be united with the core material, shrinks together with the core material, and has a fiber textile structure formed by weaving a number of fiber threads.

Owner:HAN KWANG HEE +1

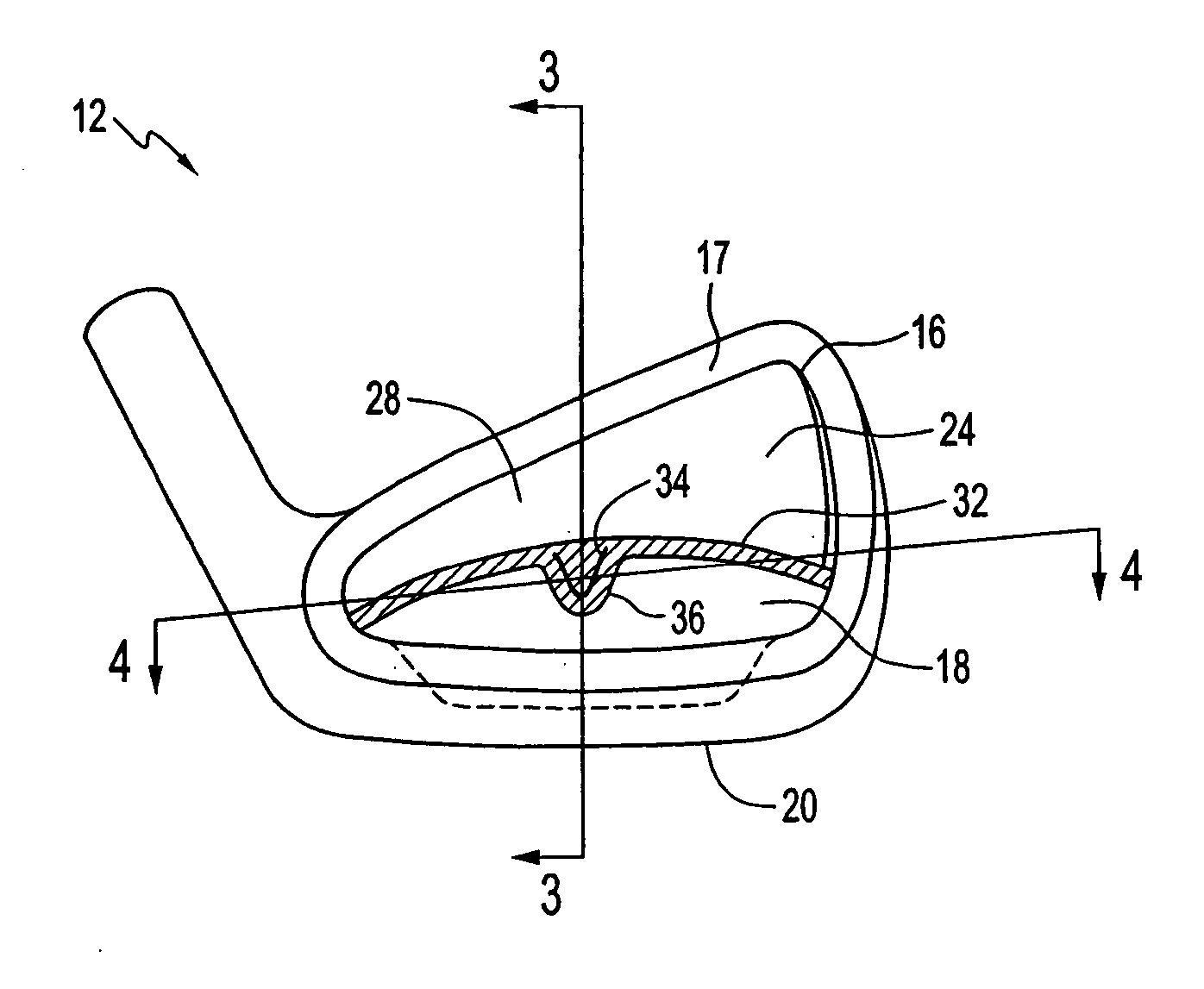

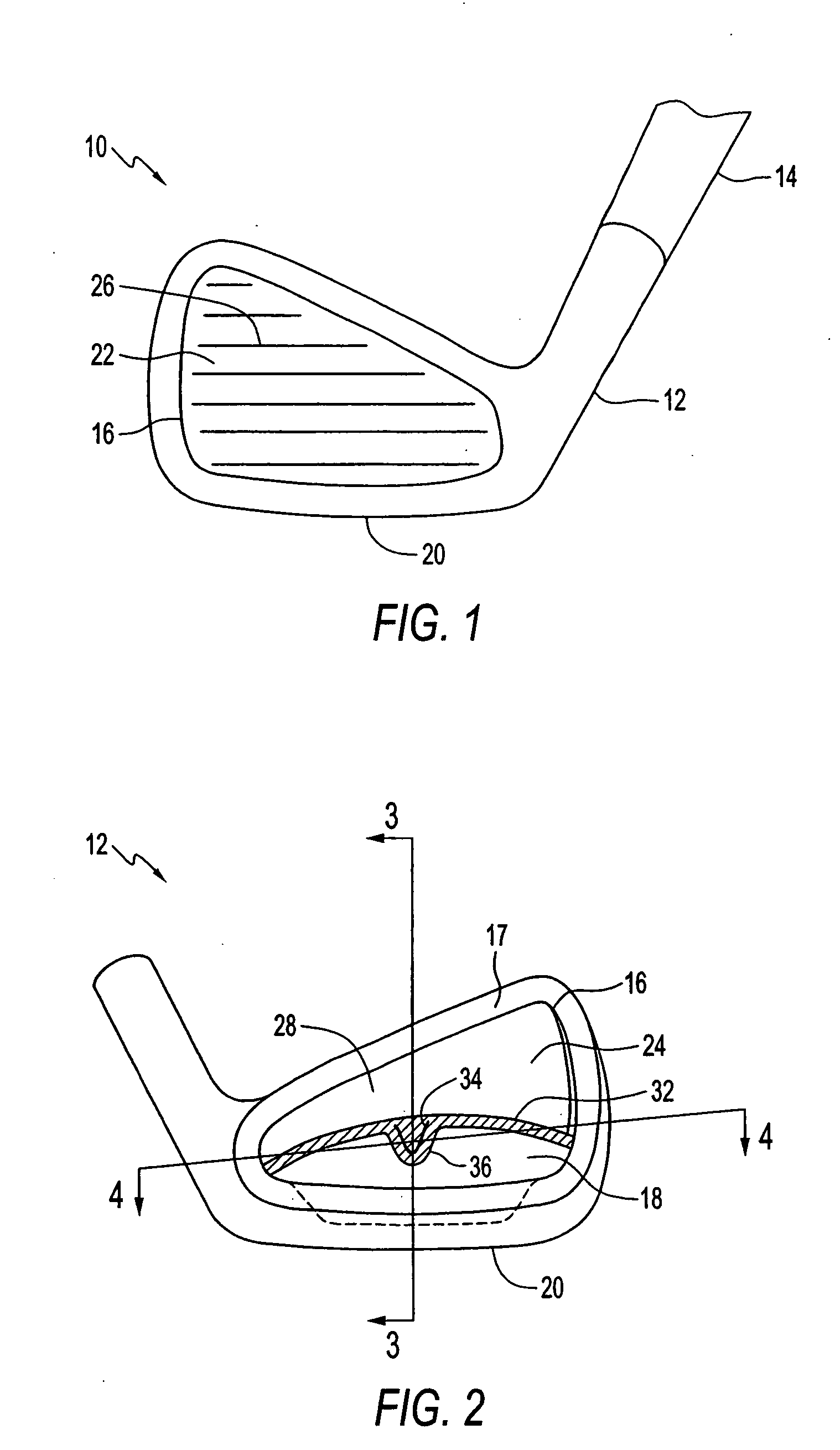

Reinforced golf club head having sandwich construction

InactiveUS20050148407A1Low densityHigh impact strengthGolf clubsRacket sportsEngineeringGravity center

Owner:ACUSHNET CO

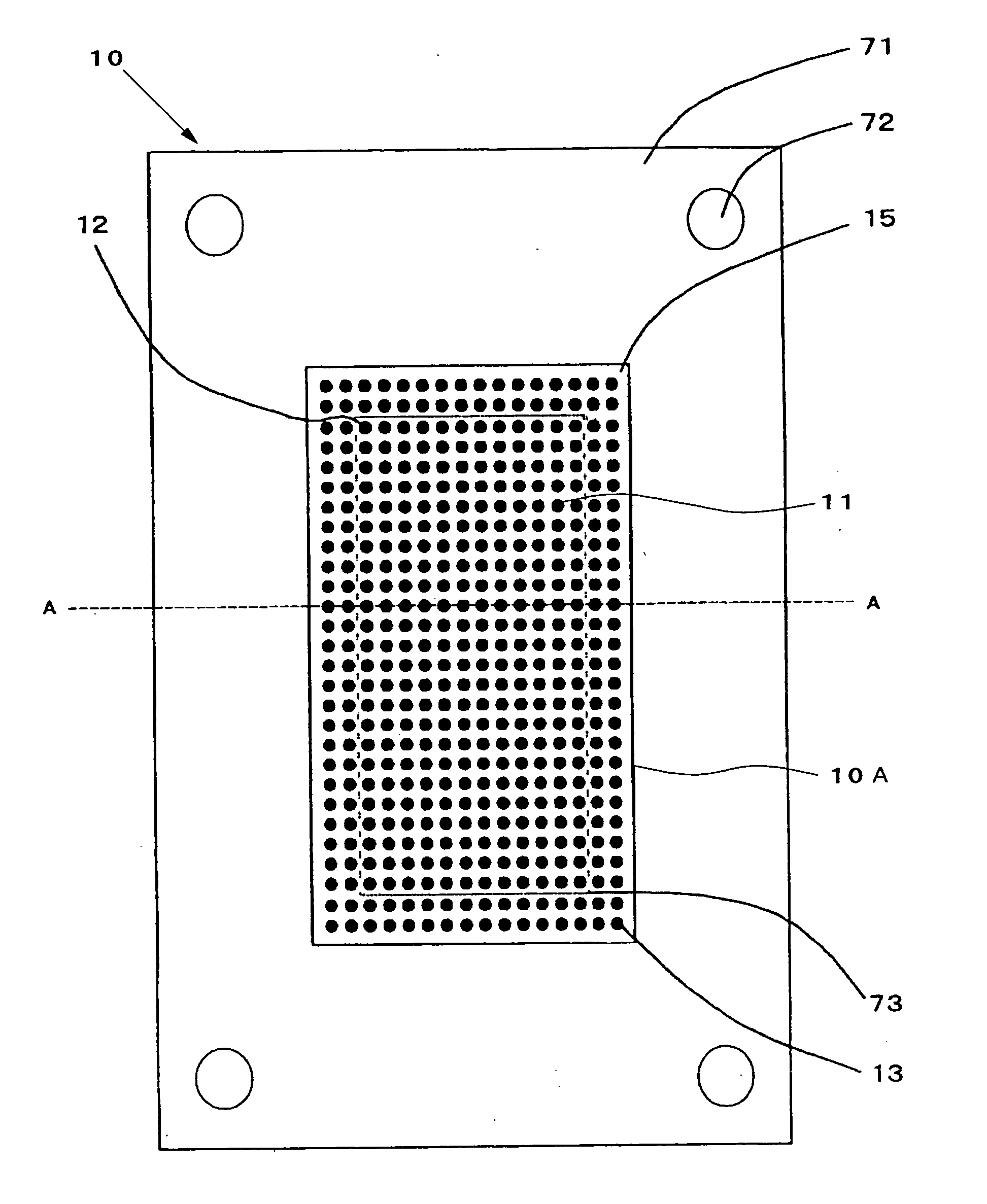

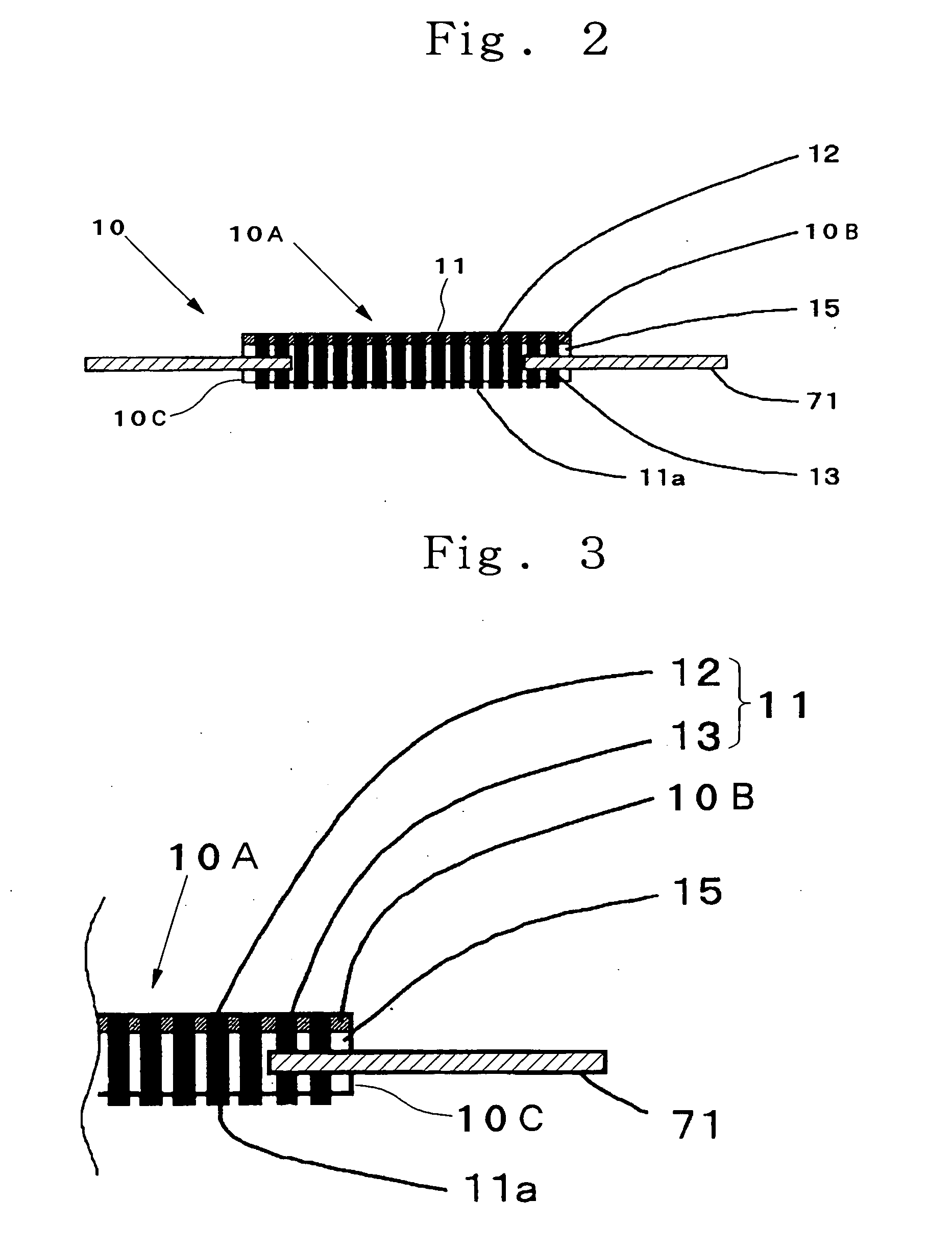

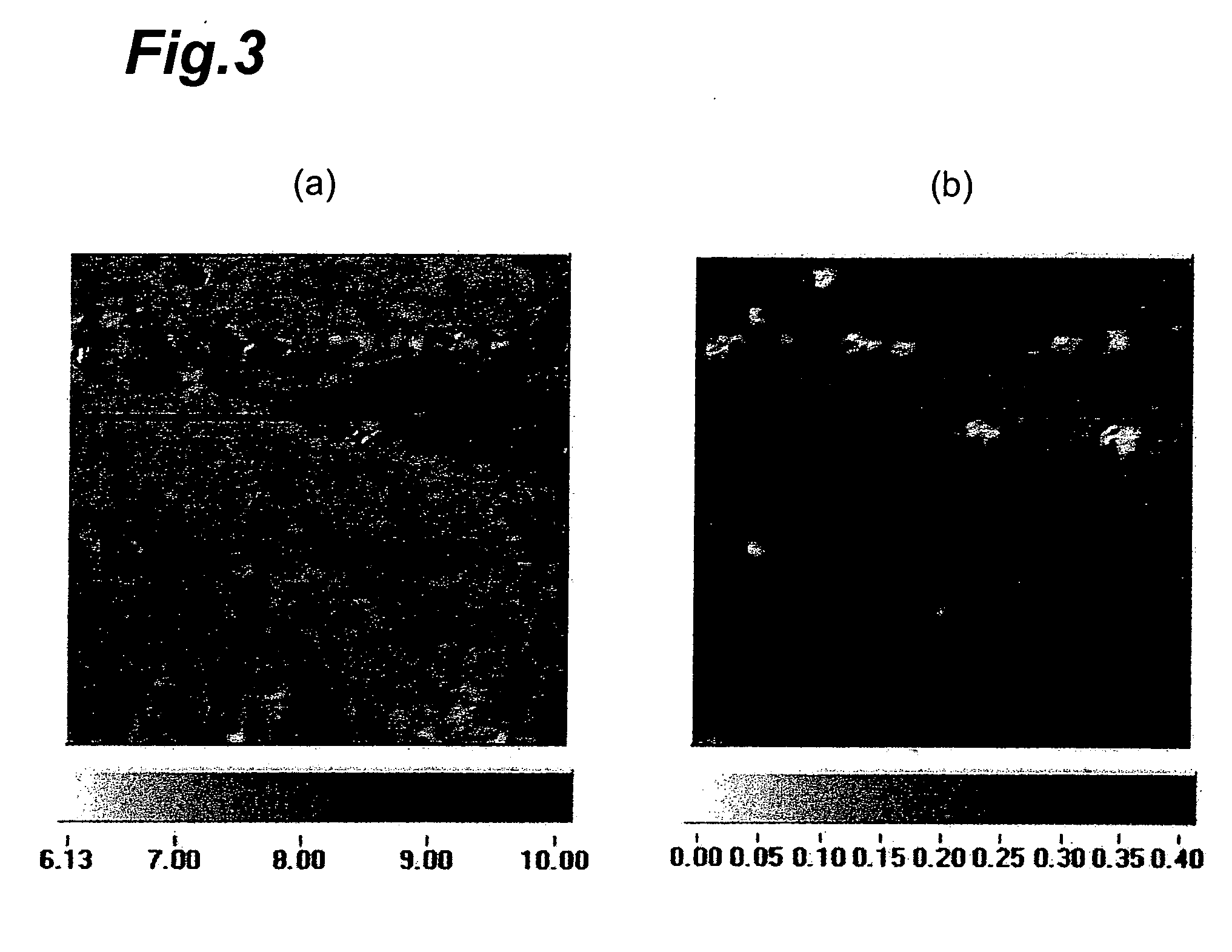

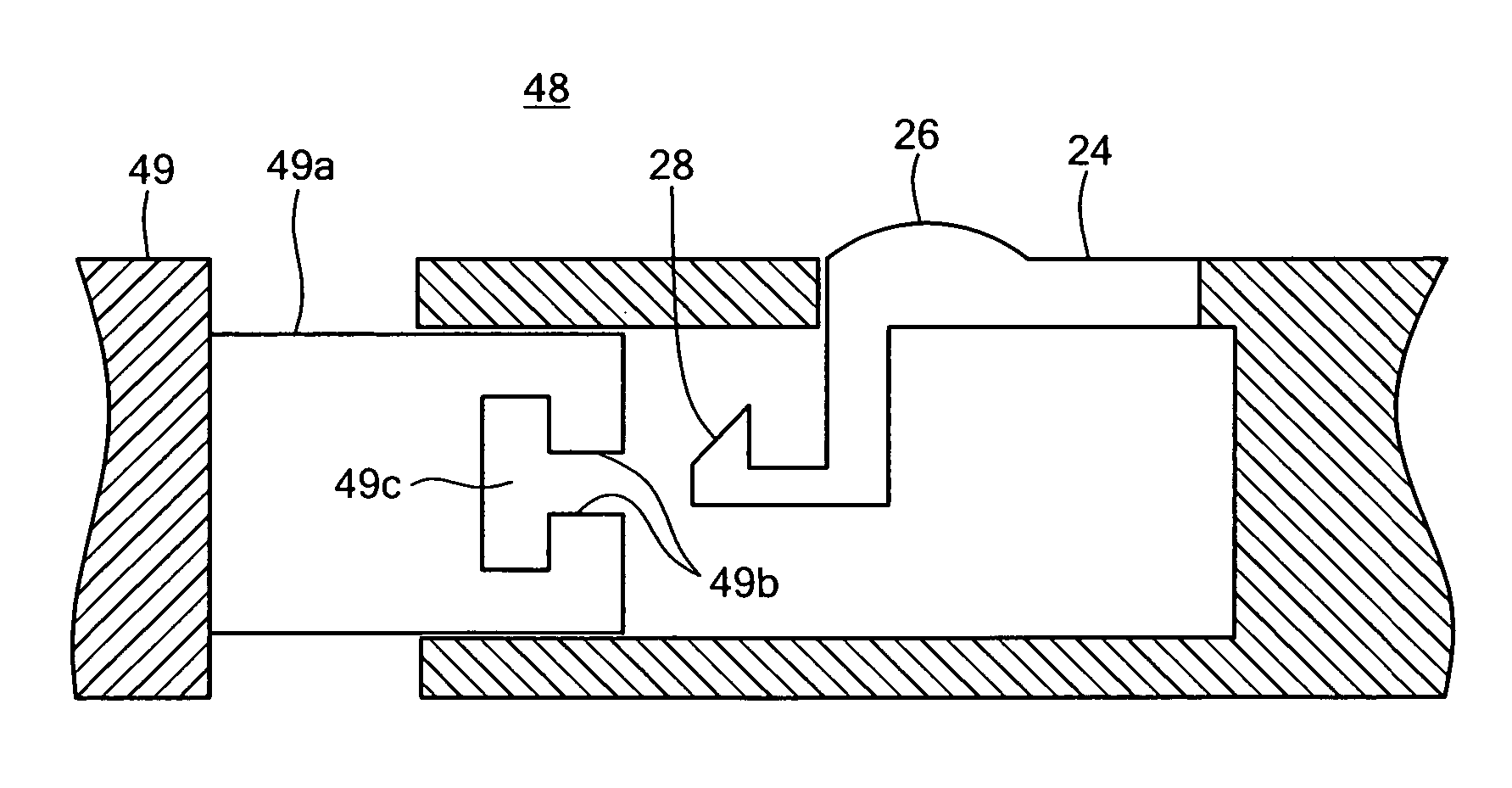

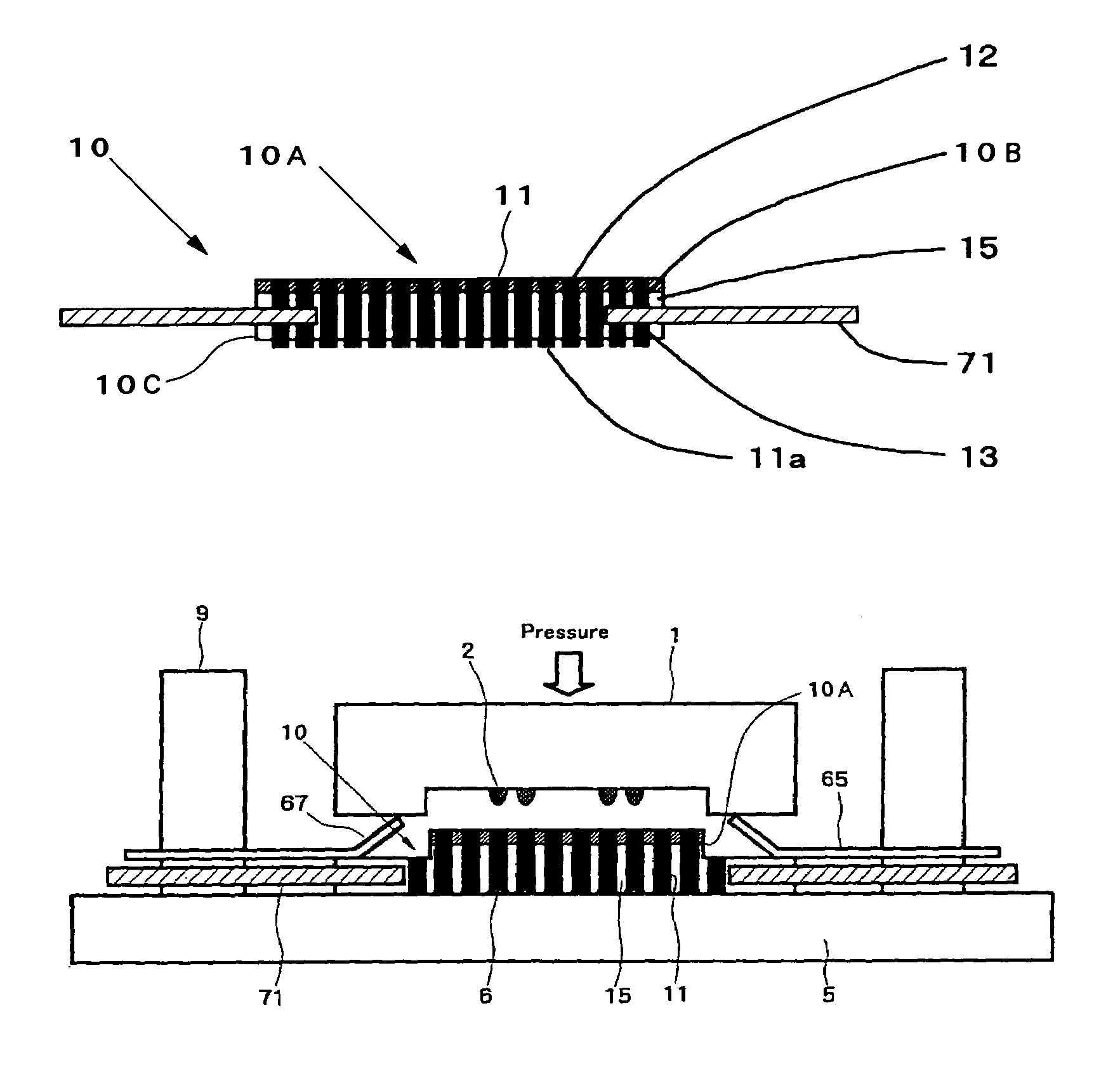

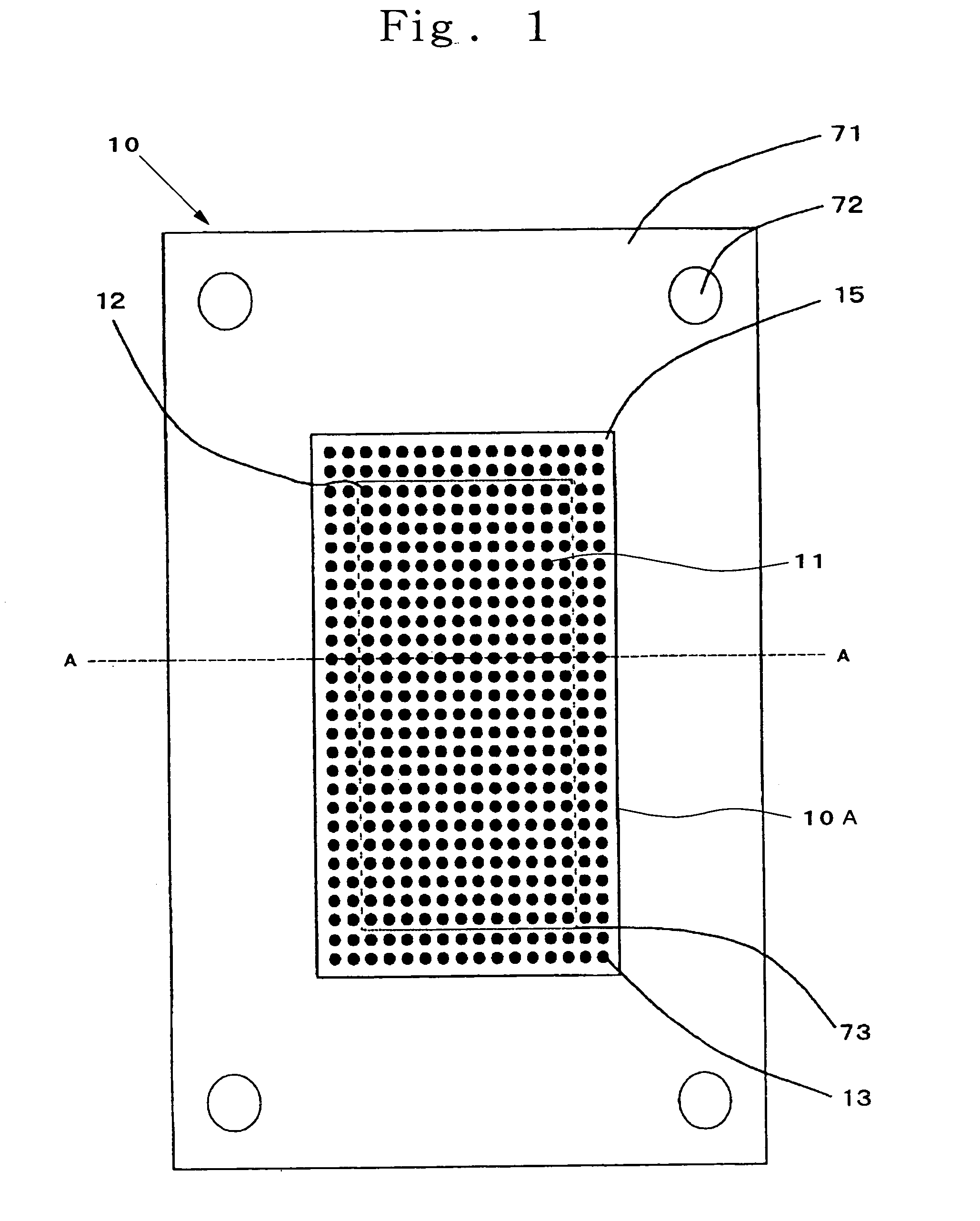

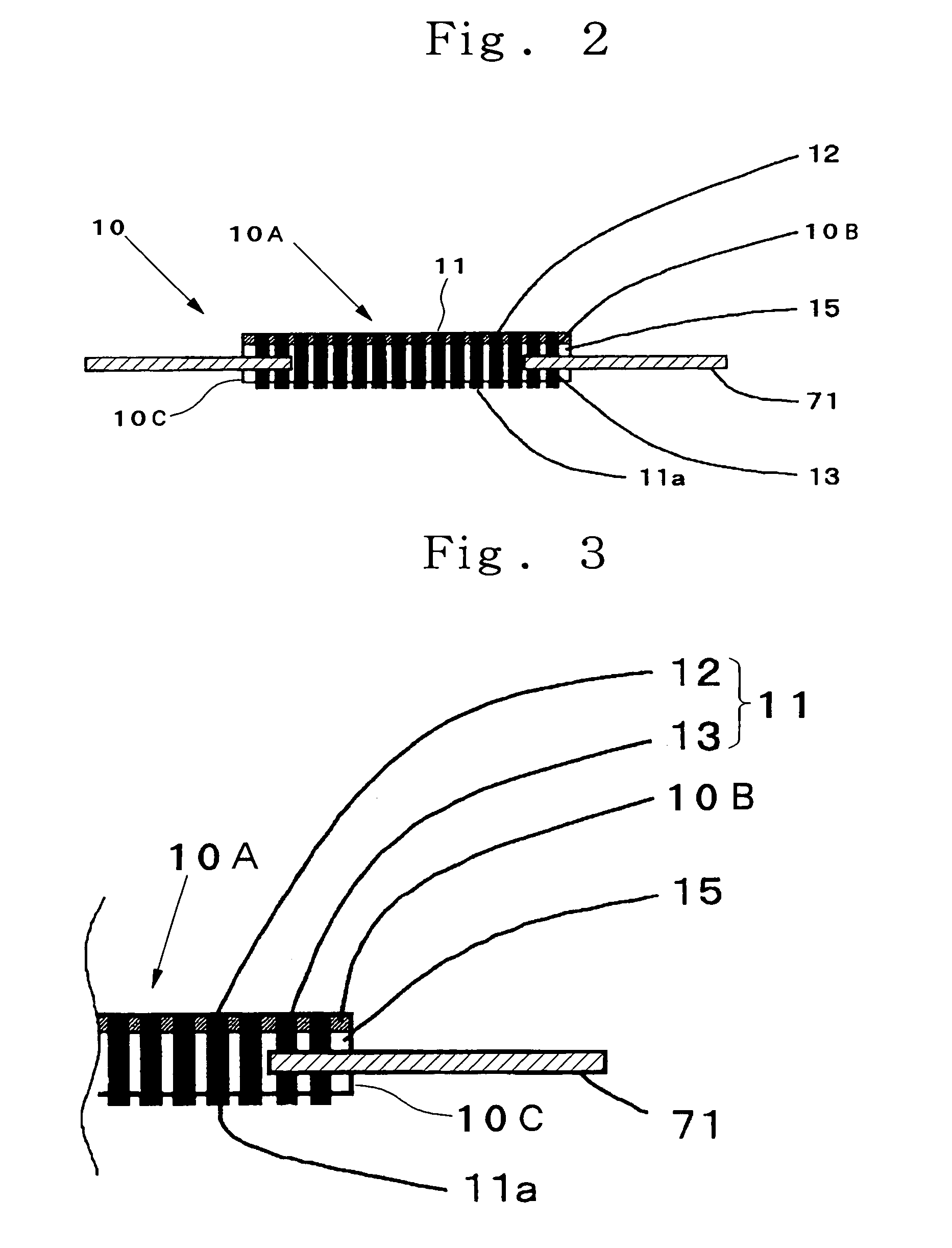

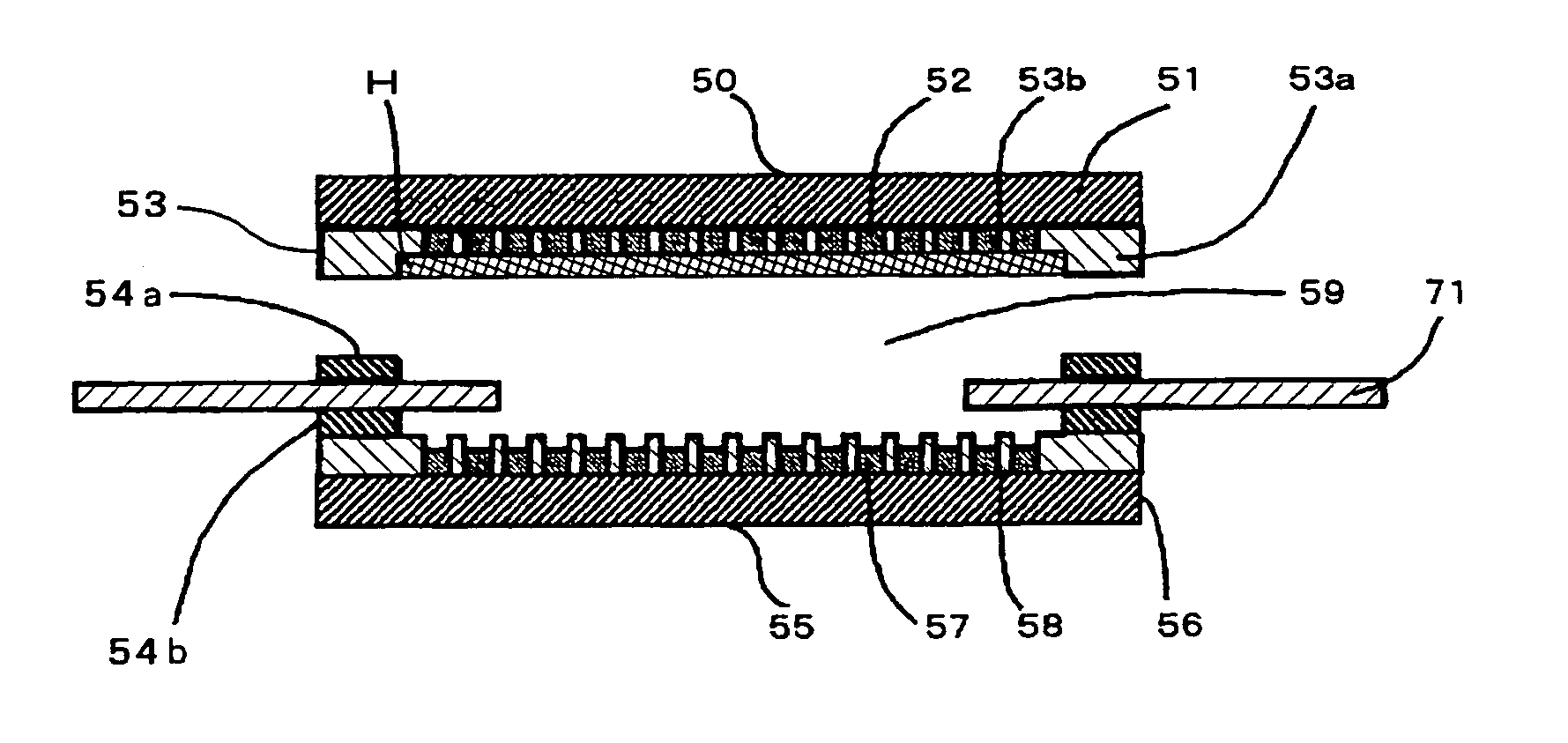

Anisotropic conductive connector and its production method, and circuit device test instrument

InactiveUS20050106907A1Improve conductivityPrevent permanent deformationElectrically conductive adhesive connectionsElectrical testingAnisotropic conductive filmEngineering

An anisotropically conductive connector, not causing permanent deformation by contact of target electrodes to be connected with pressure and deformation by abrasion even if the target electrodes are projected, and achieving stable conductivity over a long time period even when pressed repeatedly, a production process thereof, and an inspection circuit board equipped with the connector. The connector includes (1) anisotropically conductive film, with plural conductive path-forming parts each extending in a thickness-wise direction of the film arranged insulated by insulating parts and including at least 2 elastic layers, which are each formed by an insulating elastic polymeric substance, and (2) conductive particles exhibiting magnetism in portions of the respective elastic layers, at which conductive path-forming parts are formed. The connector satisfies H1≧30, and H1 / H2≧1.1, H1, H2 being durometer hardnesses of the elastic polymeric substance of one of elastic layers forming surfaces of the film, and of the elastic polymeric substance of the other, respectively.

Owner:ISC CO LTD

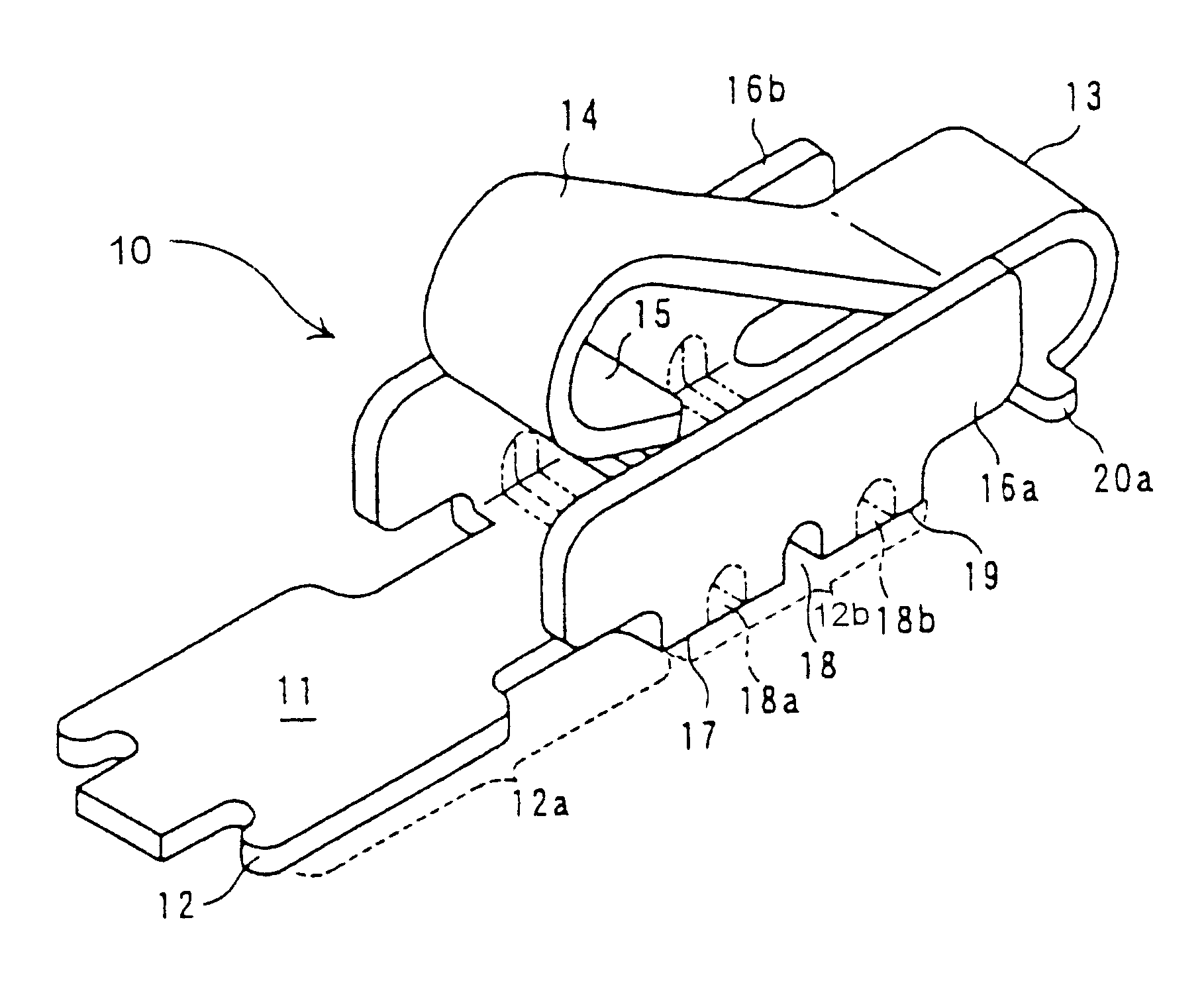

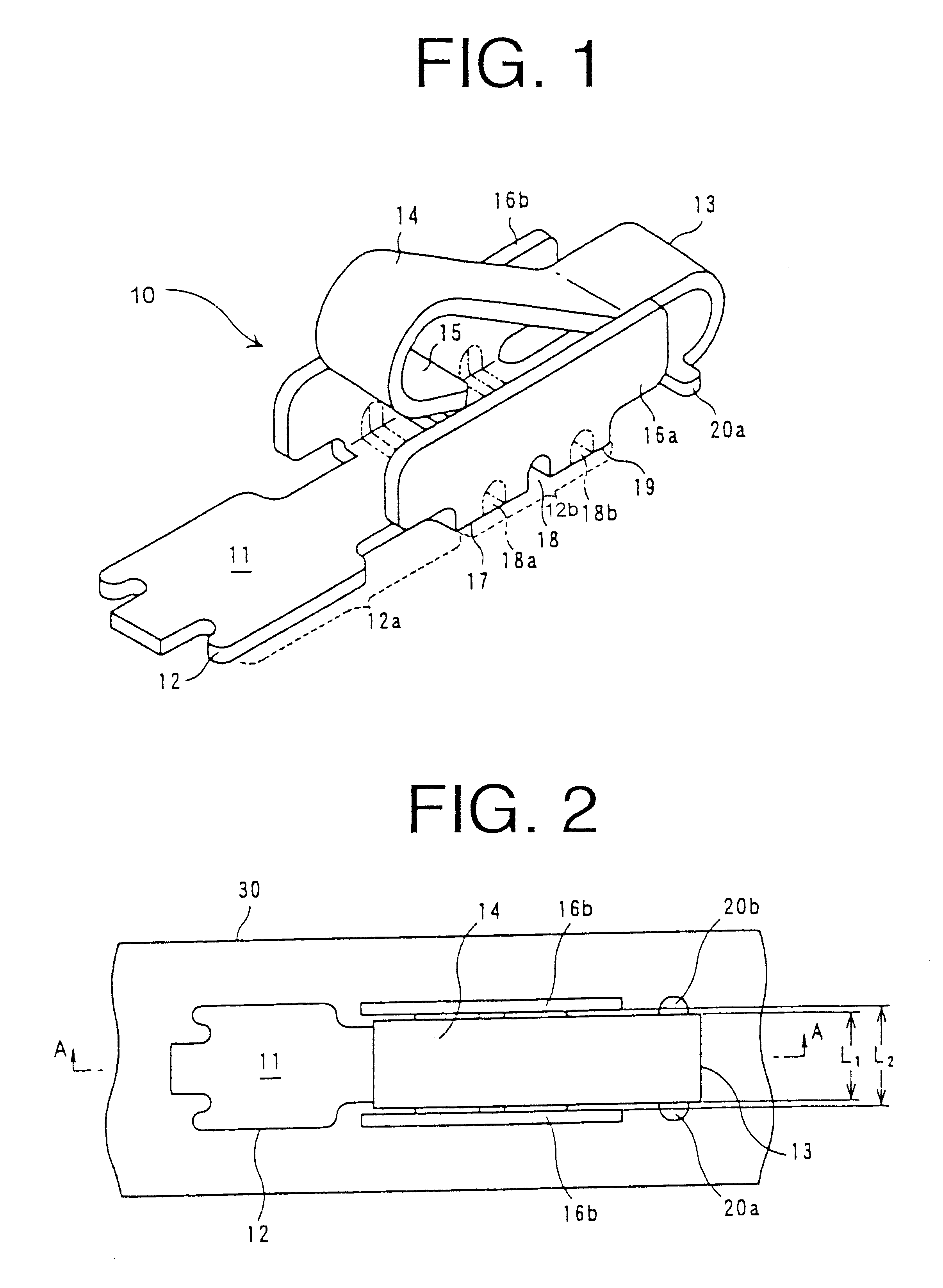

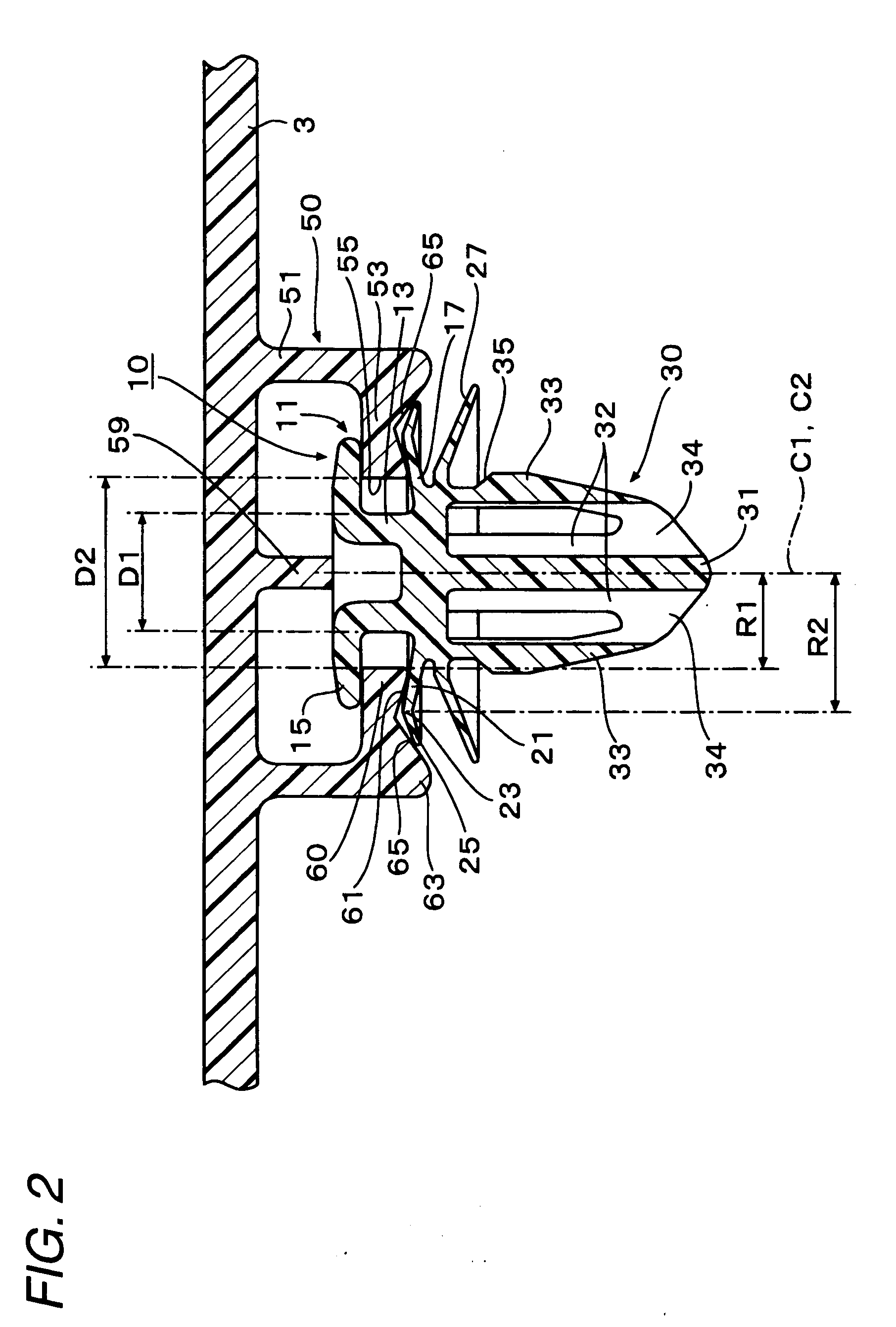

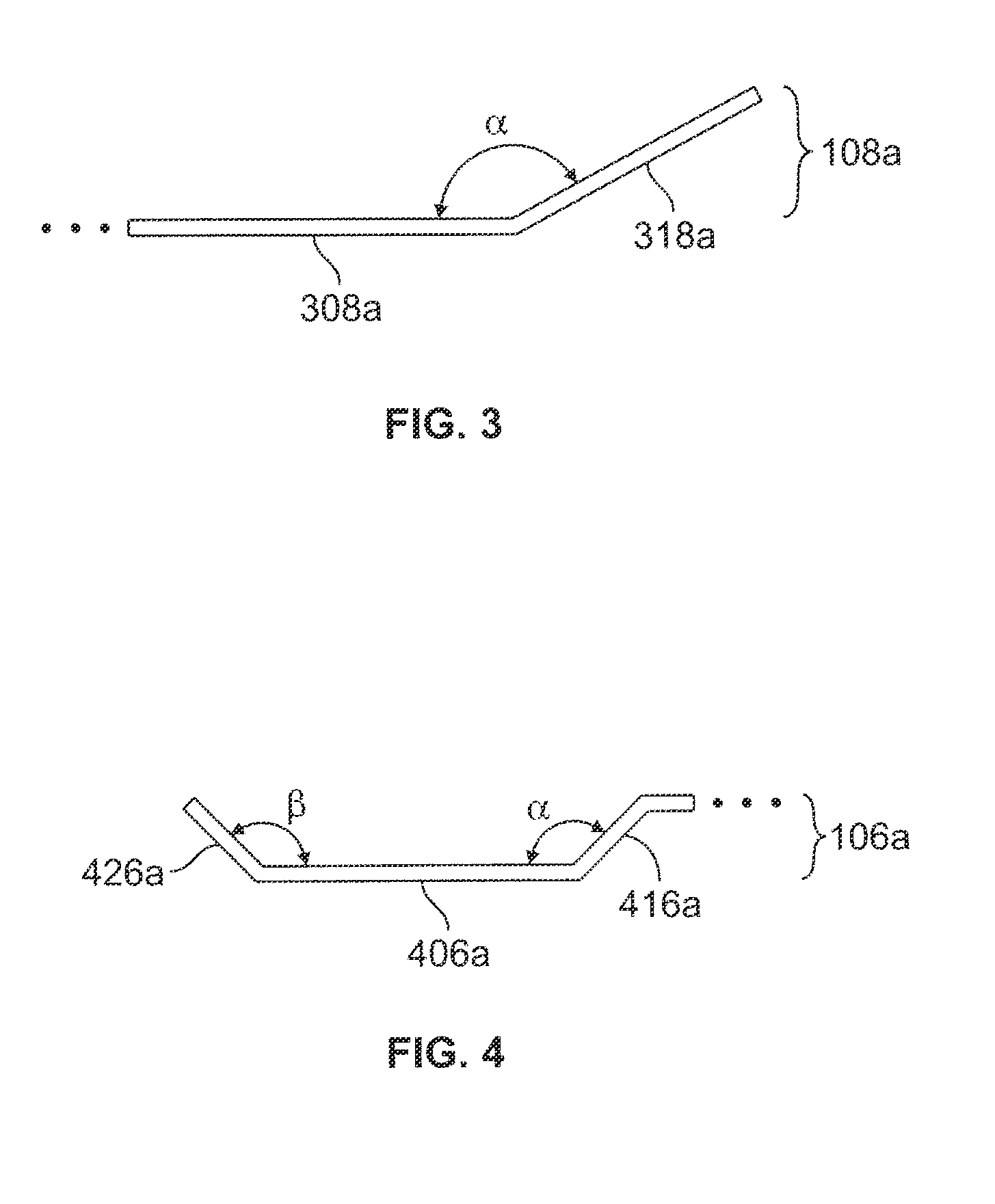

Connecting terminal and method of mounting the same onto a circuit board

InactiveUS6551149B2Prevent permanent deformationPrevent excessive deformationPrinted circuit assemblingSoldered/welded conductive connectionsElectrical conductorContact pressure

A connecting terminal for allowing a circuit board to come into compression contact with a flat conductor with certainty, particularly to a connecting terminal having a contact part which is not irregularly deformed even if the contact part comes into compression contact with the flat conductor oblique or in the lateral direction and which maintains an optimum contact pressure. The connecting terminal is made of a substantially strip conductive plate and comprises a fixed part provided at one end of the conductive plate to be mounted onto a circuit board, and a contact part extended from the fixed part and formed by bending the conductive plate toward the fixed part to form a curved part, wherein the contact part is elastically deformed about the curved part to come into compression contact with the substantially flat conductor, and the connecting terminal further comprises a pair of side wall parts formed by bending the conductive plate 11 at the fixed part in a width direction thereof, wherein the side wall parts have a height to an extent to restrict excessive deformation of the contact part when the contact part comes into compression contact with the flat conductor. Further, an interval between the pair of side wall parts is made larger than a width of the contact part, and both end sides of the contact part contact or approach inner surfaces of the side wall parts.

Owner:JST MFG CO LTD

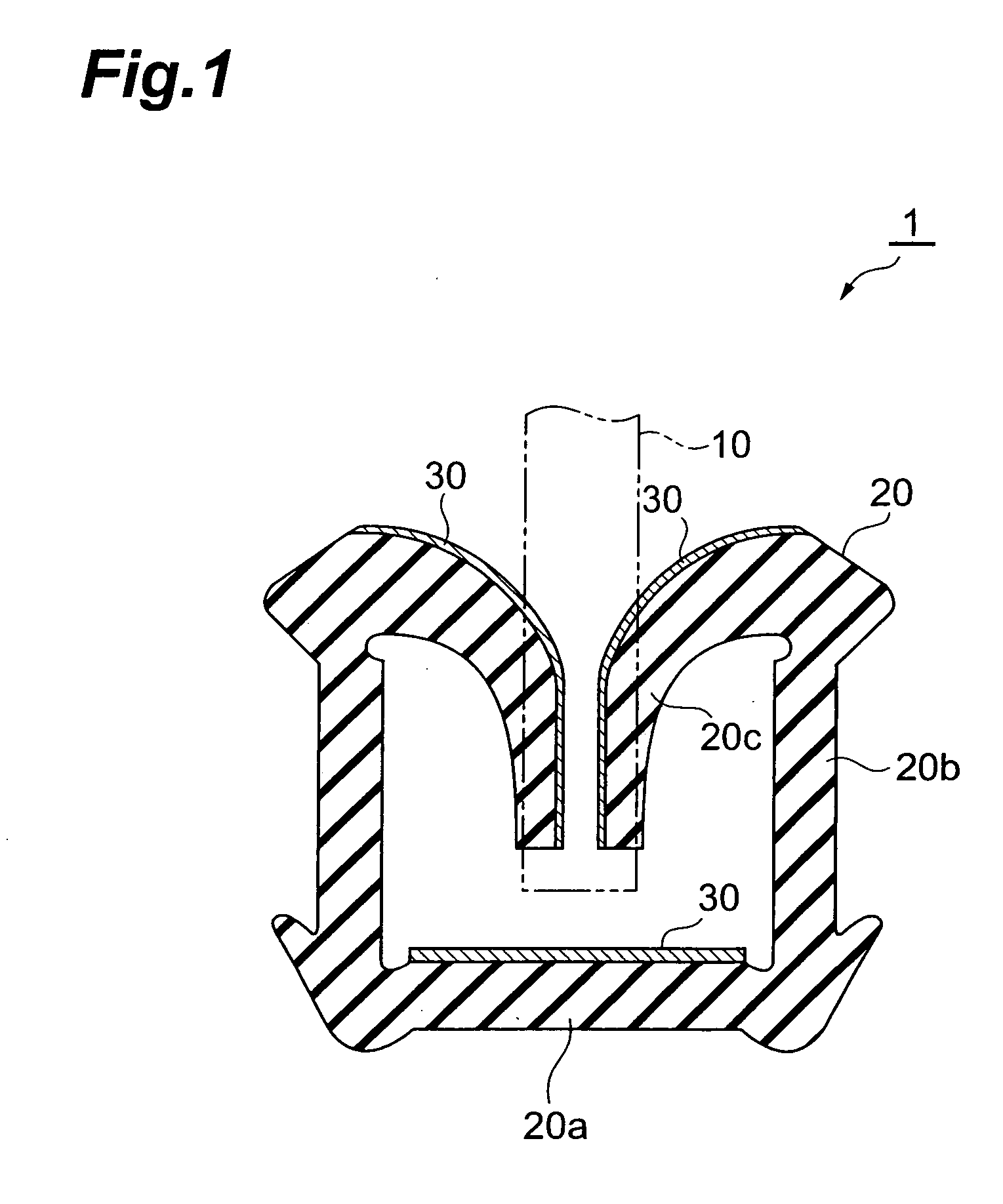

Weatherstrip

ActiveUS20070122570A1Improve the immunityAvoid noiseSynthetic resin layered productsVehicle componentsEthylene PolymersPropylene Polymers

A weatherstrip in which the sliding part of a lip in sliding contact with window glass is covered by a sliding member, wherein the sliding member is composed of a weatherstrip composition containing a polymer A group and a polymer B group, 40 to 100 wt % of the total weight of this composition is accounted for by the polymer A group, and 0 to 40 wt % by the polymer B group, the polymer A group is made up of a domain 1 consisting of crosslinked product of ethylene polymer and the like, and a domain 2 consisting of crosslinked product of ethylene polymer or ethylene / α-olefin copolymer, the storage elastic modulus E′ of domain 1 is at least 3 GPa and less than 9 GPa, and the loss tangent tanδ is from 0.1 to 0.4, the storage elastic modulus E′ of domain 2 is at least 9 GPa and no more than 13 GPa, and the loss tangent tanδ is from 0.1 to 0.3, and the ratio of domain 1 and domain 2 in the polymer A group (domain 1:domain 2) is from 50:50 to 95:5 (wt %), and the polymer B group is made up of a propylene polymer or other thermoplastic resin, in which the storage elastic modulus E′ is from 5 to 17 GPa, and the loss tangent tanδ is greater than 0.4 and no more than 0.7.

Owner:SHIN-ETSU POLYMER CO LTD

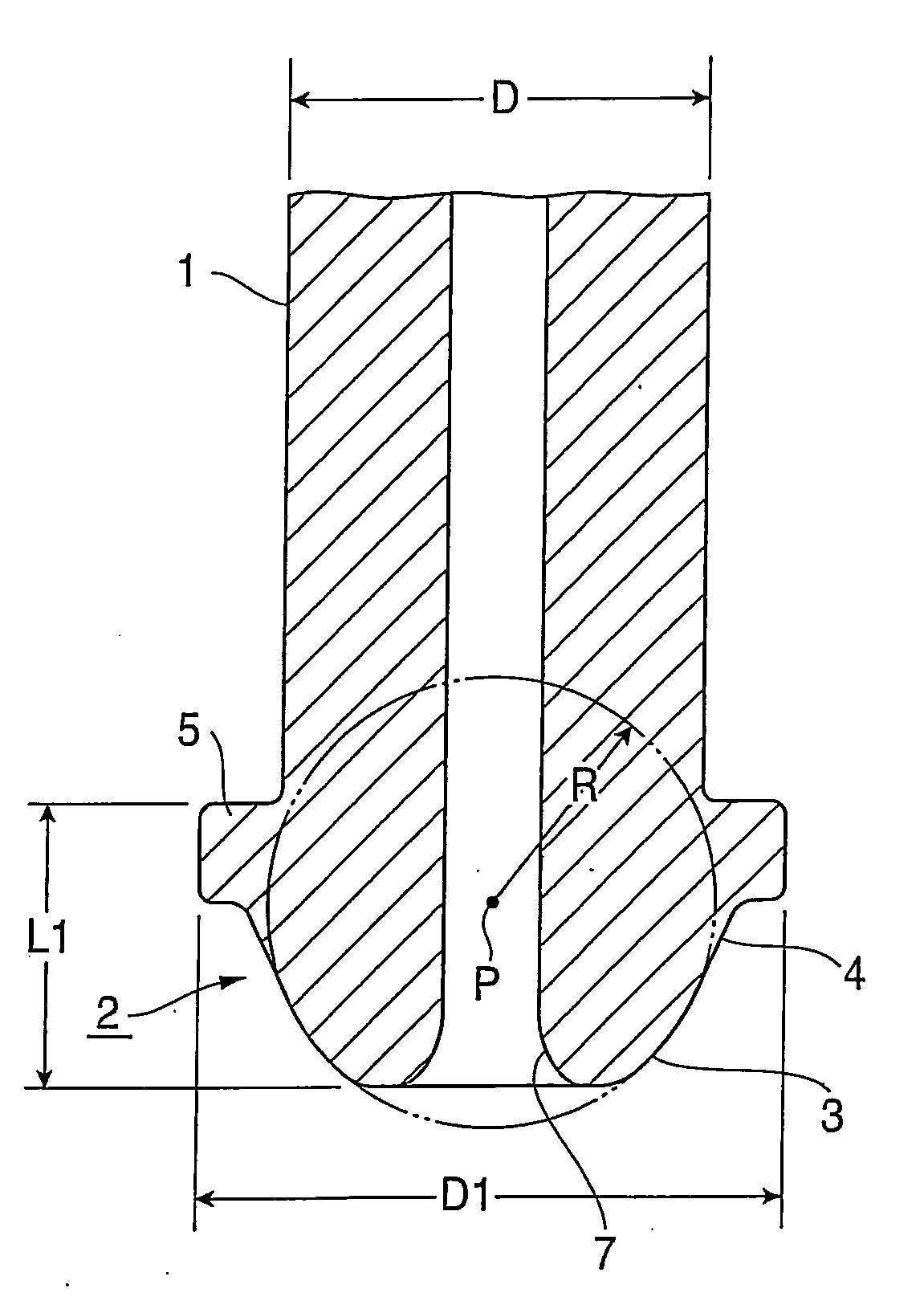

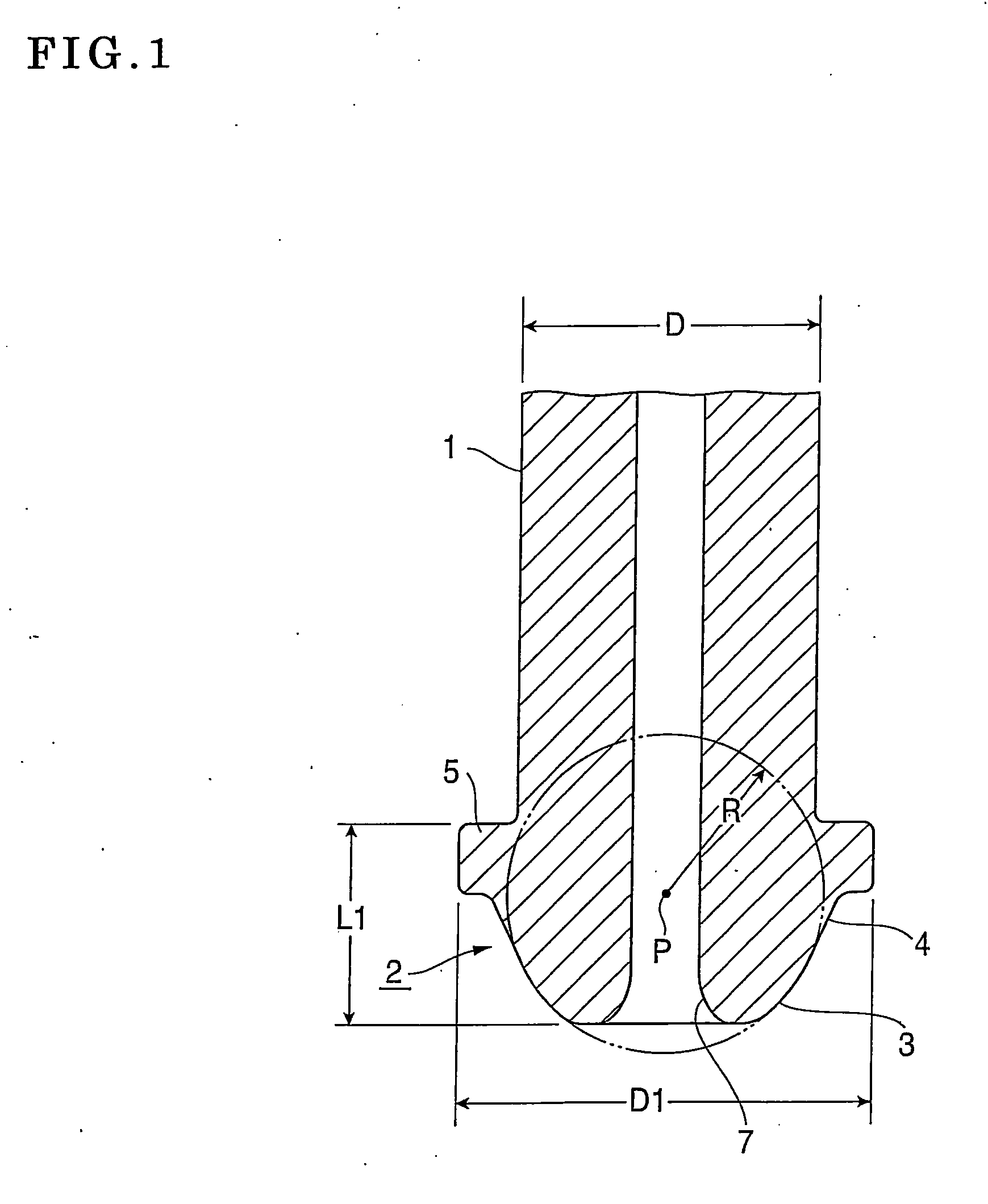

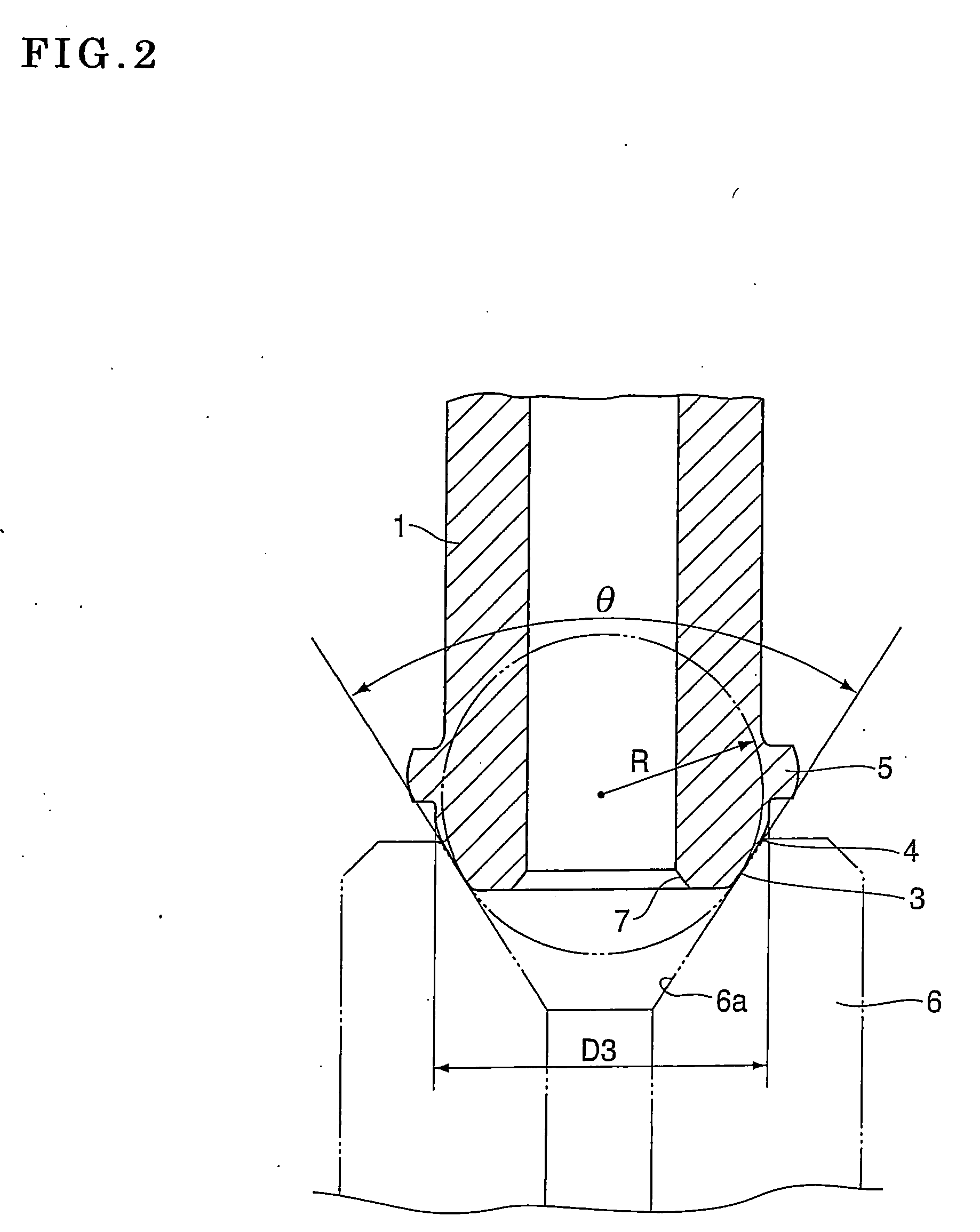

Connecting Head Stucture For High-Pressure Fuel Injection Pipes

ActiveUS20090139595A1Increase the diameterImprove stress conditionJoints with sealing surfacesMachines/enginesEngineeringThick wall

A thick-wall small-diameter high-pressure fuel injection pipe has a spherical seat surface, an annular flange, and a conical surface continued from the seat surface at a connecting end of the pipe. If the pipe is configured so that t (thickness) / D (outer diameter)<0.3, then an axial distance from the connecting head end to the back face of the annular flange is 0.38D to 0.6D, a spherical radius of the seat surface is 0.45D to 0.65D, the annular flange outer diameter is 1.2D to 1.4D, and an inner peripheral surface of the head has a substantially flat cylindrical surface or a conical surface. If the pipe is configured so that t (thickness) / D (outer diameter)≧0.3, then the axial distance from the connecting head end to the back face of the annular flange is 0.38D to 0.7D.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

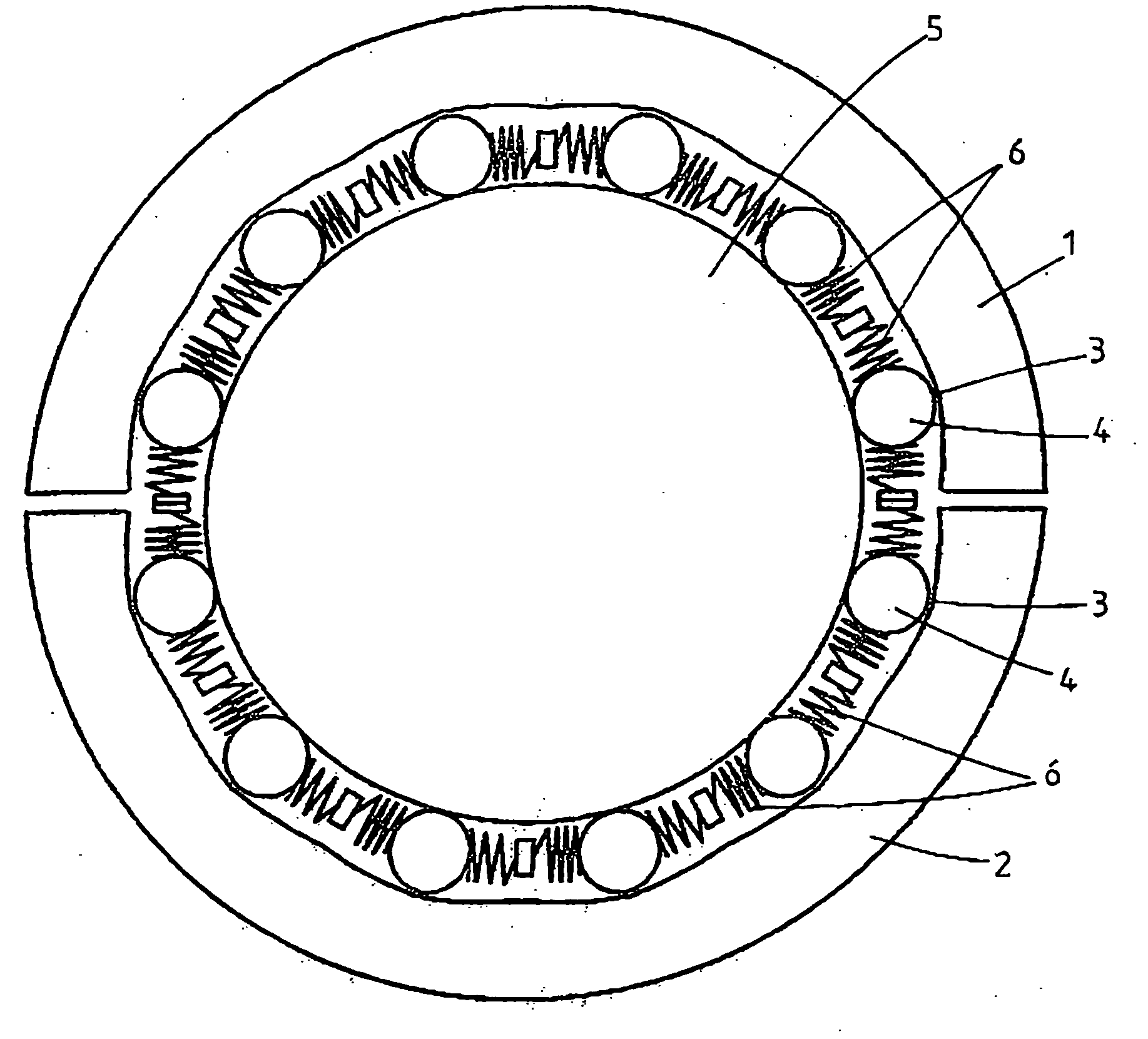

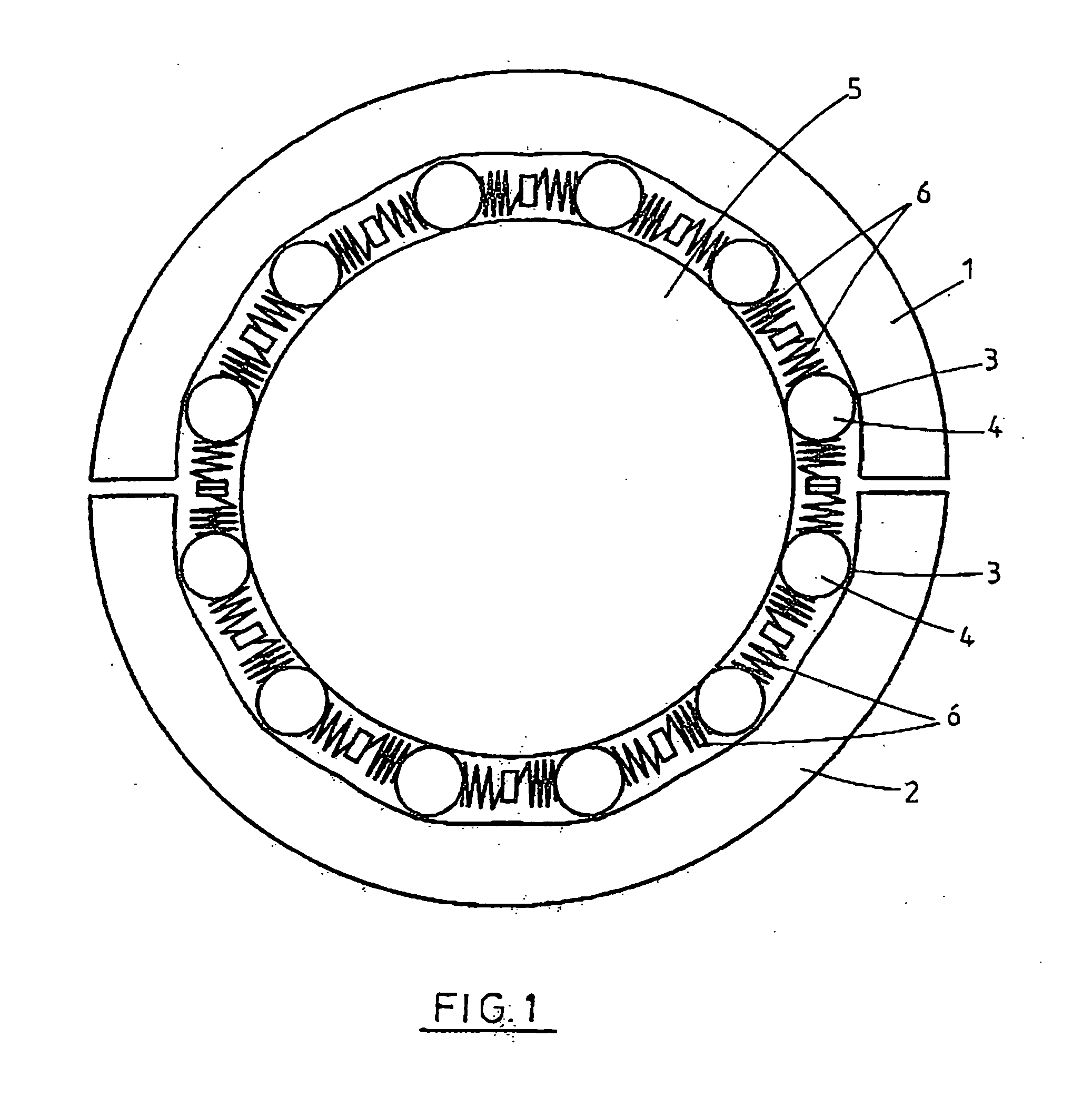

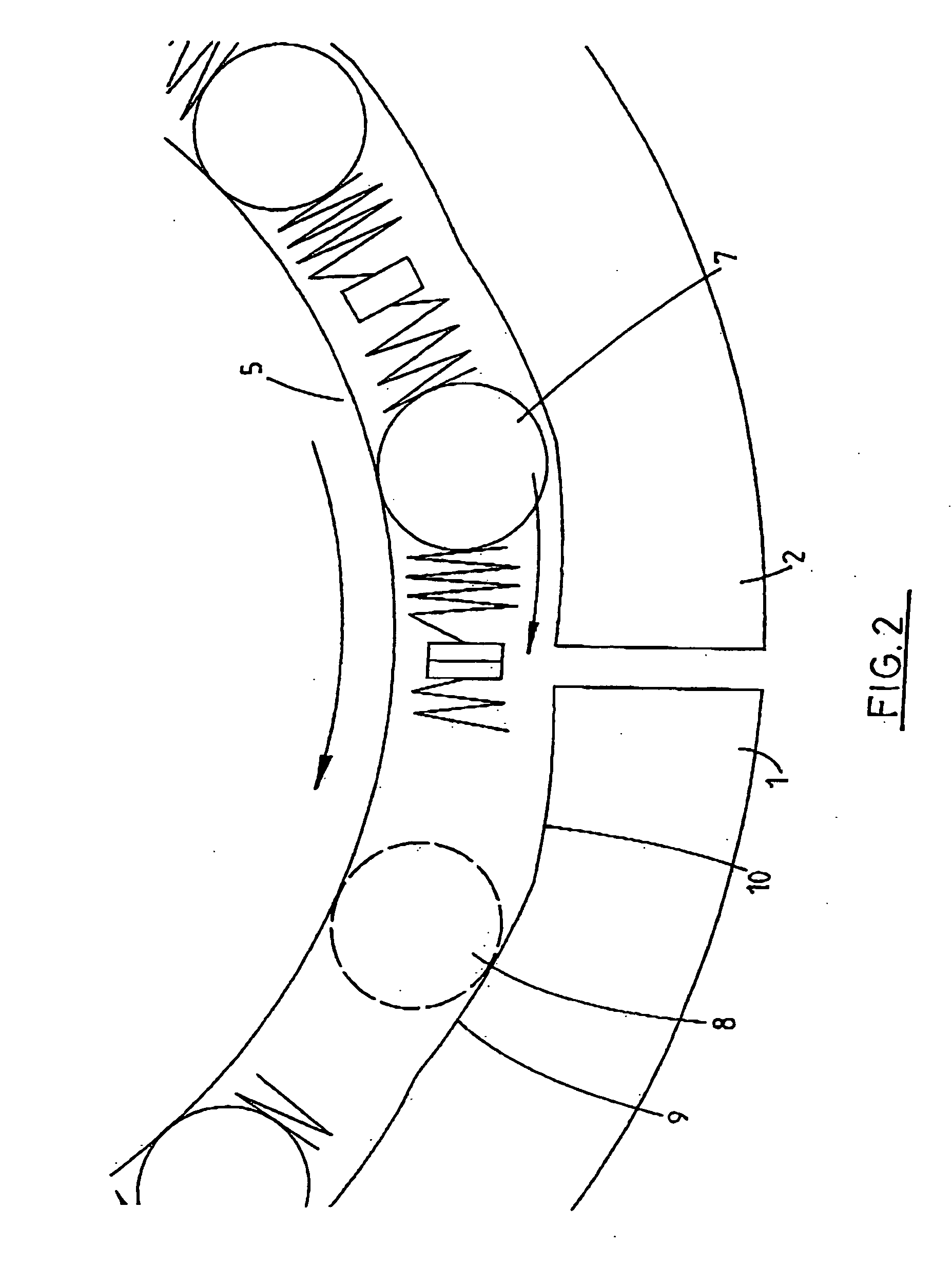

Gripping or clamping mechanisms

A clamping mechanism having two or more jaws which may be opened to allow a tubular to be introduced within the jaws and closed to retain the tubular therewithin. The rollers are located within concave recesses and maintained in spaced apart relationship by biasing means, whereby rotation of tubular may cause the rollers to be wedged between a wall of the recess and the tubular to grip the tubular within the jaws. The clamping mechanism may be utilized as an oil field tubular clamp, a slip, a pipe clamp, and other mechanisms. There is also disclosed a clutch comprising an outer race, a cage, and an inner ring. Recesses are provided in an outer race and accommodate rollers therewith and maintained in spaced apart relationship by the cage. The cage may be moved by an actuator to selectively allow free wheeling or prevent rotation. A socket ratchet incorporating such a clutch is also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

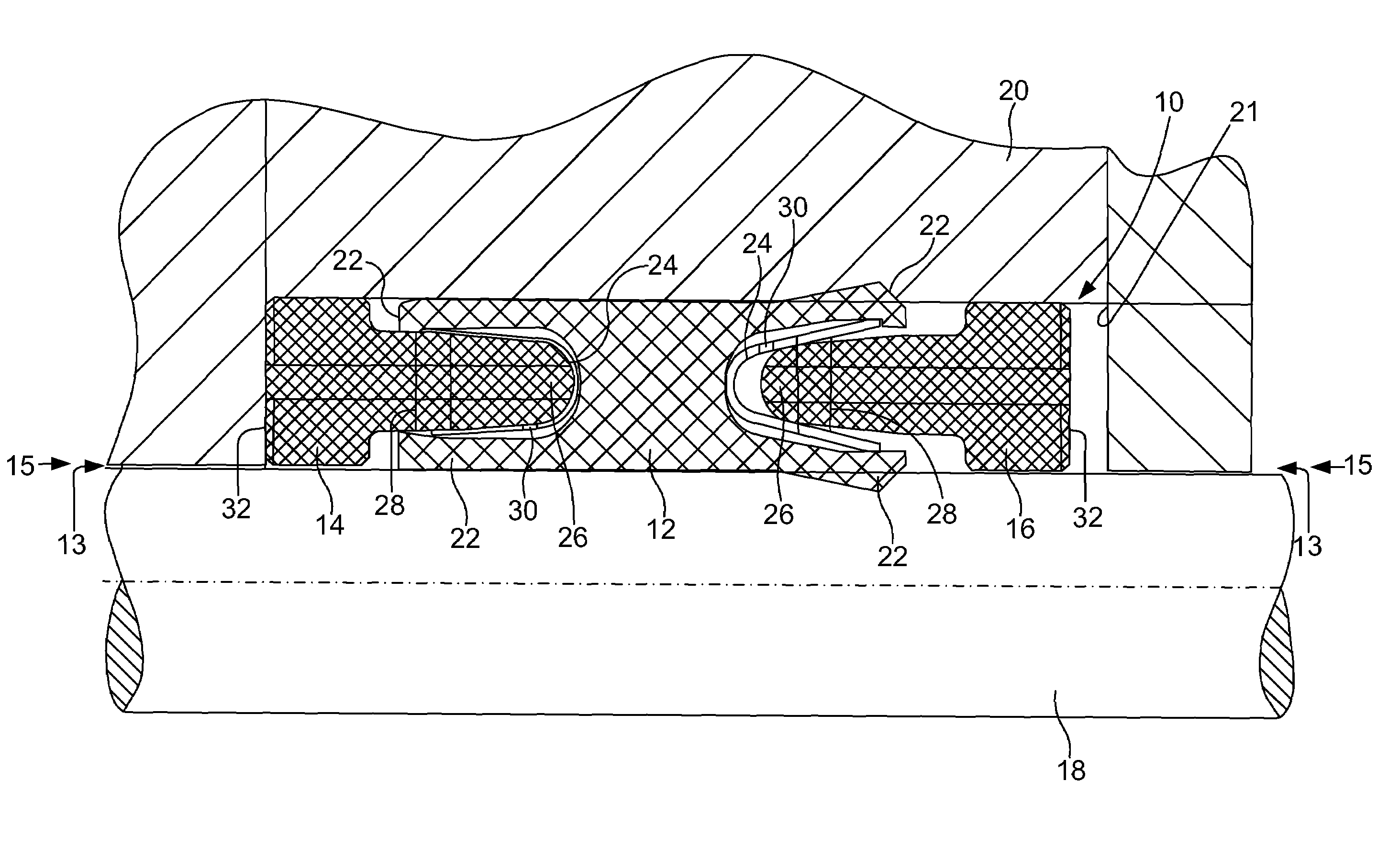

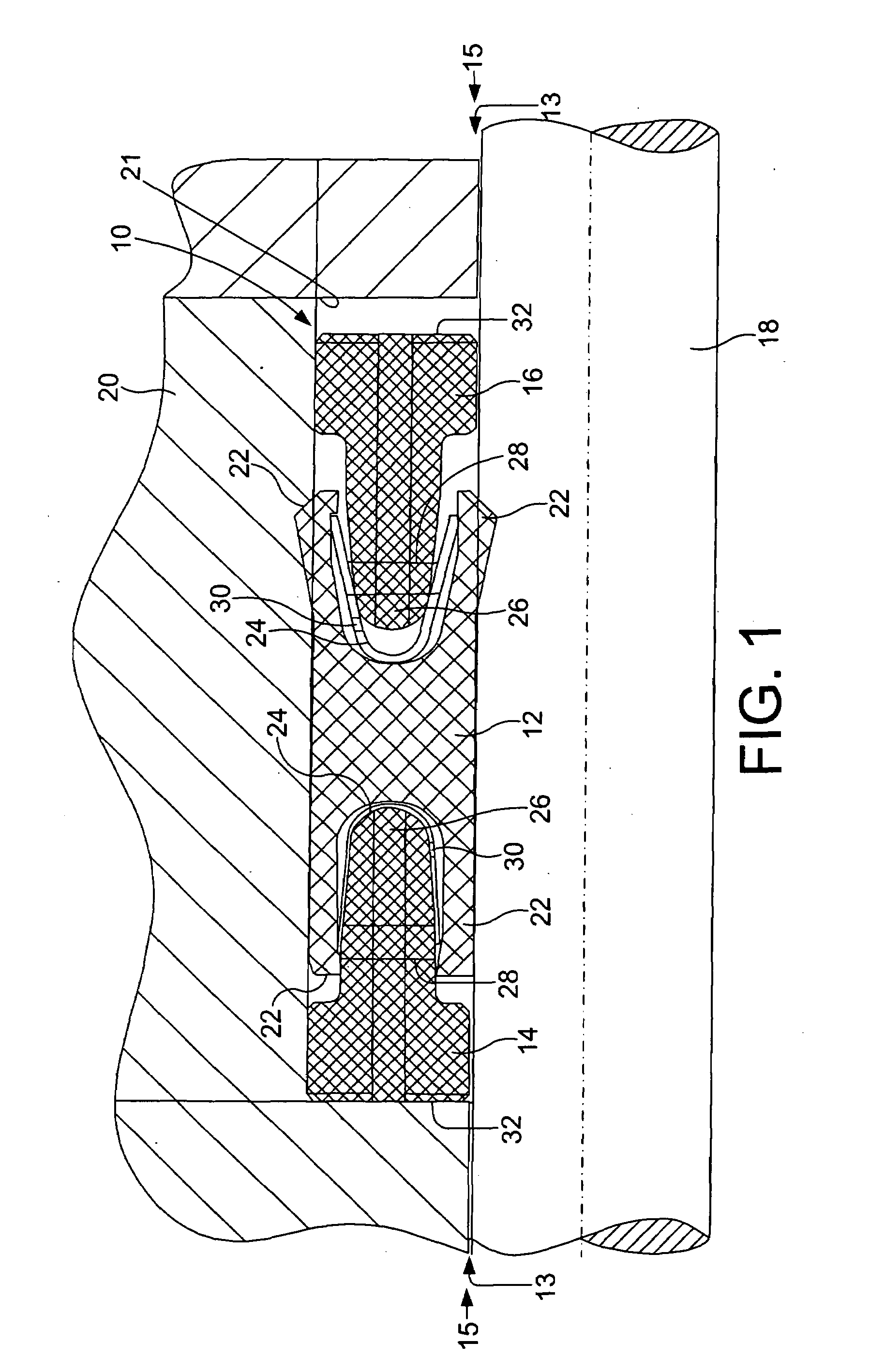

Seal assembly

ActiveUS20100052267A1Suitable environmentPrevent permanent deformationEngine sealsSealingEngineeringMechanical engineering

A sealing assembly for a shaft includes a sealing component, a first ring, a second ring, and at least one energizer. The first ring is annularly disposed about the shaft, the first ring having at least one first protuberance interfittable with the sealing component. The second ring is annularly disposed about the shaft in facing opposition to the first ring, the second ring having at least one second protuberance interfittable with the sealing component. The at least one energizer energizes the seal component, the at least one energizer being adjacent the at least one first protuberance or the at least one second protuberance.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

Gripping or clamping mechanisms

ActiveUS8186246B2The implementation process is simpleCounteracting forceDrilling rodsWrenchesEngineeringActuator

A clamping mechanism having two or more jaws which may be opened to allow a tubular to be introduced within the jaws and closed to retain the tubular therewithin. The rollers are located within concave recesses and maintained in spaced apart relationship by biasing means, whereby rotation of tubular may cause the rollers to be wedged between a wall of the recess and the tubular to grip the tubular within the jaws. The clamping mechanism may be utilized as an oil field tubular clamp, a slip, a pipe clamp, and other mechanisms. There is also disclosed a clutch comprising an outer race, a cage, and an inner ring. Recesses are provided in an outer race and accommodate rollers therewith and maintained in spaced apart relationship by the cage. The cage may be moved by an actuator to selectively allow free wheeling or prevent rotation. A socket ratchet incorporating such a clutch is also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

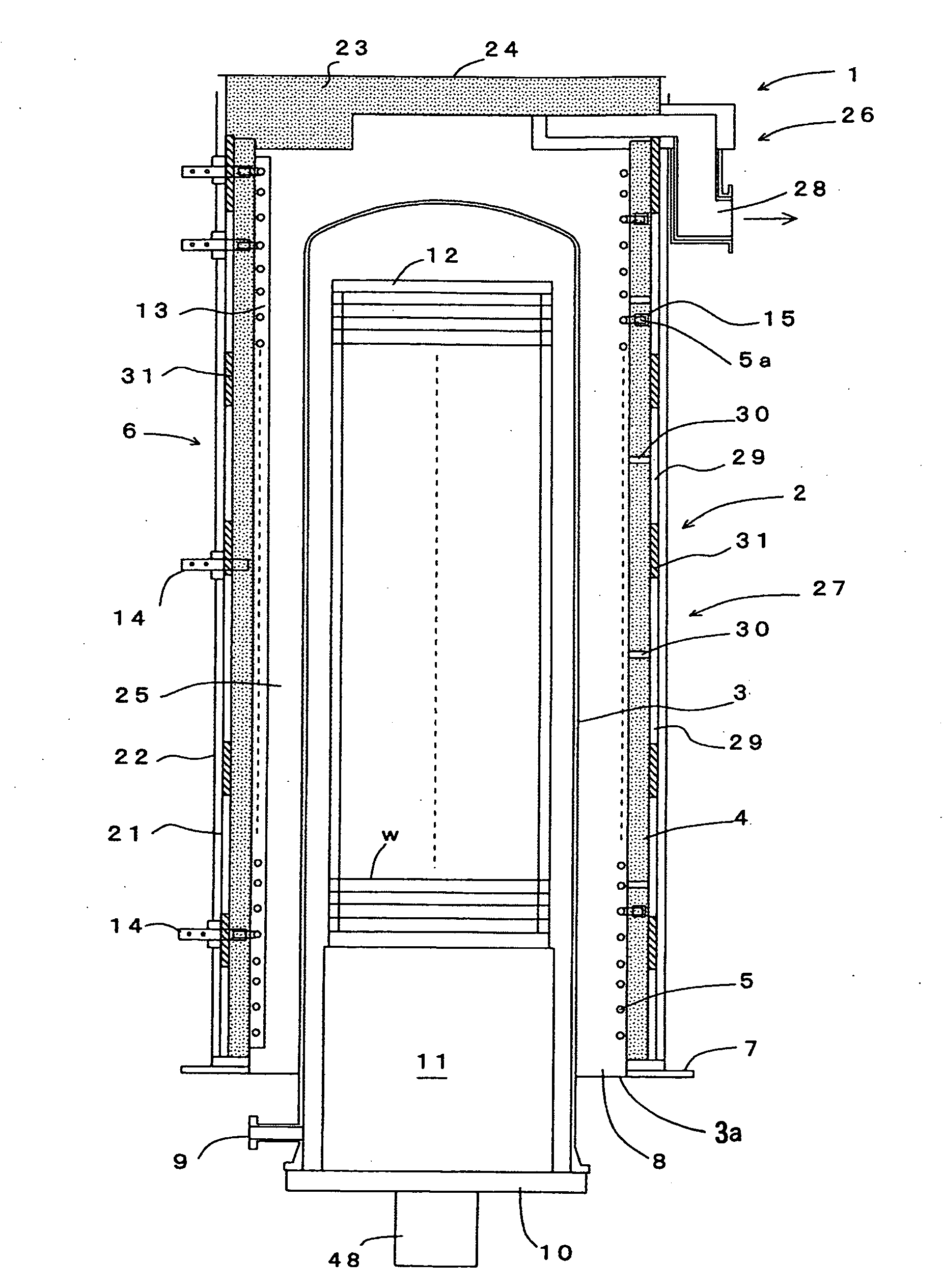

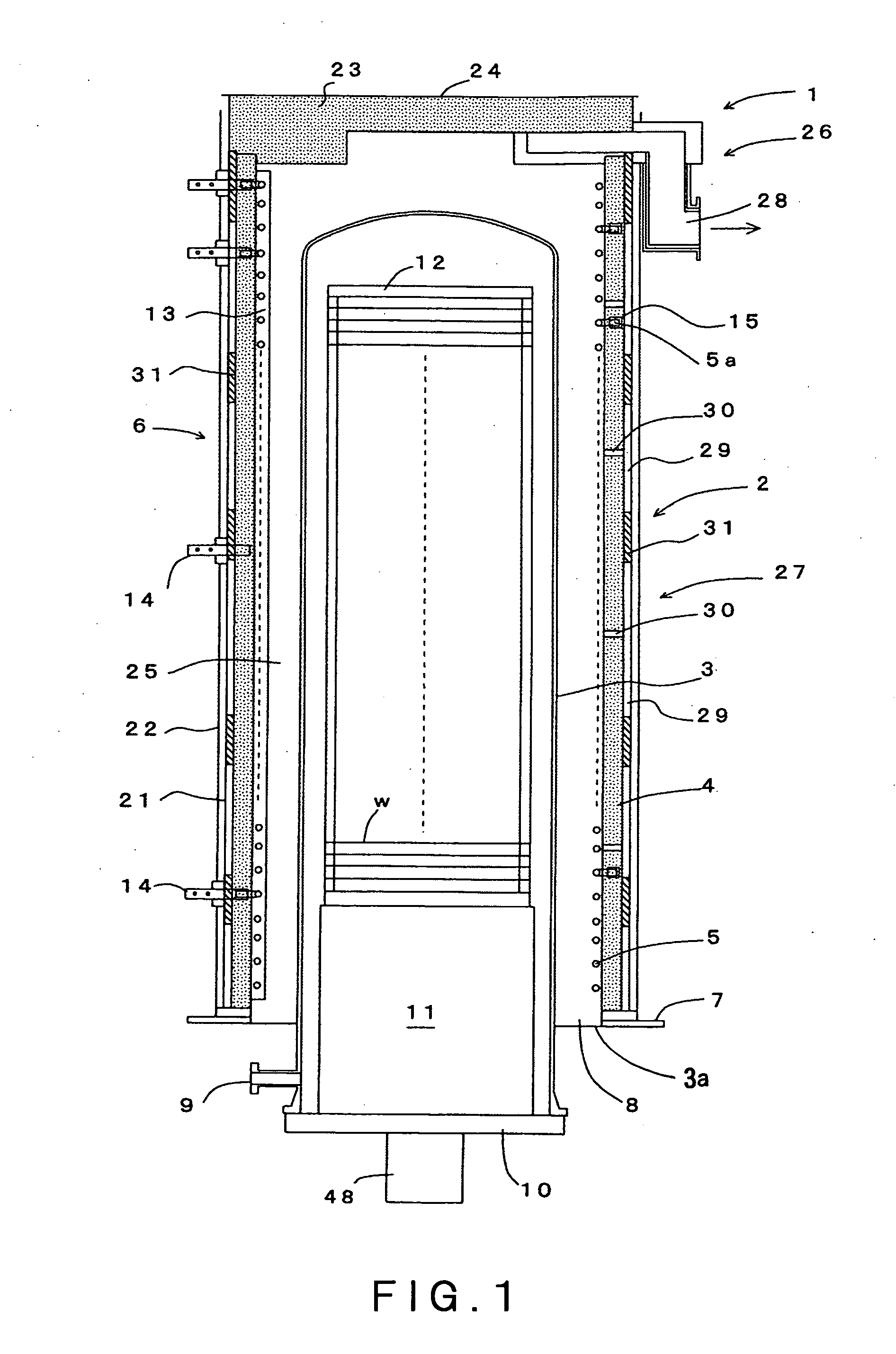

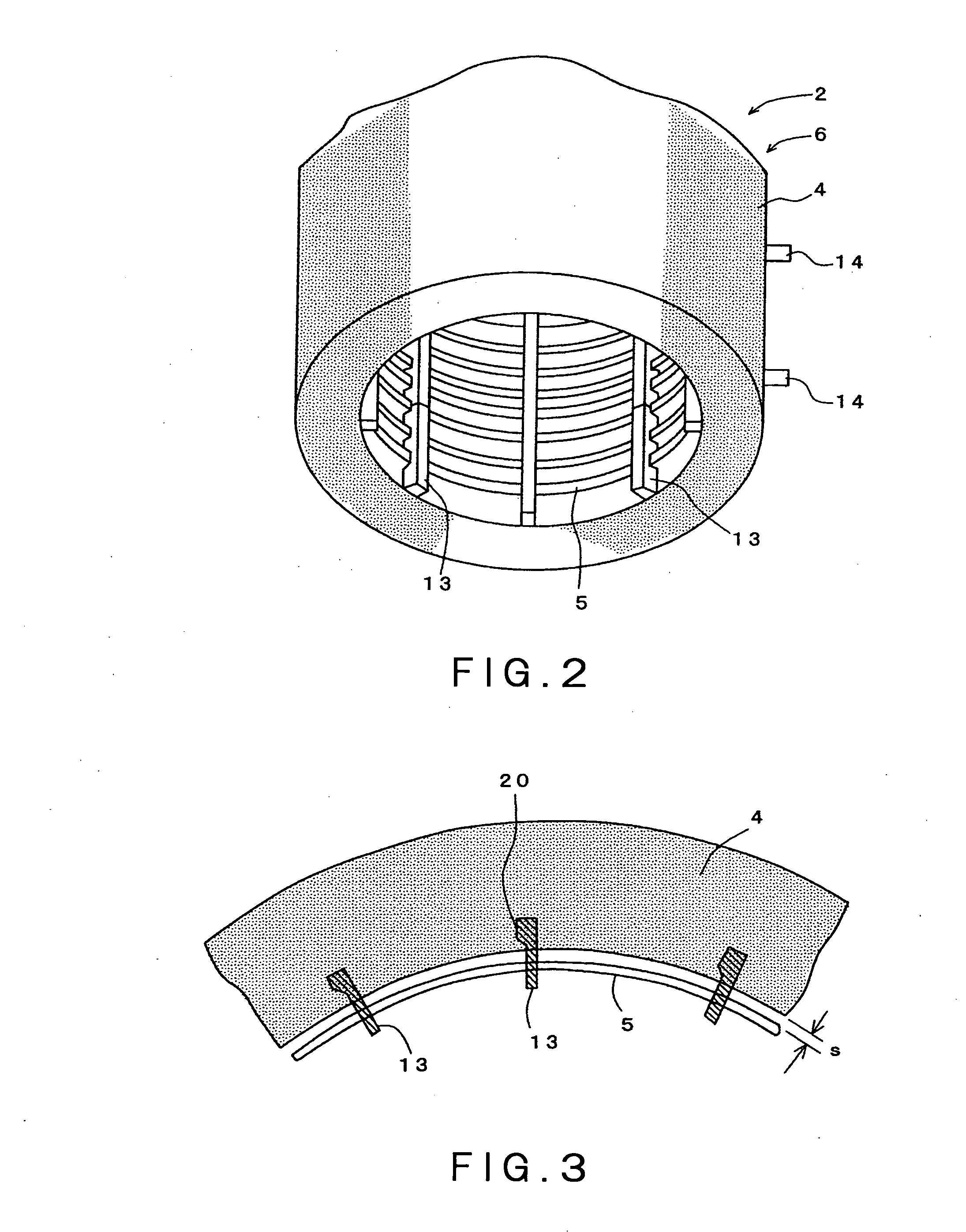

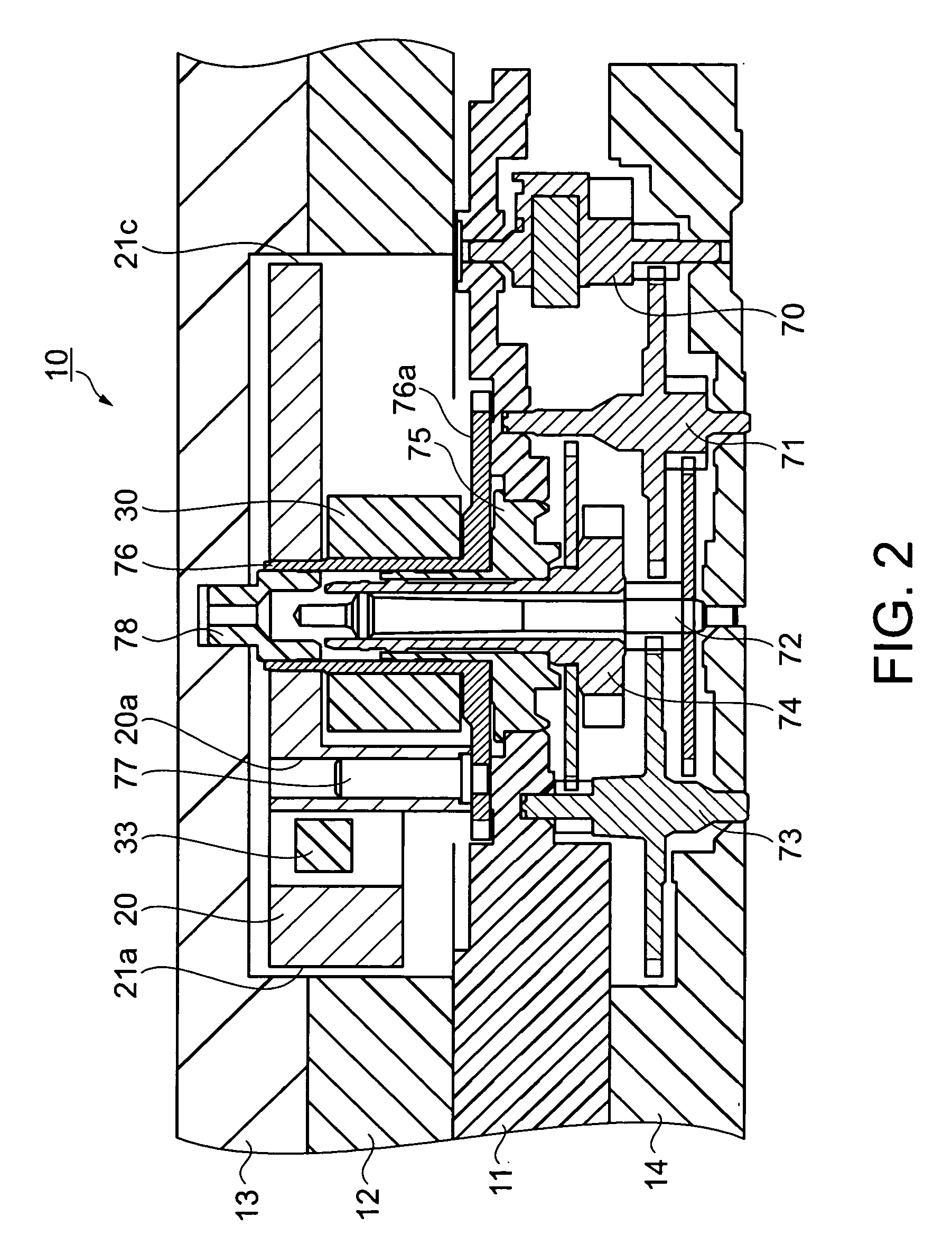

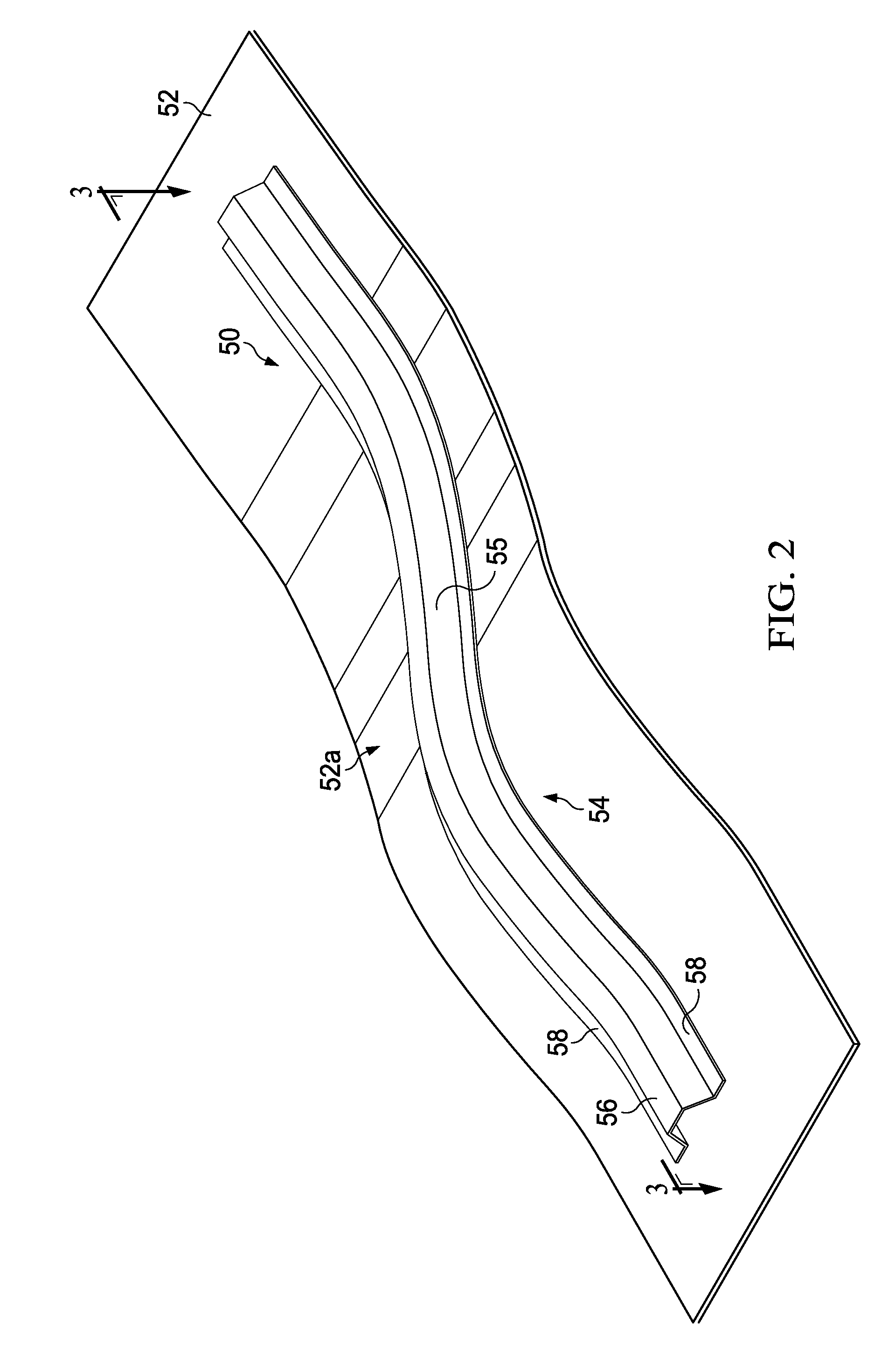

Heat processing furnace and method of manufacturing the same

ActiveUS20080296282A1Increased durabilityReduce frictional resistanceOhmic-resistance electrodesRotary drum furnacesCurve shapeEngineering

The object of the present invention is to reduce a frictional resistance which is generated between a support member and a heating resistor when the heating resistor is thermally expanded and thermally shrunk, whereby generation of a permanent deformation of the heating resistor caused by a residual stress thereof can be restrained, to thereby improve the durability. A heat processing furnace comprises: a processing vessel 3 capable of accommodating an object to be processed w and subjecting the object to be processed w to a heat process; a cylindrical heat insulation member 4 surrounding the processing vessel 3; a helical heating resistor 5 arranged along an inner peripheral surface of the heat insulation member 4; a support member 13 disposed on the inner peripheral surface of the heat insulation member 4 in parallel with an axial direction thereof, for supporting the heating resistor 5 at predetermined pitches along the axial direction; and a plurality of terminal plates 14 axially arranged on an outside of the heating resistor 5 at suitable intervals therebetween, the terminal plates 14 radially passing through the heat insulation member 4 so as to be extended outside. The support member 13 includes a base part 17 positioned on an inside of the heating resistor 5, and a plurality of support pieces 18 extending radially outward from the base part through spaces between adjacent portions of the heating resistor 5 so as to support the heating resistor 5, the support member 13 being formed to have a comb-like shape. An upper surface part of each of the support pieces 18 is formed to have a curved shape in order to reduce a frictional resistance generated when the heating resistor 5 is moved upon a thermal expansion and a thermal shrinkage thereof.

Owner:TOKYO ELECTRON LTD

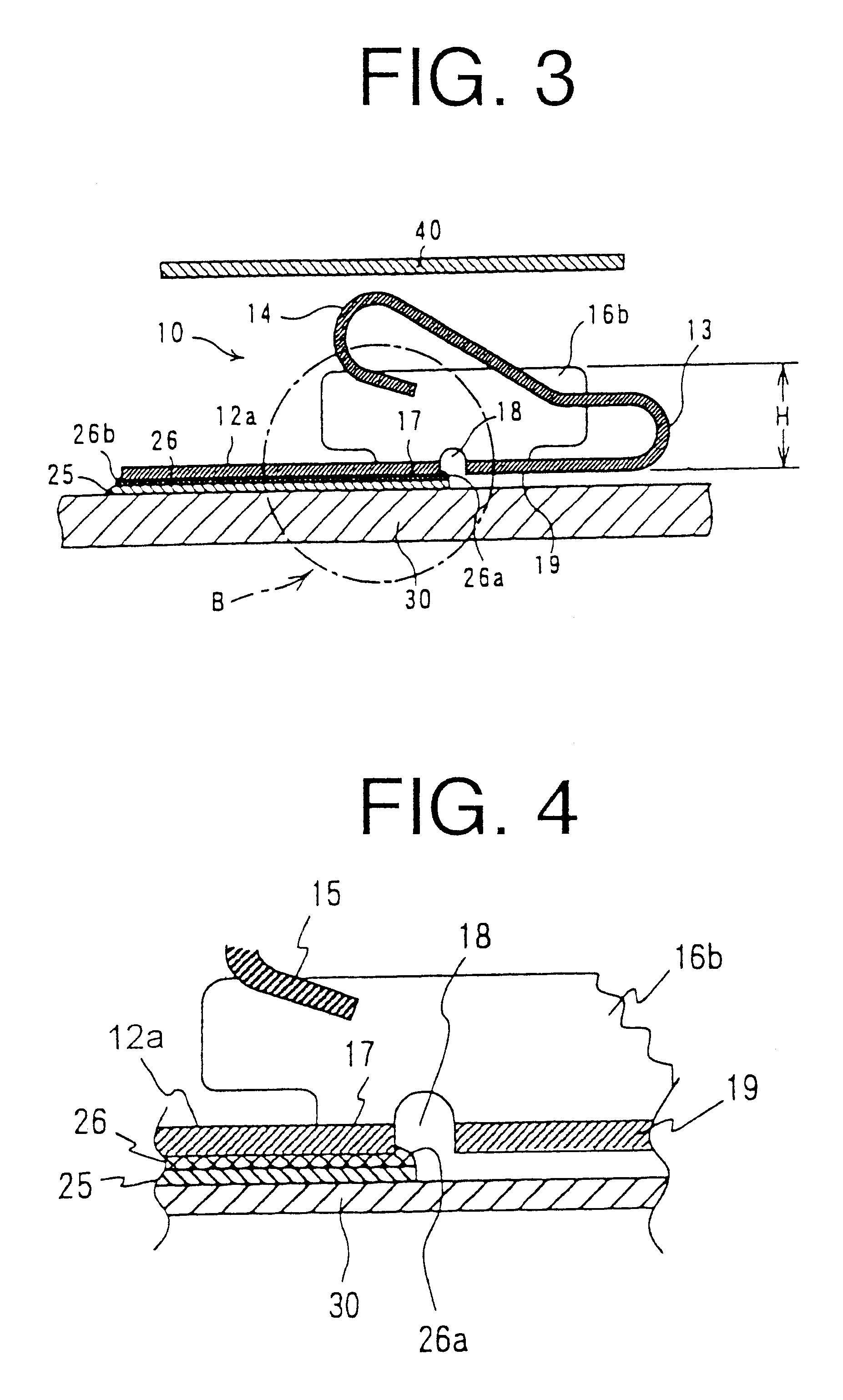

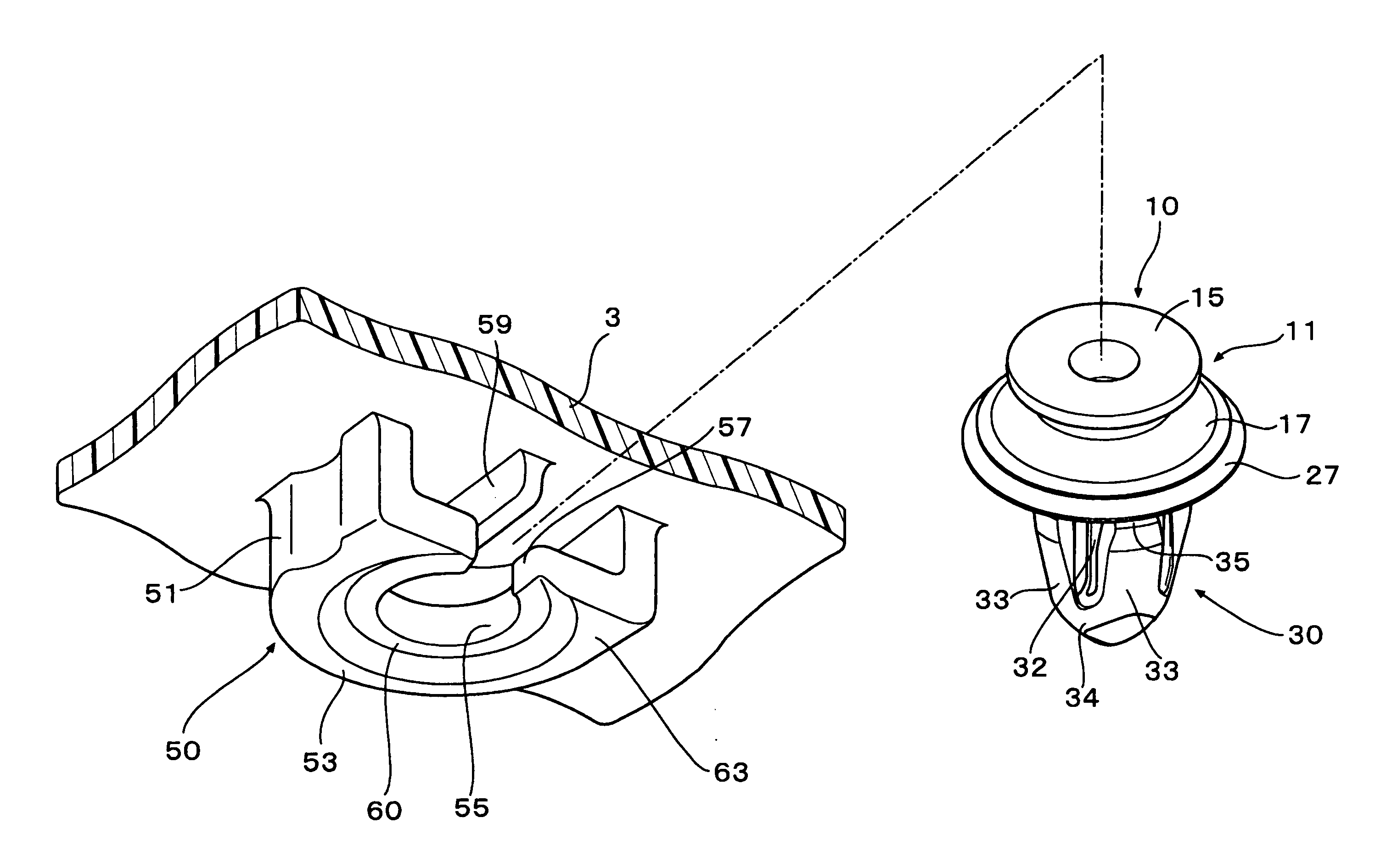

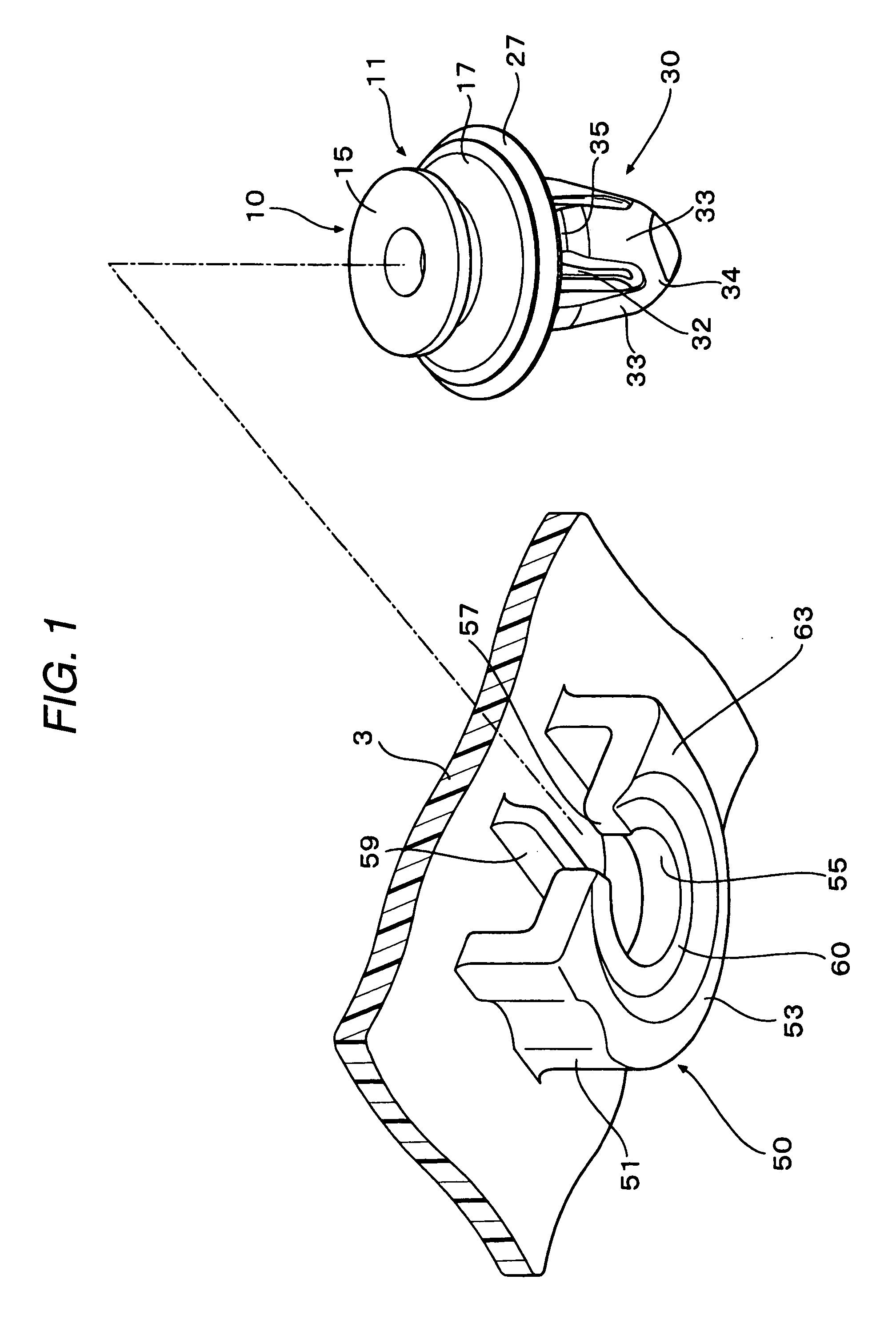

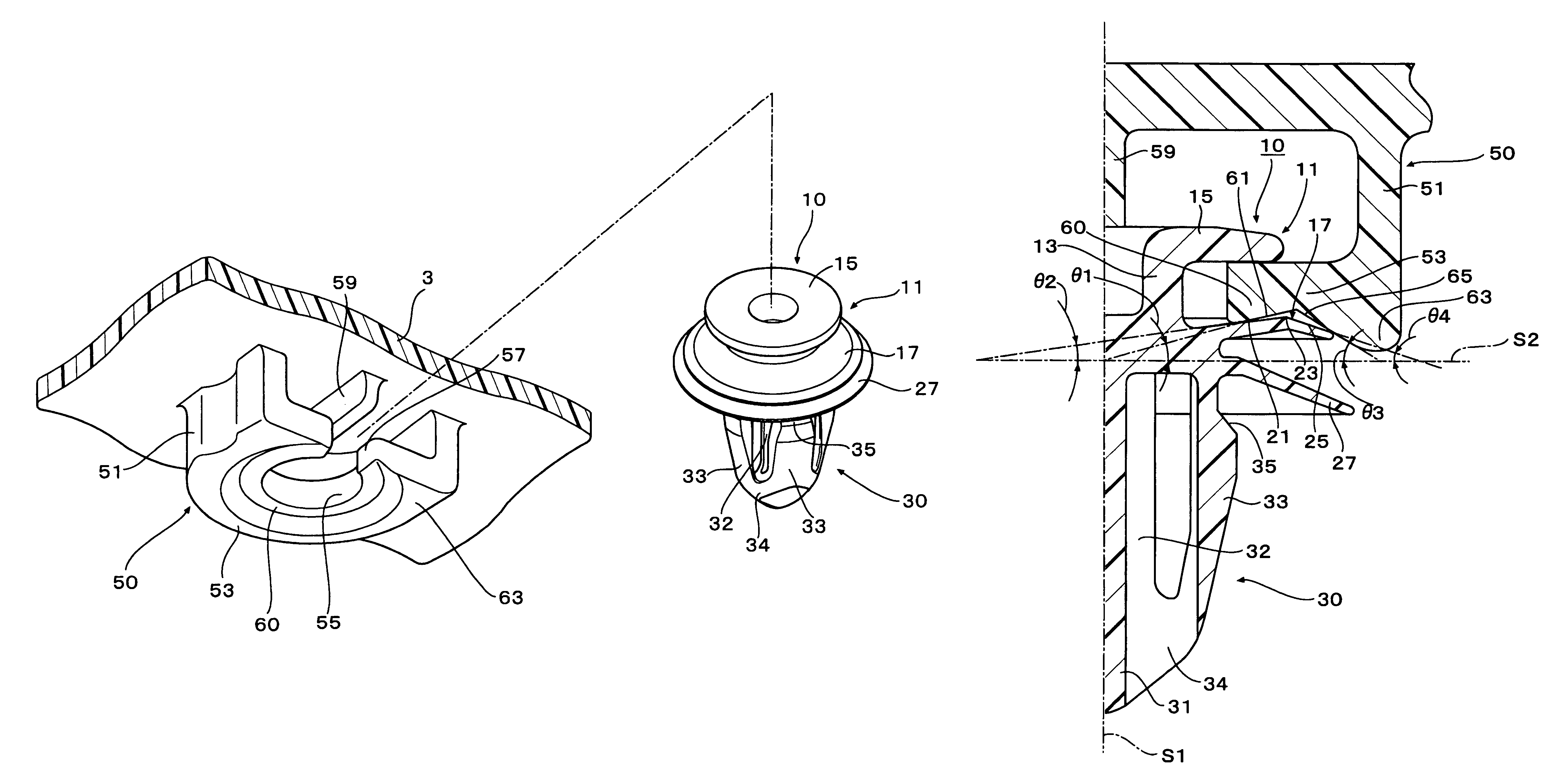

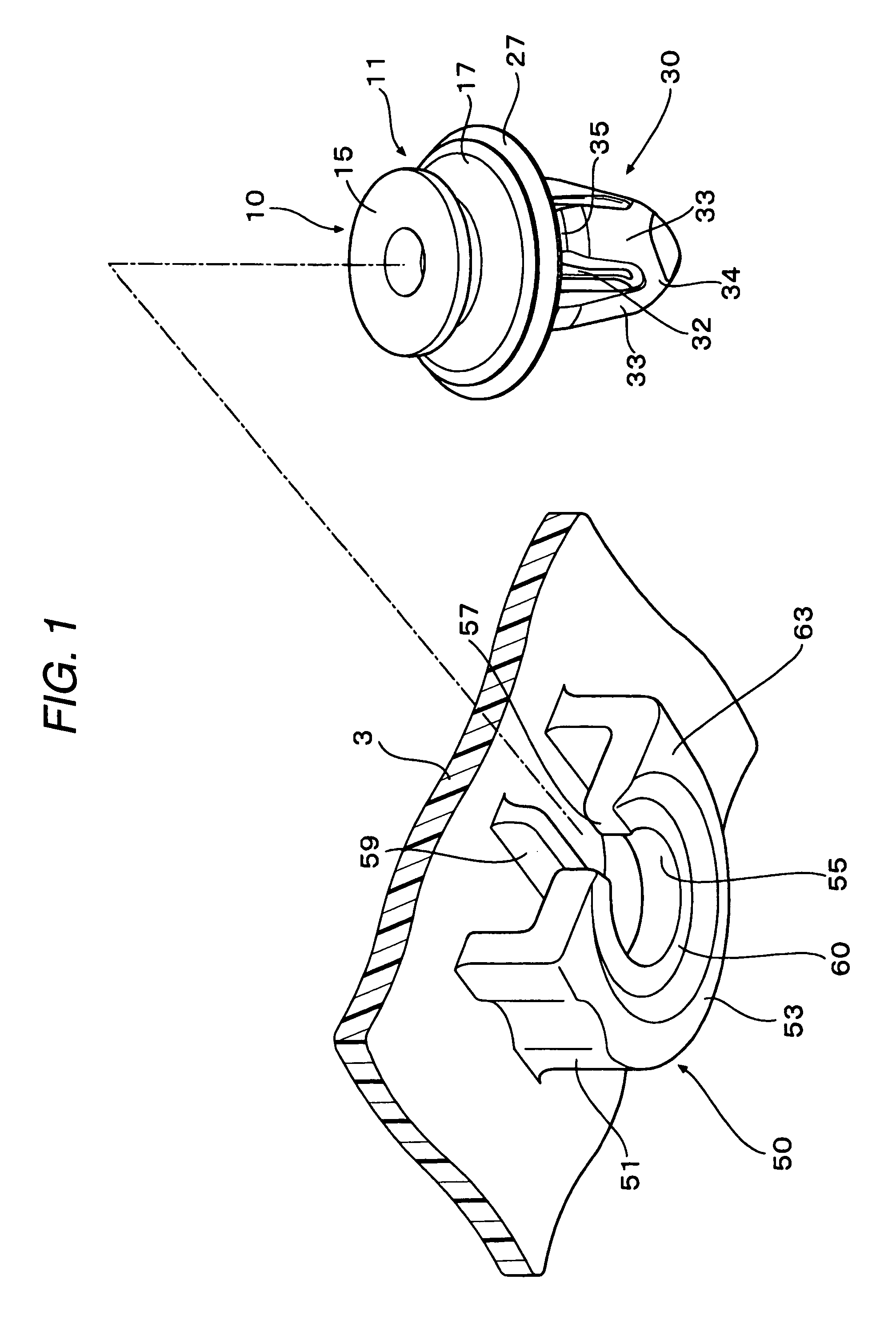

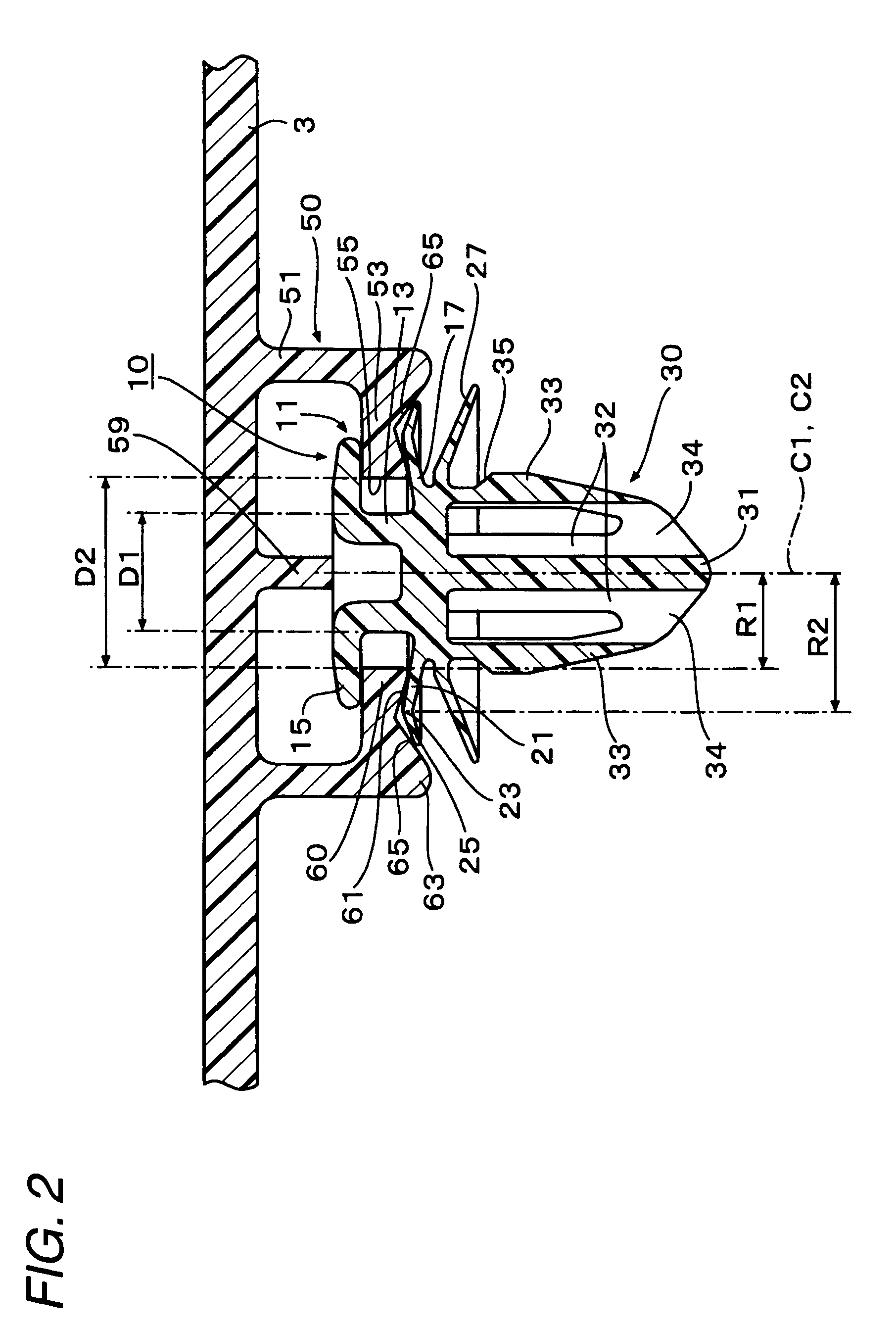

Assembling structure of clip and mounting member

InactiveUS20090218464A1Prevent permanent deformationKeep elasticSnap fastenersPicture framesEngineeringFlange

According to an aspect of the present invention, there is provided an assembling structure including: a mounting member having a mounting seat; and a clip having a head and a leg. The head includes: a neck portion; and first and second flanges outwardly protrudes therefrom to sandwich the mounting seat therebetween, wherein the mounting seat includes: a hole having a diameter larger than that of the neck portion; a groove formed to communicate the hole with outside the mounting seat; and a projection protruding from a peripheral edge of the hole, wherein the second flange includes: an inner face radially-outwardly extending therefrom to gradually come close to the first flange; a top portion; and an outer face further extending to gradually separate from the first flange, and wherein the inner face abuts the projection in an assembled state.

Owner:PIOLAX CO LTD

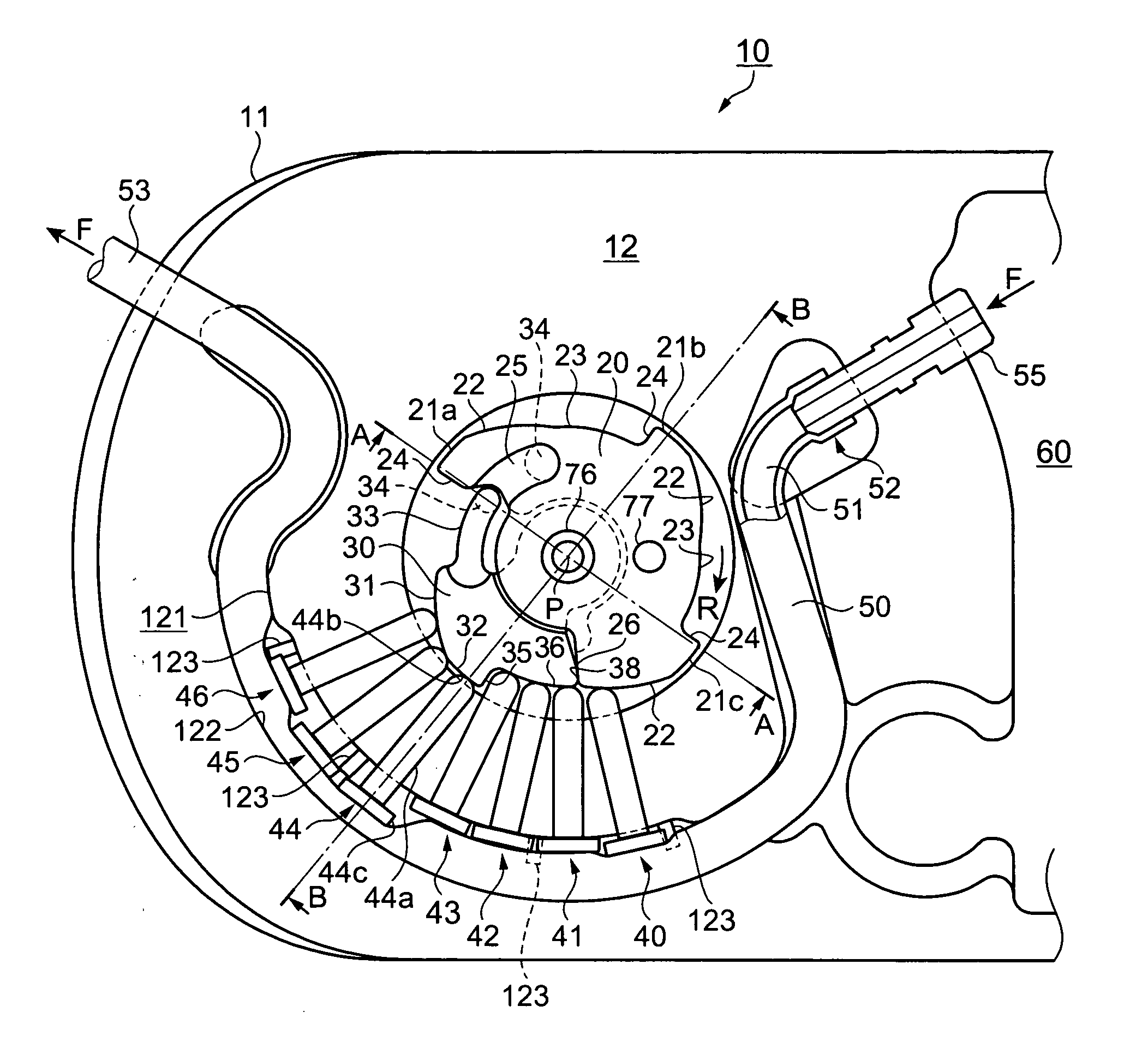

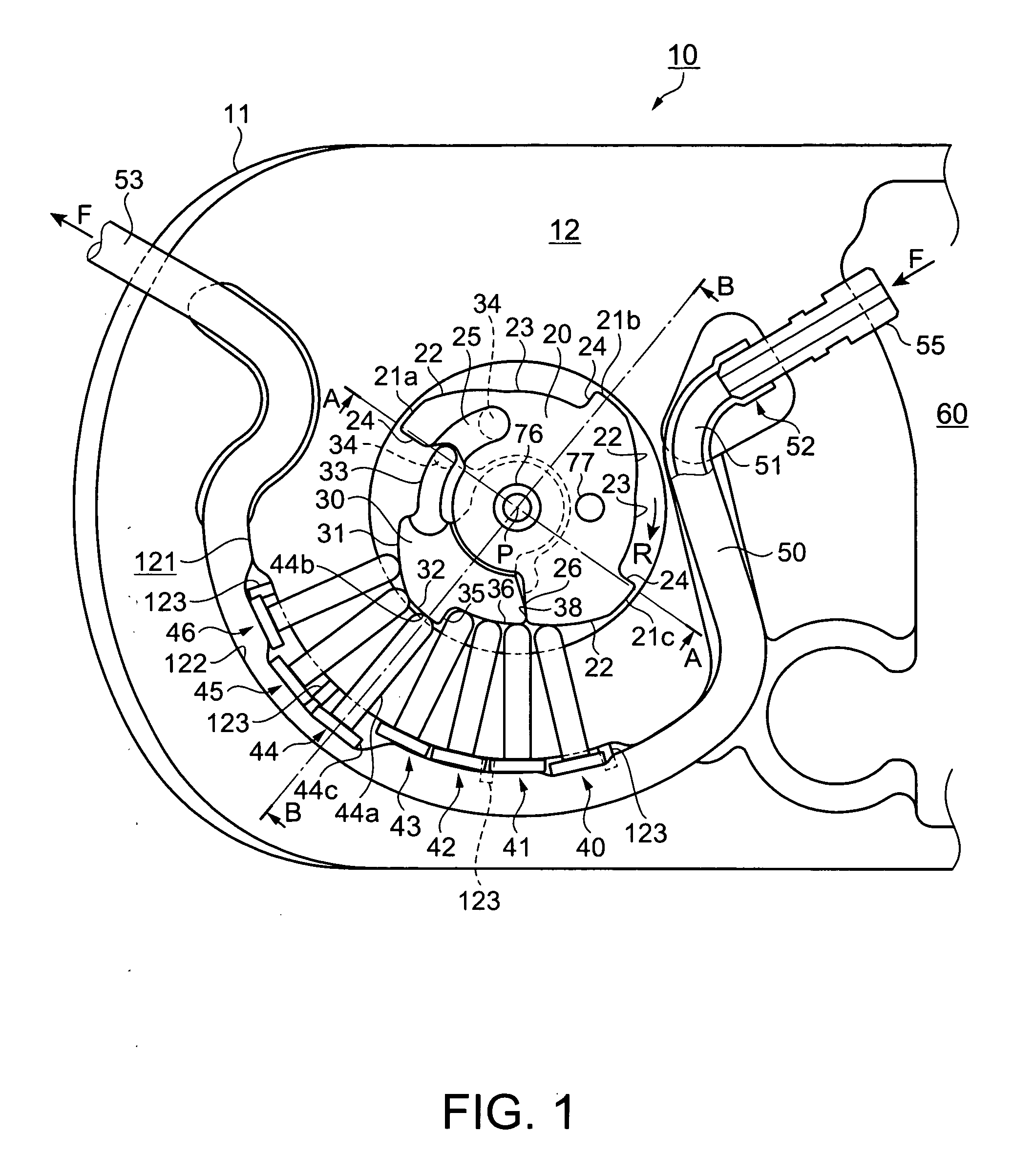

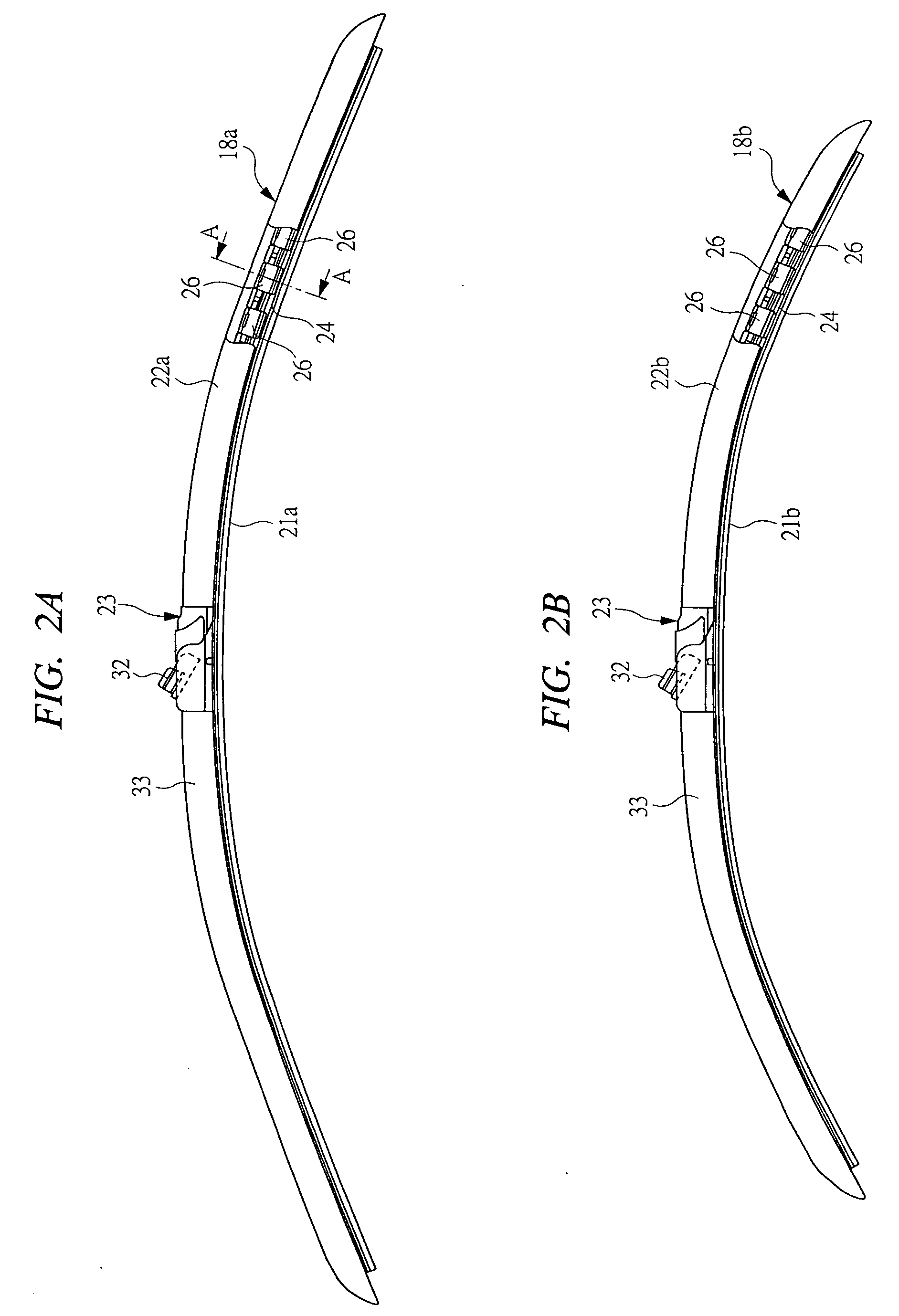

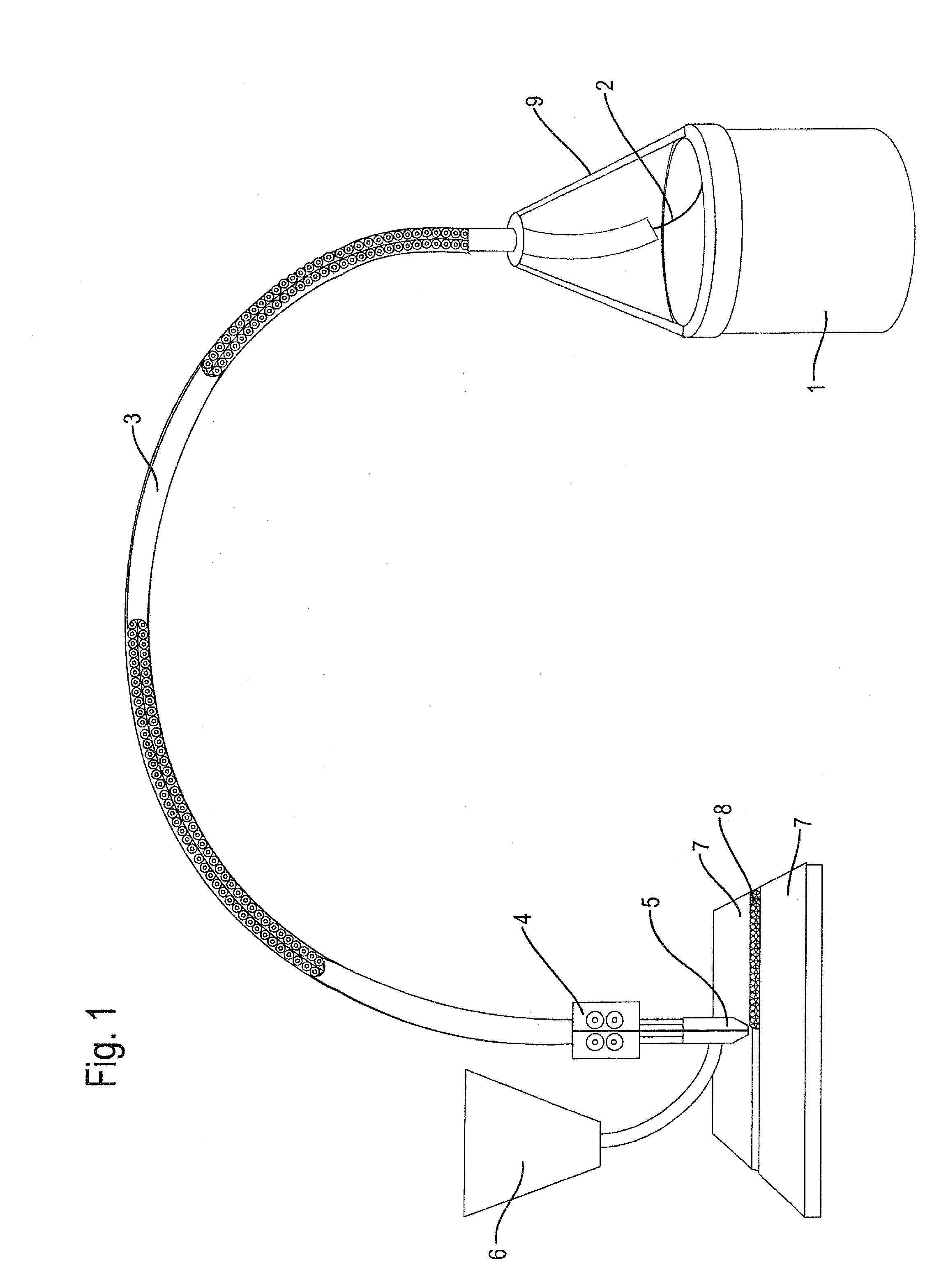

Fluid transportation system, method for setting discharge amound of fluid

InactiveUS20070128060A1Stable flowSimple structureFlexible member pumpsIntravenous devicesEngineeringCam

A fluid transportation system includes an elastic tube, a tube frame to which the tube is attached such that the tube forms a circular arc, a first cam and a second cam disposed inside the tube, and fingers which radially extend from a rotation center in the space between the tube and the first and second cams. The first and second cams produce a first condition where the fingers are all released and a second condition where at least one of the fingers constantly closes the tube. The first and second cams sequentially press the fingers, and the fingers sequentially repeat closure and release of the tube so that fluid can continuously flow.

Owner:SEIKO EPSON CORP

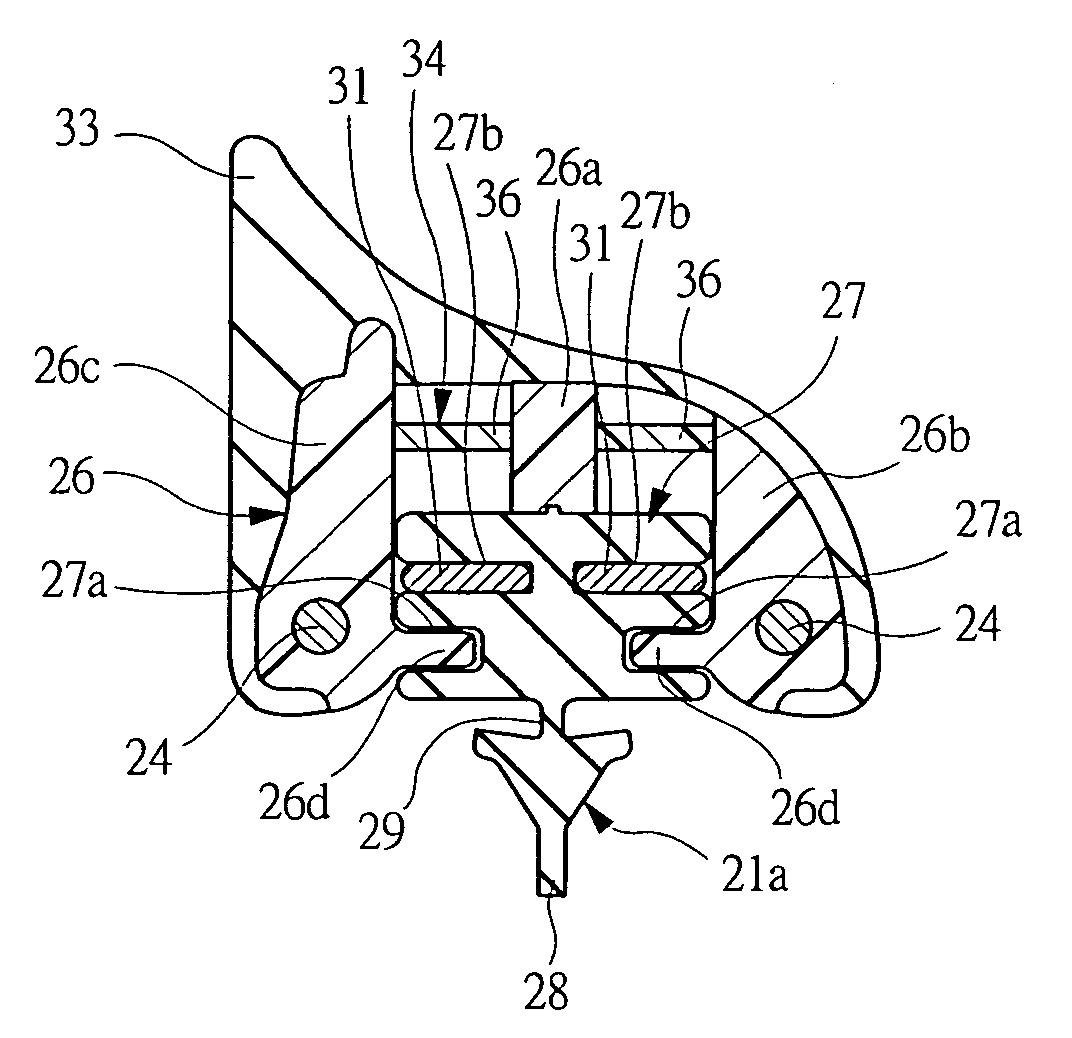

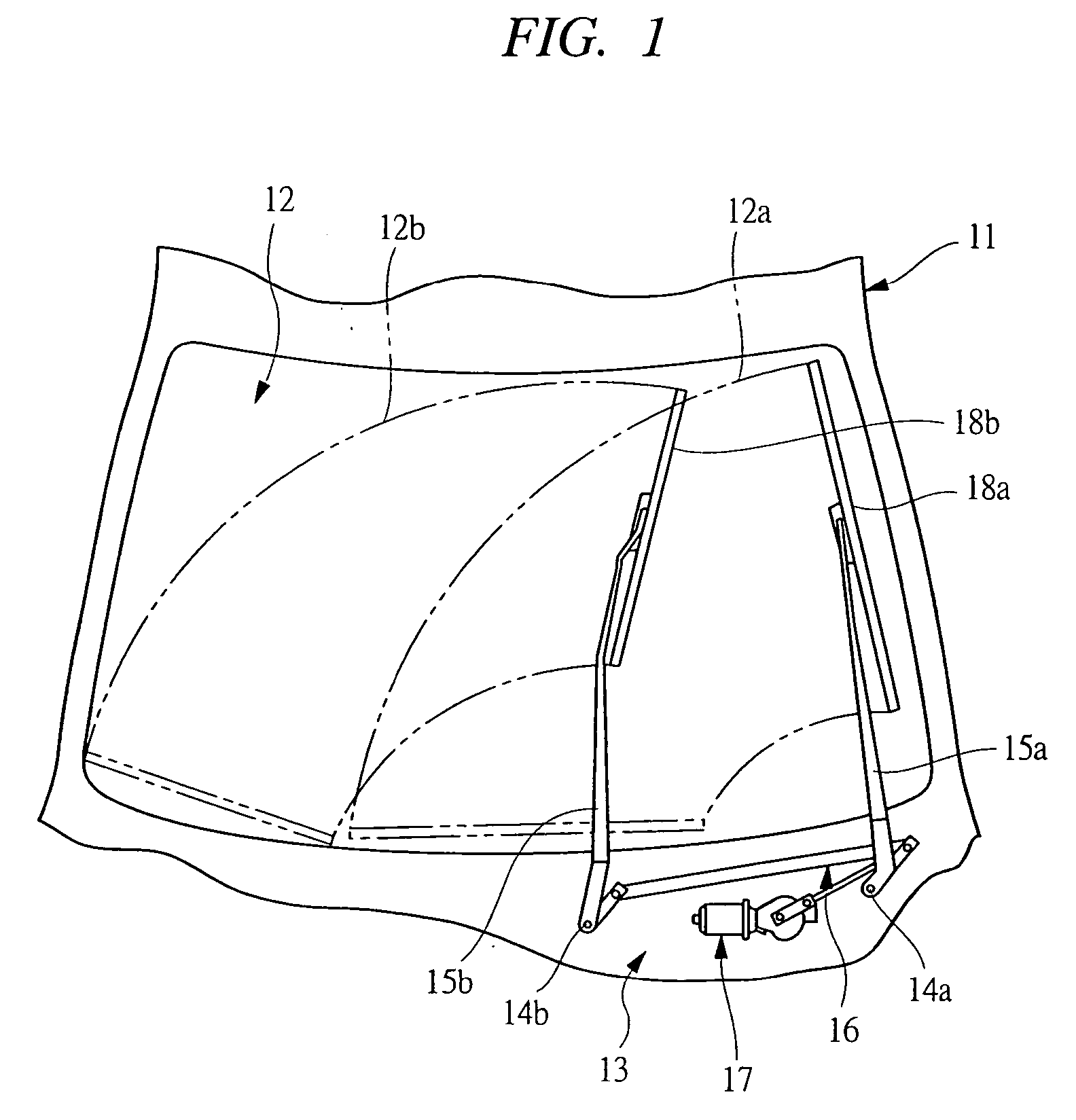

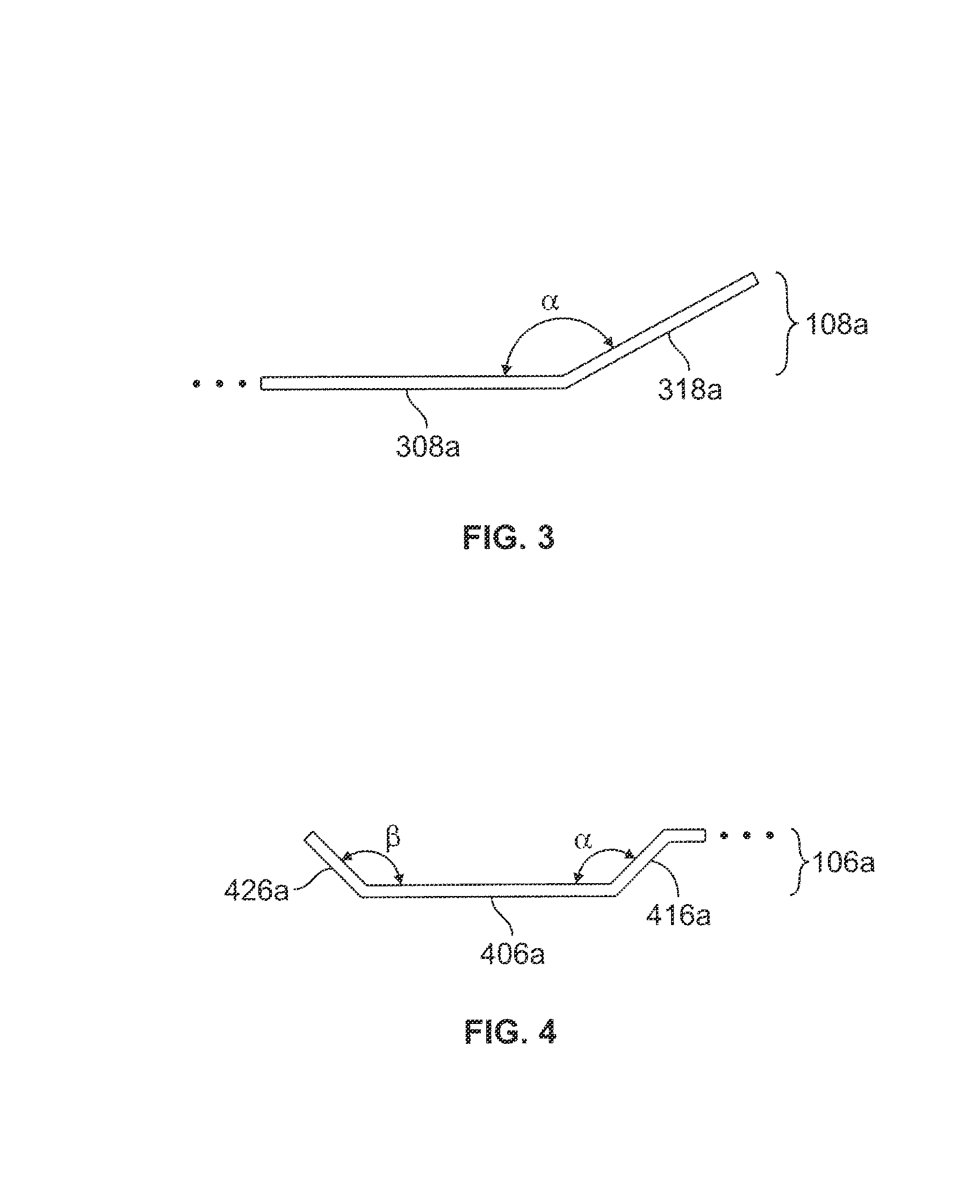

Wiper blade

InactiveUS20060090282A1Prevent permanent deformationIncreased durabilityWindow cleanersVehicle cleaningEngineeringBending force

A rubber holder on the DR side (22a) having rod-shaped spring members fixed to holding blocks and a plurality of holding bridges (26) fixed to these rod-shaped members at specified intervals is provided on a wiper blade on the DR side, and a stopper (34) is attached to the rubber holder on the DR side (22a). The stopper (34) has a plurality of deformation restricting blocks (35) disposed between engaging portions (37) formed on the holding bridges (26) and linking strip portions (36) for linking the deformation restricting blocks (35). When excessive bending force is applied to the wiper blade on the DR side, the deformation restricting blocks (35) interfere with the engaging portions (37), or the linking strip portions (36) restrict the increase of the distance between the deformation restricting blocks (35), thereby restricting the deformation of the rubber holder on the DR side (22a) within the range of elastic deformation of the rod-shaped spring members.

Owner:MITSUBA CORP

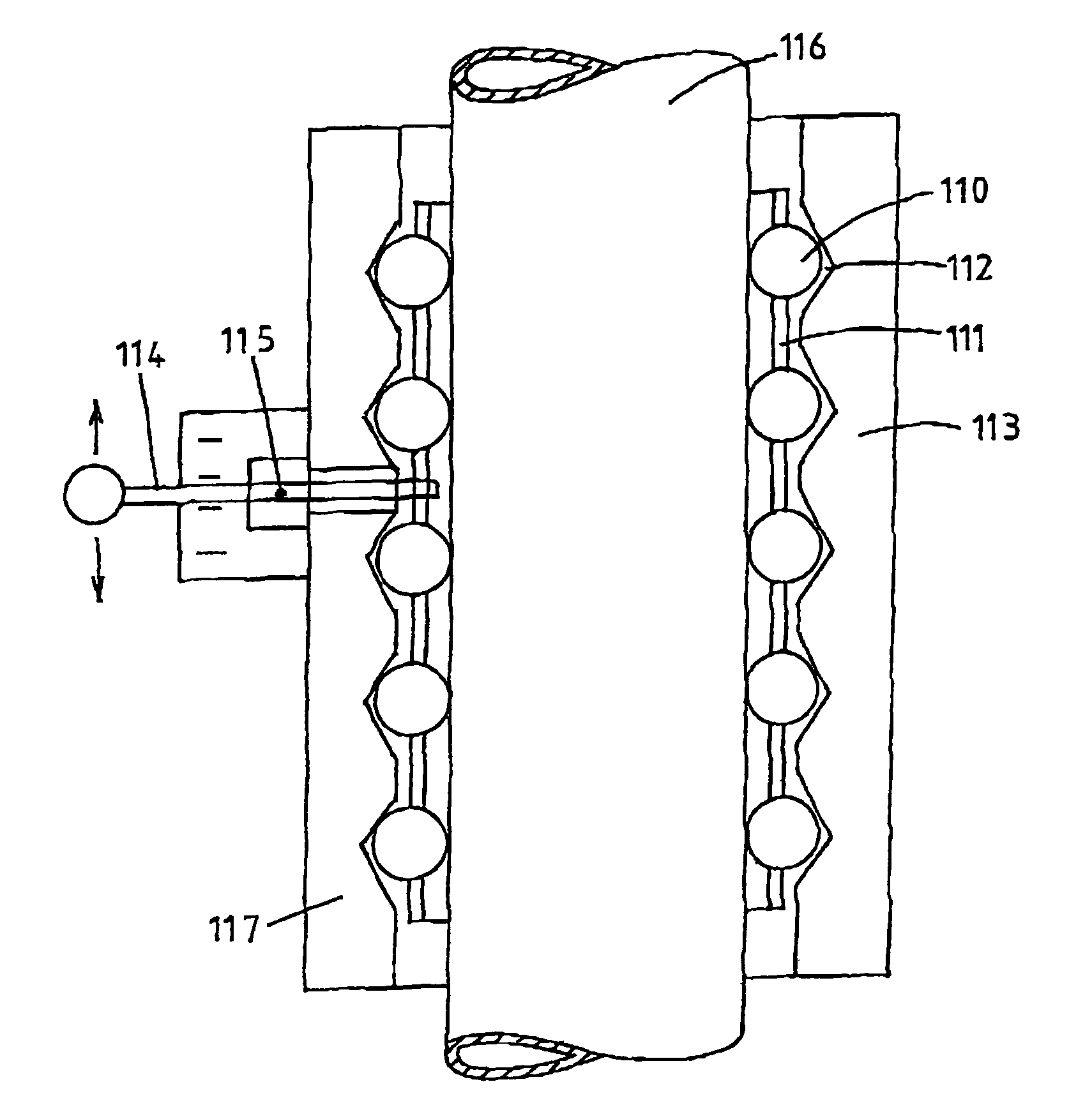

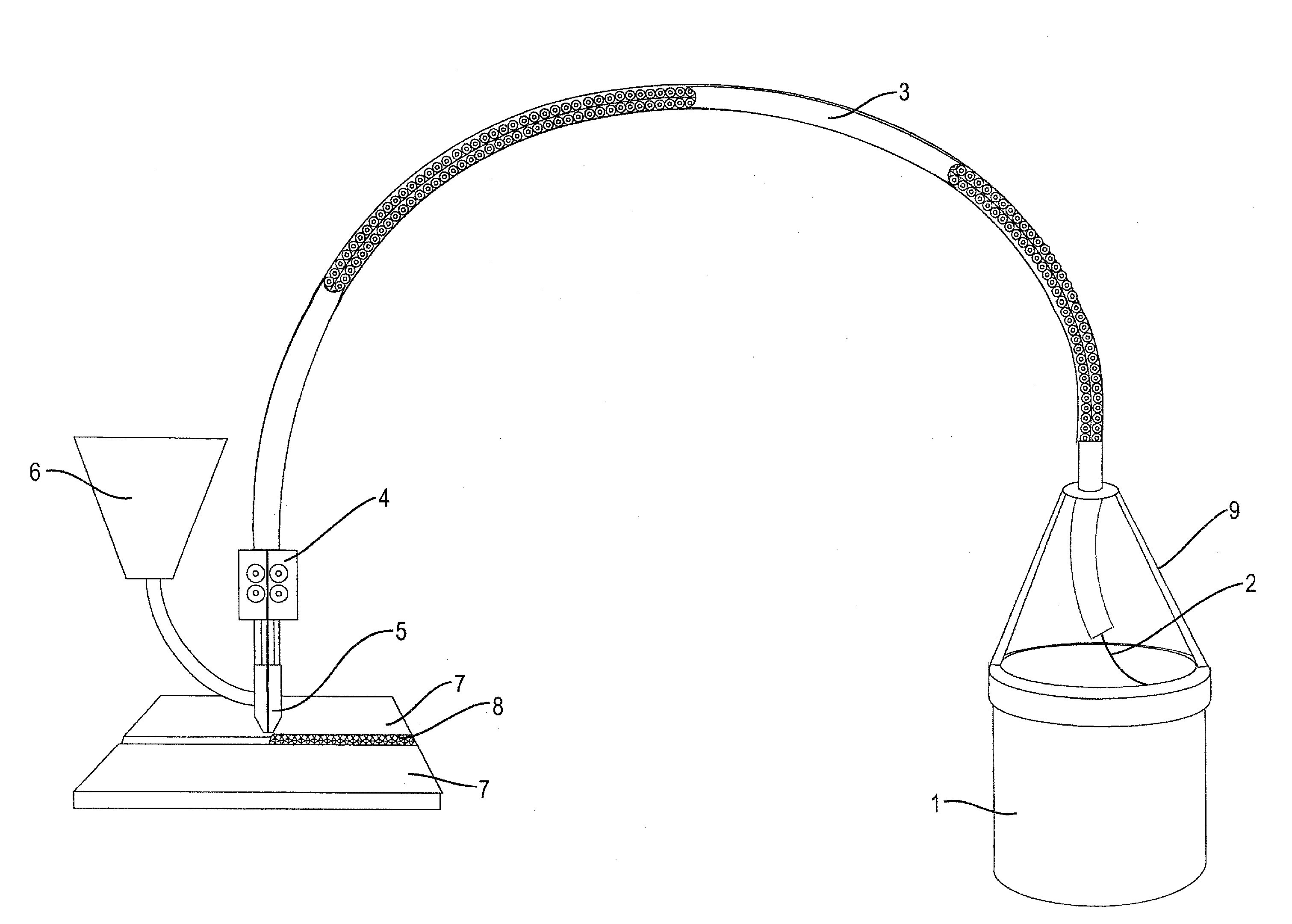

Feeding system for a welding wire for a submerged welding process

InactiveUS20110042355A1Easy constructionReduce frictionPipe supportsFilament handlingFront and back endsWelding process

A system for submerged arc welding, having a container in which welding wire is stored so as to be available for welding, a welding torch, a guiding system for guiding the welding wire from the container towards the welding torch, and a feeder for moving the welding wire from the container through the guiding system towards the welding torch, the guiding system using at least one rolling element for guiding the welding wire. A method of operating a submerged arc welding system, wherein a first supply of welding wire and a second supply of welding wire are provided, the first and the second supplies each having a forward end and a rearward end, wherein the rearward end of the first supply is welded to the forward end of the second supply such that a weld is formed which can be fed through the submerged arc welding system.

Owner:SIDERGAS +1

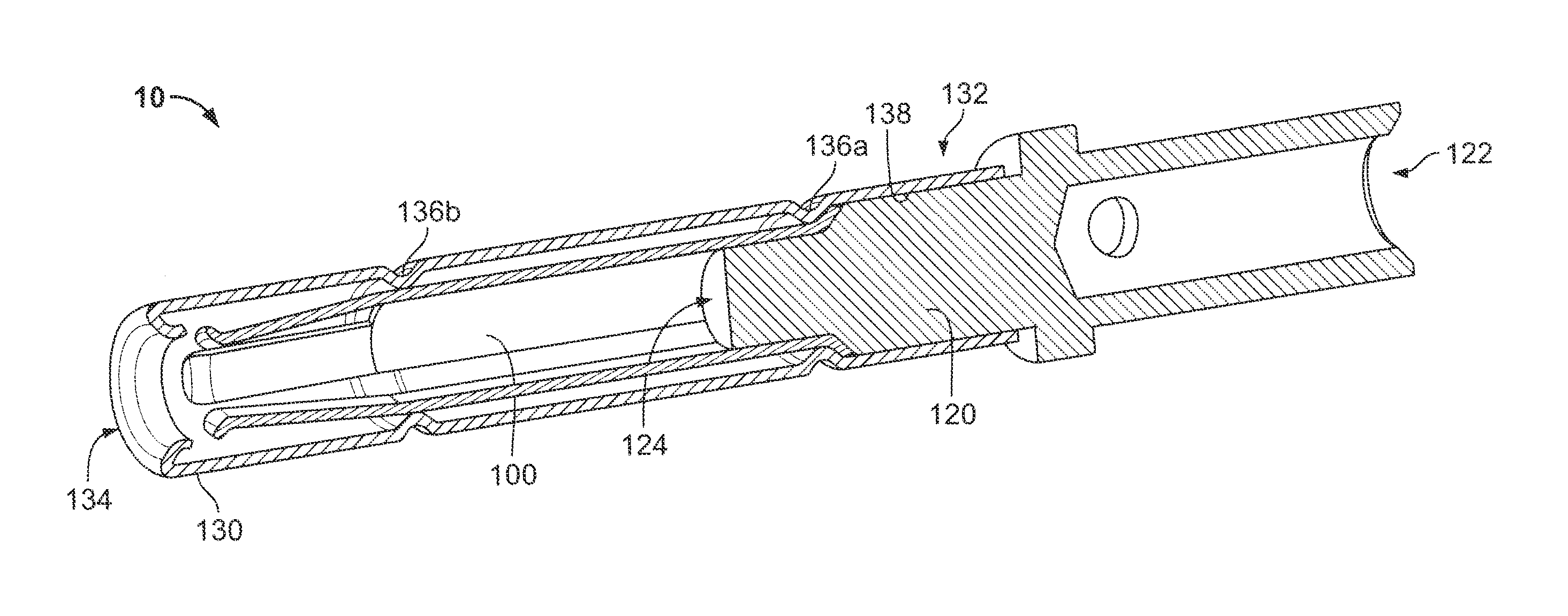

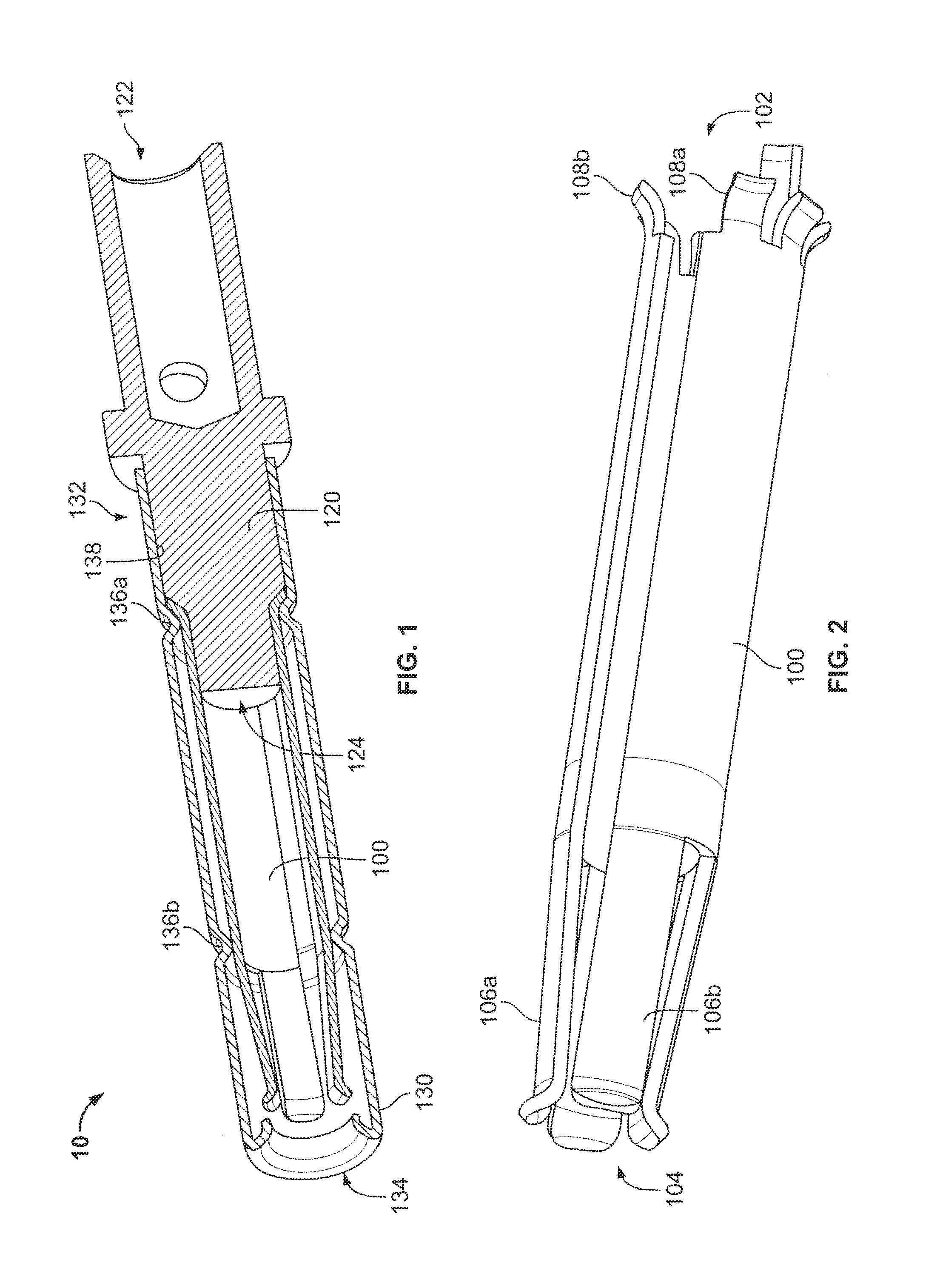

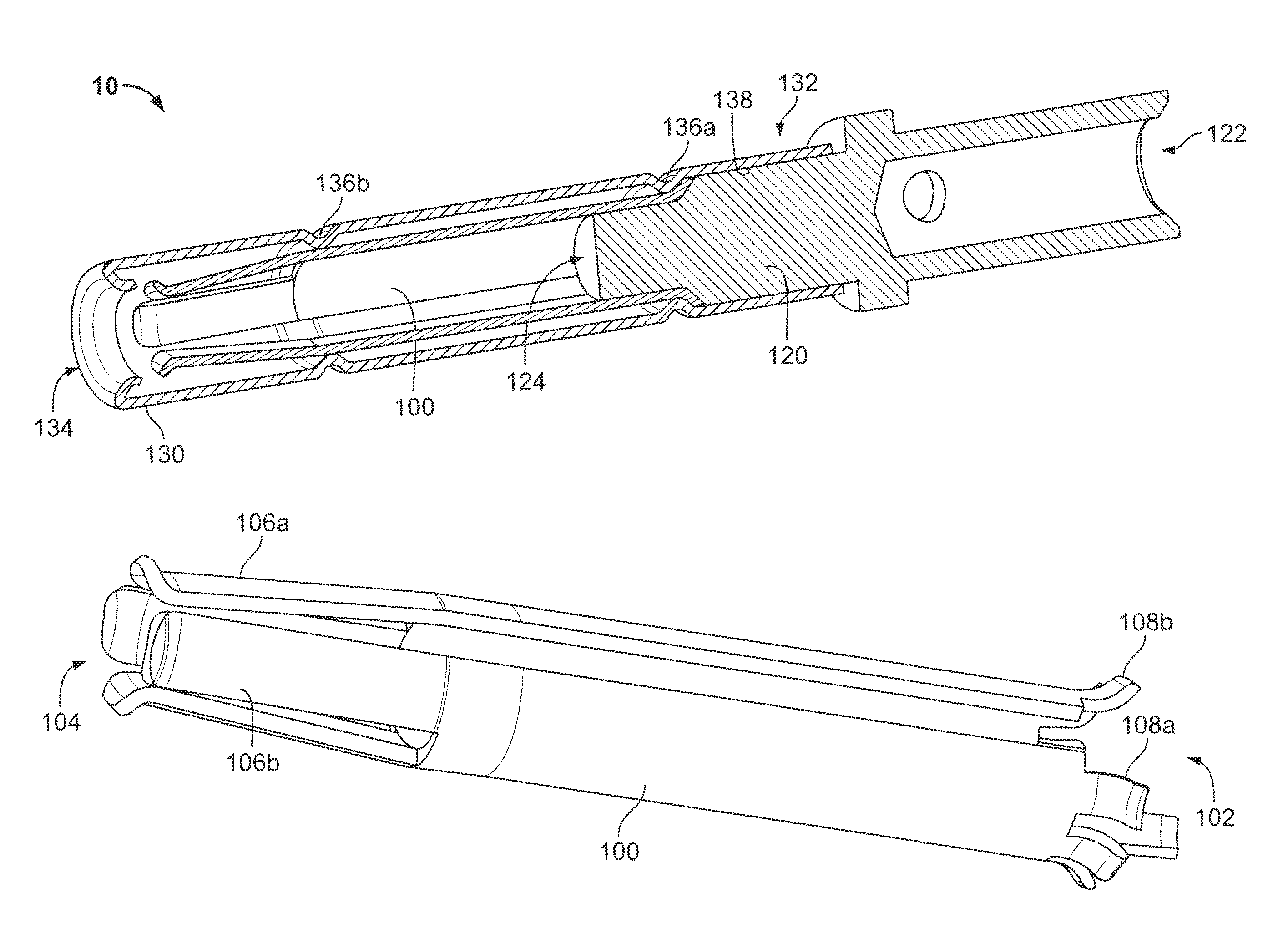

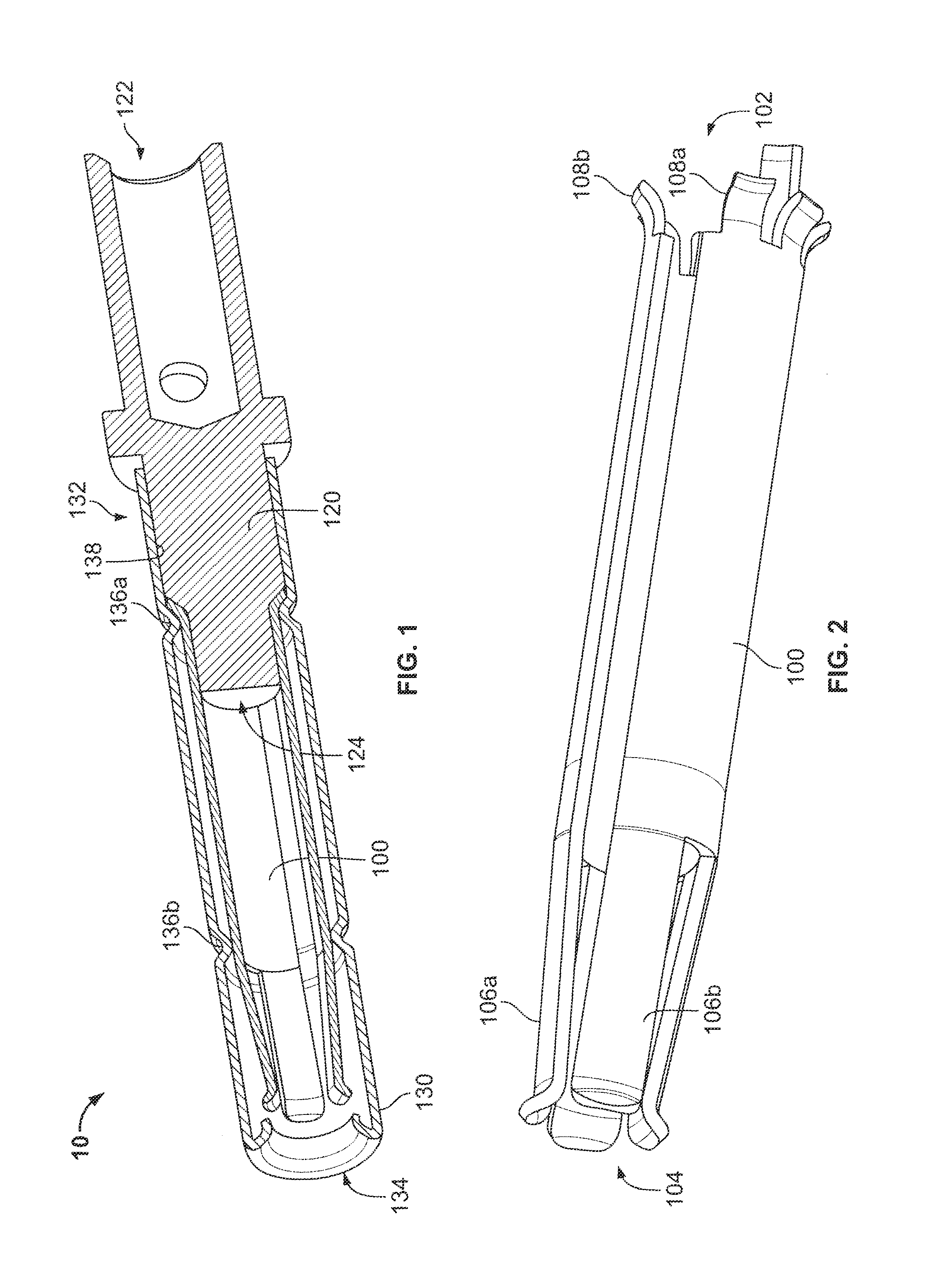

Multi-piece socket contact assembly

ActiveUS20140017960A1Prevent movementLess amountContact member manufacturingContact member assembly/disassemblyProximal pointEngineering

A system and method is provided for securing a spring body against a socket body, thereby reducing movement of the spring body during periods of vibration. Preferred embodiments of the present invention operate in accordance with a socket body that includes at least a proximal end, a spring body that includes at least a distal end, and a sleeve. In one embodiment of the present invention, the distal end of the spring body is configured to be placed over the proximal end of the socket body, and the sleeve is configured to be placed over the distal end of the spring body. The sleeve preferably includes an inner circumference that is sized to creating a frictional engagement between an inner surface of the sleeve and an outer surface of the spring body, and between an inner surface of the spring body and an outer surface of the socket body.

Owner:DEUT ENGINEERED CONNECTING DEVICES

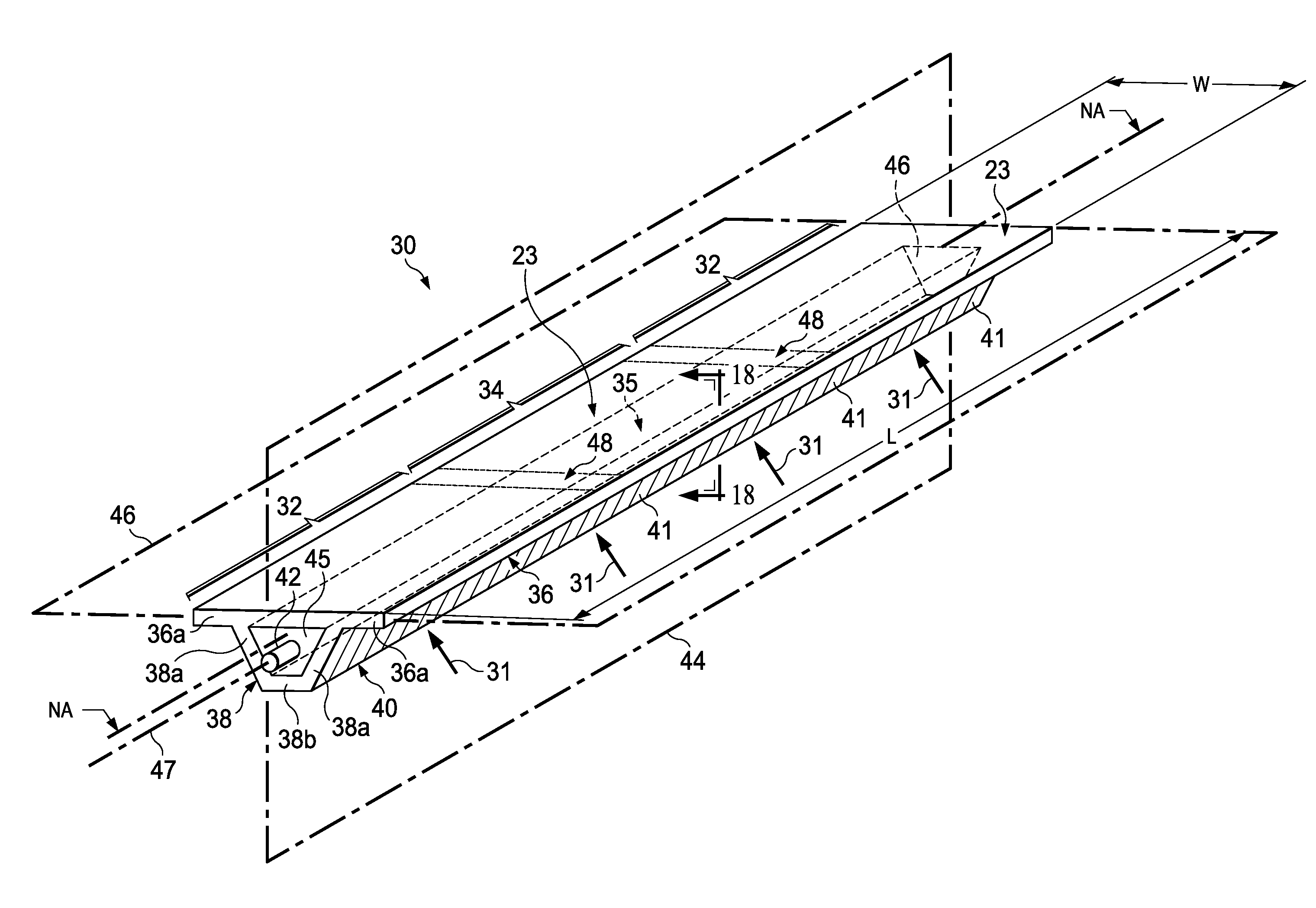

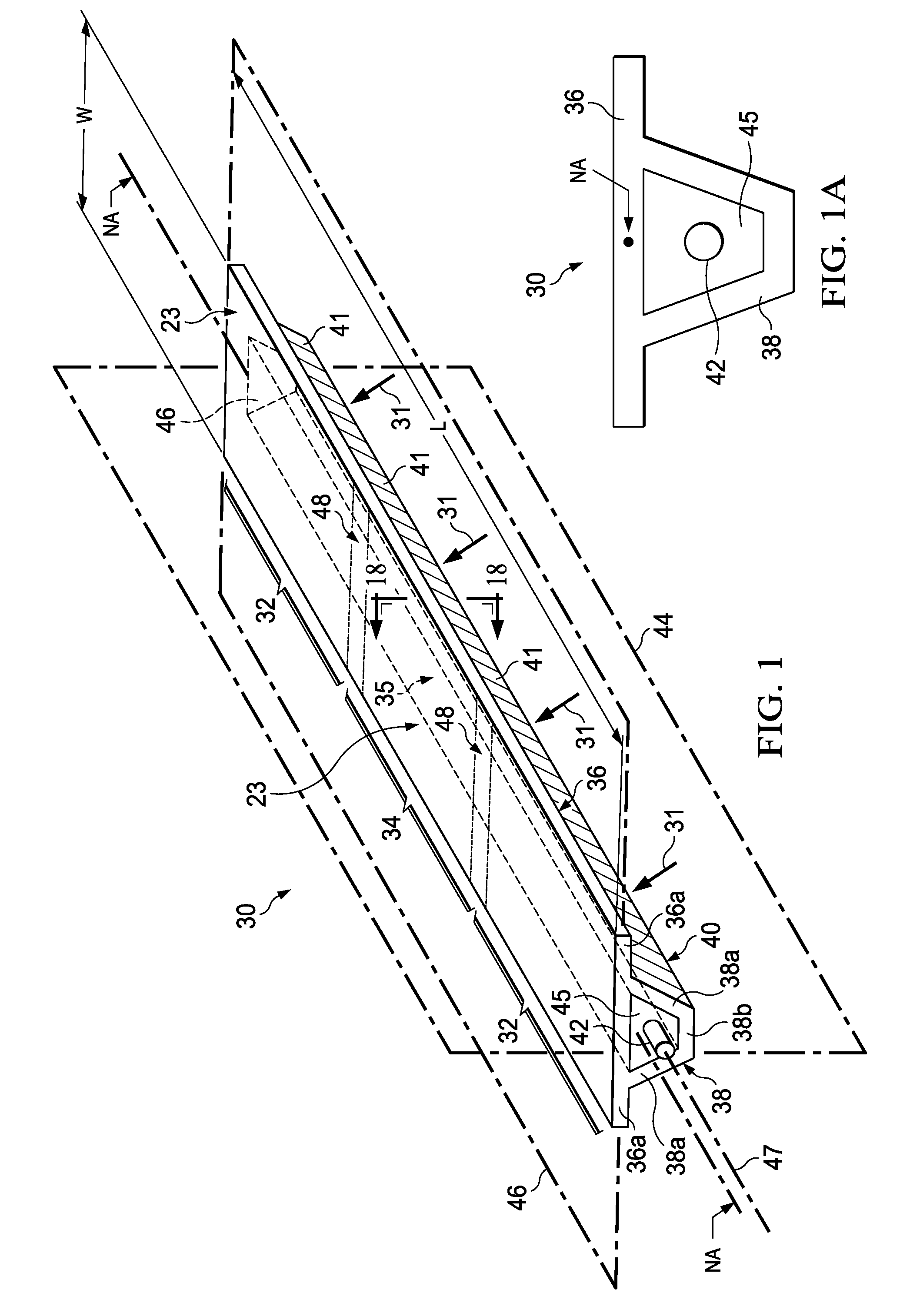

Flexible Compactor with Reinforcing Spine

ActiveUS20130333830A1Improve part qualityImprove performanceConfectioneryLaminationSacroiliac jointMechanical engineering

A device for compacting a contoured elongate composite layup includes flexible first and second fiber reinforced resin flexible sections flexible along their lengths. The first section is flexible within a first plane and the second section is flexible within the first plane as well as within a second plane. The second section includes flexible joints reinforced by a spine.

Owner:THE BOEING CO

Assembling structure of clip and mounting member

InactiveUS8511631B2Prevent permanent deformationKeep elasticSnap fastenersPicture framesEngineeringFlange

Owner:PIOLAX CO LTD

Double-sided flexible printed circuits

InactiveUS7301104B2Low profileFlexure of the end of the base is preventedPrinted circuit aspectsFlat/ribbon cablesEngineeringCopper foil

A double-sided flexible printed circuit comprises: an electrically insulating base; a first copper layer having a first conductive pattern; a second copper layer having a second conductive pattern, the second conductive pattern disposed offset from the first conductive pattern; and electrically insulating coverlays. A first area opposing a first contact point of first contacts that press upon the first conductive patterns, is reinforced by copper foil extending from the second conductive patterns, and a second area opposing a second contact point of second contacts that press upon the second conductive patterns, is reinforced by copper foil extending from the first conductive patterns.

Owner:JST MFG CO LTD

Safety buckle with multiple orientation clasp

ActiveUS20050210641A1Secure child resistant featureSufficient clearanceSnap fastenersClothes buttonsEngineering

Owner:SAFE STRAP

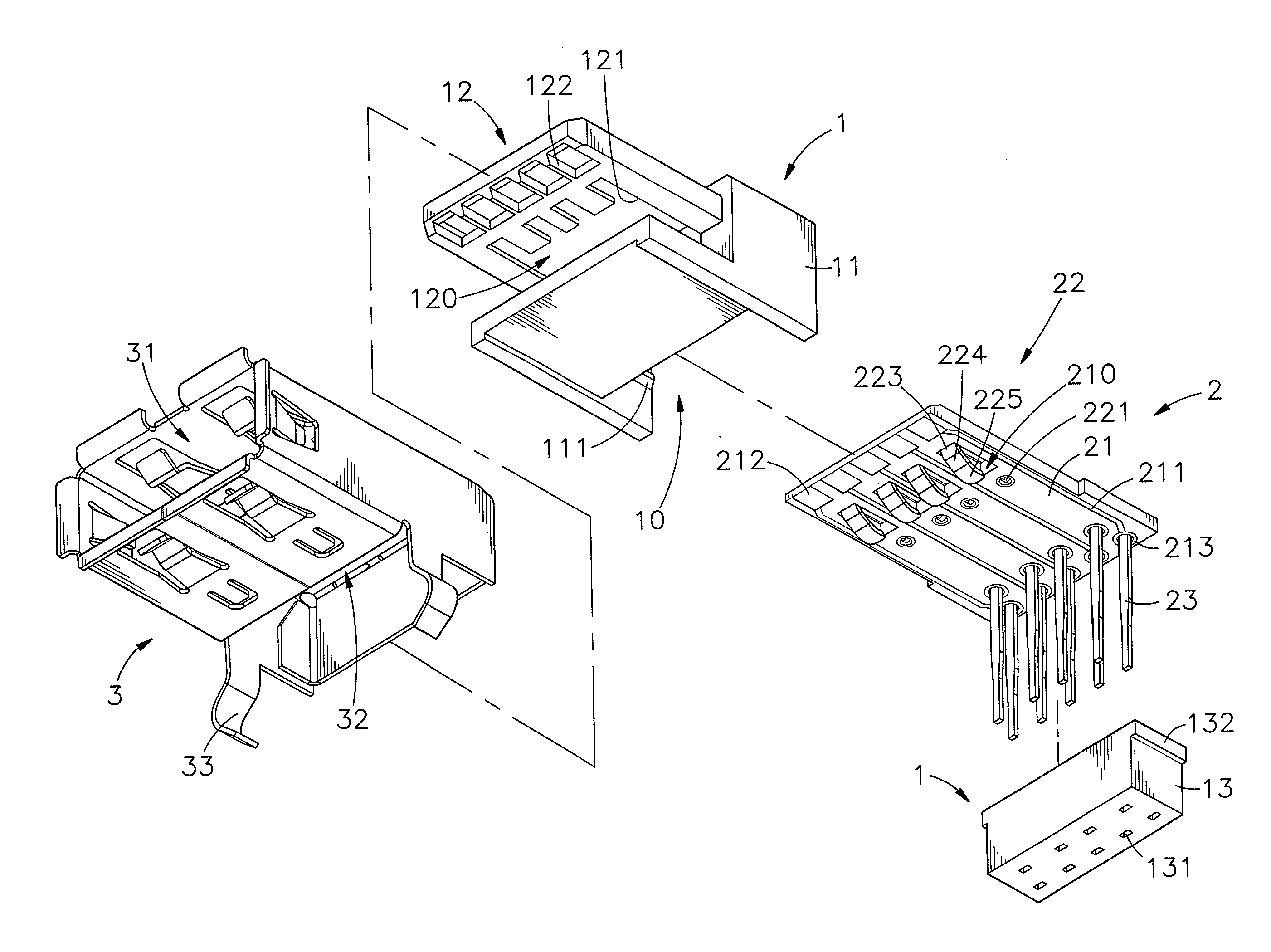

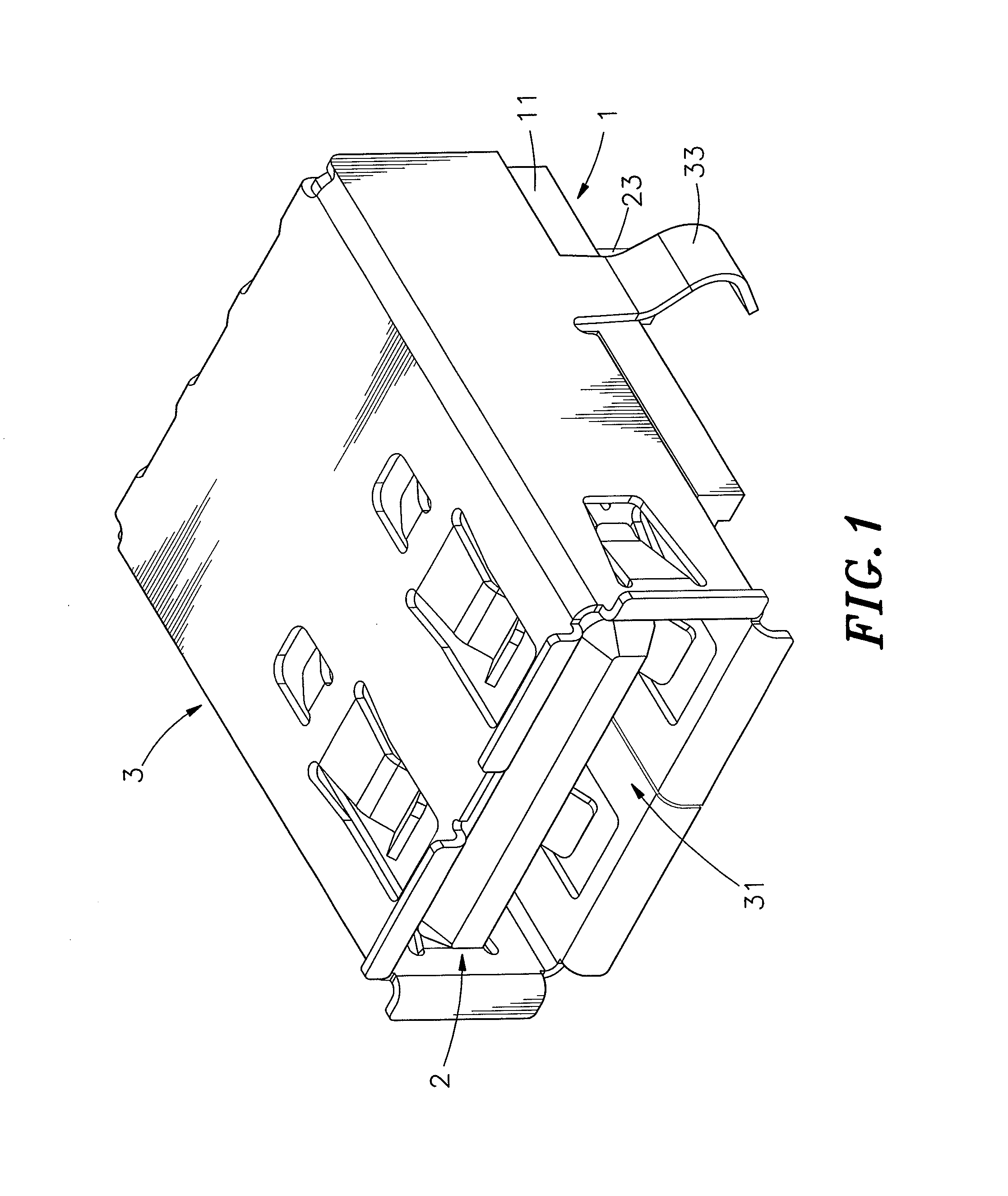

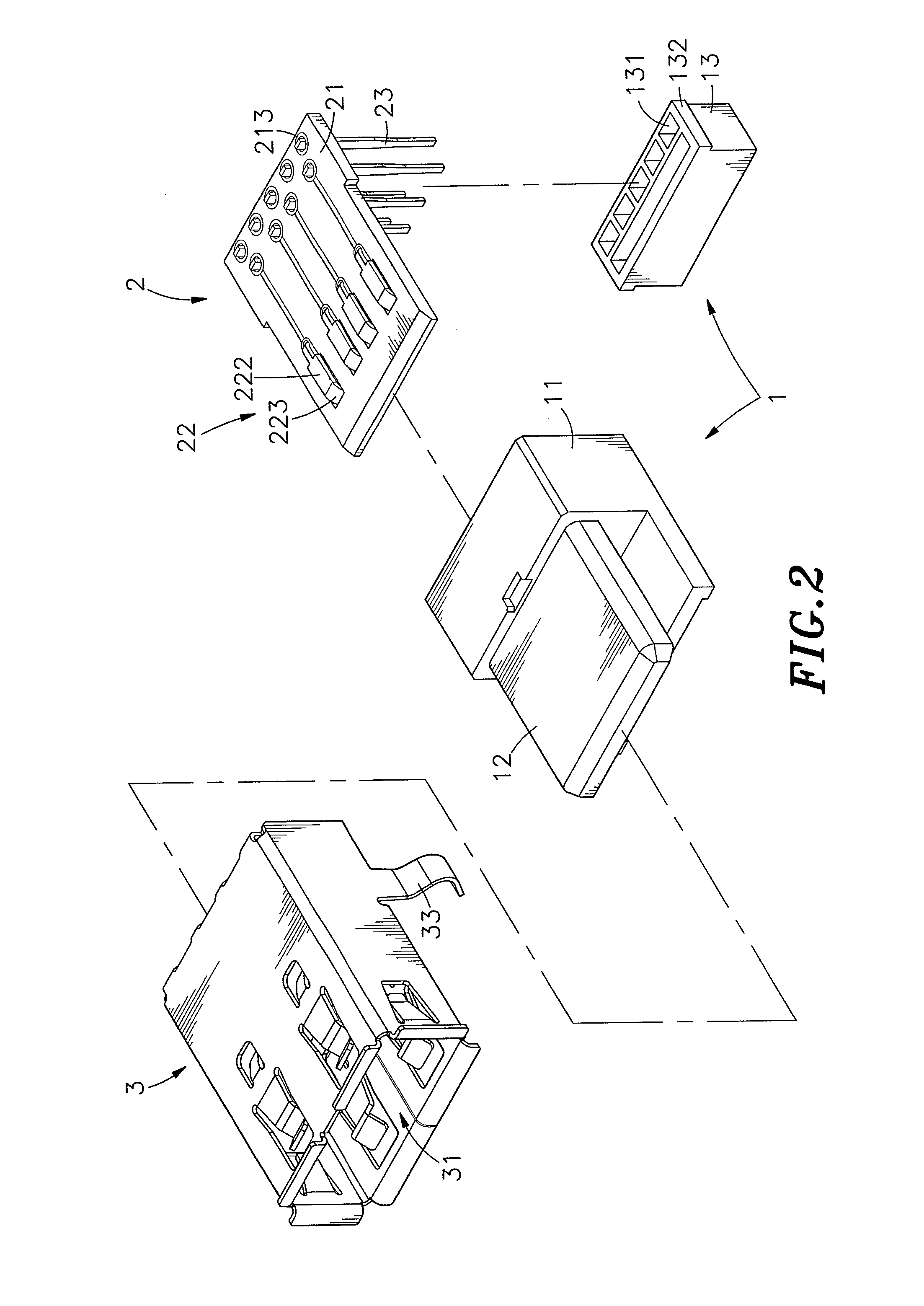

Electrical connector with specially designed metal contact terminals to avoid solder-off

InactiveUS8602825B2Prevent permanent deformationControl deformationElectric discharge tubesCoupling contact membersElectricityComputer module

An electrical connector includes an electrically insulative holder member, a signal module formed of a circuit board with longitudinal terminal holes, circuit lines, electrical contacts and via-holes, metal contact terminals and metal mounting terminals, and a metal shield. The metal contact terminals have rear soldering end portions thereof soldered to respective circuit lines, an extension arm forwardly extended from the rear soldering end portion along one longitudinal terminal hole, a turn portion extended from the extension arm and curved into the associating longitudinal terminal hole to enhance vertical deformation stroke of the respective metal contact terminal, a front contact portion suspending below the associating longitudinal terminal hole, and an oblique spring arm connected between the turn portion and the front contact portion to flexibly support the front contact portion.

Owner:U D ELECTRONIC CORP

Plural layer anisotropic conductive connector and its production method

InactiveUS7160123B2Improve conductivityPrevent permanent deformationElectrical testingElectrically conductive adhesive connectionsEngineeringMechanical engineering

An anisotropically conductive connector, not causing permanent deformation by contact of target electrodes to be connected with pressure and deformation by abrasion even if the target electrodes are projected, and achieving stable conductivity over a long time period even when pressed repeatedly, a production process thereof, and an inspection circuit board equipped with the connector. The connector includes (1) anisotropically conductive film, with plural conductive path-forming parts each extending in a thickness-wise direction of the film arranged insulated by insulating parts and including at least 2 elastic layers, which are each formed by an insulating elastic polymeric substance, and (2) conductive particles exhibiting magnetism in portions of the respective elastic layers, at which conductive path-forming parts are formed. The connector satisfies H1≧30, and H1 / H2≧1.1, H1, H2 being durometer hardnesses of the elastic polymeric substance of one of elastic layers forming surfaces of the film, and of the elastic polymeric substance of the other, respectively, the resulting connector includes one harder elastic layer to limit permanent deformation and one softer layer for compliance.

Owner:ISC CO LTD

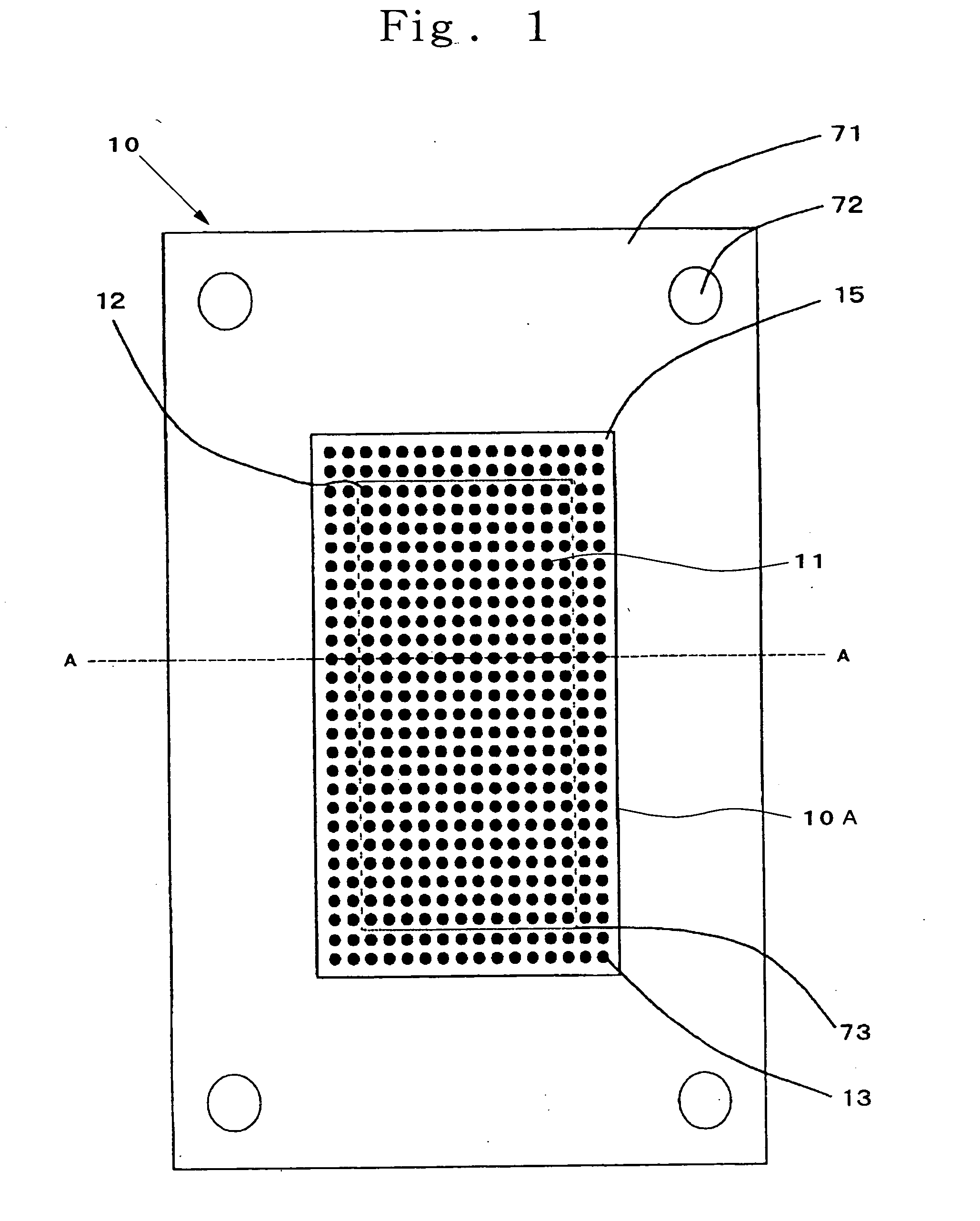

Anisotropic conductive connector and production method therefor and inspection unit for circuit device

ActiveUS7190180B2Necessary conductivity can be surely achievedImprove conductivityLine/current collector detailsElectrical measurement instrument detailsAnisotropic conductive filmSurface layer

An anisotropically conductive connector, inhibits permanent deformation by contact of target electrodes to be connected with pressure and deformation by abrasion from occurring even if the target electrodes to be connected are those projected, achieves stable conductivity over a long period of time even when it is pressed repeatedly, and prevents or inhibits an object of connection from adhering, a production process thereof, and an inspection apparatus for circuit devices equipped with the anisotropically conductive connector. The anisotropically having an anisotropically conductive film, in which a plurality of conductive path-forming parts each extending in a thickness-wise direction of the film are arranged in a state mutually insulated by insulating parts. The anisotropically conductive film is formed by an insulating elastic polymeric substance, conductive particles exhibiting magnetism are contained in the conductive path-forming parts, and a reinforcing material formed of insulating mesh or nonwoven fabric is contained in a surface layer portion on one surface side of the anisotropically conductive film.

Owner:ISC CO LTD

Multi-piece socket contact assembly

A system and method is provided for securing a spring body against a socket body, thereby reducing movement of the spring body during periods of vibration. Preferred embodiments of the present invention operate in accordance with a socket body that includes at least a proximal end, a spring body that includes at least a distal end, and a sleeve. In one embodiment of the present invention, the distal end of the spring body is configured to be placed over the proximal end of the socket body, and the sleeve is configured to be placed over the distal end of the spring body. The sleeve preferably includes an inner circumference that is sized to creating a frictional engagement between an inner surface of the sleeve and an outer surface of the spring body, and between an inner surface of the spring body and an outer surface of the socket body.

Owner:DEUT ENGINEERED CONNECTING DEVICES

Stent having struts with reverse direction curvature

ActiveUS7763064B2Increase the compression ratioRaise the ratioStentsBlood vesselsMedicineDiameter ratio

Disclosed is a stent having struts with reverse direction curvature for providing a reduced compressed profile and an increased expanded profile. The strut configuration comprises a plurality of arcuate sections facing in opposite convex and a concave orientation. The strut width may be gradually decreased from its ends towards the strut's mid-section to redistribute maximal strains away from portions of the stent more susceptible to permanent deformation, such as the loop portions. Varying strut lengths to offset the maximum circumferential widths of adjacent portions of the stent may further reduce the compressed stent profile. The varied stent lengths may also contribute to an increased expanded stent profile. Stents with the reverse direction curvature strut design can obtain an expanded to compressed stent diameter ratio of about 7:1 compared to conventional stents that have a ratio of up to about 5:1. The curved strut can be utilized with any stent design.

Owner:MEDINOL LTD

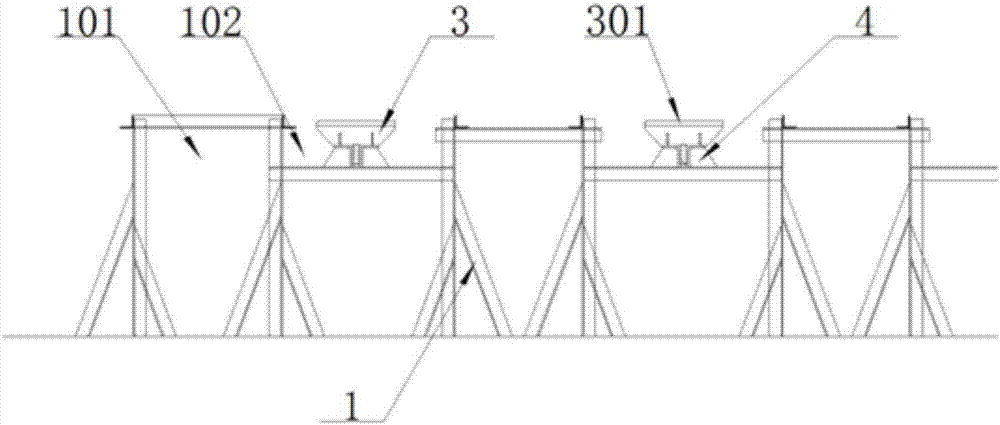

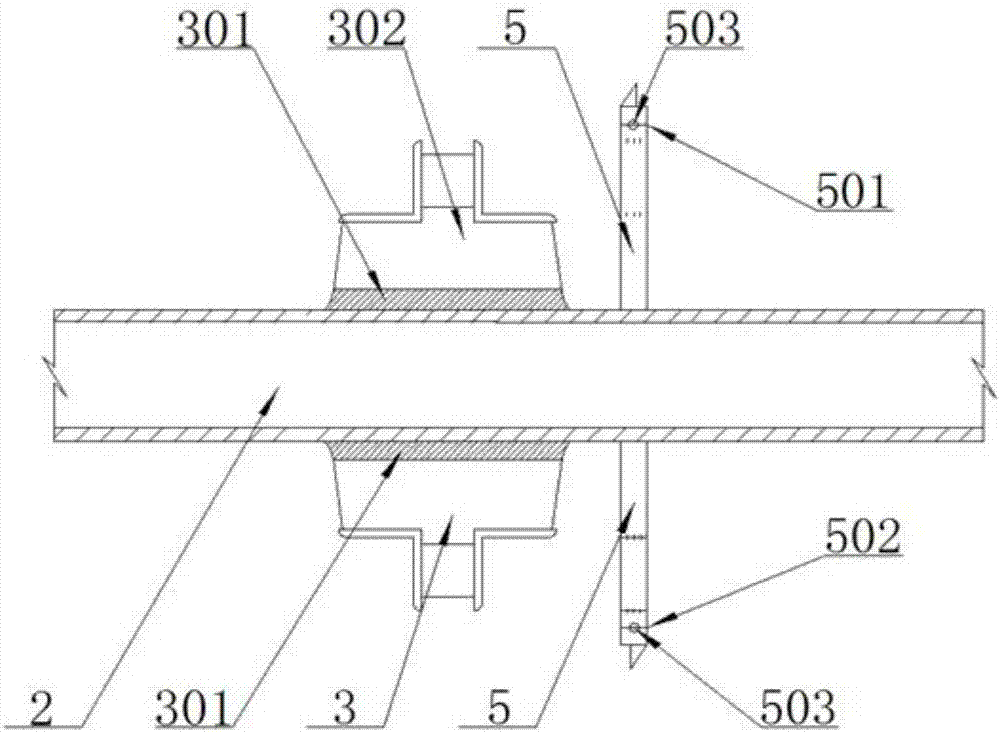

Double-sided mounting method for guide rail brackets in front jig states of transverse bulkheads of container ships

InactiveCN107985504AAvoid permanent deformationMake sure the base is the sameVessel designingEngineeringMechanical engineering

The invention relates to a double-sided mounting method for guide rail brackets in front jig states of transverse bulkheads of container ships. The double-sided mounting method includes steps of firstly, mounting jig frames; secondly, embedding the guide rail brackets; thirdly, constructing the transverse bulkheads in a sectionalized manner; fourthly, mounting angle steel marker posts; fifthly, mounting the embedded guide rail brackets; sixthly, mounting the non-embedded guide rail brackets; seventhly, checking the dimensions. The double-sided mounting method has the advantages that the guiderail brackets can be embedded in the jig frames owing to grooves and can be conveniently mounted on the back surfaces of the transverse bulkheads, the transverse bulkheads do not need to be turned over by 180-degree angles, and accordingly permanent deformation generated in turnover procedures can be prevented; unification of reference can be guaranteed by primary reference surfaces and secondaryreference surfaces, accordingly, the assembly precision can be improved, and the double-sided mounting method can bring convenience for detecting the mounting precision of the double-sided guide railbrackets; the double-sided mounting method is high in mounting precision, accordingly, modification rework load in later periods can be reduced, the cost can be lowered, and the shipbuilding periods can be shortened.

Owner:CHINA SHIPPING IND JIANGSU

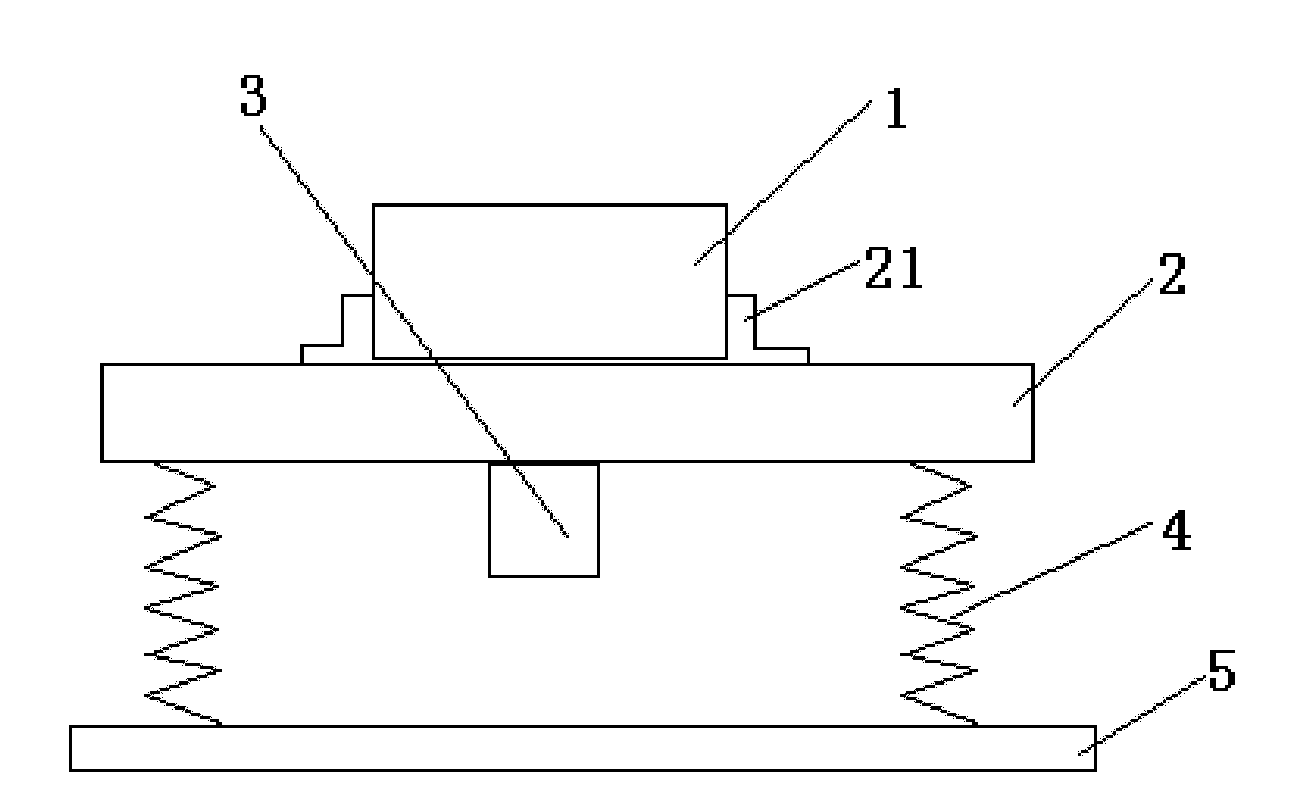

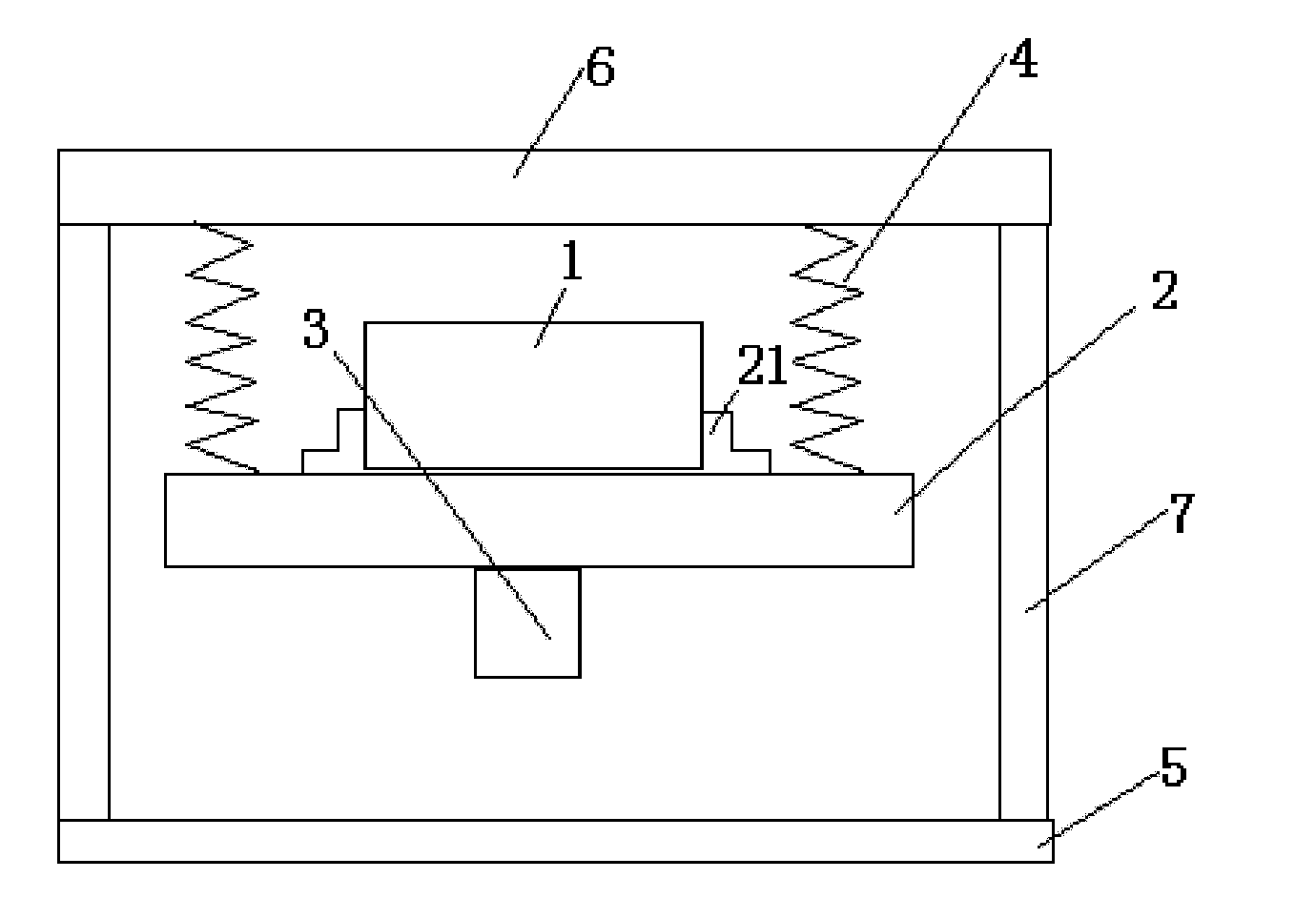

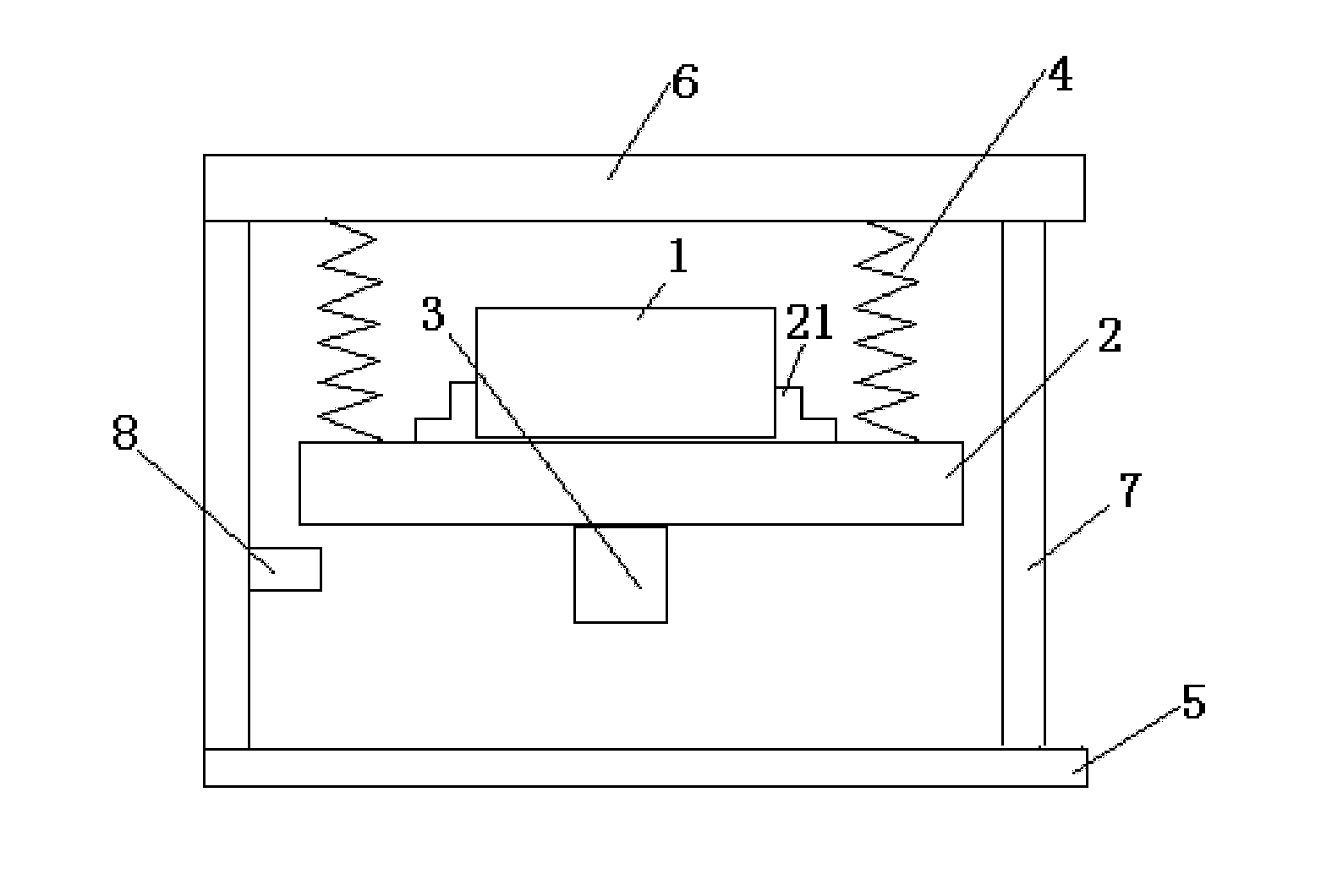

Vibration detection platform

InactiveCN102141461AAccurate vibration resistanceAccurate and reliableVibration testingAviationEngineering

The invention relates to a vibration detection platform. A vibration exciter of the detection platform is fixed below a worktable with a locking device on the upper surface; a bracket is fixed on a base; one end of an extension spring is connected with a bracket, and the other end of the extension spring is connected with the worktable; and the worktable is suspended over the base. The vibration exciter generates a vibrating force to allow the worktable to drive a detected product fixed on the worktable to vibrate, the completeness of the product is observed after a given time period of vibration, and thus, the vibration resistance and reliability of the product can be evaluated. In the invention, accurate vibration resistance and reliability evaluation can be delivered no matter the mass of the product is high or low or variable in a detection process, and the vibration detection platform is particularly suitable for detecting the vibration resistance and reliability of products in aerospace field.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com