Patents

Literature

90results about How to "Improve part quality" patented technology

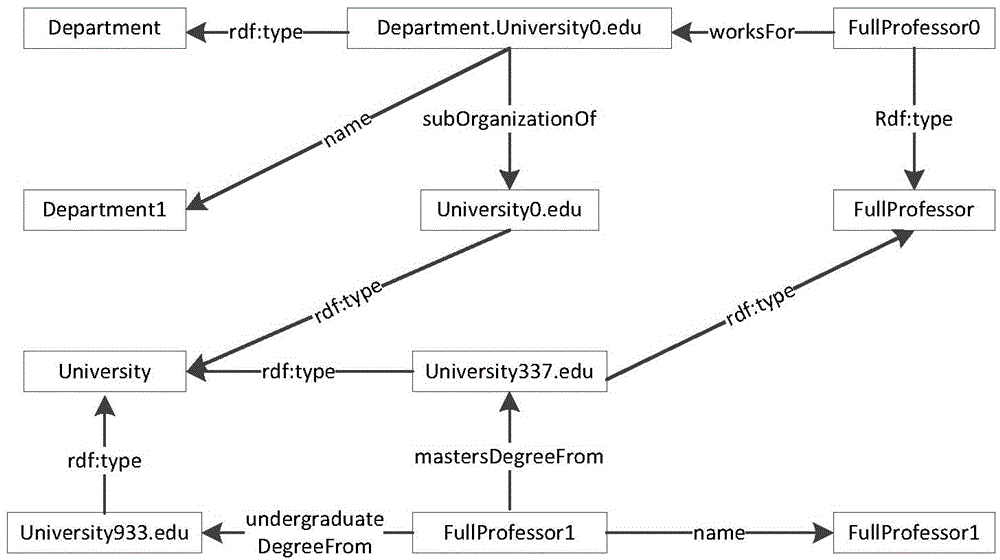

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

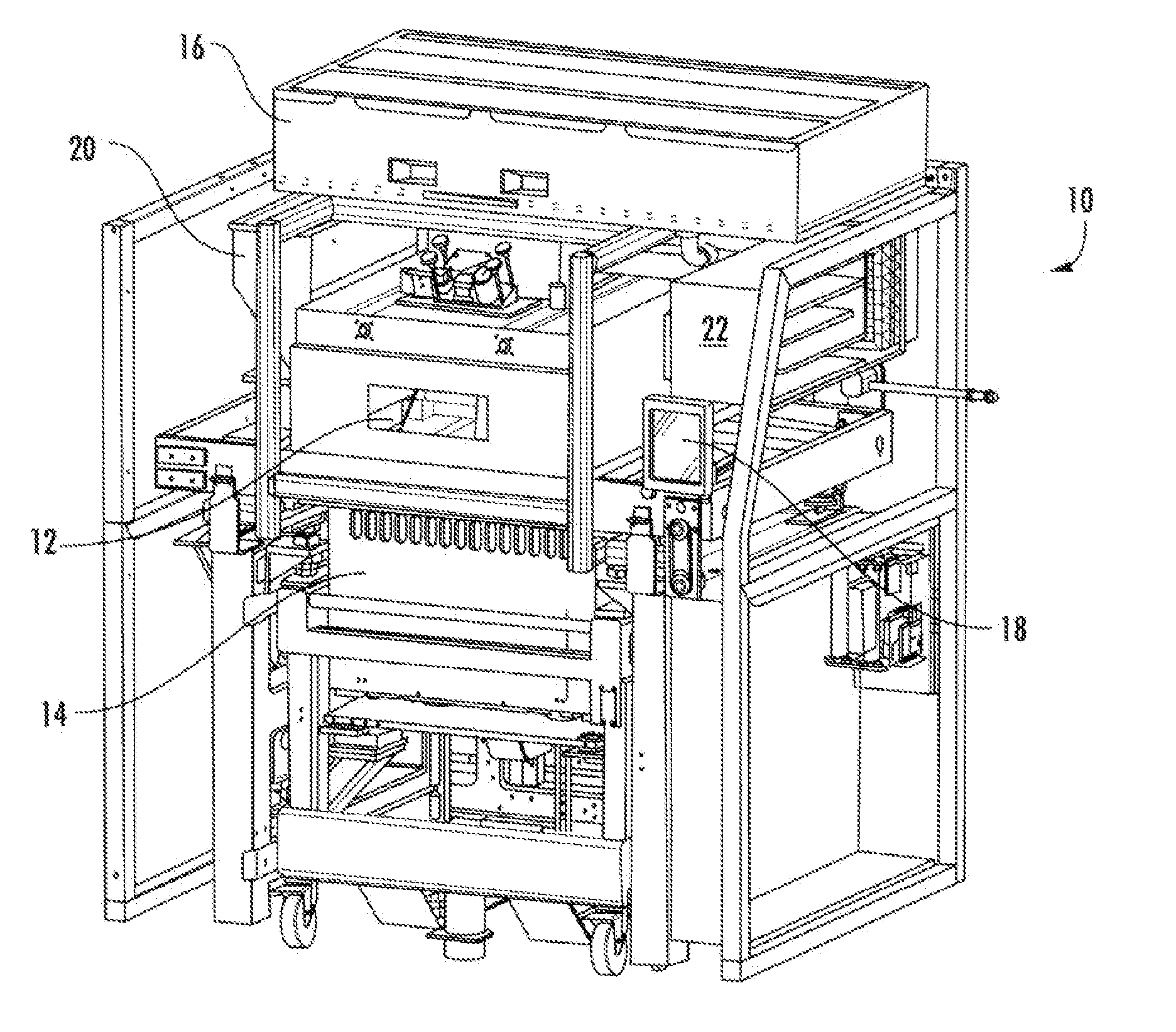

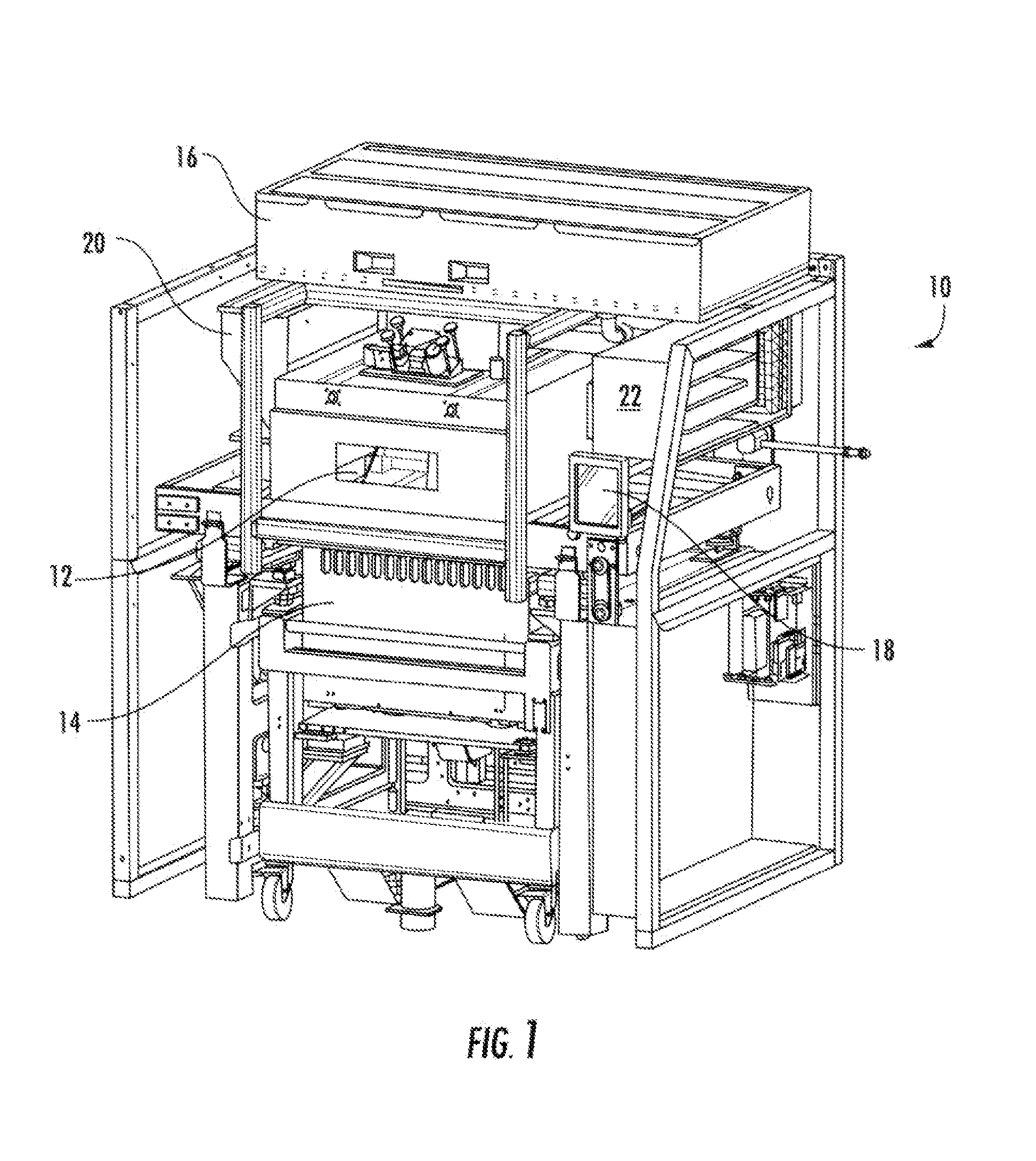

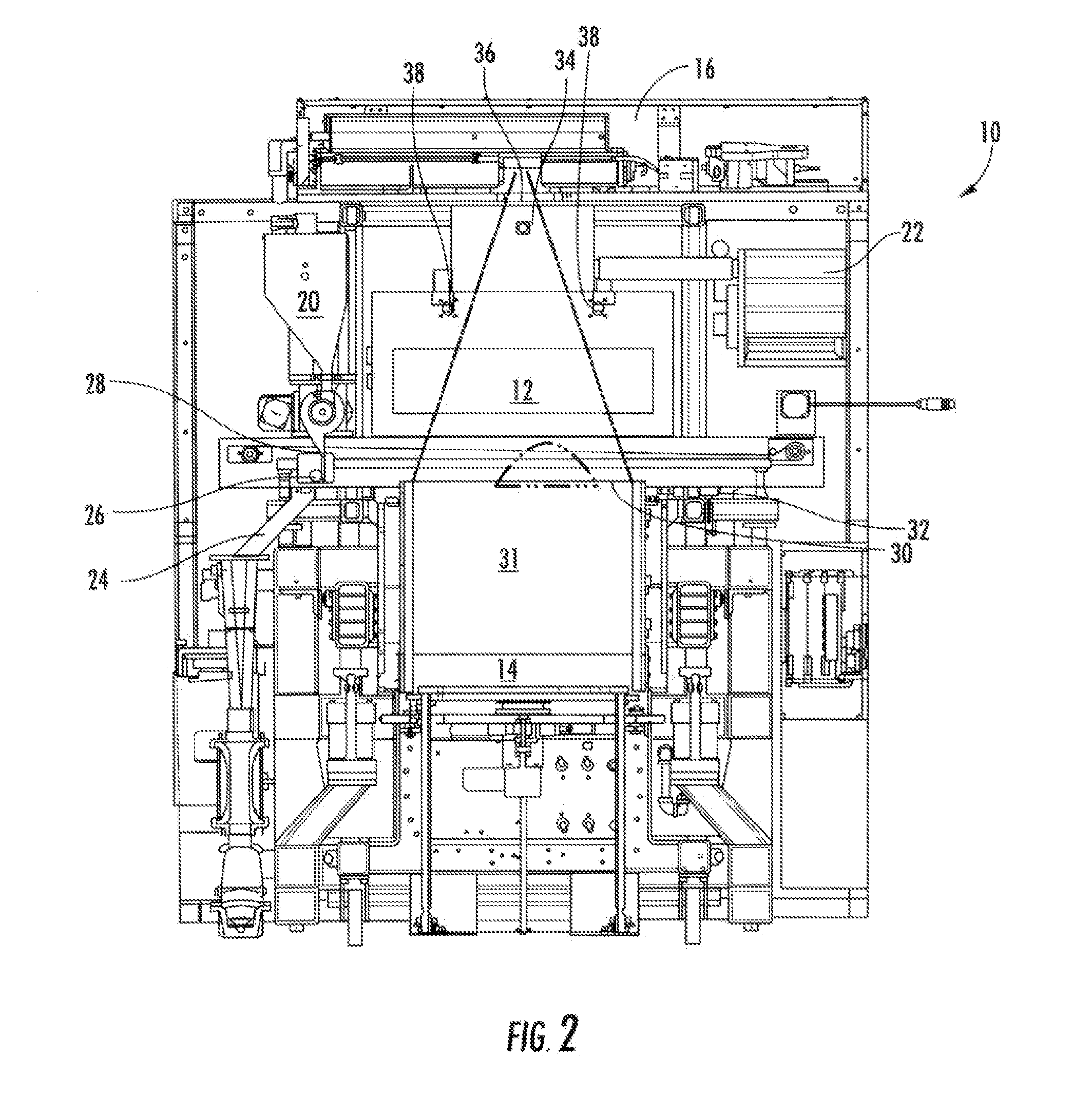

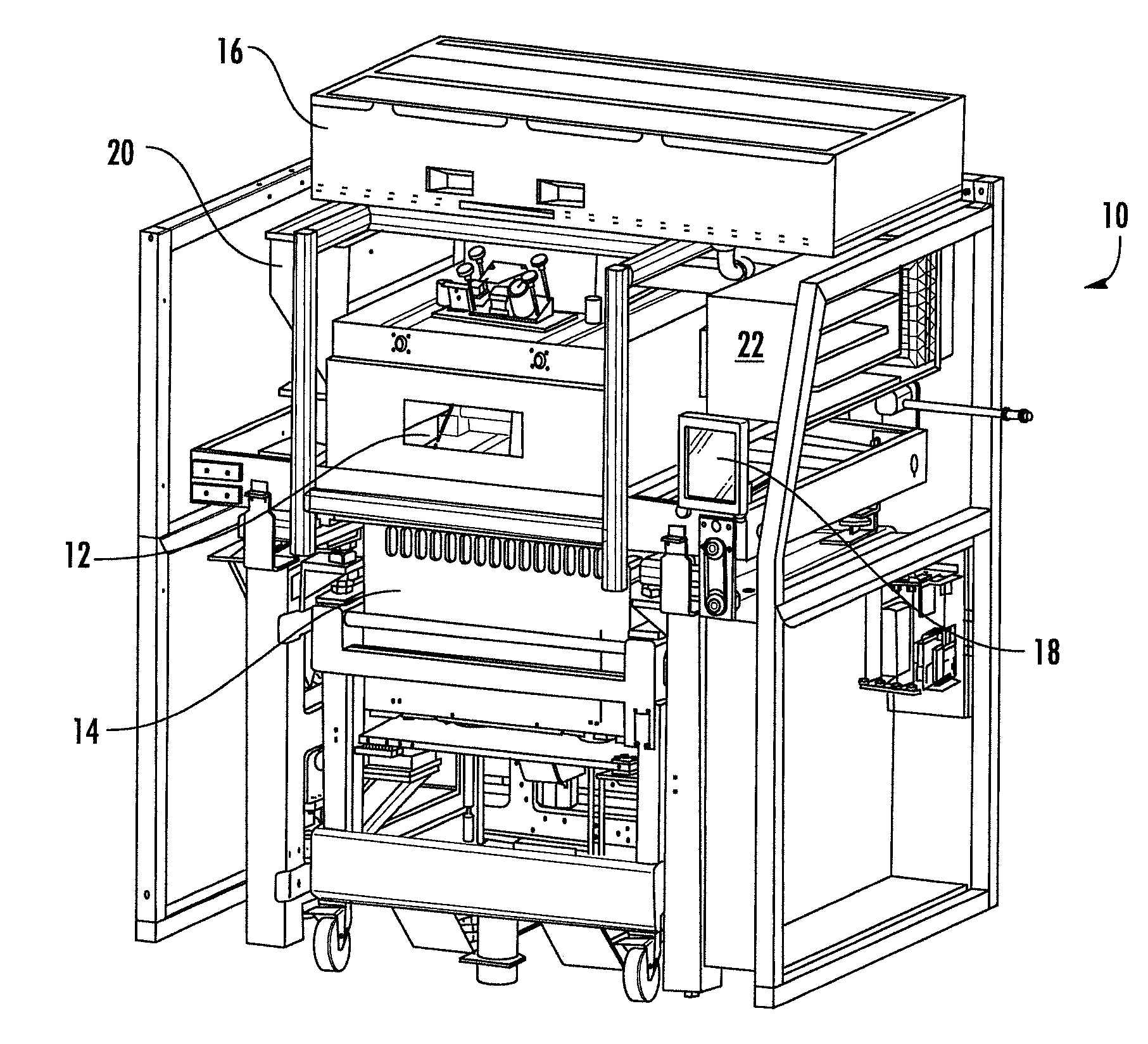

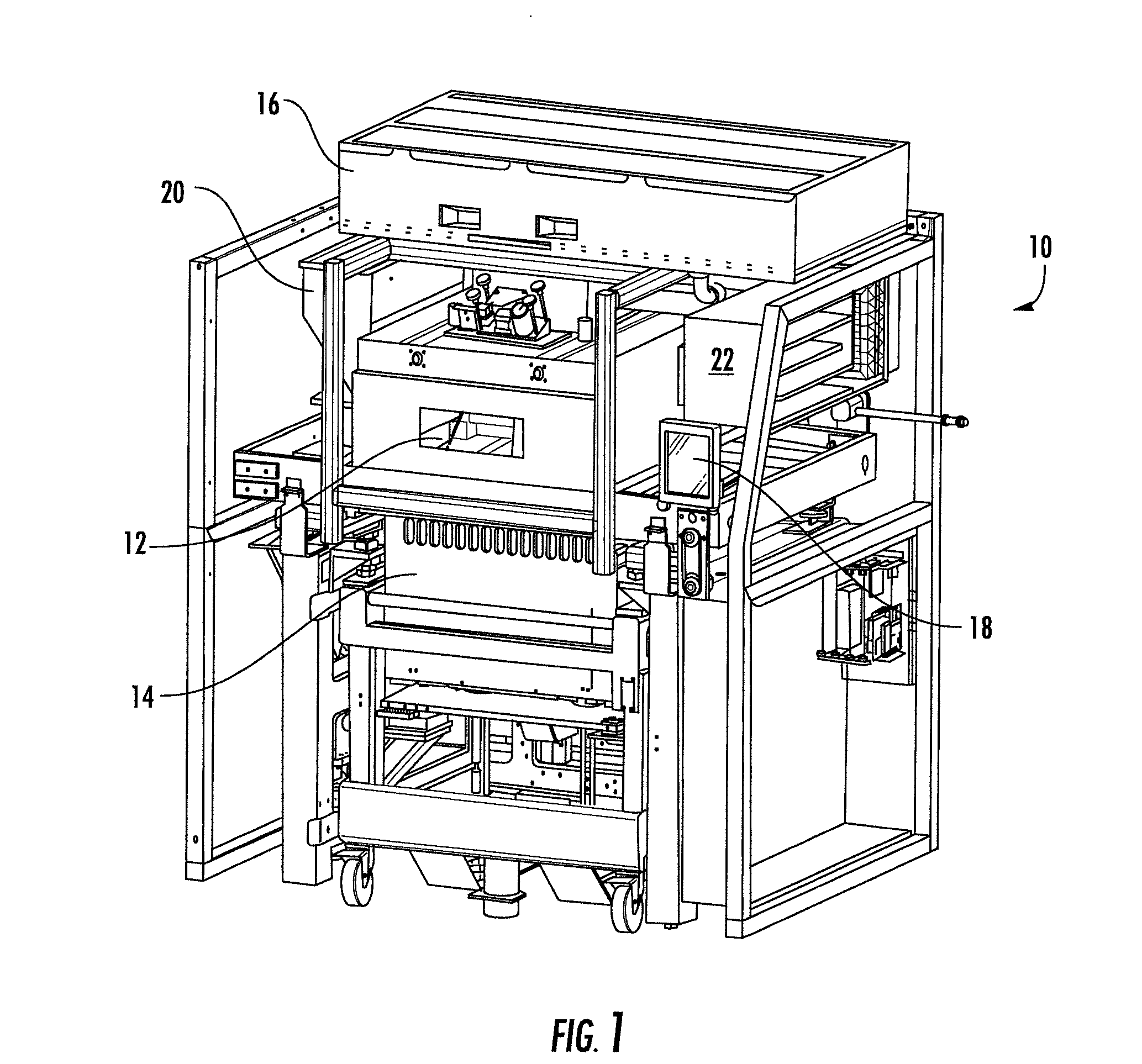

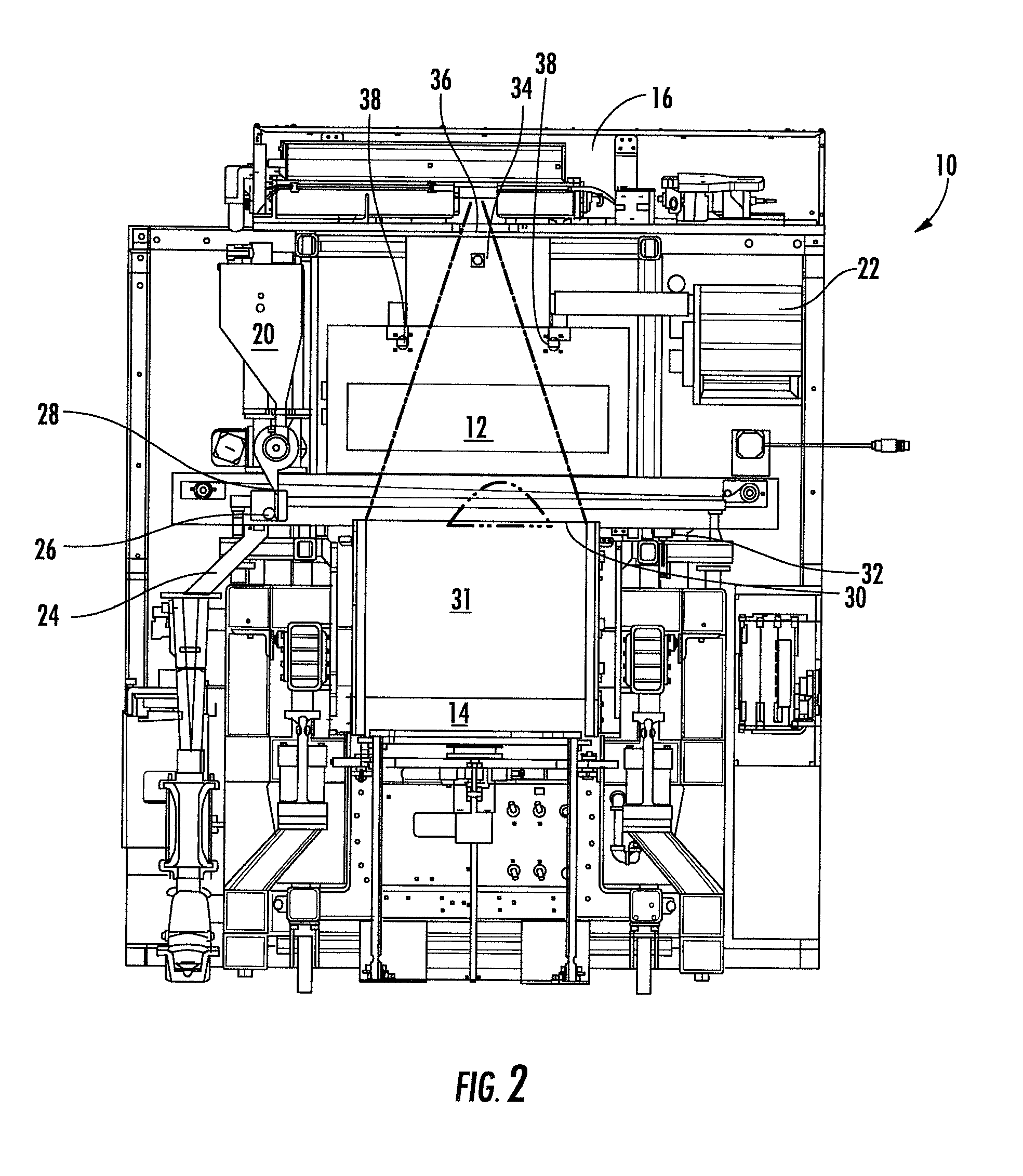

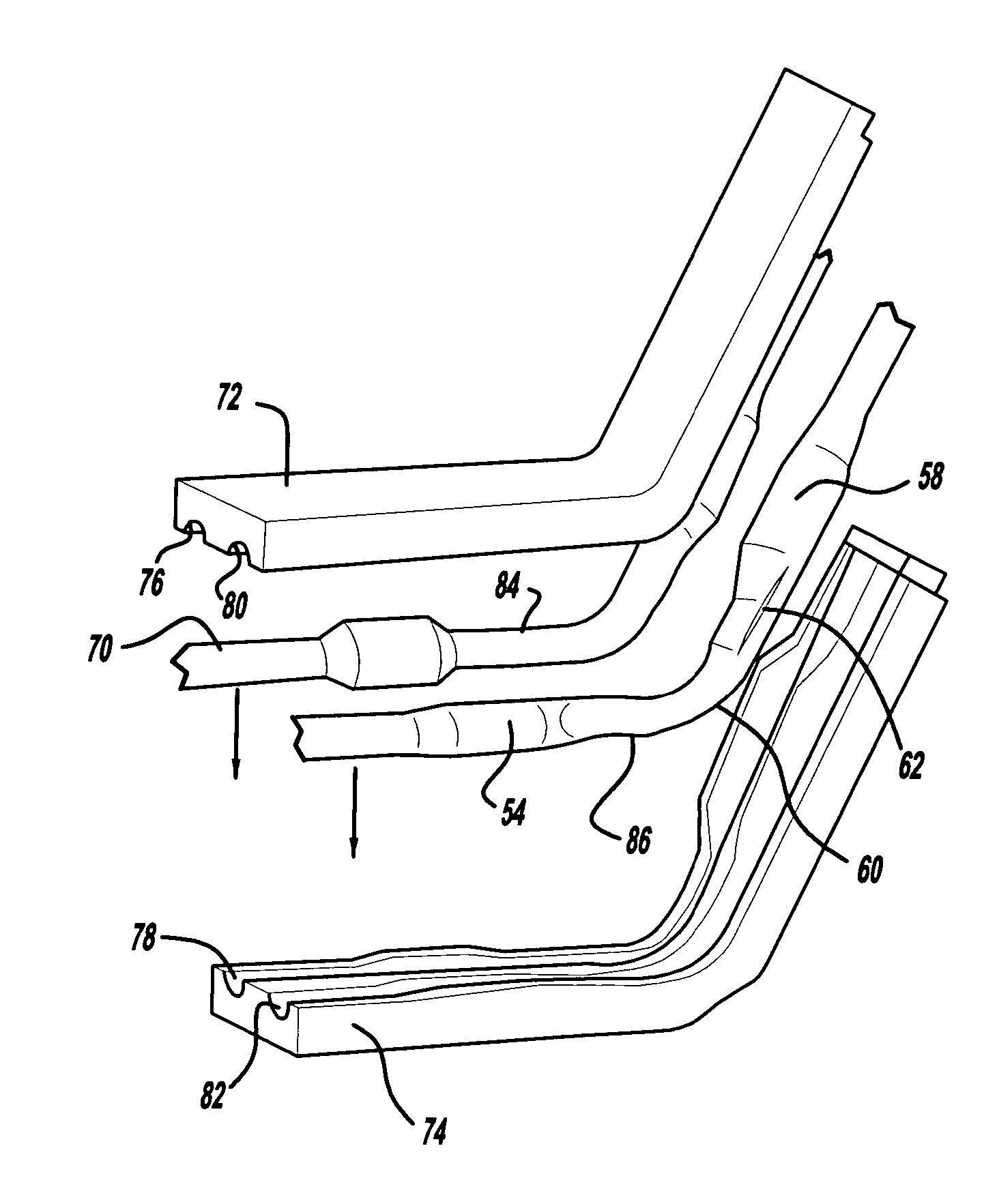

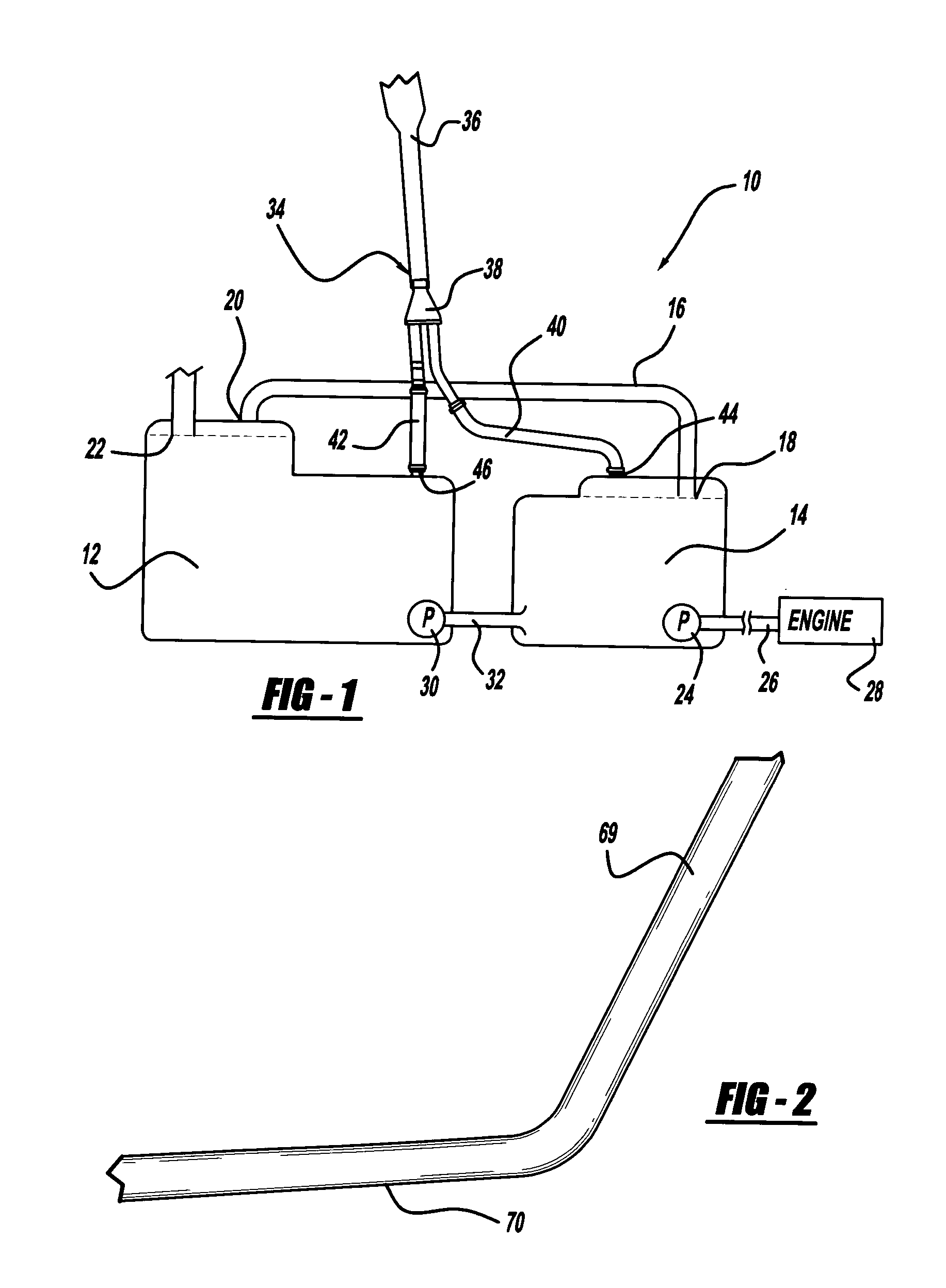

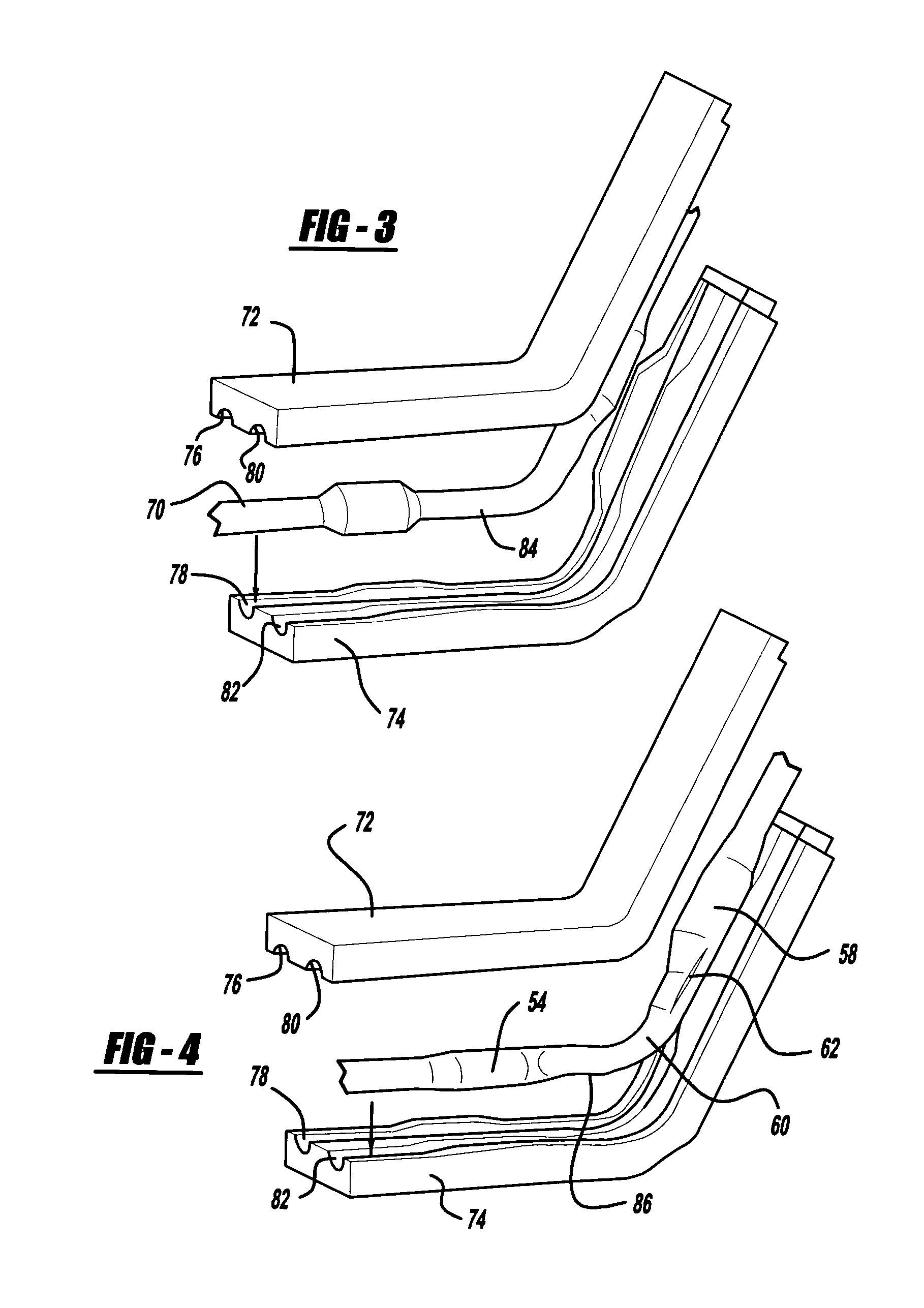

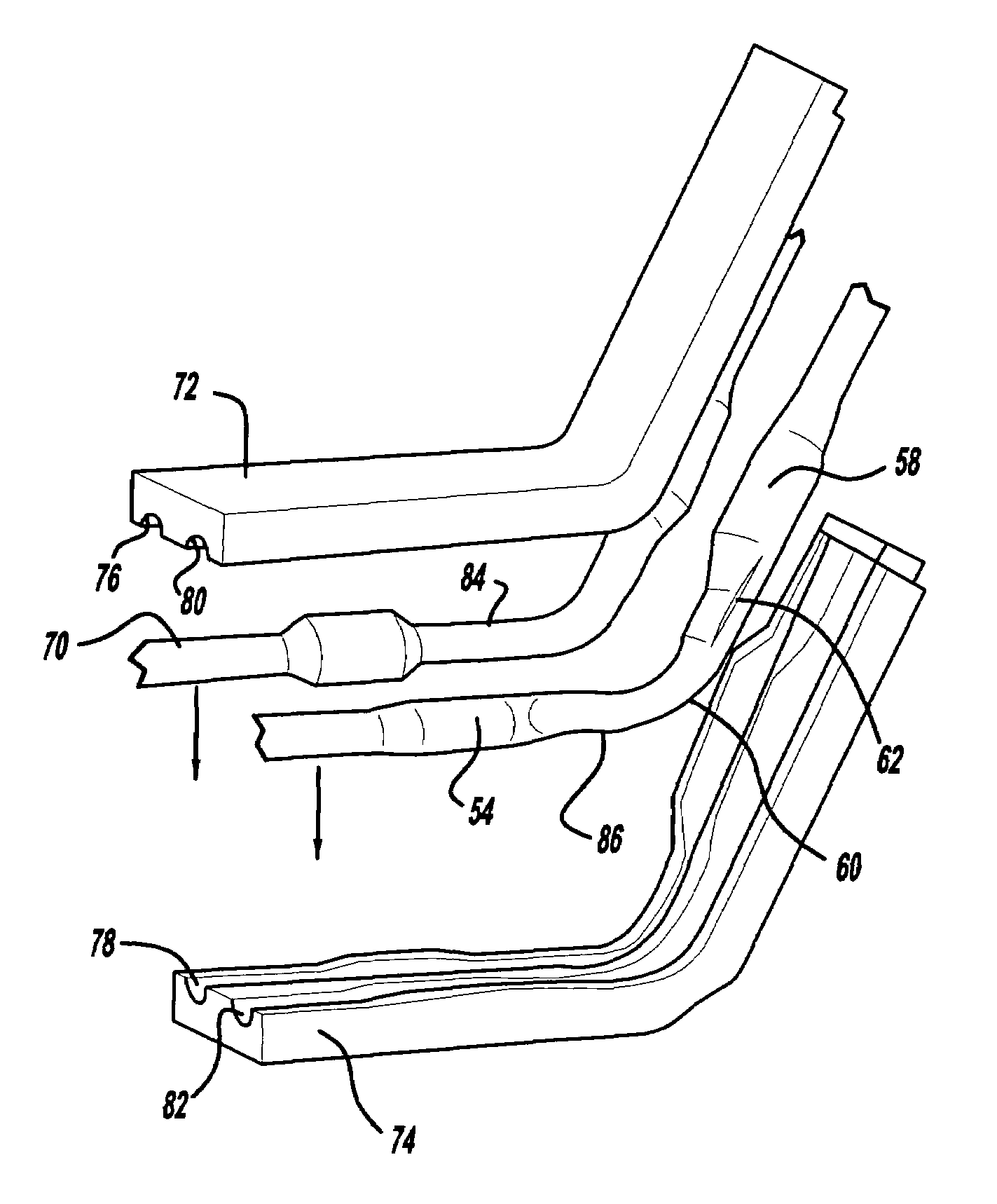

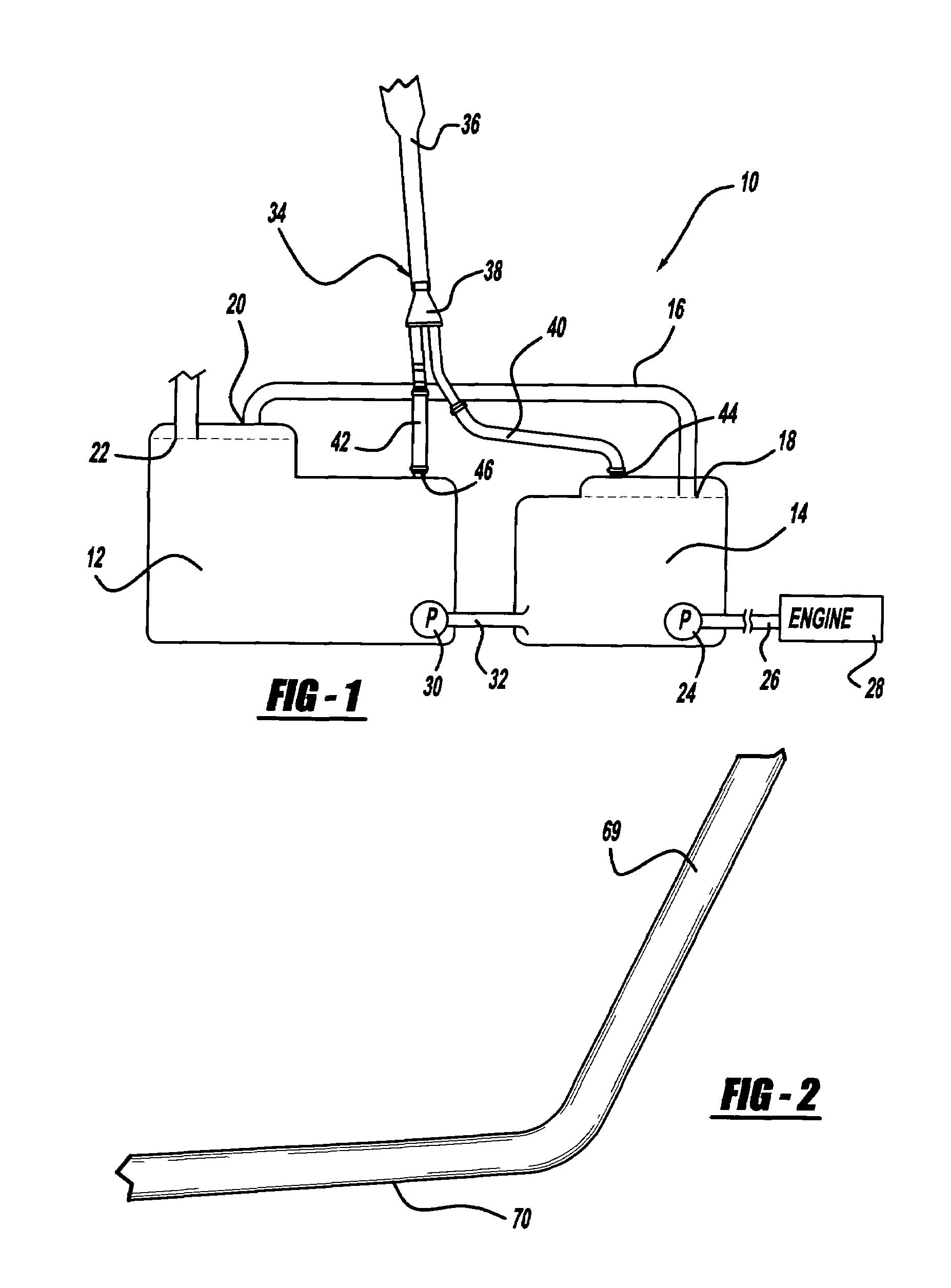

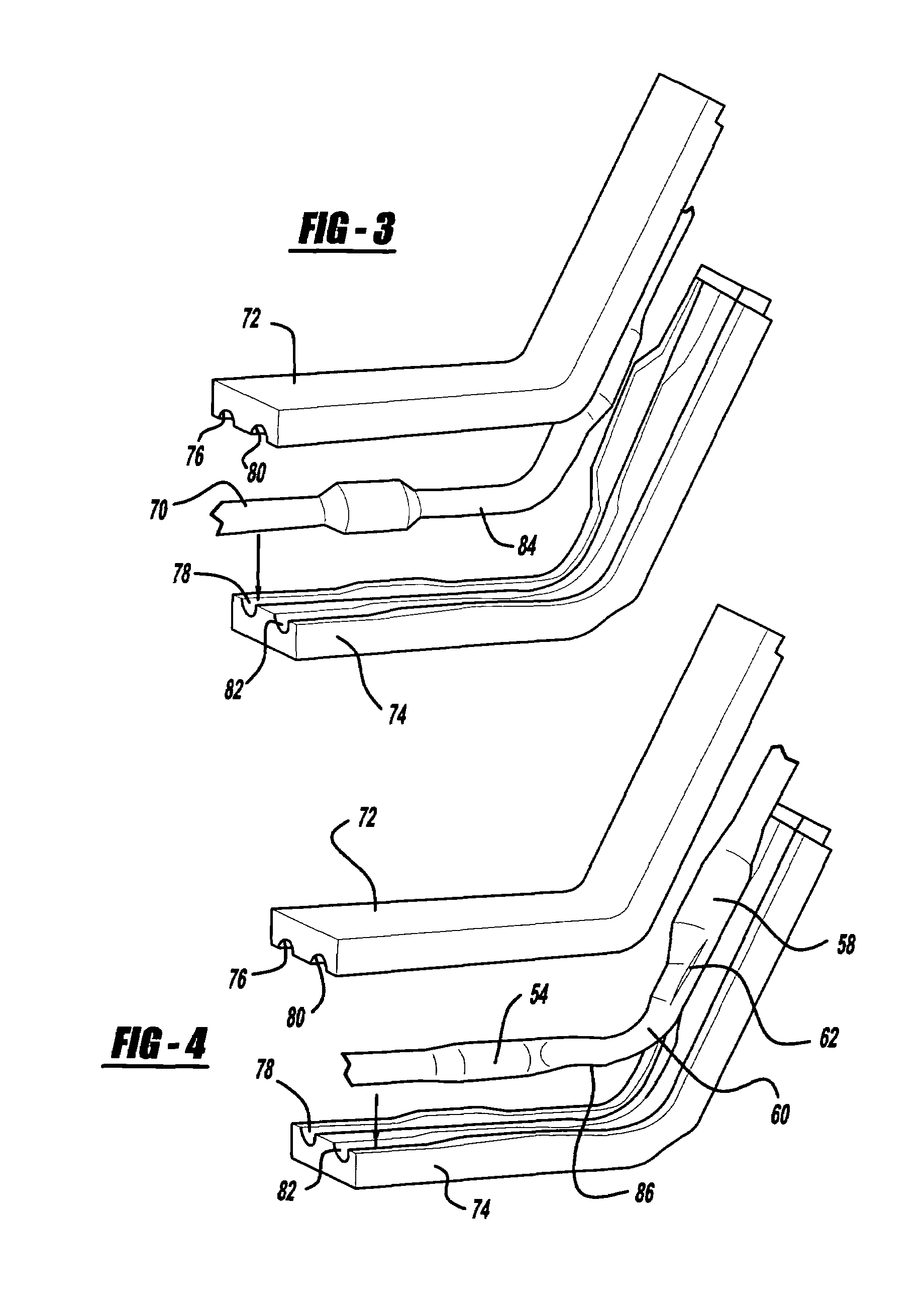

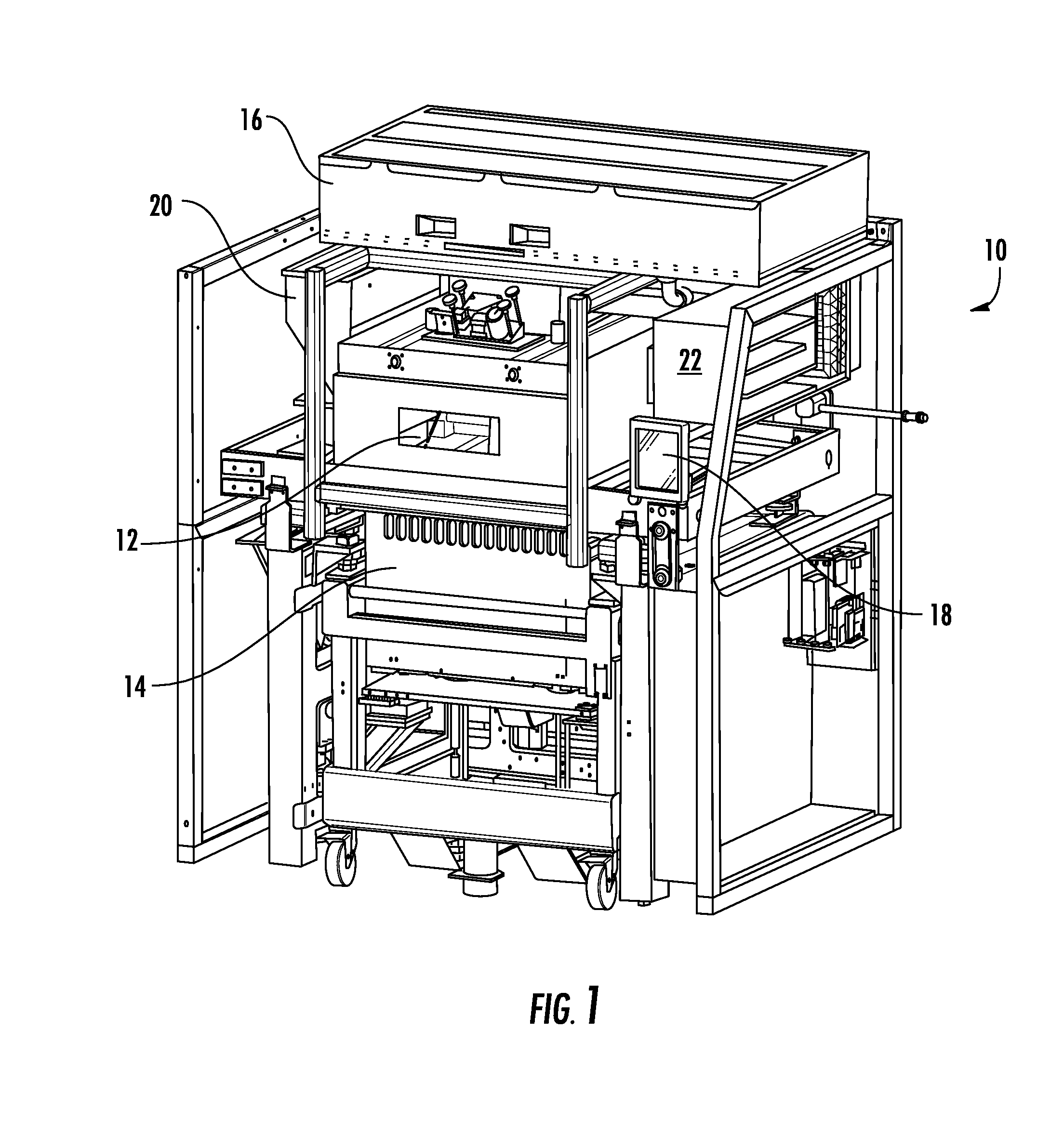

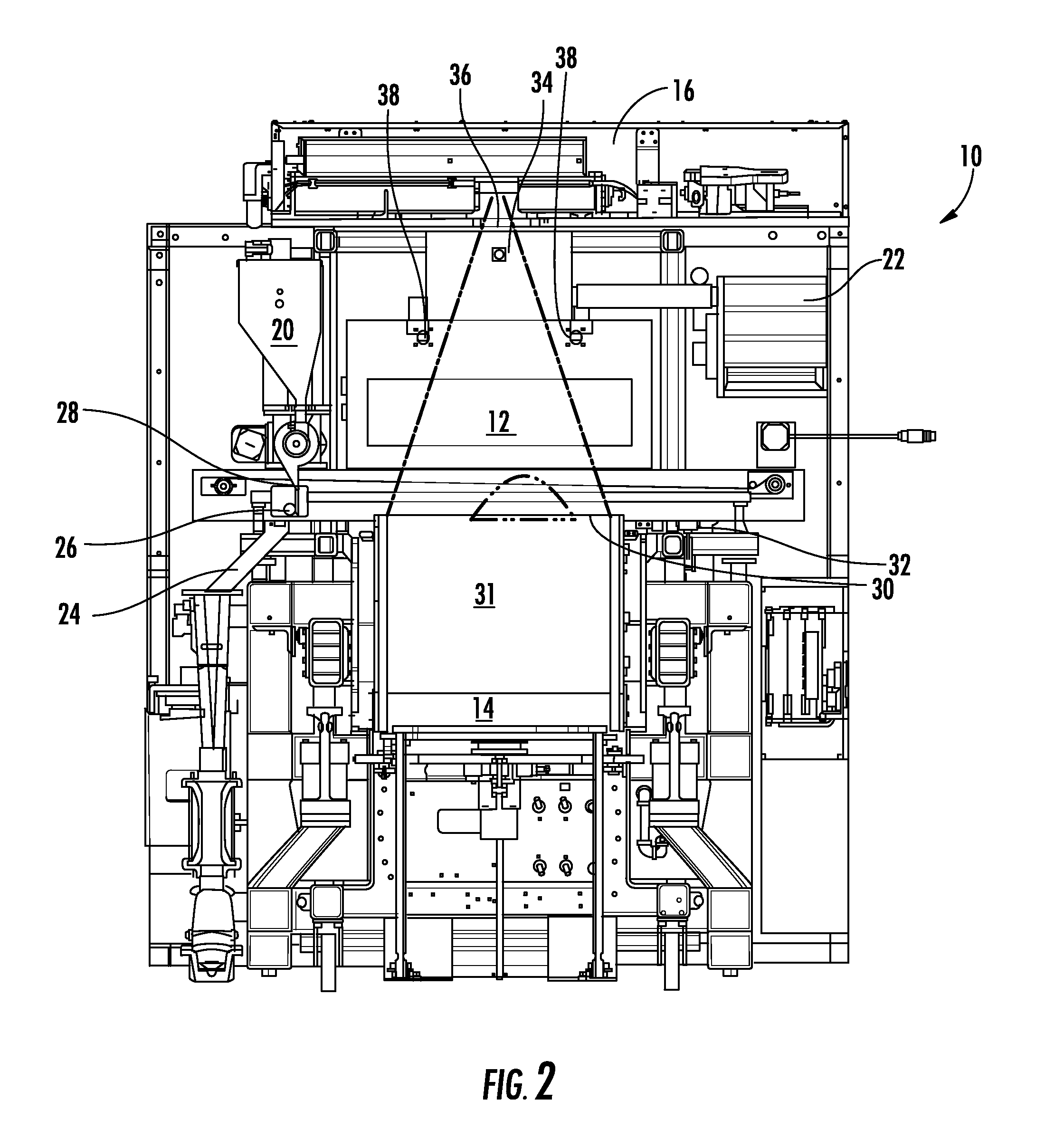

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

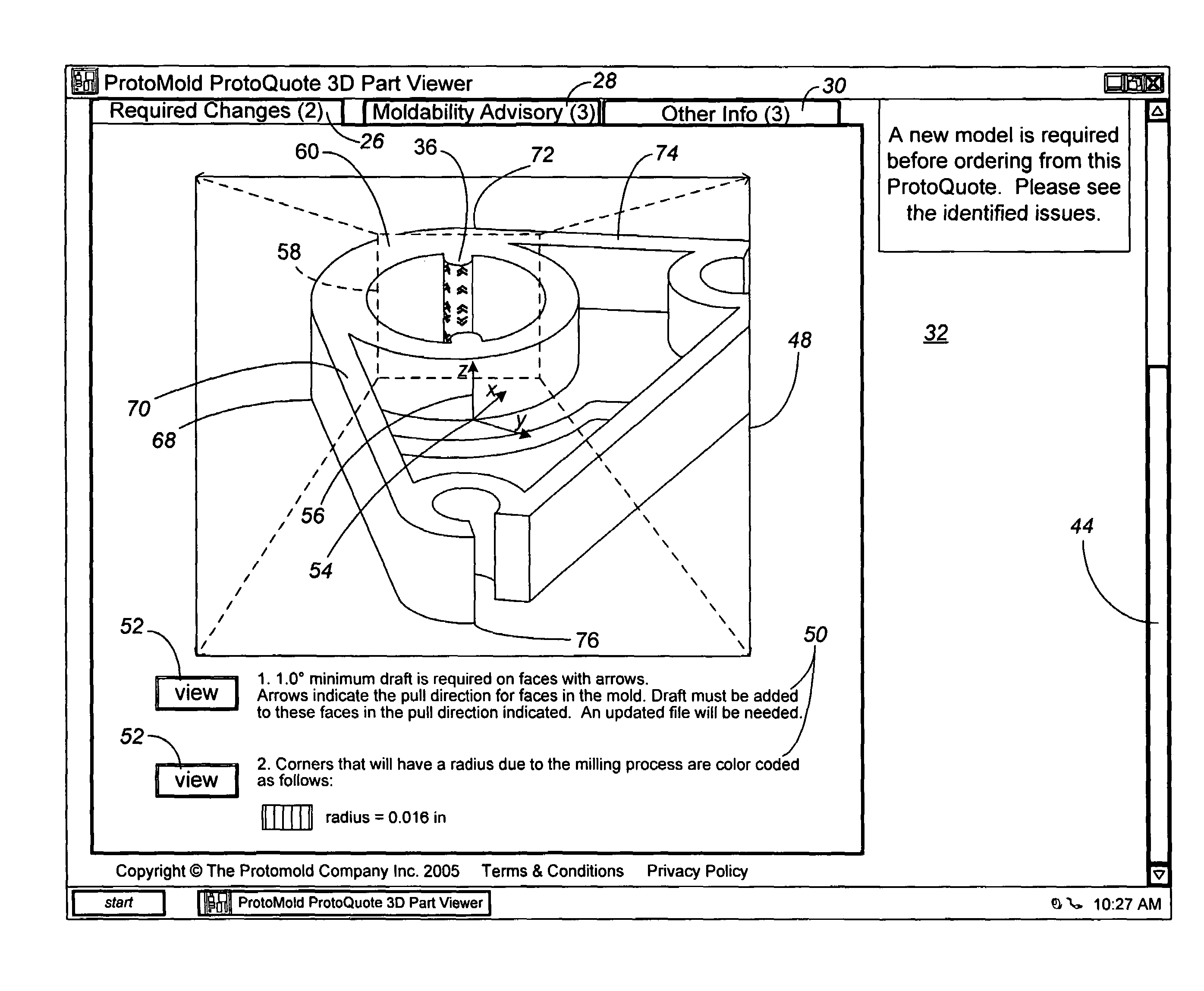

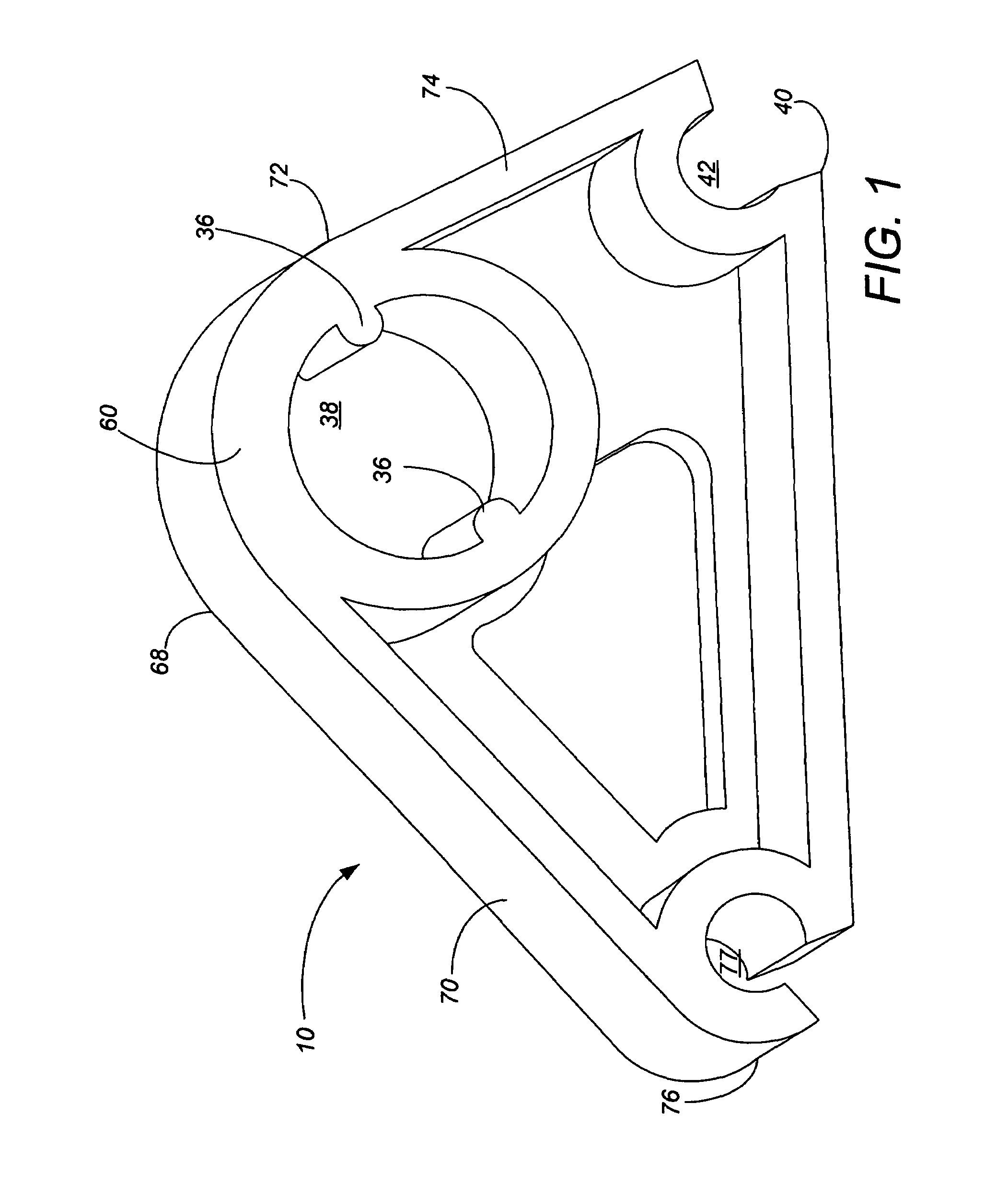

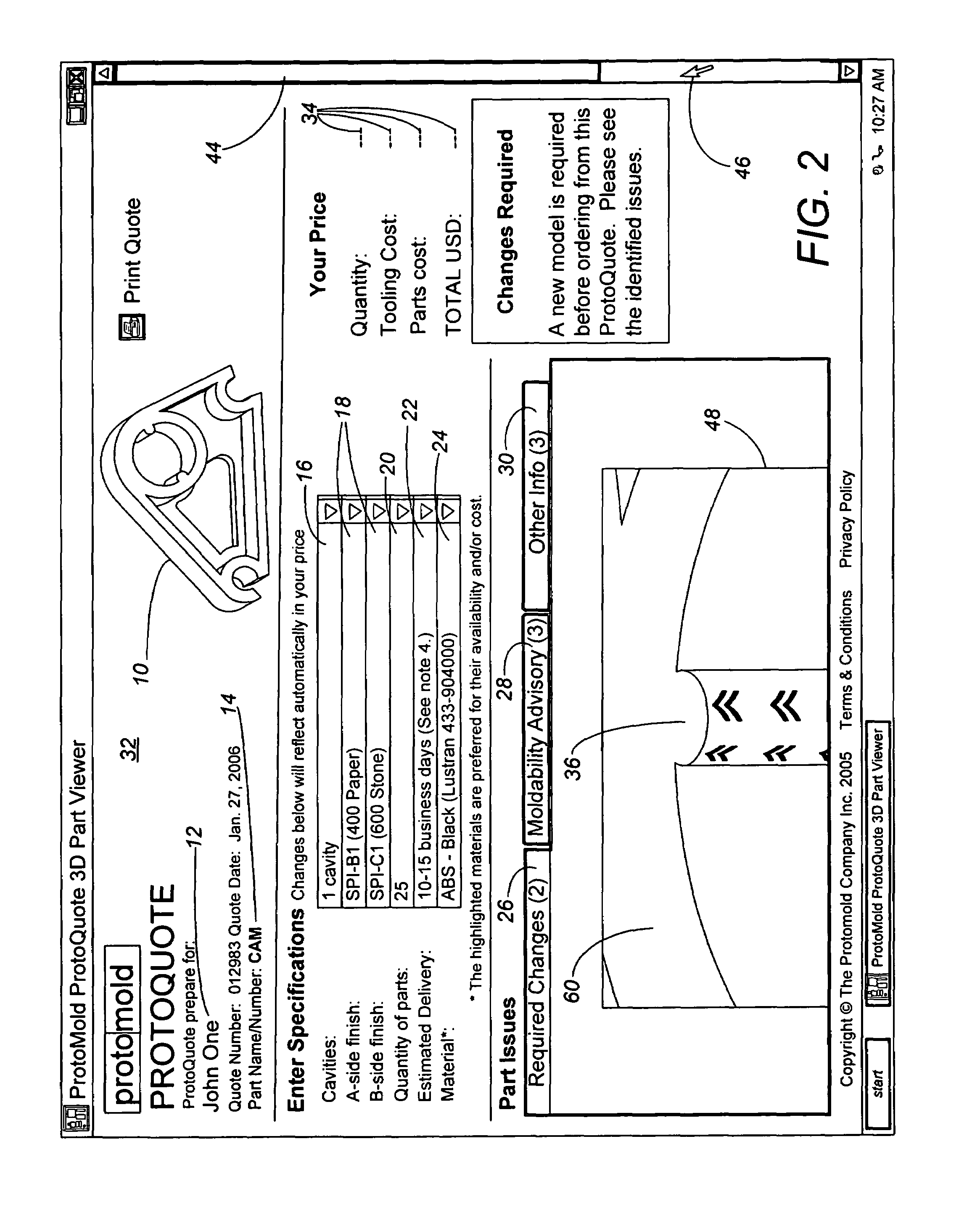

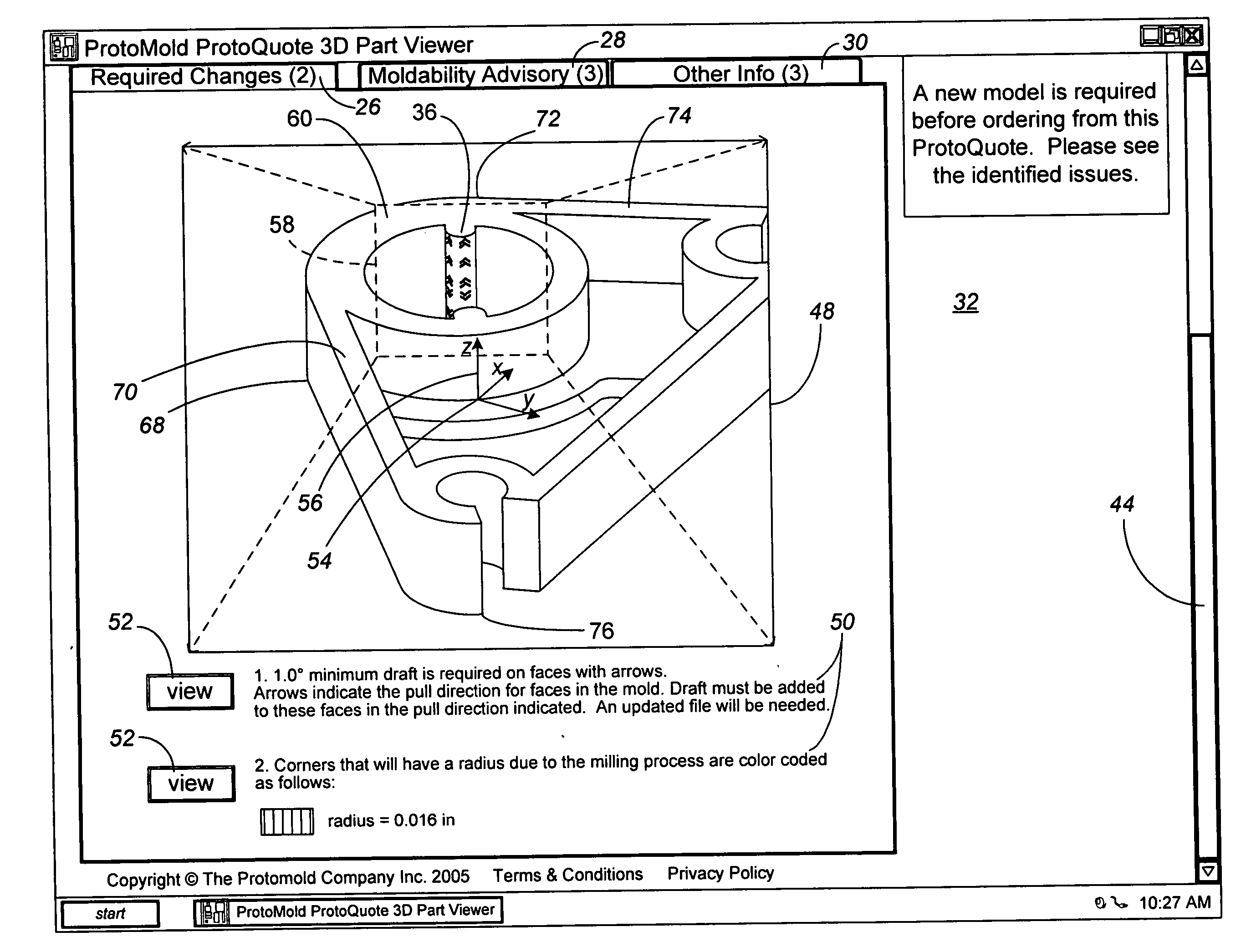

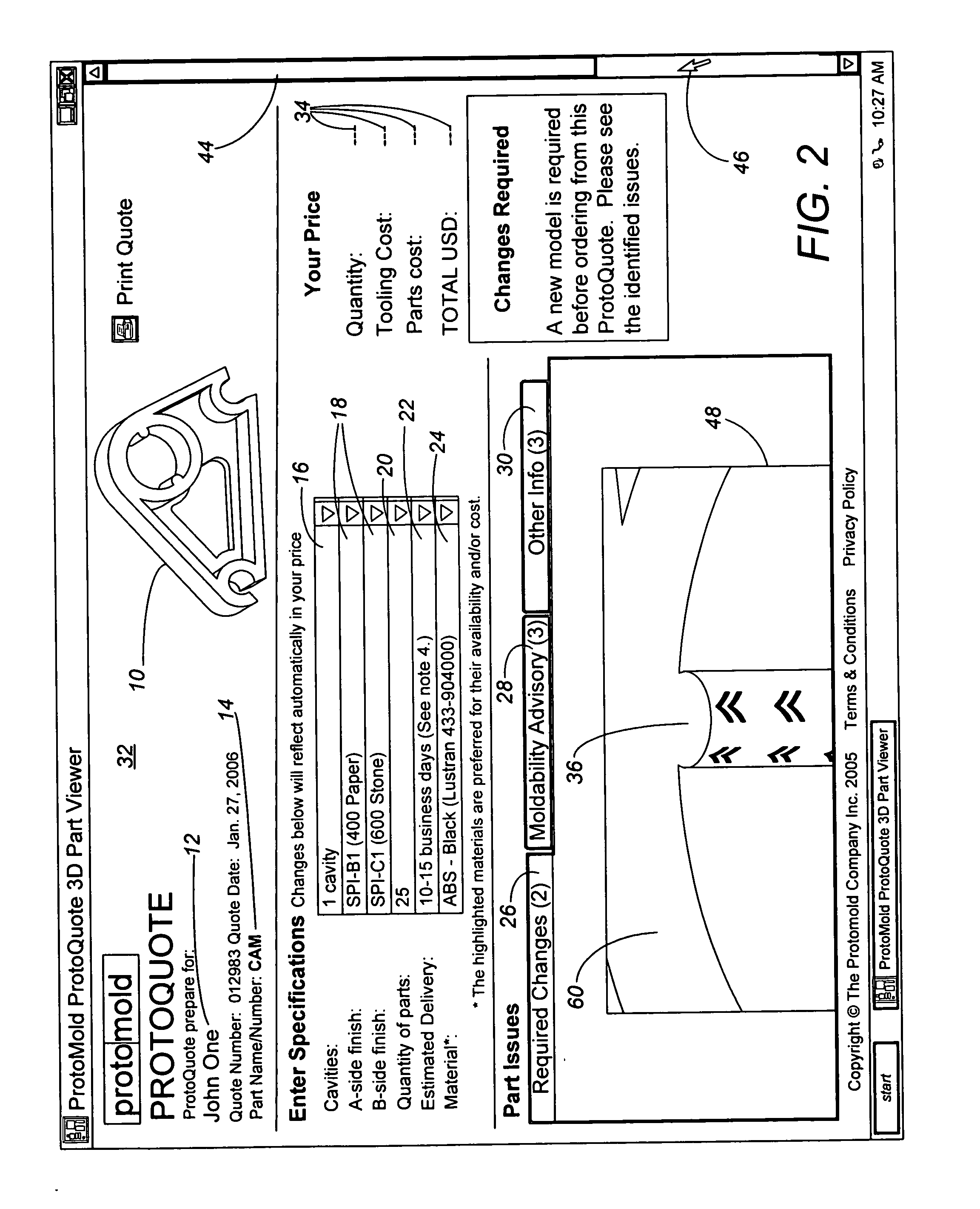

Manipulatable model for communicating manufacturing issues of a custom part

ActiveUS7299101B2Better understandingImprove part qualityTelevision system detailsCathode-ray tube indicatorsSystem usageComputer science

Any issues associated with manufacture of a part are identified and highlighted on a part model. A software method and system then uses motion of the part model for communicating the manufacturability issues to the customer. The motion can include a repositioning of a part rendering to a preferred orientation position, a fly-around so the customer can appreciate the next zoom location, and then a zooming in on the issue desired to be shown. Alternatively or in conjunction with the zooming and fly-around motion, the orientation of the part rendering showing the manufacturability issues can be three-dimensionally manipulated such as with a click-drag-drop command of the customer's computer mouse. By adding a moveable aspect to the communication, customers can much better understand which changes are recommended or required of the part.

Owner:PROTOLABS INC

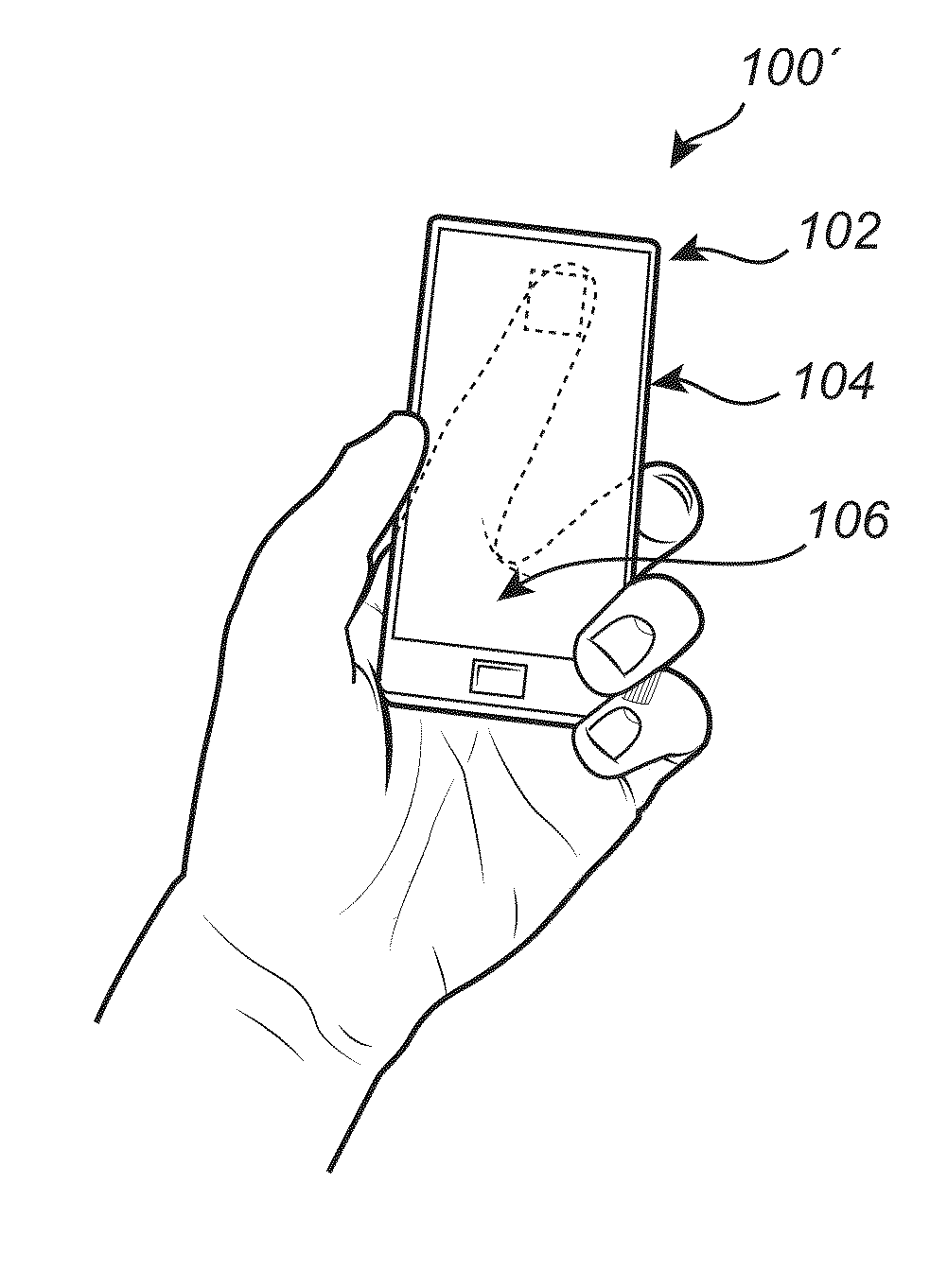

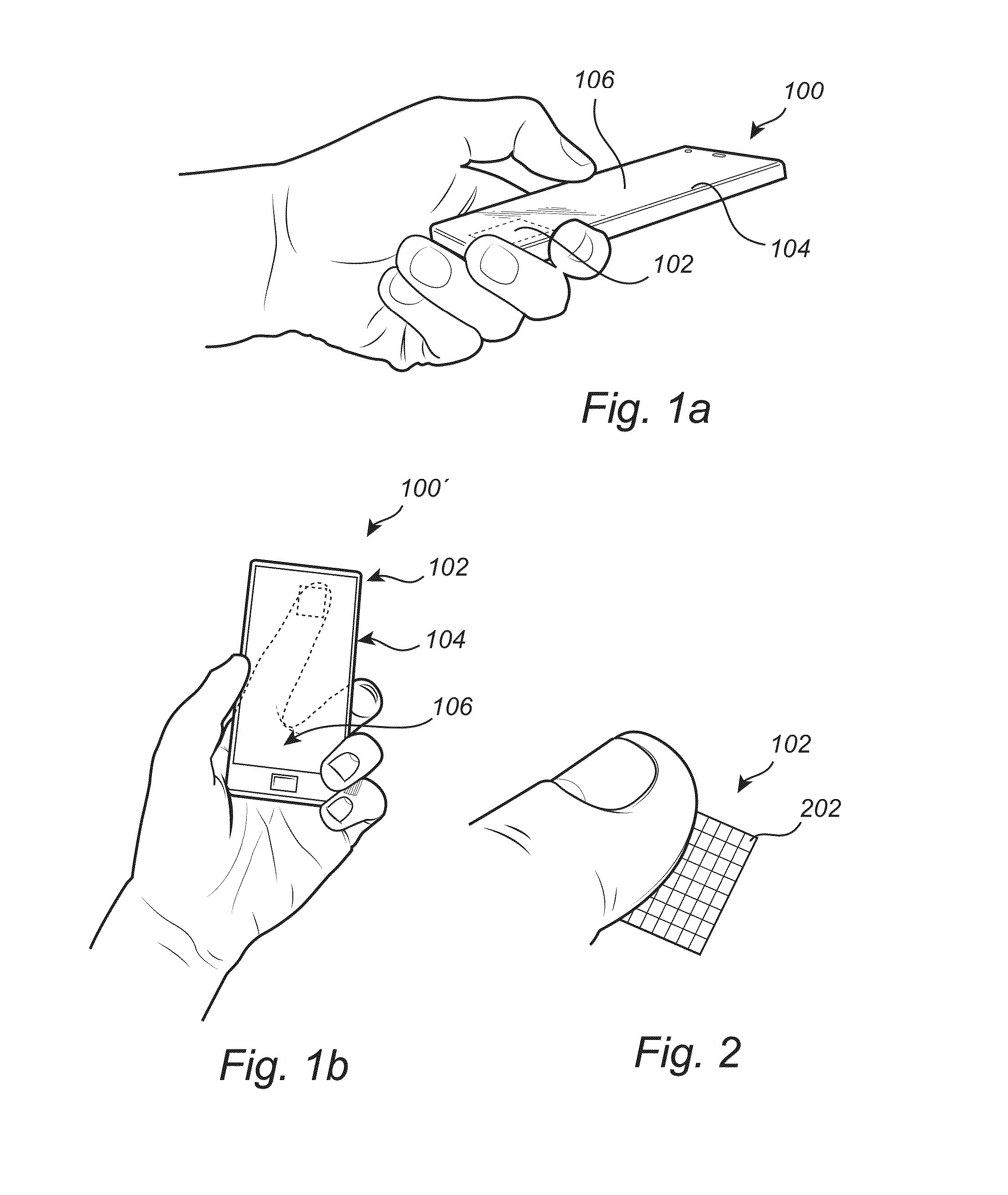

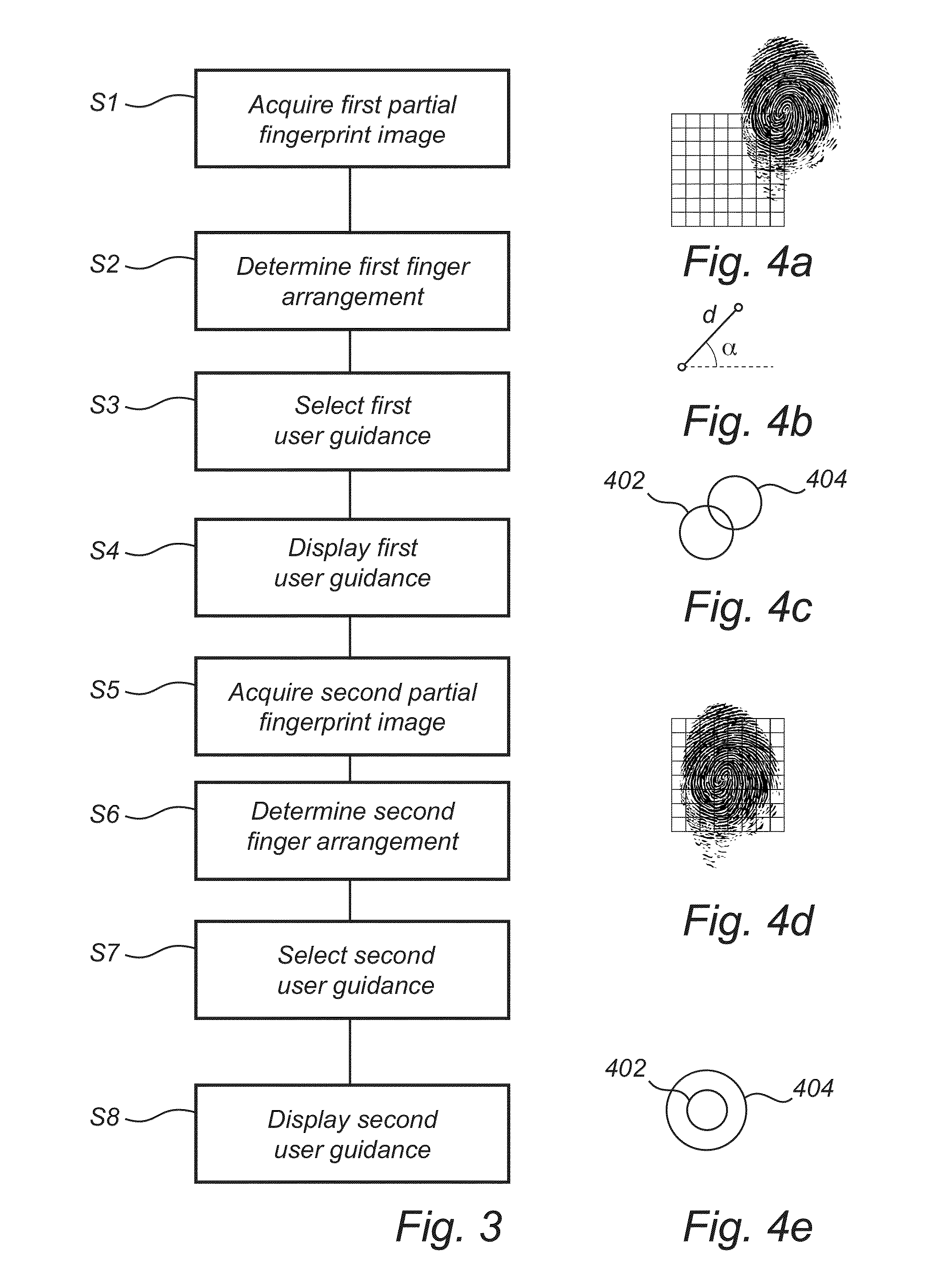

Method of guiding a user of a portable electronic device

ActiveUS20160253544A1Accurate guidanceImprove performanceDigital data processing detailsAcquiring/reconising fingerprints/palmprintsHuman–computer interactionFingerprint

The present invention relates to a method of guiding a user of a portable electronic device when operating a fingerprint sensor comprised with the portable electronic device. The invention allows for an improved enrollment process as well as for general improvements when using the fingerprint sensor. The invention also relates to a corresponding electronic device and to a computer program product.

Owner:FINGERPRINT CARDS ANACATUM IP AB

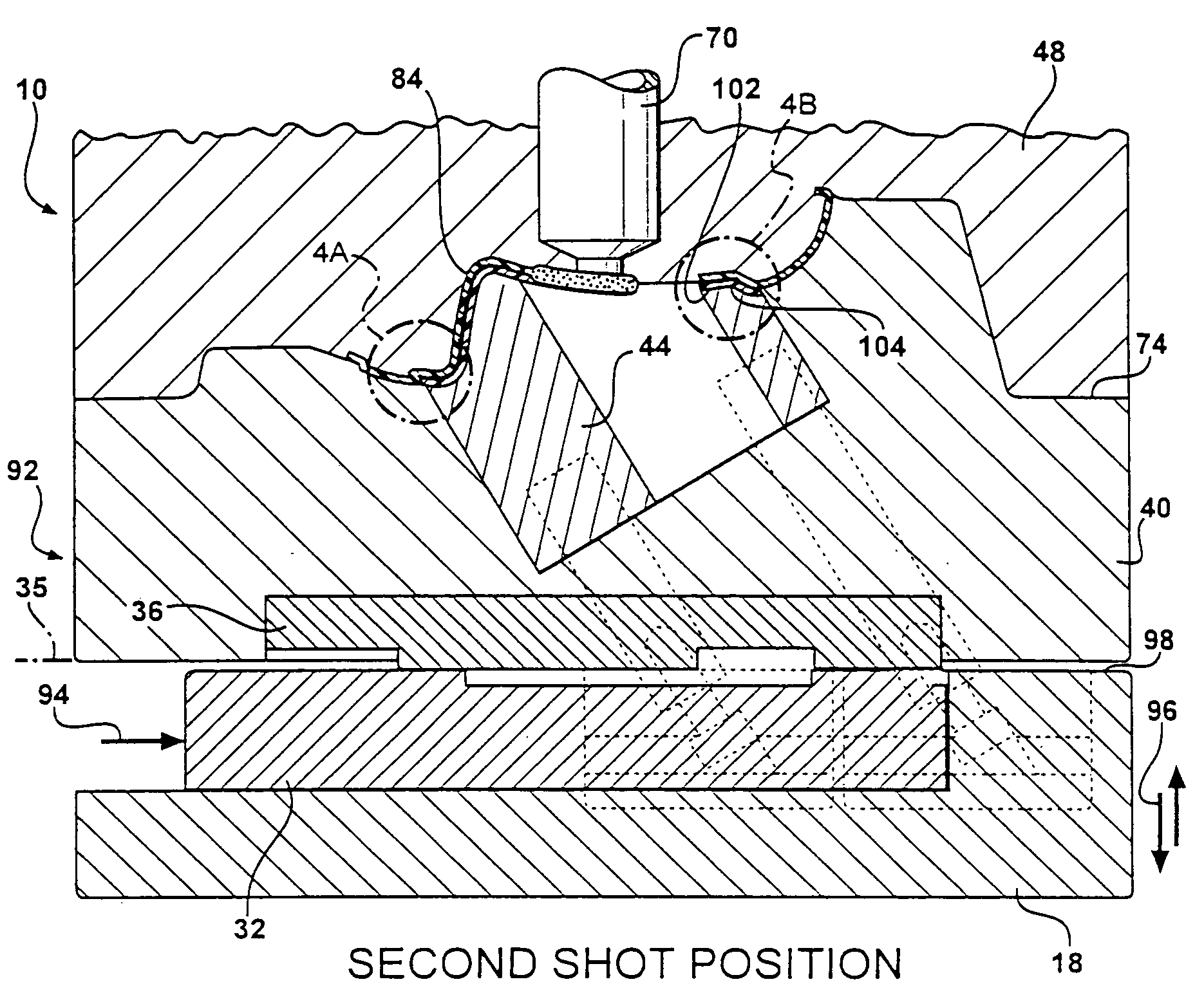

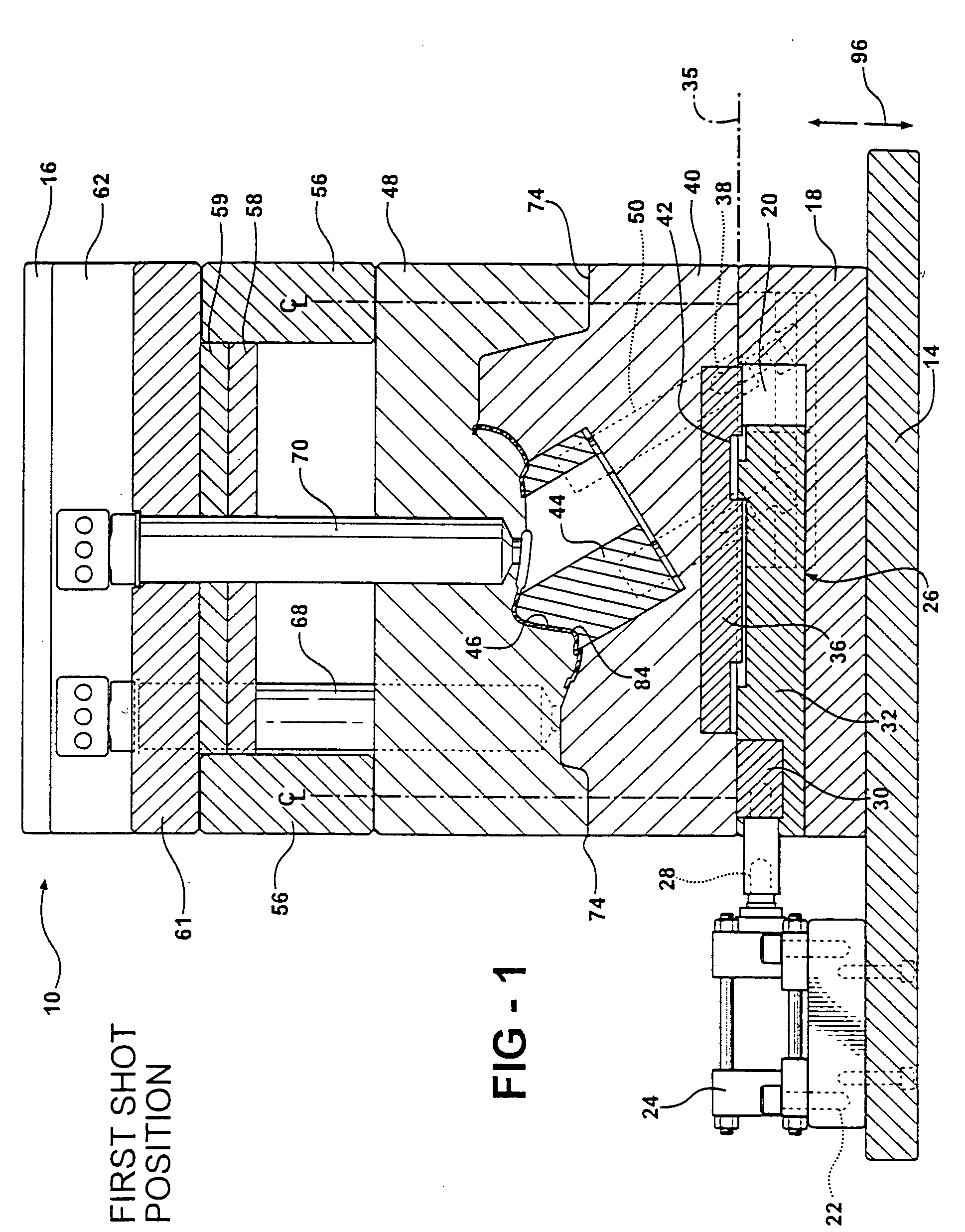

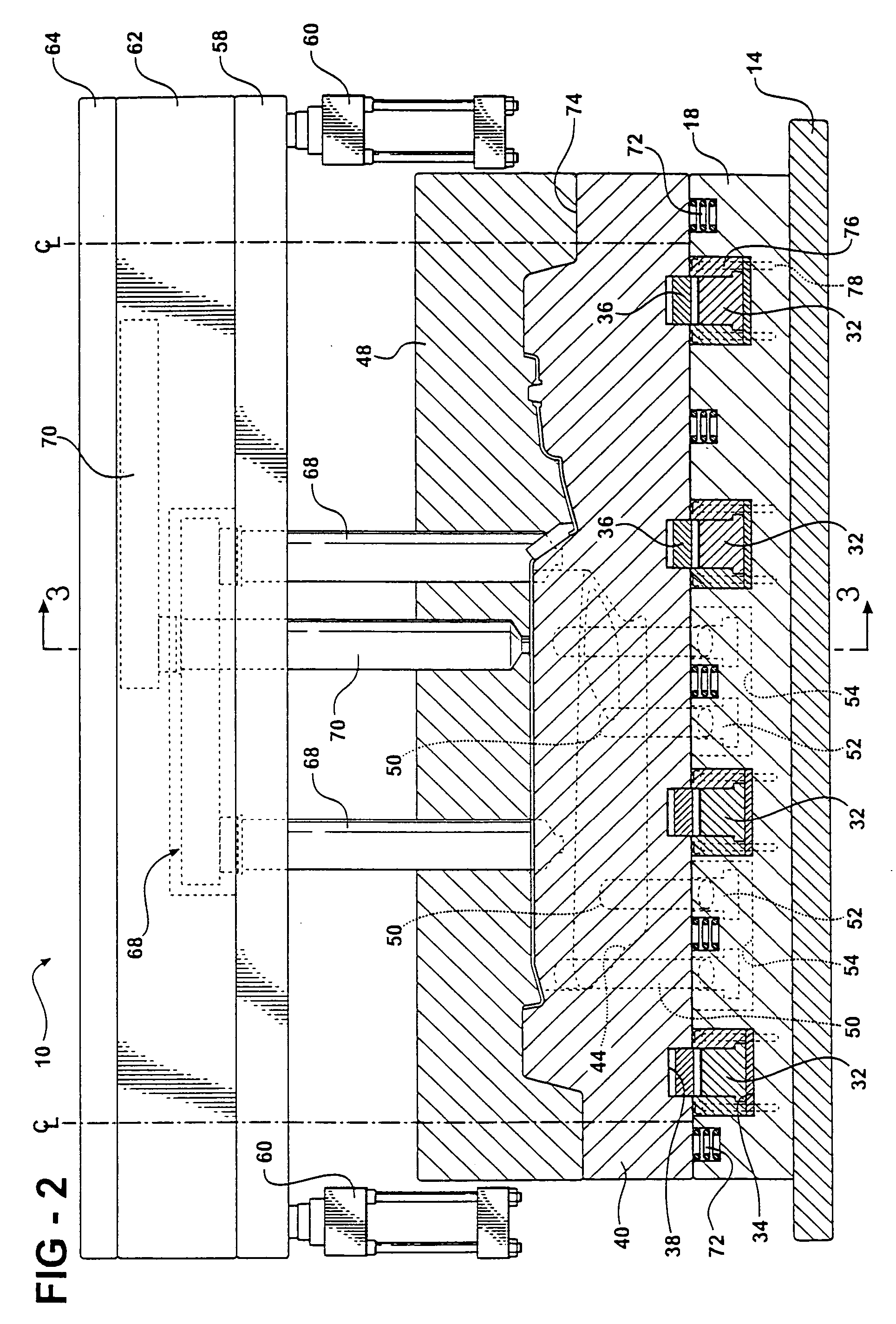

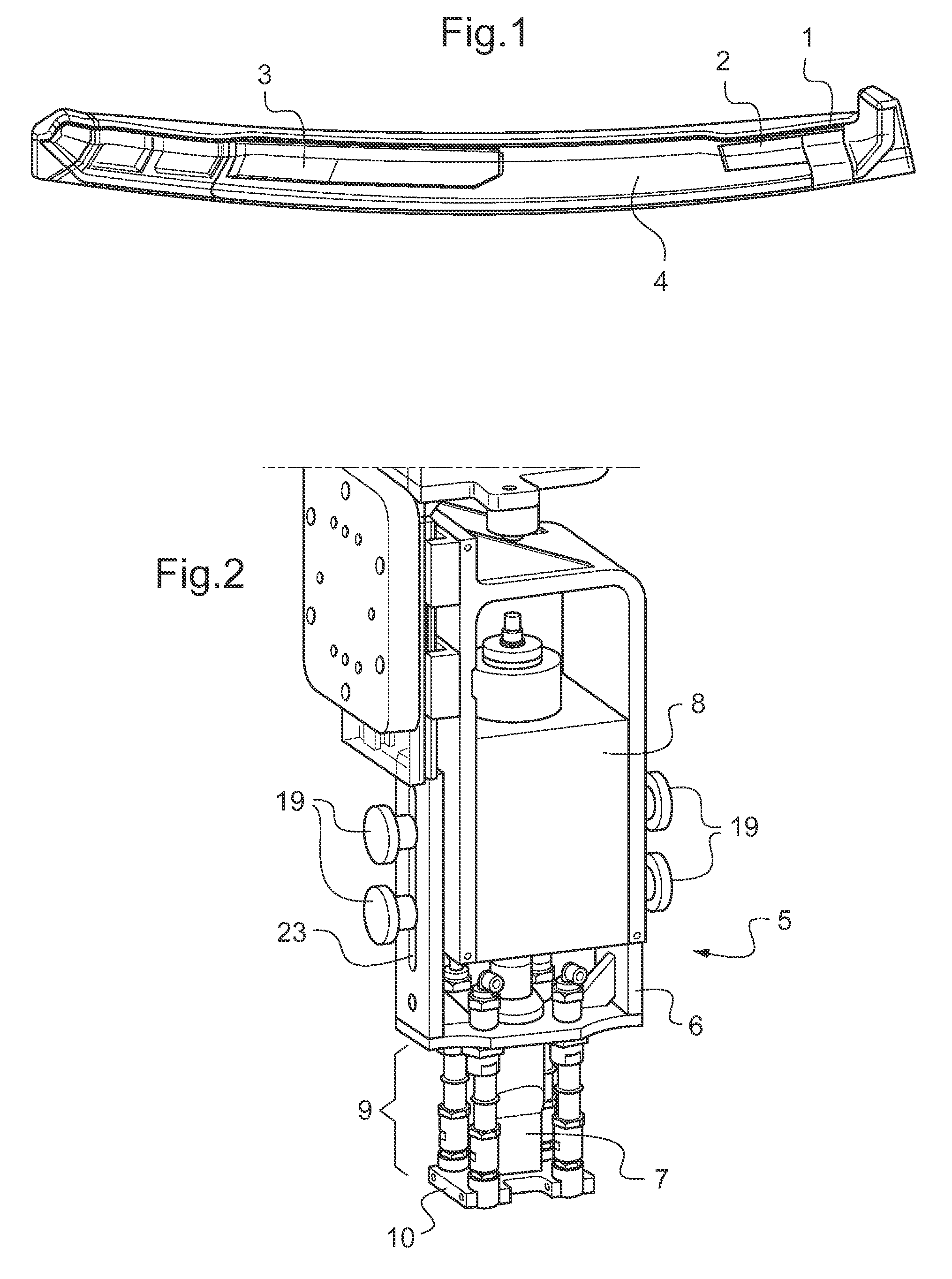

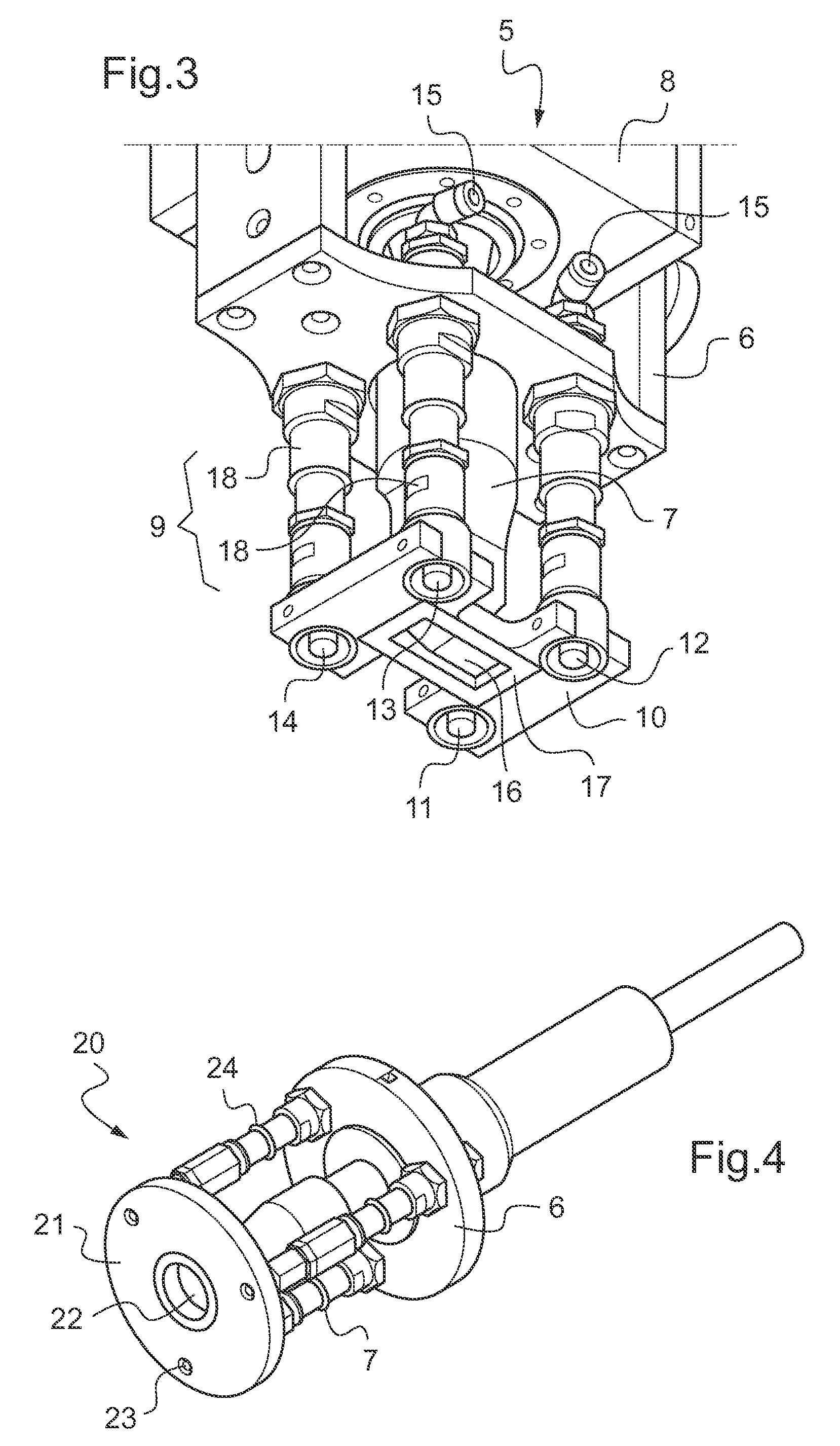

Multi-color injection molded door panel and process

InactiveUS20050285303A1Improve fitQuality improvementTailstocks/centresMouldsComing outMulti material

A tool for manufacturing a multi-colored plastic automotive part, such as a door panel, is manufactured using multiple molding shots without opening the mold between each shot. The door panel comes out finished with no scuffing, warping, or shrinkage. The process for manufacturing the panel includes selectively locating spacers within the tool to a first position and then injecting a first material. The parting line is held closed while the spacers are then advanced to a second position so as to set the inner insert to a desired second shot wall thickness position. A second shot of material is then introduced into the rear of the injection unit through an opening in the first shot part. The process can be repeated for additional colors and materials to create a multi-colored or even multi-material final assembly. Once the part is cured, it is ejected and the process is complete.

Owner:YANFENG CZECHIA AUTOMOTIVE INTERIOR SYST SRO +1

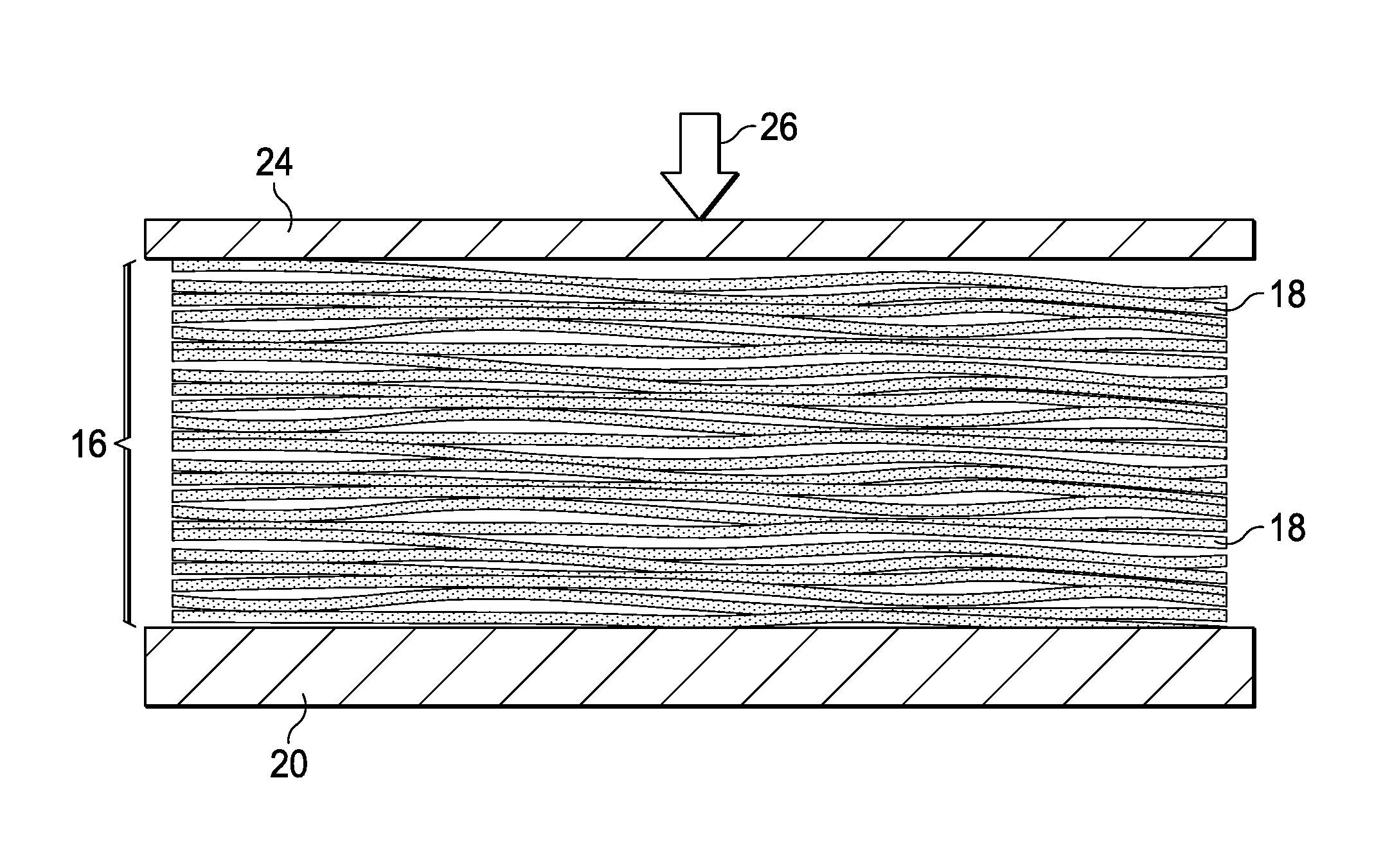

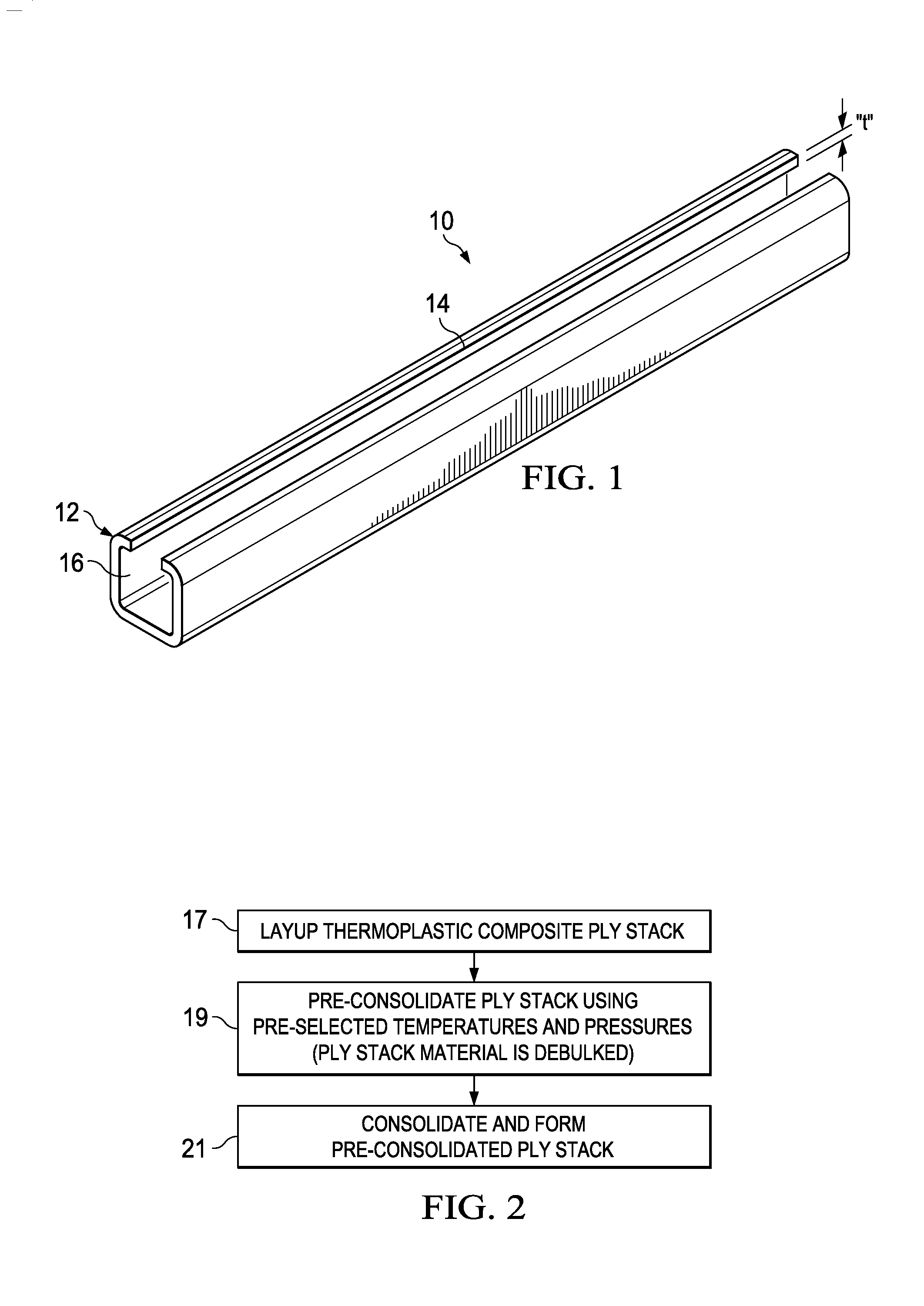

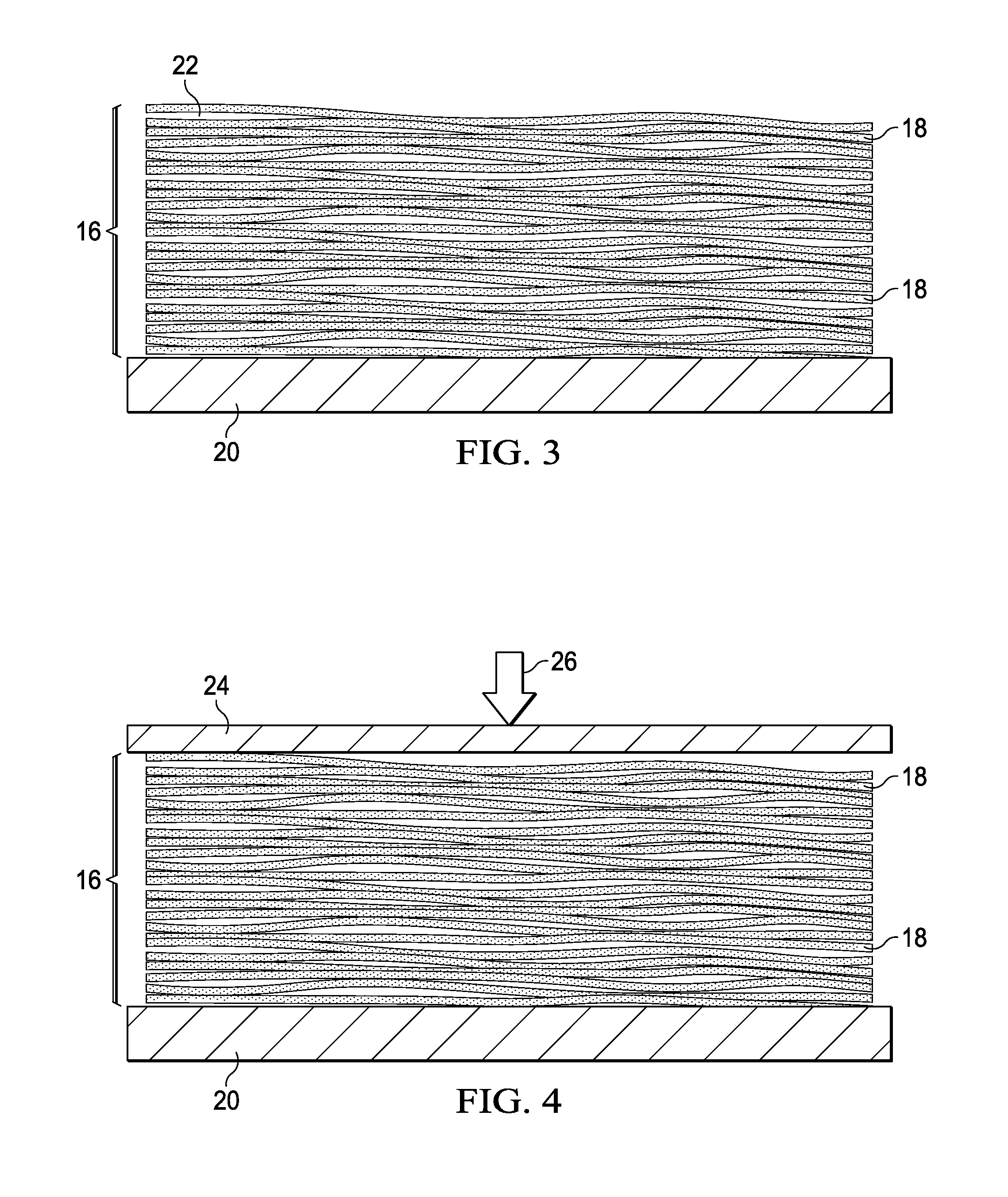

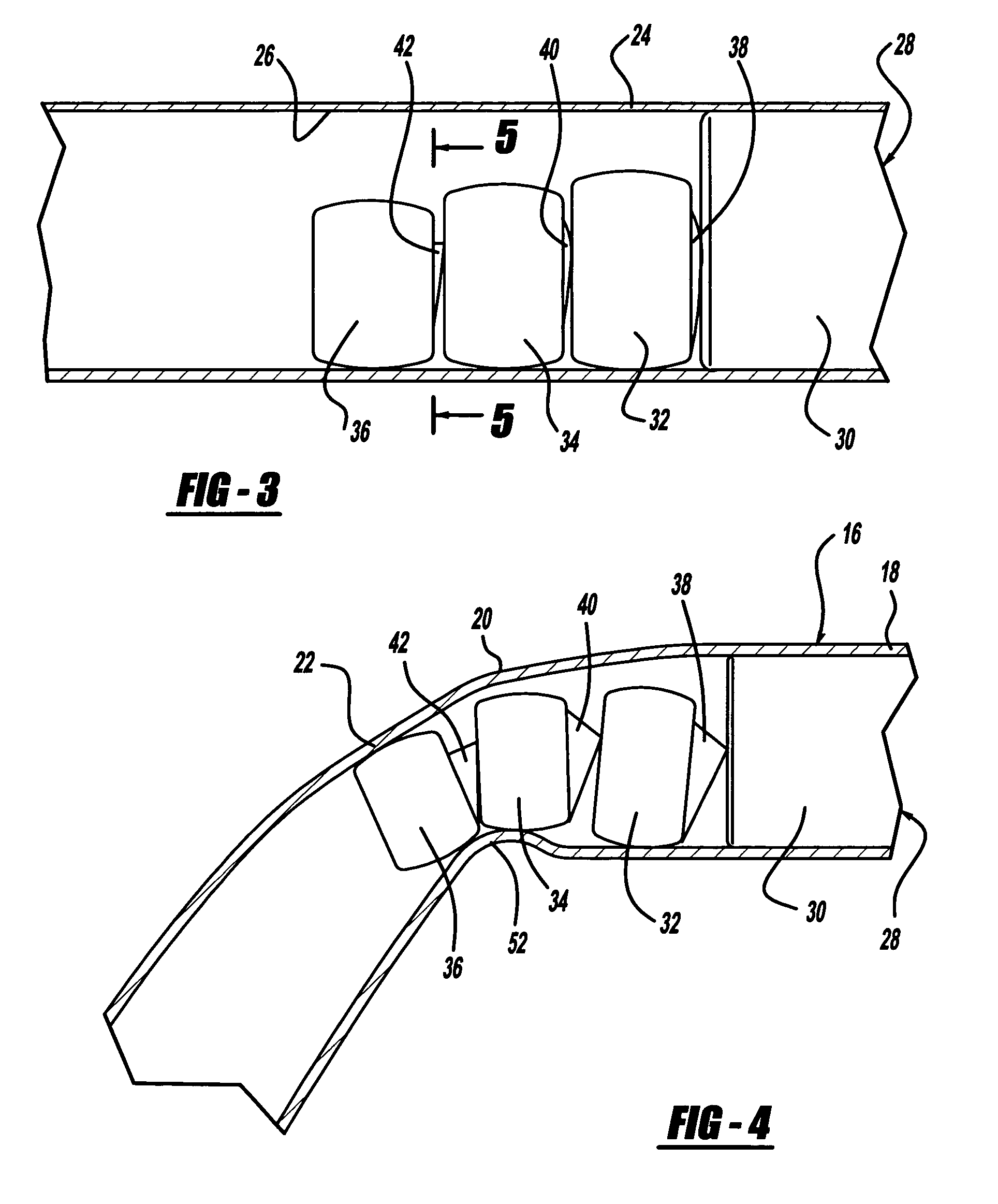

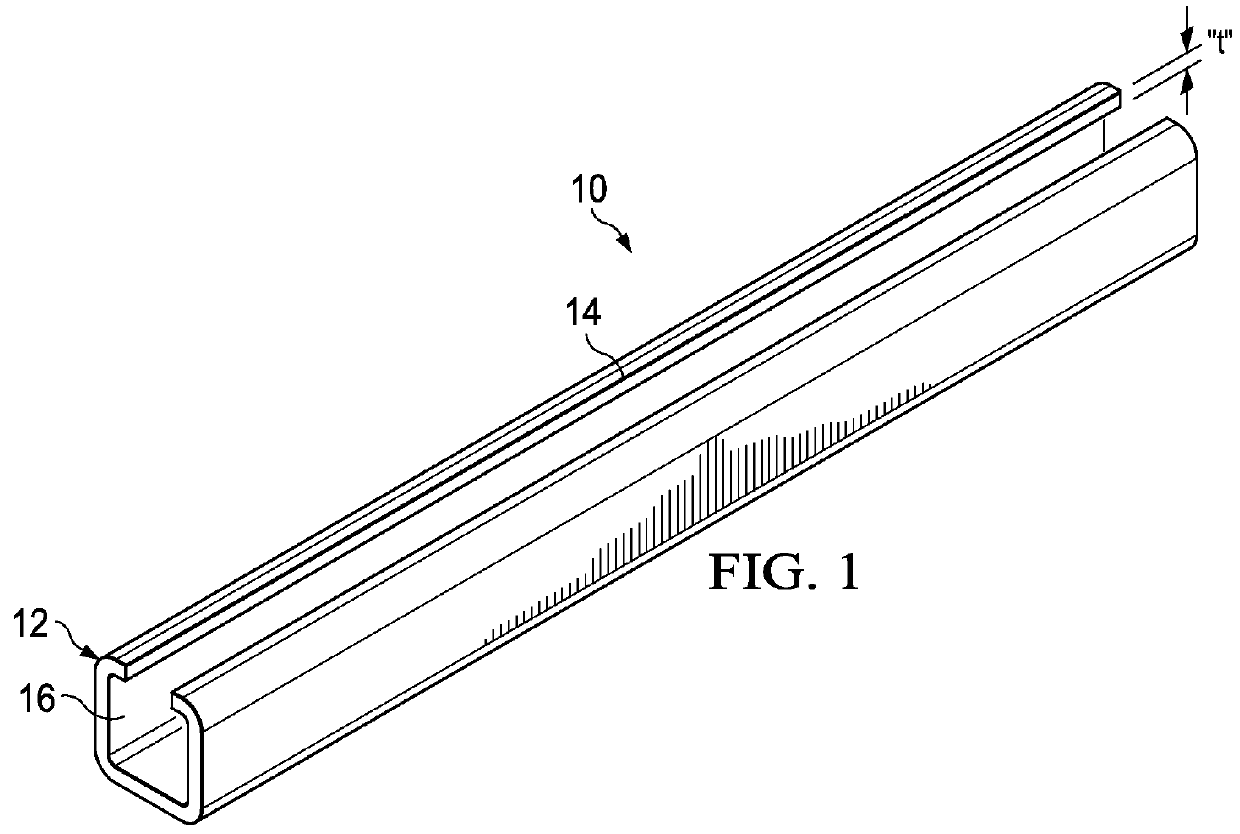

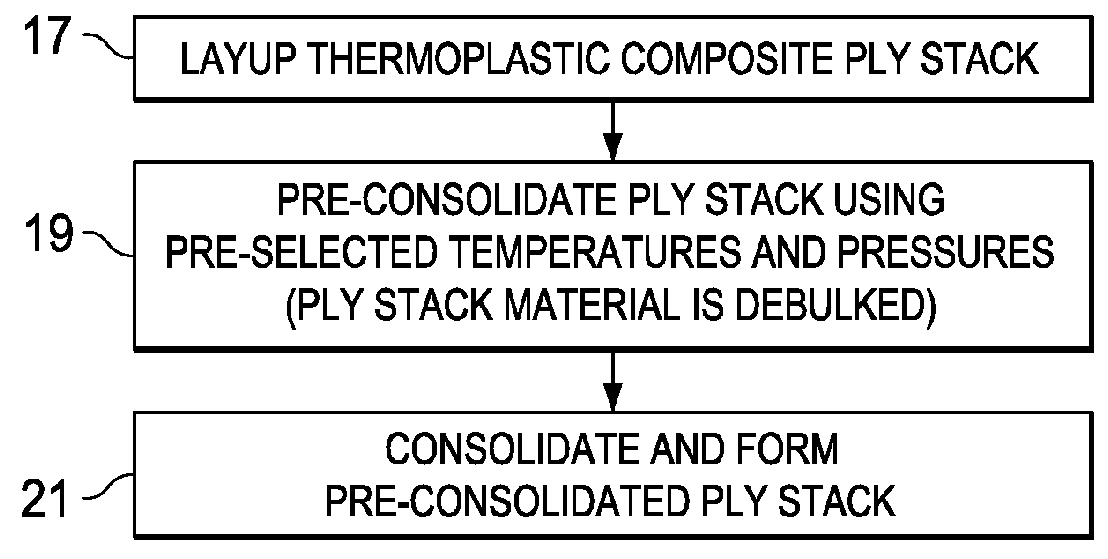

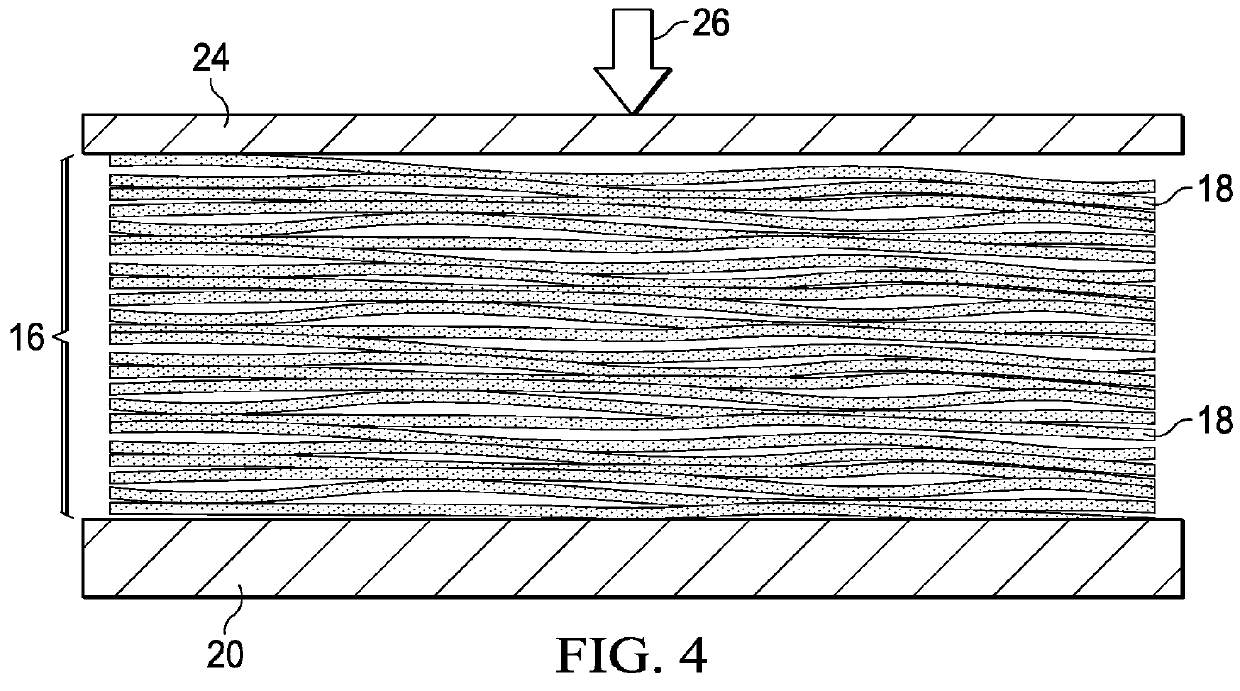

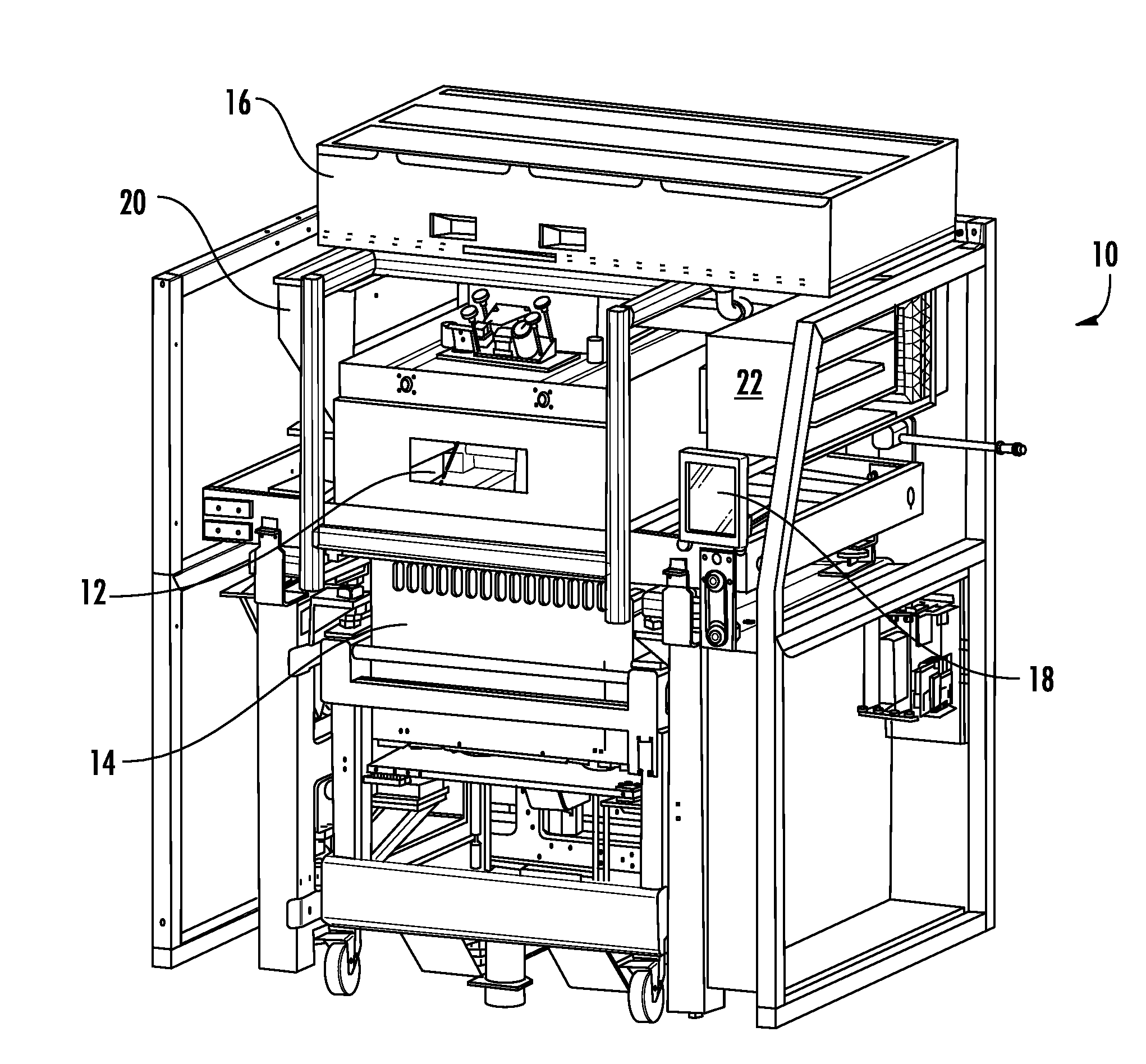

Method and Apparatus for Forming Thick Thermoplastic Composite Structures

ActiveUS20140117582A1Material bulkSoften the thermoplastic resinTailstocks/centresLayered productsThermoplastic compositesPlastic property

A method and apparatus are used to pre-consolidate and de-bulk a thermoplastic composite ply stack prior to full consolidation and forming to the final part shape. Pre-consolidation and de-bulking is achieved by heating the ply stack to a temperature below the melting point of the thermoplastic in order to soften the plies, and then compress the ply stack.

Owner:THE BOEING CO

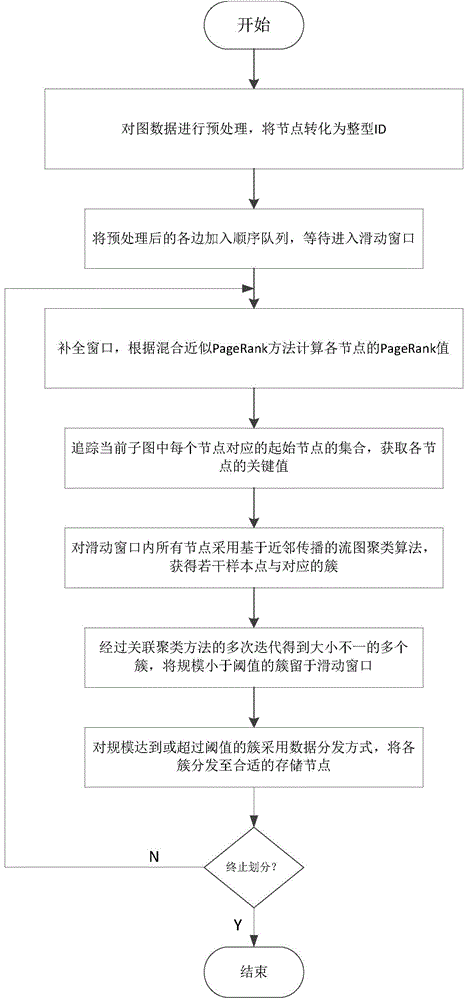

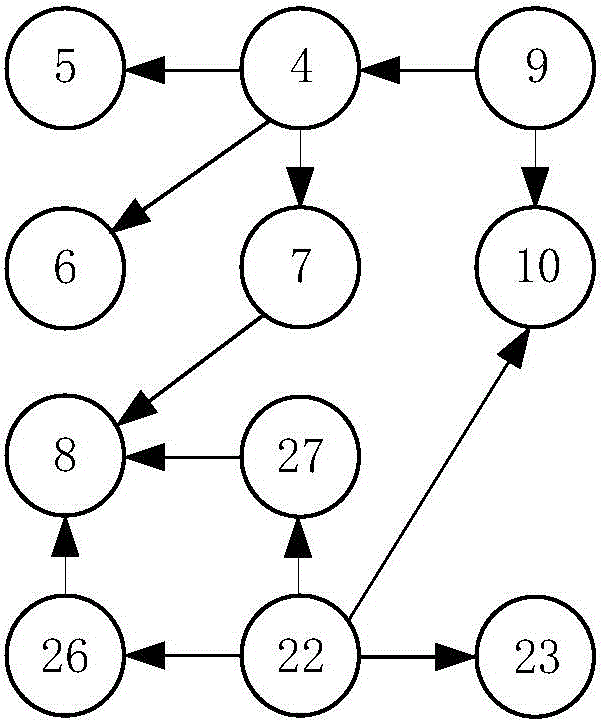

Extensible partition method for associated flow graph data

ActiveCN104820705AImprove relevanceIntegrity guaranteedRelational databasesSpecial data processing applicationsNODALCluster algorithm

The invention discloses an extensible partition method for associated flow graph data, comprising the following steps: (1) preprocessing graph data and converting a node as the node ID; (2) adding each preprocessed side which is existed in an ID form in FIFO and waiting to enter into a sliding window to process; 3) completing the sliding window and calculating the PageRank value of each node according to a mixing approximation PageRank method; (4), tracking the collection of the initial node corresponded by each node in a subgraph, which is composed of sides in the sliding window and obtaining associated value of each node; (5) obtaining a plurality of centroids and corresponding clusters by adopting an affinity propagation clustering algorithm to all nodes in the window; (6) obtaining a plurality of partitioning results which are not of uniform size via associating repeated iteration of a clustering method and storing the partitioning results whose scales are less than threshold value in the sliding window; (7) transmitting the partitioning results whose scales reach or exceed the threshold value to the appropriate storage node by using a data distribution method; and finishing the graph data partitioning. Compared with the prior art, the method provided by the invention has higher partitioning quality.

Owner:HUAZHONG UNIV OF SCI & TECH

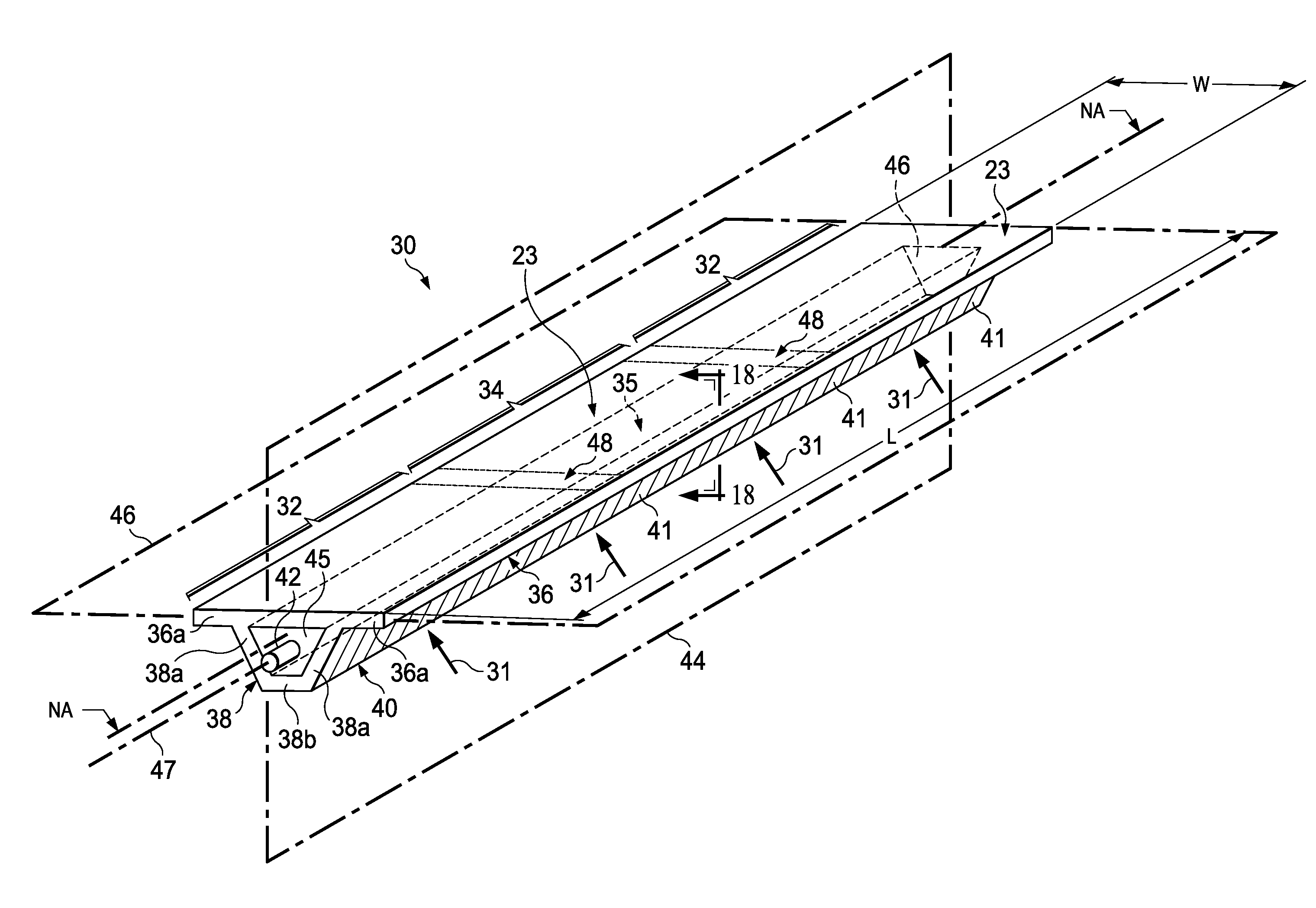

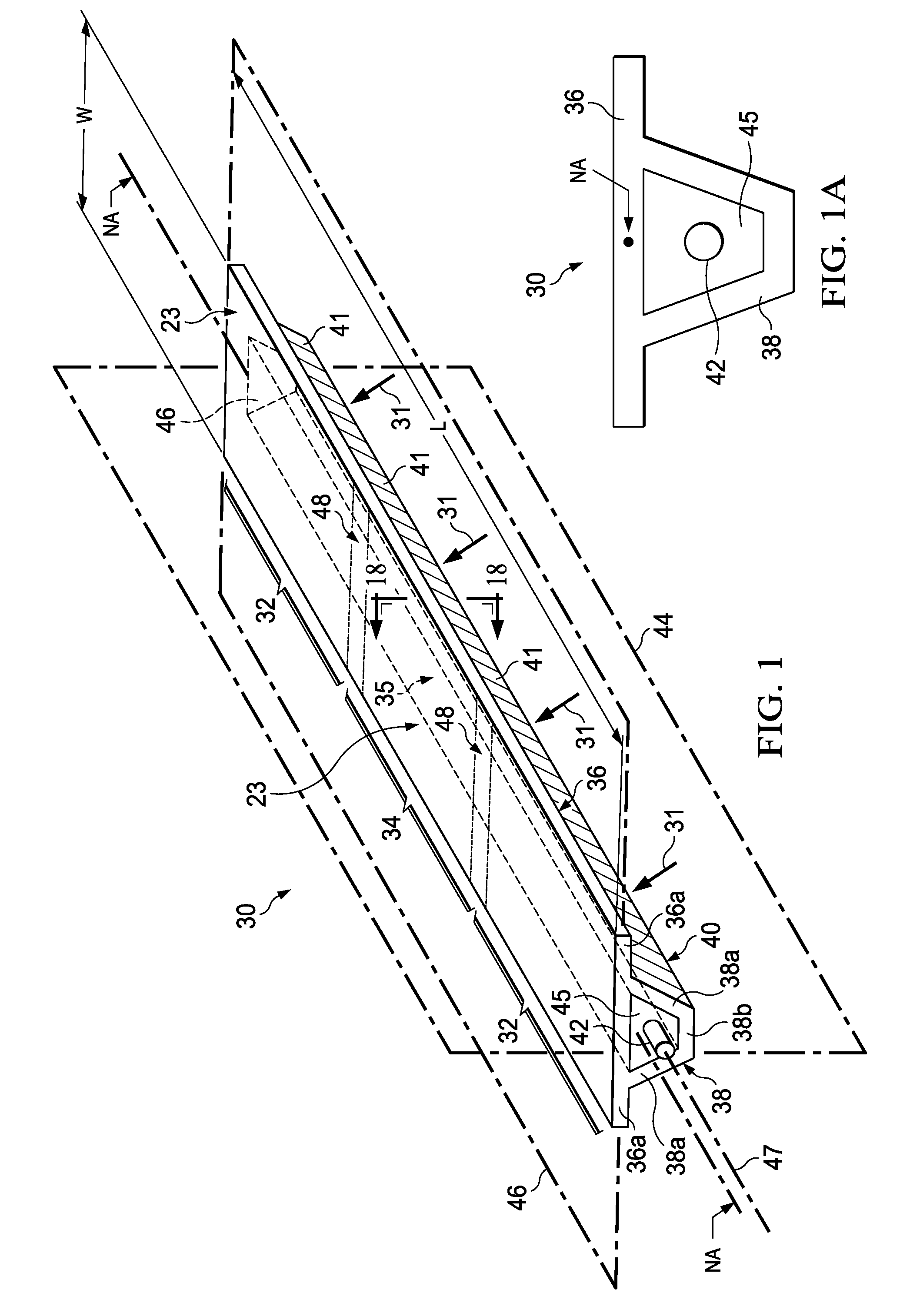

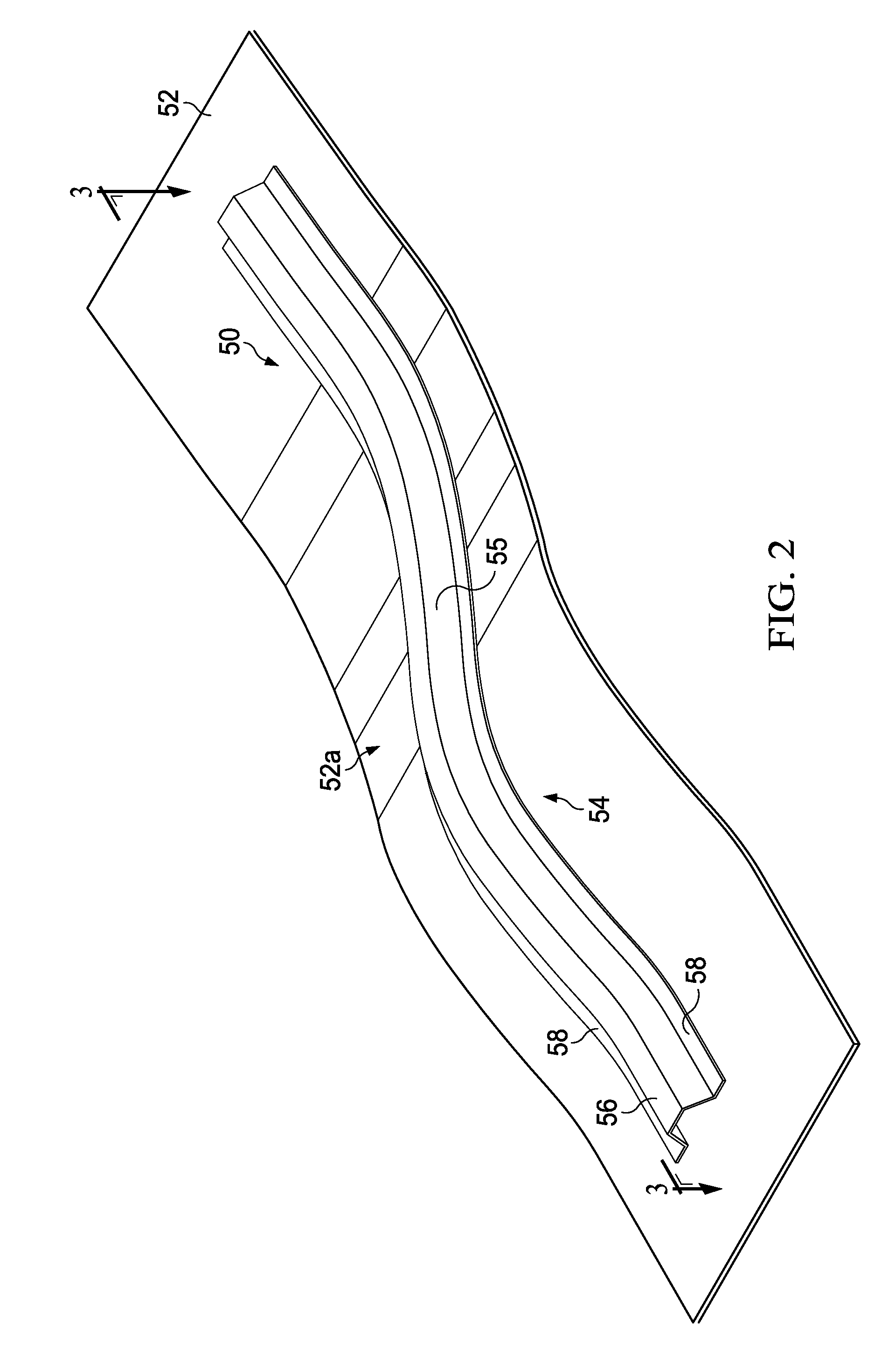

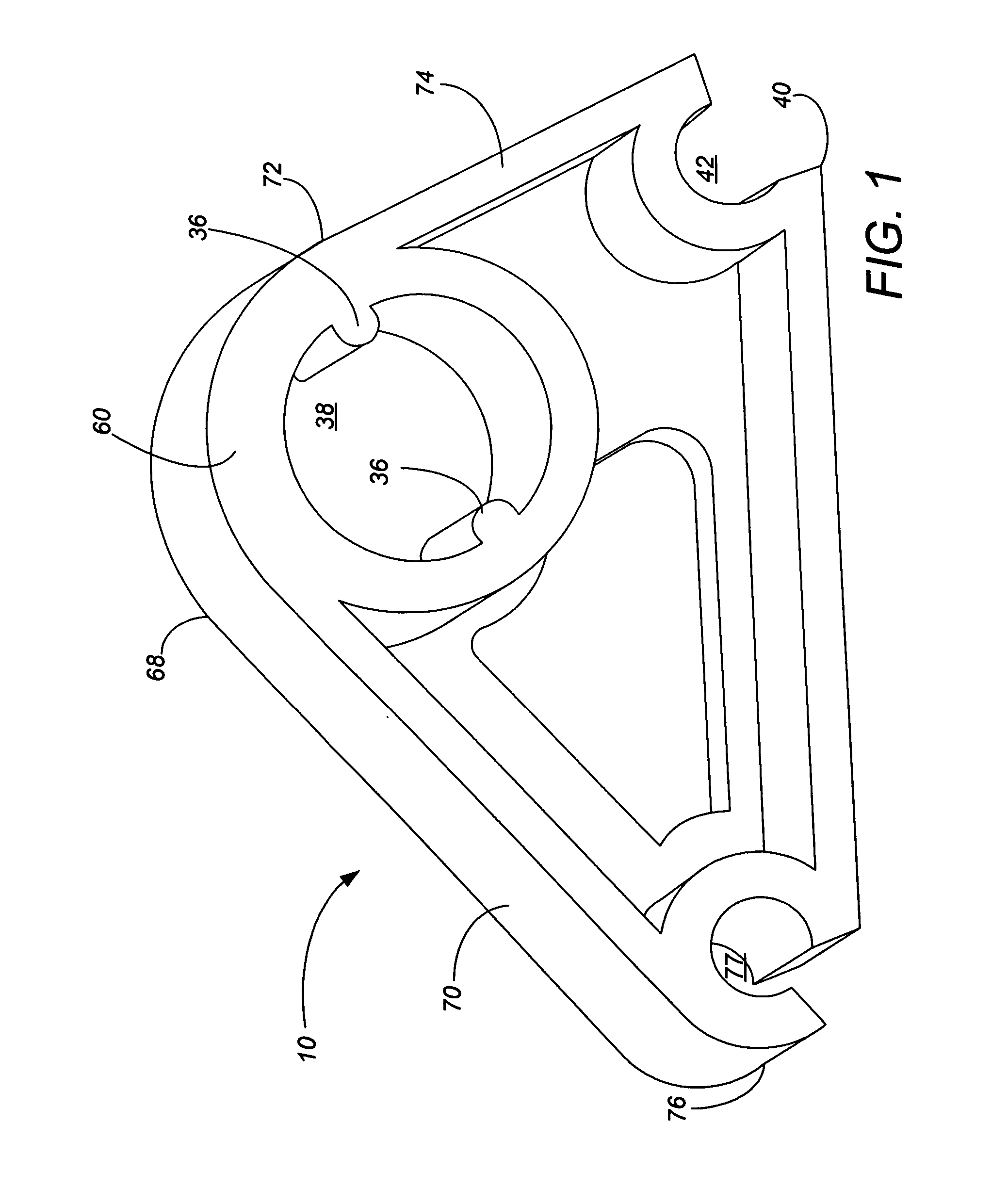

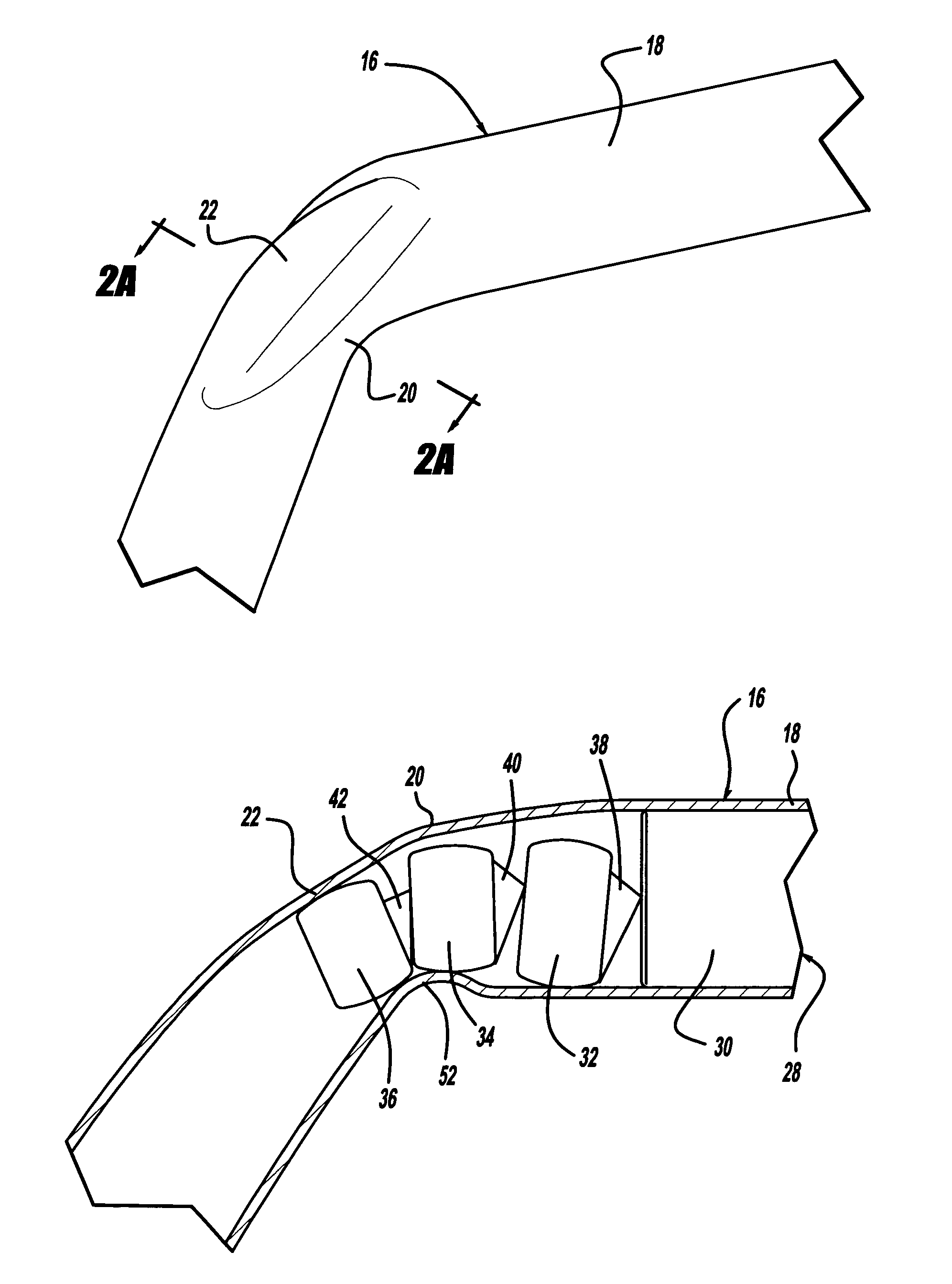

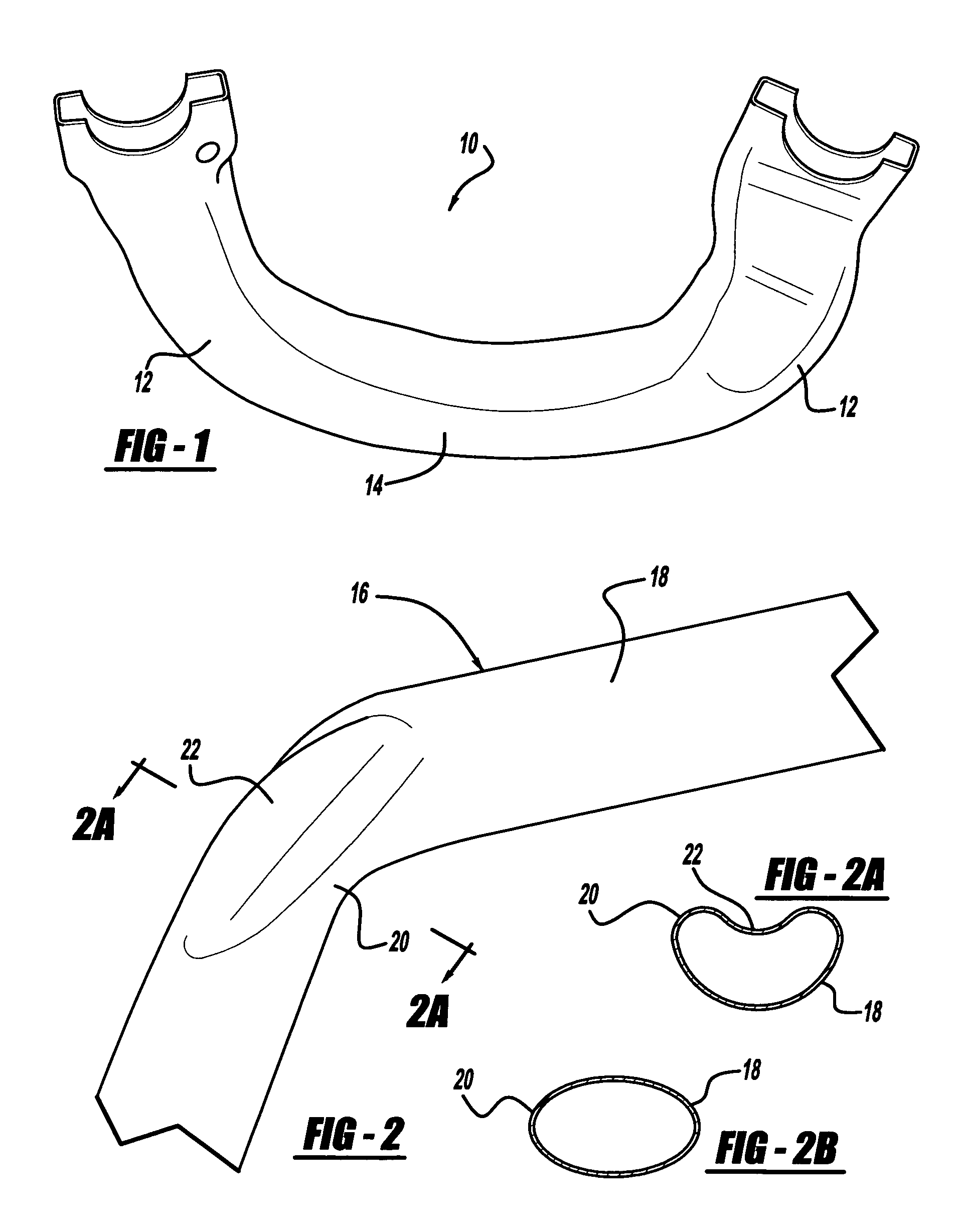

Flexible Compactor with Reinforcing Spine

ActiveUS20130333830A1Improve part qualityImprove performanceConfectioneryLaminationSacroiliac jointMechanical engineering

A device for compacting a contoured elongate composite layup includes flexible first and second fiber reinforced resin flexible sections flexible along their lengths. The first section is flexible within a first plane and the second section is flexible within the first plane as well as within a second plane. The second section includes flexible joints reinforced by a spine.

Owner:THE BOEING CO

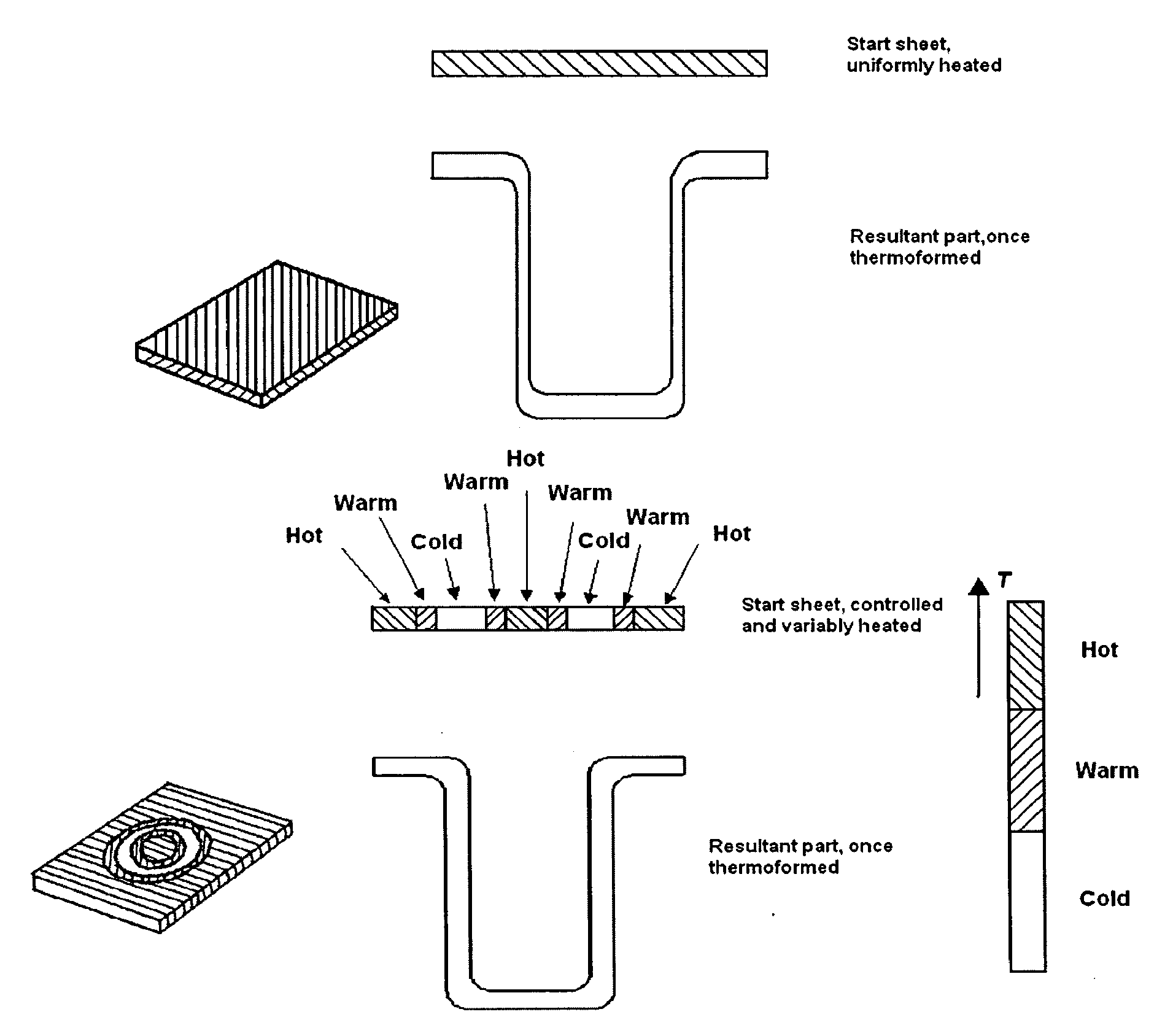

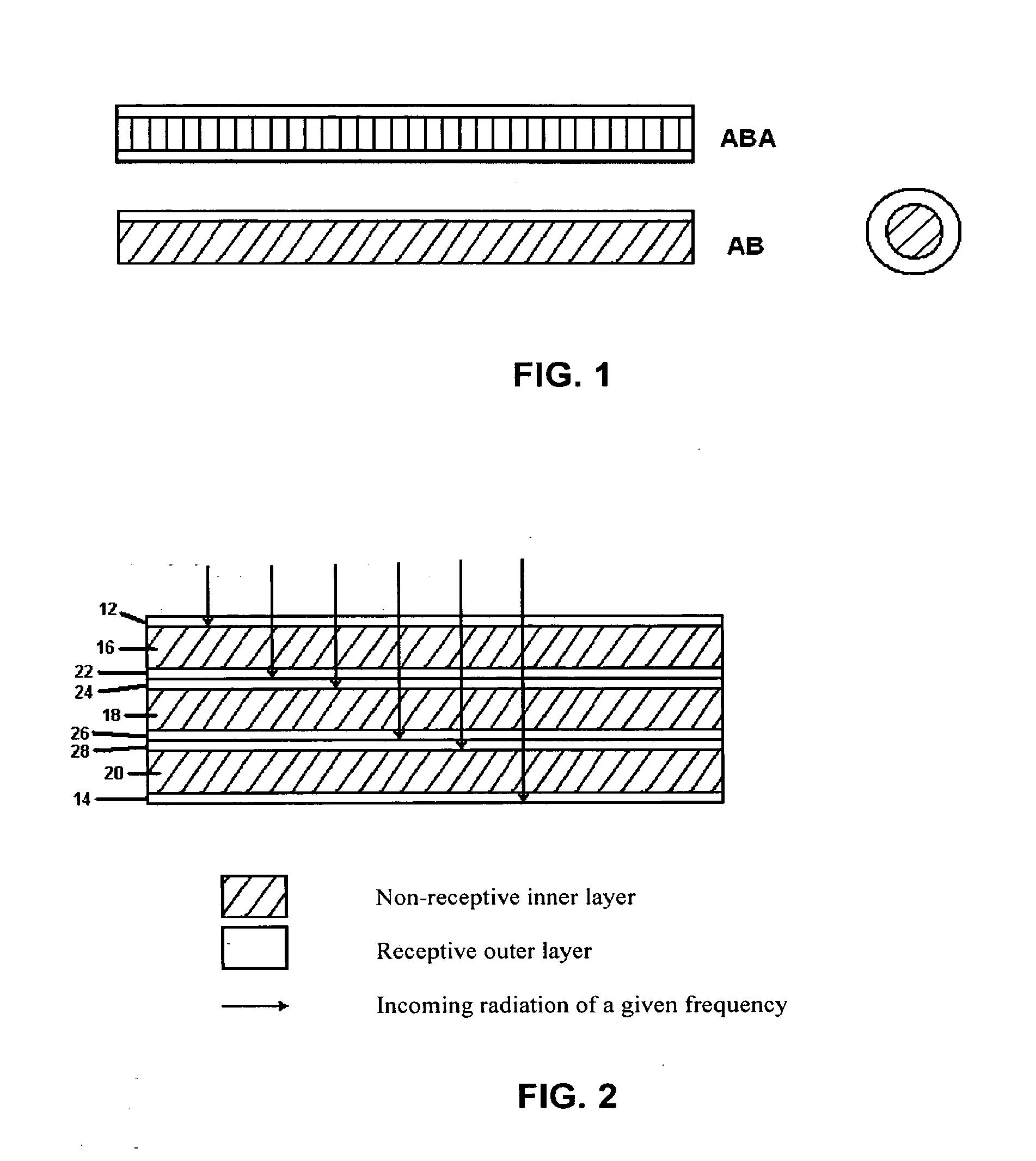

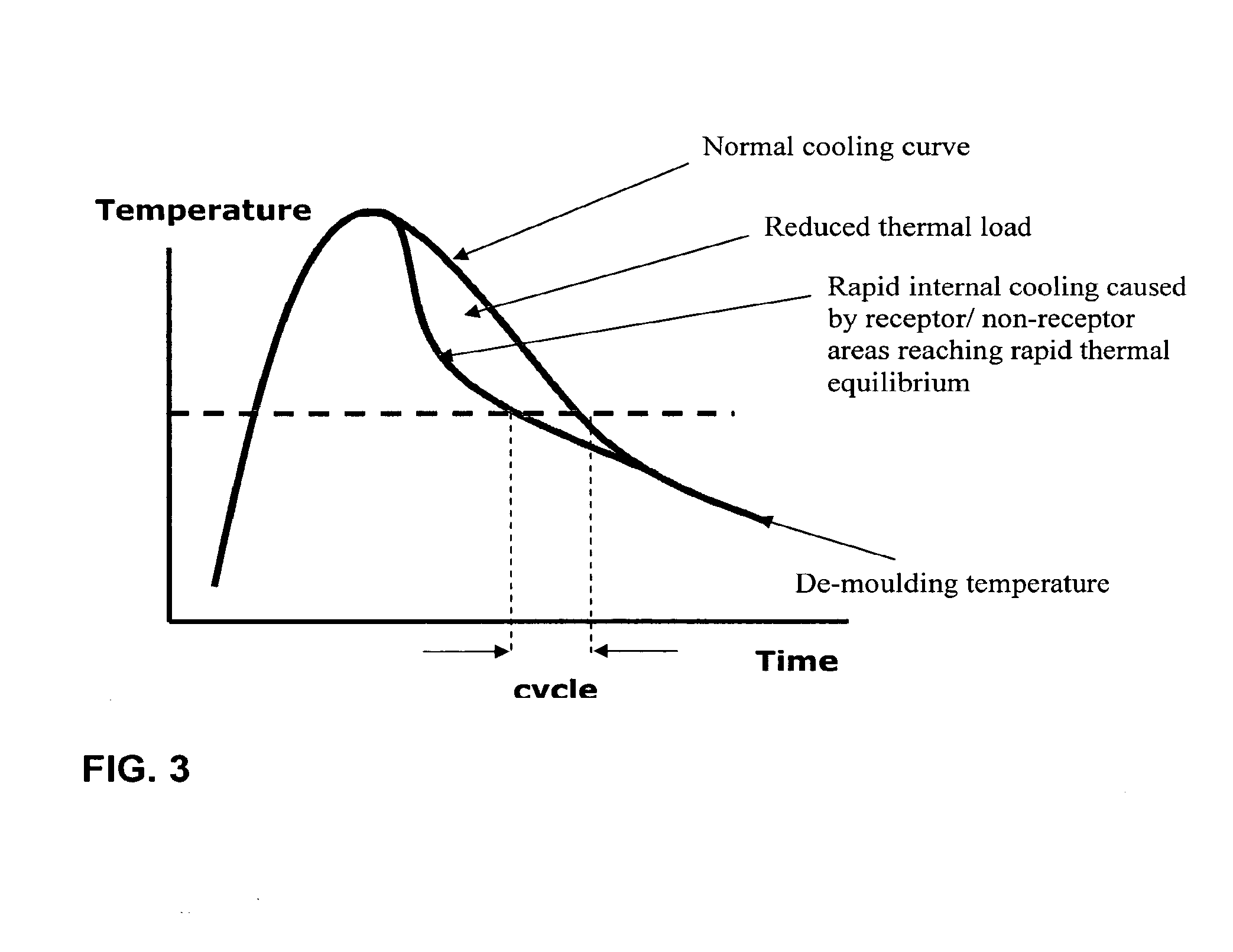

Method and apparatus for producing formable products

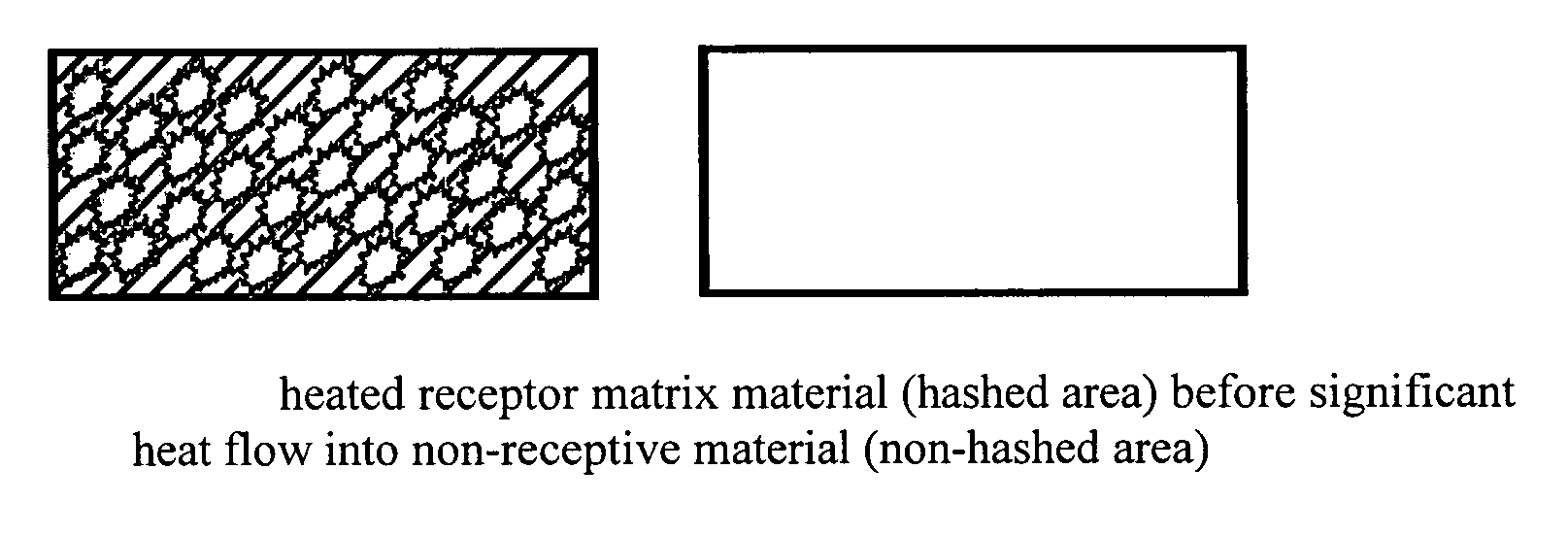

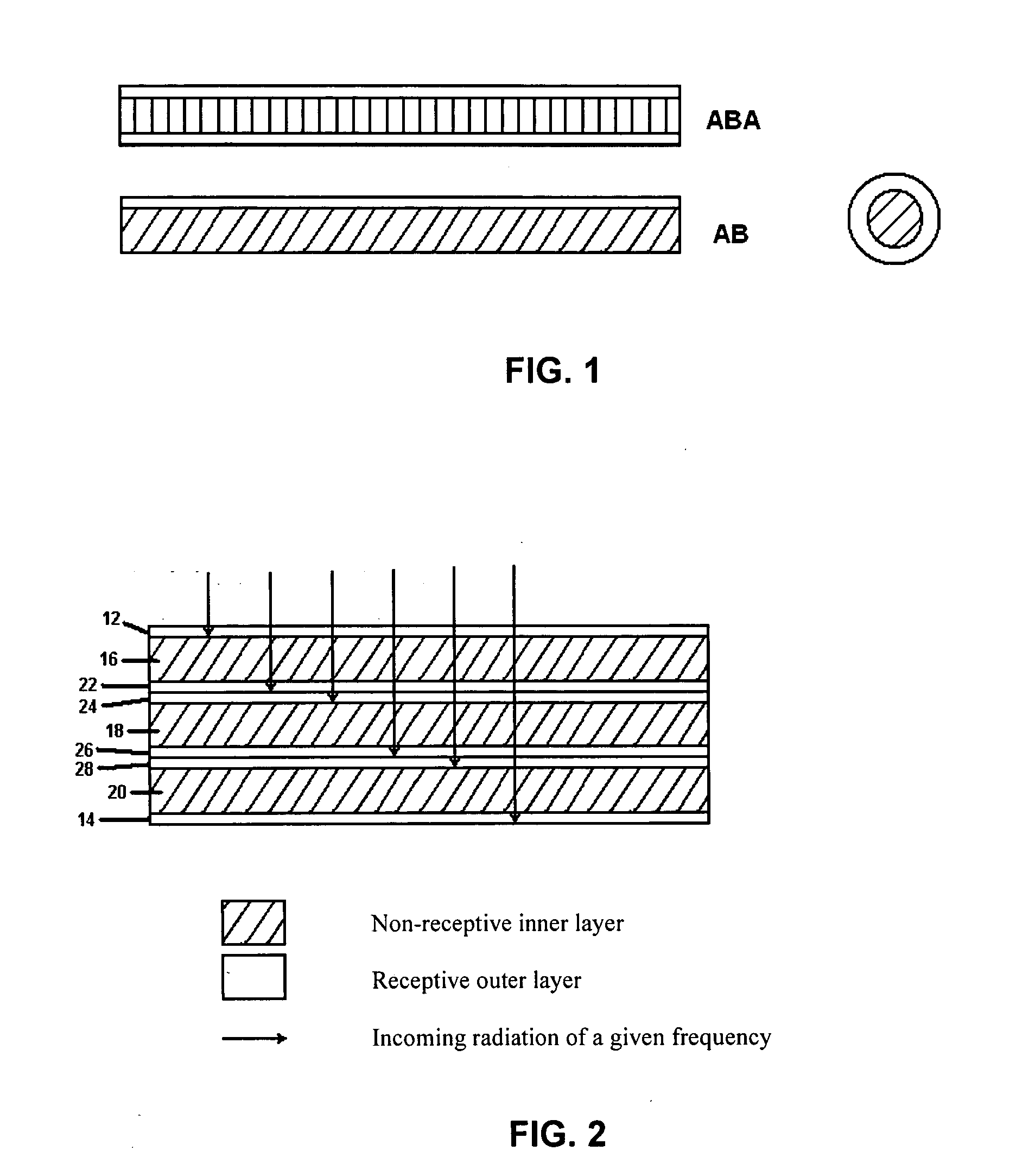

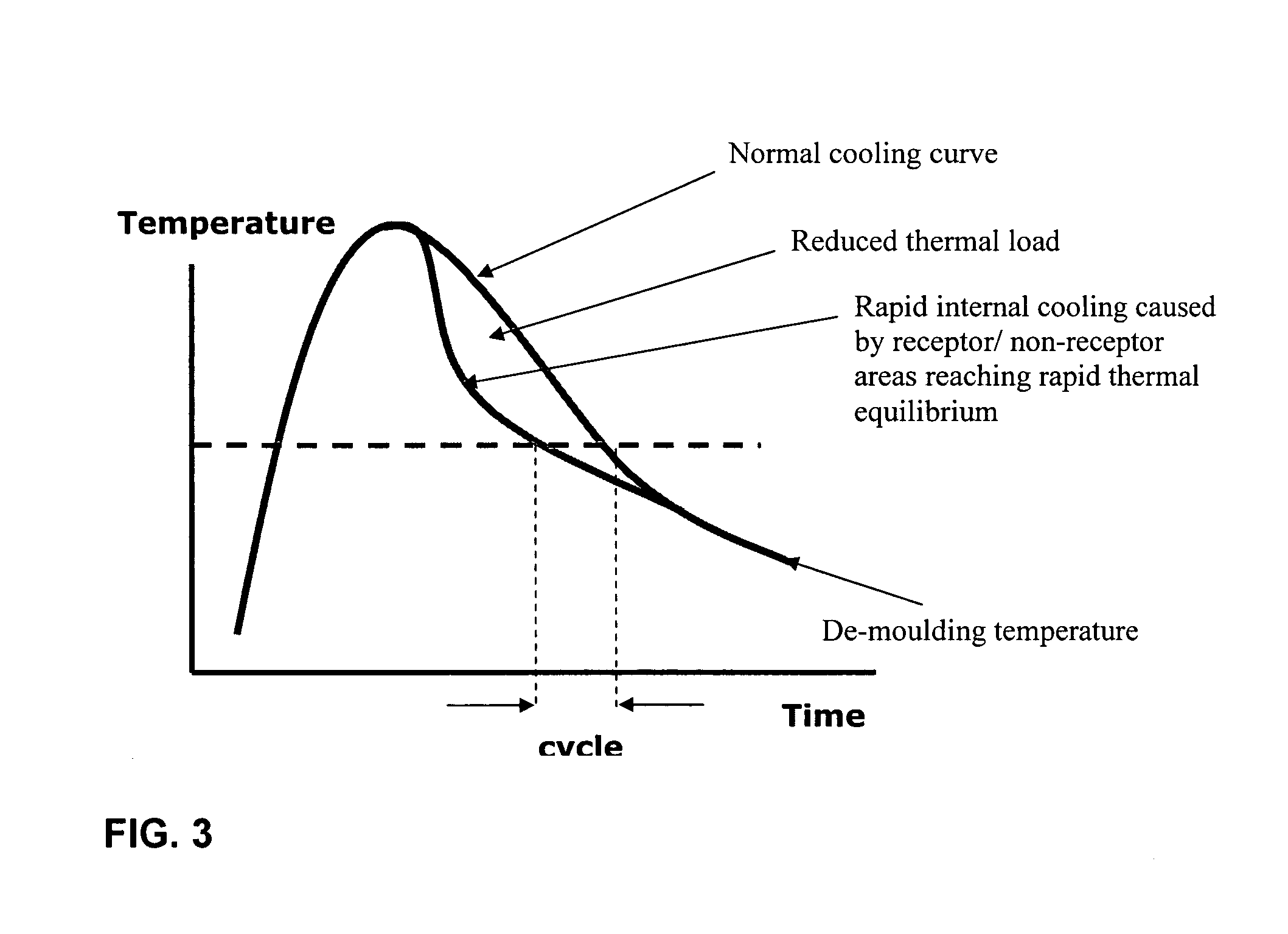

InactiveUS20130270747A1Improve part qualityHigh strengthCeramic shaping apparatusElectric/magnetic/electromagnetic heatingPolymer scienceMaterials processing

Described are methods for processing material, material processing systems, and processable materials. Preferred embodiments relate to a method of and apparatus for producing formable products such as polymer products and thermoplastic materials.

Owner:PERA TECH

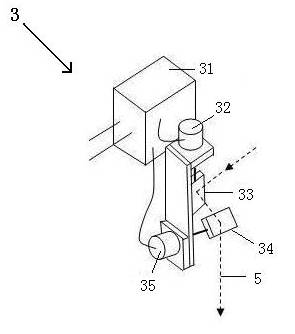

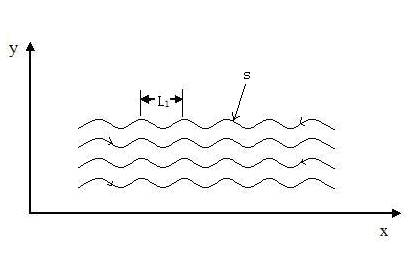

Laser scanning method for selective laser firing

InactiveCN102116933AReduce warpageHigh precisionMetallic material coating processesOptical elementsLaser scanningOptoelectronics

The invention discloses a laser scanning method for selective laser firing, wherein the cross section of prepared parts is supplementarily scanned by using laser beams in the process of selective laser firing. The supplementary scanning path of the laser beam is curve, interrupted curve or interrupted straight line. The method is convenient in process, has strong practicability, and plays an important role in reducing the buckling deformation of parts and increasing the parts precision.

Owner:许小曙

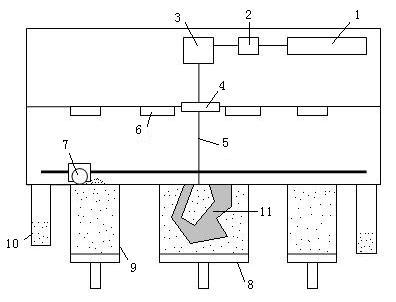

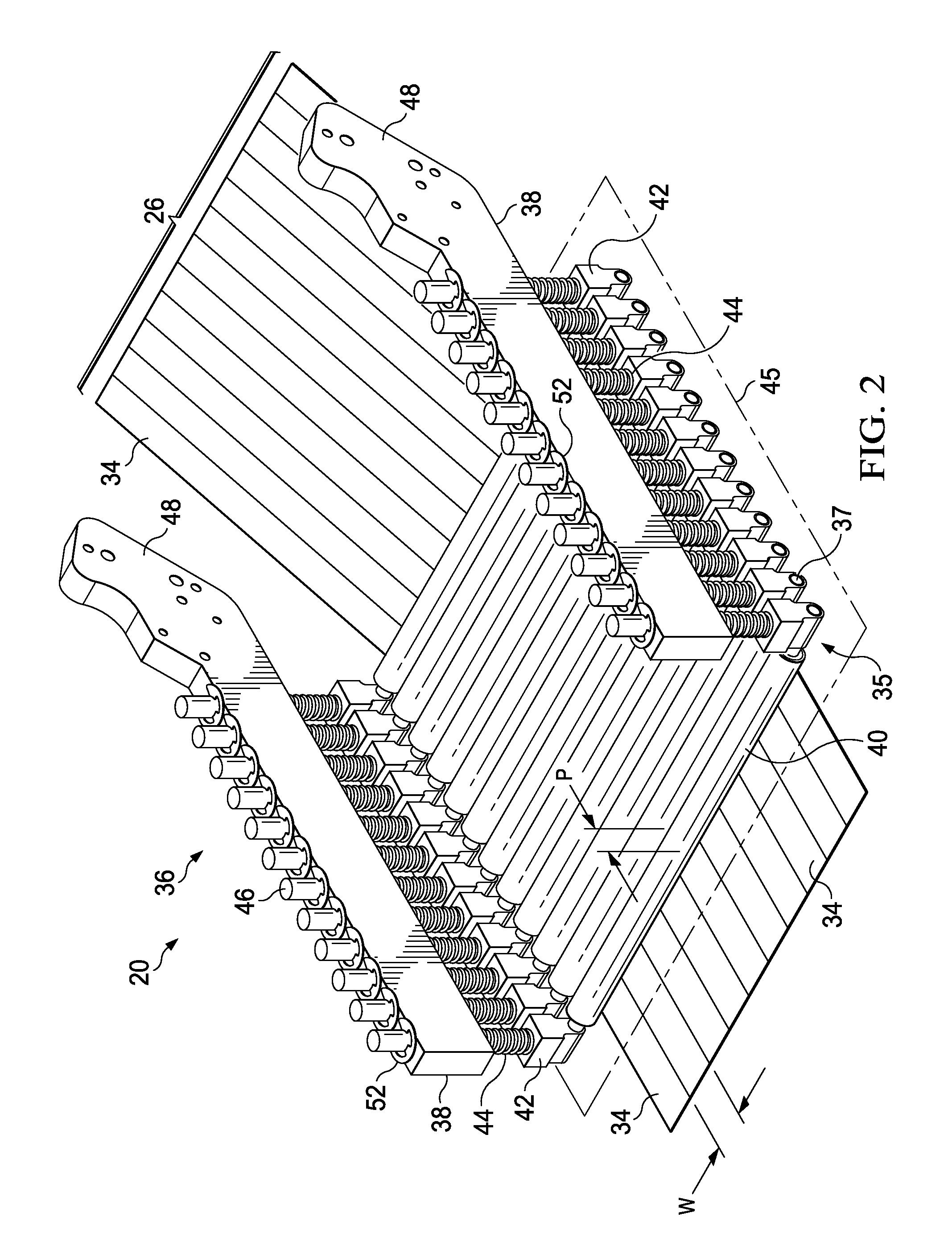

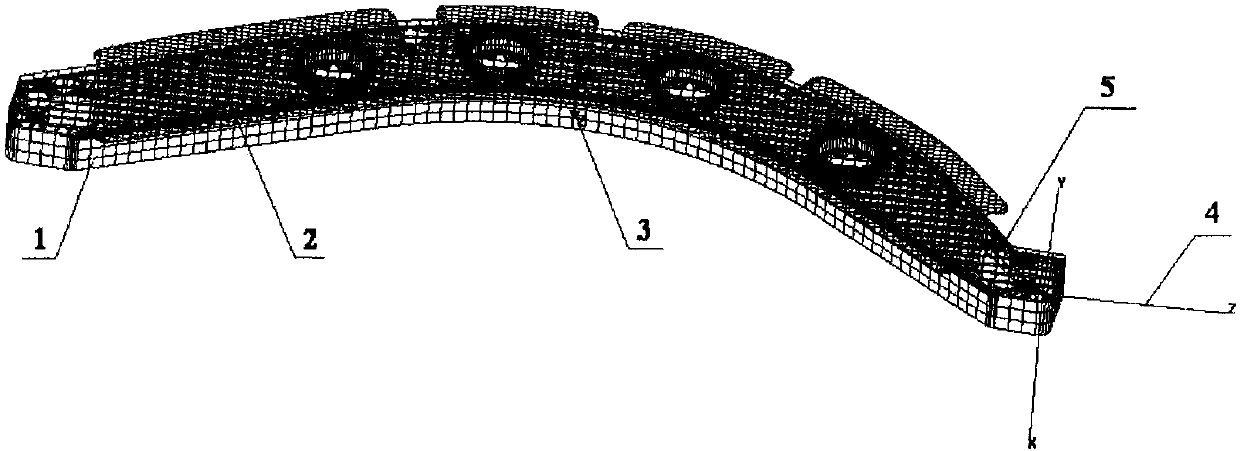

Powder Distribution for Laser Sintering Systems

ActiveUS20170008234A1Reduce the possibilityHigh densityManufacturing heating elementsCeramic shaping apparatusRadiant heaterMetallurgy

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

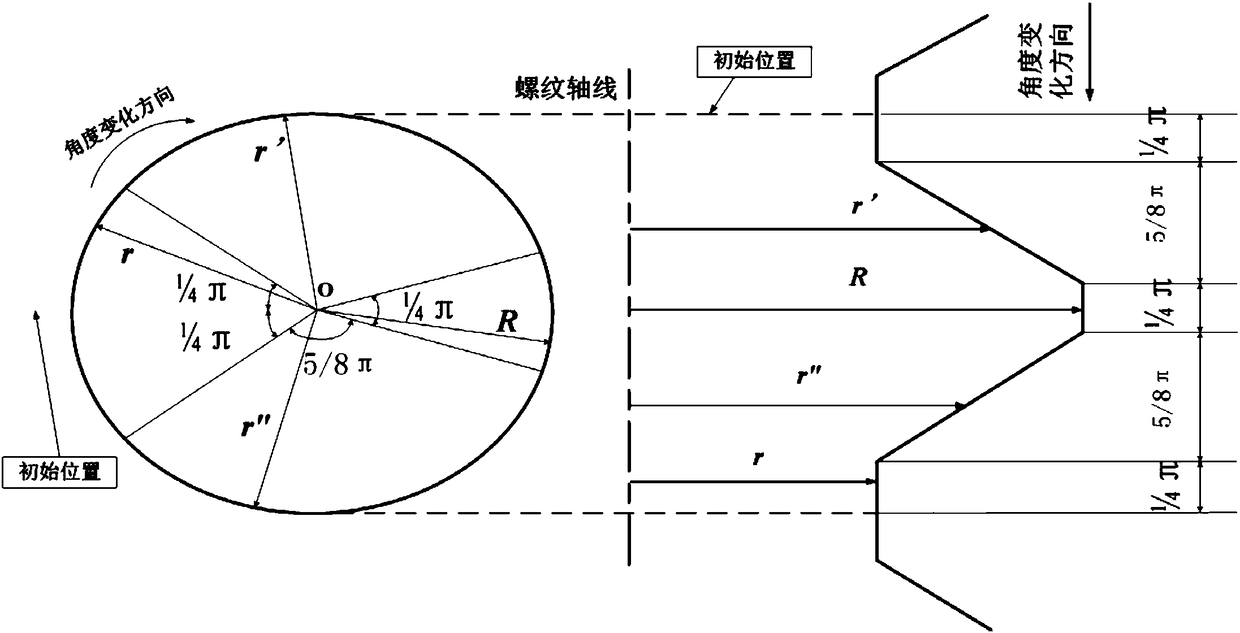

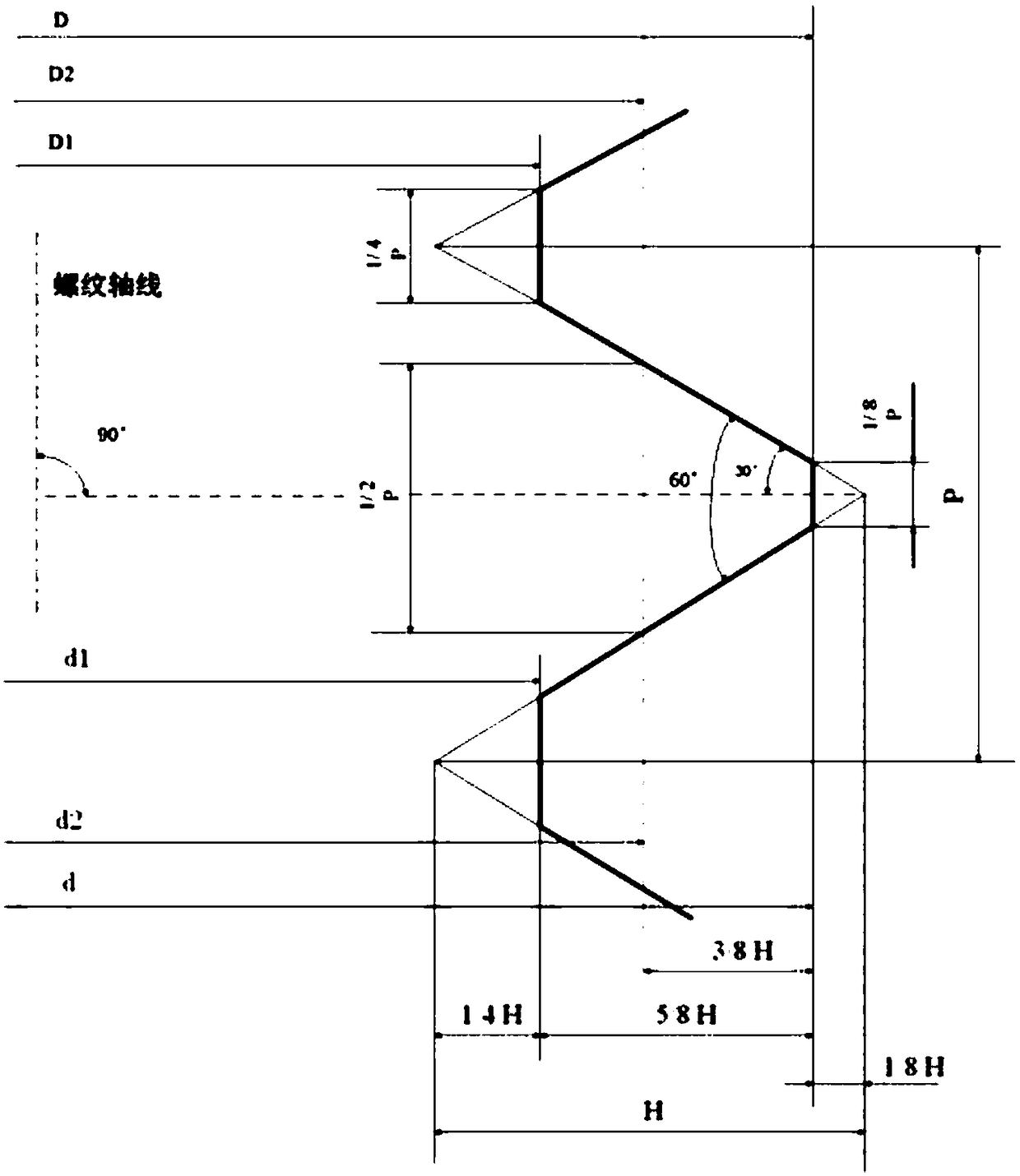

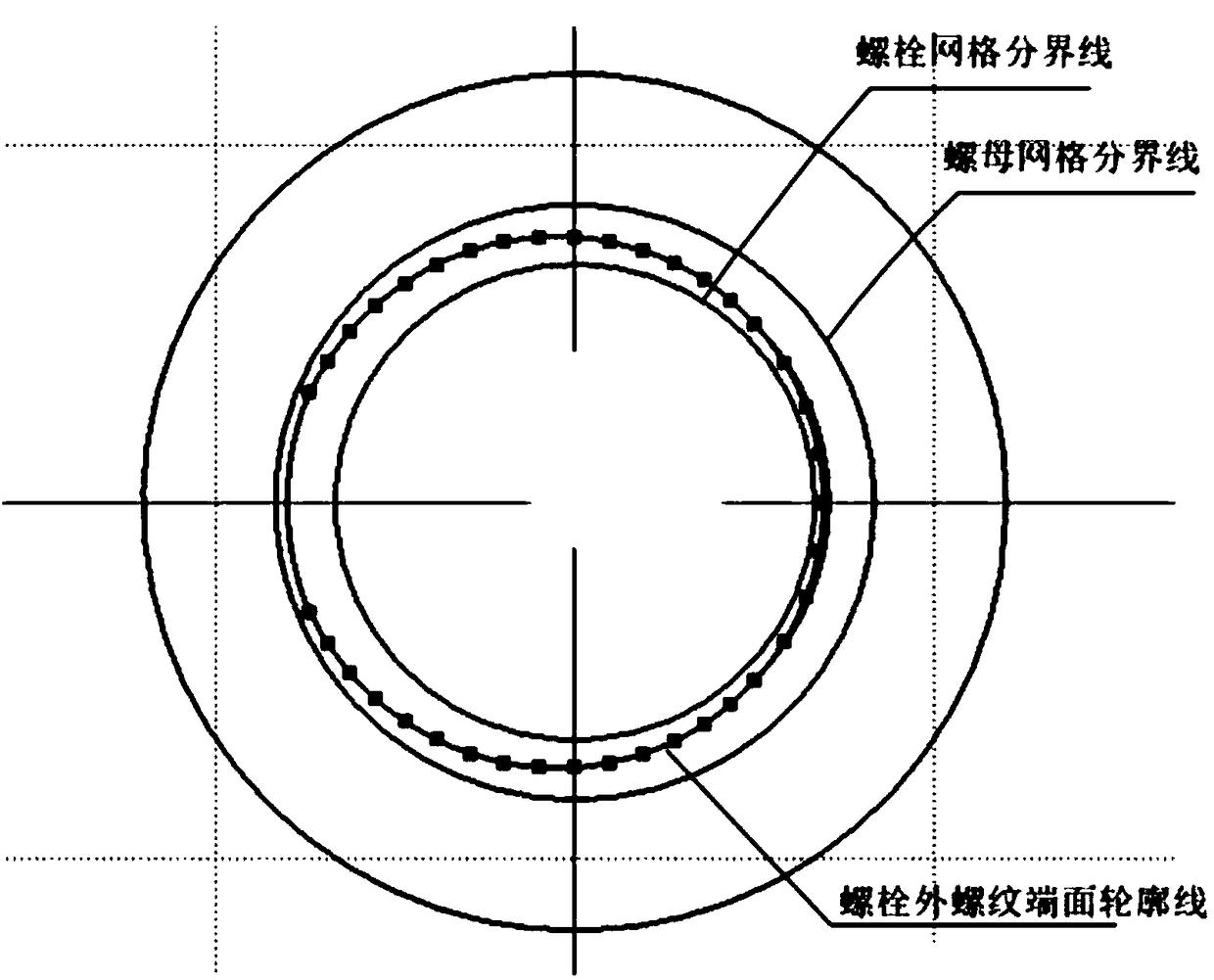

Hexahedron finite element grid partitioning method for simulating screw-thread fit

ActiveCN108197418AImprove partition qualityHigh precisionGeometric CADDesign optimisation/simulationRegular patternTooth number

The invention relates to a hexahedron finite element grid partitioning method for simulating screw-thread fit. The method comprises the following steps: firstly, according to a distance change rule ofa thread surface and a thread axis, determining a single-layer thread cross section contour line, and using a minimum feature of a thread as the axial finite element grid size; and according to a rotation angle relation between the number of the grid layers axially partitioned within a single thread pitch and the adjacent layer, determining the circumferential finite element grid number, throughthe quadrilateral grid stretching of the bolt thread end face, forming a single-layer hexahedral grid, and performing the copy, the rotation and the node replacement on the single-layer hexahedral grid so as to obtain a single-pitch bolt hexahedral grid model; finally, according to the male-female thread tooth number, performing the copy and the translation on the single-pitch grid so as to obtaina hexahedral grid model of the whole bolt thread part. So, the hexahedron finite element grid partitioning method does not need to build a solid three-dimensional model of a male-female thread, and does not need a lot of the node coordinate calculation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

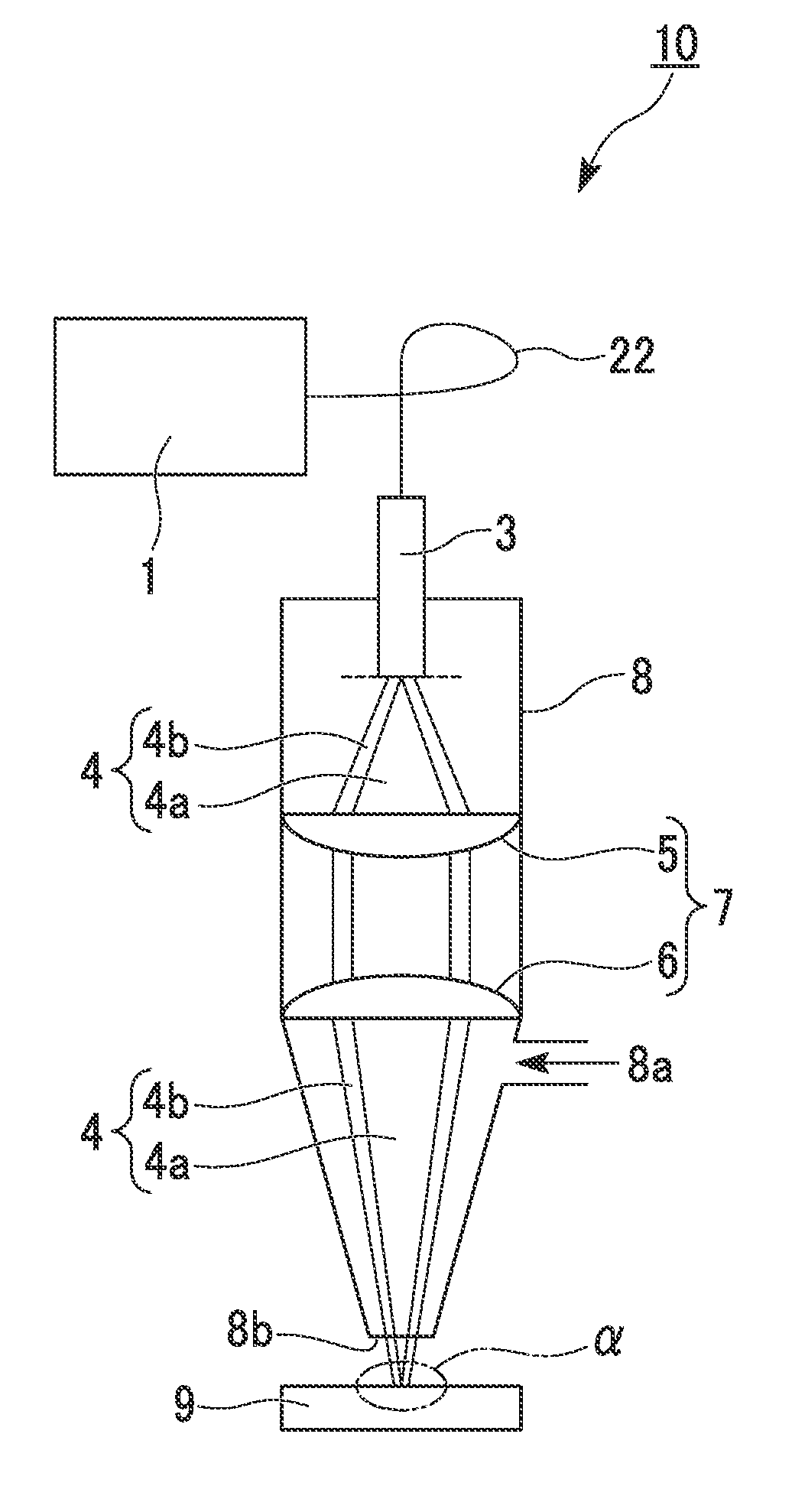

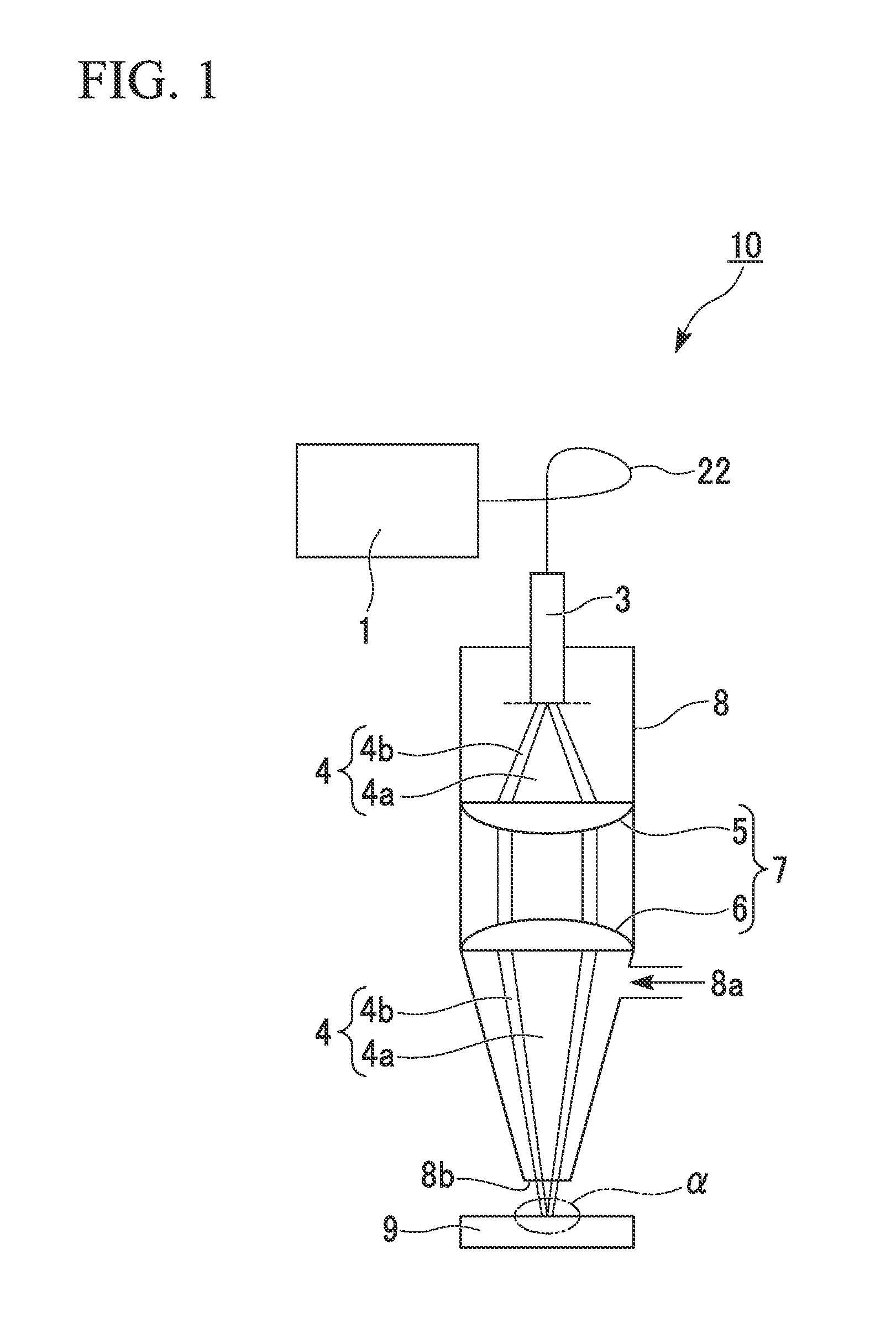

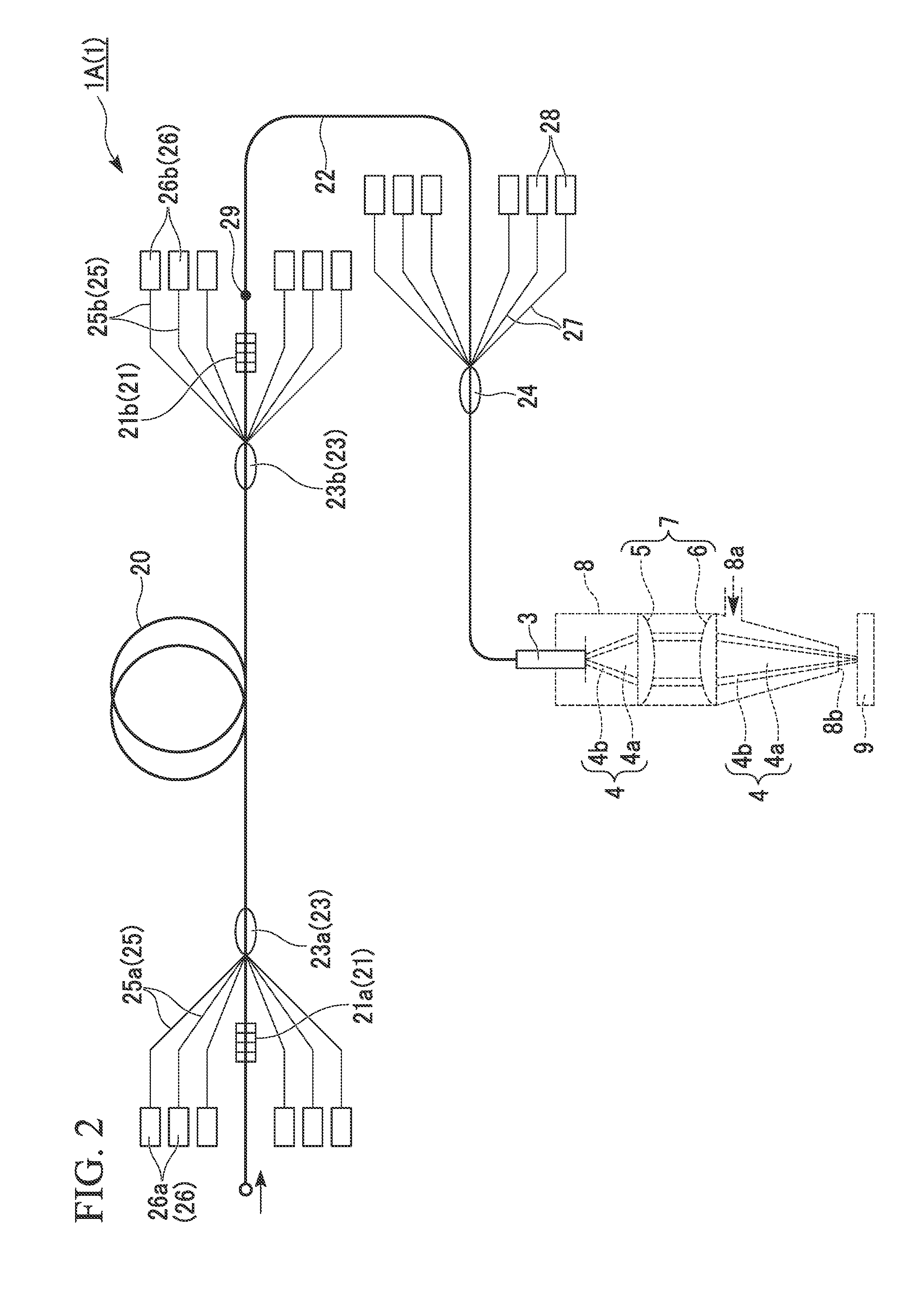

Laser apparatus and laser materials processing apparatus provided with same

ActiveUS20130215914A1Improve processing qualityReduce the amount requiredLaser using scattering effectsLaser arrangementsFiberDouble-clad fiber

A laser apparatus of the present invention has a first laser oscillator that emits a first laser beam; a passive fiber that is a double-clad fiber that transmits the first laser beam through a core; and a second laser oscillator that emits a second laser beam that is coupled into inner cladding of the passive fiber. Additionally, a laser materials processing apparatus of the present invention is provided with the laser apparatus; and an irradiation optical system having a collimating lens and a condenser lens.

Owner:NIPPON STEEL CORP

Method of and apparatus for producing formable products

InactiveUS20090267264A1Improve part qualityHigh strengthLaminationSpecial tyresPolymer scienceMaterials processing

Described are methods for processing material, material processing systems, and processable materials. Preferred embodiments relate to a method of and apparatus for producing formable products such as polymer products and thermoplastic materials.

Owner:PERA INNOVATION

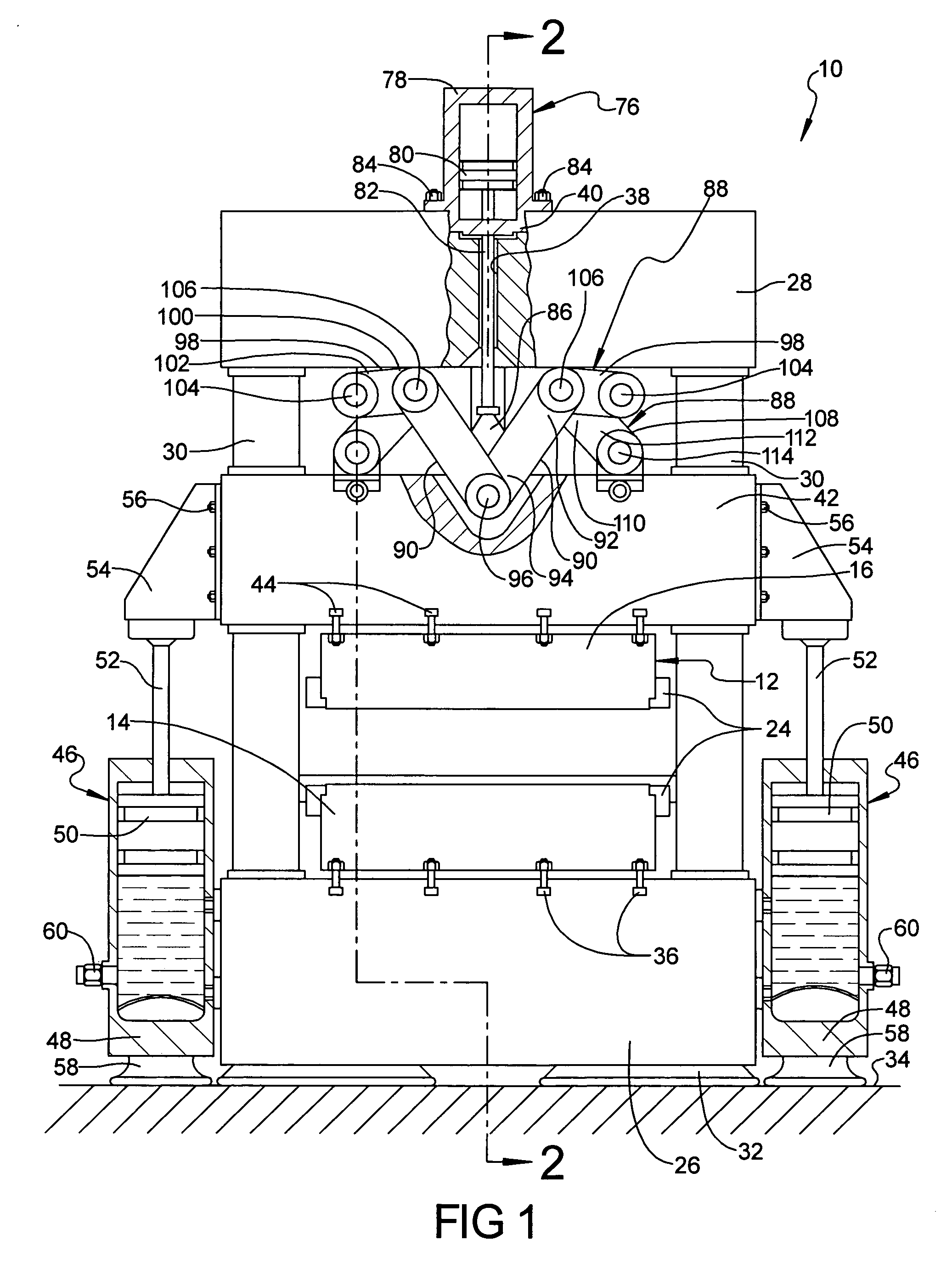

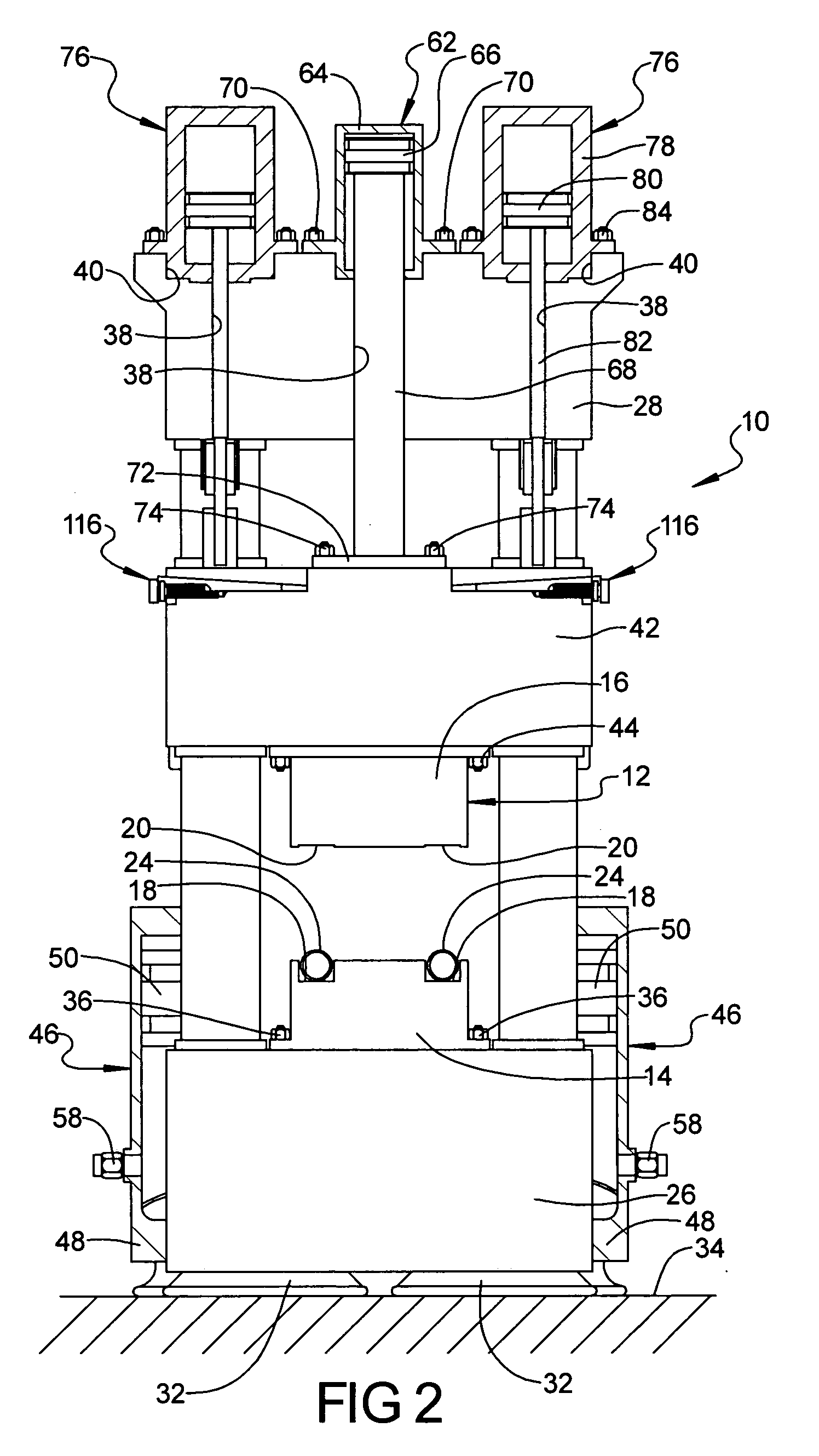

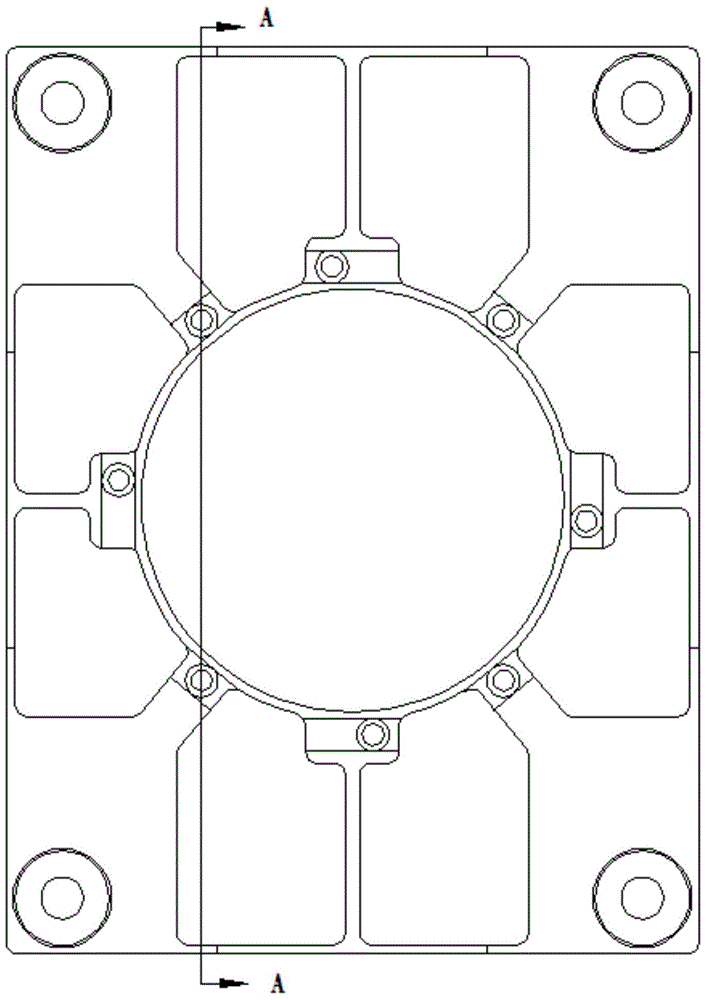

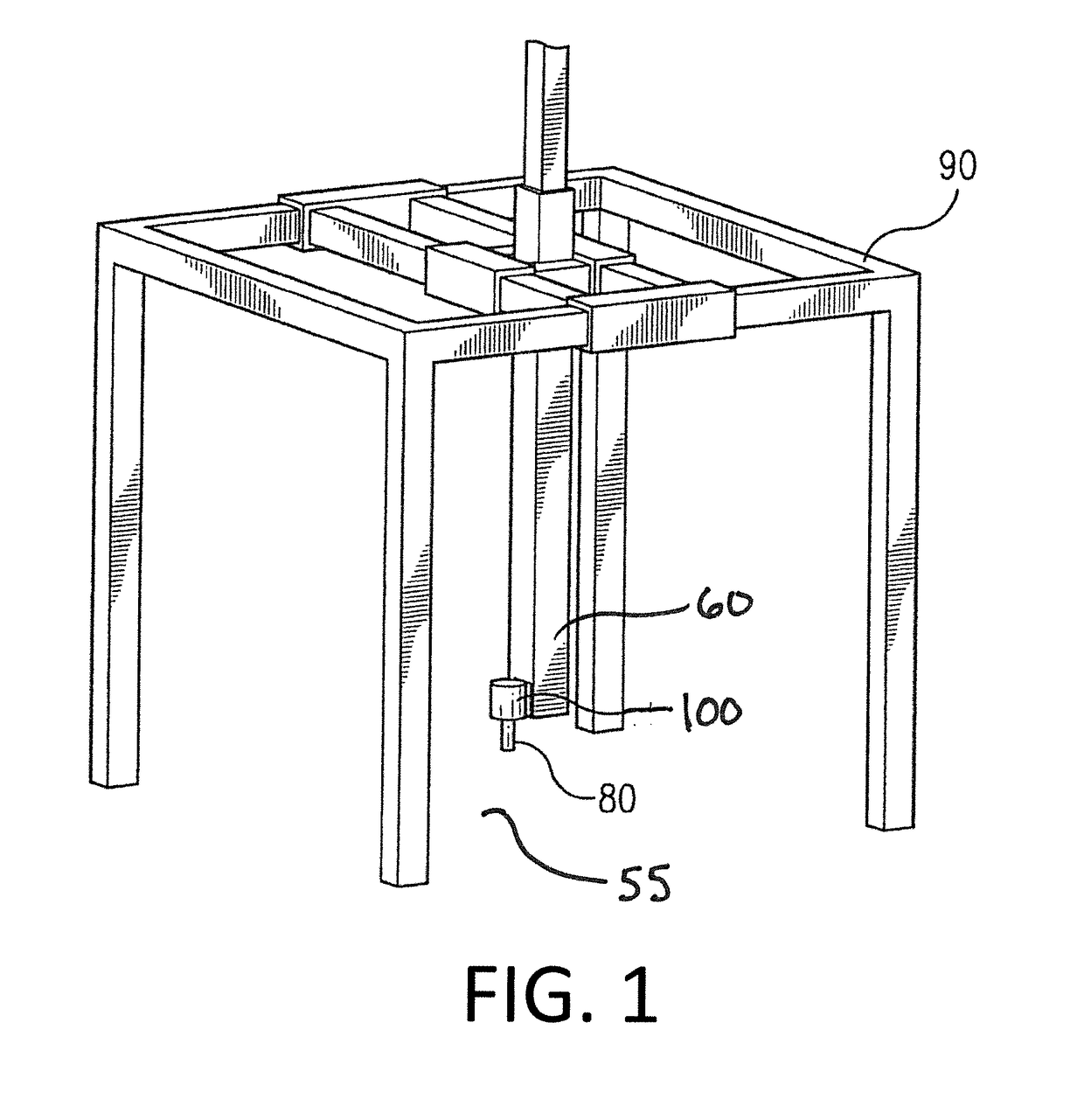

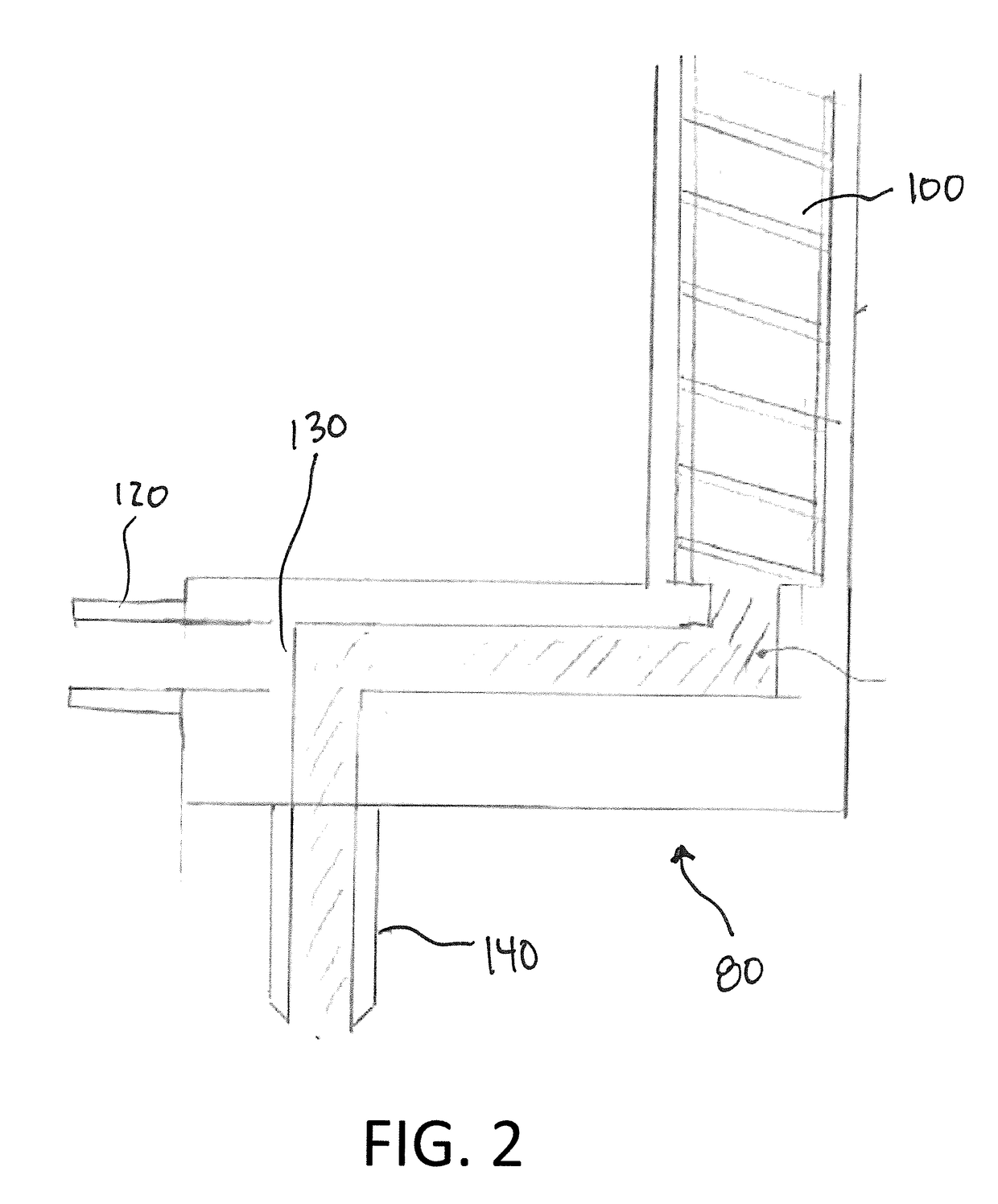

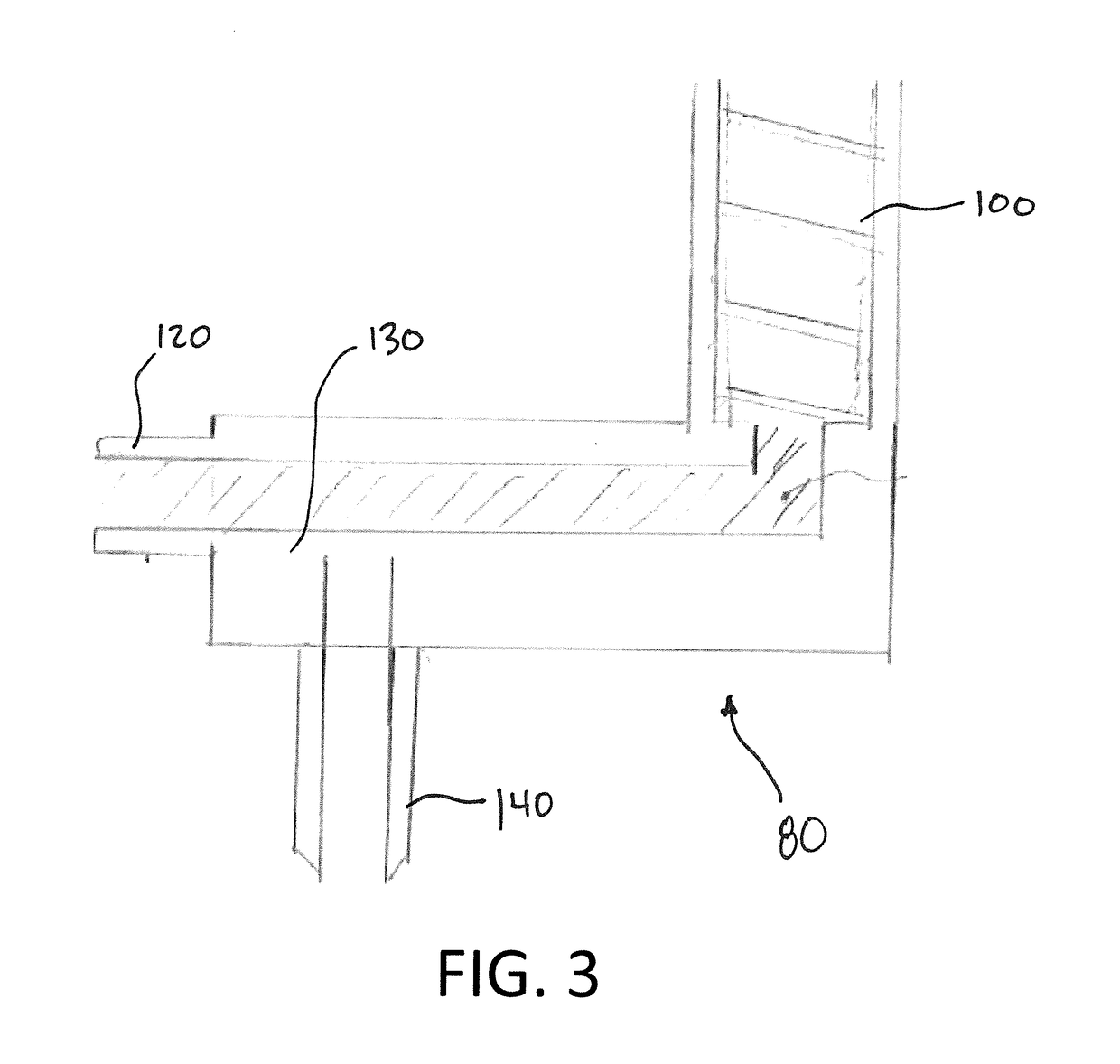

Clamp assembly for hydroforming die

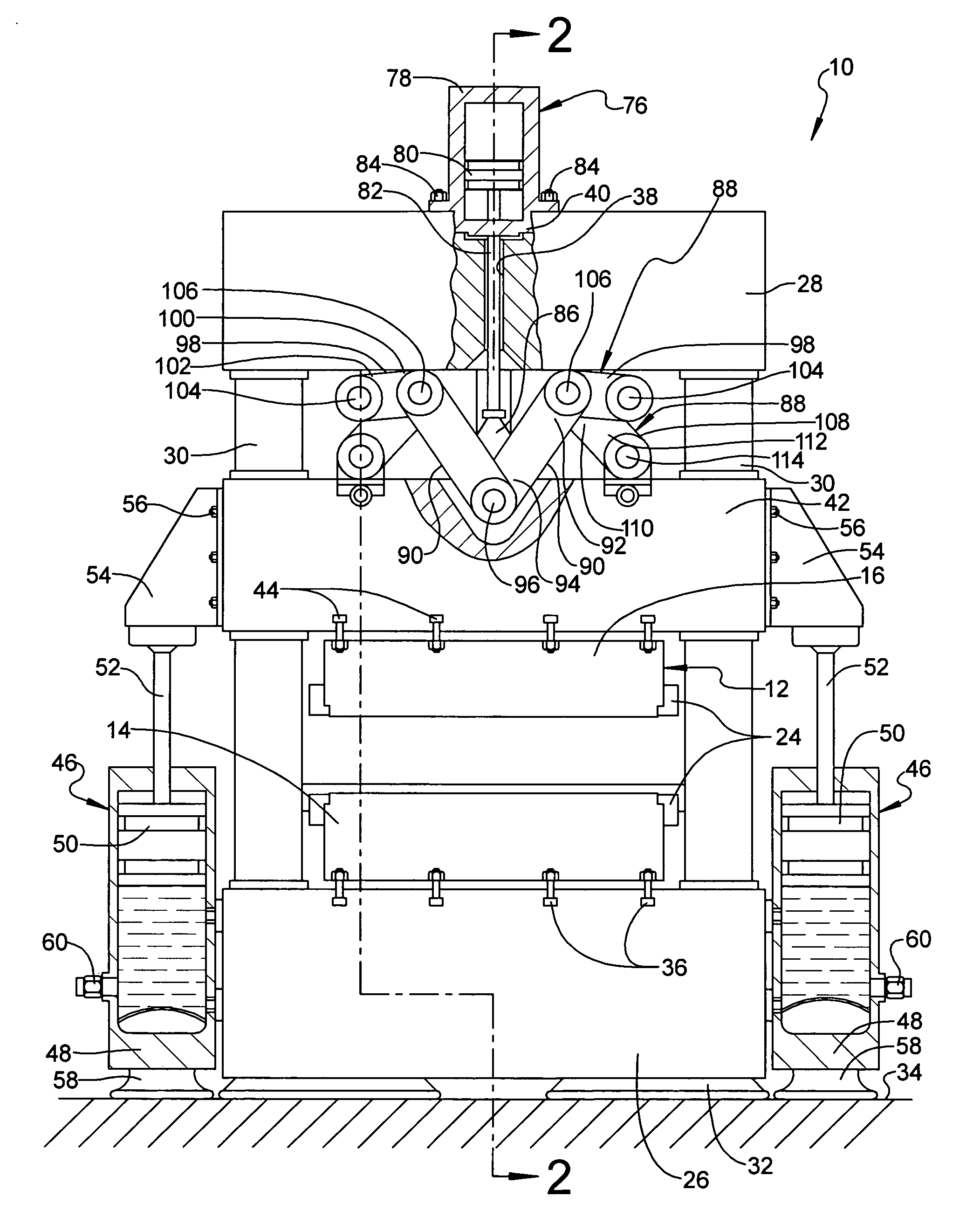

InactiveUS7124618B1Withstand extremely high forceReduce operating costsForging press detailsForging press drivesHydroforming

A clamp assembly for a hydroforming die includes a stationary lower bed to support a lower die half of the hydroforming die, a stationary upper bed spaced above the lower bed, at least one guide post extending between the lower bed and the upper bed, a movable slide disposed between the upper bed and the lower bed and movable along the at least one guide post to support an upper die half of the hydroforming die, a lifting cylinder operatively connected to the movable slide to move the movable slide and upper die half toward and away relative to the lower die half, at least one link mechanism connected to the upper bed and the movable slide to equalize a force on the hydroforming die, and at least one linkage cylinder operatively connected to the at least one link mechanism to activate the at least one link mechanism to prevent the movable slide and upper die half from moving away from the lower die half to keep the hydroforming die closed during a hydroforming process.

Owner:GM GLOBAL TECH OPERATIONS LLC

Manipulatable model for communicating manufacturing issues of a custom part

ActiveUS20070208452A1Increase qualityReduce expenseTelevision system detailsCathode-ray tube indicatorsSystem usageSoftware

Any issues associated with manufacture of a part are identified and highlighted on a part model. A software method and system then uses motion of the part model for communicating the manufacturability issues to the customer. The motion can include a repositioning of a part rendering to a preferred orientation position, a fly-around so the customer can appreciate the next zoom location, and then a zooming in on the issue desired to be shown. Alternatively or in conjunction with the zooming and fly-around motion, the orientation of the part rendering showing the manufacturability issues can be three-dimensionally manipulated such as with a click-drag-drop command of the customer's computer mouse. By adding a moveable aspect to the communication, customers can much better understand which changes are recommended or required of the part.

Owner:PROTOLABS INC

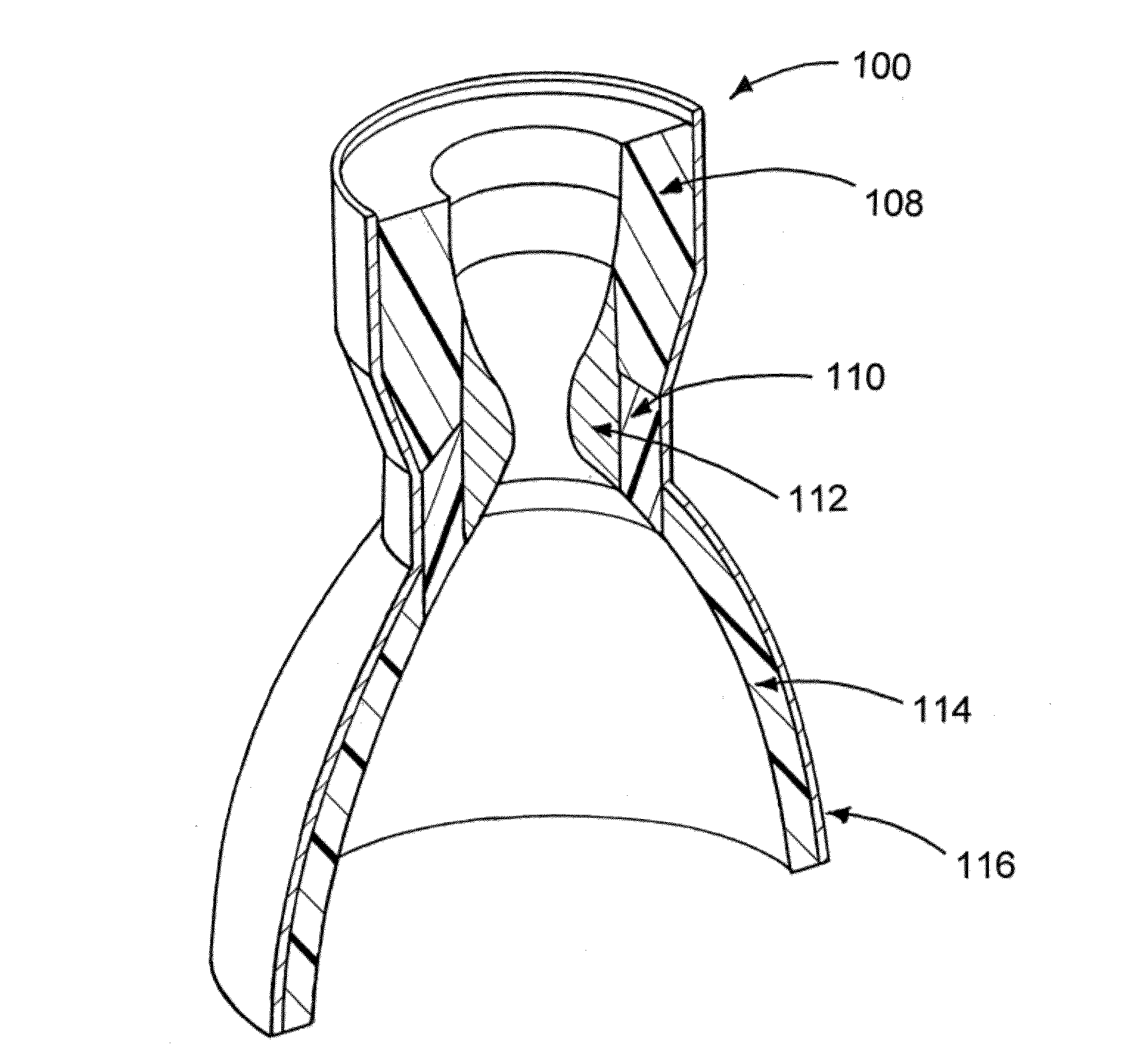

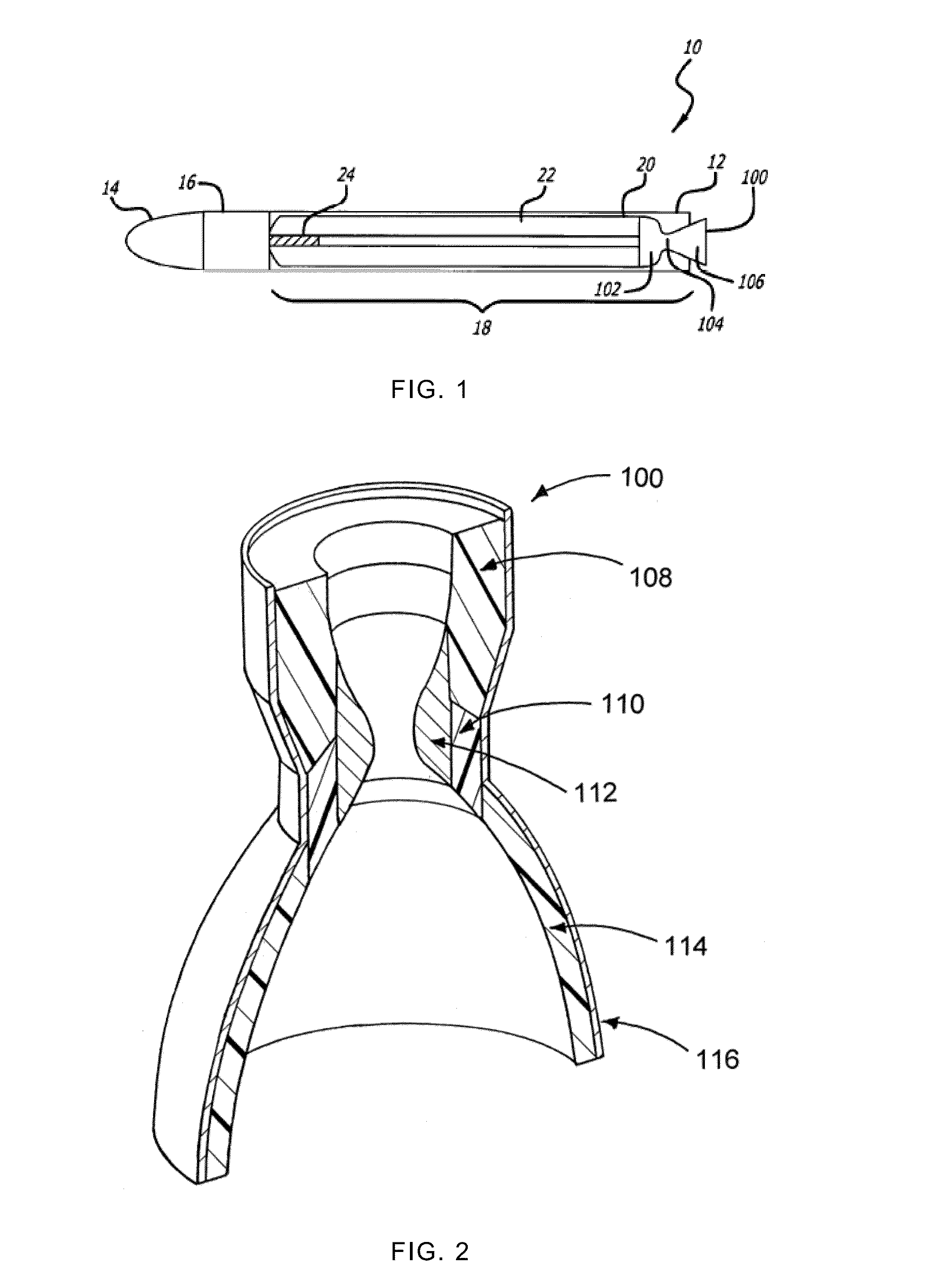

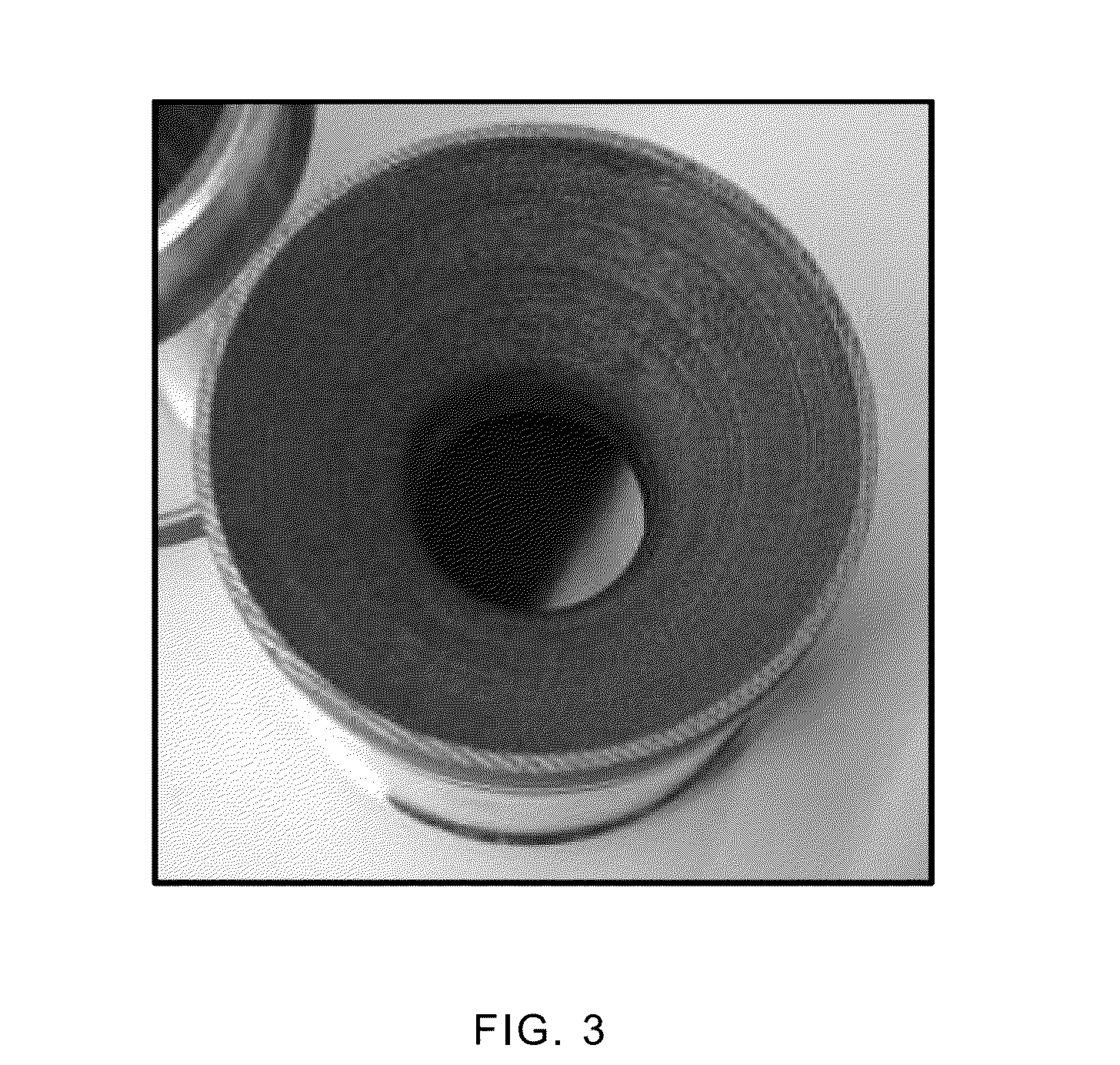

Resin transfer molded rocket motor nozzle

InactiveUS20150204274A1Low costReduce processing stepsPower plant exhaust arrangementsCeramic shaping apparatusShell moldingTransfer molding

A resin transfer molding process is used to manufacture a fiber reinforced composite for a rocket motor nozzle, the composite including a benzoxazine resin and a reinforcing fabric.

Owner:RAYTHEON CO

Method of progressive hydro-forming of tubular members

A method of progressive hydro-forming of a tubular member includes the steps of positioning a tubular member between open die halves mating with one another to define a first tubular cavity portion in a first stage. The method also includes the steps of progressively closing the die halves and applying hydraulic pressure to expand and conform the tubular member to the first tubular cavity portion in the first stage. The method includes the steps of positioning the expanded tubular member in a second tubular cavity portion in a second stage and progressively closing the die halves to progressively deform the expanded tubular member within the second tubular cavity portion. The method includes the steps of applying hydraulic pressure to expand and conform the expanded tubular member to the second tubular cavity portion in the second stage.

Owner:GM GLOBAL TECH OPERATIONS LLC

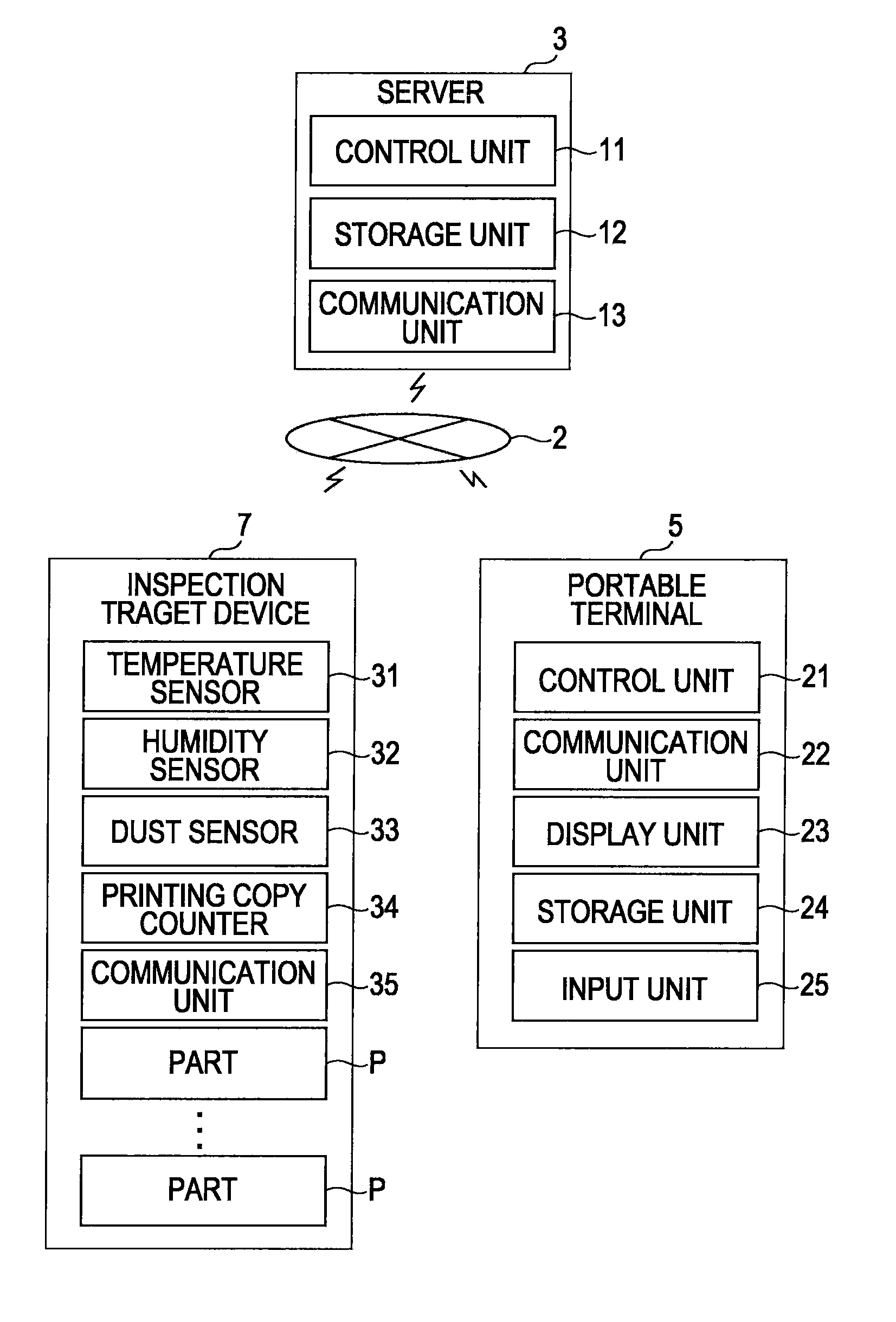

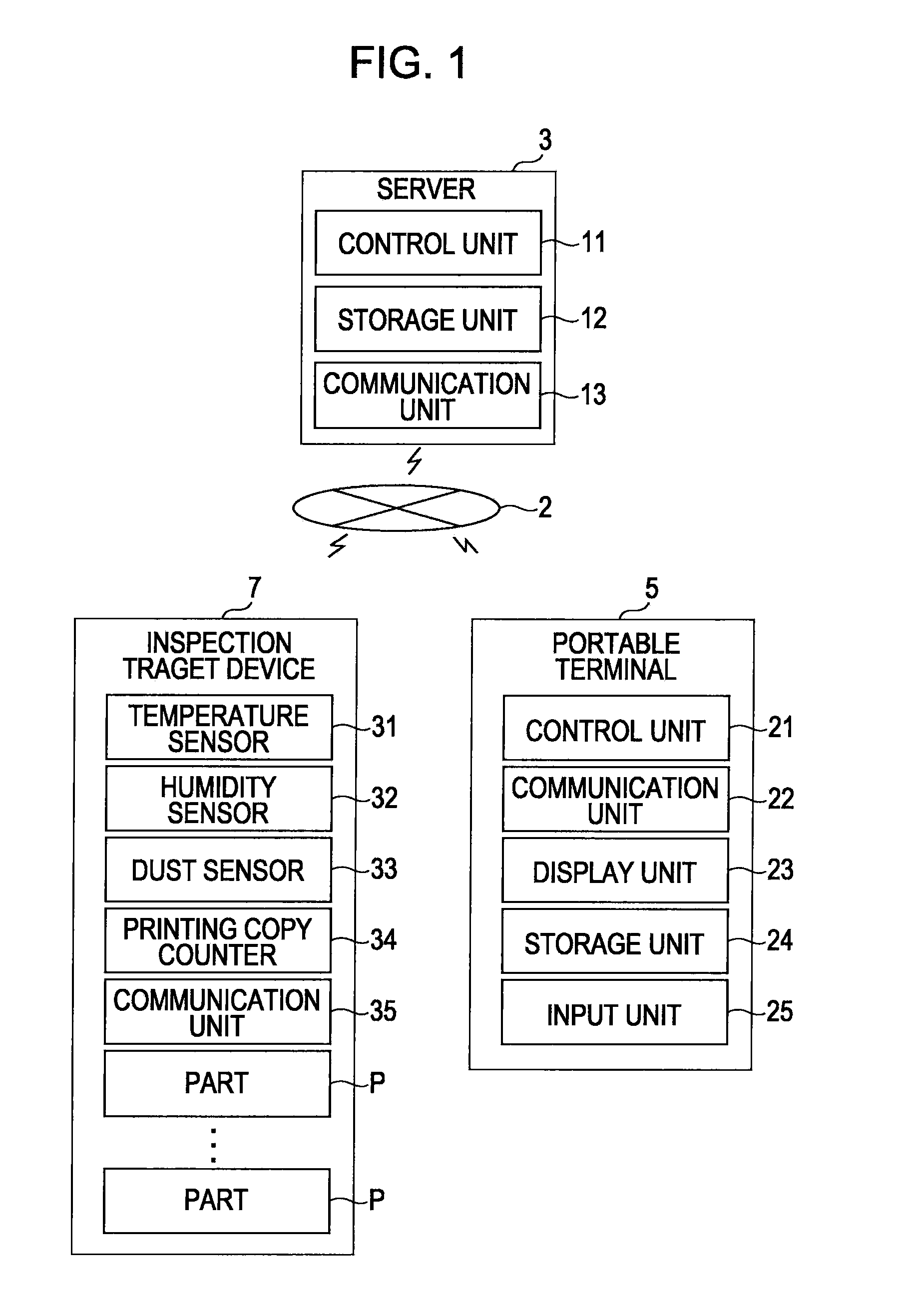

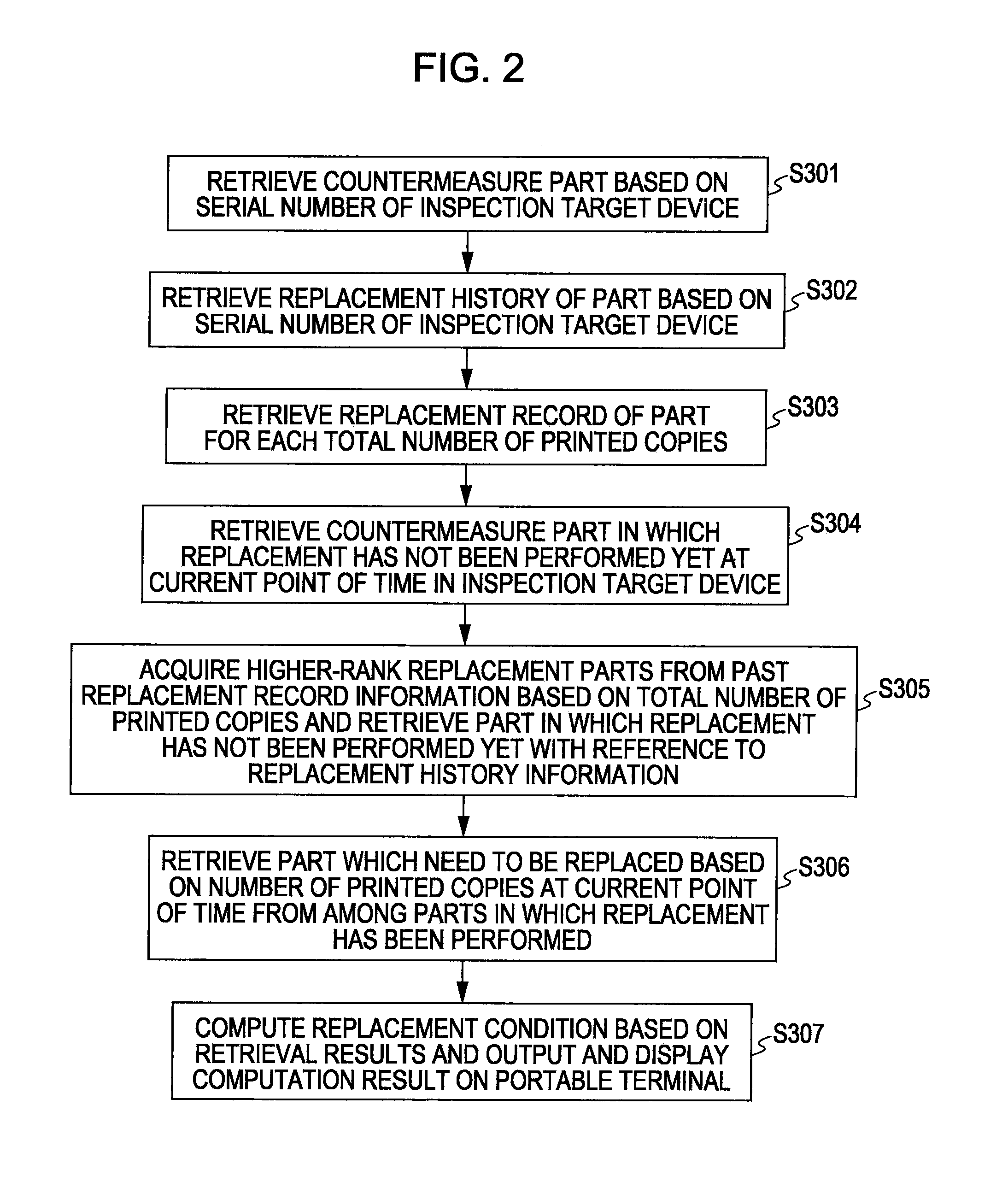

Maintenance work support device, maintenance work support method, and program

InactiveUS20100177359A1Improve part qualityImprove efficiencyData processing applicationsPictoral communicationRetrieval resultStorage cell

A maintenance work support device which computes replacement information of a part configuring a device and supports maintenance work of the device includes: a storage unit storing information; and a control unit controlling the maintenance work support device according to the stored information. The storage unit comprises: a unit storing identification information and a replacement state for improving part quality as quality information; a unit storing device identification information and a replacement state by a past part failure as replacement history information; and a unit storing a part replacement record associated with a device use state as replacement record information. The control unit comprises a unit retrieving quality information, replacement history information, and part replacement record information based on identification information and a use state of an inspection target device and computes information of a part that needs to be replaced as replacement information based on the retrieval result.

Owner:SEIKO EPSON CORP

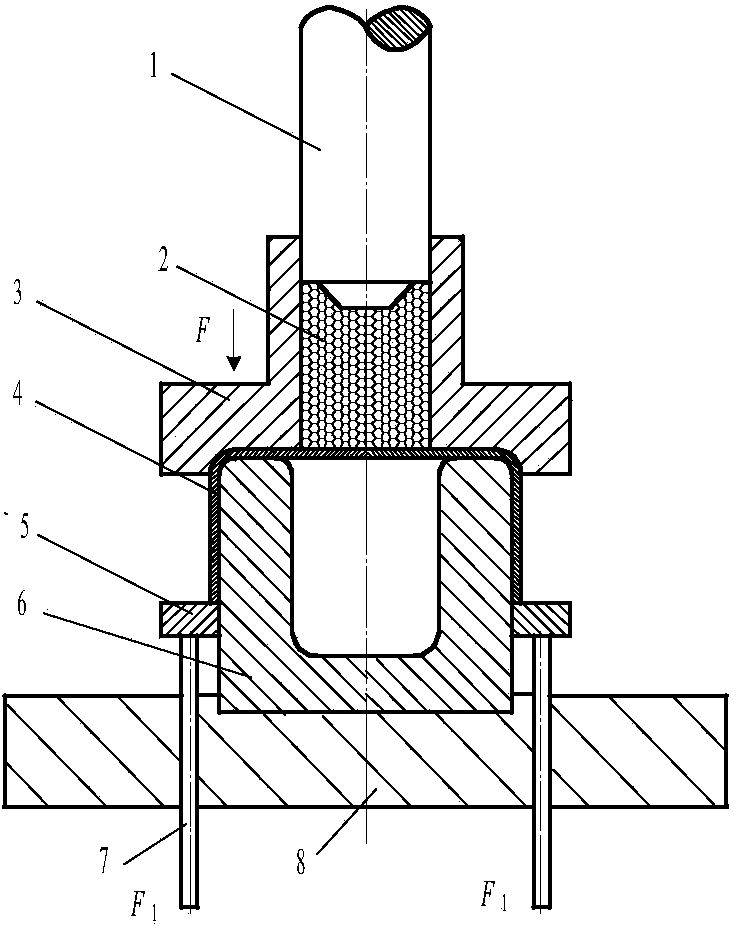

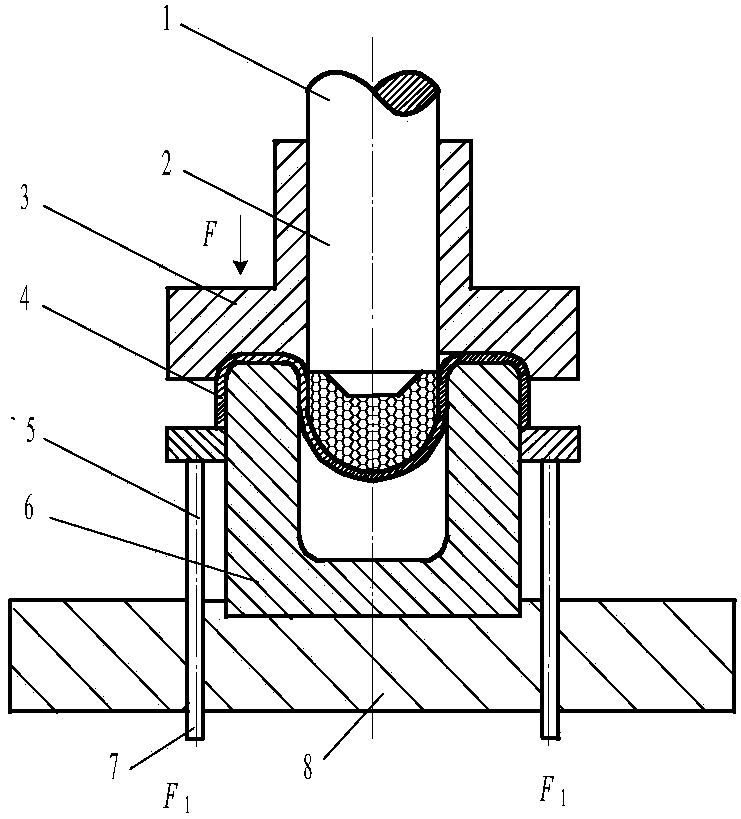

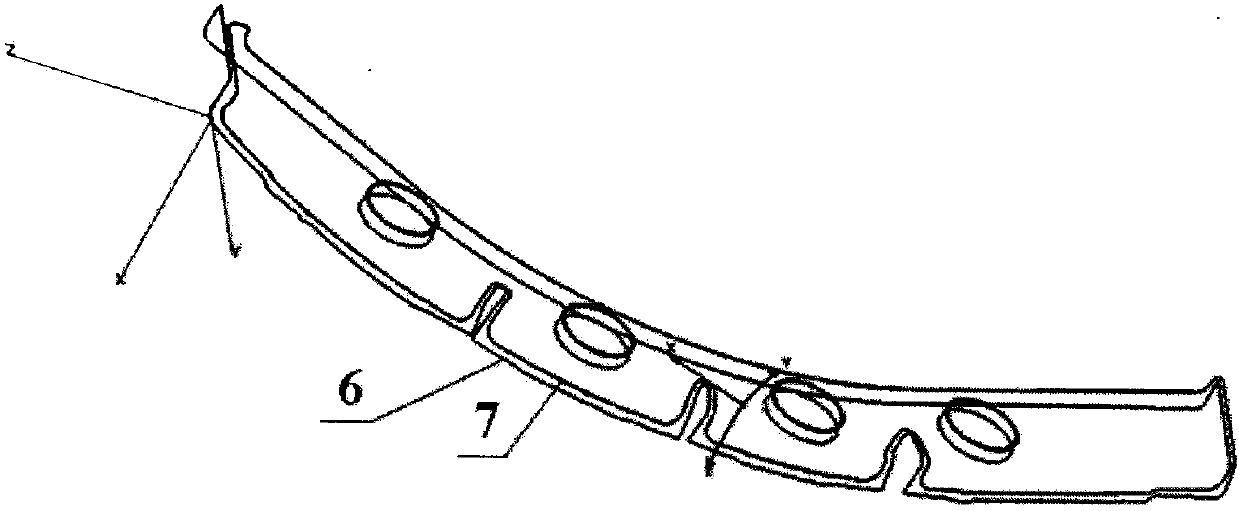

Reverse drawing method for soft die with peripheral auxiliary thrust

The invention discloses a reverse drawing method for a soft die with peripheral auxiliary thrust. Reverse drawing equipment for implementing the reverse drawing method mainly comprises a punch, granular media, a blank holder, a plate, a thrust ring, a female die, an ejector rod, a base and the like. When the plate is formed, a preliminarily formed cylindrical part of the plate is fastened on the female die, the blank holder exerts blank holding force, the punch descends to compress the granular media, pressure is applied to the preliminarily formed cylindrical part of the plate, a soft male die can be formed, force is applied to the thrust ring by the ejector rod, and accordingly the peripheral auxiliary thrust can be applied to the cylindrical part; after drawing is completed, a workpiece clings to the inner wall of the female die, and can be finally shaped. Compared with the traditional forming method, the reverse drawing method has the advantages of simple structure, energy conservation, environmental protection and capability of obviously upgrading forming limit on plate parts.

Owner:YANSHAN UNIV

Method of progressive hydro-forming of tubular members

Owner:GM GLOBAL TECH OPERATIONS LLC

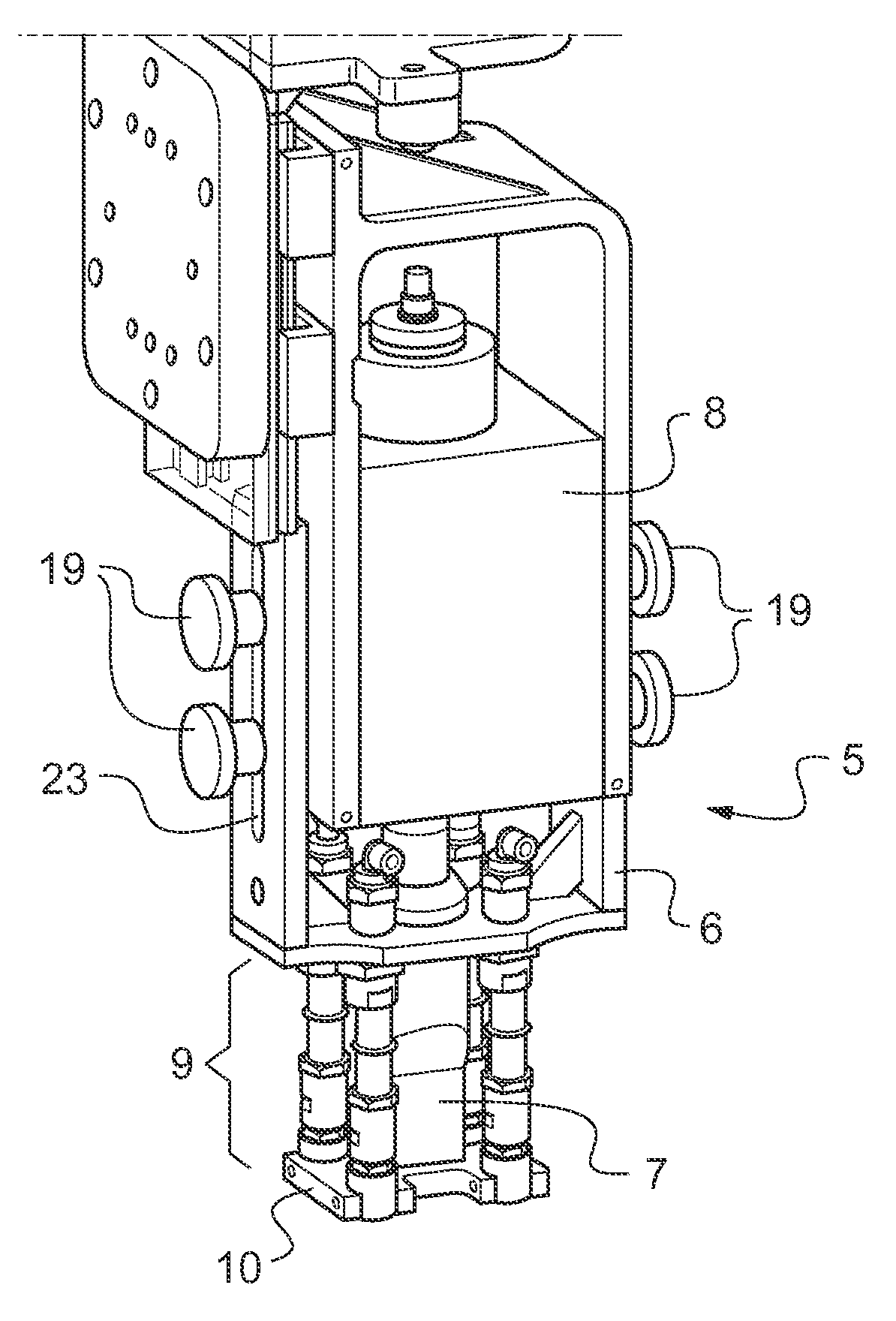

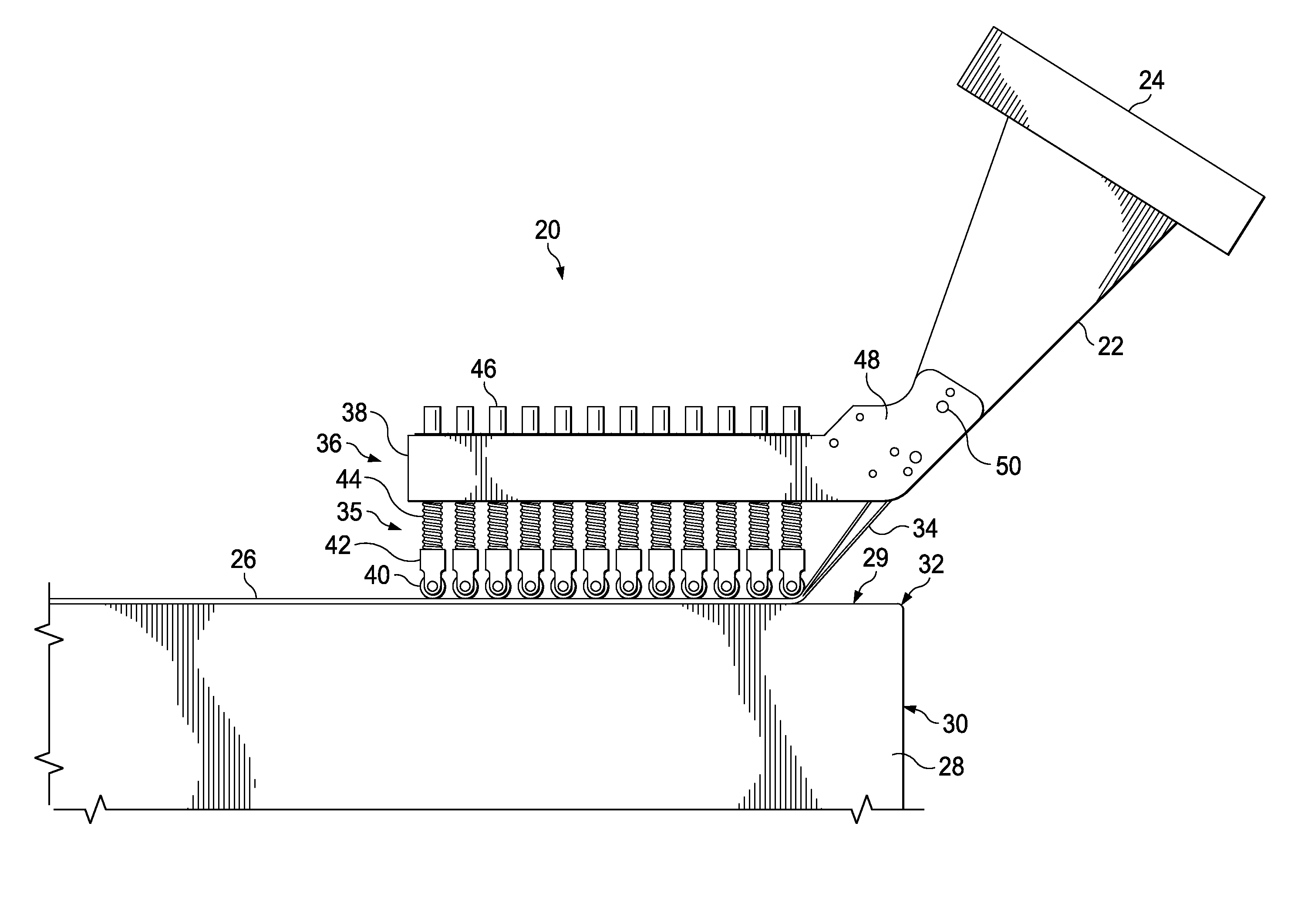

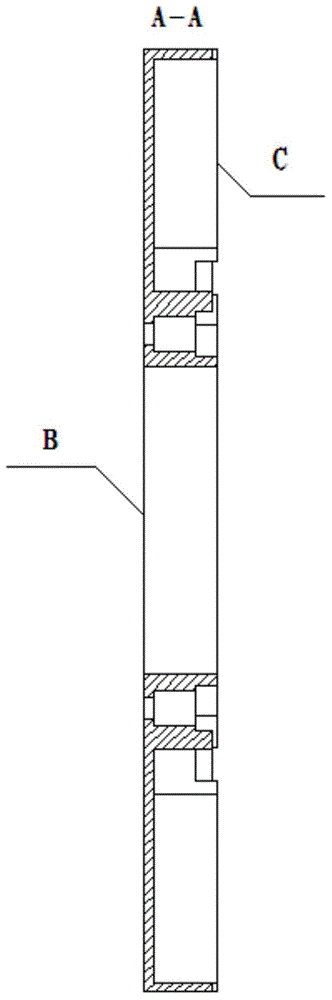

Ultrasonic welding device and method of operating said device

ActiveUS20130263999A1Avoid restrictionsLack of reproducibilityLaminationLamination apparatusUltrasonic weldingEngineering

The invention is related to an ultrasonic welding device (5) comprising: an adapter frame (6); an ultrasonic horn (7) driven by a adapter frame mounted converter (8). A pick member (9) comprises grippers (11-14). Passive clamping means are provided with a press pad (10). Control means and activation means (15) are provided for controlled activation of the pick member (9) and the ultrasonic horn (7). The invention is further related to a method of operating said device.

Owner:AIRBUS HELICOPTERS DEUT GMBH

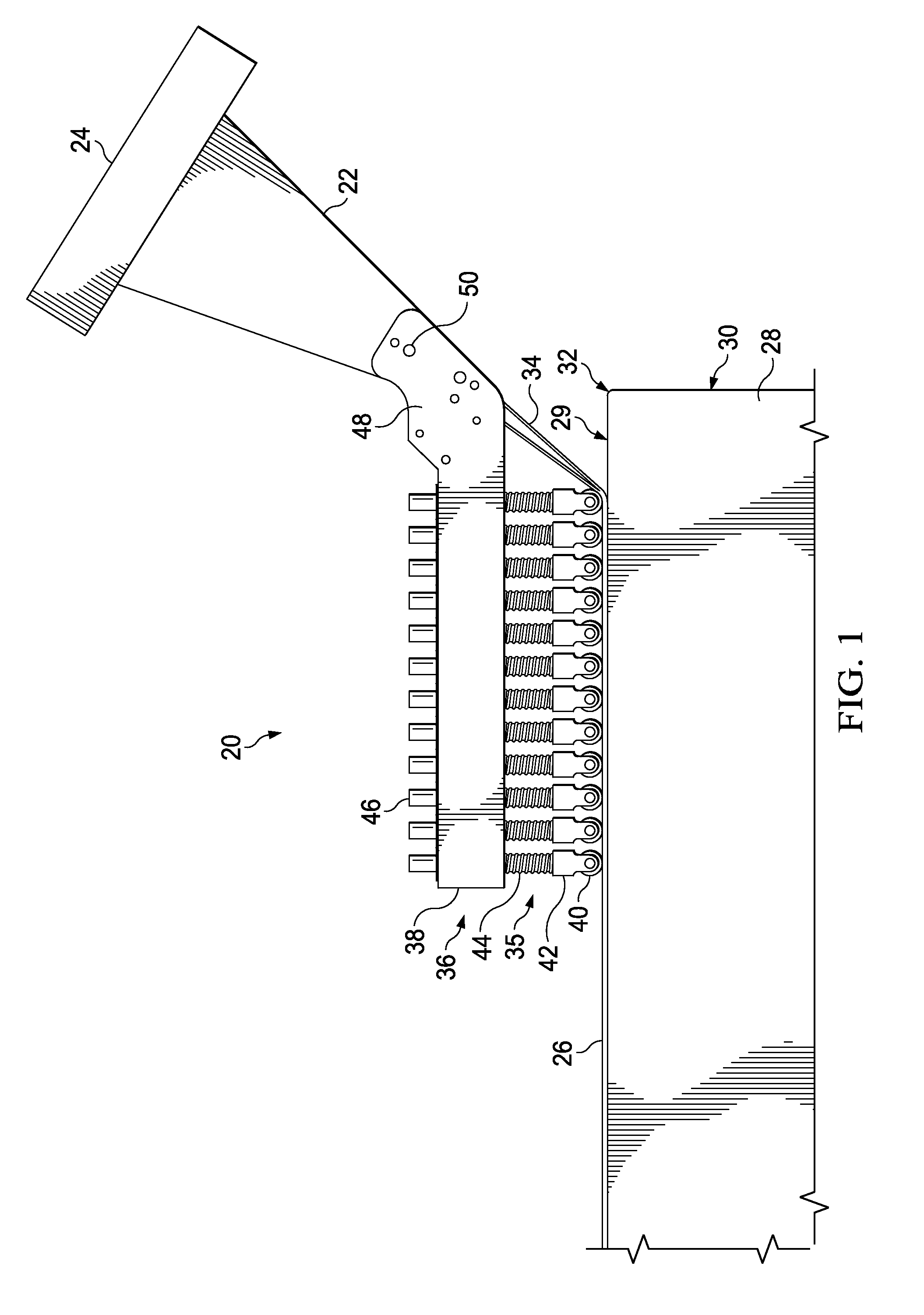

Compaction Method and Device for Automated Fiber Placement

A compaction device for use with an automated fiber placement machine includes multiple compaction rollers mounted for independent displacement on a supporting frame. The attitude of the compaction rollers change relative to each other when fiber tows are laid up at an angle over an edge of a tool in order to maintain compaction pressure on the tows and thereby reduce non-compacted areas of the tows.

Owner:THE BOEING CO

Plate-type structural component machining method

ActiveCN104924040AImprove part qualityShorten the manufacturing cycleAircraft componentsStructural componentManufacturing engineering

The invention belongs to the technical field of plate part forging machining and discloses a plate-type structural component machining method. The plate-type structural component machining method comprises the steps of machining technology process design, machining allowance distribution, numerical control milling and microscale bore cutting. According to the plate-type structural component machining method, through the addition of a rough milling procedure and an artificial ageing procedure and the reasonable distribution of machining allowances, the problems that the parts are deformed, the machining period is long and the form and location tolerance is difficult to be guaranteed are solved; through the design of cutting parameters and a tool path route, the machining efficiency of products and the yield of the parts are improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Blank preparation method for rubber bladder formed thin-walled part

ActiveCN104392016AAccurate and reasonable shapeNo trimming allowanceSpecial data processing applicationsThin walledComputer Aided Design

The invention relates to a blank preparation method for a rubber bladder formed thin-walled part. The method comprises the following steps of 1) performing digital-analogue design on a blank in CAD (computer-aided design) software CATIAV5 according to the part and a die; 2) performing rubber bladder process accurate forming simulation analysis on the blank in CAE (computer-aided engineering) software PAMSTAMP2G; 3) after calculation, activating a simulation result of the last step of a forming stage in a post-processing module, importing the edge line of the part, and comparing the simulation result with the edge line; 4) activating the first step of the forming stage in the simulation result, and obtaining the edge line of the initial accurate blank required by actual forming; 5) outputting the edge line of the blank as an IGS file. The method is based on the real property of a material, and an actual rubber bladder forming process is implemented under optimized process parameter and boundary conditions, so that the blank prepared by the method is accurate and reasonable in shape, free of trimming allowance and convenient to accurately form, and the production efficiency and the quality of the part are improved.

Owner:SHENYANG AIRCRAFT CORP

Method of making pre-formed tubular members

A method of making a pre-formed tubular member includes the steps of providing a tubular member extending longitudinally and providing a bending assembly having a mandrel with at least one ball and a bending die. The method also includes the steps of positioning the at least one ball inside of the tubular member. The method further includes the steps of bending the tubular member about the bend die to form a bent pre-formed tubular member having at least one curved portion having a recess therein.

Owner:GM GLOBAL TECH OPERATIONS LLC

Polymer exhaust for eliminating extruder transients

ActiveUS20190047219A1Improve printing qualityReduced post-processingAdditive manufacturing with liquidsManufacturing recyclingEngineeringAdditive layer manufacturing

An additive manufacturing method that includes an extruder providing a supply of working material and a nozzle connected with respect to the extruder, the nozzle directing the working material to a deposit surface. A diverter valve is positioned between the extruder and the nozzle to direct the working material to an exhaust port away from the deposit surface under certain conditions.

Owner:UT BATTELLE LLC

Method for forming thick thermoplastic composite structures

ActiveUS9248613B2Material bulkSoften the thermoplastic resinDomestic articlesThermoplastic compositesMaterials science

A method and apparatus are used to pre-consolidate and de-bulk a thermoplastic composite ply stack prior to full consolidation and forming to the final part shape. Pre-consolidation and de-bulking is achieved by heating the ply stack to a temperature below the melting point of the thermoplastic in order to soften the plies, and then compress the ply stack.

Owner:THE BOEING CO

Powder Distribution for Laser Sintering Systems

InactiveUS20140271326A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterMetallurgy

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

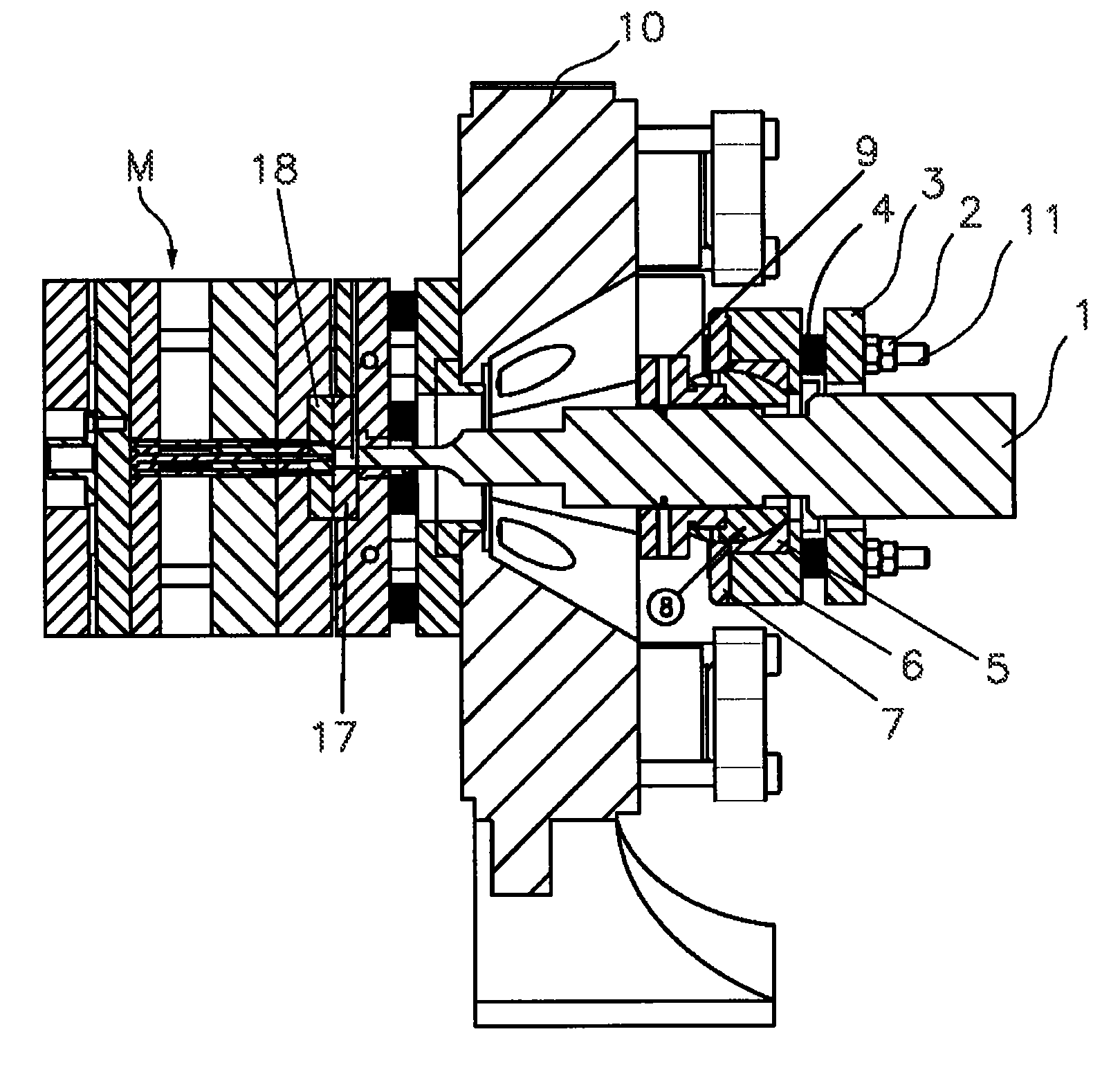

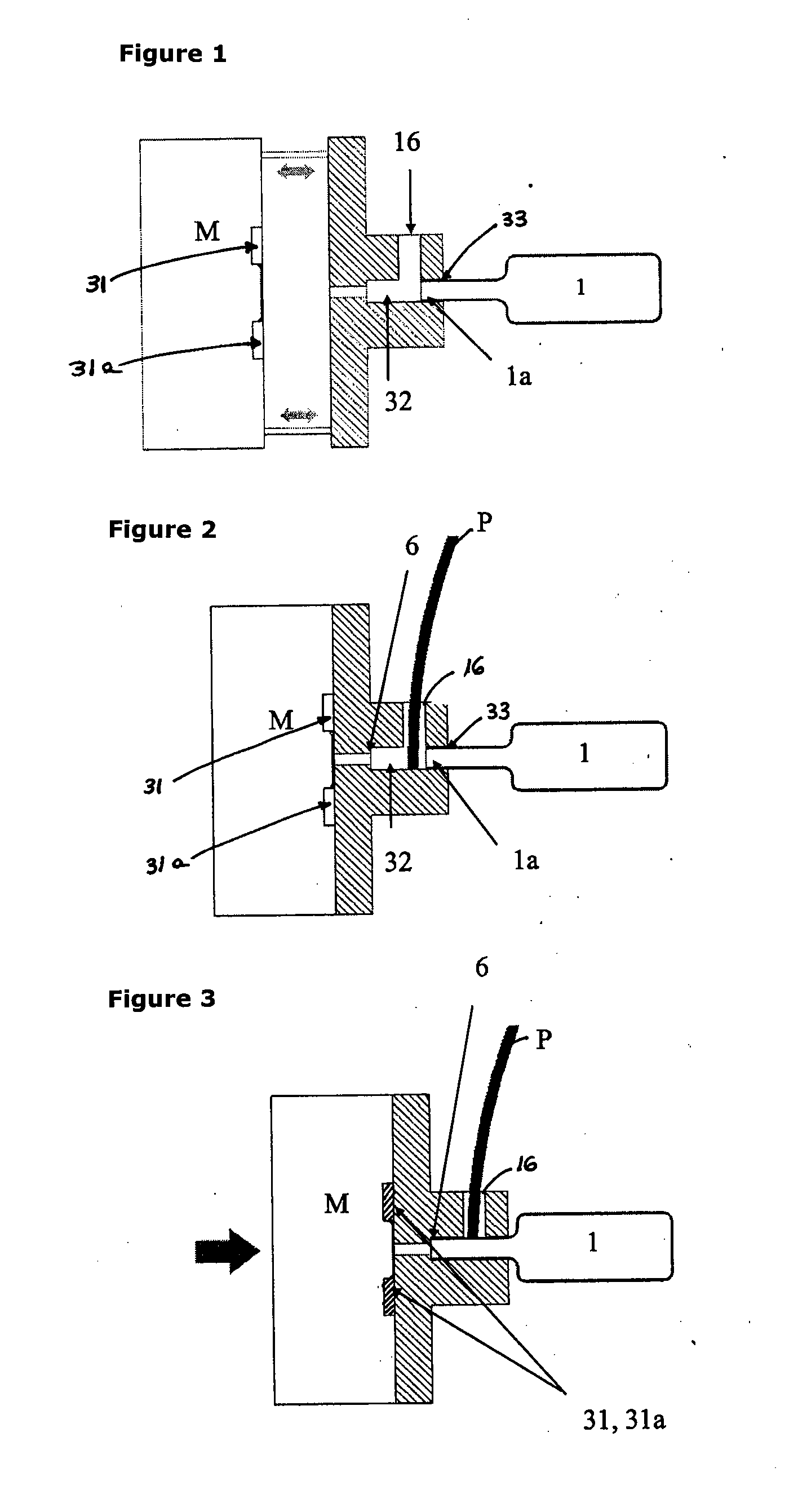

Ultrasonic device for moulding micro plastic parts

ActiveUS20100272843A1Simple moldingImprove part qualityAuxillary shaping apparatusMechanical vibrations separationPlastic materialsEngineering

The invention relates to an ultrasonic device for molding micro plastic parts, which combines: a) a mold cavity configured in a mold having an inlet for supplying plastic material to a chamber with an access opening and the chamber facing the cavity at a distal end in relation to its access opening; b) a cantilevered ultrasonic vibration element associated with an ultrasound generator, with an end portion or tip inserted tightly into the chamber through the access opening in an axially centered manner; c) a movement device for generating a relative movement between the end portion and the parts of the mold so that the end portion engages with the supplied plastic material and exerts a pressure of pre-determined magnitude thereon upon activation of the ultrasonic vibration element.

Owner:ULTRASION SL

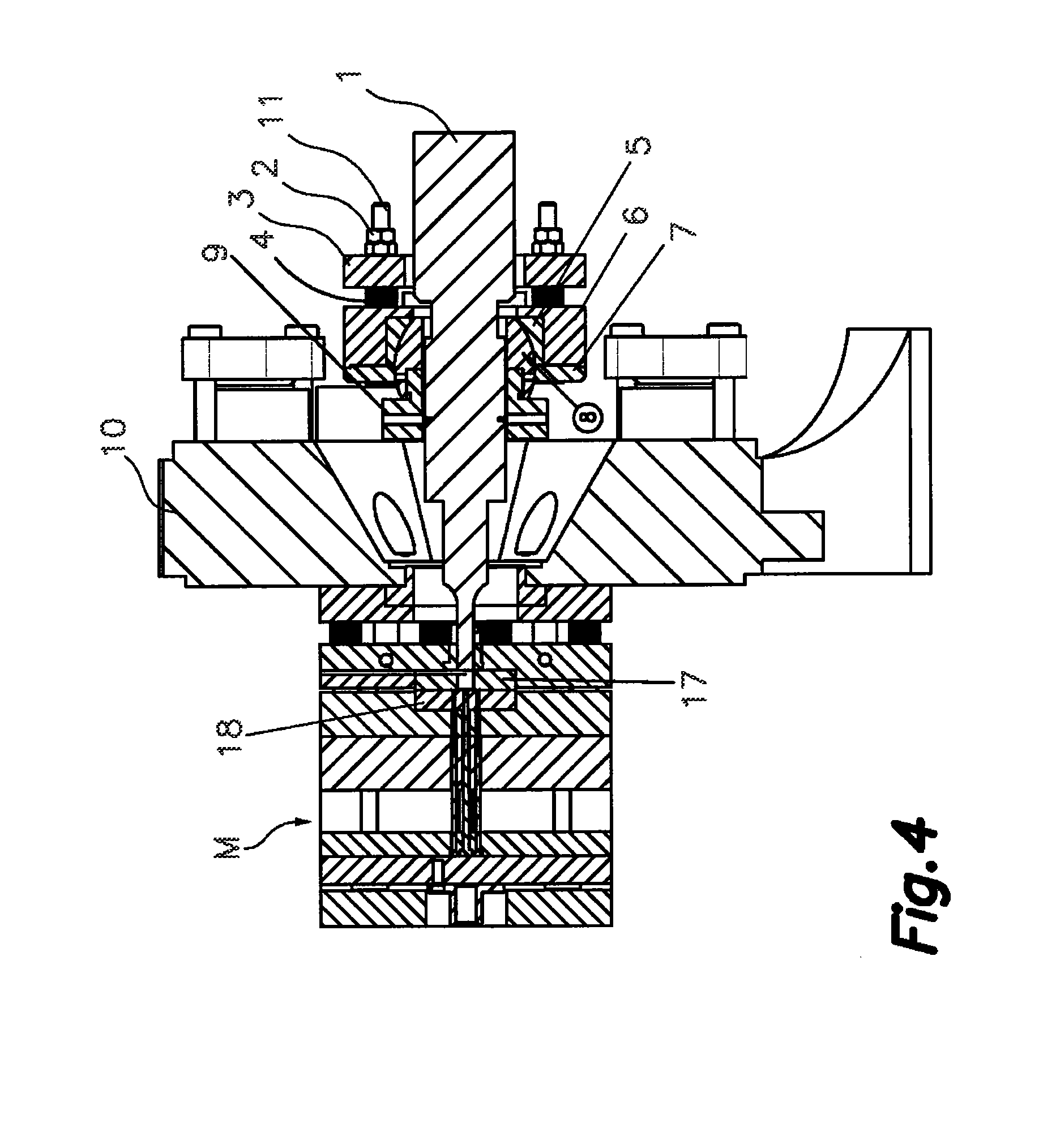

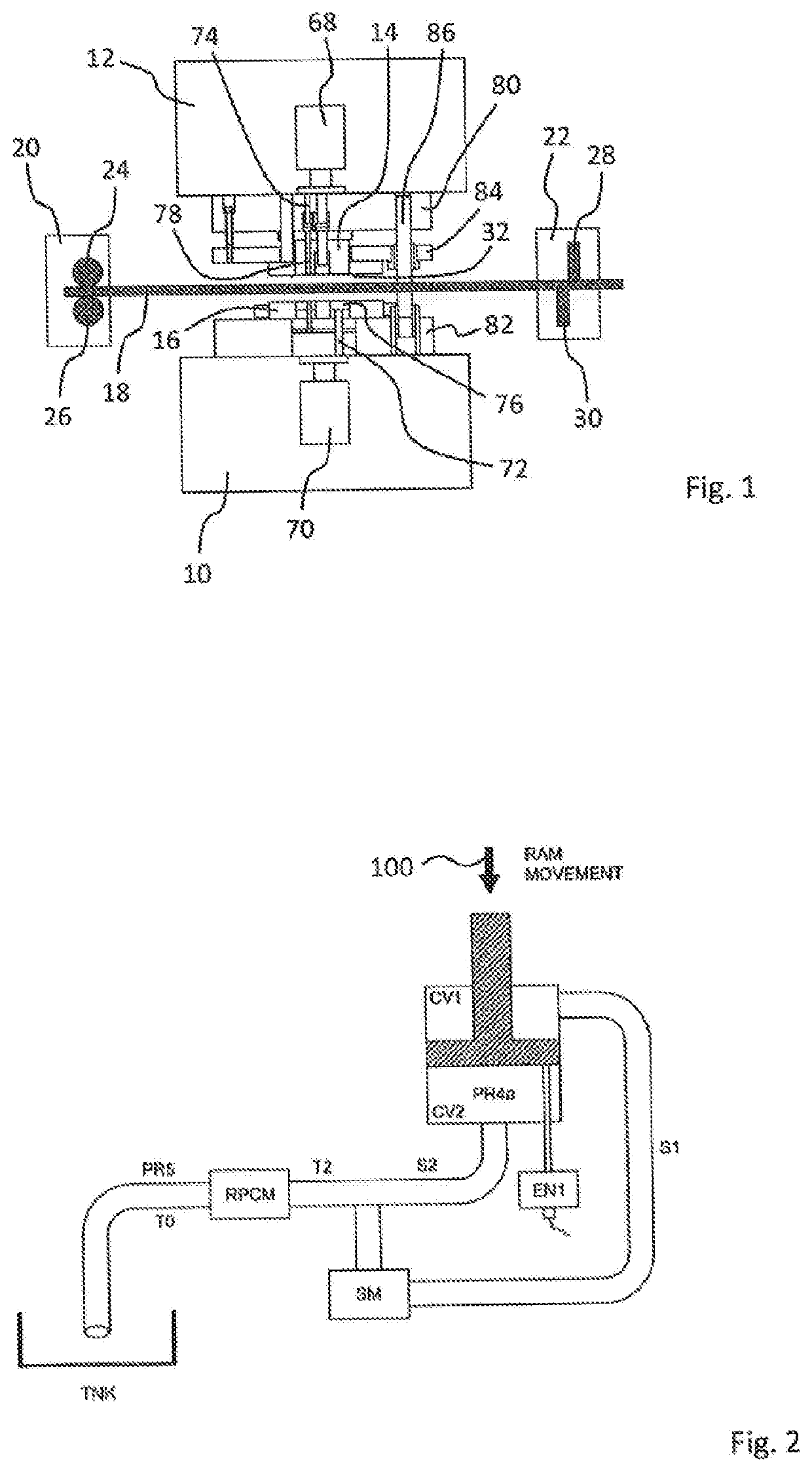

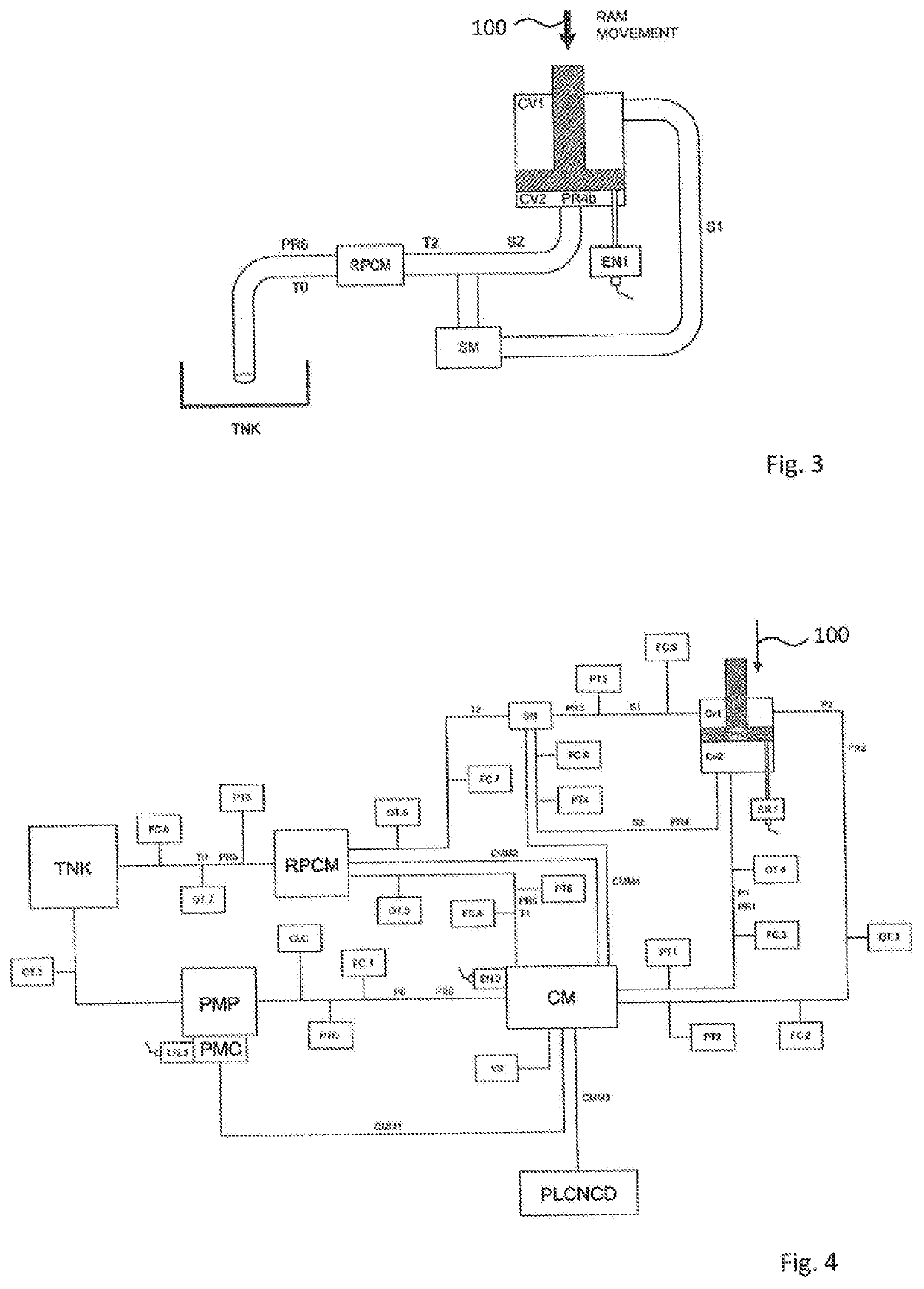

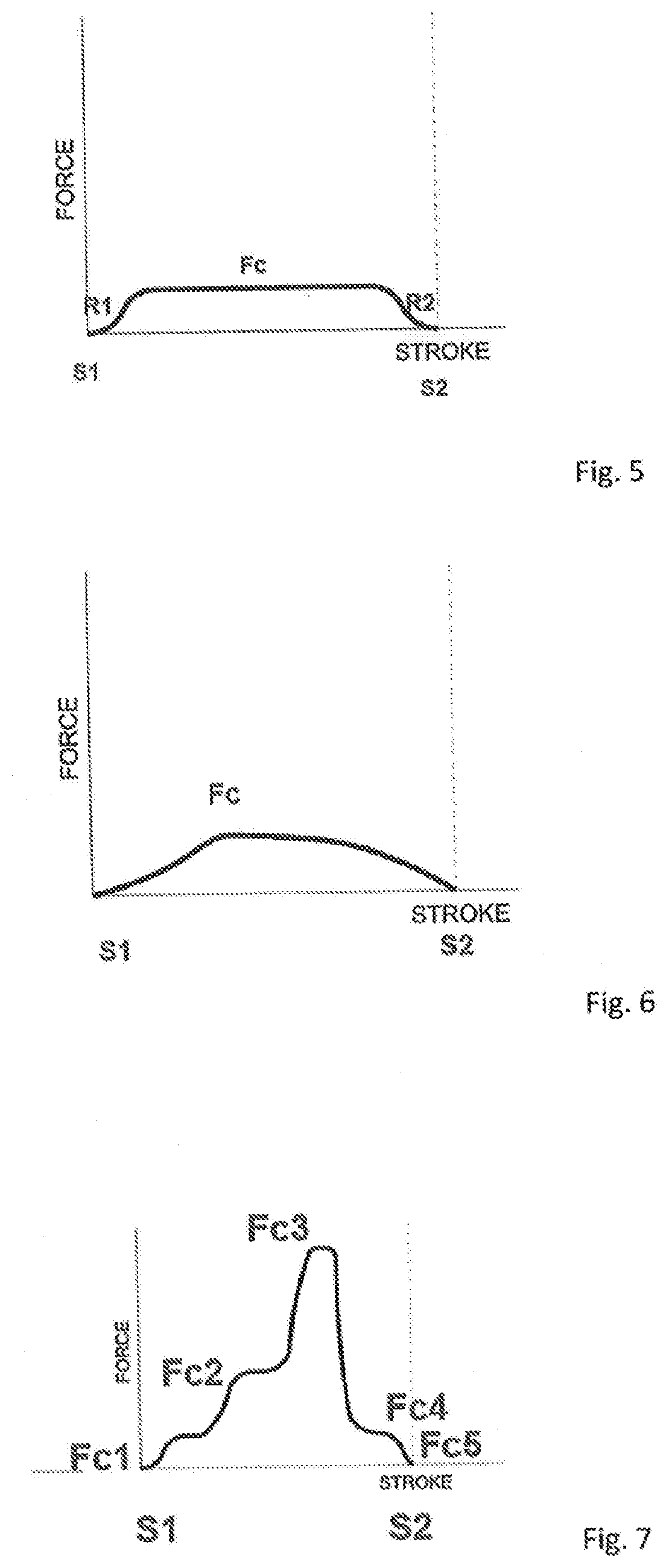

Fine blanking press and method for operating the same

PendingUS20200188983A1Improve tool lifeHigh geometric accuracyPerforating toolsMetal-working feeding devicesPressure.driveControl engineering

The disclosure pertains to a fine blanking press comprising a first press unit comprising a first press drive for driving the first press unit in a first driving movement during a fine blanking process step, and a second press unit wherein the second press unit is driven in a second driving movement at least partially during the first driving movement of the first press unit, and wherein a force control unit exerts a counter force against a force exerted by the first press unit during its first driving movement, and wherein the force control unit comprises at least one sensor and a controller operative to receive measuring data collected by the at least one sensor, and wherein the controller is configured to carry out a closed loop control on basis of the received measuring data. The disclosure further pertains to a method for operating a fine blanking press.

Owner:PETER WOLTERS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com