Patents

Literature

181 results about "Granular media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granular Media Filters. Granular media filtration is generally used after gravity separation. It removes additional suspended solids and oils before other treatment processes. It is also a polishing step that lowers the levels of suspended solids and associated contaminants in treated wastes.

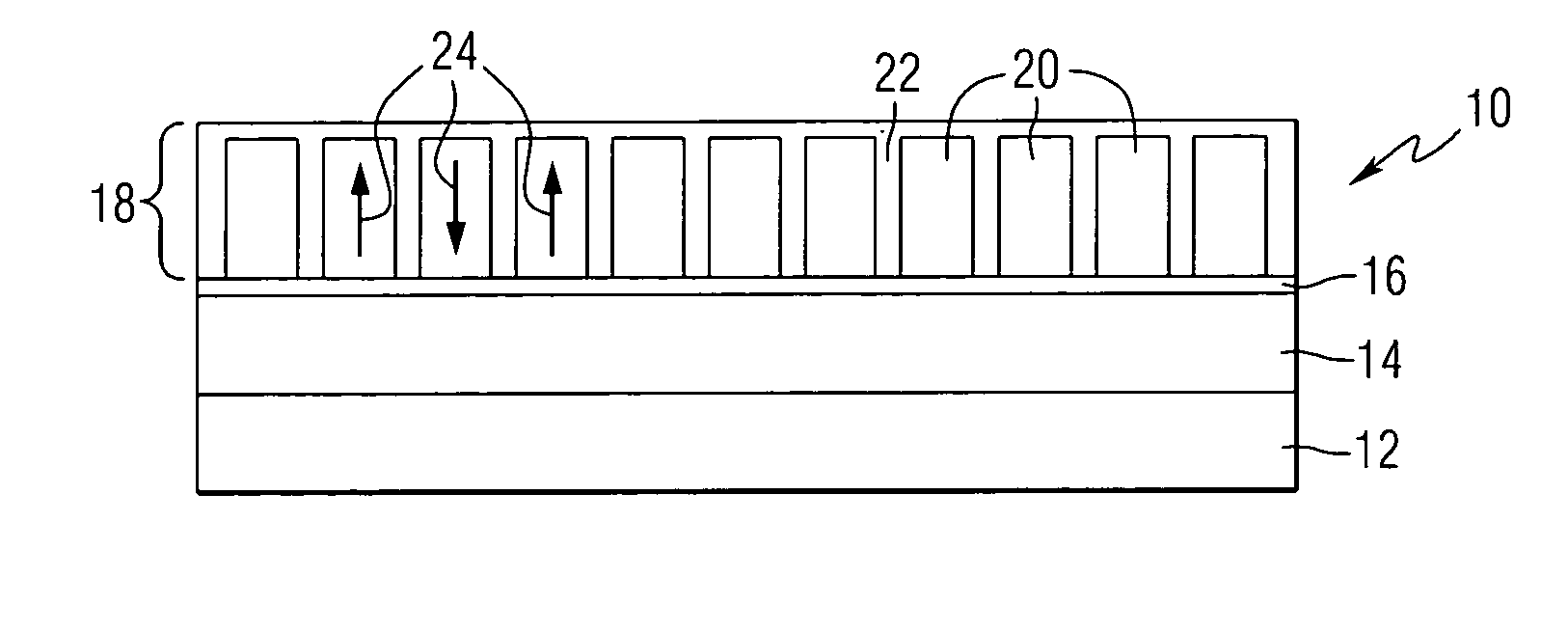

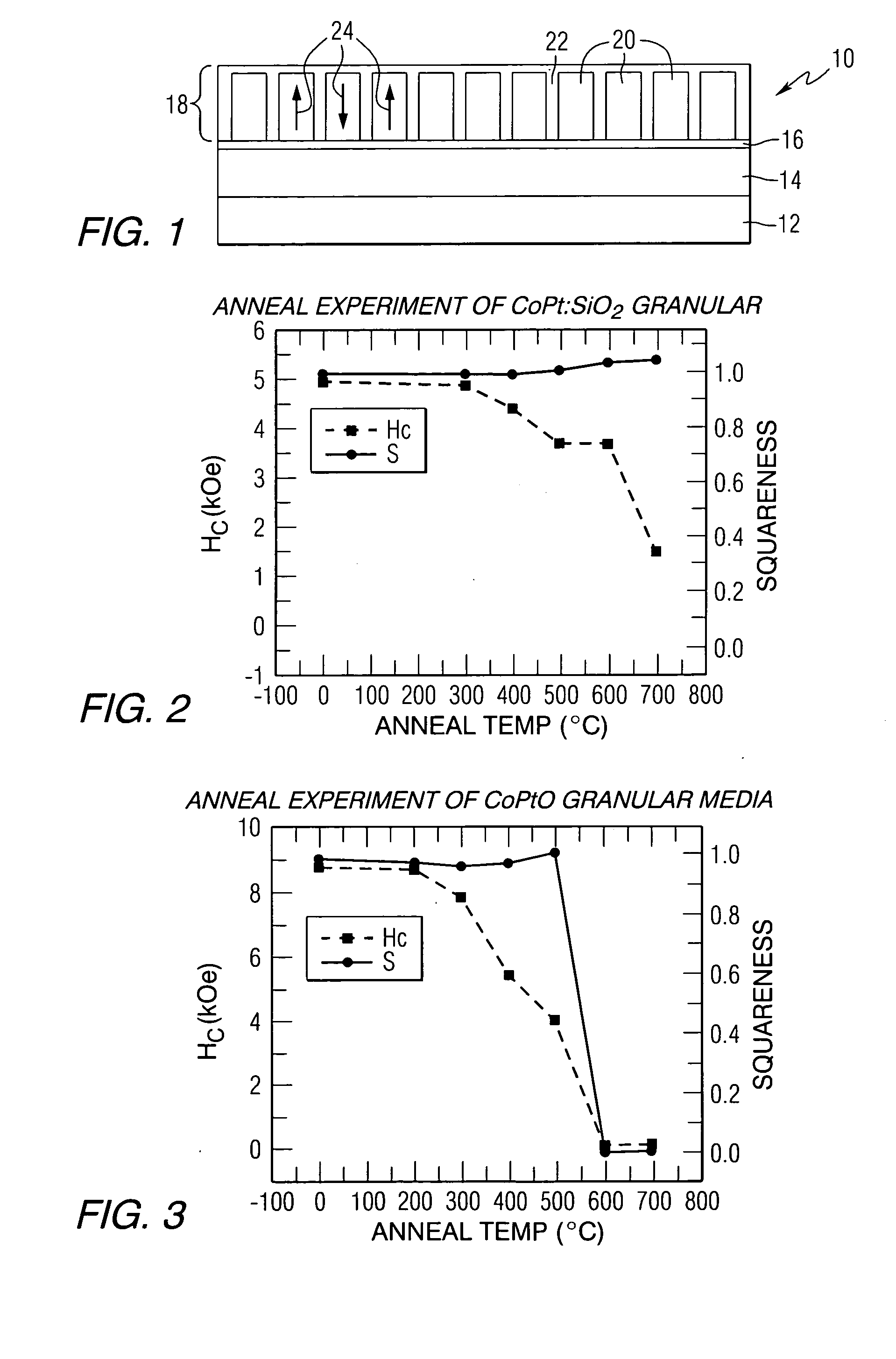

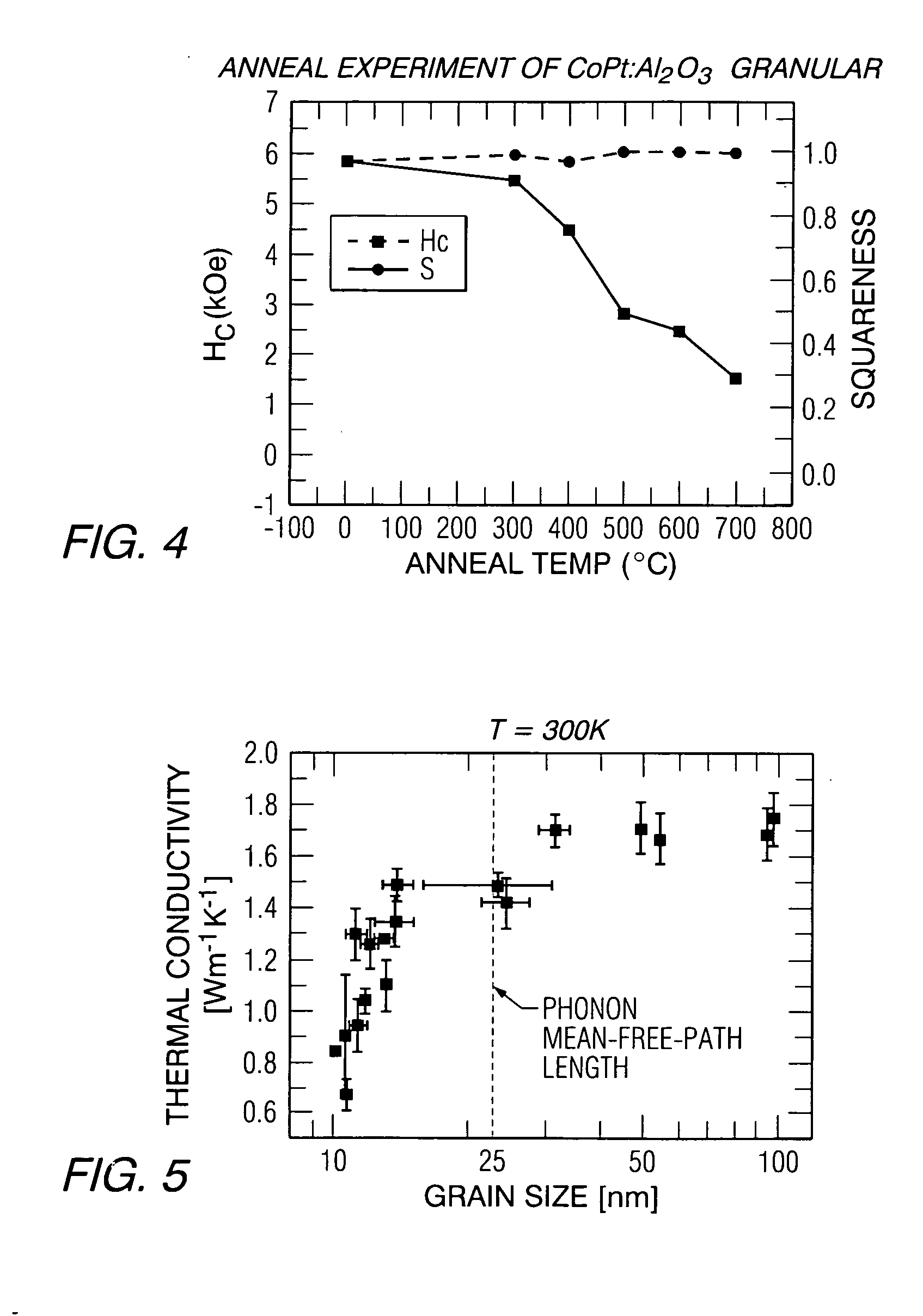

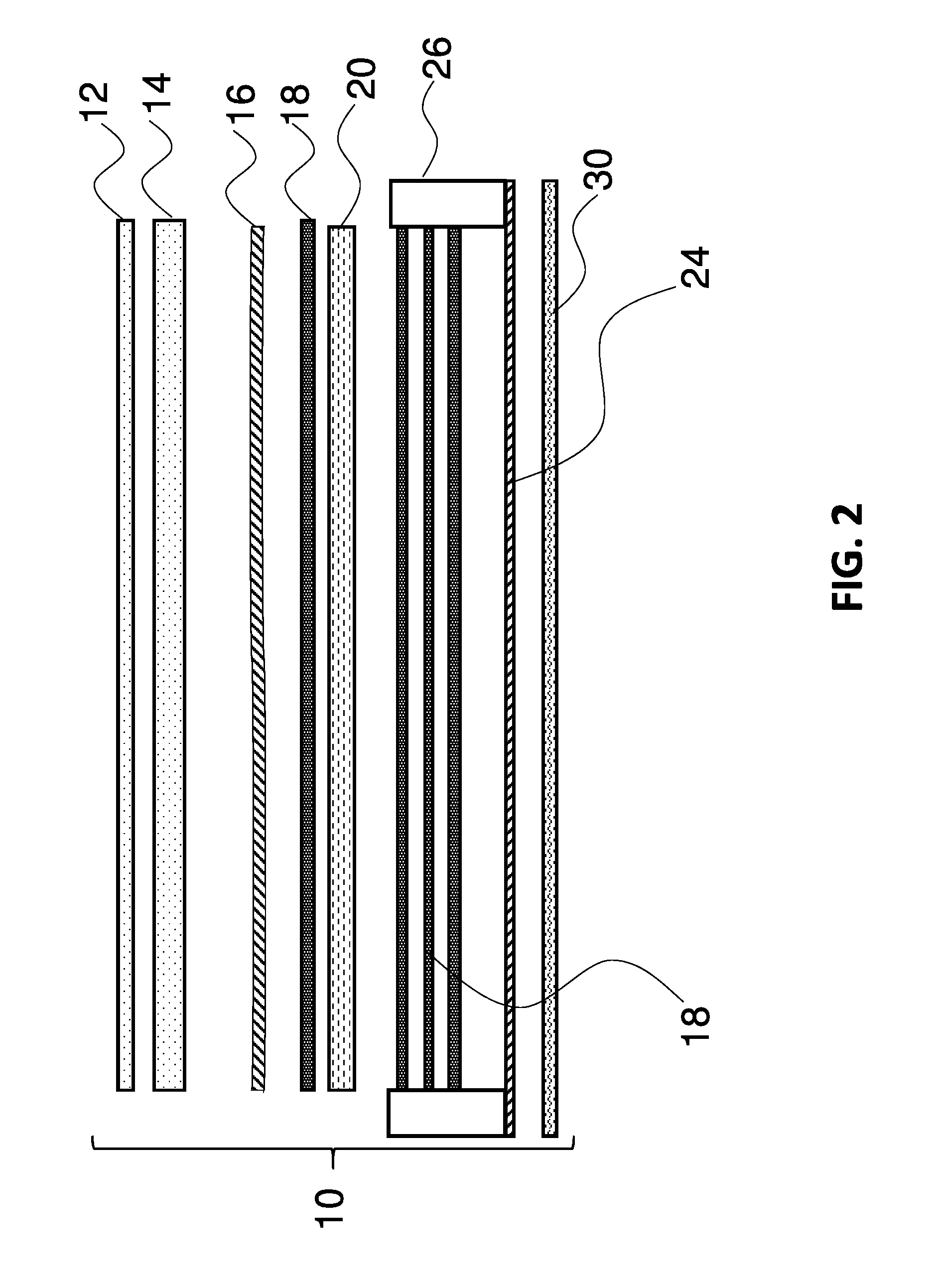

Thermally isolated granular media for heat assisted magnetic recording

InactiveUS20050202287A1Protective coatings for layersVacuum evaporation coatingHeat-assisted magnetic recordingMagnetic storage

A method of fabricating a magnetic storage medium comprises: forming an underlayer on a heat sink layer; co-sputtering a magnetic material and a thermally insulating nonmagnetic material to form a recording layer on the underlayer, wherein the recording layer includes grains of the magnetic material in a matrix of the thermally insulating nonmagnetic material; and heating the recording layer to align an easy axis of magnetization of the magnetic material in a direction perpendicular to the underlayer. A magnetic storage medium fabricated using the method is also provided.

Owner:SEAGATE TECH LLC

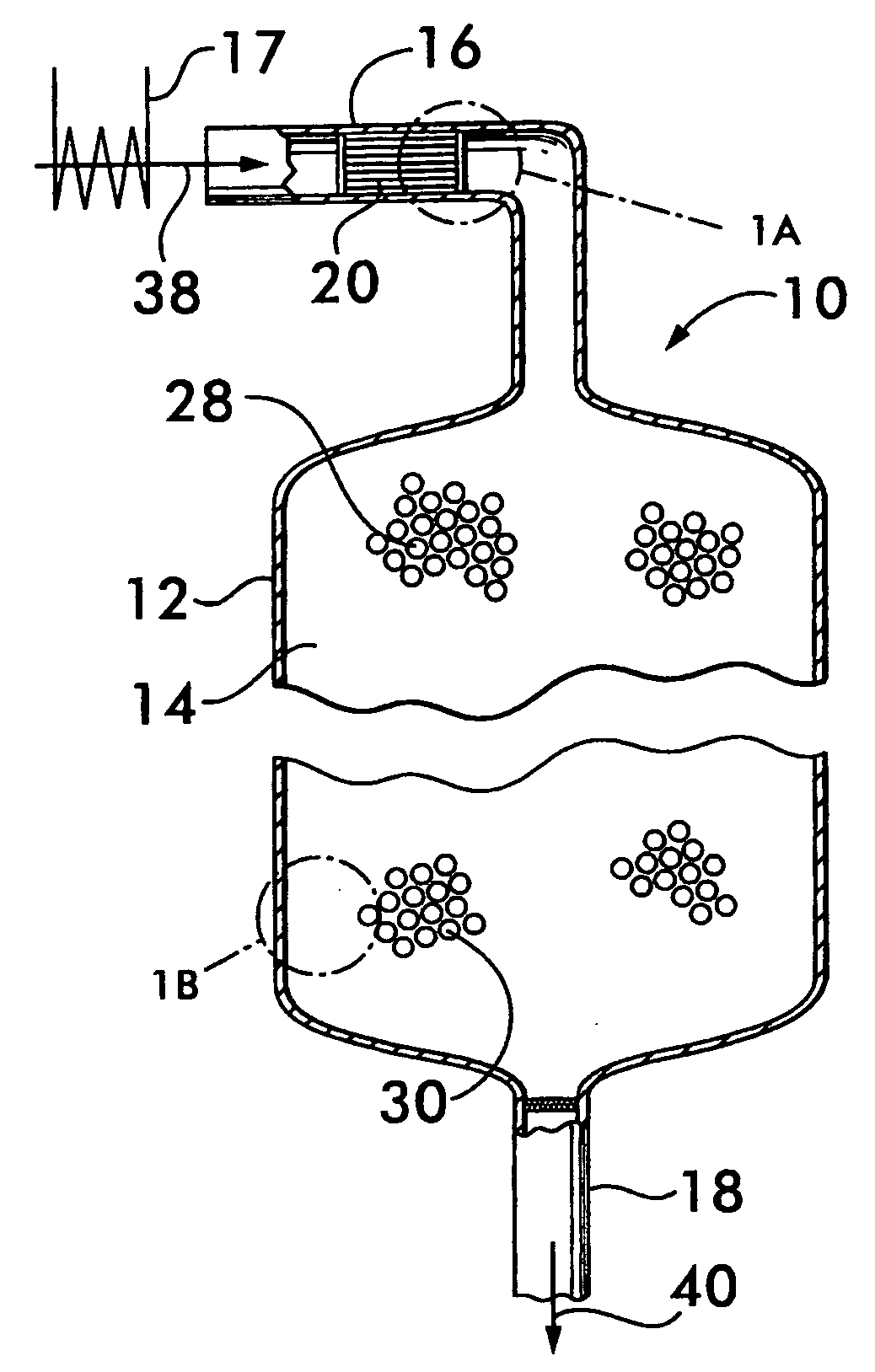

Process and apparatus for production of hydrogen using the water gas shift reaction

InactiveUS20080128655A1Lower carbon dioxide levelsCatalytic gas-gas reactionHydrogenForming gasWater-gas shift reaction

A process and a reactor vessel for production of hydrogen via the water gas shift reaction at CO / CO2 ratios above 1.9, and steam to gas rations below 0.5, are disclosed. The process includes first reacting a feed gas mixture of carbon monoxide and steam in the presence of a precious metal catalyst on a structural support, yielding a resultant gas, and then reacting the resultant gas in the presence of a non-precious metal catalyst on a support medium. The reactor vessel includes a chamber having an inlet duct and an outlet. A structural support having the precious metal catalyst is positioned upstream of the non-precious metal catalyst positioned within the chamber. The structural support may be positioned within the inlet duct or within the chamber. The support medium may be a granular medium or a structural support.

Owner:AIR PROD & CHEM INC

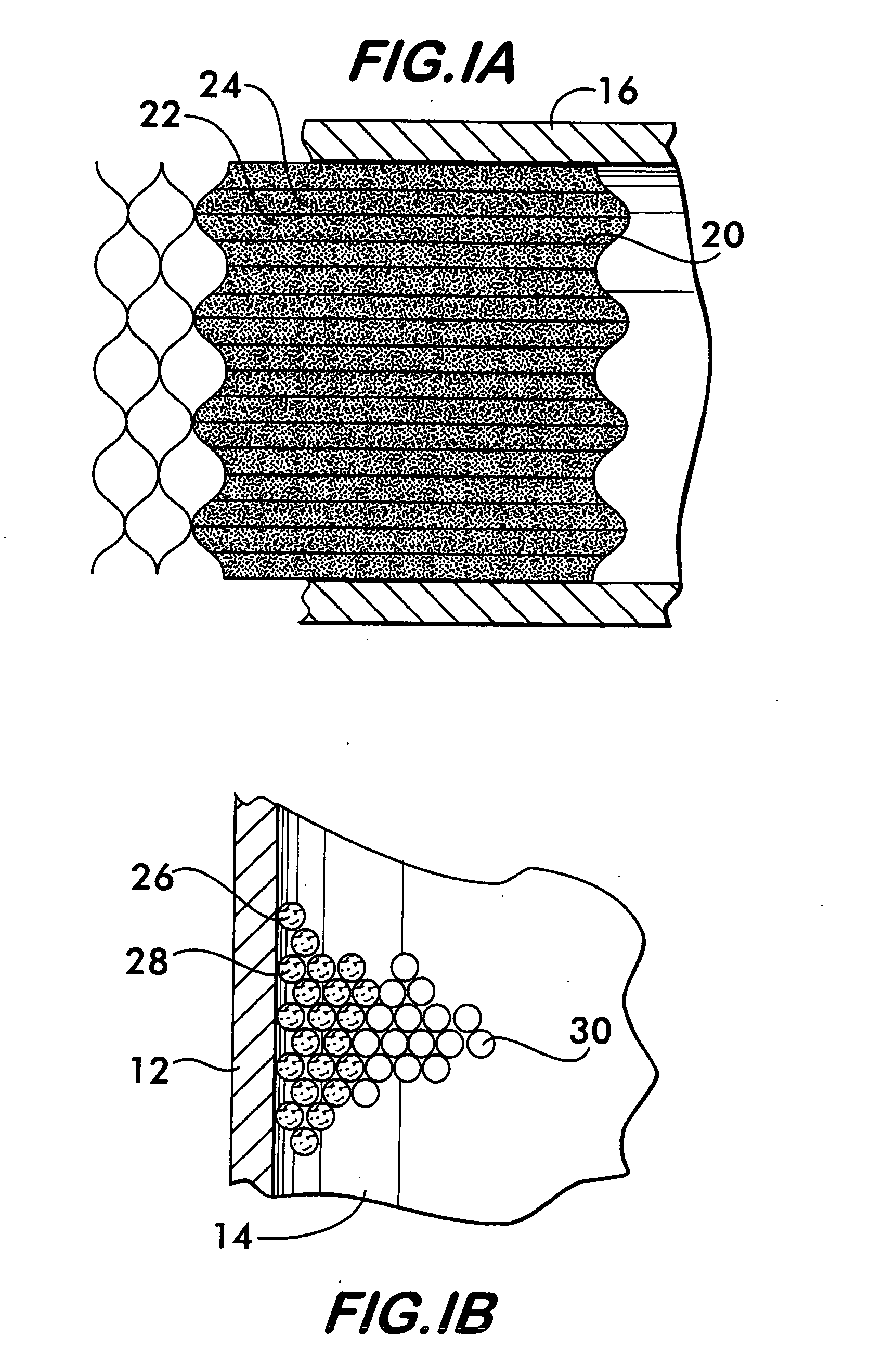

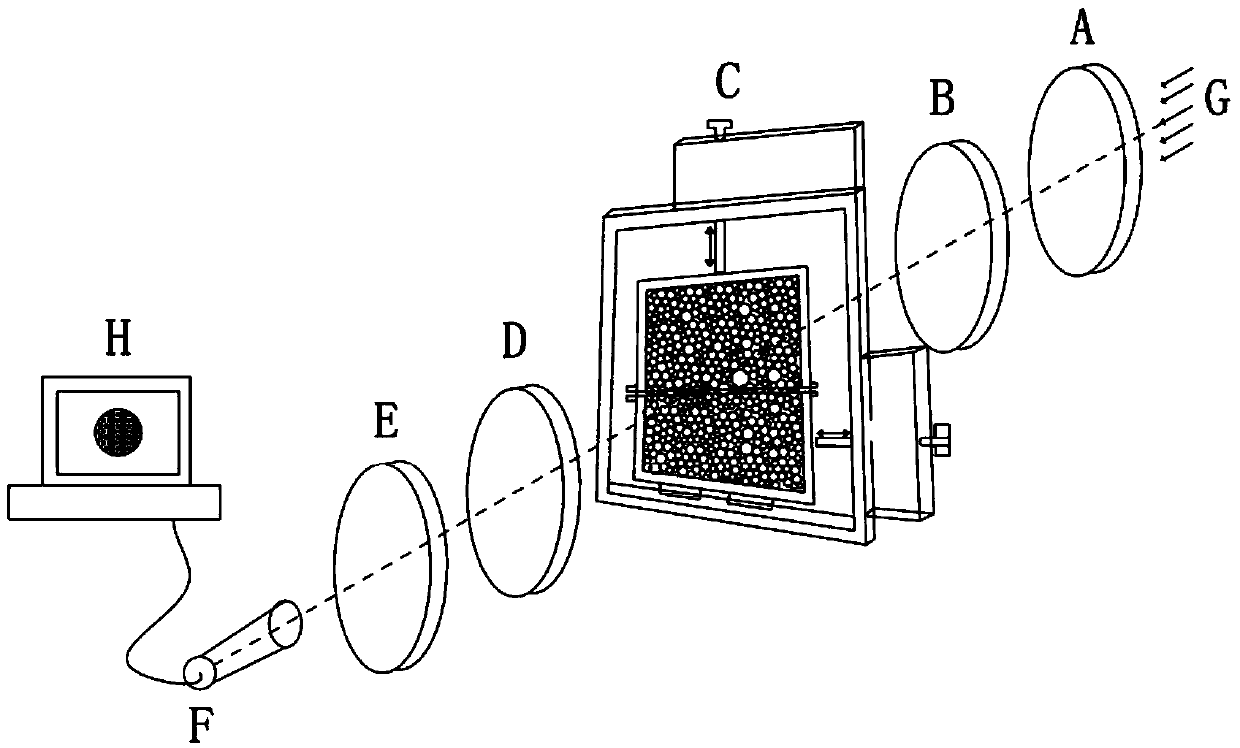

Visualization testing method and device for granular material mechanics experiment

InactiveCN103630441AHigh transparencyIntuitive visualization of medium characteristic testMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesSize changePolarizer

The invention discloses a visualization testing method and device for a granular material mechanics experiment. The method comprises the following steps: putting luminous millimeter-sized granules into a visualization loading device capable of applying a compression / shear load; starting a light source to propagate light emitted by the light source along a polarizer, a quarter-wave plate, the visualization loading device, a quarter-wave plate, an analyzer and a camera in sequence; and applying the compression load, the shear load or the combination of the compression load and the shear load to the granules according to corresponding experimental requirements. In a loading process, fringes which are alternately dark and bright are formed in an image acquired by the camera; according to a stress-optical law, the size change of the stresses at different positions in the millimeter-sized granules can be directly observed through the density of the fringes or the light intensity; and after the image acquired by the camera is processed, the stress distribution in granular media can be identified and metered, and the contact stress between the granules, the thickness and angle of shear bands in the granular media and the distribution and trend of mechanical chains can be visualized.

Owner:SOUTH CHINA UNIV OF TECH

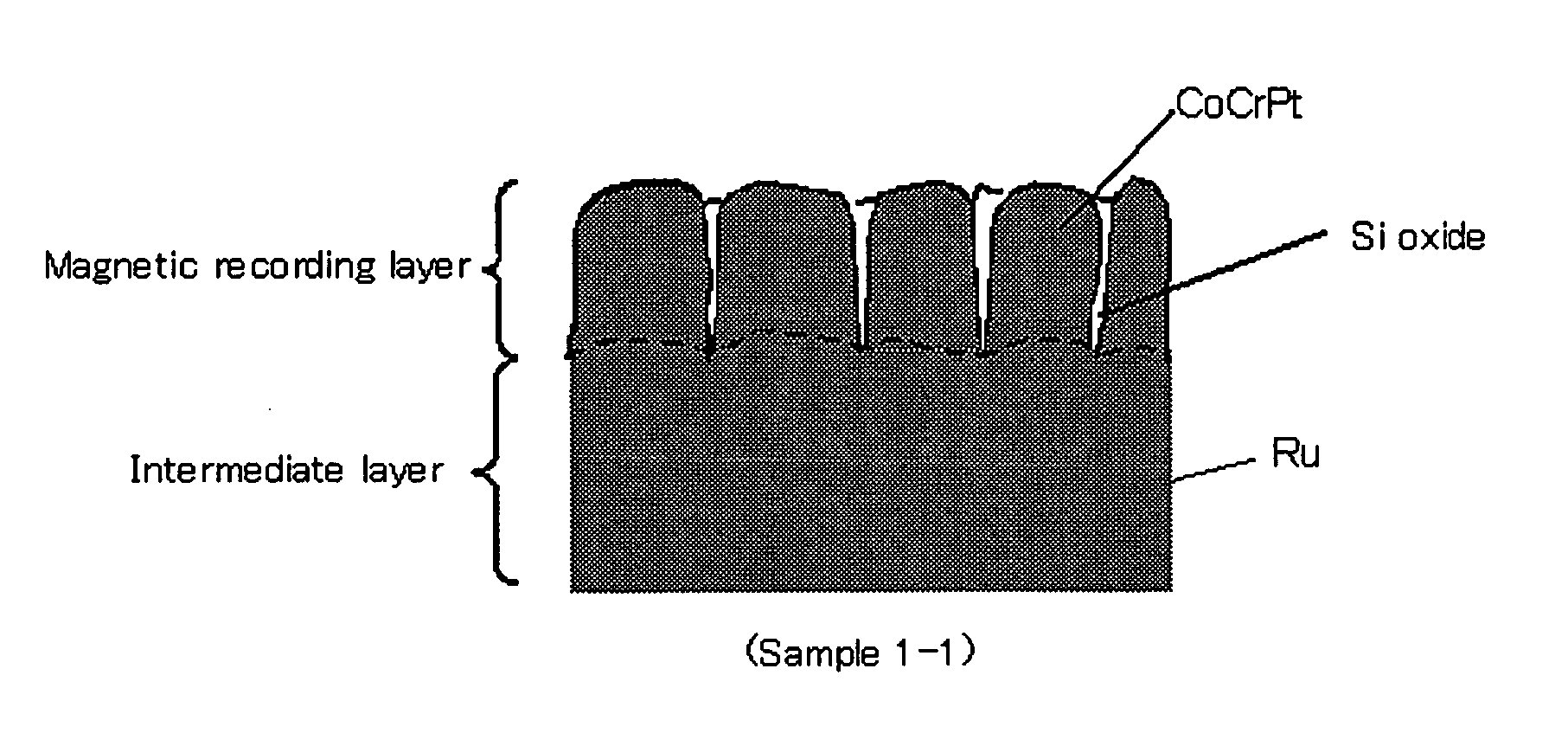

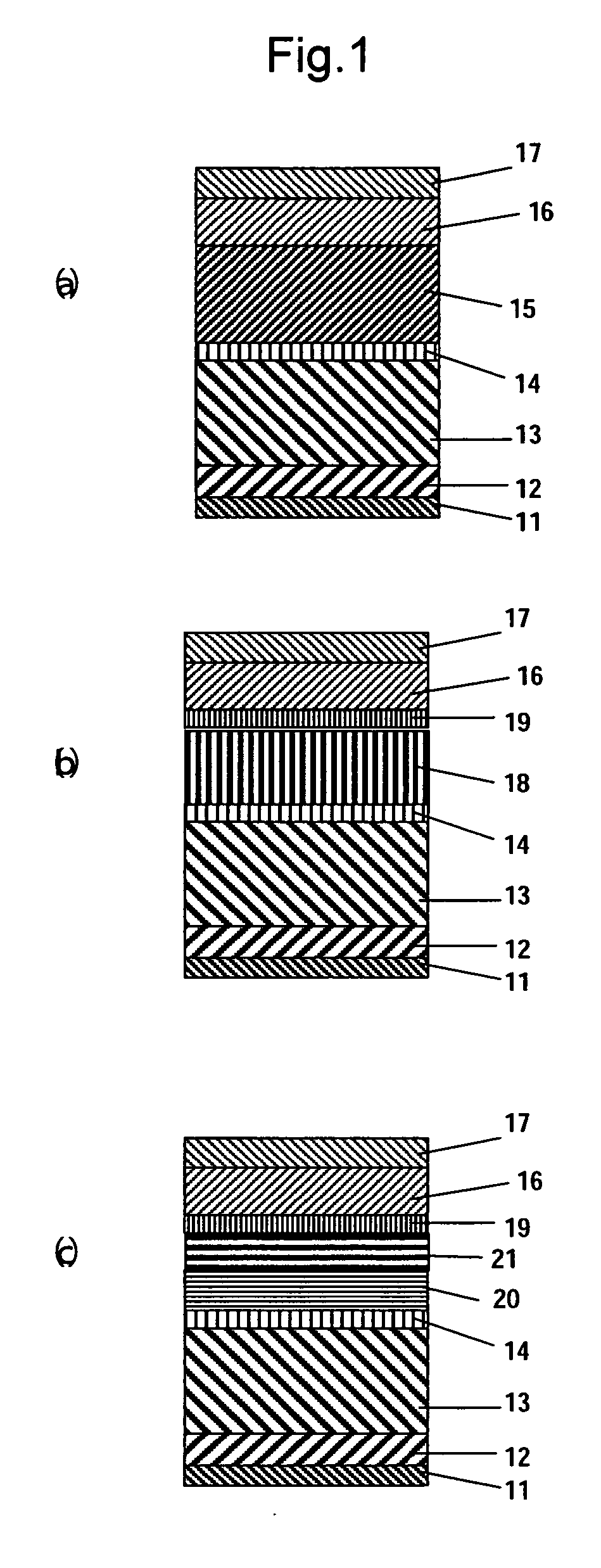

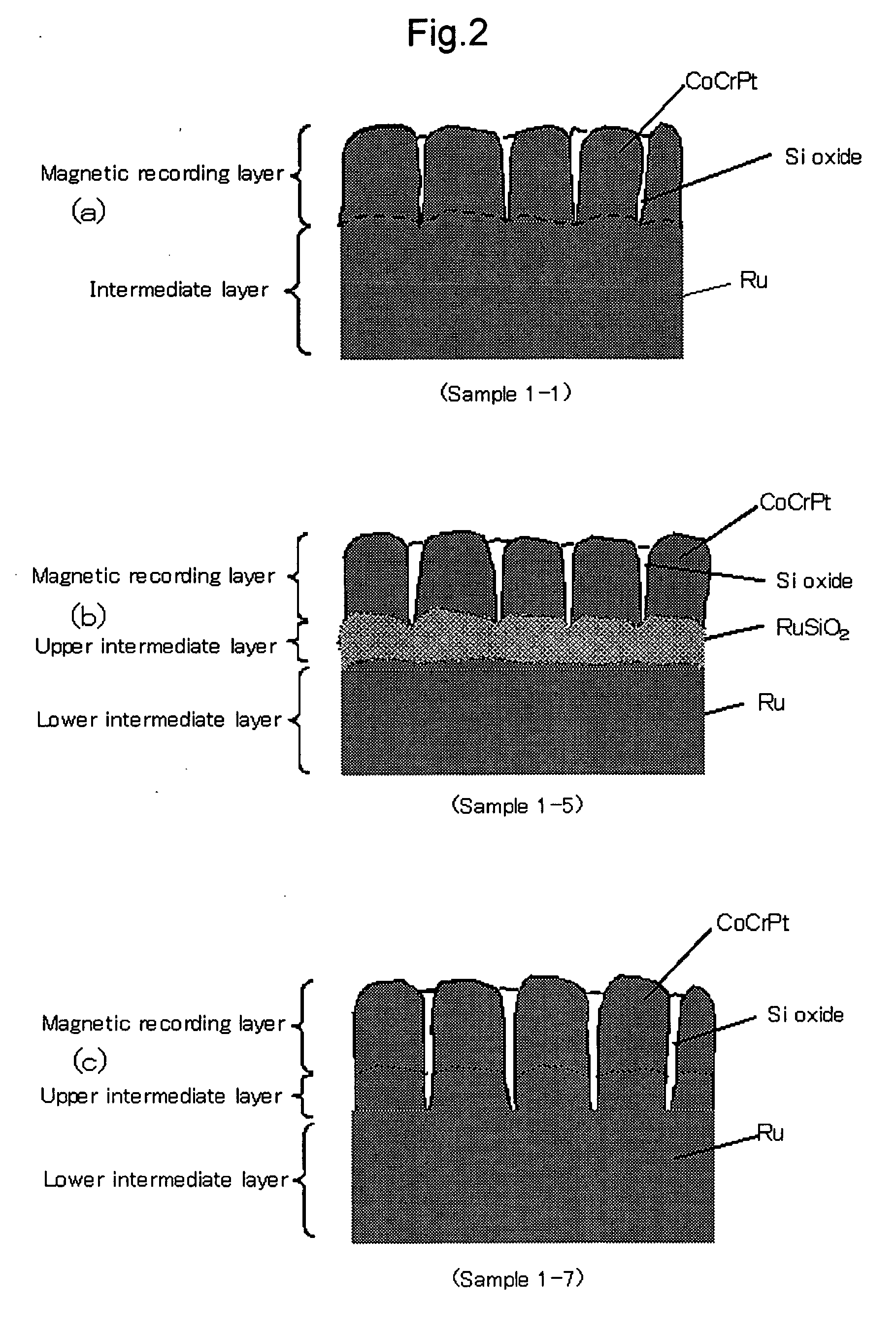

Perpendicular magnetic recording medium and manufacturing of the same

InactiveUS20060057431A1Improve signal-to-noise ratioReduce couplingBase layers for recording layersVacuum evaporation coatingRecording densityRecording layer

Embodiments of the embodiment are directed to reducing the inter-granular exchange coupling of an oxide granular medium and obtaining a high media S / N value, resulting in an areal recording density greater than 23 gigabits per square centimeter or more being achieved. In one embodiment, a magnetic recording medium comprises a structure laminating a soft-magnetic underlayer, a lower intermediate layer including Ru, an upper intermediate layer consisting of Ru crystal grains and oxide crystal grain boundaries, a magnetic recording layer consisting of crystal grains and oxide crystal grain boundaries, in order, on a substrate, growing crystal grains of the magnetic recording layer epitaxially on the Ru crystal grains of the upper intermediate layer, and growing the crystal grain boundaries of the magnetic recording layer on the crystal grain boundaries of the upper intermediate layer.

Owner:WESTERN DIGITAL TECH INC

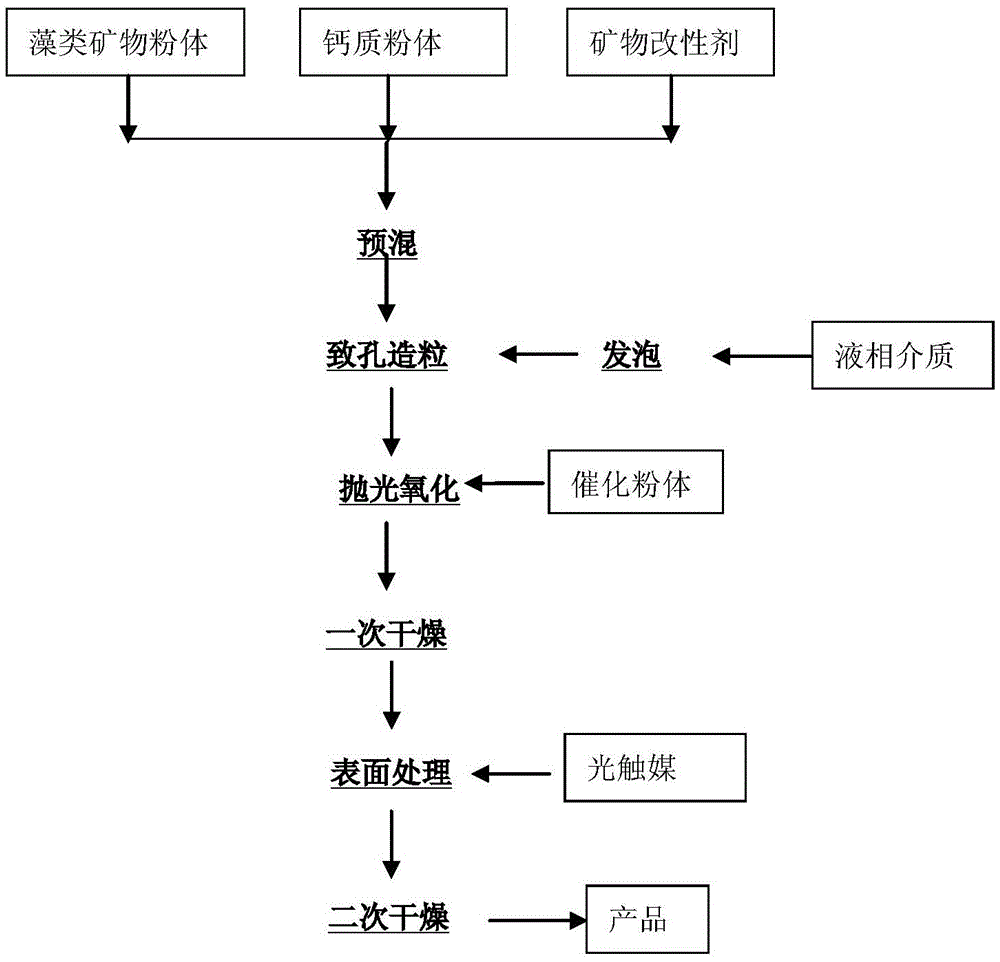

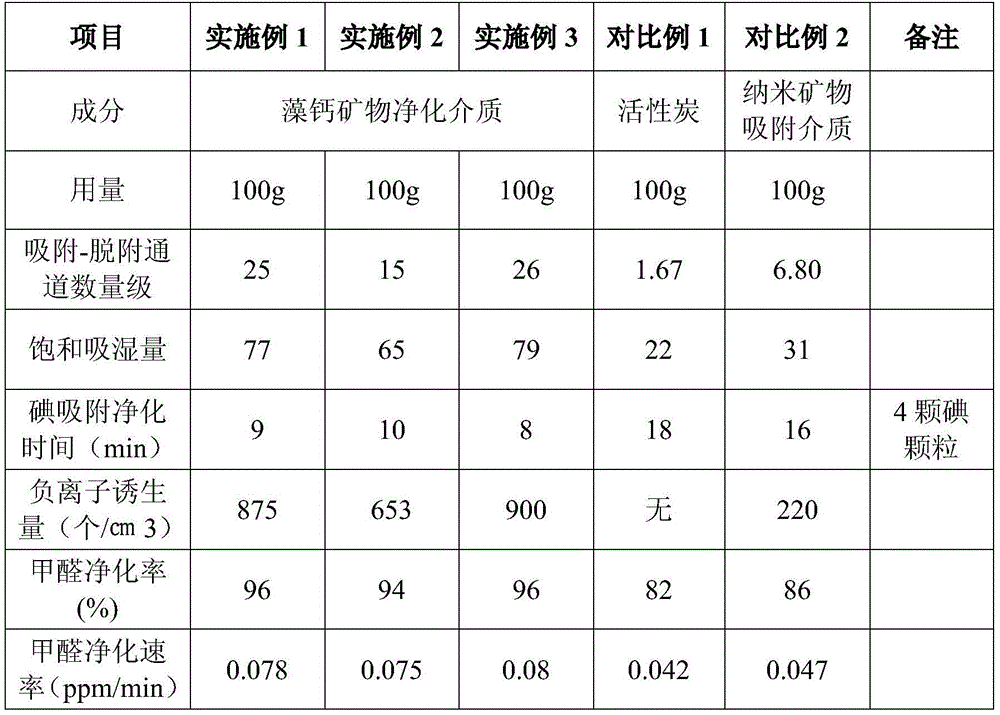

Alga-calcium-mineral air purification medium and preparation method and application thereof

ActiveCN105413629ADeodorantAldehyde removalGas treatmentOther chemical processesCalcium in biologyMildew

The invention provides an alga-calcium-mineral air purification medium. The air purification medium is mainly prepared from, by weight, 42-48.44 parts of alga mineral powder, 4.2-9.8 parts of calcium powder, 0.8-1.2 parts of catalysis powder, 2.4-3.0 parts of mineral modifiers, 36-48 parts of liquid-phase media and 1.5-1.8 parts of photocatalyst. The raw materials are subjected to pre-stirring, hole forming and granulating, polishing and oxidation, primary drying, photocatalyst surface treatment and secondary drying to form particle medium carriers. The air purification medium has the advantages that the absorption-catalysis-purification performance is outstanding, the preparation process is mild and free of rigorous requirements, product application is flexible, and an air purification device with de-odoring, deodorization, taste removal or bacteria resistance and mildew-proof functions by applying appropriate matched application components.

Owner:湖北格林森绿色环保材料股份有限公司

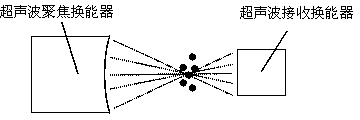

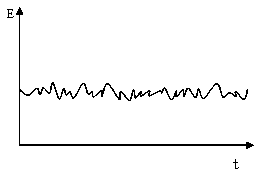

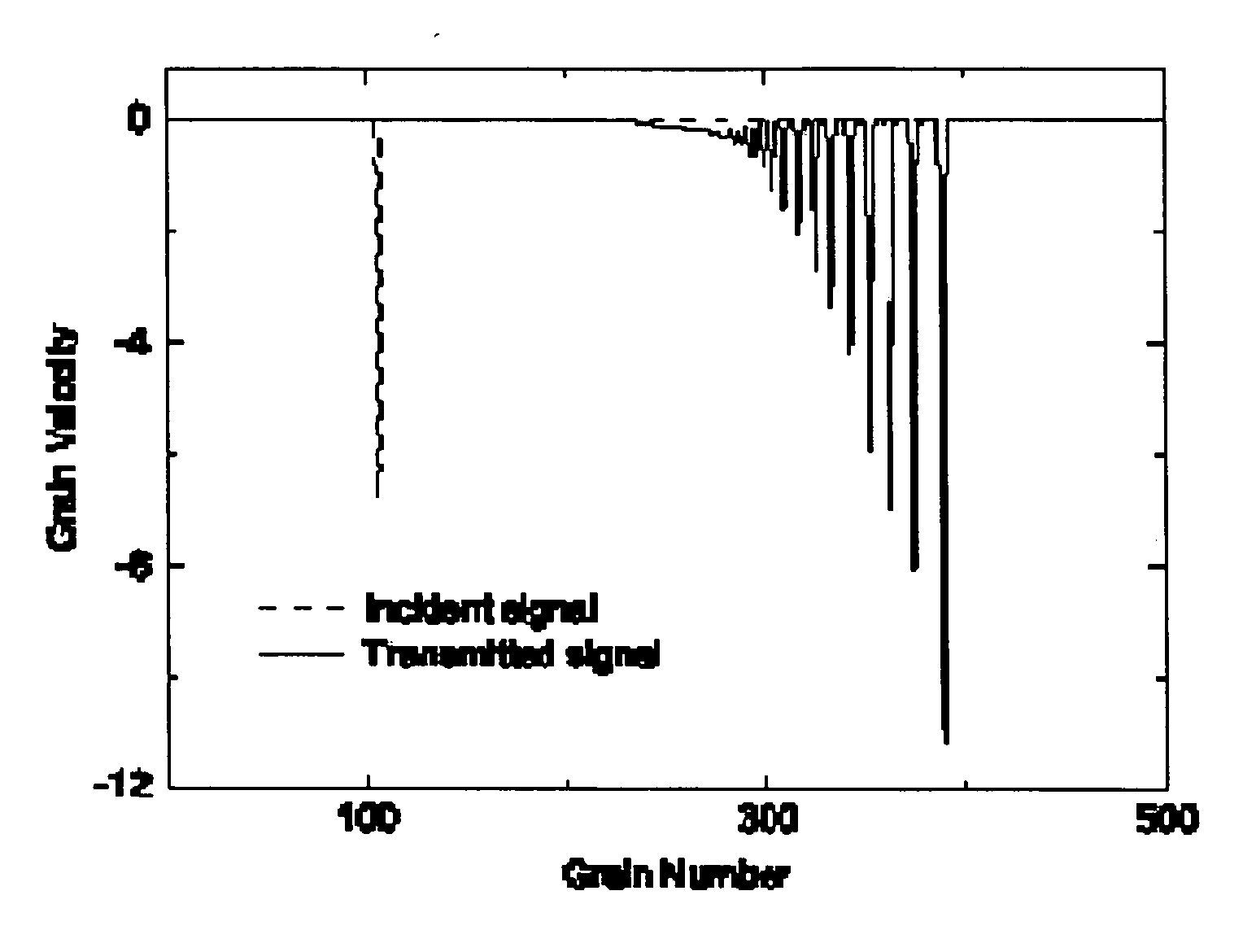

Method for measuring particle diameter and concentration based on ultrasonic pulsation principle

InactiveCN103983549ASimple structureSmall structureParticle size analysisParticle suspension analysisSonificationBeam diameter

The invention relates to a method for measuring particle diameter and concentration based on an ultrasonic pulsation principle. A transmitted acoustic intensity is attenuate when an incidence ultrasonic wave is scattered and absorbed through a granular medium; focused ultrasound is adopted and a measurement area is arranged in an ultrasonic focused acoustic beam band; when a ratio of the particle diameter to ultrasonic focused acoustic beam diameter is controlled within a scope of 0.1-20, quantity and diameters of particles passing the acoustic beam vary with time, and transmitted acoustic intensity fluctuates and varies with time, to generate an acoustic pulse effect; random pulsation of the ultrasonic signal is related to quantity and diameters of particles in the ultrasonic focused acoustic beam measurement area at the moment of measuring; a random variation sequence of the transmitted ultrasonic intensity is measured and is calculated and analyzed, therefore, average particle diameter and concentration of particles are calculated through the ultrasonic pulsation principle. The method disclosed by the invention can realize online measurement; the method is applicable to laboratory scientific research, and is specifically applicable to the industrial field.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

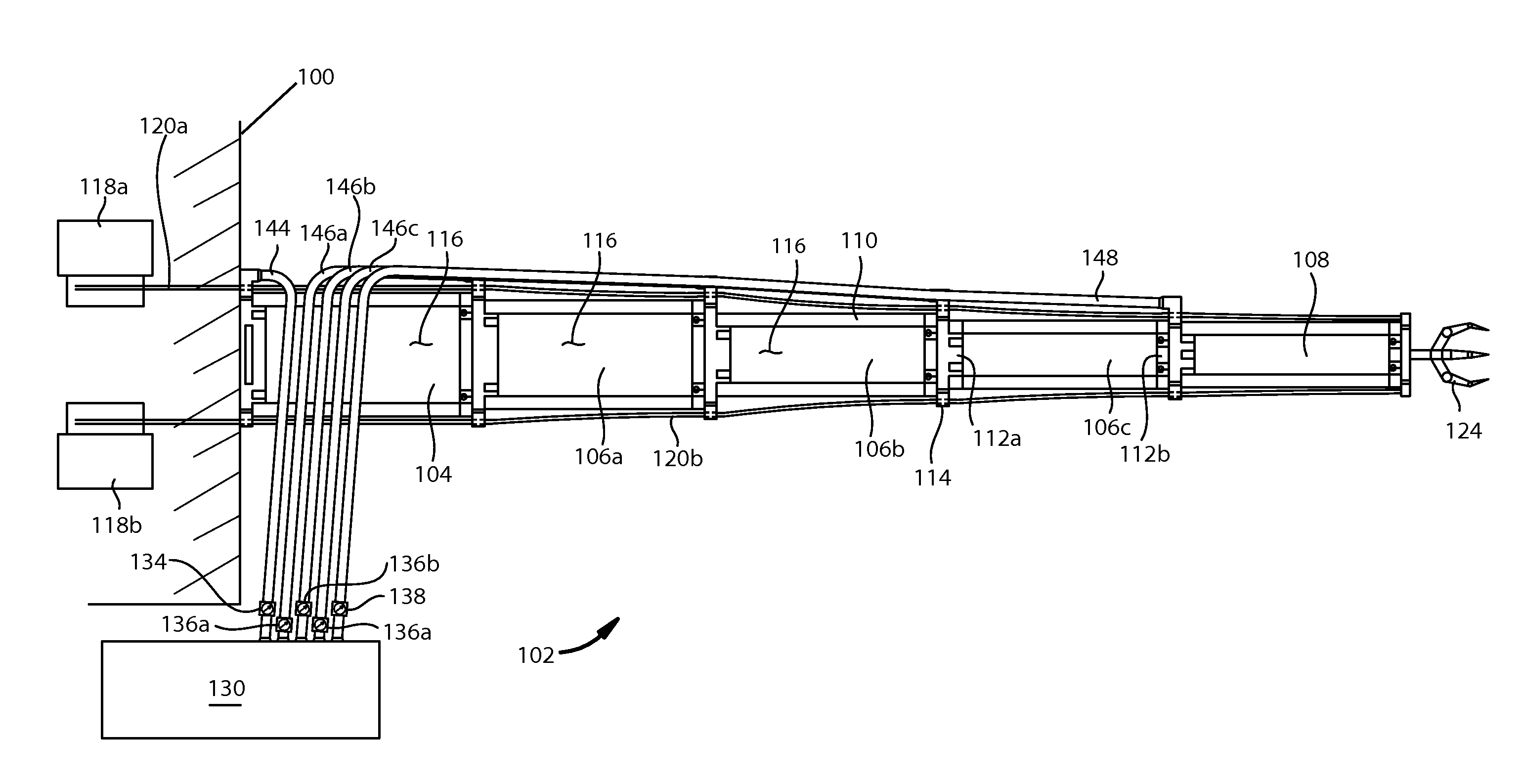

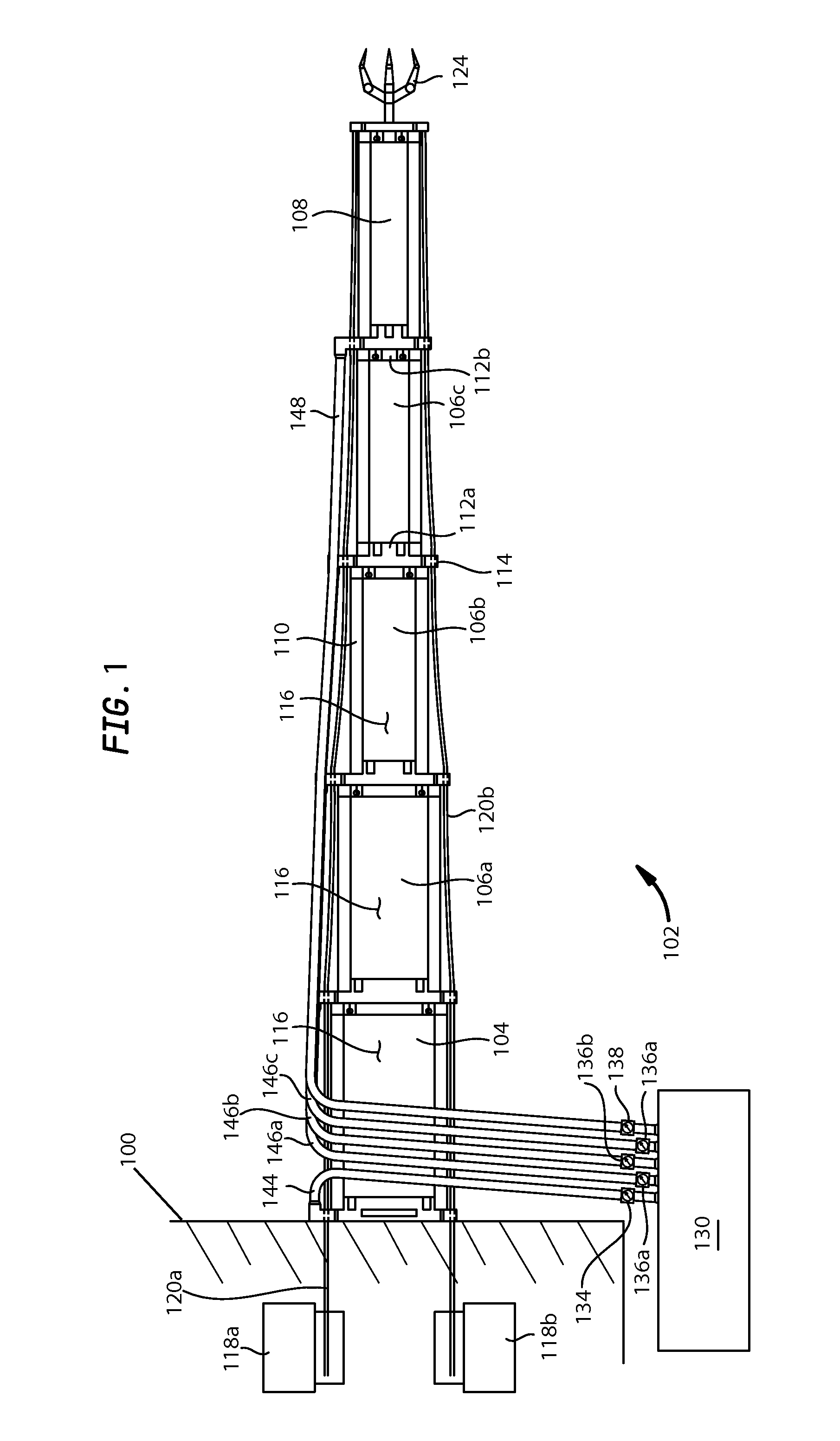

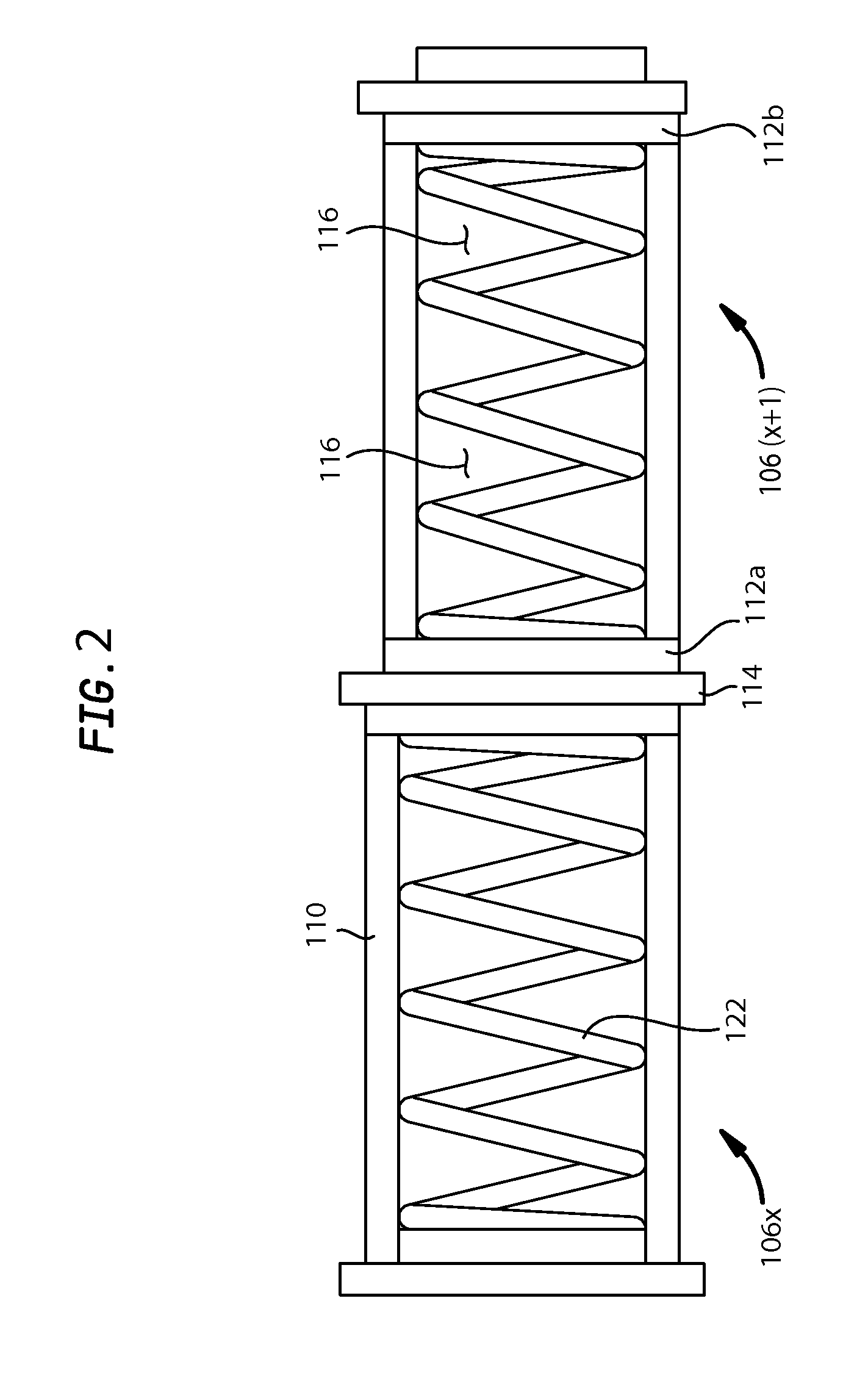

Continuum style manipulator actuated with phase change media

ActiveUS20150141756A1High strengthSpeed up the flowProgramme-controlled manipulatorMechanical apparatusEngineeringFriction angle

A continuum style manipulator is actuated by jammable media within an envelope of a module, which is also actuated by a tensile element, such as a cable and spooler motor. Multiple modules may be reversibly added. Two or more tensile elements may also be used. Three or more actuated tensile elements can actuate three DOFs of each module, and the terminal module, as well as the entire manipulator. Jammable media may be granular, actuated by a pressure change. Coarsely ground coffee works well. Rather than a jammable media, tensile elements may alternatively be used with other phase change media, such as magnetorheological and electrorheological media. A high friction angle of the granular media is desirable, and has been achieved with a particle size dispersion including both small and relatively larger particles. Applications include endoscopes, proctoscopes, laparoscopic instruments, manufacturing and medical manipulators. Methods of actuating include unjamming all modules, positioning the manipulator with tensile elements or otherwise, jamming the base-most module, and then repositioning remaining, not-jammed modules, followed by jamming the base-most not-jammed module, and so on, until all modules are positioned and jammed.

Owner:MASSACHUSETTS INST OF TECH

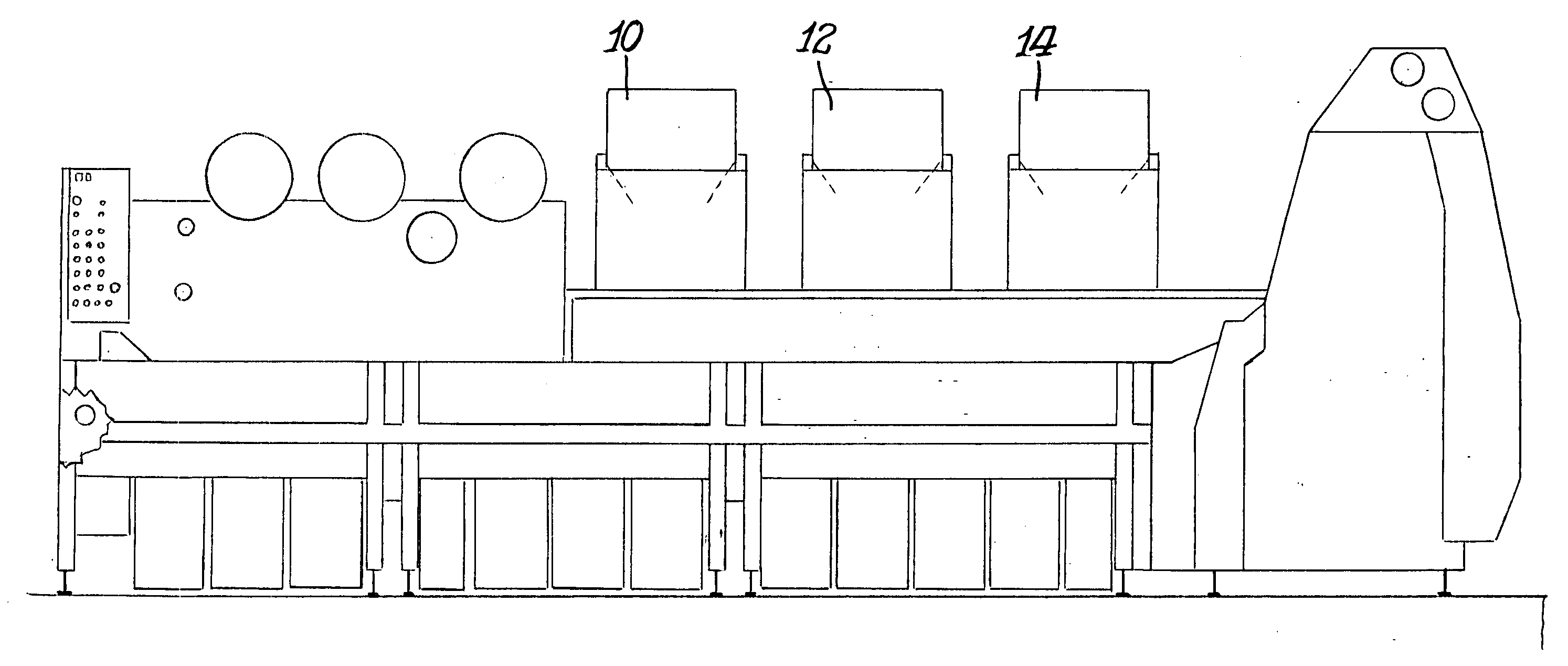

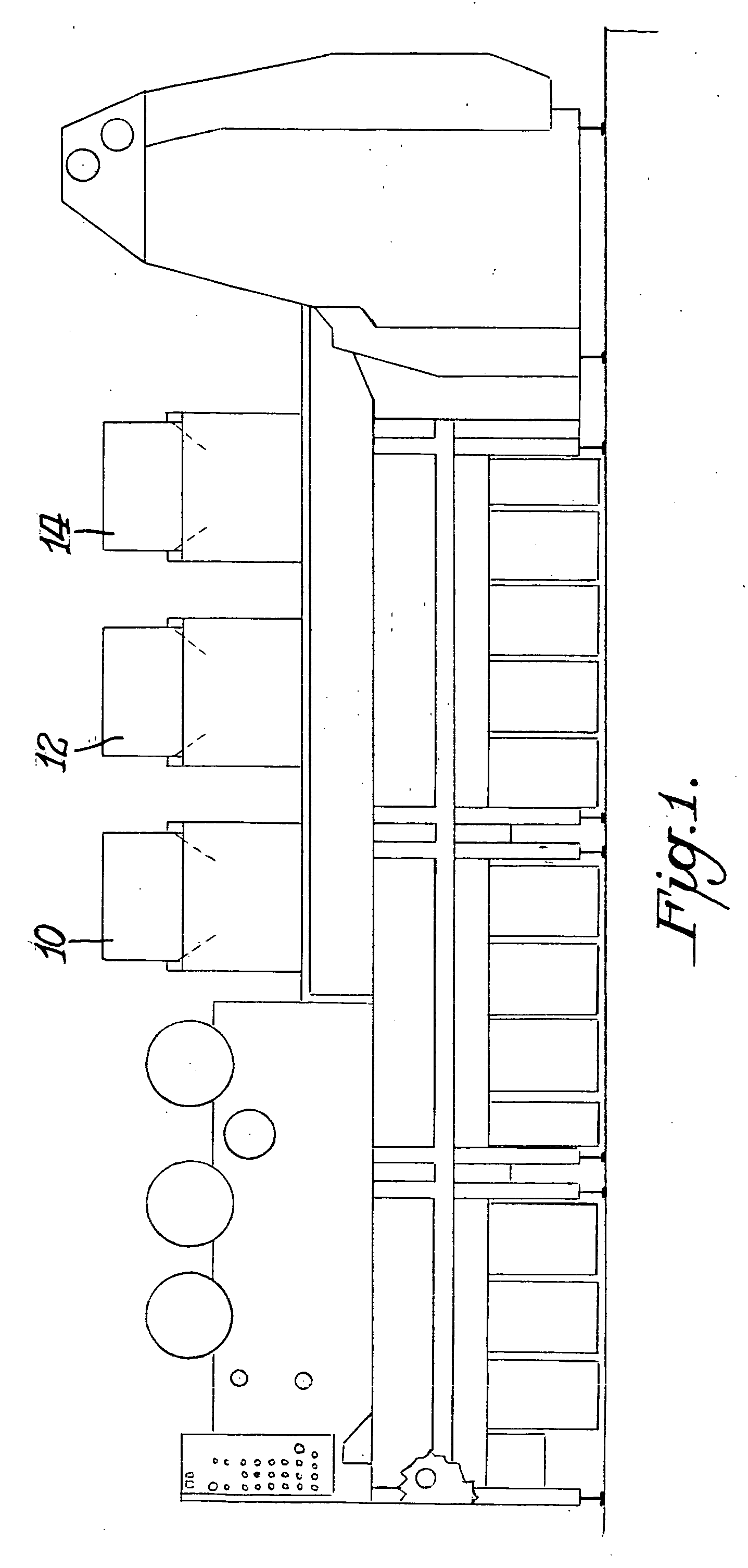

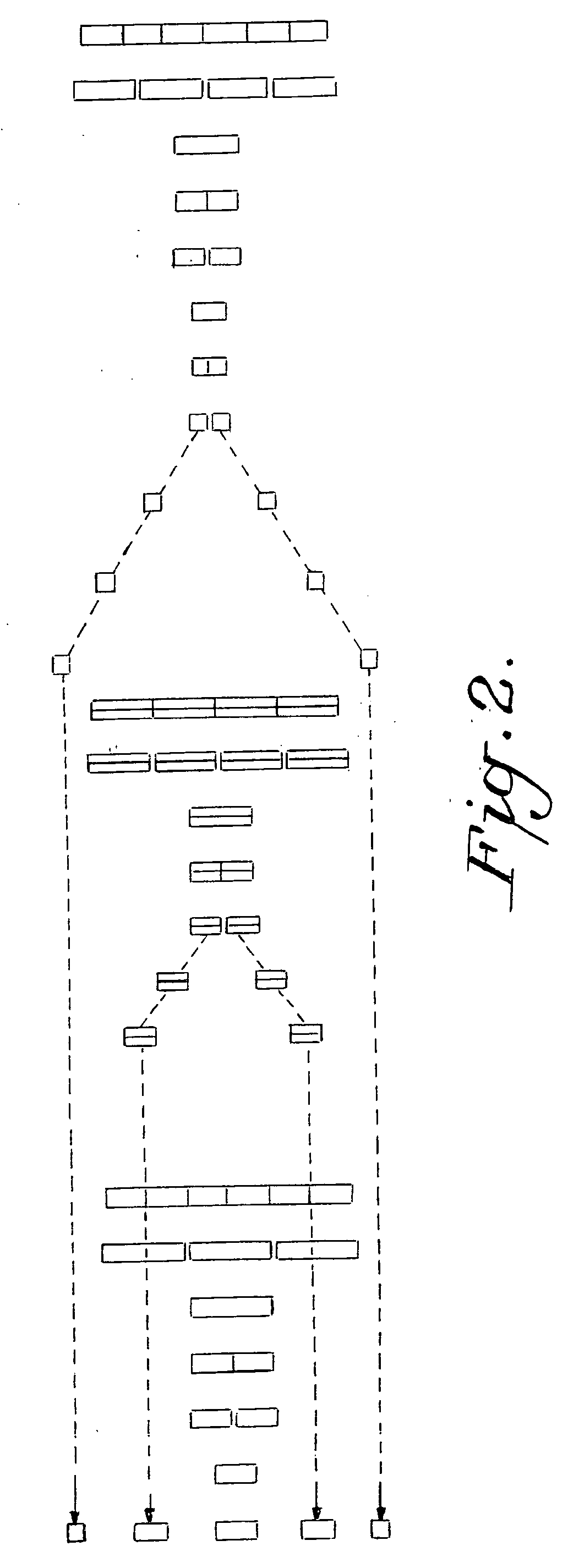

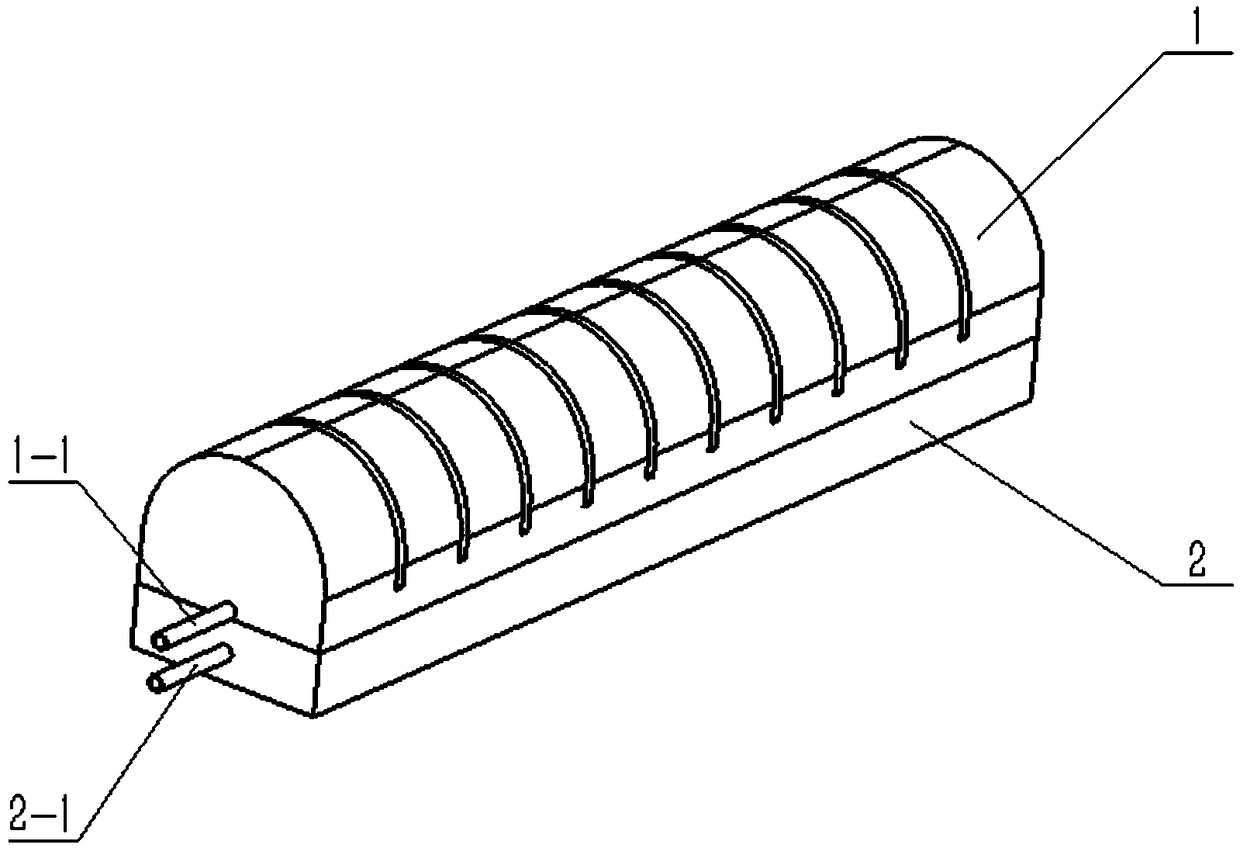

Triple hopper max with built-in granulated cavity filling capability

InactiveUS20060196513A1Reduce in quantityIncrease costCigar manufacturePaper/cardboard wound articlesEngineeringGranular media

Methods and apparatus for forming smoking products include a triple hopper for forming filter components of multiple sizes. The filter components are partially wrapped, and at a downstream location granular media is dispended onto the partially wrapped components. A cover cap is placed over the partially wrapped components to thereby form a complete wrap. Subsequently, the fully wrapped filter components may be joined to tobacco rods with tipping paper.

Owner:PHILIP MORRIS USA INC

Perpendicular magnetic recording medium having alternatively layered structure of Co alloy and Pt thin film, its production method and apparatus

InactiveUS20050142378A1Excellent effect in information retaining stabilityDecreased SNRRecord information storageCoating by sputteringHigh densityAlloy

Embodiments of the invention provide a granular medium structure and a significant increase of the Ku value of a magnetic material at the same time using a non-metal material, thereby obtaining a magnetic recording medium capable of high density recording. In one embodiment, a magnetic metal grain in a granular magnetic film made of magnetic metal grains and a non-magnetic material is obtained by laminating a ferromagnetic exchange metallic element that contains mainly Co or Fe and a Pt element alternately and the lamination period is set between about 0.35 nm and 0.9 nm, preferably between about 0.4 nm and 0.55 nm.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

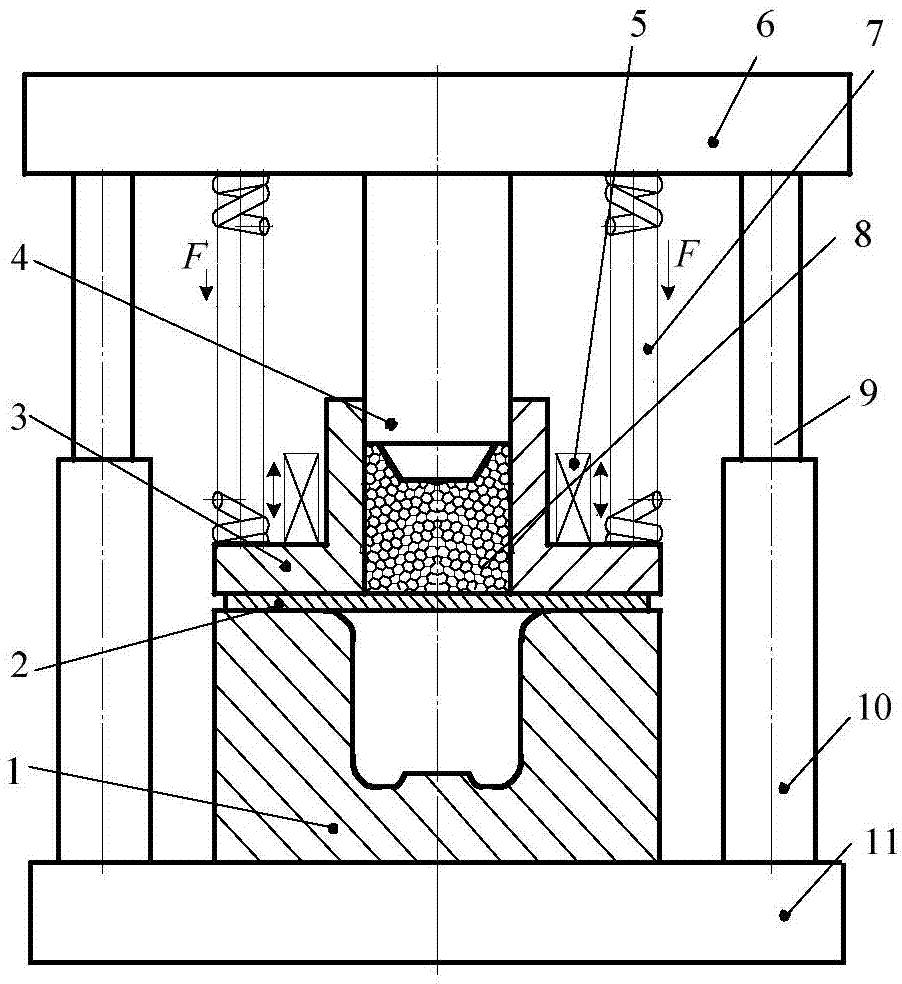

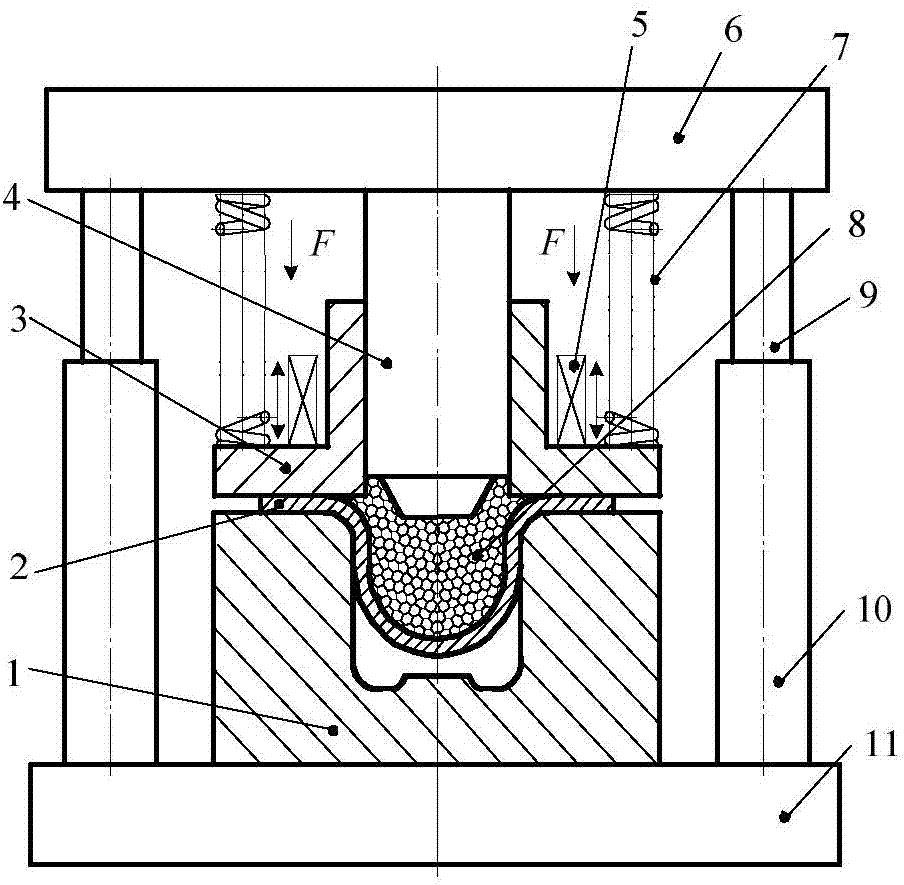

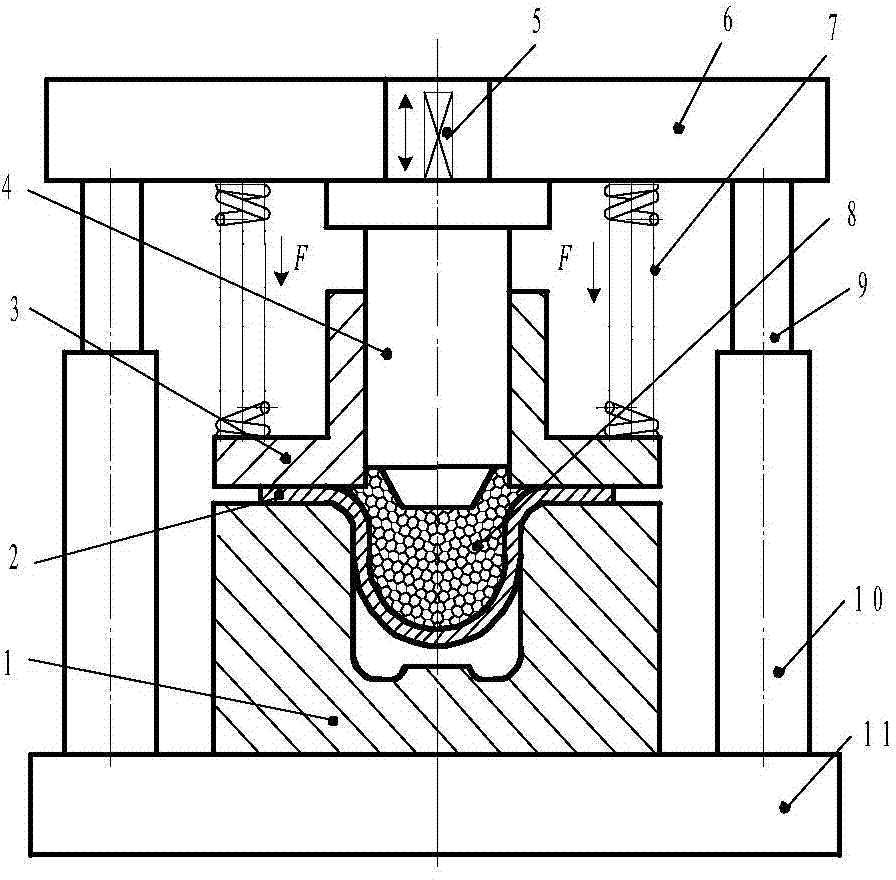

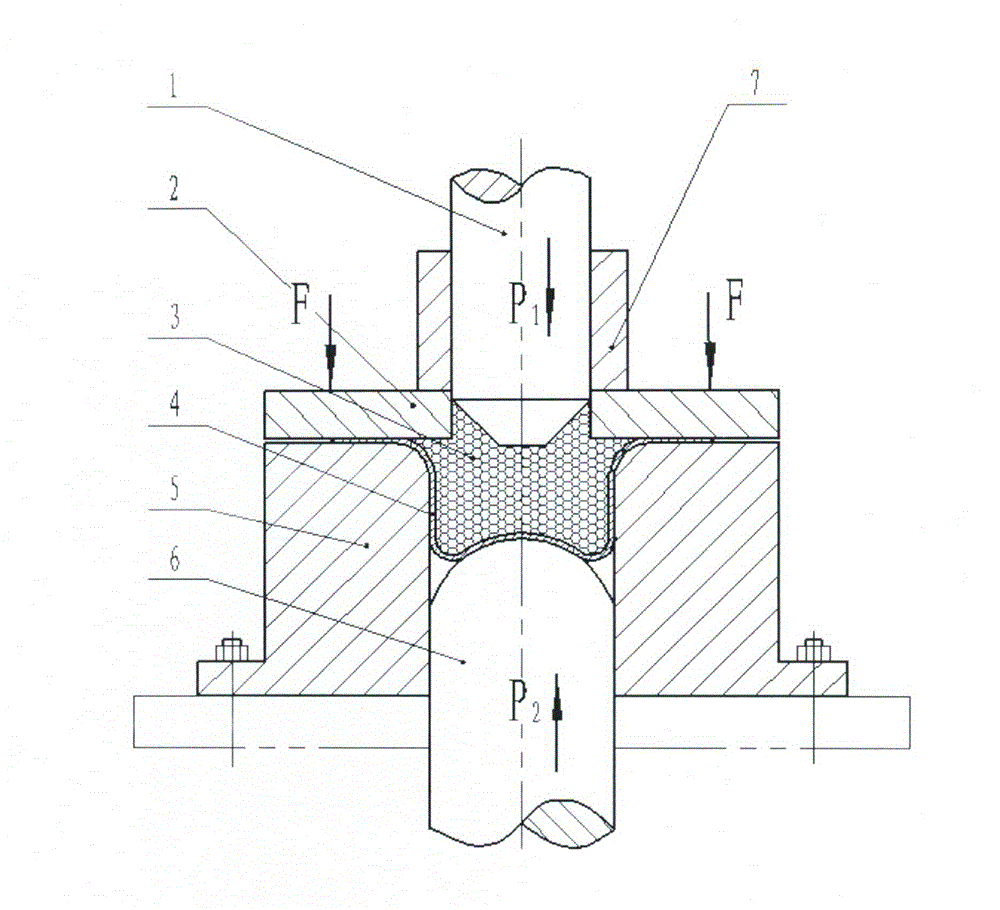

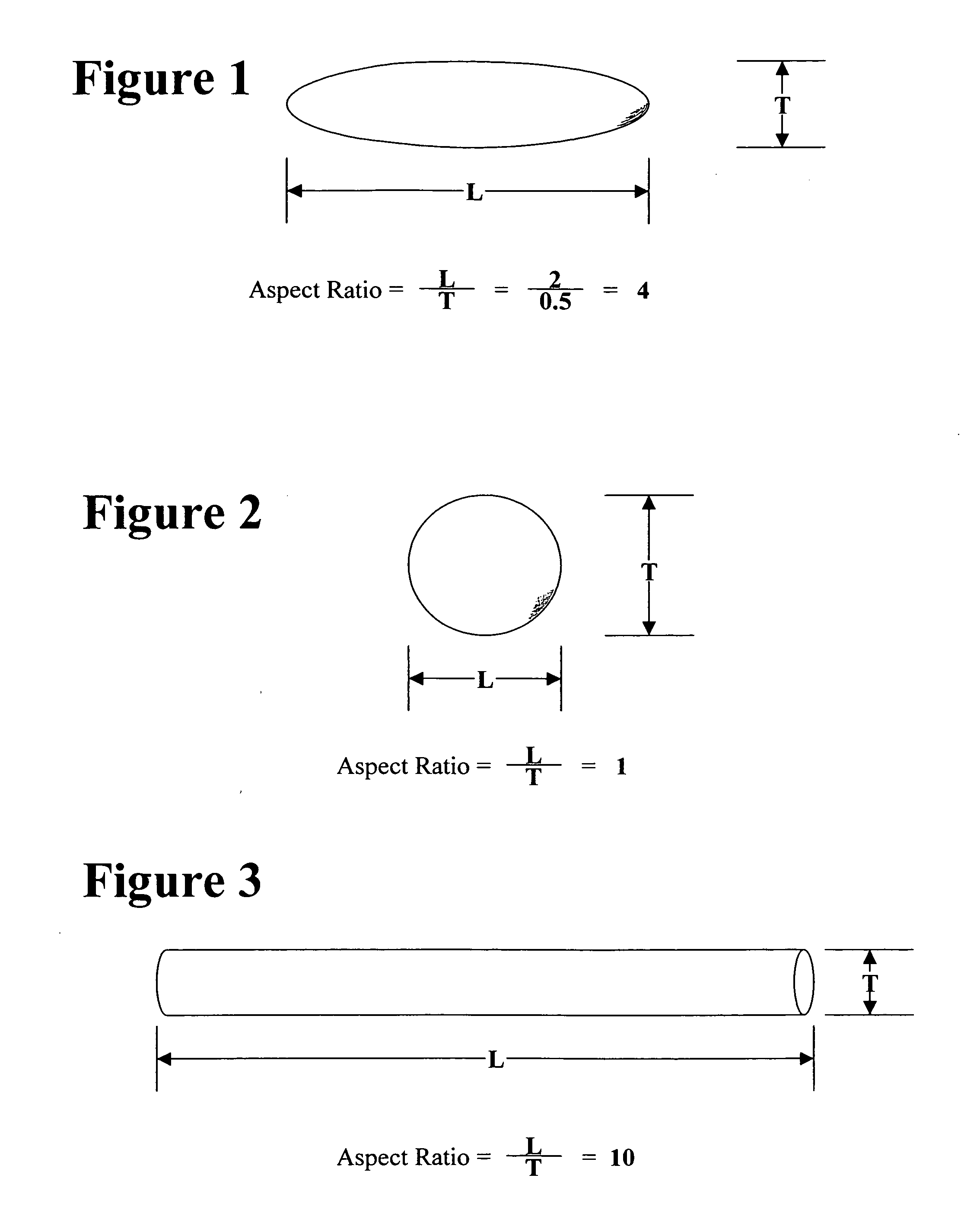

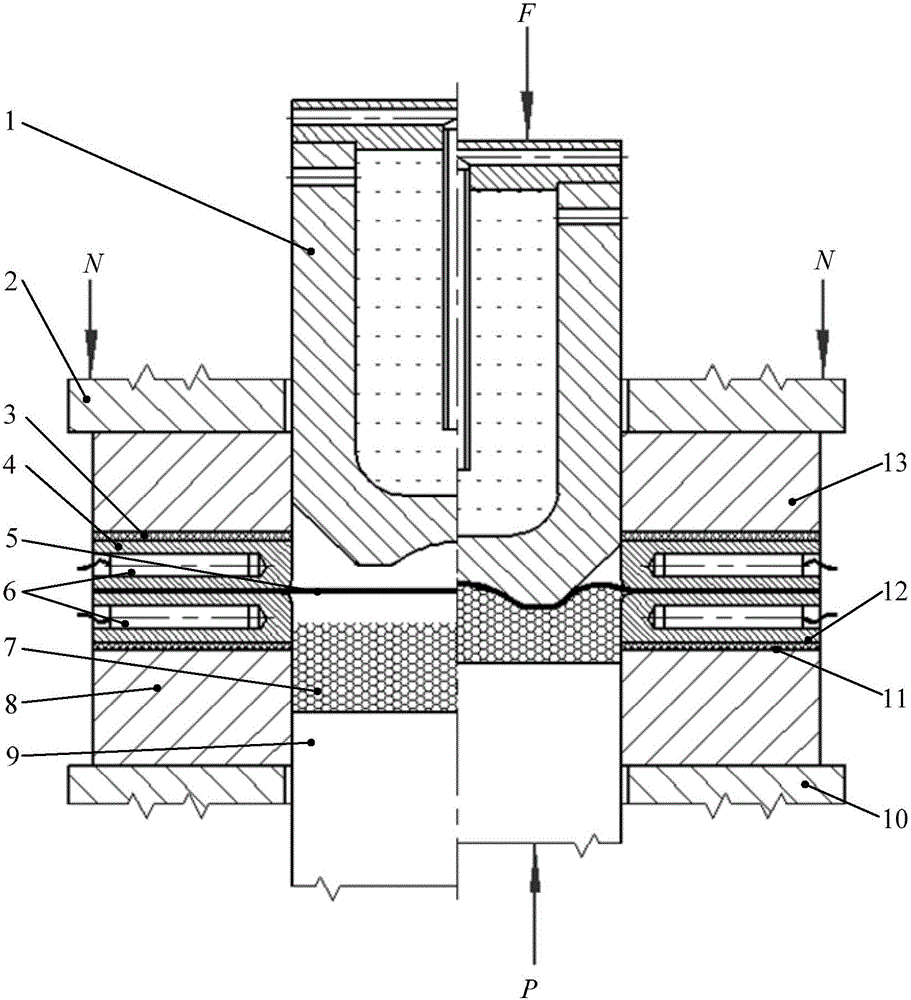

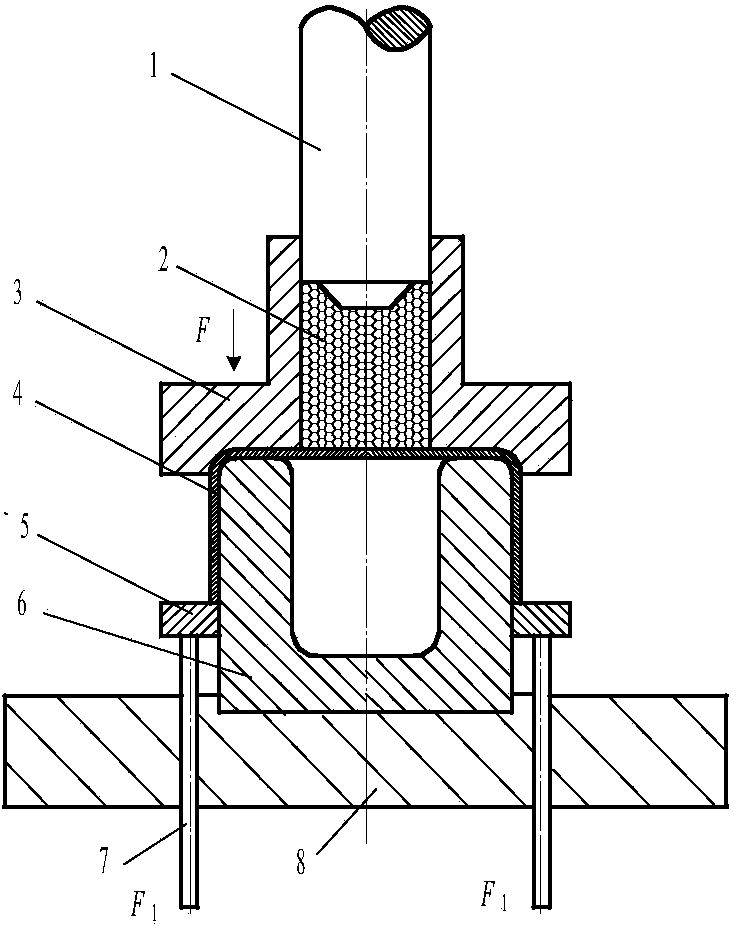

Method for forming plates on basis of vibration by aid of flexible male die

The invention discloses a method for forming plates on the basis of vibration by the aid of a flexible male die. Machining equipment for implementing the method mainly comprises a lower die holder, a female die, a blank holder, granular media, a blank holder force applying device, a vibration device, a punch, an upper die holder, guide columns, guide sleeves and the like. The method includes placing a metal plate between the female die and the blank holder when the metal plate is about to be machined and formed, enabling the blank holder to apply blank holder force, then adding the granular media into a barrel formed by the blank holder and the metal plate, enabling a pressure head to compress the media under the effect of pressure, applying the pressure to the plate and performing deep drawing forming on the plate by the aid of the flexible male die; enabling the vibration device to apply vibration on the punch, the blank holder and the female die individually or jointly. The method has the advantages that friction and deformation resistance among the plate and the dies can be reduced under the effect of vibration excitation, the flowability and the force transfer property of the granular media can be promoted, plate forming limit can be upgraded, and the method is favorable for machining and forming components in complicated shapes; the granular media can be reused, accordingly, the die machining cost and energy consumption can be reduced, and the method is favorable for environmental protection.

Owner:YANSHAN UNIV

Method and die for back-pressure deep drawing of metal plate

Disclosed is a die for deep drawing of a metal plate. The lower end of a concave die of the die is fixed onto a worktable of a press, a back-pressure head is disposed on the lower portion of a cavity of the concave die, the shape of the back-pressure head corresponds to that of a formed part, a blank holder is disposed on the concave die, the upper portion of the blank holder is a feeding barrel for containing solid granular media, and a punch is disposed on the granular media in the feeding barrel. During deep drawing, the metal plate is placed on the upper surface of the concave die, the lower surface of the plate simultaneously contacts with the back-pressure head, bland pressing force is applied to the blank holder, the solid granular media are added into the barrel, the punch moves downwards so that the solid granular media generate forming pressure, back pressure is simultaneously applied to the back-pressure head below the metal plate, the back pressure is lower than the pressure of the punch, and the process is carried out until the plate deforms to have a required forming height; and then the punch and the blank holder return, the back-pressure head is jacked up, and a workpiece is unloaded. The die is simple in structure, the wall thickness difference of the formed part is obviously reduced, the plate part can be deeply drawn at one step, sealing is omitted, pollution is prevented, and the granular media can be recycled.

Owner:YANSHAN UNIV

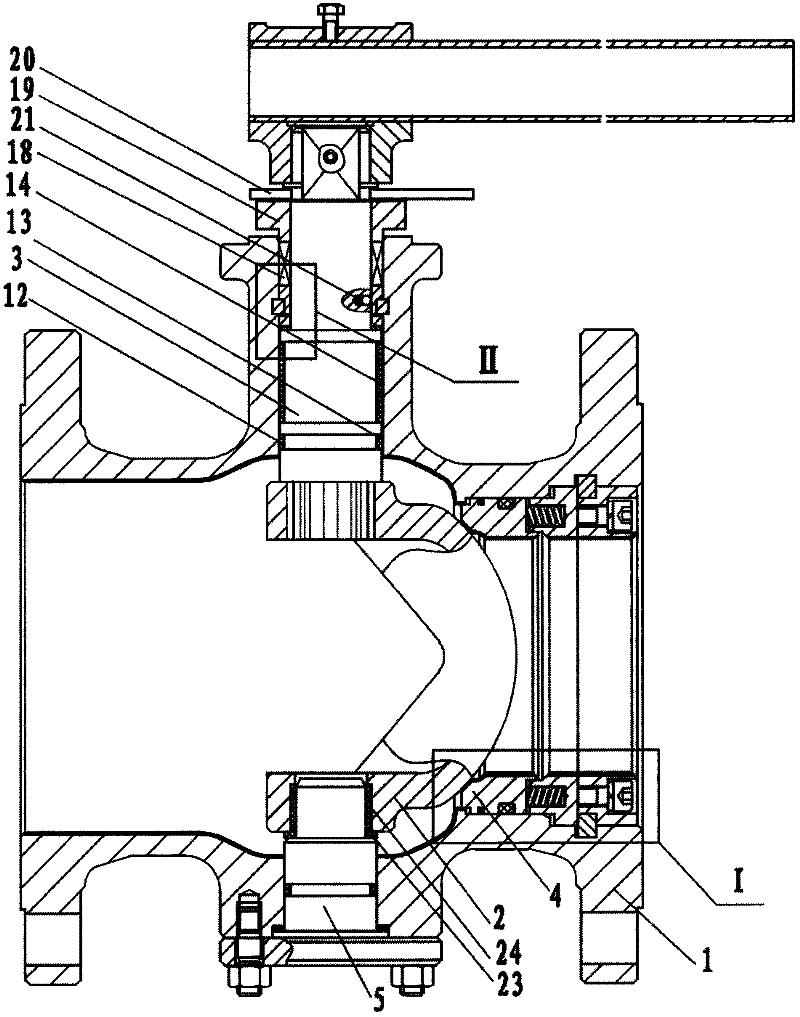

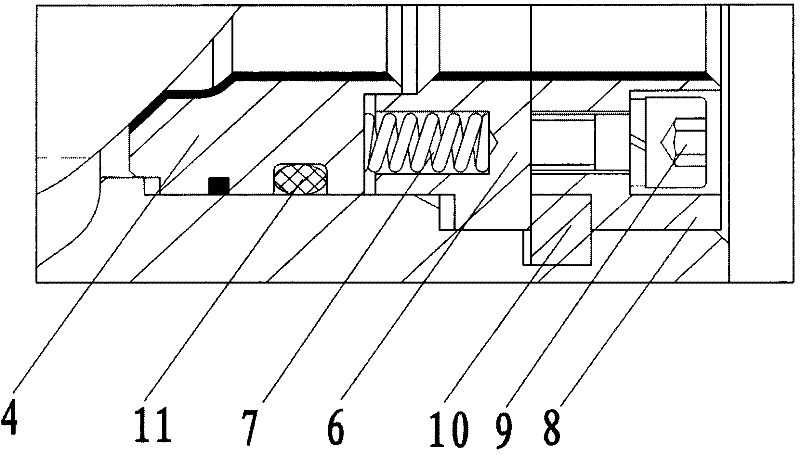

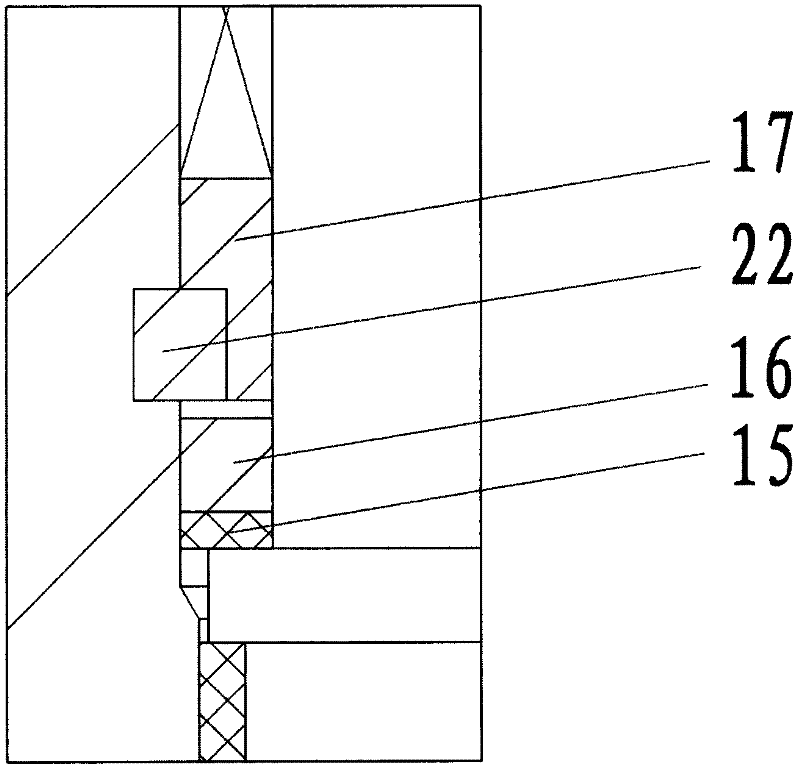

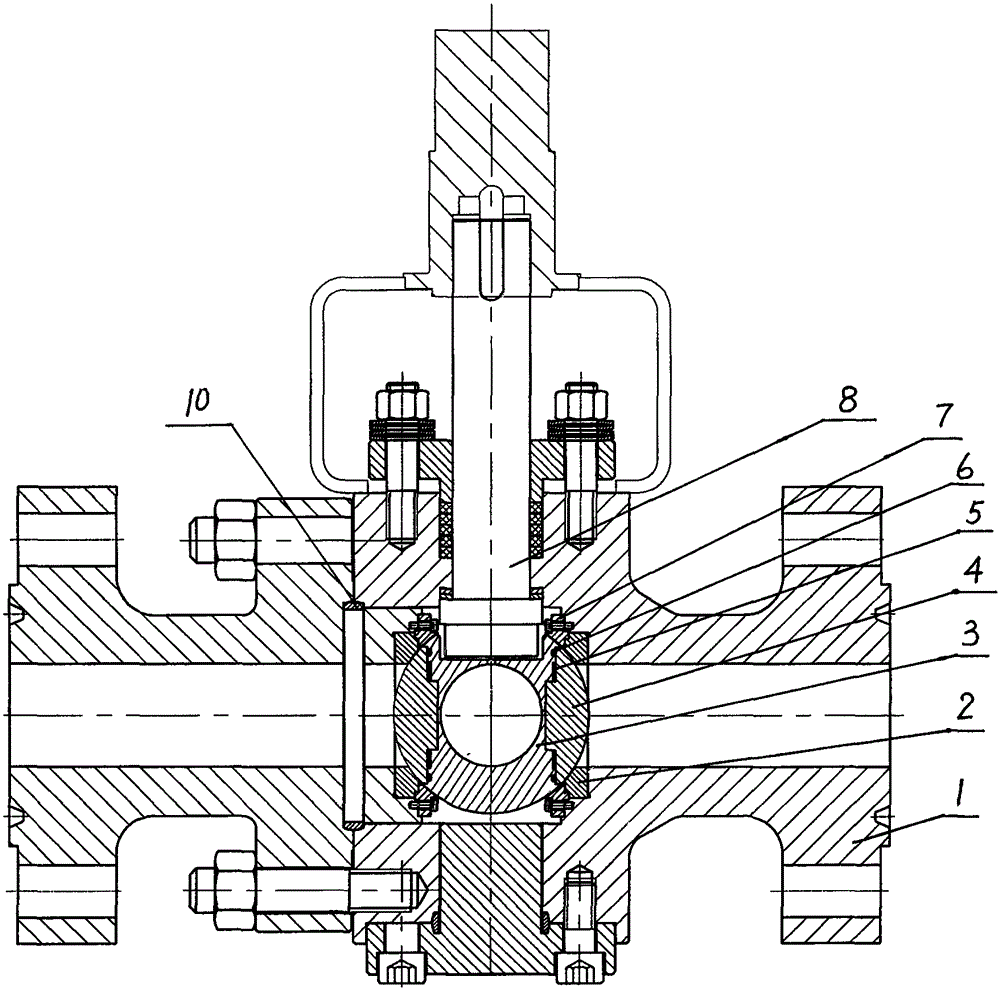

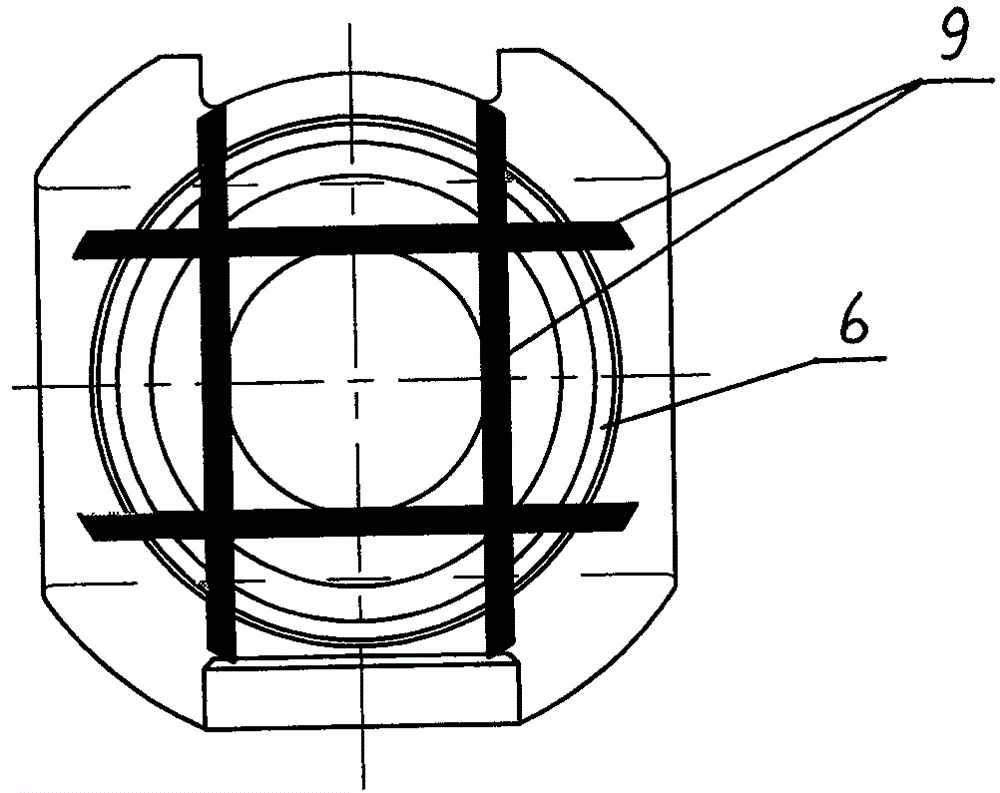

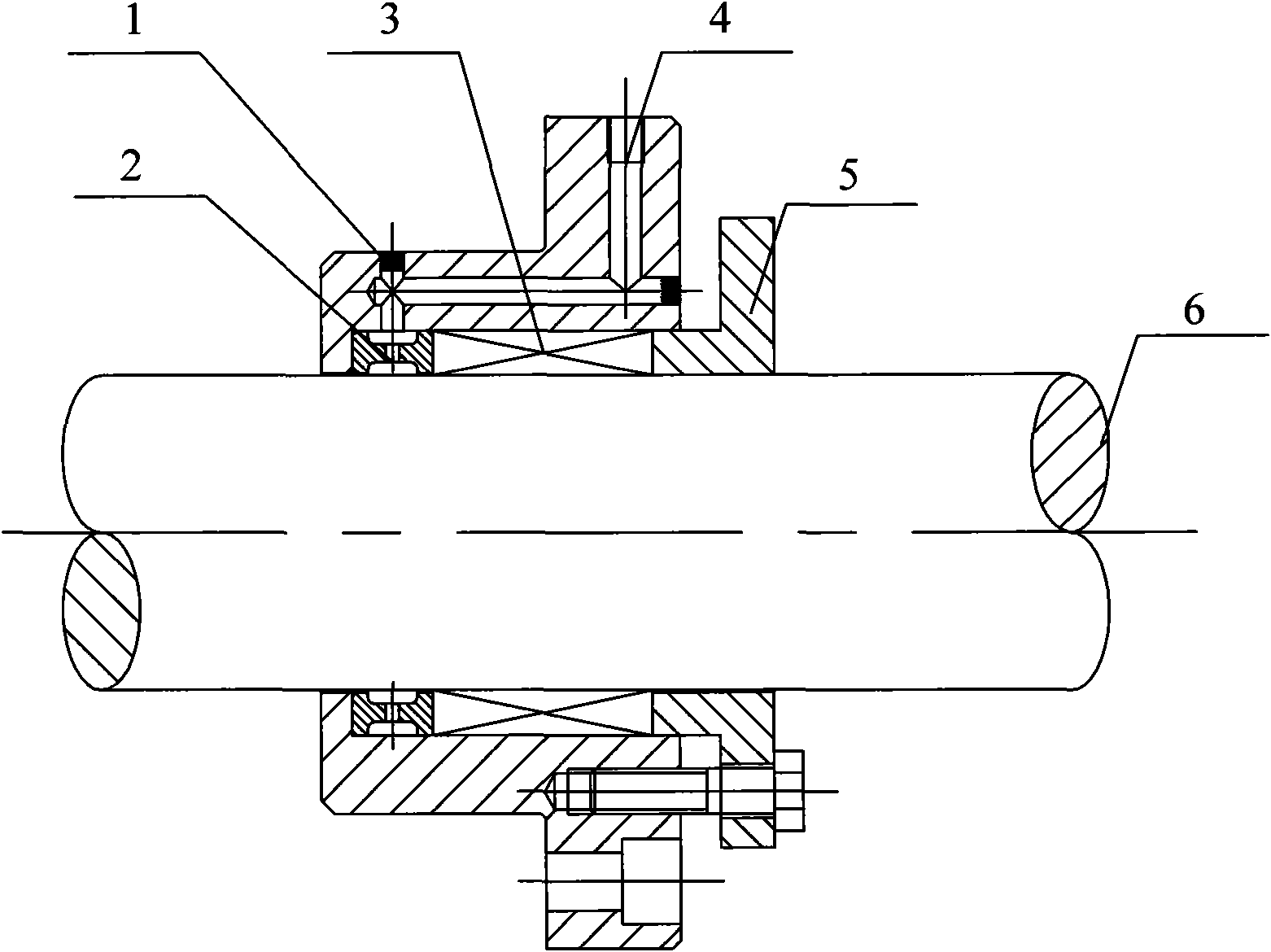

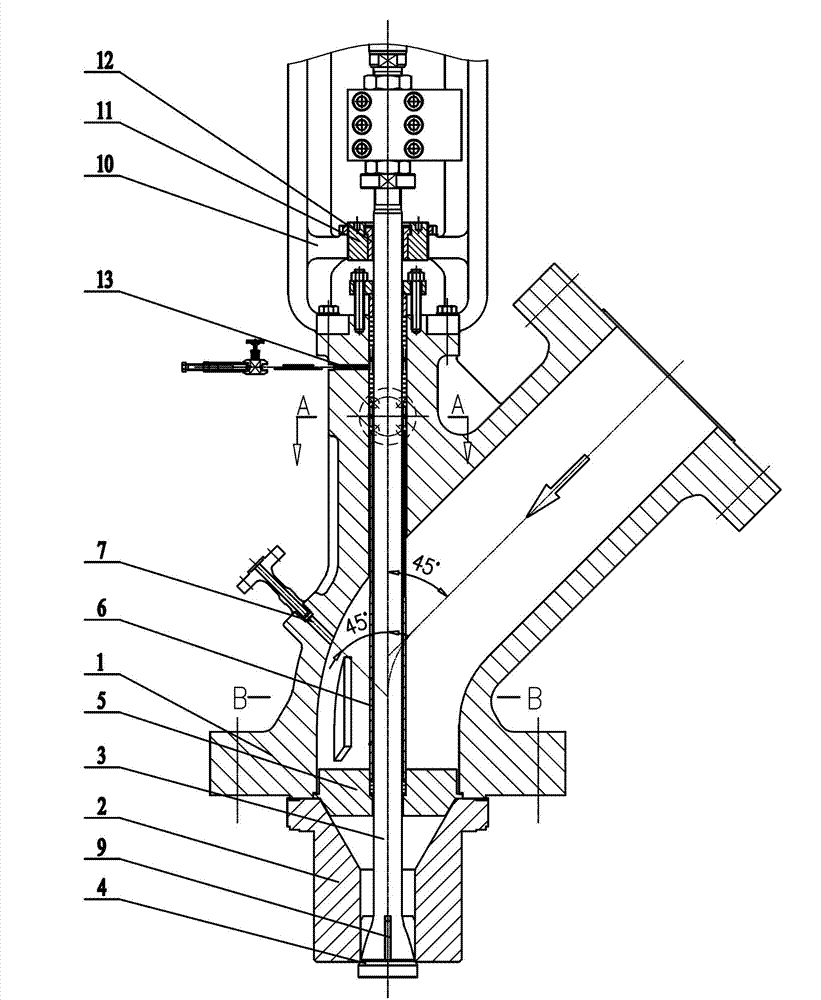

High-temperature metal hard seal ball valve for granular media

ActiveCN102654202AAvoid damageImprove sealingSpindle sealingsPlug valvesMetallic materialsEngineering

The invention provides a high-temperature metal hard seal ball valve for granular media. The high-temperature metal hard seal ball valve comprises a valve body, a ball body, a valve rod, a valve seat and a bottom cover, wherein the ball body is arranged in a cavity in the valve body, the valve rod connected with the ball body extends out of the valve body through a center through hole at the upper part of the valve body, the bottom cover is positioned at the bottom of the valve body and comprises a bottom cover baseplate and a bottom cover shaft, the bottom cover baseplate is movably connected with the valve body, the bottom cover shaft penetrates through a through hole at the lower part of the valve body and is connected with the ball body in the cavity of the valve body, the ball body and the valve seat are made of metal materials, the valve seat is mounted in the valve body and on the inner wall which is in contact with the ball body, a spring seat is arranged on the outer side of the valve seat, a disc spring is mounted in a groove between the spring seat and the valve seat, a pressure ring is arranged on the outer side of the spring seat, the pressure ring is fixedly mounted on the spring seat through a screw, a pendant collet for playing a sealing role is arranged in the contact position of the spring seat, the pressure ring and the valve body, an O ring is arranged in the groove between the valve seat and the valve body, and the O ring is made of fluorine rubber.

Owner:OVIKO GRP CO LTD

Novel liquid flow facilitator

InactiveUS20060163136A1Improved and optimal level of filtration performanceHigh trafficTreatment involving filtrationWater/sewage treatment by ion-exchangeSolventSand granules

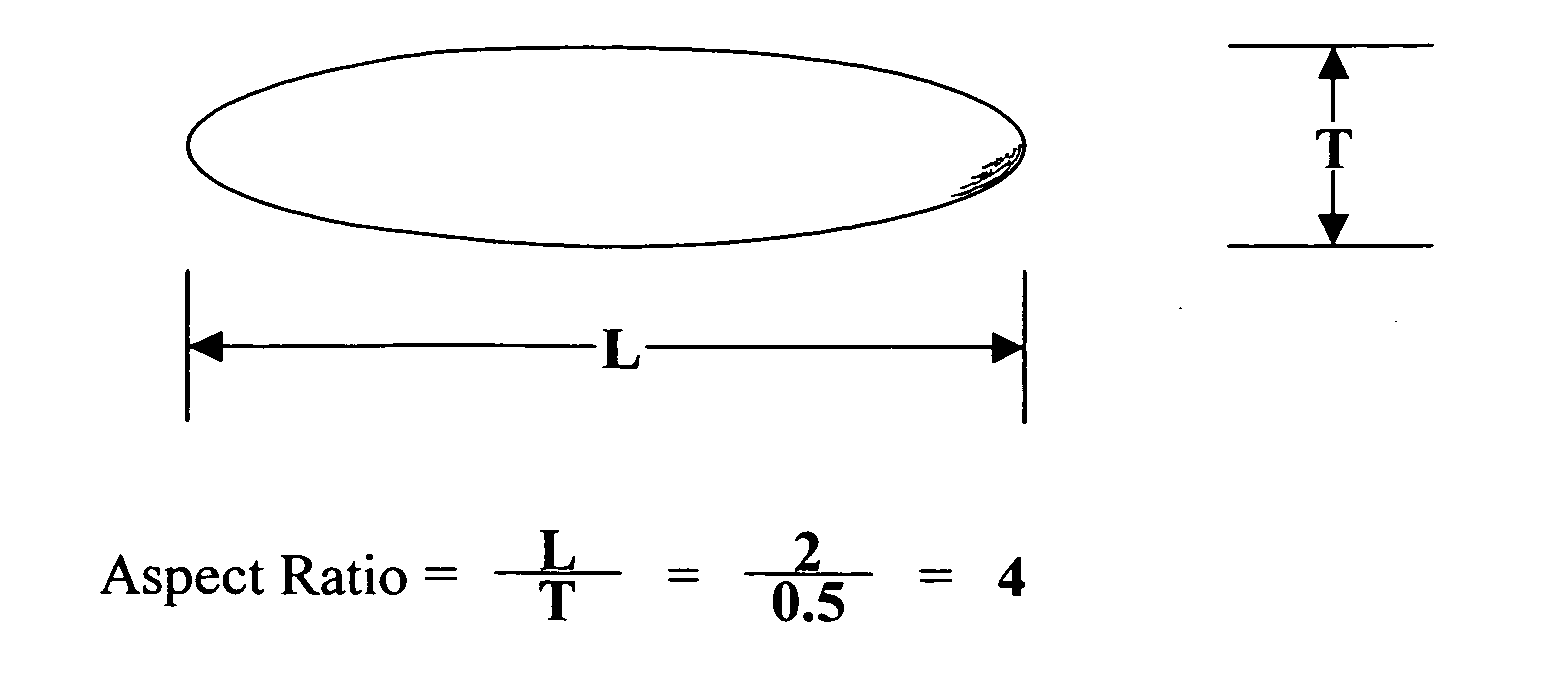

A novel water flow facilitator for granular filter devices that operate under gravity and contain granular particles, further consisting of plastic pellets that are 2 to 100 times, preferably 5 to 20 times larger than the granular particles; the plastic pellets having an aspect ratio of 0.5 to 10, preferably 1 to 4; that comprise about 1 to 50%, preferably 5 to 15% of the weight of the filter media; that have a specific gravity of 0.5 to 2, preferably 0.9 to 1.5. The plastic pellets should contain antimicrobial agents that protect the granular media from microbiological growth. The plastic pellets are made from any of the following plastics: polyolefins, various kinds of polyacrylates, polyvinyl polymers, nylon, polycarbonates etc. The plastic pellets may contain fillers such as calcium carbonate, titania, silica, or alumina. The invented flow facilitator is utilized in a gravity fed granular filter device to remove contaminants such as chlorine, taste and odor-causing compounds, solvents, pesticides, dissolved organic impurities, dissolved heavy metals and non-metallic impurities such as perchlorates. The invented flow facilitator is utilized in a gravity fed granular filter device in which the media consists of activated carbon, synthetic ion exchange resins, silica, alumina, titania, green sands, iron oxides or mixtures thereof.

Owner:RICURA TECH

Warm forming method for metal sheet material

The invention relates to a warm forming method for a metal sheet material. The warm forming method is characterized by comprising the following steps: the metal sheet material is arranged on a female mold, a blank pressing ring is arranged on the metal sheet material, and a part, which is opposite to a molding cavity of the female mold, of the blank pressing ring is made into a cylindrical structure which serves as a feeding cylinder; heating elements (e.g. heating rods) are arranged inside the blank pressing ring and the female mold so as to heat the sheet material, and meanwhile, temperature sensors are mounted inside the blank pressing ring and the female mold; a solid granular medium is added from the feeding cylinder of the blank pressing ring, and a compressing head is arranged above the solid granular medium; and when the difference in temperature of a flange part and a center position of the metal sheet material is stable, a blank pressing force is applied to the blank pressing ring, meanwhile, the compressing head descends to compress the solid granular medium so as to apply a compressing force to the metal sheet material, and the metal sheet material is then formed. The warm forming method for the metal sheet material has the advantages that the forming property of the metal sheet material can be effectively improved, the mold structure is simple, and the forming quality of parts is good. Compared with the hydraulic forming method, the warm forming method disclosed by the invention has the advantages that the sealing is not required, no pollution exists, and the solid granular medium can be recycled, thus the requirements for low carbon and environmental protection are met.

Owner:YANSHAN UNIV

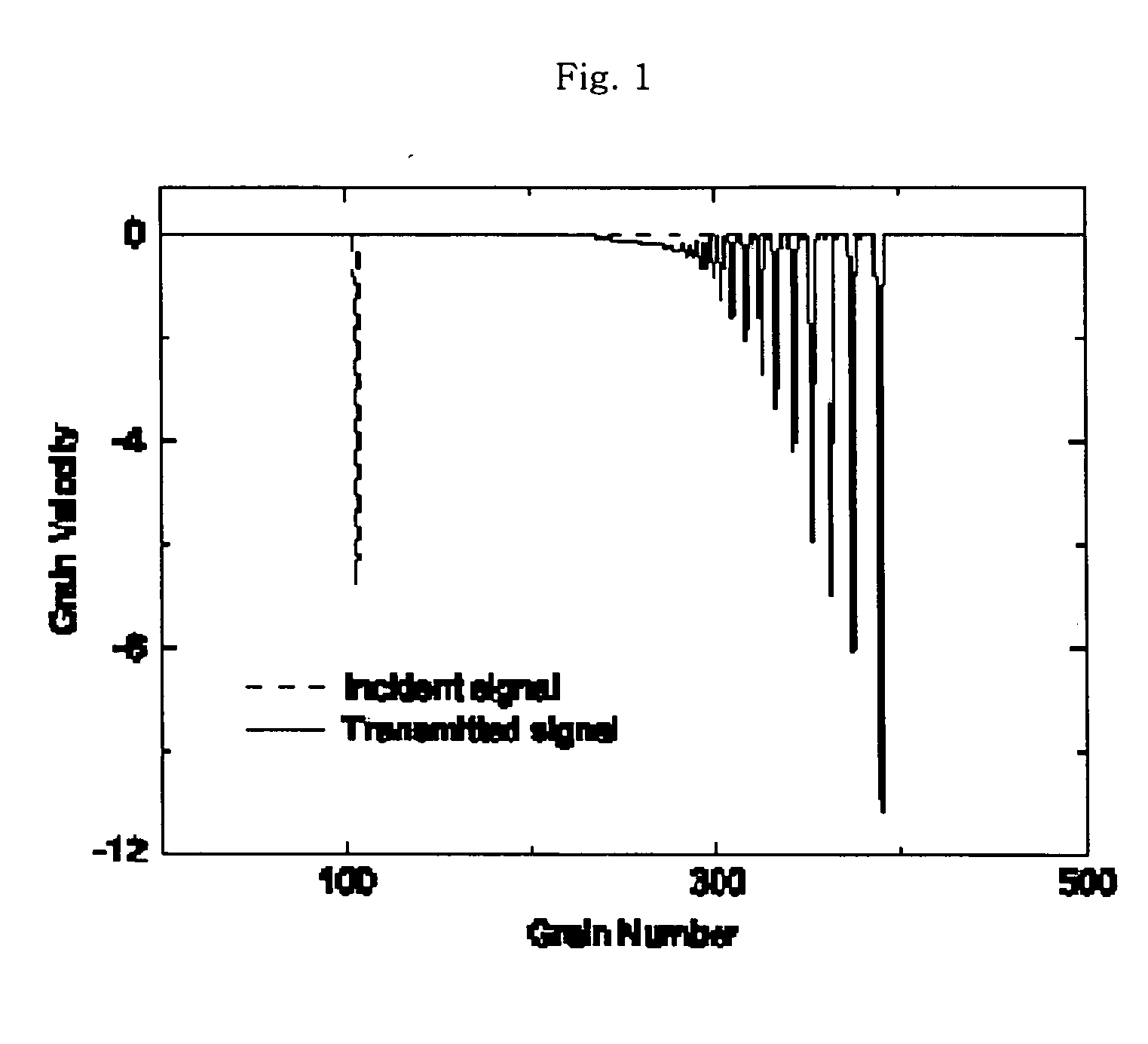

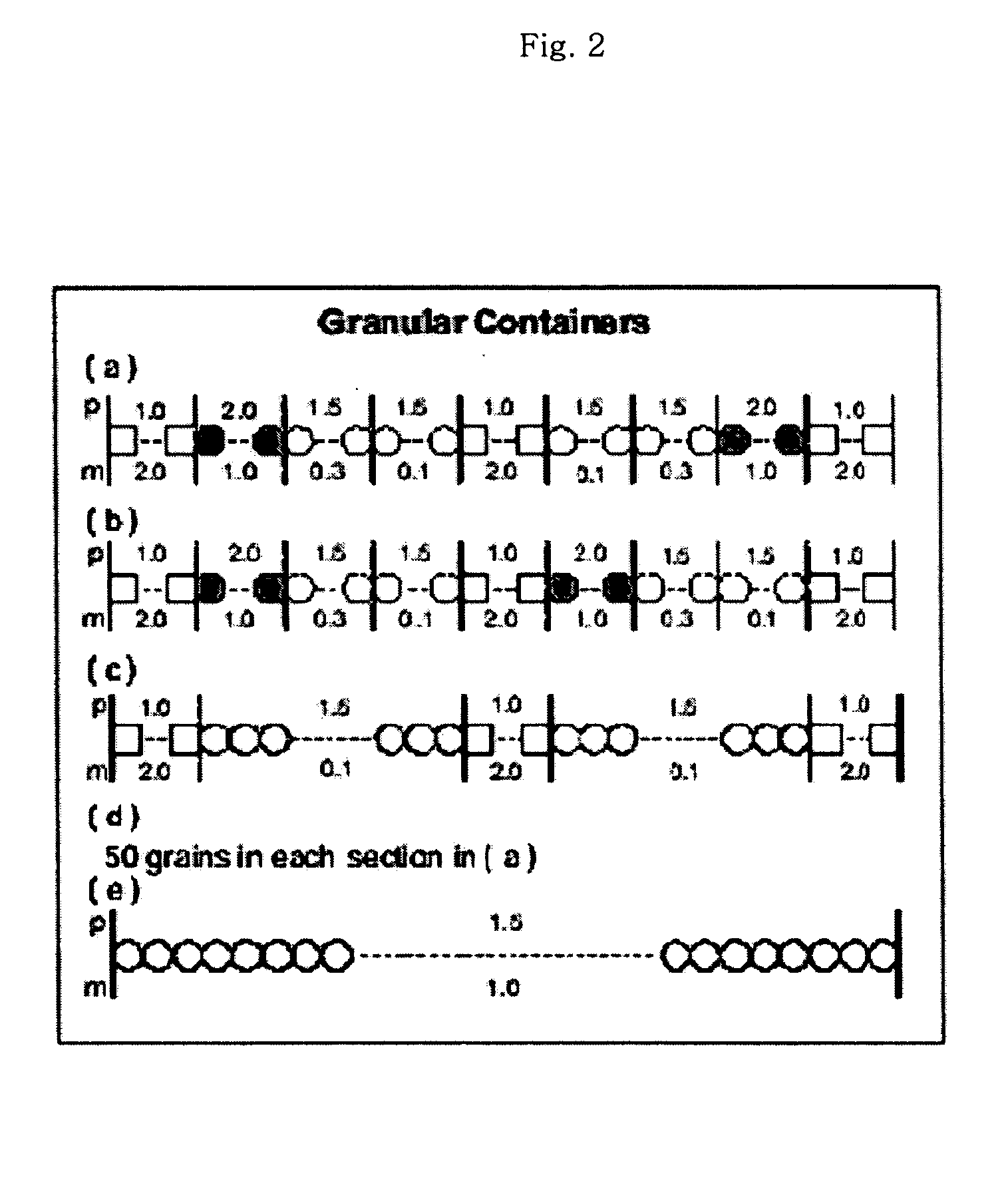

Granular container protector for protecting impulse

InactiveUS20060207913A1Reduce decreaseReduce a strong impulseAmmunitionBlastingEngineeringGranular media

The present invention discloses a granular container protector for protecting impulse comprising a plurality of granular media each having a certain elastic property and a certain mass; wherein the plurality of granular media is arranged one-dimensionally into a plurality of sections, each section including one or more granular medium having same elastic property and same mass; wherein the plurality of sections is arranged in a manner that a ratio of mass to elastic property of the granular media in each section decreases toward a central section from both side sections; wherein the plurality of sections is arranged to be a mirror image about the central section; and wherein the side sections and the central section form walls of the granular container protector.

Owner:SEOUL NAT UNIV FOUND

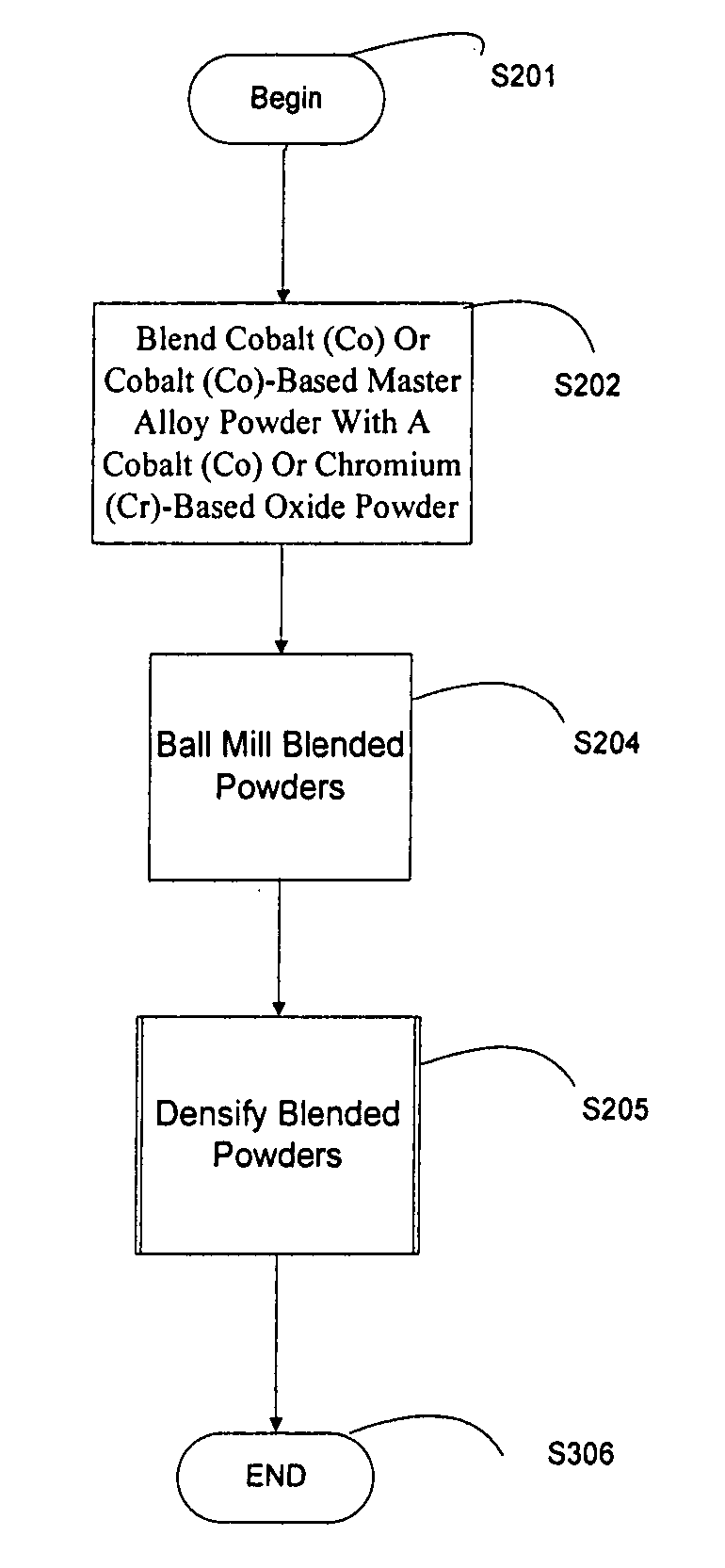

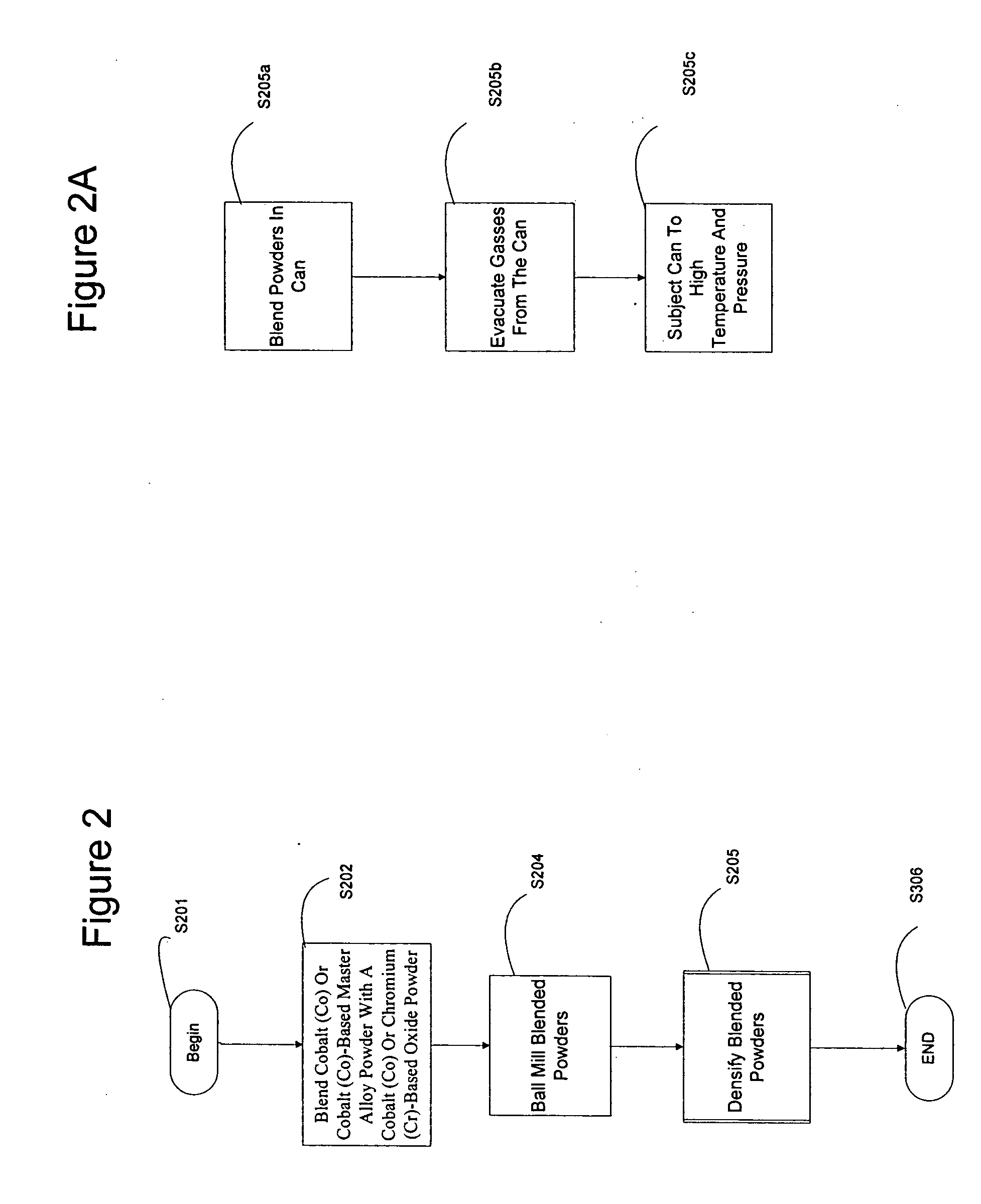

Enhanced formulation of cobalt alloy matrix compositions

InactiveUS20060233658A1Good sputtering performanceOptimize allocationCellsMagnetic materials for record carriersIndiumHafnium

A method for manufacturing a single-element matrix cobalt-based granular media alloy composition formulated as Cof<sub2>1< / sub2>-(MuOv)f<sub2>2< / sub2>, M representing a base metal selected from the group consisting of magnesium (Mg), titanium (Ti), vanadium (V), chromium (Cr), manganese (Mn), iron (Fe), nickel (Ni), copper (Cu), zinc (Zn), aluminum (Al), silicon (Si), yttrium (Y), zirconium (Zr), niobium (Nb), molybdenum (Mo), ruthenium (Ru), indium (In), lanthanum (La), hafnium (Hf), tantalum (Ta), and tungsten (W), u and v representing the number of atoms of base metal M and oxygen (O) per oxide formula, respectively, and f1 and f2 being mole fractions represented by the equation f1+(u+v)f2=1. The method includes the steps of blending a Co-M master alloy powder and a Cou′Ov′ powder into a corresponding (CoaM1−a)f<sub2>1< / sub2>′-(Cou′Ov′)f<sub2>2< / sub2>′ formula, and densifying the blended powders.

Owner:HERAEUS INC

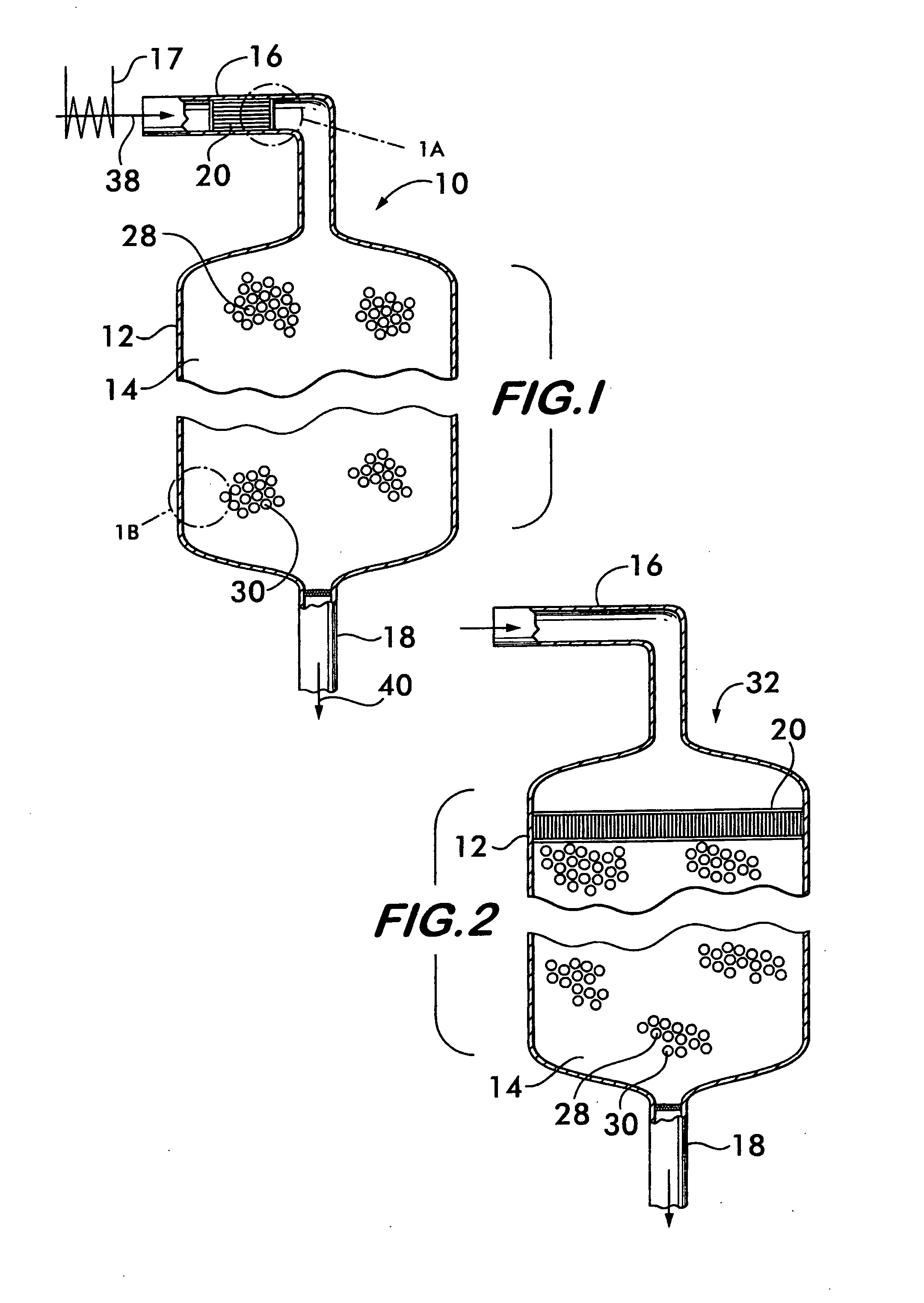

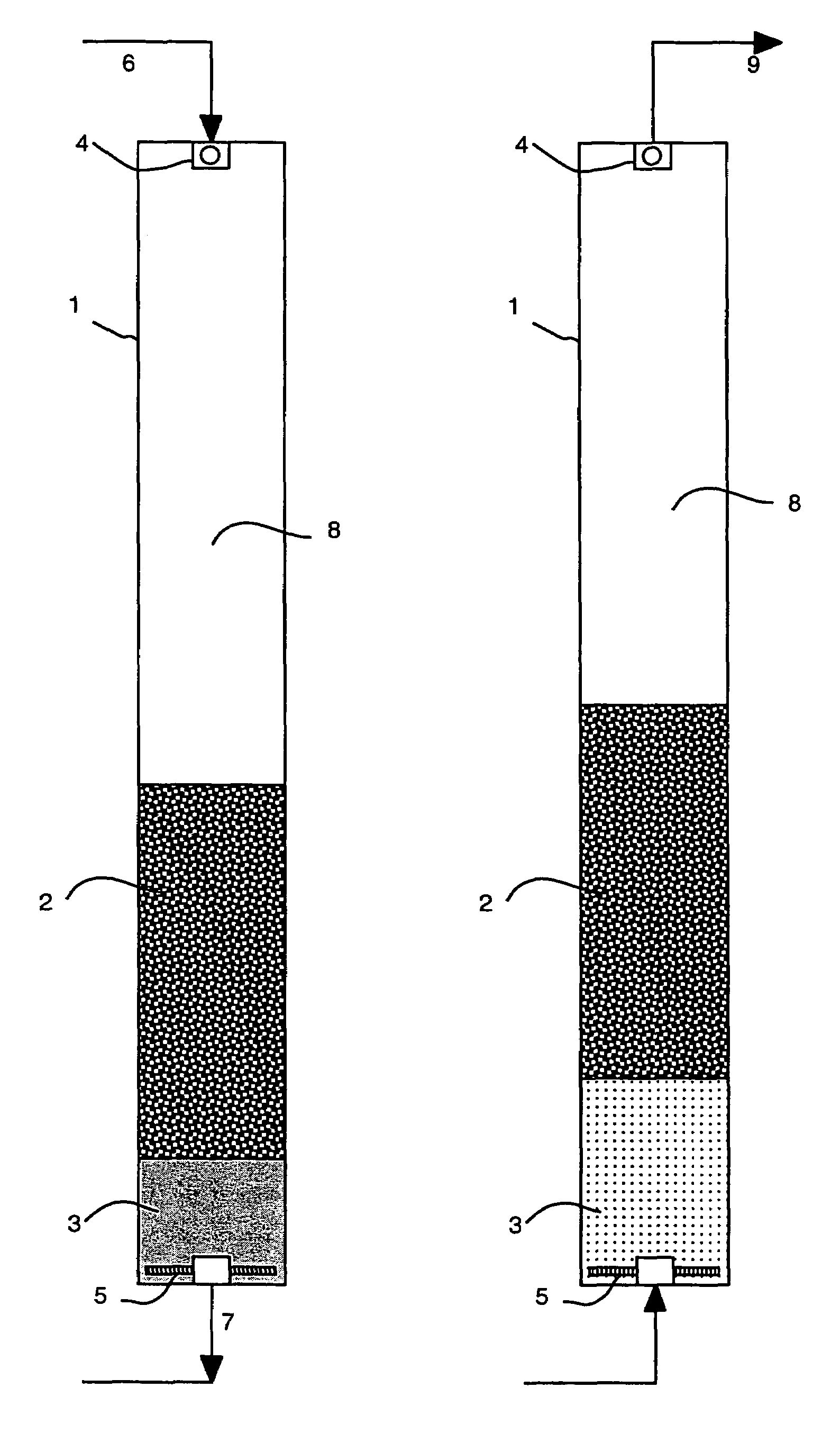

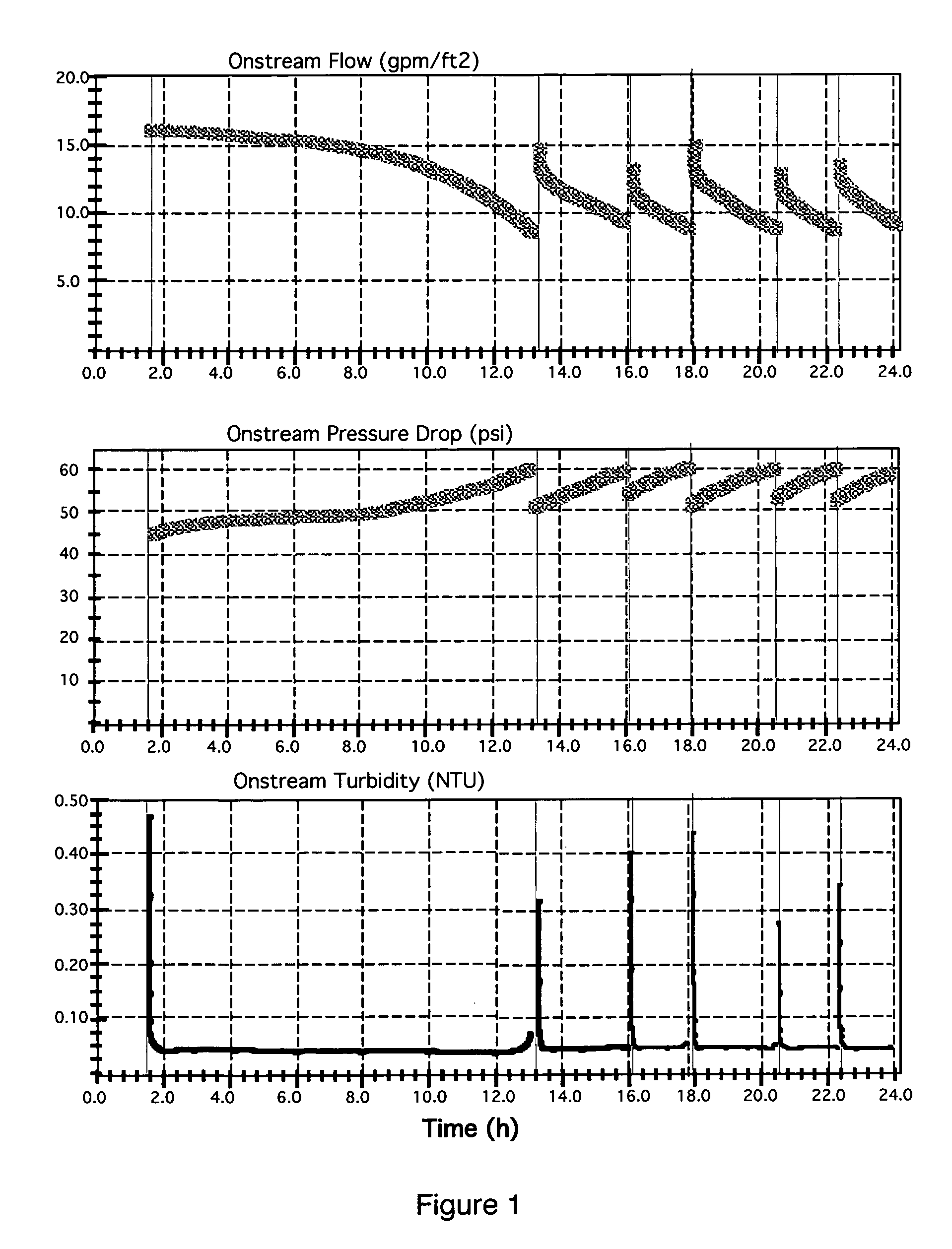

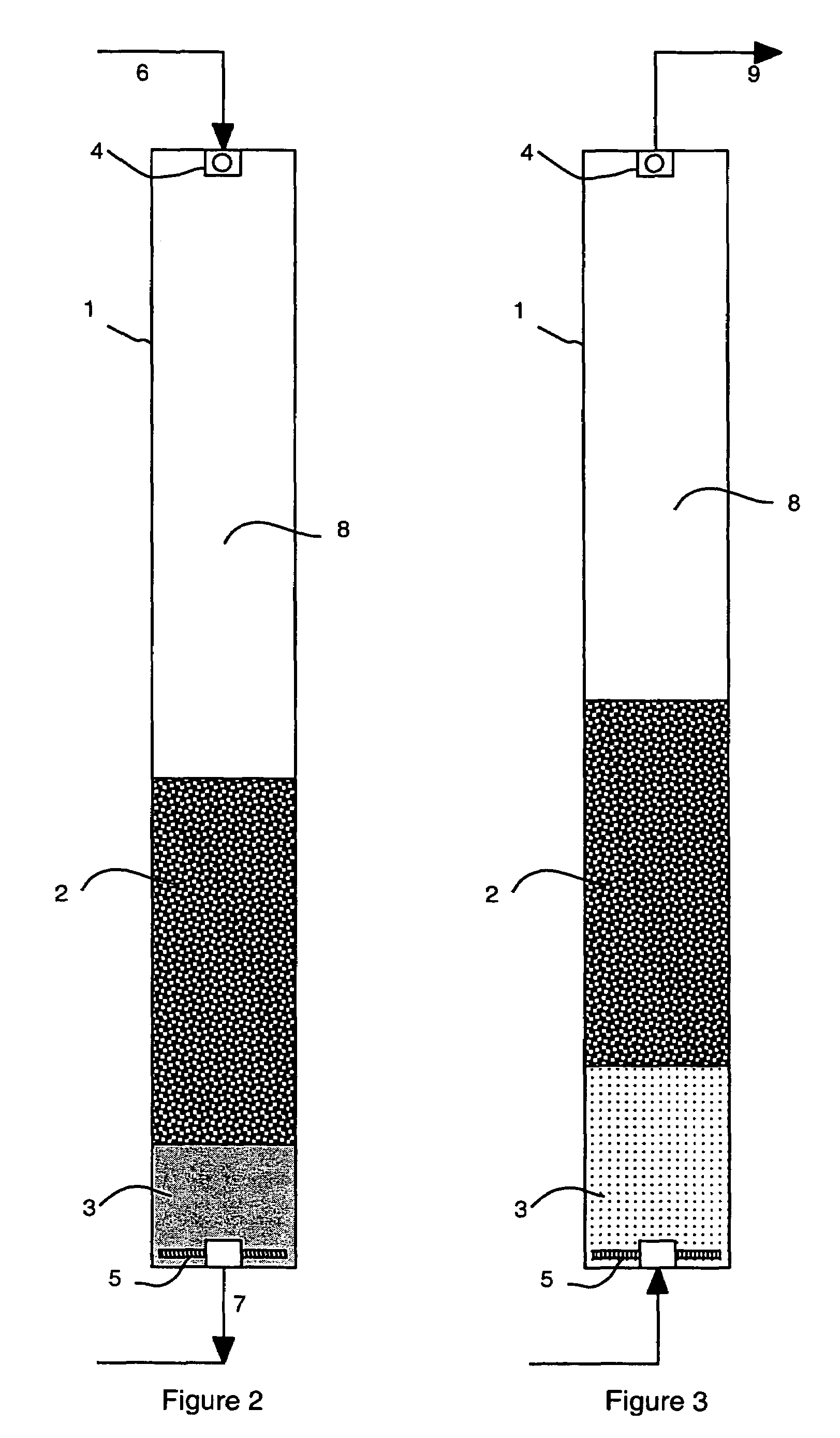

Method and apparatus for increasing filter contaminant loading capacity

ActiveUS7045067B2Shorten the length of timeReduce penetrationWater/sewage treatmentLoose filtering material filtersEngineeringVolumetric Mass Density

The filter contaminant loading capacity of a depth granular media filter is increased by imposing a so-called “back-slip” on the filter bed. At intervals between normal backwashing, a volume of liquid is passed upwardly through the media bed under flow conditions selected to displace at least some of the contaminants upwardly in the bed while essentially removing none of the contaminants from the filter vessel. Preferably, the filter bed comprises at least two media types of different but uniform particle sizes and densities, the media types each forming a distinct layer in which the effective particle size of the media in each successive layer decreases in a downward direction in the vessel.

Owner:ECO TEC INC

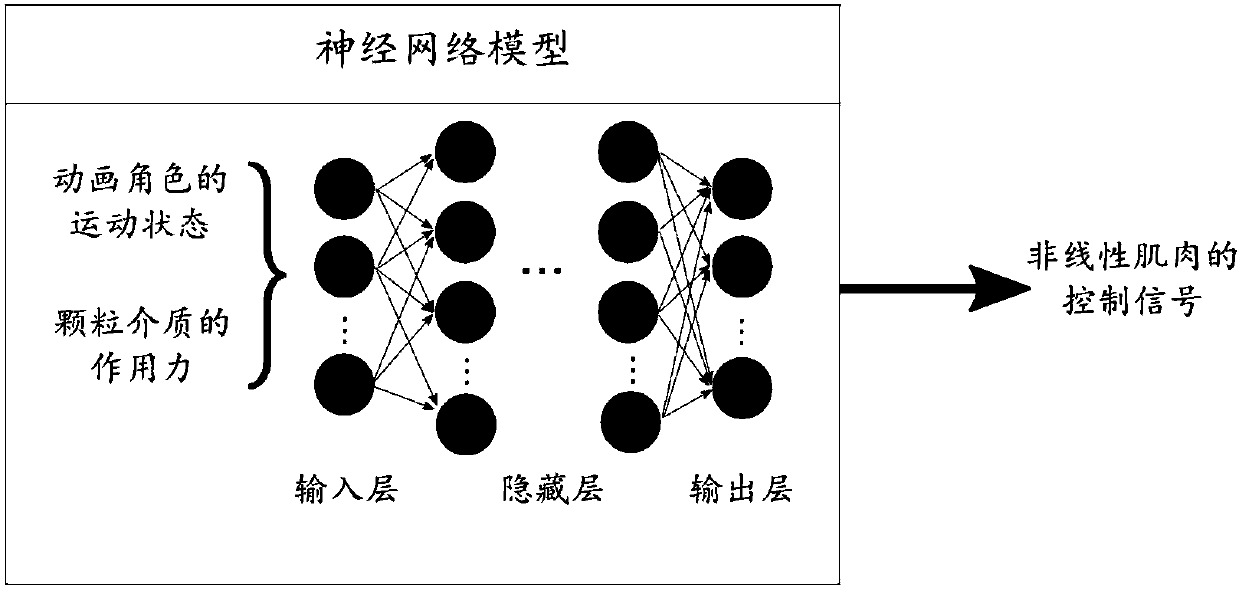

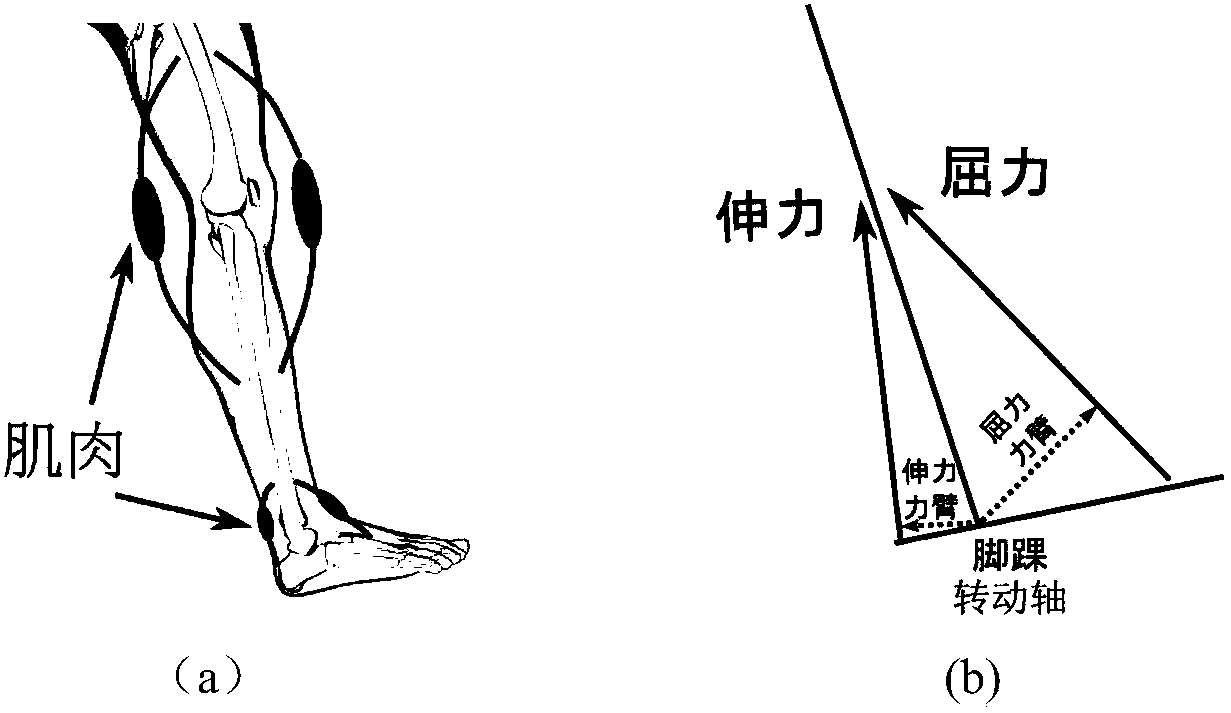

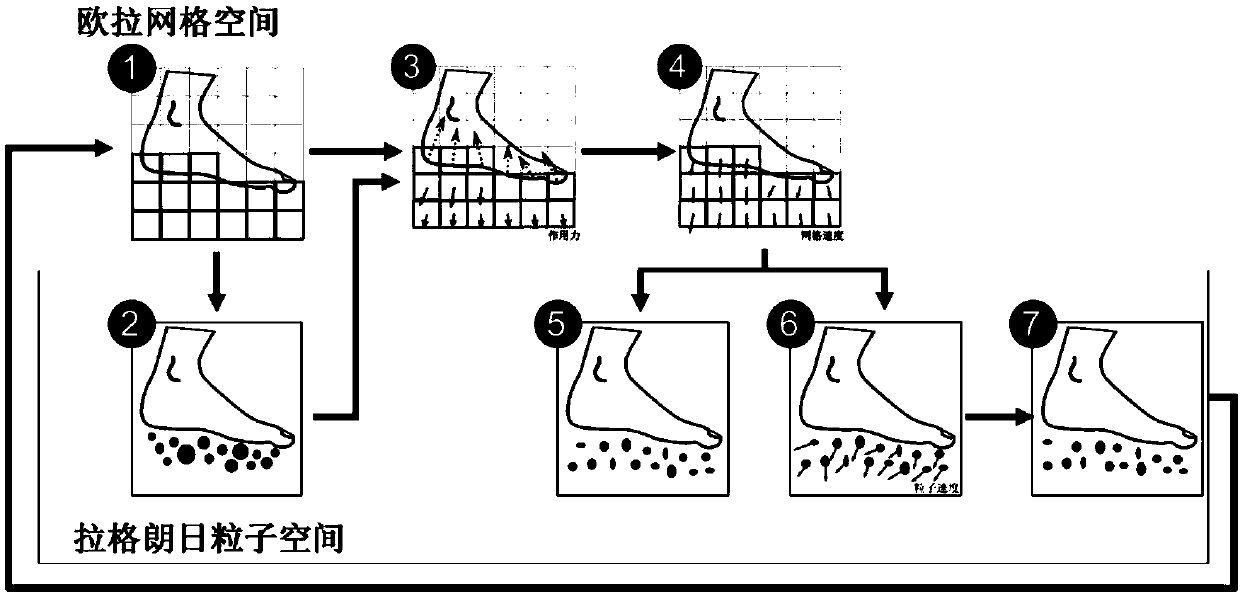

Motion simulation method of animation character under granular medium environment

ActiveCN107610208AVisual natureExpand the scope of applicationAnimationNeural architecturesFault toleranceAnimation

The invention provides a motion simulation method of an animation character under the granular medium environment, and relates to computer graphics. According to the motion simulation method of the animation character under the granular medium environment, the motion of natural vision, stable physics and controllable user of the animation character under the granular medium environment can be realized, the making efficiency of motion simulation of the animation character under the granular medium environment in the field of movies, animation and games can be greatly enhanced after industrialization, the algorithm is clear and the process is clear. An animation character motion simulation model based on nerve-muscle-bone is established; an animation character-granular medium interactive anddynamical model is established; and parameter optimization of an animation character control model based on the neural network model is completed and a large-scale motion control unit is introduced,the motion mechanism of real living things is further simulated and the stability of motion and the fault tolerance of the controller can be enhanced.

Owner:XIAMEN UNIV

High-temperature and high-pressure metal sealing ball valve

The invention relates to a high-temperature and high-pressure metal sealing ball valve. The high-temperature and high-pressure metal sealing ball valve comprises a valve body, a valve base, a sphere and a valve rod. Mainly, the potions, on the two sides of a center line of a sphere through hole, of the sphere are each provided with a plane; the planes on the two sides of the sphere are each internally provided with a ball clack; the ball clacks are in movable fit connection with round concave holes in the sphere through round convex columns; annular spring cavities and springs in the cavities are manufactured between the ball clack planes on the radial outer sides of the round convex columns and the sphere planes; annular anti-blocking grooves are manufactured in the portions, on the outer sides of the annular spring cavities, of the sphere planes; medium dredging grooves which lead to the outer surface of the sphere and are communicated with the annular anti-blocking grooves are manufactured in the portions, close to the spring cavities in the outer round faces of the round convex column, of the sphere planes; the valve base is fixedly installed in a valve body channel through a positioning ring; and a concave spherical face, matched with the sphere and the spherical faces of the ball clacks, of a positioning ball clack is manufactured on the positioning ring valve cavity side. The ball clacks of the high-temperature and high-pressure metal sealing ball valve are reliable in floatation, good in temperature resistance and suitable for the high-temperature and high-abrasion working condition of particle media.

Owner:应建忠

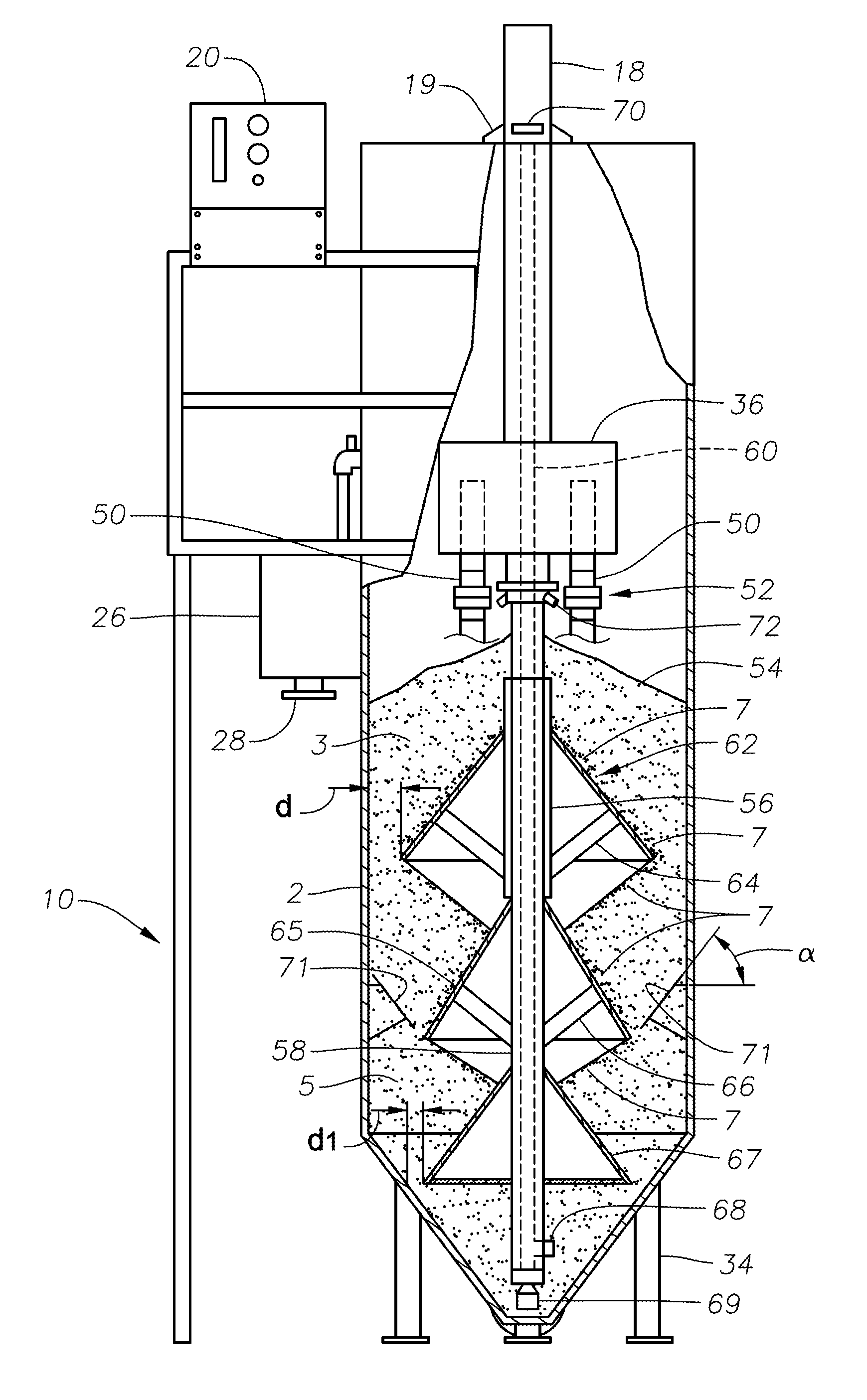

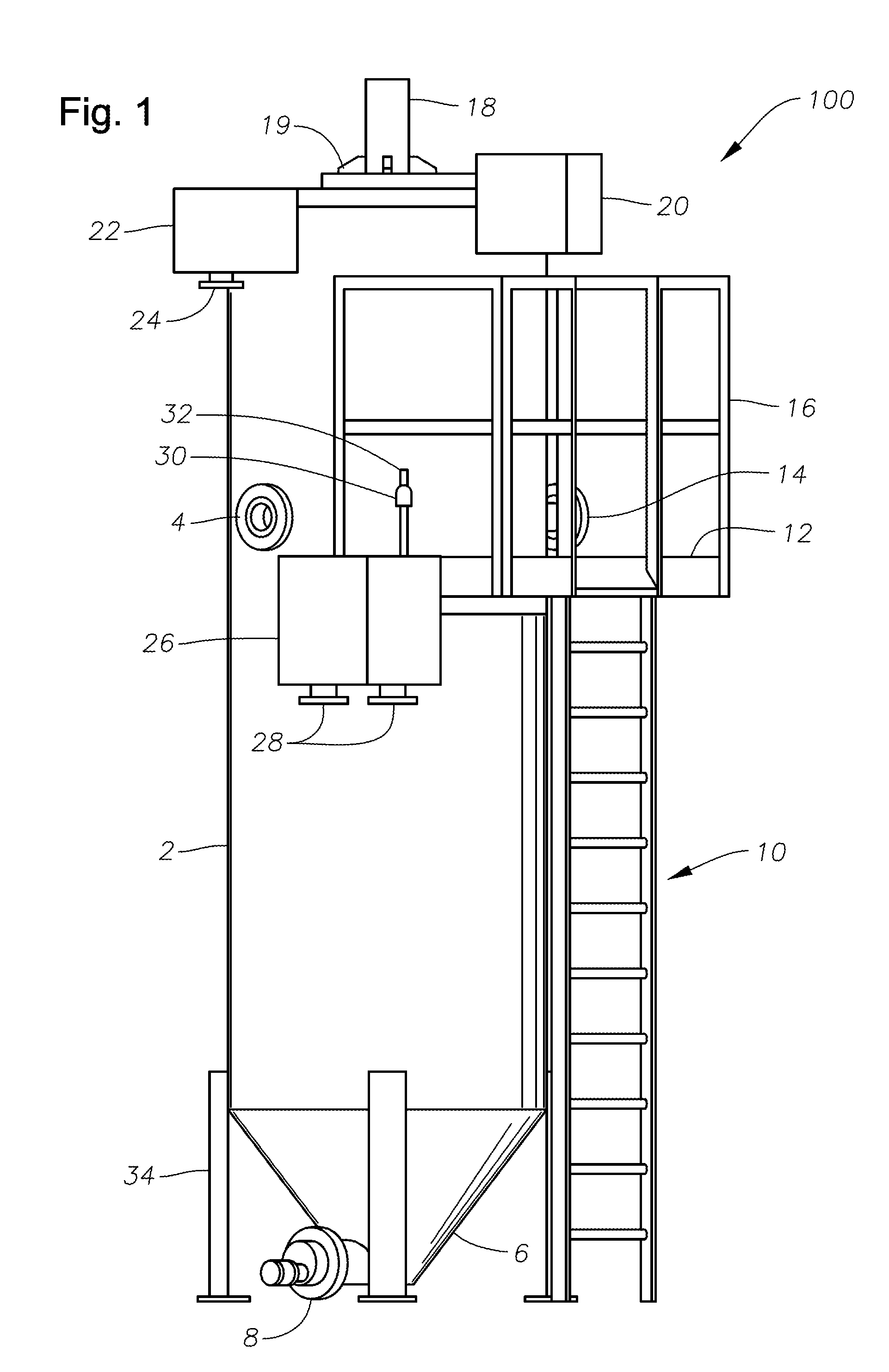

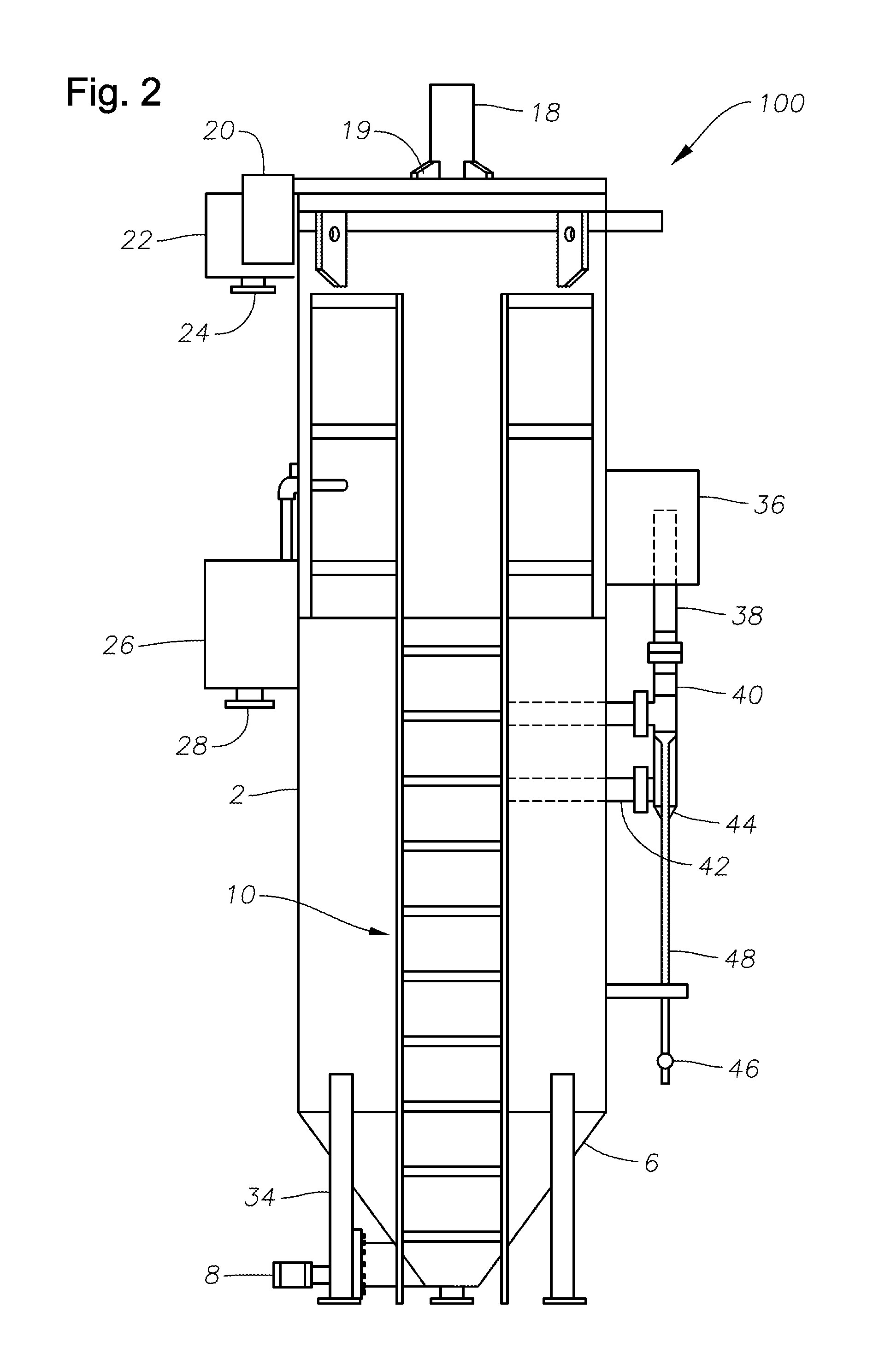

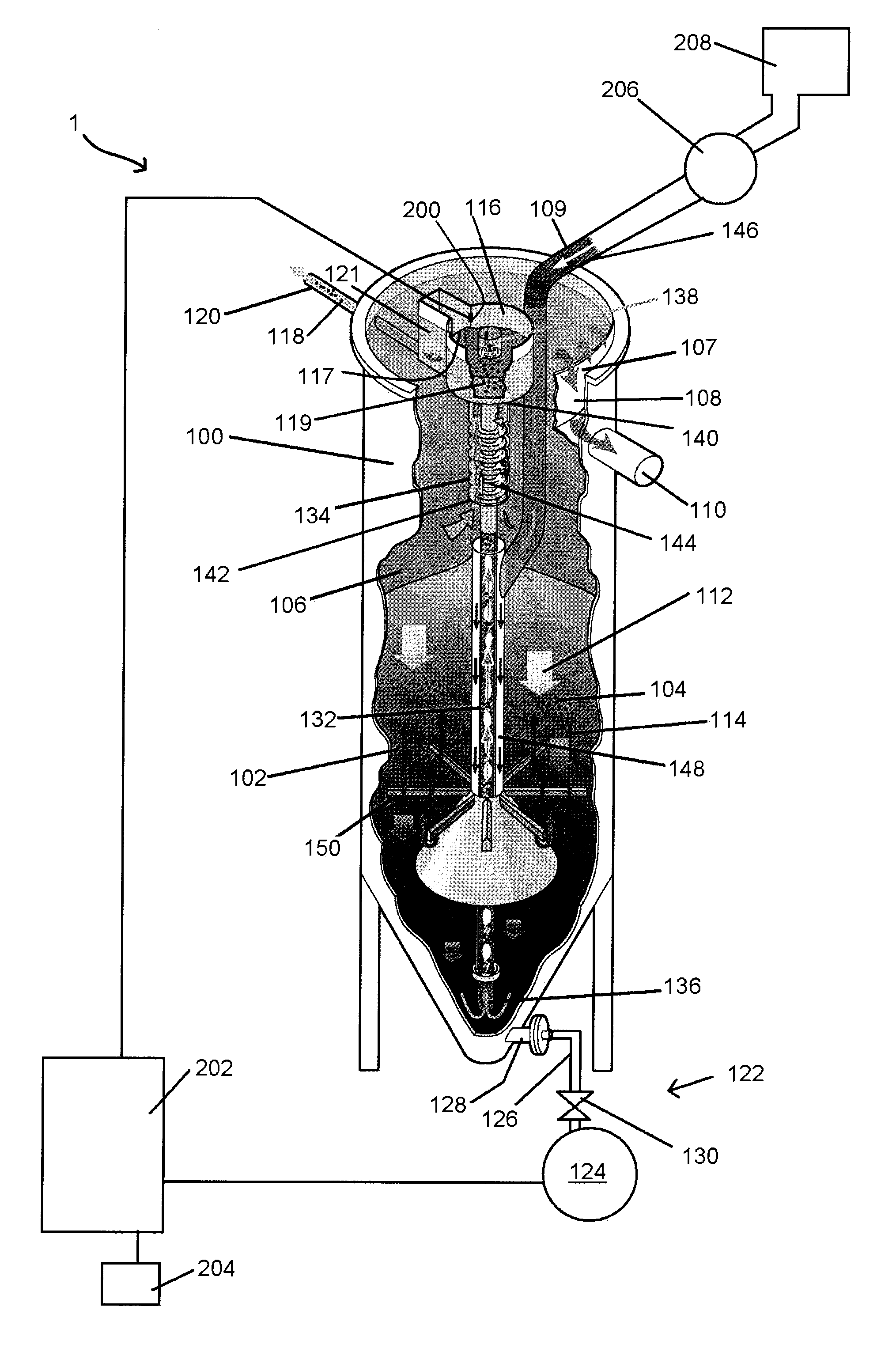

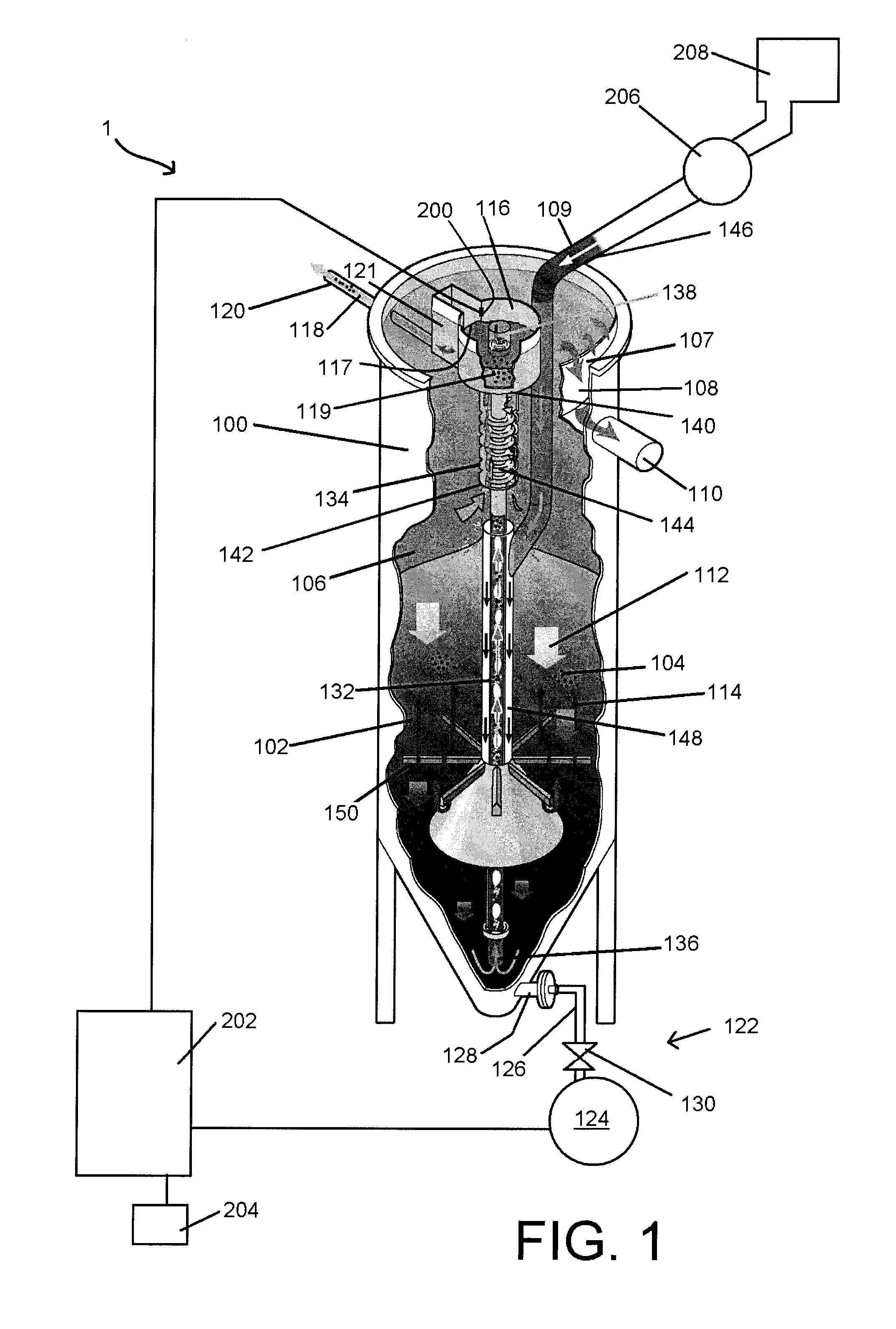

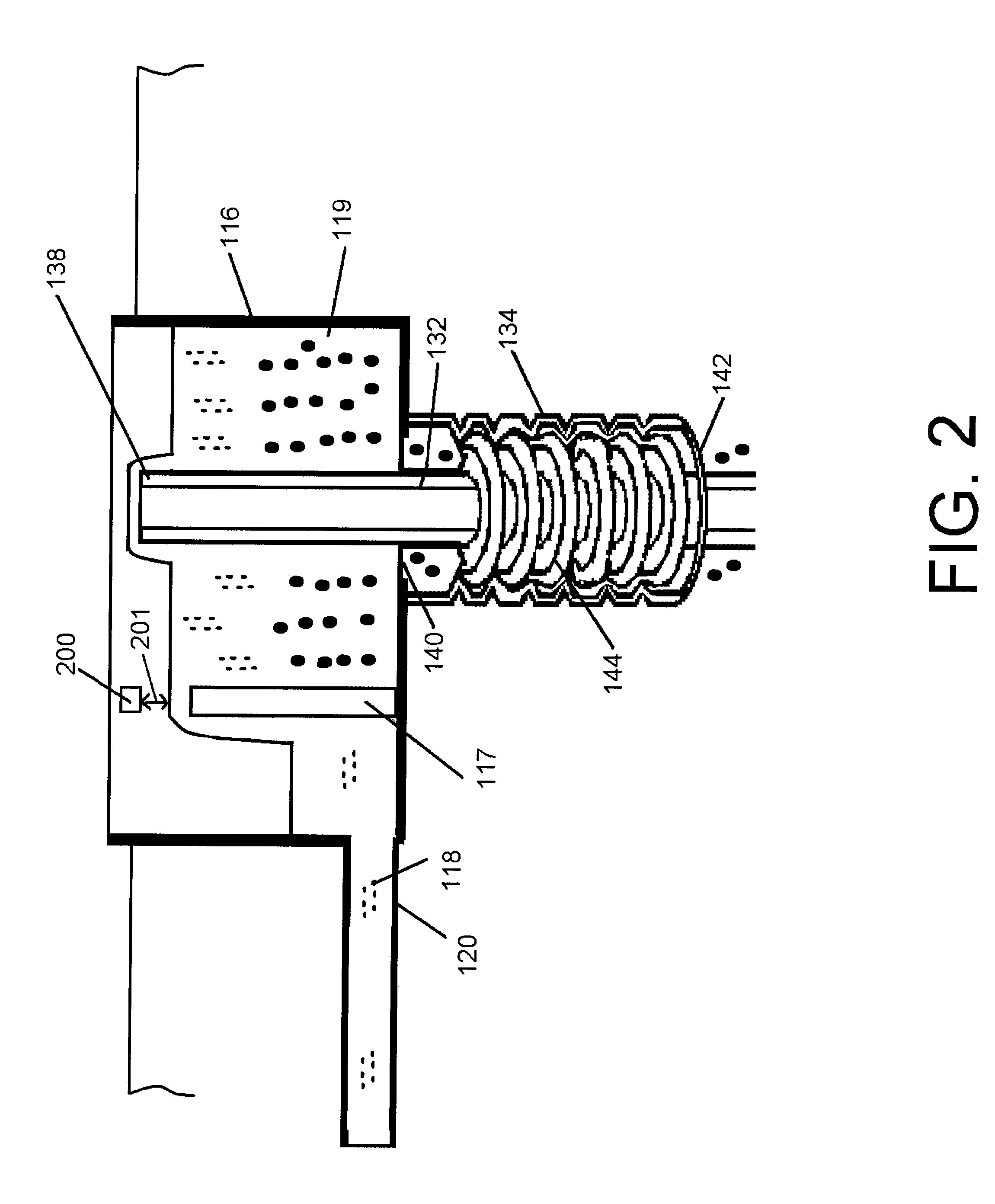

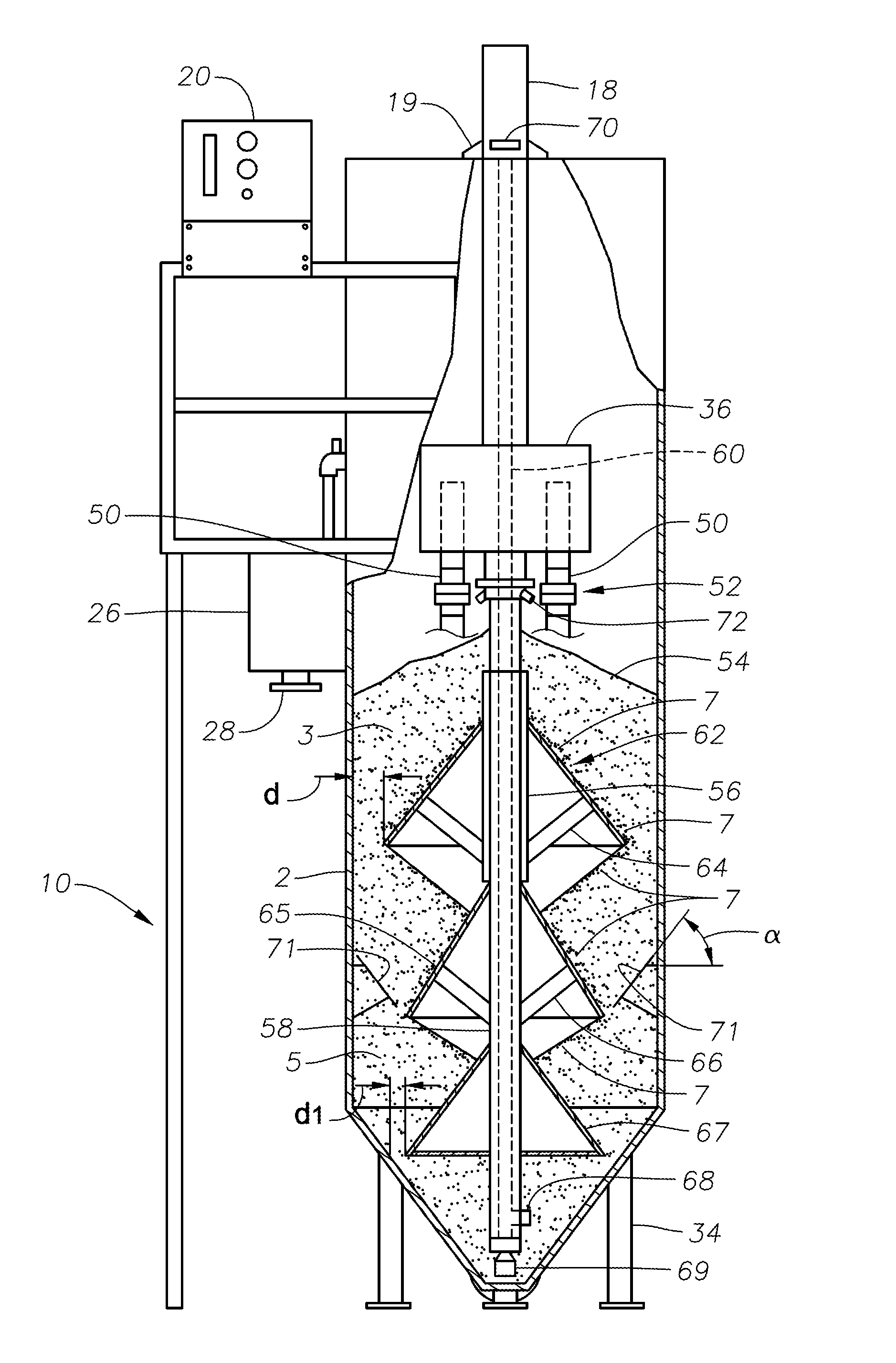

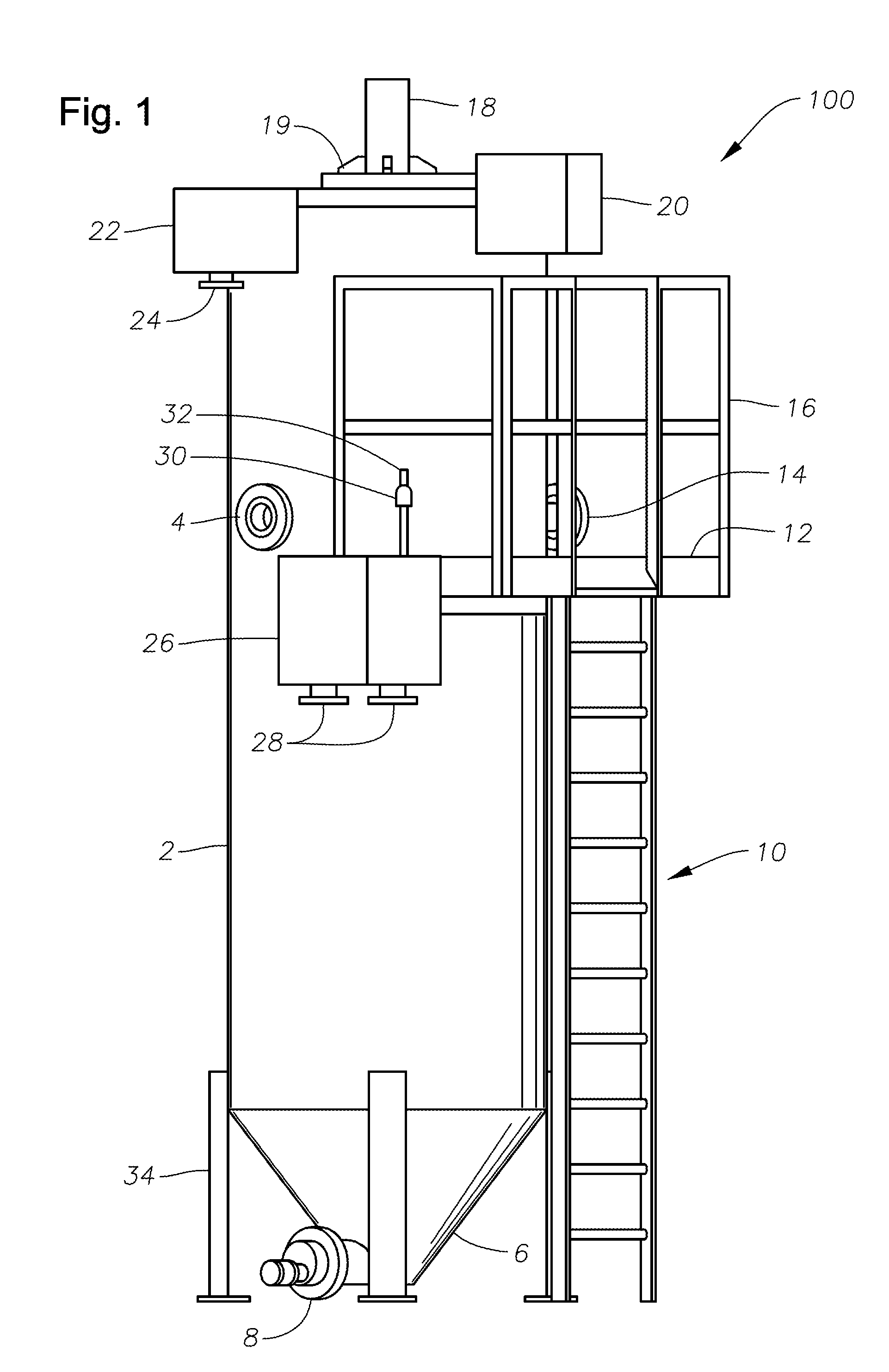

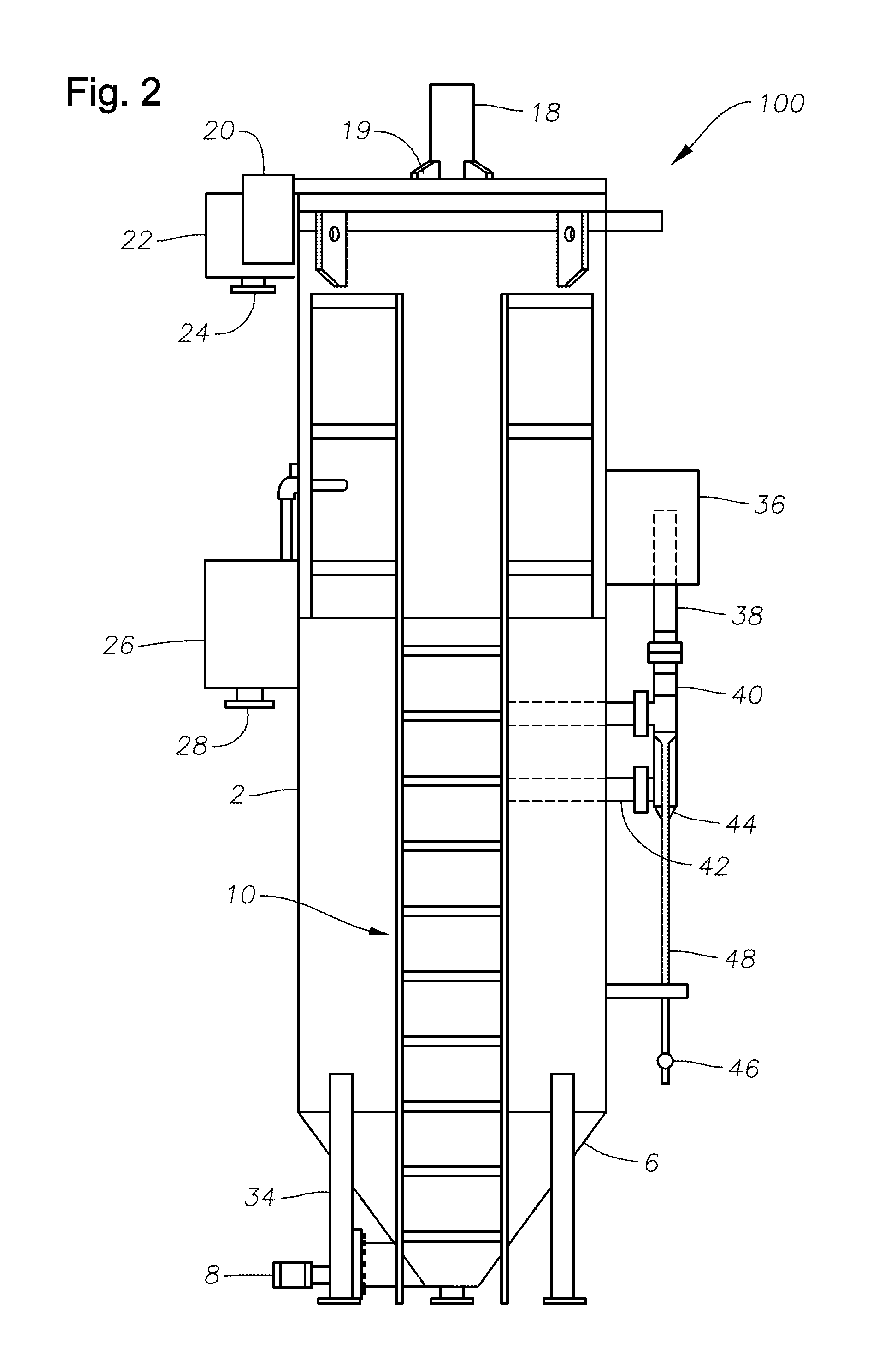

Screenless granular media filters and methods of use

InactiveUS20110290734A1Ion-exchanger regenerationWater/sewage treatment by ion-exchangeFilter mediaGranular media

A liquid filtering apparatus is placed in a vessel having a bed of filtration material, the bed comprising at least two different sizes of filter media wherein the filtration material is stratified using upper and lower spaced apart inverted cones so that the unfiltered liquid first contacts coarse grained filtration material and then finer grained filtration material. The apparatus includes an intake for introducing unfiltered liquid that includes a washbox, an airlifting tube extending from the washbox and including an intake end and means for introducing a primary gas to the airlifting tube, the airlifting tube passing through a central pipe, which extends from just below the washbox to a position just above the intake end. The apparatus is devoid of screen cartridges. Methods of filtering and cleaning the filtration material are also disclosed.

Owner:ALFA LAVAL ASHBROOK SIMON HARTELY INC

Method and apparatus for treating liquid containing impurities

ActiveUS20110168643A1Precise transportationProgramme controlWater treatment parameter controlEnvironmental engineeringEngineering

A method and an apparatus for treating a liquid containing impurities may include a filtering chamber configured to permit granular media to interact with liquid containing impurities, thereby removing impurities from the liquid to produce filtrate; a filtrate section for receiving the filtrate; a gas supplying system for delivering gas to the granular media in the filtering chamber for transport of a portion of the granular media to a granular media washer; a reject section in fluid communication with the granular media washer for receiving a reject mixture comprising liquid and impurities from the granular media washer; and a control unit that is configured to determine whether the portion of the granular media is being transported properly based on an amount of reject mixture in the reject section.

Owner:PARKSON

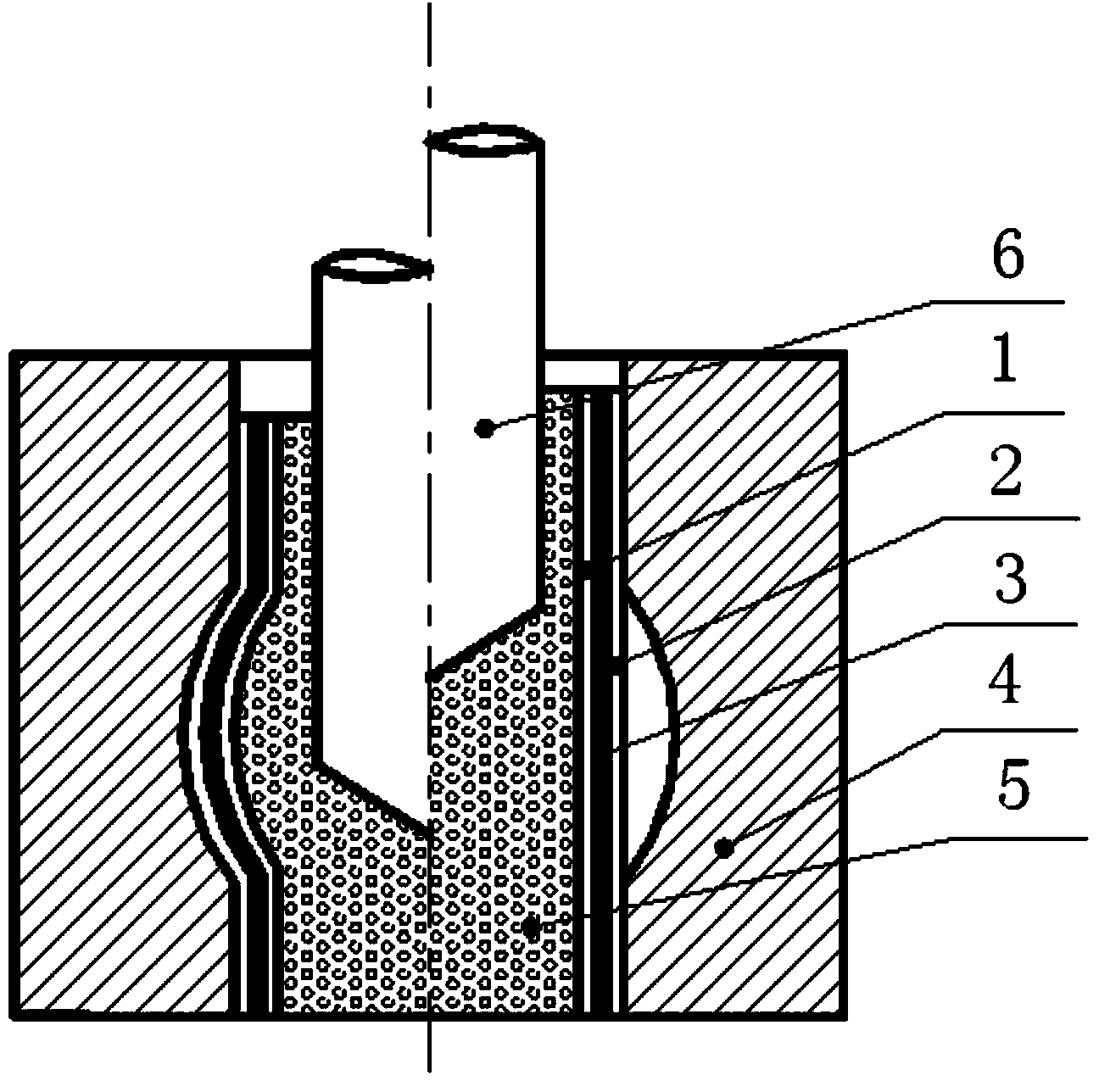

Ti-Al intermetallic compound laminated composite material tube and preparation method thereof

The invention provides a Ti-Al intermetallic compound laminated composite material tube and a preparation method thereof. The preparation method comprises the steps of with titanium alloy tubular products as an inner tube blank and an outer tube blank, filling a middle interlayer between the inner tube blank and the outer tube blank, welding two end parts of the inner tube blank and the outer tube blank together to seal an annular cavity between the inner tube blank and the outer tube blank, vacuumizing the annular cavity between the inner tube blank and the outer tube blank, placing the inner tube blank, the outer tube blank and the middle interlayer into a mold, fully filling granular mediums into the inner tube blank, and heating the inner tube blank, the outer tube blank, the middle metal interlayer, the mold and the granular mediums to reach a setting temperature to ensure that the middle metal interlayer is at a solid state; and moving a pressing head downwards to extrude the granular mediums to enable the outer tube blank to be attached to the inner wall of the mold, and maintaining the pressure for a certain time period S to enable the contact interfaces between the inner tube blank and the middle metal interlayer and between the outer tube blank and the middle metal interlayer to be subjected to Ti and Al diffusion and reaction, thus generating a Ti-Al intermetallic compound.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

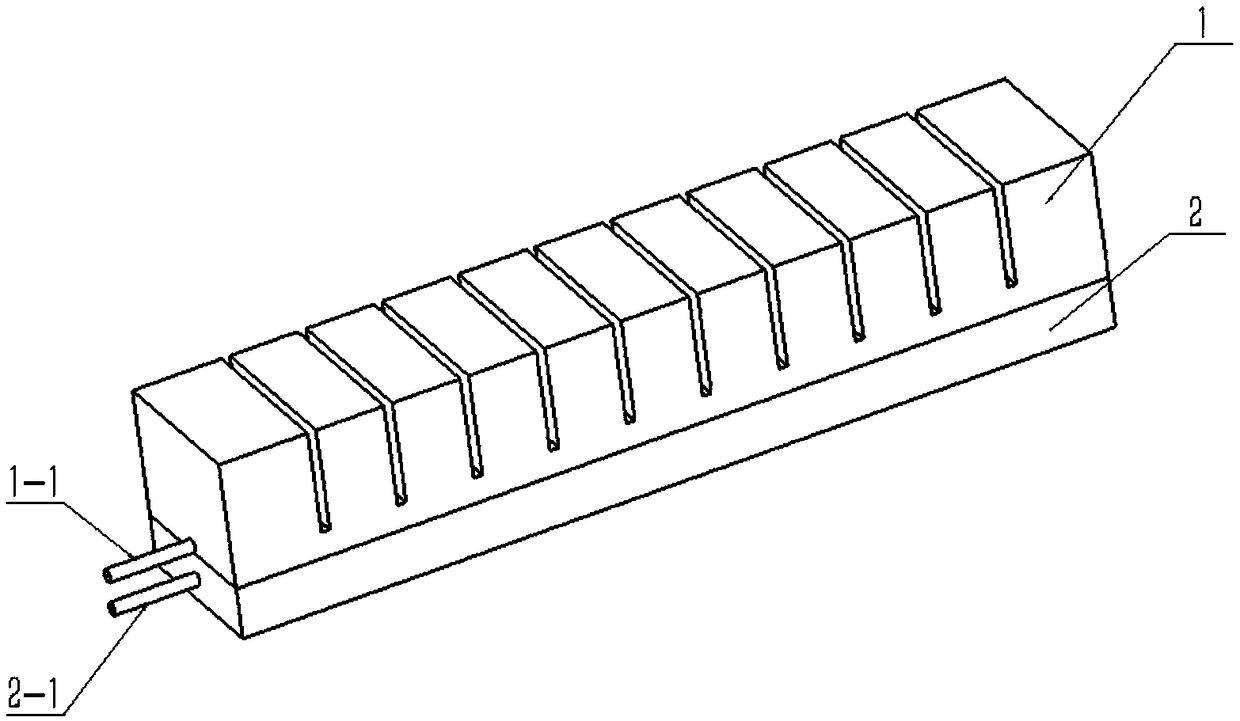

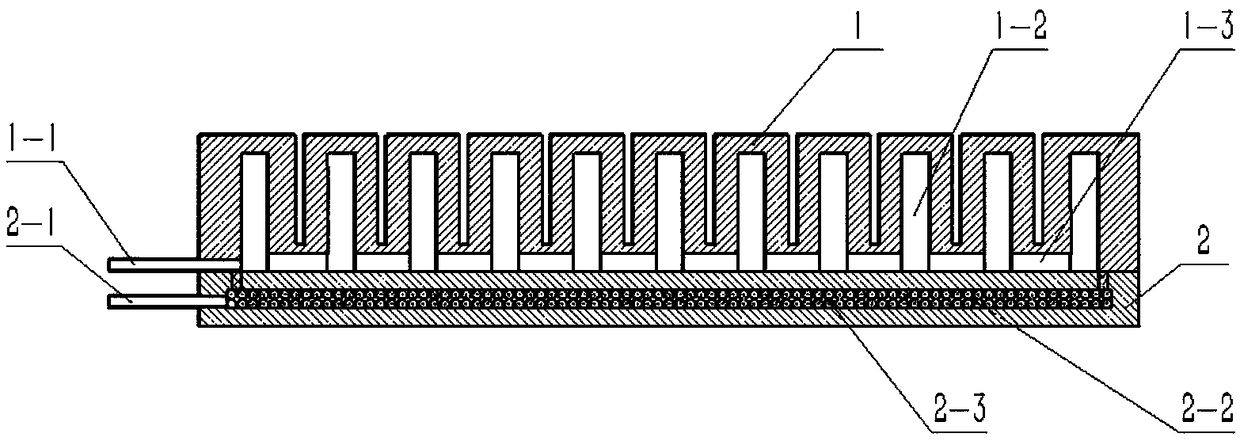

Thermal molding method of high-strength aluminum alloy sheet

ActiveCN106040817AIncreased drawing limitReduce deformation resistanceGranular mediaThermal treatment

The invention discloses a thermal molding method of a high-strength aluminum alloy sheet. The thermal molding method is mainly characterized by comprising the steps of placing a thermal-insulated granular medium into a charging barrel; heating an aluminum alloy sheet to a temperature which is 10-20 DEG C higher than the melting point of an eutecticum; heating an upper blank holder and a lower blank holder of a mold, keeping the temperatures of the upper blank holder and the lower blank holder of the mold consistent with the heating temperature of the aluminum alloy sheet, then, rapidly moving the heated high-temperature sheet into the heated upper blank holder and lower blank holder of the mold, rapidly closing the mold to keep the temperature, and applying a blank holder force by a blank holder slide; loading the thermal-insulated granular medium through a backpressure head; and pressing a cooling male mold to take a combined action with the thermal-insulated granular medium of a soft female mold, and after finishing molding, rapidly transferring a workpiece by clamping to 20-60 DEG C water for quenching treatment. According to the thermal molding method, thermal treatment of the aluminum alloy sheet and a flexible molding technology realized by using the soft female mold are combined by virtue of the characteristic of the thermal-insulated granular medium, and the differential temperature molding process of the sheet is realized through the synergic effect of the cooling male mold, the thermal-insulated granular medium and the high-temperature blank holders, so that the molding property of the sheet can be effectively improved; and the thermal molding method has the characteristics of high molding quality, convenience in realization, low equipment requirement and the like.

Owner:YANSHAN UNIV

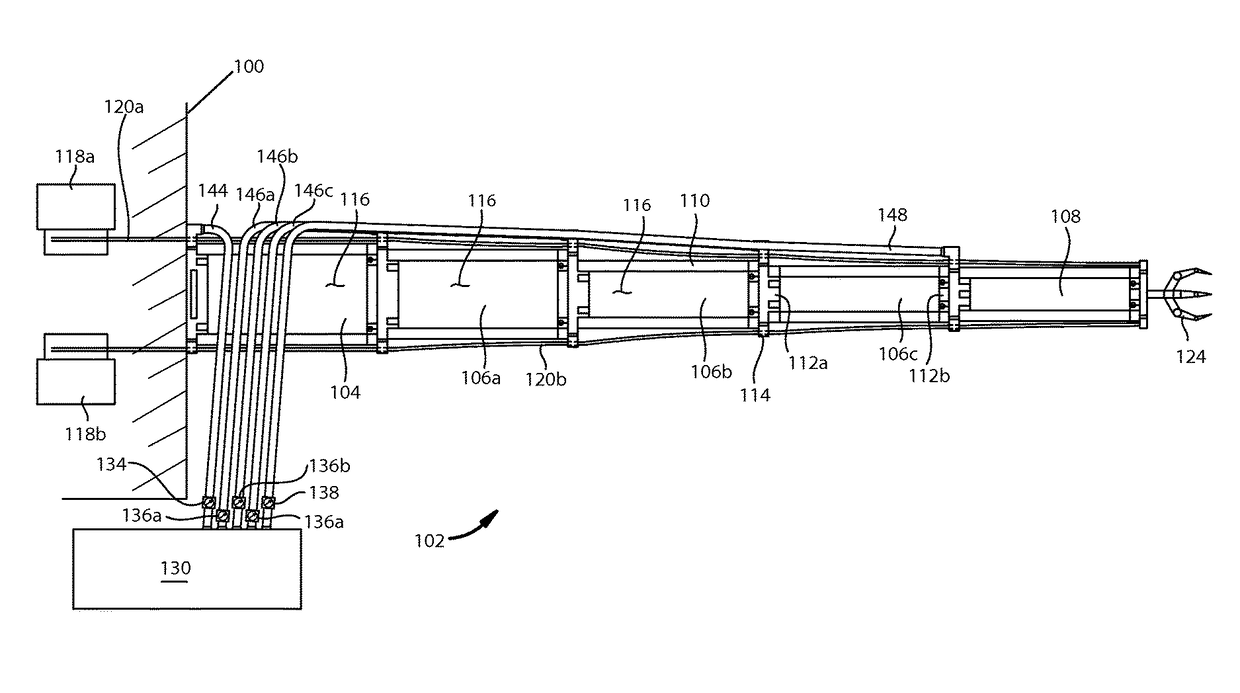

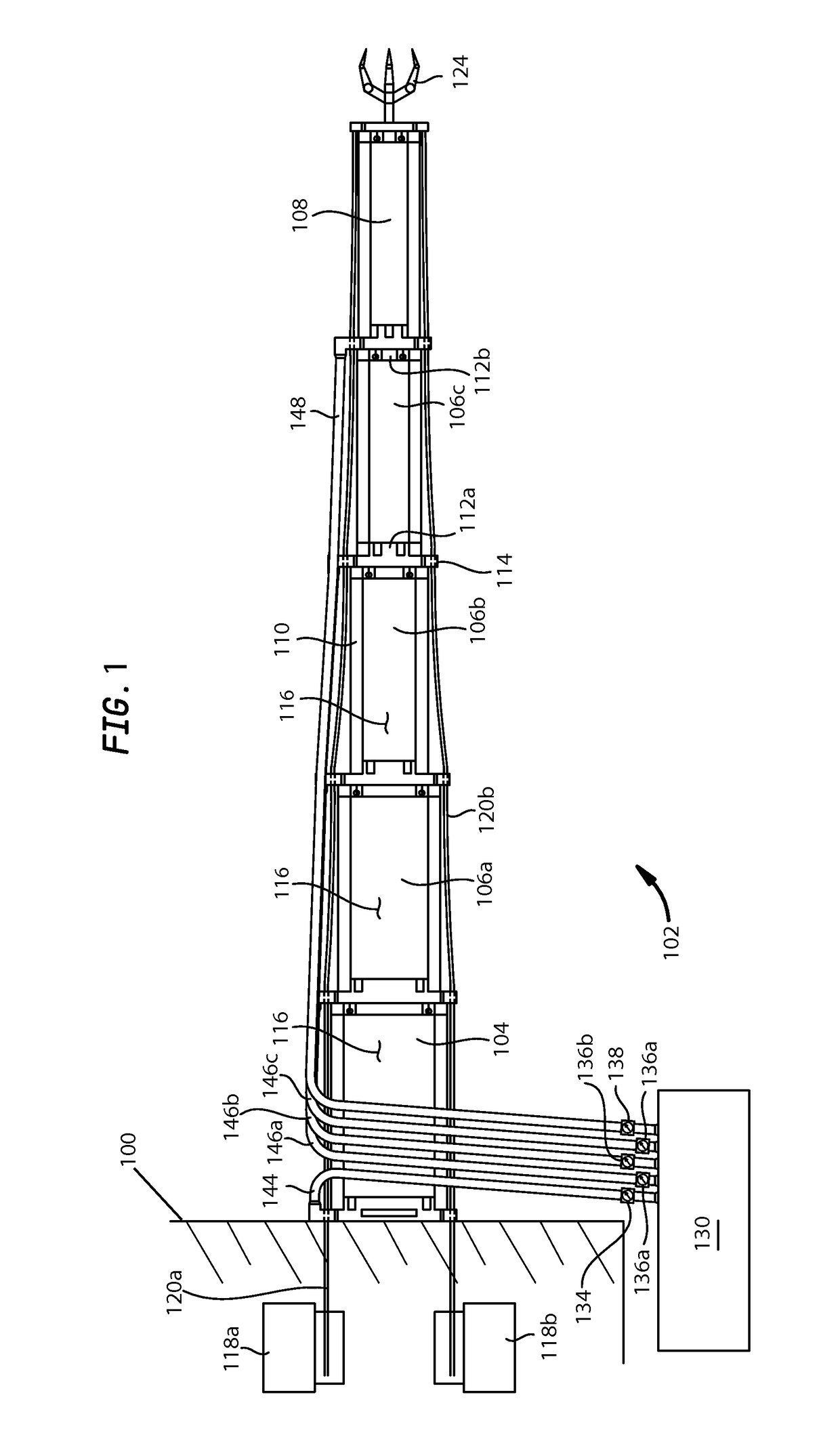

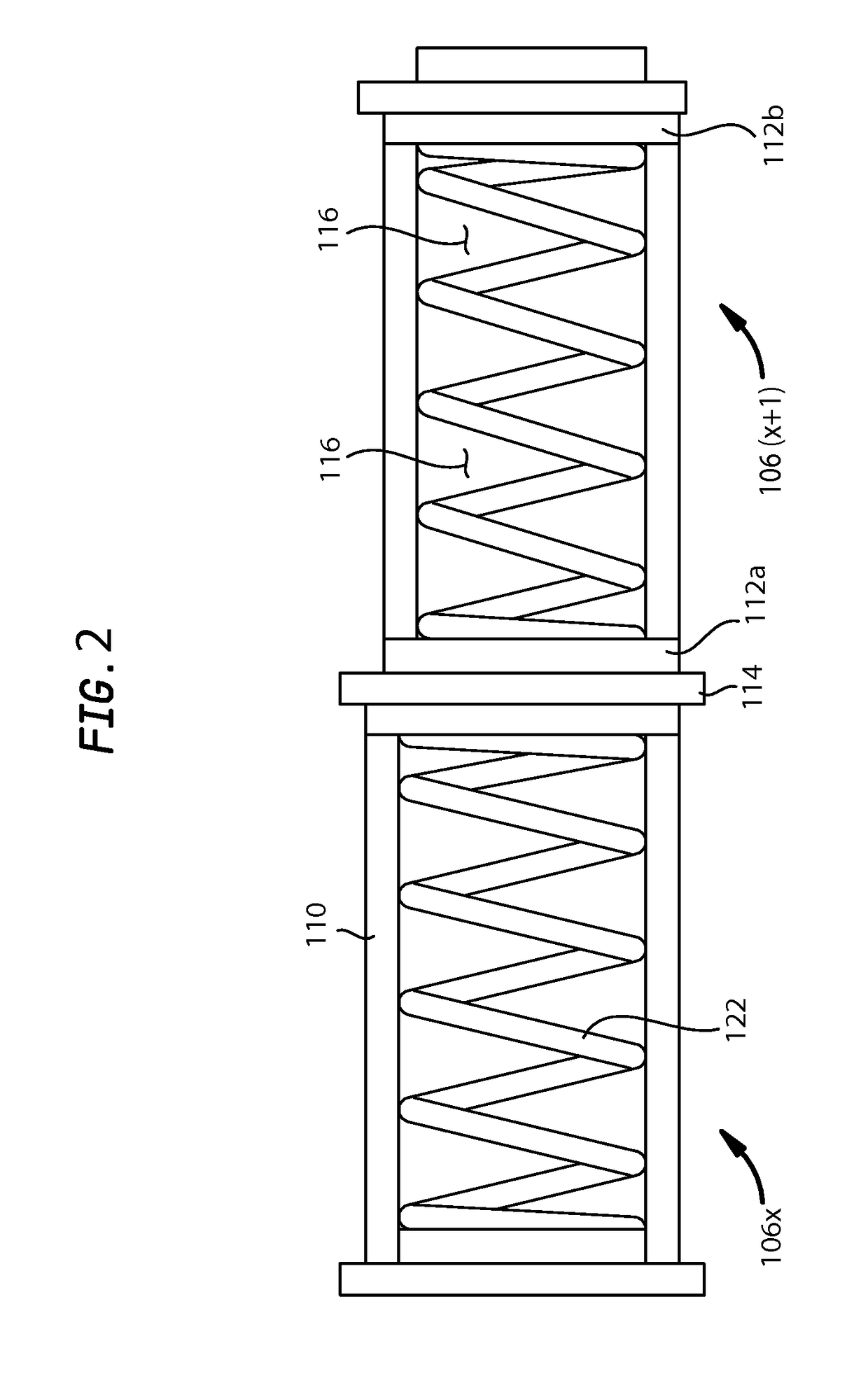

Continuum style manipulator actuated with phase change media

ActiveUS9713873B2Low costImprove clarityProgramme-controlled manipulatorMechanical apparatusEngineeringFriction angle

A continuum style manipulator is actuated by jammable media within an envelope of a module, which is also actuated by a tensile element, such as a cable and spooler motor. Multiple modules may be reversibly added. Two or more tensile elements may also be used. Three or more actuated tensile elements can actuate three DOFs of each module, and the terminal module, as well as the entire manipulator. Jammable media may be granular, actuated by a pressure change. Coarsely ground coffee works well. Rather than a jammable media, tensile elements may alternatively be used with other phase change media, such as magnetorheological and electrorheological media. A high friction angle of the granular media is desirable, and has been achieved with a particle size dispersion including both small and relatively larger particles. Applications include endoscopes, proctoscopes, laparoscopic instruments, manufacturing and medical manipulators. Methods of actuating include unjamming all modules, positioning the manipulator with tensile elements or otherwise, jamming the base-most module, and then repositioning remaining, not-jammed modules, followed by jamming the base-most not-jammed module, and so on, until all modules are positioned and jammed.

Owner:MASSACHUSETTS INST OF TECH

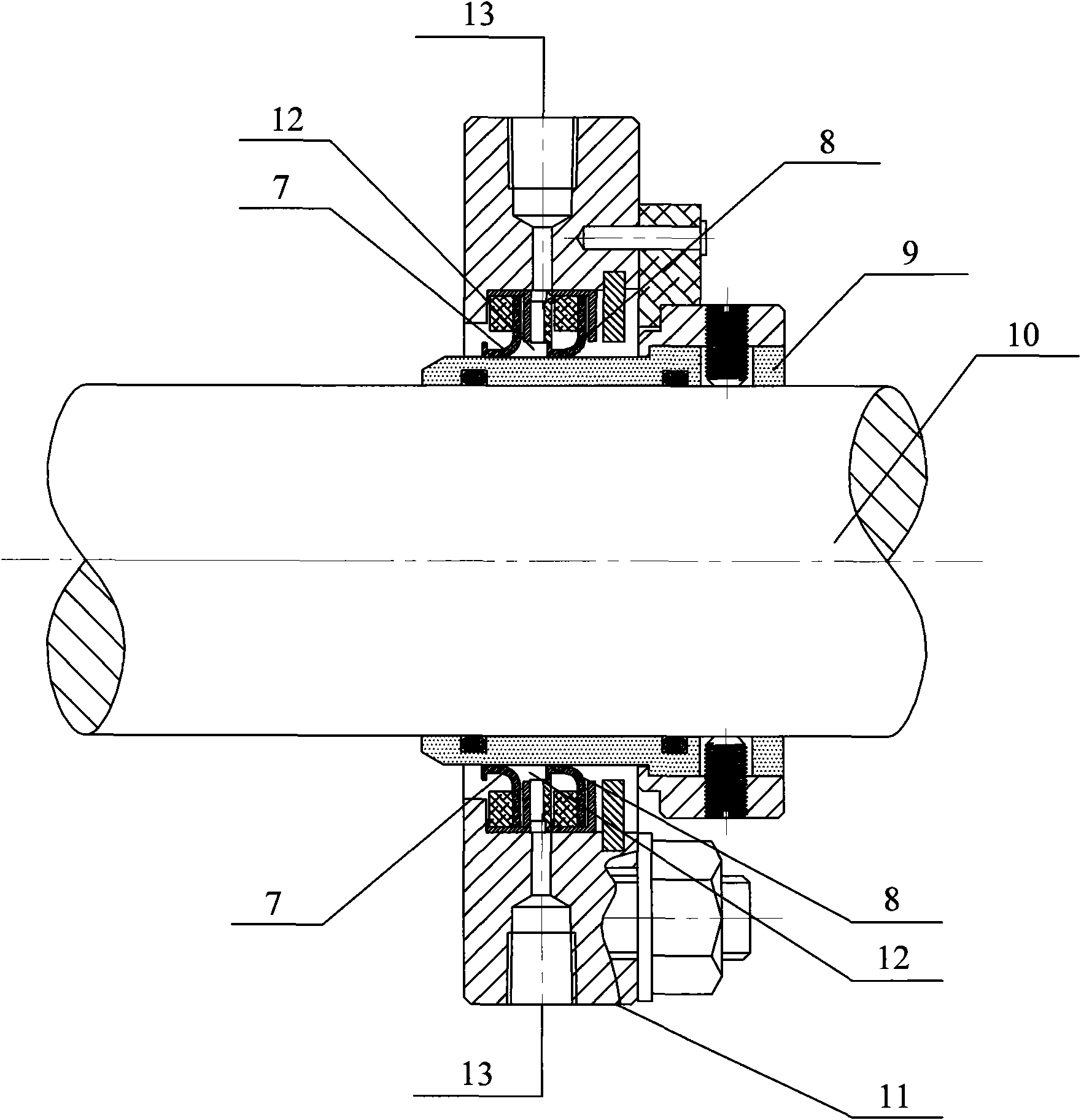

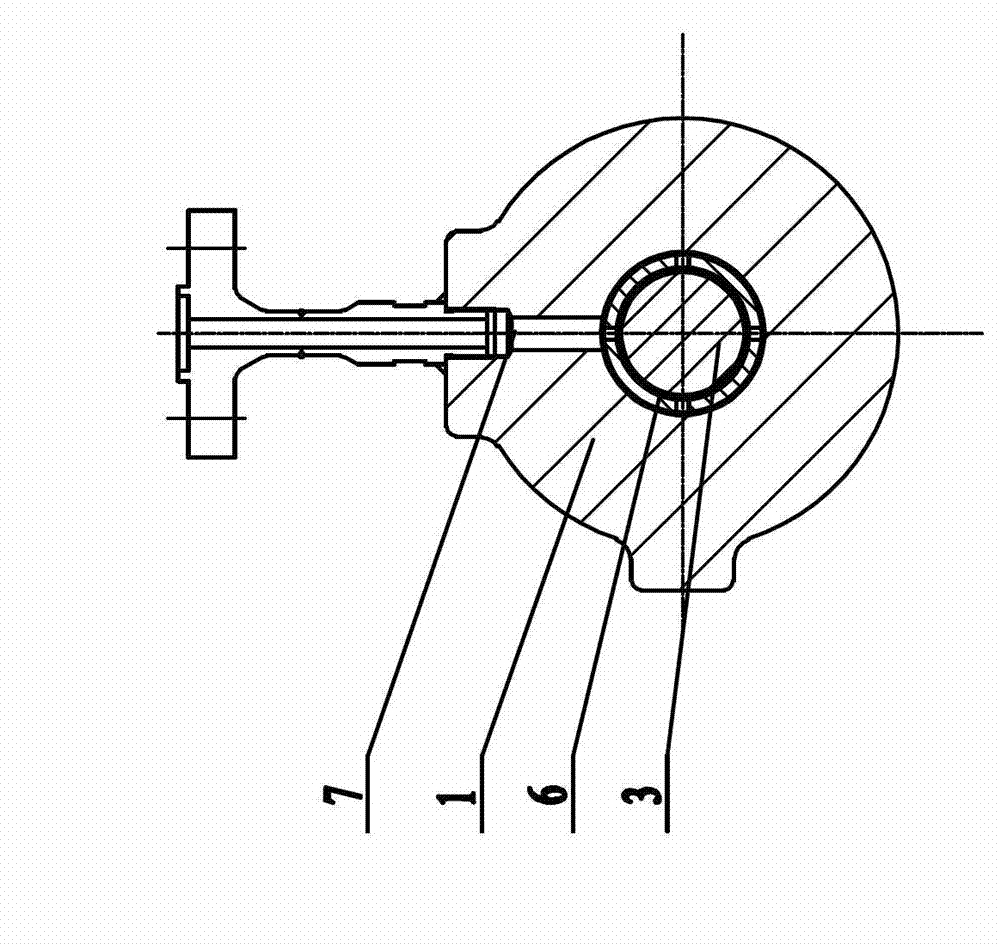

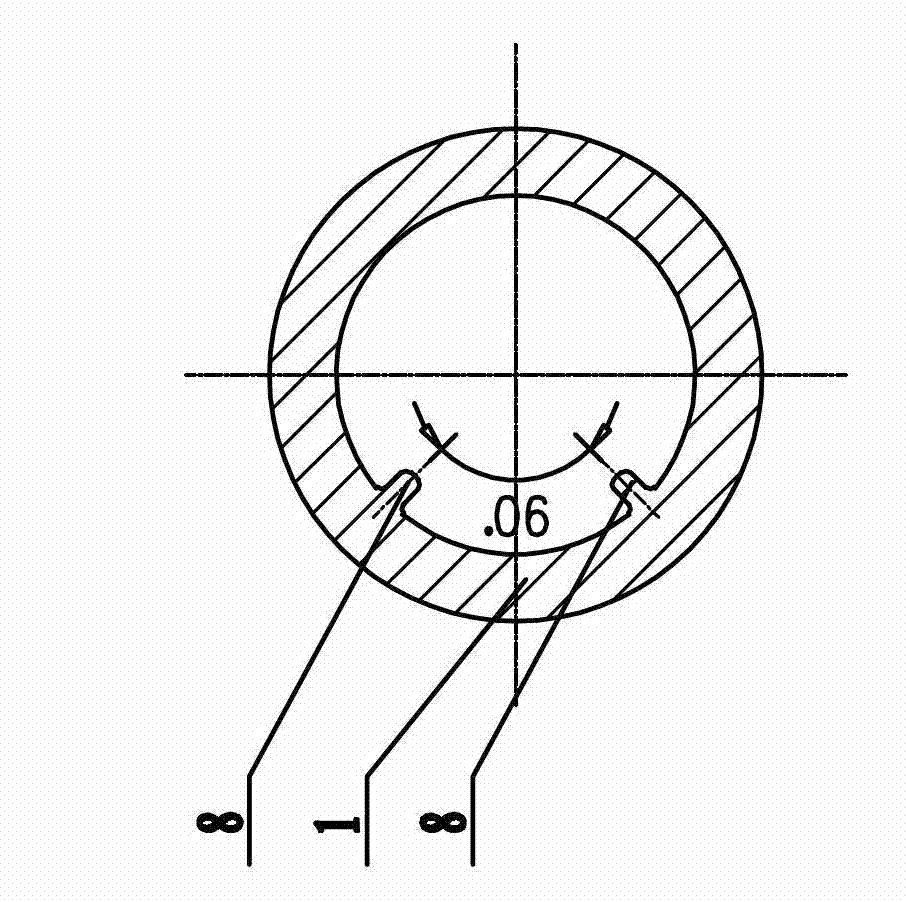

Shaft sealing device for high-temperature pressure-proof star-type feeder

The present invention provides a shaft sealing device for high-temperature pressure-proof star-type feeder, which applies mechanical sealing to combine with gas sealing phase, including a rotation shaft 4, high abrasion-proof shaft sleeve 3, a first lip seal 1, a second lip sealing 2 and a body case 5, in pneumatic conveying device of dry granular medium, the invention provided technical scheme can assure to prolong service life of the shaft end sealing device and improve its performance at a certain pressure (0.6 MPa) and temperature (maximum 300DEG).

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

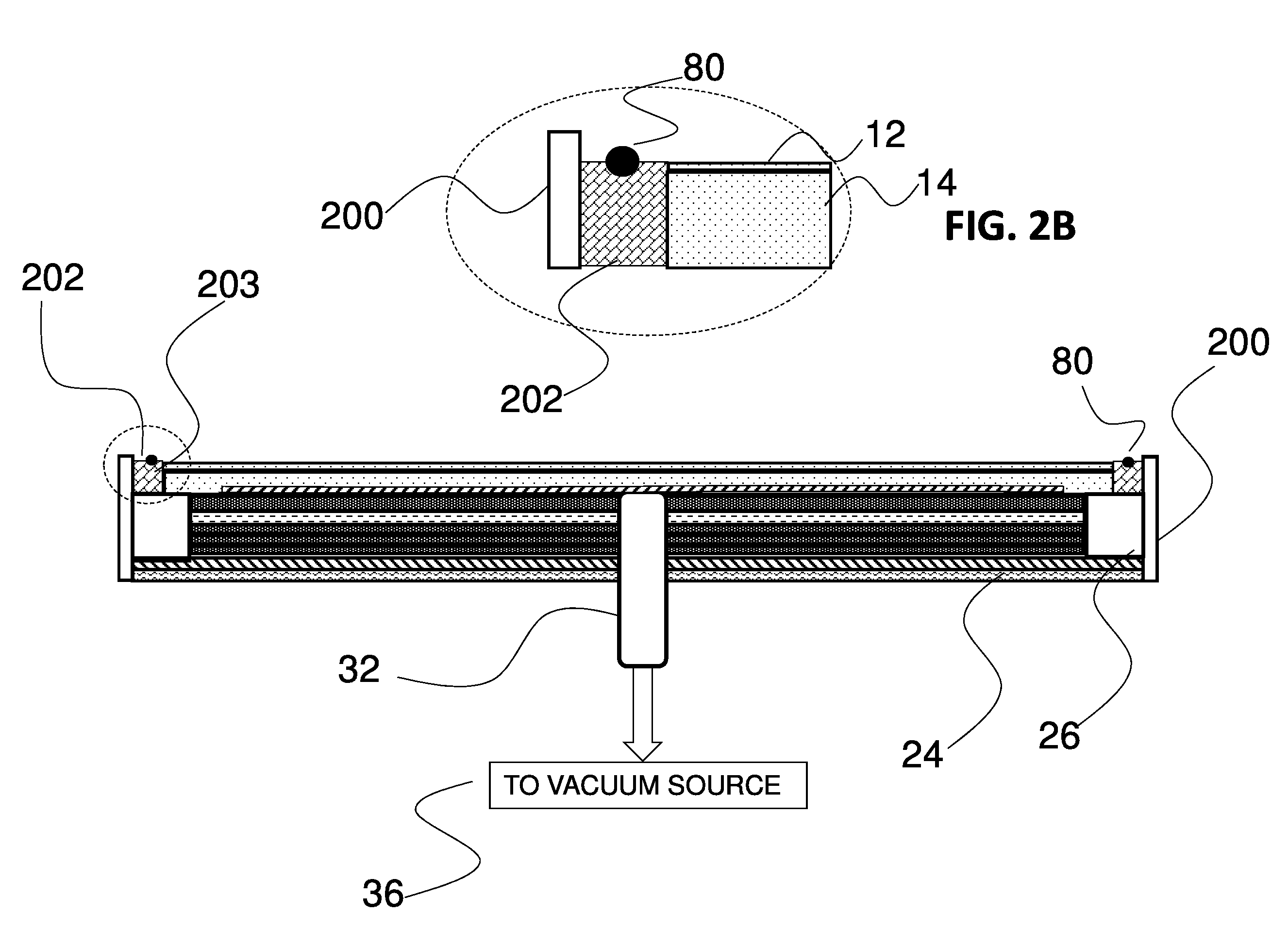

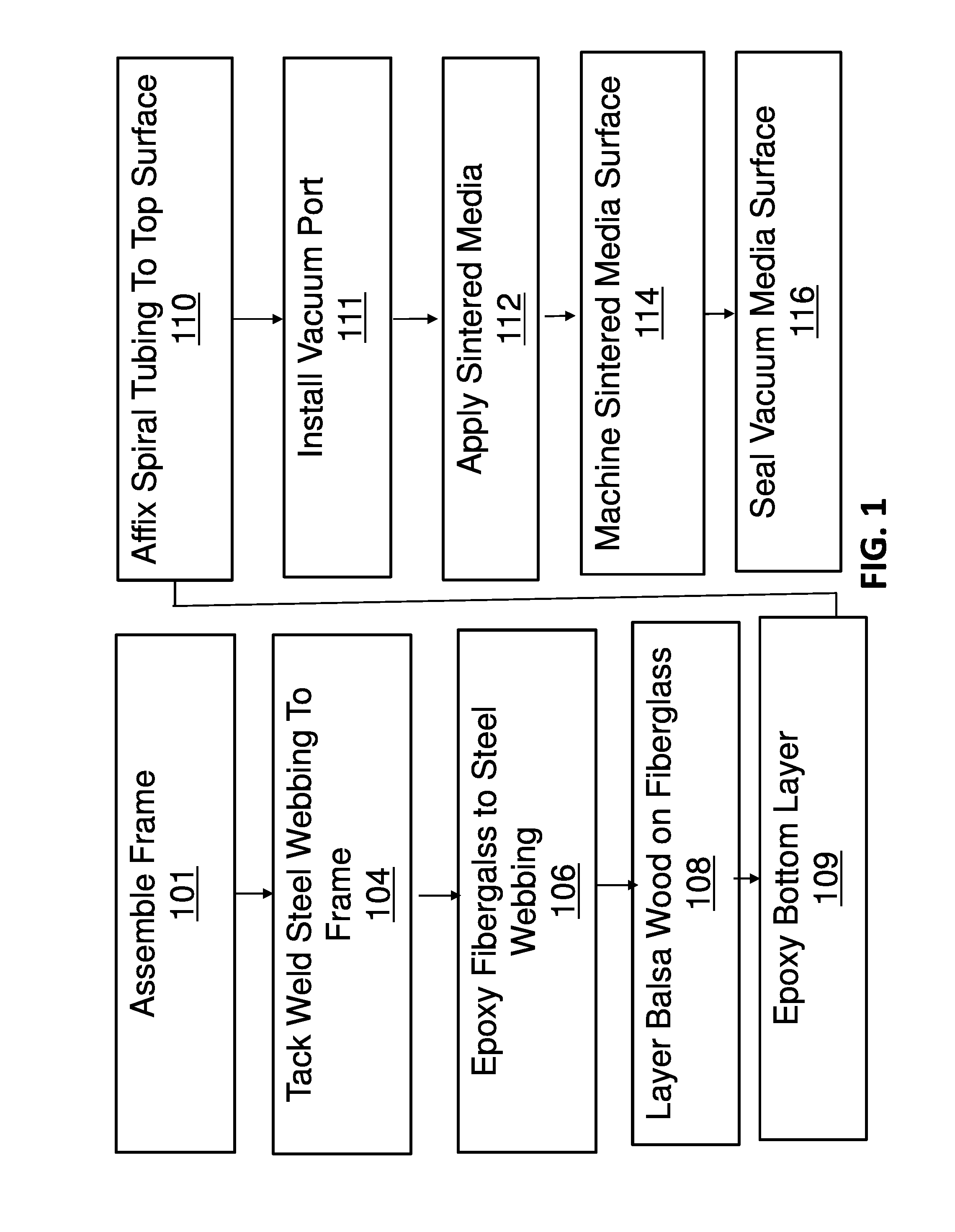

Method for fabricating vacuum fixturing using granular media

A method for fabricating vacuum tooling is disclosed using porous granular media. A sheet of steel webbing is affixed to a frame. A plurality of layers of fiberglass is affixed to the webbing. A vacuum port is installed through the webbing and plurality of layers of fiberglass. A granular media is mixed with epoxy to form a granular mixture. The granular mixture is layered over the plurality of layers of fiberglass to form a flat surface and machined for uniformity before sealing.

Owner:TECHNICAL TOOLING L L C +1

Screenless granular media filters and methods of use

InactiveUS8152998B2Ion-exchanger regenerationWater/sewage treatment by ion-exchangeFilter mediaEngineering

A liquid filtering apparatus is placed in a vessel having a bed of filtration material, the bed comprising at least two different sizes of filter media wherein the filtration material is stratified using upper and lower spaced apart inverted cones so that the unfiltered liquid first contacts coarse grained filtration material and then finer grained filtration material. The apparatus includes an intake for introducing unfiltered liquid that includes a washbox, an airlifting tube extending from the washbox and including an intake end and means for introducing a primary gas to the airlifting tube, the airlifting tube passing through a central pipe, which extends from just below the washbox to a position just above the intake end. The apparatus is devoid of screen cartridges. Methods of filtering and cleaning the filtration material are also disclosed.

Owner:ALFA LAVAL ASHBROOK SIMON HARTELY INC

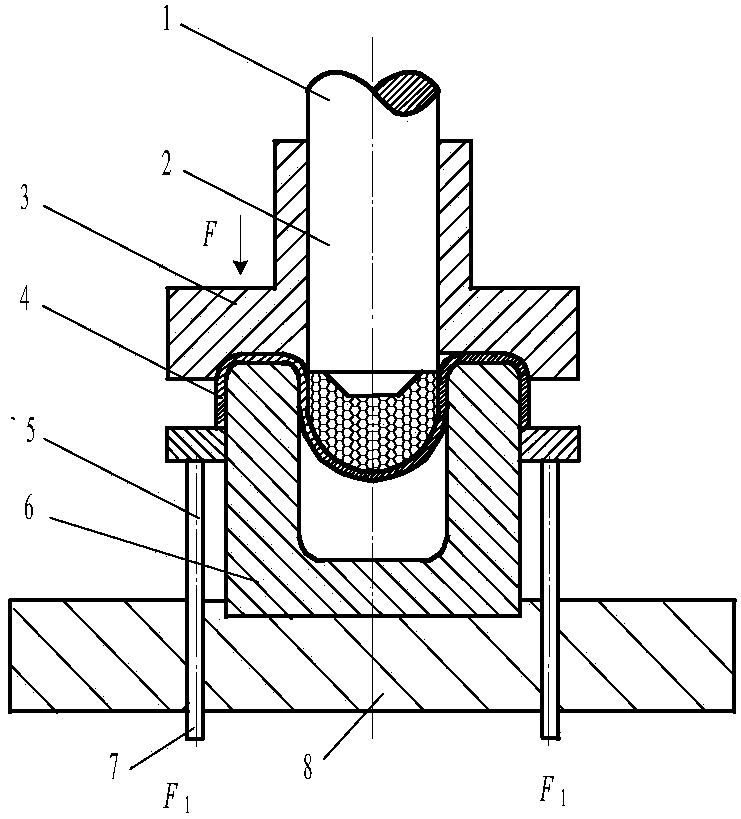

Reverse drawing method for soft die with peripheral auxiliary thrust

The invention discloses a reverse drawing method for a soft die with peripheral auxiliary thrust. Reverse drawing equipment for implementing the reverse drawing method mainly comprises a punch, granular media, a blank holder, a plate, a thrust ring, a female die, an ejector rod, a base and the like. When the plate is formed, a preliminarily formed cylindrical part of the plate is fastened on the female die, the blank holder exerts blank holding force, the punch descends to compress the granular media, pressure is applied to the preliminarily formed cylindrical part of the plate, a soft male die can be formed, force is applied to the thrust ring by the ejector rod, and accordingly the peripheral auxiliary thrust can be applied to the cylindrical part; after drawing is completed, a workpiece clings to the inner wall of the female die, and can be finally shaped. Compared with the traditional forming method, the reverse drawing method has the advantages of simple structure, energy conservation, environmental protection and capability of obviously upgrading forming limit on plate parts.

Owner:YANSHAN UNIV

Software robot actuator with rigidity independently controllable

InactiveCN109048856AChange the stiffnessIncrease stiffnessProgramme-controlled manipulatorGripping headsExpansion chamberActuator

The invention provides a software robot actuator with rigidity independently controllable. The software robot actuator with rigidity independently controllable comprises a gas actuation portion and arigidity adjustment portion. The rigidity adjustment portion comprises a rigidity adjustment chamber and a granular medium yarn bag. The rigidity adjustment chamber is located at the bottom of the gasactuation portion. The granular medium yarn bag is tiled inside the rigidity adjustment chamber. The rigidity of the actuator is changed by changing the gas pressure in the rigidity adjustment chamber. The upper surface of the gas actuation portion is zigzag. The rigidity adjustment chamber is adhered to the lower surface of the gas actuation portion. The gas actuation portion comprises a plurality of gas actuation expansion chambers. Each gas actuation expansion chamber is arranged inside one single saw tooth, and every two adjacent gas actuation expansion chambers communicate with each other through an internal channel. According to the software robot actuator with rigidity independently controllable, the rigidity of the gas actuator can be changed on the premise that the motion flexibility is not affected, and the controllability is higher.

Owner:JIANGSU UNIV

Special material regulating angle valve for high-pressure hydrogenation reaction

InactiveCN102927299AAffect the circulation capacityEliminate dead zoneLift valveValve housingsHydrogenation reactionGranular media

The invention relates to a special material regulating angle valve for a high-pressure hydrogenation reaction. A valve seat is fixed on a valve body, a valve rod is spliced in the valve body in a sealing and sliding manner, a valve core is in integrated connection with the bottom end part of the valve rod, an auxiliary guide seat is mounted between the valve body and the valve seat, an anti-erosion sleeve is mounted on the auxiliary guide seat, one end of the anti-erosion sleeve is embedded into the auxiliary guide seat, the other end of the anti-erosion sleeve is embedded into the valve body, and the valve rod is spliced in the anti-erosion sleeve in a sliding manner. With the adoption of the special material regulating angle valve, the accumulation of a medium on an inner wall is prevented, the erosion of the high speed medium to internal pieces of the valve is reduced, the valve rod is not blocked by the granular medium, the service life of the valve rod is prolonged, and the stability and reliability of the auxiliary guide seat are ensured.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com