Patents

Literature

125results about How to "Lower carbon dioxide levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

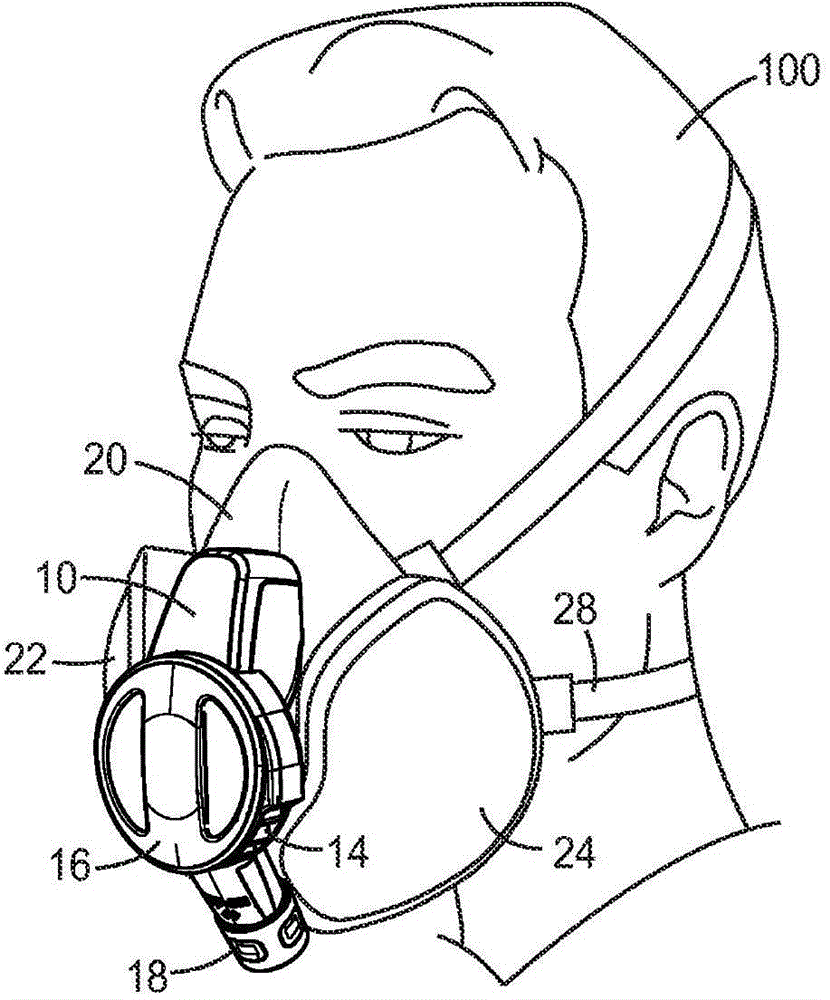

Personal protective suit with partial flow restriction

InactiveUS6948191B2Lower carbon dioxide levelsReduced measured CO levelChemical protectionHeat protectionNoseEngineering

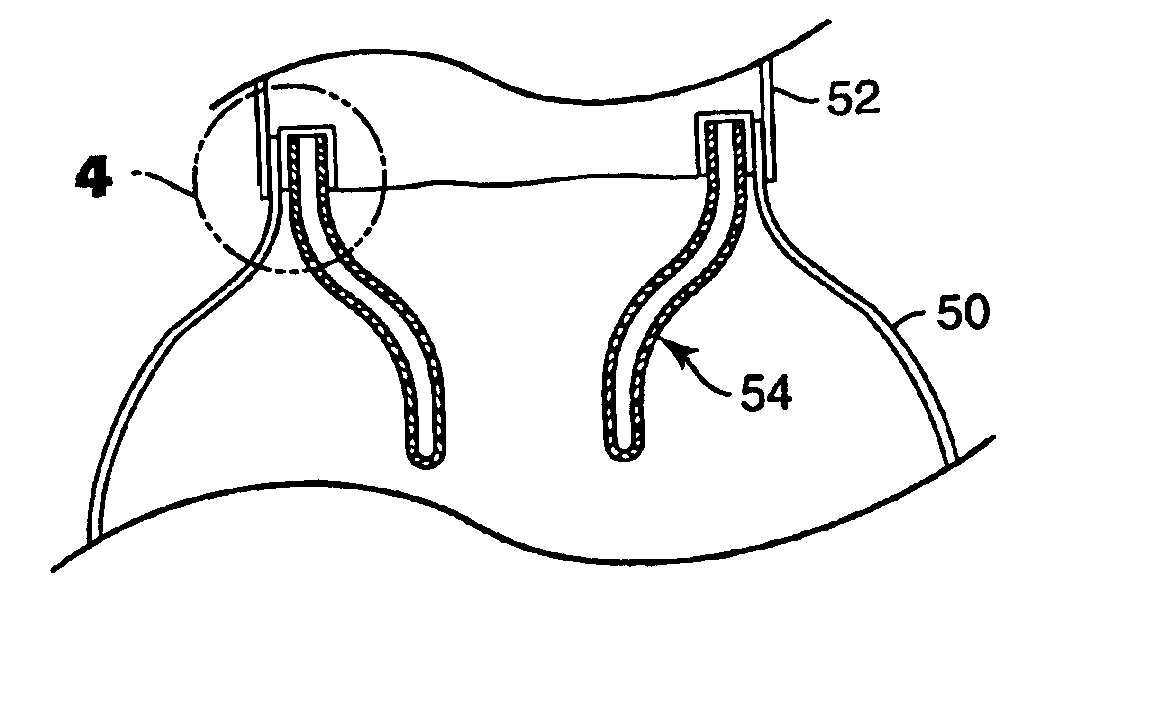

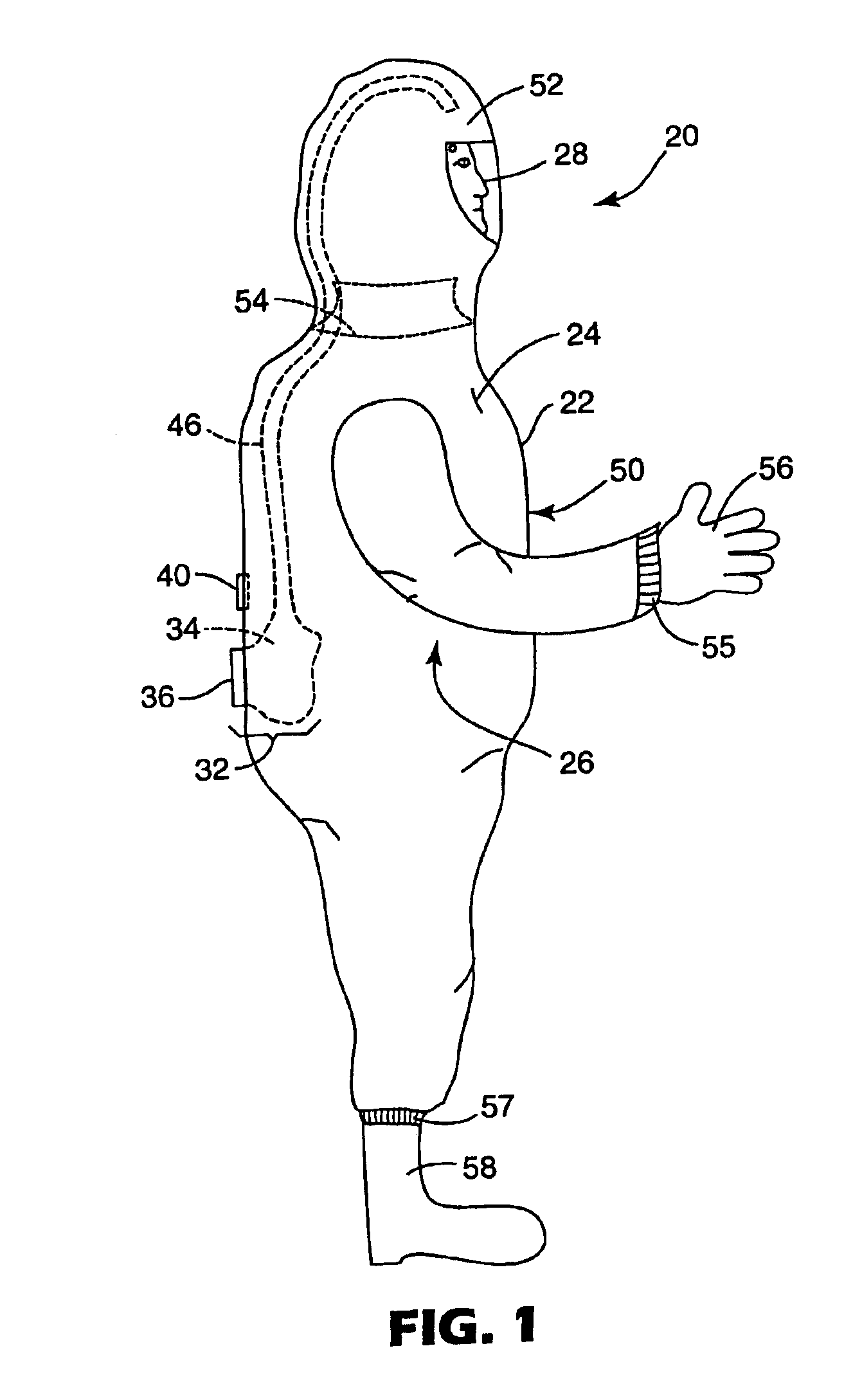

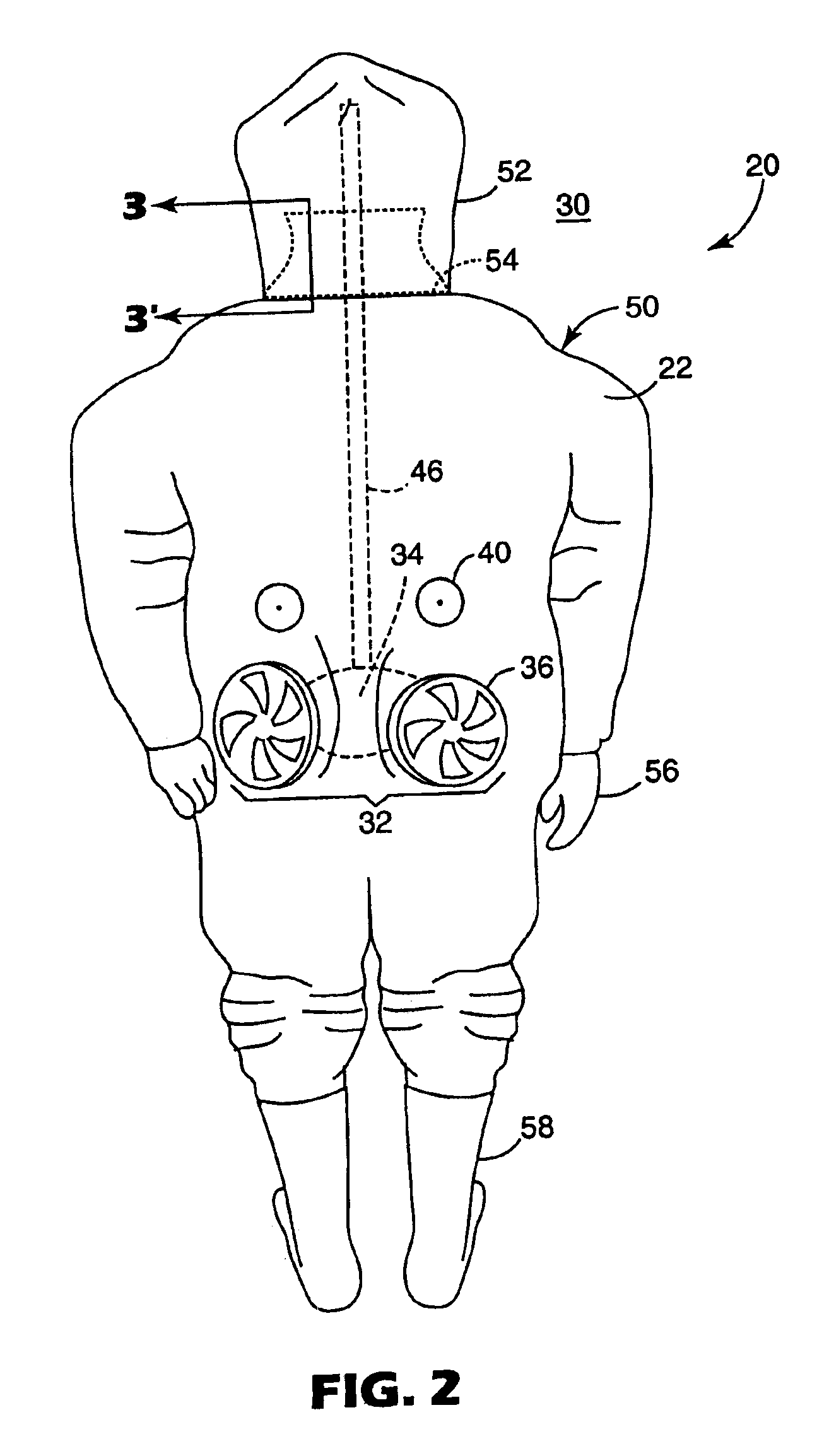

A personal protective suit for a wearer includes a hood portion located generally above the wearer's neck and at least partially enveloping the wearer's nose and mouth, a body portion located generally below the wearer's neck and at least partially enveloping the wearer's torso, an air delivery system that can deliver air to the hood portion, a vent that can permit gasses to escape from the body portion, and a partial flow restriction between the hood portion and body portion of the suit. The partial flow restriction permits gasses to pass from the hood portion to the body portion while reducing carbon dioxide levels in front of the wearer's mouth. The suit can be fabricated without requiring a face piece.

Owner:3M INNOVATIVE PROPERTIES CO

Absorbent for deeply removing carbon dioxide

The invention provides an absorbent with deep removal of carbon dioxide, comprising water and alcohol amine; the improvement thereof is as follows, the alcohol amine is mixed solution of more than two types of alcohol amine, one of which is methyldiethanolamine (MDEA); the concentration by the weight percentage of the mixed alcohol amine solution is 45 percent to 50 percent; the concentration by the weight percentage of the methyldiethanolamine (MDEA) in the mixed alcohol amine solution is 30 percent to 40 percent; the absorbent is used in the deep removal technology of the carbon dioxide of natural gas, the content of the carbon dioxide in purified gas can be reduced to 50ppmv; the energy consumption of a reboiler of a regeneration tower can also be reduced, the degree of degradation and metamorphism of the absorbent can be reduced; the corrosion to a decarbonization system device and a pipeline can further be alleviated, the loss of the absorbent can be simultaneously reduced, the operation cost is low and the effect is satisfactory.

Owner:CHINA NAT OFFSHORE OIL CORP +1

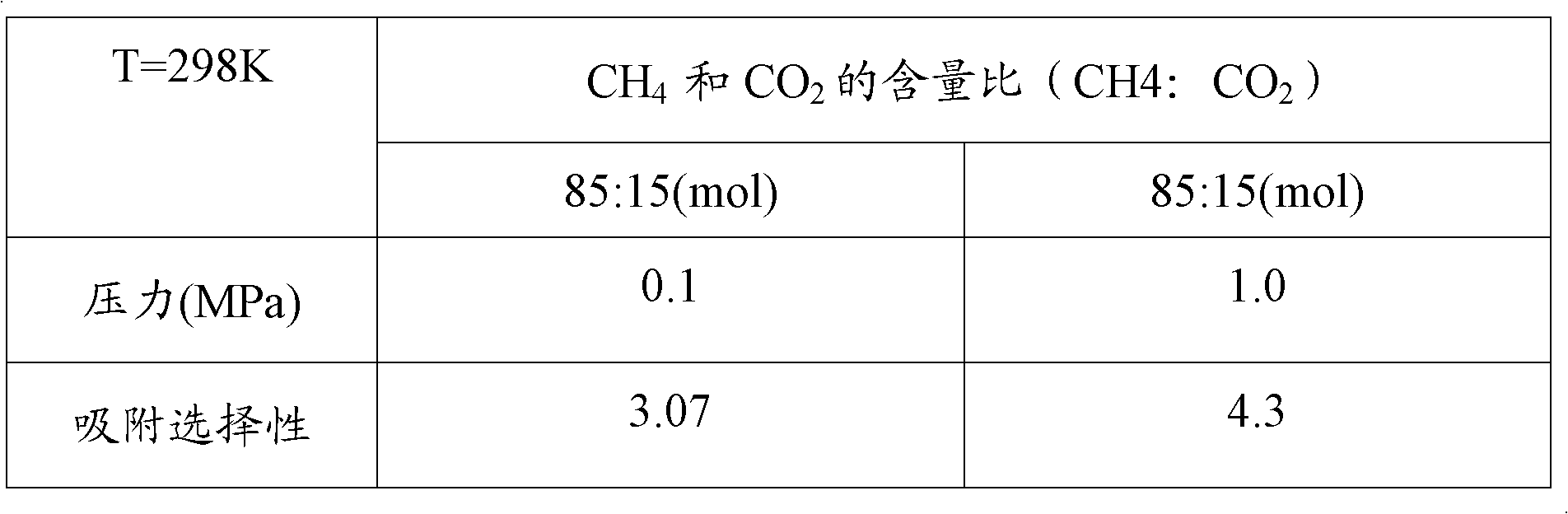

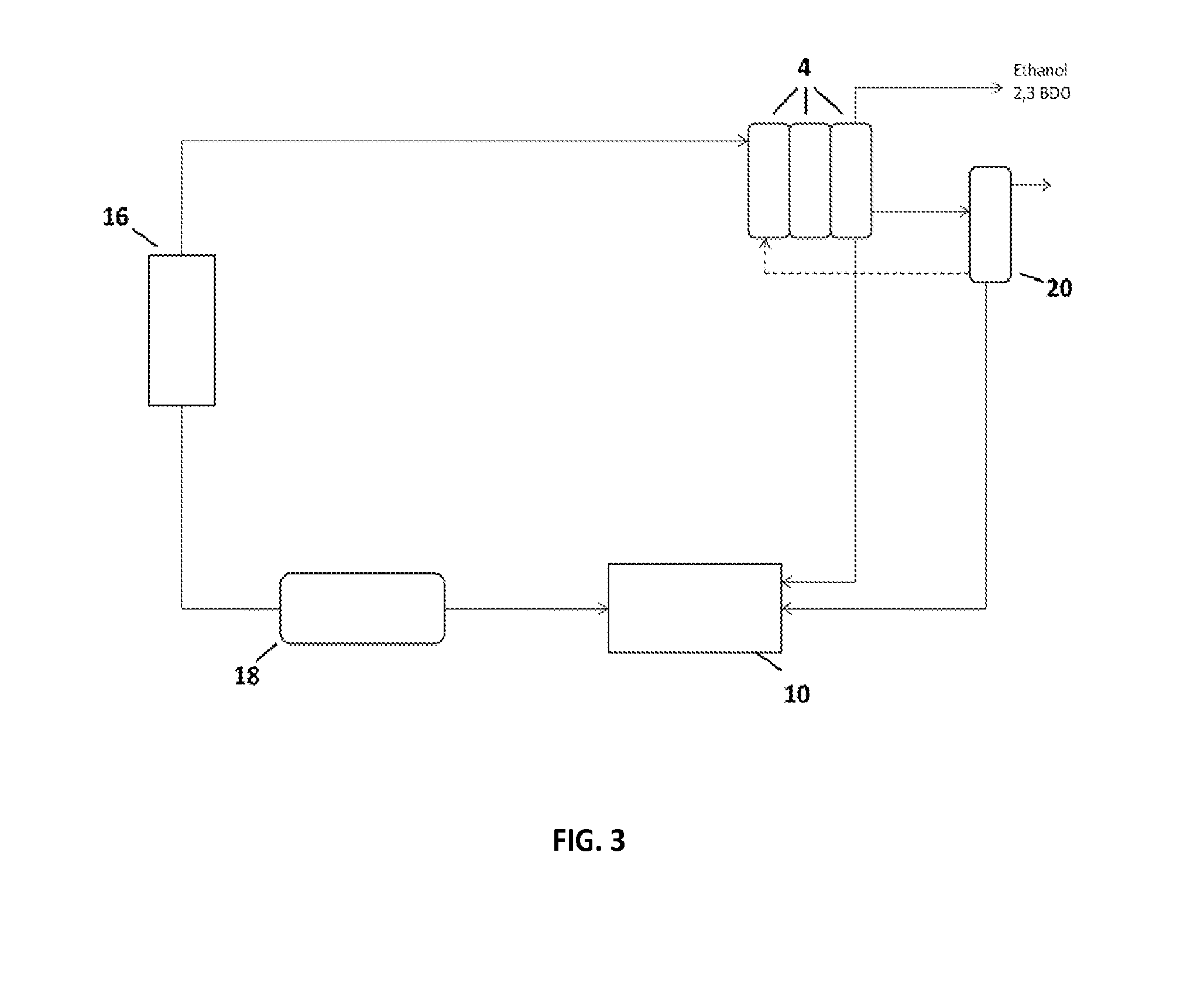

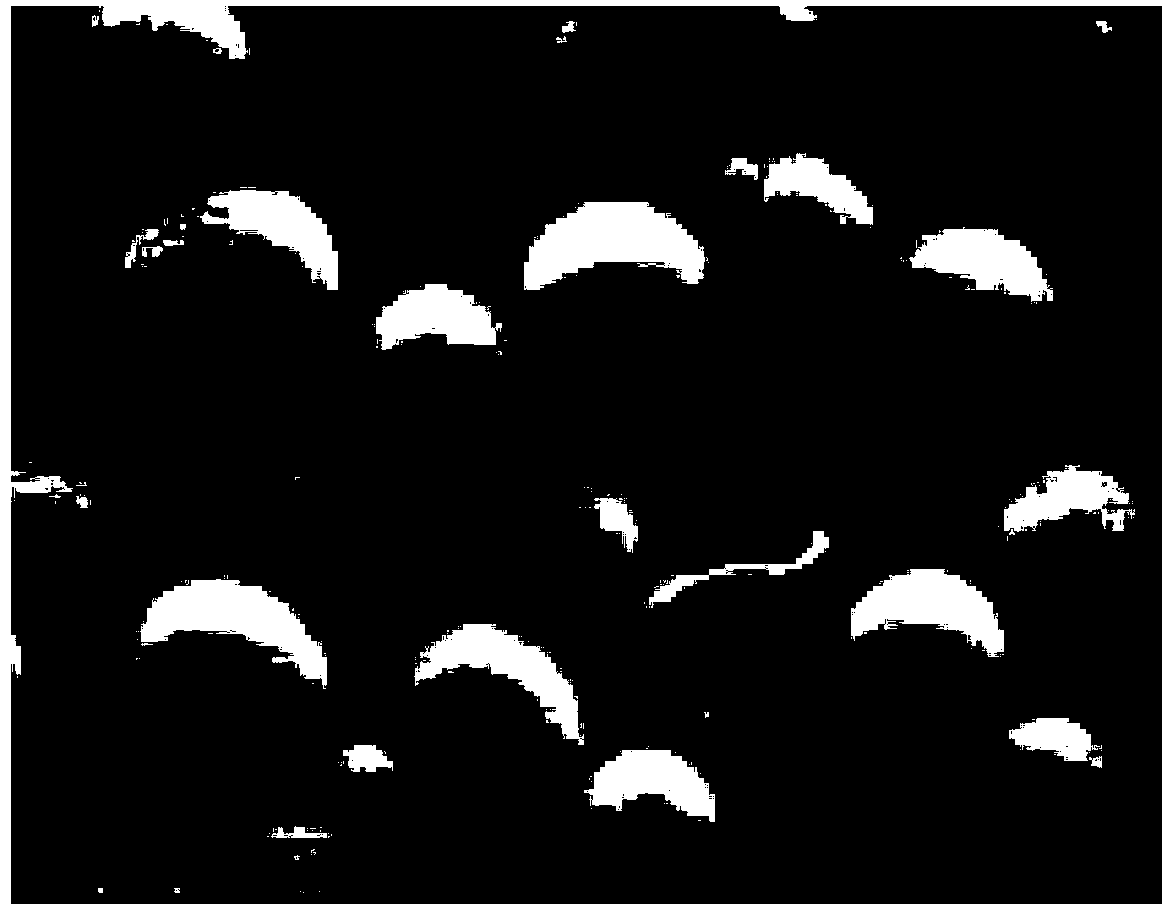

Method for removing carbon dioxide in natural gas by utilizing novel high specific surface active carbon material

InactiveCN102031171AGuaranteed selectivityLower carbon dioxide levelsOther chemical processesGaseous fuelsActivated carbonDesorption

The invention relates to a method for removing carbon dioxide in natural gas by utilizing a novel high specific surface active carbon material. The method comprises the following steps of: washing the active carbon material in a reactor by utilizing an inert gas; heating and removing impurities; vacuumizing, and introducing the natural gas to the reactor filled with the active carbon material; adsorbing the carbon dioxide and discharging the carbon dioxide-removed natural gas; then reducing the pressure to a normal pressure, and then desorbing a nitrogen gas through the active carbon material at the room temperature to obtain the carbon dioxide-removed natural gas. By utilizing the adsorption method of the active carbon material, the content of the carbon dioxide in the natural gas can be reduced to 0.05 volume%, the volume of the treated natural gas is more than 1,000 times that of the active carbon material of the method, the selectivity is still kept through adsorption and desorption cycles, therefore, the active carbon material of the method can satisfy the actual use requirement and has favorable application prospect.

Owner:BEIJING UNIV OF CHEM TECH

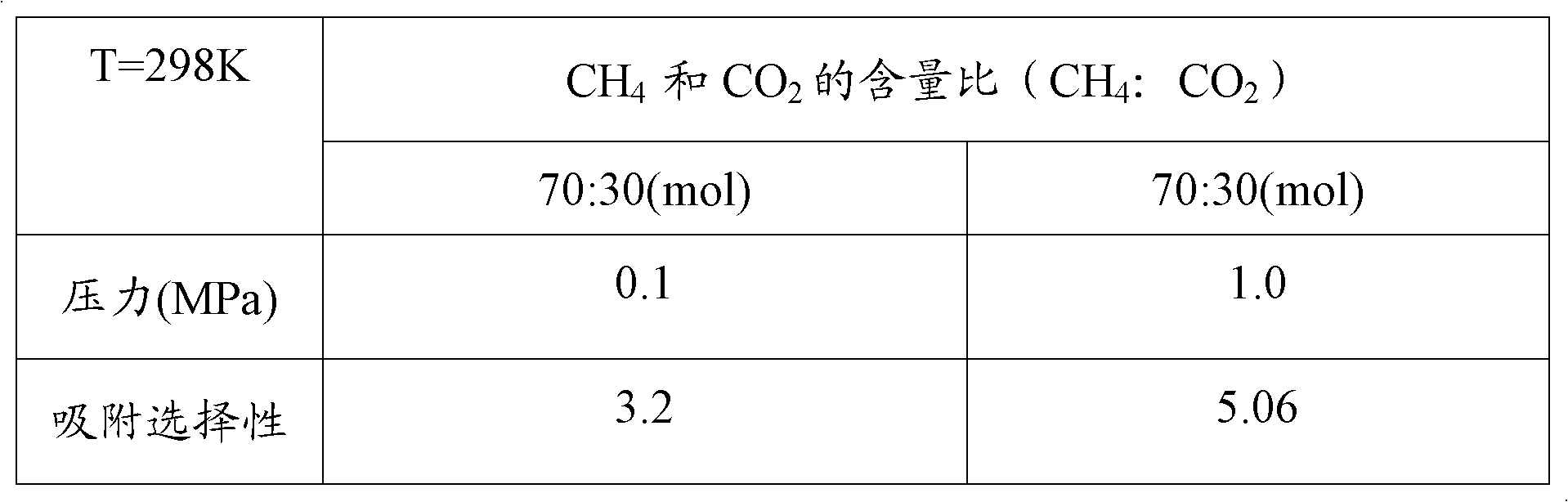

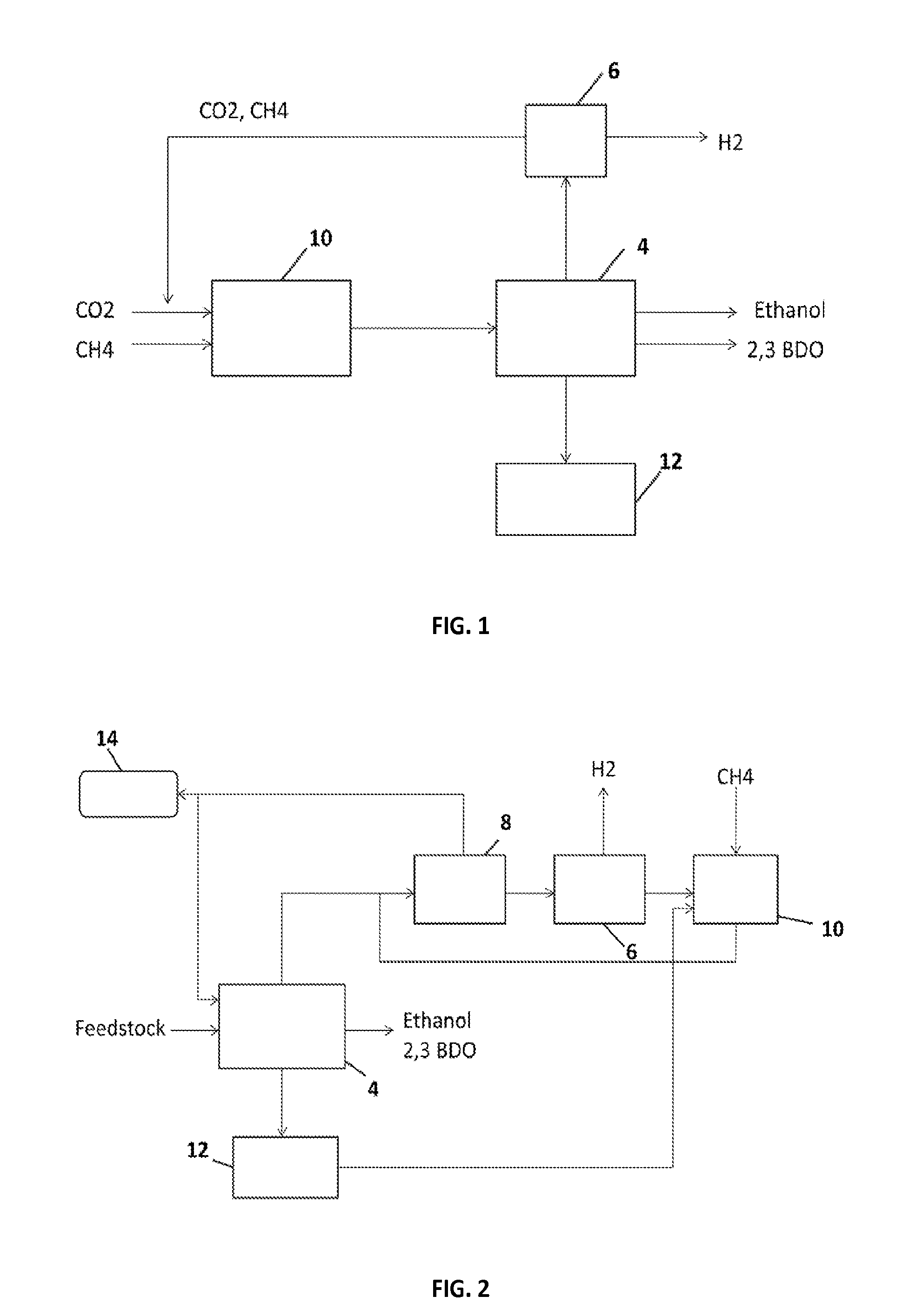

Methods and Systems for the Production of Hydrocarbon Products

InactiveUS20130203143A1Lower carbon dioxide levelsImprove filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorHydrocarbon

Methods and systems for the production of hydrocarbon products, including providing a substrate comprising CO to a bioreactor containing a culture of one or more micro-organisms; and fermenting the culture in the bioreactor to produce one or more hydrocarbon products. The substrate comprising CO is derived from a CO2 reforming process.

Owner:LANZATECH NZ INC

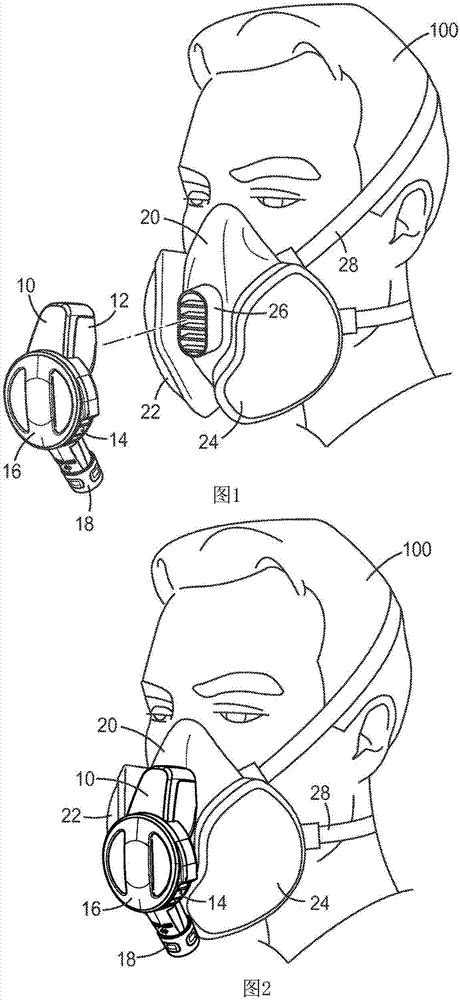

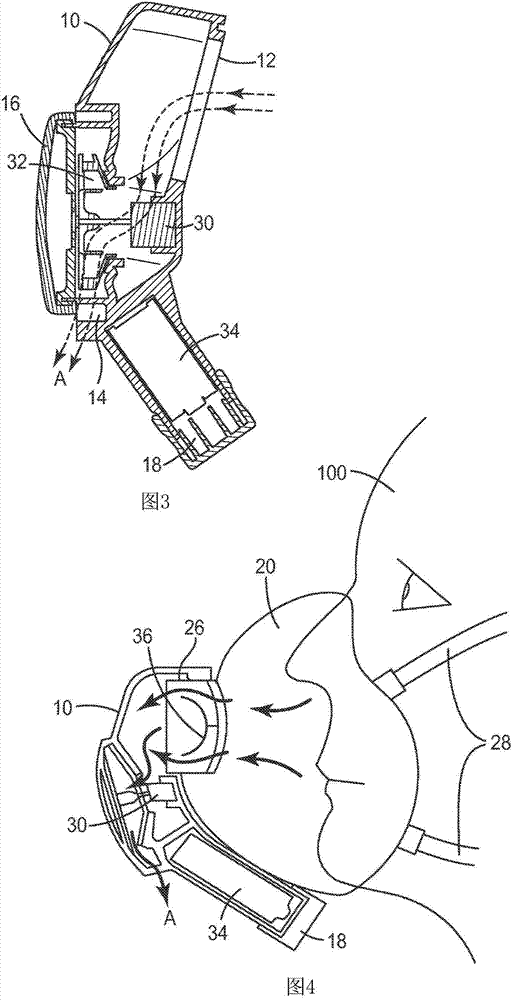

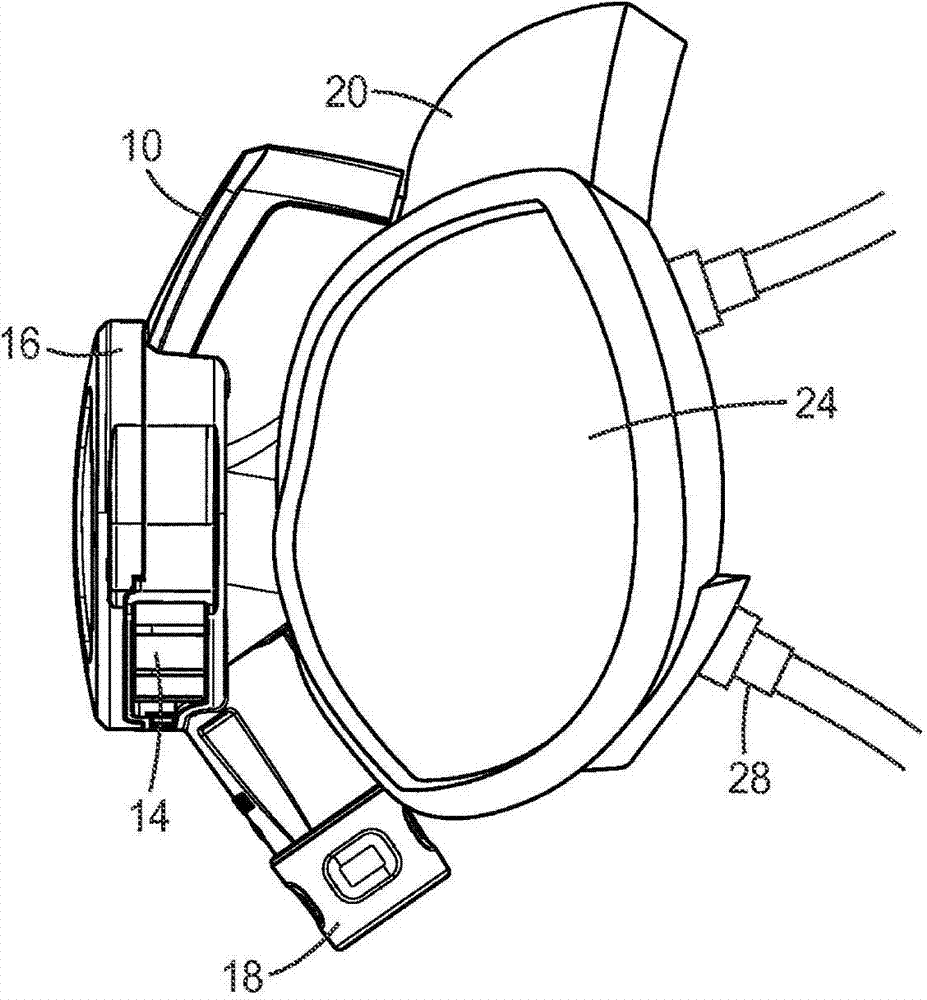

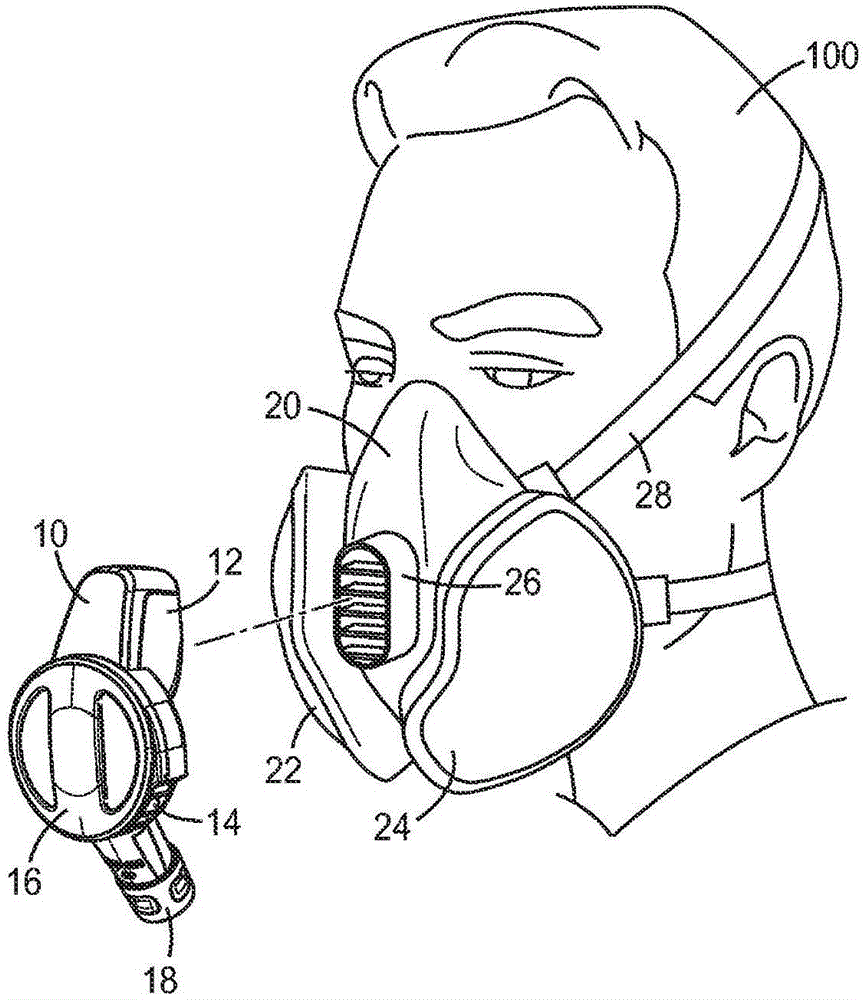

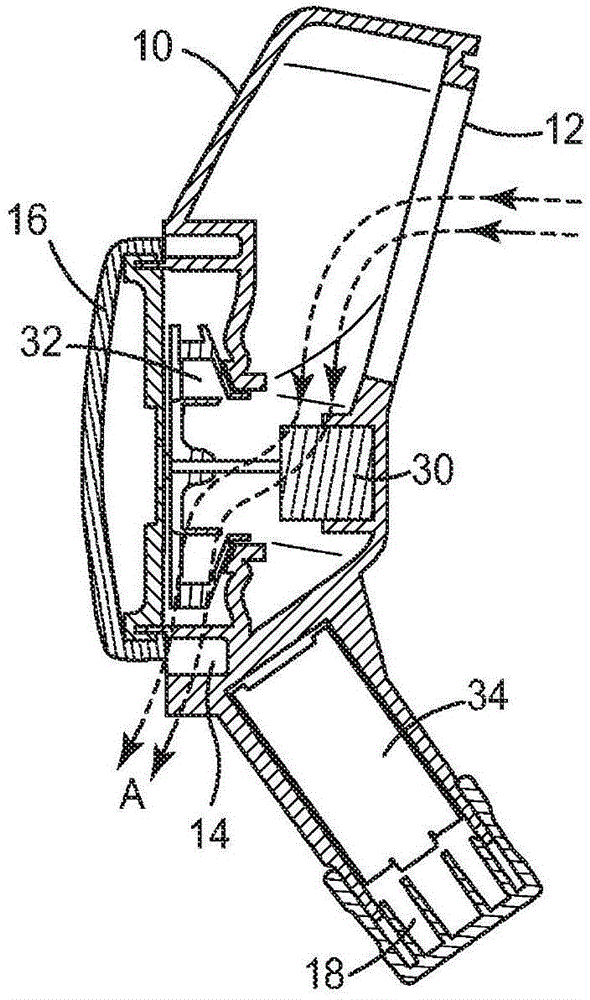

Powered exhaust apparatus for a personal protection respiratory device

InactiveCN104780979AImprove comfortImprove experienceBreathing filtersBreathing masksAir volumeRespirator

The present invention relates to an exhaust apparatus for releasable or permanent connection to a personal protection respiratory device that defines a filtered air volume adjacent to the face of a wearer and comprises at least one exhalation valve. The exhaust apparatus comprising a powered blower in fluid connection with the at least one exhalation valve, the blower being operable to draw a portion of the wearer's exhaled breath through the at least one exhalation valve. Using such an exhaust apparatus for releasable connection to a personal protection respiratory device improves the comfort and overall experience for respirator wearers who use the respirator for intensive work, and / or for long periods of time, and / or in hot and humid environmental conditions by removing the heat and moisture build-up inside the respirator.

Owner:3M INNOVATIVE PROPERTIES CO

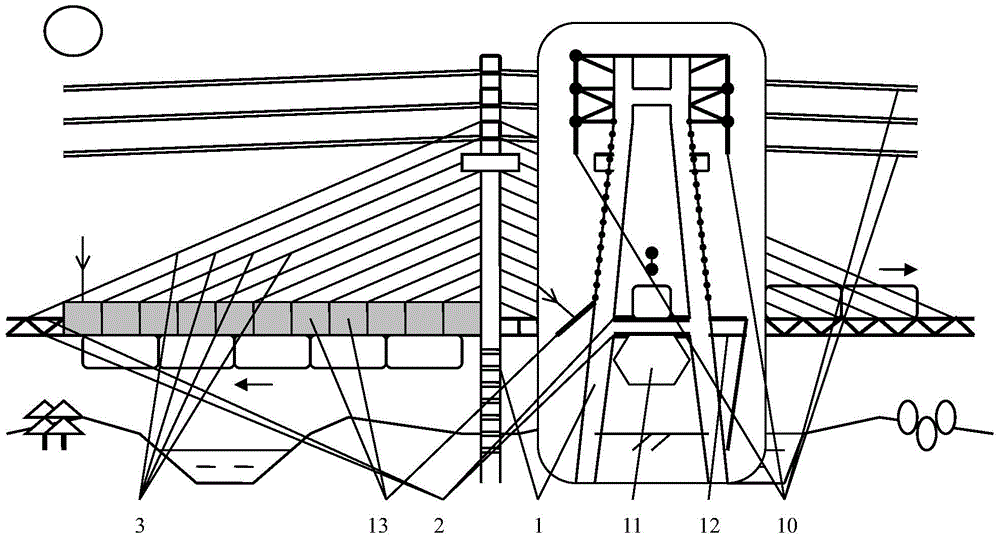

Delivery vehicle with embedded driving-cab connection interface

InactiveCN105015556ALow costInsensitive to geological conditionsElevated railway without suspended vehicleRailway transportControl systemDelivery vehicle

The invention discloses a delivery vehicle with an embedded driving-cab connection interface. The delivery vehicle comprises a compartment, a vehicle lamp system, and pneumatic tyres at front-rear rows. The delivery vehicle is characterized by comprising a connection interface of an embedded driving cab, wherein the embedded driving cab comprises a direction control system, a power storage-battery box, the vehicle lamp system, an electrical connection interface of electric wheel groups of the delivery vehicle, and a control-signal connection interface of the electric wheel groups of the delivery vehicle; one hydraulic regulating device is arranged between each of the pneumatic tyres at the front-rear rows and the compartment. The invention provides low-environment-load transportation equipment for food energy which can be provided in vast undeveloped land.

Owner:潘香凤

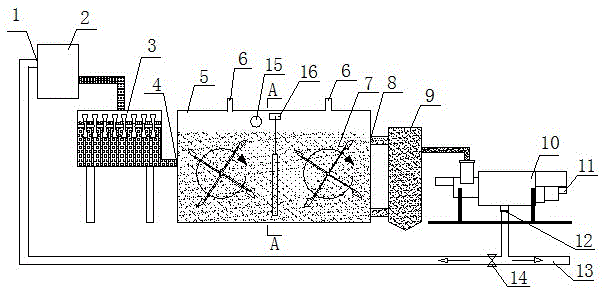

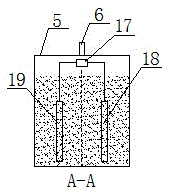

Organic waste anaerobic digestion-microbial electrolysis coupling reaction system and method thereof

InactiveCN105601070AIncrease productionLower carbon dioxide levelsBioreactor/fermenter combinationsBio-organic fraction processingElectrolysisHydrolysis

The invention discloses an organic waste anaerobic digestion-microbial electrolysis coupling reaction system. The system comprises an anaerobic digestion reactor, an extracting device, a dehydrating device and a water electrolysis device, wherein a feeding opening, a discharging opening and a gas outlet are formed in the anaerobic digestion reactor; the extracting device communicates with the anaerobic digestion reactor through the discharging opening; the dehydrating device communicates with the extracting device; a microbial electrolysis device is arranged in the anaerobic digestion reactor; and gas generated by the water electrolysis device enters the anaerobic digestion reactor through a gas inlet. The microbial electrolysis device comprises an anode, a cathode and a power supply. The invention further discloses a method for generating methane by using the system. The method comprises the following steps: water electrolysis, microbial electrolysis of organic waste, anaerobic digestion and the like. The organic waste anaerobic digestion-microbial electrolysis coupling reaction system is wide in treatment range, hydrolysis rate of organic substances is increased effectively, concentration of hydrogen sulfide is reduced, and the yield of methane is improved.

Owner:CHANGSHA SHANGYI ELECTRONICS TECH CO LTD

Method for preparing carbon-fixation filling paste from waste concrete

InactiveCN109650805AAffect qualityIncrease carbon sequestrationGas treatmentDispersed particle separationCarbonizationToxic industrial waste

The invention discloses a method for preparing a carbon-fixation filling paste from waste concrete. The method comprises the following steps: industrial waste gas is dedusted, and then is mixed with normal temperature air, a waste concrete and a gangue mixture is crushed in the obtained industrial exhaust gas atmosphere, and coarse aggregates, fine aggregates and fine powder obtained after screening and carbon dioxide in the industrial exhaust gas undergo a carbonization reaction in a carbon fixation chamber; and the carbon-fixation coarse aggregates, the carbon-fixation fine aggregates, a filling paste additive, cement, phase change material microcapsules and water are stirred and mixed to form a filling body mixture, and the industrial exhaust gas is continuously injected in the stirring, mixing and conveying process of the filling paste to make the filling paste and the carbon dioxide in the industrial exhaust gas undergo the carbonization reaction in order to obtain the carbon-fixation filling paste. The carbonization reaction of the waste concrete and carbon dioxide is fully used, so the damages of the waste concrete to the environment are reduced, and the emission of greenhouse gases is reduced; and hydration heat is fully used in the carbonization reaction, so the filling effect of the carbon-fixation filling paste is good.

Owner:XUZHOU UNIV OF TECH

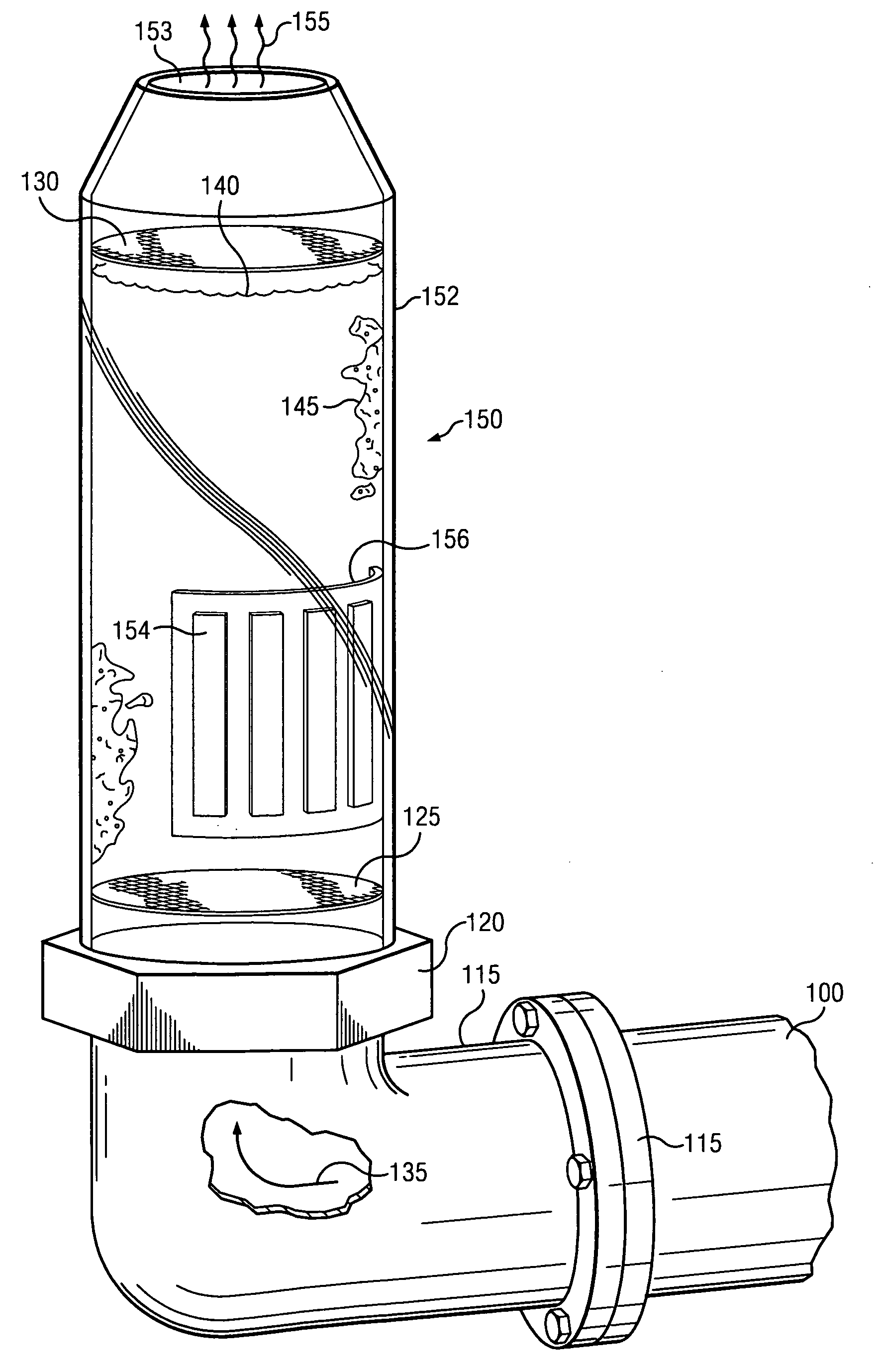

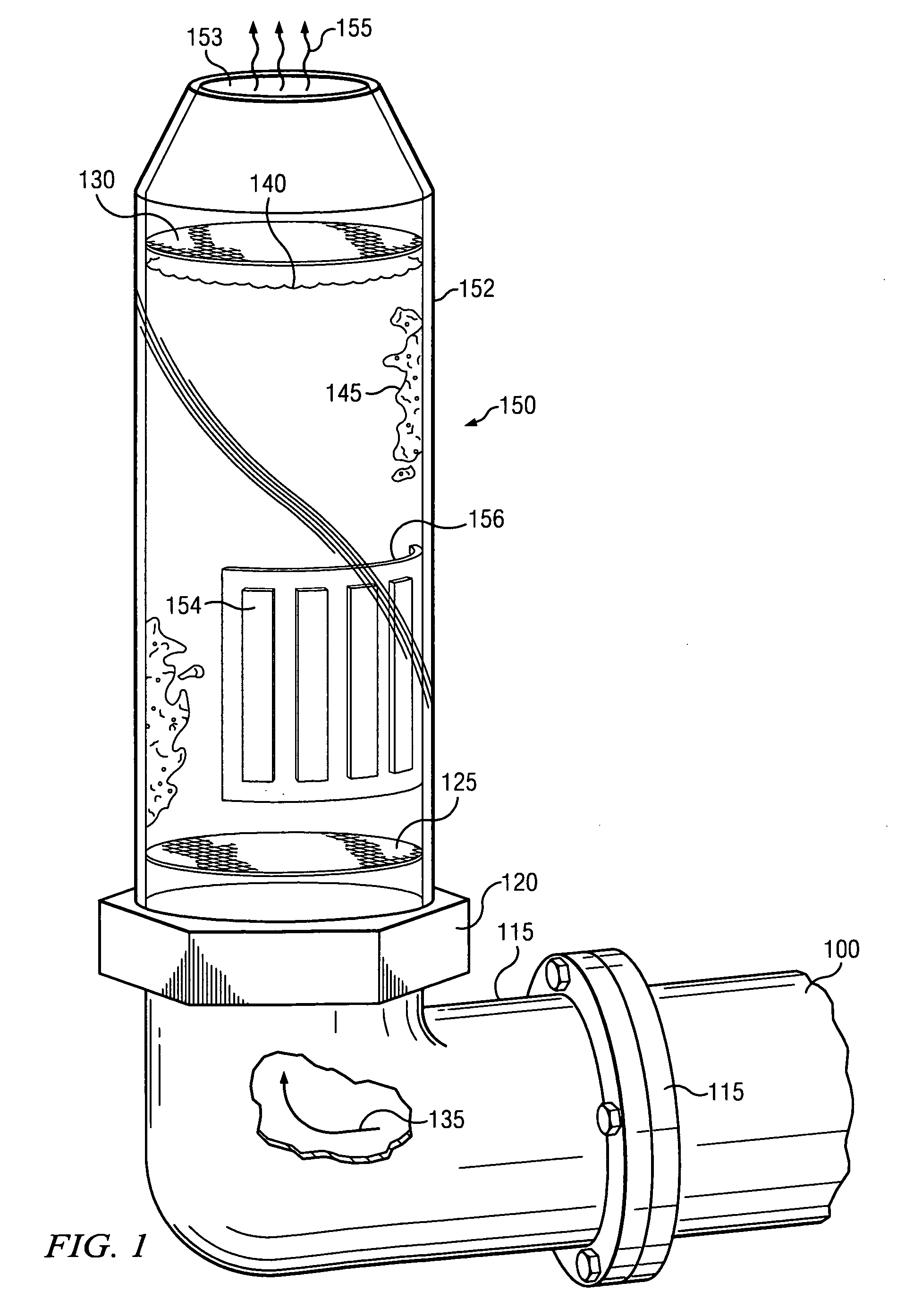

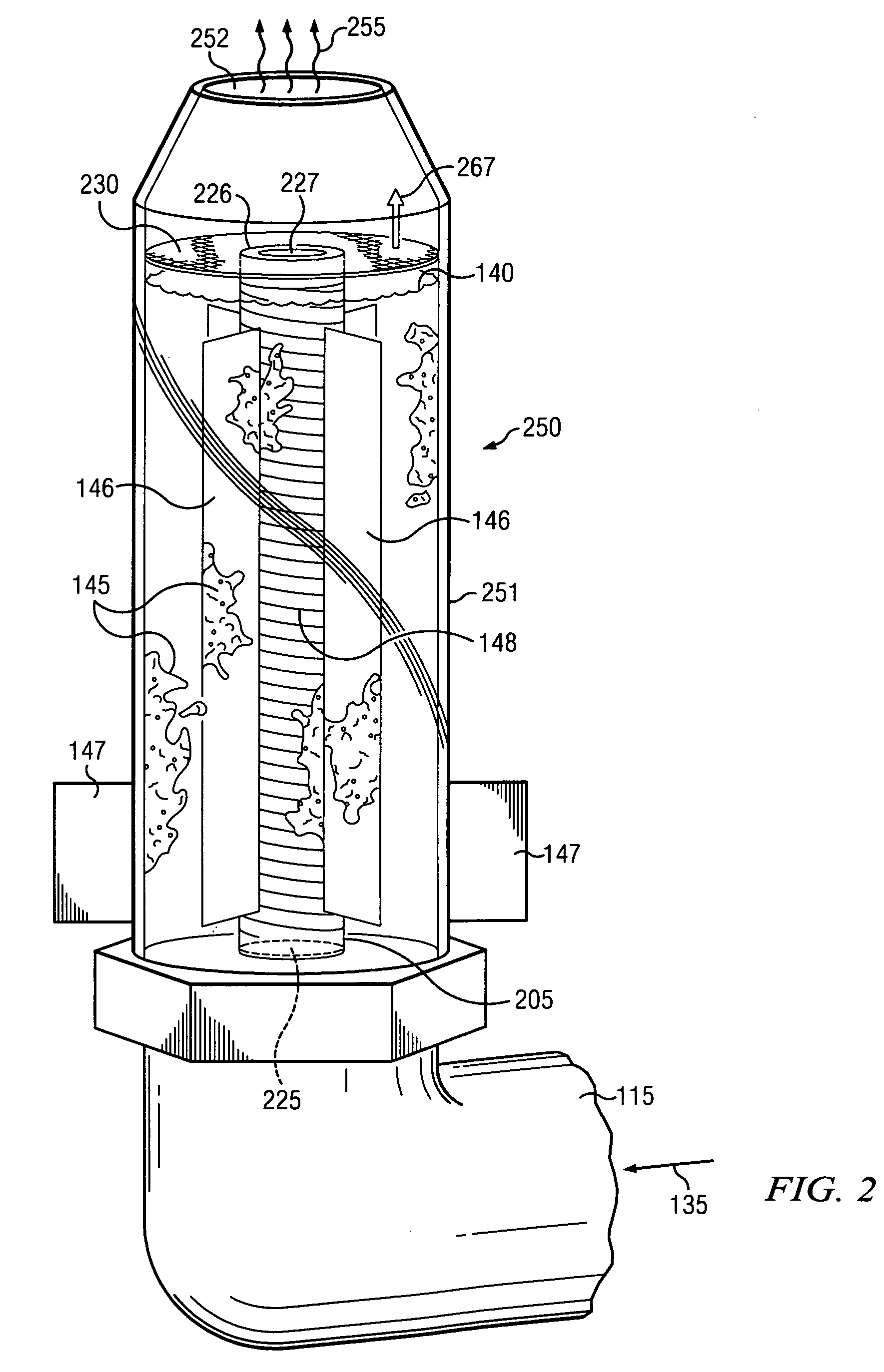

Bioactive carbon dioxide filter apparatus and method therefor

InactiveUS20100190241A1Lower carbon dioxide levelsLower Level RequirementsBioreactor/fermenter combinationsBiological substance pretreatmentsOxygenSugar

A bioactive filter is provided which comprises a transparent canister having gas permeable membranes as entry and exit ports. A source of carbon dioxide in gaseous form is allowed to enter the entry membrane and pass through a solution contained in the canister which supports a live colony of algae. The algae carries out photosynthesis thereby altering the carbon dioxide to oxygen and sugar. The oxygen is released through the exit port.

Owner:JAGGI PARAM

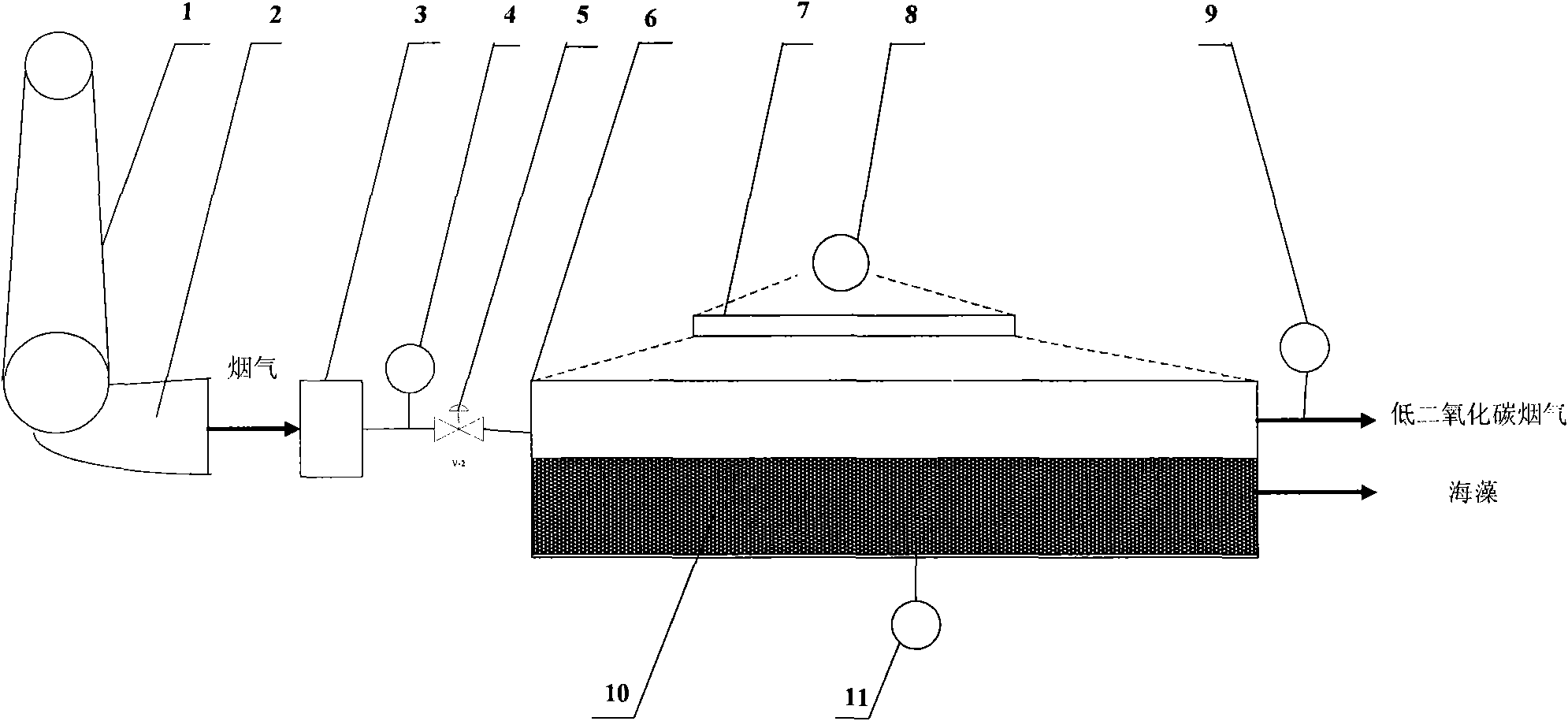

Method for preparing biofuel by using flue gases as raw materials

InactiveCN101525551APromote growthIncrease productionClimate change adaptationLiquid carbonaceous fuelsBiodieselIron plant

The invention belongs to the technical field of greenhouse gas emission reduction and biofuels and relates to a method for preparing a biofuel by using fuel gases as raw materials. Fuel gases emitted in large volume from power plants, steel plants and the like are used as the raw materials for producing the biofuel; in a specially designed bioreactor with light irradiation, rich carbon dioxide in the fuel gases are absorbed by seaweed through photosynthesis, and culture fluid is added at the same time to allow the seaweed to grow rapidly; and the produced seaweed can be converted to biodiesel and other fuels. The technology not only achieves the aims of dramatically reducing the carbon dioxide in the fuel gases and rapidly culturing a large amount of seaweed at low cost, but also solves the problems of greenhouse gas emission reduction and biofuel shortage. The method can be used as greenhouse gas emission reduction technology and used for producing biofuel oil containing seaweed as a by-product to obtain a biofuel for producing biodiesel at the same time in industries continuously emitting carbon dioxide containing flue gases, such as power plants, iron plants, and building material and cement industries.

Owner:饶文涛 +1

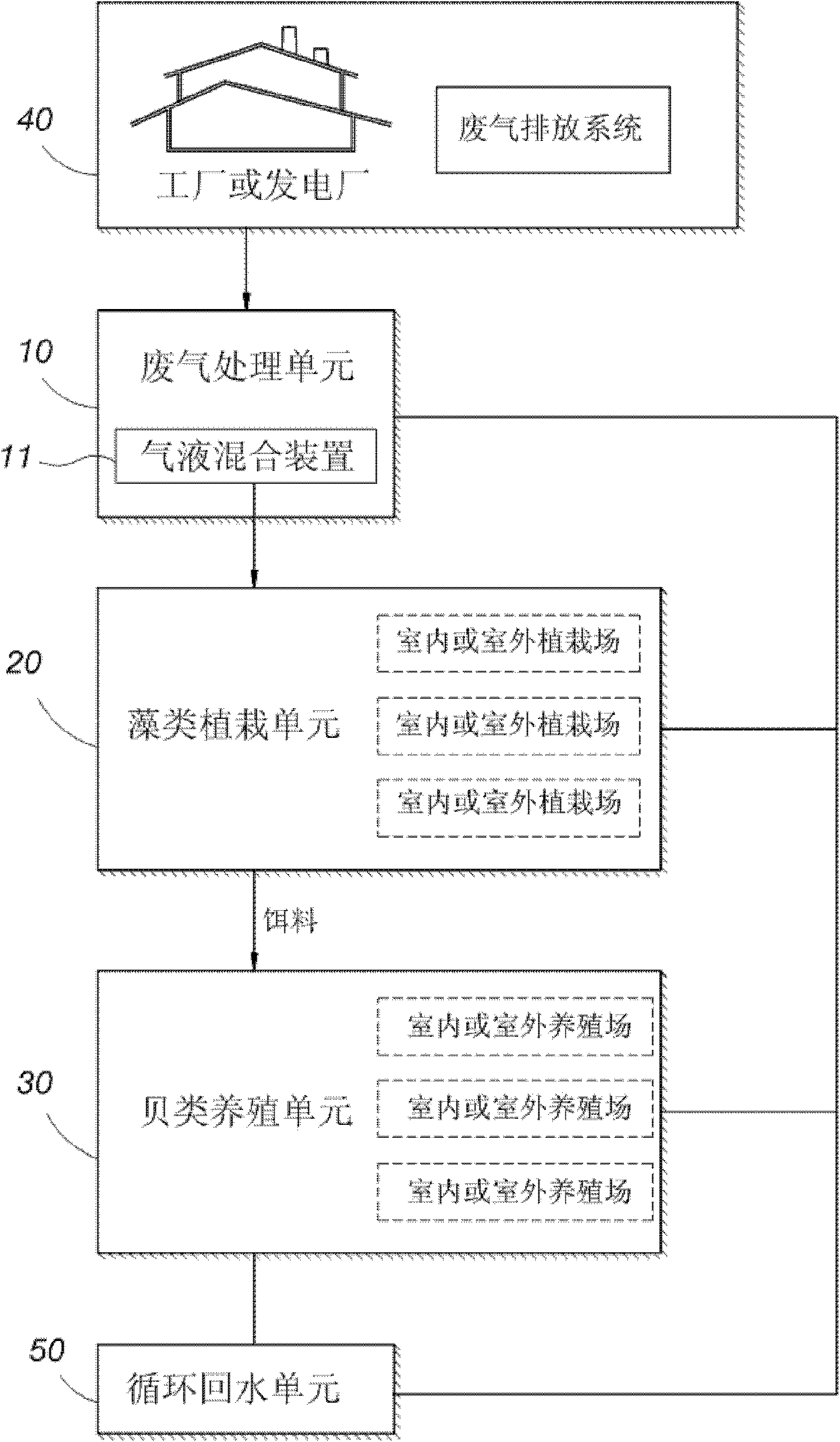

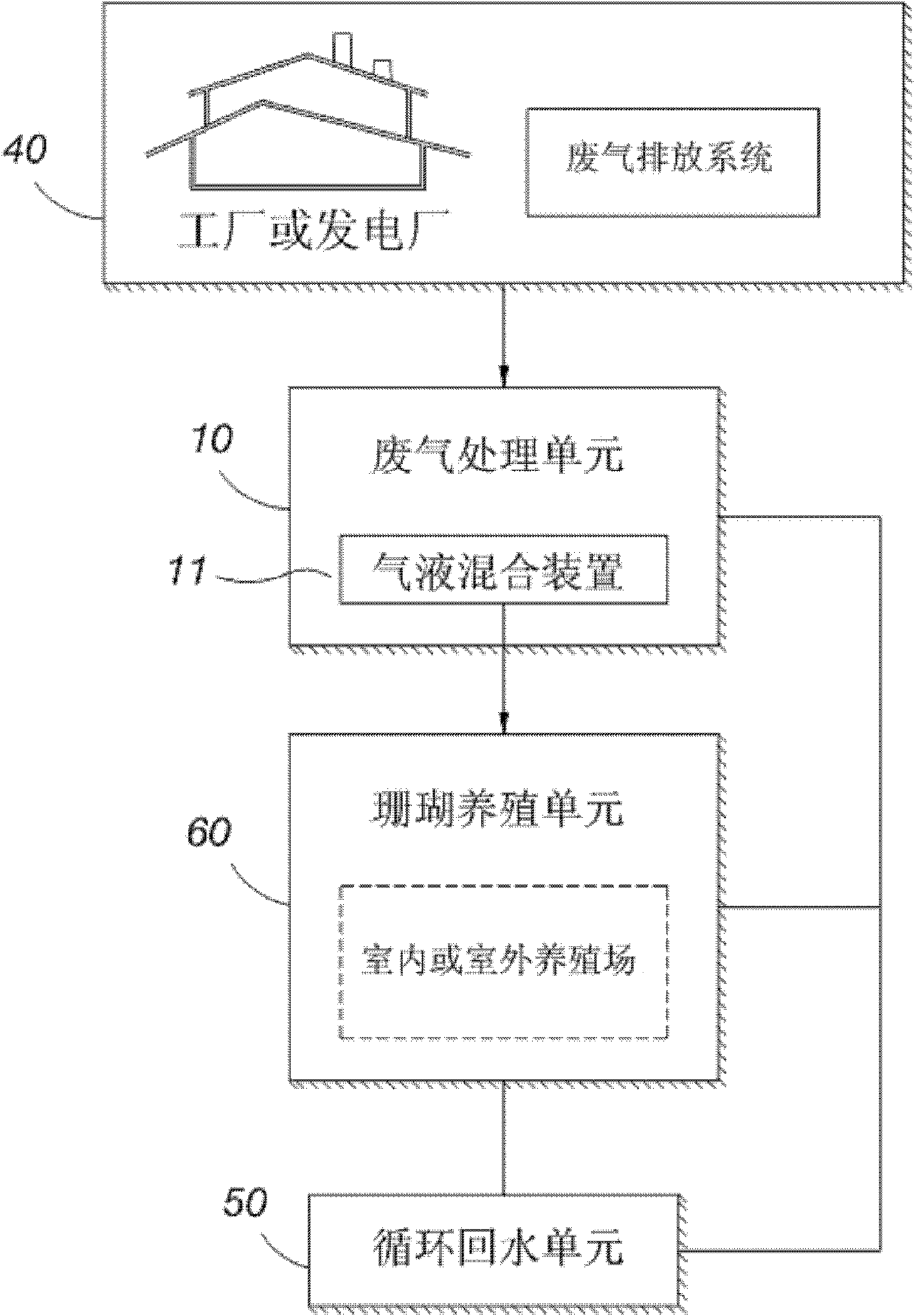

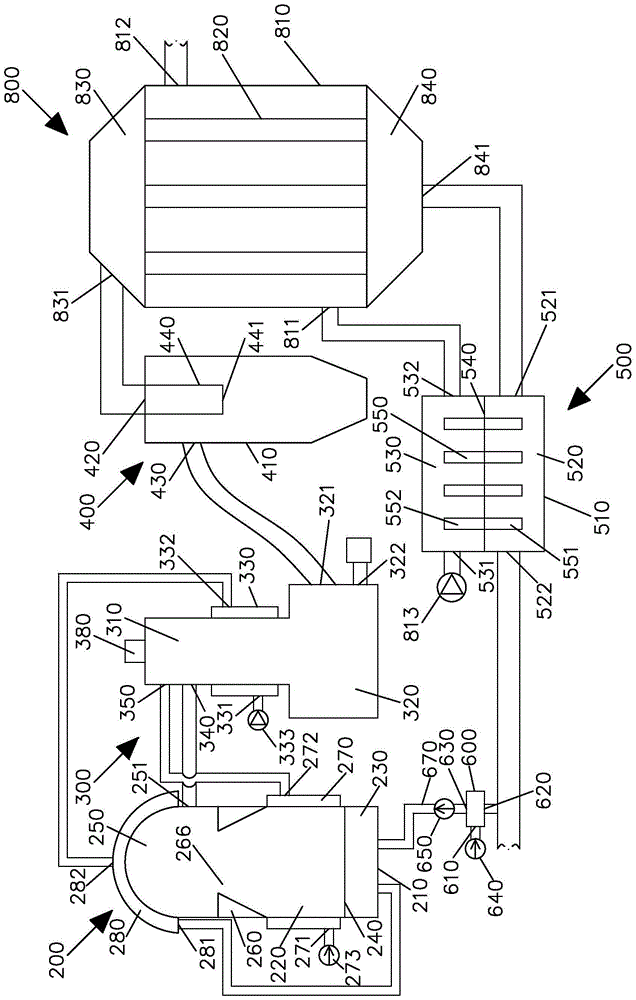

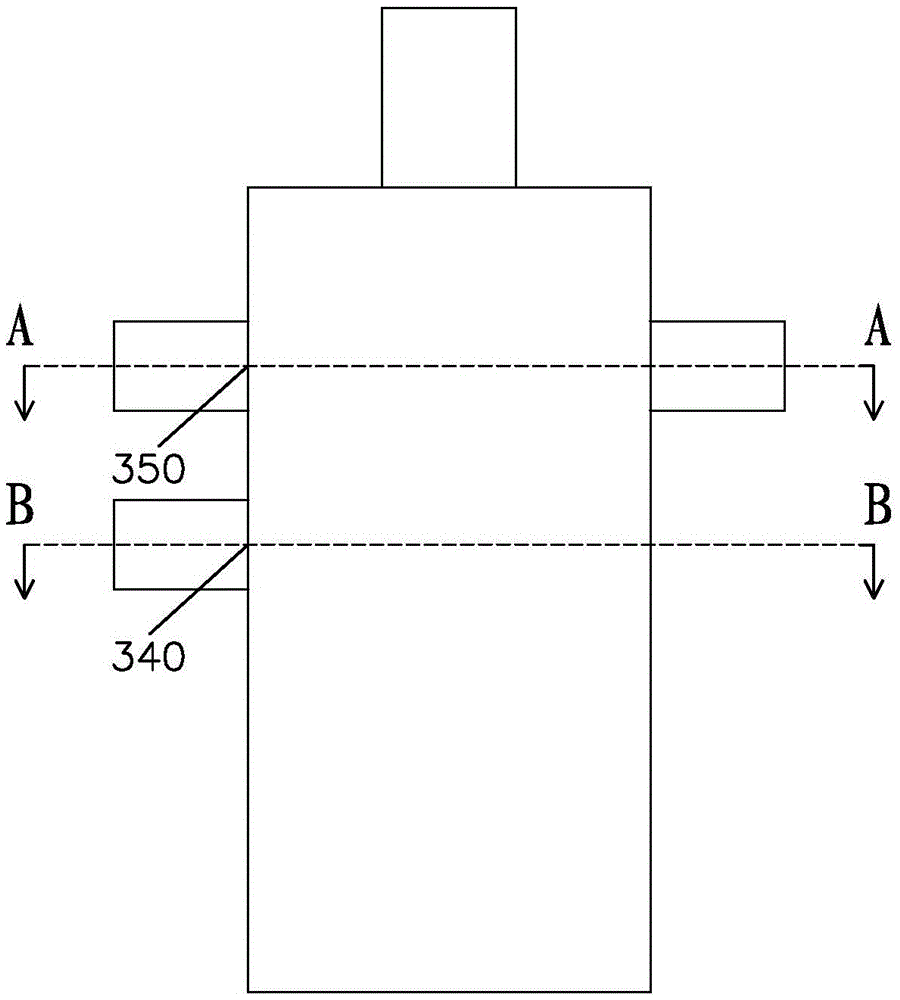

Method and system for fixing carbon dioxide by combining shellfish or coral breeding

InactiveCN103301746ALower carbon dioxide levelsWill not emitCarbon compoundsDispersed particle separationAlgaeWaste gas

The invention relates to a method and system for fixing carbon dioxide by combining shellfish or coral breeding. The invention aims to fix carbon by utilizing a shellfish or coral breeding system, so that the carbon dioxide in the waste gas is absorbed, and the carbon in the carbon dioxide can be semi-permanently fixed. The method provided by the invention comprises the following steps: dissolving carbon dioxide in the waste gas in water through a mist spray washing method, cultivating algae by utilizing water containing carbon dioxide, and providing the algae for the shellfish to serve as foods required by growth, or directly providing the algae for symbiotic algae of corals for growing the corals, wherein in the process, the carbon element in the carbon dioxide can be converted into the calcium carbonate as the main component of the shellfish and coral bones. Furthermore, because the calcium carbonate is difficultly decomposed, the carbon can be semi-permanently fixed, so that the aims of cultivation and environment friendliness can be fulfilled, and the method is a highly technical thought by utilizing the natural law and has a high industrial value.

Owner:赖珏光 +1

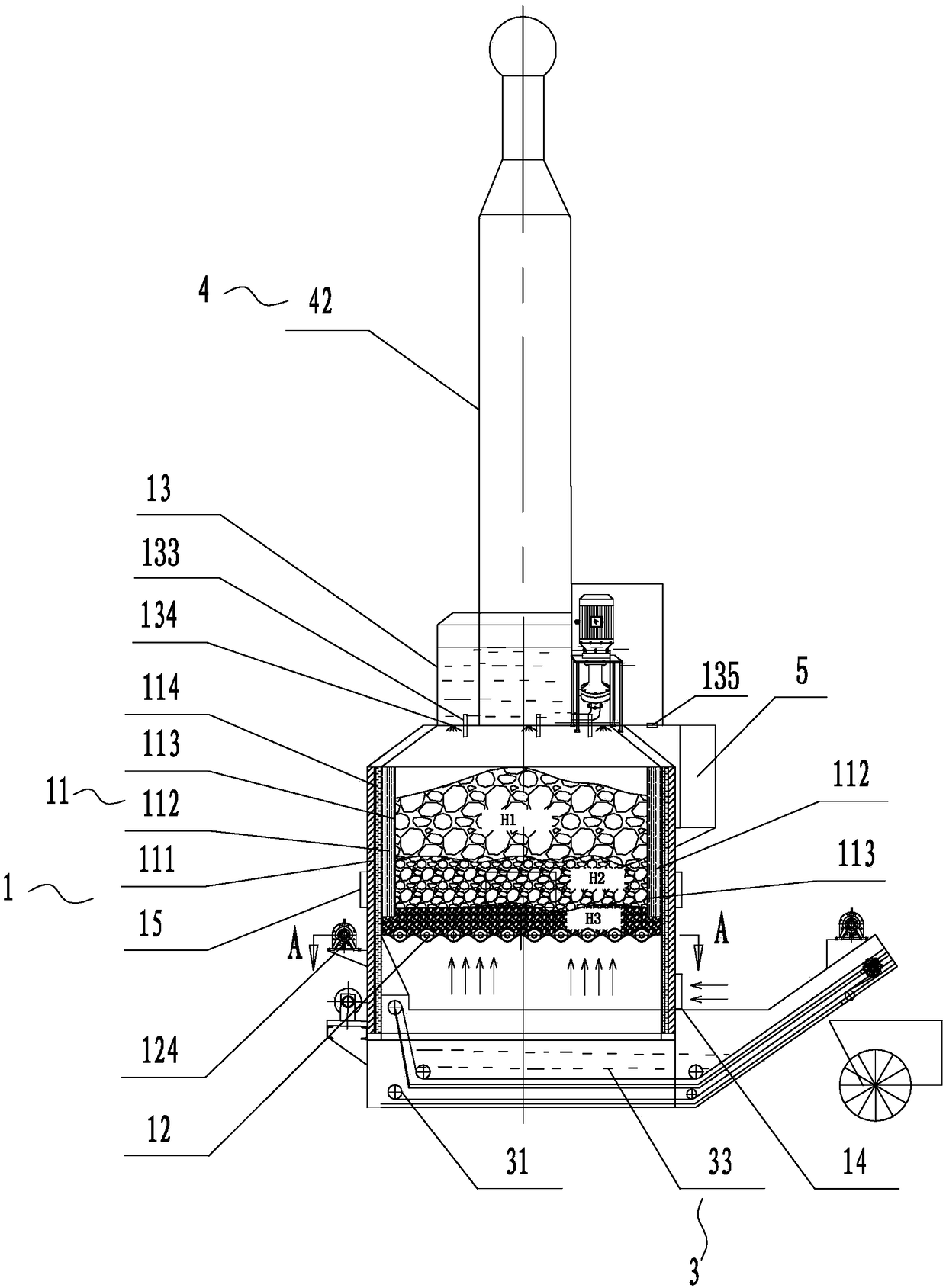

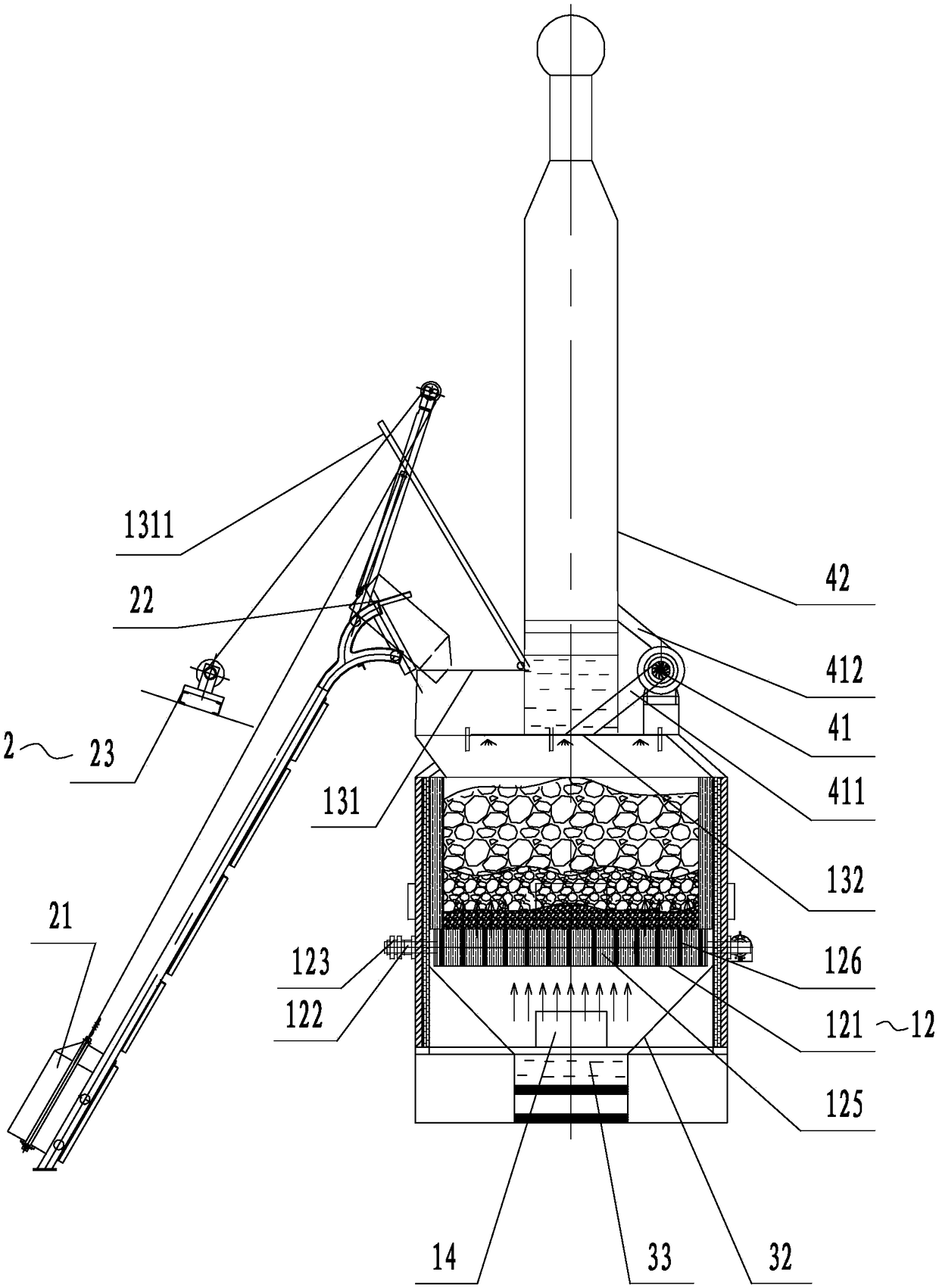

Built-in biomass gasification combustion hot water boiler

ActiveCN105485895AAvoid safety hazardsReduce wasteSolid fuel combustionWater heatersCold airCombustion chamber

The invention discloses a built-in biomass gasification combustion hot water boiler which comprises a water heater, a biomass gasification device and a combustion chamber. The water heater comprises a water tank and a plurality of smoke pipes. The biomass gasification device is used for generating biomass gas. The combustion chamber is arranged between the water heater and the biomass gasification device and used for combusting the biomass gas and conveying smoke generated after combustion into the water heater so as to heat water in the water tank. The biomass gasification device comprises a device body, a fire grate, a fire barrier, an air sleeve and a first water jacket, wherein the interior of the device body is divided by the fire grate into a gasification reaction chamber in the middle and an air chamber on the lower portion, and the interior of the device body is divided by the fire barrier into a gas storage chamber on the upper portion and the gasification reaction chamber in the middle. Generated water vapor is supplied to the gasification reaction chamber through the first water jacket to serve as a gasification agent, cold air is preheated in the air sleeve into hot air through the air sleeve, then the hot air is supplied to the combustion chamber for combustion supporting, and the biomass gas is supplied to the combustion chamber to be combusted through the gas storage chamber.

Owner:GUANGZHOU QIYADIAN BOILER CO LTD

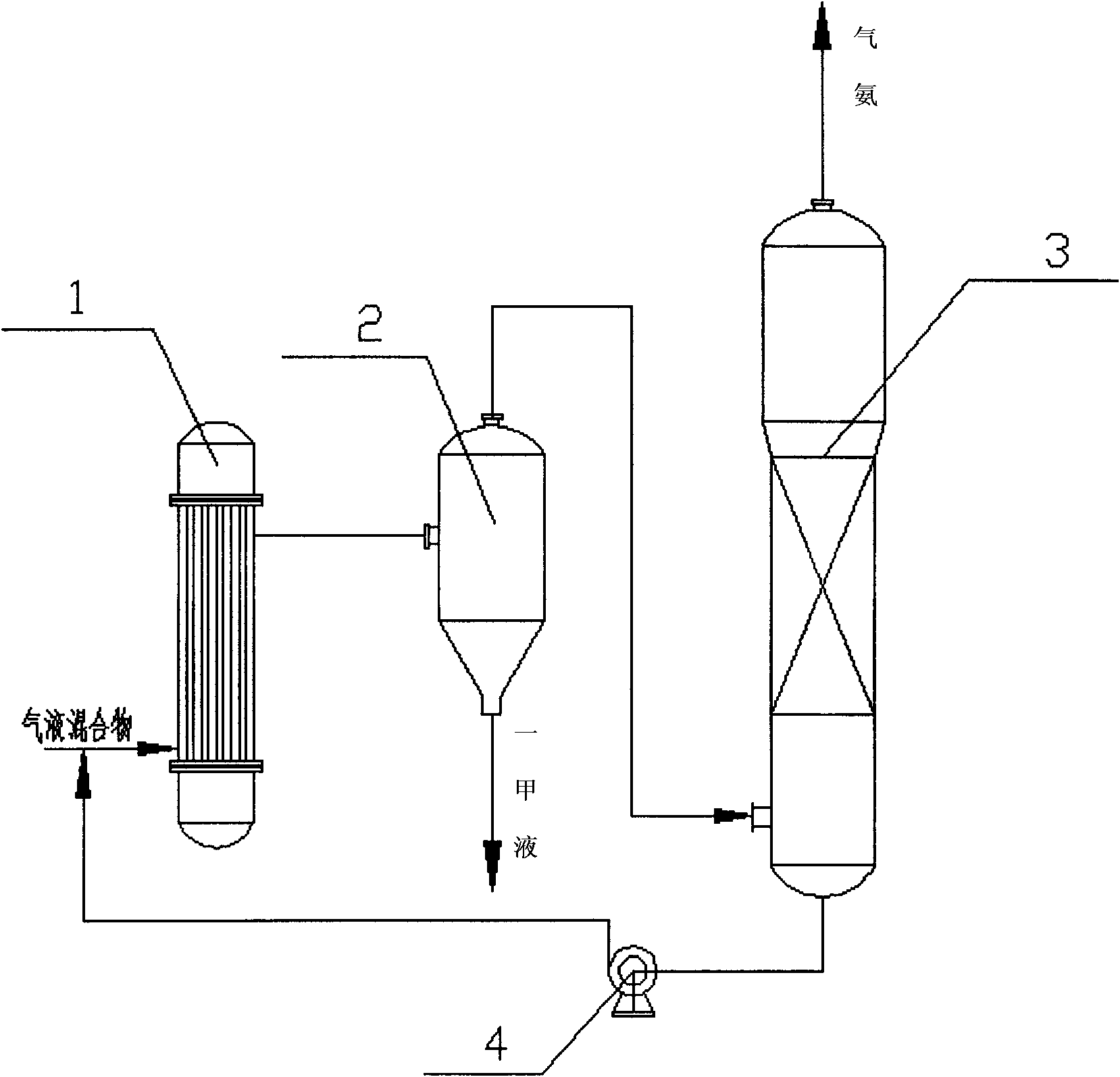

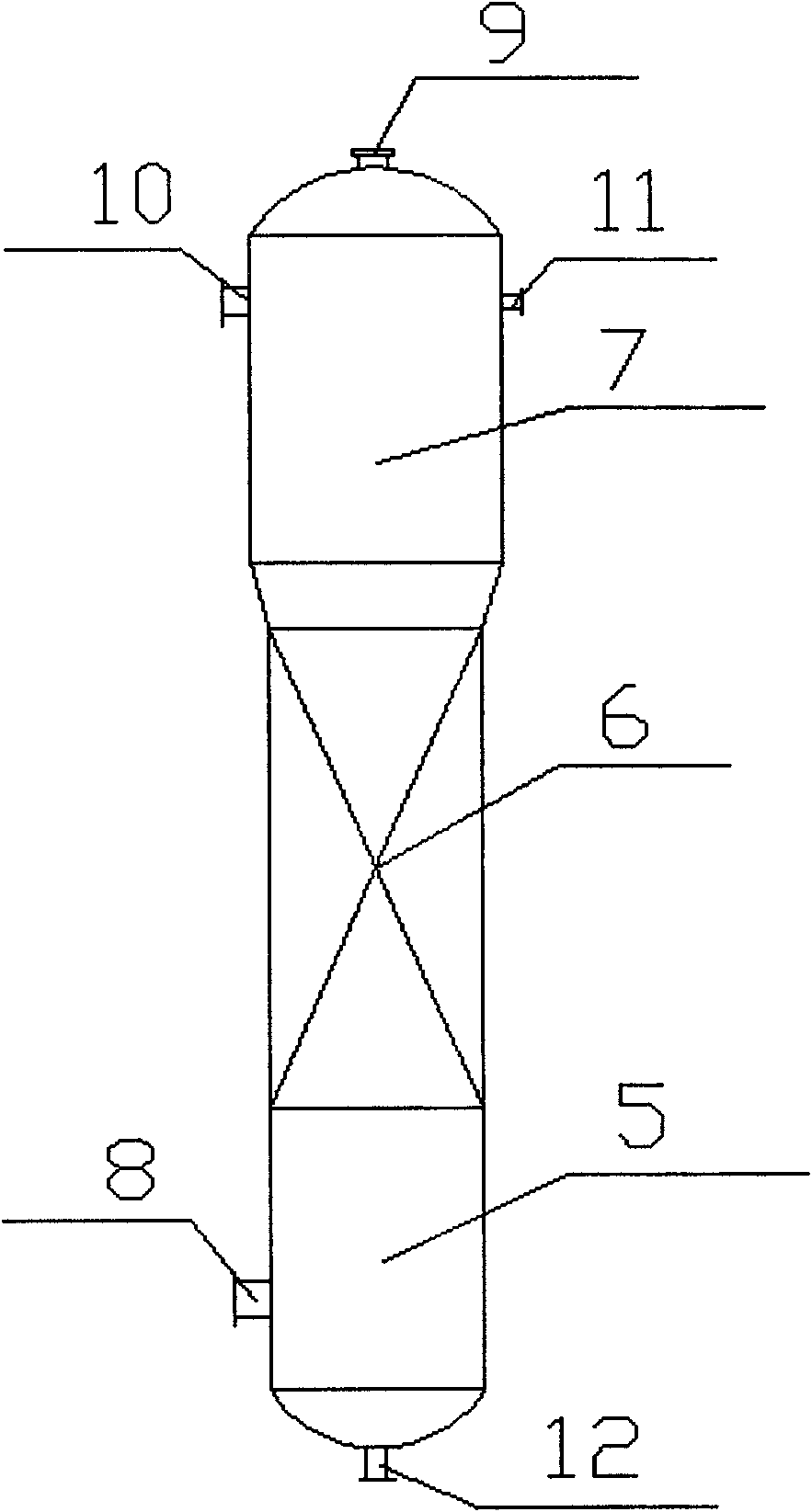

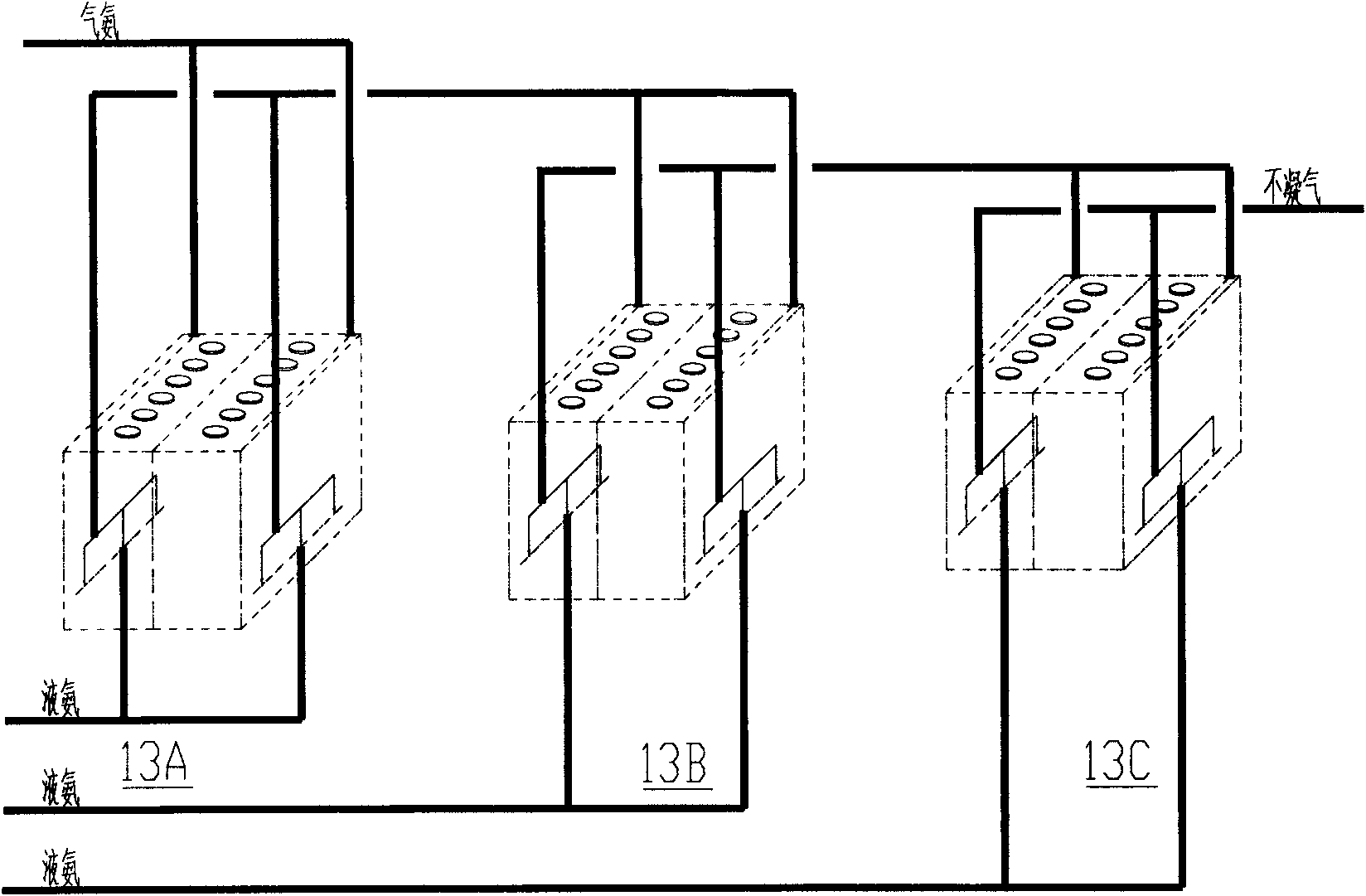

Medium-pressure recovery process of low steam/carbon ratio-three-section adsorption-evaporative ammonia-cooling carbamide production

ActiveCN101624355AHigh synthesis rateReduce energy consumptionUrea derivatives preparationOrganic compound preparationGas phaseTower

The invention discloses a medium-pressure recovery process of carbamide production, comprising four process steps: condensation adsorption, separation, medium-pressure adsorption and ammonia condensation recovery; wherein the temperature of the condensation adsorption is improved to 105 DEG C from 90 DEG C to 95 DEG C of traditional process, the medium-pressure adsorption is improved into three-section adsorption from two-section adsorption, and an ammonia condenser of the ammonia condensation recovery is changed into an evaporative ammonia condenser from a tubular heat exchanger, so as to lead steam / carbon mole ratio in ammonium carbamate solution recycled and returned to a carbamide synthesis tower in a system to be reduced to 1.5 from 2.0, the carbon dioxide content in gas phase exhausted from a medium-pressure adsorption tower is greatly reduced, and is decreased within 5ppm from 100ppm, thereby being beneficial to improving the carbamide synthetic ratio and reducing the investment and consumption; in addition, the operation is convenient and safe.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Air purification method and system adopting fresh air

InactiveCN106247522ACut offLower carbon dioxide levelsCombination devicesMechanical apparatusFresh airAir treatment

The invention discloses an air purification method and system adopting fresh air and belongs to the indoor environment purification technology. The air purification system is characterized by comprising a casing, an air quantity regulation part and at least one primary filter screen layer, wherein an air inlet and an air outlet are formed in the casing, and the air inlet is used for introducing outdoor air; a first air treatment assembly and a second air treatment assembly are arranged in the casing, the first air treatment assembly comprises a power fan, the second air treatment assembly comprises a reusable dust collecting device, and the purification performance of the dust collecting device does not get poor after cleaning; the air quantity regulation part is used for controlling the rotating speed of the power fan, so that the speed range of air output from the air outlet ranges from 0.3 m / s to 5 m / s, and the primary purification efficiency of the dust collecting device for PM 2.5 is enabled to be as high as 80%-99.9%.

Owner:格林韦尔(北京)科技发展有限公司

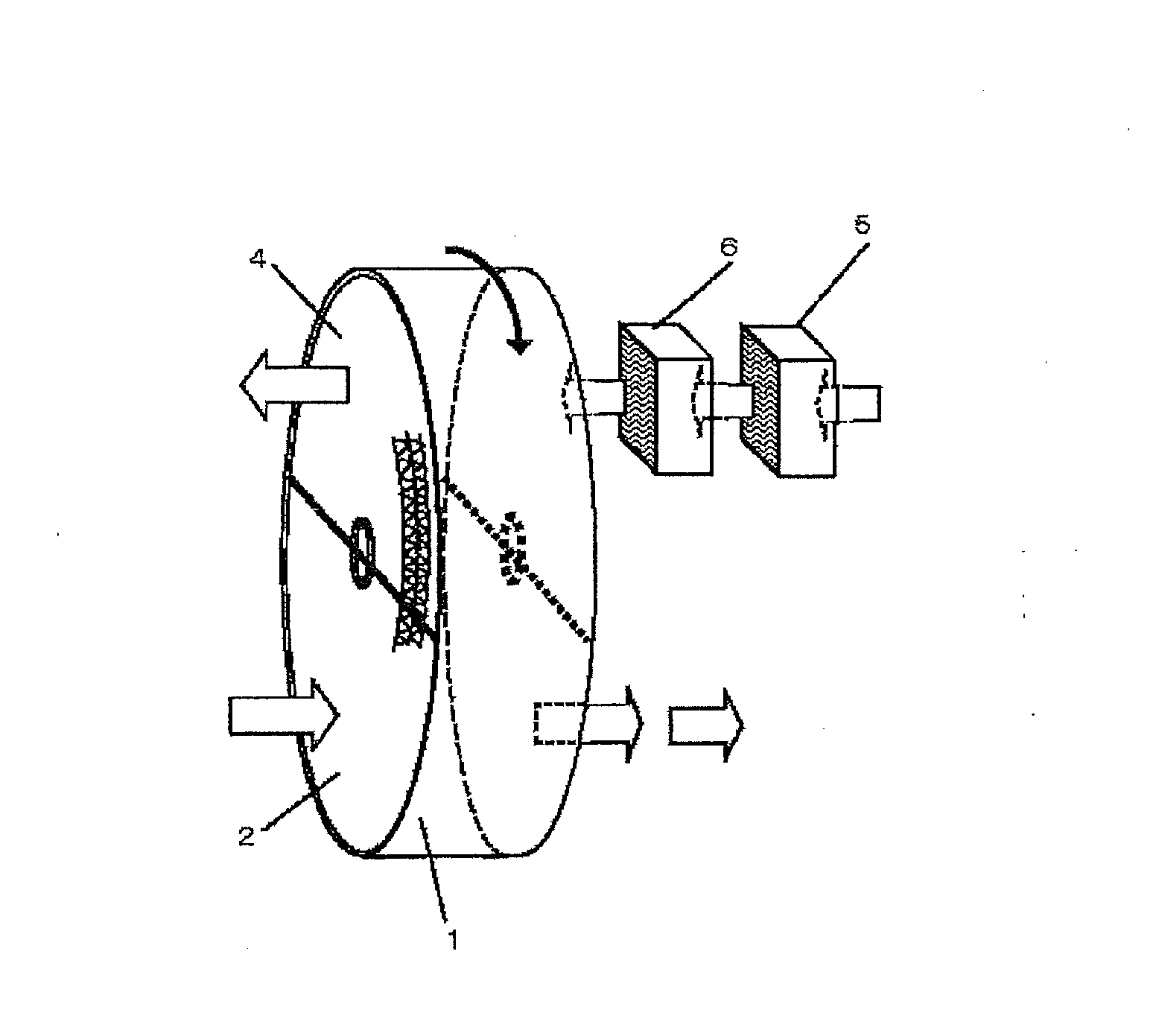

Absorption type - removal / condensing apparatus

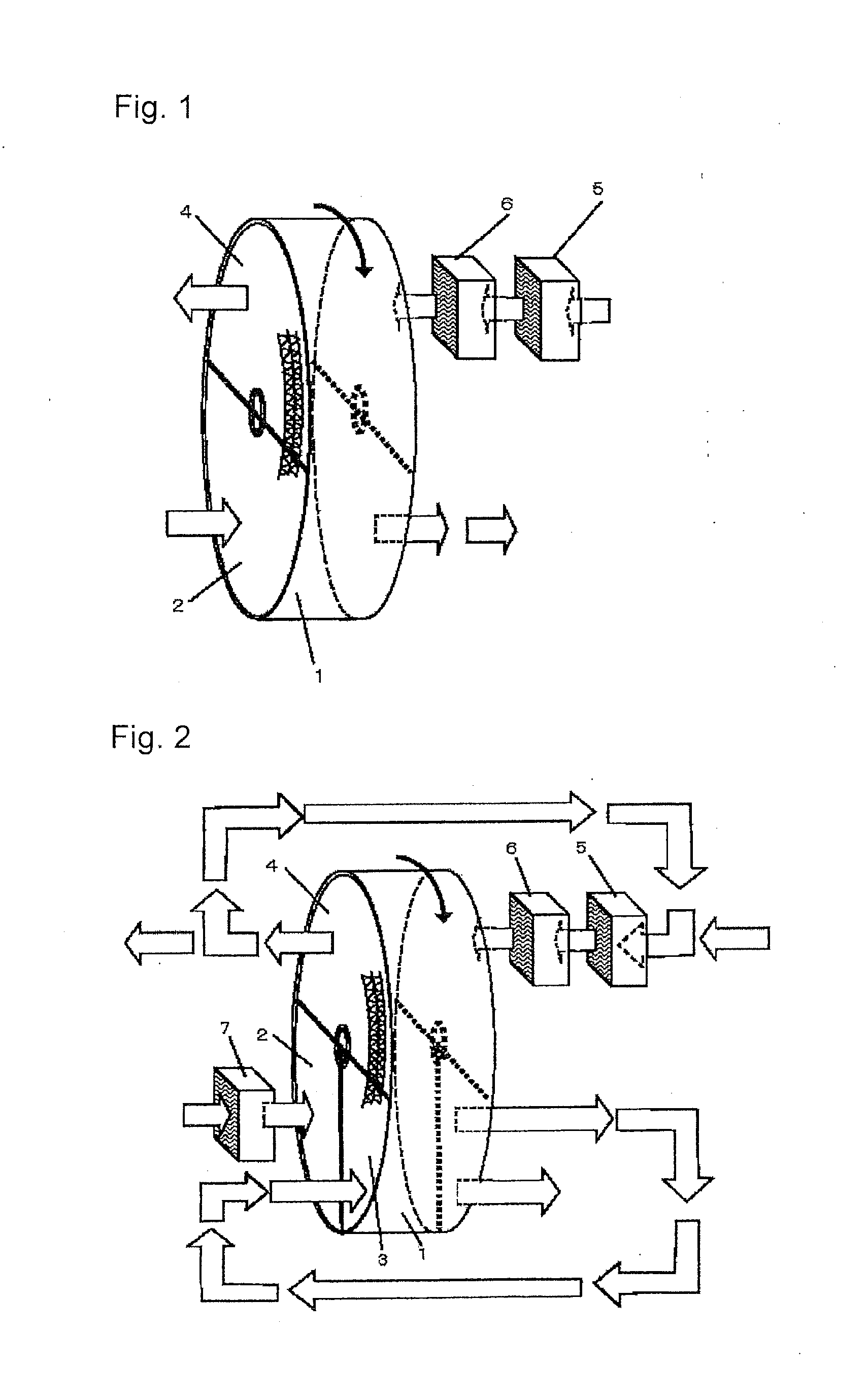

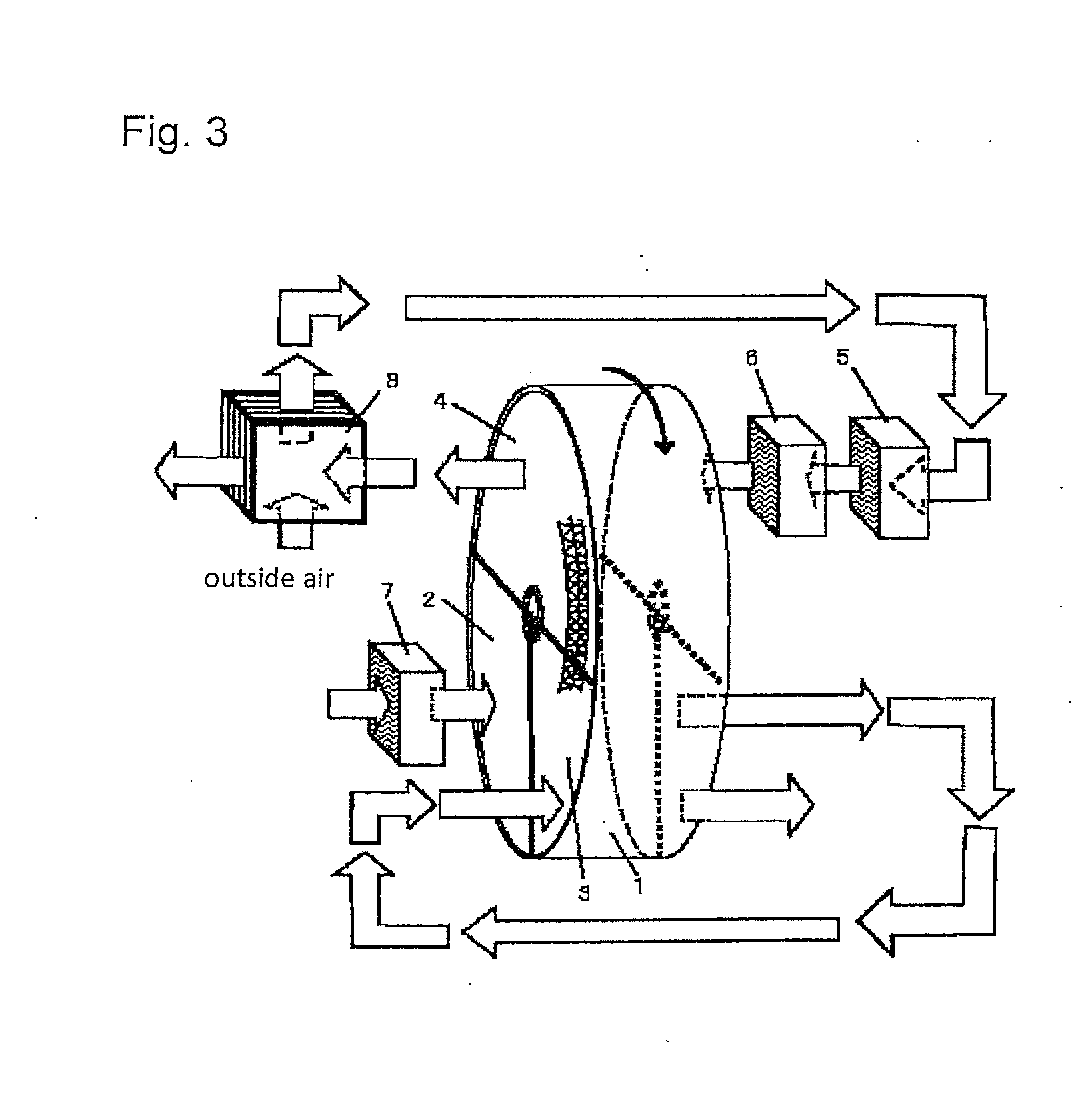

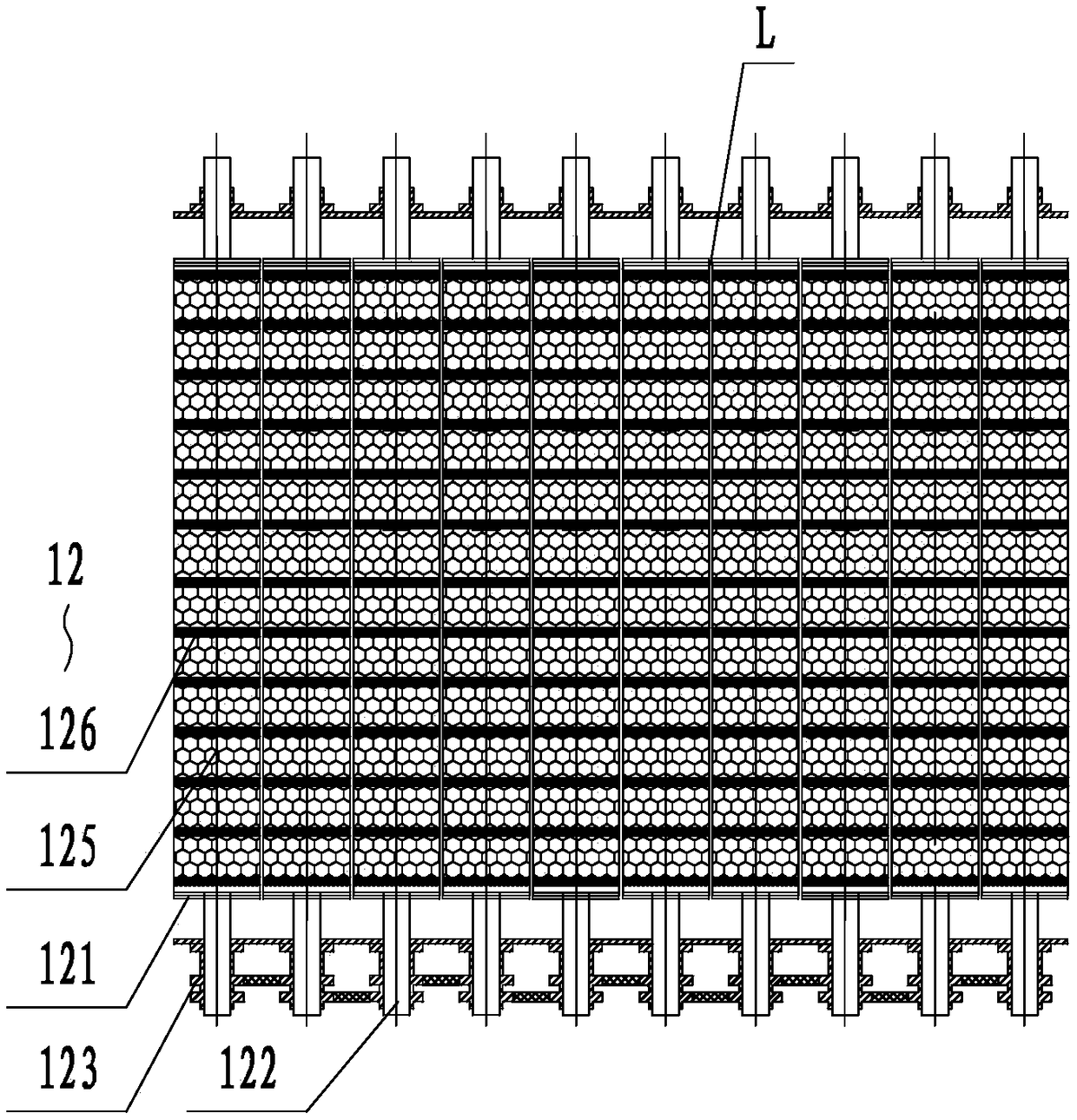

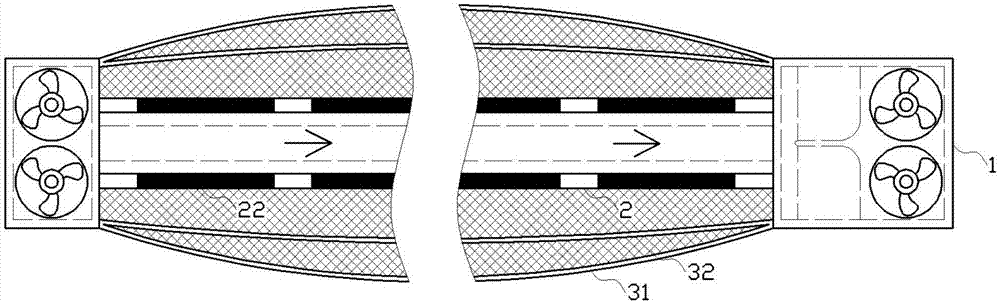

ActiveUS20160175772A1Improvement in removal/density performanceLow density of carbonCombination devicesGas treatmentHoneycombProcess region

An absorption-type carbon dioxide removal / condensing apparatus is removes or condenses carbon dioxide so that the apparatus secures high recovery efficiency. The apparatus has a honeycomb rotor holding a carbon dioxide absorbent, which is divided into at least a processing zone and a reproduction zone. After anyone of reproduction air for heating and a processing air is humidified by a humidifying device, both airs are ventilated into the zones, respectively. Thereby, the apparatus can improve absorption performance and density performance. If the honeycomb rotor is further divided into at least first and second processing zones, an air to be processed is humidified by a humidifier to ventilate into the first processing zone, and then a portion or all of the processing air which passed through the first procession zone is passed through the second procession zone (second pass).

Owner:SEIBU GIKEN CO LTD

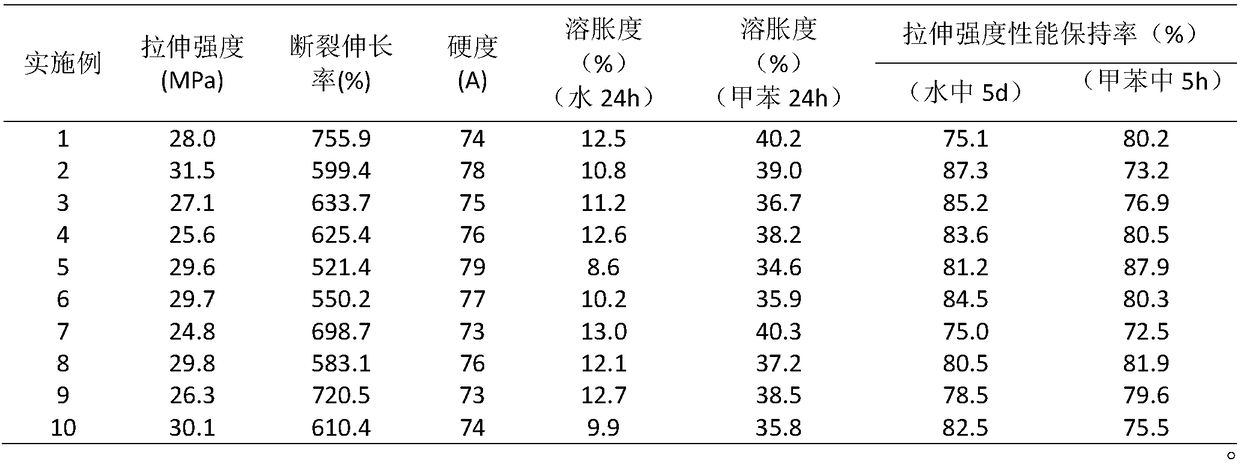

Method of improving water resistance or solvent resistance of waterborne polyurethane

Disclosed is a method of improving water resistance or solvent resistance of waterborne polyurethane. The method herein comprises subjecting cyclic carbonates and amine compounds to aminolysis to prepare an alcohol amine chain extender; pre-polymerizing polymer polyols, isocyanate compounds and a carboxyl-containing hydrophilic agent, then adding 1,4-butanediol and a solvent for reaction, and adding a salt-forming agent into the reaction product for reaction to obtain a prepolymer; emulsifying the prepolymer in water, adding the prepared chain extender for chain extension to obtain a waterproof or solvent-resistant polyurethane emulsion, pouring the waterproof or solvent-resistant emulsion into a mold for drying at normal temperature, and evaporating water to obtain waterborne polyurethane. The method herein has the advantages of being simple to perform, low in cost and good in waterproofness and solvent resistance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method of preparing polystyrene extrusion molding cystosepiment by polystyrene recovery material

The invention relates to a method for using foam polyphenylacetylene to produce polyphenylacetylene extruded plastic foam plate, which comprises: (1), classifying the foam polyphenylacetylene material via colors; (2) breaking said material, and making particle in the particle maker, while the temperature is 160-200Deg. C; (3), collecting the particles, adding agent, mixing, while the ratio between the particles and the agent is 100:0-10; (4) mixing and fusing said particles in plastic extruder, adding carbon dioxide foaming agent, to foam, while the mass ratio between the particle and the foaming agent is 100:4-15, to be extruded from mould, to obtain the foam plastic plate.

Owner:南京法宁格节能科技股份有限公司

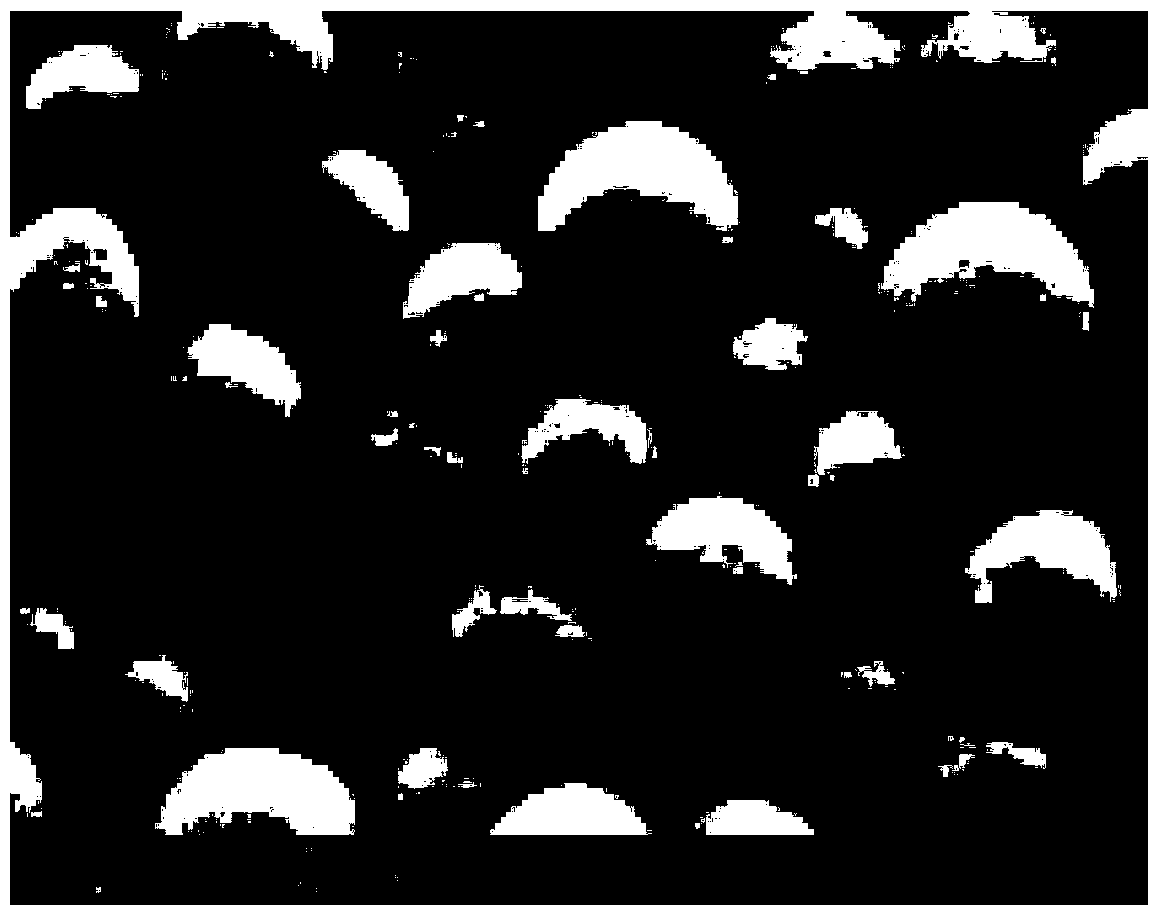

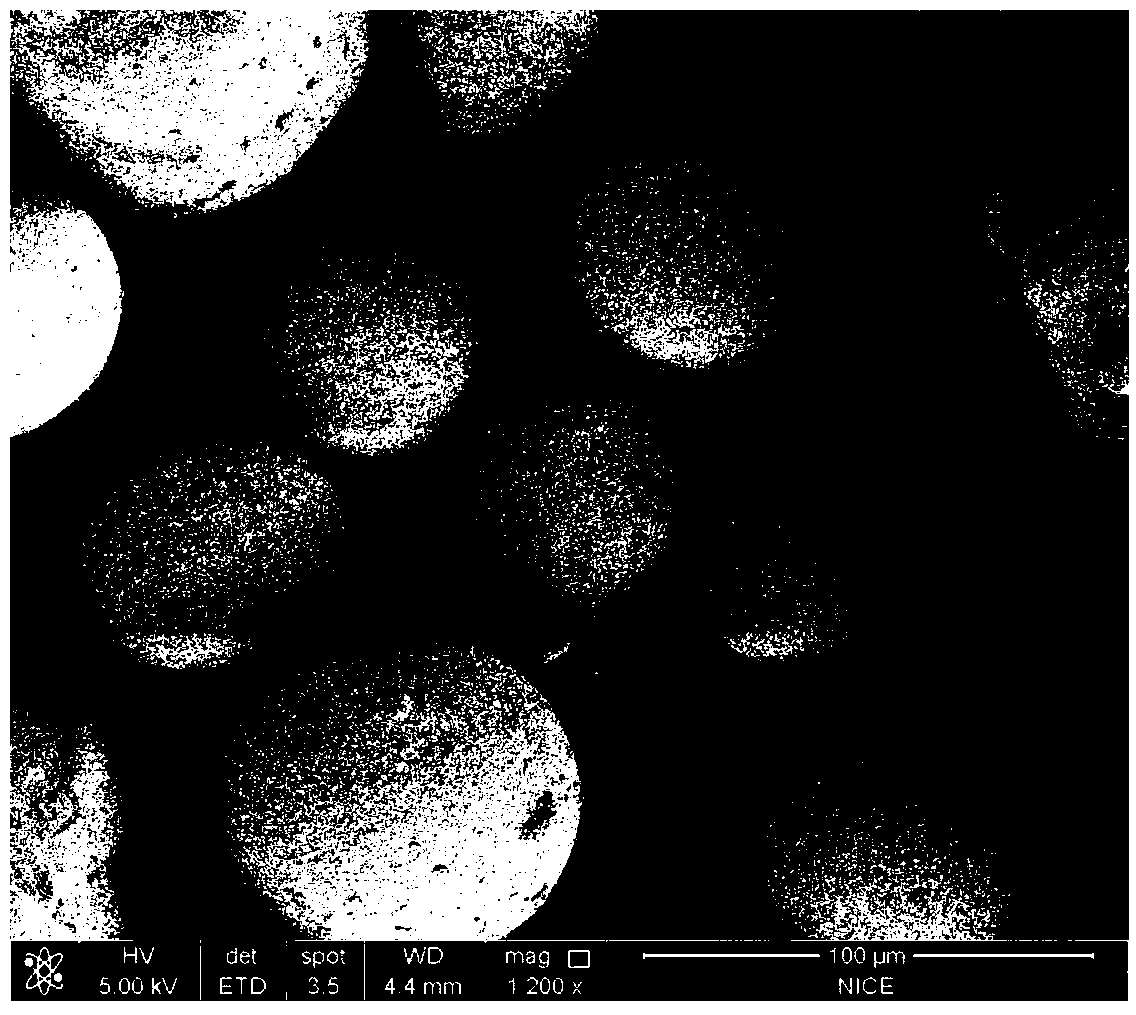

Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

ActiveCN103801324AGood sphericityHigh abrasion strengthLiquid hydrocarbon mixture productionMineral wax recovery/refiningWaxCarbon dioxide

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Seedling growing method for Dendrobium huoshanense

InactiveCN107593025AIncrease vitalityImprove absorption and utilizationBio-organic fraction processingSeed and root treatmentDendrobium huoshanenseAlkaloid

The invention discloses a seedling growing method for Dendrobium huoshanense. The method comprises the following steps: (1) processing seeds: sterilizing Dendrobium huoshanense seeds, mixing the sterilized seeds with a nutrient matrix, and burying the obtained mixture in a sand pool for 2-3 months; (2) accelerating germination of the seeds: activating the seeds, and using a fermentation solution to carry out constant temperature immersion in order to accelerate the germination; (3) sowing the seeds in a greenhouse: laying a nutrient matrix layer, a plant fertilizer layer and loess to form soilin the planting area of the greenhouse, and sterilizing the soil by the fermentation solution; and (4) regulating the greenhouse: regulating the illumination intensity and the carbon dioxide concentration within and after one month after the sowing. Compared with the traditional methods, the method improves the germination rate by 28.83%, improves the polysaccharide content by 6.66% and improvesthe co of the total alkaloid content by 0.025%; and Dendrobium huoshanense cultivated through has the characteristics of fast growth and strong drug functions.

Owner:ANHUI SHANZHENCANG ECOLOGICAL AGRI CO LTD

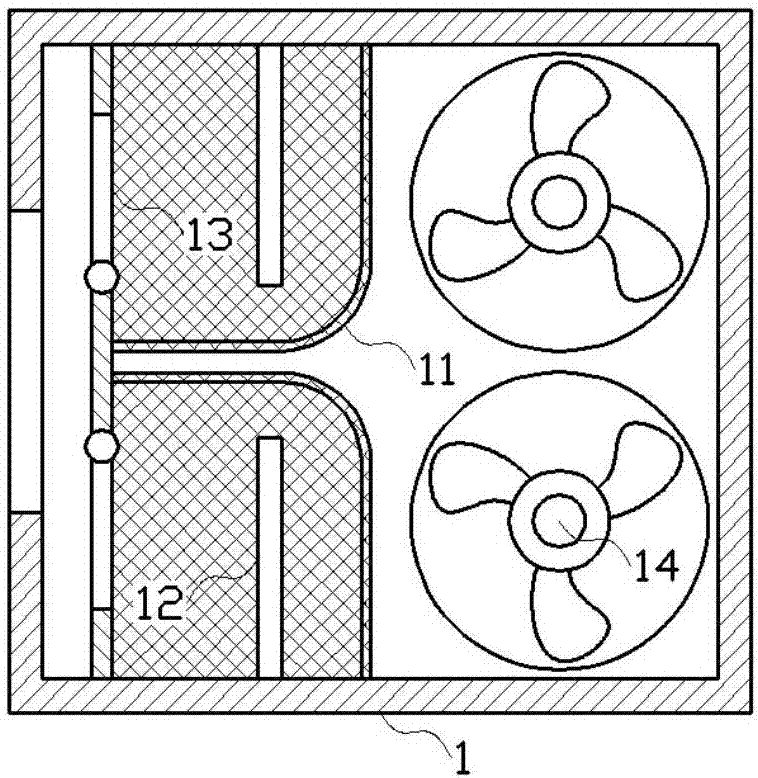

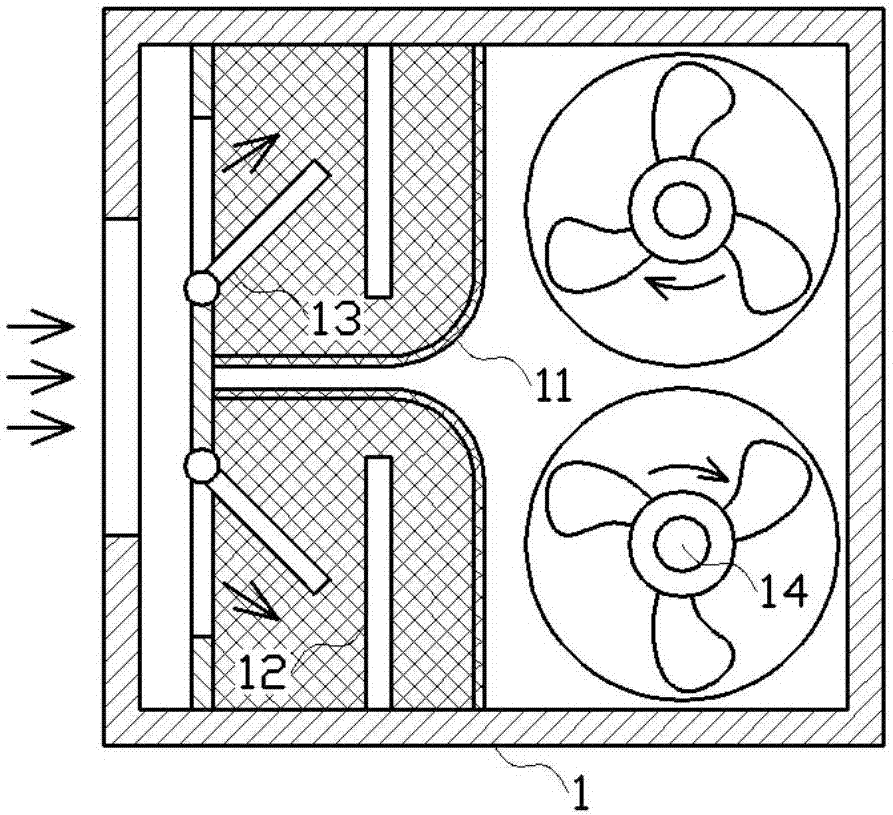

Powered exhaust apparatus for a personal protection respiratory device

ActiveCN104797301AImprove comfortImprove experienceChemical protectionRespiratorsAir volumeRespirator

The present invention relates to an exhaust apparatus 10 for releasable or permanent connection to a personal protection respiratory device 20 that defines a filtered air volume adjacent to the face of a wearer and comprises at least one exhalation valve 26. The exhaust apparatus 10 comprising a powered blower 30 in fluid connection with the at least one to exhalation valve 26, the blower 30 being operable to draw a portion of the wearer's exhaled breath through the exhalation valve 26. Using such an exhaust apparatus 10 improves the comfort and overall experience for respirator wearers who use the respirator for intensive work, and / or for long periods of time, and / or in hot and humid environmental conditions by removing the heat and moisture build-up inside the respirator.

Owner:3M INNOVATIVE PROPERTIES CO

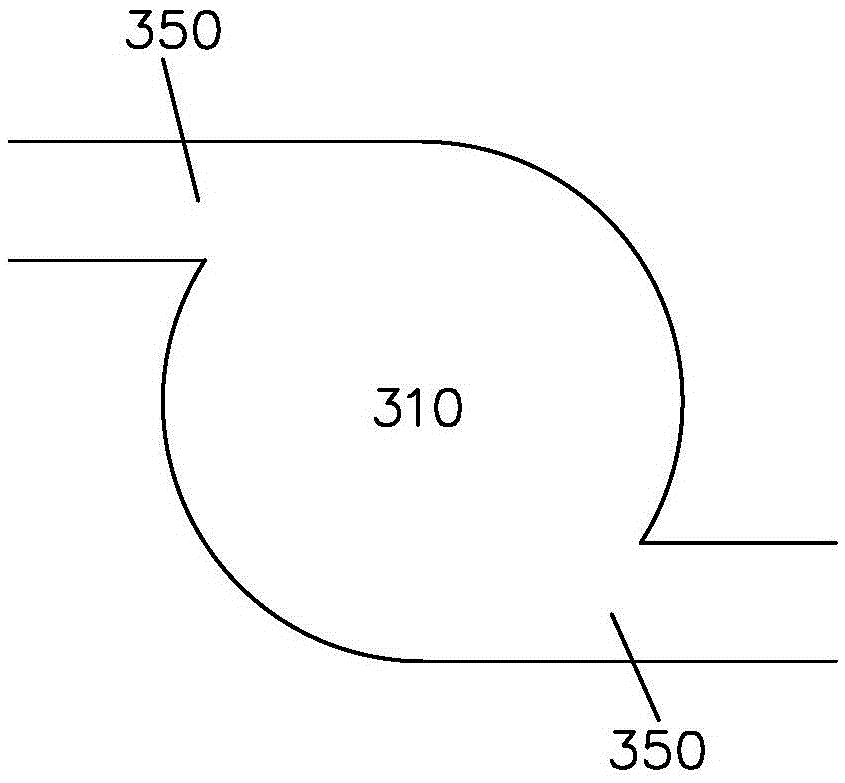

Household garbage flash mineralization processor

PendingCN109365488AHarmlessAccelerated reaction decompositionSolid waste disposalTransportation and packagingElectricityFlue gas

The invention discloses a household garbage flash mineralization processor, and relates to a household garbage processor. The household garbage flash mineralization processor comprises a furnace body,a feeding system, a slag discharging system, a flue gas purification system and an electric appliance control box, the furnace body comprises a furnace wall positioned at the side part of the furnacebody and a fire grate positioned at the lower part of the furnace body, the fire grate is a movable fire grate capable of rotating by 360 degrees, the fire grate comprises a grate shell, a rotating shaft, a chain wheel, a speed reducing transmission mechanism and a pyroelectric honeycomb ceramic body and a permanent magnet, vent holes are uniformly formed in the grate shell, the rotating shaft penetrates through the grate shell, and the two ends of the rotating shaft can be rotationally arranged on the furnace body, one end of the rotating shaft is connected with the speed reducing transmission mechanism through the chain wheel; the permanent magnet and the pyroelectric honeycomb honeycomb ceramic body are arranged in the grate shell in a spaced mode, the N pole of the permanent magnet isopposite to the S pole, and are grouped interval to establish an original magnetic field. The household garbage flash mineralization processor can realize harmless and daily-production daily cleaningtreatment of garbage, and has the advantages of being safe, clean, high in efficiency, economical, energy-saving, and is very suitable for rural large-scale application.

Owner:广西昇跃环保科技有限公司

Light-weight and energy-saving plastering mortar and construction method thereof

ActiveCN101891431ALight weightLow thermal conductivitySolid waste managementBuilding constructionsPortland cementThermal bridge

The invention relates to light-weight and energy-saving plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 40 parts of ordinary Portland cement, 2 to 4 parts of hydrated lime, 10 to 20 parts of light aggregate, 40 to 50 parts of heavy aggregate and 1.0 part of compound aid, wherein the light aggregate is an inorganic vitrified hollow microporous material of which the fineness is below 100 meshes; and the heavy aggregate is aeolian sand. During construction, the light-weight and energy-saving plastering mortar is diluted by water added in an amountwhich is 30 to 50 percent based on the weight of the light-weight and energy-saving plastering mortar, and is stirred and mixed mechanically or manually and uniformly until the plastering mortar has the suitable viscosity, and then mechanical spraying or manual construction Is performed. According to the concept of light weight and eco-environmental protection, the light-weight and energy-saving plastering mortar is made light by adopting the inorganic vitrified hollow microporous material, and is matched with the primary elastic modulus of a light-weight wall body to reduce coefficients of heat conductivity and reduce the thermal bridge effect, so the light-weight and energy-saving plastering mortar prevents hollowing, cracking and shedding, insulates heat and reduces noise, and is favorable for mechanized construction. The aeolian sand is used as aggregates, so the plastering mortar has excellent grading distribution and has the prominent three-dimensional texture; and the special compound aid is adopted to improve the peaceability of the mortar to achieve the excellent construction effect.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Non-fluorine series refrigerant based on carbonic anhydride

InactiveCN101173163ANon-destructiveReduce the greenhouse effectHeat-exchange elementsCyclobutaneRefrigerant

The invention discloses a carbon dioxide based non-fluorine refrigerant, which is characterized in that THE carbon dioxide with mass percentage between 5 and 20 percent is mixed with one or more components as the propane, butane and cyclobutane, so as to produce environmental protection and green refrigerant. The invention has the advantages of no toxicity, no pollutions, no corrosions or less combustibleness.

Owner:HUNAN UNIV

Manufacturing method of veneered wood-based panel with formaldehyde-free resin impregnated decorative paper capable of adsorbing carbon dioxide

ActiveCN108708213ALower carbon dioxide levelsSolve the real problemNon-fibrous pulp additionPaper/cardboardIndoor air qualityAcrylic resin

The invention discloses a manufacture method of a veneered wood-based panel with formaldehyde-free resin impregnated decorative paper capable of adsorbing carbon dioxide. The manufacturing method comprises preparing nano-cellulose capable of adsorbing the carbon dioxide, regulating acrylic resin capable of adsorbing the carbon dioxide, preparing acrylic resin impregnated decorative paper capable of adsorbing the carbon dioxide, and compounding the acrylic resin impregnated decorative paper capable of adsorbing the carbon dioxide with a wood-based panel. The manufacturing method has the advantages that the acrylic resin is free of free formaldehyde; the wood-based panel is selected from products produced from isocyanate or formaldehyde-free adhesive such as formaldehyde-free soybean glue, such as shaving boards, plywood and fiberboards; the nano-cellulose capable of adsorbing the carbon dioxide is added into the formaldehyde-free acrylic resin; therefore, the veneered wood-based panel with the formaldehyde-free resin impregnated decorative paper can have a carbon dioxide adsorption function and can serve as an indoor household material, the indoor carbon dioxide content is favorablyreduced, the free formaldehyde is eliminated, and indoor air quality is favorably improved.

Owner:佛山市顺德区康强装饰材料有限公司

Mortar for decorating external wall

The invention discloses a natural aeolian sand mortar for decorating an external wall, which is mixed by the following components in parts by weight: 10-20 of ordinary portland cement, 2-3 of slaked lime, 3-5 of lightweight aggregate, 71-84 of heavy aggregate (aeolian sand), 1.0 of complex additive, wherein the lightweight aggregate is an inorganic vitrified hollow micropore material; the heavy aggregate is the aeolian sand; the preferred fineness of the inorganic vitrified hollow micropore material is 80-100 mesh, the weight content of the aeolian sand with 50-70 mesh preferred fineness is more than 90 percent, and the rest aeolian sand has more than 100-mesh fineness. The invention has the advantages that the mortar has prominent stereo texture, endurance and stability, light weight, saved energy and good crack- resistant and anti-drop properties, and exhibits natural and rich European style customs decoration effect; and the mortar also has good smear workability and simple process, and is suitable for mechanization construction. The construction method is as follows: the mortar is diluted by adding water based on 30-50 percent of the mortar by weight, mechanical agitation or hand stirring is carried out to be evenly mixed to reach a proper viscosity for mechanical spray or hand construction.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Absorbing type automatic heat-dissipating mosquito repellent device for livestock raising

InactiveCN107509709ALower carbon dioxide levelsReach the effect of automatic mosquito repellentLighting and heating apparatusInsect catchers and killersEngineeringElectric shock

The invention provides an absorbing type automatic heat-dissipating mosquito repellent device for livestock raising. The mosquito repellent device comprises a mosquito removing module and an absorbing module; the mosquito removing module comprises a mosquito catching net, an electric shock net, an opening and closing plate and a fan, an air inlet and an air outlet are designed in a shell, the opening and closing plate comprises a rotating plate, a torsional spring and a rotating shaft, and an opening is designed in the opening and closing plate; the absorbing module comprises a ventilating pipeline and a trapping strip, air suction holes are designed in the side face of the ventilating pipeline, a groove is designed in the trapping strip, and a trapping agent is designed in the groove. The absorbing type automatic heat-dissipating mosquito repellent device for livestock raising is capable of attracting mosquitoes with the trapping agent, absorbing the mosquitoes into the device through negative pressure suction and killing the mosquitoes through electric shock and capable of promoting indoor air flow to dissipate heat.

Owner:狄乃青

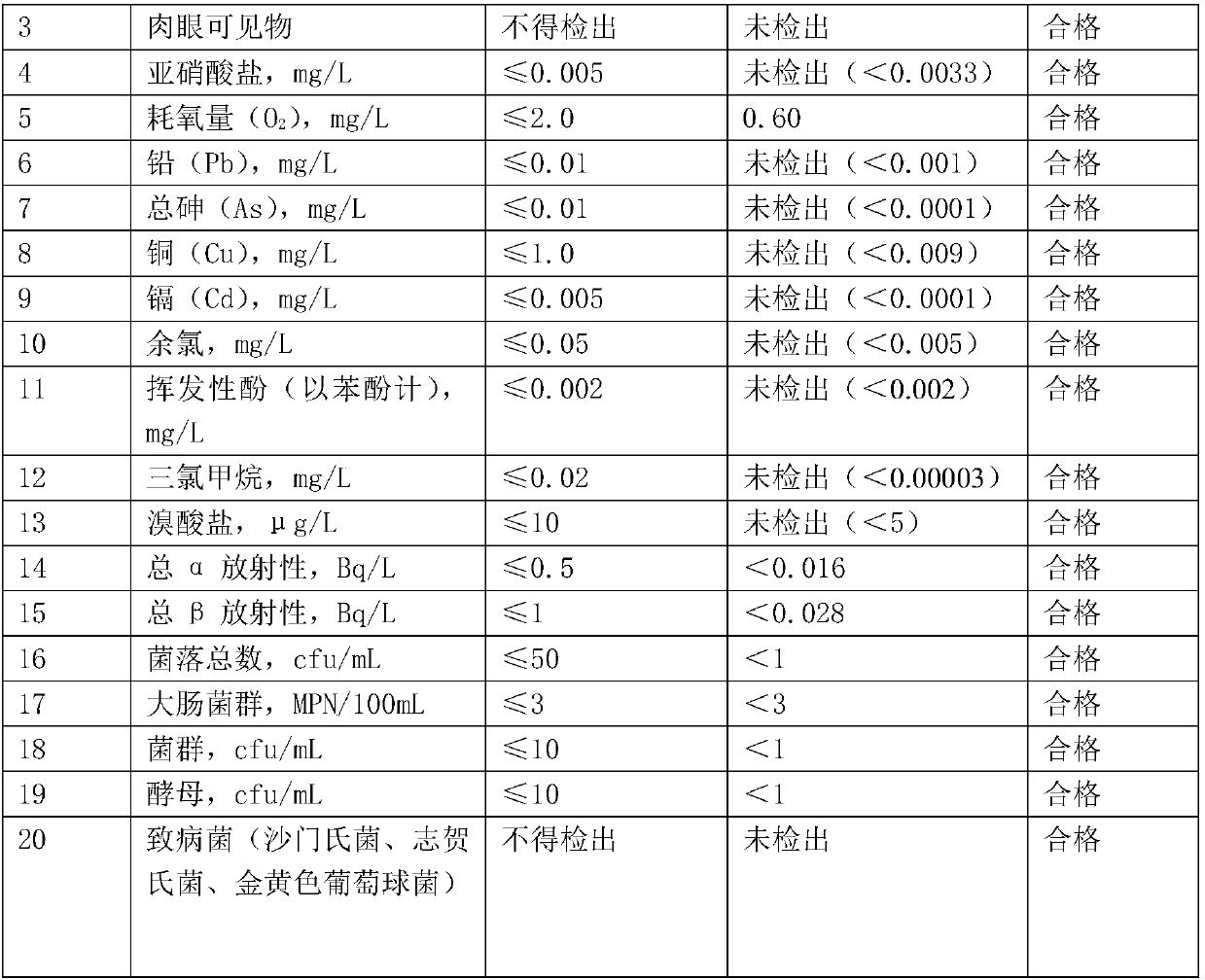

Process for producing mineral water

InactiveCN107585932ASimple production processIncrease oxygen contentMultistage water/sewage treatmentActivated carbon filtrationWater velocity

The invention relates to a process for producing mineral water. The process comprises the following steps: (1) selecting spring water of a main peak of Dabie Mountain, filtering the spring water withcocoanut shell activated charcoal, and filtering the water again by using sandstone and activated charcoal; (2) carrying out reverse osmosis filtering on the water treated in the step (1) to remove colloidal microbes from the water; (3) carrying out iron removal by using a manganese sand filtering device, wherein a water velocity is 18m<3> / h to 20m<3> / h during iron removal; (4) carrying out sterilization by using ozone, and then, carrying out disinfection by ultraviolet rays; (5) introducing clean carbon dioxide into the water; (6) introducing clean mixed gas into the water so as to enable theoxygen content of water of 25 DEG C to reach 65mg / L; (7) carrying out sterile filling on the water. The process provided by the invention is simple, the amount of chemical additives is small, and themineral water is good in taste and high in oxygen content and has very good health-care value.

Owner:ANHUI YELING BEVERAGE & FOOD

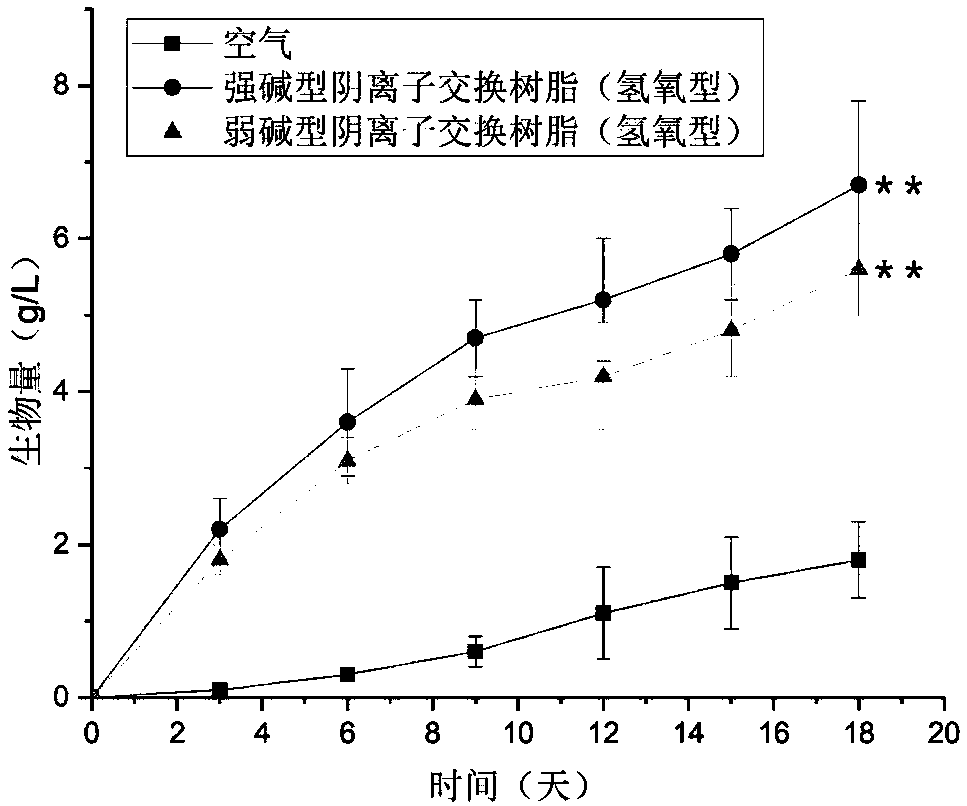

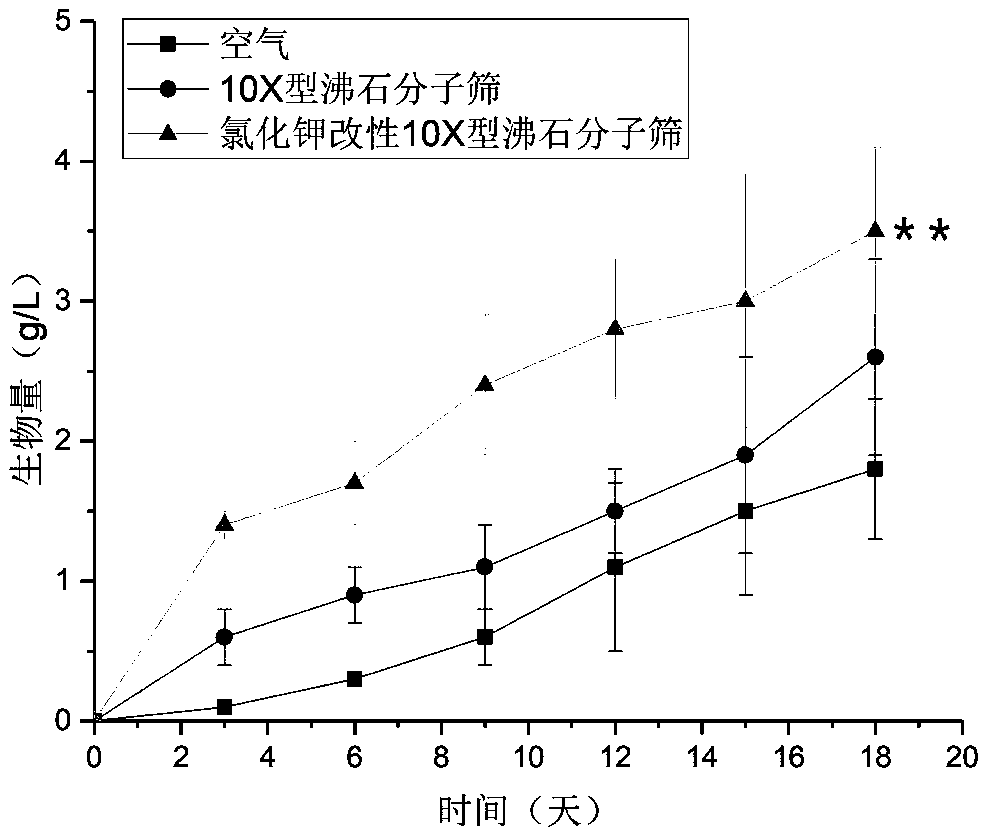

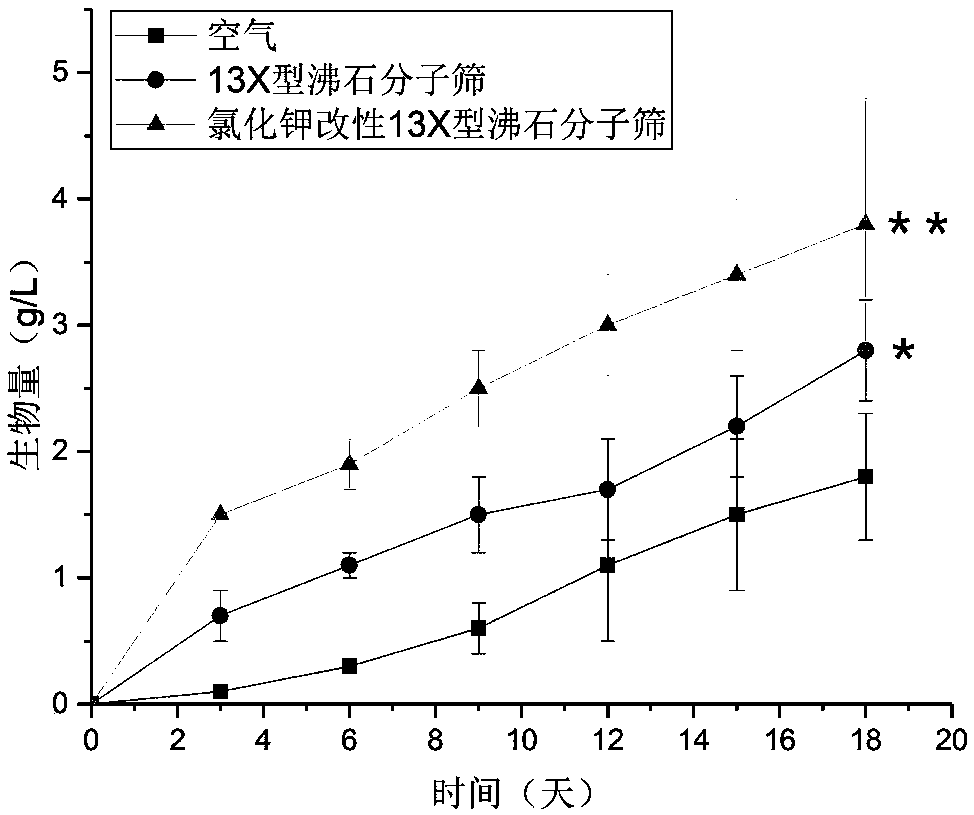

Method for capturing and enriching carbon dioxide by using active material or modified active material and application thereof

PendingCN108970590ALower carbon dioxide levelsImprove adsorption capacityGas treatmentOther chemical processesMolecular sieveActivated carbon

The invention discloses a method for capturing and enriching carbon dioxide by using an active material or a modified active material and an application thereof and belongs to the technical field of environmental protection. In order to absorb carbon dioxide in air efficiently for a long time, the invention provides the method for capturing and enriching carbon dioxide by using the active materialor the modified active material. The active material is ion exchange resin, a zeolite molecular sieve, activated aluminium oxide or activated carbon, and the modified active material is a modified zeolite molecular sieve, modified activated aluminium oxide or modified activated carbon. The method can be used for adsorbing carbon dioxide in air efficiently at a constant temperature and a constantpressure and desorbs the adsorbed carbon dioxide. The carbon dioxide can be also taken as a carbon dioxide gas fertilizer for promoting growth of organisms, including growth of microalgae. Carbon dioxide is fully utilized, and the carbon dioxide content in air is reduced.

Owner:四川芯意成科技有限公司

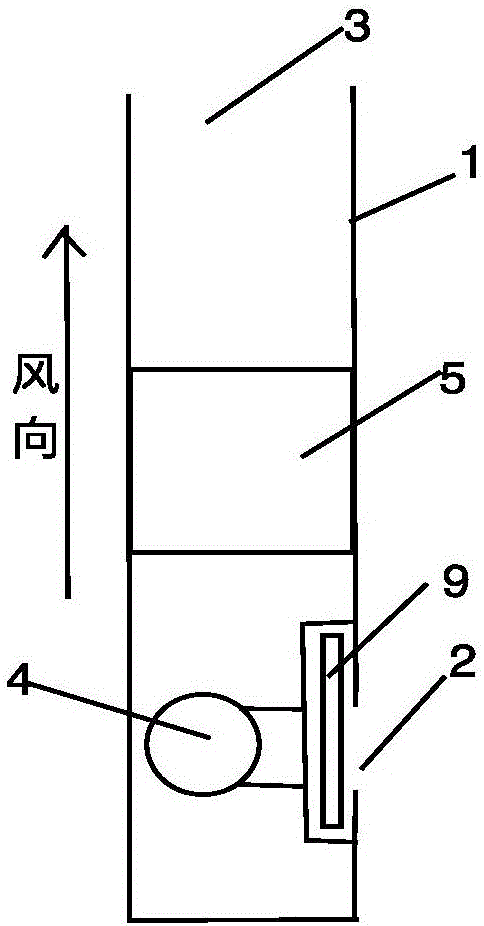

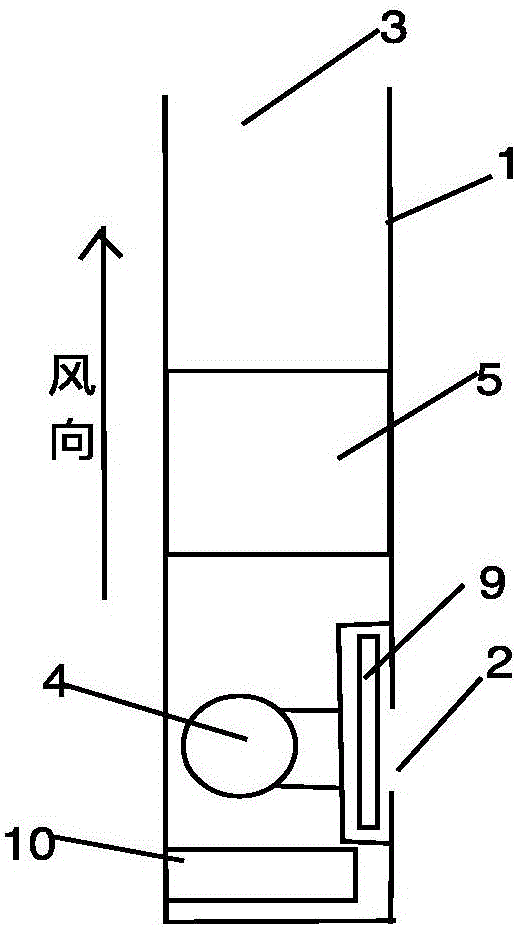

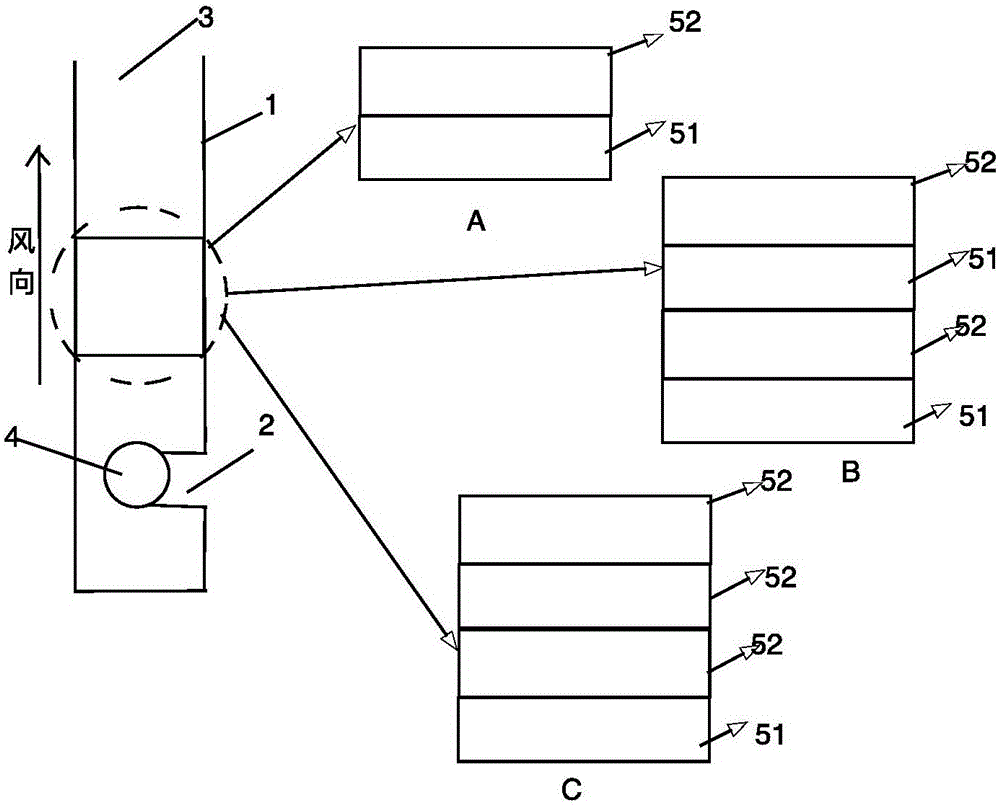

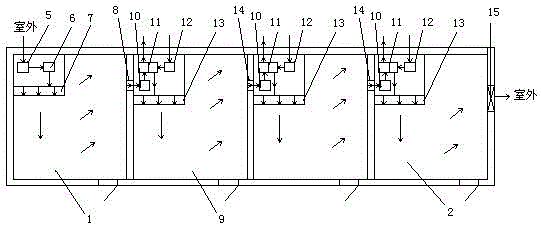

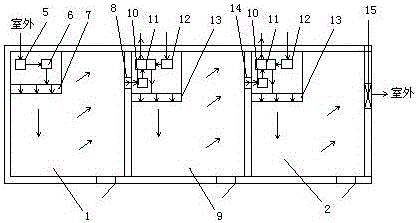

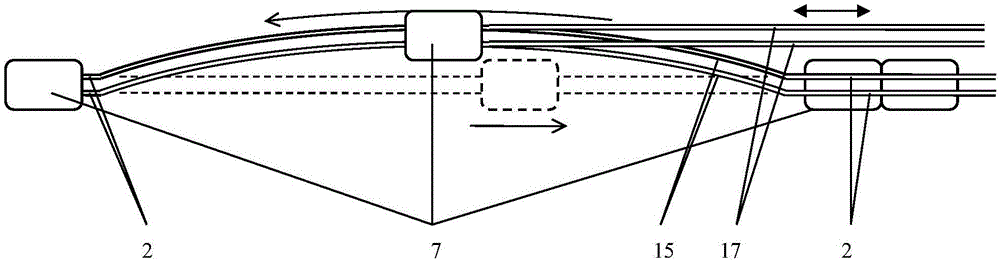

Series type fresh air system used for classrooms

PendingCN106765581AReduce installation costsReduce use costLighting and heating apparatusSpace heating and ventilation detailsFresh airEngineering

The invention provides a series type fresh air system used for classrooms. A purifying system is mounted between a front-end classroom (1) and a tail-end classroom (2); a first fresh air unit is mounted on a rear wall of the front-end classroom (1); the first fresh air unit comprises a fan unit I (5), an auxiliary heating unit (6) and a filter unit I (7); an air inlet of the fan unit I (5) communicates with the outdoor, and an air outlet of the fan unit I (5) communicates with the auxiliary heating unit (6); the auxiliary heating unit (6) communicates with the filter unit I (7); a first ventilation hole (8) is formed in the front wall of the front-end classroom (1); a second fresh air unit is mounted on the rear wall of a second classroom (9); and the second fresh air unit comprises a fan unit II (10), a first heat exchange unit I (11), a fan unit III (12) and a filter unit II (13). The fresh air system is not used in single classroom, and is used by acting between adjacent classrooms, and an air return pipeline does not need to be independently laid in each classroom, so that time and labor are saved, mounting and using cost is greatly reduced, use threshold is low, and energetic popularization is facilitated.

Owner:张树信

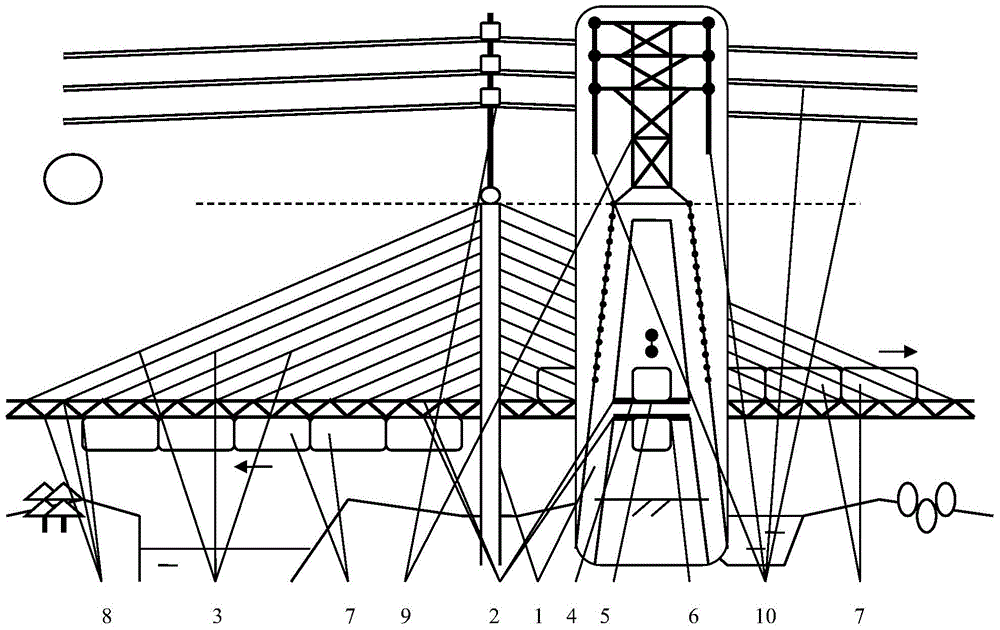

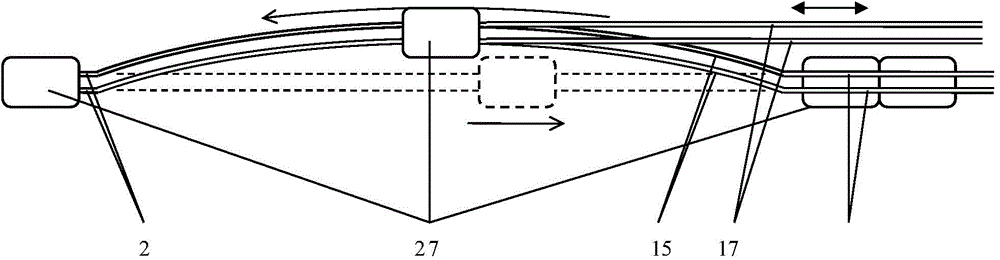

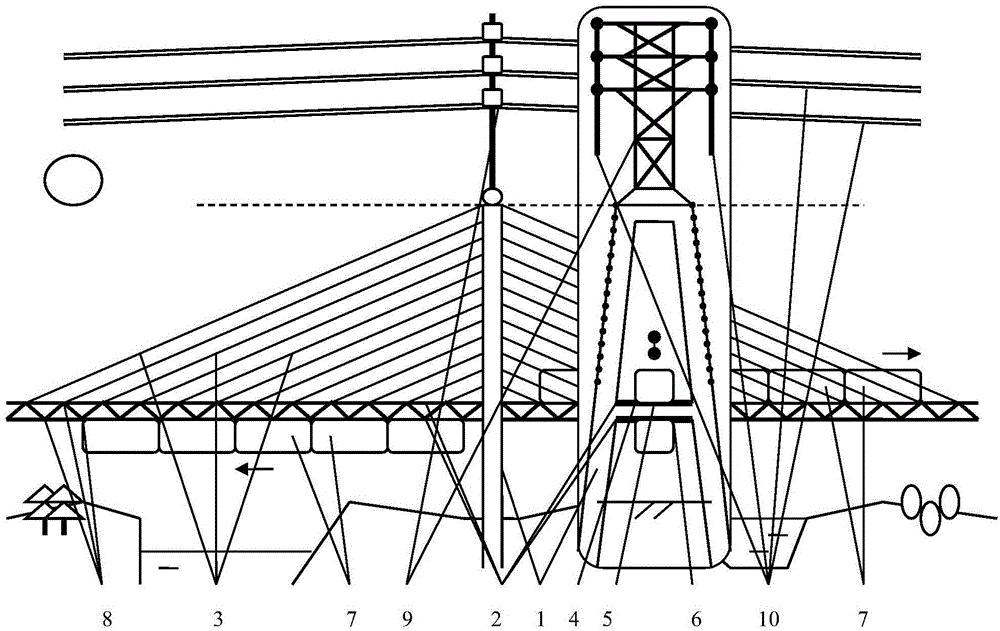

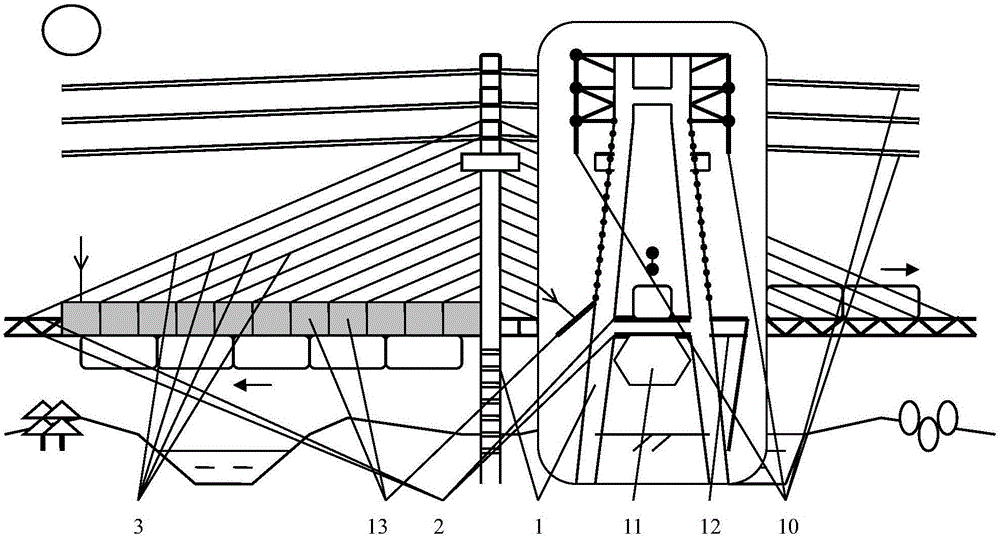

Upper and lower two-way logistics rail method and Upper and lower two-way logistics rail device

ActiveCN105015365ALow costInsensitive to geological conditionsRailway componentsTrolley linesElectrical connectionEngineering

The present invention relates to an upper and lower two-way logistics rail construction method. A stay cable overhead rail manufactured by the method comprises a stay cable tower, an overhead rail constructed by using the stay cable tower as the basis, and stay cables connecting with the stay cable tower and the overhead rail. The stay cable overhead rail is characterized in that the overhead rail is a double-layer structure, the upper-layer structure is the upper dual rails, and the lower-layer structure is the lower dual rails; the upper dual rails and the lower dual rails are used as a connection interface of the overhead rail and a logistics vehicle, a wheel group at the top of the logistics vehicle is in rolling connection with the lower dual rails, and the upper dual rails and the lower dual rails are connected via connecting rods, transmit the gravity to the ground by the stay cables and the stay cable tower, and are equipped with the logistics vehicle power supply electrical connection interfaces respectively. According to the present invention, a low environmental load transport pathway is provided for the grain energy which is possibly produced from the vast and undeveloped land, even 20% of the uncultured land is constructed into the production base of the grain, the bioplastic and the energy, more than three trillion yuan of wealth can be increased at every year.

Owner:台州长天能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com