Household garbage flash mineralization processor

A domestic waste and processor technology, applied in the field of domestic waste disposer, can solve problems such as unsuitable for small-scale processing capacity requirements in rural areas, high technical content, discounted production and processing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

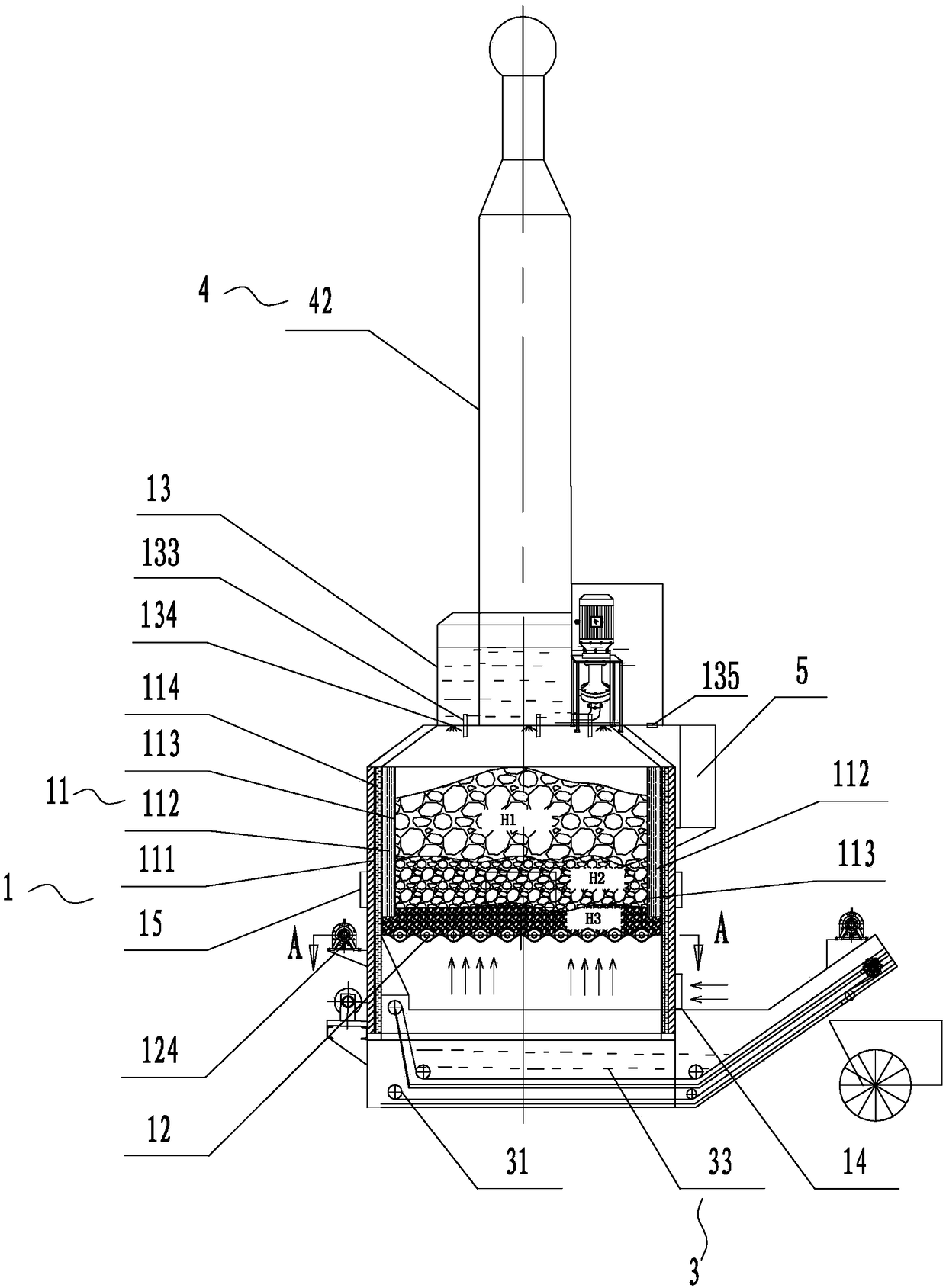

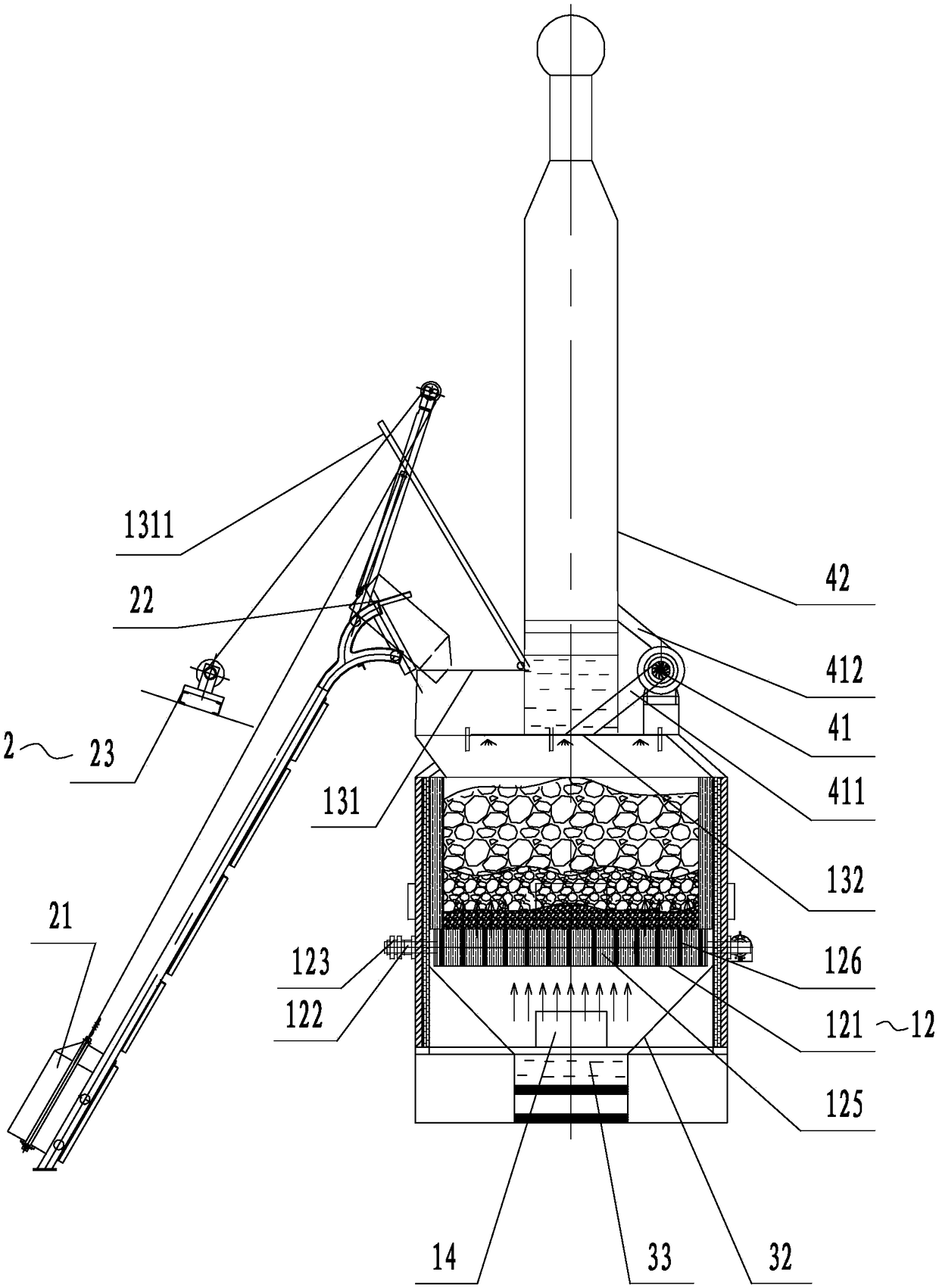

[0090] A domestic garbage flash mineralization processor, including a furnace body 1, a material feeding system 2, a slag discharge system 3, a flue gas purification system 4, and an electrical control box 5, wherein:

[0091] The furnace body 1 includes a furnace wall 11 at the side of the furnace body, a fire grate 12 at the lower part of the furnace body, and a water tank 13 at the top of the furnace body. The outer side of the furnace wall 11 is a sealed steel plate 111, and the inner side is lined with a side pyroelectric honeycomb ceramic body 112. A furnace insulation layer 114 is also arranged between the side pyroelectric honeycomb ceramic bodies 112 .

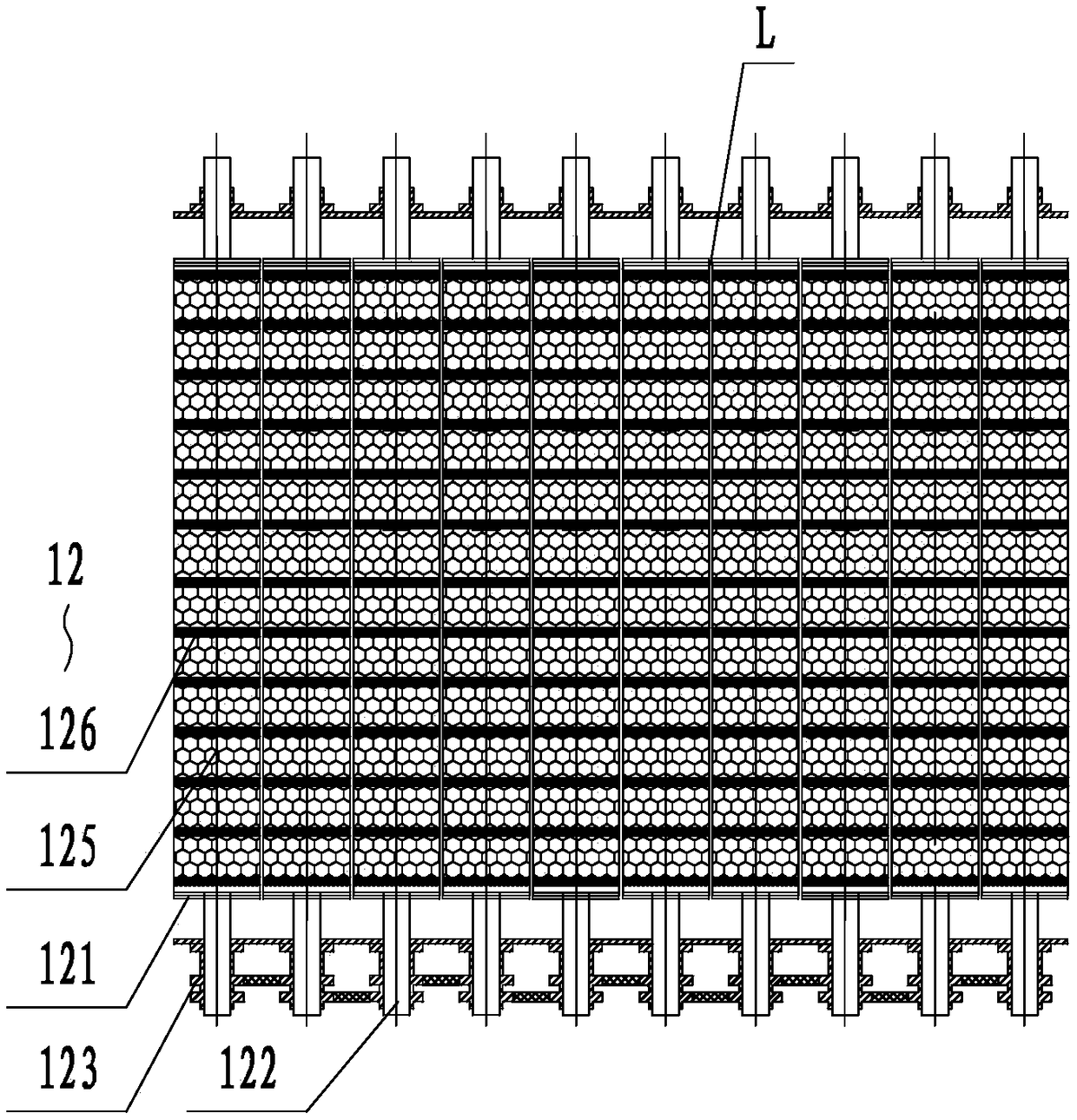

[0092] The fire grate 12 is a movable fire grate that can rotate 360°, and the fire grate 12 includes a fire grate housing 121, a rotating shaft 122, a sprocket wheel 123, a pyroelectric honeycomb ceramic body 125, and a permanent magnet 126; The fire grate housing 121 is evenly provided with ventilation holes, and t...

Embodiment 2

[0101] A domestic garbage flash mineralization processor, the basic structure of the device is the same as that of Embodiment 1, the difference is that the cross sections of the fire grate shell 121 and the pyroelectric honeycomb ceramic body 125 are rhombus-shaped, Figure 13 Shown in is the rhombus cross-sectional view of the pyroelectric honeycomb ceramic body, Figure 14 Shown in is the schematic cross-section of the grate, Figure 15 Shown in is a schematic view of the grate rotated 90 degrees.

Embodiment 3

[0103] A domestic garbage flash mineralization processor, the basic structure of the device is the same as that of Embodiment 1, the difference is that the cross sections of the fire grate shell 121 and the pyroelectric honeycomb ceramic body 125 are all triangular, Figure 16 Shown in is the triangular cross-sectional view of the pyroelectric honeycomb ceramic body, Figure 17 Shown in is the schematic cross-section of the grate, Figure 18Shown in is a schematic view of the grate rotated 90 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com