Patents

Literature

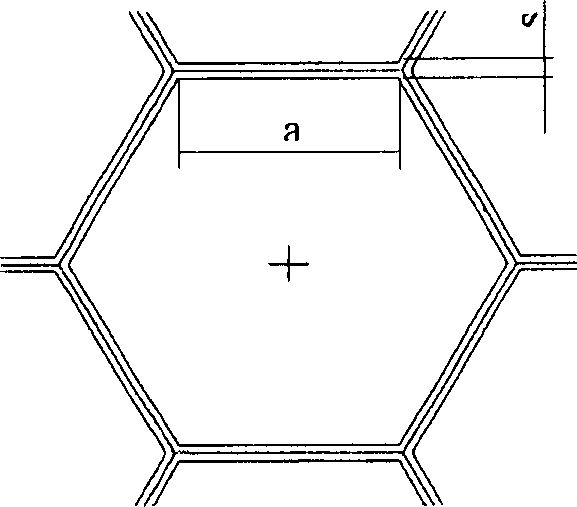

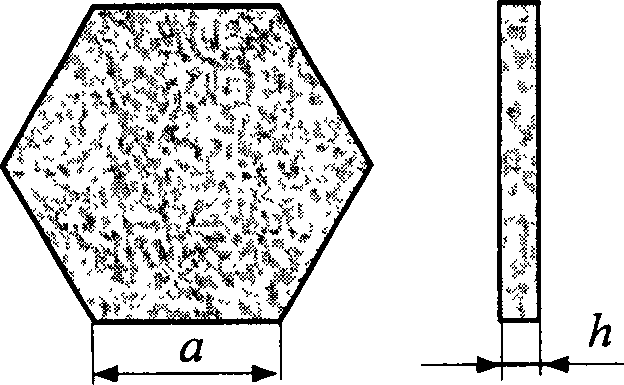

1590 results about "Honeycomb ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supported nano gold catalyst for clearing formaldehyde from indoor air and method for preparing the same

InactiveCN1698932ALow costHigh catalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHoneycombRare earth

This invention relates to a supported nanometer gold catalyst which is used for cleaning formaldehyde of room air, in addition to its preparing method. The method comprises the following steps: a) using cordierite honeycomb ceramics as the carrier; b) coating a layer of rare earth oxide or composite rare earth oxide in the carrier surface evenly; c) depositing 3-10nm golden grain in the rare earth oxide or composite rare earth oxide, wherein the weight of gold is 1%-3% of the coating. Said catalyst can clean the formaldehyde of the air and the formaldehyde has a high conversion ratio. Meanwhile, the catalytic activity of said catalyst is larger by a magnitude order compared with Mn, Co oxide or rare earth composite oxide catalyst.

Owner:INNER MONGOLIA UNIVERSITY

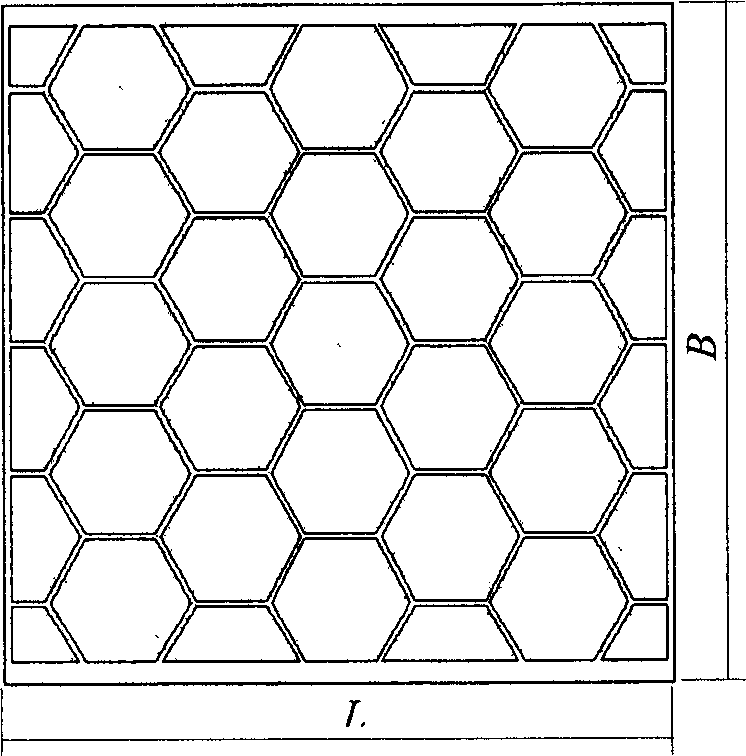

Ceramic honeycomb structural body

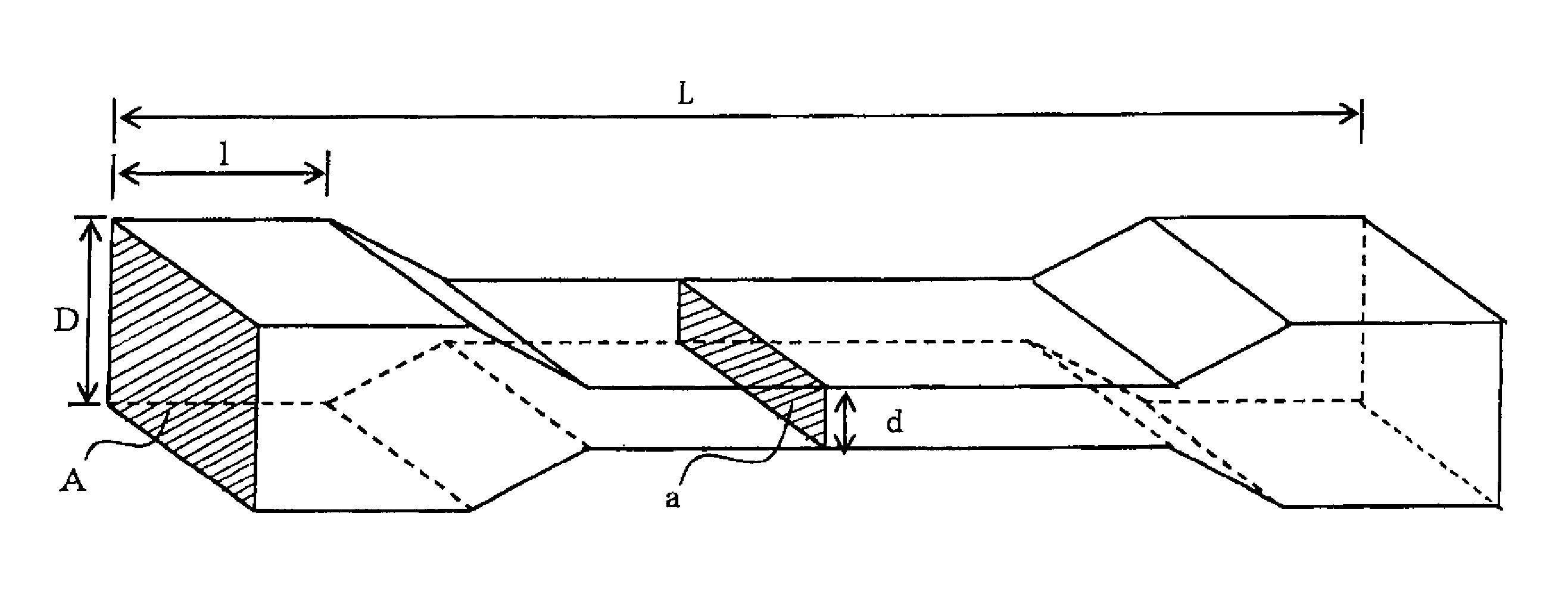

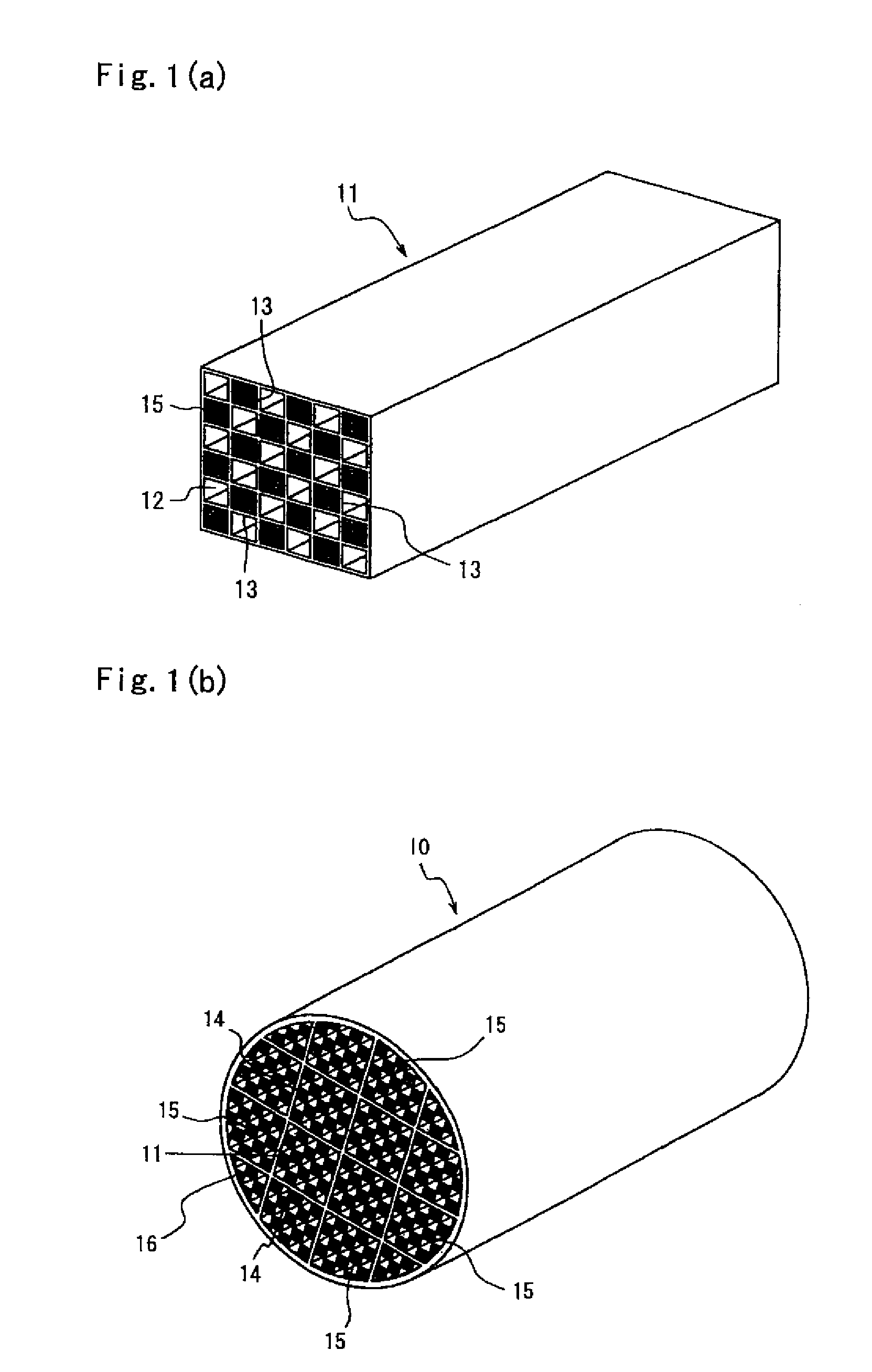

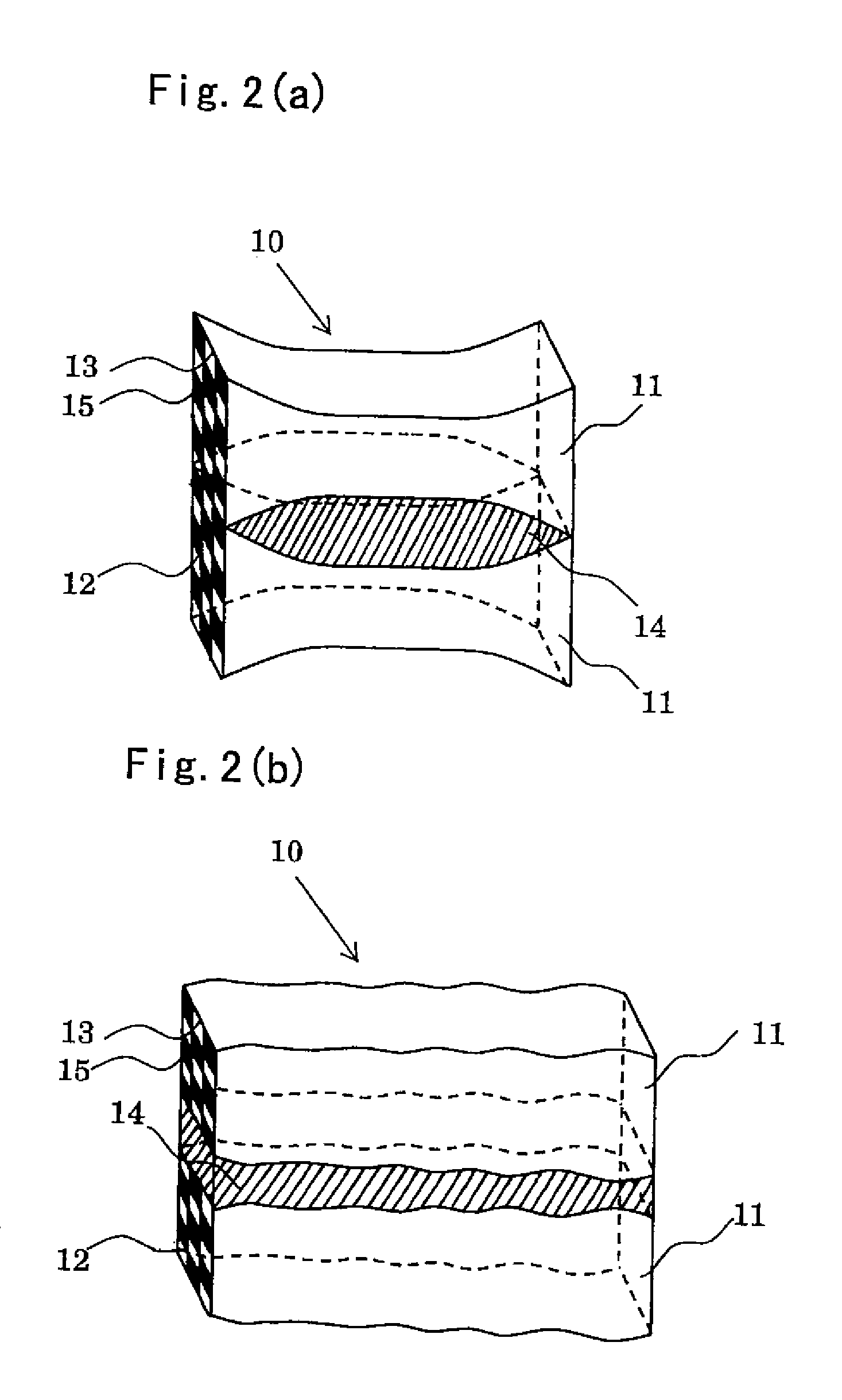

ActiveUS7438967B2Increase the cross-sectional areaPhysical/chemical process catalystsDispersed particle filtrationCell wallMaterials science

Owner:IBIDEN CO LTD

Catalyzer for catalyzing combustion and its preparing method

InactiveCN1415410AReduced activityAvoid overwritingCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

A catalyst for the catalytic combustion of combustible waste gas is prepared by dipping the Pt as active component on the coated layer of cellular ceramics as carrier. The said coated layer contains Al2O3 (20-80 wt.%), TiO2 (10-40 wt.%), CeO2 (5-30 wt.%) and ZrO2 (5-20 wt.%). Its advantages are high utilization rate of Pt, and high distribution uniformity.

Owner:CHINA PETROLEUM & CHEM CORP +1

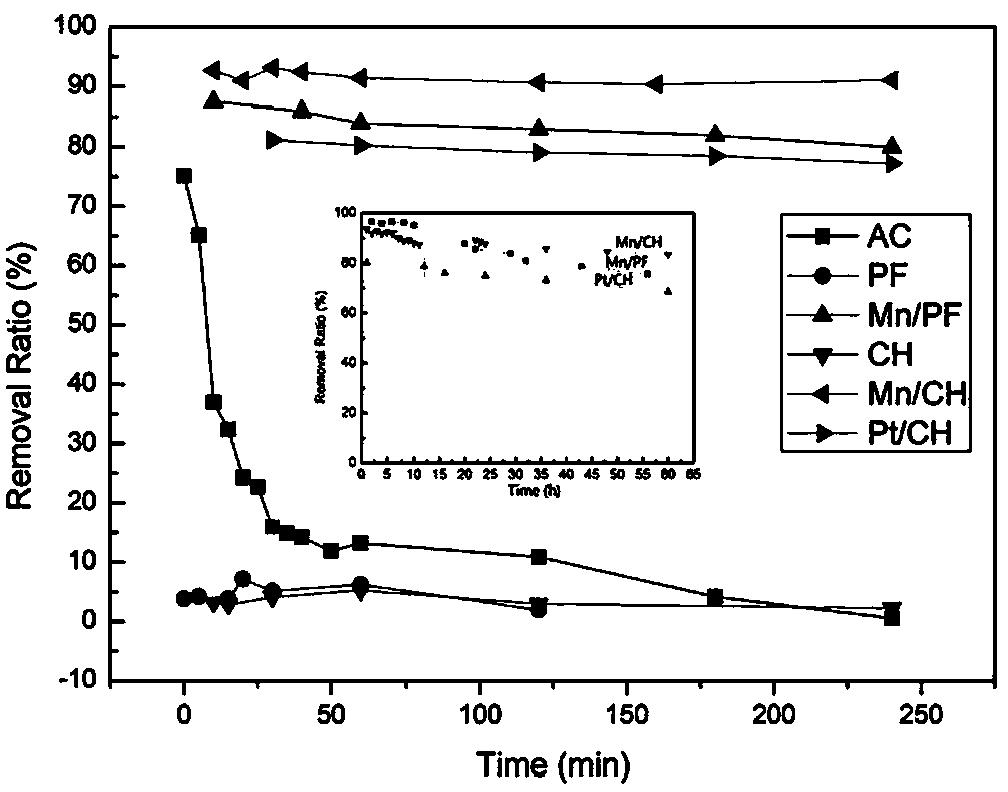

Nano Au catalyst for eliminating formaldehyde at room temperature and preparation method thereof

InactiveCN101612578AGood resistance to water vapor poisoningImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporRoom temperature

The invention relates to a loading type nano Au catalyst for eliminating formaldehyde in a room, a car and a microenvironment and a preparation method thereof. The corresponding nano Au catalyst is prepared mainly by adopting a coprecipitation method, a depositing precipitation method, an improved soaking method, and the like, taking metallic oxide, composite carrier oxide MOx / Al2O3, composite carrier oxide MOx / CeO2, glass, honeycomb ceramics and a metal mesh as matrixes and taking metallic oxide MOx as a second carrier. Compared with the prior art, the invention has the advantages that (1) the effect of eliminating the formaldehyde by 100 percent at room temperature can be achieved; (2) the nano Au catalyst has good steam poisoning resistance; (3) the CO is catalyzed to be completely converted into CO2; (4) the nano Au catalyst has the favorable active stability and the service life; and (5) the nano Au catalyst can be made into a molded catalyst to be applied in various occasions.

Owner:NO 63971 TROOPS PLA

Cellular ceramic type catalyst for catalytic combustion of perovskite as well as preparation and application thereof

InactiveCN101439290AHigh activityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioManganese

The invention discloses a honeycomb ceramics perovskite catalytic combustion catalyst; the honeycomb ceramics with a metal oxide coating is used as a carrier; the catalytic activity components disclosed in formula (I) are loaded; wherein, La, Sr, Co, and Mn respectively represent lanthanum, strontium, cobalt, and manganese; x is equal to 0 to 0.7 and y is equal to 0 to 0.7; the honeycomb ceramics with a metal oxide coating is to load a metal oxide coating of gamma-Al2O3, CemZr1-mO2, LaMnAl11O19, BaMnAl11O19 or Sr12Al14O21 on the surface of the honeycomb ceramics of a dichroite material; wherein, m is equal to 0.1 to 0.8; the mass ratio of the honeycomb ceramics, the metal oxide coating and the catalytic activity components is 1.0 : 0.03 to 0.2 : 0.05 to 0.15. The invention also relates to a preparation method for the catalyst and the applications of the catalytic combustion thereof to eliminate the waste gases of volatile organic compound; the dichroite honeycomb ceramics carrier and the catalytic activity components of the prepared honeycomb ceramics perovskite catalytic combustion catalyst are combined by one metal oxide coating with high adhesiveness and thermal stability, thus leading the catalyst to have the advantages of high mechanical intensity, high activity and good thermal stability. The catalyst provided by the invention is simple in preparation method, is low in the price of the used materials, and has excellent industrial application prospect. La1-xSrxCoyMn1-yO3 (I).

Owner:ZHEJIANG UNIV OF TECH

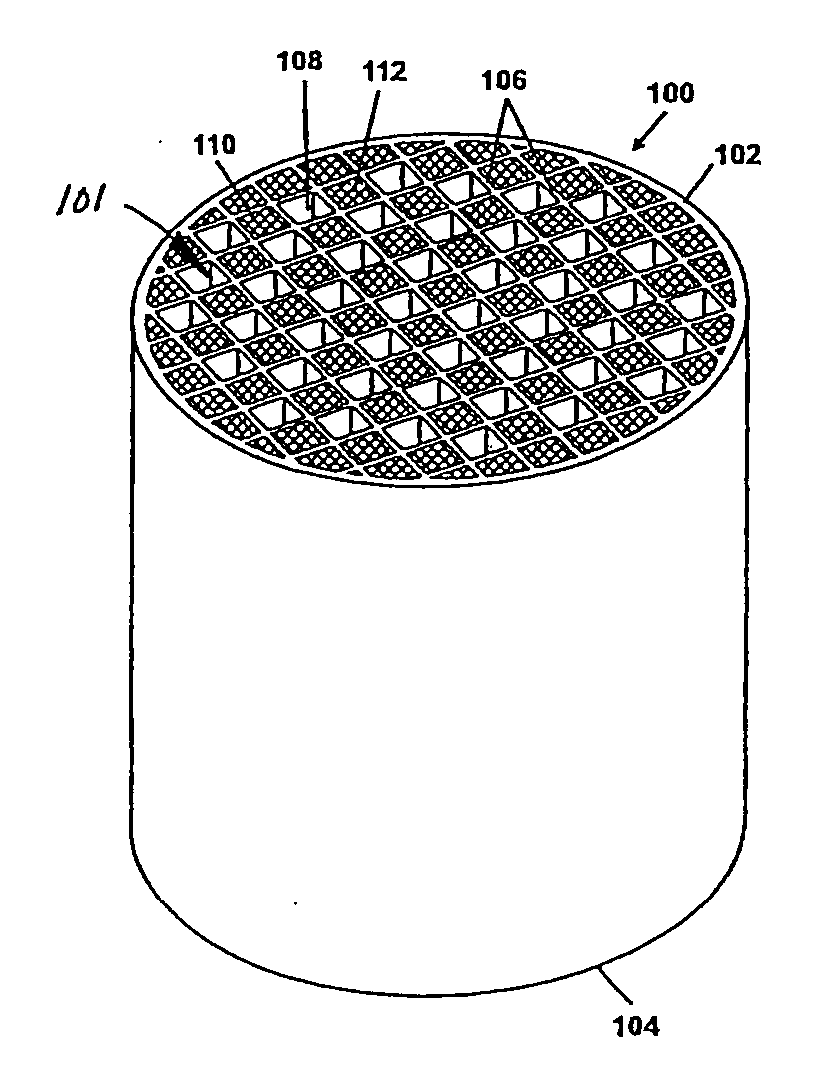

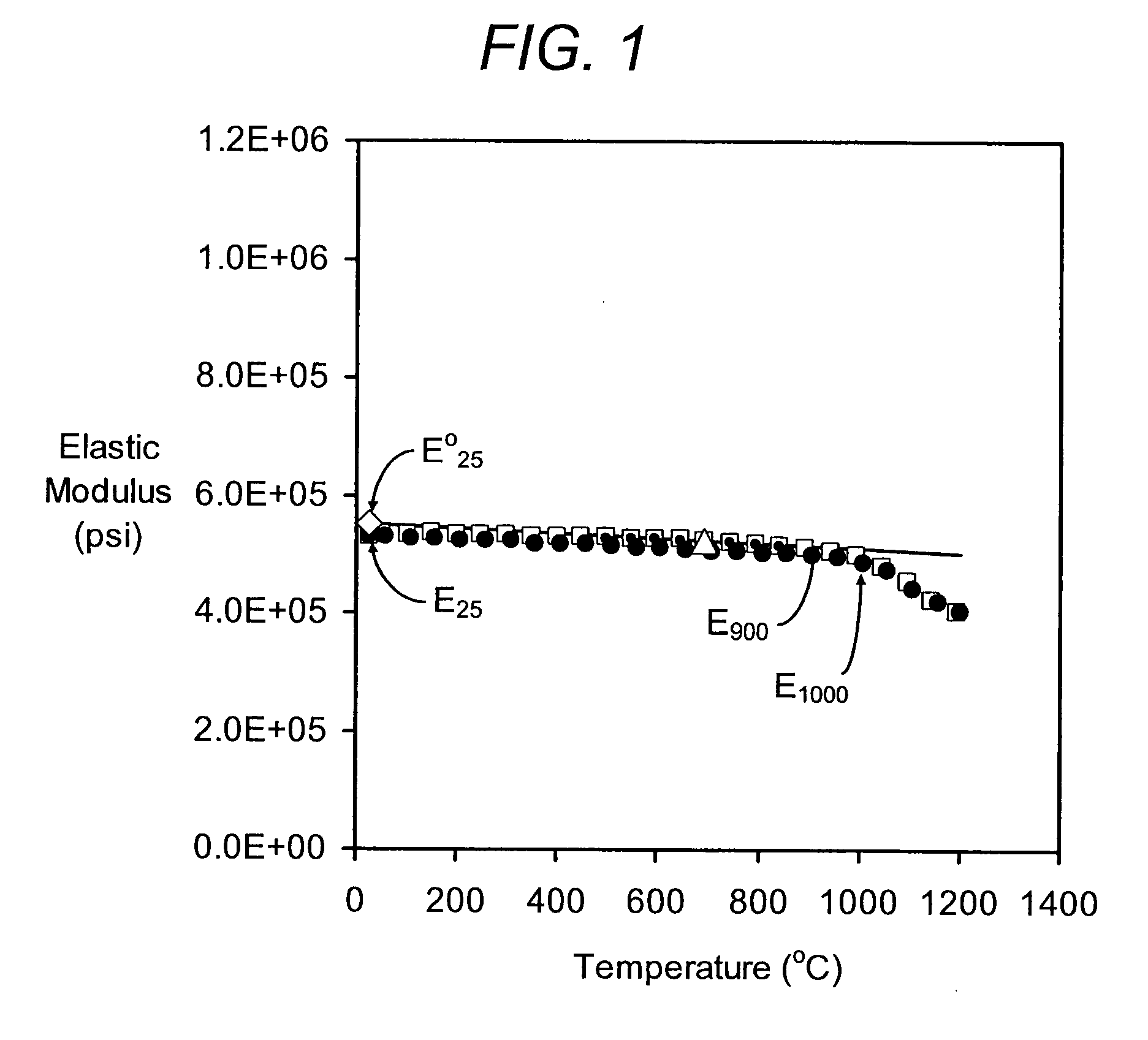

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

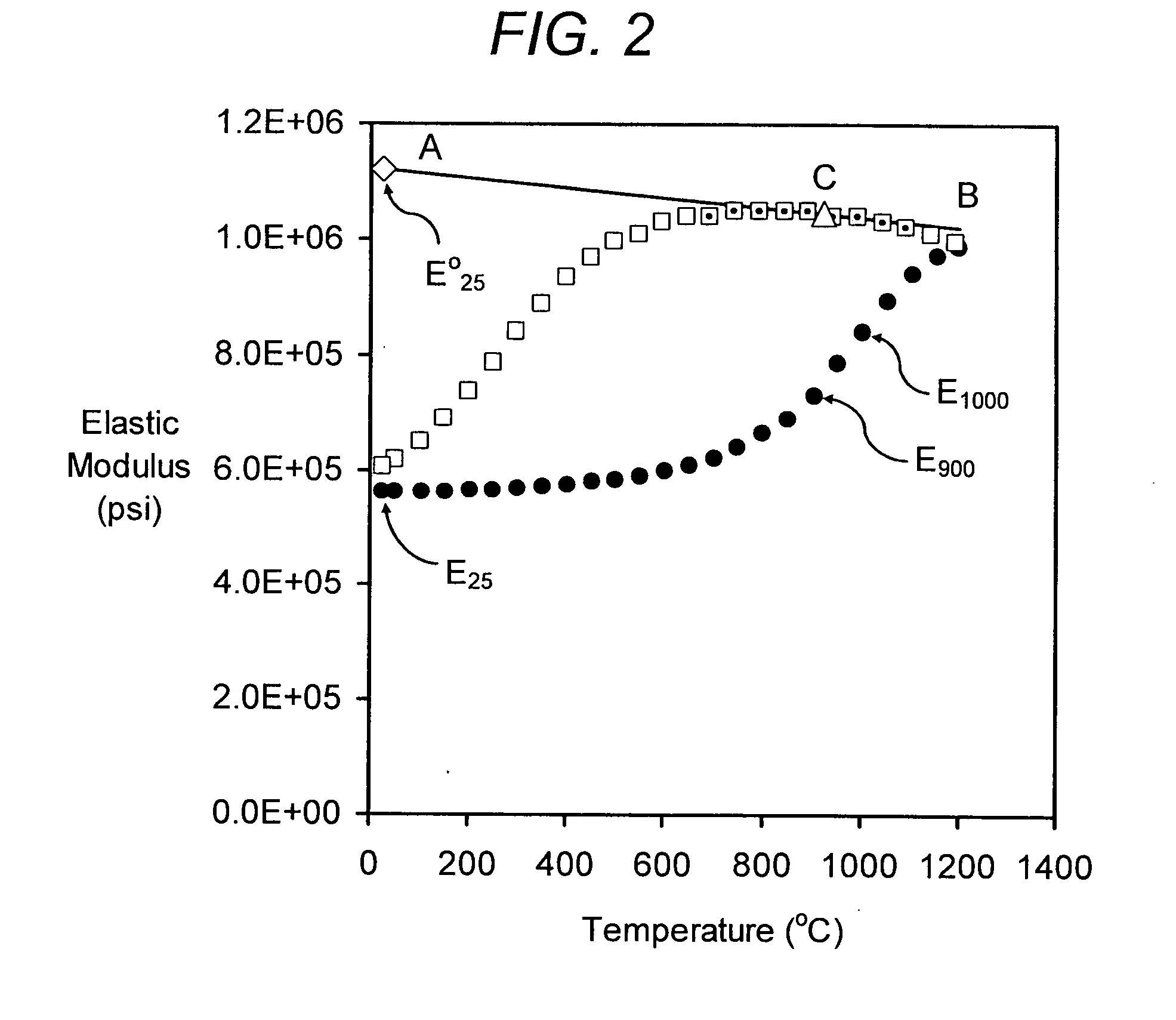

ActiveUS20080032090A1Improve efficiencyHigh strengthLayered productsCeramic shaping apparatusThermal expansionInterconnected porosity

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

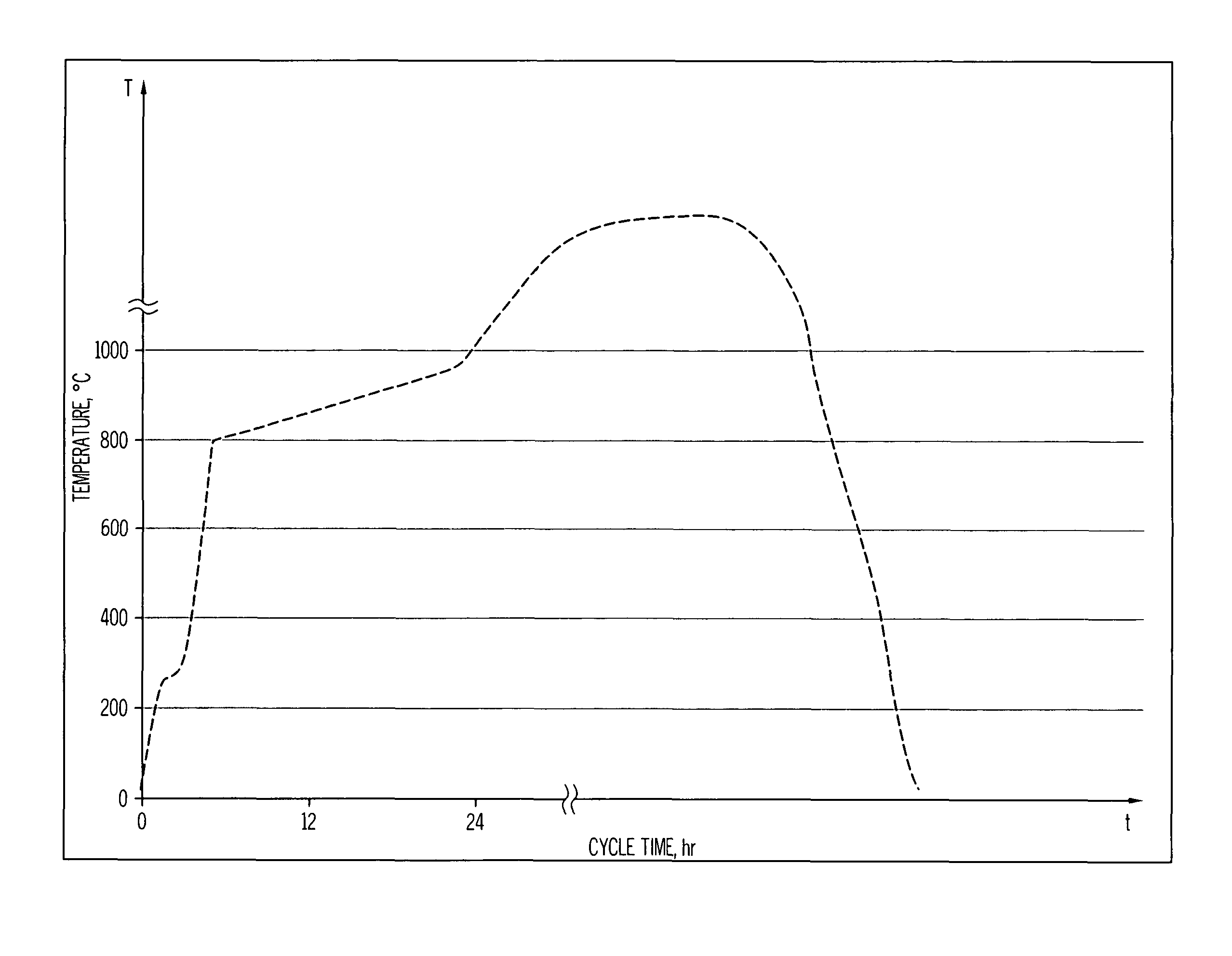

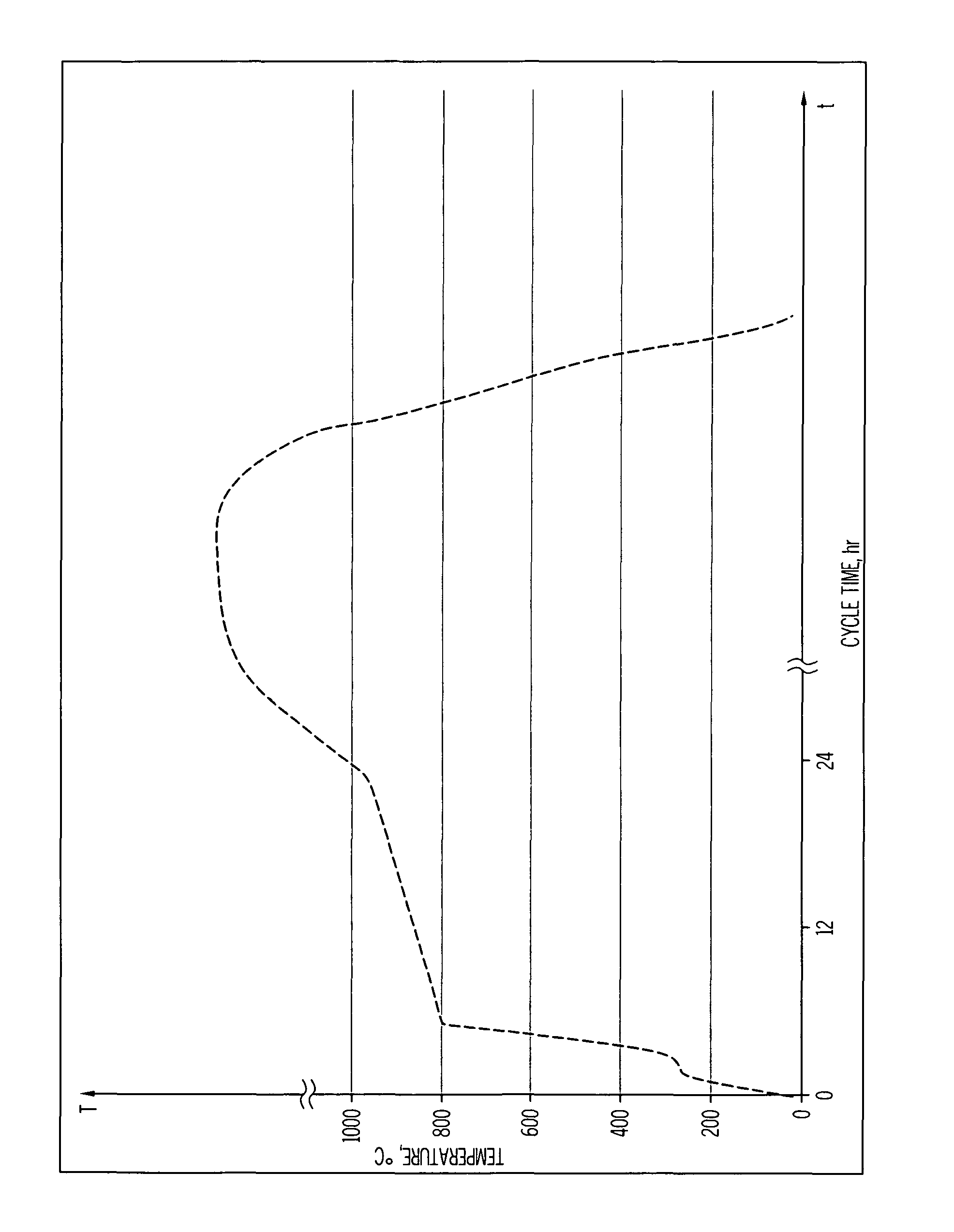

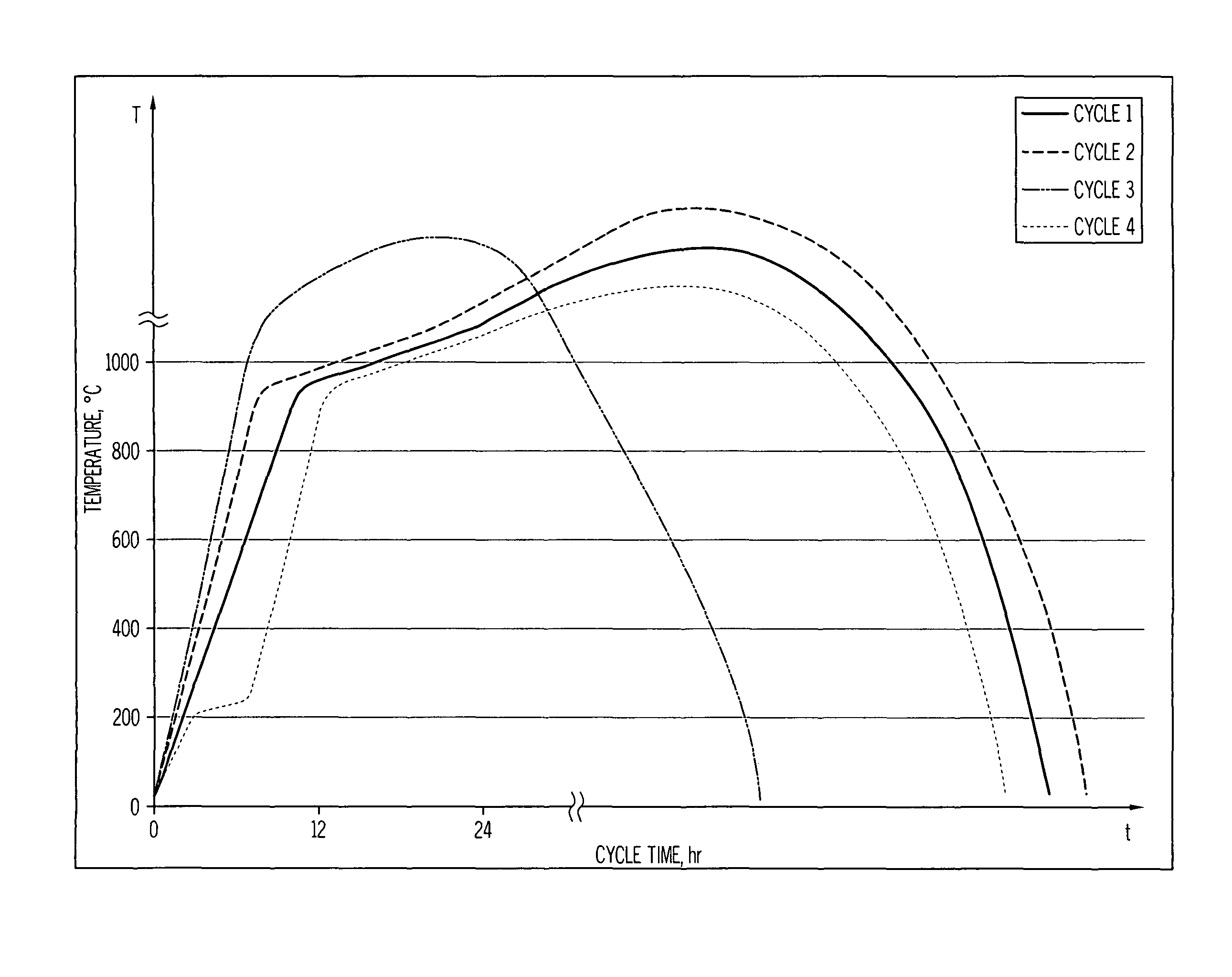

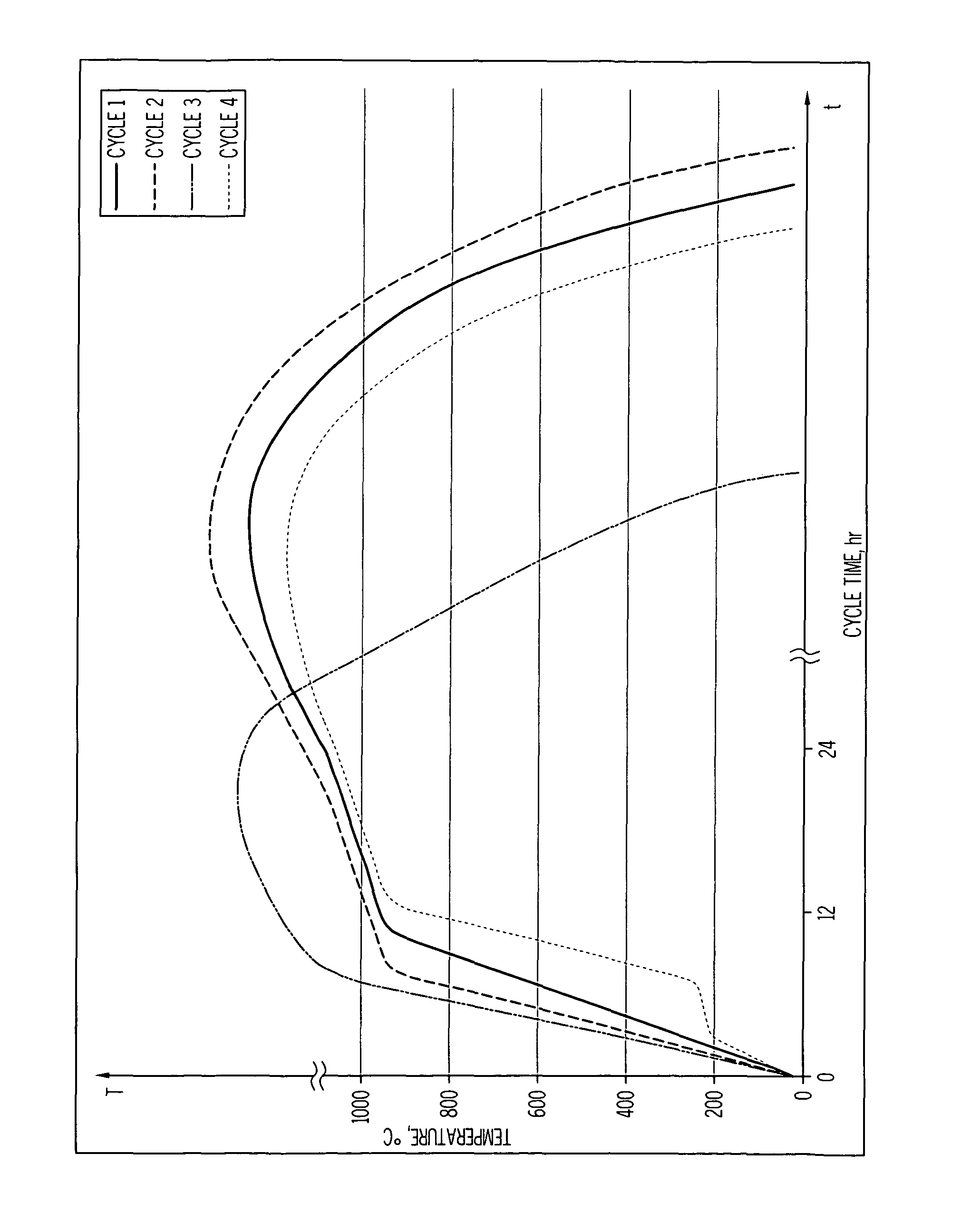

Fast firing method for high porosity ceramics

A method for firing a green honeycomb ceramic body including heating the green honeycomb ceramic body from room temperature to a first temperature of less than or equal to about 350° C. with at least one heating rate of greater than or equal to about 80° C. / hr. The green honeycomb ceramic body may be heated from the first temperature to a second temperature of greater than or equal to about 800° C. at a heating rate of greater than or equal to about 90° C. / hr. The green honeycomb ceramic body may be heated from the second temperature to a third temperature of greater than or equal to about 1000° C. The green honeycomb ceramic body may include aluminum raw materials for forming an aluminum titanate ceramic body.

Owner:CORNING INC

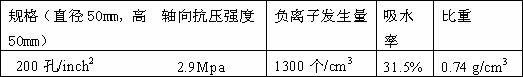

Tourmaline monolithic honeycomb ceramic and preparation method thereof

ActiveCN102285816AImprove adsorption capacityEnhance the efficacy of toxic and harmful substances in liquidsCeramicwareMicrowaveHoneycomb

The invention discloses a tourmaline integral honeycomb ceramic and the ceramic mainly comprises the following components by weight percent: 10-75% of tourmaline, 2-20% of clay, 2-40% of fluxing agent and 1-30% of auxiliary material. The preparation method of the tourmaline integral honeycomb ceramic comprises the following steps: adding tourmaline, clay, the fluxing agent, the auxiliary materialand a dry powder forming agent in a medium mill in proportion to grind and mix so as to obtain a mixture, then adding a appropriate amount of water and a liquid forming agent in the mixture to knead and obtain mud, granulating the mud, aging, extruding to obtain mud sections, moulding the mud sections, performing microwave forming, drying to prepare a semi-finished product, and placing the semi-finished product in a kiln at 500-850 DEG C to fire. Compared with the existing tourmaline products, the characteristics of the existing honeycomb ceramics, namely large specific surface area and porescan be ensured, the effect of tourmaline can be extremely exerted, the amount of tourmaline can be greatly reduced and the ceramic has good energy-saving effect. The energy consumption of the tourmaline integral honeycomb ceramic is one tenth of the energy consumption of the tourmaline ball fired at the same temperature.

Owner:曹南萍

Fast firing method for high porosity ceramics

ActiveUS9446560B2Easy to operateCeramic shaping apparatusHollow wall articlesPorosityRoom temperature

A method for firing a green honeycomb ceramic body including heating the green honeycomb ceramic body from room temperature to a first temperature of about 300° C. The green honeycomb ceramic body is then heated from the first temperature to a second temperature of greater than or equal to about 800° C. at a heating rate of greater than or equal to about 90° C. / hr. The green honeycomb ceramic body may have a diameter of from greater than or equal to about 4.0 inches to less than or equal to about 9.0 inches, and it may include a carbon-based pore former in a concentration of from greater than or equal to about 10% to less than or equal to about 45% by weight.

Owner:CORNING INC

Catalytic combustion catalyst and preparing method thereof

InactiveCN1488435AImprove high temperature resistanceNot easy to fall offDispersed particle separationCatalyst activation/preparationActive componentAlkali metal oxide

The invention refers to a kind of catalyst in organic waster gas purification. It is made up of honeycomb pottery carrier and the paint layer on the carrier, and the precious metal active components. The layer has characters such as stable paint layer, excellent high temperature resistant performance, the efficiency is high. The paint layer is made up of Al2O3, SiO2 and a one kind of or more alkali metal oxide. The paint layer combines with the honeycomb pottery carrier stably.

Owner:CHINA PETROLEUM & CHEM CORP +1

Air purification material and preparation method and application thereof

ActiveCN104190251AEfficient decompositionQuick removalDispersed particle separationFiberParticulates

The invention relates to an air purification material and a preparation method and application thereof, belonging to the technical field of chemical catalytic decomposition, in particular belonging to the technical field of decomposition of formaldehyde pollutants in environment air. The air purification material comprises a base material and manganese oxide, wherein the manganese oxide is supported on the base material, the base material is honeycomb ceramics or a fiber material with a particle filtering function, and the manganese oxide is birnessite manganese oxide prepared from permanganate and oxalate. The air purification material can effectively decompose formaldehyde pollutants in indoor air and can rapidly and constantly remove the formaldehyde pollutants in indoor air at room temperature. The air purification material can be regenerated through heating, so that the service life of the material is prolonged and the practical application is facilitated.

Owner:TSINGHUA UNIV

Composite bulletproof armour with steel honeycomb ceramic sandwich and manufacture thereof

In the invention, the composite bullet-proof armour plate consists of a metal panel, a honeycomb core board, a ceramic wafer core and a metal rear panel bonded with the metal brazing layer via the organic adhesive layer. The preparing method is that using the brozing and the line-cutting method are finished the honeycomb core board and the plain or curved ceramic wafer core, whose size must fit in that of the honeycomb hole of the honeycomb core board. The panel and the rear panel must be made of the bullet-proof steel plate through heat treating after cold rolling. The Ag72Cu metal brazing material and the epoxy resin group high strength structural sizing for connecting the interface are assembly welded.

Owner:UNIV OF SCI & TECH BEIJING

Metallic oxide mixture catalyzer for purifying organic waste gas and method of preparing the same

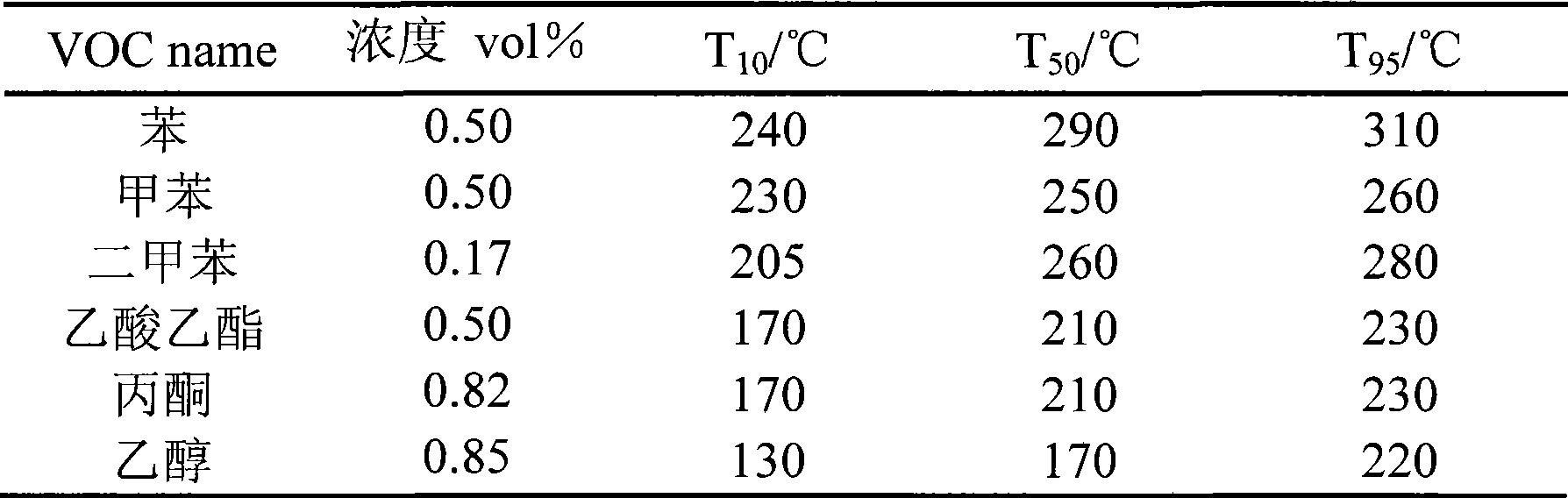

ActiveCN101138728AKeep aliveImprove performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCordierite

The present invention relates to a catalyst of a metal oxide compound used for organic exhaust gas purification, and a preparation method for the catalyst. The catalyst uses the cordierite honeycomb ceramic intensively pretreated with the nitric acid as a carrier, and an active aluminum oxide coating modified by a mixed oxide of cerium, lanthanum and zirconium, and an active component comprising a plurality of metallic oxide mixtures are loaded on the carrier in a lump. For the catalyst preparation method, heat treatment is conducted on the carrier with the nitric acid, the concentration of which is 5 to 15 percent; after a specific surface area of the carrier is increased, the coating, which comprises and is loaded with the mixed oxide active component, is immersed in a lump. The catalyst is provided with the large specific surface area. The active component is a transition metal oxide mixture, which comprises no noble metal. Moreover, the catalyst is provided with the excellent performance and the low cost, and can be spread and applied easily. The catalyst is provided with the high catalytic combustion efficiency for the organic exhaust gas comprising benzene, toluene, dimethybenzene, polycyclic aromatic hydrocarbon and so on, and the ignition temperature is low. Thus, the catalyst is widely applicable for purification of the industrial organic exhaust gas. The technique of one-time immersion, drying and calcination is adopted, so the manufacture equipment needed is simple.

Owner:SOUTH CHINA UNIV OF TECH

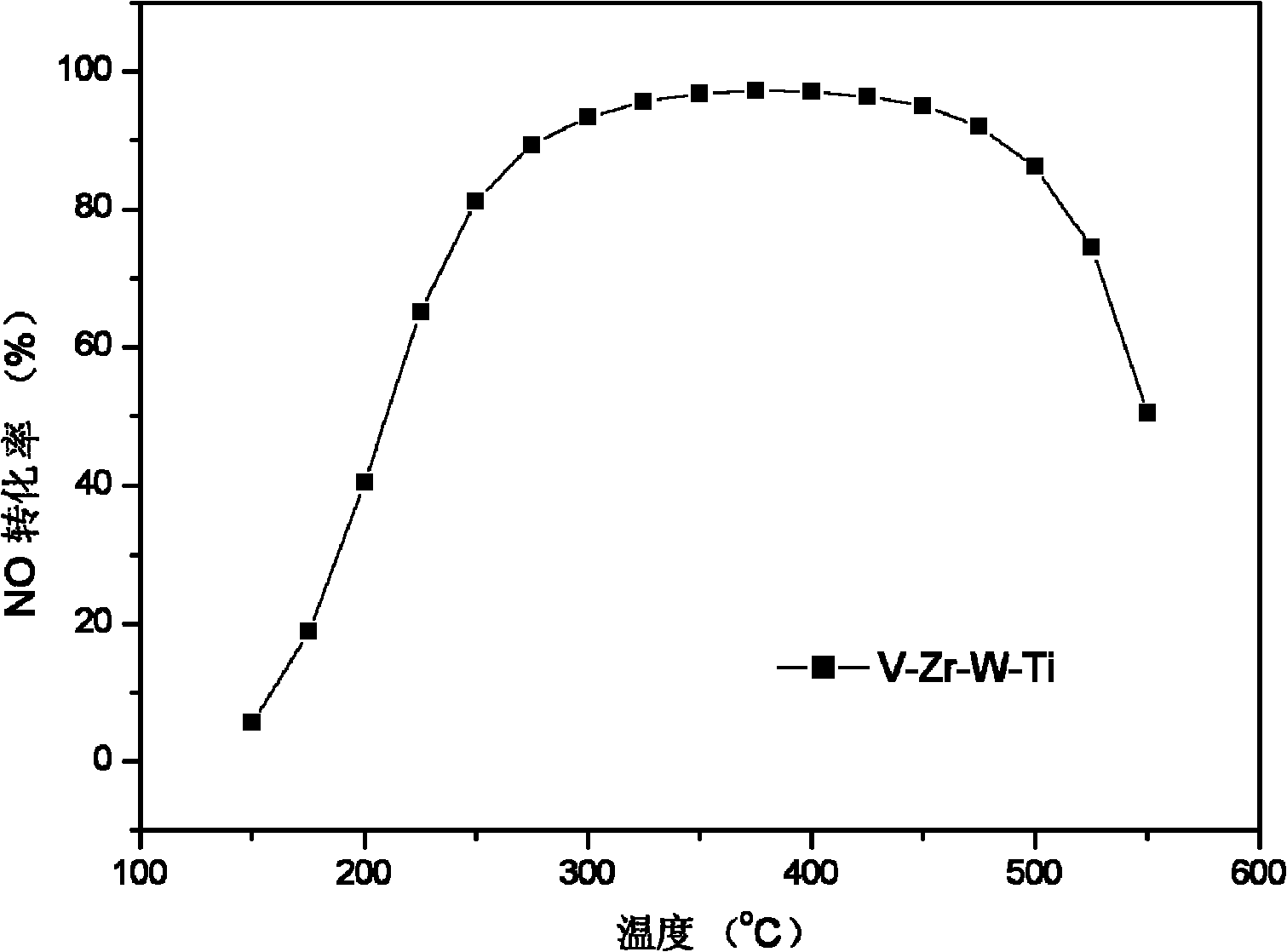

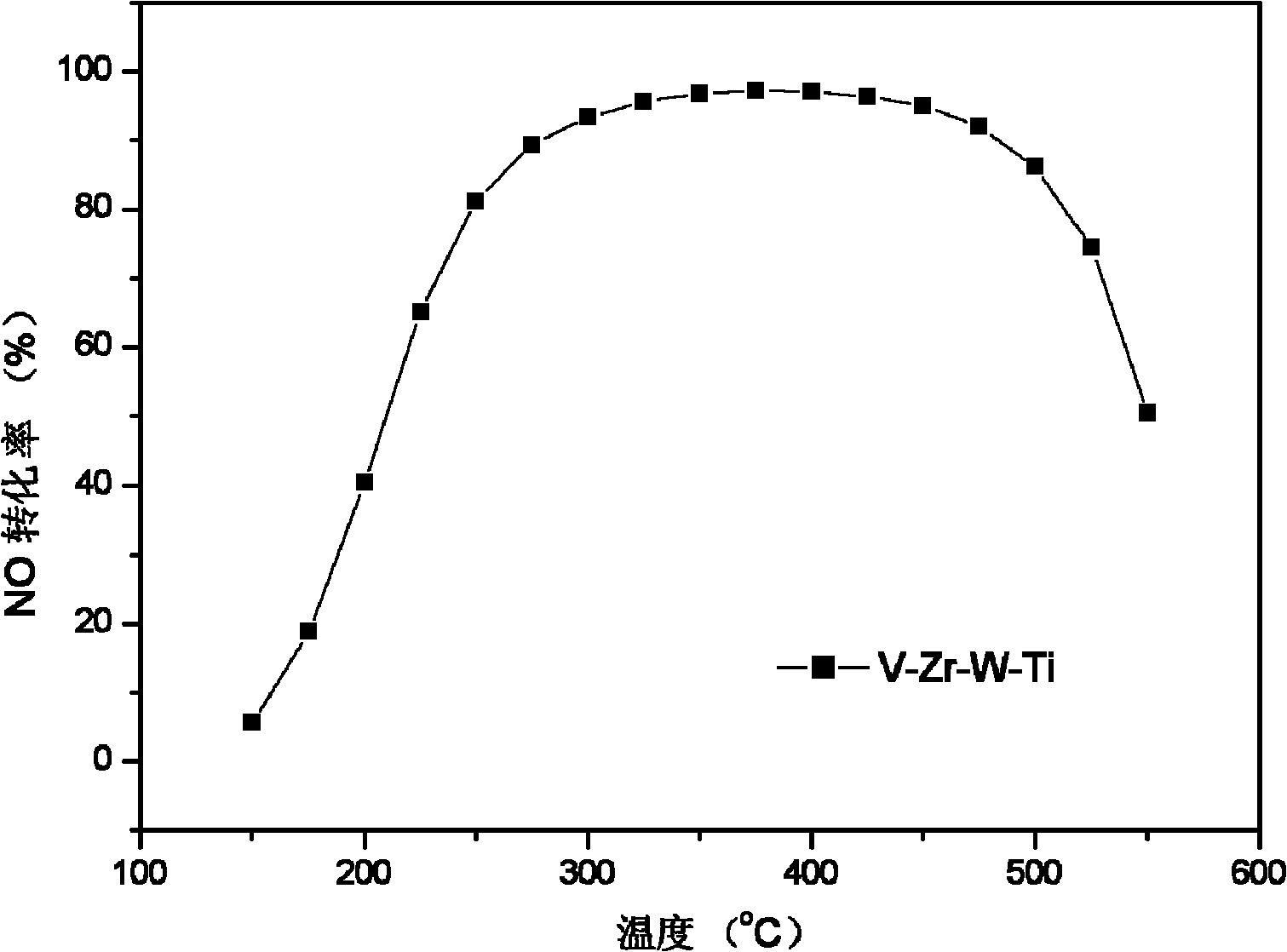

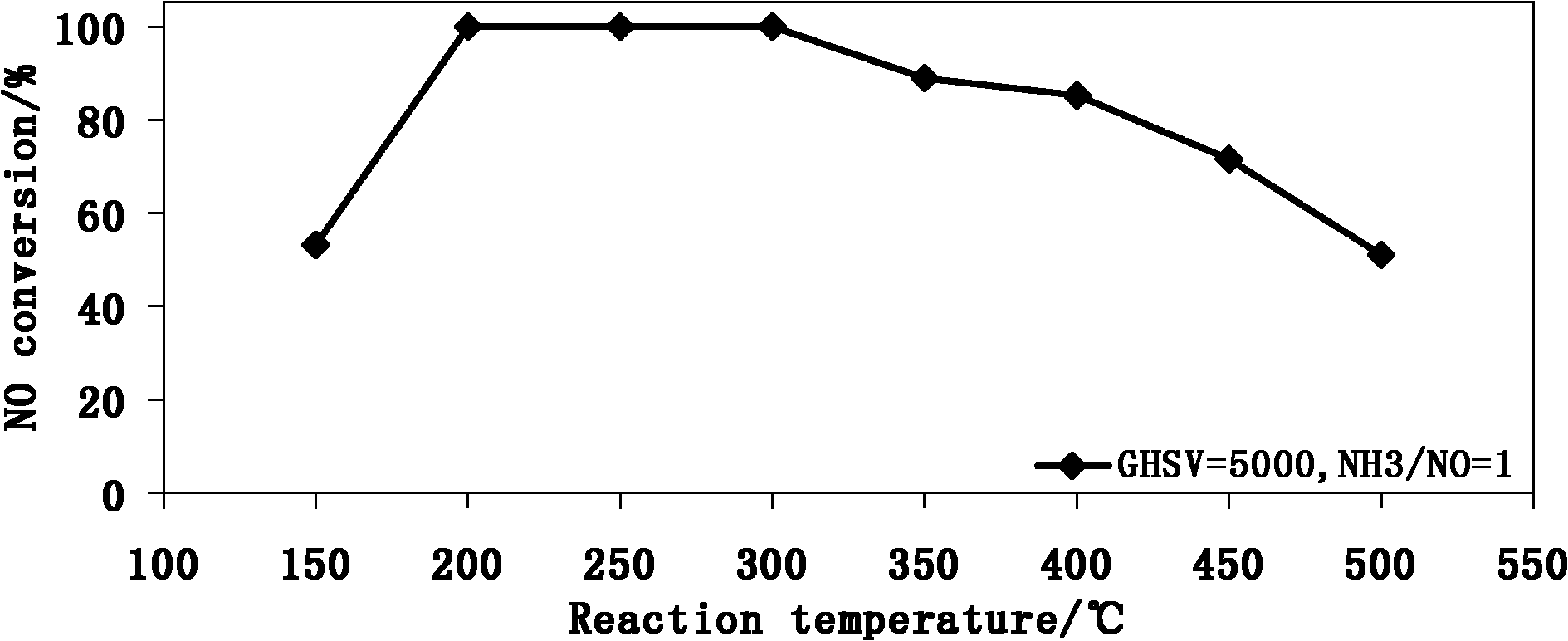

Selective catalyst for removing oxynitrides from tail gases of diesel vehicles and preparation method thereof

InactiveCN101912775AImprove smoothnessSatisfy and attain purifyingInternal combustion piston enginesDispersed particle separationWater vaporCordierite

The invention discloses a selective catalyst for removing oxynitrides from tail gases of diesel vehicles and a preparation method thereof. Cordierite honeycomb ceramic serves as a carrier, and the oxides of vanadium, zirconium, tungsten and titanium form a catalytic active site. The preparation method comprises the following steps of: sequentially dissolving vanadium pentoxide, a zircon salt, tungsten trioxide and titanium dioxide into the aqueous solution of oxalic acid, adding a bonder into the mixed solution to prepare pulp, impregnating the cordierite honeycomb ceramic in the pulp, drying the cordierite honeycomb ceramic for 1 to 3 hours at 100 to 150 DEG C, and roasting the cordierite honeycomb ceramic for 2 to 4 hours at 450 to 550 DEG C. In the invention, the preparation method is improved, and a powder catalyst is improved into a honeycomb selective catalytic reduction (SCR) catalyst applied to the removal of the oxynitrides from the tail gases of the diesel vehicles, so the high-efficiency catalytic removal of the oxynitrides can be realized at the temperature of 205 to 515 DEG C; and in the presence of steam or SO2, the activity of the catalyst is kept over 80 percent.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

Honeycomb ceramic catalyst for simultaneously desulfurizing and denitrifying fume and its preparation and use

InactiveCN1457920AReduce resistanceSuitable for industrial applicationsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentGram

The honeycomb ceramic catalyst has surface treated honeycomb iolite ceramic as carrier, coated active alumina film and coated active components CuO and Na2O; and is prepared through soaking process. It has a normal pressure fume denitrifying rate as high as 88 %, desulfurizing rate higher than 80 %, SO2 adsorbing amount of 62 mg each gram of the catalyst and small bed resistance; and is suitable for industrial application.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Denitration catalyst and preparation method thereof

ActiveCN104415780ASimple structureLarge specific surface areaMolecular sieve catalystsDispersed particle separationPtru catalystReaction temperature

The invention discloses a denitration catalyst and a preparation method thereof, the catalyst takes pretreated cordierite honeycomb ceramics as a matrix, a silicon-aluminum coating, a composite coating and an active component are coated on the surface of the matrix, by measuring gross weight of the catalyst, the catalyst contains 80-90wt% of cordierite honeycomb ceramics, 2-9wt% of silicon-aluminium coating, 3-10wt% of composite coating, and 0.01-15wt% of active component, wherein the active component can be Mn and Fe; by measuring gross weight of the silicon-aluminum coating, the silicon-aluminum coating comprises 10-50wt% of silica, and 50-90wt% of alumina; by measuring gross weight of the composite coating, the composite coating contains 40-80wt% of titanium dioxide, 5-35wt% of ZSM-5 molecular sieve, and 10-40wt% of auxiliary agent; wherein the auxiliary agent is selected from one or more of cerium oxide, zirconia or lanthana. The denitration catalyst has the advantages of large coating load capacity, high firmness, good poison-resistance performance and activity, and wide reaction temperature window; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cordierite-base copper oxide/ gamma-aluminium oxide catalyst used for flue gas denitration and preparation method and application

InactiveCN101053838AReduce coating cracksImprove smoothnessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasHigh intensity

Weight percent ratio of a flue gas Cuo / gamma-Al2O3 catalyst based on cordierite is in that: cordierite carrier is 78.7-93.8%, Al2O3 is 5-16% and CuO is 1.2-5.3%. Cordierite honeycomb ceramic with high intensity is adopted as a substrate, which is impregnated with CuO of a certain concentration after coated with the carrier gamma-Al2O3. The invention can reduce coating crack of the gamma-Al2O3 film and increase firmness of the gamma-Al2O3 coating and uploading capacity of the gamma-Al2O3 by using a simple and effective coating method, and has advantages of enhanced denitrification activity, life and stability of the catalyst.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of honeycomb carrier catalyst for molecular sieve denitration

InactiveCN104353485AHigh catalytic activityReduce mechanical vibrationMolecular sieve catalystsDispersed particle separationMolecular sieveOrganic solvent

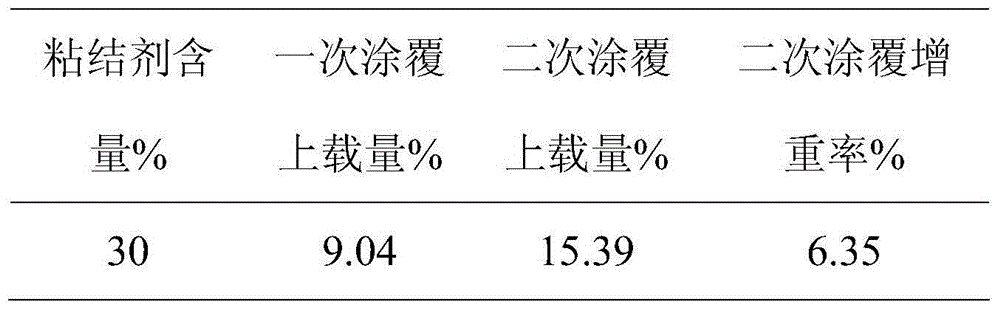

The invention discloses a preparation method of a honeycomb carrier catalyst for molecular sieve denitration. The preparation method comprises the following steps: 1, preparing a Cu / ZSM-5 catalyst which contains 1.5%-2.5% by weight of Cu by adopting an ion exchange method; 2, pretreating and drying a cordierite honeycomb ceramic carrier under the conditions of acid-base and an organic solvent; 3, preparing slurry, wherein the mass ratio of an adhesion agent to Cu / ZSM-5 catalyst to ethanediol to deionized water is (0.2-0.3):1:1.165:1.165 in the slurry; 4, preparing a primary coating honeycomb carrier denitration catalyst; and 5, preparing a secondary coating honeycomb carrier denitration catalyst. The honeycomb carrier catalyst prepared through the method disclosed by the invention is difficultly plugged in a slurry coating process, firm in coating and high in stability; the prepared honeycomb carrier catalyst is high in denitration efficiency, achieves the denitration efficiency more than 90% at a temperature interval of 170-500 DEG C and can be widely applied to the catalytic reduction of nitrogen oxide in a motor vehicle tail gas post-processing system.

Owner:TSINGHUA UNIV

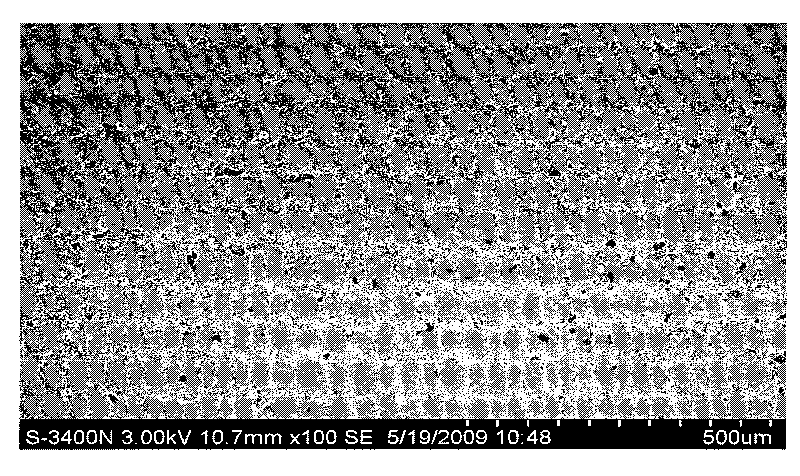

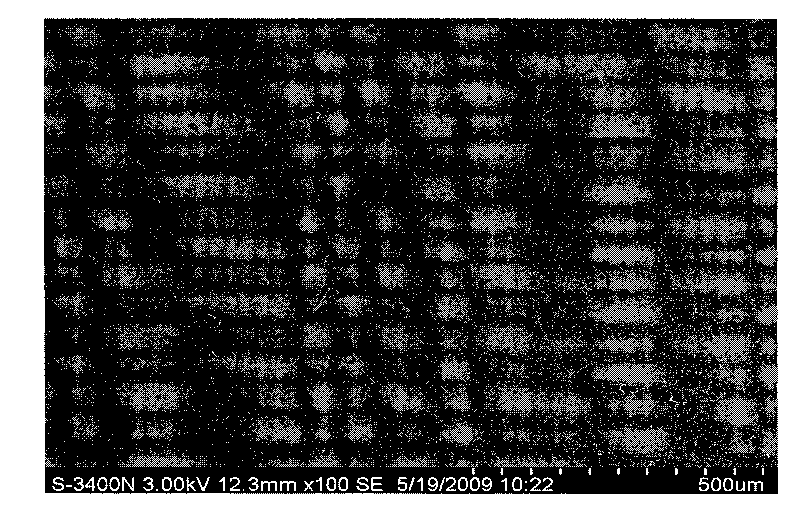

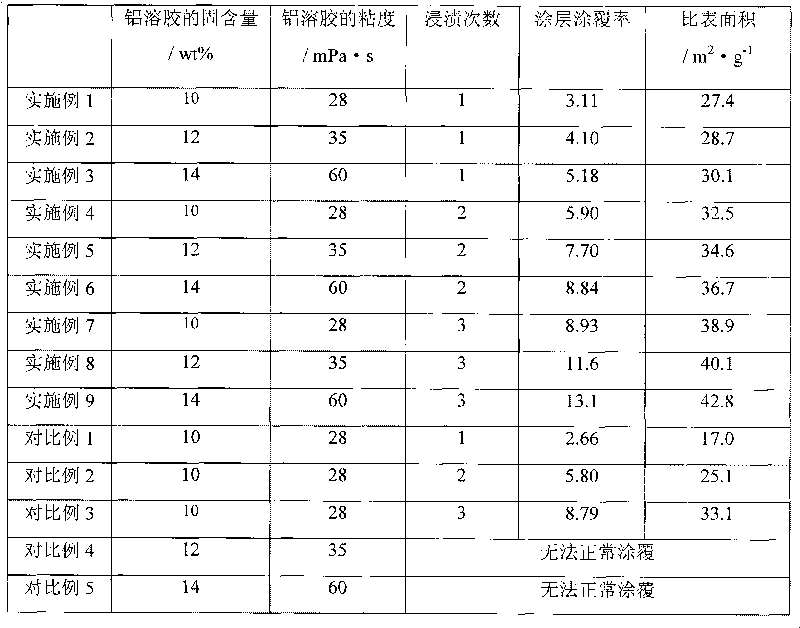

Method for applying coating on cordierite honeycomb ceramics and applications thereof

ActiveCN101734946AIncrease coverageIncrease the areaCatalyst carriersCatalyst activation/preparationVacuum extractionHoneycomb

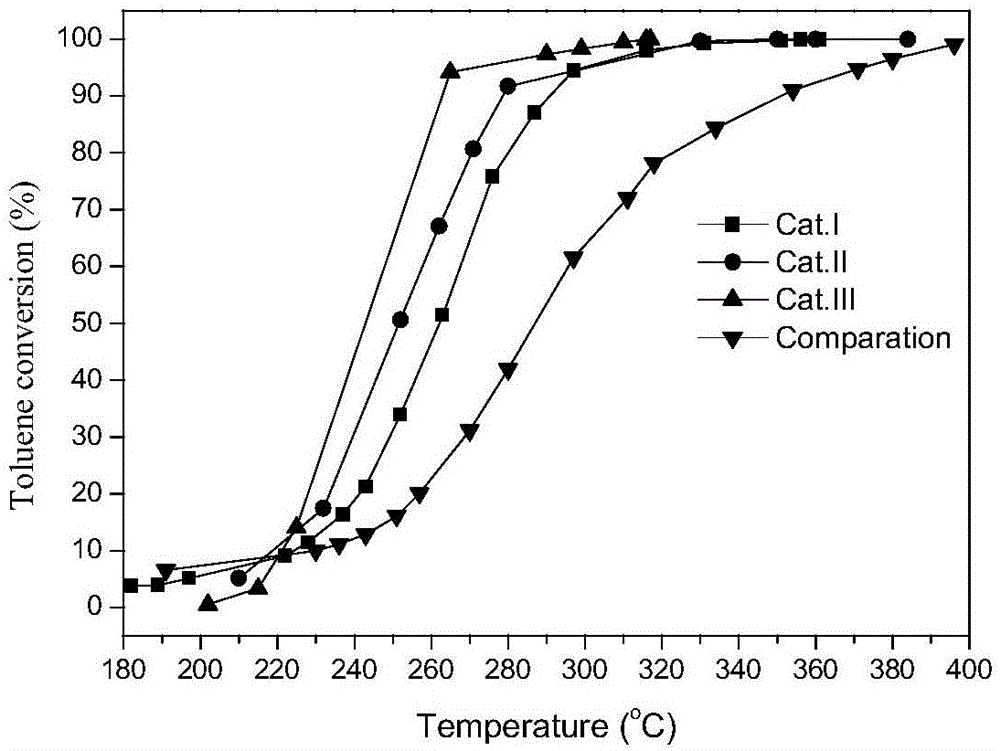

The invention discloses a method for applying a coating on cordierite honeycomb ceramics and applications thereof. Started with the improvement of the immersion coating technique, the invention applies a thick dense alumina coating with uniform distribution, high coating rate and high specific area on the surface of pore canals of the cordierite honeycomb ceramics by using a vacuum extraction immersion method. In particular, when the viscosity of the alumina sol is greater than or equal to 35 mPa.s, the alumina sol can not easily enter the interior of the pore canals of the honeycomb ceramics by using the common immersion method, and the coating can not be applied normally, while the vacuum extraction immersion technique of the invention does not have the defect, and can be used for uniformly applying the alumina coating with high coating rate. When the honeycomb ceramics applied with the alumina coating by using the method of the invention is loaded with an integral catalyst prepared from noble metal Pd and used for cleaning treatment of toluene catalytic combustion, the percent conversion of toluene can reach 99% at the low temperature of 215 DEG C, and the concentration of toluene is reduced to below 40 mg / m<3>.

Owner:FOSHAN SHUNDE KINGLEI ENVIRONMENT & TECH CO LTD

VOCs (volatile organic chemcials) catalytic combustion integral catalyst and preparation method thereof

ActiveCN106732585ATightly boundImprove anti-sintering performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationAir volumeAdhesive

The invention provides a VOCs (volatile organic chemcials) catalytic combustion integral catalyst, and belongs to the technical field of catalysts. The VOCs catalytic combustion integral catalyst is prepared from the following raw materials in parts by mass: 82 to 87 parts of cordierite honeycomb ceramic carrier, 10 to 14 parts of gamma-Al2O3, 0.8 to 1.5 parts of oxide additive, and 0.01 to 0.05 part of active component Pd, wherein the gamma-Al2O3, the oxide additive and the active component Pd are used as coating layers. The invention also relates to a preparation method of the catalyst. The preparation method comprises the following steps of firstly, dispersing the Pd onto the special gamma-Al2O3 carrier, drying, and calcining, so as to obtain powder; adding an adhesive, a lubricant and water for preparing slurry, coating the cordierite honeycomb ceramic carrier with the slurry, drying and calcining, so as to obtain the catalyst. The catalyst has the characteristics that by using low-content noble metal Pd as the active component, the cost is low, the low-temperature ignition is quick, the anti-vulcanizing and anti-aging properties are realized, the catalyst is suitable for large air volume and high air speed, the dispersion property is good, the easiness in sintering is avoided, and the like; the catalyst is especially suitable for the catalyst combustion of sulfur-containing VOCs.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Integral catalyst for catalytic combustion of toluol exhaust gas and preparation method thereof

InactiveCN101474566ASimple preparation processSimple coating processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCordierite

The invention relates to a monolithic catalyst for catalytic combustion of toluene waste gas and a preparation method thereof. The catalyst is composed of a honeycomb ceramic carrier, gamma-Al2O3 coat on the carrier and non-noble metallic Cu / Mn / Ag composite oxide. The catalyst is prepared by the following steps: coating the aluminum sol on the cordierite honeycomb ceramic carrier to produce the gamma-Al2O3 coat after drying and baking, weighing a certain amount of nitrate of Ag, Cu and Mn to prepare the mixed solution, loading the solution on the monolithic carrier which is coated on the active coat by incipient impregnation method and obtaining the monolithic catalyst after drying, baking and other post treatment. The ignition temperature of the catalyst to toluene can be lower than 135 DEG C and the full conversion temperature can be lower than 262 DEG C. Compared with the generally used noble metallic catalyst, not only the monolithic catalyst in the invention has high catalytic activity, but also the effective utilization is high and the cost is greatly lowered by adopting incipient impregnation method for active components loading.

Owner:SOUTHEAST UNIV

Cellular SCR (selective catalytic reduction) denitration composite oxide catalyst and preparation method thereof

ActiveCN102008952AIncreased crush strengthImprove thermal stabilityDispersed particle separationCatalyst activation/preparationEnvironmental resistanceHeat stability

The invention relates to a cellular SCR (selective catalytic reduction) denitration composite oxide catalyst and a preparation method thereof. In the method, the composite oxide of tin, cerium and tungsten is taken as the active component of the catalyst, and the composite oxide of titanium and zirconium is taken as a carrier, a honeycomb ceramic is taken as a supporter, and the mass of the honeycomb ceramic supporter is taken as the basis, wherein the mass capacity of the composite oxide of titanium and zirconium is 3-20wt%, the mass capacity of the composite oxide of tin, cerium and tungsten is 5-18wt. The method comprises the following steps: dipping the pre-treated honeycomb ceramics into a titanium-zirconium sol or thickener, drying and roasting; and dipping the obtained product into the composite solution or thickener of the tin, cerium and tungsten, drying and roasting to prepare a Sn-Ce-W-Ox composite oxide active component coating. In the invention, the denitration effect of the catalyst at low and middle temperature is improved, the crushing resistance and heat stability of the catalyst can be enhanced, the cost of the catalyst is lowered, and the preparation process is simple; and the active component of the catalyst is low in toxicity and is environment-friendly, and is suitable for denitration of a flue at low and middle temperature in harsh temperature-changing environment.

Owner:NANJING UNIV OF TECH

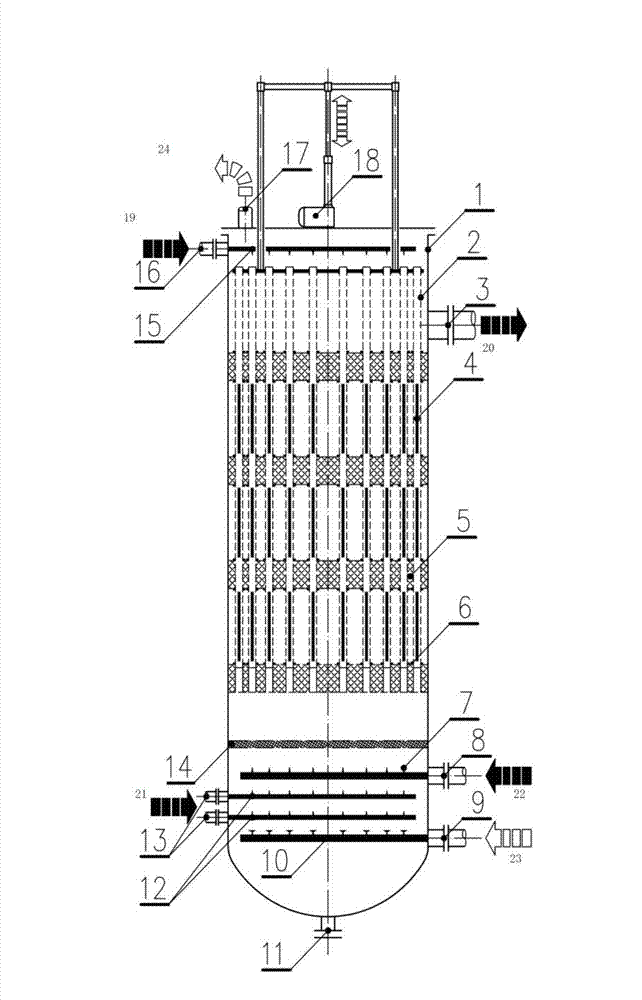

Efficient photocatalysis water treatment method and device

ActiveCN103086469AReduce COD valueIncreased efficiency in the rearWater/sewage treatment by irradiationWater/sewage treatment by oxidationHigh pressure waterEngineering

The invention provides an efficient photocatalysis water treatment device. The efficient photocatalysis water treatment device comprises a tank body, a quartz tube, a backflow port, an extra-ultraviolet tube, a three-dimensional ceramic honeycomb net photochemical reaction chamber, a sewage distributor, a sewage port, an aeration port, an aeration assembly, a sewage draining port, a medicine distributing assembly, a medicine port, a coarse filtering net, a high-pressure backwashing device, a high-pressure water port, a tail gas recovering port and a reciprocating motion device; three ports are formed at the lower part of the tank body, namely, an organic sewage port, the aeration port and the medicine port; the three-dimensional ceramic honeycomb net photochemical reaction chamber for loading the extra-ultraviolet lamp and a nanometer TiO2 photocatalyst are formed at the upper part of the tank body; and the tail gas recovery port is formed at the upper part of the tank body.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

Integral automobile exhaust purification catalyst and preparation method thereof

InactiveCN101947456AEasy to makeLow priceCatalyst carriersDispersed particle separationRare earthCordierite

The invention discloses an integral automobile exhaust purification catalyst and a preparation method thereof, and relates to preparation of aluminum oxide sol, modification of a plurality of oxides in the introduced La2O3, CeO2, BaO, SrO, CaO, ZrO2, CuO, SiO2 and the like, load of the modified aluminum oxide sol on cordierite honeycomb ceramic and loads of a plurality of catalyst active ingredients in La, Sr, Co, Cu, Mn, Fe, Pd and the like. The cordierite honeycomb ceramic is used as a carrier; the modified aluminum sol is loaded on the cordierite honeycomb ceramic carrier by adopting a vacuum impregnation method; and the catalyst active ingredients are loaded on a modified aluminum oxide coating by adopting the vacuum impregnation method. When the modified aluminum oxide coating with large specific surface area is used for loading a perovskite type rare-earth catalyst, the load is uniform, the bonding property is strong, the crystal form structure of the catalyst is not changed; and the catalyst has good catalytic activity, air-fuel ratio fluctuation resistance and sulfur dioxide poisoning resistance.

Owner:SOUTH CHINA UNIV OF TECH

Low-temperature flue gas SCR (Selective Catalytic Reduction) denitrating catalyst and preparation method and application thereof

ActiveCN102019187ALarge specific surface areaHighly active phaseDispersed particle separationCatalyst activation/preparationSlurryAcid strength

The invention discloses a low-temperature flue gas SCR (Selective Catalytic Reduction) denitrating catalyst, comprising a carrier and an active component loaded on the carrier, wherein the carrier is cordierite honeycomb ceramic loaded with a TiO2-SiO2 coating; the ratio of the amount of substances of Ti to Si in the TiO2-SiO2 coating is 1:0.1-2.0; the active component is an oxide composed of Mn,Fe, Ce, Zr, and W; the loading amount of the active component is 2-20 wt%; the ratio of the amount of substances of Mn to Fe to Ce to Zr to W in the active component is 1.0:0.1-2.0:0.1-2.0:0.02-1.0:0.01-1.0. In the invention, a uniform and firm TiO2-SiO2 coating is formed by using in situ precipitation method; the obtained coating has high specific surface area and appropriate acid strength, and can effectively play promoting catalytic action role; and the active component can be prepared by using in situ coprecipitation method. The preparation process avoids the problems that the seriflux isin serious loss and the coating is not uniform during the suspension dip-coating, and maintains the highly activity phase of the composite oxide.

Owner:ZHEJIANG UNIV OF TECH

Ferrotitanium composite oxides catalyst for ammonia selective reduction nitric oxides

ActiveCN101380578ALow priceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideHigh activity

The invention relates to a catalyst of selective reduction of nitrogen oxide by ammonia, which mainly solves the existing problems that the commonly used NH3-SCR catalyst system is toxic to environment and human body, the anti-SO2 poisoning ability of the catalyst system is poor in the reference and the catalyst system can not adapt to the conditions of high space velocity. The invention adopts cheap and non-toxic raw materials to prepare a Fe-Ti oxide catalyst with high activity, selectivity, stability and anti-S2 poisoning ability by the simple and practicable co-precipitation method, which can better solve the existing technical problems. If the catalyst is loaded on honeycomb ceramics after being made into pulp, the catalyst is hopeful to be put into practical application of flue gas denitrification of coal-fired power plants.

Owner:江西中科鸿虔新材料有限公司

Honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof

InactiveCN102133537AIncrease roughnessPromote nucleationMolecular sieve catalystsDispersed particle separationMass ratioCordierite

The invention discloses a honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof. The monolithic catalyst takes honeycomb ceramic as a carrier, a Beta molecular sieve is coated on the surface of the honeycomb ceramic and taken as a coating layer, and then active component, namely precious metal, is loaded on the surface of Beta molecular sieve; the active component of the precious metal is one or two selected from palladium or platinum; in the honeycomb-ceramic-type monolithic catalyst, the mass ratio of the coating layer of the Beta molecular sieve to the honeycomb ceramic is 0.02-0.2:1, the mass ratio of the precious metal to the coating layer of the Beta molecular sieve is 0.02-0.2:1, the honeycomb ceramic is cordierite honeycomb ceramic; and in the invention, the high-silicon or full-silicon Beta molecular sieve is taken as the coating layer of the monolithic catalyst, and has the characteristics of good water resistance, high heat stability andthe like, and the monolithic burning catalyst taking the Beta molecular sieve as the coating layer can keep better activity and stability under high temperature, and suitable for being taken as catalytic combustion catalyst for application.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

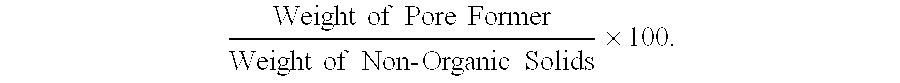

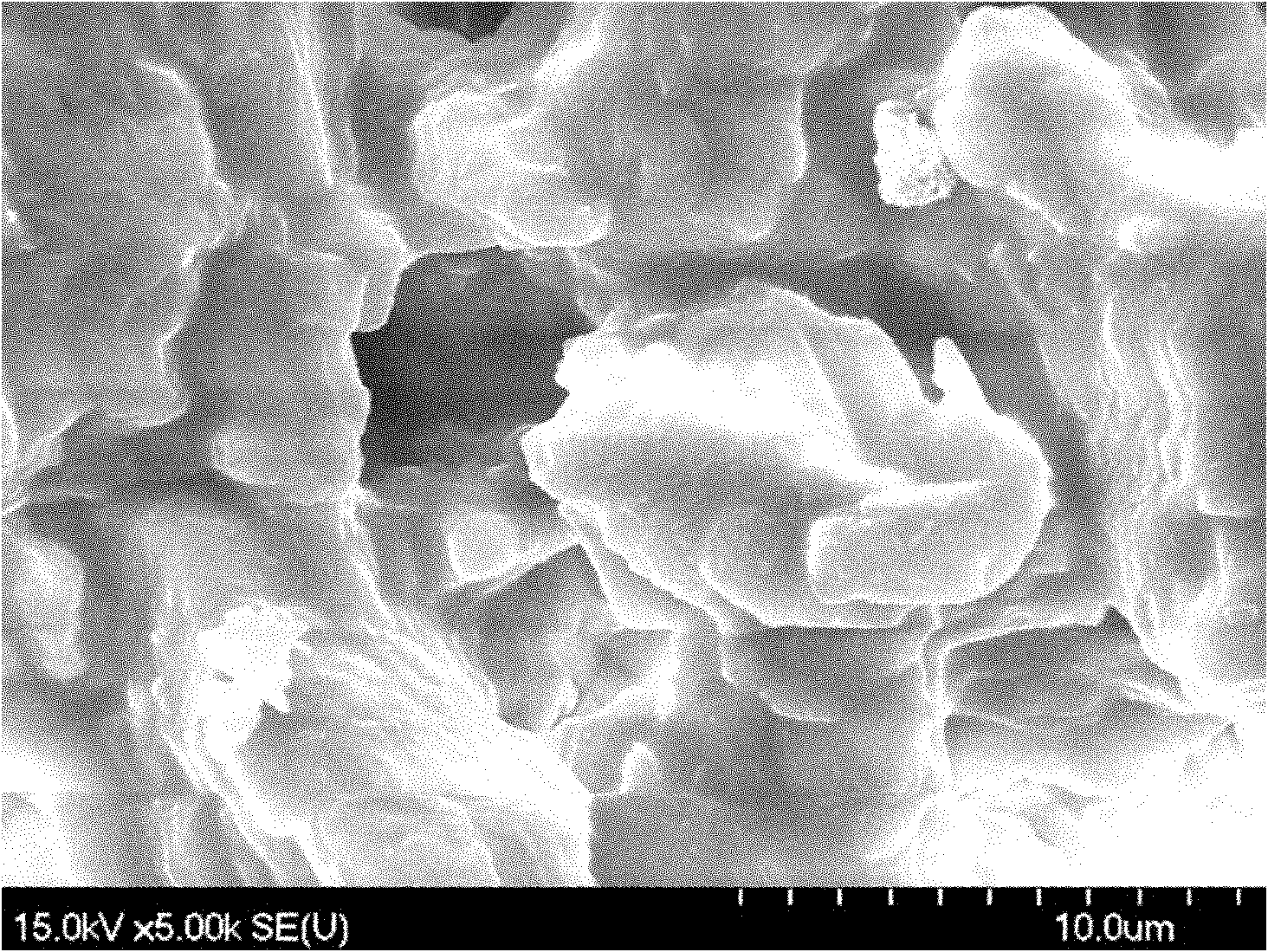

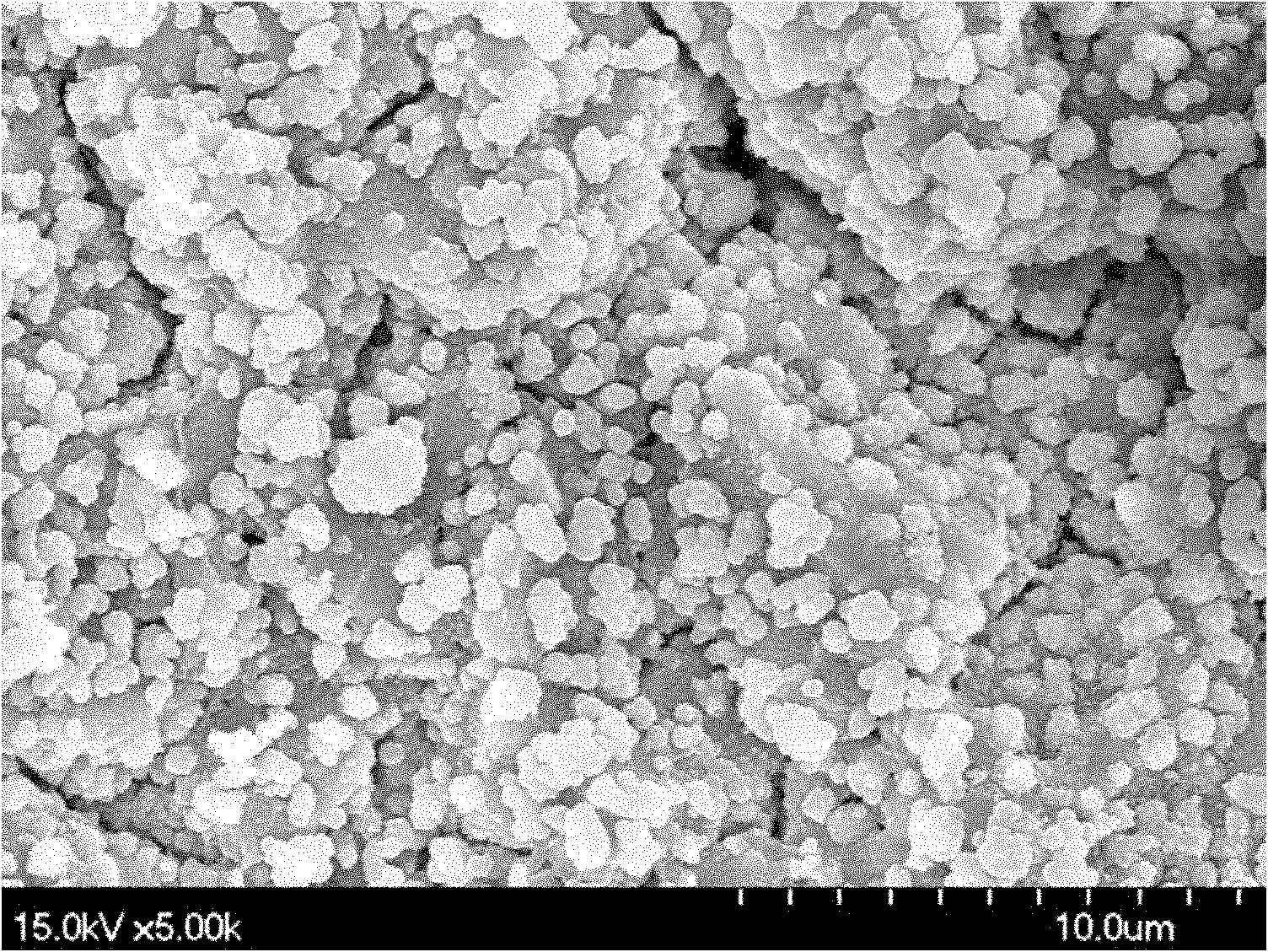

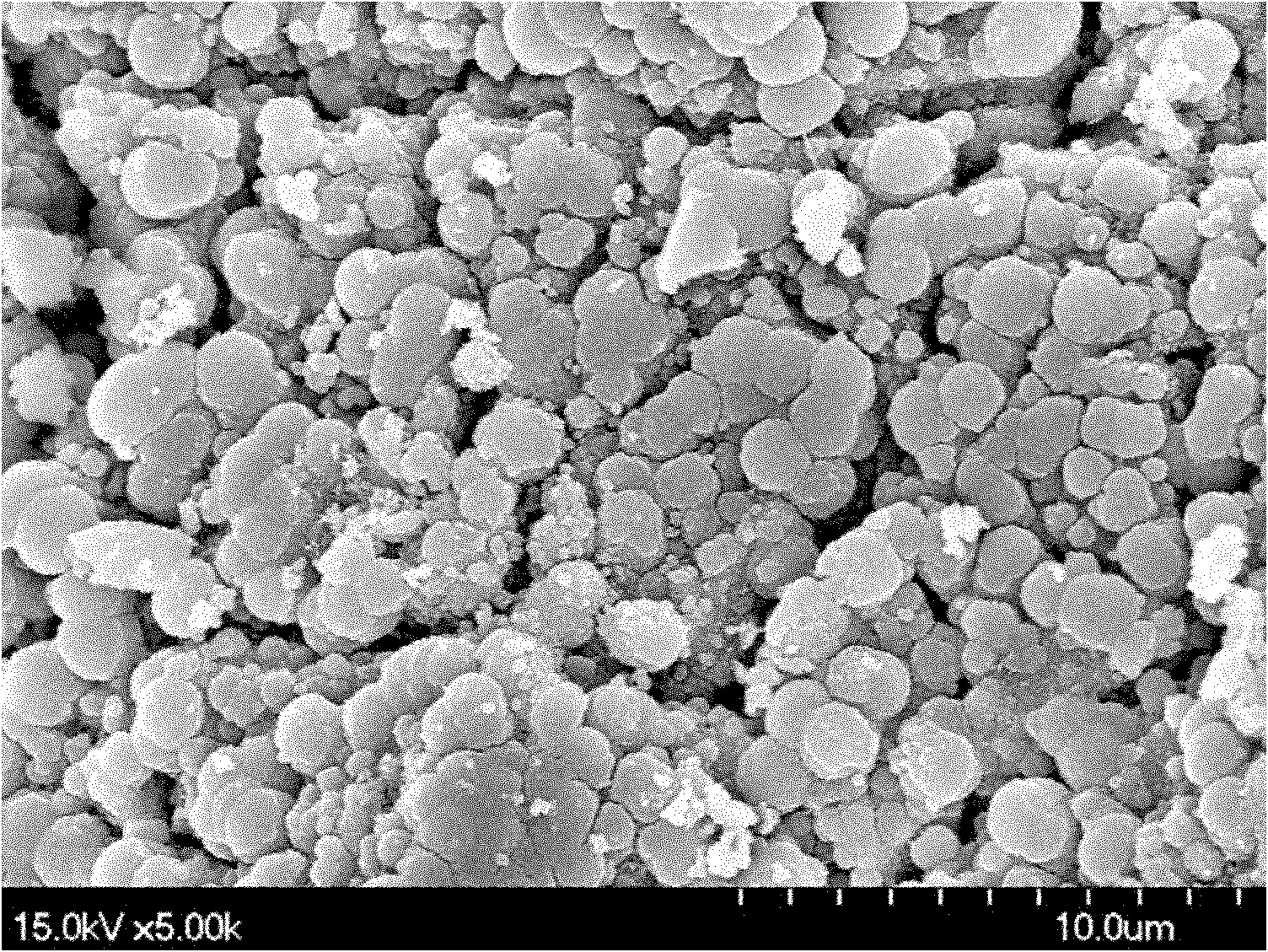

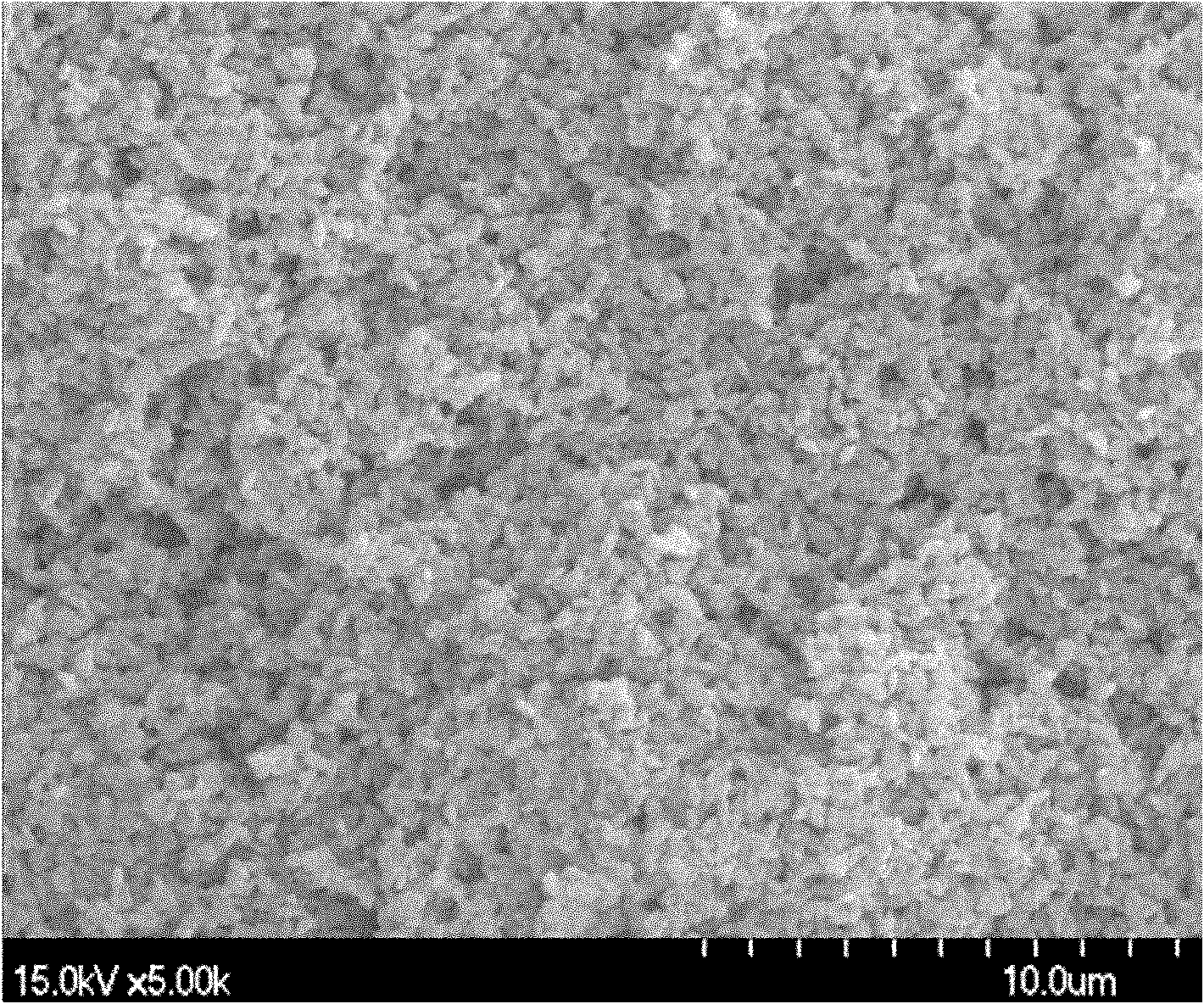

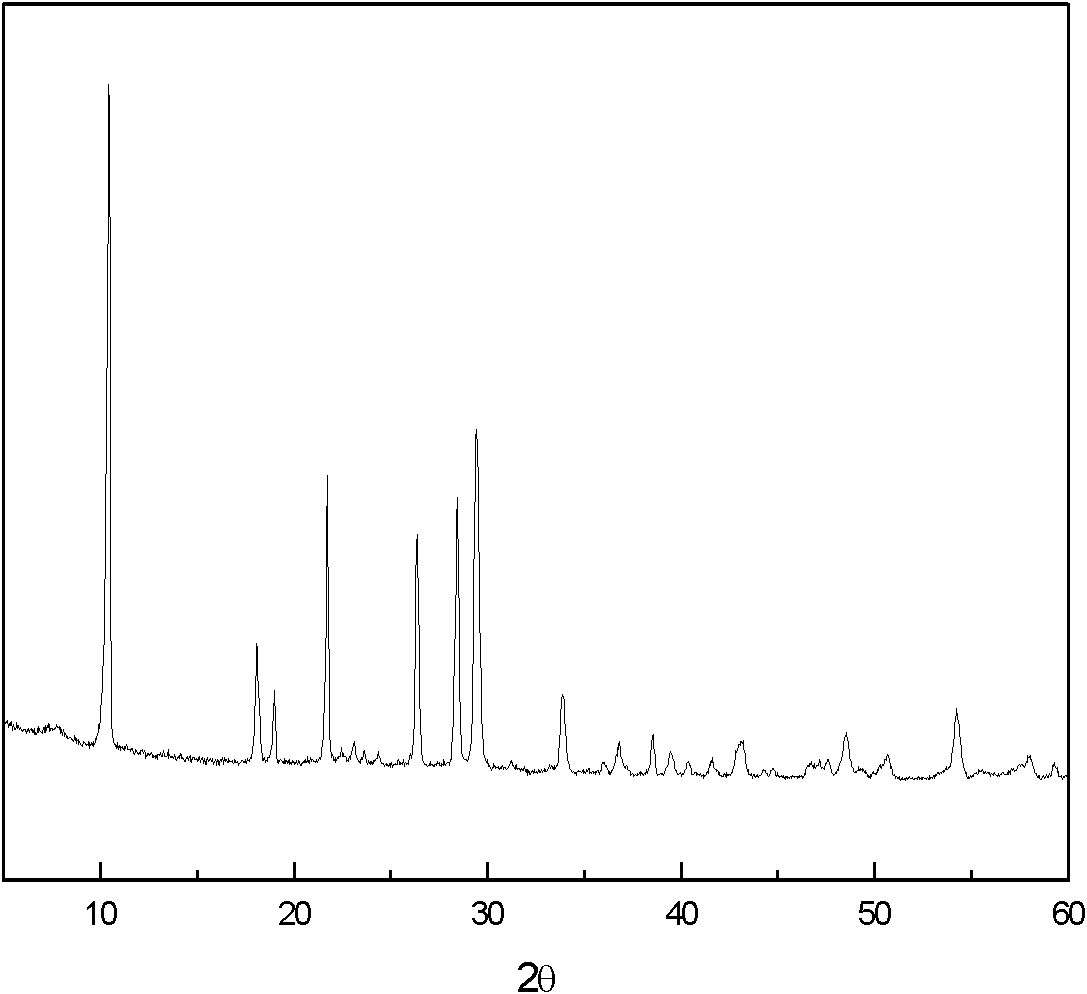

Honeycomb ceramic carrier and preparation method thereof

ActiveCN103449840AMeet needsMeet the needs of the carrier for catalyst removalCeramicwarePorosityAluminium hydroxide

The invention discloses a honeycomb ceramic carrier with large aperture and high porosity, and a preparation method thereof. The diameters of holes of the honeycomb ceramic carrier are 15-40 microns; the porosity is 40-65%. The honeycomb ceramic carrier is prepared from the following raw materials: 30-50 parts of soapstone, 20-30 parts of aluminum oxide, 5-10 parts of aluminium hydroxide, 10-20 parts of silicon oxide, 5-10 parts of kaoline, a surfactant, a binder and a pore forming agent.

Owner:BEIJING ZHONGAN SIHAI ENERGY

Monolithic nitrogen oxide selective reduction catalyst and preparation method thereof

ActiveCN102039205AEasy to operateAvoid multiple coatsDispersed particle separationCatalyst activation/preparationAdhesiveActive component

The invention discloses a monolithic nitrogen oxide selective reduction catalyst and a preparation method thereof. The monolithic nitrogen oxide selective reduction catalyst comprises a honeycomb ceramic matrix, a first coating, a second coating and active components, wherein the first coating is an Al2O3 coating, the second coating contains TiO2, CeO2 and ZrO2, and the active components include V2O5 and WO3. The process for applying the TiO2 second coating comprises the following steps: uniformly mixing anatase structural TiO2 solid powder and an adhesive, preparing into an applying slurry, impregnating the honeycomb ceramic matrix applied with the Al2O3 first coating in the applying slurry, blowing off residual liquid, drying, and roasting, thus finishing the application of the TiO2 second coating. Compared with the prior art, the method provided by the invention has the advantages of simple preparation process and low cost, and the prepared monolithic catalyst has higher activity when being used for selective reduction of nitrogen oxide in flue gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for concurrently removing CO, CH, NOx and PM, and preparation method thereof

ActiveCN102941088AGood removal effectIncreased resistance to poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCerium

The present invention relates to a catalyst for concurrently removing CO, CH, NOx and PM, and a preparation method thereof, and belongs to the field of an atmosphere pollution treatment technology and environment protection catalysis materials. According to the catalyst, a solid solution of rare earth and a rare metal zirconium, a perovskite-type composite oxide and a small amount of a noble metal are adopted as active components, a self-made honeycomb ceramic is adopted as a carrier, the total loading amount of the solid solution of the rare earth and the rare metal zirconium, and the perovskite-type composite oxide in the active components is 5-20% of the mass of the catalyst, the loading amount of the noble metal is 0.01-1% of the mass of the catalyst, a general formula of the active components is AgqE1-qAyZr1-yBCOx, E is a noble metal, A and B are rare earth, C is a transition metal, y is more than 0 and less than 1, q is more than 0 and less than 1, E is one or two selected from noble metals such as platinum (Pt), palladium (Pd) and rhodium (Rh), A and B are two selected from rare earth such as lanthanum (La), cerium (Ce), praseodymium (Pr) and neodymium (Nd), and C is one selected from transition metals such as copper (Cu), cobalt (Co), manganese (Mn), iron (Fe) and nickel (Ni).

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com