Low-temperature flue gas SCR (Selective Catalytic Reduction) denitrating catalyst and preparation method and application thereof

A denitration catalyst, low temperature flue gas technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can maintain high active phase, high specific surface area and avoid serious loss of slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

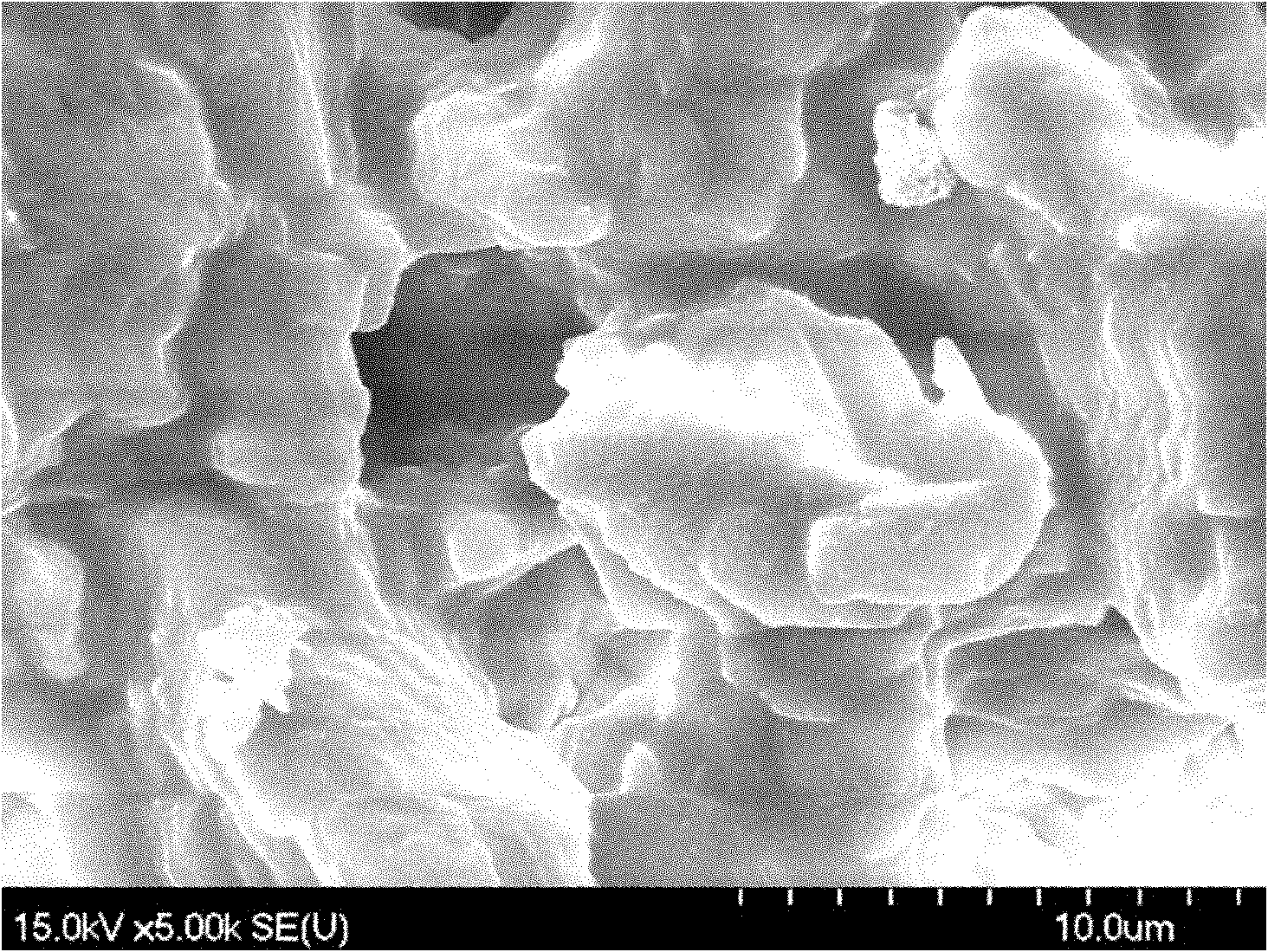

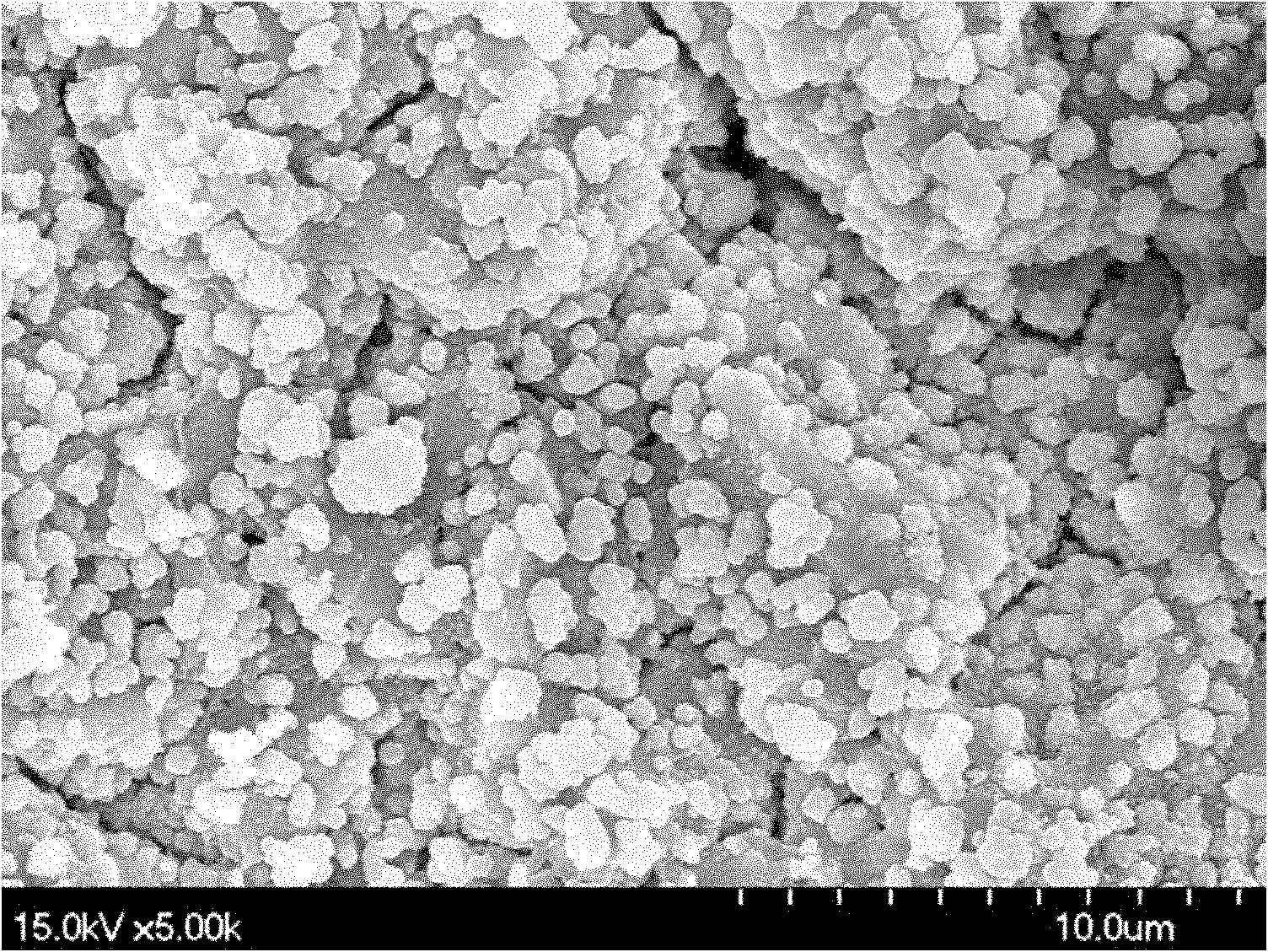

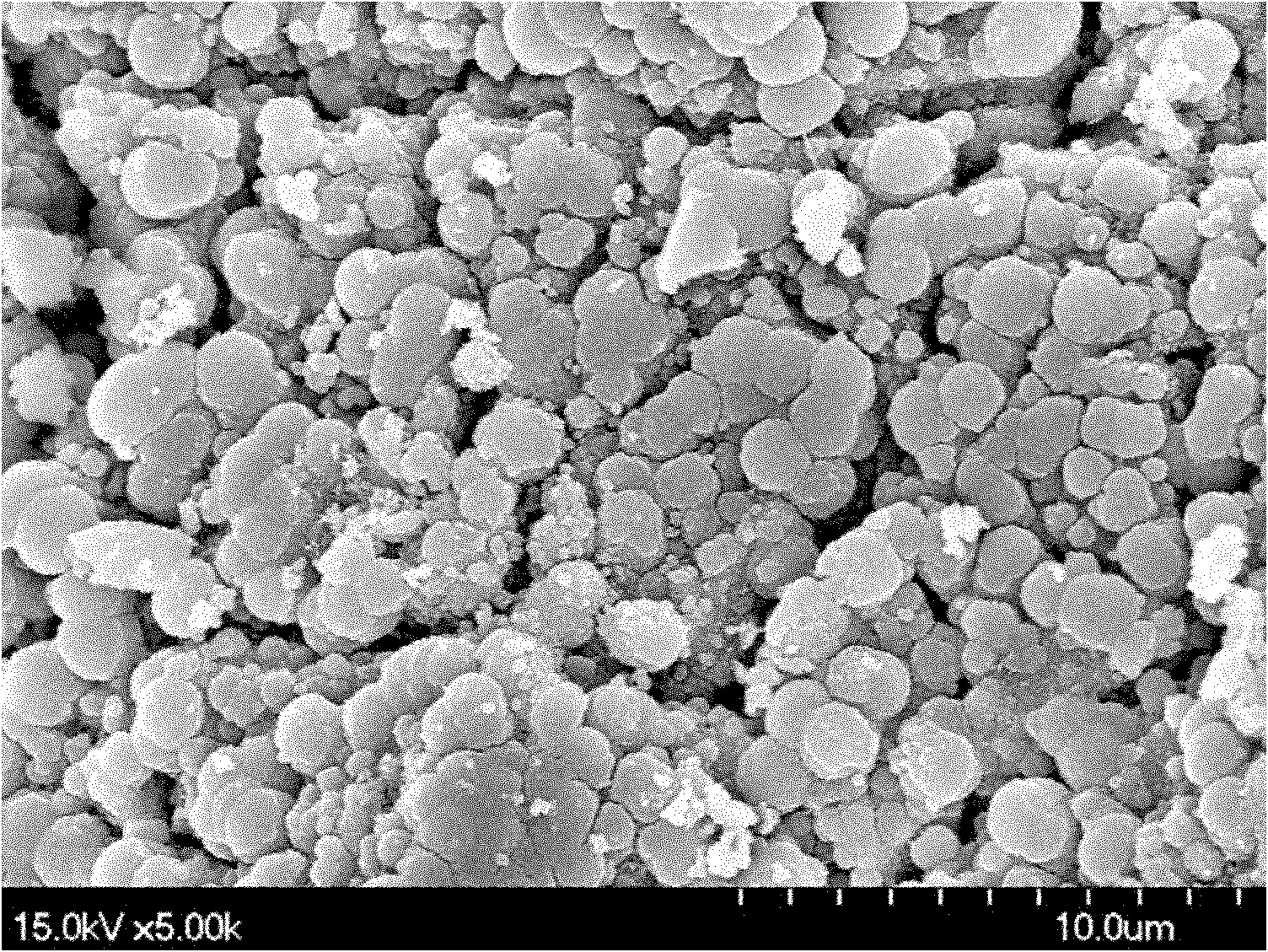

Image

Examples

Embodiment 1

[0031] Take 2.5g of cordierite honeycomb ceramics (Φ10mm×50mm, pore diameter 3mm), completely immersed in 1wt% nitric acid solution for 60 minutes, then rinse the cordierite with deionized water to remove surface impurities, put it into an oven at 110 After drying at ℃ for 12 hours, the surface-activated cordierite honeycomb ceramics were obtained for future use.

[0032] Get 30wt% silica sol 20.0g, titanyl sulfate (TiOSO 4 2H 2 (2) 30.0g was dissolved in 150ml of water to obtain a coating impregnation solution. The surface-activated cordierite honeycomb ceramics was completely immersed in the coating impregnation solution for 20 minutes, the cordierite was taken out, and the flow on the surface was blown off with a high-pressure air gun. The droplets were then dried at 110°C for 30 minutes. The dried cordierite was completely immersed in 25 wt% ammonia water for 20 minutes to carry out in-situ hydrolysis precipitation. After taking it out, blow off the ammonia water drople...

Embodiment 2

[0035] Take 2.5g of cordierite honeycomb ceramics (Φ10mm×50mm, pore diameter 3mm), completely immerse in 5wt% nitric acid solution for 60 minutes, then rinse the cordierite with deionized water, wash away the surface impurities, put it into an oven at 80 After drying at ℃ for 12 hours, the surface-activated cordierite honeycomb ceramics were obtained for future use.

[0036] Get 30wt% silica sol 60.0g, titanyl sulfate (TiOSO 4 2H 2 (2) 30.0g was dissolved in 150ml of water to obtain a coating impregnation solution. The surface-activated cordierite honeycomb ceramics was completely immersed in the coating impregnation solution for 20 minutes, the cordierite was taken out, and the flow on the surface was blown off with a high-pressure air gun. The droplets were then dried at 60°C for 100 minutes. The dried cordierite was completely immersed in 25 wt% ammonia water for 10 minutes to carry out in-situ hydrolysis precipitation. After taking it out, blow off the ammonia water dro...

Embodiment 3

[0039] Take 2.5g of cordierite honeycomb ceramics (Φ10mm×50mm, pore diameter 3mm), completely submerged in 1wt% nitric acid solution for 60 minutes, then rinse the cordierite with deionized water to remove surface impurities, put it into an oven at 150 Dry at ℃ for 3 hours to obtain a surface-activated cordierite honeycomb ceramic for future use.

[0040] Get 30wt% silica sol 3.1g, titanyl sulfate (TiOSO 4 2H 2 (2) 30.0g was dissolved in 150ml of water to obtain a coating impregnation solution. The surface-activated cordierite honeycomb ceramics was completely immersed in the coating impregnation solution for 20 minutes, the cordierite was taken out, and the flow on the surface was blown off with a high-pressure air gun. The droplets are then dried at 120 for 10 minutes. The dried cordierite was completely immersed in 5wt% ammonia water for 60 minutes to carry out in-situ hydrolysis precipitation. After taking it out, blow off the ammonia water droplets on the surface with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com