Patents

Literature

520results about How to "Play a catalytic role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing functional biological carbon by in-situ impregnation

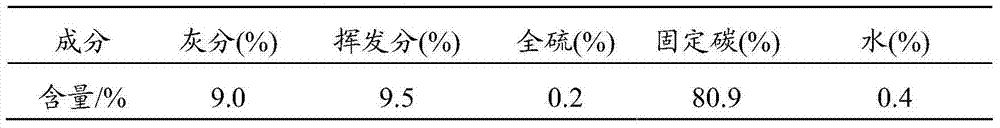

ActiveCN104437361APlay a catalytic roleFixed uniformOther chemical processesAlkali metal oxides/hydroxidesIonWater content

The invention discloses a method for preparing functional biological carbon by in-situ impregnation. The method comprises the following steps: (1) adding a biomass raw material into a pre-treating solution, stirring, dipping and then filtering to obtain a pretreated biomass raw material; (2) adding the pretreated biomass raw material into a impregnation ion solution, stirring, dipping and then filtering to obtain a biomass raw material which contains water and impregnation ions and has water content by weight of 50% to 150%; (3) heating the biomass raw material which contains water and impregnation ions to the temperature of 100-280 DEG C at a speed of 1-3 DEG C / min, and then keeping the temperature for 0.5-2 hours; (4) heating to the temperature of 400-800 DEG C at a speed of 10-100 DEG C / min in an anaerobic or oxygen-limited atmosphere, and keeping the temperature for 1-6 hours; and (5) cooling to obtain the functional biological carbon. According to the method disclosed by the invention, abundant agriculture and forestry wastes are used as raw materials for preparing the functional biological carbon, an in-situ impregnation process is used for regulating a biological carbon structure, and functional particles are controllably and uniformly supported, so the specific surface area and the porosity of the biological carbon are greatly increased, and the biological carbon can be widely applied to the fields such as sewage treatment.

Owner:DONGHUA UNIV

Cement grinding aid strengthening agent

The invention relates to a cement grinding-aid intensifier. The weight percent is that alkylol amine: polyalcohol: amide: initiator is equal to 1:1.2-1.6:0.1-0.5:0.01-0.04. The alkylol amine and the polyalcohol are mixed in a reaction tank evenly, the reaction acidity is controlled under stirring at 100-110 DEG C; the reaction time is 2-6 hours; the alkylol amine and the initiator are added, the pH value is adjusted to 7-7.5, then stirring is carried out for reaction for 3-5 hours; alkali is used for neutralization, the pH value is 8-10, and the finished product is obtained. The cement grinding-aid intensifier has the advantages that static electricity produced during powder grinding can be eliminated, thus facilitating the materials not to bond each other and penetrate into the cracks of grains and improving powder grinding efficiency; catalysis is acted during cement hydration, the diffluent complexing ions are produced, and the intensity of the testing body is improved; separation of cement powder grains in super thin grinding powder milling is restrained, thus avoiding the phenomenon of sticky balls, wall built-up and static electricity absorption; powder grinding ability of millers is improved, the specific surface of the thin powder is increased, and early strength, fast coagulation and hydration are fast; product cost is lowered, effect for aiding grinding is outstanding, the working environment is improved, performance of cement is improved obviously, production process is simple, and the products can be stored for a long period.

Owner:淄博宜龙实业有限公司

Aerobic bio-particle carrier for directly removing ammonia nitrogen from sewage with low carbon nitrogen ratio and preparation method thereof

ActiveCN103145234ANo secondary pollutionEfficient denitrificationTreatment using aerobic processesSustainable biological treatmentTotal nitrogenOxygen

The invention relates to an aerobic bio-particle carrier for directly removing ammonia nitrogen from sewage with low carbon nitrogen ratio and a preparation method thereof, belongs to the field of water treatment, and is used for solving the deficiencies of low biological denitrifying efficiency caused by insufficient carbon source of sewage with low carbon nitrogen ratio, complex process, high physicochemical treatment cost, secondary pollution and the like, so that efficient denitrification low in cost and free from secondary pollution is realized. The aerobic bio-particle carrier for directly removing ammonia nitrogen from sewage with low carbon nitrogen ratio comprises simple iron powder, active carbon powder, gypsum powder, copper powder and a catalyst, wherein the catalyst is one or any combination of manganese powder, titanium powder, magnesium powder and vanadium powder. The preparation method comprises the following steps of: taking and mixing materials according to material composition to prepare particles which are 5-20mm, drying and then roasting and cooling; and finally, cultivating the prepared particles in sewage through a microbial biofilm to obtain the aerobic bio-particle carrier for directly removing ammonia nitrogen from sewage with low carbon nitrogen ratio. According to the invention, sewage with low carbon nitrogen ratio is efficiently treated, so that the total nitrogen of sewage is removed over 90%.

Owner:BEIJING JIAOTONG UNIV

Method for preparing 5-hydroxymethylfurfural by taking glucose as raw material

ActiveCN101628902AHigh reaction conversion and selectivityAvoid side effectsOrganic chemistryBulk chemical productionChemistrySupercritical carbon dioxide

The invention discloses a method for preparing 5-hydroxymethylfurfural by taking glucose as a raw material, which comprises the steps of: mixing the glucose with water according to the mass ratio of 1: 3-10, loading the mixture into a high-pressure reactor, sealing the high-pressure reactor, increasing the reaction temperature to be between 120 and 250 DEG C, injecting liquid carbon dioxide into the reactor, and controlling the pressure to be between 10 and 25MPa; performing the separation of carbon dioxide and a product on supercritical carbon dioxide with the product dissolved therein through a separator during the reaction, and controlling the separation pressure to be between 5 and 8MPa and the separation temperature to be between 25 and 70 DEG C; and discharging the product from the bottom of the separator, and obtaining a 5-hydroxymethylfurfural product through drying, dehydration and crystallization. The method has the advantages of high selectivity of the 5-hydroxymethylfurfural, continuous production, high product content, green and environment-friendly process, and easy industrialized production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

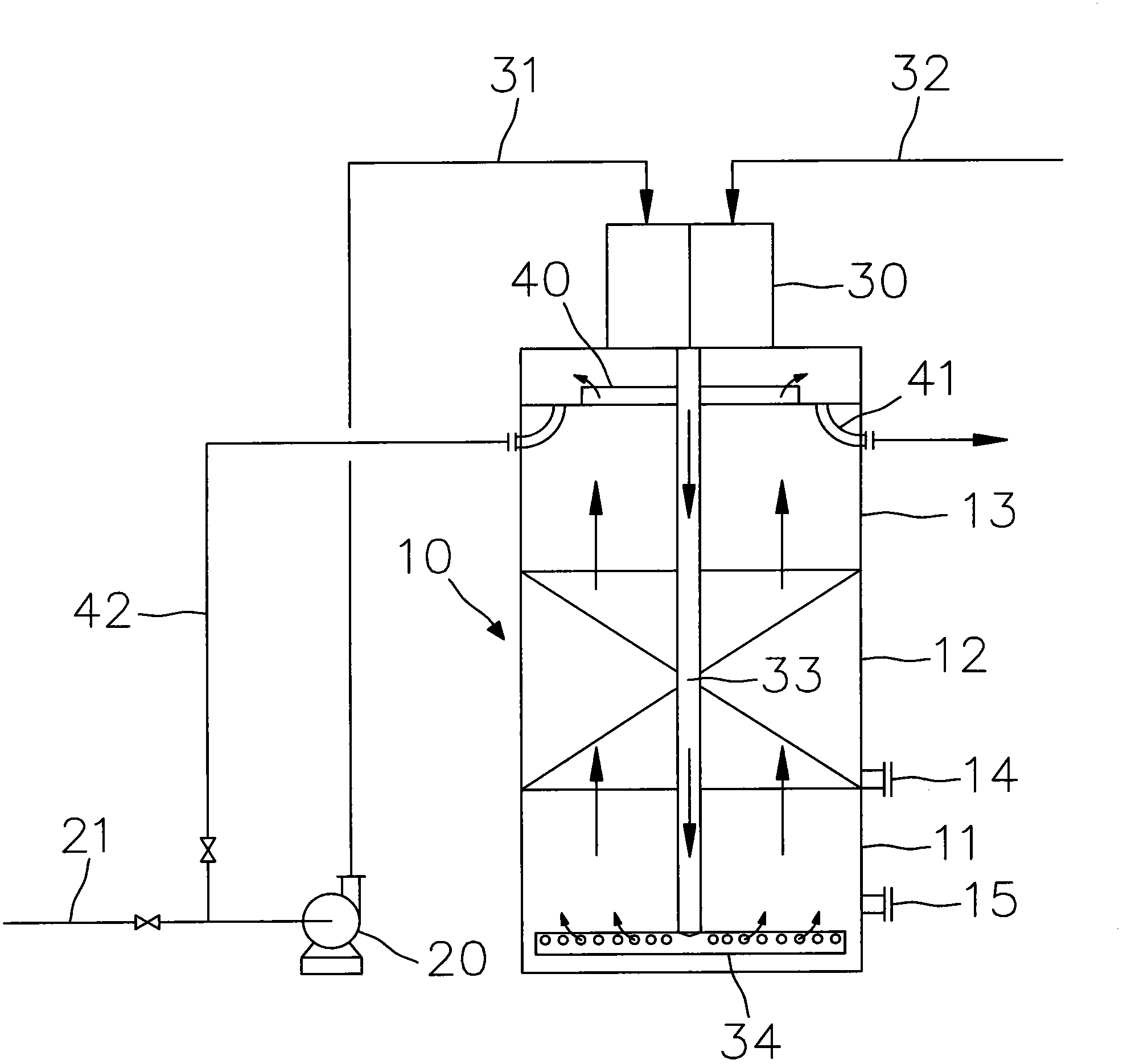

Microelectrolysis-fenton oxidizing reaction device

ActiveCN103663802AReduce the additional amountPlay a catalytic roleMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrochemical responseElectrolysis

The invention belongs to the technical field of sewage treatment, and in particular relates to a microelectrolysis-fenton oxidizing reaction device. The oxidizing reaction device comprises a wastewater supply device, and a hollow-out reactor made of anti-corrosive materials; a barrel body of the reactor is internally divided into a fenton oxidizing reaction area, a microelectrolysis reaction area and a flocculoreaction area from bottom to top; the microelectrolysis reaction area is full of iron-carbon fillers. The device also comprises a draining device arranged at the upper side of the reactor. The draining device is convenient for draining the treated wastewater to the outside of the oxidizing reaction device. The microelectrolysis-fenton oxidizing reaction device has the advantages that the microelectrolysis technology and the fenton oxidizing technology are integrated, so that the effective space of the reactor can be furthest utilized, i.e.,, the electrochemical reaction and the oxidization-reduction reaction can be carried out synchronously within the effective space of every independent unit device, therefore, the wastewater treatment process can be greatly simplified, the impact of various factors on wastewater treatment operation can be reduced, the purification performance of unit equipment in wastewater treatment can be improved, and as a result, an ideal treatment effect can be obtained.

Owner:安徽南风环境工程技术有限公司

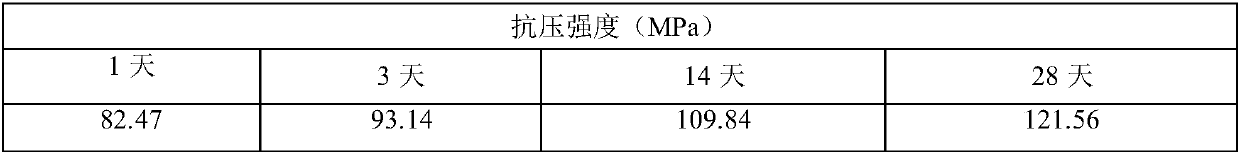

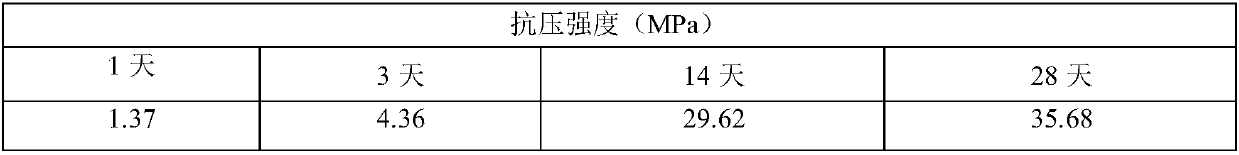

Method for efficiently preparing low-cost carbonized brick by utilizing steel slags

The invention provides a method for efficiently preparing a low-cost carbonized brick by utilizing steel slags, and belongs to the technical field of comprehensive utilization of resources. The methodincludes, firstly, mixing 45-100% of steel slags, 0-30% of desulfurized gypsum and 0-50% of fine aggregate to prepare a solid mixture; then, adding water accounting for 5-25% of the dry basis mass ofthe solid mixture and uniformly stirring; and after pressing and forming, curing the mixture in a carbonization chamber to obtain the steel slag carbonized building material. The method overcomes thedifficult problem of low comprehensive utilization rate of the steel slags, improves the production efficiency in a compression molding mode, absorbs carbon dioxide in industrial waste gas, can further alleviate the greenhouse effect to a certain extent, and has certain economic benefits, environmental benefits and social benefits, so that the prepared building material has excellent early strength and stability.

Owner:UNIV OF SCI & TECH BEIJING

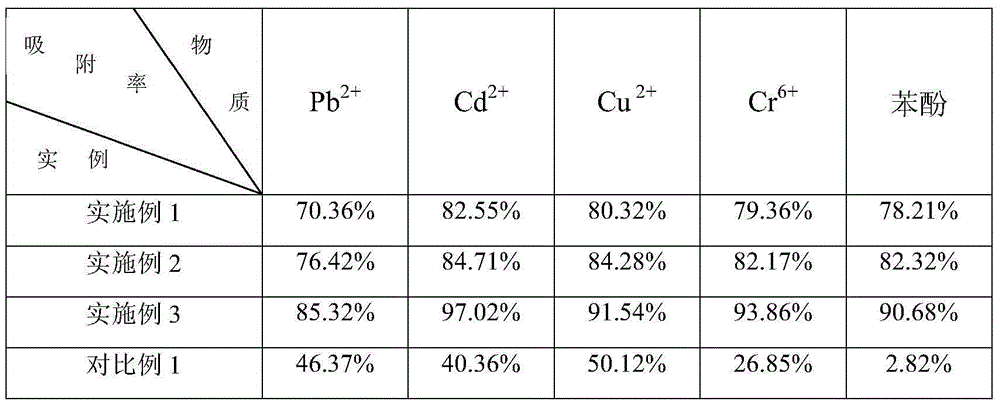

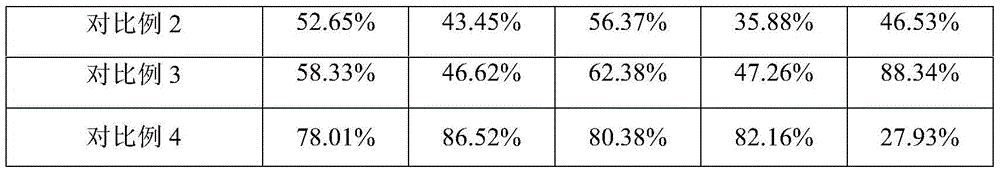

Sepiolite modification method and application of modified sepiolite to wastewater treatment

ActiveCN105617981ALow costReduce usageOther chemical processesWater contaminantsCellulosePtru catalyst

The invention discloses a sepiolite modification method and application of modified sepiolite to wastewater treatment. Cellulose and molysite are jointly adopted for modification of sepiolite, and the method particularly includes acid treatment of the sepiolite and joint hydrothermal reaction of acid-modified sepiolite, the cellulose and the molysite. The preparation method is quite simple, mild in preparation condition, low in related reaction temperature and low in energy consumption. The cellulose for modification is low in cost, the molysite can be combined with the sepiolite to improve adsorption effects and also plays a role in catalysis in a hydrothermal synthesis process to enhance catalysis effects, and utilization of toxic catalysts such as ammonium ferrous sulfate hexahydrate is avoided. The modified sepiolite prepared according to the method is excellent in performance and high in adsorption rate of heavy metals and organic pollutants such as phenol.

Owner:XIANGTAN UNIV +1

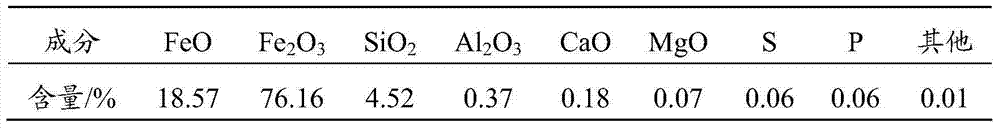

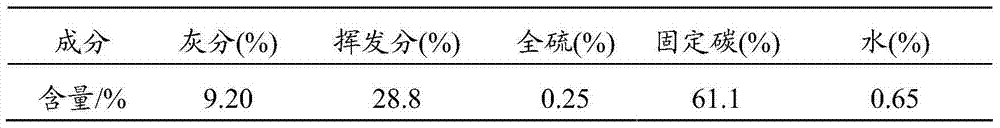

Hot briquetted iron coke for iron-making and preparation method thereof

The invention belongs to the technical field of iron-making and specifically relates to hot briquetted iron coke for iron-making and a preparation method thereof. The hot briquetted iron coke is composed of the following raw materials in percentage by mass: 10%-30% of iron ore powder, 60%-80% of pulverized soft coal and 10%-20% of pulverized blind coal. The preparation method comprises the following steps: thoroughly and evenly mixing the raw materials to obtain a mixture, heating the mixture in a heating furnace to 200-350 DEG C, performing instant hot briquetting on the mixture to obtain a hot briquetted iron coke green ball, putting the hot briquetted iron coke green ball in a tunnel kiln and performing high-temperature destructive distillation and carbonization at a certain temperature increased previously at a certain rate, and then taking out the braised material for cooling, thereby obtaining the hot briquetted iron coke. The prepared hot briquetted iron coke has excellent compressive strength, abrasive resistance, reactivity and post-reaction strength; the hot briquetted iron coke is used for blast furnace iron-making instead of partial coke, and therefore, the adaptability of blast furnace iron-making to fuels is improved. The preparation method of the hot briquetted iron coke is wide in raw material source, low in production cost, simple in process flow and free from the use of a binder, and has wide industrial application prospect.

Owner:NORTHEASTERN UNIV

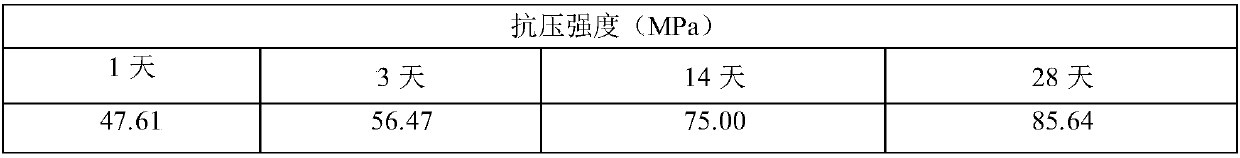

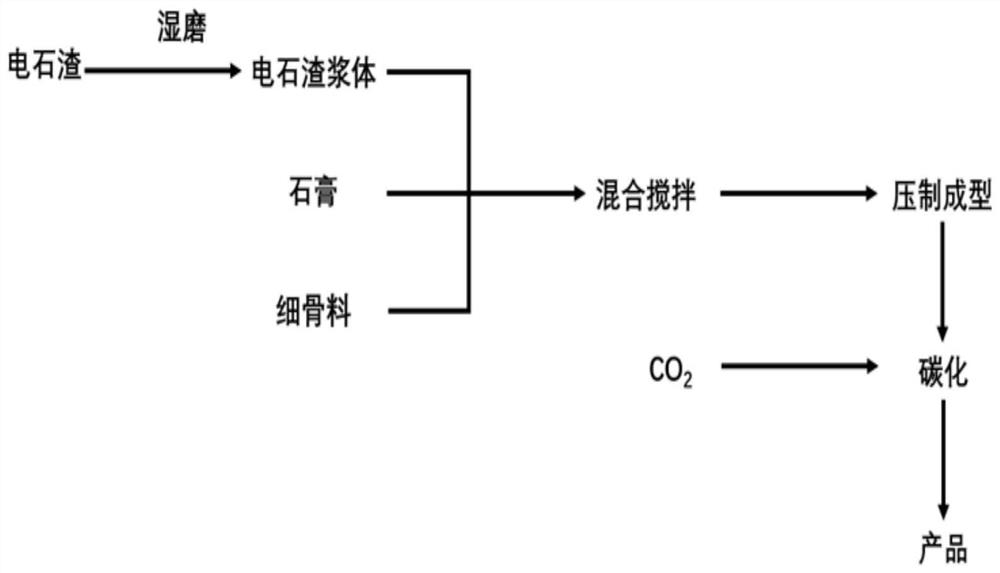

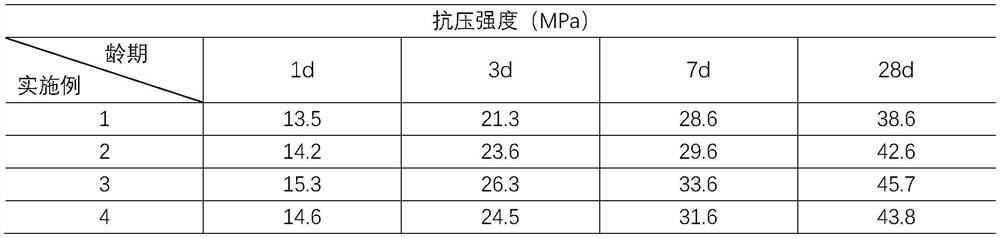

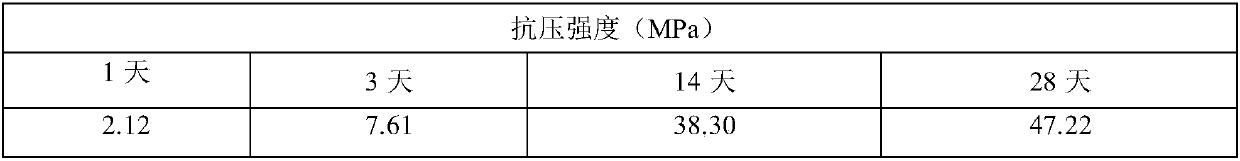

Method for preparing carbonized brick from wet-milling carbide slag

The invention provides a method for preparing a carbonized brick from wet-milling carbide slag. The method comprises the following steps: carrying out wet milling on 150-300 parts of carbide slag and75-150 parts of water to realize refining of carbide slag particles and high alkalinity of a liquid phase; preparing 120-200 parts of wet-milled carbide slag slurry, 10-35 parts of gypsum and 50-120 parts of slag as cementing materials, adding 420-865 parts of fine aggregate and 0-18 parts of wate and fully and evenly stirring the components, press-shaping the the stirred raw materials, and performing maintenance in a carbonization chamber to obtain the wet-milling carbide slag carbonized brick. By adopting the method, gas carbon dioxide can be cured, and environmental pollution caused by industrial waste gas is reduced; by utilizing the advantage that the wet-milling carbide slag is easy to carbonize and is easy to react with carbon dioxide to form calcium carbonate, and precipitate and crystal growth have cohesion, the prepared brick is high in strength and short in curing age, the production efficiency is improved, and the brick can effectively replace a common brick for construction.

Owner:HUBEI UNIV OF TECH

Method for preparing lithium-sulfur battery cathode material

ActiveCN110190262AHighlight substantiveImprove adsorption capacityPositive electrodesLi-accumulatorsMolecular sieveLithium–sulfur battery

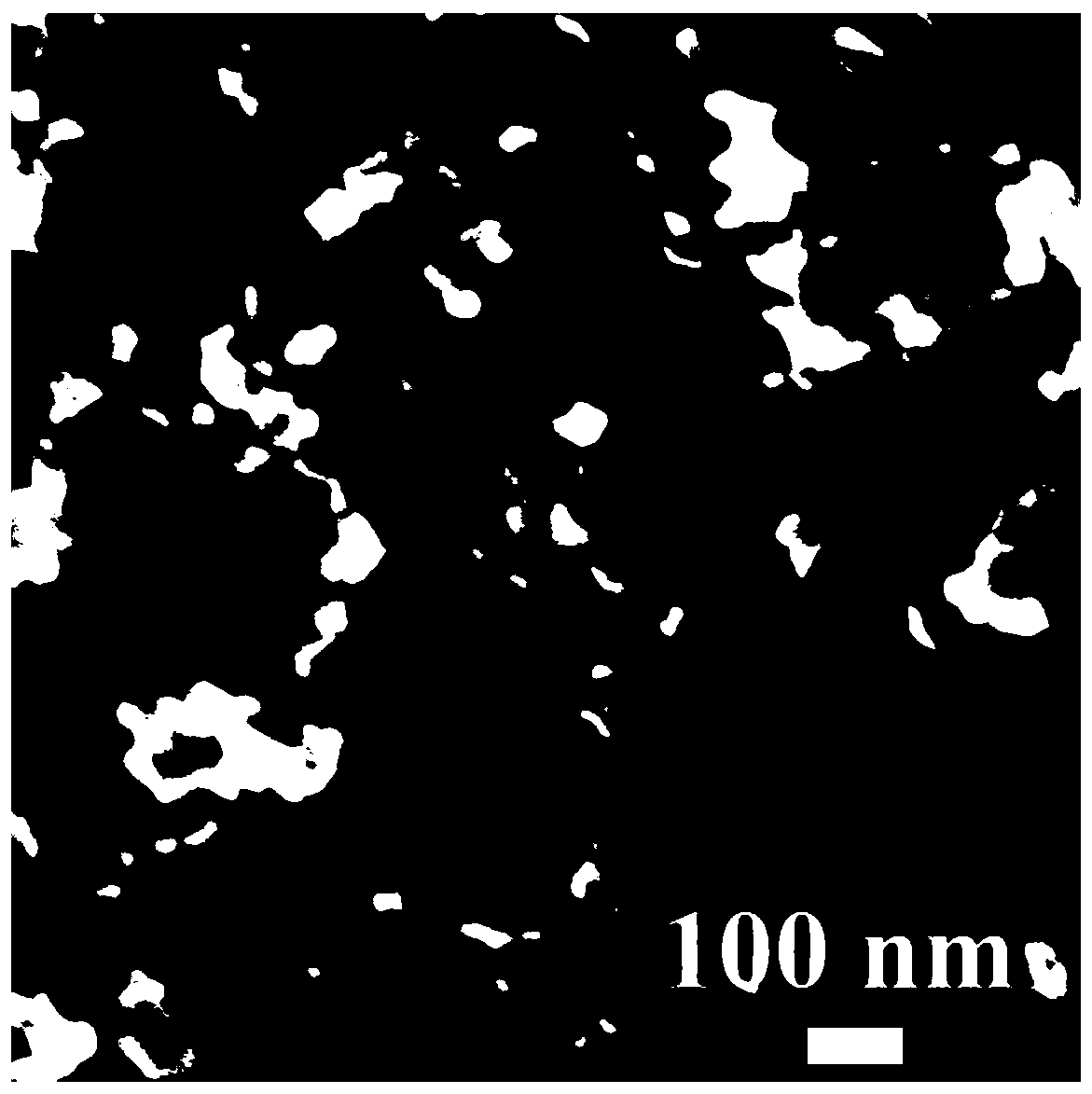

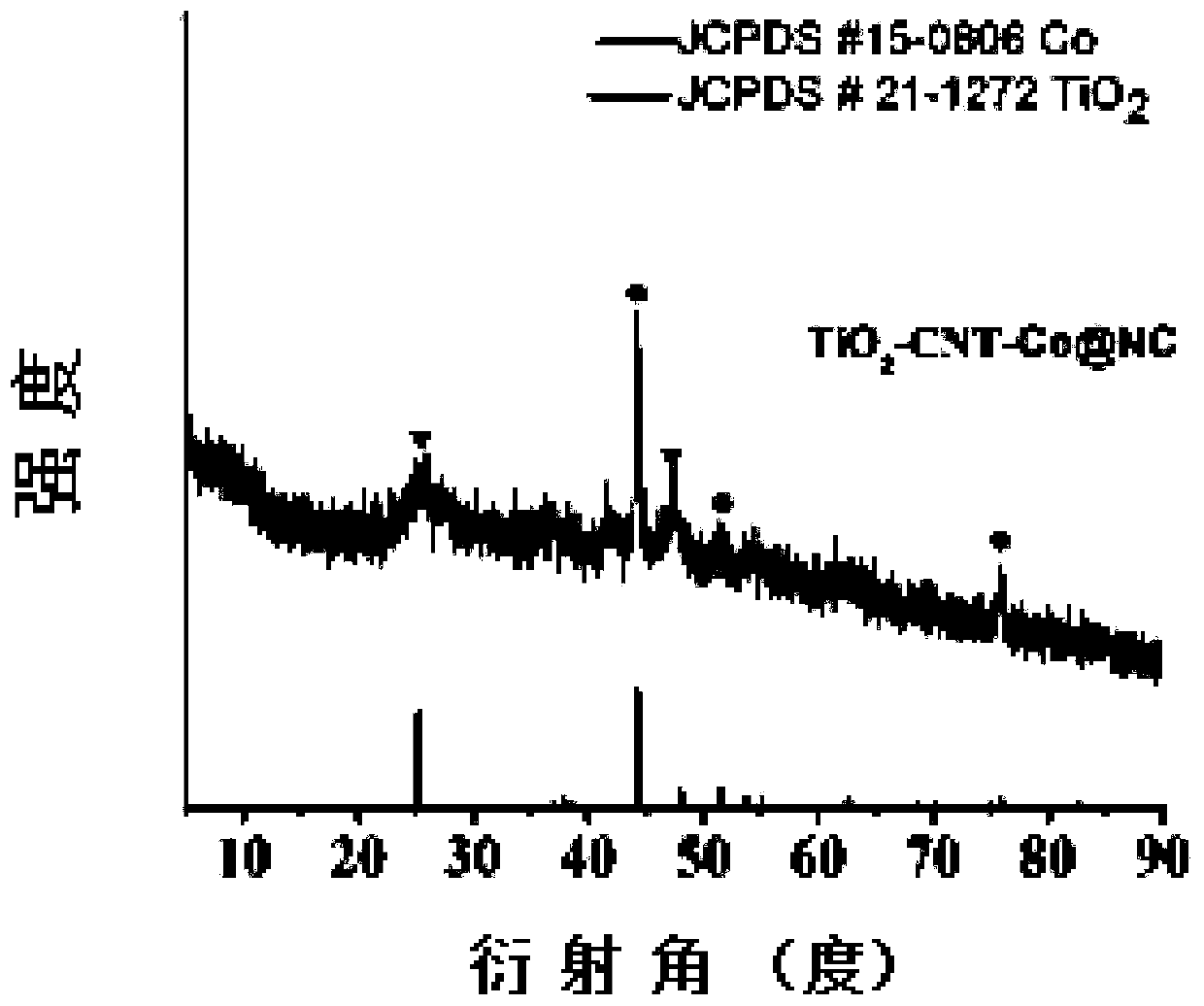

The invention relates to a method for preparing a lithium-sulfur battery cathode material, which relates to an electrode consisting of active materials. The method comprises the following steps of: firstly, preparing a multi-metal imidazole type molecular sieve framework TiO2-Co-ZIF-8 growing in a three-dimensional ordered titanium dioxide framework, then obtaining cobalt nano-particles TiO2-CNT-Co@NC coated with porous N-doped carbon and serially loaded on the three-dimensional ordered titanium dioxide framework through in-situ growth, and compounding the nano-particles and the with sublimedsulfur powder to obtain the S / TiO2-CNT-Co@NC lithium-sulfur battery cathode material. The method for preparing a lithium-sulfur battery cathode material overcomes the defects of low utilization rate of active substances, poor conductivity and shuttle effect in the prepared cathode material of the lithium-sulfur battery in the prior art.

Owner:HEBEI UNIV OF TECH

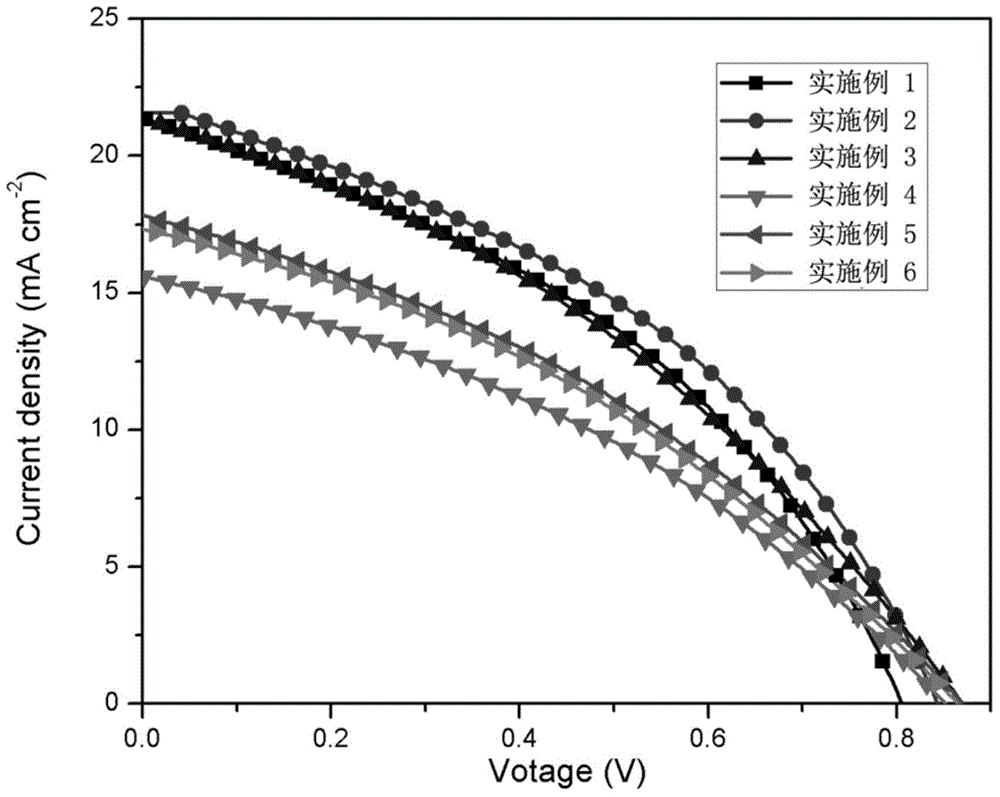

Perovskite solar cell conductive carbon paste, carbon counter electrode, cell and method of manufacturing the conductive carbon paste

InactiveCN104966548ABlocking compositeIncrease photocurrentSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingOrganic solvent

The invention discloses perovskite solar cell conductive carbon paste which comprises organic solvents, binders and conductive filling materials. The conductive carbon paste further comprises inorganic additives. The inorganic additives are ZrO2 or NiO powder. By mass percent, the conductive carbon paste comprises 6%-15% of binders, 14%-20% of conductive filling materials and 3%-5% of inorganic additives. The invention further discloses a carbon counter electrode for a perovskite solar cell. The carbon counter electrode is prepared and acquired by adopting the above-mentioned conductive carbon paste in a screen printing means. The invention further discloses the perovskite solar cell comprising the above-mentioned carbon counter electrode. A method of preparing the conductive carbon paste is further disclosed. The conductive carbon paste which does not make a perovskite film corroded further increases the photoelectric conversion efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Multieffect nano air purificant and preparation method thereof

The invention provides a multieffect nano air purificant including the following components by part by weight: 1 to 5 parts of photocatalyst functional powder, 2 to 10 parts of nanometer silica, 0.1 to 0.3 part of inorganic antibacterial powder, 2 to 5 parts of propanediol, 0.3 to 1 part of sodium hexametahposphate, 0.5 to 5 parts of surface active agent, 0.5 to 4 parts of dimethyl silicone polymer and 70 to 100 parts of deionized water. The nano multieffect air purificant of the invention solves the problem of wideband of nano concatemer, develops visible photocatalyst materials, and can give play to the effectiveness of the photocatalyst thereof under the long wave light near 600nm, namely, under the irradiation of an indoor fluorescent lamp, the photocatalyst can still have high activity.

Owner:贺燕婷 +2

Non-nitrine gas generating agent and production thereof

ActiveCN1644574AReduce dosageReduce generationExplosivesPressure gas generationParaffin waxGas composition

A non-laminated gas producing agent and its production are disclosed. The non-laminated gas producing agent consists of oxygen-enriched carbamidine nitrate 40-60% with granularity 0.5-6mu, basic copper nitrate 10-28% as oxidant with granularity 0.5-6mu, copperon oxide of catalyst with primary oxidant 15-30% with granularity 0.1-6mu, and clay or paraffin wax 0.1-3% as process assistant with granularity 1-20mu. The production is carried out by: breaking the materials, adding into mixer by proportioning, mixing, sieving by screen, adding water 10-30%, agitating, drying, sieving the dried materials by screen with 20-80 mesh to obtain medicine particles, pressing into tablets, and drying the tablets under 100-120deg.C for 1.5-2.5hrs with water content <0.4%. It achieves wide regulating range, high gas output efficiency, and clean gas composition.

Owner:HUBEI HANGPENG CHEM POWER TECH

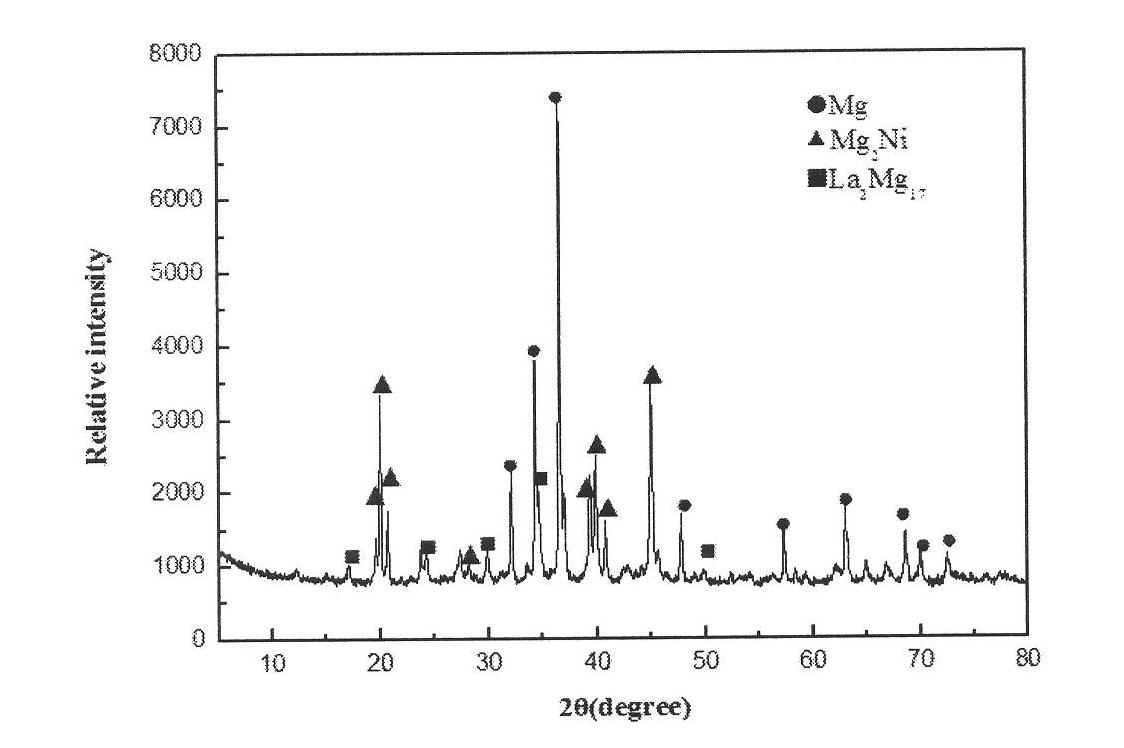

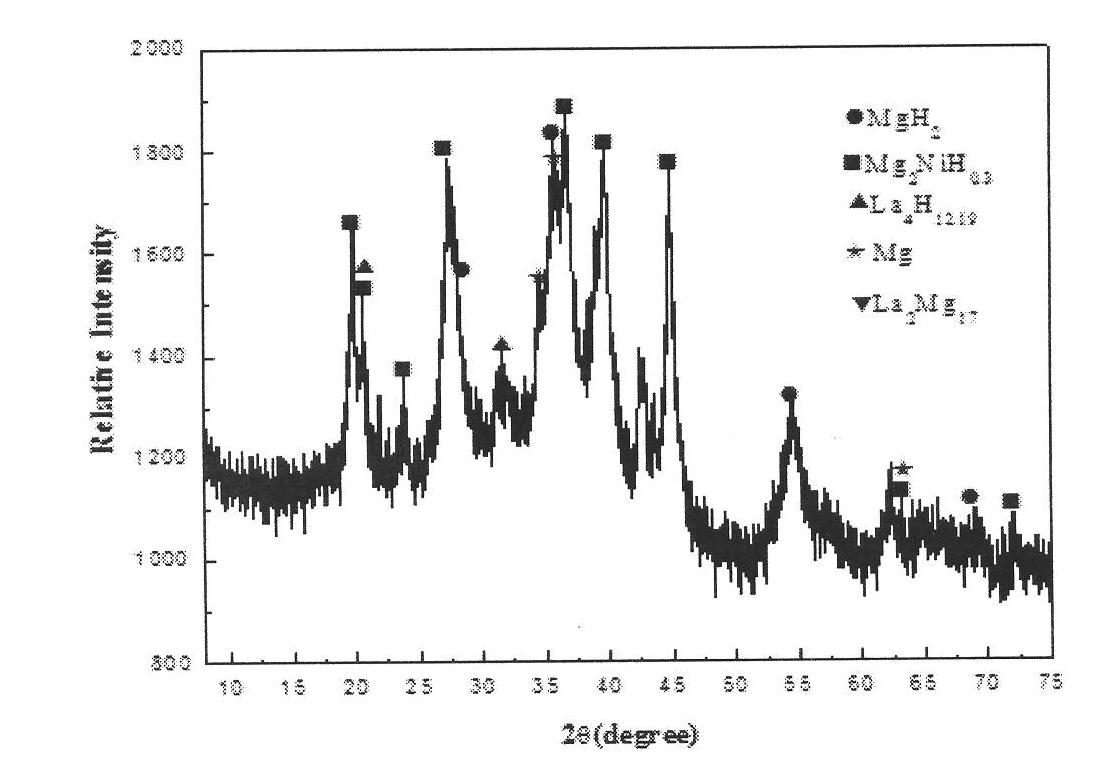

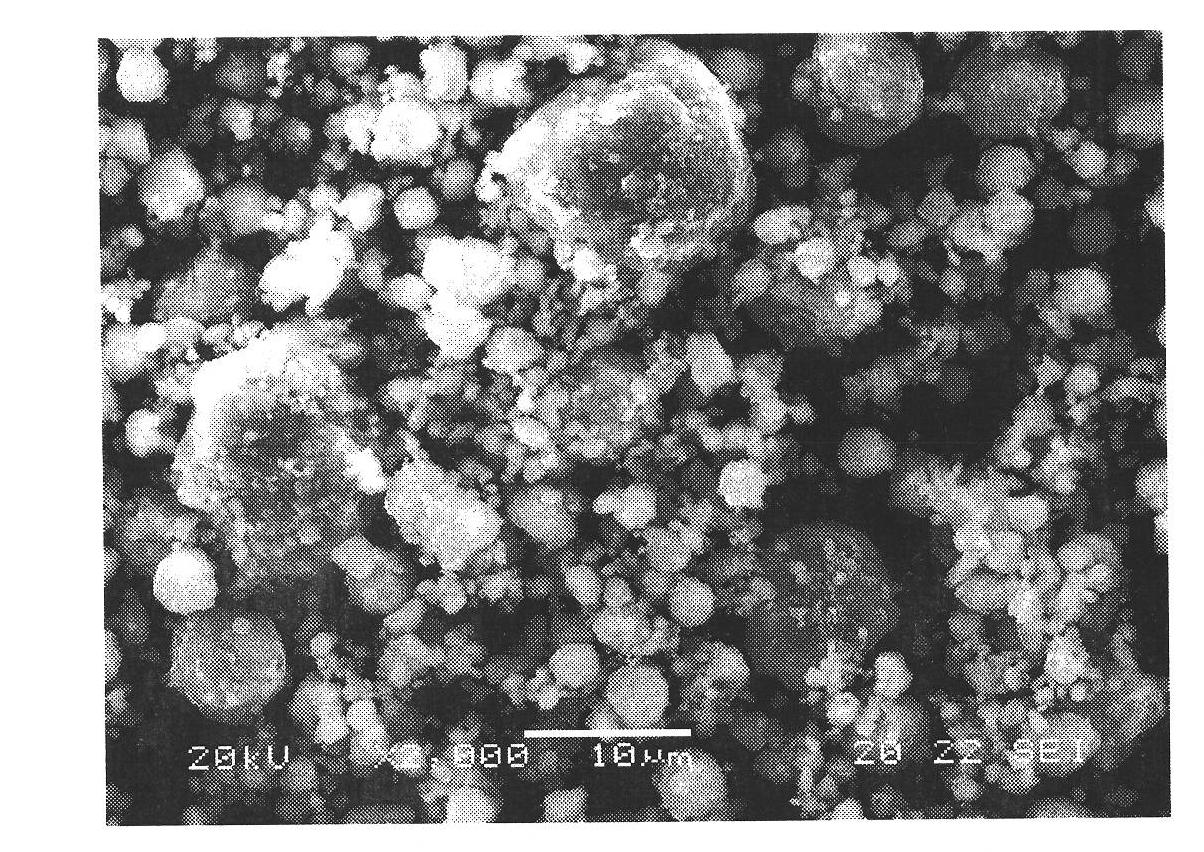

Preparation method of Mg-RE-Ni alloy hydrogen storage material

The invention relates to a preparation method of Mg-RE-Ni alloy hydrogen storage material, comprising the following steps: (1) mixing Mg powder, RE powder and Ni powder in percentage by molar of 60-89:1-10:10-30, and evenly grinding powder in the atmosphere of argon protection to obtain mixture; (2) tabletting the mixture under the argon protection, and sealing by graphite powder; (3) putting a sealed die in a tube furnace or a muffle furnace under argon or air atmosphere for sintering powder, and obtaining sintered alloy; (4) polishing the surface of the sintered alloy, and obtaining alloy powder by smashing and grinding; and (5) carrying out intermittent ball milling on the alloy powder under the argon protection to obtain nanocrystalline / amorphous magnesium base composite hydrogen storage material. The invention combines a powder sintering method with a mechanical ball milling method, which simplifies technology, leads operation to be easier, lowers equipment cost and ensures that the component of the obtained production is easy to control.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

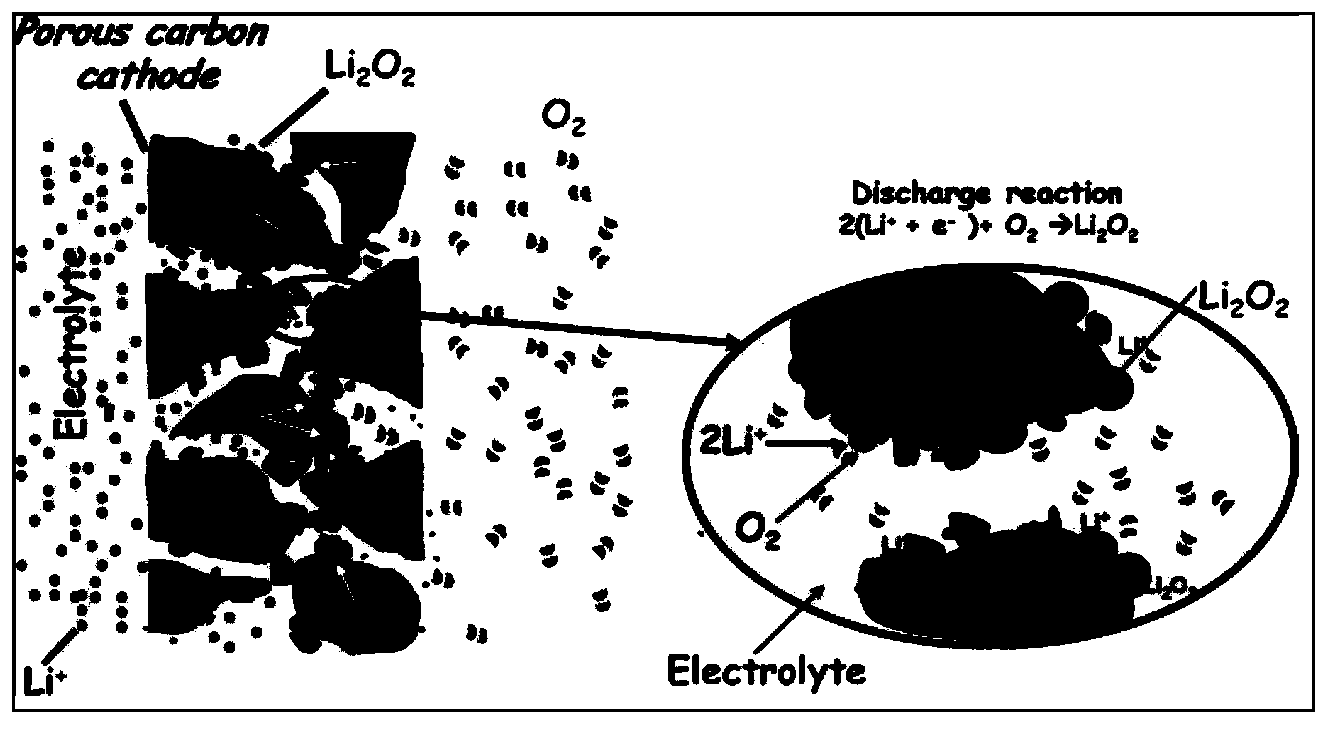

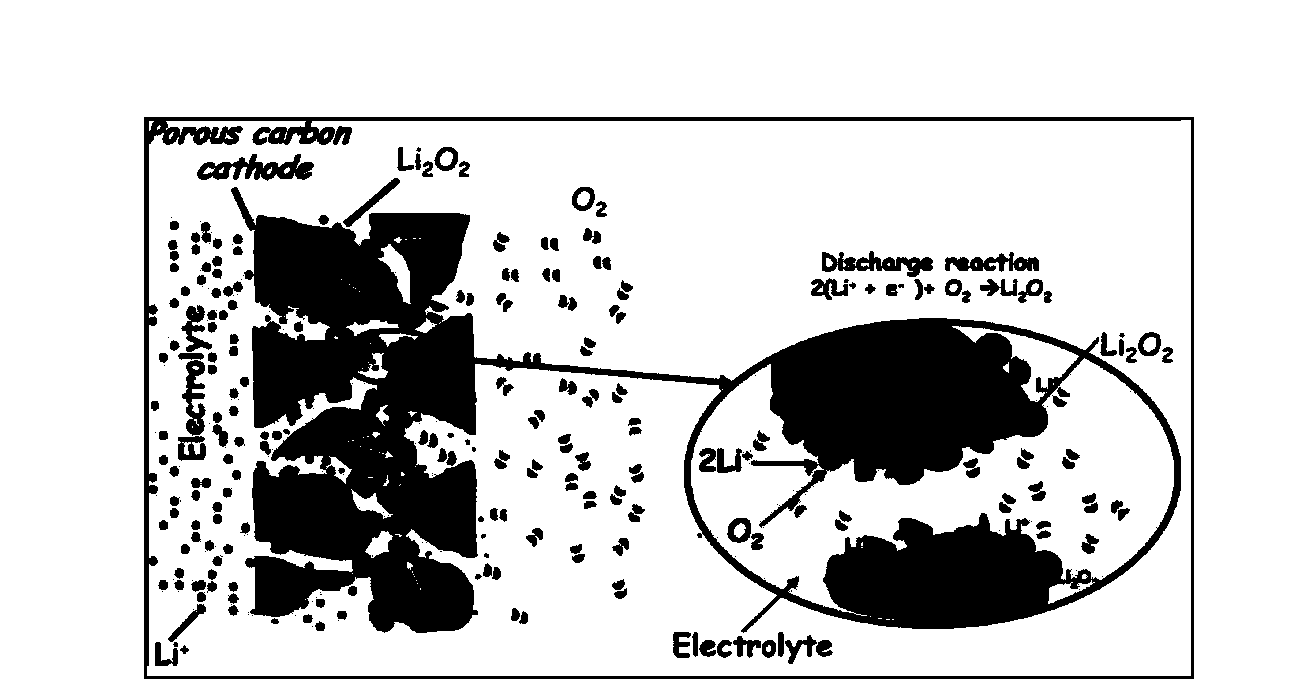

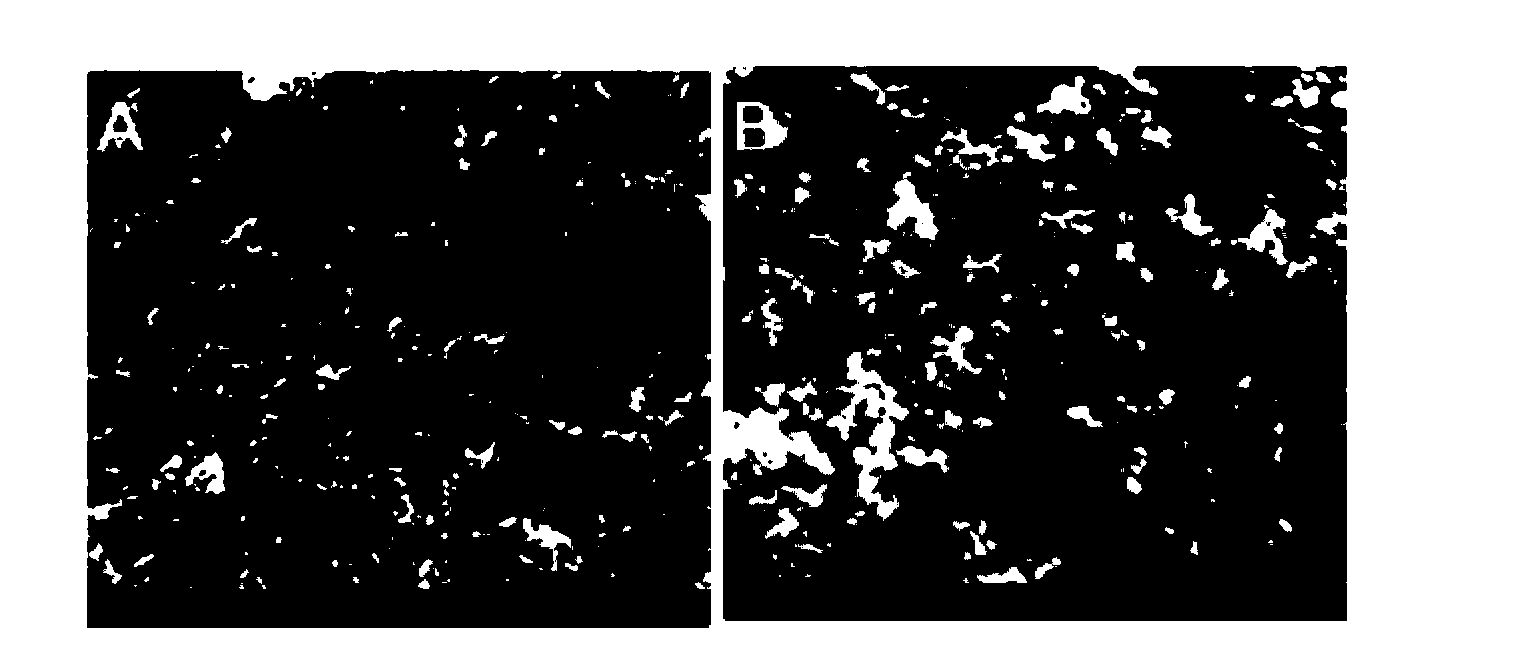

Nitrogen-doped porous carbon material used for anode of lithium-air cell

ActiveCN103855367AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesLithiumPorous carbon

The invention relates to a nitrogen-doped porous carbon material used for anode of a lithium-air cell, which has a mutually communicated graded pore structure, N is uniformly doped in a C frame, wherein N accounts for 0.2-15% of carbon material, the graded pore comprises a mass transfer pore and a deposition pore, the pore volume of the deposition pore accounts for 40-95% of total pore volume, and the pore volume of the mass transfer pore accounts for 4-55% of total pore volume. The carbon material as the lithium-air cell material can greatly increase the space utilization rate of the carbon material during a charge and discharge process at maximum limit, so that lithium-air cell energy density and power density can be effectively increased. The nitrogen-doped porous carbon material used for anode of lithium-air cell has the advantages that the preparation technology is simple, the material source is wide, the pore structure of the graded aperture carbon material enables regulation and control, and the regulation and control modes are various, and the nitrogen doping mode is easy to realize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-content environmental alcohol ether fuel used for compression ignition engine

InactiveCN105505484AEmission reductionLarge latent heat of evaporationLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol fuel

The invention discloses a high-content environmental alcohol ether fuel used for a compression ignition engine, which belongs to the technical field of alcohol ether fuel clean energy. The alcohol ether fuel comprises the following raw materials: methanol or ethanol or a mixture of methanol and ethanol, toluene, stearic acid, hexamethylphosphoric triamide, a nitryl solvent, acetone, fatty acid methyl ester, n-alkane, N-toluidine, plant oil, an alcohol fuel ether stabilizing agent, a catalysis combustion-supporting agent, an anti-knock reinforcing agent, a cetane number regulator, an eduction agent, an alcohol fuel recognition agent, an alcohol fuel rubber / plastic part corrosion and swelling inhibitor, an alcohol fuel metal corrosion inhibitor, an antioxidant anti-gum inhibitor, a metal deactivator, a corrosion inhibitor, an antistatic agent, a purification dispersant, an anti-wear repair agent, and an alcohol fuel sterilizing agent. The high-content environmental alcohol ether fuel has the advantages of stable performance, strong power, full combustion, good anti-knock property, good acceleration speed, easy starting, no air resistance, and low fuel consumption, and is especially suitable for the compression ignition engine.

Owner:SICHUAN ZHENGJIA NEW ENERGY TECH CO LTD

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855365AIncrease profitImprove space utilizationFuel and secondary cellsCell electrodesLithium–air batteryPower density

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode. The nitrogen-doped porous carbon material is characterized in that the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Application of modified calcium carbonate in plastics

InactiveCN107501891AHigh tensile strengthHigh elongation at breakFlexural strengthThermal deformation

The invention provides application of modified calcium carbonate in plastics. The plastics are prepared from the following raw materials in parts by weight: 3 to 5 parts of modified calcium carbonate, 1 to 3 parts of ethyl propionate, 4 to 6 parts of glass fibers, 40 to 50 parts of polycarbonate, 0.5 to 1 part of alunite, and 0.5 to 1 part of cross-linking agent. The modified calcium carbonate provided by the invention is added in the production process of the plastics, and the prepared plastics have good tensile strength, elongation at break, bending strength and brinell hardness, and high thermal deformation temperature.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Replacement gilt feed as well as preparation and using methods thereof

ActiveCN103719634AImprove longevity and reproductive capacityEnsure systematic and scientificAnimal feeding stuffSOYBEAN SEED OILChemistry

The invention discloses a replacement gilt feed as well as preparation and using methods thereof. The formula of the feed comprises the following raw materials: 20-70% of corn, 0-30% of wheat, 0-20% of rice bran, 3-20% of wheat bran, 0-4% of rice bran and hull, 5-17% of soybean meal, 0-2% of soybean oil and 1.34-7.95% of feed premix, wherein the feed premix comprises a nutrition enhancer, feed additive, vitamin premix, microelement premix and a feed mildew removing agent; both the vitamin premix and microelement premix are mixtures containing carriers. The preparation method comprises the following very simple operating steps of mixing, smashing, conditioning, compressing and the like. According to the using method, different feed intakes are adopted according to different weights of gilts; the using method is simple and easy to handle; in the actual production process, the energy level and the source of replacement gilt daily ration can be effectively improved and increased, and thus the replacement gilt feed has extremely high market value.

Owner:JIEYANG TONGWEI FEED

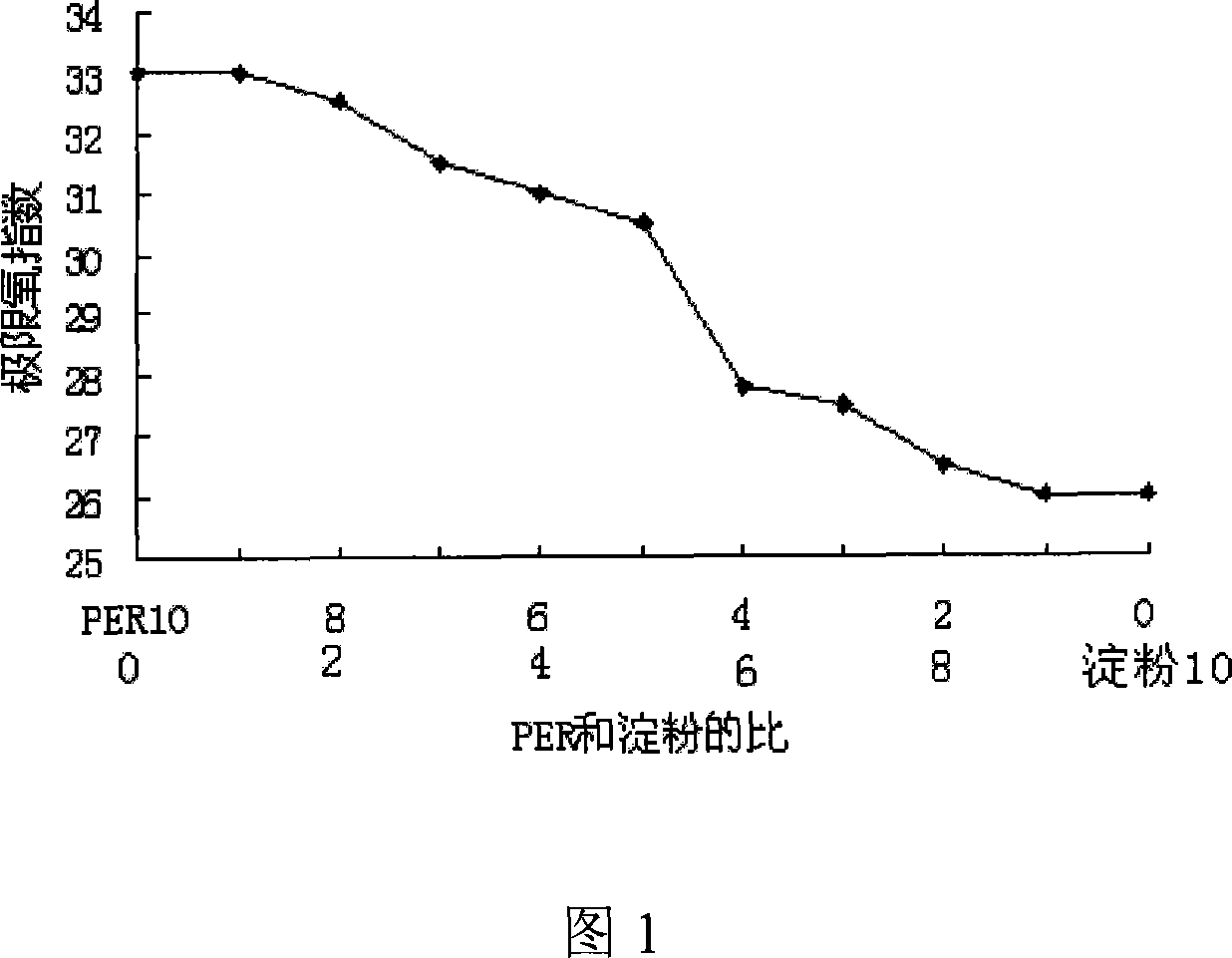

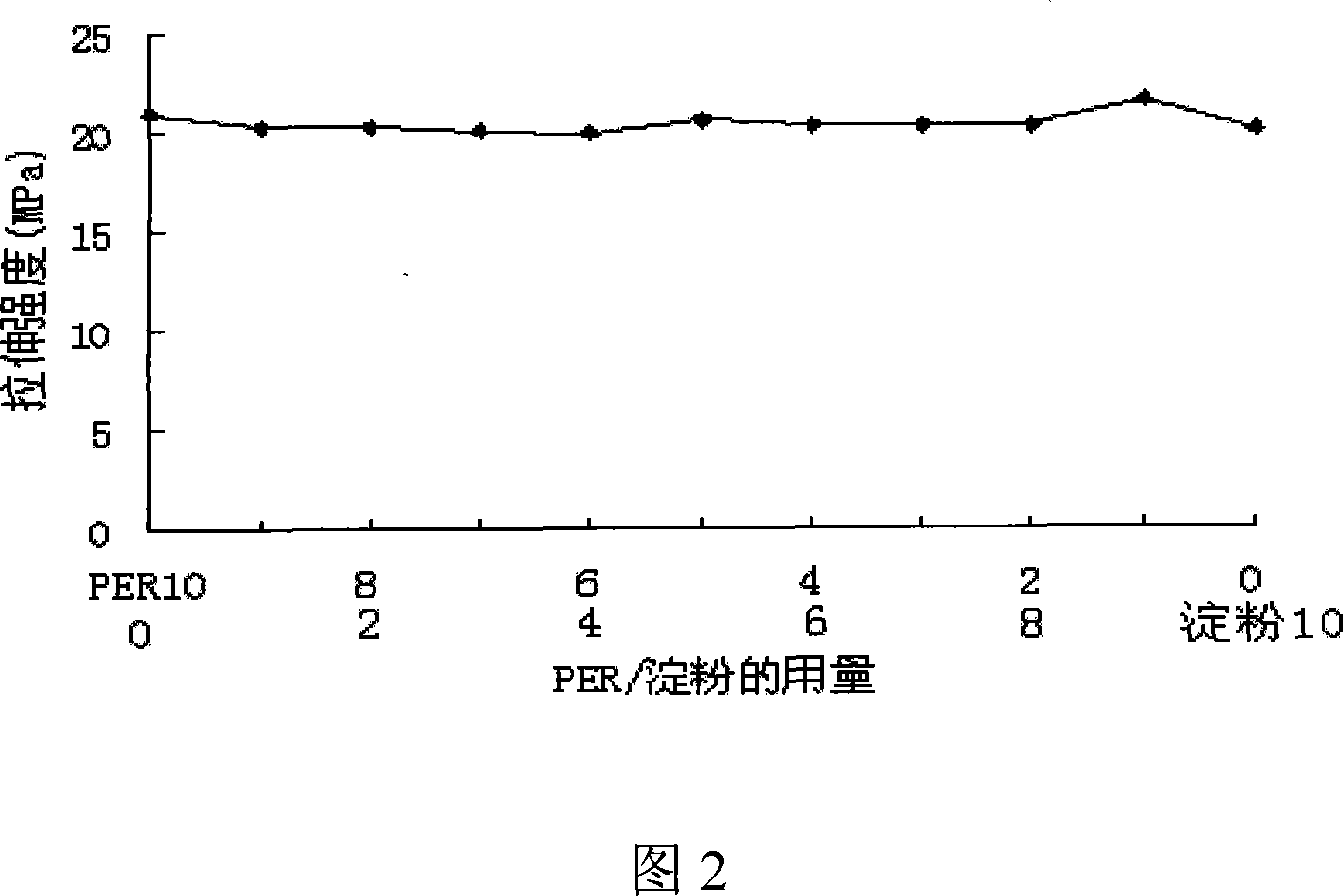

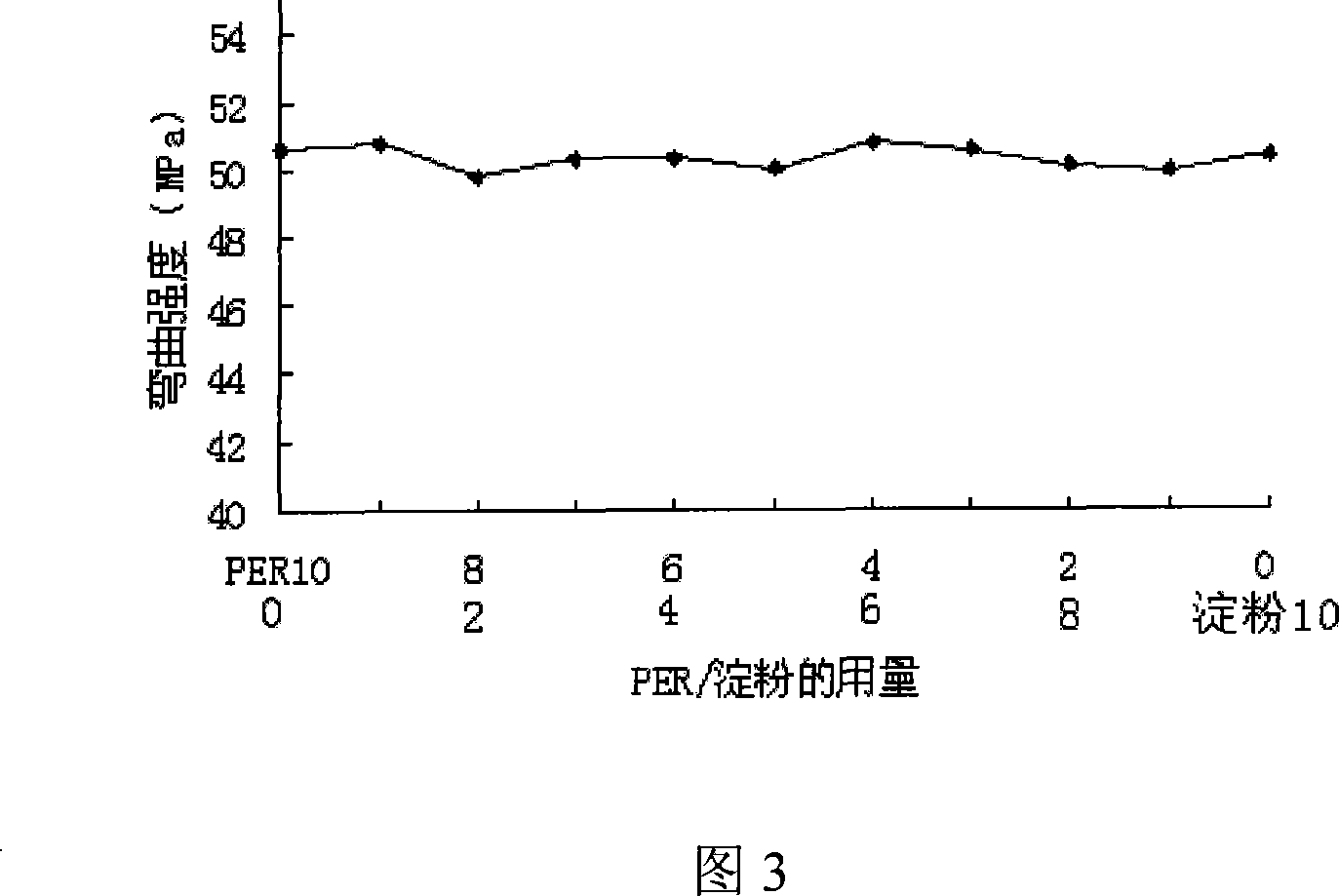

Non-bittern expanding flame-proof material and method for making same

InactiveCN101134830ARaise the maximum thermogravimetric rate temperatureIncrease the residual rate of thermogravimetric lossFireproof paintsHalogenPolypropylene

The present invention relates to one kind of no-halogen expanding fire retardant material and its preparation process. The no-halogen expanding fire retardant material consists of polypropylene and expanding fire retardant in 30-50 wt% of polypropylene. It is prepared through melting and rolling polypropylene at 160-170 deg.c, adding expanding fire retardant and additive and mixing for 8-15 min, hot pressing at 15 MPa and 180 deg.c for 2-5 min and cooling to set. The no-halogen expanding fire retardant material of the present invention has excellent fire retardant effect and high mechanical performance.

Owner:SOUTH CHINA UNIV OF TECH

Transparent polycarbonate/polybutylece terephthalate alloy and preparation method thereof

InactiveCN101759985AEnsure transparencyPlay a catalytic rolePolytetramethylene terephthalateGlass fiber

The invention discloses a transparent polycarbonate / polybutylece terephthalate (PC / PBT) alloy and a preparation method thereof. The PC / PBT alloy is prepared from the following ingredients in percentage by weight: 70 to 75 percent of polycarbonate, 20 to 25 percent of polybutylece terephthalate, 3 to 5 percent of compatilizers and 1 to 2 percent of antioxidizers, wherein the compatilizers are copolyester. The transparent PC / PBT alloy of the invention has the advantages that the PC / PBT alloy prepared by the recipe and the process has good mold filling flowability, good processing performance, hydrolytic resistance, chemical resistance, high harness and difficult scratch formation, the excellent transparency is mainly maintained, glass fiber with the similar refractive index to PC can also be added as required for reinforcement, and the alloy can be used as substitute materials of PC and glass in special fields.

Owner:ANHUI KEJU NEW MATERIALS

Method for preparing counter electrode of dye sensitization solar battery based on carbon nanotube and platinum

InactiveCN101510471APlay a catalytic roleImprove photoelectric conversion efficiencyLight-sensitive devicesSolid-state devicesCarbon nanotubeDissolution

The invention discloses a preparation method of a counter electrode of a dyestuff sensitized solar cell on the basis of a carbon nanotube and platinum. The method comprises the following steps: chloroplatinic acid is added into isopropyl alcohol for complete dissolution, thus obtaining a chloroplatinic acid isopropyl alcohol solution which is added with carbon nanotube and evenly stirred, thus obtaining a chloroplatinic acid isopropyl alcohol solution containing the carbon nanotube; conductive glass which is taken as a substrate is cleaned; the solution is coated on the surface of the conductive glass in a spin coating way and naturally dried for more than 24h in the air; and the conductive glass coated with the solution is put into a sintering furnace.

Owner:IRICO

Lead acid storage battery of electric booster car and cream technique

InactiveCN1971977AGood dispersionEvenly distributedFinal product manufactureLead-acid accumulator electrodesFulgurationLead dioxide

This invention relates to automatic aid trolley lead acid storage battery blending process in the blend process method, which is characterized by the following steps: adding special float liquid in blending; adding nanometer silicon dioxide and glue graphite in anode float liquid and adding acetylene black into float liquid, wherein, the float liquid is added with pure water for five minutes before adding fulguration acid.

Owner:SHUANGDENG GRP

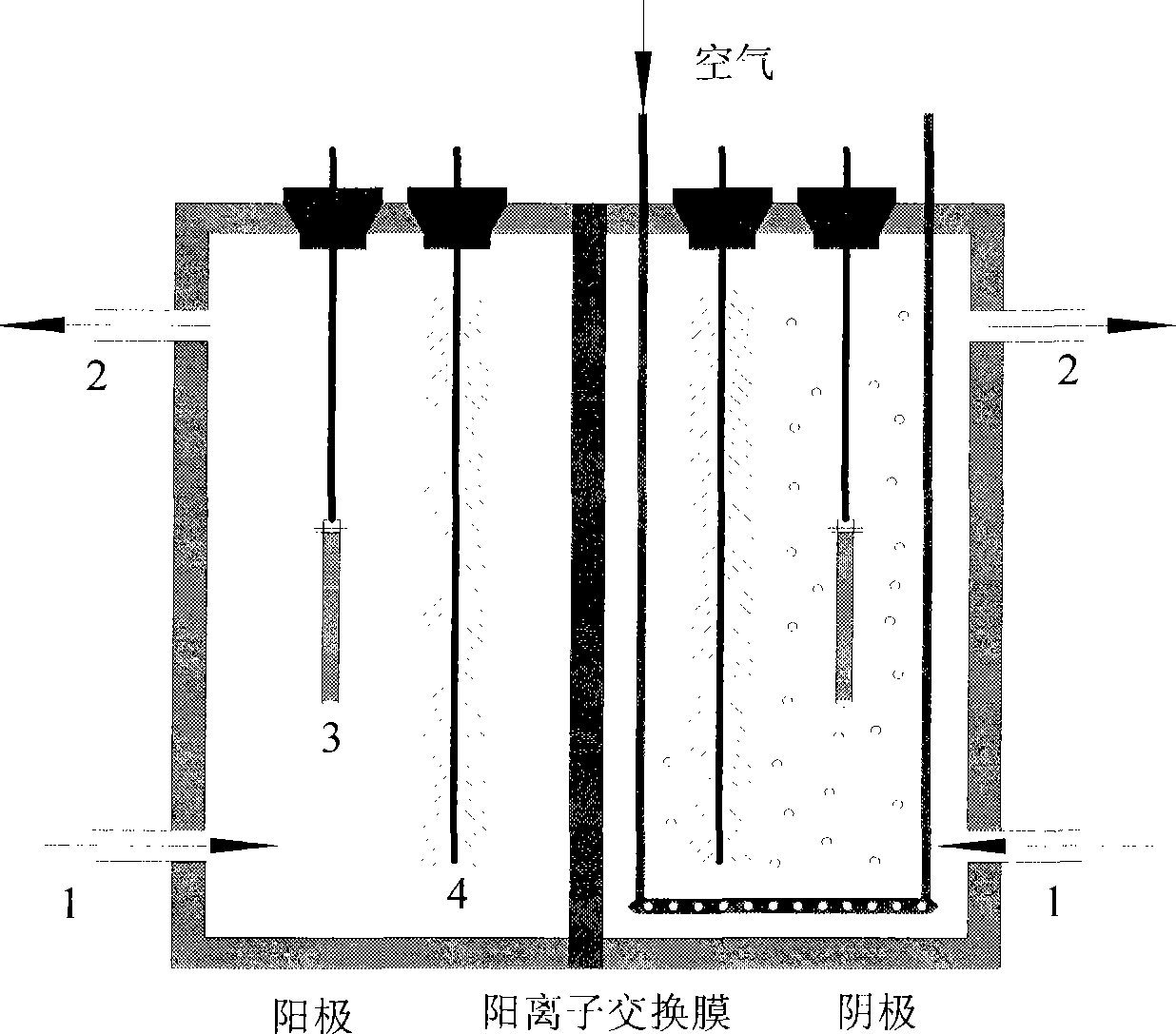

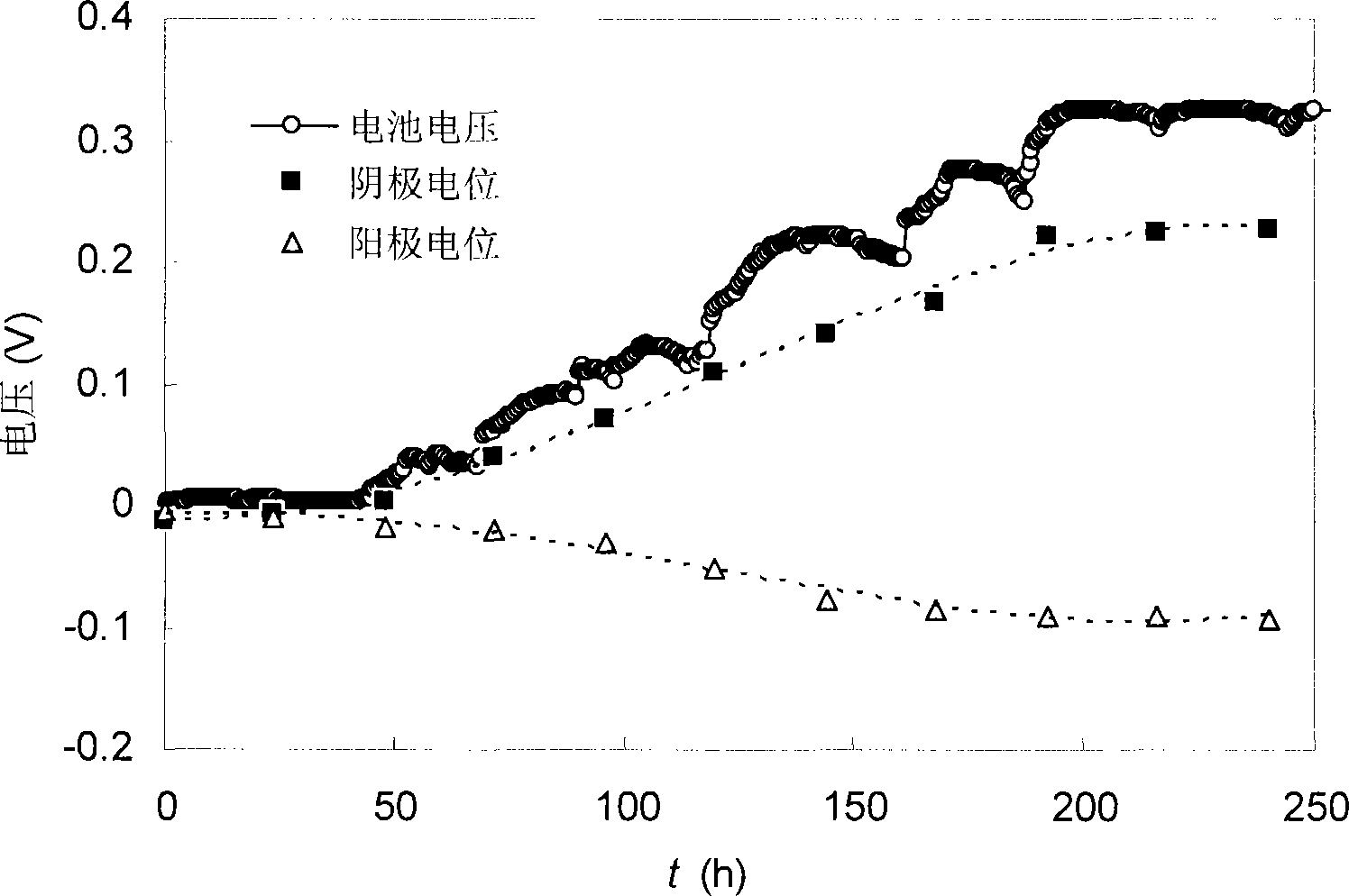

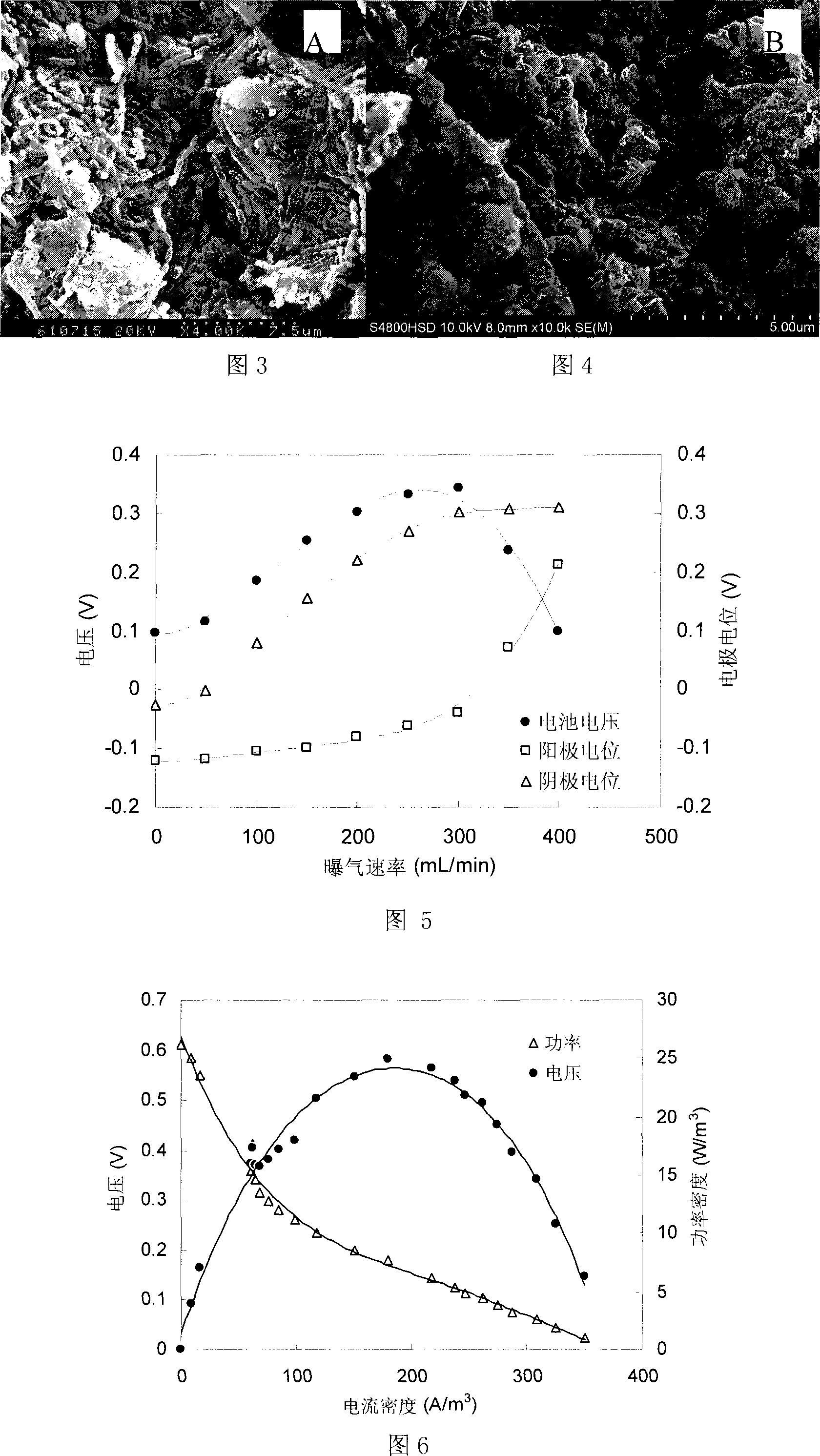

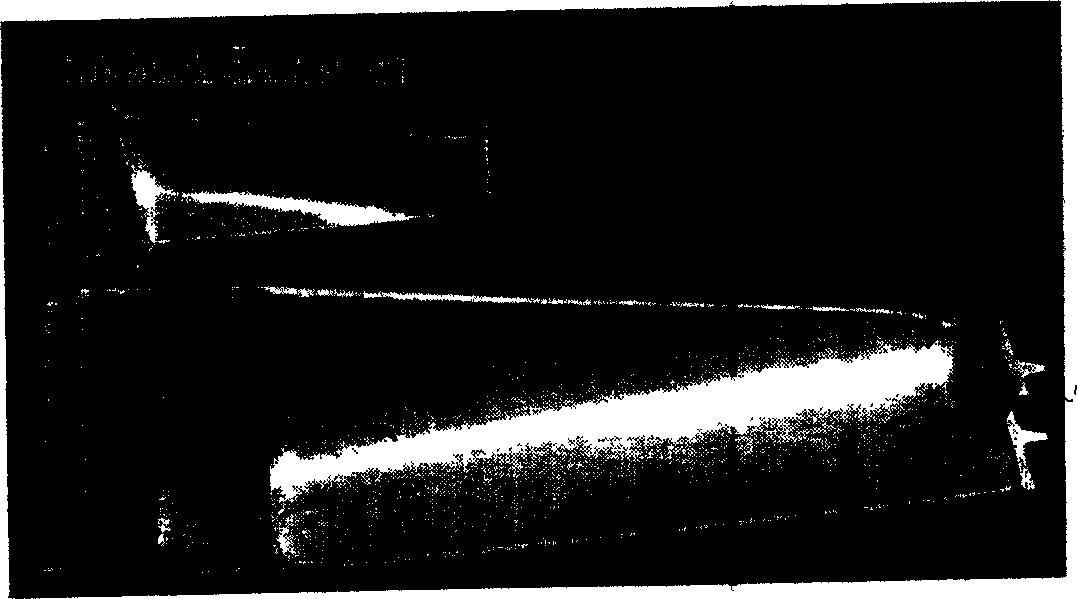

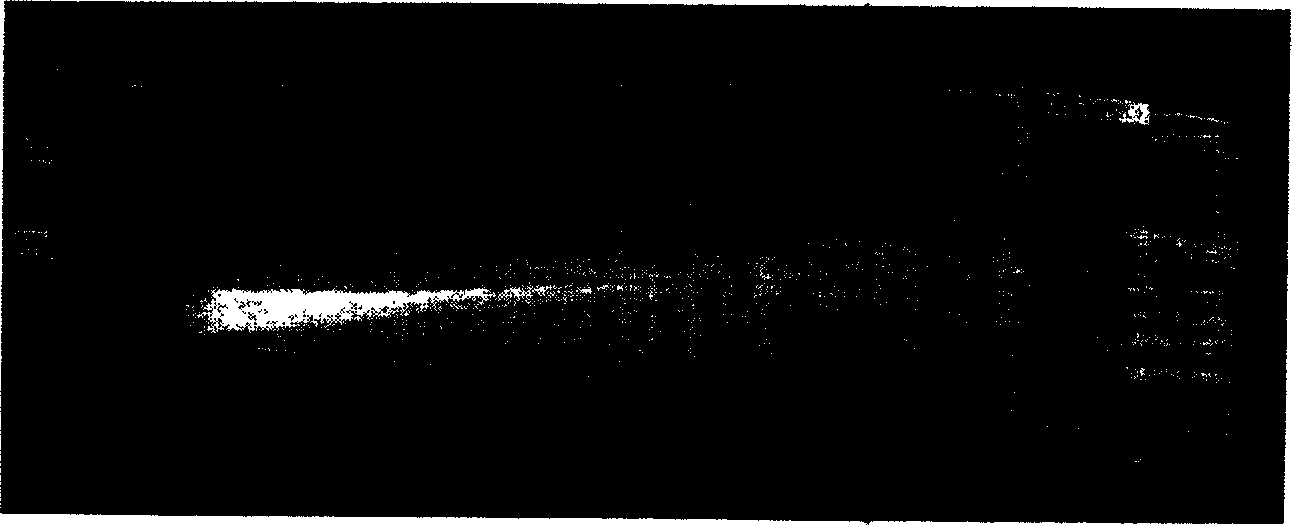

A MFC making method for using aerobic microbe as the cathode catalyzer

InactiveCN101242004ALow costFast bioaccumulation rateFinal product manufactureCell electrodesCarbon sourceCathode catalyst

The present invention provides an MFC preparing method which uses the aerobic microorganism as the cathode catalyst, the catalyst which adopts the microorganism as the cathode successfully actuates the biological cathode biological fuel cell which has a double-cell structure, the electrode material is conductive carbon fiber and the anode takes the glucose as substrate, the cathode takes NaHCO3 as inorganic carbon source and the perforated pipe aerates. The result showed that after 9d actuation the battery voltage gets to 0.324V(R=500 omega), the maximum power density is 24.7W / m<3> when the aeration amount is 300Ml / min, as the metal catalyst is saved and the fabricating cost of MFC is reduced the application of MFC in project is provided with a novel approach and possibility.

Owner:HARBIN INST OF TECH

Crystalloid laminae composited from single crystal and directional column crystal and preparing method

InactiveCN1660524AImprove performanceQuality improvementPolycrystalline material growthBlade accessoriesDirected crystallizationEngineering

A monocrystal and orientational cylindrical crystal combined blade used for gas turbine features that its middle region is orientational cylindrical crystals and its gas inlet and outlet edges have monocrystal form. Its manufacture method includes such steps as installing a composite crystallizer to the crystallizer of orientational crystallizing furnace, smelting by 100-150 of overheat, regulating the temp of mould heater to 1500-1530 deg.C for upper region and 1550-1580 deg.C for lower region, casting, and moving mould downward at 5-7 mm / S.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

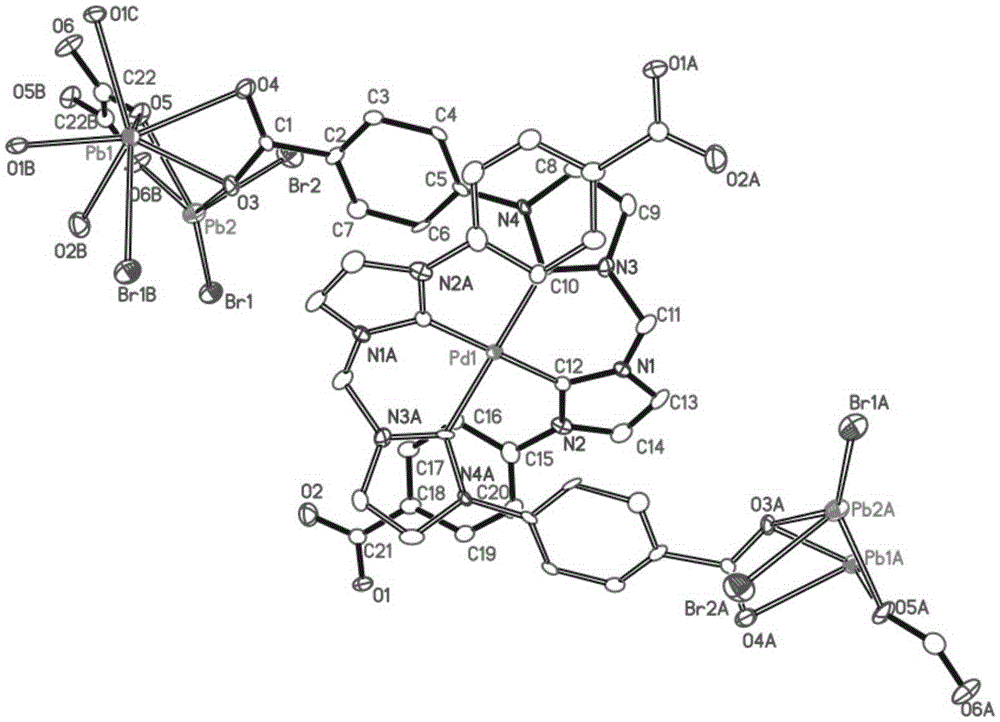

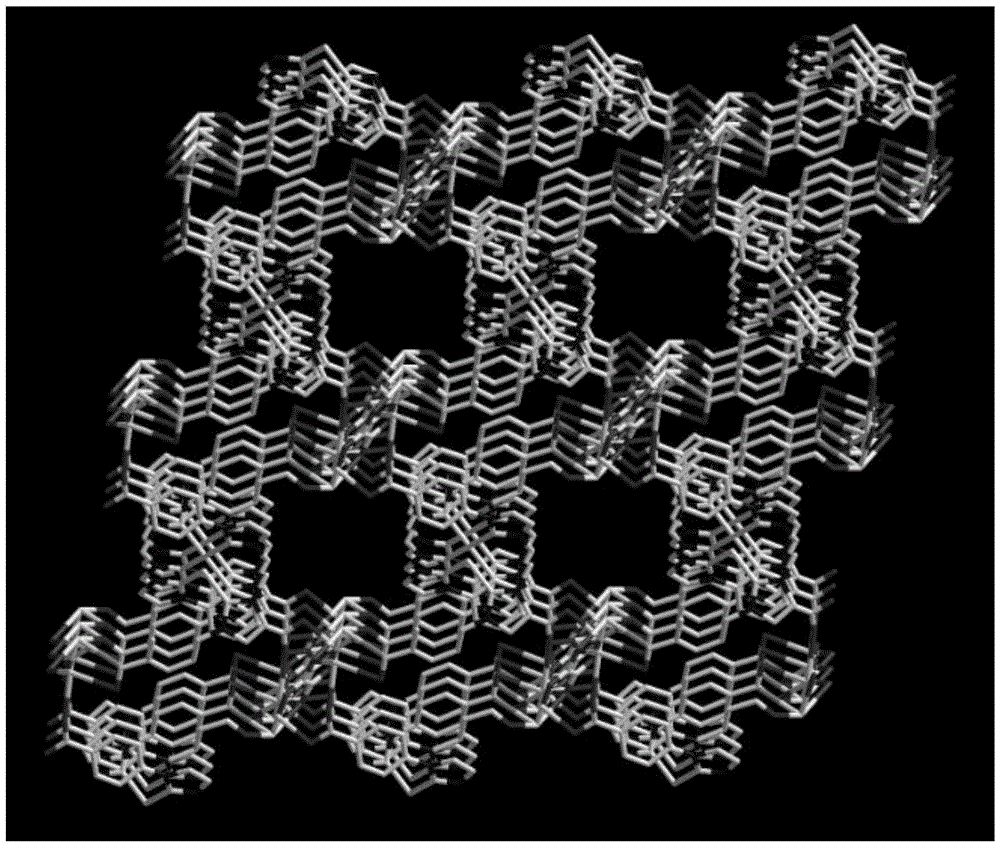

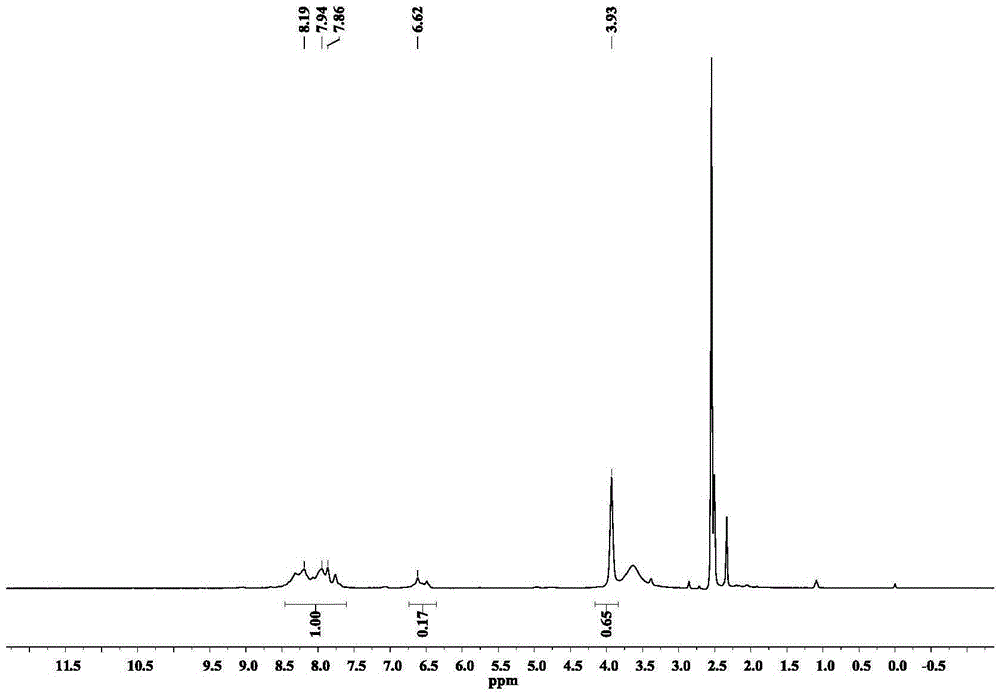

Organic ligand and Pd/Pb-based bi-metal organic framework as well as synthetic method and application thereof

InactiveCN105348327AHarm reductionPlay a catalytic roleOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsHalohydrocarbonReactive site

The invention discloses an organic ligand and a Pd / Pb-based bi-metal organic framework as well as a synthetic method and application of the organic ligand and the Pd / Pb metal organic framework. A structural formula of the Pd / Pb-based bi-metal organic framework (Pd / Pb-MOF) is [Pb4(C42H28N8O8Pd)(C2O4)Br4]n, wherein n is a nonzero natural number. The Pd / Pb-based bi-metal organic framework (Pd / Pb-MOF) is used as a catalyst to be applied to catalyzing benzyne homocoupling and catalyzing three-component coupling reaction of benzyne, boracic acid and allyl halohydrocarbon. The MOF catalyst with active sites can be used for replacing some heavy metals to achieve a catalytic effect, so that the harm of the heavy metals to the environment is reduced. The MOF catalyst with the active sites is used for catalysis, so that heterocatalysis is realized; additionally, the bi-metal organic framework catalyst can be recycled for more than four times, and the catalyst is easy to recycle, so that the utilization rate of the catalyst is increased, and the cost is reduced.

Owner:SHANDONG NORMAL UNIV

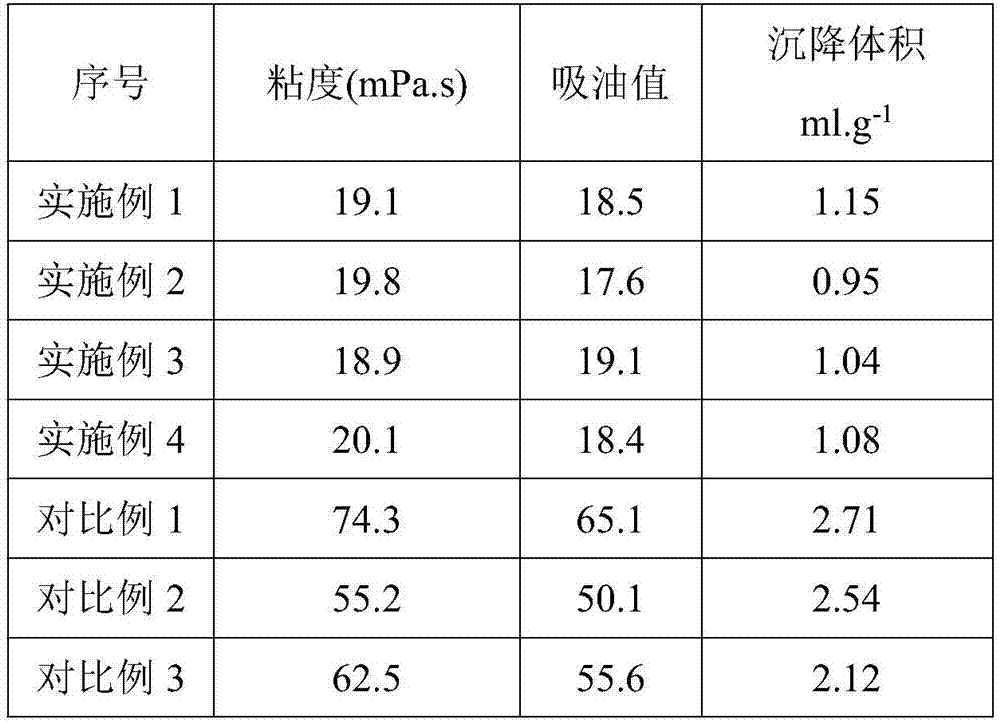

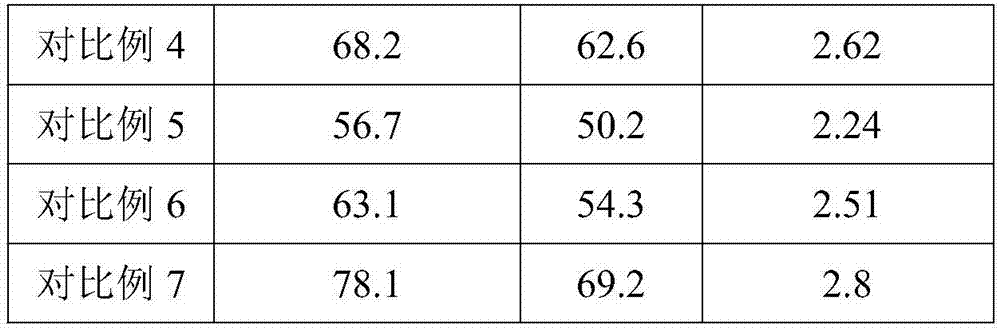

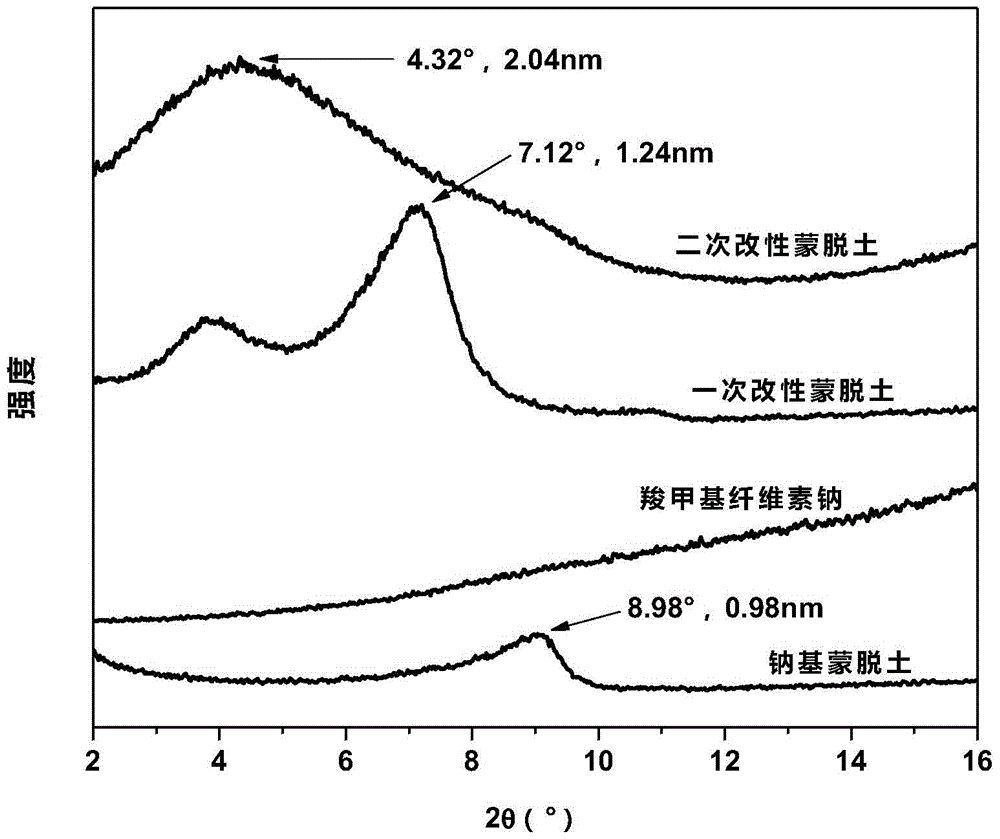

Preparation method of sodium carboxymethylcellulose intercalated modified montmorillonite

ActiveCN105733315AOpen efficientlyGood compatibilityPigment treatment with macromolecular organic compoundsFiltrationIon exchange

The invention relates to a preparation method of sodium carboxymethylcellulose intercalated modified montmorillonite, belonging to the technical field of nano materials. The preparation method comprises the following steps: 1) firstly adding 0.1-3.0CEC of inorganic salt to montmorillonite suspension to carry out ion exchange reaction; removing a solvent in the product through centrifugation, filtration or rotary evaporation, washing the product many times with deionized water and ethanol and drying, grinding and sieving the product, thus preparing primary modified montmorillonite; 2) adding 0.1-4.0CEC of anionic modifier sodium carboxymethylcellulose to suspension of primary modified montmorillonite; removing the solvent in the product through centrifugation, filtration or rotary evaporation, washing the product many times with deionized water and ethanol and drying, grinding and sieving the product, thus preparing secondary modified montmorillonite. The preparation method has the beneficial effects that the preparation method is easy and convenient to operate and is low in cost; the interlamellar spacing of montmorillonite can be effectively opened; prepared secondary modified montmorillonite not only has the catalytic performance but also can conduce to improving the thermal stability and flame retardance of a polymer.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for treating water through Fenton oxidation of activated molecular oxygen by utilizing ultrasonic catalysis

InactiveCN104386866AReduce investmentImprove reaction efficiencyWater/sewage treatment with mechanical oscillationsTreatment involving filtrationActivated charcoal powderPtru catalyst

The invention relates to a method for treating water through Fenton oxidation of activated molecular oxygen by utilizing ultrasonic catalysis. The method comprises the following specific steps: (1) adding activated carbon powder into waste water, wherein the addition amount of the activated carbon powder is 0.7 weight percent of the weight of the waste water; (2) after the activated carbon powder adsorbs impurities, filtering the waste water, and then injecting the waste water into an ultrasonic reactor; (3) performing ultrasonic crushing reaction, wherein the sound energy density of an ultrasonic wave is 0.2 w / m<3>; (4) after the reaction is performed for 30 minutes, adding transition metal ions, transition metal or a transition metal oxide catalyst into the ultrasonic reactor, introducing air or oxygen, catalyzing the activated molecular oxygen at room temperature to generate a hydroxyl free radical, adjusting the PH value to be 4, and performing stirring; (5) after the stirring is performed for 2 hours, performing sedimentation and solid-liquid separation after the reaction is completed so as to treat the waste water. Sewage is purified by adding the transition metal ions, the transition metal or the transition metal oxide catalyst into the Fenton oxidation under an ultrasonic environment. The method has the advantages of wide oxygen source, low cost, high economy and high reaction rate.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

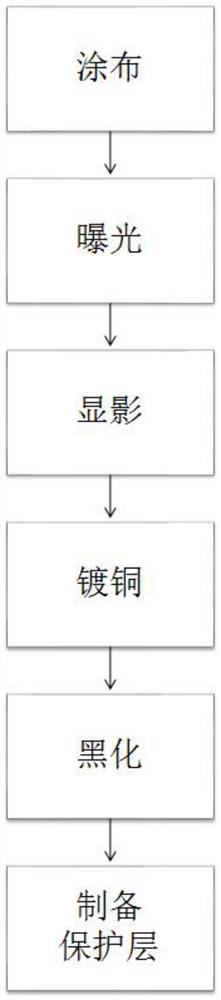

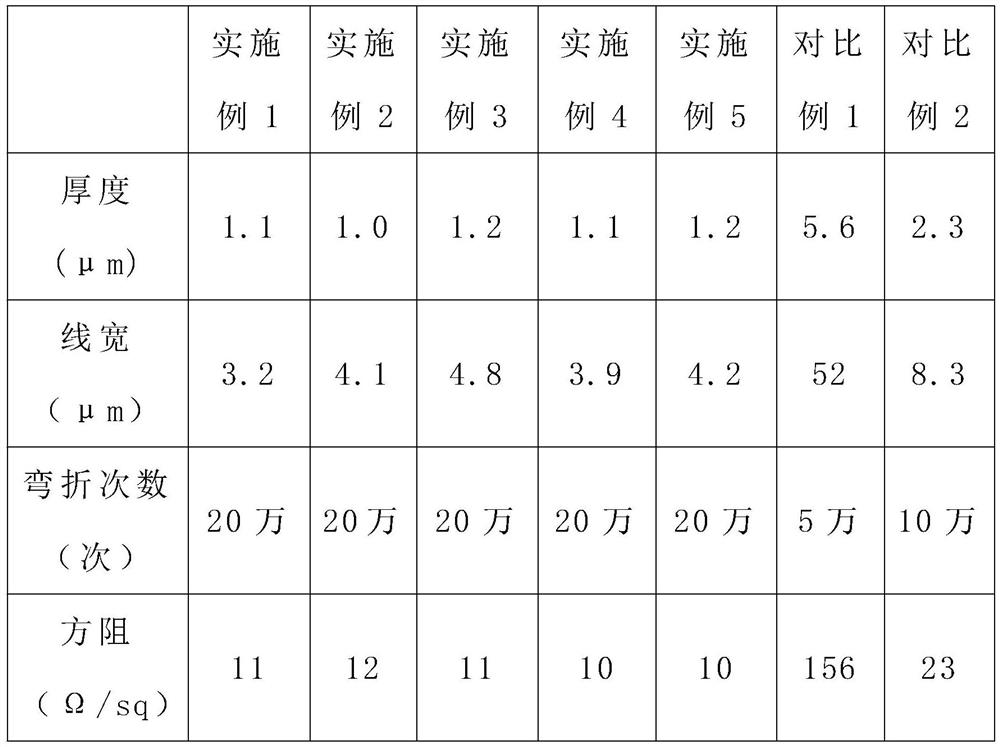

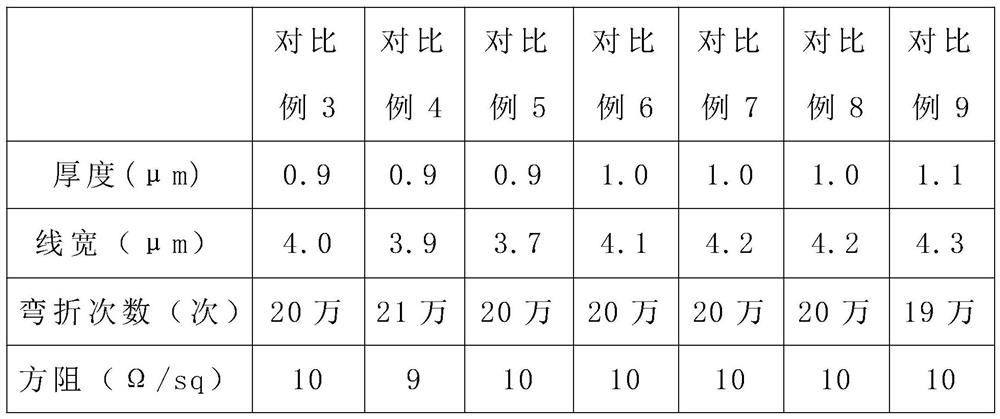

Double-sided metal grid flexible conductive film and manufacturing method thereof

ActiveCN111933329AAchieve protectionPlay a catalytic roleConductive layers on insulating-supportsCable/conductor manufactureMetal gridPhotoresist

The invention discloses a double-sided metal grid flexible conductive film and a manufacturing method thereof. The double-sided metal grid flexible conductive film comprises a base material, metal grids and a protective layer, wherein the metal grids are arranged on the upper side and the lower side of the base material, and the protective layer is arranged on the side, which deviates from the base material, of each metal grid. According to the manufacturing method of the conductive film, firstly a photoresist layer and a catalyst layer are exposed and developed to form a circuit pattern, thenmetal plating and blackening are carried out, only the photoresist needs to be etched, the required exposure energy is relatively low, the circuit pattern is clearer and more accurate, the distance between two adjacent parallel metal wires is reduced, and the touch sensitivity of the conductive film is improved. According to the manufacturing method, the thicknesses of the photoresist layer, thecatalyst layer, the metal layer, the blackening layer and the protective layer are limited, the overall thickness of the conductive film is reduced, the finished product is light and thin, flexible expression of the conductive film is more convenient, the needed photoresist amount is smaller, the processing technology is simple, the cost is lower, and the manufacturing method is suitable for wideapplication and popularization.

Owner:江苏软讯科技有限公司

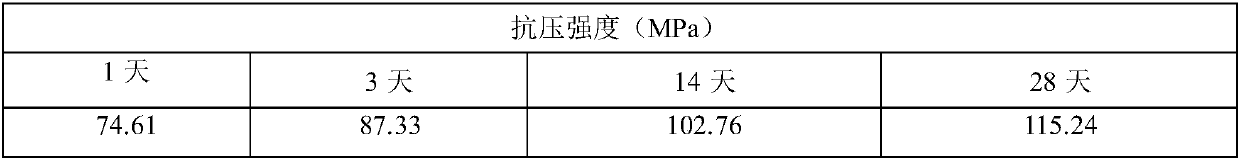

Method for using steel slags to prepare lightweight carbonized building material

The invention provides a method for using steel slags to prepare a lightweight carbonized building material, and belongs to the technical field of comprehensive utilization of resources. The method comprises the steps that firstly, 45-100% of the steel slags, 0-30% of desulphurization gypsum and 0-50% of lightweight aggregates are mixed and prepared into a solid mixture, then, a water reducing agent accounting for 0-0.9% of the total mass of the mixture and water accounting for 15-40% of the dry basis mass of the solid mixture are added to the solid mixture and stirred evenly, and the stirredmixture is poured into a die for casting; the mixture is subjected to constant-temperature constant-humidity curing in a concrete standard curing box, after shaping and die removal, curing is conducted in a carbonization chamber, and thus the steel slag carbonated building material is obtained. By the adoption of the method, the difficulty of low comprehensive utilization rate of the steel slags is overcome, the density of the building material is greatly lowered due to admixture of the lightweight aggregates, and the building material absorbs carbon dioxide in industrial waste gas, can also mitigate the greenhouse effect to a certain degree, and has certain economic benefits, environmental benefits and social benefits. The prepared building material has excellent early strength and stability.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com