Patents

Literature

1101 results about "Cathode catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

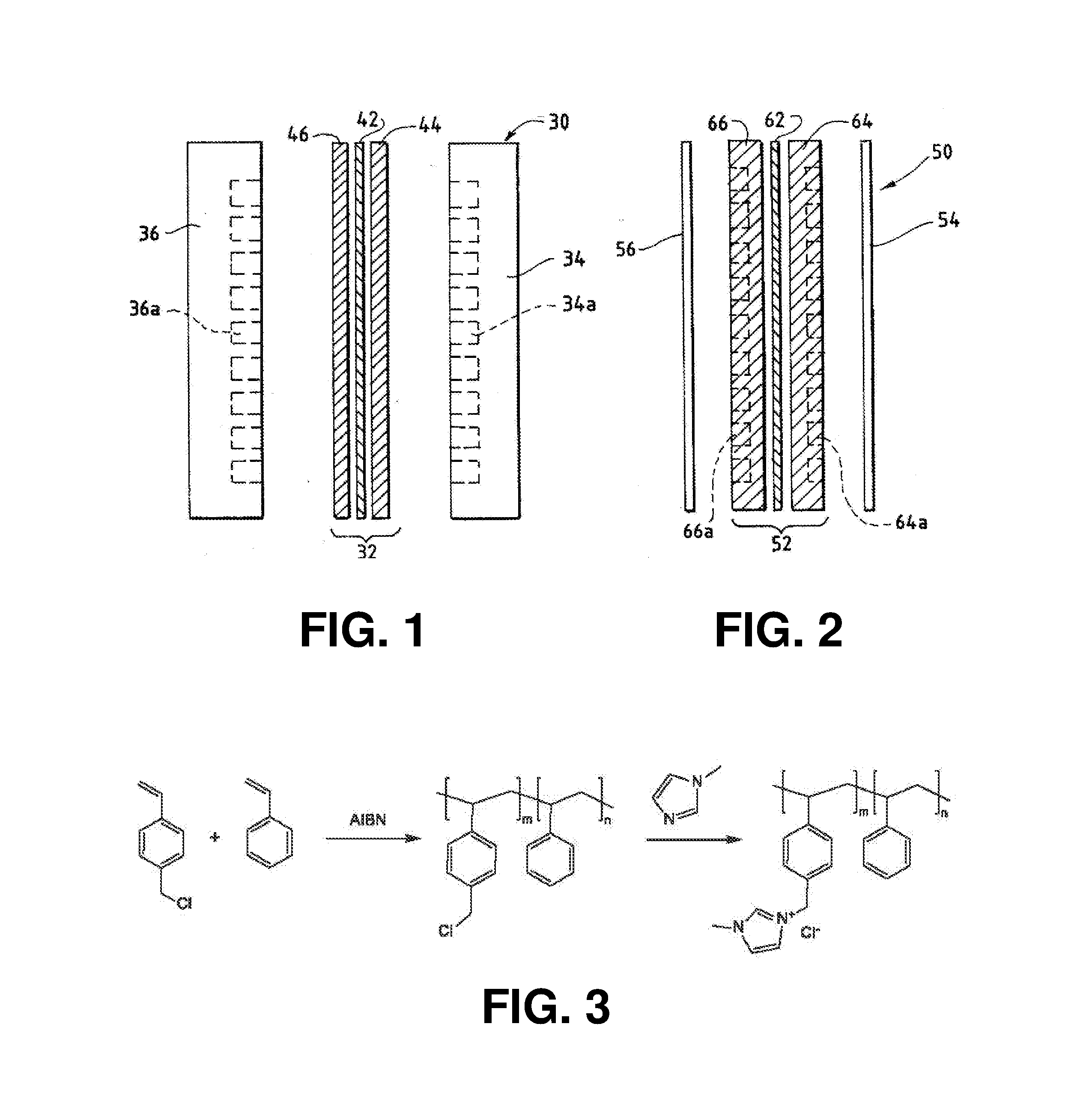

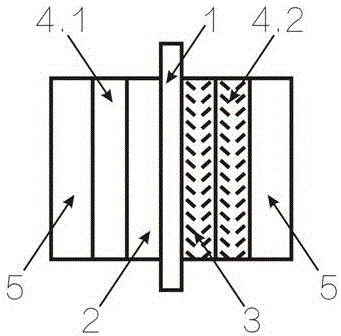

Method And System For Electrochemical Production Of Formic Acid From Carbon Dioxide

An electrochemical device converts carbon dioxide to a formic acid reaction product. The device includes an anode and a cathode, each comprising a quantity of catalyst. The anode and cathode each have reactant introduced thereto. Two membranes, a cation exchange polymer electrolyte membrane and an anion exchange polymer electrolyte membrane, are interposed between the anode and the cathode, forming a central flow compartment where a carbon dioxide reduction product, such as formic acid, can be recovered. At least a portion of the cathode catalyst is directly exposed to gaseous carbon dioxide during electrolysis. The average current density at the membrane is at least 20 mA / cm2, measured as the area of the cathode gas diffusion layer that is covered by catalyst, and formate ion selectivity is at least 50% at a cell potential difference of 3.0 V. In some embodiments, at least one polymer electrolyte membrane comprises a polymer in which a constituent monomer is (p-vinylbenzyl)-R, where R is selected from the group consisting of imidazoliums, pyridiniums and phosphoniums. In some embodiments, the polymer electrolyte membrane is a Helper Membrane comprising a polymer containing an imidazolium ligand, a pyridinium ligand, or a phosphonium ligand.

Owner:DIOXIDE MATERIALS

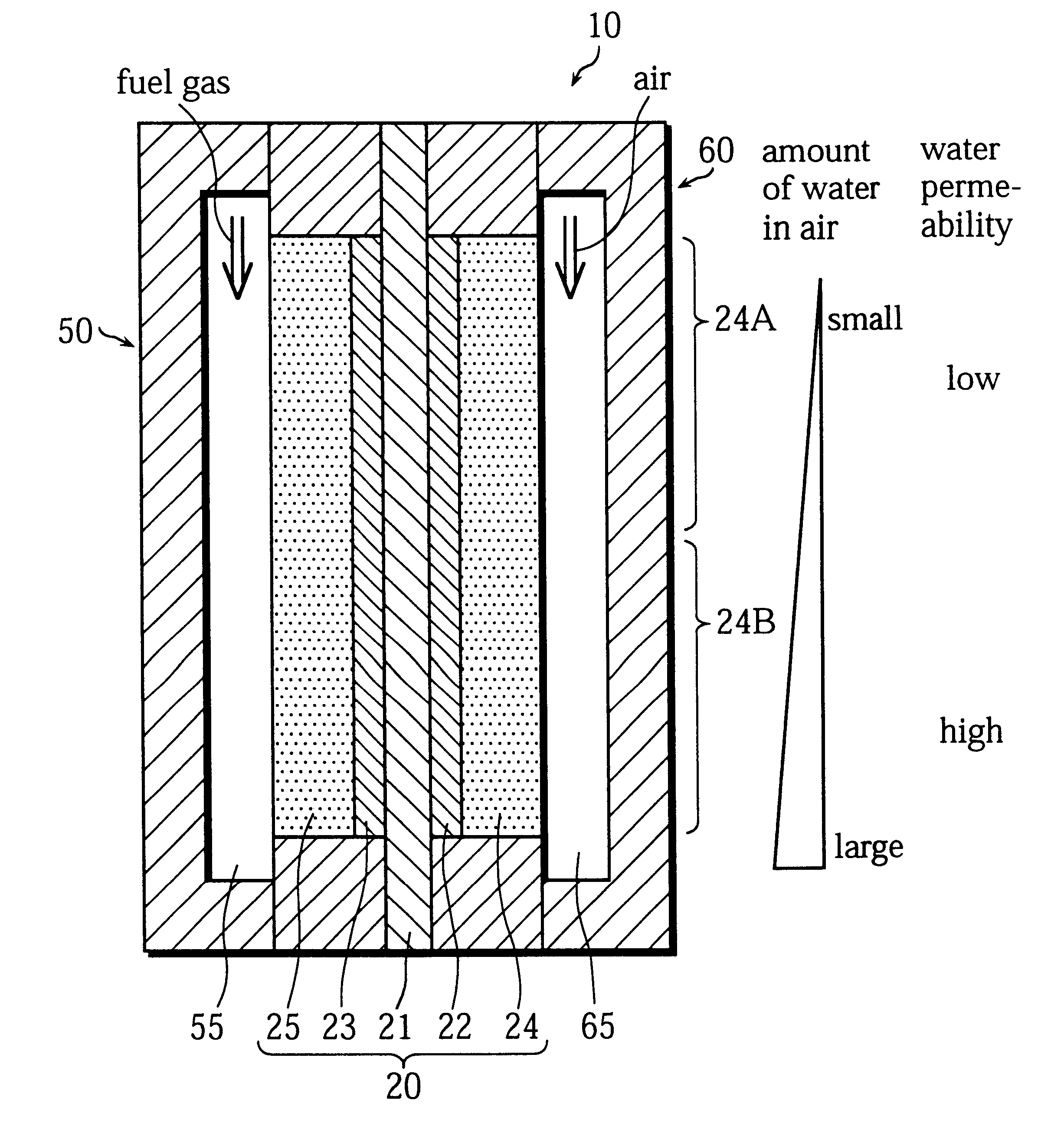

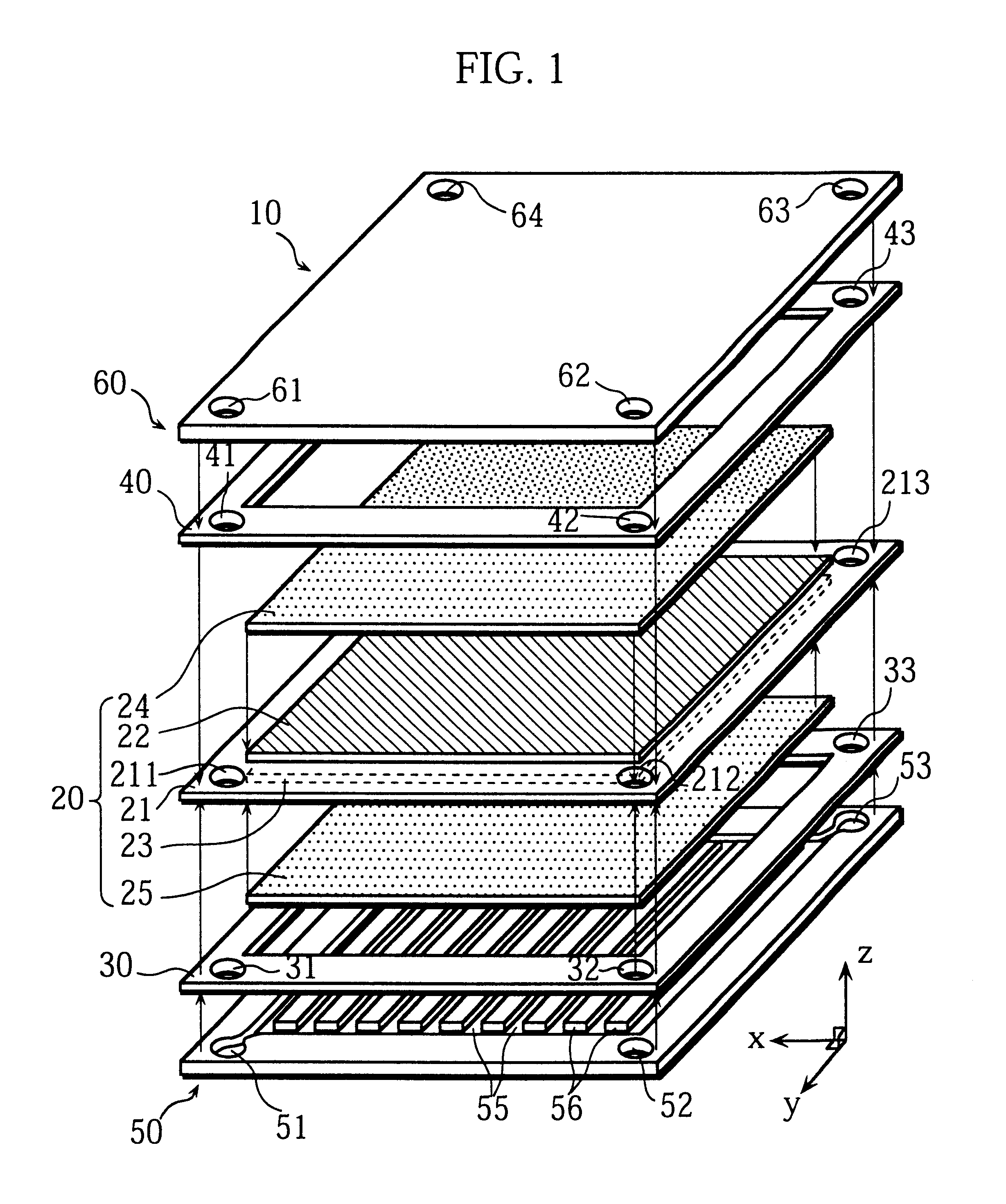

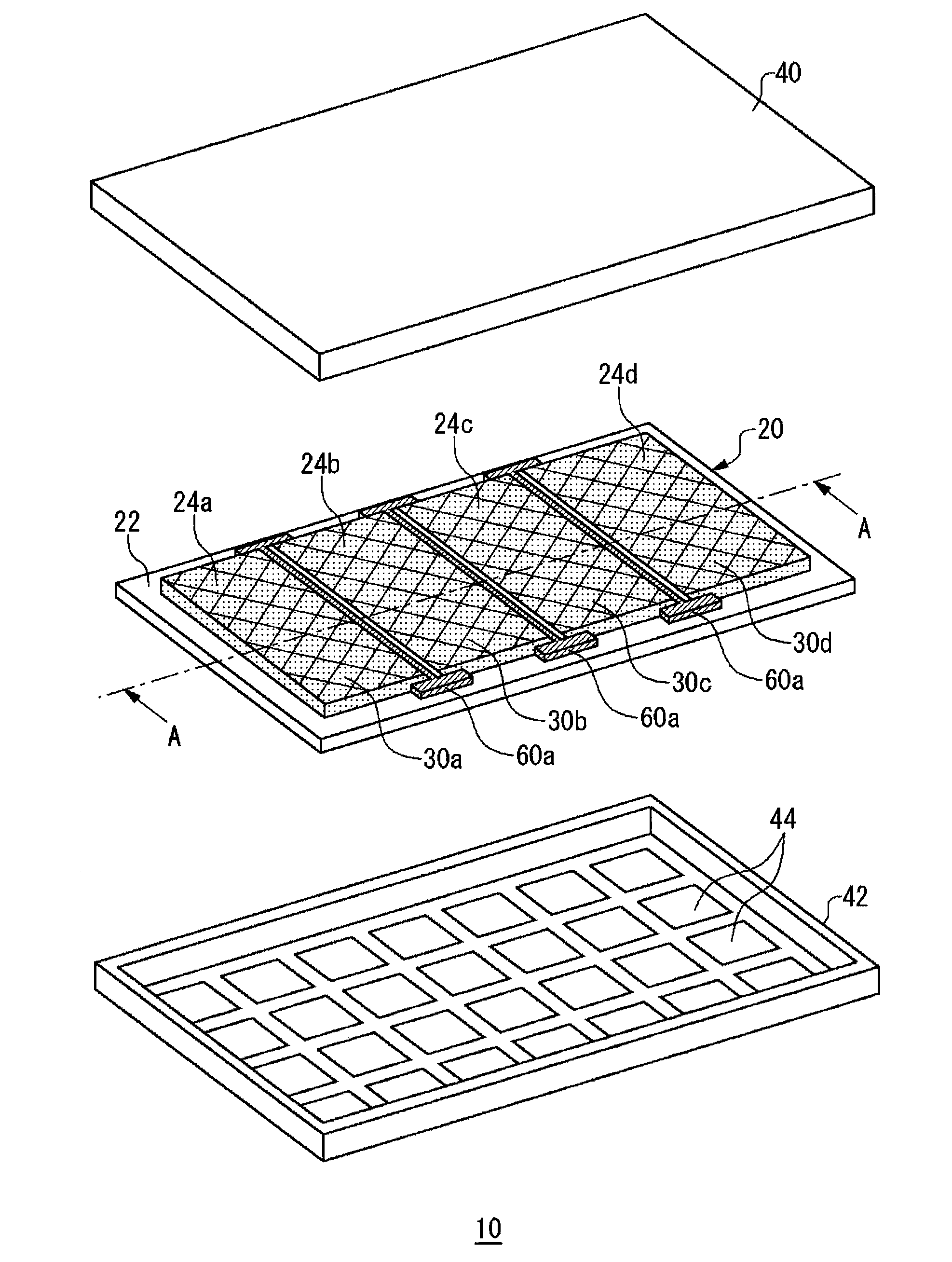

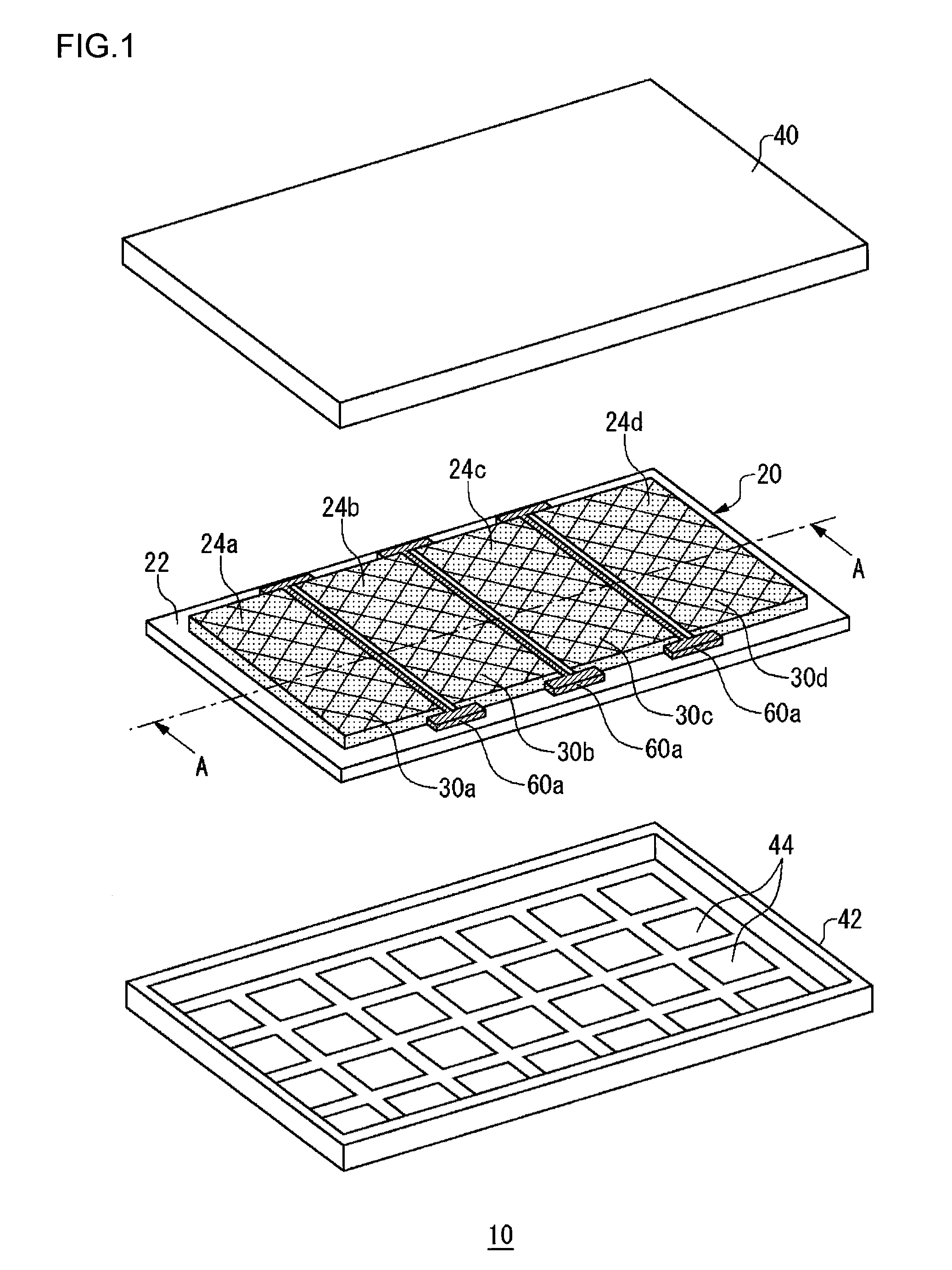

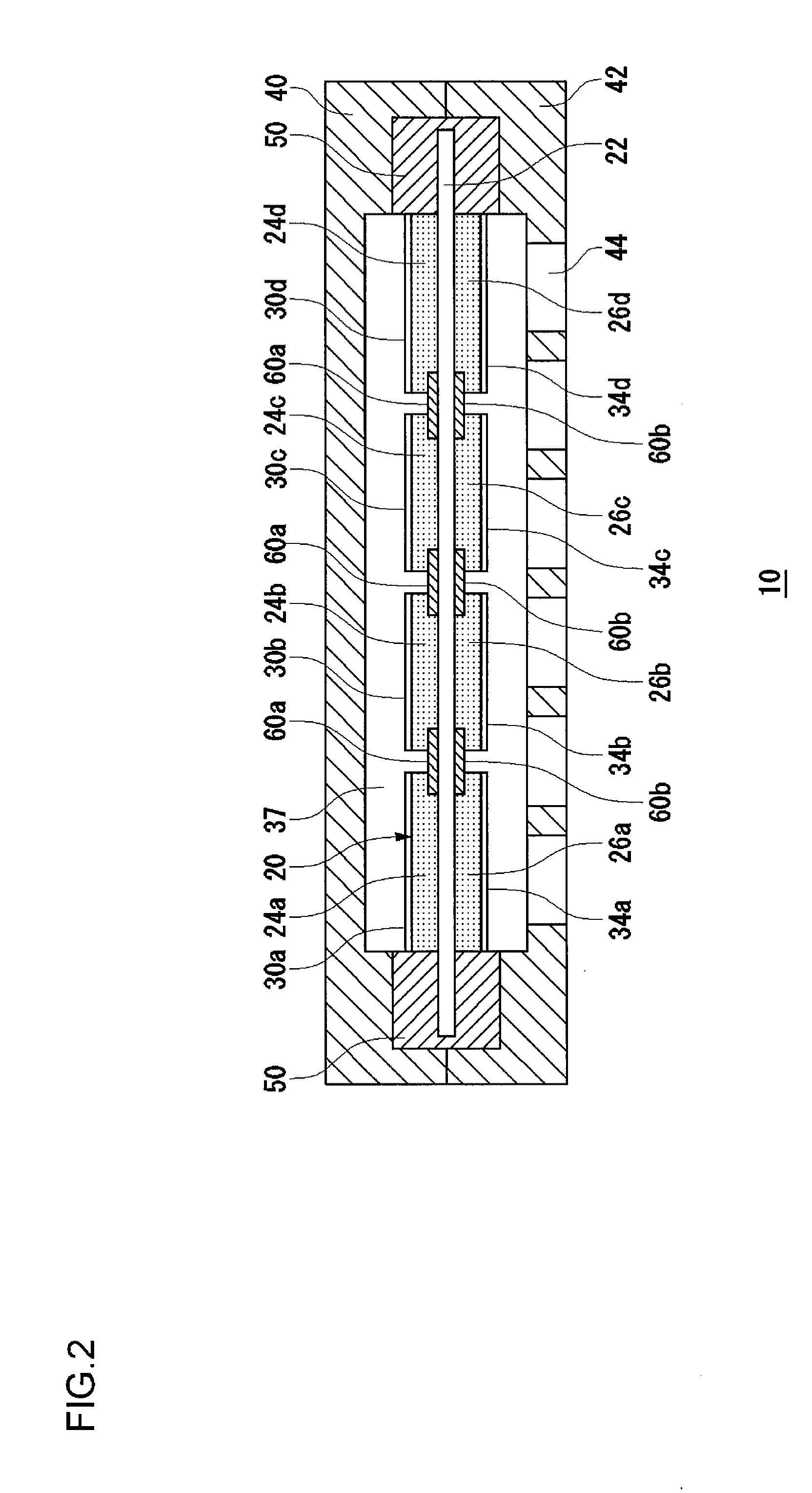

Fuel cell having water permeability adjustment capability

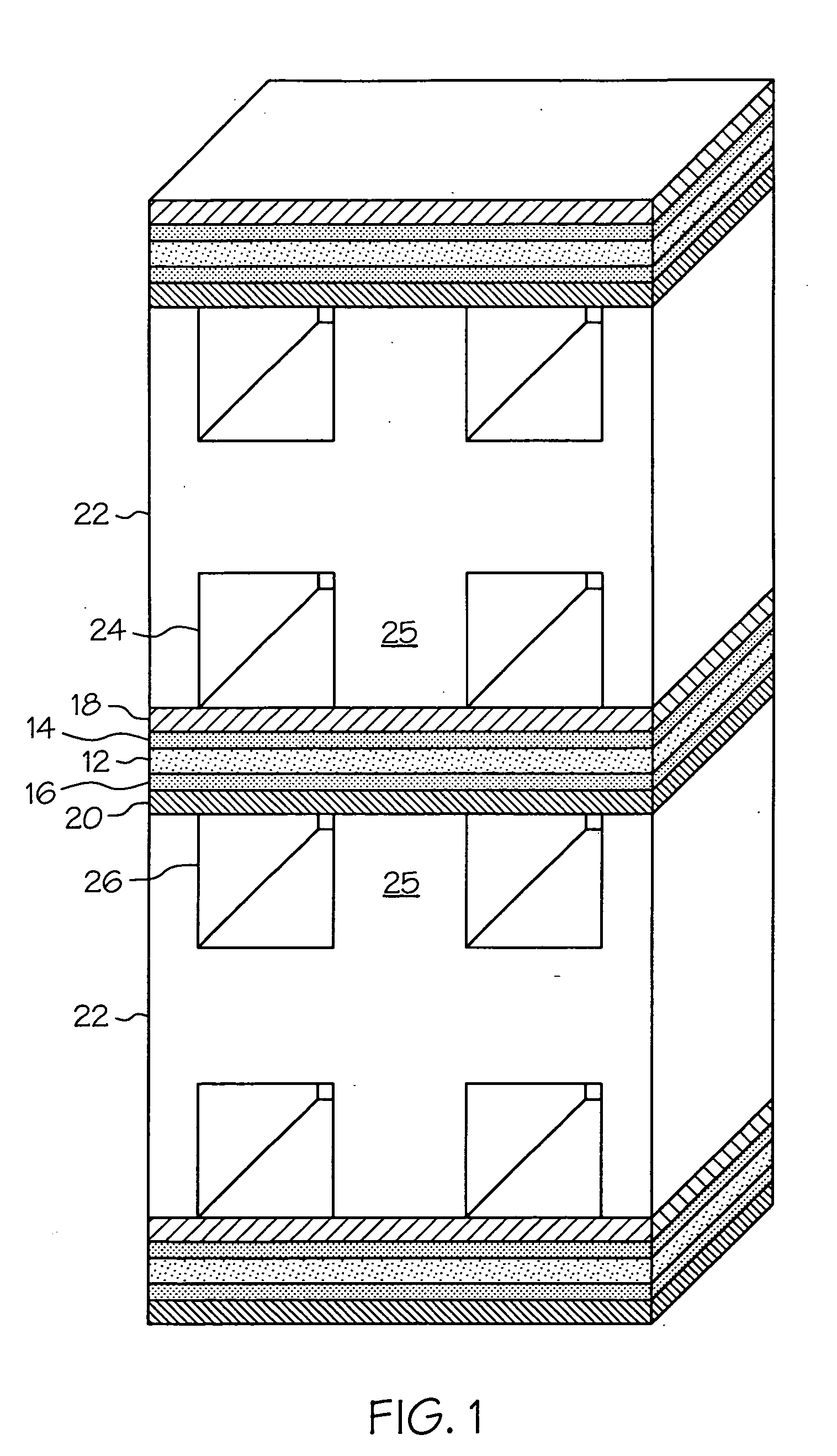

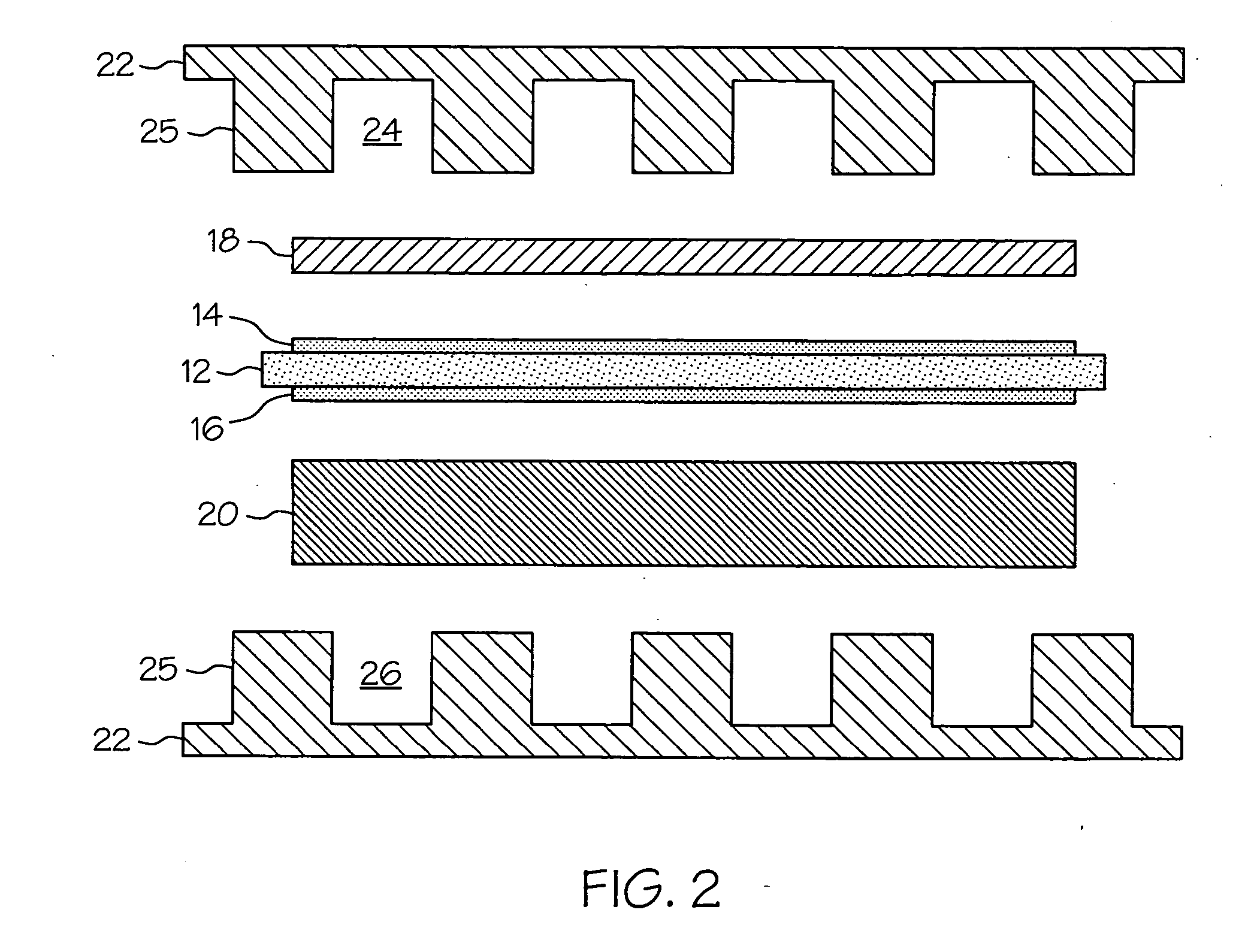

The object of the present invention is to provide fuel cell including a cell that is formed by sandwiching solid polymer membrane between an anode and a cathode that generates electricity with stability and high performance by evenly moistening the solid polymer membrane. For this purpose, in a gas diffusion layer 24, which is positioned adjacent to a cathode catalyst layer 22, the content of fluororesin in an area on the side of the entrance for the oxidizer is set to be higher than in another area on the side of the exit so that the water repellency in the entrance side area is higher than in the exit side area. As a result, a water permeation suppressing part 24A, where the water permeability is relatively low, is formed in the area on the entrance side, while a water permeable part 24B, where the water permeability is relatively high, is formed in the area on the exit side.

Owner:SANYO ELECTRIC CO LTD

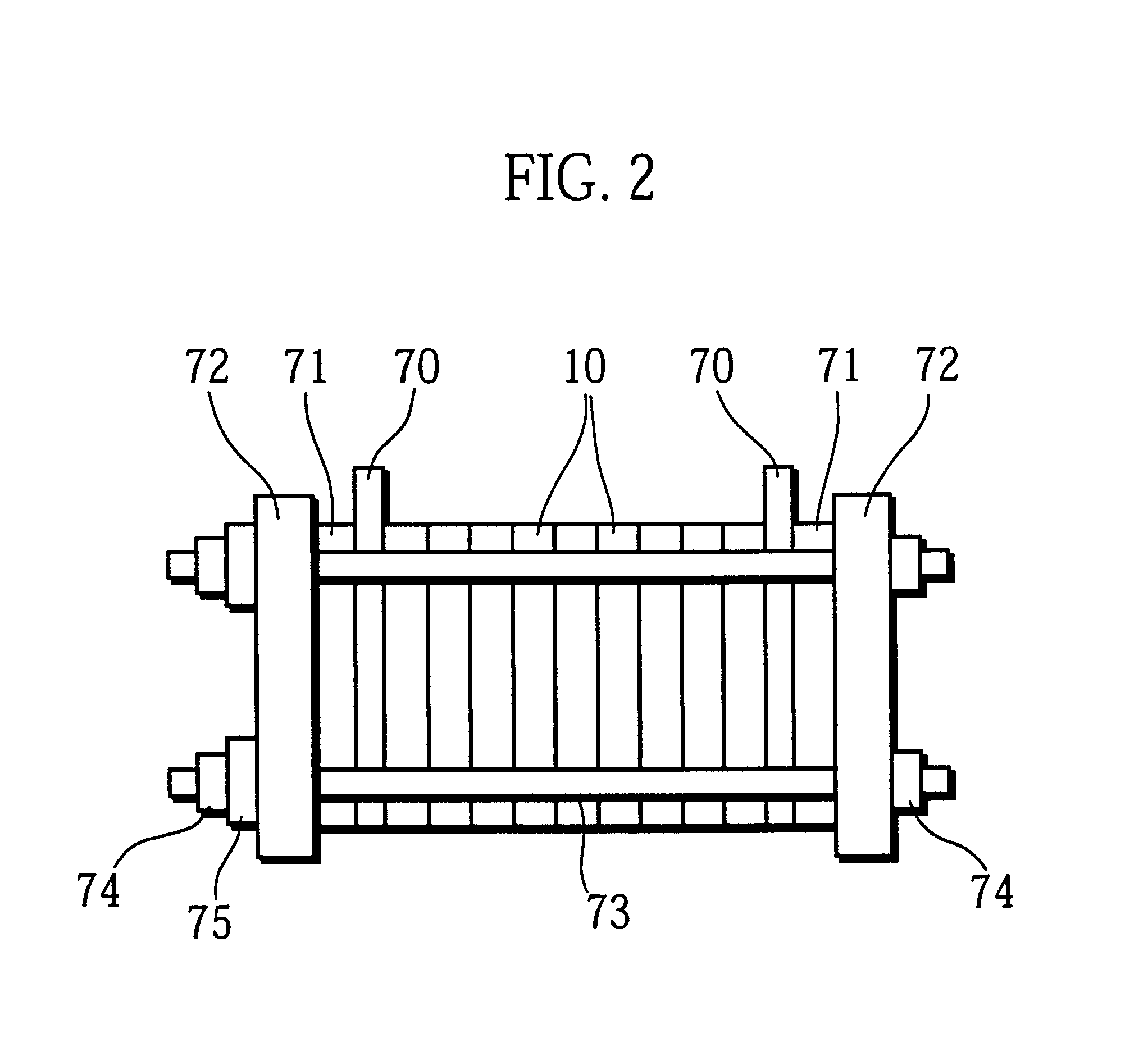

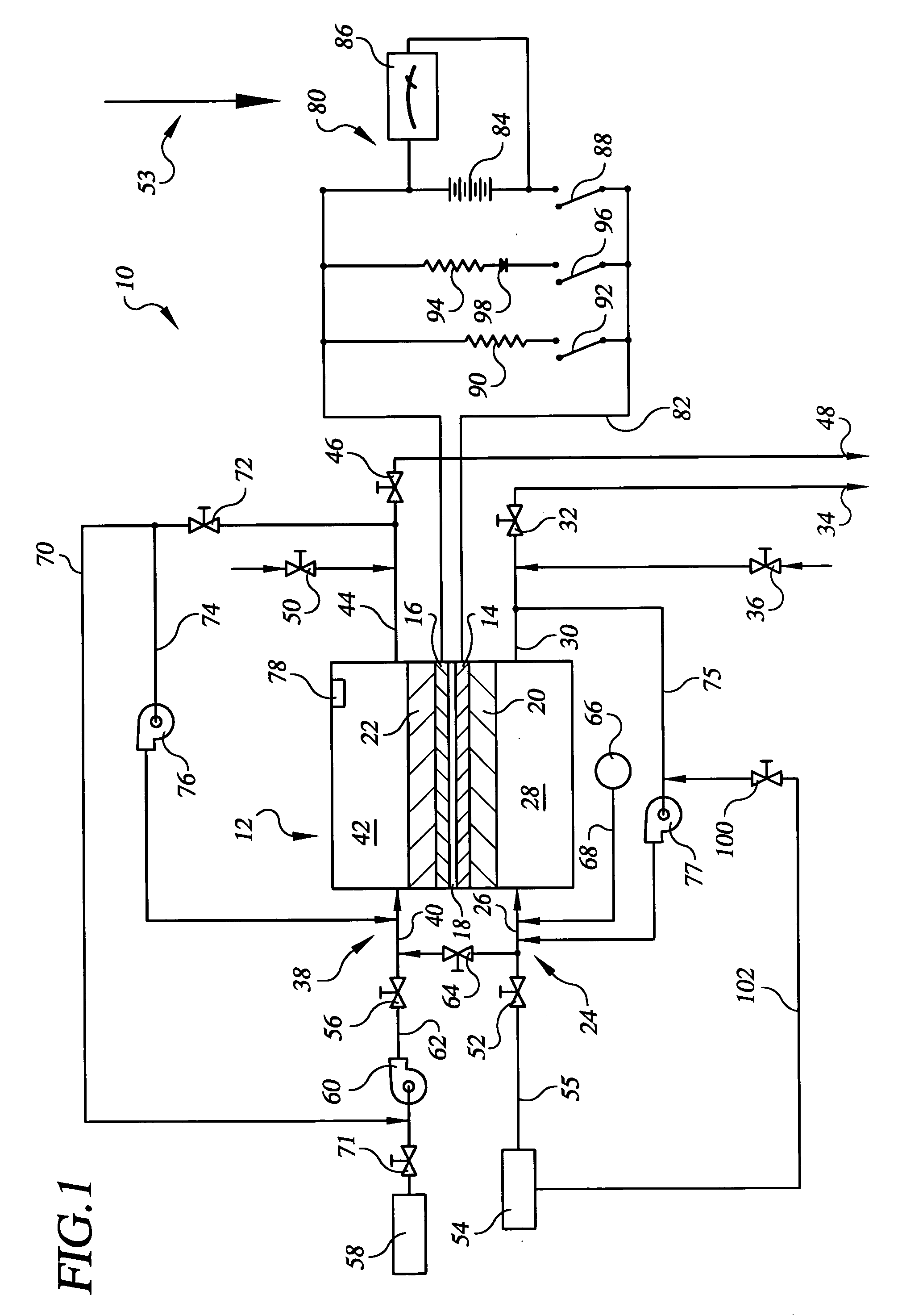

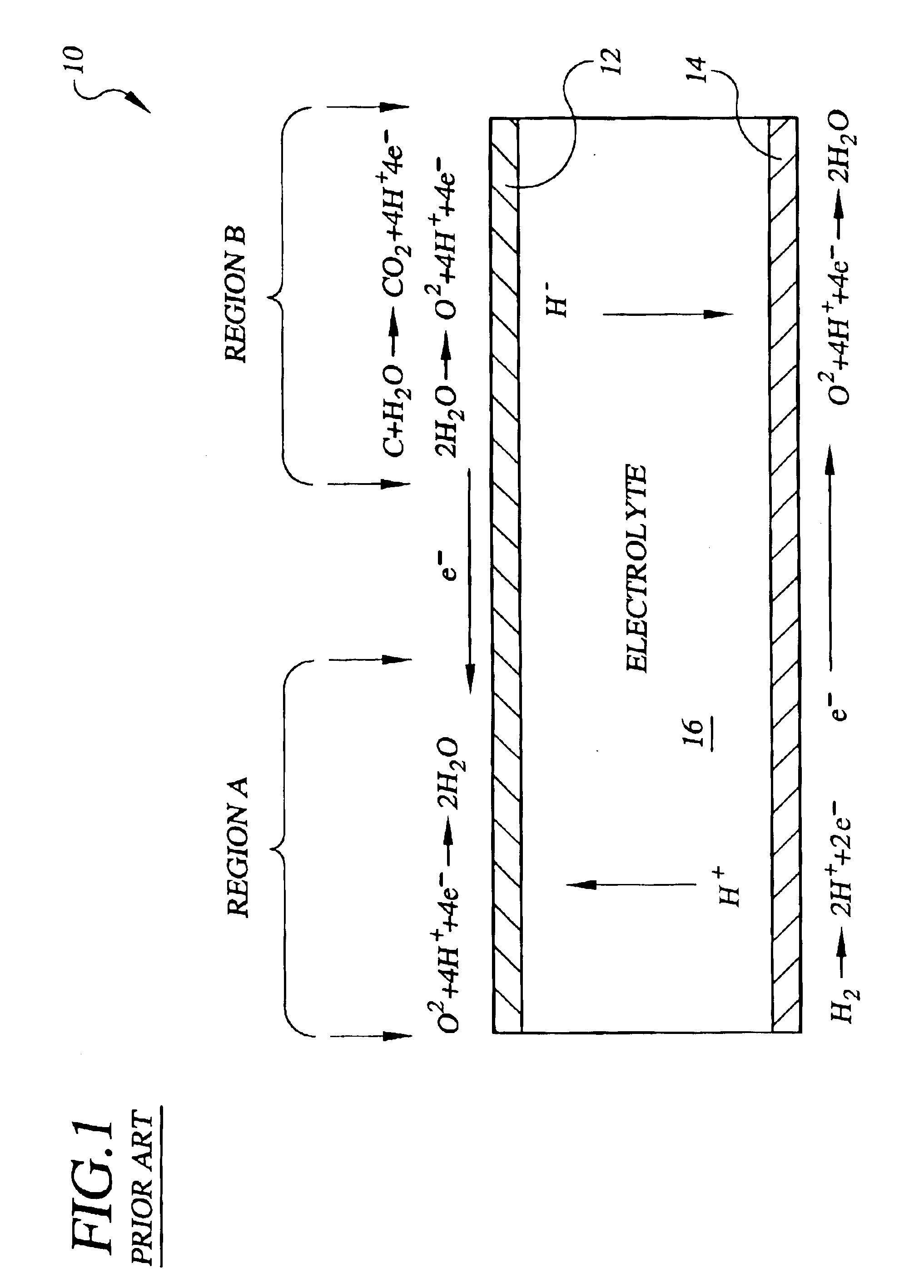

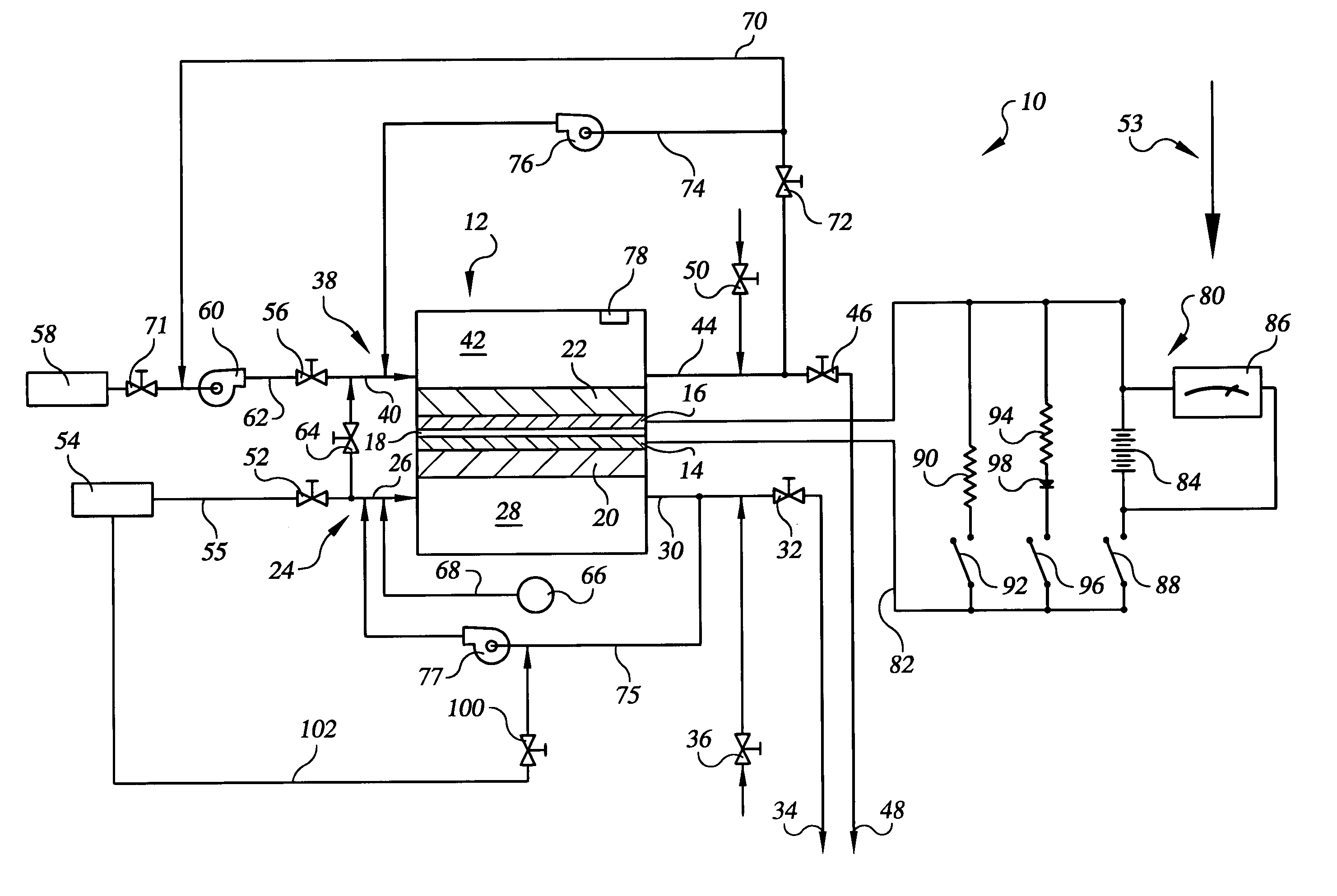

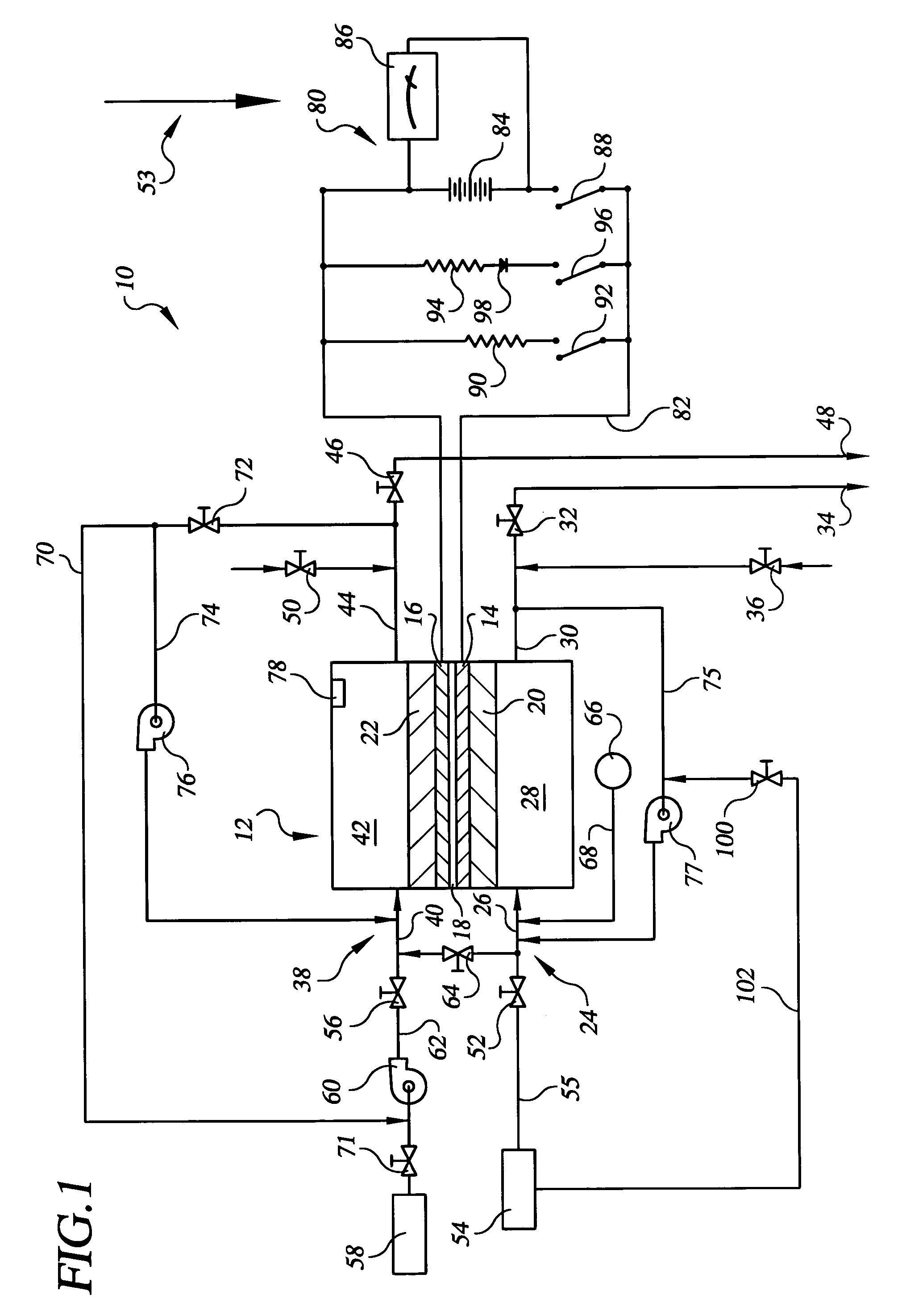

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS20050031917A1Move quicklyMinimize oxidation corrosionReactant parameters controlFuel cells groupingPower stationEngineering

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

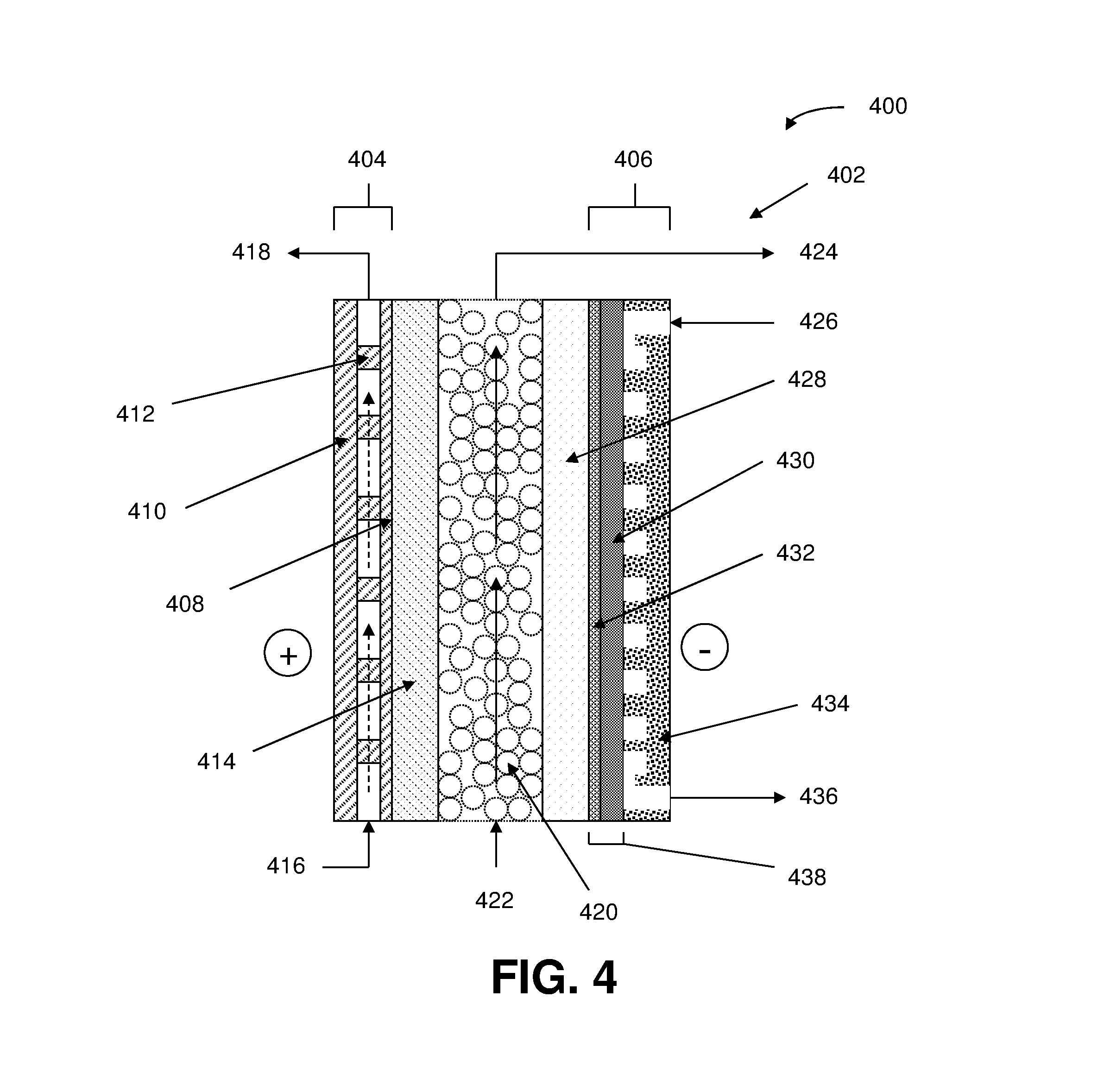

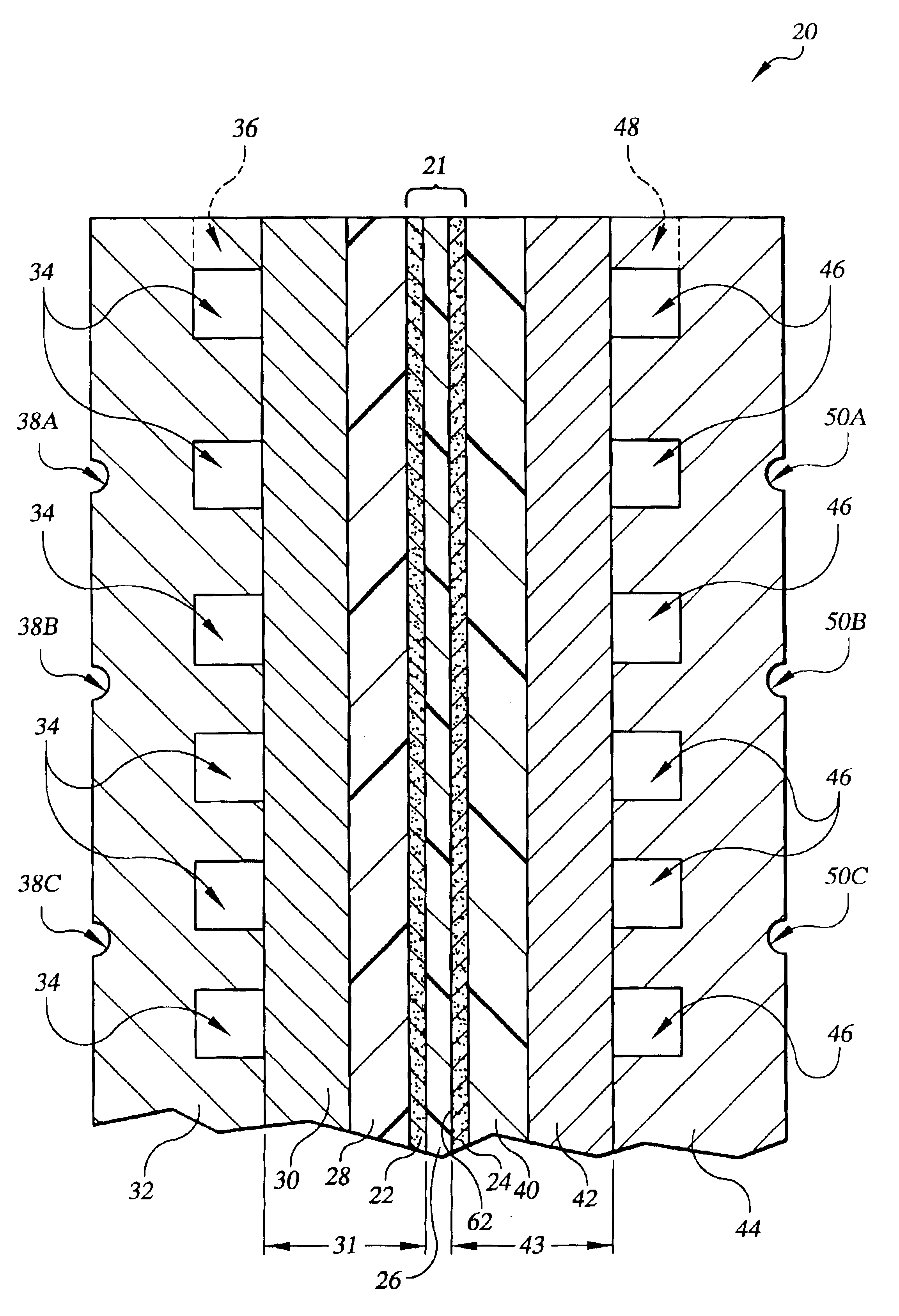

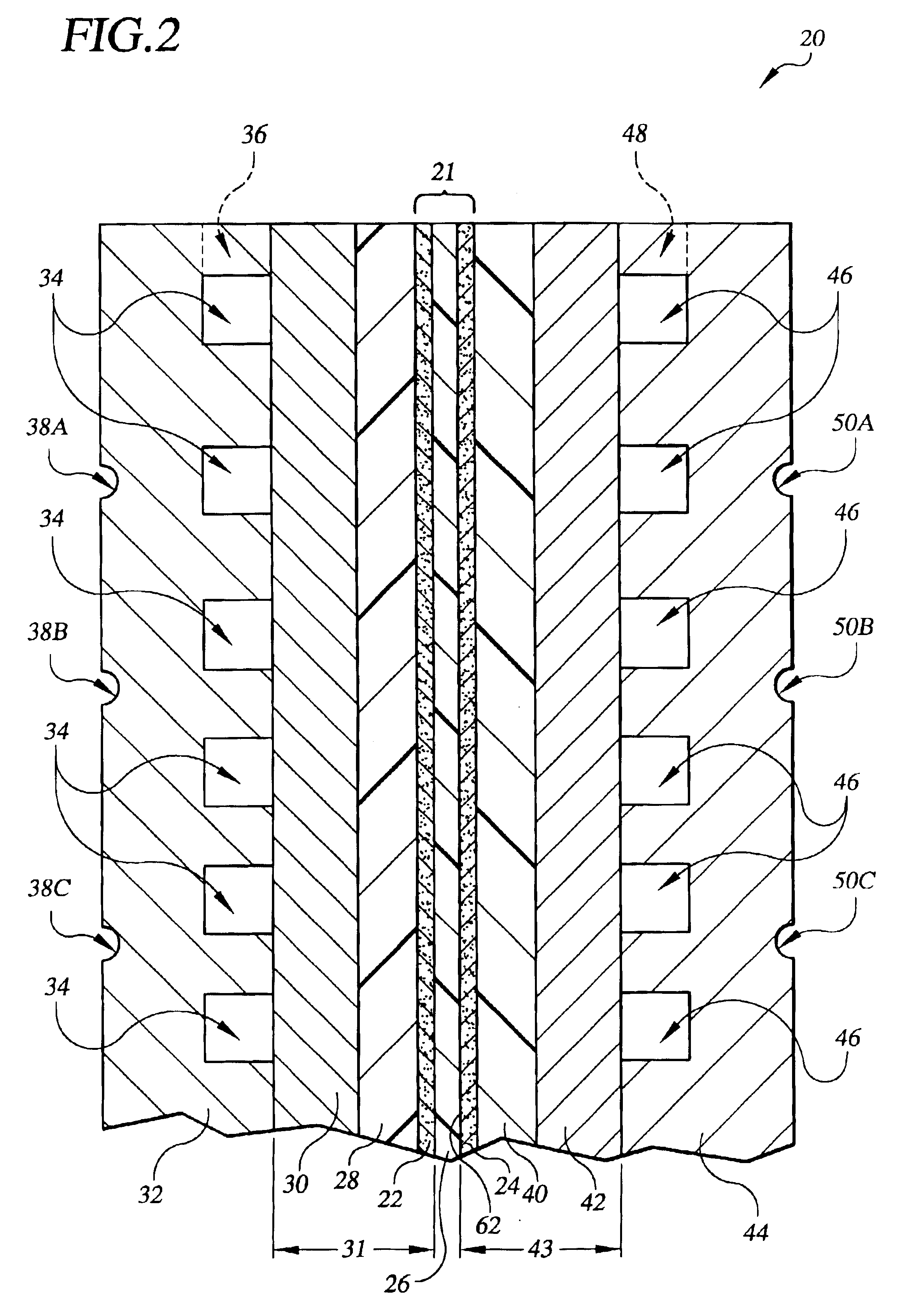

Fuel cell having a corrosion resistant and protected cathode catalyst layer

InactiveUS6855453B2Corrosion minimizationHigh areaActive material electrodesSolid electrolyte fuel cellsOver potentialOxygen evolution

The invention is a fuel cell (20) having a corrosion resistant and protected cathode catalyst layer (24). The cathode catalyst layer (24) includes a platinum oxygen reduction catalyst and an oxygen evolution catalyst selected from the group consisting of catalysts that are more active than platinum for oxygen evolution. The oxygen evolution catalyst may be uniformly applied within the cathode catalyst layer, or non-uniformly applied to identified high corrosion areas (82) (84) of the cathode catalyst layer (24). The cathode catalyst layer (24) may include heat-treated carbon support material, and / or a heat-treated carbon black within a diffusion layer (40) supporting the cathode catalyst layer (24). The fuel cell (20) may also include an anode catalyst layer (22) having a poor oxygen reduction catalyst having a greater oxygen reduction over potential than platinum.

Owner:AUDI AG

Hydrogen passivation shut down system for a fuel cell power plant

InactiveUS6984464B2Minimize oxidation corrosionRapid fuelReactant parameters controlFuel cells groupingPower stationEngineering

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

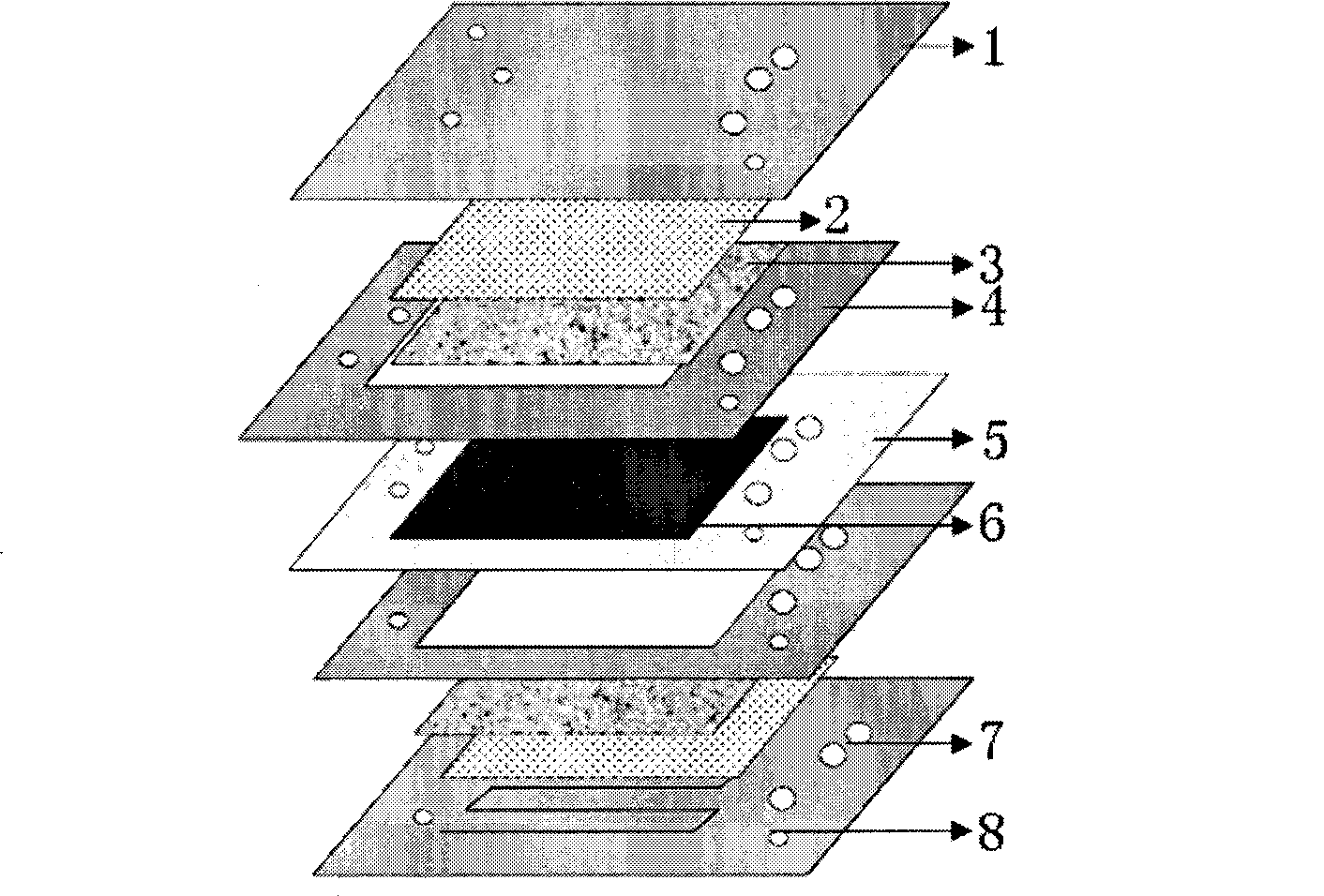

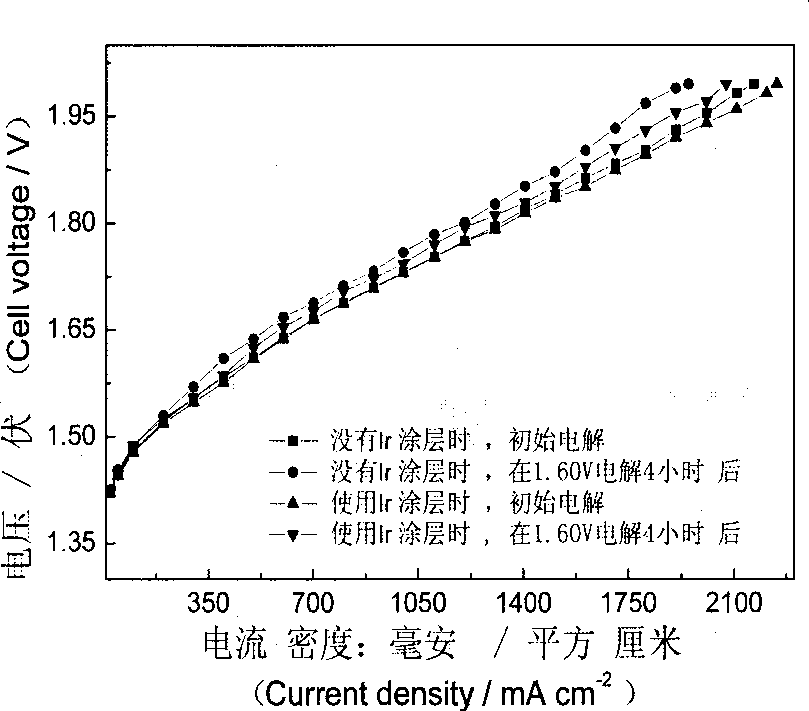

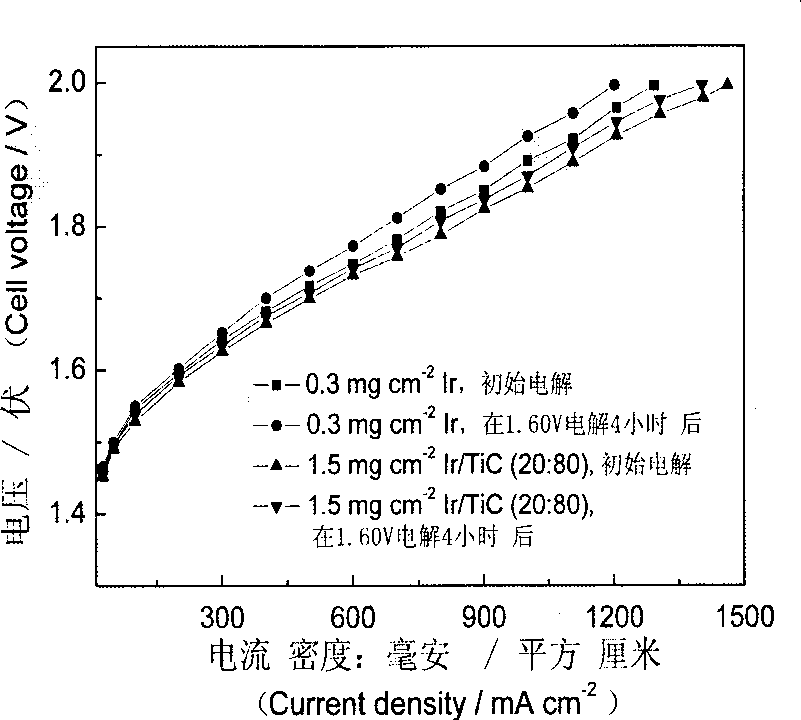

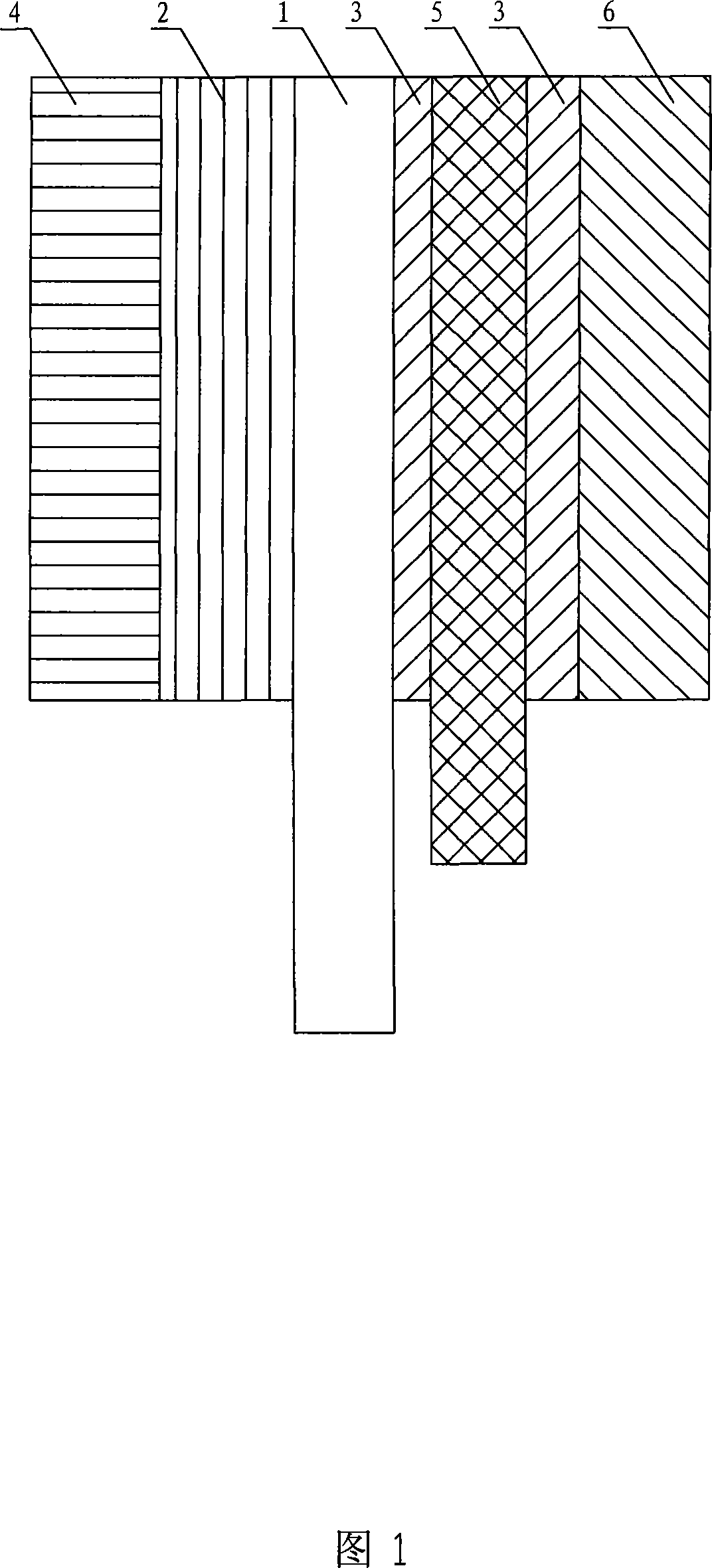

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

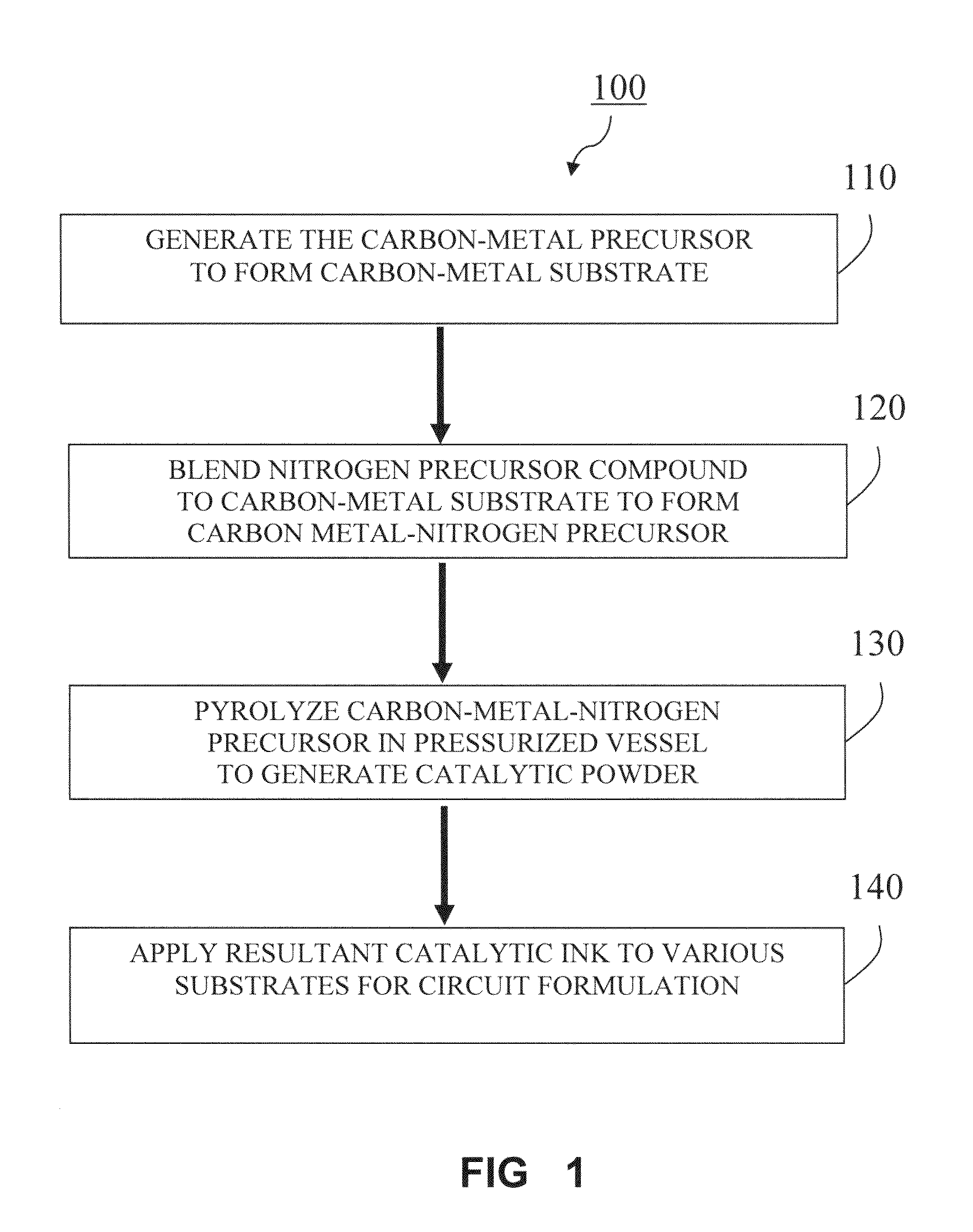

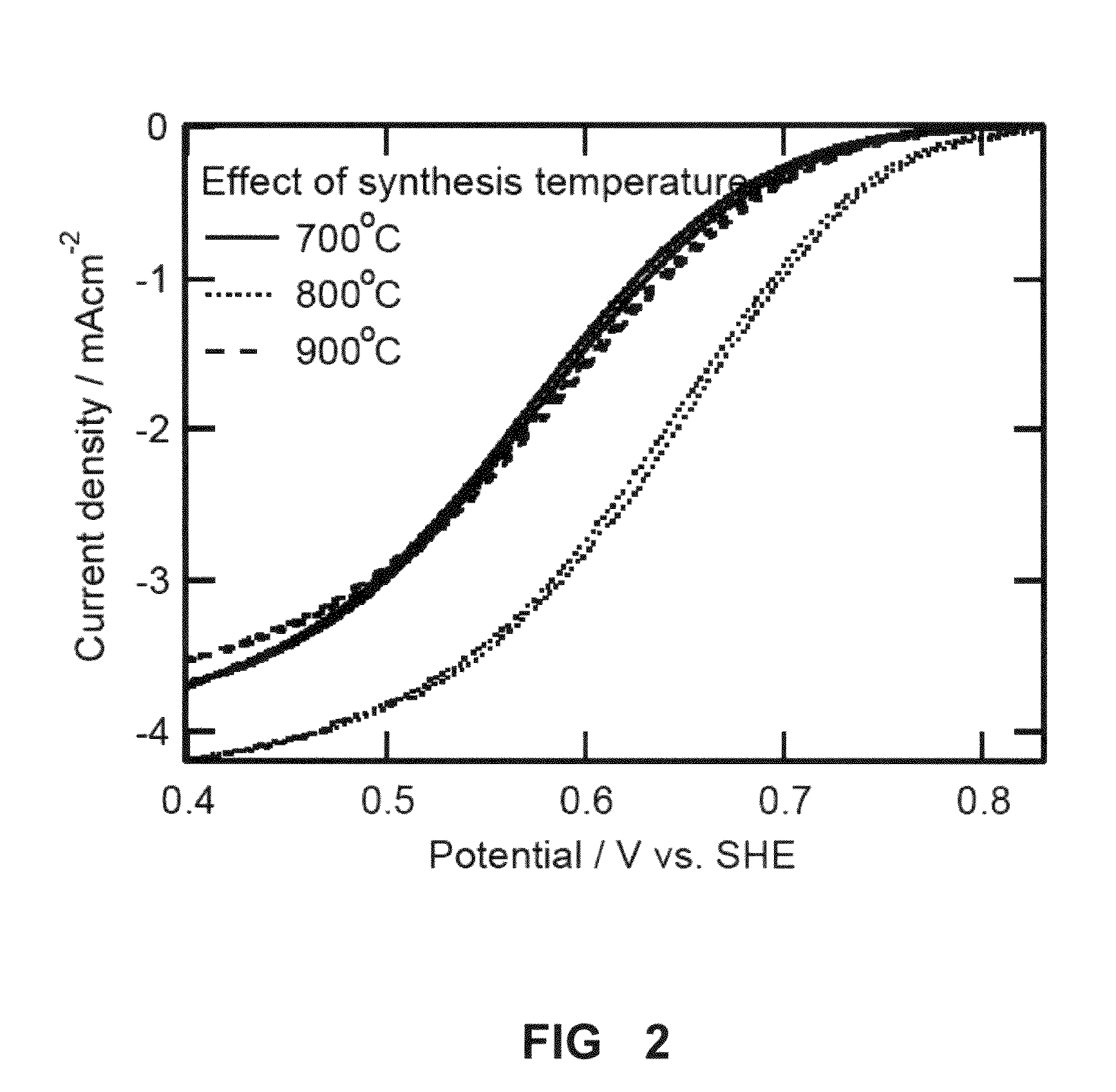

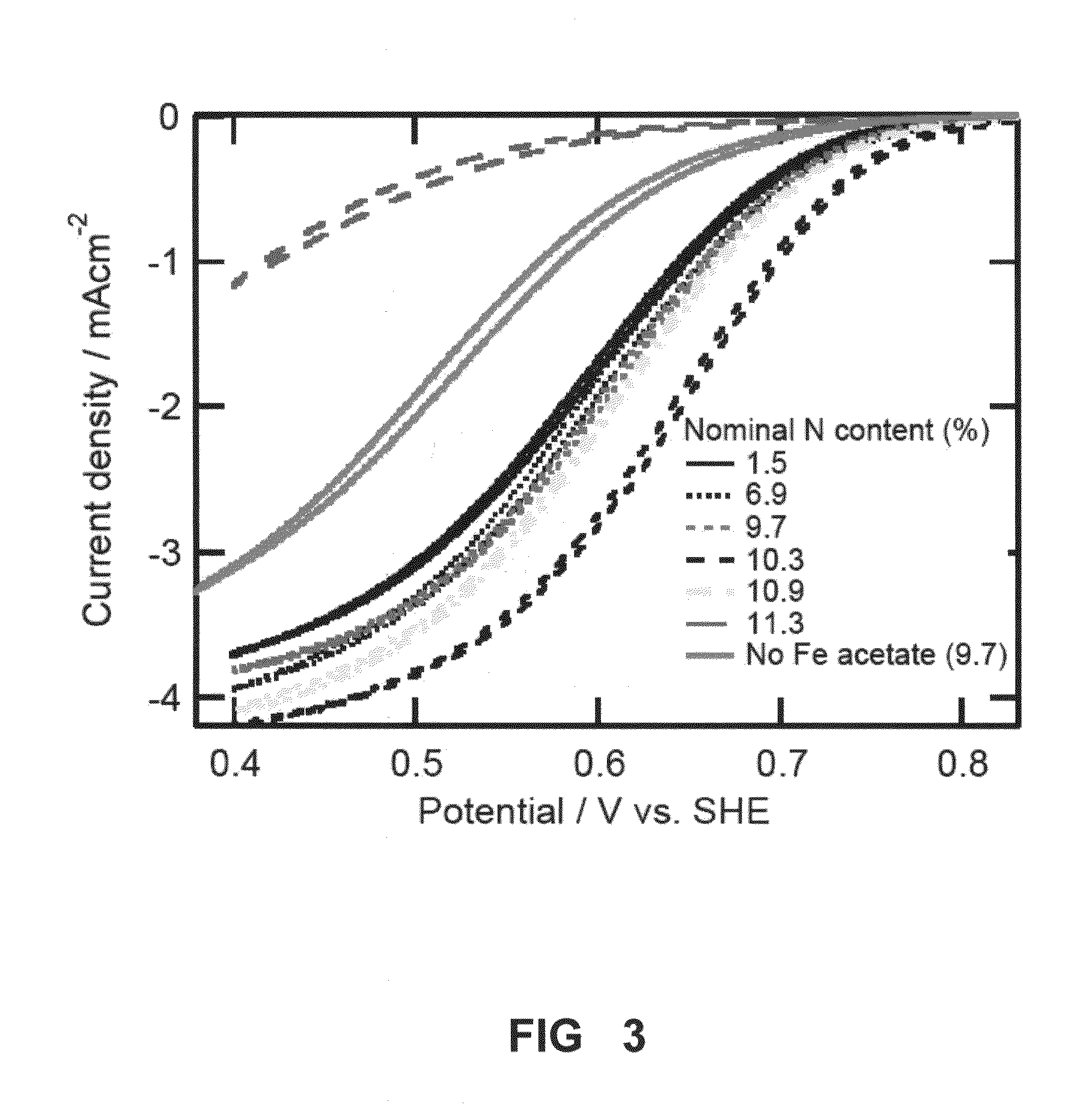

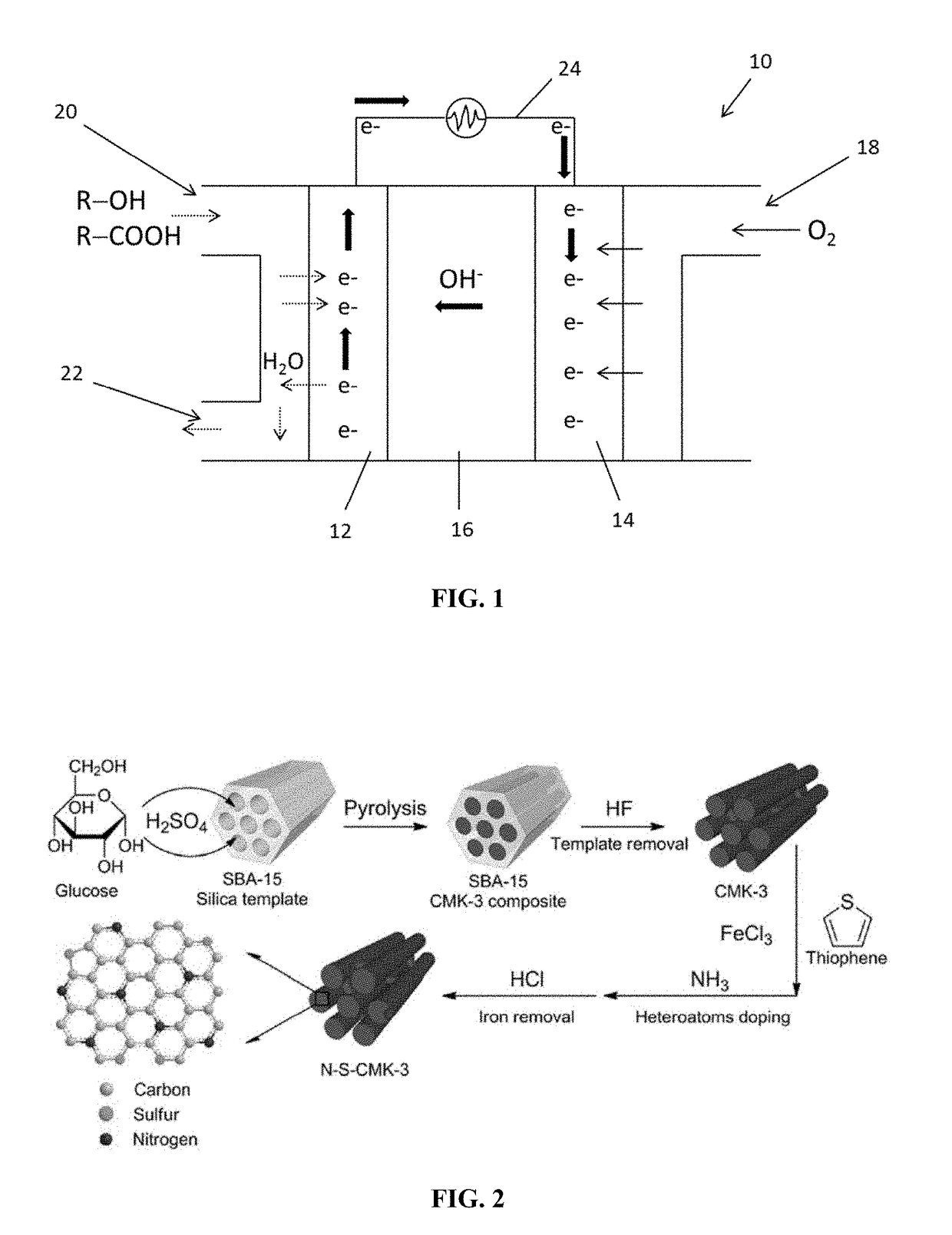

Novel catalyst for oxygen reduction reaction in fuel cells

InactiveUS20110287174A1High catalytic activityImprove usabilityFinal product manufactureCell electrodesFuel cellsNitrogen

A method for making a carbon-metal-nitrogen oxygen reducing cathode catalyst, the method comprising mixing a carbon source with a transition metal precursor to form a metal precursor loaded carbon substrate; adding a nitrogen precursor compound to the metal precursor loaded carbon substrate to form a carbon-metal-nitrogen precursor; and pyrolyzing the carbon-metal-nitrogen precursor in a closed vessel, thereby forming an oxygen reducing cathode catalyst. The carbon-metal-nitrogen catalyst requires no precious metal such as Pt, and also provides benefits such as controlled deposition of catalytically active nitrogenous compounds that can increase the catalytic activity of the catalyst when compared to gaseous deposition of nitrogen to the surface of the carbon support.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

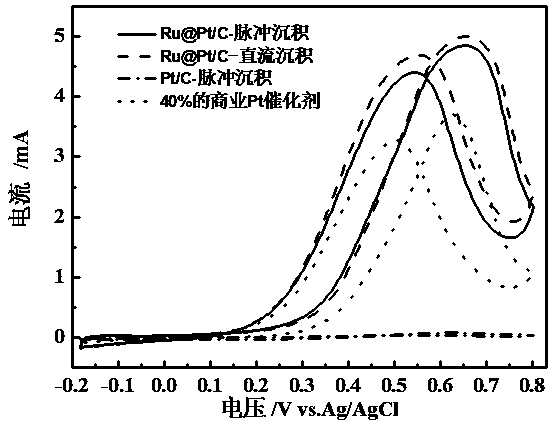

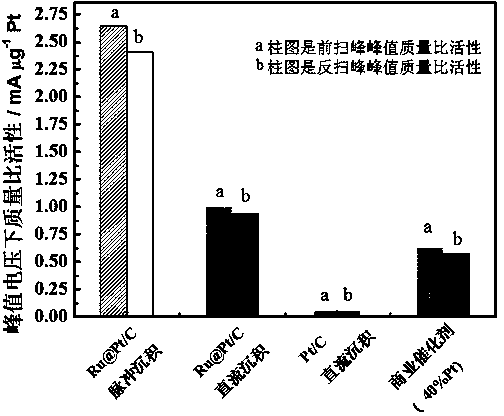

Core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method

ActiveCN103638925AIncrease profitReduce usageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlatinumPtru catalyst

The invention discloses a core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method. The active component of the catalyst is a nanoparticle with a core-shell structure, and an active metal is cladded in the form of an ultrathin shell on the surface of a carbon carrier loaded metal or alloy nanoparticle serving as a core. The catalyst takes a non-platinum noble metal or transition metal as the core, and adopts more than one of Pt, Ir or Au as the shell. The preparation method includes: preparation of the nanoparticle serving as the core, making of a working electrode for pulse electrodeposition, and preparation of the catalyst by pulse electrodeposition. The catalyst can be used as an anode or cathode catalyst of a low temperature fuel cell. The obtained catalyst has very high stability. Compared with underpotential deposition, the method is simple to operate, has no need for inert atmosphere protection, and is more suitable for large-scale industrial production, also can greatly reduce the noble metal consumption of fuel cells, and greatly reduce the cost of fuel cells, thus having great significance in promoting the commercialization process of fuel cells.

Owner:SOUTH CHINA UNIV OF TECH

Modified diffusion layer for use in a fuel cell system

InactiveUS6890680B2Improve fuel efficiencyEasy to operateCell electrodesFuel cell auxillariesPreferential flowFuel cells

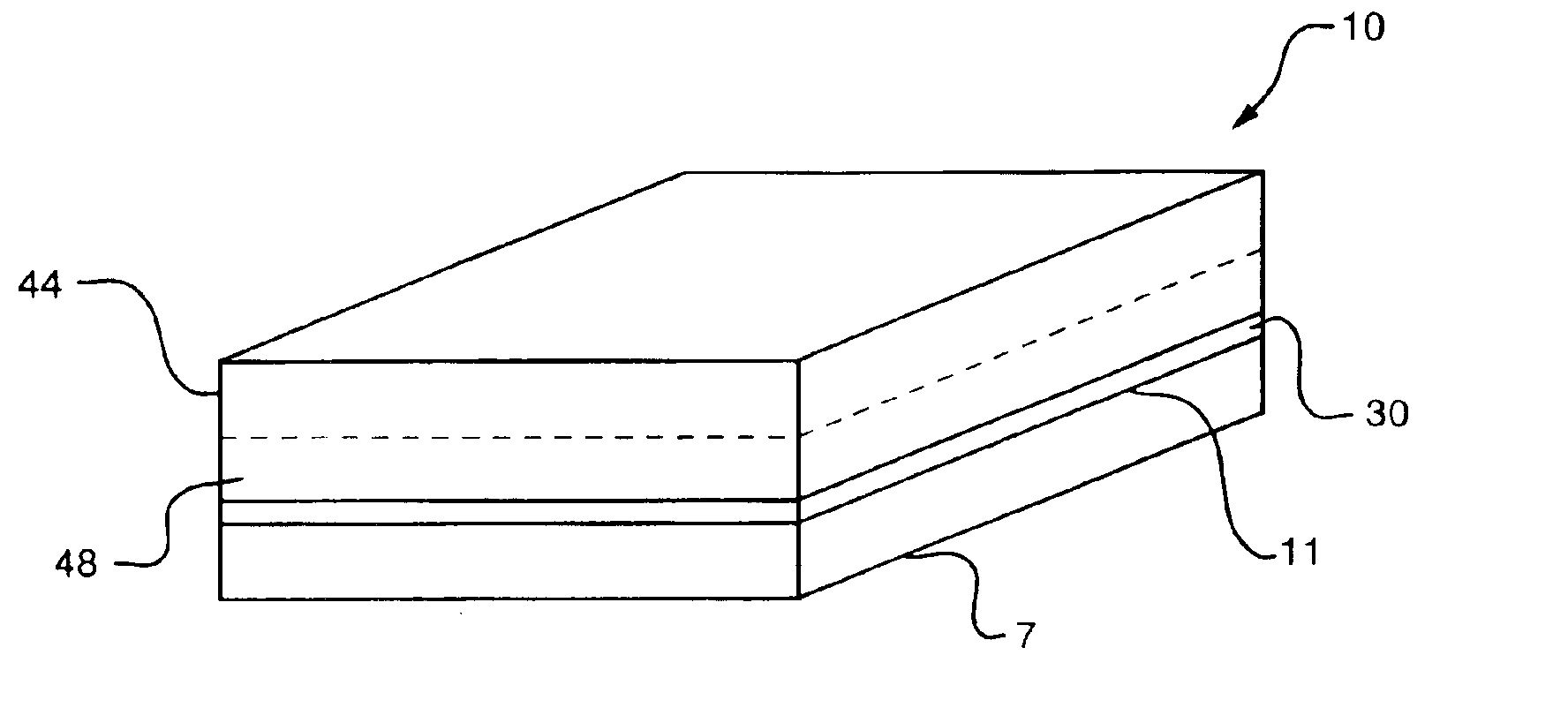

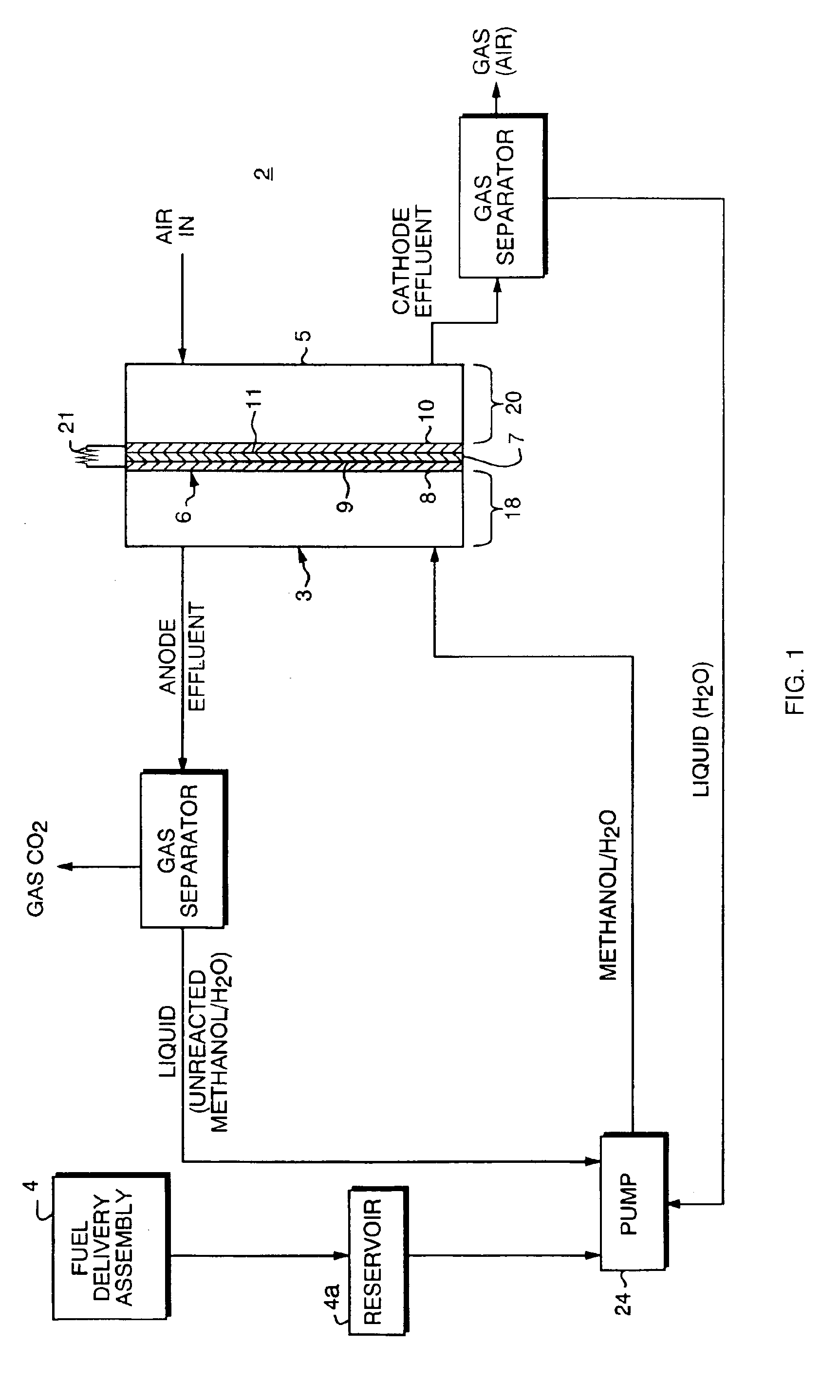

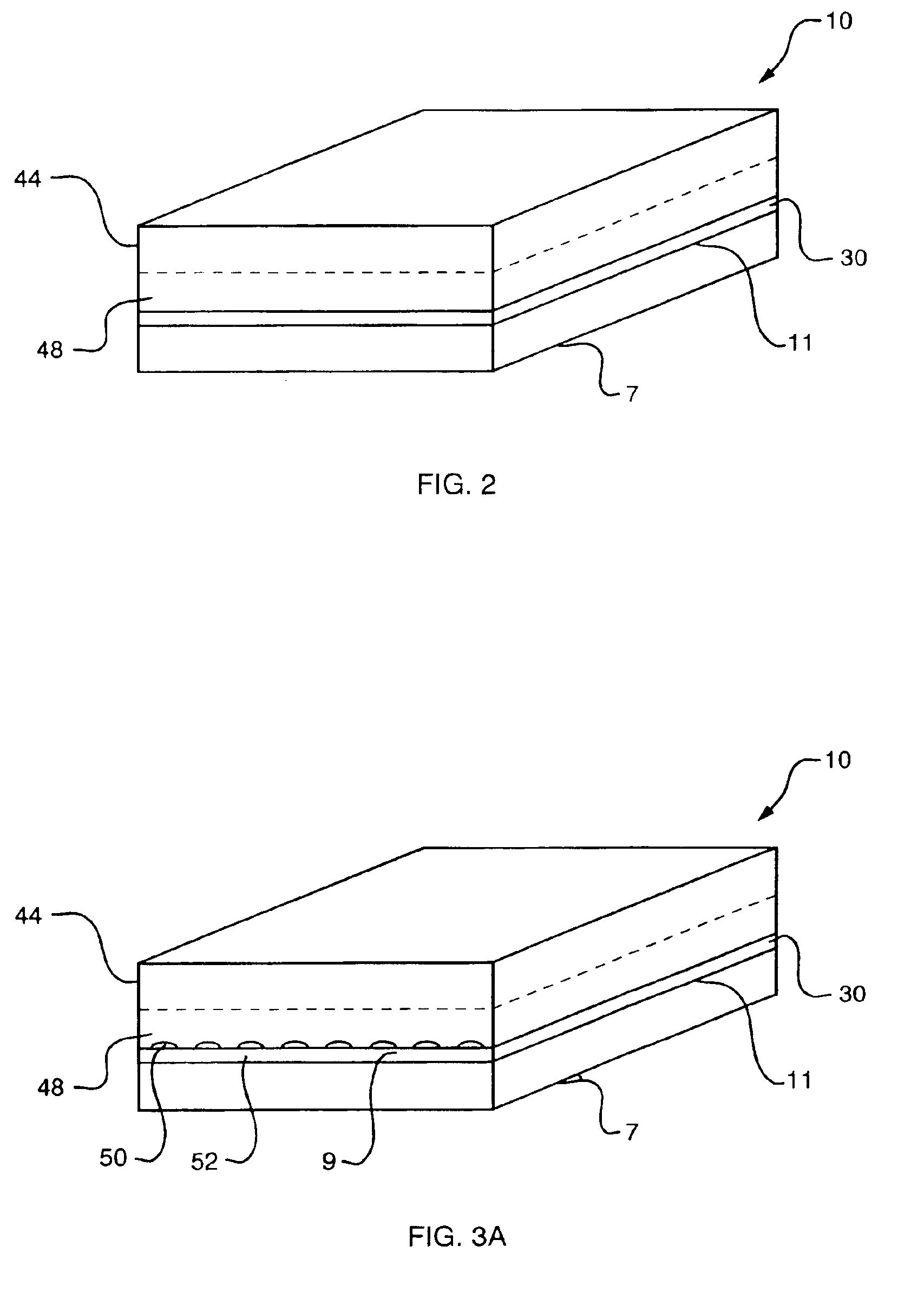

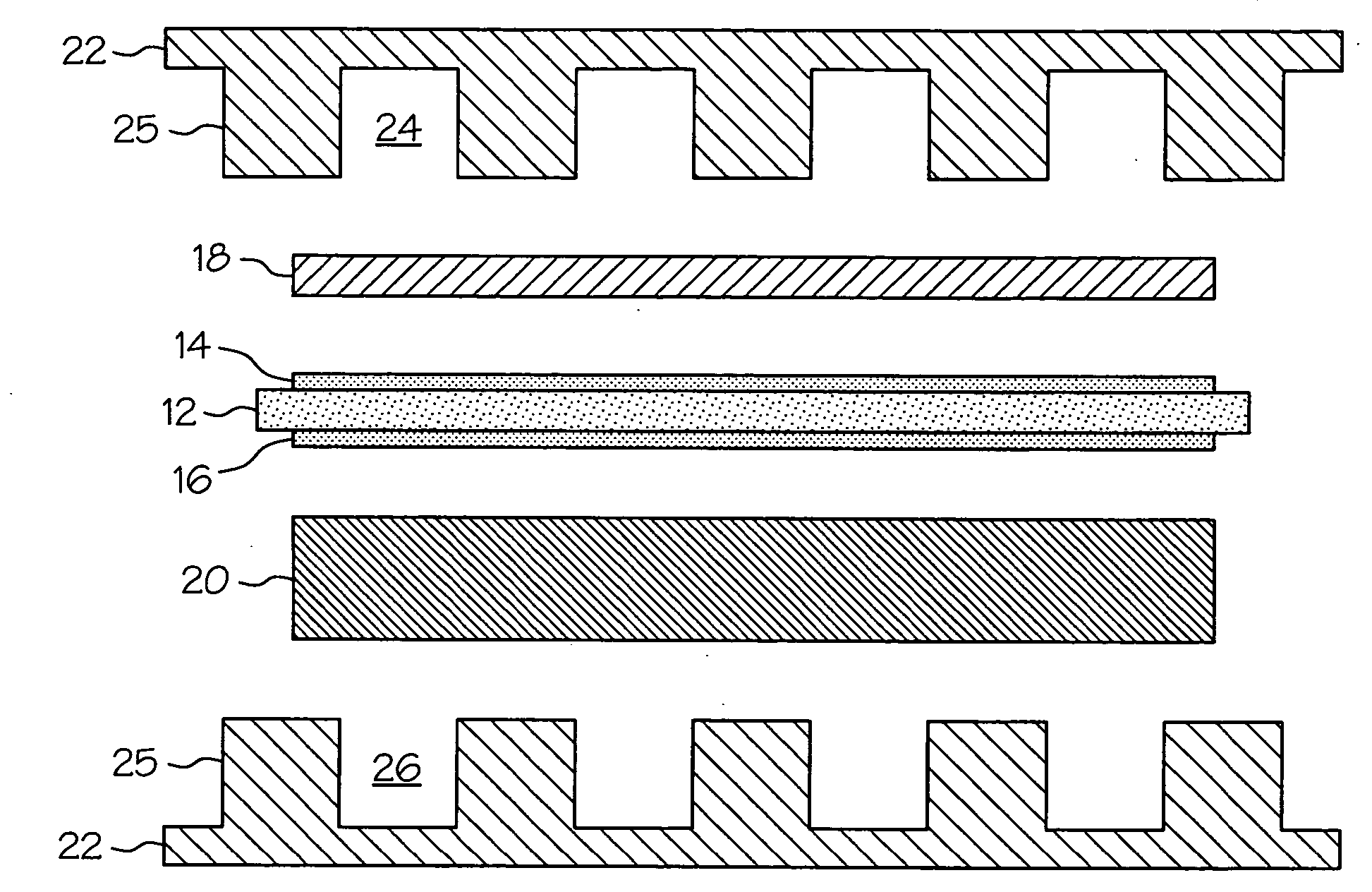

A fuel cell diffusion layer providing a preferential path by which liquid reactants or byproducts may be supplied to or removed from a direct oxidation fuel cell is described. The modified diffusion layer will be typically on the cathode side of the fuel cell and its use is to eliminate or minimize flooding of the cathode diffusion layer area, which is a performance limiting condition in direct methanol fuel cells. In accordance with one embodiment of the invention, the diffusion layer includes a substrate that is coated with a microporous layer. A pattern may be embossed into the diffusion layer, to create preferential flow paths by which water will travel and thereby be removed from the cathode catalyst area. This avoids cathode flooding and avoids build up of potentially destructive pressure by possible cathodic water accumulation. This also provides a means for collecting cathode water for redirection In accordance with another aspect of the invention, the preferential path is established by applying a thicker microporous layer to the carbon cloth or carbon paper and drying it in such a fashion so that when it dries, the surface of the microporous layer cracks to provide the pathways.

Owner:MTI MICROFUEL CELLS

Proton exchange membrane fuel cell

A fuel cell system with a proton exchange membrane. There is a cathode catalyst layer overlying the first face of the proton exchange membrane, and a cathode diffusion layer overlying the cathode catalyst layer. There is an anode catalyst layer overlying the second face of the proton exchange membrane, and an anode diffusion layer overlying the anode catalyst layer. The cathode diffusion layer has a water vapor permeance of less than about 3×10−4 g / (Pa s m2) at 80° C. and 1 atmosphere. The invention also relates to cathode diffusion layers for fuel cell systems.

Owner:GM GLOBAL TECH OPERATIONS LLC

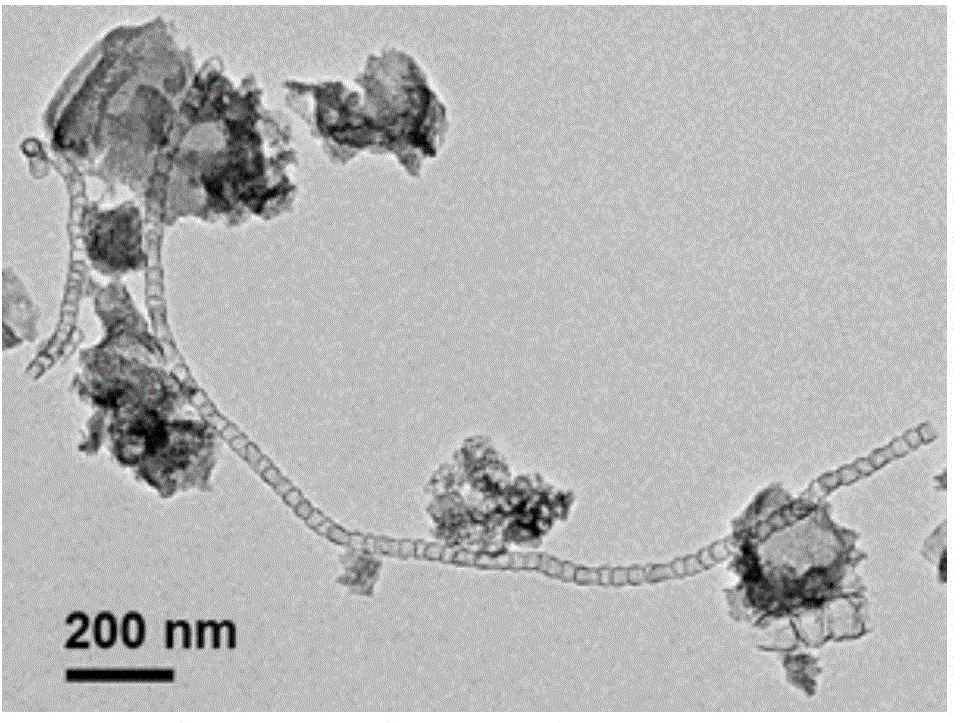

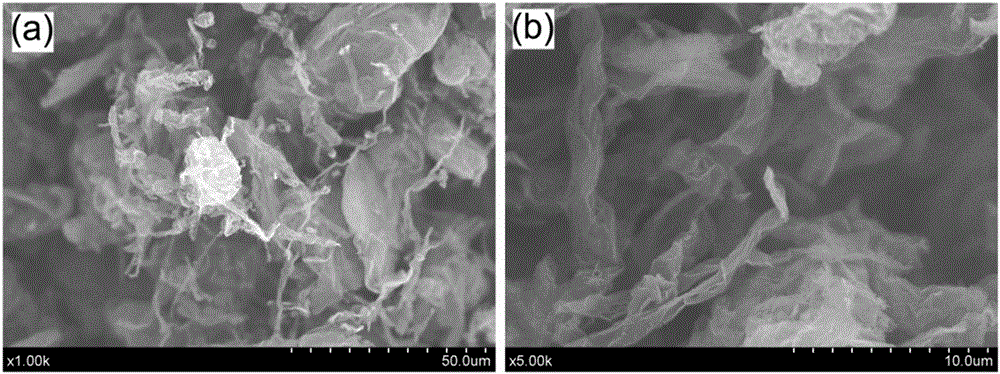

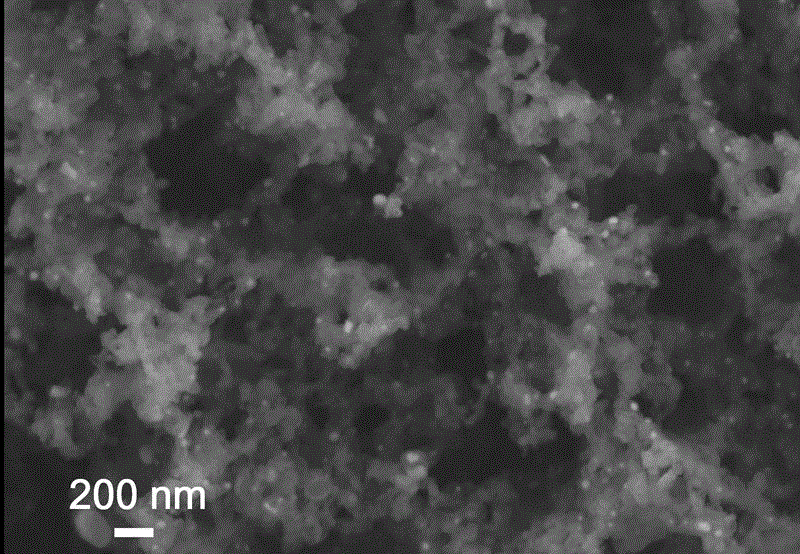

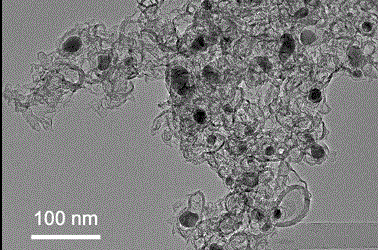

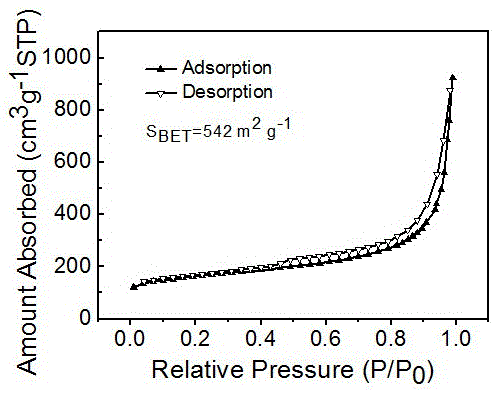

Compound type fuel cell cathode catalyst NGPC/NCNTs and preparation method thereof

ActiveCN106159287AThe preparation method is simple and controllableLower synthesis costCell electrodesMetal-organic frameworkCarbon nanotube

The invention discloses a compound type fuel cell cathode catalyst NGPC / NCNTs and a preparation method thereof, belongs to the technical field of catalyst preparation and aims to develop a cheap and efficient non-precious metal catalyst to solve the problem of high cost of a fuel cell cathode catalyst made of a Pt-based material. An MOF (metal-organic framework) material as a C source of the NGPC / NCNTs is pre-carbonized at a low temperature firstly, a graphitization catalyst and a N source are introduced step by step, two times of corresponding high-temperature heat treatment are performed, and the NGPC / NCNTs are prepared. The active component of the NGPC / NCNTs is N-doped graphitized porous C or CNTs, a pore structure is in a micropore-mesopore compound type, and a continuous conduction framework in three-dimensional space is formed through structural connection of dispersed porous C particles by the CNTs, so that the NGPC / NCNTs have good conductivity and higher mass transfer rate and can show efficient catalytic activity, methyl alcohol tolerance and cycle stability, which are better than those of a commercial Pt / C electrocatalyst, in an alkaline medium.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

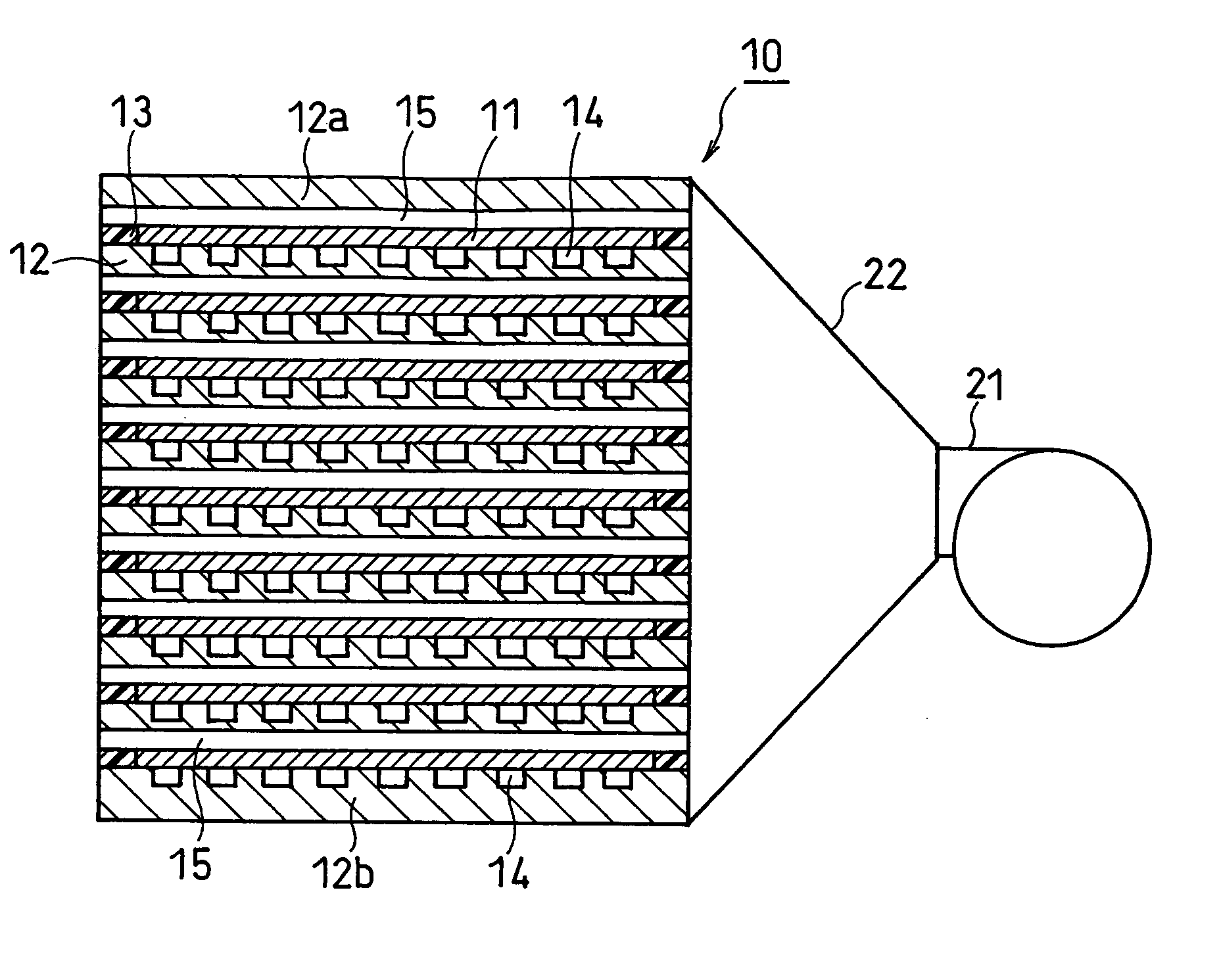

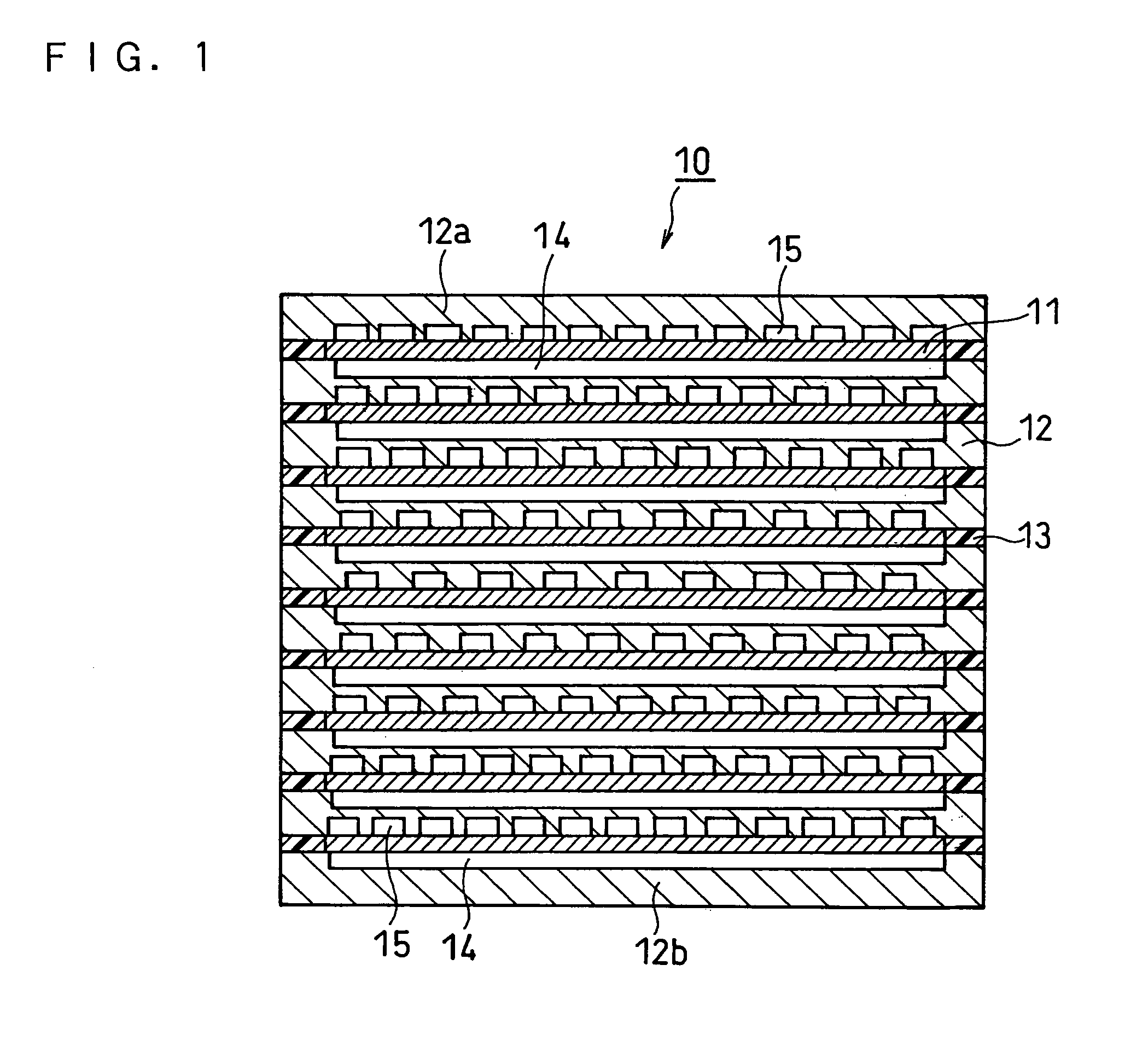

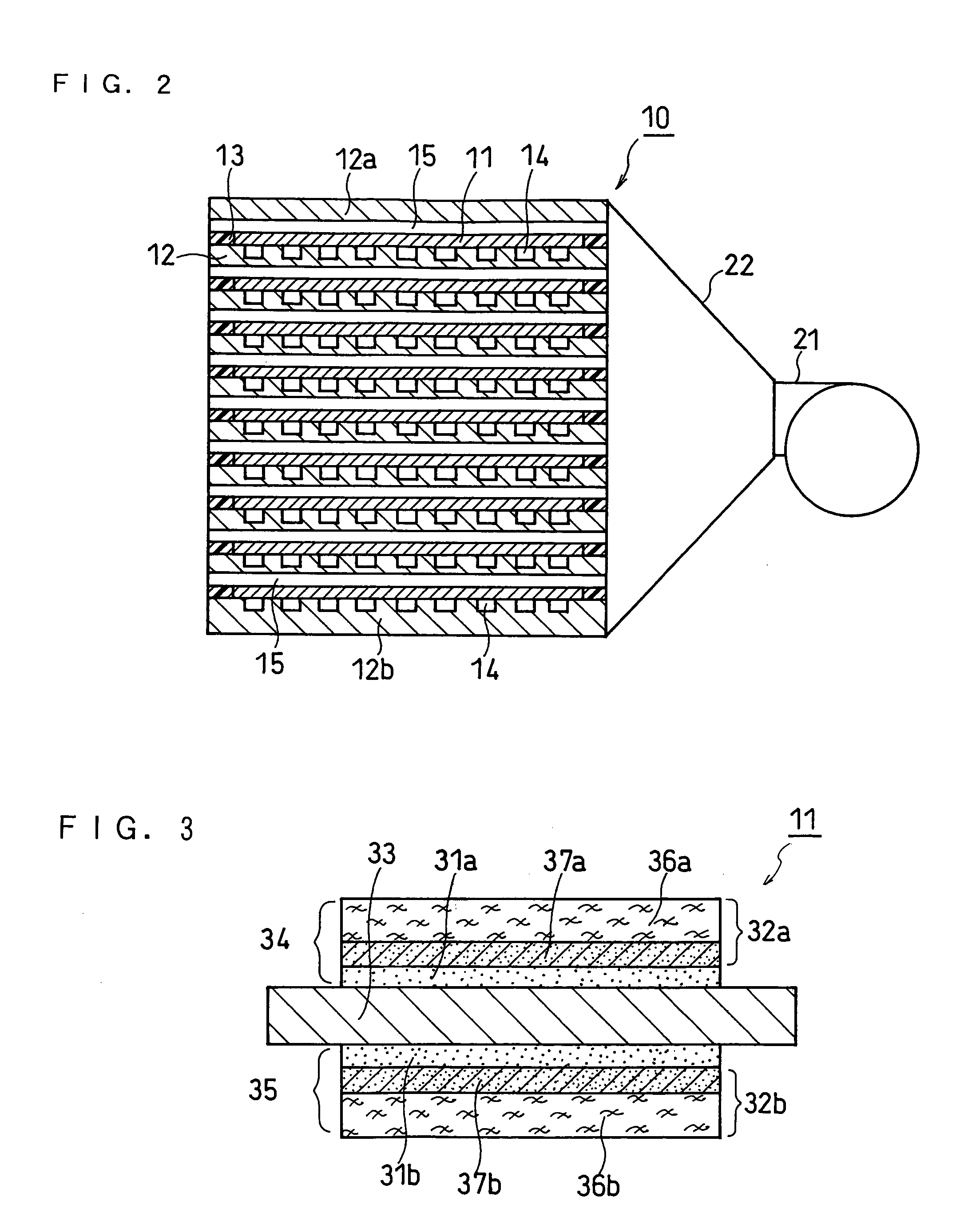

Fuel cell stack

InactiveUS20050238943A1Decreasing variation incidencePrevent overall voltage from decreasingFuel cells groupingCell electrodesFuel cellsEngineering

To prevent the flooding phenomenon at the cathode in a unit cell where the temperature is relatively low or the supply of air is small, a fuel cell stack includes at least three flat unit cells stacked with separators interposed therebetween, the unit cells comprising an anode, a cathode and an electrolyte membrane sandwiched therebetween, and having an oxidant channel formed on the surface of the separator adjacent to the cathode, and the anode and the cathode comprising a catalyst layer attached to the electrolyte membrane and a diffusion layer, wherein the cross-sectional area of the inlet side of the oxidant channel, the area of the cathode catalyst layer, the thickness of the electrolyte membrane or the amount of a water repellent contained in the combination of the cathode and the oxidant channel is the largest in at least one of the unit cells at the ends of the stack.

Owner:PANASONIC CORP

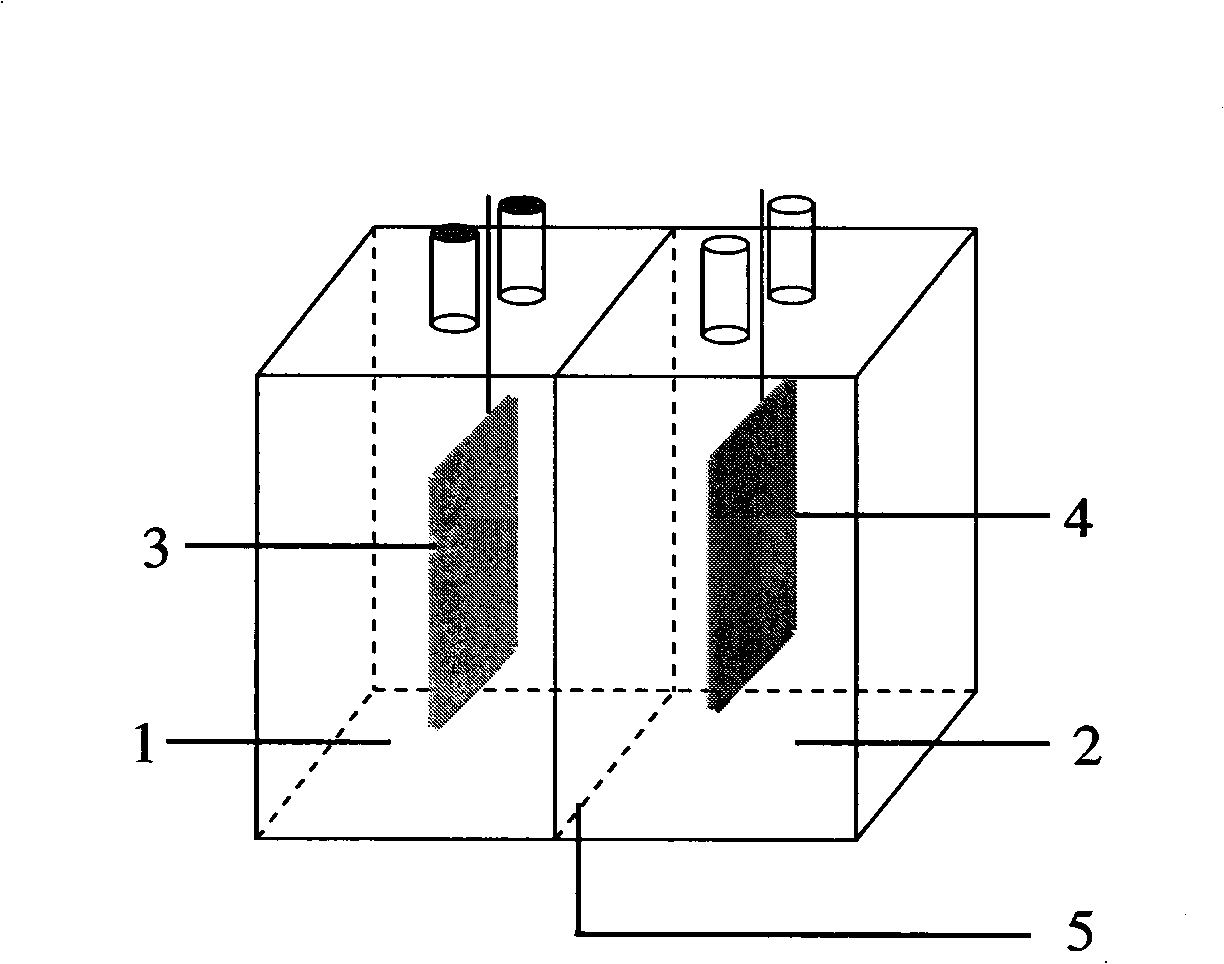

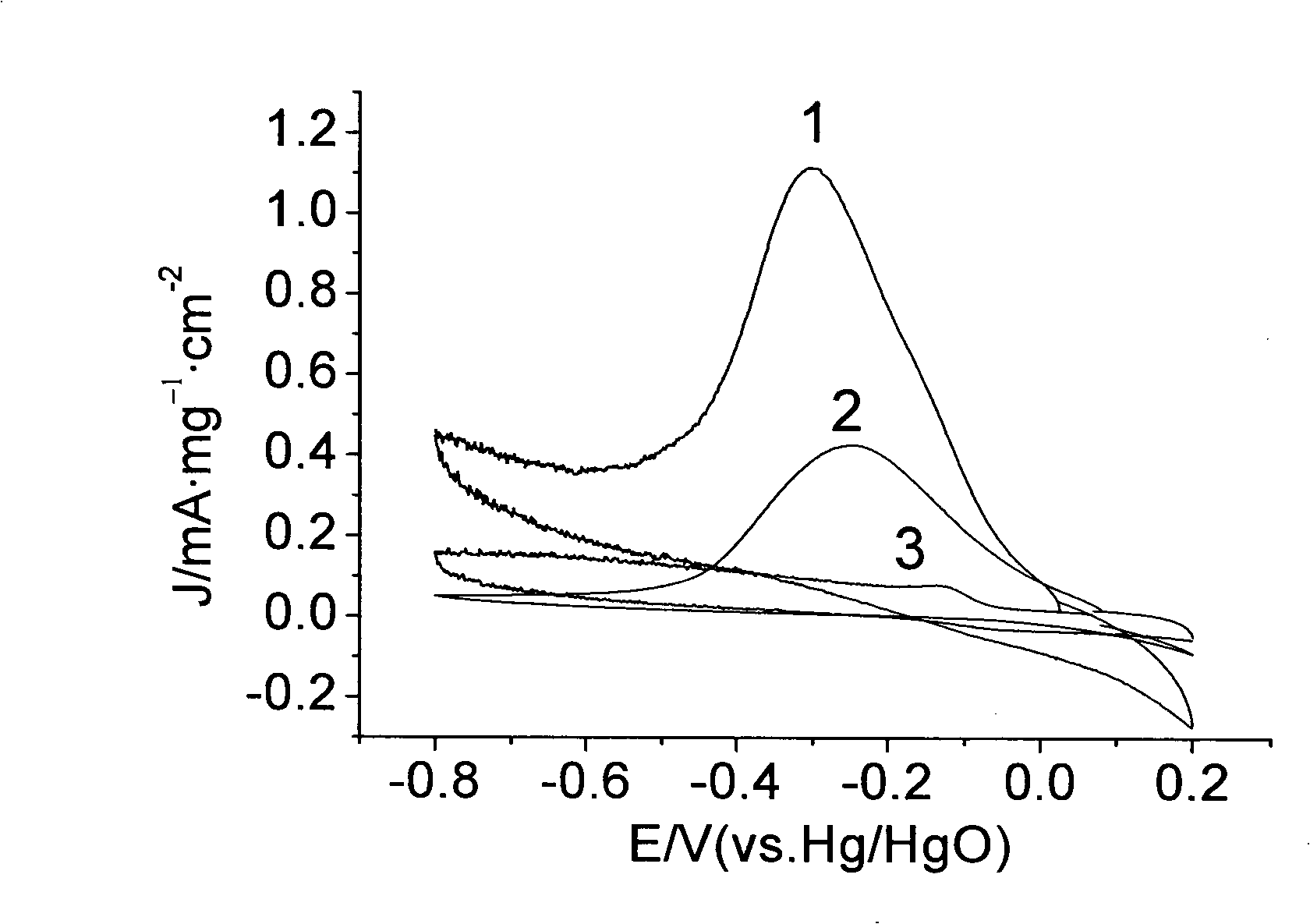

Application of manganese dioxide for preparing microorganism fuel cell cathode

InactiveCN101355170AGuaranteed uptimeHigh power outputCell electrodesMicrobial fuel cellMicroorganism

The invention discloses application of manganese dioxide for preparing a cathode of a microorganism fuel battery. The method comprises the following steps: the manganese dioxide is taken as a catalyst, the mixture of the catalyst, a conductive carbon material and a caking agent is coated on a conductive substrate to prepare the cathode of the microorganism fuel battery and a membrane composite cathode applied to the microorganism fuel battery. Compared with a non-catalytic electrode, MnO2 is taken as a cathode catalyst for remarkably increasing the reducing speed, reducing the polarization of the cathode and improving the energy output of the microorganism fuel battery; compared with the prior Pt catalyst, MnO2 has low price and wide source, and the microorganism fuel battery assembled by the catalyst of the cathode can operate stably for a long time and has high power output. The manganese dioxide for preparing the microorganism fuel battery electrode provides solid foundation for the commercial application of the microorganism fuel battery.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

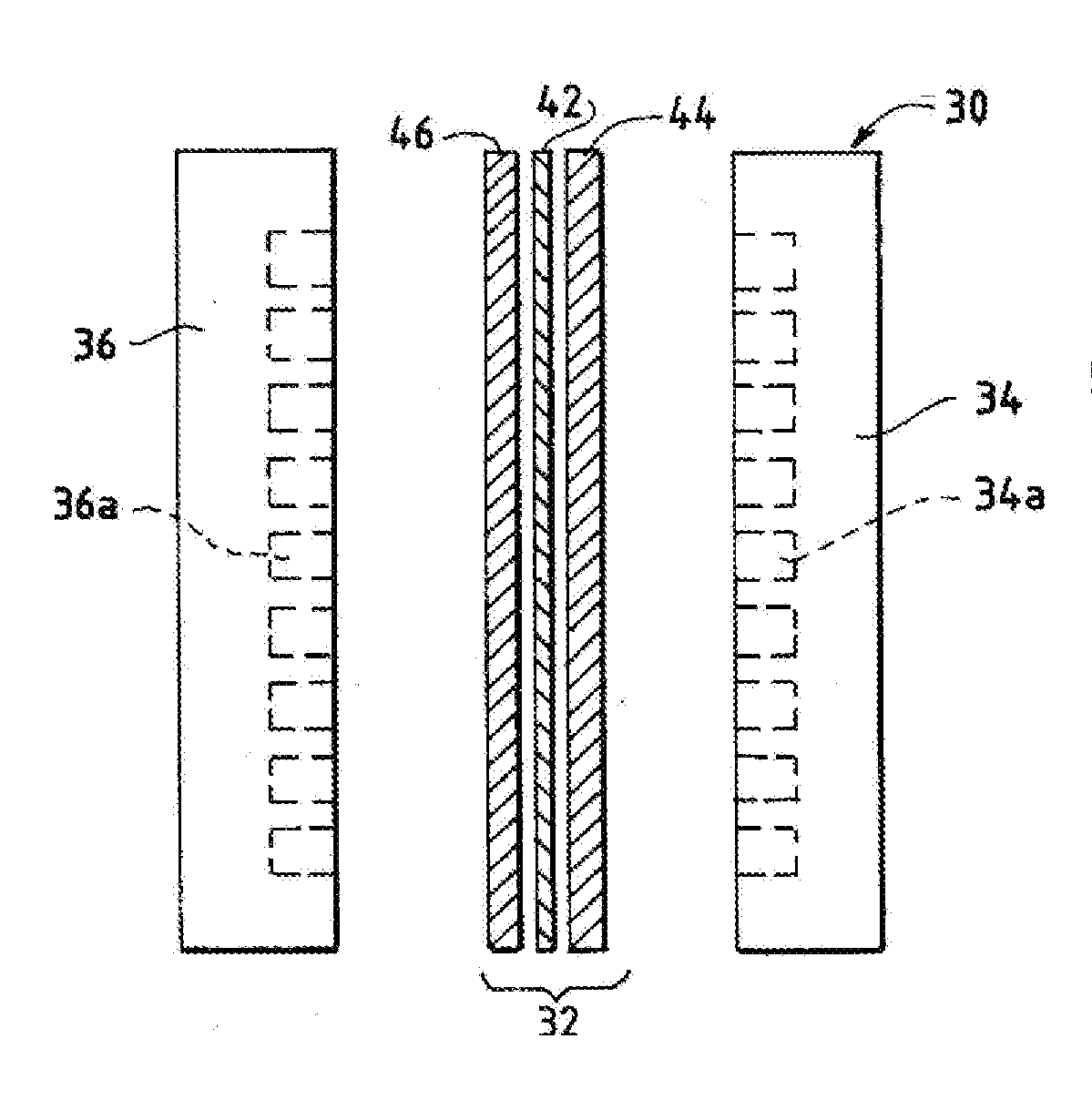

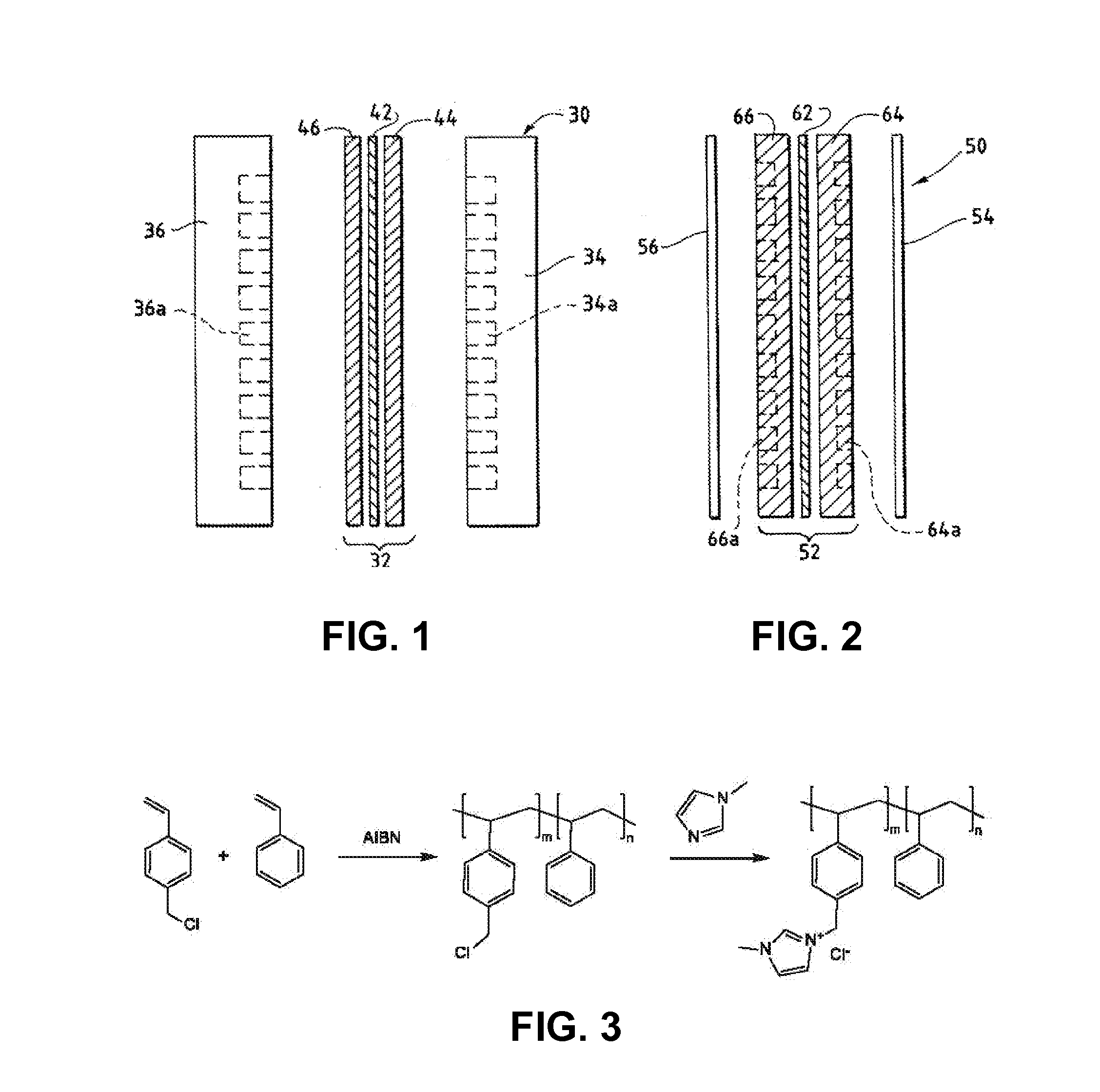

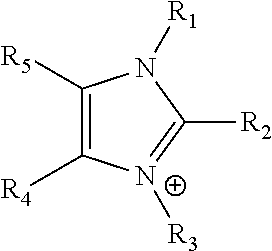

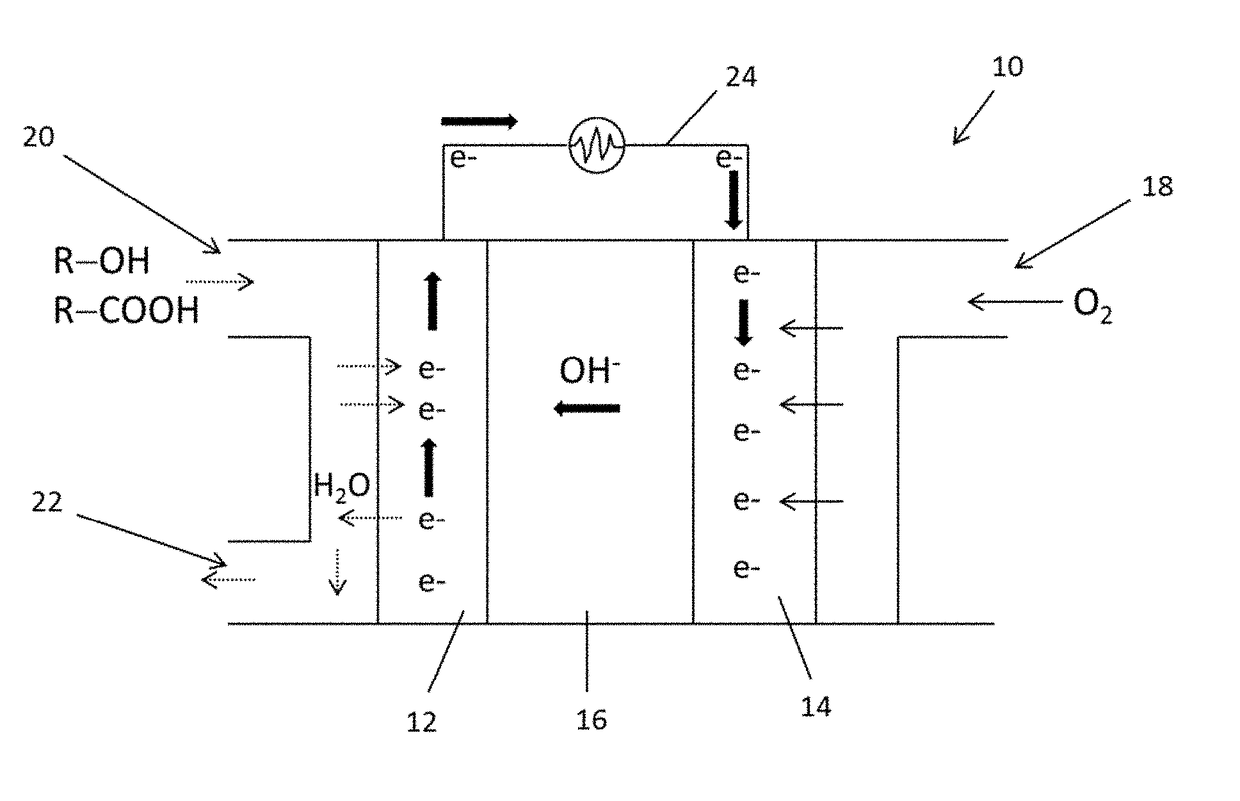

Electrochemical Device For Converting Carbon Dioxide To A Reaction Product

ActiveUS20160108530A1Low faradaic efficiencyLow conversion currentCellsSolid electrolytesElectrolysisPyridinium

An electrochemical device converts carbon dioxide to a reaction product. The device includes an anode and a cathode, each comprising a quantity of catalyst. The anode and cathode each has reactant introduced thereto. A polymer electrolyte membrane is interposed between the anode and the cathode. At least a portion of the cathode catalyst is directly exposed to gaseous carbon dioxide during electrolysis. The average current density at the membrane is at least 20 mA / cm2, measured as the area of the cathode gas diffusion layer that is covered by catalyst, and CO selectivity is at least 50% at a cell potential of 3.0 V. In some embodiments, the polymer electrolyte membrane comprises a polymer in which a constituent monomer is (p-vinylbenzyl)-R, where R is selected from the group consisting of imidazoliums, pyridiniums and phosphoniums. In some embodiments, the polymer electrolyte membrane is a Helper Membrane comprising a polymer containing an imidazolium ligand, a pyridinium ligand, or a phosphonium ligand.

Owner:DIOXIDE MATERIALS

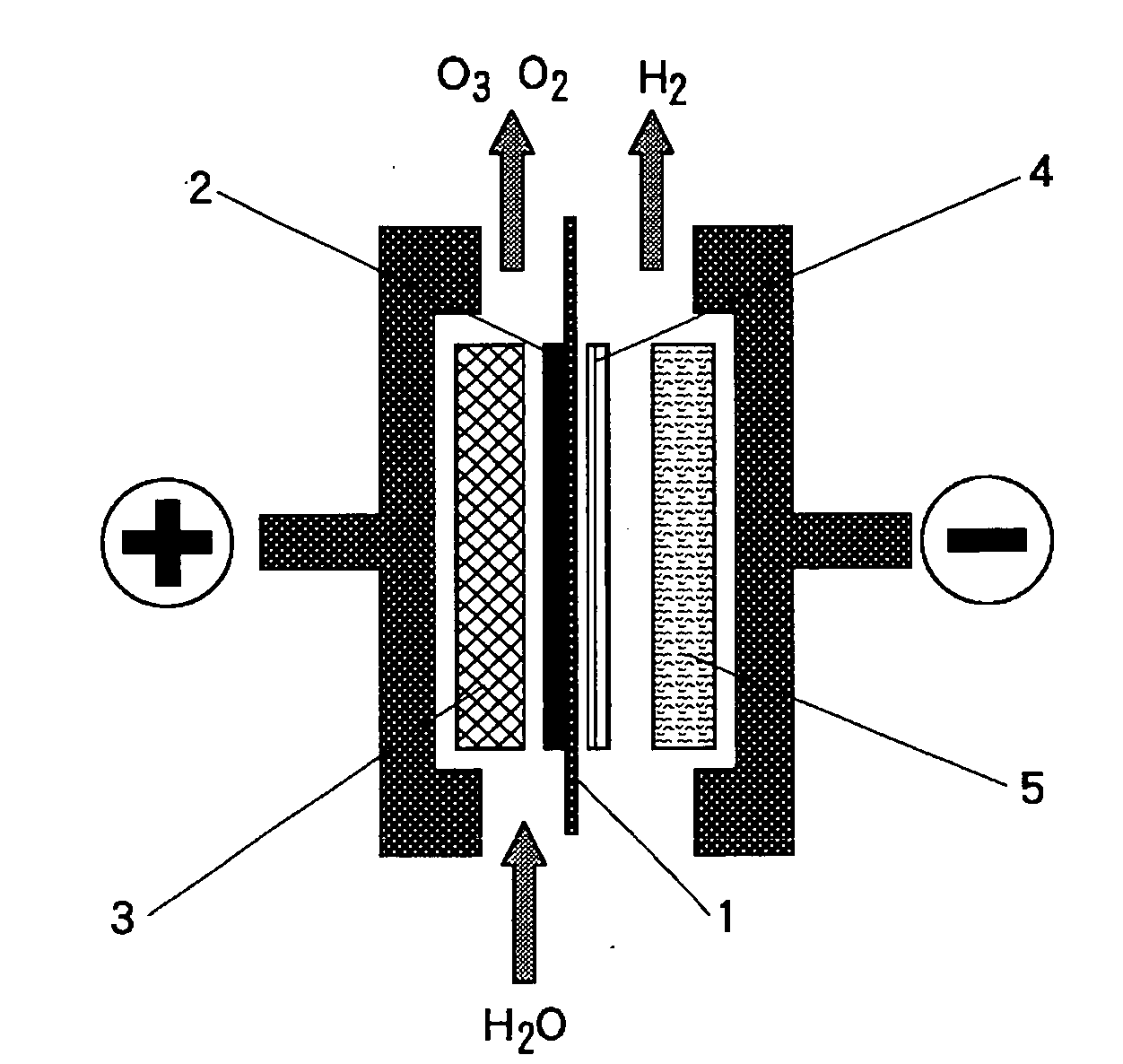

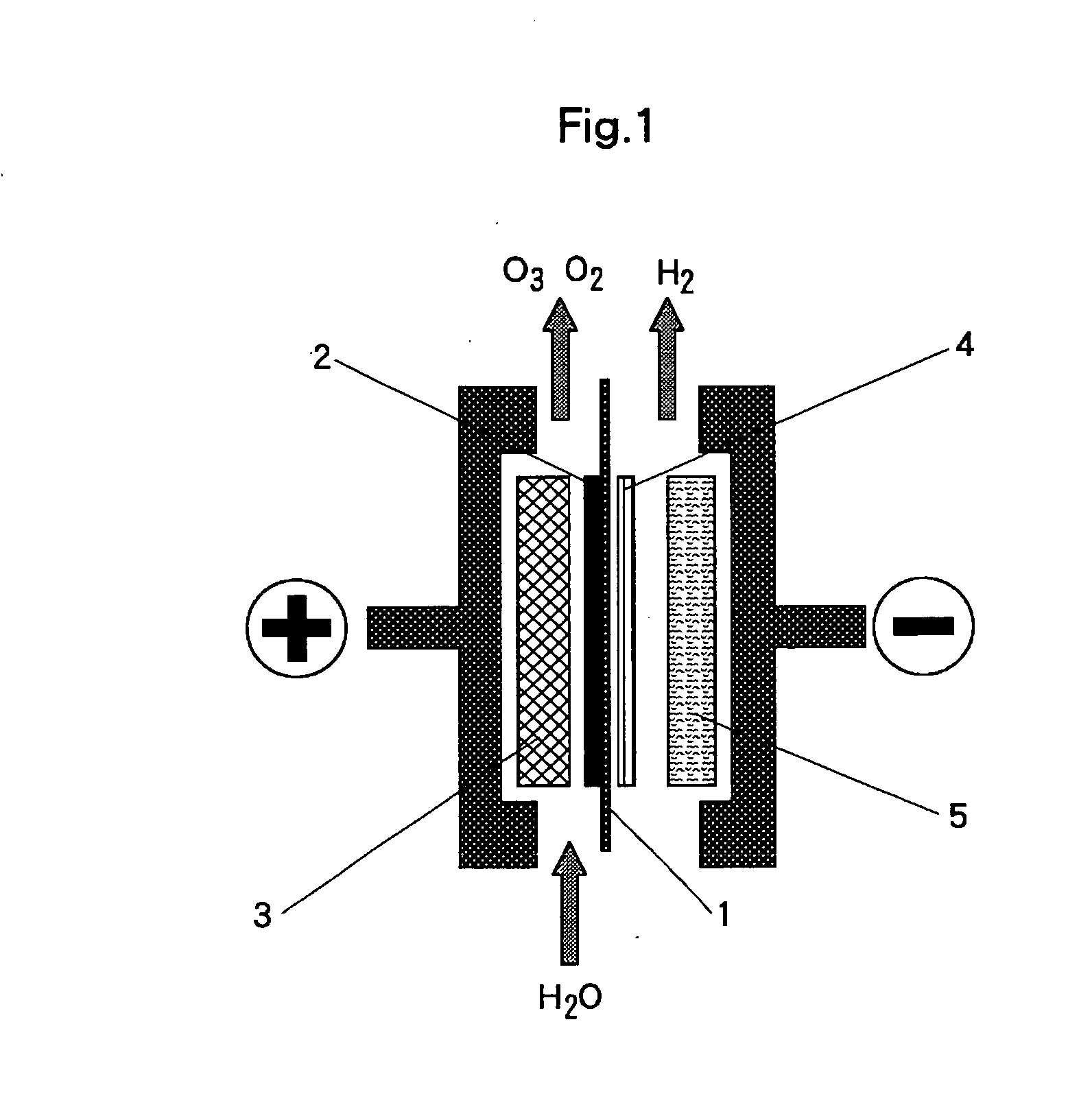

Water electrolysis system

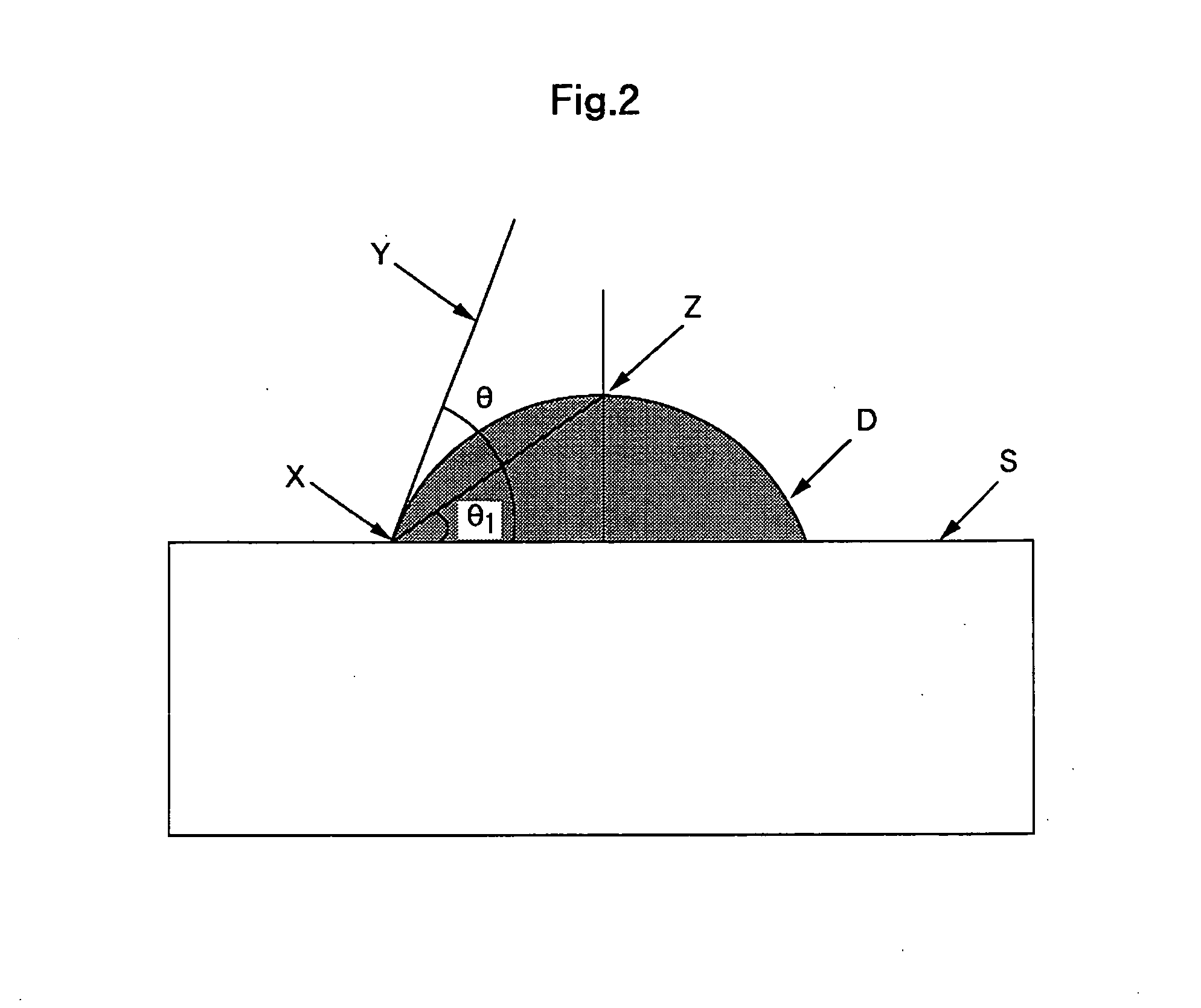

In a water electrolysis system having an anode catalyst layer containing anode catalyst and a cathode catalyst layer containing cathode catalyst tightly attached, respectively, to each surface of a solid polymer electrolyte membrane comprising a cation exchange membrane, wherein at least one catalyst layer of said anode catalyst layer and cathode catalyst layer comprises a porous structure of anode catalyst or cathode catalyst dispersed in fluorine resin containing resin, featuring the surface of the anode catalyst layer or the cathode catalyst layer being hydrophobized and the water contact angle with the surface of the anode catalyst layer or the cathode catalyst layer of said porous structure being 90 degrees or more, whereby the transfer of gas to the counter electrode can be significantly suppressed, gas purity and current efficiency be improved, and safety operation of the electrolysis system be secured, without a major change in configuration of the water electrolysis system.

Owner:CHLORINE ENGINEERS CORP LTD

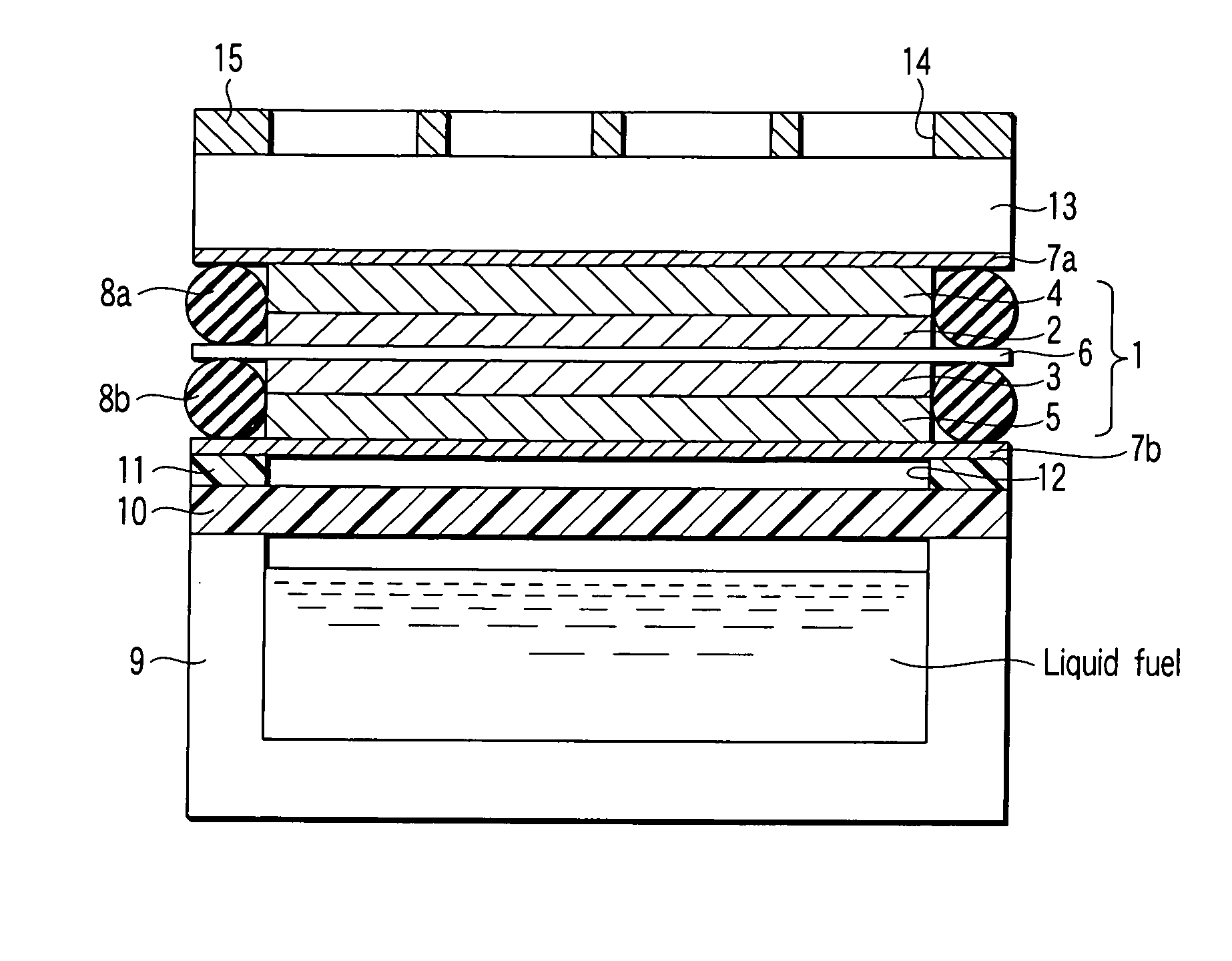

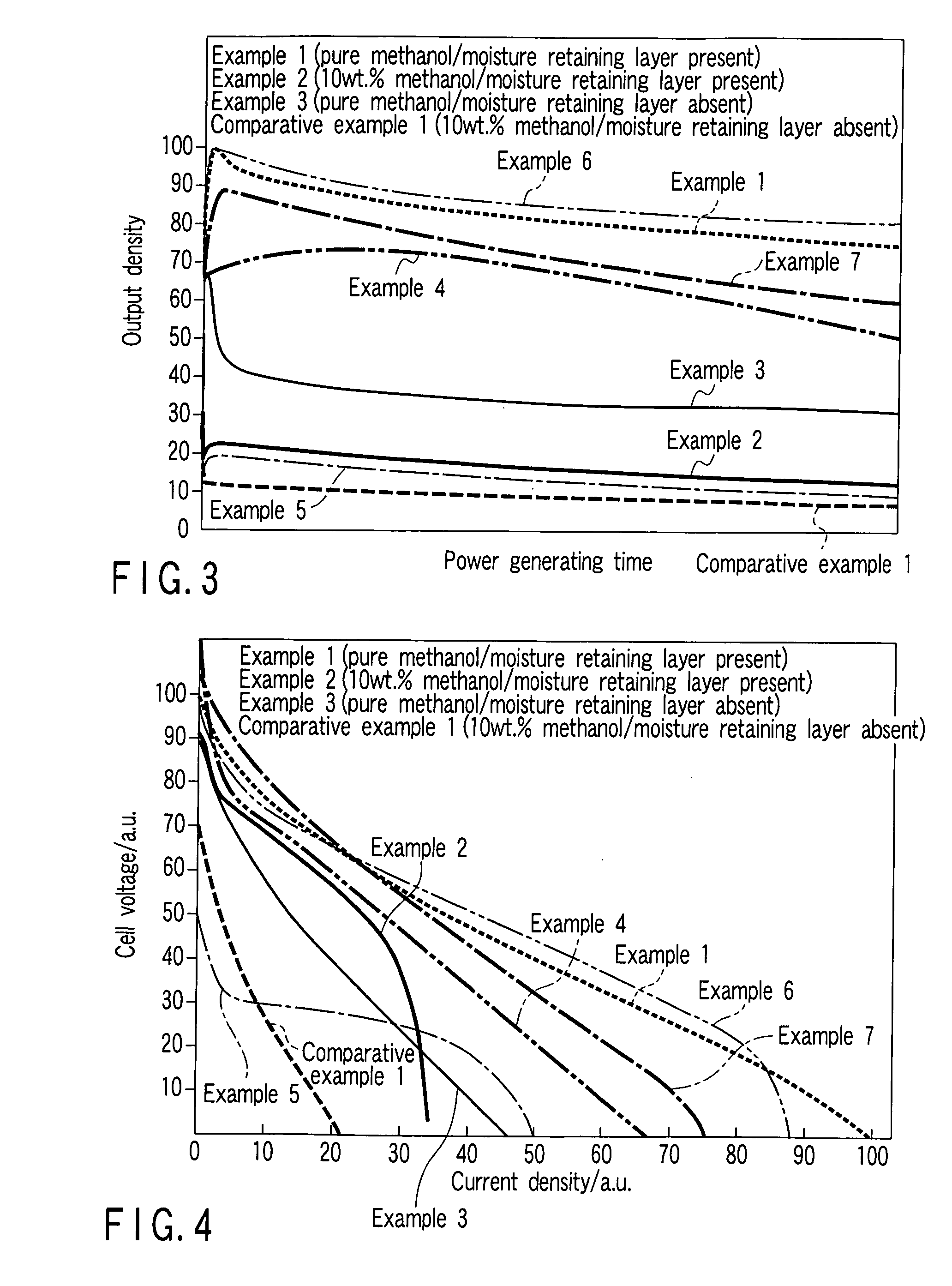

Fuel cell

InactiveUS20070059575A1Improve output performancePrevent evaporationWater management in fuel cellsCell component detailsFuel cellsProton

A fuel cell includes a cathode catalyst layer, an anode catalyst layer, a proton-conductive membrane provided between the cathode catalyst layer and the anode catalyst layer, and a fuel transmitting layer that supplies a vaporized component of a liquid fuel to the anode catalyst layer. Water generated in the cathode catalyst layer is supplied to the anode catalyst layer via the proton-conductive membrane. The liquid fuel is one of a methanol aqueous solution having a concentration of over 50% by molar and liquid methanol.

Owner:KK TOSHIBA

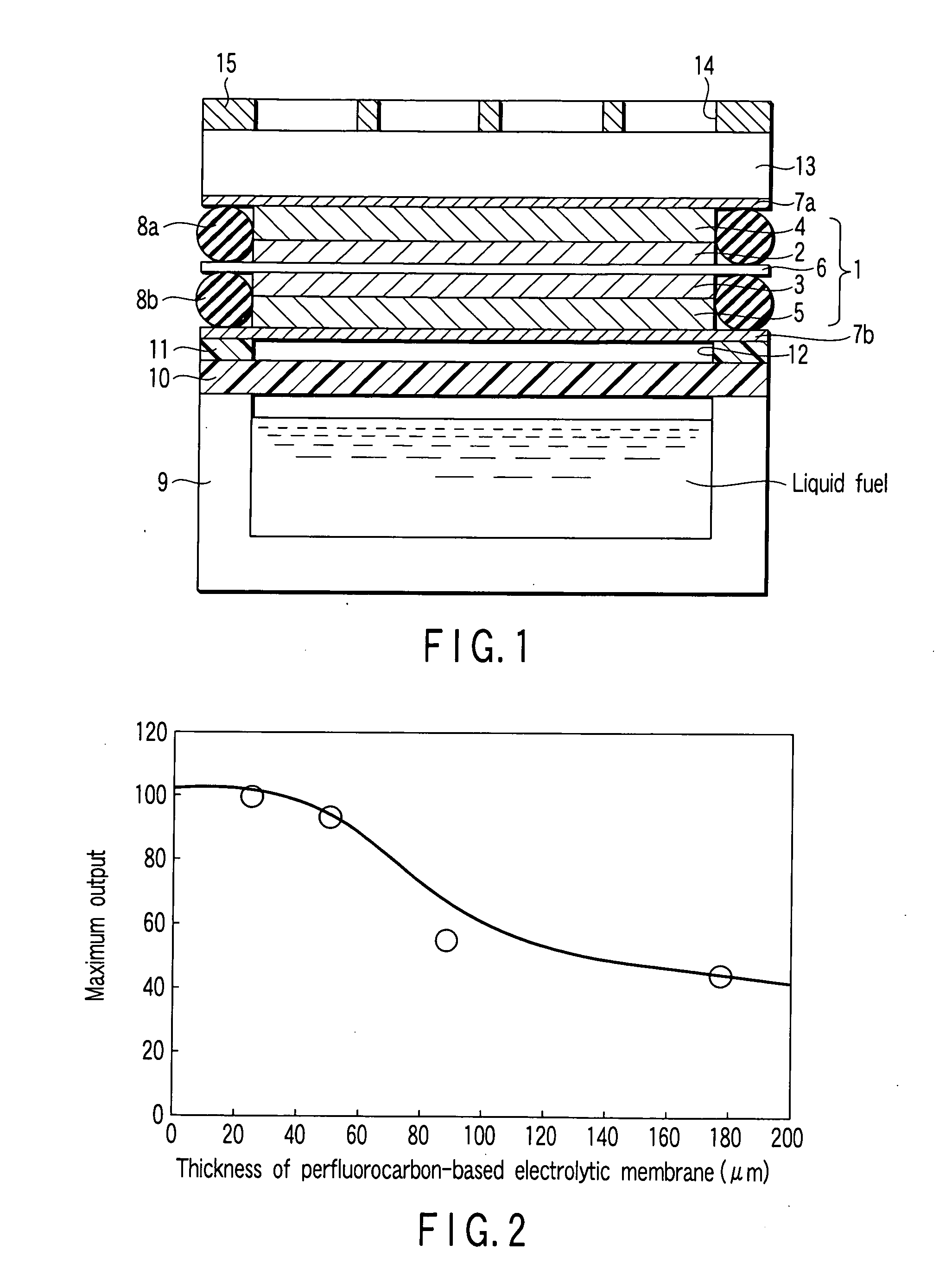

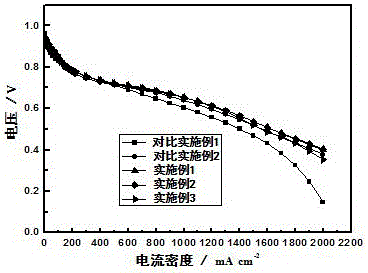

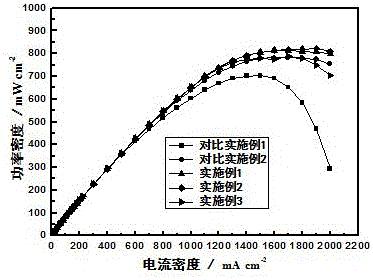

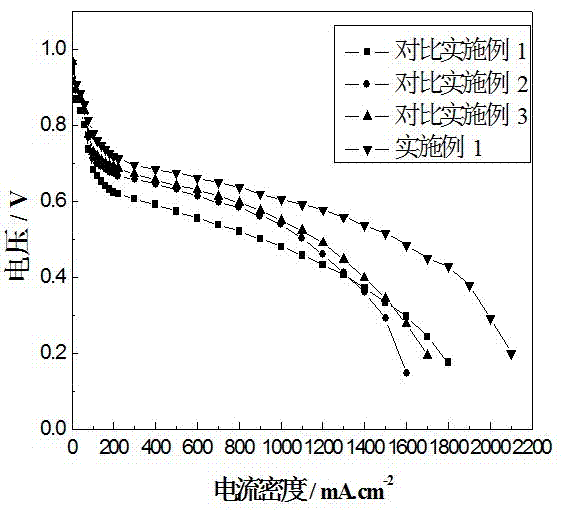

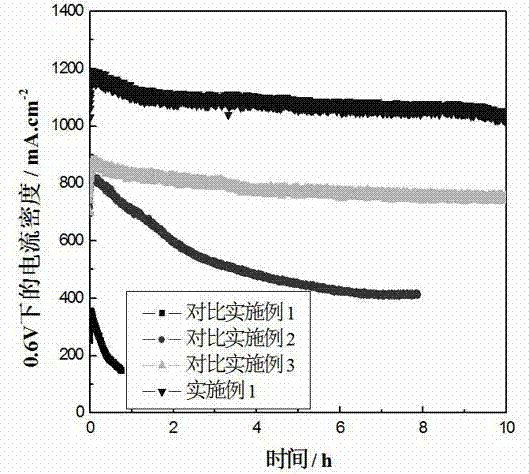

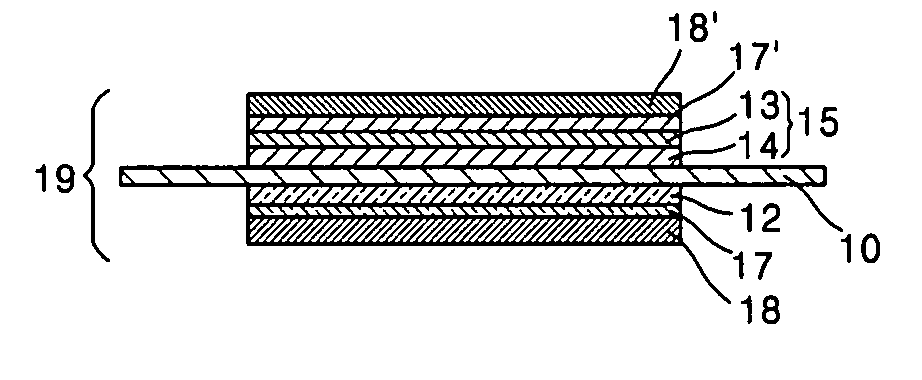

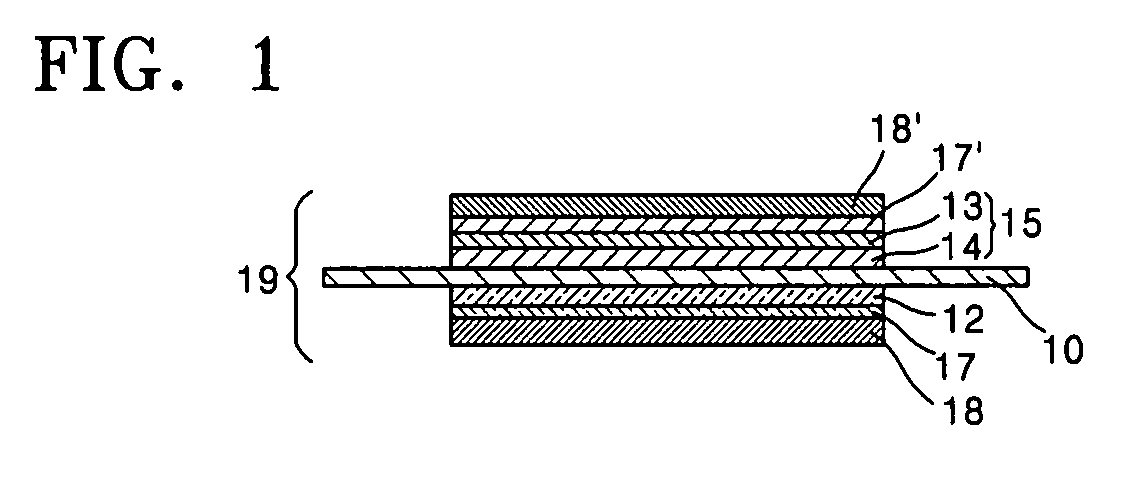

High-power-density membrane electrode for proton exchange membrane fuel cell and preparation method thereof

The invention discloses a high-power-density membrane electrode for a proton exchange membrane fuel cell and a preparation method thereof. According to the method, the thickness of solid electrolyte is reduced, the thickness of a catalyst layer is reduced by using a high-content catalyst, and a nano-carbon tube or carbon fiber is introduced into a cathode catalyst layer and / or gas diffusion layer to improve mass transfer of the catalyst layer and the diffusion layer, so that the power density of a membrane electrode is greatly improved. The preparation method is simple in steps, is practical and feasible and is low in cost, can be used for reducing the thickness of the membrane electrode while improving the performance of the membrane electrode, and is favorable to preparation of high-power-density fuel cells, galvanic piles and systems.

Owner:SOUTH CHINA UNIV OF TECH

Biomass carbon catalyst and preparation method and application thereof

The invention discloses a biomass carbon catalyst and a preparation method and application thereof. The precursor of the catalyst comprises biomass and metal salts, wherein the biomass includes one or more of maize straw, corncob, rice straw, cotton straw, peanut straw, peanut shell, wheat hull, rice hull, wood, sawdust, bamboo wood and weed. Through controlling addition of metal salts in different amounts, adjusting impregnation concentration of the precursor and reaction ambient and carbonization and nitriding treatment temperatures, the biomass carbon catalyst with controllable and adjustable pore structure and specific surface area can be prepared. When used as a fuel battery cathode catalyst, the biomass carbon catalyst shows excellent oxygen reduction reaction activity and stability. The preparation process is simple in flow, short in period and free of environment, provides a novel high-value-added resource recycling way for waste biomass and has dual effects of biomass disposal and energy and power generation.

Owner:SHENYANG AGRI UNIV

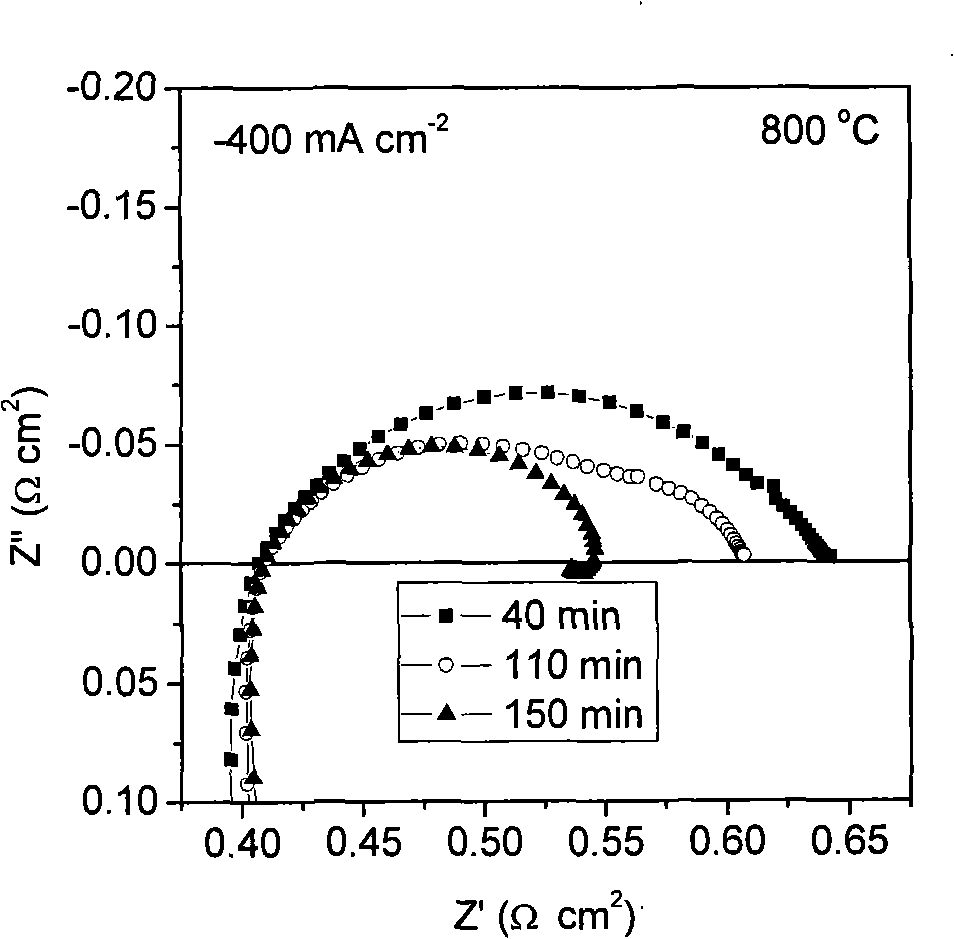

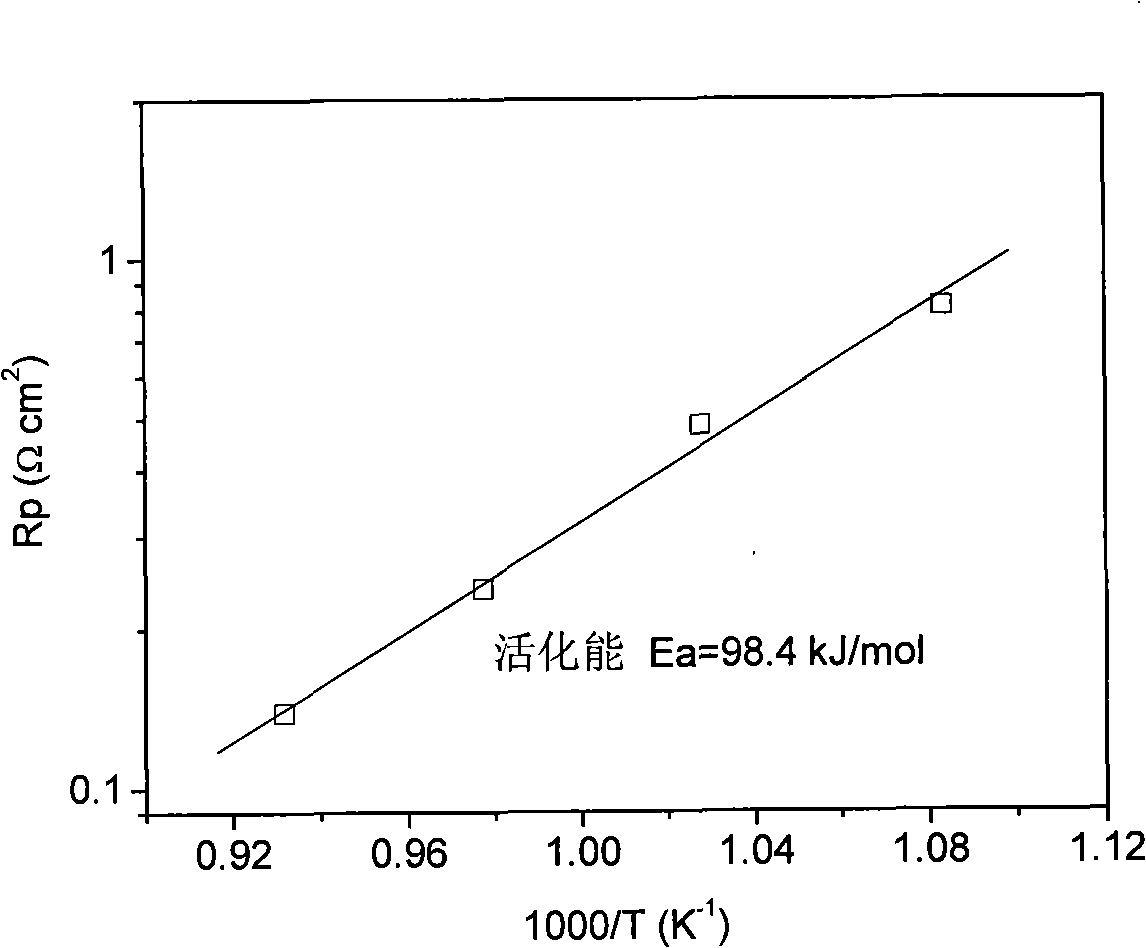

Cathode material for solid-oxide fuel cell and method for preparing the same

InactiveCN101359739AExtended service lifeImprove stabilityCell electrodesFuel cell detailsCeramic compositeDip-coating

The invention relates to a solid oxide fuel battery cathode material and a preparation method thereof. The chemical formula of the material is MxA(1-x)M`yB(1-y)O(3-Delta). The material is prepared by adopting an EDTA-citrate combination and complexation method or a glycine combustion method. The cathode material can be smeared onto the electrolyte surface by screen printing, spraying, dip coating or flow casting, and then calcined at high temperatures to obtain a cathode catalyst layer. The catalyst layer is in the working state, that is, the negative current passes through the electrode, so that the precious metal oxides can obtain electrons to take the reduction reaction, emerge out of the lattice of the perovskite or perovskite-like ceramic material to enrich on the surface of the material and to form the precious metal-ceramic composite cathode. The precious metals can be re-oxidized and enter the ceramic oxide lattice when the positive current passes through the electrode.

Owner:NANJING UNIV OF TECH

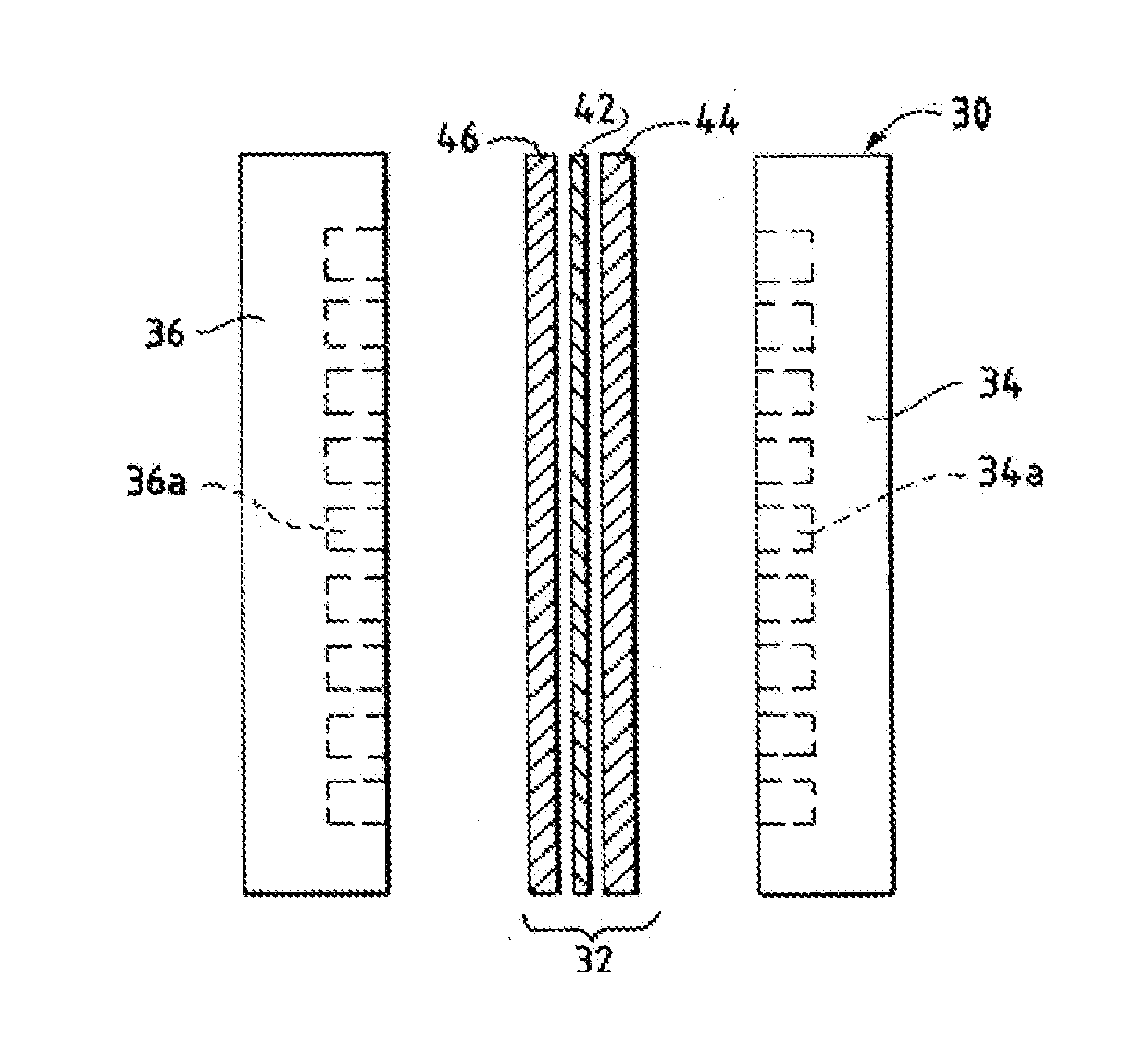

Membrane electrode assembly and fuel cell

InactiveUS20090246593A1Reduce intervalAvoid damageFuel cells groupingActive material electrodesFuel cellsOrganic chemistry

A membrane electrode assembly includes an electrolyte membrane, anode catalyst layers, and cathode catalyst layers provided counter to the anode catalyst layers, respectively. An insulating layer is provided on the electrolyte membrane between adjacent anode catalyst layers. An insulating layer is provided on the electrolyte membrane between adjacent cathode catalyst layers. The resistivity of the insulating layer is preferably identical to or higher than that of the electrolyte membrane.

Owner:SANYO ELECTRIC CO LTD

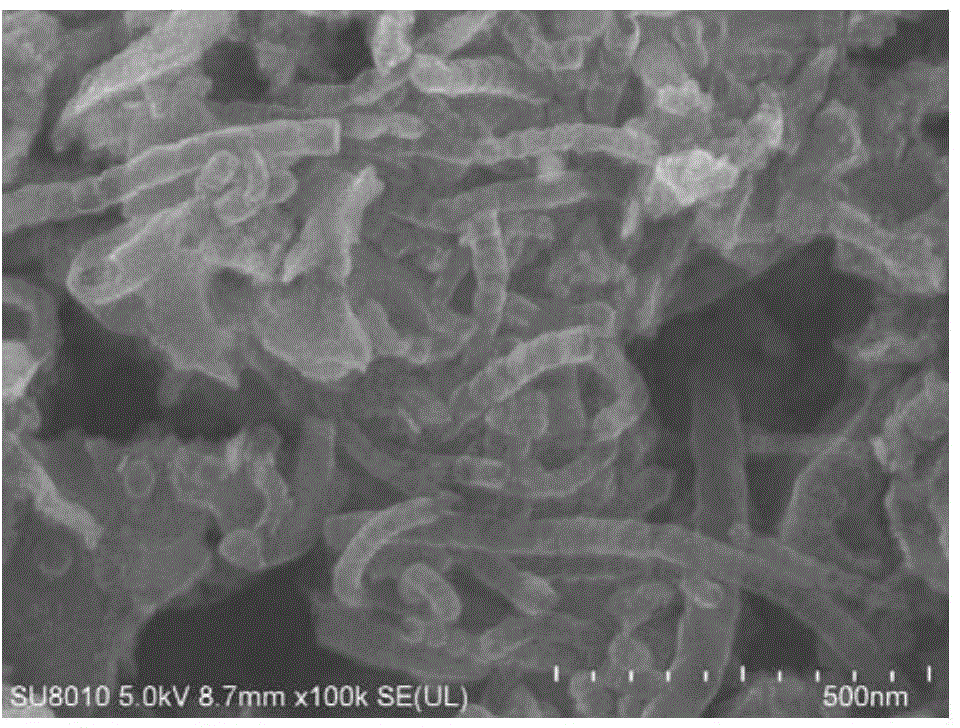

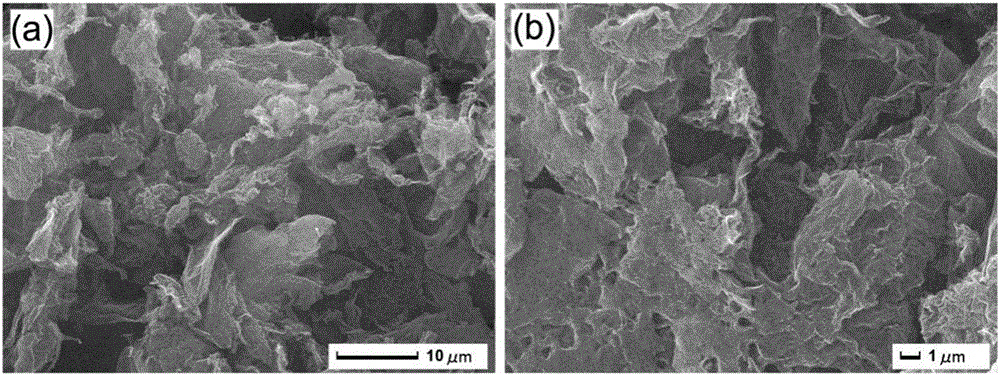

Nitrogen-doped three-dimensional graphene catalyst and preparation method thereof

ActiveCN105938908AOvercome demanding process requirementsLarge specific surface areaCell electrodesNew energyNitrogen doped

The invention relates to a nitrogen-doped three-dimensional graphene catalyst and a preparation method thereof, and belongs to the technical field of new energy nanometer materials and catalysis. The nitrogen-doped three-dimensional graphene catalyst is characterized in that a generated three-dimensional graphene material with formaldehyde resin is prepared by graphene oxide, a nitrogen-containing compound and formaldehyde through hydrothermal reaction; and nitrogen-doped three-dimensional graphene is prepared through high-temperature heat treatment in a protective atmosphere. The nitrogen-doped three-dimensional graphene with different nitrogen content is prepared by adjusting the feed ratio and the heat treatment temperature before reaction; and the prepared nitrogen-doped three-dimensional graphene has relatively high catalytic activity and stability and can be applied to an electrode material of a super capacitor and a cathode catalyst material of a fuel cell.

Owner:JIANGSU UNIV

Self-humidification membrane electrode for proton exchange membrane fuel cell and preparation method thereof

InactiveCN103078122AImprove hydrophilicityGood moisturizing effectCell electrodesPtru catalystOrganic polymer

The invention discloses a self-humidification membrane electrode for a proton exchange membrane fuel cell and a preparation method thereof. The preparation method comprises the following steps of 1, pre-treating a proton exchange membrane, 2, mixing a carbon-supported platinum or platinum-ruthenium catalyst, a perfluorinated sulfonic acid resin, a hydrophilic organic polymer and an inorganic oxide and in water or a low-boiling point solvent, carrying out ultrasonic treatment to obtain catalyst slurry, and carrying out spray-coating of the catalyst slurry on one side of the proton exchange membrane by an illumination direct-coating technology to obtain an anode catalyst layer, 3, carrying out spray-coating of slurry without the hydrophilic organic polymer and the inorganic oxide on the other side of the proton exchange membrane to obtain a cathode catalyst layer, and 4, carrying out lamination of a gas diffusion layer and the proton exchange membrane of which the two sides are coated with the catalyst layers to obtain the self-humidification membrane electrode. The anode catalyst layer contains the hydrophilic organic polymer and the inorganic oxide so that the self-humidification membrane electrode has excellent self-humidification performances at a high cell temperature and low humidity.

Owner:SOUTH CHINA UNIV OF TECH

Catalyst coated membrane, membrane electrode assembly containing the same, method of producing the same, and fuel cell including the membrane electrode assembly

InactiveUS20070269699A1Improve unit performanceMaximum catalyst activityActive material electrodesNon-aqueous electrolyte accumulator electrodesCoated membraneFuel cells

A catalyst coated membrane (CCM) comprising an anode catalyst layer having a first catalyst layer composed of a non-supported catalyst and a second catalyst layer composed of a supported catalyst, a cathode catalyst layer composed of a supported catalyst, and an electrolyte membrane interposed between the anode catalyst layer and a cathode catalyst layer, the first catalyst layer of the anode catalyst layer being disposed adjacent to the electrolyte membrane; a membrane electrode assembly (MEA) comprising the catalyst coated membrane; a method of preparing the membrane electrode assembly; and a fuel cell comprising the membrane electrode assembly, are provided. The CCM, which comprises a bilayered anode catalyst layer including the first catalyst layer composed of a non-supported catalyst and the second catalyst layer composed of a supported catalyst, exhibits reduced electrical resistance and interfacial resistance, and has increased catalyst availability. The use of the CCM and an MEA having the same results in a decrease in the interfacial resistance between the electrodes and the electrolyte membrane, a decrease in the amount of the catalyst used in the electrode catalyst layer, and a decrease in the thickness deviation in the electrode layers. The fuel cell employing the MEA exhibits maximal activity of the supported catalyst, and has improved cell characteristics such as output voltage, output density, efficiency, and the like.

Owner:SAMSUNG SDI CO LTD

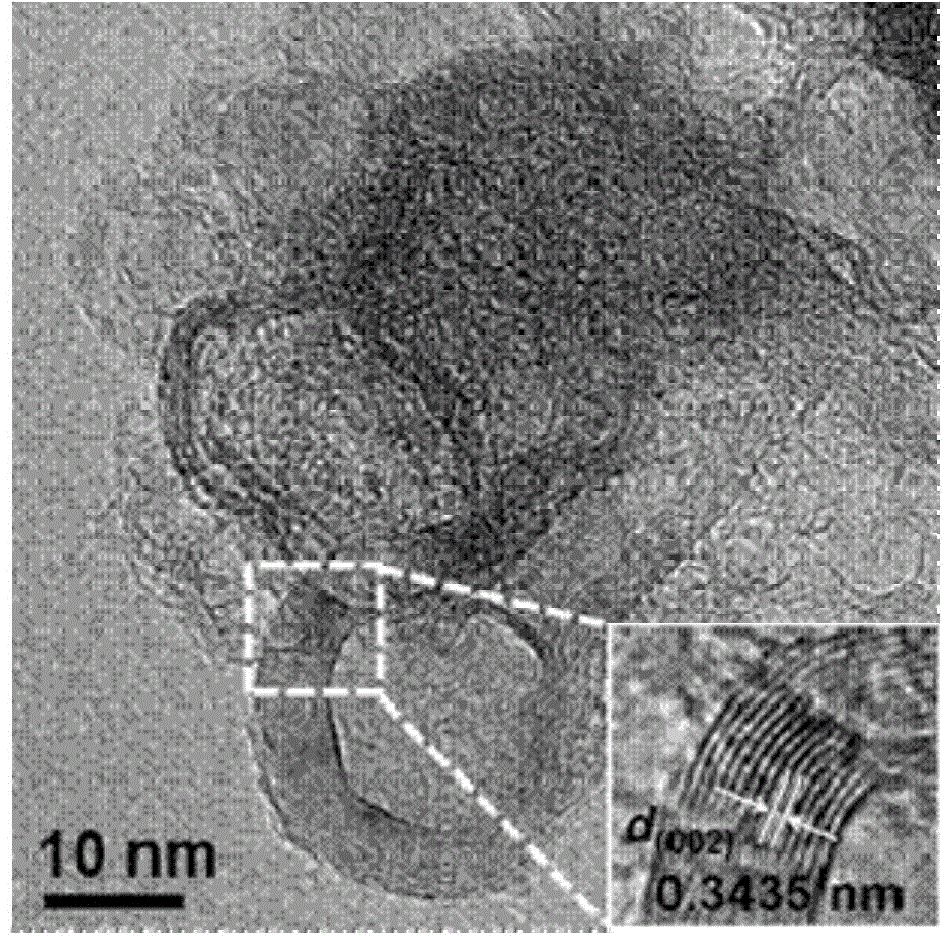

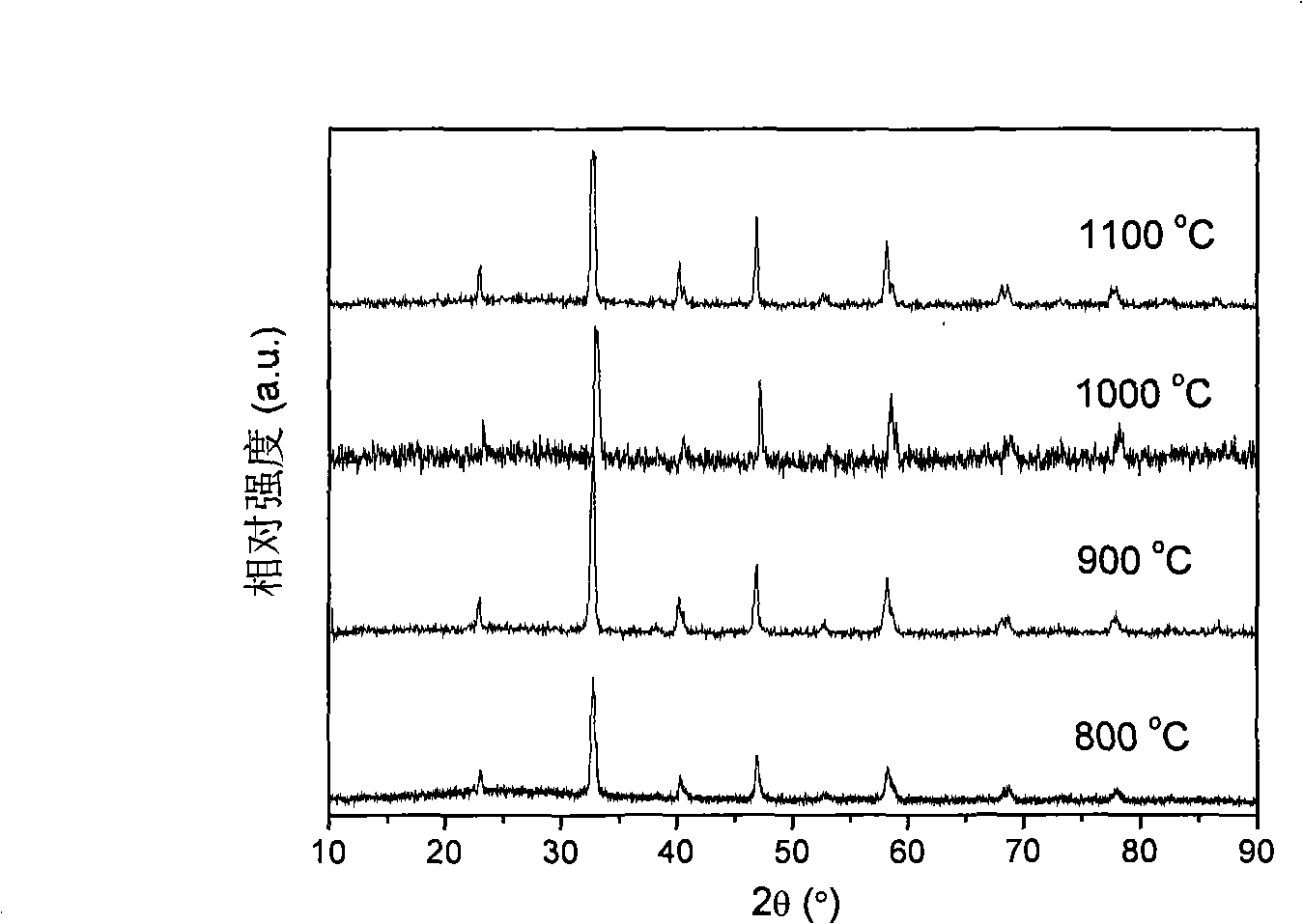

Production method of high stability CoSe2 / graphene composite electrode material

InactiveCN104971747AImprove stabilityStrong chemical resistancePhysical/chemical process catalystsCell electrodesPtru catalystCrystallinity

The invention discloses a production method of a high stability CoSe2 / graphene composite electrode material. The method comprises the steps: (1), synthesis of graphene oxide; (2) preparation of a cobalt hydroxide and graphene oxide mixed sol; (3) constant temperature vacuum aging; and (4) preparation of a CoSe2 / graphene composite electrode material. The present invention has the advantages of: (1), according to the above preparation method, CoSe2 is uniformly loaded on the graphene surface to achieve synthesis of a high stability CoSe2 / graphene composite electrode material; (2) the synthesis process is simple and easy to operate, and has mild conditions and low cost of raw materials; (3) compared with the existing non-noble metal electrode material, the CoSe2 / graphene composite electrode material prepared by the present invention has high efficiency electro-catalytic activity; and (4), the CoSe2 / graphene composite electrode material prepared by the present invention has good crystallinity, high stability and strong resistance to poison. The high stability CoSe2 / graphene composite electrode material can be used as a cathode catalyst for a polymer electrolyte membrane (PEMFC) fuel cell, has significantly increased catalytic activity in acid medium, reduces catalyst costs, and significantly enhances battery performance.

Owner:SUIHUA UNIV

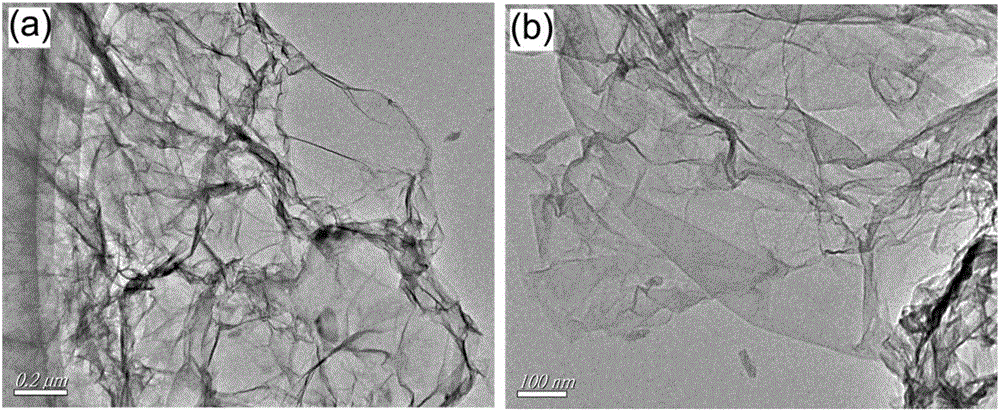

Iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and preparation method and application therefor

InactiveCN105609793ALarge specific surface areaMany active sitesCell electrodesPyrroleNitrogen doped

The invention belongs to the technical field of a nanomaterial, and specifically relates to an iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and a preparation method and an application therefor. The porous material is formed by embedding graphite-carbon-coated iron carbide into a nitrogen-doped porous graphene band network structure; the preparation method for the iron-nitrogen-doped graphene porous material comprises the steps of preparing a graphene oxide solution; adding a proper amount of conductive macromolecular pyrrole to the graphene oxide solution; obtaining uniform hydrogel through a hydrothermal process; performing oxidative polymerization on the hydrogel by ferric iron; then dispersing the hydrogel into a fresh ferric iron solution to complete adsorption; then performing drying and high-temperature carbonization thermal processing; and finally removing non-active and free iron phase from the reaction system by dilute acid so as to obtain the iron-nitrogen-doped graphene porous material. The porous material can be used as the negative electrode catalyst for a fuel cell, and shows quite high catalytic oxygen reduction activity, so that the porous material has quite important research meaning and bright application prospects.

Owner:FUDAN UNIV

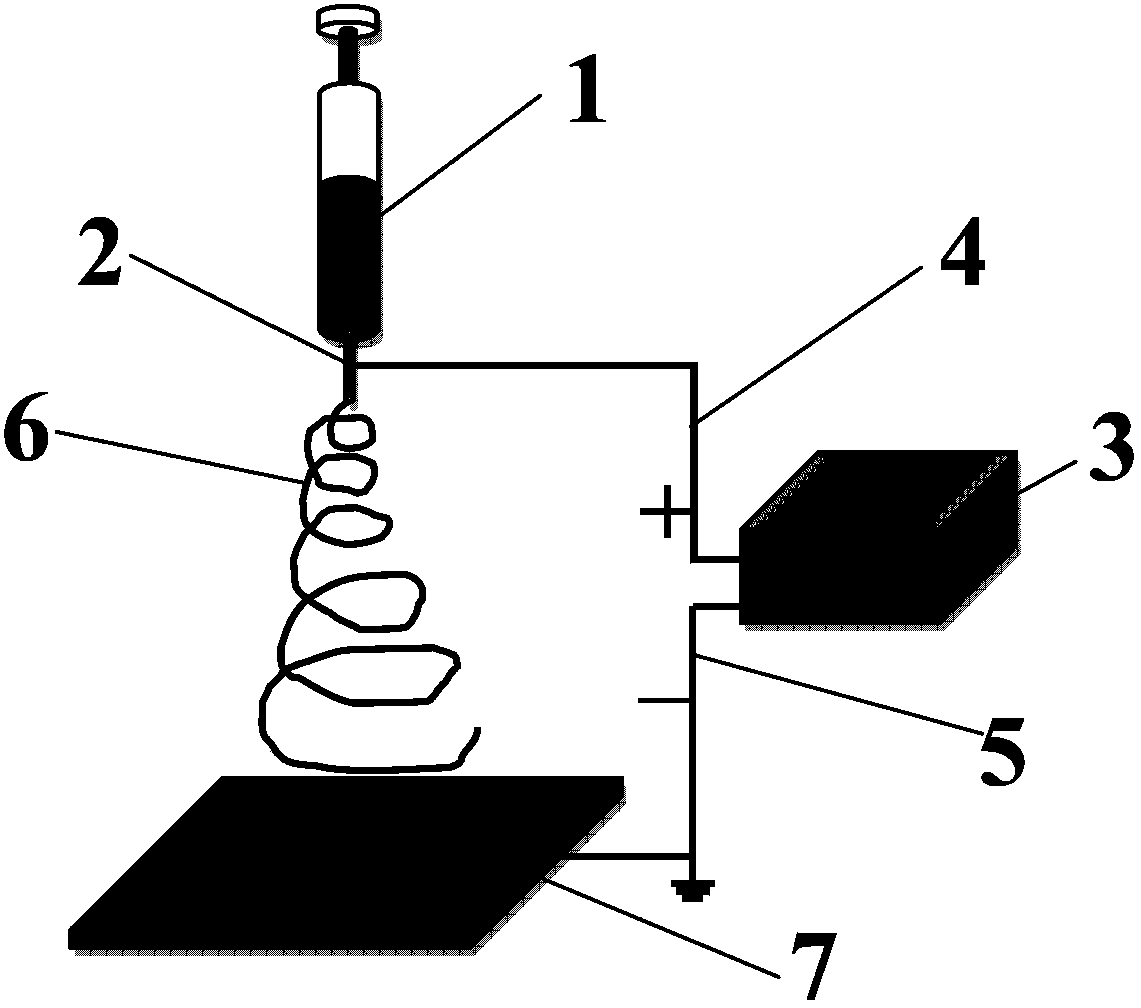

Preparation method of membrane electrode of direct methanol fuel cell

The invention relates to a preparation method of the membrane electrode of a direct methanol fuel cell. The method comprises the following steps: an electrostatic spinning technology is adopted to construct a nano-fiber network structure thin membrane mixed by active carbon powder and Nafion resin; a precious metal nano-catalyst is deposited on the surface of the manufactured nano-fiber network structure thin membrane, so that a cathode catalyst layer thin membrane and an anode catalyst layer thin membrane are manufactured respectively; or the mixture of the precious metal nano-catalyst and the Nafion resin is taken as raw materials to directly construct the cathode catalyst layer thin membrane and the anode catalyst layer thin membrane through the electrostatic spinning technology; a cathode gas diffusion layer, the anode catalyst layer thin membrane, a Nafion membrane, the cathode catalyst layer thin membrane and a cathode gas diffusion layer are hot-pressed finally, so that the aggregation of the membrane electrode of the direct methanol fuel cell is manufactured; the membrane electrode with a nano-fiber three-dimensional network structure is constructed through the electrostatic spinning technology, so that the maximization of the three-phase reaction interface of the membrane electrode is achieved, and the improvement of electrocatalytic activity, mass-transfer efficiency and utilization efficiency of the catalyst is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Fuel-cell system and method of generating energy from crude fuel

ActiveUS20170263945A1Improve performanceImprove adsorption capacityCell electrodesFuel cellsFuel cellsIon-exchange membranes

The present invention relates to a fuel-cell system. This system includes an anode electrode; a cathode electrode; a separator positioned between the anode electrode and the cathode electrode, wherein the separator is not an ion exchange membrane; an anode catalyst; and a cathode catalyst, wherein the cathode catalyst is a non-precious metal catalyst or metal-free catalyst. The present invention also relates to a method of generating energy from crude fuel. This method involves providing a fuel-cell system and contacting the fuel-cell system with a crude fuel under conditions effective to generate energy from the crude fuel.

Owner:IOWA STATE UNIV RES FOUND

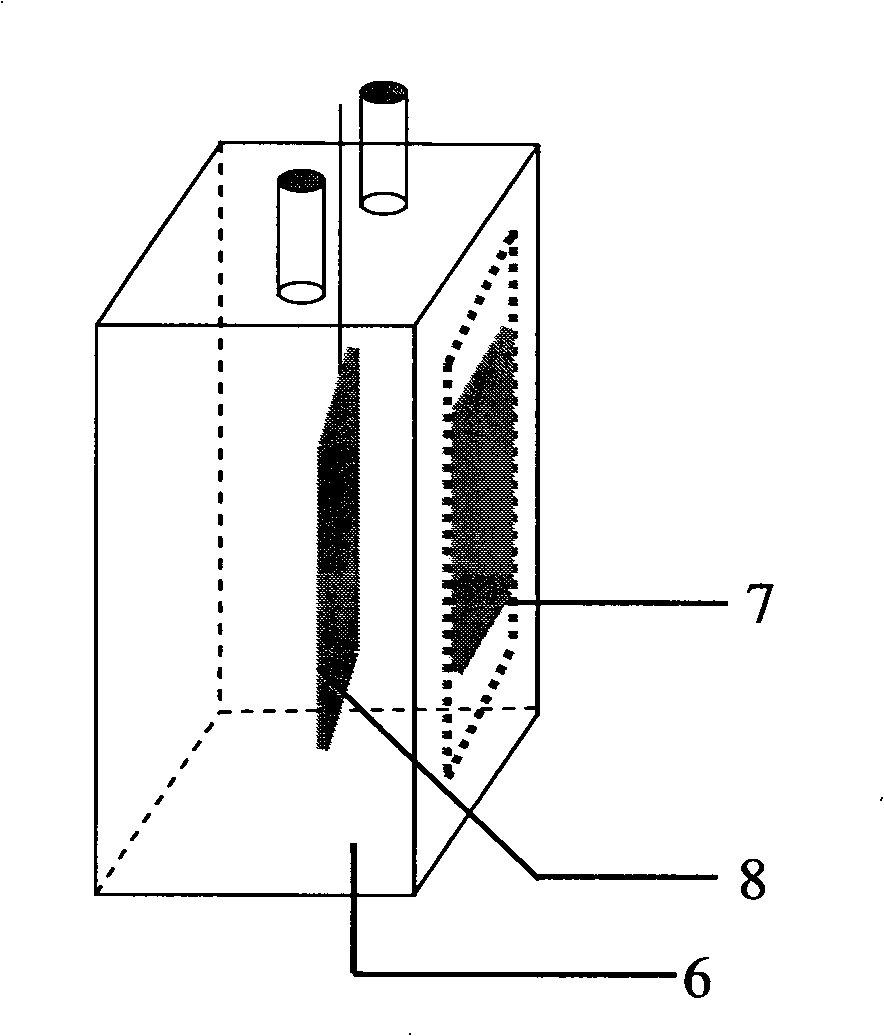

Nitrogen-doped Fe/Fe3C/C microbial fuel cell cathode catalyst material and preparation method thereof

The invention discloses a nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material and a preparation method thereof, and relates to a microbial fuel cell cathode catalyst material and a preparation method thereof, which aim to solve the problem that the cost is high due to a platinum-carbon catalyst adopted as the microbial fuel cell cathode catalyst material in the prior art. The nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material is a composite material prepared from a ferrum source and a carbon source, and is a composite material with Fe particles and Fe3C particles uniformly distributed on a graphitization carbon framework, and the particle diameter is 10nm-300nm. The method comprises the following steps of dissolving, water bath heating, drying, and high-temperature carbonization reduction, thereby obtaining the nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material. The preparation method is used for preparing the nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material.

Owner:哈尔滨市道外区大化化验仪器批发站

Self-respiration type fuel battery membrane electrode and method for producing the same

InactiveCN101159333ALower resistanceImprove performanceCell electrodesSolid electrolyte fuel cellsEngineeringContact resistance

The invention discloses a membrane electrode of air-breathing fuel cells and a fabrication method thereof, relating to the membrane electrodes of air-breathing fuel cells and the fabrication method. The invention resolves the problem that the contact resistance of the electron current collection mode of the prior film electrode is large, which is harmful to electric pile integration. In the membrane electrode in the invention, a porous metal reticular current collector (5) is longitudinally provided inside a cathode catalyst layer (3), and a proton exchange membrane (1), an anode catalyst layer (2), the cathode catalyst layer (3), an anode diffusion layer (4), the porous metal reticular current collector (5) and a cathode diffusion layer (6) are solidified by hot pressing into a unity. The fabrication method includes that: 1. fabricating the anode diffusion layer; 2. fabricating the cathode diffusion layer; 3. integrating the porous metal reticular current collector with the cathode catalyst layer; 4. fabricating the anode catalyst layer; 5. fabricating the cathode catalyst layer; 6. the membrane electrode is formed by hot pressing. The invention uses the internal current collection mode, allowing the air-breathing fuel cells to reduce the resistance of membrane electrodes and enhancing the performance of membrane electrodes.

Owner:HARBIN INST OF TECH

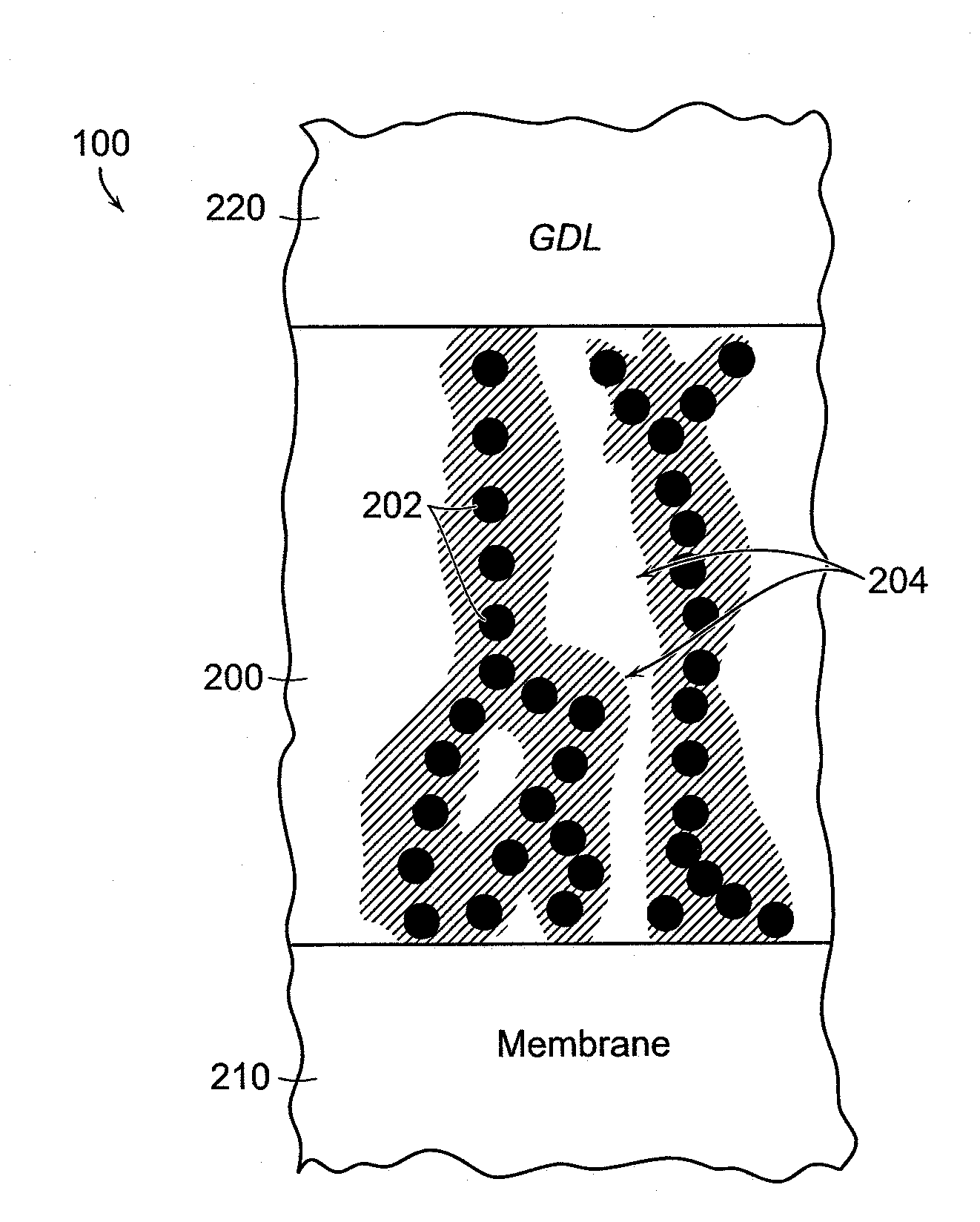

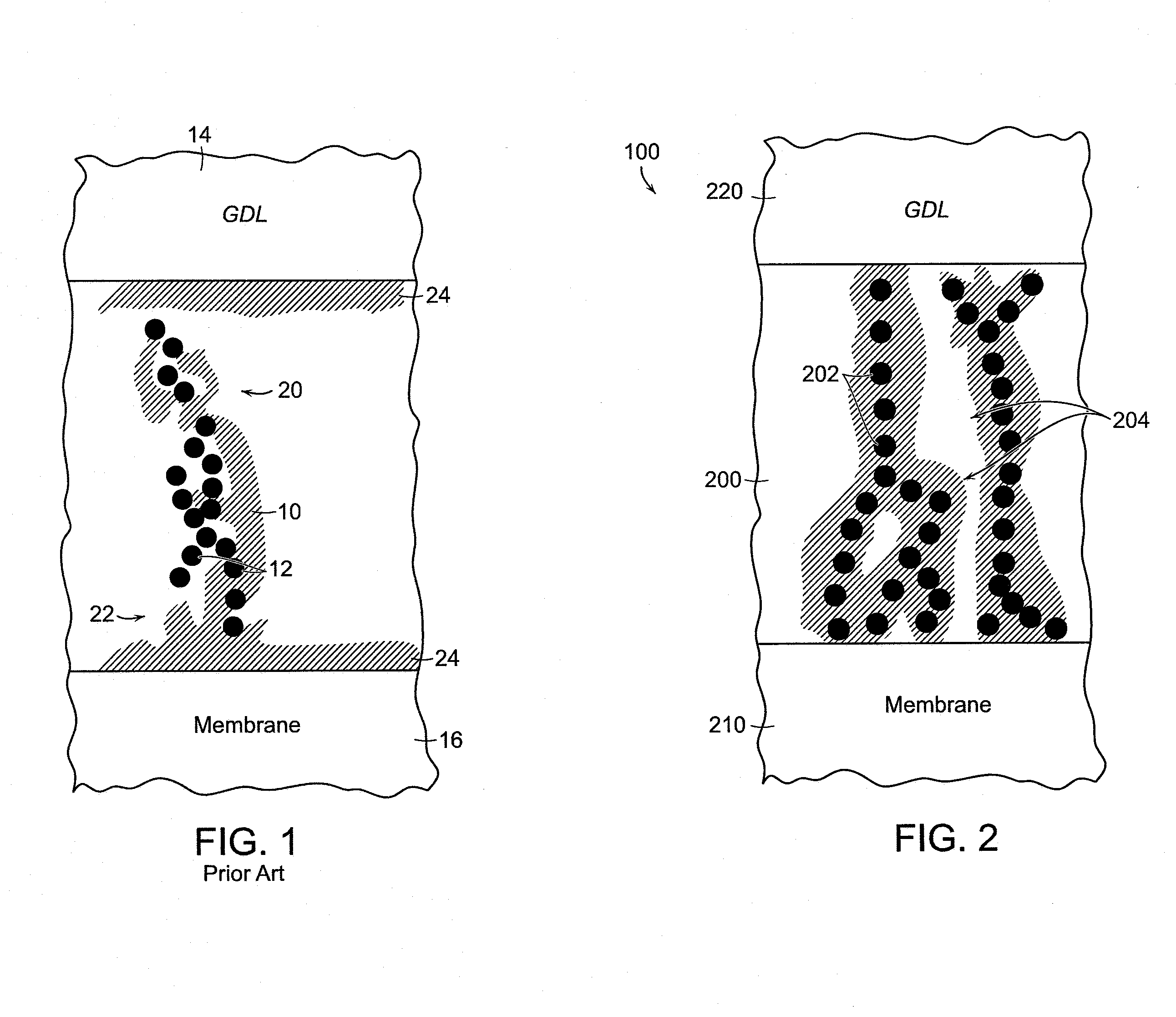

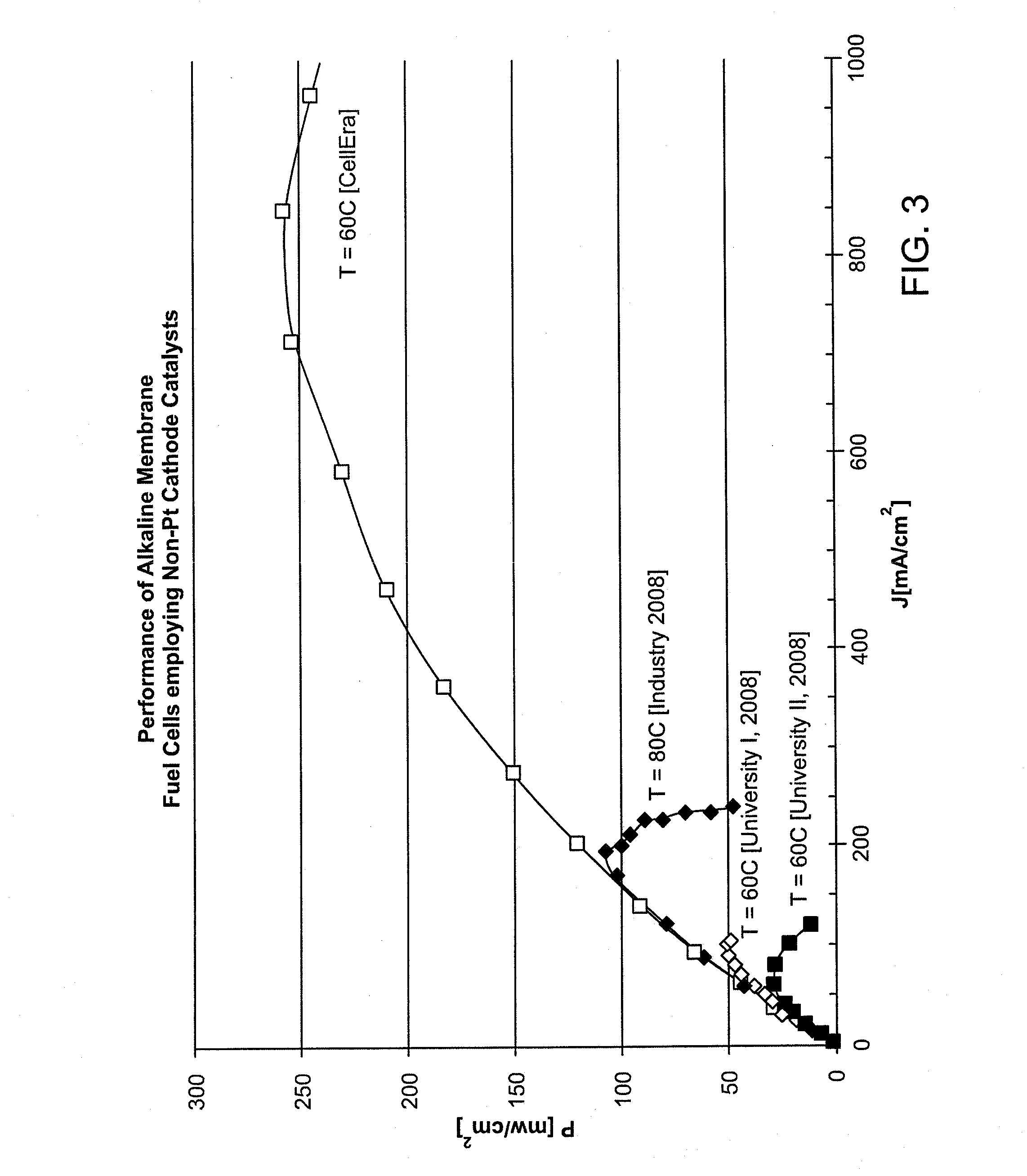

Catalyst Coated Membrane (CCM) and Catalyst Film/Layer for Alkaline Membrane Fuel Cells and Methods of Making Same

Alkaline membrane fuel cells designed with silver cathode catalysts include a catalyst layer comprising silver metal nano-particles and an anion-conducting ionomer. The silver nano-particles are mixed with a solution of the ionomer to form a catalyst ink that is applied to an alkaline membrane to form an ultra-thin cathode catalyst layer on the membrane surface.

Owner:POCELL TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com