Application of manganese dioxide for preparing microorganism fuel cell cathode

A fuel cell cathode, manganese dioxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, slow dissolution, loss of active centers, etc., and achieve the effect of high power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1: Electrode Preparation

[0052] Mix manganese dioxide powder, graphite powder, and polyvinylidene fluoride (PVDF) at a mass ratio of 65:20:15, add N-methylpyrrolidone into the mixture, stir into a paste and disperse ultrasonically for 30 minutes; Spread the paste mixture evenly on graphite paper, and then dry it at 100°C to obtain MnO 2 catalytic electrode. In the same way, high-purity graphite powder and binder are mixed at a mass ratio of 85:15 to prepare a graphite non-catalytic electrode for experimental comparison.

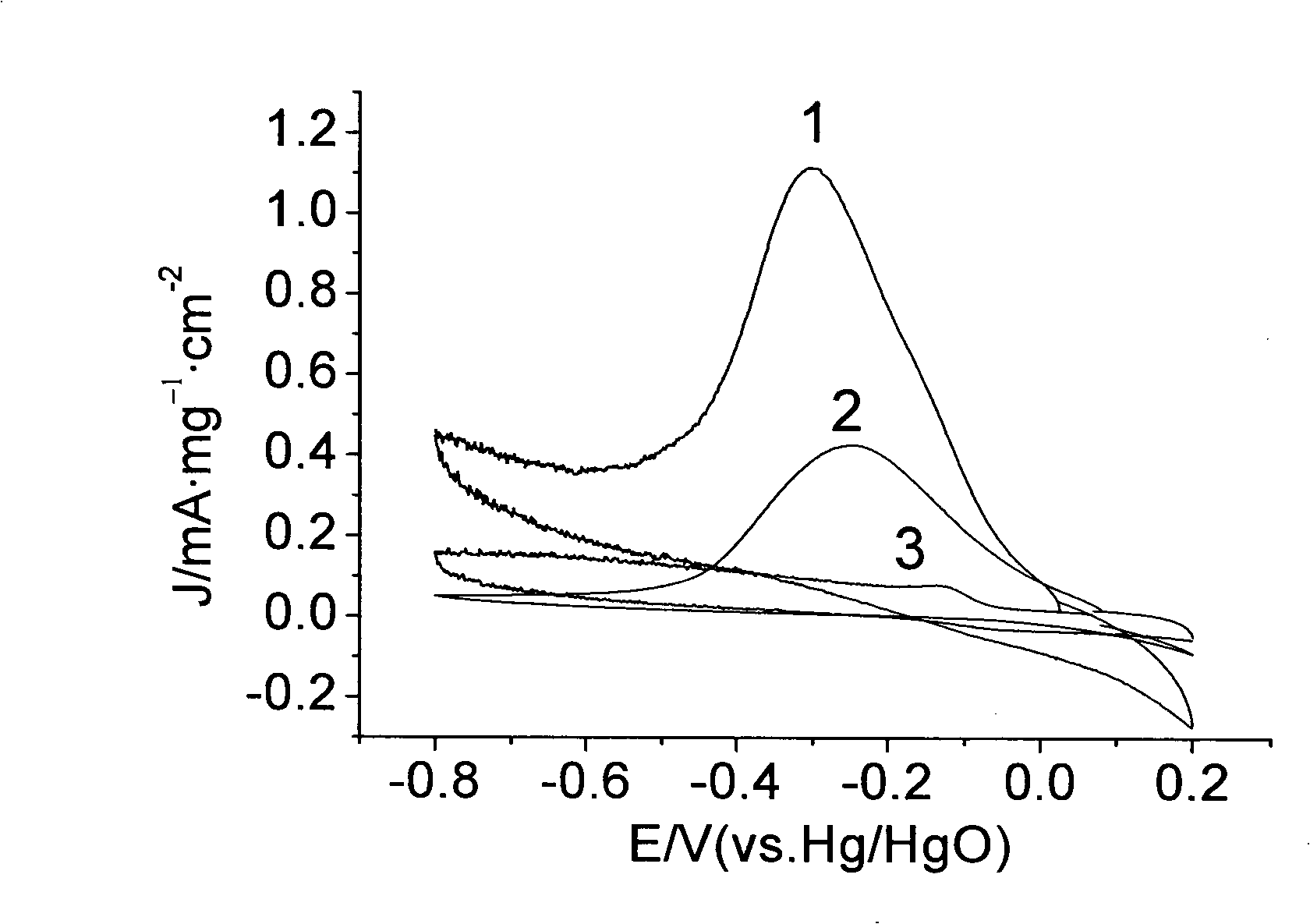

[0053] Step 2: Electrochemical Test

[0054] Cyclic Voltmetry (CV) uses a three-electrode system, with Pt rods ( ) is the counter electrode, potential range: -0.8~0V, Hg / HgO is the reference electrode, 1mol / L KOH is the electrolyte, nitrogen (or air) is passed for 15 minutes before the test, and the ventilated state is kept during the test. Investigating MnO at a scan rate of 1mV / s 2 Cyclic voltammetry performance of catalytic and graphite...

Embodiment 2

[0063] Step 1: Preparation of Catalytic Matrix Electrode

[0064] Mix manganese dioxide powder, graphite powder, and polyvinylidene fluoride (PVDF) at a mass ratio of 57:28:15 to 73:12:15, add N-methylpyrrolidone to the mixture, stir to form a paste and Ultrasonic dispersion for 30 minutes; spread the paste mixture evenly on carbon fiber cloth (4.0cm×4.0cm, MnO 2 Loading capacity 5.0±0.2mg / cm 2 ), and then dried at 100°C to obtain MnO 2 Catalytic substrate electrodes.

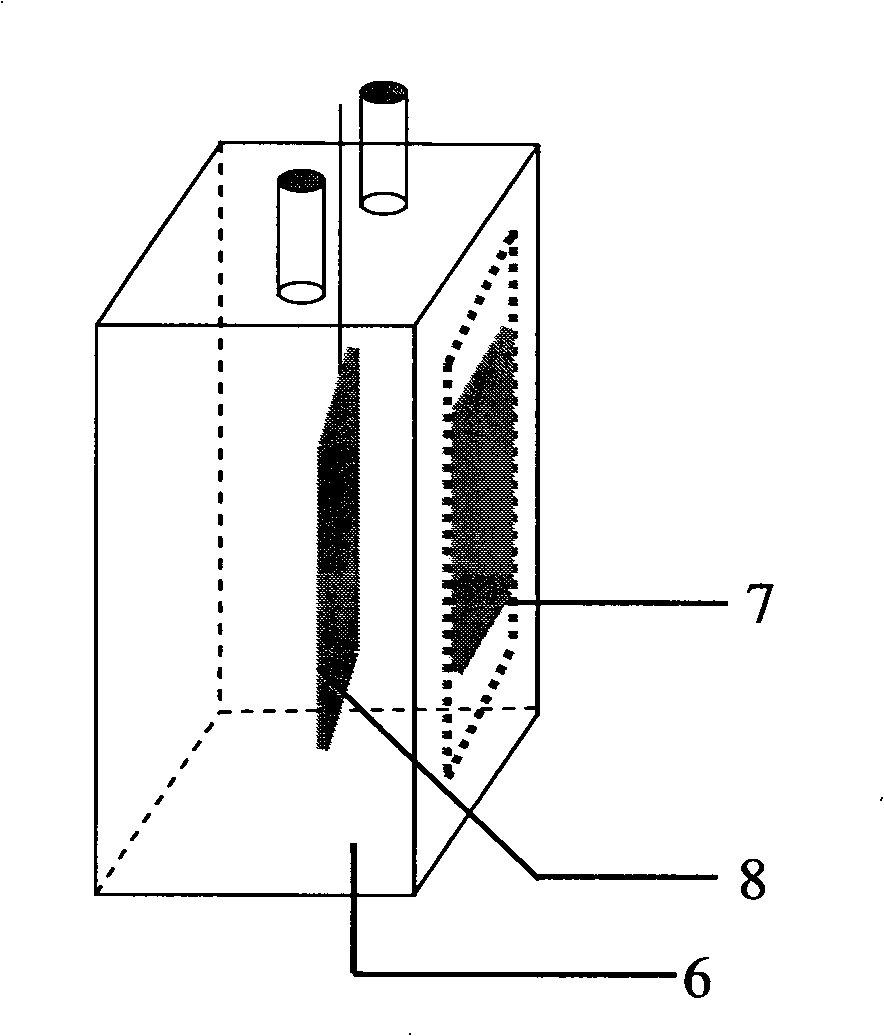

[0065] Step 2: Preparation of Membrane Composite Cathode

[0066] will be loaded with MnO 2 Catalytic substrate electrode cation exchange membrane (the side coated with the catalyst is in contact with the membrane) was hot-pressed at a temperature of 115° C. and a pressure of 14 MPa for 3 minutes, taken out and cooled to room temperature.

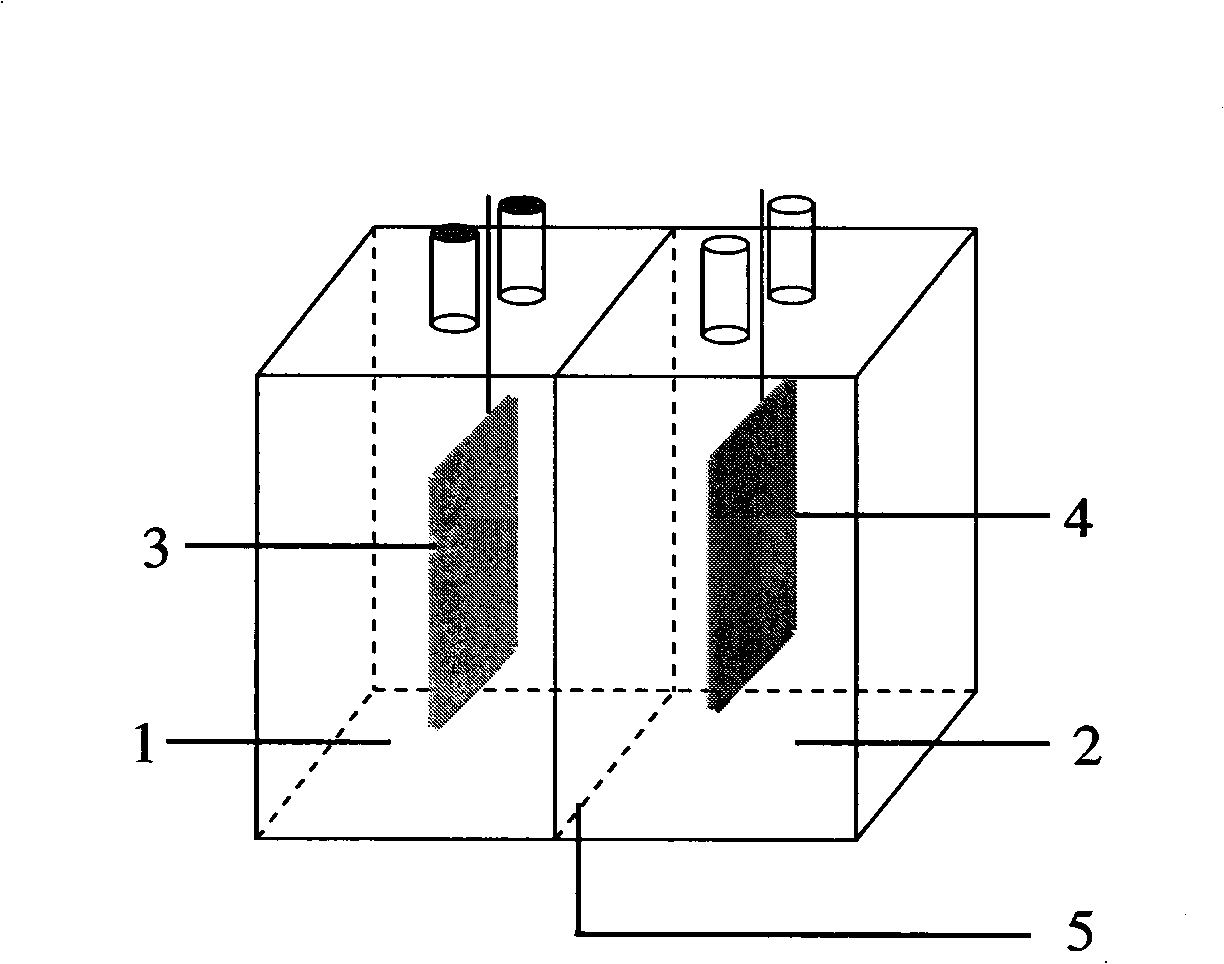

[0067] Step 3: Single-chamber MFC performance test

[0068] The electrogenic strain and the anolyte are the same as the double-chamber MFC in Example 1, but the anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com