Nitrogen-doped Fe/Fe3C/C microbial fuel cell cathode catalyst material and preparation method thereof

A fuel cell cathode and microorganism technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of high cost, and achieve the effects of energy saving, good conductivity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

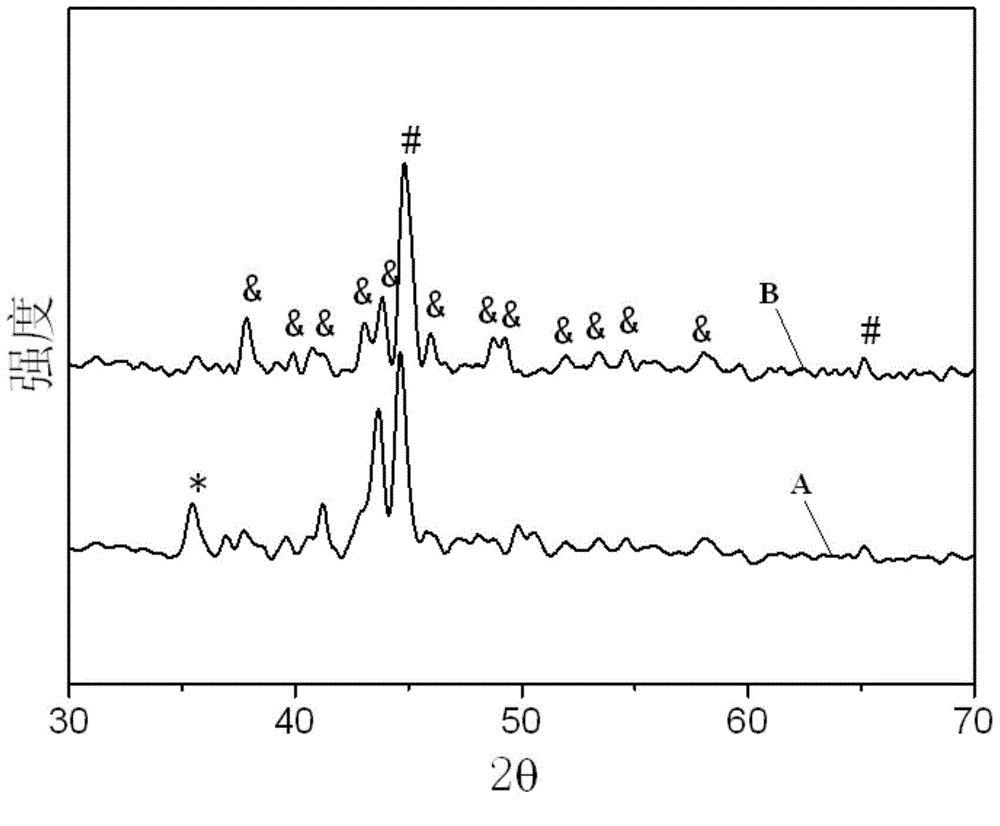

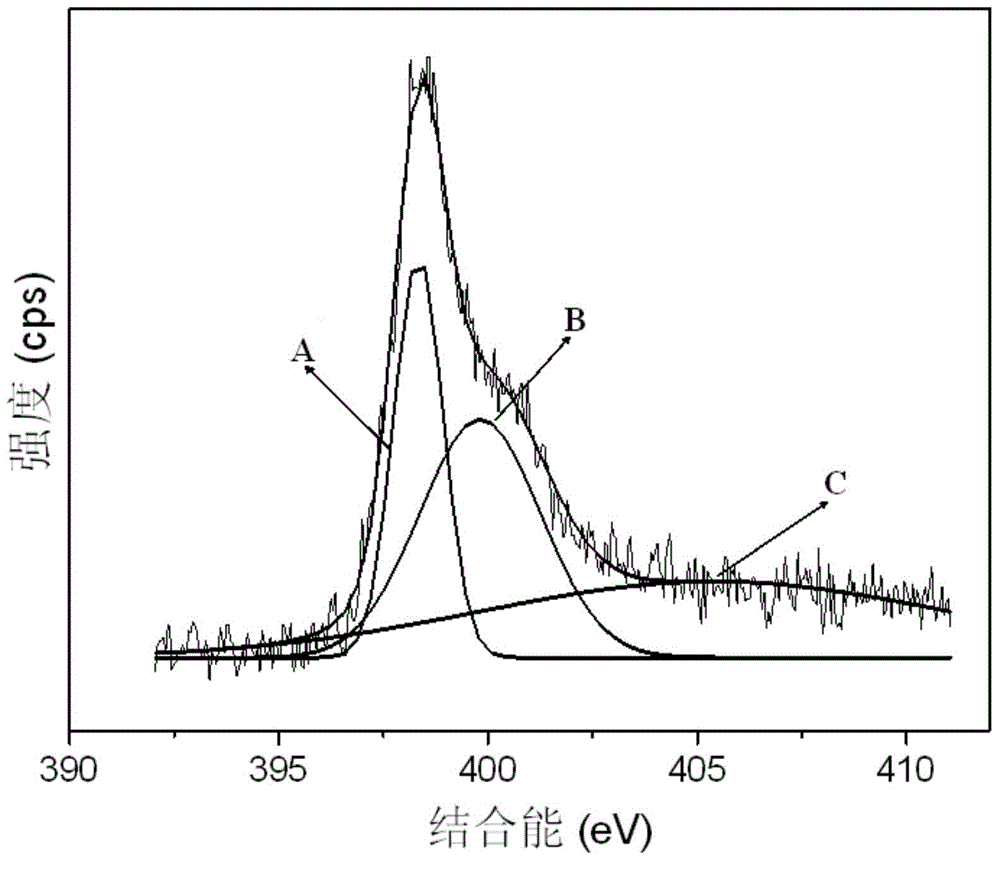

[0018] Specific implementation mode 1: This implementation mode is a nitrogen-doped Fe / Fe 3 C / C microbial fuel cell cathode catalyst material, composite material prepared by iron source and carbon source, described composite material is Fe particle and Fe 3 C particles are evenly distributed in the graphitized carbon skeleton, and Fe / Fe with a particle size of 10nm to 300nm 3 C / C composite material; the mass ratio of the carbon source to the iron source is 1:(0.1-0.5).

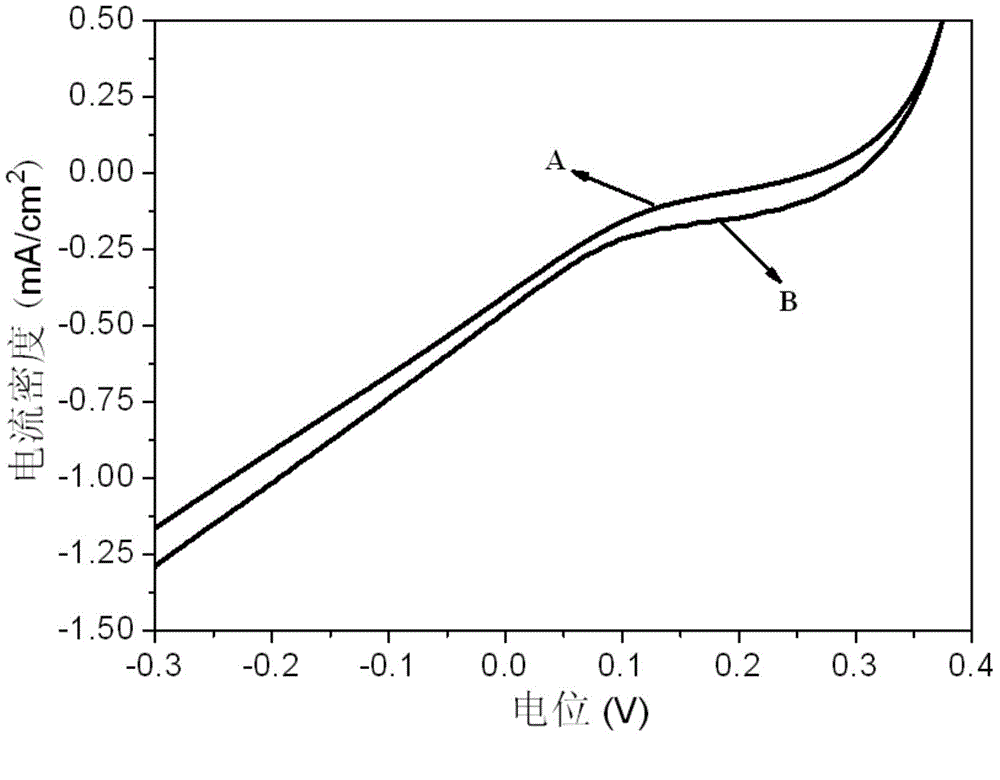

[0019] MFCs have a large energy loss in the process of converting bioenergy into electricity. On the one hand, these losses come from Coulomb losses, that is, the organic matter in wastewater is not used for power generation, but the energy is lost in other ways; On the one hand, it comes from the energy loss caused by electrode polarization and ohmic internal resistance. In general, in the face of challenges from traditional wastewater energy technologies, one of the main tasks of MFCs research is to "reduc...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the iron source is one or more of ferric chloride, ferric nitrate, ferric sulfate, ferrous sulfate and ferrous chloride mixture. Others are the same as the first embodiment.

[0022] When the iron source described in this embodiment is a mixture, each component in the mixture is mixed in any ratio.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the carbon source is melamine or cyanamide. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com