Patents

Literature

318 results about "Carbon skeleton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term carbon skeleton is used to describe the pattern in which the carbon atoms are bonded together in a molecule, disregarding atoms of other elements and differences between single and multiple bonds. Most chemical reactions of organic compounds do not break bonds between carbon atoms and….

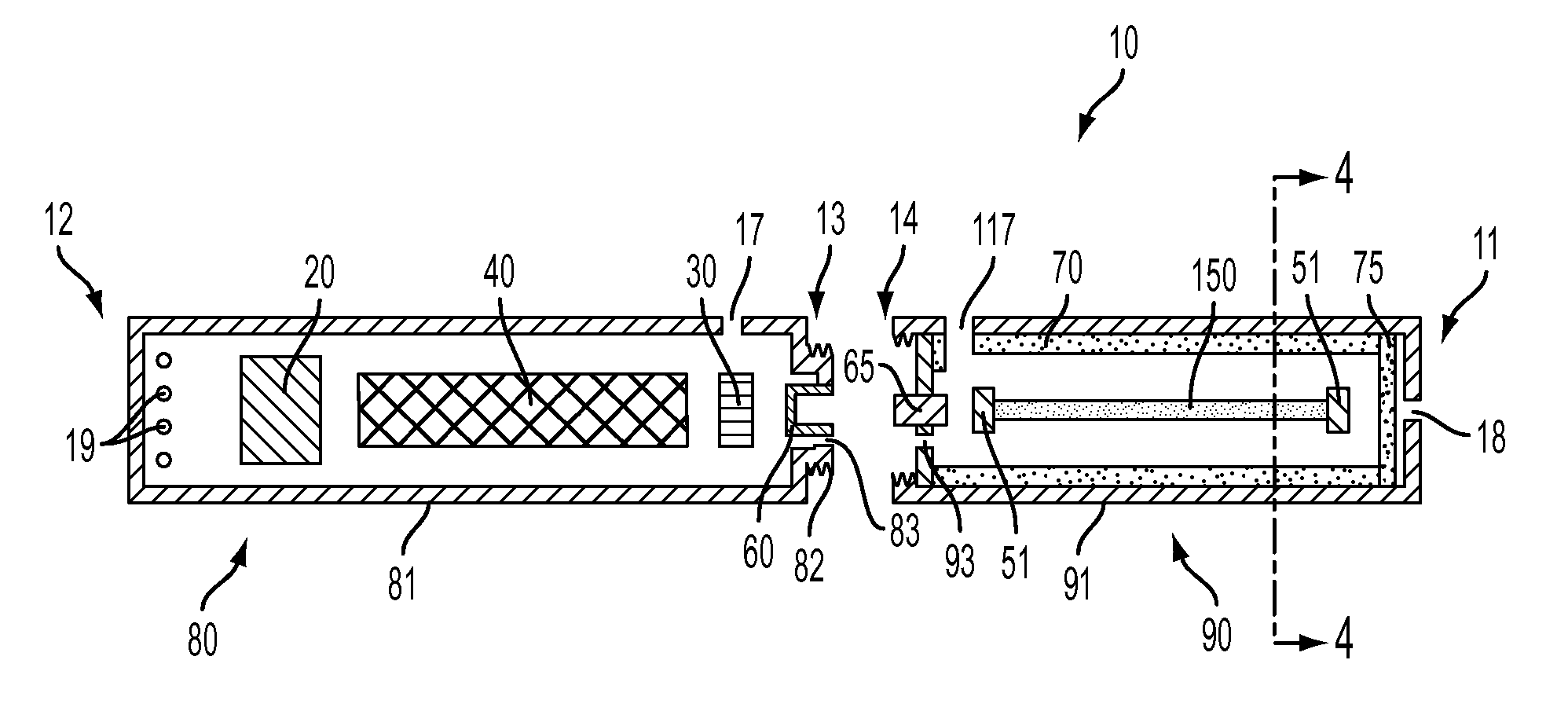

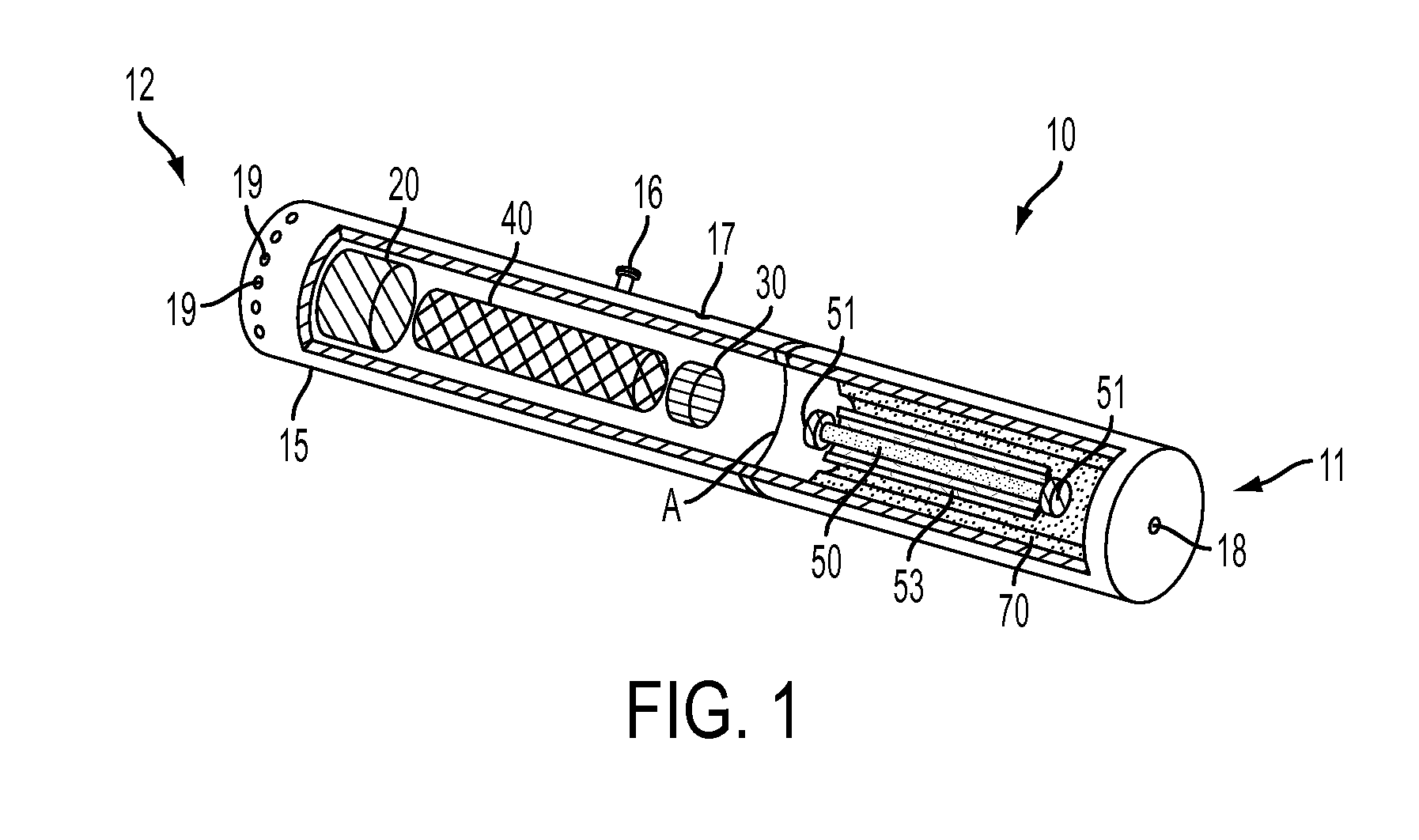

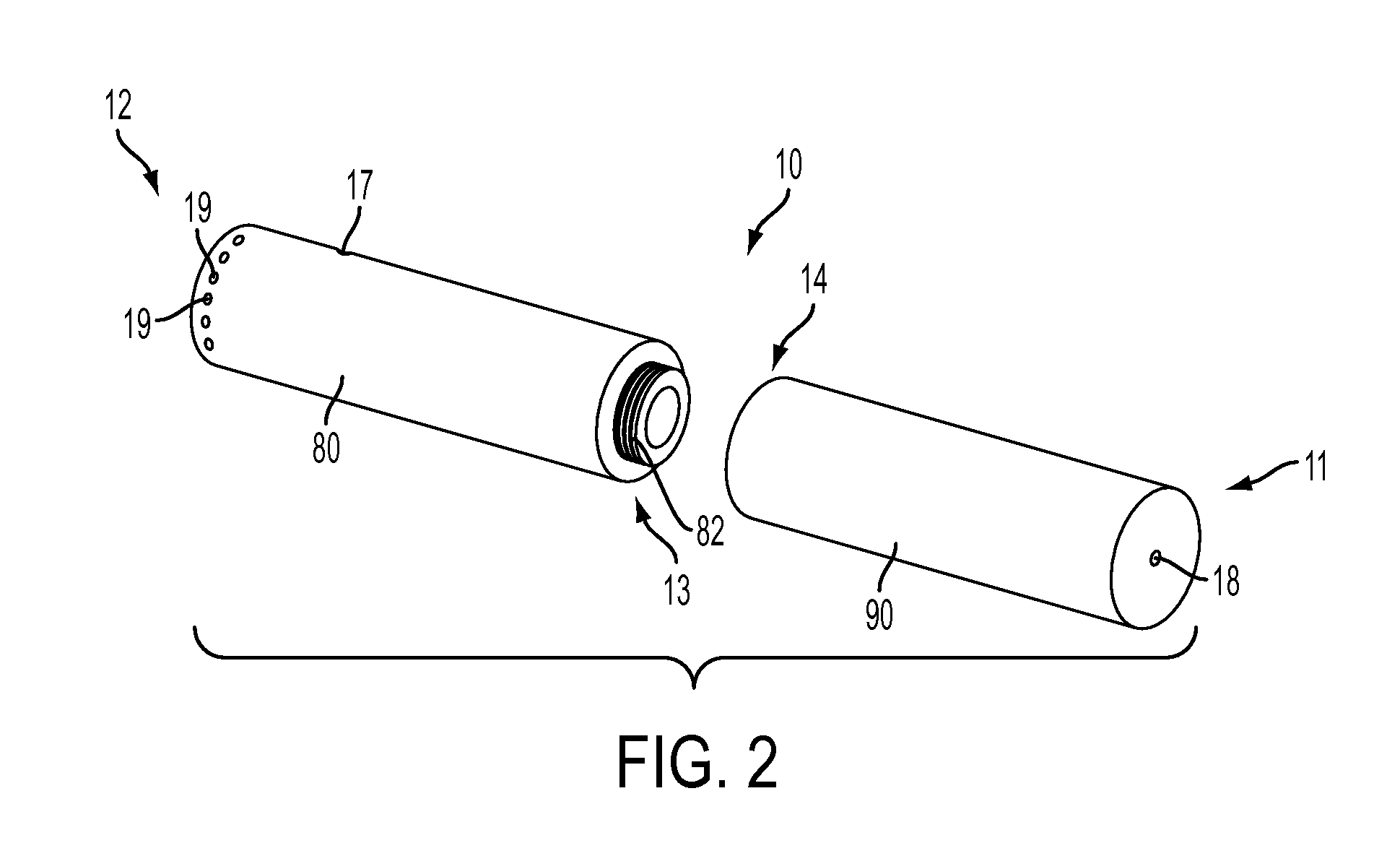

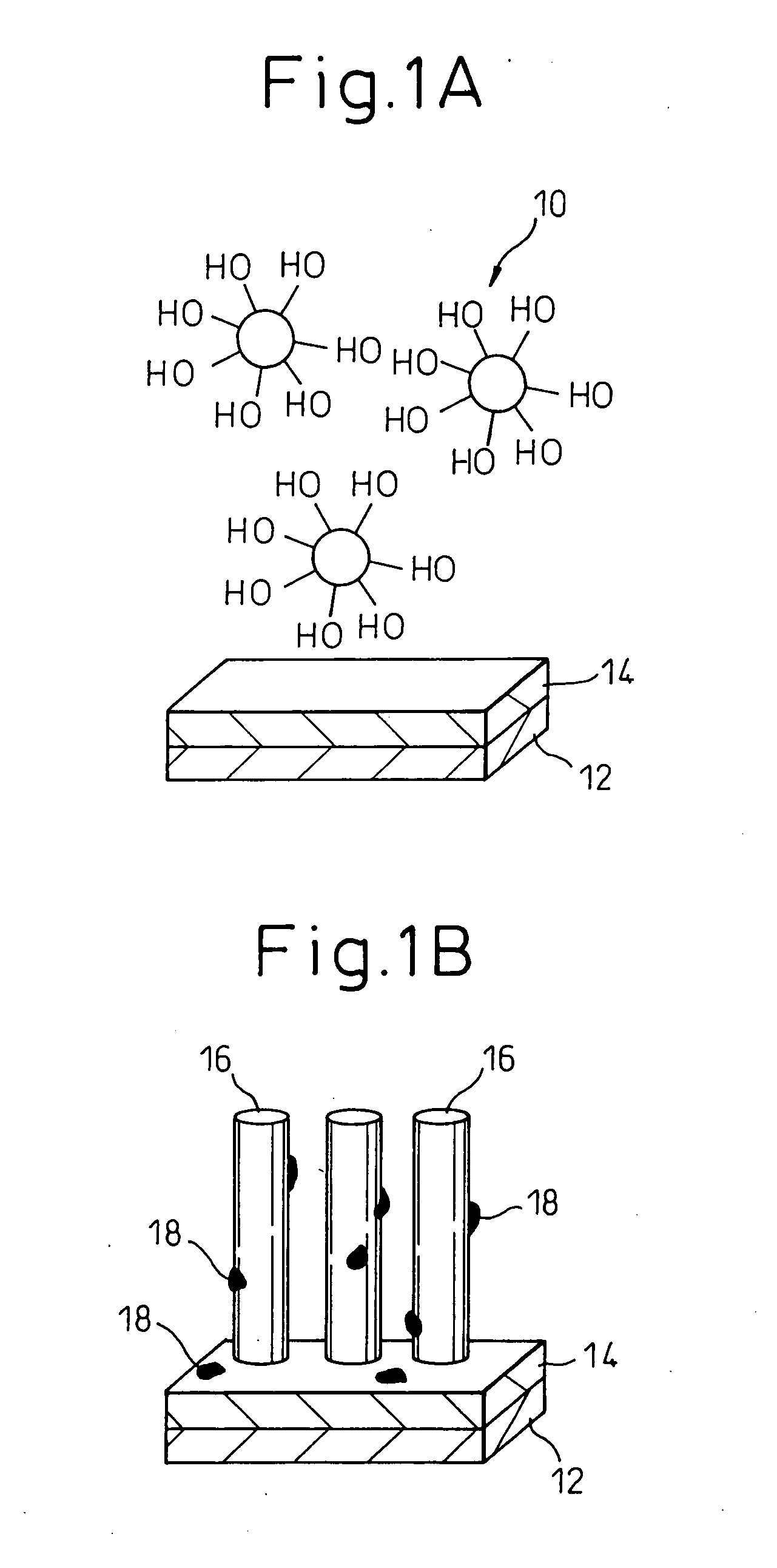

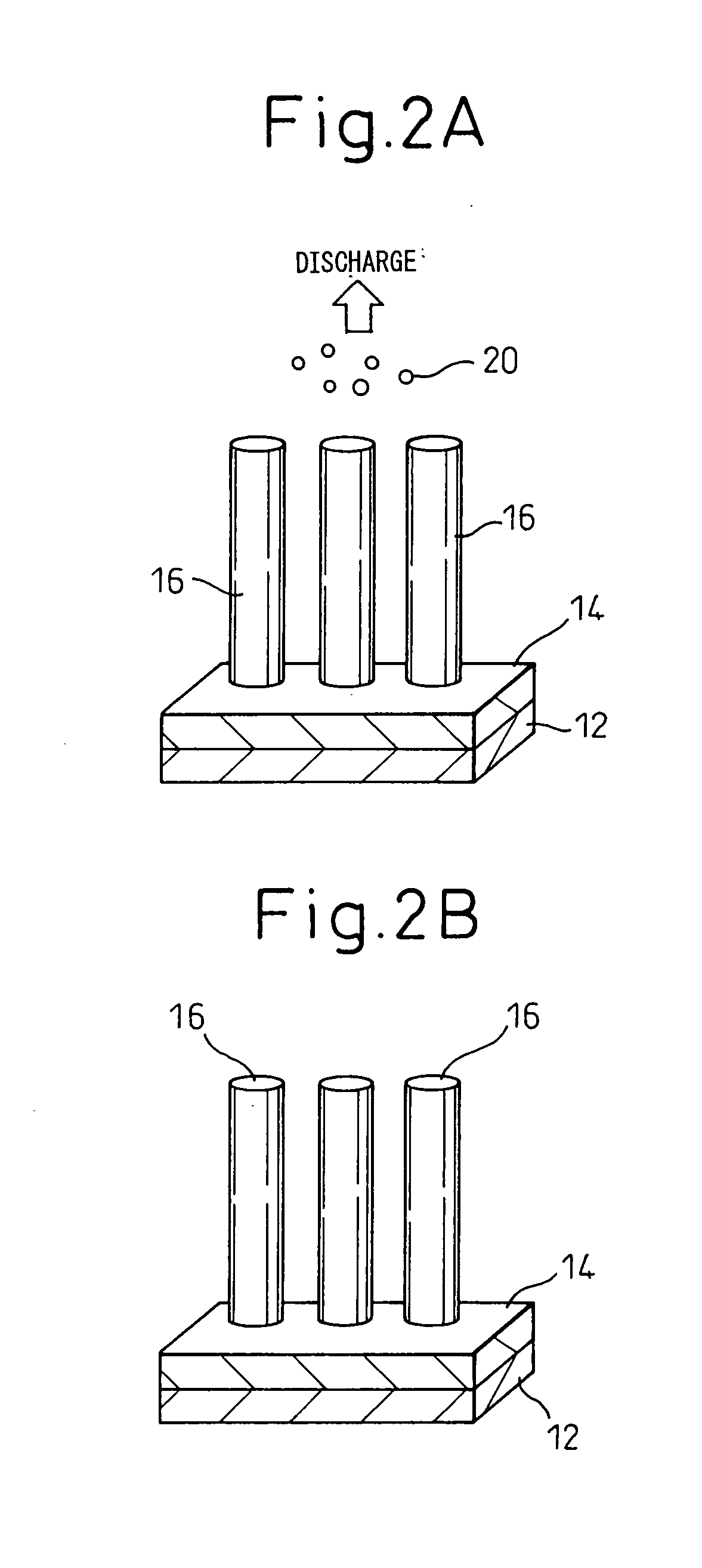

Smoking article incorporating a conductive substrate

The present invention provides a conductive substrate useful for Joule heating, such as in an electronic smoking article. Particularly, the invention provides a resistive heating element formed of a conductive substrate. The conductive substrate comprises an electrically conductive material and a carbonaceous additive, such as a binder material. The conductive substrate is carbonized in that it is subjected to calcining conditions to effectively reduce the carbonaceous additive to its carbon skeleton. It has been found that such carbonized substrate has surprisingly improved resistance properties in relation a substrate of the same formulation that is not carbonized. The carbonized substrate can include an aerosol precursor material. The formed resistive heating element can be included in an electronic smoking article to simultaneously provide resistive heating and aerosol formation with a single, unitary component.

Owner:RAI STRATEGIC HLDG INC

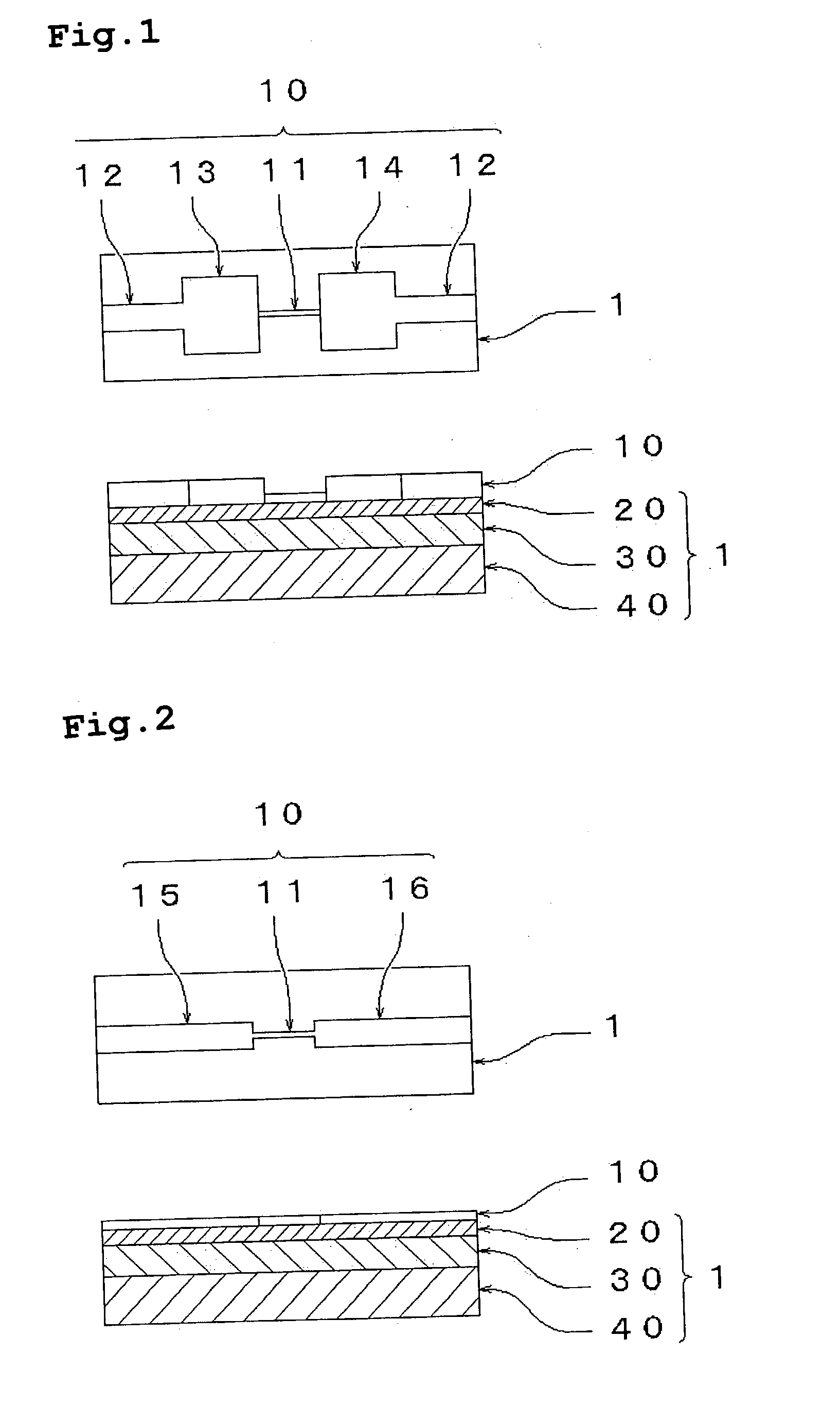

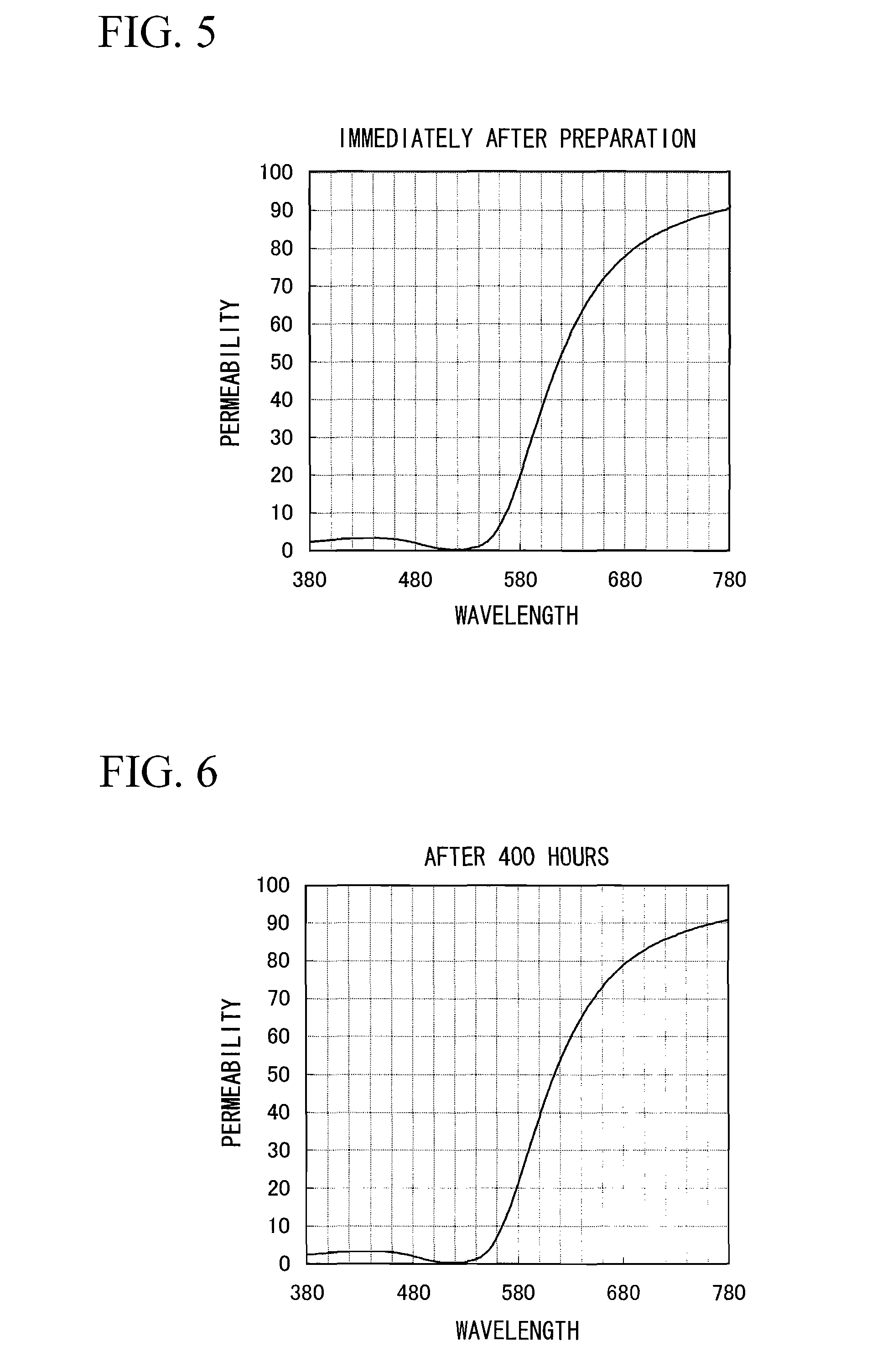

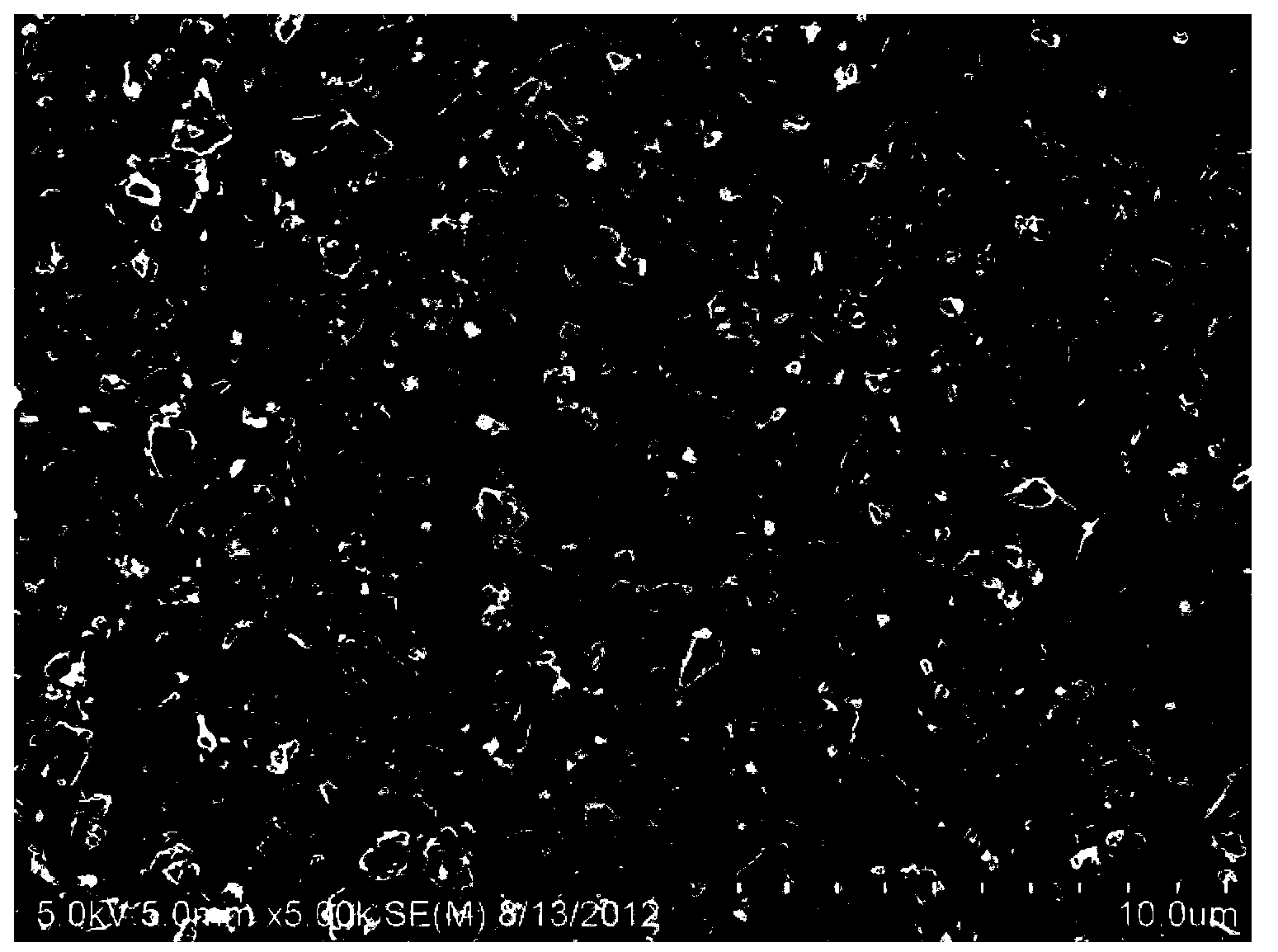

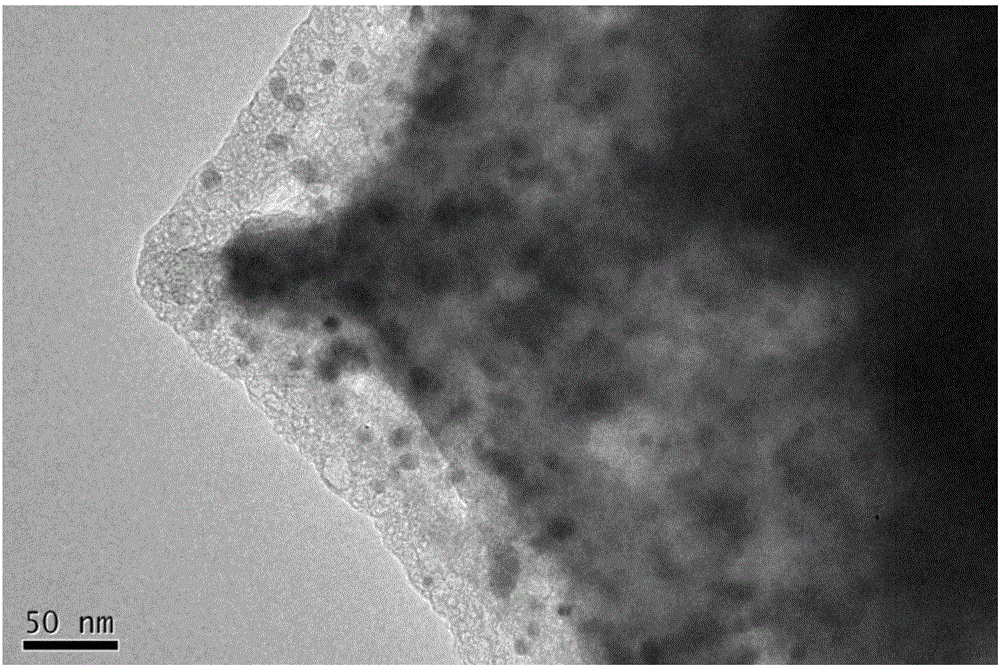

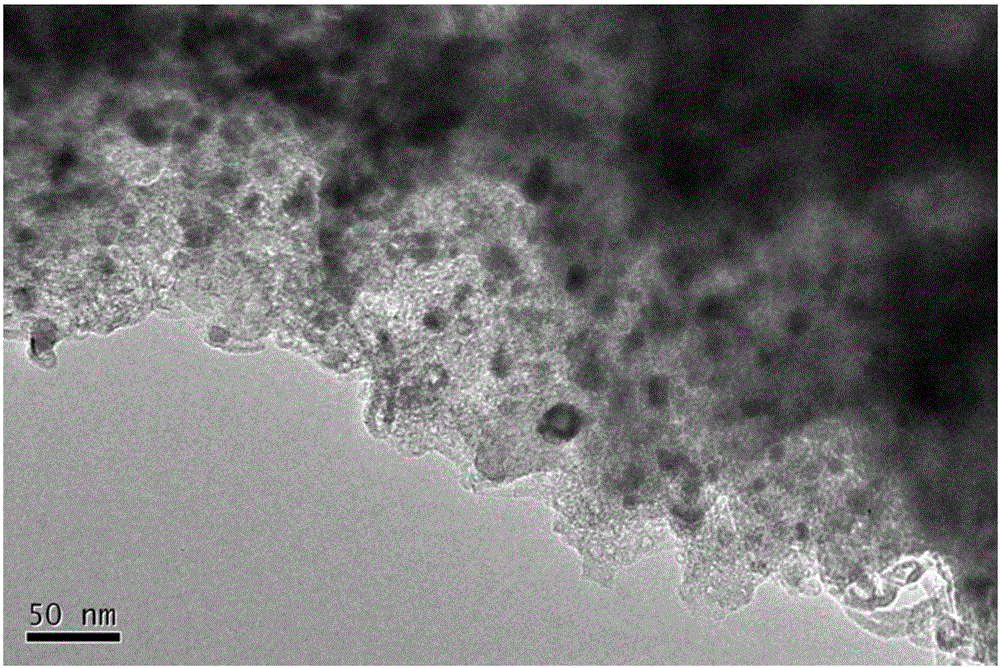

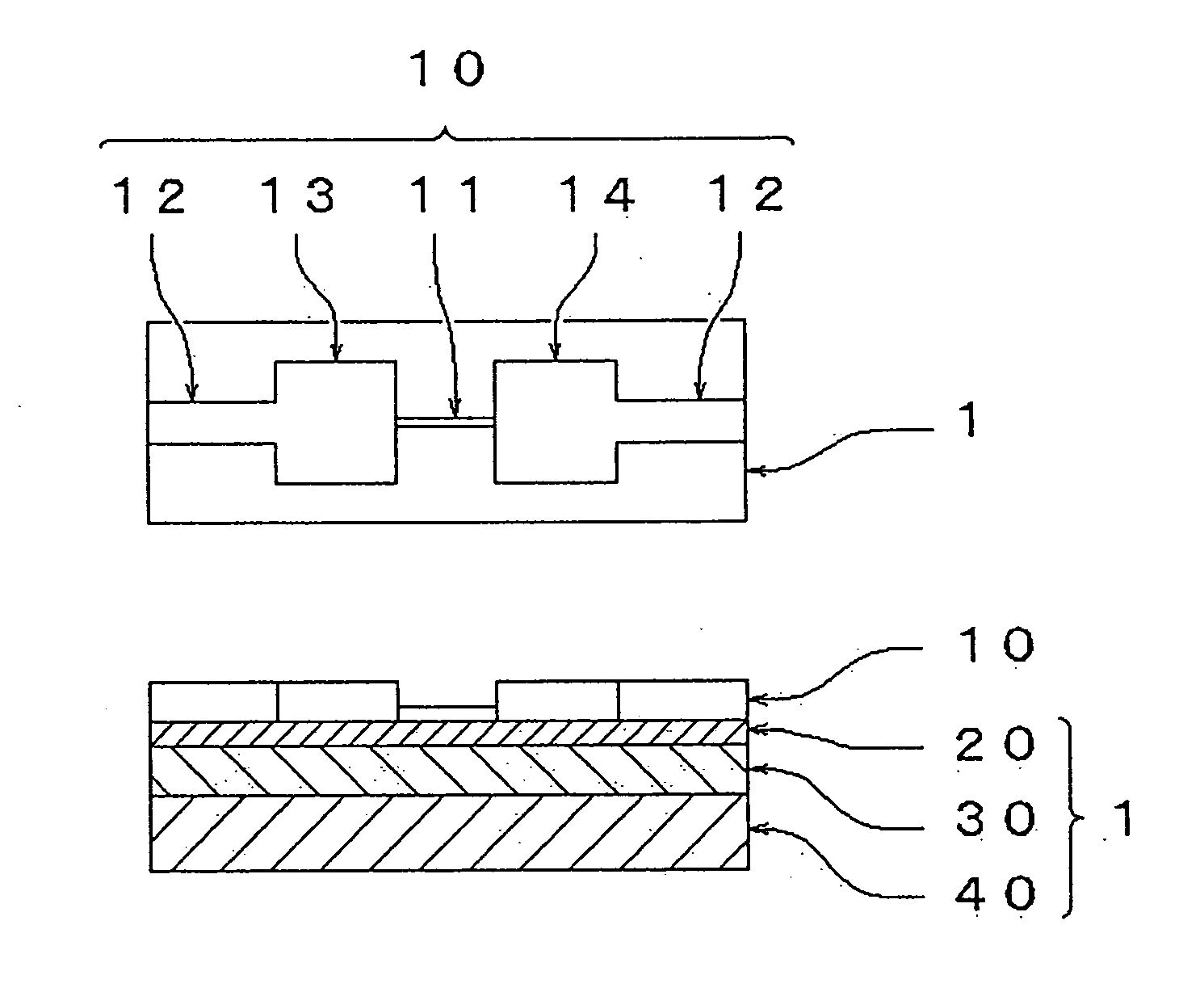

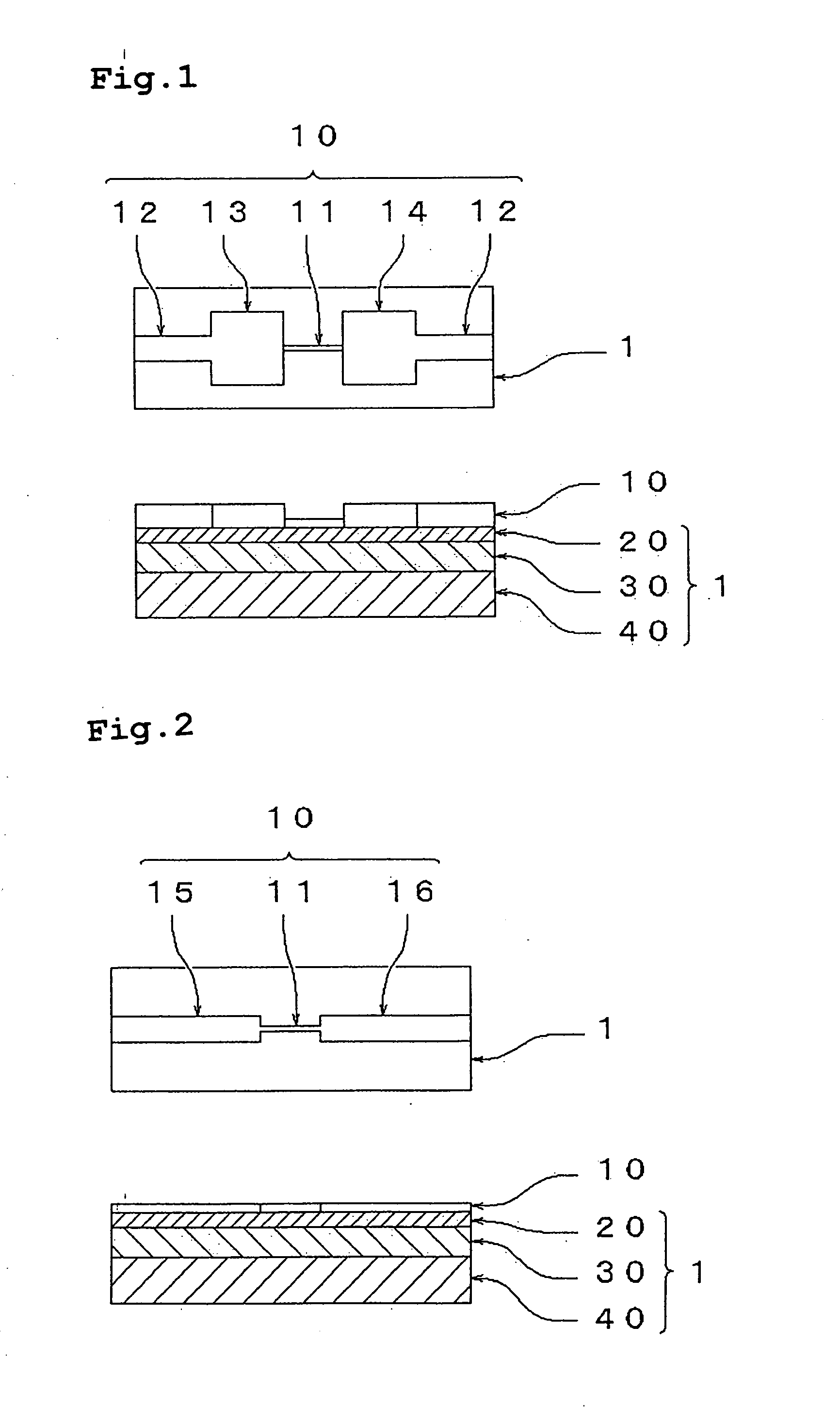

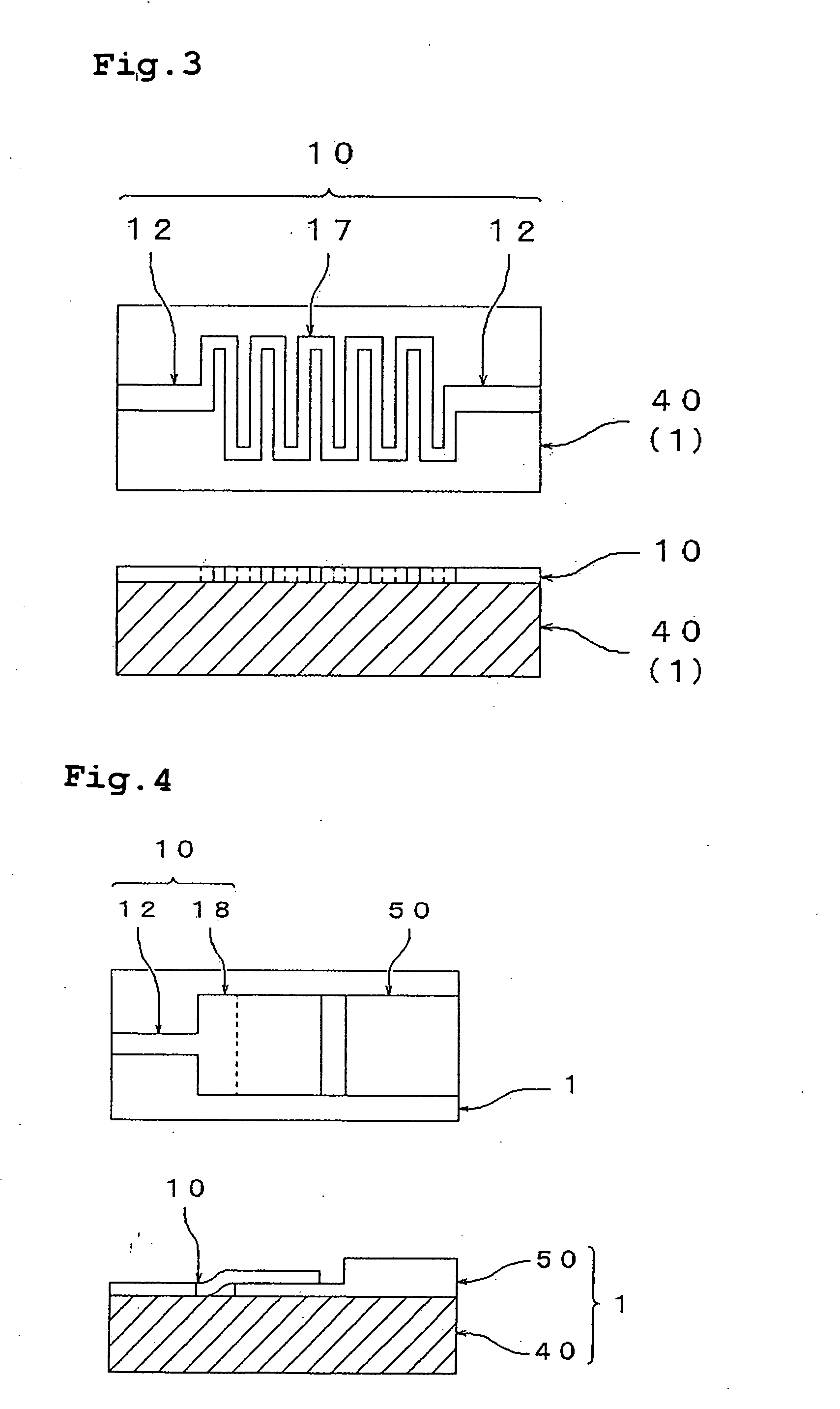

Structure matter of thin film particles having carbon skeleton, processes for the production of the structure matter and the thin-film particles and uses thereof

InactiveUS20030186059A1Easy to useImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceThin membrane

The present invention provides a structure matter composed of (a) oxidized form thin film particle(s) which are obtained by oxidizing graphite, have a thickness of 0.4 nm to 10 mum and a planar-direction size at least twice as large as the thickness, have lyophilic to a liquid having a relative dielectric constant of 15 or more and have a carbon skeleton or an oxidized form lamination layer aggregate in which the oxidized form thin film particles are combined with each other, or (b) reduced form thin film particle(s) or a reduced form lamination layer aggregate obtained by partially or completely reducing the above oxidized form thin film particle(s) or the above oxidized form lamination layer aggregate so as to have an oxygen content of 0 to 35 wt %, and (c) a substrate, the oxidized form thin film particle(s), the oxidized form lamination layer aggregate, the reduced form thin film particle(s) or the reduced form lamination layer aggregate being in contact with the substrate, its use and a method for reducing thin film particles having a carbon skeleton.

Owner:MITSUBISHI GAS CHEM CO INC

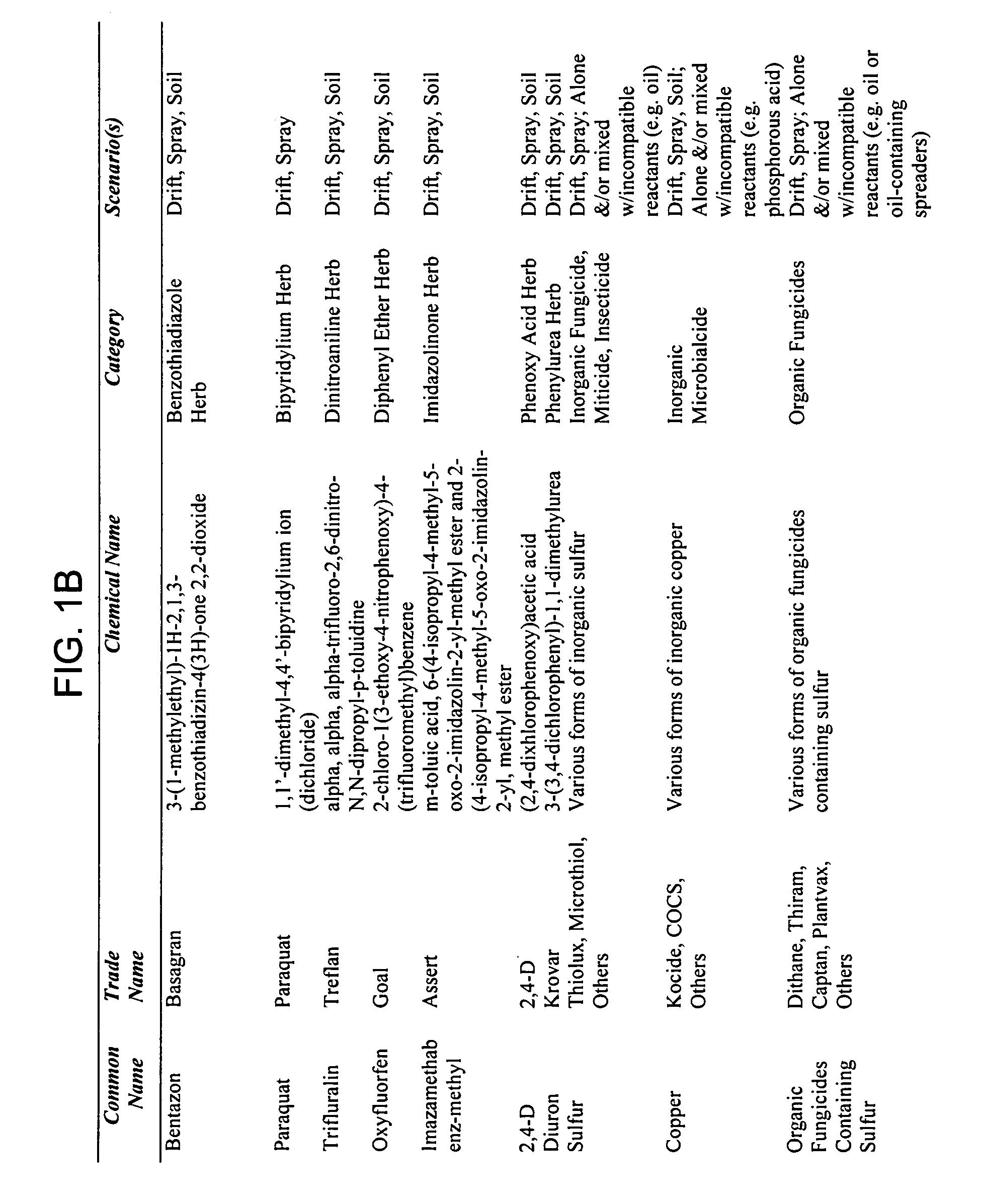

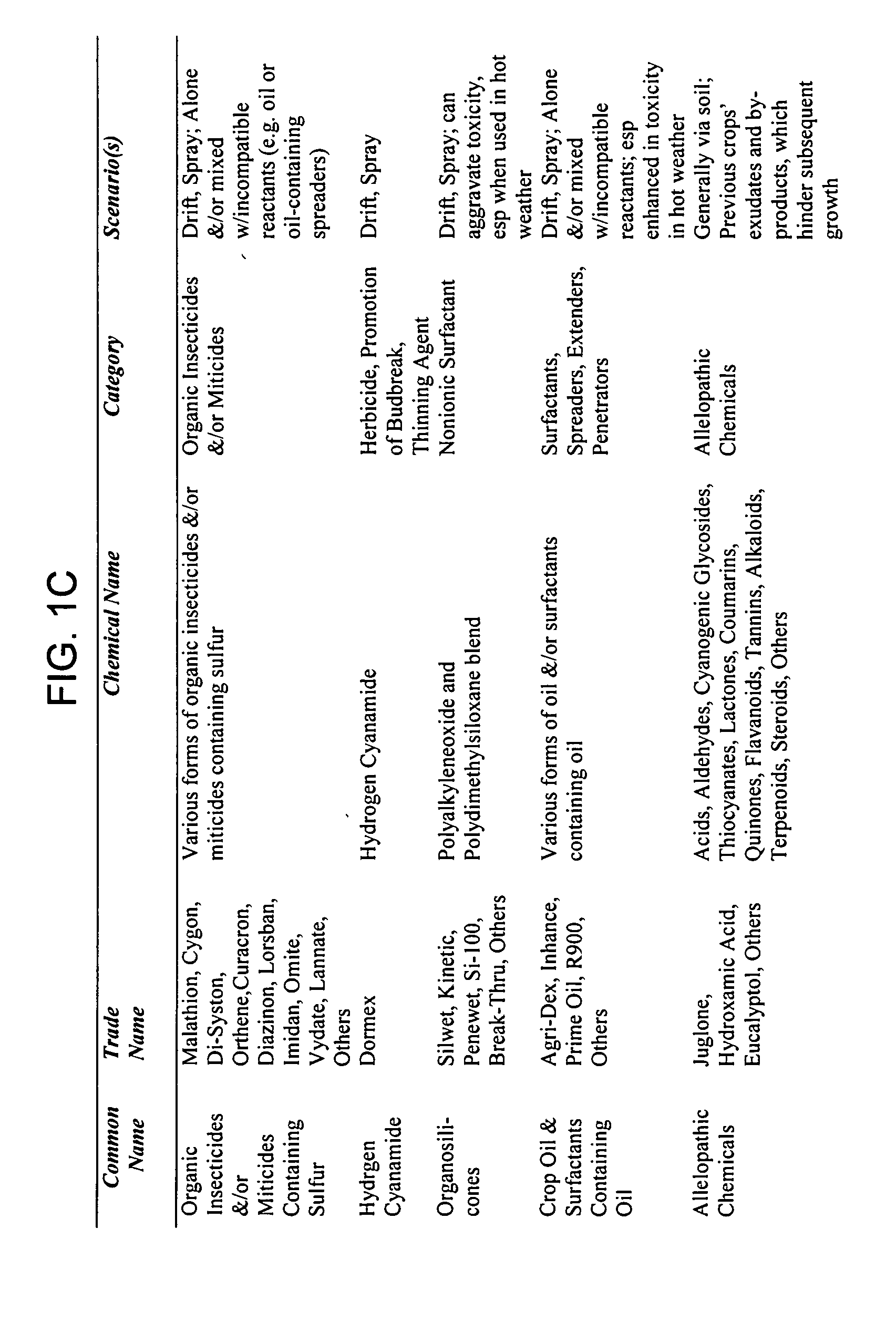

Detoxification of soil

InactiveUS6336772B1Economy of resultSpeed of resultBiocideContaminated soil reclamationPesticide contaminationOrganism

Compositions for and method of degrading organic chemicals in soil. The composition is a nutrient medium serving as a substrate for micro-organisms in the soil, preferably containing a major proportion of a source of carbon skeleton and energy, a macronutrient component preferably including nitrogen and other macronutrients, and a micronutrient component, preferably also a complexing agent and a vitamin / co-factor component. This nutrient material is added to soil, e.g. soil contaminated by a pesticide, to cause proliferation of micro-organisms which are effective, or which develop effectiveness to degrade the organic chemicals. Preferably the micro-organisms are those naturally present in the soil but useful micro- organisms may be added with the nutrient medium.

Owner:YAMASHITA THOMAS T

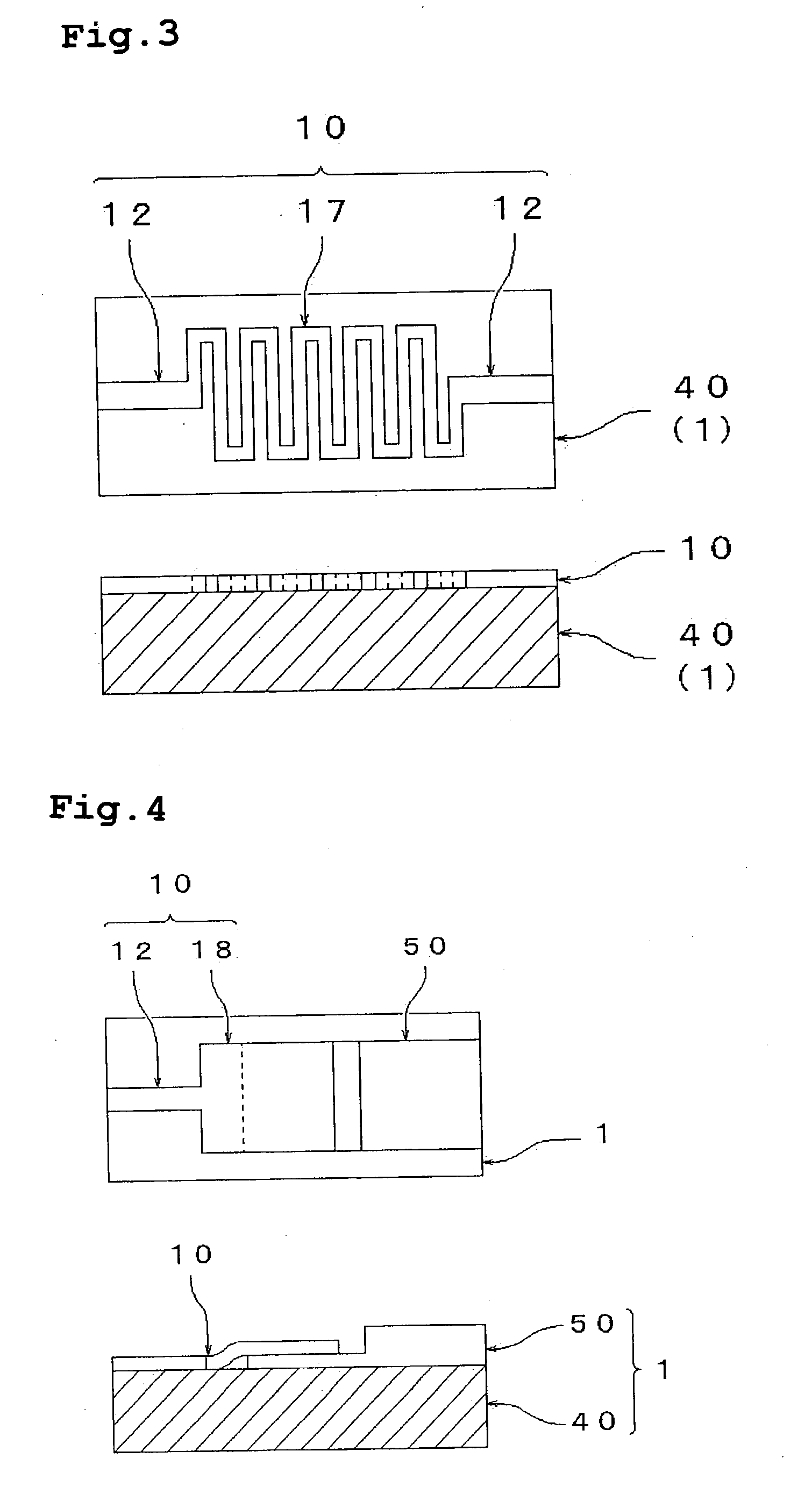

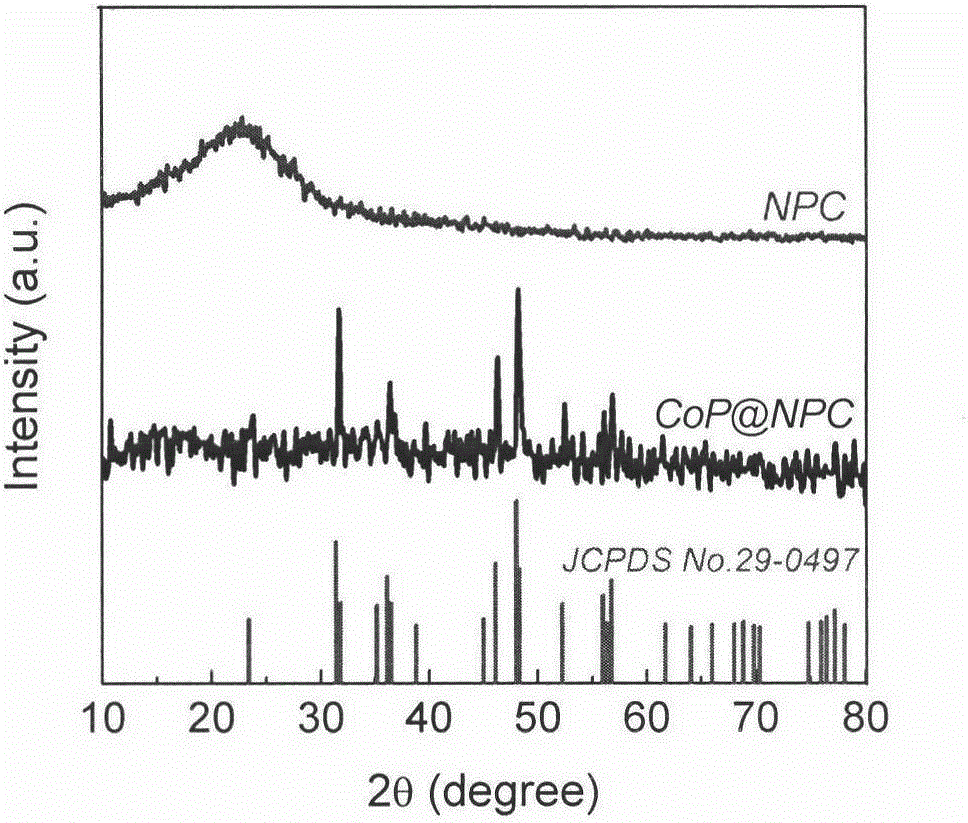

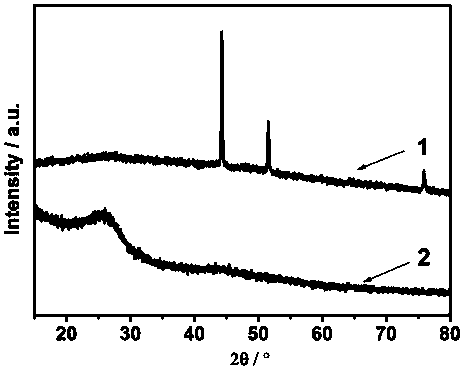

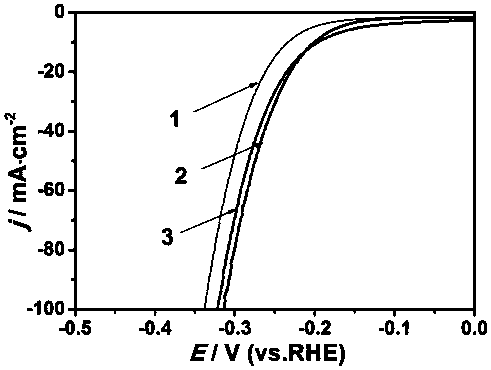

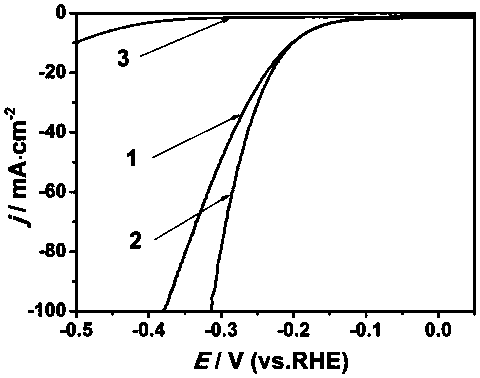

Preparation method of porous carbon-doped high-dispersion cobalt-phosphide-loaded material and application of porous carbon-doped high-dispersion cobalt-phosphide-loaded material in electro-catalysis hydrogen evolution

InactiveCN105214699AImprove protectionChange the ratioPhysical/chemical process catalystsElectrodesPorous carbonCarbonization

The invention belongs to preparation of a porous nano catalytic material, and particularly relates to a preparation method and application of a porous carbon-doped high-dispersion cobalt-phosphide-loaded material. The material is a carbon-based composite material which is of a mesoporous-macropore hierarchical porous structure and in which nitrogen atoms and phosphorus atoms are chemically doped in carbon skeletons and cobalt phosphide nanoparticles are loaded in a high-dispersion mode, and the specific surface area reaches up to 867 m<2> / g. The material is synthesized through the method comprising the steps that prepolymerization is firstly performed on organic phosphonic acid and melamine, and then high-temperature carbonization is performed. The material is applied to electro-catalysis hydrolysis hydrogen production and has the good effect. Used equipment is simple, the synthesis conditions are mild, the raw materials are easy to obtain, and the material is suitable for industrialized mass production.

Owner:NANKAI UNIV

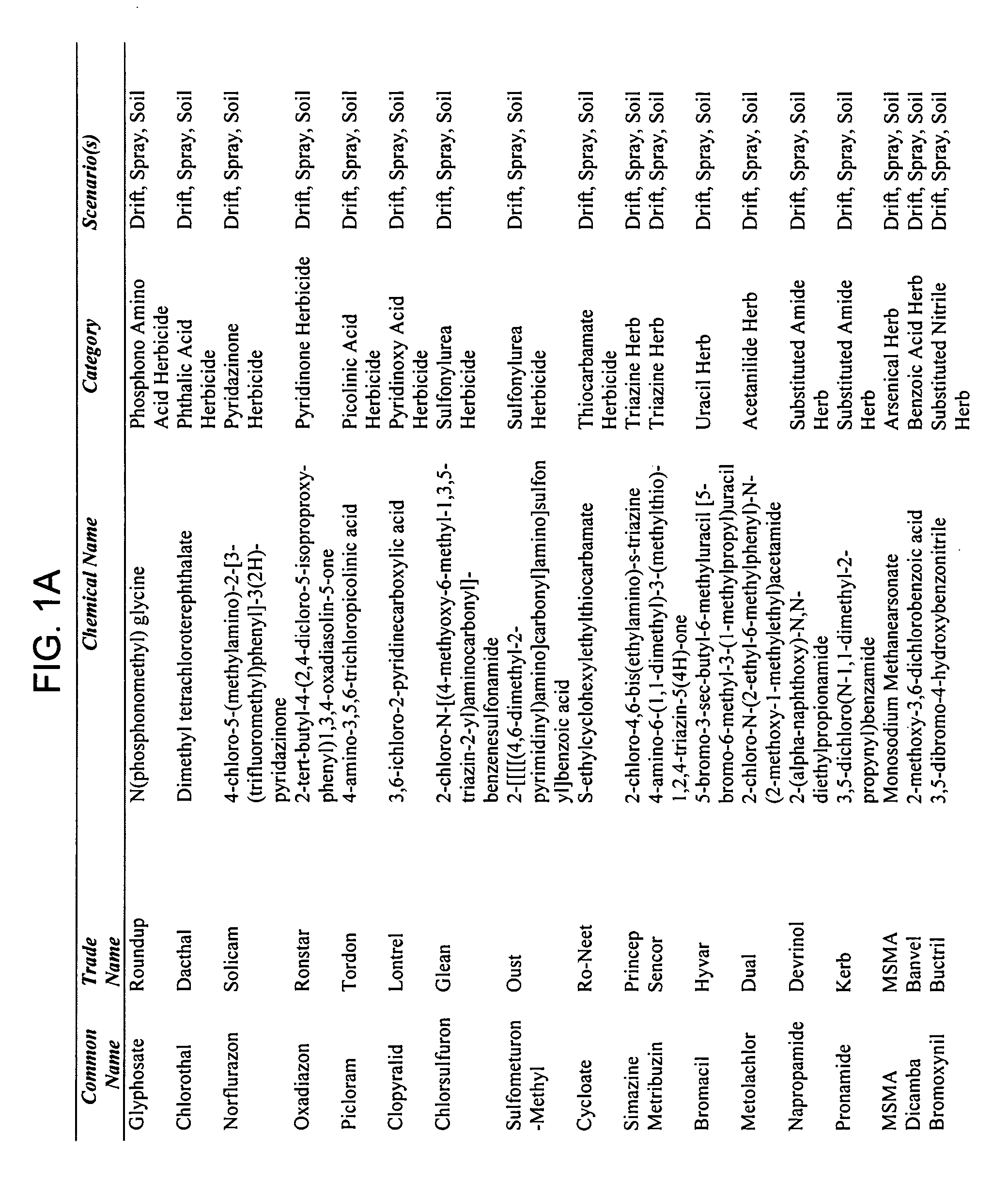

Pesticide compositions and methods for their use

Pesticide compositions and methods for their use are provided. Embodiments of the subject pesticide compositions include a pesticide and an assimilable carbon skeleton energy component. Embodiments of the subject compositions may include a pesticide and one or more of a macronutrient component, micronutrient component, vitamin / cofactor component and a complexing agent. Also provided are methods that include preparing an assimilable carbon skeleton energy containing-pesticide composition and methods for administering an assimilable carbon skeleton energy containing-pesticide composition to a plant. Kits for use in practicing the subject invention are also provided. The subject pesticide compositions find use in a variety of different applications, and are particularly suited for use in at least mollifying pesticide-induced phytotoxicity of a plant.

Owner:YAMASHITA THOMAS T

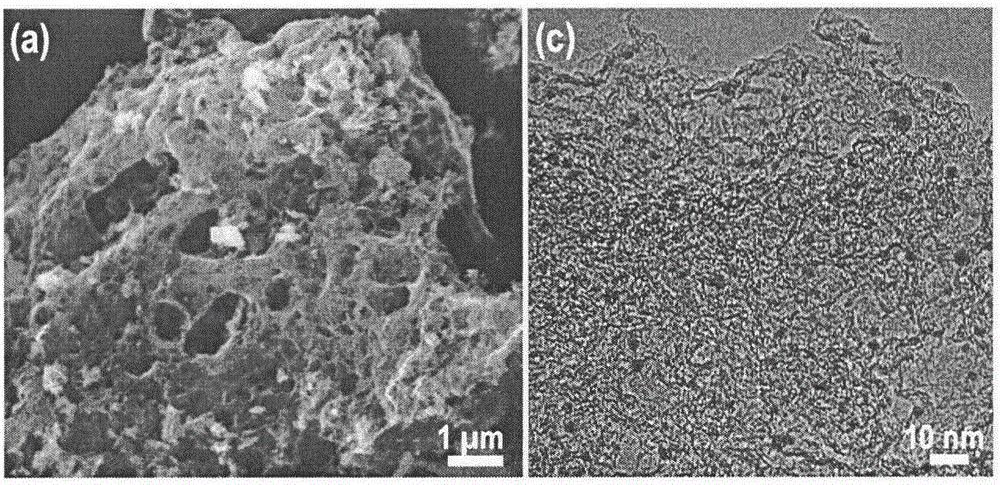

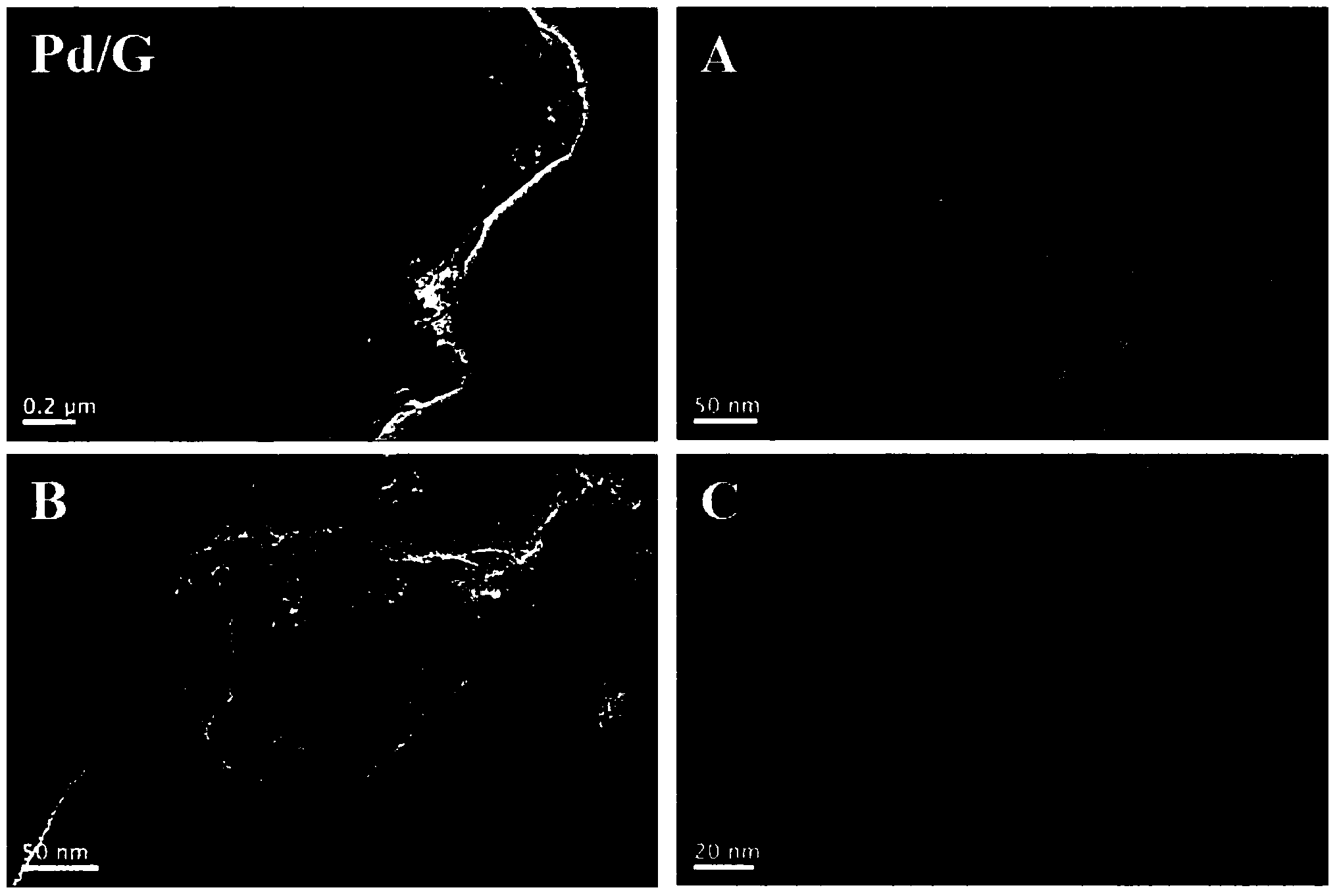

Method for preparing low-temperature nitrogen-doped graphene supported nano Pd hydrogenation catalyst

InactiveCN104028293AHigh catalytic activityImprove reusabilityPhysical/chemical process catalystsHydrocarbon by hydrogenationDispersityDoped graphene

The invention relates to a method for preparing a low-temperature nitrogen-doped graphene supported nano Pd hydrogenation catalyst. The method comprises the following steps: ultrasonically stripping graphite oxide, thereby obtaining an aqueous solution of highly dispersed graphite oxide; selecting different nitrogen sources, and synthesizing nitrogen-doped graphene at low temperature through a hydrothermal method; and performing ultrasonic treatment on the nitrogen-doped graphene, adding a certain amount of PdCl2 solution, and adding a reducing agent, thereby preparing the highly dispersed supported nano Pd hydrogenation catalyst by a chemical reduction method. Because nitrogen atoms, which contain lots of lone pair electrons and can achieve a coordination effect with metal nanoparticles, are mixed into a carbon skeleton of graphene, runoff and conglomeration of the metal nanoparticles are effectively avoided, and the dispersity of the metal nanoparticles on the surface of graphene is improved. The catalyst is used for a hydrogenation reaction of olefins and has extremely high catalytic activity and high reusability. The catalyst is simple in preparation method and low in cost, the nitrogen content is high, doped nitrogen is controllable, and industrial production is easily realized.

Owner:CHANGZHOU UNIV

Method of manufacturing carbon nanotubes

A method of manufacturing carbon nanotubes that is capable of growing carbon nanotubes on a substrate by a CVD method without giving rise to residual carbon impurities is provided. The method of manufacturing carbon nanotubes according to the present invention is a method in which carbon nanotubes are grown on a substrate by a chemical vapor deposition (CVD) process using a reaction gas containing a compound for the carbon source, wherein a compound having a carbon skeleton and a functional group which is effective for removing carbon impurities that deposit during the growth of carbon nanotubes is used as the compound for the carbon source.

Owner:FUJITSU LTD

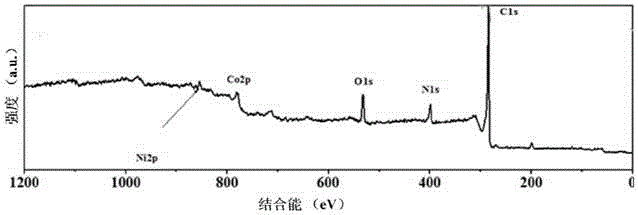

Preparation method of mono-atomic cobalt based nitrogen-sulfur dually-doped carbon material catalyst

InactiveCN108686693AImprove mass transfer effectImprove conductivityPhysical/chemical process catalystsCarbon layerCarbonization

A metal ligand is changed, and through precisely controlled carbonization and metal high temperature reduction, a metal mono-atomic nitrogen-sulfur dually-doped carbon material is obtained. An S-containing ligand is added to prevent the generation of metal carbides during the pyrolysis process; the temperature and time of pyrolysis are controlled to avoid the precipitation of a carbon layer; metalions are anchored in a carbon skeleton of graphene; exposed metal nitrides and metal sulfides on the surface can be easily removed by acids; mono-atom level dispersion of metals in a graphene structure is realized, and at the same time, more active sites are exposed. The adjusting function of S during the pyrolysis process is smartly utilized to synthesize a metal mono-atomic catalyst, all metalatoms (100%) are utilized, and the dispersion, stability, and characteristic activity of the catalyst are all improved. Furthermore, the synergistic effect is generated by co-doping of nitrogen and sulfur and the catalytic activity is further enhanced. The prepared mono-atomic catalyst has excellent hydrogen evolution / oxygen reduction catalytic activity, the operation is simple, the industrial production is easy, and the catalyst can be widely applied to fuel cells that take a proton exchange membrane as the electrolyte.

Owner:CHONGQING UNIV

Methods for treating a plant exposed to a phytotoxicant

Methods of treating a plant exposed to a phytotoxicant are provided. Embodiments of the subject methods include identifying a plant exposed to a phytotoxicant and applying an assimilable carbon-skeleton energy component-comprising composition to the identified plant. Embodiments of the subject compositions may include one or more of a macronutrient component, micronutrient component, vitamin / cofactor component, complexing agent and microbe. Kits for use in practicing the subject invention are also provided. The subject methods find use in a variety of different applications in which a plant is phytotoxic or at least in danger of becoming phytotoxic due to exposure or potential exposure to a phytotoxicant.

Owner:YAMASHITA THOMAS T

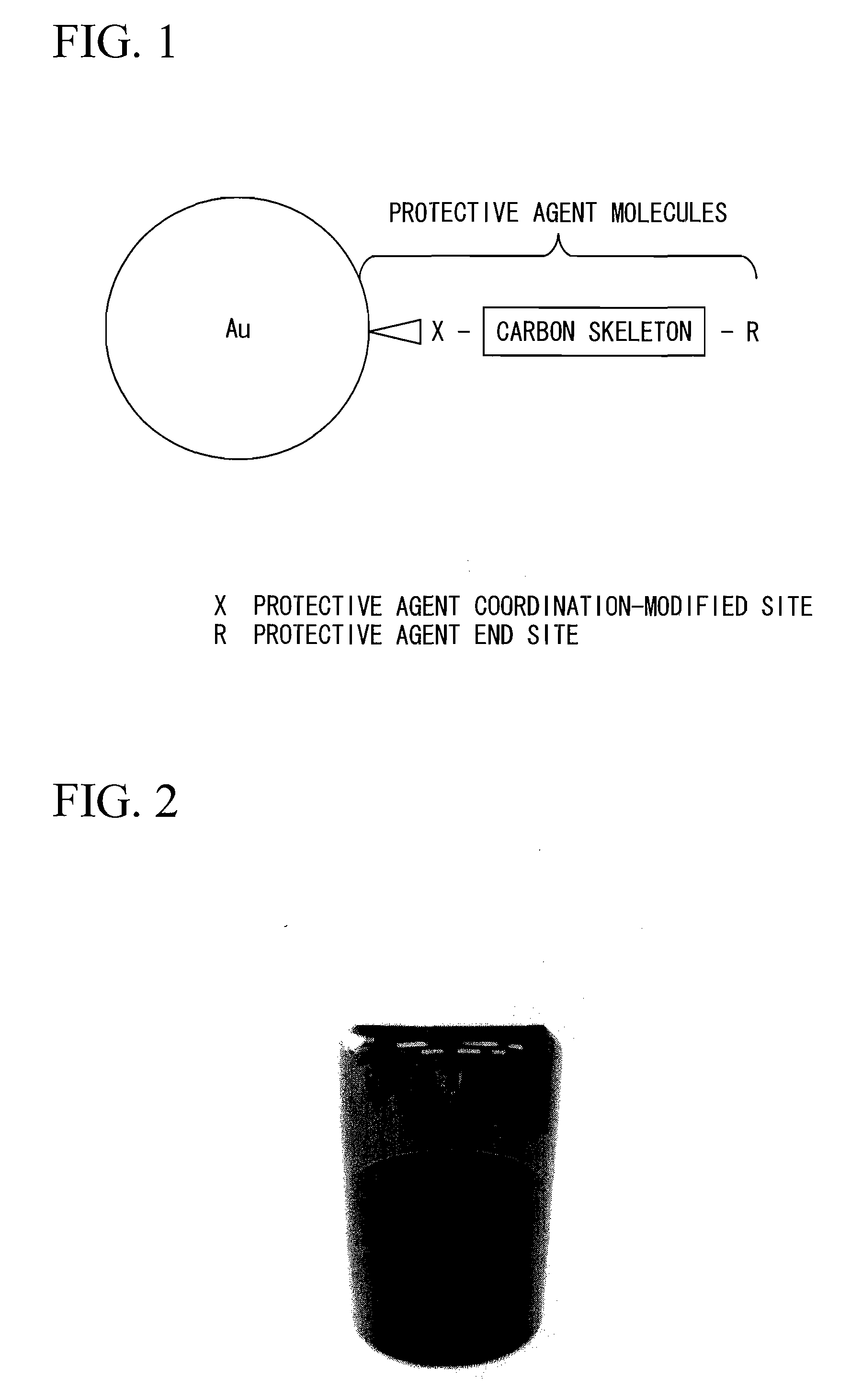

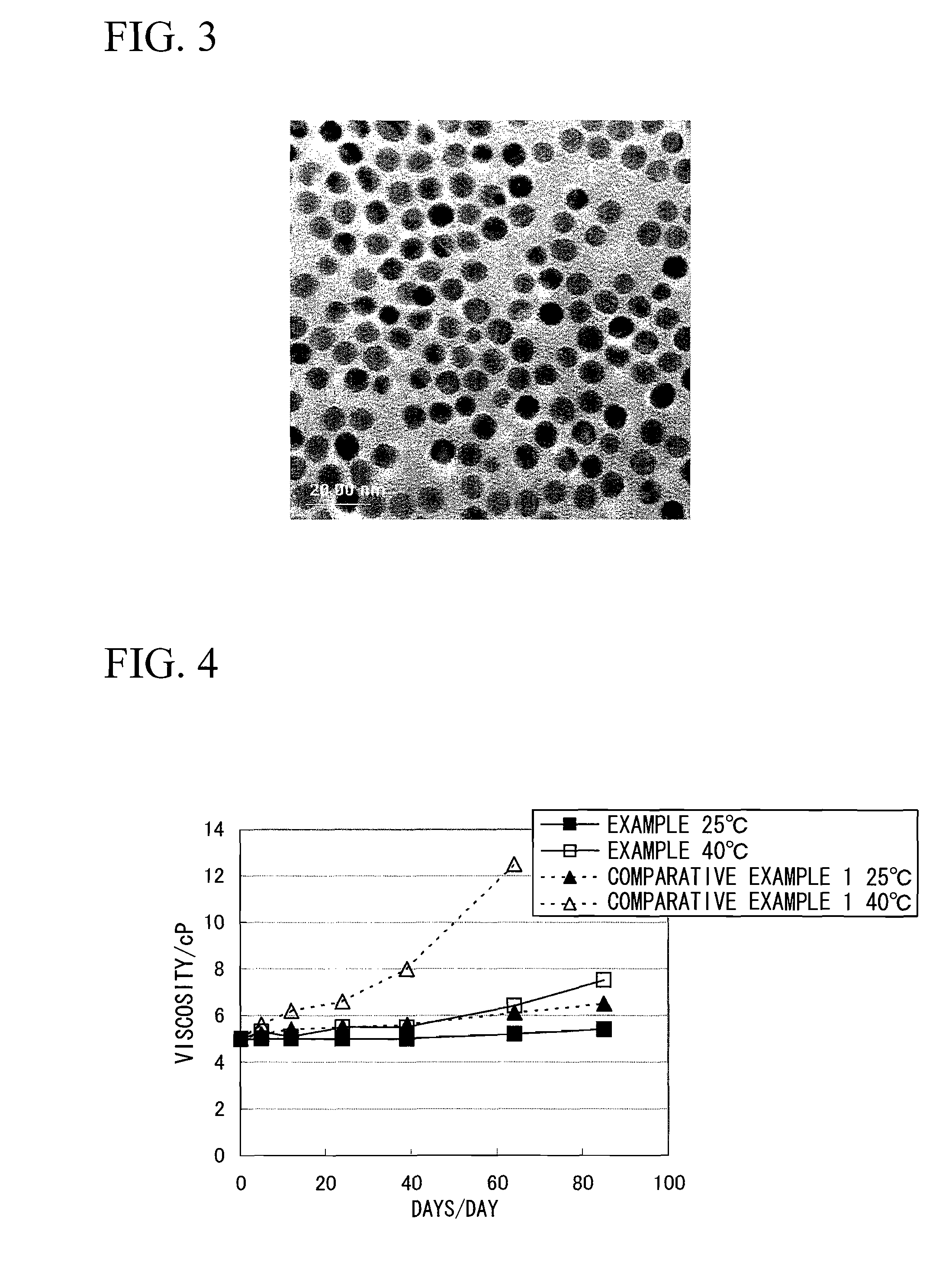

Metal Colloidal Particles, Metal Colloid and Use of Metal Colloid

InactiveUS20080277630A1Improve heat resistanceGood quality effectMaterial nanotechnologyPigmenting treatmentAtomic groupSulfur

With respect to the metal colloid of the present invention, metal colloidal particles capable of forming a metal colloid by dispersing in either or both of an aqueous dispersion medium and a nonaqueous dispersion medium in a predetermined proportion while mixing, comprise metal particles and a protective agent coordination-modified on the surface of the particles, the protective agent having a carbon skeleton containing either or both of sulfur and oxygen in the molecule, and having a structure of being coordination-modified on the surface of the metal particles using an atom or an atomic group of either or both of sulfur and oxygen as an anchor, wherein the protective agent has one, or two or more functional groups selected from the group consisting of alkoxysilyl group, silanol group and hydroxyalkyl group in a molecular structure.

Owner:MITSUBISHI MATERIALS CORP +1

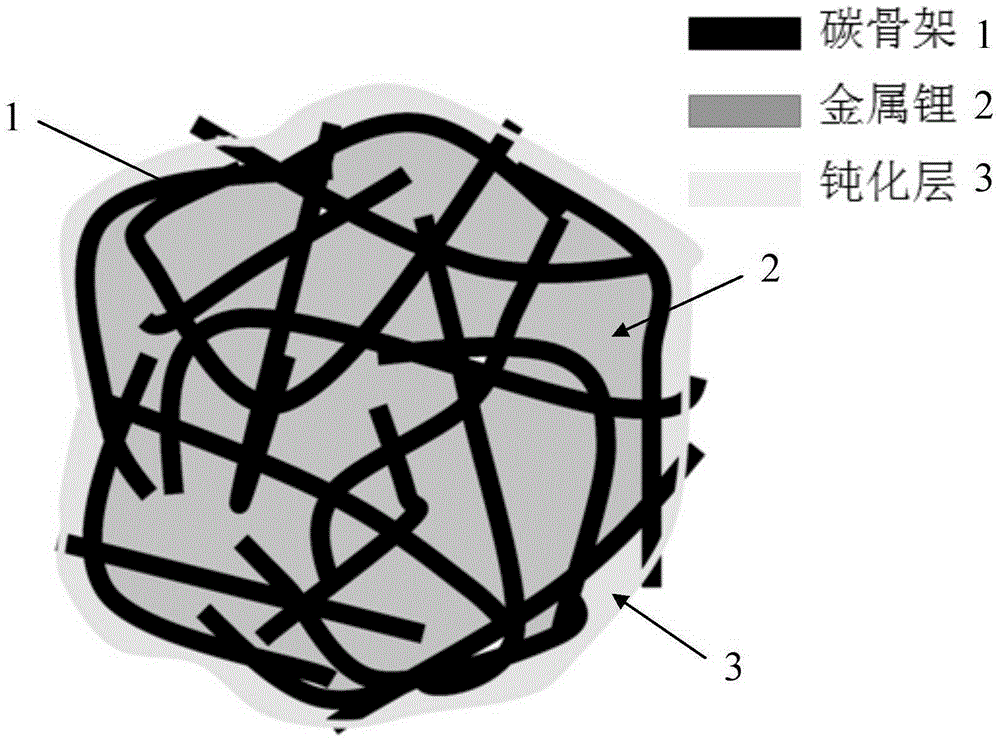

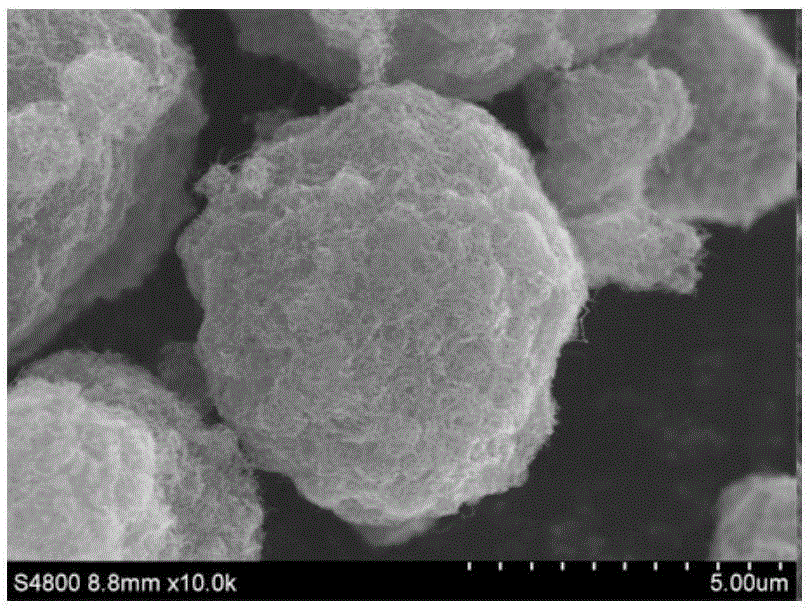

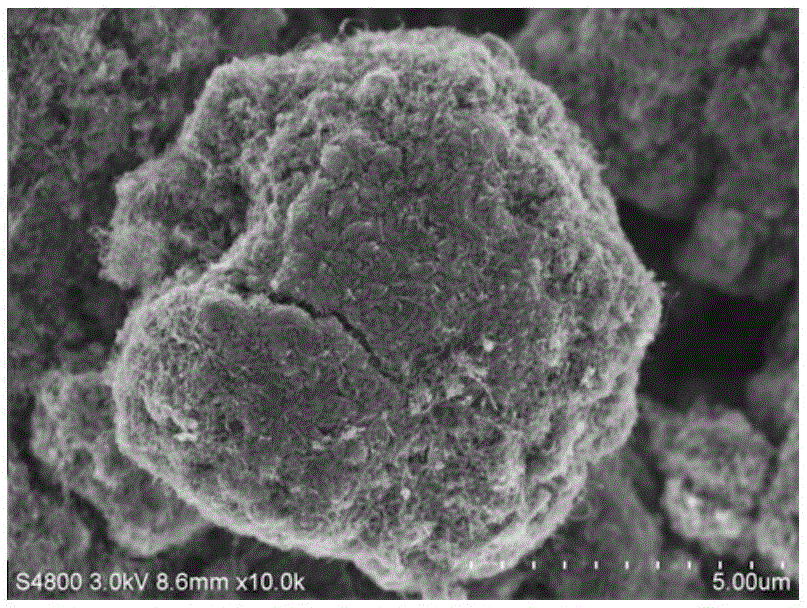

Passivated lithium metal-carbon skeleton composite material and preparation method and application thereof

ActiveCN106711456AReduce corrosionImprove cycle stabilityFuel and secondary cellsNegative electrodesCarbon compositesPorous carbon

The invention discloses a passivated lithium metal-skeleton carbon composite material and a preparation method and application thereof. The composite material is prepared from a lithium metal-skeleton carbon composite material and a passivated layer, wherein the lithium metal-skeleton carbon composite material is prepared from a porous carbon material carrier and lithium metal which is at least distributed in holes of the porous carbon material carrier, and the passivated layer is at least used for stopping the lithium metal in the lithium metal-skeleton carbon composite material from directly contacting the outside world. As the artificial passivated layer is formed on the particle surface of the lithium metal-carbon skeleton composite material, the phenomenon that lithium metal is corroded by electrolyte in a circulating process is effectively reduced, and lithium dendrites are prevented from forming; thus, the obtained passivated lithium metal-carbon skeleton composite material has the advantages of good circulating stability, high coulombic efficiency and the like in electrochemical circulation, can be widely applied to chemical energy storing devices of rechargeable lithium batteries, rechargeable lithium ion batteries and the like, can effectively improve coulombic efficiency, circulating stability and energy density of batteries.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

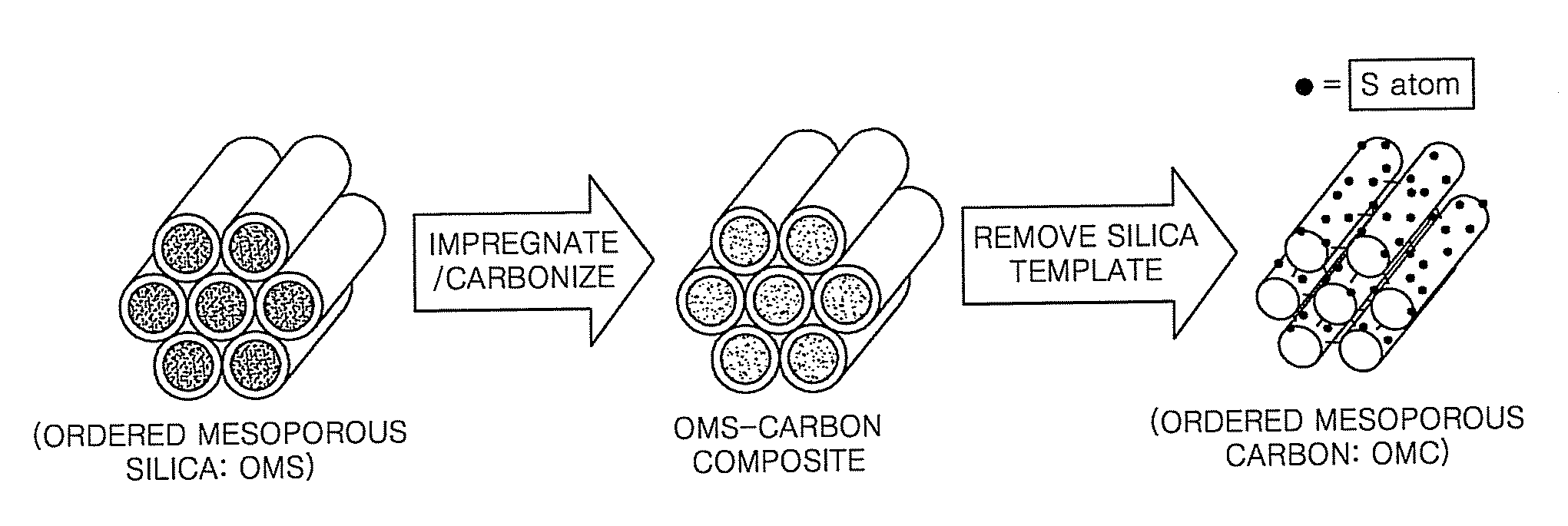

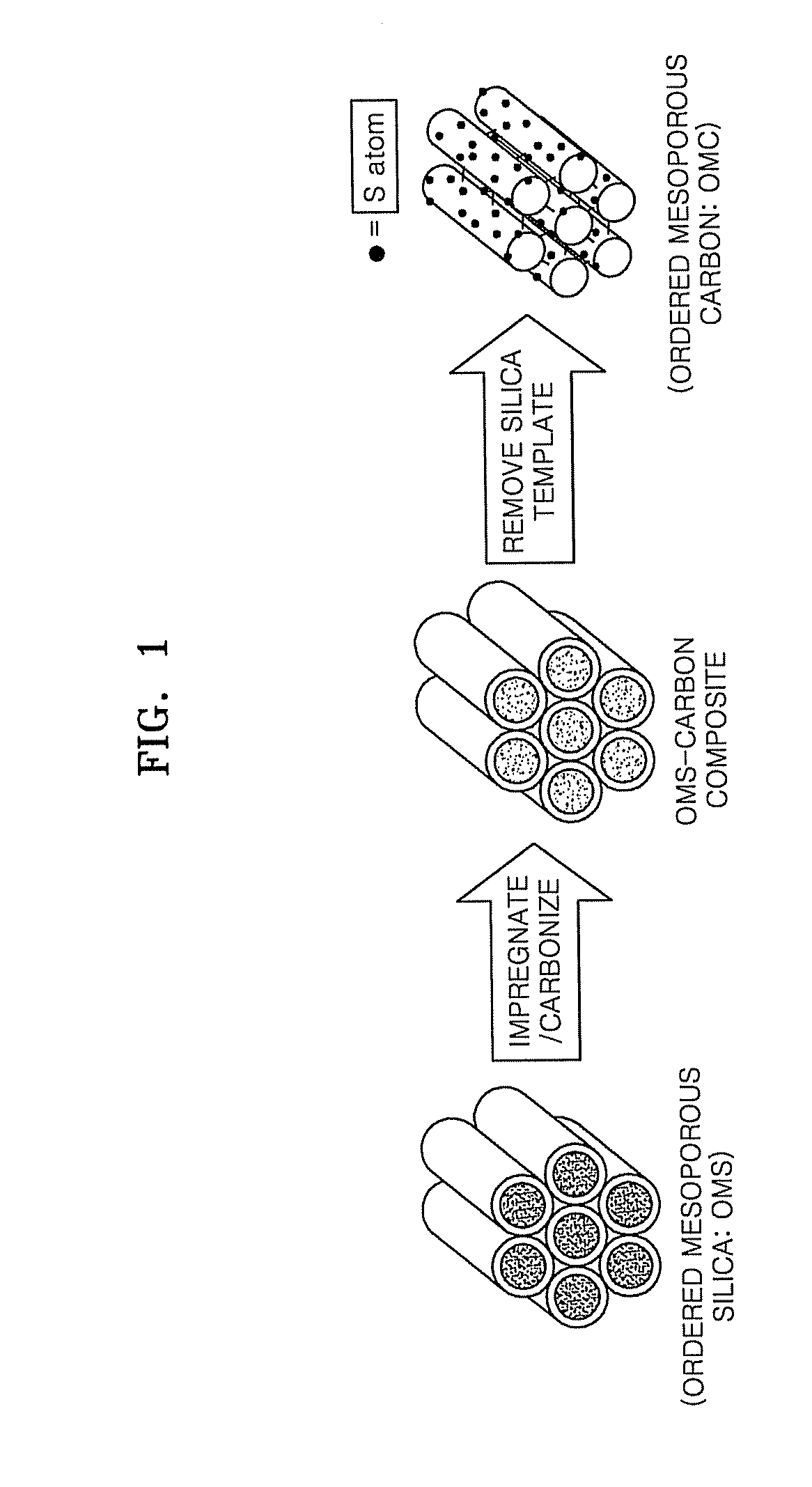

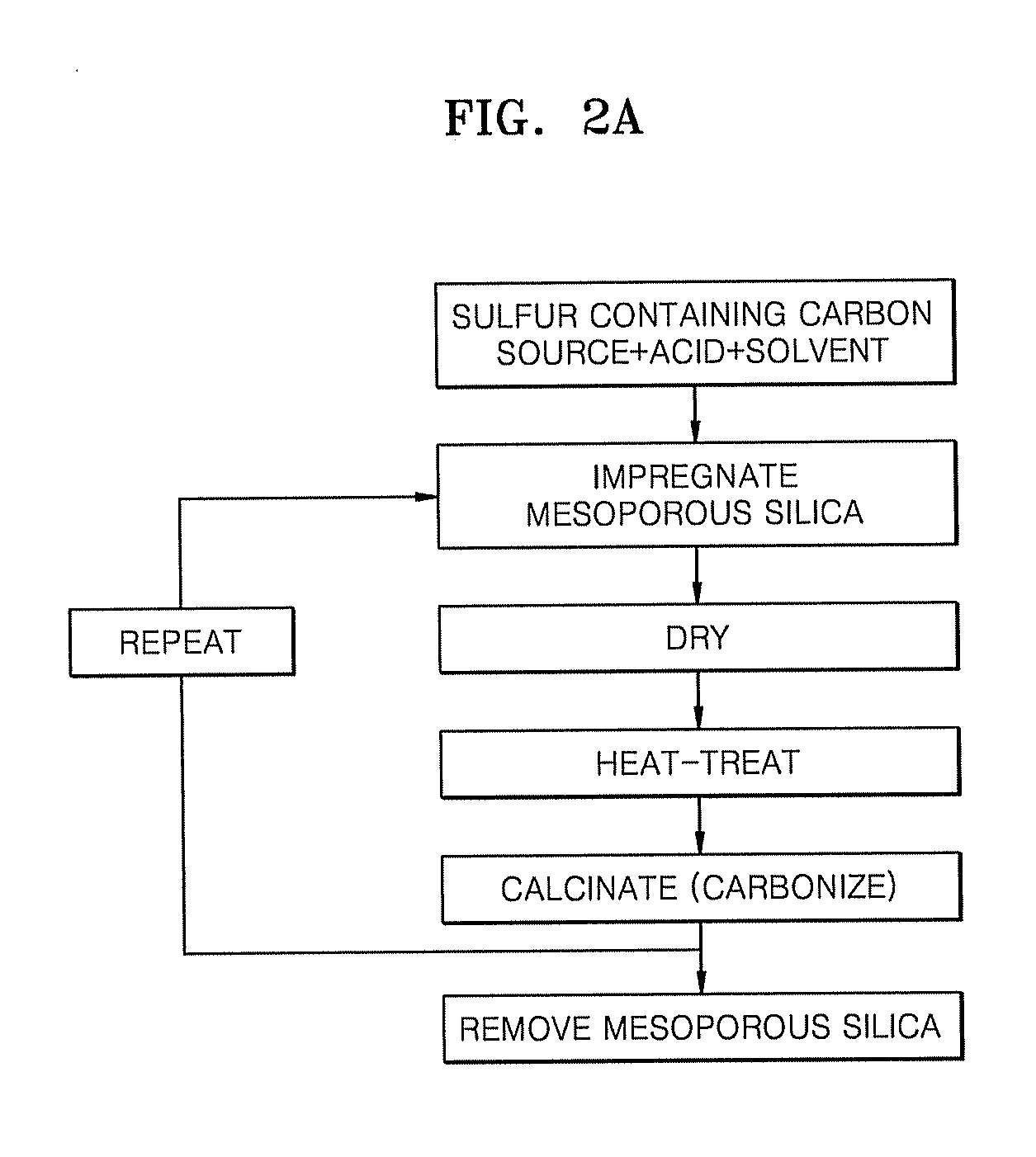

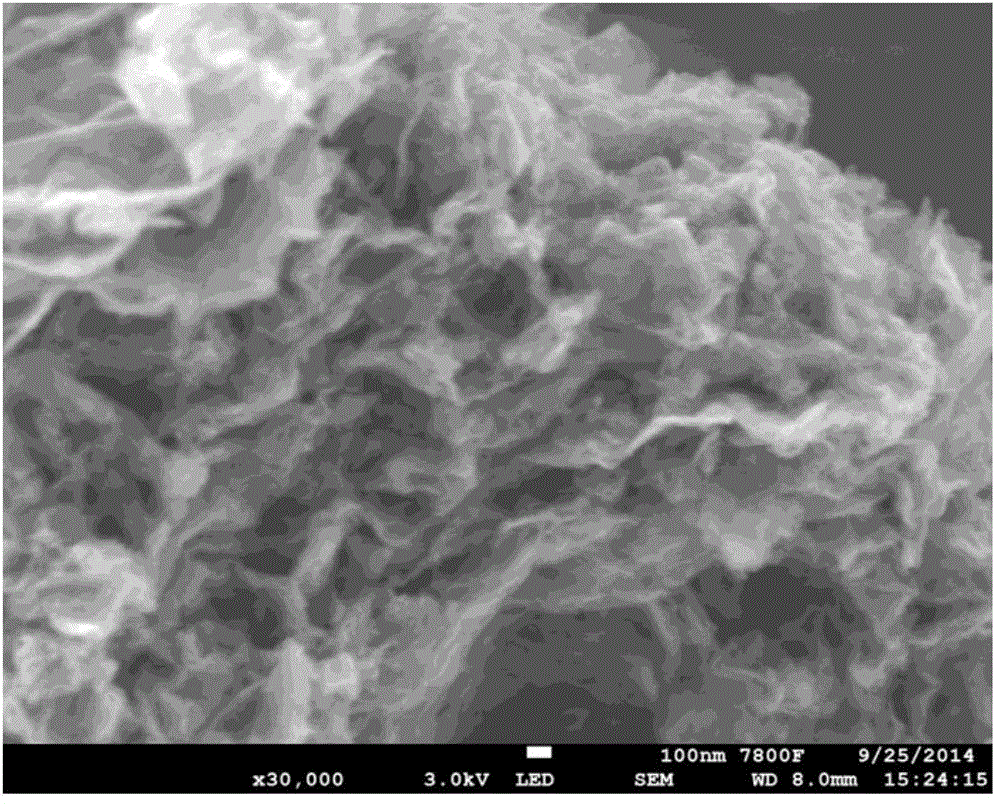

Sulfur-containing mesoporous carbon, method of manufacturing the same, and fuel cell using the mesoporous carbon

InactiveUS20080160391A1Inhibition of agglomerationHigh catalytic activityCarbon compoundsFinal product manufactureFuel cellsMetal catalyst

A sulfur-containing mesoporous carbon that has mesopores with an average diameter of 2 to 10 nm, a method of preparing the same, a catalyst containing the mesoporous carbon as a catalyst support, and a fuel cell using the catalyst in which the sulfur-containing mesoporous carbon has a good affinity for and adhesion to catalyst particles so as to strongly support the catalyst particles due to the sulfur atoms substituting for carbons in an OMC carbon skeleton structure. The growth of metal catalyst particles is prevented when heat-treating the metal catalyst particles. The catalyst using the sulfur-containing mesoporous carbon can be applied to a fuel cell to prevent a reduction in catalytic activity due to increased particle size by an accumulation of catalyst particles. The catalyst containing the sulfur-containing mesoporous carbon as a catalyst support can be used to manufacture a fuel cell having an improved performance.

Owner:SAMSUNG ELECTRONICS CO LTD +1

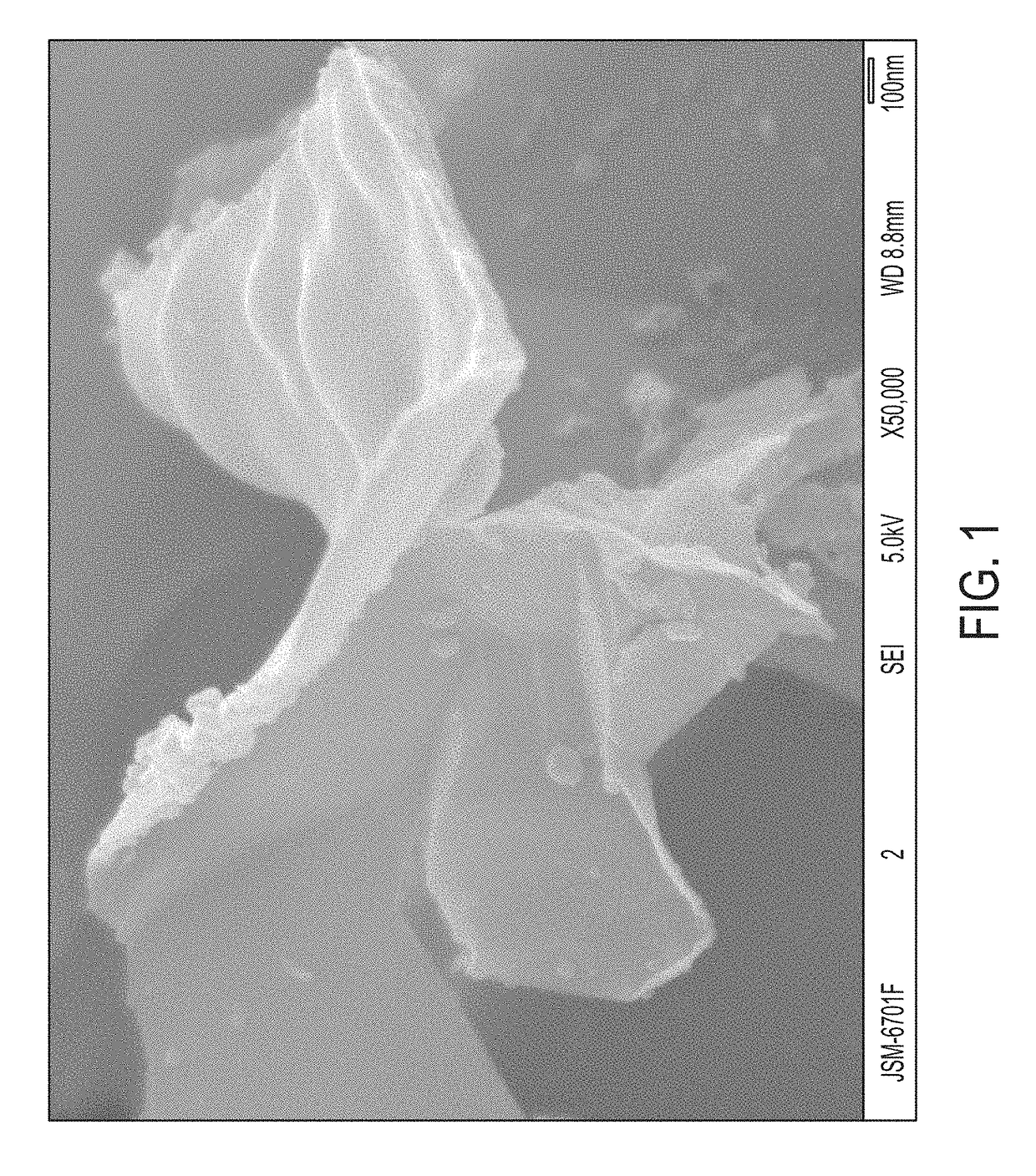

Non-noble metal catalyst for oxygen reduction, and preparation and application of catalyst

ActiveCN105749947AIncreased oxygen reduction activityHigh activityPhysical/chemical process catalystsCell electrodesReduction ActivityFreeze-drying

Disclosed is a non-noble metal catalyst for oxygen reduction. The catalyst comprises a flake-like graphene carrier; a nitrogen-doped carbon skeleton arranged between neighbor flake layers of the flake-like graphene carrier; the graphene flake layers are separated by the nitrogen-doped carbon skeleton; and nanometer particles are adhered to the flake layers of graphene. The nanometer particles are one or more than two of carbon-coated non-noble metal particles, carbon-coated non-noble metal carbide particles, and carbon-coated non-noble metal nitride particles. A preparation method of the non-noble metal catalyst for oxygen reduction comprises: adding graphite oxide and non-noble metal precursor salt into water; performing mixing and standing; adding nitrogen-containing micro-molecules, a Nafion solution, and an oxidizing agent; performing uniform mixing; allowing the obtained solution to be evaporated; performing freeze-drying; and performing temperature programming thermal treatment and other after-treatment to obtain the non-noble metal catalyst for oxygen reduction. The catalyst has advantages of high oxygen reduction activity, good mass transfer performance, and low price.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

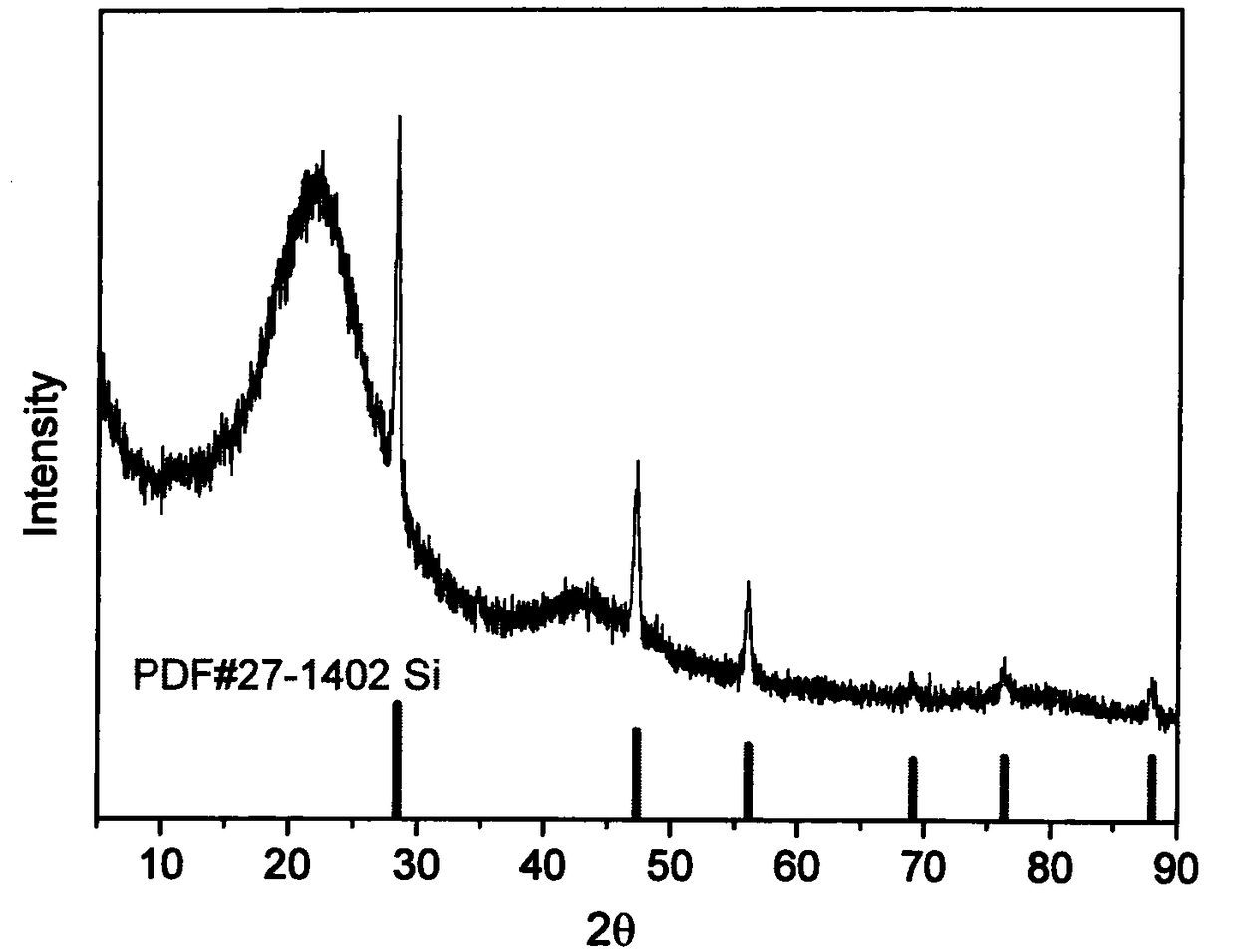

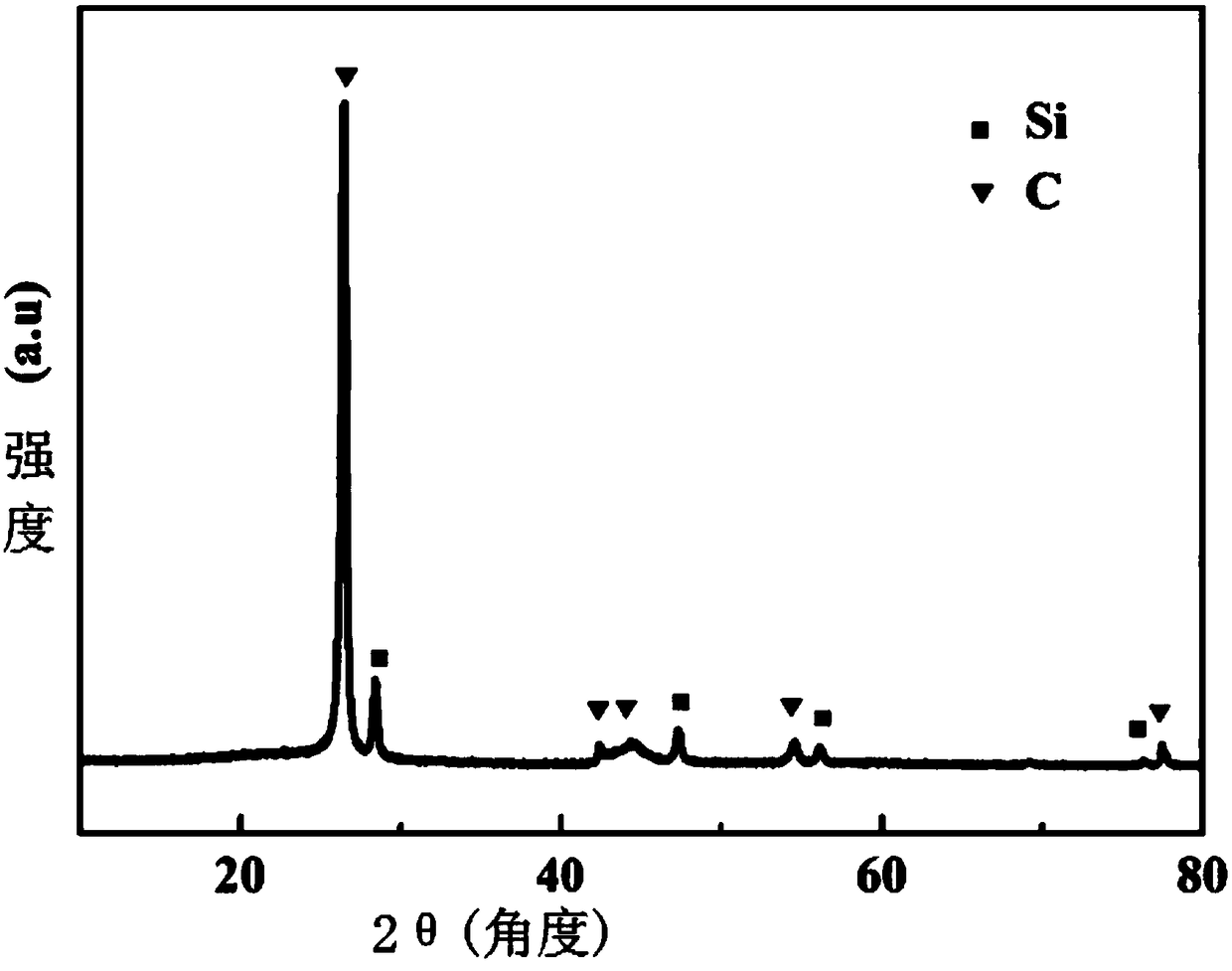

Method for preparing silicon-carbon composite anode and lithium ion battery

ActiveCN104681797APromote circulationSimple preparation processCell electrodesSecondary cellsCarbon compositesCyclic process

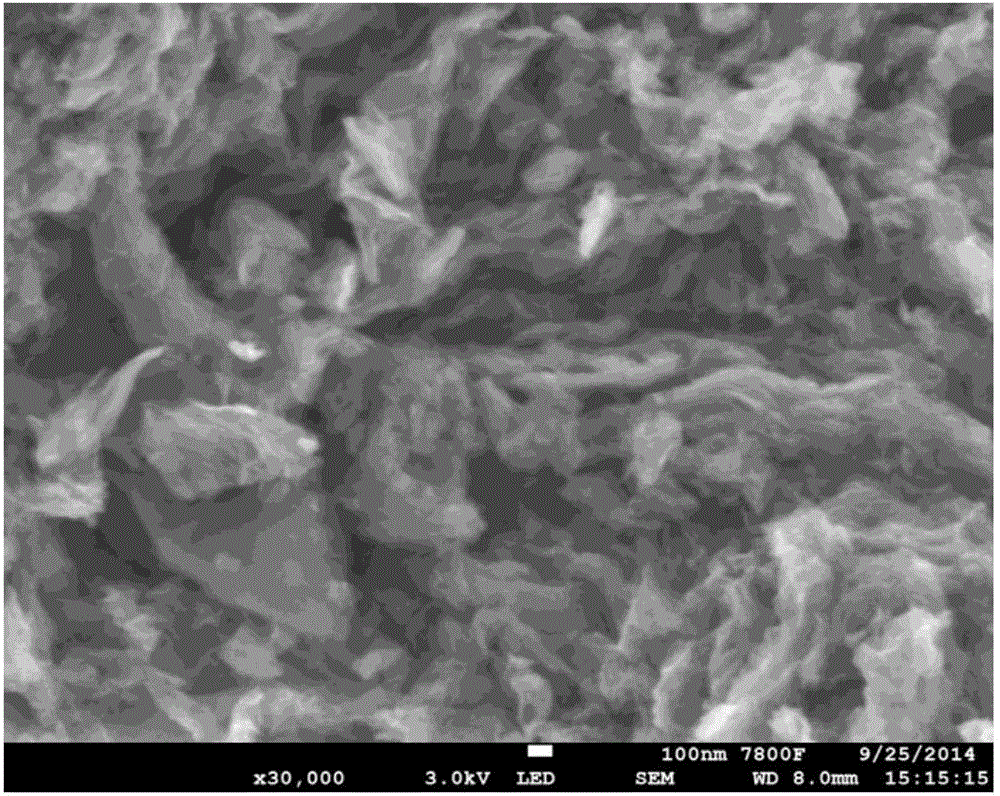

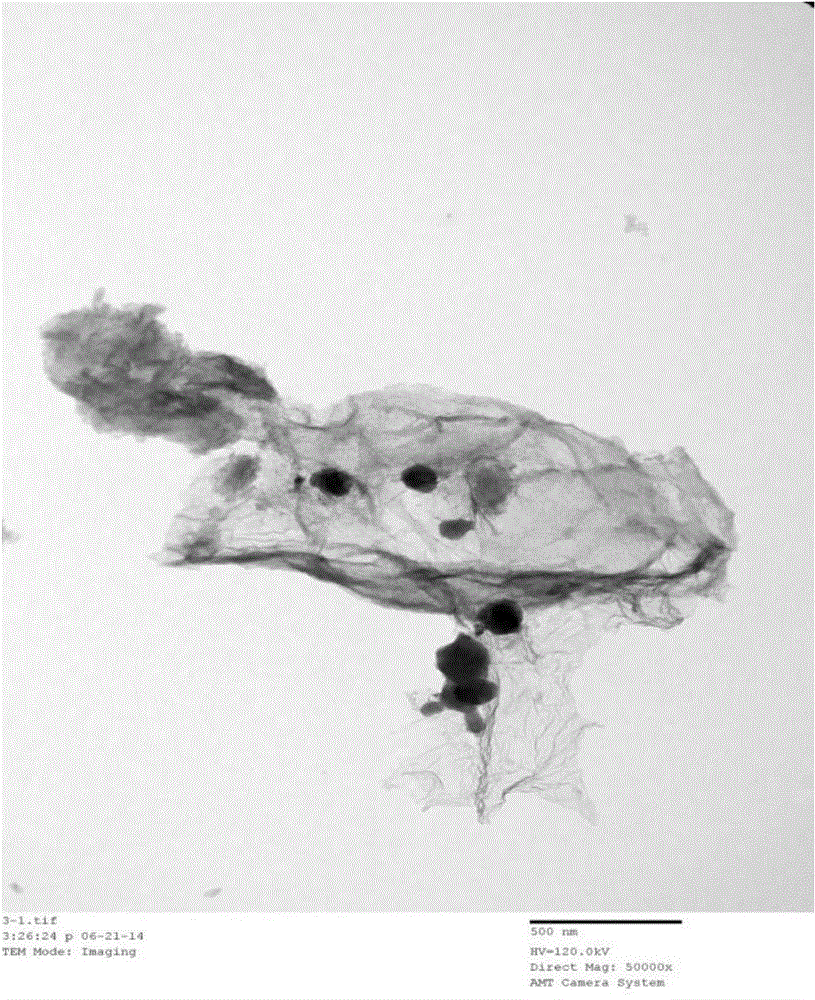

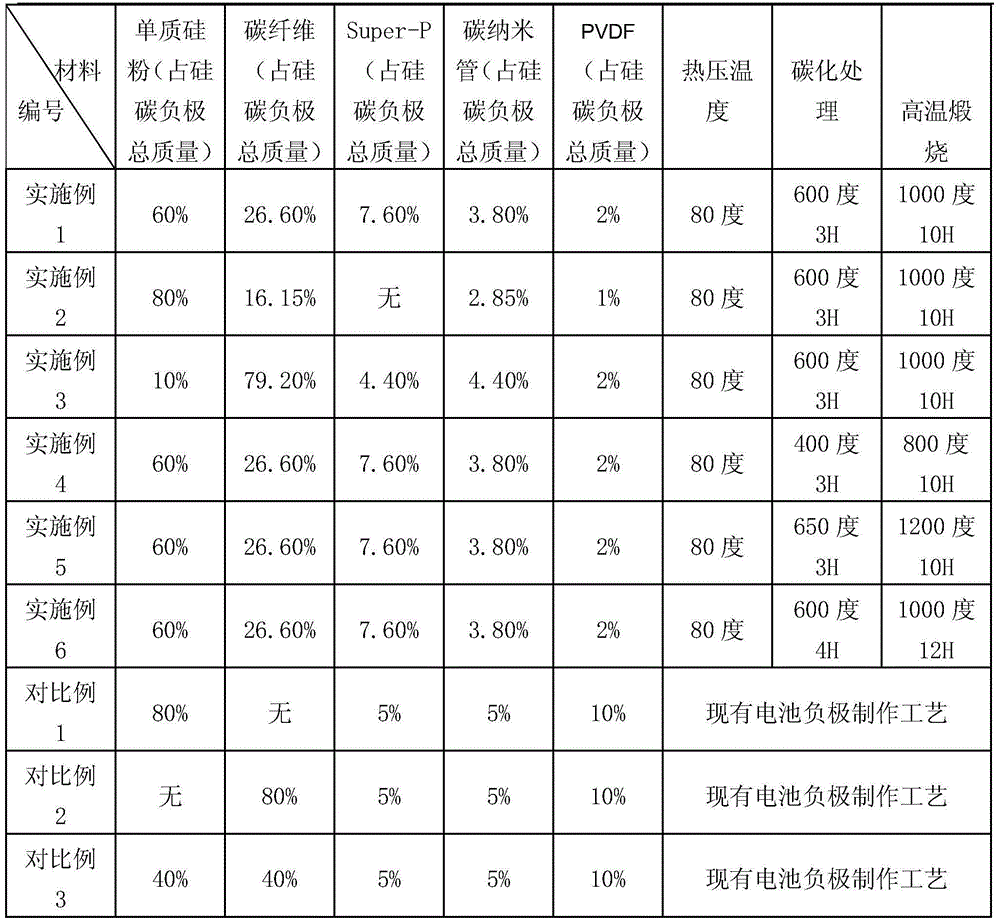

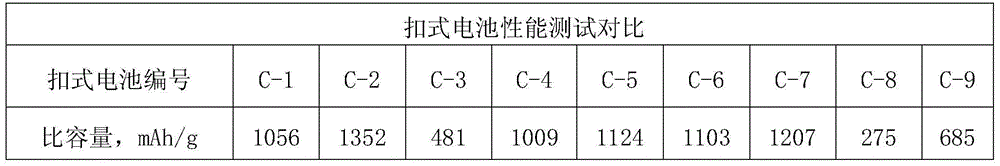

The invention discloses a silicon-carbon composite anode comprising a silicon source and a carbon source, wherein silicon source is monatomic silicon, the particle size distribution is 100 nm to 80 microns, and the mass of the silicon source accounts for 10-80% of the total mass of the silicon-carbon composite anode; the carbon source comprises a carbon anode material and a conductive agent, the carbon anode material is one or more of carbon fiber, graphite and mesocarbon microbead, and the mass of the carbon anode material accounts for 10-90% of the total mass of the carbon source. According to the silicon-carbon composite anode disclosed by the invention, one-step coating forming, hot pressing flaking, carbonization treatment and high-temperature calcination are carried out on anode slurry prepared by mixing the silicon source with the carbon source, so as to guarantee that the silicon material is effectively dispersed in a carbon skeleton, the prepared silicon-carbon anode can effectively relieve the volume expansion of the silicon material in charging and discharging processes in a circulation process and guarantee excellent cycle performance of the battery; the silicon-carbon composite anode is prepared by one-step coating forming, and no current collector is needed, so that the production process is simplified and the battery is guaranteed to have high energy density; meanwhile, the invention further provides a lithium ion battery containing the silicon-carbon composite anode.

Owner:江苏中兴派能电池有限公司

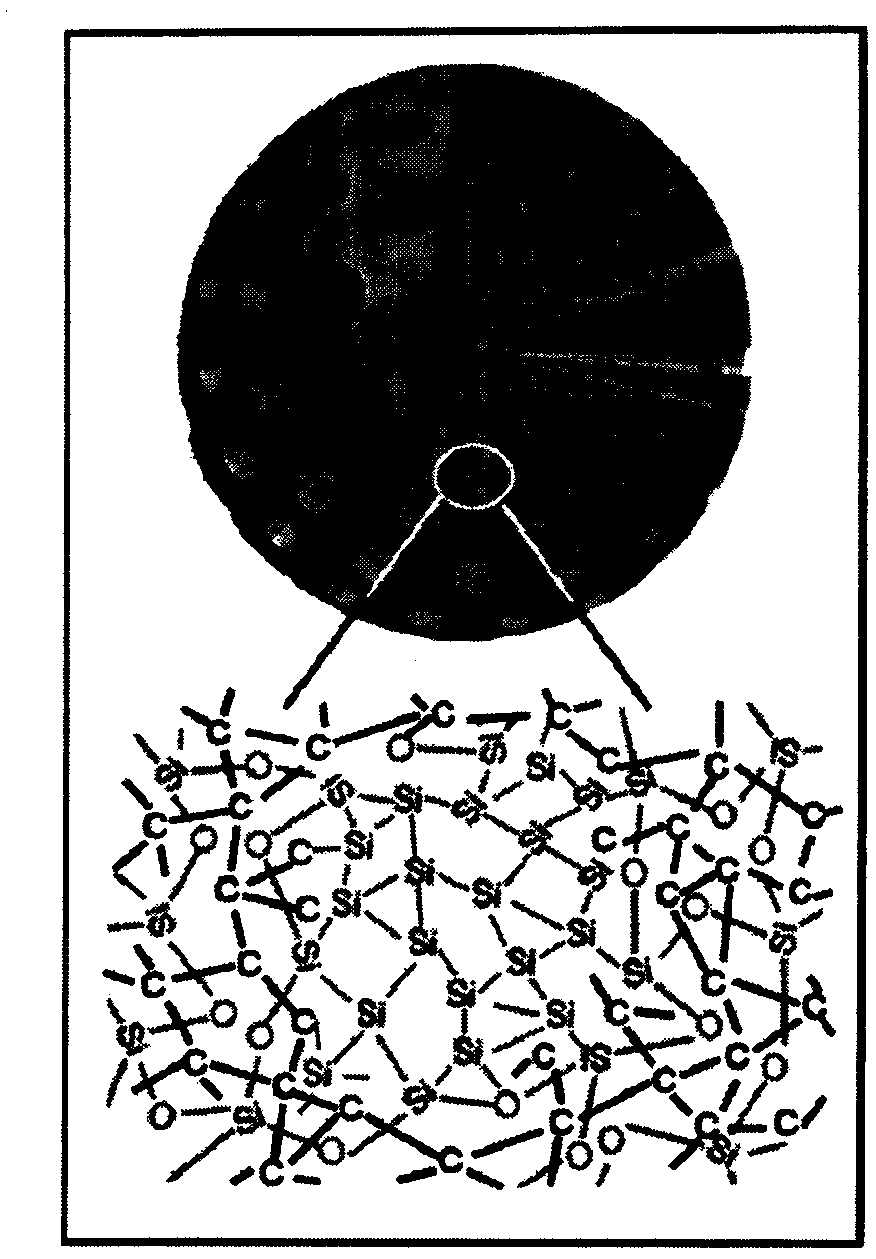

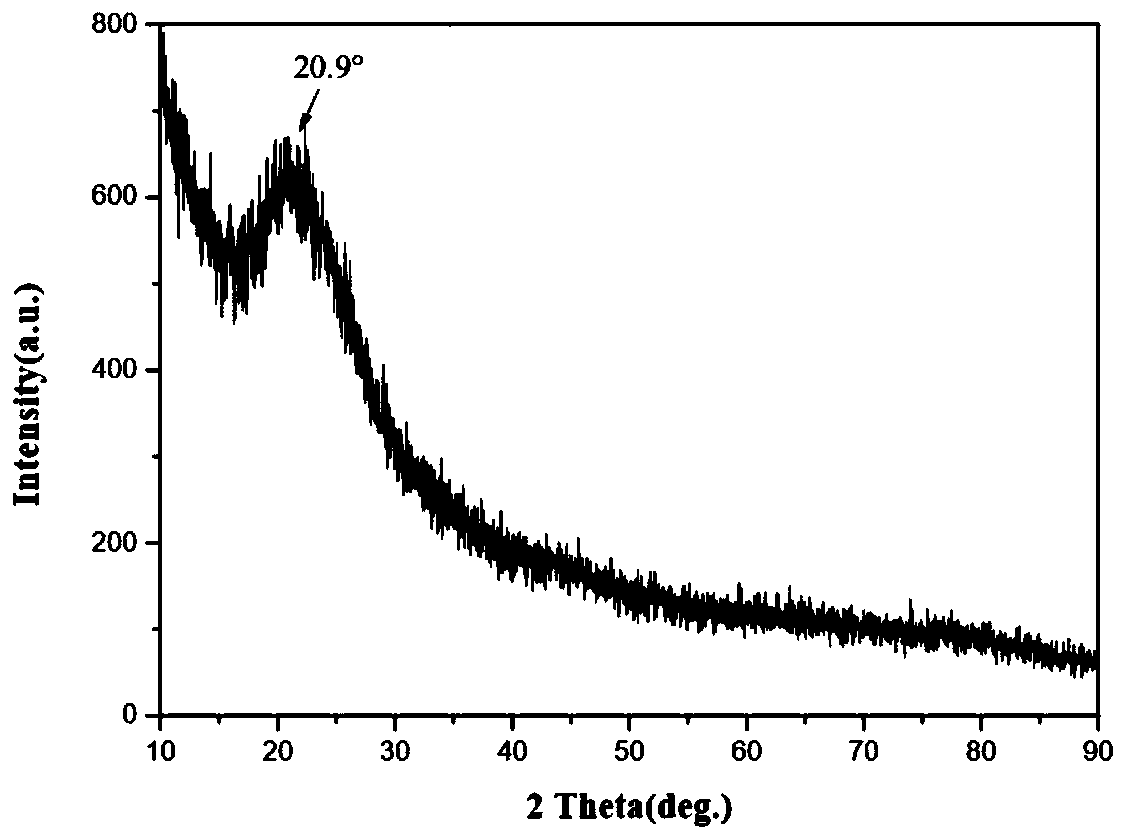

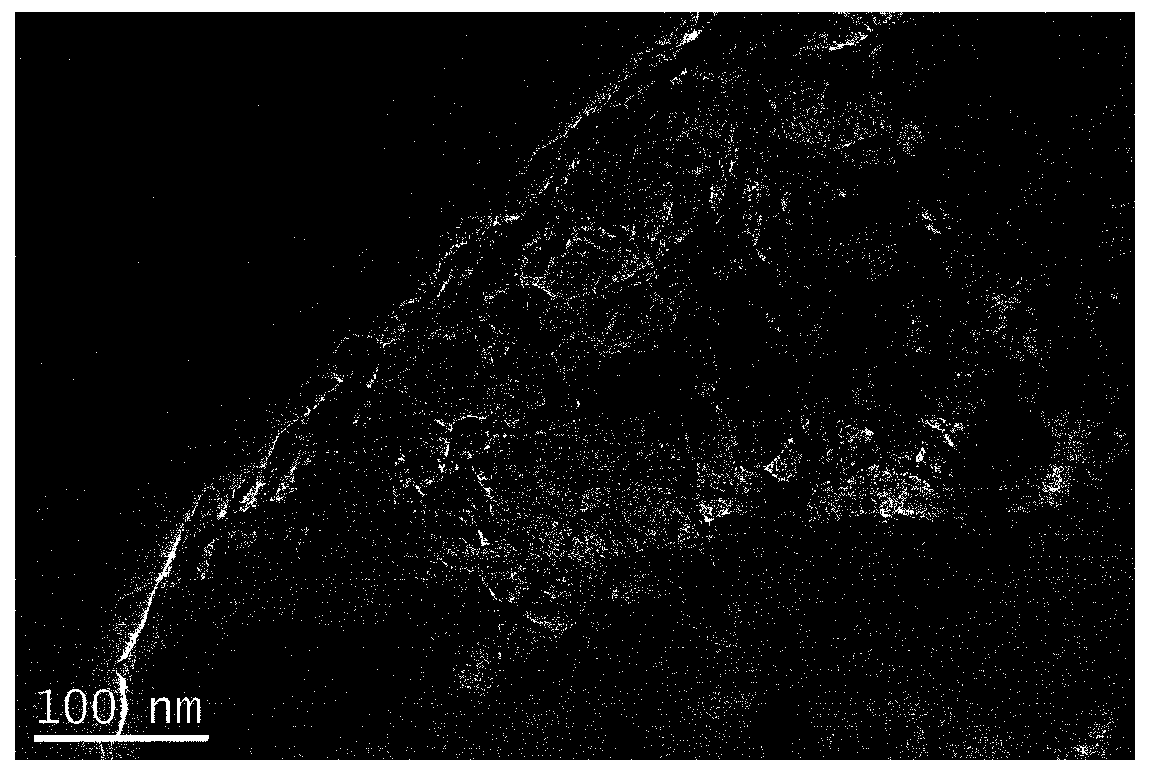

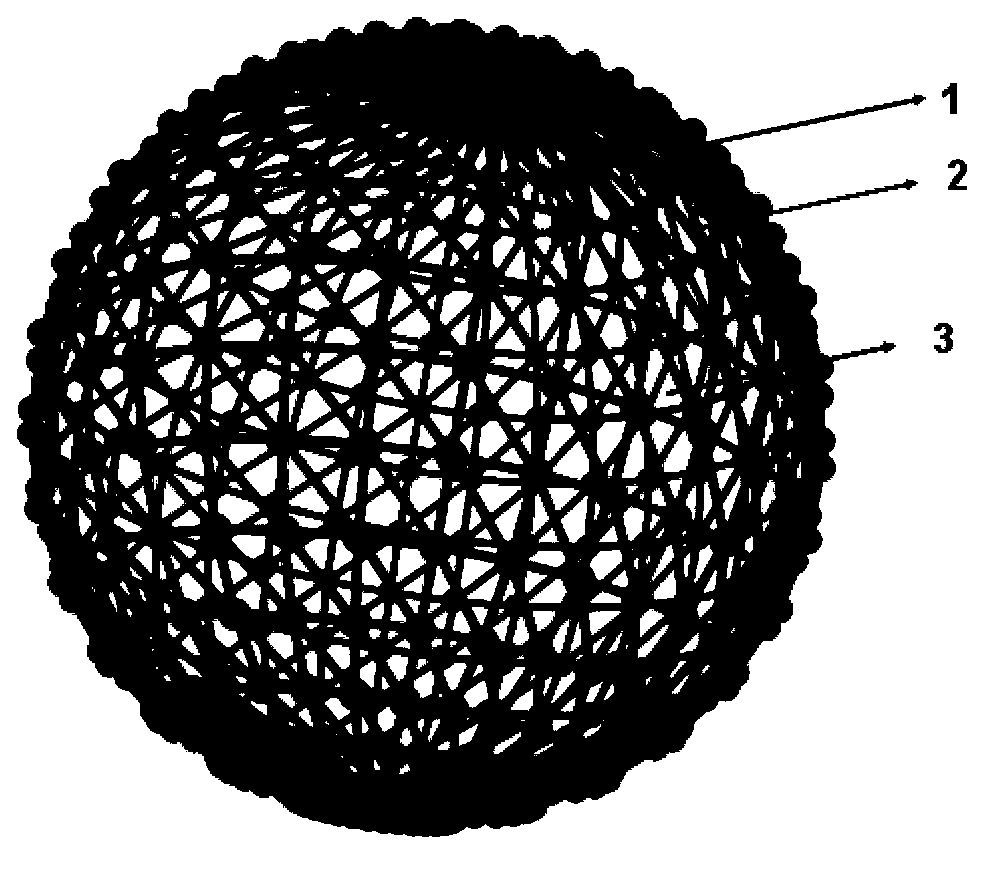

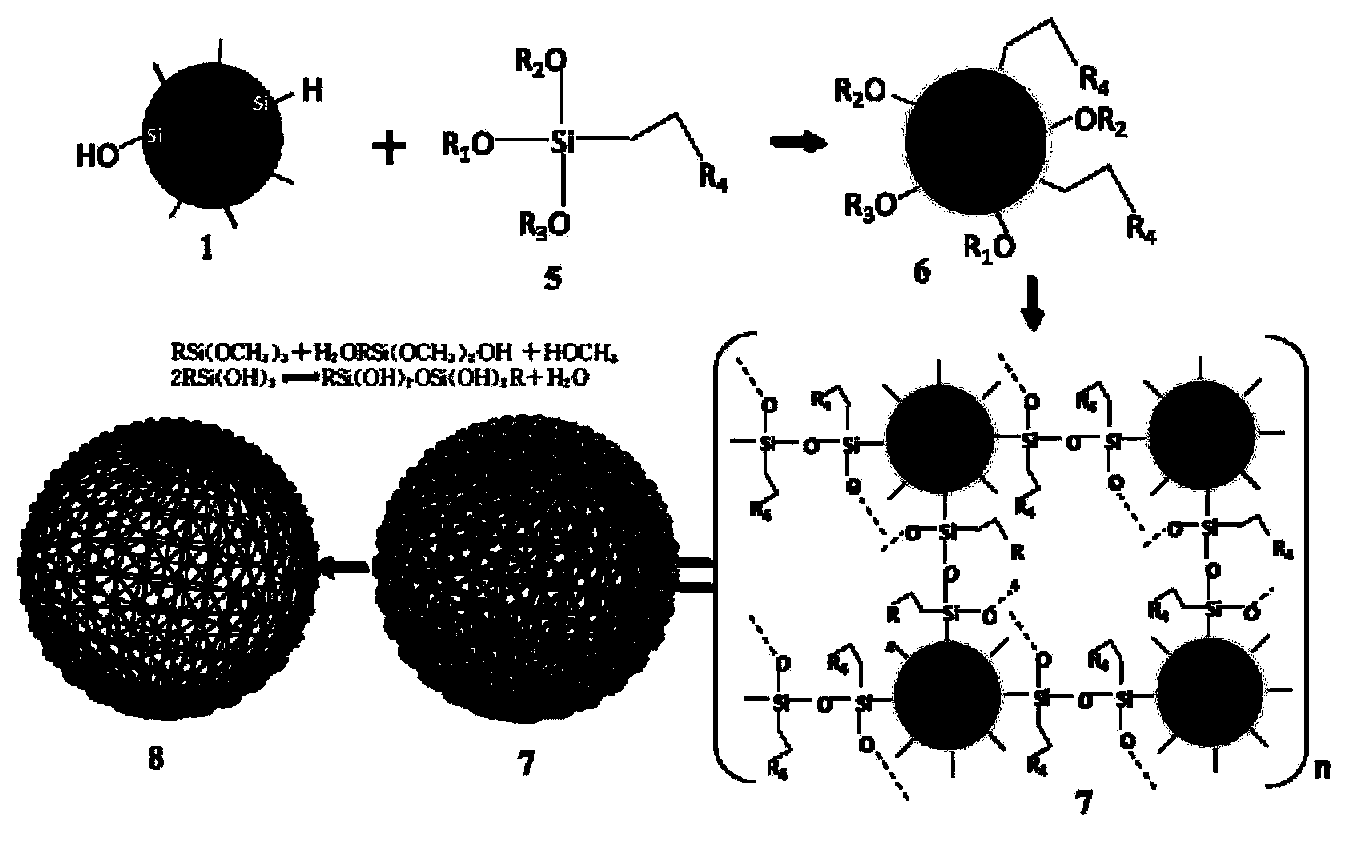

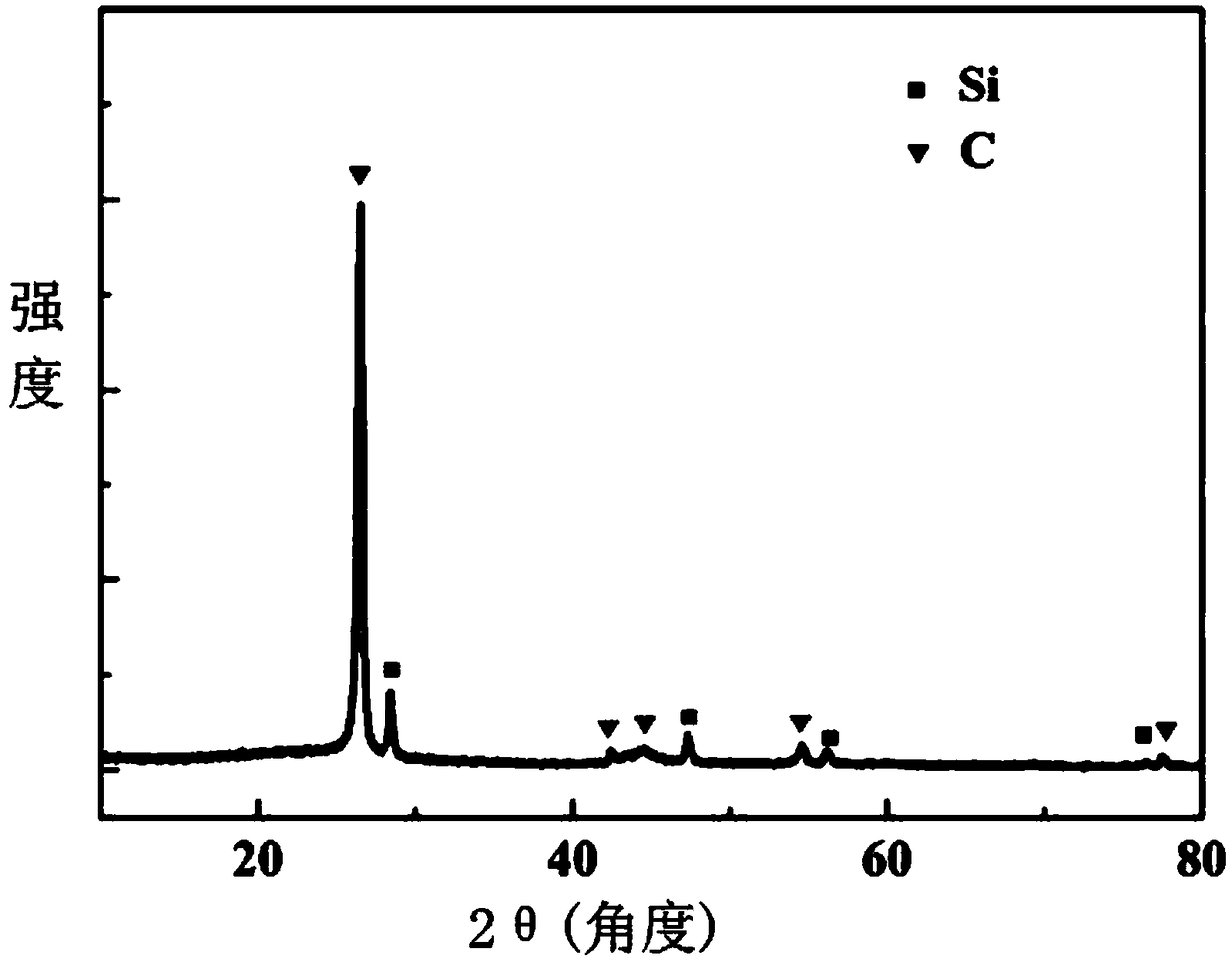

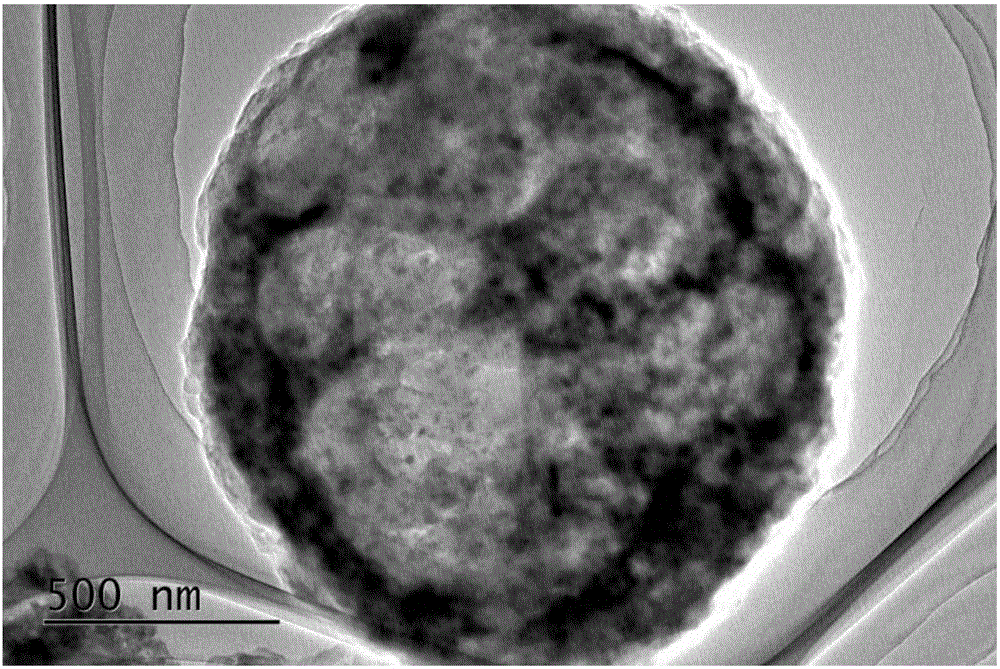

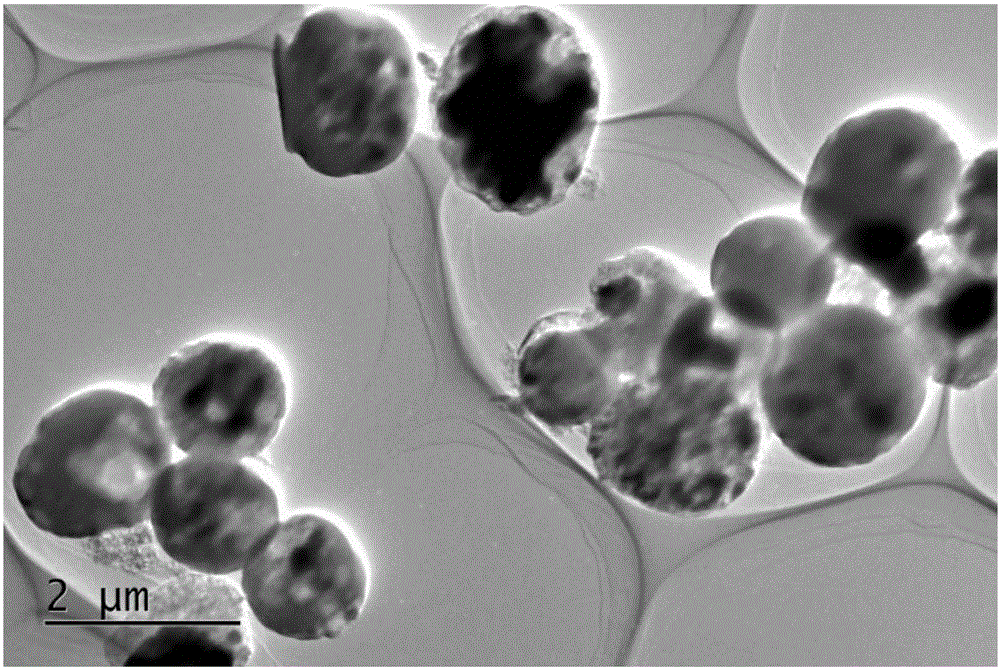

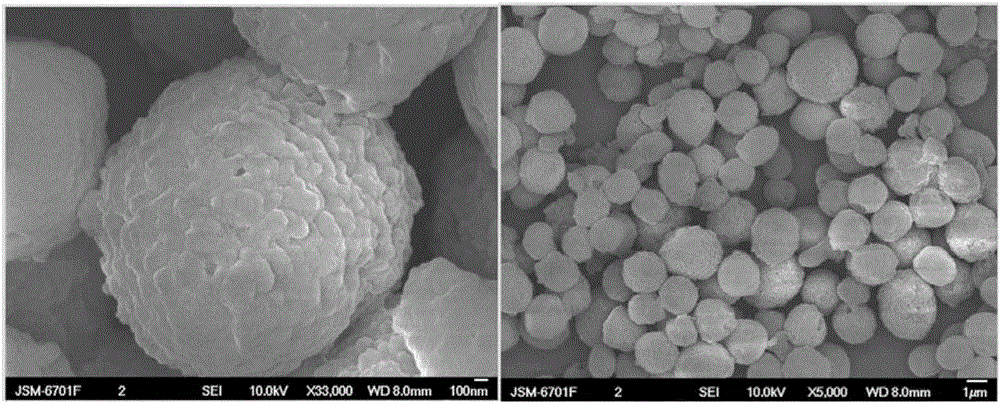

High-performance silicon/carbon anode nanocomposite and preparation method thereof

ActiveCN108428876ARich varietyGuaranteed stabilityMaterial nanotechnologyCell electrodesLithiumCarbon nanosphere

The invention provides a high-performance silicon / carbon anode nanocomposite and a preparation method thereof. The high-performance silicon / carbon anode nanocomposite is characterized by containing carbon nano-spherical particles with mesoporous channels, and the spherical particles and / or the mesoporous channels are filled with elementary silicon particles. The prepared silicon / carbon anode nanocomposite is of a porous structure, the elementary silicon particles are dispersed in a carbon skeleton and the mesoporous channels, the volume expansion effect during lithium-ion charge and dischargeis low, and electrochemical cycle performance is stable.

Owner:DONGHUA UNIV

Preparation method of covalent organic framework material derivative carbon skeleton loaded metallic monatomic composite material

PendingCN110368931AFacilitate the realization of industrial applicationSimple preparation processCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMaterials scienceSolid phases

The invention discloses a preparation method of a covalent organic framework material derivative carbon skeleton loaded metallic monatomic composite material. The preparation method comprises the following steps that firstly, a covalent organic framework material is synthesized through a room-temperature solid phase method, then the covalent organic framework material and a transition metal salt are mixed, stirred and dried, and a precursor is obtained; and finally, the precursor is calcinated through an in-situ pyrolysis method under protection of inert gas, and thus a target product is obtained. According to the preparation method, the monatomic catalytic material with high catalytic activity site dispersion and high catalytic stability is successfully constructed, the coverage of the metal types is wide, the cost is low, the operation steps are simple, reaction process conditions are easy to adjust and control, expensive equipment, special raw materials and complex processes are notneeded, and large-scale production can be achieved.

Owner:HEFEI UNIV OF TECH

Potassium permanganate lysis/ferric chloride flocculation/biological carbon skeleton combined conditioning method for municipal sludge

InactiveCN105254153AExcellent net yieldLow costSludge treatment by de-watering/drying/thickeningSludgeMoisture

The invention discloses a potassium permanganate lysis / ferric chloride flocculation / biological carbon skeleton combined conditioning method for municipal sludge, belonging to the technical field of environmental management. The method comprises the step of feeding certain amounts of potassium permanganate, ferric chloride and biological carbon into excess sludge at a certain stirring speed according to a certain feeding sequence, so as to condition the municipal sludge, so that the dehydration property of the municipal sludge is improved. The method has the beneficial effects that the cost of conditioning agents is low, and the operation is simple; meanwhile, the sludge breakage, flocculating constituent reconstruction and filter cake skeleton structure construction are achieved by virtue of three conditioning agents, so that the dehydration property of the sludge is overall improved, and the limitations of a single method and the combination of two methods in the past are broken through; by virtue of combined conditioning of the three conditioning agents, the dehydration property of the sludge can be obviously improved, and the moisture content of dehydrated sludge reaches 62%-67%; the cost is low, and the process is simple. The method is significant for the solving of the pollution problem of sludge.

Owner:HUNAN UNIV

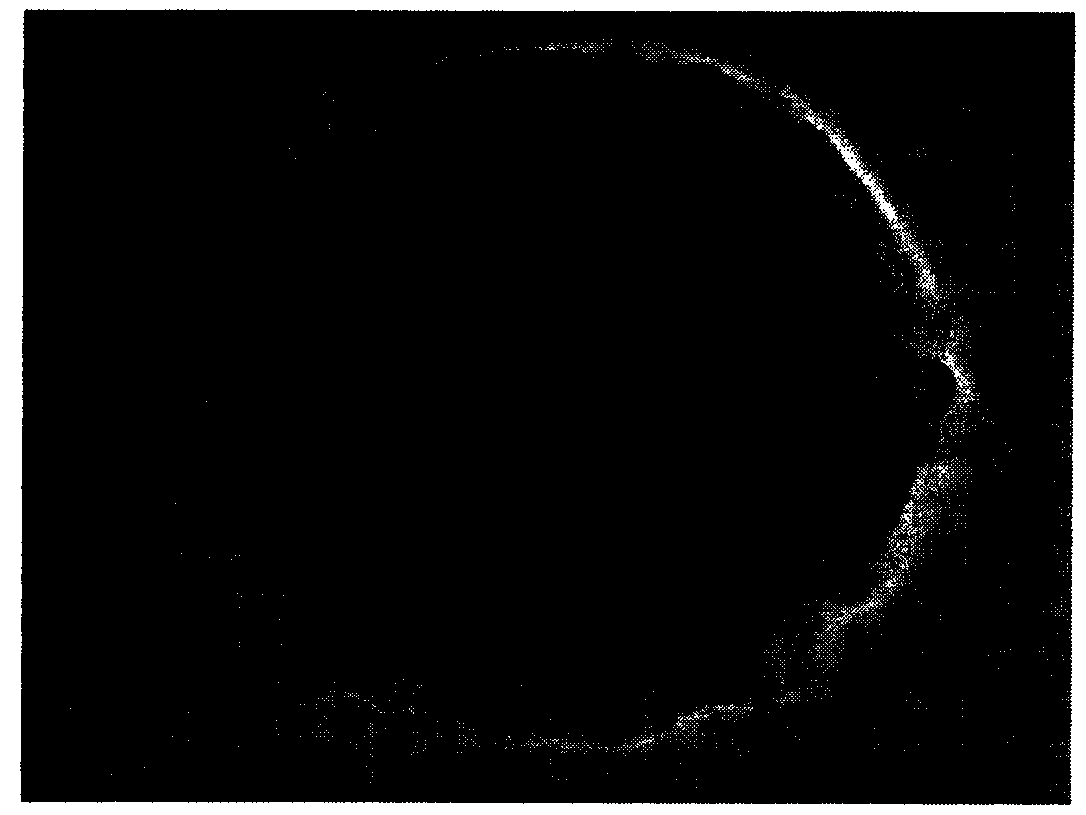

Silicon-based composite negative electrode material for lithium ion battery

ActiveCN104241621AAlleviate volume changesEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryOxygen

The invention relates to a silicon-based composite negative electrode material for a lithium ion battery, wherein a silicon-containing material with the size of less than 0.3 [mu]m is dispersed uniformly in a porous silicon oxygen carbon skeleton. The invention also provides a method for preparing the composite negative electrode material, wherein the method includes the steps: dispersing the silicon-containing material in a liquid organo-siloxane monomer, successively adding an ethanol-water acidic solution, a curing agent and an amorphous carbon source precursor solution into the dispersion liquid, and carrying out heat preservation to make the mixed solution cured; carrying out high temperature calcination on the precursor after curing in a protective atmosphere, to obtain a bulk silicon-based composite material; and crushing the bulk silicon-based composite material by ball milling to obtain the silicon-based lithium ion battery negative electrode material having various different particle sizes. The silicon-containing material in the silicon-based composite negative electrode material is firmly and evenly distributed in the porous silicon oxygen carbon skeleton, and the structure can effectively bear a volume effect brought by embedding and stripping of lithium and has the characteristics of adjustable charge / discharge specific capacity and high electrochemical cycle stability.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

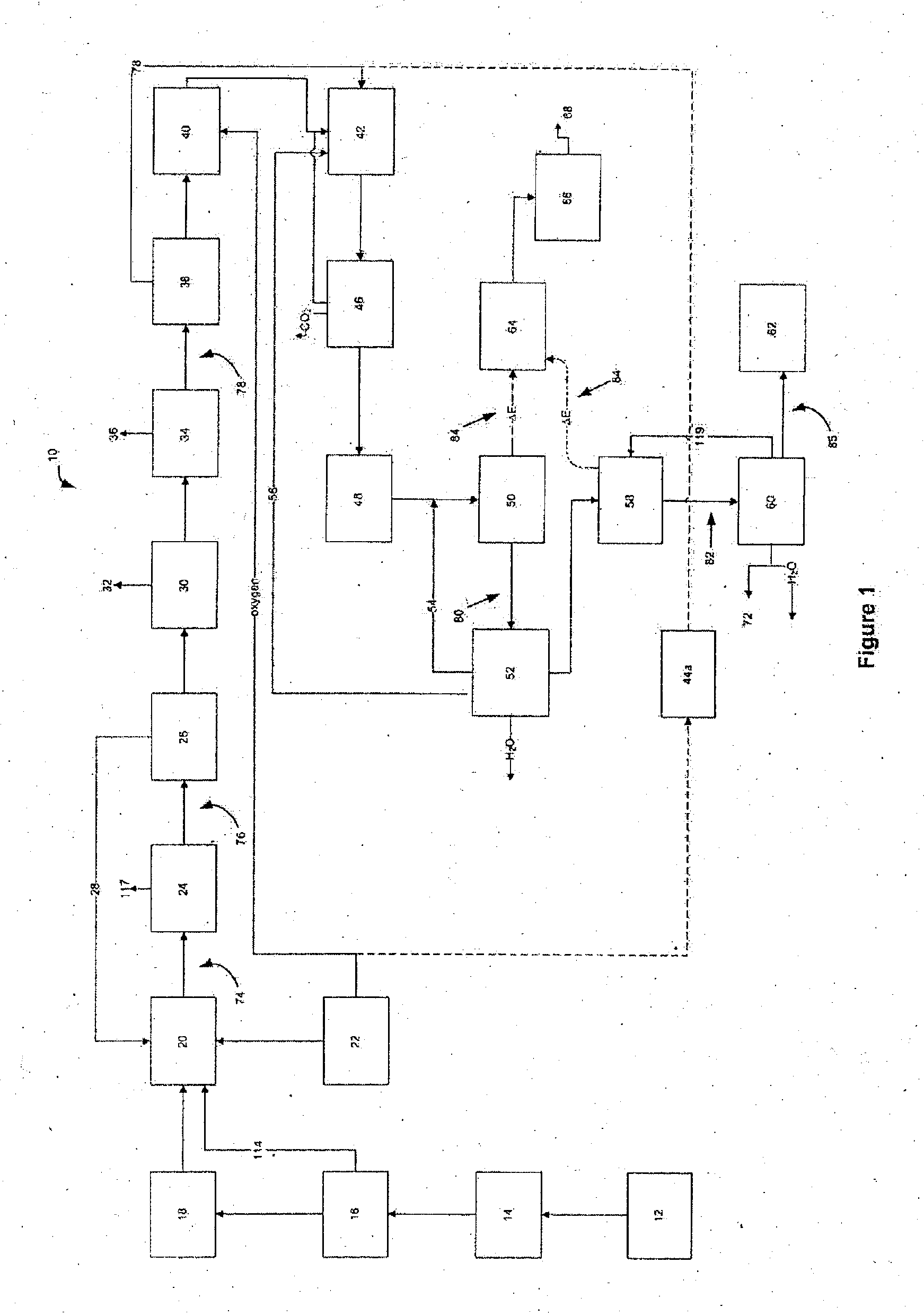

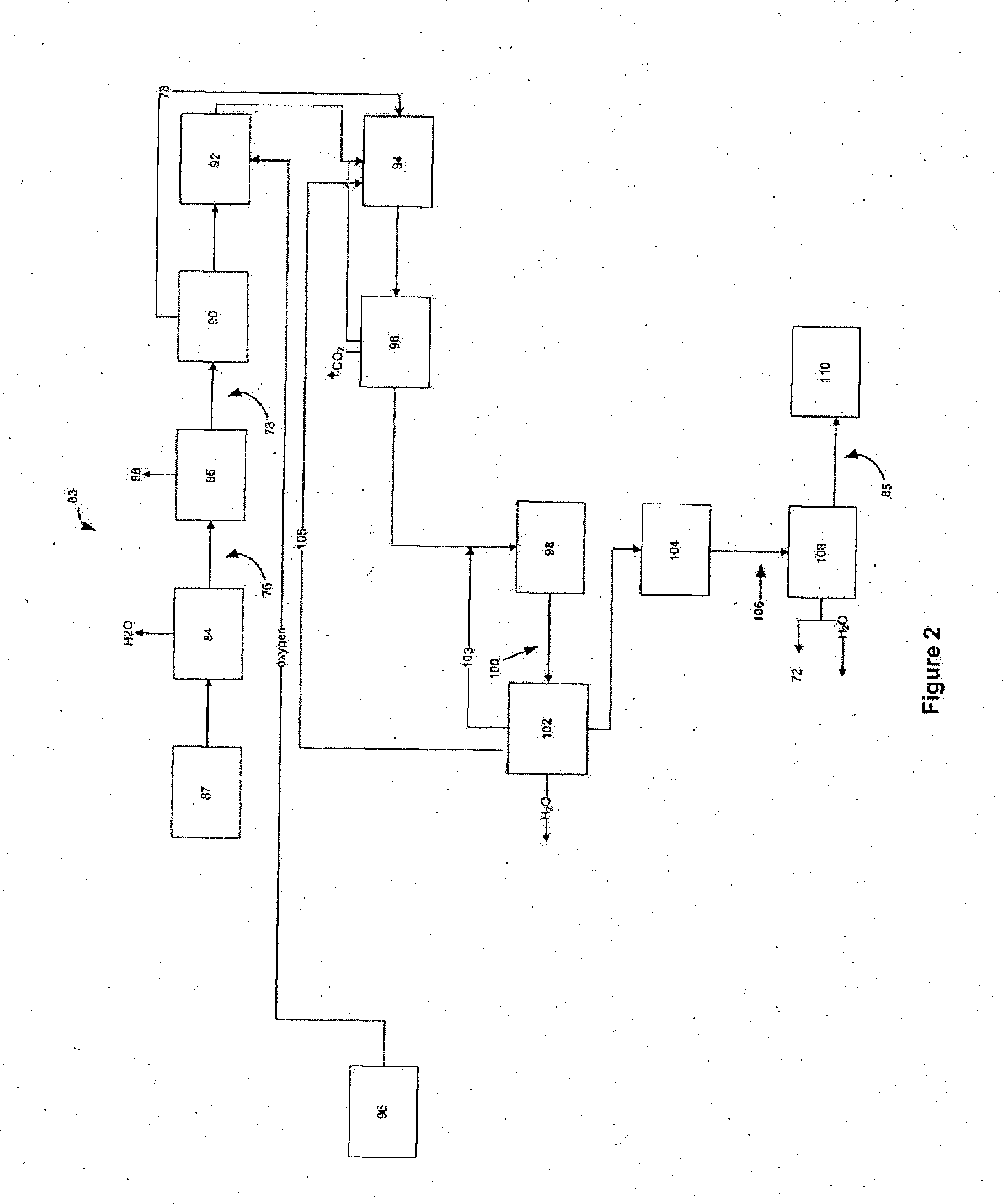

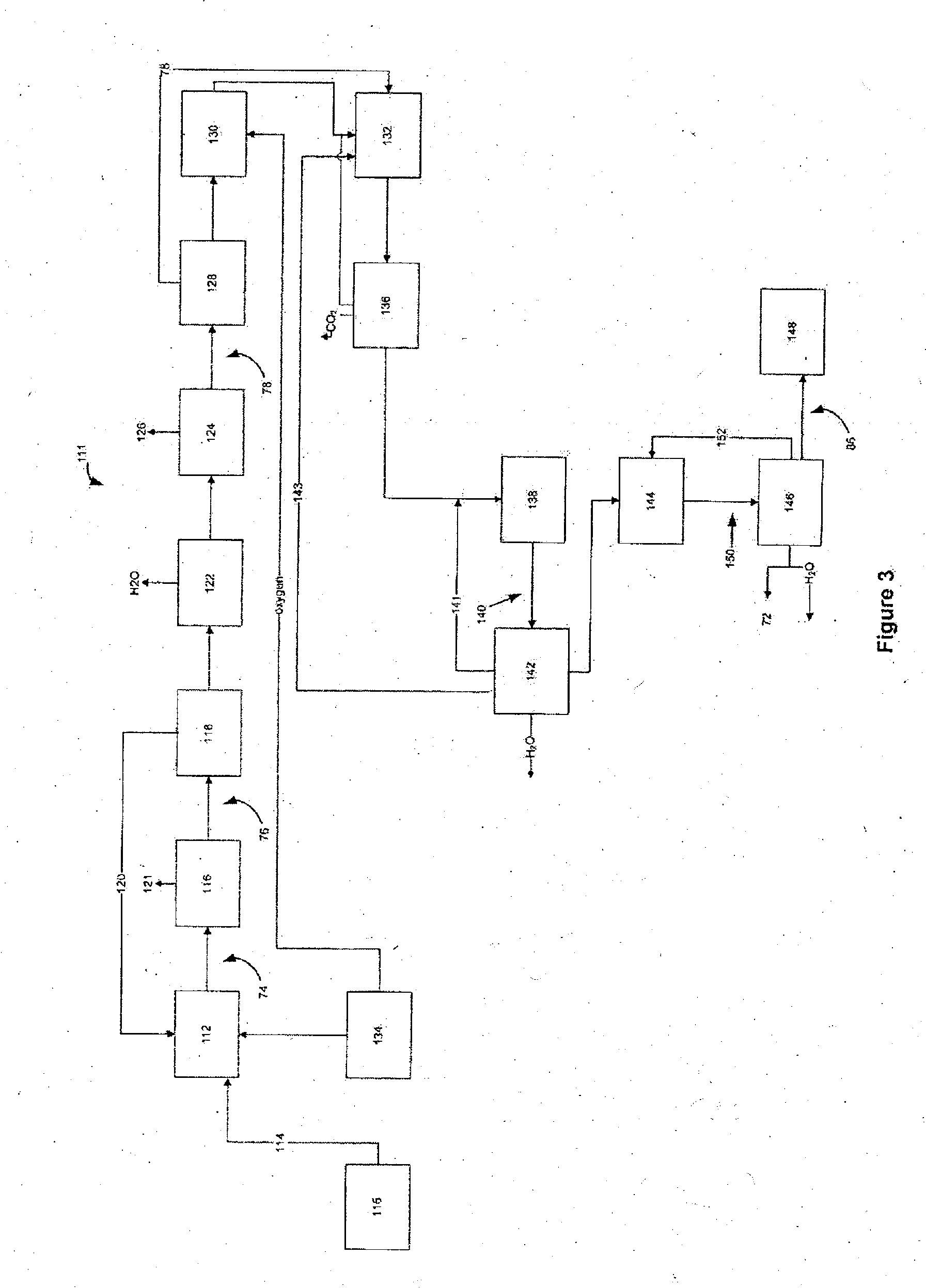

Production of hydrocarbon liquids

InactiveUS20110152593A1Combustible gas catalytic treatmentLiquid hydrocarbon mixture productionSyngasChemical reaction

A process to efficiently convert organic feedstock material into liquid non-oxygenated hydrocarbons in the C5 to C12 carbon skeleton range is disclosed. The process can utilize gaseous, liquid or solid organic feedstocks containing carbon, hydrogen and, optionally, oxygen. The feedstock may require preparation of the organic feedstock for the process and is converted first into a synthesis gas containing carbon monoxide and hydrogen. The synthesis gas is then cleaned and conditioned and extraneous components removed, leaving substantially only the carbon monoxide and hydrogen. It is then converted via a series of chemical reactions into the desired liquid hydrocarbons. The hydrocarbons are suitable for combustion in a vehicle engine and may be regarded a replacement for petrol made from fossil fuels in the C5 to C12 carbon backbone range. The process also recycles gaseous by-products back through the various reactors of the process to maximize the liquid hydrocarbon in the C5 to C12 carbon skeleton range yield.

Owner:KELLY KAREN SUE +1

Pesticide compositions and methods for their use

Pesticide compositions and methods for their use are provided. Embodiments of the subject pesticide compositions include a pesticide and an assimilable carbon skeleton energy component. Embodiments of the subject compositions may include a pesticide and one or more of a macronutrient component, micronutrient component, vitamin / cofactor component and a complexing agent. Also provided are methods that include preparing an assimilable carbon skeleton energy containing-pesticide composition and methods for administering an assimilable carbon skeleton energy containing-pesticide composition to a plant. Kits for use in practicing the subject invention are also provided. The subject pesticide compositions find use in a variety of different applications, and are particularly suited for use in at least mollifying pesticide-induced phytotoxicity of a plant.

Owner:YAMASHITA THOMAS T

Preparing method of lithium ion battery silicon carbon negative electrode material

InactiveCN109285994AImprove electrochemical performanceMild conditionsMaterial nanotechnologyCell electrodesCarbon compositesCharge discharge

The invention discloses a preparing method of a lithium ion battery silicon carbon negative electrode material. A compound containing amidogens or ammonium ions is adopted for modifying nanometre silicon, so that the nanometre silicon carries positive charges, a scheme of modifying negative ions or oxidizing the negative ions is adopted, so that a carbon skeleton carries negative charges, in a solvent, the silicon and the carbon skeleton which carry the opposite charges are self-assembled to a composite material, and then the surface of the composite material is coated with pyrolytic carbon. Compared with existing methods for preparing silicon / carbon composite materials, the adopted self-assembly method is mild in condition and simple in step, complicated and expensive equipment is not needed, and large-scale popularization is facilitated; meanwhile, after the prepared silicon / carbon composite material is subjected to charge-discharge cycles 200 times, the discharge specific capacity is still larger than 500 mAh.g<-1>, and the electrochemical performance of the lithium ion battery silicon carbon negative electrode material is obviously improved compared with silicon / carbon composite materials which are prepared through simple mixing.

Owner:TIANJIN UNIV

Metallic carbon-containing catalyst and preparation method and application thereof

InactiveCN106669765AHigh specific surface areaImprove catalytic performancePhysical/chemical process catalystsCarbonizationSolvent

The invention relates to a preparation method for a metallic carbon-containing catalyst. The preparation method dissolves at least two types of transition metal compounds into a solvent A, so that a solution a is obtained; an imidazole compound is dissolved into a solvent B, so that a solution b is obtained; the solution a and the solution b are mixed and stirred, solid-liquid separation is carried out, obtained precipitate is calcined under inert gas protection, and thereby the metallic carbon-containing catalyst is obtained. By the method of preparing MOFs and then carrying out in-situ carbonization, the preparation method obtains the catalyst with an M-N-C structure, and because the carbon skeleton has a large specific surface area, the catalytic performance of the catalyst is further increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

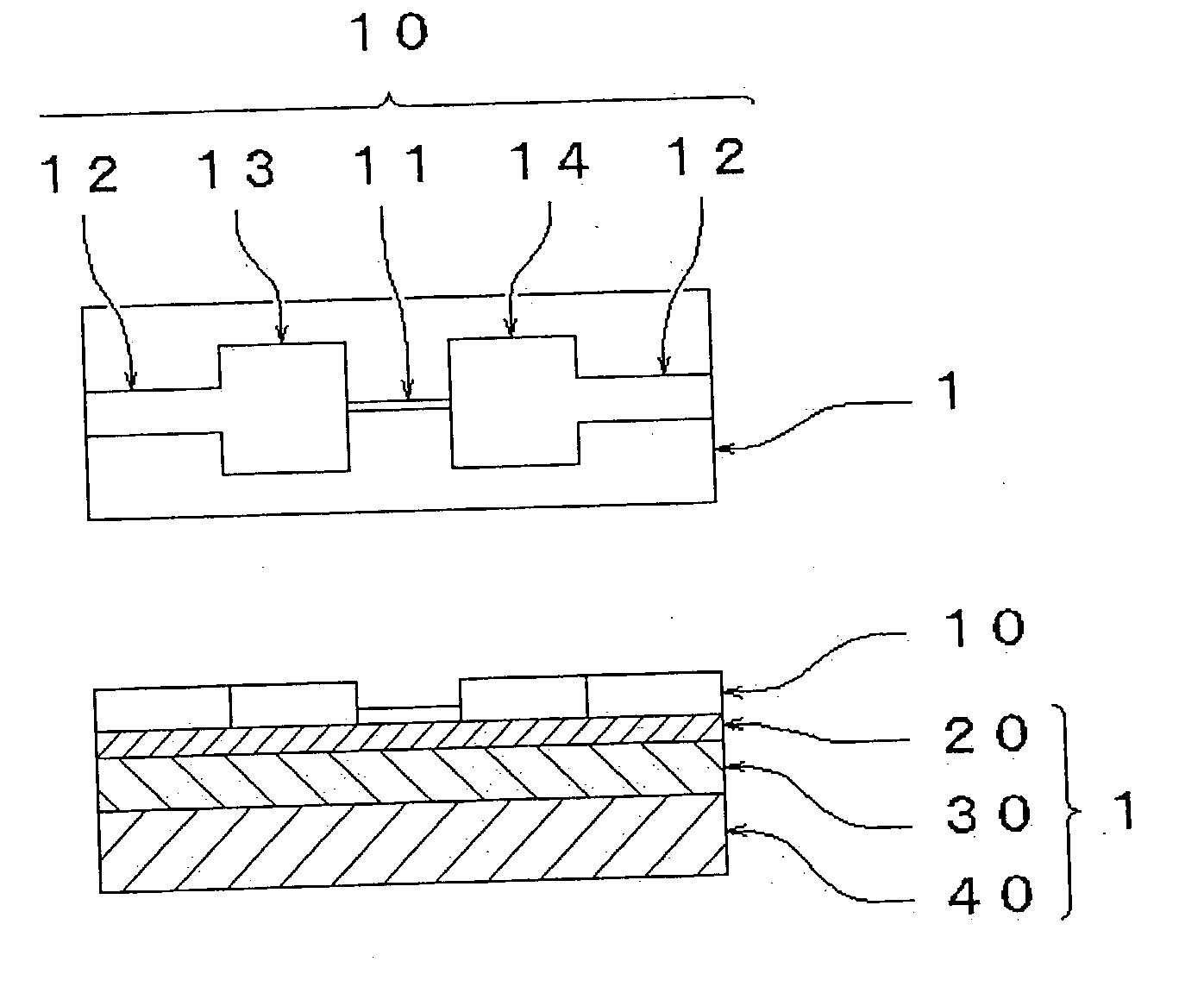

Structure matter of thin-film particles having carbon skeleton, processes for the production of the structure matter and the thin-film particles and uses thereof

InactiveUS20070160842A1Easily utilize electronic nature and stabilityImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceThin membrane

The present invention provides a structure matter composed of (a) oxidized form thin film particle(s) which are obtained by oxidizing graphite, have a thickness of 0.4 nm to 10 μm and a planar-direction size at least twice as large as the thickness, have lyophilic to a liquid having a relative dielectric constant of 15 or more and have a carbon skeleton or an oxidized form lamination layer aggregate in which the oxidized form thin film particles are combined with each other, or (b) reduced form thin film particle(s) or a reduced form lamination layer aggregate obtained by partially or completely reducing the above oxidized form thin film particle(s) or the above oxidized form lamination layer aggregate so as to have an oxygen content of 0 to 35 wt %, and (c) a substrate, the oxidized form thin film particle(s), the oxidized form lamination layer aggregate, the reduced form thin film particle(s) or the reduced form lamination layer aggregate being in contact with the substrate, its use and a method for reducing thin film particles having a carbon skeleton.

Owner:HIRATA MASUKAZU +2

Positive electrode material of lithium sulfur battery, preparation method of positive electrode material and lithium sulfur battery containing positive electrode material

ActiveCN106450195AImprove cycle stabilityImprove pollutionSecondary cellsNon-aqueous electrolyte accumulator electrodesCyclic processPorous carbon

The invention discloses a positive electrode material, a preparation method thereof and a lithium sulfur battery containing the positive electrode material. The positive electrode material uses yeast bacteria as a carbon precursor (namely a carbon source), in-situ trapping on metal ions is realized by adsorbing the metal ions in a hydrothermal carbonizing process, and a carbon skeleton material obtained after high-temperature heat treatment is used for filling elemental sulfur. A porous carbon / metal oxide / sulfur (namely S / metal oxide@C (carbon)) with a three-dimensional nanometer structure can effectively adsorb polysulfide ions in the circulating process of the lithium sulfur battery, the relevant capacity loss is inhibited, and the composite material has higher charging and discharging capacity and cyclic life. The positive electrode material has the advantages that the preparation method is simple, the implementing is easy, the cost is low, and the obvious practical value and application value are realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

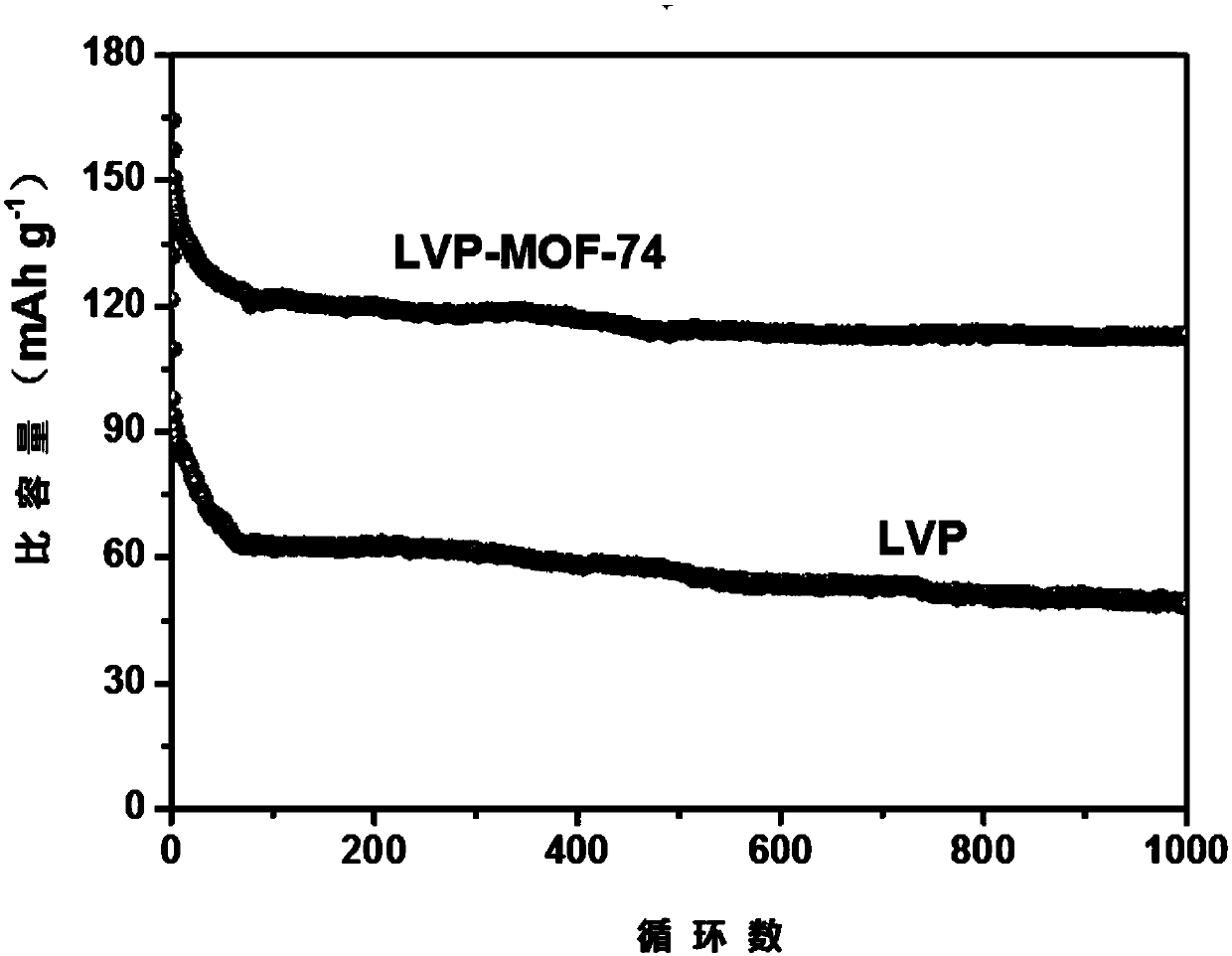

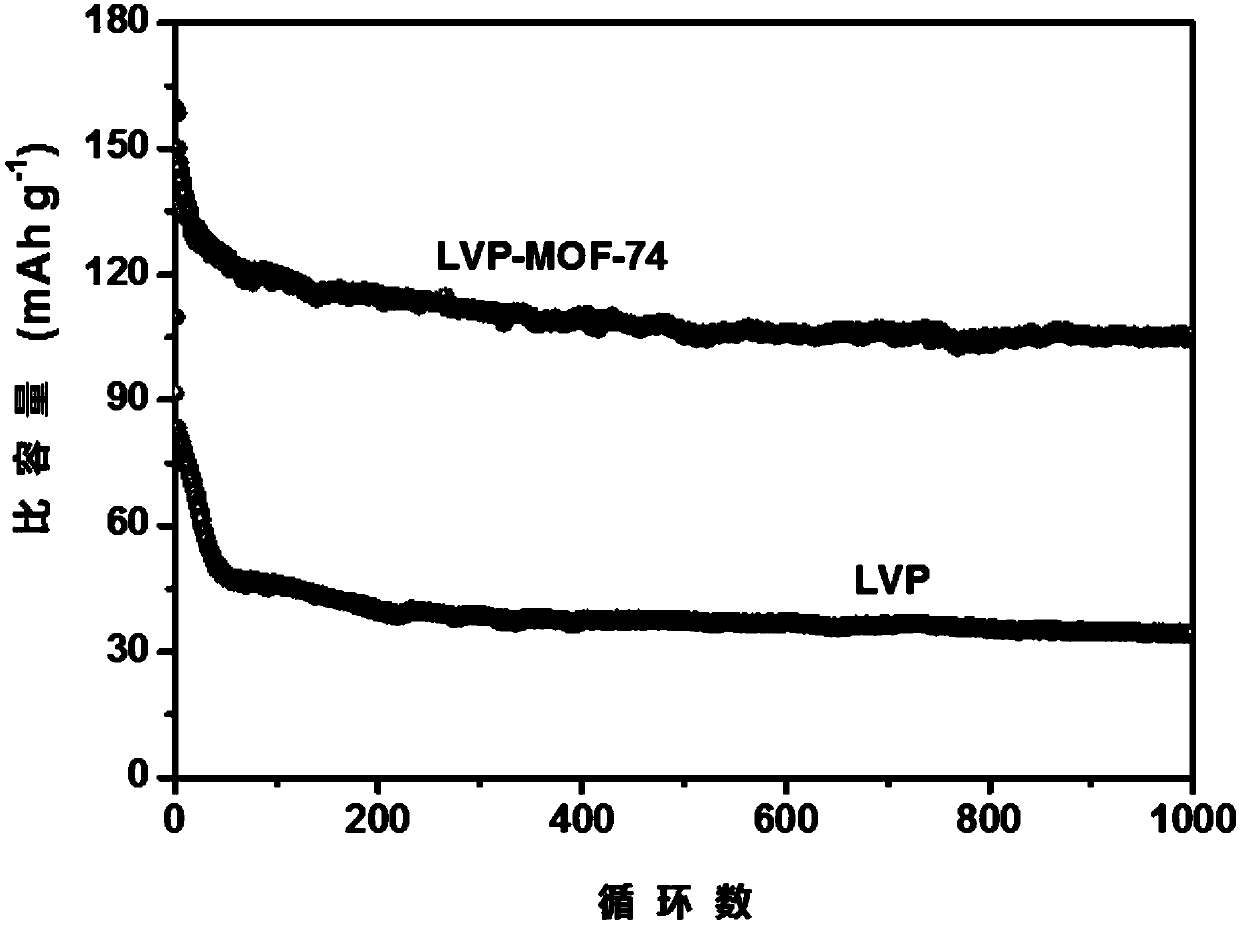

Metal organic framework-derived phosphate composite anode material and preparation method thereof

InactiveCN109616653ASmall sizeHigh porosityActive material electrodesSecondary cellsElectrochemical responsePhosphate

The invention discloses a metal organic framework-derived phosphate composite anode material and a preparation method thereof. The anode structure is a phosphate material, the surface is coated with carbon, and a microporous bubble structure is arranged in the anode structure; the phosphate is LiMO4 or Li3M'2(PO4)3; M is selected from any one or combination of Fe, Co, Ni and Mn; and M' is selectedfrom any one of combination of Fe, V and Ti. A metal organic framework (MOF) material serves as a metal source and a carbon source at the same time, and is used for preparing the composite anode material by adoption of a high-temperature solid state method after being dispersed with a lithium source compound and a phosphorus source via ball milling; and the material is capable of keeping the highsafety and high specific capacity of polyanion anode materials and greatly improving the specific surface area and electrochemical reactivity on MOF carbon skeleton coating layers generated on the surface of phosphate. The material is capable of improving the conductivity of polyanion phosphate materials and the cycling stability of batteries, and greatly improving the electrochemical performanceof LiMPO4 and Li3M'2(PO4)3 materials.

Owner:SHANGHAI AEROSPACE POWER TECH

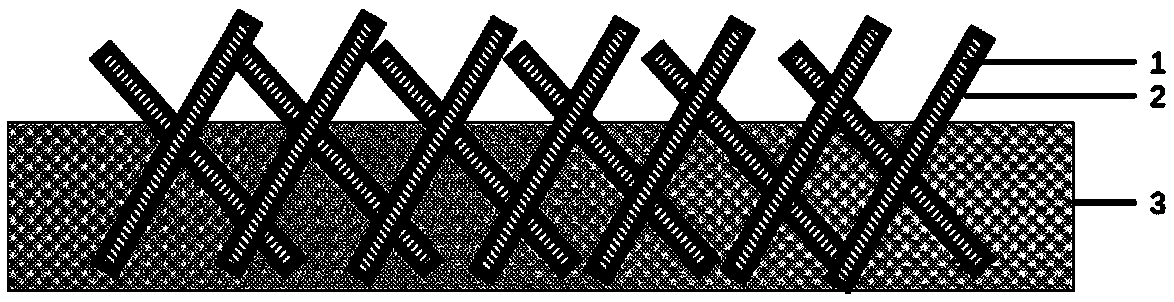

Composite metal lithium cathode with lithium-carbon composite interface layer and preparation method thereof

ActiveCN109686921APromote growthImprove cycle performanceCell electrodesSecondary cellsCyclic processCarbon composites

The invention discloses a composite metal lithium cathode with a lithium-carbon composite interface layer and a preparation method thereof and belongs to the technical field of secondary batteries. The outer surface of the carbon framework material of the composite metal lithium cathode is coated with the lithium-carbon composite interface layer, and the structure of the composite interface layeris a lithium-carbon intercalation structure formed by intercalating metal lithium atoms into the carbon skeleton material layer. The forming method comprises the following steps: pressing lithium metal into pores of the carbon framework material in a pressurizing mode, and forming a lithium-carbon composite interface layer, which is conductive and stable to lithium, on the surface of the carbon framework material after activation for a certain time due to the adsorption or intercalation effect. The preparation method is simple and feasible, and the generated lithium-carbon composite interfacelayer is very uniform in distribution and thickness in the carbon framework material. The interface layer can effectively improve the volume expansion problem of the lithium metal cathode in the circulation process and prolong the cycle life of the batteries.

Owner:TSINGHUA UNIV

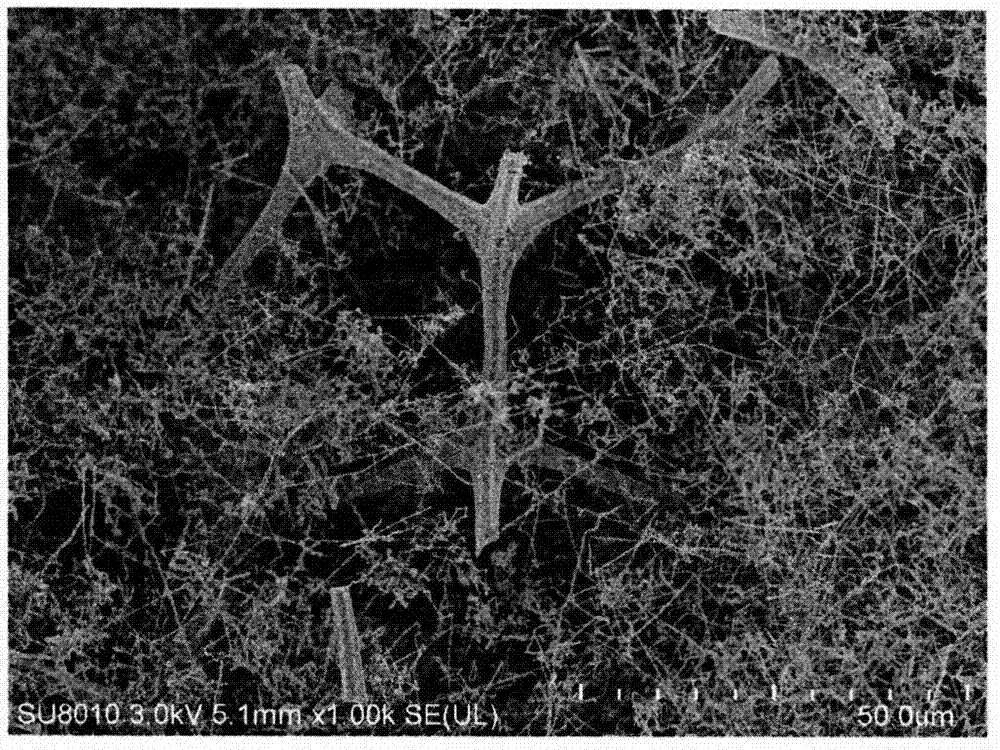

Foamy carbon based heat-insulation composite material with light weight and high strength

ActiveCN106904973AImprove antioxidant capacityImprove mechanical propertiesCeramicwareChemical vapor depositionMechanical property

The invention provides a foamy carbon based heat-insulation composite material with light weight and high strength. The foamy carbon based heat-insulation composite material with light weight and high strength is characterized by comprising a base material foamy carbon, an SiC coating and reticulated SiC nanowires, wherein a foamy carbon skeleton is coated with the SiC coating; three-dimensional pores are filled with the reticulated SiC nanowires, porosity is 90%-95%, average pore diameter is 50 nm-500 nm, apparent density is 0.05-0.2 g / cm<3>, and compressive strength is 5-15 MPa. Foamy carbon is flexible foamy carbon and is prepared from melamine foam through high-temperature pyrolysis, the porosity is 99% or higher, and the average pore diameter is 20-50 mu m; the thickness of the SiC coating is 0.5-1 mu m, the diameter of the SiC nanowires is 50-300 nm, the average length is 30-50 mu m, and all the SiC nanowires are prepared with a chemical vapor deposition method. The light foamy carbon based heat-insulation composite material with high strength has the advantages as follows: 1, the foamy carbon skeleton is coated with SiC, so that oxidation resistance of the composite material is improved; 2, the foamy carbon skeleton is coated with SiC, and mechanical properties of the composite material are improved accordingly; 3, internal pores of foam are segmented by the SiC nanowires, the internal pore diameter is reduced, and the heat conductivity of the composite material is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

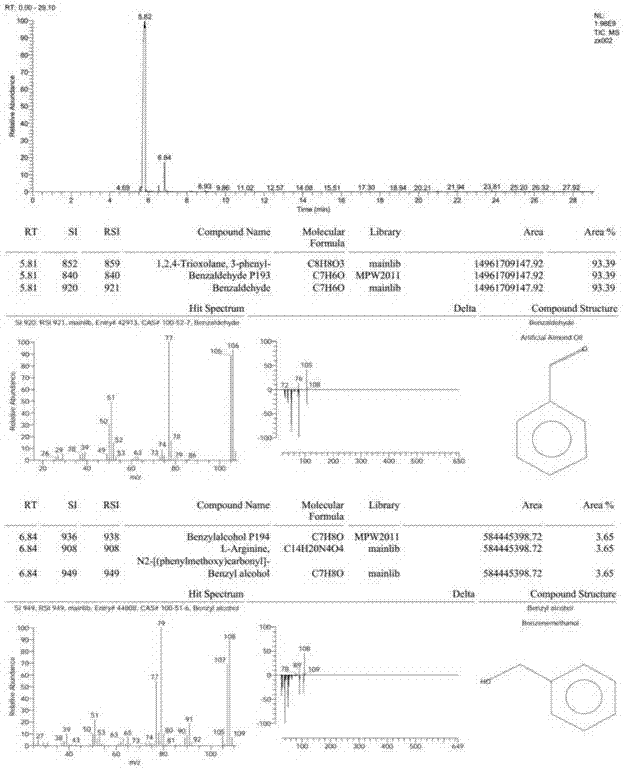

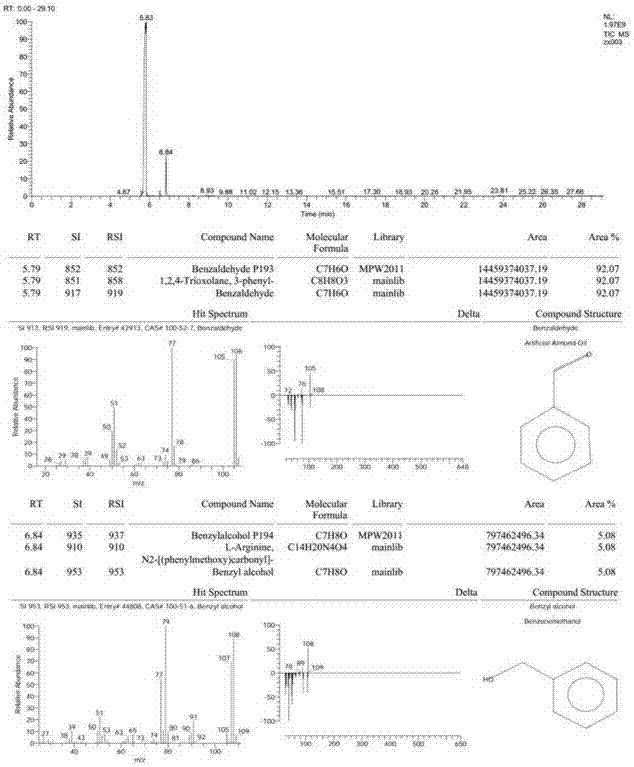

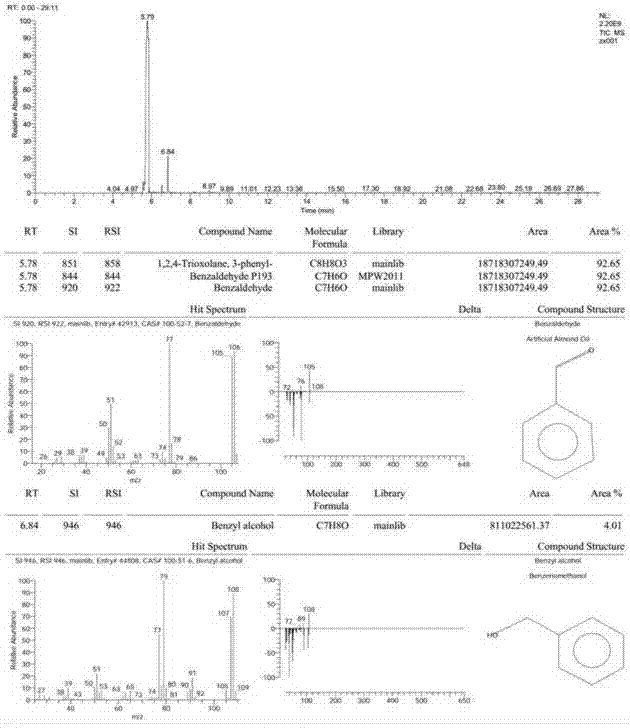

Method for preparing supported nano-cobalt catalyst by pyrolysis of deep eutectic solvent and application

InactiveCN107952462AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationCatalytic oxidationHigh activity

The invention discloses a method for preparing a supported nano-cobalt catalyst by pyrolysis of a deep eutectic solvent and an application. The method comprises the following steps: firstly, preparinga carbon black mixture supported with the deep eutectic solvent, then pyrolyzing the mixture at high temperature in an inert gas atmosphere to obtain the supported nano-cobalt catalyst, and applyingthe supported nano-cobalt catalyst to an aromatic alcohol liquid phase selective oxidation system with molecular oxygen as an oxygen source. Compared with the prior art, the supported nano-cobalt catalyst prepared with the method has the advantages that a nitrogen-doped carbon skeleton with high specific surface is effectively integrated with the catalytic active center of uniformly dispersed metal cobalt, oxygen can be activated as an oxidant in the absence of alkalinity and aids, aromatic alcohol is catalyzed and oxidized in a green and efficient way, aromatic aldehyde or aromatic ketone isobtained, and the problems about difficulty in recovery, discharge of three wastes and the like caused by extra need of homogeneous organic alkali in the catalytic oxidation process of traditional catalysts are solved. The catalyst prepared with the method has the advantages of high selectivity, high activity, high stability, magnetic recyclability and the like, and has good application value andprospect.

Owner:JIANGXI NORMAL UNIV

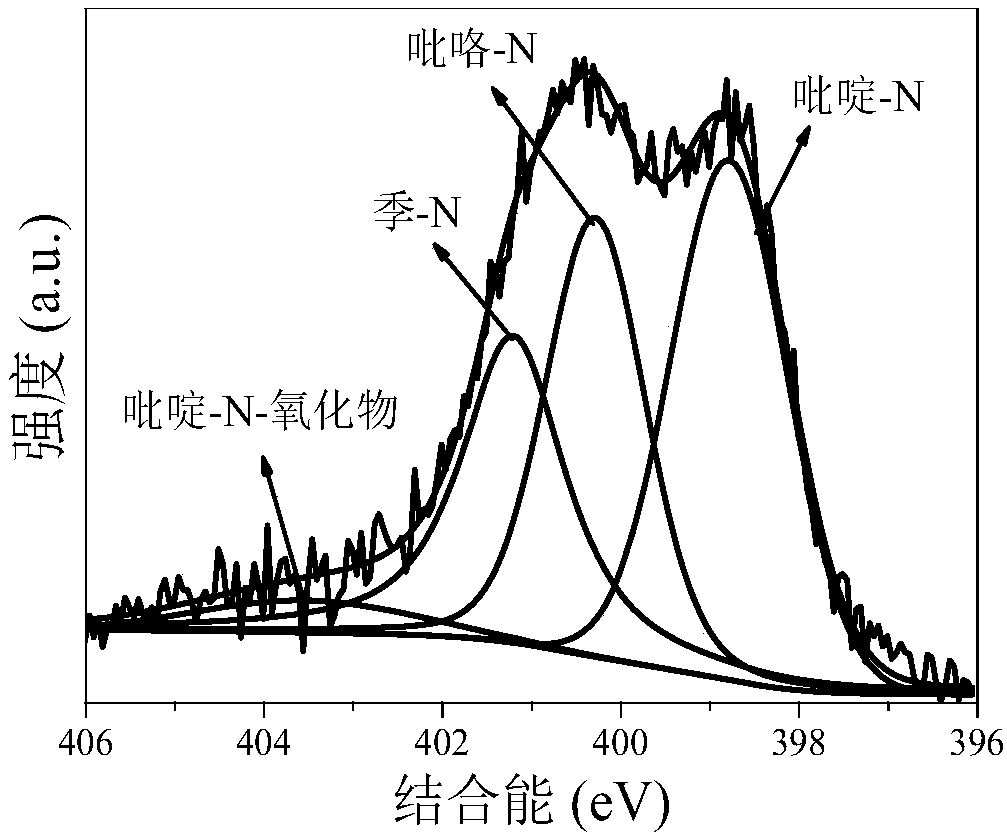

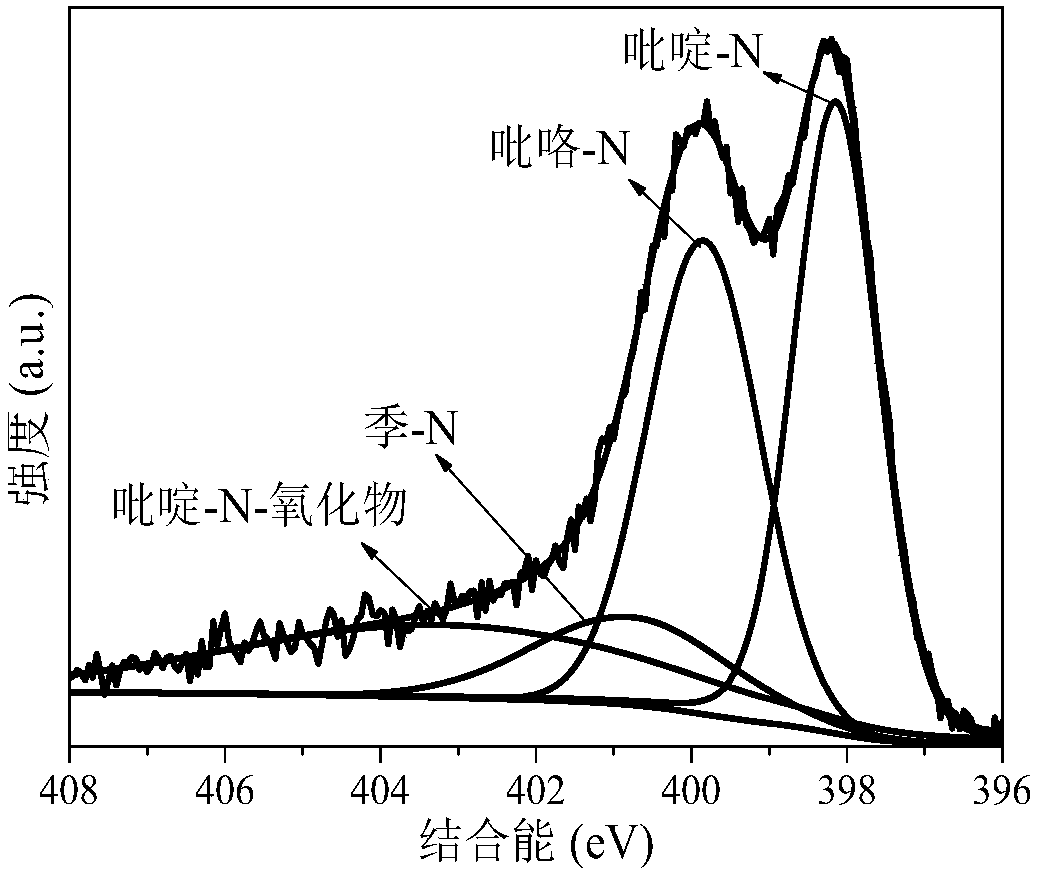

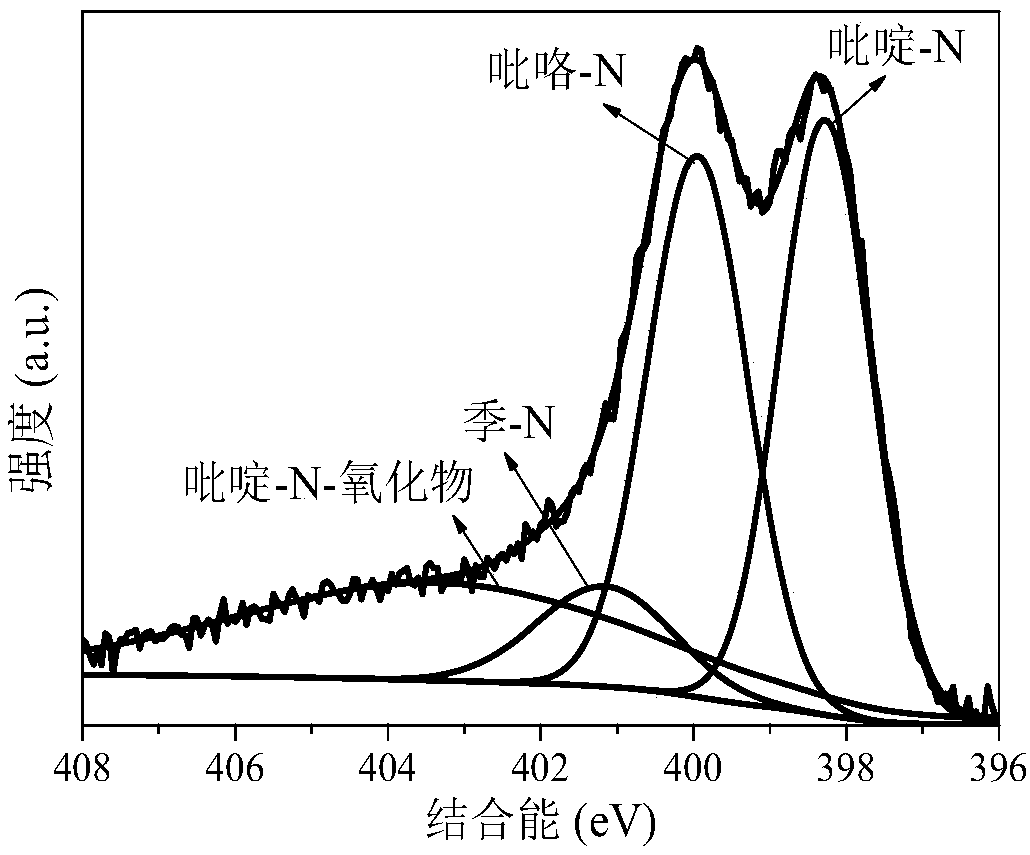

Method for preparing high-nitrogen-content porous carbon material by utilizing biomass, product and application thereof

InactiveCN108163853AWell-developed pore structurePromote formationCarbon compoundsPorous carbonSorbent

The invention discloses a method for preparing a high-nitrogen-content porous carbon material by utilizing biomass, a product and application thereof. The preparation process is as follows: pulverizing and drying the biomass, mixing the biomass and an activating agent uniformly, performing rapid pyrolysis on the mixture under the atmosphere of ammonia gas, and carrying out reaction between the activating agent and the biomass waste to etch a carbon skeleton to form a developed pore structure; meanwhile, a large amount of holes are formed, nitrogen atoms in the ammonia gas occupy the holes rapidly to form rich active nitrogen-containing functional groups (pyridine-N, pyrrole-N, quaternary-N and pyridine-N-oxide), so that a large amount of nitrogen elements are enriched in pyrolytic carbon;furthermore, the own action of the ammonia gas and the synergistic effect of the activating agent and the ammonia gas can promote formation of coke pores and nitrogen-containing functional groups, anda functional high-nitrogen-content porous carbon material with rich activated nitrogen-containing functional groups is finally formed and has wide application prospect in the fields of catalysts, adsorbents, electrode materials and the like, so that high-additional-value utilization of the biomass is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

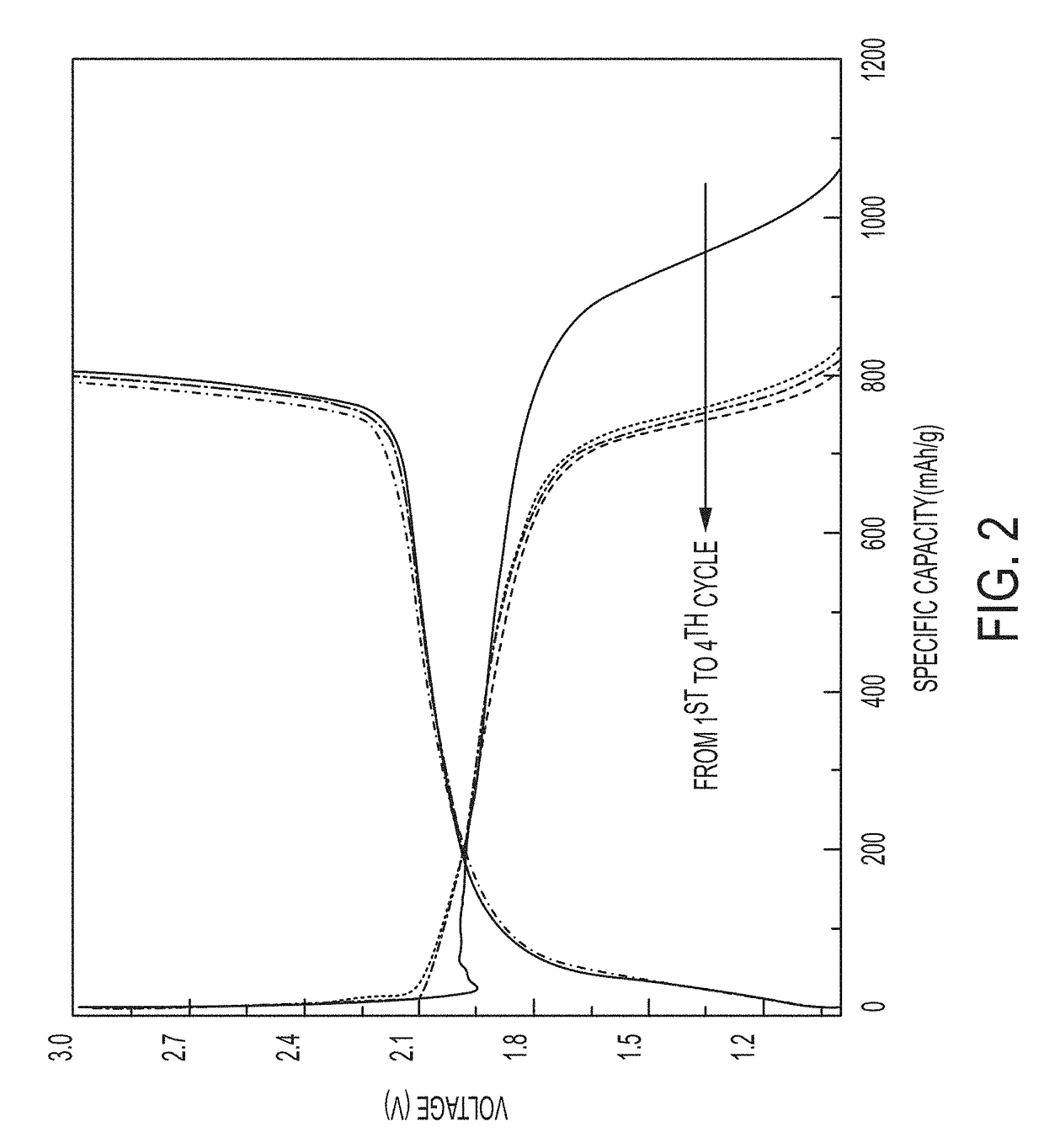

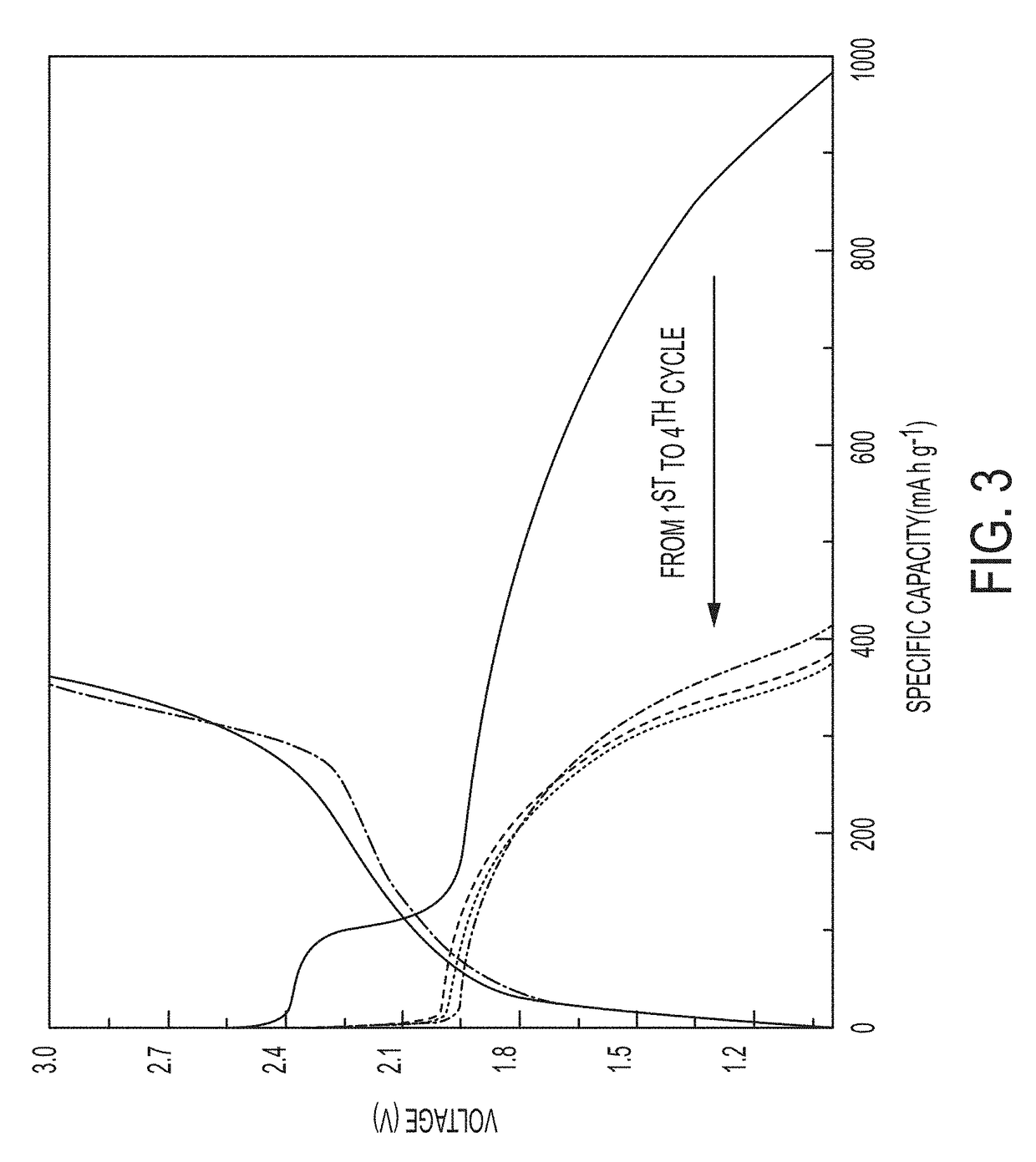

Immobilized Selenium, a Method of Making, and Uses of Immobilized Selenium in a Rechargeable Battery

ActiveUS20170301914A1High degree of graphitizationImprove electrochemical performancePositive electrodesLi-accumulatorsSulfurRechargeable cell

An immobilized selenium body, made from carbon and selenium and optionally sulfur, makes selenium more stable, requiring a higher temperature or an increase in kinetic energy for selenium to escape from the immobilized selenium body and enter a gas system, as compared to selenium alone. Immobilized selenium localized in a carbon skeleton can be utilized in a rechargeable battery. Immobilization of the selenium can impart compression stress on both the carbon skeleton and the selenium. Such compression stress enhances the electrical conductivity in the carbon skeleton and among the selenium particles and creates an interface for electrons to be delivered and or harvested in use of the battery. A rechargeable battery made from immobilized selenium can be charged or discharged at a faster rate over conventional batteries and can demonstrate excellent cycling stability.

Owner:II VI DELAWARE INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com