Positive electrode material of lithium sulfur battery, preparation method of positive electrode material and lithium sulfur battery containing positive electrode material

A technology for lithium-sulfur batteries and cathode materials, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of fast capacitance decay and short cycle life, and achieve high production efficiency, low cost, and improved environment Effects of Pollution Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] As mentioned above, the present invention provides a positive electrode material for a lithium-sulfur battery, a preparation method thereof, and a lithium-sulfur battery containing the positive electrode material.

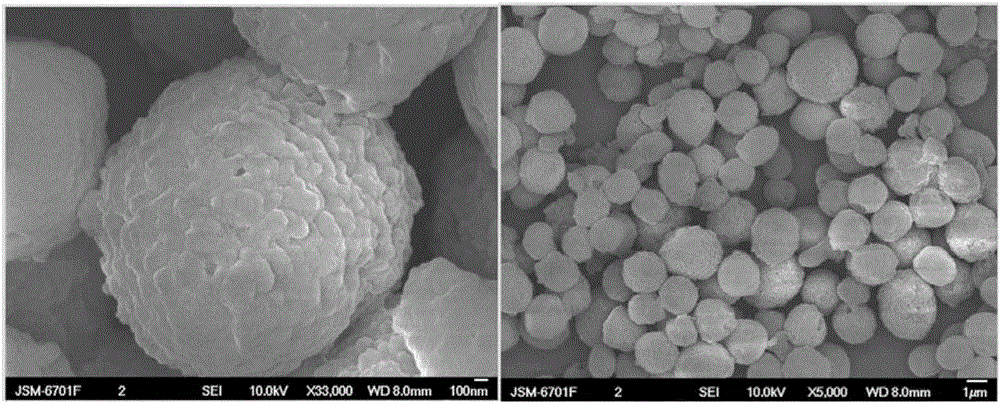

[0054] Specifically, the present invention provides a method for preparing a positive electrode material for a lithium-sulfur battery, wherein the positive electrode material is a carbon / metal oxide / sulfur ternary composite material (referred to as S / metal oxide@C); The ternary composite material is prepared by a hydrothermal method, wherein carbon-containing biomass material (specifically such as yeast) is used as a carbon precursor. Further, a metal salt is used as a metal oxide precursor.

[0055] In a preferred embodiment of the present invention, described method comprises the following steps:

[0056] 1) Using yeast and metal salts as raw materials, an amorphous carbon-metal ion complex is prepared by hydrothermal method, which is recorded as intermed...

Embodiment 1

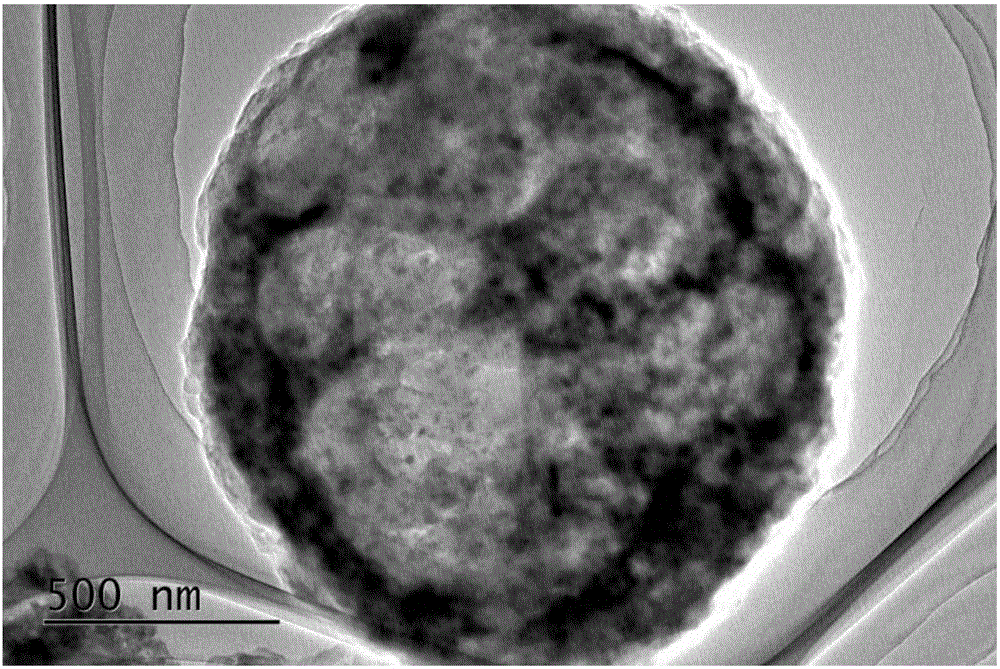

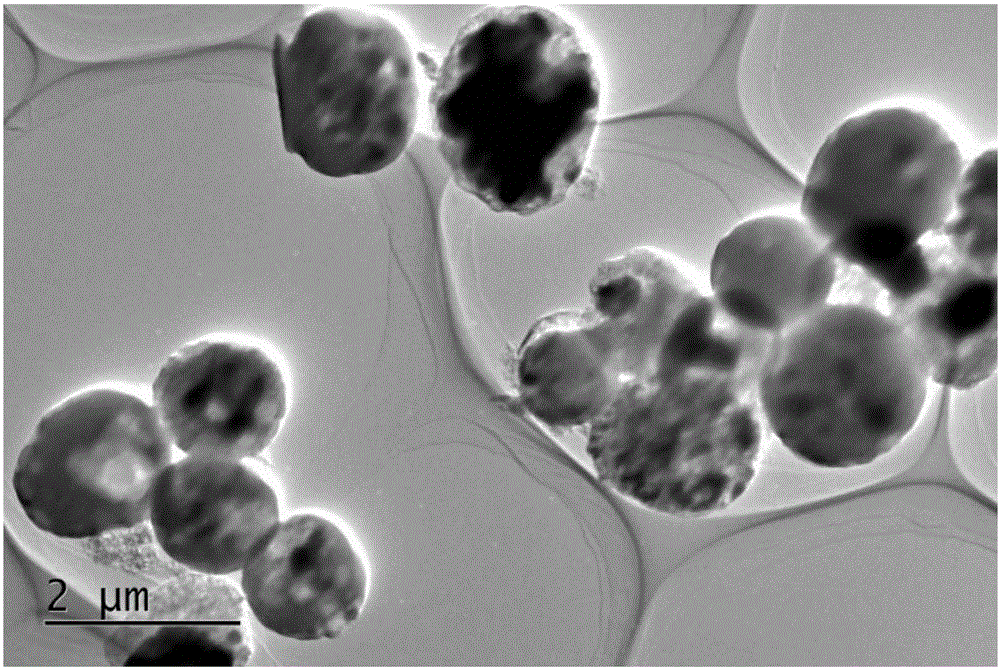

[0085] S / MnO 2 @C

[0086] 1. The preparation method of the ternary composite positive electrode material: the carbon precursor yeast and the metal oxide precursor MnCl 2 Mix according to the mass ratio of 1:0.05, the specific operation steps are as follows: wash 4g of yeast with deionized water, disperse in 40mL of deionized water, add 2g of sodium chloride, 100μL of glutaraldehyde and 0.2g of metal oxide Precursor MnCl 2 , put into a 100mL beaker and stir evenly. Transfer the above solution into a polytetrafluoroethylene-lined autoclave and react at 180°C for 8 hours. After the reaction, collect it by centrifugation and wash it with water for 3 times and ethanol for 3 times. The collected precipitate is put into an oven for 45 ℃ drying for 8h, to obtain the intermediate product a. After cooling to room temperature, it was placed in a tube furnace under an inert atmosphere at 900°C for 6 hours to obtain the intermediate product b (denoted as MnO 2@C). After cooling and ...

Embodiment 2

[0097] S / ZnO@C

[0098] 1. The preparation method of the ternary composite positive electrode material: mix the carbon precursor yeast and the metal oxide precursor zinc acetate according to the mass ratio of 1:0.1. Wash and disperse in 40mL deionized water, add 2g sodium chloride, 100μL glutaraldehyde and 0.4g metal oxide precursor zinc acetate, put into a 100mL beaker and stir at room temperature for 30min to disperse evenly. Transfer the above solution into a polytetrafluoroethylene-lined autoclave and react at 200°C for 6 hours. After the reaction, collect it by centrifugation and wash it with water for 3 times and ethanol for 3 times. The collected precipitate is put into an oven for 80 ℃ dry 4h. The intermediate product a is obtained. Cool to room temperature and put it into a tube furnace under an inert atmosphere at 700°C for 4 hours to obtain intermediate product b. After it is cooled and weighed, add sulfur according to the mass ratio of carbon / metal oxide to sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com