Method for preparing nitrogen-doped porous carbon nanofiber cloth

A nanofiber, porous carbon technology, applied in microfiber electrodes, hybrid/electric double layer capacitor manufacturing, active material electrodes, etc. problems, to achieve the effect of less demanding operation and environmental requirements, low cost and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Use melamine as the nitrogen-rich compound and PAN as the polymer to prepare the precursor solution. First prepare a 10% PAN solution, add Melamine (Mel) with Mel:PAN=1:2 (mass ratio), and mechanically stir in a constant temperature water bath at 70°C for 10 hours.

[0032] (2) Dilute the precursor solution in 1.0 mL h -1 The constant rate is pumped to the electrospinning device with a micro-quantitative pump. The electrospinning uses a flat stainless steel needle as a nozzle with an inner diameter of about 1mm. The collecting plate is graphite paper. The distance between the needle and the graphite plate is 20cm, and the voltage is 25kV.

[0033] (3) Pre-oxidation: the obtained electrospun fiber cloth, 5°C min -1 Rise from room temperature to 250°C for 1h, then at 2°C for min -1 , rise to 260°C and 270°C, and keep warm for 1h and 2h respectively to achieve the purpose of pre-oxidation.

[0034] Carbonization and activation: under the protection of nitrogen, the ...

Embodiment 2

[0038]The nitrogen-doped porous carbon nanofiber cloth was prepared using the same method as in Example 1, except that it was activated with ammonia gas.

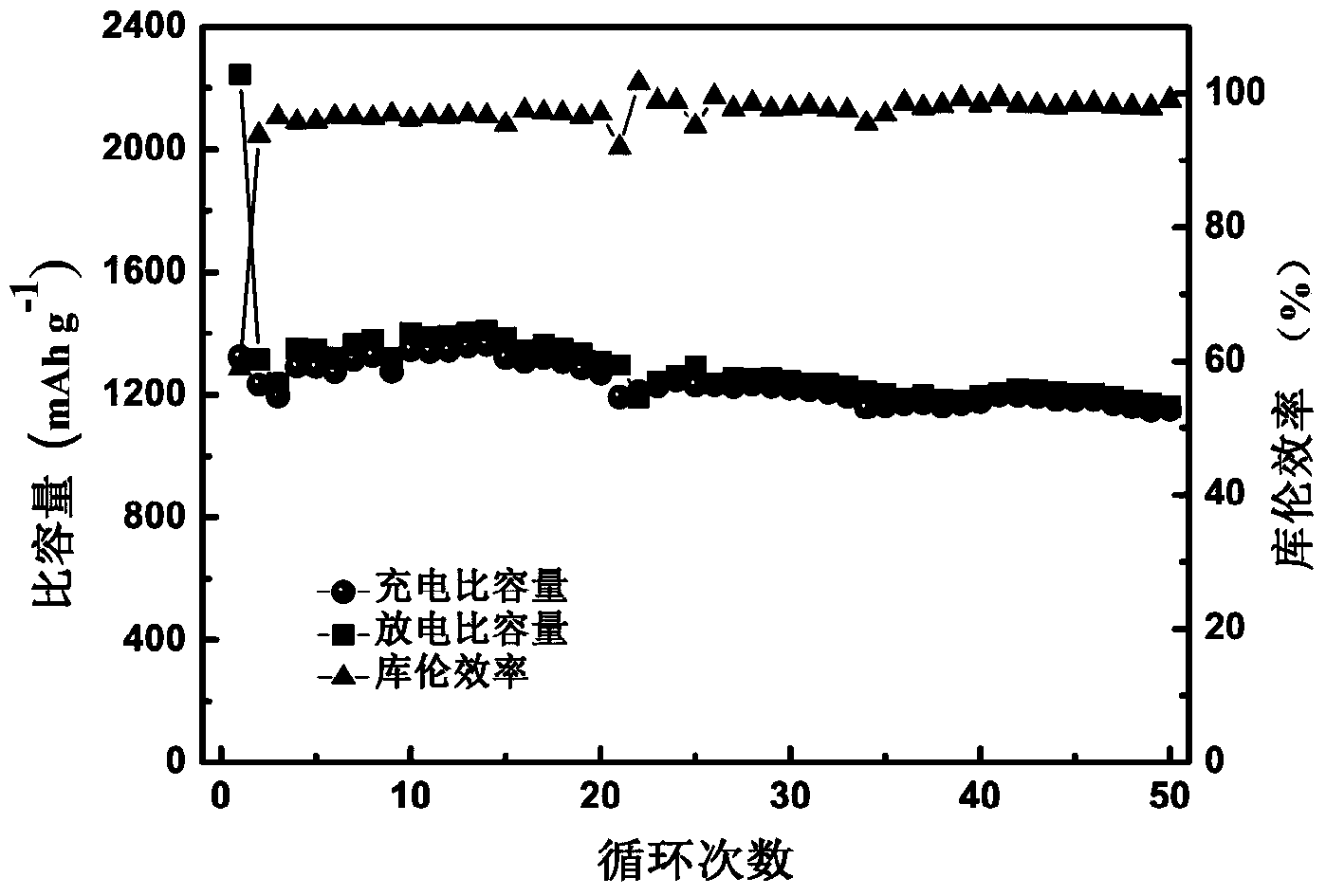

[0039] refer to figure 1 , the nitrogen-doped porous carbon nanofiber cloth prepared in this example is used as the negative electrode material of lithium-ion battery at 25°C, 50mA g -1 Charge-discharge capacity, Coulombic efficiency, and cycle stability graphs at current densities.

[0040] The nitrogen-doped porous carbon nanofiber cloth lithium ion negative electrode material obtained by this method has high specific capacity, good rate performance and cycle stability performance. at 50mAg -1 Under the current density, the first charge and discharge specific capacity is 1323mAh g -1 and 2245mAh g -w , the first Coulombic efficiency is 59%. After 50 cycles, the charging capacity is 1150mAh g -1 .

[0041] figure 2 Scanning electron micrograph of the nitrogen-doped porous carbon nanofiber cloth prepared for this e...

Embodiment 3

[0043] A nitrogen-doped porous carbon nanofiber cloth was prepared using the same method as in Example 1, except that urea was used as the nitrogen-enriched compound.

[0044] The nitrogen-doped porous carbon nanofiber cloth lithium ion negative electrode material that this method obtains is in 50mA g -1 Under the current density, the first charge and discharge specific capacity is 750mAh g -1 and 1445mAh g -1 , the first Coulombic efficiency is 52%. After 50 cycles, the charging capacity is 550mAh g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com