Patents

Literature

87results about "Microscopic fiber electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrode Including Nanostructures for Rechargeable Cells

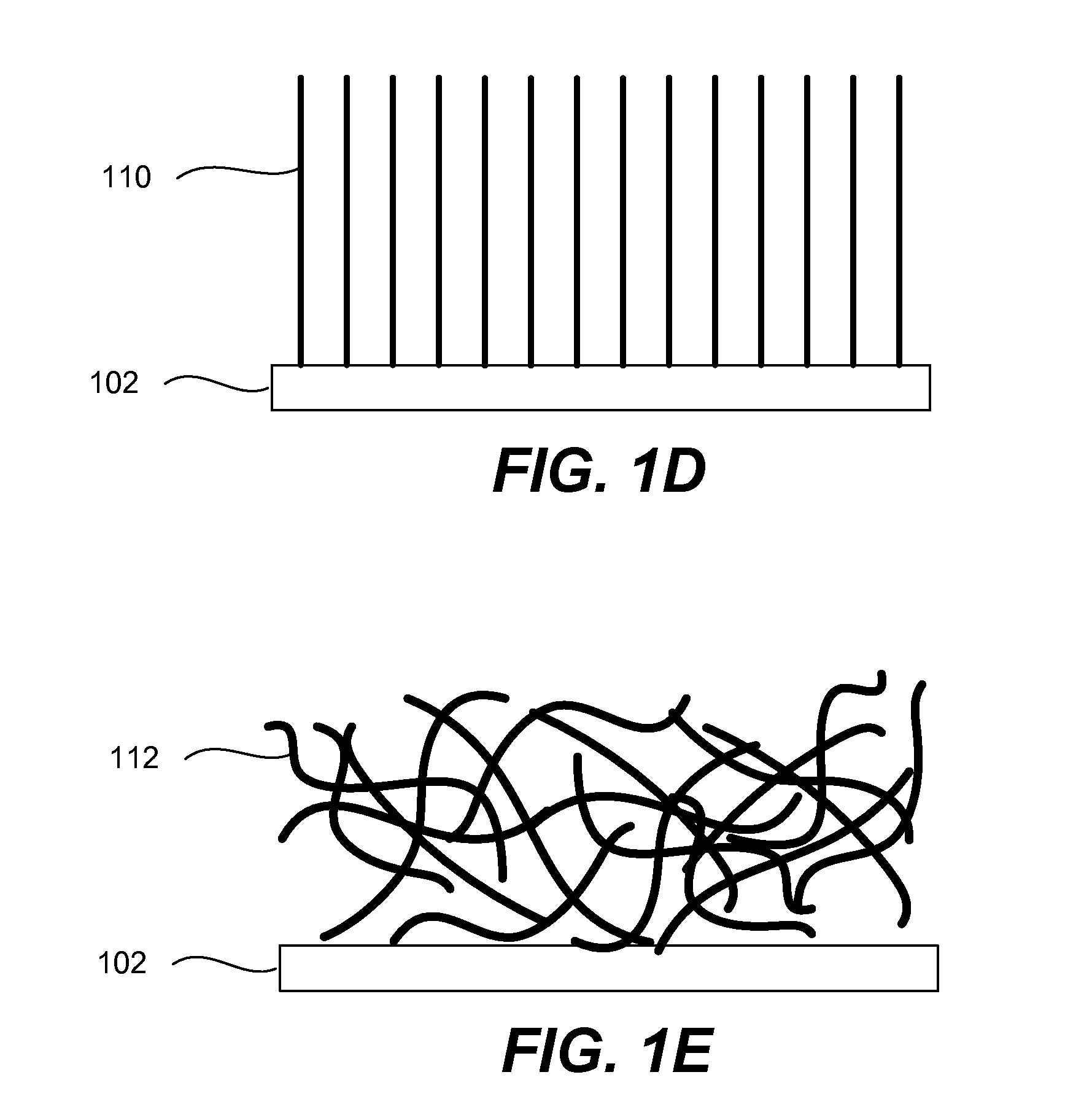

InactiveUS20100285358A1Lower resistanceNanostructure manufactureMicroscopic fiber electrodesRechargeable cellSilicon nanowires

A lithium ion battery electrode includes silicon nanowires used for insertion of lithium ions and including a conductivity enhancement, the nanowires growth-rooted to the conductive substrate.

Owner:AMPRIUS INC

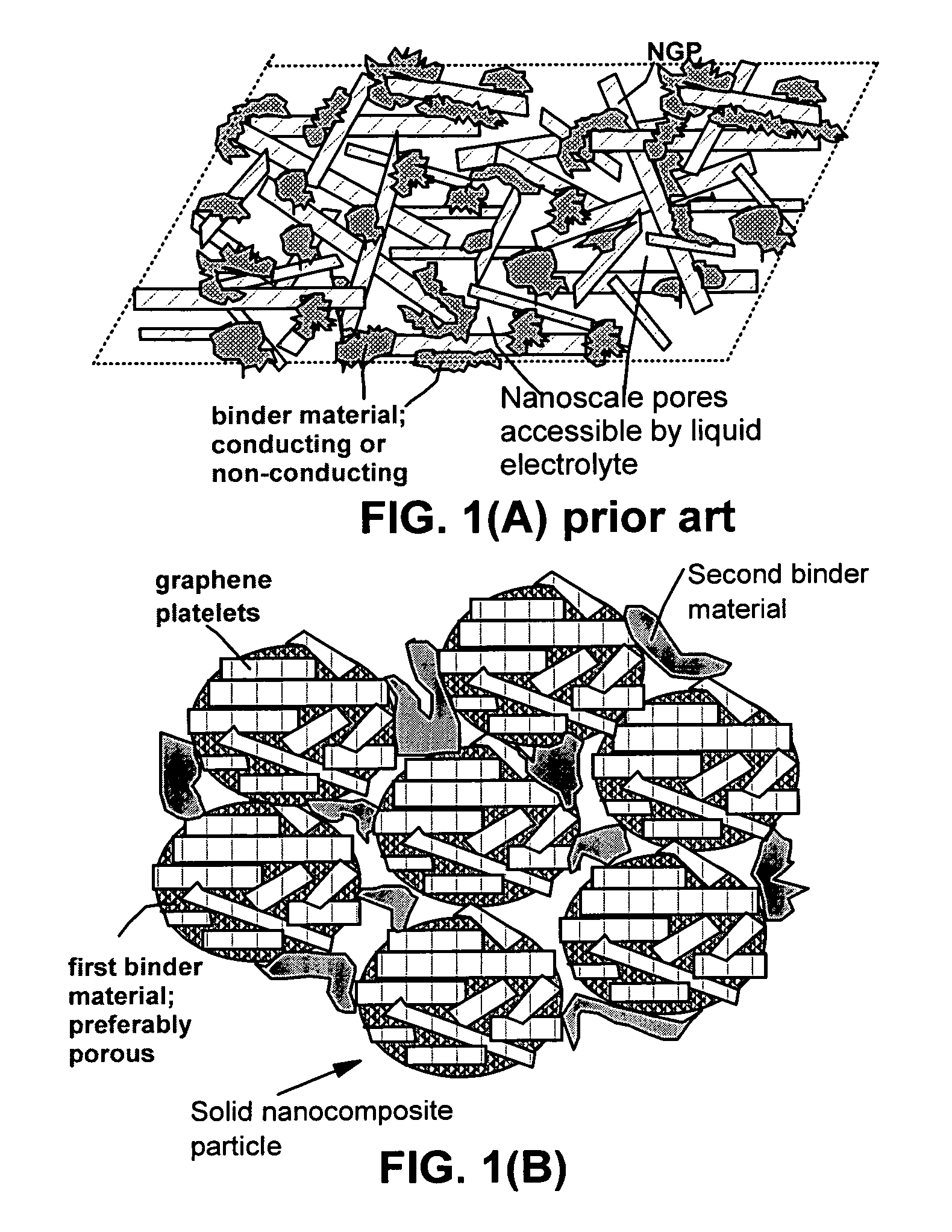

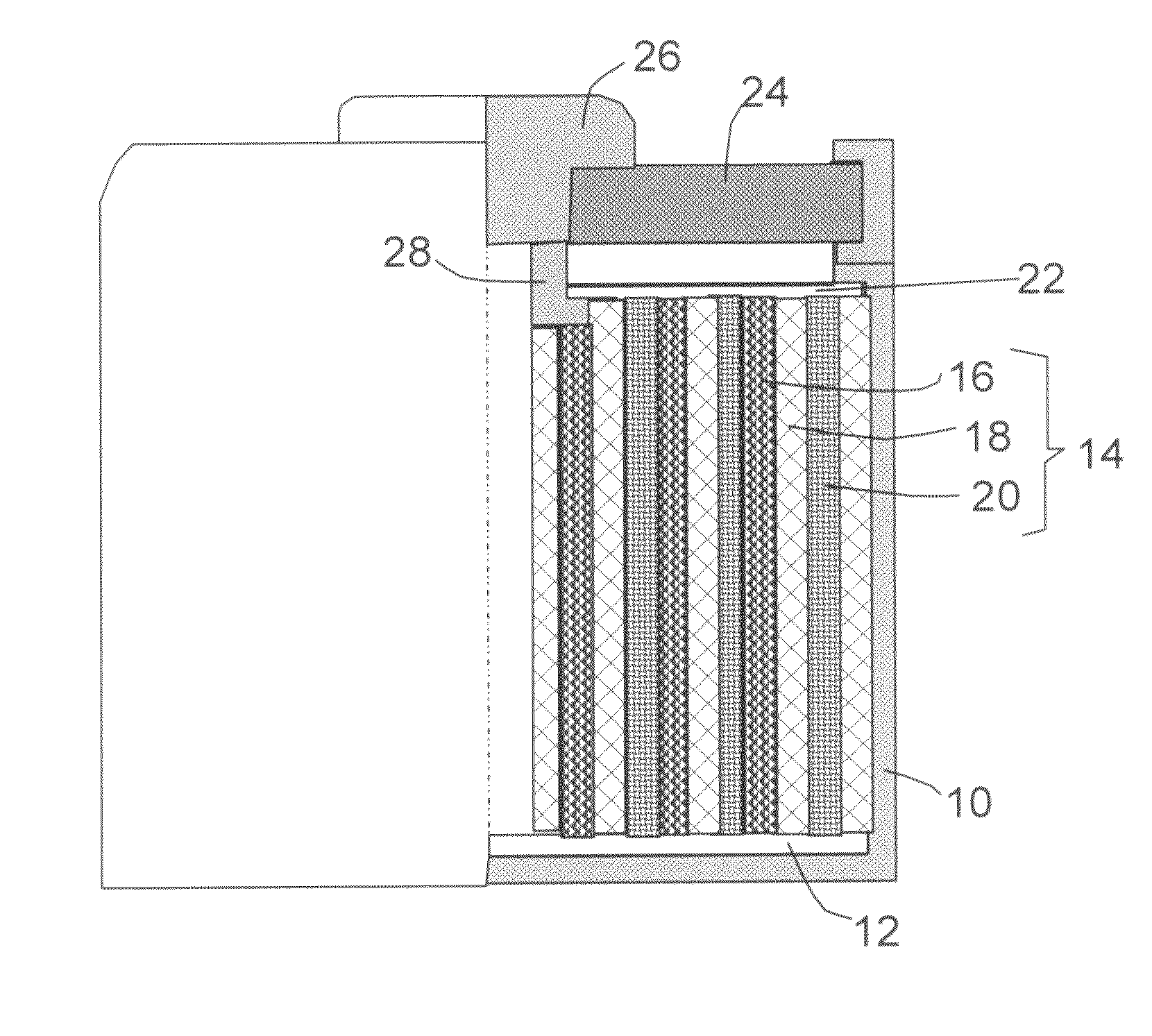

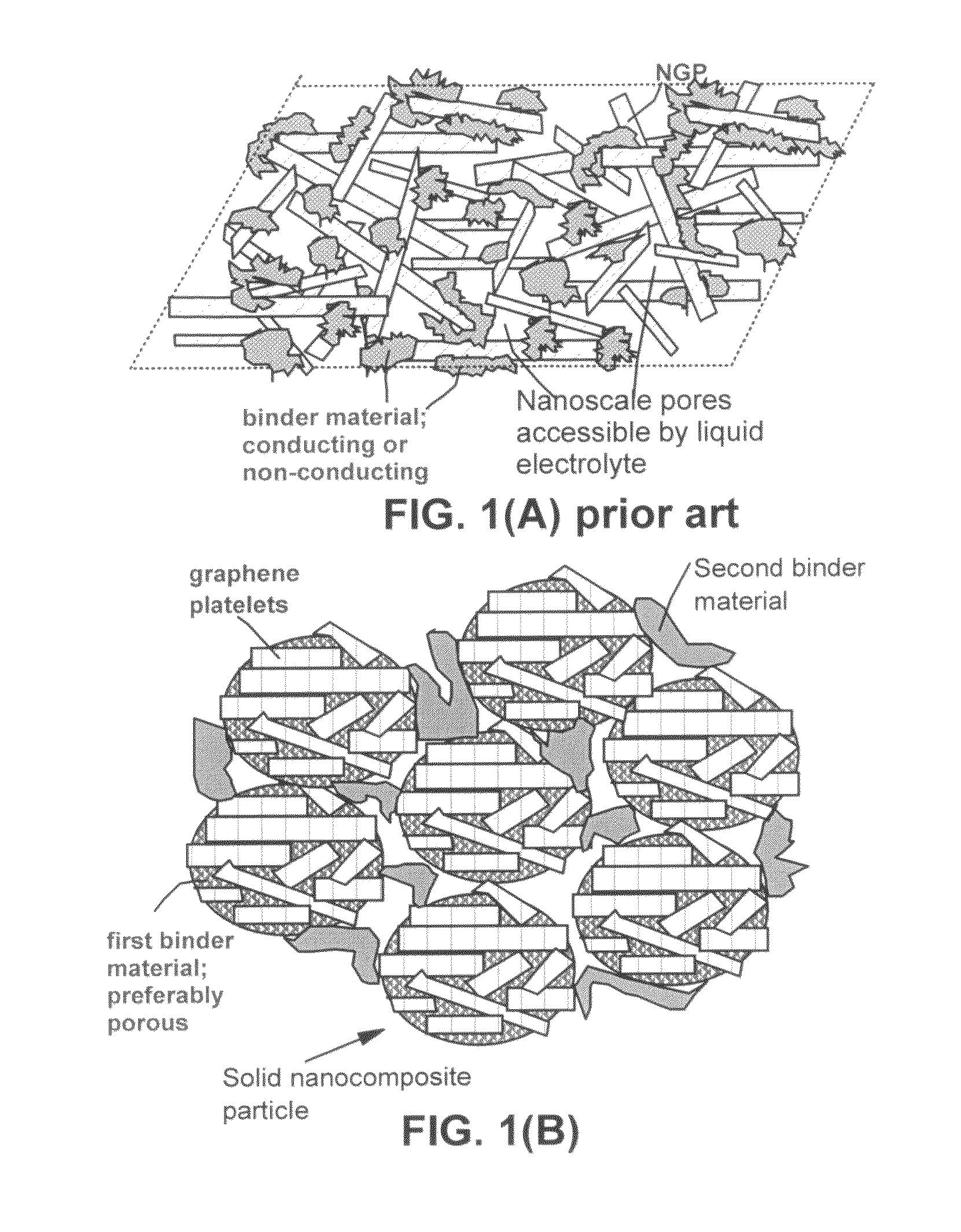

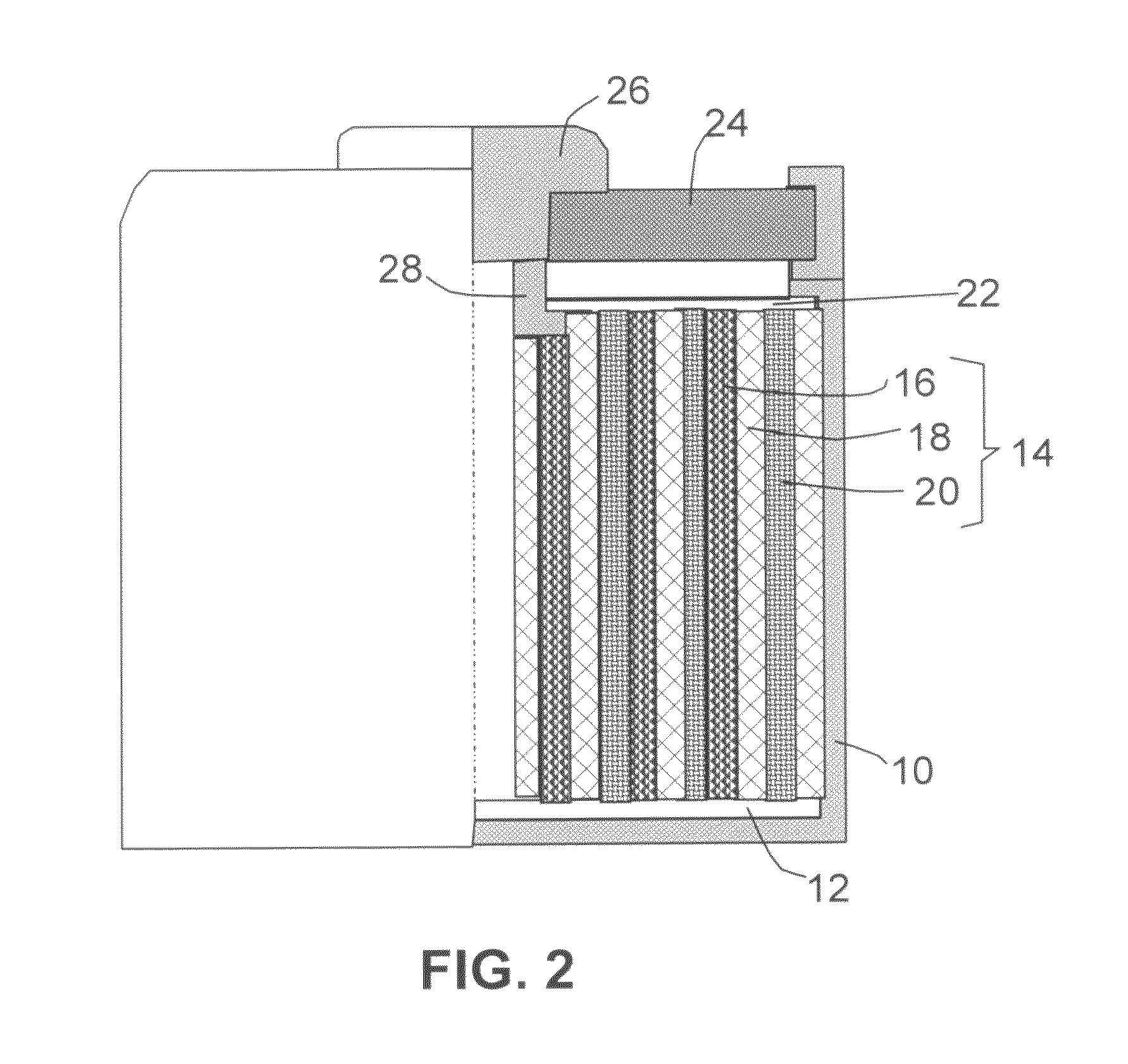

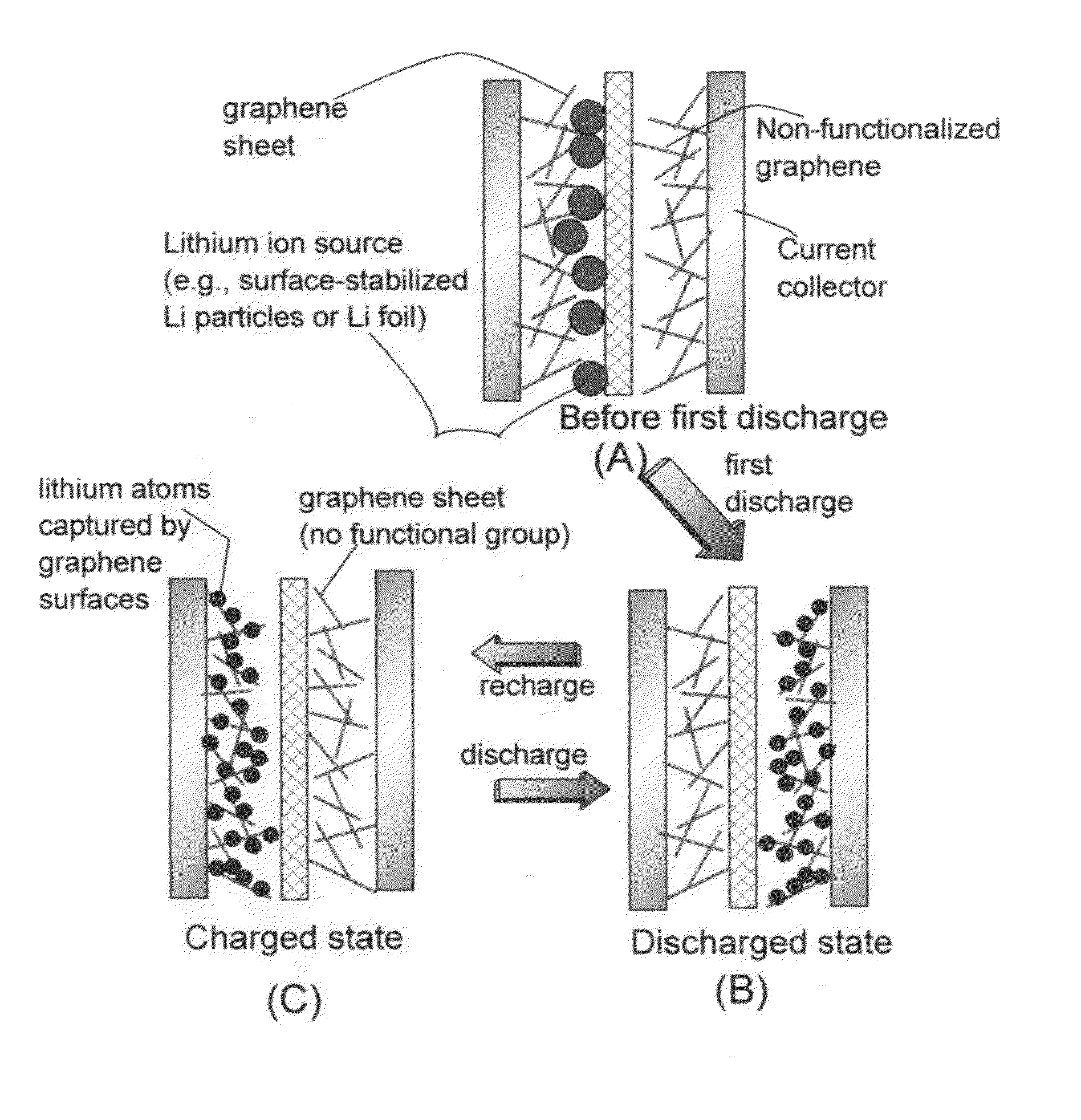

Graphene nanocomposites for electrochemical cell electrodes

ActiveUS20100021819A1High and reversible anode capacityTedious and energy-intensiveMicroscopic fiber electrodesHybrid capacitor electrodesGraphene nanocompositesSolid particle

A composite composition for electrochemical cell electrode applications, the composition comprising multiple solid particles, wherein (a) a solid particle is composed of graphene platelets dispersed in or bonded by a first matrix or binder material, wherein the graphene platelets are not obtained from graphitization of the first binder or matrix material; (b) the graphene platelets have a length or width in the range of 10 nm to 10 μm; (c) the multiple solid particles are bonded by a second binder material; and (d) the first or second binder material is selected from a polymer, polymeric carbon, amorphous carbon, metal, glass, ceramic, oxide, organic material, or a combination thereof. For a lithium ion battery anode application, the first binder or matrix material is preferably amorphous carbon or polymeric carbon. Such a composite composition provides a high anode capacity and good cycling response. For a supercapacitor electrode application, the solid particles preferably have meso-scale pores therein to accommodate electrolyte.

Owner:NANOTEK INSTR GRP LLC

Electrode including nanostructures for rechargeable cells

ActiveUS20120183856A1Lower resistanceMaterial nanotechnologyNanostructure manufactureRechargeable cellSilicon nanowires

A lithium ion battery electrode includes silicon nanowires used for insertion of lithium ions and including a conductivity enhancement, the nanowires growth-rooted to the conductive substrate.

Owner:AMPRIUS TECH INC

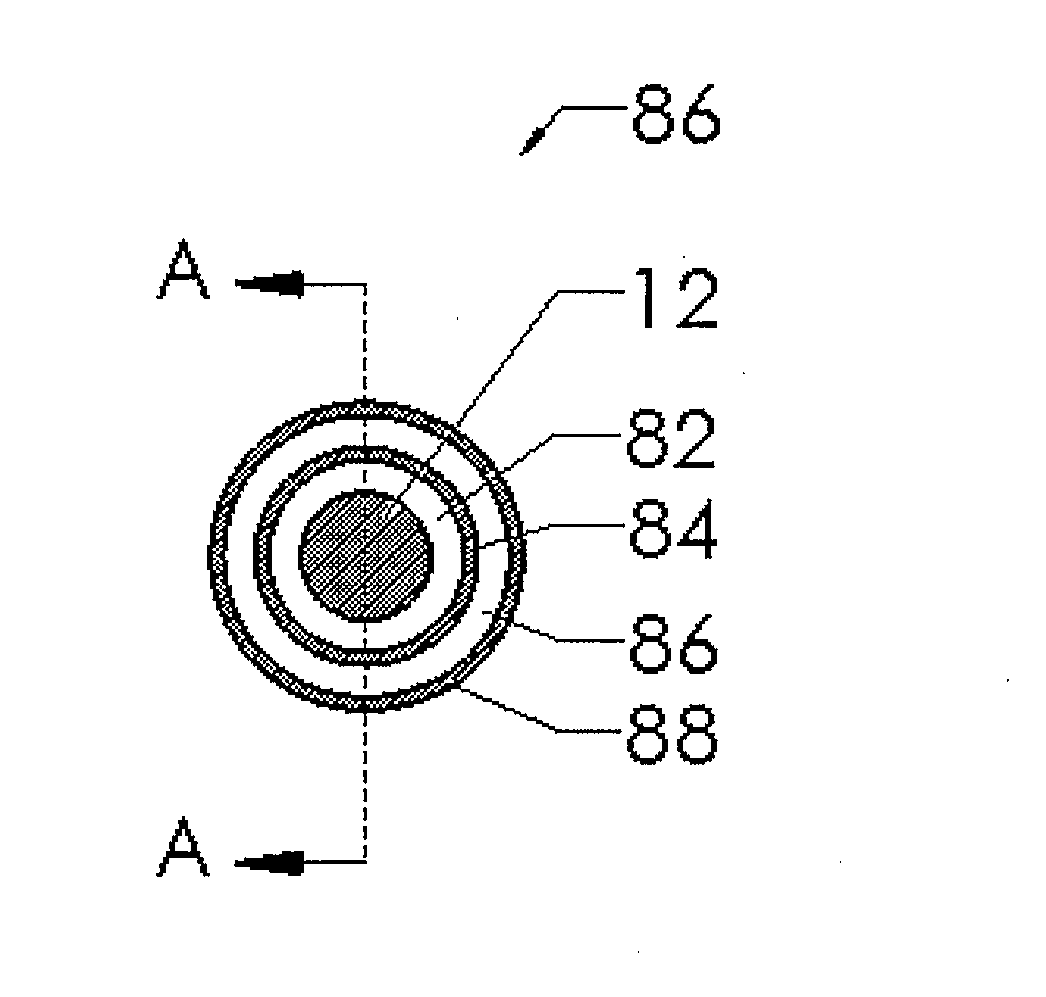

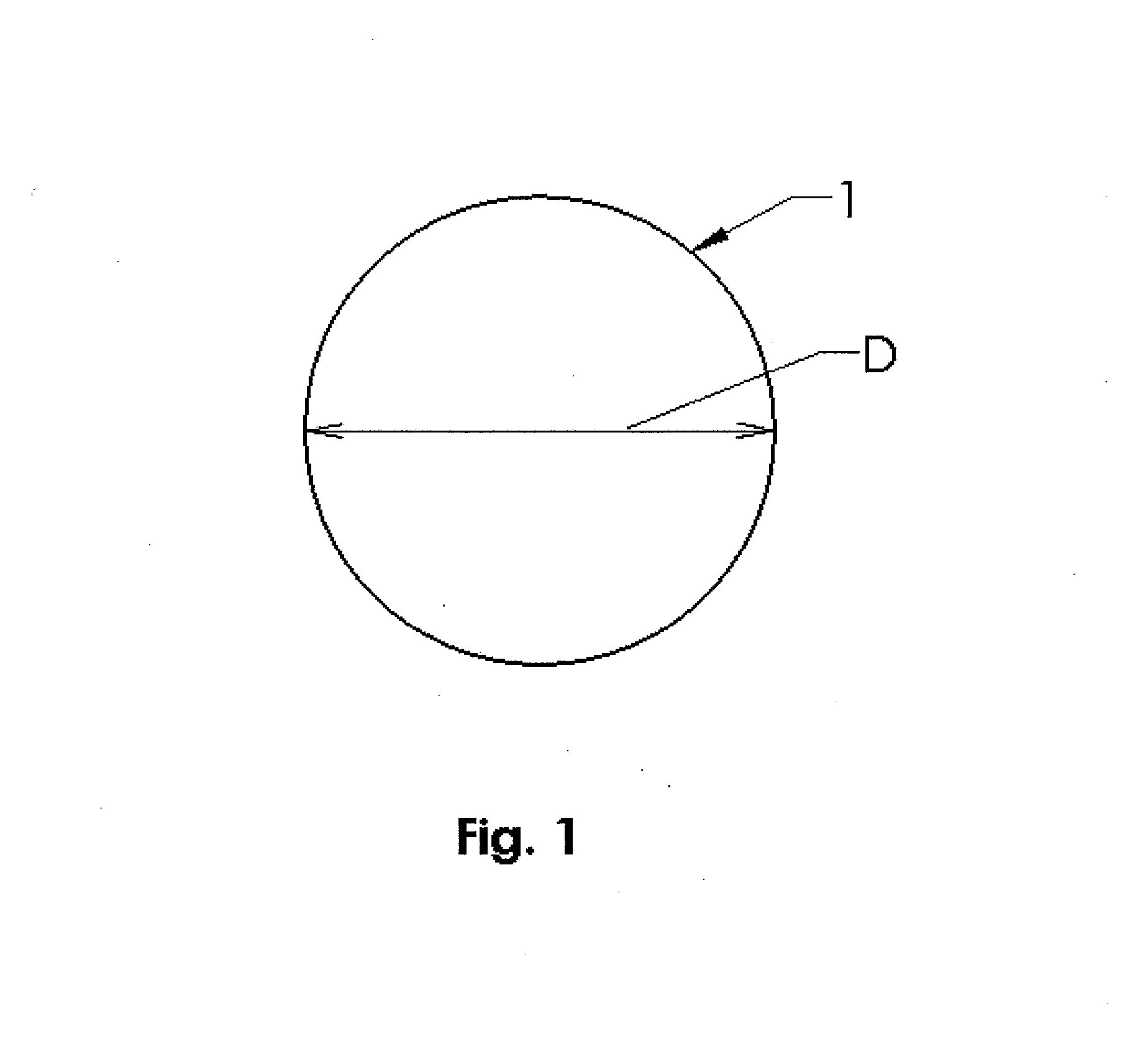

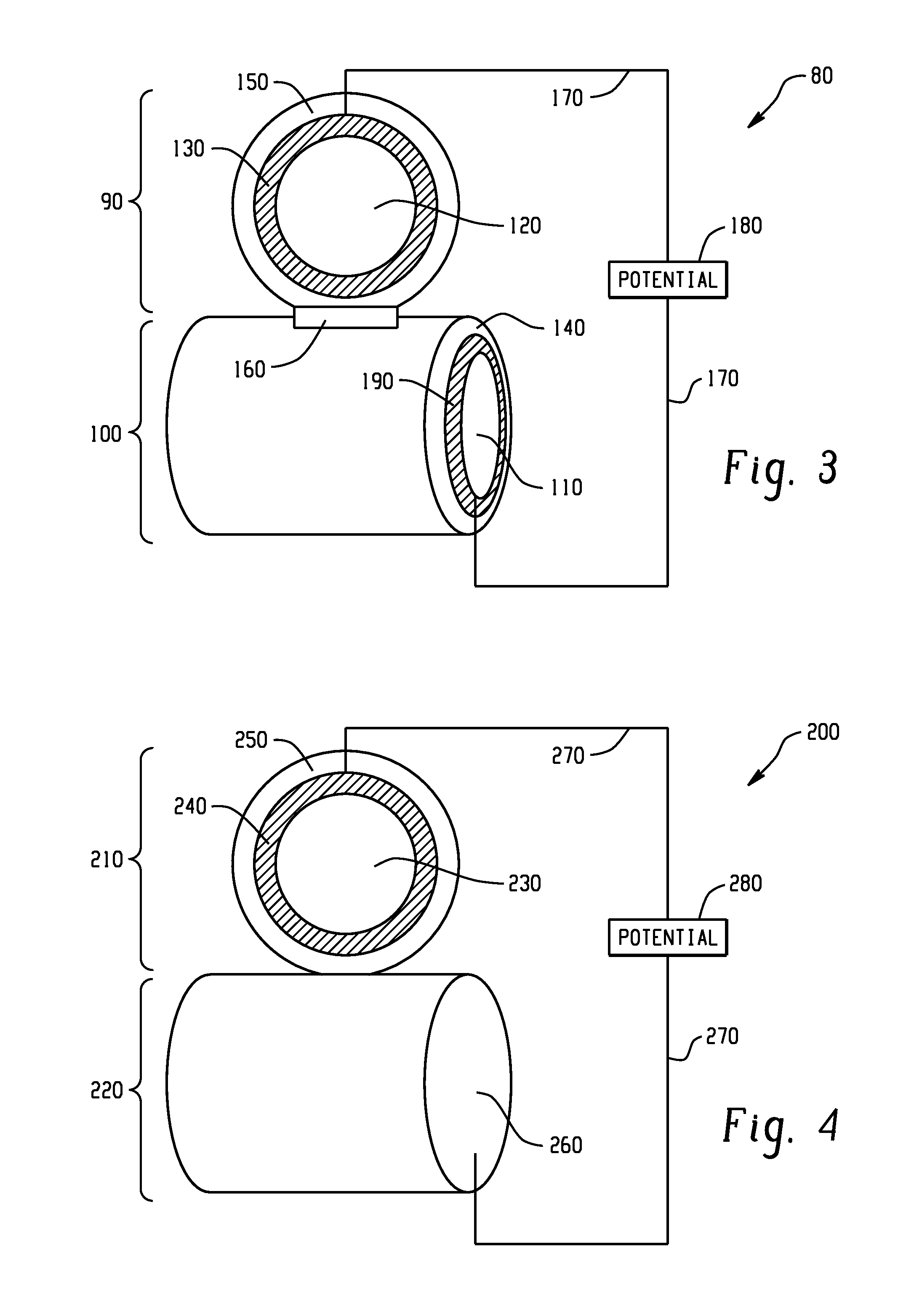

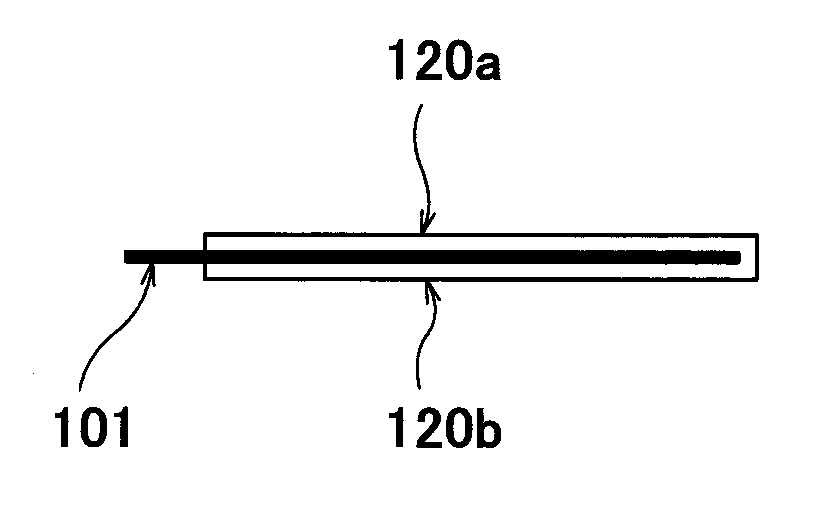

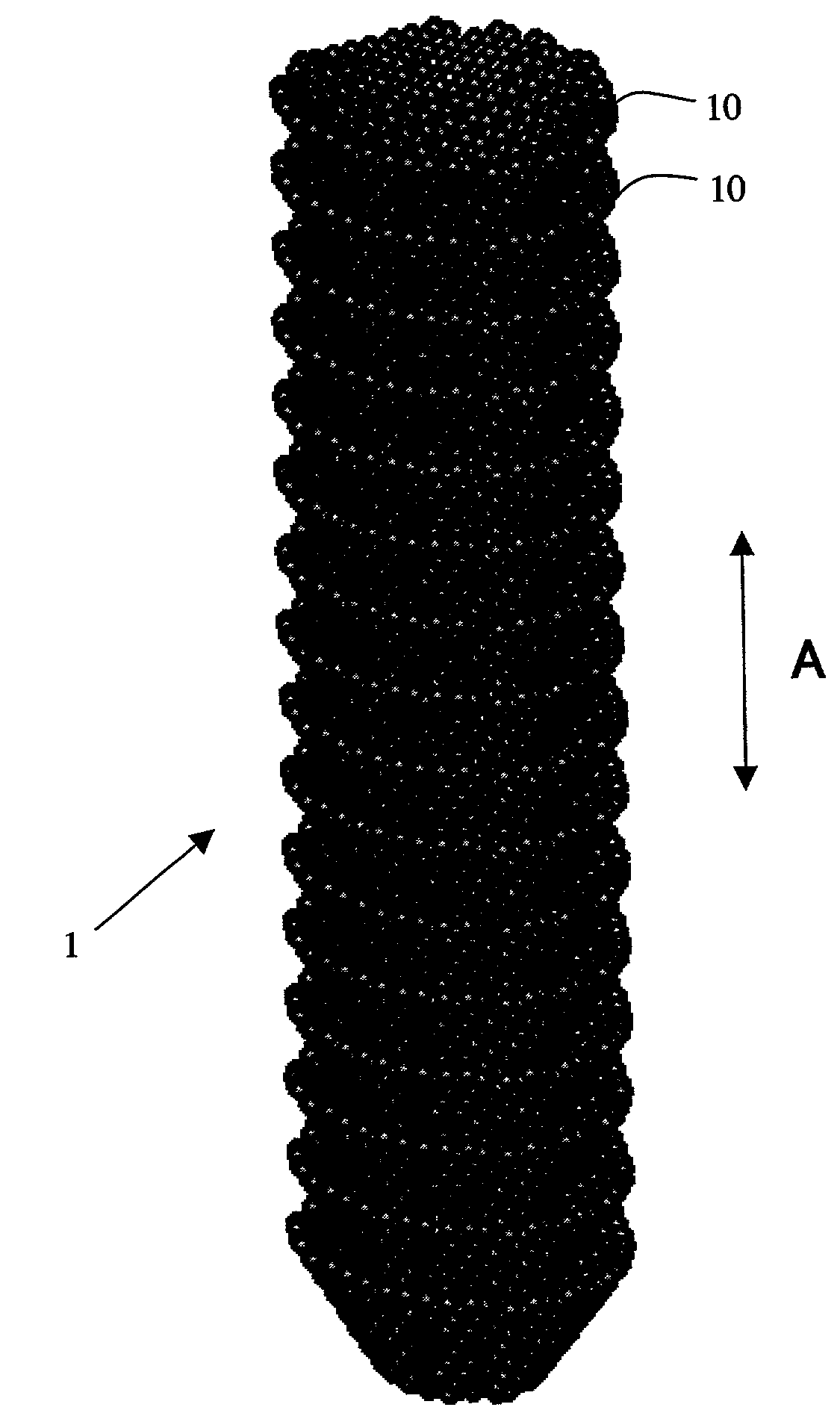

Li-ion battery and battery active components on metal wire

InactiveUS20130344363A1Improve performanceFast charging rateElectrode thermal treatmentFinal product manufactureIon exchangeMaterials science

A battery on a conductive metal wire and components of a battery on a conductive metal wire of circular cross section diameter of 5-500 micrometers and methods of making the battery and battery components are disclosed. In one embodiment, the battery features a porous anode or cathode layer which assist with ion exchange in batteries. Methods of forming the porous anode or cathode layer include deposition of an inert gas or hydrogen enriched carbon or silicon layer on a heated metal wire followed by annealing of the inert gas or hydrogen enriched carbon silicon layer. Energy storage devices having bundles of batteries on wires are also disclosed as are other energy storage devices.

Owner:KALPTREE ENERGY

Stretchable devices and methods of manufacture and use thereof

Stretchable electrochromic devices are disclosed including a stretchable electrochromic substrate; and a stretchable and transparent polymeric electrolyte coating or impregnating the stretchable electrochromic substrate. The stretchable electrochromic devices can find utility in the preparation of wearable electronic garments. Other devices using a stretchable and transparent polymeric electrolyte are disclosed.

Owner:UNIV OF CONNECTICUT

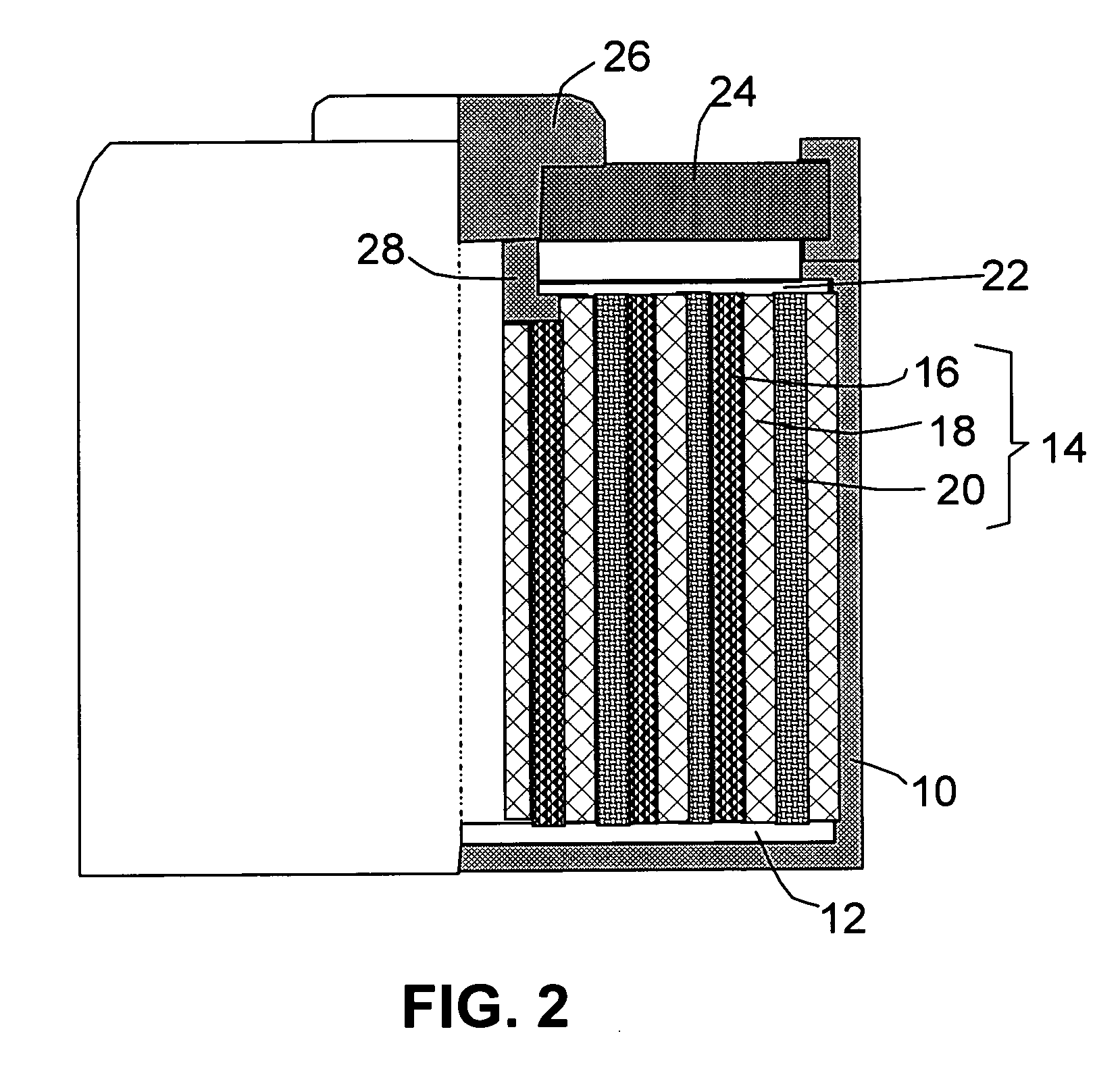

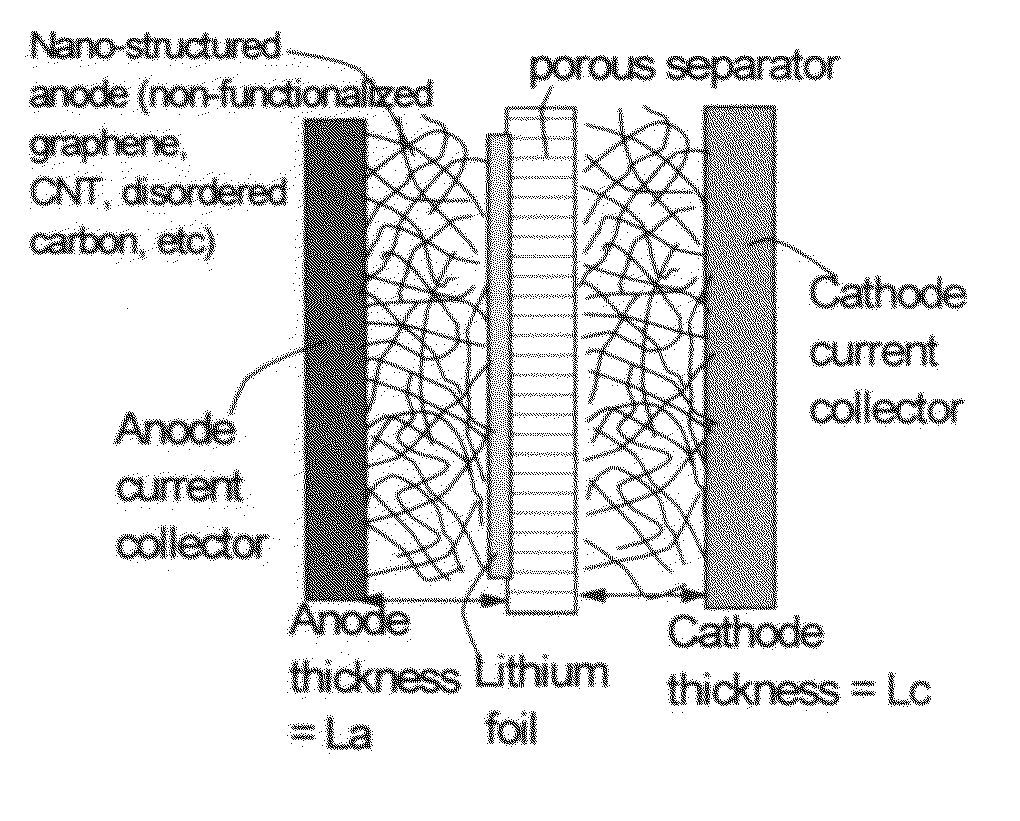

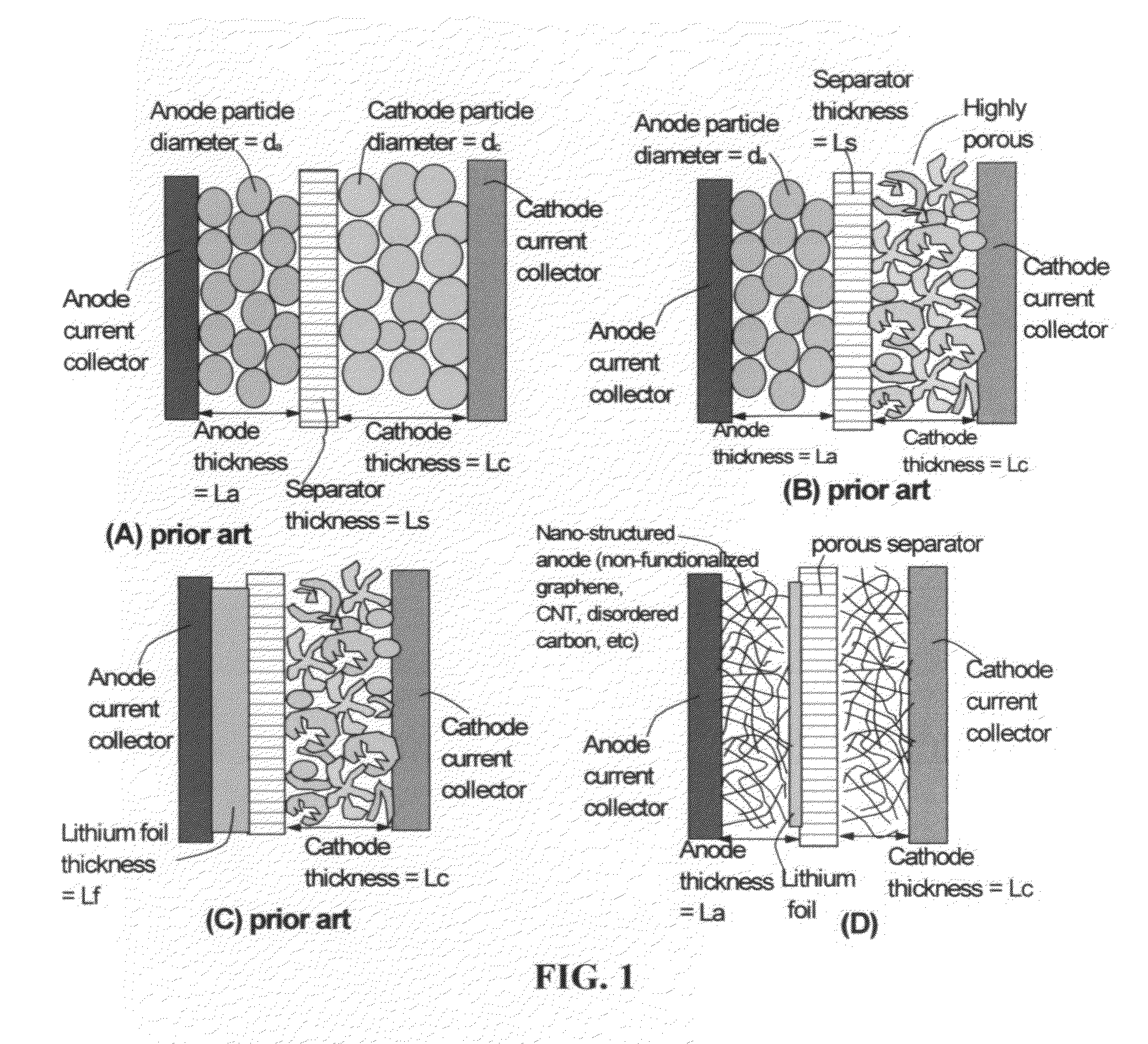

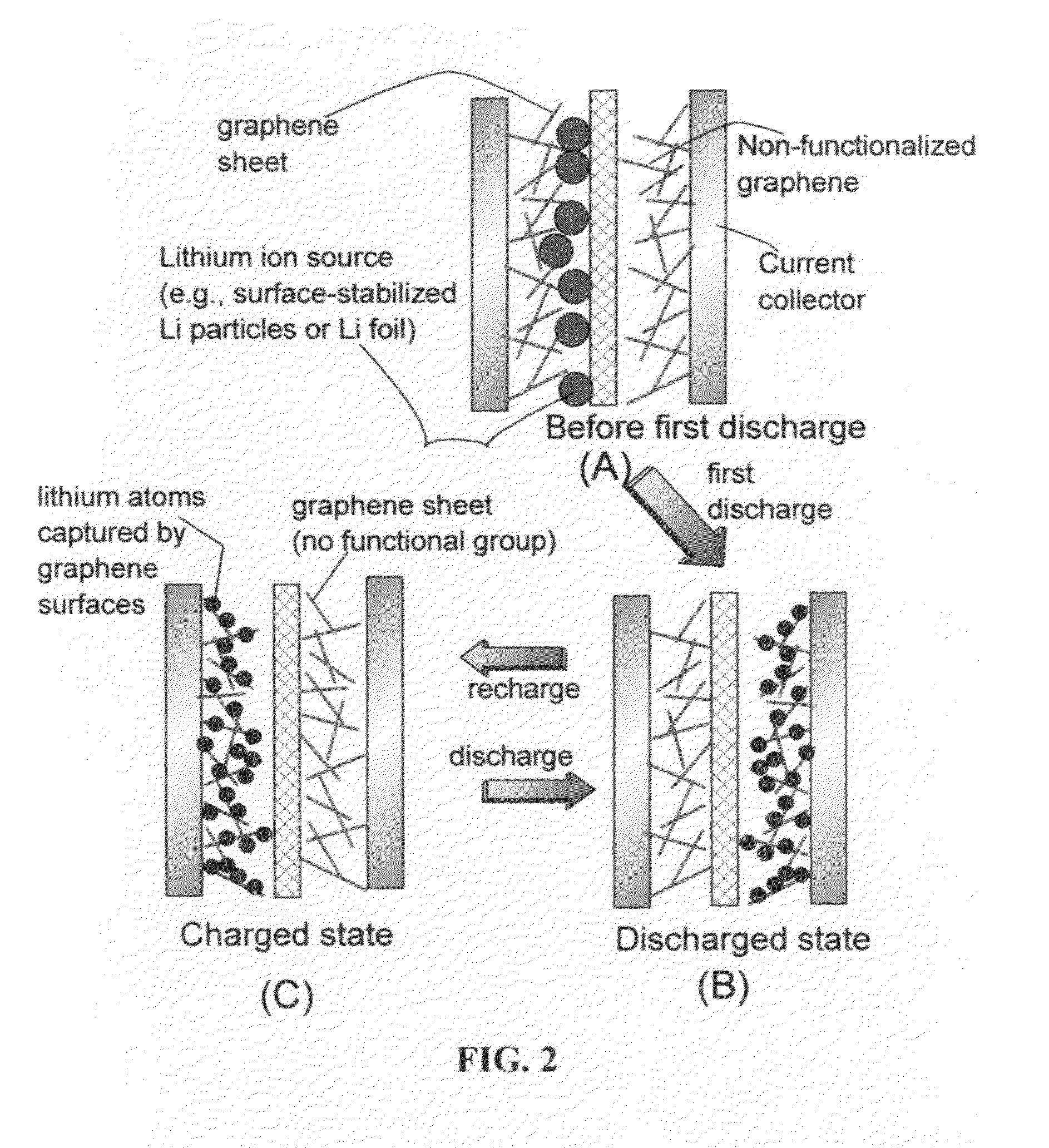

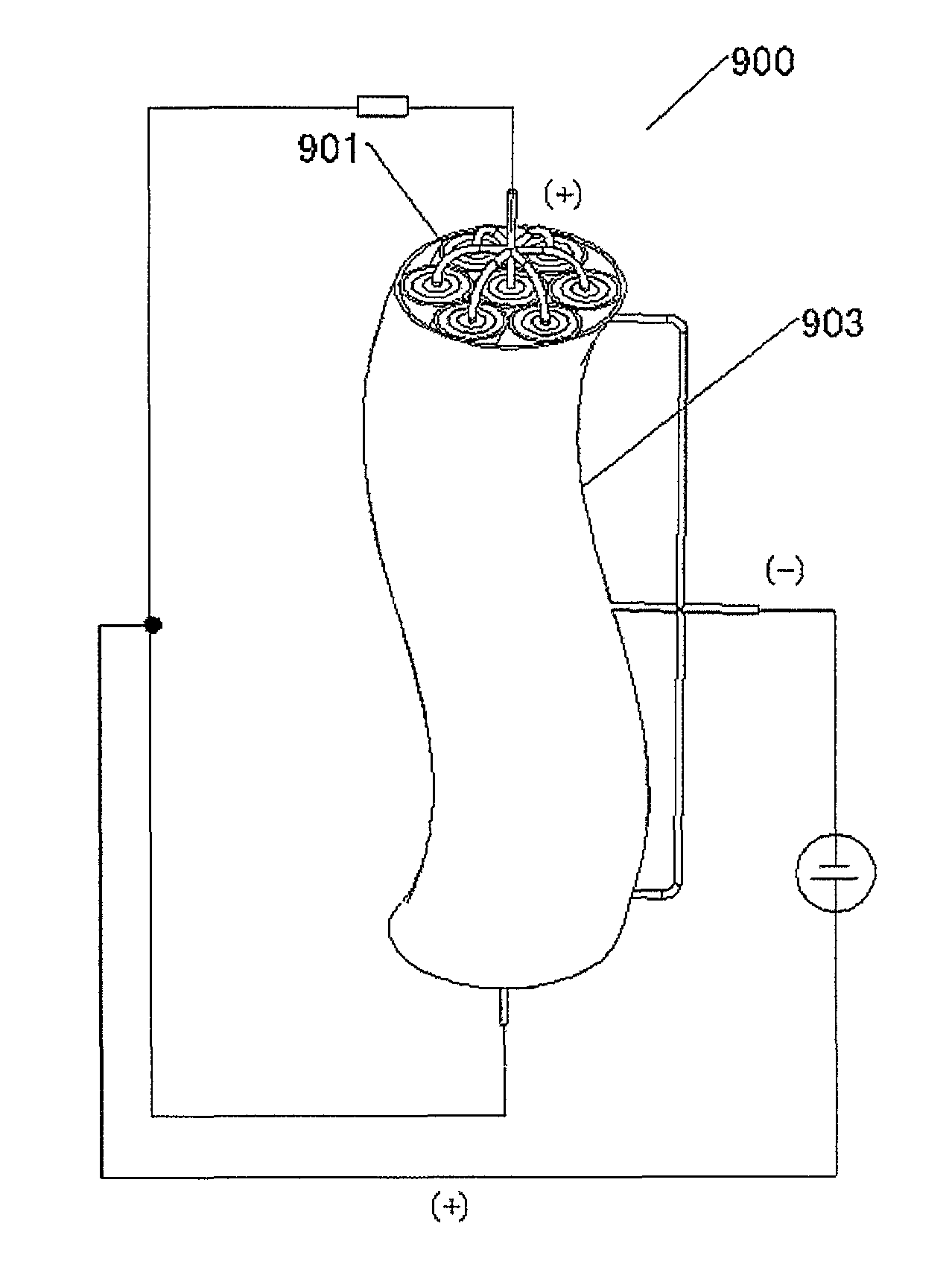

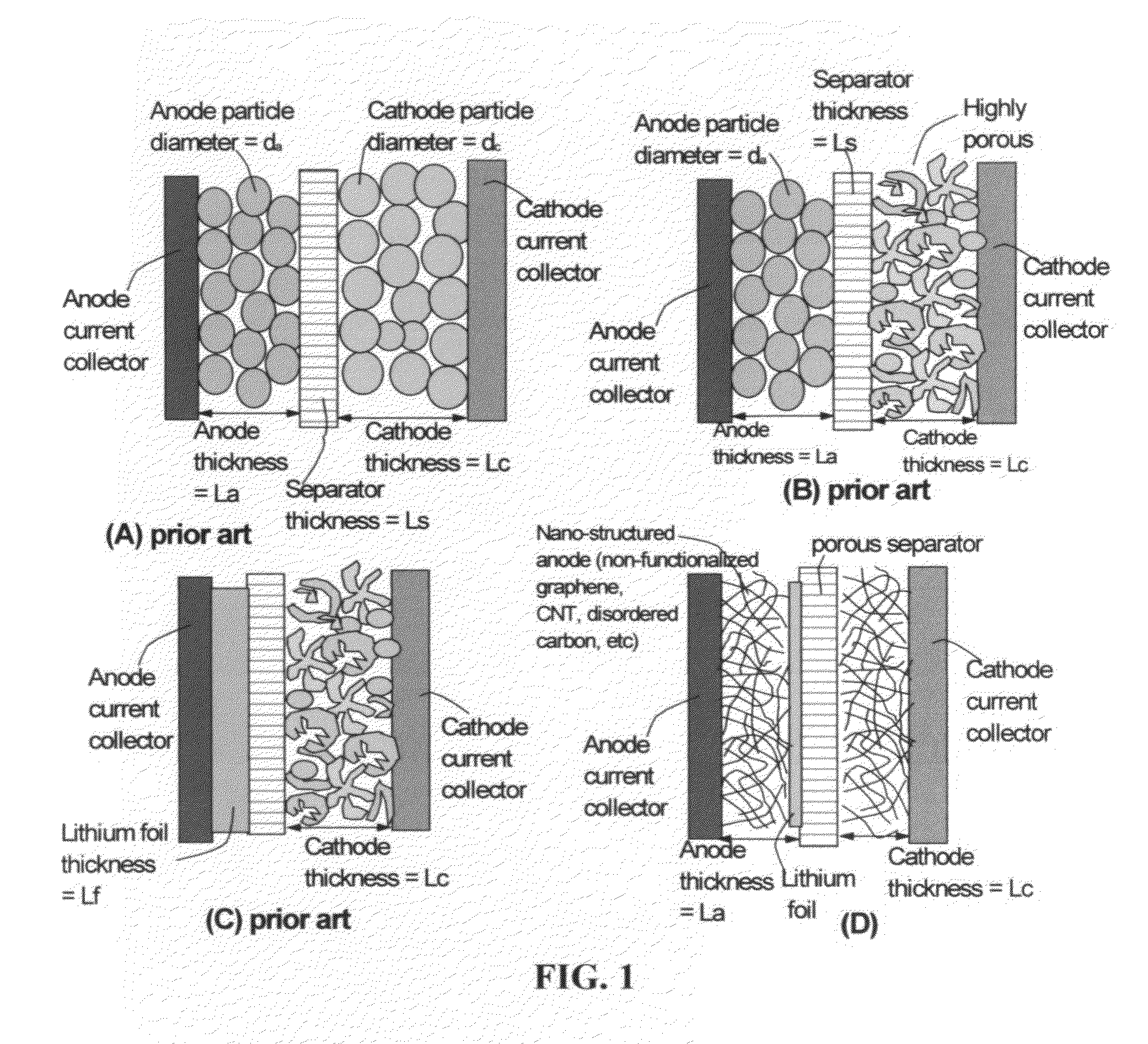

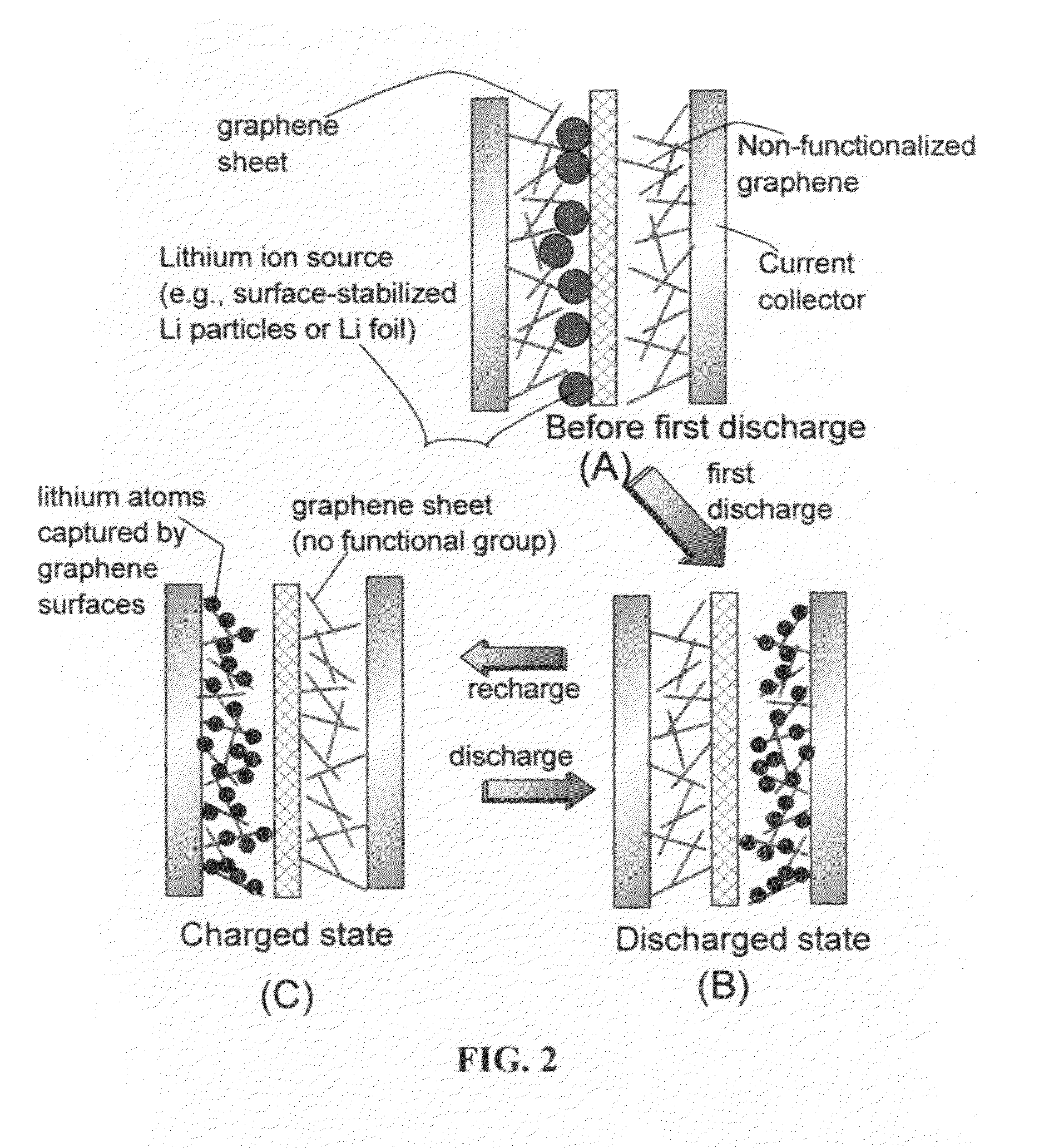

Surface-mediated lithium ion-exchanging energy storage device

ActiveUS20130052489A1High dischargeEliminates potential formation of dendriteMaterial nanotechnologyHybrid capacitor electrolytesElectrical batteryIon exchange

A surface-mediated, lithium ion-exchanging energy storage device comprising: (a) A positive electrode (cathode) comprising a cathode active material that is not a functional material (bearing no functional group reactive with lithium), but having a surface area to capture or store lithium thereon; (b) A negative electrode (anode) comprising an anode active material having a surface area to capture or store lithium thereon; (c) A porous separator disposed between the two electrodes; and (d) A lithium-containing electrolyte in physical contact with the two electrodes, wherein the anode active material and / or the cathode active material has a specific surface area of no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; wherein at least one of the two electrodes contains therein a lithium source prior to a first charge or a first discharge cycle of the energy storage device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

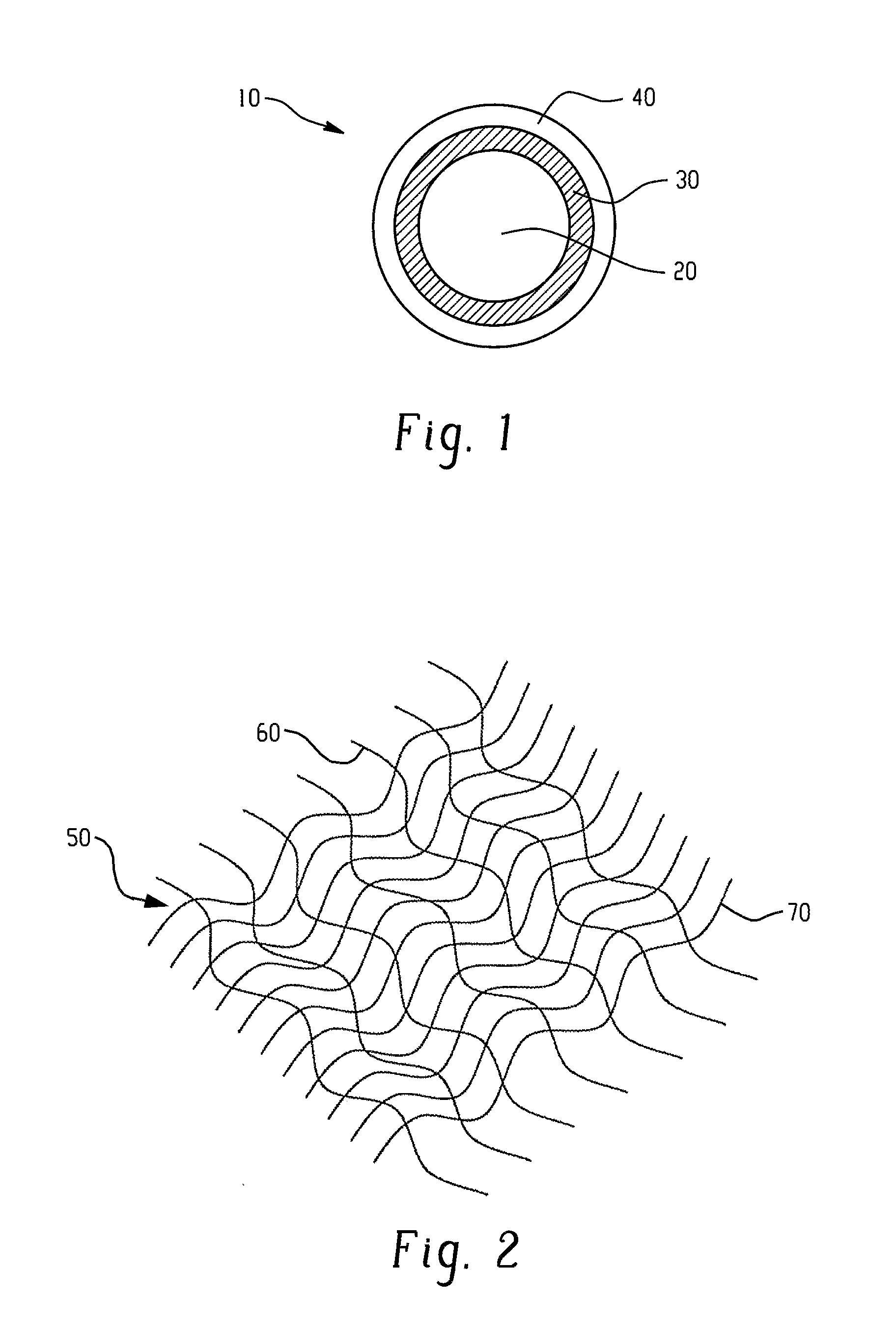

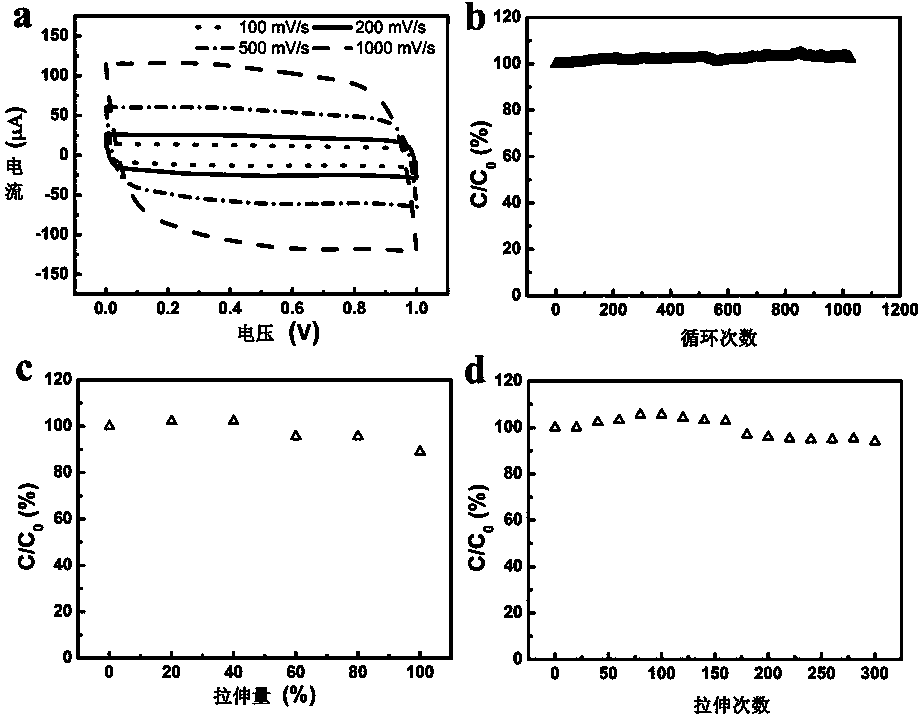

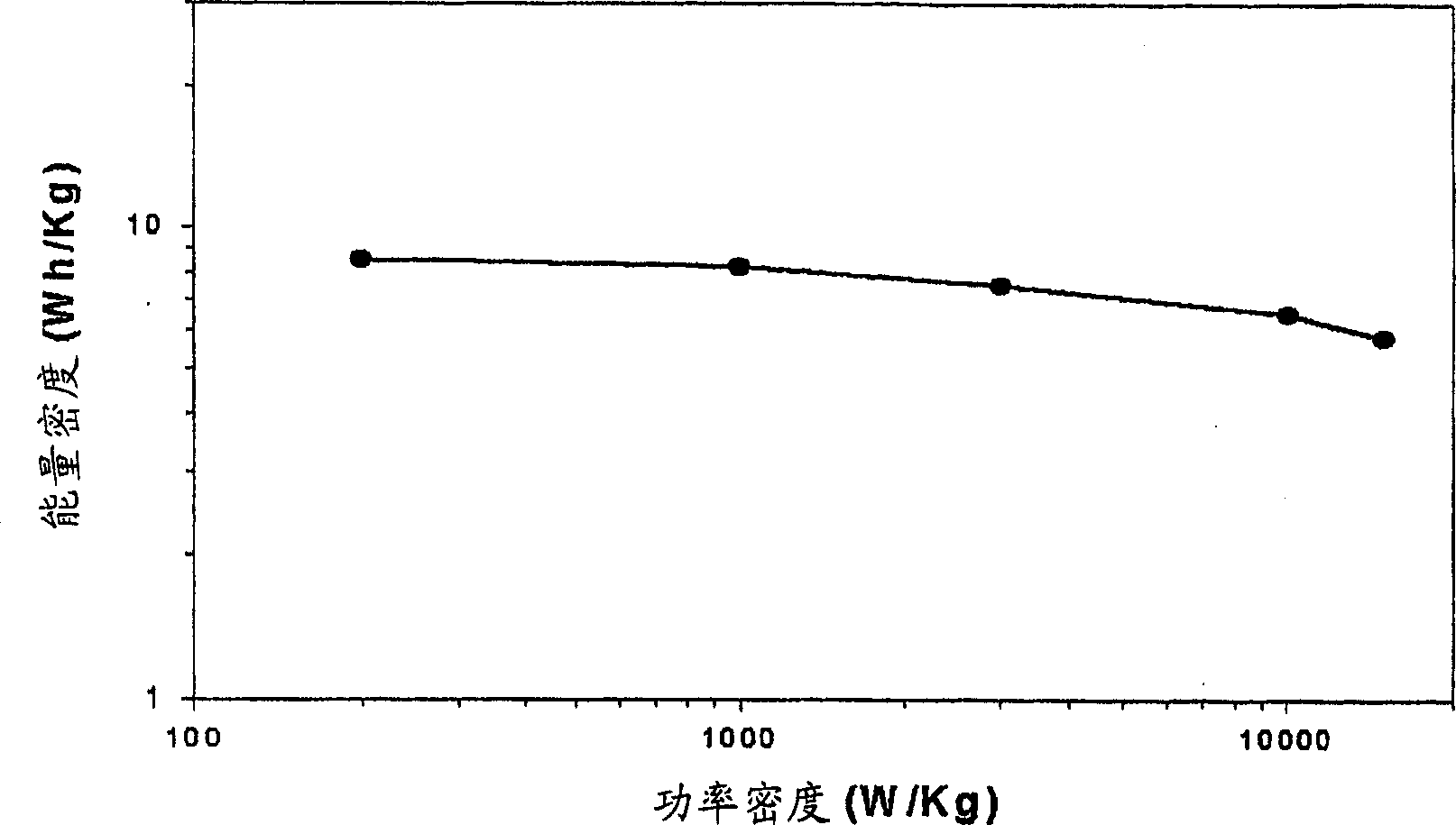

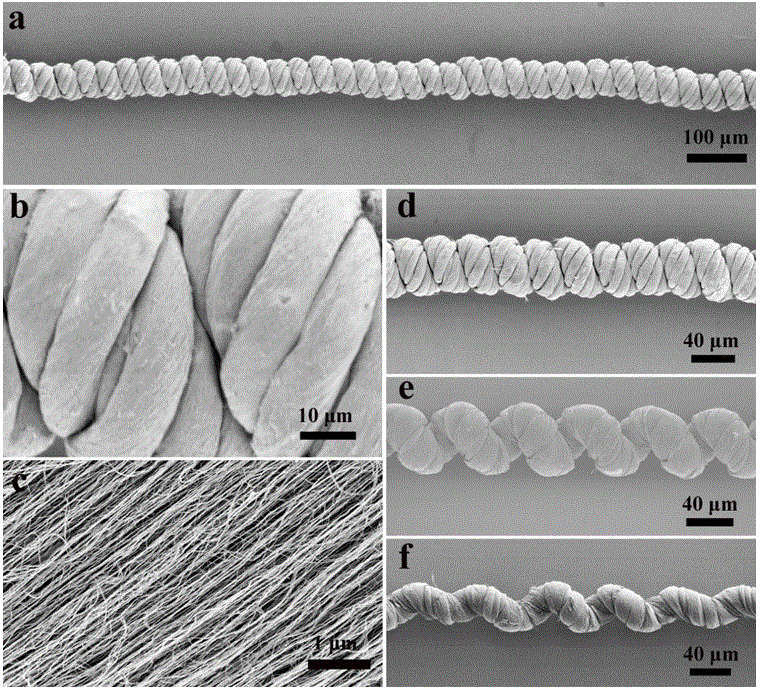

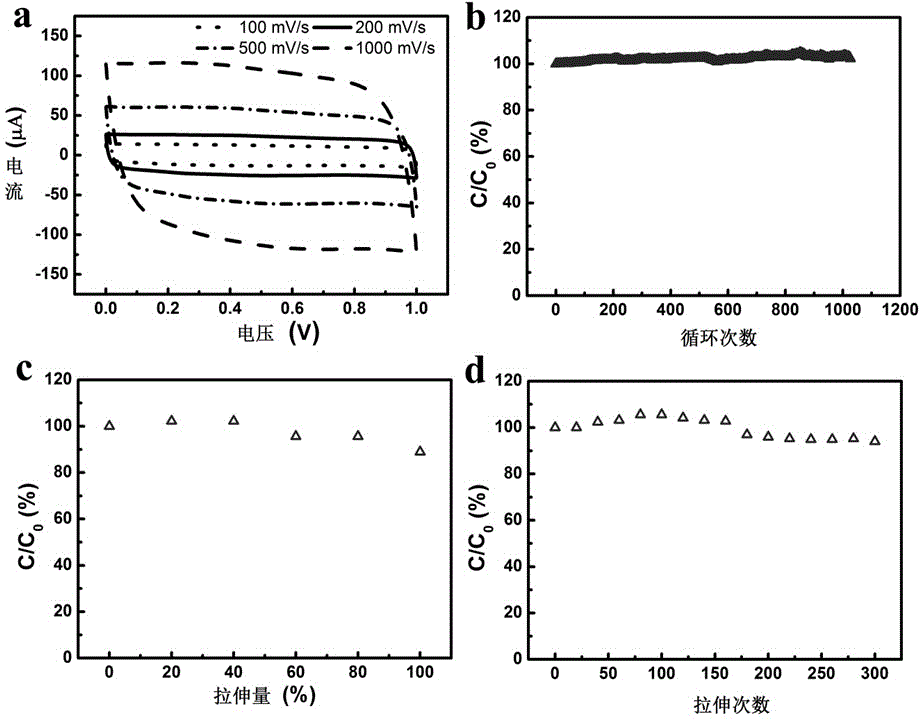

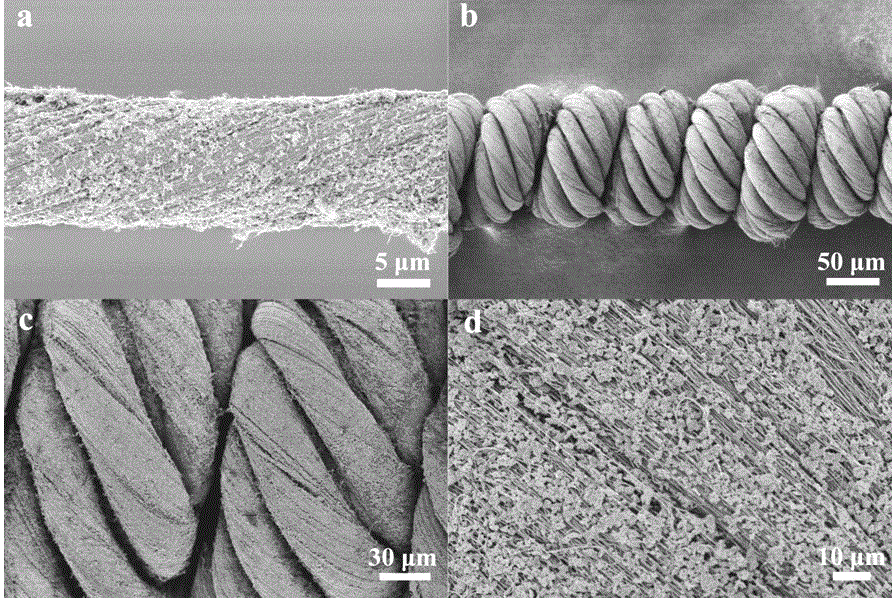

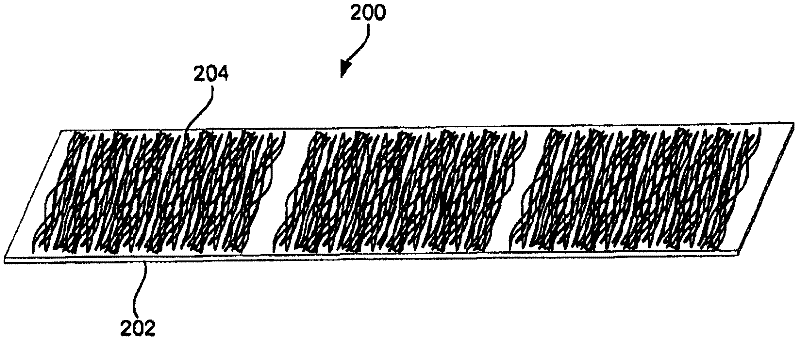

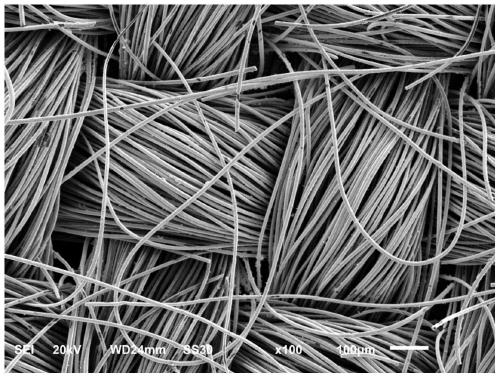

Stretchable linear supercapacitor and lithium ion battery preparation method

ActiveCN104392845AEvenly dispersedReduce weightMicroscopic fiber electrodesHybrid capacitor electrodesFiberElastic substrate

The invention, which belongs to the technical field of the micro energy storage device, particularly relates to a stretchable linear supercapacitor and a lithium ion battery preparation method. A spring-like oriented carbon nanotube fiber is prepared and is twisted to form a spiral unit, wherein the spiral unit can be stretched by over 300%; and then the processed fiber is used as the electrode to construct a stretchable supercapacitor. Moreover, the fiber can be combined with lithium manganate and lithium titanate nano particles to form composite fibers respectively used as the positive electrode and the negative electrode; and thus a stretchable lithium ion battery can be constructed. According to the invention, compared with other micro devices, the stretchable linear supercapacitor and stretchable linear lithium ion battery have novel structures. The stretching function can be realized without the need of an elastic substrate, thereby reducing the weight and size of the device and improving the specific capacity and the energy density of the device and thus providing the important innovation for the micro device field. Meanwhile, the supercapacitor and the battery having high flexibility are easy to manufacture and integrate and have good application prospects.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Graphene nanocomposites for electrochemical cell electrodes

ActiveUS9190667B2Reduce the amount of solutionIncreased rate capacityMicroscopic fiber electrodesHybrid capacitor electrodesGraphene nanocompositesSolid particle

Owner:NANOTEK INSTR GRP LLC

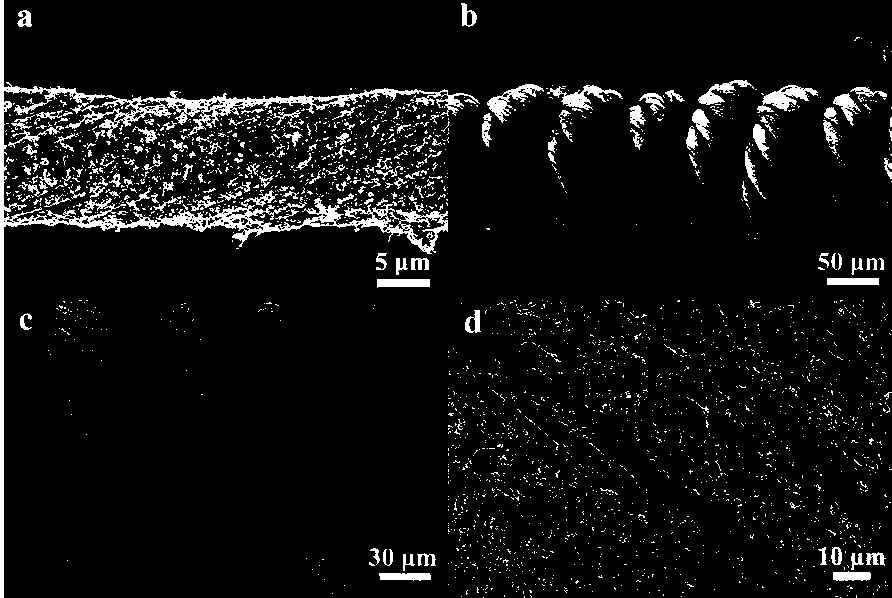

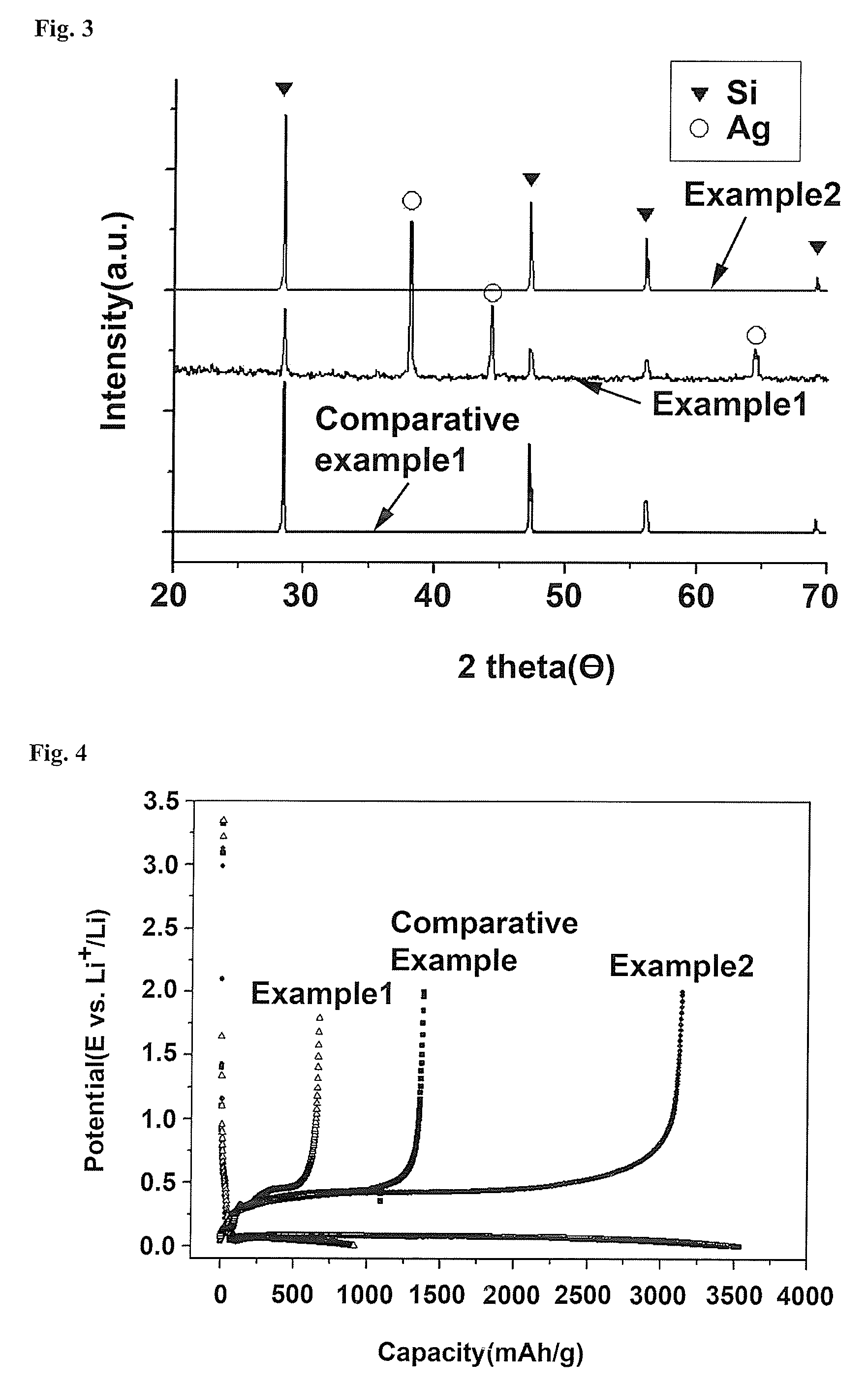

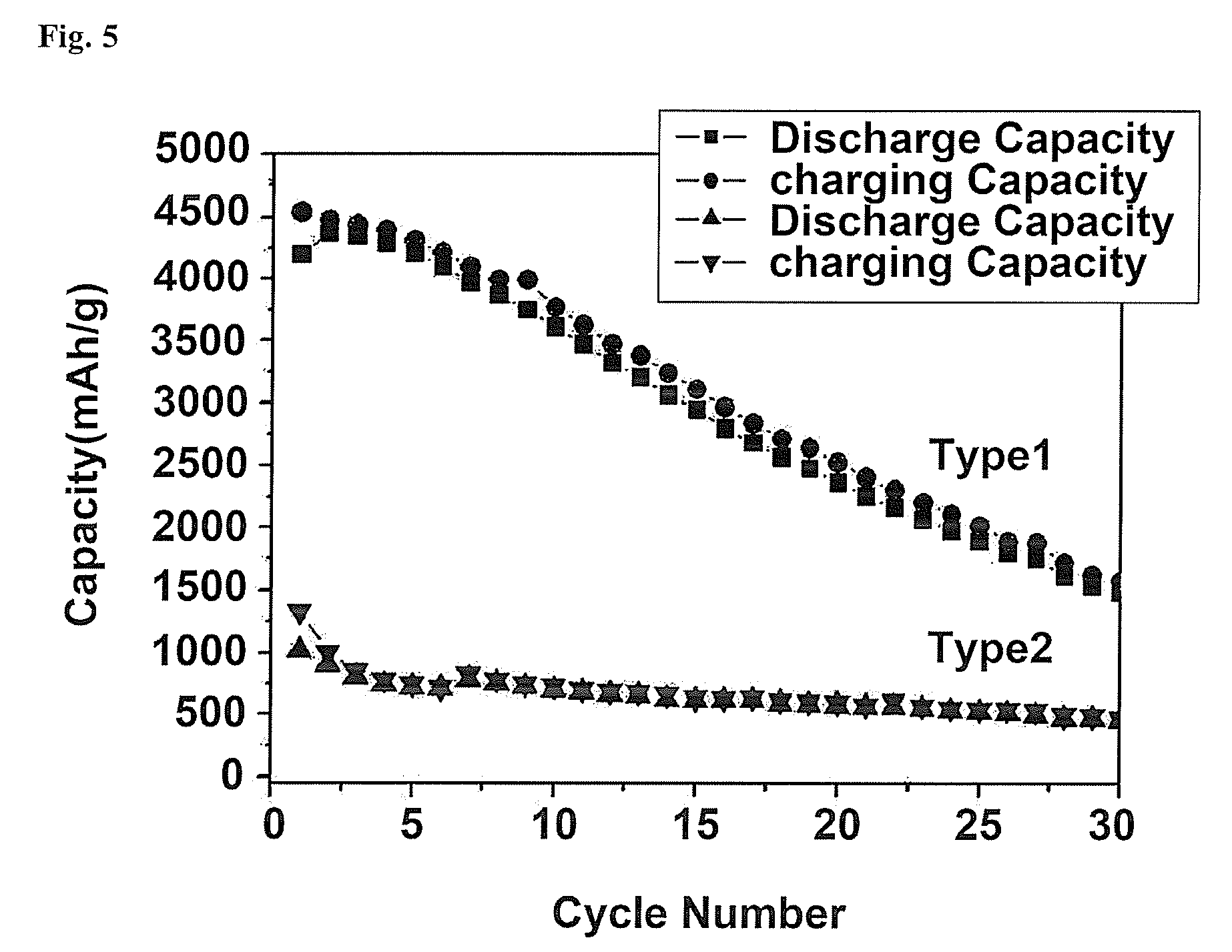

Method of preparing bundle type silicon nanorod composite through electroless etching process using metal ions and anode active material for lithium secondary cells comprising the same

InactiveUS20100301276A1Stably maintain cell capacityPreventing life deteriorationElectrochemical processing of electrodesMicroscopic fiber electrodesHydrofluoric acidLithium

The present invention relates to a method of preparing a porous silicon nanorod structure composed of columnar bundles having a diameter of 50-100 nm and a length of 2-5 μm, and a lithium secondary cell using the porous silicon nanorod structure as an anode active material. The present invention provides a high-capacity and high-efficiency anode active material for lithium secondary cells, which can overcome the low conductivity of silicon and improve the electrode deterioration attributable to volume expansion because it is prepared by electrodepositing the surface of silicon powder with metal and simultaneously etching the silicon powder partially using hydrofluoric acid.

Owner:KOREA INST OF SCI & TECH

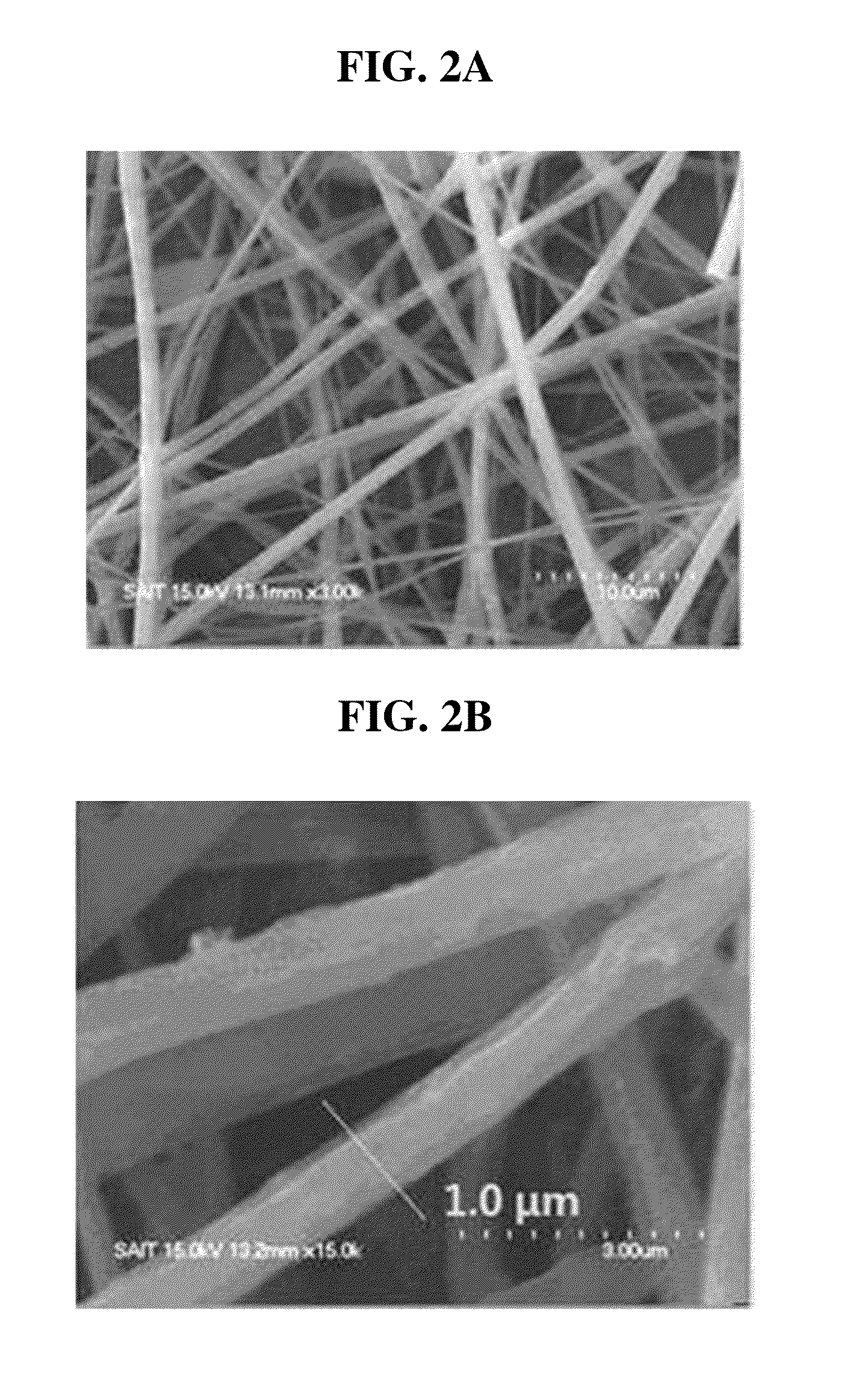

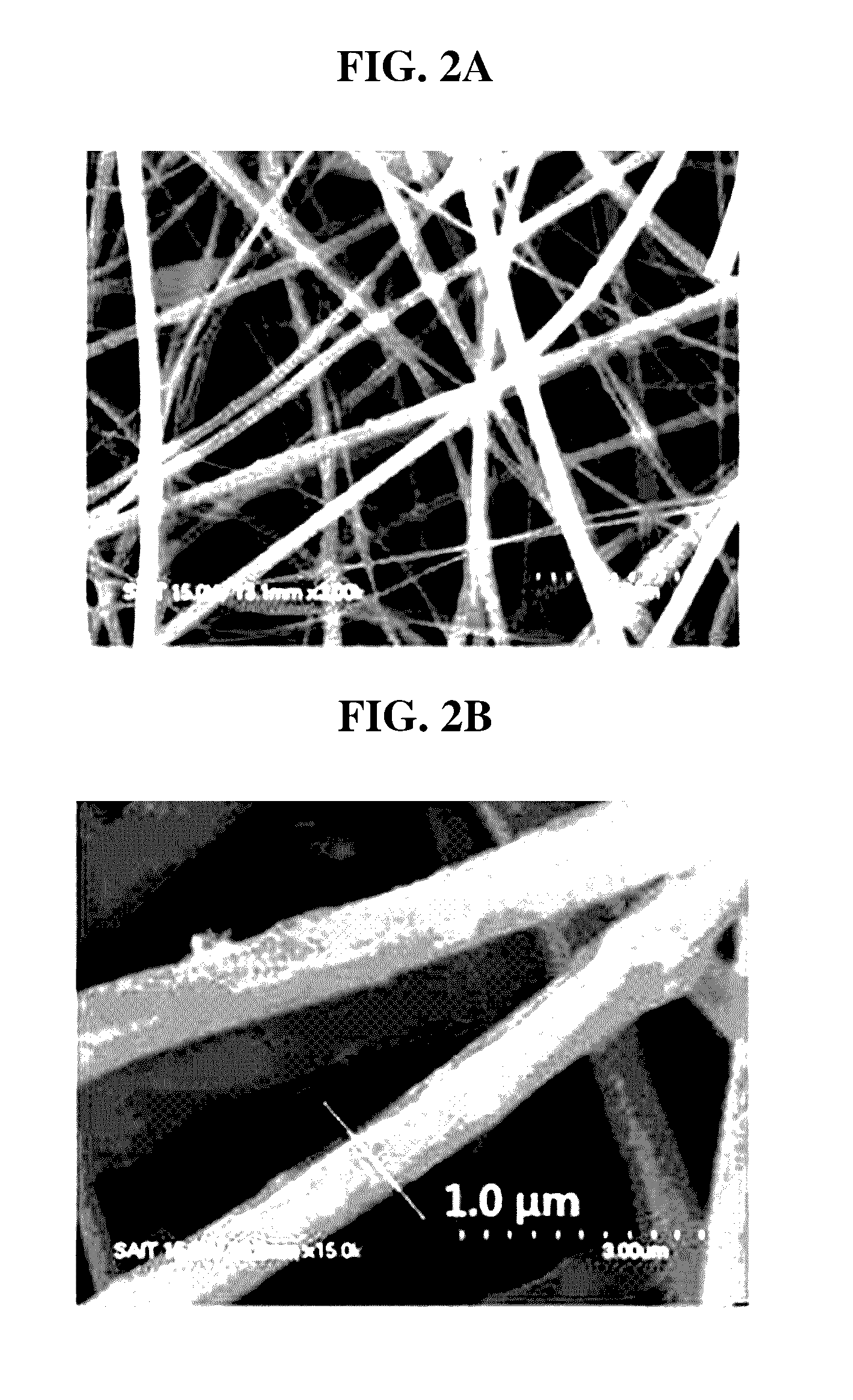

Carbon nanotube or carbon nanofiber electrode comprising sulfur or metal nanoparticles as a binder and process for preparing the same

InactiveCN1910771AIncreased durabilityReduce contact resistanceMaterial nanotechnologyMicroscopic fiber electrodesFiberFuel cells

The present invention provides an electrode made of carbon nanotubes or carbon nanofibers and a process for preparing the same. The electrode comprising a current collector, sulfur or metal nanoparicles as a binder, and carbon nanotubes or carbon nanofibers is characterized in that the sulfur or metal nanoparticles are bonded, deposited, or fused on the surfaces of the carbon nanotubes or carbon nanofibers so that the carbon nanotubes or carbon nanofibers are bonded to each other and also bonded to the current collector. The electrode prepared according to the present invention exhibits low internal resistance, strong durability and low equivalent series resistance, and therefore the electrode can be effectively used for secondary batteries, supercapacitors or fuel cells.

Owner:KH CHEM CO LTD

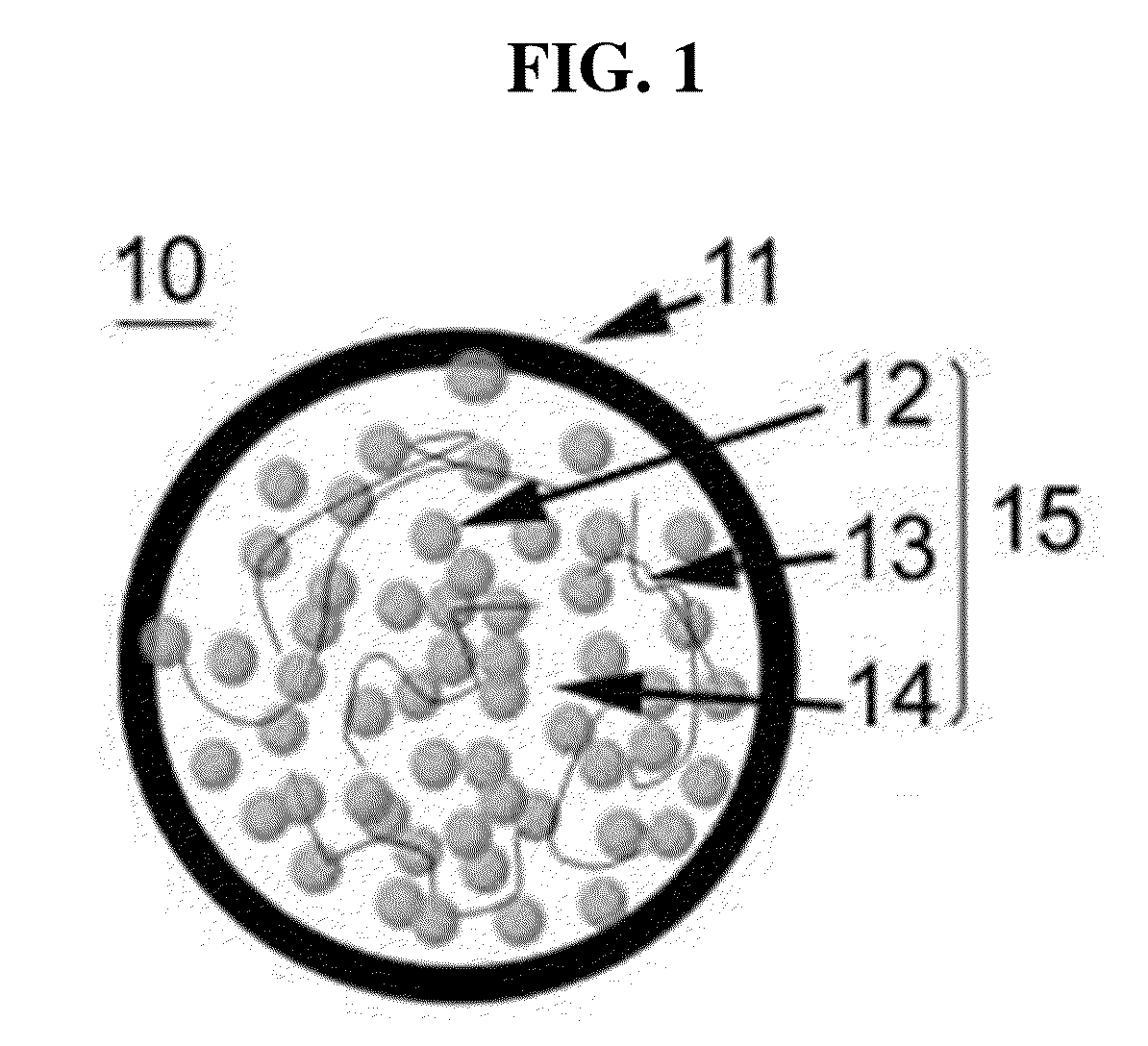

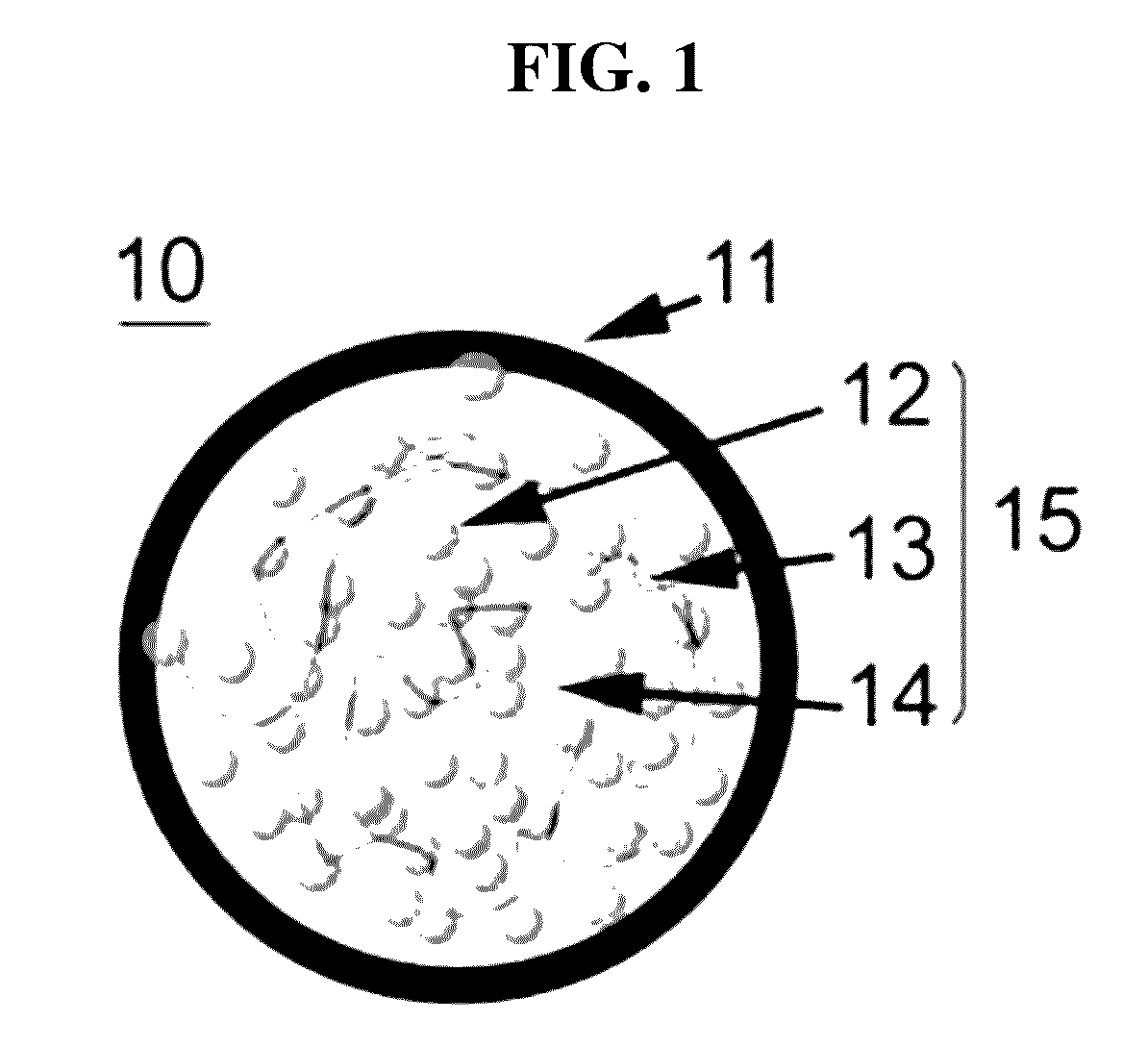

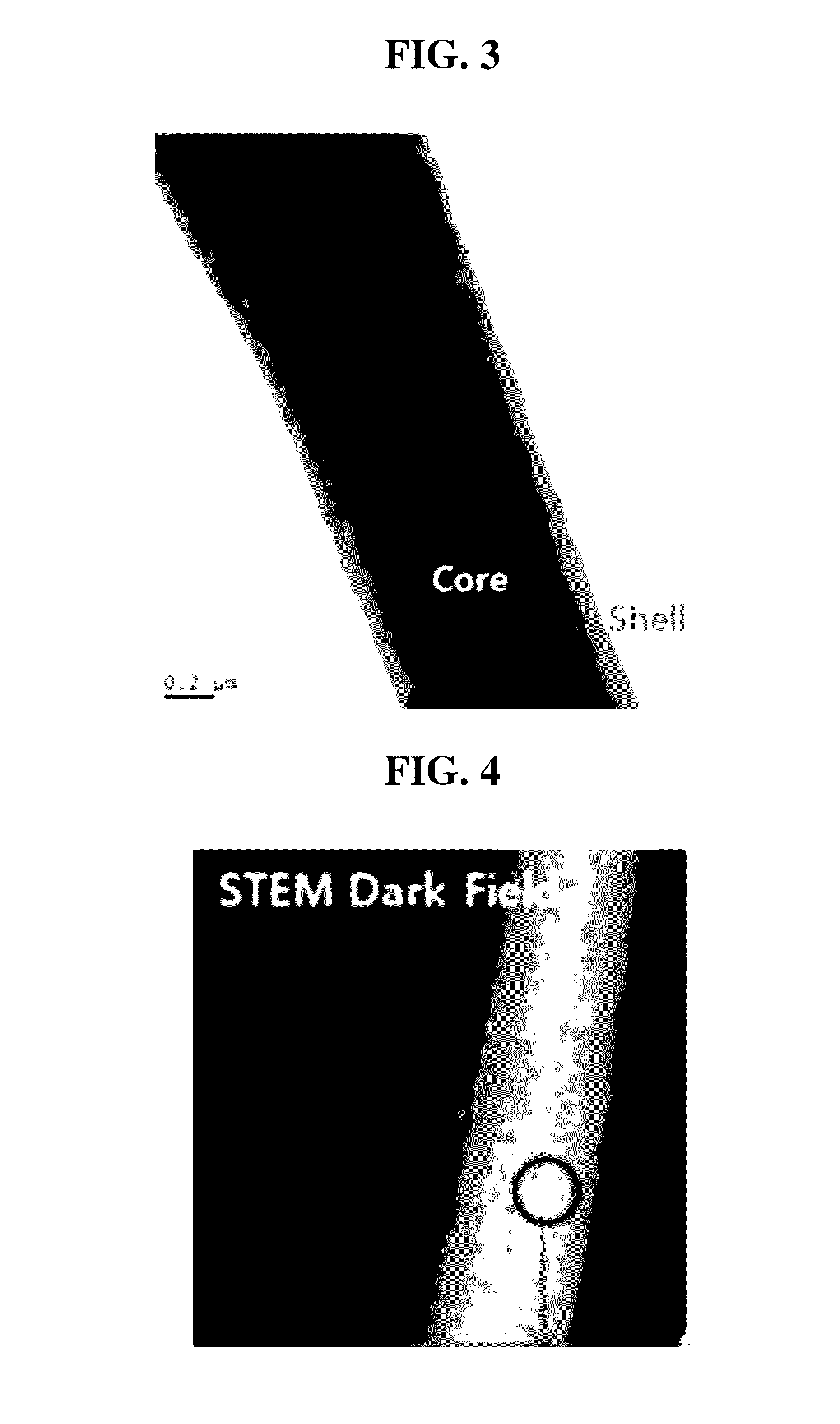

Composite anode active material, anode and lithium battery each including the composite anode active material, method of preparing the composite anode active material

ActiveUS20140087255A1Increase capacityImprove featuresSilver accumulatorsMicroscopic fiber electrodesFiberCarbon fibers

A composite anode active material, an anode including the composite anode active material, a lithium battery including the anode, and a method of preparing the composite anode active material. The composite anode active material includes: a shell including a hollow carbon fiber; and a core disposed in a hollow of the hollow carbon fiber, wherein the core includes a first metal nanostructure and a conducting agent.

Owner:SAMSUNG ELECTRONICS CO LTD

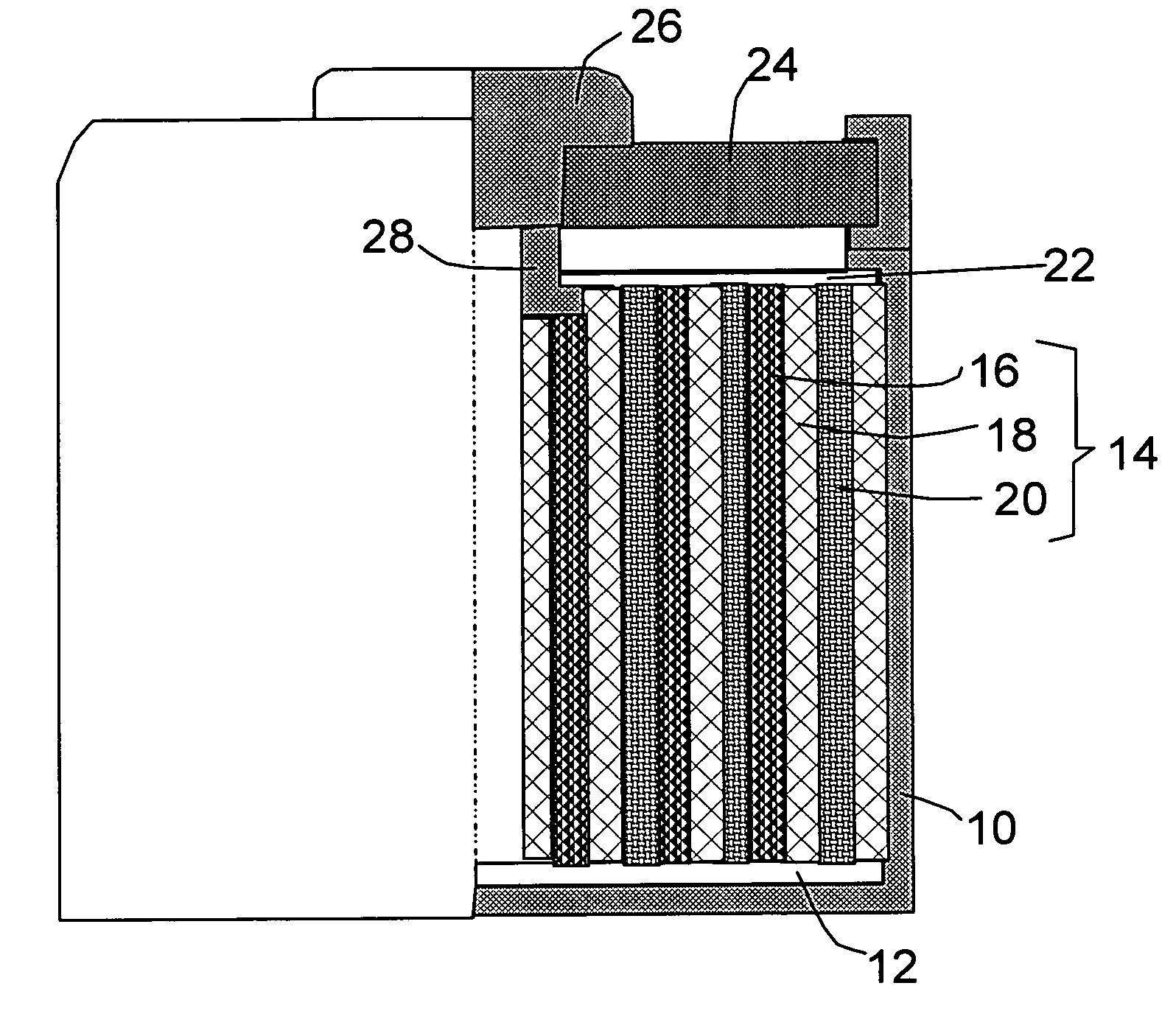

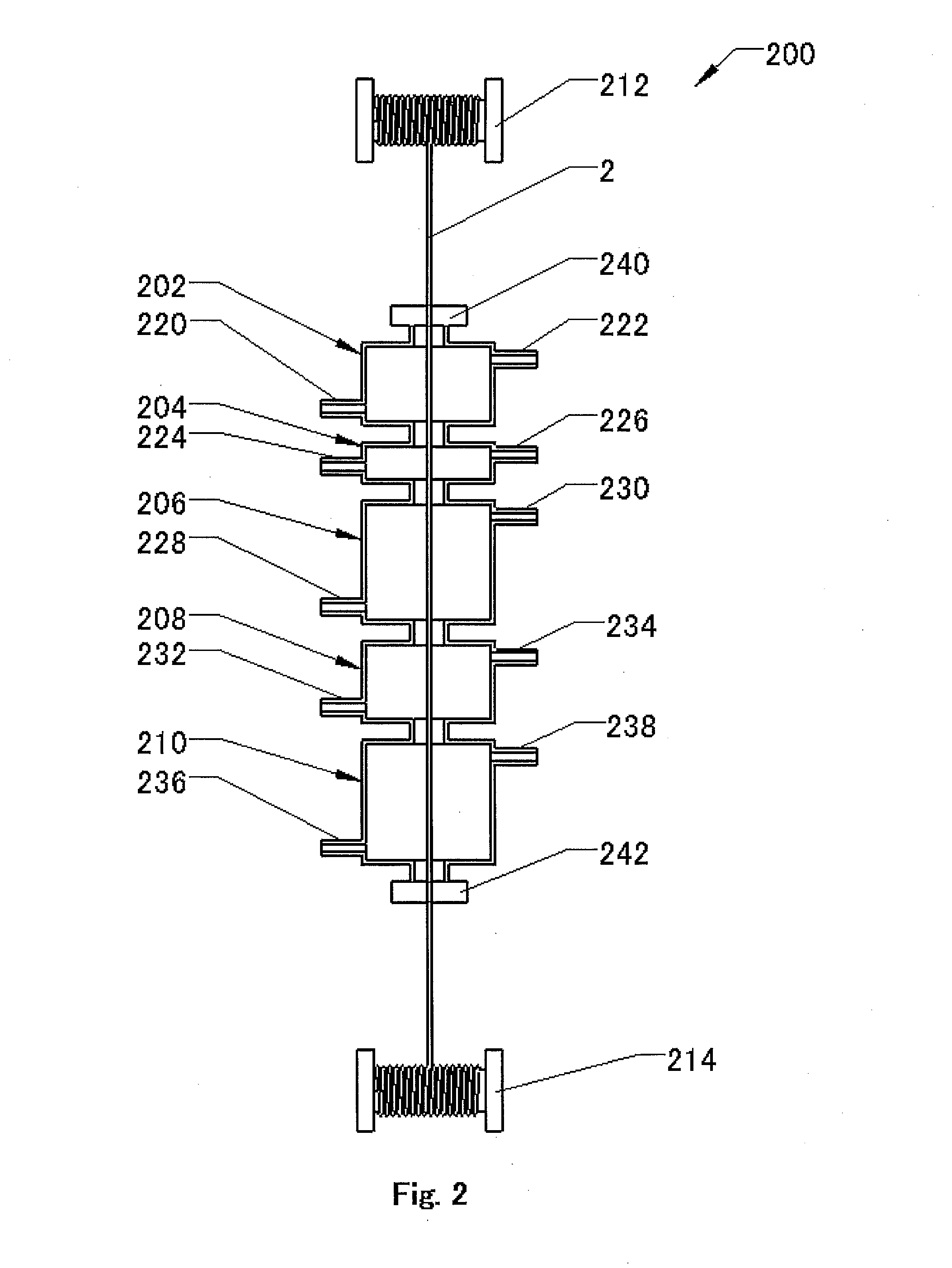

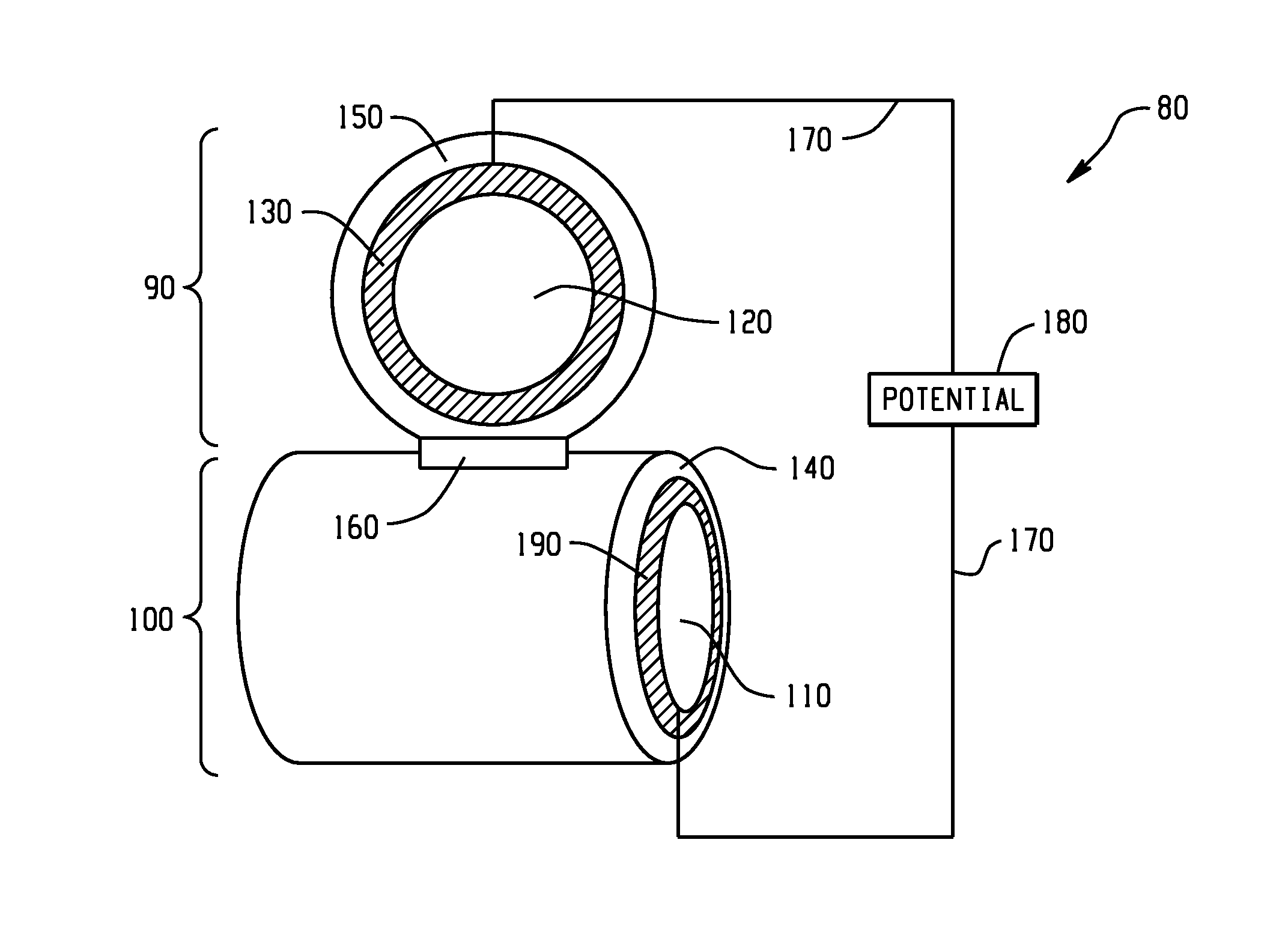

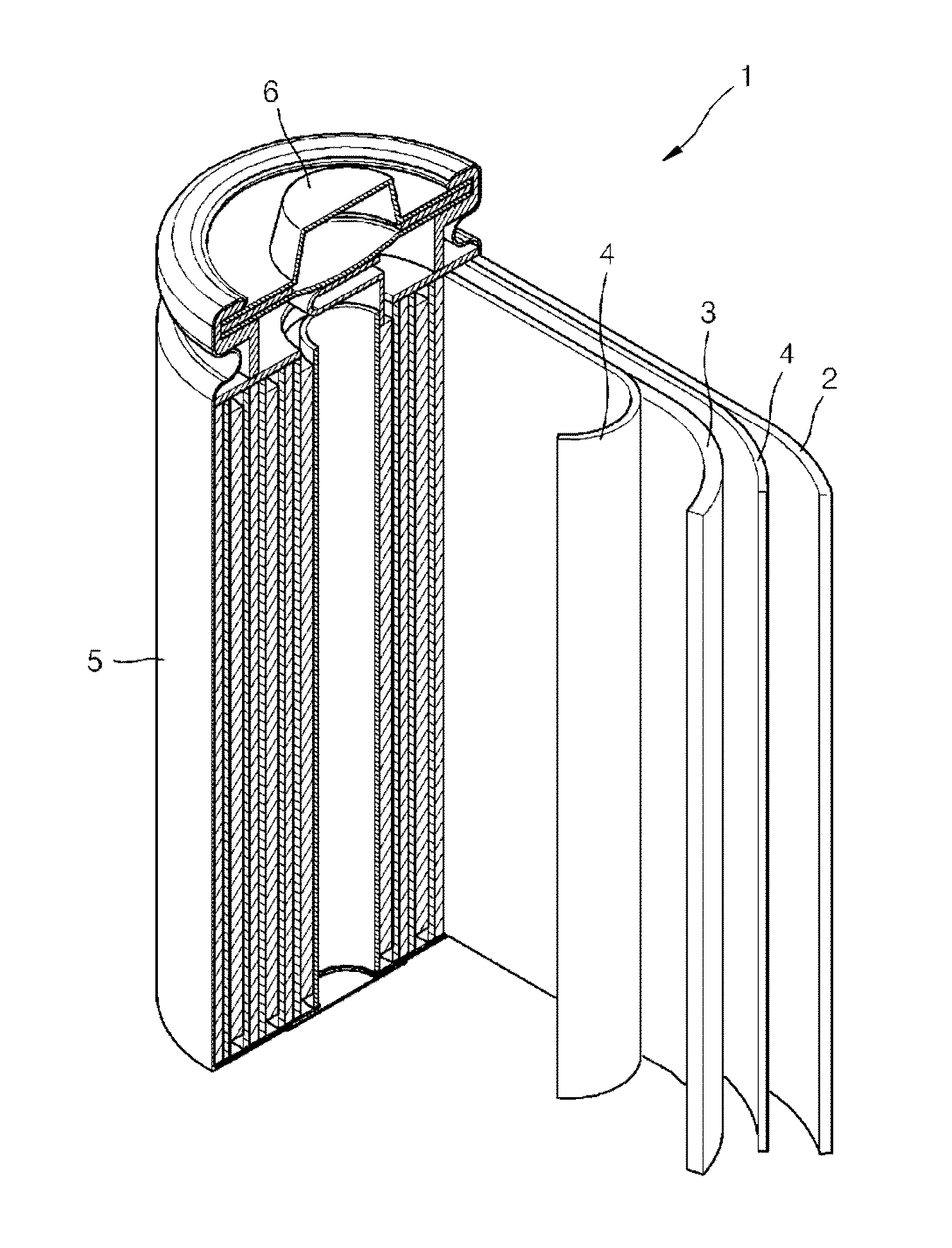

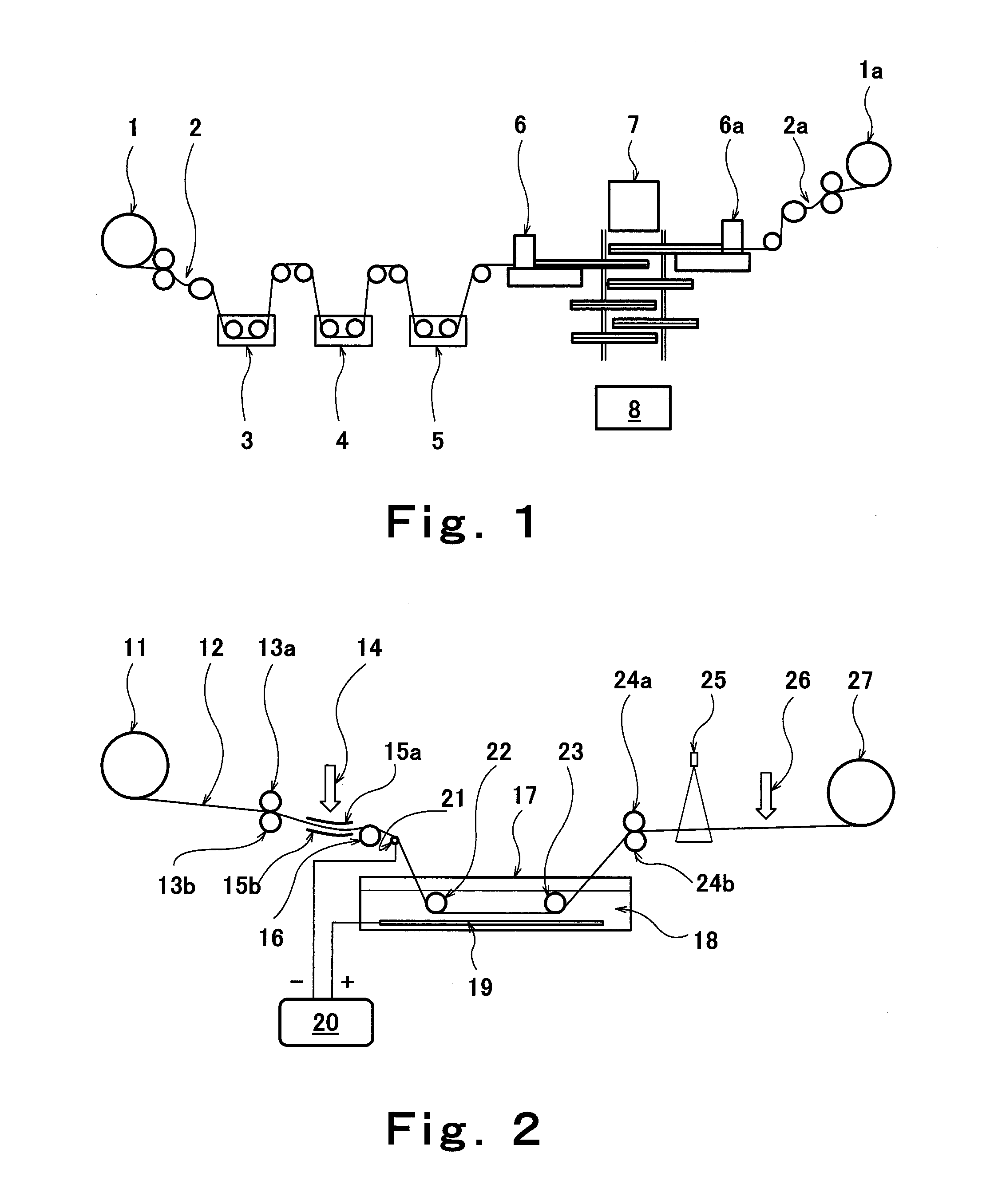

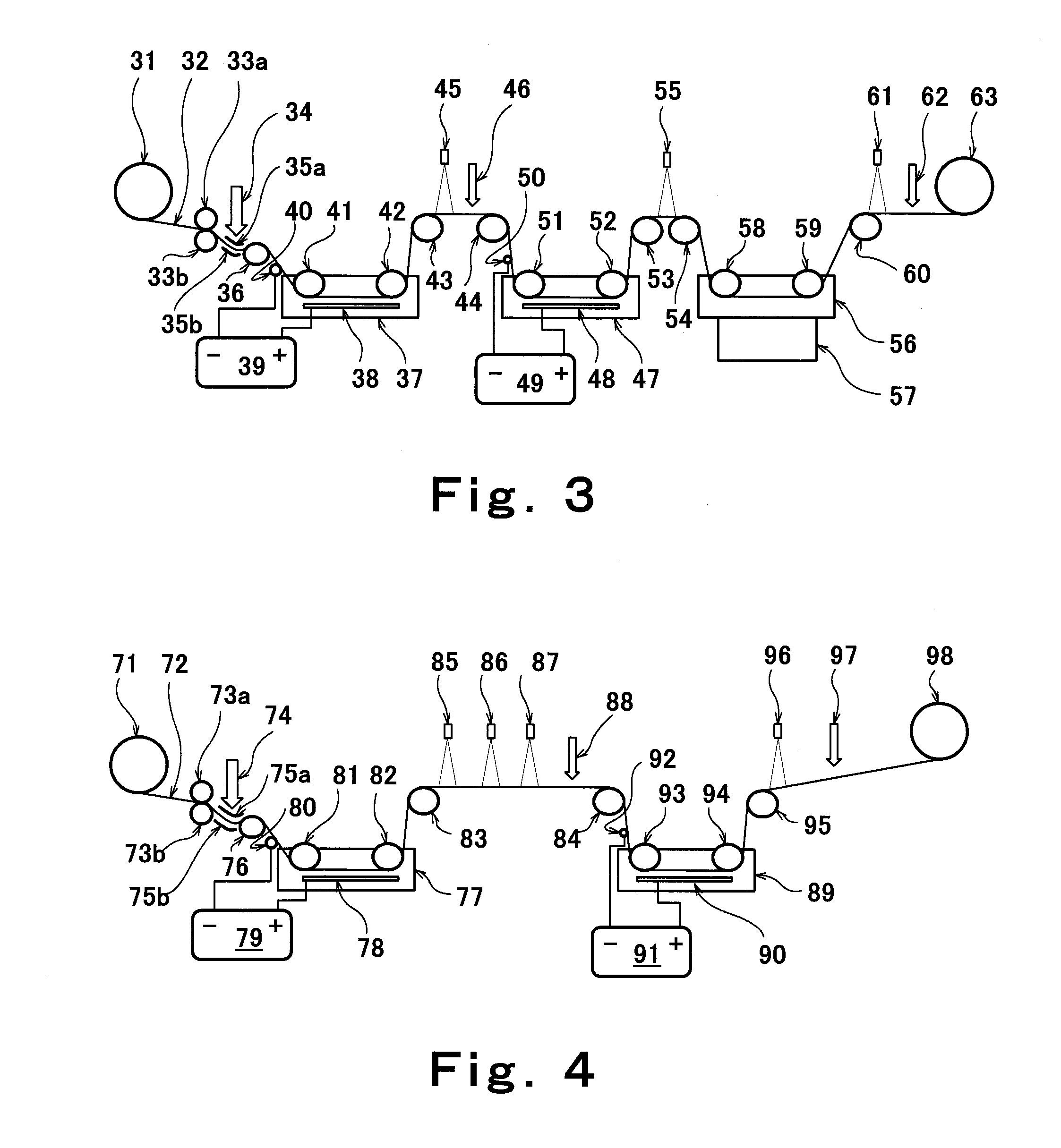

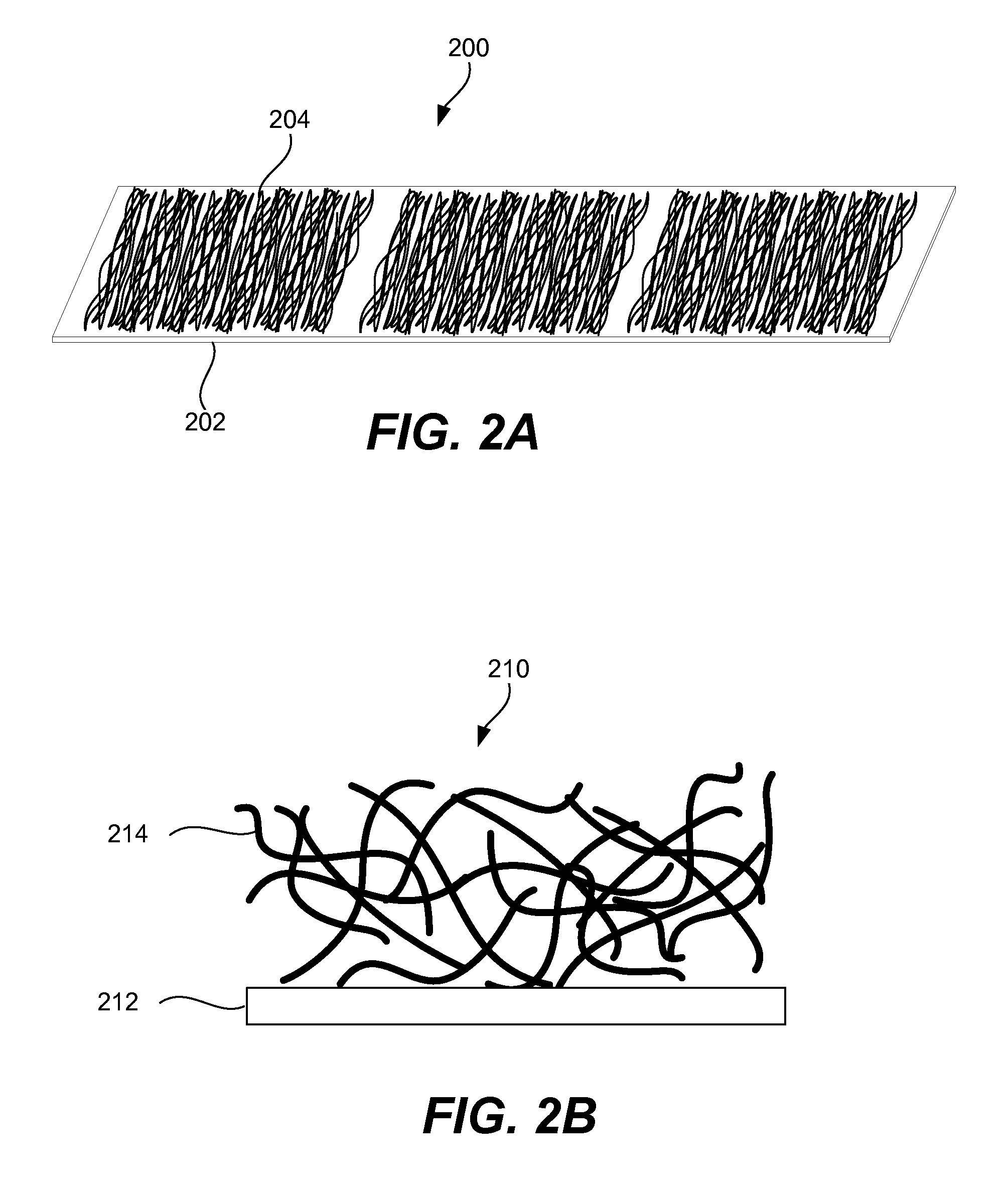

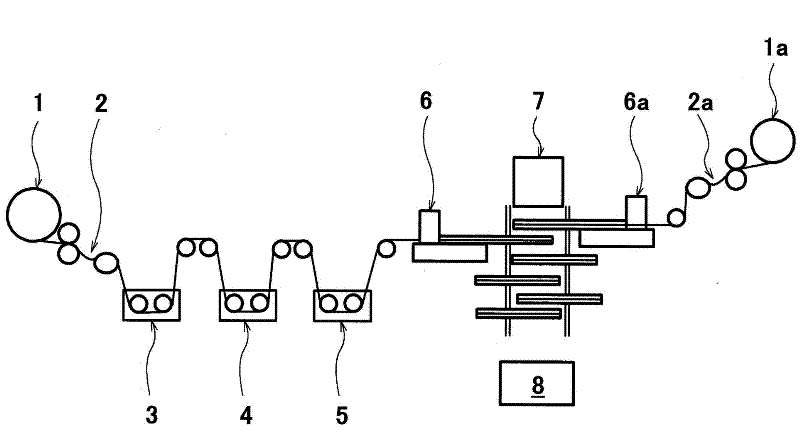

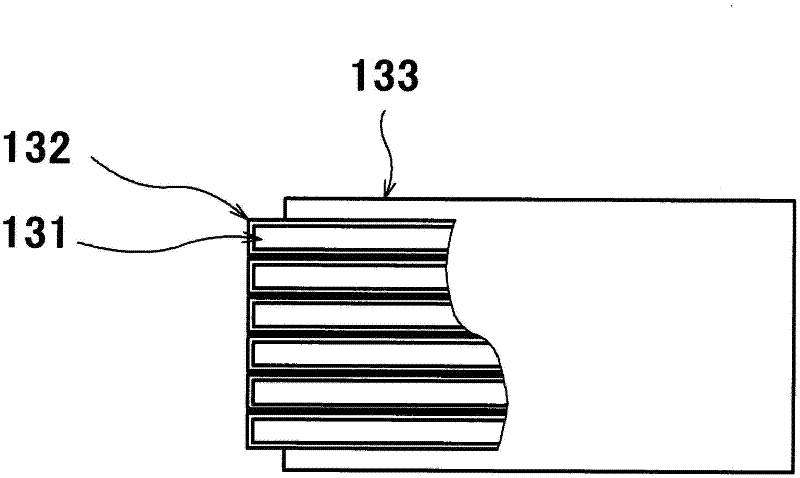

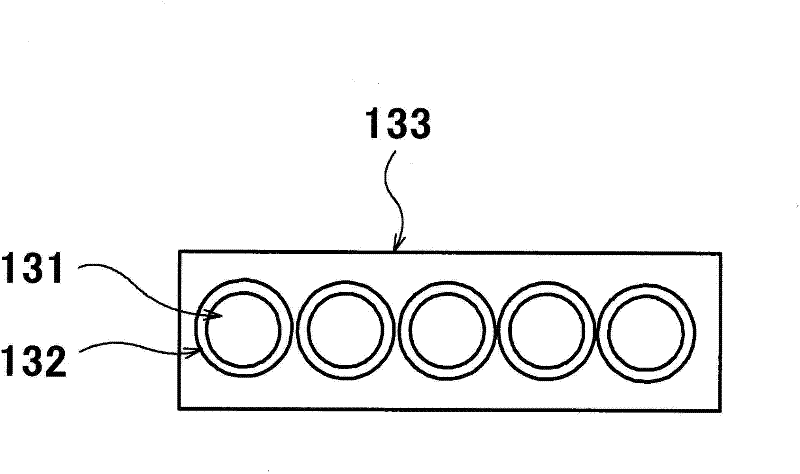

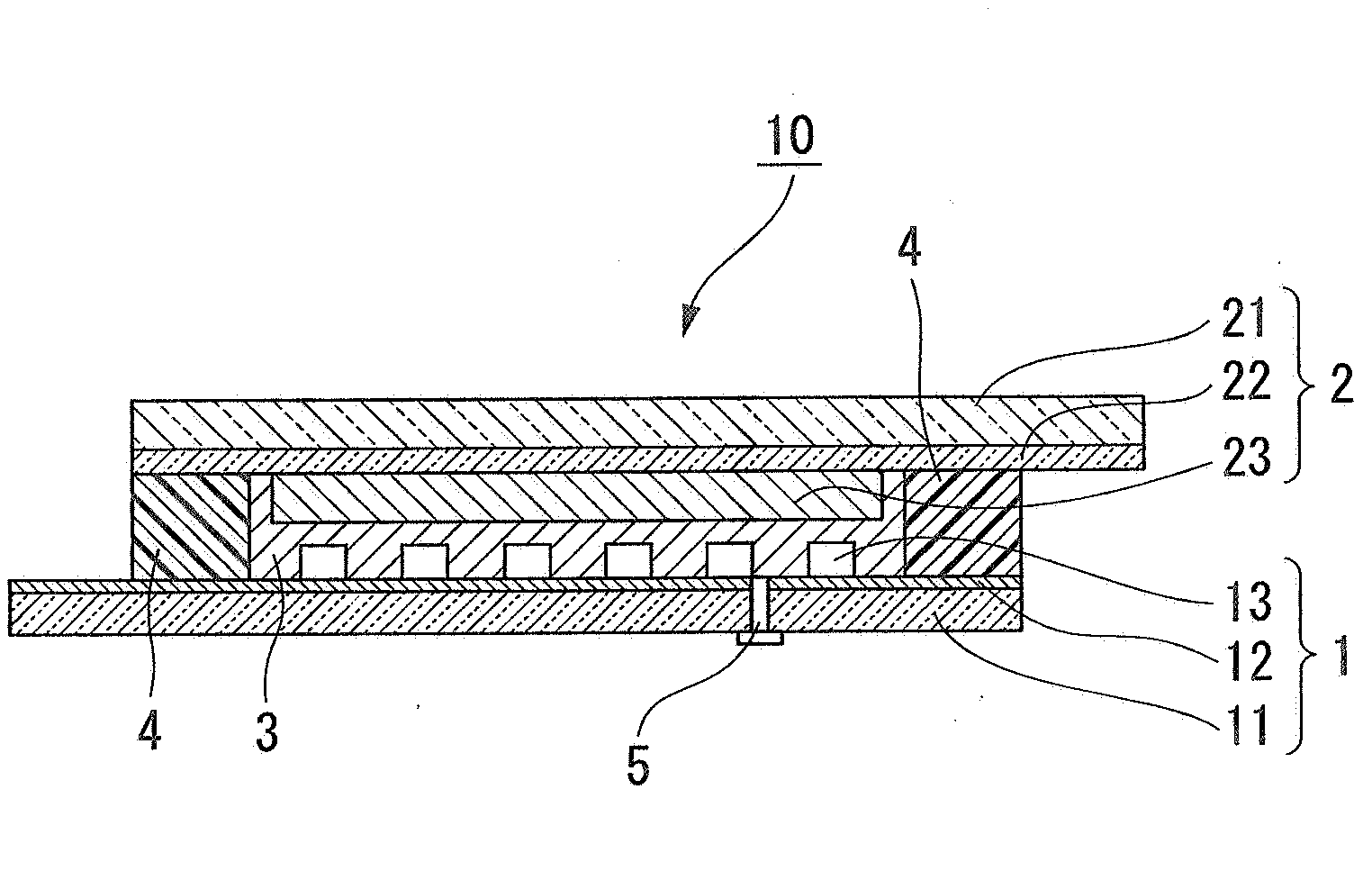

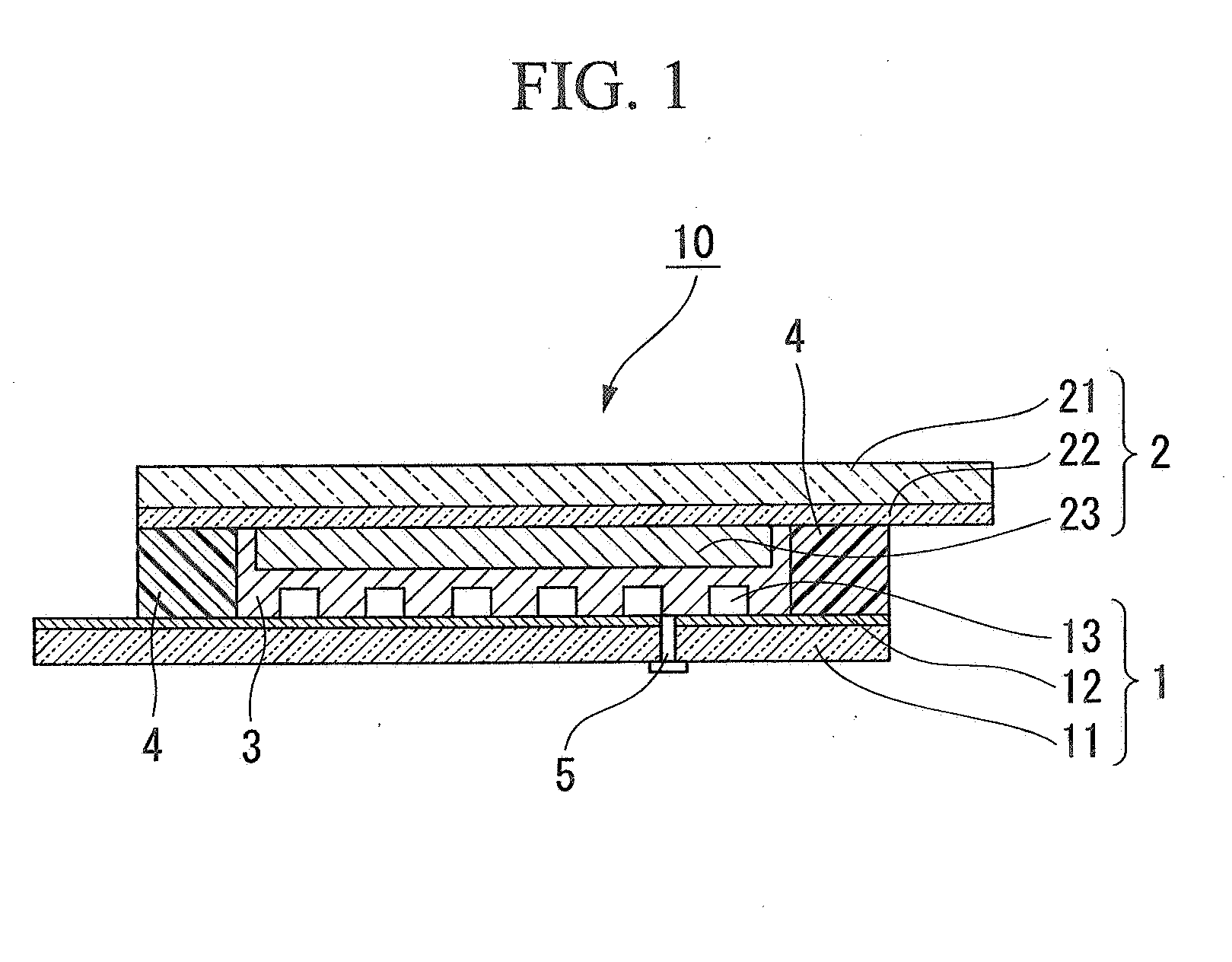

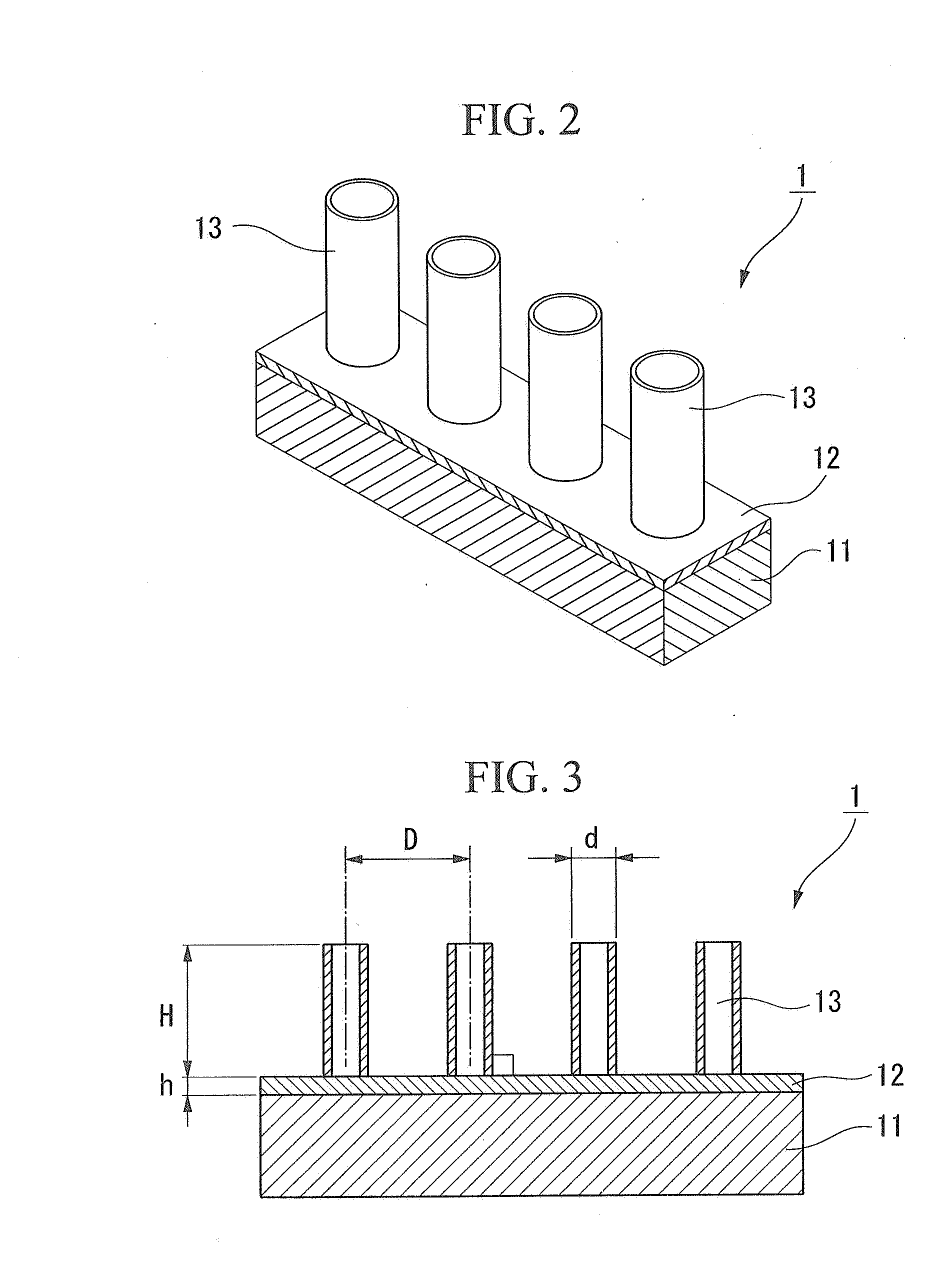

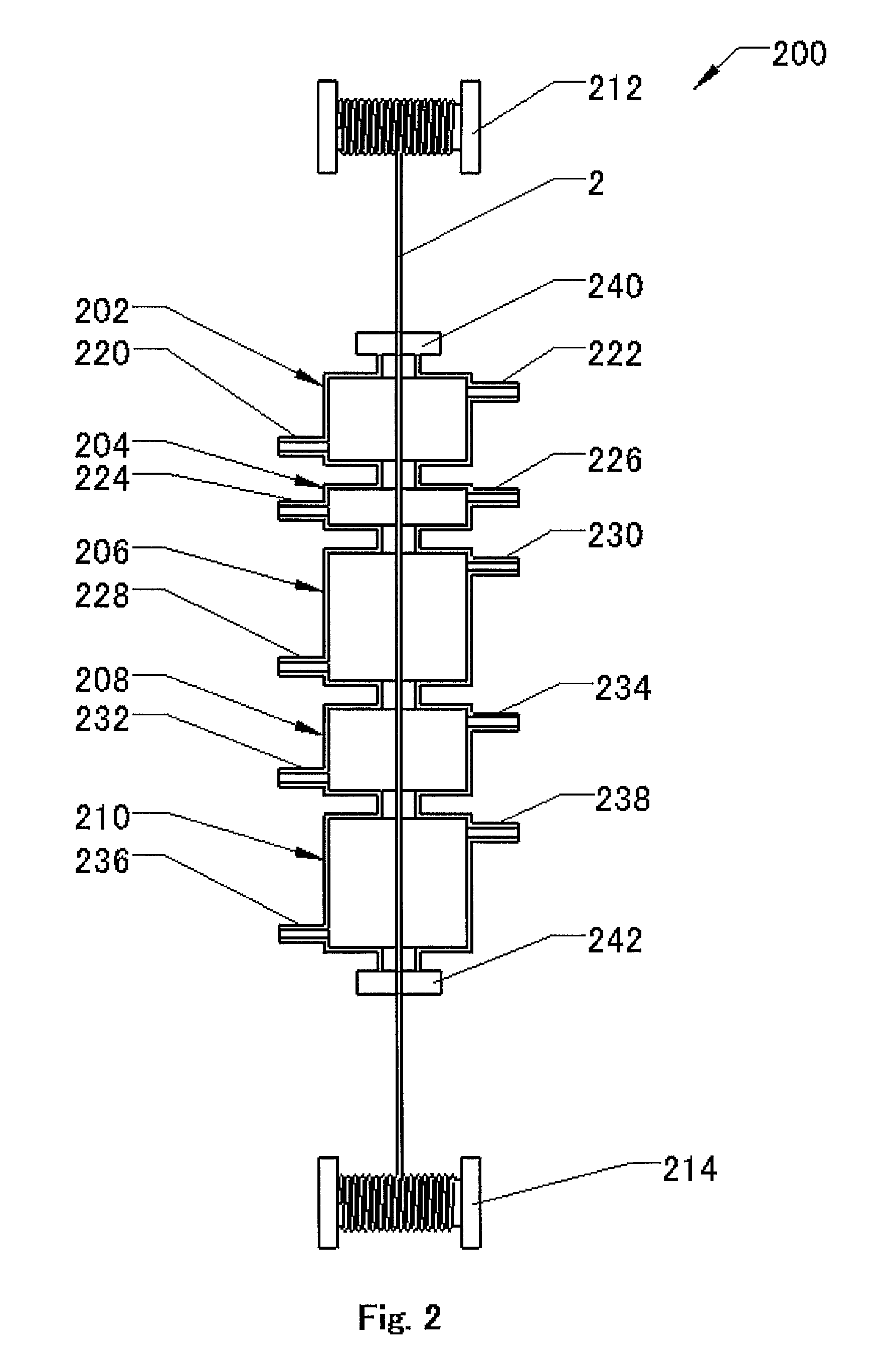

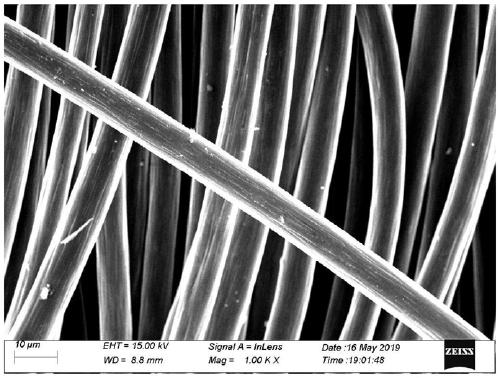

Fiber electrode and fiber battery, method of fabricating the same, and fiber electrode and fiber battery fabrication apparatus

InactiveUS20120214040A1Efficient manufacturingReduce distanceFinal product manufactureElectrode carriers/collectorsSingle fiberOptoelectronics

The present invention provides a method of efficiently fabricating a large number of fiber electrodes at the same time from a large number of fibers while taking advantage of inherent characteristics of fiber electrodes.A fiber electrode fabrication method according to the present invention includes: a step (2, 2a) of spreading a fiber tow; a step (3, 4, 5) of obtaining fiber positive electrodes or fiber negative electrodes by forming a positive electrode active material coating or a negative electrode active material coating on each of single fibers that are obtained by spreading the fiber tow; and a step (6, 6a) of forming a separator coating on the fiber positive electrodes or the fiber negative electrodes.

Owner:KAWASAKI HEAVY IND LTD

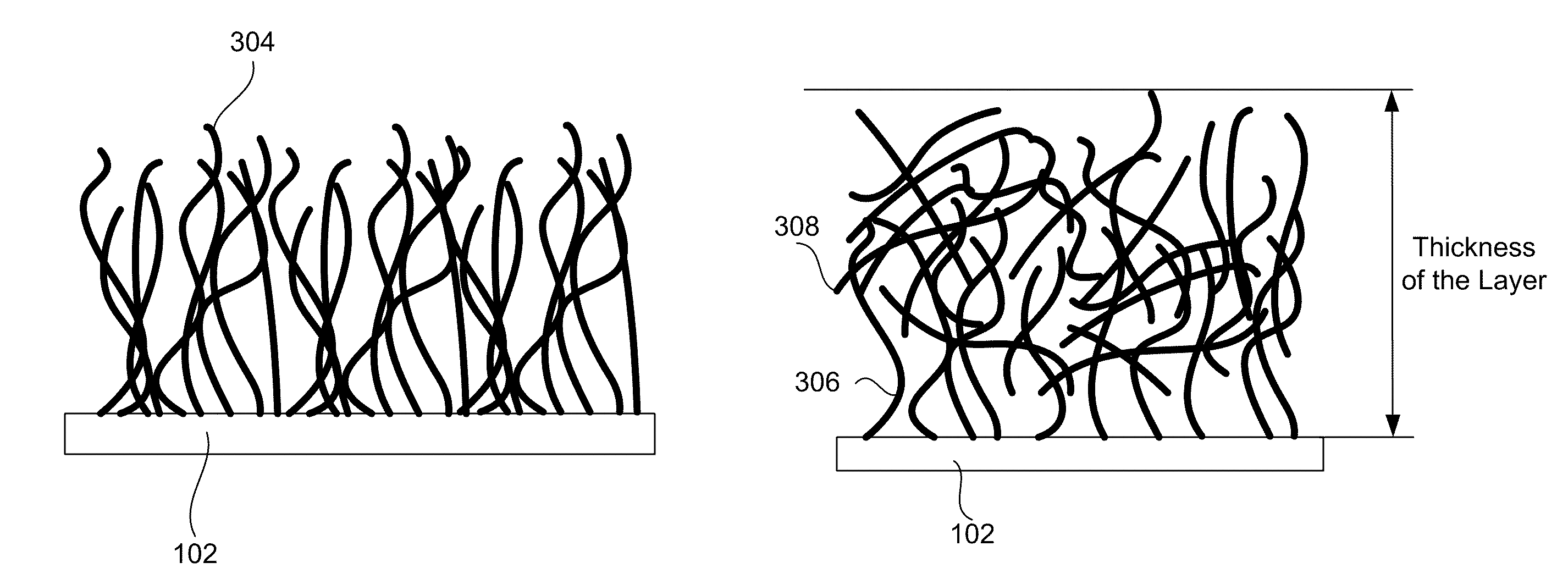

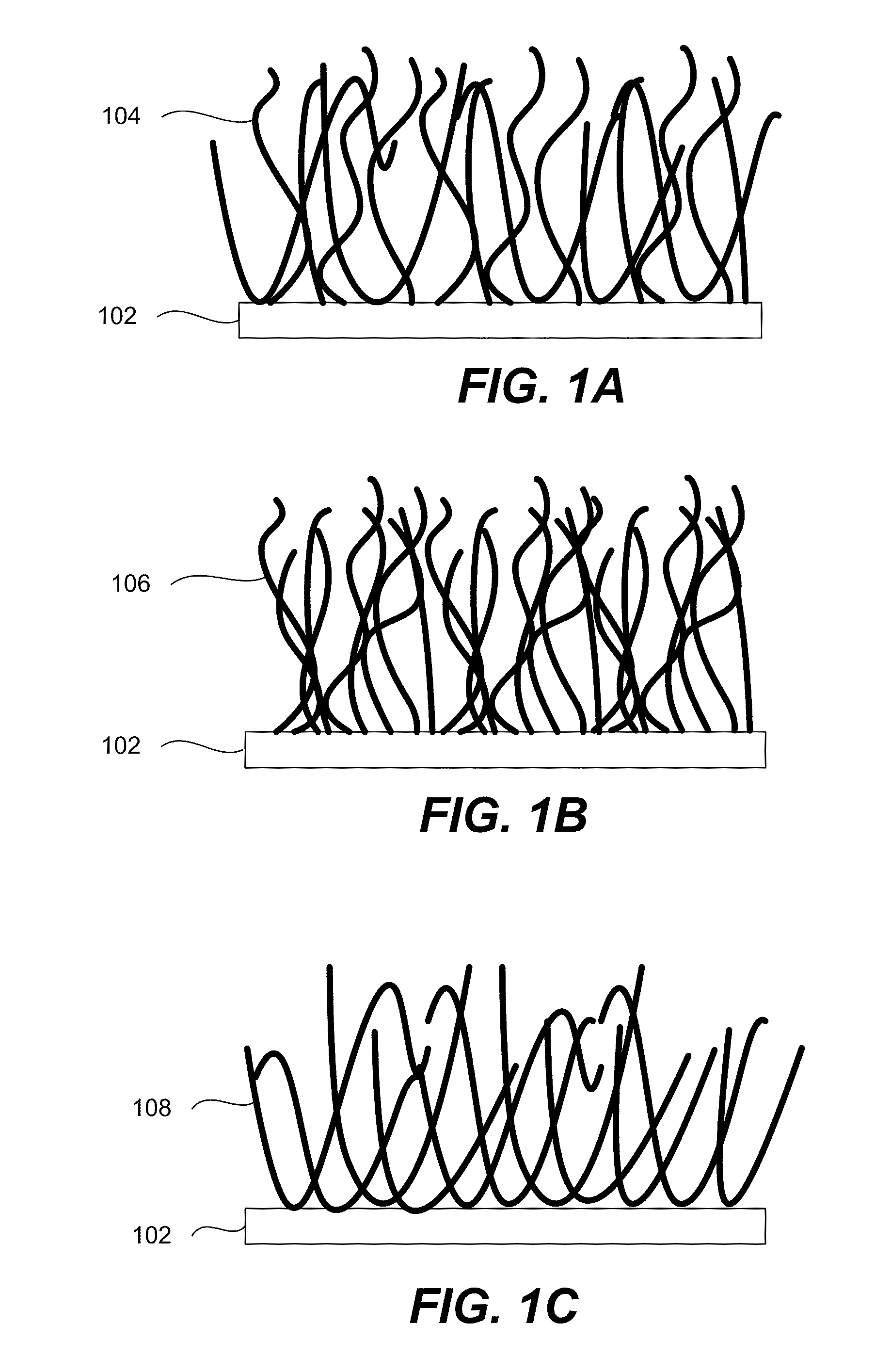

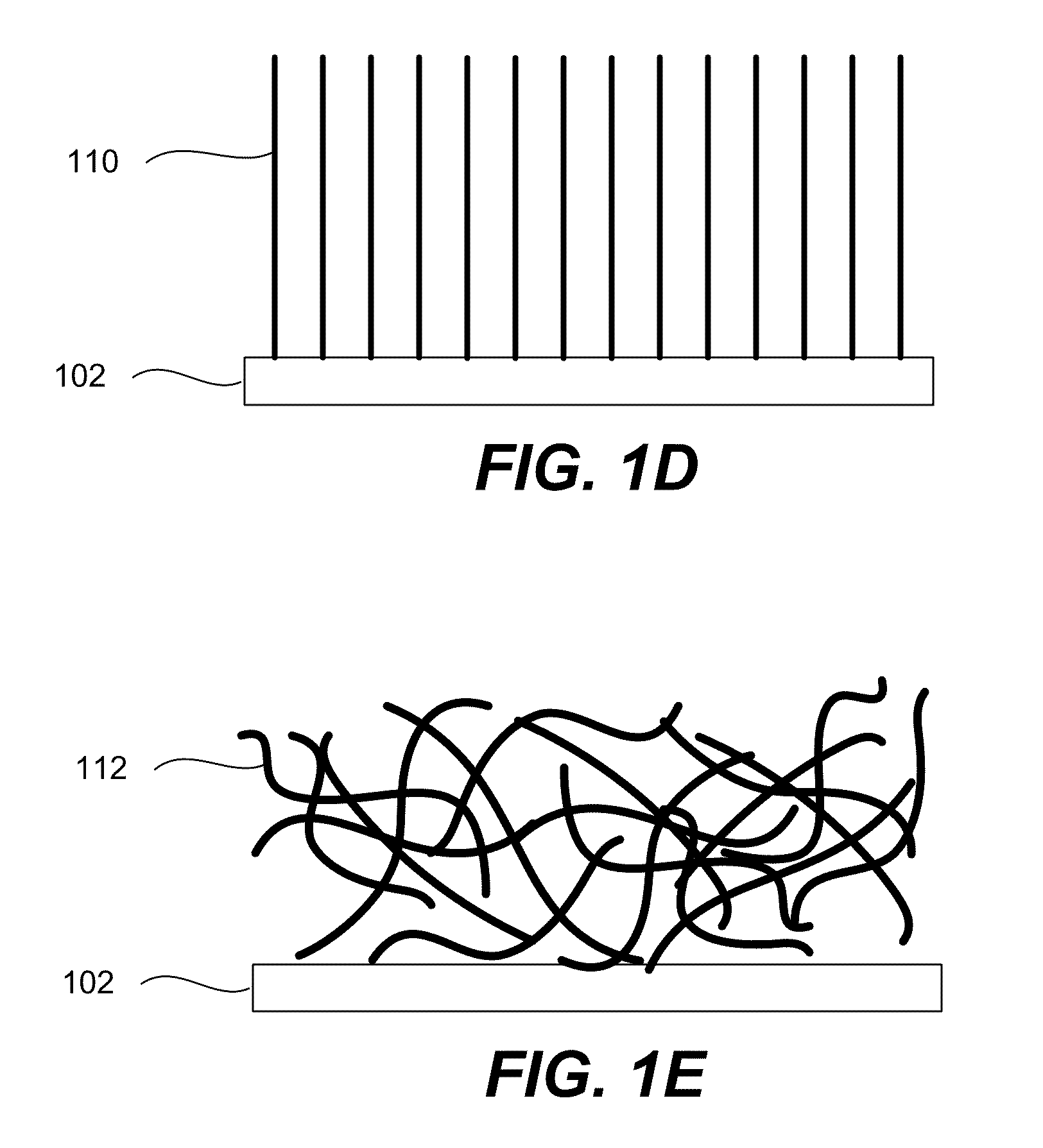

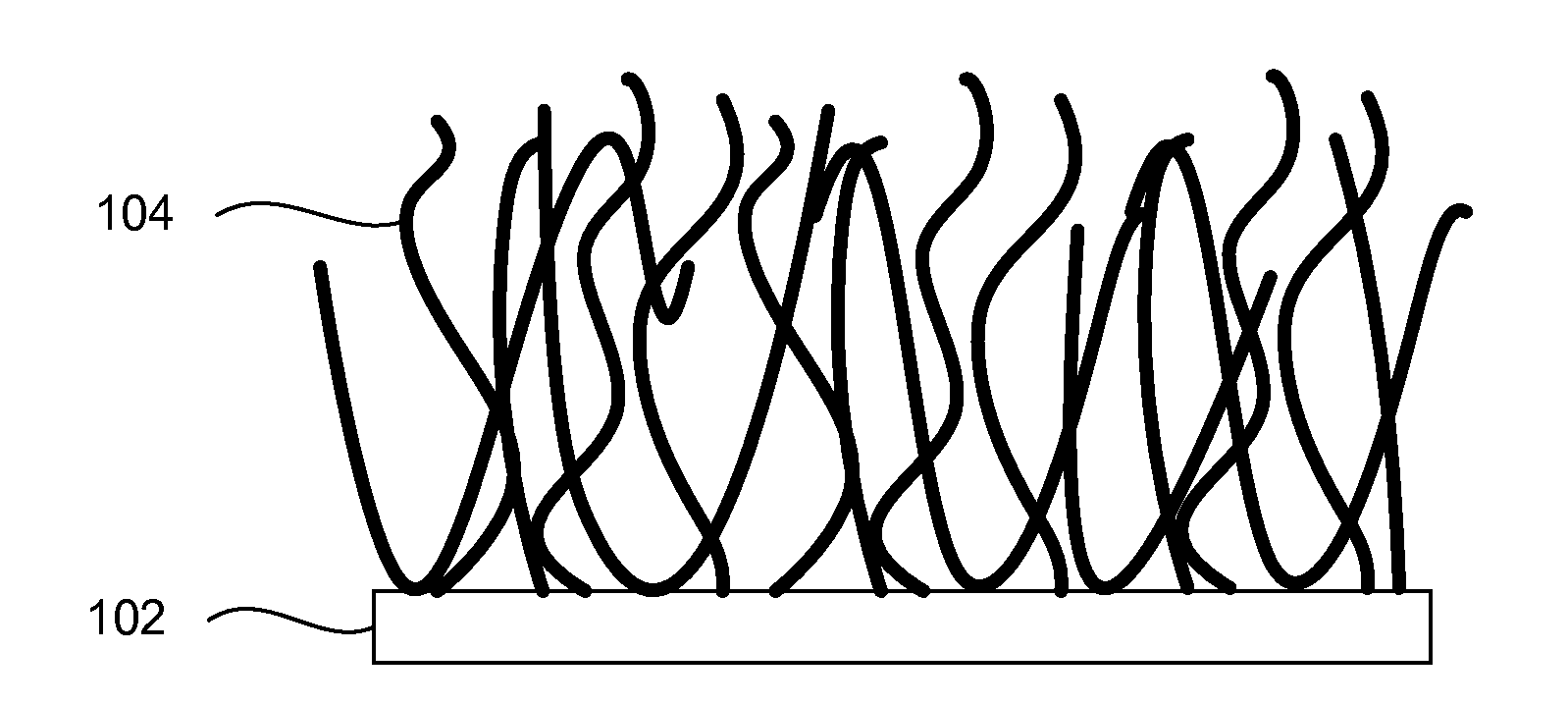

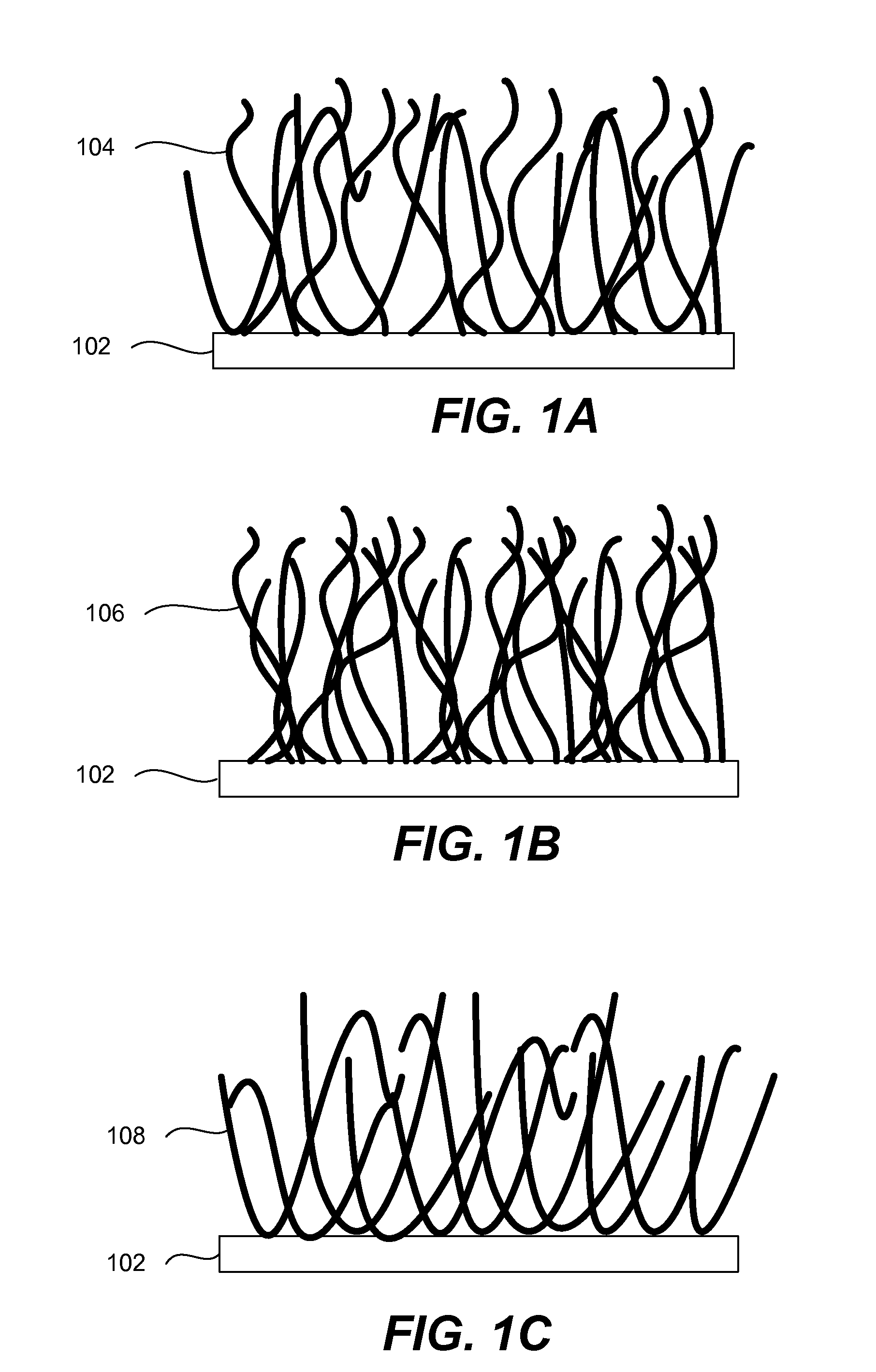

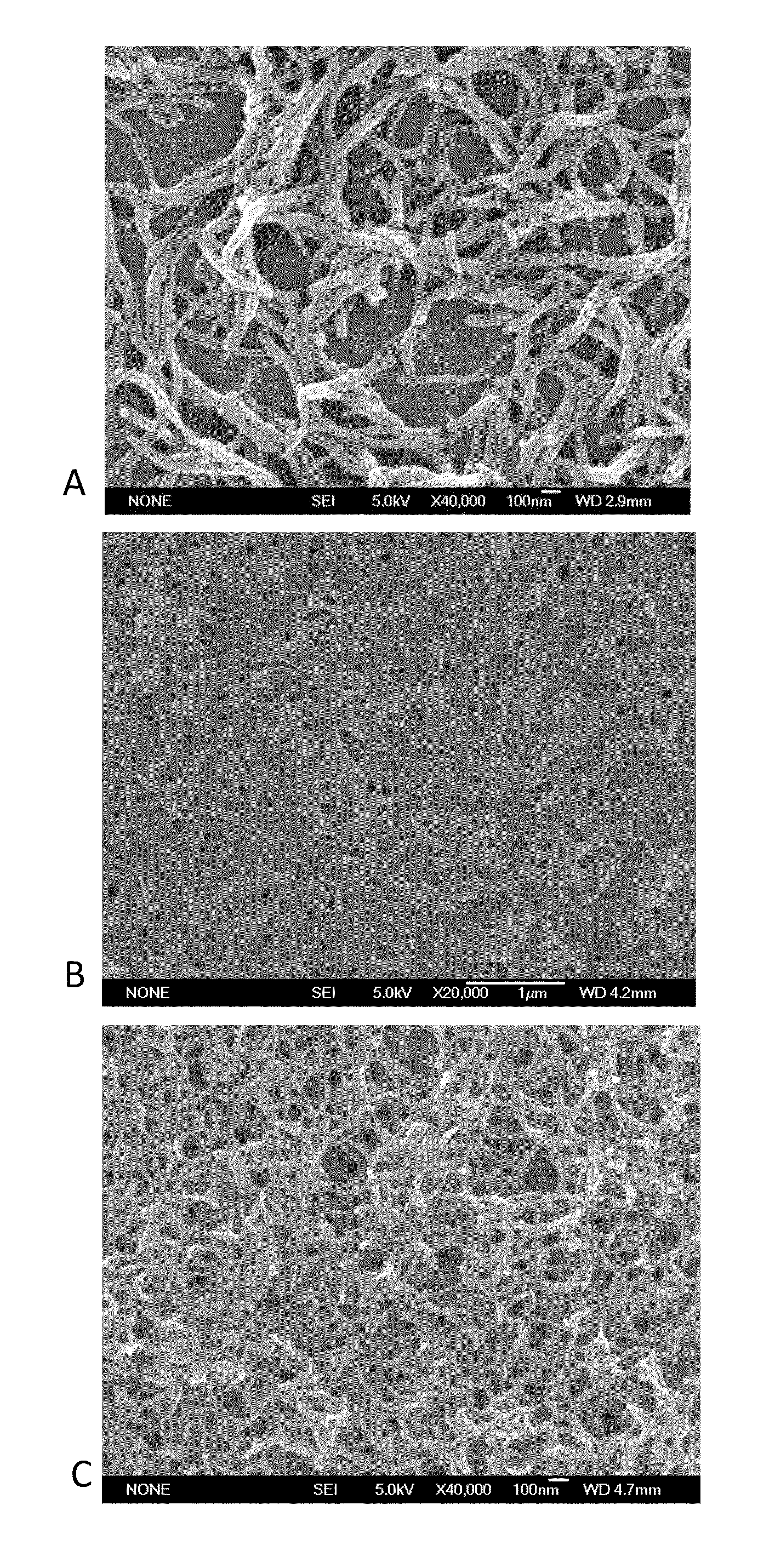

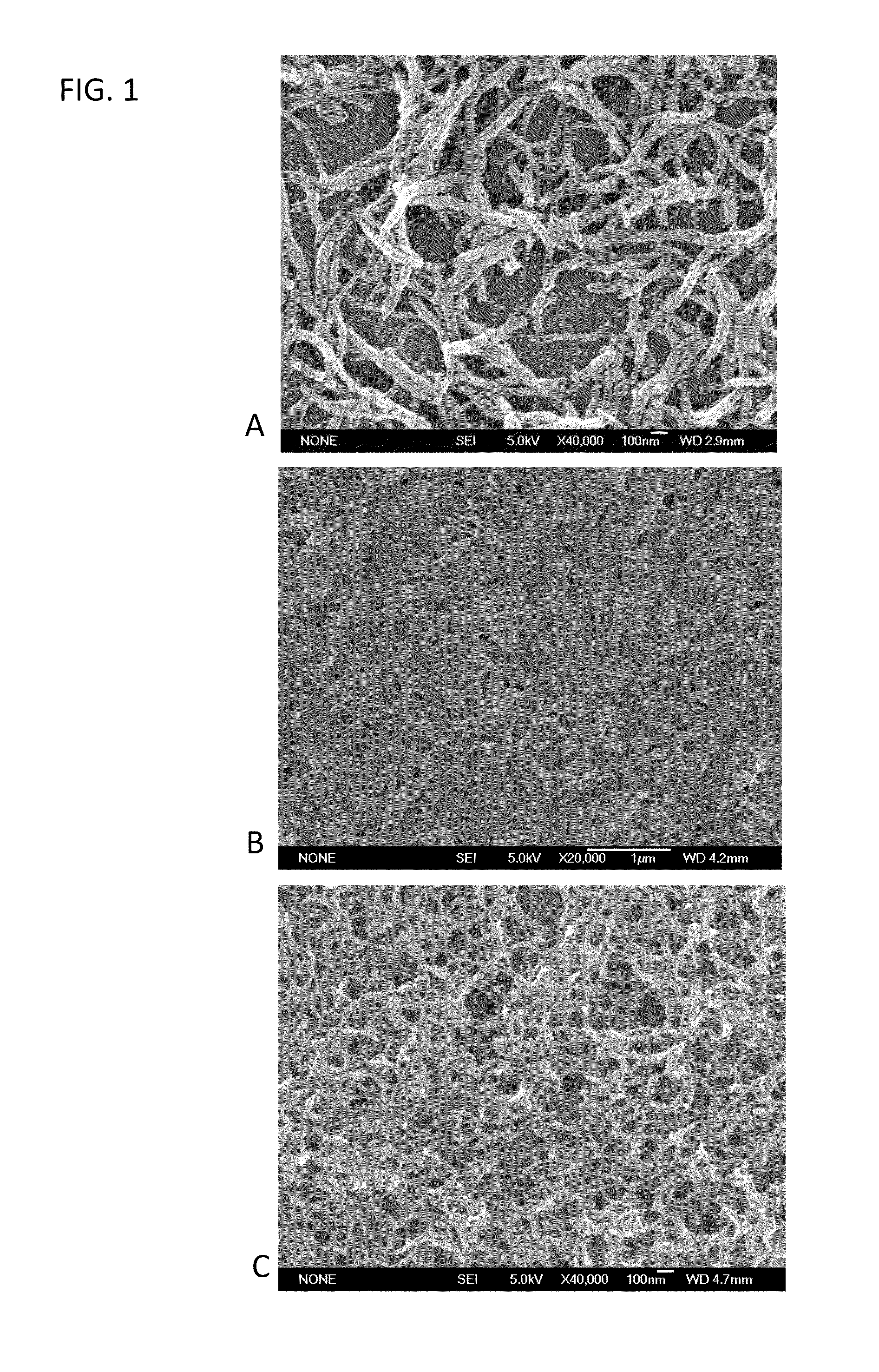

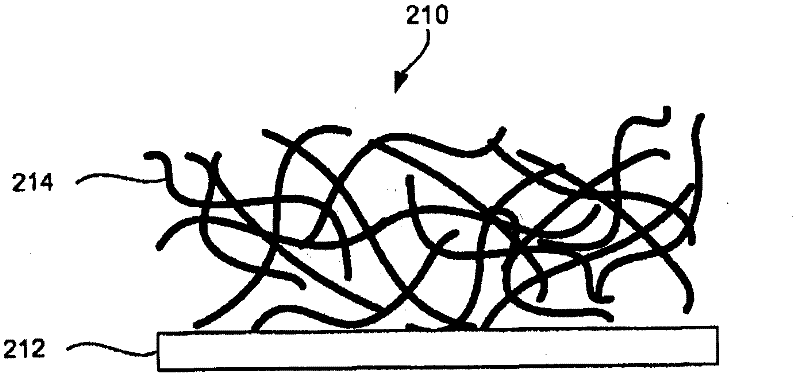

Electrodes incorporating nanostructured polymer films for electrochemical ion storage

Ion storage electrodes formed by coating an underlying substrate with a nanofibrillar film of structured conjugate polymer nanofibers and methods of forming such electrodes are described herein. The electrical properties of the electrodes may be customized by modifying the structure of the polymer nanofibers, the thickness of the nanofiber film, and the pore size of the nanofiber films.

Owner:CALIFORNIA INST OF TECH +2

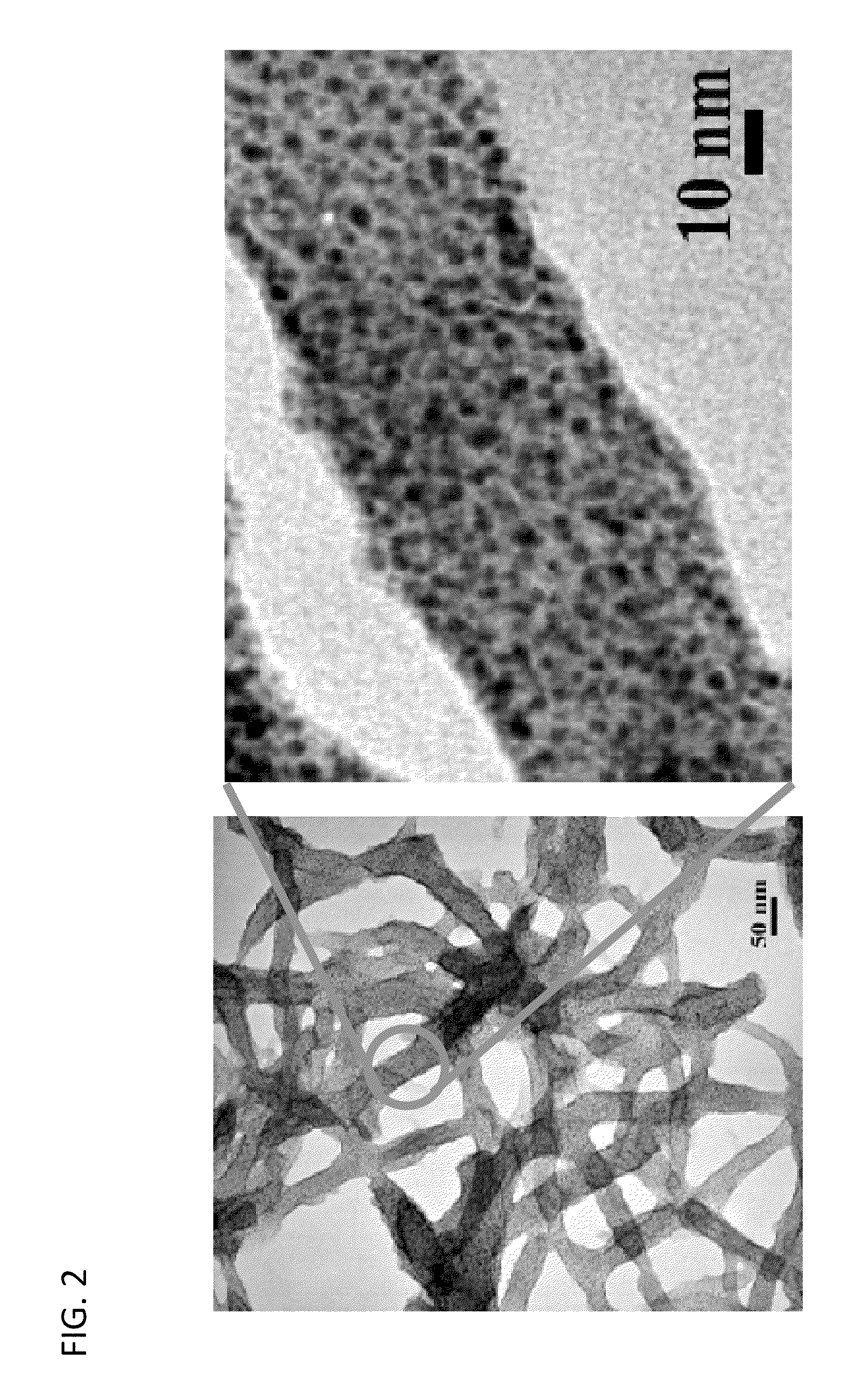

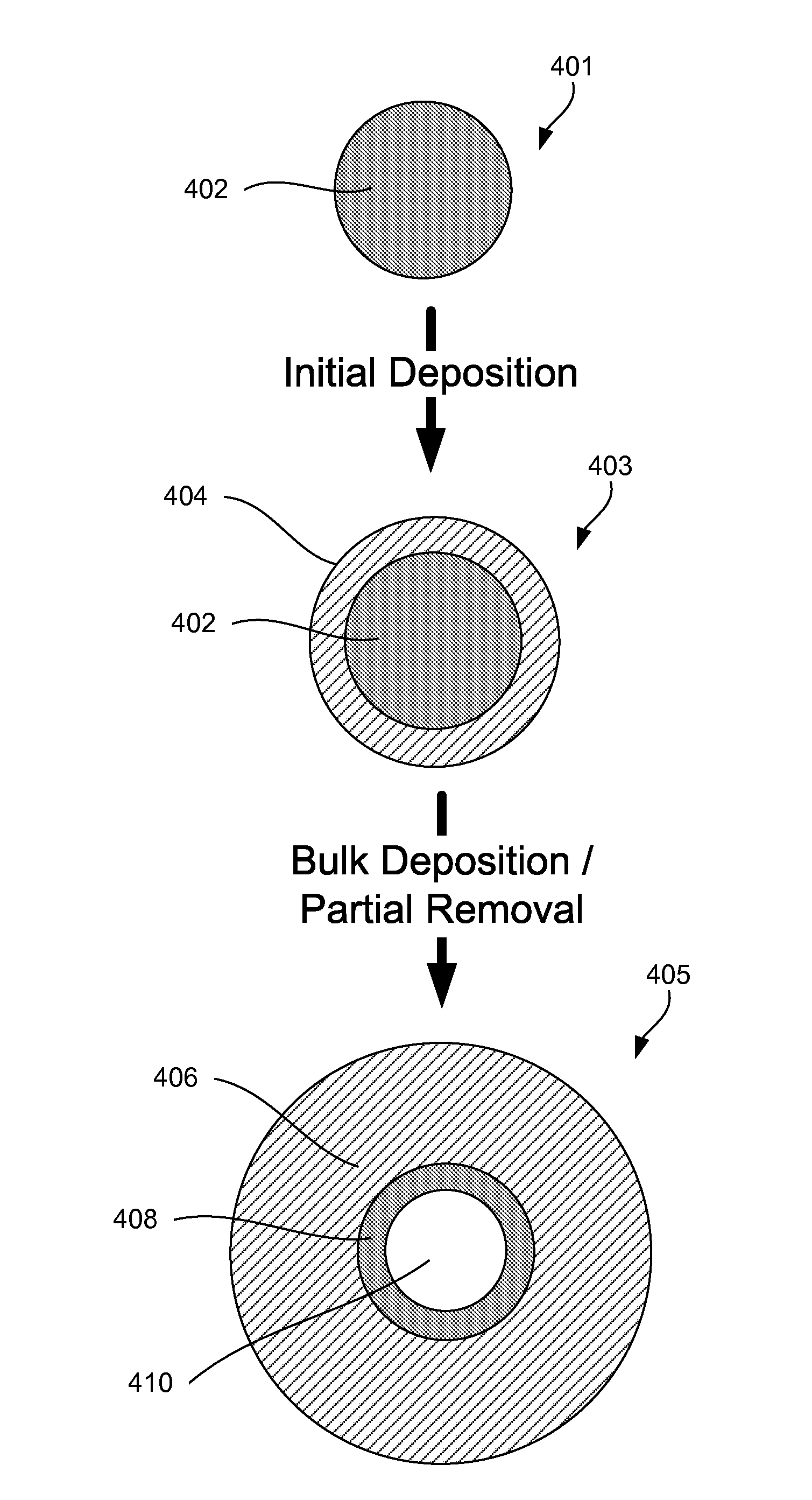

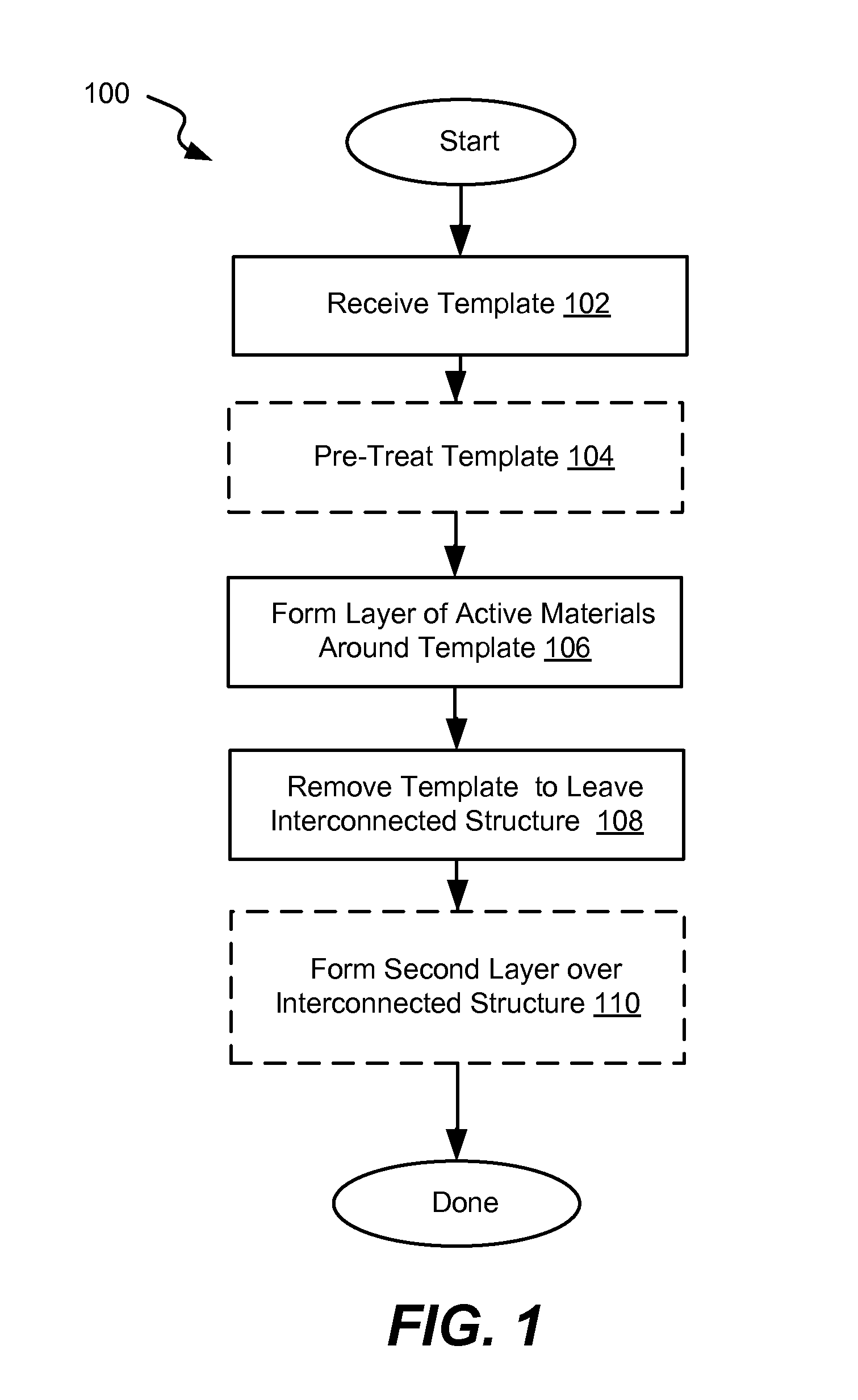

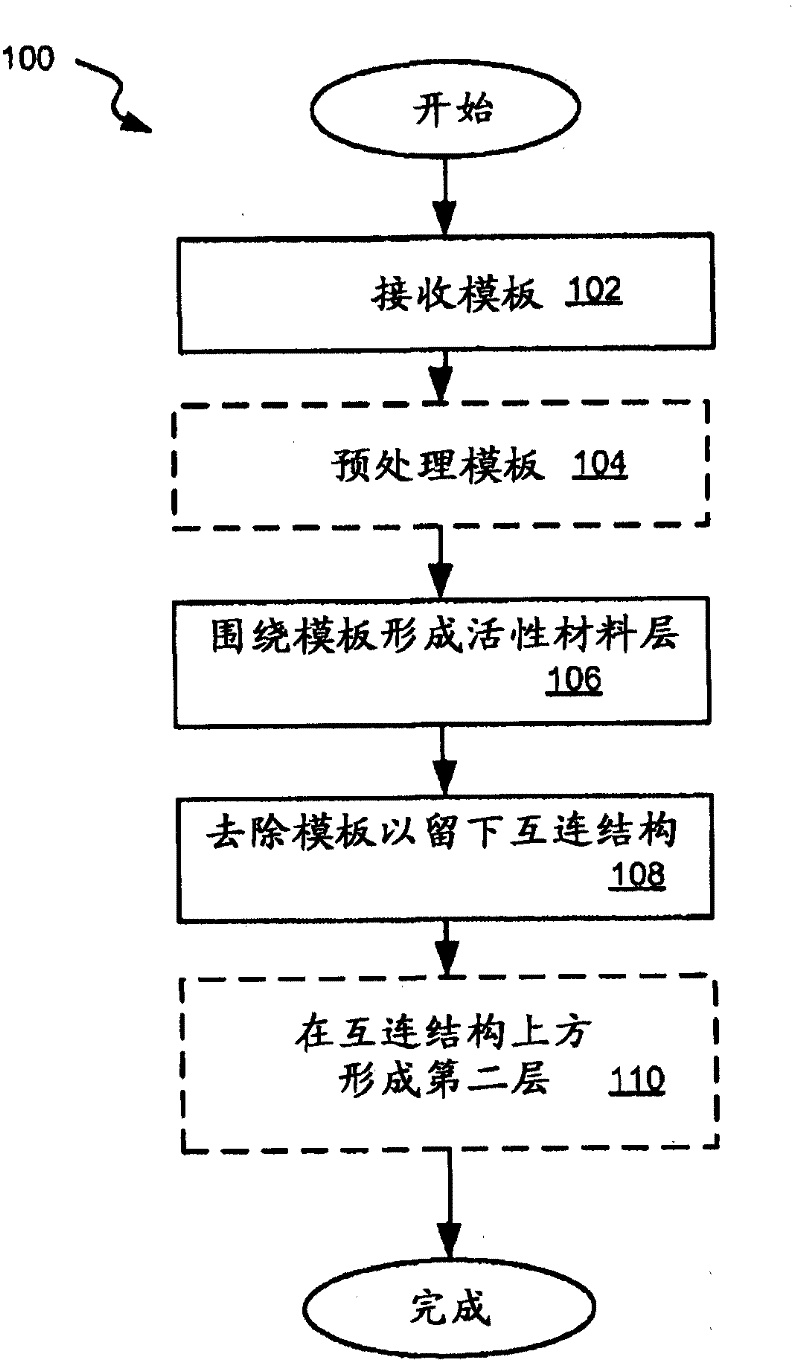

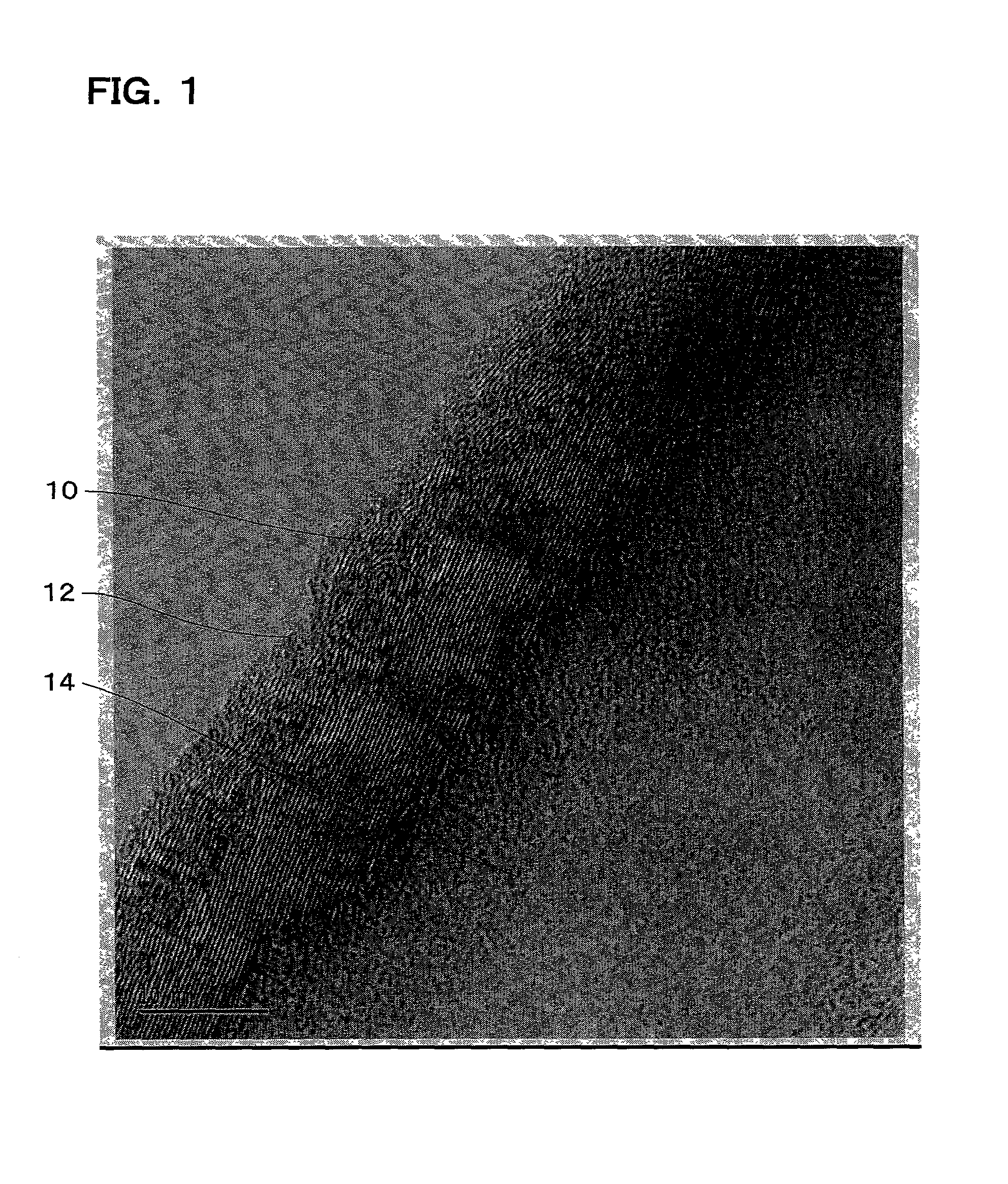

Interconnected hollow nanostructures containing high capacity active materials for use in rechargeable batteries

ActiveUS20160190600A1Reduce riskLarge capacityMaterial nanotechnologyNanostructure manufactureManufacturing technologyElectrochemistry

Provided are electrode layers for use in rechargeable batteries, such as lithium ion batteries, and related fabrication techniques. These electrode layers have interconnected hollow nanostructures that contain high capacity electrochemically active materials, such as silicon, tin, and germanium. In certain embodiments, a fabrication technique involves forming a nanoscale coating around multiple template structures and at least partially removing and / or shrinking these structures to form hollow cavities. These cavities provide space for the active materials of the nanostructures to swell into during battery cycling. This design helps to reduce the risk of pulverization and to maintain electrical contacts among the nanostructures. It also provides a very high surface area available ionic communication with the electrolyte. The nanostructures have nanoscale shells but may be substantially larger in other dimensions. Nanostructures can be interconnected during forming the nanoscale coating, when the coating formed around two nearby template structures overlap.

Owner:AMPRIUS TECH INC

A kind of preparation method of stretchable linear supercapacitor and lithium ion battery

ActiveCN104392845BReduce weightReduce volumeMicroscopic fiber electrodesHybrid capacitor electrodesCarbon nanotubeLithium-ion battery

The invention belongs to the technical field of micro energy storage devices, in particular to a stretchable linear supercapacitor, a lithium ion battery and a preparation method thereof. The present invention first prepares a spring-like oriented carbon nanotube fiber, which can be stretched over 300% by twisting to form a helical shape, and then uses this fiber as an electrode to construct a stretchable supercapacitor; this fiber can be further combined with Lithium manganate and lithium titanate nanoparticles are combined to form composite fibers, which serve as positive and negative electrodes, respectively, to construct a stretchable lithium-ion battery. Compared with other micro-devices, the linear stretchable supercapacitor and lithium-ion battery obtained by the present invention have a brand-new structure, and can realize stretchability without an elastic substrate, which reduces the weight and volume of the device, thereby improving the performance of the device. The specific capacity and energy density are important innovations in the field of micro-devices; at the same time, the device has good flexibility and is easy to prepare and integrate, so it has good application prospects.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Fiber electrode and fiber cell, and method for producing same, facility for producing fiber electrode and fiber cell

InactiveCN102473903AEfficient manufacturingIncrease surface areaMicroscopic fiber electrodesHybrid capacitor electrodesFiber bundleSingle fibre

Disclosed is a method for efficiently producing a plurality of fiber electrodes simultaneously from a plurality of fibers, which takes advantage of the advantages that fiber electrodes conventionally have. The method for producing fiber electrodes has steps (2,2a) for opening a bundle of fibrous material, steps (3,4,5) for obtaining a fiber cathode or a fiber anode by means of forming a cathode active material coat layer or an anode active material coat layer on each monofilament obtained by means of opening, and steps (6,6a) for forming a separator coat layer on the abovementioned fiber cathode or fiber anode.

Owner:KAWASAKI HEAVY IND LTD +1

Counter electrode for a photoelectric conversion element and photoelectric conversion element

InactiveUS20090272431A1Enhanced electron emission capabilityImprove conductivityMaterial nanotechnologyMicroscopic fiber electrodesCarbon nanotubeEngineering

A photoelectric conversion element including: (1) a window electrode having a transparent substrate and a semiconductor layer provided on a surface of the transparent substrate, a sensitizing dye being adsorbed on the semiconductor layer; (2) a counter electrode having a substrate and a conductive film, provided on a surface of the substrate, that is arranged so as to face the semiconductor layer of the window electrode, and wherein the counter electrode has carbon nanotubes provided on the substrate surface via the conductive film; and (3) an electrolyte layer disposed at least in a portion between the window electrode and the counter electrode.

Owner:THE FUJIKURA CABLE WORKS LTD

Interconnected hollow nanostructures containing high capacity active materials for use in rechargeable batteries

ActiveCN102449815AMaterial nanotechnologyNanostructure manufactureManufacturing technologyNanostructure

Provided are electrode layers for use in rechargeable batteries, such as lithium ion batteries, and related fabrication techniques. These electrode layers have interconnected hollow nanostructures that contain high capacity electrochemically active materials, (such as silicon, tin, and germanium). In certain embodiments, a fabrication technique involves forming a nanoscale coating around multiple template structures and at least partially removing and / or shrinking these structures to form hollow cavities. These cavities provide space for the active materials of the nanostructures to swell into during battery cycling. This design helps to reduce the risk of pulverization and to maintain electrical contacts among the nanostructures. It also provides a very high surface area available ionic communication with the electrolyte.; The nanostructures have nanoscale shells but may be substantially larger in other dimensions. Nanostructures can be interconnected during forming the nanoscale coating, when the coating formed around two nearby template structures overlap.

Owner:AMPRIUS INC

Li-ion battery and battery active components on metal wire

InactiveUS8993172B2Improve performanceProlong lifeElectrode thermal treatmentFinal product manufactureElectrical batteryIon exchange

A battery on a conductive metal wire and components of a battery on a conductive metal wire of circular cross section diameter of 5-500 micrometers and methods of making the battery and battery components are disclosed. In one embodiment, the battery features a porous anode or cathode layer which assist with ion exchange in batteries. Methods of forming the porous anode or cathode layer include deposition of an inert gas or hydrogen enriched carbon or silicon layer on a heated metal wire followed by annealing of the inert gas or hydrogen enriched carbon silicon layer. Energy storage devices having bundles of batteries on wires are also disclosed as are other energy storage devices.

Owner:KALPTREE ENERGY

Surface-mediated lithium ion-exchanging energy storage device

ActiveUS8889298B2Easy to handleShort charging timeMaterial nanotechnologyHybrid capacitor electrolytesChemical physicsElectrical battery

A surface-mediated, lithium ion-exchanging energy storage device comprising: (a) A positive electrode (cathode) comprising a cathode active material that is not a functional material (bearing no functional group reactive with lithium), but having a surface area to capture or store lithium thereon; (b) A negative electrode (anode) comprising an anode active material having a surface area to capture or store lithium thereon; (c) A porous separator disposed between the two electrodes; and (d) A lithium-containing electrolyte in physical contact with the two electrodes, wherein the anode active material and / or the cathode active material has a specific surface area of no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; wherein at least one of the two electrodes contains therein a lithium source prior to a first charge or a first discharge cycle of the energy storage device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

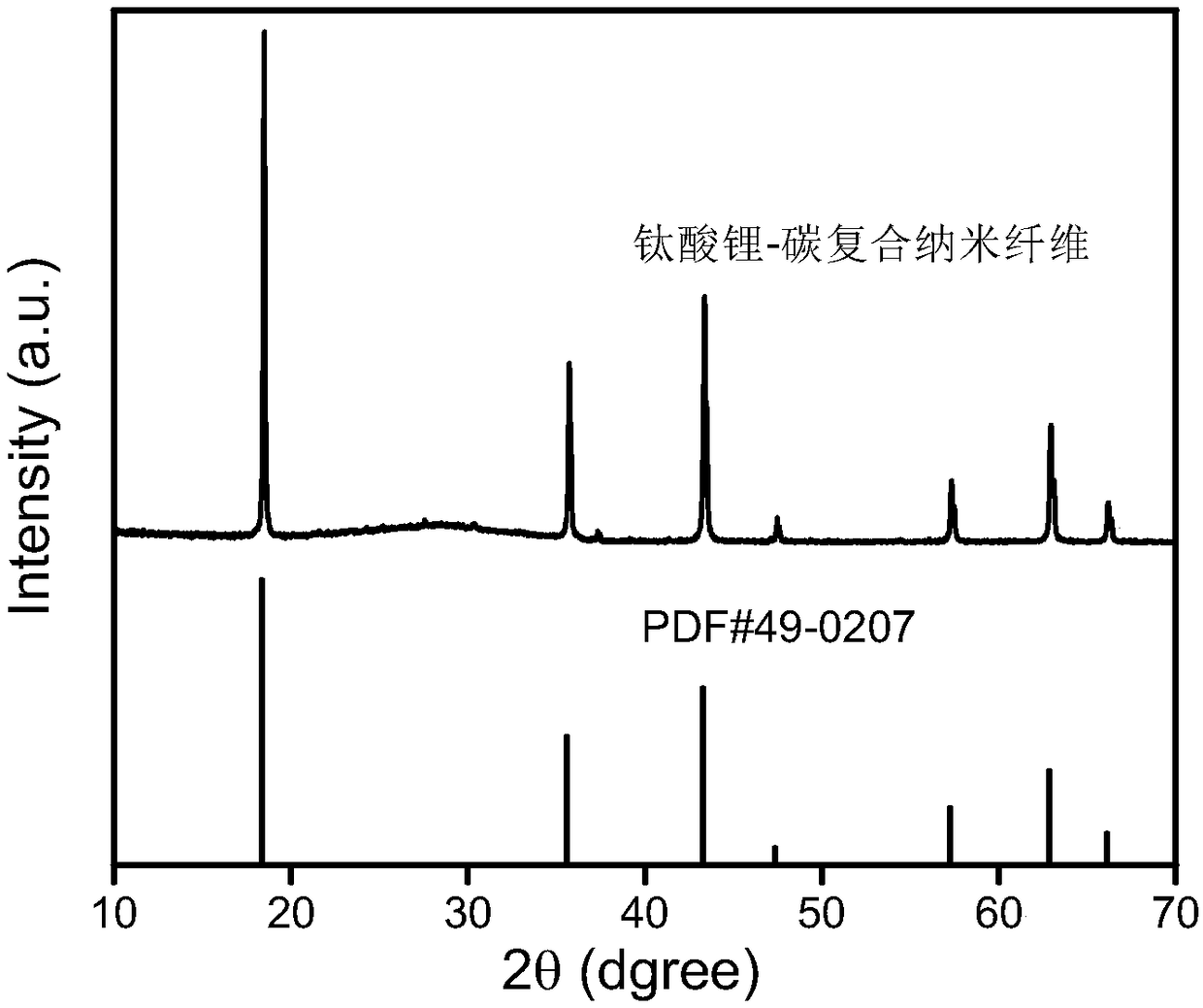

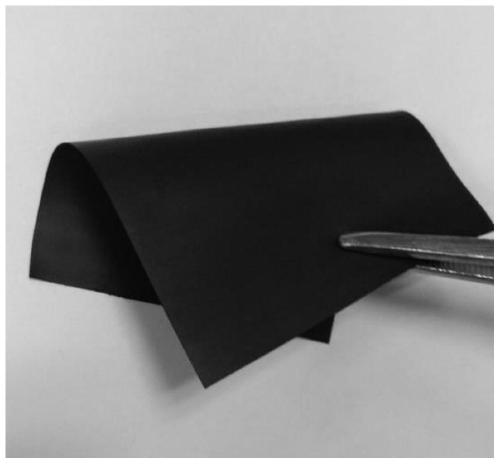

Lithium titanate-carbon nanometer fiber flexible non-woven fabric, preparation method and applications thereof

InactiveCN108183222AIncrease contentAvoid gatheringMicroscopic fiber electrodesSecondary cellsCarbon nanofiberSpecific mass

The invention discloses a lithium titanate-carbon nanometer fiber flexible non-woven fabric, a preparation method and applications thereof. The preparation method comprises: dissolving a lithium source in a titanium source dispersion liquid, carrying out a hydrothermal reaction to obtain lithium titanate precursor nanoparticles with uniform size, dispersing the lithium titanate precursor nanoparticles in polyacrylonitrile / dimethylformamide, and carrying out electrospinning and high-temperature calcination to finally obtain the lithium titanate-carbon nanometer fiber flexible non-woven fabric.According to the present invention, with the method, the proportion of lithium titanate in the composite material can be substantially increased so as to improve the specific mass capacity of the whole lithium titanate battery; and the inexpensive raw materials are used, and the particles are directly and simply dispersed in the sol to be spin, such that the spinning method is suitable for industrial mass production.

Owner:NANJING UNIV

Printed three-dimensional (3D) functional part and method of making

ActiveUS10462907B2Semiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringStructural material

A printed 3D functional part includes a 3D structure comprising a structural material, and at least one functional electronic device is at least partially embedded in the 3D structure. The functional electronic device has a base secured against an interior surface of the 3D structure. One or more conductive filaments are at least partially embedded in the 3D structure and electrically connected to the at least one functional electronic device.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

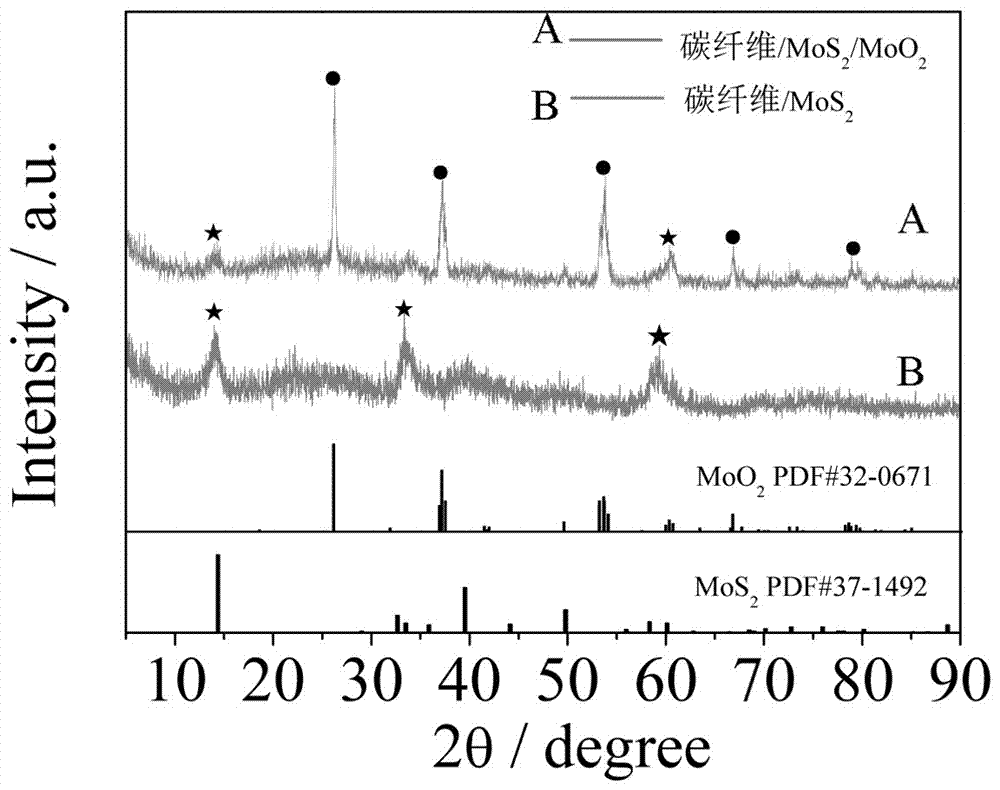

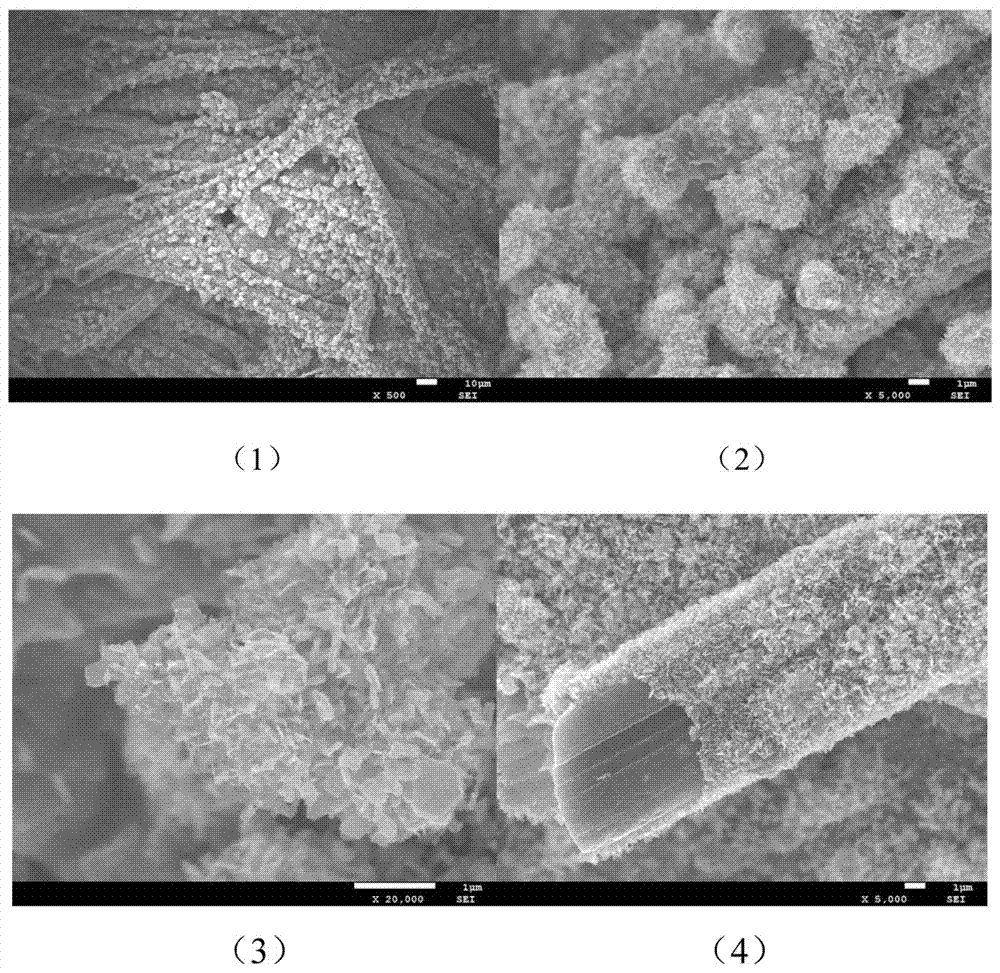

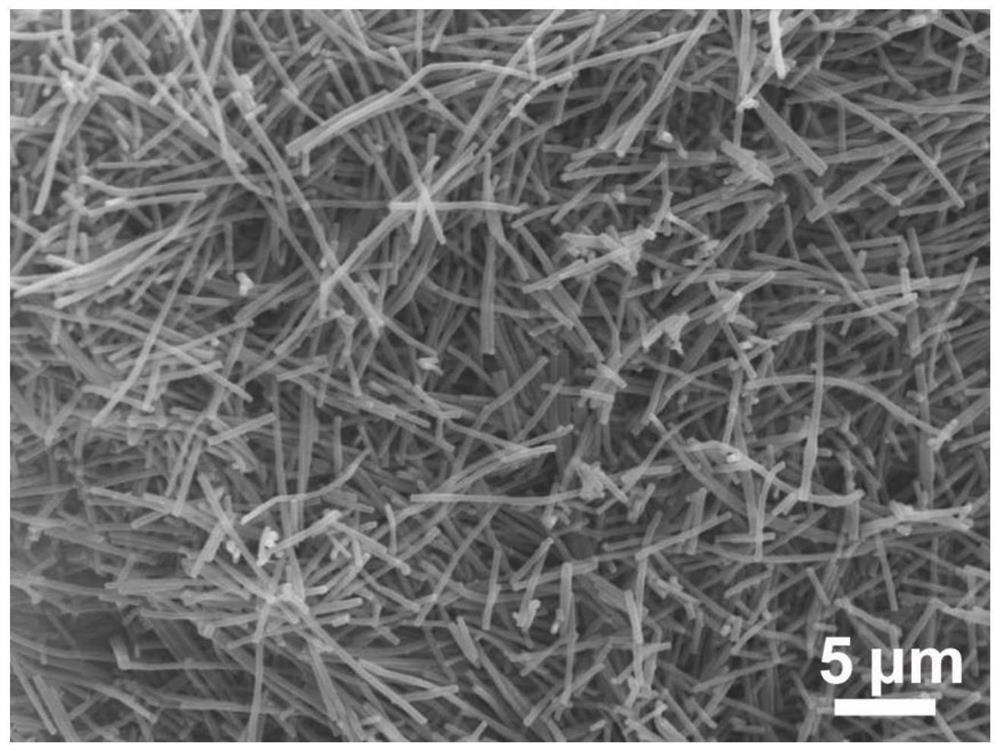

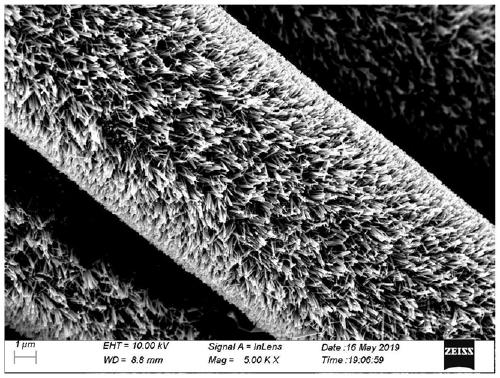

Wire structure carbon fiber / MoS2 / MoO2 flexible electrode material and preparation method thereof

ActiveCN107221635AImprove conductivityImprove cycle stabilityMicroscopic fiber electrodesElectrode thermal treatmentFiberCarbon fibers

The present invention discloses a wire structure carbon fiber / MoS2 / MoO2 flexible electrode material and a preparation method thereof, and belongs to the field of electrochemistry and new energy materials. The inner layer of the electrode material is carbon fiber, the intermediate layer is MoS2, the outermost layer is MoO2, and the electrode material is a three-layer-covered wire structure. The inner layer carbon fiber is used as an electron and ion transmission path, and the intermediate layer MoS2 provides high capacity, and the outer layer MoO2 coating can not only improve the capacity of the material, but also improves the conductivity of the material. The wire structure material is used as a negative electrode material of a lithium ion battery. Wet paper towel is treated by removing impurity, and calcined at high temperature, and the wet paper towel is carbonized at high temperature to form the flexible carbon fiber, and then the carbon fiber / MoS2 composite is formed by hydrothermal reaction with sodium molybdate and thiourea. The composite material is further calcined in oxygen at low temperature in oxygen to form the wire structure carbon fiber / MoS2 / MoO2 flexible electrode material. The three-layer-covered wire structure significantly improves the specific capacity and cycle stability of the material.

Owner:CHINA THREE GORGES UNIV

Flexible electrode fibrous membrane, flexible electrode plate, and manufacturing method and application thereof

InactiveCN111416101AReduce capacityImprove conductivityElectroconductive/antistatic filament manufactureFuel and secondary cellsFiberAdhesive

The invention provides a flexible electrode fibrous membrane, a flexible electrode plate and a manufacturing method and application thereof, and the method comprises the following steps: adding a volatile solvent into a mixed material containing a thermoplastic binder, and performing stirring to form a paste; carrying out fibration treatment on the paste under the action of high shear, and then spraying the paste to form filaments; drawing the filaments obtained by spraying, and then spreading the filaments into a fiber net; and rolling and molding the fiber net to obtain the flexible electrode fiber membrane. A three-dimensional network system is arranged among the active substance, the conductive agent and the thermoplastic adhesive in the flexible electrode fiber membrane to replace a point contact system in the traditional technology. While the conductivity of the whole flexible electrode fiber membrane is enhanced, the flexible electrode fiber membrane is endowed with strong physical strength and larger elastic modulus.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

Composite anode active material, anode and lithium battery each including the composite anode active material, method of preparing the composite anode active material

ActiveUS9564631B2Increase capacityImprove featuresMicroscopic fiber electrodesElectrode thermal treatmentFiberCarbon fibers

A composite anode active material, an anode including the composite anode active material, a lithium battery including the anode, and a method of preparing the composite anode active material. The composite anode active material includes: a shell including a hollow carbon fiber; and a core disposed in a hollow of the hollow carbon fiber, wherein the core includes a first metal nanostructure and a conducting agent.

Owner:SAMSUNG ELECTRONICS CO LTD

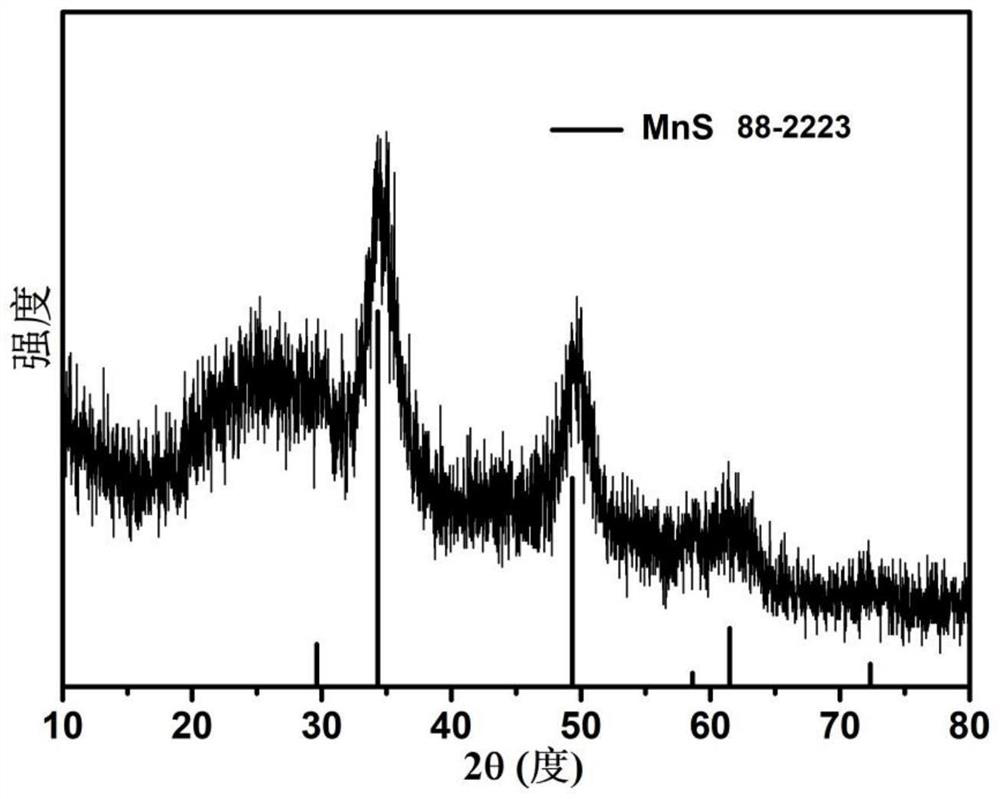

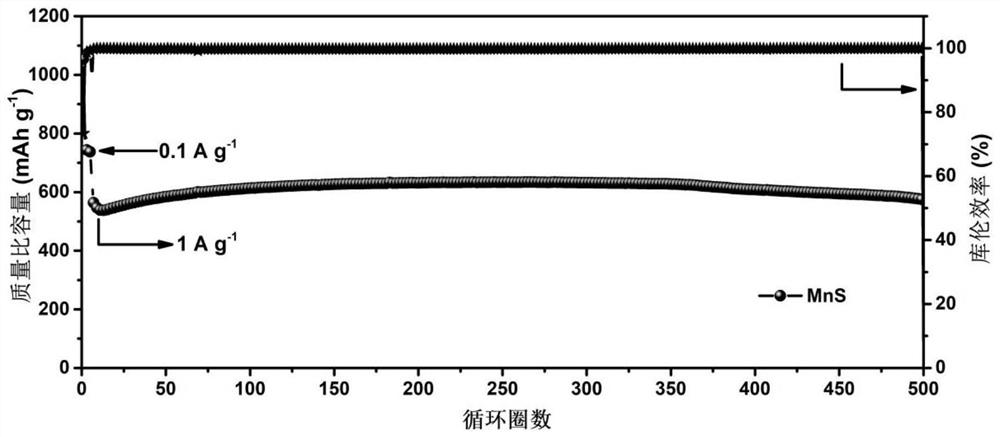

Preparation method and application of transition metal sulfide/nitrogen-sulfur co-doped carbon composite fiber electrode material

ActiveCN112599777AThe synthesis process is easy to controlImprove applicabilityMaterial nanotechnologyMicroscopic fiber electrodesFiberSpinning

The invention relates to a preparation method and application of a transition metal sulfide / nitrogen-sulfur co-doped carbon composite fiber electrode material. The transition metal sulfide / nitrogen-sulfur co-doped carbon composite fiber is prepared by utilizing the bonding effect of acetylacetone metal salt and sulfur in N, N-dimethylformamide, adopting an electrostatic spinning technology to prepare polymer fiber and carrying out air curing and carbonization in an inert atmosphere. The transition metal sulfide nanoparticles in the composite material are uniformly embedded in the nitrogen-sulfur co-doped carbon composite fiber. The preparation method disclosed by the invention is simple and high in applicability, and the obtained transition metal sulfide / nitrogen-sulfur co-doped carbon composite fiber shows good electrochemical performance when being used as a lithium ion battery negative electrode material, and has a very good application prospect.

Owner:HEBEI UNIV OF TECH

Vapor grown carbon fiber and electrode material for battery

A carbon fiber has a coaxial stacking morphology of truncated conical tubular graphene layers, wherein each of the graphene layers includes a hexagonal carbon layer and has a large ring end at one end and a small ring end at the other end in the axial direction. When the carbon fiber is subjected to a heat treatment in a non-oxidizing atmosphere, the large ring ends of each two of the hexagonal carbon layers are linked by layer link sections in at least one of groups of the hexagonal carbon layers arranged in an axial direction, and an outer surface is closed to have a multi-semiring structure in cross section. When the carbon fiber is then subjected to a heat treatment in an oxidizing atmosphere, the layer link sections are released, whereby the edges of the hexagonal carbon layers are exposed at the large ring ends in a regularly arranged manner.

Owner:GSI CREOS CORP

Carbon fiber-zinc oxide nanorod composite material as well as preparation method and application thereof

InactiveCN111293304AUniform growthSimple processMaterial nanotechnologyMicroscopic fiber electrodesFiberCarbon fibers

The invention relates to the technical field of lithium ion battery negative electrode materials, and particularly relates to a carbon fiber-zinc oxide nanorod composite material as well as a preparation method and application thereof. According to the invention, a magnetron sputtering and hydrothermal combined method is adopted, and zinc oxide nanorods can uniformly grow on a carbon cloth substrate under the condition that a template does not need to assist the forming growth of the nanorods. The obtained zinc oxide nanorod is of a hexagonal wurtzite structure, the length is 1-3 microns, andthe size is uniform; and the carbon fiber-zinc oxide nanorod composite material can be directly used as a current collector of a negative electrode material, the zinc oxide nanorod directly grows on the carbon fiber and is in good contact with a carbon fiber substrate, an additional binder and a conductive additive are not needed, and the technological process of battery preparation is simplified.The prepared composite material shows relatively high specific capacity and cycling stability when being used as a lithium ion battery negative electrode material.

Owner:HUBEI UNIV

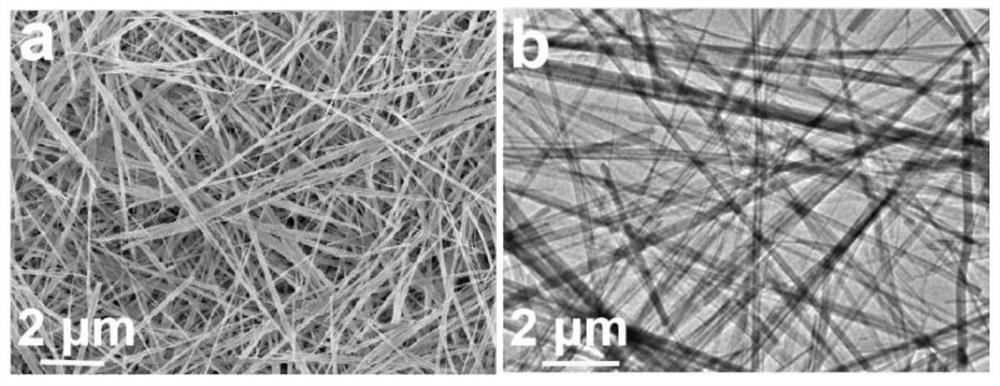

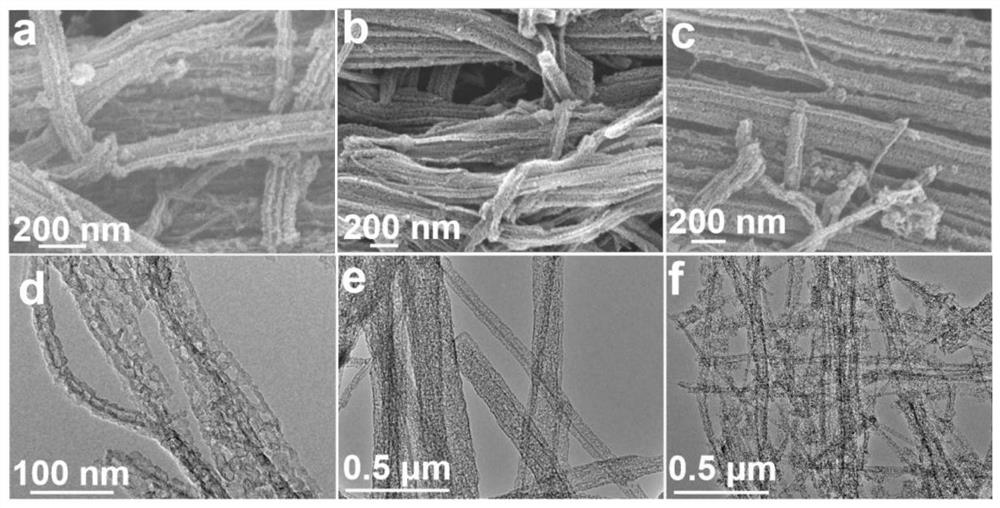

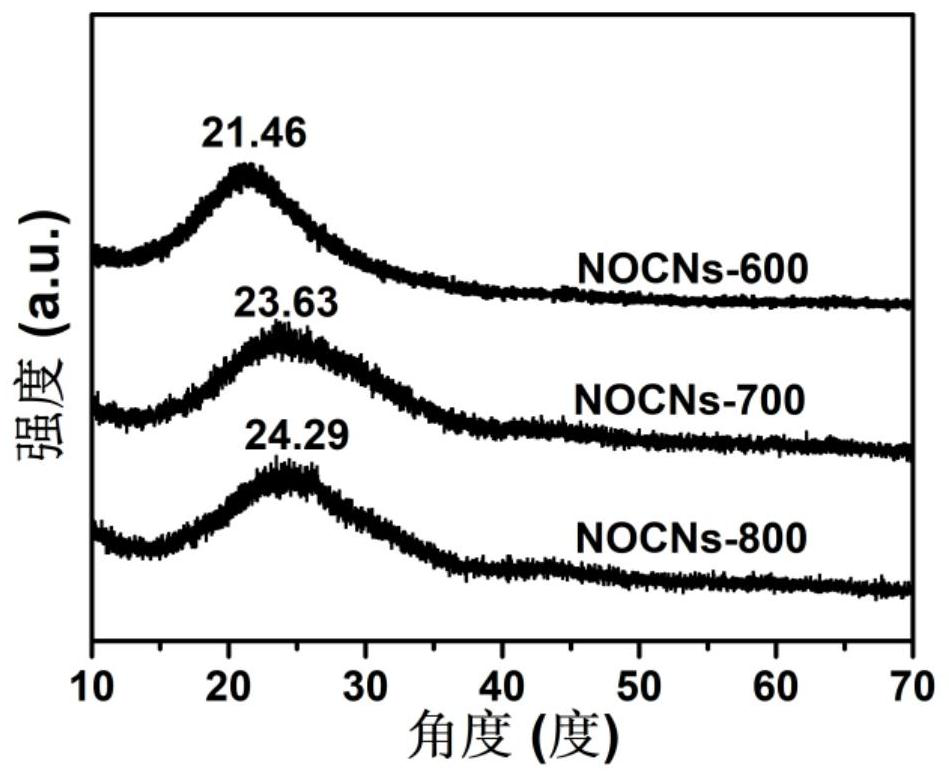

Preparation method of nitrogen and oxygen co-doped carbon nanofiber material, product and application

ActiveCN112582619ASimple manufacturing methodStable structureMaterial nanotechnologyMicroscopic fiber electrodesPorous carbonTube furnace

The invention discloses a preparation method of a nitrogen and oxygen co-doped carbon nanofiber material, and relates to the technical field of nano materials. The preparation method comprises the following steps of (1) preparing a precursor; and (2) putting the precursor into a tubular furnace filled with nitrogen, respectively calcining at 600-800 DEG C for 2 hours, naturally cooling to room temperature to obtain MnO nanocrystals embedded with nitrogen-doped porous carbon, finally etching the sample with a 3mol / L hydrochloric acid solution for 3 hours, and washing to obtain the nitrogen-oxygen co-doped carbon nanofiber material. The invention also provides a product prepared by the preparation method and an application thereof. The beneficial effects of the present invention are that thepreparation process is simple and efficient, is safe and easy to implement and is short in synthesis period and is expected to be popularized and industrially produced, and the prepared nanofiber material has a loose and porous composite structure.

Owner:ANHUI UNIVERSITY

Preparation method of nitrogen-doped porous carbon coated silicon composite nanofibers

ActiveCN112382759ASimple operating conditionsEfficient operating conditionsMicroscopic fiber electrodesNegative electrodesSpinningPolypyrrole

The invention belongs to the field of lithium ion batteries, and discloses a preparation method of nitrogen-doped porous carbon coated silicon composite nanofibers. The method comprises the followingsteps: (1) electrostatic spinning: mixing a polymer binder, nano silicon powder and a solvent to obtain a spinning solution, and carrying out electrostatic spinning to obtain a precursor nanofiber membrane; (2) in-situ polymerization coating of polypyrrole: adsorbing elemental iodine on the surface of the precursor nanofiber membrane by a gas phase method, then adsorbing a pyrrole monomer, and carrying out a polymerization reaction to obtain composite nanofibers; (3) heat treatment: calcining the composite nanofibers in a protective atmosphere. According to the preparation method, polypyrrolecoating is more uniform in the gas-phase adsorption in-situ polymerization polypyrrole coating process, uniform nitrogen-doped porous carbon coated silicon particle composite nanofibers are obtained after heat treatment, and the method is simple, convenient and reliable in production process, cheap and easily available in raw materials, low in equipment requirement and easy to realize large-scaleproduction.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com