A kind of preparation method of stretchable linear supercapacitor and lithium ion battery

A technology for supercapacitors and lithium-ion batteries, applied in hybrid capacitor electrodes, electrolyte storage battery manufacturing, hybrid/electric double-layer capacitor manufacturing, etc., can solve specific capacity and specific energy density decline, low mechanical strength and operating temperature, increase device Problems such as mass and volume can be achieved to improve specific capacity and energy density, reduce weight and volume, and achieve the effect of wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

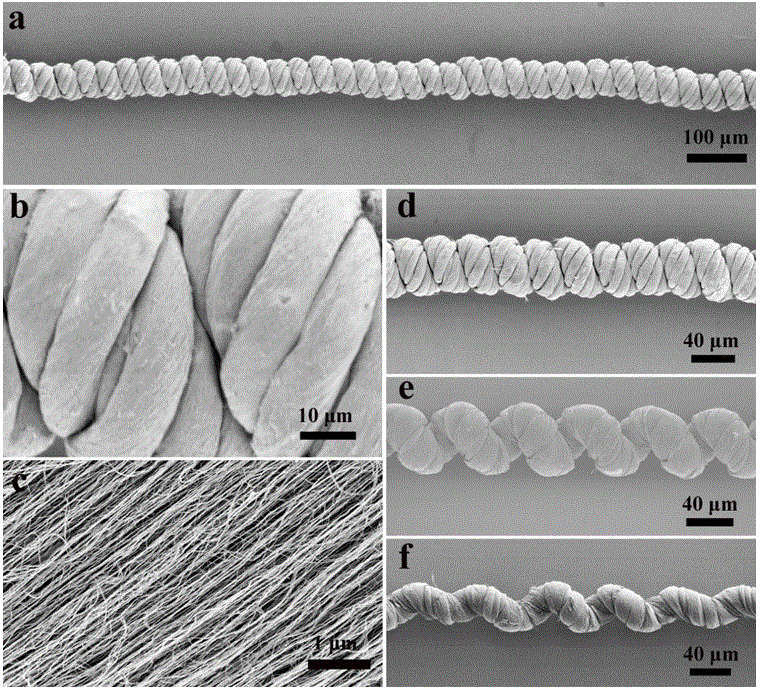

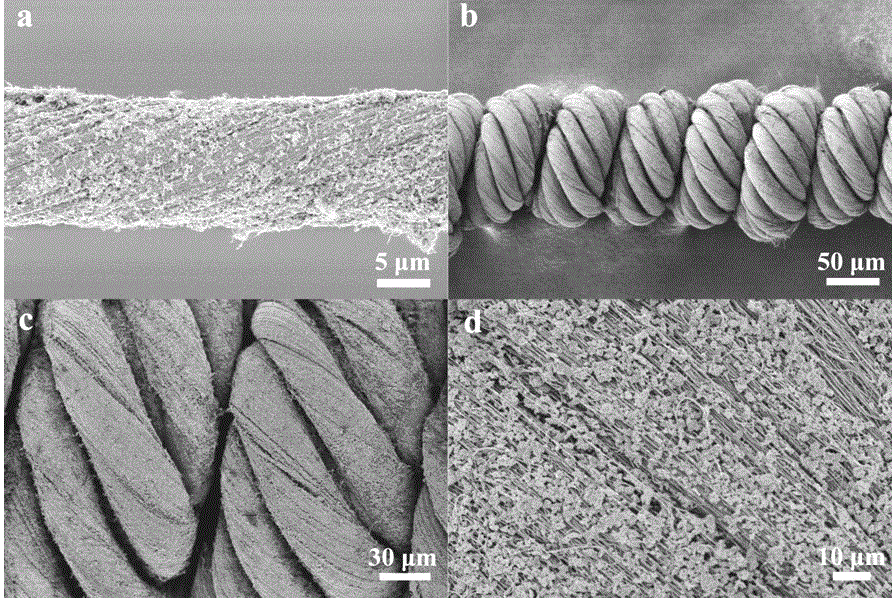

[0025] Carbon nanotubes are prepared by chemical vapor deposition. The catalyst adopts the structure form Si / SiO 2 / Al 2 o 3 / Fe composites, where Al 2 o 3 It is located in the middle of the silicon wafer and Fe, as a buffer layer, and Fe as the active component of the catalyst. They are prepared by depositing a nanometer-thick film on the silicon wafer (Si) by an electron beam evaporation coating device. Among them, SiO 2 Layer thickness 200-1200 μm, Al 2 o 3 The layer thickness is 10-50 nm, and the Fe layer thickness is 0.5-2.0 nm. Put the catalyst-coated silicon base catalyst face up, use a larger silicon dioxide support, put it into the quartz tube of the tube furnace, and be close to the temperature sensing device of the tube furnace. The flow rate of the ventilation pipeline is adjusted as follows: Argon: 300-600sccm Hydrogen: 20-100sccm; Ethylene: 60-200sccm. Connect the tubing. First turn on the argon, turn off the hydrogen and ethylene gases. Ventilate at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com