Patents

Literature

16853results about "Electrolyte accumulators manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protected active metal electrode and battery cell structures with non-aqueous interlayer architecture

ActiveUS7282295B2Avoid harmful reactionsFinal product manufactureElectrode carriers/collectorsMetal electrodesBattery cell

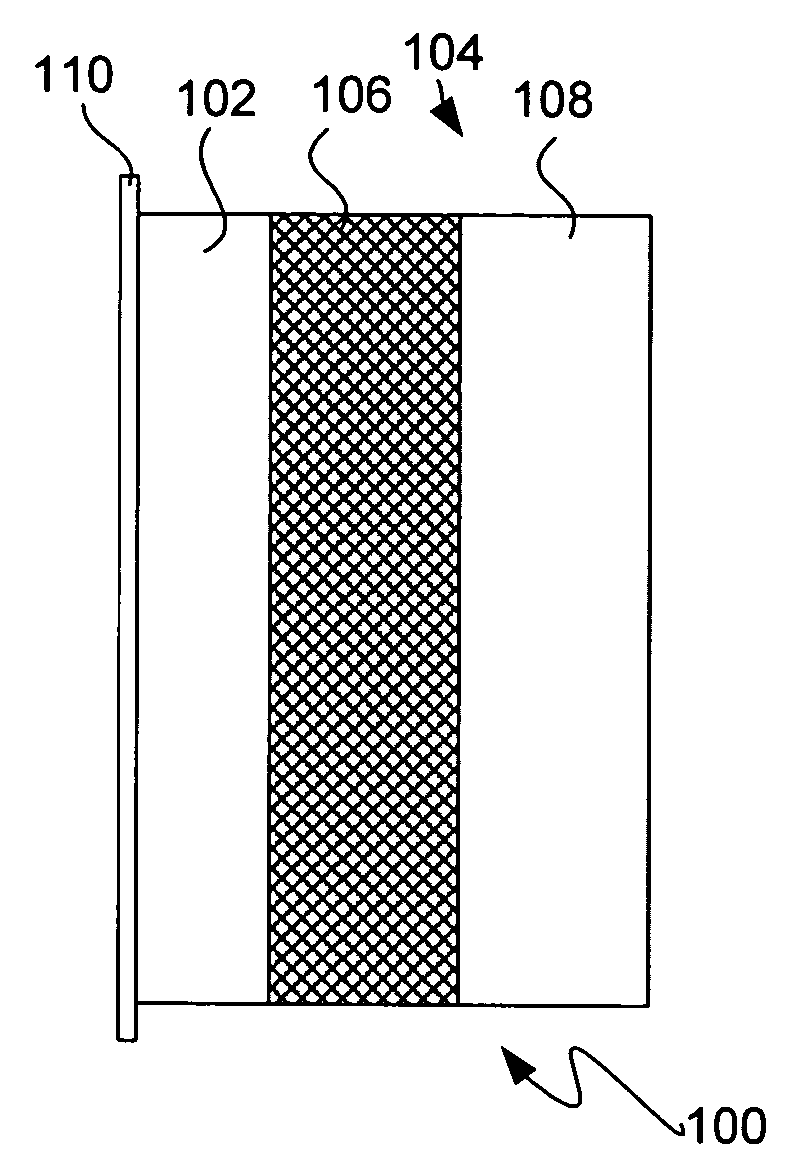

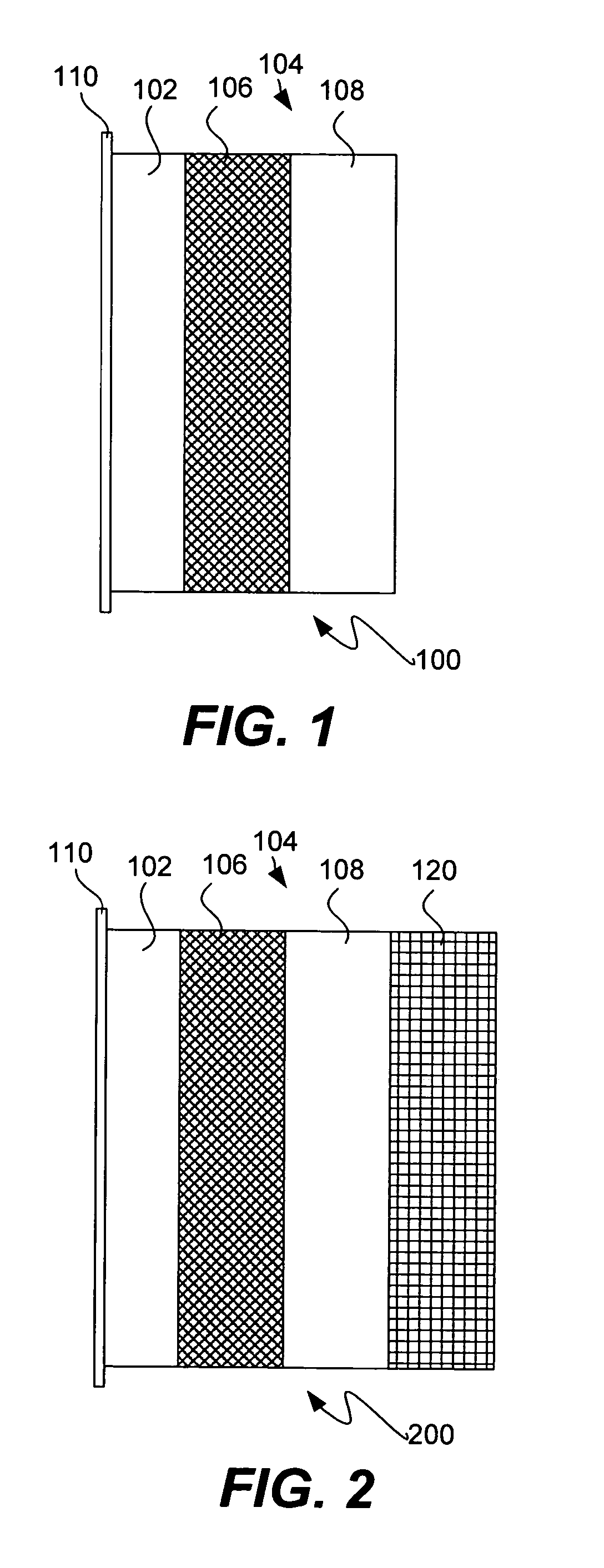

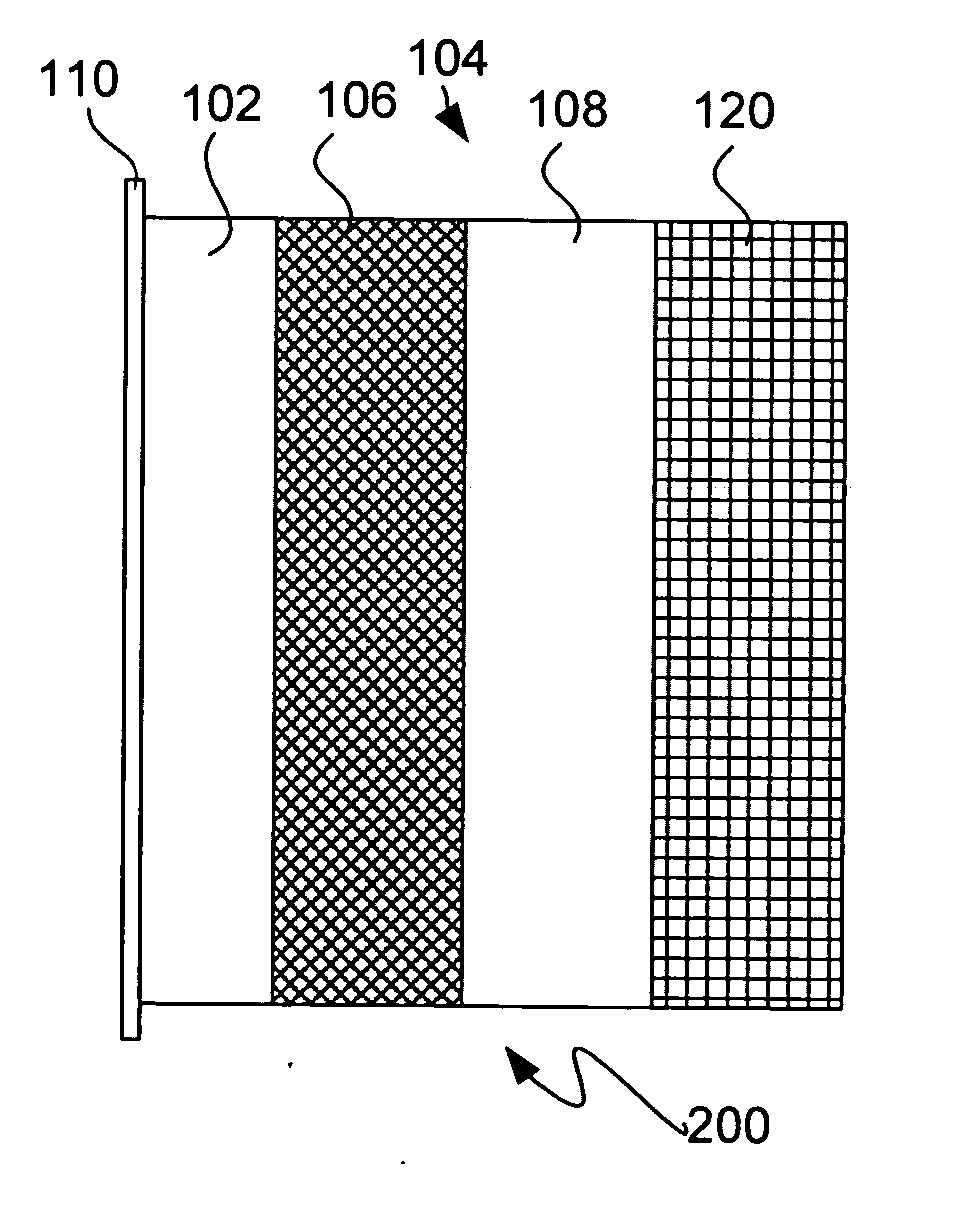

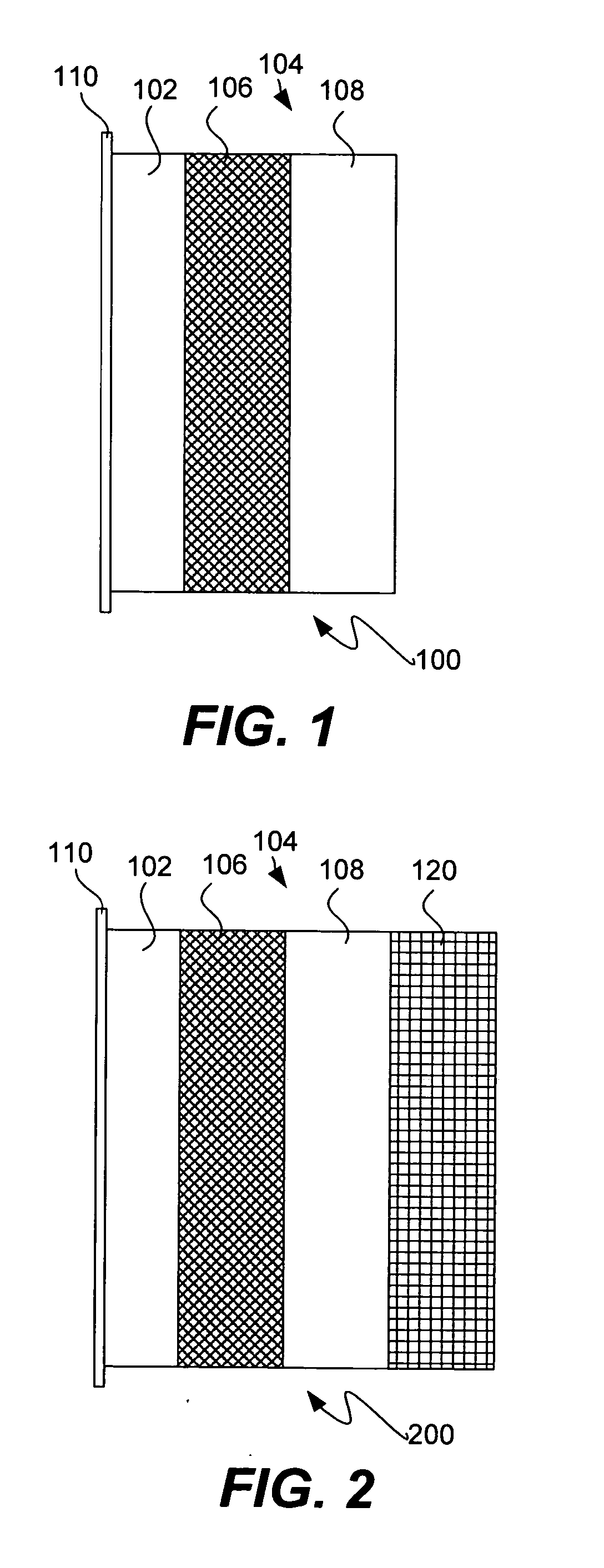

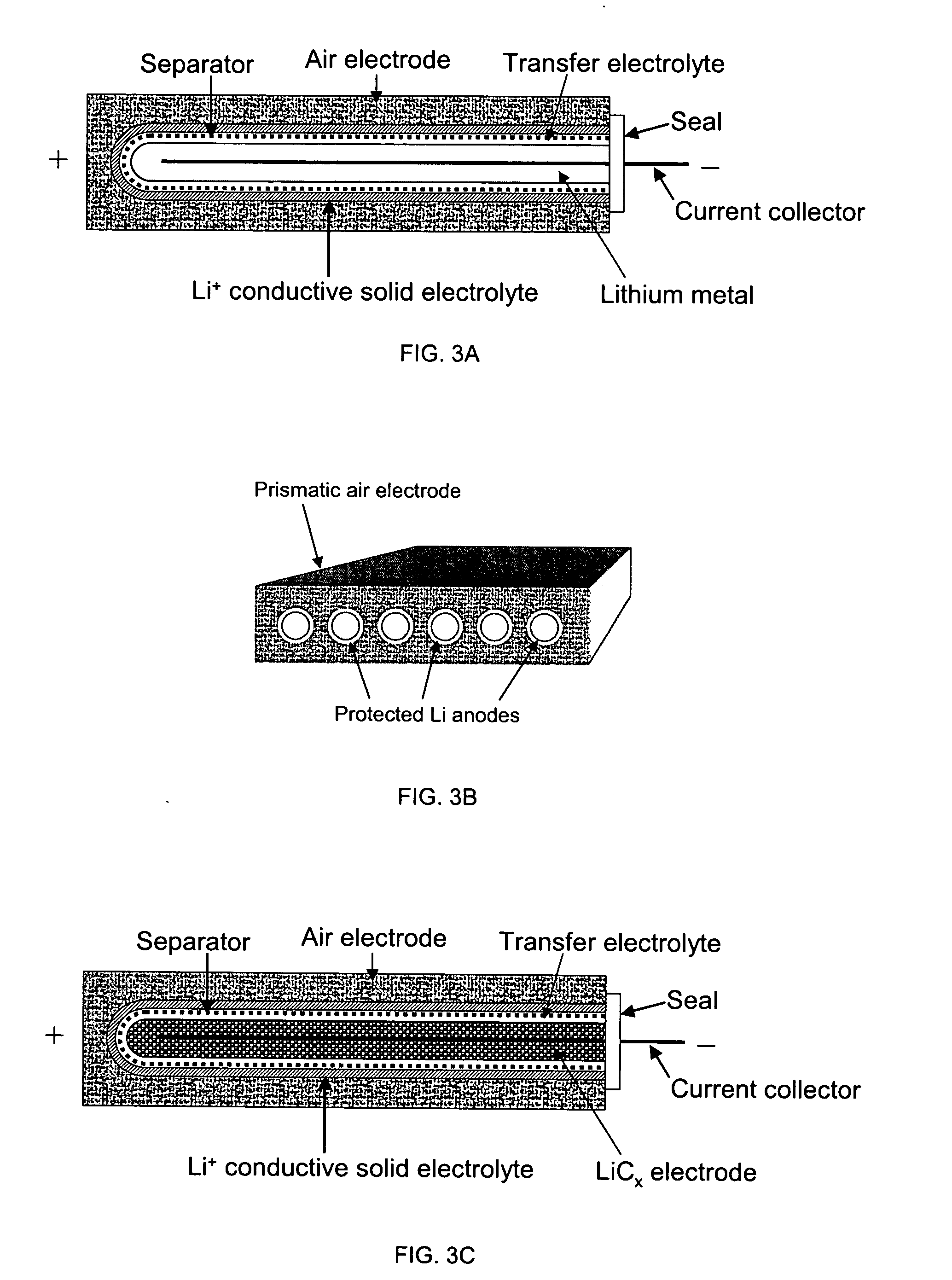

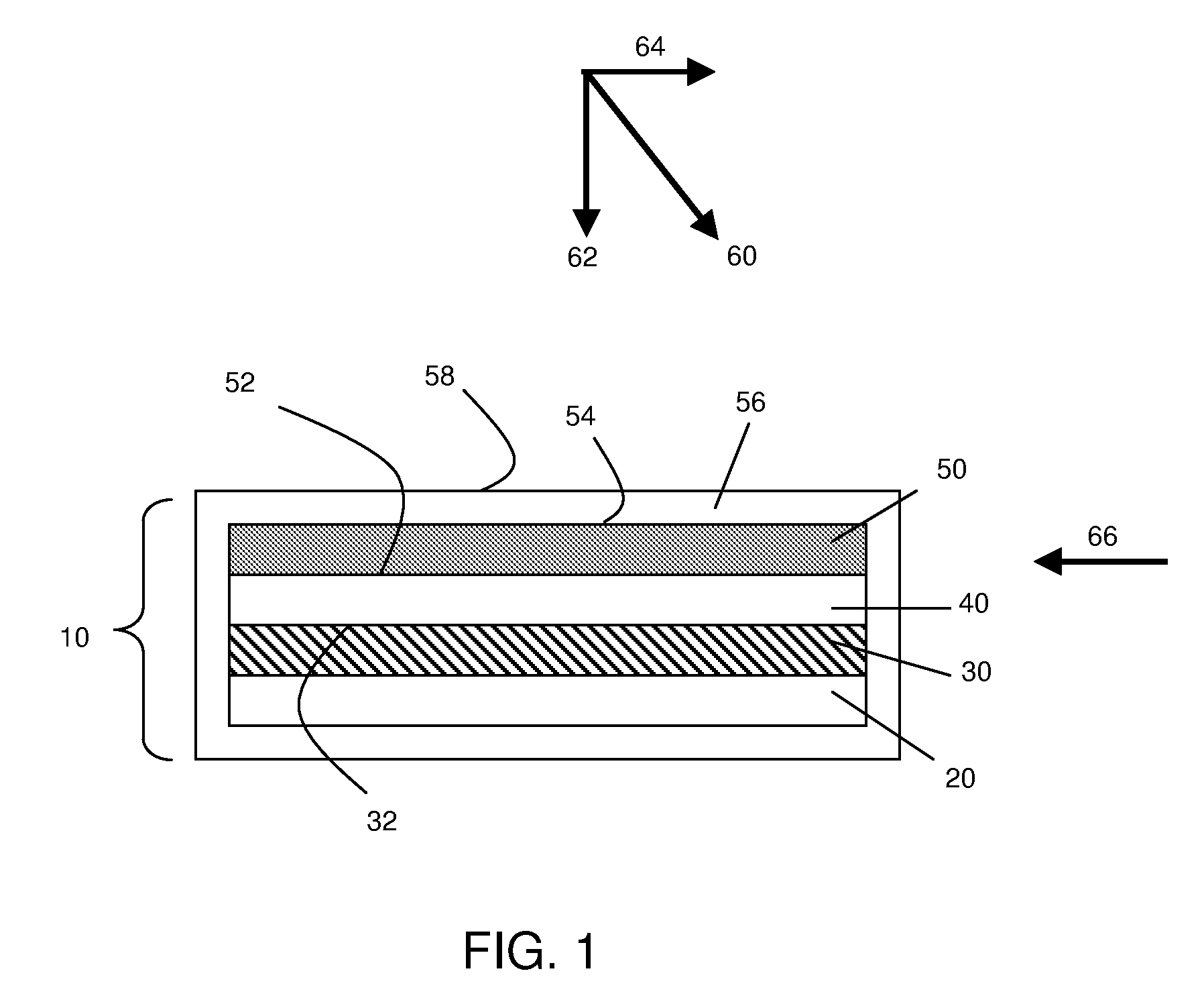

Active metal and active metal intercalation electrode structures and battery cells having ionically conductive protective architecture including an active metal (e.g., lithium) conductive impervious layer separated from the electrode (anode) by a porous separator impregnated with a non-aqueous electrolyte (anolyte). This protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the impervious layer, which may include aqueous or non-aqueous liquid electrolytes (catholytes) and / or a variety electrochemically active materials, including liquid, solid and gaseous oxidizers. Safety additives and designs that facilitate manufacture are also provided.

Owner:POLYPLUS BATTERY CO INC

Protected active metal electrode and battery cell structures with non-aqueous interlayer architecture

ActiveUS20050175894A1Avoid harmful reactionsHybrid capacitor separatorsHybrid capacitor electrolytesMetal electrodesBattery cell

Active metal and active metal intercalation electrode structures and battery cells having ionically conductive protective architecture including an active metal (e.g., lithium) conductive impervious layer separated from the electrode (anode) by a porous separator impregnated with a non-aqueous electrolyte (anolyte). This protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the impervious layer, which may include aqueous or non-aqueous liquid electrolytes (catholytes) and / or a variety electrochemically active materials, including liquid, solid and gaseous oxidizers. Safety additives and designs that facilitate manufacture are also provided.

Owner:POLYPLUS BATTERY CO INC

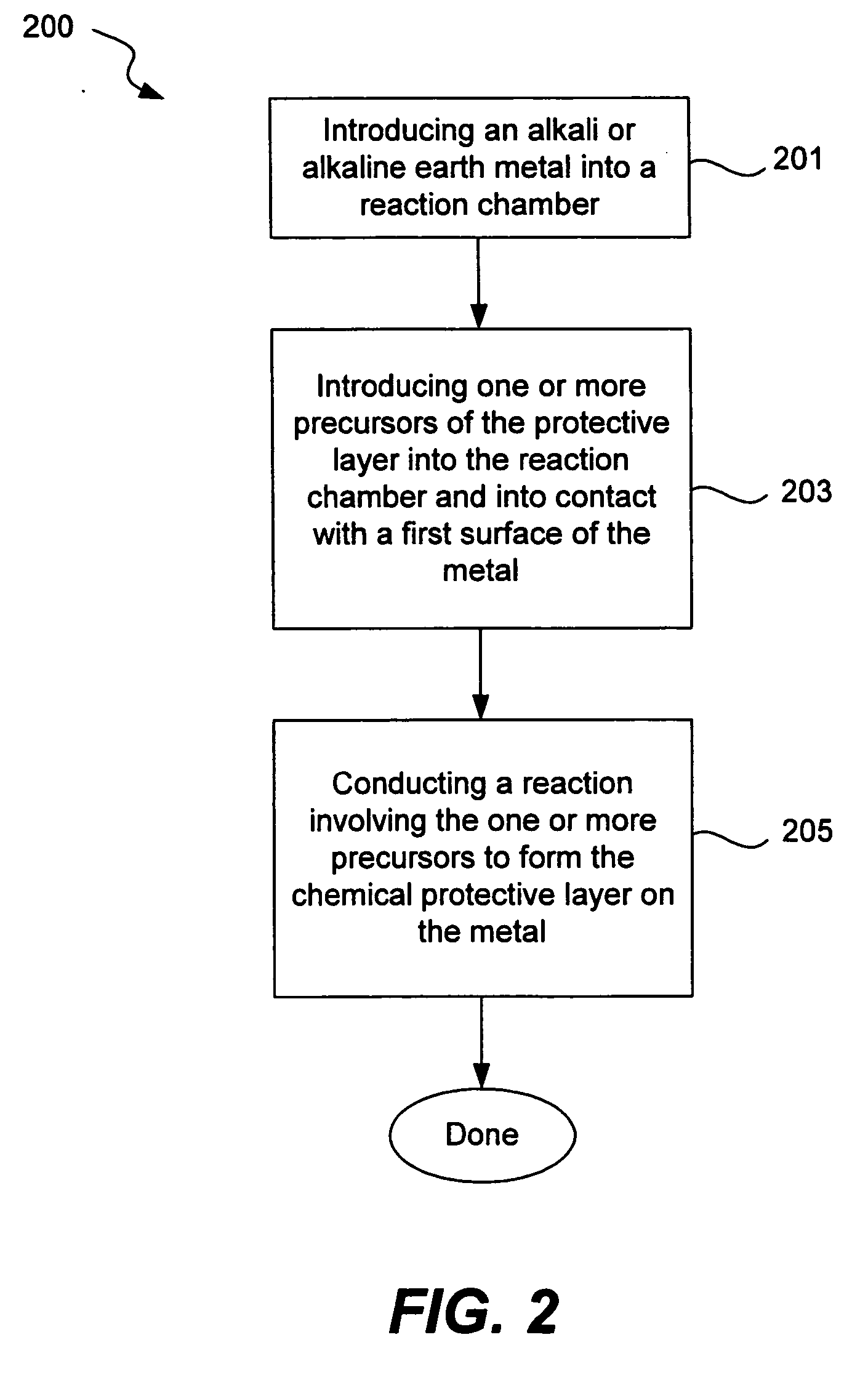

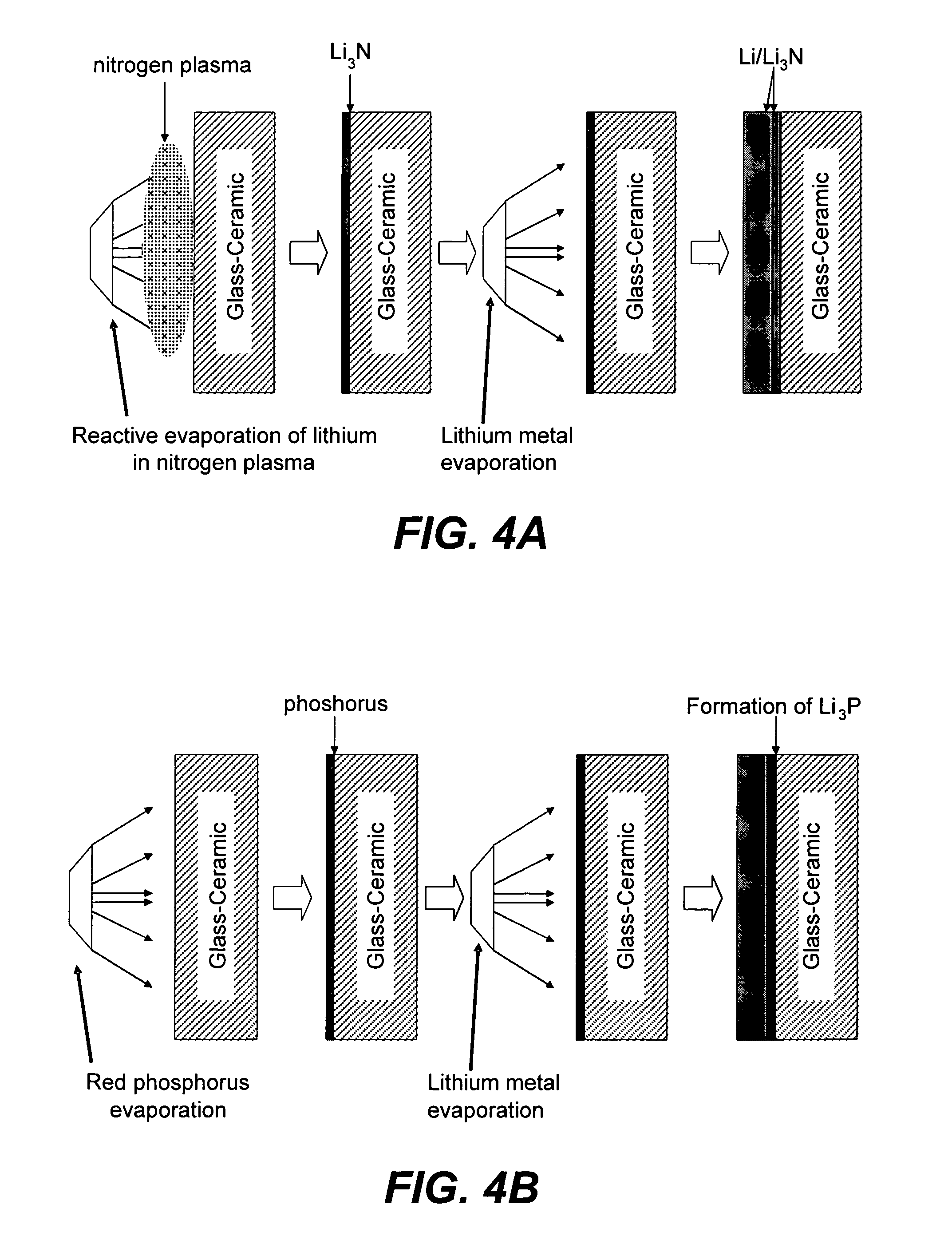

Chemical protection of a lithium surface

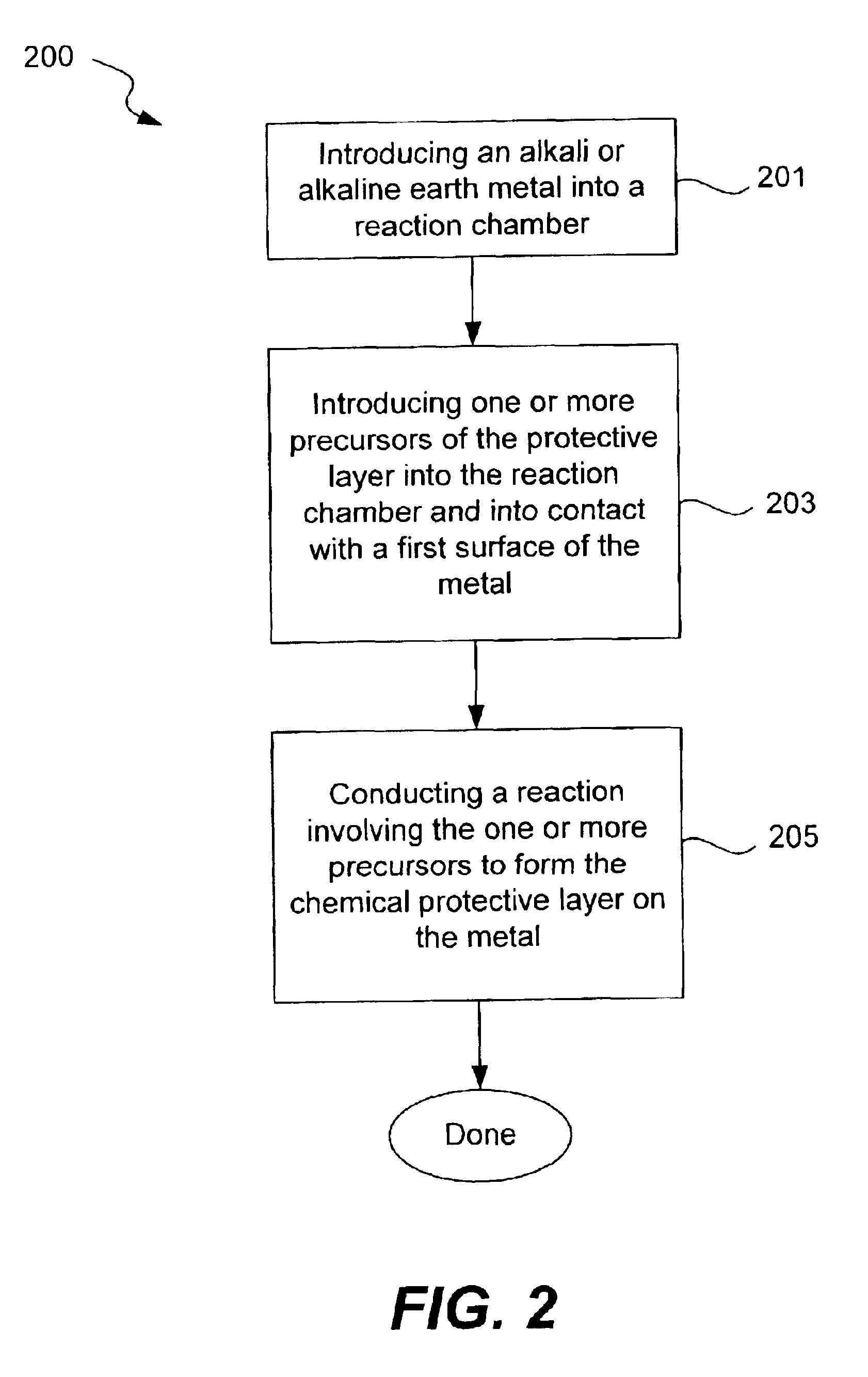

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

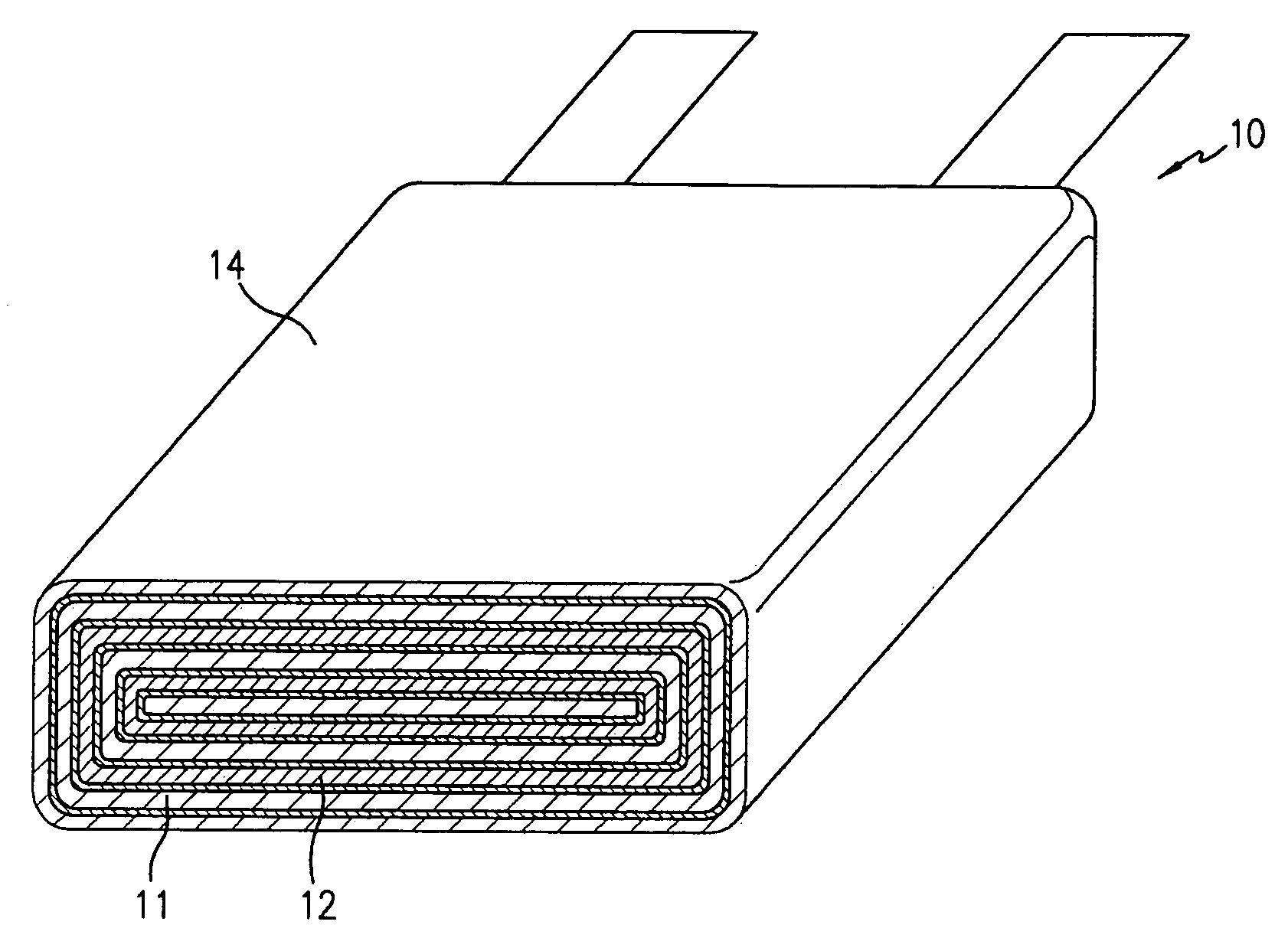

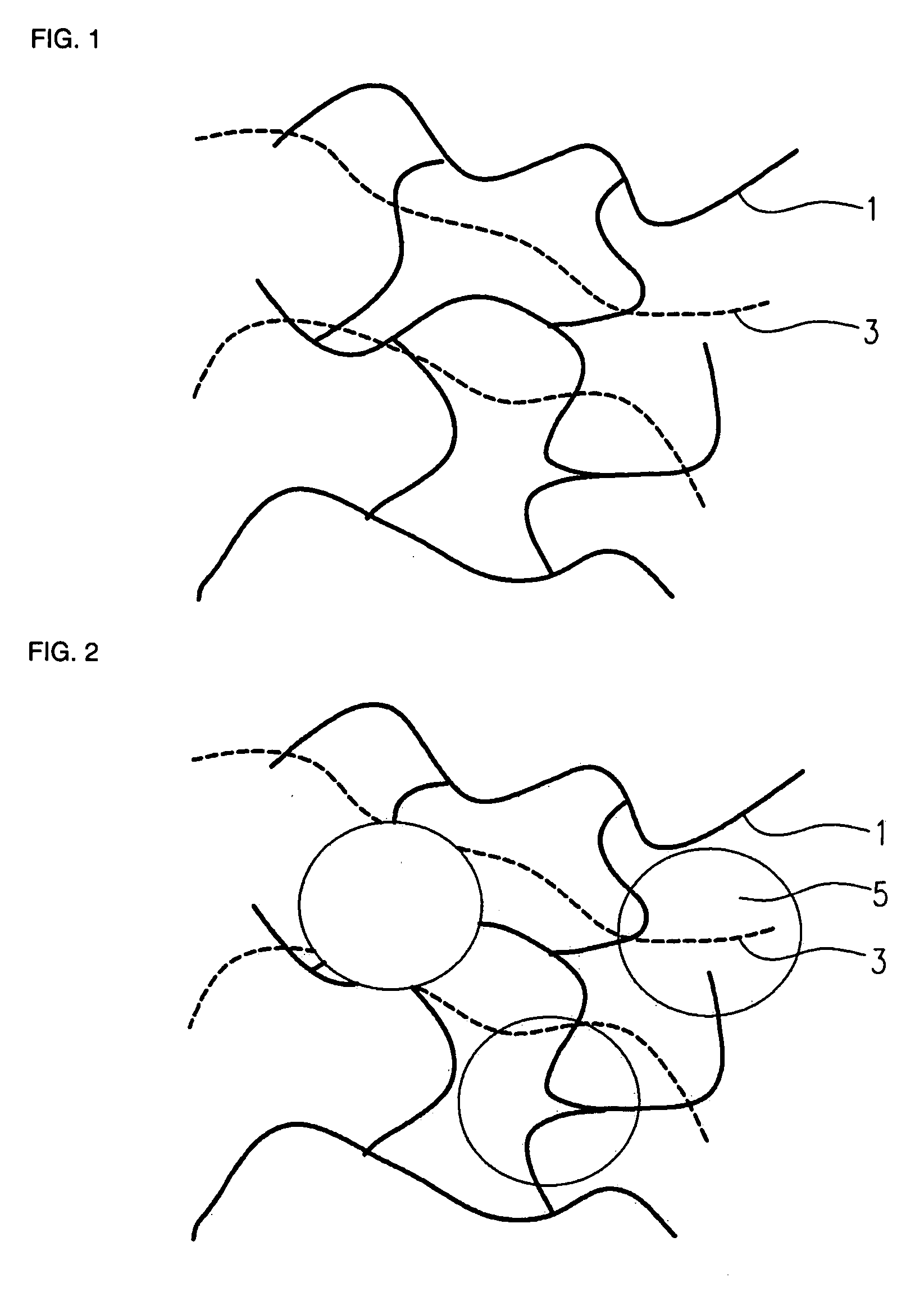

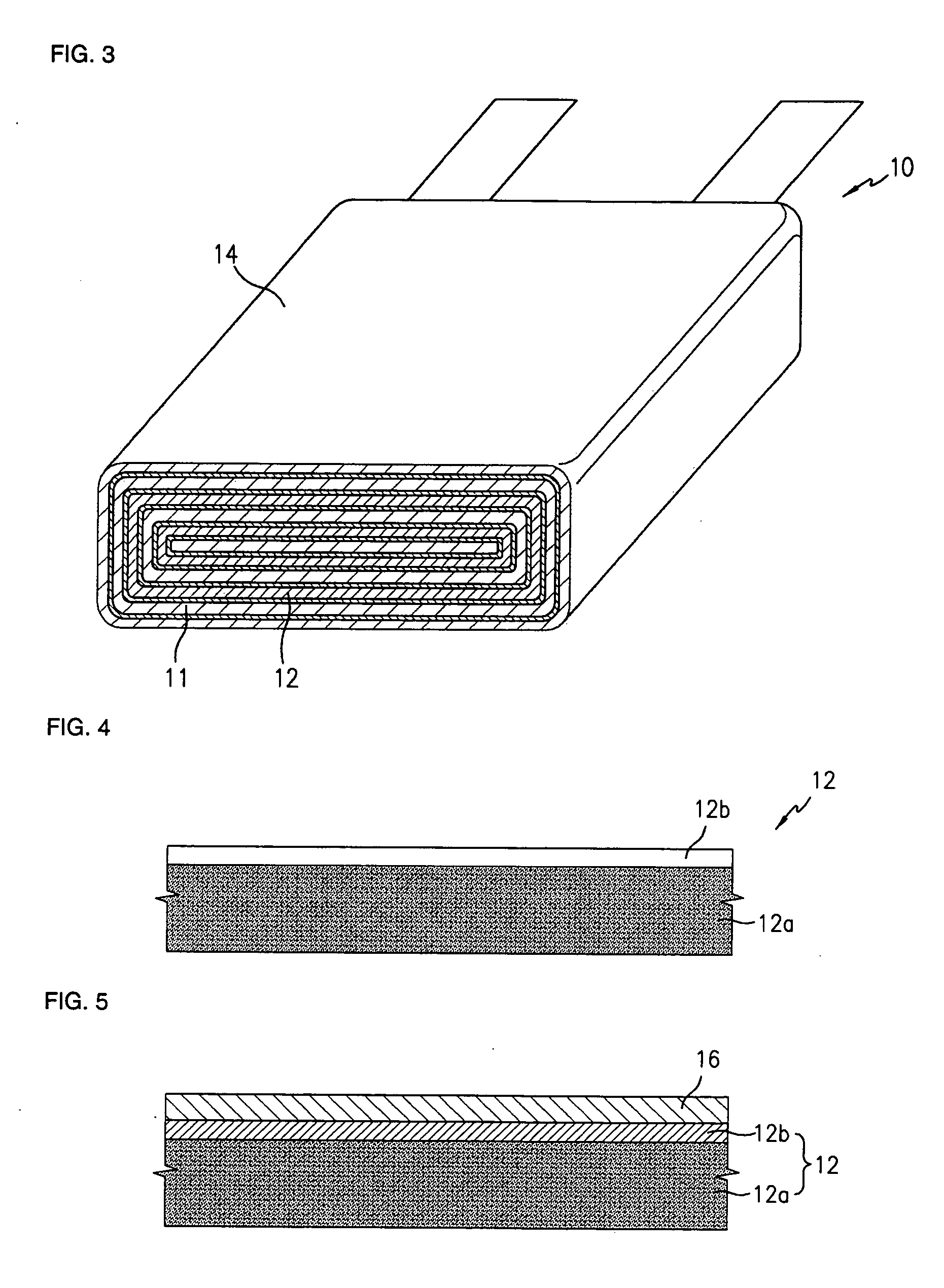

Negative electrode for lithium metal battery and lithium metal battery comprising the same

InactiveUS20050095504A1Improving life-cycle characteristicInhibit side effectsFinal product manufacturePretreated surfacesCross-linkMetallic lithium

The present invention relates to a negative electrode for a lithium metal battery and a lithium metal battery comprising the same. The negative electrode of the present invention comprises a negative active material layer of metallic lithium or a lithium alloy, and a passivation layer formed on the negative active material layer. The passivation layer has a structure comprising a 3-dimensionally cross-linked polymer network matrix penetrated by linear polymers. The passivation layer formed on the surface of the negative electrode reduces reactivity of the negative electrode and stabilizes the surface, so that it offers a lithium metal battery having superior life cycle characteristics.

Owner:SAMSUNG SDI CO LTD

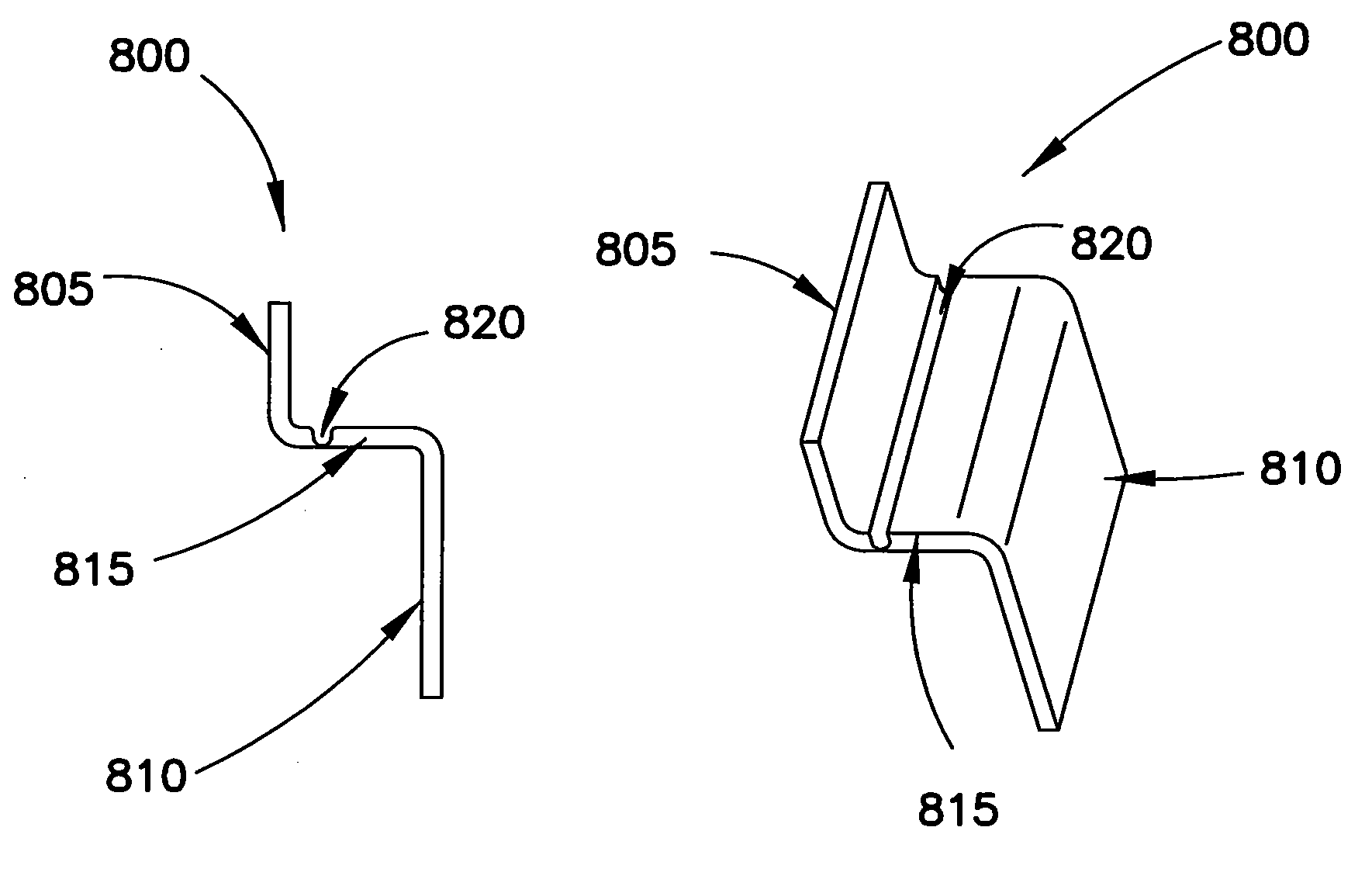

Three dimensional free form battery apparatus

A battery apparatus comprising a casing, at least two stacked lithium ion cells a member for maximizing the utilization of the casing and a member for precluding inadvertent deformation of the casing. The casing includes a non-uniform inner periphery. Each of at least two stacked lithium ion cells is positioned within the casing. The utilization maximizing member maximizes the utilization of the inner periphery of the casing by facilitating the independent shaping of each of the at least two stacked lithium ion cells to confirm to the inner periphery. As a result, the shape of one cell does not limit or dictate the shape of any other cell. The deformation precluding member is associated with each of the at least two lithium ion cells, and, substantially precludes inadvertent deformation of the casing by the at least two lithium ion cells, during cell cycling and storage. The invention further includes a process for fabricating a battery apparatus.

Owner:MITSUBISHI CHEM CORP

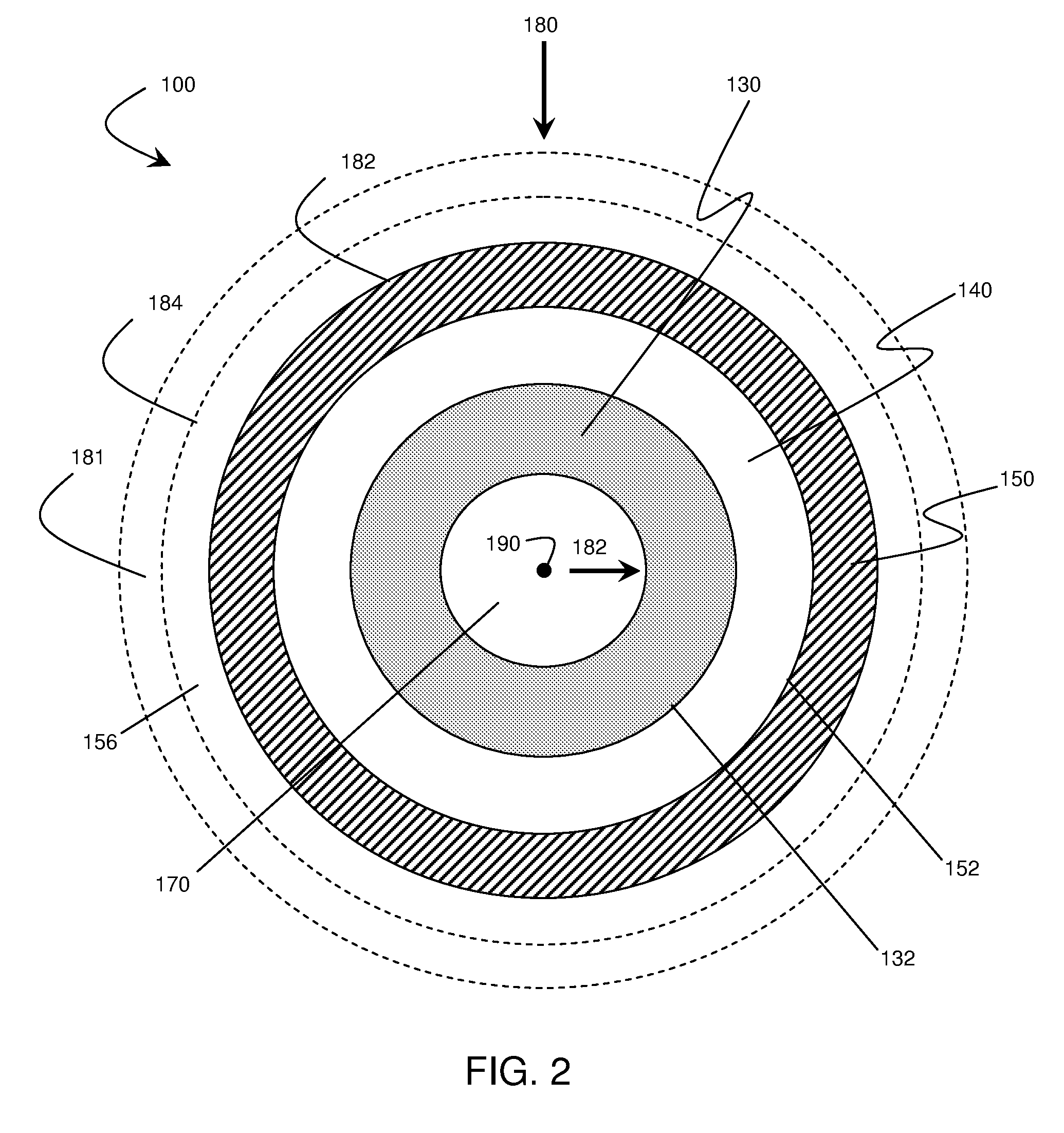

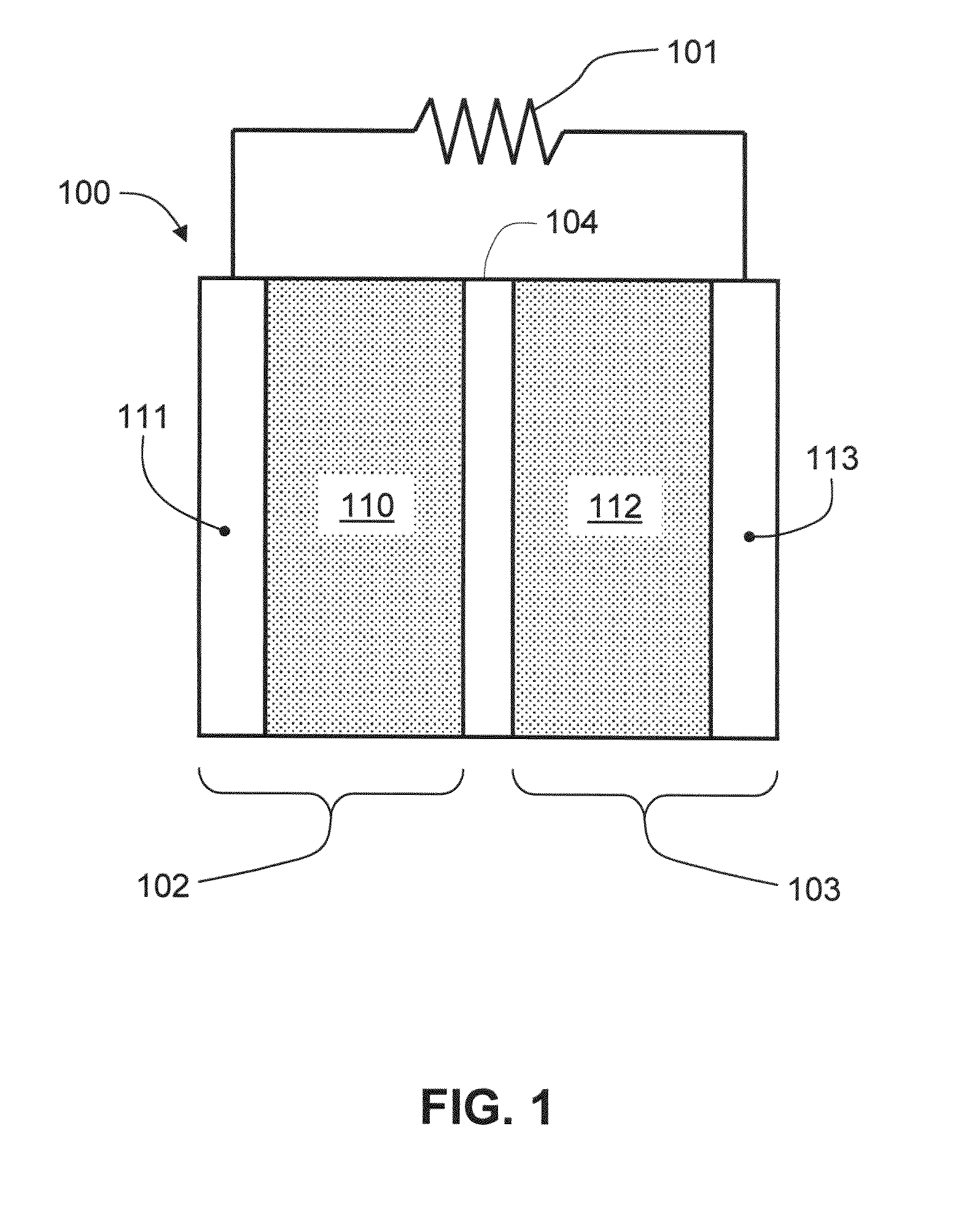

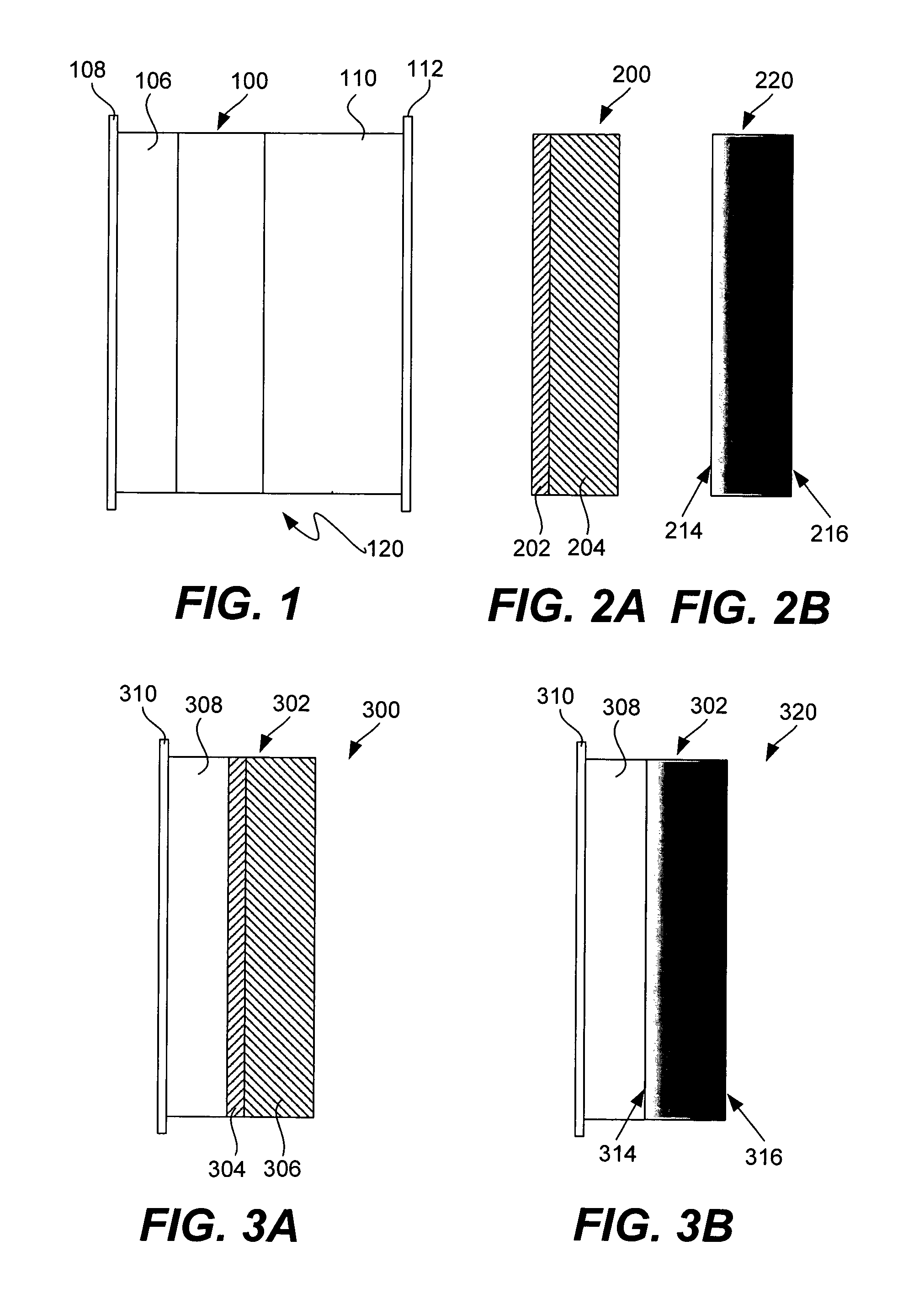

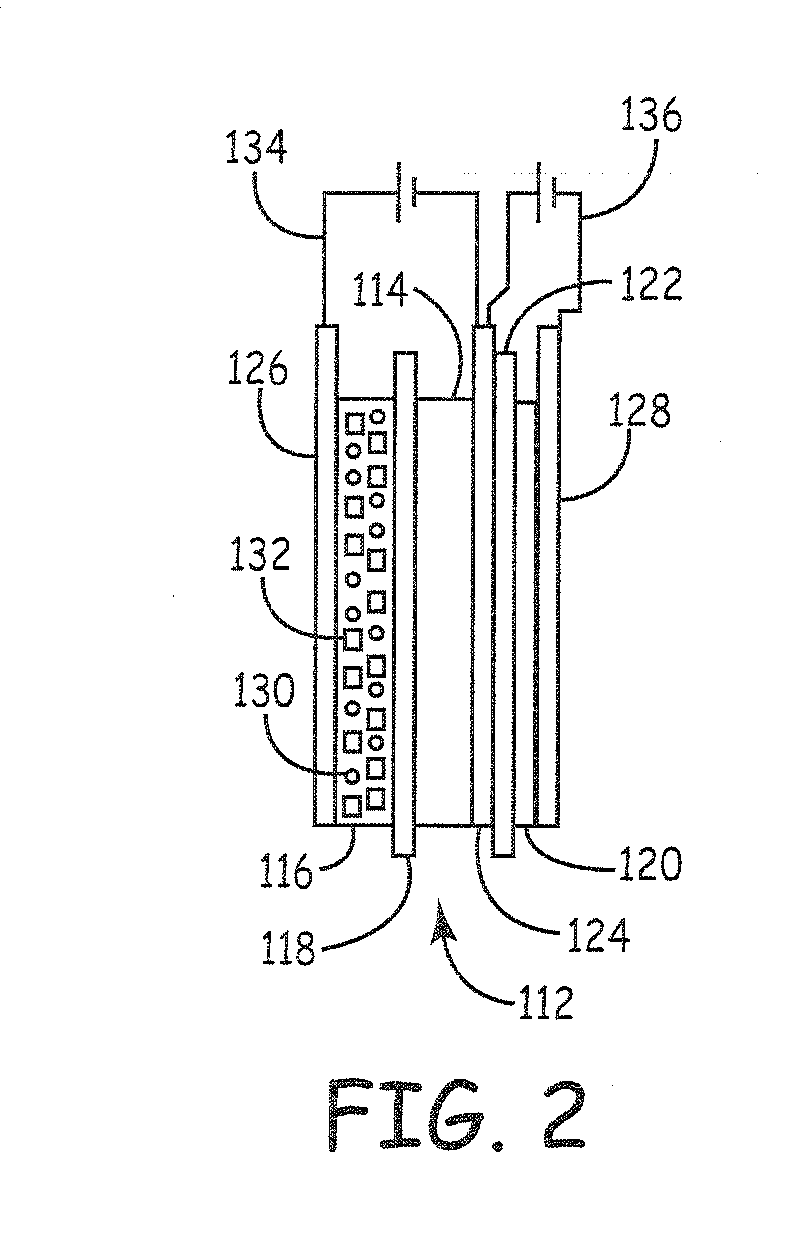

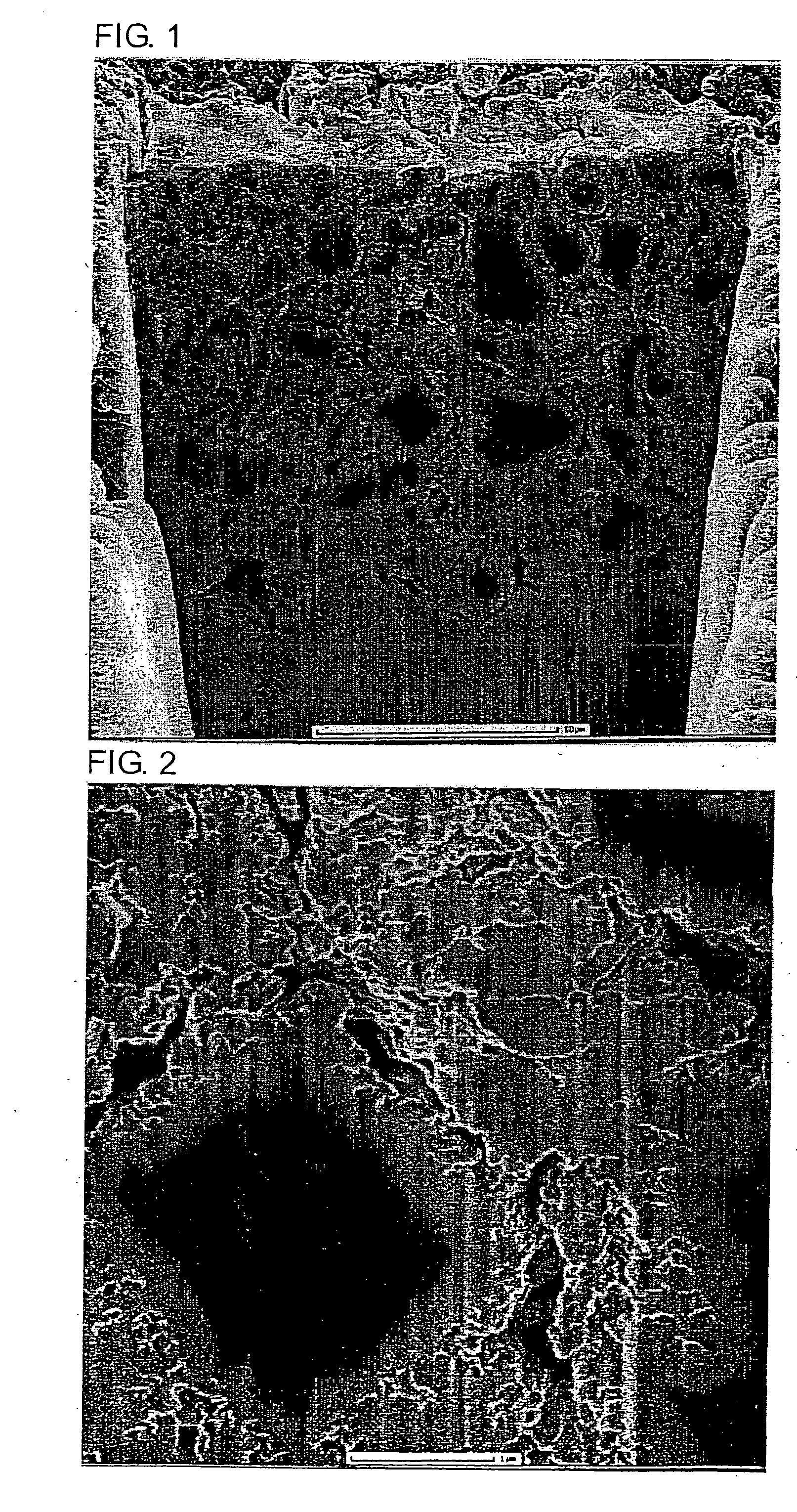

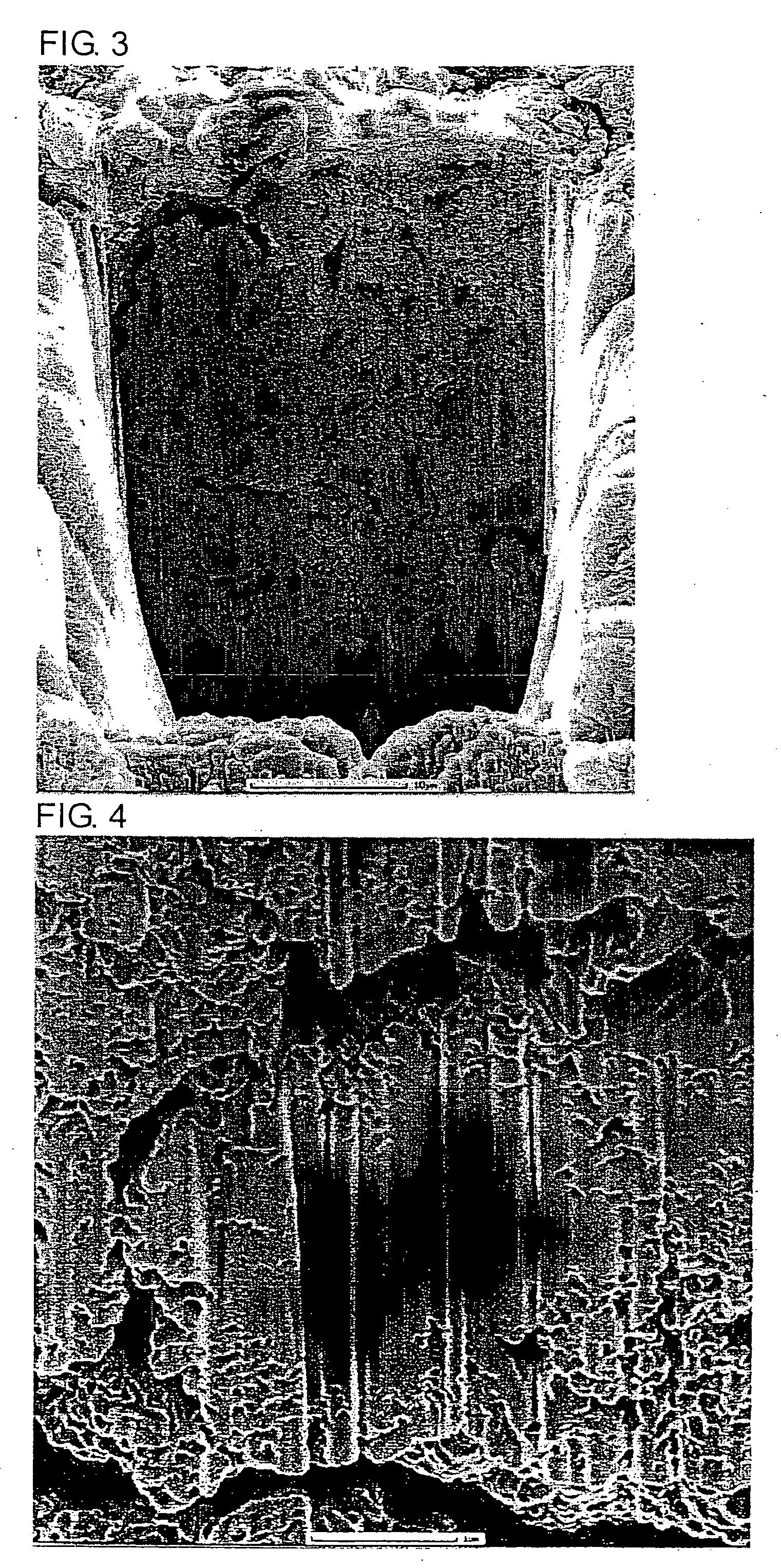

Application of force in electrochemical cells

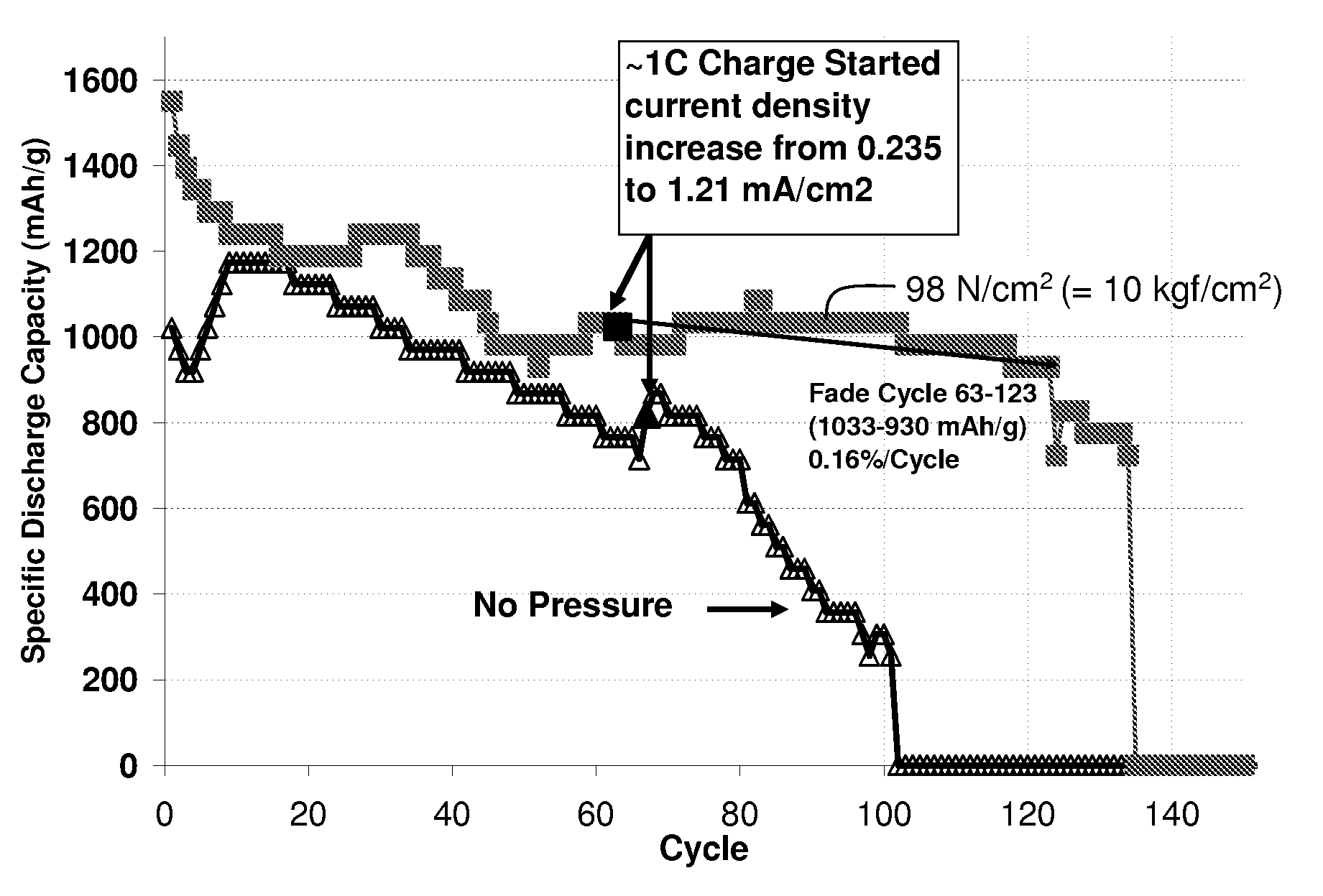

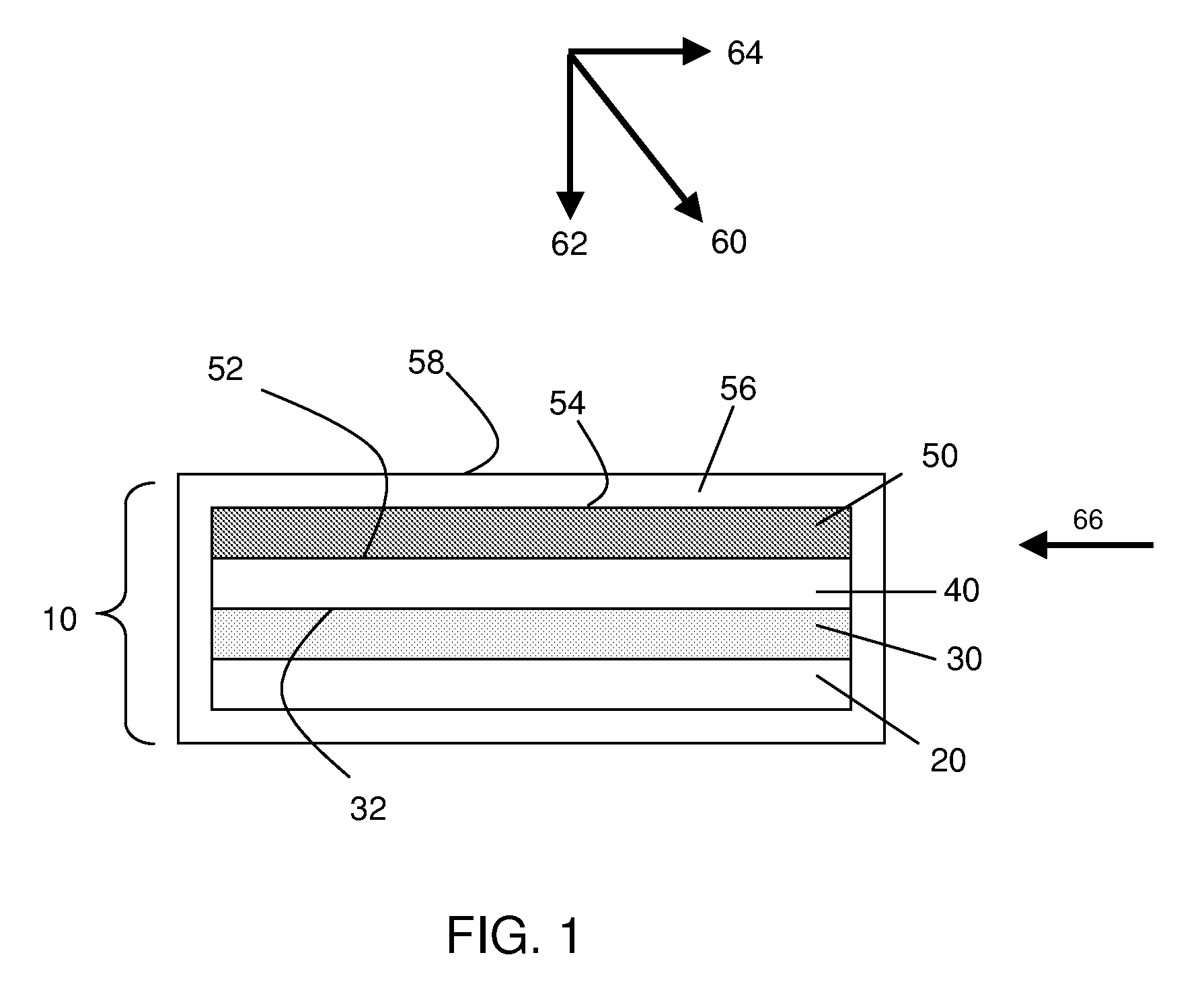

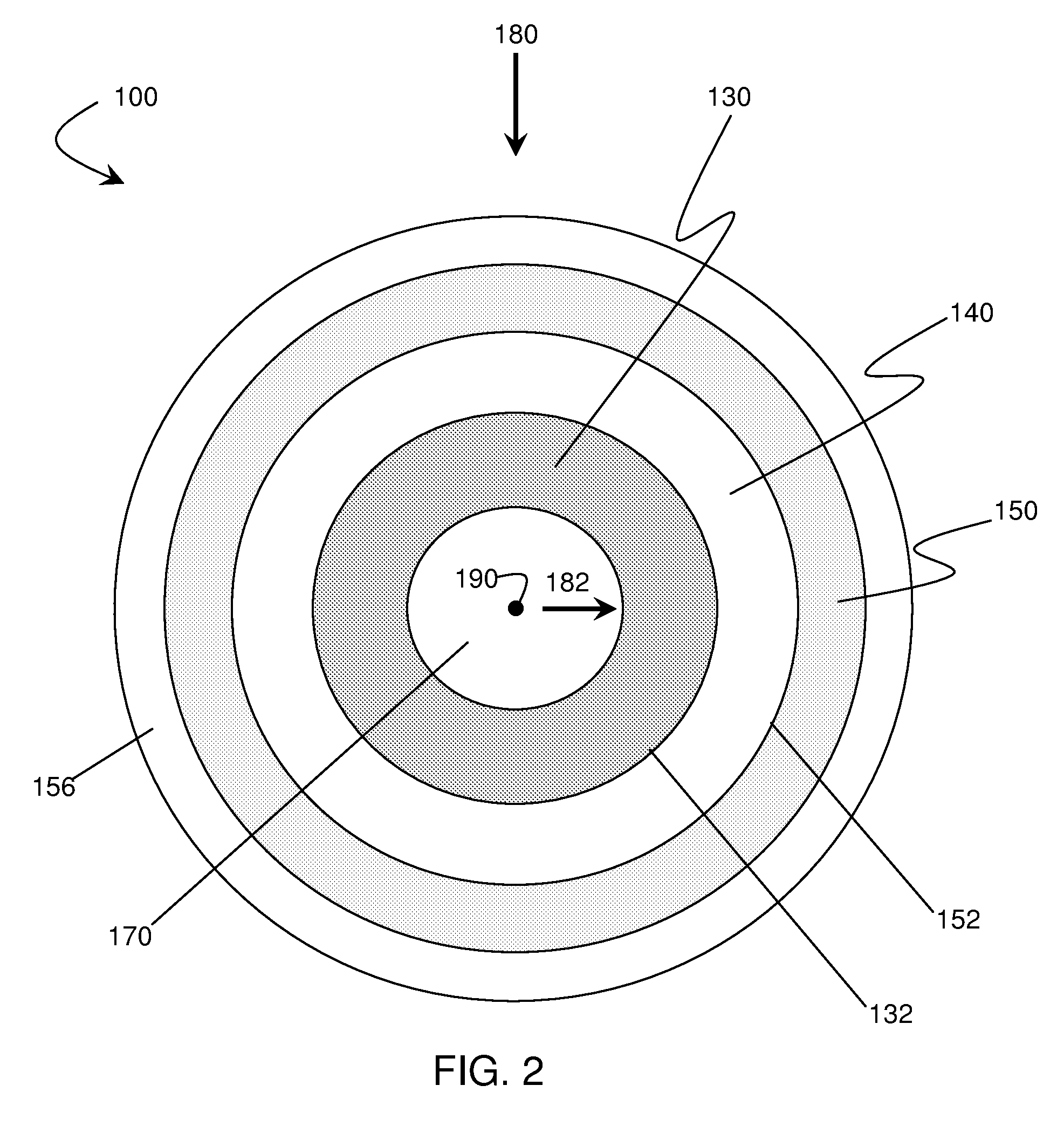

ActiveUS20100035128A1Improve performancePrimary cell to battery groupingCell seperators/membranes/diaphragms/spacersRough surfaceChemical reaction

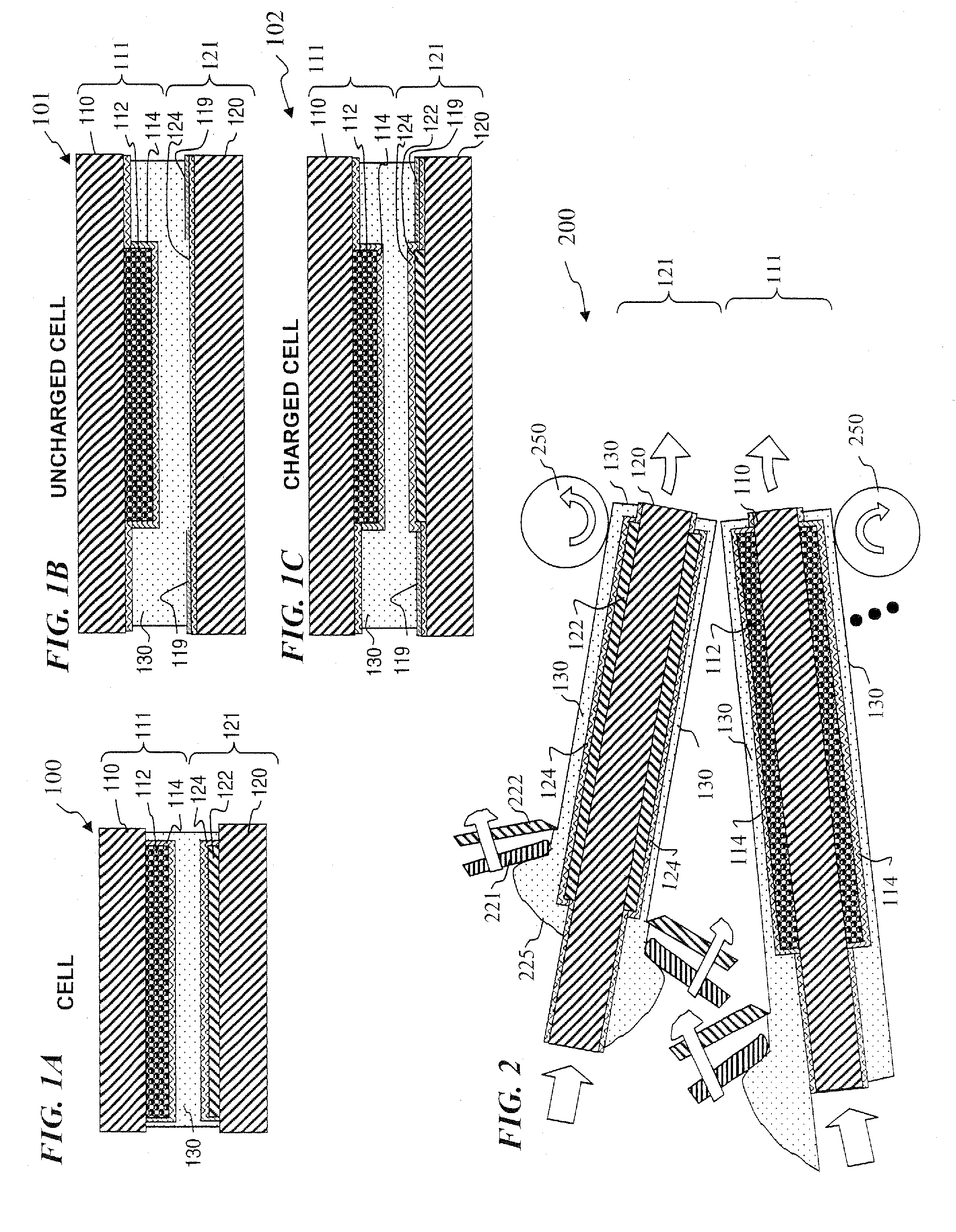

The present invention relates to the application of a force to enhance the performance of an electrochemical cell. The force may comprise, in some instances, an anisotropic force with a component normal to an active surface of the anode of the electrochemical cell. In the embodiments described herein, electrochemical cells (e.g., rechargeable batteries) may undergo a charge / discharge cycle involving deposition of metal (e.g., lithium metal) on a surface of the anode upon charging and reaction of the metal on the anode surface, wherein the metal diffuses from the anode surface, upon discharging. The uniformity with which the metal is deposited on the anode may affect cell performance. For example, when lithium metal is redeposited on an anode, it may, in some cases, deposit unevenly forming a rough surface. The roughened surface may increase the amount of lithium metal available for undesired chemical reactions which may result in decreased cycling lifetime and / or poor cell performance. The application of force to the electrochemical cell has been found, in accordance with the invention, to reduce such behavior and to improve the cycling lifetime and / or performance of the cell.

Owner:SION POWER CORP

Chemical protection of a lithium surface

InactiveUS20050186469A1Easy to produceEasy to processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process is the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

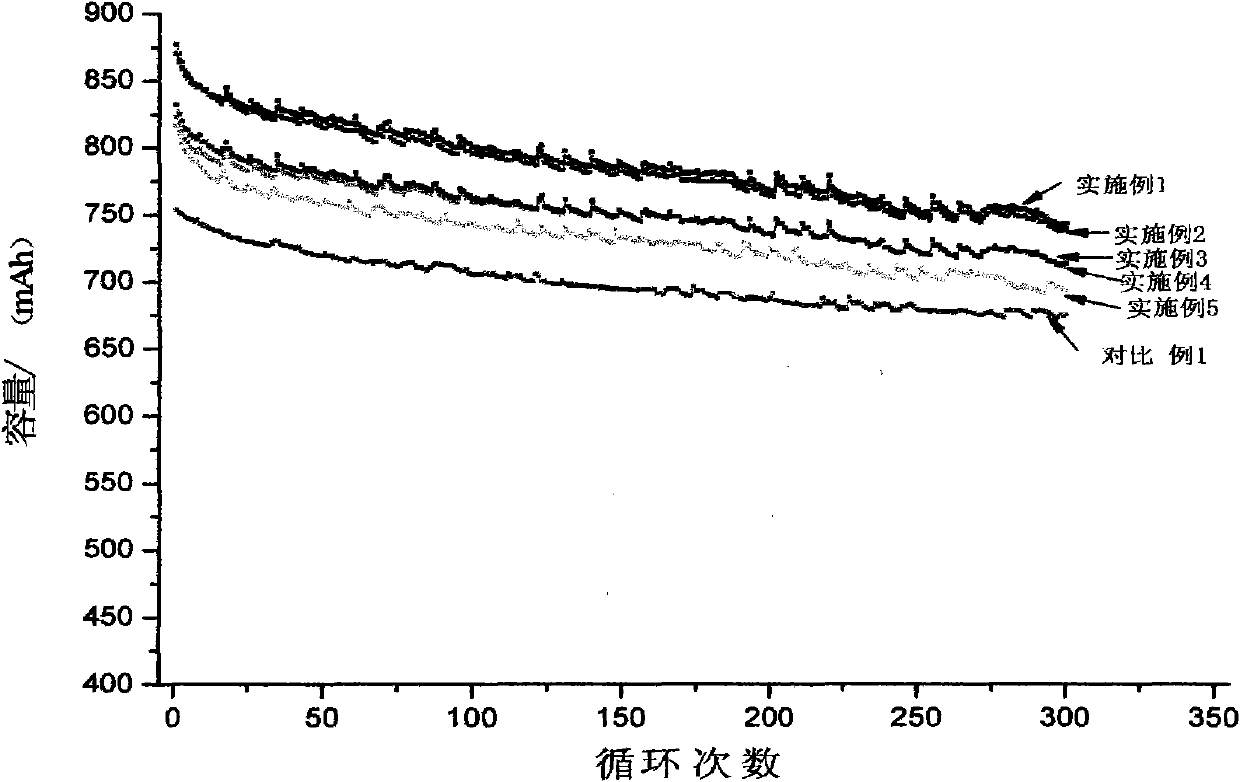

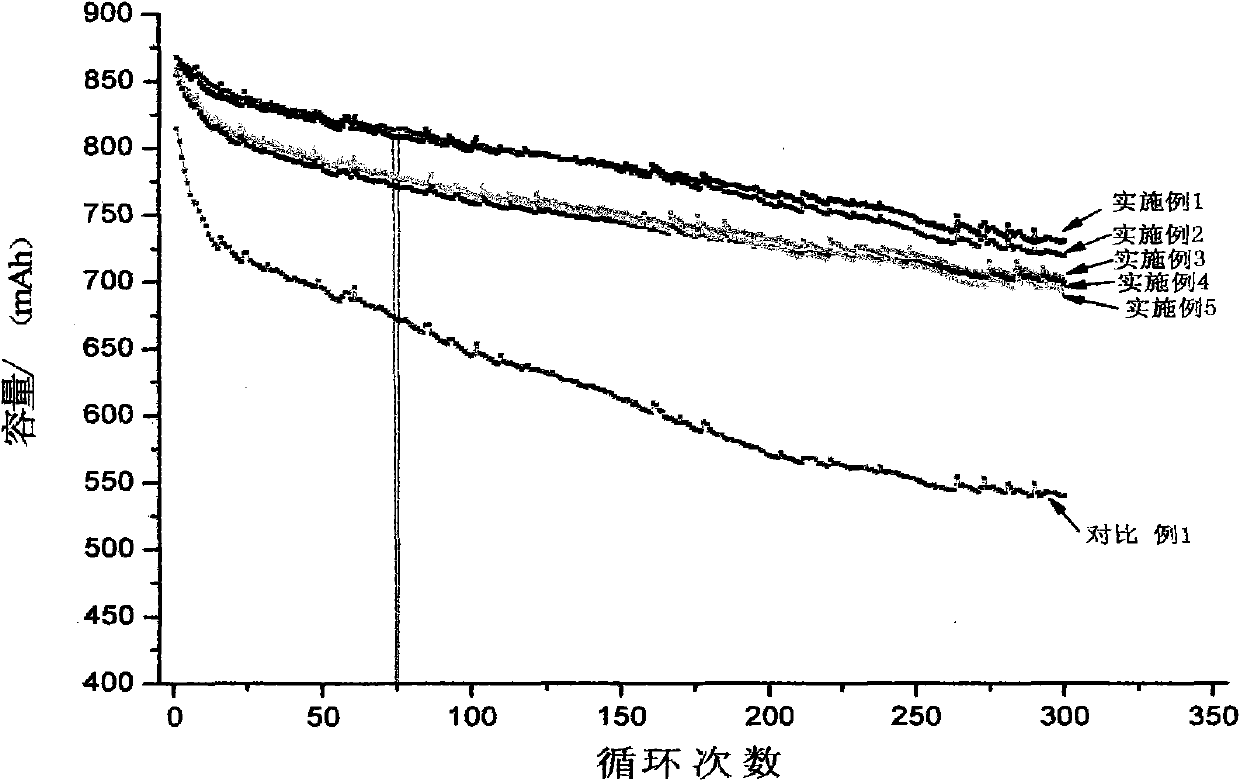

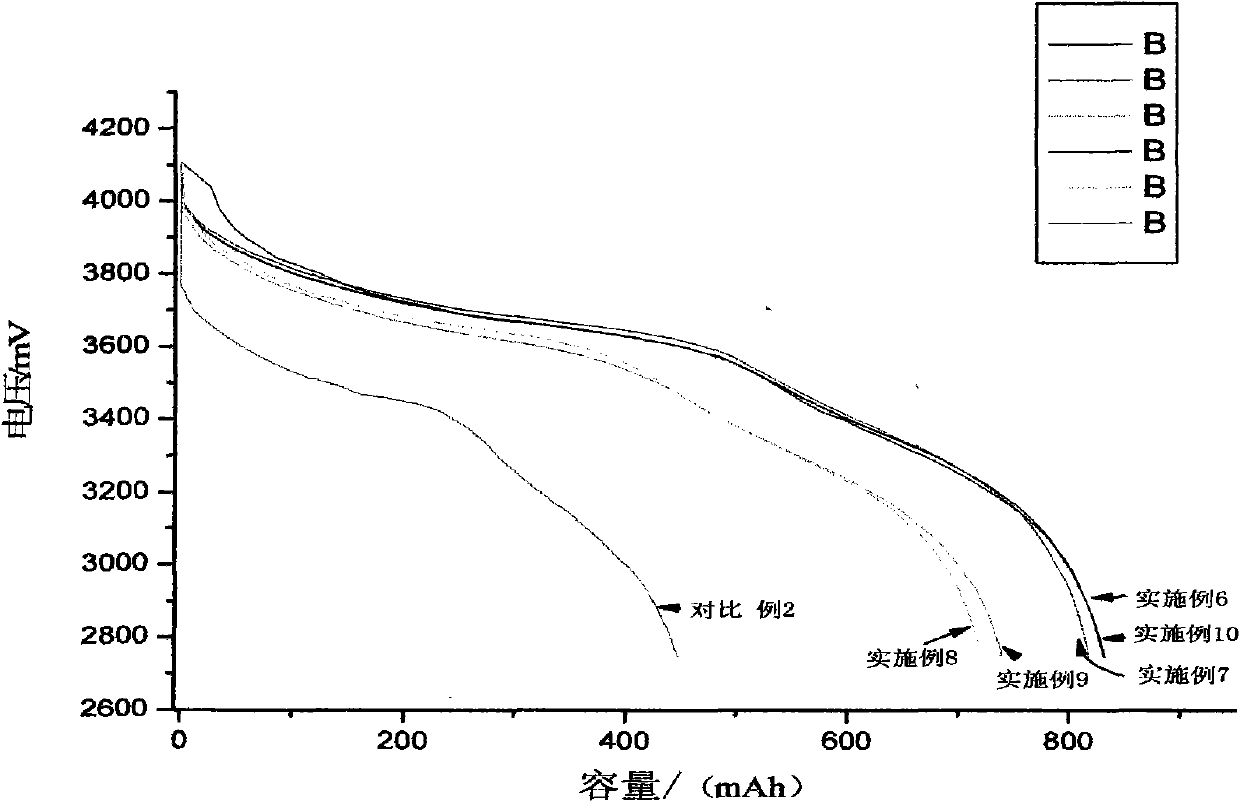

High-capacity lithium-ion electrolyte, battery and preparation method of battery

ActiveCN101771167AIncrease capacityLow costFinal product manufactureCell electrodesElectrolytic agentPhysical chemistry

The invention relates to a high-capacity lithium-ion electrolyte, a battery and a preparation method of a battery, in particular to the high-capacity lithium-ion electrolyte and the battery using the high-capacity lithium-ion electrolyte and the preparation method of the battery. The electrolyte disclosed by the invention comprises lithium salt and non-aqueous organic solvent, and also consists of the following components in weight percent in terms of the total weight of the electrolyte: 0.5-7% of film-forming additive, 0-15% of flame-retardant additive, 2-10% of antiovefill additive, 0.01-2% of stabilizer and 0.01-1% of wetting agent; the electrolyte can enable the anode with high Ni content to work stably, and reduce the battery cost; the high-capacity lithium-ion battery can perform high ratio capacity and excellent safety and high temperature property and cyclic life fully due to the addition and synergetic functions of various functional additives.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

Cathode for lithium battery

The present invention relates to cathodes used in electrochemical cells. A force, or forces, applied to portions of an electrochemical cell as described in this application can reduce irregularity or roughening of an electrode surface of the cell, improving performance. The cathodes described herein may possess enhanced properties that render them particularly suitable for use in electrochemical cells designed to be charged and / or discharged while a force is applied. In some embodiments, the cathode retains sufficient porosity to charge and discharge effectively when a force is applied to the cell. Cathodes described herein may also comprise relatively high electrolyte-accessible conductive material (e.g., carbon) areas. The cathode may comprise a relatively low ratio of the amount of binder and / or mass of electrolyte to cathode active material (e.g., sulfur) ratio in some instances. In some embodiments, electrochemical cells comprising the cathodes described herein may achieve relatively high specific capacities and / or relatively high discharge current densities. In addition, the cathode described herein may exhibit relatively high cathode active material (e.g., sulfur) utilization during charge and discharge. In still further cases, the electrical conductivity between conductive material in the cathode (e.g., carbon) may be enhanced during the application of the force.

Owner:SION POWER CORP

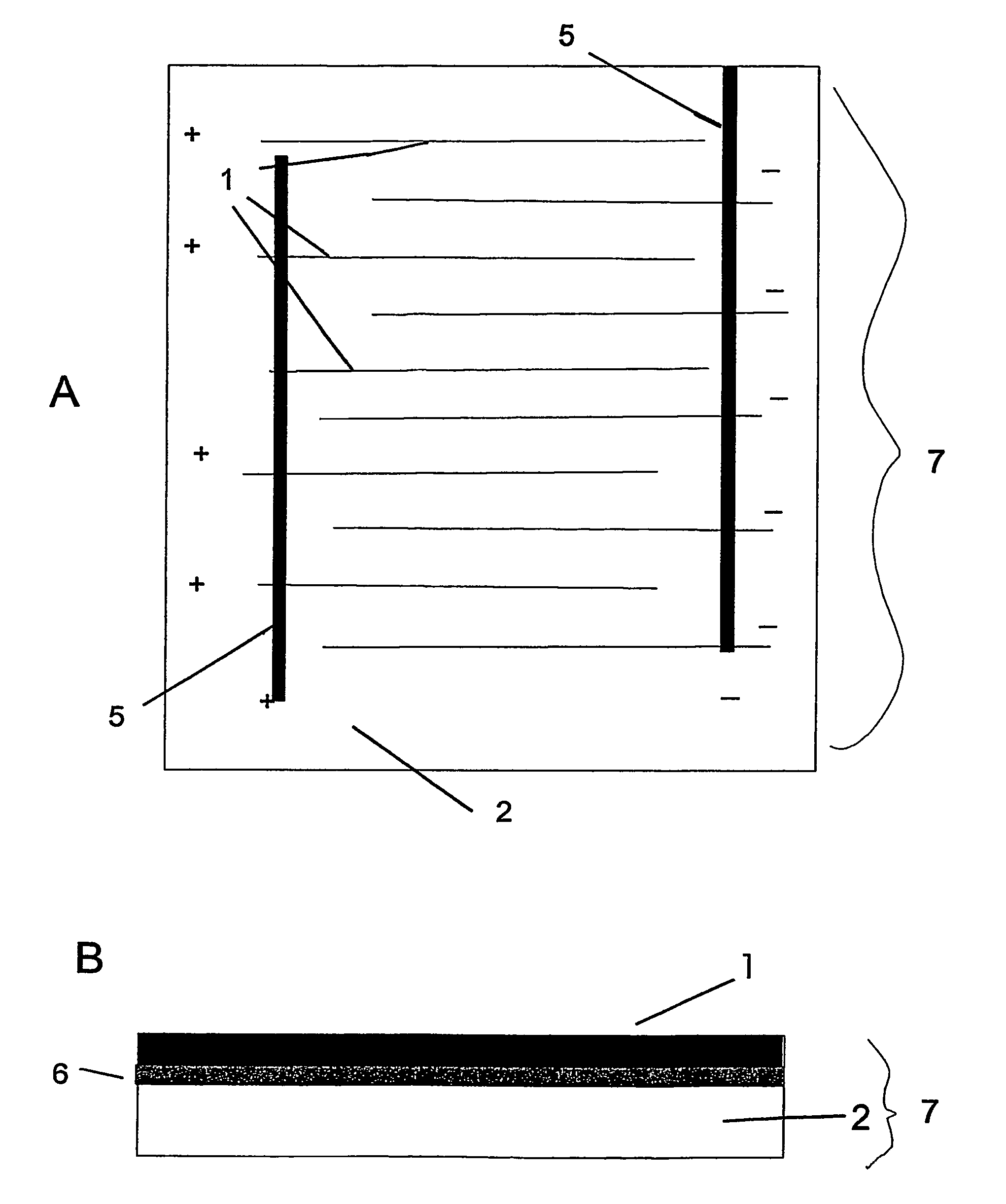

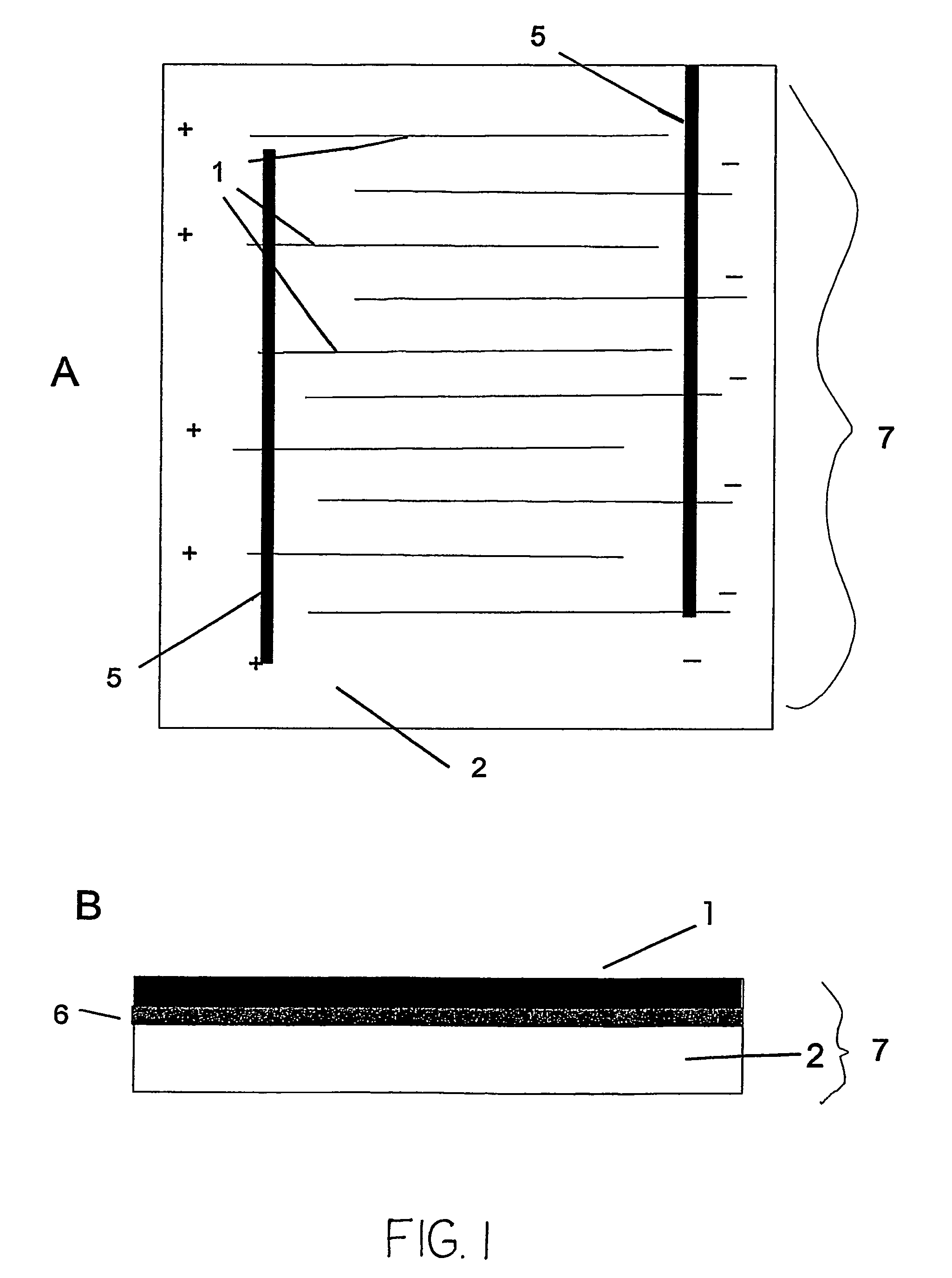

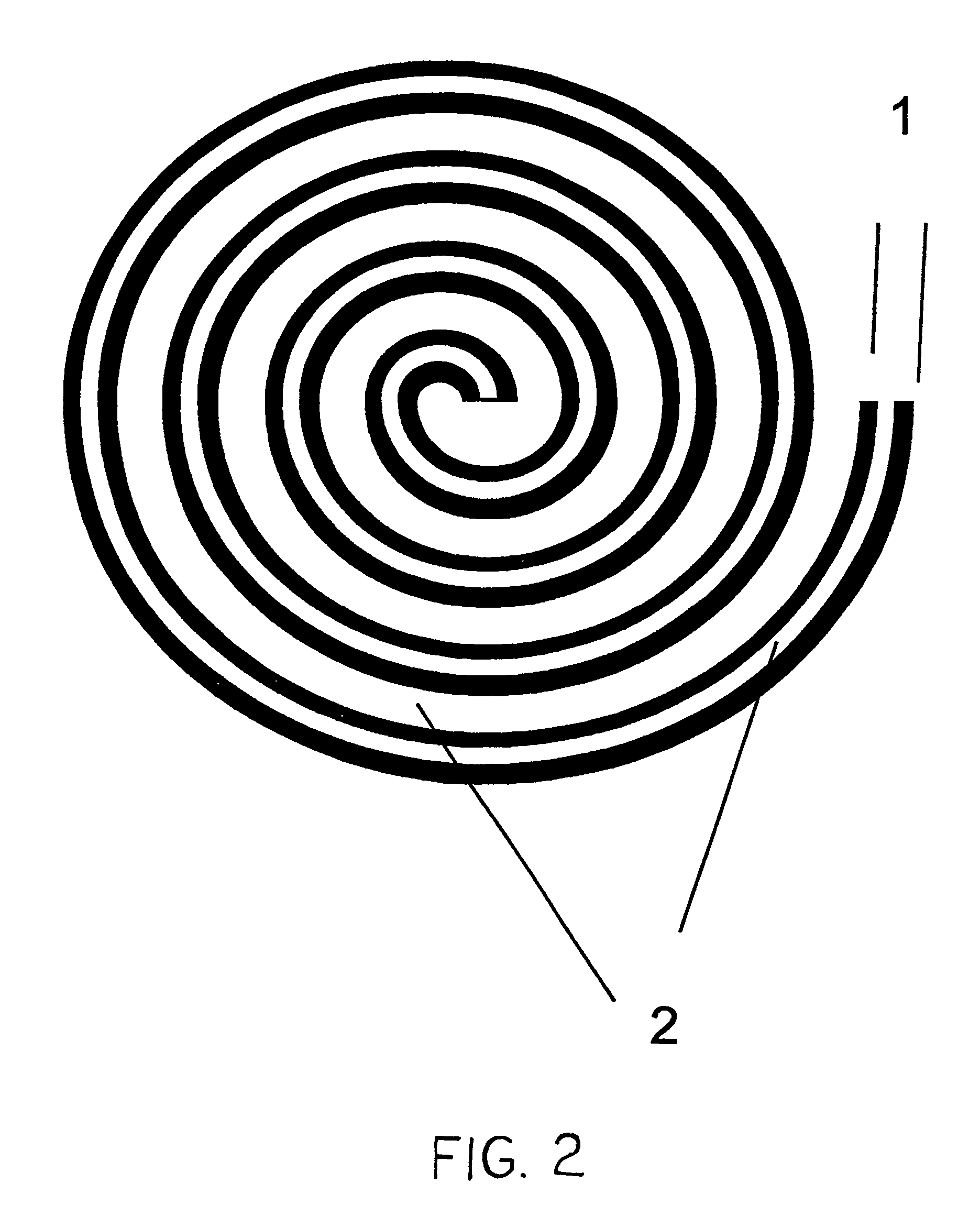

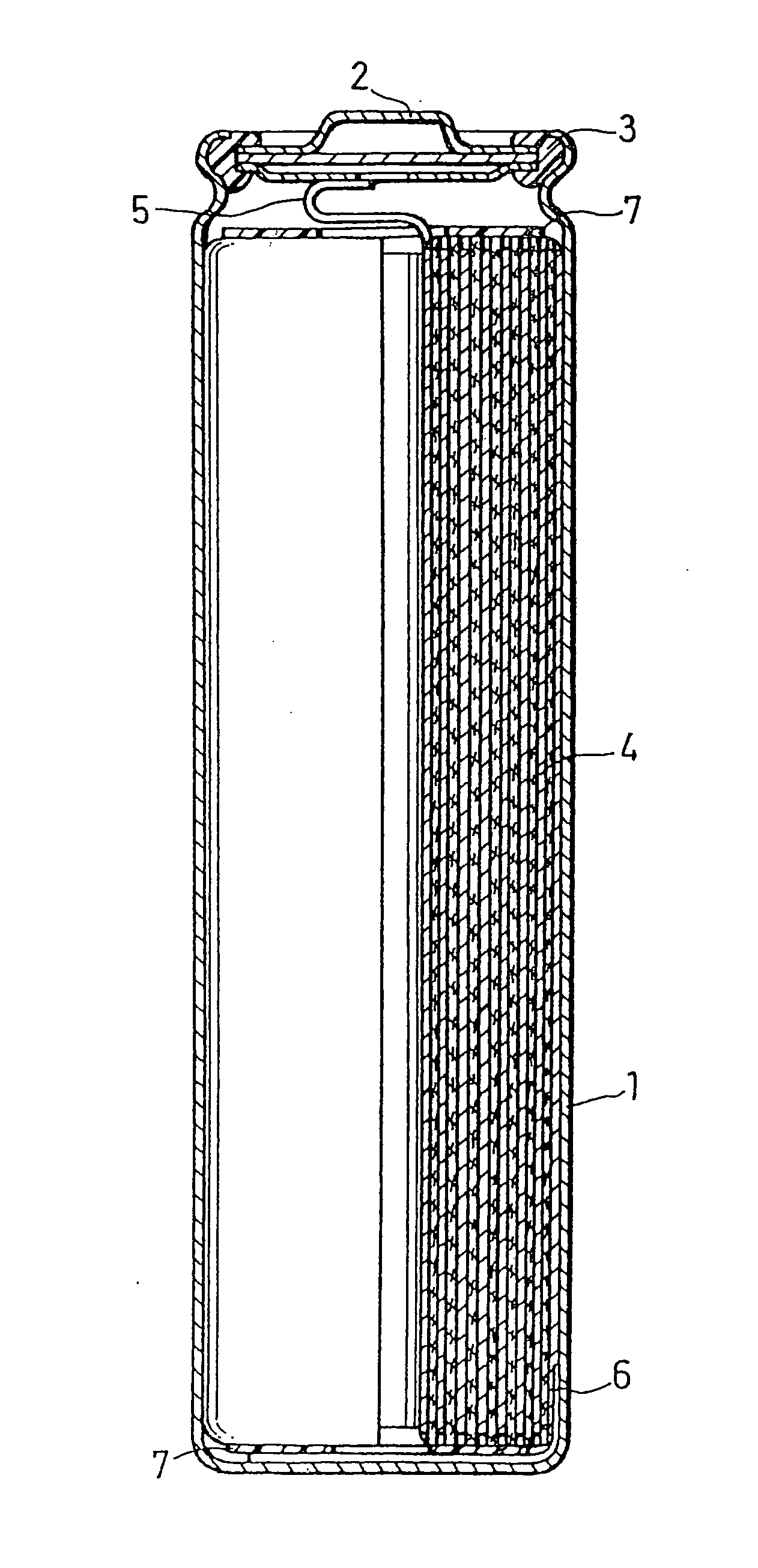

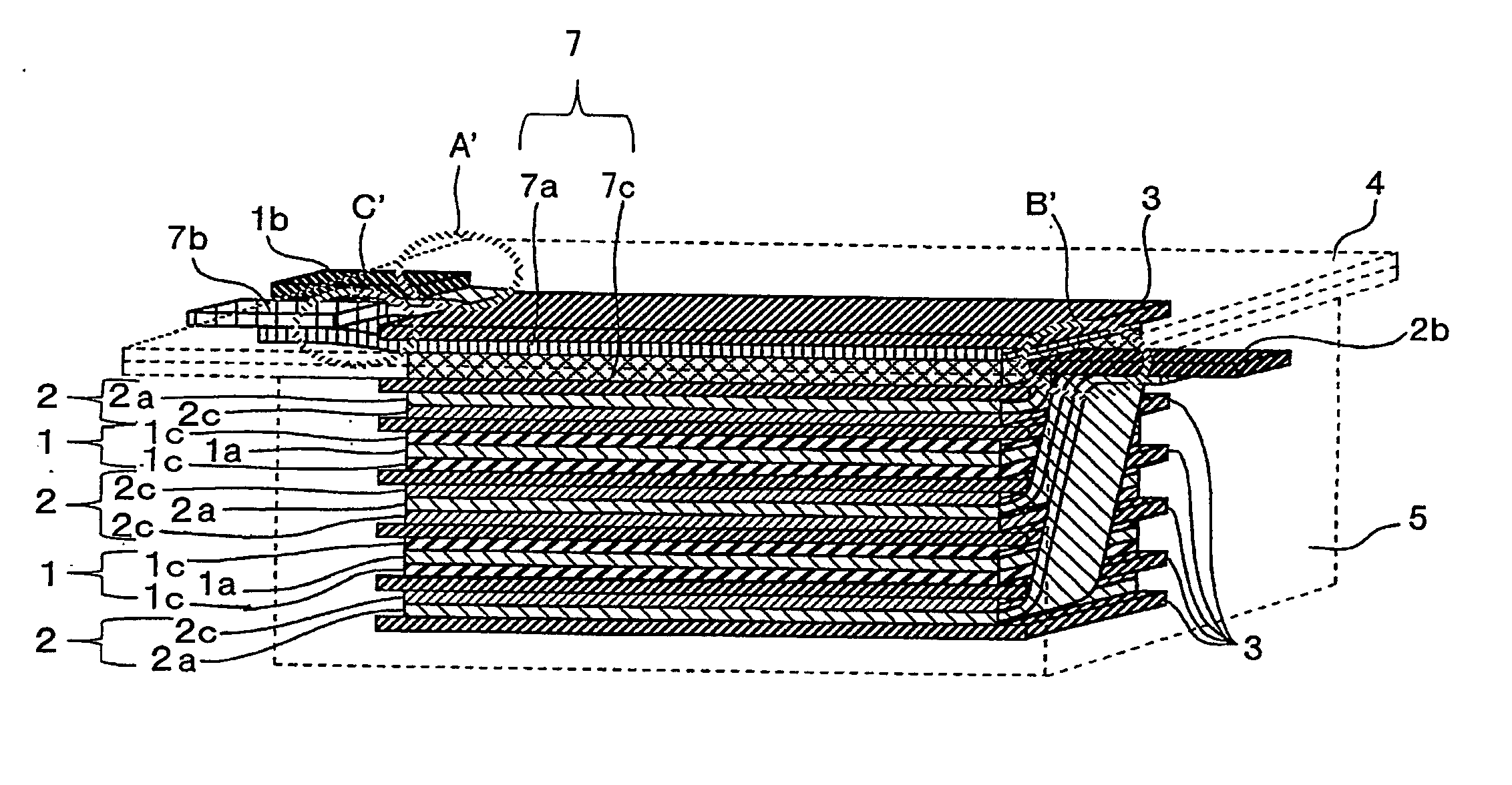

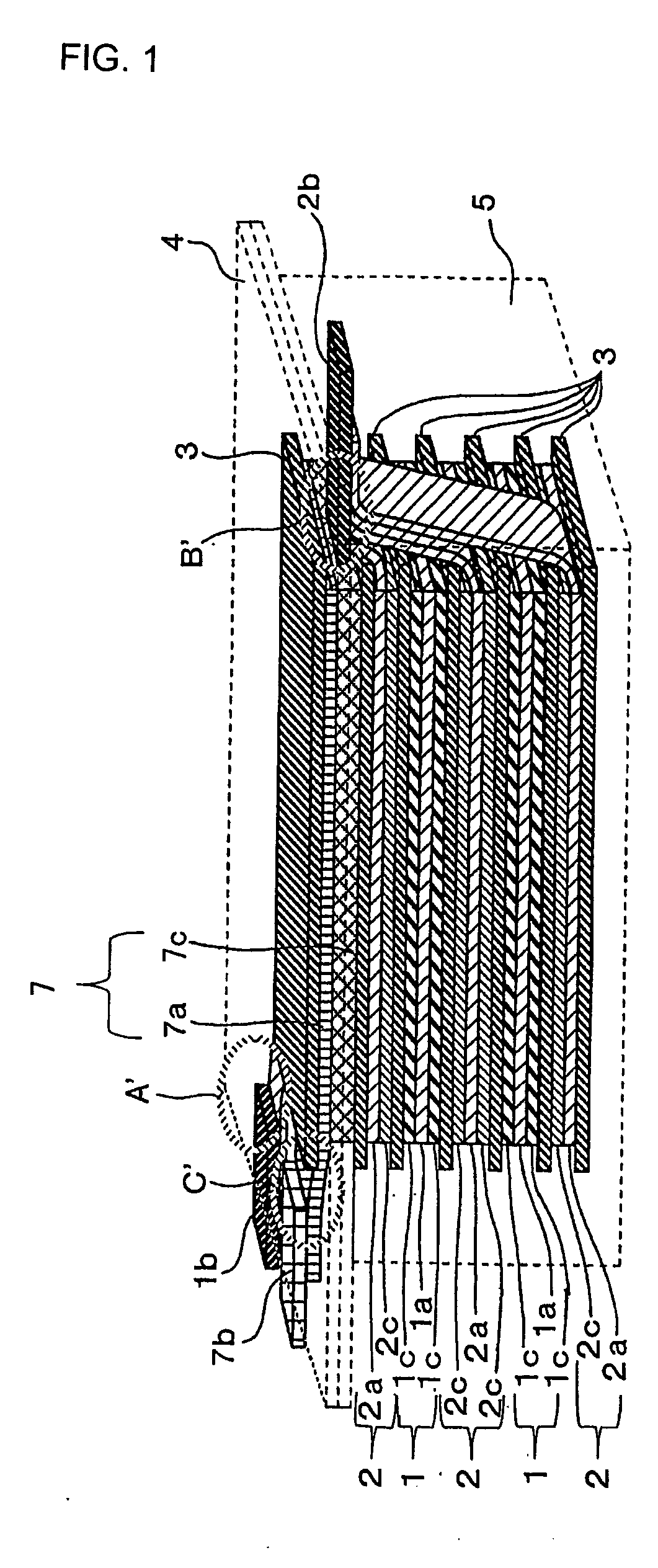

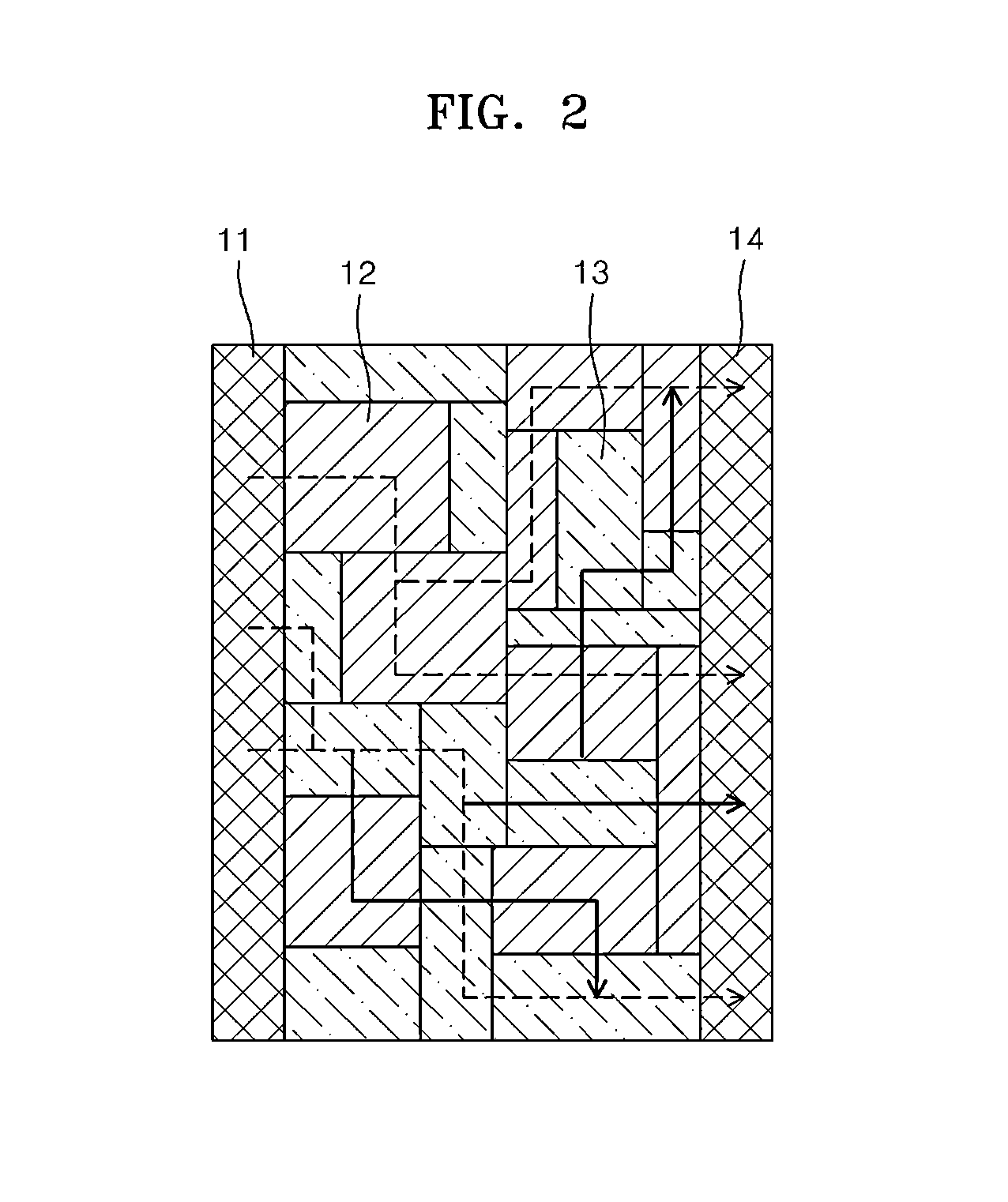

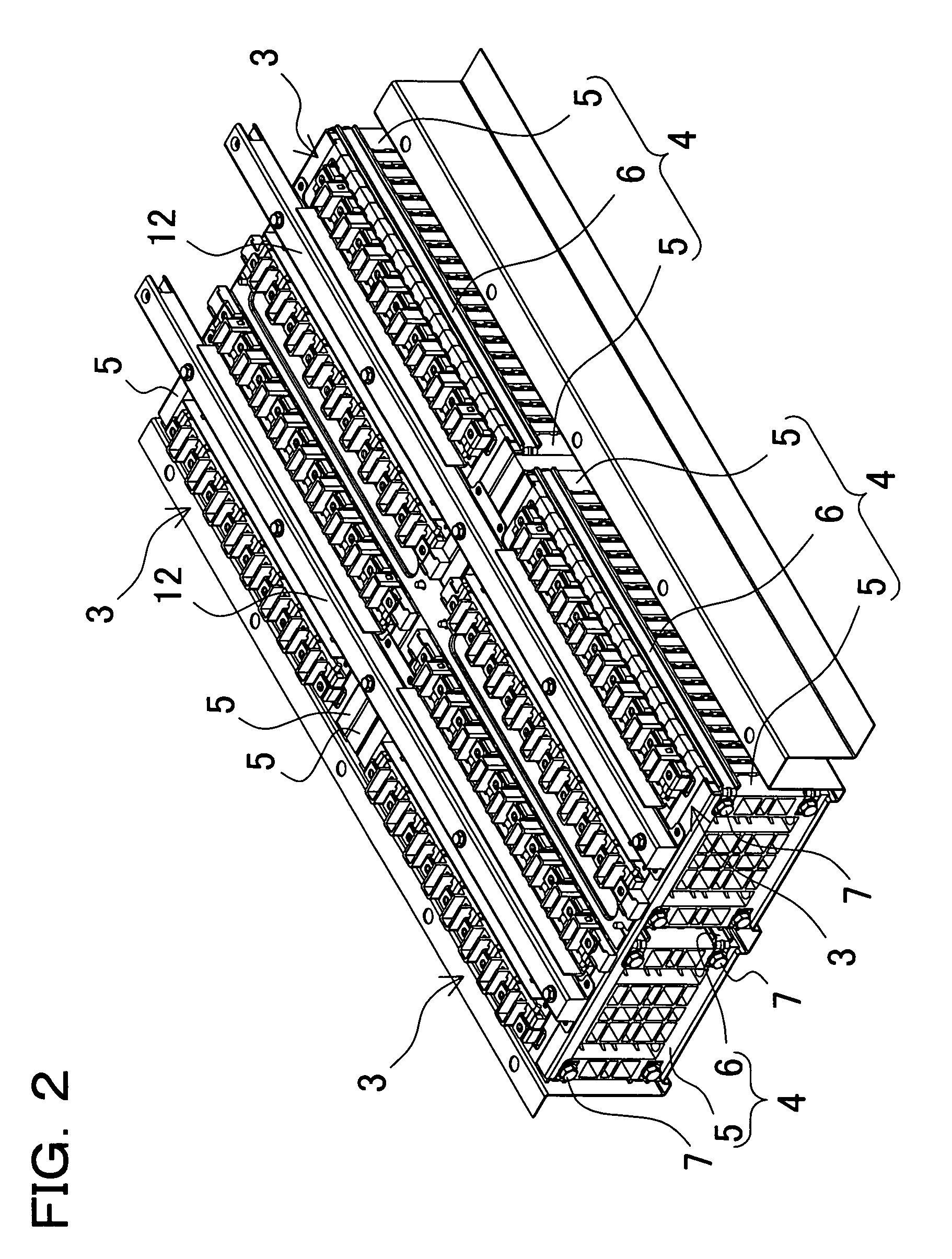

Electrode array for use in electrochemical cells

InactiveUS7368191B2Reduce leakageReduced series resistanceFinal product manufactureFuel cell auxillariesFuel cellsEngineering

The invention features an electrode array (7) in which pairs of electrodes (1) are geometrically arranged so that the broadest faces of the exposed electrodes are not directly opposing to each other. Rather, the broadest facing surfaces of the electrodes in the array are parallel, adjacent, or offset at an angle. The electrode geometry of an electrode array of the invention permits electrodes to be in close proximity, thereby lowering series resistance, while minimizing the possibility for short circuits that can cause electrical leakage. An electrode array of the invention can be used in an electrochemical cell, such as a battery, e.g., a lithium battery, a capacitor, a flow-through capacitor, or a fuel cell.

Owner:BIOSOURCE INC

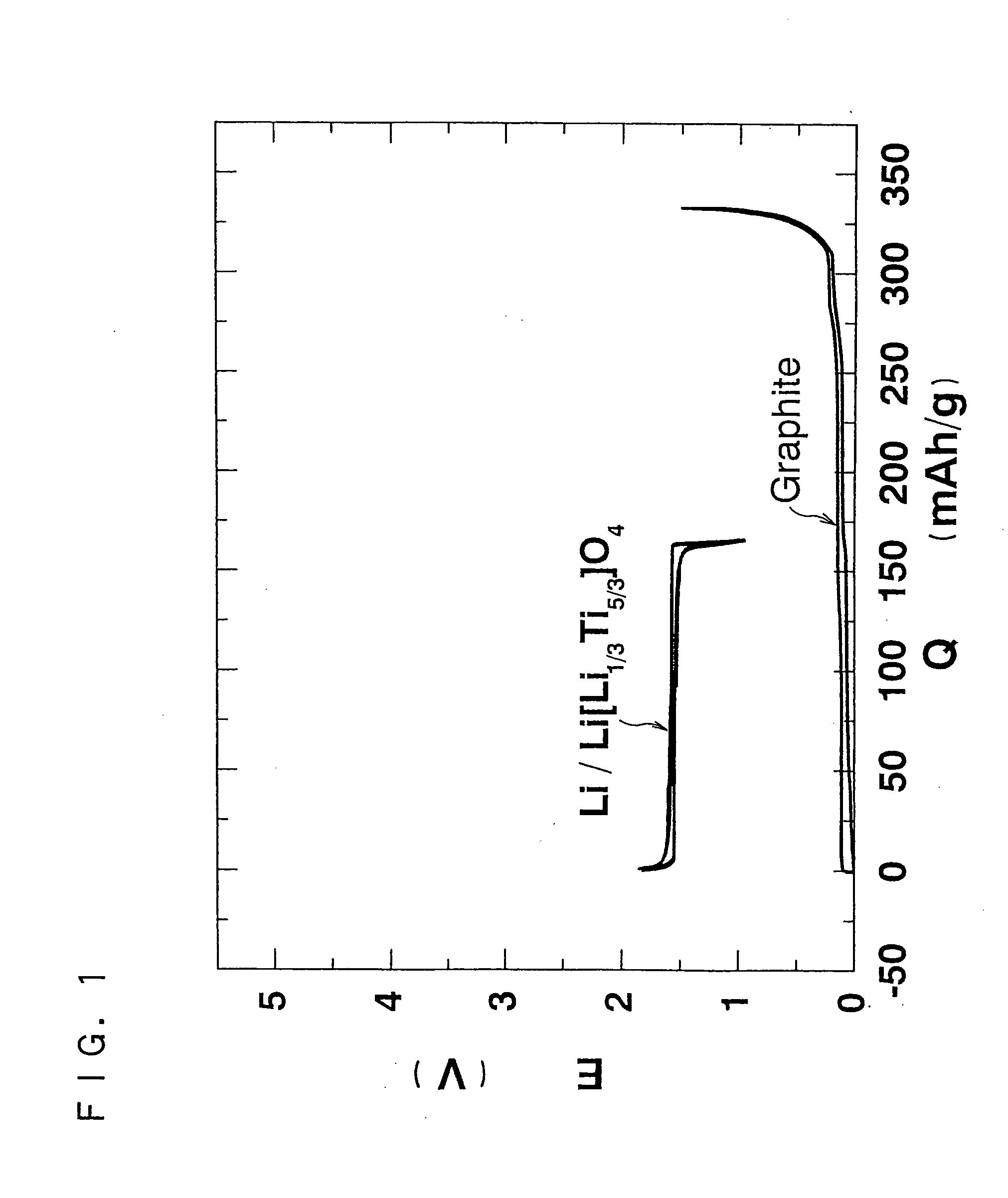

Non-aqueous electrolyte secondary battery

ActiveUS20050147889A1Reduce the possibilityIncrease resistanceFinal product manufactureElectrode carriers/collectorsHigh rateCobalt

As an alternative technique to lead-acid batteries, the present invention provides an inexpensive 2 V non-aqueous electrolyte secondary battery having excellent cycle life at a high rate by preventing volume change during charge and discharge. The non-aqueous electrolyte secondary battery uses: a positive electrode active material having a layered structure, being represented by chemical formula Li1±α[Me]O2, where 0≦α<0.2, and Me is a transition metal including Ni and at least one selected from the group consisting of Mn, Fe, Co, Ti and Cu, and including elemental nickel and elemental cobalt in substantially the same ratio; and a negative electrode active material including Li4Ti5O12(Li[Li1 / 3Ti5 / 3]O4).

Owner:OSAKA CITY UNIV +1

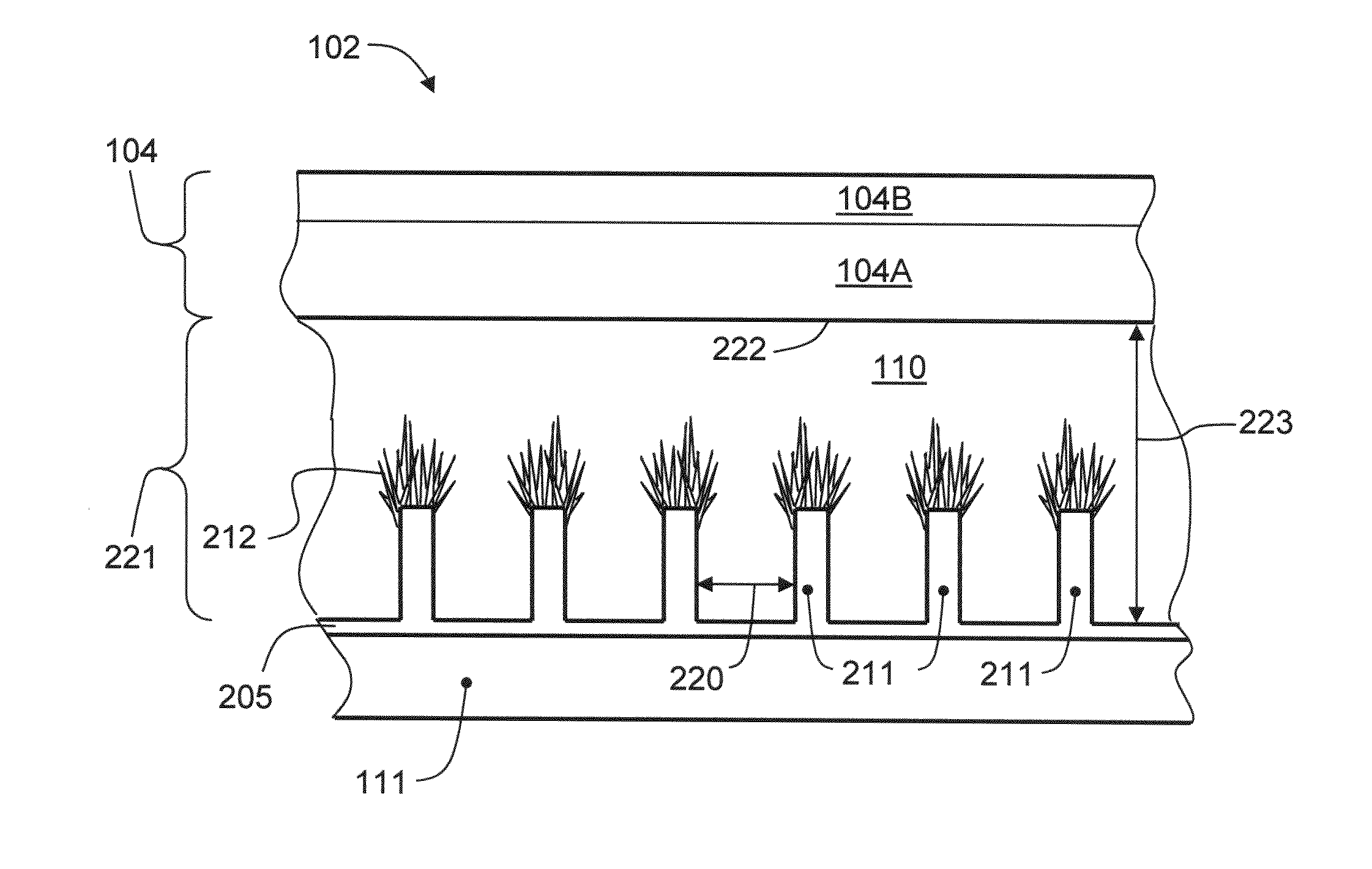

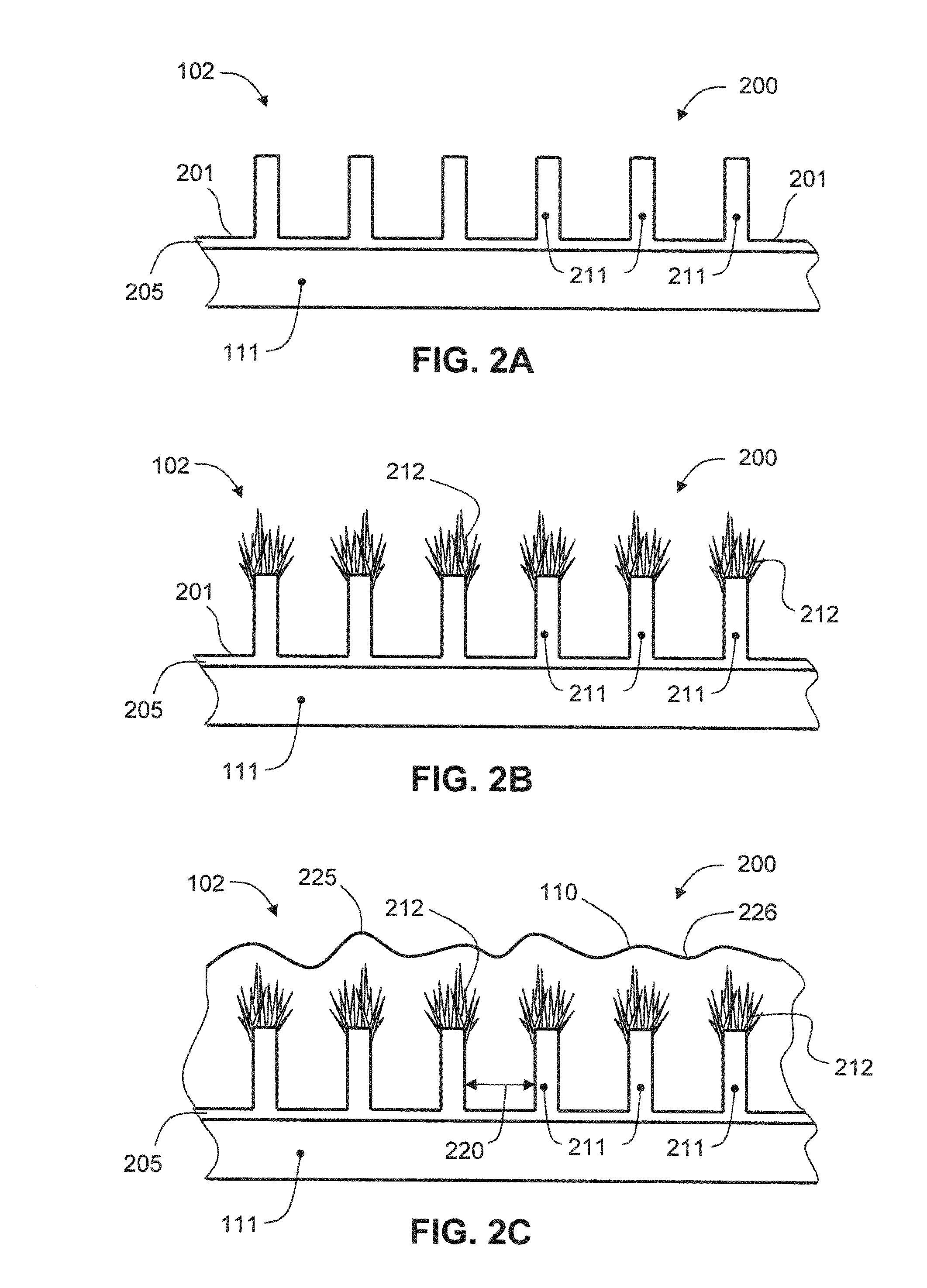

Thin film electrochemical energy storage device with three-dimensional anodic structure

InactiveUS20100216026A1Final product manufactureElectrode carriers/collectorsPorosityMicro structure

A method for forming a battery from via thin-film deposition processes is disclosed. A mesoporous carbon material is deposited onto a surface of a conductive substrate that has high surface area, conductive micro-structures formed thereon. A porous, dielectric separator layer is then deposited on the layer of mesoporous carbon material to form a half cell of an energy storage device. The mesoporous carbon material is made up of CVD-deposited carbon fullerene “onions” and carbon nano-tubes, and has a high porosity capable of retaining lithium ions in concentrations useful for storing significant quantities of electrical energy. Embodiments of the invention further provide for the formation of an electrode having a high surface area conductive region that is useful in a battery structure. In one configuration the electrode has a high surface area conductive region comprising a porous dendritic structure that can be formed by electroplating, physical vapor deposition, chemical vapor deposition, thermal spraying, and / or electroless plating techniques.

Owner:APPLIED MATERIALS INC

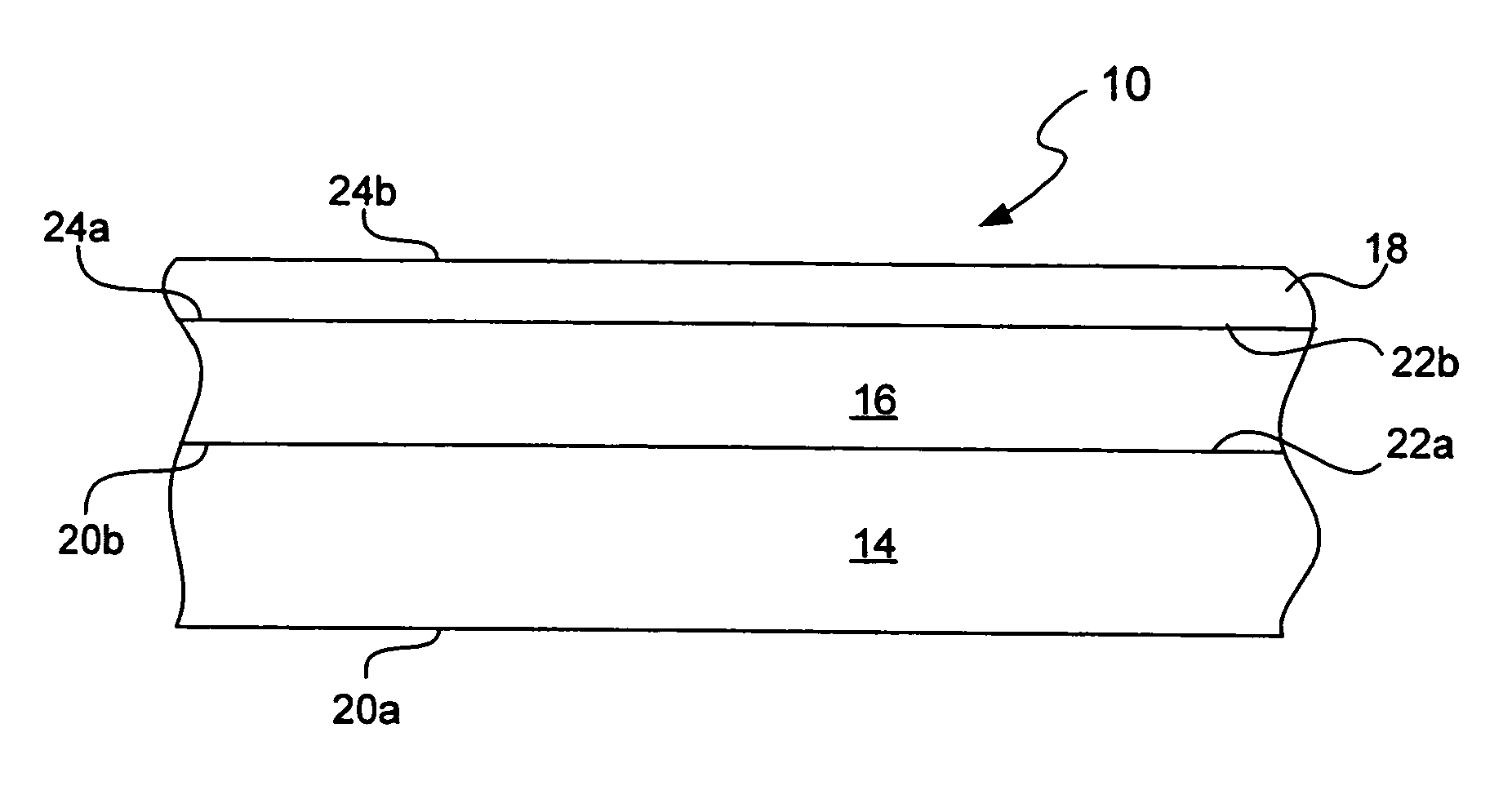

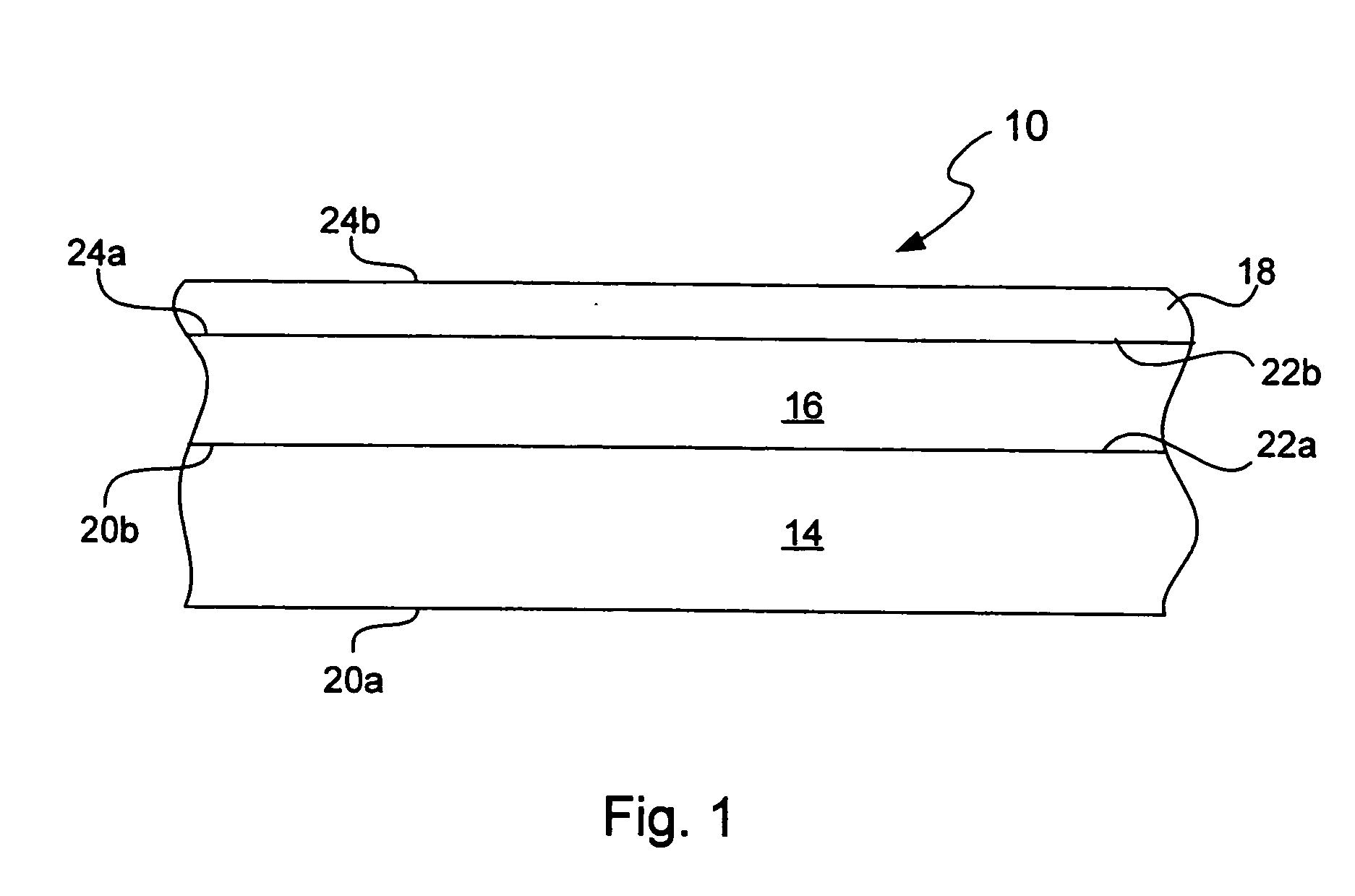

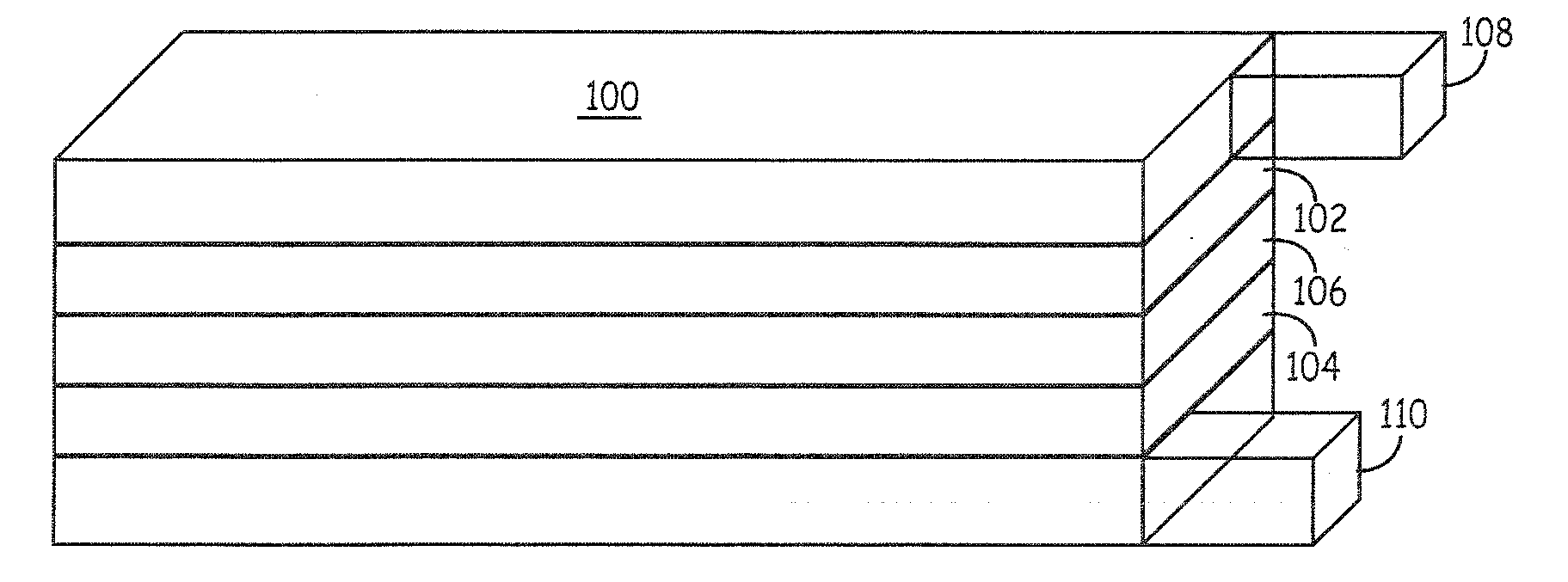

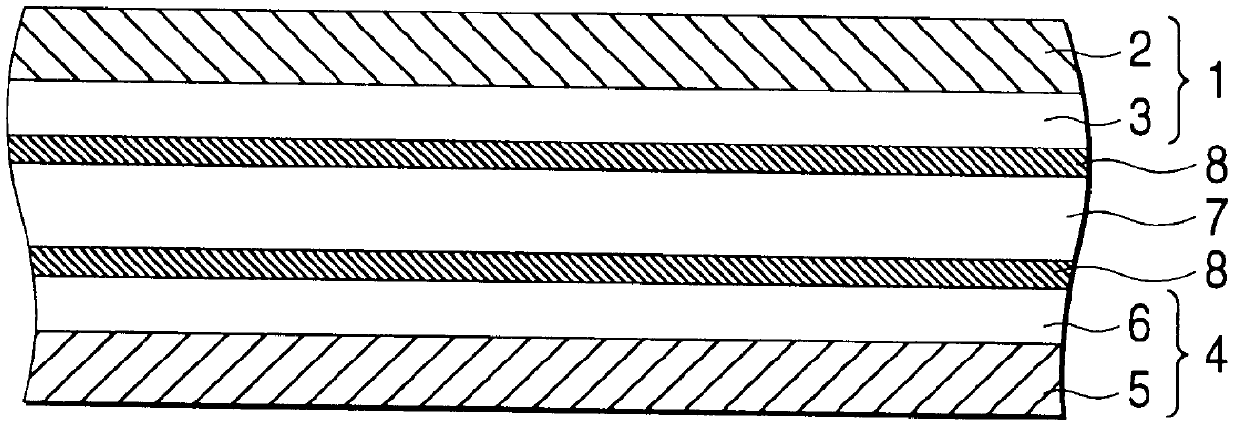

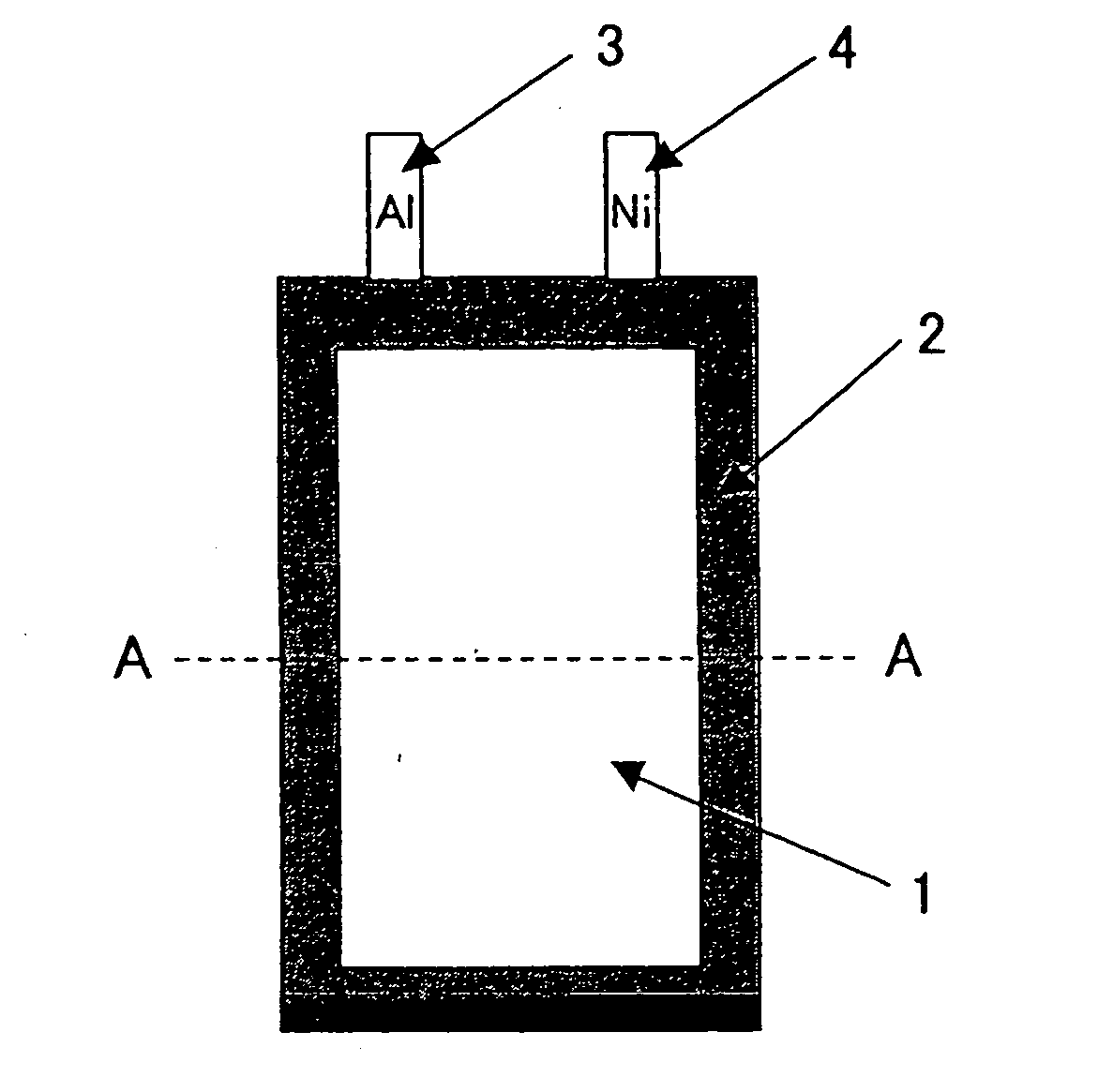

Thin-film batteries with soft and hard electrolyte layers and method

InactiveUS20070015060A1Improve environmental resistanceInhibition formationFinal product manufactureConductive materialLithium metalPolymer gel

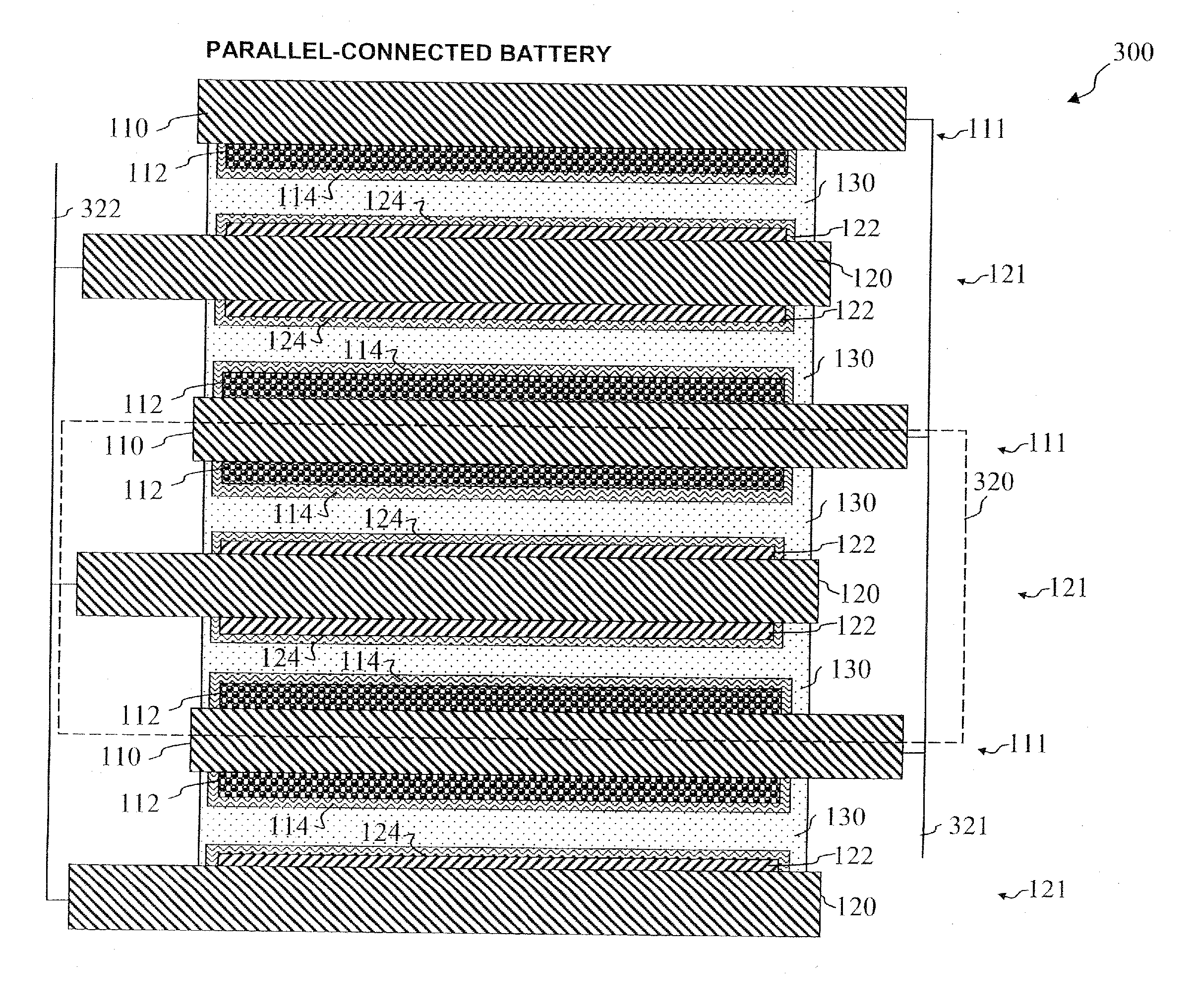

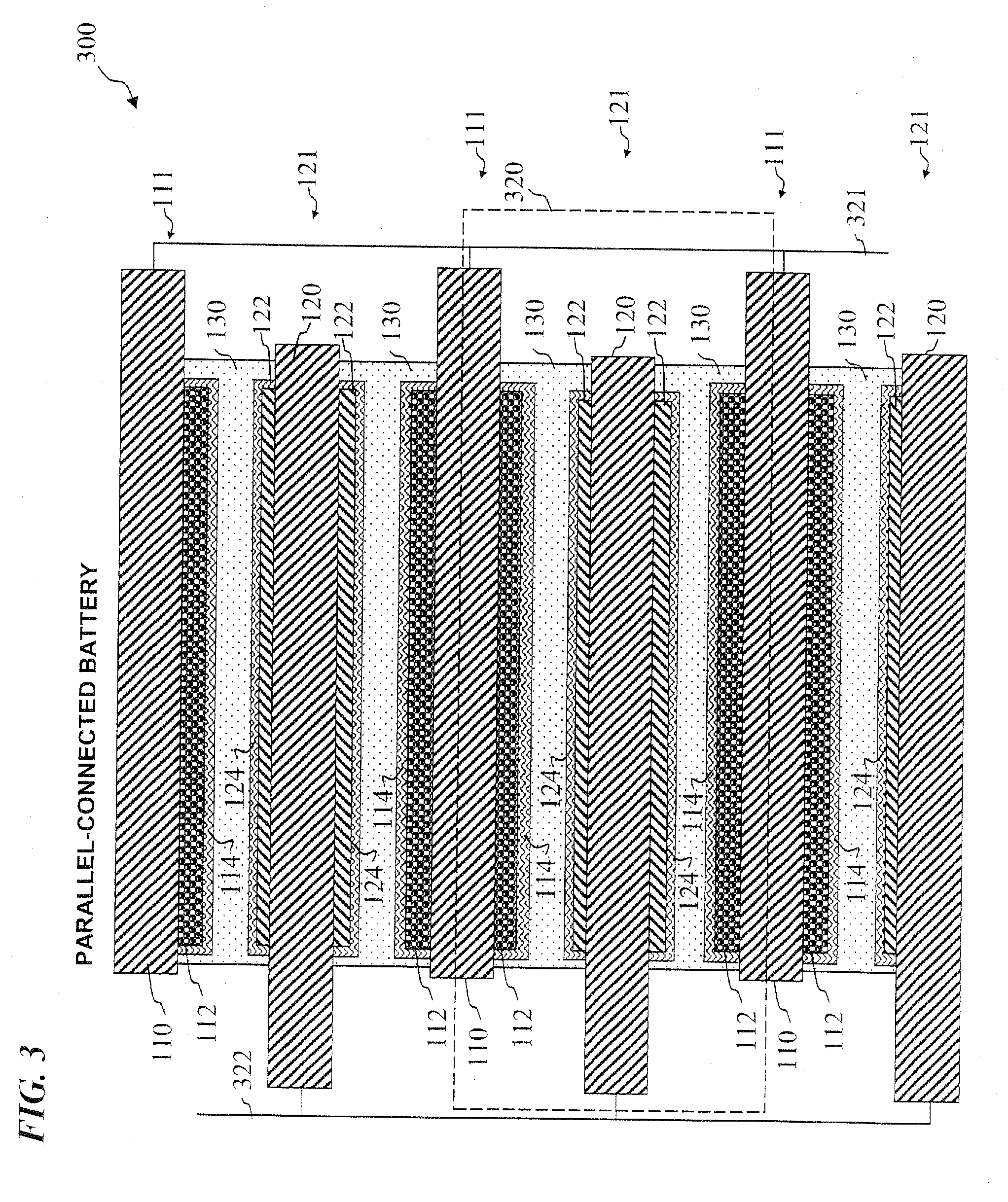

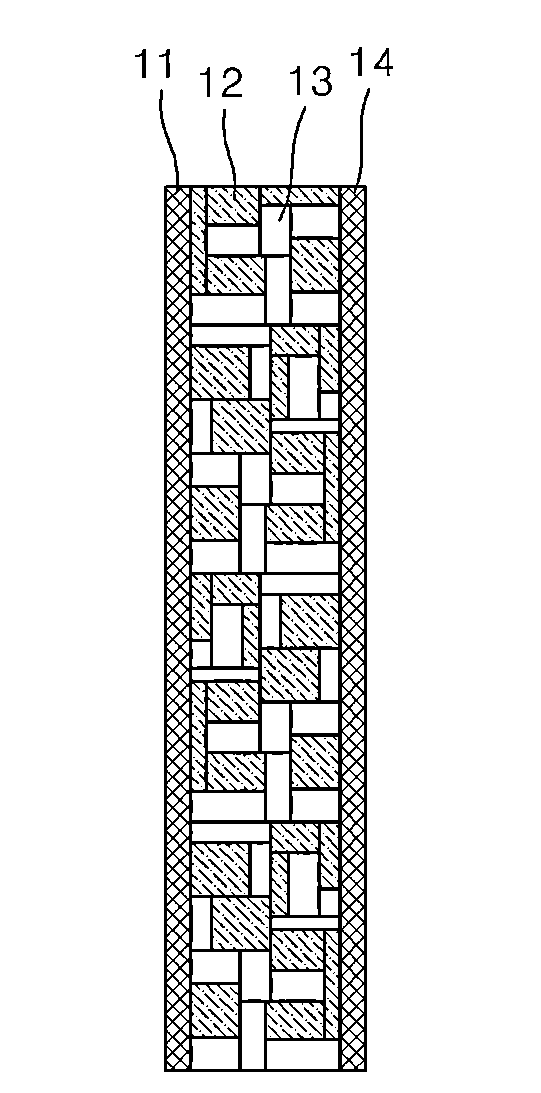

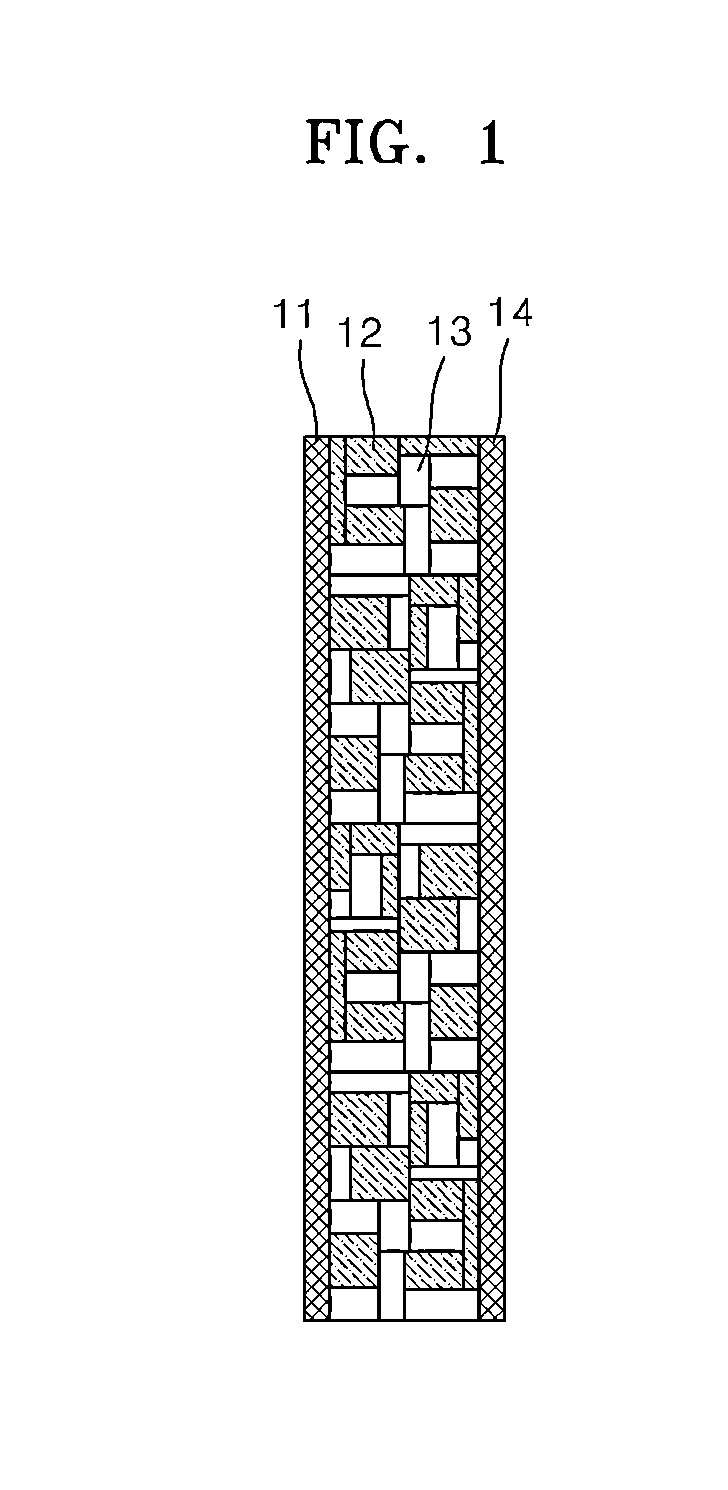

A method and apparatus for making thin-film batteries having composite multi-layered electrolytes with soft electrolyte between hard electrolyte covering the negative and / or positive electrode, and the resulting batteries. In some embodiments, foil-core cathode sheets each having a cathode material (e.g., LiCoO2) covered by a hard electrolyte on both sides, and foil-core anode sheets having an anode material (e.g., lithium metal) covered by a hard electrolyte on both sides, are laminated using a soft (e.g., polymer gel) electrolyte sandwiched between alternating cathode and anode sheets. A hard glass-like electrolyte layer obtains a smooth hard positive-electrode lithium-metal layer upon charging, but when very thin, have randomly spaced pinholes / defects. When the hard layers are formed on both the positive and negative electrodes, one electrode's dendrite-short-causing defects on are not aligned with the other electrode's defects. The soft electrolyte layer both conducts ions across the gap between hard electrolyte layers and fills pinholes.

Owner:CYMBET CORP

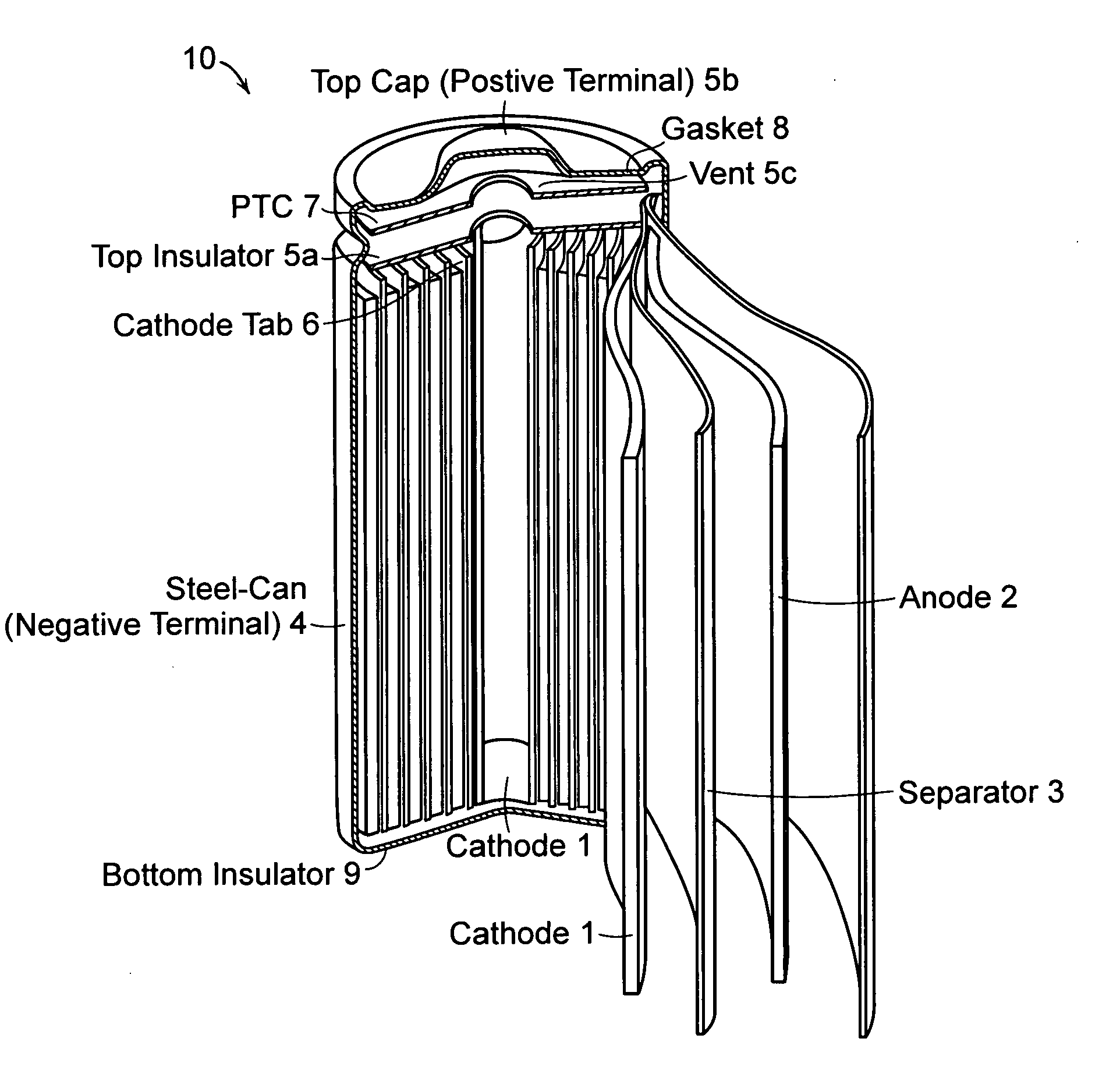

Lithium-ion secondary battery

InactiveUS20070026315A1Safer chemistry characteristicLow cathode costPrimary cell to battery groupingFinal product manufactureManganateSpinel

A lithium-ion battery includes a cathode that includes an active cathode material. The active cathode material includes a cathode mixture that includes a lithium cobaltate and a manganate spinel a manganate spinel represented by an empirical formula of Li(1+x1)(Mn1−y1A′y2)2−x2Oz1. The lithium cobaltate and the manganate spinel are in a weight ratio of lithium cobaltate: manganate spinel between about 0.95:0.05 to about 0.55:0.45. A lithium-ion battery pack employs a cathode that includes an active cathode material as described above. A method of forming a lithium-ion battery includes the steps of forming an active cathode material as described above; forming a cathode electrode with the active cathode material; and forming an anode electrode in electrical contact with the cathode via an electrolyte.

Owner:BOSTON POWER INC

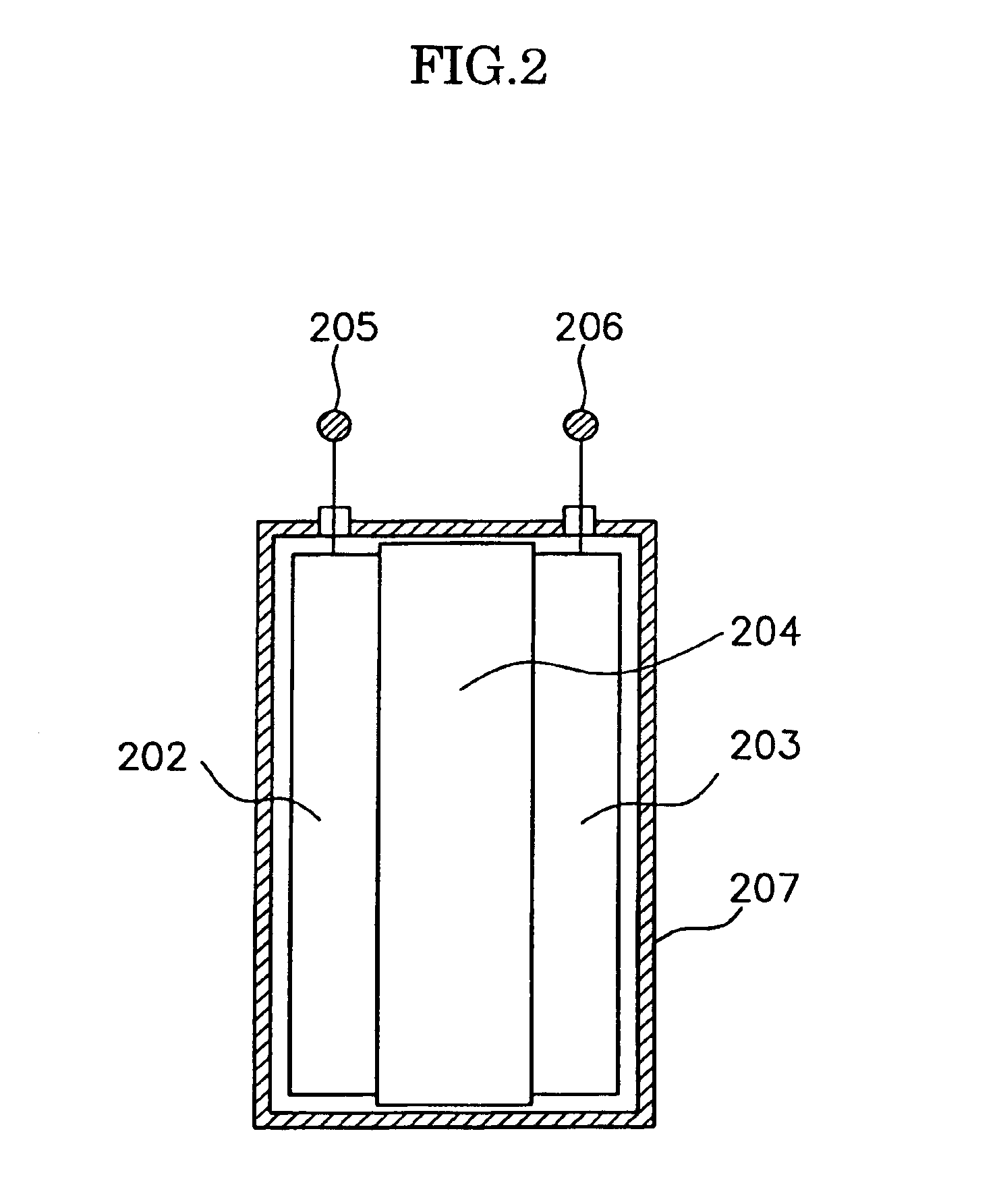

Electrical storage device and manufacturing electrical storage device

InactiveUS20060057433A1Improve breakdown voltageIncrease energy densityFinal product manufactureElectrolyte/reactants regenerationElectrode potentialShape change

An electrical storage device of the present invention is characterized in that a positive electrode, a negative electrode, a lithium electrode, and an electrolyte capable of transferring lithium ion is included, the lithium electrode is arranged to be out of direct contact with the negative electrode, and lithium ion can be supplied to the negative electrode by flowing a current between the lithium electrode and the negative electrode through an external circuit. With the above characteristic, problems such as non-uniform carrying of lithium ion to the negative electrode, shape-change of a cell, and temperature increase of an electrolytic solution under incomplete sealing of a cell and the like can be easily solved. A using method of the electrical storage device is characterized in that, by using the lithium electrode as a reference electrode, the positive electrode potential and negative electrode potential can be measured, and the potential of the positive or negative electrode can be controlled when the electrical storage device is charged or discharged. Therefore, the potentials of the positive electrode and negative electrode can be monitored, thereby it can be easily determined whether deterioration of the electrical storage device is caused by the positive electrode or the negative electrode. Also, it is possible to control the device with the potential difference between the negative electrode and reference electrode, that is, the negative potential. In addition, when characteristics deteriorate such as the internal resistance increase, an appropriate amount of lithium ion can be supplied to the negative electrode and / or positive electrode by the lithium electrode.

Owner:FUJI JUKOGYO KK

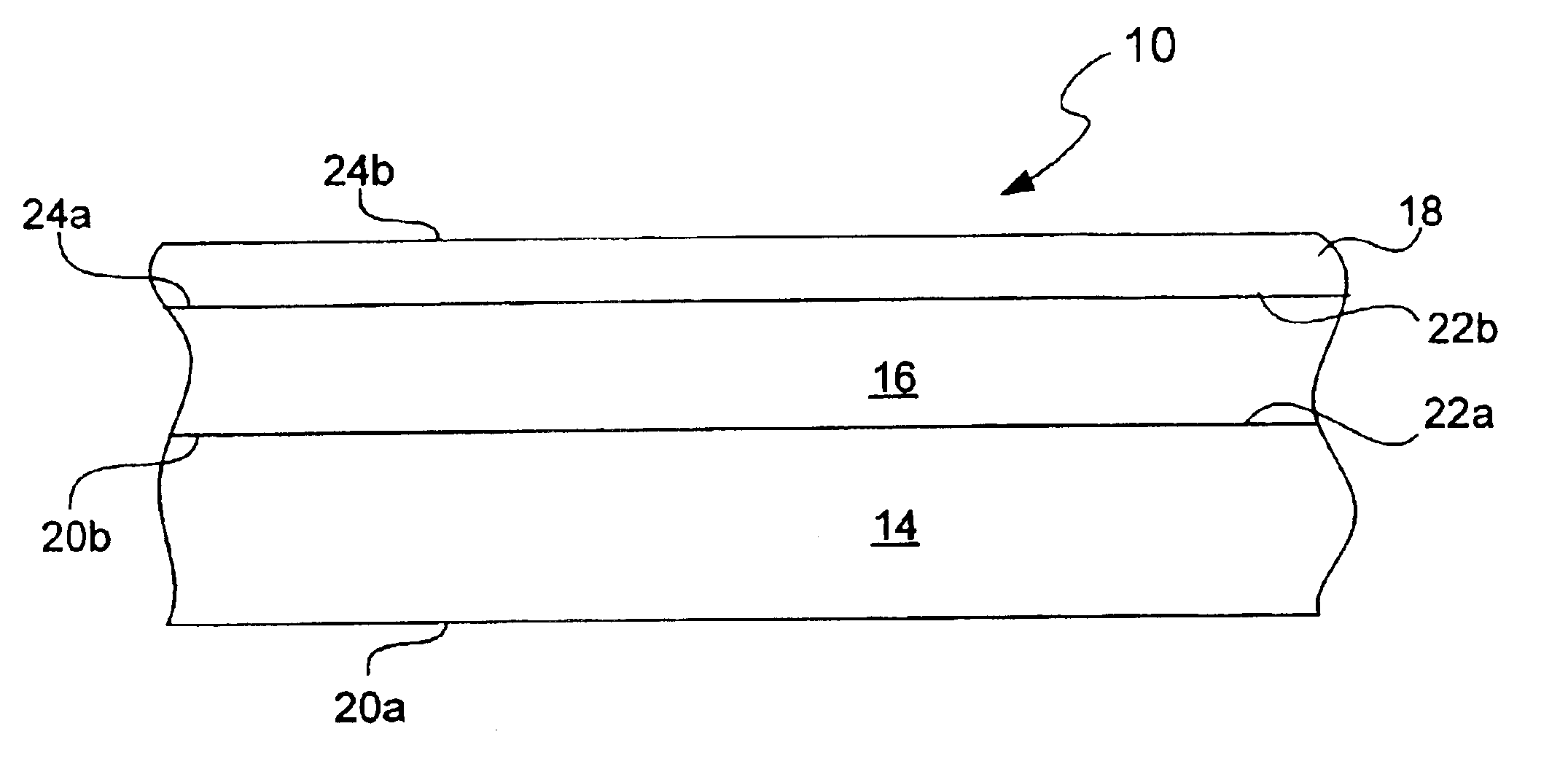

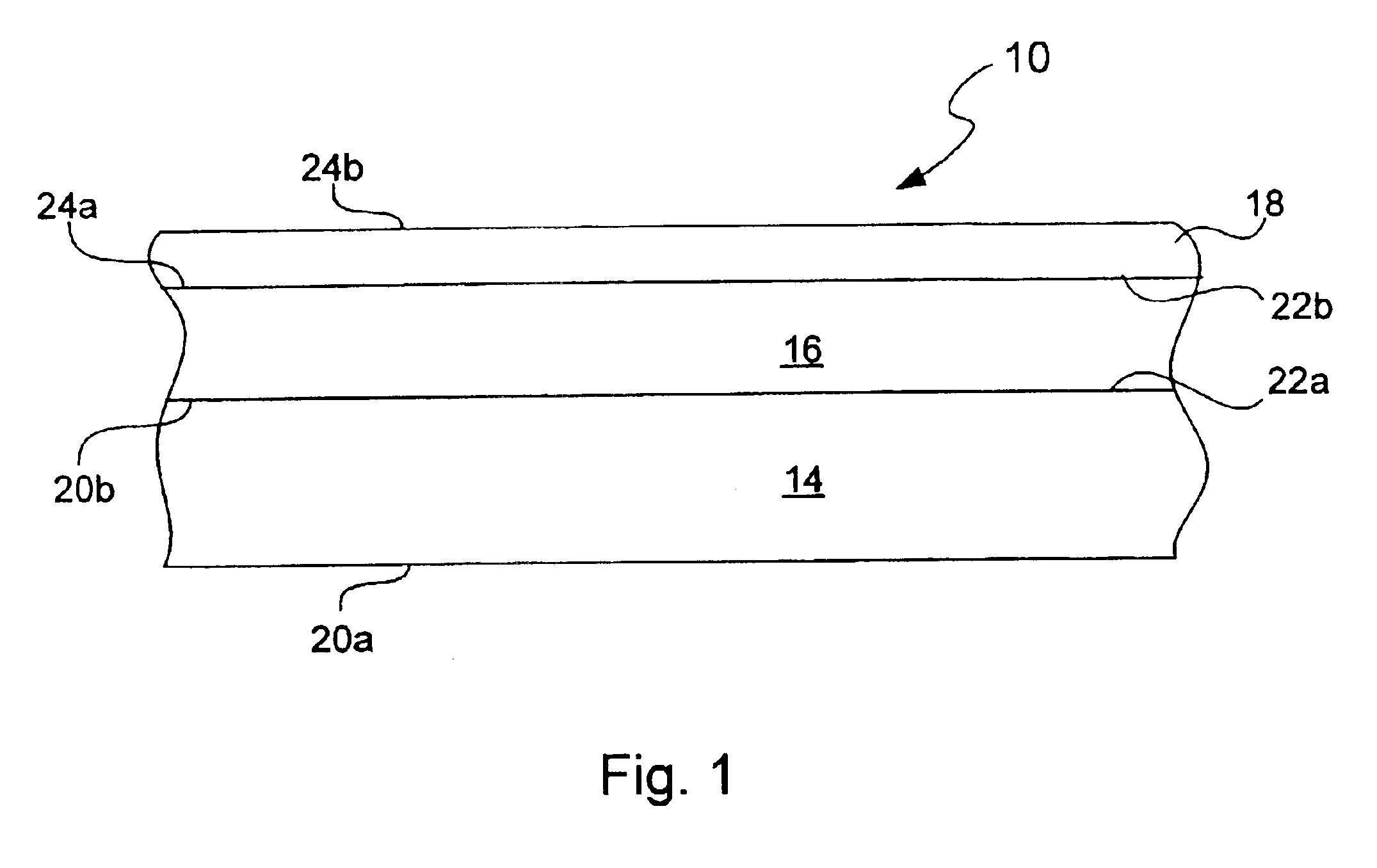

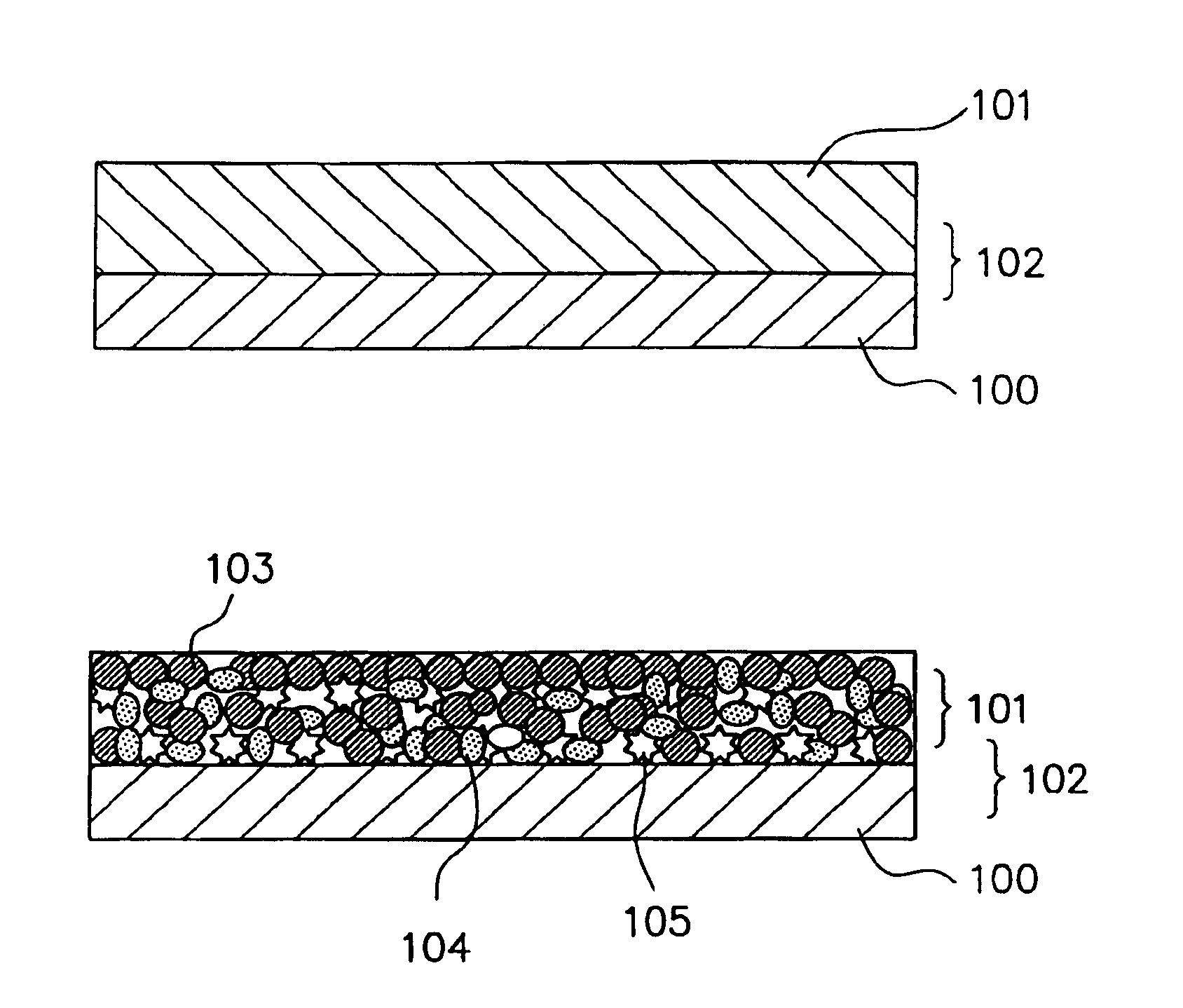

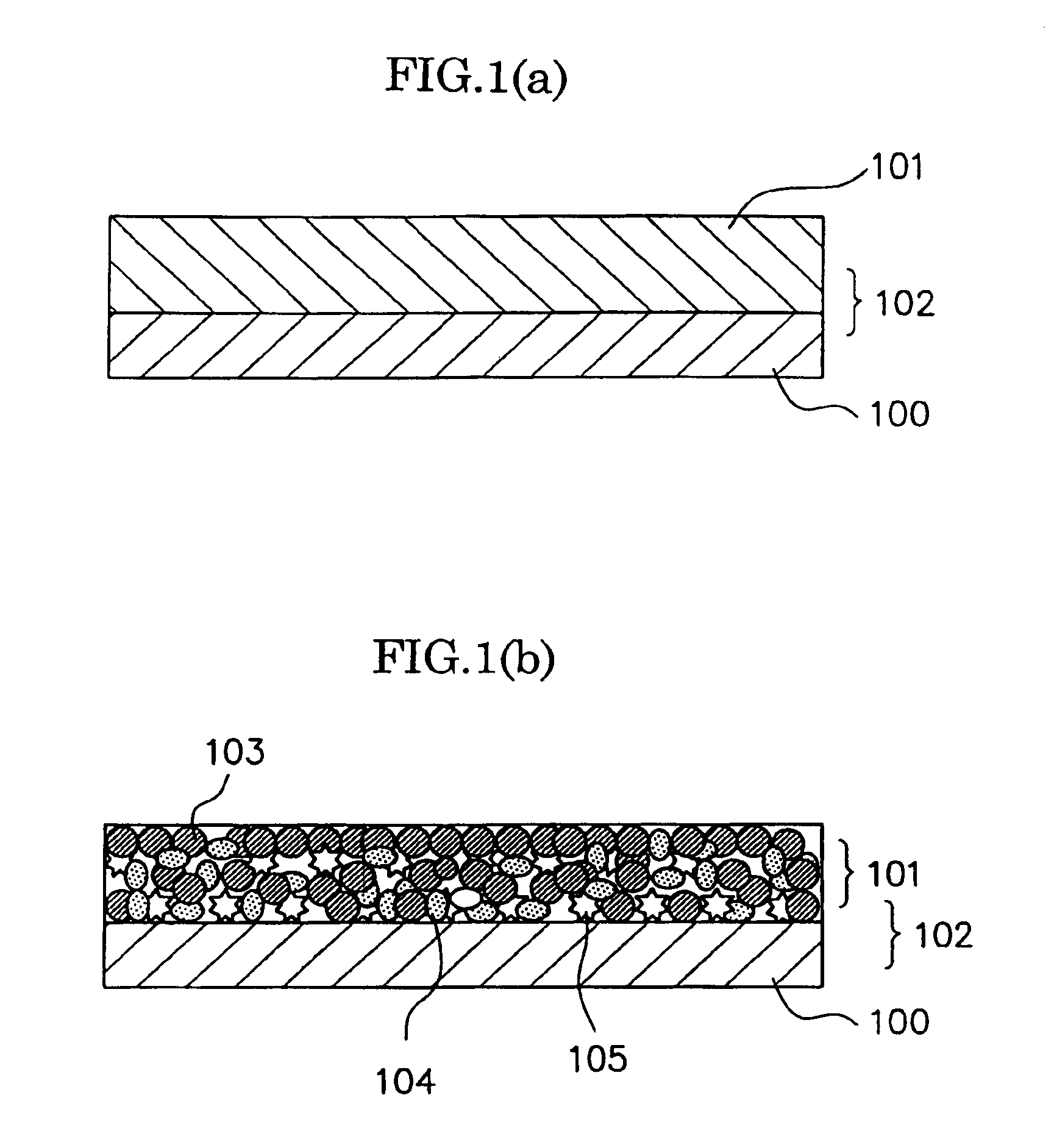

Flexible solid electrolyte, all-solid-state lithium battery including the flexible solid electrolyte, and method of preparing the flexible solid electrolyte

InactiveUS20140170504A1Improve ionic conductivityFinal product manufactureAbrasion apparatusAll solid stateComposite electrolyte

A flexible solid electrolyte includes a first inorganic protective layer, an inorganic-organic composite electrolyte layer including an inorganic component and an organic component, and a second inorganic protective layer, where the inorganic-organic composite electrolyte layer is disposed between the first inorganic protective layer and the second inorganic protective layer, and the inorganic component and the organic component collectively form a continuous ion conducting path.

Owner:SAMSUNG ELECTRONICS CO LTD

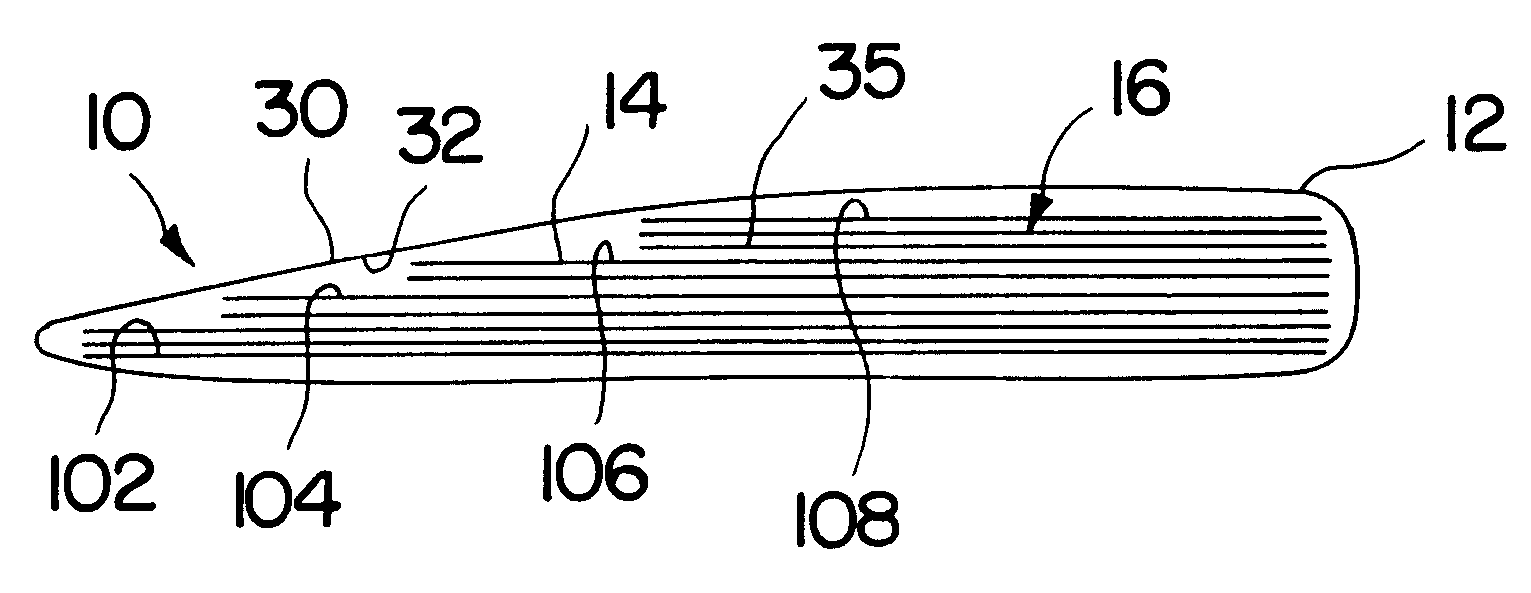

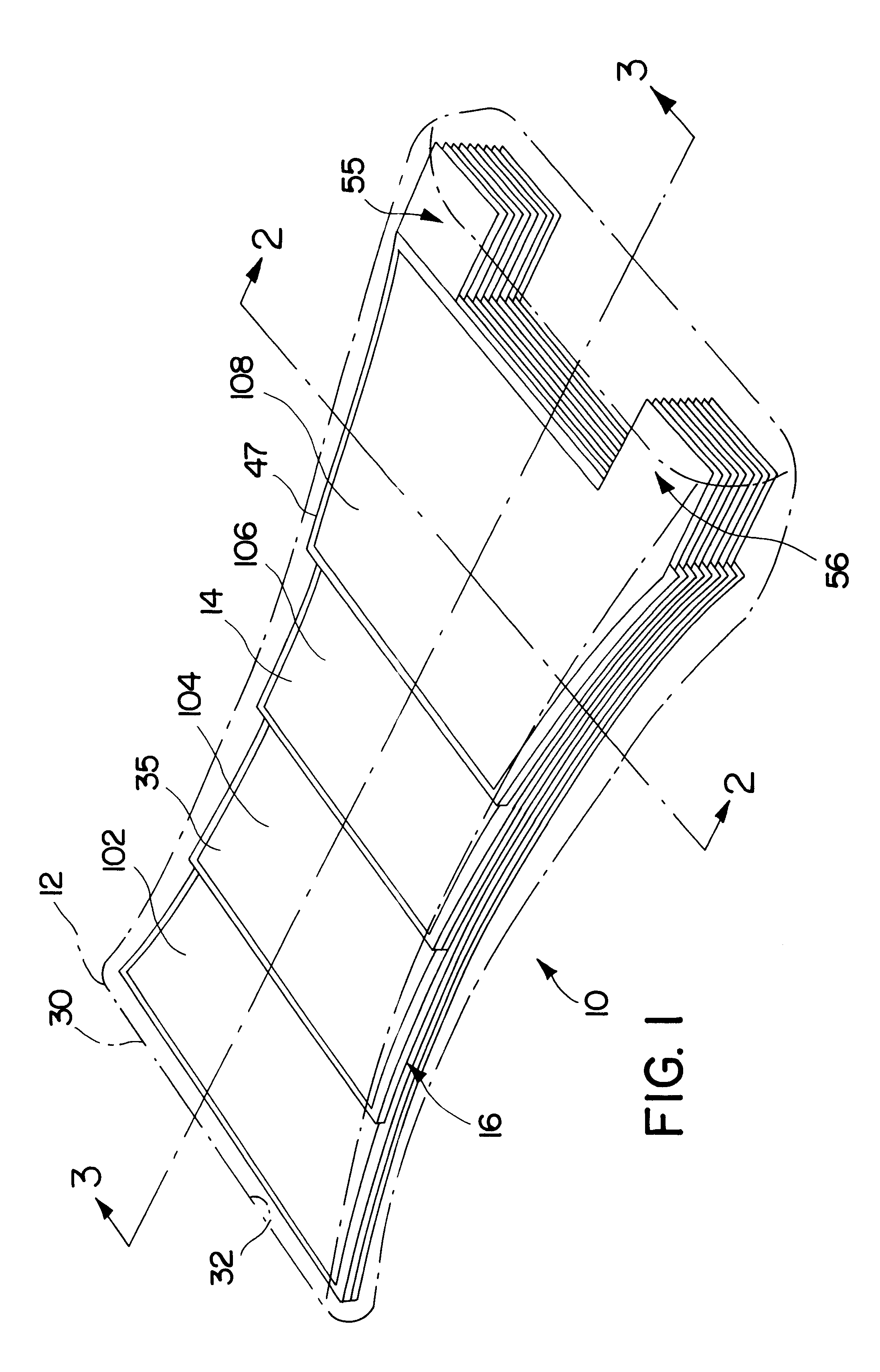

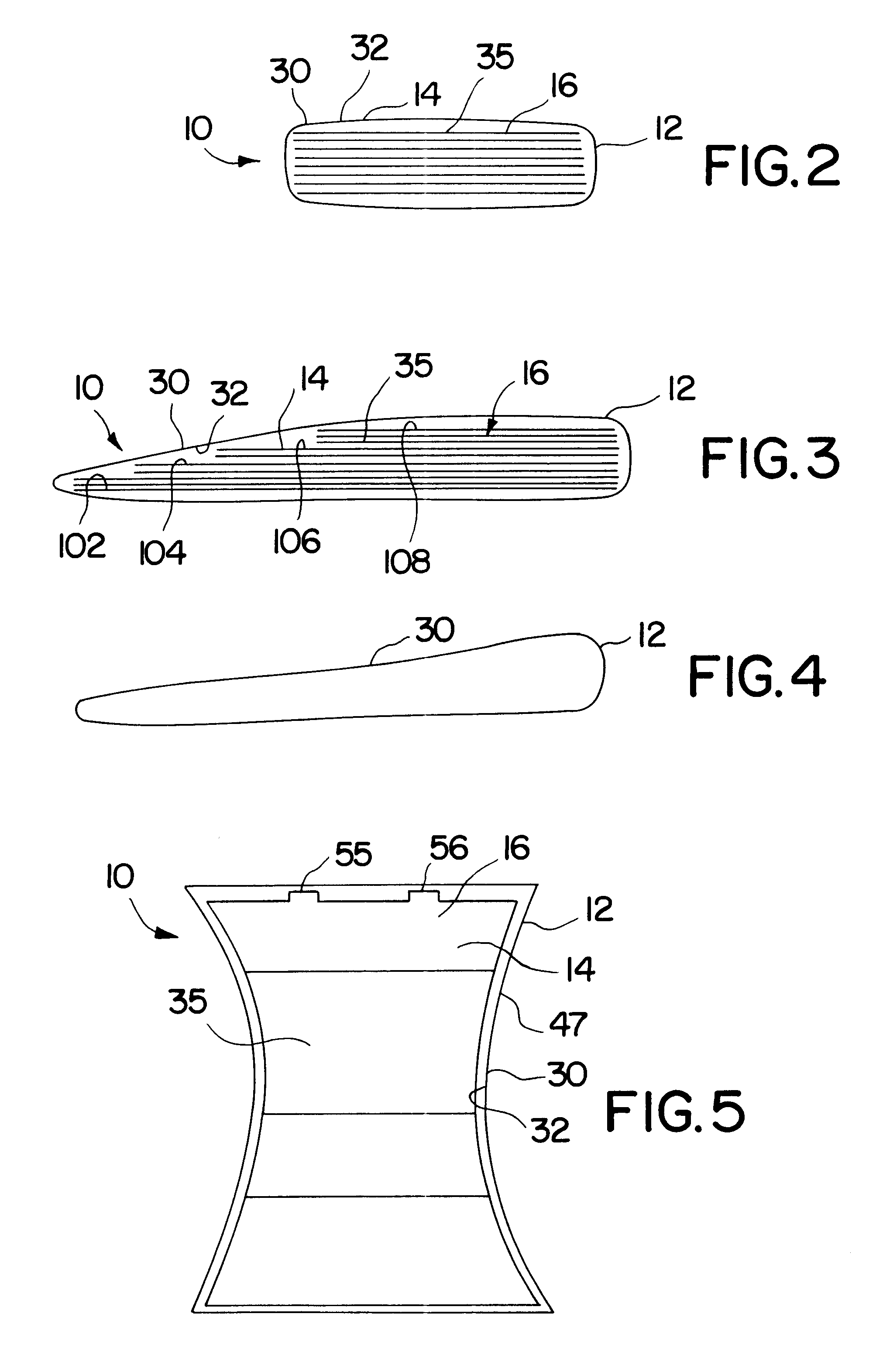

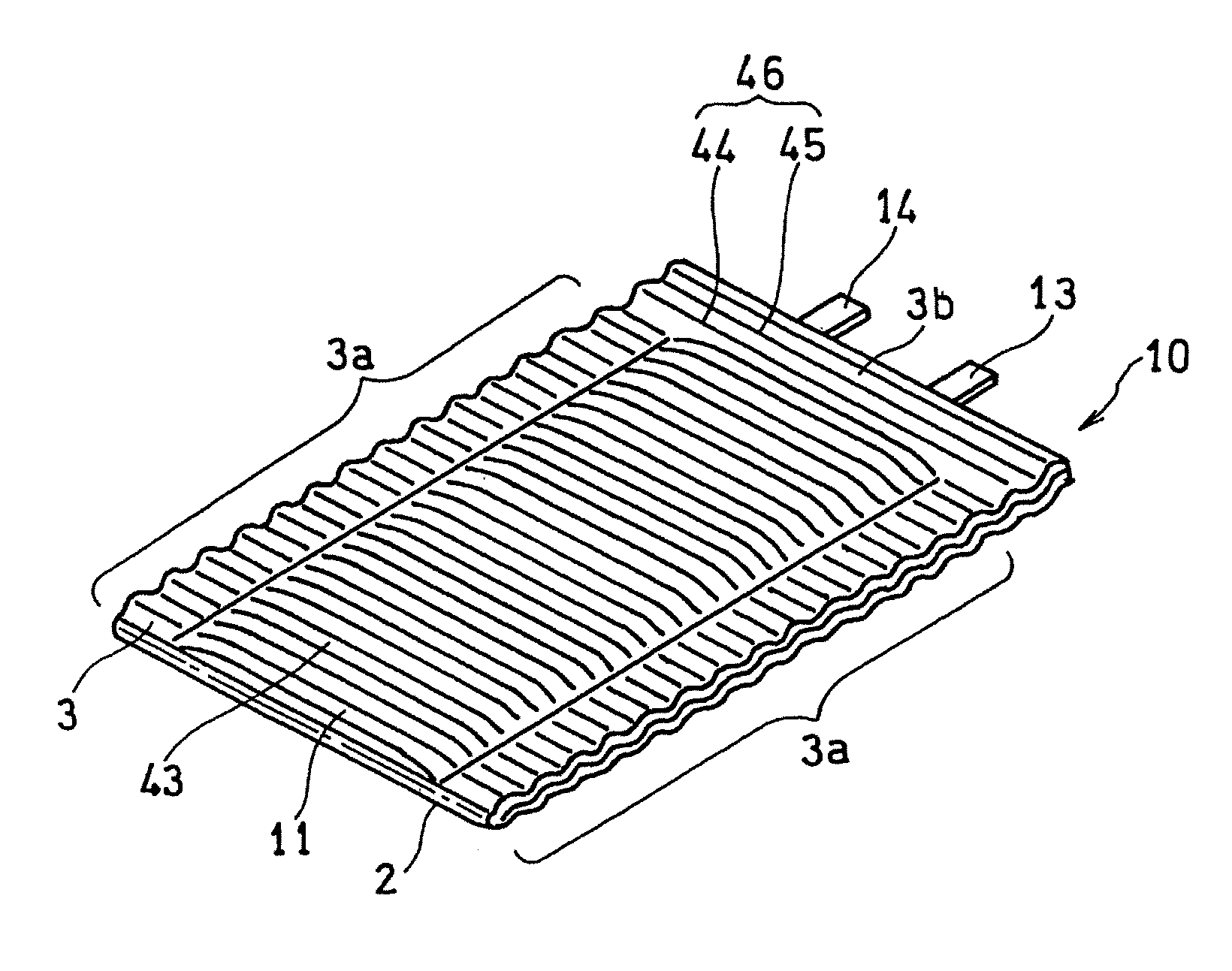

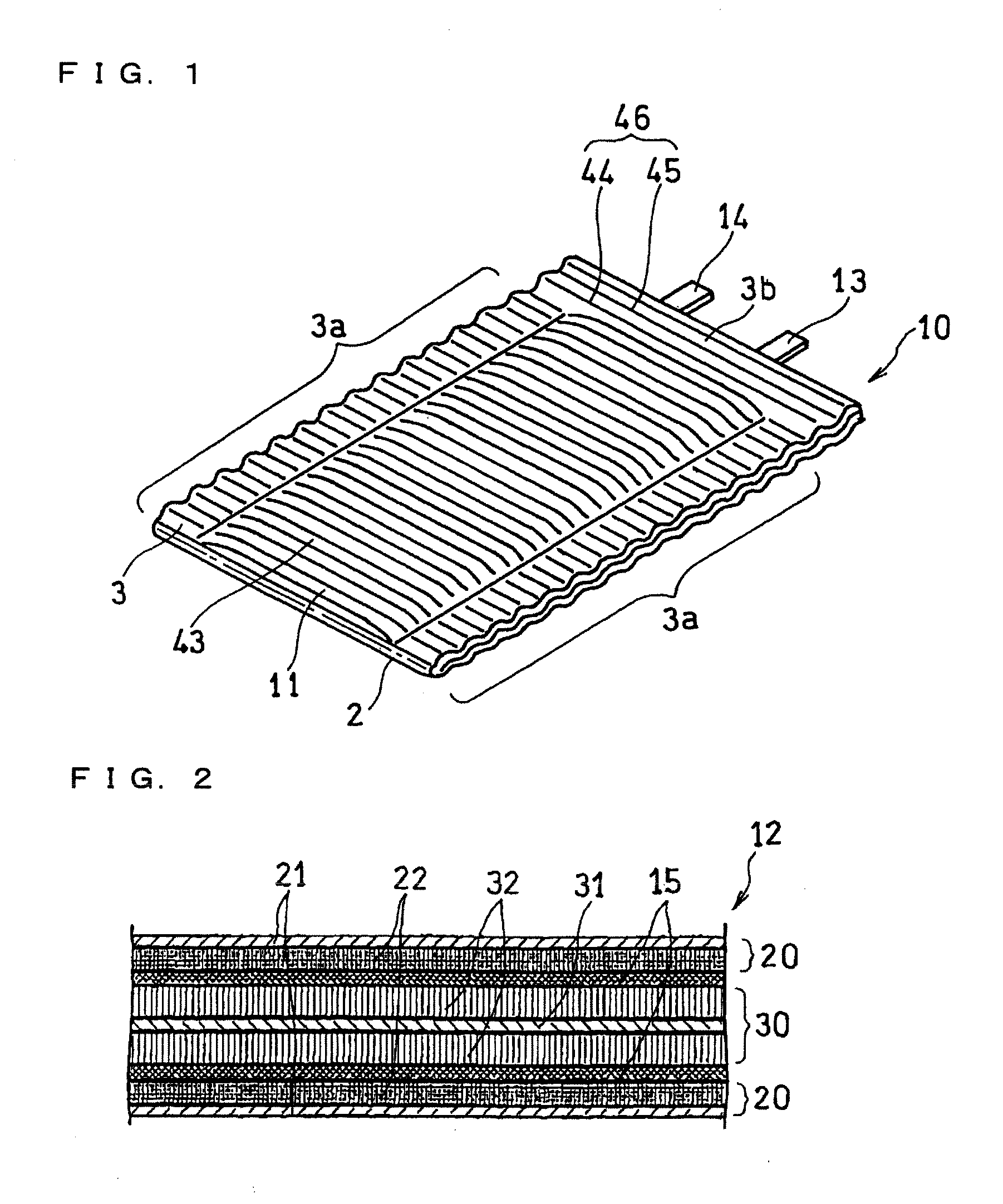

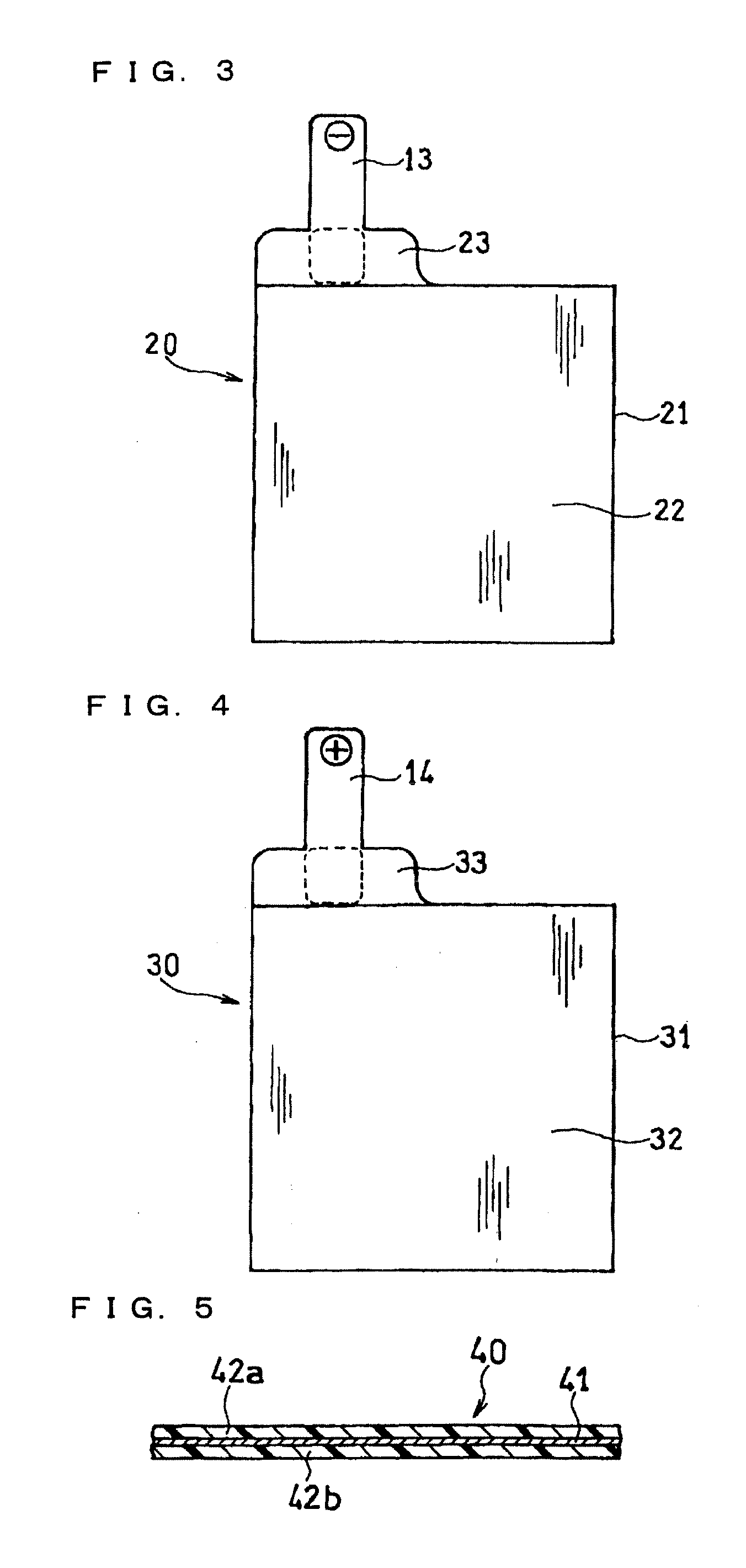

Flexible battery and method for producing the same

InactiveUS20130101884A1Impart high flexibilityImproves sealing reliabilityFinal product manufactureSmall-sized cells cases/jacketsEngineeringFlexible battery

Disclosed is a flexible battery including a sheet-like electrode group, an electrolyte, and a housing with flexibility enclosing the electrode group and electrolyte. The housing includes a film material folded into two in which the electrode group is inserted. The film material has two facing portions respectively facing two principal surfaces of the electrode group, a fold line which is between the two facing portions and along which the film material is folded, and two bonding margins respectively set around the two facing portions. The two bonding margins are bonded to each other into a bonded portion. At least the two facing portions of the film material are formed in a corrugated shape having a plurality of ridge and valley lines arranged in parallel to each other. The ridge lines in one of the two facing portions are overlapped with the valley lines in the other. The fold line is parallel to the ridge and valley lines.

Owner:PANASONIC CORP

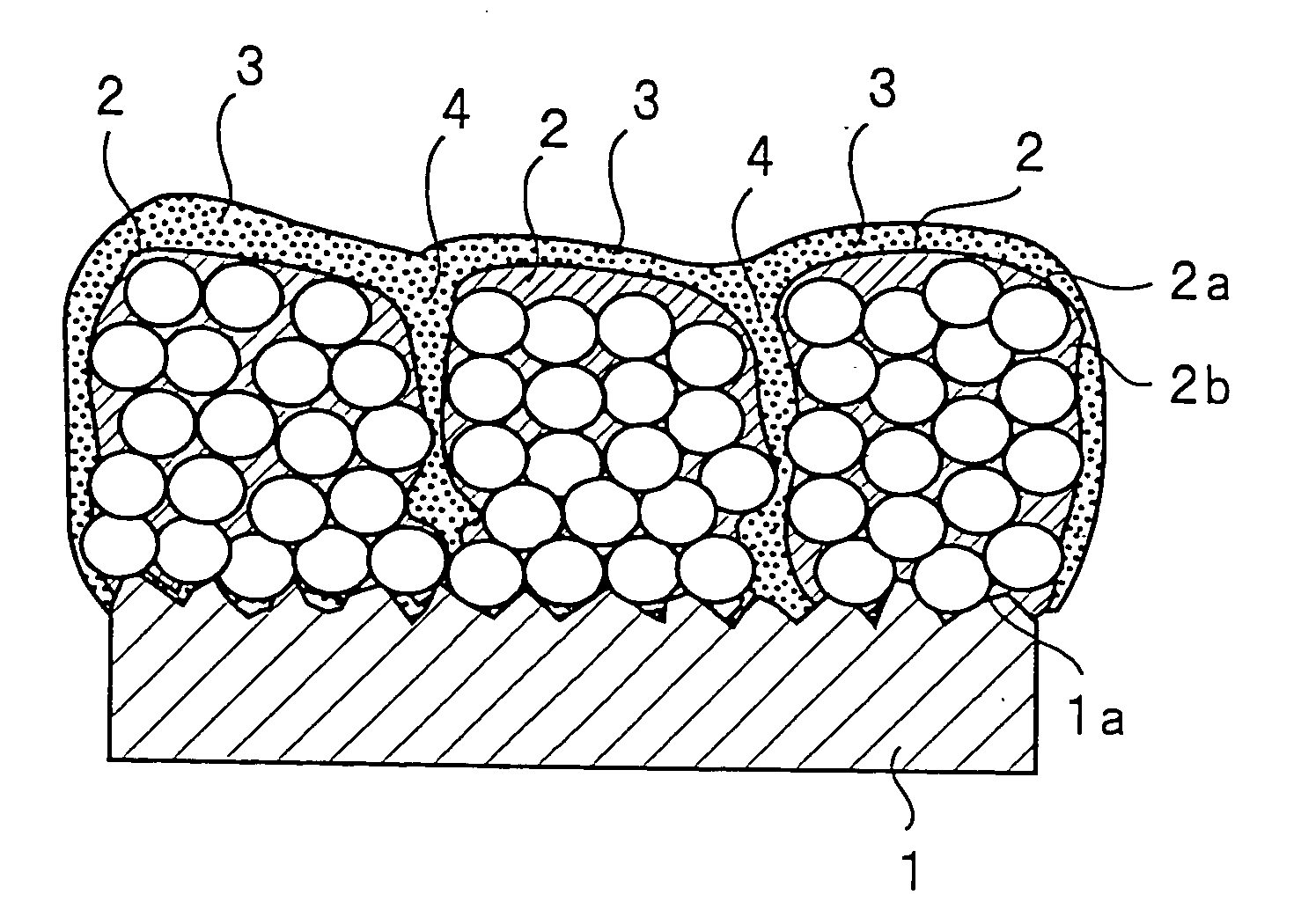

Lithium secondary battery and method for manufacturing thereof

InactiveUS20040072067A1Increase currentExtended discharge cycleFinal product manufactureElectrode carriers/collectorsLithiumElectrochemistry

A lithium secondary battery comprising an electrode in which an active material layer which includes an active material that electrochemically occludes and releases lithium is formed on a current collector, wherein cracks are formed in the active material layer by occlusion and release of lithium ions and thereafter a solid electrolyte is formed in the cracks in the active material layer.

Owner:SANYO ELECTRIC CO LTD

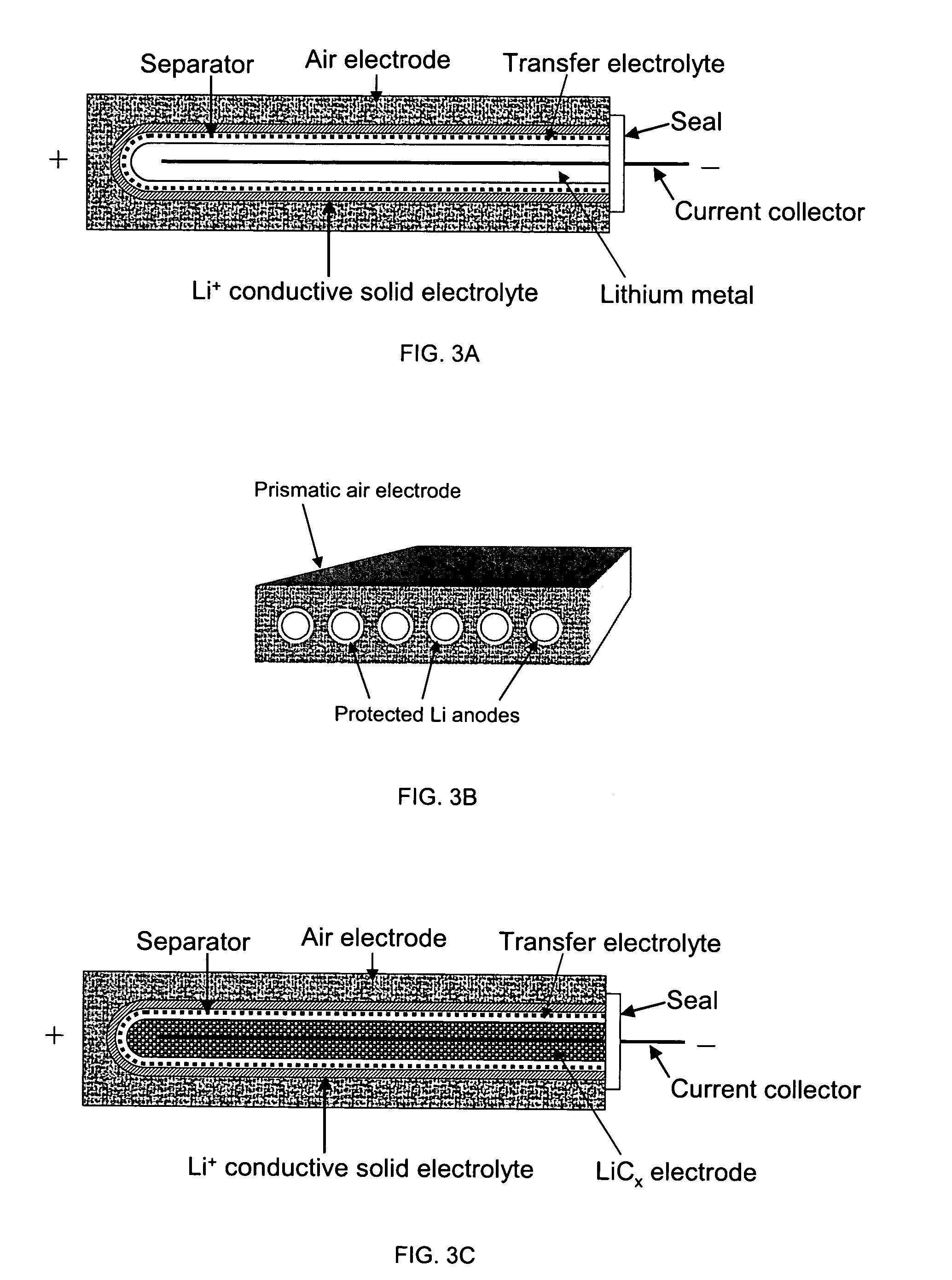

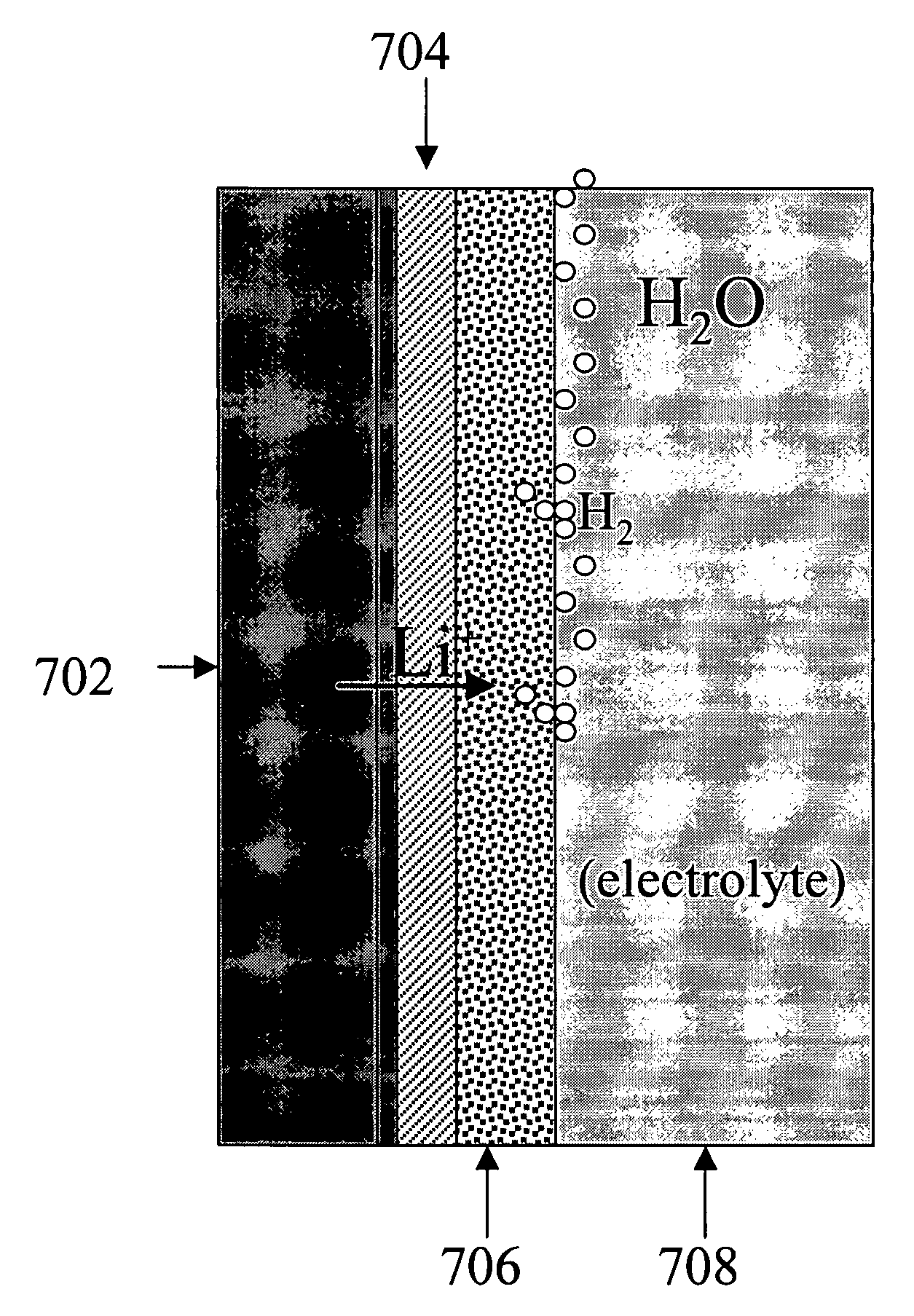

Active metal/aqueous electrochemical cells and systems

InactiveUS7645543B2Degree of flexibilityWithout performanceFuel and primary cellsAlkaline accumulatorsElectrochemical cellBattery cell

Alkali (or other active) metal battery and other electrochemical cells incorporating active metal anodes together with aqueous cathode / electrolyte systems. The battery cells have a highly ionically conductive protective membrane adjacent to the alkali metal anode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the anode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or cathode material in conjunction with the anode. Also, optimization of electrolytes or cathode-side solvent systems may be done without impacting anode stability or performance. In particular, Li / water, Li / air and Li / metal hydride cells, components, configurations and fabrication techniques are provided.

Owner:POLYPLUS BATTERY CO INC

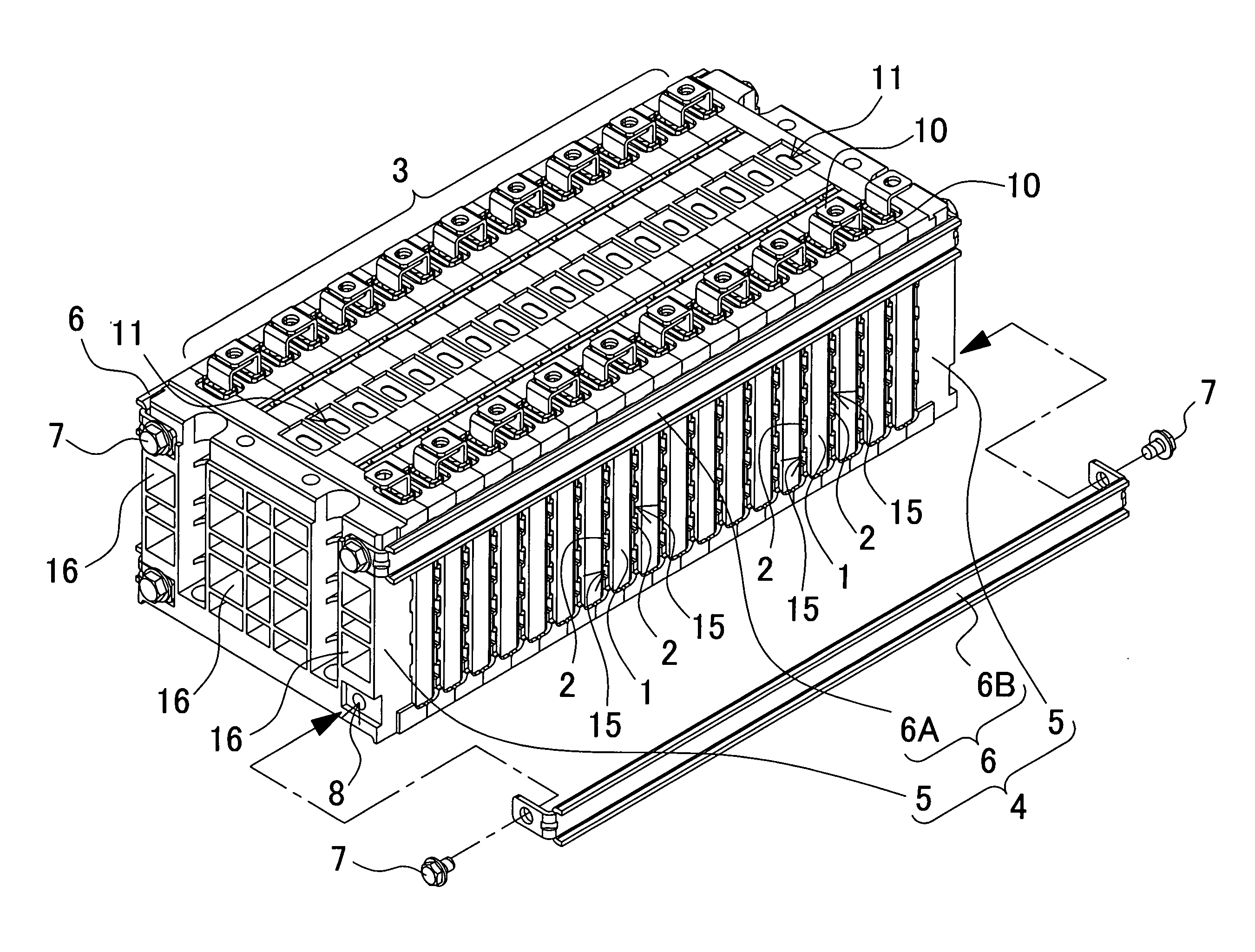

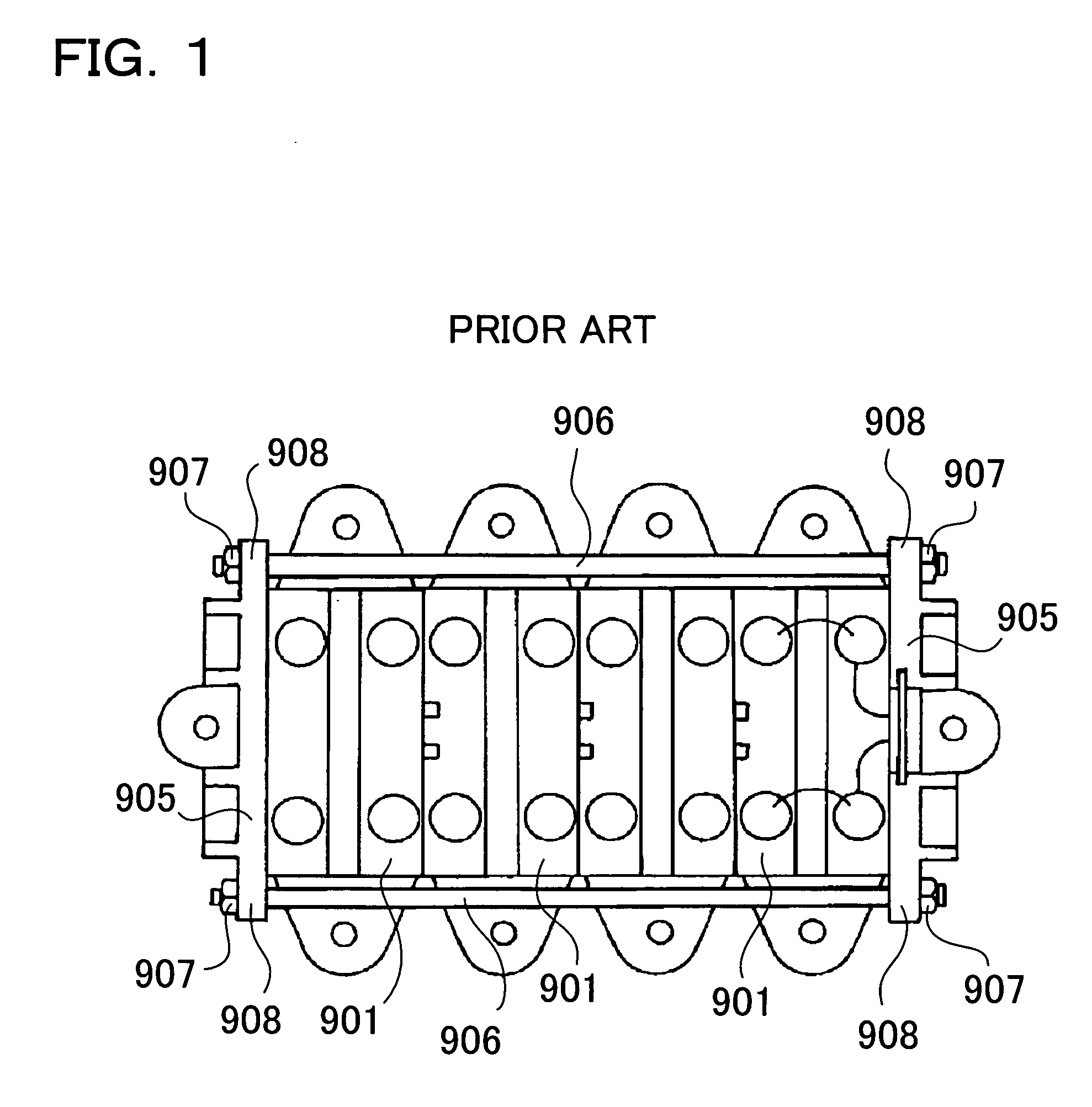

Battery pack

InactiveUS20080280194A1Performance of cell in use can be preventedOvercomes drawbackPrimary cell to battery groupingCell temperature controlBattery packMetal

The battery pack includes a battery block in which a plurality of electric cells being rectangular cells are layed, and a fixture component for fixing the electric cells in the battery block. The fixture component includes a pair of end plates disposed on opposite side faces of the layered rectangular cells, and a metal strap with which the layered rectangular cells are fixed in their compressed state by connecting the tip of the metal strap to the end plate.

Owner:SANYO ELECTRIC CO LTD

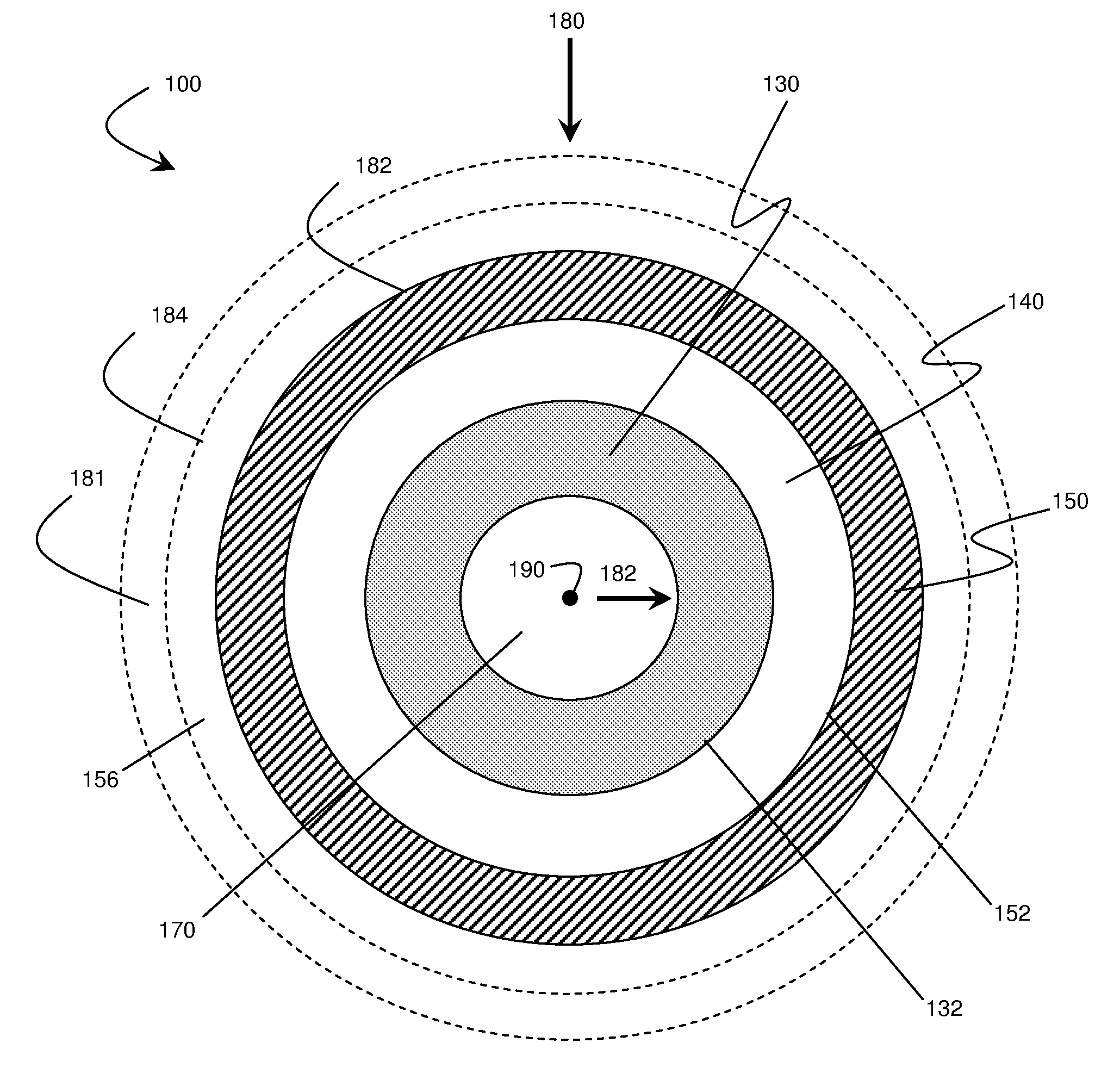

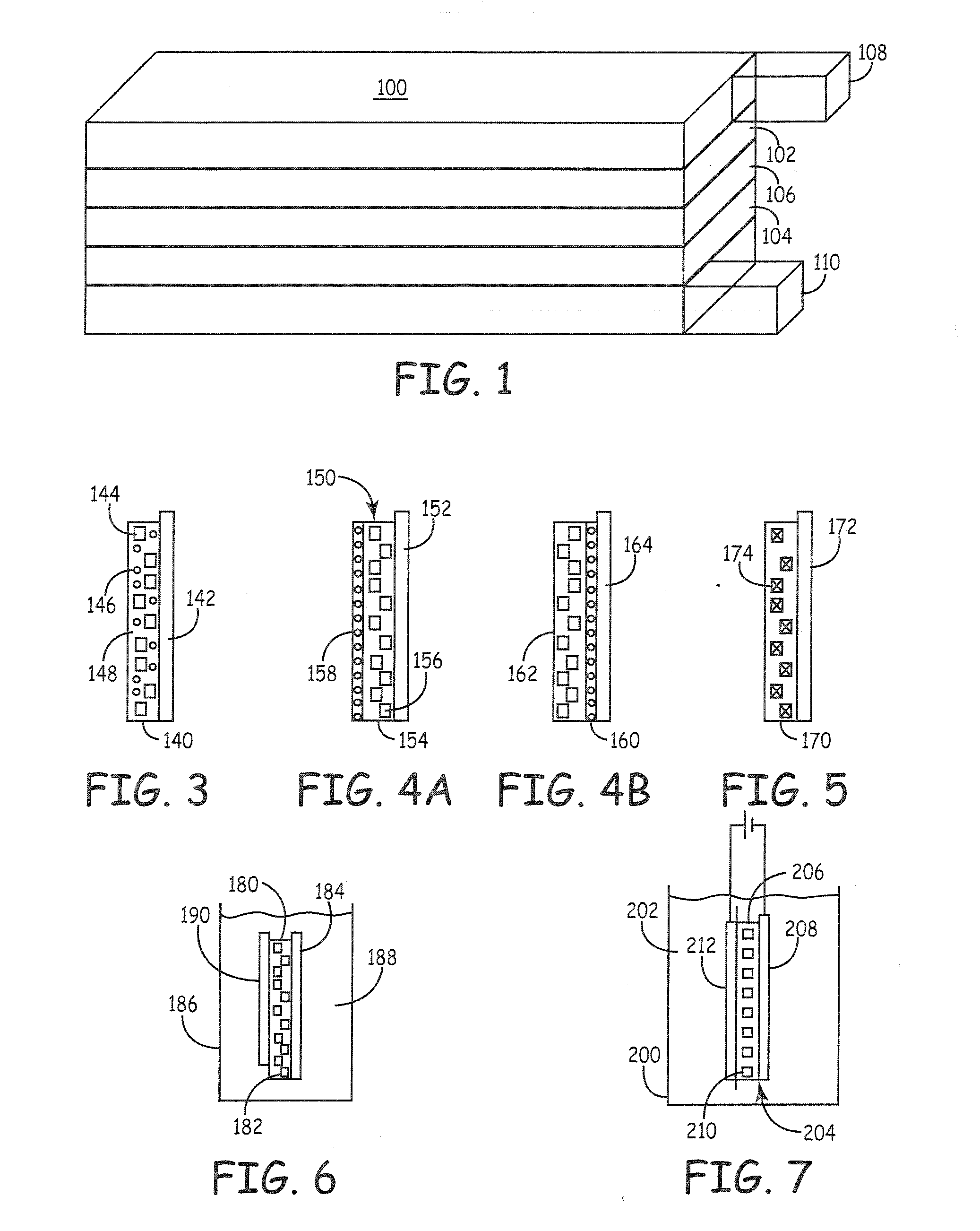

Lithium reservoir system and method for rechargeable lithium ion batteries

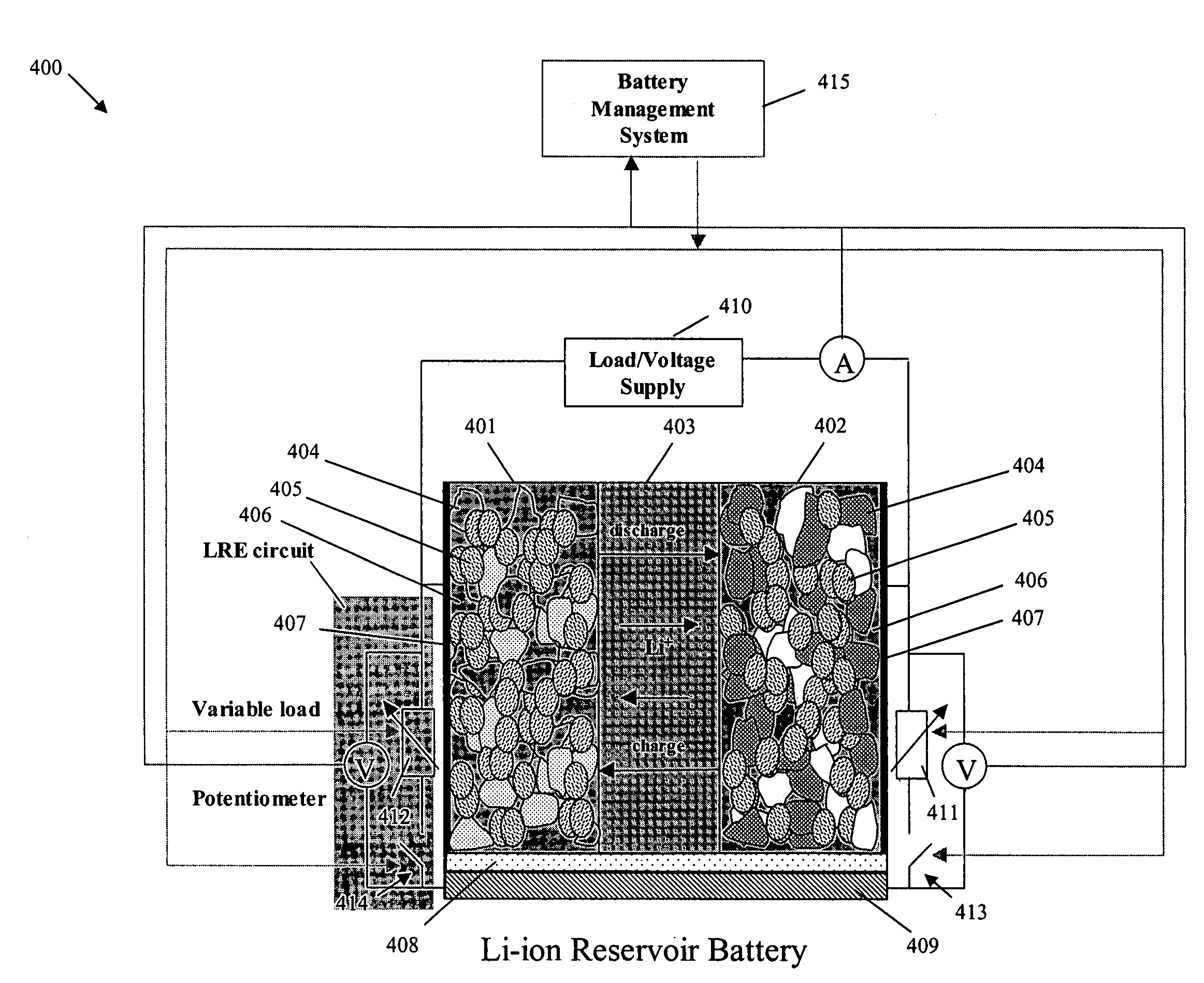

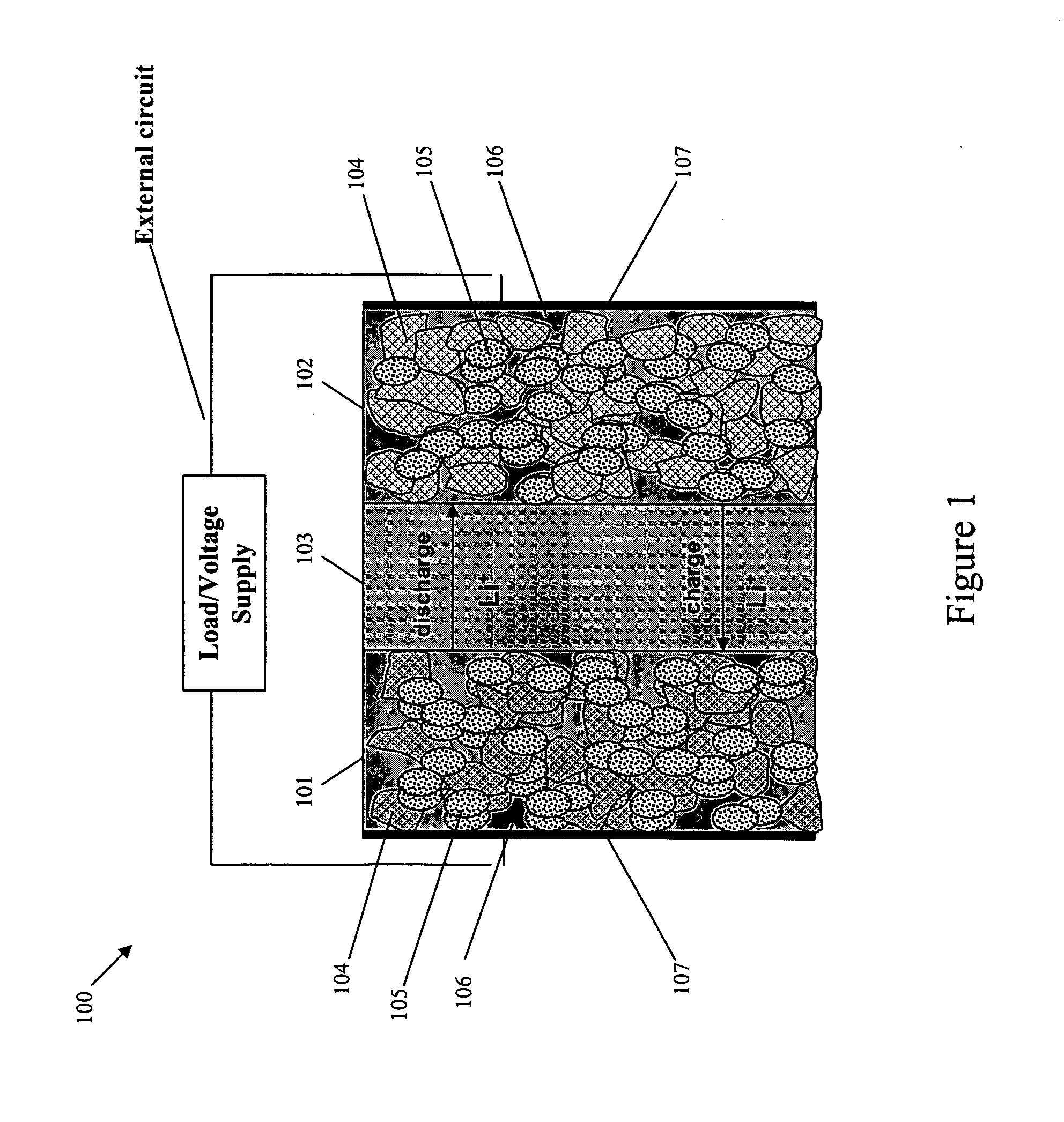

ActiveUS20080003490A1Extend battery lifeEffective controlFinal product manufactureElectrolyte/reactants regenerationEngineeringAuxiliary electrode

A lithium-ion battery cell includes at least two working electrodes, each including an active material, an inert material, an electrolyte and a current collector, a first separator region arranged between the at least two working electrodes to separate the at least two working electrodes so that none of the working electrodes are electronically connected within the cell, an auxiliary electrode including a lithium reservoir, and a second separator region arranged between the auxiliary electrode and the at least two working electrodes to separate the auxiliary electrode from the working electrodes so that none of the working electrodes is electronically connected to the auxiliary electrode within the cell.

Owner:ROBERT BOSCH GMBH

Anode and cathode conductive additive for secondary lithium battery, method for preparing conductive additive, and method for preparing secondary lithium battery

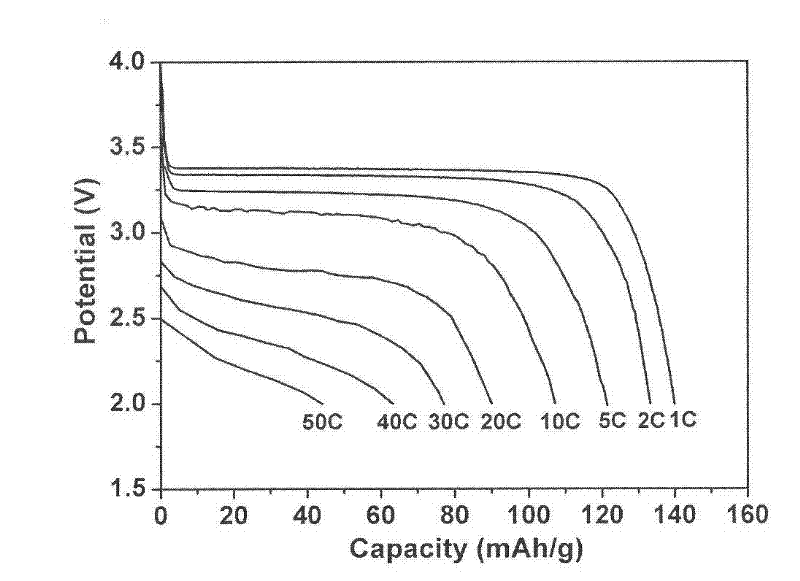

ActiveCN102544502AImprove conductivityQuick migrationFinal product manufactureCell electrodesHigh rateOrganic solvent

The invention discloses an anode and cathode conductive additive for a secondary lithium battery, a method for preparing the conductive additive, and a method for preparing the secondary lithium battery. The conductive additive is graphene or a mixture of the graphene and other conductive materials, is graphene powder or mixture powder of graphene and other conductive materials, and also can be graphene or mixture conductive agent slurry of the graphene and other conductive materials, which is uniformly dispersed in water or an organic solvent or in water or an organic solvent which contains a dispersing agent. The graphene conductive additive is suitable for preparing the anode and cathode of the secondary lithium battery, and has the obvious advantage of improving the high-rate performance and cycle stability of the secondary lithium battery compared with other conductive additives at present.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Phosphonate additives for nonaqueous electrolyte in alkali metal electrochemical cells

InactiveUS6096447AGood charge and discharge cycleImprove efficiencyOrganic electrolyte cellsHeart stimulatorsPermittivityPropylene carbonate

An alkali metal, solid cathode, nonaqueous electrochemical cell capable of delivering high current pulses, rapidly recovering its open circuit voltage and having high current capacity, is described. The stated benefits are realized by the addition of at least one phosphonate additive to an electrolyte comprising an alkali metal salt dissolved in a mixture of a low viscosity solvent and a high permittivity solvent. A preferred solvent mixture includes propylene carbonate, dimethoxyethane and an alkyl phosphonate additive.

Owner:WILSON GREATBATCH LTD

All-solid secondary battery

ActiveUS20120237834A1Increase battery capacityFacilitates electron conductionSolid electrolytesFinal product manufactureElectrolyteMaterials science

In the all-solid secondary battery of the present invention, a positive electrode layer and a negative electrode layer are disposed on both sides of a solid electrolyte layer, a first inorganic solid electrolyte and a second inorganic solid electrolyte are included into at least one of the positive electrode layer, the negative electrode layer, and the solid electrolyte layer, the content of transition metal in the first inorganic solid electrolyte is less than 15% by mass on oxide basis, and the content of transition metal in the second inorganic solid electrolyte is 15% by mass or more on oxide basis.

Owner:OHARA

Battery system for a vehicle with severable connections

ActiveUS20090159311A1Primary cell to battery groupingBatteries circuit arrangementsElectricityElectrical connection

A battery system for storing electrical power and supplying electrical power to a vehicle is disclosed. The system includes multiple battery packs, each with a plurality of cells. The cells in each battery pack are electrically connected with one another and the multiple battery packs are also electrically connected with one another to combine the total energy output of the cells of the system. The electrical connections between at least some of the cells include a severable feature, whereby the electrical connection is severed locally at the severable feature in response to an impact force that is in excess of a predetermined magnitude and / or an overcurrent / overtemperature condition.

Owner:BYD CO LTD

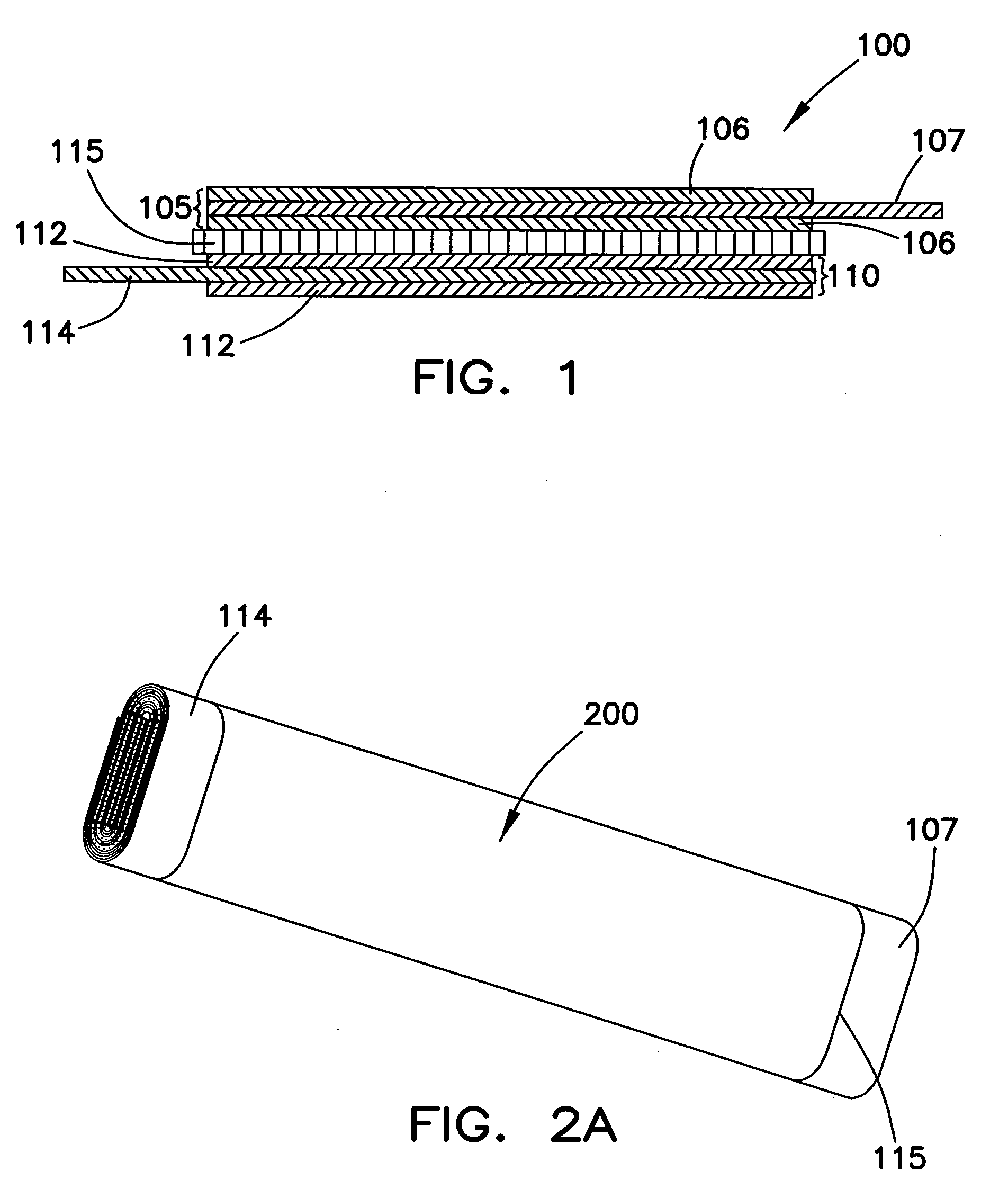

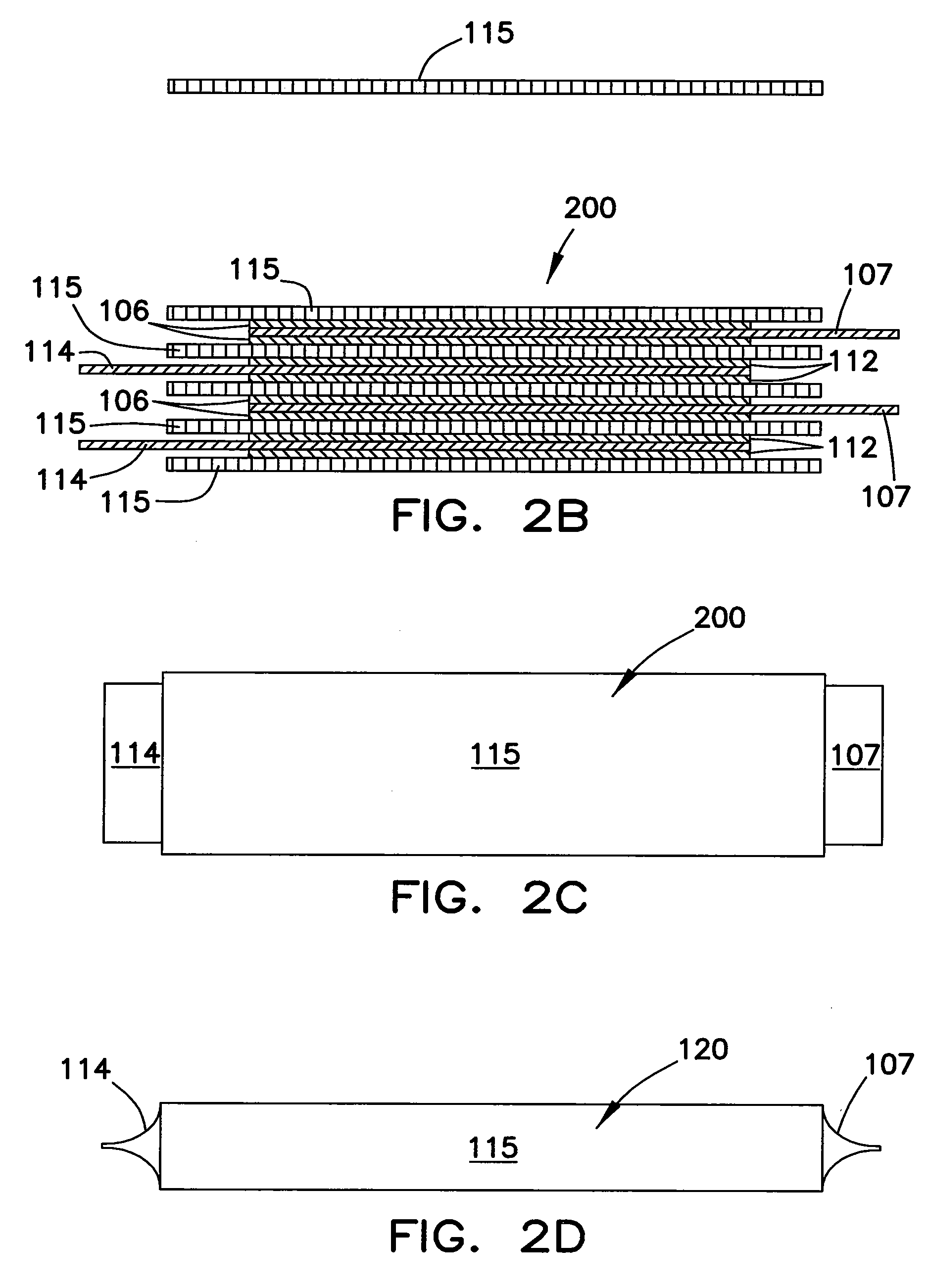

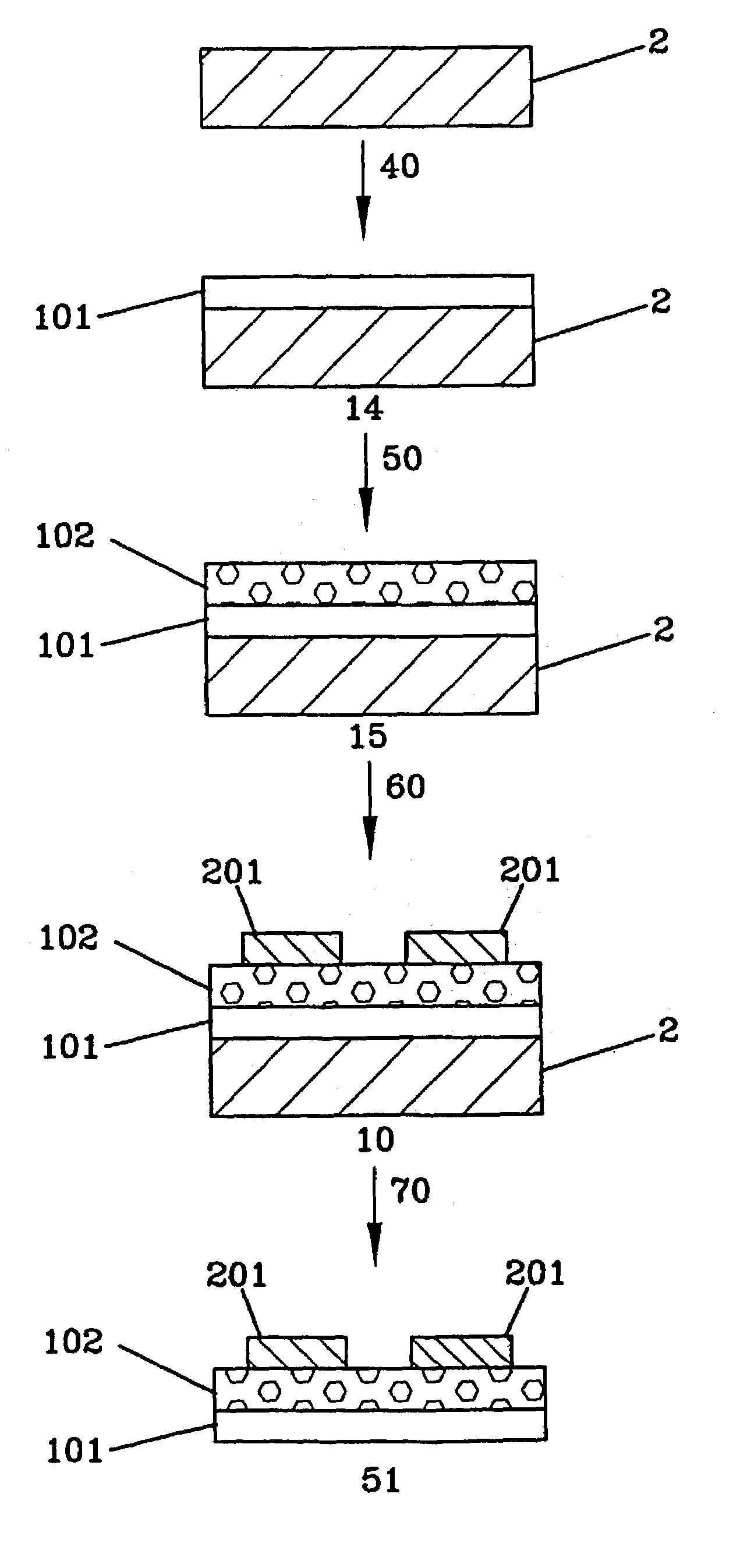

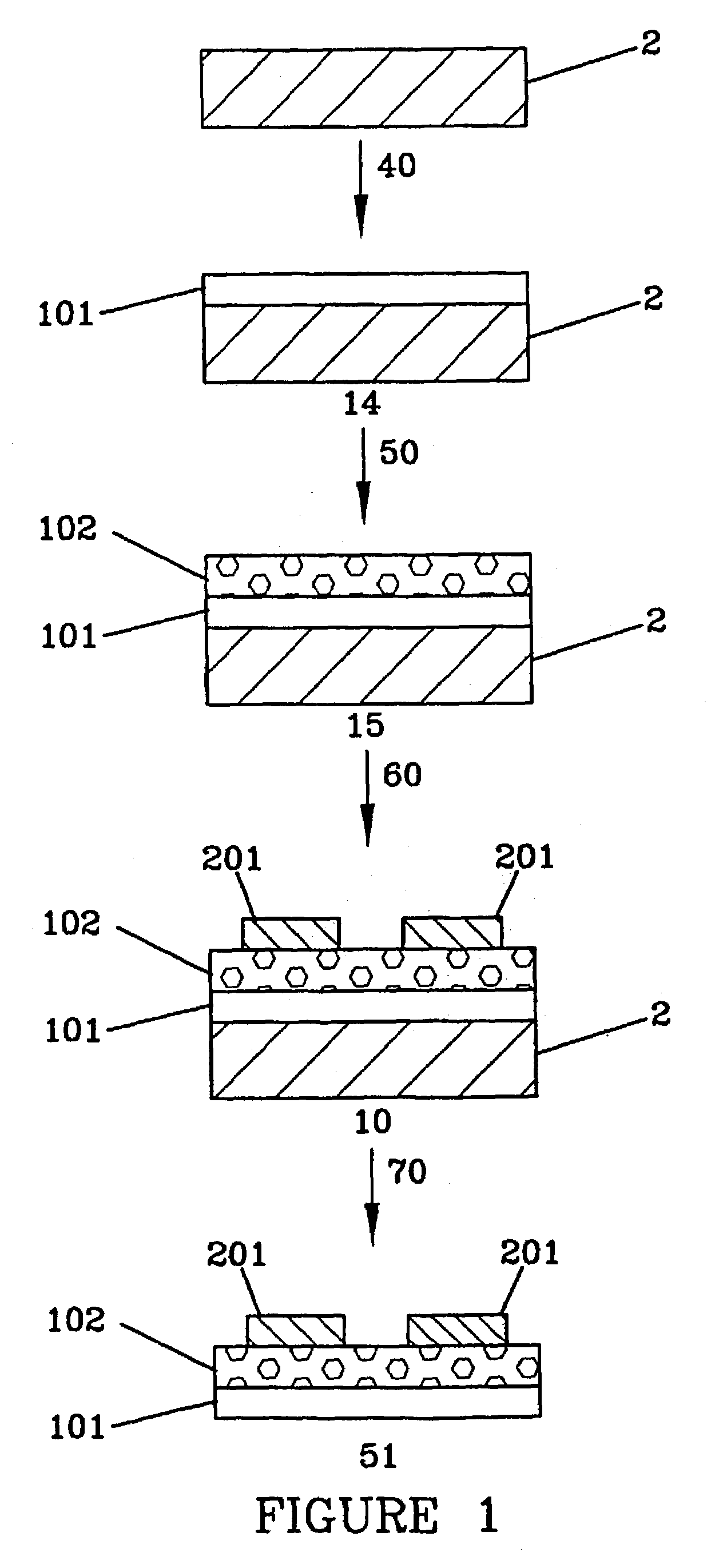

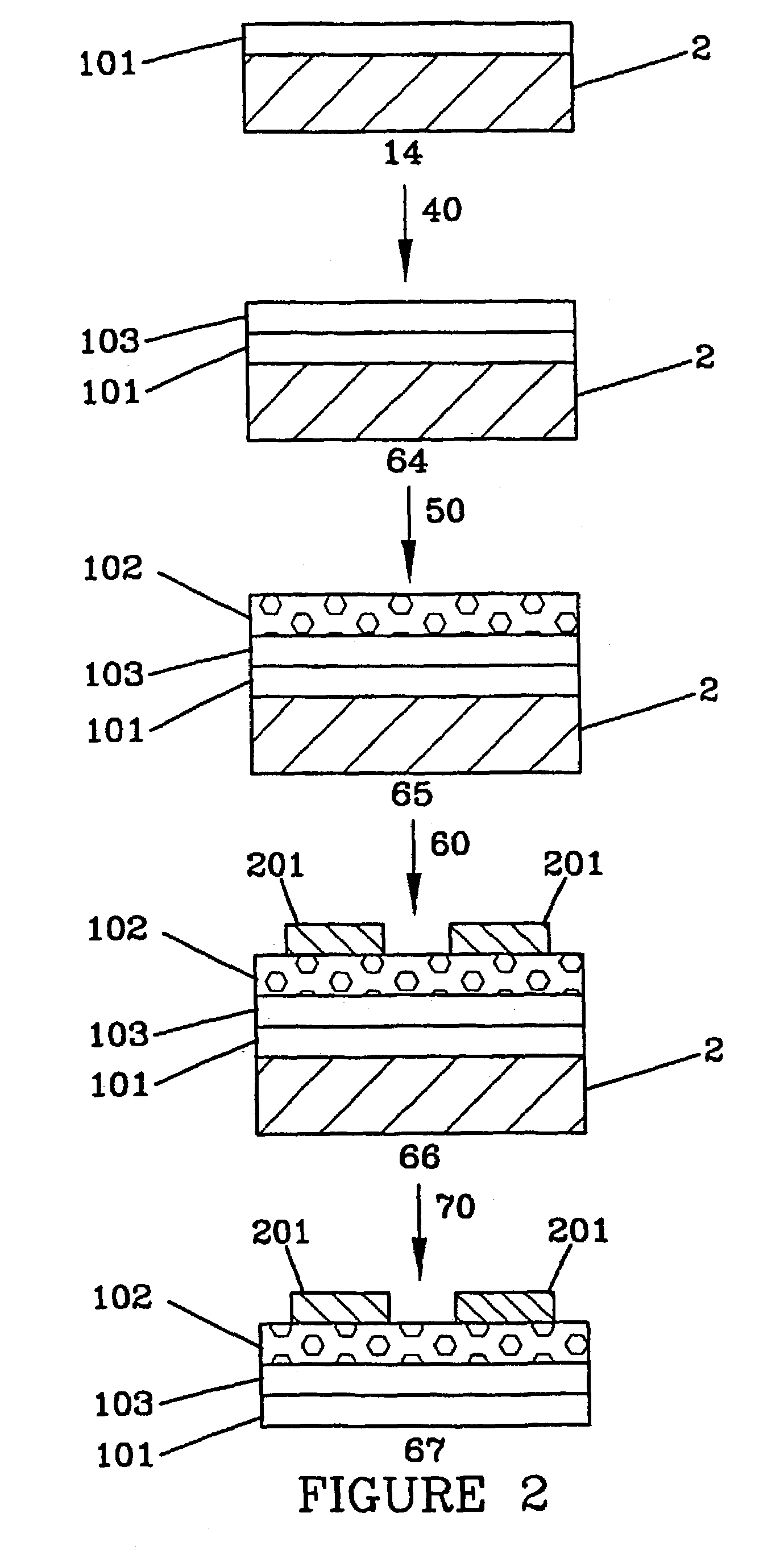

Methods of preparing electrochemical cells

InactiveUS7081142B1Final product manufactureElectrode carriers/collectorsElectrochemical cellChemistry

Methods of preparing a cathode / separator assembly for use in electrochemical cells in which a protective coating layer is coated on a temporary carrier substrate, a microporous separator layer is then coated on the protective coating layer, and a cathode is then coated or laminated on the separator layer, prior to removing the temporary carrier substrate from the protective coating layer. Also, methods of preparing electrochemical cells utilizing cathode / separator assemblies prepared by such methods, and cathode / separator assemblies and electrochemical cells prepared by such methods.

Owner:OPTODOT CORP +1

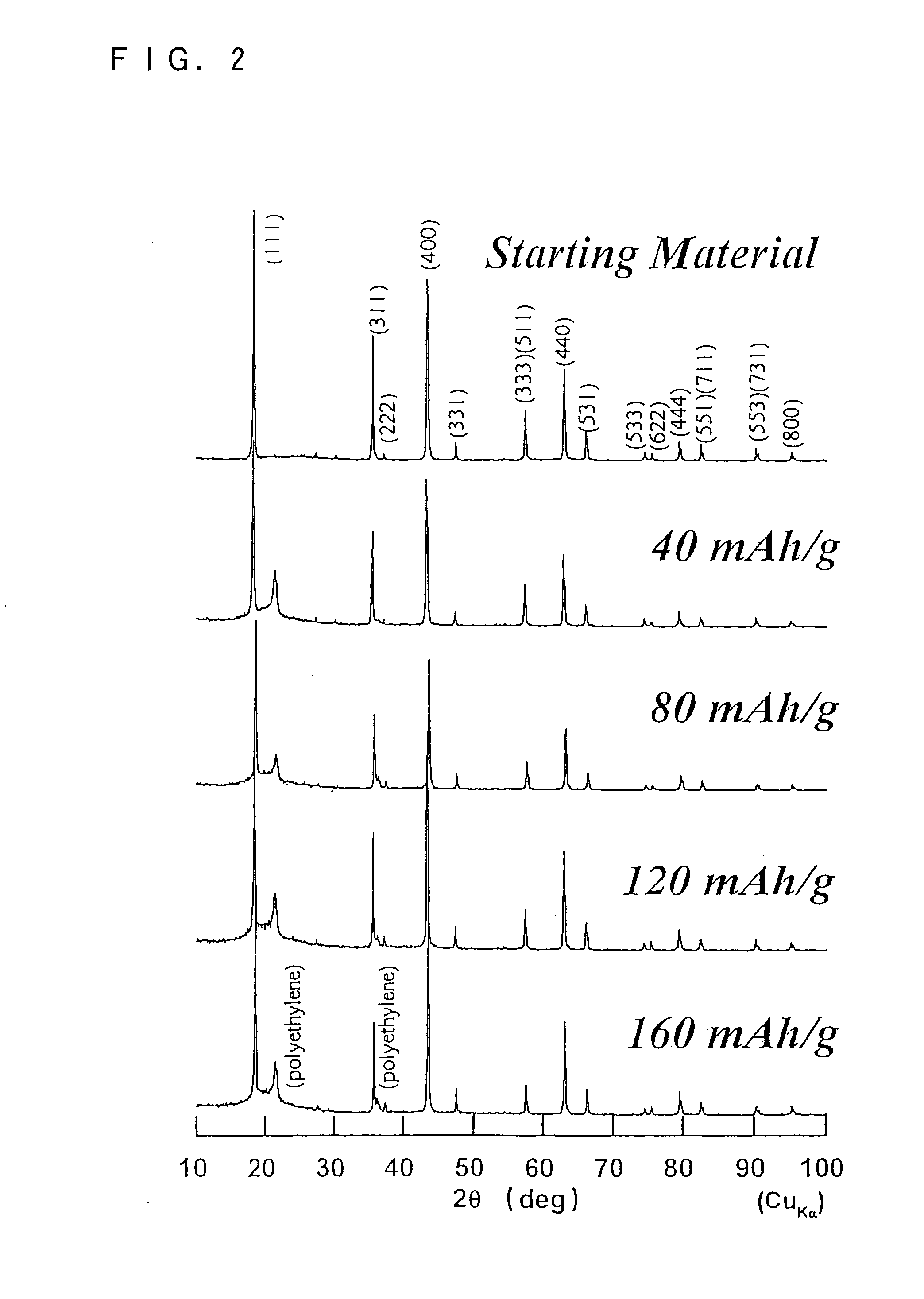

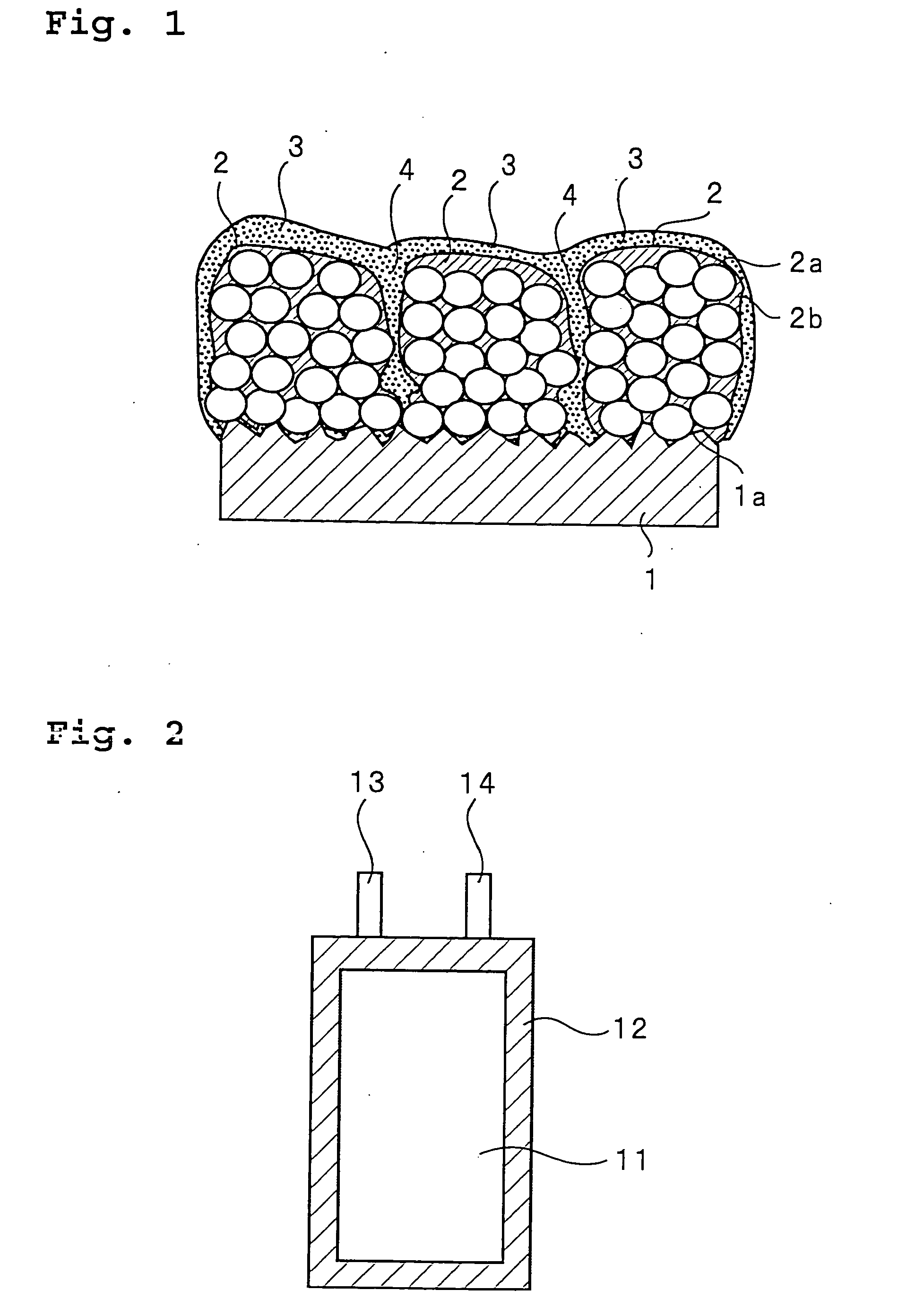

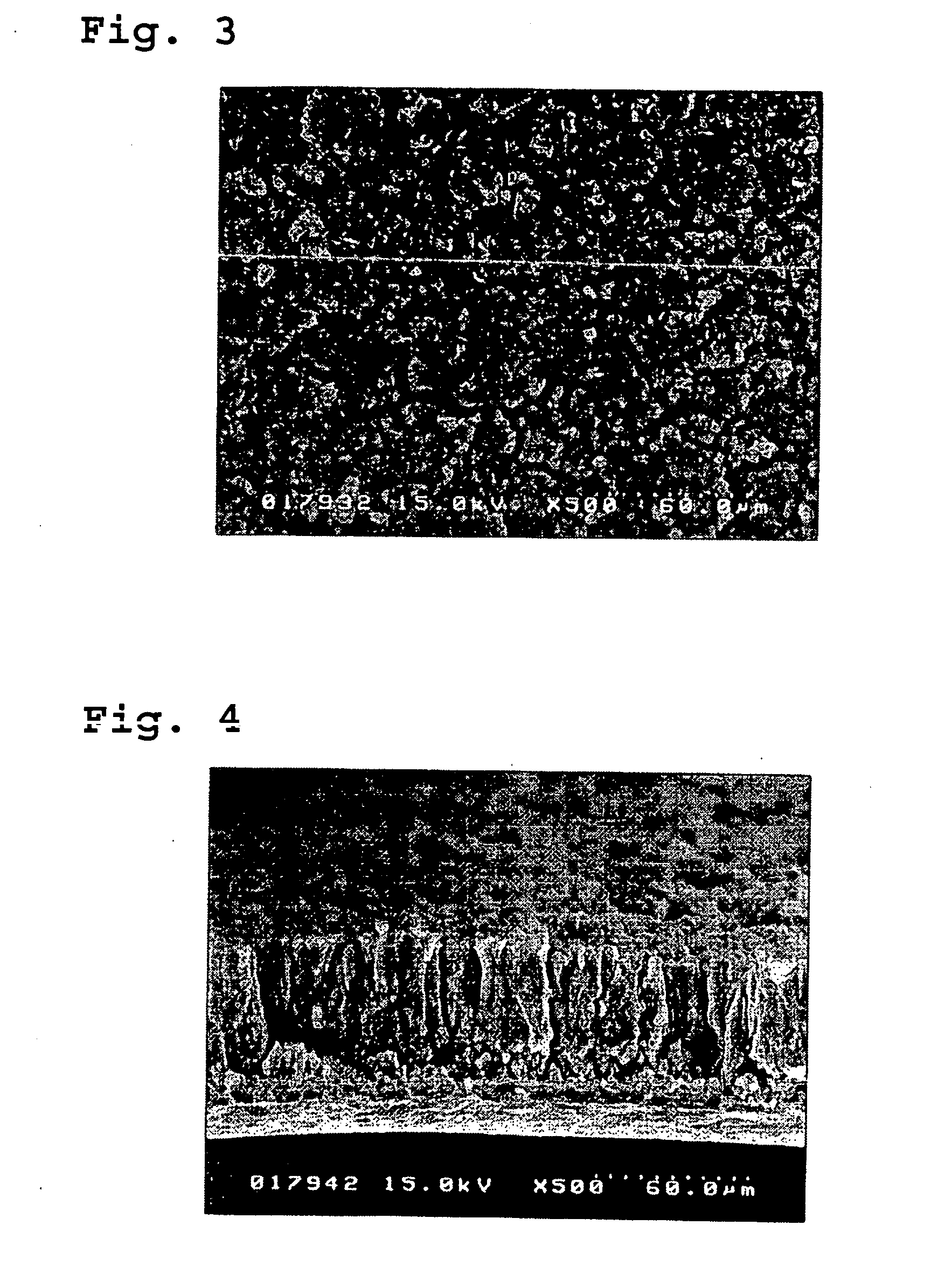

Electrode material for anode of rechargeable lithium battery, electrode structural body using said electrode material, rechargeable lithium battery using said electrode structural body, process for producing said electrode structural body, and process for producing said rechargeable lithium battery

InactiveUS6949312B1Improve featuresLarge capacitySilver accumulatorsFinal product manufactureElectrochemical responseElectrode material

An electrode material for an anode of a rechargeable lithium battery, containing a particulate comprising an amorphous Sn.A.X alloy with a substantially non-stoichiometric ratio composition. For said formula Sn.A.X, A indicates at least one kind of an element selected from a group consisting of transition metal elements, X indicates at least one kind of an element selected from a group consisting of O, F, N, Mg, Ba, Sr, Ca, La, Ce, Si, Ge, C, P, B, Pb, Bi, Sb, Al, Ga, In, Tl, Zn, Be, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, As, Se, Te, Li and S, where the element X is not always necessary to be contained. The content of the constituent element Sn of the amorphous Sn.A.X alloy is Sn / (Sn+A+X)=20 to 80 atomic %. An electrode structural body for a rechargeable lithium battery, comprising said electrode material for an anode and a collector comprising a material incapable of being alloyed with lithium in electrochemical reaction, and a rechargeable lithium battery having an anode comprising said electrode structural body.

Owner:CANON KK

Lithium Ion Batteries with Supplemental Lithium

Supplemental lithium can be used to stabilize lithium ion batteries with lithium rich metal oxides as the positive electrode active material. Dramatic improvements in the specific capacity at long cycling have been obtained. The supplemental lithium can be provided with the negative electrode, or alternatively as a sacrificial material that is subsequently driven into the negative electrode active material. The supplemental lithium can be provided to the negative electrode active material prior to assembly of the battery using electrochemical deposition. The positive electrode active materials can comprise a layered-layered structure comprising manganese as well as nickel and / or cobalt.

Owner:IONBLOX INC

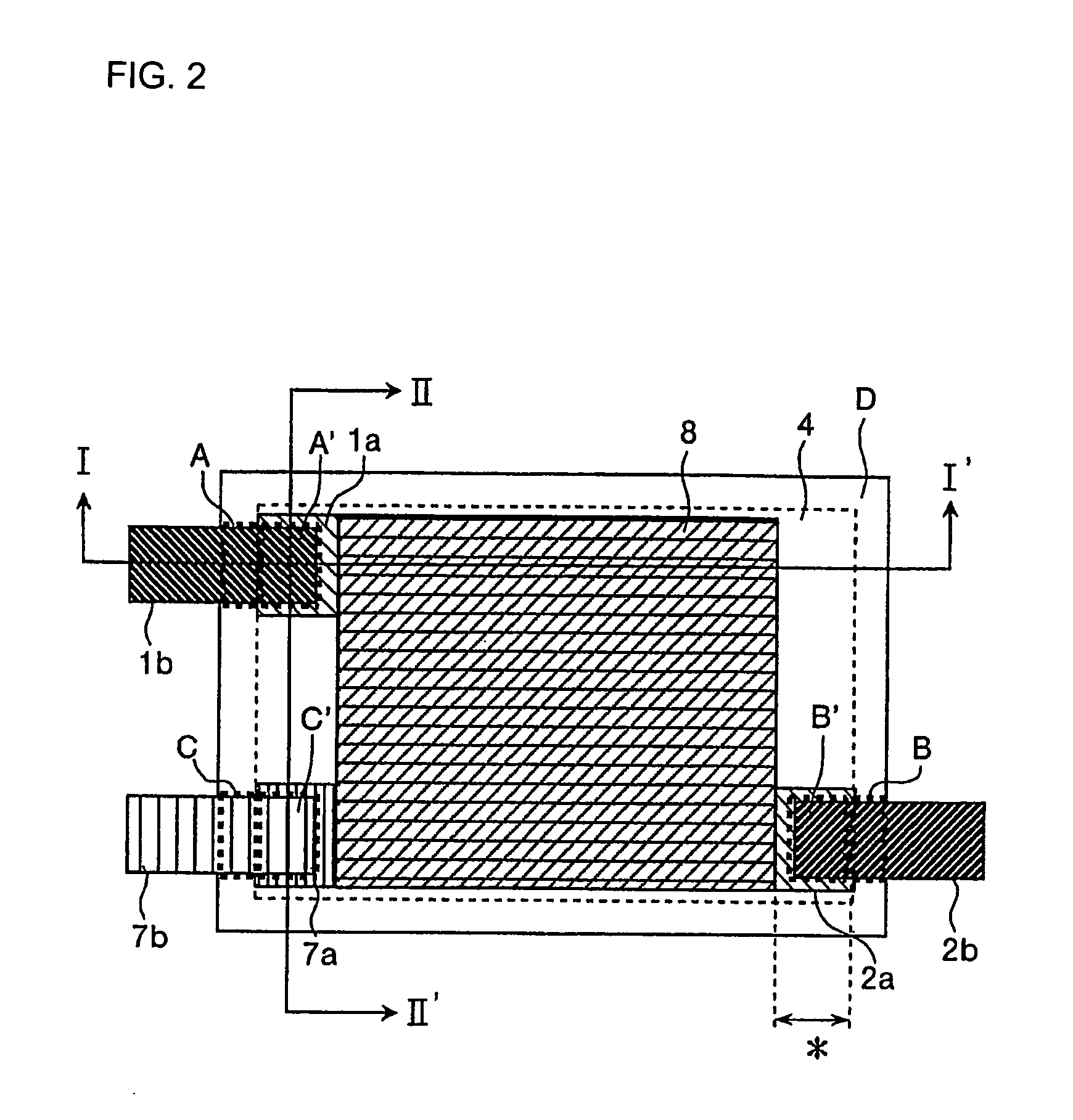

Method of fabricating a lithium ion secondary battery

To provide a process for producing a lithium ion secondary battery which can have any arbitrary shape, such as thin shape, and yet exhibits high performance. In a method of fabricating a battery comprising a positive electrode 1, a negative electrode 4, and a separator 7, a binder resin solution mainly comprising polyvinylidene fluoride is applied to the separator 7, and the positive electrode 1 and the negative electrode 4 are laid thereon, followed by drying to form a battery laminate, which is then impregnated with an electrolytic solution.

Owner:MITSUBISHI ELECTRIC CORP

Lithium secondary battery and method for producing same

ActiveUS20060003226A1High charge and discharge capacityExcellent cycle characteristicsElectrode thermal treatmentFinal product manufactureSilicon alloyMetal foil

A rechargeable lithium battery including a negative electrode made by sintering, on a surface of a conductive metal foil as a current collector, a layer of a mixture of active material particles containing silicon and / or a silicon alloy and a binder, a positive electrode and a nonaqueous electrolyte, characterized in that the nonaqueous electrolyte contains carbon dioxide dissolved therein.

Owner:SANYO ELECTRIC CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com