Patents

Literature

1797 results about "Metallic lithium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium is an extremely soft, silvery-gray metallic element, identified by the symbol Li on the periodic table of elements. The metal is used in a range of industries, typically in the form of alloys and compounds, since it is extremely reactive.

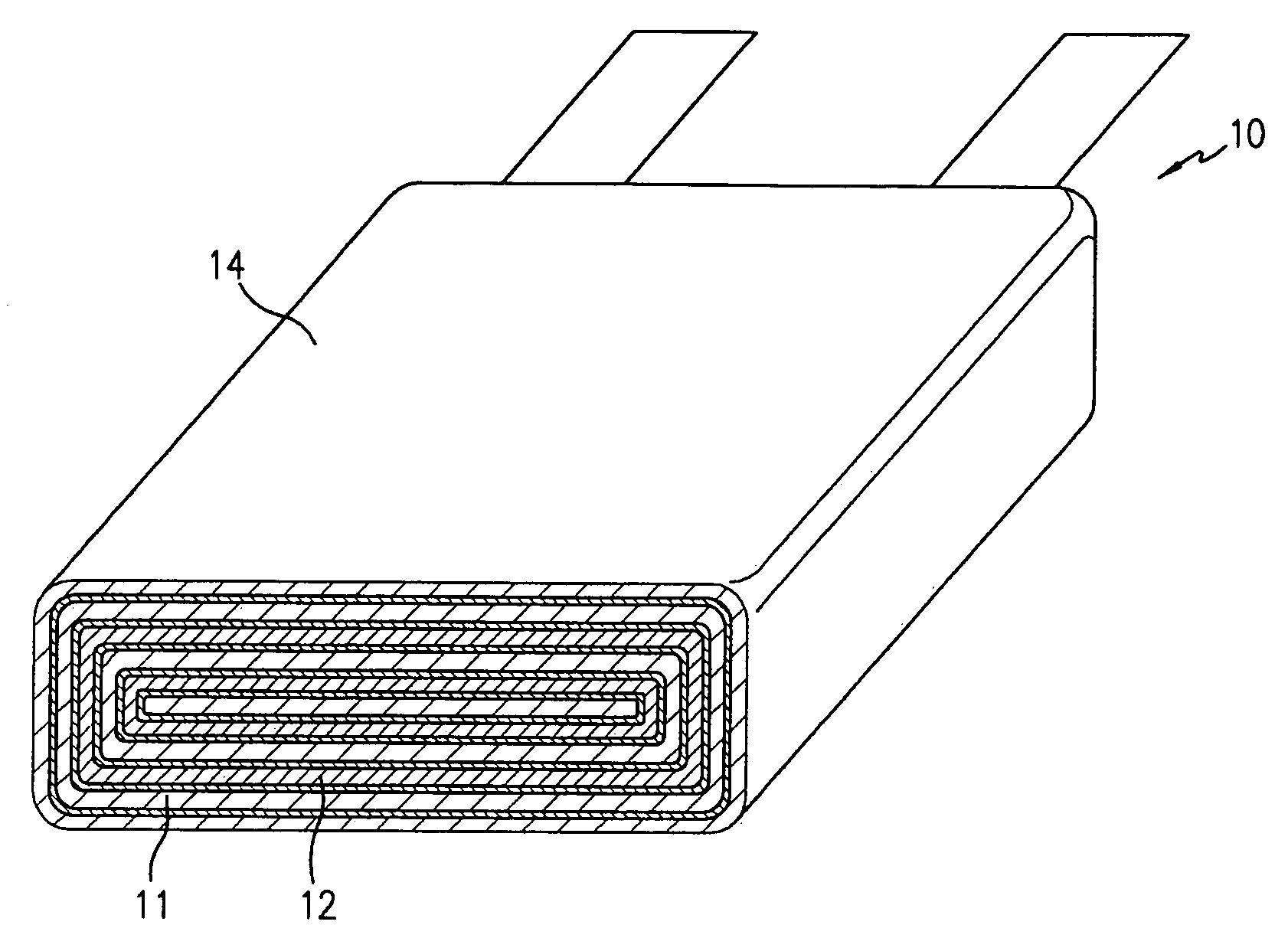

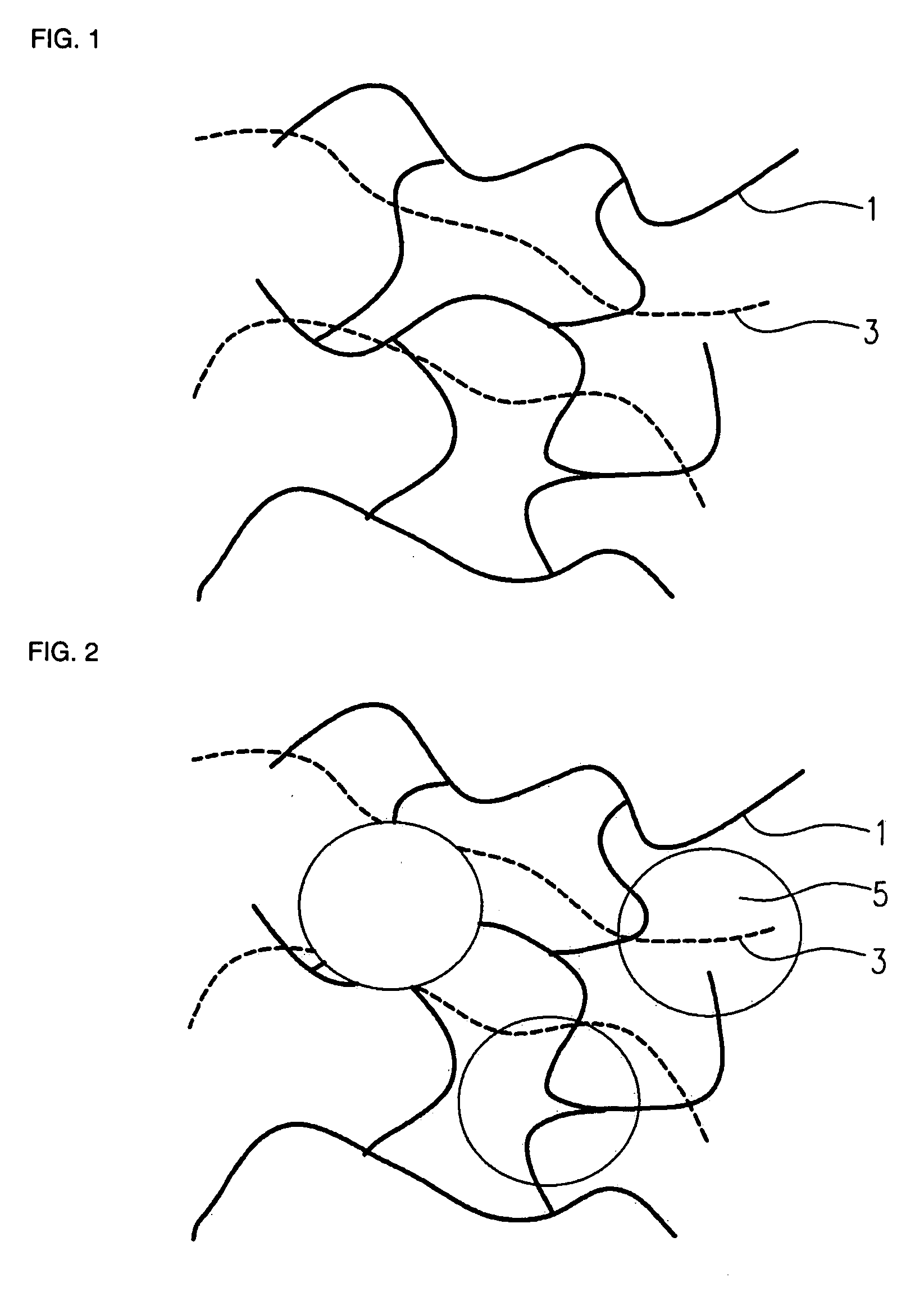

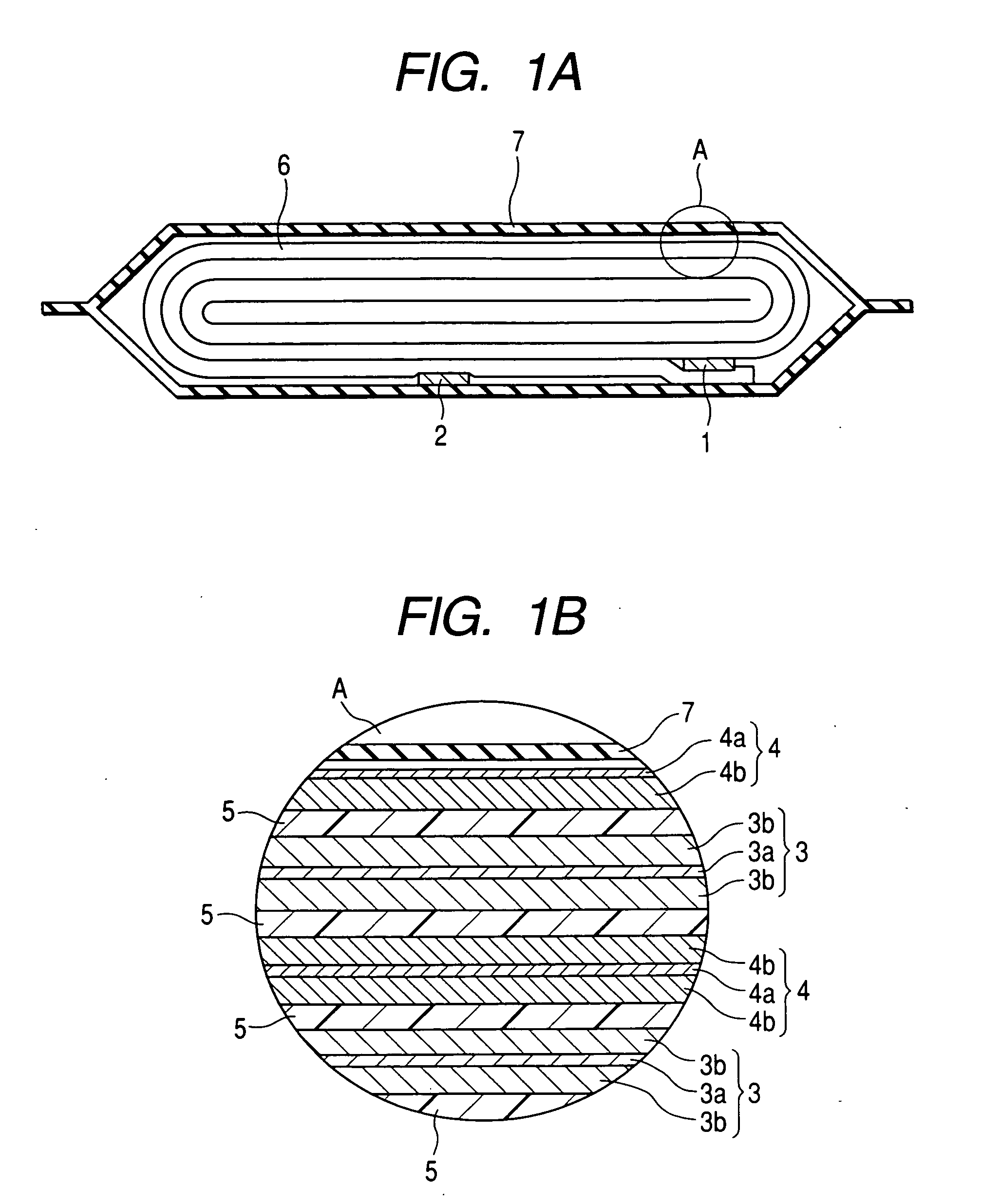

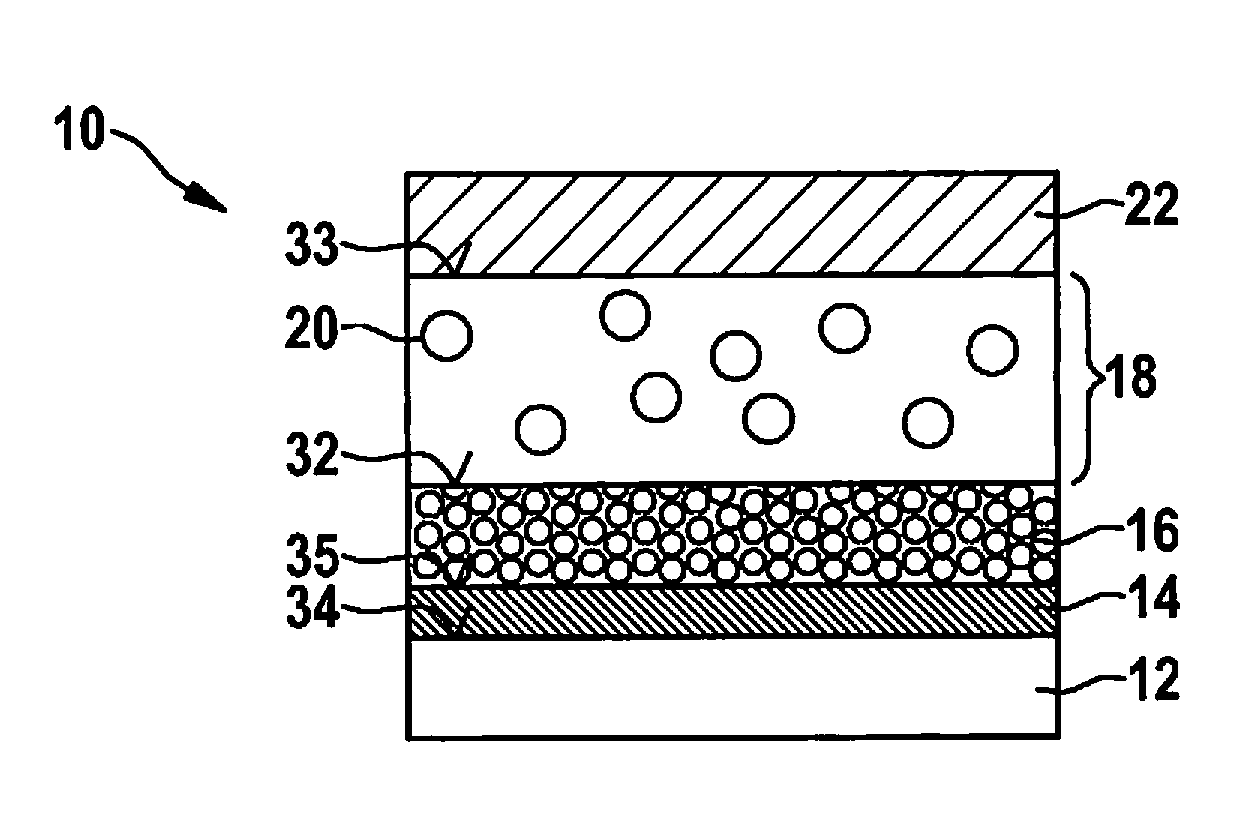

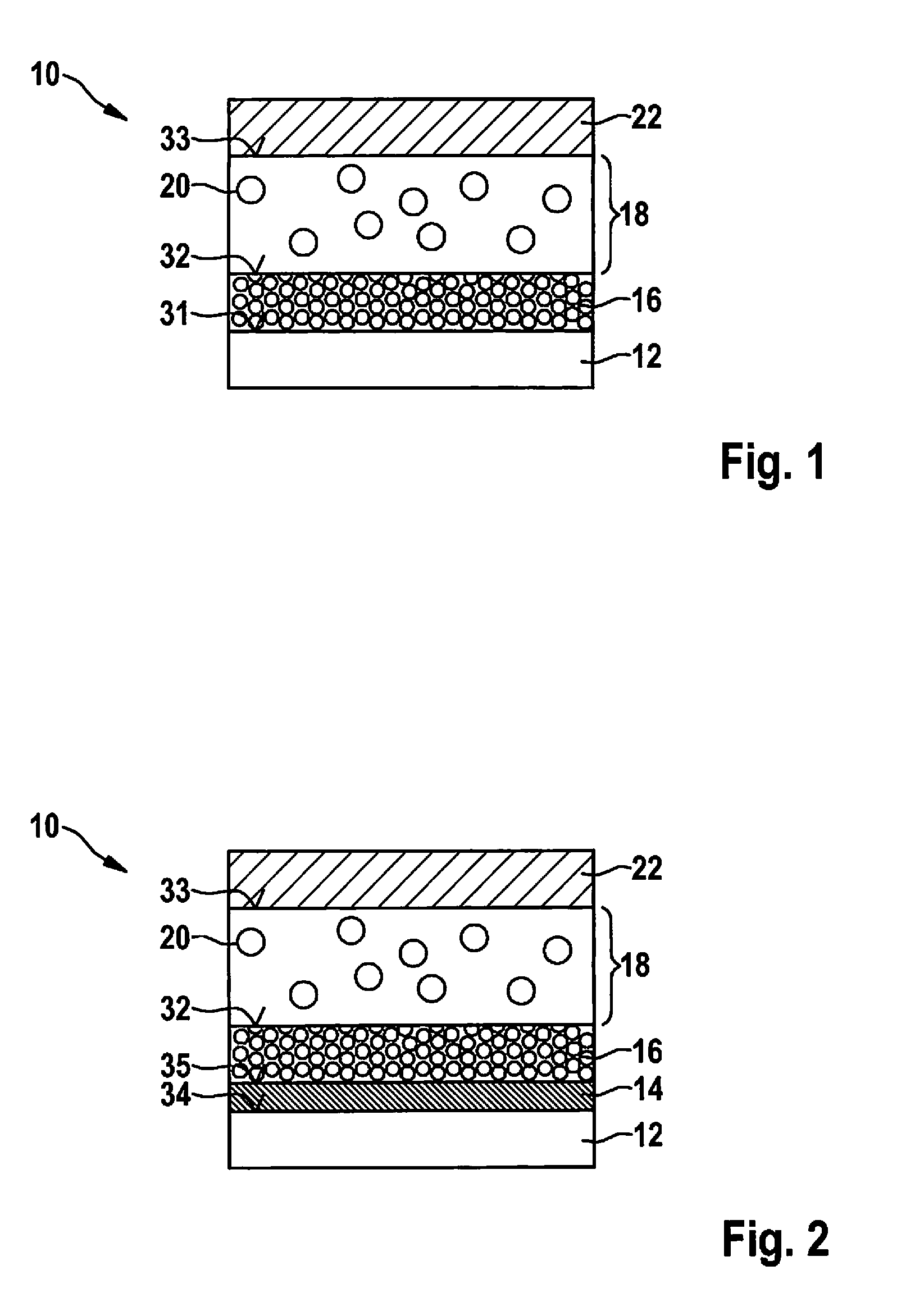

Negative electrode for lithium metal battery and lithium metal battery comprising the same

InactiveUS20050095504A1Improving life-cycle characteristicInhibit side effectsFinal product manufacturePretreated surfacesCross-linkMetallic lithium

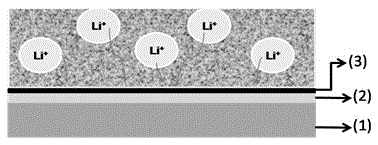

The present invention relates to a negative electrode for a lithium metal battery and a lithium metal battery comprising the same. The negative electrode of the present invention comprises a negative active material layer of metallic lithium or a lithium alloy, and a passivation layer formed on the negative active material layer. The passivation layer has a structure comprising a 3-dimensionally cross-linked polymer network matrix penetrated by linear polymers. The passivation layer formed on the surface of the negative electrode reduces reactivity of the negative electrode and stabilizes the surface, so that it offers a lithium metal battery having superior life cycle characteristics.

Owner:SAMSUNG SDI CO LTD

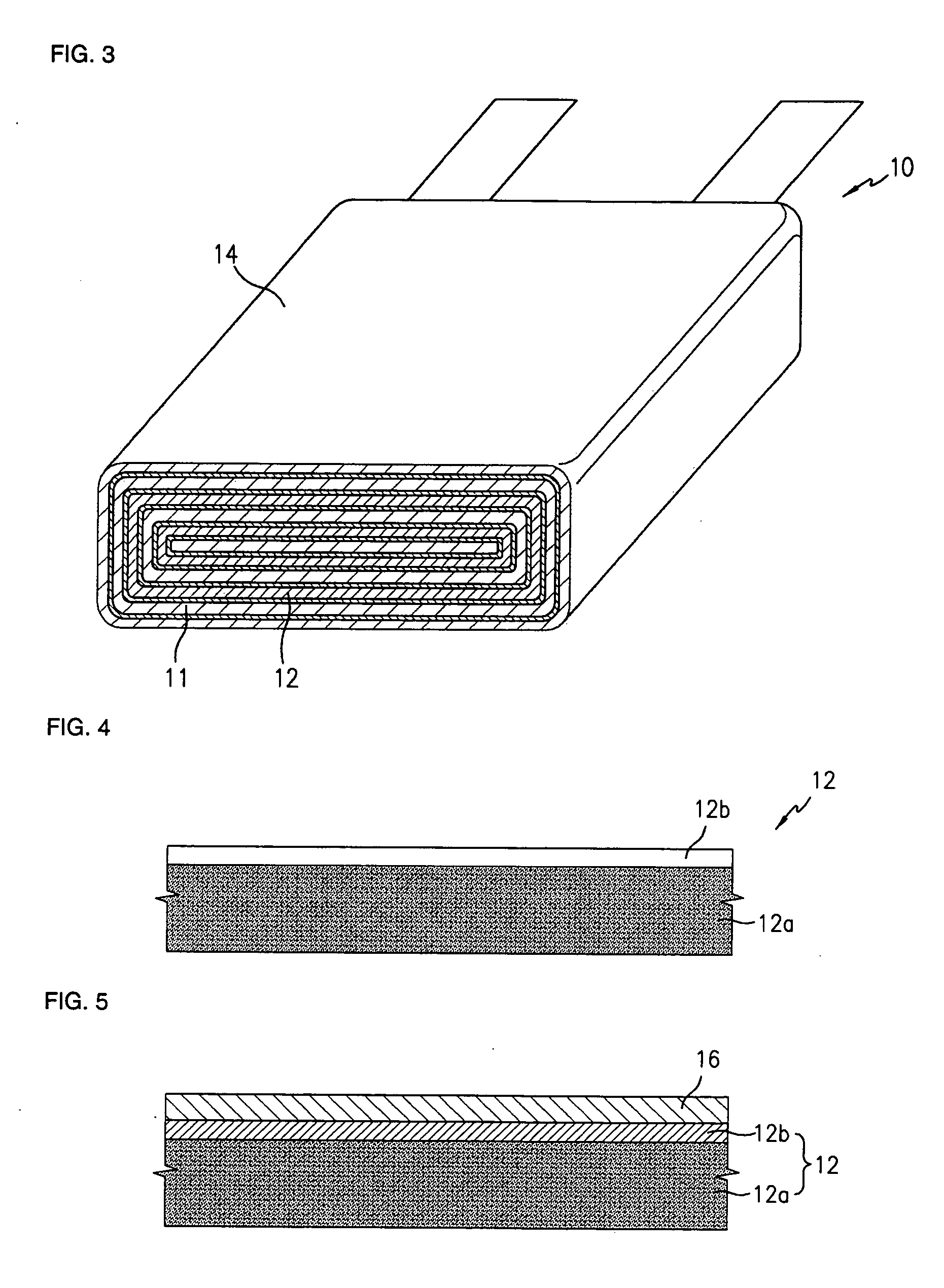

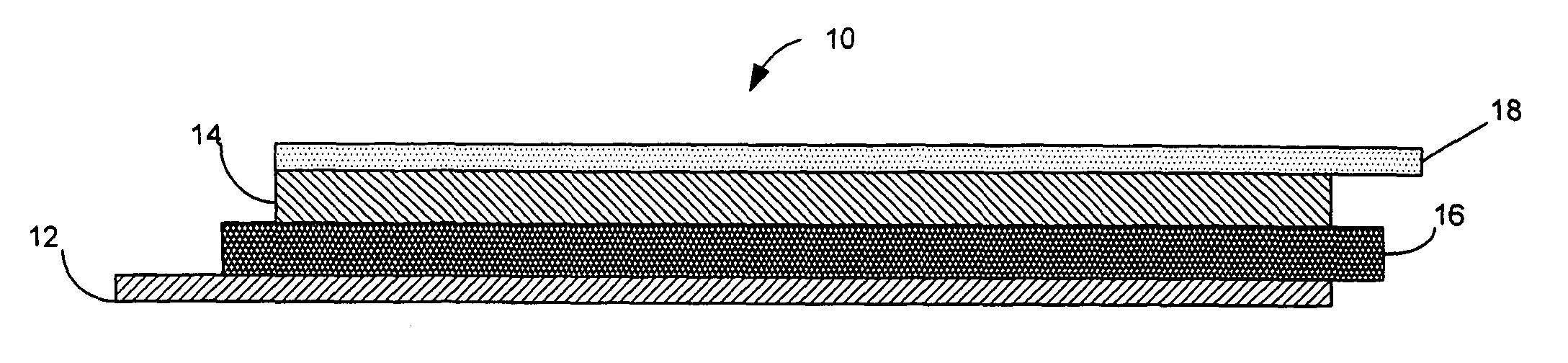

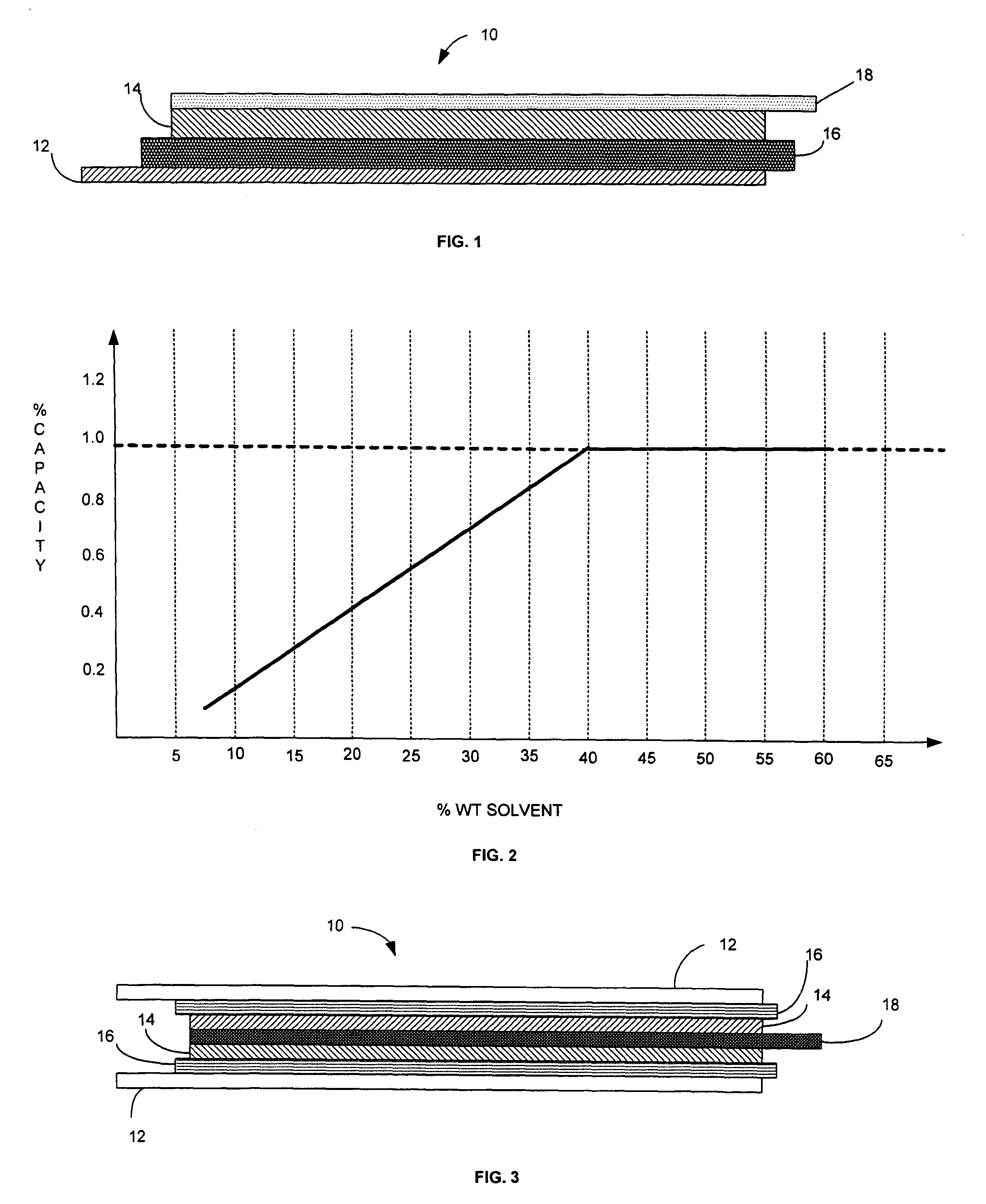

Lithium secondary cell with high charge and discharge rate capability

ActiveUS20050233219A1Final product manufactureActive material electrodesElectrode potentialMetallic lithium

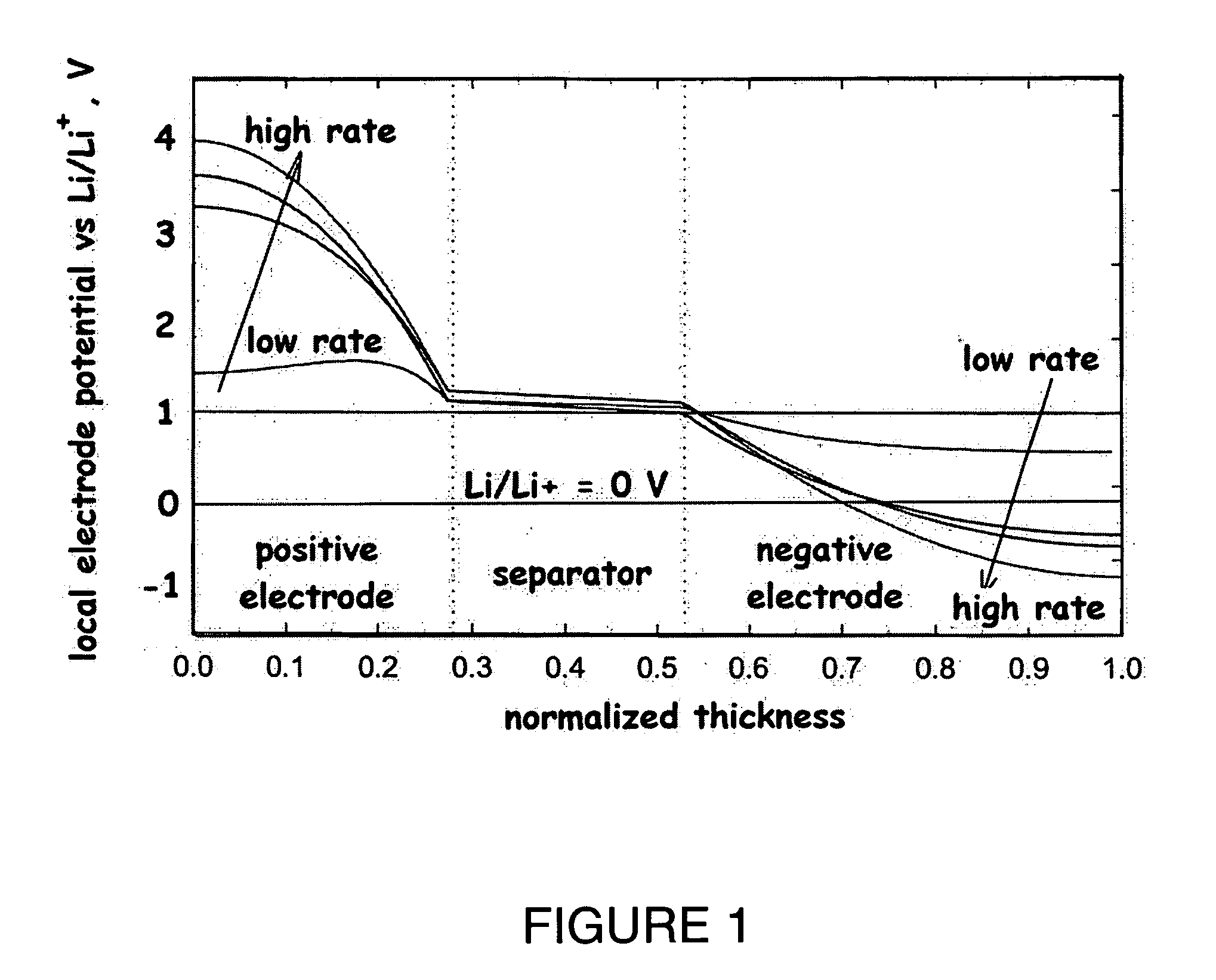

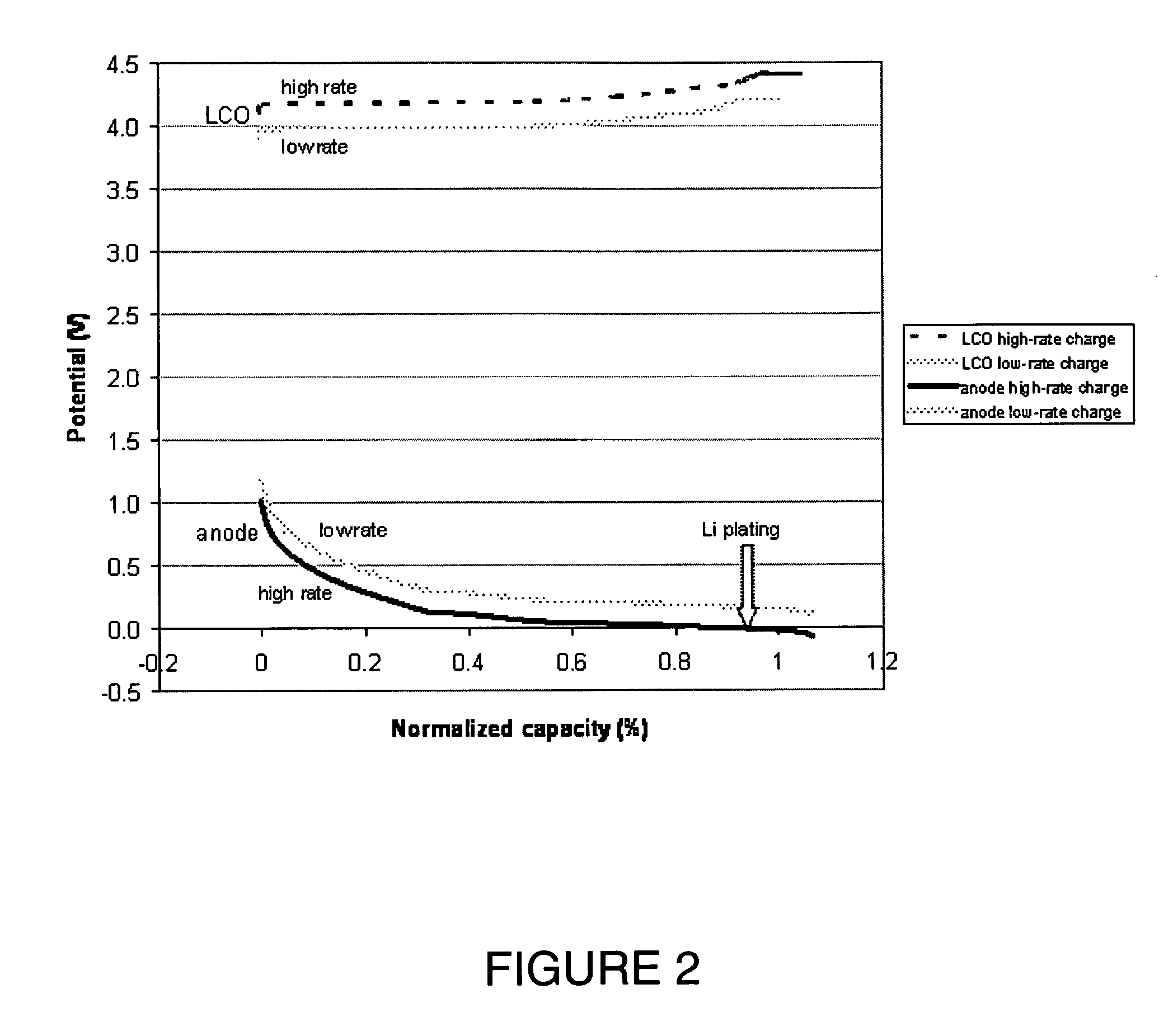

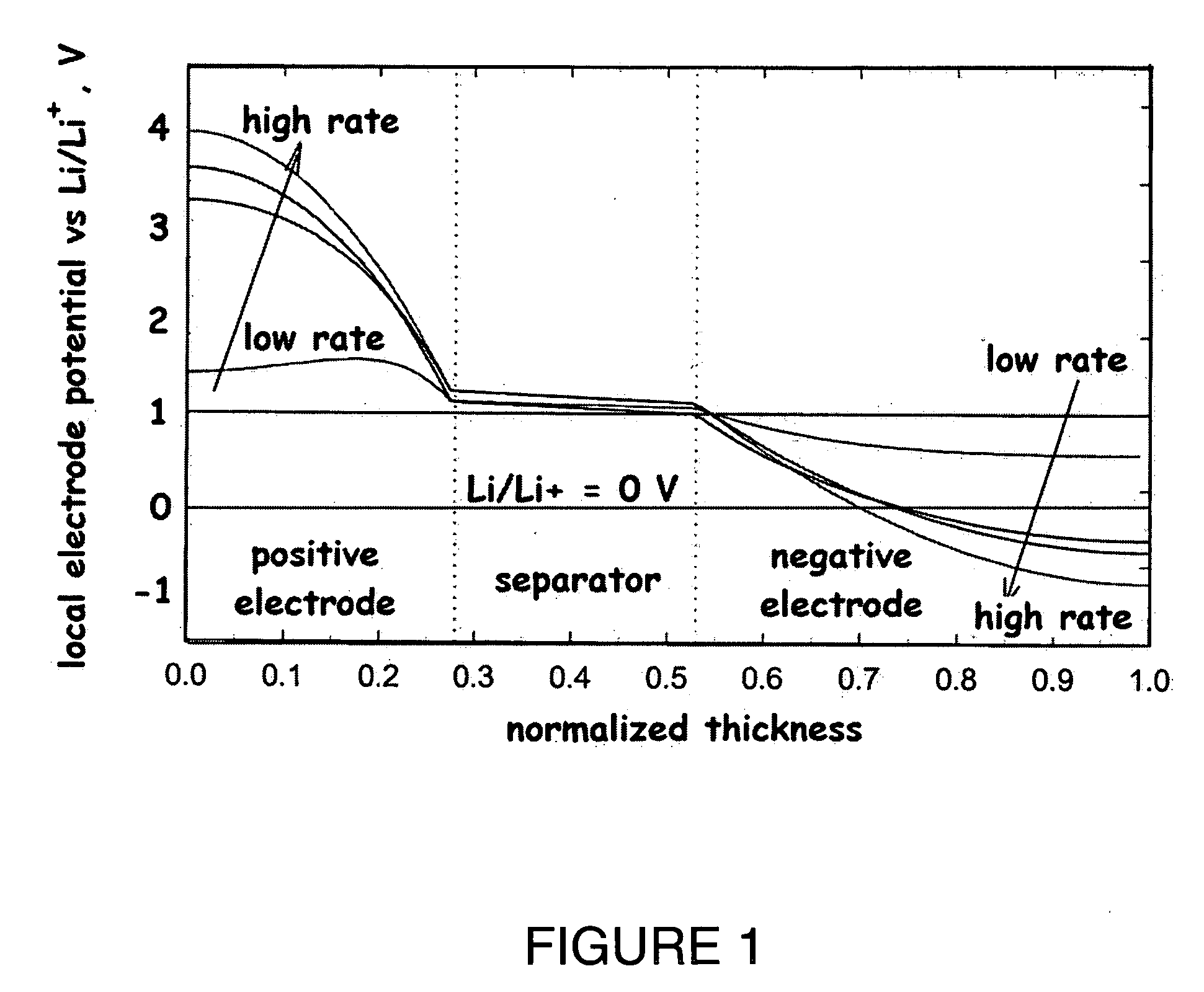

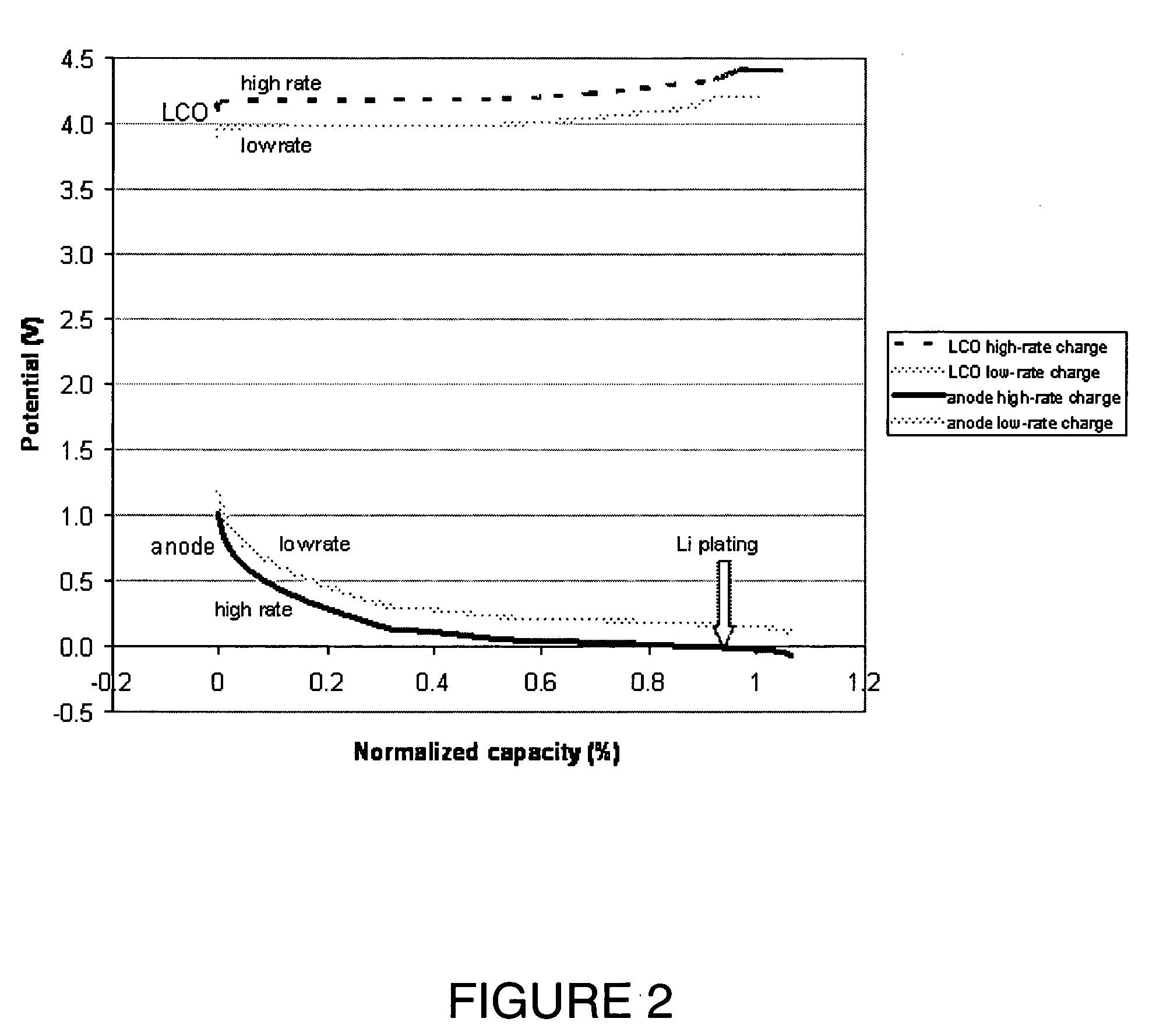

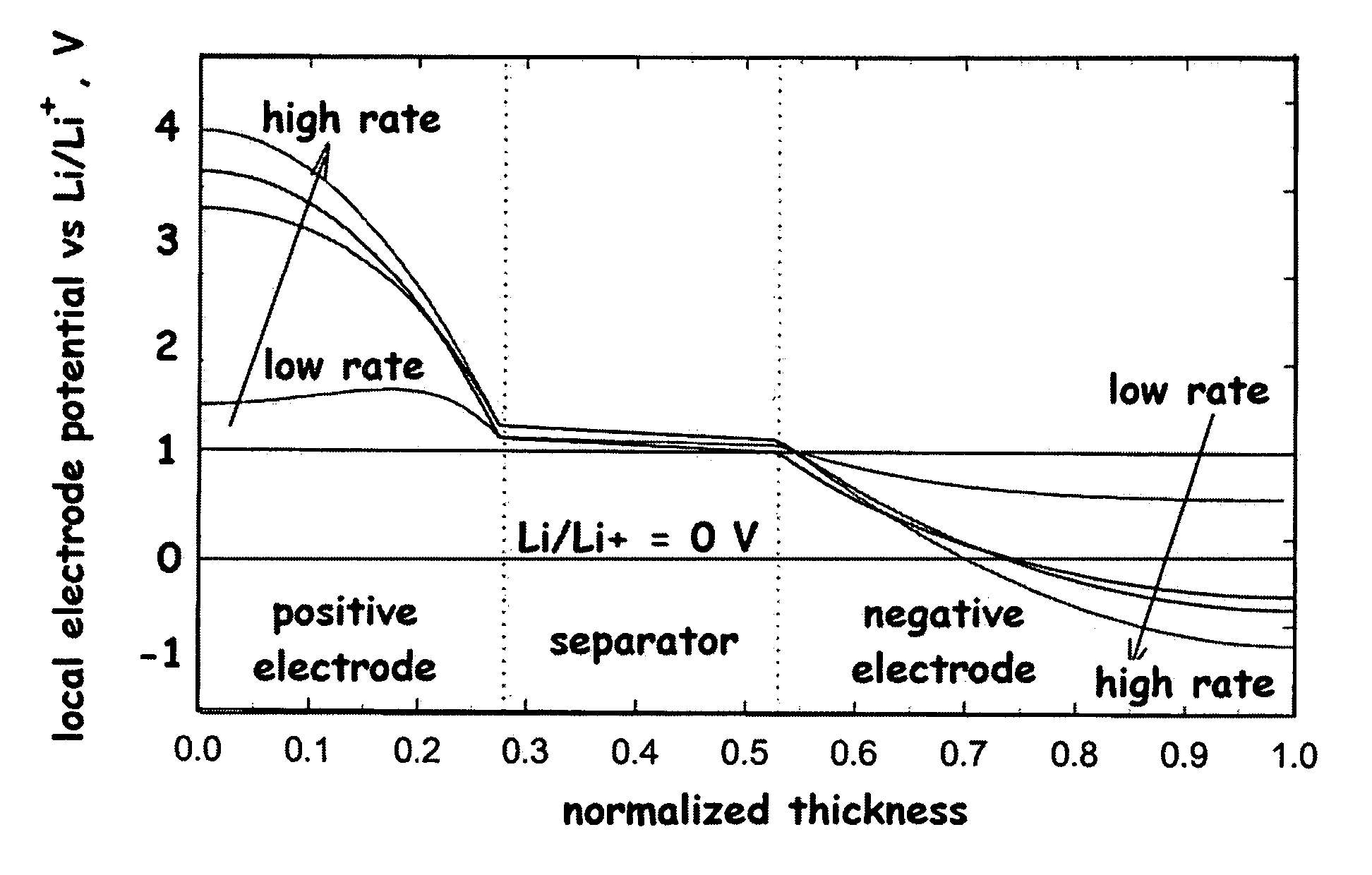

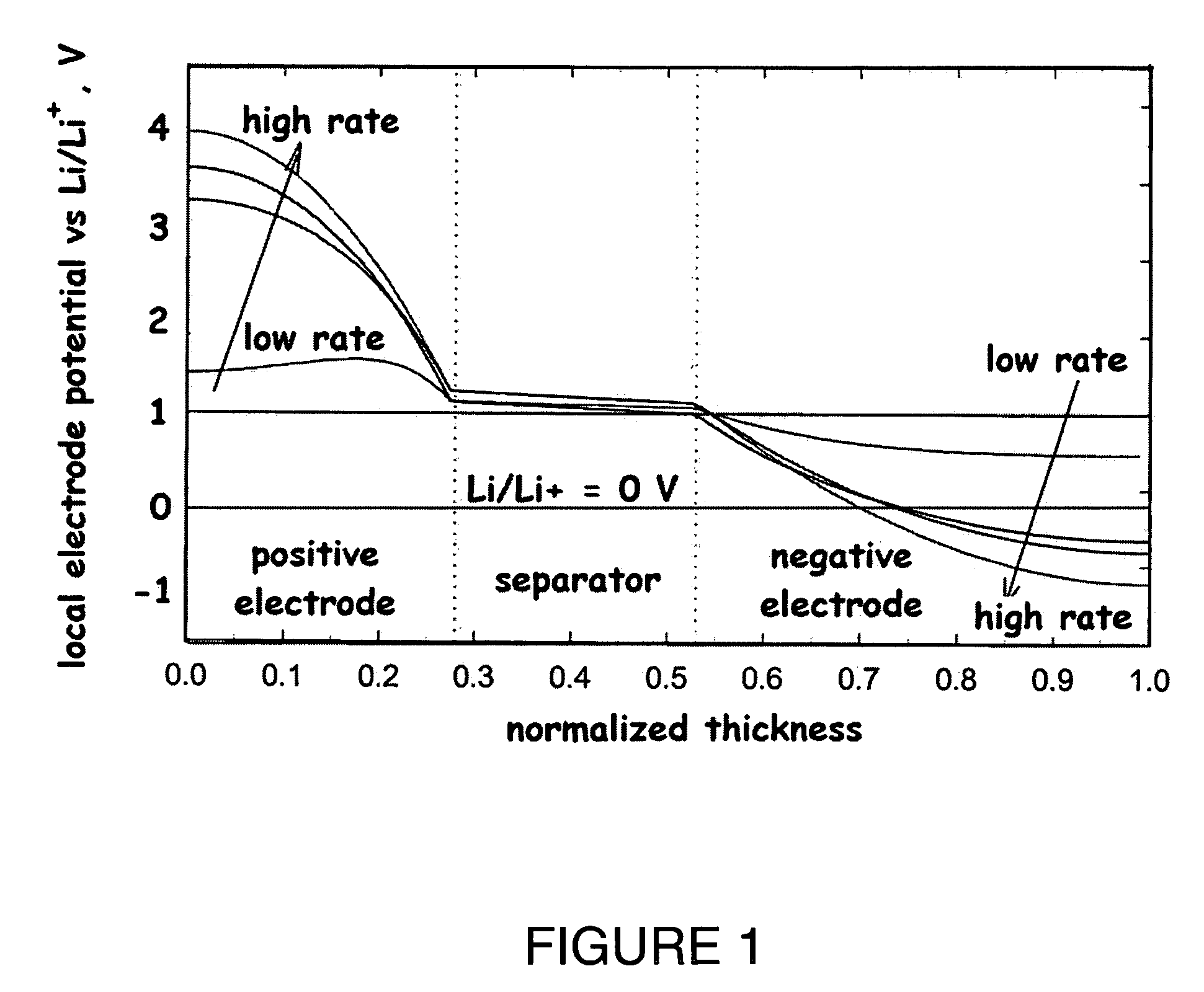

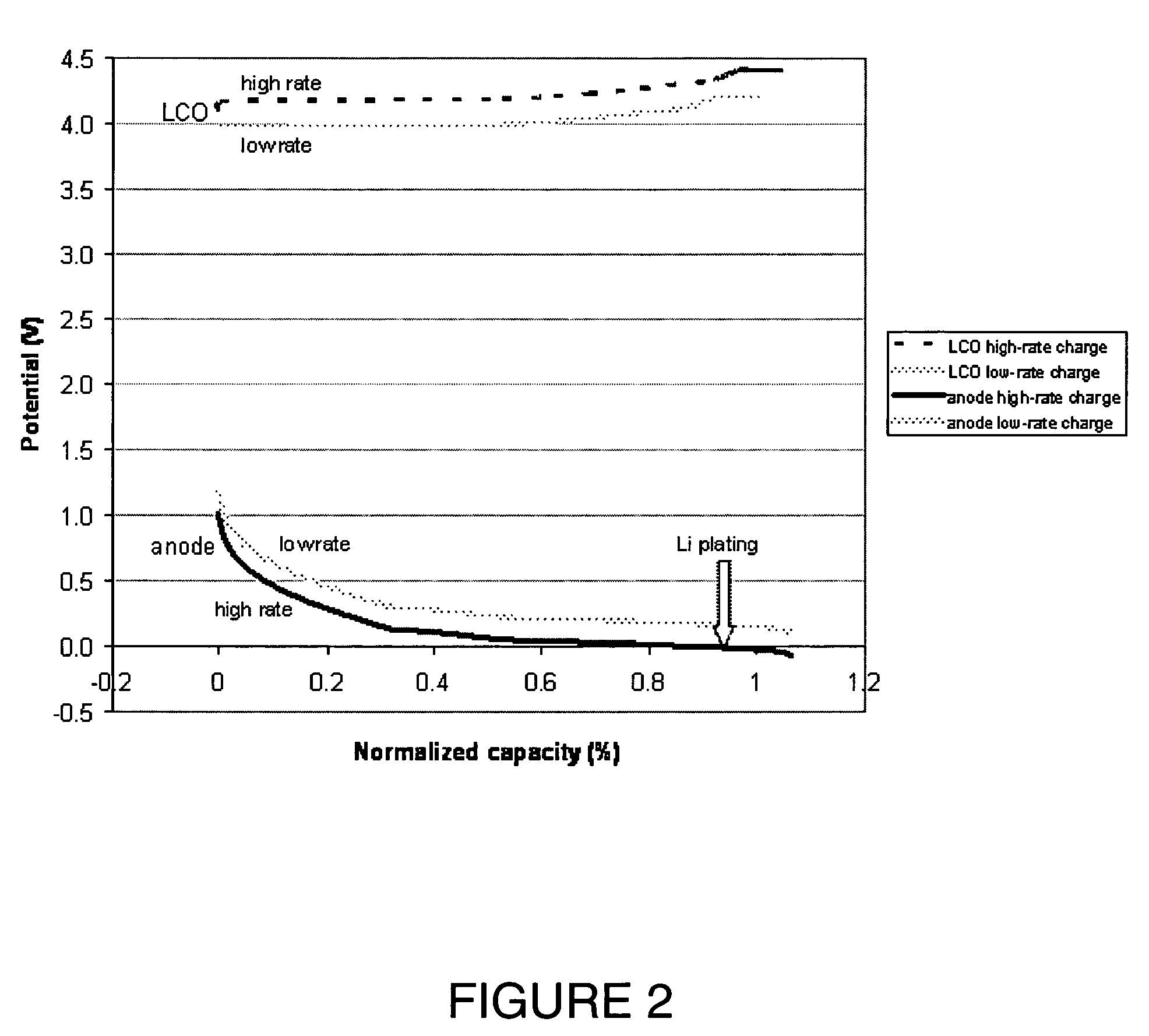

A high capacity, high charge rate lithium secondary cell includes a high capacity lithium-containing positive electrode in electronic contact with a positive electrode current collector, said current collector in electrical connection with an external circuit, a high capacity negative electrode in electronic contact with a negative electrode current collector, said current collector in electrical connection with an external circuit, a separator positioned between and in ionic contact with the cathode and the anode, and an electrolyte in ionic contact with the positive and negative electrodes, wherein the total area specific impedance for the cell and the relative area specific impedances for the positive and negative electrodes are such that, during charging at greater than or equal to 4C, the negative electrode potential is above the potential of metallic lithium. The current capacity per unit area of the positive and negative electrodes each are at least 3 mA-h / cm2, the total area specific impedance for the cell is less than about 20 Ω-cm2, and the positive electrode has an area specific impedance r1 and the negative electrode has an area specific impedance r2, and wherein the ratio of r1 to r2 is at least about 10.

Owner:A123 SYSTEMS LLC

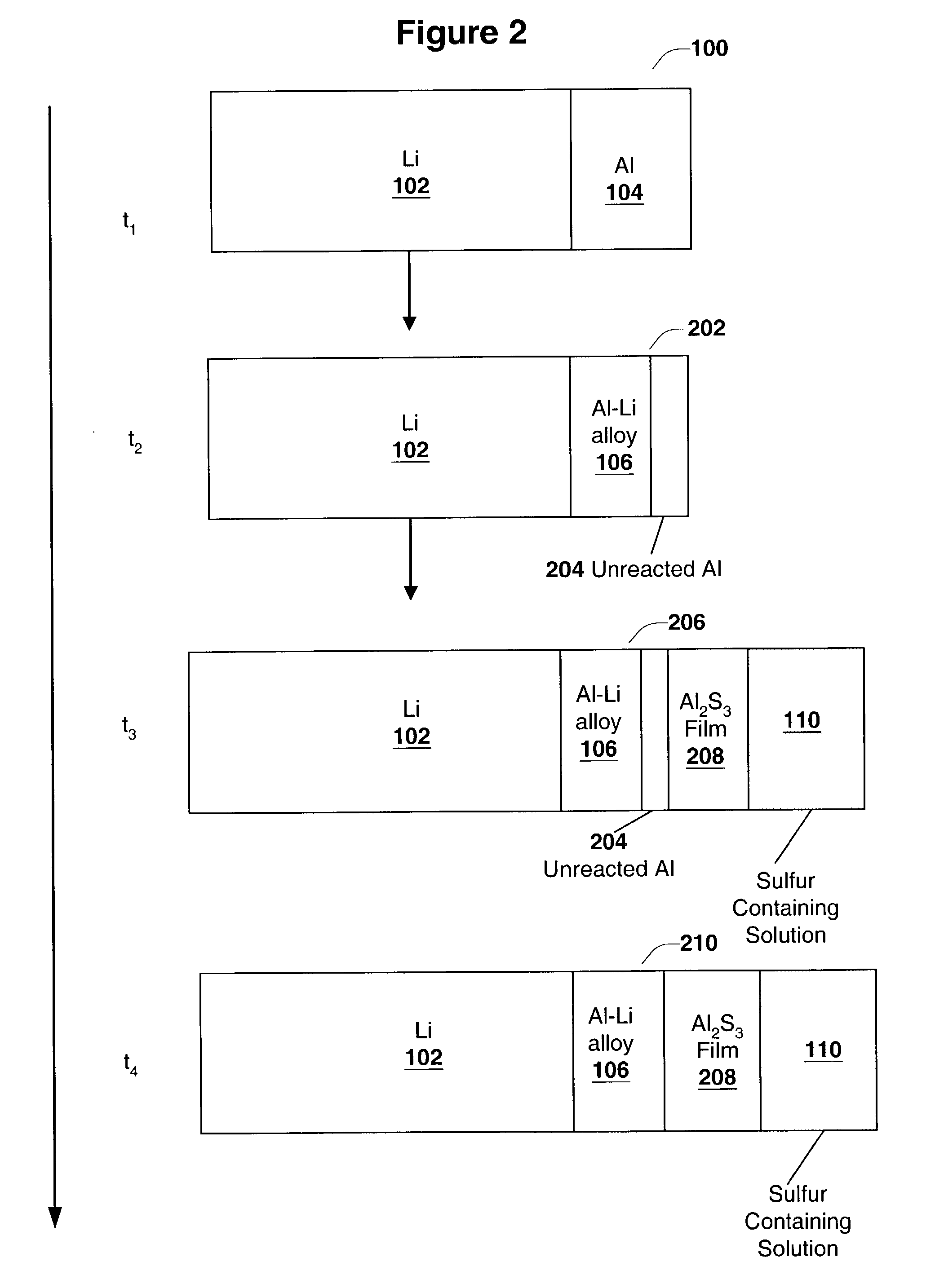

Coated lithium electrodes

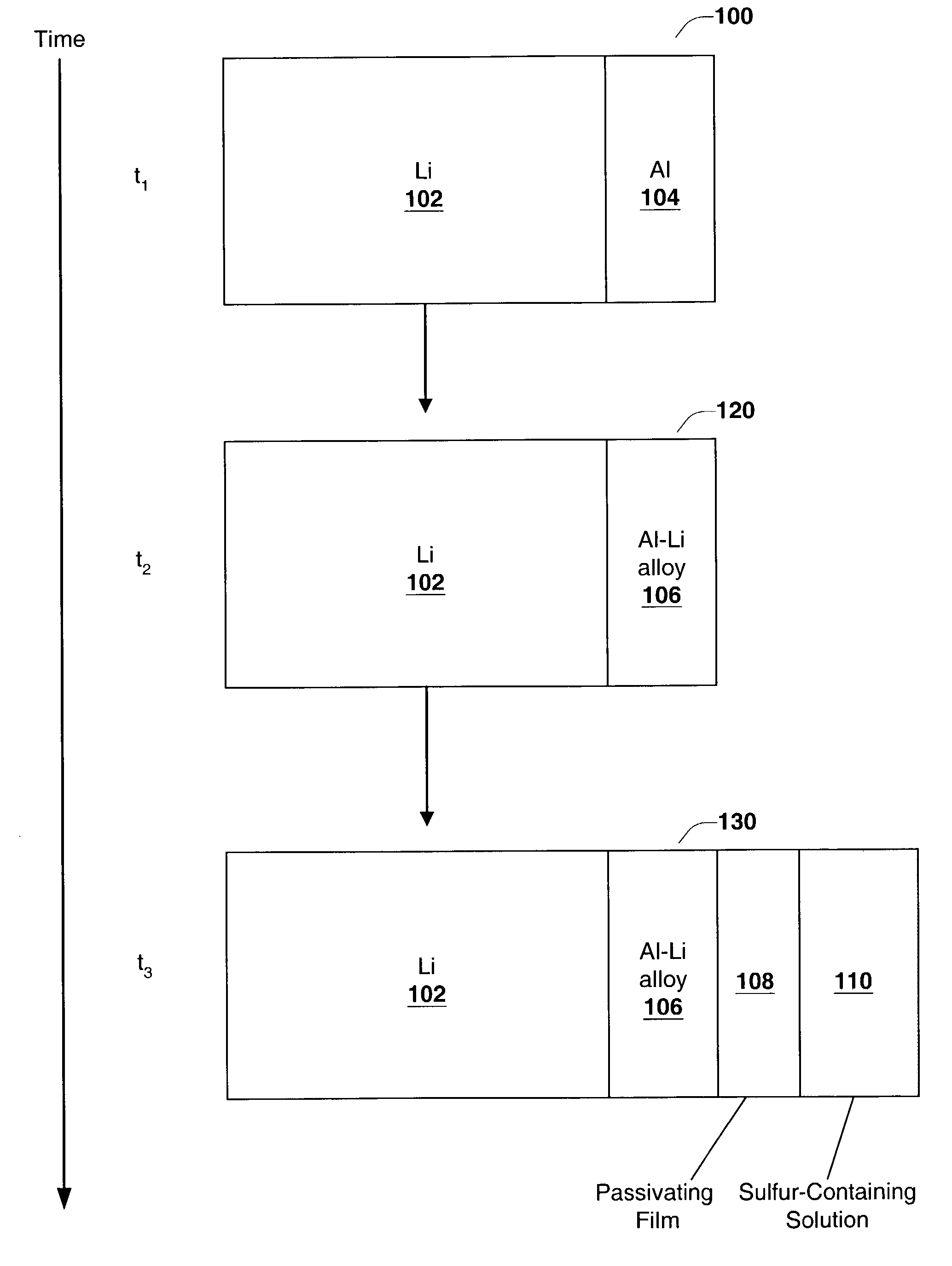

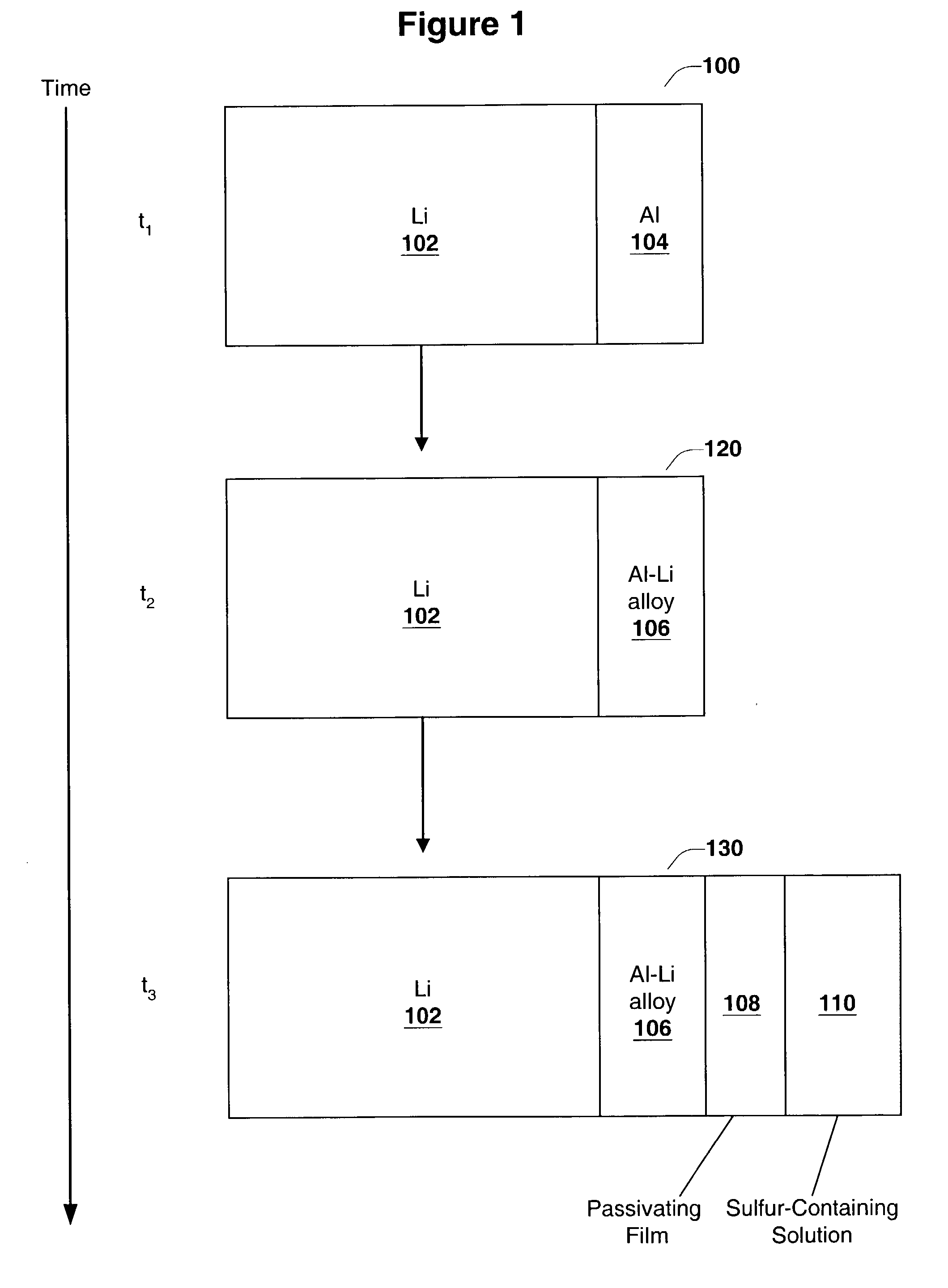

InactiveUS6955866B2Improve cycle lifeIncrease storageabilityCellsOrganic electrolyte cellsSulfur electrodePolysulfide

Batteries including a lithium anode stabilized with a metal-lithium alloy and battery cells comprising such anodes are provided. In one embodiment, an electrochemical cell having an anode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The anode includes a lithium core and a ternary alloy layer over the lithium core where the ternary alloy comprises lithium and two other metals. The ternary alloy layer is effective to increase cycle life and storageability of the electrochemical cell. In a more particular embodiment, the ternary alloy layer is comprised of lithium, copper and tin.

Owner:POLYPLUS BATTERY CO INC

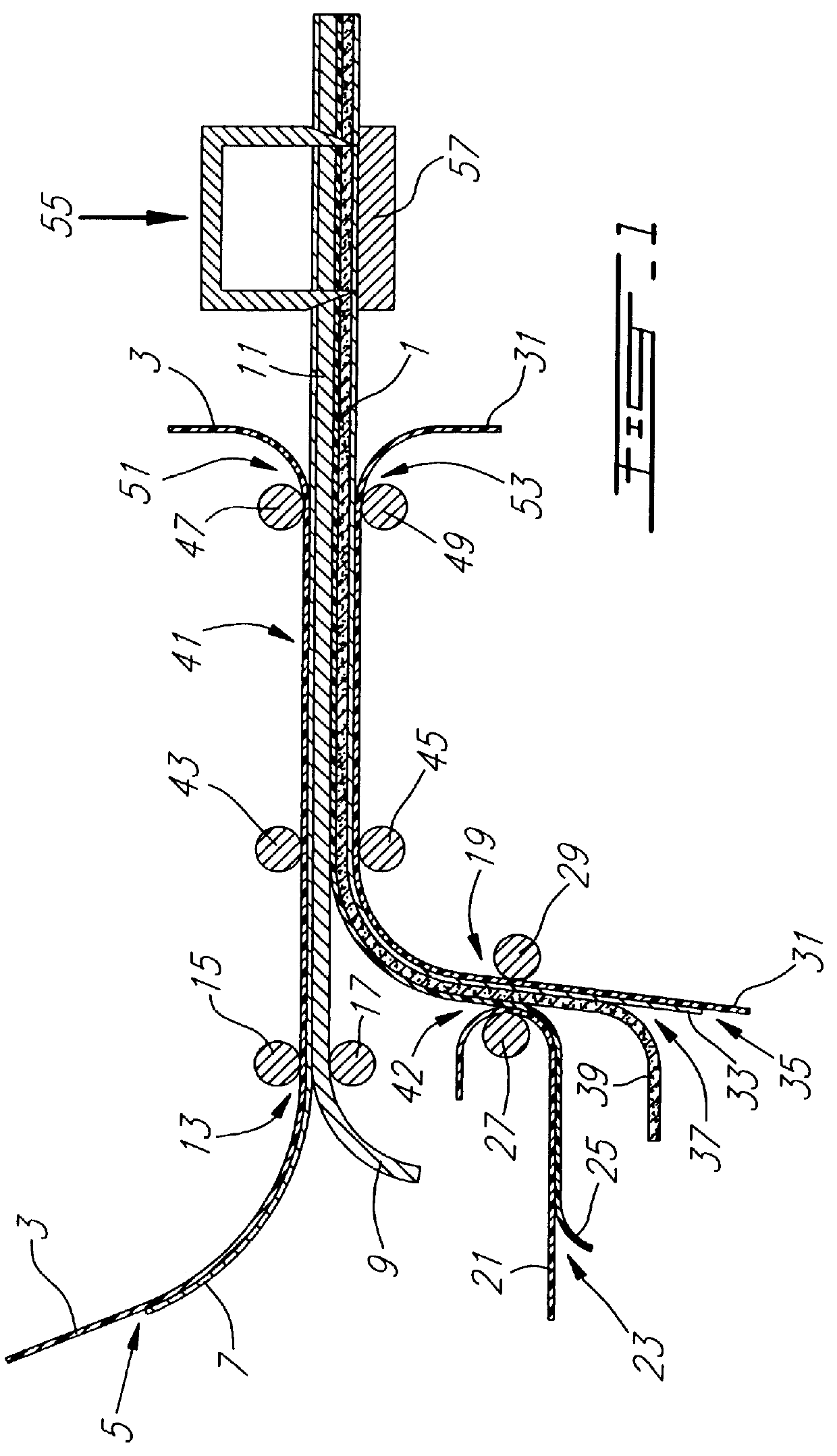

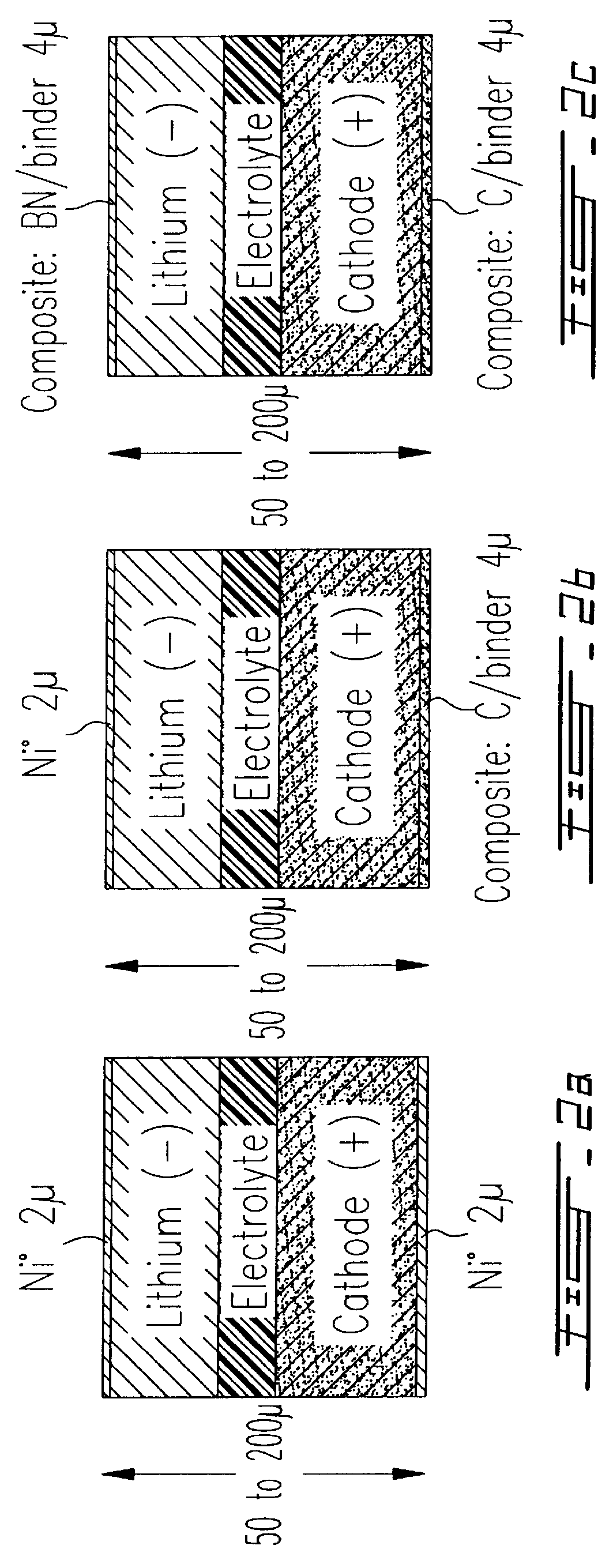

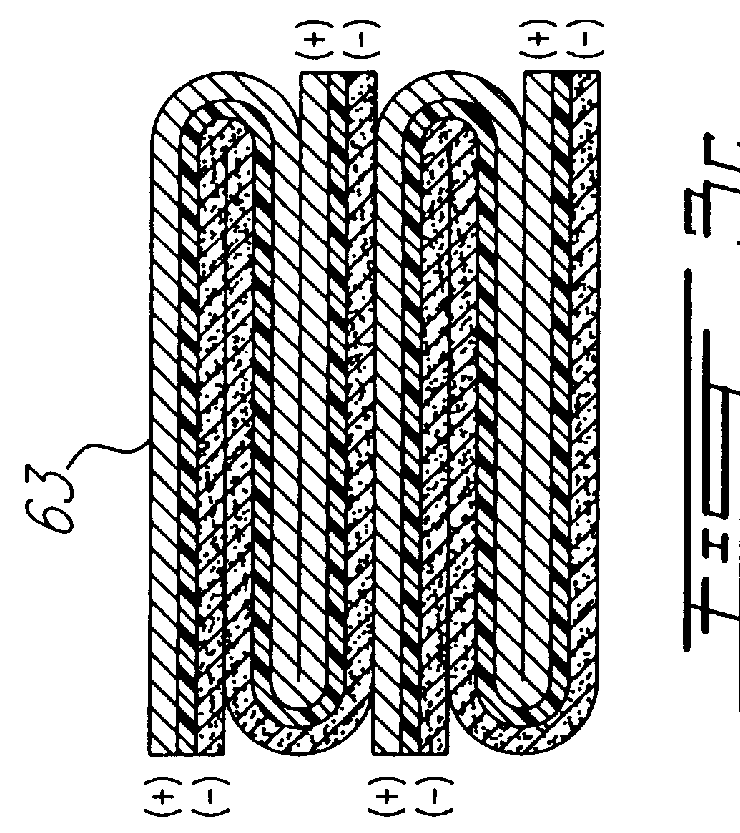

Ultra thin solid state lithium batteries and process of preparing same

InactiveUS6030421ASimple manufacturing processEasy to operateElectrode manufacturing processesFinal product manufactureMetallic lithiumConductive materials

There is provided a mother-battery containing at least the following films: an anode of metallic lithium or sodium, a polymer electrolyte which is conductive towards the alkaline ions of the anode and also acts as a separator between the electrodes, and a composite cathode consisting of a compound which is reducible to lithium or sodium, an additive of electronic conduction and a polymer electrolyte binder. The mother battery also includes an electronically conductive thin coating on the external face of the anode and, possibly of the cathode, in which the conductive material is chemically inert towards the electrode material and which also serves to establish permanent electrical contacts on the external faces. The laminated mother-battery of larger surface area and at least partially charged is thereafter subjected to a sharp mechanical cutting out to give thin polymer electrolyte batteries with lithium or sodium anode. The thus cut out batteries preserve substantially their voltage after mechanical cutting out which is recovered by a mechanism of self-healing.

Owner:BATHIUM CANADA

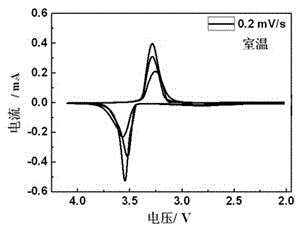

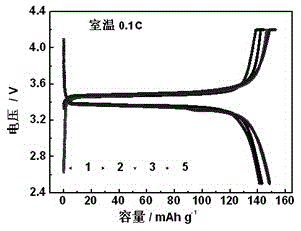

Organic-inorganic all-solid-state composite electrolyte as well as preparation and application methods thereof

PendingCN106785009AIncrease transport activityImprove wettabilitySolid electrolytesSecondary cellsElectrical conductorComposite electrolyte

The invention relates to organic-inorganic all-solid-state composite electrolyte as well as preparation and application methods thereof, belonging to the field of lithium ion batteries. According to the organic-inorganic all-solid-state composite electrolyte, a highly-ordered three-dimensional connection network skeleton is formed by an inorganic fast lithium ion conductor, and a three-dimensional connection network is filled with a polymer and lithium salt. The organic-inorganic all-solid-state composite electrolyte which is flexible and has a controllable three-dimensional connection network structure is prepared. The electrolyte is high in lithium ion conductivity, wide in electrochemical window, good in mechanical property and stable to lithium metal. A lithium ion secondary battery assembled by a composite electrolyte membrane prepared by the method is high in capacity, stable in cycle performance, low in interface impedance and good in interface stability.

Owner:UNIV OF SCI & TECH BEIJING

Method for supplementing lithium for negative electrode of lithium ion battery

ActiveCN102916165AAvoid LithiumAvoid deformationElectrode manufacturing processesElectrolyte/reactants regenerationMetallic lithiumElectrical battery

The invention belongs to the technical field of lithium ion batteries, in particular to a method for supplementing lithium for a negative electrode of a lithium ion battery. The method comprises the following steps: spraying or dripping an organic lithium solution on a surface of a negative electrode in an inert atmosphere, so that lithium ions in the organic lithium solution are reverted to metal lithium which is embedded into the negative electrode; and drying the negative electrode. Compared with the prior art, in the method, the organic lithium solution is sprayed or dipped on the surface of the negative electrode evenly so as to realize lithium supplementation in a wet process, thereby effectively avoiding metallic lithium powders floating in the air in a dry process to ensure safe production; and the whole process is simple, the cost is lower, the amount of the lithium supplementation can be controlled accurately through the amount and the time by spraying or dripping the organic lithium solution so as to supplement the lithium evenly, thereby preventing lithium precipitation and deformation of the negative electrode and improving the initial efficiency of the battery. Therefore, the the energy density of the battery is improved. Additionally, the invention further discloses another method for supplementing the lithium for the negative electrode of the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH +1

Positive electrode active material and nonaqueous electrolyte secondary cell including the same

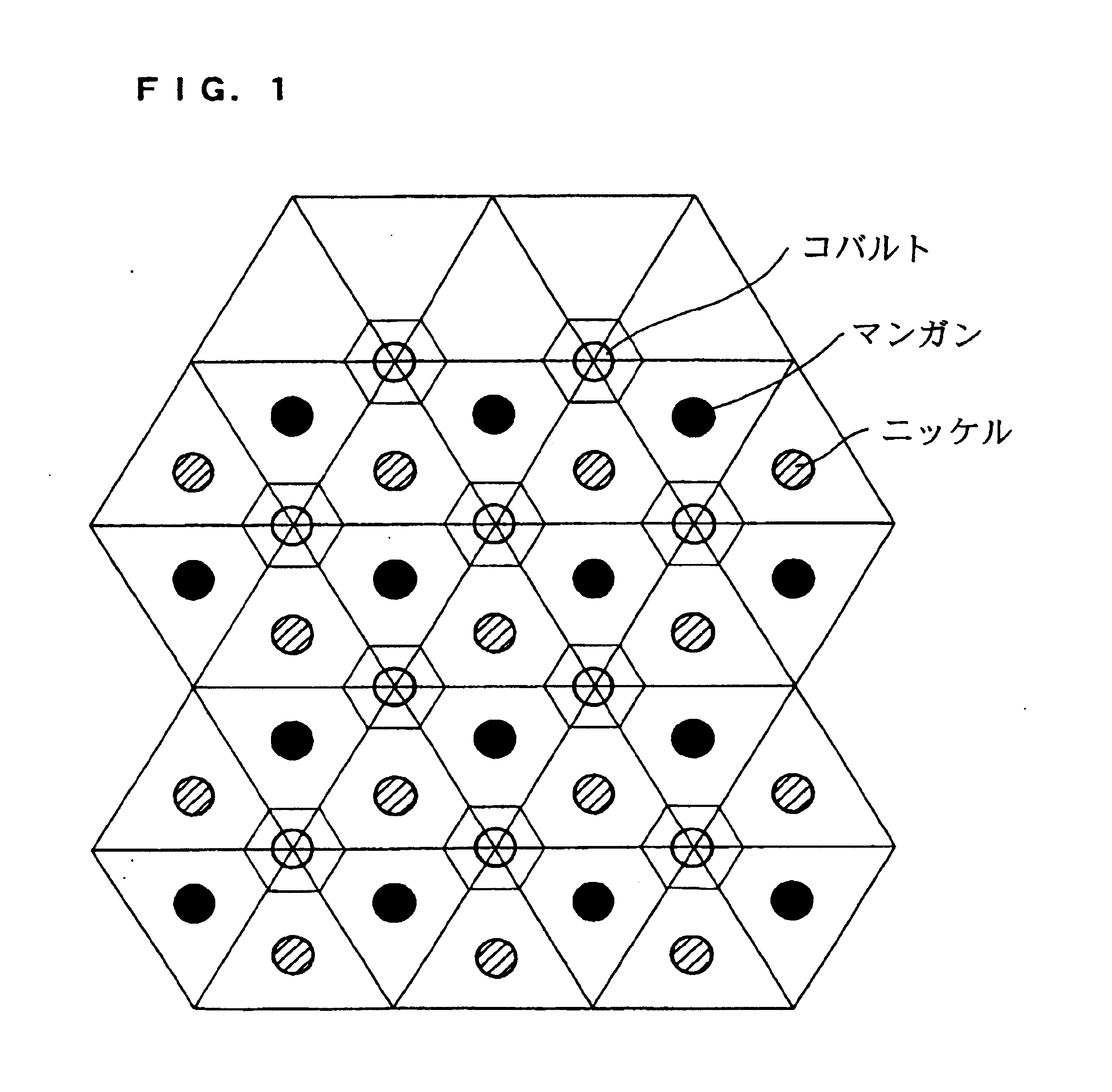

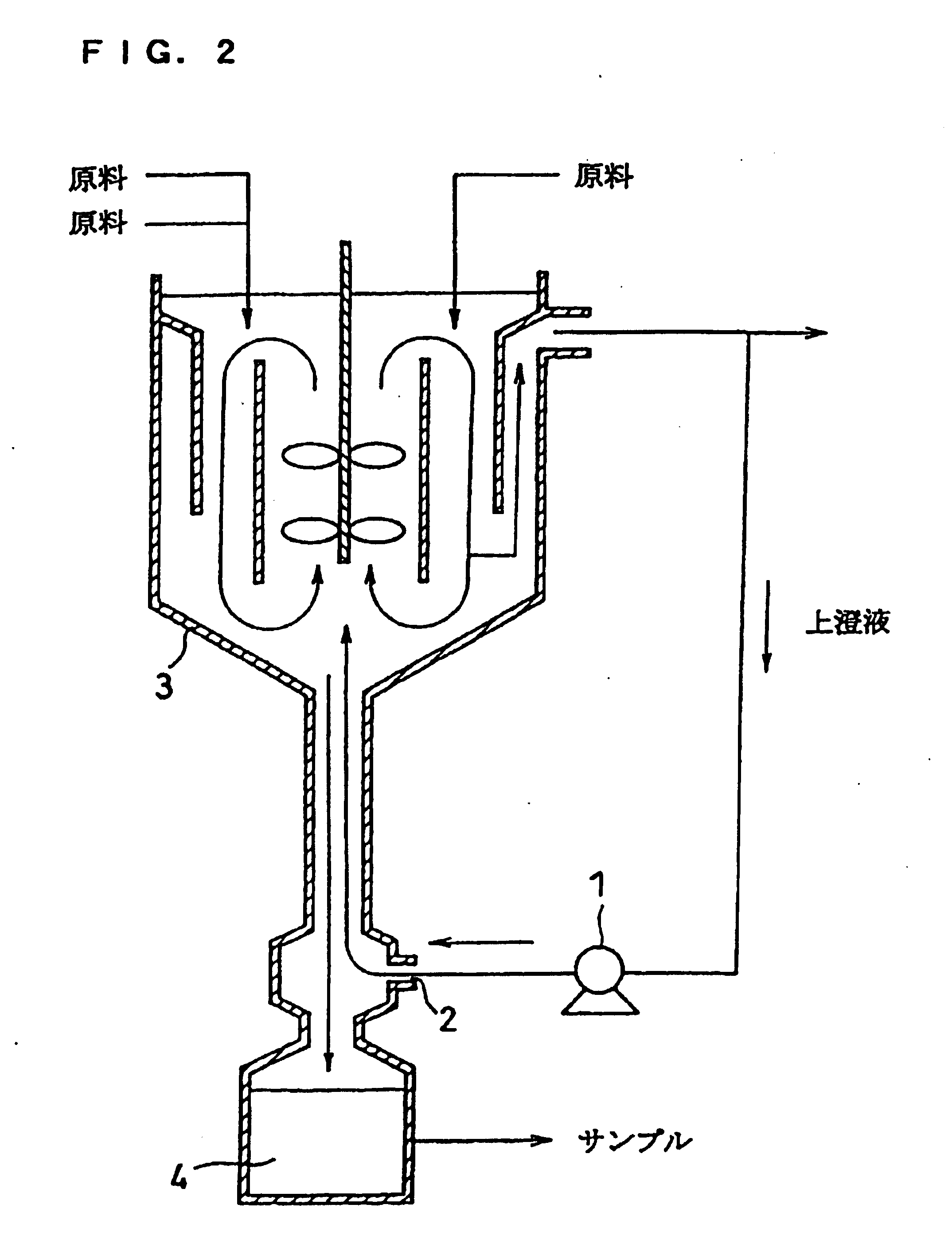

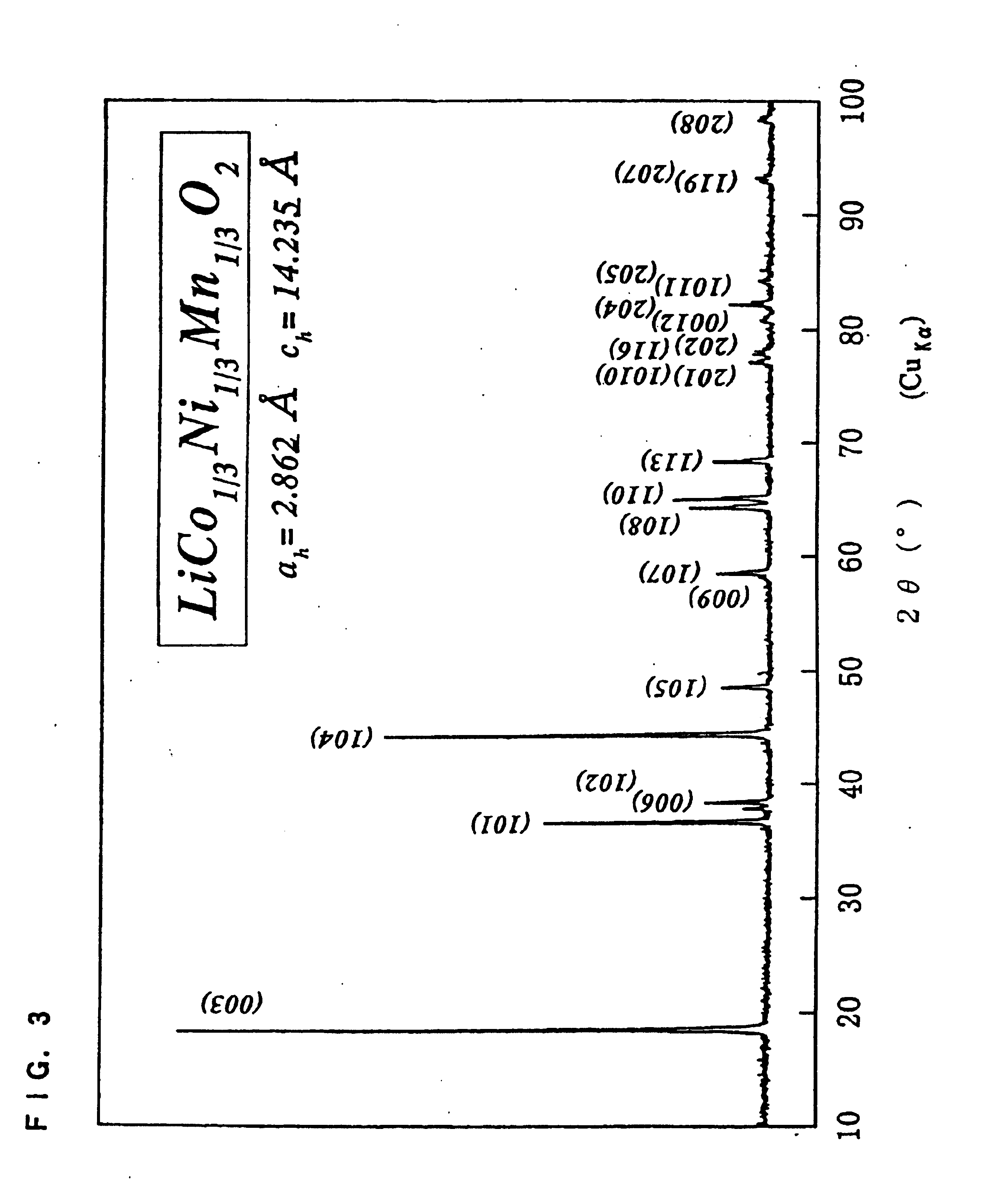

InactiveUS20050079416A1Large capacityImprove charge and discharge efficiencyOxygen/ozone/oxide/hydroxideIron oxides/hydroxidesMetallic lithiumManganese

A nonaqueous electrolytic secondary cell produced at low cost and having a large capacity comprises a negative electrode having an active material mainly composed of a material that at least absorbs and releases lithium ions or metallic lithium, a positive electrode, and an electrolyte. The active material of the positive electrode is an oxide containing nickel, manganese, and cobalt, and the contents of the elements are substantial the same.

Owner:PANASONIC CORP +1

Lithium secondary cell with high charge and discharge rate capability

ActiveUS20050233220A1Final product manufactureActive material electrodesElectrode potentialMetallic lithium

A high capacity, high charge rate lithium secondary cell includes a high capacity lithium-containing positive electrode in electronic contact with a positive electrode current collector, said current collector in electrical connection with an external circuit, a high capacity negative electrode in electronic contact with a negative electrode current collector, said current collector in electrical connection with an external circuit, a separator positioned between and in ionic contact with the cathode and the anode, and an electrolyte in ionic contact with the positive and negative electrodes, wherein the total area specific impedance for the cell and the relative area specific impedances for the positive and negative electrodes are such that, during charging at greater than or equal to 4C, the negative electrode potential is above the potential of metallic lithium. The current capacity per unit area of the positive and negative electrodes each are at least 3 mA-h / cm2, the total area specific impedance for the cell is less than about 20 Ω-cm2, and the positive electrode has an area specific impedance r1 and the negative electrode has an area specific impedance r2, and wherein the ratio of r1 to r2 is at least about 10.

Owner:A123 SYSTEMS LLC

Fluoride ion electrochemical cell

ActiveUS20090029237A1Improve performanceHigh energyAlkaline accumulatorsLead-acid accumulatorsMetallic lithiumState of art

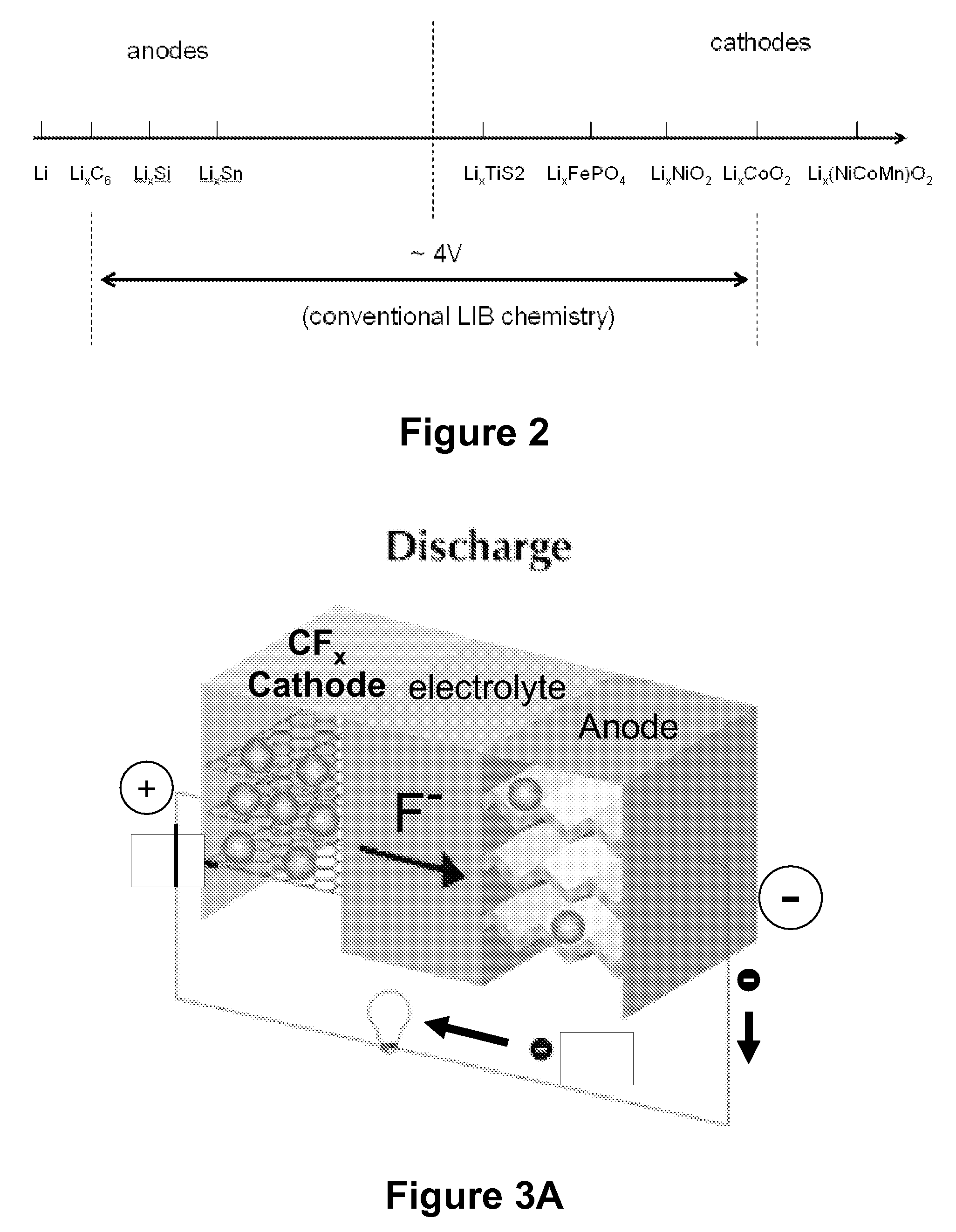

The present invention provides electrochemical cells capable of good electronic performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical cells of the present invention are versatile and include primary and secondary cells useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art primary lithium batteries and lithium ion secondary batteries. For example, electrochemical cells of the present invention include secondary electrochemical cells using anion charge carriers capable of accommodation by positive and negative electrodes comprising anion host materials, which entirely eliminate the need for metallic lithium or dissolved lithium ion in these systems.

Owner:CALIFORNIA INST OF TECH +1

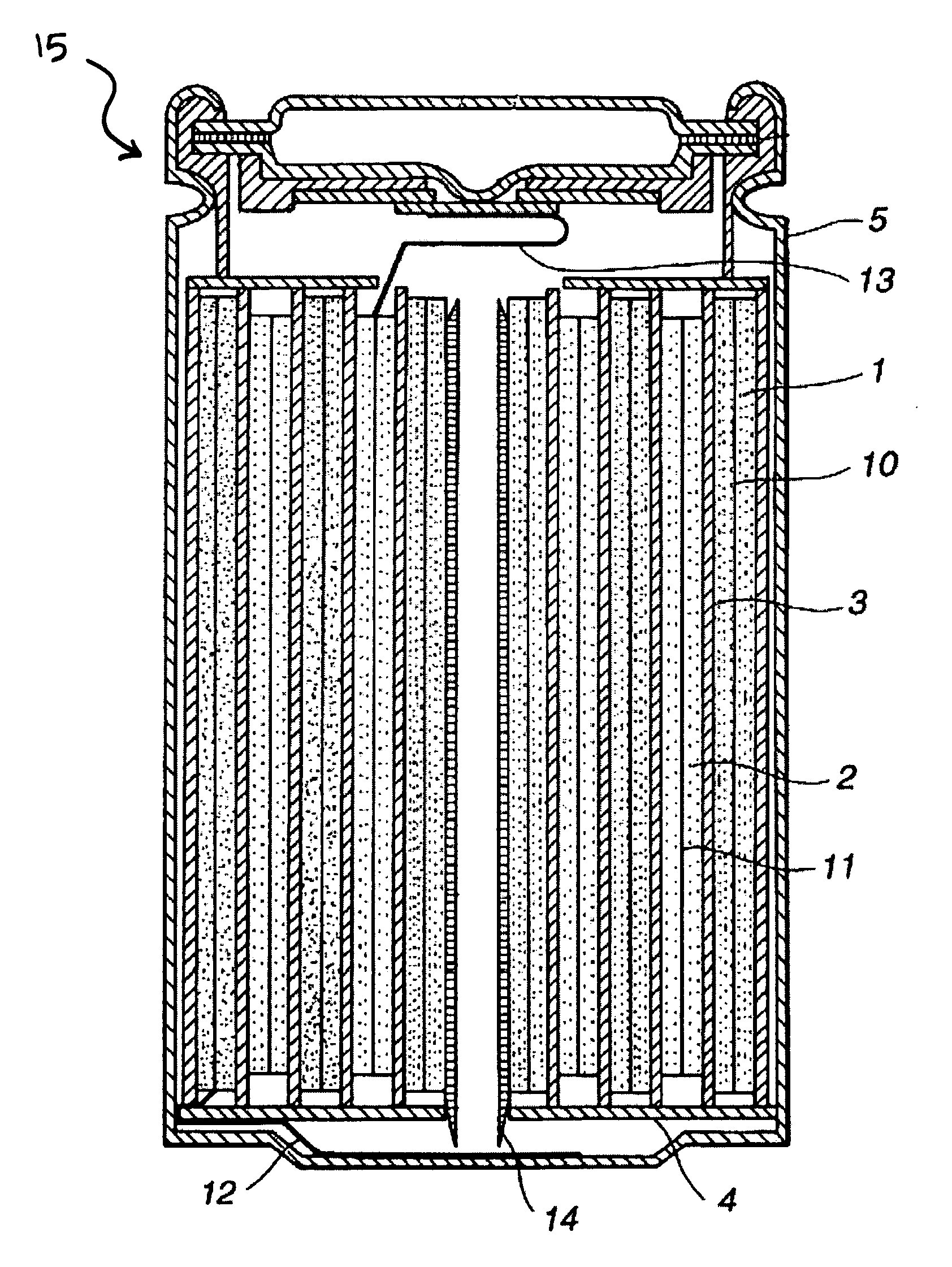

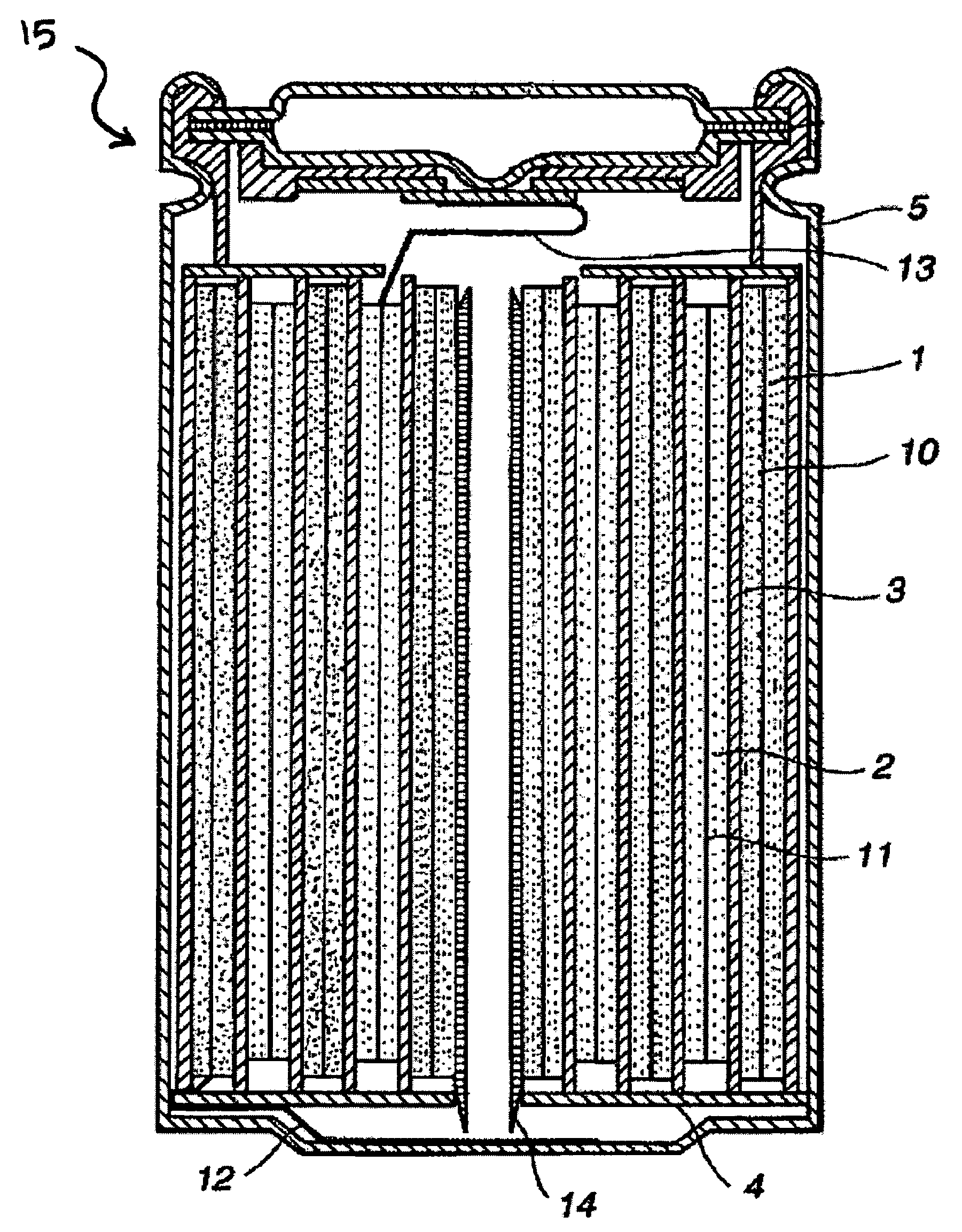

Nonaqueous electrolyte lithium secondary cell

InactiveUS7029793B2Improve securityImprove battery performanceSolid electrolyte cellsTwo electrolyte cellsMetallic lithiumMolten salt

A nonaqueous electrolyte lithium secondary cell comprising a positive electrode (1), a negative electrode (2) and a nonaqueous electrolyte containing a lithium salt is characterized by that the nonaqueous electrolyte contains a room temperature molten salt as a main component, a material wherein a working potential of the negative electrode (2) is nobler by above 1V than a potential of a metallic lithium is used for a negative active material of the negative electrode. This nonaqueous electrolyte lithium secondary cell has excellent safety and cell performance.

Owner:GS YUASA INT LTD +1

Nonaqueous electrolyte secondary battery

ActiveUS20060046155A1Excellent in high-temperature cycle capabilityOrganic electrolyte cellsActive material electrodesMetallic lithiumElectrode potential

A nonaqueous electrolyte secondary battery includes: an outer housing; a nonaqueous electrolyte filled in the outer housing, a positive electrode housed in the outer housing, a negative electrode housed in the outer housing and a separator disposed between the negative electrode and the positive electrode. The nonaqueous electrolyte comprises a nonaqueous solvent including diethyl carbonate and at least one of ethylene carbonate and propylene carbonate, and the nonaqueous electrolyte has a content of the diethyl carbonate of from 80 to 95% by volume. The positive electrode comprises a positive electrode active substance having a positive electrode potential in a full charged state of 4.4 V or higher with respect to a potential of metallic lithium. The negative electrode comprises a negative electrode active substance having a negative electrode potential in a full charged state of 1.0 V or higher with respect to a potential of metallic lithium.

Owner:KK TOSHIBA

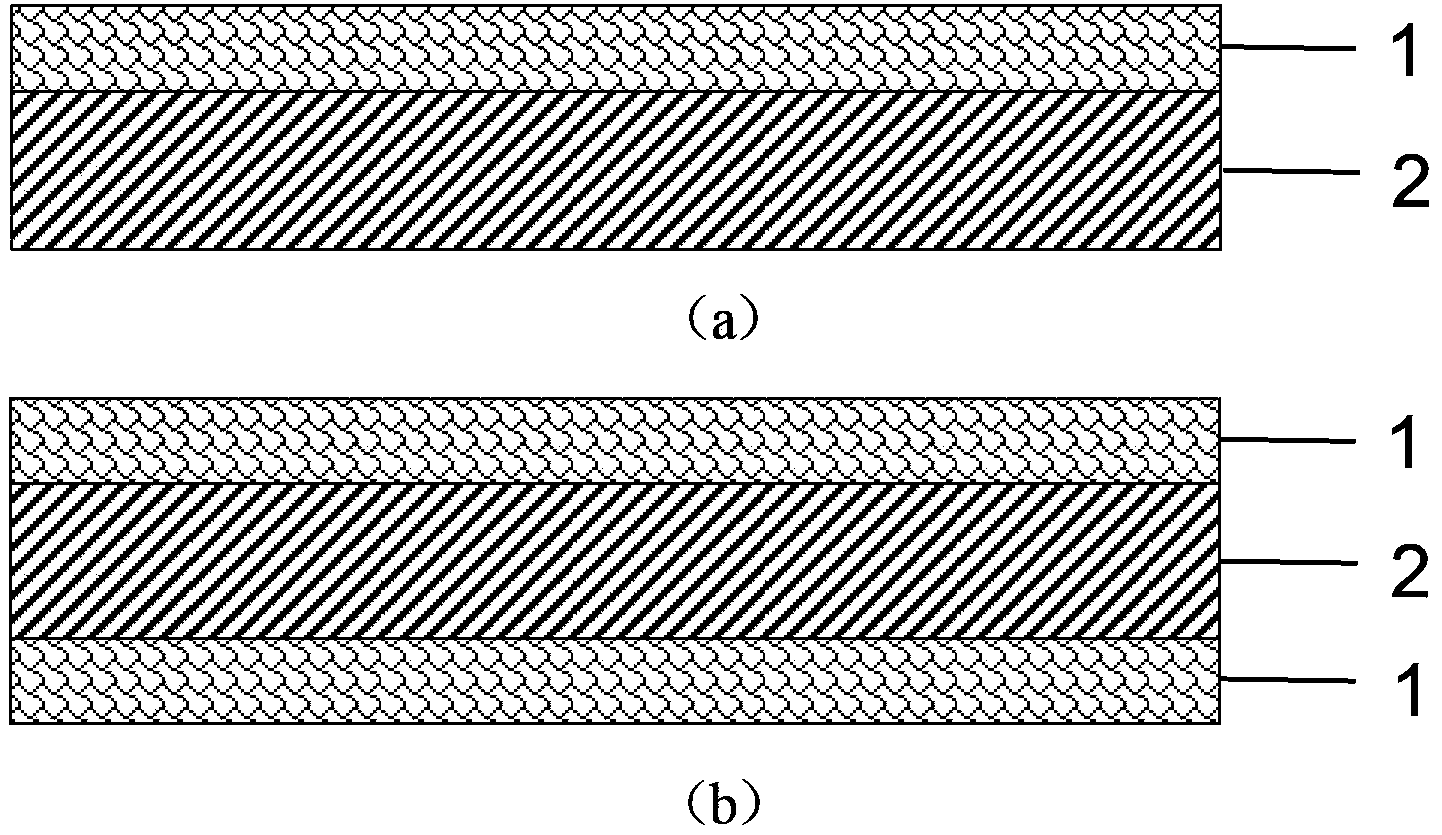

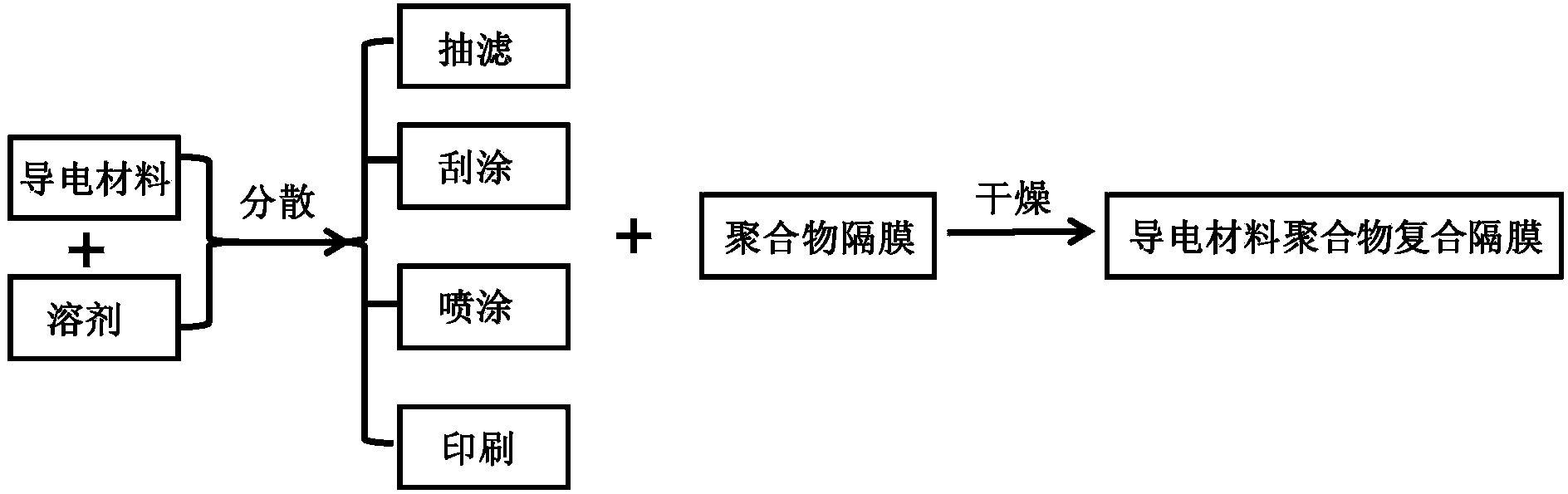

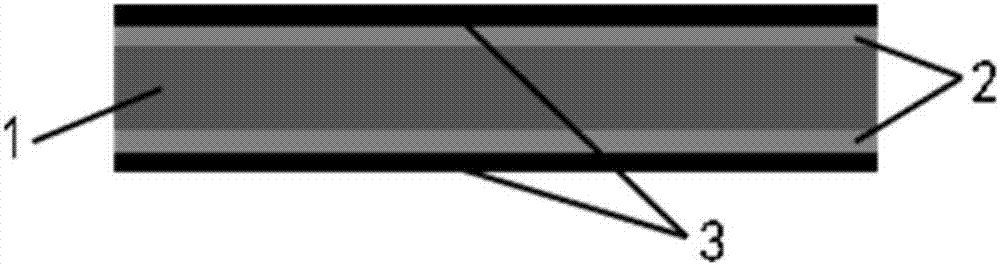

Composite diaphragm for battery and preparation method thereof

InactiveCN104103791ALower internal resistanceIncrease contactCell component detailsMetallic lithiumDiaphragm structure

The invention discloses a composite diaphragm for a battery and a preparation method thereof, belonging to the field of electrochemical cells. The composite diaphragm is a multilayer composite diaphragm structure composed of a conducting layer / a polymer layer or a conducting layer / a polymer layer / a conducting layer, wherein the conducting layer mainly comprises a carbon material or a conductive polymeric material and forms a film on a single surface or double surfaces of a polymer diaphragm. The composite diaphragm has the following characteristics: the conducting layer has strong electrolyte adsorption and storage capability, the process of ion transport is shortened, and large-current charge and discharge performance of the battery is improved; when the composite diaphragm is used in a metallic lithium battery, the conducting layer in the composite diaphragm contacting with metallic lithium can alleviate nonuniform corrosion on the surface of lithium and inhibit formation of lithium dendrite crystals. The preparation method for the composite diaphragm is simple and easily controllable, can realize large-quantity and low-cost industrial preparation of the composite diaphragm and has a high application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for producing sulfide glass or sulfide glass ceramic capable of conducing lithium ion, and whole solid type cell using said glass ceramic

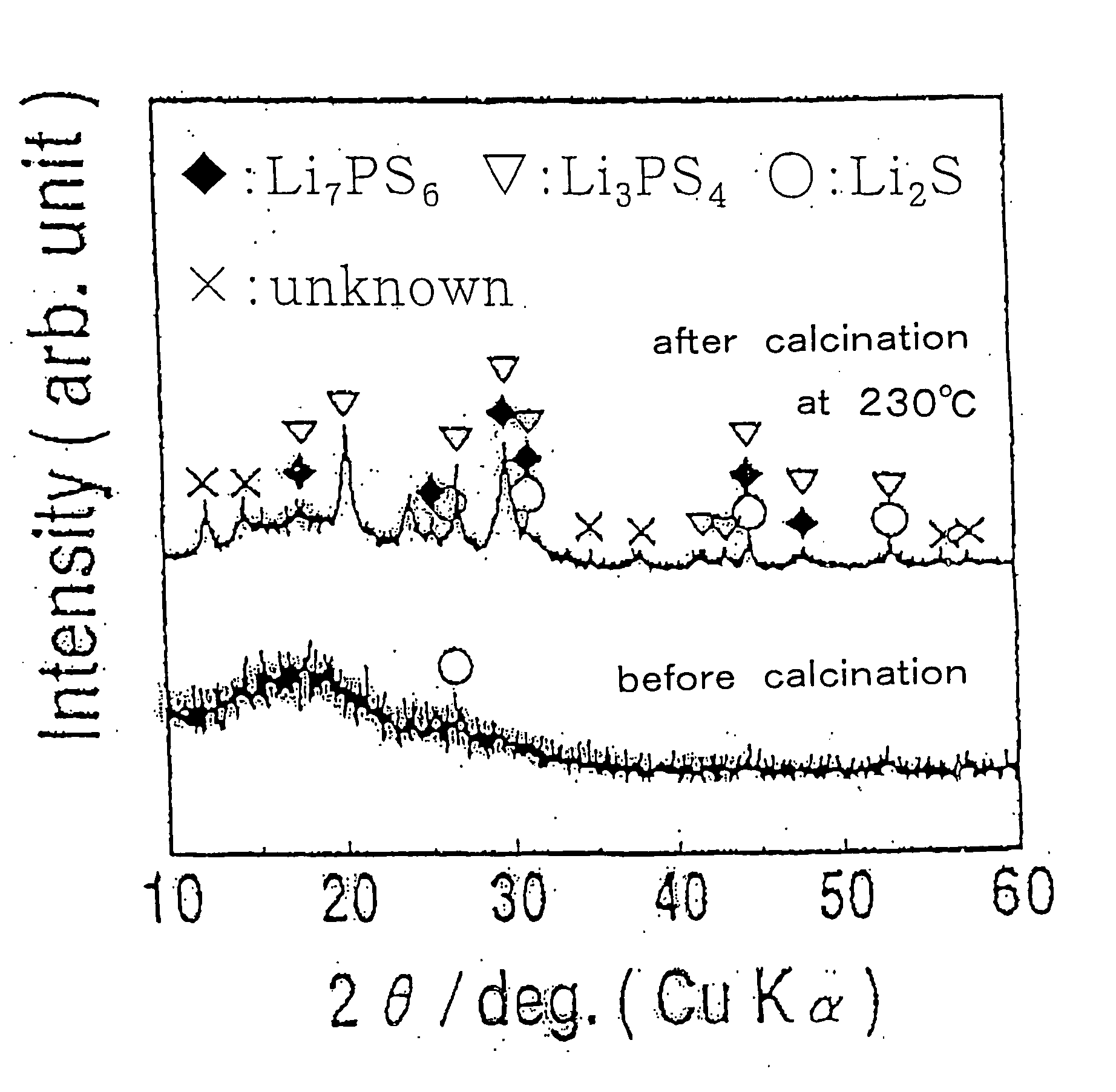

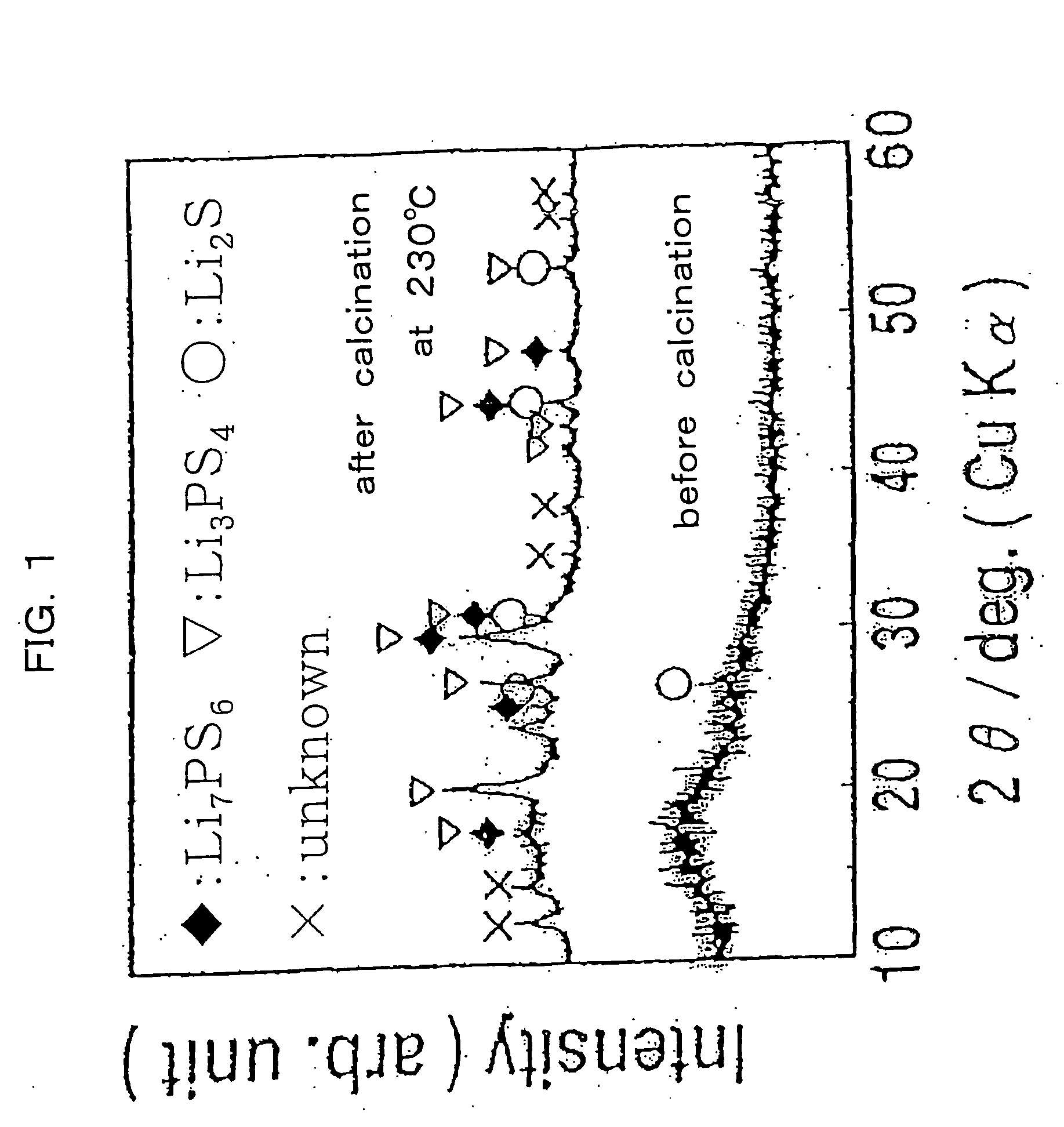

InactiveUS20050107239A1Simple and convenient and easily availableSolid electrolytesConductive materialMetallic lithiumSulfur

The present invention relates to a process for producing sulfide glass or sulfide glass ceramic each capable of conducting a lithium ion, comprising subjecting metallic lithium, sulfur as a simple substance and phosphorus as a simple substance as starting raw materials, which constitute the sulfide glass and sulfide glass ceramic, to mechanical milling to thereby convert them into sulfide glass or sulfide glass ceramic; and a whole solid type cell using the above-mentioned sulfide glass ceramic as a solid electrolyte. According to the present invention, it is made possible to produce sulfide glass and sulfide glass ceramic which are each capable of conducting a lithium ion and which have high electroconductivity at room temperature by a simple and advantageous process from starting raw materials being easily available and inexpensive.

Owner:IDEMITSU KOSAN CO LTD +1

Method for protective treatment of lithium cathodes in lithium secondary batteries

ActiveCN104617259AEasy to controlEasy to prepareCell electrodesElectrolyte accumulators manufactureMetallic lithiumSilicon dioxide

The invention discloses a method for in-situ protective treatment of lithium cathodes. The metallic lithium for the in-situ protective treatment of lithium cathodes can be applied to high-performance lithium secondary batteries. The method for in-situ protective treatment of lithium cathodes comprises a method for in-situ generation of silicon dioxide on the surfaces of the lithium cathodes. At a certain temperature, the treating fluid reacts with a passivation layer on the surface of the metallic lithium to obtain a silicon dioxide-containing protective layer. The method for preparing the in-situ protective treatment of lithium cathodes is simple, easy to control and high in practical degree. By applying the metallic lithium for in-situ protection to the lithium secondary batteries, the energy density and cycle performance of the batteries at present can be greatly improved and high practical value is provided.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Modified lithium-based composite negative material for solid state battery and preparation and application of material

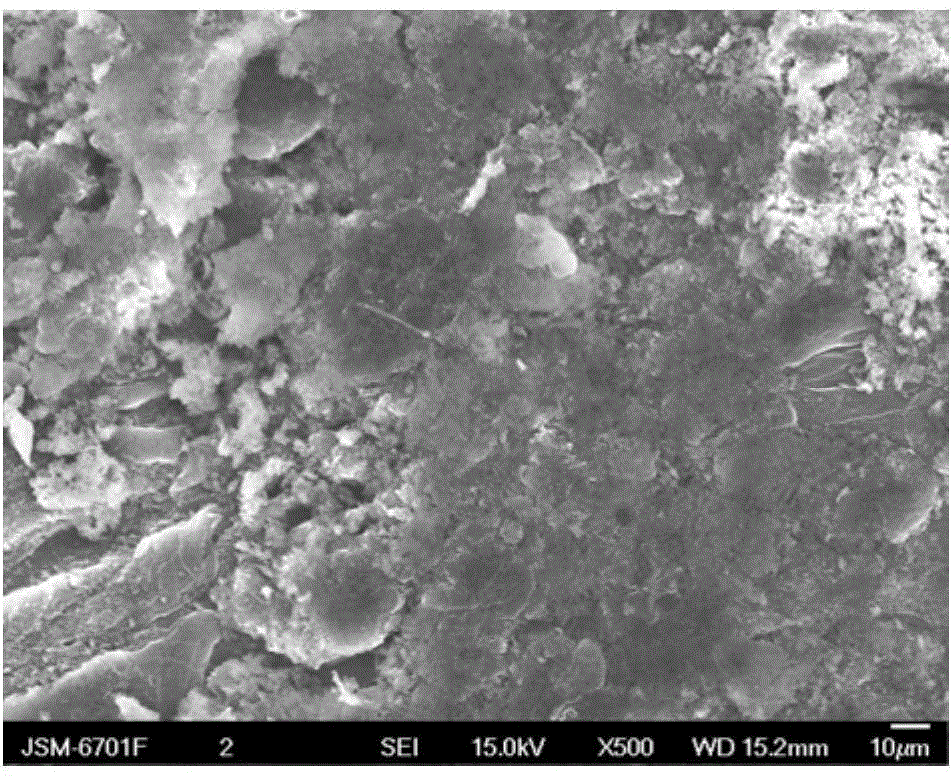

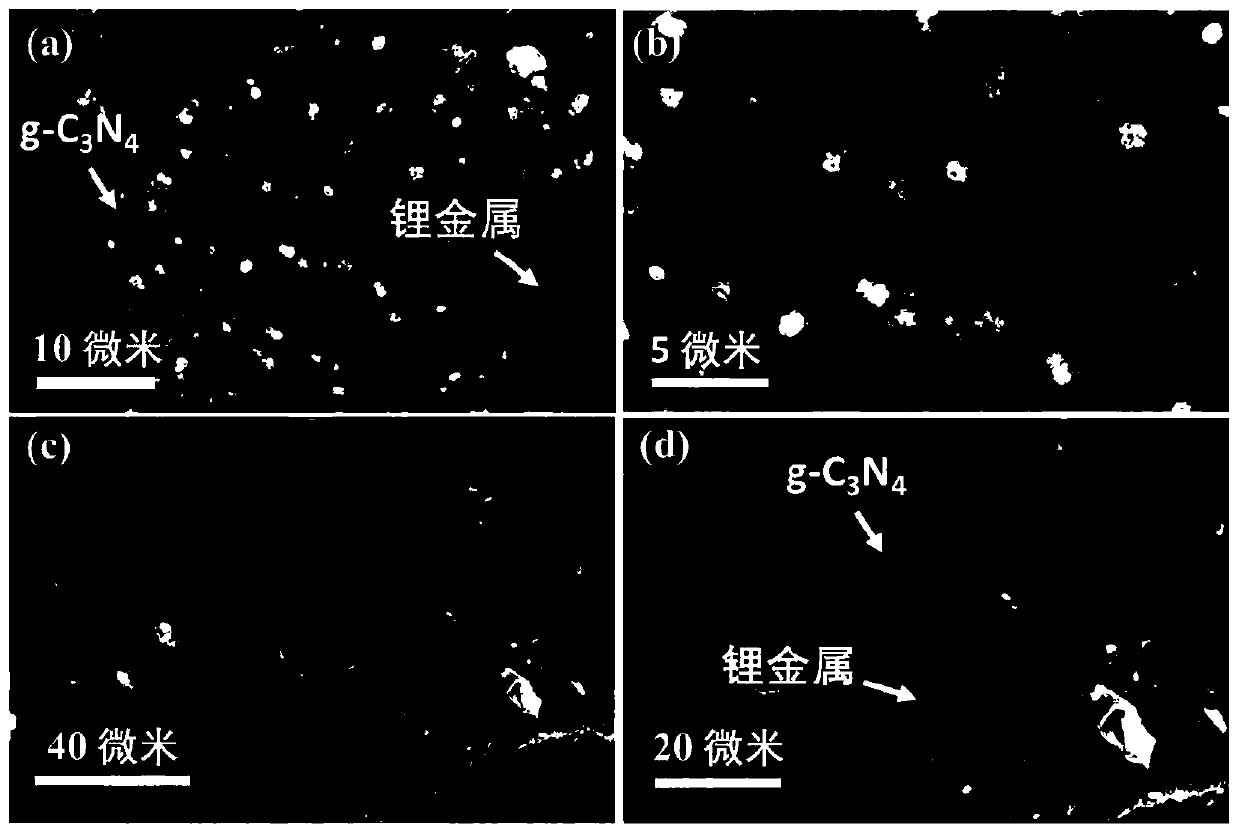

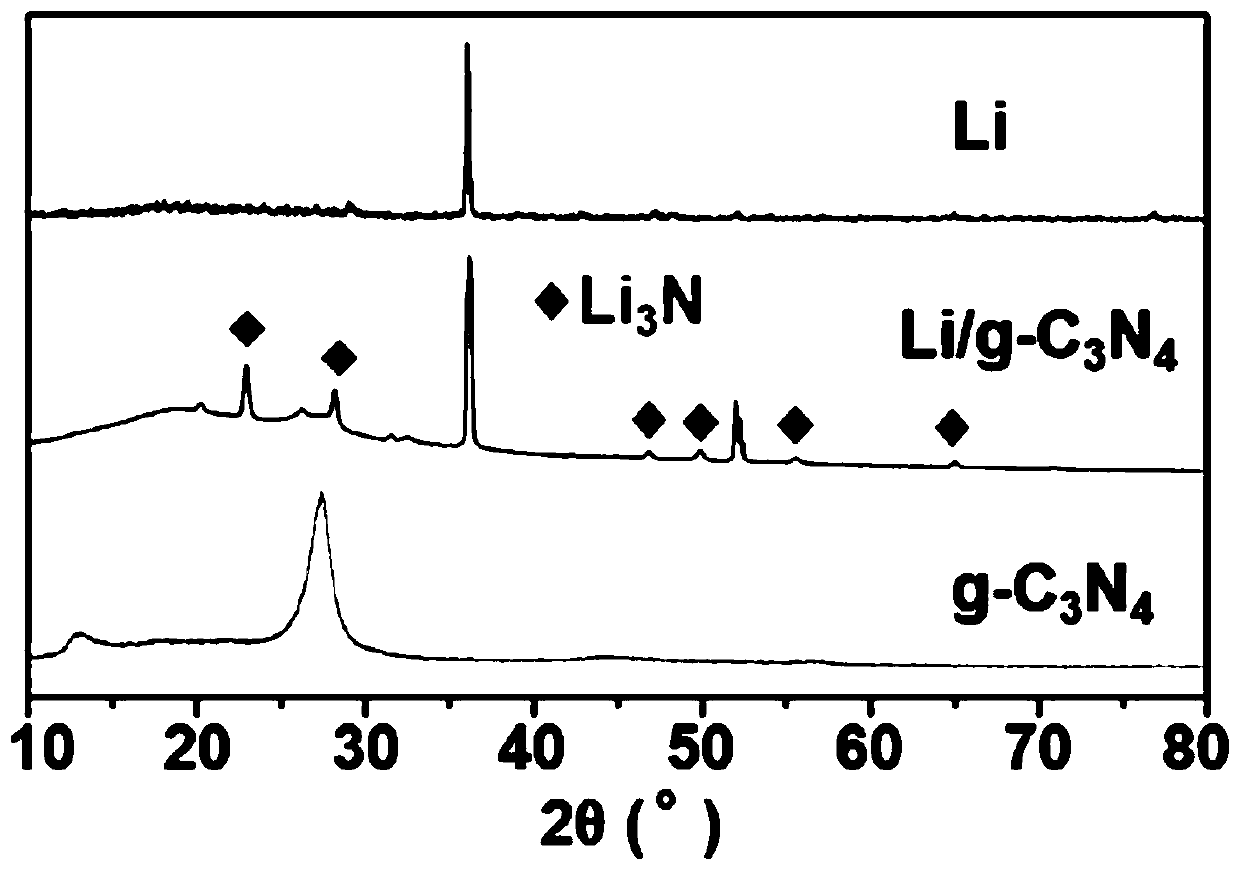

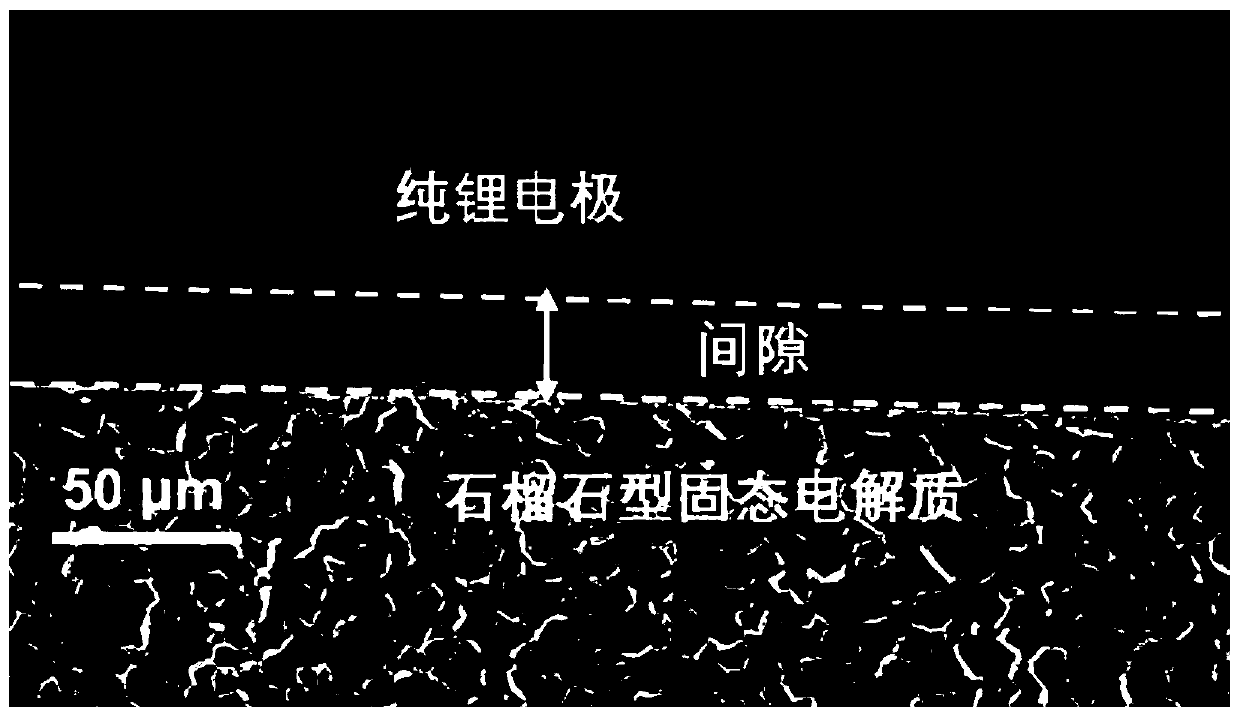

InactiveCN109841817AOptimize interface compositionImprove cyclic charge and discharge capacityElectrode manufacturing processesSecondary cellsSolid state electrolyteInterfacial resistance

The invention relates to a modified lithium-based composite negative material for a solid state battery and preparation and application of the material. The modified lithium-based composite negative material comprises 50-95 parts of lithium and 5-50 parts of a modified additive by weight; and the modified additive comprises one or multiple nitride or fluoride. The preparation method comprises thatthe lithium and modified additive are mixed, heated to 180-400 DEG C, stirred uniformly, and cooled to the room temperature; and the modified composite negative material is used to the solid state battery, and combined with a solid electrolyte. Compared with the prior art, the lithium metal is mixed with the modified additive by mixing in a heating fusing way, the surface energy of the lithium metal can be reduced effectively, elements including nitrogen and fluorine are introduced in a controllable way, the interfacial resistance between the solid electrolyte and lithium cathode is reduced effectively, the limit current that can be born by the solid electrolyte is increased, the recyclable charge and discharge capacity is improved, and the solid electrolyte and cathode interface is stable for a longer time in the long circulation process.

Owner:TONGJI UNIV

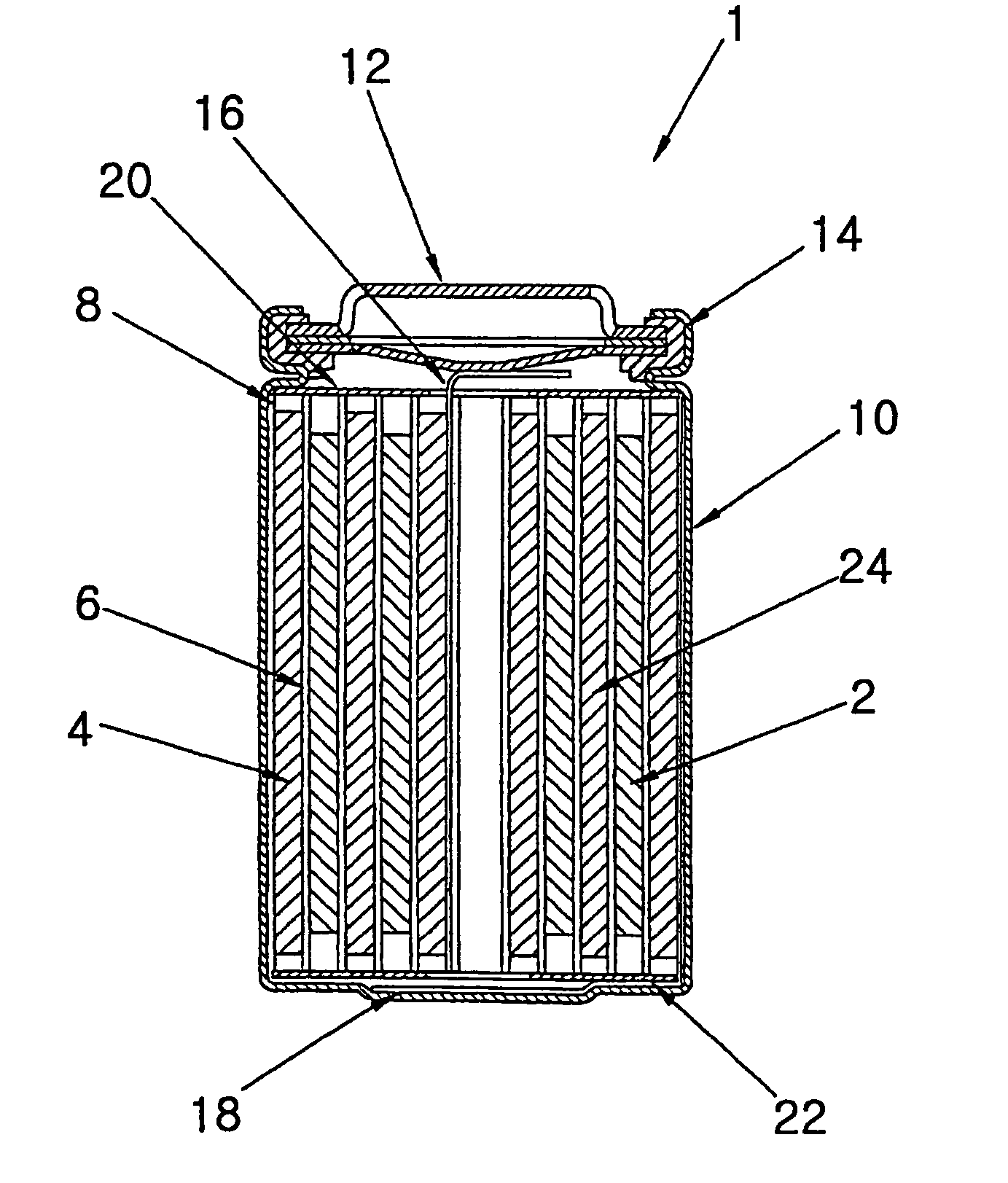

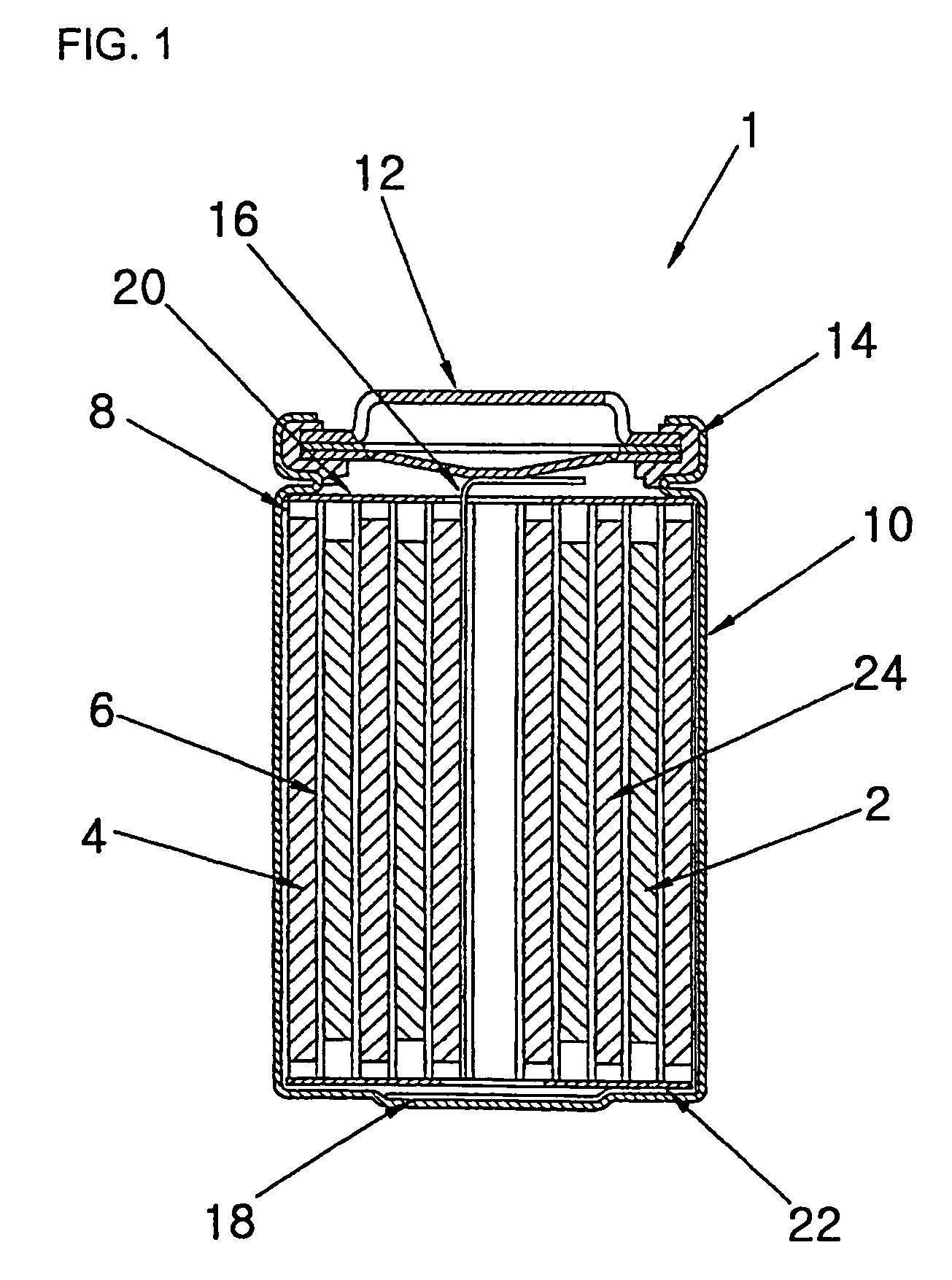

Lithium secondary cell with high charge and discharge rate capability

ActiveUS7261979B2Final product manufactureActive material electrodesElectrode potentialMetallic lithium

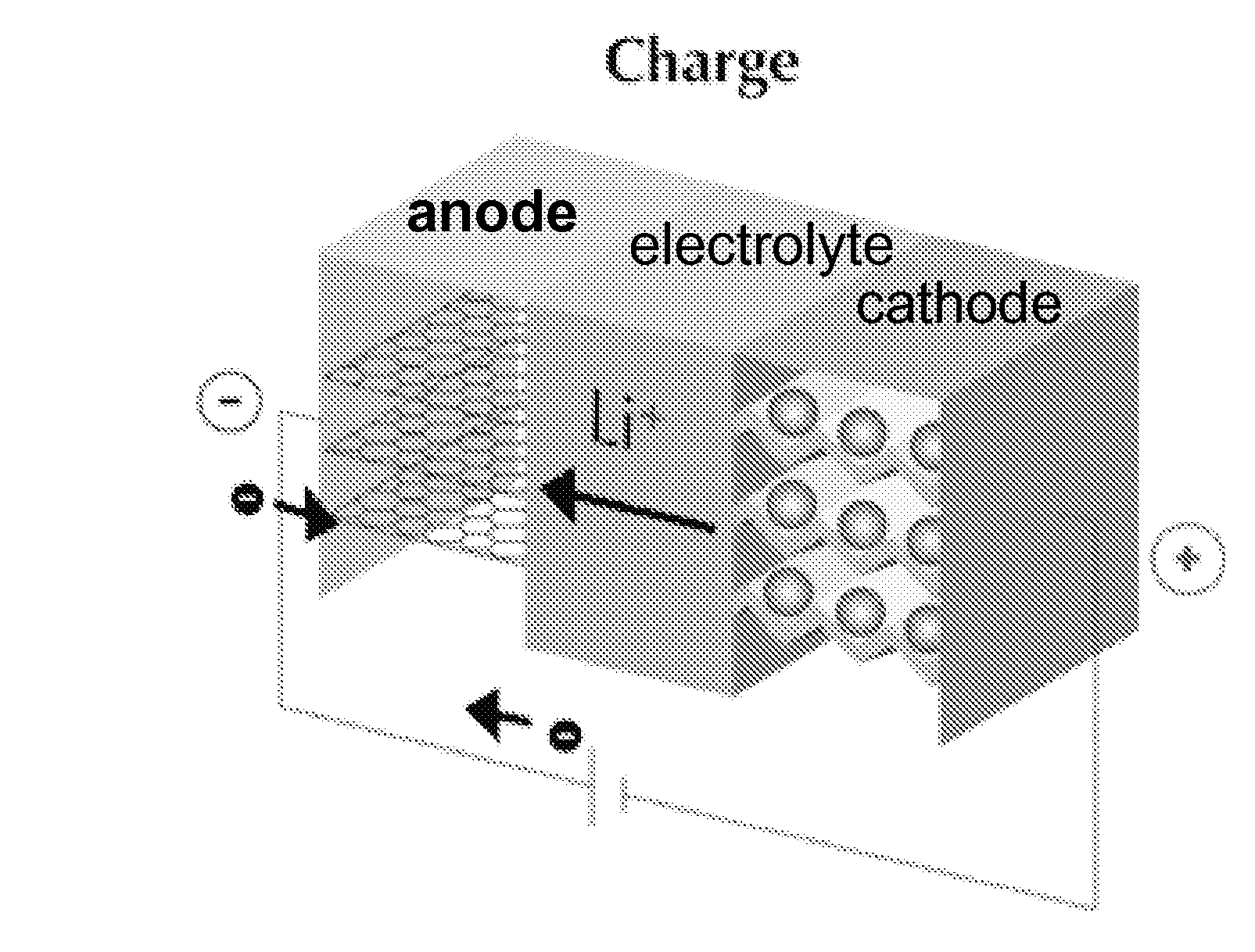

A high capacity, high charge rate lithium secondary cell includes a high capacity lithium-containing positive electrode in electronic contact with a positive electrode current collector, said current collector in electrical connection with an external circuit, a high capacity negative electrode in electronic contact with a negative electrode current collector, said current collector in electrical connection with an external circuit, a separator positioned between and in ionic contact with the cathode and the anode, and an electrolyte in ionic contact with the positive and negative electrodes, wherein the total area specific impedance for the cell and the relative area specific impedances for the positive and negative electrodes are such that, during charging at greater than or equal to 4C, the negative electrode potential is above the potential of metallic lithium. The current capacity per unit area of the positive and negative electrodes each are at least 3 mA-h / cm2, the total area specific impedance for the cell is less than about 20 Ω-cm2, and the positive electrode has an area specific impedance r1 and the negative electrode has an area specific impedance r2, and wherein the ratio of r1 to r2 is at least about 10.

Owner:A123 SYSTEMS LLC

Method for supplementing lithium to lithium-ion battery positive plate

ActiveCN102916164AAvoid LithiumAvoid deformationElectrode manufacturing processesMetallic lithiumPhysical chemistry

The invention belongs to the technical field of lithium-ion batteries, in particular to a method for supplementing lithium to a lithium-ion battery positive plate. The method includes: spraying or dropwise adding organic lithium solution onto the surface of the positive plate in the inert atmosphere to enable lithium ions in the organic lithium solution to be reduced to metallic lithium, embedding the metallic lithium into the positive plate, and drying the positive plate. Compared with the prior art, the method has the advantages that 'lithium supplement by a wet method' is achieved by spraying or dropwise adding the uniform organic lithium solution on the surface of the negative plate, so that floatation of metallic lithium powder in air is effectively avoided during lithium supplement by a dry method, production safety is guaranteed, the whole process is simple, and cost is low; and amount of supplemented lithium can be accurately controlled by the aid of the amount of the sprayed or dropwise added organic lithium solution and the spraying or dropwise adding time so as to achieve uniform lithium supplement, lithium precipitation and deformation of the negative plate are prevented, initial battery efficiency is improved, and further battery energy density is increased. Besides, the invention further discloses another method for supplementing lithium to a lithium-ion battery positive plate.

Owner:DONGGUAN AMPEREX TECH +1

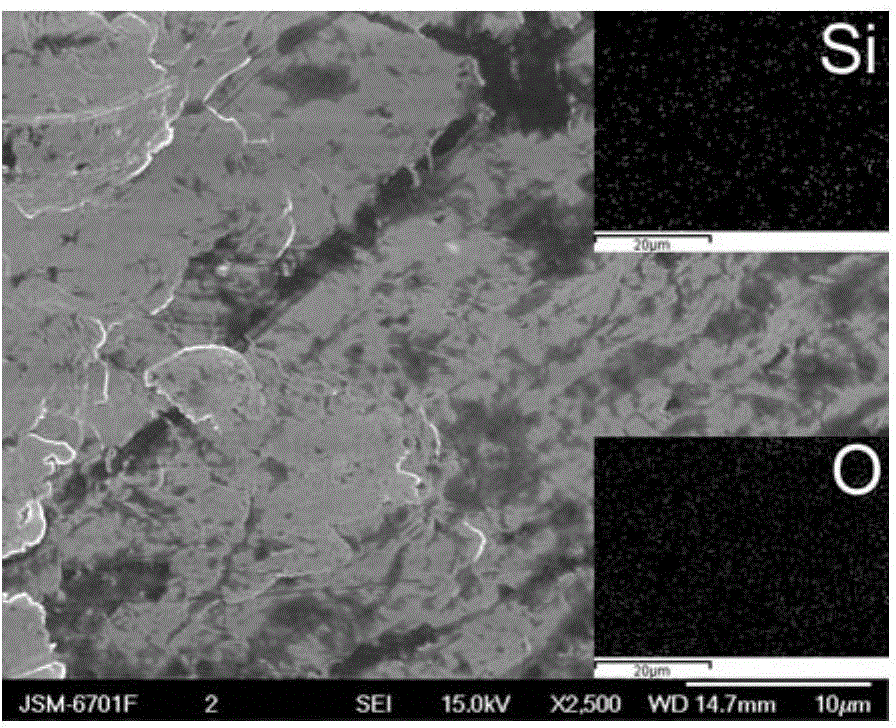

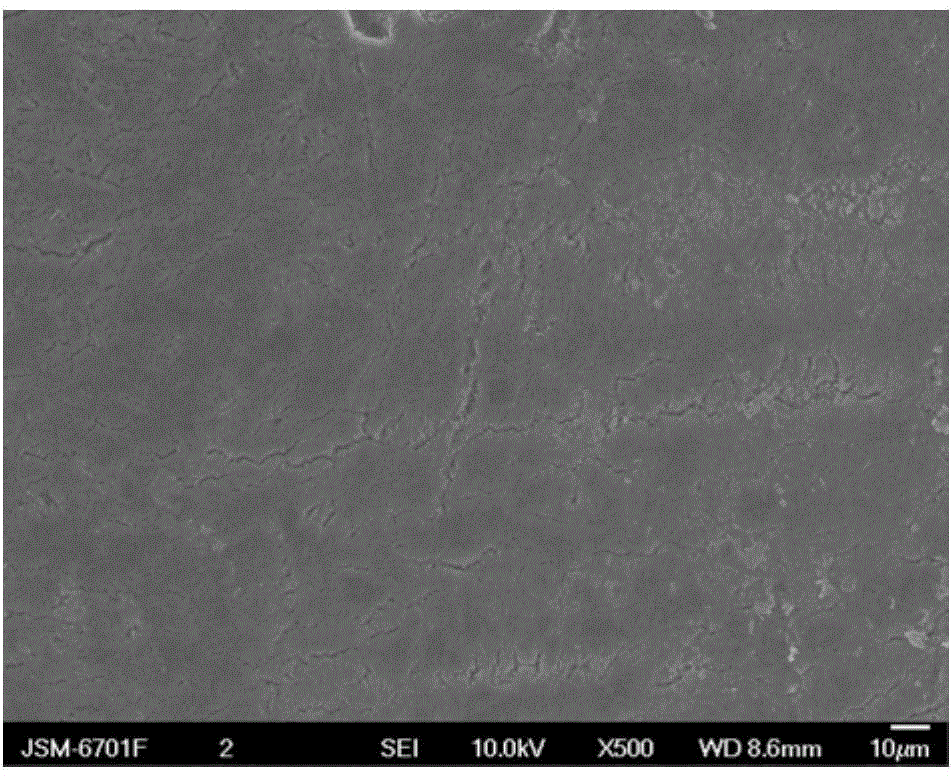

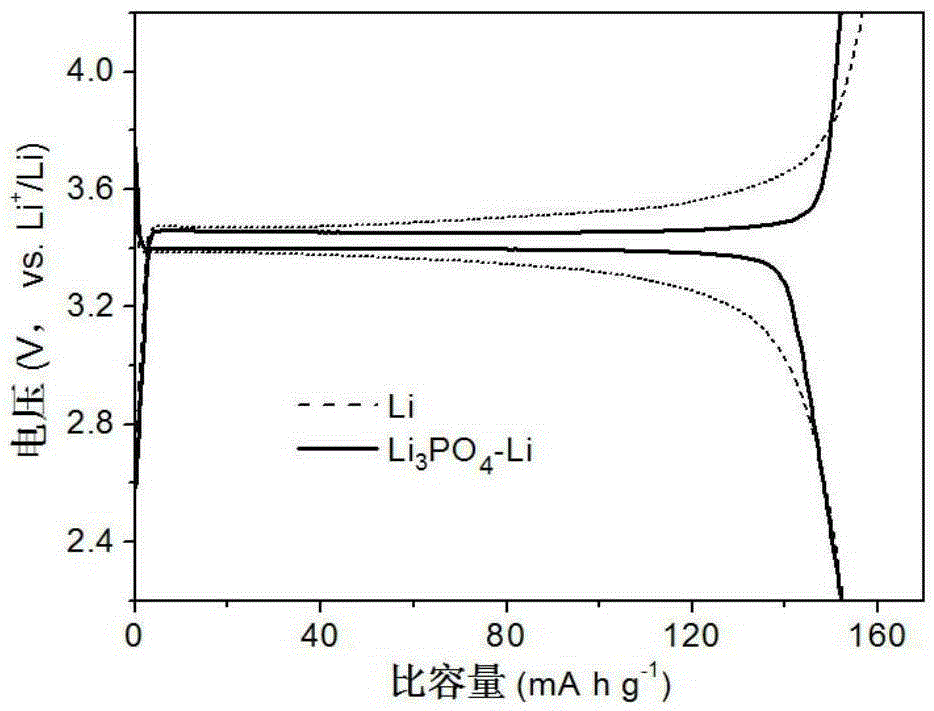

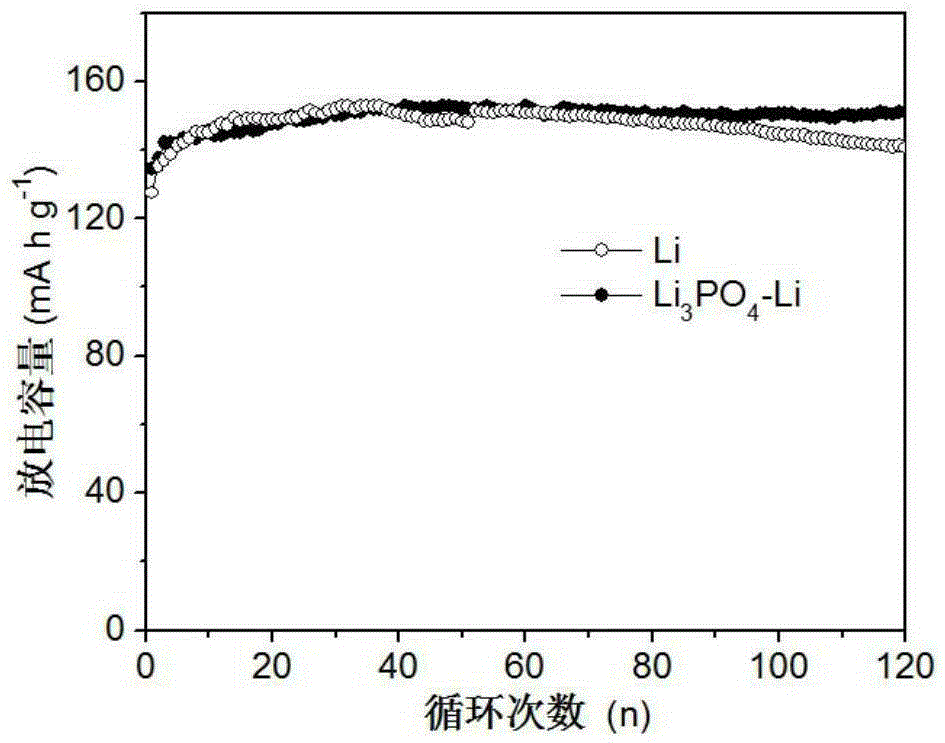

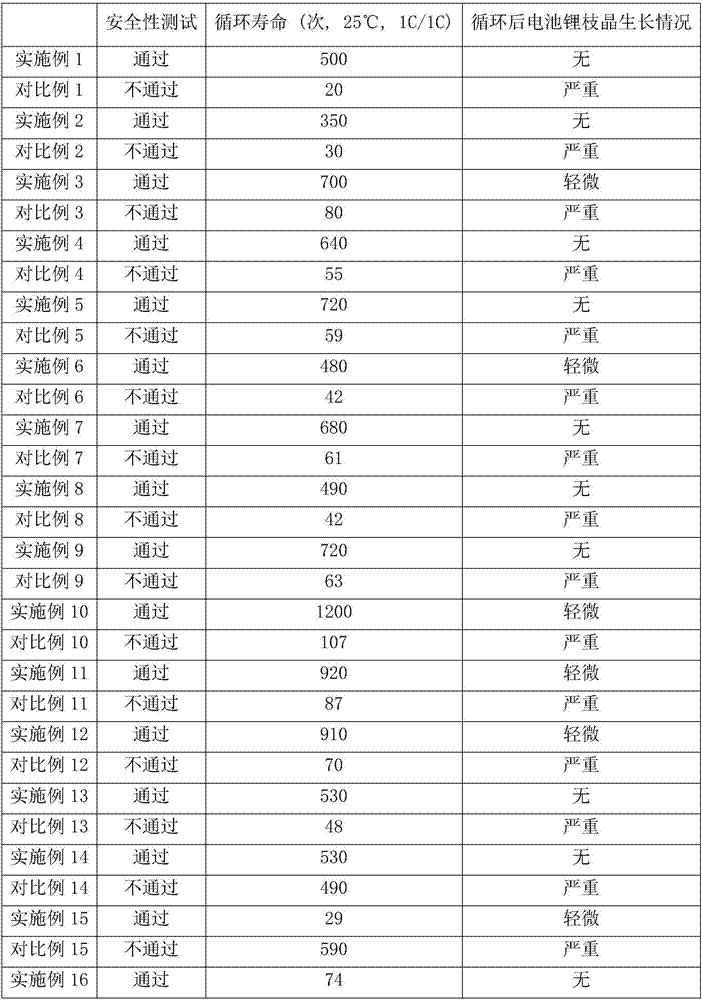

Surface in-situ processing method of metal lithium negative electrode and application

ActiveCN105280886ASolve the problem of uneven depositionSolution to constant ruptureCell electrodesSecondary cellsElectrical batteryPhosphoric acid

The invention discloses a surface in-situ processing method of a metal lithium negative electrode. And such metal lithium subjected to in-situ processing can be applicable for a high-performance metal lithium secondary battery. According to the surface in-situ processing method of the metal lithium negative electrode, provided by the invention, a processing liquid containing a few amount of phosphoric acid matters reacts with metal lithium and a passivation layer on the surface of the metal lithium to generate an interface protection layer taking lithium phosphate as a center. The in-situ processing technology has the advantages of simplicity in method, easiness in regulation and control and high practical degree; and the metal lithium negative electrode subjected to in-situ processing is used in the metal lithium secondary battery, the energy density and the cycle performance of the current battery can be substantially improved, and high practical value is achieved.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Metal lithium negative electrode piece, preparation method thereof and metal lithium secondary battery

InactiveCN107579204AIncrease surface areaReduce current densityCell electrodesLi-accumulatorsPolymer electrolytesSolvent

The invention discloses a metal lithium negative electrode piece, a preparation method thereof and a metal lithium secondary battery. The metal lithium negative electrode piece comprises a current collector, wherein a metal lithium layer is formed on the current collector; a composite conductive film is formed on the metal lithium layer. The preparation method of the metal lithium negative electrode piece comprises the following steps: laminating a metal lithium foil and the current collector together, or plating lithium metal on the surface of the current collector; dissolving a polymer electrolyte in a solvent to prepare a polymer electrolyte solution; adding a conductive agent into the polymer electrolyte solution; stirring uniformly and then coating a mixed solution on the metal lithium layer; after evaporating the solvent, forming the composite conductive film on the surface of the metal lithium layer to obtain the metal lithium negative electrode piece; or, coating the mixed solution on a substrate and evaporating the solvent to obtain the composite conductive film, laminating the composite conductive film on the surface of the metal lithium layer to form the composite conductive film and obtain the metal lithium negative electrode piece. The metal lithium negative electrode piece provided by the invention can inhibit lithium dendrites, prevent batteries from being short-circuited, and improve safety performance and cycling performance of lithium batteries.

Owner:ZHUHAI COSMX BATTERY CO LTD

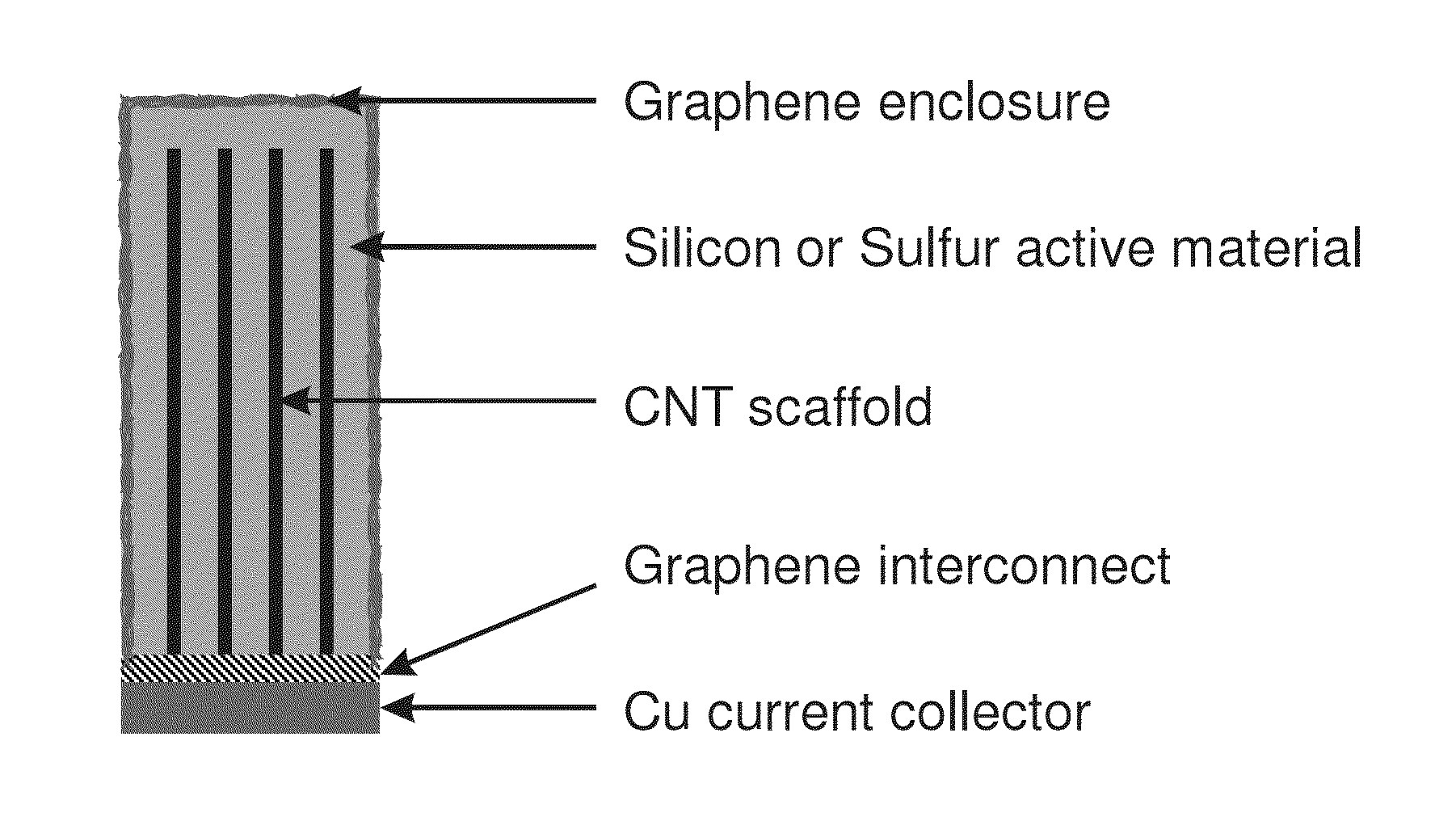

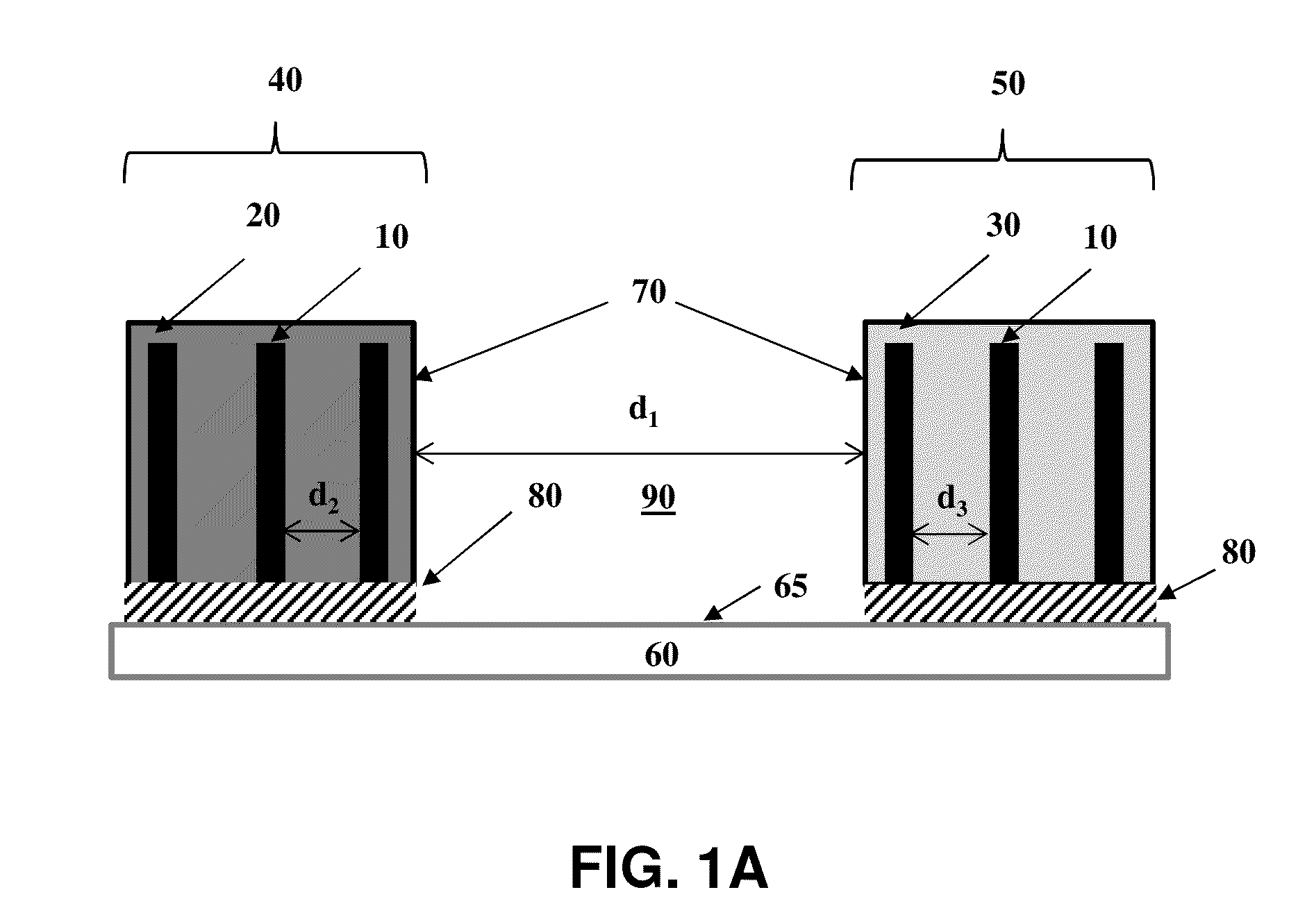

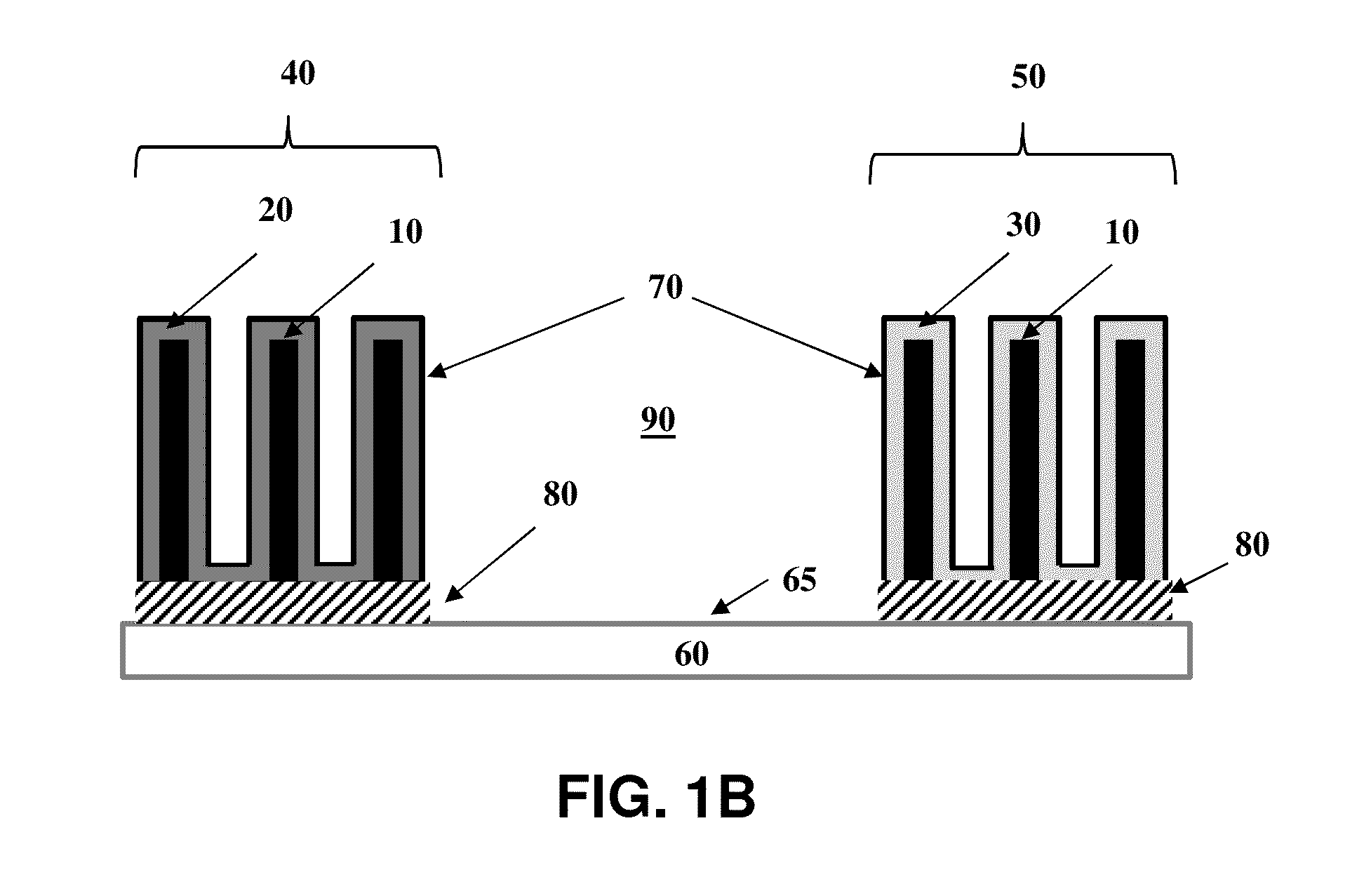

Carbon Nanotubes - Graphene Hybrid Structures for Separator Free Silicon - Sulfur Batteries

ActiveUS20150010788A1Improve power performanceImprove cycle lifeMaterial nanotechnologyFinal product manufactureMetallic lithiumDischarge rate

Provided herein are electrochemical systems and related methods of making and using electrochemical systems. Electrochemical systems of the invention implement novel cell geometries and composite carbon nanomaterials based design strategies useful for achieving enhanced electrical power source performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical systems of the invention are versatile and include secondary lithium ion cells, such as silicon-sulfur lithium ion batteries, useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art lithium ion secondary batteries by using prelithiated active materials to eliminate the use of metallic lithium and incorporating carbon nanotube and / or graphene, composite electrode structures to manage residual stress and mechanical strain arising from expansion and contraction of active materials during charge and discharge.

Owner:CALIFORNIA INST OF TECH

Lithium-sulphur battery with a high specific energy and a method of operating same

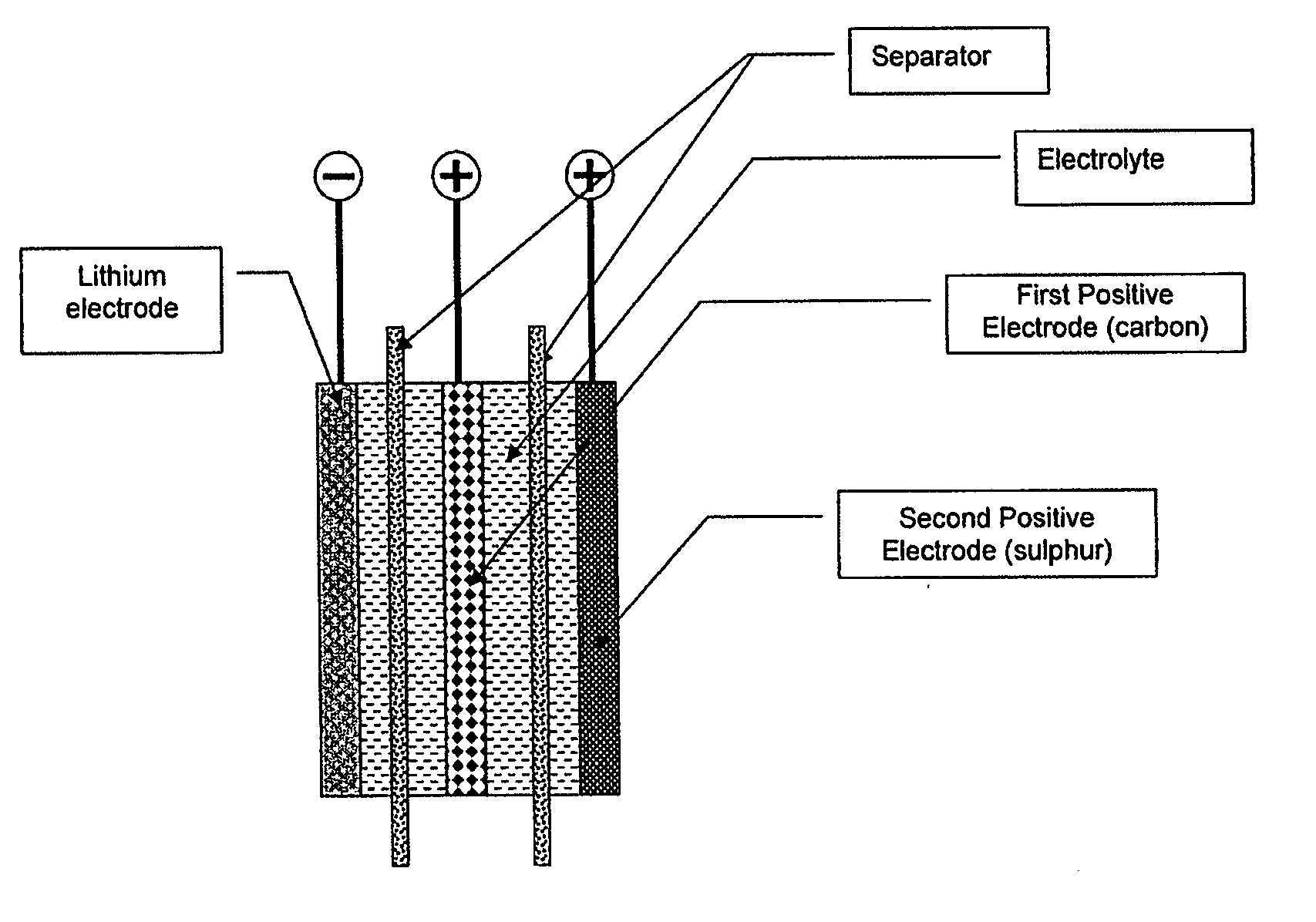

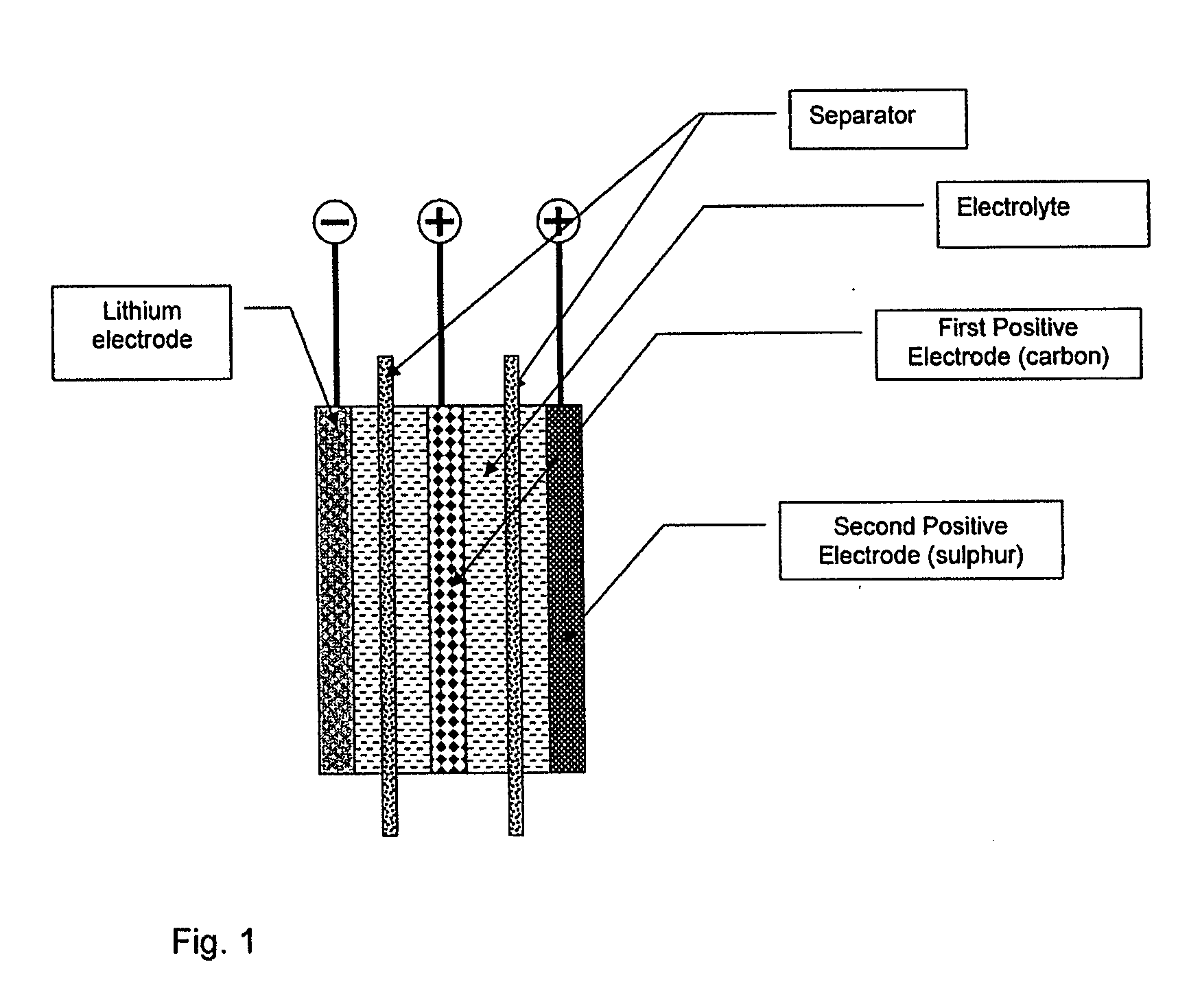

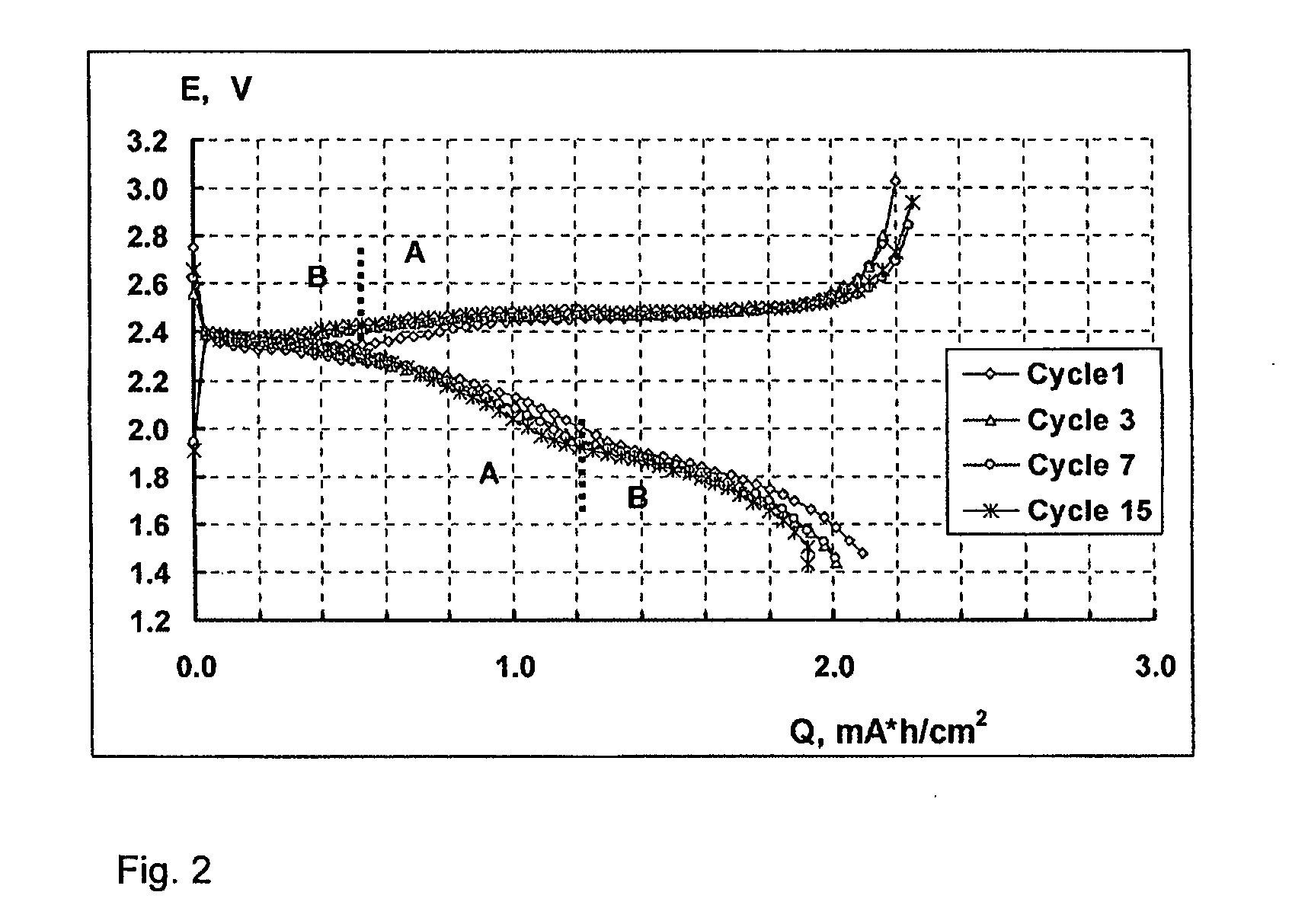

InactiveUS20080100264A1High energyInhibition formationBatteries circuit arrangementsFinal product manufactureLithium–sulfur batteryAlloy

A multi-electrode lithium-sulphur cell or battery including for example a negative electrode made of metal lithium, lithium alloys or lithium-absorbing materials; at least first and second distinct positive electrodes or groups of positive electrodes; and an electrolyte that is a solution of one or several salts in one or several solvents disposed between the negative and positive electrodes. The first positive electrode or group of positive electrodes is configured for charging, and the second positive electrode or group of positive electrodes is configured for discharging. The cell or battery has a high specific energy. Other embodiments of the present invention may include other structures and properties.

Owner:WACHOVIA CORP +1

Method for preparing thin-layer lithium metal anode for all-solid-state lithium-ion battery based on PVD

InactiveCN105489845AIncrease energy densityEnsure safetySecondary cellsVapour deposition manufacturingMetallic lithiumAll solid state

The invention discloses a method for preparing a thin-layer lithium metal anode for an all-solid-state lithium-ion battery based on a PVD. The method comprises the following steps: (1) cleaning a current collector copper foil surface for a commercial lithium-ion battery anode, and putting the current collector copper foil surface into a physical vapor deposition chamber as a deposition base; (2) preparing target materials from a to-be-deposited lithium metal source and a protection layer metal source respectively, and putting the target materials into the chamber as a deposition layer metal source; and (3) setting physical vapor deposition parameters, and sequentially depositing a lithium metal anode material deposition layer and a protective metal layer on the copper foil surface by a PVD method in a vacuum state, and controlling the thickness of the deposition layer by deposition time. A thin-layer lithium metal anode material deposited on the anode current collector copper foil surface is prepared by the physical vapor deposition (PVD) method; and the thin-layer metal protection layer is deposited on the surface of the thin-layer lithium metal anode material. According to the method, the safety of the all-solid-state lithium-ion battery in the production process can be greatly strengthened; and the limit energy density of the all-solid-state lithium-ion battery is improved.

Owner:HARBIN INST OF TECH

Negative electrode for lithium battery and lithium battery comprising same

InactiveUS20050238956A1Large capacityStrengthen the strength of attachmentElectrode manufacturing processesNon-aqueous electrolyte cellsPorosityMetallic lithium

The present invention relates to a negative electrode for a lithium battery, and a lithium battery including the same. A negative electrode for a lithium battery includes a metallic lithium plate and a negative electrode tab attached to a surface of the metallic lithium plate, wherein an average surface roughness of the metallic lithium plate on an area attached to the negative tab is 0.1 to 5 μm; a negative electrode for a lithium battery including a metallic lithium plate and a negative electrode tab having a porosity of 50 to 100% and being attached to the metallic lithium plate; a negative electrode for a lithium battery including a metallic lithium plate and a negative electrode tab attached to both the upper and lower end surfaces of the metallic lithium plate; or a negative electrode for a lithium battery including a metallic lithium plate and a negative electrode tab attached to the surfaces of the metallic lithium plate, wherein the surface area of the negative electrode tab to be attached to the metallic lithium plate is 10% larger than the geographical area.

Owner:SAMSUNG SDI CO LTD

Lithium secondary cell and nonaqueous electrolyte

InactiveUS20040028996A1Preventing sudden heat generationAvoid reactionFinal product manufactureCell temperature controlMetallic lithiumSimple Organic Compounds

The sudden generation of heat being frequently caused in the case of the overcharge of a lithium secondary cell which have a positive electrode comprising a composite metal oxide of lithium and cobalt or a composite metal oxide of lithium and nickel, a negative electrode comprising metallic lithium, a lithium alloy or a material capable of occluding and releasing lithium, and a nonaqueous electrolyte solution comprising a nonaqueous solvent and an electrolyte dissolved therein can be efficiently prevented by the addition, to the nonaqueous electrolyte solution, of an organic compound which, when the lithium secondary cell is overcharged, decomposes into a decomposition product capable of dissolving out the cobalt or nickel contained in the positive electrode and depositing it ion the negative electrode (for example, a tert-alkylbenzene derivative).

Owner:UBE IND LTD

Galvanic element and method for the production thereof

InactiveUS20170054139A1Increase capacitanceLarge energy densitySolid electrolytesElectrode manufacturing processesMetallic lithiumElectrical conductor

A method for producing a galvanic element that includes the following steps: a) production of a layer sequence including, in this order, a current conductor assigned to an anode, an ion-conducting and electrically insulating separator, a cathode having lithium-containing cathode material, and a current conductor assigned to the cathode, and b) charging of the galvanic element, an anode including metallic lithium forming between the current conductor assigned to the anode and the separator during charging of the galvanic element. In addition, a battery cell including such a galvanic element, and a battery including a plurality of such battery cells, are also described.

Owner:ROBERT BOSCH GMBH

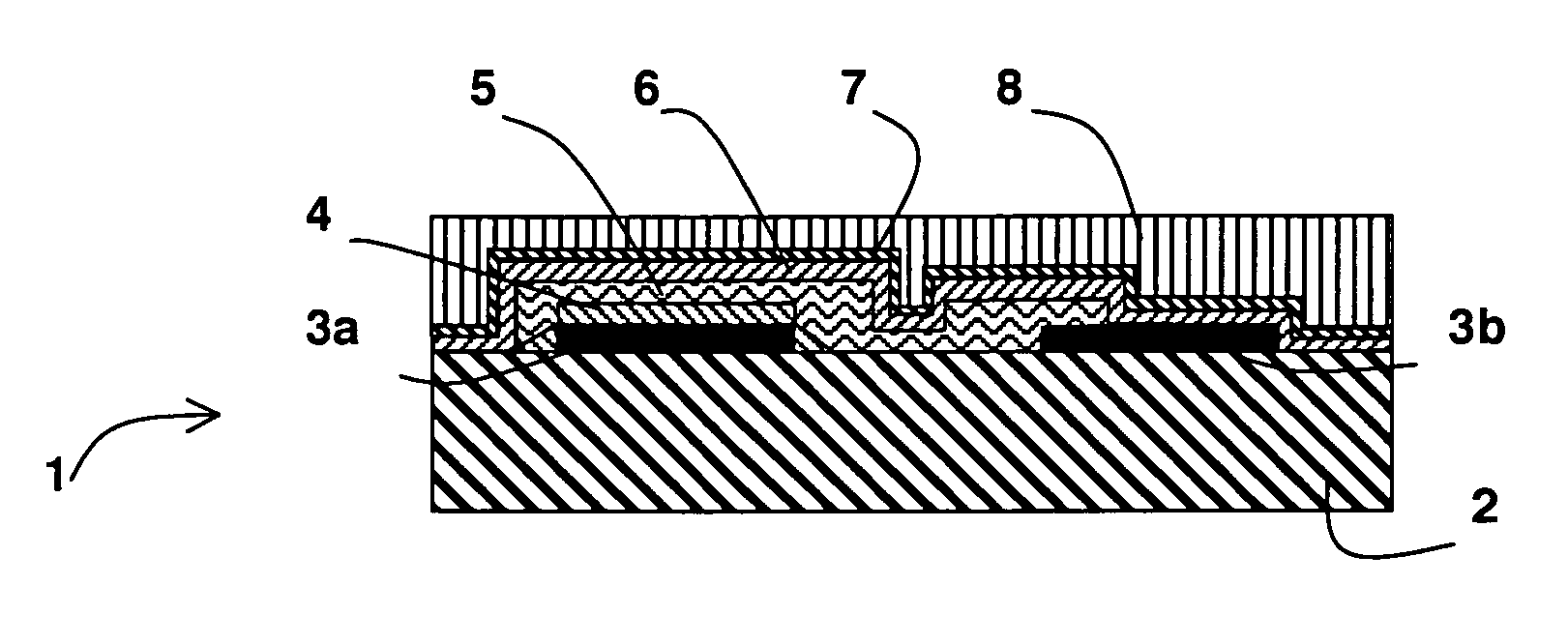

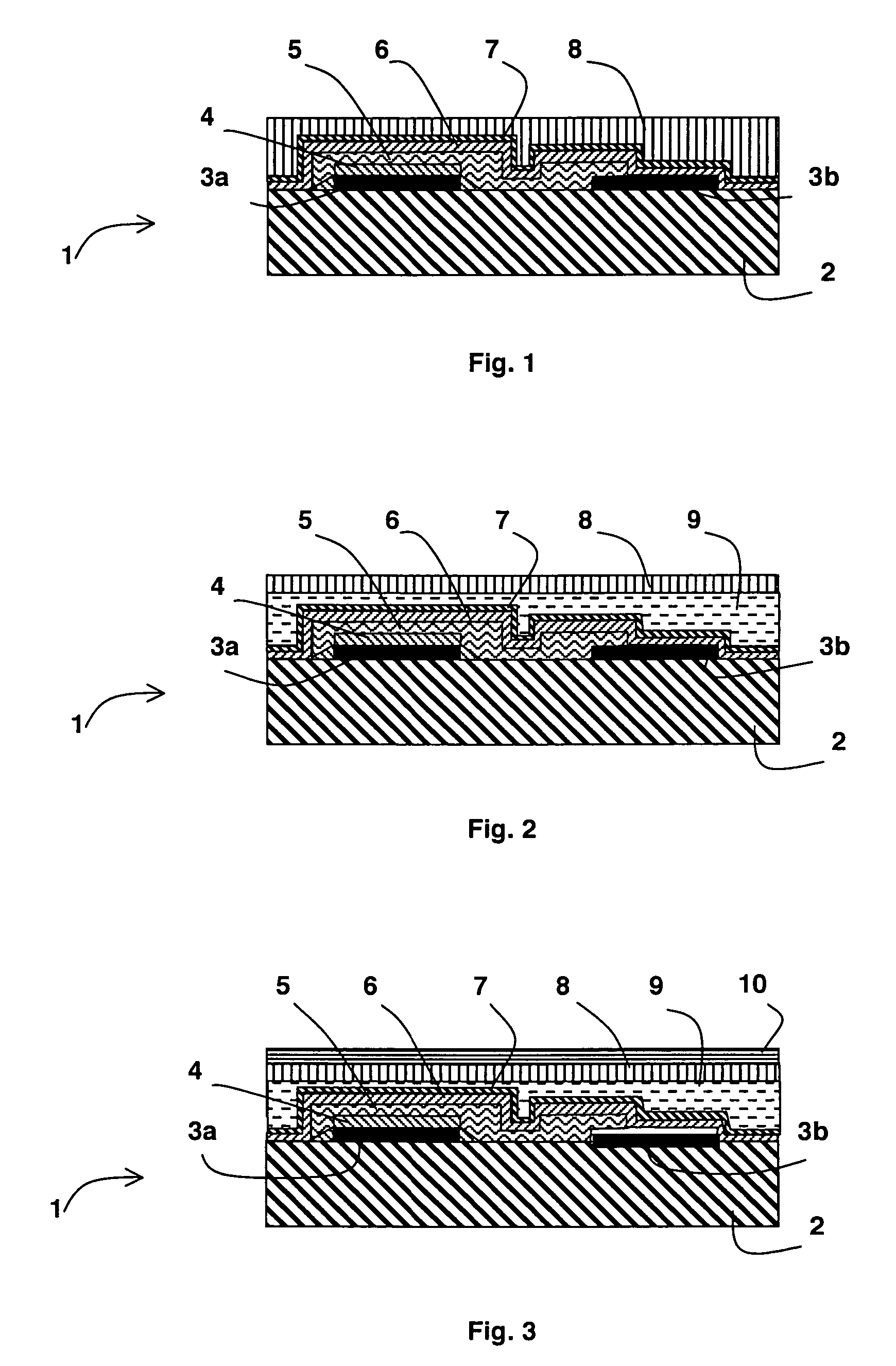

Lithium microbattery provided with a protective envelope, and method for producing one such microbattery

InactiveUS20070048604A1Easily compatibleEasy to implementPrimary cellsElectrode carriers/collectorsMetallic lithiumCarbide

A lithium microbattery comprises a substrate on which at least one stack is arranged successively comprising a cathode, an electrolyte containing lithium and an anode consisting of metallic lithium. A protective envelope comprising at least first and second distinct superposed layers covers the stack to protect the same against external contamination. The first layer, deposited on the whole of the anode, comprises at least one material that is chemically inert with regard to lithium, selected from the group consisting of a hydrogenated amorphous silicon carbide, a hydrogenated amorphous silicon oxycarbide, hydrogenated amorphous carbon, fluorinated amorphous carbon and hydrogenated amorphous silicon. The second layer comprises a material selected from the group consisting of a hydrogenated amorphous silicon carbonitride, a hydrogenated amorphous silicon nitride and a fluorinated amorphous carbon.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Rechargeable battery with negative lithium electrode

InactiveUS20100129724A1Improve solubilityReduce and prevent cathodic depositionAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersMetallic lithiumRedox

There is disclosed rechargeable cell or battery comprising a negative electrode, a separator, a positive electrode and non-aqueous electrolyte. The negative electrode comprises at least one or more of metallic lithium, a lithium alloy or a material (compound) capable of intercalating lithium ions. At least the positive electrode and optionally also the electrolyte includes a redox shuttle additive to facilitate dissolution of dendritic lithium in the electrolyte.

Owner:OXIS ENERGY

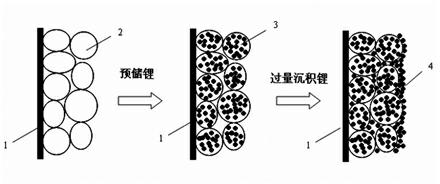

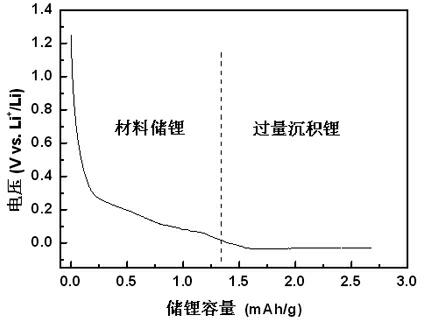

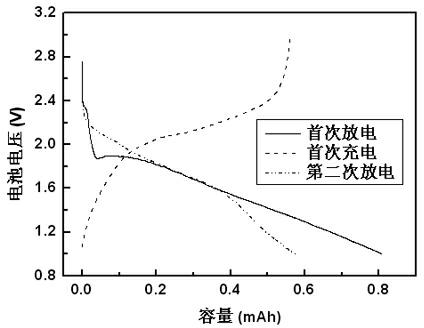

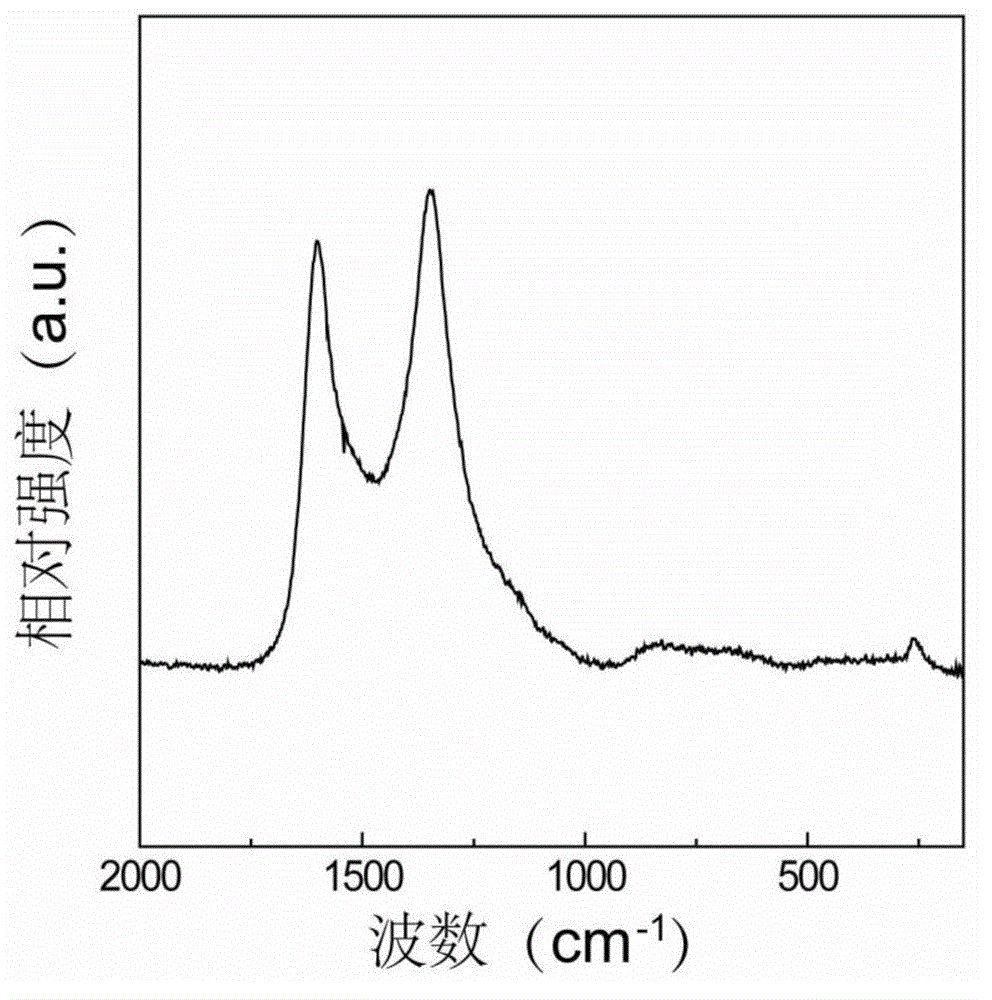

Silicon-containing lithium cathode, preparation method thereof and lithium sulfur battery with silicon-containing lithium cathode

InactiveCN102694158AImprove cycle performanceImprove securityCell electrodesLi-accumulatorsPole pieceAnode

The invention relates to a silicon-containing lithium cathode, a preparation method thereof and a lithium sulfur battery with the silicon-containing lithium cathode. The preparation method of the lithium cathode comprises the steps of: 1) mixing a silicon-containing cathode material with conducting agent and binder, coating the mixture on a current collector and drying the current collector to obtain a silicon-containing pole piece; using the silicon-containing pole piece as an anode and a metal lithium piece as a cathode, assembling a battery, and conducting a discharge-charge cycle within 0.01-2V at current density of 10-1000mA / g to obtain a silicon-containing lithium cathode piece with lithium which is electrochemically prestored; and 2) continuously discharging the battery which is discharged to 0.01V and is subject to a lithium storage step to obtain a silicon-containing lithium cathode piece with lithium which is electrochemically and excessively deposited. Since a high-capacity silicon-containing cathode material is used as a carrier and a lithium source is replenished through an electrochemical method, compared with the traditional lithium foil cathode, the silicon-containing lithium cathode for the lithium sulfur battery provided by the invention has the advantages that the specific area is larger, the probability of forming dendritic crystals is reduced, the amount of used metal lithium is decreased and the cycle performance and the safety performance of the battery are improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

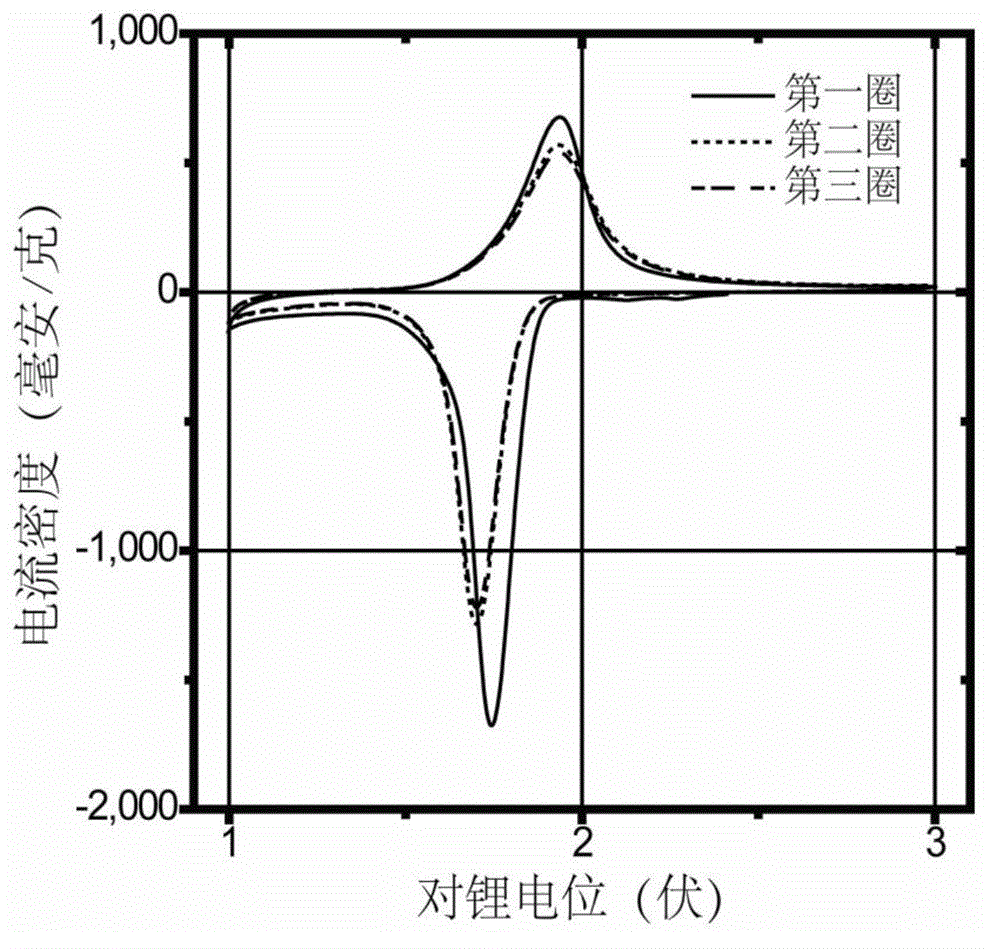

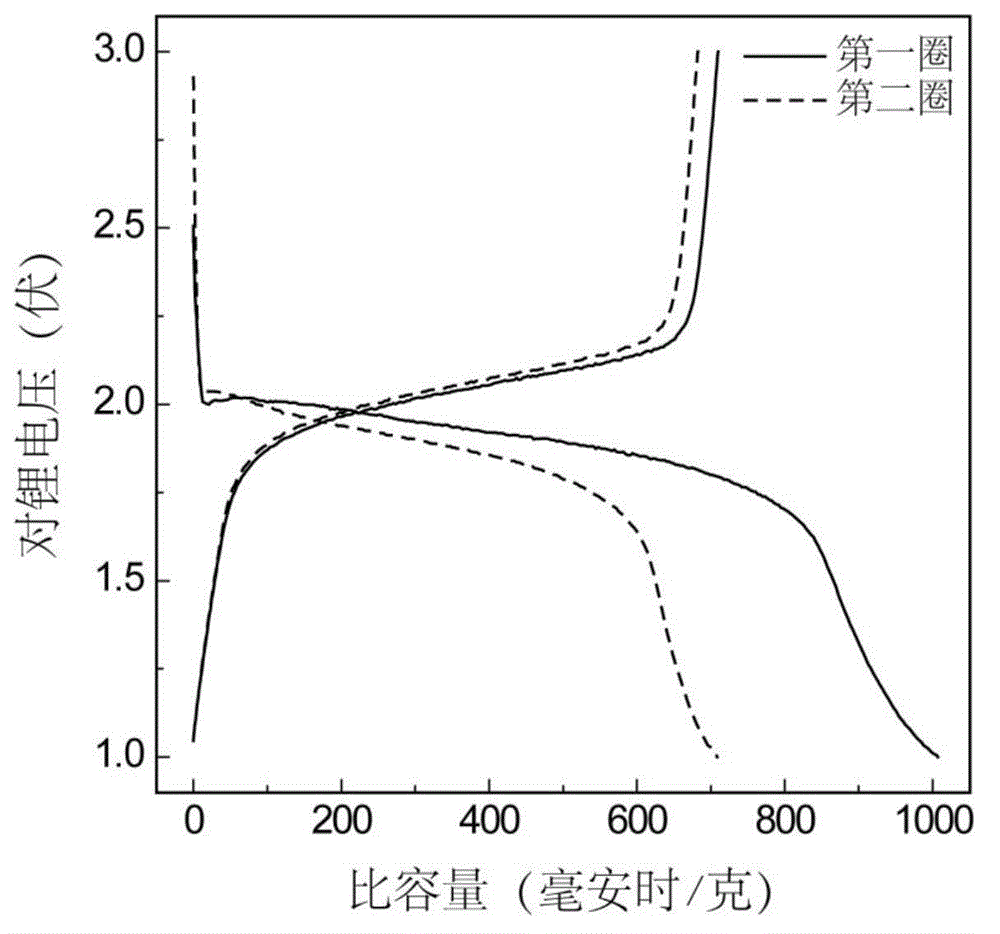

Selenium-micropore carrier composite, preparation method and application thereof

The invention discloses a lithium-selenium battery and a preparation method thereof. A lithium-selenium battery comprises a metal lithium cathod, a selenium-micropore carrier composite anode and organic electrolyte. The selenium-micropore carrier composite anode is prepared by mixing selenium and a micropore carrier and heating; and the selenium is uniformly dispersed inside micropore channels of the micropore carrier in a short-chain molecule manner. The micropore carrier comprises a carbon micropore carrier, a non-carbon micropore carrier and a composition. The lithium-selenium battery can maintain a high circulation capacity, excellent stable circulation property and good high-magnification (large-current density charging and discharging) property in a large-temperature range such as room temperature and the like; the main composite part, namely, the selenium-micropore carrier composite anode, is simple in preparation method, easily accessible in raw material, applicable to large-scale production and has very high practicability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyimide-based lithium metal battery

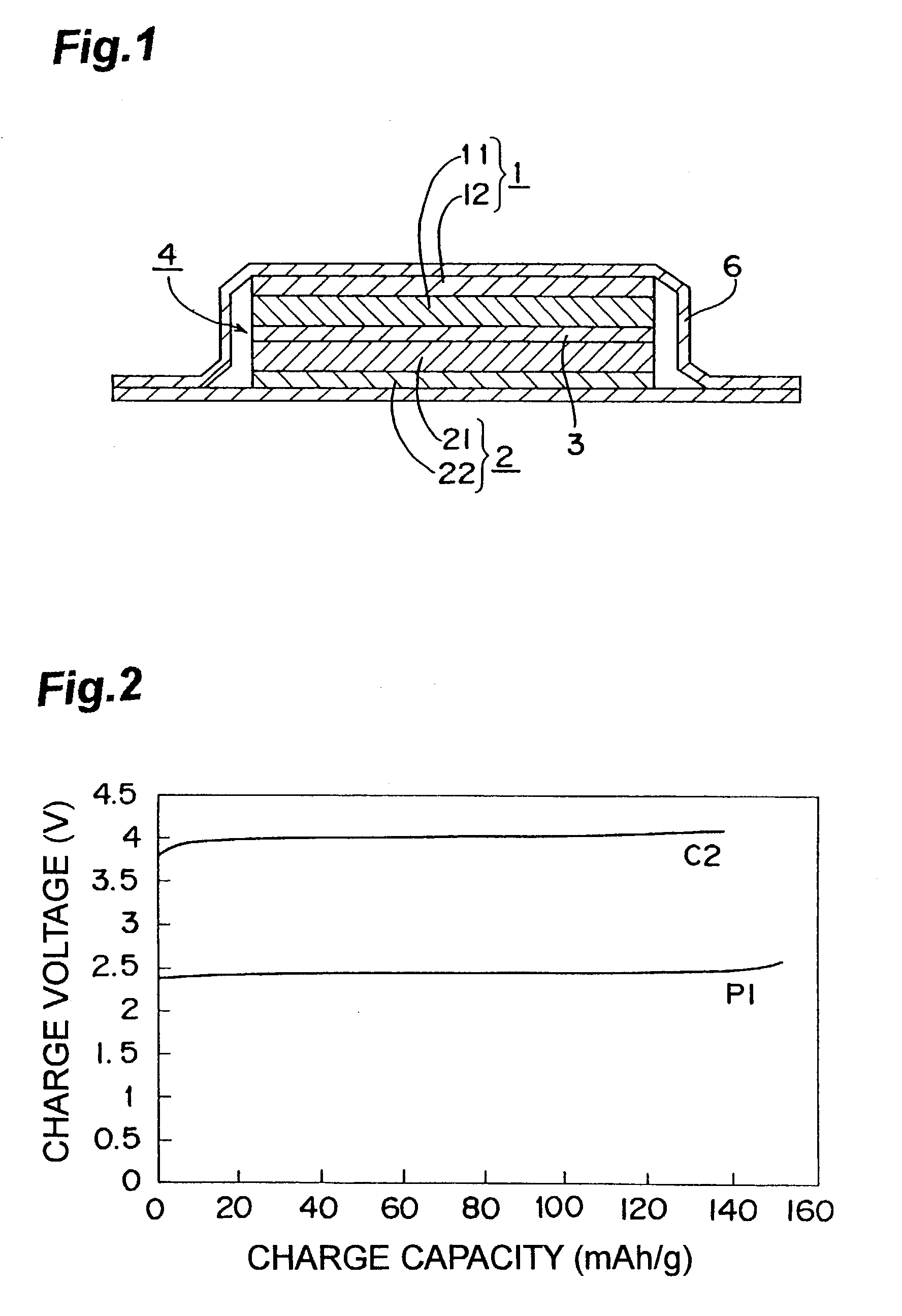

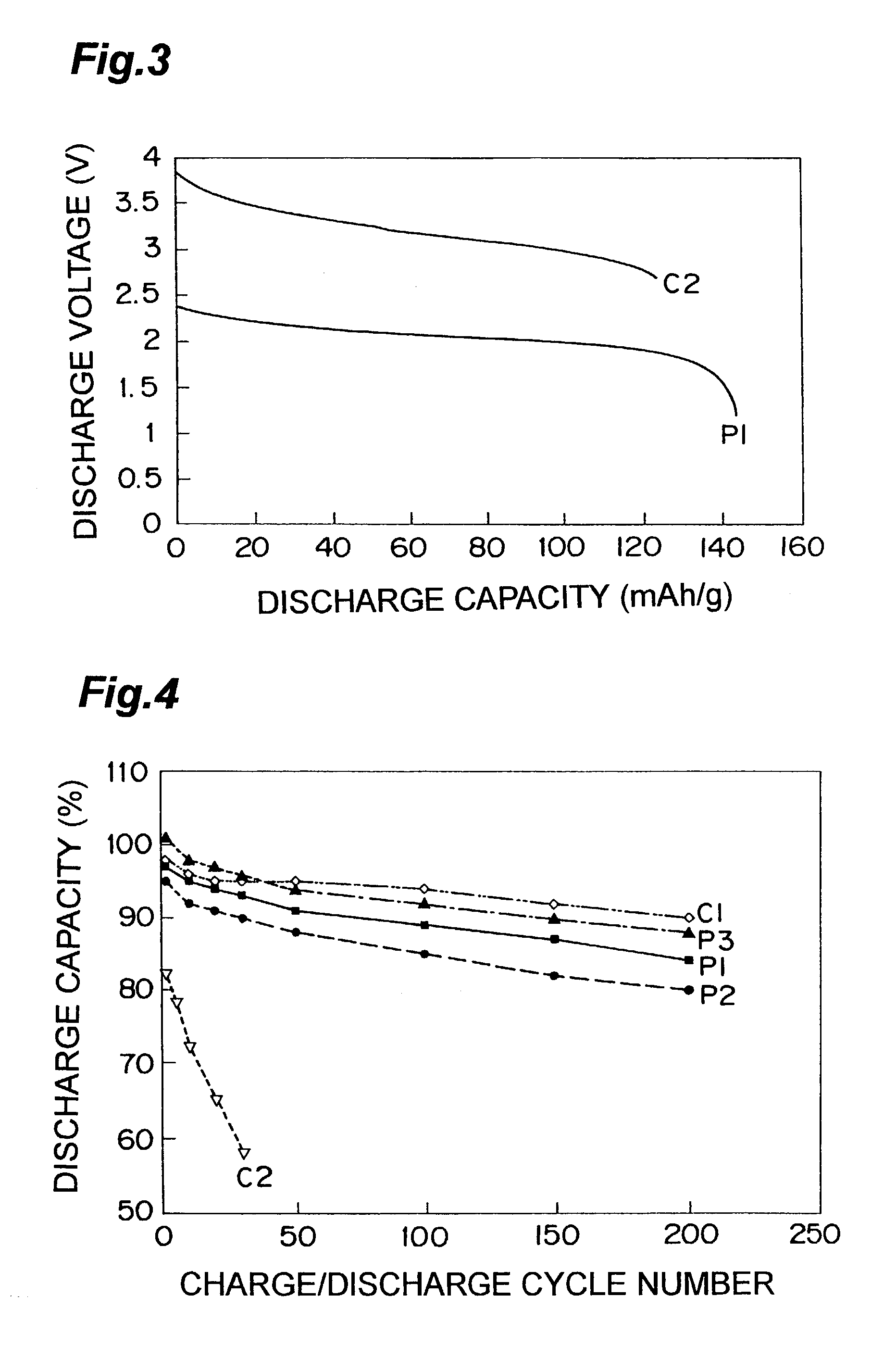

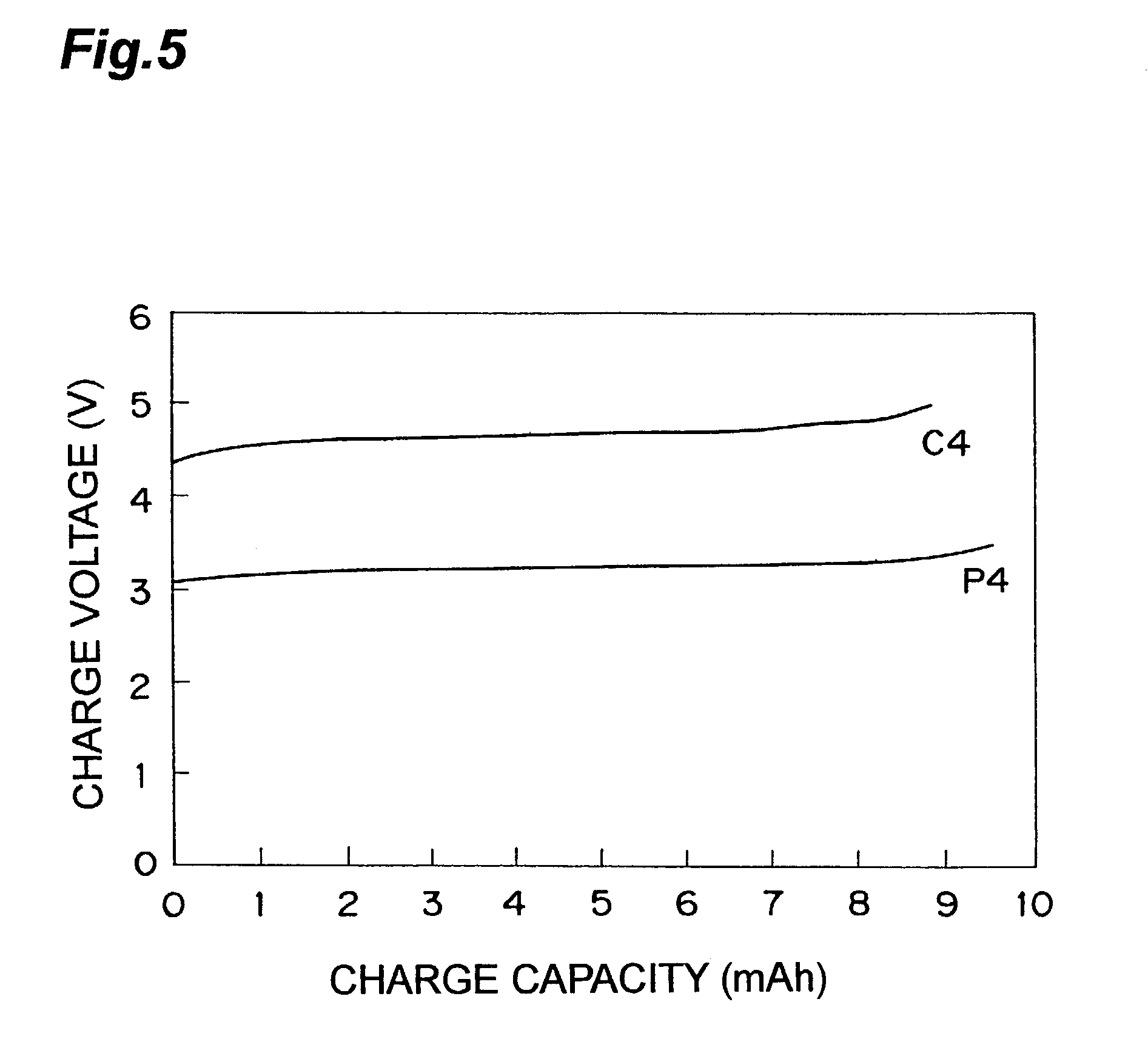

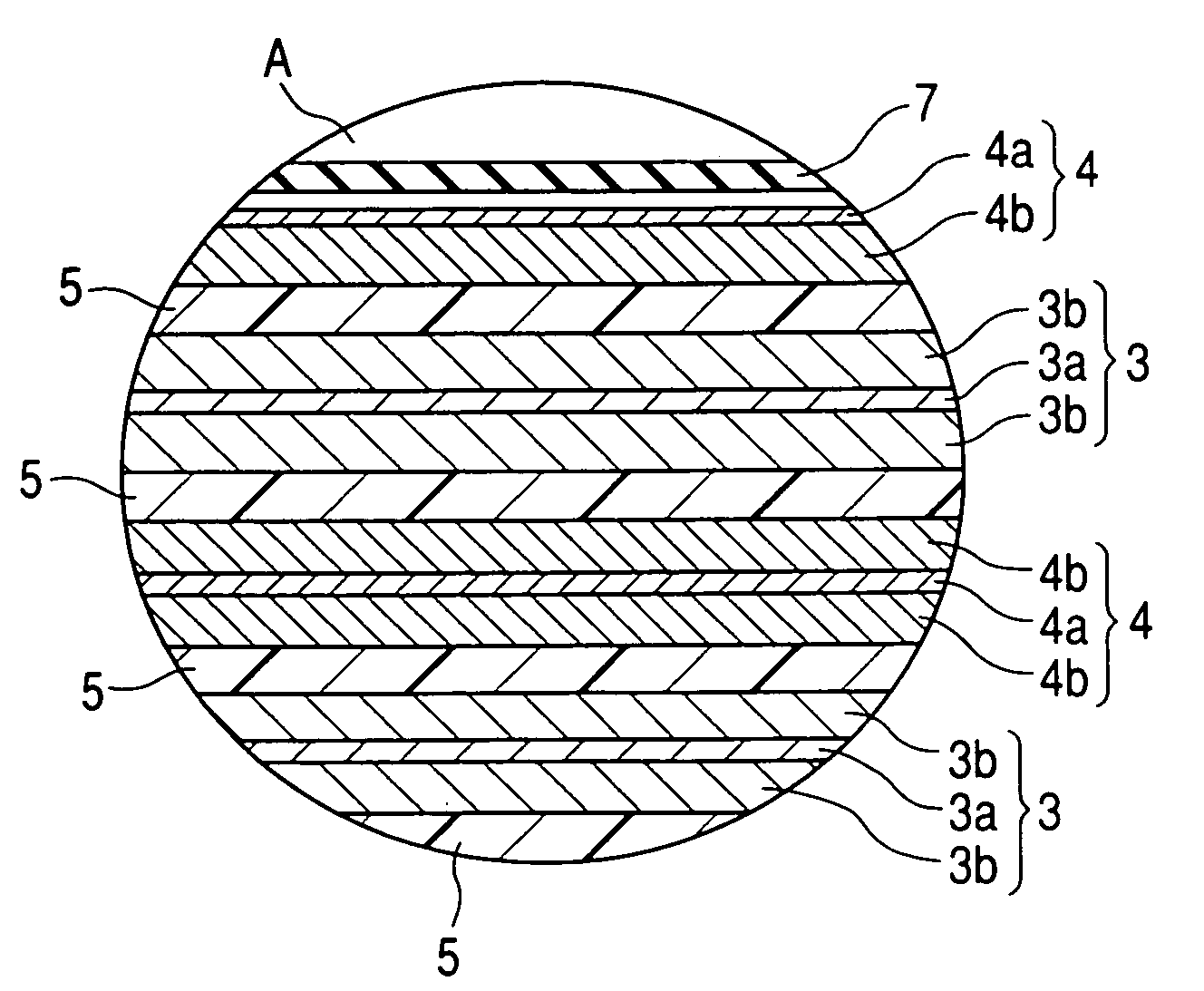

ActiveUS20050153209A1Improve ionic conductivityGrowth inhibitionFinal product manufactureElectrode carriers/collectorsMetallic lithiumLithium metal

The present invention relates to Lithium Metal batteries. In particular, it is related to lithium metal batteries containing a polyimide-based electrolyte. The present invention concerns a new concept of polyimide-based electrolytic component having an electrolyte consisting of at least one solvent and at least one alkali metal salt, with specific amounts of solvents, to optimize the properties of conductivity of the polyimide-based electrolyte and the mechanical properties of the polyimide-based electrolyte separator towards metallic lithium anode to prevent dendrites growths.

Owner:BRIGHTVOLT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com