Patents

Literature

703 results about "Metal anode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal Anodes. Metal anodes are pieces of metals that are used in electrochemical processes like electroplating or corrosion protection. Many different metals are used such as aluminum, zinc, magnesium, titanium, tin, cadmium, lead, copper, or various alloys such as bronze and brass.

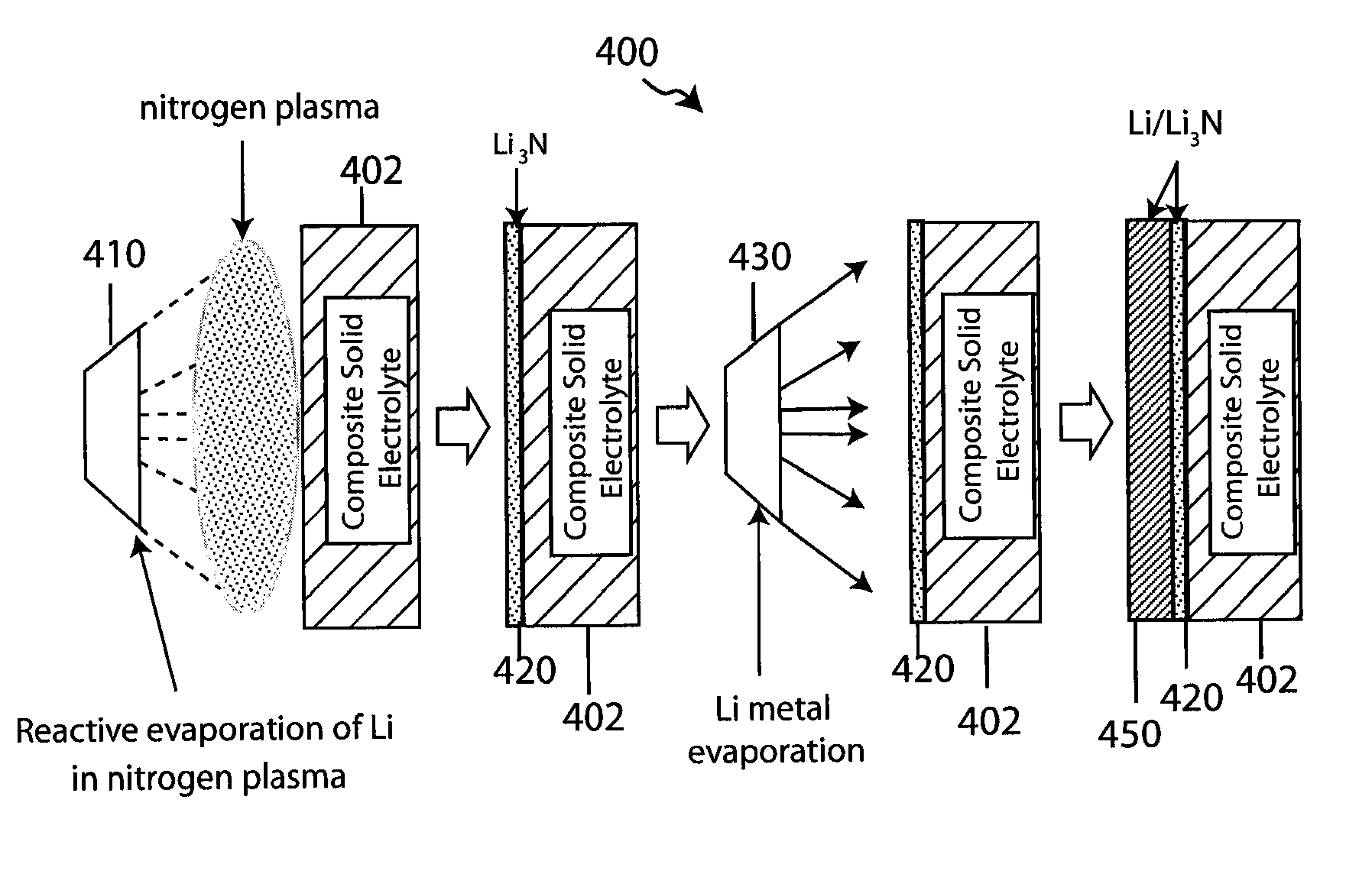

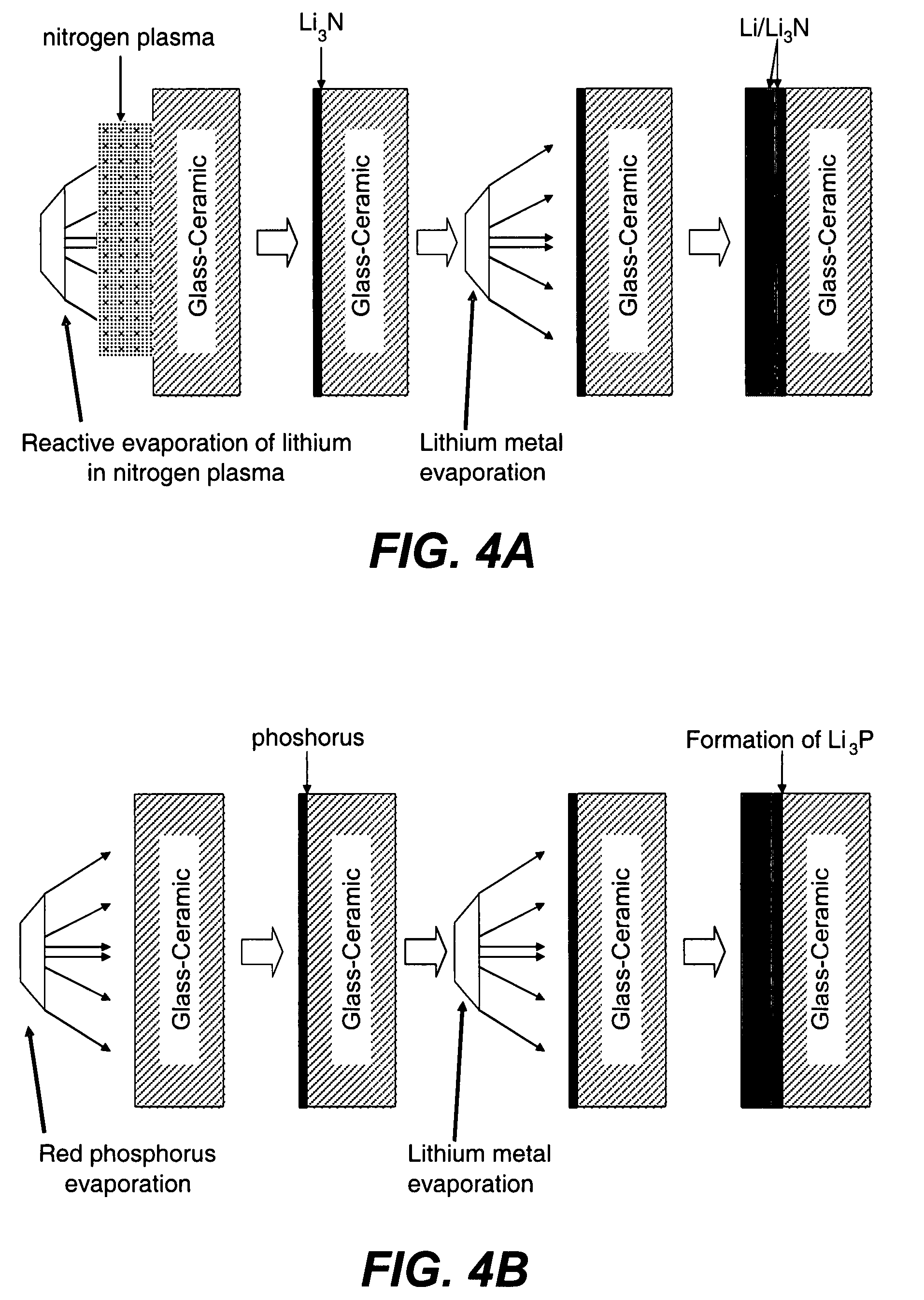

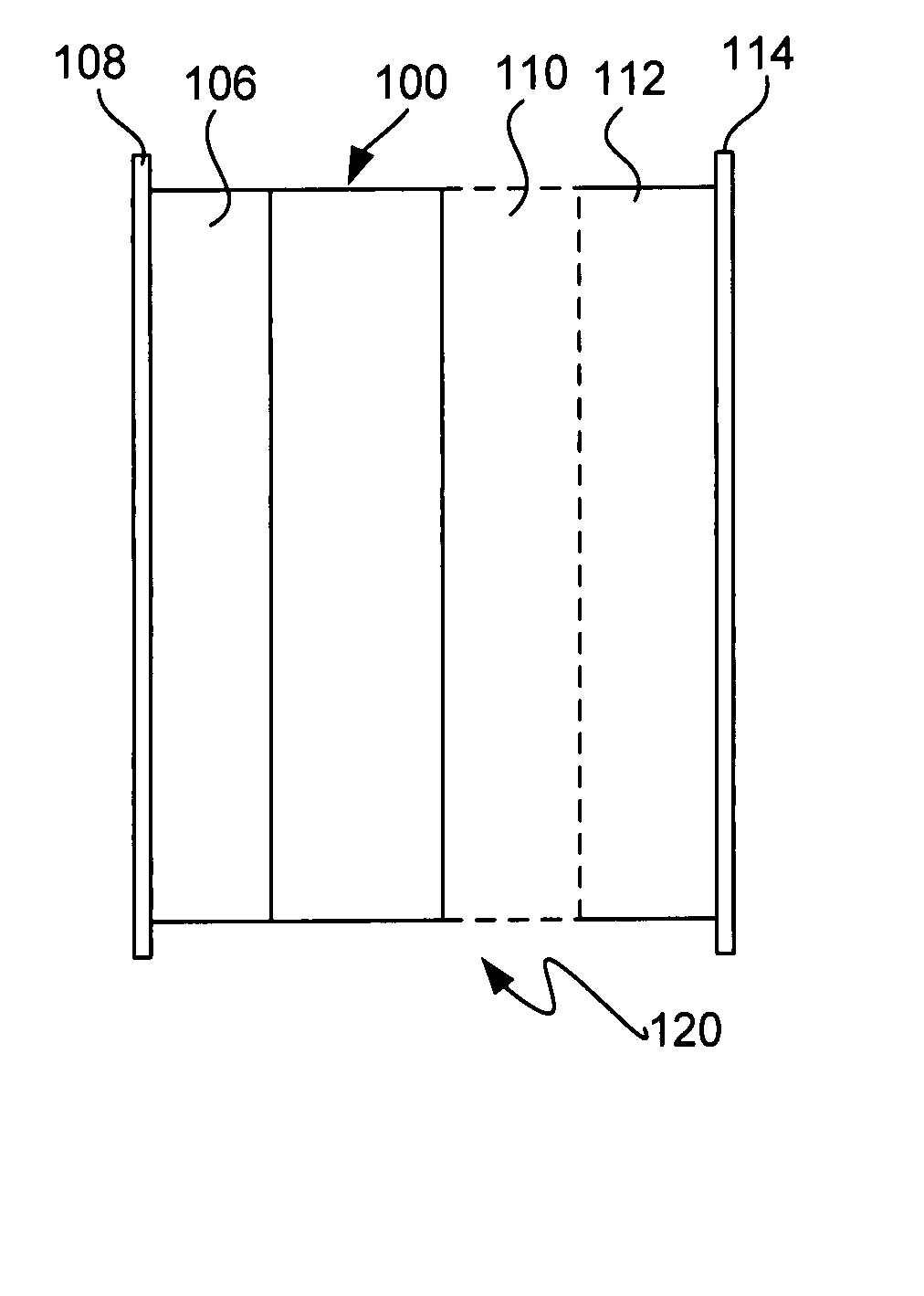

Composite solid electrolyte for protection of active metal anodes

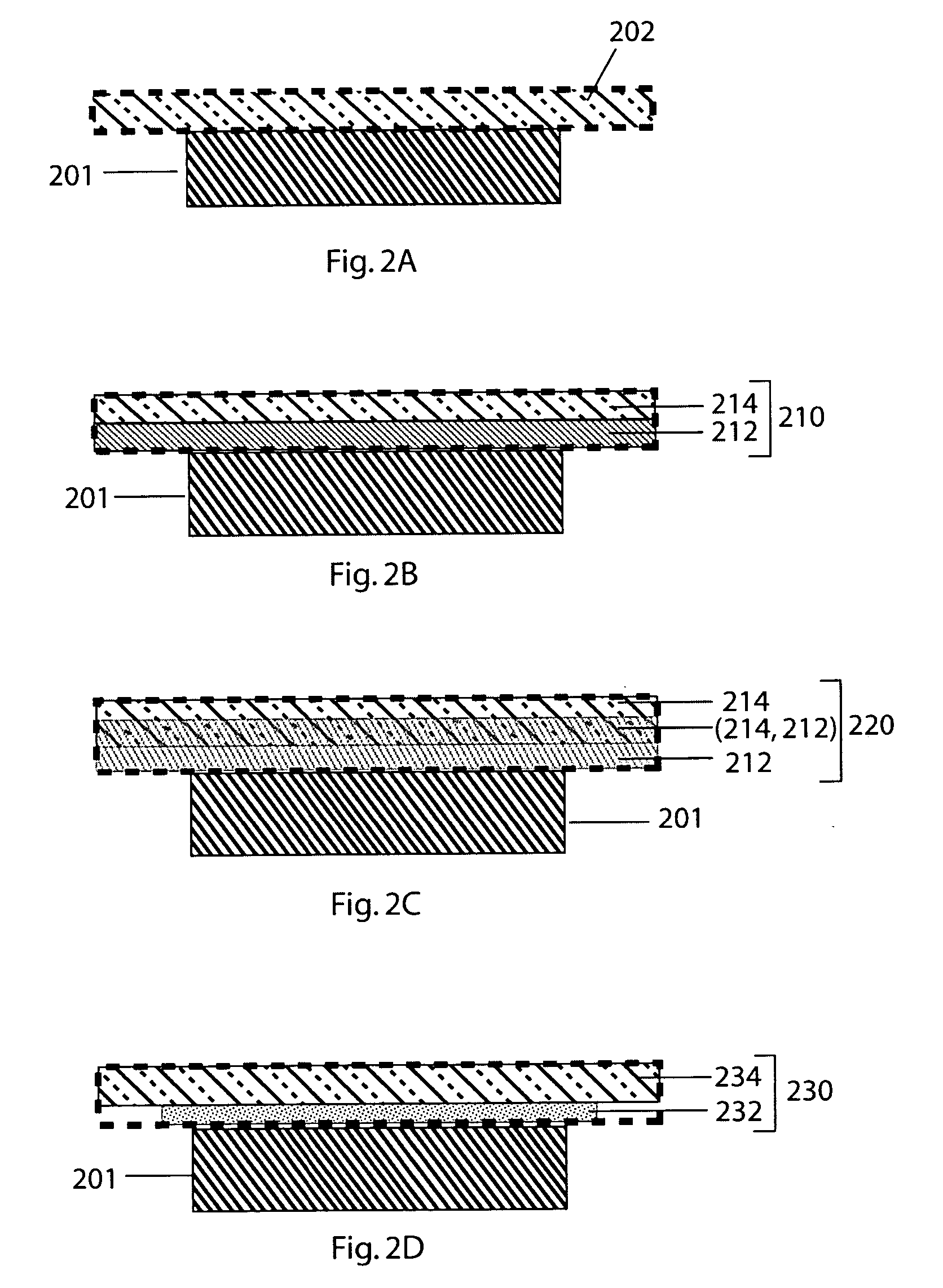

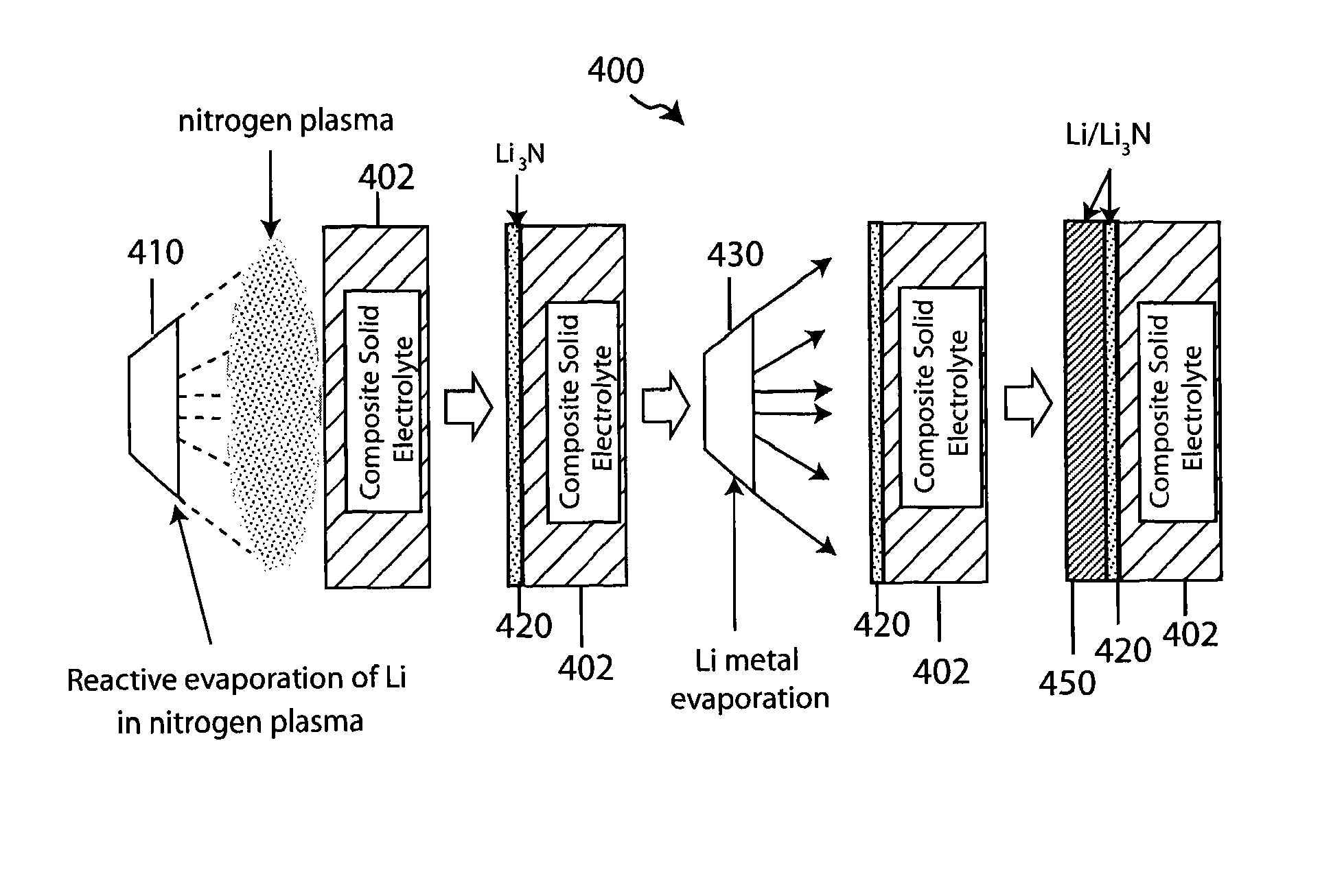

ActiveUS20070172739A1Eliminate through-porosityHigh metal ion conductivityCell electrodesPrimary cellsPorosityTectorial membrane

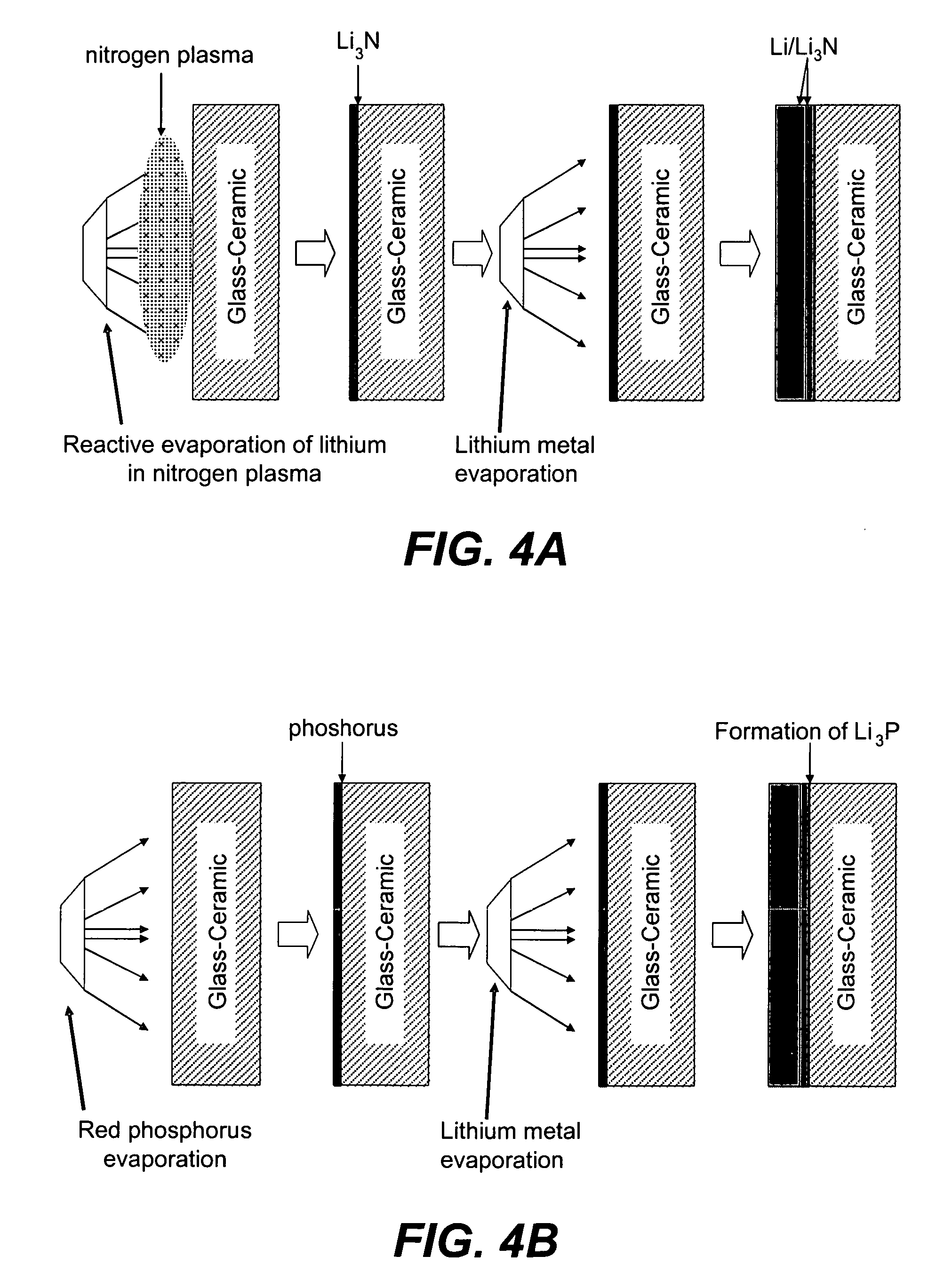

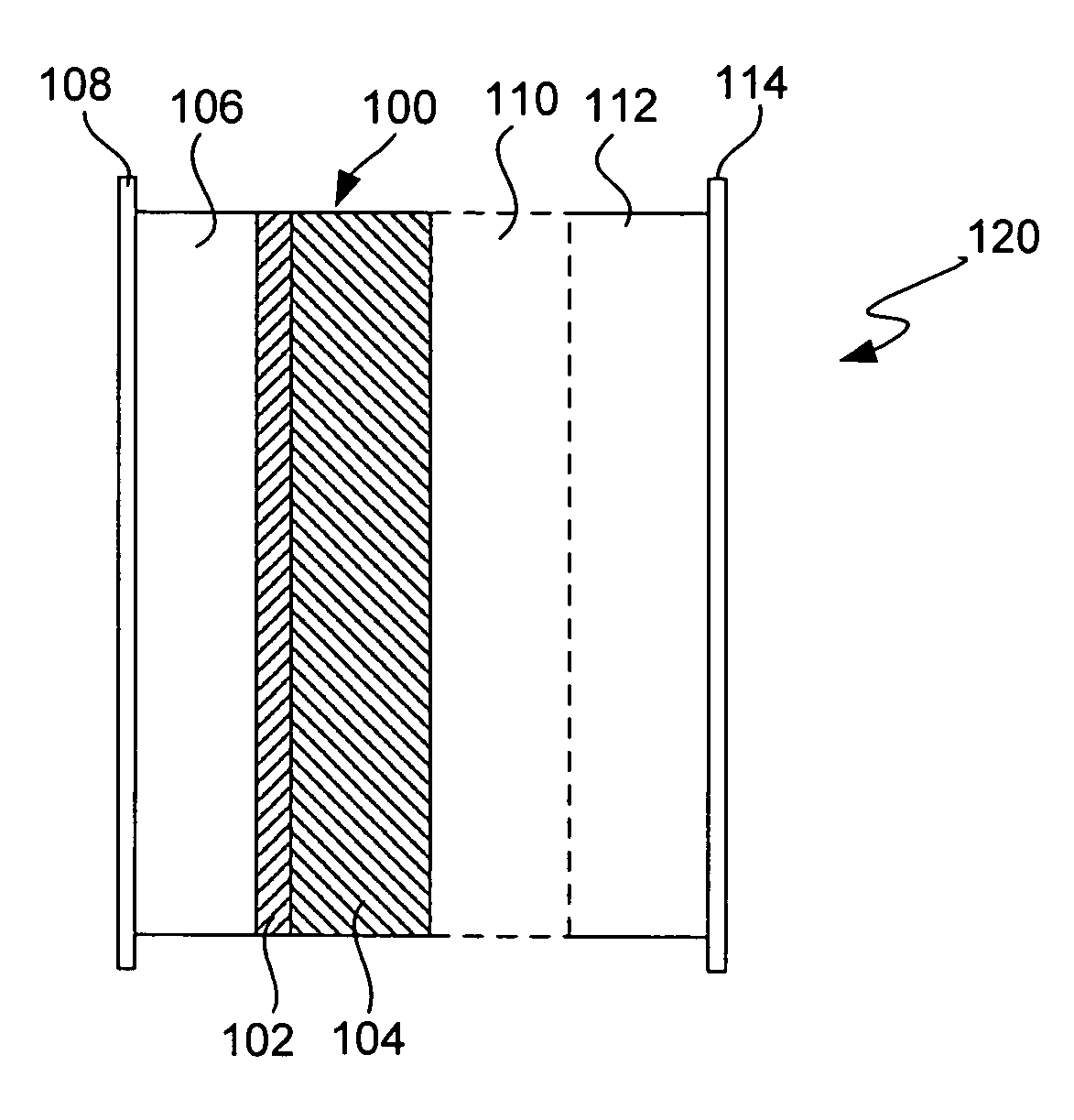

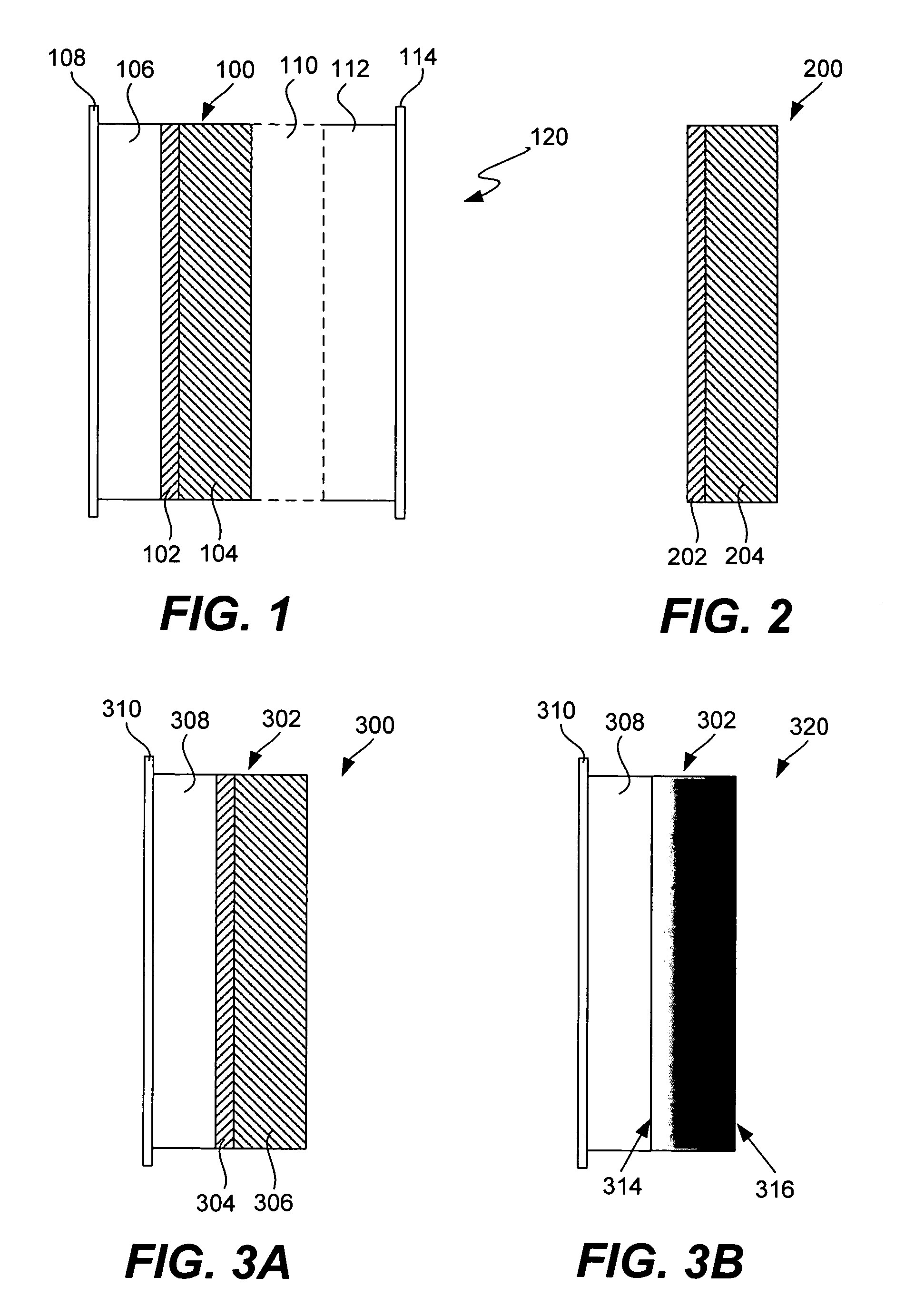

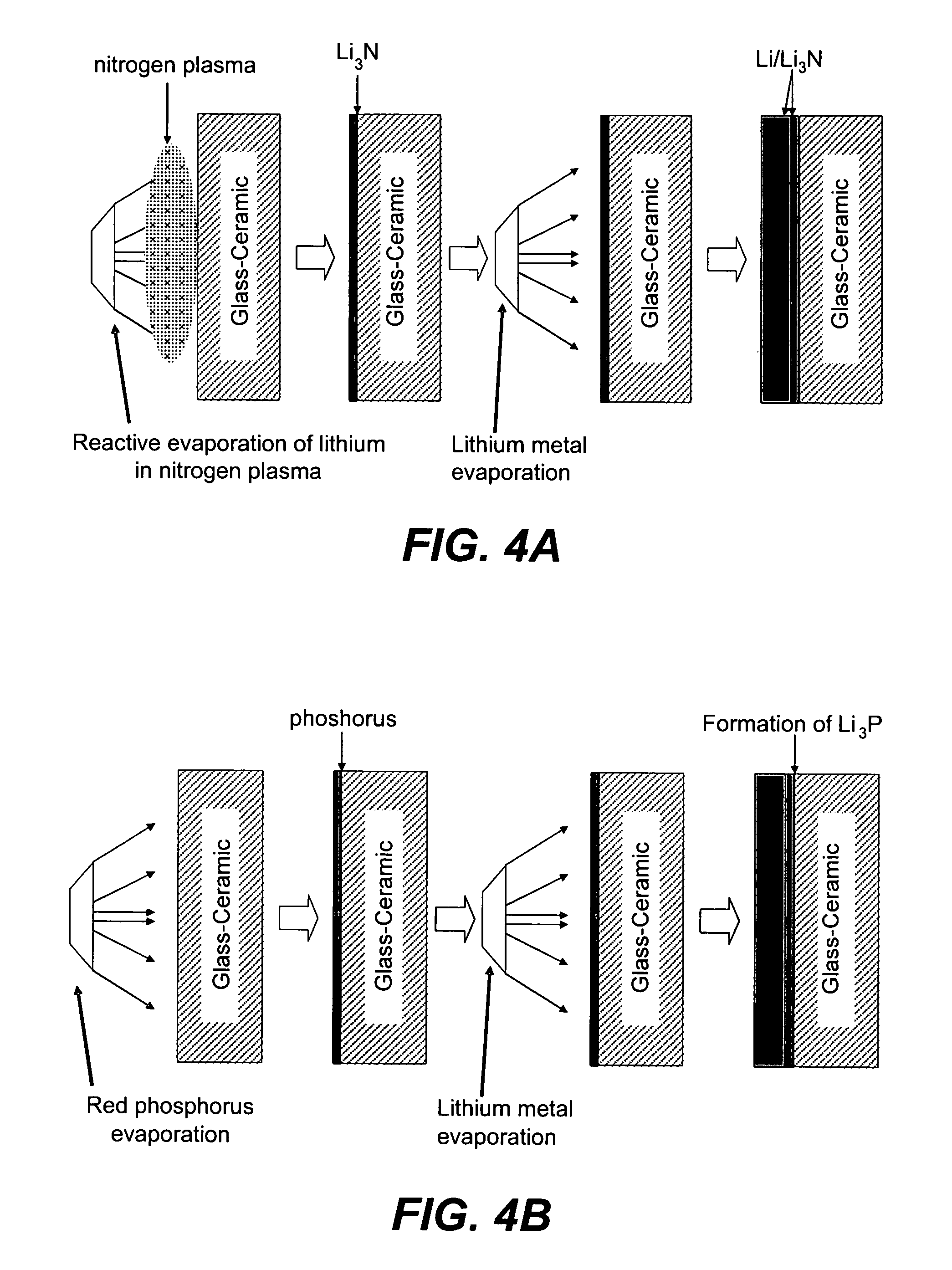

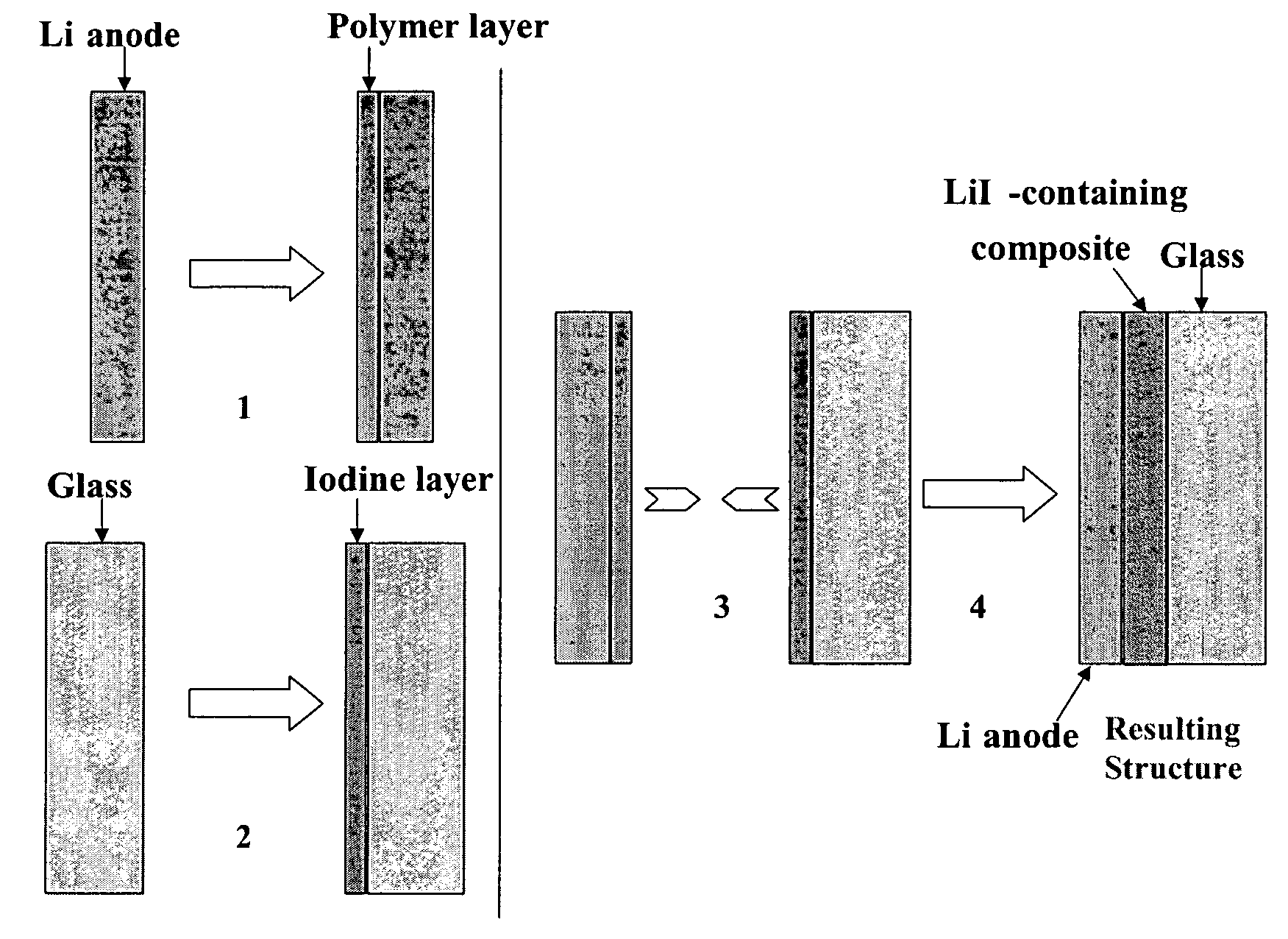

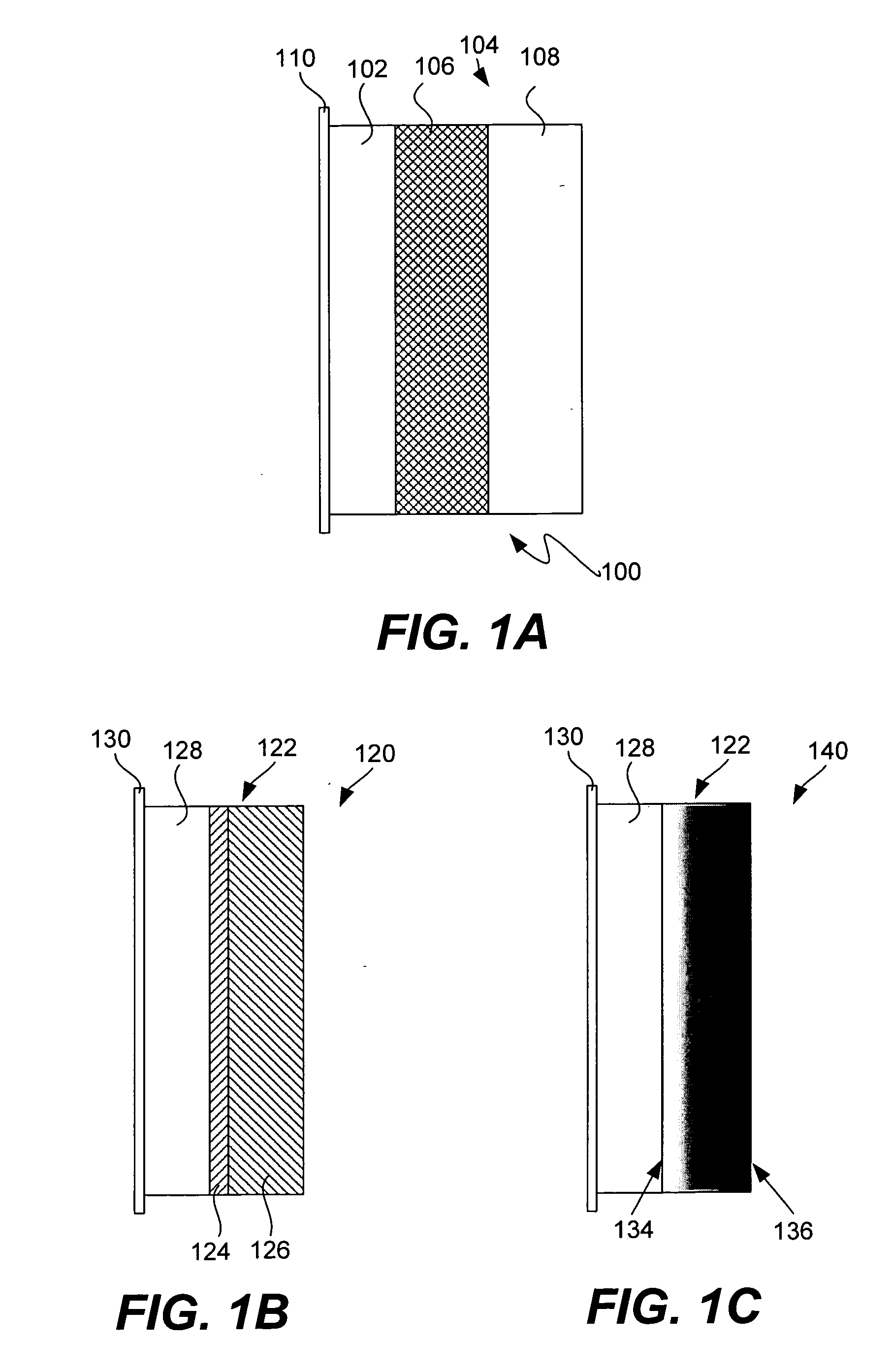

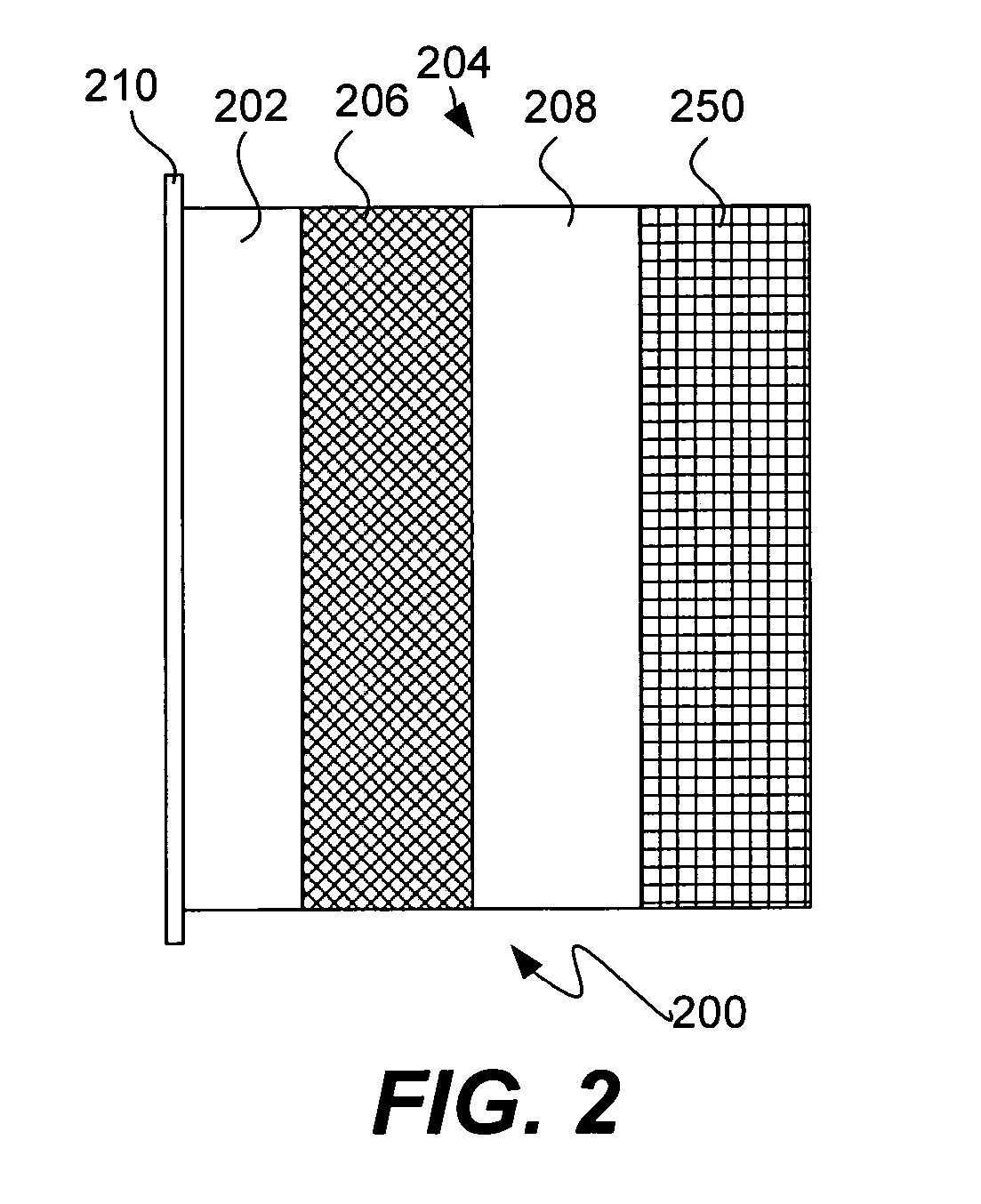

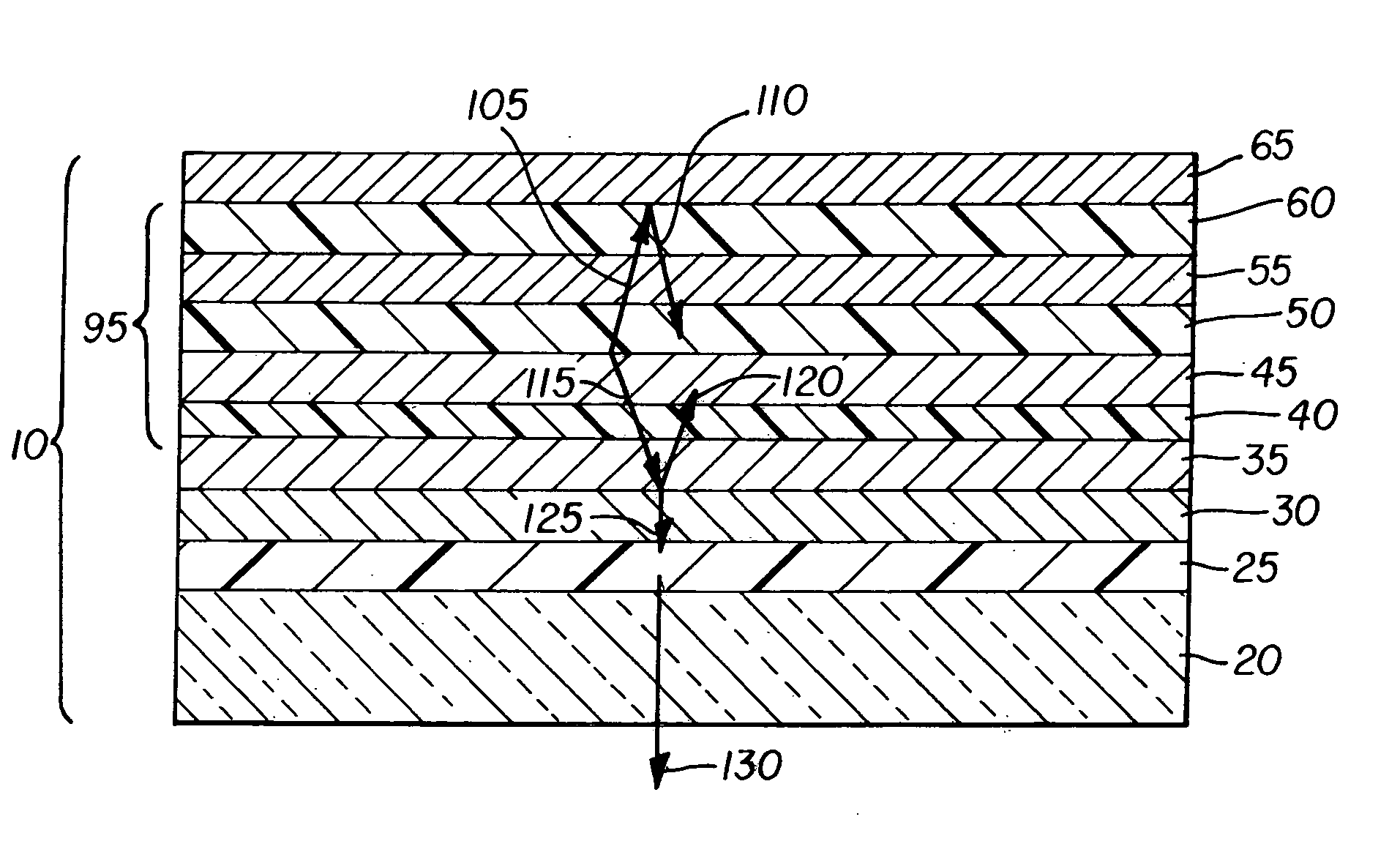

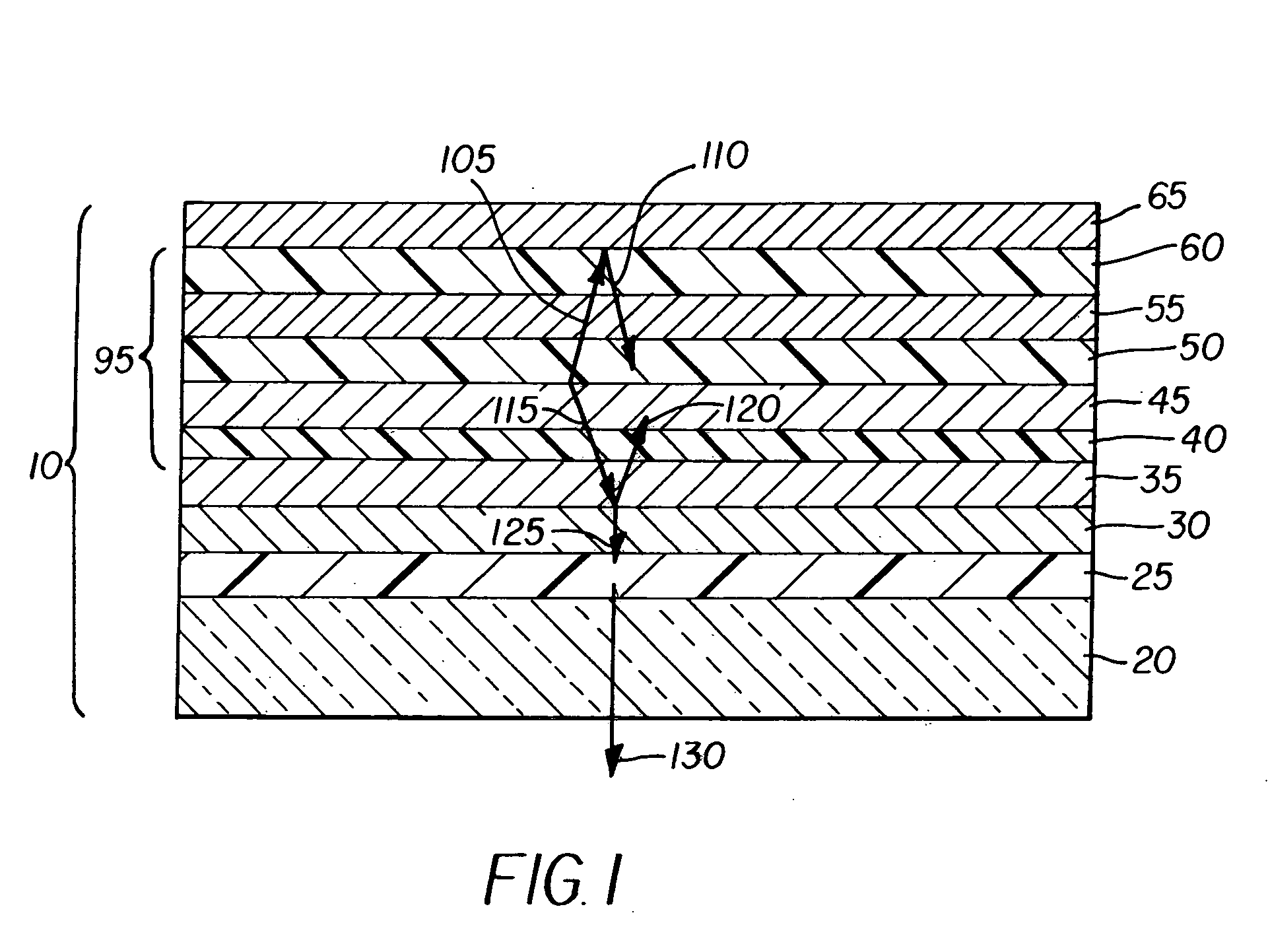

A composite solid electrolyte include a monolithic solid electrolyte base component that is a continuous matrix of an inorganic active metal ion conductor and a filler component used to eliminate through porosity in the solid electrolyte. In this way a solid electrolyte produced by any process that yields residual through porosity can be modified by the incorporation of a filler to form a substantially impervious composite solid electrolyte and eliminate through porosity in the base component. Methods of making the composites is also disclosed. The composites are generally useful in electrochemical cell structures such as battery cells and in particular protected active metal anodes, particularly lithium anodes, that are protected with a protective membrane architecture incorporating the composite solid electrolyte. The protective architecture prevents the active metal of the anode from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air and organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

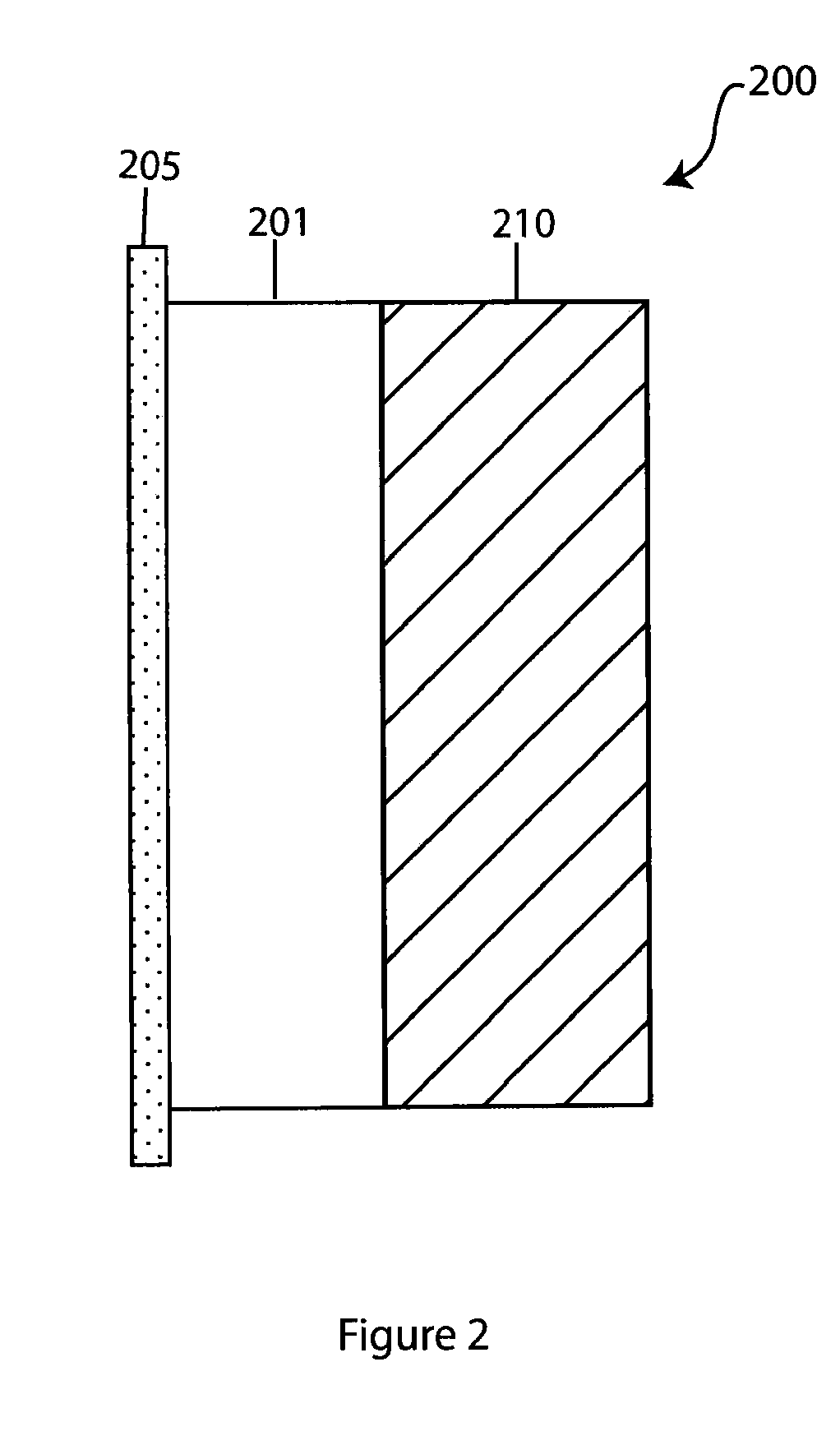

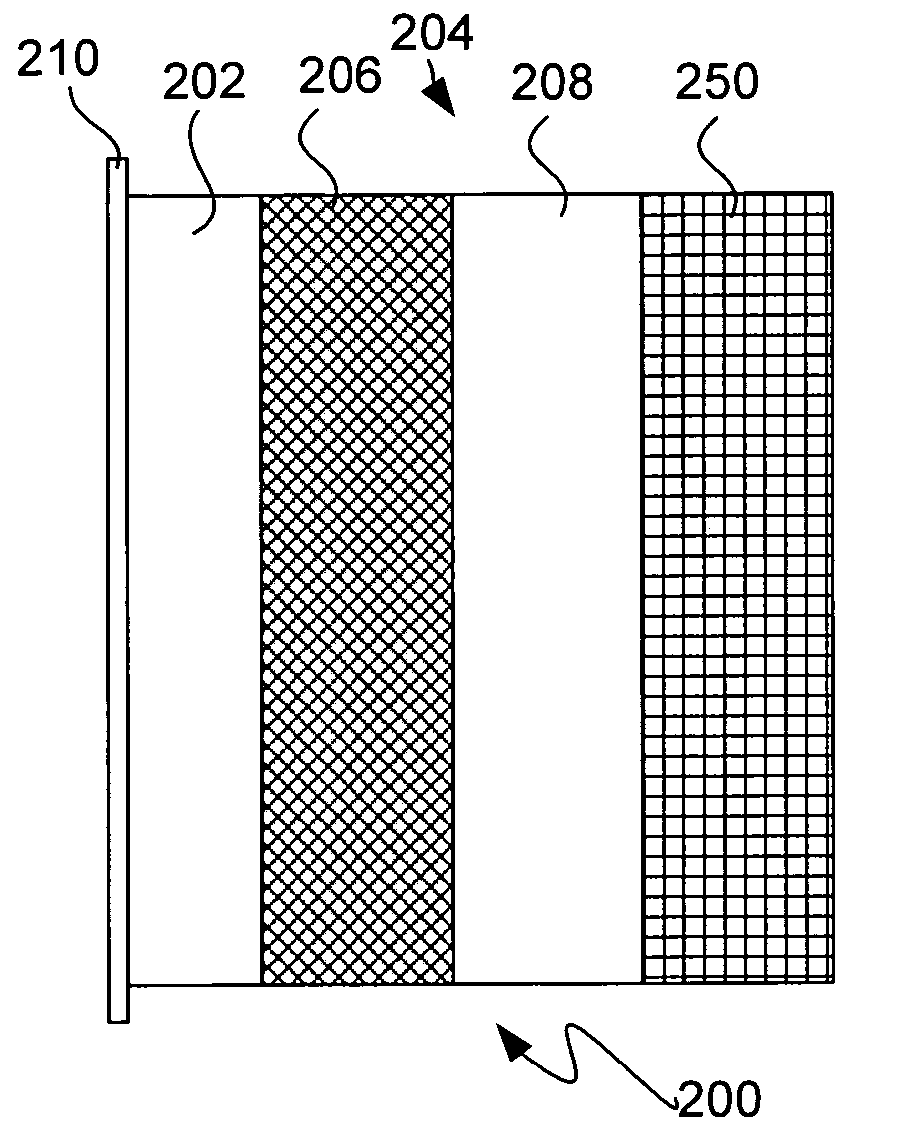

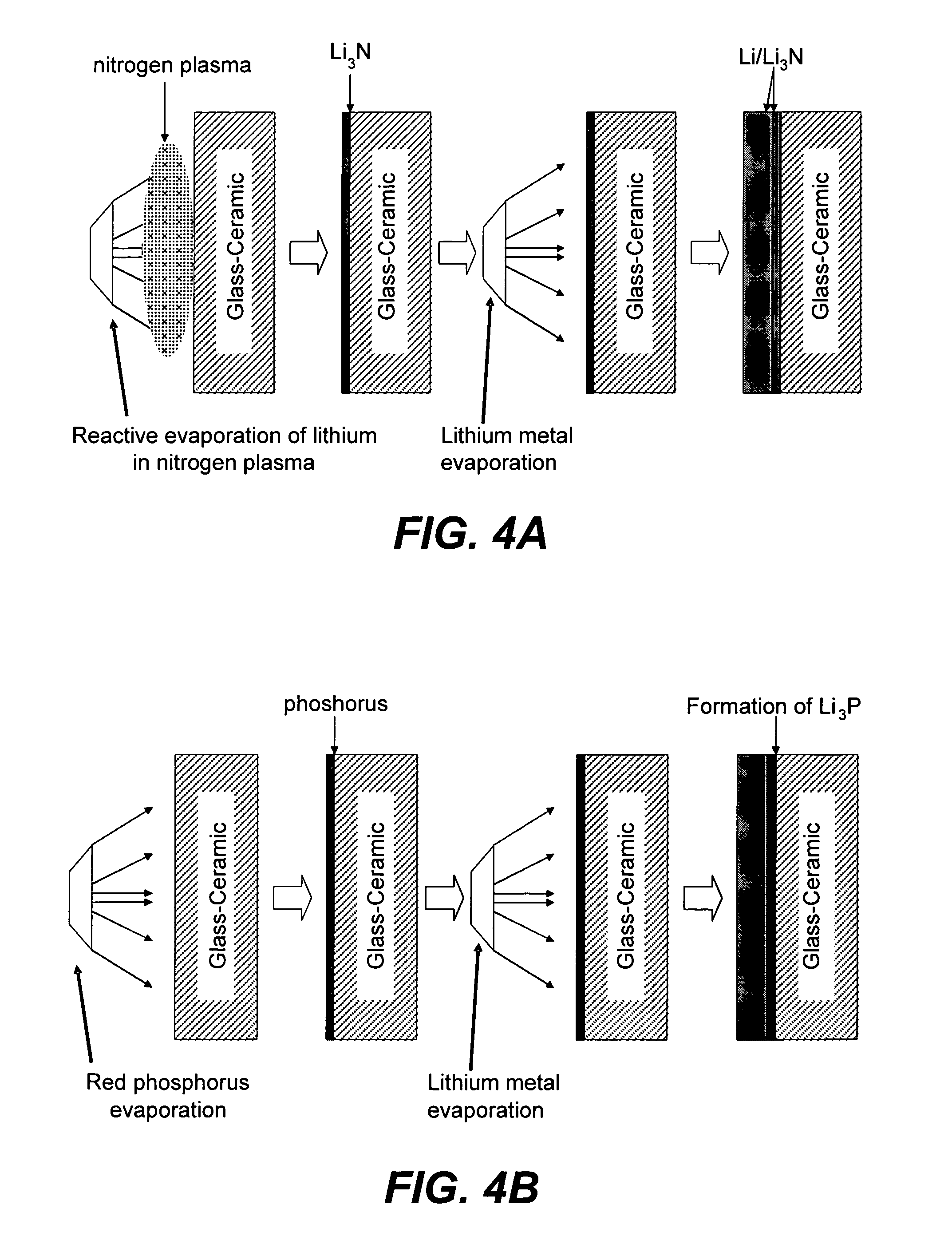

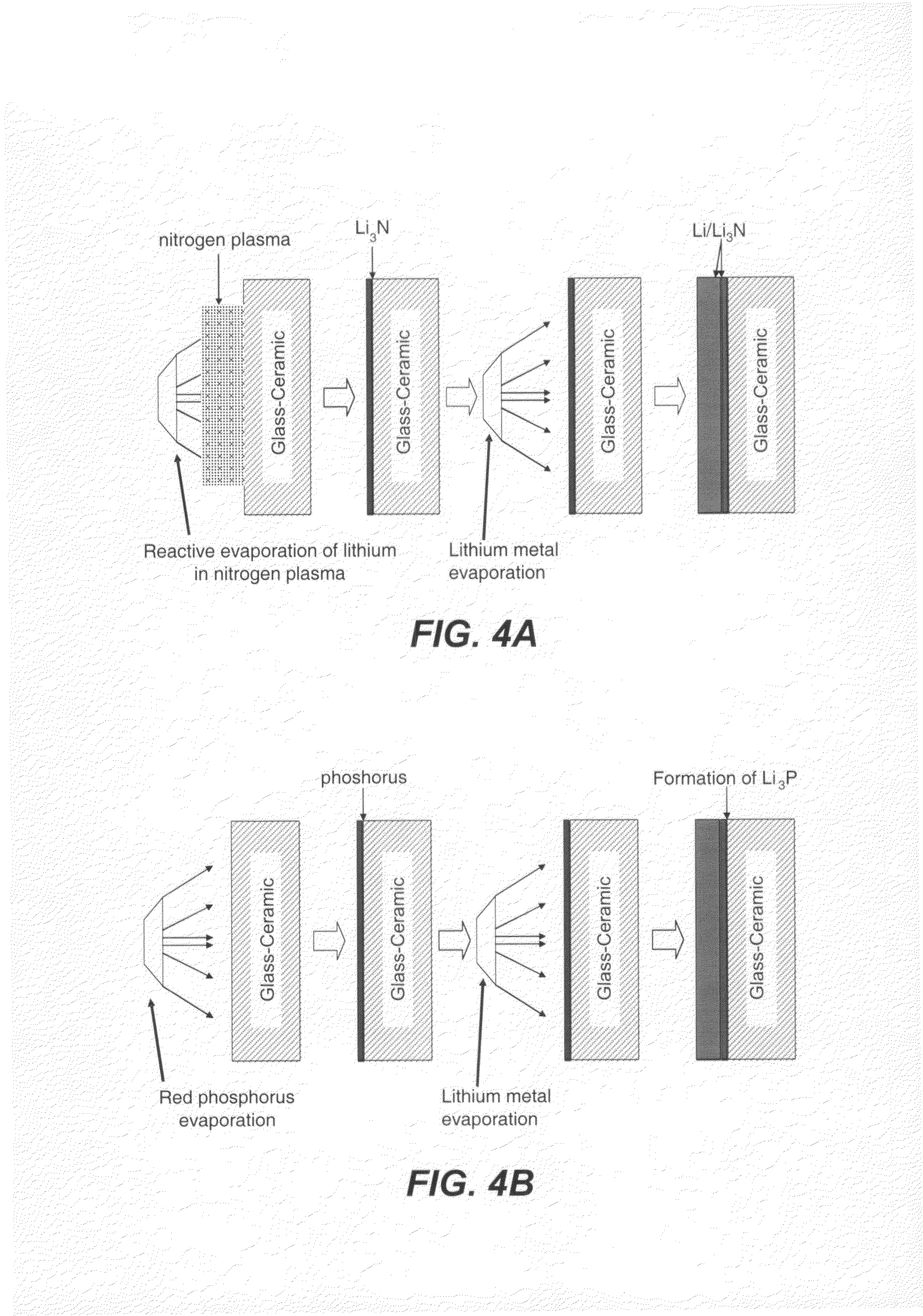

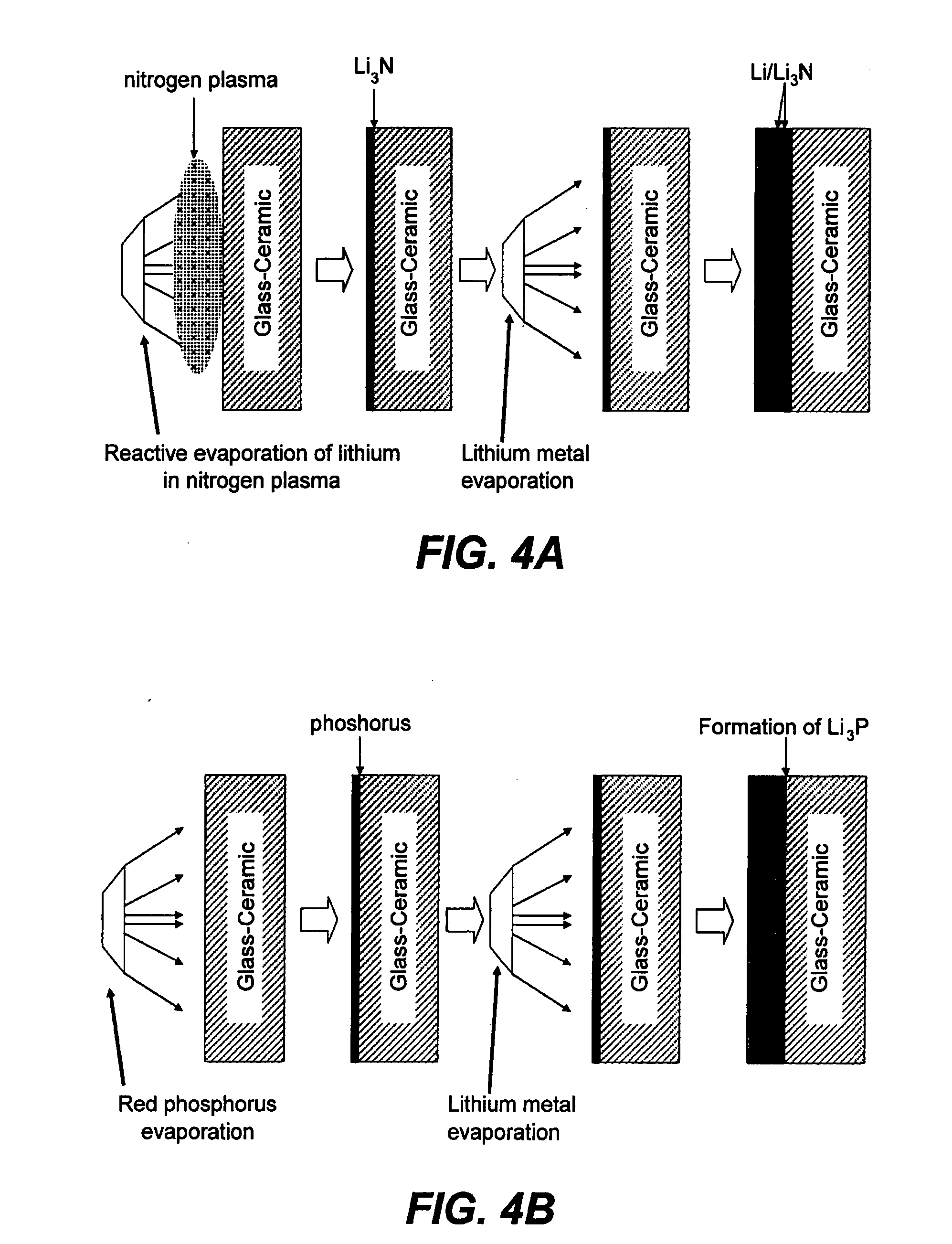

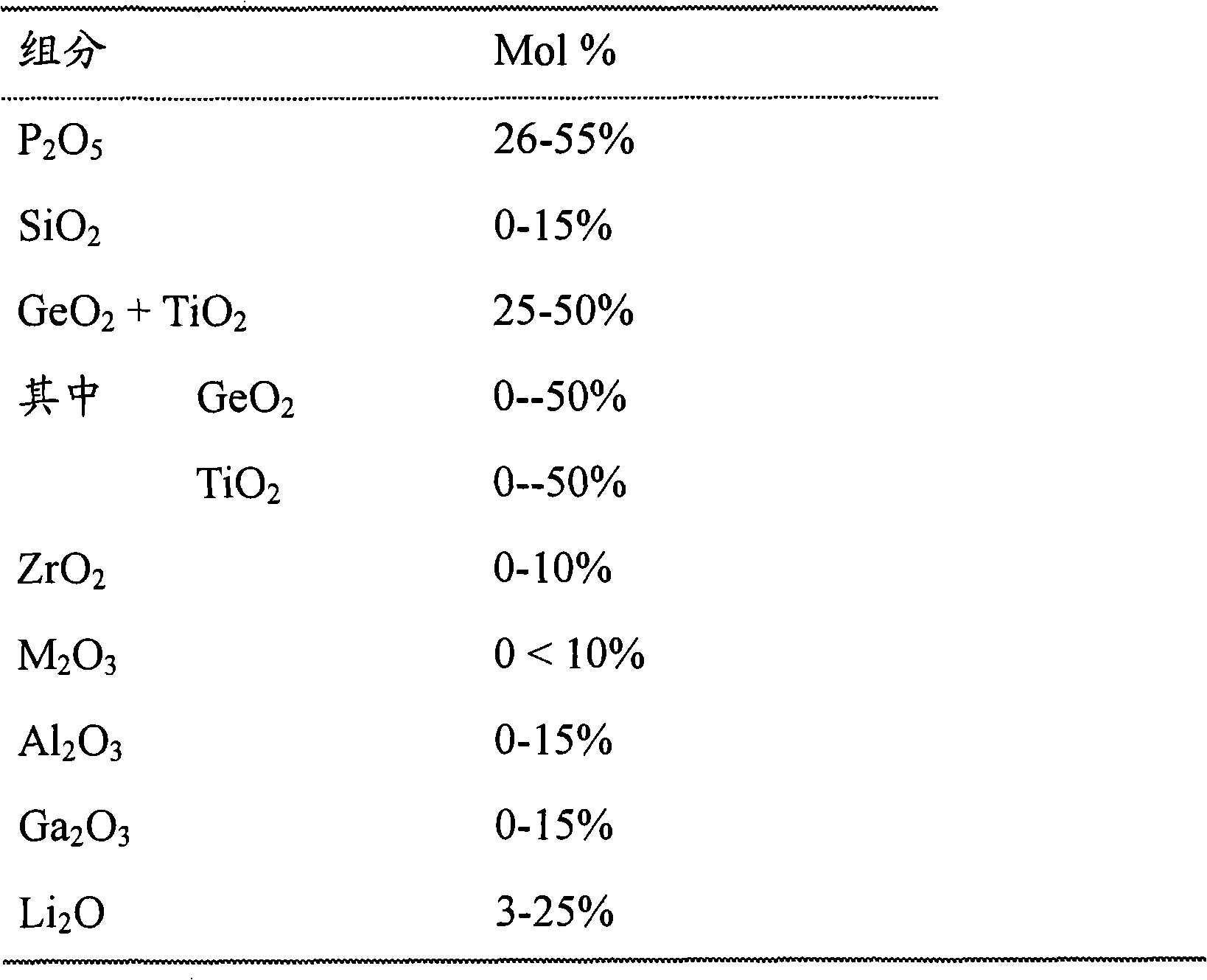

Ionically conductive membranes for protection of active metal anodes and battery cells

InactiveUS20040191617A1Improve propertiesImprove ionic conductivitySolid electrolytesSolid electrolyte cellsChemical stabilityBattery cell

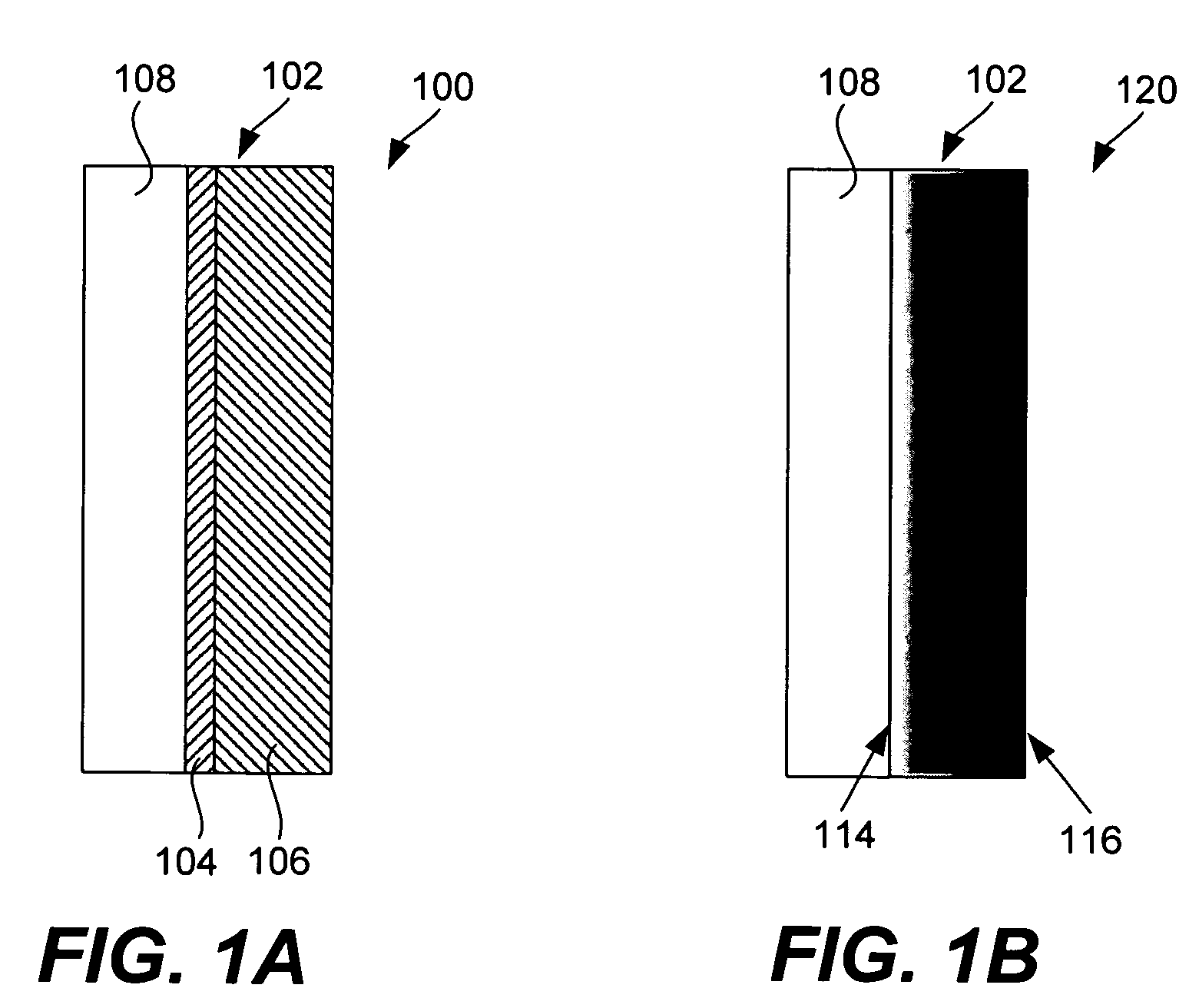

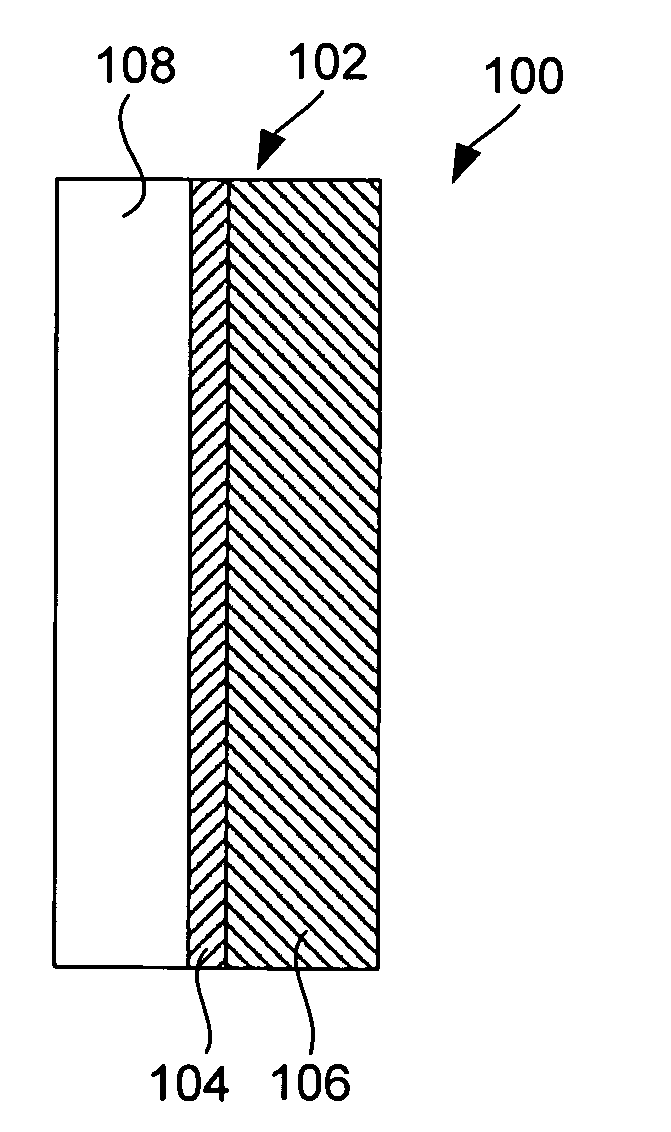

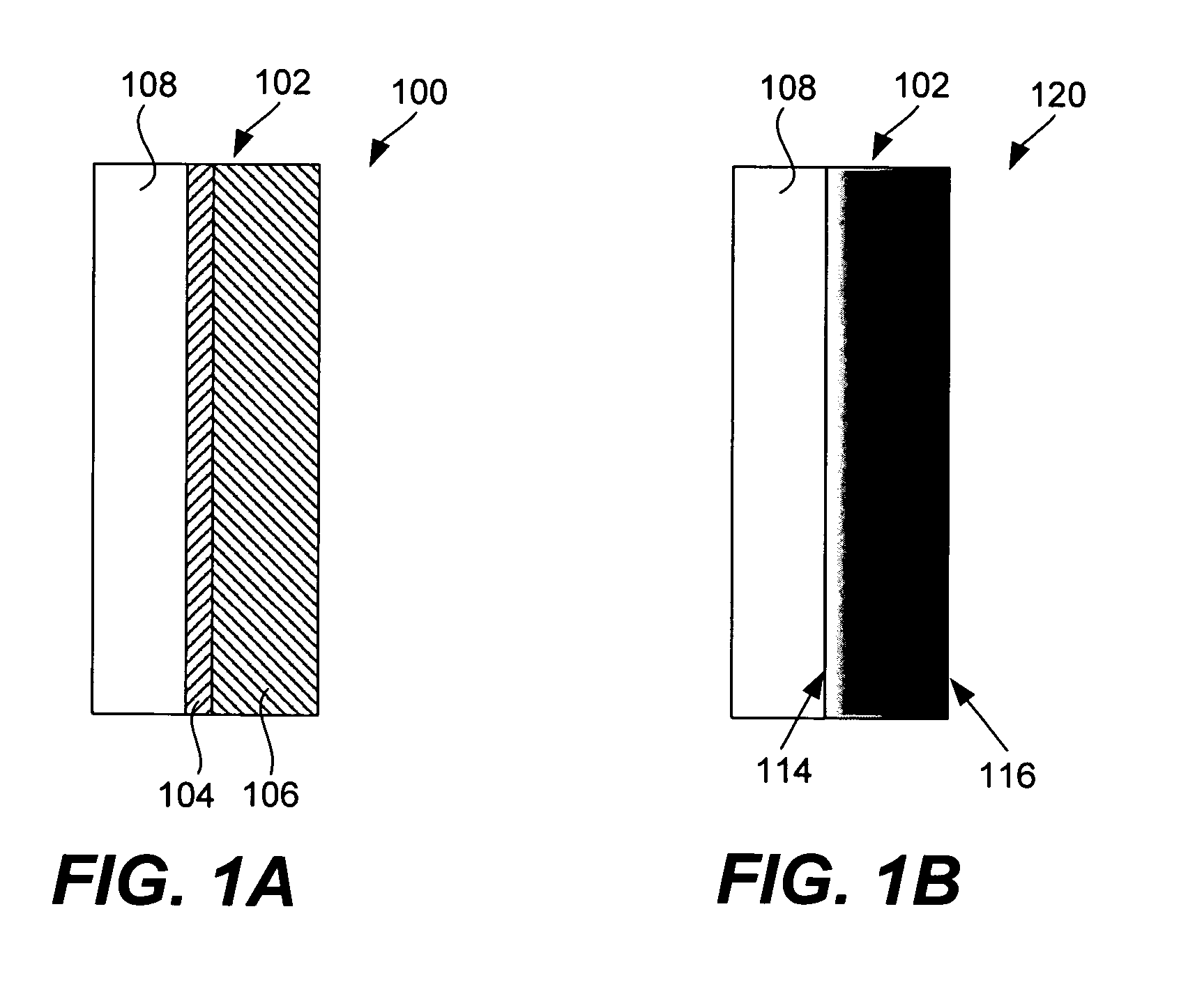

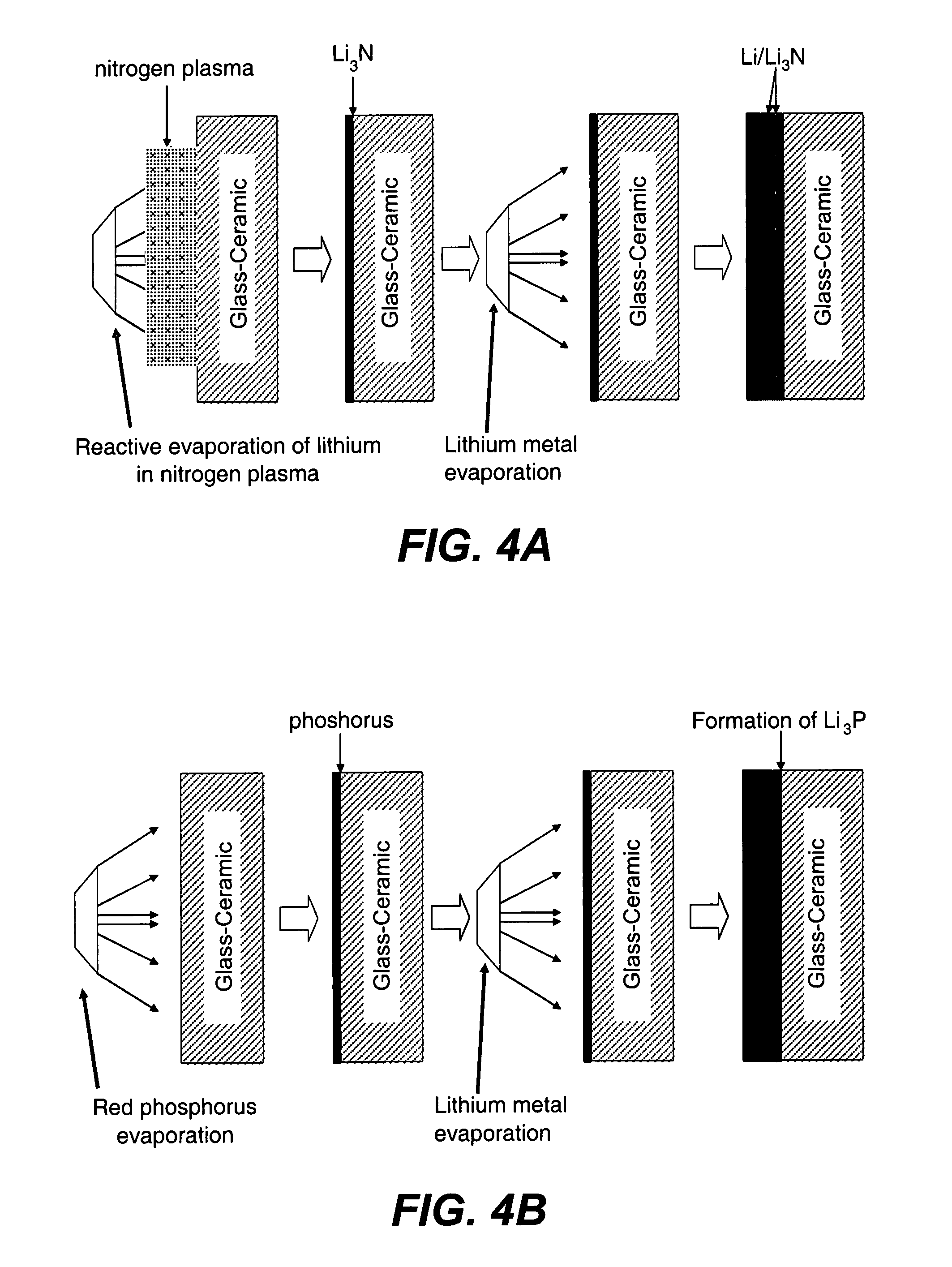

Disclosed are ionically conductive membranes for protection of active metal anodes and methods for their fabrication. The membranes may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the membrane has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The membrane is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the membrane is incorporated.

Owner:POLYPLUS BATTERY CO INC

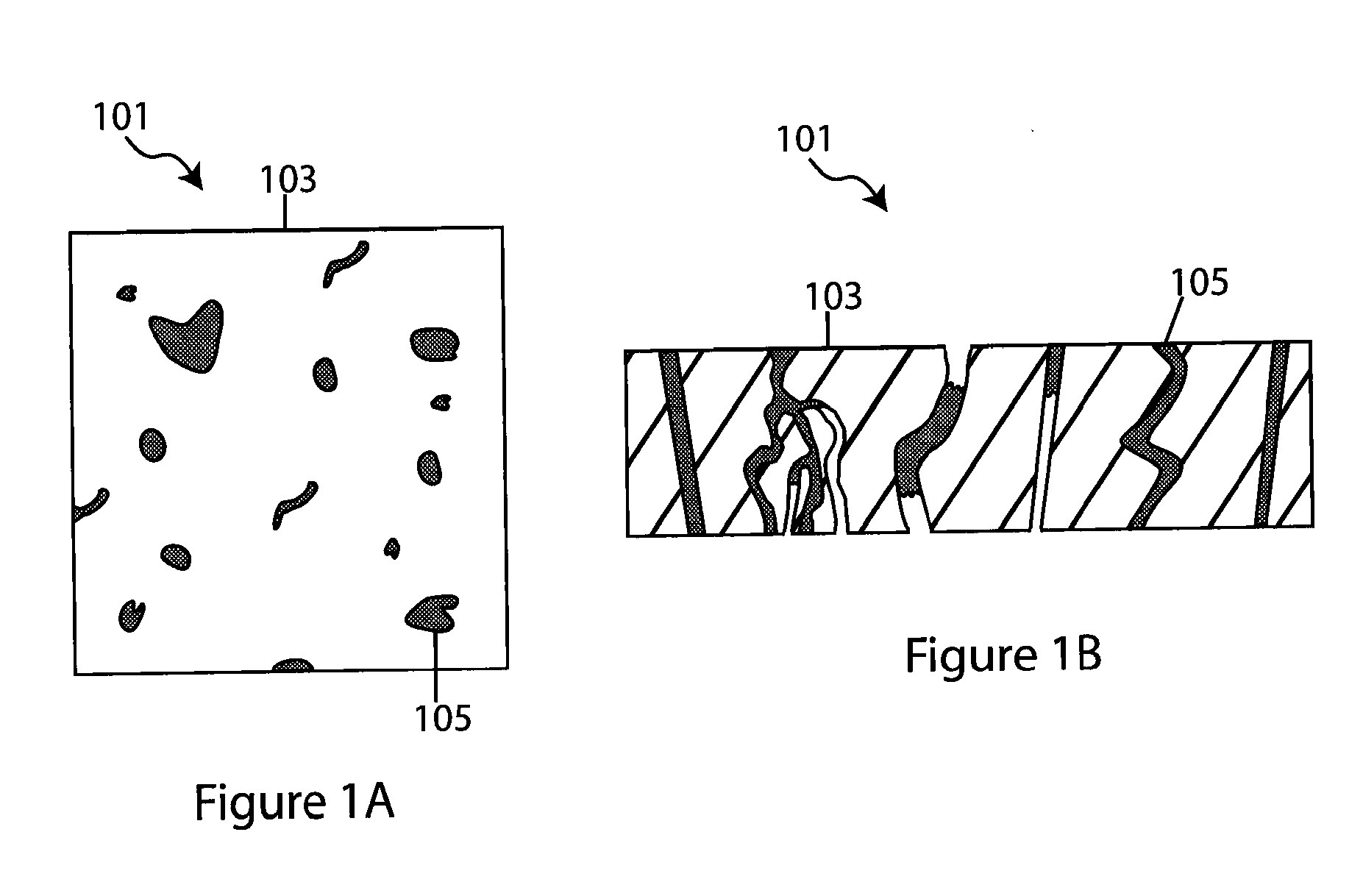

Ionically conductive composites for protection of active metal anodes

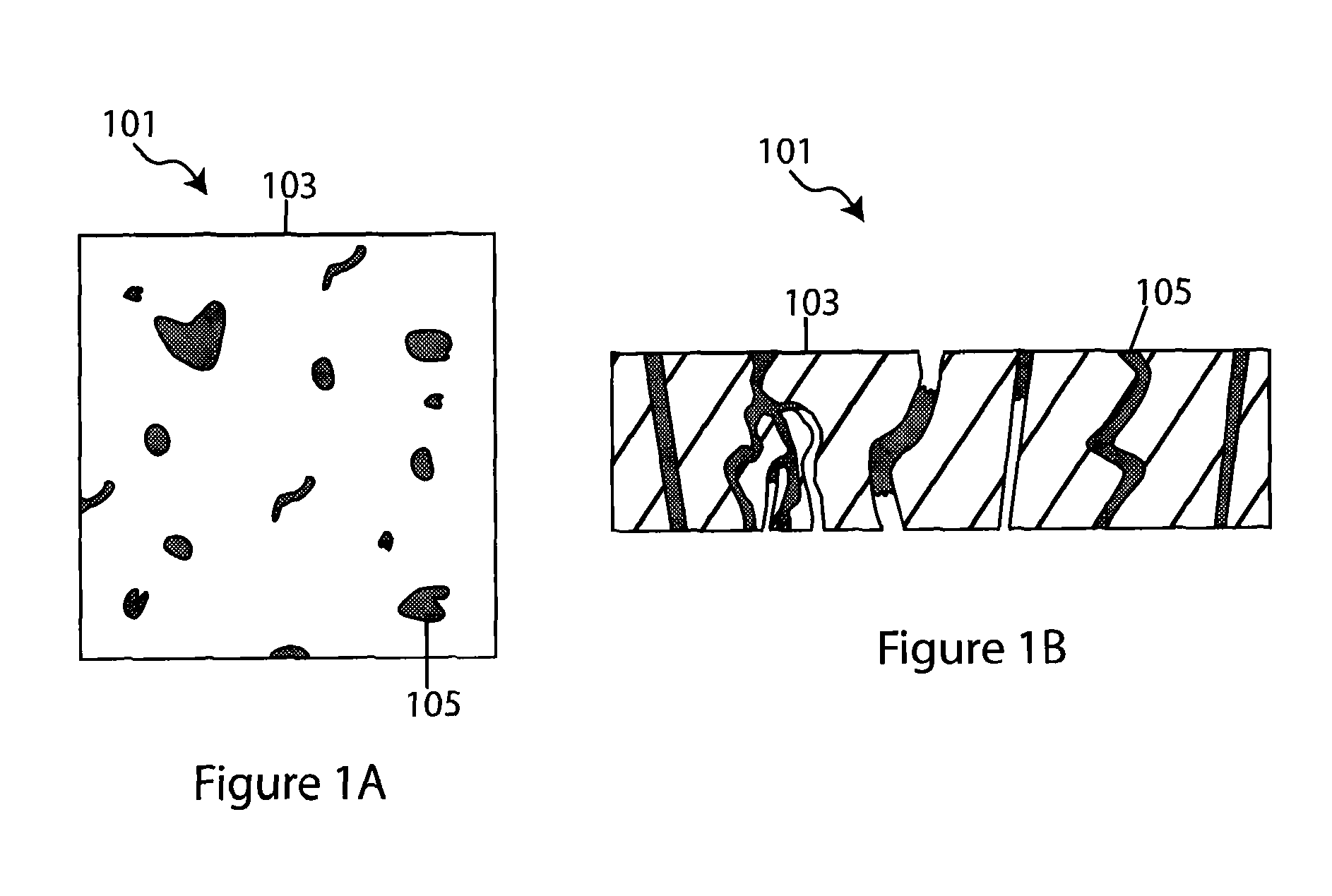

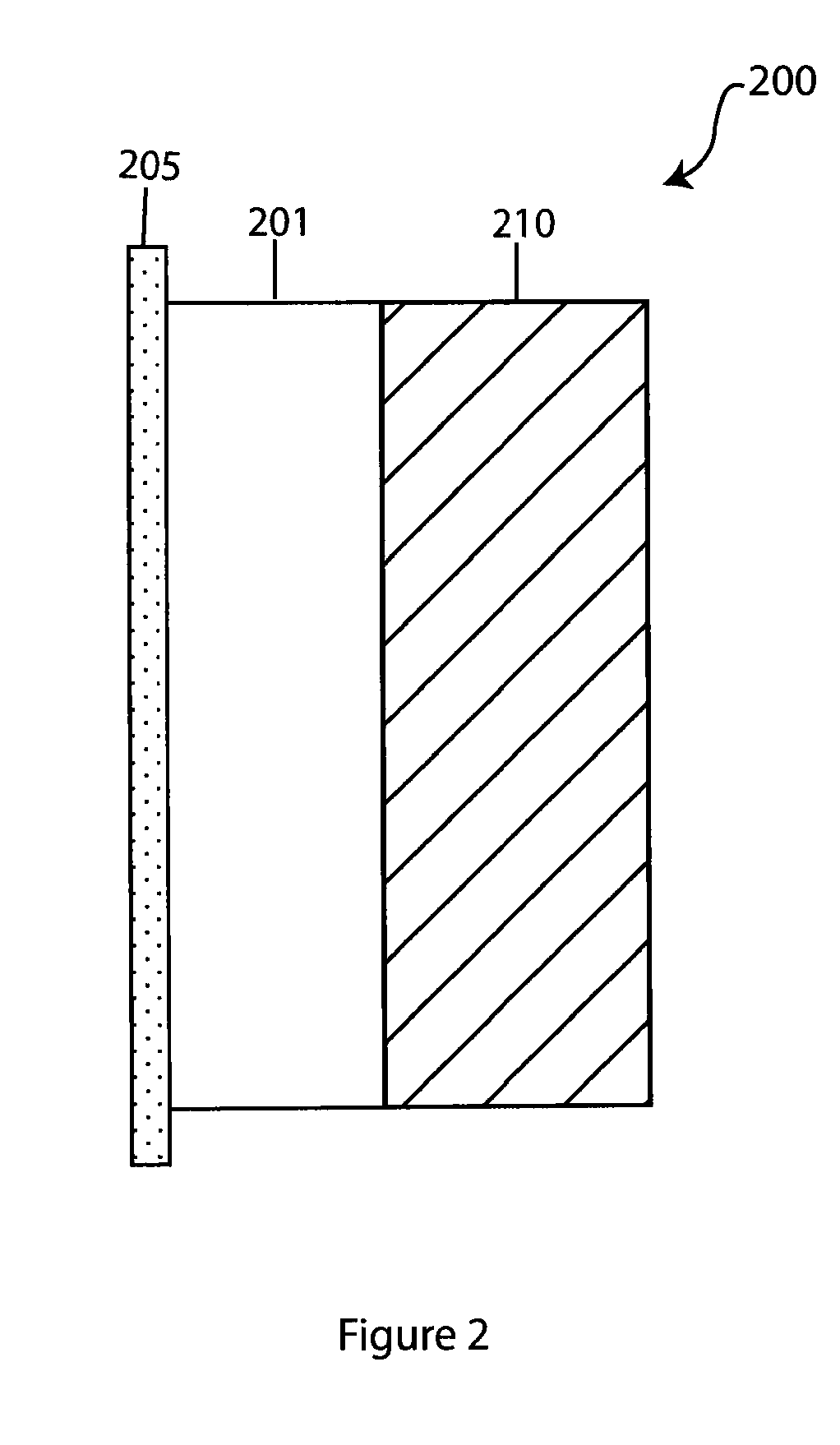

ActiveUS7282296B2Easy to manufactureImprove battery performanceFinal product manufactureElectrode carriers/collectorsChemical stabilityIonic conductivity

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

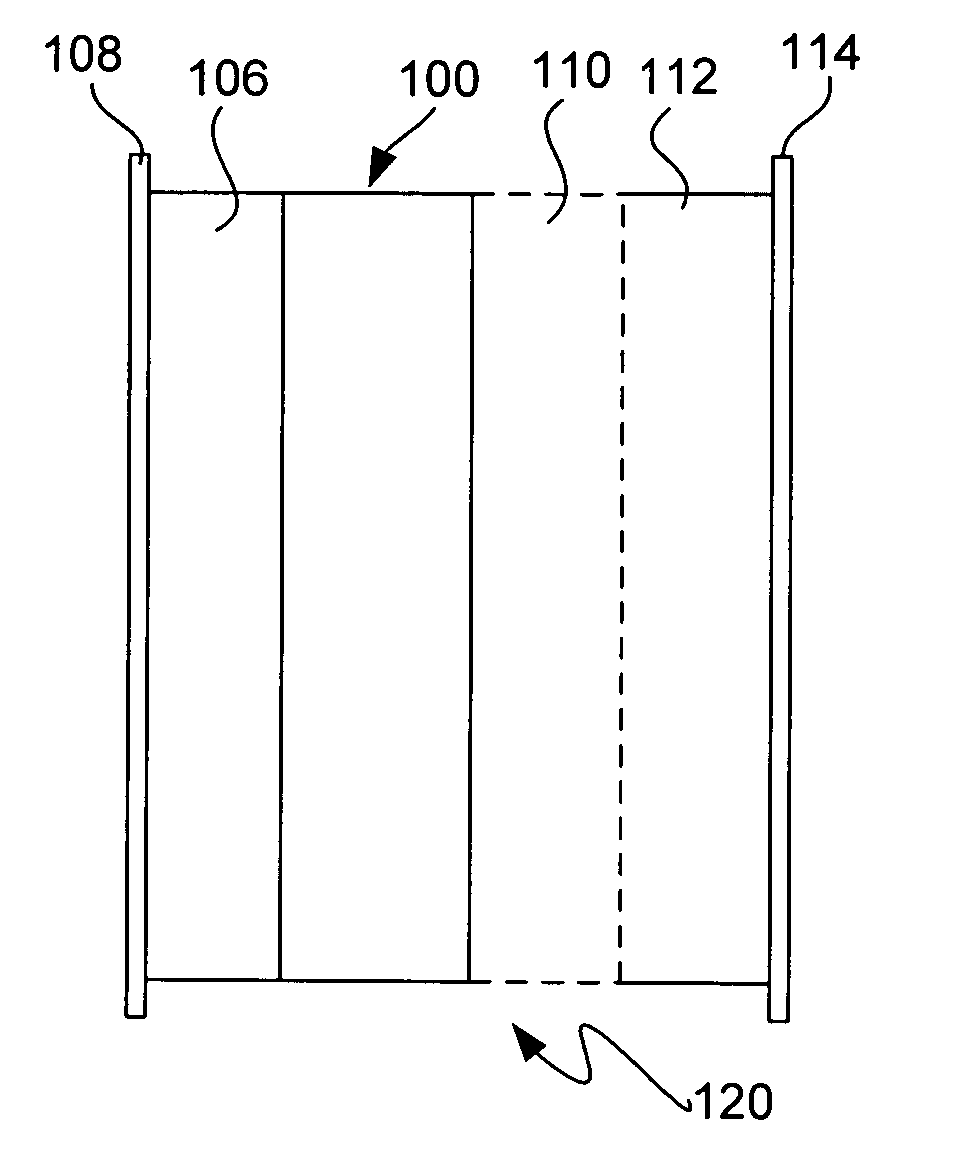

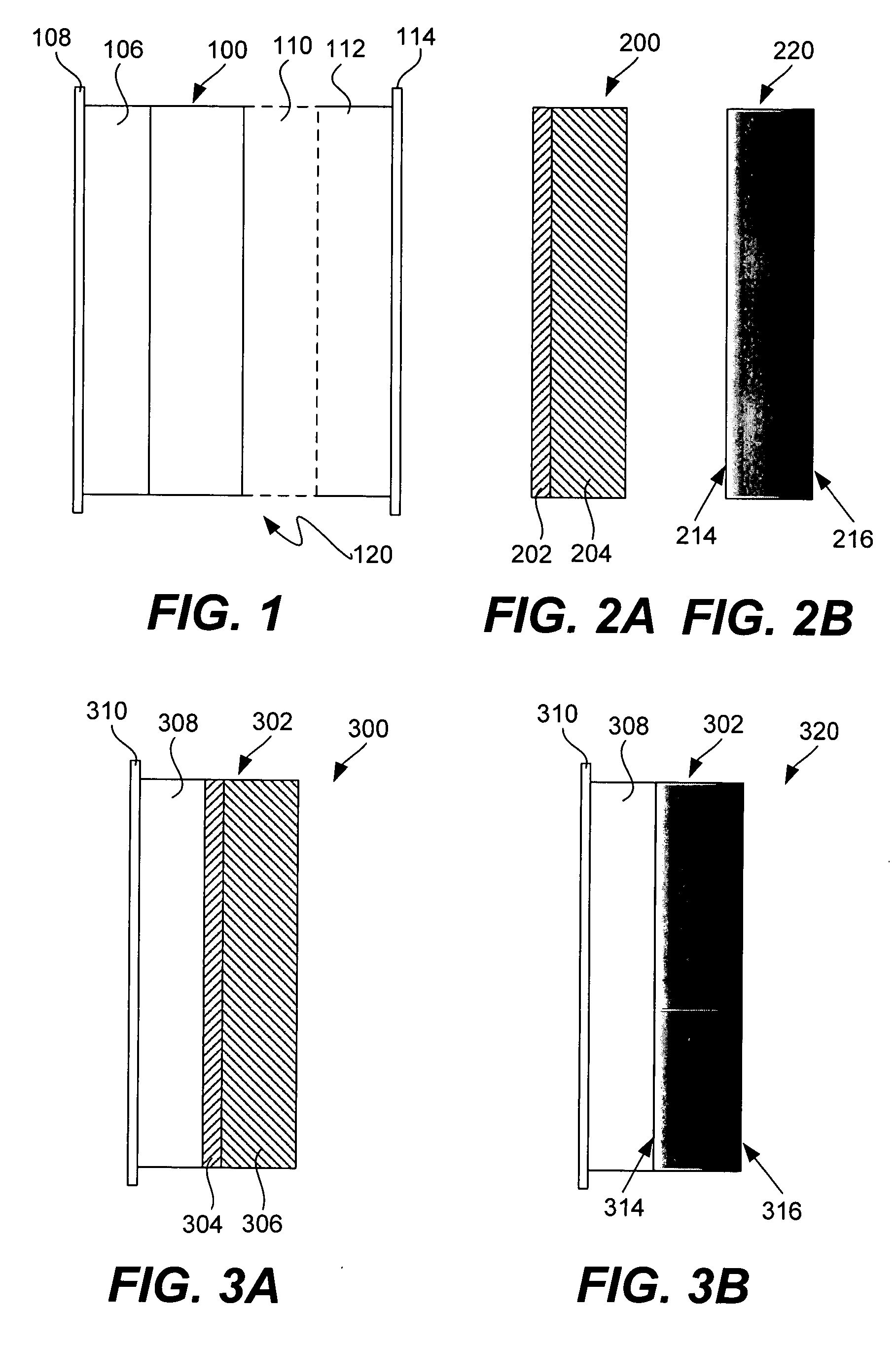

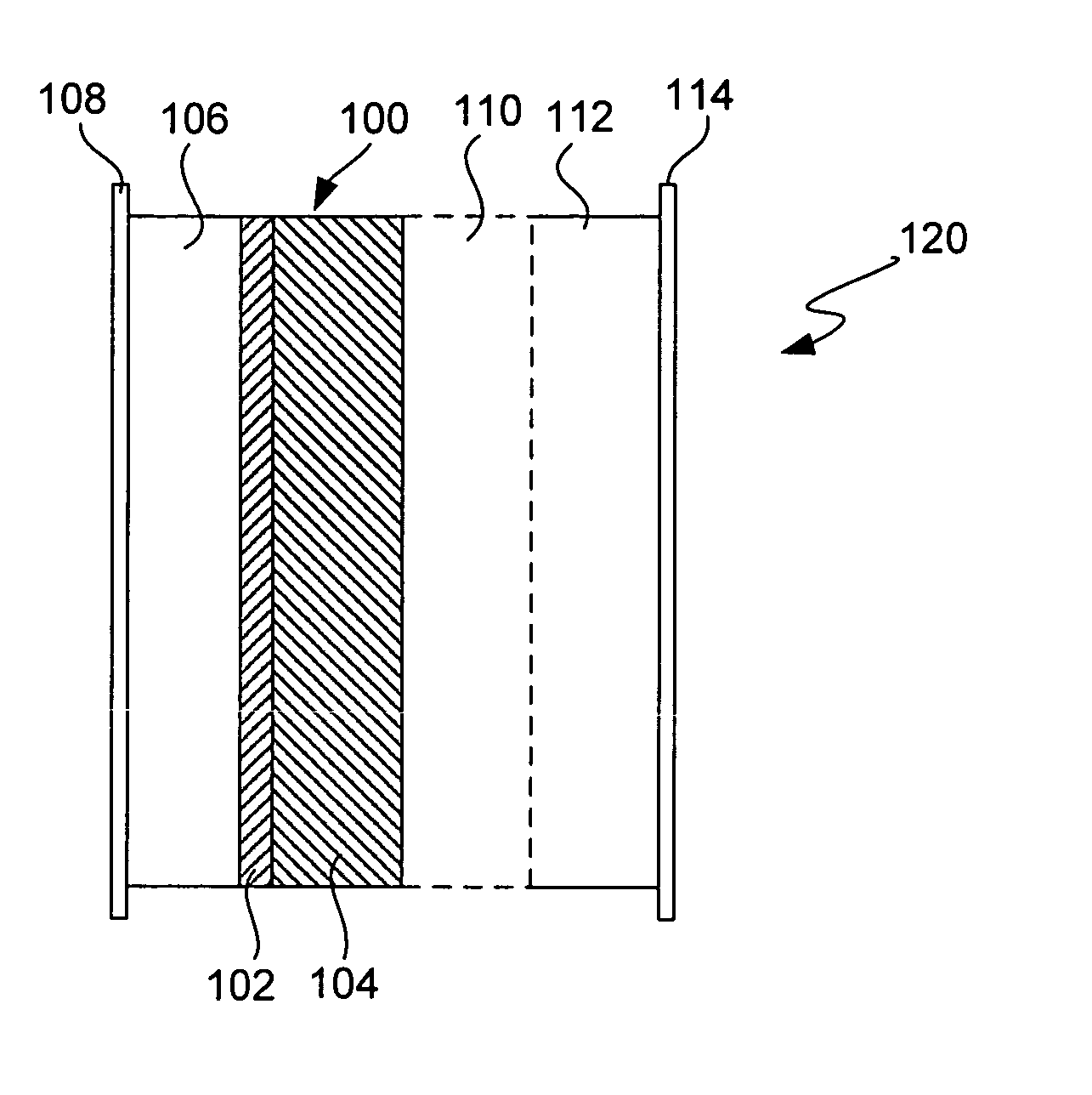

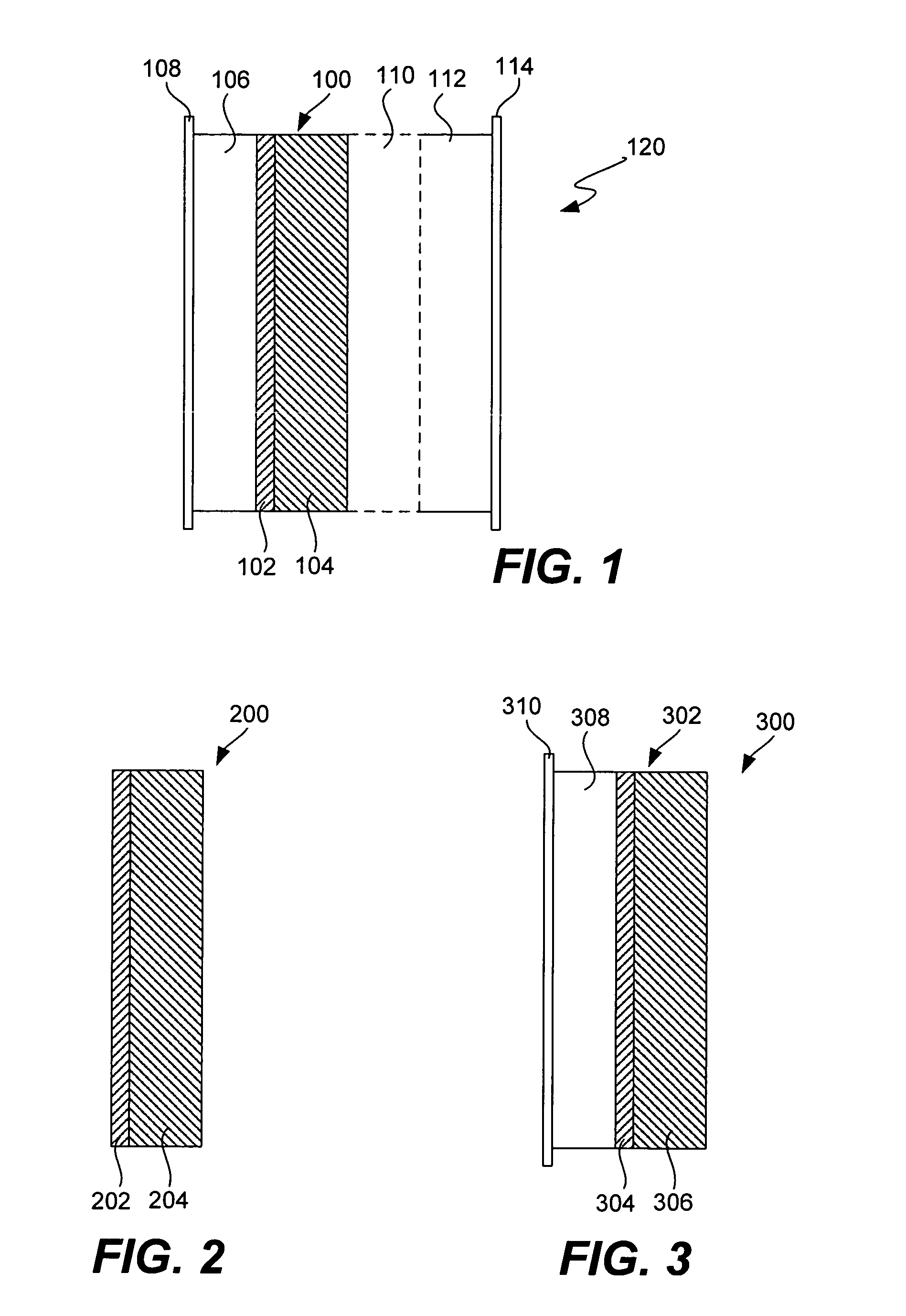

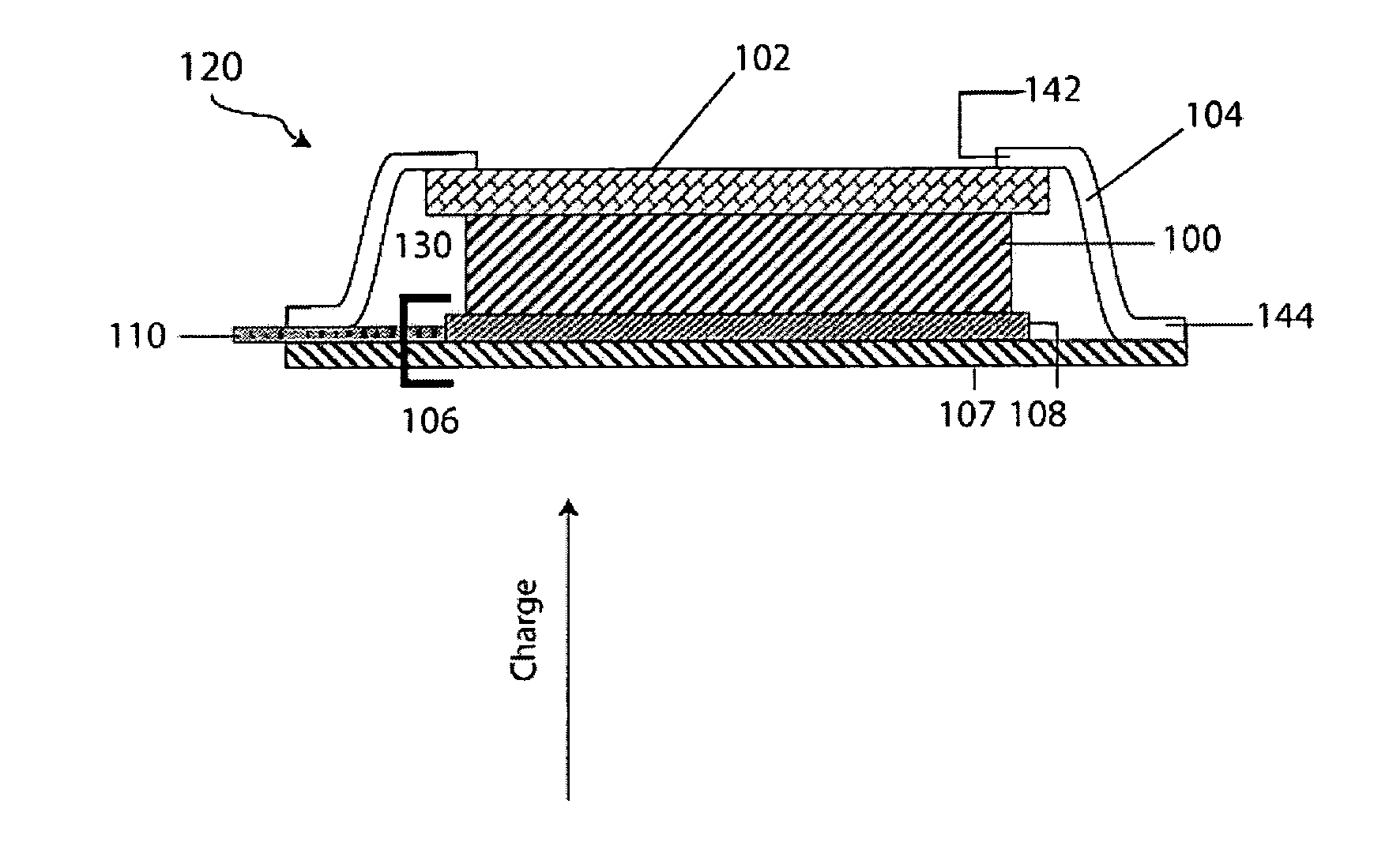

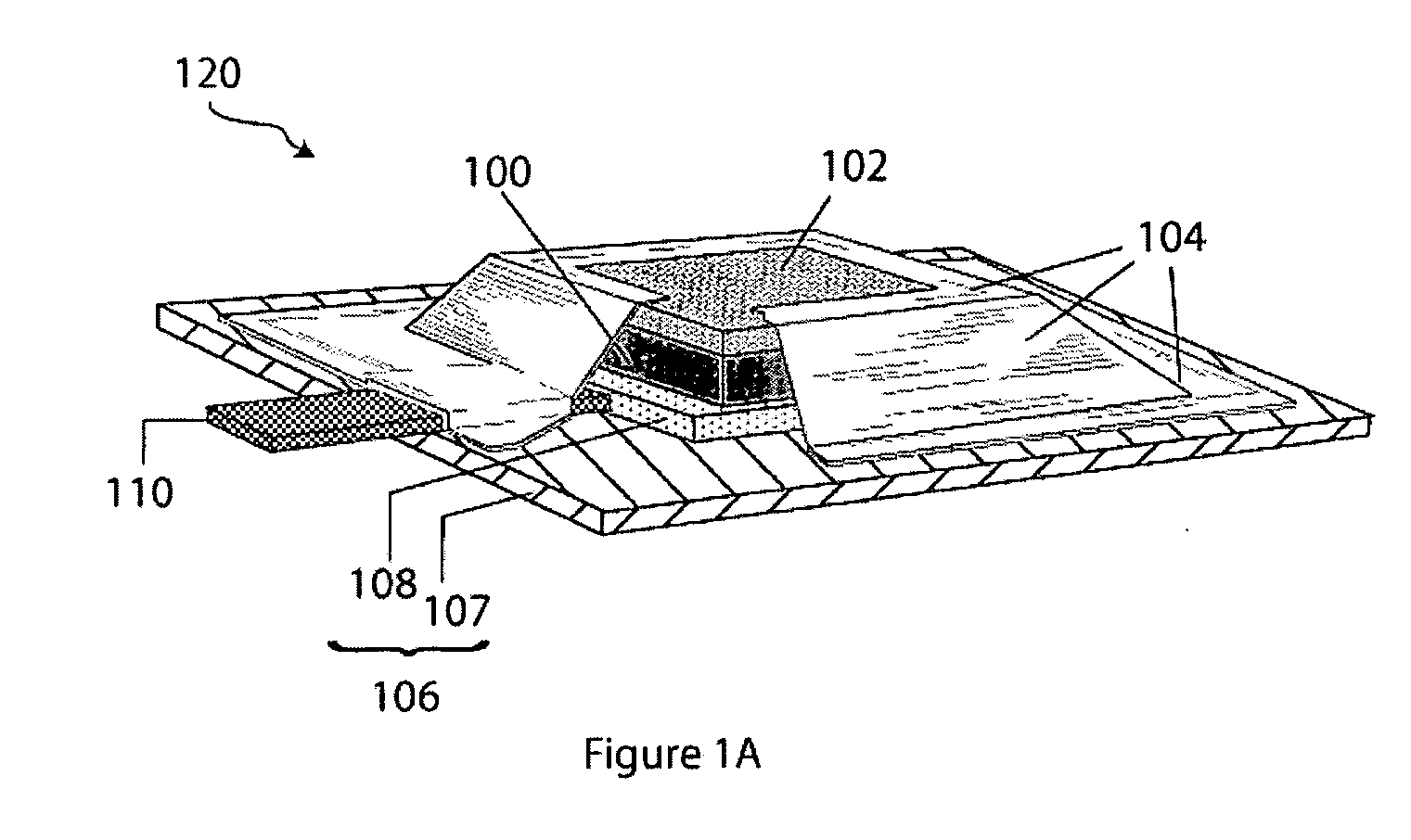

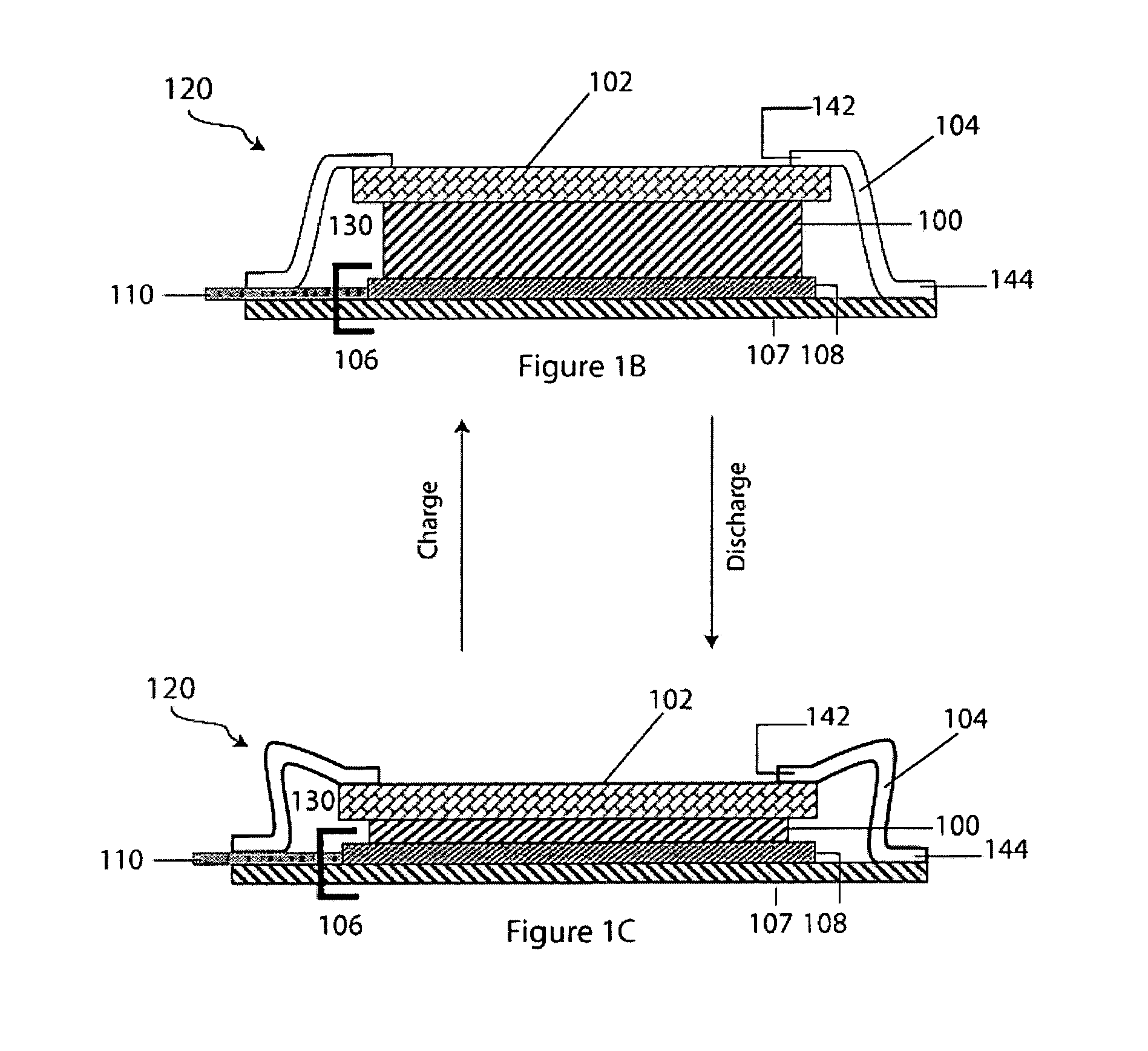

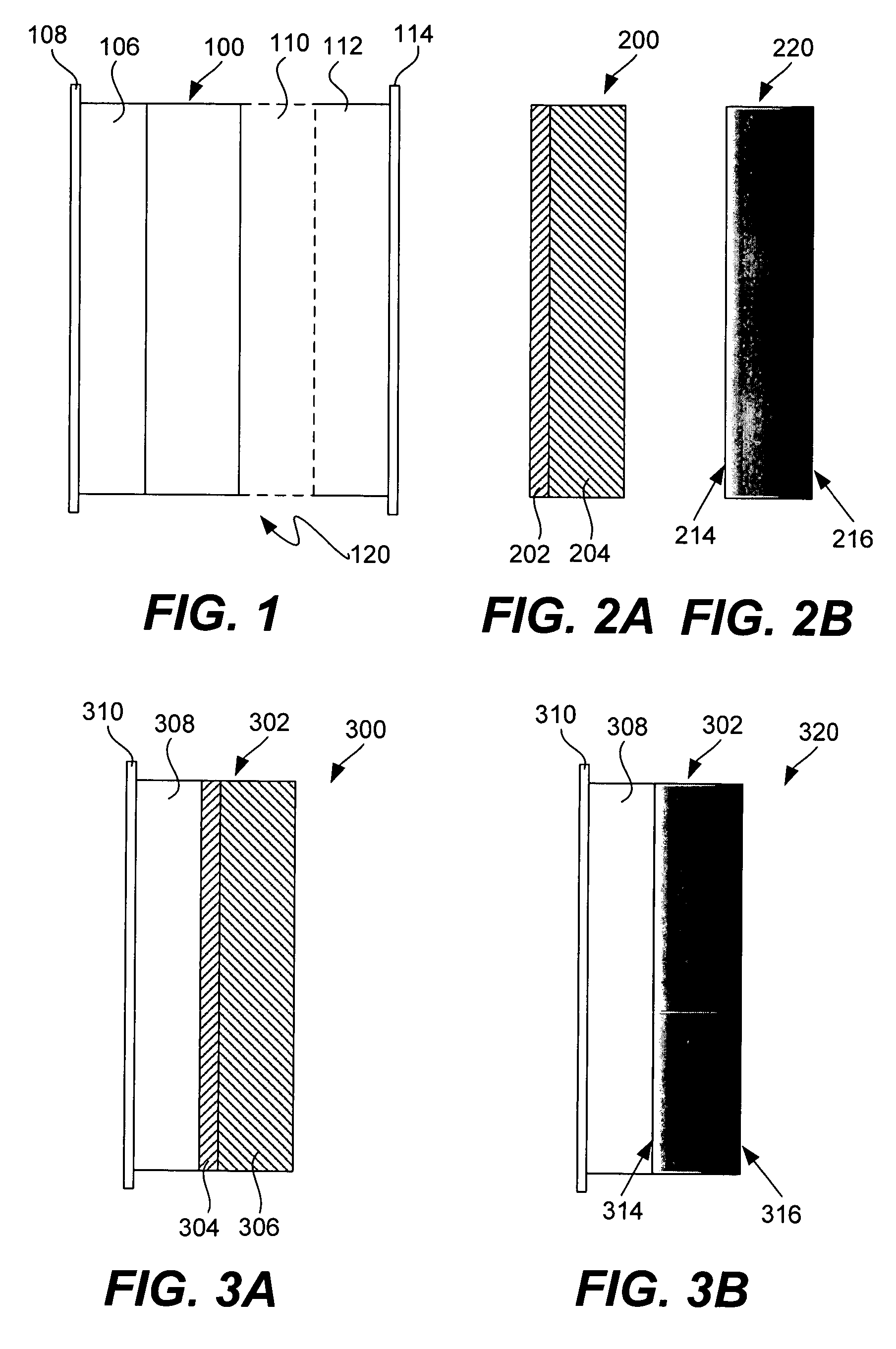

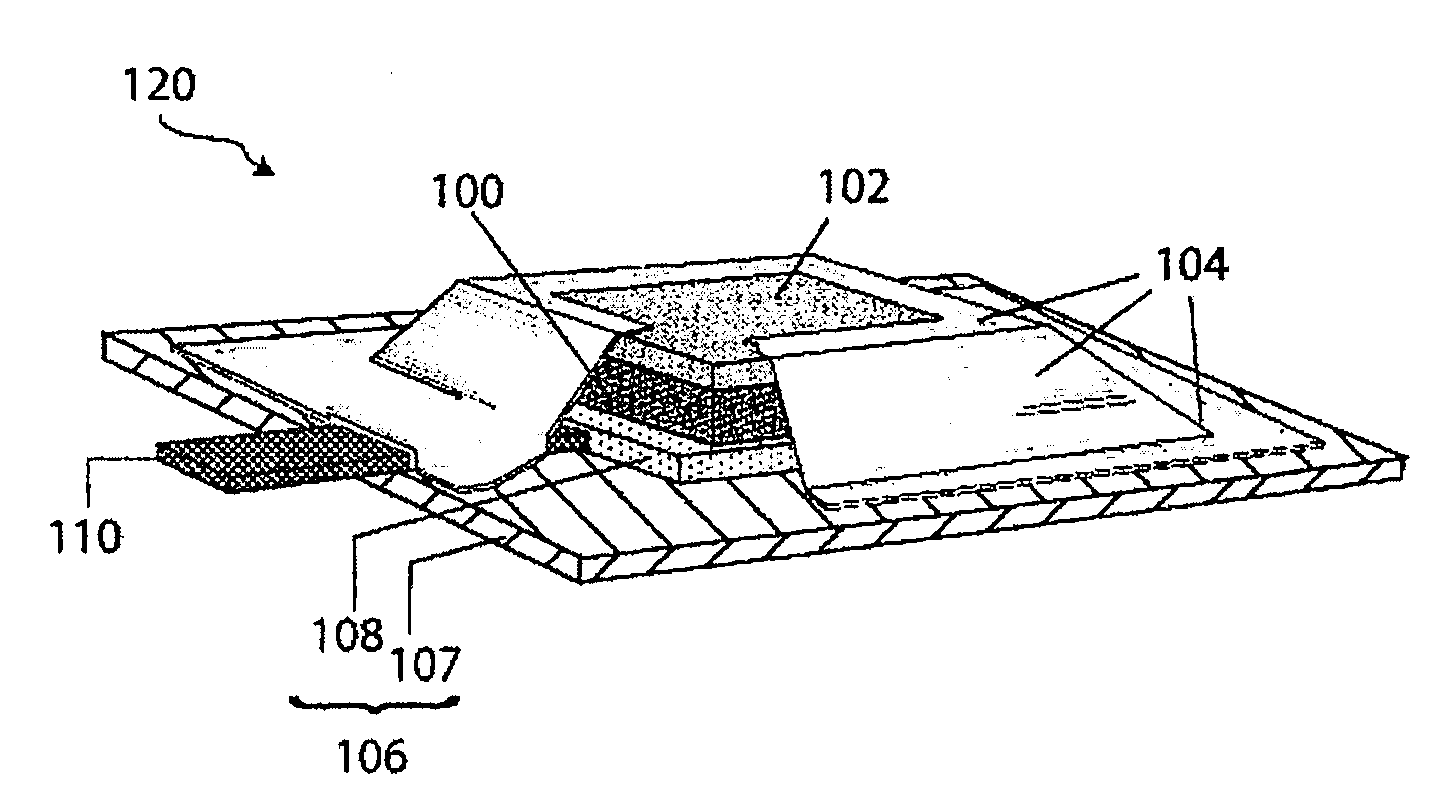

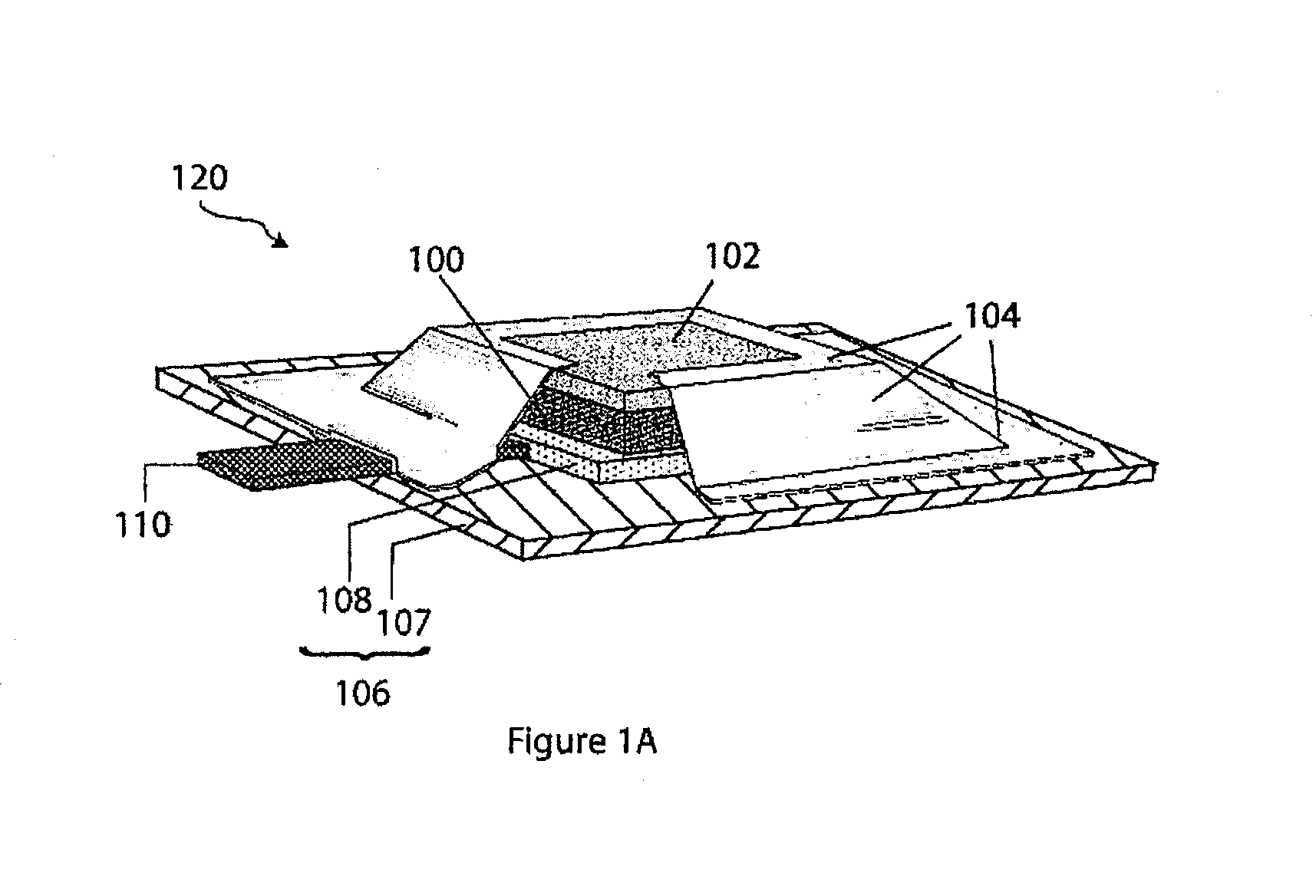

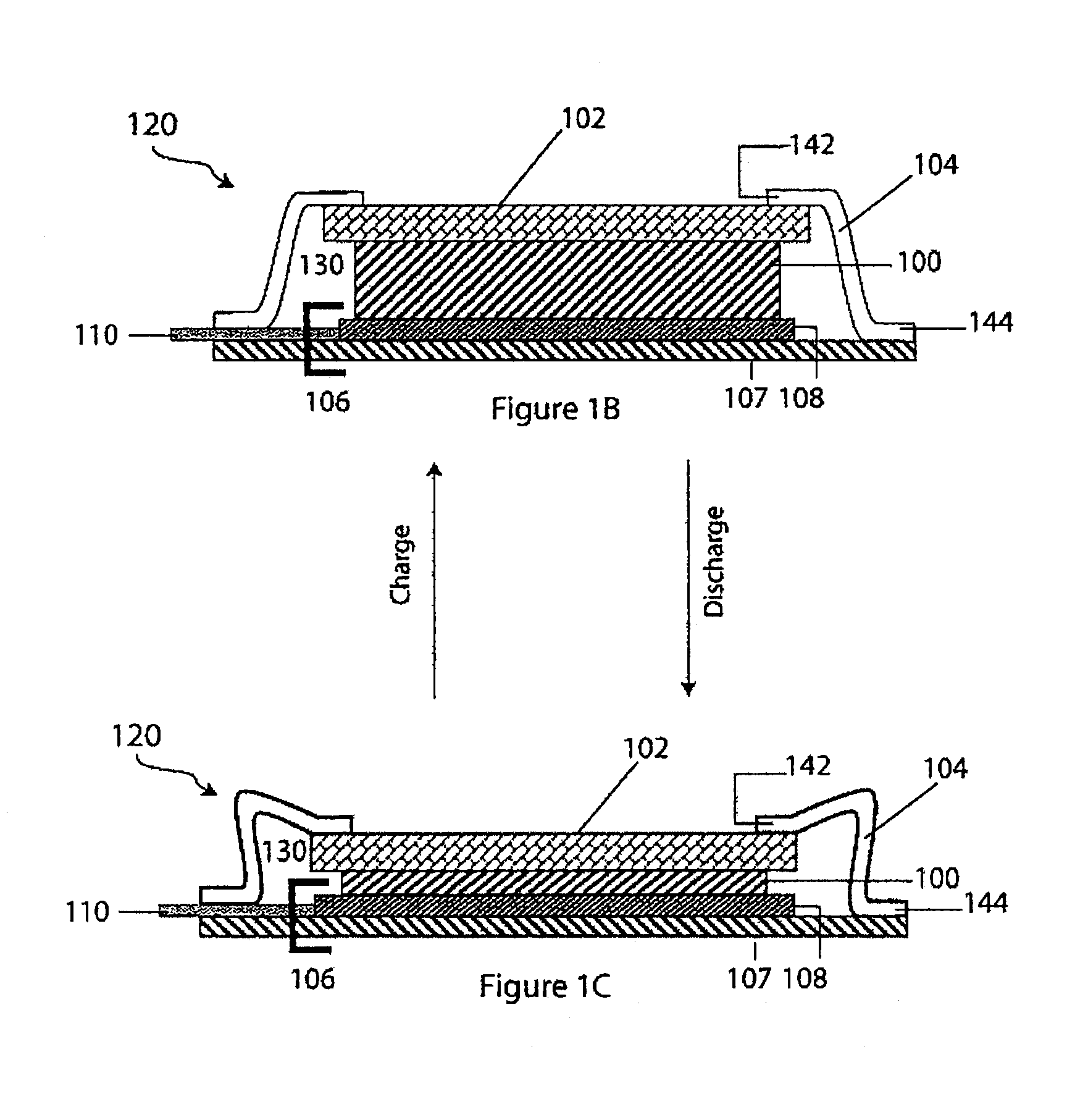

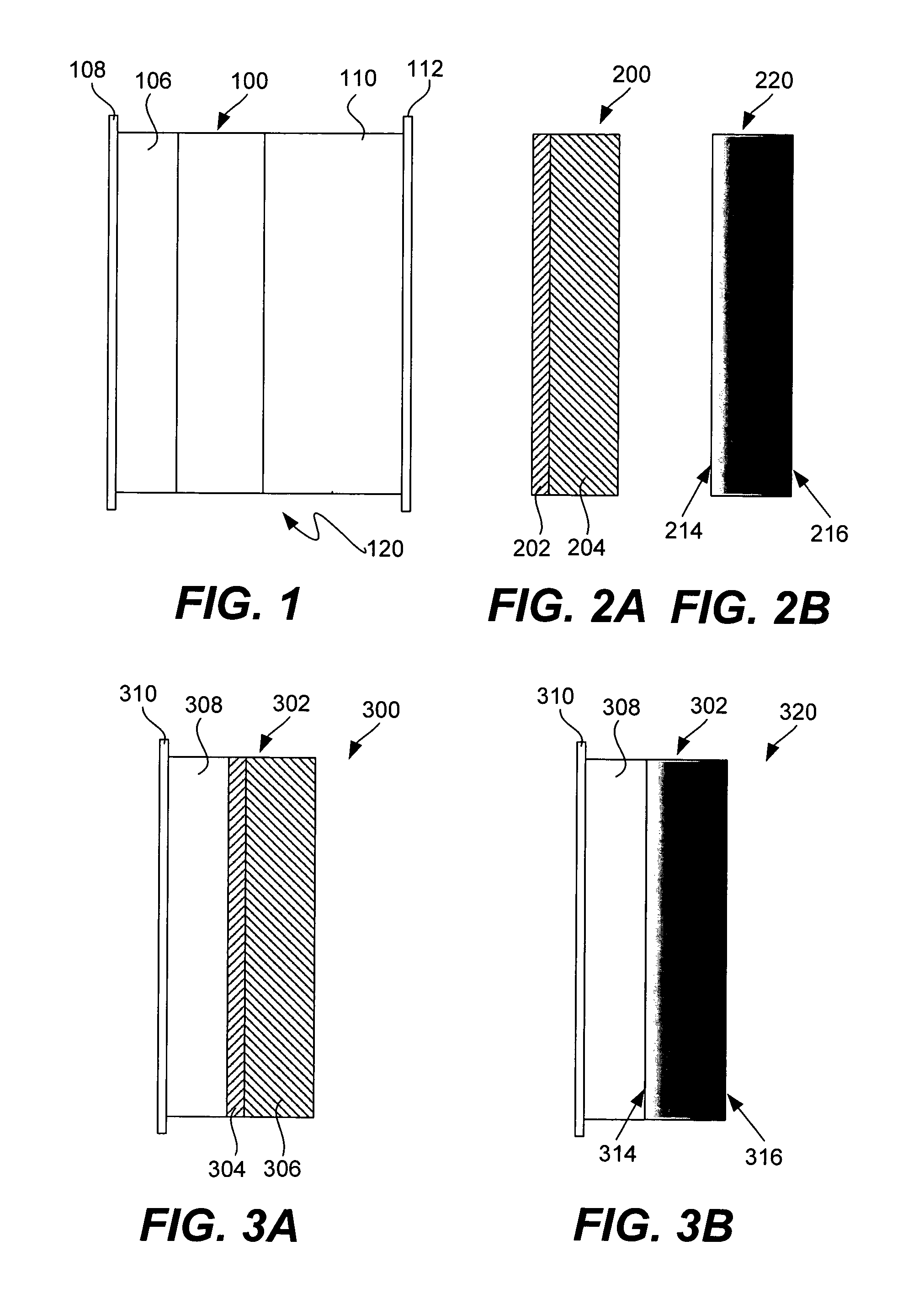

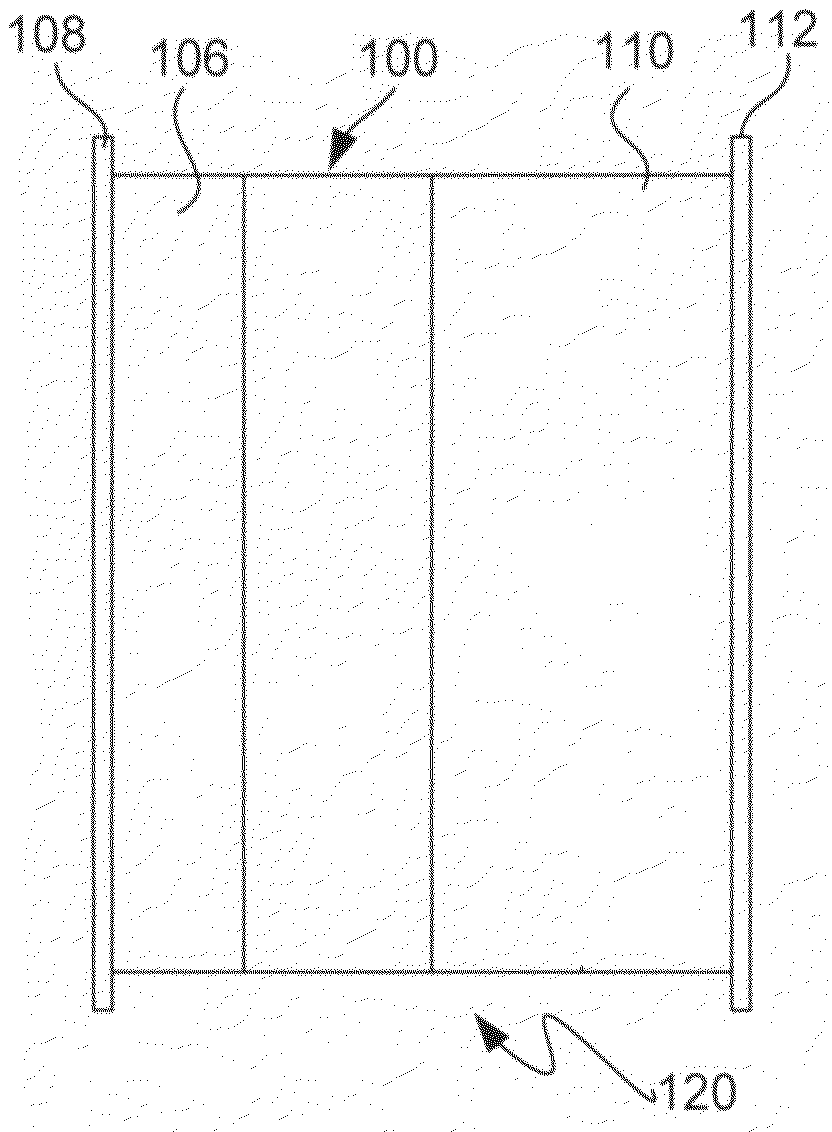

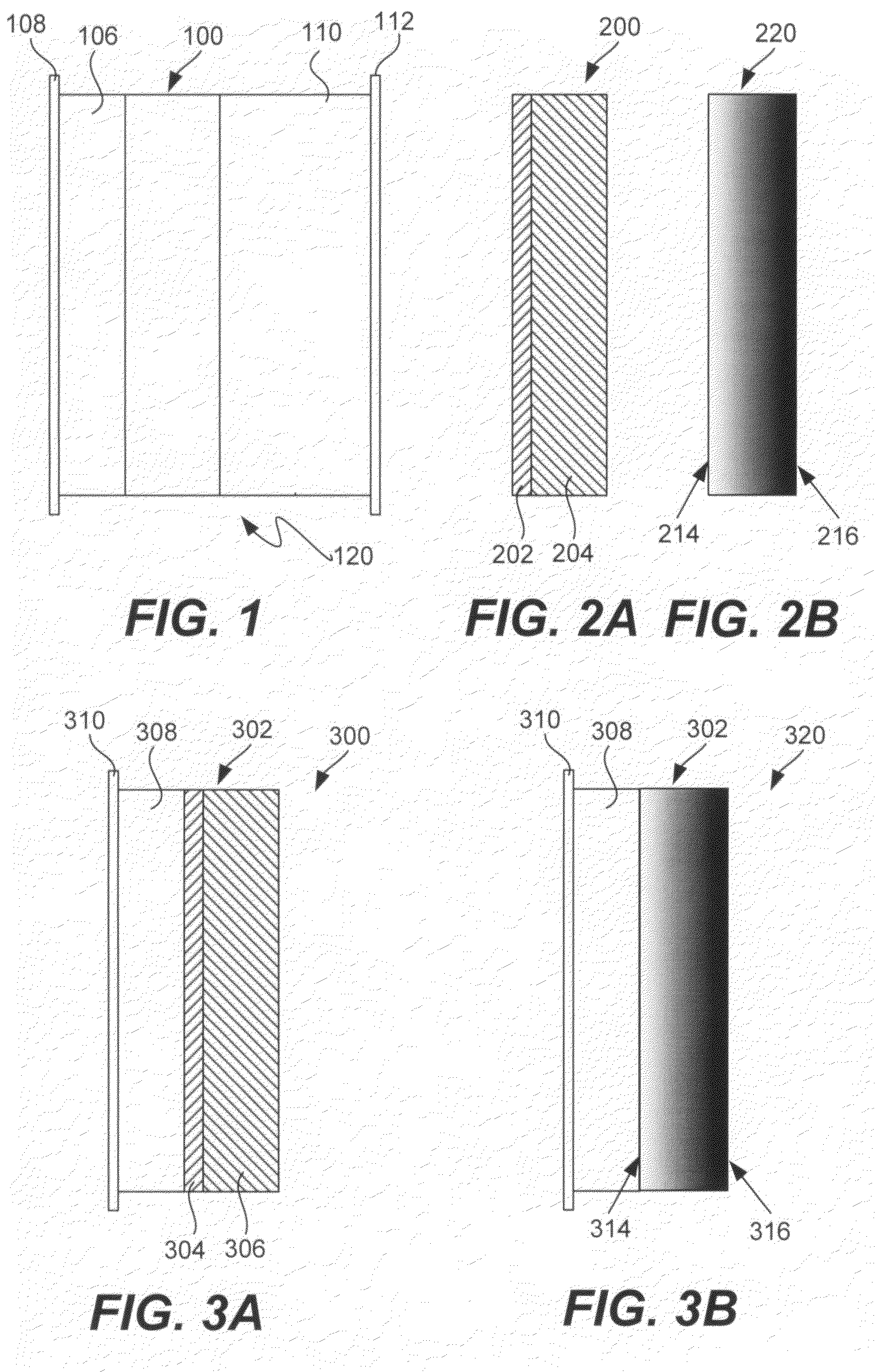

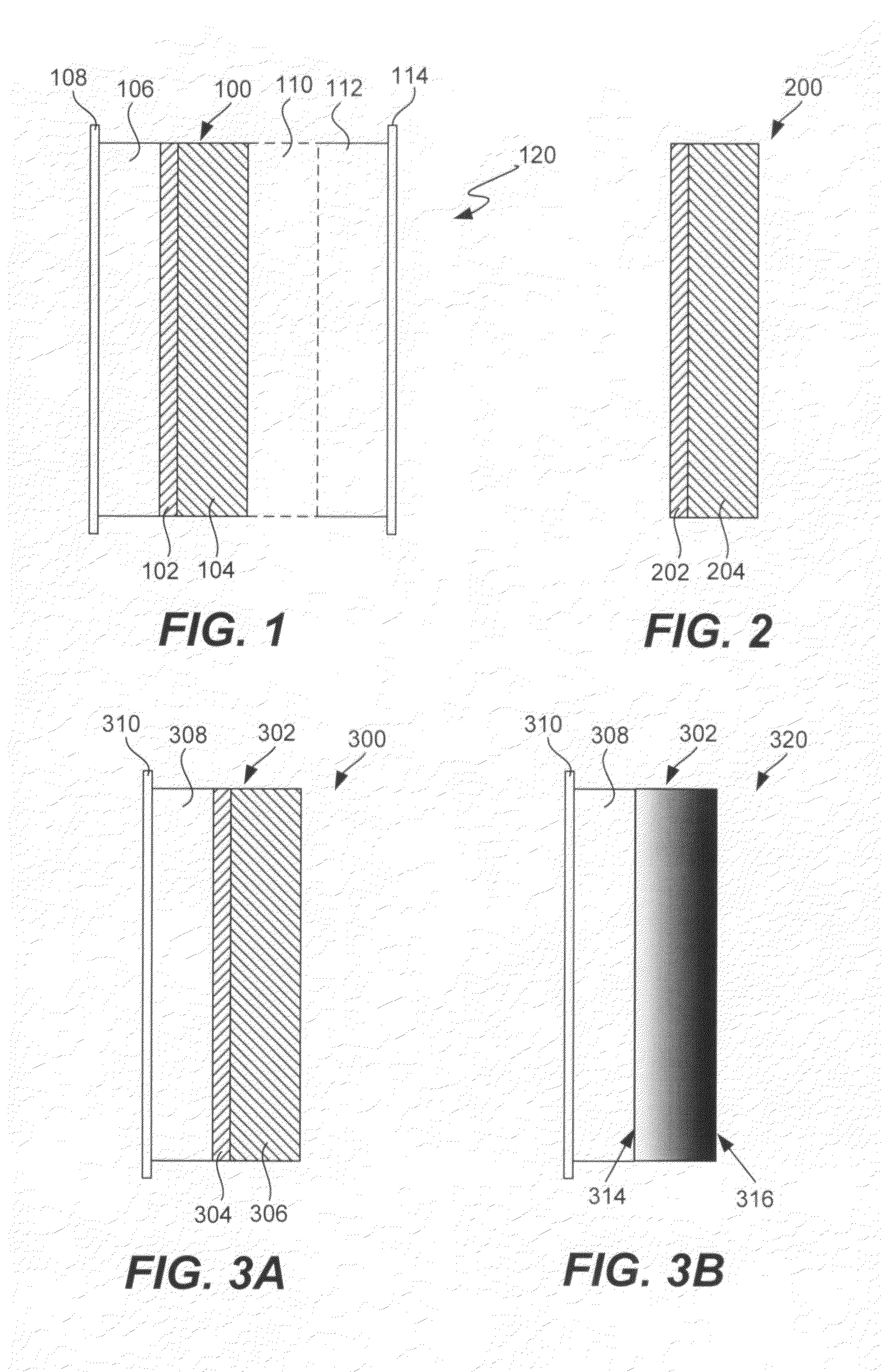

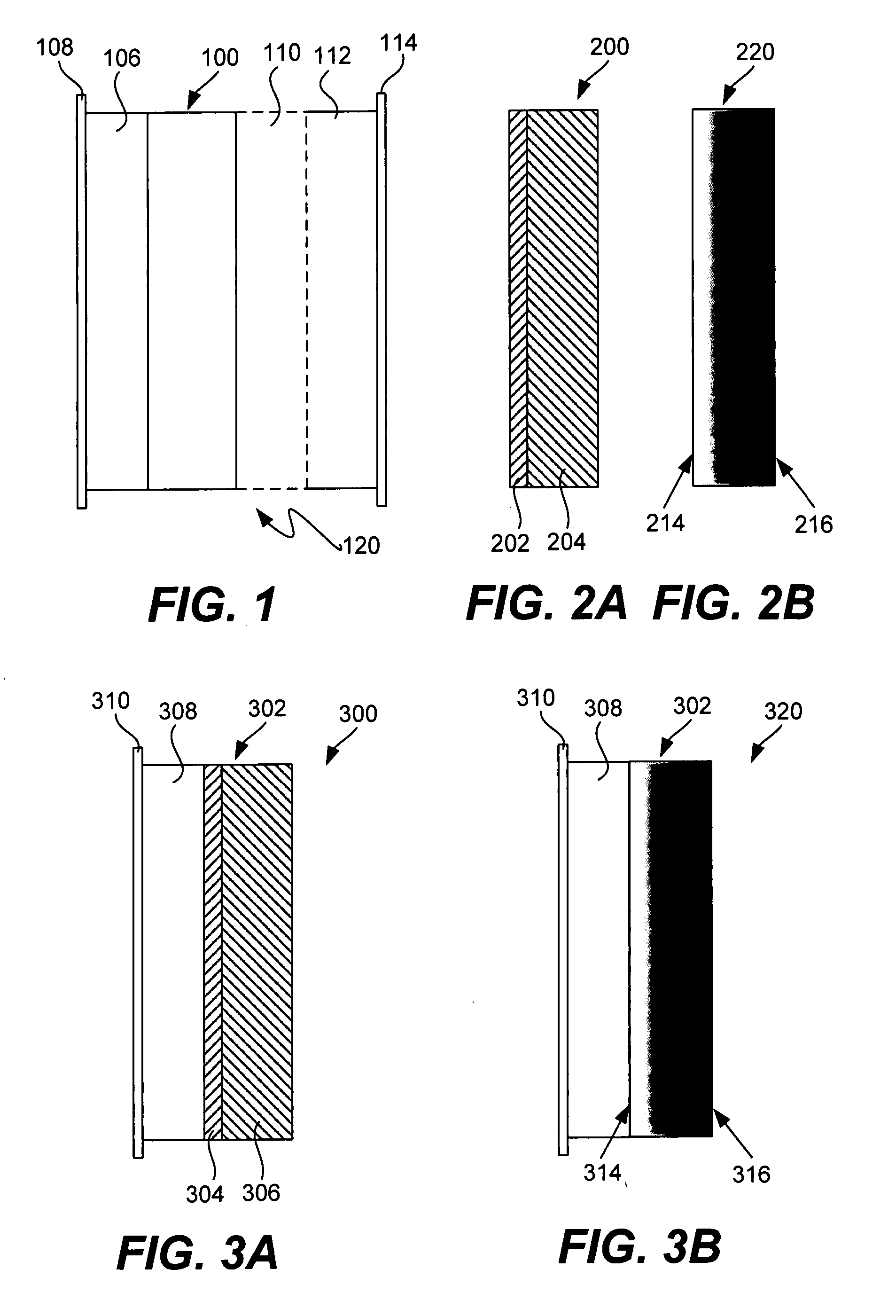

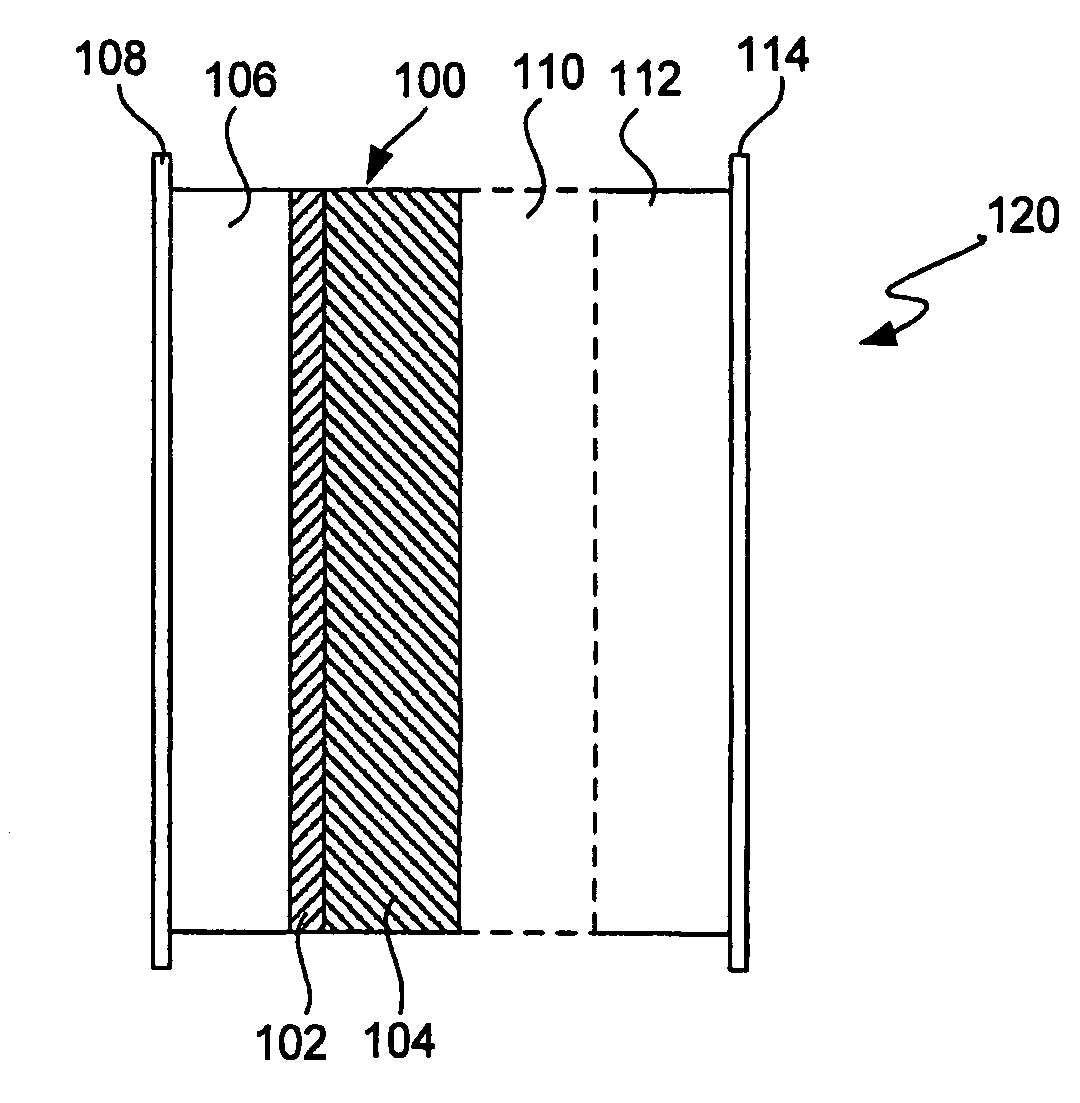

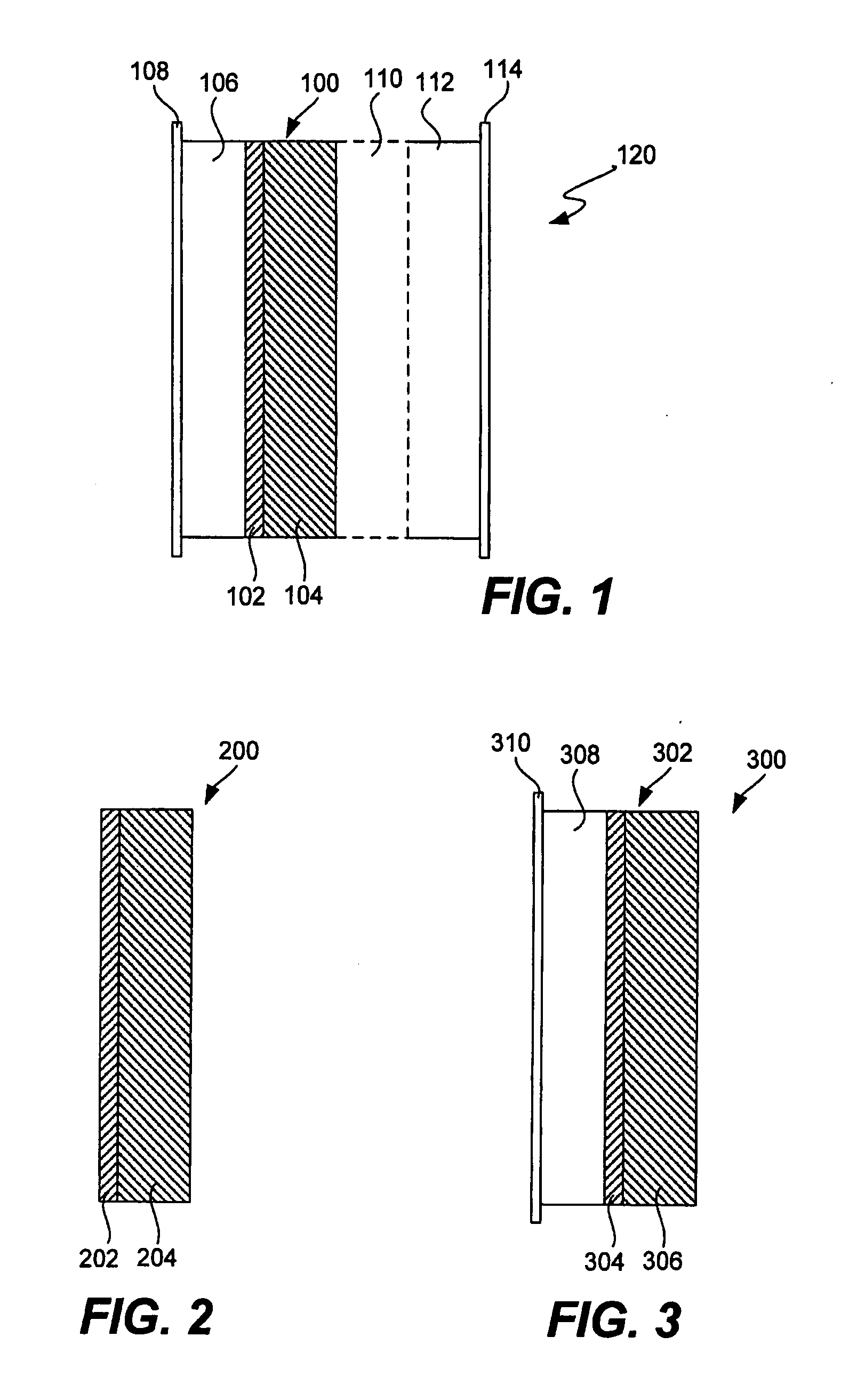

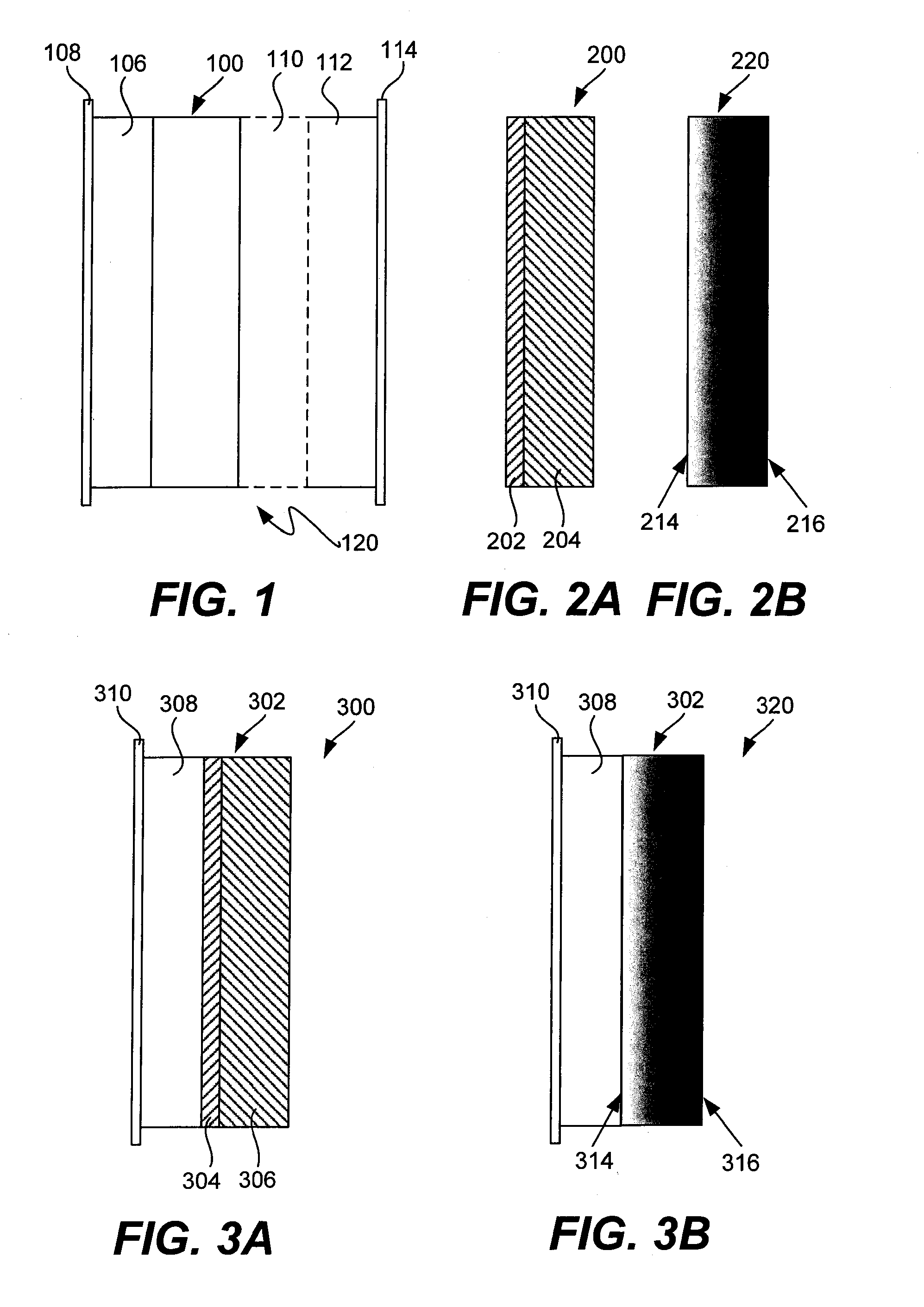

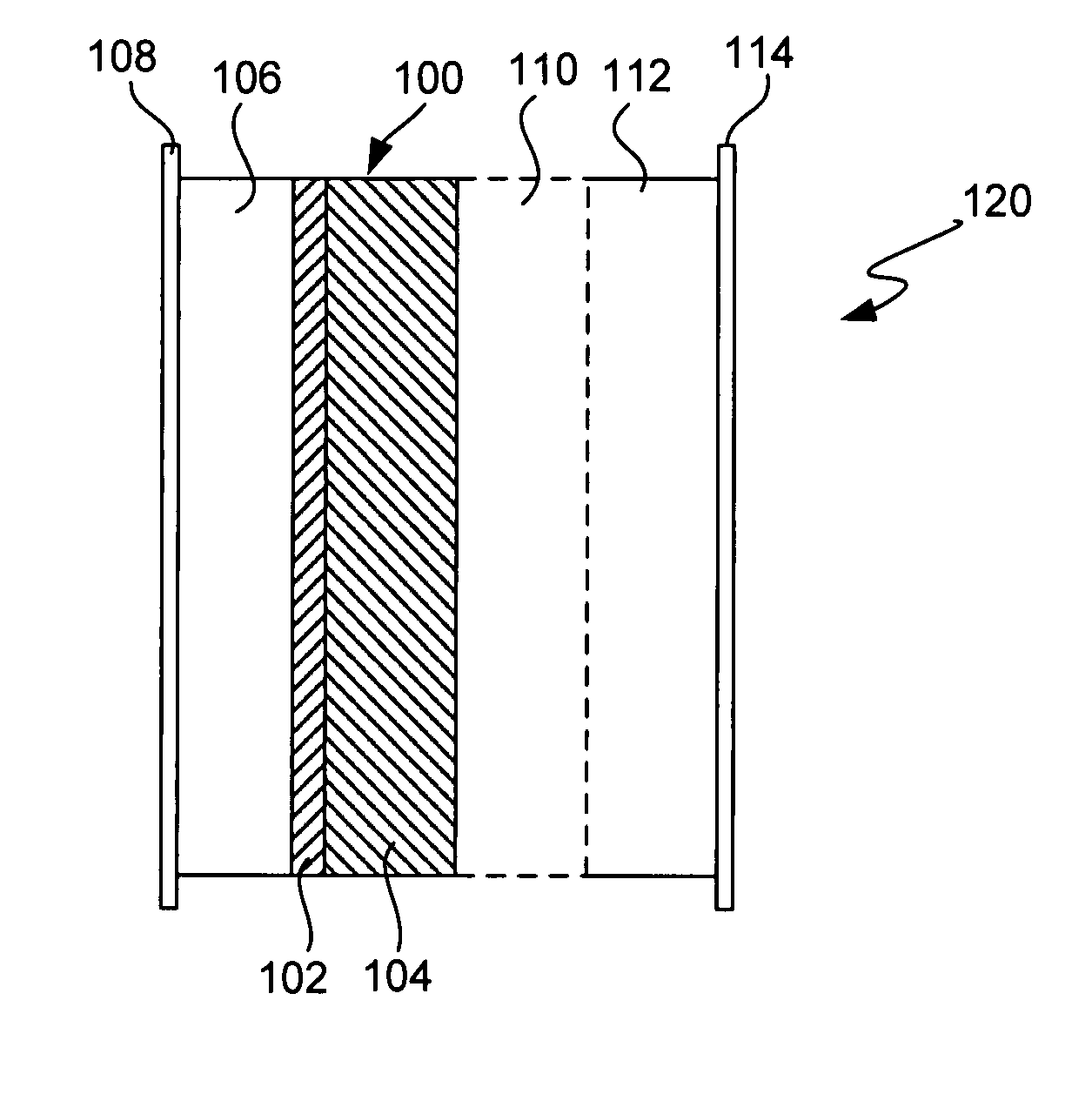

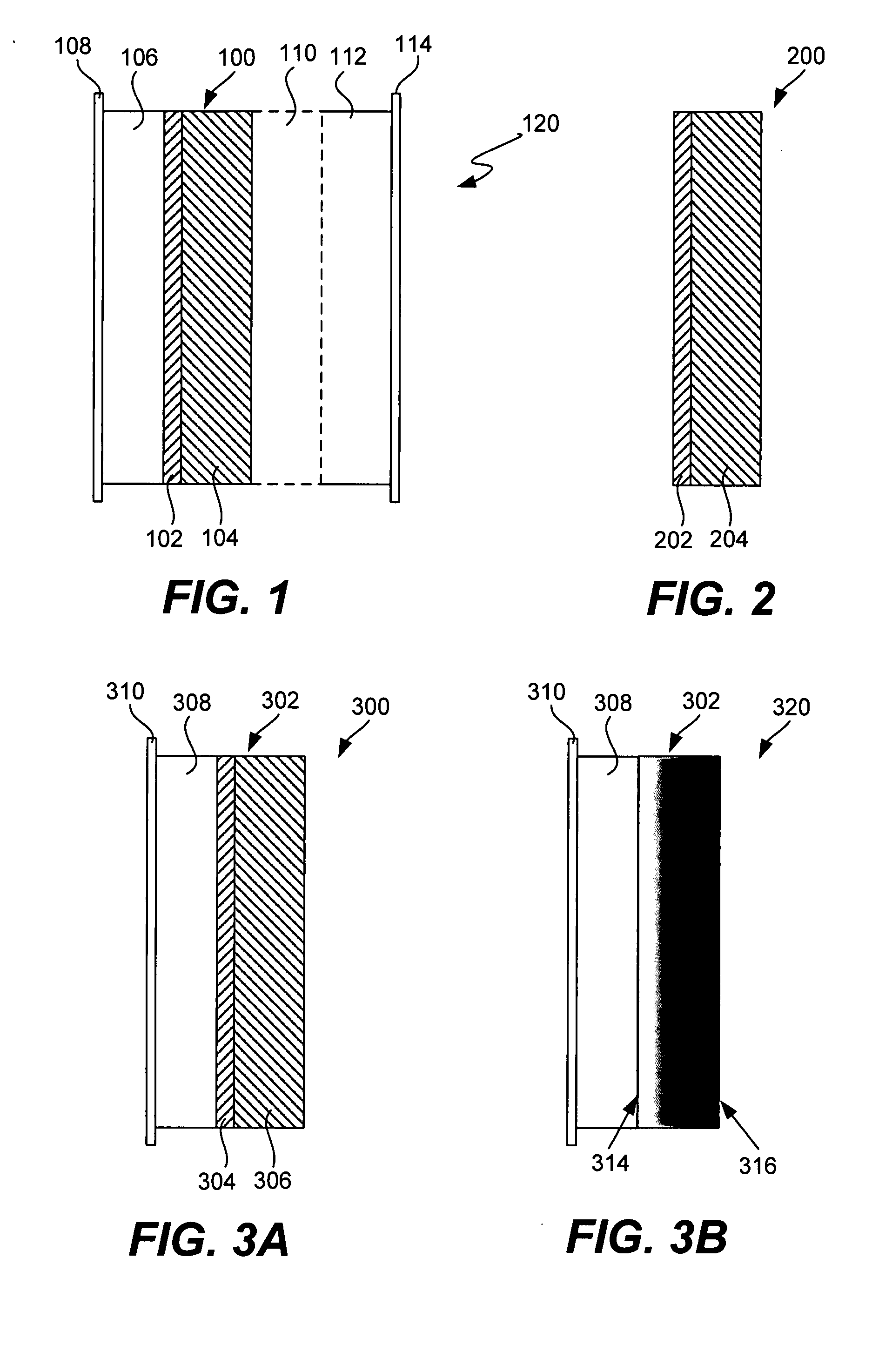

Compliant seal structures for protected active metal anodes

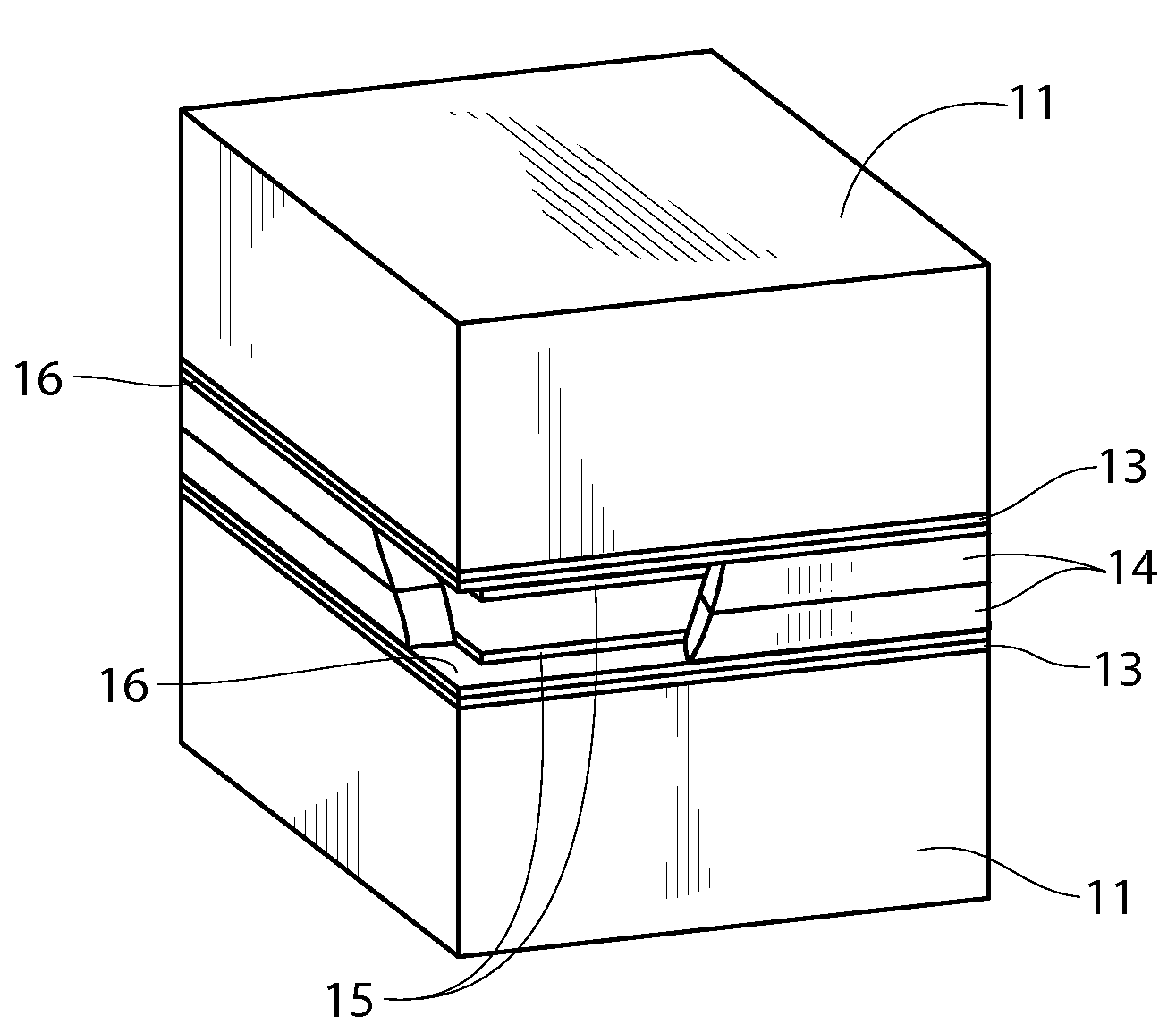

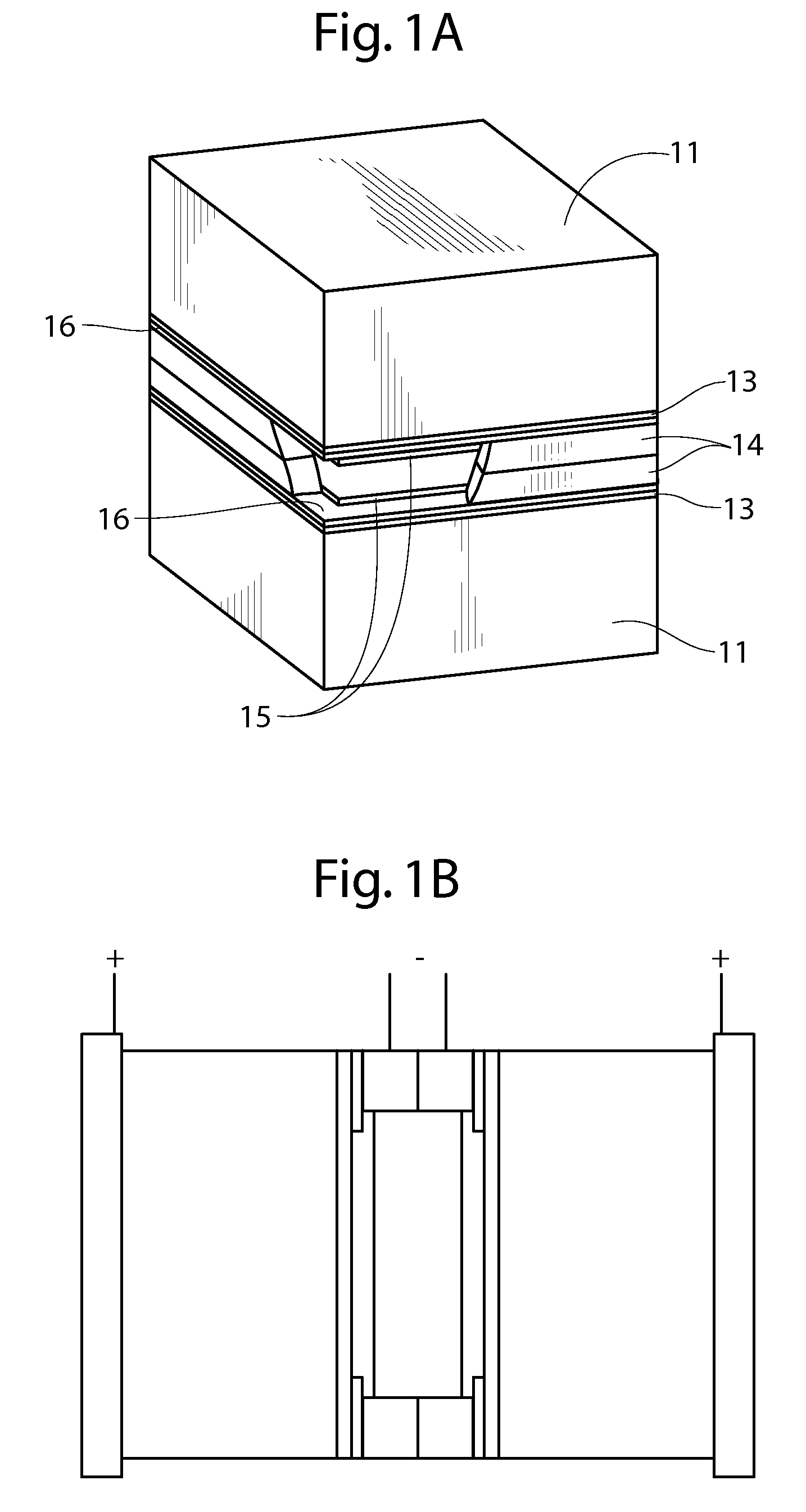

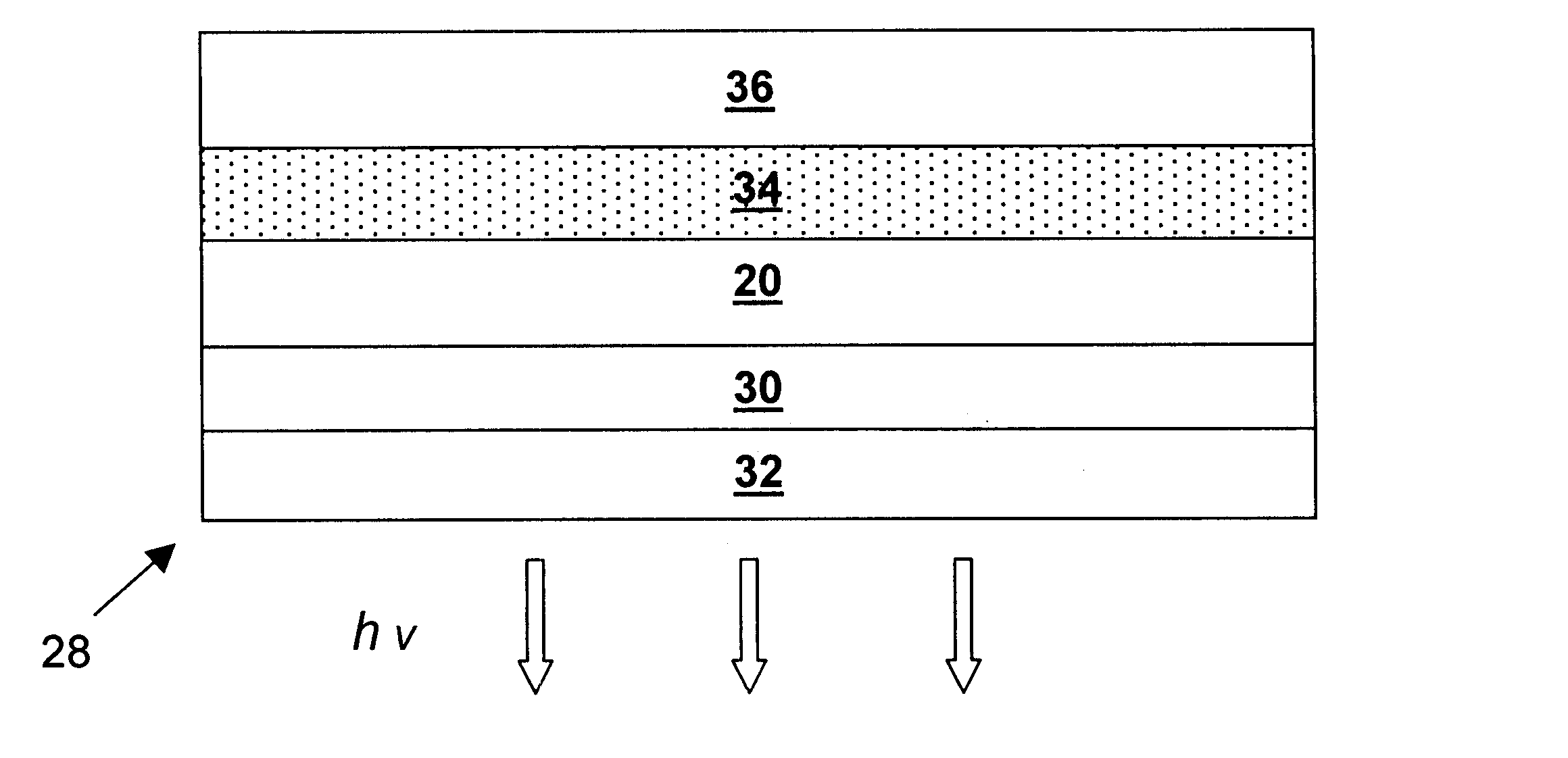

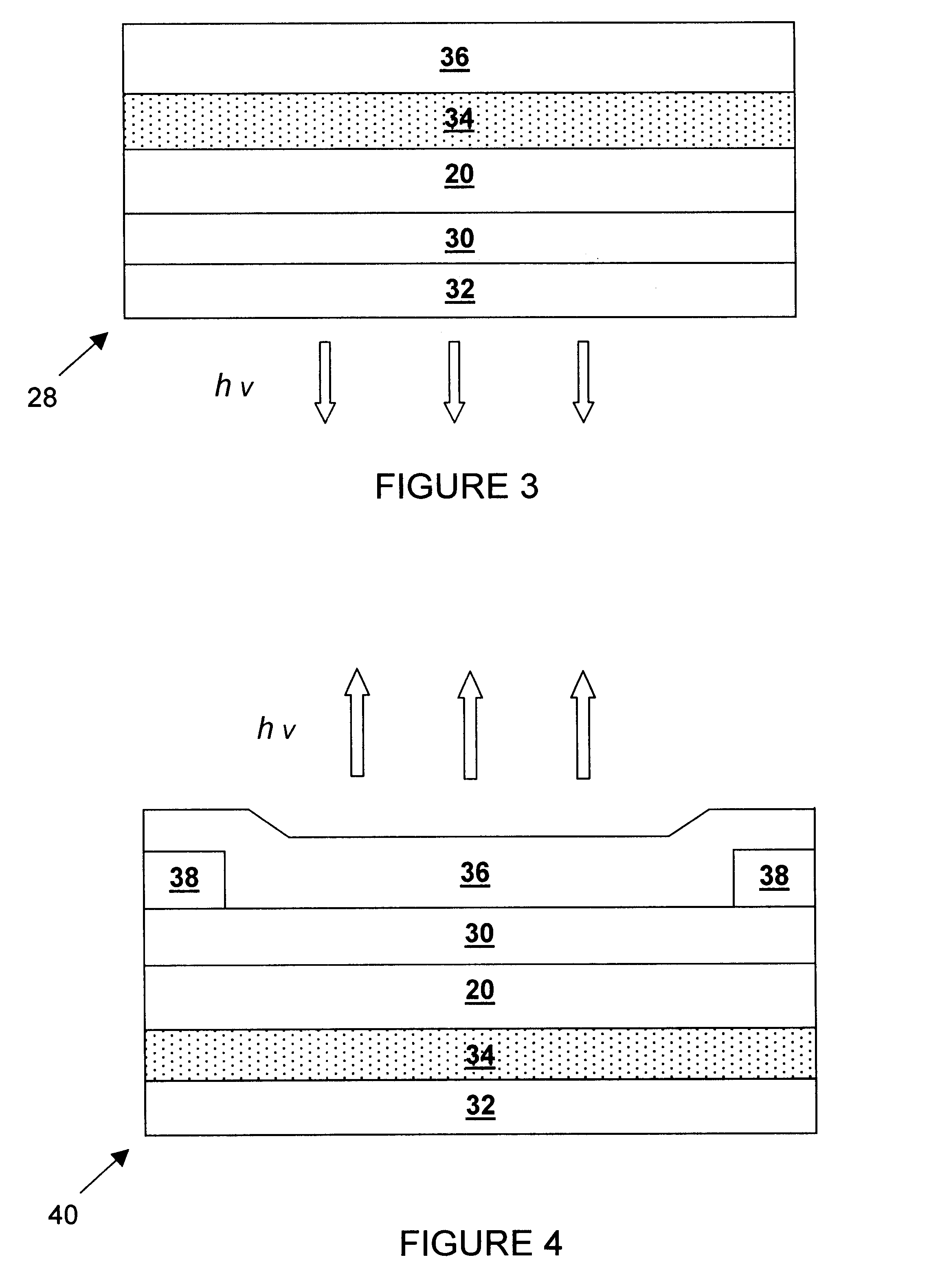

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

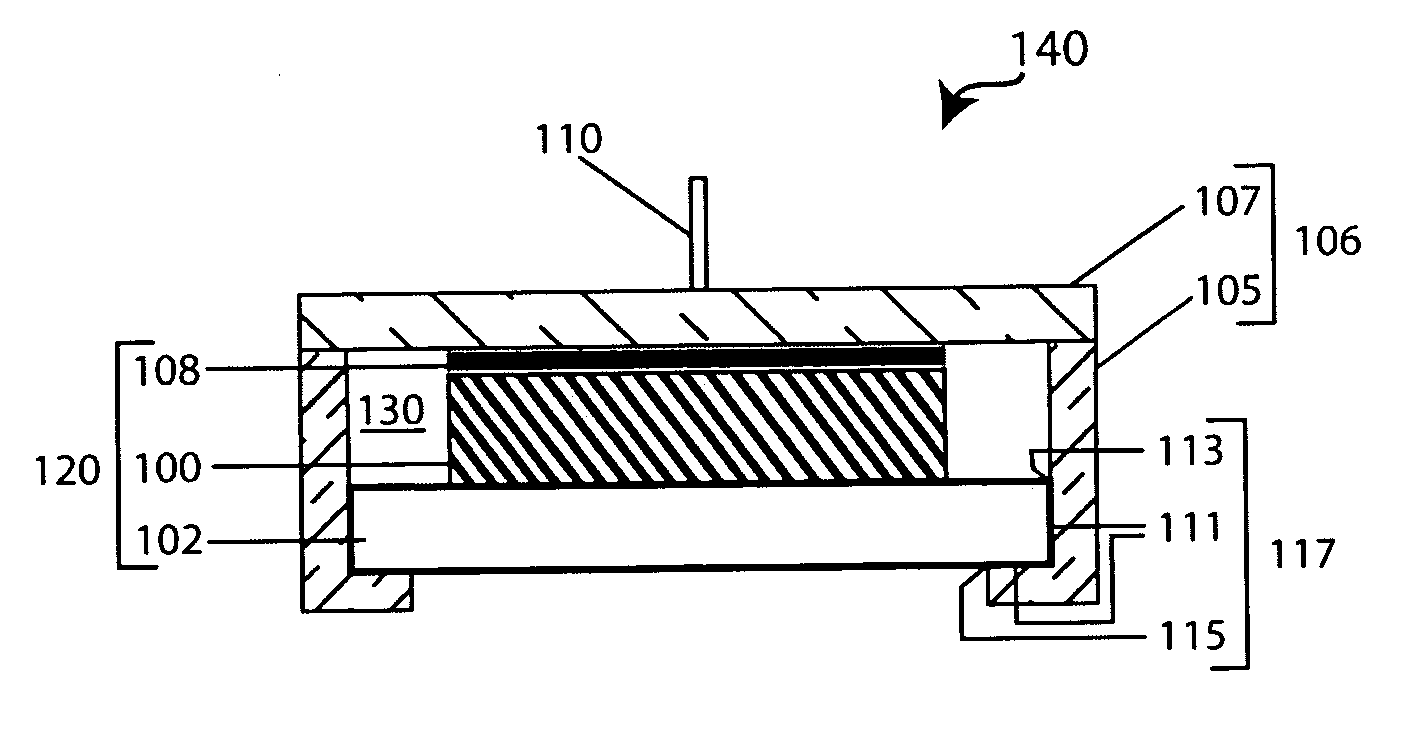

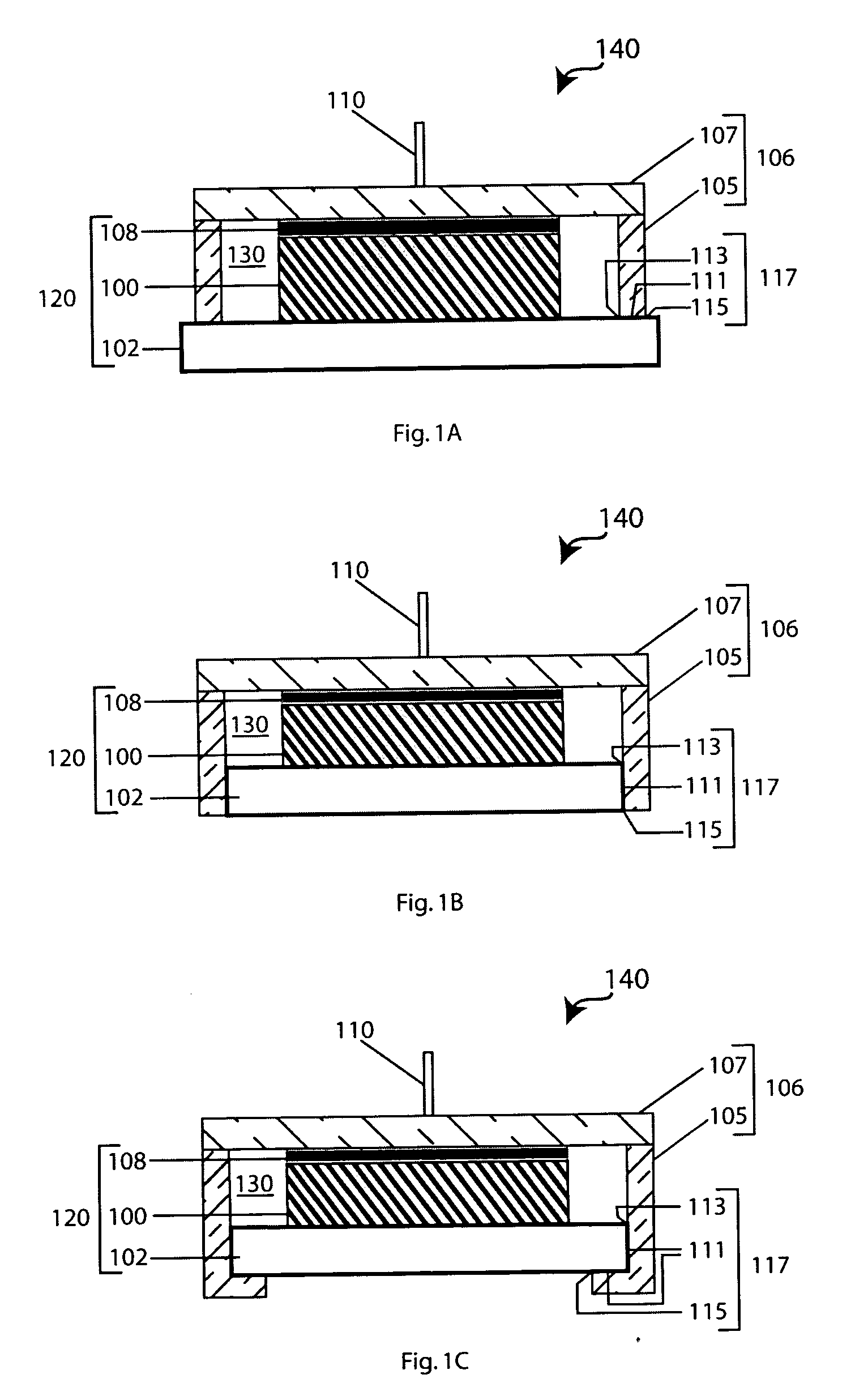

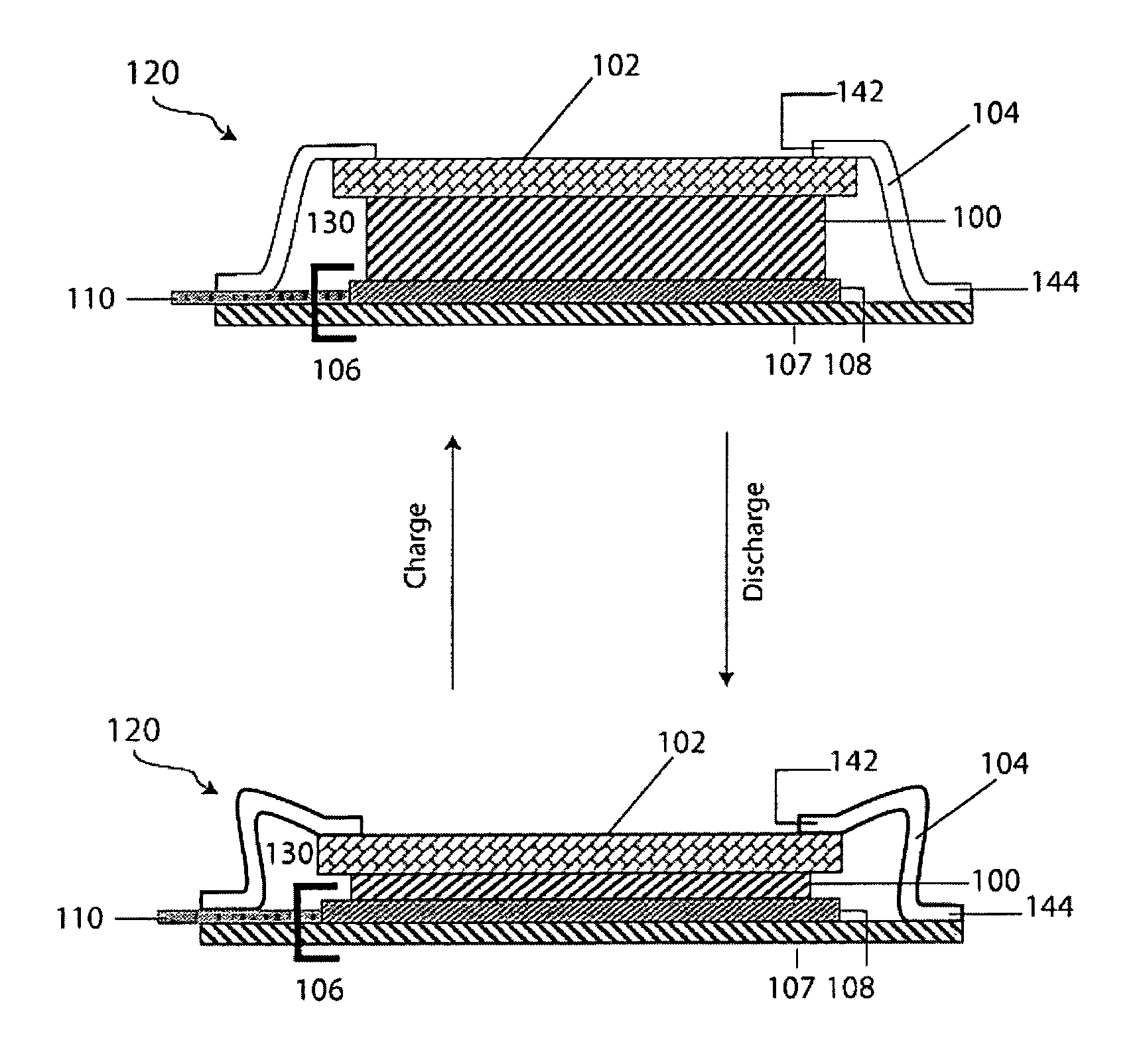

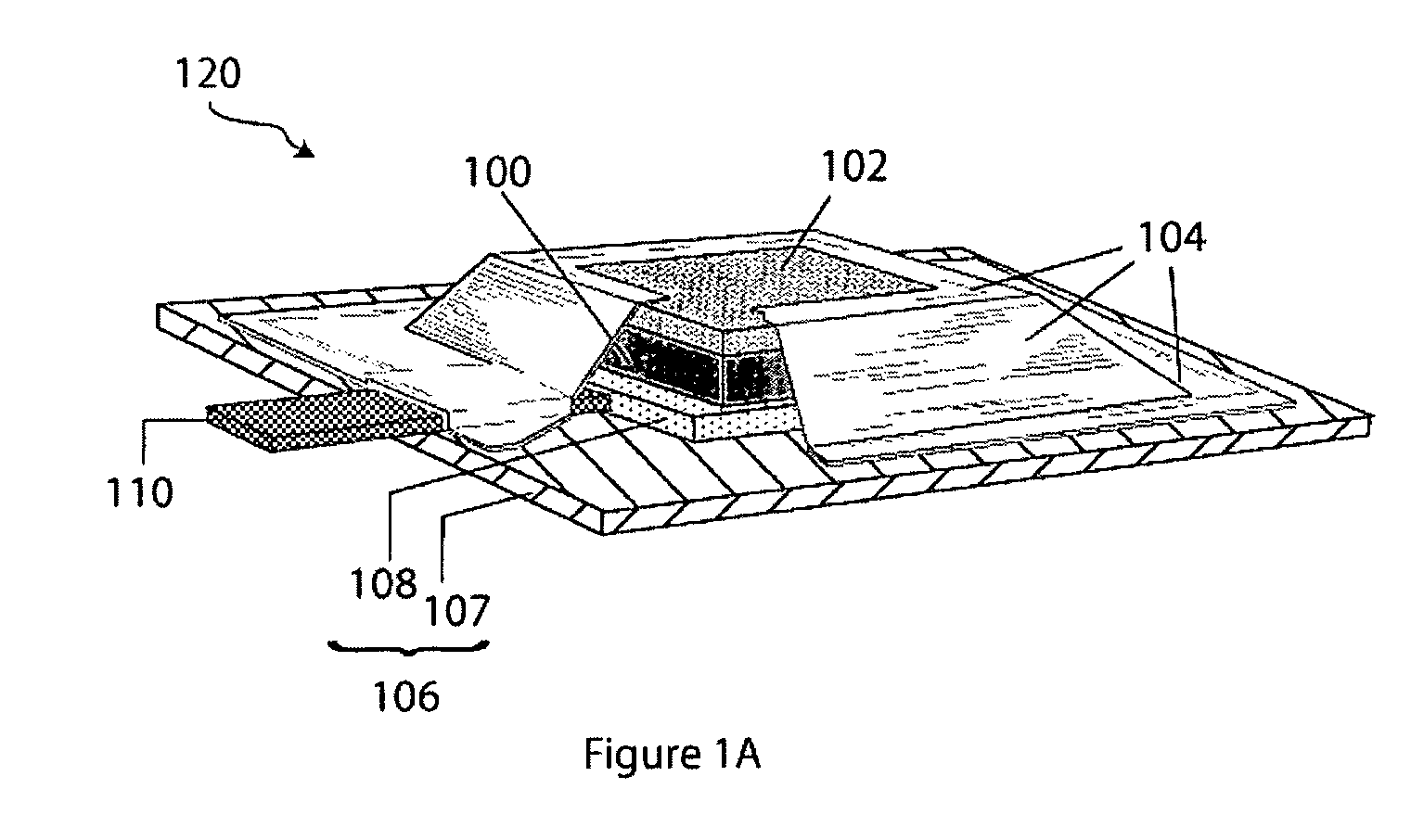

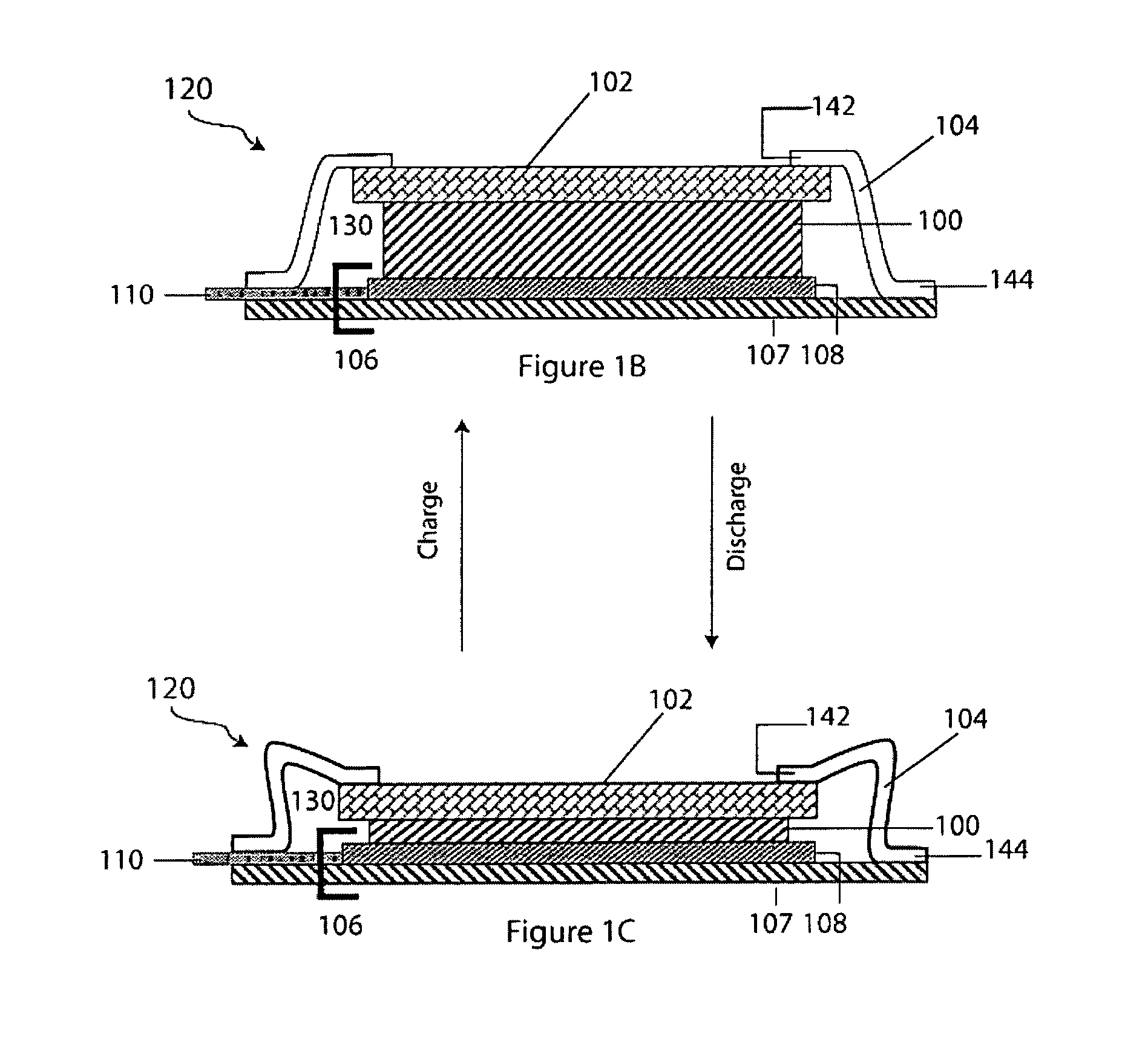

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Ionically conductive composites for protection of active metal anodes

ActiveUS7282302B2Good chemical stabilityImprove ionic conductivitySolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityBattery cell

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

Ionically conductive membranes for protection of active metal anodes and battery cells

InactiveUS7390591B2Improve conductivityEasy to manufactureSolid electrolytesSolid electrolyte cellsChemical stabilityBattery cell

Disclosed are ionically conductive membranes for protection of active metal anodes and methods for their fabrication. The membranes may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the membrane has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The membrane is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the membrane is incorporated.

Owner:POLYPLUS BATTERY CO INC

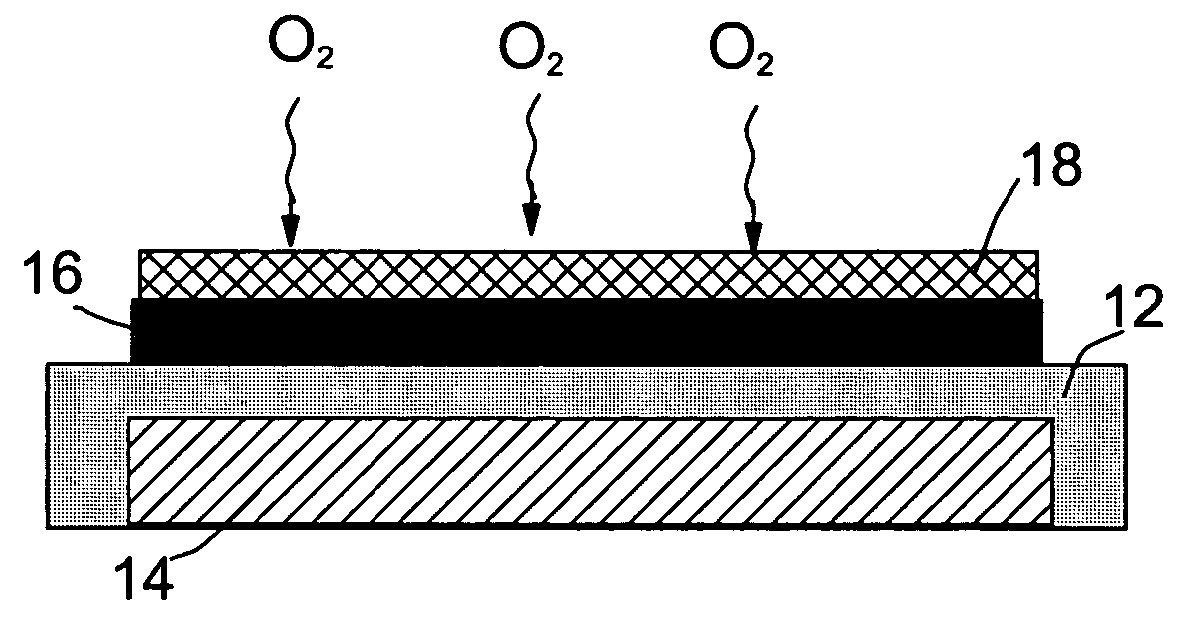

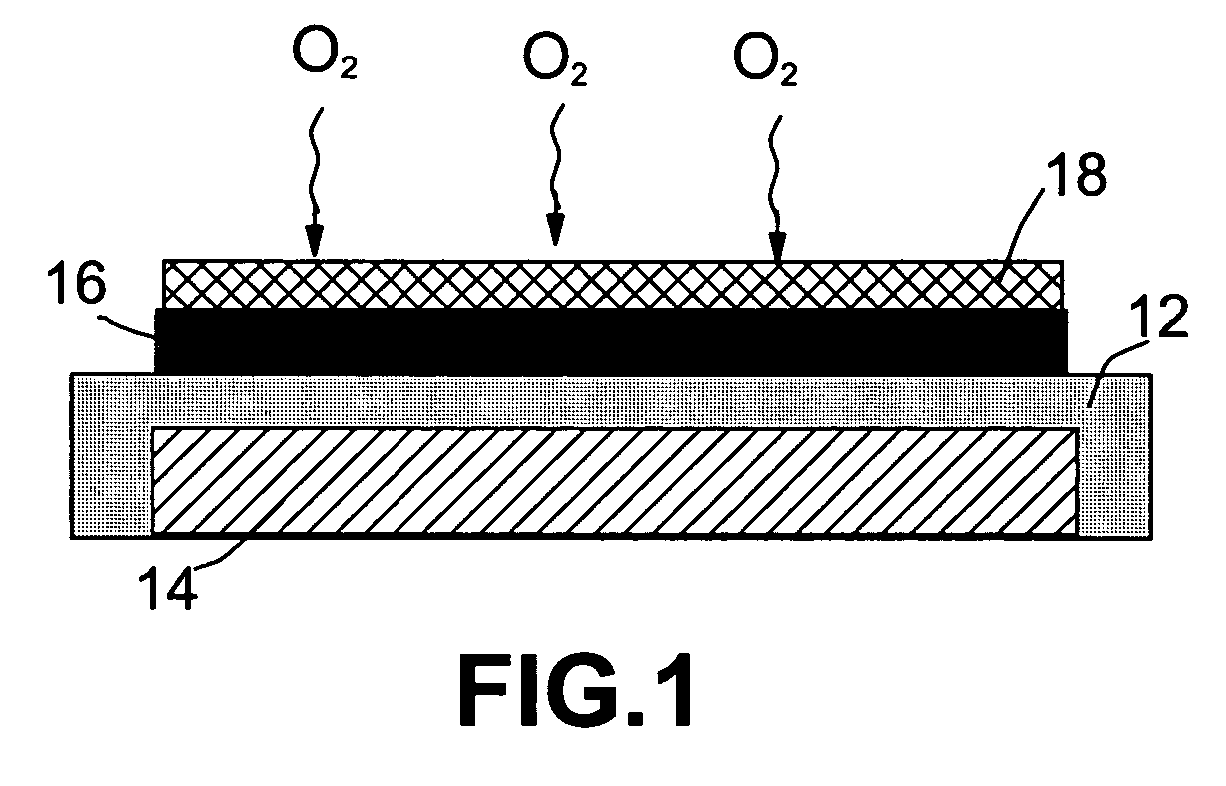

Metal-air battery with ion-conducting inorganic glass electrolyte

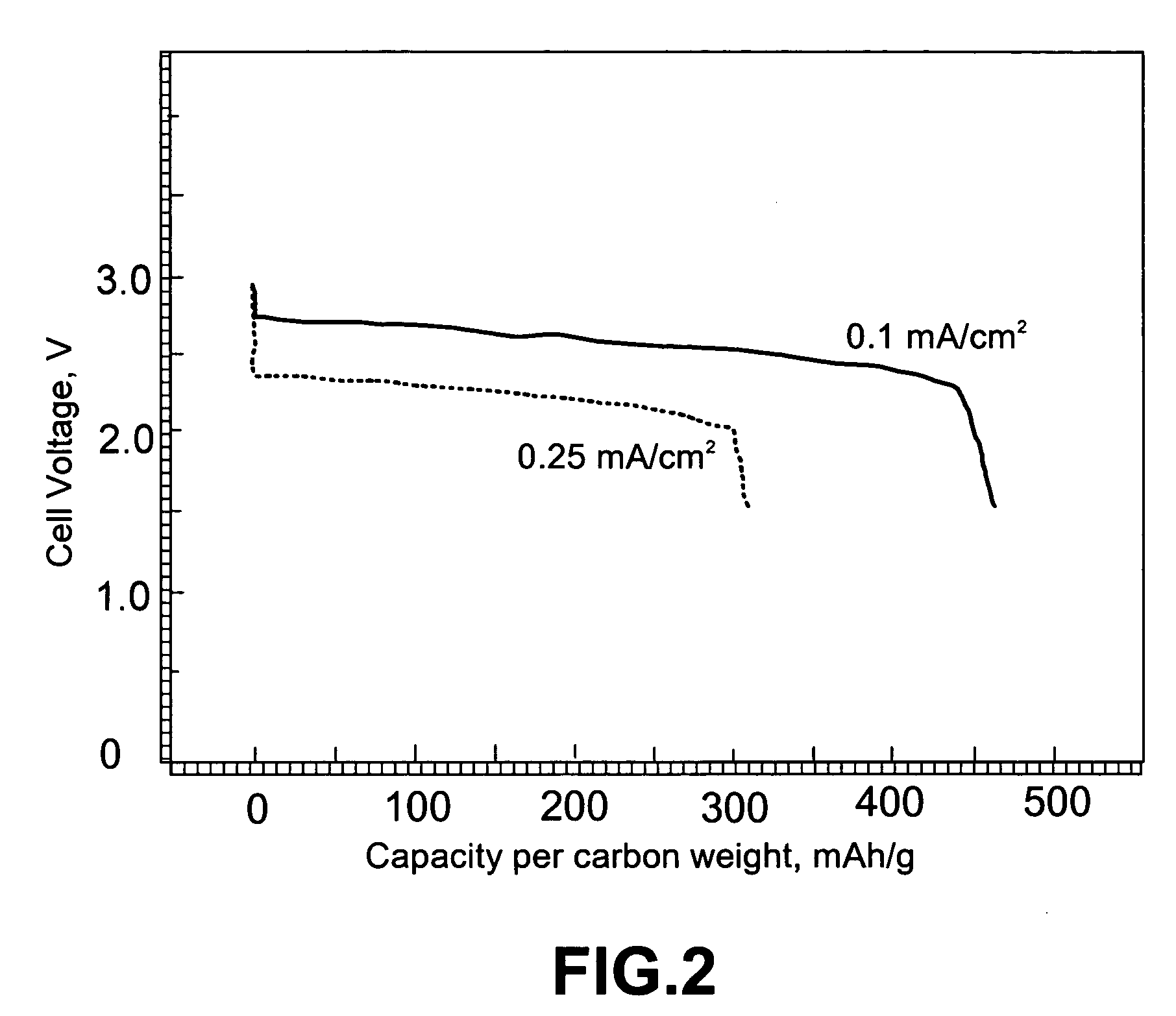

InactiveUS20060063051A1Safe and reliable solid-stateIncrease energy densityFuel and primary cellsSolid electrolytesMetal–air electrochemical cellIonic conductivity

A solid-state metal-air electrochemical cell comprising: (A) a metal-containing electro-active anode; (B) an oxygen electro-active cathode; and (C) an ion-conducting glass electrolyte disposed between the metal-containing anode and the oxygen electro-active cathode. The cathode active material, which is oxygen gas, is not stored in the battery but rather fed from the environment. The oxygen cathode is preferably a composite carbon electrode which serves as the cathode current collector on which oxygen molecules are reduced during discharge of the battery to generate electric current. The glass electrolyte typically has an ion conductivity in the range of 5×10−5 to 2×10−3 S / cm. The electrolyte layer is preferably smaller than 10 μm in thickness and further preferably smaller than 1 μm. The anode metal is preferably lithium or lithium alloy, but may be selected from other elements such as sodium, magnesium, calcium, aluminum and zinc.

Owner:JANG BOR Z

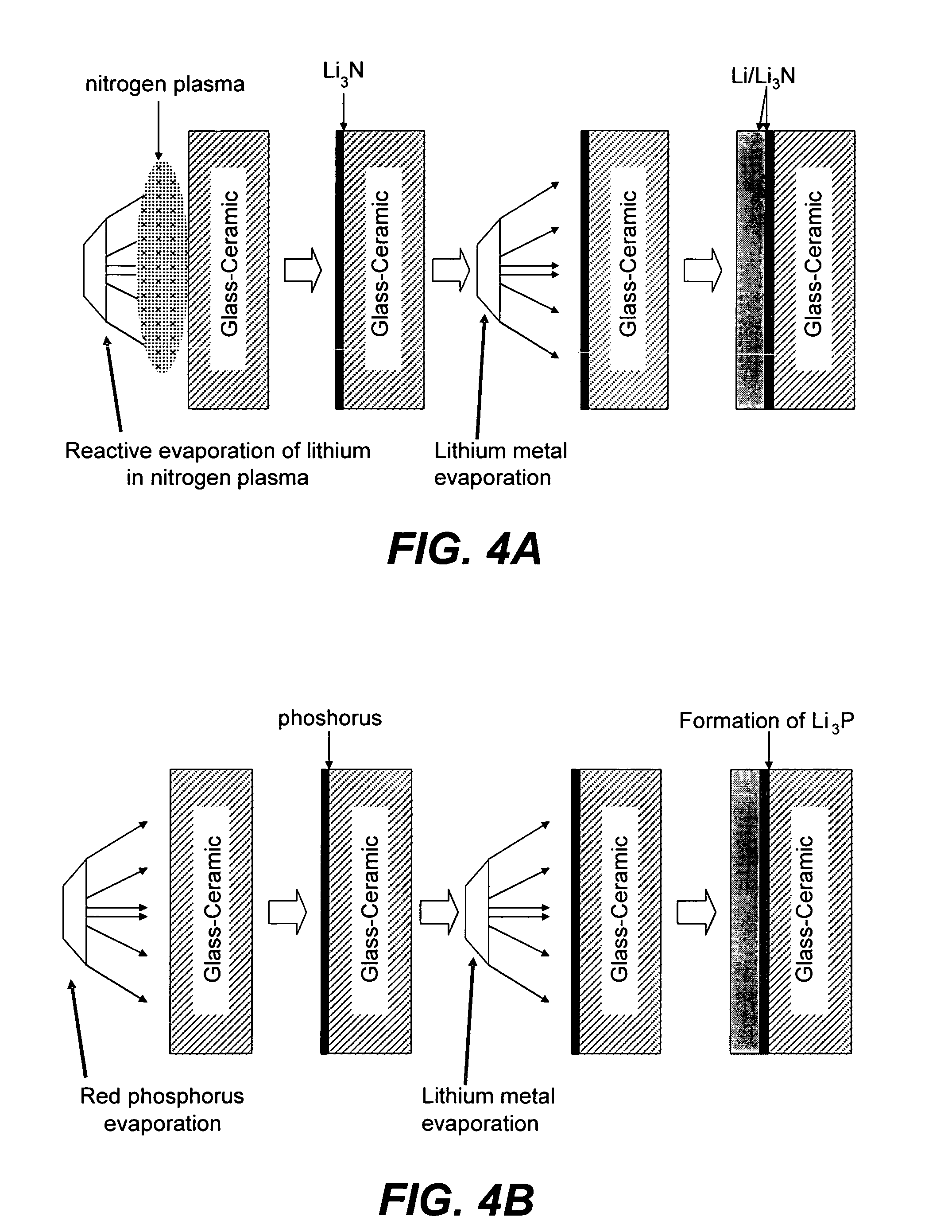

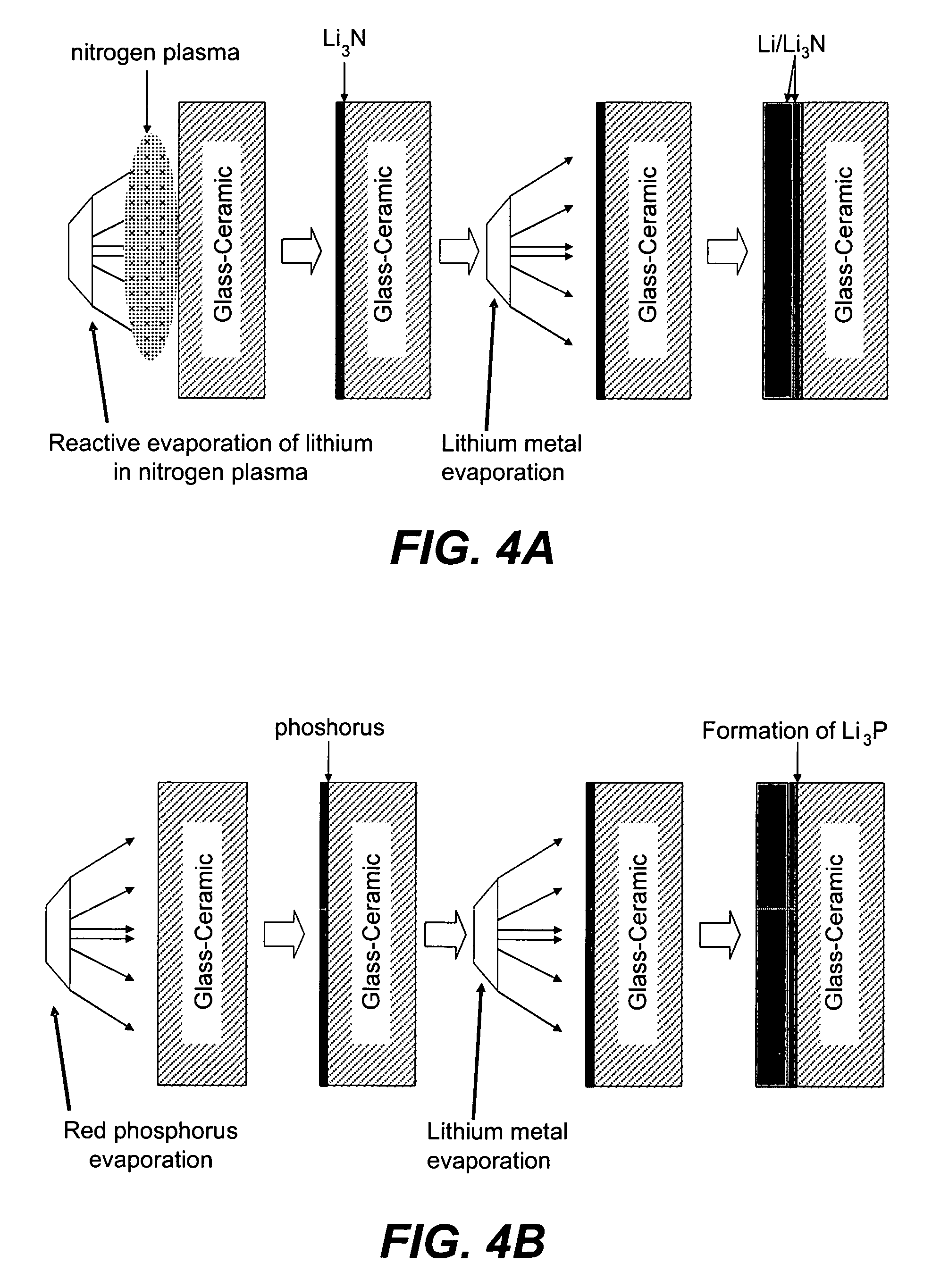

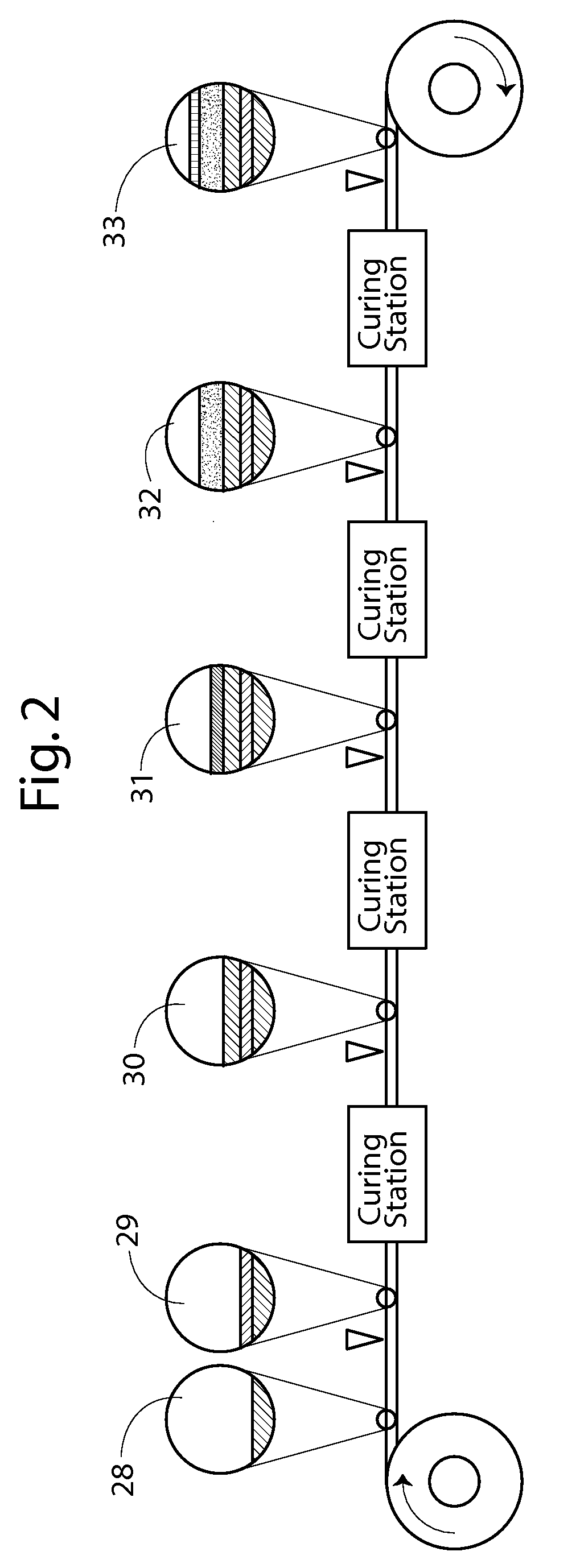

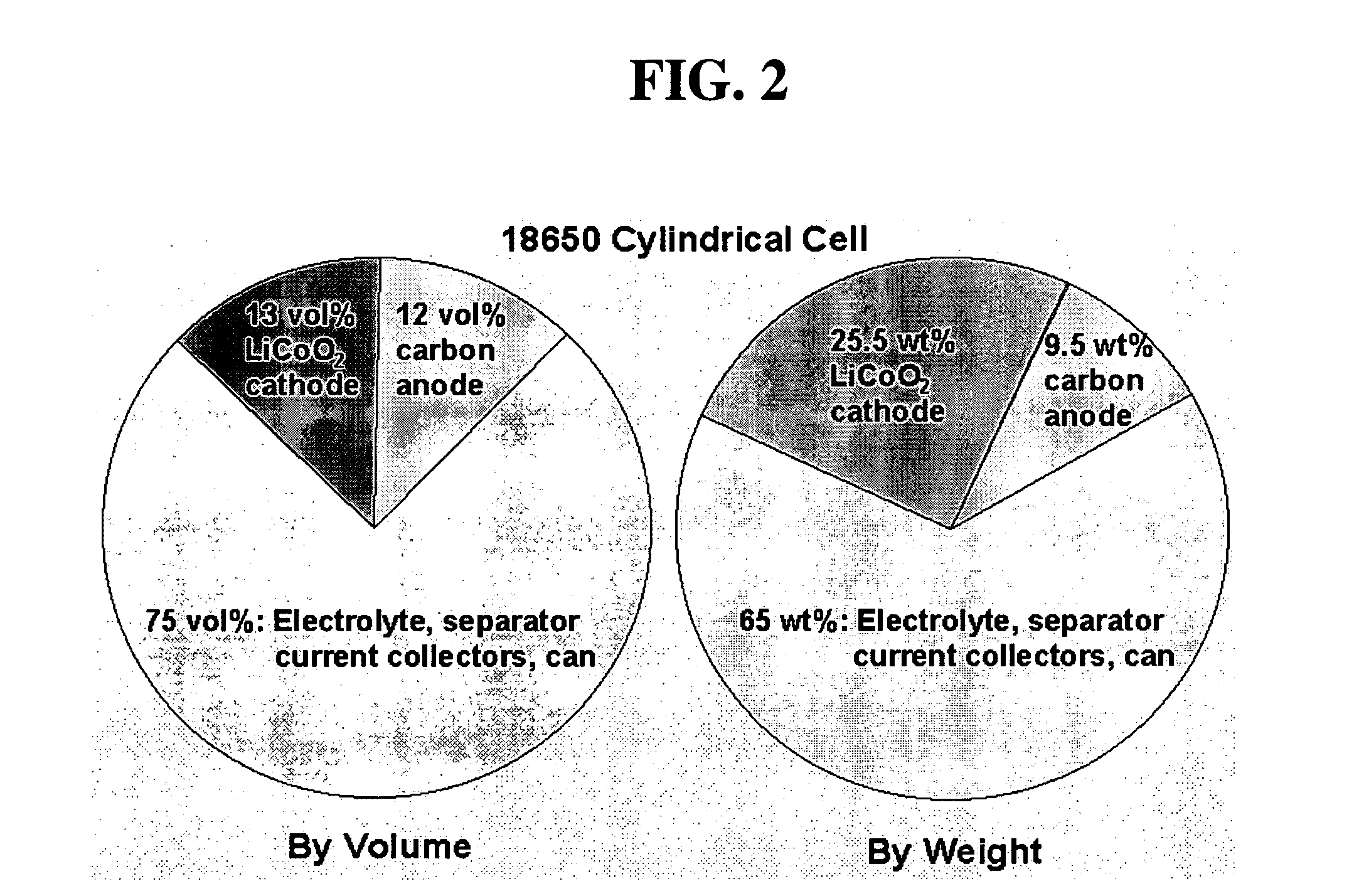

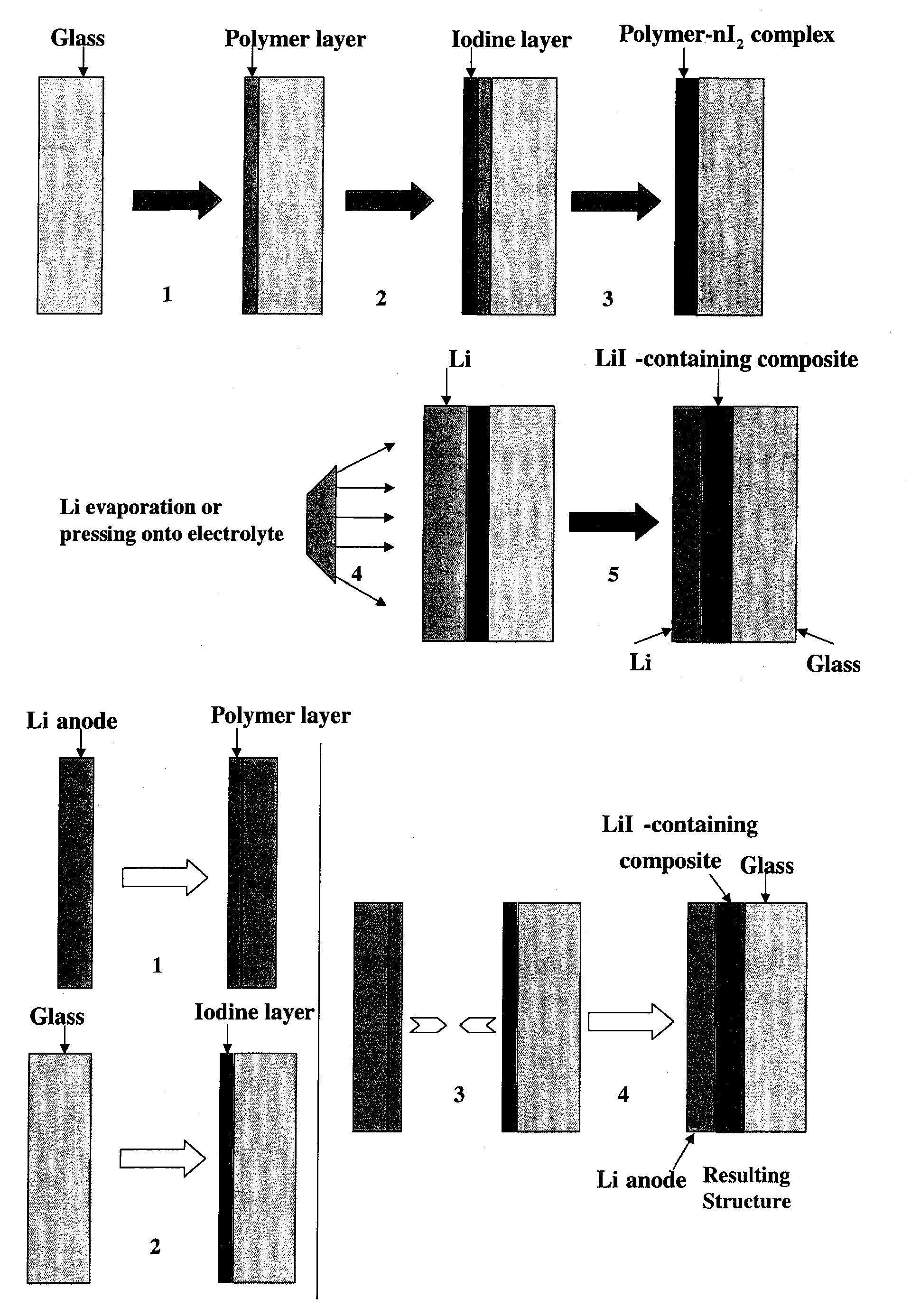

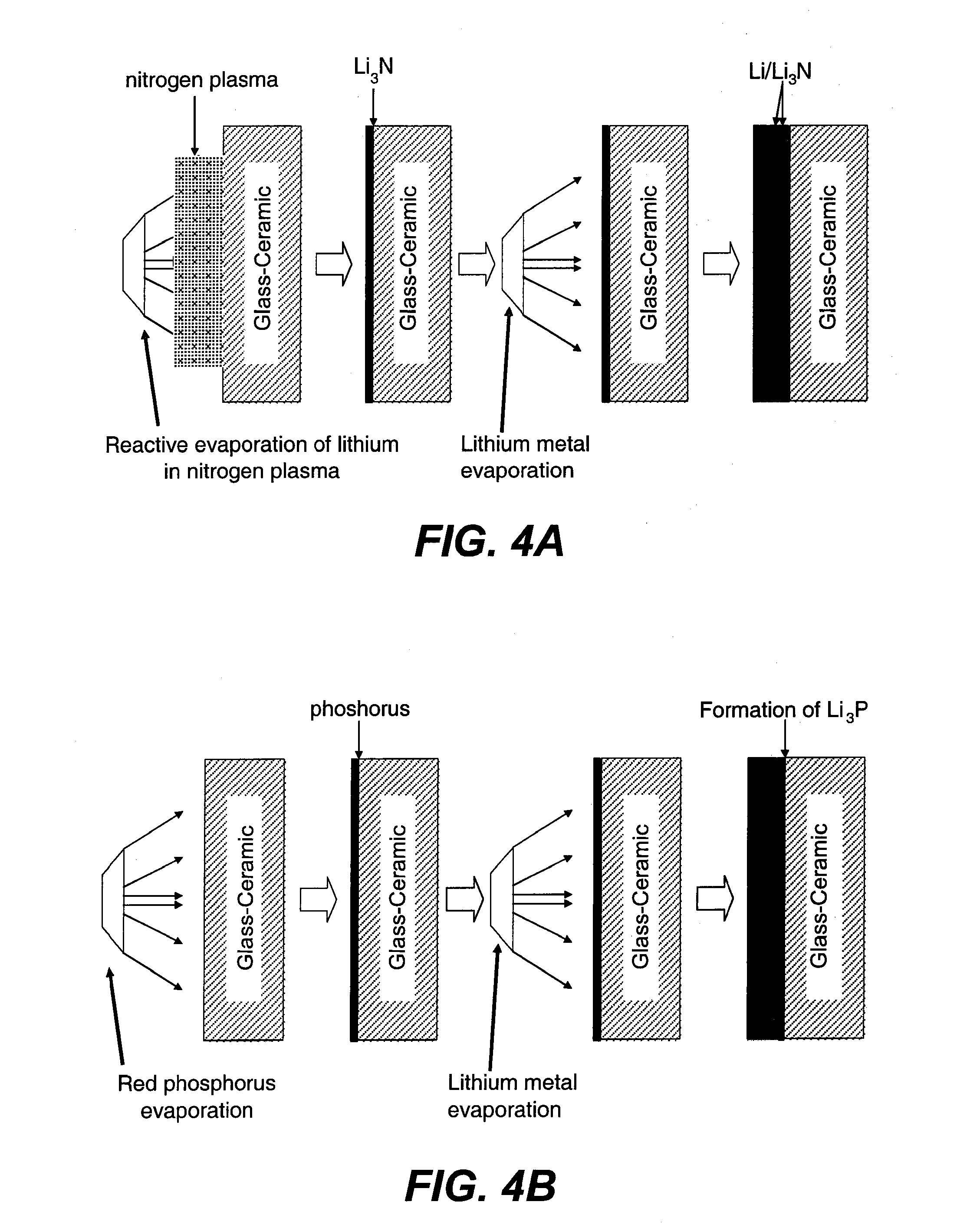

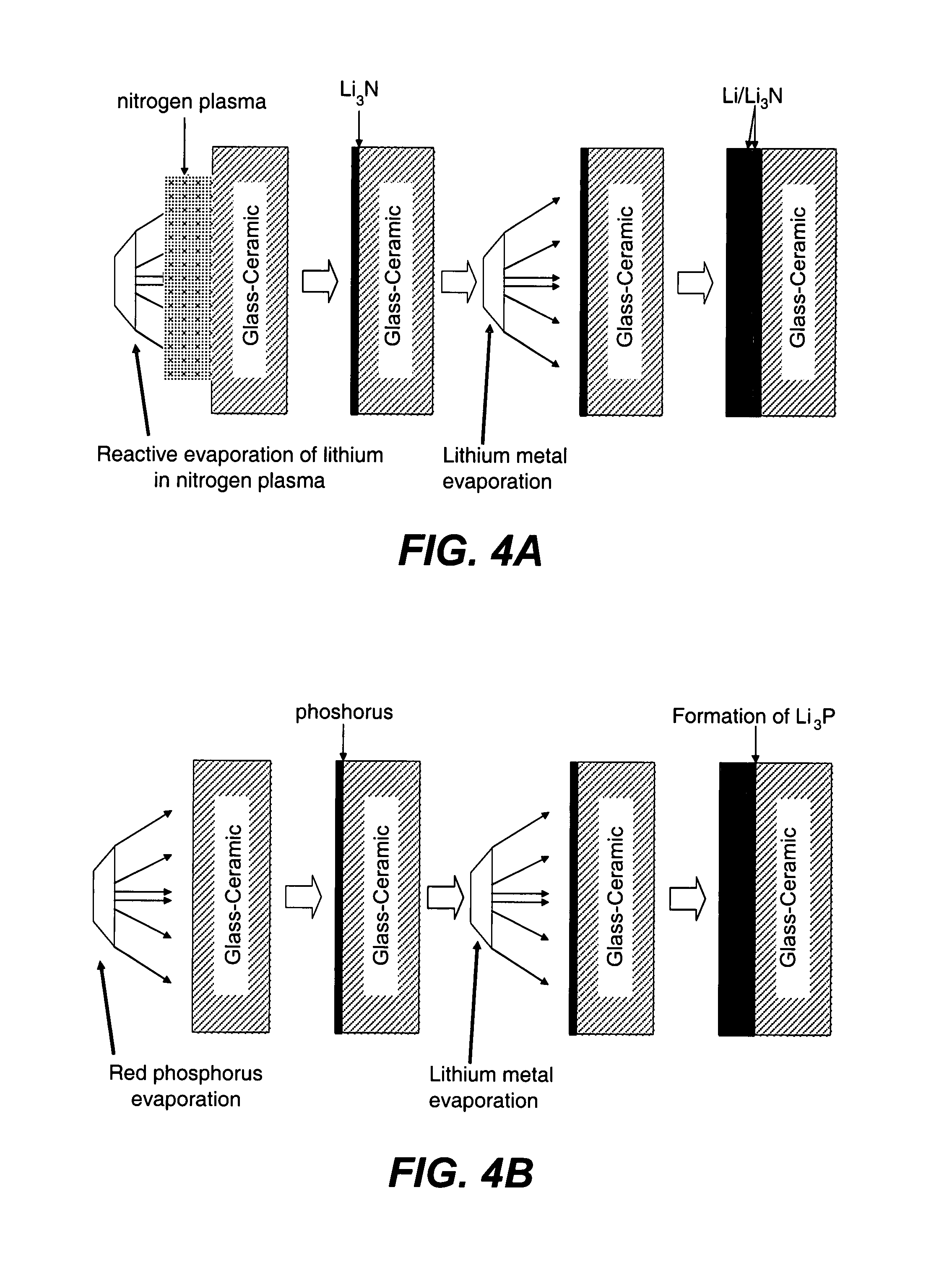

Low Cost Solid State Rechargeable Battery and Method of Manufacturing Same

InactiveUS20090092903A1Solid electrolytesElectrode thermal treatmentOptoelectronicsConductive materials

A solid state Li battery and an all ceramic Li-ion battery are disclosed. The all ceramic battery has a solid state battery cathode comprised of a mixture of an active cathode material, an electronically conductive material, and a solid ionically conductive material. The cathode mixture is sintered. The battery also has a solid state battery anode comprised of a mixture of an active anode material, an electronically conductive material, and a solid ionically conductive material. The anode mixture is sintered. The battery also has a solid state separator positioned between said solid state battery cathode and said solid state battery anode. In the solid state Li battery the all ceramic anode is replaced with an evaporated thin film Li metal anode.

Owner:JOHNSON IP HLDG LLC

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Solid electrolytes based on lithium hafnium phosphate for active metal anode protection

InactiveUS20060078790A1Avoid harmful reactionsCell electrodesNon-aqueous electrolyte cellsPhosphateOrganic liquids

Active metal electrochemical structure, in particular an active metal negative electrode (anode) protected with an ionically conductive protective architecture incorporating a glassy, ceramic or glass-ceramic solid electrolyte material based on lithium hafnium phosphate, and associated electrochemical devices and methods, provides advantages over conventional structures. The protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air or organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

Polymer adhesive seals for protected anode architectures

ActiveUS20070051620A1Avoid componentsEasy to useFuel and primary cellsHybrid cell detailsPolymer adhesiveHermetic seal

Protected anode architectures for active metal anodes have a polymer adhesive seal that provides an hermetic enclosure for the active metal of the protected anode inside an anode compartment. The compartment is substantially impervious to ambient moisture and battery components such as catholyte (electrolyte about the cathode), and prevents volatile components of the protected anode, such as anolyte (electrolyte about the anode), from escaping. The architecture is formed by joining the protected anode to an anode container. The polymer adhesive seals provide an hermetic seal at the joint between a surface of the protected anode and the container.

Owner:POLYPLUS BATTERY CO INC

Composite solid electrolyte for protection of active metal anodes

ActiveUS8182943B2Eliminate through-porosityImprove ionic conductivityCell electrodesPrimary cellsPorosityLithium

A composite solid electrolyte include a monolithic solid electrolyte base component that is a continuous matrix of an inorganic active metal ion conductor and a filler component used to eliminate through porosity in the solid electrolyte. In this way a solid electrolyte produced by any process that yields residual through porosity can be modified by the incorporation of a filler to form a substantially impervious composite solid electrolyte and eliminate through porosity in the base component. Methods of making the composites is also disclosed. The composites are generally useful in electrochemical cell structures such as battery cells and in particular protected active metal anodes, particularly lithium anodes, that are protected with a protective membrane architecture incorporating the composite solid electrolyte. The protective architecture prevents the active metal of the anode from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air and organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

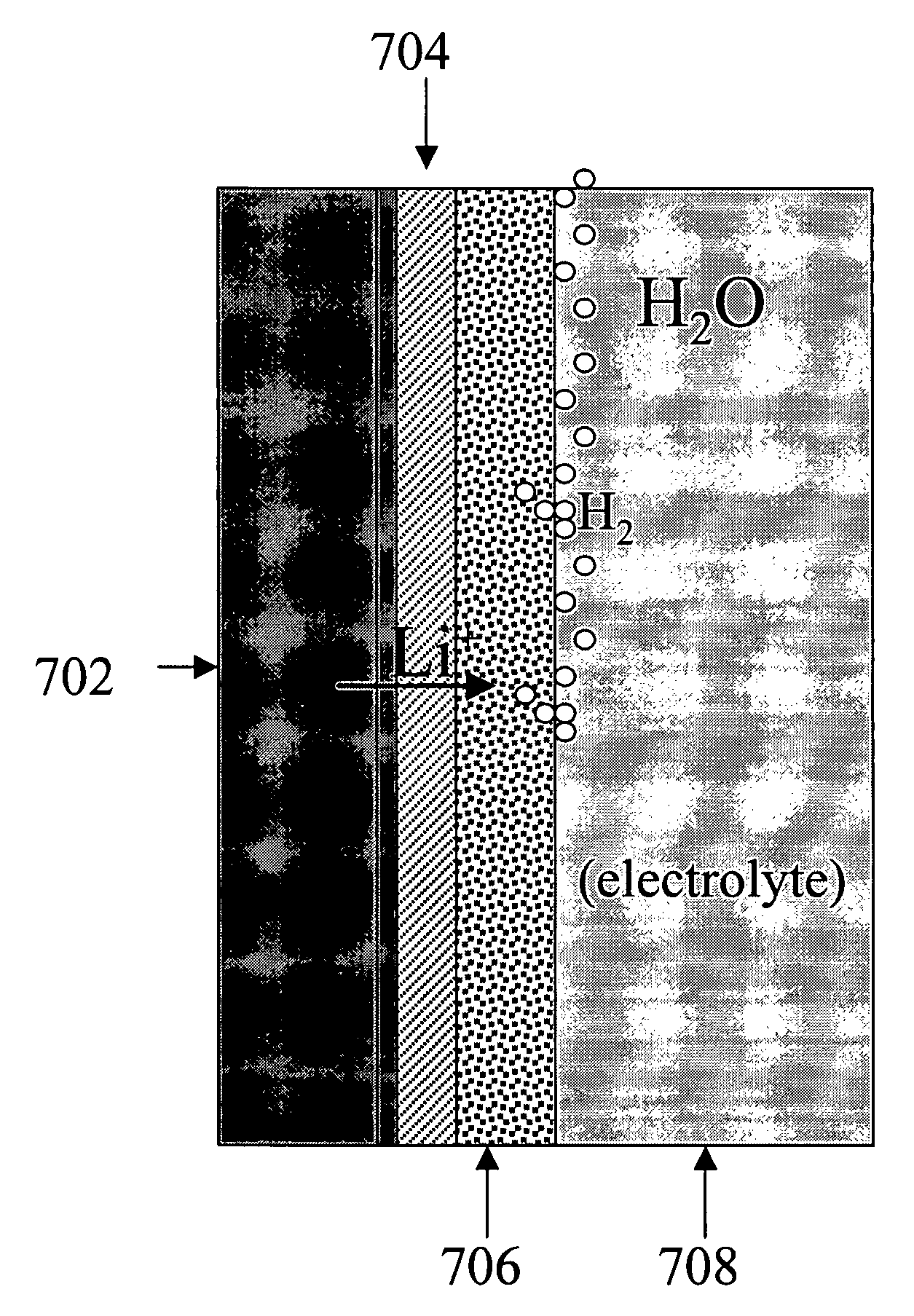

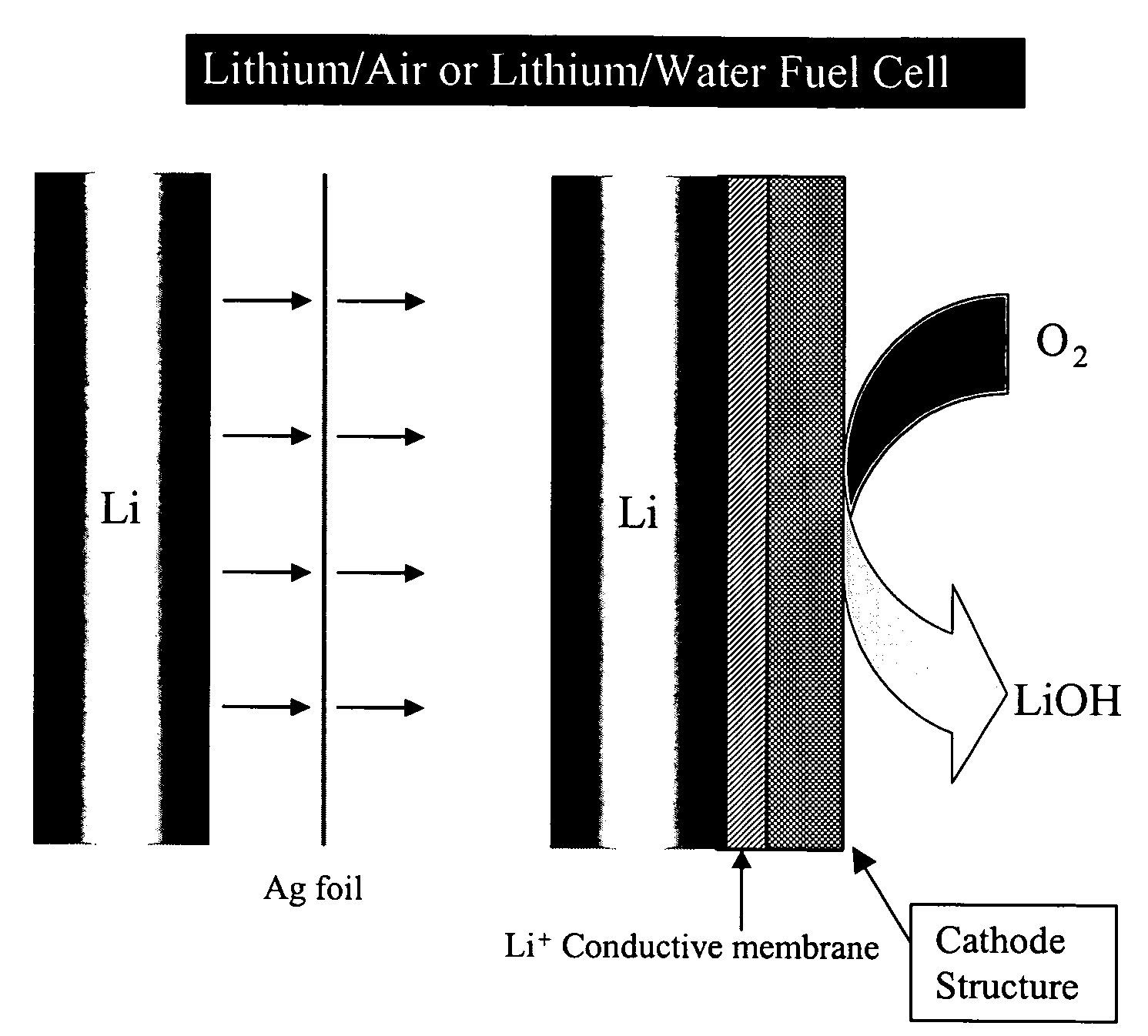

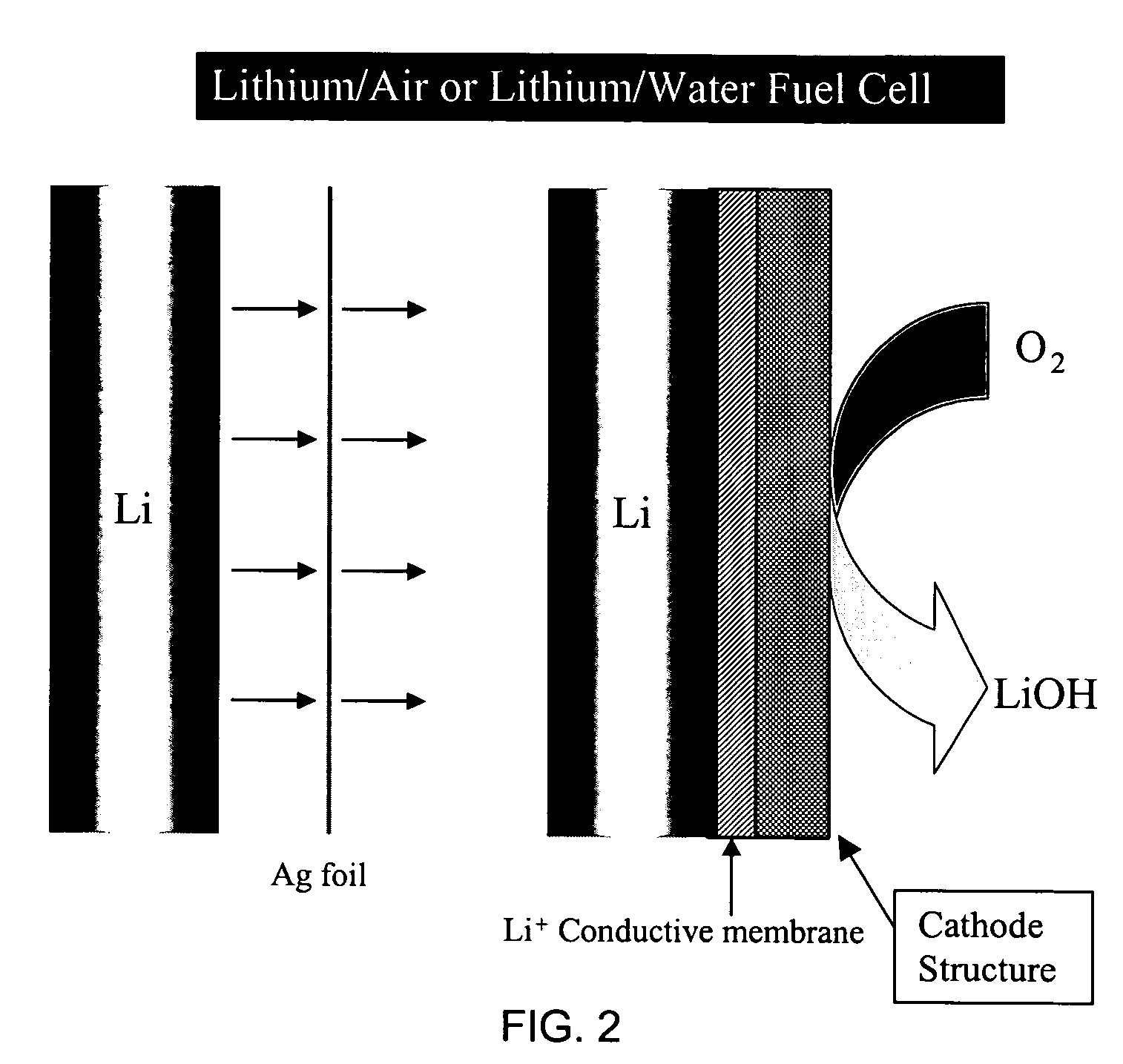

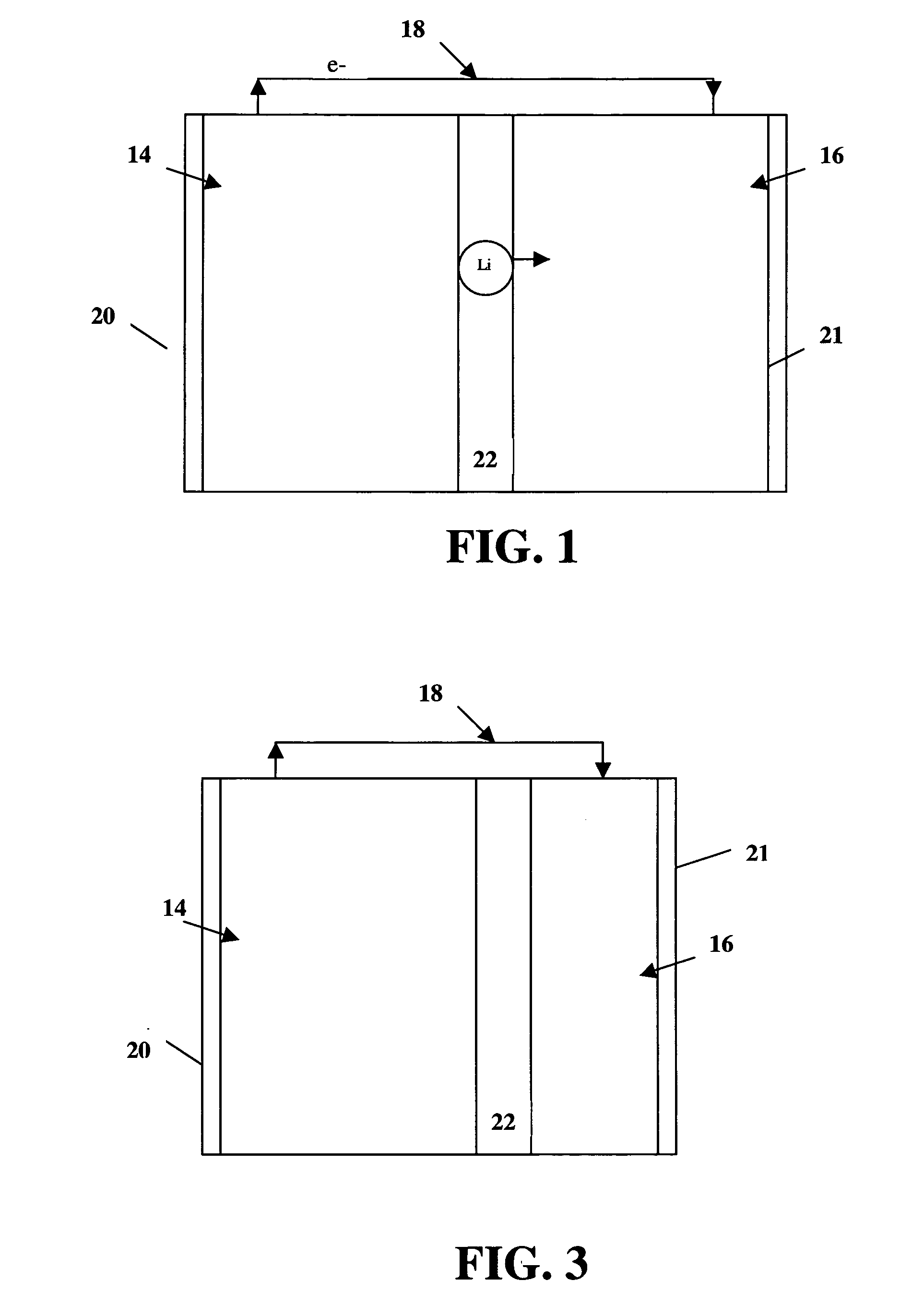

Active metal/aqueous electrochemical cells and systems

InactiveUS7645543B2Degree of flexibilityWithout performanceFuel and primary cellsAlkaline accumulatorsElectrochemical cellBattery cell

Alkali (or other active) metal battery and other electrochemical cells incorporating active metal anodes together with aqueous cathode / electrolyte systems. The battery cells have a highly ionically conductive protective membrane adjacent to the alkali metal anode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the anode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or cathode material in conjunction with the anode. Also, optimization of electrolytes or cathode-side solvent systems may be done without impacting anode stability or performance. In particular, Li / water, Li / air and Li / metal hydride cells, components, configurations and fabrication techniques are provided.

Owner:POLYPLUS BATTERY CO INC

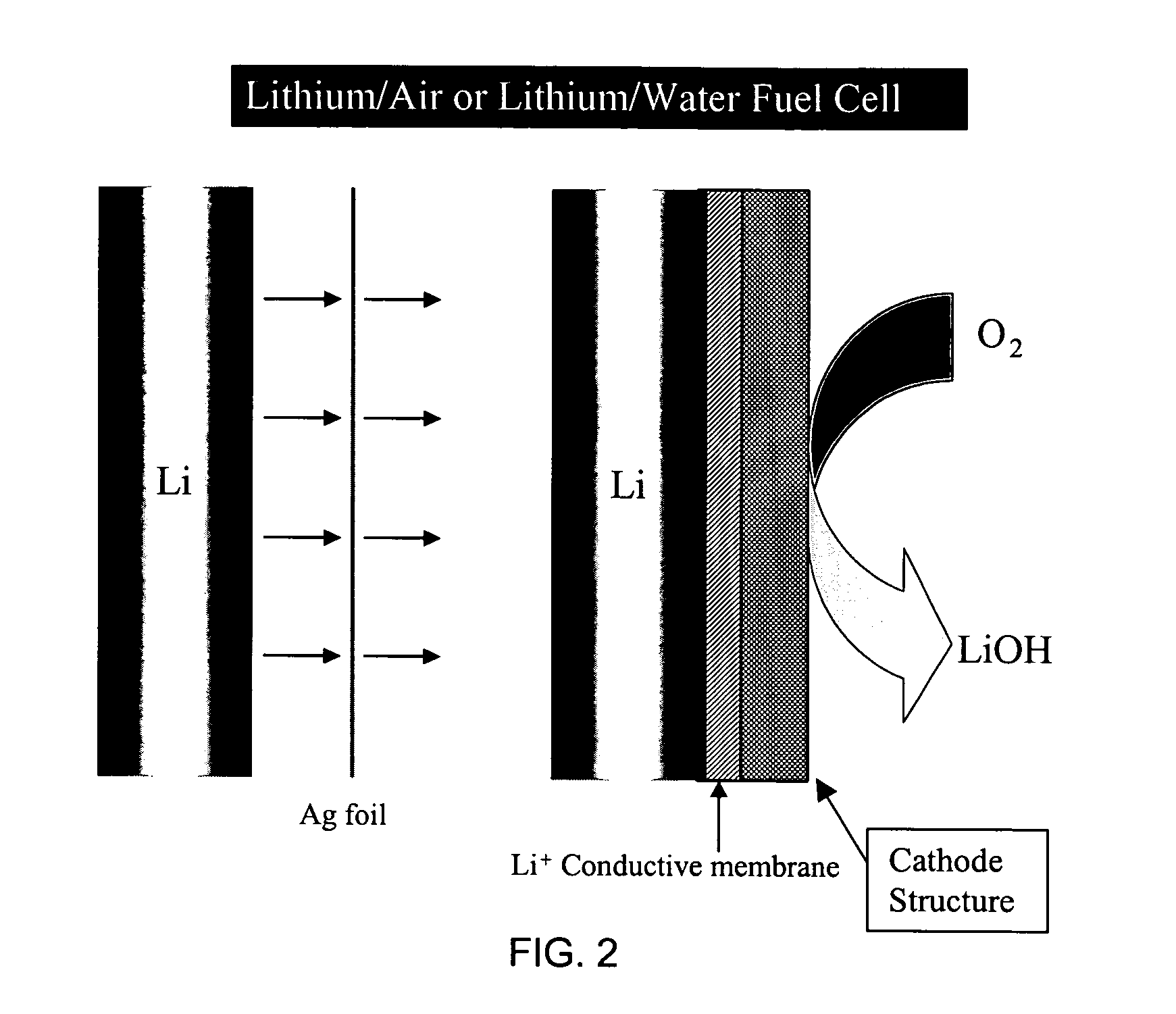

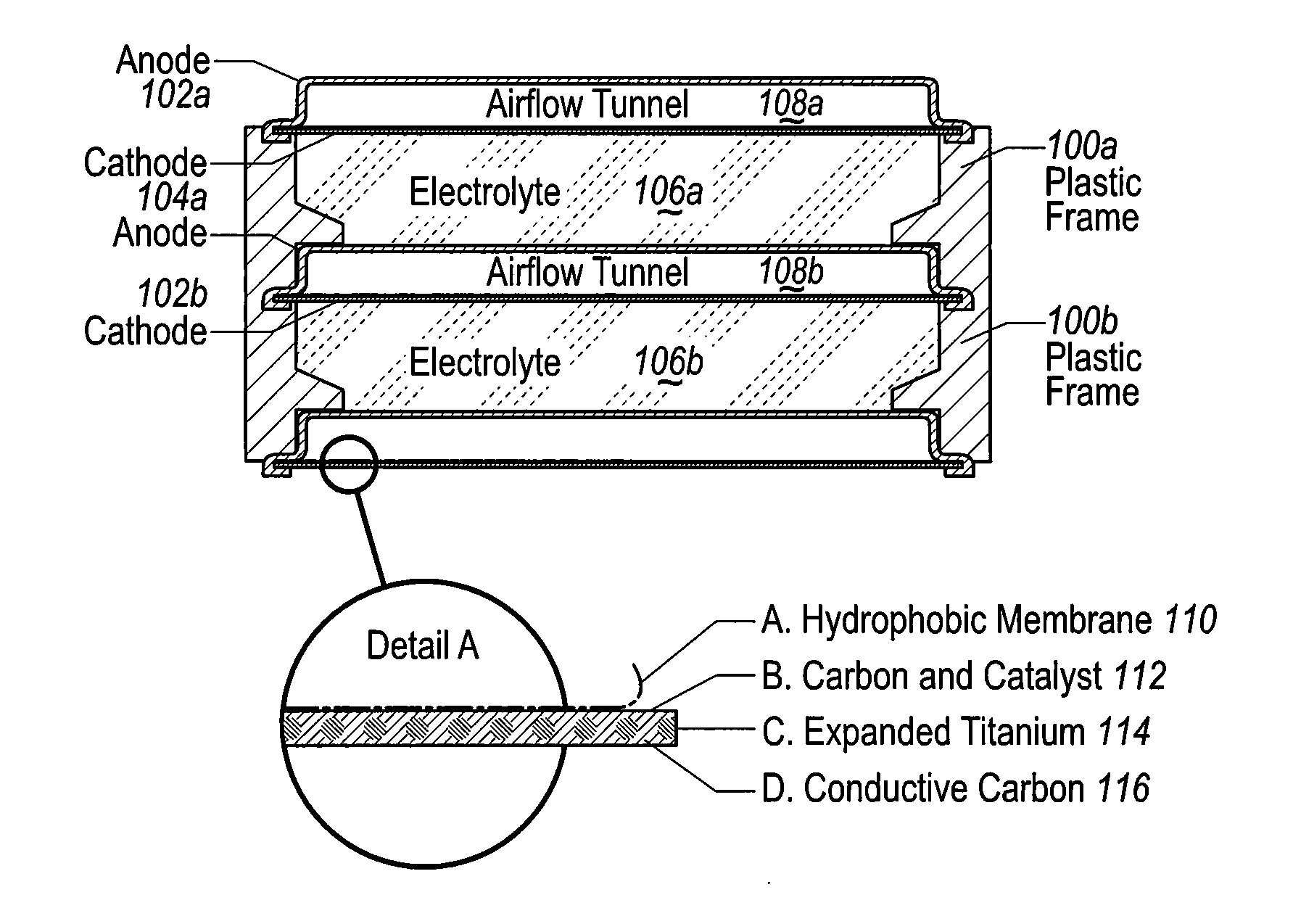

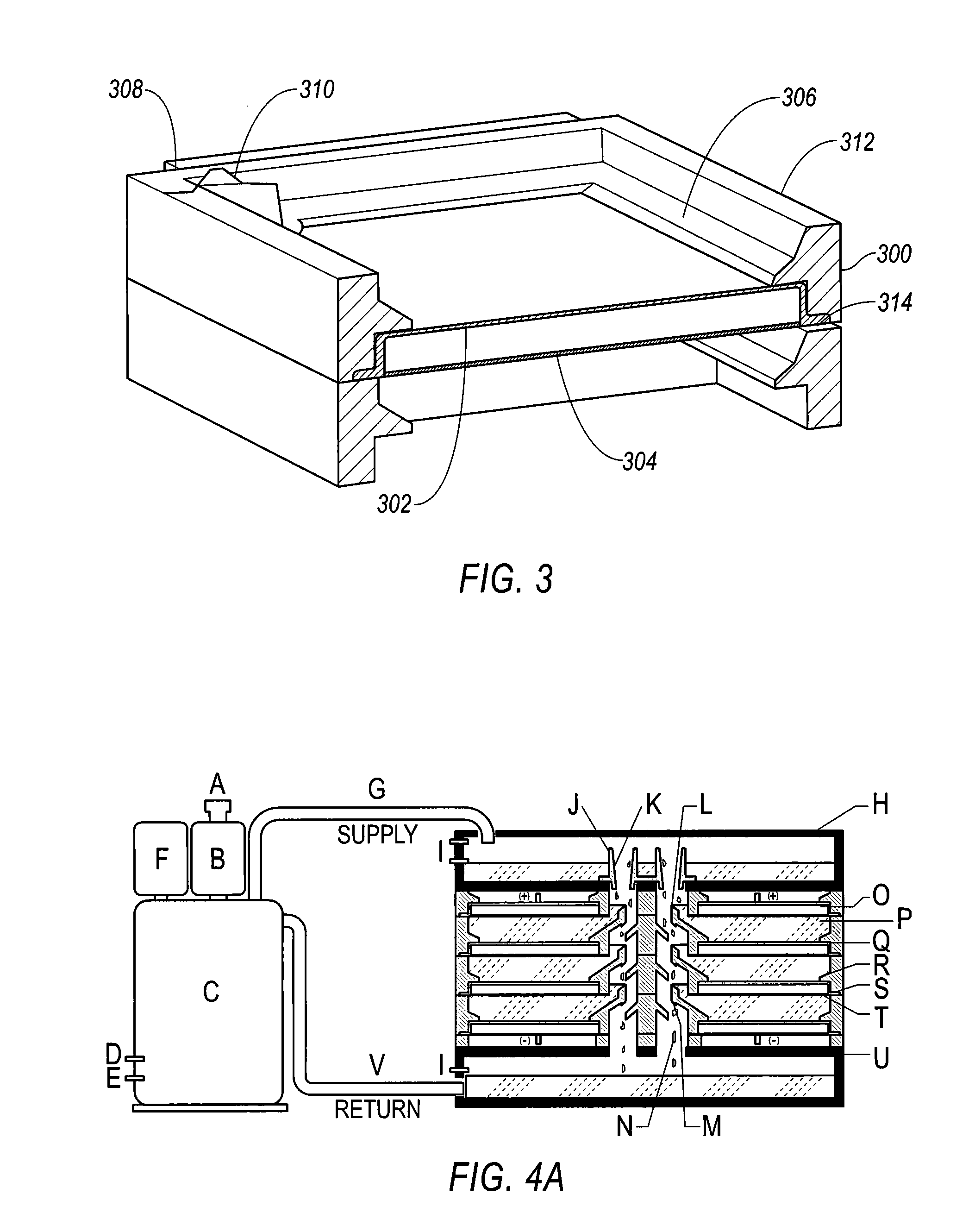

Active metal fuel cells

InactiveUS7491458B2High densityImprove efficiencyFuel and primary cellsFuel and secondary cellsLithiumFuel cells

Active metal fuel cells are provided. An active metal fuel cell has a renewable active metal (e.g., lithium) anode and a cathode structure that includes an electronically conductive component (e.g., a porous metal or alloy), an ionically conductive component (e.g., an electrolyte), and a fluid oxidant (e.g., air, water or a peroxide or other aqueous solution). The pairing of an active metal anode with a cathode oxidant in a fuel cell is enabled by an ionically conductive protective membrane on the surface of the anode facing the cathode.

Owner:POLYPLUS BATTERY CO INC

Active metal fuel cells

InactiveUS20050100792A1Increase energy densityImprove fuel efficiencyFuel and primary cellsFuel and secondary cellsLithiumFuel cells

Owner:POLYPLUS BATTERY CO INC

Active metal/aqueous electrochemical cells and systems

InactiveUS7666233B2Degree of flexibilityWithout performanceFuel and primary cellsElectrode manufacturing processesManufacturing technologyElectrochemical cell

Owner:POLYPLUS BATTERY CO INC

Electronic light emissive displays incorporating transparent and conductive zinc oxide thin film

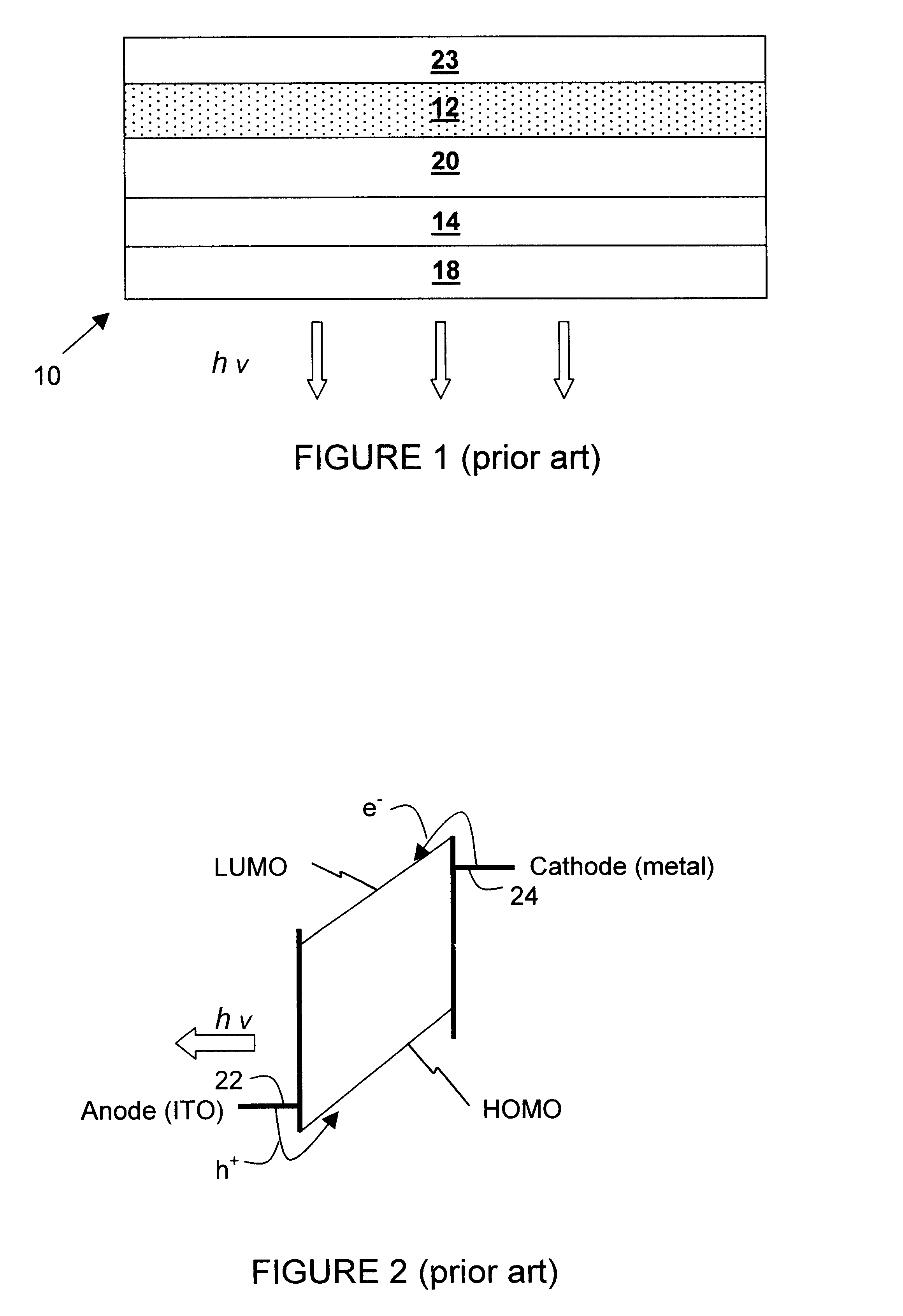

InactiveUS6541908B1Discharge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOxide cathode

The present invention provides co-doped zinc oxide to flat panel, light emissive display devices and vacuum microelectronic devices to improve their efficiency and lifetime. This material has a low growth temperature and is compatible with metal oxide semiconductor (MOS) processing technology. It is tranparent, chemically stable and has a low work function, which result in many advantages when being used as the cathode for the aforementioned devices. In one embodiment of the emissive display device, an organic light diode (OLED) display has a high work function metal anode, such as platinum (Pt), gold (Au) or nickel (Ni) and a low work function co-doped zinc oxide cathode. Because of the energy level alignment provided by these two materials, the potential energy barriers to injection of electrons from the cathode and holes from the anode into the organic emissive medium are minimized so the display device operates more efficiently.

Owner:TELEDYNE SCI & IMAGING

Electrochemical device component with protected alkali metal electrode

InactiveUS7858223B2Easy to manufactureImprove battery performanceSolid electrolytesCell seperators/membranes/diaphragms/spacersElectrochemistryChemical stability

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

Ionically conductive membranes for protection of active metal anodes and battery cells

InactiveUS20080057386A1Improve conductivityFacilitates cell fabricationSolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityIonic conductivity

Disclosed are ionically conductive membranes for protection of active metal anodes and methods for their fabrication. The membranes may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the membrane has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The membrane is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the membrane is incorporated.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveUS7824806B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesTectorial membraneOptoelectronics

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Ionically conductive composites for protection of active metal anodes

InactiveUS20080057399A1Easy to manufactureImprove battery performanceFinal product manufactureCell electrodesChemical stabilityIonic conductivity

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

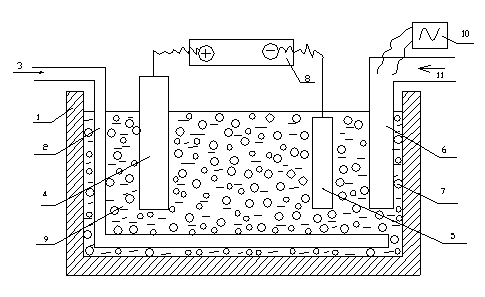

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

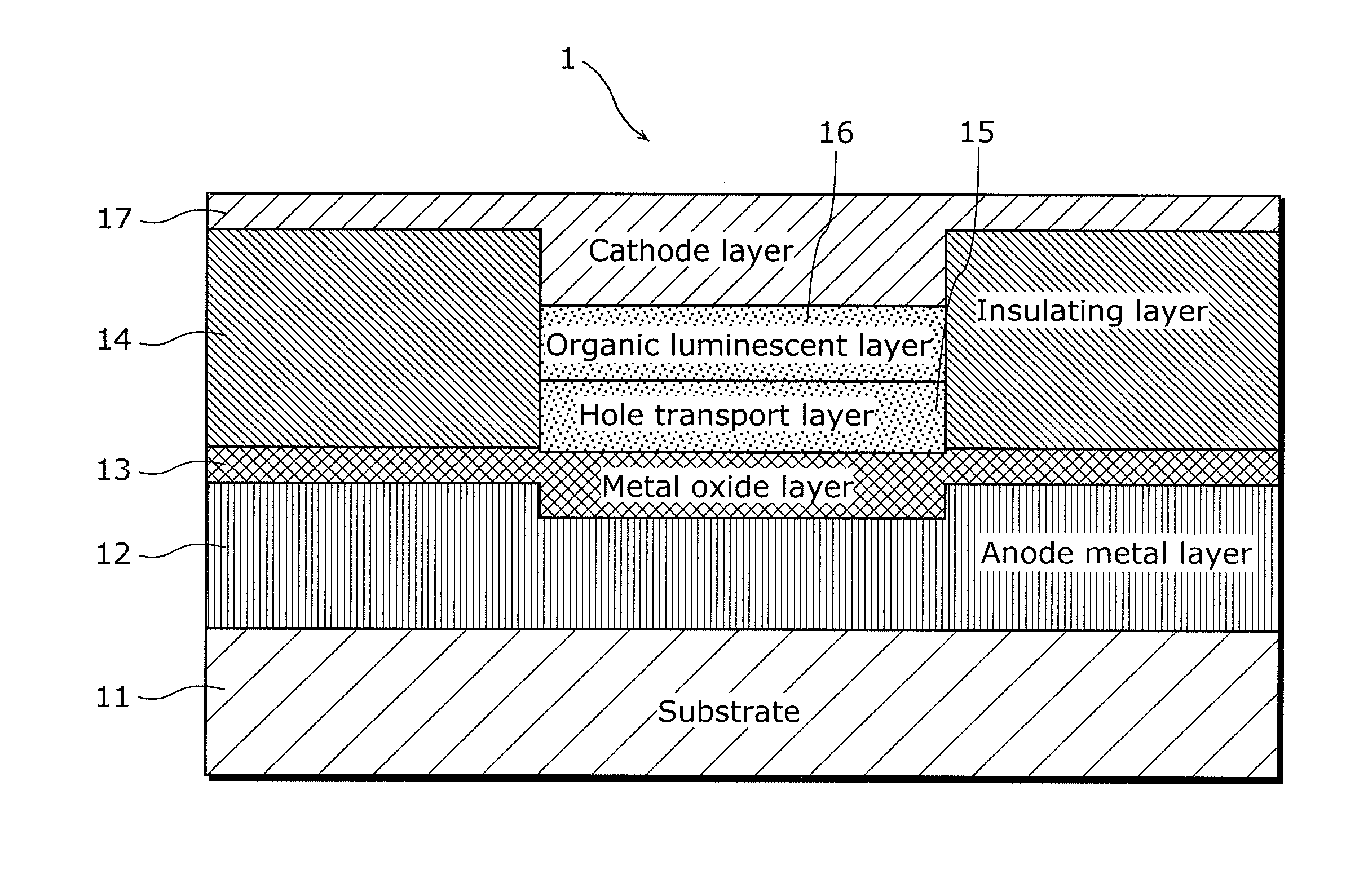

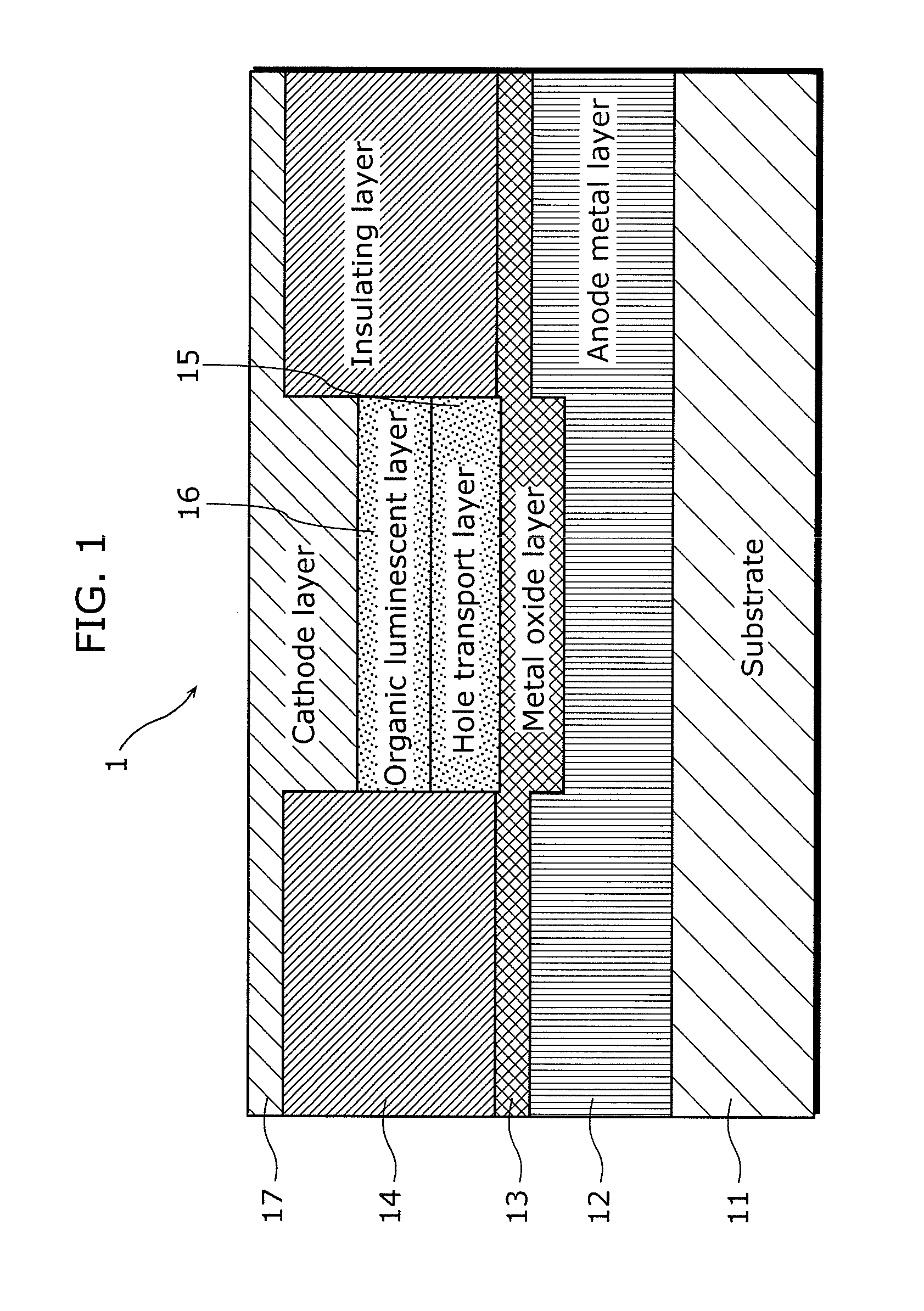

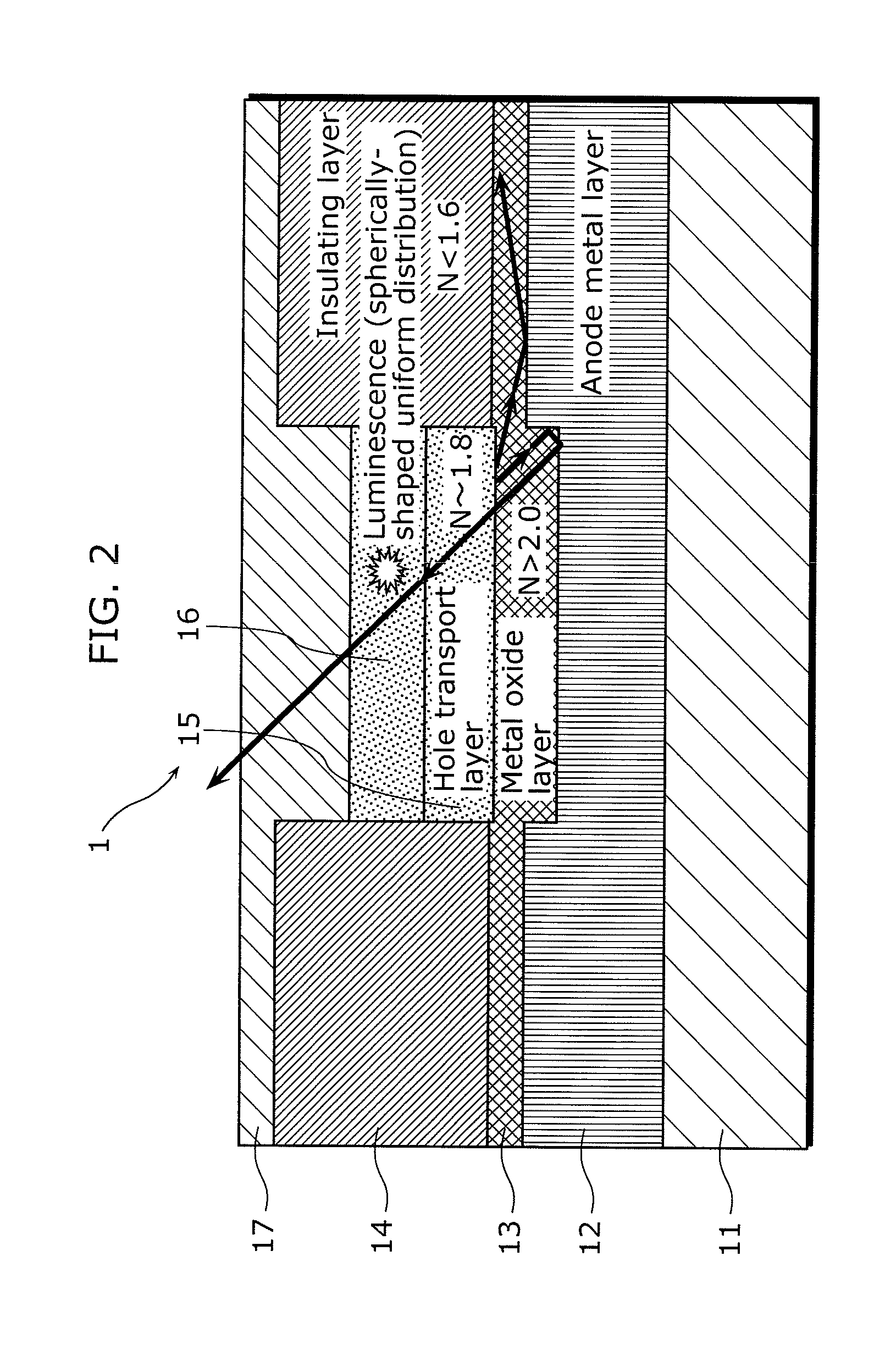

Organic electroluminescence element and manufacturing method thereof

ActiveUS20100258833A1Excellent hole injectionReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOrganic electroluminescence

The organic electroluminescence element includes an anode metal layer above a substrate. The anode metal layer comprises an inner region and an outer region. The inner region is adjacent to and different than the outer region. An upper surface of the inner region is lower than an upper surface of the outer region. A metal oxide layer is on the inner region of the metal anode layer. A hole transport layer is above the metal oxide layer and the inner region. The hole transport layer comprises a hole-transporting organic material. An organic luminescent layer is above the hole transport layer and the inner region. A cathode layer is above the organic luminescent layer and the inner region. The cathode layer injects electrons into the organic luminescent layer. An insulating layer is above the outer region of the anode metal layer.

Owner:JOLED INC

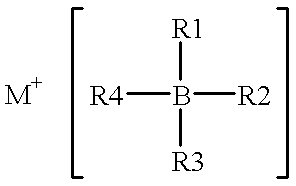

High-energy, rechargeable, electrochemical cells with non-aqueous electrolytes

InactiveUS6316141B1Non-aqueous electrolyte accumulatorsGroup 5/15 element organic compoundsElectrolysisHigh energy

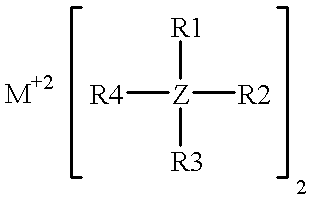

A non-aqueous electrolyte for use in an electrochemical cell comprising: (a) at least one organic solvent; (b) at least one electrolytically active salt represented by the formula:in which: M' is selected from a group consisting of magnesium, calcium, aluminum, lithium and sodium; Z is selected from a group consisting of aluminum, boron, phosphorus, antimony and arsenic; R represents radical selected from the following groups: alkyl, alkenyl, aryl, phenyl, benzyl, and amido; X is a halogen (I, Br, Cl, F); m=1-3; and n=0-5 and q=6 in the case of Z=phosphorus, antimony and arsenic, and n=0-3 and q=4 in the case of Z=aluminum and boron. Rechargeable, high energy density electrochemical cells containing an intercalation cathode, a metal anode, and an electrolyte of the above-described type are also disclosed.

Owner:BAR ILAN UNIV

Compliant seal structures for protected active metal anodes

ActiveCN101313426APrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholytes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

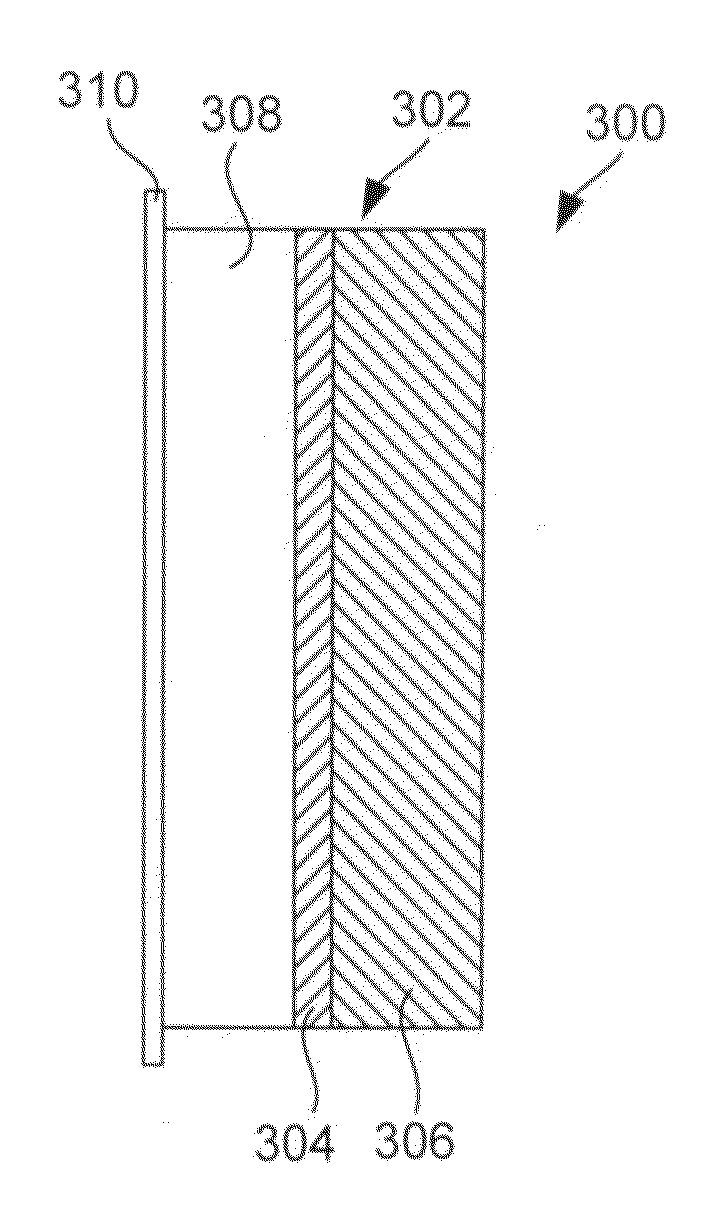

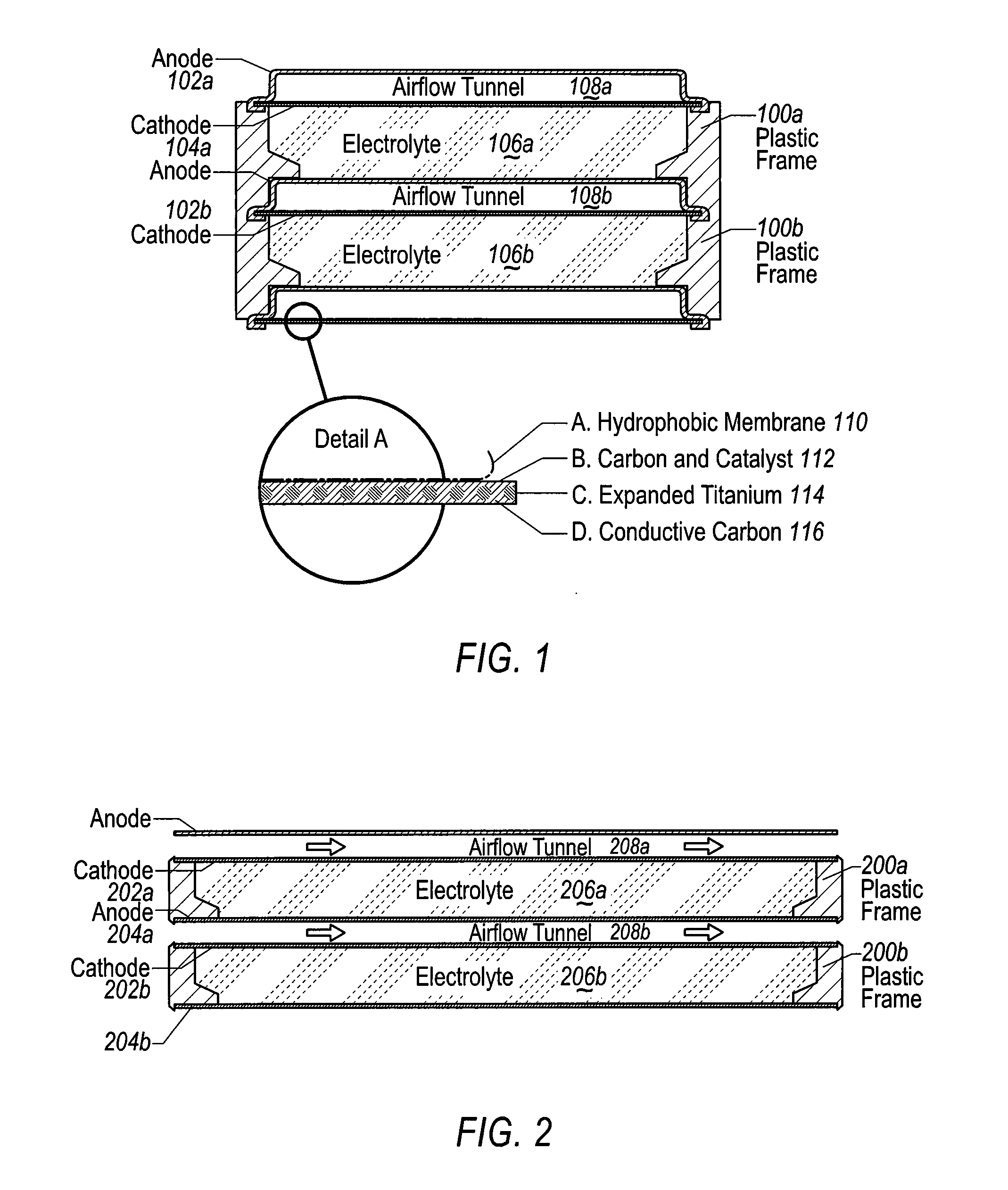

Electrically rechargeable, metal anode cell and battery systems and methods

ActiveUS20150010833A1Increased operating lifeAffordable and practicalAlkaline accumulatorsFuel and secondary cellsElectricityElectrical battery

The invention provides for a fully electrically rechargeable metal anode battery systems and methods of achieving such systems. An electrically rechargeable metal anode cell may comprise a metal electrode, an air contacting electrode, and an aqueous electrolyte separating the metal electrode and the air contacting electrode. In some embodiments, the metal electrode may directly contact the liquid electrolyte and no separator or porous membrane is needed between the air contacting electrode and the electrolyte. Rechargeable metal anode cells may be electrically connected to one another through a centrode connection where a metal electrode of one cell and an air contacting electrode of a second cell are electrically connected. Air tunnels or pathways may be provided between individual metal anode cells arranged in a stack. In some embodiments, an electrolyte flow management system may also be provided to maintain liquid electrolyte at constant levels during charge and discharge cycles.

Owner:EOS ENERGY TECH HLDG LLC

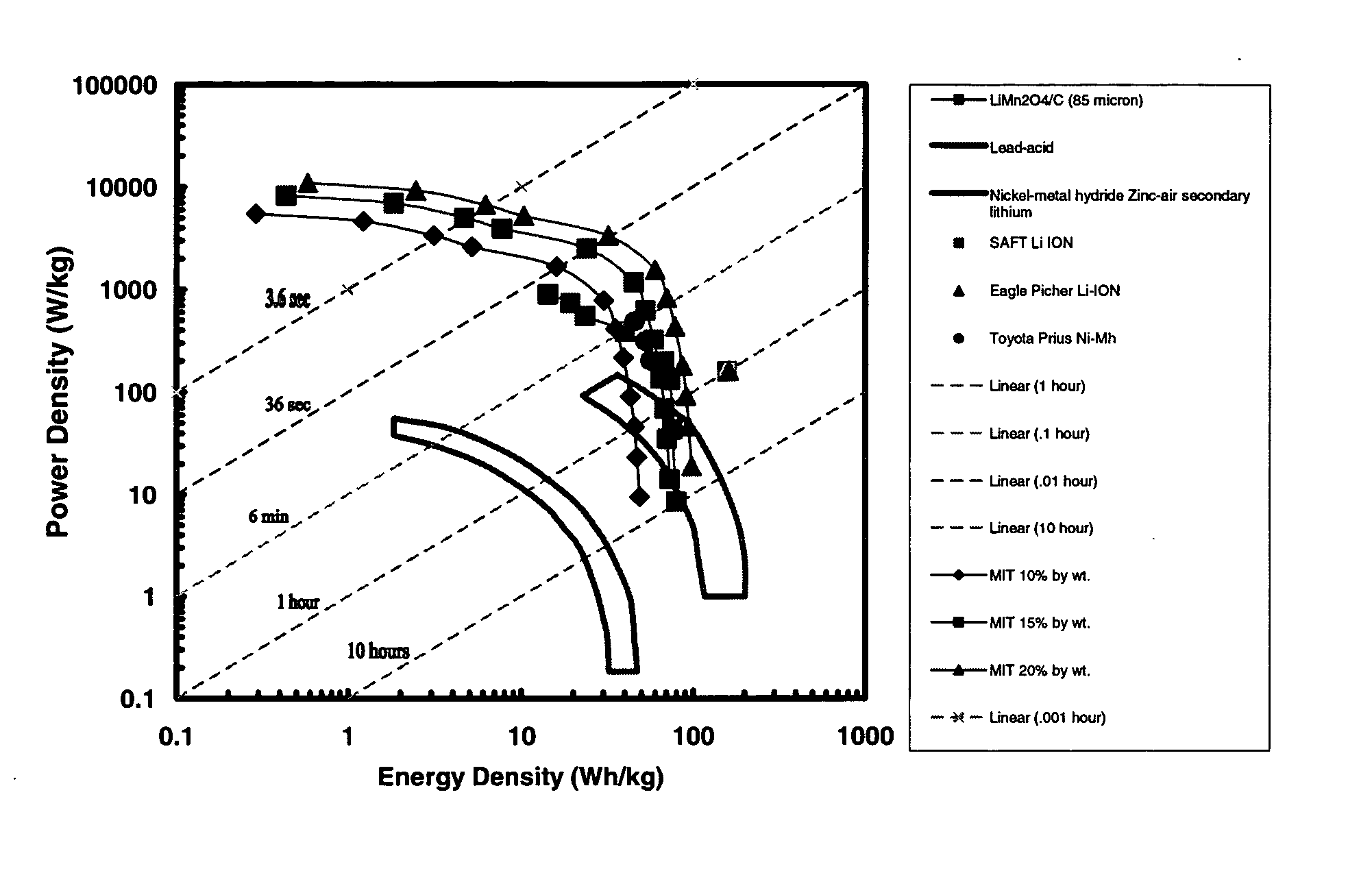

High energy and power density electrochemical cells

ActiveUS20060292444A1Improve electrochemical performanceExtreme safetyPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh energyMetalloid

The energy density of the entire cell may be improved while retaining high power density by use of an alkali metal transition metal polyanion compound as the cathode and a thin film metal or metalloid anode. The thin film anode may be initially unalloyed or partially unalloyed. During use, the thin film anode may be only partially unalloyed relative to the theoretical maximum. The high volumetric capacity of the metal anode makes it possible to use a dense or porous thin film anode in conjunction with a relatively thin particle-based cathode to thereby improve the energy density of the cell.

Owner:A123 SYSTEMS LLC

Stabilized OLED device

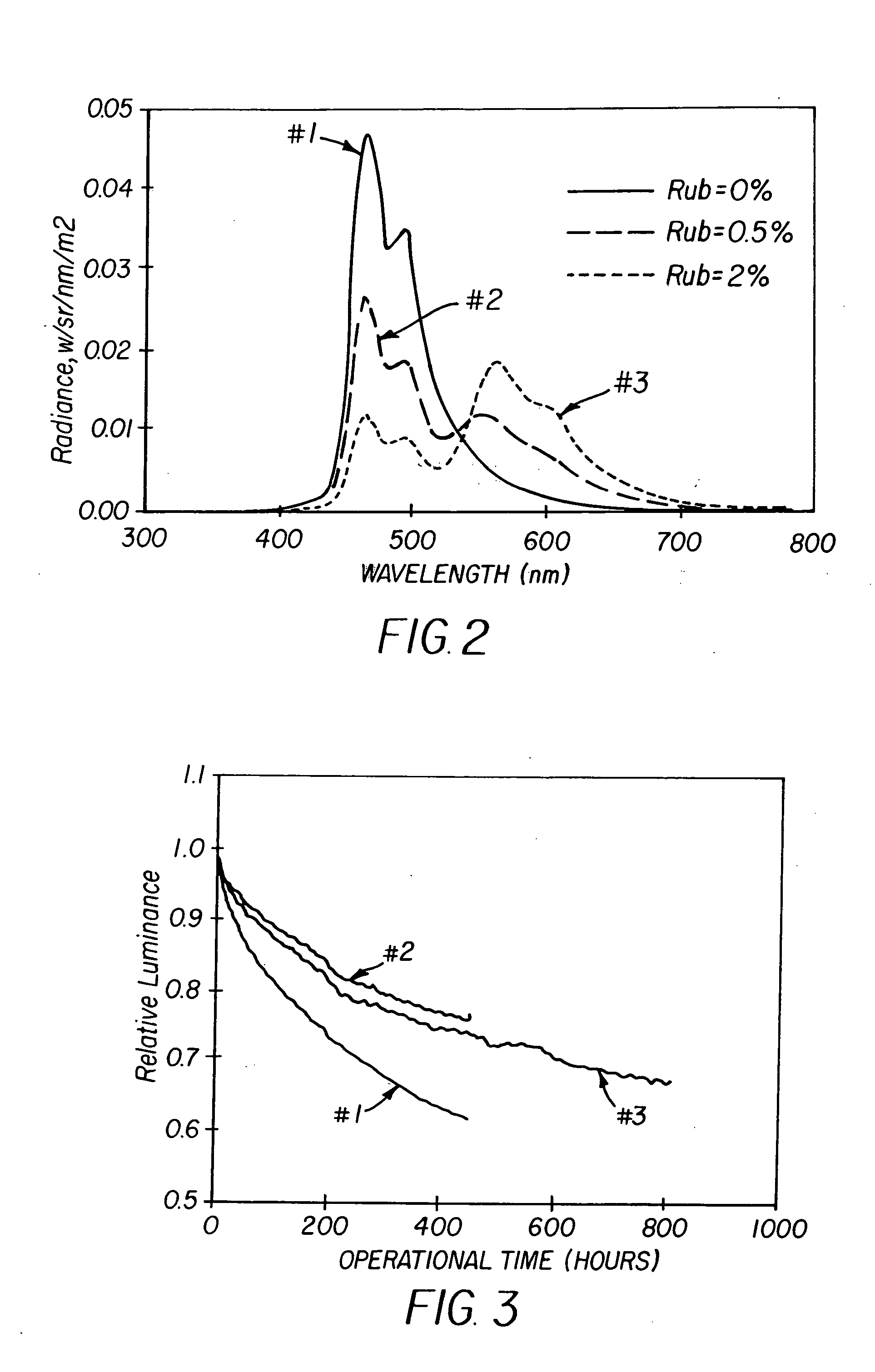

ActiveUS20050058852A1Improve stabilityImprove performanceIncadescent screens/filtersDischarge tube luminescnet screensDopantDevice form

A stabilized OLED device for emitting light of a specific color includes a metallic anode and a metallic cathode spaced from the metallic anode. The device also includes a light-emitting layer including a host and a dopant, the dopant selected to produce light having a spectrum including light of the specific color, and a stabilizer provided in one of the device layers which improves the useful lifetime of the OLED device, wherein the stabilizer has an emission spectrum different from that of the light-emitting layer. One of the electrode layers is semitransparent and the other one is substantially opaque and reflective such that the stabilized OLED device forms a microcavity that emits a narrow band light with the specific color.

Owner:GLOBAL OLED TECH

Ionically conductive membranes for protection of active metal anodes and battery cells

InactiveUS20090297935A1Improve conductivityEasy to manufactureSolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityBattery cell

Disclosed are ionically conductive membranes for protection of active metal anodes and methods for their fabrication. The membranes may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the membrane has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The membrane is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the membrane is incorporated.

Owner:POLYPLUS BATTERY CO INC

Ionically conductive composites for protection of active metal anodes

InactiveUS20080057387A1Easy to manufactureImprove battery performanceSolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityBattery cell

Owner:POLYPLUS BATTERY CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com