Wearable compound layer material for machine parts and manufacturing method and equipment thereof

A technology for mechanical parts and manufacturing methods, which is applied in the field of vulnerable and consumable parts of mechanical equipment, and can solve problems such as low service life and poor wear resistance of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

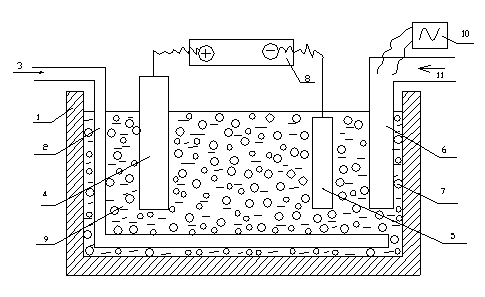

[0054] Embodiment 1: adopt the method for controlling current electroplating, on the surface of the plate type stirring blade, adopt nickel-cobalt-manganese alloy as matrix metal, diamond is used as the wear-resistant particle that " floating sand method " and " buried sand method " use, adopt diamond micropowder as The particles co-deposited with nickel-cobalt-manganese alloy are electroplated with Ni-Co-Mn diamond wear-resistant composite layer on a single plane.

[0055] Nickel cobalt manganese alloy electroplating solution main salt nickel sulfate is 150-500G / L; auxiliary salt nickel chloride is 10-50G / L, its role is to improve the conductivity of the electroplating solution and enhance the dissolution of nickel anode; additives cobalt sulfate and Manganese sulfate is mainly to form an alloy with metal nickel to make its hardness, softness and wear resistance meet an ideal requirement; boric acid is to stabilize and adjust the pH value of the electroplating solution; sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com