Patents

Literature

648 results about "Cobalt Sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

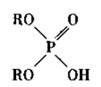

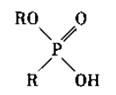

Cobalt Sulfate is a moderately water and acid soluble Cobalt source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

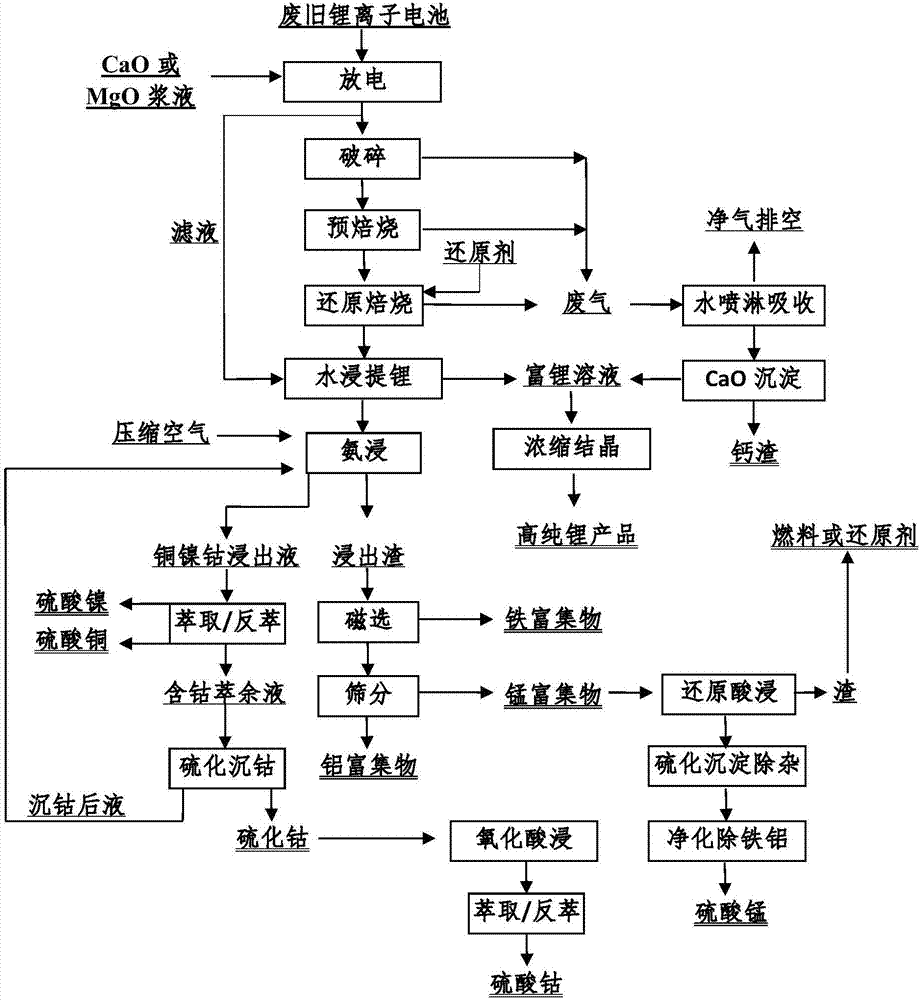

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

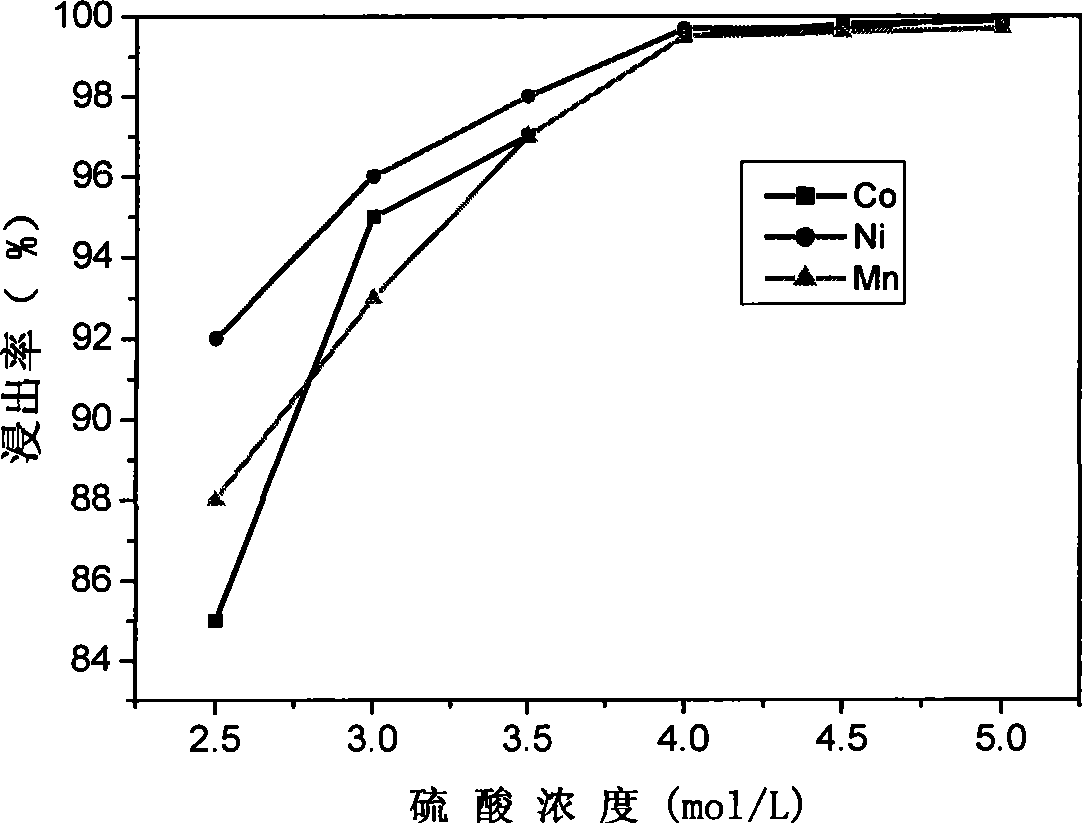

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

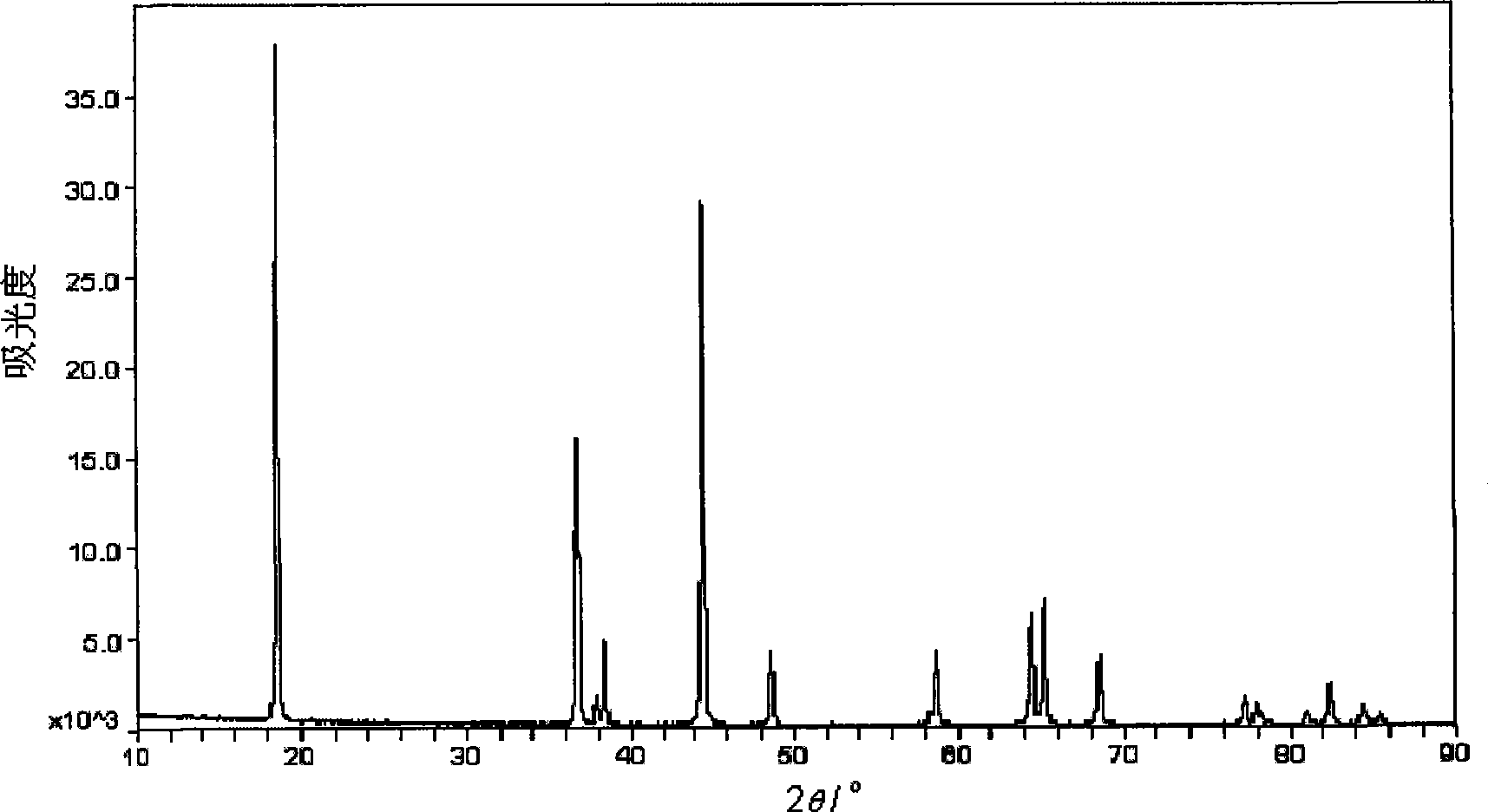

Method for preparing nickel and cobalt doped lithium manganate by using waste and old lithium ionic cell as raw material

InactiveCN101450815ASimultaneous recyclingShort processManganates/permanganatesManganateManganese oxide

The invention discloses a method for preparing lithium nickel cobalt manganese oxide by taking a waste lithium ion battery as a raw material. The method is mainly characterized in that a waste lithium ion battery taking the lithium nickel cobalt manganese oxide, lithium nickel cobalt oxide and so on as a battery positive material is selected as the raw material and is pretreated through disassembly, separation, crushing, screening and so on, and then processes such as adhesive removal at high temperature and aluminum removal by sodium hydroxide are adopted to obtain an inactivated positive material containing nickel, cobalt and manganese; then a sulfuric acid and hydrogen peroxide system is adopted to leach, and P204 is adopted to remove impurities by extraction to obtain pure nickel, cobalt and manganese solution, and proper manganese sulfate, nickel sulfate or cobalt sulfate is blended to ensure that the mol ratio of nickel, cobalt and manganese elements in the solution is 1: 1: 1; and then ammonium carbonate is adopted to adjust the pH value to form a nickel cobalt manganese carbonate precursor, and then a proper amount of lithium carbonate is blended for high temperature sintering to synthesize a lithium nickel cobalt manganese oxide battery material. The first discharge capacity of the material is 150 mAh / g, the discharge capacity is still kept more than 130mAh / g after the circulation for 30 times, and the material has good electrochemical performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Method for producing positive plate material for lithium secondary cell

InactiveUS20050265909A1Improve battery performanceElectrode manufacturing processesActive material electrodesAlkaline earth metalLithium carbonate

A positive plate material for lithium secondary cells stably exhibiting excellent performance including the cell initial capacity, cycle characteristics, and the safety. The material is produced by dripping an aqueous solution of a salt (e.g., cobalt sulfate) of a doping element (e.g., a transition metal, an alkaline metal, an alkaline-earth metal, B, or Al) into an alkaline solution, a carbonate solution, or a hydrogencarbonate solution in any one of which a compound (e.g., manganese oxide) of a metal (Mn, Co, Ni, or the like) which is the major component of the positive plate material so as to precipitate the compound of the doping element on the major component compound and to cover the major component compound, mixing the major component compound covered with the doping element with a lithium compound (e.g., lithium carbonate), and firing the mixture.

Owner:NIKKO MATERIALS CO LTD

Comprehensive recycling method of waste and old lithium-ion battery

ActiveCN103326088ANo pollution in the processReduce pollutionWaste accumulators reclaimingProcess efficiency improvementSulfite saltEngineering

The invention provides a comprehensive recycling method of a waste and old lithium-ion battery, and relates to the lithium-ion battery. The method comprises the following steps of: performing explosion-proof magnetic smashing and atomized spraying smashing on the waste and old lithium-ion battery, thereby separating an outer shell and a battery material; carbonizing and roasting in a constant-temperature roaster at high temperature and under negative pressure, thereby removing an isolated membrane and a cathode; recycling the outer shell and an anode material in a grading manner by using a centrifugal disintegrator, thereby separating the outer shell and the anode material containing nickel and cobalt; leaching out by adding sodium sulfite into H2SO4 at the normal pressure by utilizing the characteristics of the anode material; regulating the pH value by adding carbonate into an leaching liquid; preliminarily removing Ca and Mg by adding a fluoride salt; extracting and removing impurities by using P2O4, thereby removing the impurities such as Fe, Cu, Zn, Ca, Mg and the like; performing selective extraction for cobalt-nickel separation by using P507, thereby obtaining a high-purity nickel sulfate solution and a high-purity cobalt sulfate solution in which the content of the Fe, the Cu, the Zn, the Ca and the Mg is respectively less than or equal to 2.0mg / L. The method is efficient, simple and convenient and low in production cost, and has wide applicability and a high additional value.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

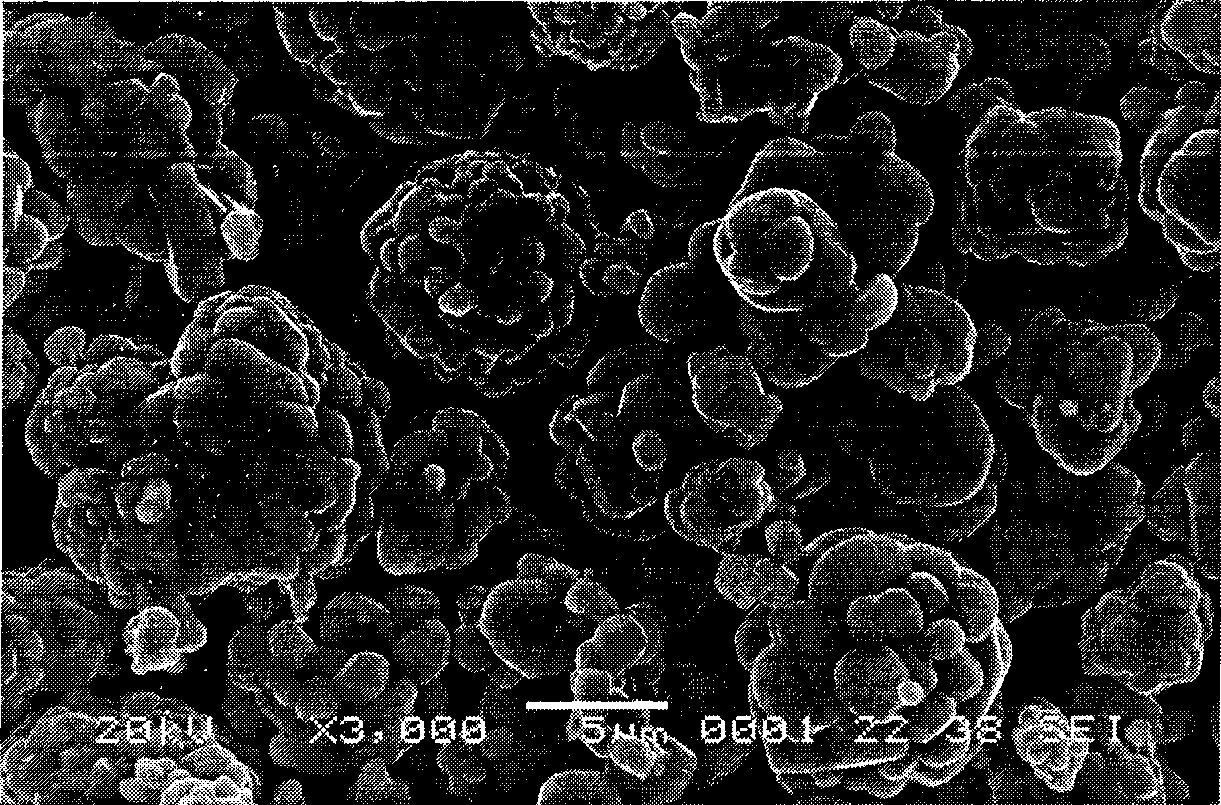

Method for preparing ternary cathode material precursor by recycling lithium-ion battery material

InactiveCN105633500AHigh purityLow costWaste accumulators reclaimingBattery recyclingManganeseLithium-ion battery

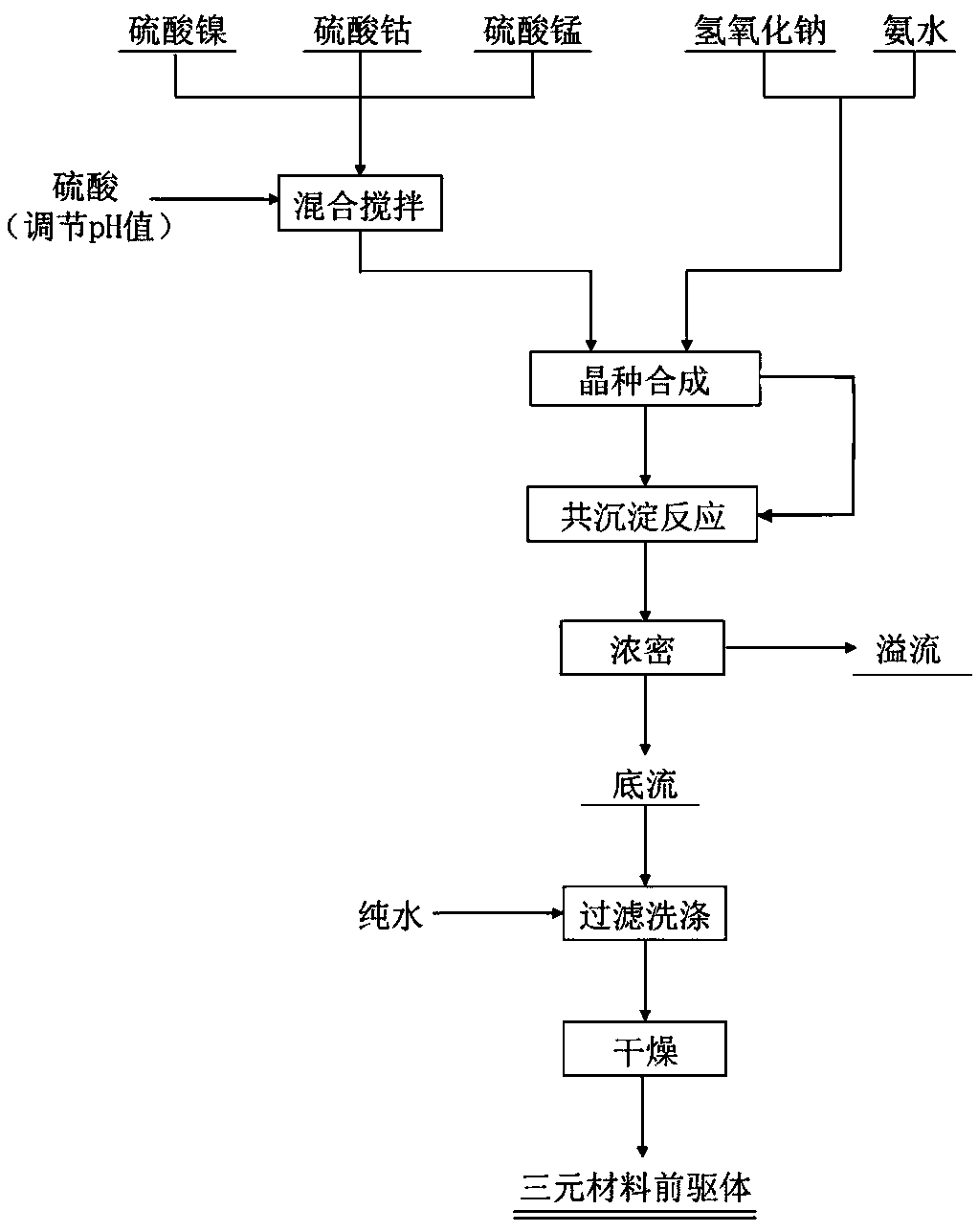

The invention relates to a method for preparing a ternary cathode material precursor by recycling a lithium-ion battery material. The method comprises the following steps: recycling a lithium-ion battery cathode material with sulfuric acid and hydrogen peroxide to obtain a first solution; adjusting the pH value of the first solution to be 5-6.5, adding a filter aid and filtering out impurities to obtain a second solution; adding nickel sulfate, cobalt sulfate and / or manganese sulfate to the second solution, adjusting the molar ratio of nickel to cobalt to manganese to be (0.4-0.6) to (0.1-0.3) to (0.2-0.4) to obtain a third solution; adding a complex precipitant to the third solution, adjusting the pH value of the third solution to be 7-9, and reacting to obtain a nickel-cobalt-manganese ternary material precursor sediment; and washing and drying the nickel-cobalt-manganese ternary material precursor sediment to obtain the ternary cathode material precursor. The method is high in recovery rate; the recycling process is simple; and the prepared ternary cathode material precursor is high in purity, small in particle size, narrow in distribution and even to mix.

Owner:TIANQI LITHIUM CORP

Method for preparing ternary positive electrode material through recovering waste ternary lithium battery

ActiveCN111206148AHigh recovery rateReduce recycling costsCell electrodesWaste accumulators reclaimingManganese sulphatePregnant leach solution

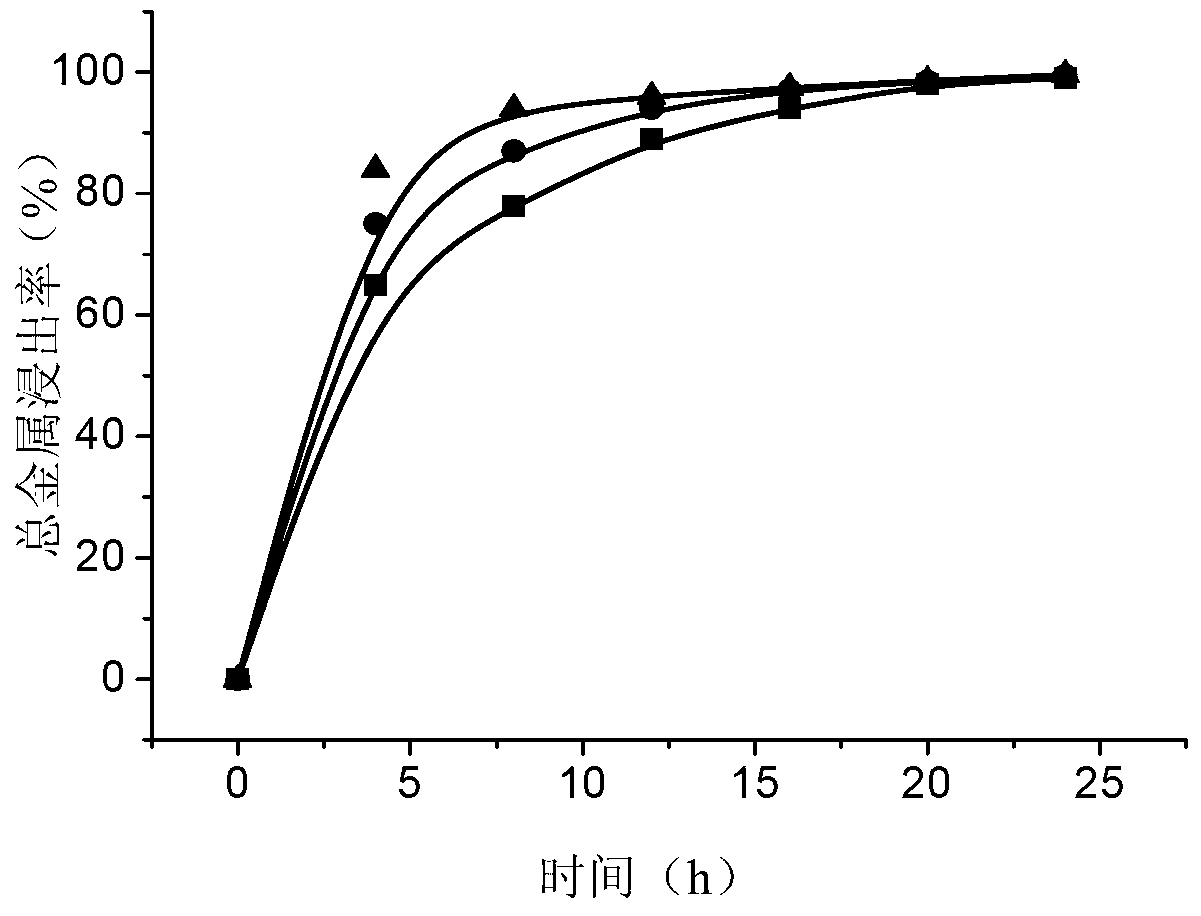

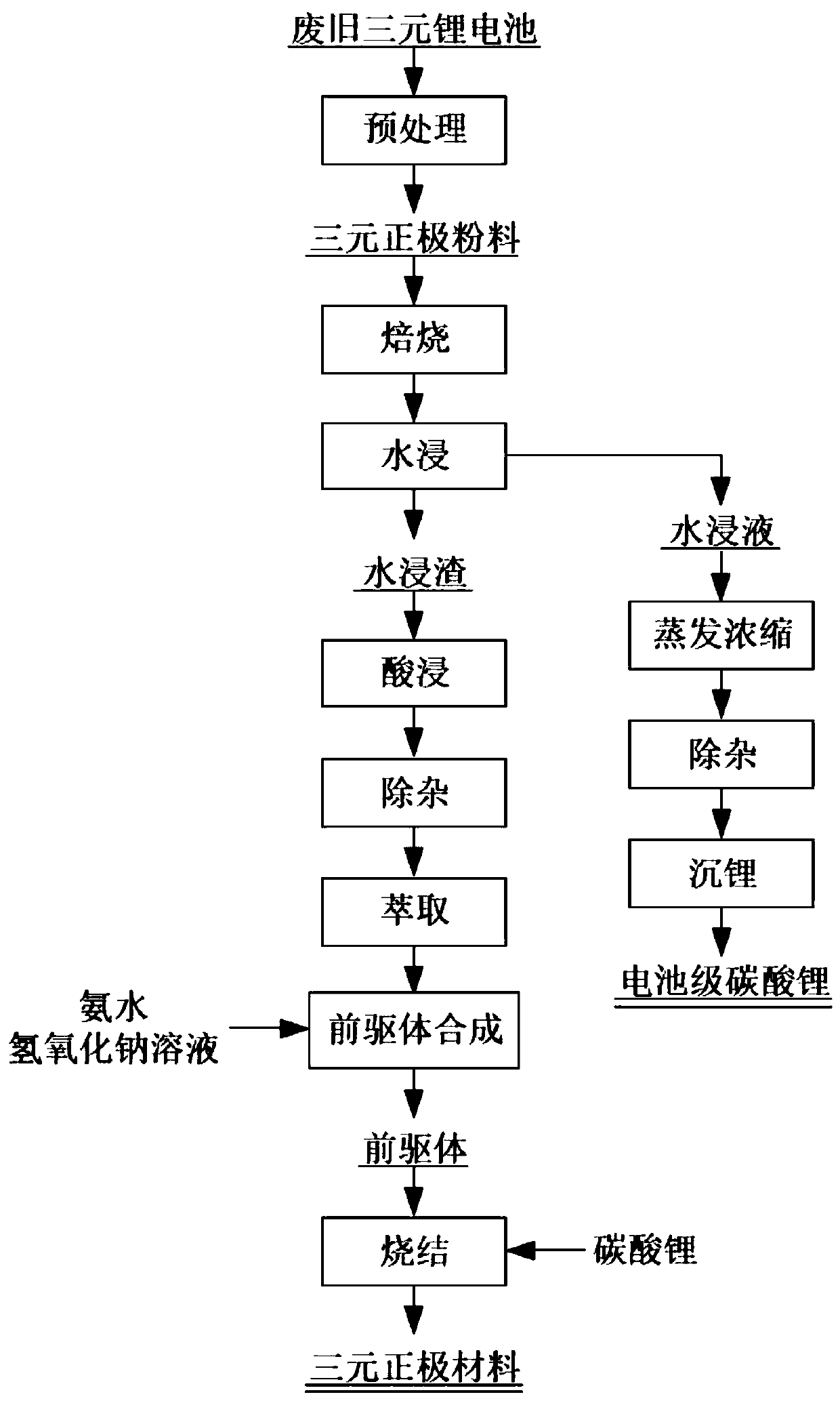

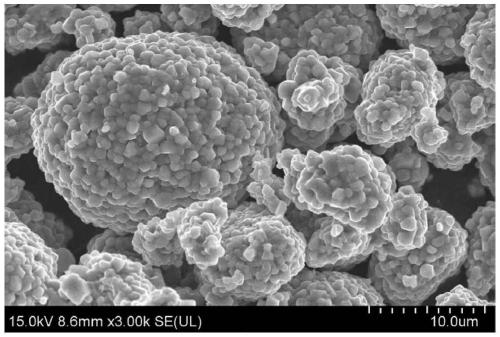

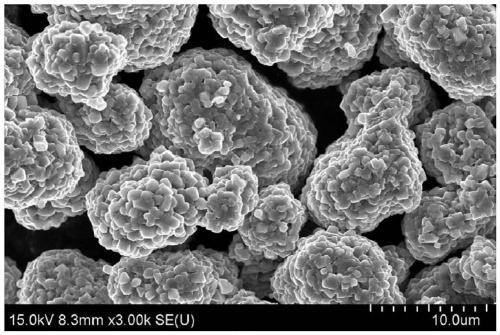

The invention provides a method for preparing a ternary positive electrode material through recovering a waste ternary lithium battery. The method comprises the following steps of 1) mixing pretreatednickel cobalt lithium manganate waste positive electrode powder with sulfate, and roasting to obtain a roasted product; 2) immersing the roasted product in water to obtain water immersion liquid andwater immersion slag; wherein the water immersion liquid contains lithium salt; 3) reacting the water immersion slag with an acid solution and hydrogen peroxide to obtain a nickel-cobalt-manganese leaching solution; 4) removing impurities from the nickel-cobalt-manganese leaching solution, then extracting cobalt, manganese and nickel, and saponifying and reversely extracting obtained organic phaseto obtain a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution; and 5) co-precipitating the nickel sulfate solution, the cobalt sulfate solution and the manganese sulfate solution with a sodium hydroxide solution and ammonia water, mixing obtained precursor with lithium carbonate, sintering, and screening iron to obtain the ternary positive electrode material. According to the method, lithium is extracted firstly, so that the influence of a lithium element on subsequent nickel-cobalt-manganese extraction is reduced, the impurity content in the ternary positiveelectrode material is reduced, and the recovery rate of nickel-cobalt-manganese is greatly improved; and meanwhile the recovery rate of the lithium can be improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Heat-stress alleviant for milk-cow, prepn. method and application thereof

InactiveCN1618316AImprove utilization rateIncreased Niacin LevelsAnimal feeding stuffAccessory food factorsSodium bicarbonateAntioxidant

Owner:FUJIAN AGRI & FORESTRY UNIV

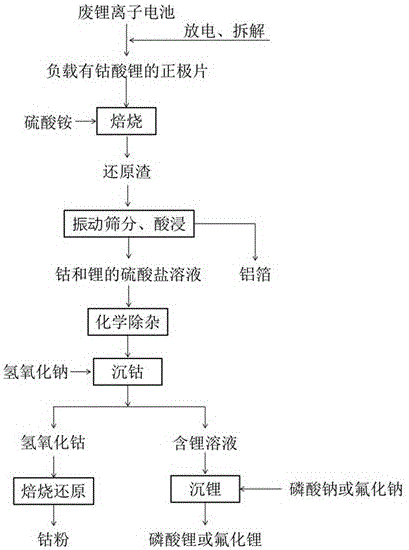

Method for recycling cobalt and lithium from positive plate of waste lithium ion battery

ActiveCN106505270AGuaranteed RecoveryHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementSlagLithium-ion battery

The invention provides a simple and high-efficiency method for recycling cobalt and lithium from a positive plate of a waste lithium ion battery, and relates to a method for recycling cobalt and lithium from the positive plate of the waste lithium ion battery. The method is characterized by comprising the following processes of ammonium sulfate roasting, in which the positive plate of the waste lithium battery is mixed with ammonium sulfate, and high-temperature roasting is performed to obtain reduction roasting slag; screening, in which the reduction roasting slag is vibrated and is screened by a vibration screening machine, and an aluminum foil is separated and removed to obtain reduction slag containing cobalt and lithium; acid leaching, in which the aluminum foil is separated and removed from the reduction roasting slag, is leached in sulfuric acid and is filtered to obtain a sulfate solution containing cobalt and lithium; impurity removal, in which pH of the solution is adjusted by sodium carbonate, and a precipitant is filtered and removed to obtain a lithium-cobalt sulfate mixture solution; cobalt deposition, in which sodium hydroxide is added into the lithium-cobalt sulfate mixture solution, the pH of the solution is controlled to be 7.5-9.5, and filtering is performed to obtain the precipitant, the precipitant is washed with deionized water at 85-95 DEG C, cobalt hydroxide is dried, cobalt hydroxide after being dried is placed in a reduction furnace, and H2 is introduced for reduction to obtain cobalt powder; and lithium deposition, in which pH of a lithium-containing solution is adjusted to 7-8, and an excessive amount of a lithium deposition agent is added to a lithium salt product.

Owner:JINGMEN GEM NEW MATERIAL

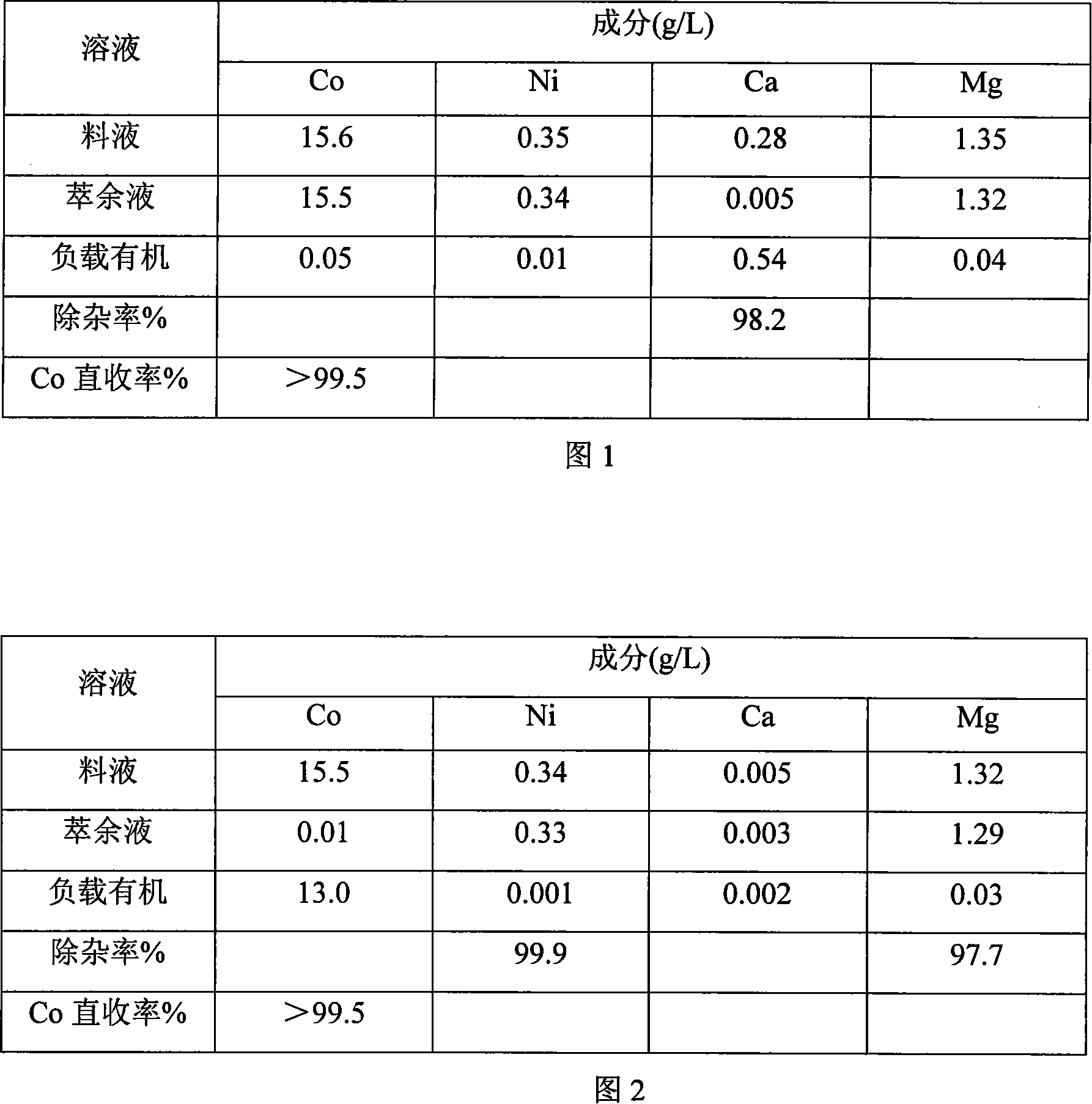

Extraction method for removing calcium and magnesium from copper-cobalt ore leachate

The process of extracting Co and eliminating Ca from copper-cobalt ore includes obtaining mixture leachate with soluble sulfate of Co, Ni, Ca and Mg; and extracting the mixture leachate with organic solvent, which comprises organic matter bis(2-ethyl hexyl) phosphoric acid or ”�2- ethyl hexyl phosphonate ester in 15-25 vol% and kerosene in 75-85 vol%. The organic solvent extracting procedure includes two steps, the first step of transferring Ca into the organic phase while leaving Co, Ni and Mg in the water phase, and the second step of transferring Co to the organic phase while leaving Ni and Mg in the water phase. The process can obtain cobalt sulfate solution with Co content up to 90-100 g / l, Ca ion content lowered to 0.01 g / l, Ni ion content lowered to 0.005 g / l, and Mg ion content lowered to 0.1 g / l and suitable for producing T-cobalt oxide and cobalt salt.

Owner:ZHEJIANG HUAYOU COBALT

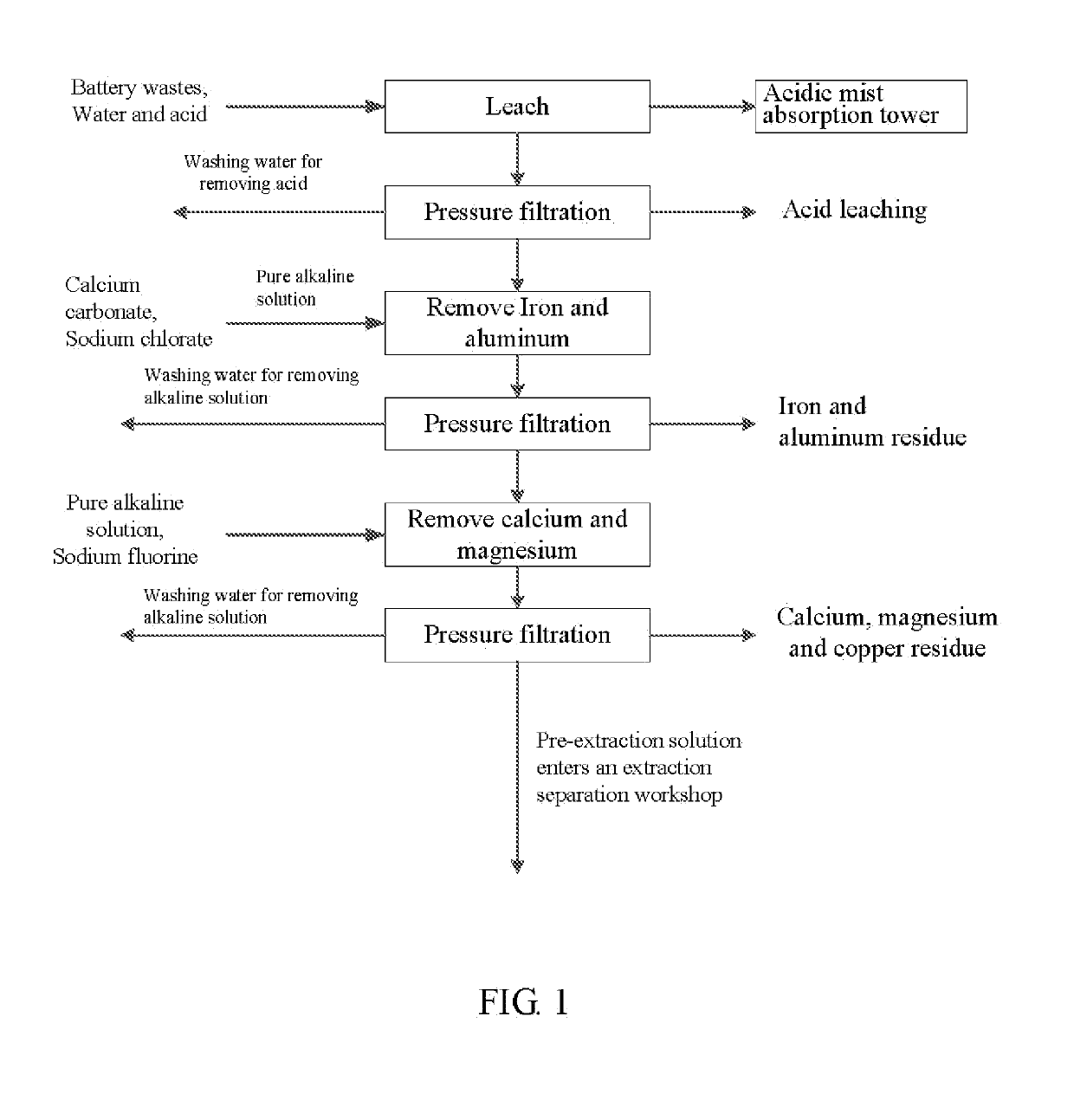

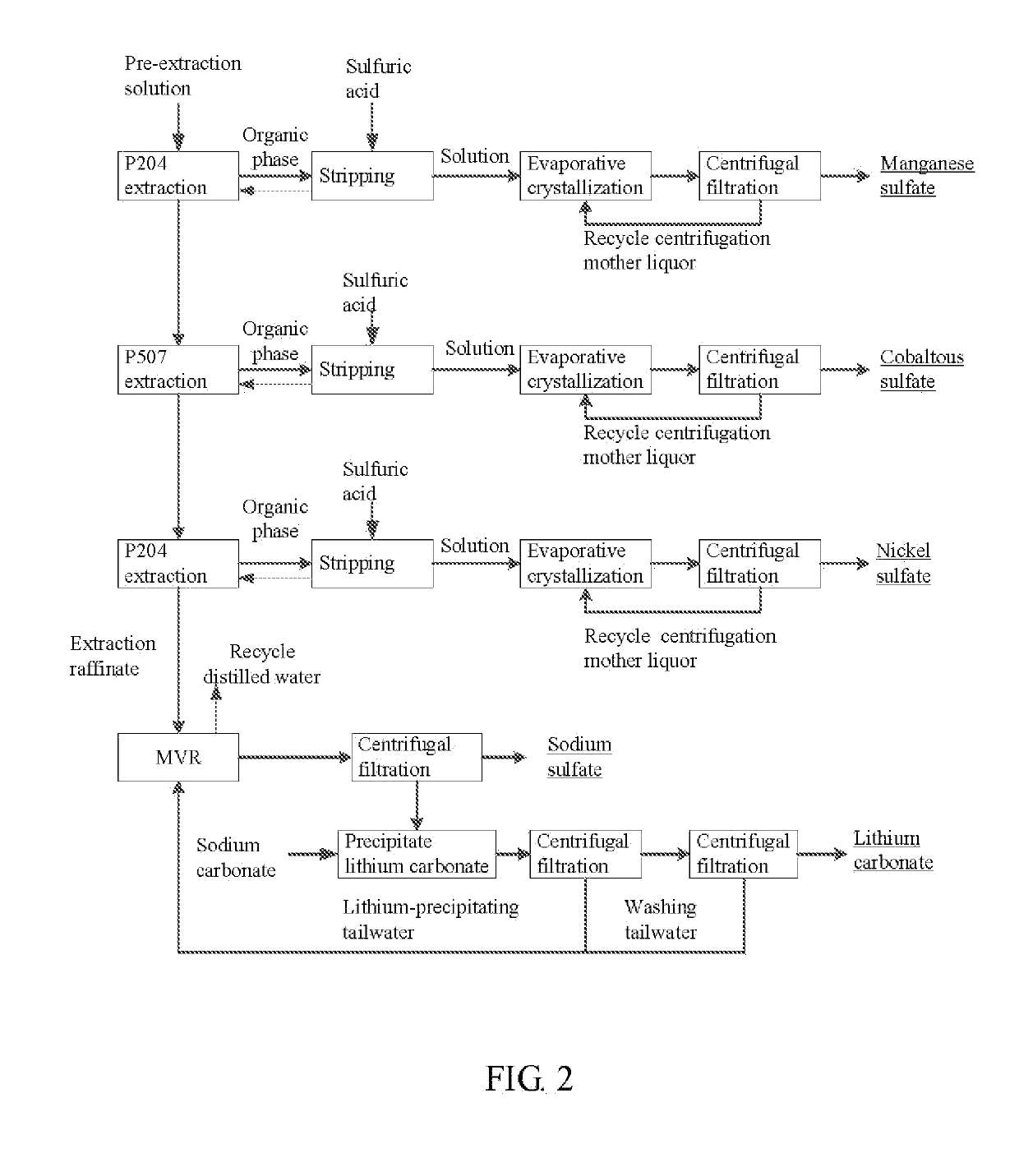

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

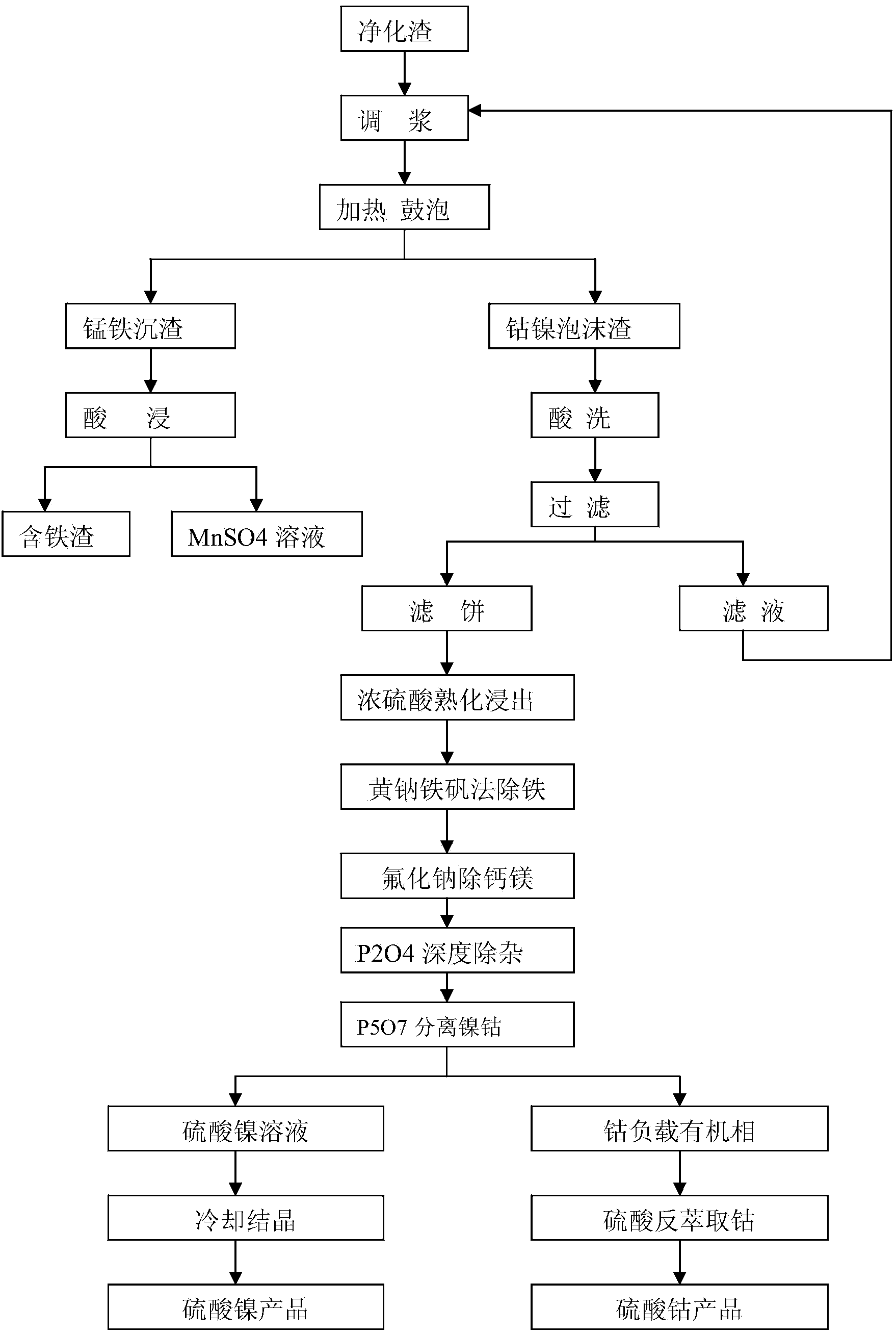

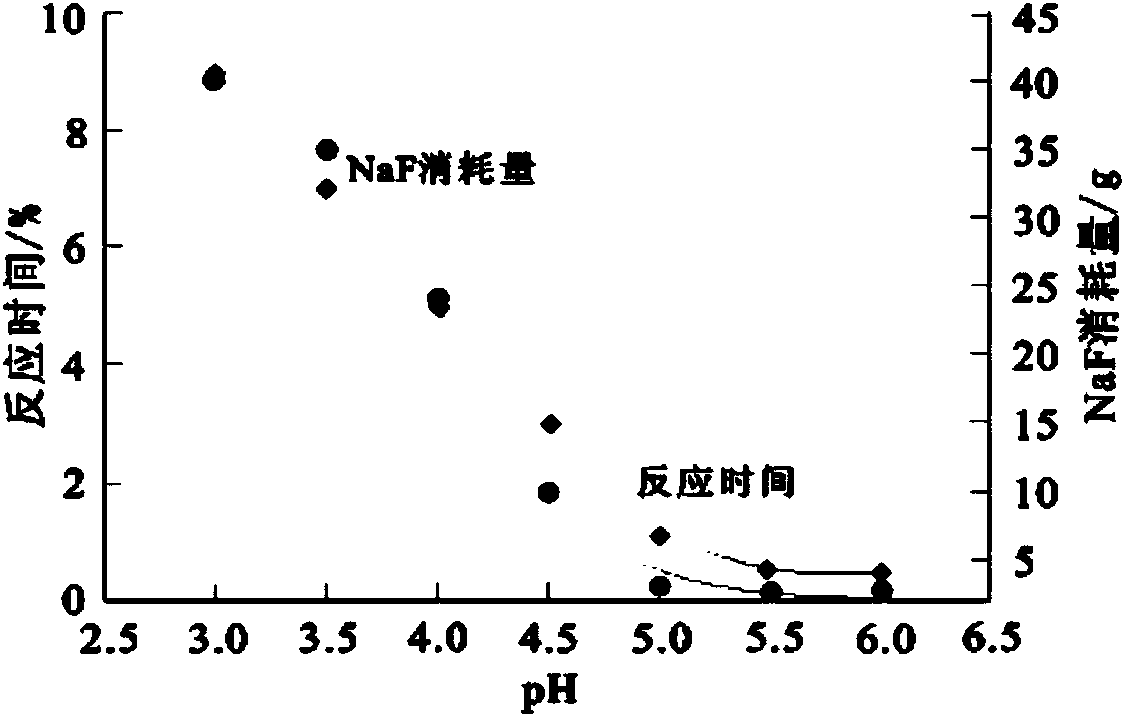

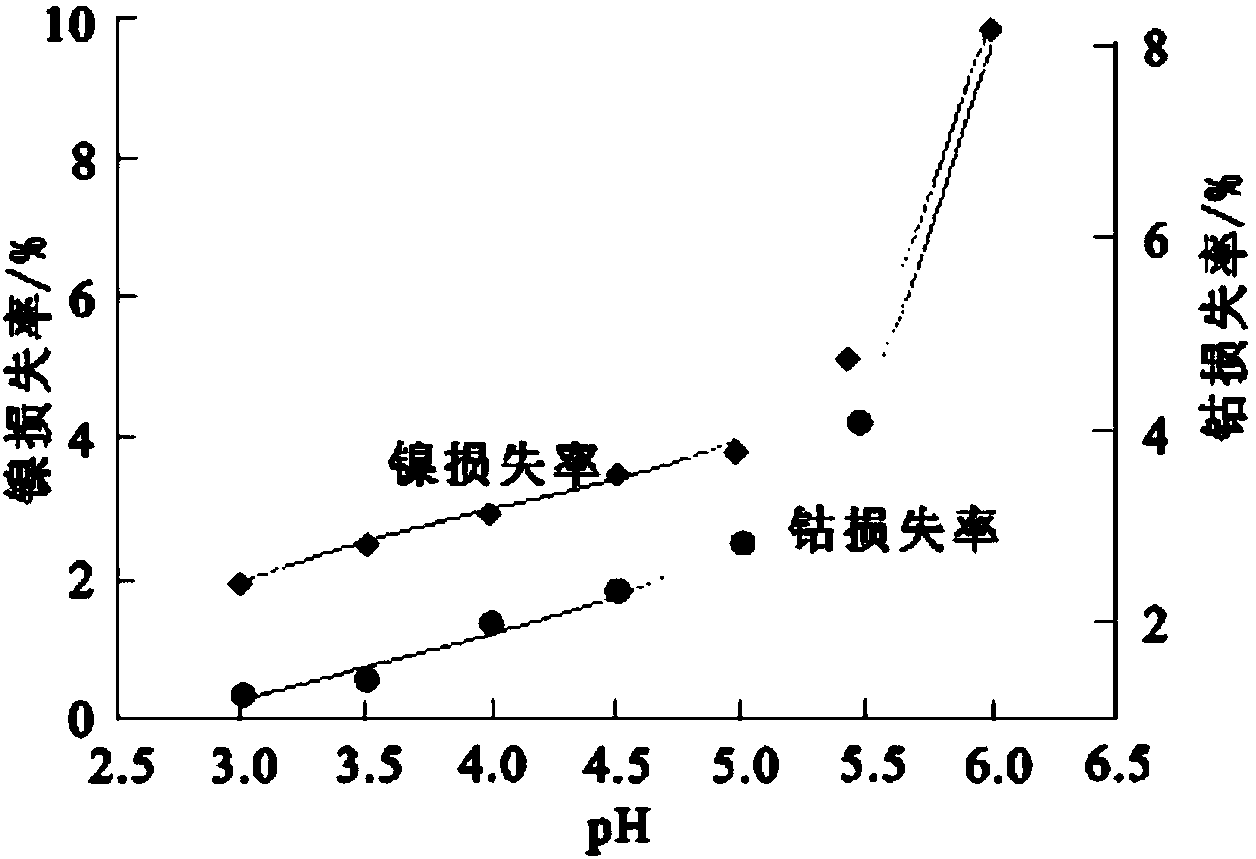

Method for extracting cobalt and nickel from manganese, cobalt and nickel waste residue

ActiveCN103773961AHigh recovery rateReduce consumptionProcess efficiency improvementLiquid ratioSlag

The invention discloses a method for extracting cobalt and nickel from a manganese, cobalt and nickel waste residue. The method sequentially comprises the following steps: a) adding water into the manganese, cobalt and nickel waste residue in a solid-to-liquid ratio of 1:(2-5) to size, and heating and bubbling under stirring to obtain cobalt and nickel foaming slags and ferromanganese sediments; b) heating, pickling and filtering the cobalt and nickel foaming slags to obtain a cobalt and nickel filter cake; c) curing and leaching the cobalt and nickel filter cake by concentrated sulfuric acid to obtain cobalt and nickel liquor; d) removing impurities in the cobalt and nickel liquor to remove impurities such as copper, iron, calcium, magnesium, manganese and zinc, wherein the mass concentration of impurities in the liquor is reduced to below 0.01g / L; e) extracting and separating the cobalt and nickel liquor without impurities by a P507 extractant to obtain nickel sulfate liquor and a cobalt-loaded organic phase; and f) cooling and crystallizing the nickel liquor, and recovering a nickel sulfate product, and carrying out reverse extraction on the cobalt-loaded organic phase by sulfuric acid to obtain cobaltous sulfate liquor. According to the invention, the production condition is relatively simple, efficient grouping is realized, and the recovery rate of cobalt and nickel is high.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

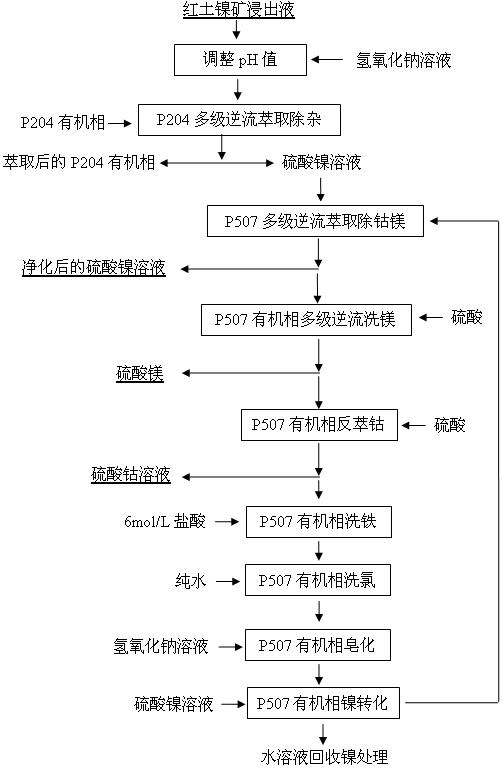

Method for treating red soil nickel ore leaching liquid

The invention discloses a method for separating nickel, magnesium and cobalt from red soil nickel ore leaching liquid based on a solvent extraction technology. The method is characterized by comprising the following steps of: adjusting the pH value of the leaching liquid to be between 3.5 and 5.5; extracting impurities by using diisooctyl acid phosphate, and adding into an organic phase; extracting the cobalt and the magnesium by using 2-ethylhexyl phosphonic acid single 2-ethylhexyl ester; making the nickel left in a water phase to separate the nickel from the cobalt and the magnesium; performing multi-stage reverser flow magnesium washing on the organic phase from which the cobalt and the magnesium are extracted by using sulfuric acid solution at slightly low concentration; adding the magnesium into the water phase, and making the cobalt left in the organic phase to separate the cobalt from the magnesium; and reversely extracting the cobalt by using sulfuric acid solution at slightly high concentration to obtain cobalt sulfate solution with high purity. In the method provided by the invention, a process is simple, a relatively expensive reagent is not required to be consumed, the nickel, the magnesium and the cobalt can be effectively separated from the red soil nickel ore leaching liquid, nickel sulfate solution and the cobalt sulfate solution which have high purity are produced, the nickel and the cobalt have high recovery rates and the magnesium can be recycled.

Owner:广西银亿新材料有限公司

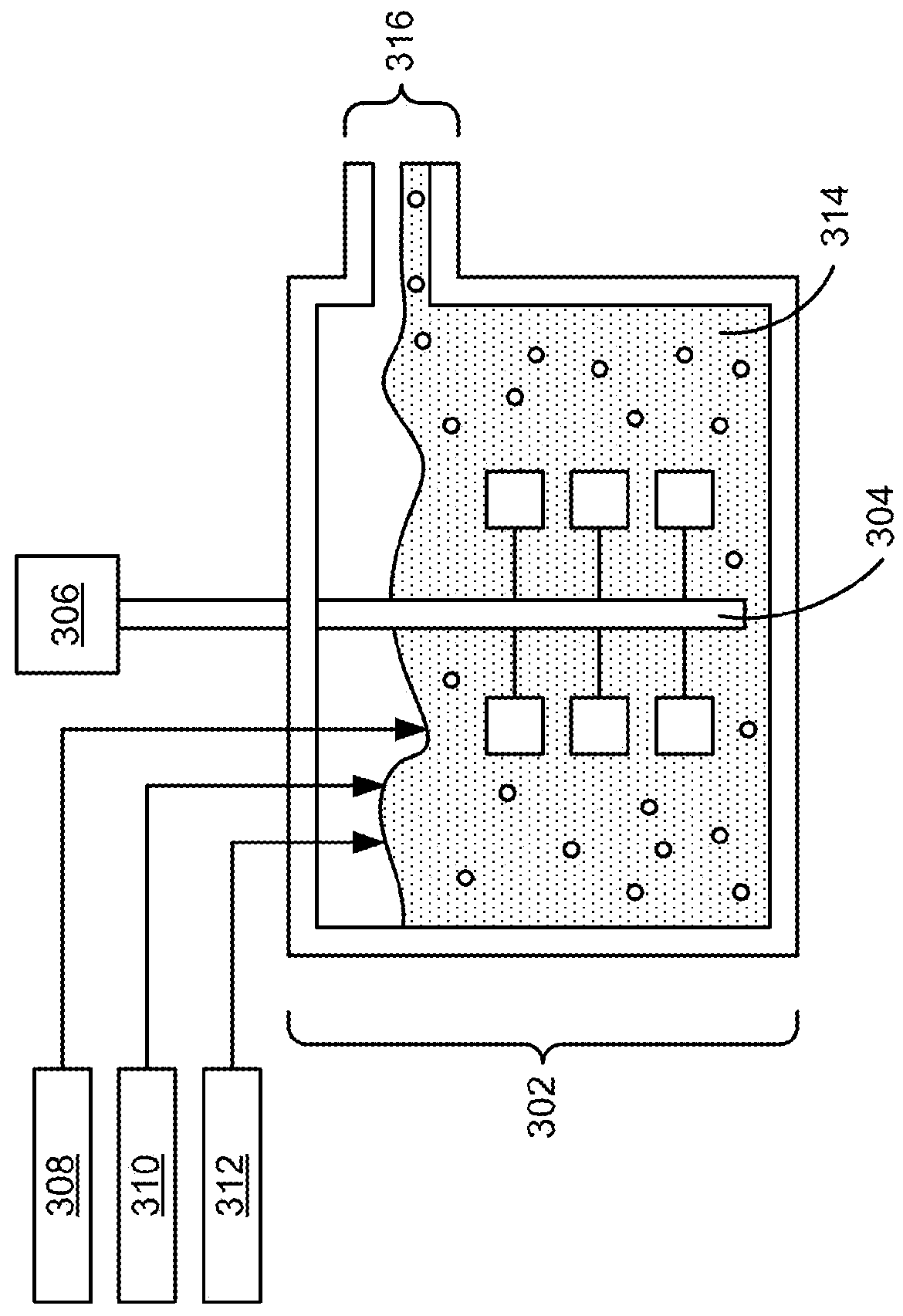

High-density precursor for manufacture of composite metal oxide cathodes for li-ion batteries

The disclosed embodiments relate to the manufacture of a precursor co-precipitate material for a cathode active material composition. During manufacture of the precursor co-precipitate material, an aqueous solution containing at least one of a manganese sulfate and a cobalt sulfate is formed. Next, a NH4OH solution is added to the aqueous solution to form a particulate solution comprising irregular secondary particles of the precursor co-precipitate material. A constant pH in the range of 10-12 is also maintained in the particulate solution by adding a basic solution to the particulate solution.

Owner:APPLE INC

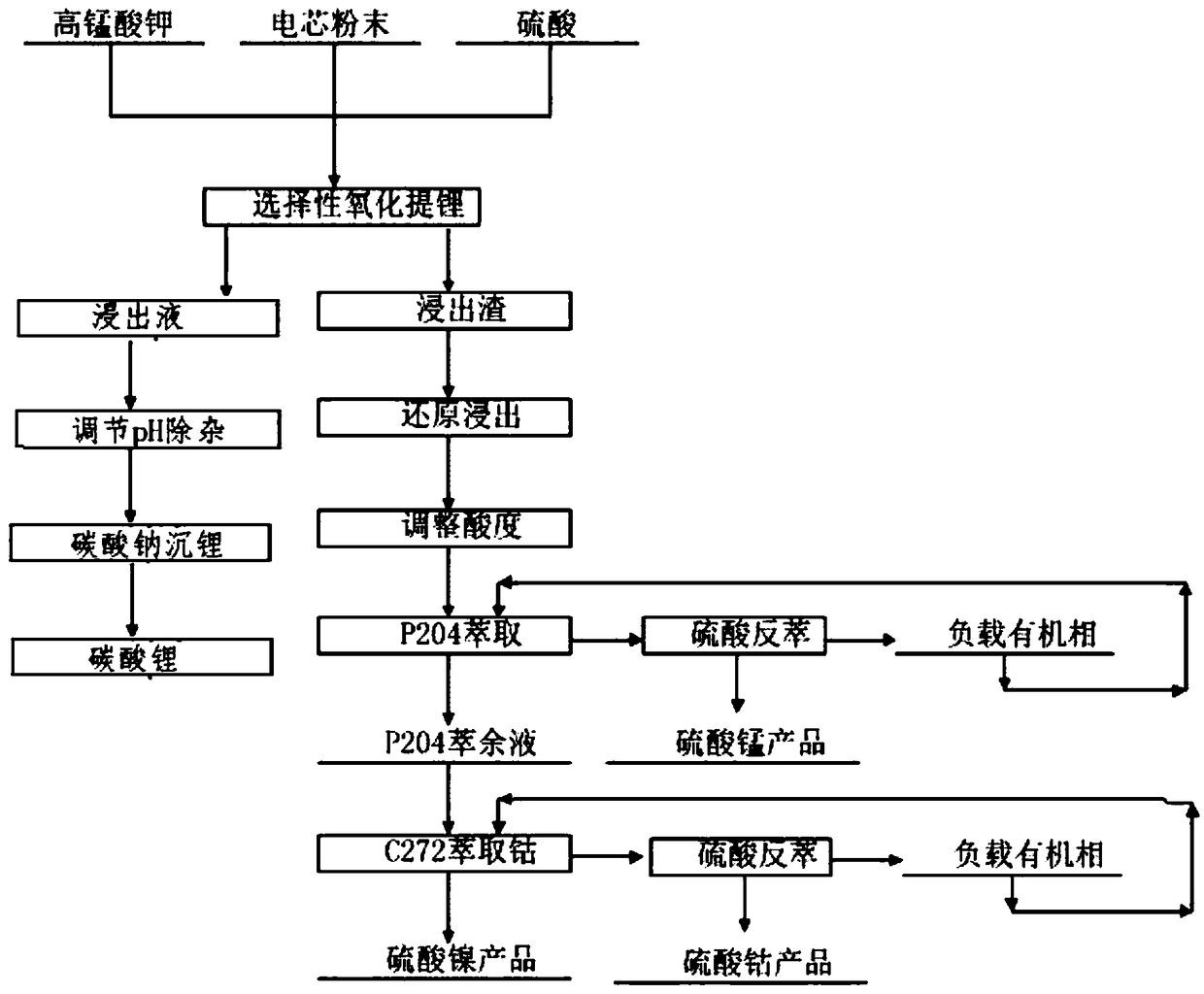

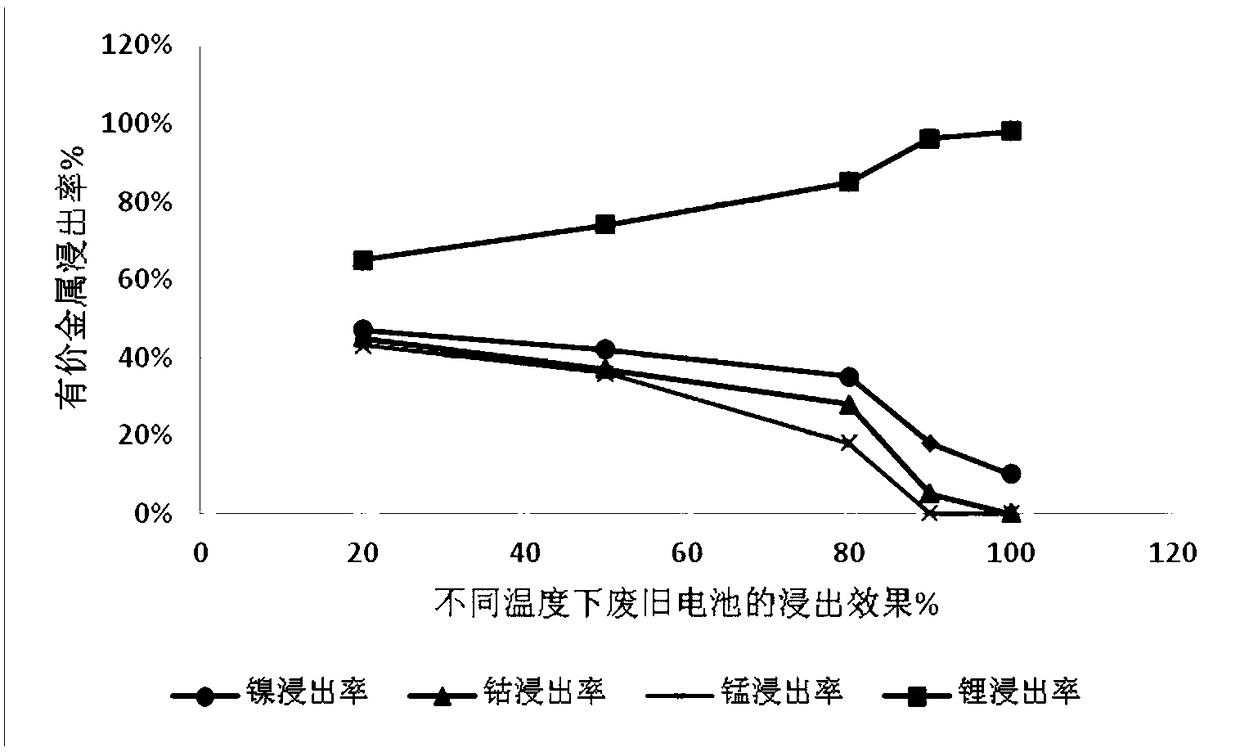

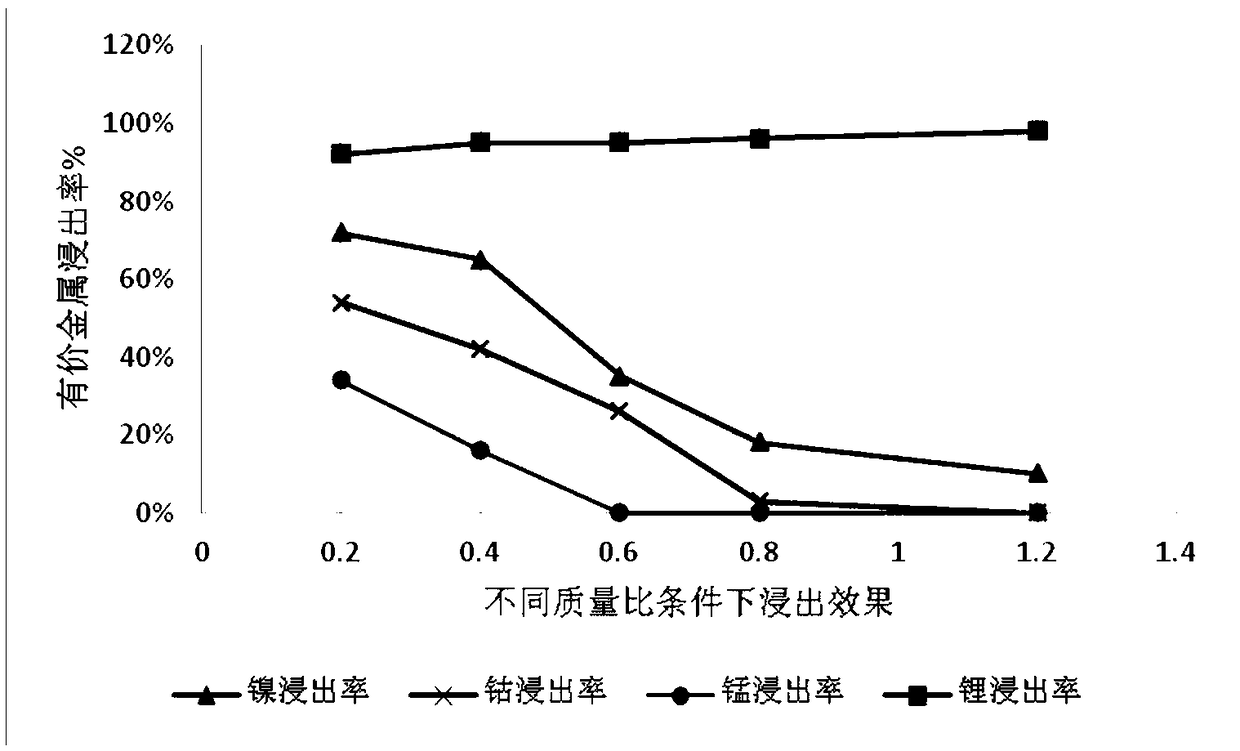

Comprehensive recovery method for waste lithium ion battery

ActiveCN109449523ASolve the problem of high concentration enrichment recoveryRealize harmless disposalWaste accumulators reclaimingProcess efficiency improvementRecovery methodLithium-ion battery

The invention provides a comprehensive recovery method for a waste lithium ion battery. The method comprises the following steps: three-element waste lithium battery cell powder is leached by sulfuricacid and potassium permanganate for the first time so as to obtain a first leaching solution and a first leaching residue; sodium carbonate is used for carrying out lithium precipitation on the firstleaching solution to obtain lithium carbonate; selective reduction leaching is carried out on the first leaching residue by using hydrogen peroxide and sulfuric acid so as to obtain a second leachingsolution and a second leaching residue; the pH value of the second leaching solution is adjusted to be 4.2-4.5, and P204 is used for extracting the second leaching solution so as to obtain a P204 raffinate and a P204 loaded organic phase; reverse extraction is carried out on the P204 loaded organic phase by using sulfuric acid, and evaporating and crystallizing are carried out to prepare manganese sulfate; the pH value of the P204 raffinate is adjusted to be 4.5-5, and the P204 raffinate is extracted by using C272 so as to obtain a C272 extracting solution and a C272 loaded organic phase; reverse extraction is carried out on a C727 loaded organic phase by sulfuric acid to obtain a cobalt sulfate solution, and evaporating and crystallizing are carried out to prepare battery-grade cobalt sulfate; and the pH value of a C272 raffinate is adjusted to be 5-5.5, the C272 extracting solution is extracted by using P507 to obtain a P507 loaded organic phase, sulfuric acid back-extraction is carried out on the P507 loaded organic phase to obtain a nickel sulfate solution, and evaporating and crystallizing are carried out to obtain nickel sulfate.

Owner:天齐锂业资源循环技术研发(江苏)有限公司

Micro arc oxidation electrolytic solution for light metals and micro arc oxidation method

ActiveCN101311326AIncrease added valueHigh hardnessAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides an electrolyte used for micro-arc oxidation of light metal. The electrolyte is aqueous solution containing sodium hexametahposphate and sodium silicate, wherein, the electrolyte also contains cobalt sulfate and ammonium metavanadate. The invention also provides a method of micro-arc oxidation by adopting the electrolyte. By adopting the electrolyte and the micro-arc oxidation method provided by the invention, light metal products with good pollution resistance, scrape resistance and compactness can be obtained.

Owner:BYD CO LTD

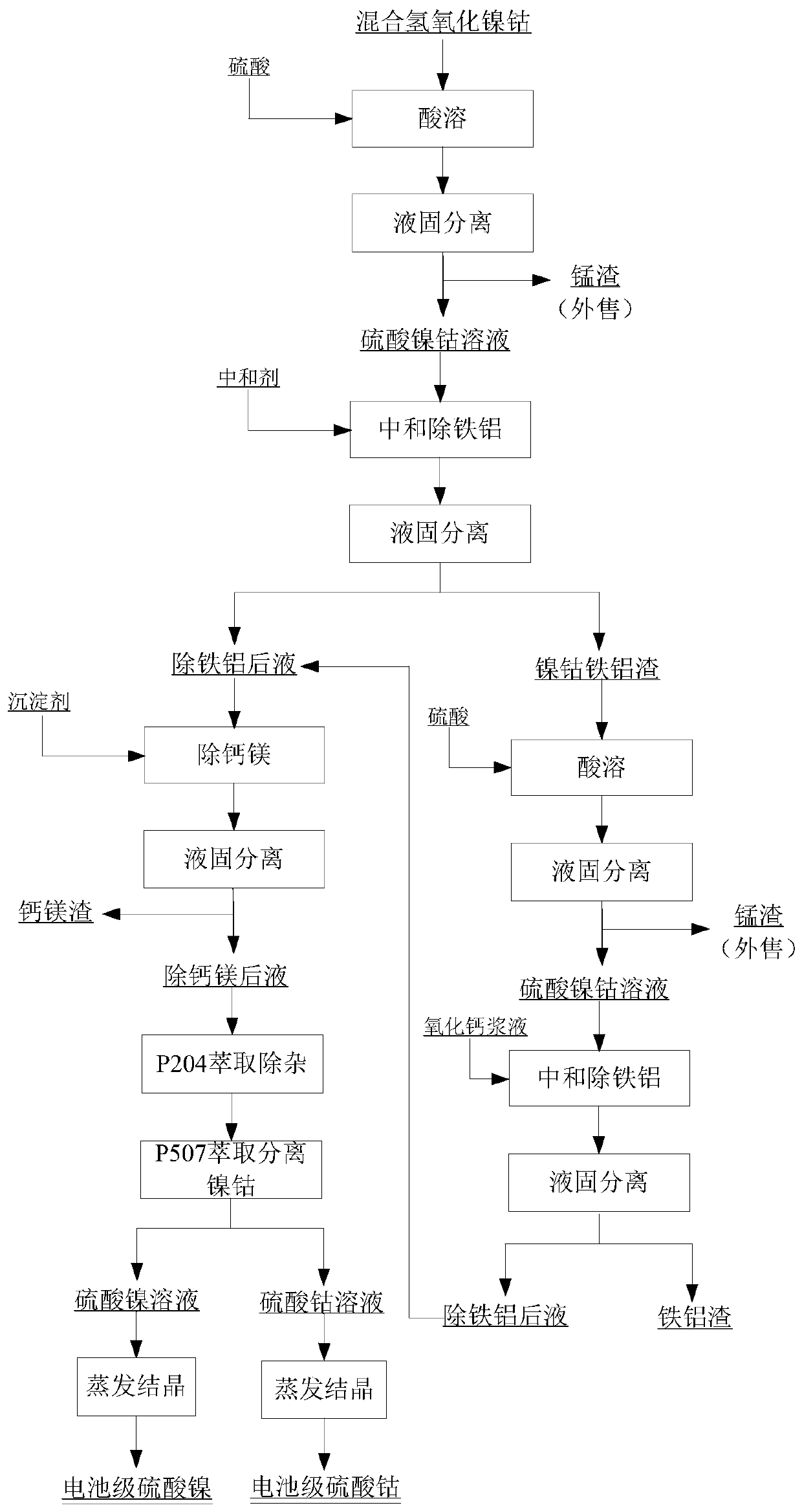

Method for preparing battery-grade nickel sulfate and cobalt sulfate from mixed nickel cobalt hydroxide

The invention discloses a method for preparing battery-grade nickel sulfate and cobalt sulfate from mixed nickel cobalt hydroxide, and belongs to the technical field of nickel cobalt hydrometallurgy.The method comprises the following steps that the mixed nickel cobalt hydroxide is leached by using sulfuric acid, iron and aluminum in the solution are removed by using a nickel / cobalt / manganese-based neutralizer, liquid-solid separation is carried out to obtain iron-removed slag, nickel and cobalt are recycled through acid dissolution, a precipitator (one or more of nickel fluoride, and cobalt fluoride and manganese fluoride) is added into iron-removed liquid to remove calcium and magnesium ions in the system. Impurities such as Mn, Cu and Zn are removed from the calcium and magnesium removed liquid by using a saponified P204 extractant, nickel and cobalt are separated from the P204 raffinate by using a saponified P507 extractant to obtain battery-grade nickel sulfate and a cobalt sulfate solution, and evaporative crystallization is carried out to obtain a product. According to the method, the use amount of calcium oxide is greatly reduced, the amount of calcium ions introduced intothe system and the corresponding nickel-cobalt loss are greatly reduced, the influence of calcium sulfate crystallization on extraction is avoided, the P507 extraction operation amount is reduced, andthe purification cost is reduced.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

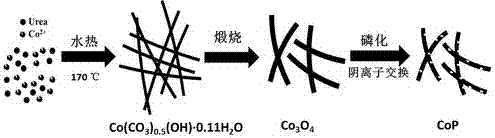

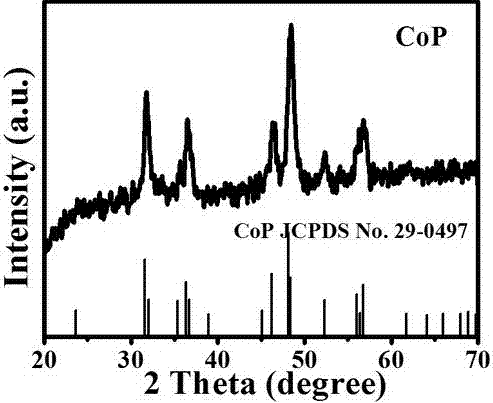

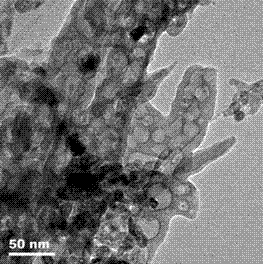

Preparation method of porous cobalt phosphide nanowire catalyst

InactiveCN107245727AImprove electrochemical activityImprove electrochemical stabilityNanotechnologyElectrode shape/formsNanowireFiltration

The invention discloses a preparation method of a porous cobalt phosphide nanowire catalyst. The method comprises the following steps that a solution is prepared by taking urea as a precipitant, taking cobalt sulfate hepathydrate as a cobalt source and taking glycerin and deionized water as solvents; the solution is added into a high pressure reactor for a hydrothermal reaction, after sufficient reaction is achieved, suction filtration and washing are conducted, vacuum drying is conducted, and then linear basic cobalt carbonate is obtained; in a tubular furnace, air burning is conducted on the linear basic cobalt carbonate at certain temperature, and cobaltosic oxide is obtained; and sodium hypophosphite serves as a phosphorus source, a cobaltosic oxide precursor and sodium hypophosphite are placed at the two ends of the same porcelain boat according to a certain proportion, the phosphorus source is placed at the upper stream of airflow, the treated porcelain boat is put into the tubular furnace for lower temperature calcination in an inert atmosphere, and preparation of the porous cobalt phosphide nanowire catalyst is achieved. The preparation method of the porous cobalt phosphide nanowire catalyst has the advantages that the production technology is simple, the cost is low, electrochemical activity and stability of the catalyst can be effectively improved, and the method is wide in application.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for separating nickel-cobalt and manganese in nickel-cobalt-manganese material with high manganese-cobalt ratio

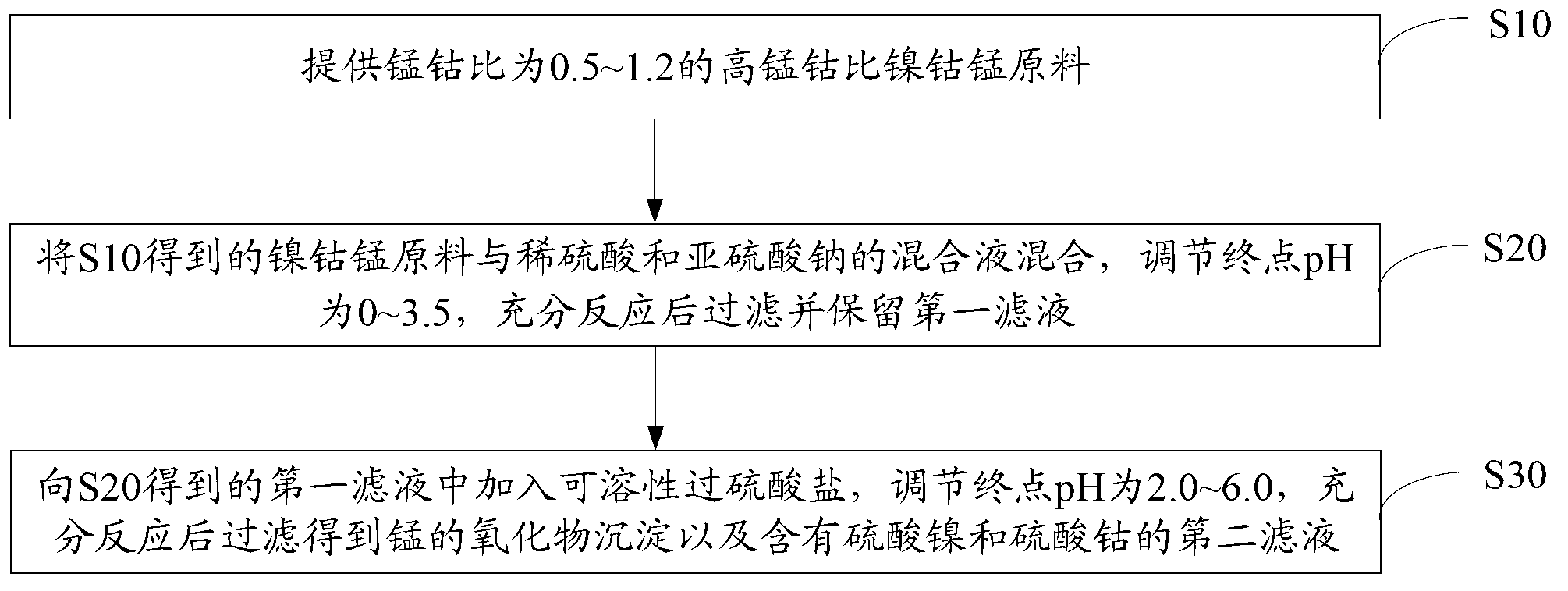

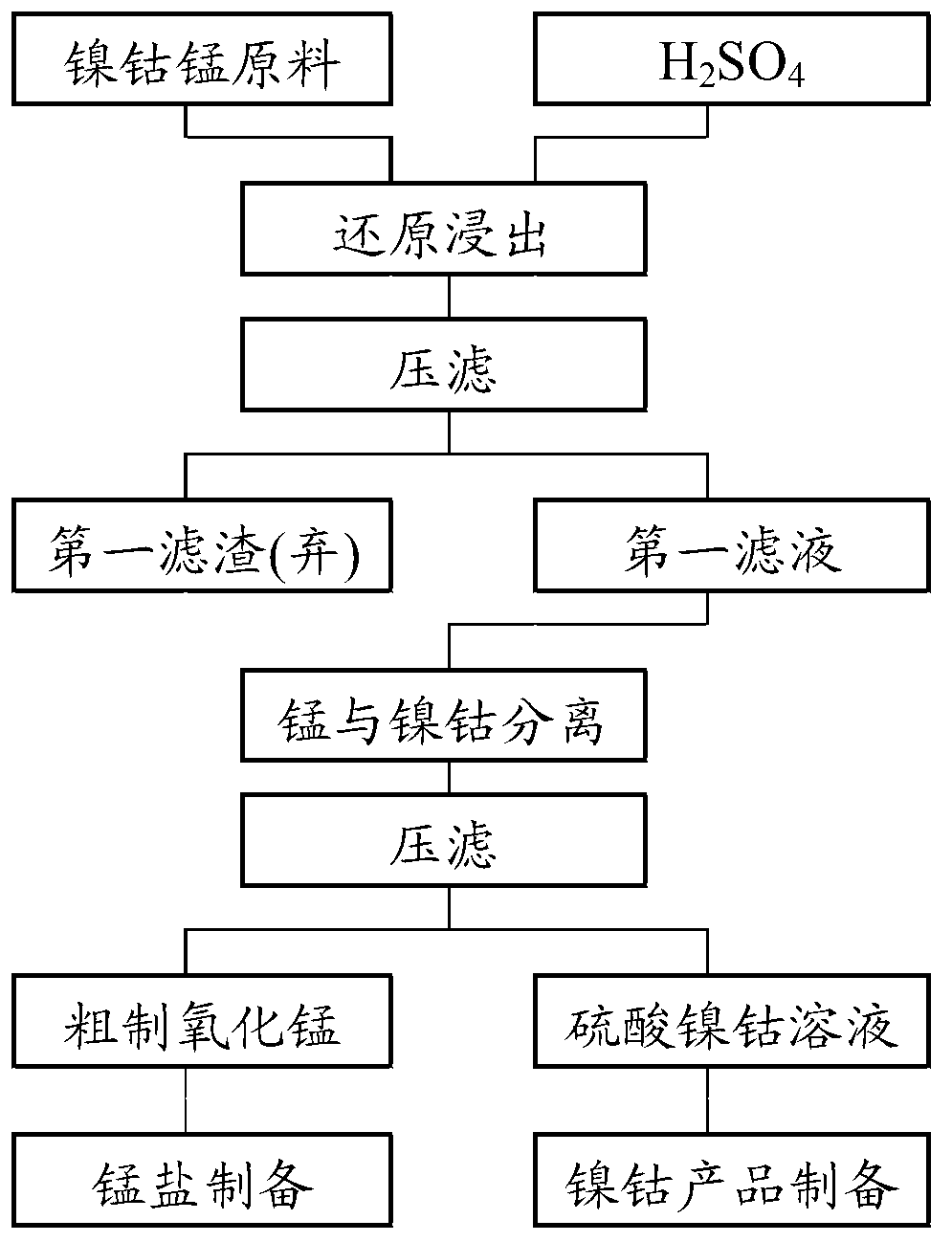

The invention discloses a method for separating nickel-cobalt and manganese in a nickel-cobalt-manganese material with a high manganese-cobalt ratio. The method comprises the following steps of: providing a nickel-cobalt-manganese material with the high manganese-cobalt ratio of 0.5-1.2; mixing the nickel-cobalt-manganese material with the high manganese-cobalt ratio with a mixed solution of dilute sulphuric acid and sodium sulfite; adjusting the final-point pH of the solution to 0-3.5; filtering and retaining first filtrate after the sufficient reaction; adding soluble persulfate to the first filtrate, adjusting the final-point pH of the mixed solution to 2-6; and filtering after the sufficient reaction to obtain second filtrate containing nickel sulfate and cobalt sulfate. According to the method for separating nickel-cobalt and manganese in the nickel-cobalt-manganese material with high manganese-cobalt ratio disclosed by the invention, the manganese is separated from nickel-cobalt in the solution by reducing and leaching out the nickel-cobalt-manganese from the mixed solution of the dilute sulphuric acid and the sodium sulfite, and then oxidizing and settling the manganese by adopting the soluble persulfate; compared with the conventional separating method for nickel-cobalt and manganese in the nickel-cobalt-manganese material, the process is simple and easy to apply, the production cost is low and the nickel-cobalt recovery rate is high.

Owner:GANZHOU HIGHPOWER TECH CO LTD

Normal temperature passivated zinc coating trivalent chromium color passivating agent

InactiveCN1858303AReduce concentrationReduce manufacturing costMetallic material coating processesMolybdateMalonic acid

The present invention discloses trivalent chromium color zinc coating passivator for passivation at normal temperature and its preparation process. The trivalent chromium color zinc coating passivator includes Cr3+ 1-7.5g / L, molybdate 1-25g / L, cobalt sulfate 5-15, ammonium bifluoride 1-8g / L, malonic acid 1-12g / L, phosphate 1-12 g / L, and silicate 0.2-6g / L. The trivalent chromium color zinc coating passivator solution has pH 1.8-2.3 regulated with sodium carbonate or nitric acid, passivating temperature of 20-35deg.c, passivating time of 30-60 sec and stoving temperature of 70-80deg.c. The present invention has the advantages of being practical and good use effect.

Owner:SUR PRECISION METAL TECH

Method for producing nickel-cobalt metal powder

The invention discloses a preparation method for nickel cobalt metal powders, which belongs to the technical field for preparation of non-ferrous metal metallurgy, powder metallurgy and material preparation. The preparation method is characterized in that nanometer or ultrafine nickel and cobalt metal powders is adopted as a seed crystal, which is mixed with ammoniacal water solution with nickel sulfate, cobalt sulfate, ammonia and ammonium sulfate, the preparation method adopts a hydrometallurgical hydrothermal hydrogen reducing technology and a device thereof, and the nanometer, ultrafine or tenuous nickel powder, cobalt powder and nickel cobalt alloy powder are prepared through the procedures such as ingredient, high-pressure hydrothermal hydrogen reduction, filtration, washing, drying and the like. The preparation method can be used for the field such as hydrogen storage alloy, galvanization, catalyst, sintering activating agent, magnetic materials, electric conduction slurry, battery materials, wave-absorbing materials, hard alloy, multi-layer porcelain capacitor, powder metallurgy and the like. The preparation method has the advantages of simple raw materials, simple process, short technological process, low manufacturing cost, controllable manufacturing process, high production efficiency, even graininess of metal powders, controllable size and composition and good quality of products.

Owner:张建玲

Electrolyte of lead-acid accumulator and preparation method thereof

InactiveCN101882694AExtended service lifeEnhanced cryogenic performanceFinal product manufactureLead-acid accumulators constructionLithium chlorideGas phase

The invention discloses an electrolyte of a lead-acid accumulator and a preparation method thereof. The electrolyte comprises the following raw materials in part by weight: 25 to 45 parts of deionized water, 60 to 70 parts of dilute sulfuric acid solution, 1.8 to 2.8 parts of gas-phase nanometer silicon dioxide and 2.5 to 3 parts of electrolyte activating agent, wherein the electrolyte activating agent is prepared from the following raw materials in part by weight: 1,000 parts of deionized water, 2 parts of nickel sulfate, 2 parts of cobalt sulfate, 25 parts of aluminum sulfate, 15 parts of sodium sulfate, 25 parts of magnesium sulfate, 20 parts of aluminium phosphate, 5 parts of lithium iodide, 5 parts of lithium chloride and 20 parts of lithium carbonate. Because the nickel sulfate, the cobalt sulfate, the lithium chloride and the lithium carbonate are added into the electrolyte activating agent, the large current charge and discharge and the ultra-low temperature performance of the accumulator are increased by 25 to 30 percent, and the service life of the accumulator is prolonged by 25 to 30 percent compared with the traditional accumulator with the traditional electrolyte. Because of the adoption of the nanometer silicon dioxide and the adoption of high-speed shearing way in the preparation method, the prepared electrolyte does not settle down within 30 days.

Owner:冯家齐

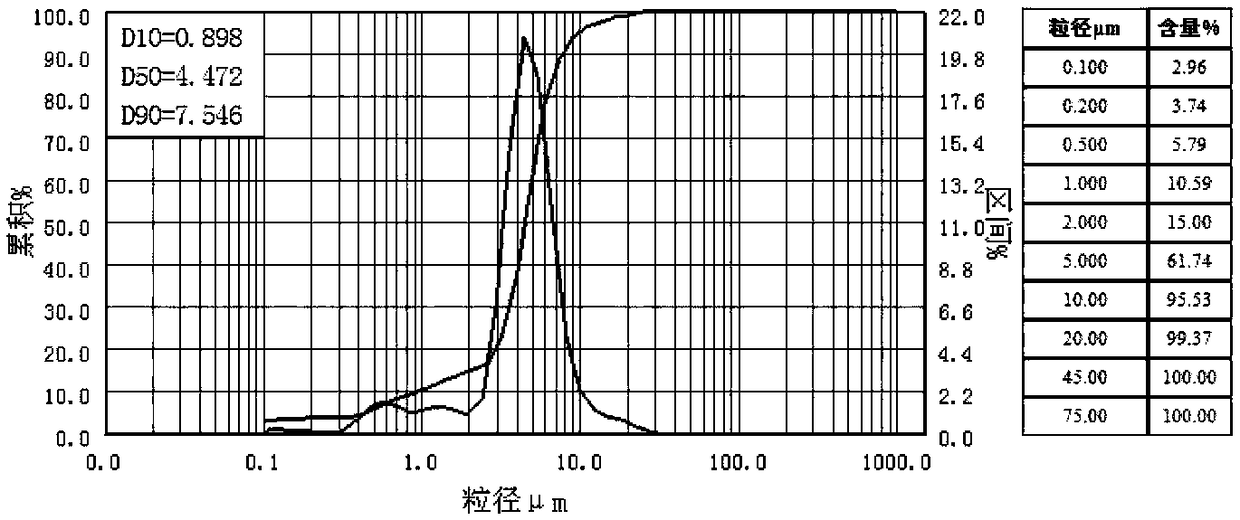

Nickel-cobalt-manganese ternary precursor material and synthetic method thereof

InactiveCN108807968ASmall particle sizeHigh tap densityCell electrodesLi-accumulatorsManganeseAmmonium hydroxide

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for electroforming nickel-cobalt alloy

The present invention relates to a method for electroforming nickel-cobalt alloy, belonging to the field of electroforming technology. The optimum composition of its electroplating solution includes nickel sulfate 220g / l, nickel chloride 15 g / l, cobalt sulfate 45g / l, sodium chloride Ig / l, boric acid 30g / l and sodium louryl sulfate 0.4 g / l. The thickness of nickel-cobalt alloy coat of the conticaster crystallizer copper plate electroformed by said invention is 2.0-3.0 mm. The binding force of the coat and base body is strong, the service life of the crystallizer copper plate is long.

Owner:ELECTROMECHANICAL APPTS PLANT MASCH MFG ANGANG GRP

Extraction process for preparing electronic-grade cobalt sulfate from cobalt-containing waste material

ActiveCN101974687AHigh recovery rateGuaranteed growthProcess efficiency improvementCobalt saltOctanol

The invention discloses an extraction process for preparing electronic-grade cobalt sulfate from a cobalt-containing waste material, and relates to an extraction method for cobalt salt. The process comprises the following steps of: performing acidolysis; filtering and separating; removing iron and copper; preparing rough Co material liquid; removing impurities by P204 extraction; and separating Co and Ni by P507 extraction; and the process is characterized in that an N235 extracting agent is prepared from 8 to 12 volume percent of N235, 8 to 12 volume percent of 2-octanol and 76 to 84 volume percent of 206 solution oil; and the prepared N235 extracting agent is added into raffinate of the P204 extraction and is subjected to six stages of extraction, two stages of hydrochloric acid washing, six stages of washing, three stages of ammonia water washing and one stage of sulfuric acid washing. The process has good impurity removal effect; compared with the prior art, the process has the advantages that: one order of magnitude is reduced, particularly, impurities such as cadmium, lead and the like which are difficult to remove are removed by P204 extraction and the P507 extraction, and the impurities reach an extremely low degree. The process has short flow, the comprehensive recovery rate of cobalt is high and the production cost is lower than the average cost of the same domestic industry.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

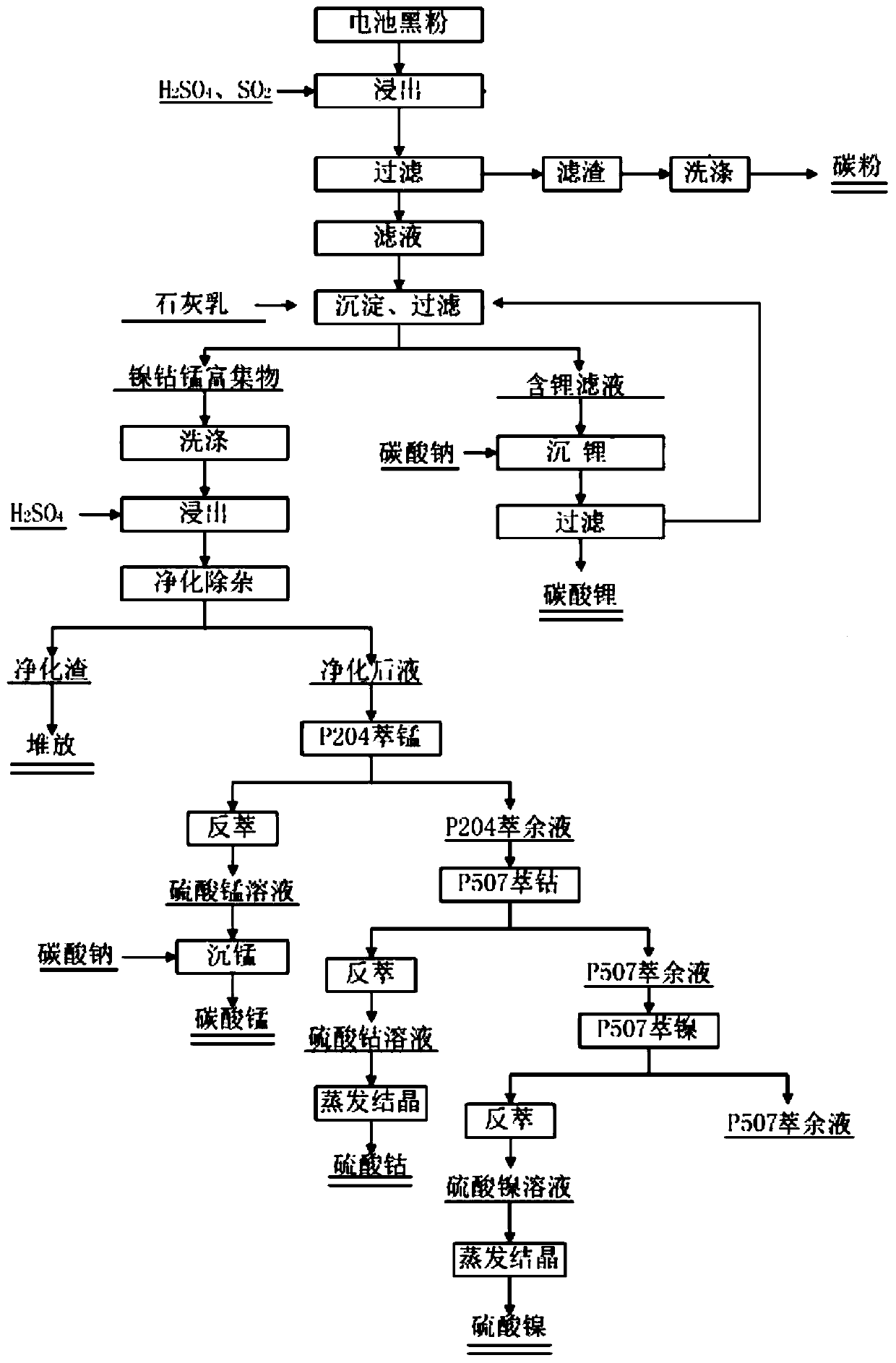

Method for recycling nickel-cobalt-manganese-lithium from waste power lithium ion battery black powder

ActiveCN111519031AHigh recovery rateImprove recycling ratesWaste accumulators reclaimingBattery recyclingLithium carbonateManganese

The invention discloses a method for recycling nickel-cobalt-manganese-lithium from waste power lithium ion battery black powder. The method comprises the steps of conducting leaching and filtering through a sulfuric acid and sulfur dioxide system, adding lime milk into filtrate, adjusting the pH to 10-12, controlling precipitation, and conducting filtering to obtain a nickel-cobalt-manganese enriched product and lithium-containing filtrate; conducting purifying and impurity removal on the lithium-containing filtrate, adding a sodium carbonate solution for precipitation of lithium to obtain lithium carbonate; leaching the nickel-cobalt-manganese enriched product through sulfuric acid, adjusting the pH to 4-6, removing impurity iron and aluminum, and conducting solid-liquid separation to obtain purified slag and purified liquid; and adjusting the pH of the purified liquid to 4-5, conducting manganese extraction with P204 as an extraction agent, conducting cobalt extraction with P507 asan extraction agent, and conducting nickel extraction with P507 as an extraction agent. Through the method provided by the invention, the lithium recovery rate is greatly increased; moreover, sodium hydroxide generated from precipitation of lithium can be returned and continuously used in the lime milk nickel-cobalt-manganese enrichment process; and meanwhile, the yield of nickel sulfate, cobalt sulfate and manganese carbonate is increased.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST

High anti-corrosion zinc coating trivalent chromium lue-white passivating agent and its preparing method

InactiveCN1858302AReduce concentrationReduce manufacturing costMetallic material coating processesAcetic acidMalonic acid

The present invention discloses anticorrosive trivalent chromium blue-white zinc coating passivator and its preparation process. The anticorrosive trivalent chromium blue-white zinc coating passivator includes Cr3+ 1-5 g / L, NaNO3 1-20 g / L, malonic acid 1-10 g / L, cobalt sulfate 5-20 g / L, acetic acid 1-10 g / L, phosphate 1-6 g / L, ammonium bifluoride 1-5 g / L and silicate 0.2-5 g / L. The preparation process includes dissolving the said materials in pure water successively through stirring to obtain transparent passivator. The present invention has the advantages of being practical and good use effect.

Owner:SUR PRECISION METAL TECH

Plating diamond tool with glass hard high-wearing feature and production method thereof

Disclosed is an electroplating diamond tool with high hardness and high wear resistance. The invention is formed by covering a coating of nano nickel-cobalt material on a green body of the diamond tool. The method of the tool comprises preparing electroplating liquid, preparing before electroplating of the green body of the diamond tool, and electroplating the green body of the diamond tool after the preparation. When electroplating the green body of the diamond tool after the preparation, the green body of the diamond tool is electroplated with the nano nickel-cobalt material by the utilization of the method of impulse electroplating. The electroplating liquid of the invention is formed by components of nickel sulfate, nickel chloride, cobalt sulfate, grain refiner, dodecyl sodium sulfate, boracic acid and the like. The tool has high hardness and high wear resistance, and thereby the service life is long. Further, the invention has the advantages of short manufacture period.

Owner:HENAN AGRICULTURAL UNIVERSITY

Method for preparing lithium carbonate and ternary precursor by recycling waste ternary lithium battery

ActiveCN112374511ACannot be recycled effectivelyImprove leaching rateWaste accumulators reclaimingNickel compoundsMetallic lithiumManganese

The invention discloses a method for preparing lithium carbonate and a ternary precursor by recycling a waste ternary lithium battery, and belongs to the field of solid waste recycling. Graphite and abinder carried in black powder obtained after pretreatment of a waste ternary battery are adopted as reducing agents, and the structure of the ternary material is destroyed through self-reduction phase inversion; lithium carbonate is converted into lithium bicarbonate which is easy to leach with water by adopting a carbonation water leaching method, so as to realize the preferential leaching of lithium; and sulfuric acid leaching is directly performed on the material subjected to lithium extraction without adding a reducing agent to obtain a nickel-cobalt-manganese solution. Copper, iron, calcium and other impurities in the solution are deeply removed through an impurity removal procedure, the content of aluminum and magnesium in the solution is controlled, then nickel, cobalt and manganese in the solution are extracted into an organic phase through synchronous extraction, a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution are obtained after reverseextraction is conducted through sulfuric acid, and a high-quality ternary positive electrode material precursor can be prepared after the metal proportion is adjusted. The method provided by the invention has the advantages of high recovery rate of valuable metals including lithium, nickel, cobalt and manganese, short flow, good product quality, economy and environment-friendliness.

Owner:UNIV OF SCI & TECH BEIJING

Brilliant tin plate chromium-free passivation solution and passivation method

InactiveCN101358342AImprove corrosion resistanceImprove antioxidant capacityPhosphatisationMetallic material coating processesChromium freeSodium molybdate

The invention discloses bright tin plate non-chromium passivation solution, wherein, each liter of passivation solution contains 20g to 70g of trisodium phosphate, 0.1g to 5g of cobalt sulfate, 0.5g to 3g of sodium molybdate, 20g to 75g of phosphoric acid, the rest is water, and the ph value of the passivation solution is 3 to 5. The invention also discloses a tinplate passivation method; in the passivation with the non-chromium passivation solution of the invention, the working temperature of the passivation solution is 50 DEG C to 80 DEG C, the passivation time is 1s to 20s, and the passivation method is electro-chemical cathode passivation or chemical passivation. The tin plate non-chromium passivation solution of the invention does not contain hexavalent chrome, conducts chemical passivation or electro-chemical cathode passivation to the tinplate, and enables the tinplate to have the same high corrosion resistance and high oxidation resistance with a chromate passivation process. The welding performance, the adhesion performance to the coating and the like of the tinplate passivated through the non-chromium passivation process also meet the level of the tinplate passivated by chromate, which fundamentally solves the harm of the tinplate passivated by chromate with hexavalent chrome to the human body and the environment.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com