Comprehensive recycling method of waste and old lithium-ion battery

A technology of lithium-ion batteries and recycling methods, which is applied in the field of comprehensive recycling of waste lithium-ion batteries, can solve problems such as unsuitable processing of waste batteries, and achieve the effects of solving recycling safety problems, high economic benefits, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

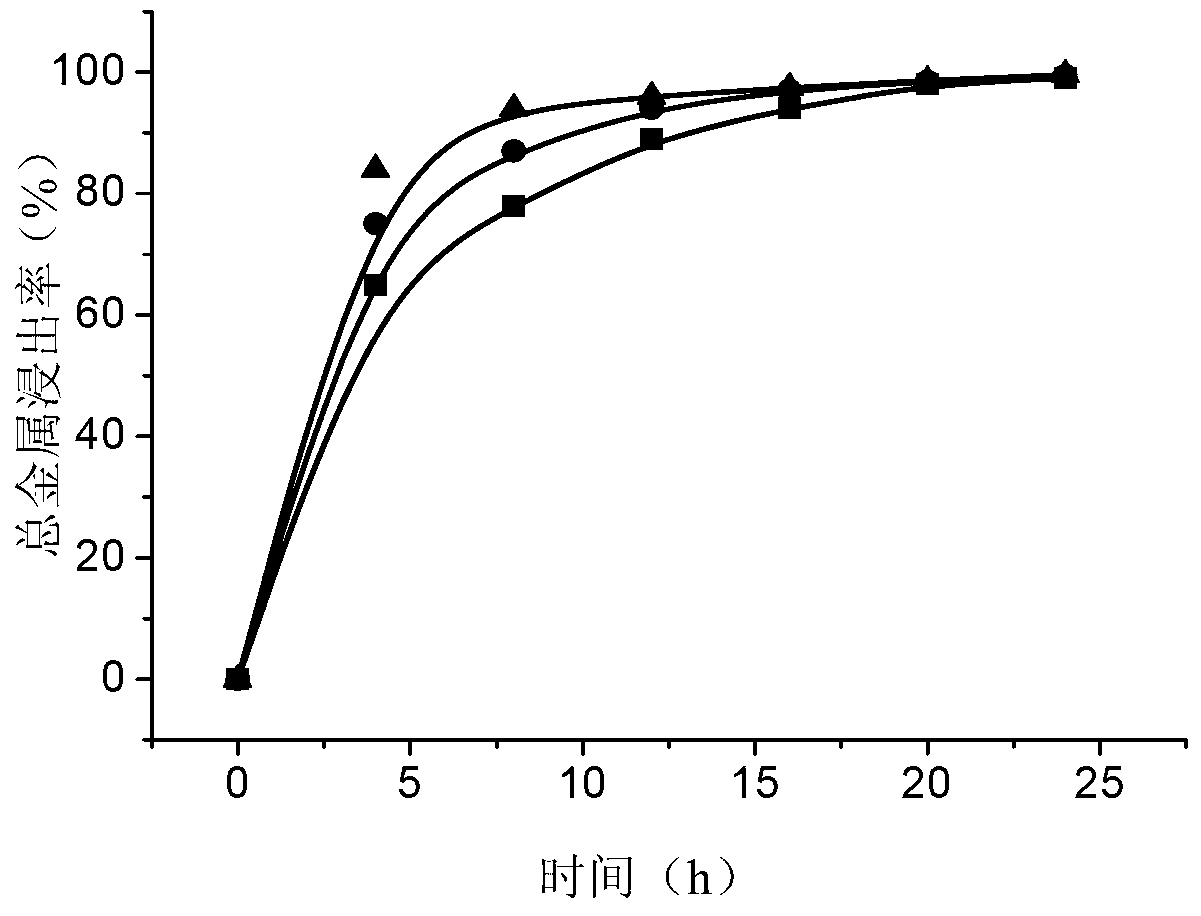

Embodiment 1

[0026] Composite waste lithium-ion batteries are crushed by the combination of explosion-proof magnetic crushing method and atomization spray crushing technology, then enter the constant temperature resistance furnace for heat treatment, control the negative pressure -2000Pa, roasting time is 4h, and use high-speed centrifugal crusher after cooling For crushing and classification, control the speed of the centrifugal crusher to 3200rpm, add 3mol / L sulfuric acid solution to the cobalt-nickel waste after separation, and add sodium sulfite at the same time. After leaching 15h, solid-liquid separation obtains cobalt-containing nickel solution (3.0mol / LH 2 SO 4 The relationship between metal leaching rate and metal leaching rate is shown in figure 1 ), add sodium carbonate to adjust the pH to 4.0, then add sodium fluoride to carry out preliminary impurity removal Ca, Mg, control Ca, Mg≤10ppm, after the impurity removal cobalt nickel solution is extracted by P204, adopt P507 extrac...

Embodiment 2

[0028] Composite waste batteries are crushed by the combination of explosion-proof magnetic crushing method and atomization spray crushing technology, then enter the constant temperature resistance furnace for heat treatment, control the negative pressure -3000Pa, roasting time is 3h, and use high-speed centrifugal crusher for crushing and classification after cooling , control the rotational speed of the centrifugal crusher at 4200rpm, add 2mol / L sulfuric acid solution to the cobalt-nickel waste after separation, and add sodium sulfite at the same time. After solid-liquid separation obtains cobalt-containing nickel solution, (2.0mol / LH 2 SO 4 The relationship between metal leaching rate and metal leaching rate is shown in figure 1 ), add sodium bicarbonate to adjust the pH to 4.5, then add sodium fluoride to carry out preliminary impurity removal Ca, Mg, control Ca, Mg≤10ppm, after the impurity removal cobalt nickel solution is extracted by P204, the cobalt nickel is separat...

Embodiment 3

[0030] Composite waste batteries are crushed by the combination of explosion-proof magnetic crushing method and atomization spray crushing technology, then enter the constant temperature resistance furnace for heat treatment, control the negative pressure -4000Pa, roasting time is 3h, and use high-speed centrifugal crusher for crushing and classification after cooling , control the rotational speed of the centrifugal crusher to 2800rpm, add the cobalt-nickel waste to the ternary composite waste battery after separation, add 4mol / L sulfuric acid solution, and add sodium sulfite at the same time, the amount of sulfurous acid used is 1.8 times the theoretical amount, and the leaching temperature is controlled by steam heating at 90°C, solid-liquid separation after leaching for 10 hours to obtain a cobalt-nickel solution (4.0mol / LH 2 SO 4 The relationship between metal leaching rate and metal leaching rate is shown in figure 1 ), add calcium carbonate to adjust the pH to 3.5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com