Patents

Literature

2422 results about "Sodium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to prevent cavities. It makes teeth stronger and more resistant to decay caused by acid and bacteria.

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

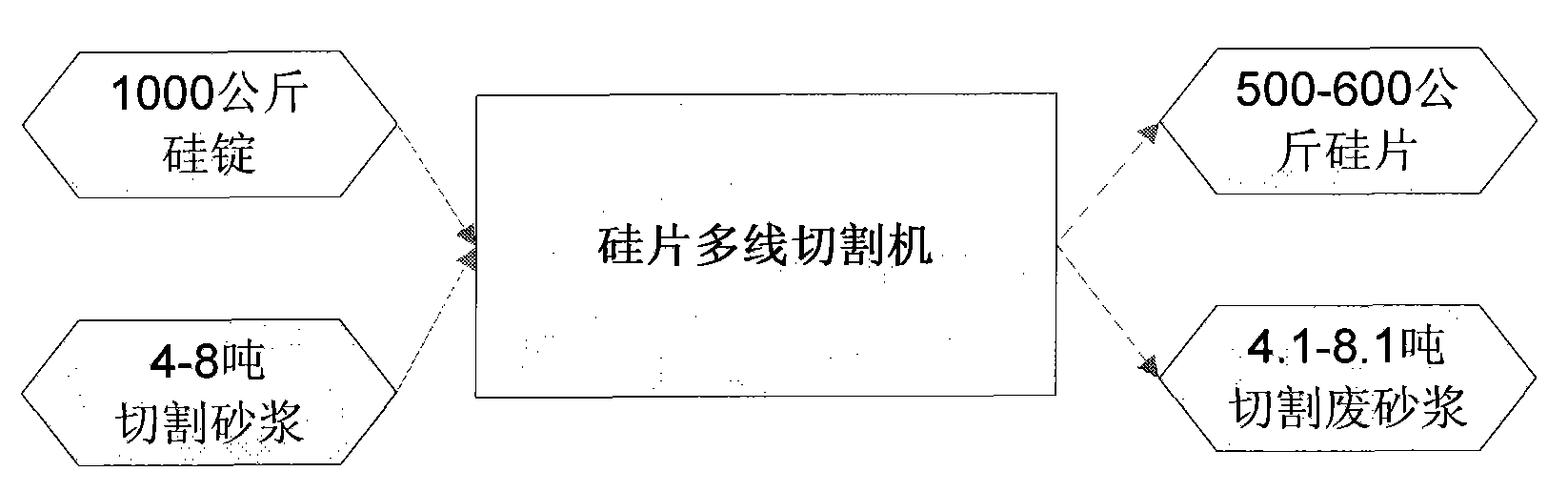

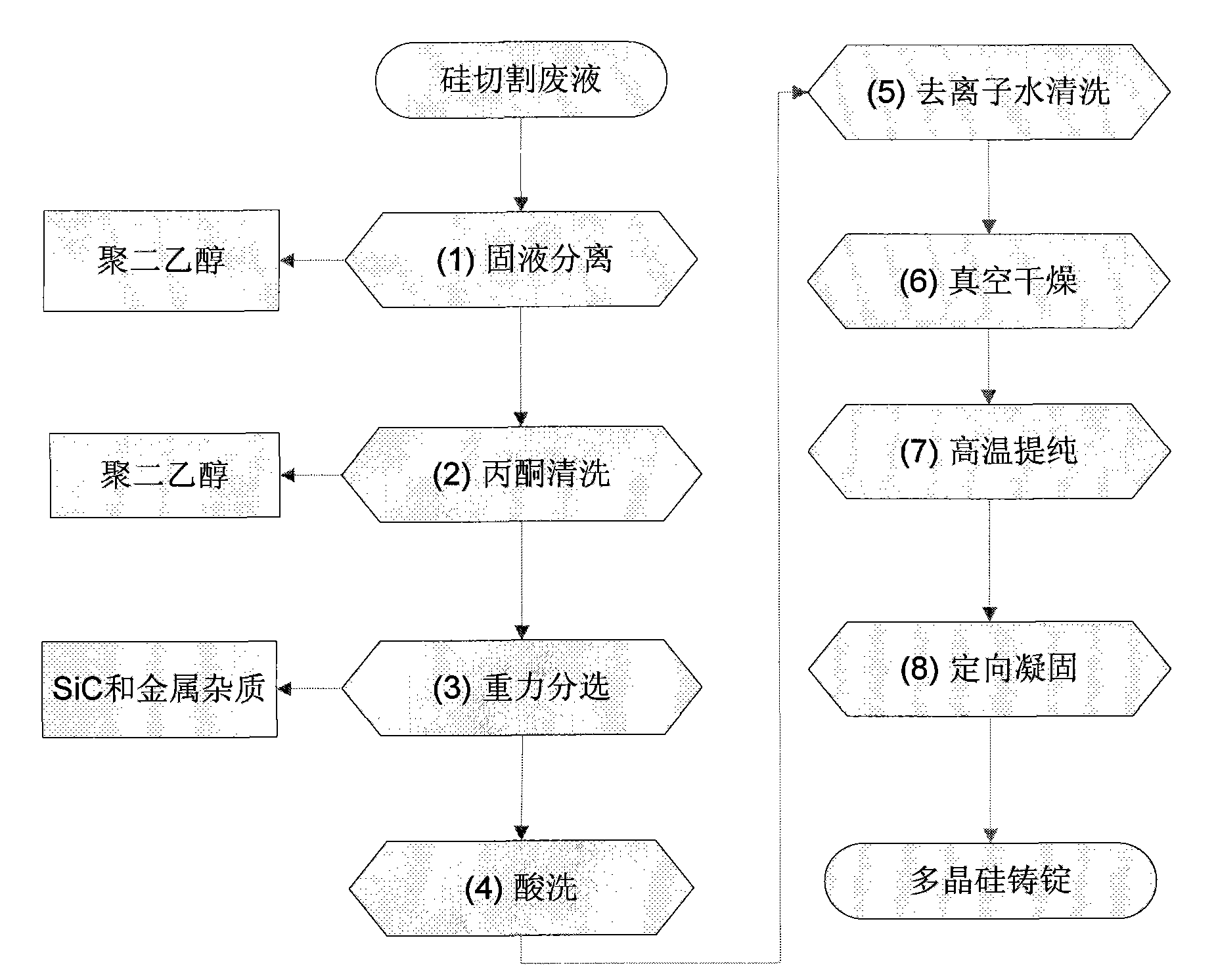

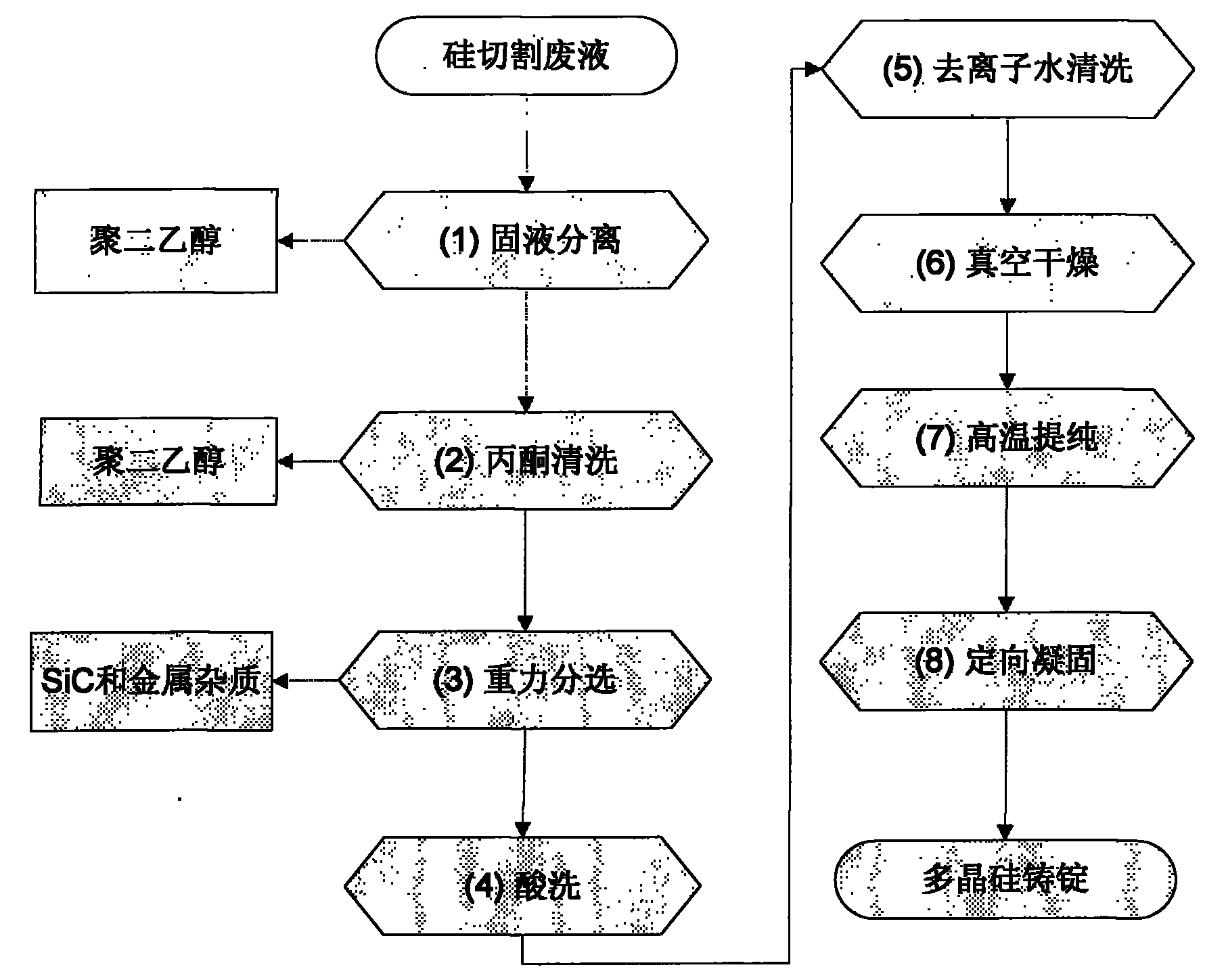

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

Method for purifying high-purity graphite

The invention discloses a method for purifying high-purity graphite, which aims to effectively remove impurities from the graphite and make 99.99 percent the fixed carbon content of the graphite. The method comprises the following steps of: performing the steps of crushing, ball-milling, sieving and the like on raw graphite ore and performing ore-dressing on the treated graphite ore by adopting floatation equipment or gravity dressing equipment to obtain graphite concentrate; performing alkali leaching on the graphite concentrate in a pressurized reaction kettle and then performing normal-pressure acid leaching in an ultrasonic wave field or a microwave field; and leaching treated graphite powder by using a hydrofluoric acid or fluoride salt-containing sodium fluoride to obtain the high-purity graphite product.

Owner:KUNMING METALLURGY INST

Method for preparing fluorescent nano material converted on NaYF4

InactiveCN101525540ASmall sizeGood dispersionPolycrystalline material growthFrom normal temperature solutionsSolubilityFluorescence

The invention relates to a method for preparing fluorescent nano material converted on NaYF4, comprising the steps: yttrium nitrate, ytterbium nitrate and erbium nitrate or yttrium chloride, ytterbium chloride, erbium chloride and thulium chloride are dissolved in de-ionized water according to the mixture radio that the mol ratio of rare earth ions which are yttrium ion, ytterbium ion and erbium ion is equal to (70-95): (1-25): (0.5-10), so that the mixed solution is prepared; water soluble polymer having the ligand radical with the rare earth ions is added into the mixed solution for stirring reaction to form complex compound; the pH value of the mixed solution is adjusted to be 2-6; sodium fluoride, ammonium fluoride or hydrofluoric acid can be added into the mixed solution and stirred until colloid solution that is approximately transparent is obtained; then, the colloid solution is put into a high pressure closed reactor and heated at the temperature of 140-200 DEG C; after that the obtained product is cooled to be the room temperature, centrifugated, separated, washed and dried, finally, the fluorescent nano material converted on NaYF4 is obtained. The method can be used for preparing the converted material at lower temperature, the particle size and the appearance can be controlled, and the water-solubility is good.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method of producing aluminium scandium alloy by electrolysis

The invention relates to the method for producing the alloy of aluminium and scandium by using oxides of aluminium and scandium as the raw materials. Fused salt electrolysis process is adopted to electrolyze and separate out aluminium and scandium so as to form the alloy. The weight ratio of the electrolyte of fused cryolite is as following: alumina 1%-10%, scandium oxide 0.1%-10%, cryolite as the rest and the unavoidable impurities. The ratio between sodium fluoride and aluminium fluoride is 2-3. The relevant parameters are as following: temperature of electrolysis 900-990 deg.C, operating voltage of the electrobath 3.0V-6.5V and the electrode distance 2.0cm-7.0 cm. The invention possesses the features of no need of high pure metal scandium, shortened technological flow and high metal yield so as to reduce the cost of the alloy greatly.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

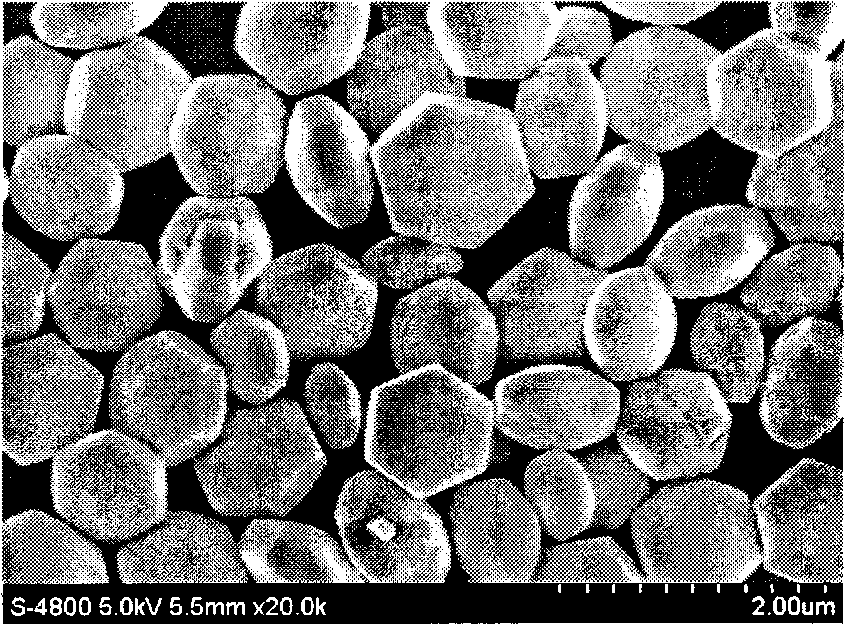

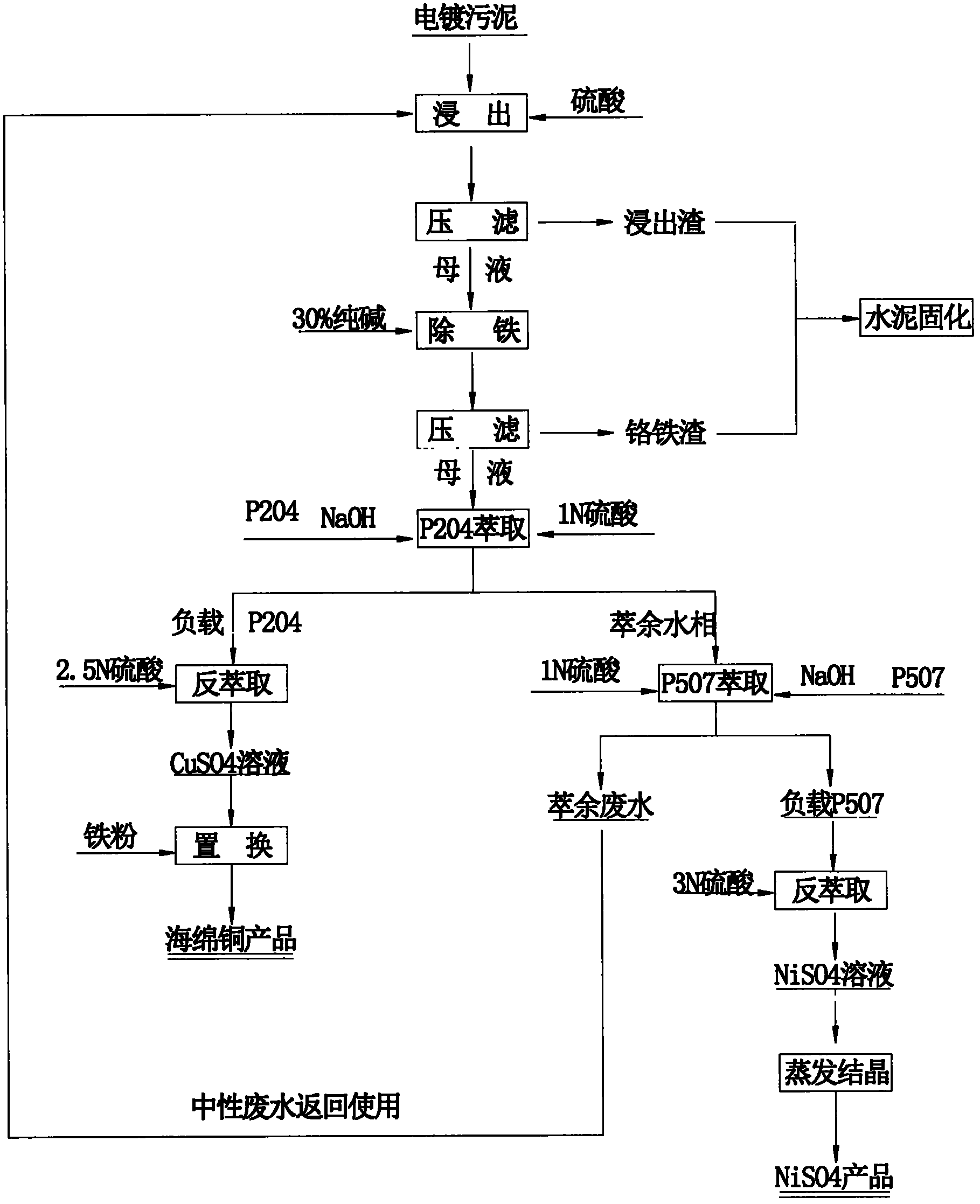

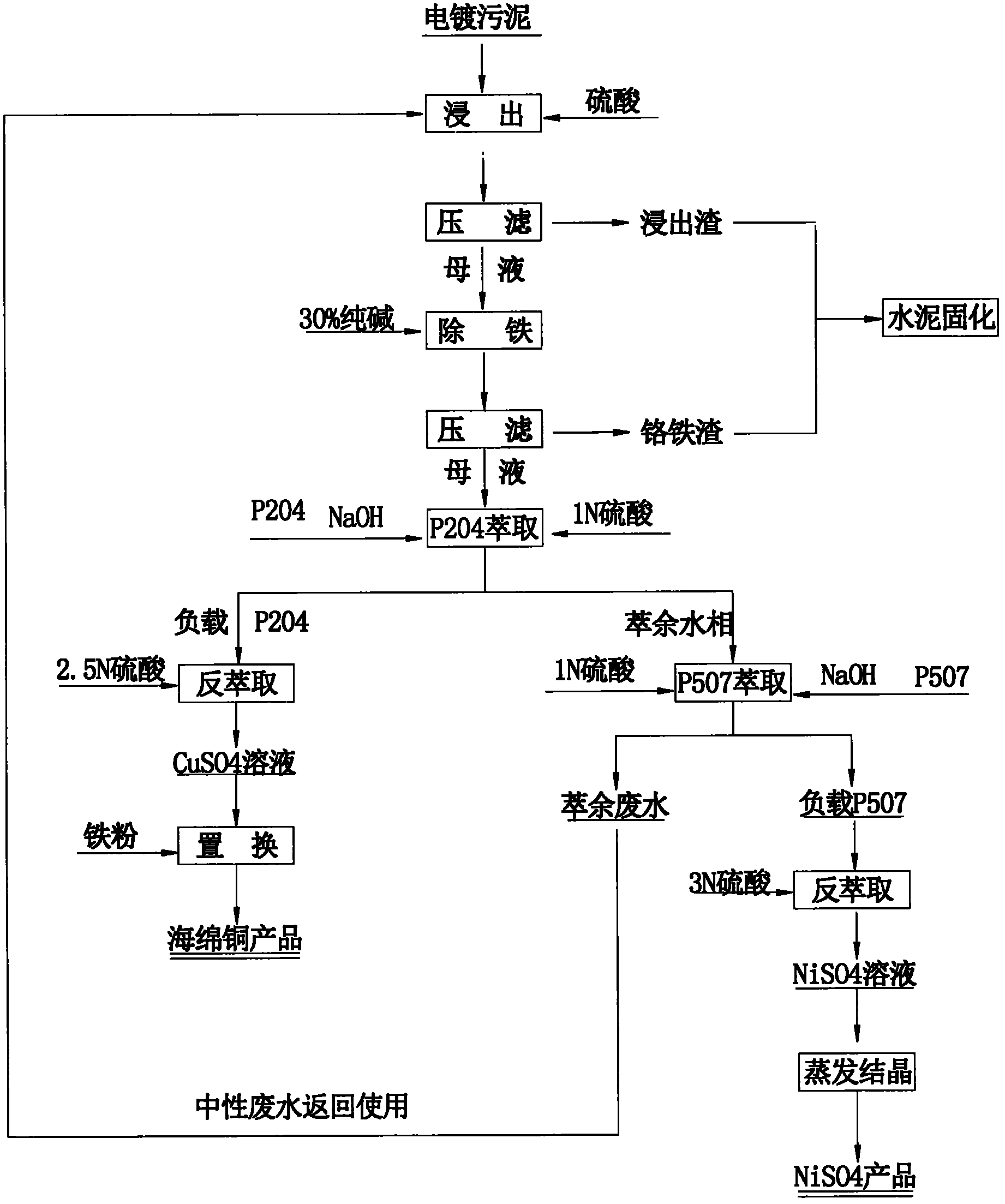

Method for recovering valuable metal from electroplating sludge

The invention relates to a method for recovering valuable metals from electroplating sludge. Electroplating sludge is used as a raw material; advanced theories and scientific means of leaching principle, redox principle, extraction principle, iron filing displacement principle and evaporation crystallization principle in a wet method metallurgy are integrally utilized; and a technology of ''acid decomposition of electroplating sludge-leachate purification to remove ferrochrome-P204 impurity removal-P507 enrichment-condensation crystallization'' is employed. Meanwhile, calcium and magnesium are removed by an extraction method, which substitutes a traditional sodium fluoride method for removing calcium and magnesium. A recovery rate of nickel reaches 95%, and copper content of recovered copper sponge is larger than 80%. Besides, acid dissolved slag and purifying slag can be solidified to reach requirements of environmental protection and will not cause secondary pollution; waste water can be recycled and has a strong technological versatility. The method is suitable for treating various routine electroplating sludge, has easily controllable technical conditions and low operating cost and is easy for realizing large scale production; therefore, the method is a practical novel technology for treating electroplating sludge in a way of quantitative reduction, harmlessness and resource.

Owner:朱小红

Dental bleaching composition and method

InactiveUS6846182B1Reducing eliminating damageImprove efficiencyCosmetic preparationsImpression capsParticulatesAdditive ingredient

A dental bleaching composition having enhanced effectiveness and reduced sensitivity, its method of use, and a kit containing the ingredients for making the composition. The dental bleaching composition comprises a bleaching agent, an inert gelling agent, a pH modifying agent, a discrete inert particulate laser enhancing material, and optionally a transparency modifying agent in the form of a gel with a pH of about 9.5 to 11. The dental bleaching composition is placed on the teeth to be bleached, exposed to laser light for a desired period of time, and removed. The process is then repeated for one or more cycles until the desired degree of bleaching is achieved. Neutral sodium fluoride is then applied to the bleached teeth for at least 10 minutes to reduce or eliminate post-bleaching sensitivity.

Owner:SIBNER JEFFREY A

Method for preparing environment-friendly micro-arc oxidation black ceramic film on aluminum alloy surface

ActiveCN102154673AUniform colorImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an environment-friendly micro-arc oxidation black ceramic film on an aluminum alloy surface, and the method comprises the following steps: firstly, pouring deionized water into an oxidation tank, weighing 1-10g / L of sodium hexametaphosphate, 1-3g / L of sodium silicate, 0.5-2g / L of potassium hydroxide, 0.2-2g / L of sodium fluoride and 0.5-20g / L of ferric ammonium oxalate in terms of the volume of the added deionized water, and uniformly stirring and mixing the sodium hexametaphosphate, the sodium silicate, the potassium hydroxide and the sodium fluoride to obtain a micro-arc oxidation base electrolyte; adding the weighed ferric ammonium oxalate into the base electrolyte, and stirring and mixing uniformly to obtain an aluminum alloy micro-arc oxidant solution; and then, sequentially carrying out surface deoiling and cleaning, water washing, aluminum alloy micro-arc oxidation, sealing and drying on the aluminum alloy to prepare the environment-friendly micro-arc oxidation black ceramic film on the aluminum alloy surface. By means of the preparation method disclosed by the invention, the problems of single color, limited application range, and environment pollution caused by a vanadate electrolyte, of the existing aluminum alloy ceramic film layer, are solved.

Owner:CSIC NO 12 RES INST

Lightening gypsum suspended ceiling

The invention discloses a light-quality plaster ceiling in the architectural decorative material domain, which comprises the following parts: 50-70% architectural plaster, 8-15% light filler, 0.5-1.5% modifier, 1-2% waterproofing agent and 5-10% polyvinyl alcohol solution, wherein the lightweight fill is one or two or three of light calcium carbonate or lightweight magnesium carbonate or white carbon black according to random rate; the modifier is composed of 100g water, 15-20g silicasol, 5-7g sodium fluoride, 4-6g aluminum potassium sulfate, 7-9g potassium bichromate and 0.5-1g tributyl phosphate; the waterproofing agent is organic silicon waterproofing agent of sodium silanol methyl or potassium silanol methyl; the glass fiber is low-alkaline or non-alkaline glass fiber.

Owner:云南天之豪装饰材料有限公司

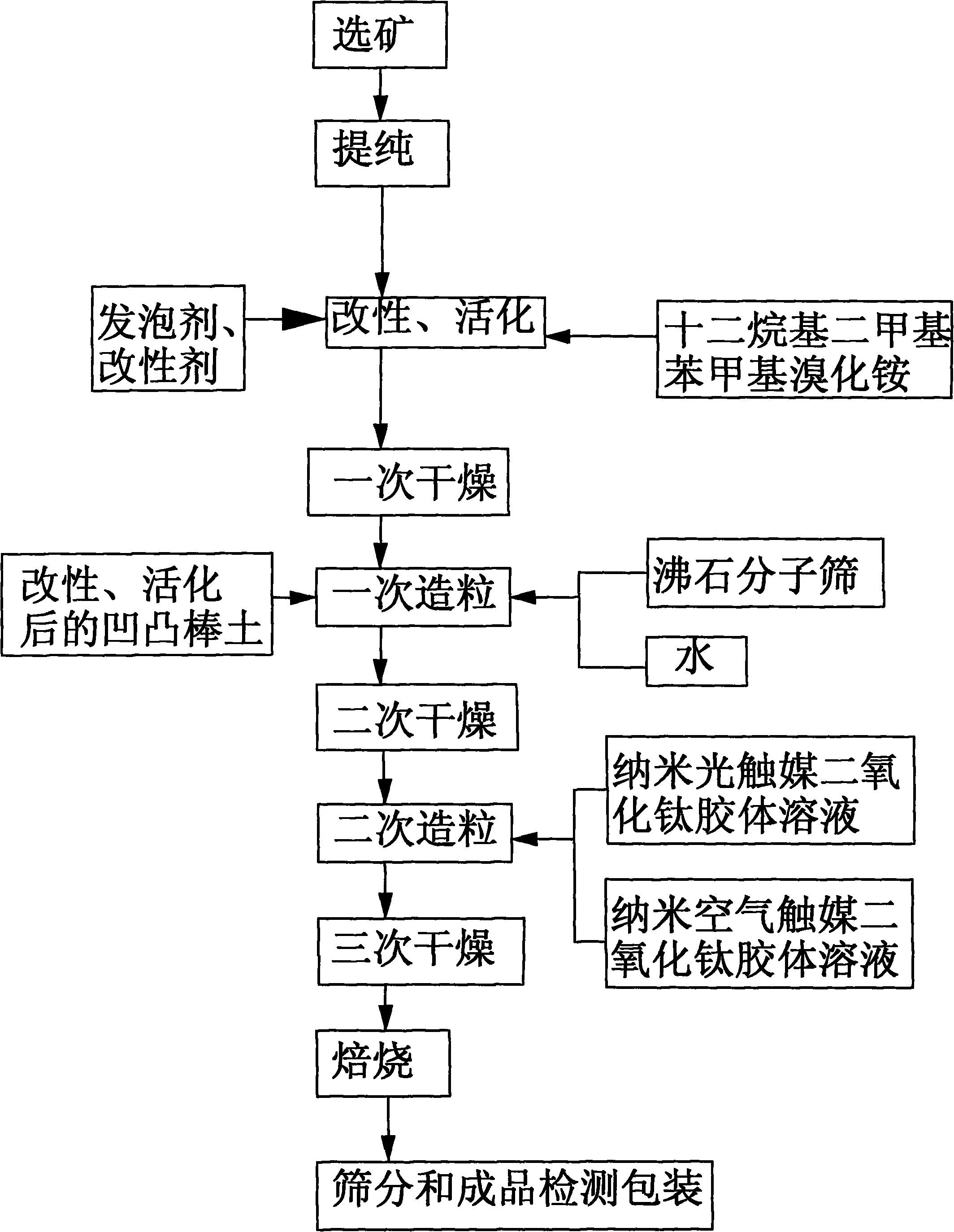

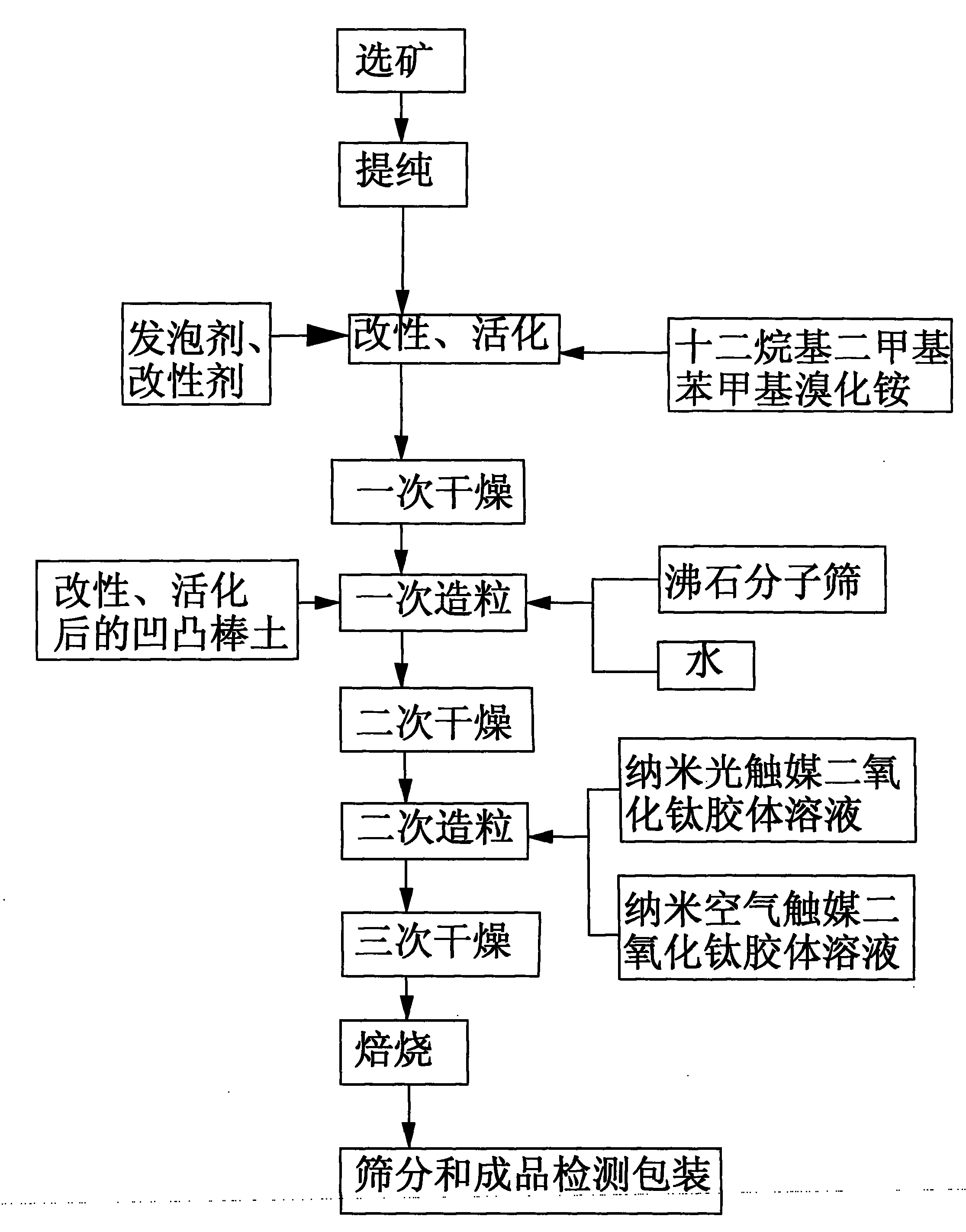

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

Fluoride varnish compositions including an organo phosphoric acid adhesion promoting agent

ActiveUS20090191279A1Big contrastProvide goodBiocideHeavy metal active ingredientsO-Phosphoric AcidFluoride varnish

Fluoride varnish compositions for temporary application and adhesion to a person's teeth. The composition includes a carrier comprising a resin and an adhesion promoting agent comprising an alkyl phosphoric acid. A fluoride ion source (e.g., a fluoride salt such as sodium fluoride) is dispersed within the carrier so as to provide biologically available fluoride ions to the tooth tissue being treated. The composition adheres only temporarily to tooth tissue (e.g., for a period of at least about 4 minutes, but not more than about 1 year), after which the composition spontaneously wears away as a natural result of the action of the tongue, saliva and / or other factors.

Owner:ULTRADENT PROD INC

Treating fluid and method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through same

ActiveCN102766862AImprove corrosion resistanceGuaranteed stabilityMetallic material coating processesMetallic bondingSodium fluoride

The invention belongs to the technical field of chemical materials, and relates to a treating fluid and a method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through the same. The method includes the steps of firstly preparing the treating fluid containing fluorozirconate, metavanadate, sodium fluoride, nitrate, an accelerate and an additive; then putting an aluminum alloy after surface pretreatment into a working fluid made of the diluted treating fluid for 2min-10min; and finally subjecting the aluminum alloy to washing, drying and cooling to obtain the vanadium-zirconium composite conversion coatings. The preparation process is simple, heavy metals such as hexavalent chromium and nickel are not contained, the environment is friendly, the conversion coatings of the aluminum alloy after a conversion coating treatment are dense and high in binding force, metal ions in the conversion coatings can bond with base metal under a corrosion environment and provided with a certain self-repairing performance, and the treating technology of vanadium-zirconium conversion coatings can effectively replace chromate treatment on aluminum alloy surfaces.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

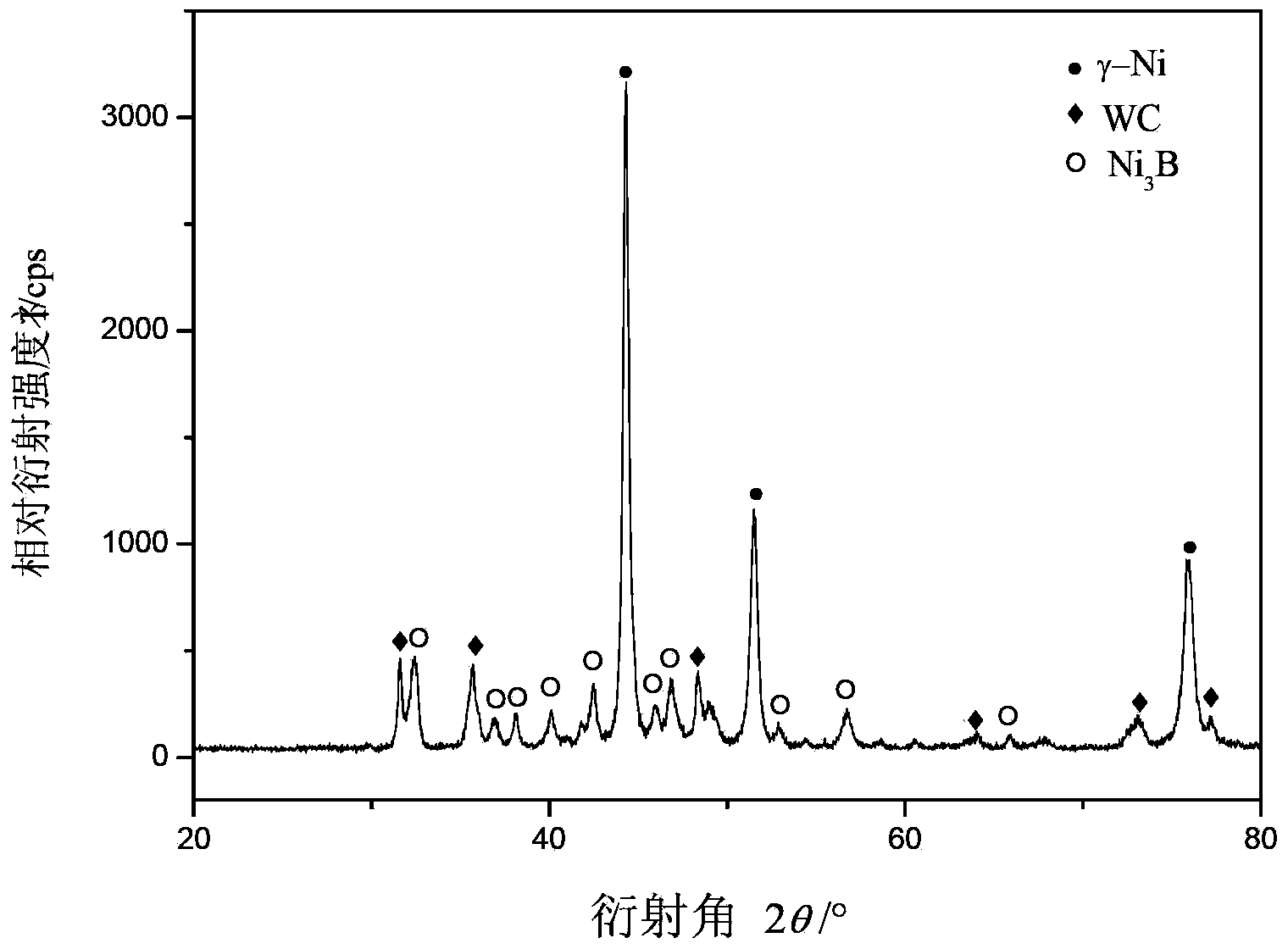

WC particle-reinforced Ni-based MIG hardfacing flux-cored wire

InactiveCN103406689AImprove toughnessGood "supportArc welding apparatusWelding/cutting media/materialsManganeseBoron carbide

The invention discloses a WC particle-reinforced Ni-based MIG hardfacing flux-cored wire and belongs to surface-modified cored wires used in the technical field of engineering application. The flux-cored wire is composed of a nickel strap wrapper and core portion powder. Core ingredients comprise, by mass, 30%-75% of tungsten carbide, 4%-17% of silicon carbide, 3%-15% of boron carbide, 1%-5% of electrolytic manganese powder, 1%-12% of sodium fluoride and the balance of nickel powder. Ingredients of obtained deposited metal comprise 11.1%-30% of tungsten carbide, 1.3%-5.6% of silicon, 1%-5% of boron, 0.3%-1.48% of manganese and the balance of nickel. A surfacing layer prepared by flux-cored wires is high in hardness (>45HRC), and the hardness of WC hard phases in the surfacing layer reaches 1800HV0.3. According to the WC particle-reinforced Ni-based MIG hardfacing flux-cored wire, the 'shadow protection' effect is achieved mainly through matching of added WC particles and a Ni-based substrate, and therefore wear resistance can be achieved; besides, welding performance of surfacing alloy is improved by adding the deoxidizing agents including silicon and manganese, alterative Na / F and the like.

Owner:BEIJING UNIV OF TECH

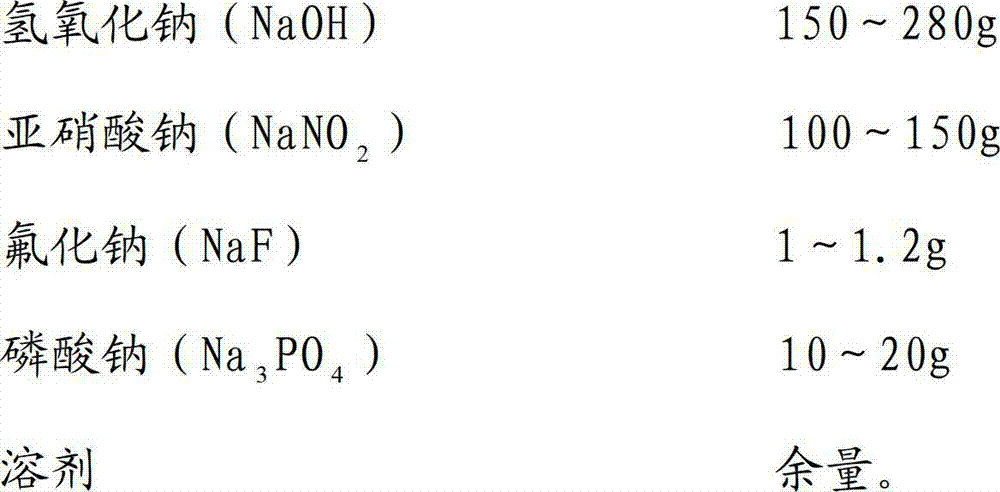

Alkaline chemical polishing solution and alkaline chemical polishing method

The invention discloses an alkaline chemical polishing solution and an alkaline chemical polishing method. Each 1 L of alkaline chemical polishing solution comprises components of 150-280 g of sodium hydroxide, 100-150 g of sodium nitrite, 1-.1.2 g of sodium fluoride, 10-20 g of sodium phosphate, and the balance of a solvent; and meanwhile, the alkaline chemical polishing solution is utilized for alkaline chemical polishing. The alkaline chemical polishing solution and the alkaline chemical polishing method, disclosed by the invention, have the beneficial effects of solving the problems of scratching and impacting of aluminum alloy parts, improving surface roughness of parts, lowering production cost and avoiding environment pollution as a selective self-dissolution function of aluminum and an aluminum alloy is utilized in an alkaline solution to flatten and polish the surface of the aluminum.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

460MPa-level flux-cored wire for ocean engineering and application thereof

ActiveCN105269174AStable mechanical propertiesImprove crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceWeld seam

The invention provides a 460MPa-level flux-cored wire for ocean engineering. The 460MPa-level flux-cored wire comprises a carbon steel sheath and a flux core, wherein the carbon steel sheath accounts for 84-87% of the total mass of the flux core; the flux core accounts for 13-16% of the total mass of the flux-cored wire; the flux-cored wire consists of the following components in percentage by mass: 30-42% of rutile, 1-2% of sodium fluoride, 3-6% of feldspar, 3-5% of ferrotitanium, 1-3% of silicon iron, 0.5-1% of rear earth, 3-5% of magnesium powder, 5-10% of electrolytic manganese, 1-2% of aluminum powder, 7-9% of nickel powder, 4-7% of ferroboron, 0.2-0.5% of graphite, 3-6% of silicon-manganese alloy, 0.5-1% of zircon sand and the balance of Fe and inevitable impurities. By virtue of control in aspects of chemical components, diffusible hydrogen, low-temperature stability and the like, the 460MPa-level flux-cored wire meets the requirements of crack resistance and low-temperature impact resistance, is good in all-position welding process, attractive in welding seam and excellent in mechanical property, has seawater corrosion resistance; and content of diffusible hydrogen of deposited metal reaches ultralow hydrogen level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

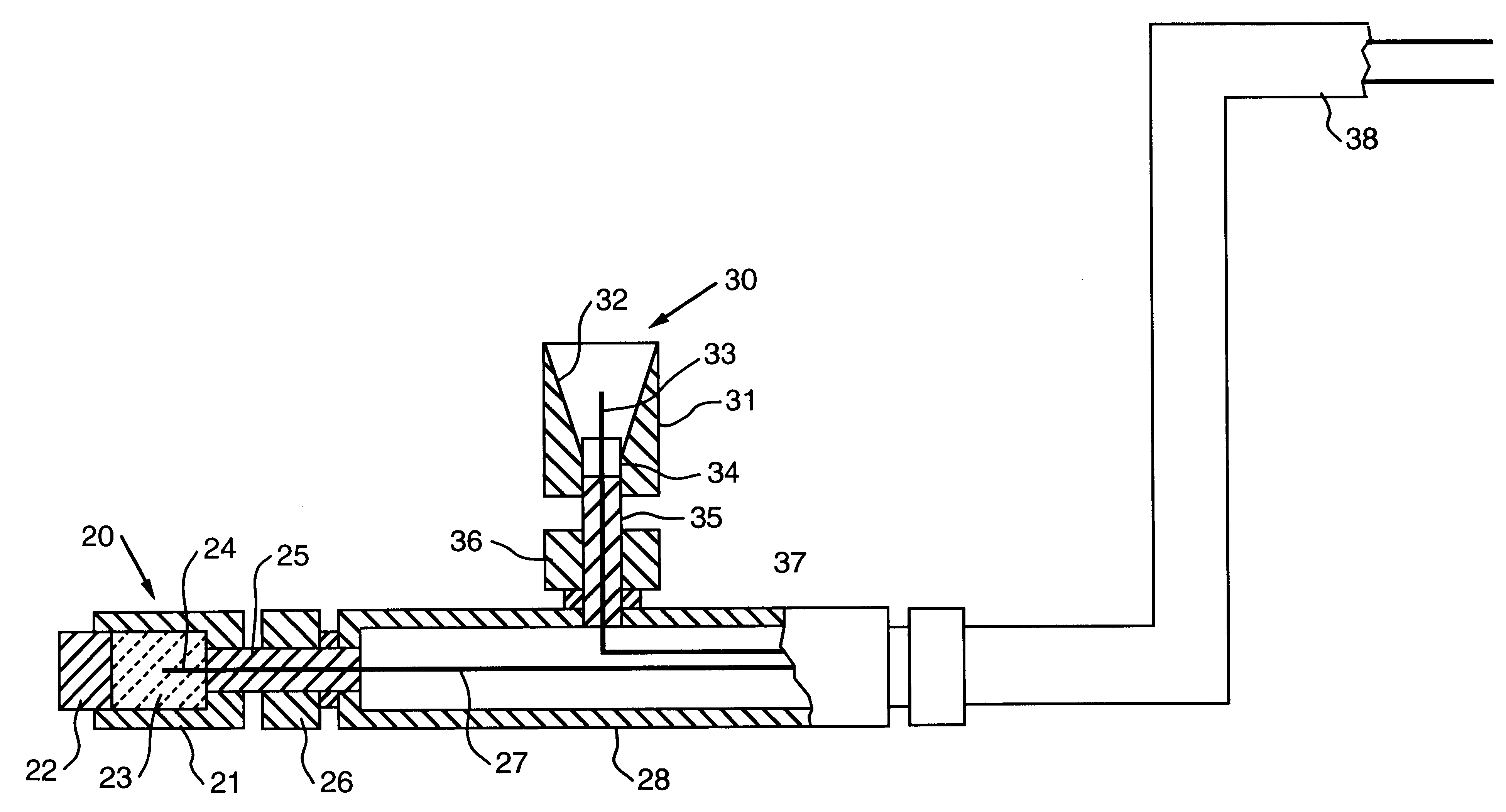

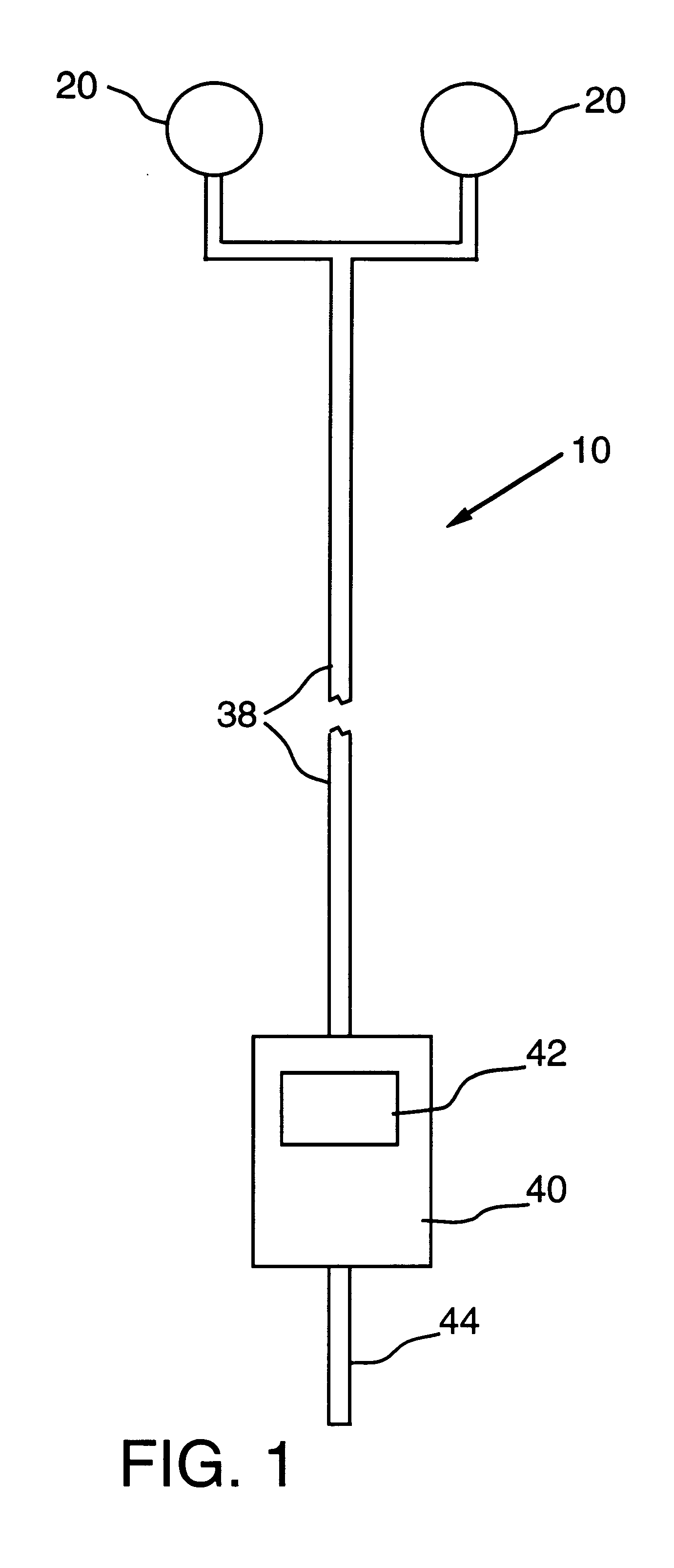

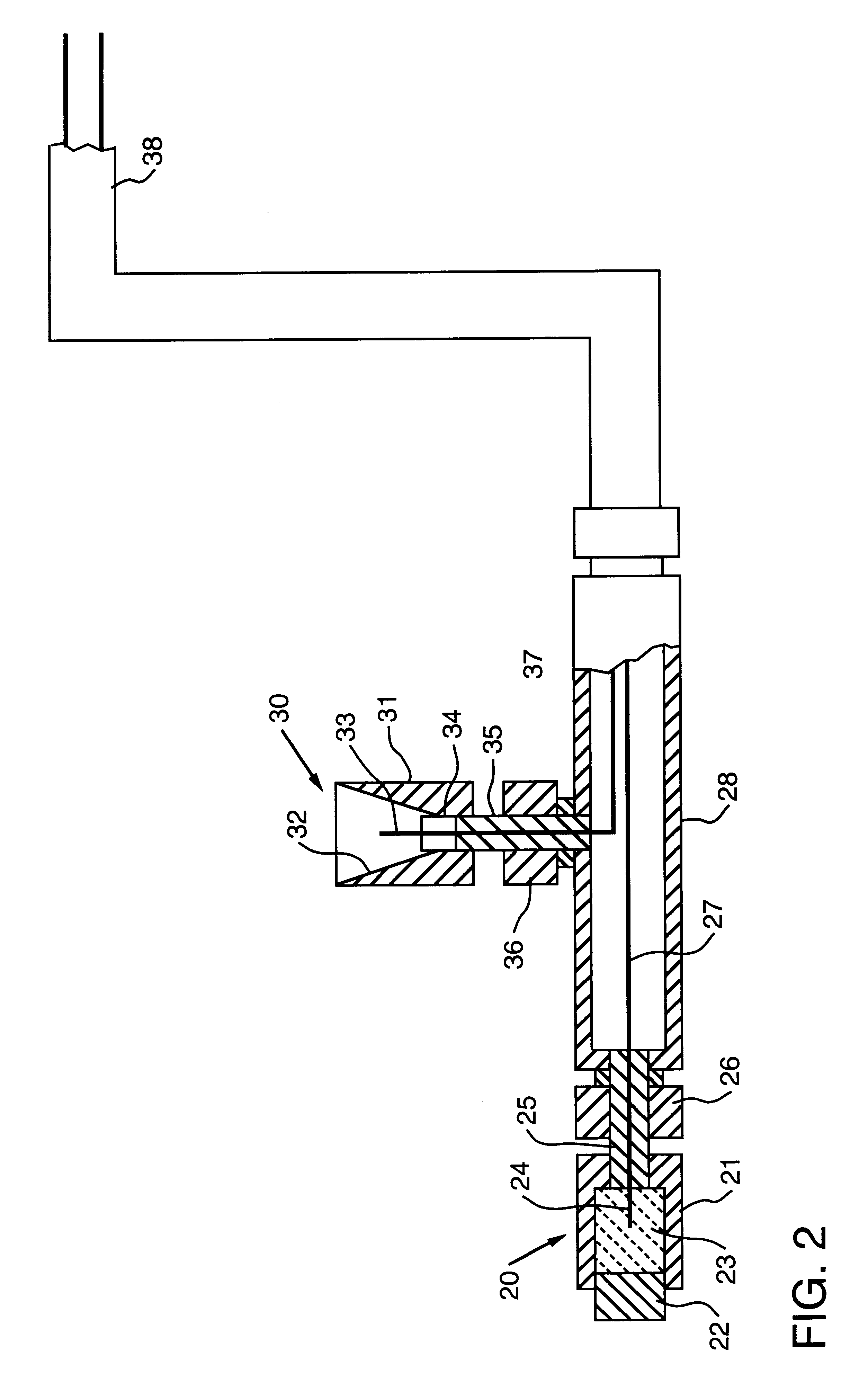

Method and apparatus for testing material utilizing differential temperature measurements

A method and apparatus for timely and accurate measurement of material parameters are disclosed. A test sensor measures the temperature of a sample of material as it is heated up and / or cooled down. A reference sensor is used to obtain differential temperature measurements as the temperature of the test sample is varied. A differential temperature trace is generated and analyzed in order to determine various characteristics of the material being tested. In one embodiment, the sodium fluoride to aluminum fluoride ratio (NaF:AlF3) and alumina concentration in a Hall bath aluminum smelting operation are determined in order to efficiently control smelting of aluminum metal. In this embodiment, bath temperature and liquidus temperature may be measured and compared in order to determine the amount of superheat of the bath and to prevent the operation of smelters at higher temperatures than necessary.

Owner:ARCONIC INC

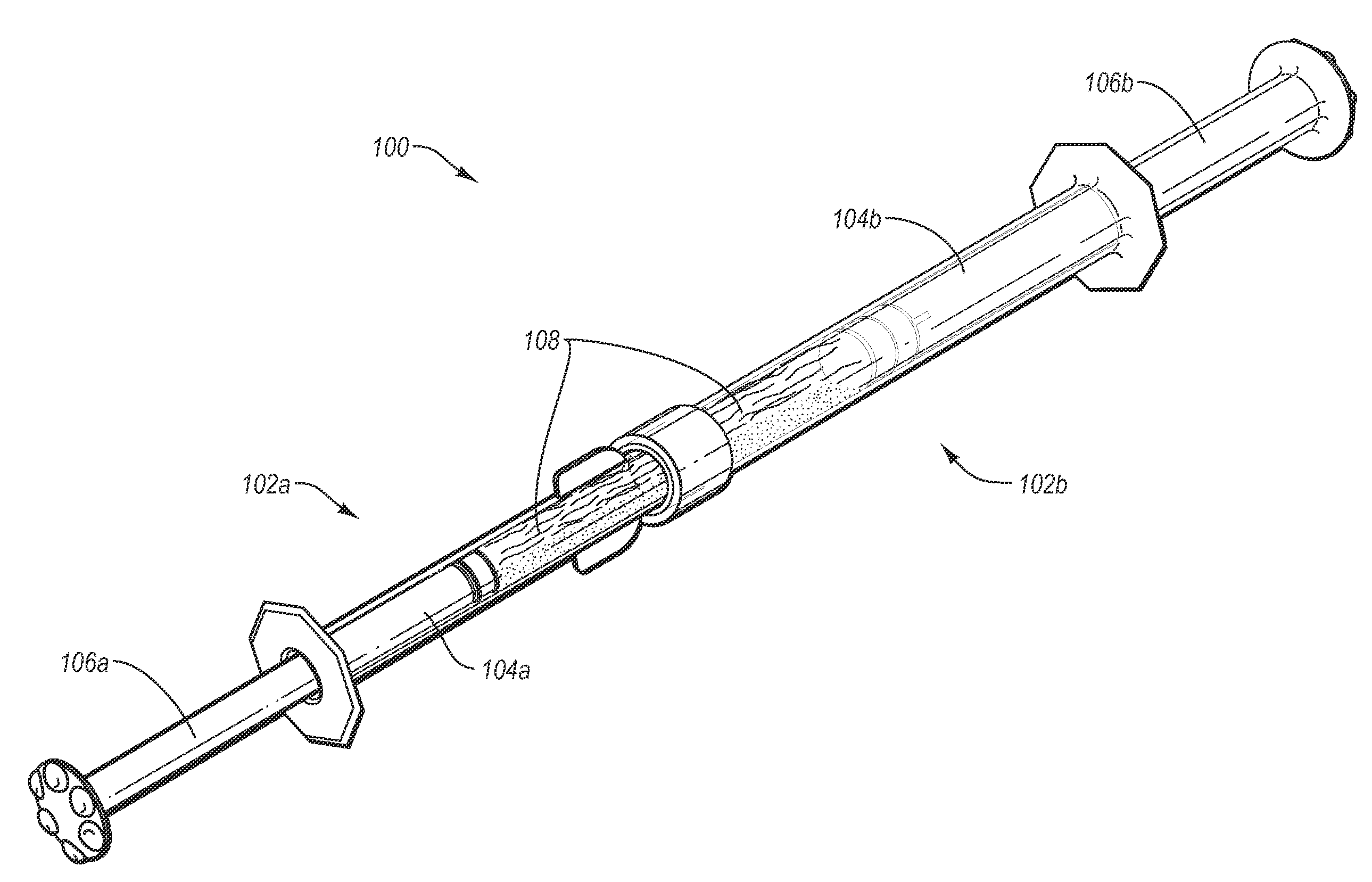

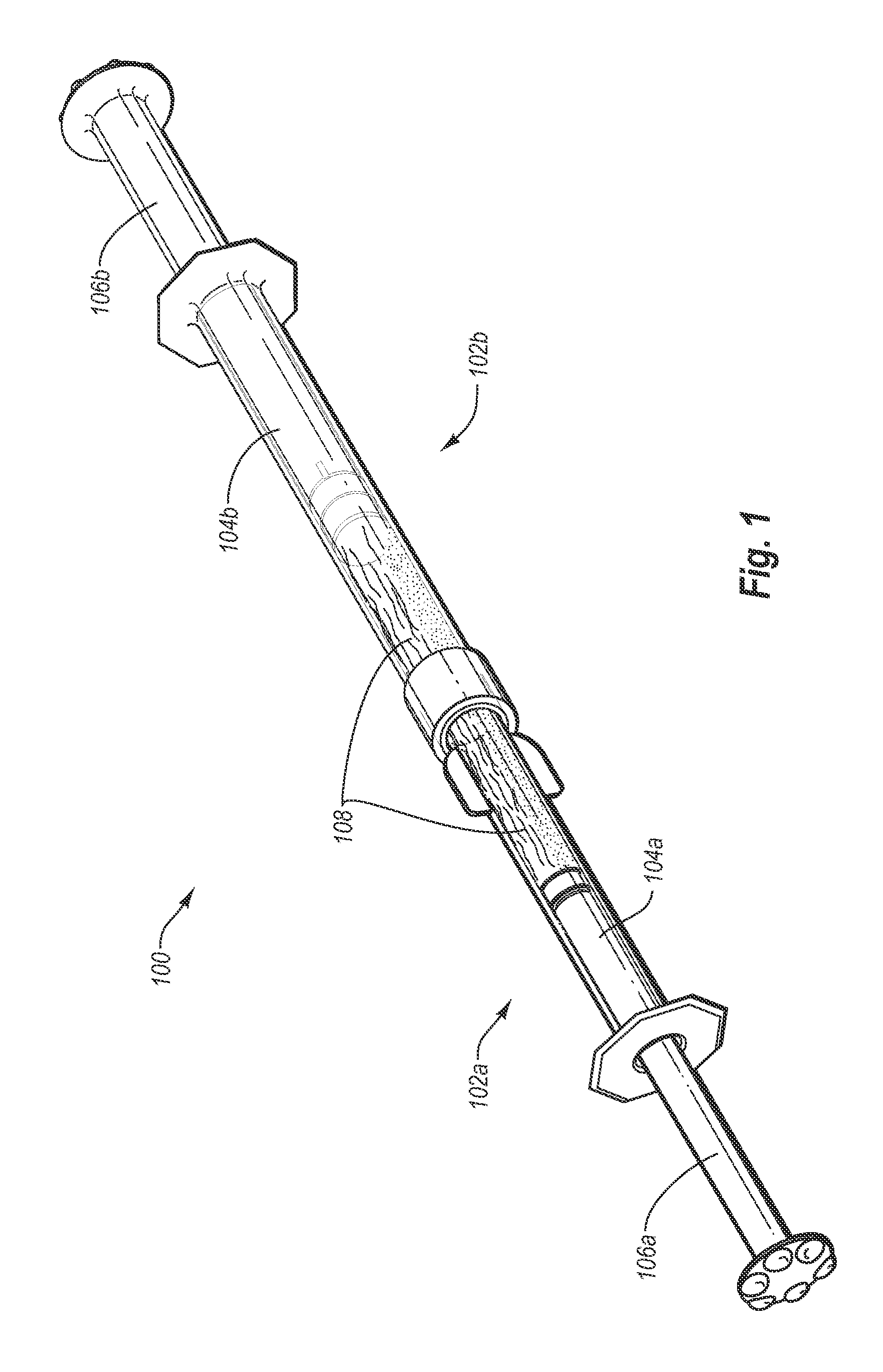

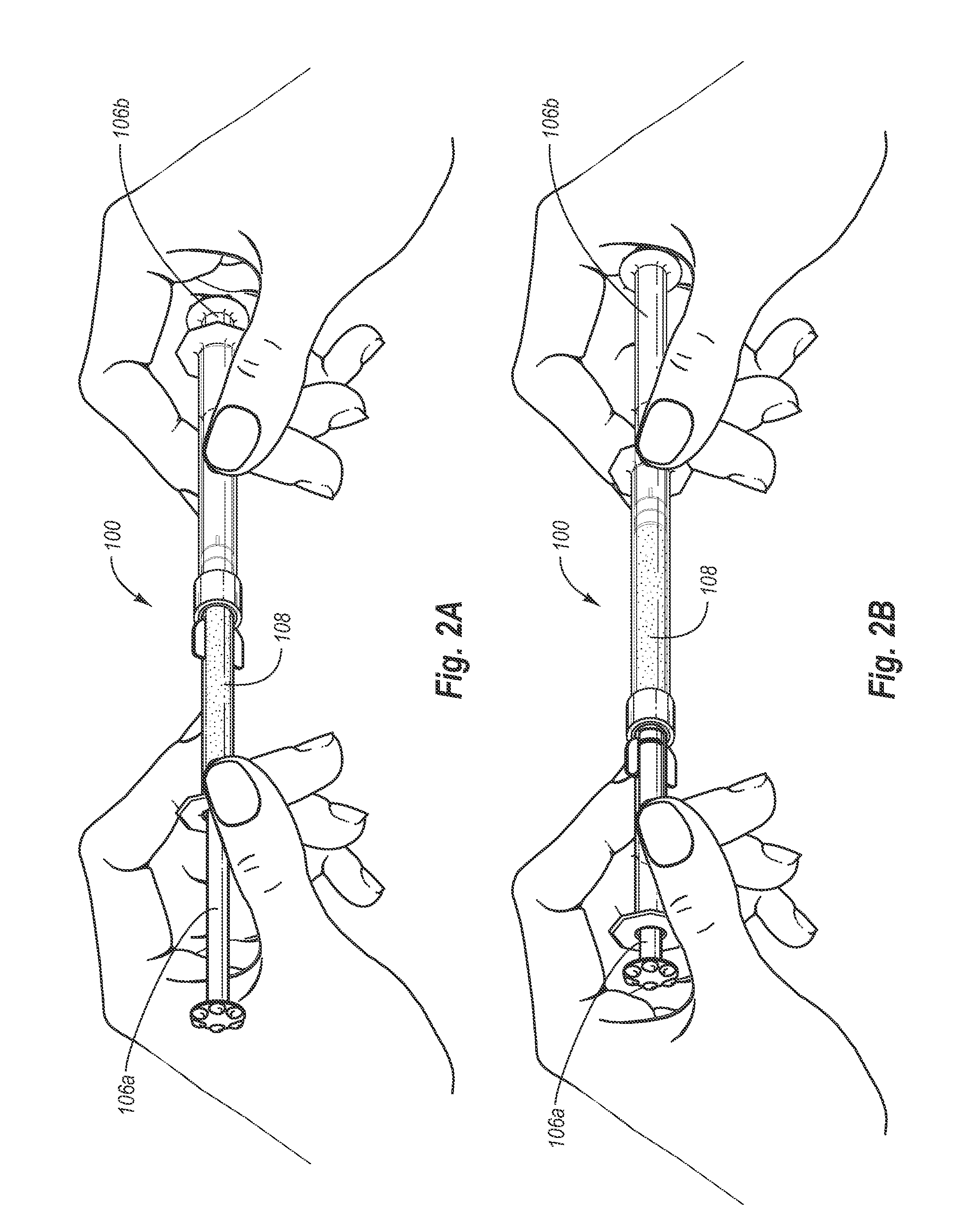

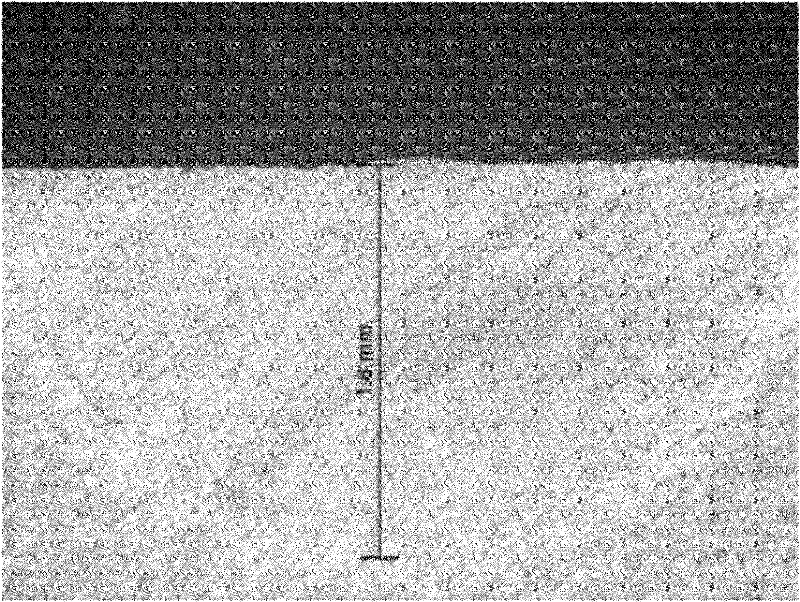

Process of forming fluoric stepped hole structure on the surface of pure titanium dental implant

InactiveCN1985774AImprove long-term clinical successGood compatibilityDental implantsArtificial teethClinical successSurface modified

The process of forming fluoric stepped hole structure on the surface of pure titanium dental implant includes sand blasting the pure titanium implant, etching in mixed solution of sulfuric acid and hydrochloric acid, etching in mixed solution of hydrofluoric acid and nitric acid, soaking in sodium fluoride solution and other steps. The pure titanium dental implant with stepped hole surface structure has excellent bone tissue compatibility, capacity of raising the combination strength of the implant to the bone tissue and raised long term clinical success rate of dental implant.

Owner:ZHEJIANG UNIV

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

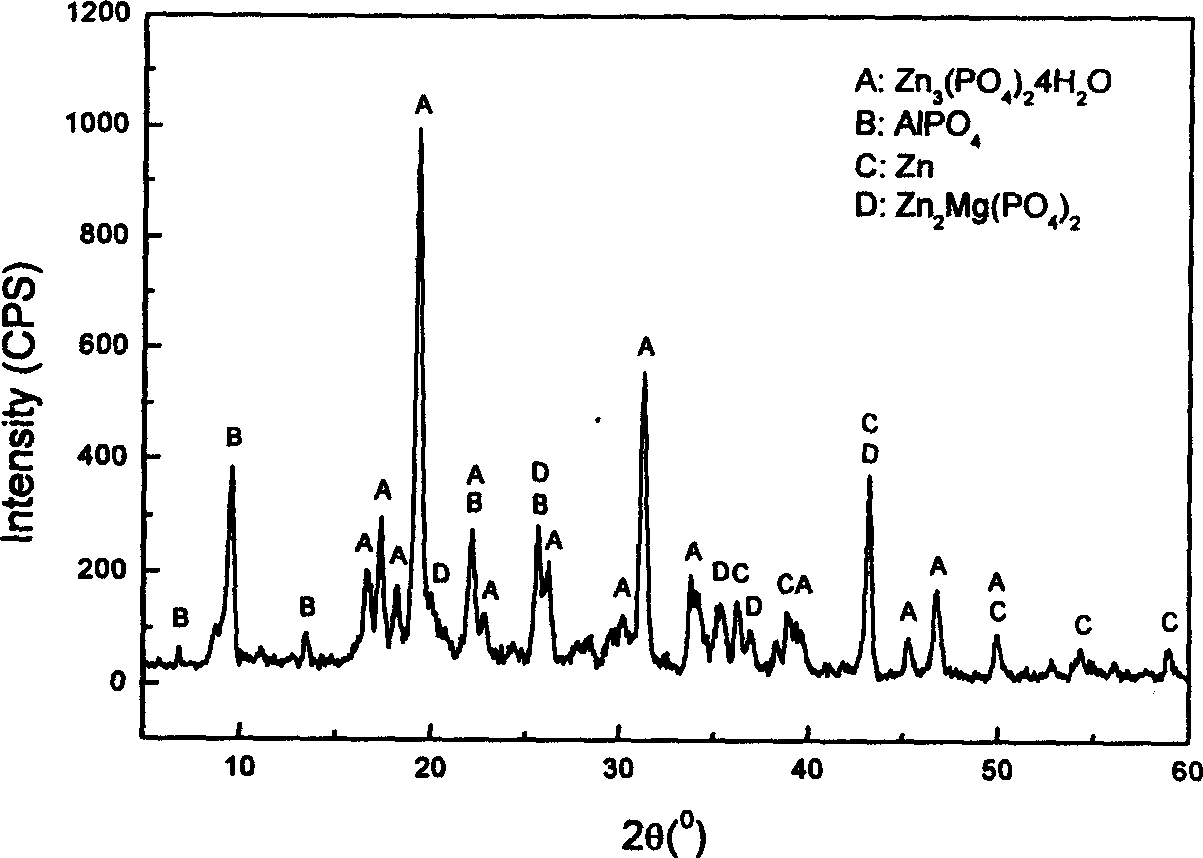

Magnesium alloy phosphorization solution and its phosphorized technology

InactiveCN1598055AProcess stabilityThe process is simple and easy to controlMetallic material coating processesPhosphatePhosphoric acid

Owner:JILIN UNIV

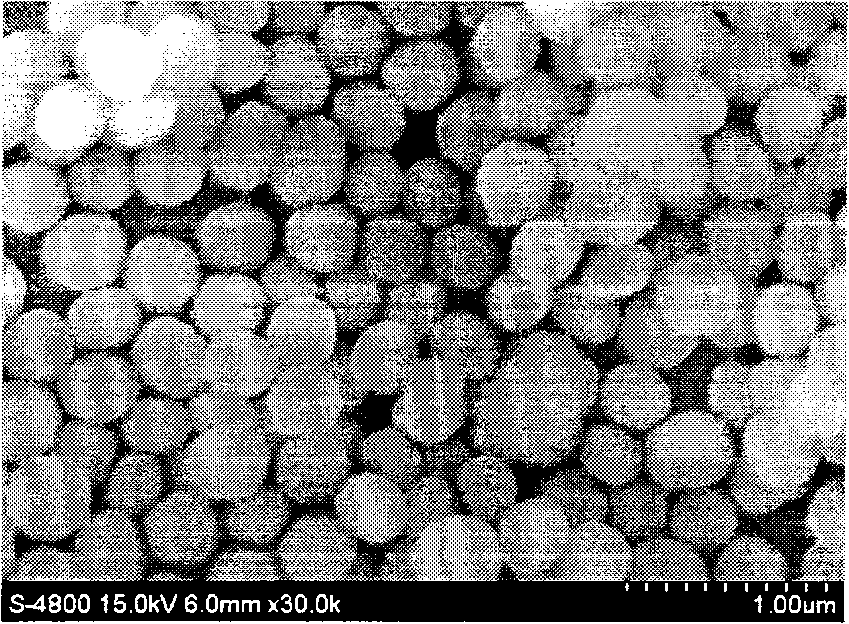

Plating solution of magnesium alloy nickle sulfate main salt and technology of chemical plating thereof

InactiveCN1598053ALow priceReduce manufacturing costLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a plating solution of magnalium alloy Nickel sulfate and its chemical plating technique. The plating solution is made up of: (1) 5 to 40g.dm-3 of Nickel sulfate, (2) 10 to 50g.dm-3 of reducing agent of hypo-phosphite sodium; (3) one or several of the 2.5 to 30g.dm-3of the citric acid or tri-sodium citric acid, 2.5 to 30g.dm-3of the lactic acid, 2.5 to 30g.dm-3of the acetic acid, 2.5 to 30g.dm-3of the malic acid, 2.5 to 30g.dm-3 of the third acid and 2.5 to 30g.dm-3of the buta-acid; (4) one or several of the 5 to 30g.dm-3of Potassium fluoride, 5 to 30g.dm-3of sodium fluoride, 5 to 30g.dm-3of lithium fluoride and 5 to 30g.dm-3of NH4HF2; (5) 0.1 to 3g.dm-3of sulphur carbamide. The plating steps include: washing with ultrasonic->washing with alkali->washing with acid->activation->dipping it in the zinc solution->getting rid of the activation solution->secondary dipping it in the zinc solution->chemical plating->passivation and sealing the holes. The invention is featured by little pollution to the environment, low cost, uniform film and simpel technique.

Owner:HUNAN UNIV

Efficient composite modifying-refining agent for hypoeutectic cast aluminium-silicon alloy and treatment process

InactiveCN1936044ASimplify the melt handling processImprove performanceStrontium carbonateSilicon alloy

The invention relates to a high efficiency compounded refiner for hypoeutectic aluminum-silicon alloy and the method of application. It contains 10-30wt% NaCl, 10-15wt% KCl, 10-20wt% sodium fluoride, 1-30wt% potassium fluoborate, and 1-20wt% potassium fluotitanate, 1-20wt% strontium carbonate, 1-15wt% cerium fluoride, 5-20wt% granular lanthanum abundant mixed rare earths and 1-5% heachloroethane. After taking the process of heating, dehydrating, mixing according to the ratio to equal, pressing to molding, it could be sealed to use. The technology includes the following steps: after the magnesium alloy melting in crucible, heating to 720-740 degree centigrade and removing the slag, standing for 3-5 minutes, pressing the refiner into alloy liquid to take refining process for 5-10 minutes, standing for 5-10 minutes after process to gain hypoeutectic aluminum-silicon alloy melt. The invention simplifies melt process technology, lowers cost and improves the capability of alloy.

Owner:重庆工学院

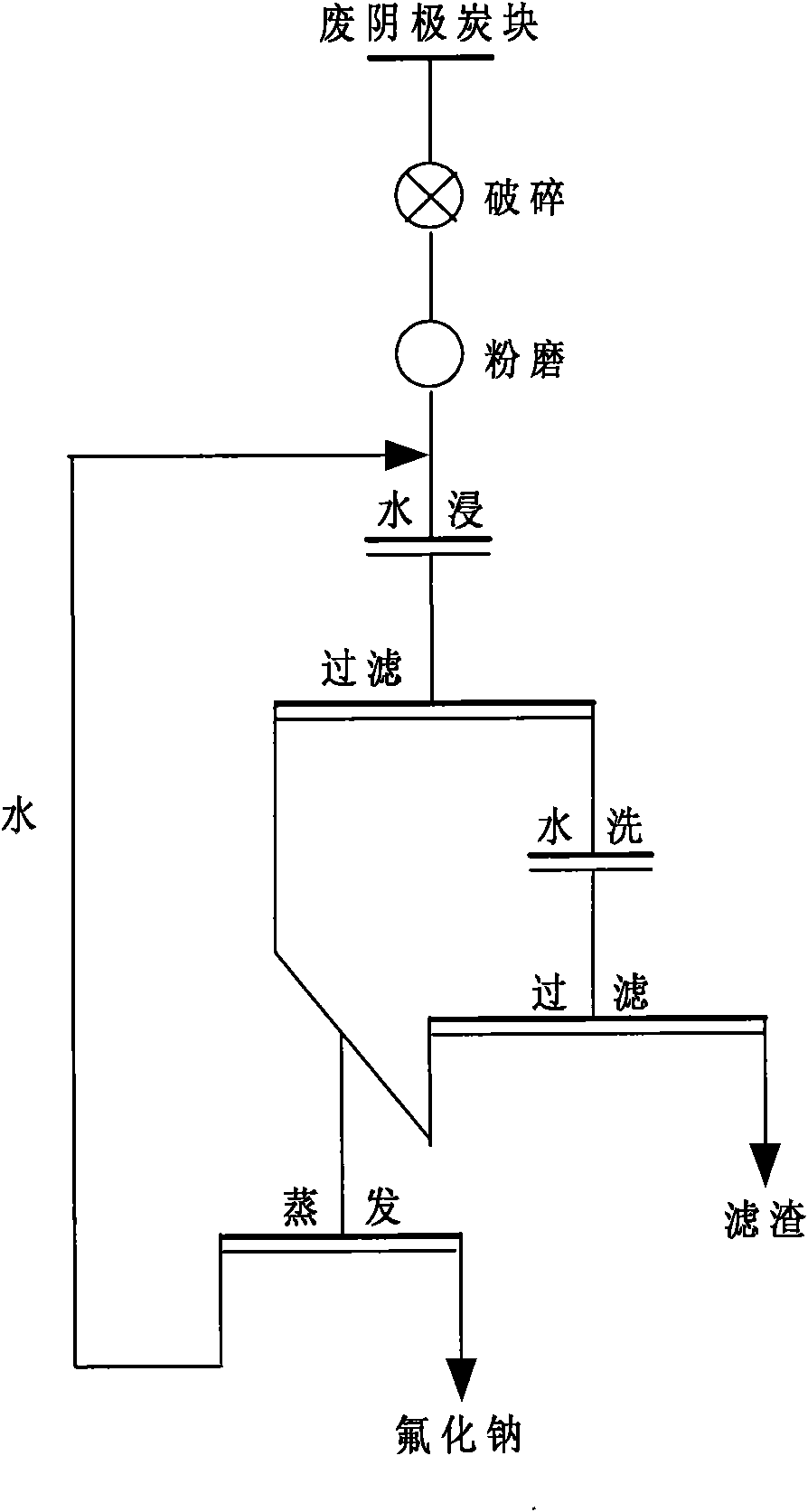

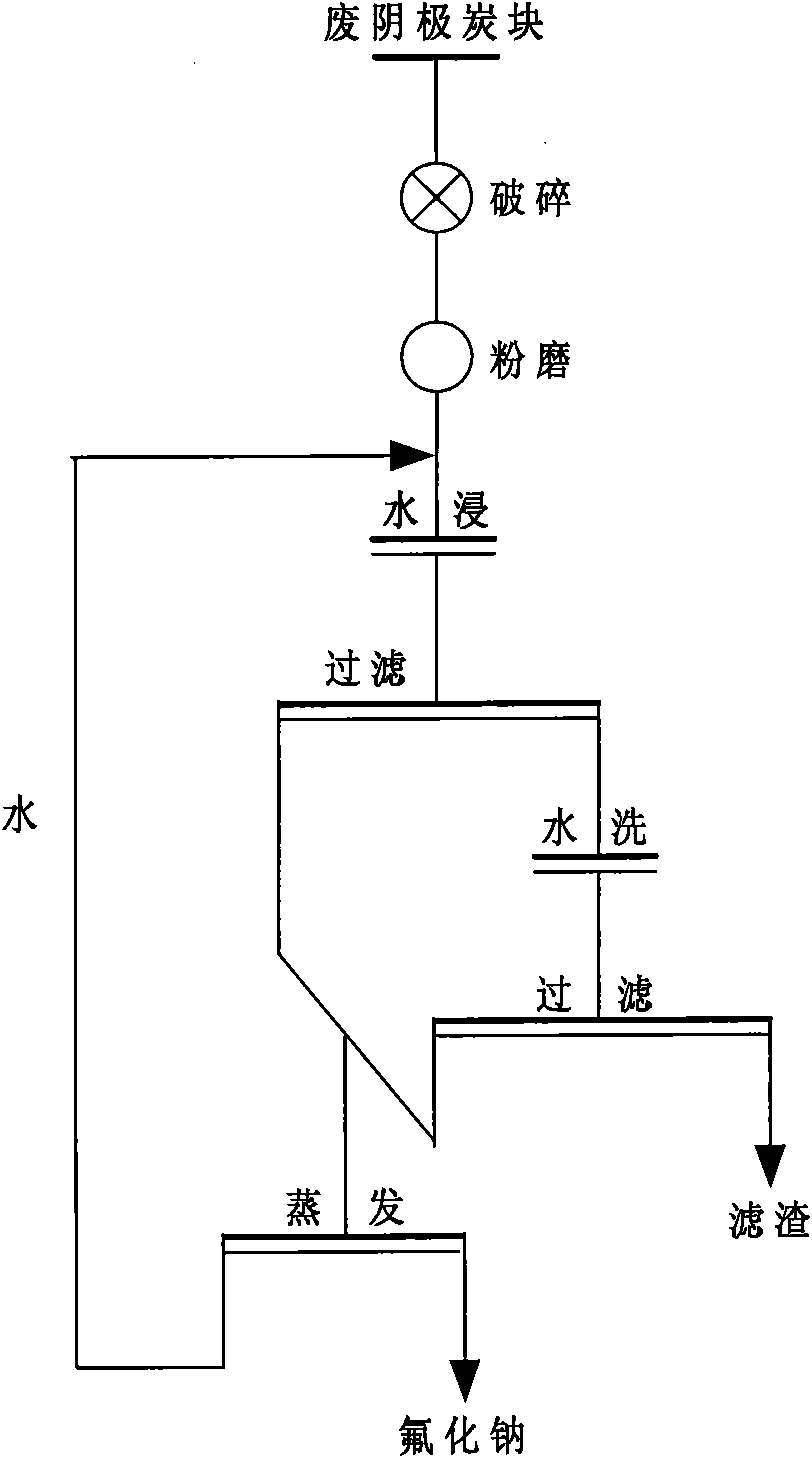

Method for recycling sodium fluoride from electrolytic aluminium waste cathode carbon block

ActiveCN101804996AReduce manufacturing costReduce pollutionSolid waste disposalAlkali metal fluoridesDistilled waterEvaporation

The invention provides a method for recycling sodium fluoride from electrolytic aluminium waste cathode carbon block, including the steps of smashing, grinding, water leaching and evaporating. The method provided by the invention has the advantages that: (1) electrolytic aluminium waste cathode carbon block is taken as raw material, sodium fluorine is recycled from the carbon block, and production cost is low; (2) the purity obtained by the method of the invention reaches more than 95%, fluoride recovery rate reaches more than 40%; (3) the method of the invention has simple technology, distilled water obtained by evaporation can be recycled, no secondary pollution is produced, and environmental pollution caused by soluble fluoride in electrolytic aluminium waste cathode carbon block is reduced, thus being beneficial to environmental protection.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

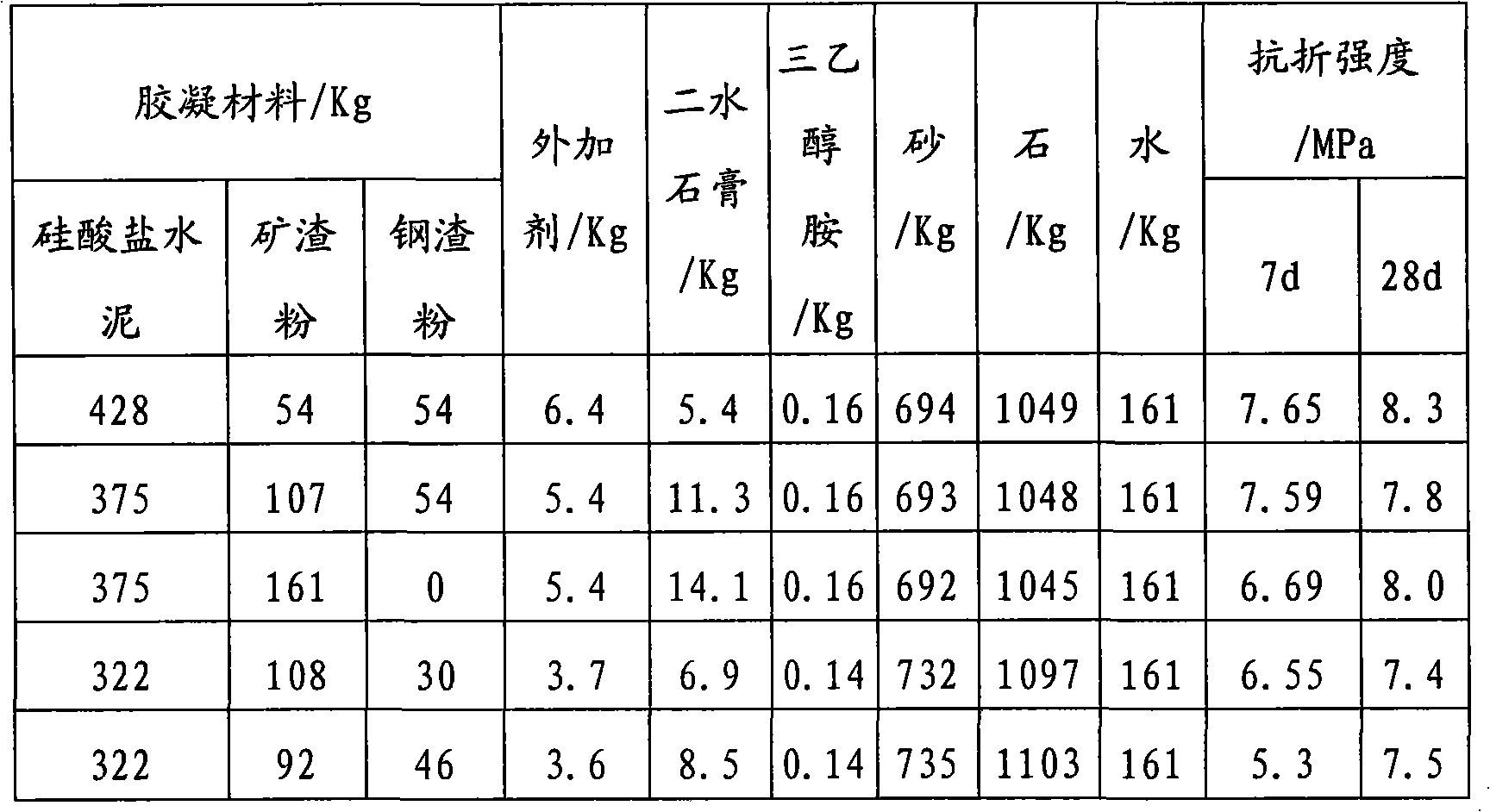

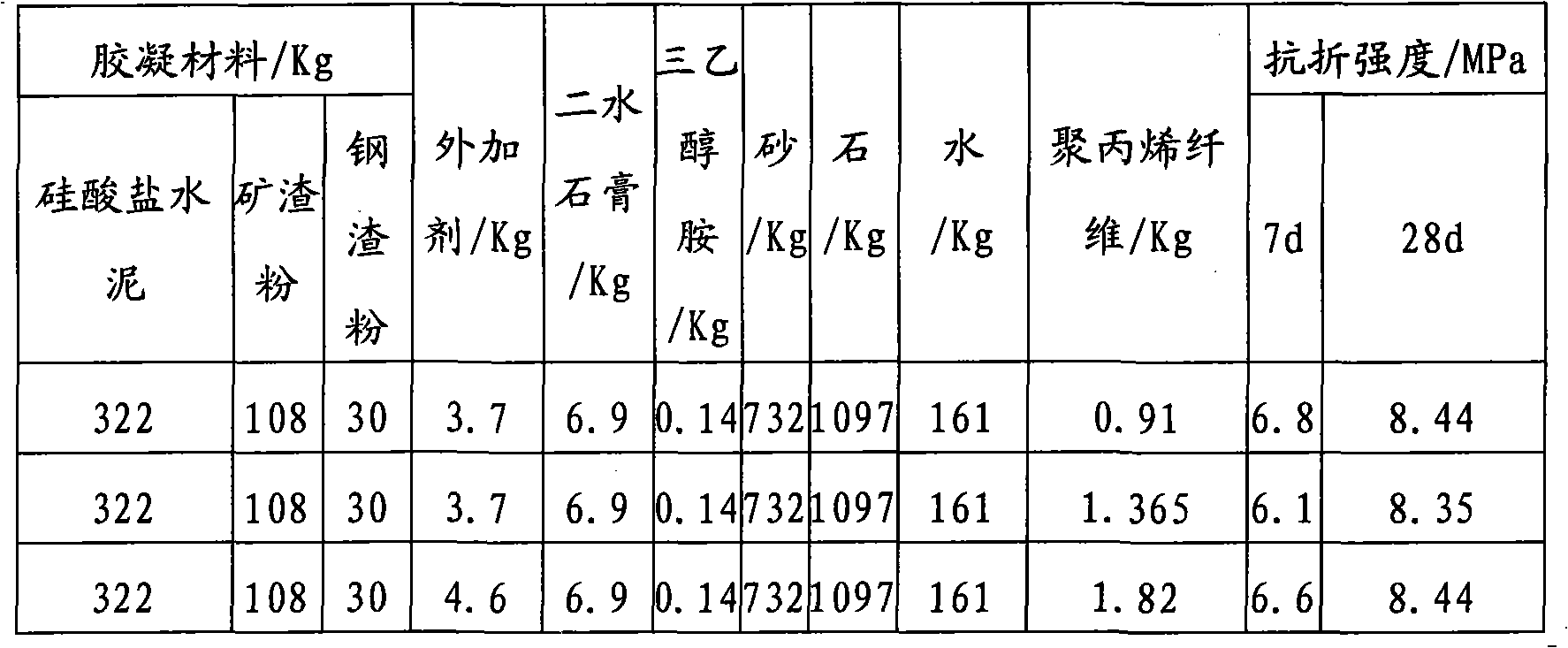

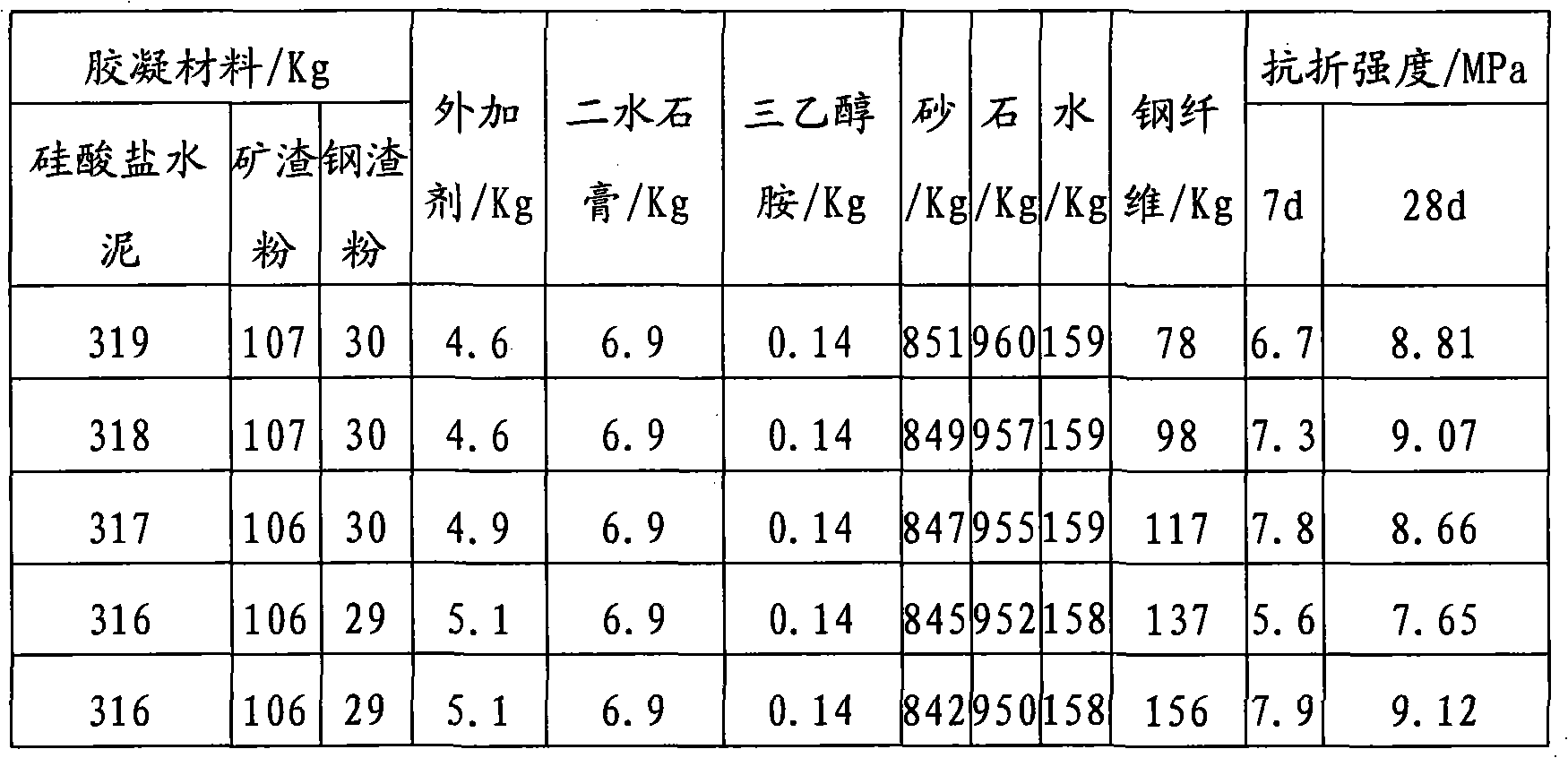

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066AImprove compactnessImprove flexural strengthSolid waste managementSlagSodium fluoride

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

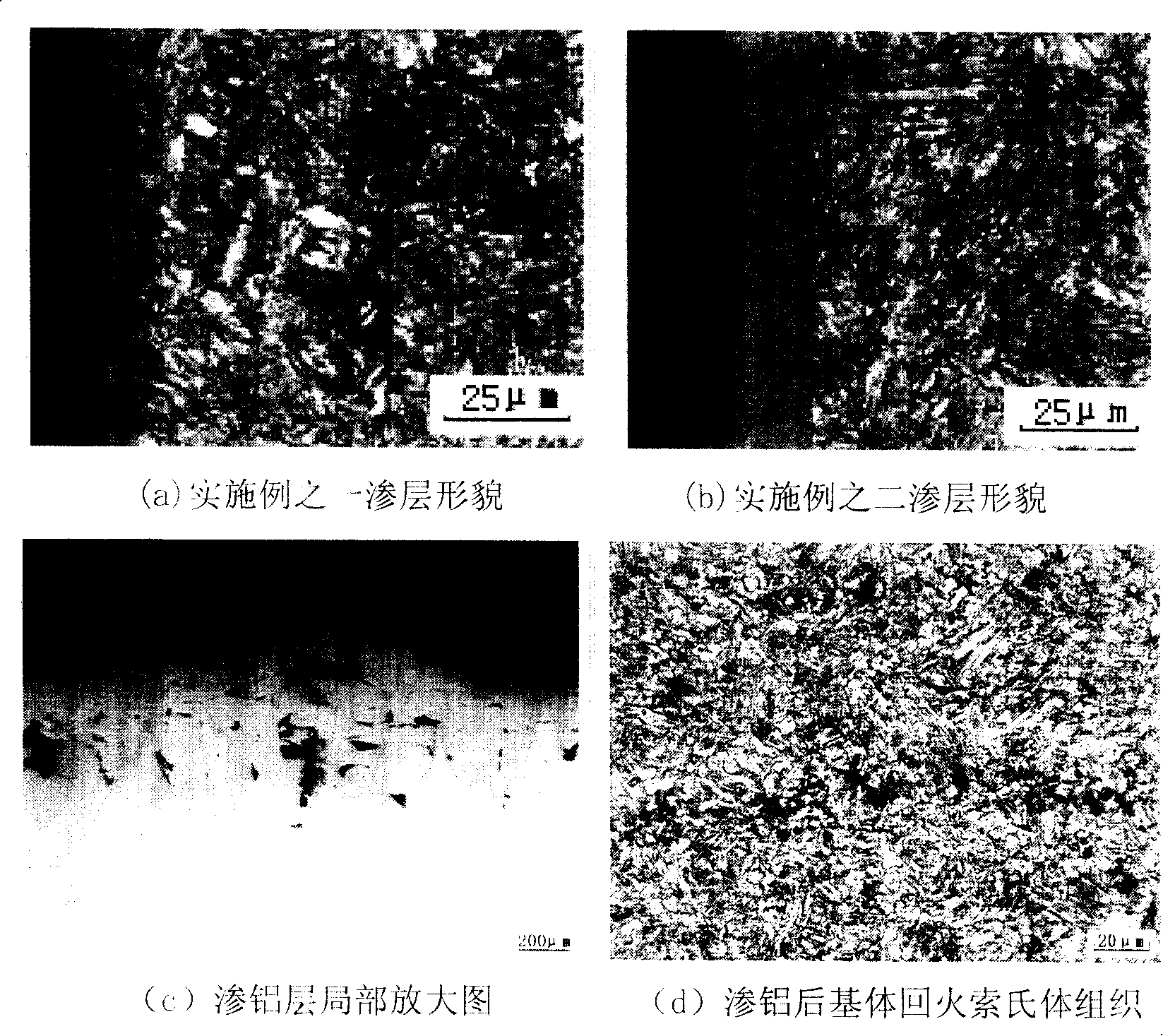

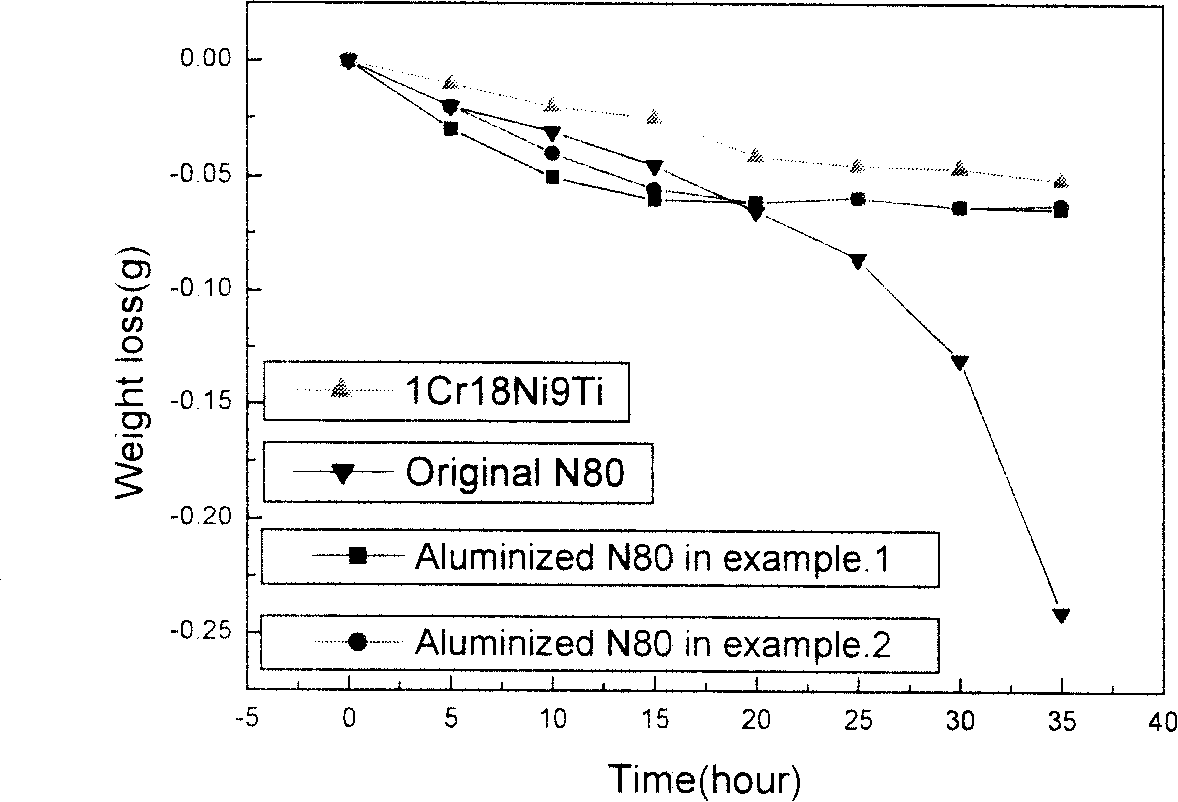

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

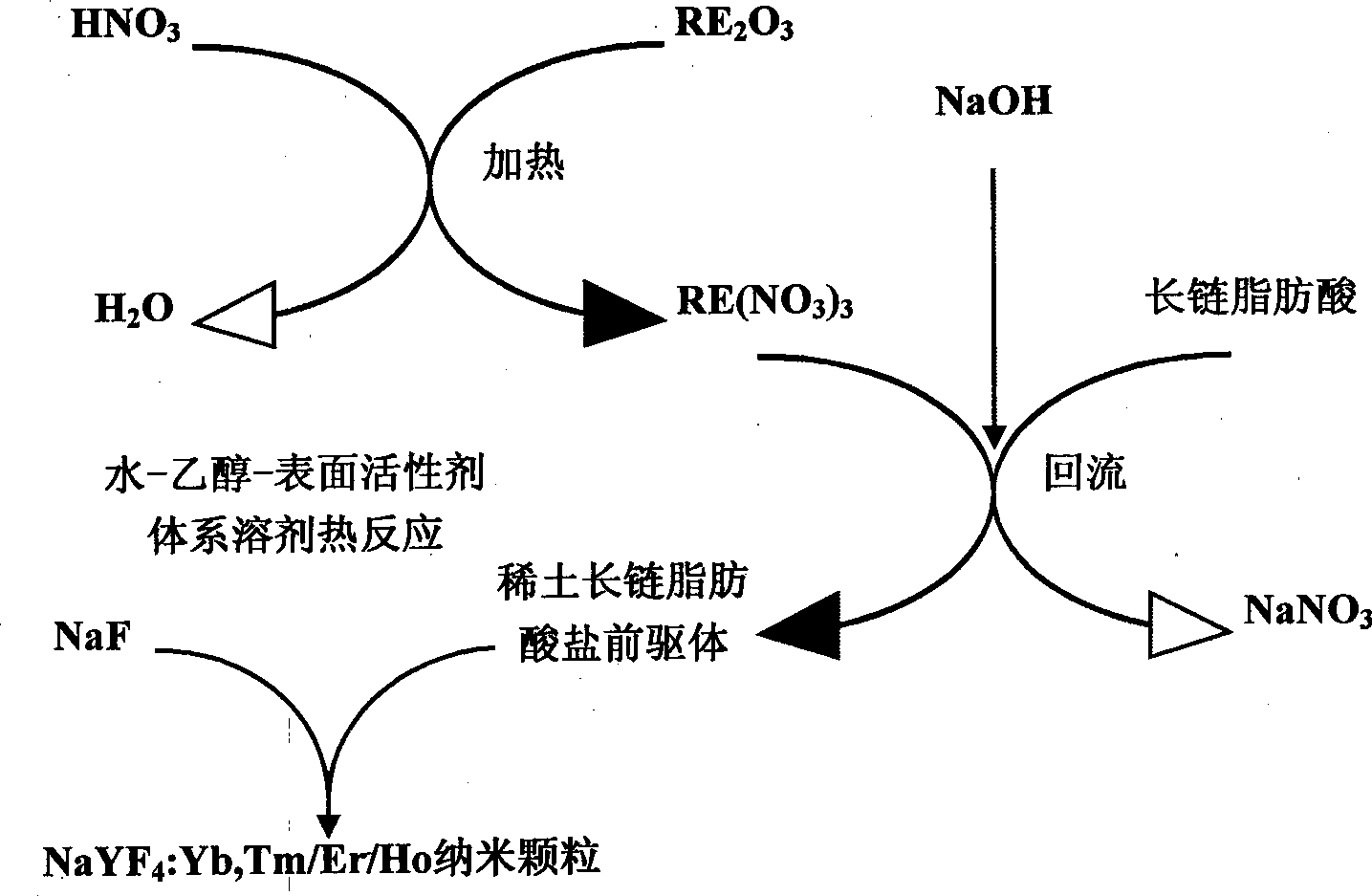

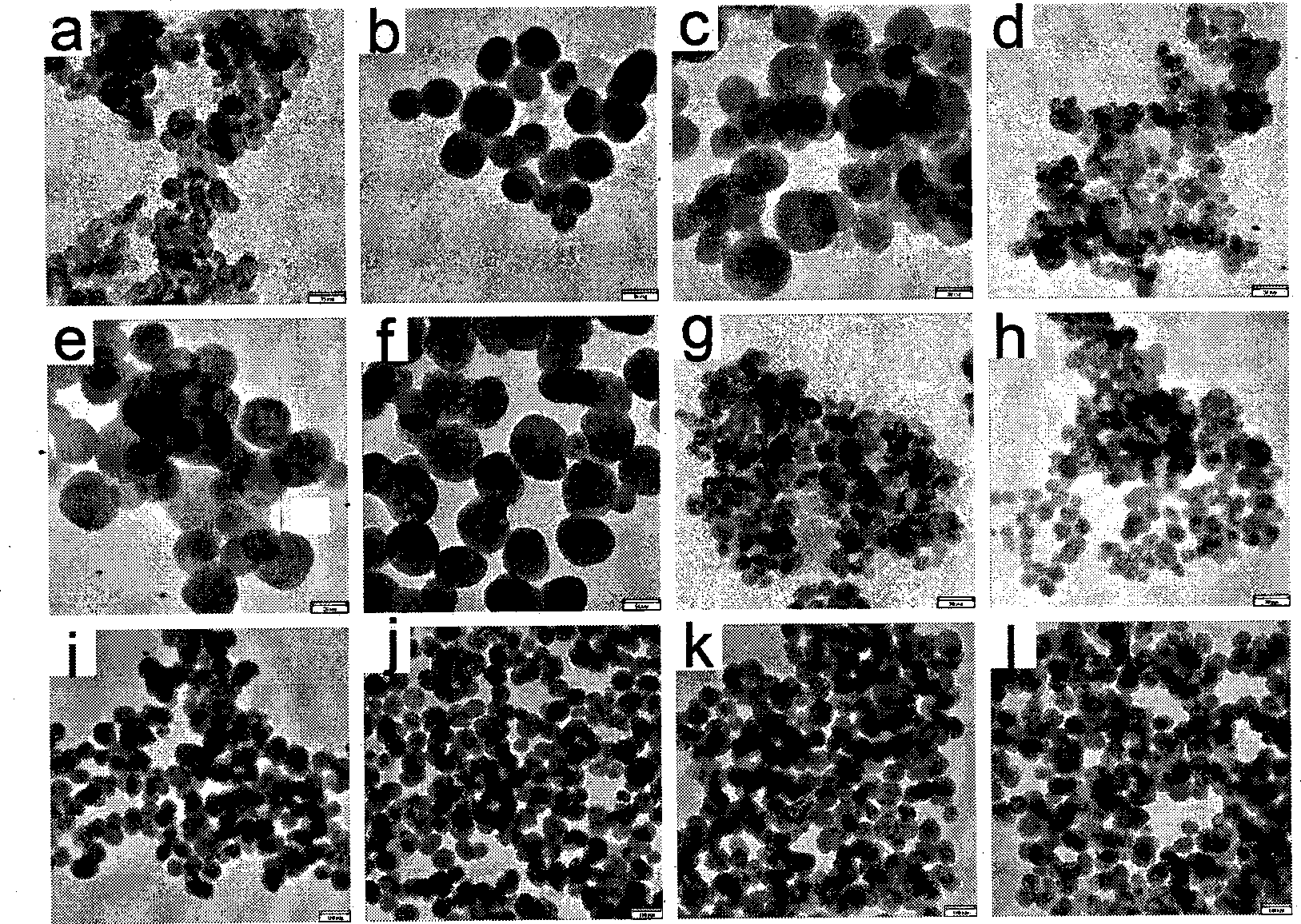

Preparation of upper conversion fluorescent nano particle

InactiveCN101497792ASmall and uniform particle sizeGood dispersionLuminescent compositionsRare earthSurface-active agents

A preparation method of up-conversion phosphor nanometer particles belongs to the technical field of materials and comprises the following steps: (1) dissolving rare-earth inorganic acid salt powder by ethanol to obtain rare-earth inorganic acid salt ethanol solution; (2) adding long-chain fatty acid, performing the reflux reaction under the mixing condition, and preparing a long-chain fatty acid precursor of rare-earth; (3) adding one of an erbium precursor, a thulium precursor and a holmium precursor as well as a yttrium precursor and a ytterbium precursor into a water-ethanol mixing system, adding and uniformly mixing sodium fluoride and surface active agent, and heating and reacting for 2-24h under the obturating condition; (4) adding organic solvent after lowering the temperature, centrifugalizing, and drying or naturally withering after washing white precipitate. The preparation method has simpler process, easy synthesis condition, good repetitiveness, low cost and higher productive rate.

Owner:NORTHEASTERN UNIV

Slag-free flux-cored wire

ActiveCN101780609AIncrease the combinationImprove toughnessWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a novel process for a formula of a slag-free flux-cored wire, and relates to a welding material. The manufacturing method adds the combination of molybdenum powder, nickel powder and rare earth silicon to a formula of raw materials, eliminates mineral powder in a common formula, and optimizes the proportion of various types of metal powder in the formula. According to the formula, the welding material comprises the following components: 4 to 8 parts of micro carbon ferrochromium, 12 to 18 parts of low carbon ferromanganese, 56 to 67 parts of iron powder, 2 to 6 parts of molybdenum powder, 0.1 to 0.4 part of ferroboron, 2 to 5 parts of rare earth silicon, 1 to 3 parts of ferrosilicon, 2 to 3 parts of ferrotitanium, 2 to 3 parts of sodium fluoride, 3 to 7 parts of ferroaluminum, 1 to 3 parts of aluminum to magnesium powder and 4 to 8 parts of nickel powder. The invention improves the toughness, strength and anti-fatigue performance of welding seams and thins welding-seam grains by adding the combination of molybdenum powder, nickel powder and rare earth silicon into the raw materials of the formula, eliminating the mineral powder in the common formula, and optimizing the proportion of various types of metal powder in the formula. Meanwhile, slagging on the surfaces of the welding seams is avoided, and welding efficiency is raised by 20 percent compared with slag-type processes.

Owner:山东聚力焊接材料有限公司

Health-care type electronic smoke liquid for preventing and treating decayed tooth

InactiveCN101473999AInhibitionGrowth inhibitionTobacco treatmentHydroxy compound active ingredientsFlavorLiquid smoke

The invention discloses a healthcare electronic cigarette juice capable of preventing and curing decayed teeth. The health electronic cigarette juice mainly contains 3-5%w / v of a tobacco extract, 40-50%w / v of propylene glycol, 10-15%w / v of purified water, 3-5%w / v of a tobacco flavor, 0.2-1%w / v of a stabilizer, 3-8%w / v of a thickener, 0.5-4%w / v of xylitol, 0.5-4%w / v of L-arabinose and 3-9% w / v of sodium fluoride solution. As the healthcare electronic cigarette juice capable of preventing and curing the decayed teeth contains the xylitol and the sodium fluoride, the healthcare electronic cigarette juice has the effect of preventing and curing the decayed teeth, and increasing the teeth strength; and the cigarette juice can also have healthcare function and prevent and cure the decayed teeth of oral cavity and teeth while enjoying smoking and smoke exhalation.

Owner:FEELLIFE BIOSCI INT

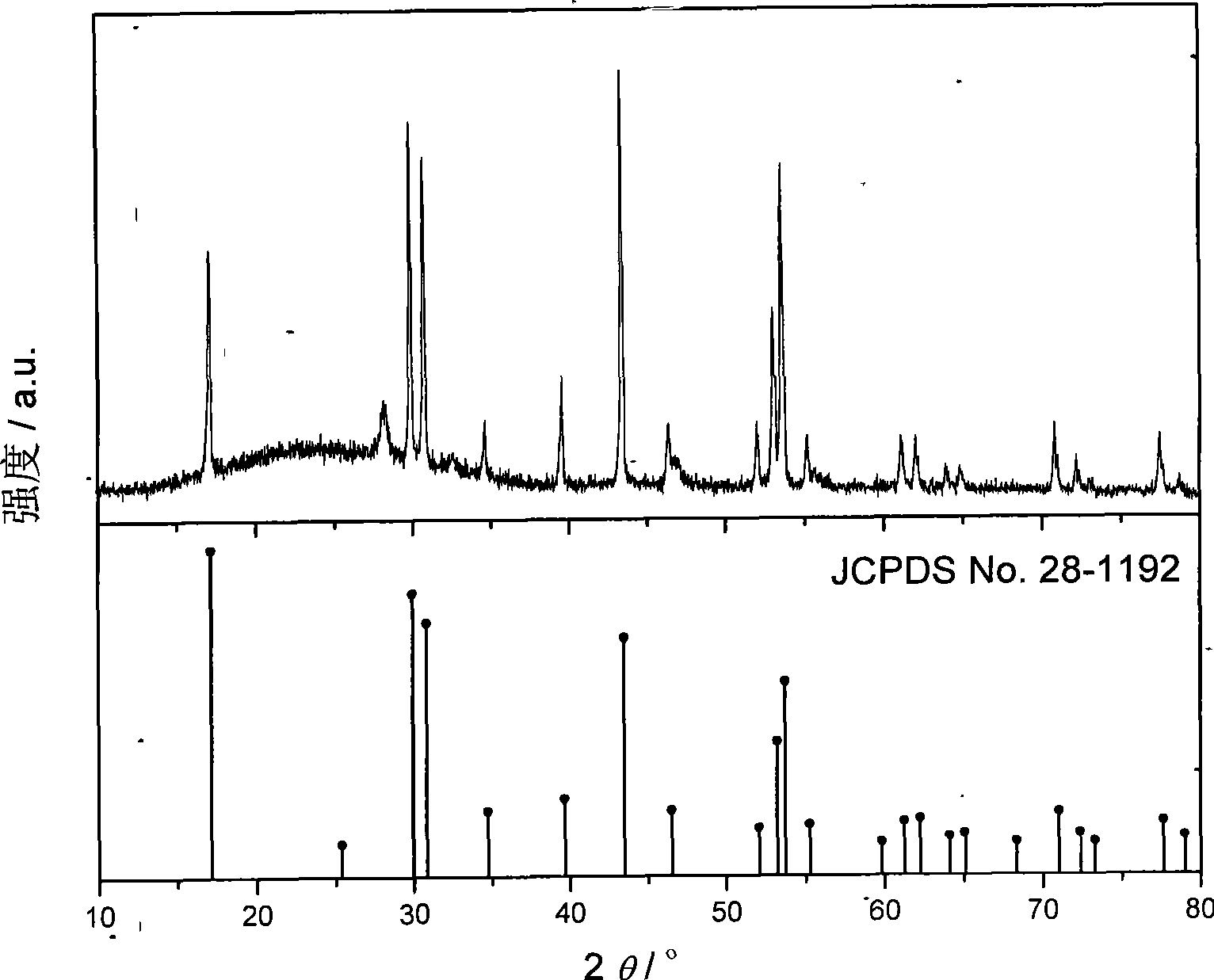

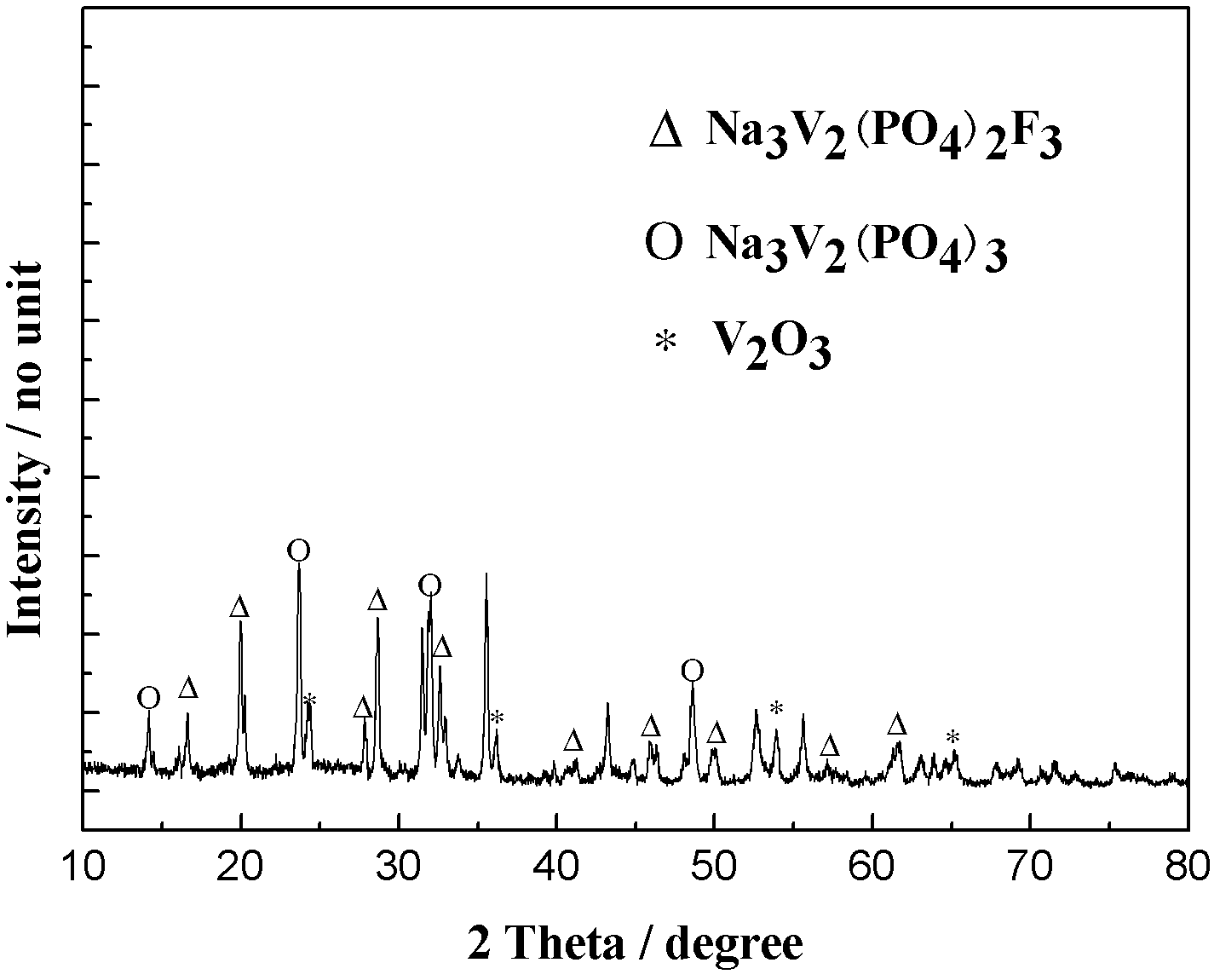

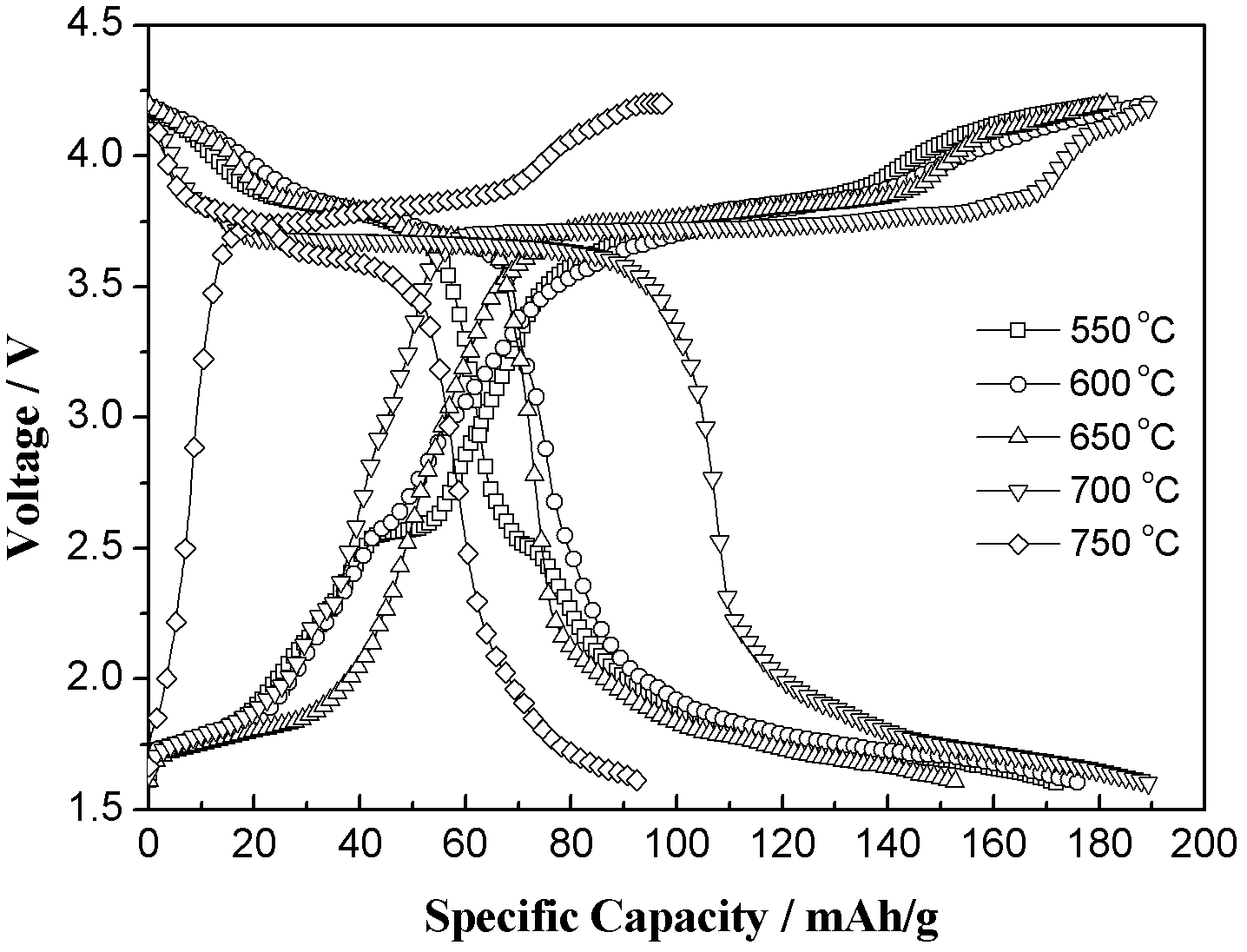

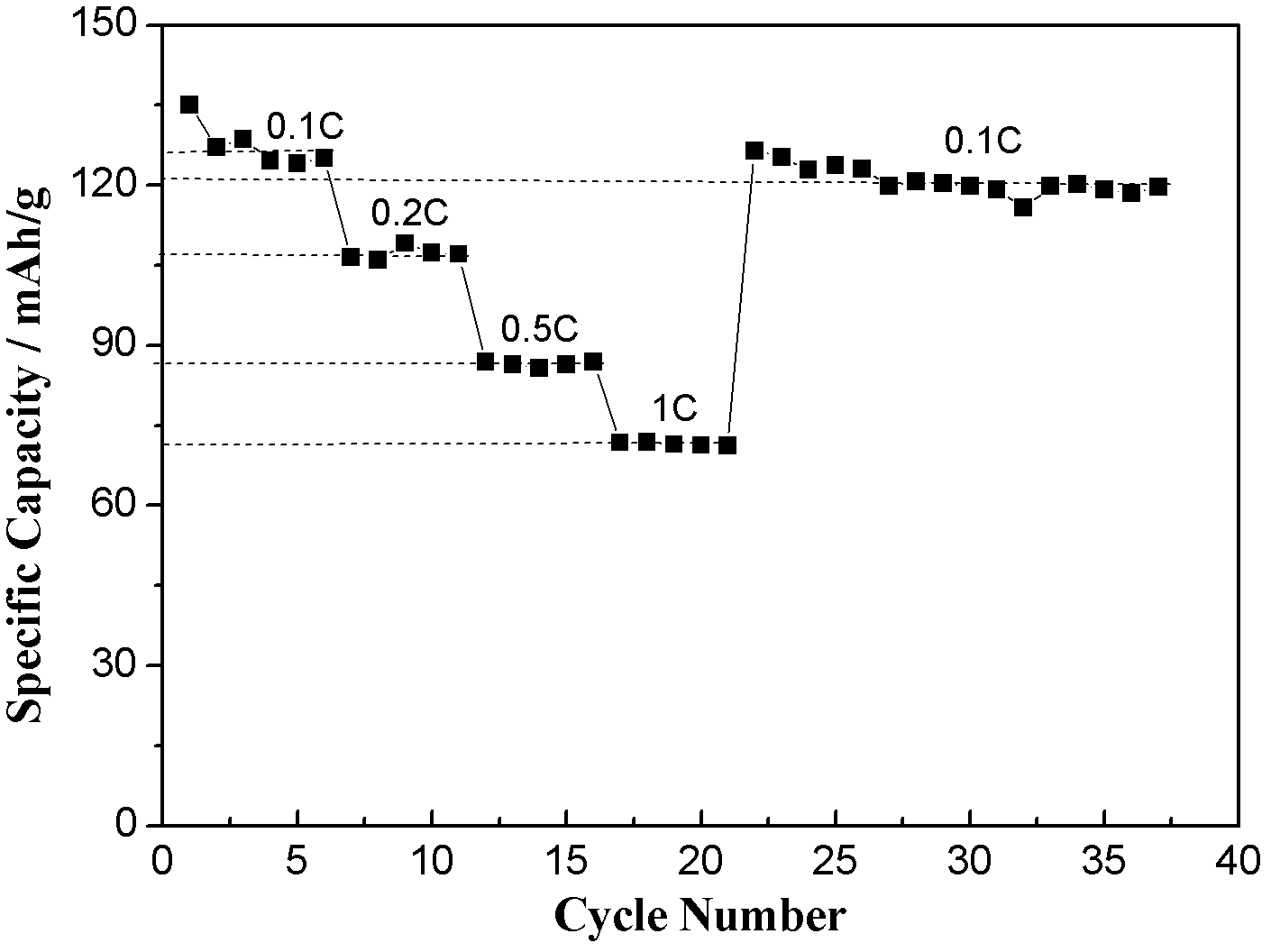

Preparation method of vanadium sodium fluophosphate cathode material of hybrid ion battery

InactiveCN102306771AShape is easy to controlGood carbon coatingCell electrodesRoom temperatureFree cooling

The invention provides a preparation method of a vanadium sodium fluophosphate cathode material of a hybrid ion battery. The method comprises the following steps: 1) grinding of a mixed material: taking trivalent or pentavalent vanadium oxide (V), ammonium dihydrogen phosphate (P), sodium fluoride (F) and a reducing agent carbon source (C) as raw materials, wherein the molar ratio of V to P to F is 2:(1.9-2.3):3, the molar ratio of V to C in the reducing agent carbon source is 1:(1-2), then weighing carbon source accounting for 3-5% of the total weight of the raw materials to serve as a conductive agent, and carrying out mixed grinding to obtain a precursor mixture; 2) precalcination: precalcinating the precursor mixture for 6-10 hours at the temperature of 300-400 DEG C at the warming speed of 3-5 DEG C per minute under the protection of inert gas, cooling the mixture to room temperature and taking out the mixture for secondary grinding; and 3) secondary calcination: carrying out the secondary calcination on the mixture ground in the step 2) for 6-10 hours at the temperature of 550-750 DEG C at the warming speed of 3-5 DEG C per minute under the protection of the inert gas, and naturally cooling to room temperature to obtain the vanadium sodium fluophosphate cathode material. The vanadium sodium fluophosphate cathode material has good electrochemical performance which is obviously improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com