Patents

Literature

30results about How to "Increase the combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag-free flux-cored wire

ActiveCN101780609AIncrease the combinationImprove toughnessWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a novel process for a formula of a slag-free flux-cored wire, and relates to a welding material. The manufacturing method adds the combination of molybdenum powder, nickel powder and rare earth silicon to a formula of raw materials, eliminates mineral powder in a common formula, and optimizes the proportion of various types of metal powder in the formula. According to the formula, the welding material comprises the following components: 4 to 8 parts of micro carbon ferrochromium, 12 to 18 parts of low carbon ferromanganese, 56 to 67 parts of iron powder, 2 to 6 parts of molybdenum powder, 0.1 to 0.4 part of ferroboron, 2 to 5 parts of rare earth silicon, 1 to 3 parts of ferrosilicon, 2 to 3 parts of ferrotitanium, 2 to 3 parts of sodium fluoride, 3 to 7 parts of ferroaluminum, 1 to 3 parts of aluminum to magnesium powder and 4 to 8 parts of nickel powder. The invention improves the toughness, strength and anti-fatigue performance of welding seams and thins welding-seam grains by adding the combination of molybdenum powder, nickel powder and rare earth silicon into the raw materials of the formula, eliminating the mineral powder in the common formula, and optimizing the proportion of various types of metal powder in the formula. Meanwhile, slagging on the surfaces of the welding seams is avoided, and welding efficiency is raised by 20 percent compared with slag-type processes.

Owner:山东聚力焊接材料有限公司

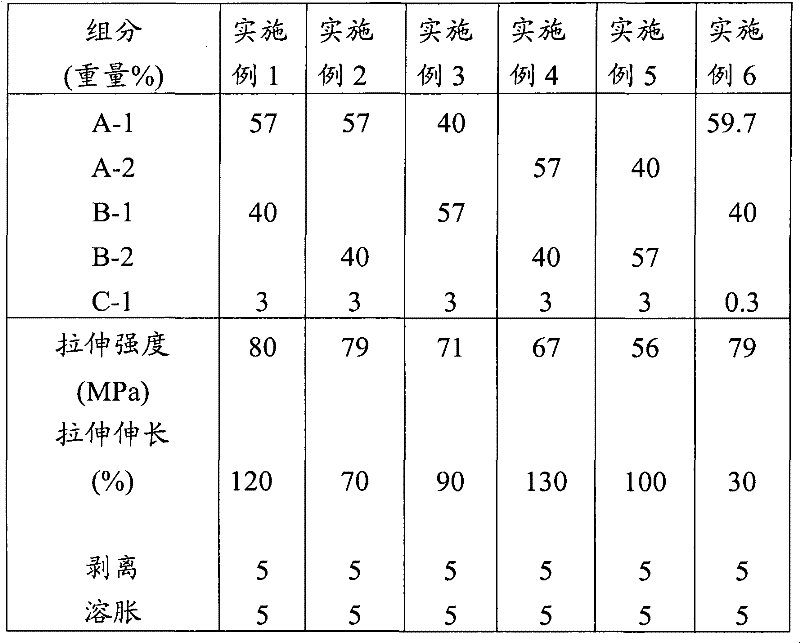

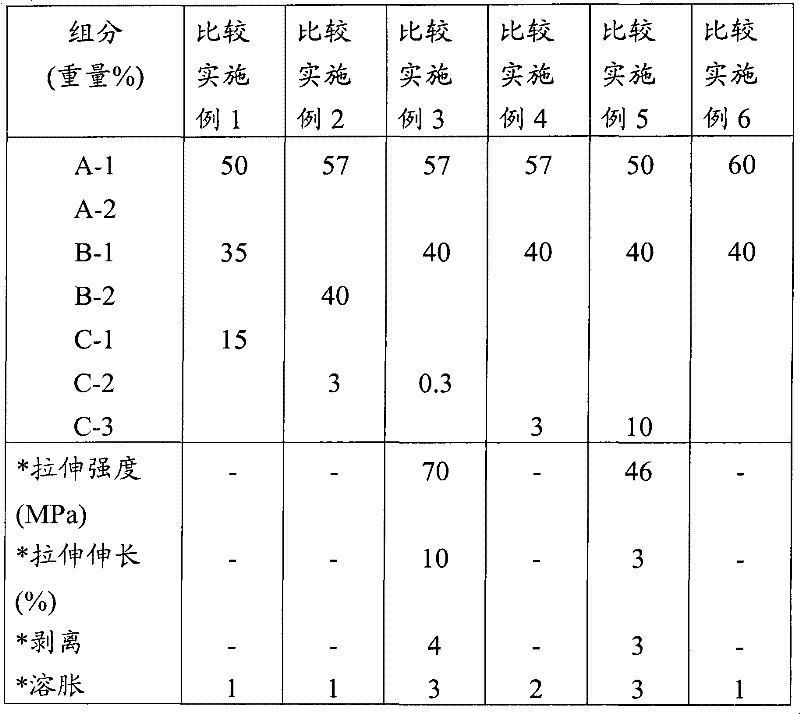

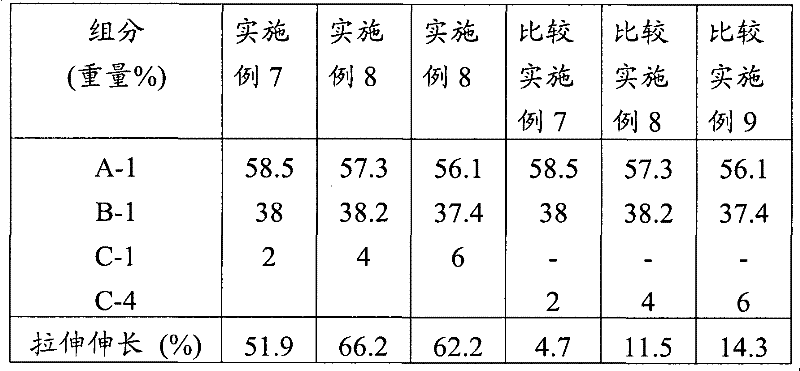

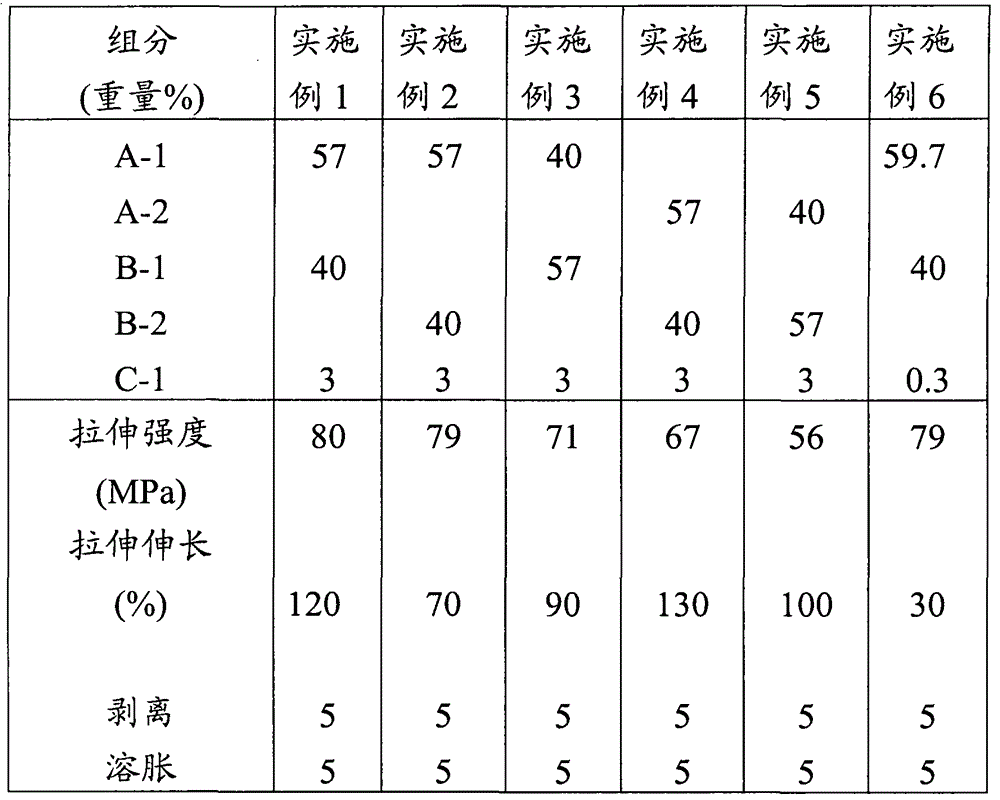

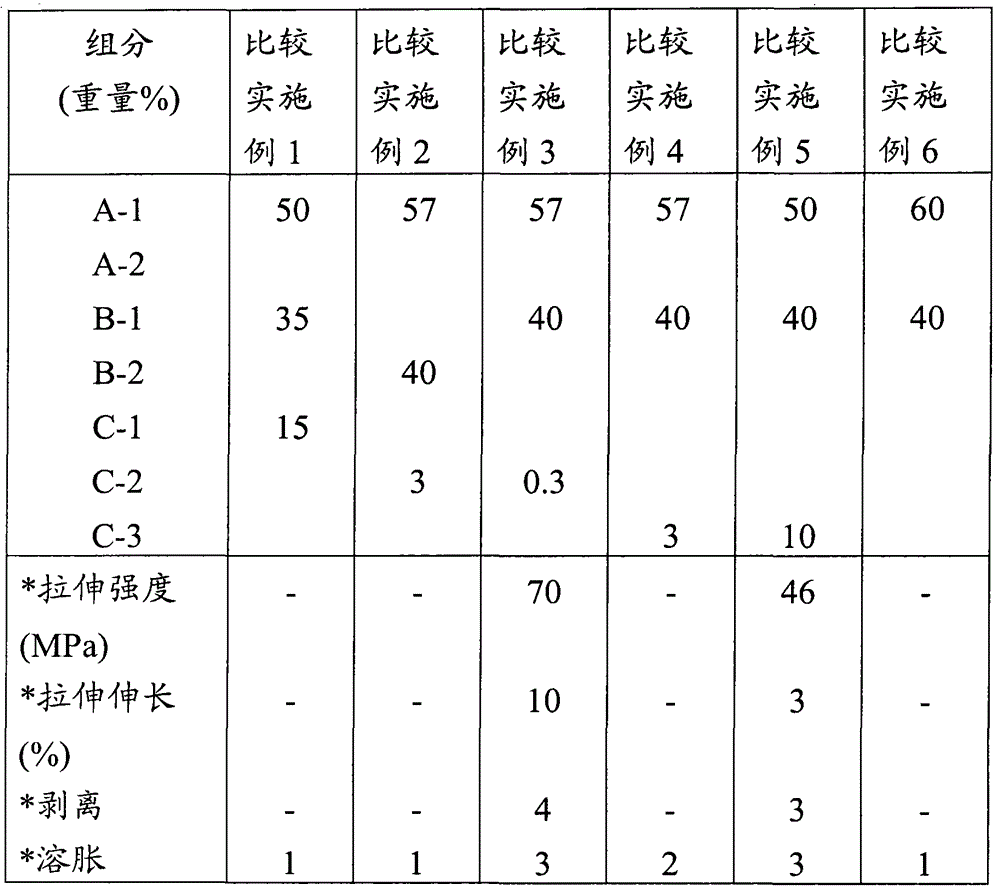

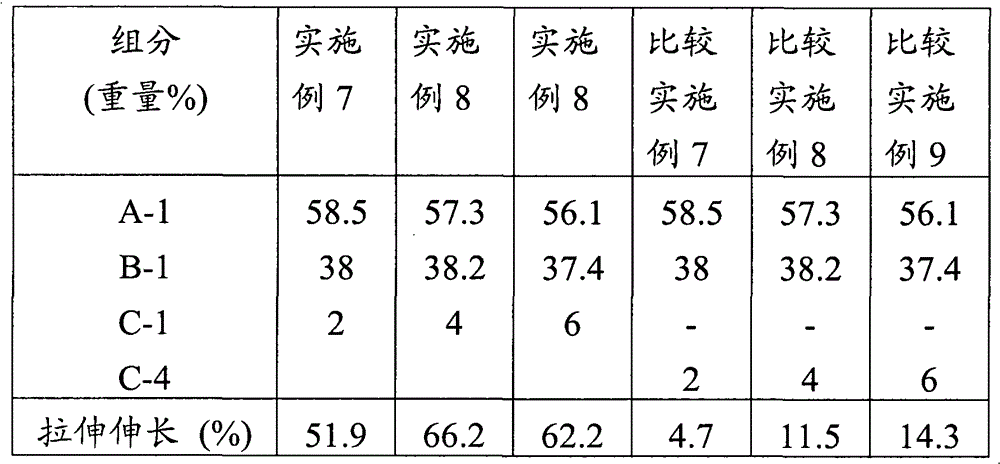

Composition of a blend of polyamide and polyester resins

The present invention relates to a resin blend composition of a polyamide resin and a polyester resin, which includes a polyamide resin, a polyester resin and an epoxy resin. The resin blend composition according to the present invention has improved compatibility between the polyamide resin and the thermoplastic polyester resin, and therefore has superior mechanical properties (strength, bending strength, elasticity, abrasion resistance, impact strength), chemical properties (solvent resistance), thermal resistance, dimensional stability, paintability, etc.

Owner:POLYAMIDE HIGH PERFORMANCE

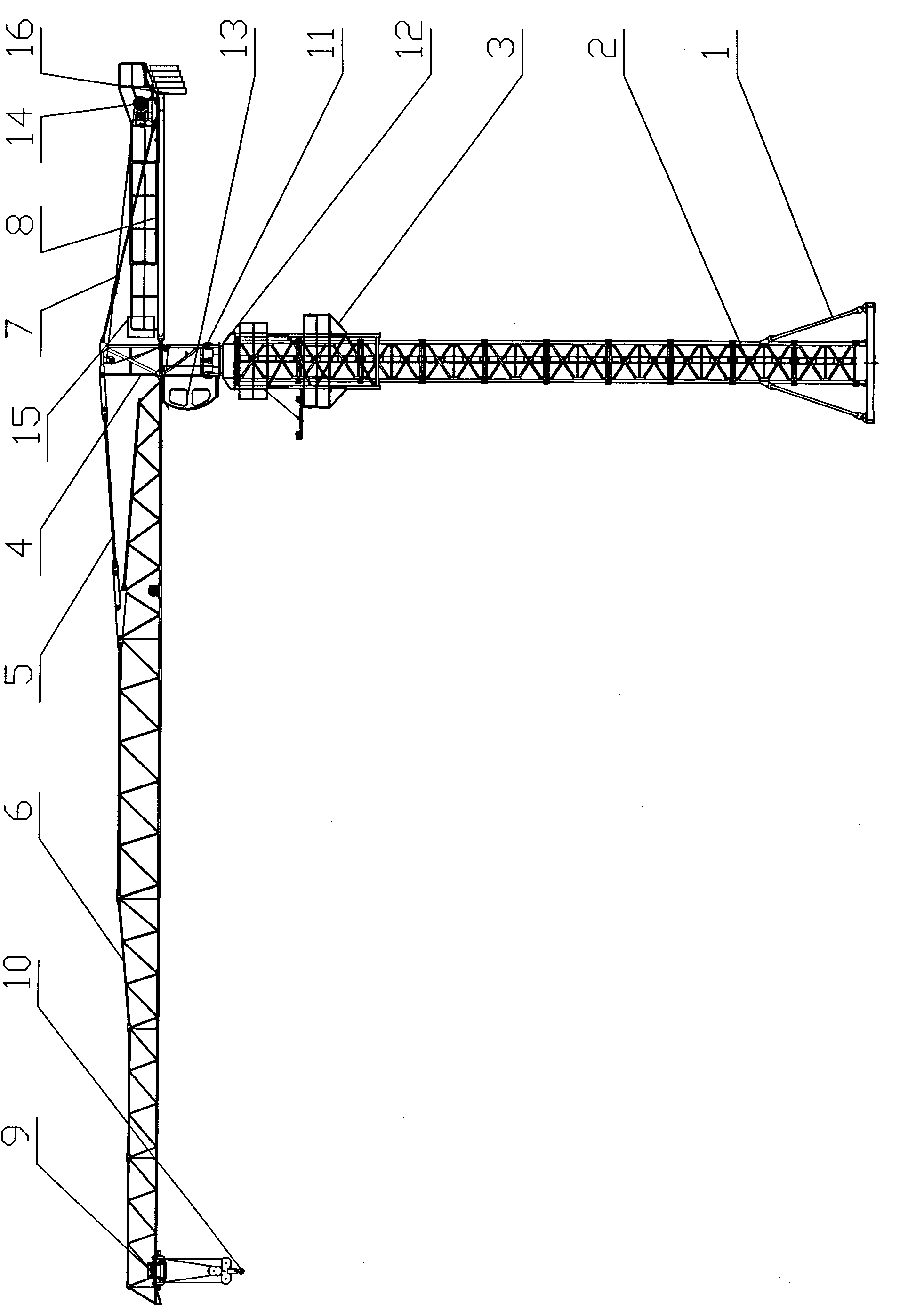

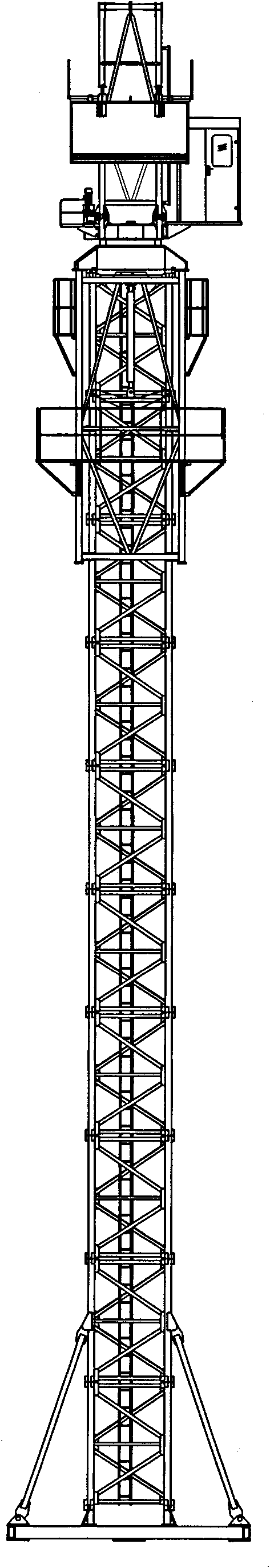

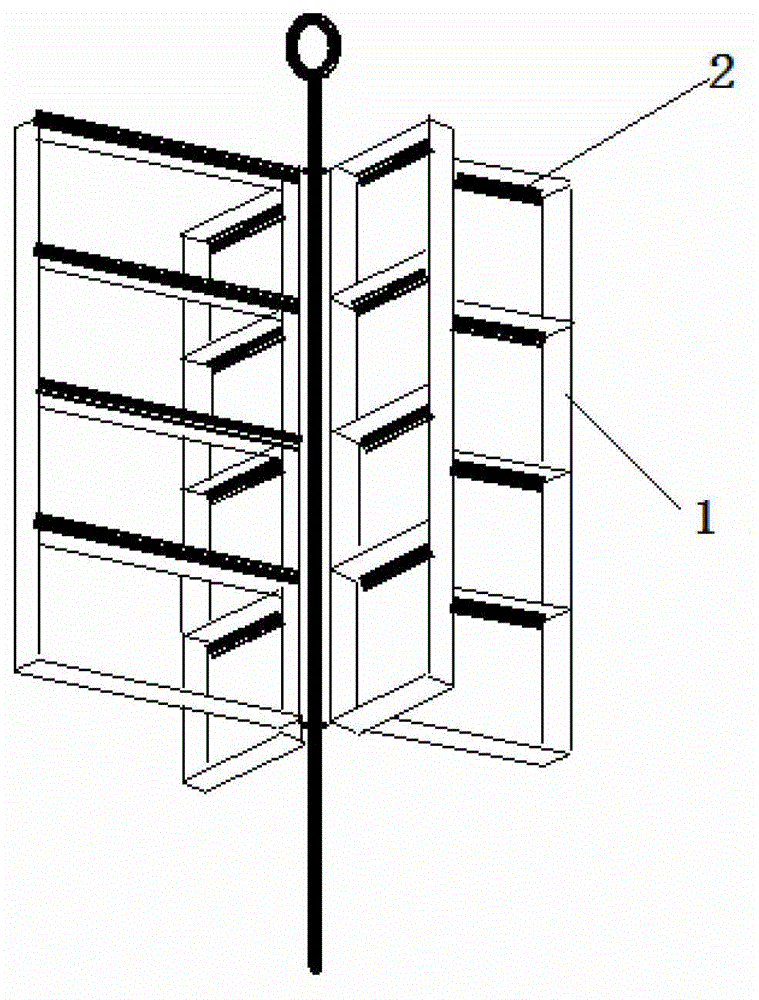

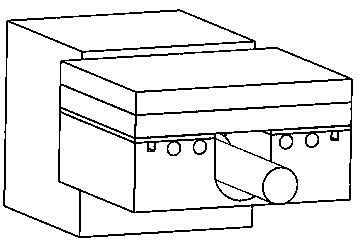

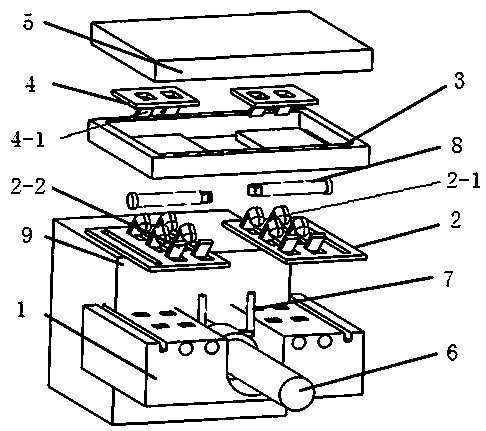

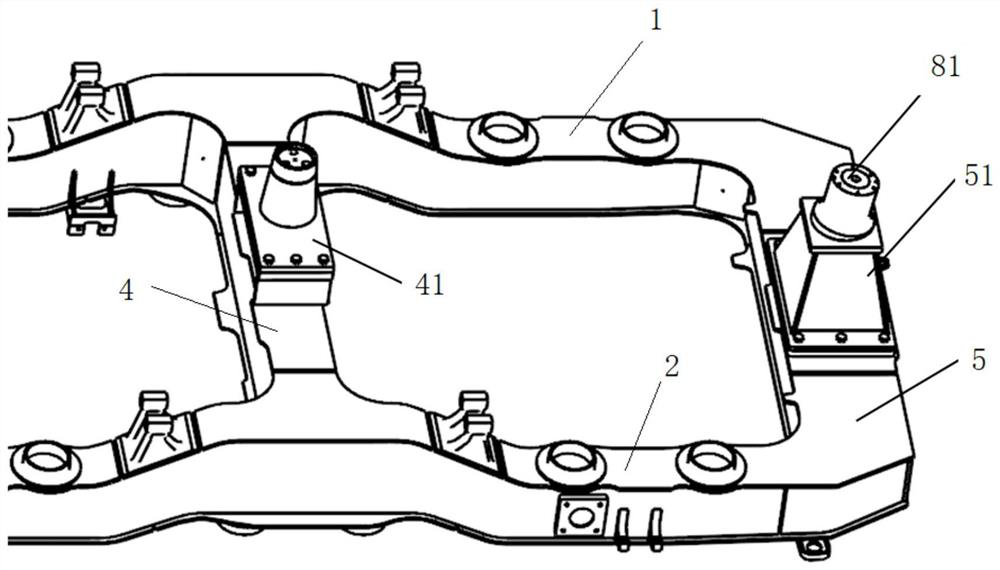

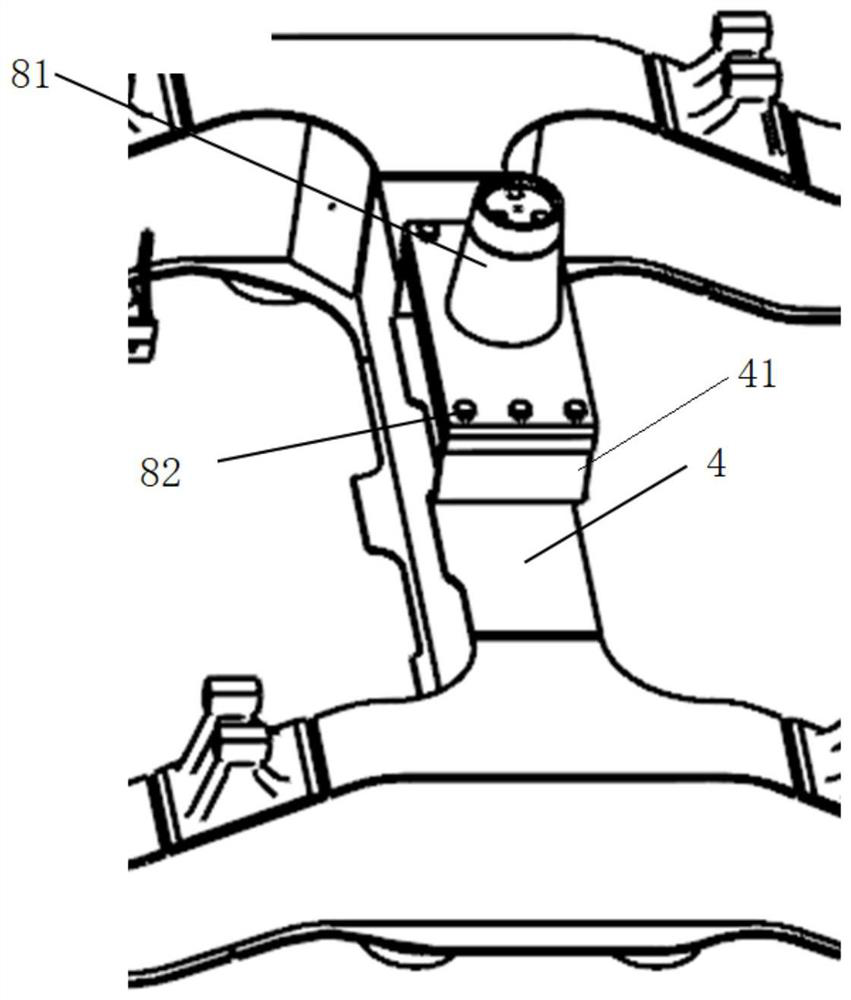

Flat-head tower crane

The invention provides a flat-head tower crane. The common tower cranes are generally provided with tower tops, and when a group of towers carry out cross operation, the common tower cranes are hard to be competent in many occasions with special requirement for height because of being limited by the tower tops. The flat-head tower crane comprises an undercarriage (1). The invention is characterized in that a group of standard sections (2) are connected on the undercarriage in order; the standard section arranged at the upper end is connected with a swivel assembly; a wrap frame (3) arranged outside the standard sections is connected with the lower part of the swivel assembly and a swivel tower body (4) is connected with the upper part of the swivel assembly; one side of the swivel tower body is connected with a boom (6) by a boom tension bar (5) and the other side thereof is connected with a balance boom (8) by a balance boom tension bar (7); the boom tension bar is connected with a speed changed trolley (9); and a hook (10) is linked with the lower part of the speed changed trolley. The tower crane serves as an elevator.

Owner:HARBIN HUATUO METAL STRUCTURE

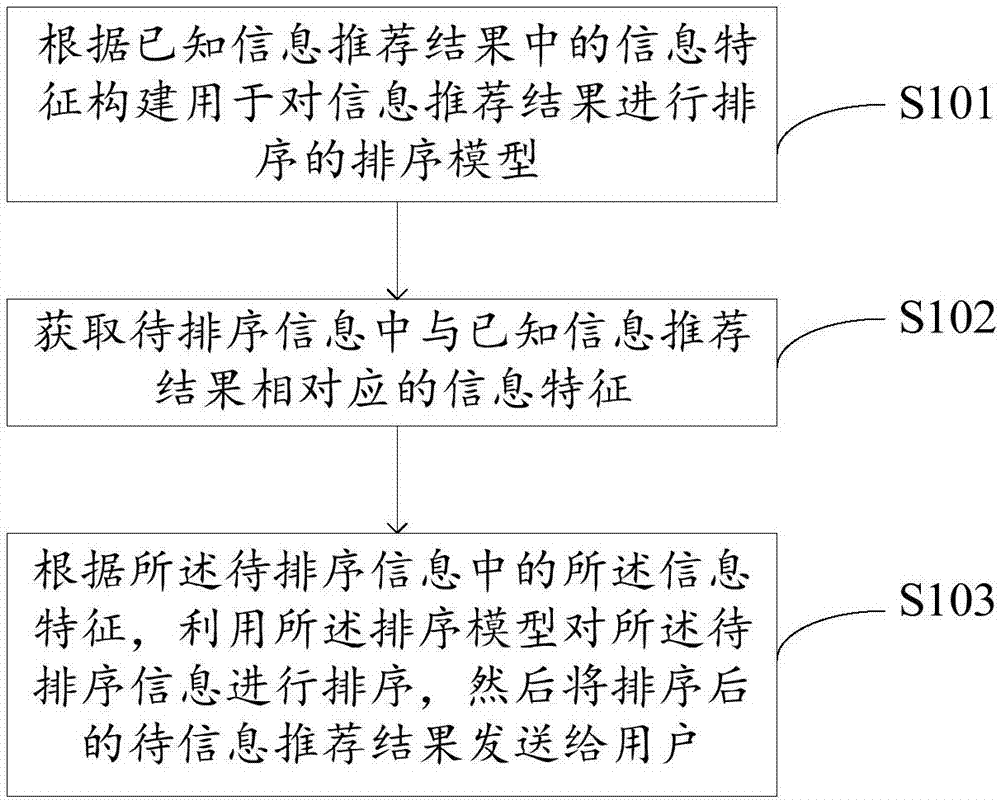

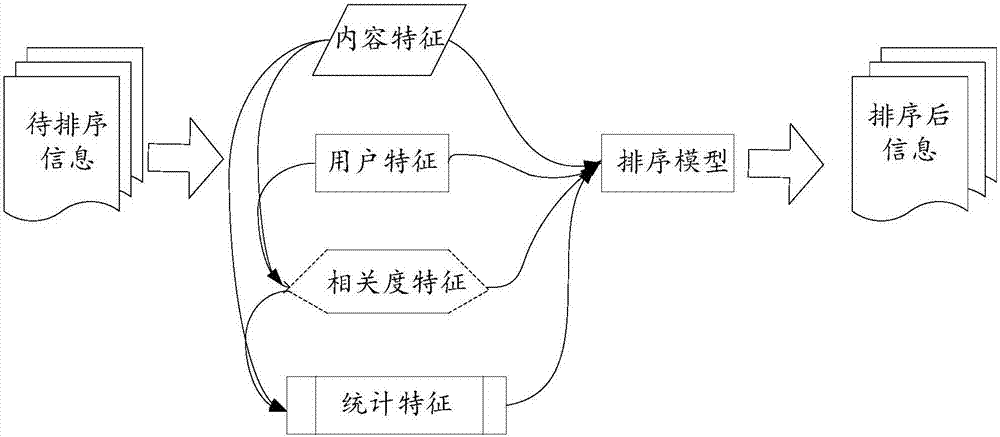

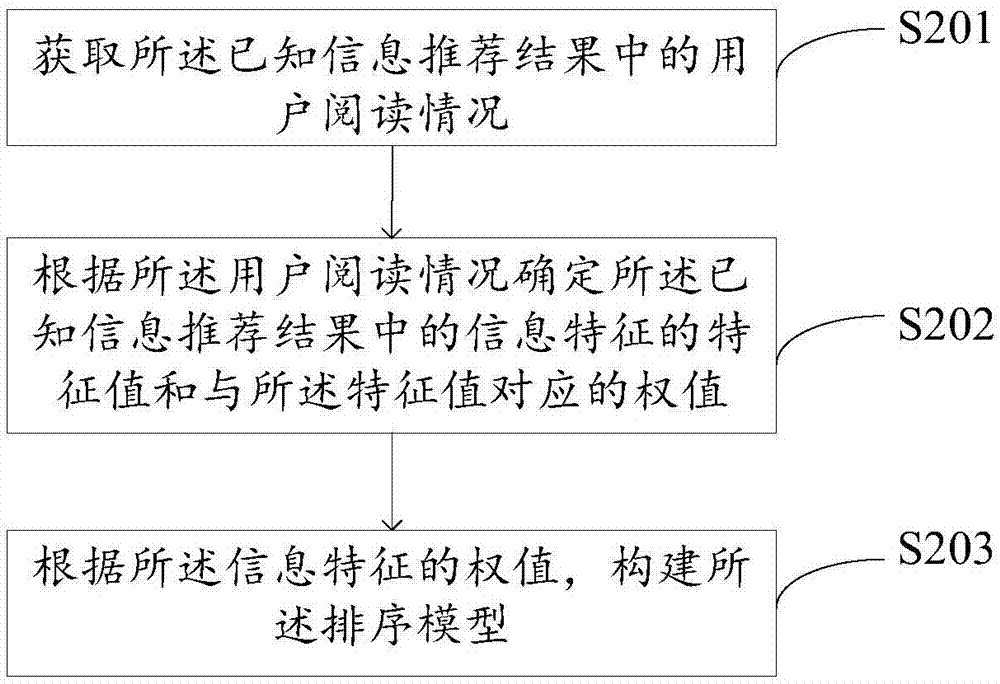

Information recommendation result sorting method and device and server

InactiveCN107885886AAdd multi-dimensional information featuresIncrease the combinationSpecial data processing applicationsData miningData science

The invention provides an information recommendation result sorting method and device and a server. The information recommendation result sorting method comprises the steps that a sorting model for sorting information recommendation results is established according to information characteristics in the known information recommendation results; the information characteristics corresponding to the known information recommendation results are obtained from the information to be sorted; according to the information characteristics in the information to be sorted, the sorting model is utilized to sort the information to be sorted, and then the sorted information recommendation results are sent to a user. One of the above technical schemes has the following advantages that the sorting model forsorting information recommendation results is established according to information characteristics included in the known information recommendation results, multi-dimension information characteristicsand characteristic combination can be increased, the characteristic complexity is reduced, and the sorting performance is greatly improved through reasonable characteristic calculation.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

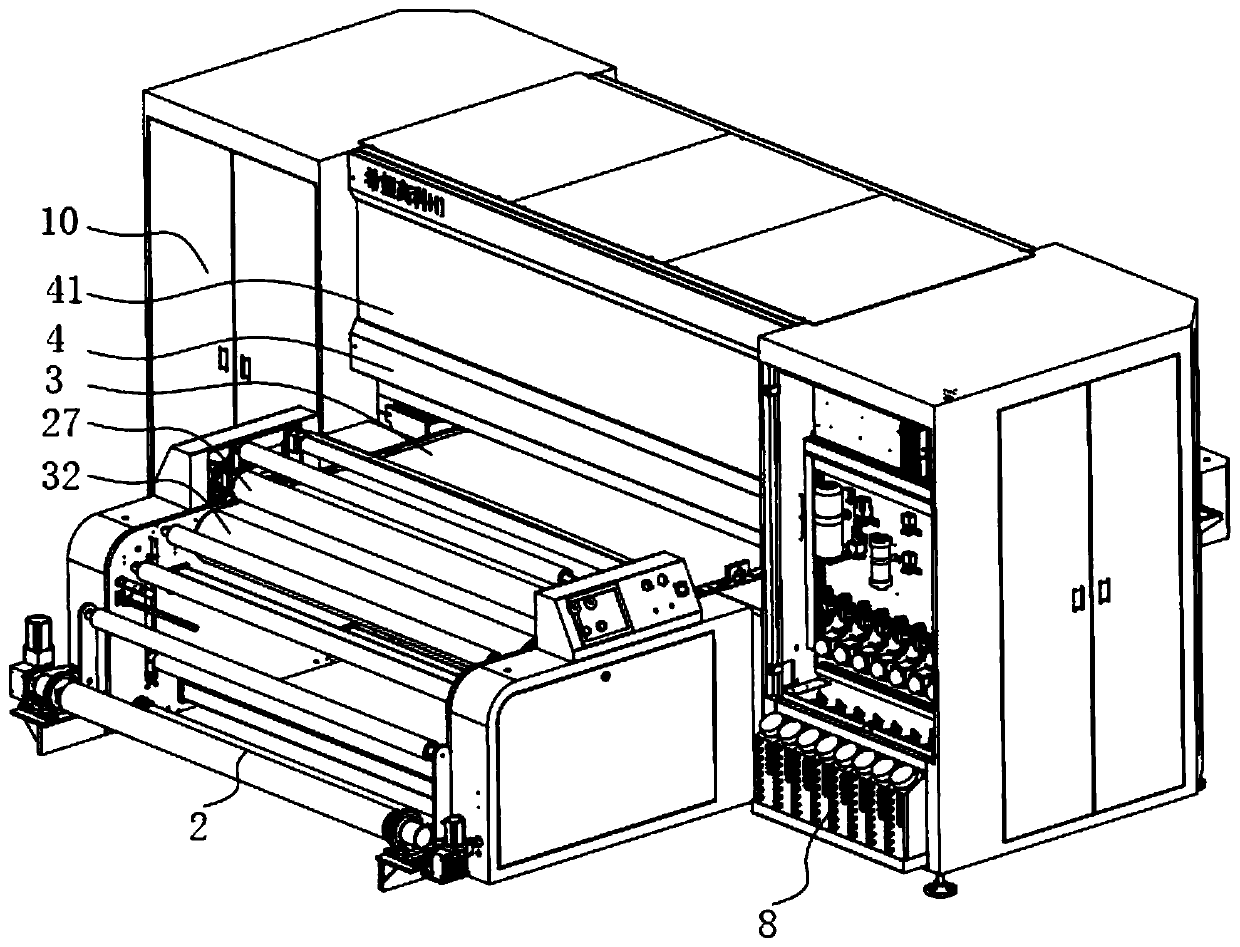

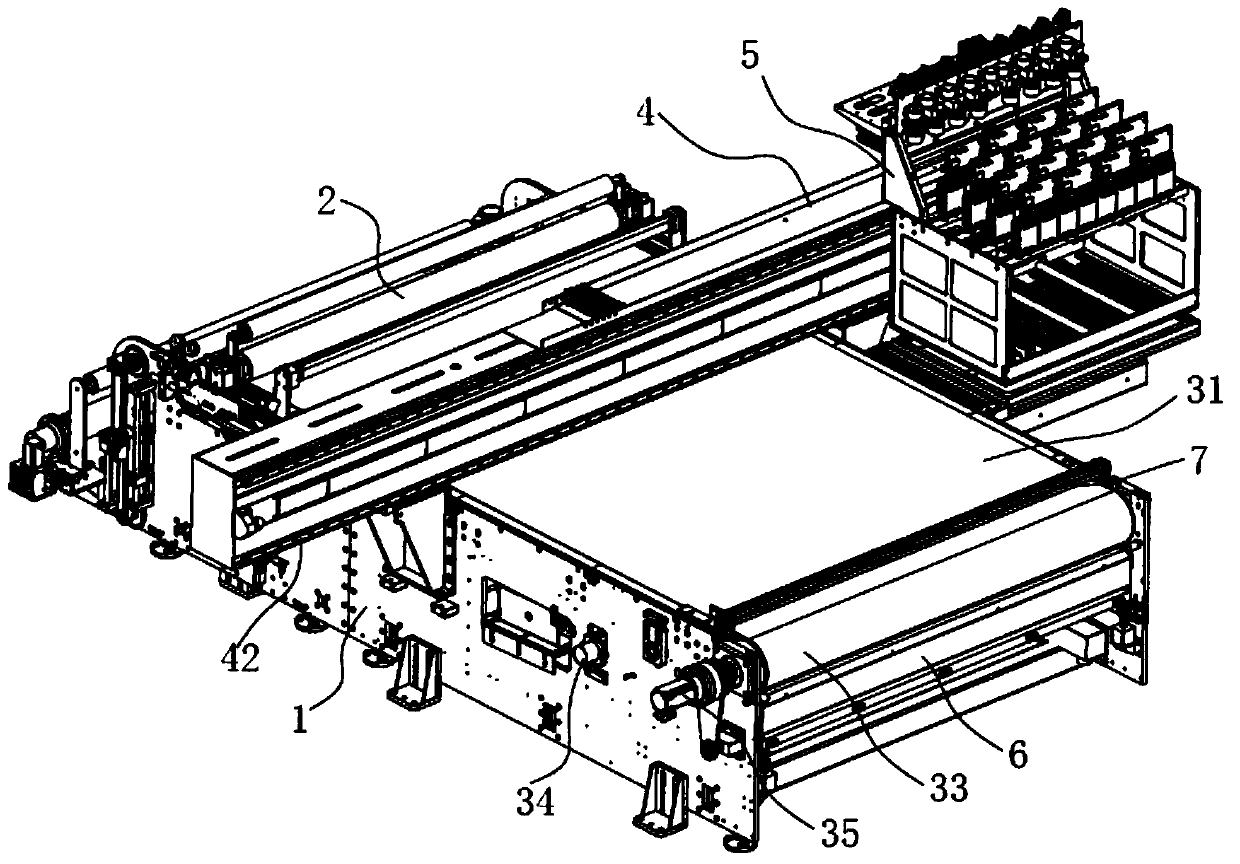

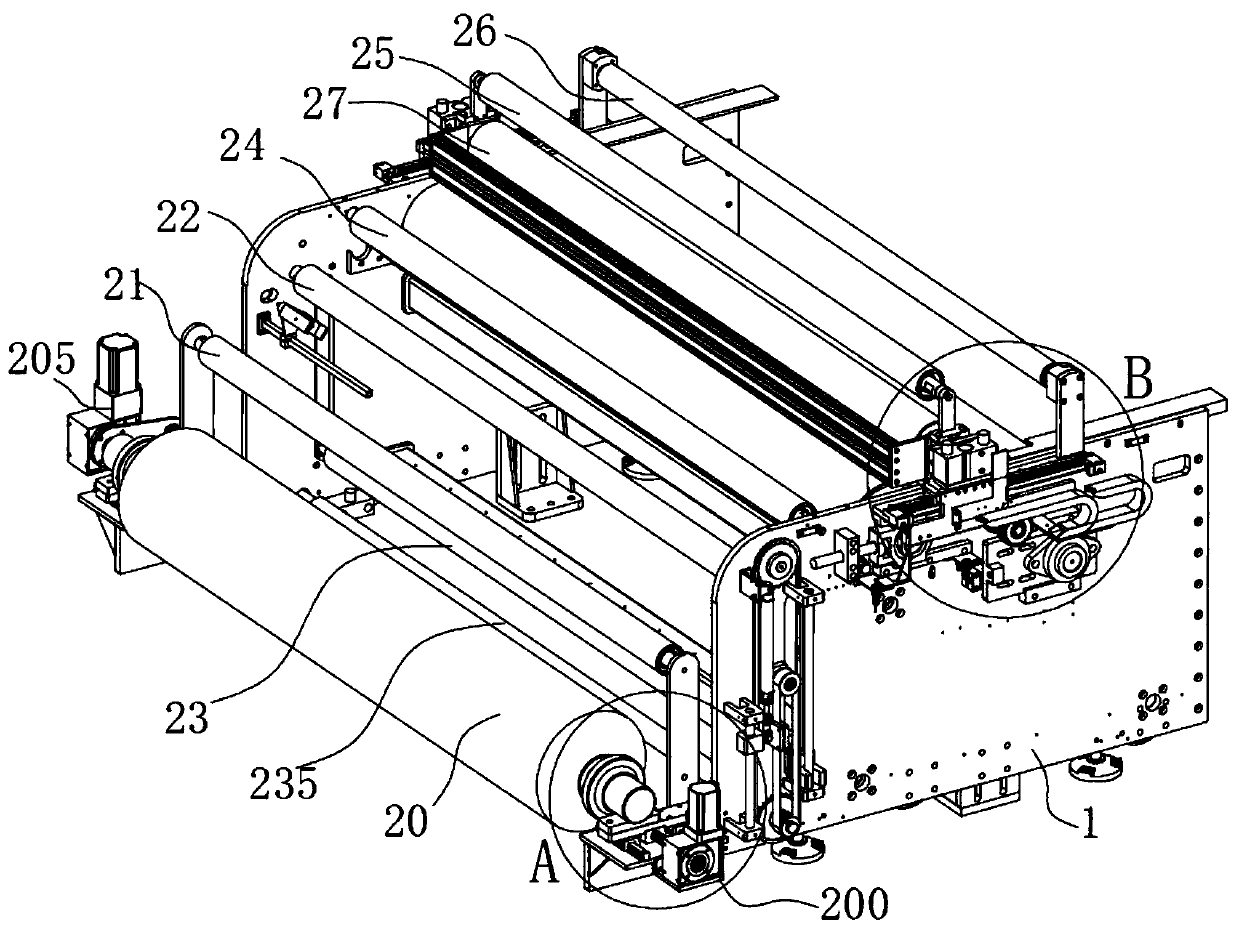

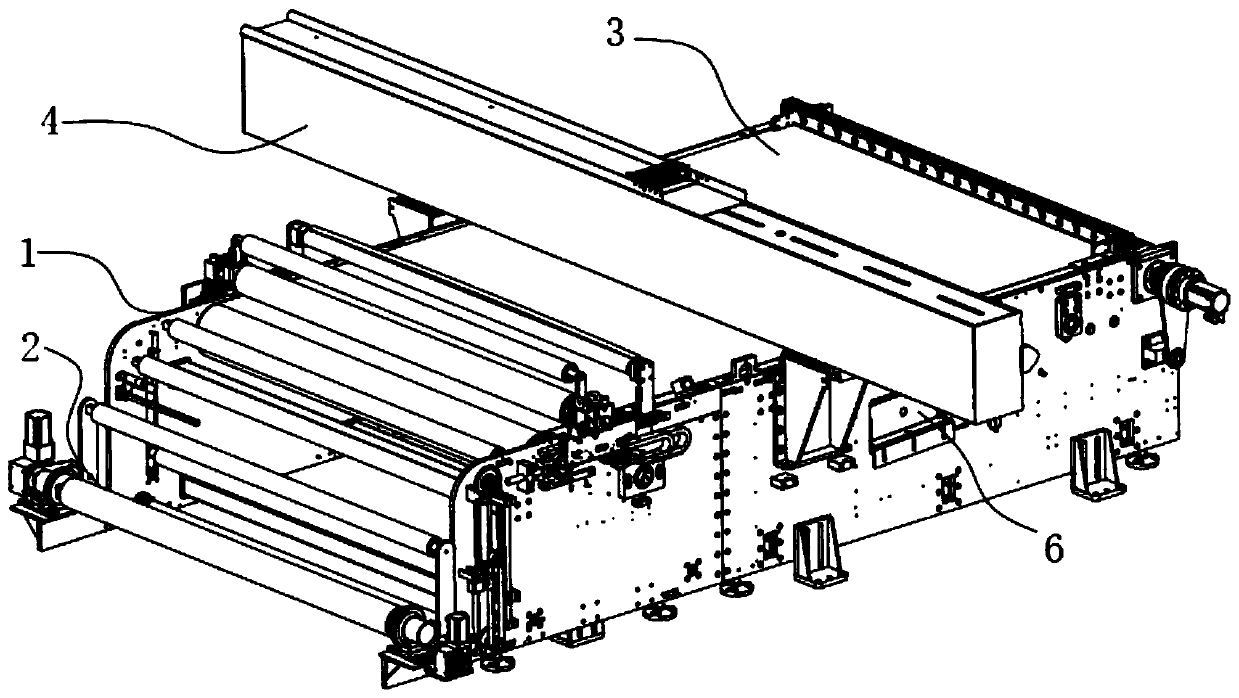

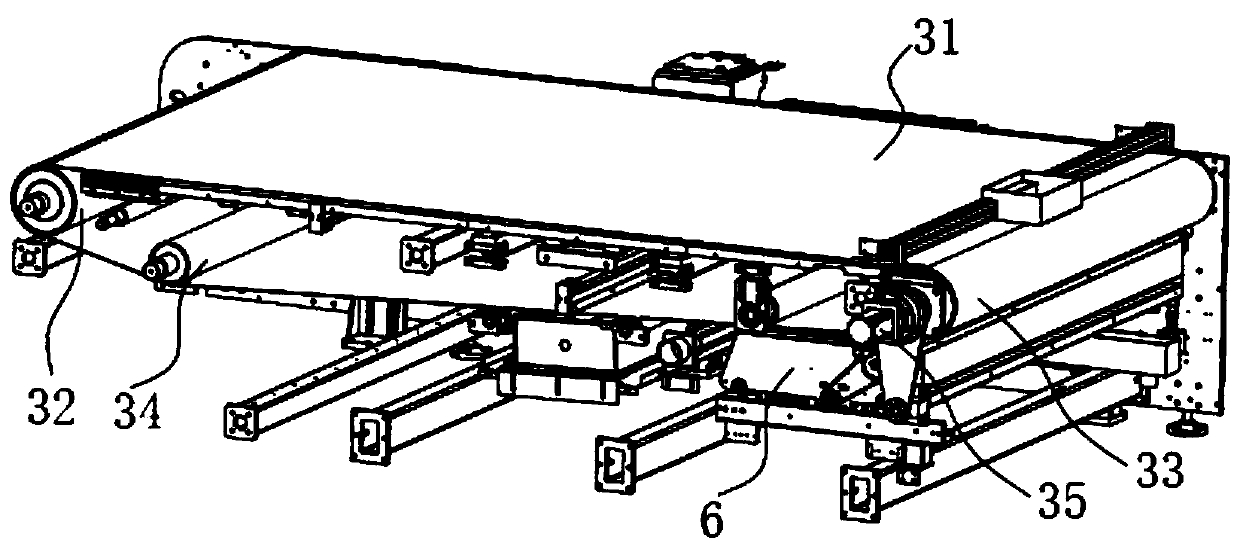

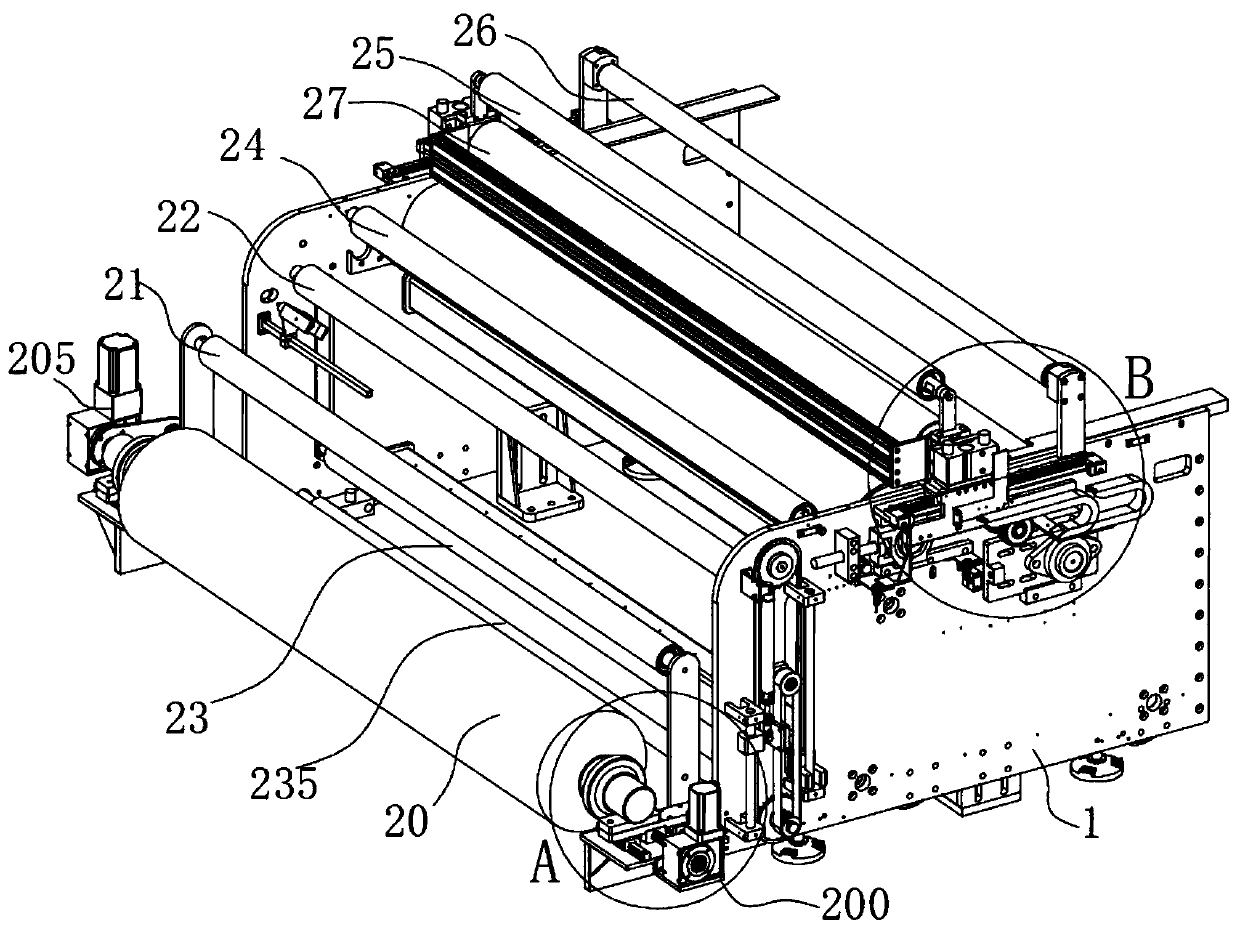

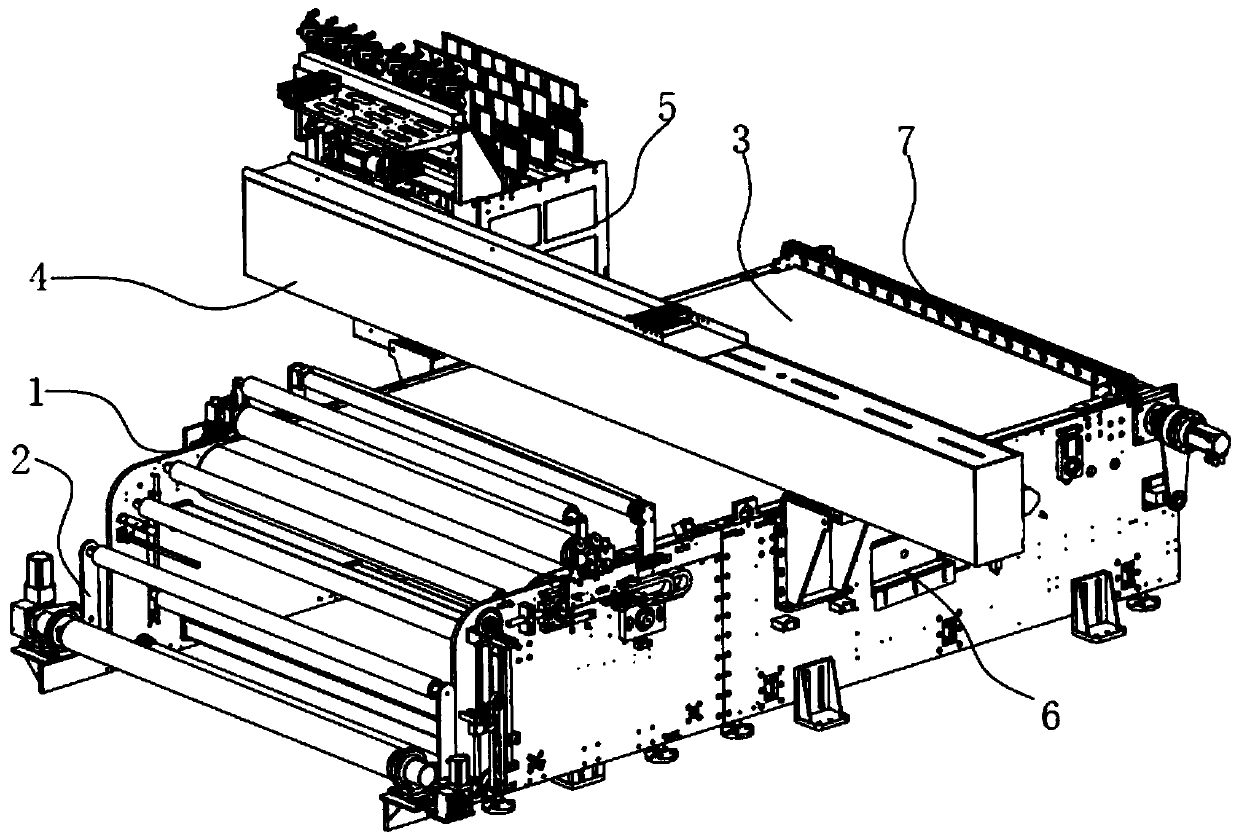

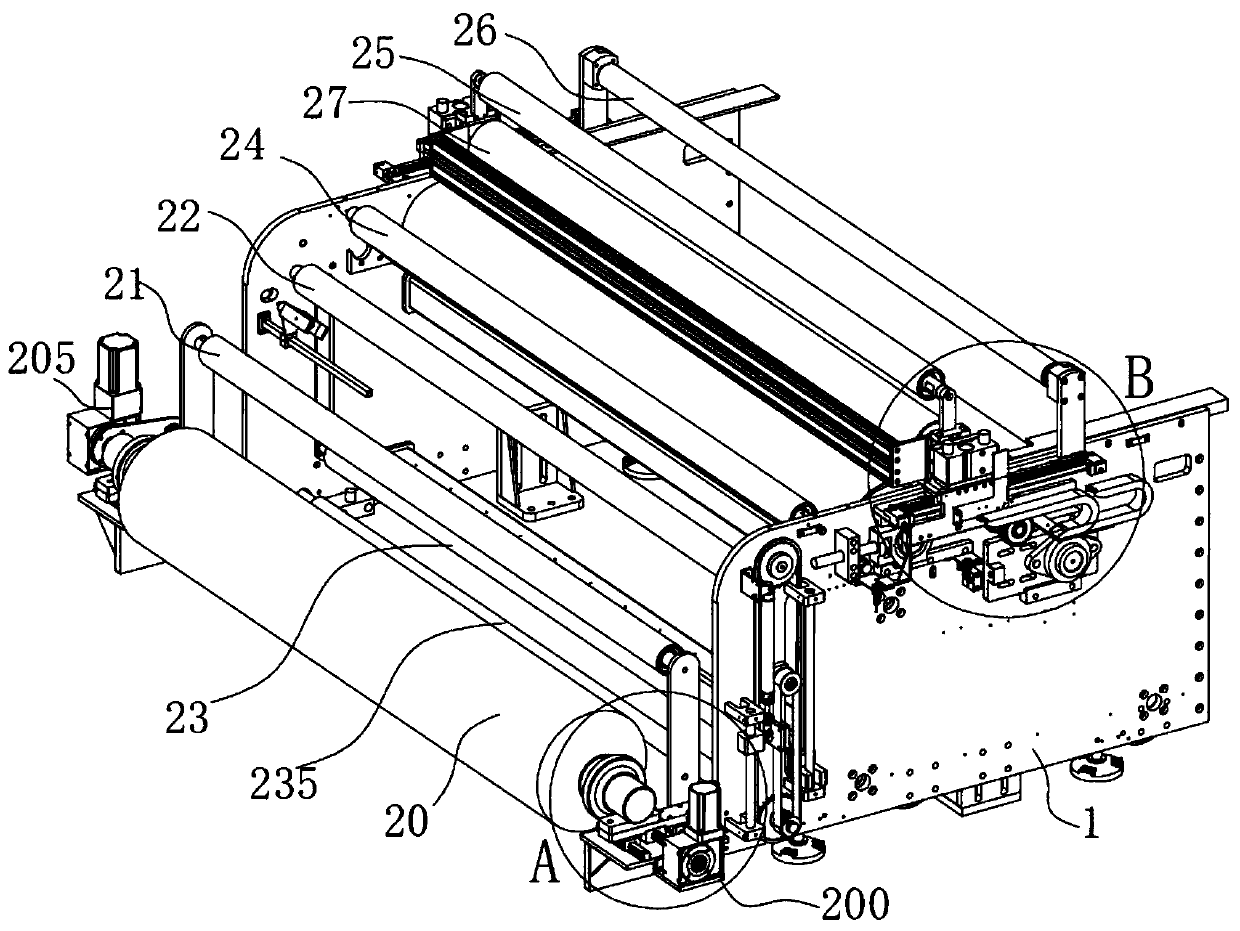

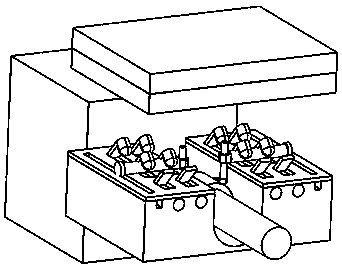

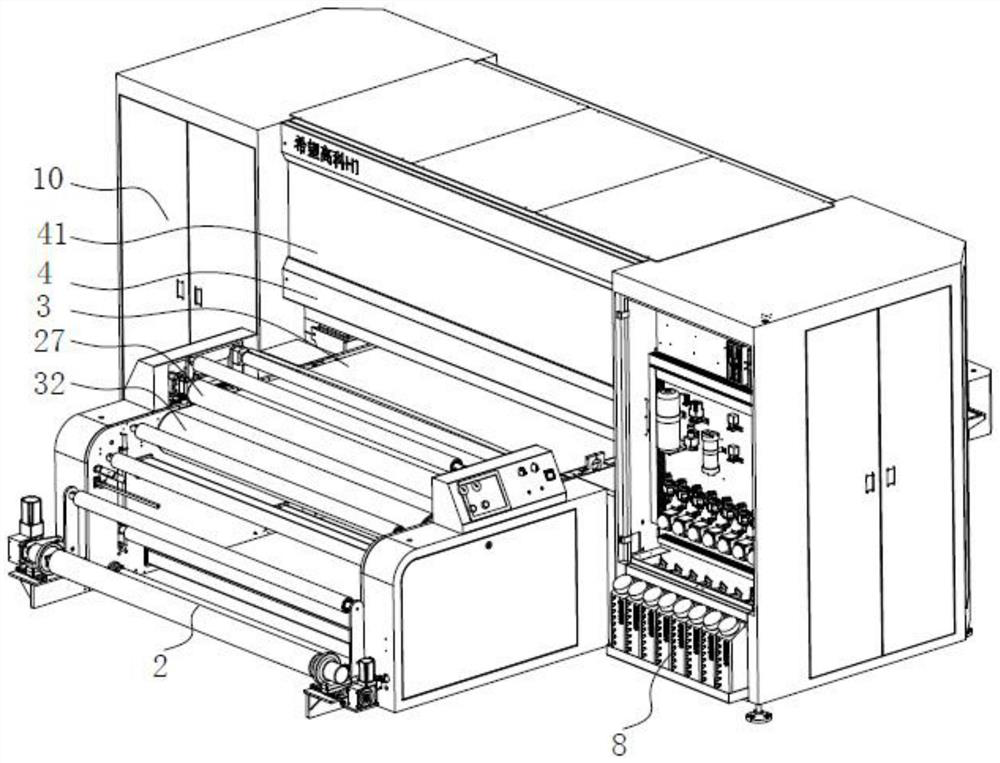

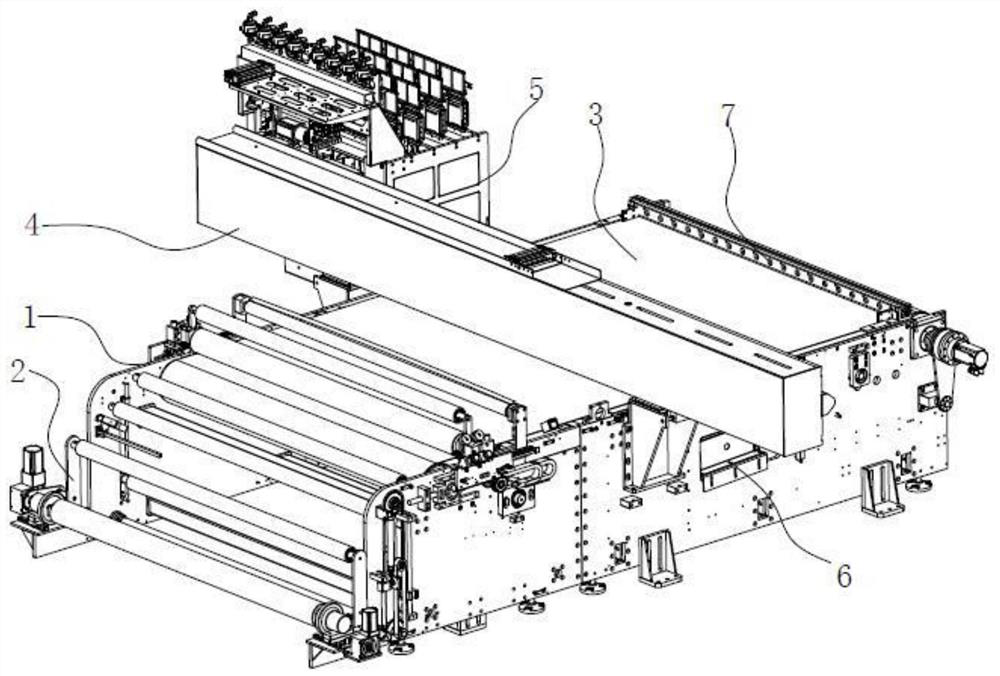

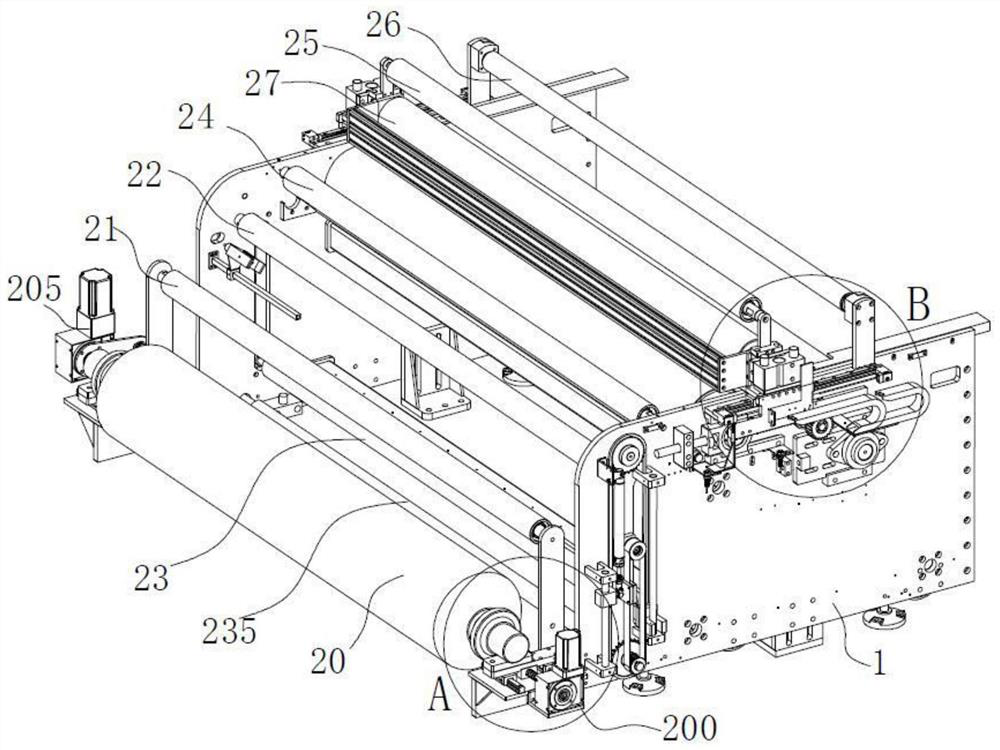

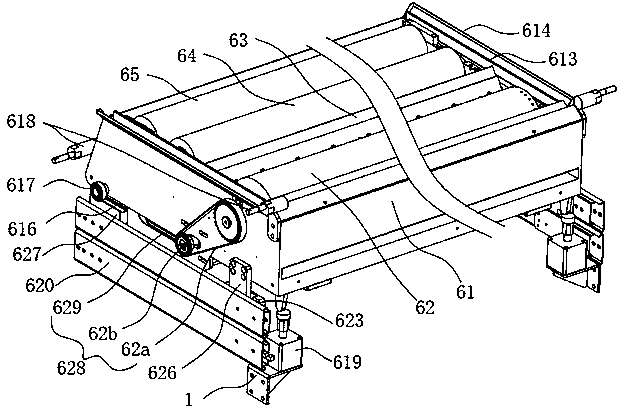

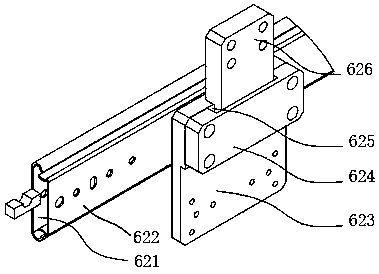

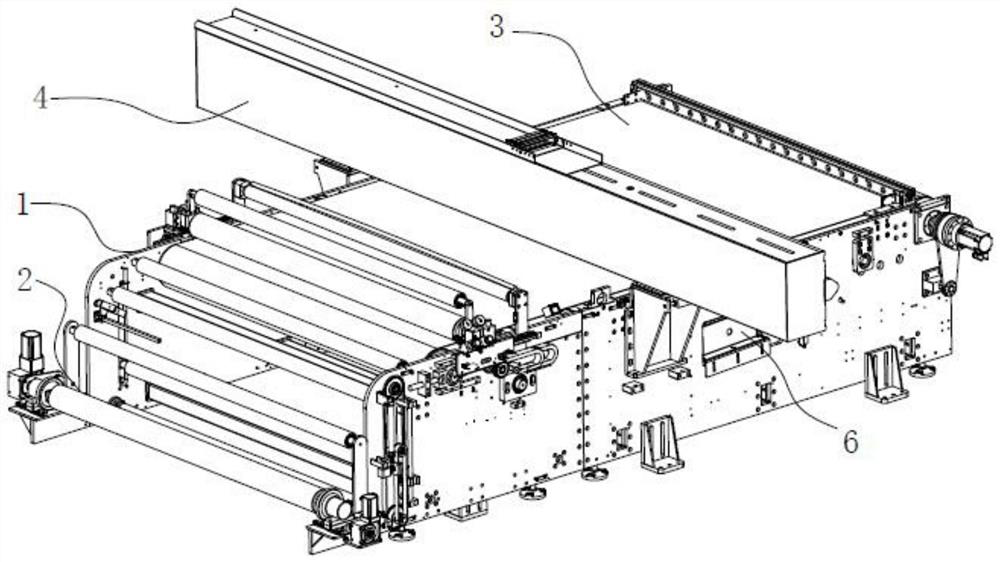

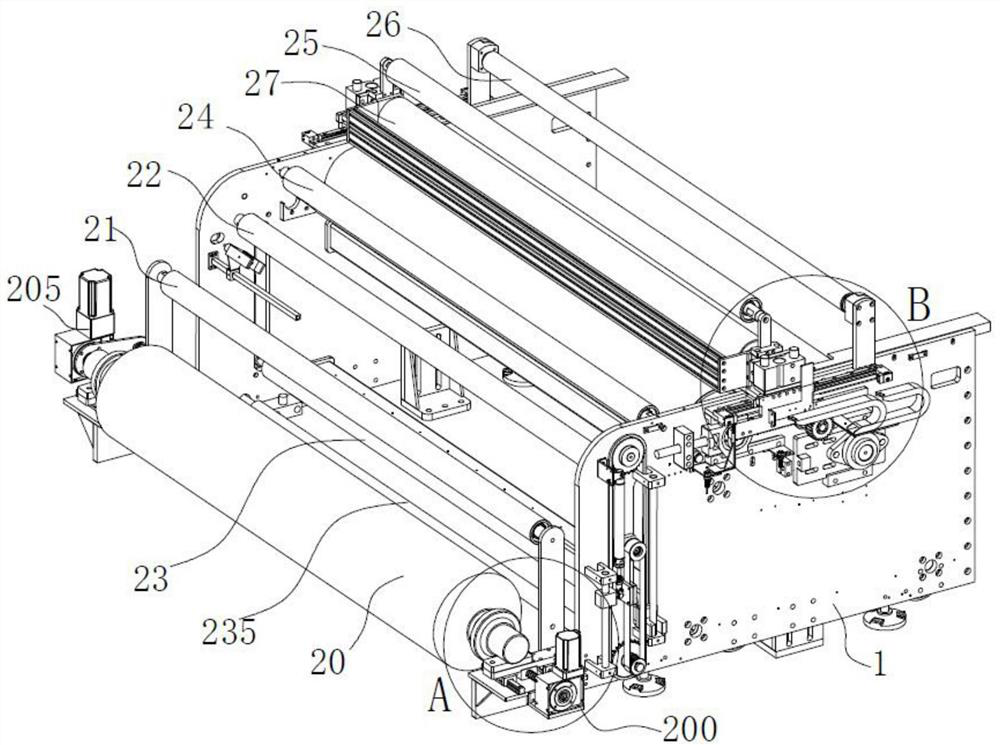

Scanning type textile digital printing equipment

ActiveCN111114130AReduce creasesAvoid wrinklesOther printing apparatusTextile printerProcess engineering

The invention discloses scanning type textile digital printing equipment. The scanning type textile digital printing equipment comprises a cloth feeding mechanism, a printing conveying belt mechanism,a gantry sliding frame, a printing scanning vehicle, a belt glue distributing and removing device, a belt cleaning device, a printing control cabinet and an ink supply system; the printing conveyingbelt mechanism is arranged at the top of the rack, the gantry sliding frame stretches across the printing conveying belt mechanism, the printing scanning vehicle is arranged on the gantry sliding frame in a sliding mode, the belt glue distributing and removing device stretches across the front portion of the printing conveying belt mechanism, and the cloth feeding mechanism is arranged behind theprinting conveying belt mechanism, and the belt cleaning device is arranged below the printing conveying belt mechanism. The printing equipment has the advantages that the cloth feeding mechanism adapts to large and small rolls of cloth; automatic online real-time deviation correction and edge alignment of the cloth are achieved; the printing quality is high; the glue distributing function and theglue removing function are integrated; the belt cleaning device adopts the combination of a composite cleaning mode and composite drying, so that the cleaning effect is improved; water consumption islow, and energy conservation and environmental protection are achieved; and the ink supply system is fast to start and high in production efficiency.

Owner:广东希望高科数字技术有限公司

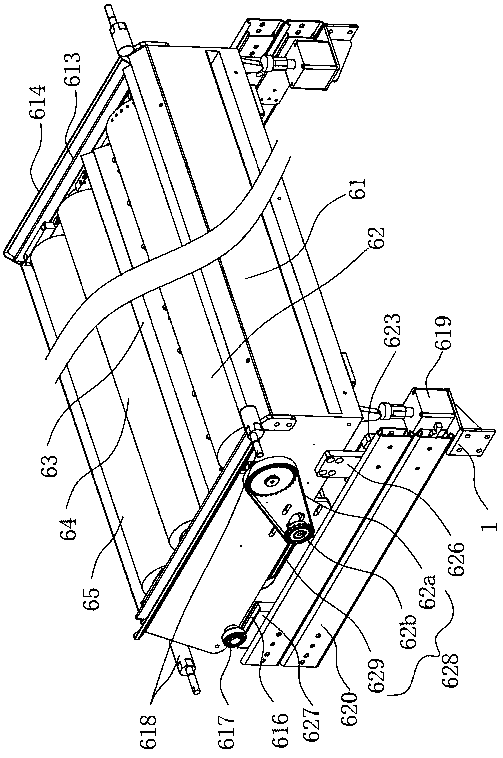

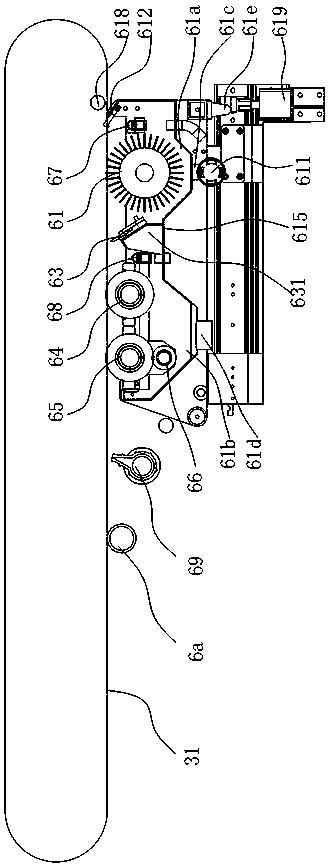

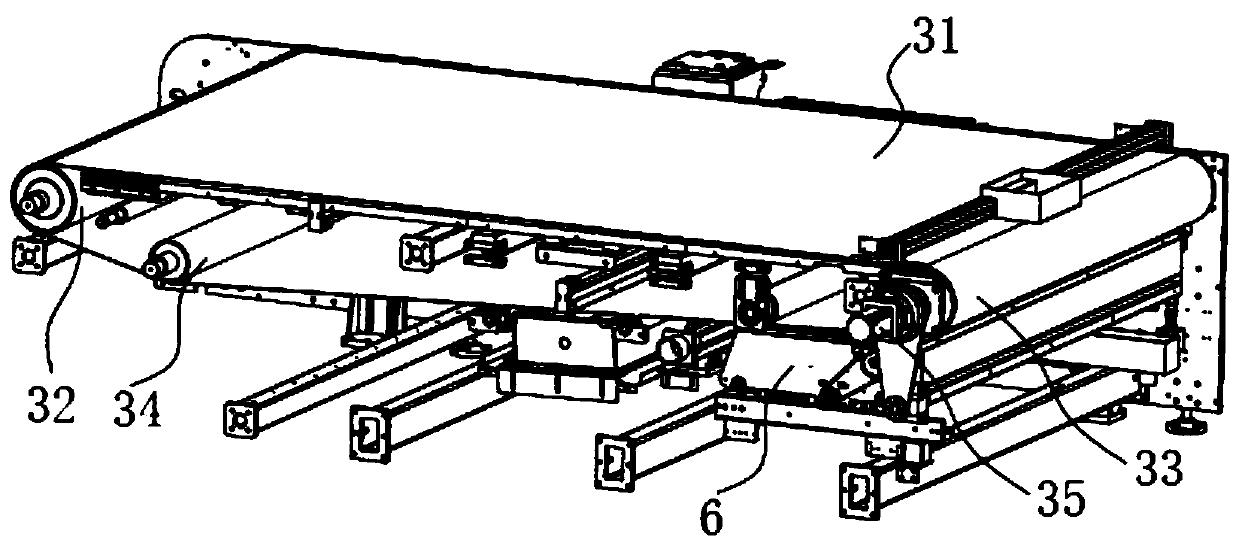

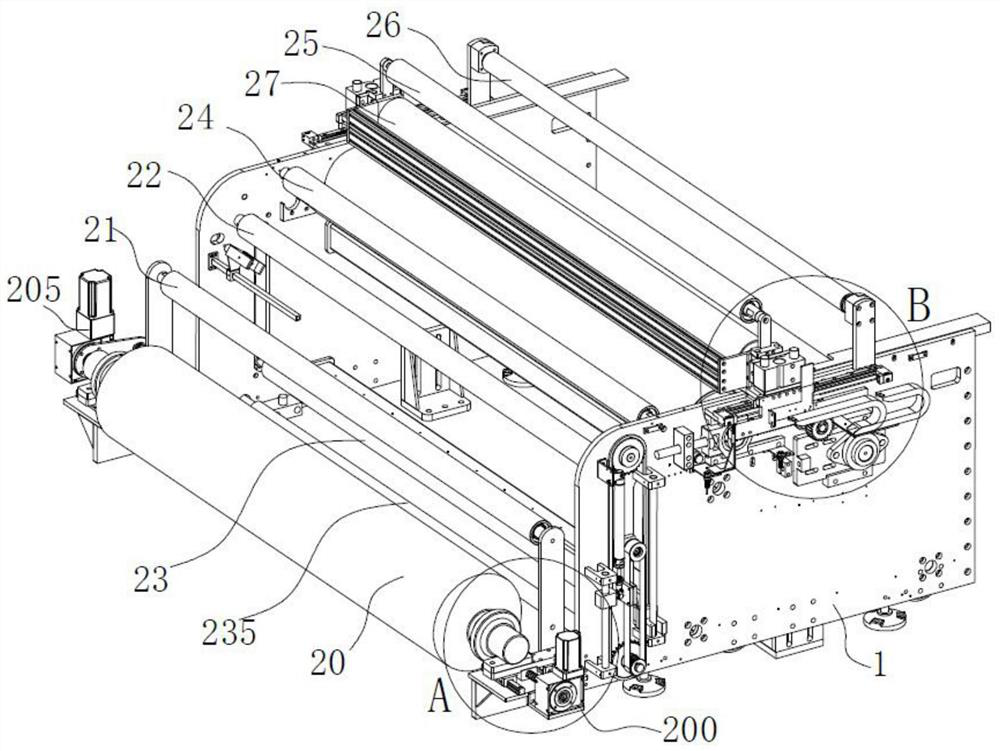

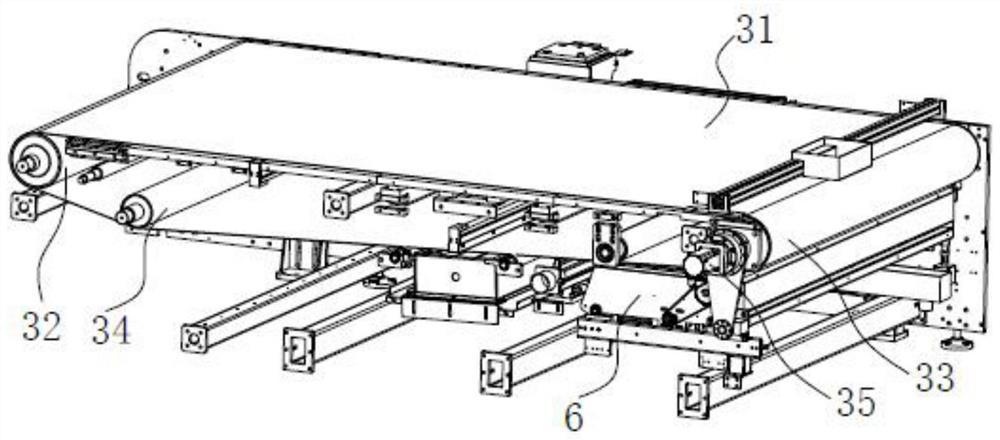

Cleaning system for conveying mechanism of digital printer

The invention discloses a cleaning system for a conveying mechanism of a digital printer. The cleaning system comprises a rack, a cleaning mechanism and a water supply system. The cleaning mechanism is located below a conveying belt. The cleaning mechanism comprises a cleaning disc, a first-stage brush roller, a front sponge roller, a rear sponge roller, a scraper plate, a front water spray pipe,a rear water spray pipe, a brush driving mechanism, an air knife and a water absorption roller, wherein the first-stage brush roller, the front sponge roller, the rear sponge roller, the scraper plate, the front water spray pipe, the rear water spray pipe, the brush driving mechanism, the air knife and the water absorption roller are sequentially arranged from front to back. The cleaning disc is arranged on the rack, can rise and fall and is of a trapezoidal structure. The water supply system comprises a circulating water tank, a water pump, a regulation valve, a dual filter screen and a liquid level meter. The cleaning system has the advantages that through a combined cleaning mode based on the first-stage brush roller used for removing fabric batting, the scraper plate used for scrapingwater and the sponge roller used for absorbing water, the cleaning effect is improved; little water is used, and little waste water is discharged and can be recovered and filtered to be used again, sothat energy saving and environmental friendliness are achieved; combined drying, cold air drying and multiple protection are adopted, so that the production efficiency is improved, and the rejectionrate is decreased; and the cleaning disk can rise and fall automatically and can slide out of a rack, so that maintenance is convenient.

Owner:广东希望高科数字技术有限公司

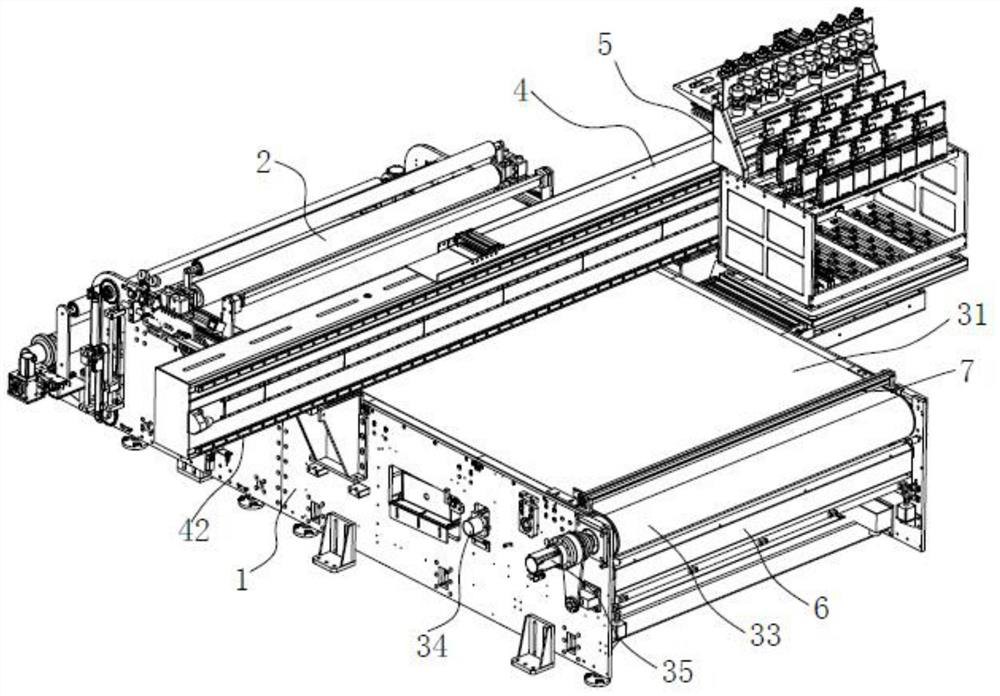

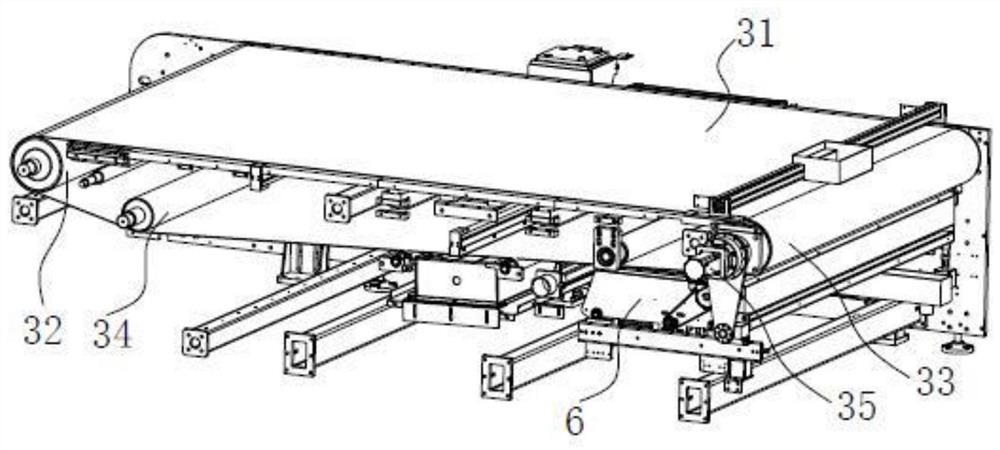

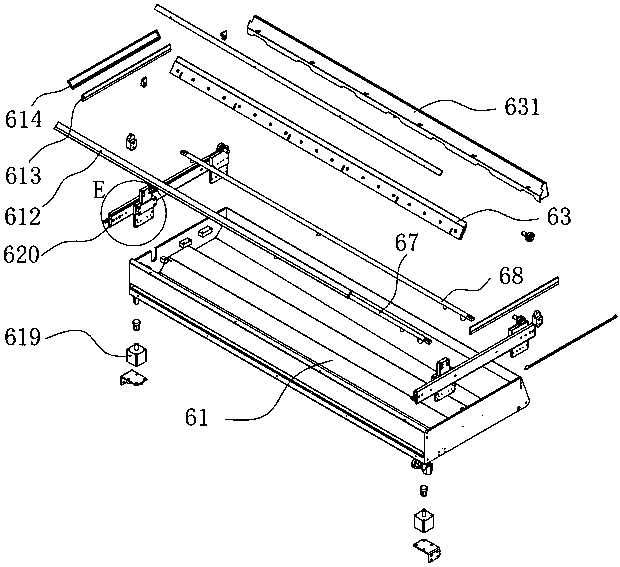

Rack system of digital printing machine

ActiveCN111055599AReduce creasesAvoid wrinklesOther printing apparatusStationary filtering element filtersTextile printerEngineering

The invention discloses a rack system of a digital printing machine. The system comprises a rack, a printing conveying belt mechanism is arranged at the top of the rack, a gantry sliding frame stretches across the upper portion of the printing conveying belt mechanism, a cloth feeding mechanism is arranged behind the printing conveying belt mechanism, and a belt cleaning device is arranged below the printing conveying belt mechanism; the cloth feeding mechanism comprises an inflatable shaft, a large roll wrap angle roller, a cloth passing roller a, a constant-tension floating roller, a cloth passing roller b, a cloth passing roller c, a moving roller and an expanding wrap angle roller which are all arranged on the rack; a lifting guide mechanism for driving the constant-tension floating roller to act is arranged; and an unwinding deviation correcting system for correcting the position of cloth is arranged. The system has the advantages that the cloth feeding mechanism simultaneously adapts to large and small rolls of cloth, so that the cost is saved; automatic online real-time deviation rectification and edge alignment of the cloth are realized; the printing quality is high; the belt cleaning device combines a composite cleaning mode and a composite drying mode, so that the cleaning effect is improved; the system is small in water consumption, energy-saving and environmentallyfriendly; and the production efficiency is improved.

Owner:广东希望高科数字技术有限公司

Scanning type textile digital printing machine

ActiveCN111114154AReduce creasesAvoid wrinklesOther printing apparatusTextile printerDigital printing

The invention discloses a scanning type textile digital printing machine. The scanning type textile digital printing machine comprises a rack, a cloth feeding mechanism, a printing conveying belt mechanism, a gantry sliding frame, a printing scanning vehicle, a belt glue spreading and removing device and a conveying belt cleaning device, the printing conveying belt mechanism is arranged at the topof the rack, the gantry sliding frame stretches across and is arranged above the printing conveying belt mechanism, the printing scanning vehicle is arranged on the gantry sliding frame in a slidingmode, the belt glue spreading and removing device stretches across and is arranged above the printing conveying belt mechanism, the cloth feeding mechanism is arranged behind the printing conveying belt mechanism, and the conveying belt cleaning device is arranged below the printing conveying belt mechanism. The scanning type textile digital printing machine has the advantages that the cloth feeding mechanism adapts to large and small rolls of cloth, the cost is saved; automatic online real-time deviation correction and edge alignment of the cloth are achieved; the printing quality is high; two functions of glue spreading and glue removing are integrated, so that the use is convenient; the conveying belt cleaning device adopts the combination of a composite cleaning mode and composite drying, so that the cleaning effect is improved; water consumption is low, and energy conservation and environmental protection are achieved; and the production efficiency is improved.

Owner:广东希望高科数字技术有限公司

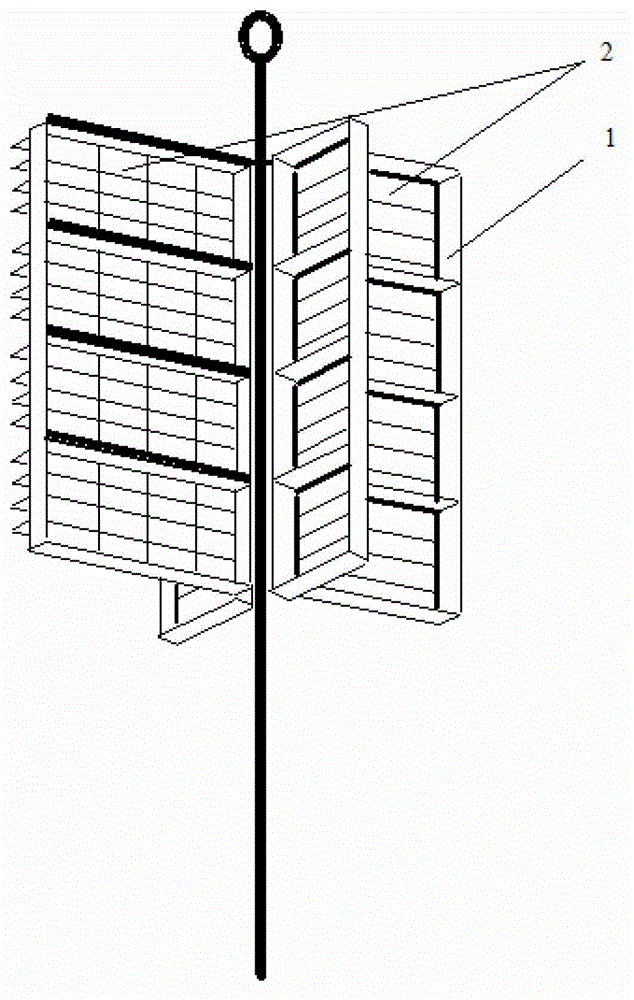

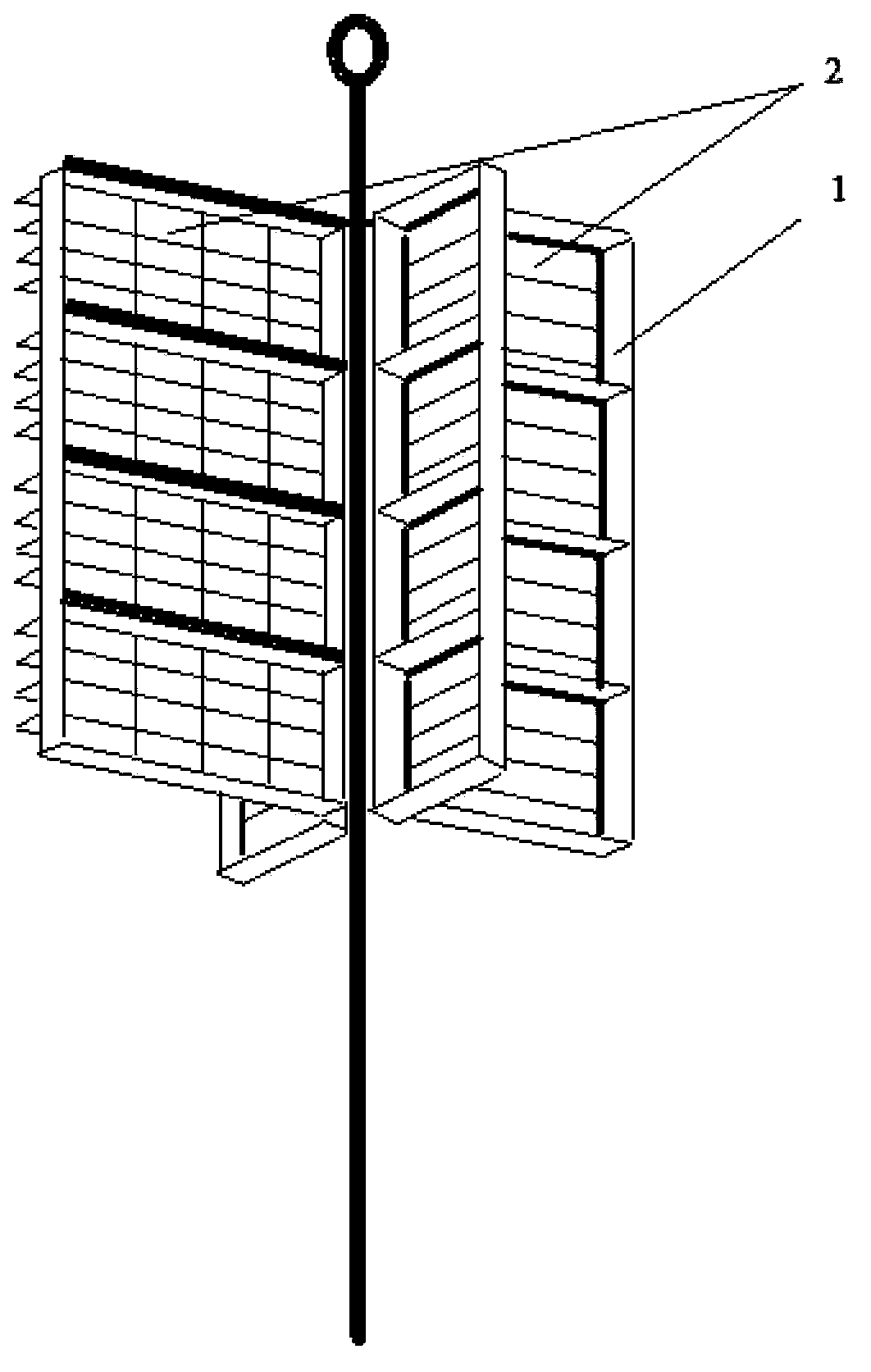

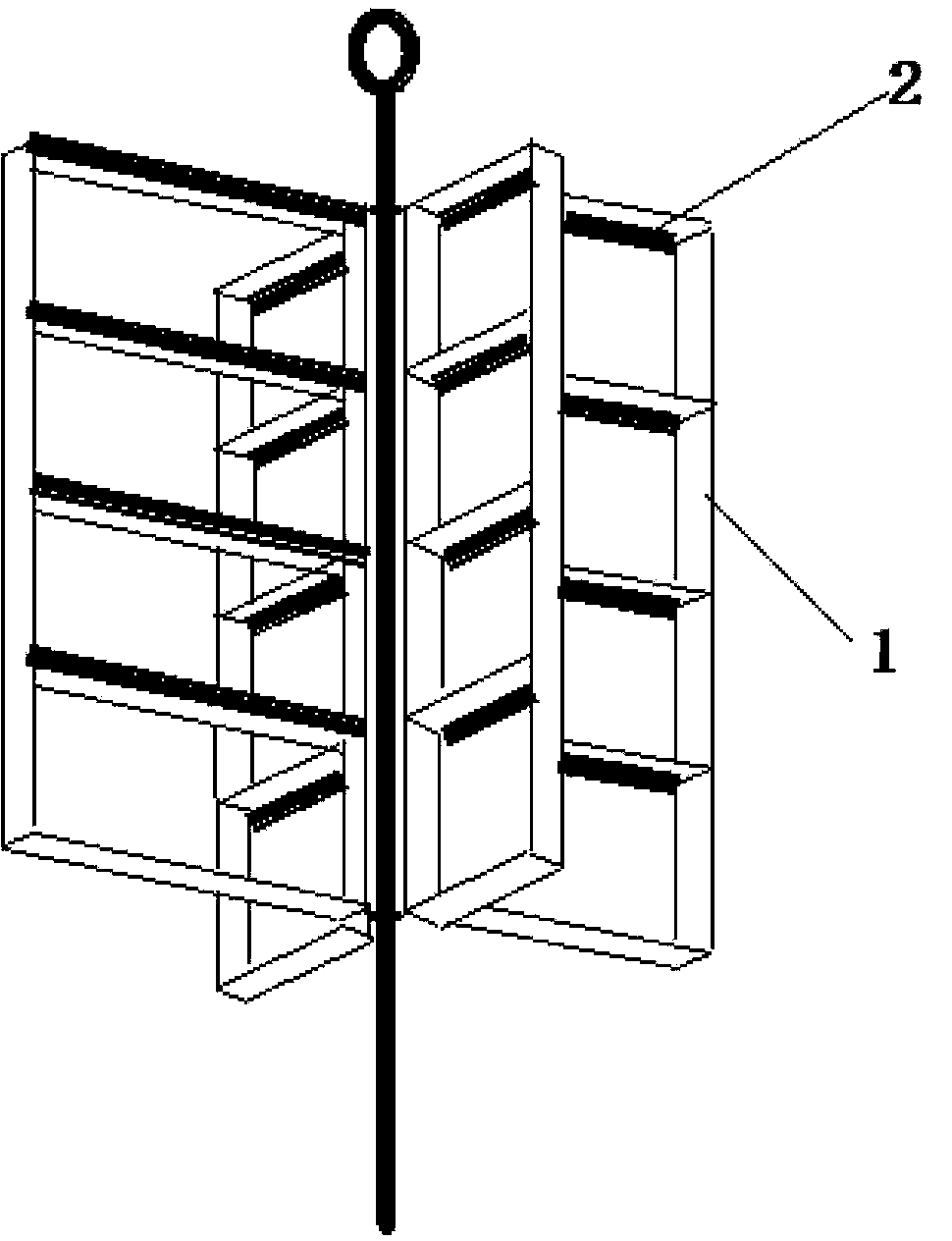

CNJT adjustable speed safe intelligent high-power vertical axis windmill sail

InactiveCN102748206AKeeping Windmills SafeEnsure security purposeRenewable energy generationMachines/enginesStormHigher Power

The invention discloses a CNJT adjustable speed safe intelligent high-power vertical axis windmill sail, which is a brand new reform of a working principle and a structure of the conventional vertical axis windmill, and overcomes the problems of no moment, low efficiency and difficult speed control at over speed of the conventional vertical axis windmill blade and low wind power utilization efficiency of the current widely applied horizontal axis windmill. The new technical scheme of CNJT is as follows: the CNJT adjustable speed safe intelligent high-power vertical axis windmill sail comprises multiple compounded motion intelligent blades, the working moment is obtained through a technical scheme capable of reducing the areas of the blades incapable of working, and the wind power utilization efficiency is greatly improved. When a storm comes, by applying a principle of reducing the working area of the working movable blades of the windmill, wind loads of the blades on the both sides are removed, and safety of the windmill rail is ensured. The CNJT adjustable speed safe intelligent high-power vertical axis windmill sail has the following innovations that: the wind power utilization efficiency is higher than a horizontal axis windmill. Through increasing the blade groups, the total power of the single windmill is increased. Without a wind alignment device, the CNJT adjustable speed safe intelligent high-power vertical axis windmill sail is suitable for power generation of marine wind power, platforms and ships, and power of marine ship rails. Through speed regulation or halt of the intelligent blades, safety of the windmill rail is ensured.

Owner:焦兆平 +2

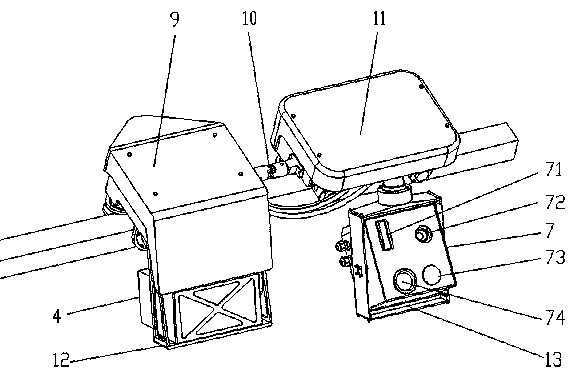

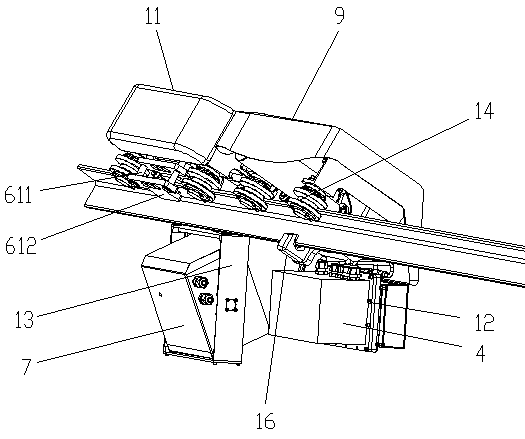

A monorail inspection robot system for belt conveyors in extreme environments

ActiveCN111217108BIncrease job securityReduce maintenance costsControl devices for conveyorsPackagingRobotic systemsNoise level

The invention discloses a single-track inspection robot system for belt conveyors in extreme environments, which includes an angle steel track composed of mutually perpendicular upper and lower sides, at least one tractor and at least one detection vehicle. The tractor and the detection vehicle are connected through a connection assembly. The tractor and the detection vehicle are erected on the angle steel track and can walk along the angle steel track. The tractor is connected with a power supply device, and the detection vehicle is connected with a detection device, and the power supply device is also electrically connected to the detection device. The present invention replaces the original manual inspection, and uses robots to monitor the temperature, noise level, surface wear, deformation, micro-cracks and jamming of conveyor belt rollers to realize fault detection, early warning and remaining life estimation of rollers. Provide a basis for planned repairs and timely replacements, thereby reducing maintenance costs and production costs, and improving personnel safety at work.

Owner:湖南中矿金禾机器人研究院有限公司

Tool steel material for saw blades

The invention relates to a tool steel material for saw blades. The tool steel material for saw blades comprises the following components in percentage by weight: 1.8-2.0% of carbon, 0.35-0.5% of silicon, 4.2-4.3% of chromium, 8.2-8.3% of tungsten, 4.2-4.5% of vanadium, 3.5-3.8% of molybdenum, 0.2-0.3% of cobalt, 1.3-1.4% of manganese, 0.12-0.15% of titanium, 0.8-1.0% of copper and aluminum, 0.5-0.6% of boron, 0.003-0.004% of rare earth containing niobium and yttrium, and the balance of iron. The technical scheme provided by the invention ensures that the vanadium, cobalt and molybdenum, which are beneficial to enhancing strength and have certain toughness, and the copper and aluminum for enhancing toughness can be better combined with the tungsten, chromium and titanium so as to reduce precipitation.

Owner:虞伟财

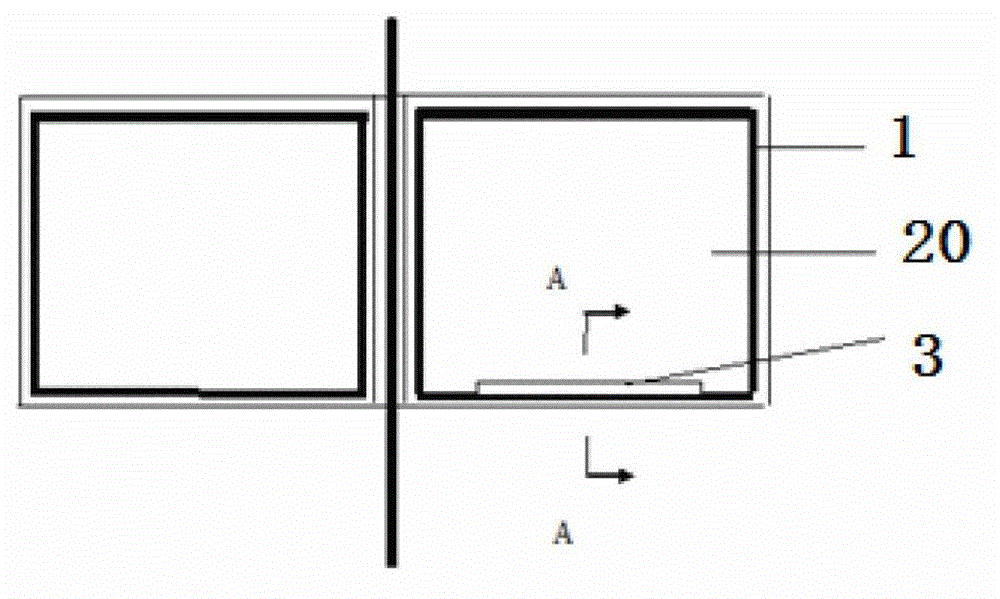

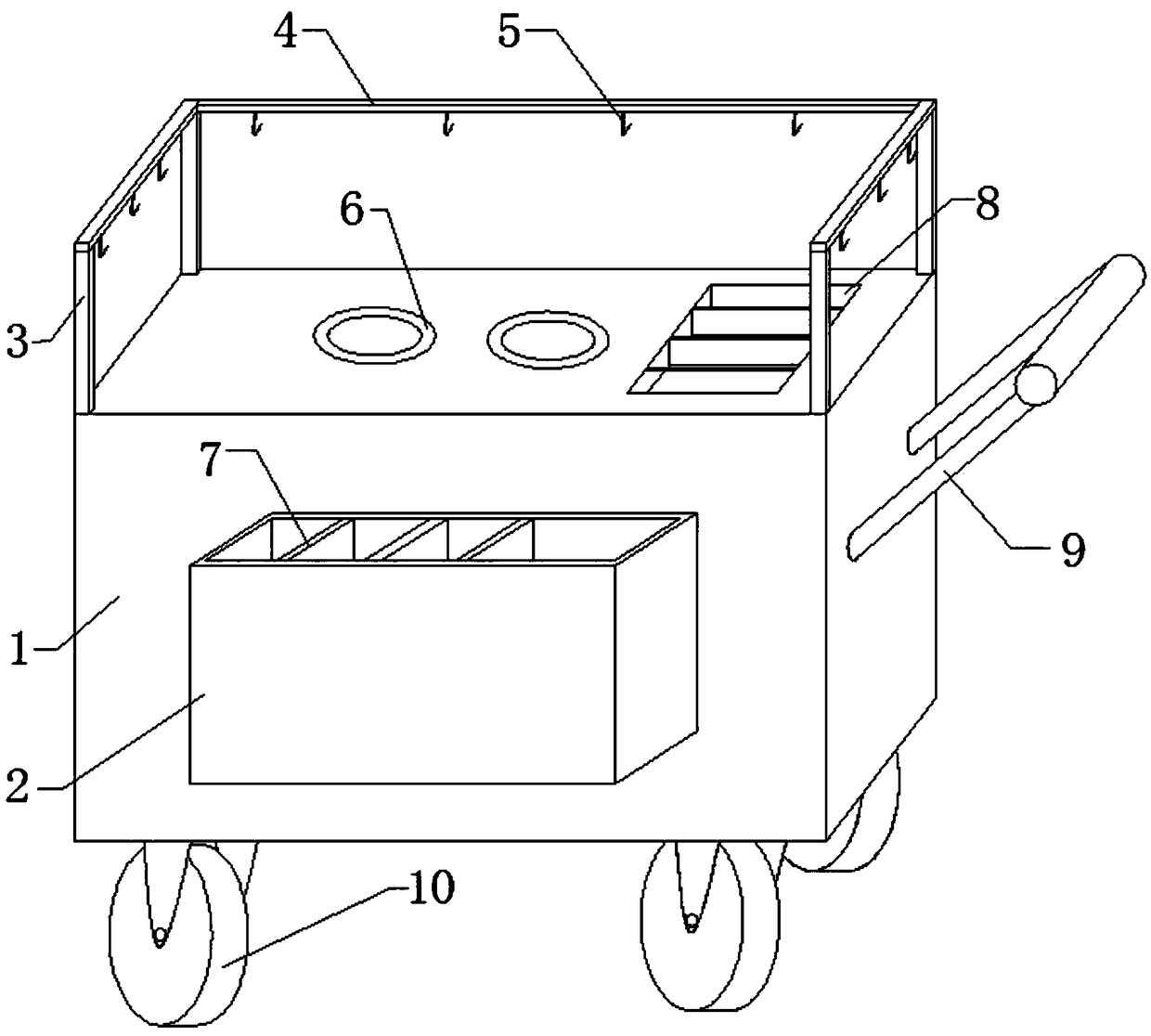

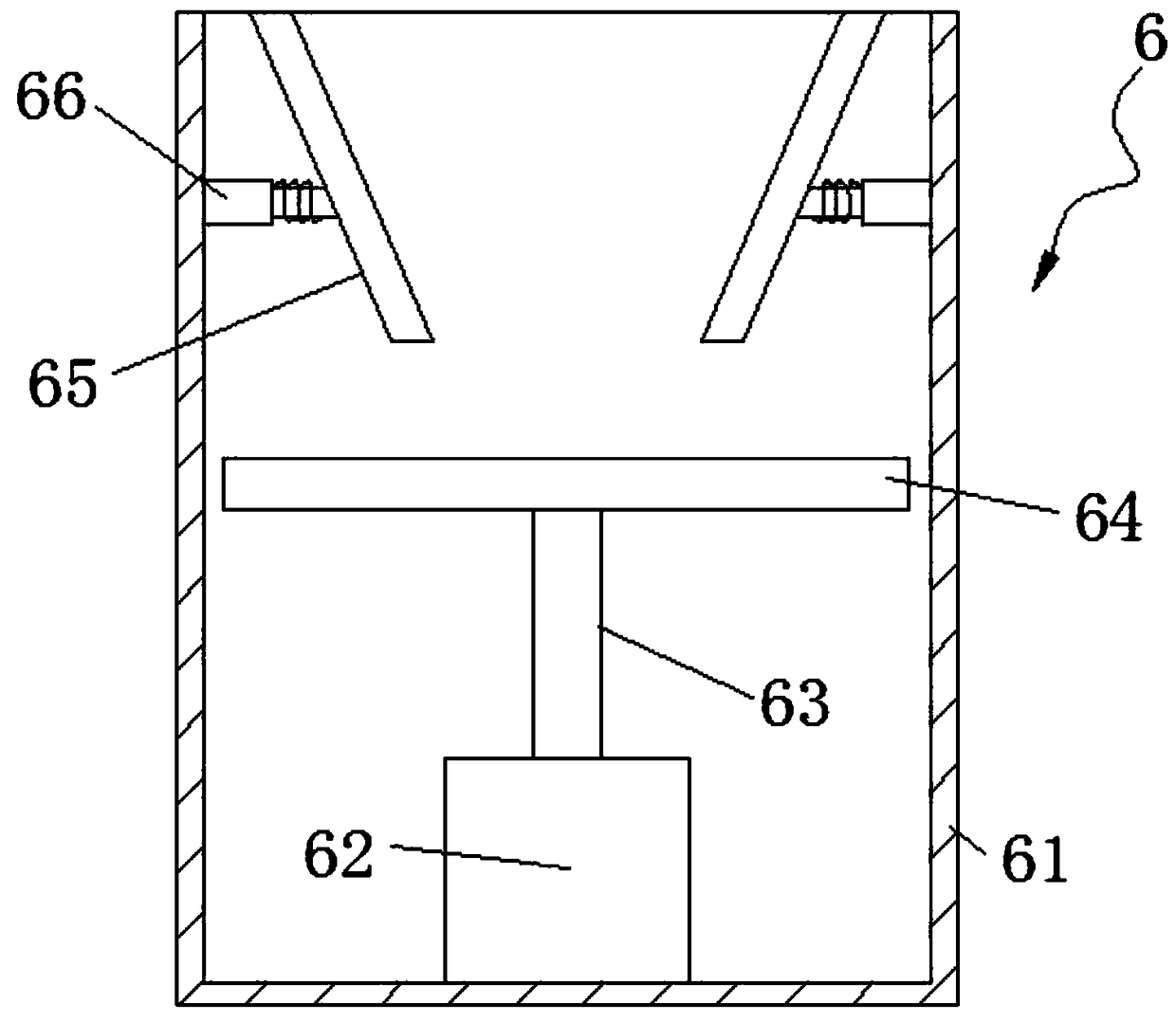

Storage device for door and window processing tools

InactiveCN109227494AIncrease the combinationEasy to moveWork tools storageOther workshop equipmentEngineering

The invention discloses a storage device for door and window processing tools. The device comprises a frame body, a placing groove is fixedly connected with the front end of the frame body, multiple separating plates are fixedly connected with the inner side wall of the placing groove, and two side supporting frames are symmetrically and fixedly connected with the edge of the frame. By adding universal wheels, the moving of the frame body can be achieved, so that the effect of time saving and labor saving can be achieved when the frame body is moved to increase the combination of limiting plates and telescopic rods, the limiting of dangerous tools of different dimensions is achieved through the coordination of the two limiting plates due to the mobility of the limiting plates, a protectingdevice is additionally arranged, a better buffering effect can be achieved by the protecting device when the dangerous tools are placed, and the protection of the dangerous tools can be achieved.

Owner:阜阳力佳门业有限公司

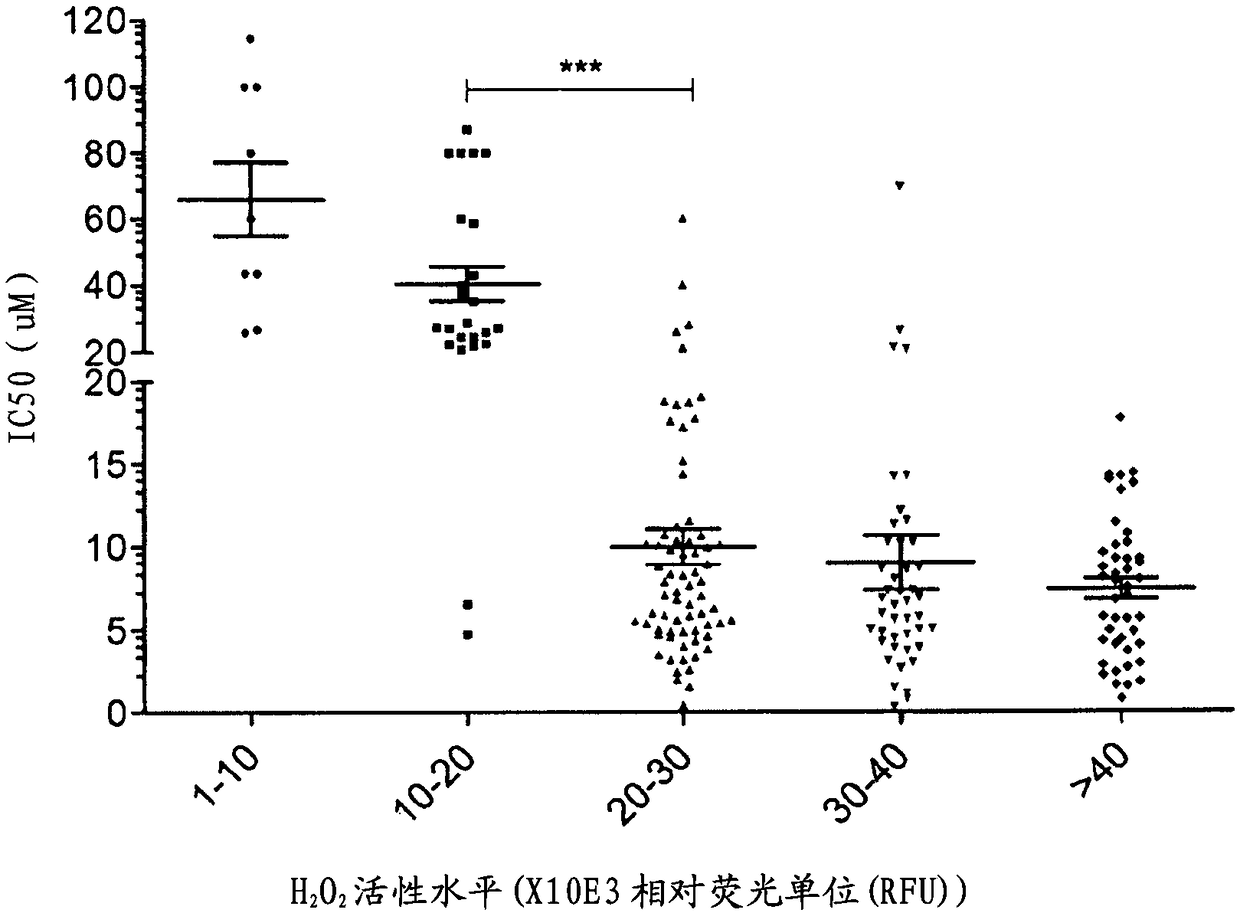

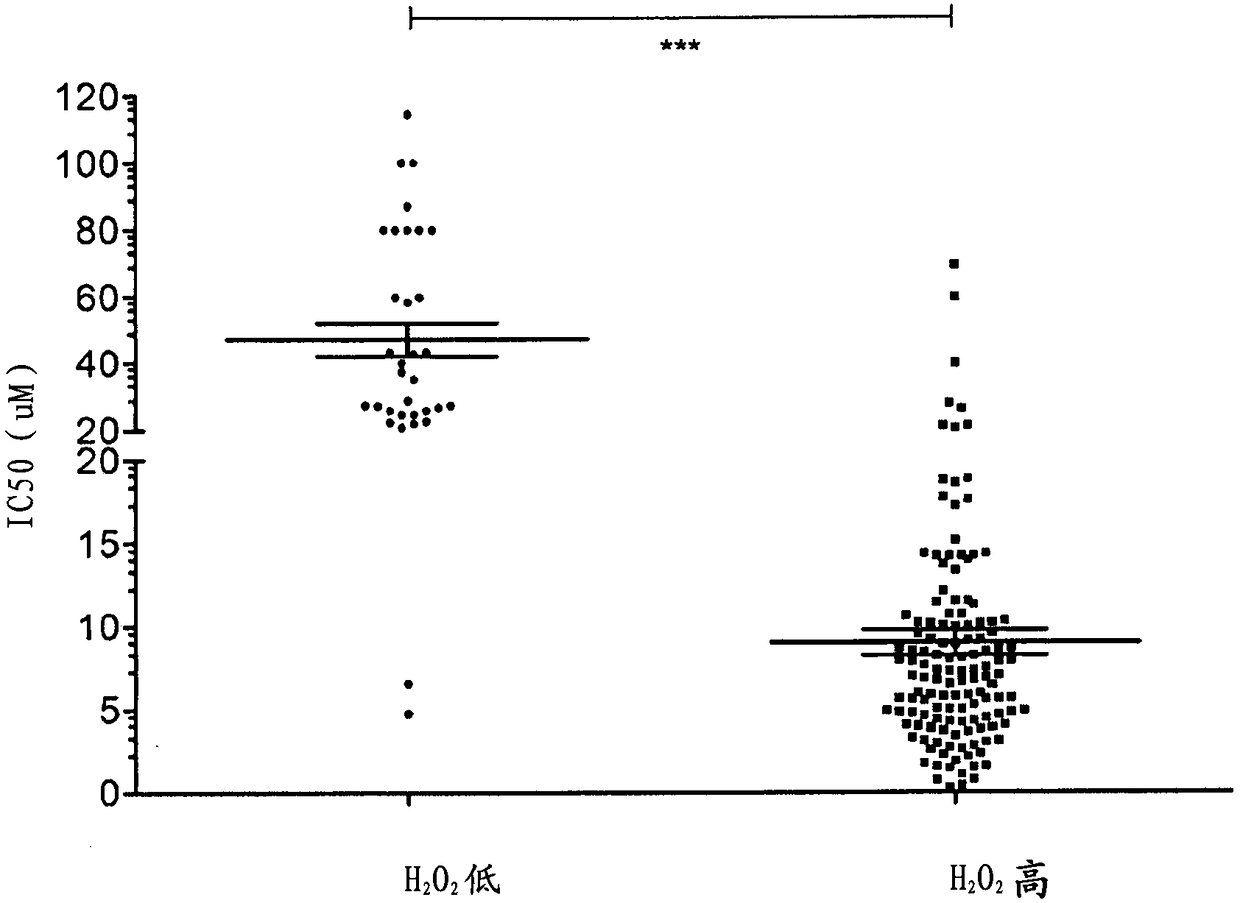

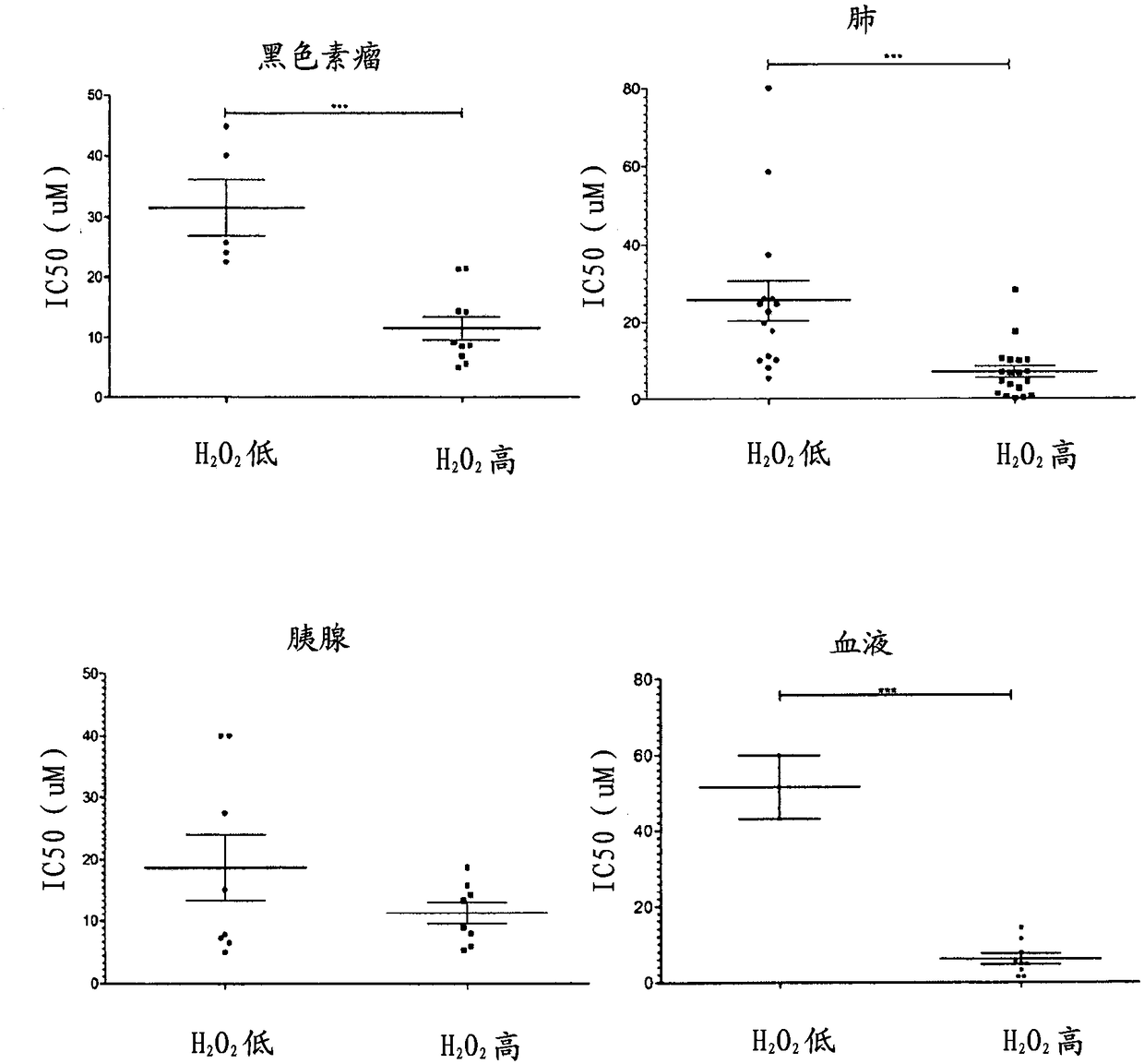

Combination comprising an aminothiolester compound or a pharmaceutically acceptable salt thereof and a compound able to increase the H2o2 level in cancer cells of a subject

PendingCN108348612AIncrease the combinationOrganic active ingredientsHeavy metal active ingredientsCancer cellOncology

Provided is a combination comprising an aminothiolester compound or a pharmaceutically acceptable salt thereof and a compound able to increase the H 2 0 2 level in cancer cells of a subject, for use as a medicament. The present invention relates to a combination comprising an aminothiolester compound or a pharmaceutically acceptable salt thereof, in particular the S-methyl 4-(dimethylamino)-4-methylpent-2-ynethioate or a pharmaceutically acceptable salt thereof, and more particularly the 4-(Dimethylamino)-4-methyl-2-pentynethioic acid S-methyl ester fumarate, and a compound able to increase H2 0 2 level in cancer cells of a subject, in particular for use for the treatment of cancer in a subject, wherein cancer cells of said subject do not overproduce H 2 0 2 in comparison to a control value and have a level of GSH below 5 nmol for 25000 cells.

Owner:ADVANCED BIODESIGN

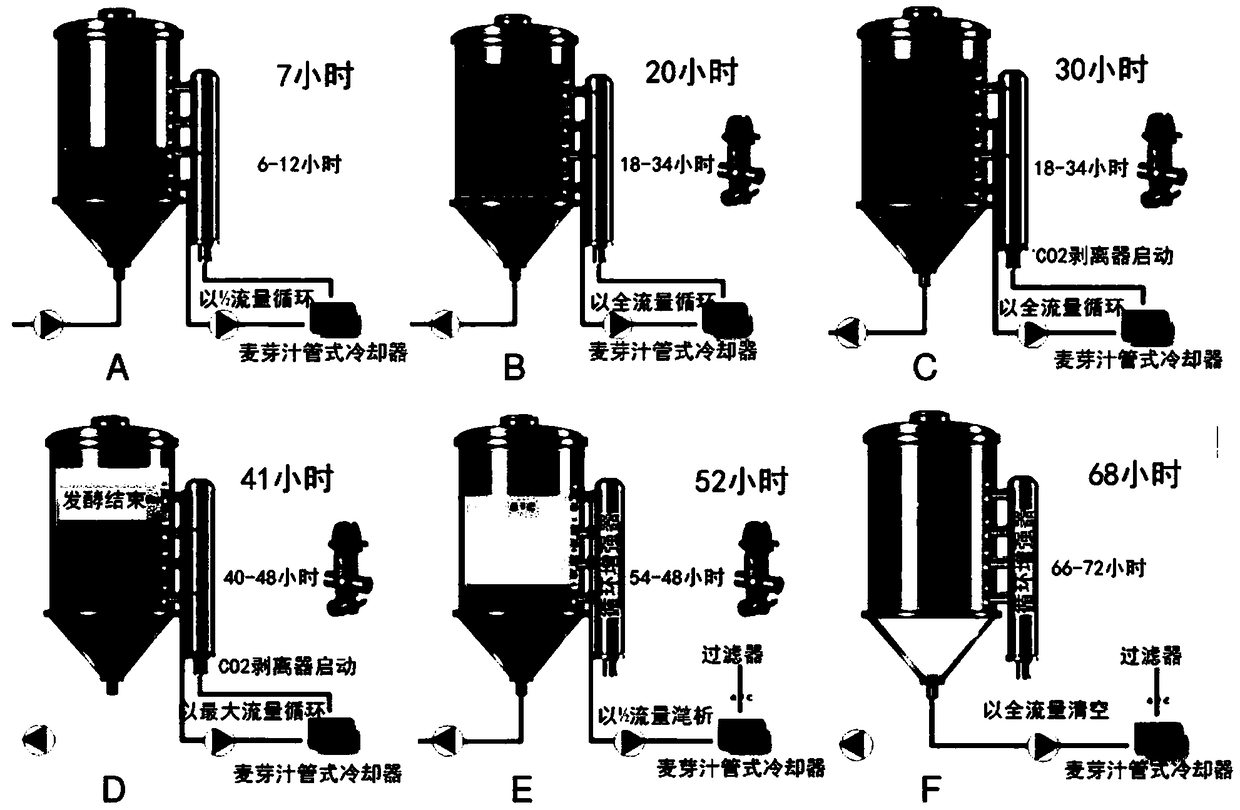

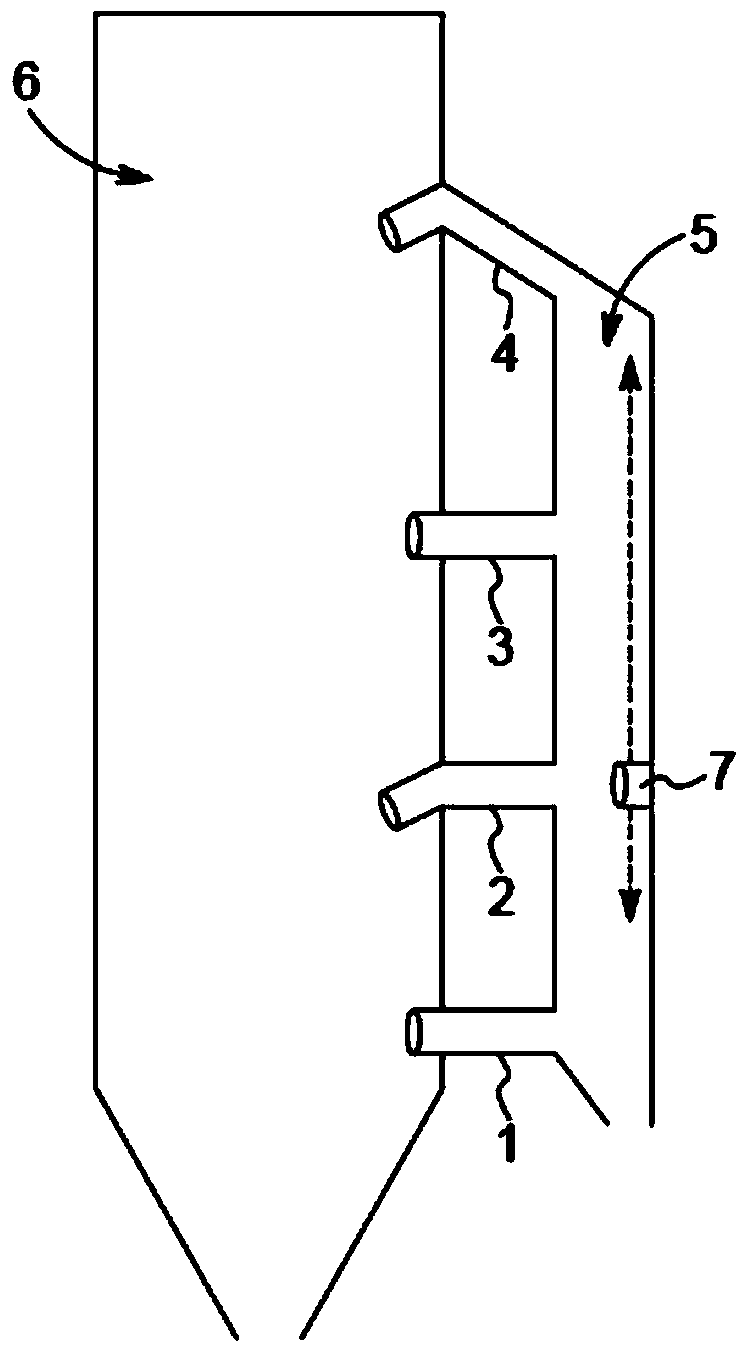

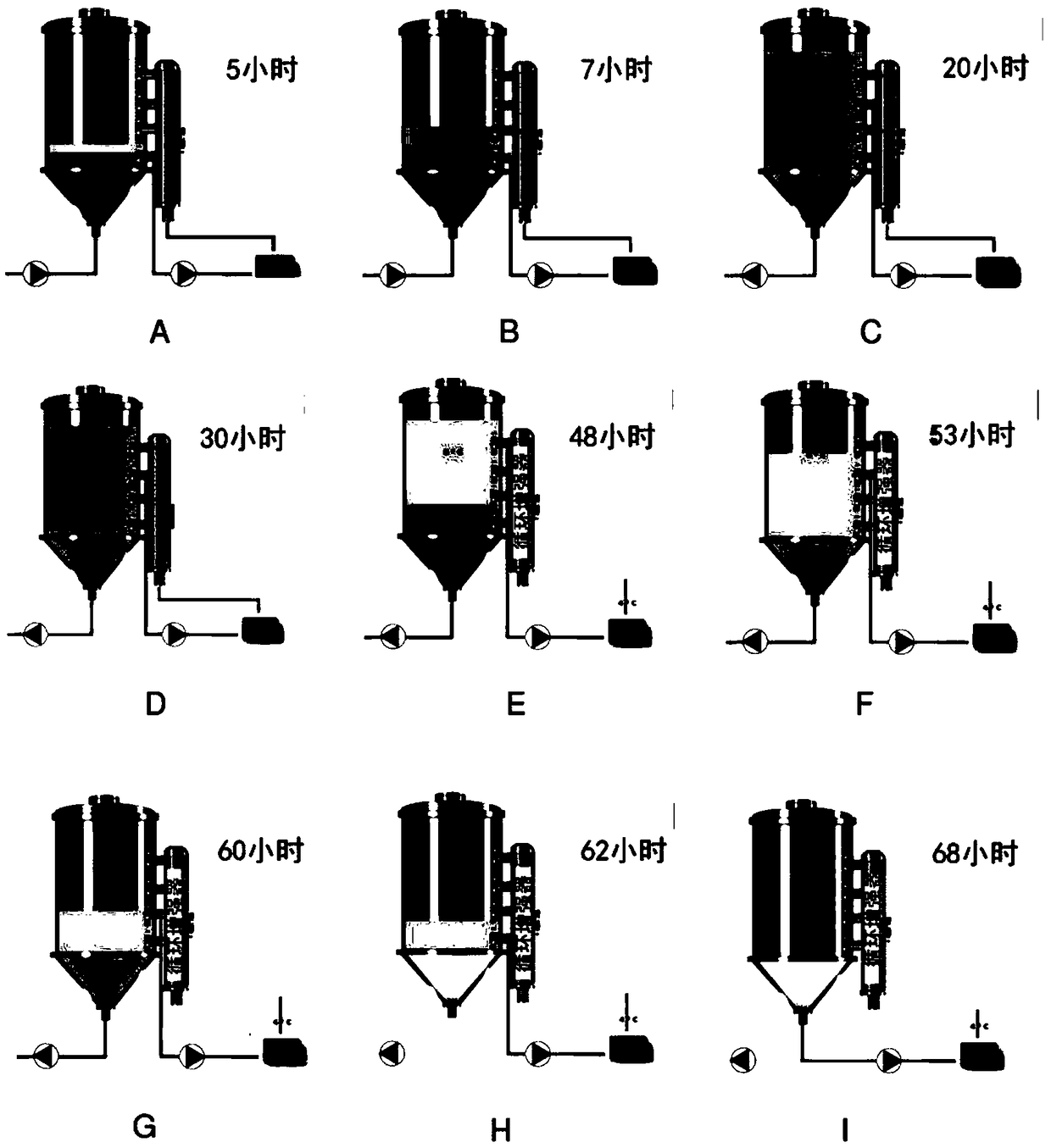

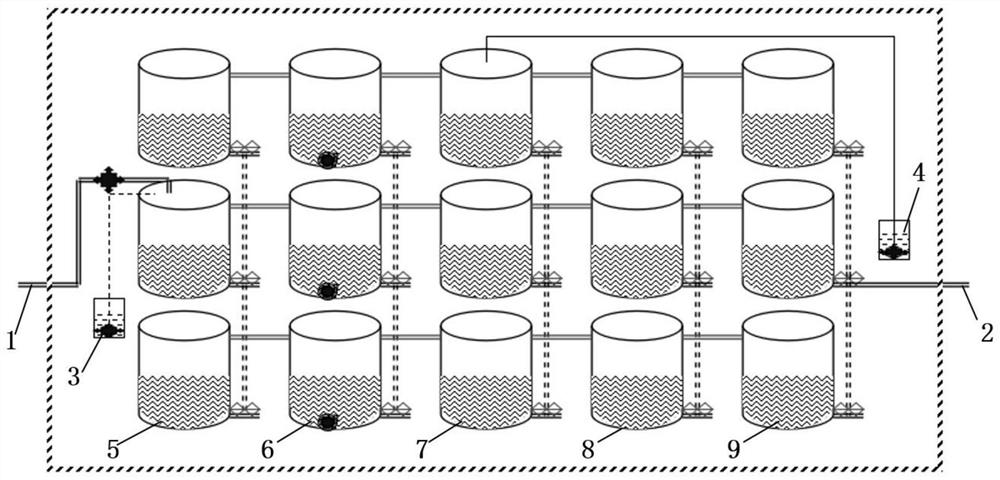

Fermentation tank with side ports and method of operation

ActiveCN109072145AIncrease the combinationIncrease contact timeBeer fermentationBiotechnologyEngineering

The present disclosure relates to a method for fermenting a wort in a fermentation tank comprising a bottom port and at least three side ports, being a first side port, a second side port, and a thirdside port, wherein said side ports are in fluid communication with each other, comprising the steps of: letting wort into the fermentation tank via the bottom port; pitching wort with yeast; incubating wort with yeast under conditions that allow the yeast to grow, thereby obtaining a partly fermented wort, and pumping the partly fermented wort out of the fermentation tank via at least one of theside ports and back into the fermentation tank via at least another of the side ports.

Owner:CARLSBERG BREWERIES AS

Hybrid composition of polyamide and polyester resins

Owner:POLYAMIDE HIGH PERFORMANCE

A reversing valve and reversing method for controlling on-off of microfluidic pipeline

ActiveCN110159822BIncrease the number ofReduce limit sizeOperating means/releasing devices for valvesMicrofluidicsClassical mechanics

The invention discloses a reversing valve for controlling on-off of a microfluidic pipeline and a reversing method thereof. The reversing valve comprises a pair of vertical push rods, and the verticalpush rods are pushed by a screw stepping motor. Mounting holes are formed in the top end of a transverse push rod, and are used for matching with the vertical push rods. An elastic sheet plate is arranged on the upper part of the shell through which the pipeline passes; elastic sheets with different combinations are arranged at different positions of the shell; different closure results of the pipeline are generated in a pressing mode; tail parts of the elastic sheets are fixedly connected with the elastic sheet plate, and are in an elastic opening state in a natural state; a clamping plate is arranged above the elastic sheet plate, and grooves are formed on two sides of the elastic sheet plate and the clamping plate to serve as tracks for movement of the transverse push rod; the transverse push rod defines the position and the movement direction through a track of the clamping plate and the matching with the vertical push rods; slopes are arranged at the initial positions and the stop positions of the movements to achieve return strokes of the push rods; and time of clockwise and counterclockwise movements of the screw stepping motor determines on-off time of the pipeline.

Owner:SOUTHEAST UNIV

Coal ash plate interlayer antitheft door sheet and manufacturing method thereof

InactiveCN105569523AImprove fire resistanceImprove deformation resistanceBurglary protectionWar-like protectionFiberWood veneer

The invention discloses a coal ash plate interlayer antitheft door sheet and a manufacturing method thereof. The door sheet comprises a coal ash plate, a wood board, and an antitheft layer. The coal ash plate contains wood fibers. The wood board is one or more selected from finger-joint board, wood veneer, solid board, core-board, chipboard, density board, plywood, and fibreboard. The antitheft layer is formed by a steel plate and asbestos. The door sheet is manufactured by respectively tailoring and cutting, gumming, sticking, and high-temperature hot pressing. The coal ash plate and the wood board are combined to enhance flintiness of a wooden door, and use ratio of coal ash is improved, and fire-resisting performance and anti-deformation performance of the door are enhanced. The hardness and tenacity of the coal ash plate, and the added combination of the steel plate and the asbestos greatly improve anti-cutting and anti-collision performance of the door sheet, so that antitheft performance of the door sheet is enhanced.

Owner:HEILONGJIANG HUAXIN FURNITURE

Tool steel material for hedge trimmer blades and preparation method thereof

The invention relates to a tool steel material for hedge trimmer blades and a preparation method thereof. The tool steel material for hedge trimmer blades comprises the following components in percentage by weight: 1.8-2.0% of carbon, 0.35-0.5% of silicon, 4.2-4.3% of chromium, 8.2-8.3% of tungsten, 4.2-4.5% of vanadium, 3.5-3.8% of molybdenum, 0.2-0.3% of cobalt, 1.3-1.4% of manganese, 0.12-0.15% of titanium, 0.8-1.0% of copper and aluminum, 0.5-0.6% of boron, 0.003-0.004% of rare earth containing niobium and yttrium, and the balance of iron. The technical scheme provided by the invention ensures that the vanadium, cobalt and molybdenum, which are beneficial to enhancing strength and have certain toughness, and the copper and aluminum for enhancing toughness can be better combined with the tungsten, chromium and titanium so as to reduce precipitation.

Owner:NINGBO YINZHOU TAILI MACHINERY

A scanning type textile digital printing equipment

ActiveCN111114130BReduce creasesAvoid wrinklesOther printing apparatusTextile printerDigital printing

The invention discloses a scanning textile digital printing equipment, which comprises a cloth loading mechanism, a printing conveying belt mechanism, a gantry carriage, a printing scanning vehicle, a belt cloth glue removing device, a belt cleaning device, a printing control cabinet and an ink supply system; The printing conveying belt mechanism is set on the top of the frame, the gantry carriage spans above the printing conveying belt mechanism, the printing scanning vehicle is slidably set on the gantry carriage, and the belt cloth glue removing device straddles the front of the printing conveying belt mechanism Above the upper part, the cloth loading mechanism is arranged behind the printing conveying belt mechanism, and the belt cleaning device is arranged below the printing conveying belt mechanism. Its advantages are: the cloth loading mechanism adapts to the large and small rolls of cloth at the same time; the cloth is automatically corrected and aligned online in real time; the printing quality is high; the two functions of cloth glue and glue removal are integrated; The cleaning effect is improved; the water consumption is small, energy saving and environmental protection; the ink supply system starts quickly and the production efficiency is high.

Owner:广东希望高科数字技术有限公司

Slag-free flux-cored wire process

ActiveCN101780609BIncrease the combinationImprove toughnessWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a novel process for a formula of a slag-free flux-cored wire, and relates to a welding material. The manufacturing method adds the combination of molybdenum powder, nickel powder and rare earth silicon to a formula of raw materials, eliminates mineral powder in a common formula, and optimizes the proportion of various types of metal powder in the formula. According to the formula, the welding material comprises the following components: 4 to 8 parts of micro carbon ferrochromium, 12 to 18 parts of low carbon ferromanganese, 56 to 67 parts of iron powder, 2 to 6 parts ofmolybdenum powder, 0.1 to 0.4 part of ferroboron, 2 to 5 parts of rare earth silicon, 1 to 3 parts of ferrosilicon, 2 to 3 parts of ferrotitanium, 2 to 3 parts of sodium fluoride, 3 to 7 parts of ferroaluminum, 1 to 3 parts of aluminum to magnesium powder and 4 to 8 parts of nickel powder. The invention improves the toughness, strength and anti-fatigue performance of welding seams and thins welding-seam grains by adding the combination of molybdenum powder, nickel powder and rare earth silicon into the raw materials of the formula, eliminating the mineral powder in the common formula, and optimizing the proportion of various types of metal powder in the formula. Meanwhile, slagging on the surfaces of the welding seams is avoided, and welding efficiency is raised by 20 percent compared with slag-type processes.

Owner:山东聚力焊接材料有限公司

A scanning digital textile printing machine

ActiveCN111114154BReduce creasesAvoid wrinklesOther printing apparatusTextile printerDigital printing

The invention discloses a scanning textile digital printing machine, which includes a frame, a cloth loading mechanism, a printing and conveying belt mechanism, a gantry carriage, a printing scanning vehicle, a belt cloth glue removing device, and a conveying belt cleaning device; the printing and conveying belt mechanism Set on the top of the frame, the gantry carriage spans above the printing conveyor belt mechanism, the printing scanning vehicle is slidably set on the gantry carriage, and the belt cloth glue removal device spans above the front part of the printing conveyor belt mechanism. The cloth loading mechanism is arranged behind the printing conveying belt mechanism, and the conveying belt cleaning device is arranged under the printing conveying belt mechanism. Its advantages are: the cloth loading mechanism adapts to the large and small rolls of cloth at the same time, saving costs; the cloth is automatically corrected and aligned online in real time; the printing quality is high; the two functions of cloth glue and glue removal are integrated, easy to use; The combination of cleaning mode and compound drying improves the cleaning effect; the water consumption is small, energy saving and environmental protection; the production efficiency is improved.

Owner:广东希望高科数字技术有限公司

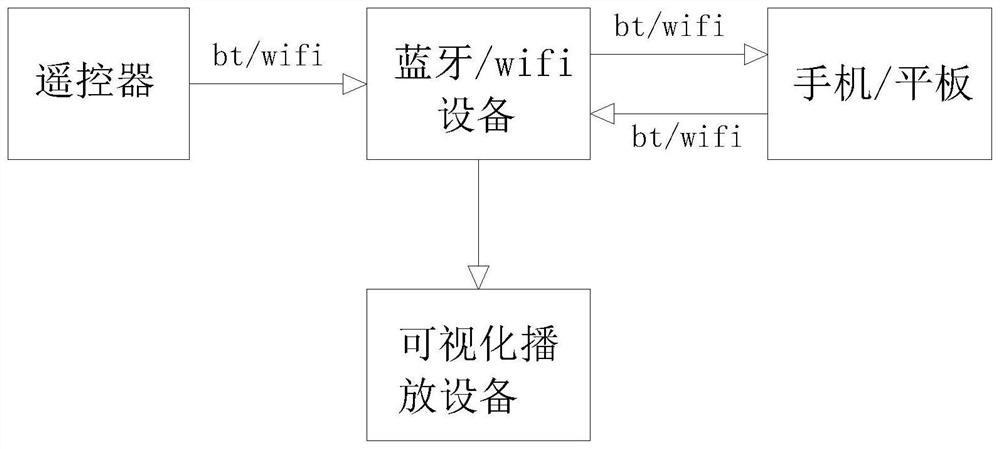

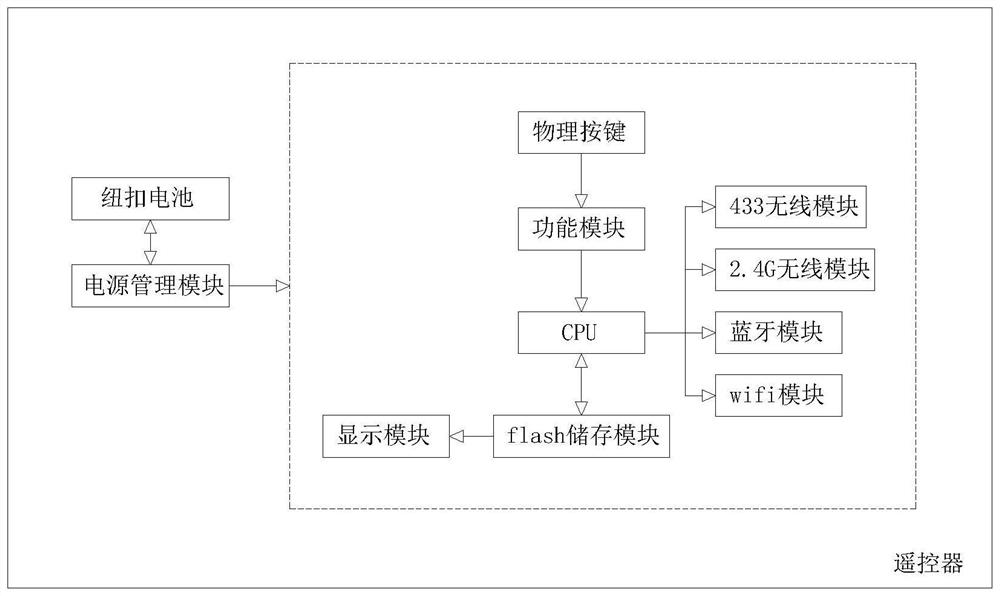

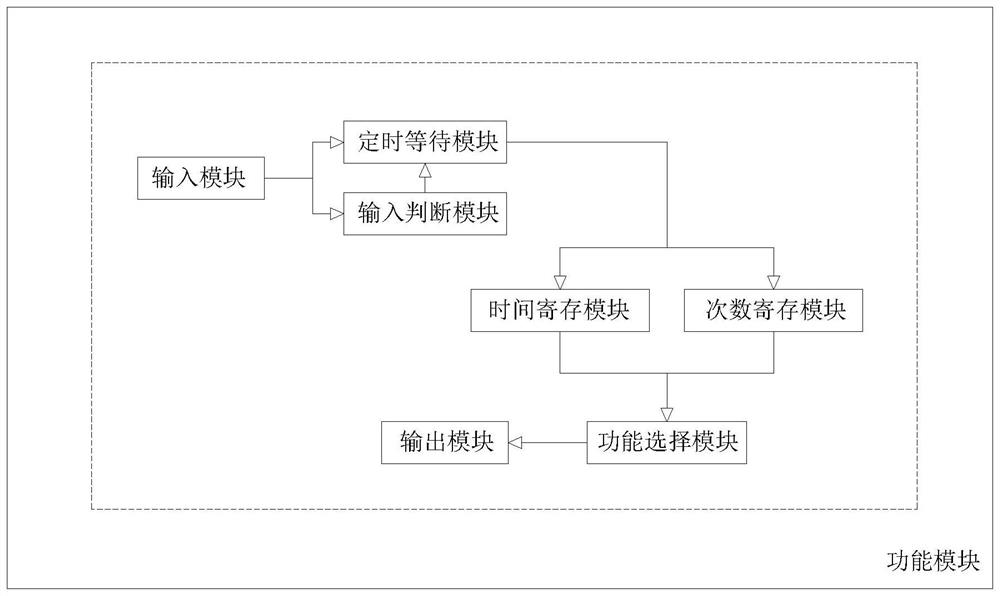

System for controlling interaction between Bluetooth or wifi device and mobile phone through wireless remote controller

InactiveCN114141002AEasy to operate blindlyReduce in quantityTransmission systemsParticular environment based servicesTraffic crashSteering wheel

The invention discloses a system for controlling interaction between Bluetooth or wifi equipment and a mobile phone through a wireless remote controller, the system comprises the remote controller, the Bluetooth / wifi equipment and the mobile phone / tablet computer, the remote controller is in communication connection with the Bluetooth / wifi equipment through bt / wifi, and the Bluetooth / wifi equipment is in communication connection with the mobile phone / tablet computer through bt / wifi; according to the remote controller, dangerous driving behaviors and traffic accidents caused by the fact that the two hands of an intelligent device including a mobile phone, a tablet personal computer and other Bluetooth or wifi intelligent devices are operated to leave a steering wheel of an automobile or handles of a bicycle, an electric vehicle and a motorcycle in the driving process are avoided; the remote controller is installed on the steering wheel or the handles of the bicycle, the electric vehicle and the motorcycle; therefore, it is guaranteed that the two hands of a driver can better interact with intelligent equipment under the condition that the two hands do not leave a steering wheel or a handle of a bicycle, an electric vehicle or a motorcycle, driving safety and pleasure are increased, meanwhile, safety is improved, and driving of various vehicles is facilitated.

Owner:匡富科

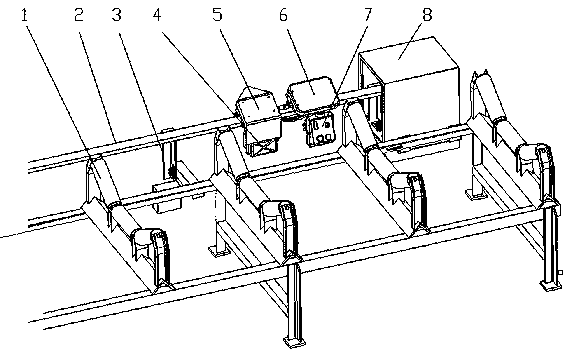

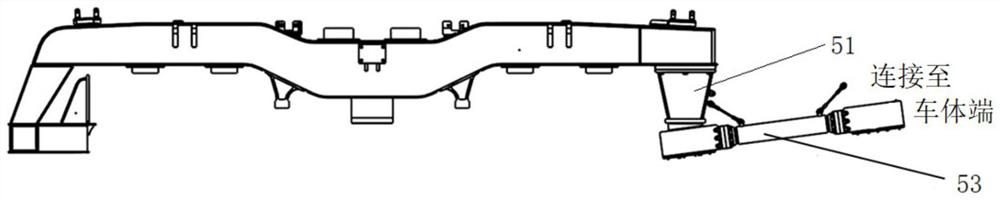

A bogie bogie for testing and testing method

ActiveCN111912635BIncrease the combinationShorten the timeRailway vehicle testingBogieClassical mechanics

The invention discloses a Bo axle bogie for testing and a testing method, comprising a first side beam and a second side beam arranged in parallel, and a parallel arrangement between the first side beam and the second side beam The front end beam, the middle beam and the traction beam are provided on the traction beam, and an end traction seat for connecting the end of the vehicle body is provided, and the end traction seat is detachably connected with the end of the vehicle body through a first traction assembly mechanism; The middle cross member is provided with a middle traction seat for connecting the end of the vehicle body, and the middle traction seat is detachably connected with the end of the vehicle body through a second traction assembly mechanism. The Bo axle bogie for testing and the testing method disclosed in the present invention can carry out bogie tests of different structures, increase the combination of tests, find parameters under a better structure, and greatly save the time required for parameter or structure adjustment. Time, labor and cost required.

Owner:CRRC DALIAN CO LTD

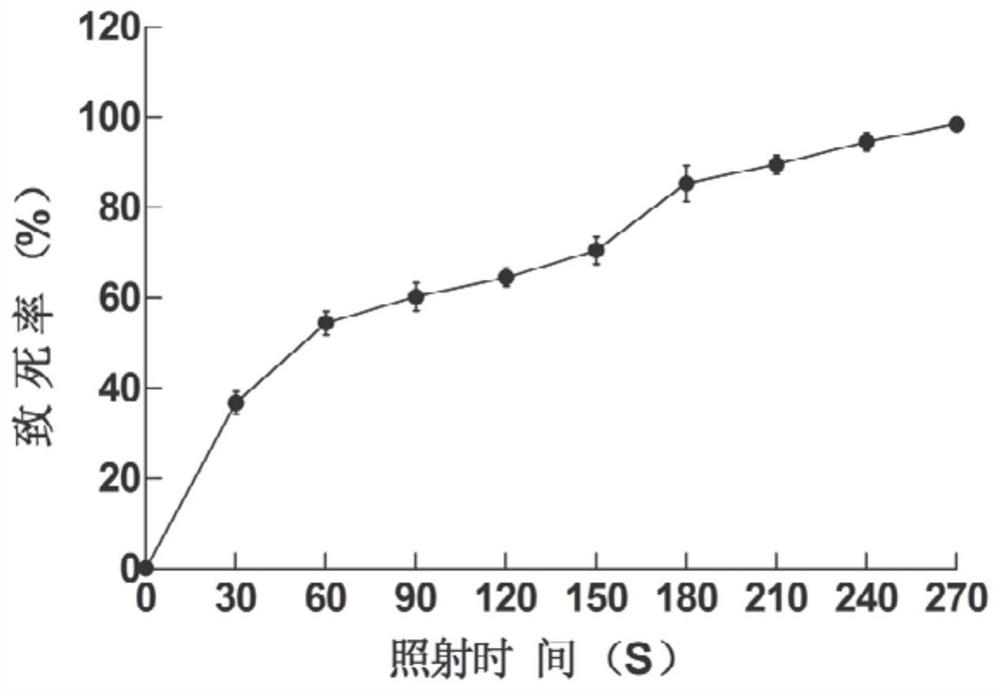

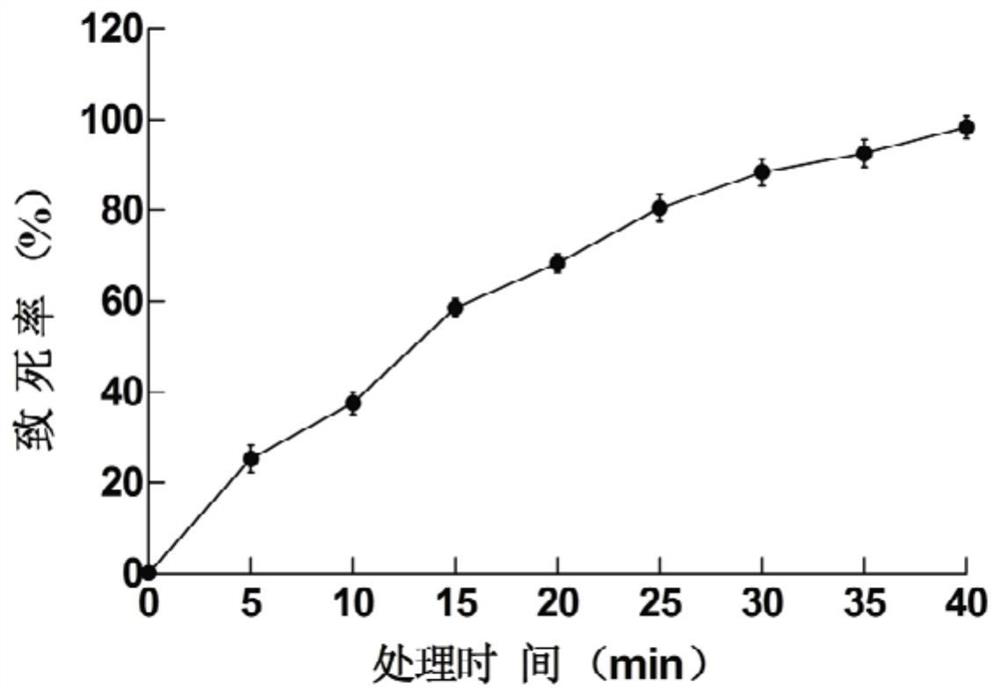

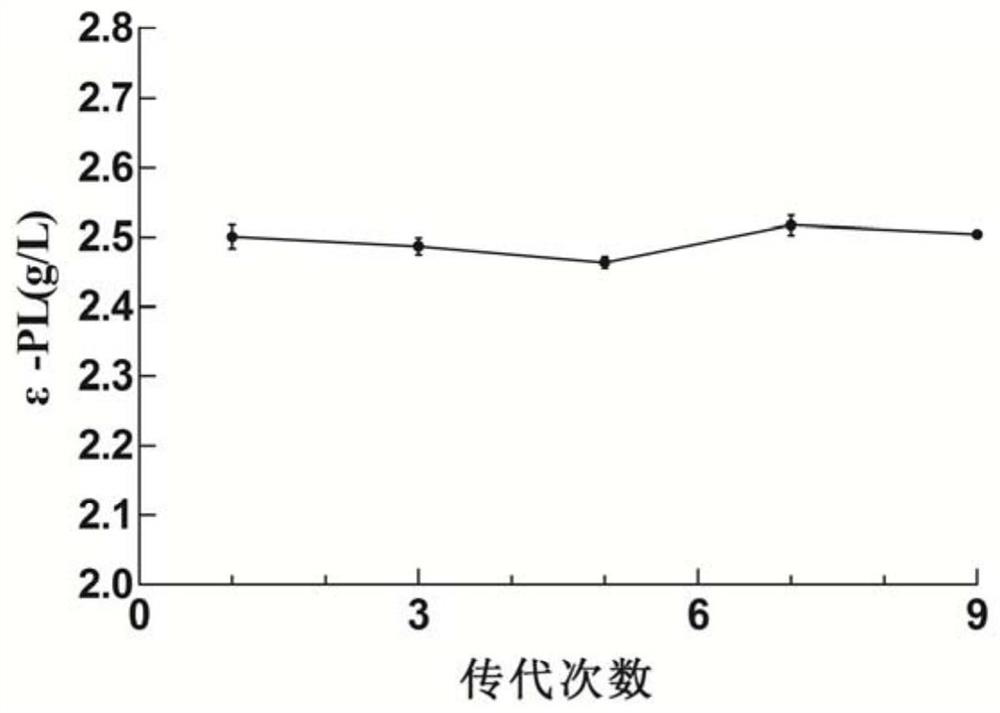

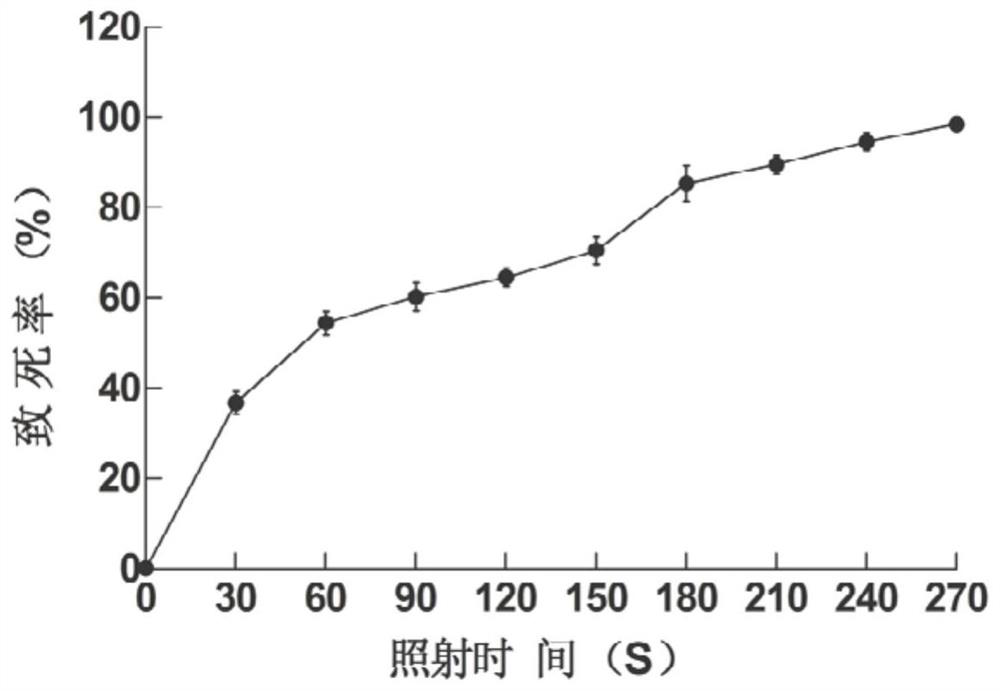

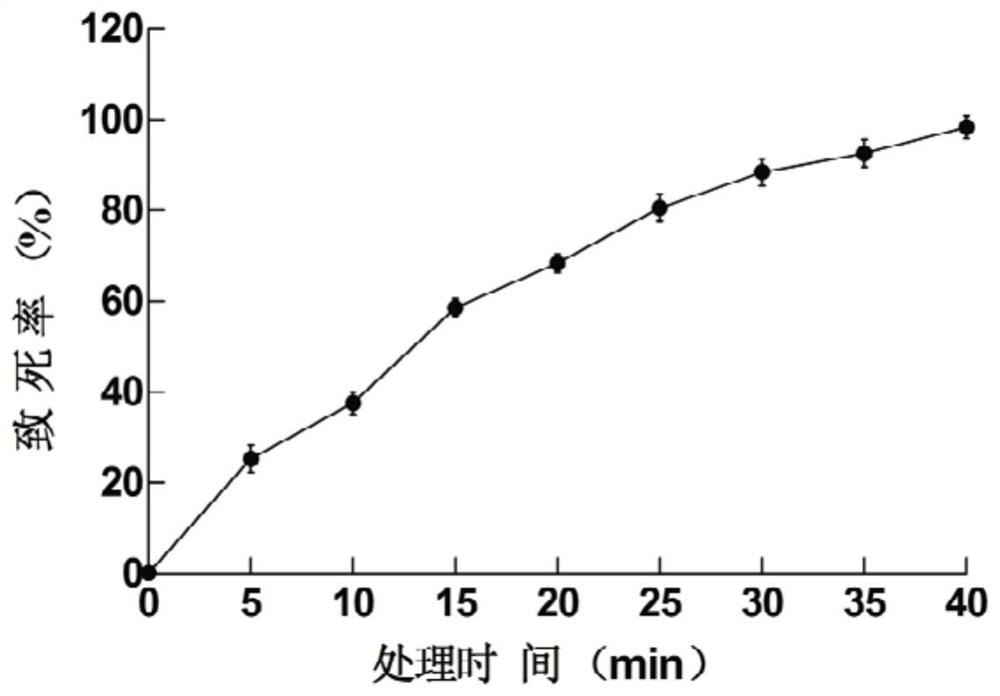

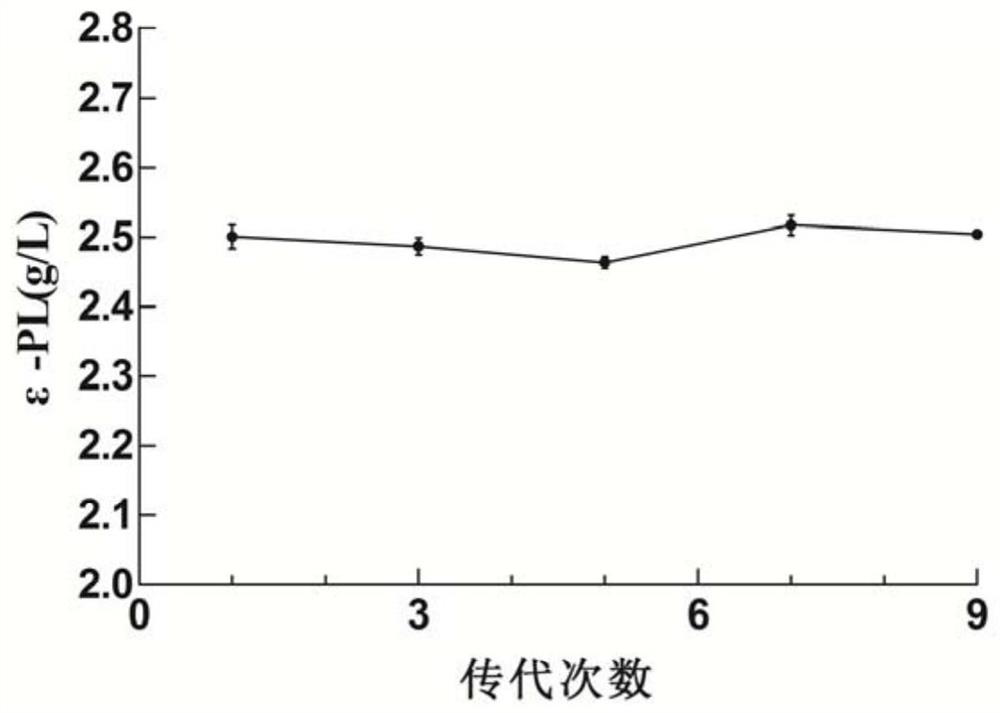

Acid-resistant high-yield epsilon-polylysine mutant strain and application thereof

ActiveCN112322567AEasy to operateIncrease the combinationBacteriaClimate change adaptationBiotechnologyMicroorganism

The invention discloses an acid-resistant high-yield epsilon-polylysine mutant strain and application thereof, and belongs to the field of microbial breeding. According to the invention, streptomycesalbulus is subjected to genetic engineering modification and mutation breeding, and a high-yield strain PL-2-AH66 is obtained. Compared with an original strain, the yield of epsilon-polylysine fermented by the strain at a shake flask level is increased by 150%, the yield of epsilon-polylysine at a 5L fermentation tank level can reach 42.69 g / L, and the production strength is 7.115 g / L / d. The high-yield strain PL-2-AH66 has good acid resistance and antibiotic tolerance, still has a higher survival rate when the pH is 2.0-3.0, and is good in genetic stability, and the yield of epsilon-polylysineafter passage 9 is basically consistent with the yield of primary generation. The fermentation process of the strain is simple, the process is easy to control, the yield of epsilon-polylysine is greatly increased, and a solid foundation is laid for industrial production and application of epsilon-polylysine.

Owner:JIANGNAN UNIV

Cleaning system for digital printing machine conveying mechanism

The invention discloses a cleaning system for a conveying mechanism of a digital printing machine, which includes a frame, a cleaning mechanism and a water supply system; the cleaning mechanism is located under the conveying belt; , front sponge roller, rear sponge roller, scraper plate, front water spray pipe, rear water spray pipe, brush drive mechanism, air knife and water suction roller; It has a trapezoidal structure; the cleaning water supply system includes a circulating water tank, a water pump and a regulating valve, a double filter and a liquid level gauge. Its advantages are: it adopts the composite cleaning mode of the first-level brush roller to sweep away the lint of the fabric, the scraper plate to wipe water, and the sponge roller to absorb water, and the cleaning effect is improved; the water consumption is small, the waste water is discharged, and the waste water can be recycled and filtered for reuse, energy saving and environmental protection; It adopts composite drying combination, cold air drying, multiple protections, increased production efficiency, and reduced waste rate; the cleaning tray can be automatically lifted and slid out from the rack, which is convenient for maintenance.

Owner:广东希望高科数字技术有限公司

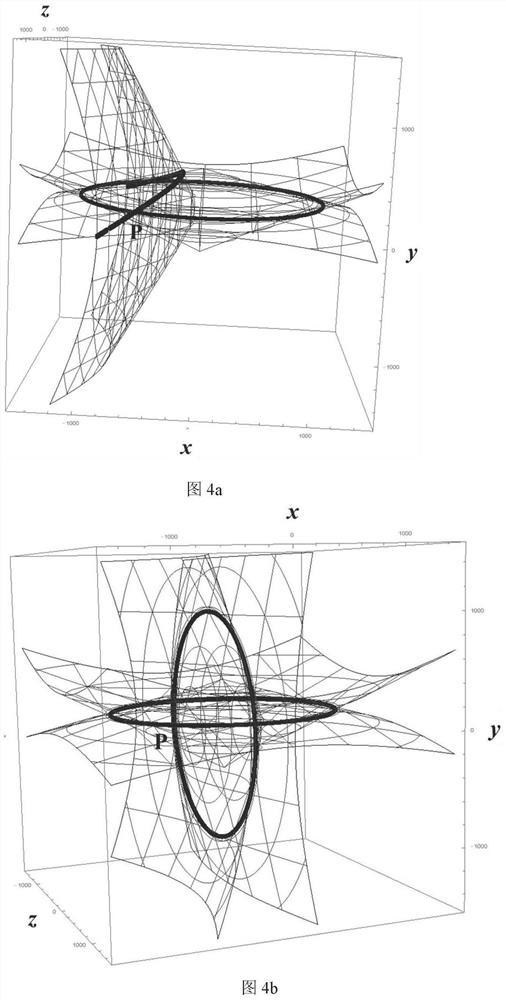

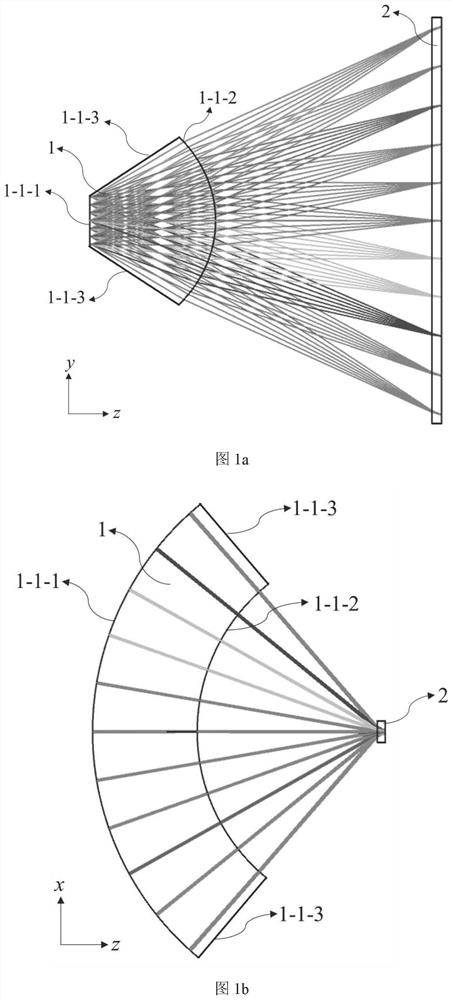

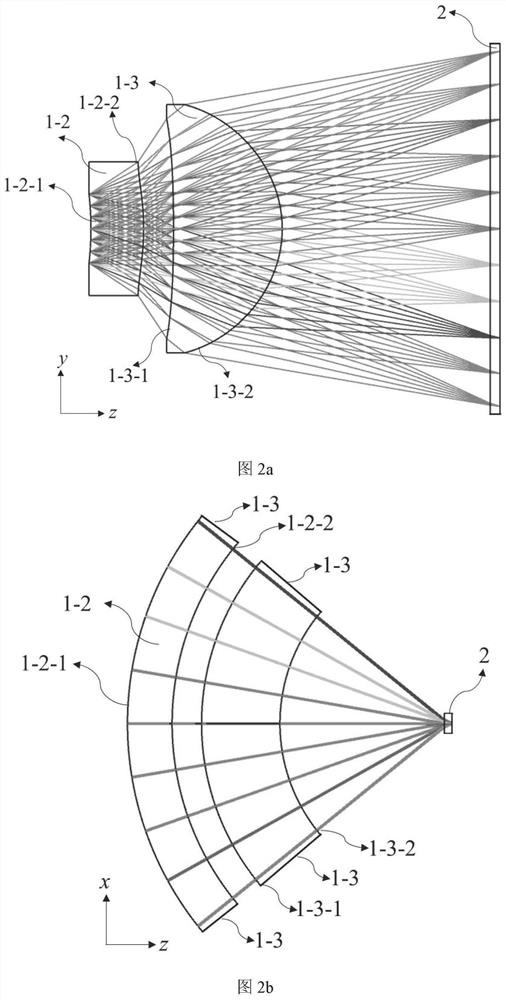

Optical space positioning system and space positioning method thereof

ActiveCN112269161AWide adaptabilityOutstanding FeaturesPosition fixationOptical spaceSpatial positioning

The invention discloses an optical space positioning system and a space positioning method thereof. The system consists of at least three groups of detection units consisting of tire tread lenses andlinear array photosensitive elements. The tire tread lens converges light emitted by the point light source in the space into a linear shape and is received by the linear array photosensitive element,and the linear array photosensitive element is located in the surrounding center of the tire tread lens. The detection units composed of at least three tire tread lenses and linear array photosensitive elements are arranged in a non-parallel mode in the space, and the position of the spatial point light source relative to the detector is calculated by obtaining intersection point position coordinates of light emitted by the point light source in the space and the linear array photosensitive elements in each detection unit. According to the invention, a function of high-precision detection ofa large-range spatial position can be realized, and the cost is low. The invention belongs to the field of space positioning.

Owner:SHANGHAI UNIV

Rack system for digital printing machines

ActiveCN111055599BEmission reductionReduce creasesOther printing apparatusStationary filtering element filtersTextile printerEngineering

The invention discloses a frame system of a digital printing machine, which comprises a frame, a printing conveying belt mechanism is arranged on the top of the frame, a gantry carriage spans above the printing conveying belt mechanism, and a cloth loading mechanism is arranged on the printing conveying belt mechanism The belt cleaning device is set at the bottom of the printing conveying belt mechanism; the cloth loading mechanism includes an air expansion shaft, a large roll angle roller, a cloth passing roller a, a constant tension floating roller, and a cloth passing roller all arranged on the frame. b. Cloth passing roller c, moving roller, widening angle wrapping roller; equipped with lifting and guiding mechanism to drive constant tension floating roller; equipped with unwinding and deviation correcting system for correcting the position of the cloth. Its advantages are: the cloth feeding mechanism adapts to large and small rolls of cloth at the same time, saving costs; the cloth is automatically corrected online and aligned in real time; the printing quality is high; the belt cleaning device adopts a combination of compound cleaning mode and compound drying, which improves the cleaning effect; water consumption is small and energy saving Environmental protection; production efficiency improvement.

Owner:广东希望高科数字技术有限公司

Extensible combined sewage treatment system, method and application

InactiveCN111689658AAdequate responseMonitor the running status from time to timeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentScrew pumpTreatment system

The invention belongs to the technical field of sewage treatment, and discloses an extensible combined sewage treatment system, method and application. A water inlet is connected with an anaerobic reaction system through a plastic pipe, and a bacterium adding device is connected with the anaerobic reaction system through a plastic ring; the anaerobic reaction system is connected with a screw pumpthrough a plastic pipe; the screw pump is connected with an aerobic aeration reaction system; the aerobic aeration reaction system is connected with the screw pump through the plastic pipe; the screwpump is connected with a dosing, disinfecting and precipitating system; the doser is connected with the dosing, disinfecting and precipitating system through a plastic pipe; the dosing, disinfecting and precipitating system is connected with the screw pump through a plastic pipe, the screw pump is connected with a secondary precipitation system through a plastic pipe, the secondary precipitation system is connected with the screw pump through a plastic pipe, the screw pump is connected with the purification treatment system through a plastic pipe, and the purification treatment system is connected with the water outlet through a plastic pipe. The screw pump is connected with a purification treatment system through a plastic pipe, and the purification treatment system is connected with a water outlet through a plastic pipe. The system is low in cost, convenient to transport, quick to install, good in mobility and convenient to operate; and automatic operation is achieved, and the working intensity of operators and resource waste are reduced.

Owner:SOUTHWEST UNIVERSITY

CNJT adjustable speed safe intelligent high-power vertical axis windmill sail

InactiveCN102748206BEnsure security purposeReduce speedRenewable energy generationMachines/enginesHorizontal axisEngineering

The invention discloses a CNJT adjustable speed safe intelligent high-power vertical axis windmill sail, which is a brand new reform of a working principle and a structure of the conventional vertical axis windmill, and overcomes the problems of no moment, low efficiency and difficult speed control at over speed of the conventional vertical axis windmill blade and low wind power utilization efficiency of the current widely applied horizontal axis windmill. The new technical scheme of CNJT is as follows: the CNJT adjustable speed safe intelligent high-power vertical axis windmill sail comprises multiple compounded motion intelligent blades, the working moment is obtained through a technical scheme capable of reducing the areas of the blades incapable of working, and the wind power utilization efficiency is greatly improved. When a storm comes, by applying a principle of reducing the working area of the working movable blades of the windmill, wind loads of the blades on the both sides are removed, and safety of the windmill rail is ensured. The CNJT adjustable speed safe intelligent high-power vertical axis windmill sail has the following innovations that: the wind power utilization efficiency is higher than a horizontal axis windmill. Through increasing the blade groups, the total power of the single windmill is increased. Without a wind alignment device, the CNJT adjustable speed safe intelligent high-power vertical axis windmill sail is suitable for power generation of marine wind power, platforms and ships, and power of marine ship rails. Through speed regulation or halt of the intelligent blades, safety of the windmill rail is ensured.

Owner:焦兆平 +2

A mutant strain with acid resistance and high production of ε-polylysine and its application

ActiveCN112322567BEasy to operateIncrease the combinationBacteriaClimate change adaptationBiotechnologyAntibiotic resistance

The invention discloses an acid-resistant and high-yield ε-polylysine mutant strain and an application thereof, belonging to the field of microbial breeding. The present invention obtains a high-yielding strain PL-2-AH66 by performing genetic engineering on Streptomyces and combining with mutation breeding. Compared with the starting strain, the ε-polylysine fermented by the strain at the shake flask level is increased by 150%, and the ε-polylysine production at the level of the 5L fermenter can reach 42.69 g / L, and the production intensity is 7.115 g / L / d. The high-yielding strain PL-2-AH66 of the present invention has good acid resistance and antibiotic resistance, still has a high survival rate at pH 2.0 to 3.0, and has good genetic stability. The yield of lysine was basically the same as that of the first passage. The fermentation process of the strain is simple, the process is easy to control, and the yield of ε-polylysine is greatly improved, which lays a solid foundation for the industrial production and application of ε-polylysine.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com