Fermentation tank with side ports and method of operation

A side port, fermenter technology, applied in the field of fluid communication units, can solve the problem that the system is not very effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Example 1 - Process of brewing beer

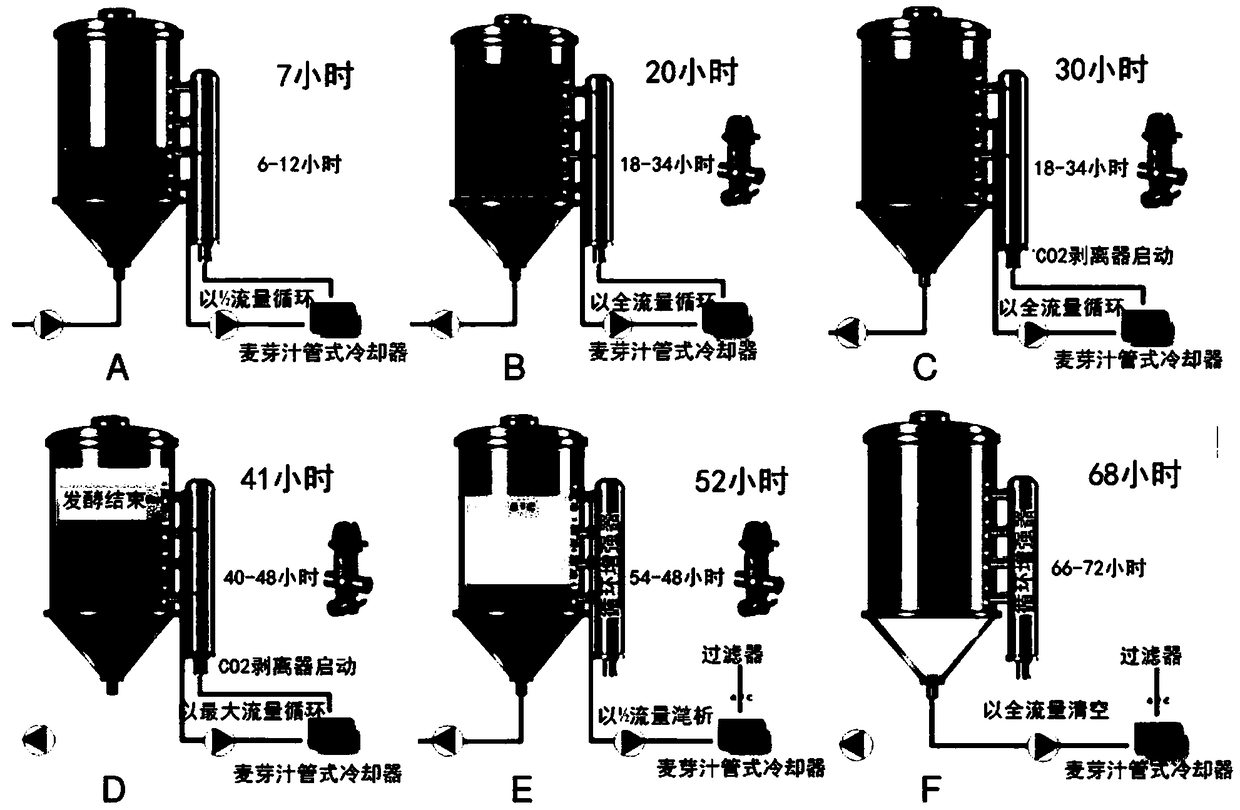

[0112] figure 1 Embodiments of the disclosed methods are shown. Embodiments of the disclosed system are also shown. In this example, six points in time during the brewing process are shown, namely figure 1 .A-1.F. The process takes a total of 68 hours, from the point of time when the wort enters the fermenter to decanting the fermented wort or beer. figure 1 .A shows wort entering the fermenter and circulating between the first and second side ports, i.e. from the first side port to the second side port, here the regulated pump flow is set to 60 of the full pump flow %. This first point in time is when the process has been running for 7 hours. After 20 hours, the fermenter was completely filled, as figure 1 .B, and the partially fermented wort is circulated through all side ports, in particular exiting from the second and fourth side ports, and returned to the fermenter through the first and third side ports, here at full pum...

Embodiment 3

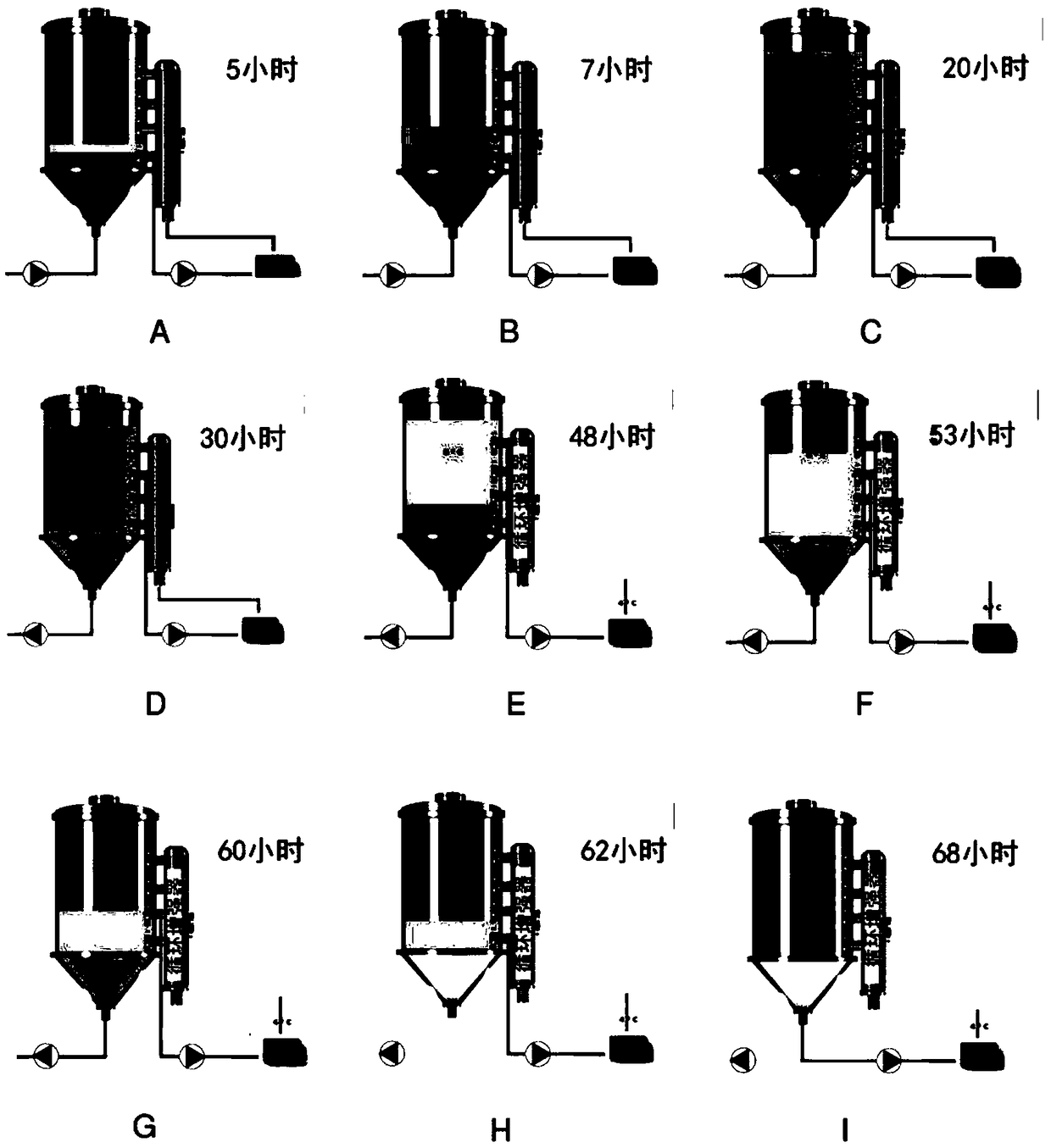

[0115] Example 3 - Another process for brewing beer

[0116] image 3 An embodiment of the method according to the invention for fermenting wort in a fermenter is shown. Embodiments of the disclosed fermentation system comprising a fermenter and a circulation system are also shown. image 3 .A-3.I show nine time points during beer brewing.

[0117] The process takes a total of 68 hours, which is the point from when the wort enters the fermenter to decanting the fermented wort or beer.

[0118] image 3 .A shows a fermenter according to the invention. The fermenter includes a bottom port and at least three side ports, the at least three side ports being a first side port, a second side port, and a third side port, wherein the side ports are in fluid communication with each other. Additionally, a fourth side port is shown. image 3 .A further shows wort first entering the fermenter through the bottom port. Here the wort can be added with yeast and incubated under conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com