Patents

Literature

2012 results about "Screw pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screw pump, also known as a water screw, is a positive-displacement (PD) pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form (the Archimedes' screw pump), a single screw rotates in a cylindrical cavity, thereby moving the material along the screw's spindle. This ancient construction is still used in many low-tech applications, such as irrigation systems and in agricultural machinery for transporting grain and other solids.

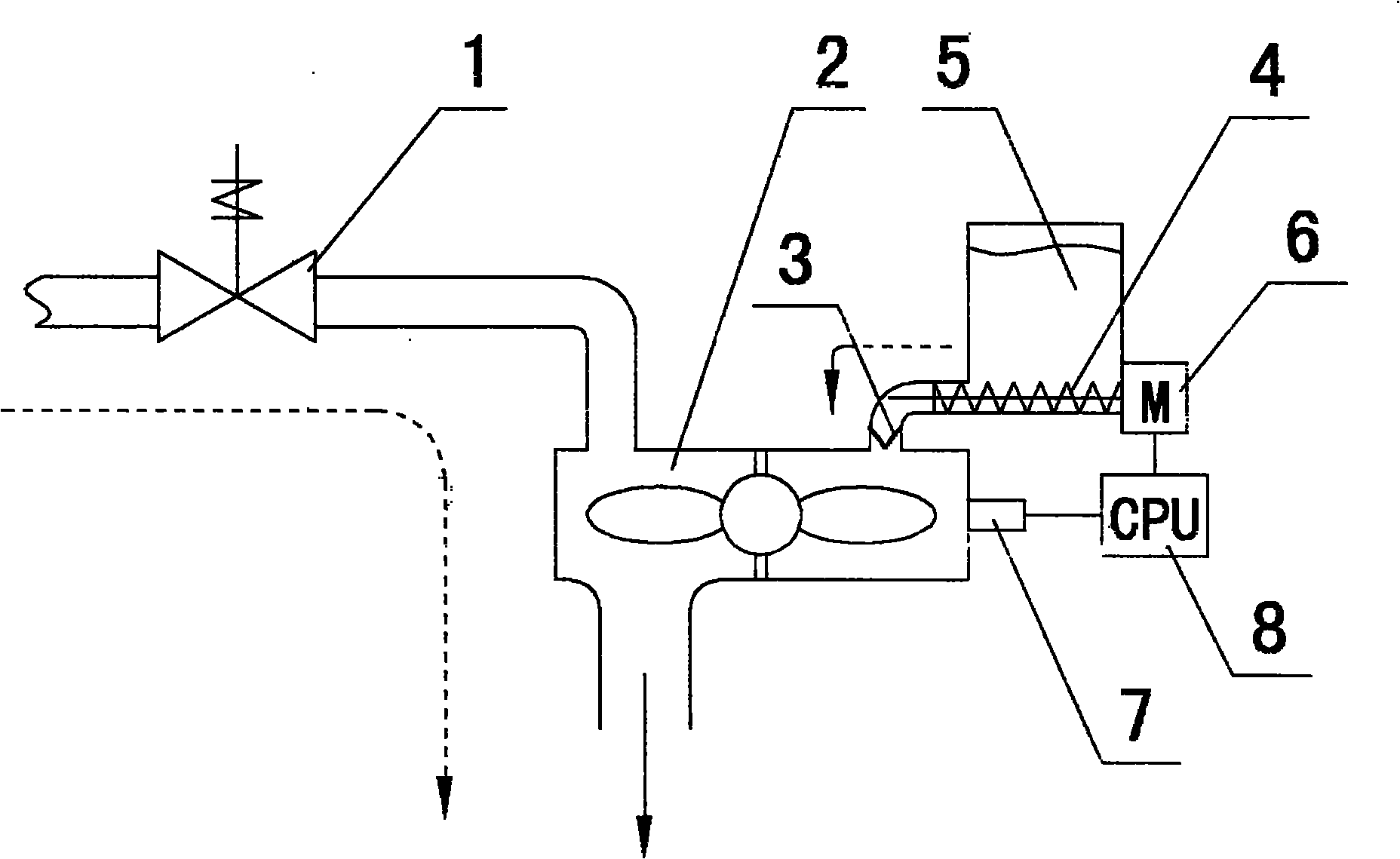

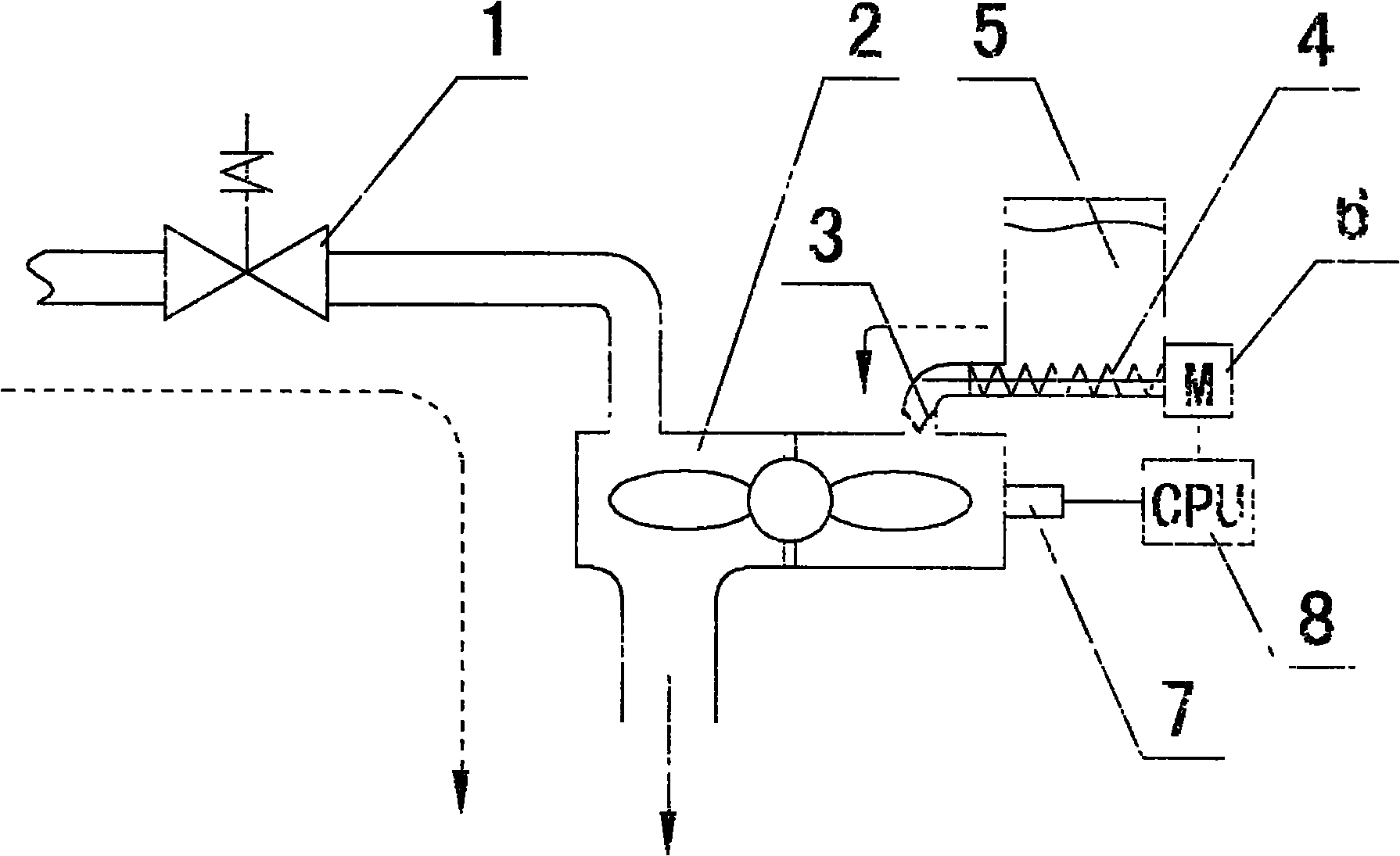

Detergent pouring and mixing device

InactiveCN102182049AWell mixedModerate concentrationOther washing machinesControl devices for washing apparatusInlet valveEngineering

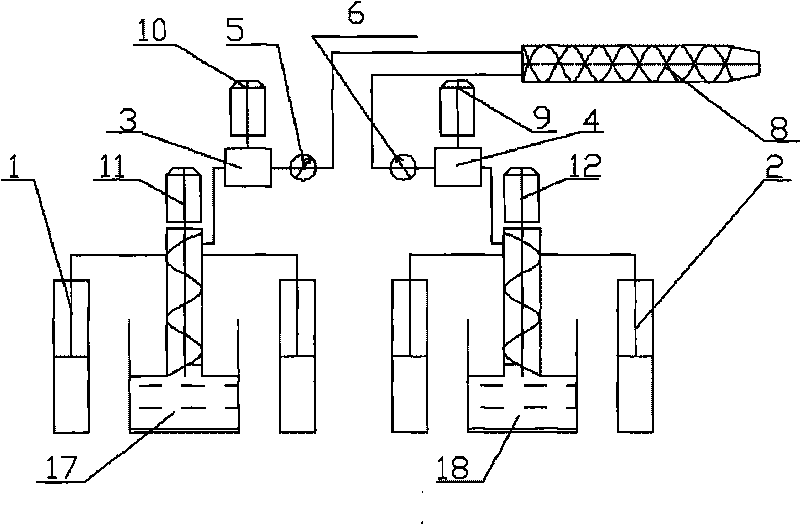

The invention provides a detergent pouring and mixing device. The device comprises an inlet valve 1, a turbine agitator 2, a discharge mouth 3, a screw pump 4, a charge basket 5, a motor 6, an inductor 7 and a controller 8, wherein the duckbilled discharge mouth 3 is arranged in the discharge hole of the charge basket 5; and the screw pump 4 driven by the motor 6 is arranged at the bottom of the charge basket 5. The device has the following beneficial effects: after being arranged on the washing machine, the device can automatically pour the detergent according to the required proportion and can fully mix the detergent with the inlet water to ensure the detergent entering into the washing basket to have an appropriate and uniform concentration.

Owner:刘立杰

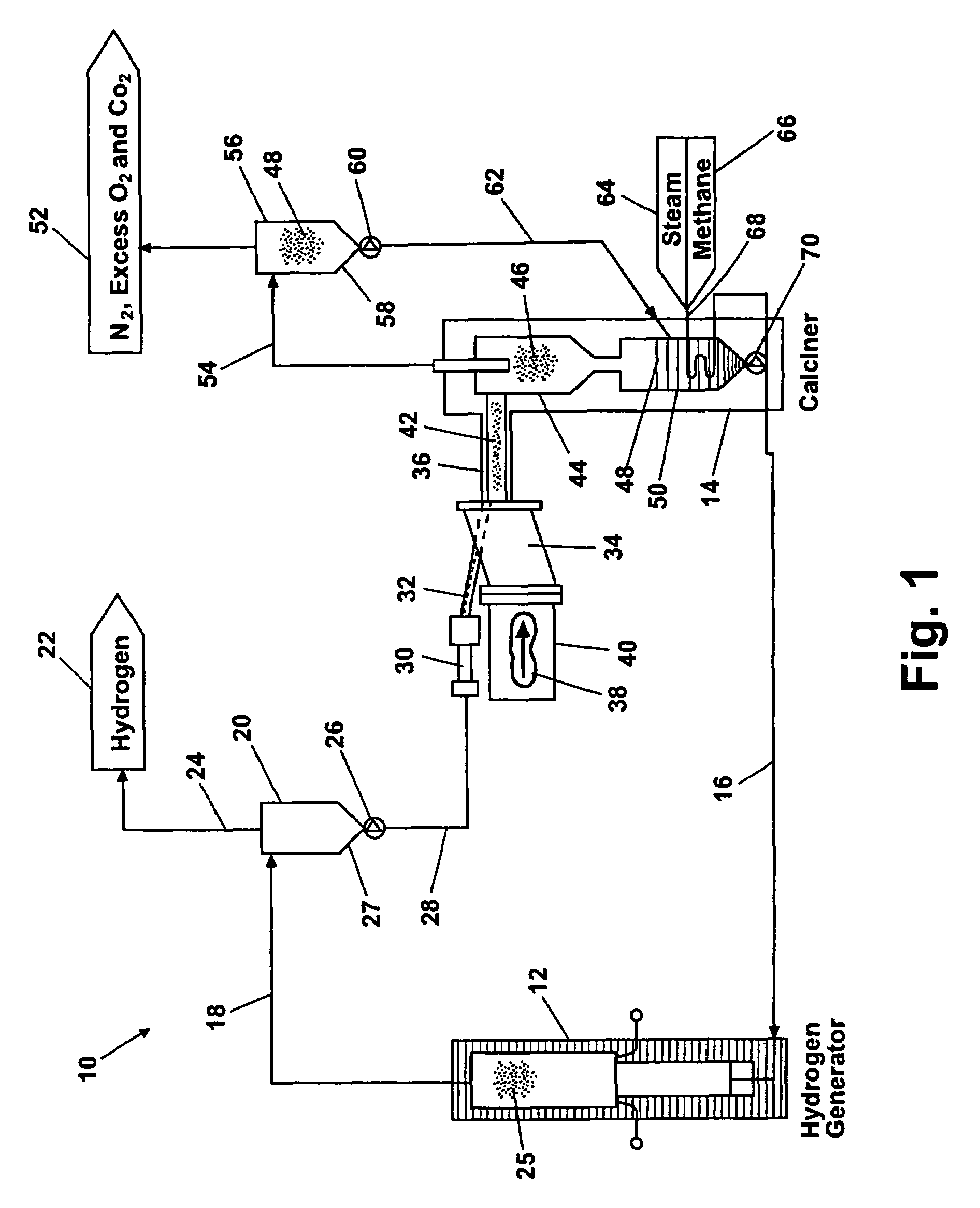

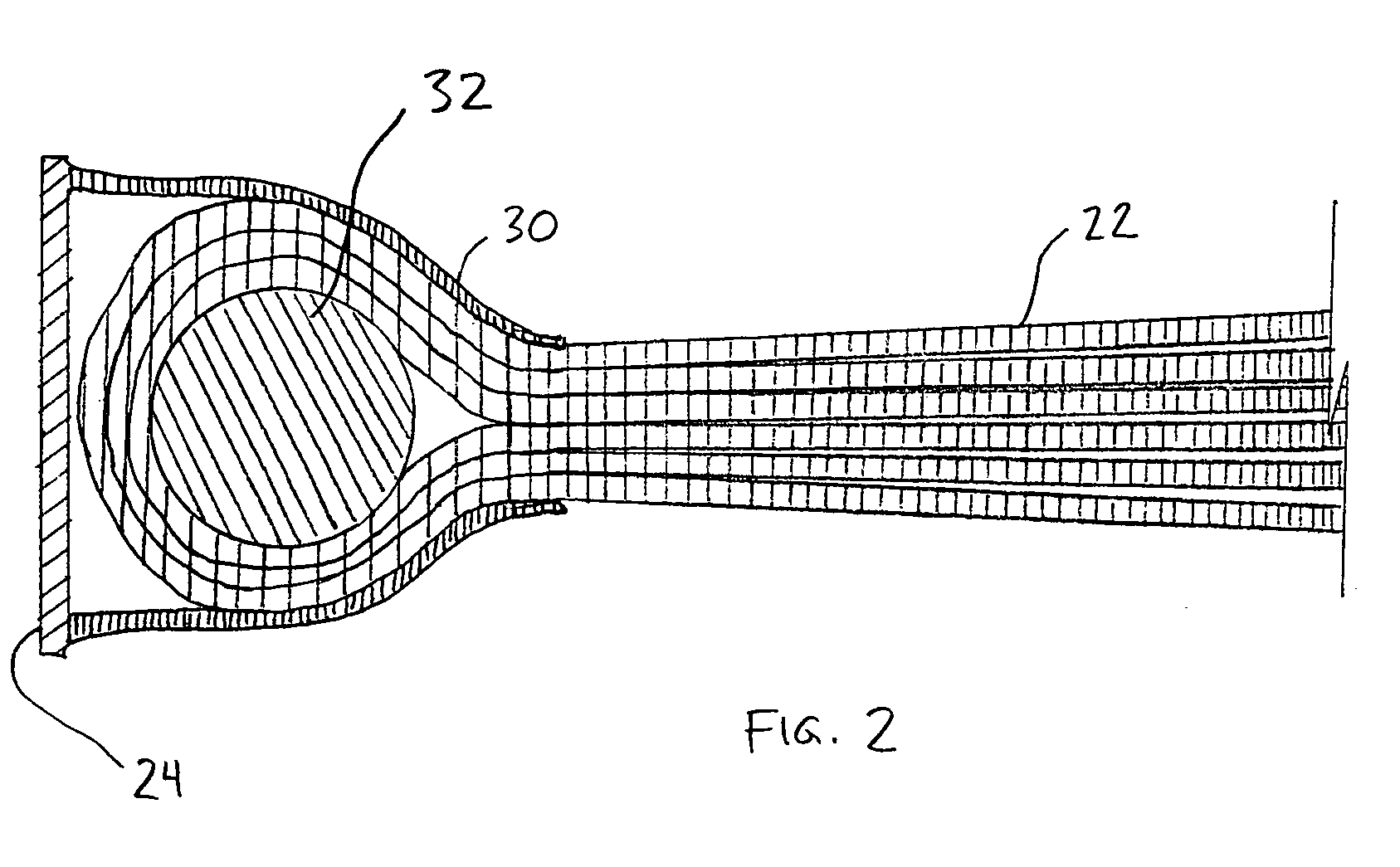

Hot rotary screw pump

ActiveUS7360639B2Eliminate movementReduce cloggingHydrogen separation using solid contactBulk conveyorsEngineeringPressure difference

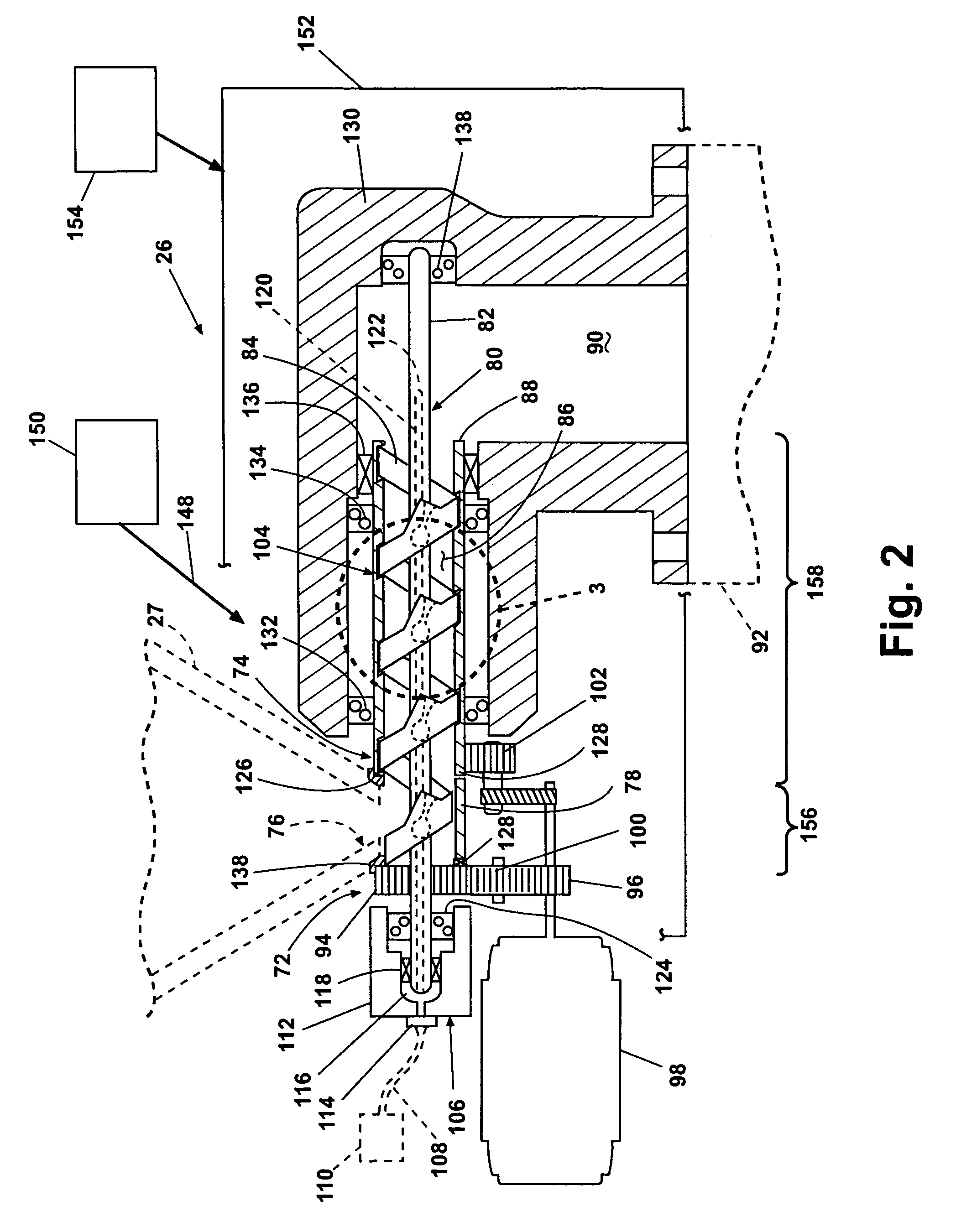

A screw feeder can be used to transport a high temperature particulate material. A housing contains the material within the screw feeder which includes an inlet and an outlet port. A screw is rotatably positioned within the housing to advance the material from the inlet port to the outlet port, which rotates axially. A labyrinth seal can be formed around and in communication with the screw to eliminate reverse movement of the material. A cooling medium can be directed into contact with at least the housing. A fluid can be injected through the screw to prevent blockage of the particulate material. A pressure differential is created from the inlet to the outlet port of at least 0.069 MPad.

Owner:GAS TECH INST +1

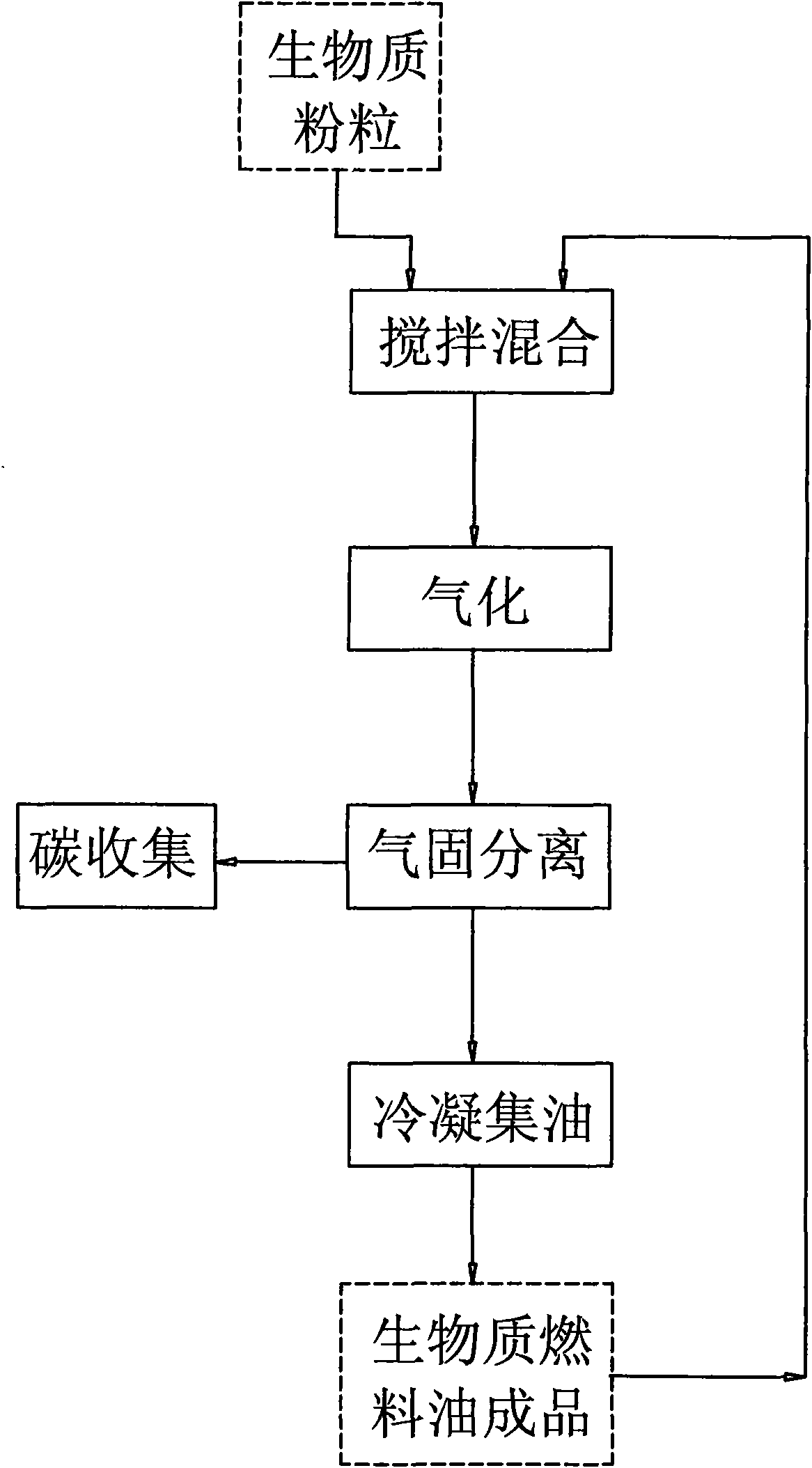

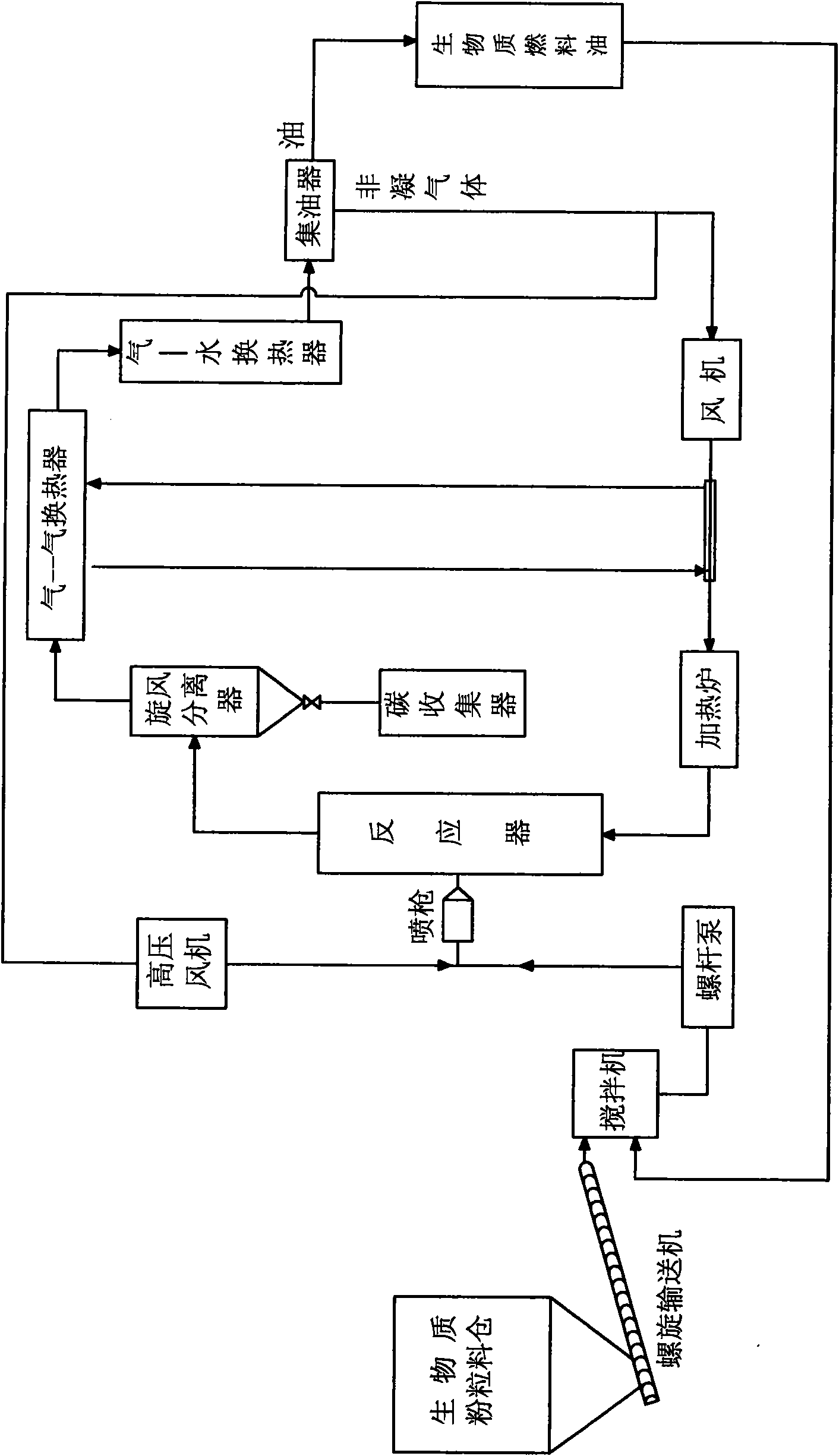

Biomass slurry atomization thermal cracking process and device

InactiveCN101550347AImprove atomization effectWell mixedLiquid hydrocarbon mixture productionProcess engineeringSlurry

The invention relates to a biomass slurry atomization thermal cracking process which comprises the following steps of stirring, mixing, gasifying, gas-solid separating, condensing and oil gathering. Adevice of the invention comprises a screw pump, an on-line grinder, a I-stage on-line filter, a slurry biomass storage tank, a slurry supply pump, a II-stage one-line filter, an atomization spray gun, a thermal cracking reactor, a cyclone separating device, a gas-gas thermal exchanger, a steam-water thermal exchanger and an oil gathering device which are sequentially connected with the output endof a stirring machine through pipes. Biomass comprises crop straws, other plant straws, branches and wooden meals. Because of adopting the slurry atomization reactor, the invention has the advantagesthat the slurry biomass atomization effect is good, the temperature field is stable, the slurry atomization realizes the uniform mixing of gas and material for ensuring the fully thermal cracking, the thermal cracking effect and the utilization ratio of the material are improved, the structure of the device is compact, the investment cost is low, the process adopts the continuous circulating operation, the production efficiency is high and the oil yield is large.

Owner:江苏东工环保科技股份有限公司

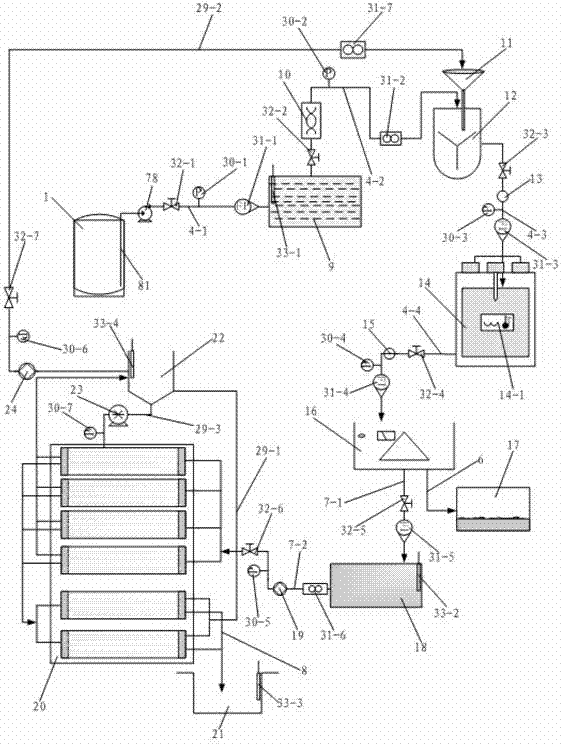

Oil sludge cleaning and processing system for oil tank

InactiveCN102825040ARealize all-round cleaningCompact structureSludge treatmentHollow article cleaningUltrafiltrationResource utilization

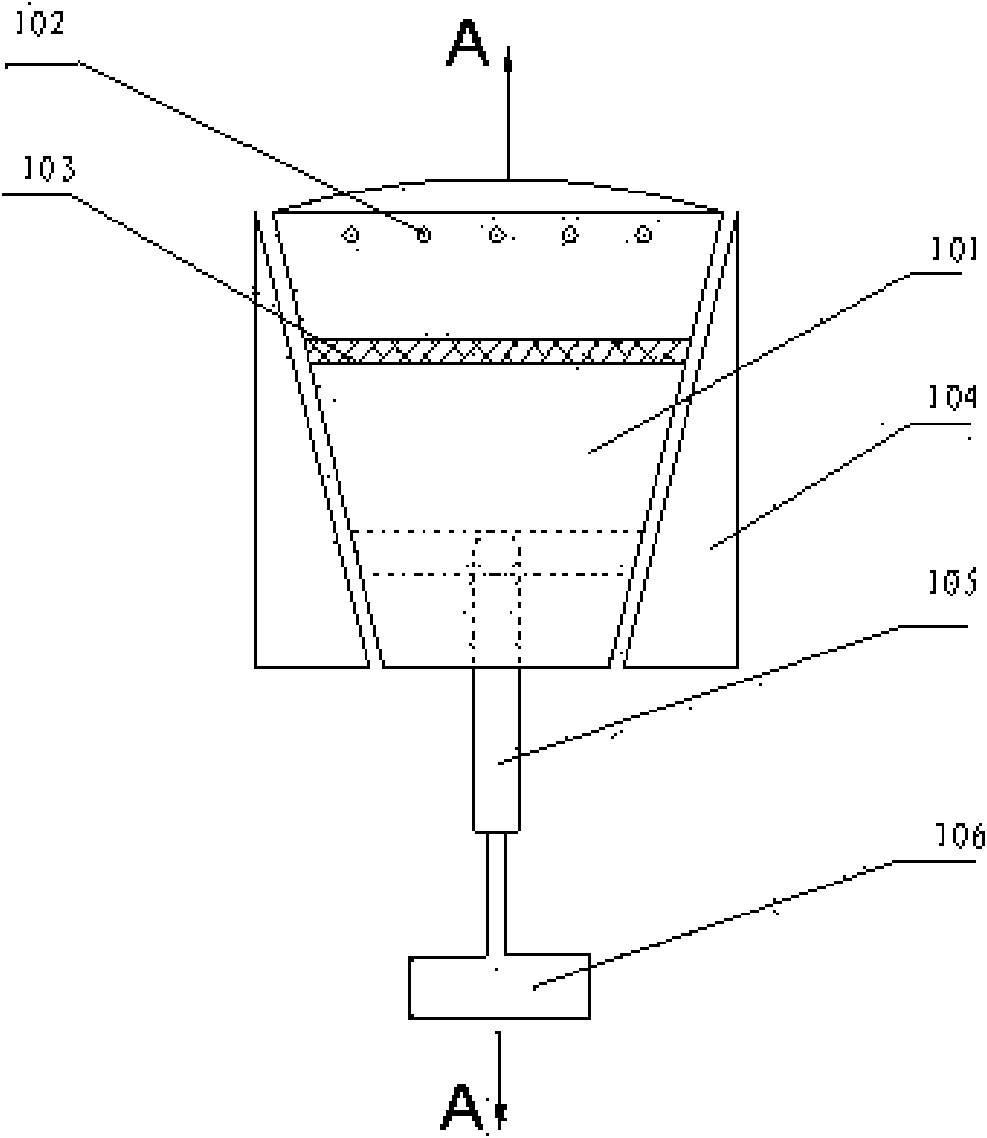

The invention discloses an oil sludge cleaning and processing system for an oil tank. The oil sludge cleaning and processing system comprises a cleaning system, an oil sludge processing system and an integrated control system, wherein the cleaning system comprises a cleaning robot, an electric hydraulic pump, a water pump, an inert gas storage tank and a screw pump; the cleaning robot comprises a machine body, a traveling unit, a cleaning unit, a robot cleaning control unit, a sensing and communication unit and a robot power supply unit; the oil sludge processing system comprises an oil sludge processing device, an oil sludge processing control system and an oil sludge processing power supply device; the oil sludge processing device comprises a stirring machine, an ultrasonic emulsion breaking device, a centrifuge and an ultrafiltration system, as well as an oil sludge storage pool, a sludge pool, a centrifugal liquid storage tank, a concentration tank and a filtrate pool; a funnel is arranged on the stirring machine; and the integrated control system comprises an integrated control computer and a communication circuit module. The oil sludge cleaning and processing system disclosed by the invention has the advantages of reasonable design and high degree of intelligentization, and can realize comprehensive cleaning of the oil tank, good safety, fast oil sludge processing speed and resource utilization of oil sludge, and further reduce environmental pollution and waste of resources.

Owner:周利坤

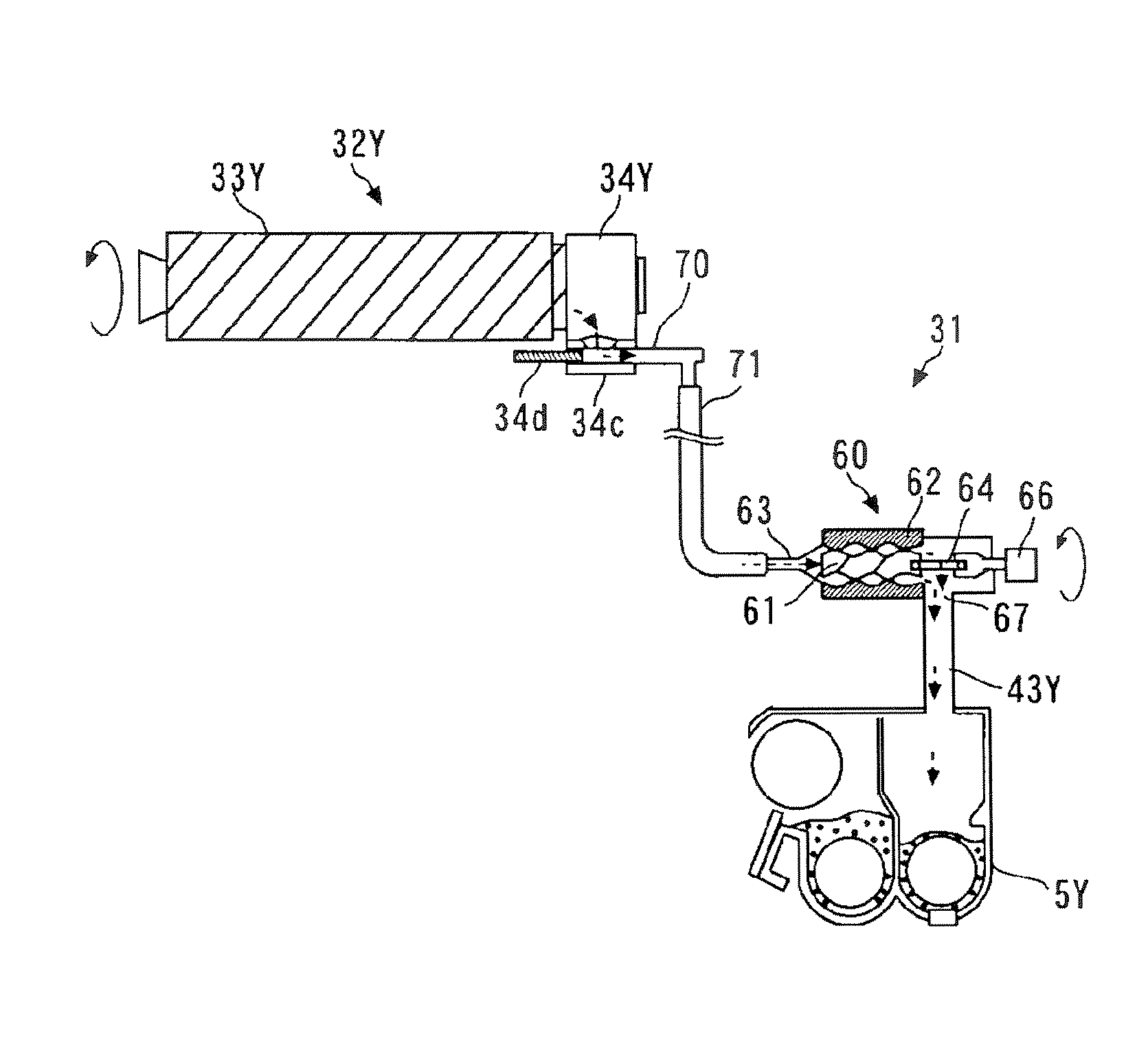

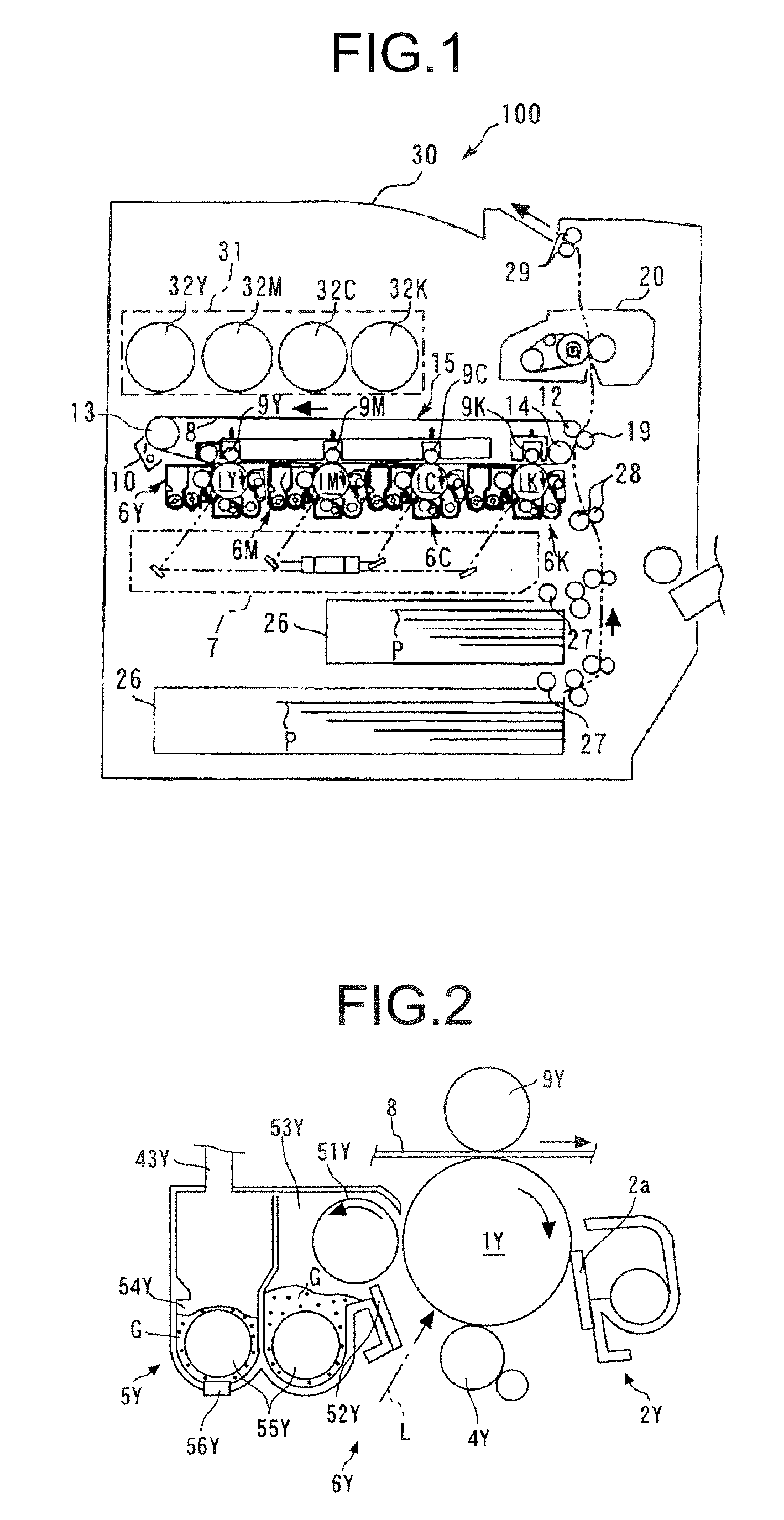

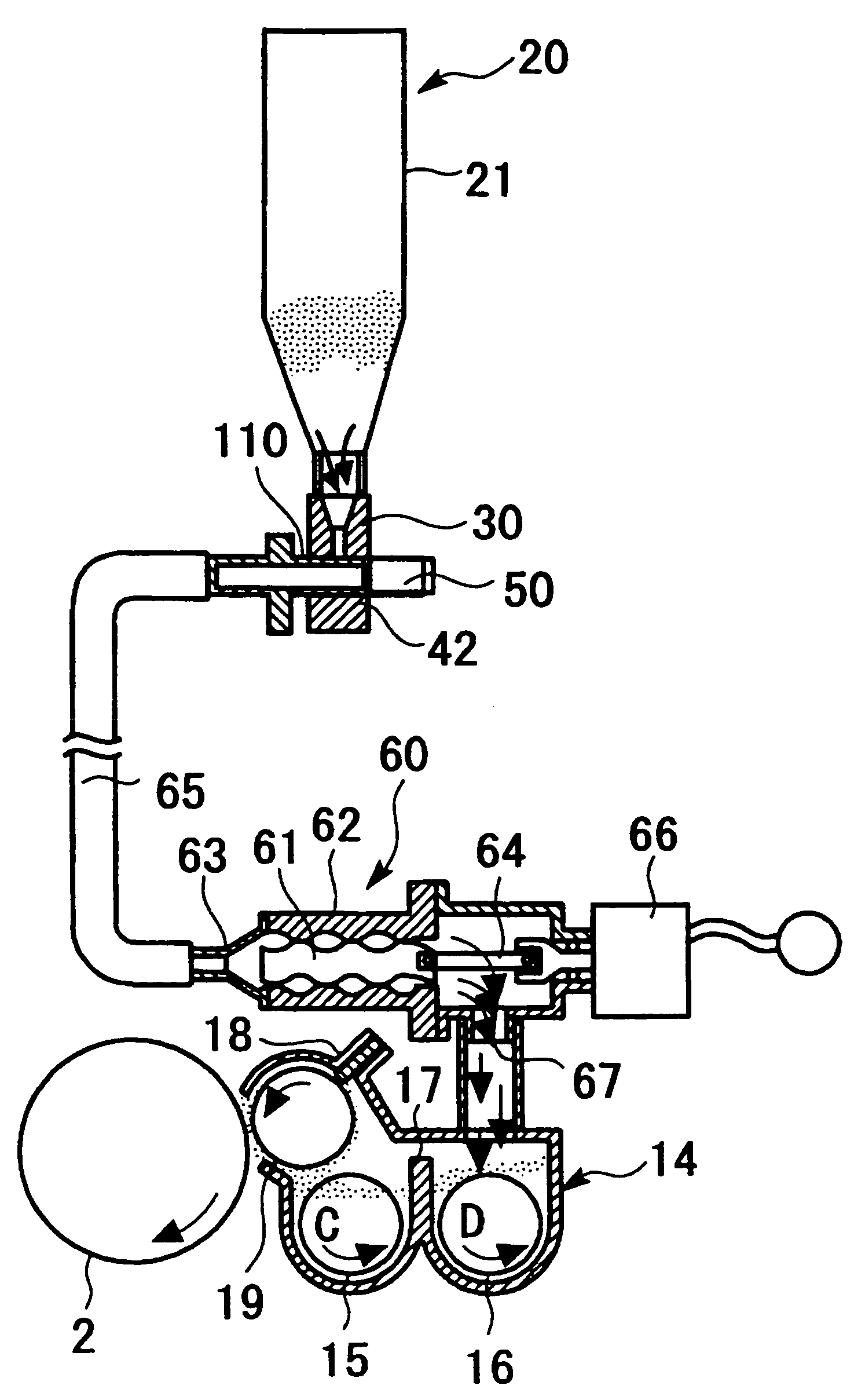

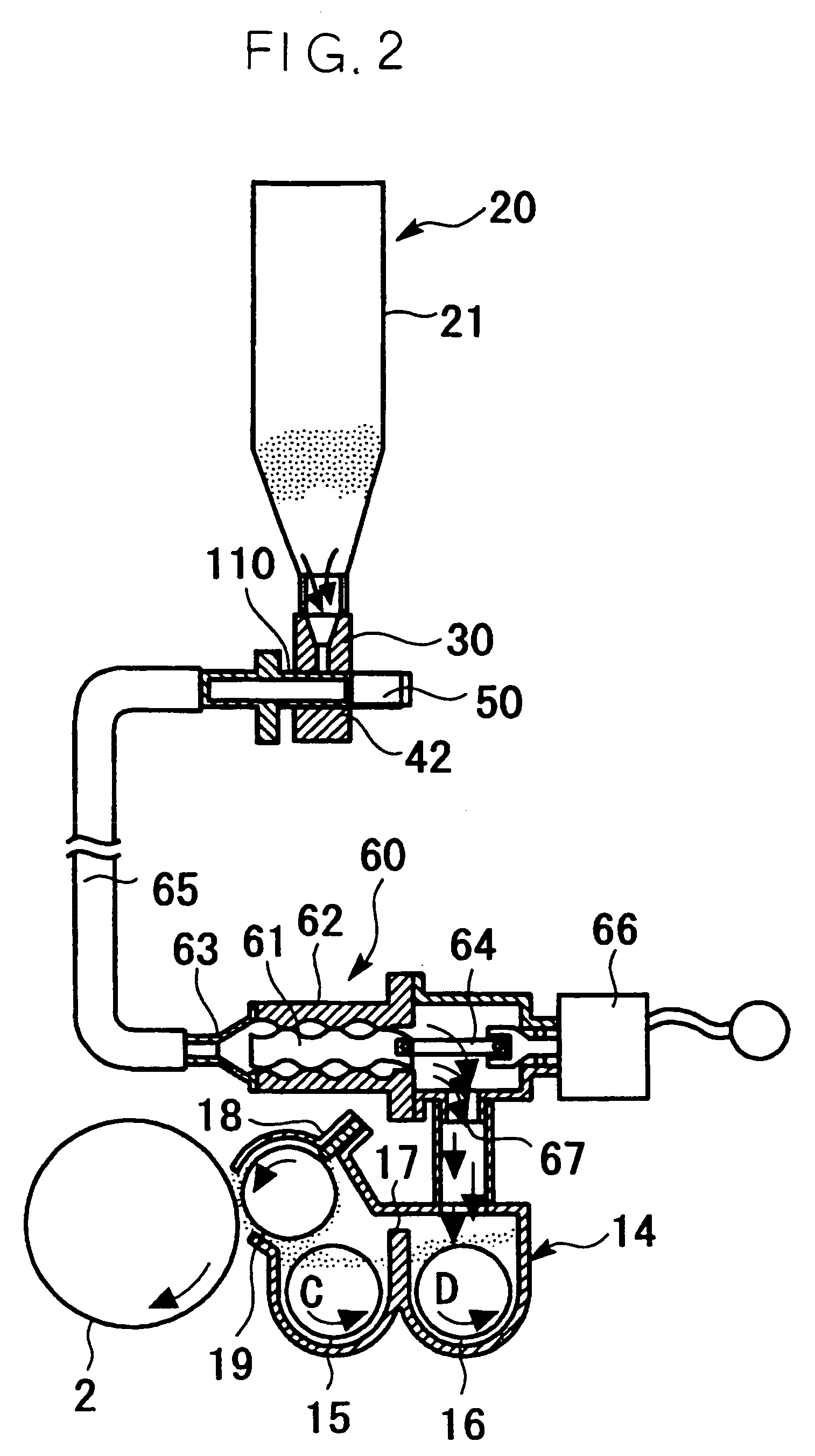

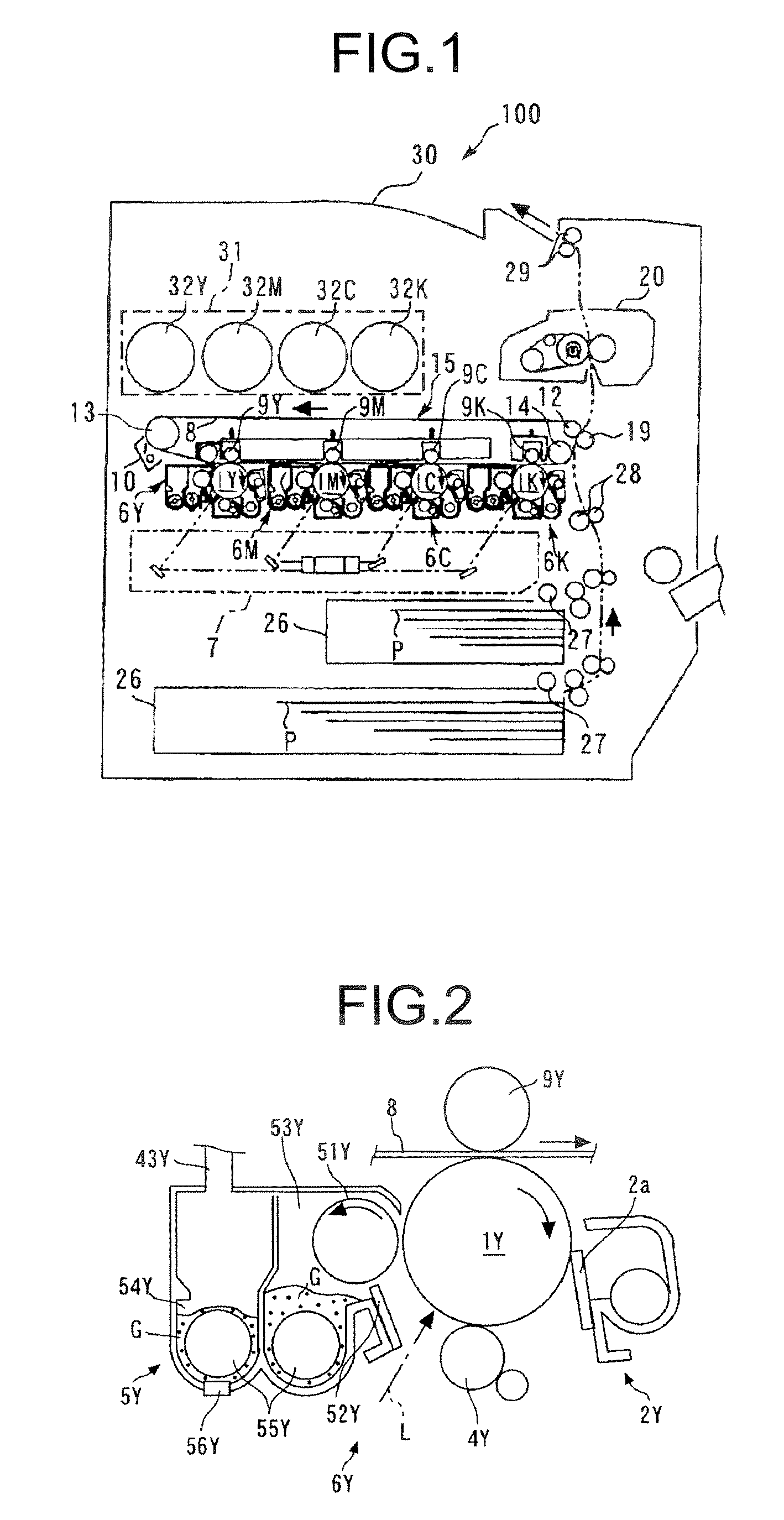

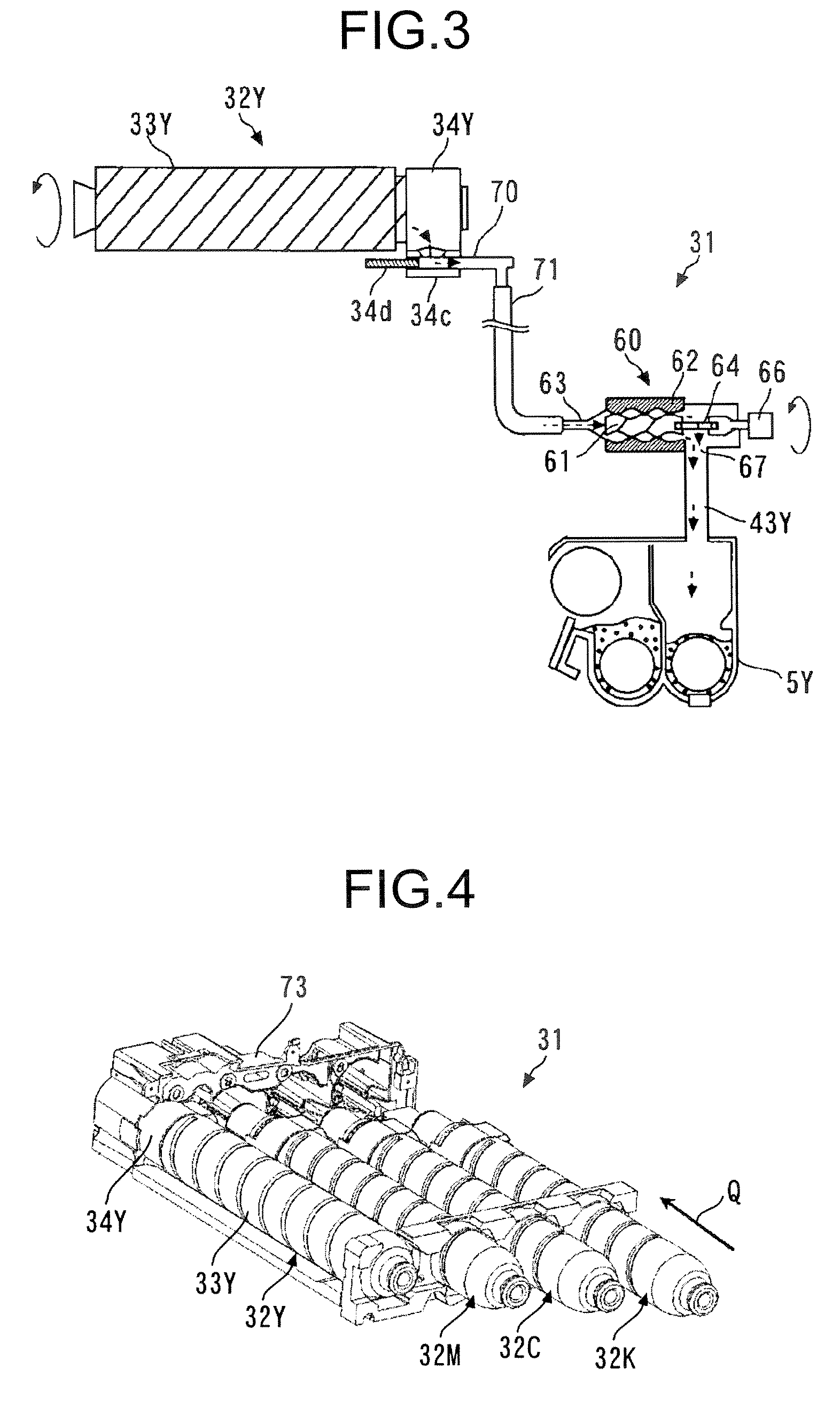

Toner container, and image forming apparatus

A toner container includes a container member with a spiral member therein that contains toner and conveys the toner toward an opening in conjunction with a rotation of the spiral member. A toner supply device includes a conveyor tube through which the toner discharged from the toner container is conveyed with gas, and a screw pump that sends gas into and evacuates gas from the conveyor tube.

Owner:RICOH KK

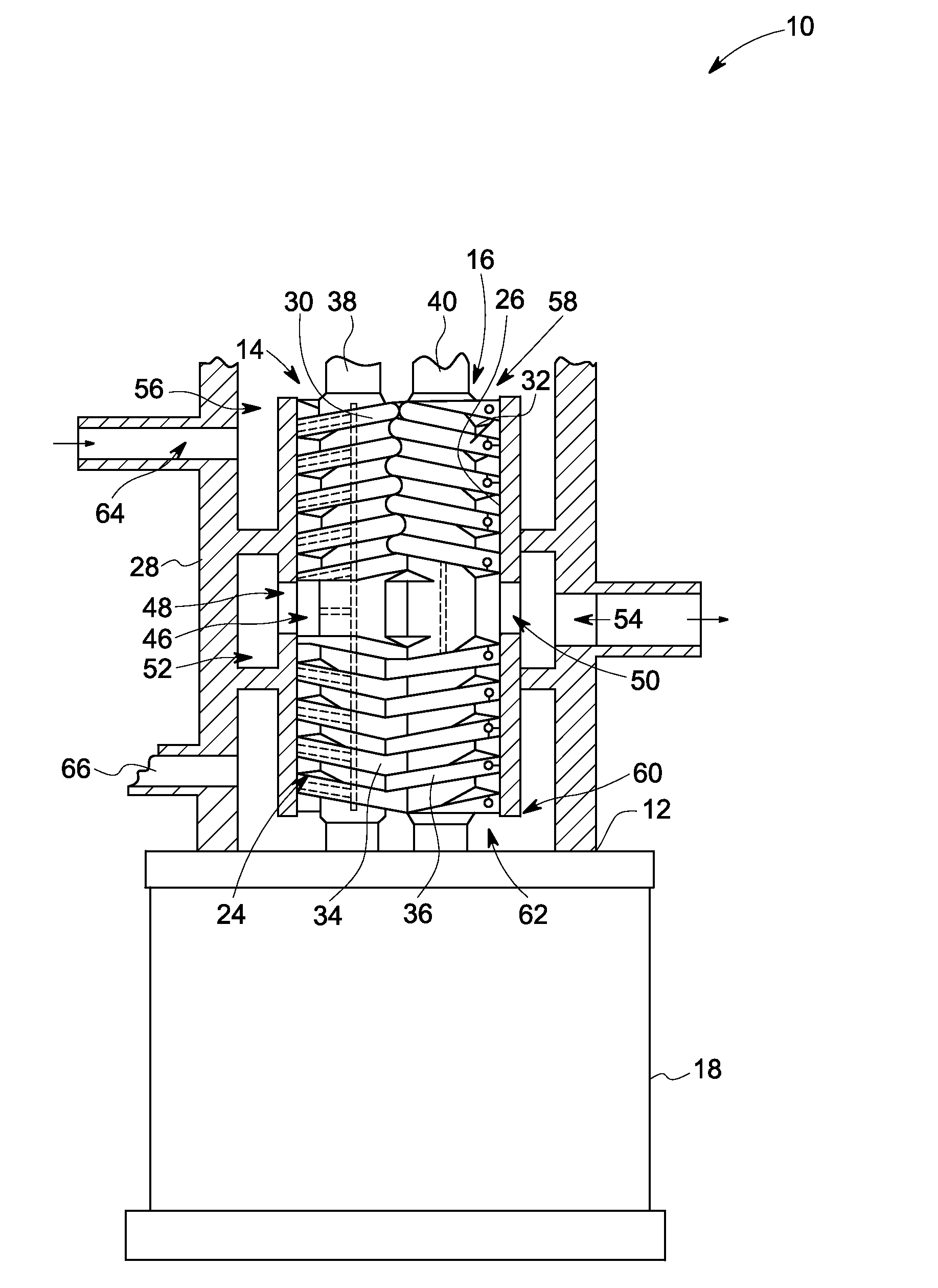

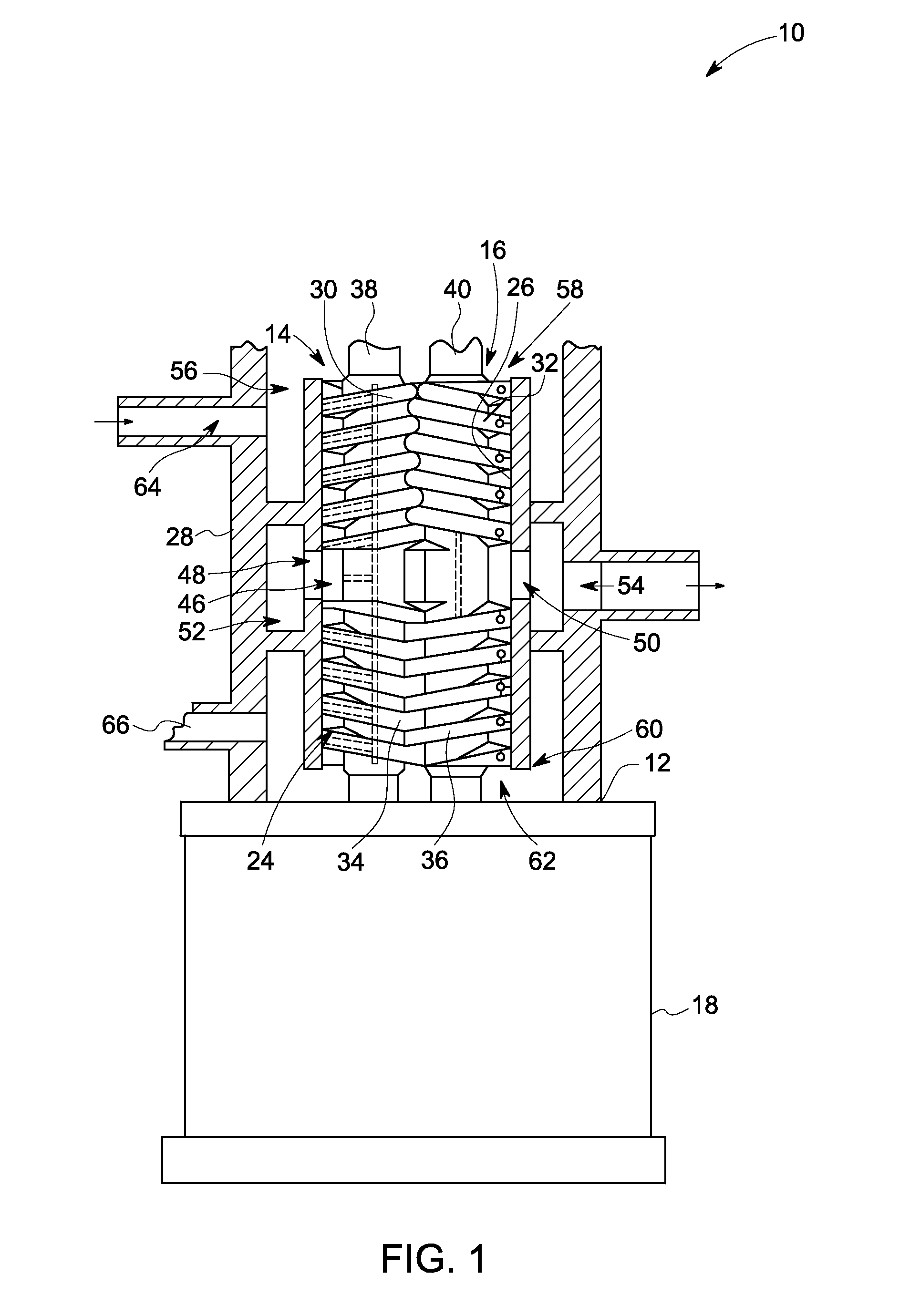

Multiphase screw pump

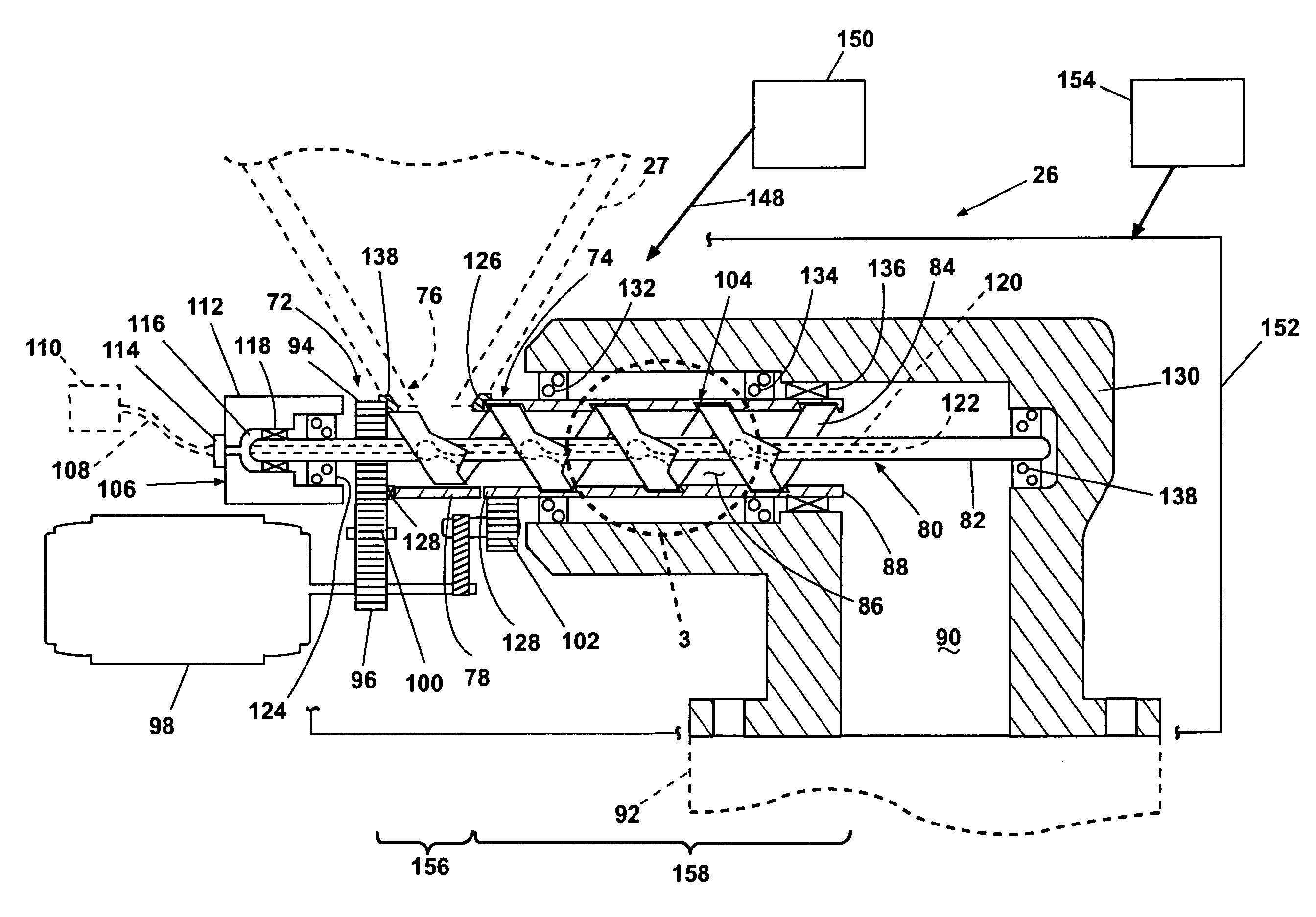

InactiveUS20090098003A1Engine of intermeshing engagement typeRotary piston pumpsLiquid mediumEngineering

A twin screw pump includes a pair of rotors disposed inside a casing having an inlet and an outlet. Each rotor includes a set of threads disposed on a portion of an outer surface of a shaft. A first bearing is coupled at a first end of the shaft and a second bearing is coupled at a second end of the shaft. The first and second bearings are not separated by one or more seals. The first and second bearings are configured for being lubricated by the liquid medium of the process fluid when the twin screw pump is in an operational mode.

Owner:GENERAL ELECTRIC CO

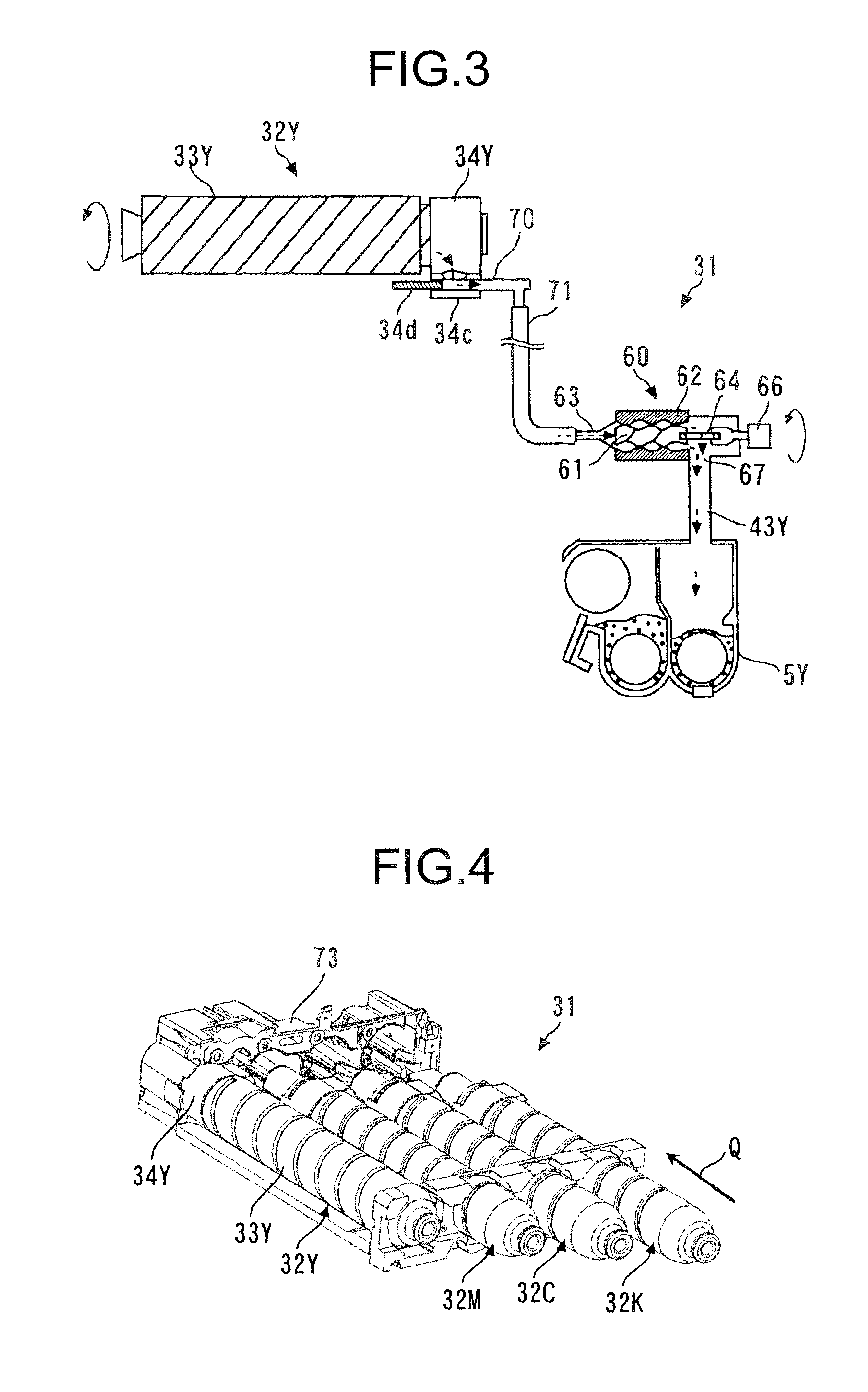

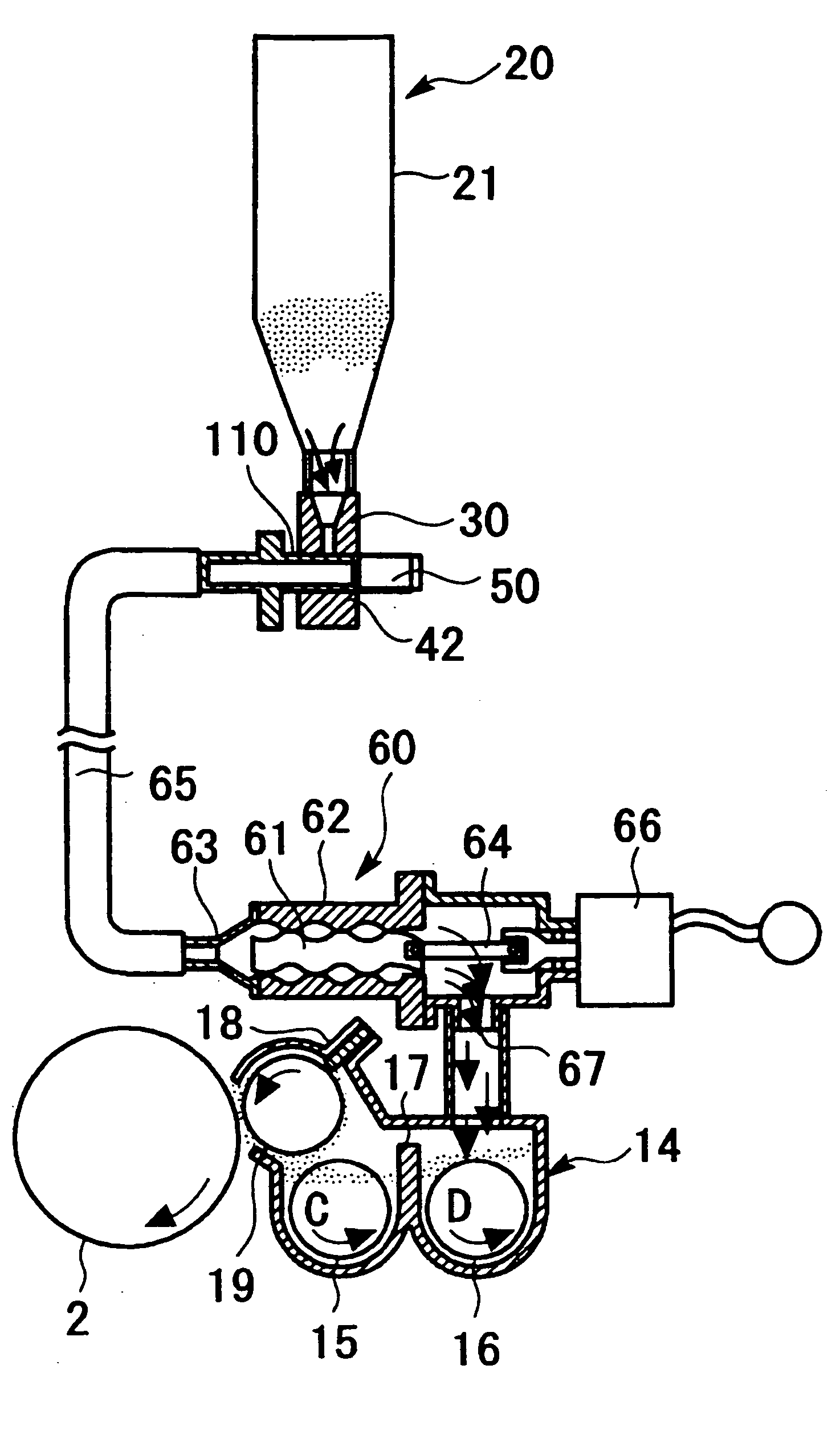

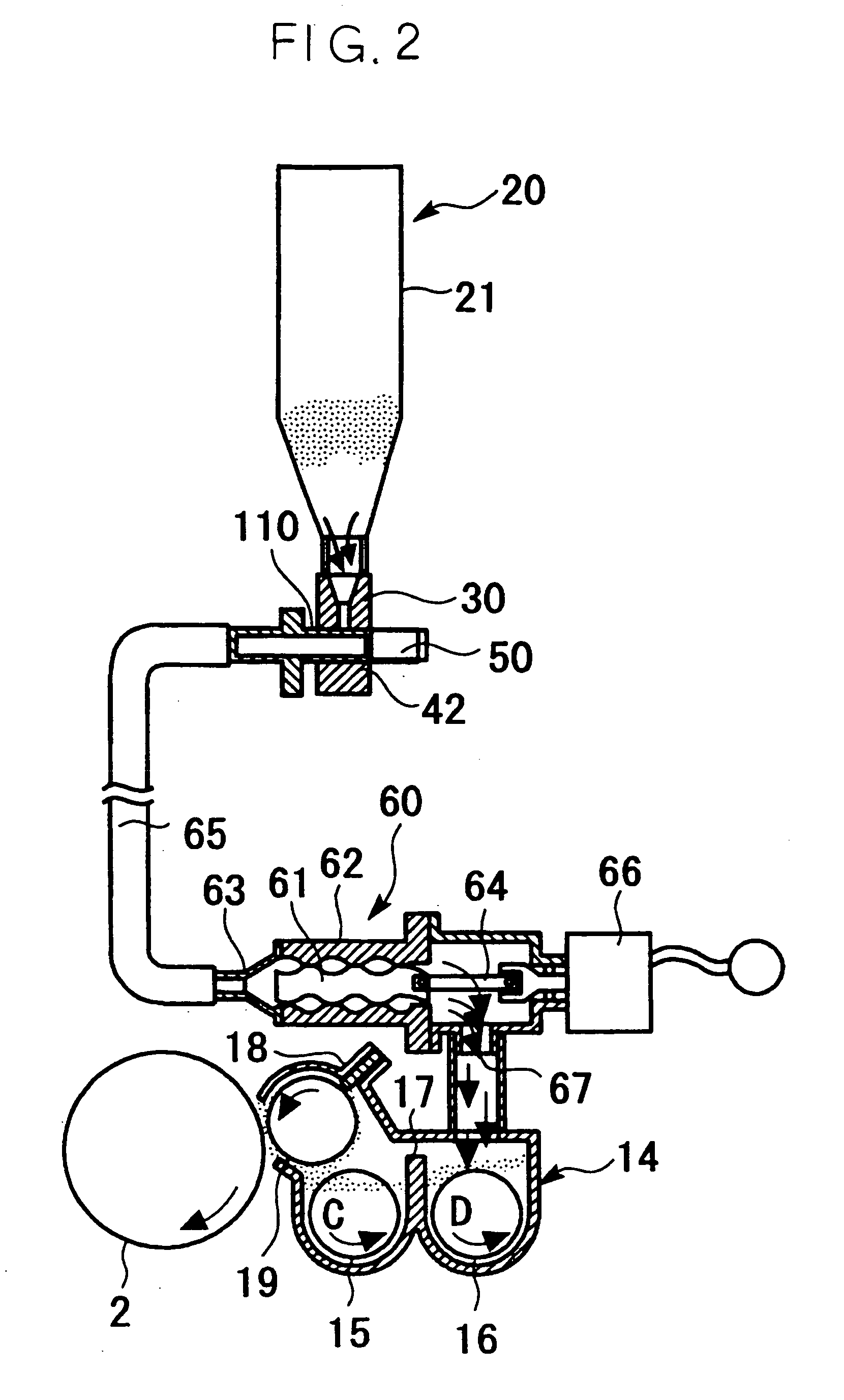

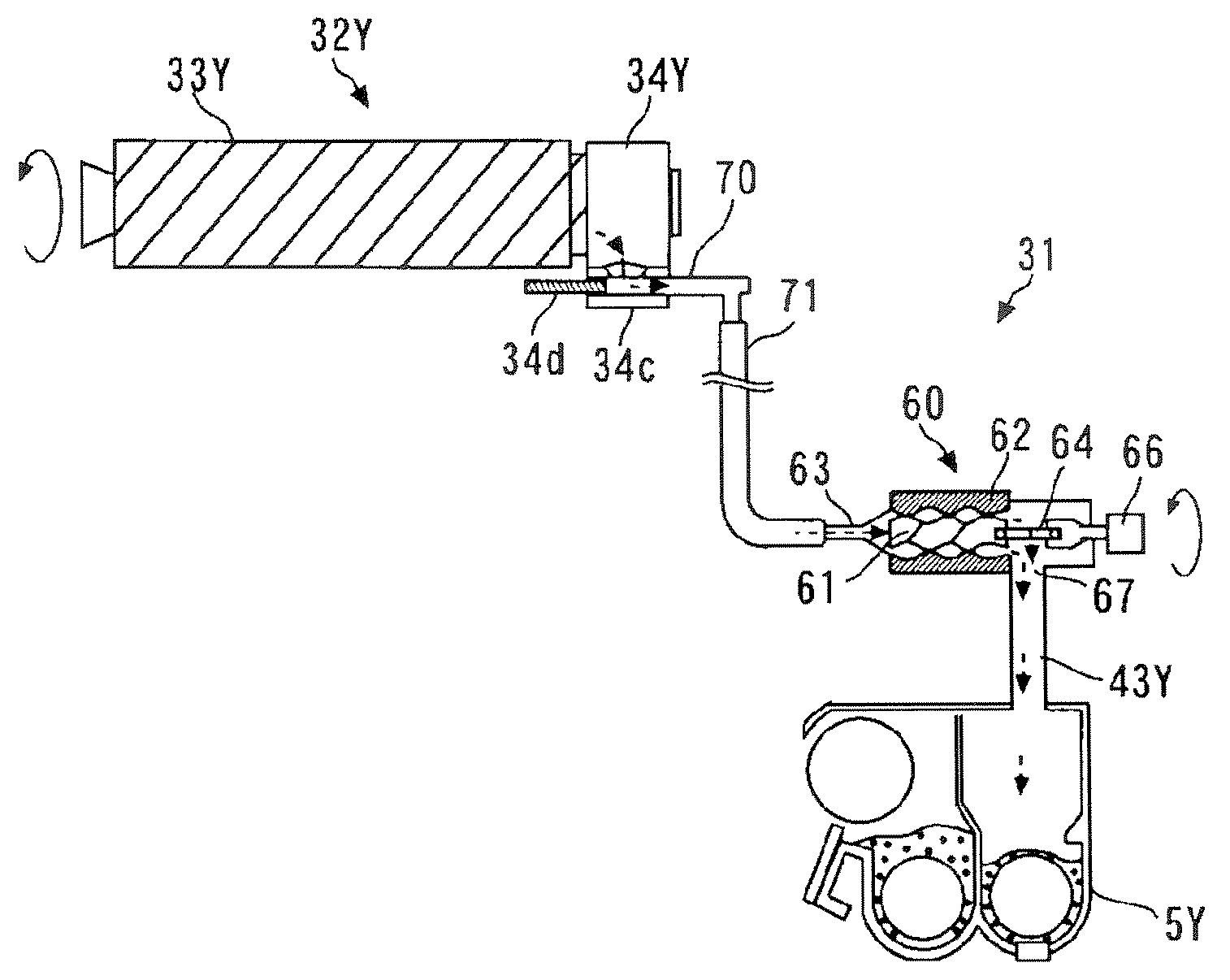

Toner replenishing device

InactiveUS20050025527A1Improve performancePowdered material dispensingElectrographic process apparatusEngineeringMaximum pressure

A toner replenishing device having a stable performance without causing variation of the toner suction pressure, even if the toner characteristics vary in a toner vessel in a volume-reducing type toner carrying device. In the toner replenishing device comprising a flexible toner storing vessel, a sucking means for arrying the toner in the toner storing vessel to a prescribed place by a negative pressure, and a substantially airtight toner carrying passage, the toner storing vessel being reduced in volume by sucking the toner, the sucking means is a single-shaft eccentric screw pump, whose operation time is longer than the time for generating a maximum pressure.

Owner:RICOH KK

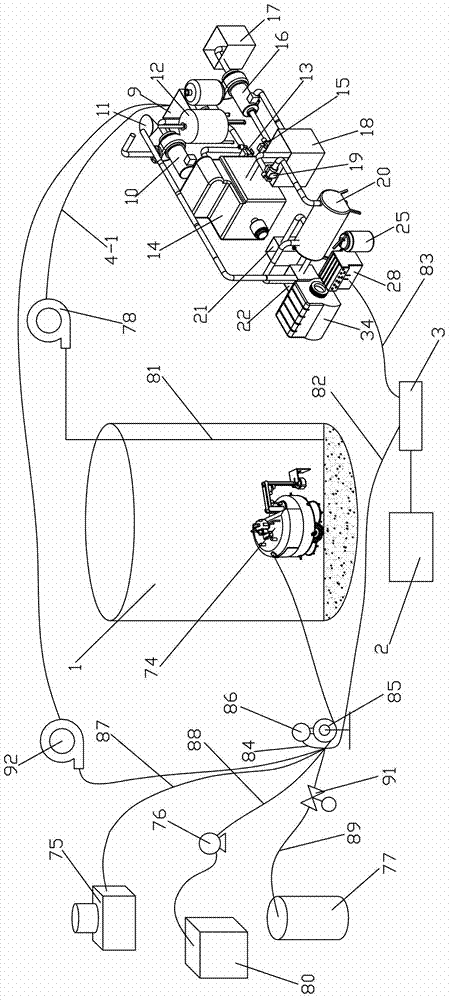

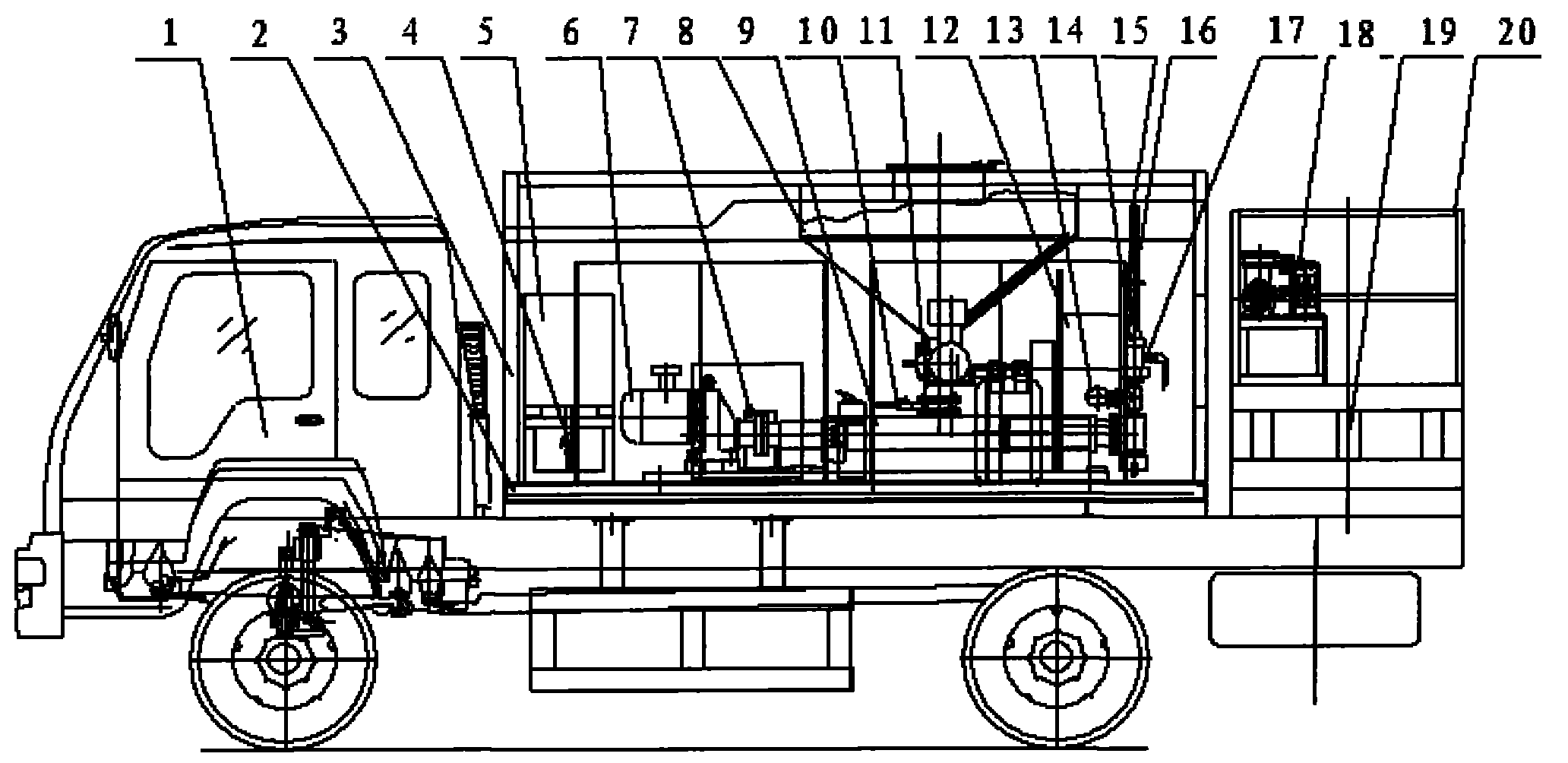

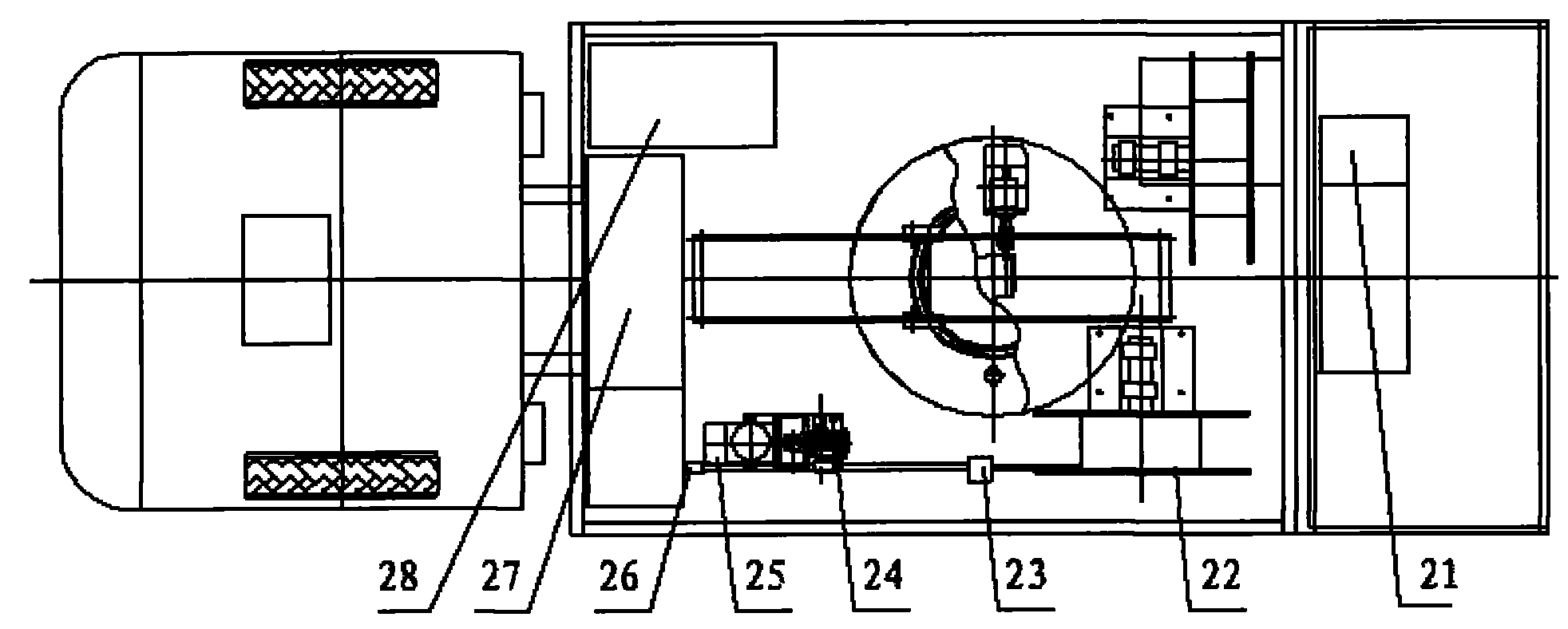

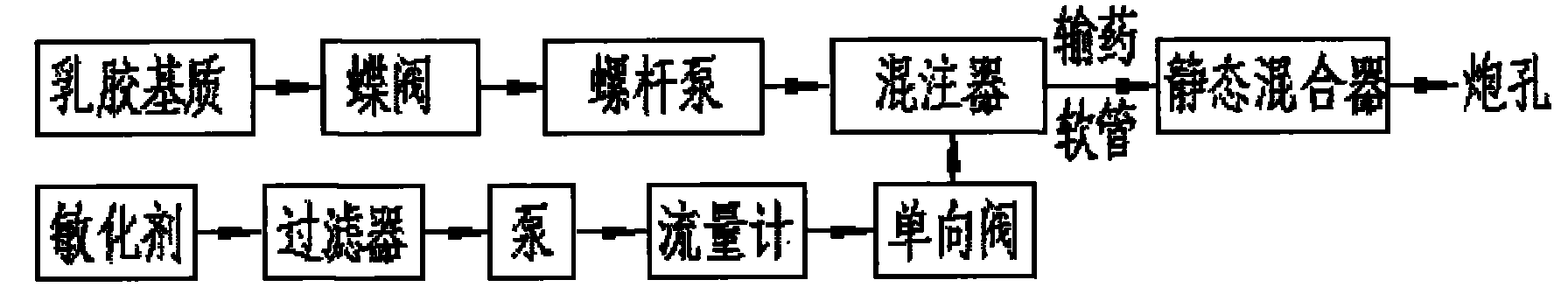

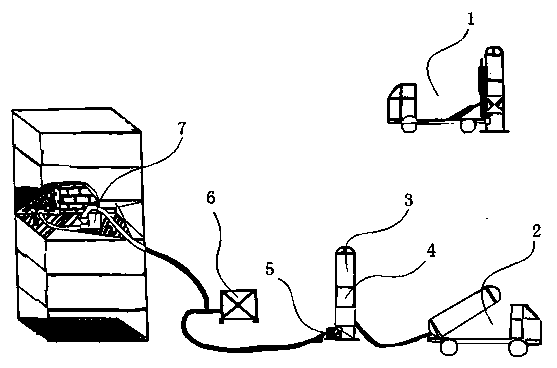

Underground in-situ emulsified explosive mixed charging vehicle

InactiveCN101968334AMeet the requirements of on-site mixingAccurate measurementBlastingVehicle frameEmulsion explosive

The invention discloses an underground in-situ emulsified explosive mixed charging vehicle, and relates to a device for underground tunneling and mining blast charging. The invention overcomes the problems that the manual charging has large labor intensity, low efficiency and poor operation safety, and a compressed explosive charger is easy to return powder and pollute the environment when charging granulose emulsion ammonium nitrate fuel oil explosive or powder ammonium nitrate explosive. The underground in-situ emulsified explosive mixed charging vehicle comprises an automobile chassis, and is characterized in that a secondary frame is installed on the front part of the automobile chassis, a lifting platform is installed on the rear part of the automobile chassis, an outer box assembly is installed on the secondary frame and internally provided with a sensitizing agent box, an emulsion matrix bin, a cleaning water tank, a screw pump, a power box and an electric cabinet. The underground in-situ emulsified explosive mixed charging vehicle is used for underground tunneling and mining blast charging, and has the advantages of simple structure, high efficiency, low cost, safety, reliability, free lifting and all-around charging.

Owner:SHANXI HUIFENG SPECIAL AUTOMOBILE

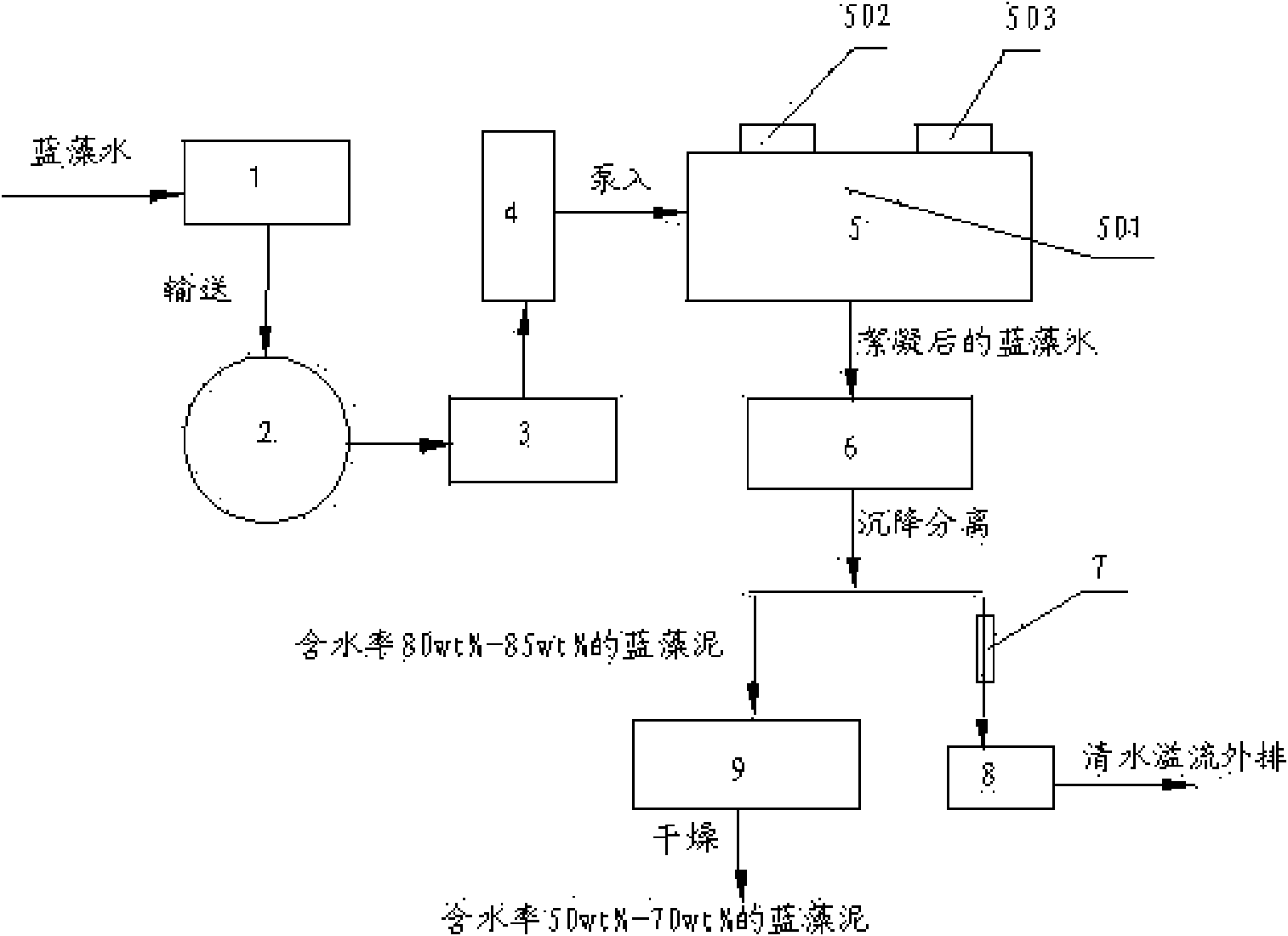

Method for controlling cyanobacteria bloom

InactiveCN101602533AImprove processing efficiencyIncreased efficiency of harvesting cyanobacteriaSludge treatment by de-watering/drying/thickeningWater cleaningPhylum CyanobacteriaResource utilization

The invention discloses a method for controlling cyanobacteria bloom, which belongs to the technical field of water pollution treatment. The method for controlling the cyanobacteria bloom comprises the steps of: (1) utilizing an acquisition system with a sucking disk to perform suction acquisition on cyanobacteria on the water surface of a water body; (2) pumping cyanobacteria water which is subjected to suction acquisition into a conveying pipeline through a suction pump, and conveying the cyanobacteria water to a storage tank; (3) pumping the cyanobacteria water in the storage tank into a dosing system through a screw pump, adding a flocculating agent into the cyanobacteria water, and mixing evenly to ensure that the cyanobacteria is flocculated; (4) sending the cyanobacteria water with the flocculated cyanobacteria into a settling separation system for solid-liquid separation to obtain water and cyanobacteria mud with the water content of 80 percent, sending the water obtained after the solid-liquid separation to a clear water tank for temporary storage through the settling separation system, and then draining the water into the water body through an overflow port; and (5) separating the obtained cyanobacteria mud to obtain cyanobacteria mud with the water content less than 70 percent after the drying. The method for controlling the cyanobacteria bloom has the advantages of environmental protection, low cost and convenient operation, and can realize the safe disposal and resource utilization of the cyanobacteria bloom.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

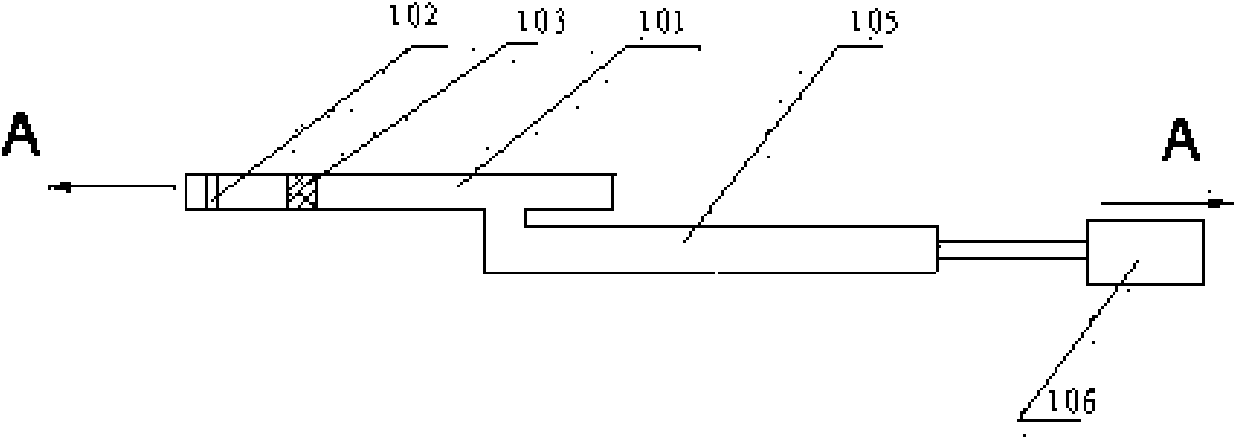

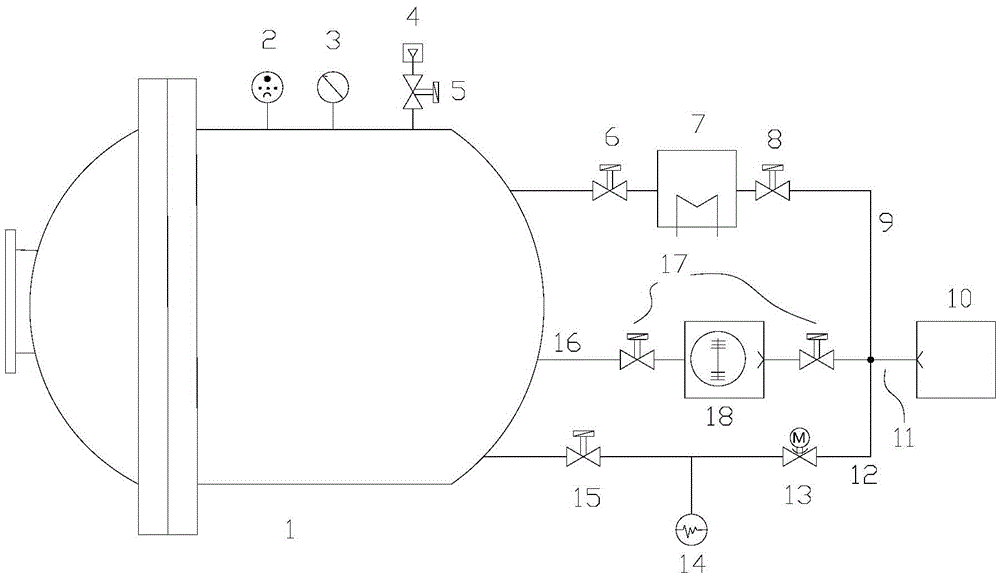

Comprehensive simulation experimental device of drilling circulation system

InactiveCN102787817ARealize closed-loop automatic controlSurveyFlushingData acquisitionAir compressor

The invention relates to a comprehensive simulation experimental device of a drilling circulation system. The comprehensive simulation experimental device of the drilling circulation system comprises a drilling liquid circulation loop, a rock debris circulation branch, an air injection branch and a data collection system. The drilling liquid circulation loop is formed by an annulus testing section, a Parshall flume, a vibration screen, a liquid storage pool and a frequency changing pump. The rock debris circulation branch is formed by sequentially connecting an air propeller, a rock debris collection tank, a packing tank and a screw pump through pipelines, wherein the air propeller is arranged on the vibration screen, and the screw pump is connected to the position of an inlet of the annulus testing section through a pipeline. The air injection branch is formed by connecting an air storage tank and an air compressor through a pipeline, wherein the compressor is connected with a tee joint through a pipeline. By means of the comprehensive simulation experimental device of the drilling circulation system, the migration rule of annulus rock debris under different hole drift angles can be observed, and radial concentration of the annulus rock debris under different hole drift angles and grain composition of the annulus rock debris in different river basins can be quantitatively measured.

Owner:NORTHEAST GASOLINEEUM UNIV

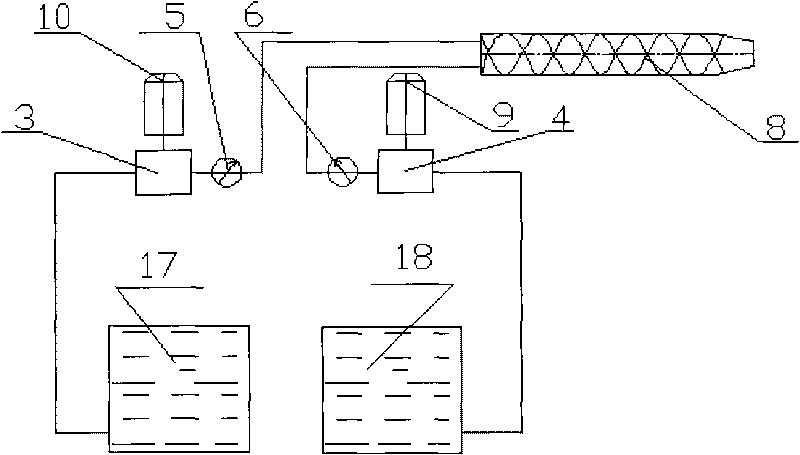

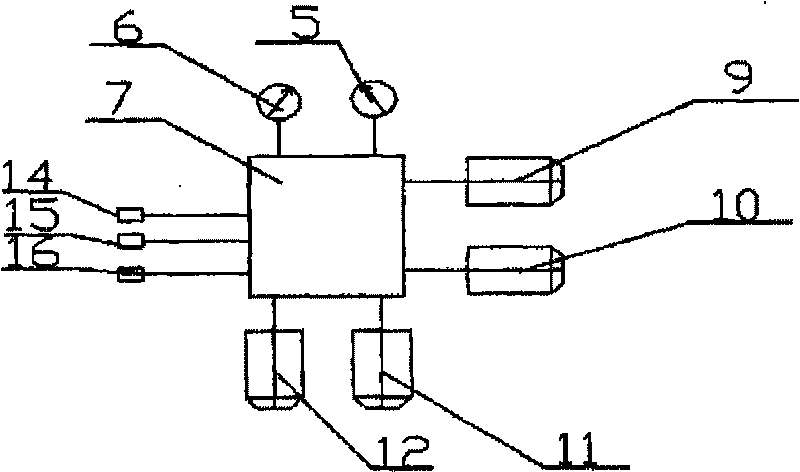

Bi-component rubber-mixing machine and closed-loop control method for rubber mixing thereof

ActiveCN101693175AFit evenlyGuaranteed pure useFlow mixersMixer accessoriesElectrical controlClosed loop

The invention relates to a bi-component rubber-mixing machine and a closed-loop control method for rubber mixing thereof. The bi-component rubber-mixing machine comprises a raw material barrel for filling rubber, a raw material barrel for filling a curing agent, an electrical control cabinet and a rubber-mixing pipe. The bi-component rubber-mixing machine is characterized by comprising two sets of primary booster pump groups, two secondary adjustable quantitative delivery pumps, a flow meter and a controller, wherein the two sets of primary booster pump groups are respectively connected with the rubber raw material barrel and the curing agent raw material barrel in a matching mode; the flow meter is used for monitoring the delivery pumps and sending signals to the controller; and the controller is used for collecting the signals sent by the flow meter, sending the signals to a frequency modulation motor of a secondary pump and feeding the signals back for controlling the rotary speed of the secondary pump. Finally, rubber is mixed statically through a rubber-mixing pipe. With simple structure, the bi-component rubber-mixing machine is easy to operate and runs closely in a pipeline without polluting the environment. The controller is used for receiving the signals sent by the flow meter and feeding the signals back for controlling the rotary speed of the delivery pumps and a bolt pump so as to control the error range of the mixing rate of the rubber to the curing agent to be smaller than plus / minus 0.5 percent and meet the rubber-mixing requirement for accurate rate control. The invention can ensure the purified use of the rubber and the curing agent and is beneficial to popularization and application.

Owner:SINOMATECH WIND POWER BLADE +1

Toner replenishing device with timing control of toner replenishing device

InactiveUS7043179B2Improve performancePowdered material dispensingElectrographic process apparatusMaximum pressureRunning time

A toner replenishing device having a stable performance without causing variation of the toner suction pressure, even if the toner characteristics vary in a toner vessel in a volume-reducing type toner carrying device. In the toner replenishing device comprising a flexible toner storing vessel, a sucking means for arrying the toner in the toner storing vessel to a prescribed place by a negative pressure, and a substantially airtight toner carrying passage, the toner storing vessel being reduced in volume by sucking the toner, the sucking means is a single-shaft eccentric screw pump, whose operation time is longer than the time for generating a maximum pressure.

Owner:RICOH KK

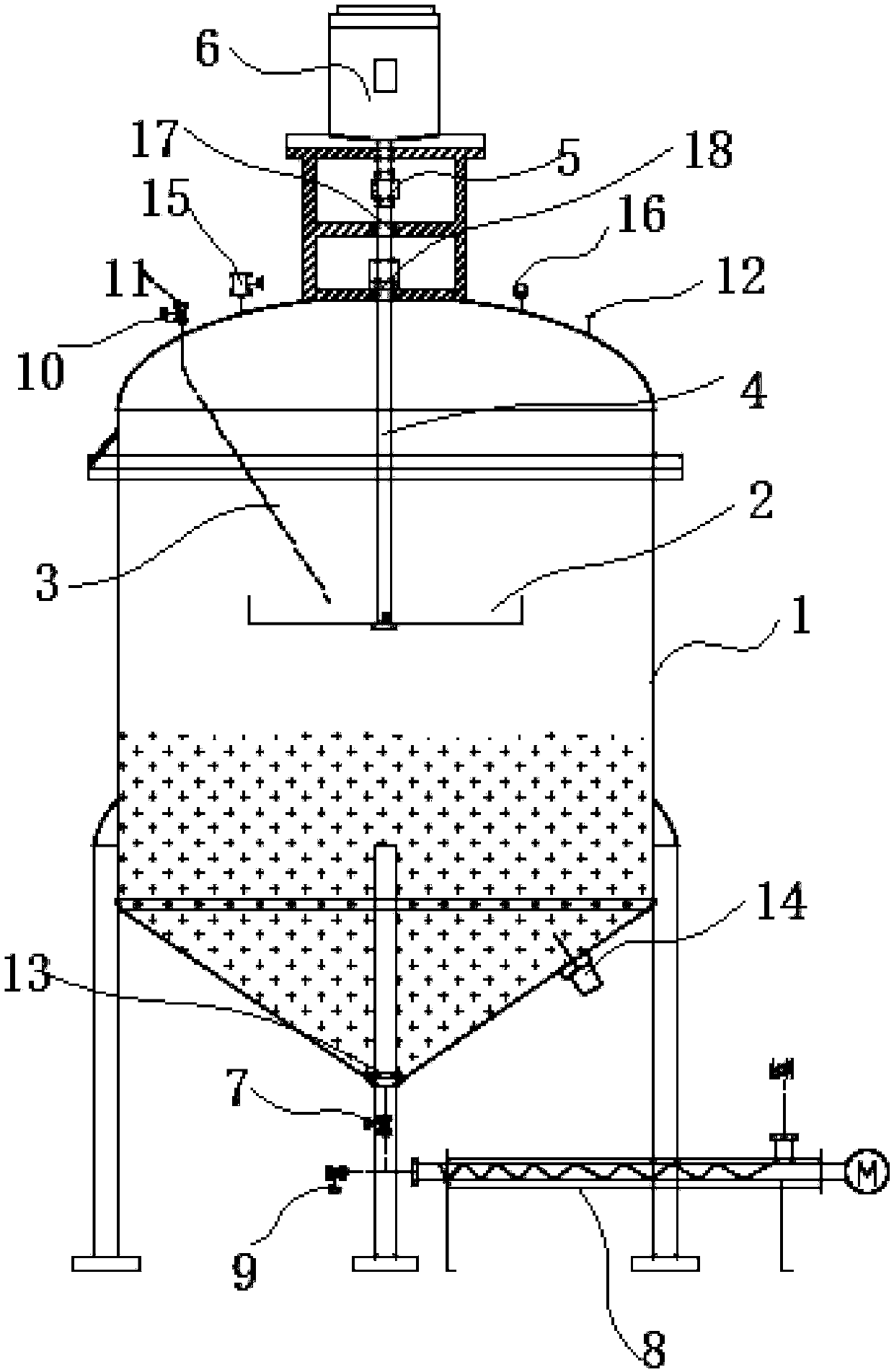

An on-line vacuum deaeration device

An on-line vacuum deaeration device is disclosed. The device includes a tank body. The tank body is provided with a material feeding port and a vacuumizing port for generating a vacuum in the tank body. A dispersing disk is in the tank body. The material feeding port is connected to the dispersing disk through a guide tube. The dispersing disk is fixedly connected to a main shaft. The main shaft is connected to a rotating shaft of a motor through a coupler, and is driven to rotate by the motor. A material discharging port is formed in the bottom of the tank body, and is provided with a material discharging valve. The material discharging valve is communicated with a screw pump. When the device is working, a material is fed through the material feeding port, and is conveyed to the dispersing disk through the guide tube, the dispersing disk is driven to rotate at a high speed by motor rotation to generate large centrifugal force so that the material is tossed out from the dispersing diskand strikes an inner drum wall, a film layer is formed at the moment that the material is tossed out, air bubbles are broken by virtue of the vacuum generated by the vacuumizing port so as to performdeaeration, and finally the material flows along the inner drum wall down to the bottom of the tank body.

Owner:DONGGUAN LONGLY MACHINERY

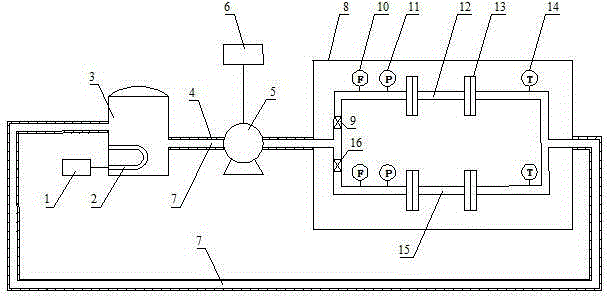

Apparatus and method for dynamic simulation of petroleum pipe scaling and wax precipitation

InactiveCN105277659AReduced over-pump shear strengthReduce distractionsWeighing by absorbing componentWater bathsLiquid storage tank

The present invention provides an experimental apparatus and a method for petroleum pipe scaling and wax precipitation, the apparatus comprises a liquid storage tank, a variable frequency motor, a screw pump, a constant temperature water bath tank, a first test tube, a second test tube, a cover plate and a lacing film test sample. The liquid storage tank is used for containing oil water needed for the experiment, and is connected with a temperature control system and a heater to ensure oil water temperature is constant at a preset value; a predetermined flow rate of oil output can be achieved by the variable frequency motor and the screw pump, the constant temperature water bath tank is used for simulation of test tube section wall temperature to study changing laws and mechanisms of sediment characteristics along with pipe wall temperature differences; the first test tube is a full size pipe segment, and is used for fully simulating pipe scaling and wax precipitation, and the second test tube is a pipe segment with an opening, and is used for study on the laws and mechanisms of the sediment characteristics along with time. The experimental apparatus and method can provide new methods and supports for research and development and evaluation of measures scaling and wax removal and prevention, and can ensure the petroleum pipe safe, economic and efficient operation.

Owner:SOUTHWEST PETROLEUM UNIV

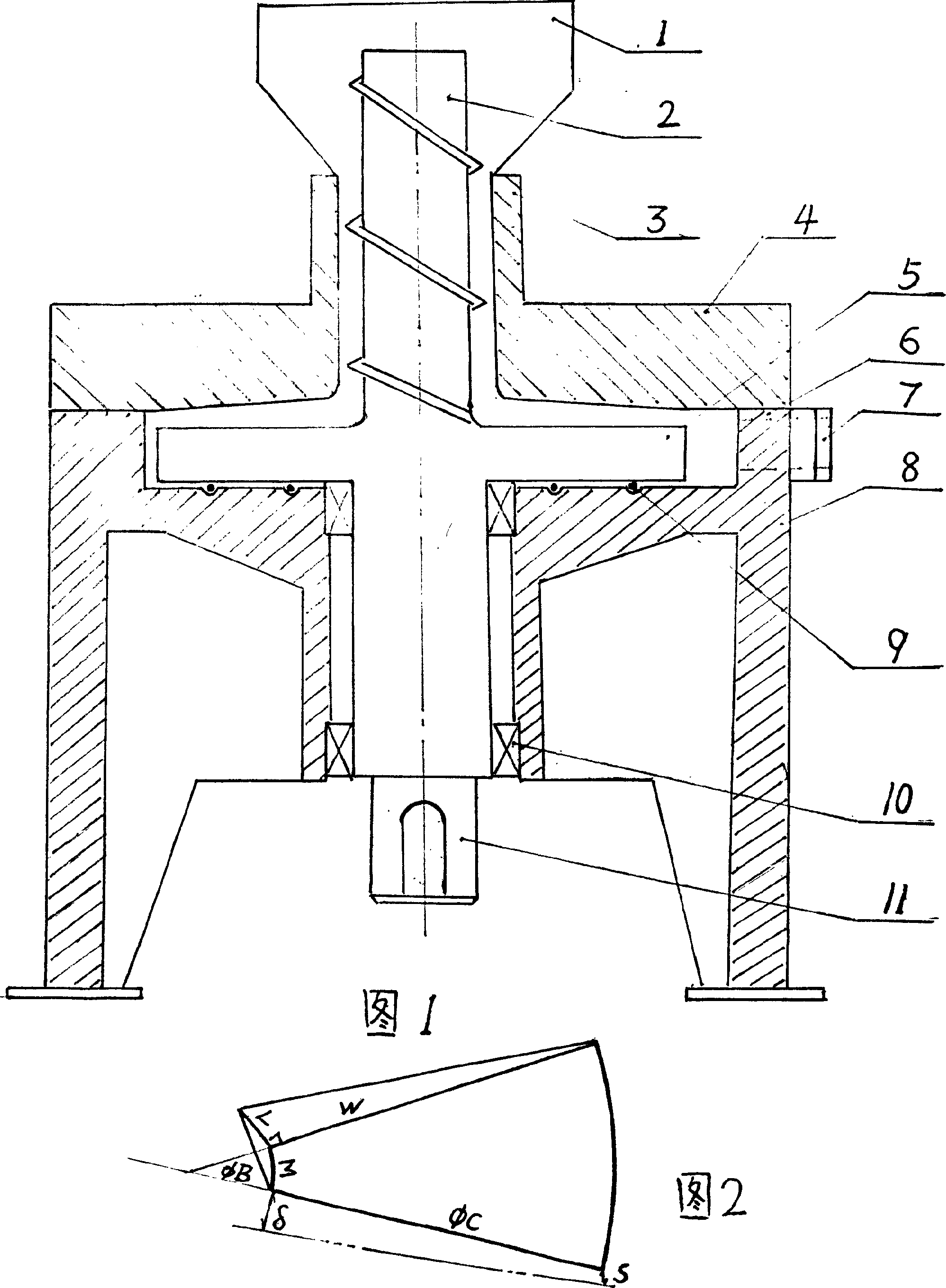

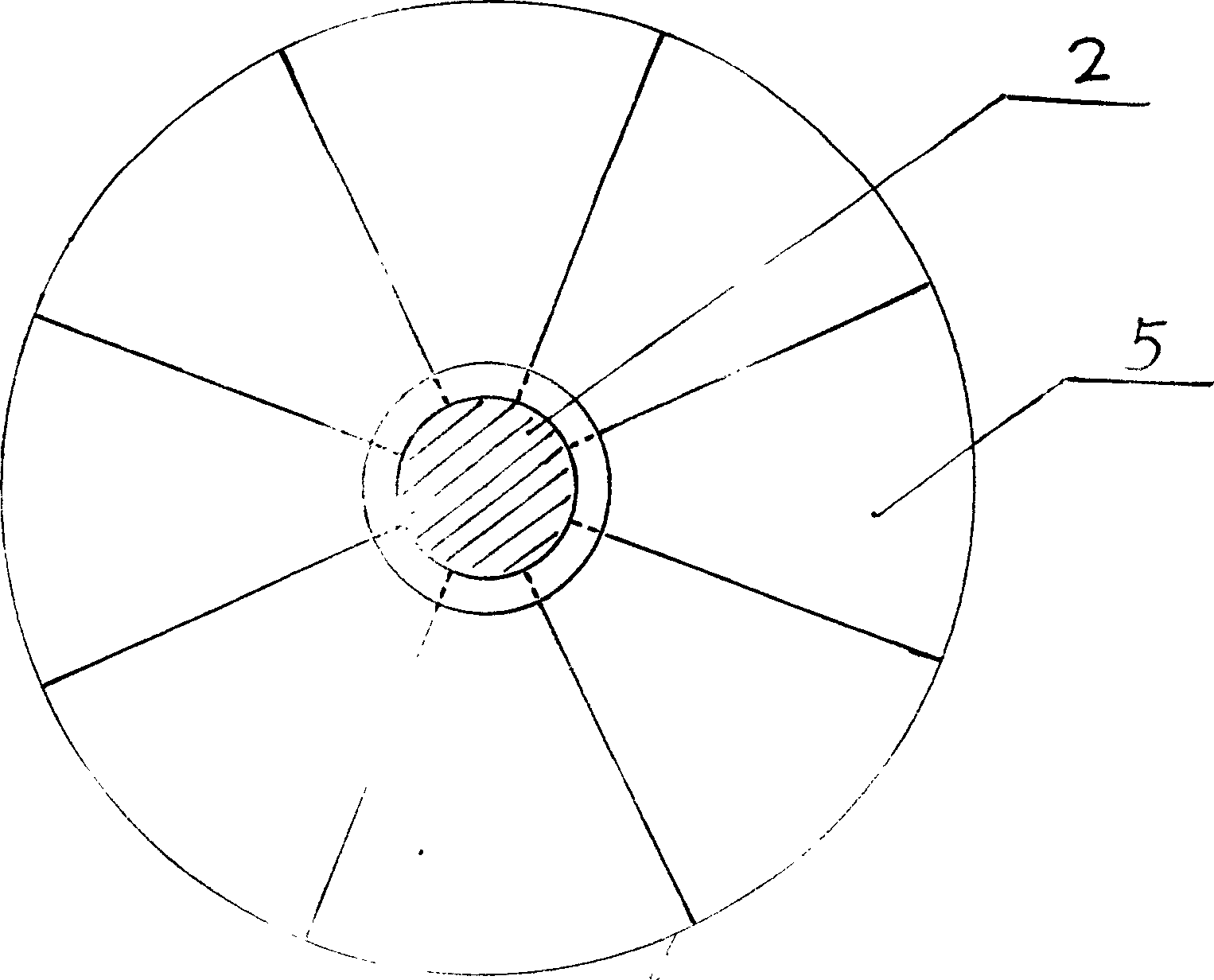

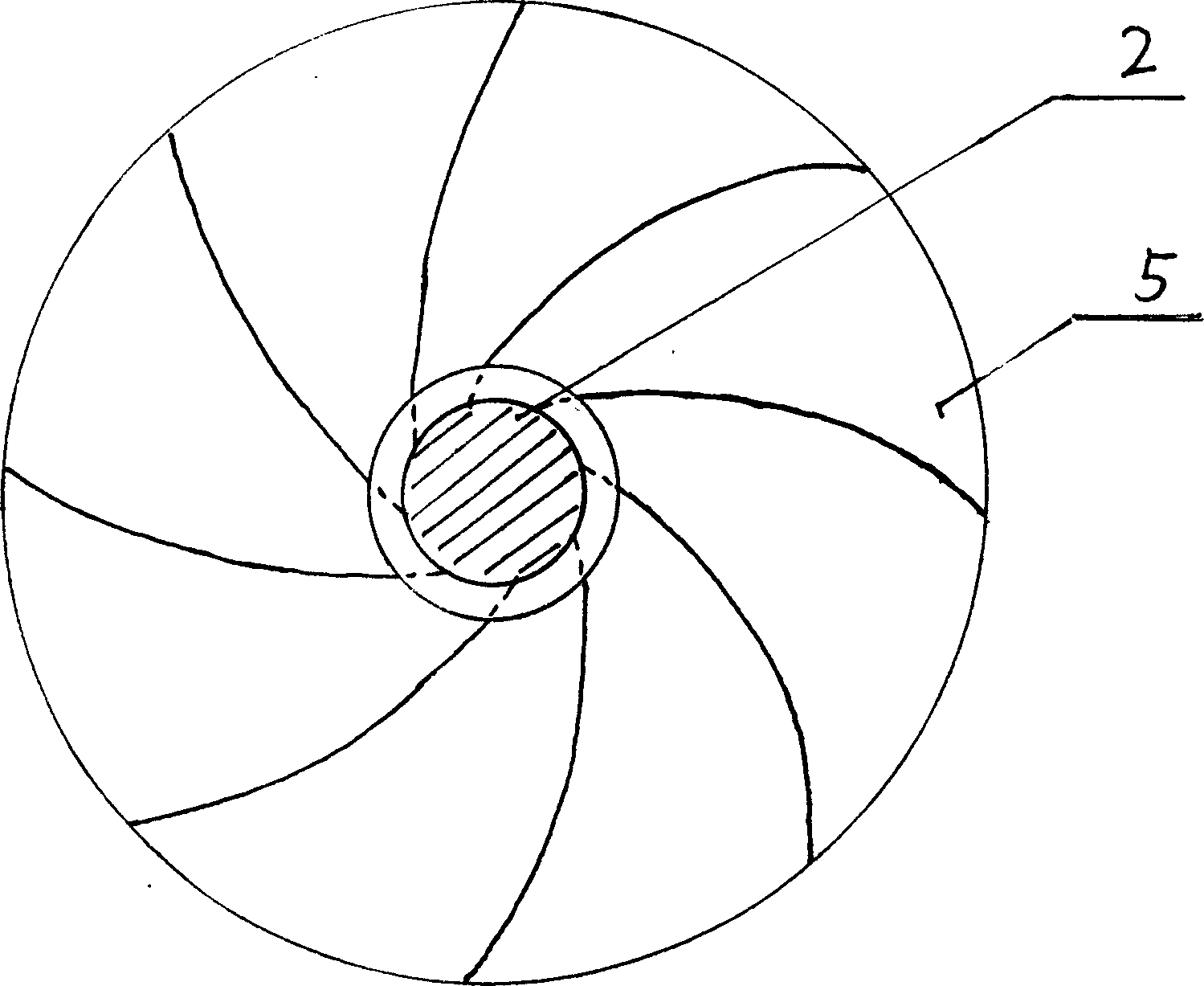

Ginding disc type high-speed extruder

A slotted disk type high-speed extruder is composed of the solid delivering segment consisting of material feeding hopper and screw pump, the material calendering-smelting segment with slotted grinding disk structure, the molten material gathering-delivering segment with volute pump, moulding head, machine frame, and motor. Its advantage is high smelting and extruding speed.

Owner:张军

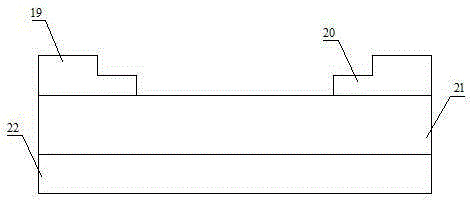

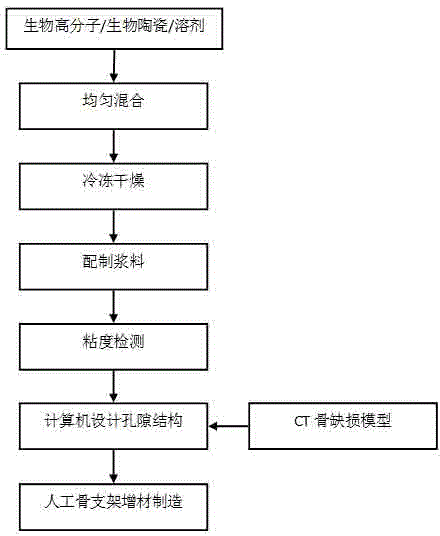

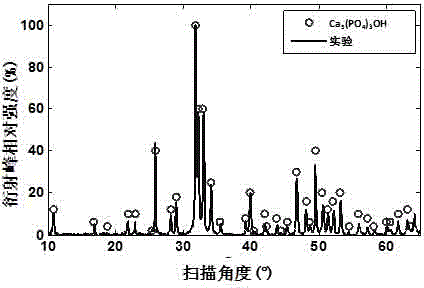

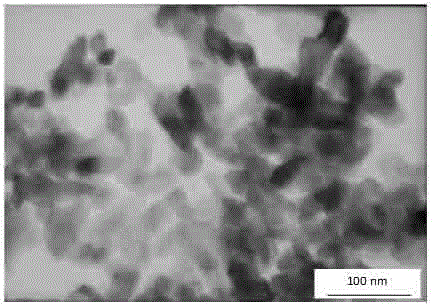

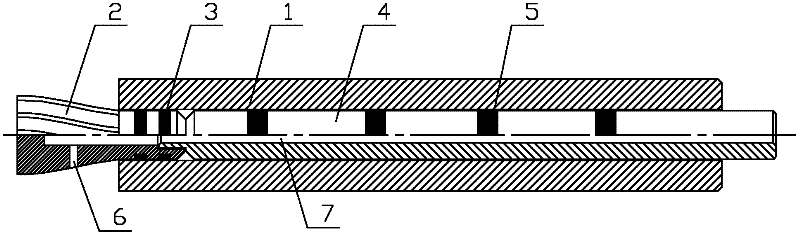

Material increase manufacturing method of multi-scale biomimetic artificial bone support

ActiveCN104826171AReduce the cost of clinical applicationMeet lifelong growth requirementsProsthesisPorosityAutologous tissue

The invention discloses a material increase manufacturing method of a multi-scale biomimetic artificial bone support. The material increase manufacturing method comprises blending a biopolymer material and a bioceramic material, blending the mixture and deionized water or an organic solvent to obtain uniform slurry, carrying out freeze drying to obtain uniform powder, blending the uniform powder and deionized water or an organic solvent, carrying out vacuum exhaust, carrying out quantitative extrusion by a screw pump, by a XYZ motion device, designing internal aperture shapes, sizes and porosity of a geometric model by computer program according to a bone defect 3D geometric model obtained by CT scanning, and carrying out material increase manufacture under control of an extruded material motion locus. Through use of a degradable biological compound material, human autologous tissue finally replaces bone defect positions so that human lifelong growth requirements are satisfied. The needed biomaterial is quantificationally extruded by the screw pump so that use amount can be accurately controlled and an artificial bone clinical application cost is substantially reduced. The material increase manufacturing method has the advantages of accurate printing material use amount, wide material application range, accurate and controllable aperture structure, and free formation of a macroscopic geometric shape.

Owner:西安点云生物科技有限公司

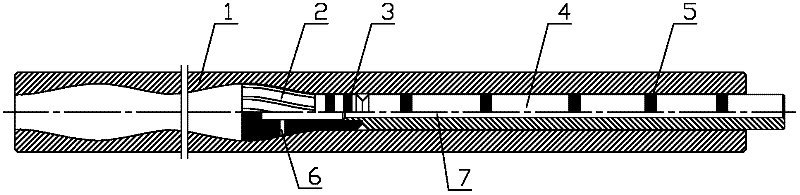

Method for machining all-metal screw pump stator

InactiveCN102501016ASolve processing difficultiesReduce processing difficultyElectrochemical machining apparatusHydroformingScrew pump

The invention discloses a method for machining an all-metal screw pump stator. The method comprises the following steps of: 1) machining a stator blank, so that a central hole for forming a stator inner cavity is formed in the stator blank; 2) forming the stator inner cavity by an electrolytic process; 3) polishing the stator inner cavity; and 4) performing surface-hardening treatment on the stator inner cavity. According to the method, the problem of difficulty in machining of the all-metal screw pump stator is solved by combining polishing treatment and surface-hardening treatment by adopting the electrolytic process. The method has obvious advantages on the machining of materials which are difficult to machine and parts with complex shapes or thin-wall parts, and has the characteristics of wide range of the machined materials, high production efficiency, high forming accuracy, capability of recycling electrode assemblies and the like. By the method, the technical blockade of hydraulically-formed all-metal screw pump stators which are used abroad is broken through, and a new method for manufacturing the all-metal screw pump stator is opened up, so that the machining difficulty of the all-metal screw pump stator is reduced effectively, and the machining efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

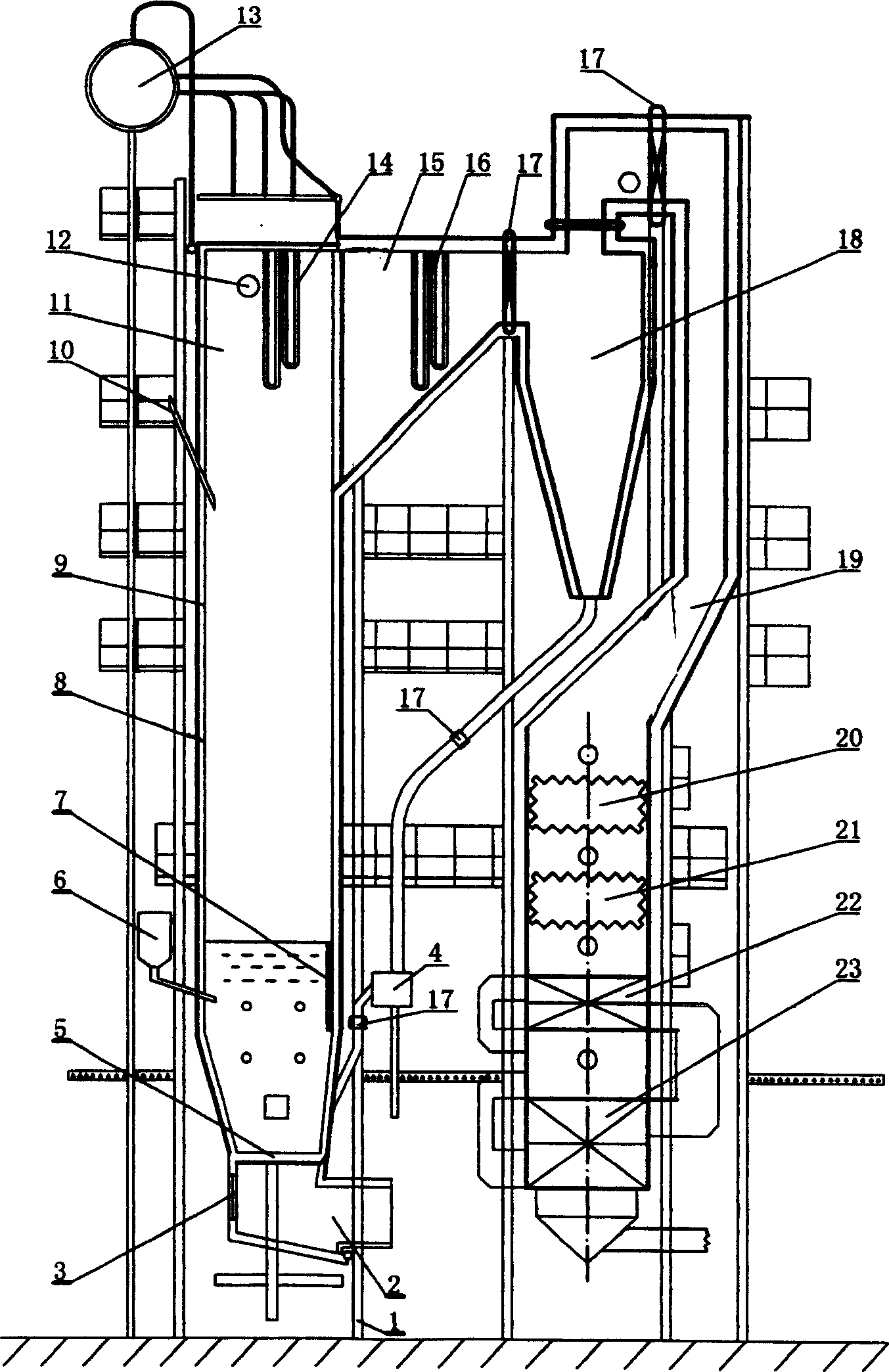

Oil field steam filling boiler of circulation fluidized bed using water coal slurry as fuel

InactiveCN1563793ACurb emissionsRealize direct desulfurizationFluidized bed combustionApparatus for fluidised bed combustionWear resistantEngineering

The oil well gas injecting boiler has screw pump in pressure of 0.2-0.4 MPa to supply fuel from the upper part of the boiler, single steam drum in naturally circulating mode to obtain high pressure steam of 17.5-21 MPa; quartzite and limestone powder as fuidizing medium for low multiplying factor circulation; and power amount of limestone powder for clean burning at temperature of 850-950 deg.c. The boiler of the present invention has water cooling furnace wall, coated heat resistant and corrosion resistant refractory material and sprayed heat resistant and wear resistant Ni-Cr alloy, pipe type backwards bent boiler top, coal economizer of ribbed spiral pipes, cyclonic separator with wear resistant material, water cooling wall with inner thread pipe, high temp alloy steel material in high temperature and high pressure sections, welded support frame structure, flexible 3D expanding section in important joint part, and hydrostats.

Owner:SHENYANG DAVID ENVIRONMENT PROTECTION & ENERGY SAVING EQUIP LTD

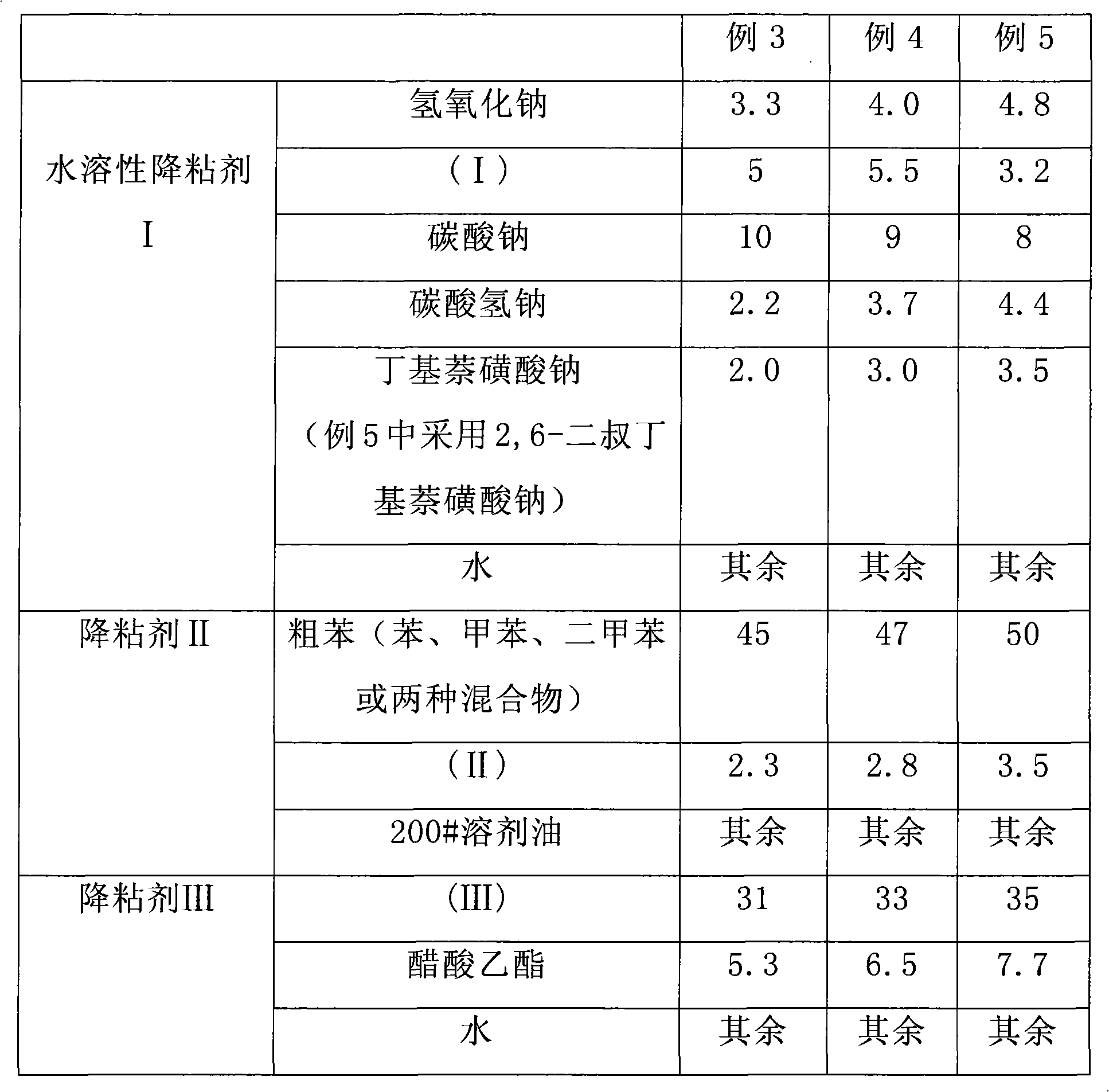

Method for extracting thick oil

ActiveCN101328798AImprove liquiditySolve the problem of difficult flow into the wellboreFluid removalDrilling compositionOil productionScrew pump

The invention provides a heavy oil cold production method applied to the production of oilfield heavy oil reservoirs at normal temperature and pressure. The method is characterized by comprising: a. a step of preparing water-soluble viscosity reducer I; b. a step of preparing viscosity reducer II; c. a step of preparing viscosity reducer III; d. a step of squeezing the water-soluble viscosity reducer I into oil reservoirs; and e. a step of using an oil pumping unit or screw pump lifting equipment to lift produced well fluid and adding the pitshaft viscosity reducer II or the pitshaft viscosity reducer III from an annular space between an oil pipe and an casing pipe of an oil well according to the different viscosity of produced fluid crude oil. The method has the advantages that: a chemical method is adopted to reduce the viscosity of heavy oil in the oil reservoirs and well fluid inside pitshafts, so as to improve heavy oil production effect; and the method has the continuous production time of the oil wells far more than that of the production methods in the prior art, greatly reduces production operation cost, and is obviously superior to the prior heavy oil production technology.

Owner:PETROCHINA CO LTD

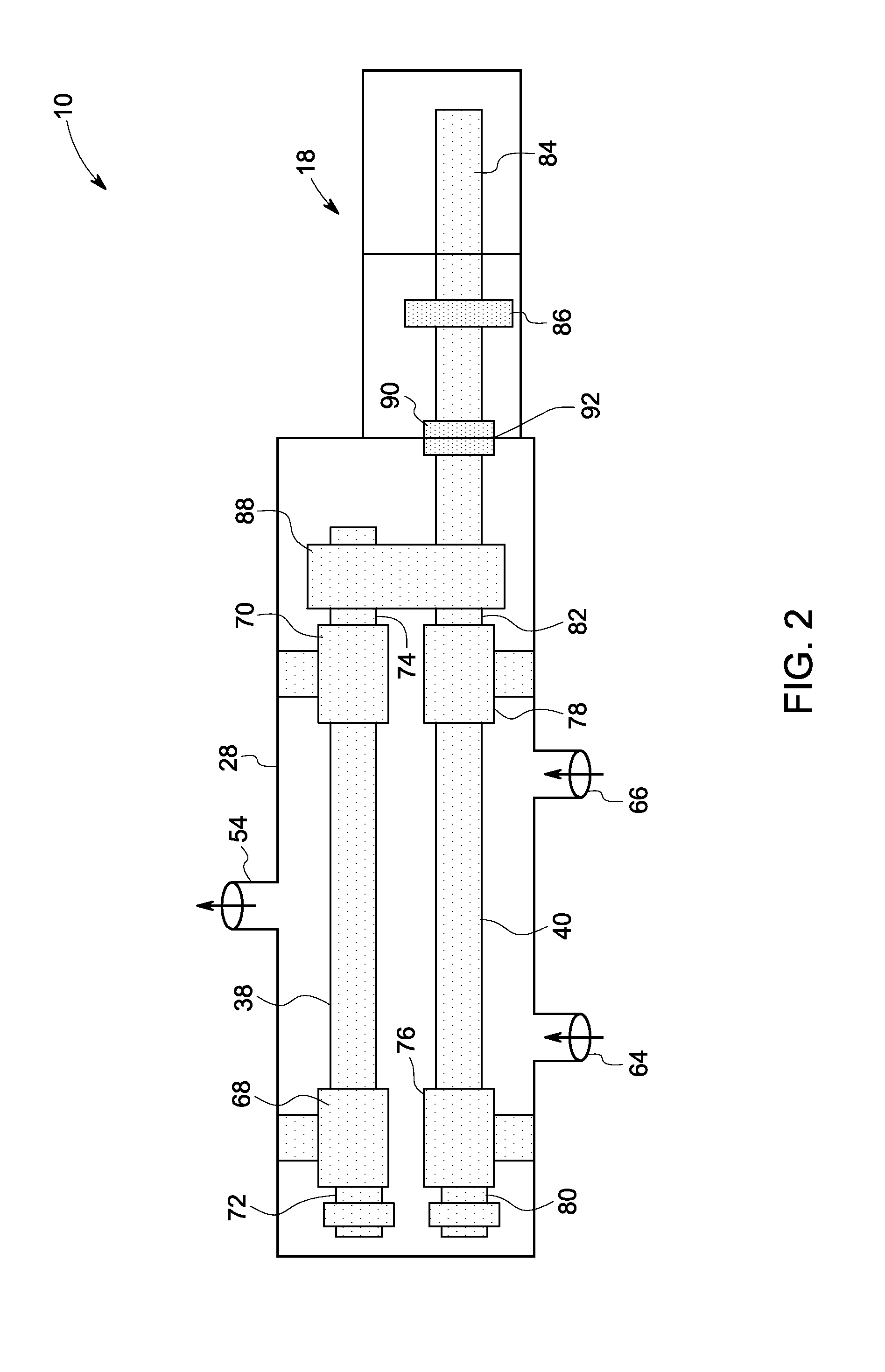

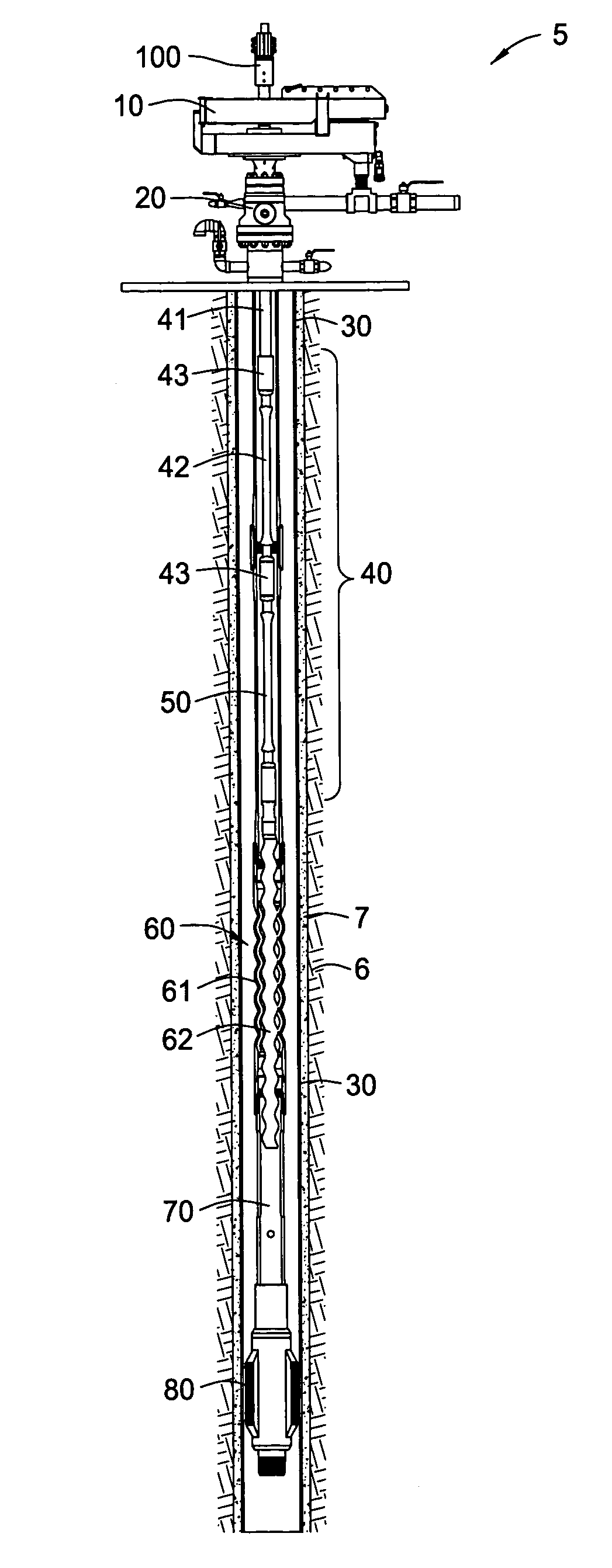

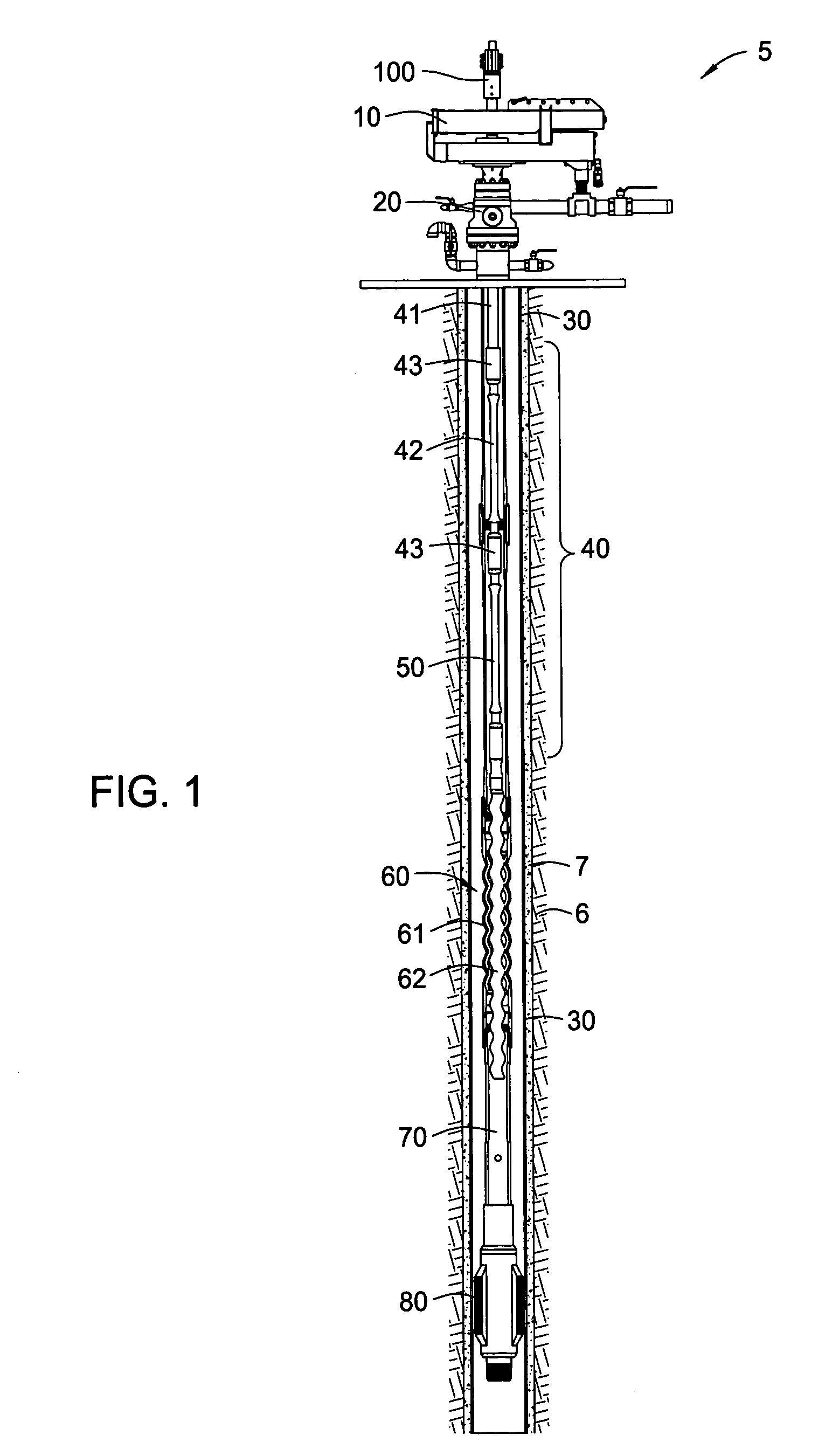

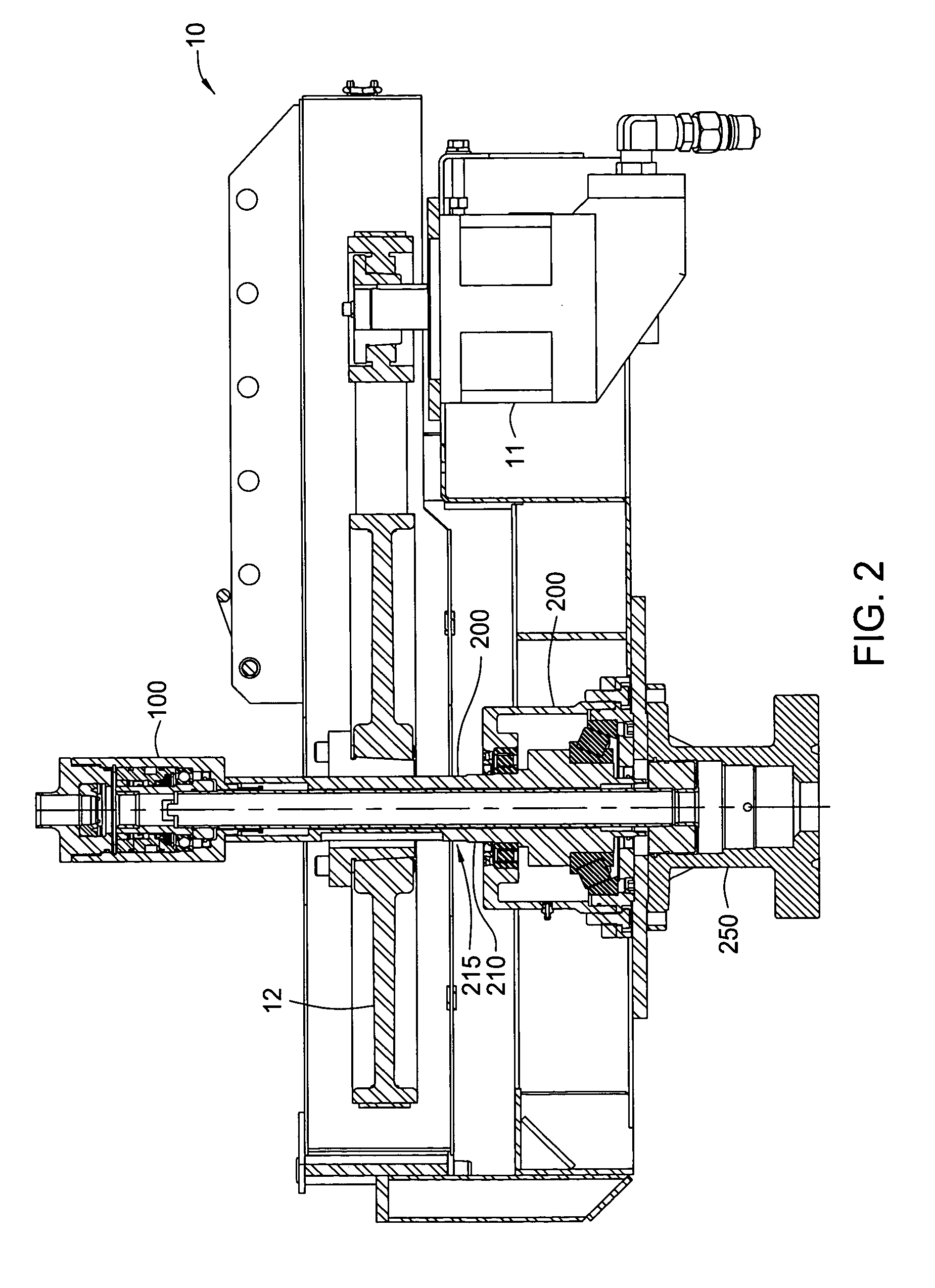

Rotating stuffing box with split standpipe

A system comprising a top mounted rotating stuffing box is provided for use with downhole pump (e.g., Progressing Cavity Pump) applications. The system also includes a split standpipe configuration that allows the stuffing box to be quickly installed or removed as needed. The split standpipe feature combined with the top-mounted aspect of the stuffing box allow for the corresponding drive units to stay intact while the stuffing box is being installed or removed.

Owner:WEATHERFORD TECH HLDG LLC

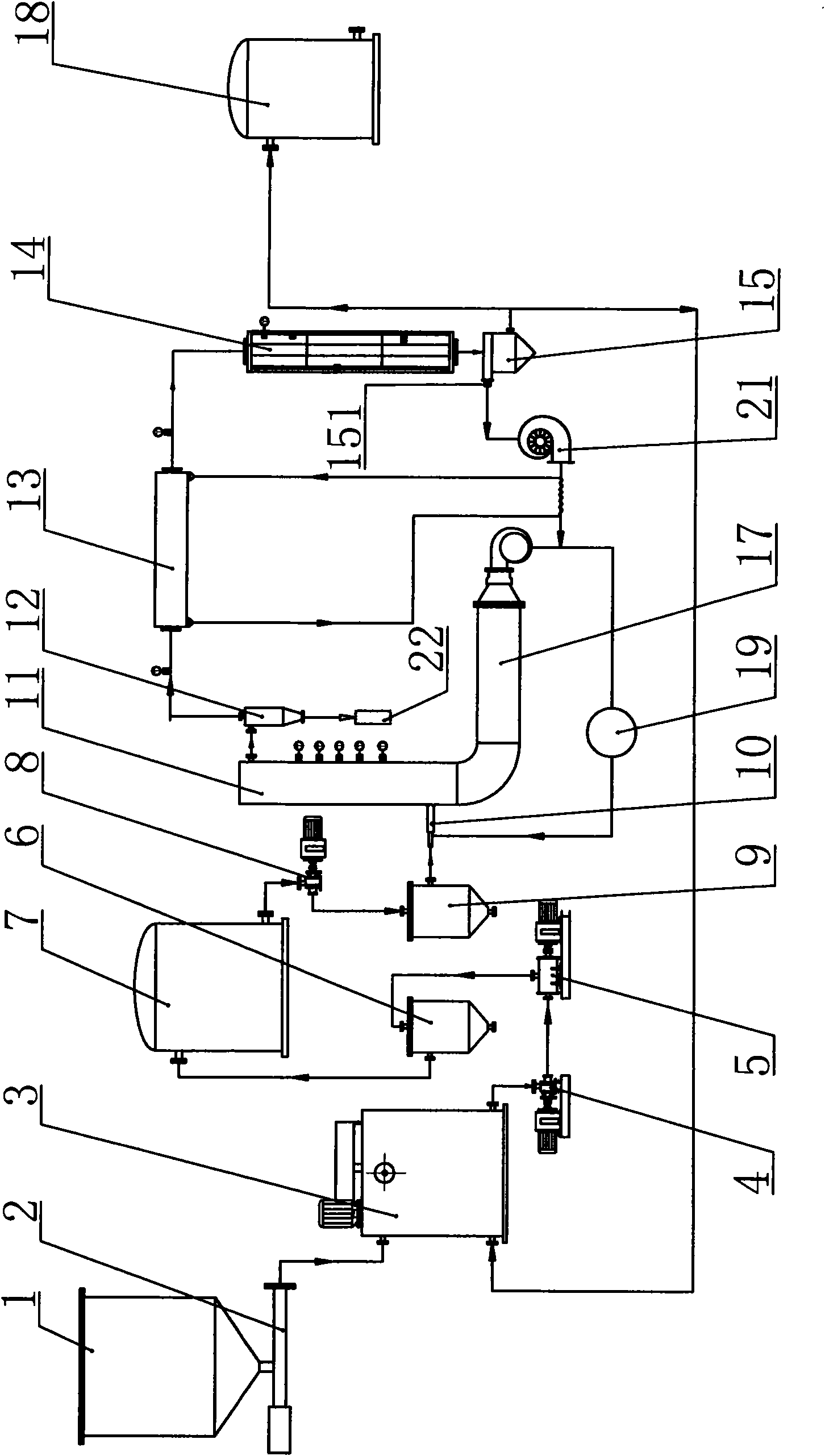

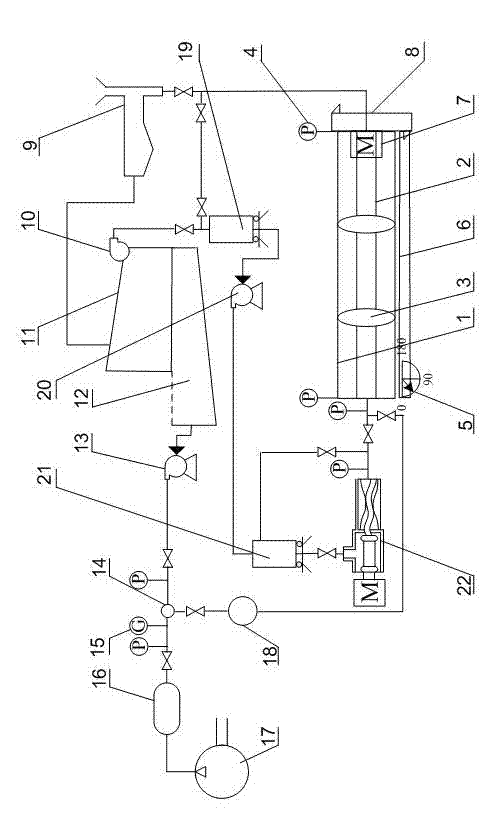

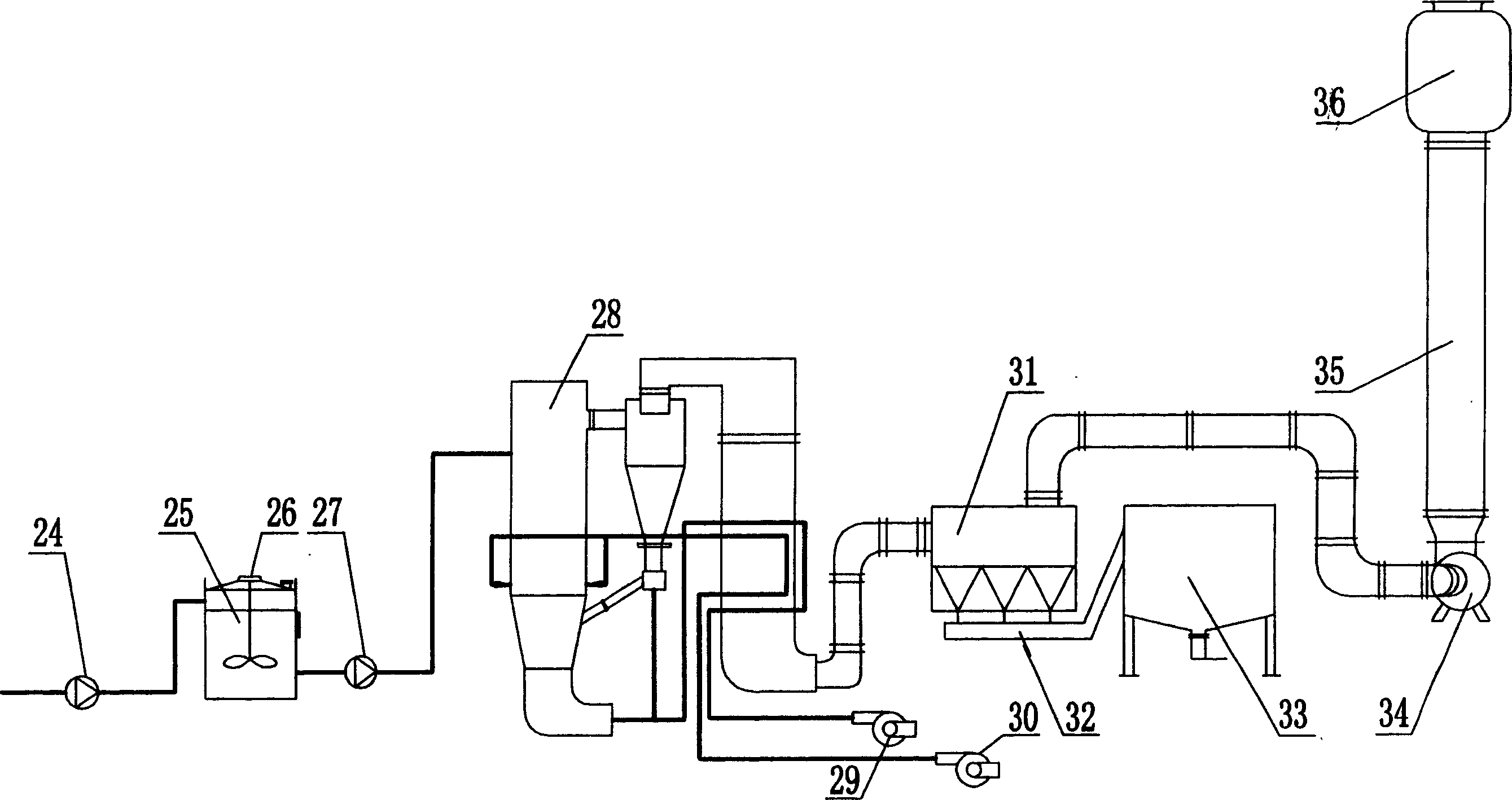

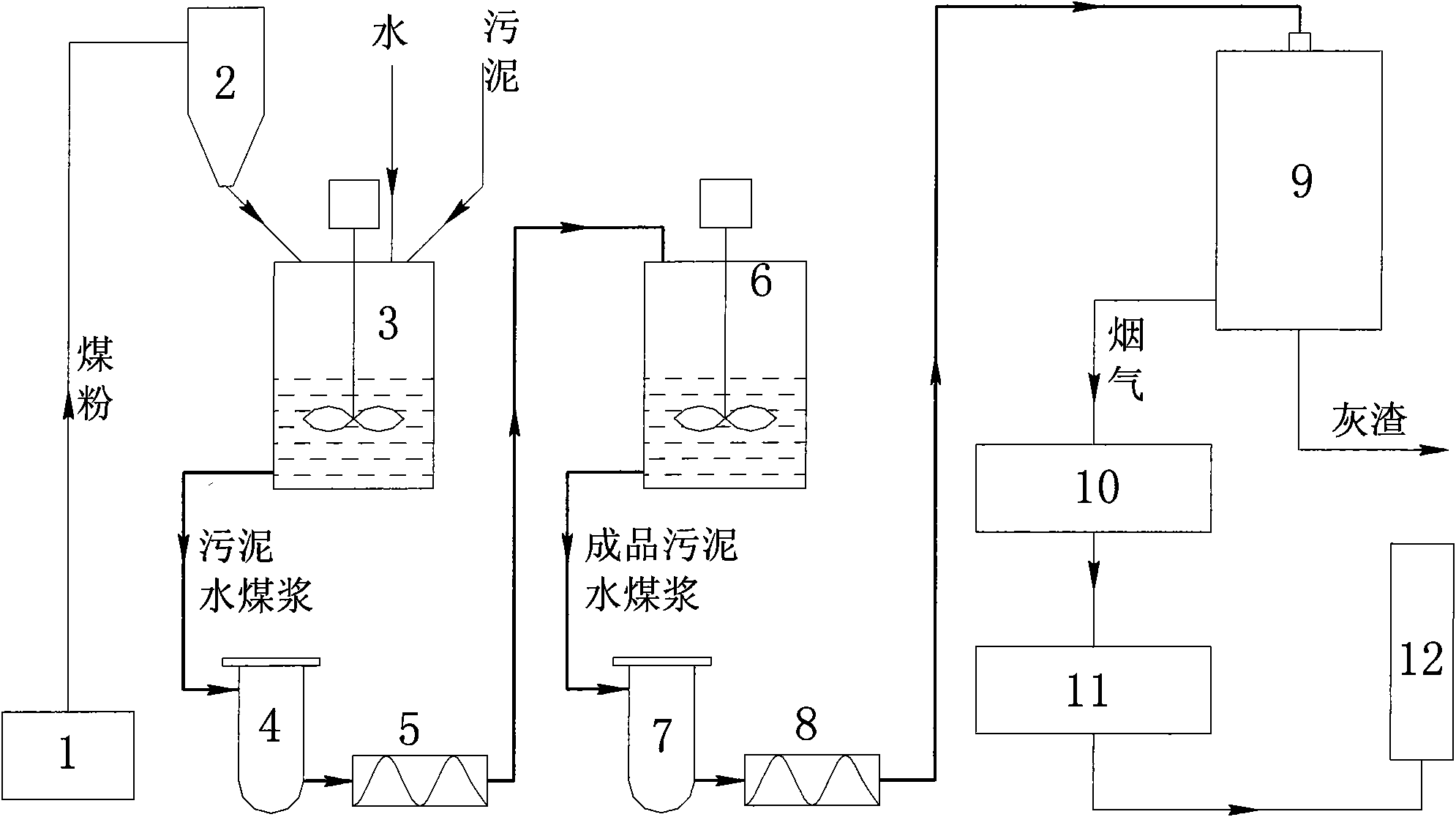

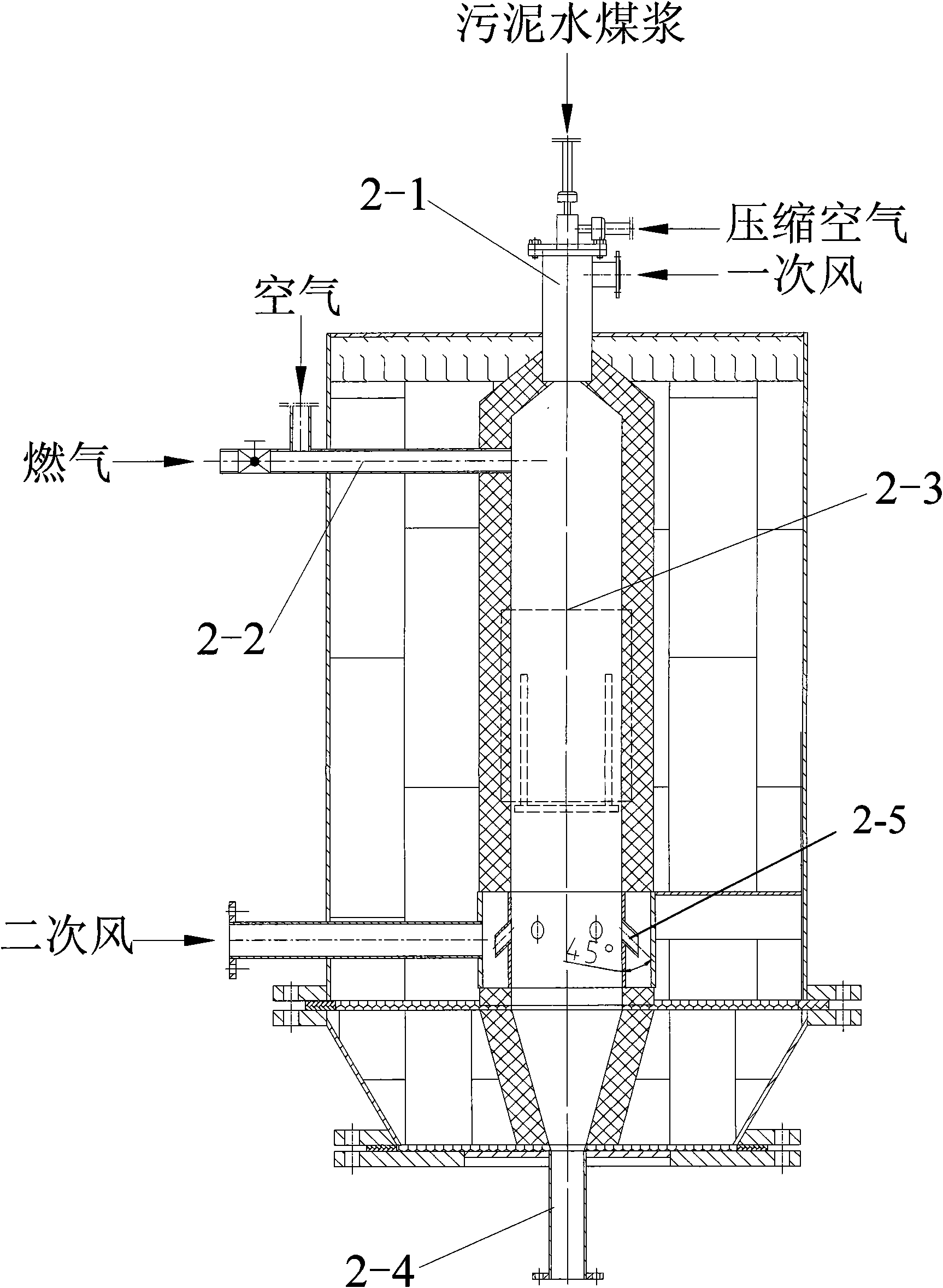

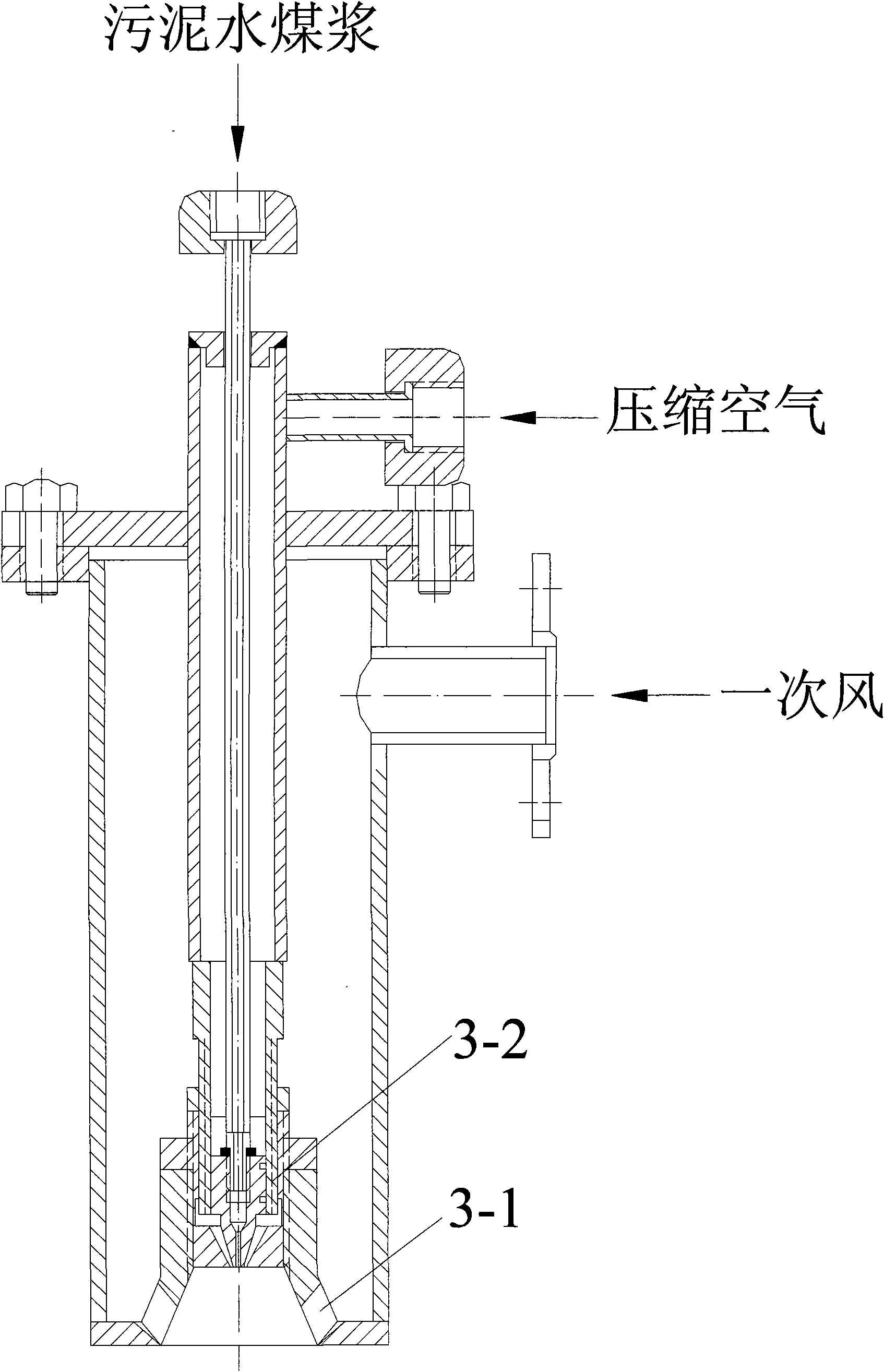

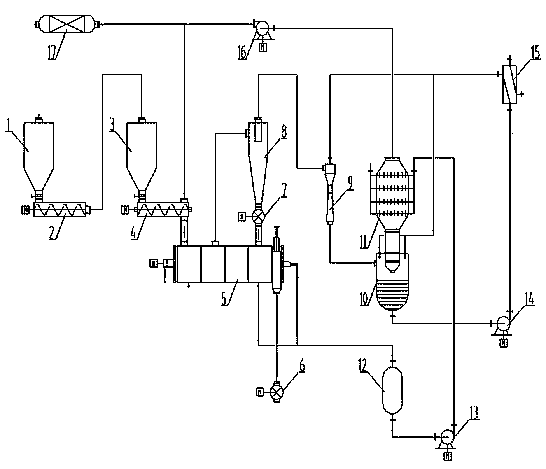

Incineration treatment method of municipal sludge and device thereof

InactiveCN101551108AReduce collectionSave storageIncinerator apparatusCombustion chamberAtmospheric air

The invention relates to an incineration treatment method of municipal sludge and a device thereof. The method comprises the steps of directly mixing powdered coal with average particle diameter of 75 to 90 micrometers, municipal sludge with water content of 95 wt percent and water according to the mass ratio of 60:25:15, then stirring for two times and filtering to manufacture finished sludge water-coal-slurry, directly adopting a screw pump for pressurizing, feeding the sludge water-coal-slurry into a sludge water-coal-slurry atomizing nozzle, and simultaneously feeding compressed air and primary air into the atomizing nozzle to ensure that the sludge water-coal-slurry is injected into a combustion chamber in a good spray pattern. Generated high-temperature flue gas is discharged into atmosphere after heat is recycled by a waste-heat boiler, and clinker is recycled. The device mainly consists of a coal grinding mill, a powder storage bin, an agitator tank, a first filter, a first screw pump, a storage tank, a second filter, a second screw pump, a combustion chamber, a waste-heat boiler and a bag-type dust collector. The disadvantages in the conventional sludge incineration method that the process is complex and the energy consumption during the sludge drying is high are overcome, and the low pollution emission of the flue gas and the comprehensive utilization of the clinker are realized.

Owner:SOUTHEAST UNIV

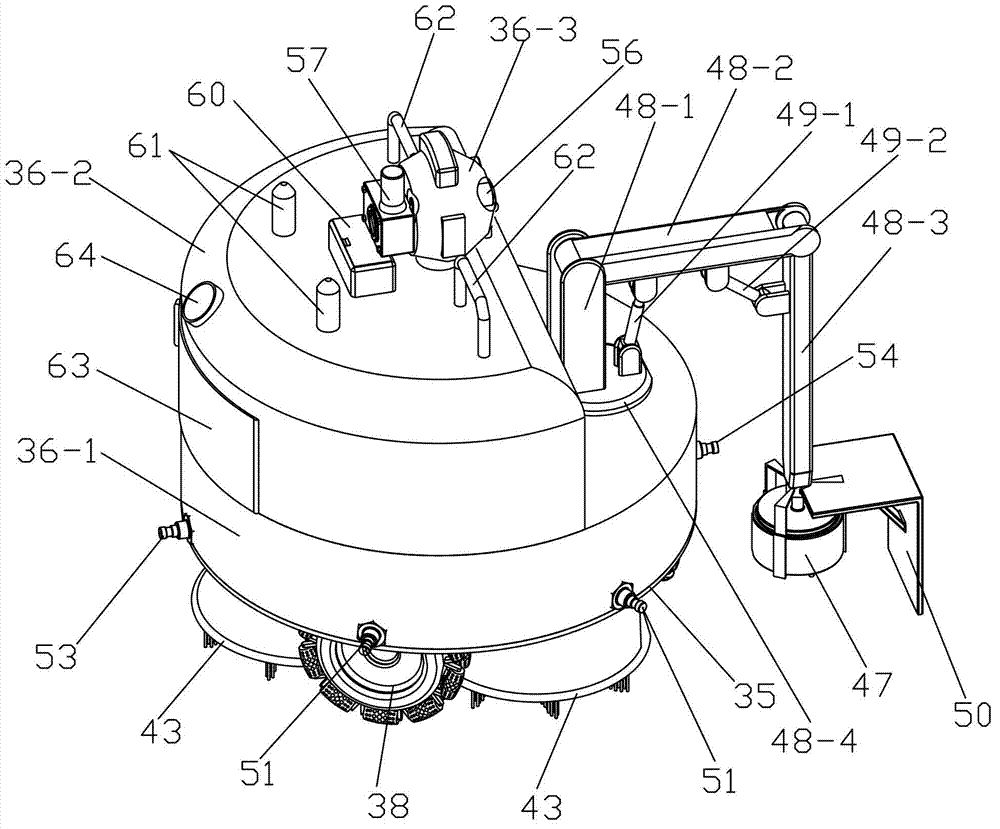

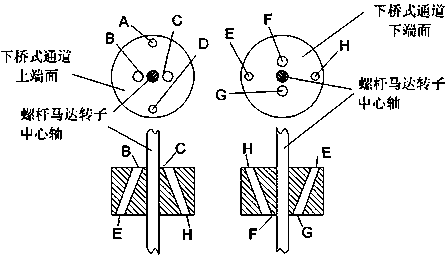

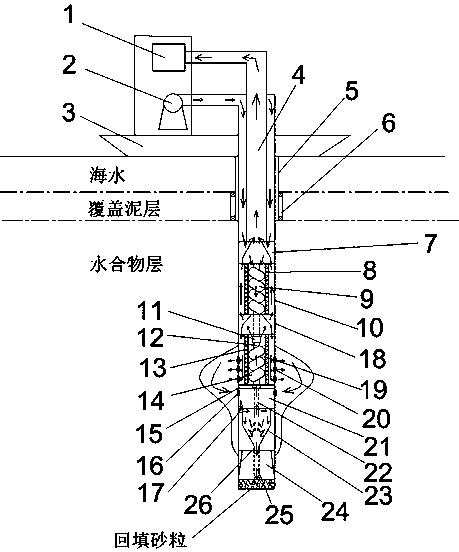

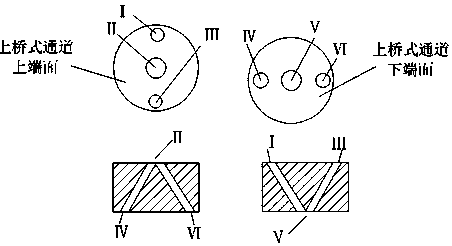

Submarine shallow-layer non-diagenetic natural gas hydrate lifting method and system

The invention discloses a submarine shallow-layer non-diagenetic natural gas hydrate lifting method and a system, which are used for lifting submarine shallow-layer non-diagenetic natural gas hydrate.A pilot hole is drilled by a drill bit, a pressure pump is started after a predetermined position is reached, high-pressure seawater drives a screw motor to rotate, and torque and rotational speed are transmitted to a screw pump by a cardan shaft; jet breaking is started by nozzles, hydrate is collected, secondarily broken and separated by collecting inlets, a secondary breaking device and a separator, separated sand is backfilled, and hydrate slurry is lifted to a solid control system on an offshore platform by the screw pump to undergo post-treatment. The invention has the following advantages: the whole process is simple, and submarine shallow-layer non-diagenetic hydrate can be effectively broken, separated and lifted; the screw pump device has the characteristics of compact structure, small size, high self-sucking capability, stable operation and long service life; and an upper bridge type passage and a lower bridge type passage ingeniously realize the pumping and lifting of seawater and hydrate slurry and save underground space.

Owner:SOUTHWEST PETROLEUM UNIV

Toner container, and image forming apparatus

A toner container includes a container member with a spiral member therein that contains toner and conveys the toner toward an opening in conjunction with a rotation of the spiral member. A toner supply device includes a conveyor tube through which the toner discharged from the toner container is conveyed with gas, and a screw pump that sends gas into and evacuates gas from the conveyor tube.

Owner:RICOH KK

Energy-saving off-gas self-lazy circular sludge drying system and application method thereof

ActiveCN103408213AReduce displacementIncrease profitCombination devicesSludge treatment by de-watering/drying/thickeningSludgeSewage

The invention relates to an energy-saving off-gas self-lazy circular sludge drying system. The system comprises a material cabin, a buffering cabin and a heat exchanger. The material cabin comprises a material inlet I and a screw pump, wherein the screw pump is connected with a buffering cabin material inlet II; the buffering cabin is connected with a disc drier; a heating medium input pipe, a dry sludge discharge port and a condensate discharge port are arranged at the bottom of the disc drier, and an off-gas discharge port I is formed in the top of the disc drier; the dry sludge discharge port is connected with a rotary unloading device I; the condensate discharge port is connected with a condensate tank connected with the heat exchanger; the off-gas discharge port I is connected with a separator connected with a rotary unloading device II and a Venturi dust collector; the rotary unloading device II is connected with the disc drier; the Venturi dust collector is connected with a cooler and a washing tank; the top of the washing tank is connected with a pipe VI, and the bottom of the washing tank is respectively connected with an effluent drainage pipe and a pipe VIII; the pipe VIII is connected with the cooler. Moreover, the invention discloses an application method of the system. According to the invention, investment is less, implementation is easy, and comprehensive utilization ratio is high.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

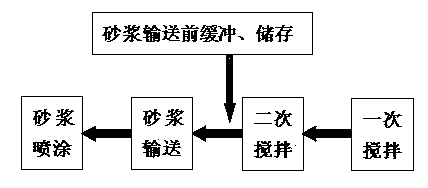

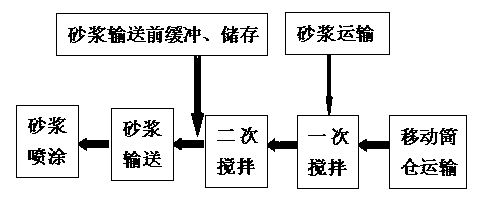

Mechanized spraying method of ordinary ready-mixed mortar

InactiveCN103485521ASimple and fast operationOvercome the problem that it is not suitable for domestic ordinary ready-mixed mortarBuilding material handlingScrew pumpMaterials science

The invention discloses a mechanized spraying method of ordinary ready-mixed mortar. Through the method, a traditional spraying design thought is changed, and key working links of a spraying system are innovatively designed and improved. The method includes firstly, subjecting ordinary dry-mixed mortar to continuous twice agitation of a mobile silo agitator and a horizontal agitator to enable wet materials to be uniformly and sufficiently mixed to obtain wet mortar, and secondly using a duplex piston pump to complete delivery of the wet mortar. The spraying technology is further optimized in a matched manner to form a mechanized spraying working system simple and convenient to operate, efficient and easy to popularize, and the problem that abroad mortar spraying machines are inapplicable to domestic ordinary ready-mixed mortar; meanwhile, the technical problems of short service life, high cost and proneness to blockage due to the fact that domestic traditional motor spraying machines deliver and spray mortar by screw pumps are solved; the method is suitable for especial mortar and more suitable for the domestic ordinary ready-mixed mortar, efficiency and construction quality are greatly improved, and construction cost is lowered.

Owner:梅州淦源建材科技有限公司

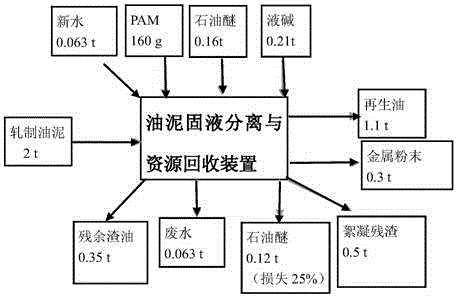

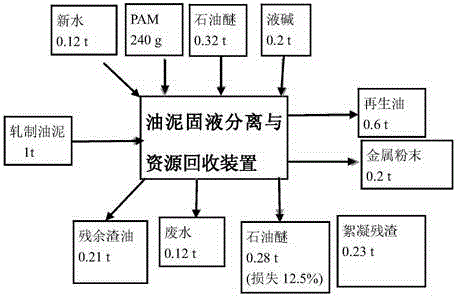

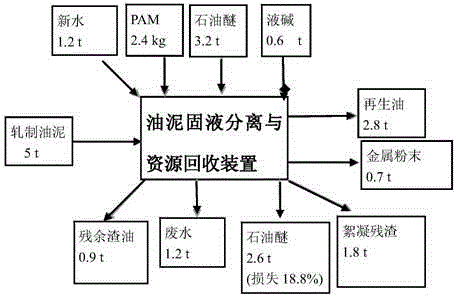

Device for solid-liquid separation and resource recovery of rolling oil sludge and use method of device

InactiveCN106147978AAchieve recyclingThe process is simple and reliableSludge treatmentProcess efficiency improvementDistillationResource recovery

The invention discloses a device for solid-liquid separation and resource recovery of rolling oil sludge and a use method of the device. The device comprises an oil sludge storage tank, a screw pump, a plate-and-frame filter press, a middle tank, an oil pump, a three-in-one reactor, a distillation column, a condenser, a clear oil tank and a vacuum pump, wherein the oil sludge storage tank communicates with the screw pump and the bottom of the three-in-one reactor, the screw pump communicates with the plate-and-frame filter press, the plate-and-frame filter press communicates with the middle tank, the middle tank communicates with the oil pump, the oil pump communicates with the top of the three-in-one reactor, the distillation column is arranged at the top of the three-in-one reactor and communicates with the clear oil tank through the condenser, and the bottom of the clear oil tank communicates with the vacuum pump. The device has the beneficial effects of being simple and reliable in process, convenient to operate, high in pertinence, safe, environment-friendly and suitable for promotion.

Owner:BAOSTEEL STAINLESS STEEL

Alloy laser-cladding method for surface of helical casing in screw pump

InactiveCN102094198AExtended service lifeHigh hardnessMetallic material coating processesLaser technologyHelical scan

The invention discloses an alloy laser-cladding method for the surface of a helical casing in a screw pump. In the method, high temperature-resistant, corrosion-resistant and abrasion-resistant alloy powder is cladded on the surface of a helical casing by using the laser technology, thus forming an alloy cladding layer. The alloy powder contains elements or oxides thereof which are capable of refining, intensifying and having other effects on crystal grains of the alloy cladding layer, so the structural characteristics of the alloy cladding layer appears as refining of the crystal grains, increase of the dislocation density and uniform and compact structure, and the alloy cladding layer also has the effects on solution strengthening of the supersaturated alloy, and dispersion strengthening of superfine compounds and the like. Thus, the rigidity, wear resistance, corrosion resistance, fatigue resistance and other mechanical properties of the surface of the helical casing can be effectively improved, thereby greatly prolonging the service life of the screw pump. In addition, the method can be also used for repairing the surface of a faulted helical casing, thereby effectively lowering the production cost.

Owner:天津市汇利通金属表面技术有限公司

Low air pressure test device

InactiveCN105539888APrecisely control the step-down ratePrecise control of boost rateCosmonautic condition simulationsSpace environmentControl system

The invention relates to a low air pressure test device which is used in a space environment simulation system. The low air pressure test device comprises a vacuum tank, an air pumping system, an air inflation system, a pressure measuring system and a control system, wherein the air pumping system comprises two air pumping pipelines, a first pneumatic valve and an electric pressure regulating valve are in tandem connection to a first air pumping pipeline, and second pneumatic valves and a molecular pump are in tandem connection to a second air pumping pipeline; one end of the first air pumping pipeline and one end of the second air pumping pipeline both communicate with the vacuum tank; the other end of the first air pumping pipeline and the other end of the second air pumping pipeline are converged in a main pipeline; a dry type screw pump is connected to the main pipeline. The pressure measuring system comprises an absolute pressure transmitter and a full measuring range vacuum gauge which are connected with the vacuum tank; the air inflation system comprises a mass flow meter and a magnetic valve; the air pumping system, the pressure measuring system and the air inflation system are all connected with the control system. According to the low air pressure test device provided by the invention, an air pumping rate and an air inflation rate can be controlled at the same time; the pressure can be stabilized in the range of pressure required by tests.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

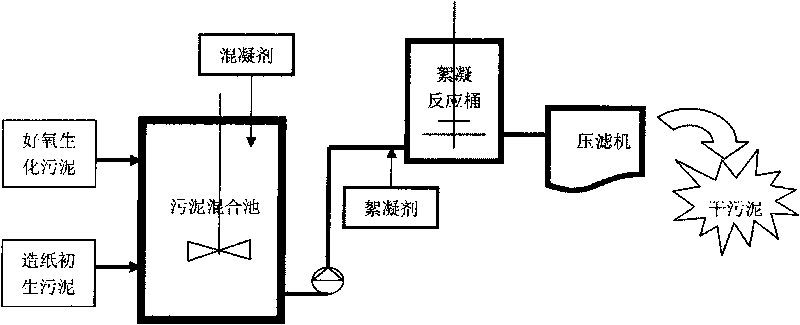

Method for dynamically controlling continuous feeding in dehydration of papermaking sludge

InactiveCN101704629ACause secondary pollutionImprove dehydration propertiesSludge treatment by de-watering/drying/thickeningFlocculationSludge

The invention discloses a method for dynamically controlling continuous feeding in the dehydration of papermaking sludge, which comprises the following process steps: 1) mixing and stirring concentrated aerobic biological sludge and the papermaking sludge to form mixed sludge; 2) adding an inorganic polymer coagulant into the uniformly-stirred mixed sludge continuously and stirring for performing a reaction; 3) conveying the reacted mixed sludge to a secondary flocculation reaction barrel by utilizing a sludge screw pump, adding the organic polymer coagulant into the mixed sludge continuously, and simultaneously, stirring to perform a flocculation reaction; and 4) performing filter-pressing and dehydration on the mixed sludge after the flocculation reaction in a filter press. The method has high dehydration efficiency, stable dehydration performance, simple process, no secondary pollution, no need of special drying equipment, economy conservation and low cost.

Owner:DONGGUAN NINE DRAGONS PAPER IND

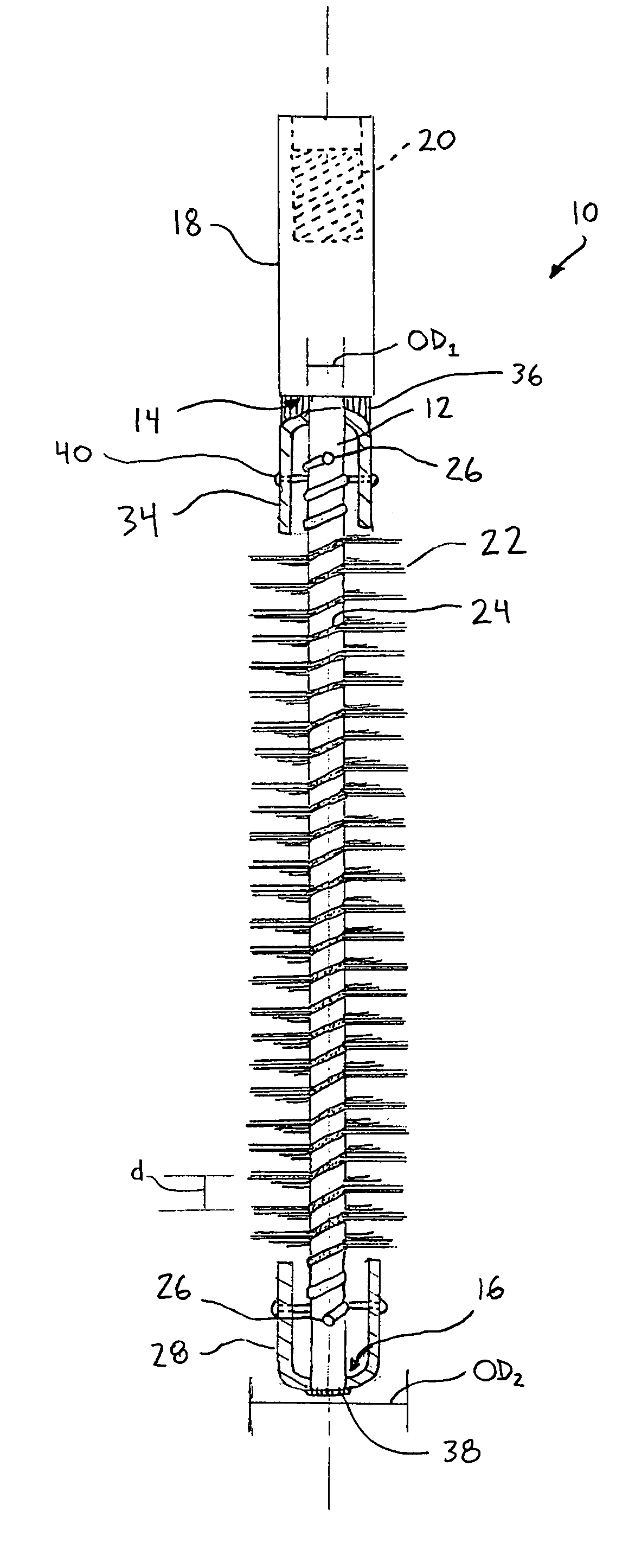

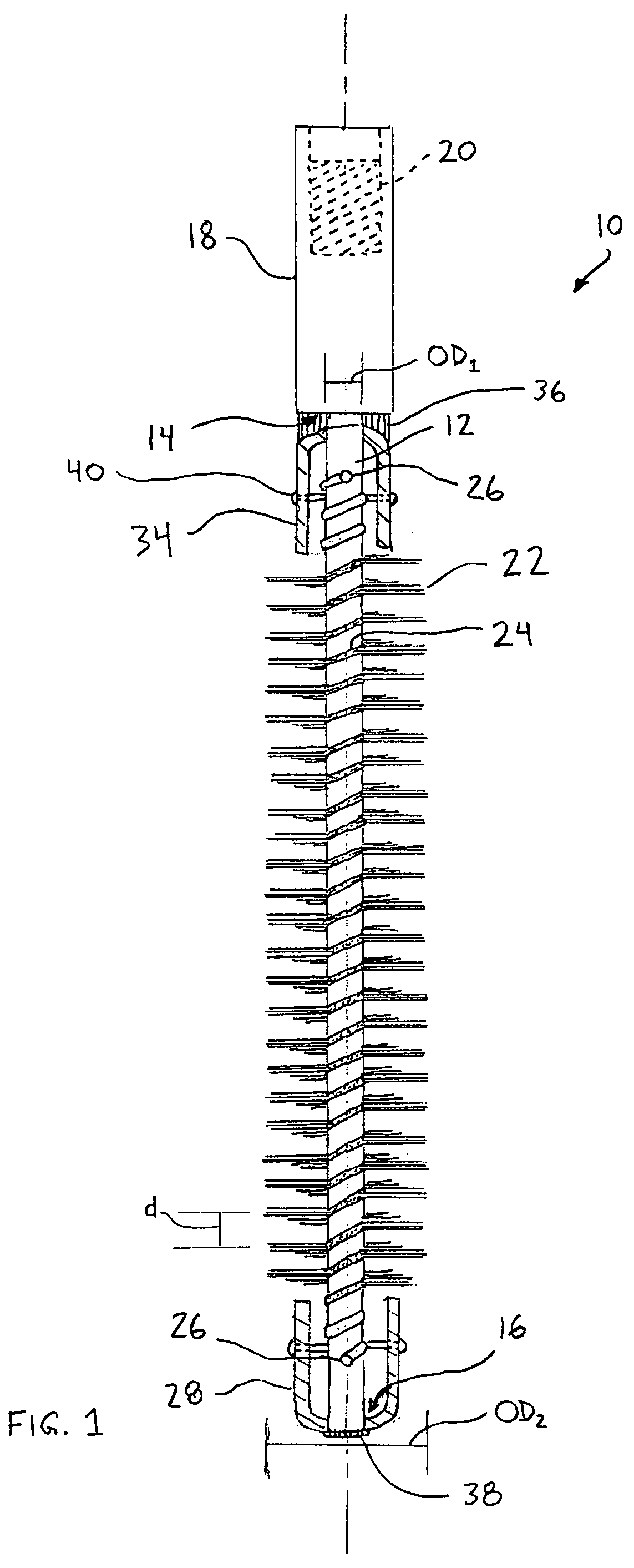

Agitator tool

InactiveUS20060048934A1Efficiently agitatedProduced cost-effectivelyDrilling rodsCleaning apparatusPush and pullScrew pump

A rotatable agitator tool is disclosed for use with a pump mechanism, for agitating production fluid comprising sand or other debris and for breaking out solution gas, comprising an elongate shaft connected to a rotating element such as a rotor, and a plurality of agitation members extending outwardly from the elongate shaft, the agitator tool extending in an upstream direction from the pump mechanism. The agitation members are preferably flexible to allow the agitator tool to be pushed and pulled through a stator (where employed with a progressive cavity pump) without damaging the elastomeric coating on the stator.

Owner:CHARABIN NEIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com