Patents

Literature

228results about How to "Moderate concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Children pigment composed of edible composition

InactiveCN104017436AImprove securityLow priceArtist's paintsPigment pastesBiotechnologyFood coloring

The invention discloses a children pigment composed of edible composition. The pigment is characterized by comprising 0.1-20 g of edible pigment, 0.1-20 g of a stabilizer, 0.1-20 g of an anti-caking agent, 0.1-20 g of a filler, 0.1-20 g of a thickening agent, 0.1-20 g of an emulsifier, 0.01-5 g of a preservative and 100 ml of water. The children pigment has improved usage safety.

Owner:NANCHANG UNIV

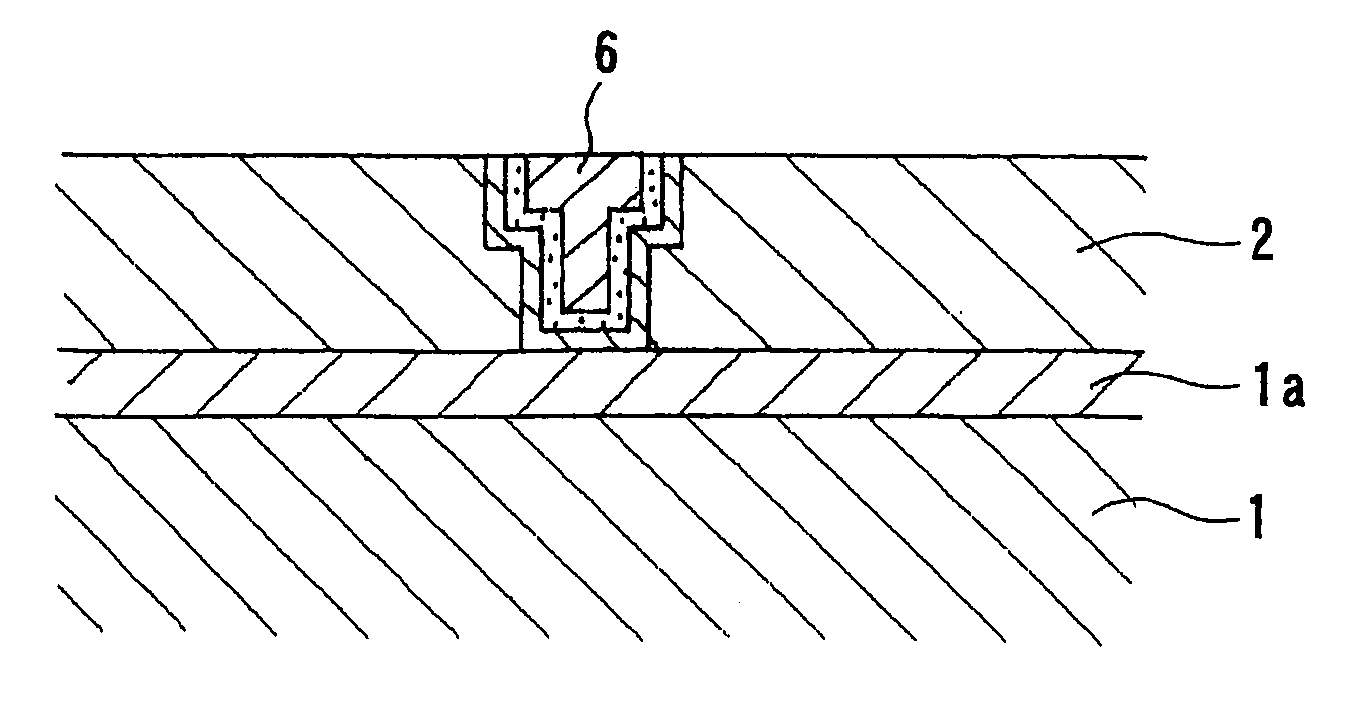

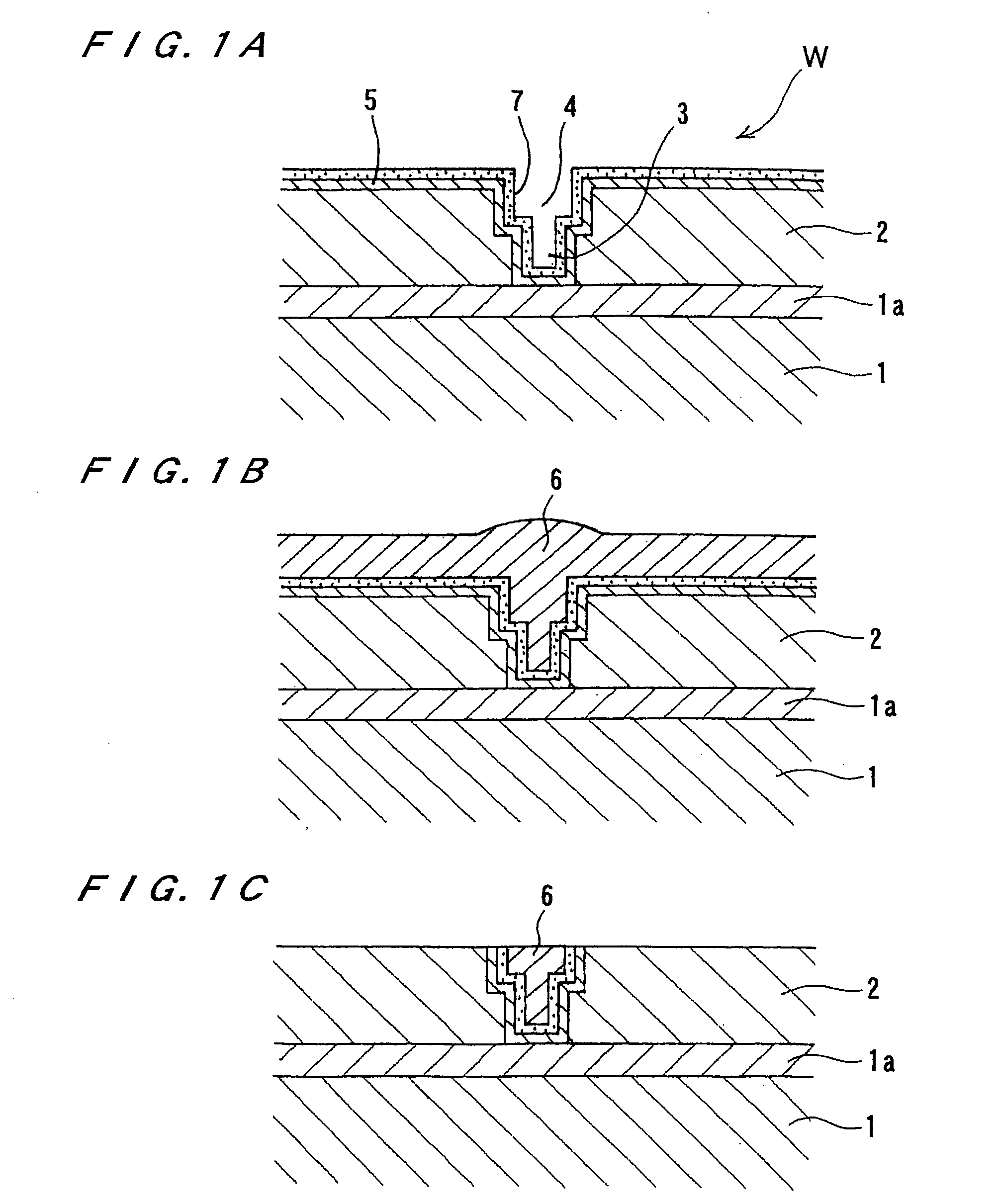

Plating method and plating solution

InactiveUS20050045486A1Moderate concentrationSemiconductor/solid-state device manufacturingPrinted element electric connection formationIonVoltage

The present invention provides a plating method which can embed copper in interconnect recesses, such as vias and interconnect trenches, having an opening width or size of several tens of μm and an aspect ratio of at least 1.5. The plating method comprises: providing a substrate having interconnect recesses, whose surfaces are covered with a conductive layer, formed in a surface of the substrate; bringing the surface of the substrate into contact with a plating solution containing copper ions, an organic or inorganic acid, chloride ions, a polymeric surfactant for suppressing electrodeposition, a sulfur-containing saturated organic compound for promoting the growth of a plated film, and a nitrogen-containing polymer for flattening a surface of the plated film; and applying a voltage between the conductive layer and an anode immersed in the plating solution.

Owner:EBARA CORP +1

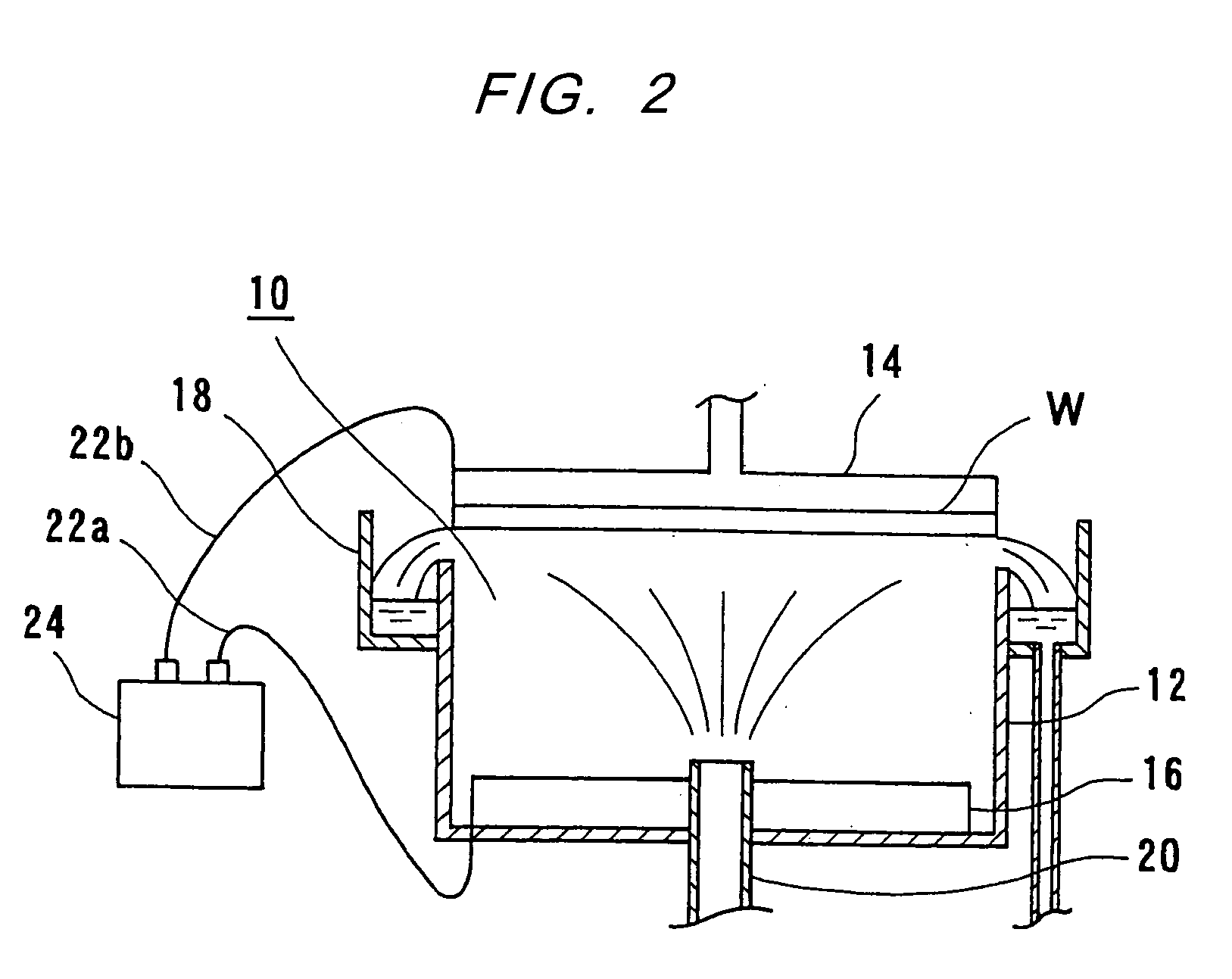

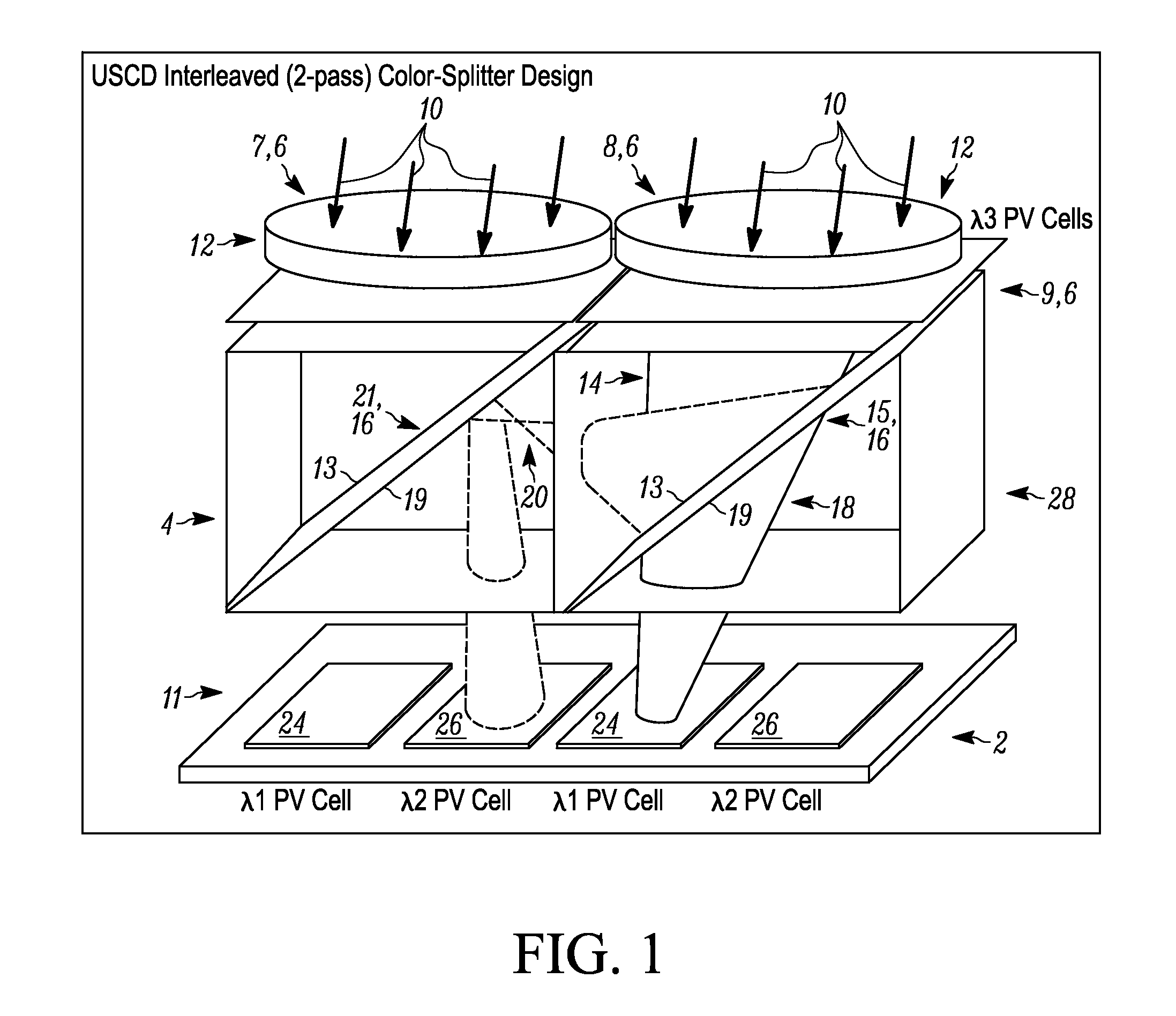

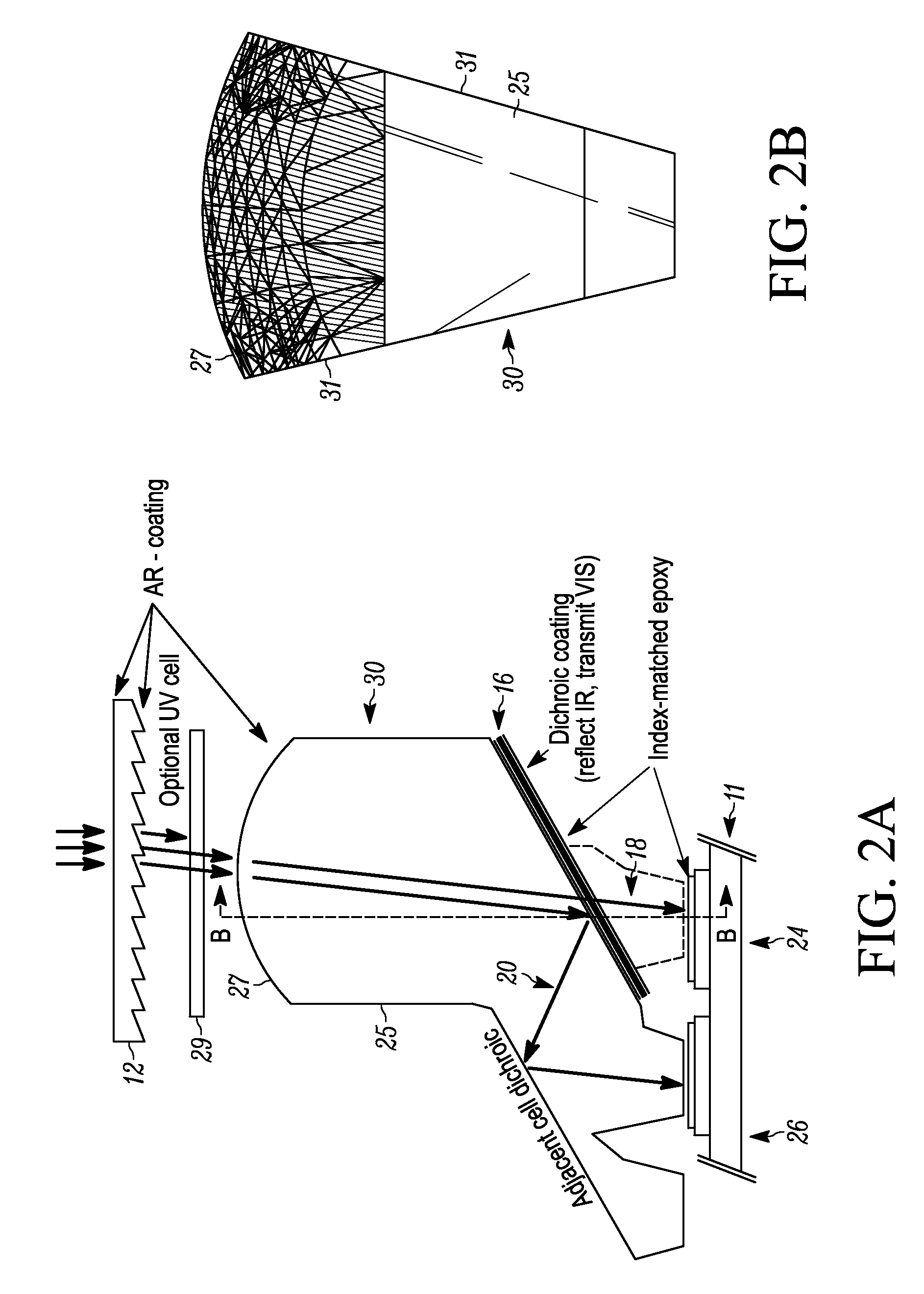

System and method for solar energy capture

InactiveUS20100032005A1Moderate concentrationPV power plantsPhotovoltaic energy generationEngineeringWavelength range

A system and a method for capturing solar energy are disclosed herein. In at least one embodiment, the method includes receiving light at a plurality of lenses, communicating the light from respective ones of the plurality of lenses toward respective ones of a plurality of dichroic mirrors, and transmitting respective first portions of the light through the respective ones of the dichroic mirrors toward respective first photovoltaic cells. The method also includes reflecting respective second portions of the light off of the respective ones of the dichroic mirrors toward respective adjacent ones of the dichroic mirrors, where the first portions are within a first wavelength range and the second portions are within a second wavelength range, and reflecting the respective second portions of the light off of the respective adjacent ones of the dichroic mirrors toward respective second photovoltaic cells.

Owner:RGT UNIV OF CALIFORNIA

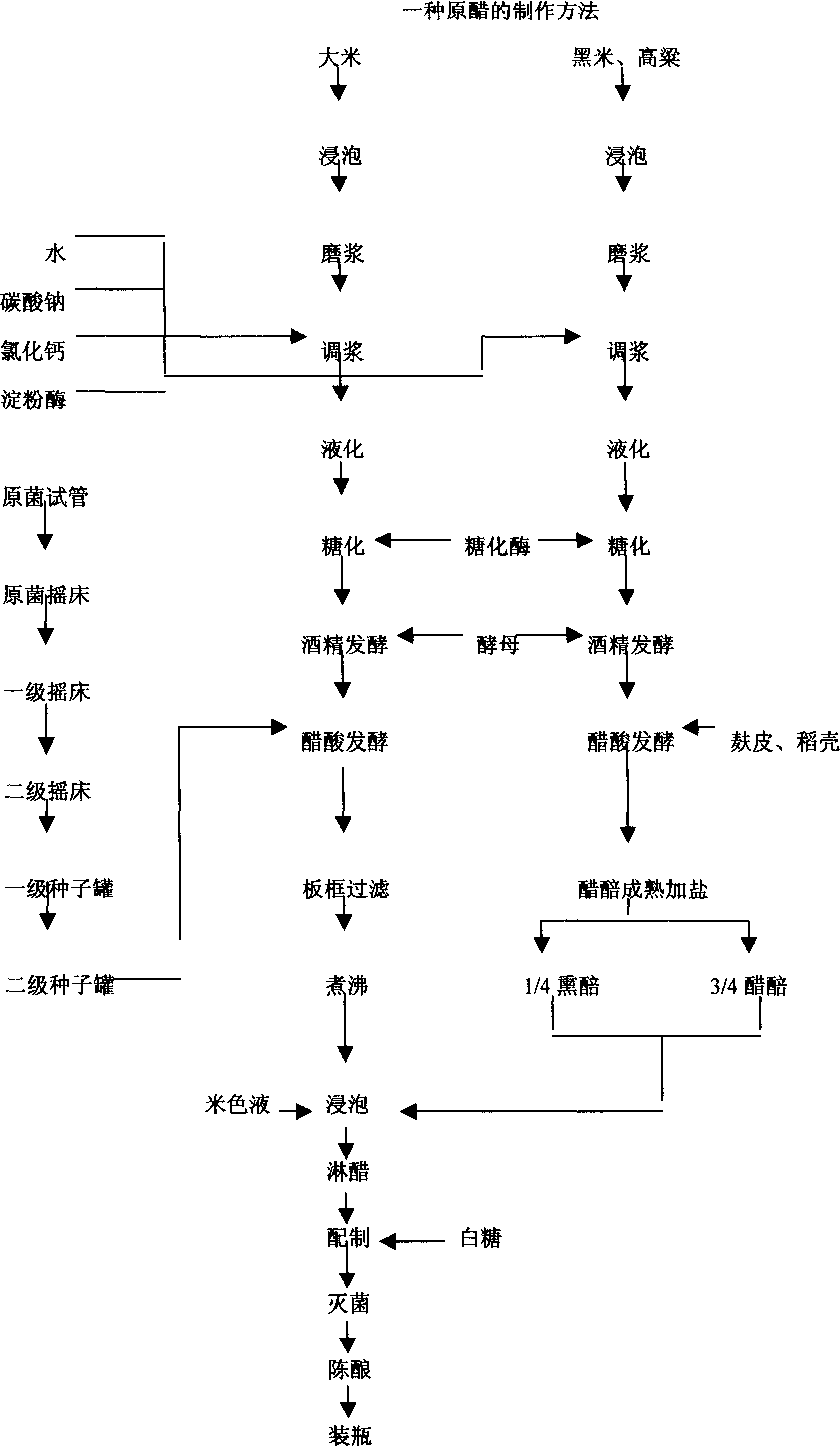

Vinegar making process

The present invention discloses vinegar making process, in which rice, sodium carbonate, salt, calcium chloride, alpha-amylase, sugar, saccharifying enzyme, yeast, water and rice hull or wheat bran in certain weight proportion are used as material. The made vinegar is brown, bight, fragrant, mildly sour and slightly sweet, and has total acid amount account with acetic acid not less than 4.0 g each 100 ml.

Owner:陈松

Pomegranate fermented lactic acid drink

The present invention discloses a pomegranate fermented lactic acid drink. The pomegranate fermented lactic acid drink is made from the following raw materials: pomegranates, skim milk, pomegranate peels, pomegranate flowers, pomegranate barks, pomegranate leaves, sophora japonica leaves, calyx kaki, picrasma quassioides, isomaltitol, gentiooligosaccharide, lactic acid bacteria, compound enzymes, and antioxidants of bamboo leaves. The drink is sour and sweet in mouthfeel, moderate in concentration, stable in state, and rich in nutrition, can promote metabolism, enhance immunity, dispel toxins and beautify feature, and prevent oxidation, aging, and tumors. The pomegranates are rich in organic selenium, help absorption and utilization, and promote the body function; each of the organs of the pomegranate is fully used and scientifically matched with other traditional Chinese medicines, the effects are complementary to each other, the raw materials are extensive, the price is low and cheap, and the costs are saved; a first lactic acid bacterium high-temperature fermentation is conducted, the lactic acid bacterium growth is promoted, and the pollution is avoided, at a second time, the gentiooligosaccharide is added, the activities of the lactic acid bacteria are enhanced, and a low-temperature long-time fermentation is conducted, which is conductive to the produce of flavor substances; and the fermented lactic acid drink is filled, and the filled lactic acid drink is subjected to low-temperature cold storage, which can maintain the activities of the lactic acid bacteria in the drink, so that the pomegranate fermented lactic acid drink promotes gastrointestinal functions.

Owner:阜阳市颍州区金湖丰种植农民专业合作社

Slow released ClO2 air disinfectant

InactiveCN1887356AImprove the activation effectProlong the evaporation timeDeodrantsDiseaseChlorine dioxide

The present invention is slow released ClO2 air disinfectant, and belongs to the field of hygienic disease controlling and sterilizing technology. The slow released ClO2 air disinfectant consists of ClO2 solution in 1-3 weight portions, silicon gel as the carrier of ClO2 solution in 3 and activator in 0.005-0.1 weight portions. The slow released ClO2 air disinfectant has homogeneous and lasting release to maintain proper ClO2 concentration in the air and reach excellent air disinfecting effect. The used silicon gel may be recovered and reused after treatment.

Owner:陈惠 +1

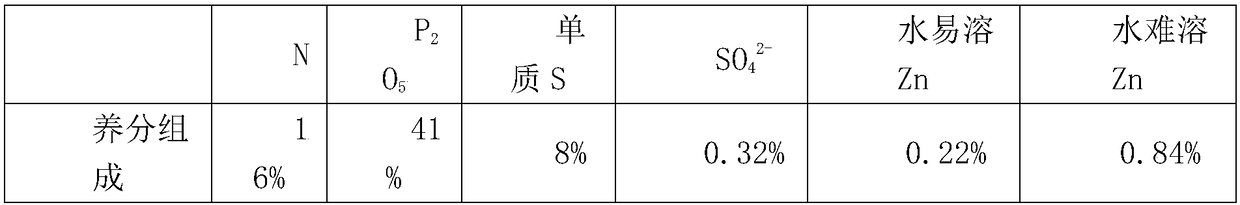

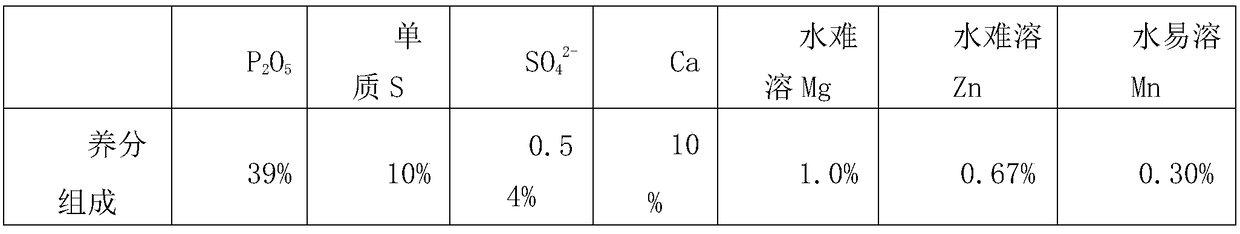

Medium trace element mixture and preparation method of medium trace element-wrapped fertilizer

InactiveCN108976018AEasy to accumulateImprove securityMagnesium fertilisersAlkali orthophosphate fertiliserLiquid stateSulfur

The invention relates to a medium trace element mixture and a preparation method of a medium trace element-wrapped fertilizer. The medium trace element mixture is prepared from the following components: 50% to 90% of sulfur, 5% to 20% of swelling material, and 5% to 45% of medium trace element other than sulfur. The preparation method comprises the following steps: adding the medium trace elementand the swelling material into liquid sulfur and evenly mixing. The preparation method of the medium trace element-wrapped fertilizer comprises the following steps: placing the conventional granular fertilizer in a wrapping device with a heating function, after heating the medium trace element mixture to a certain temperature, spraying on the surface of the granular fertilizer, and forming a medium trace element film on the surface of the fertilizer by cooling and curing. The medium trace element mixture and the preparation method of the medium trace element-wrapped fertilizer provided by theinvention have the advantages that the medium trace elements are quickly and flexibly added; the problem of uniform dispersion of the medium trace elements in soil is solved, and the local poisoning is avoided; the film formed by wrapping the medium trace element material is firmly combined with fertilizer particles, and is not easy to fall off; fast-acting and long-acting combined medium trace element materials can be wrapped, which is beneficial to the nutritional needs of crops in the whole growth cycle.

Owner:HUBEI FORBON TECH

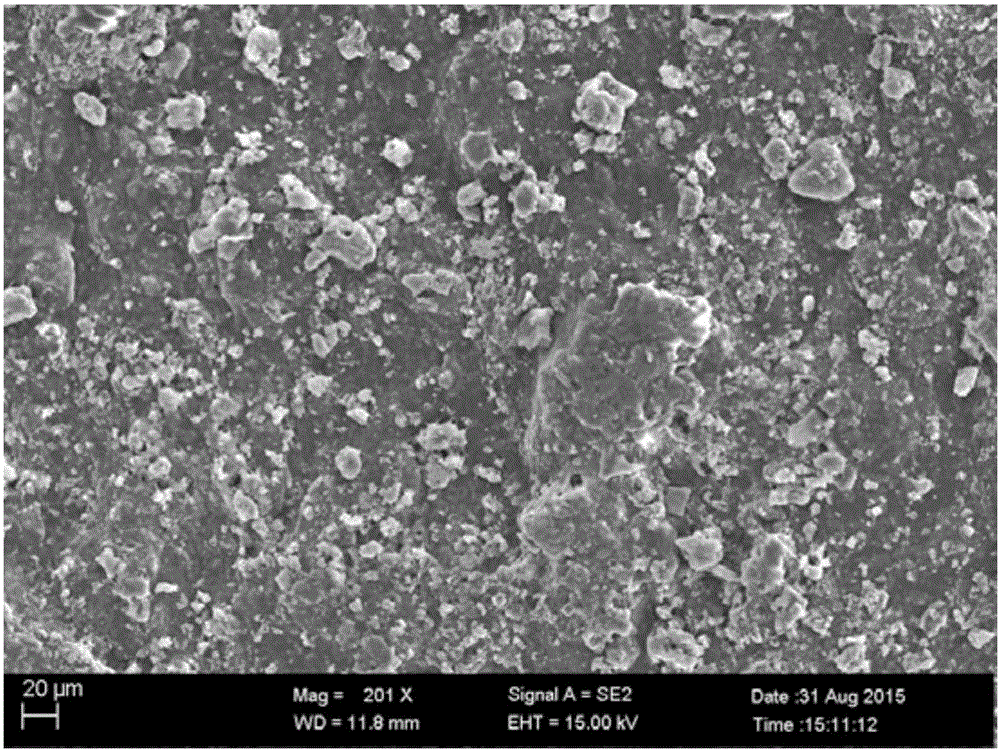

Chemical and mechanical water-free polishing liquid for lithium-cessium borate crystal and leveling method

InactiveCN1858134AGood suspensionModerate concentrationPolishing machinesAqueous dispersionsLithiumOrganic solvent

The present invention discloses a kind of chemical and mechanical water-free polishing liquid for polishing lithium-cesium borate crystal and its polishing method. The polishing liquid of the present invention consists of nanometer silica abrasive 4-8 wt%, organic solvent 72-95 wt%, organic alkali 0.5-10 wt% and surfactant 0.5-10 wt%. It is used in polishing lithium-cesium borate crystal at polishing pressure of 0.05 MPa to 0.1 MPa, polishing disc speed of 30 rpm to 60 rpm, and polishing time of 5-10 min. The water-free polishing liquid of the present invention has high flowability, no toxicity, no pollutant, no corrosion, moderate concentration and good floatability, and can obtain polished lithium-cesium borate crystal surface with high smoothness and no crack.

Owner:HEBEI UNIV OF TECH

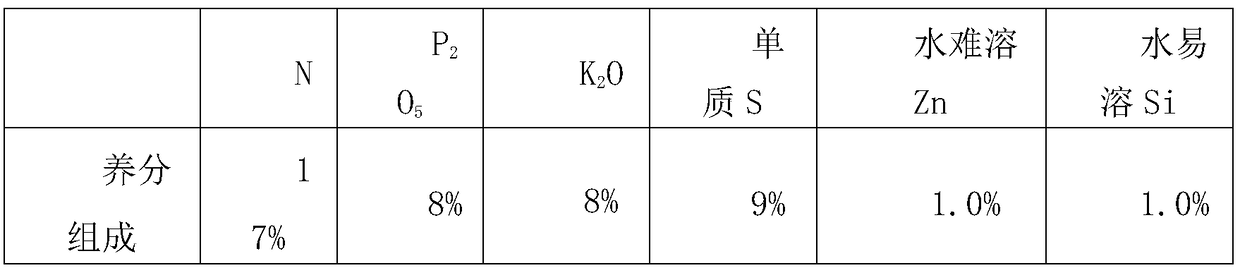

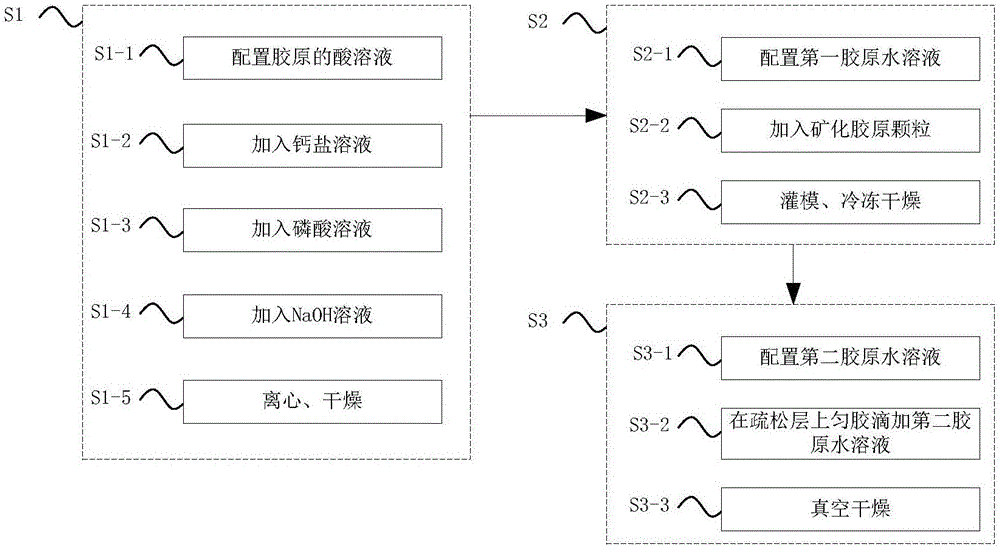

Mineralization guided tissue regeneration membrane and preparation method and application thereof

ActiveCN106492283AGood tissue compatibilityHigh tensile strengthProsthesisPhysical BarrierNano hydroxyapatite

The invention relates to a mineralization guided tissue regeneration membrane and a preparation method and application thereof, wherein the mineralization guided tissue regeneration membrane comprises: a loose layer formed by compositing type I collagen and nano hydroxyapatite; a compact layer positioned on the loose layer and formed from type collagen. The double-layer mineralization guided tissue regeneration membrane is constructed herein, wherein the loose layer is consistent to autogenous bone in terms of composition, and the membrane may be attached to diseased oral bone defect surface to induce the generation of new bones; the surface of the compact layer is smooth, a diseased area may be isolated from surrounding tissues by making good use of physical barrier function of the membrane, regenerating capacity of a specific tissue is given to maximum play, and the prepared mineralization guided tissue regeneration membrane has high tensile strength and elasticity.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

Water-soluble ink compositions, their manufacturing method and use

This invention relates a water soluble ink that utilizes dyes, protective glue, dispersant, leveling agent, emulsifier and water absorbing resin to prepare. This invention also relates to the making method of the water soluble ink and its utilization in printing, watercolor and paper keir. The product of this invention can overcome the oxidation decoloring phenomenon of colorful paper and rice paper when meeting water or ultraviolet irradiation; the decoloring phenomenon of traditional Chinese painting and watercolor painting; the ink marks of the characters are bright, the color is proper and the writing is smooth, the intensity is proper, the fragrance is moderate and it is dry quickly and decreases the environmental pollution.

Owner:李联江

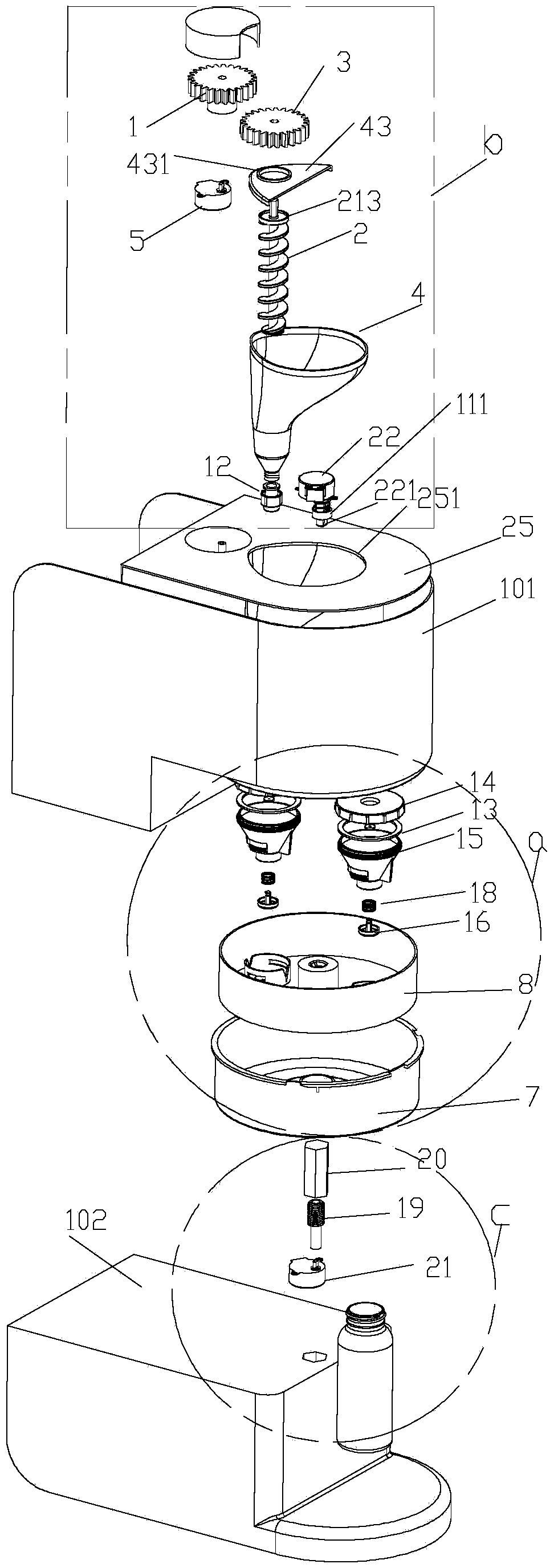

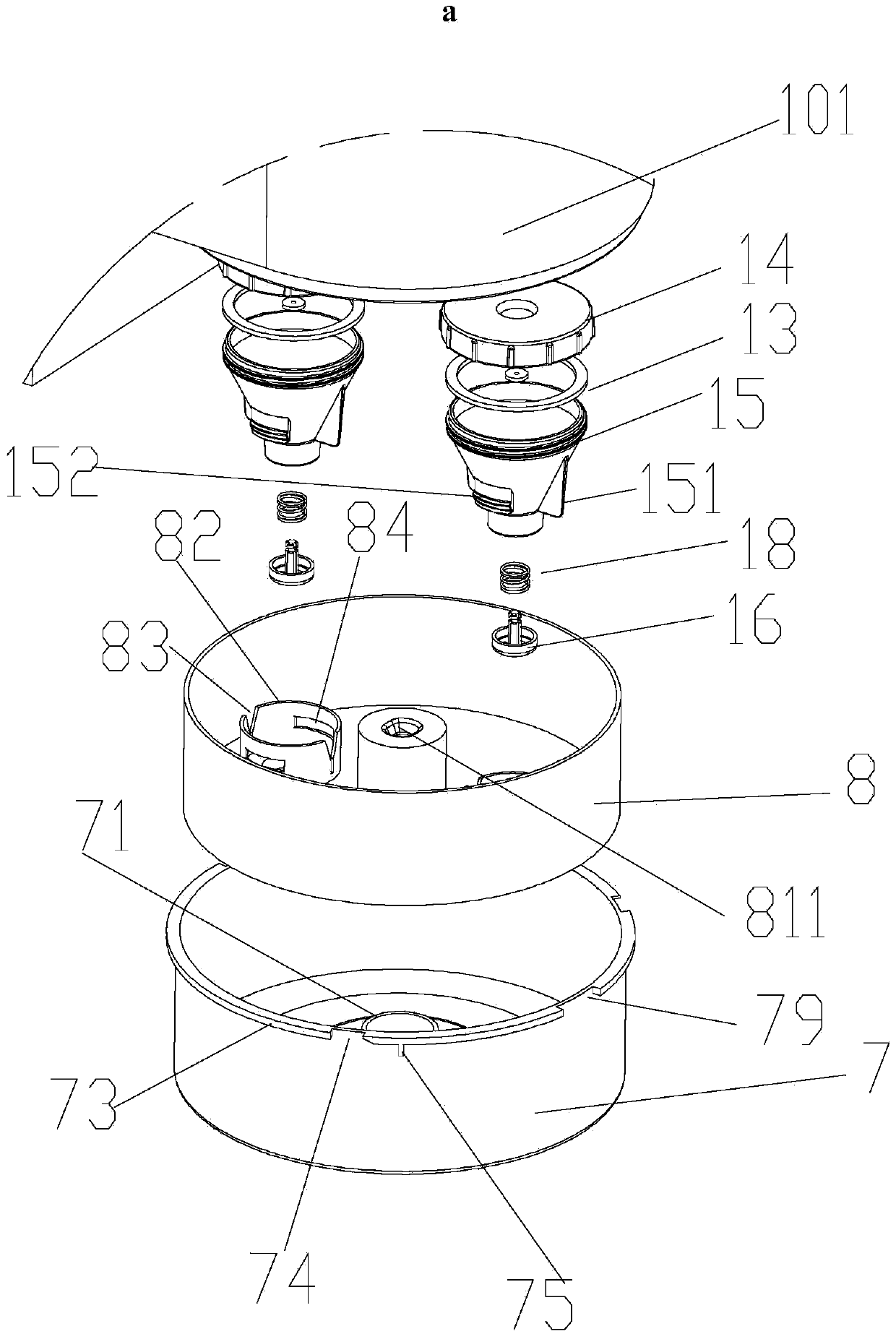

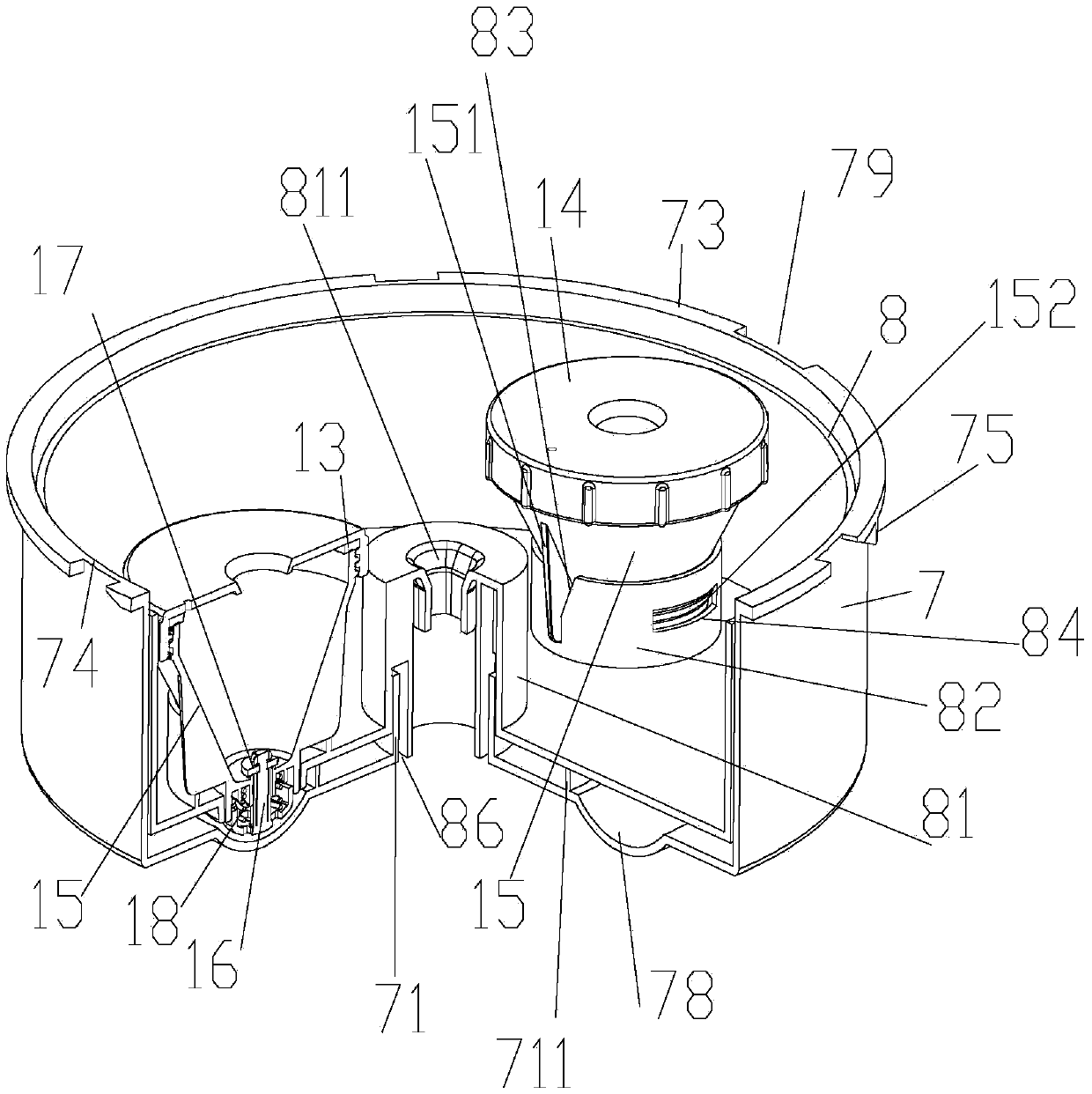

Milk making machine

PendingCN105361703ACause health problemsProblems in preventing moisture deteriorationBeverage vesselsInjection portTorque transmission

The invention discloses a milk making machine, which comprises a machine shell, a water supply unit, a milk supply unit and mixing containers, and further comprises a container fixing base and a rotation driving mechanism, wherein the water supply unit is arranged on the machine shell and is used for controlling water temperature and a water supply amount; the milk supply unit is used for controlling a milk amount; and the mixing containers are used for mixing milk powder with warm boiled water, so that milk liquid is formed, and is exported to a milk bottle; the mixing containers are centrifugally installed on the container fixing base; the rotation driving mechanism is arranged on the machine shell and is connected to the container fixing base by virtue of a torque transmission structure; the rotation driving mechanism is used for driving the container fixing seat to rotate for rotating the mixing container to various stations; an injection port for injecting water and milk powder is arranged in the top surface of the mixing container, and a milk liquid outlet, which is controlled by a valve, is additionally arranged at the bottom of the mixing container; the milk outlet of the milk supply unit and the water outlet of the water supply unit are respectively aligned with the injection ports of the mixing containers on different stations; and a milk outlet station of the milk making machine is located below the water outlet. The milk making machine disclosed by the invention can be used for effectively protecting the milk powder from being affected with damp.

Owner:GUANGDONG SHUNDE CHINNO IND DESIGN

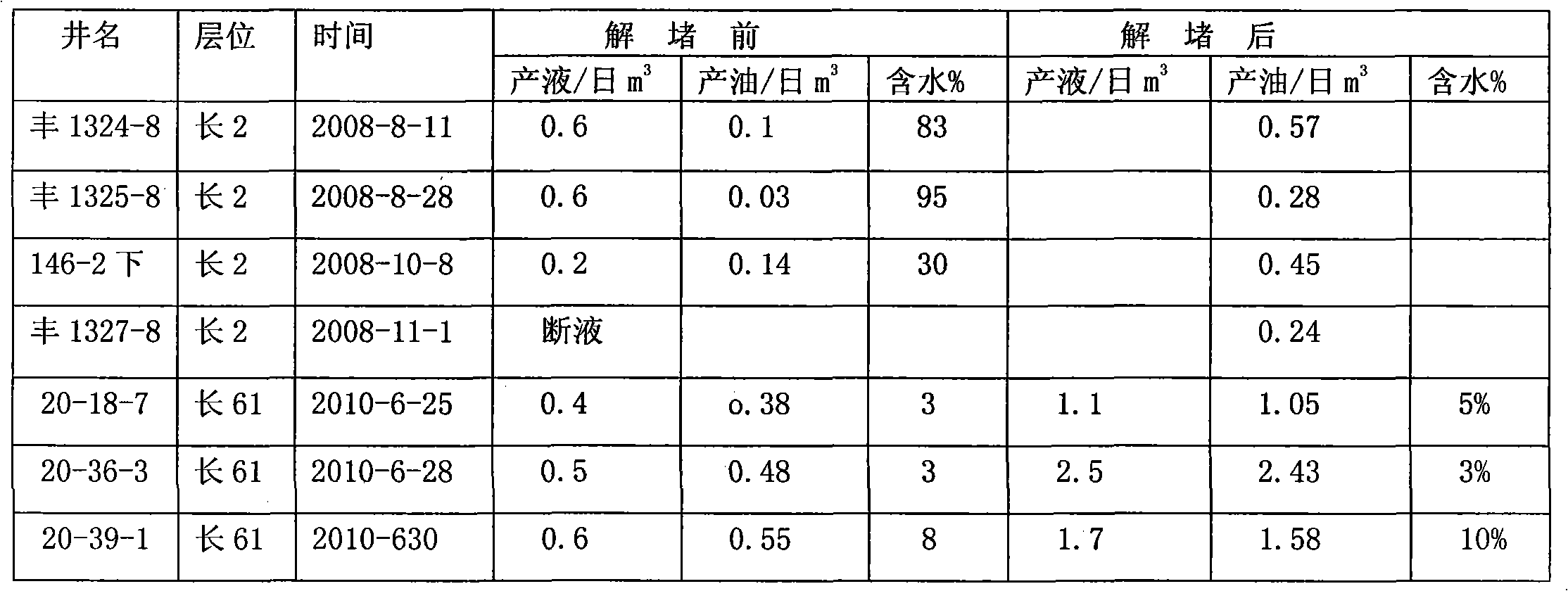

Environment-friendly composite blocking remover composition for oil fields

InactiveCN102399546ANo toxicitySection Tension ReductionDrilling compositionChlorine dioxideCorrosive acid

The invention discloses an environment-friendly composite blocking remover composition for oil fields, comprising 5-10 weight portions of surface active oil displacement agent, 6-11 weight portions of solid chlorine dioxide, and 4-8 weight portions of solid disinfection type activator. The composite blocking remover composition has the characteristics of cleaning and containing no corrosive acid,increases wetting and percolating capacity of the blocking remover, reduces the interfacial tension of the oil-water surface, increases the sweep capacity of the blocking remover, and has the advantages of high efficiency, safety and environmental protection.

Owner:SHAANXI HAIAN IND

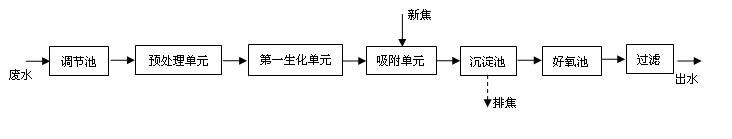

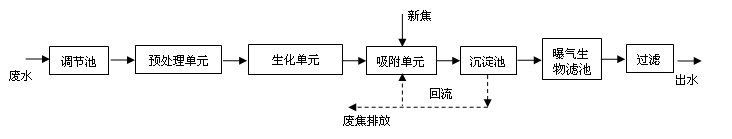

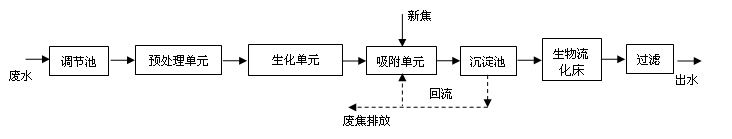

Method for treating coal chemical wastewater

InactiveCN102211839AEfficient treatment processHandling process safetyMultistage water/sewage treatmentWastewaterWater quality

The invention relates to a method for treating coal chemical wastewater, which comprises the following steps in turn: pretreatment, biochemical treatment with a first biochemical unit, adsorption treatment with an adsorption unit, sedimentation treatment with a sedimentation tank, and advanced biochemical treatment. The method solves the technical problems of high ozone electric power consumption, high cost and influence on yielding water quality because ozone is used for performing advanced treatment in the method for treating the coal chemical wastewater in the prior art. In the method for treating the coal chemical wastewater, the ozone is not used, resources are saved, and the yielding water quality can be well guaranteed, so the method is particularly suitable for treating the coal chemical wastewater.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

Technology for extracting tea polyphenol in tea leaves

InactiveCN105693781AReduce particulate impuritiesReduce other unwanted chemicalsOrganic chemistryWater bathsAcetic acid

The invention discloses the field of tea deep processing, and in particular relates to a technology for extracting tea polyphenol in tea leaves. The method comprises the following steps: weighing a sample of dry tea leaves, and grinding; leaching: weighing 25g of tea chips, putting the weighed tea chips into a 100ml of conical flask, adding 60ml of water, soaking the tea chips for 10-20 minutes in a sealing way, and then carrying out ultrasonic extraction for 20-25 minutes, wherein the water bath temperature is 75-85 DEG C; filtering an extracting solution to remove residue; carrying out vacuum centrifugal treatment: centrifuging filtrate after tea residue is removed, and collecting supernatant to prepare tea polyphenol crude extract; concentrating the tea polyphenol crude extract: using a reverse osmosis membrane to concentrate the tea polyphenol crude extract until the water content is reduced by 75-80 percent; extracting: extracting caffeine, namely, mixing petroleum ether and ethyl acetate according to the ratio of 4: 1 and then extracting the caffeine in the tea polyphenol crude extract; extracting the tea polyphenol, using the ethyl acetate to extract the tea polyphenol in upper water phase, and collecting ethyl acetate extract; volatilizing the ethyl acetate, and drying the residue, wherein the residue is the tea polyphenol. The technology is simple in method and low in cost, and the purity of the extracted tea polyphenol reaches up to 98.8 percent.

Owner:GUIZHOU QIANSHANG ECOLOGICAL AGRI TECH CO LTD

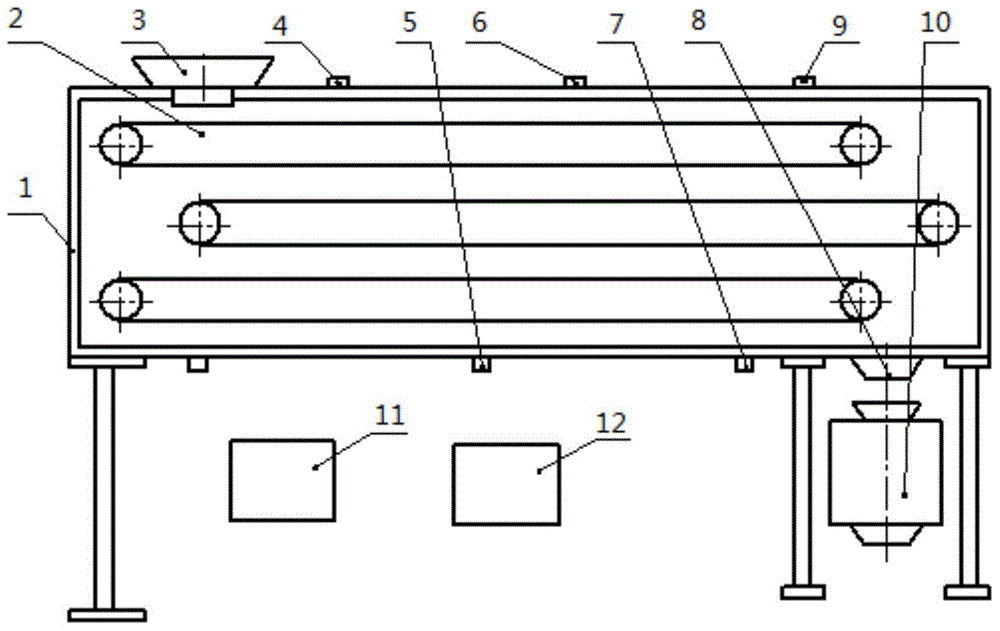

System and method of removing green peels of walnuts through ethylene gas ripening

ActiveCN104544491AReduce moisture contentThe amount of liquid squeezed out is reducedHuskingHullingRipeningBreakage rate

The invention discloses a system and a method of removing green peels of walnuts through ethylene gas ripening. Green-peeled walnuts are poured into a box from a feeder and dropped onto a top wire mesh conveying belt in the box, the green-peeled walnuts are slowly conveyed from an entry of the box to an exit of the box, and a gas ethylene generator enters the box during conveying and performs ethylene gas ripening to the green peels of the walnuts; after the green peels are ripened, the walnuts directly fall into a rubbing stripping unit from the tail end of a bottom wire mesh conveying belt, and the green peels and inner hard shells of the walnuts are separated. Gas ethylene is used to ripen the green peels o the walnuts and remove the green peels; removal rate of the green peels is high; breakage rate is low; yield of commercial walnuts is high; efficiency is high; the use of the gas ethylene in ripening the green peels prevents kernels from being contaminated, resulting in food contamination; meanwhile, the processing process is green.

Owner:SHAANXI UNIV OF SCI & TECH

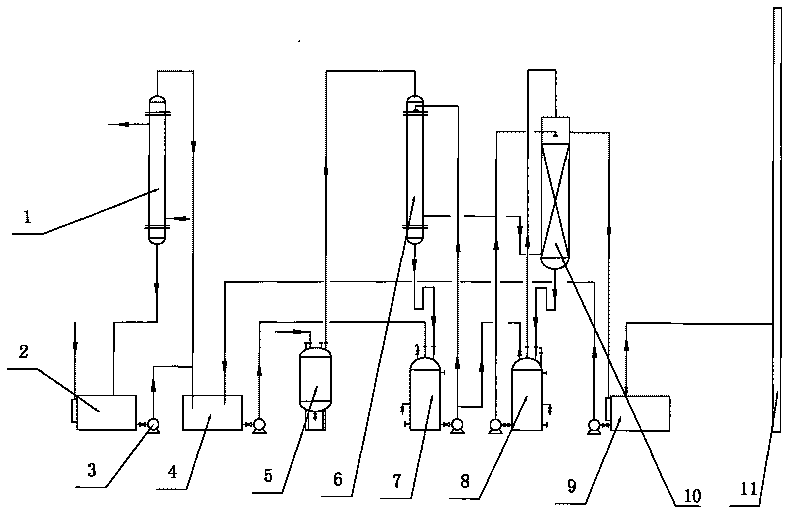

Production process for brewing apricot fruit vinegar from apricot peel pomace

InactiveCN101475900AEliminate pollutionIncrease profitMicroorganism based processesVinegar preparationCelluloseAlcohol content

The invention discloses production technology for brewing apricot fruit vinegar by utilization of apricot bark residue, which comprises: firstly, collecting the apricot bark residue into a stainless steel jar, adding water for stirring, adjusting the content of soluble solid to be between 7 and 9 DEG BX, adjusting the product temperature to be between 42 and 45 DEG C, and transferring an apricot skin residue mixture into an alcohol fermenter; secondly, simultaneously adding active dry yeast and mashed fruit cellulose complex enzyme, controlling the fermentation temperature to be between 28 and 32 DEG C and the fermentation time to be between 48 and 52 hours, and making alcohol fermentation finished when the sugar degree of juice is reduced to be less than or equal to 0.5 percent and the alcohol content of the juice reaches 5 to 7 percent; thirdly, transferring mash obtained in the prior step into an acetic acid fermenter, adding acetic acid bacteria for acetic fermentation, and controlling the fermentation temperature to be between 32 and 38 DEG C; and fourthly, obtaining finished products after the steps of brewing, aging, mixing, filtration, sterilization, filling and sealing in turn.

Owner:轮台县华隆农林业开发有限公司 +1

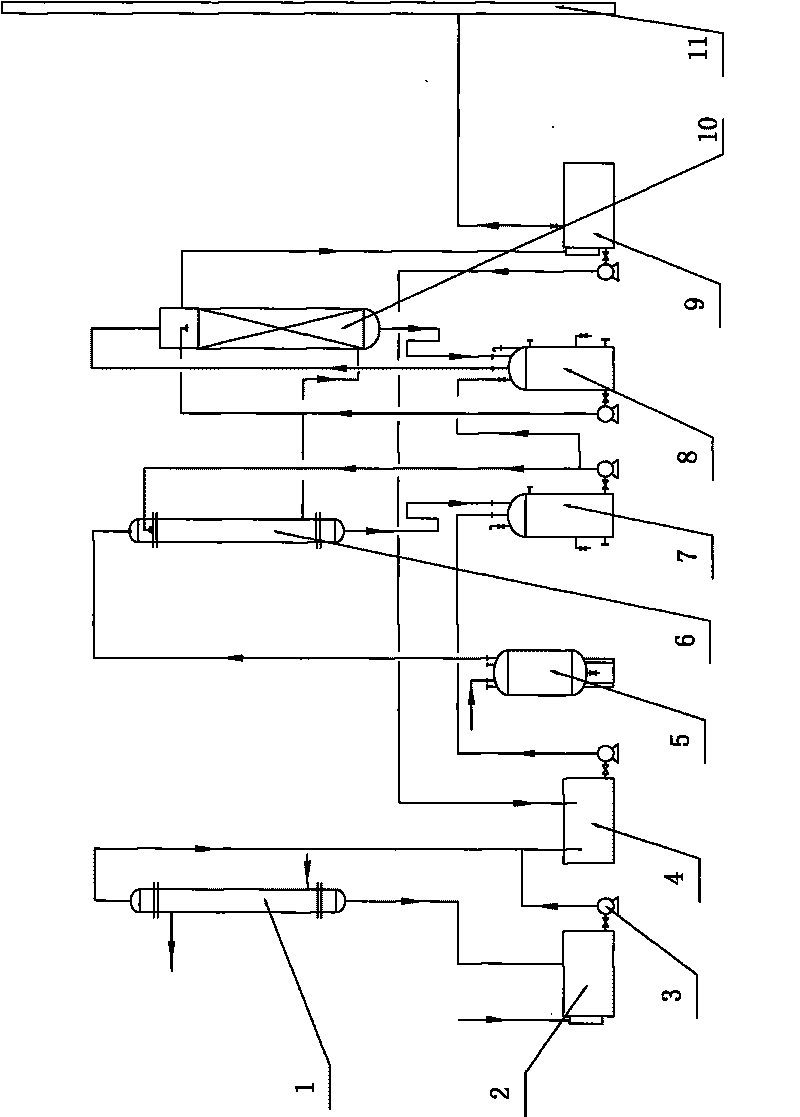

Hydrochloric acid absorption tower and process for producing hydrochloric acid for production

InactiveCN101723327AFully absorbedModerate concentrationChlorine/hydrogen-chlorideDispersed particle separationBuffer tankEconomic benefits

The invention relates to a hydrochloric acid absorption tower and a process for producing hydrochloric acid for production. The absorption tower comprises a heat exchanger, a first vacuum pump, a circulating pump, a hydrochloric acid storage tank, a tail gas buffer tank, a falling film absorber, a first hydrochloric acid tank, a second hydrochloric acid tank, a second vacuum pump, an absorption tower and a tail gas chimney. The process for producing the hydrochloric acid for production comprises the following steps: buffering, primary absorption, secondary absorption, circulating absorption and storage. The absorption tower and the process have the advantages that the environment pollution is reduced, the waste is changed into valuable, the economic benefit is produced, and the process is compact and simple to operate.

Owner:LIAONING DINGJIDE PETROCHEM

Aroma-producing material for heat-not-burn tobacco and preparation method thereof

ActiveCN107594612ARich aromaGood aroma textureCigar manufactureEssential-oils/perfumesHeat not burnCotton material

The invention relates to an aroma-producing material for heat-not-burn tobacco and a preparation method thereof. The preparation method comprises the steps of preparing coating medium and coating. Aroma quality of the aroma-producing material prepared by the natural extracts-based coating medium is closer to that of traditional tobacco. The aroma-producing material is applied to the heat-not-burntobacco, heat conduction uniformity and smoke amount of the tobacco can be increased, the whole smoking quality of the tobacco can be improved, and the aroma-producing material can be effectively usedwhen the heat-not-burn tobacco is smoked.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

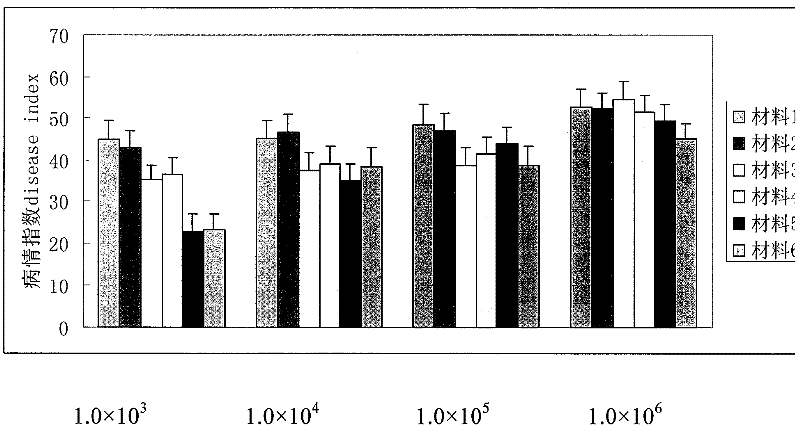

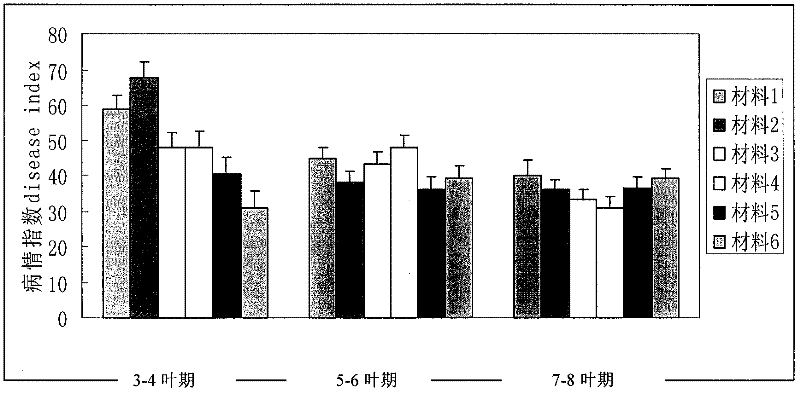

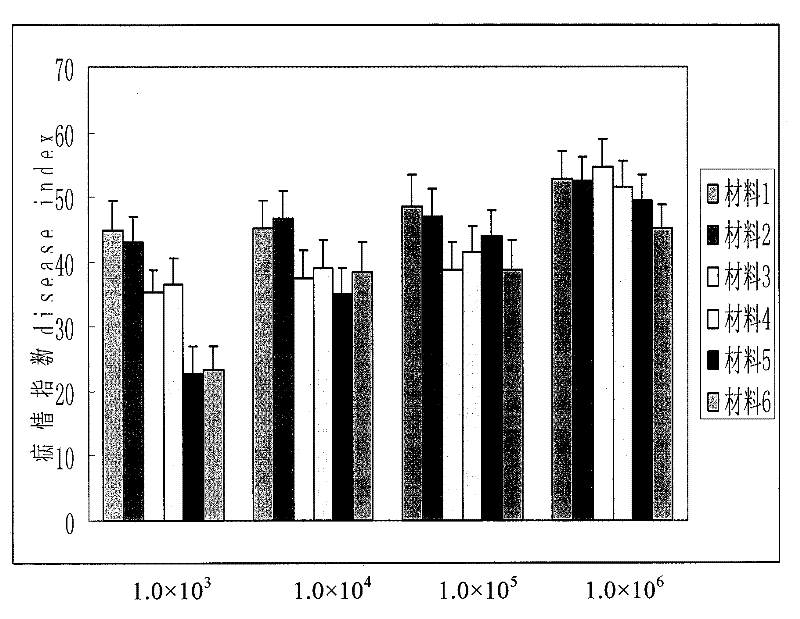

Method for quickly identifying resistance of Chinese cabbage germplasm to black-spot disease

InactiveCN102239779AAvoid conditionsAvoid environmental problemsHorticulture methodsDiseaseGrowth plant

The invention provides a method for quickly identifying the resistance of Chinese cabbage germplasm to a black-spot disease, which is characterized by comprising the following sequential steps of: firstly, preparing a material to be tested; secondly, inoculating; and thirdly, grading a disease index, wherein appropriate concentration of black-spot disease suspending liquid and the seedling age for screening disease-resistant Chinese cabbage are determined; and compared with the inoculation during the adult-plant growth period in field, the method avoids influences of the factors of unsuitability of climatic conditions, plant diseases and insect pests in the environment, and the like, is easy to control the conditions for indoor disease resistance screening during the seedling period, and has short cycle of identification and high speed; and a great amount of manpower and material resources can be saved.

Owner:INST OF ECONOMIC CROP HUBEI ACADEMY OF AGRI SCI

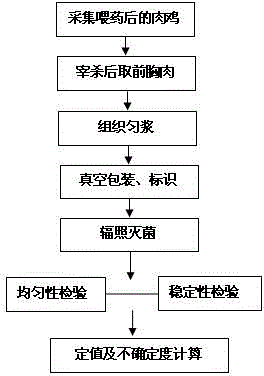

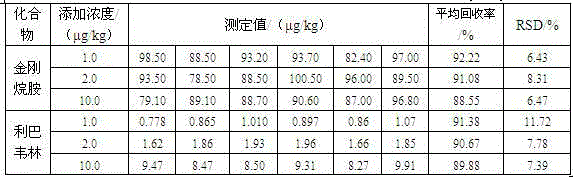

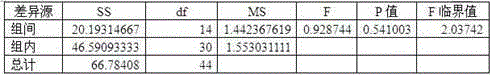

Chicken matrix reference material containing amantadine and ribavirin and preparation method of chicken matrix reference material

InactiveCN104596824AEasy to useModerate concentrationComponent separationPreparing sample for investigationBiotechnologyReference sample

The invention discloses a chicken matrix reference material containing amantadine and ribavirin and a preparation method of the chicken matrix reference material, wherein the preparation method comprises the following steps: feeding live white feather broilers with water containing amantadine and ribavirin, slaughtering the live broilers after amantadine and ribavirin are metabolized to a proper concentration in the live broilers, taking the brisket end, and obtaining the matrix reference material after homogenization and sterilization. According to the invention, the chicken matrix reference material is a natural pollution reference sample, the reference sample can be used for the quality control of relevant detection and analysis, and the sample is homogeneous, stable, convenient to transport and reliable to use.

Owner:INSPECTION & QUARANTINE TECH CENT OF FUJIAN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Abrasive cluster and air hole three-dimensional controllable arrangement CBN (cubic boron nitride) grinding wheel and manufacturing method thereof

ActiveCN103846817ASimple and fast operationLow costAbrasion apparatusGrinding devicesBoron nitrideSharpening

The invention relates to an abrasive cluster and air hole three-dimensional controllable arrangement CBN (cubic boron nitride) grinding wheel and a manufacturing method thereof. The grinding wheel is composed of a base body and an abrasive layer adhered to the base body, wherein the abrasive layer comprises two parts, i.e. an abrasive cluster area and a carcass area; an abrasive cluster is continuously or discretely distributed in the abrasive layer. The abrasive cluster and air hole controllable arrangement is realized in a layered mode by controlling positions and sizes of slot holes or round holes of an abrasive cluster arrangement template, a carcass material arrangement template and a ceramic hollow sphere arrangement template relative to a mold cavity; the position of the slot hole of the abrasive cluster arrangement template is complementary with the position of the slot hole of the carcass material arrangement template; an air hole arrangement template hole cluster area is coincident with a carcass material arrangement template slot hole area. The method is simple in process and low in cost; the prepared grinding wheel is long in service life, excellent in self-sharpening performance, high in grinding efficiency and suitable for effectively and precisely grinding materials which are high in obdurability and difficult to process, such as high-temperature alloy and titanium alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Drinking wine cola

InactiveCN1586333AFragrant and sweet tasteModerate acidityUnknown materialsFood scienceMedicineThirst

Drinking cola as one kind of beverage is prepared with over ten kinds of Chinese medicinal materials including Hovenia dulcis, kudzu vine root, etc. as main material and proper amount of supplementary material. It has sweet and smooth taste, scent, cola color and the health functions of sobering up, protecting liver and stomach, clearing away heat, quenching thirst, tranquilizing, etc. It can eliminate various harms caused by overdrinking, and is a kind of novel safe, fast, efficient and delicious sobering up beverage.

Owner:张传印

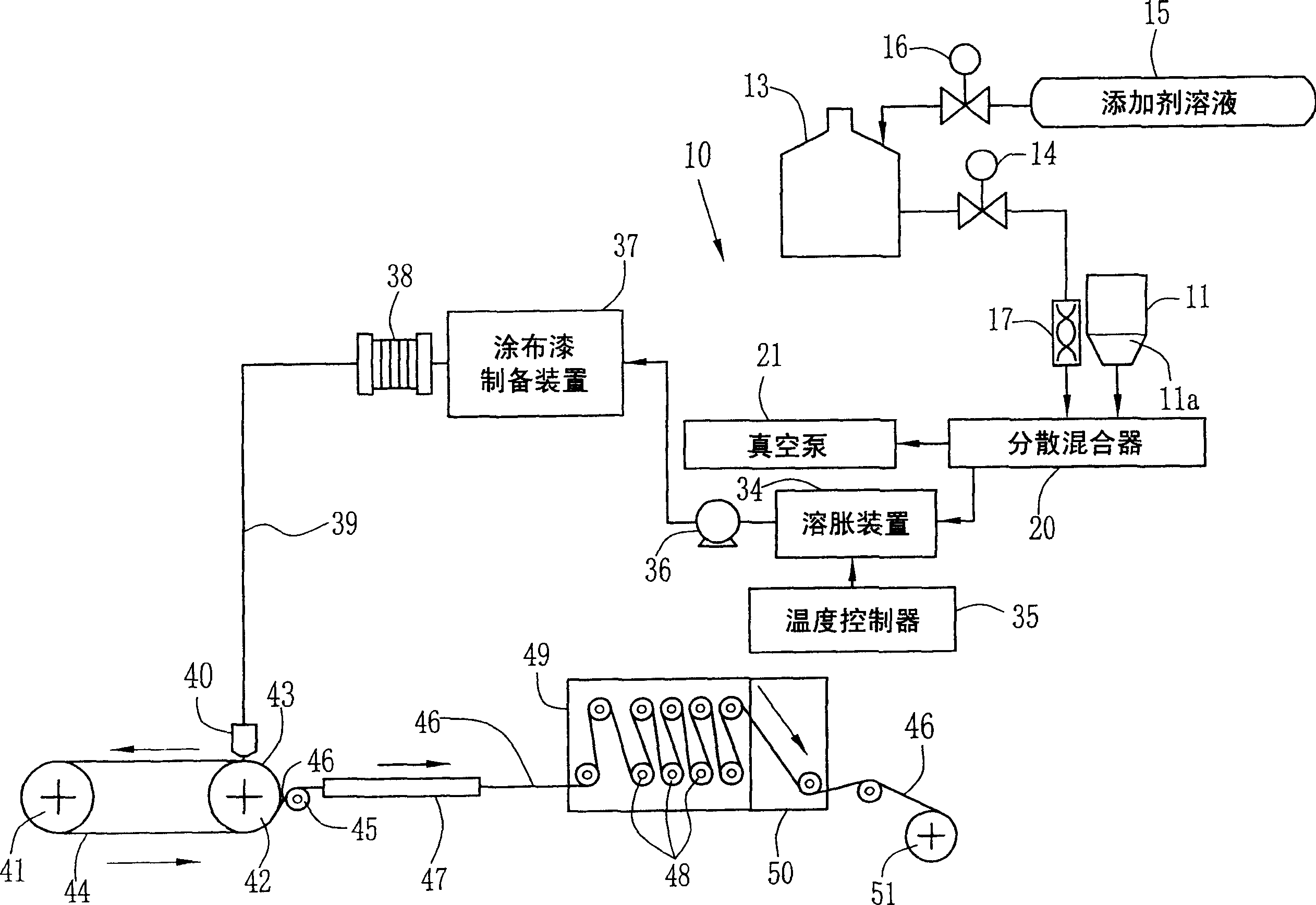

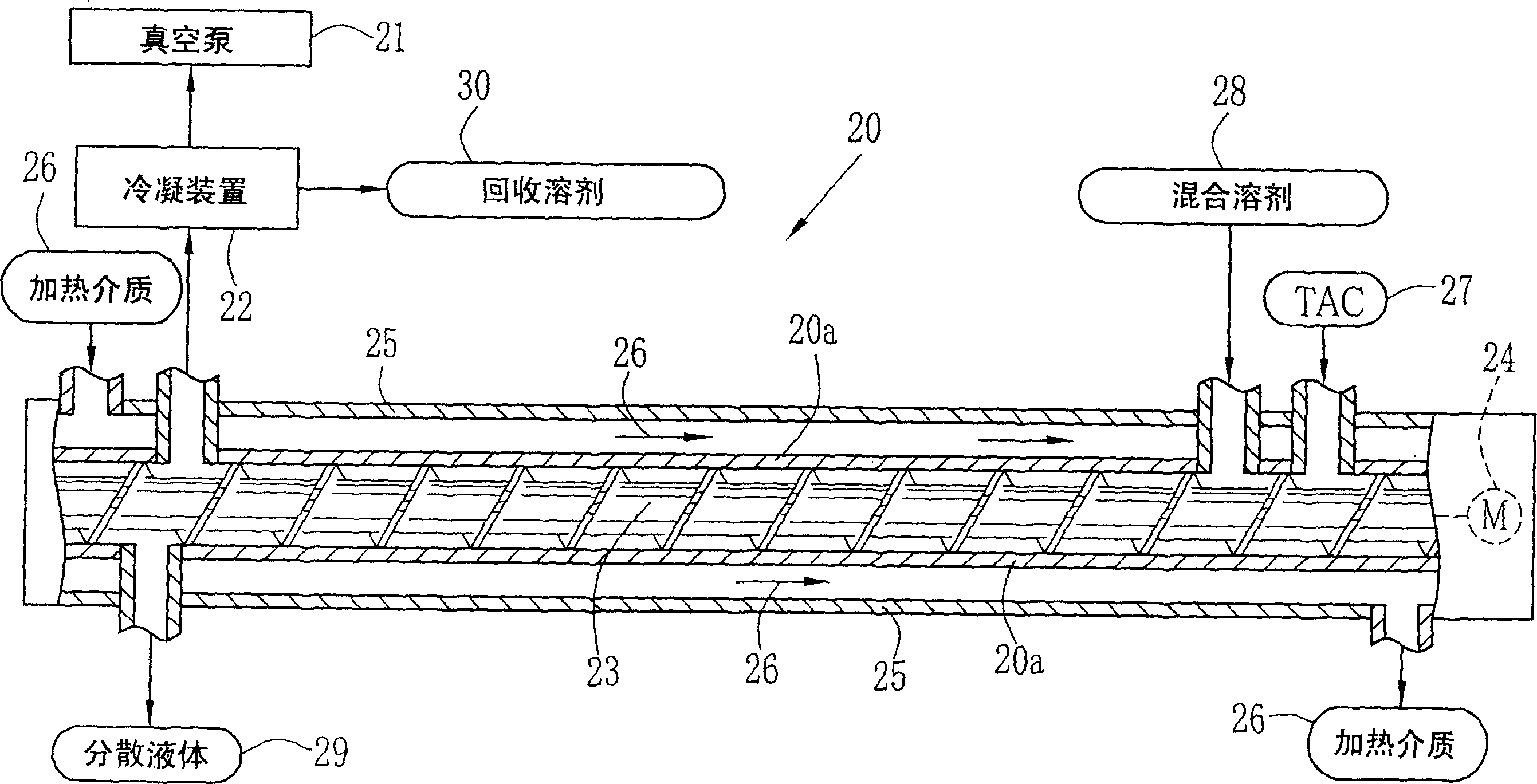

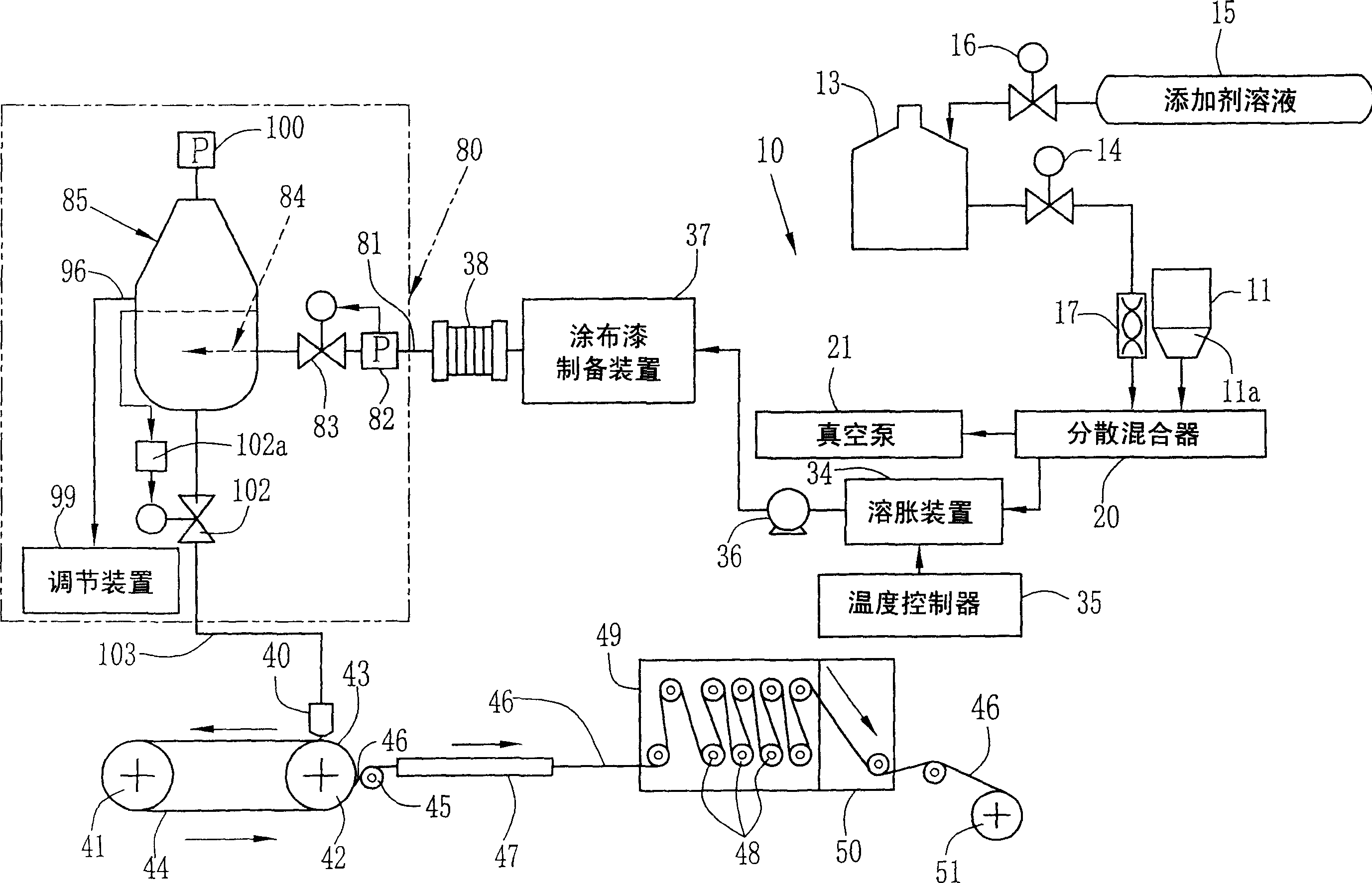

Solution casting method for producing film

InactiveCN1669765AGood film surface propertiesCost advantageFlat articlesCoatingsInternal pressureForeign matter

Owner:FUJIFILM CORP

Special self-controlled multi-stage-releasing biological source physiological regulation antistaling agent for cherries and preparation method thereof

ActiveCN104054816AEnhanced inhibitory effectTogether play a bactericidalFruit and vegetables preservationControl releasePorous starch

The invention discloses a special self-controlled multi-stage-releasing biological source physiological regulation antistaling agent for cherries. The regulation antistaling agent is prepared by the following steps: step 1, preparing a porous quick-release starch physiological regulation antistaling agent used in the first stage; step 2, preparing a porous starch water soluble hole controlled release physiological regulation antistaling agent used in the second stage; step 3, preparing a porous starch swelling hole controlled release physiological regulation antistaling agent used in the third stage; and step 4, mixing the antistaling agents prepared in the step 1 to step 3 according to weight ratio of (1 to 2 to 3)-(1 to 2 to 5) and packing into small packages to obtain the antistaling agent. The special antistaling agent has the advantages of being efficient, free from pollution, good in antistaling effect and free from influence on the cherry flavor.

Owner:FARM PROD STORAGE & FRESHENING INST SHANXI ACADEMY OF AGRI SCI

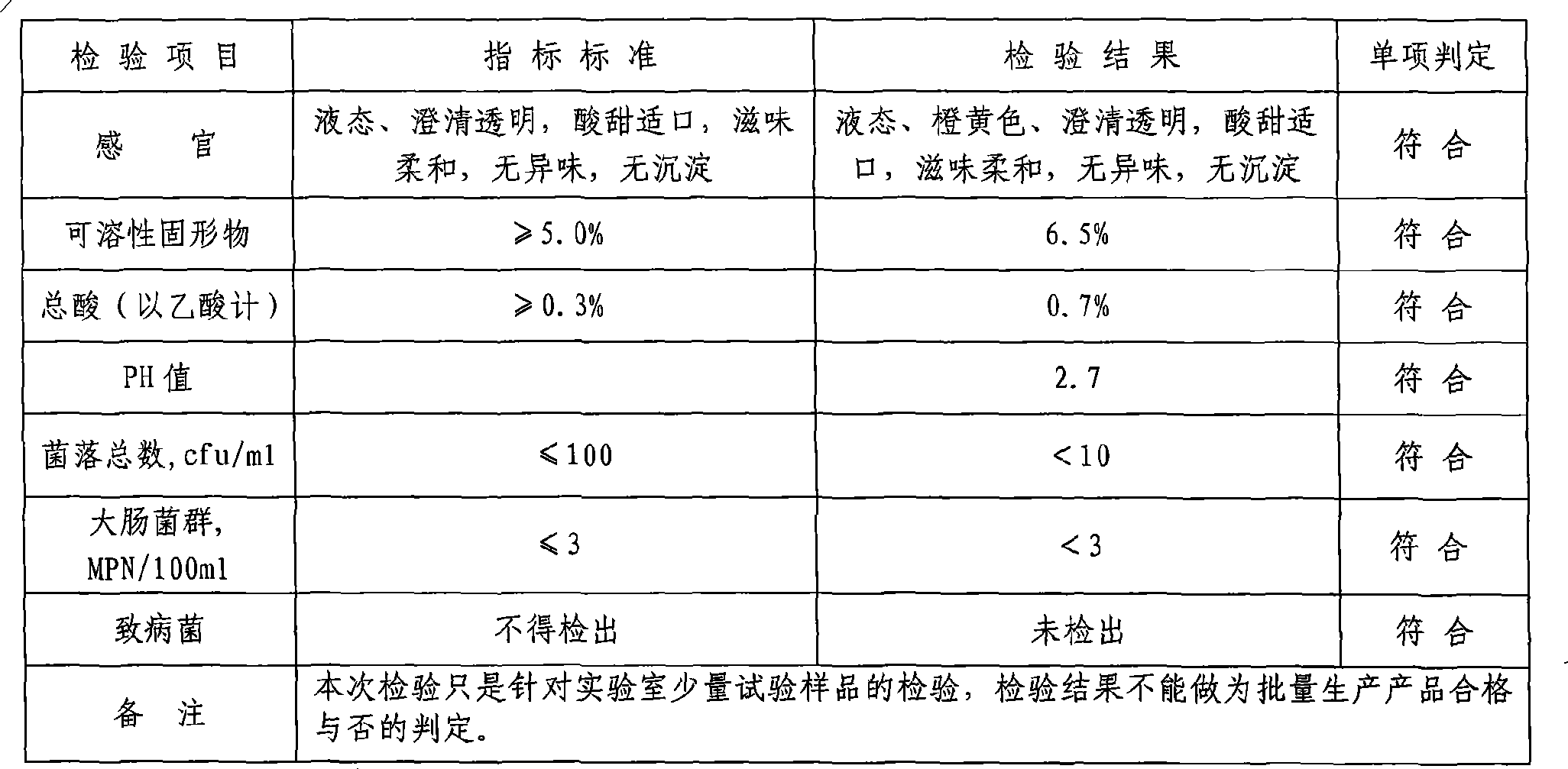

Houttuynia beverage and its production method

The houttyuynia beverage with the functions of clearing heat away, removing toxic material, elimianting summer-heat and allaying thirst is made up by using drinking water, houttuynia, peppermint, sugar, natural stevioside and citric acid according to a certain mixing ratio through the processes of water extraction, filtering, mixing materials, secondary filtering, homogenizing, sterilizing, filling, sealing and quality inspection. Said product is sweet-sour palatable in taste and has golden yellow colour, and is suitable for large-scale production.

Owner:湖南省岳阳市君山区麒英食品厂

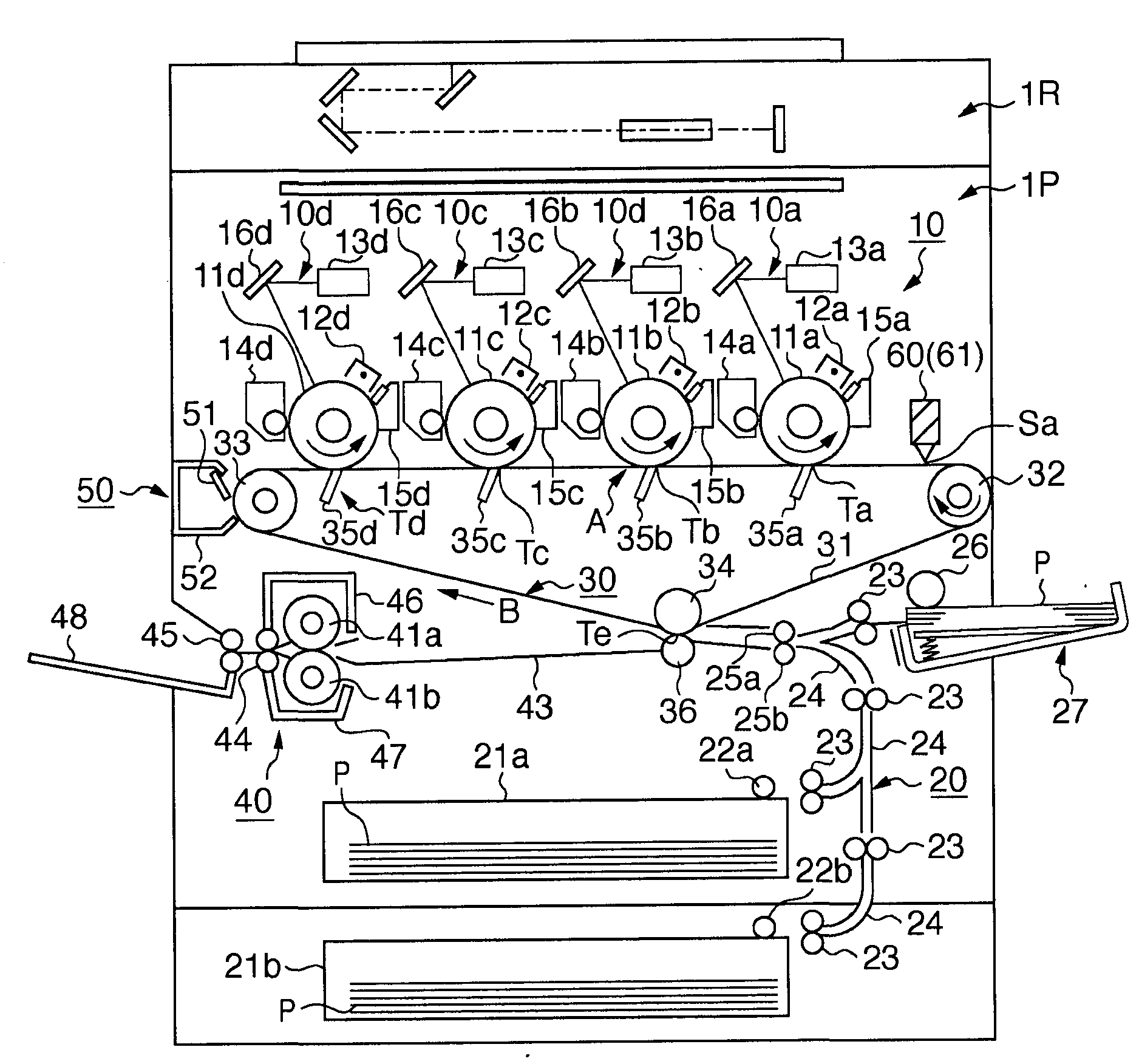

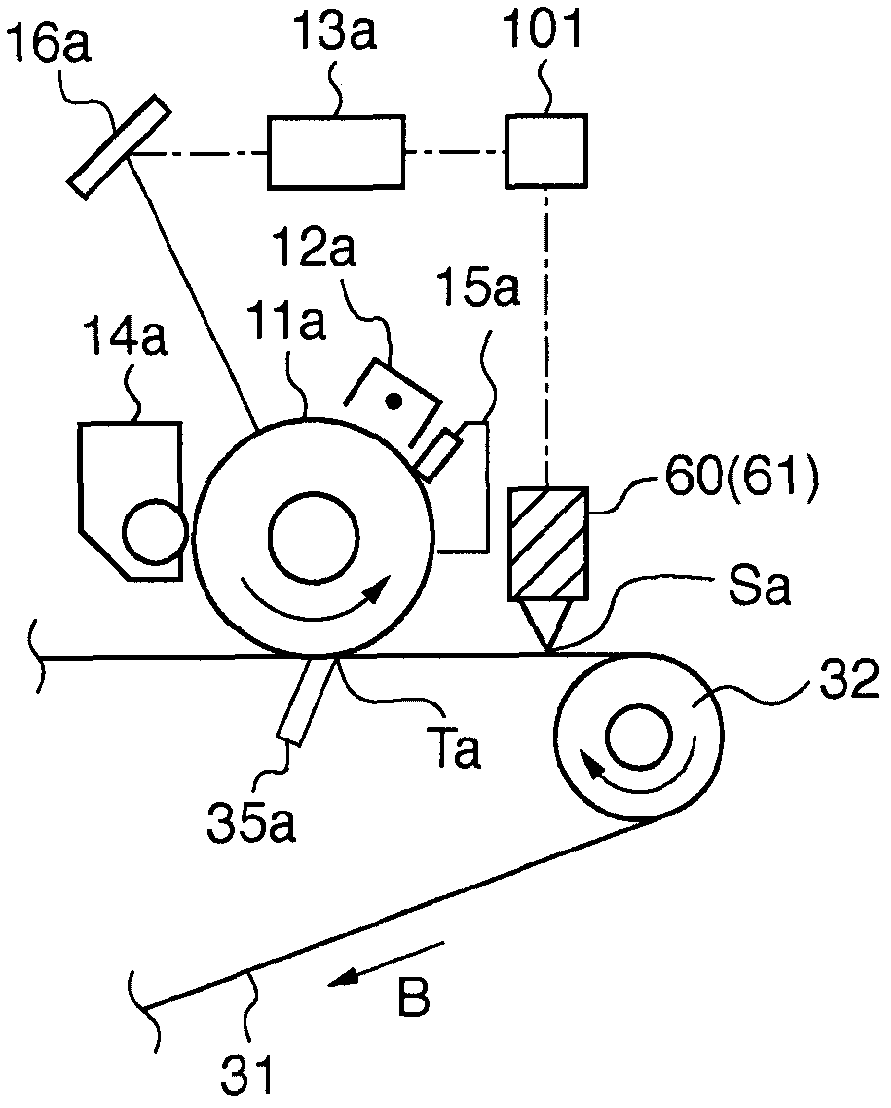

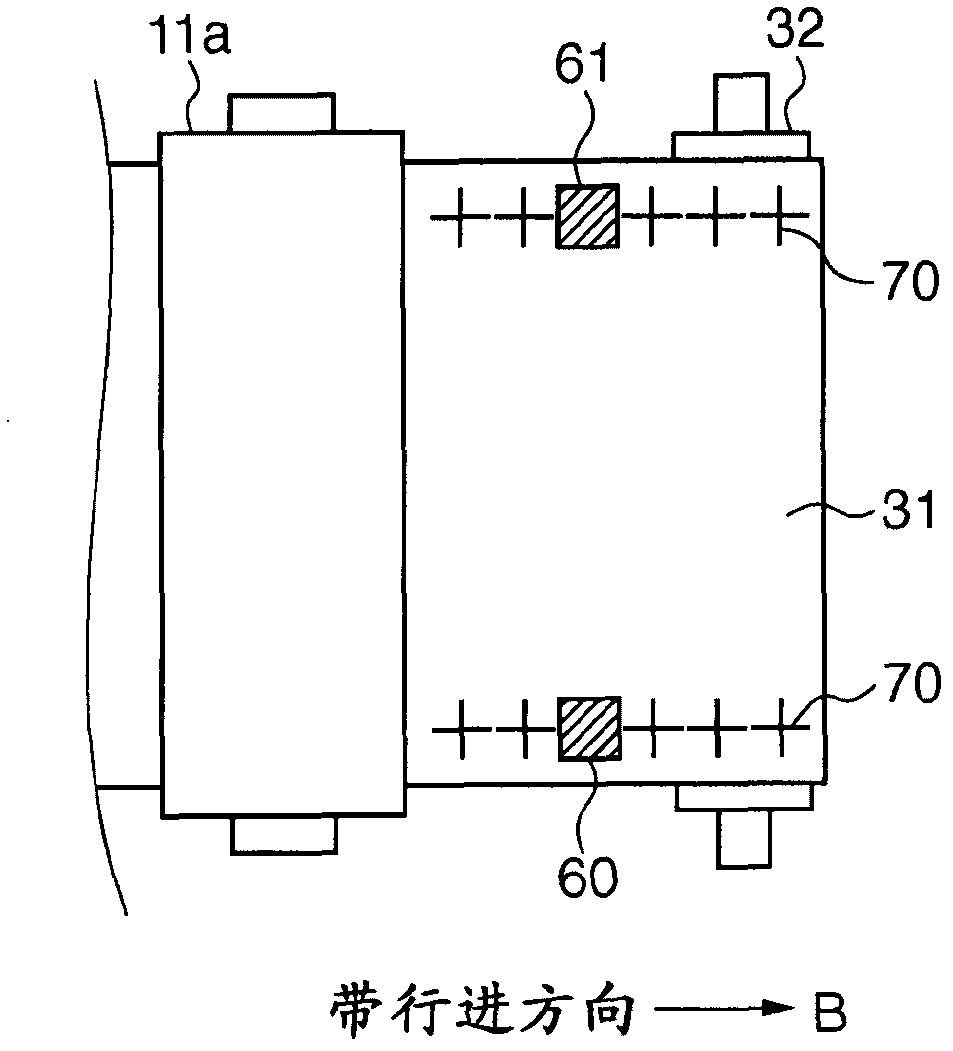

Image forming apparatus

InactiveCN102375362AModerate concentrationElectrographic process apparatusImage transferLatent image

An image forming apparatus comprises: an exposure unit configured to irradiate each of a plurality of photosensitive members with a light beam, a light amount control unit configured to control a light amount of the light beam, a plurality of developing units configured to develop electrostatic latent images, formed on the plurality of photosensitive members by exposure with the light beams, and a transfer unit configured to transfer toner images formed on the plurality of photosensitive members onto an image carrier; a pattern forming unit configured to control the image forming unit to form, a misalignment detection pattern for detecting a relative misalignment between the toner images transferred onto the image carrier; a pattern reading unit configured to read the misalignment detection pattern; and a correction unit configured to correct the relative misalignment between the toner images based on the reading result obtained by the pattern reading unit.

Owner:CANON KK

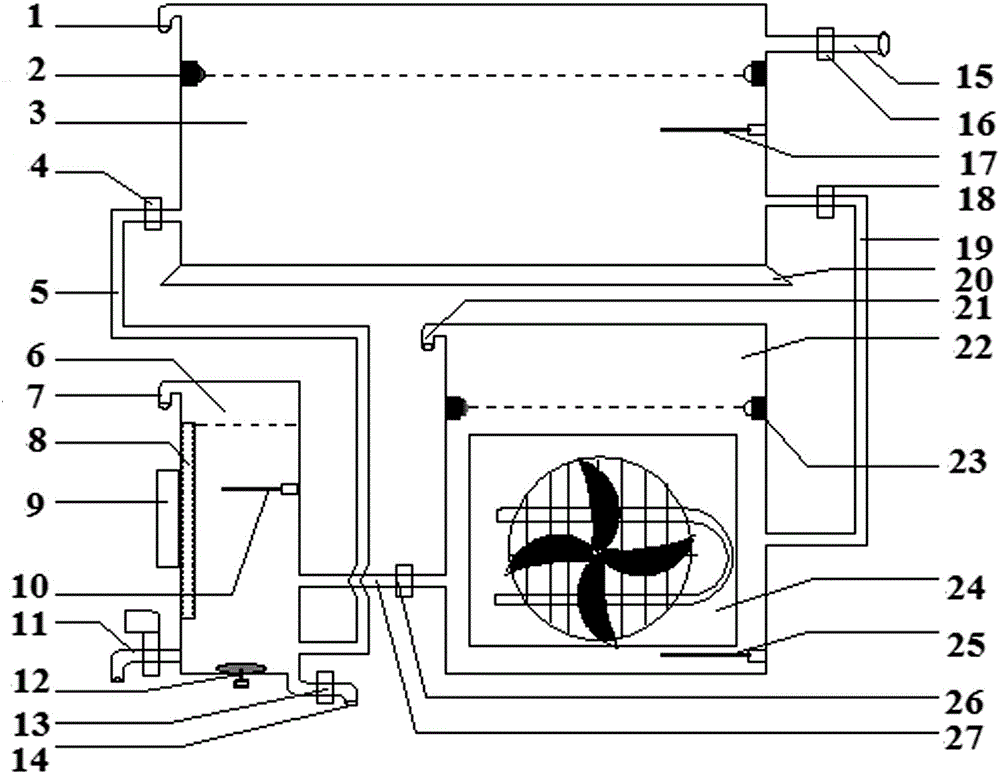

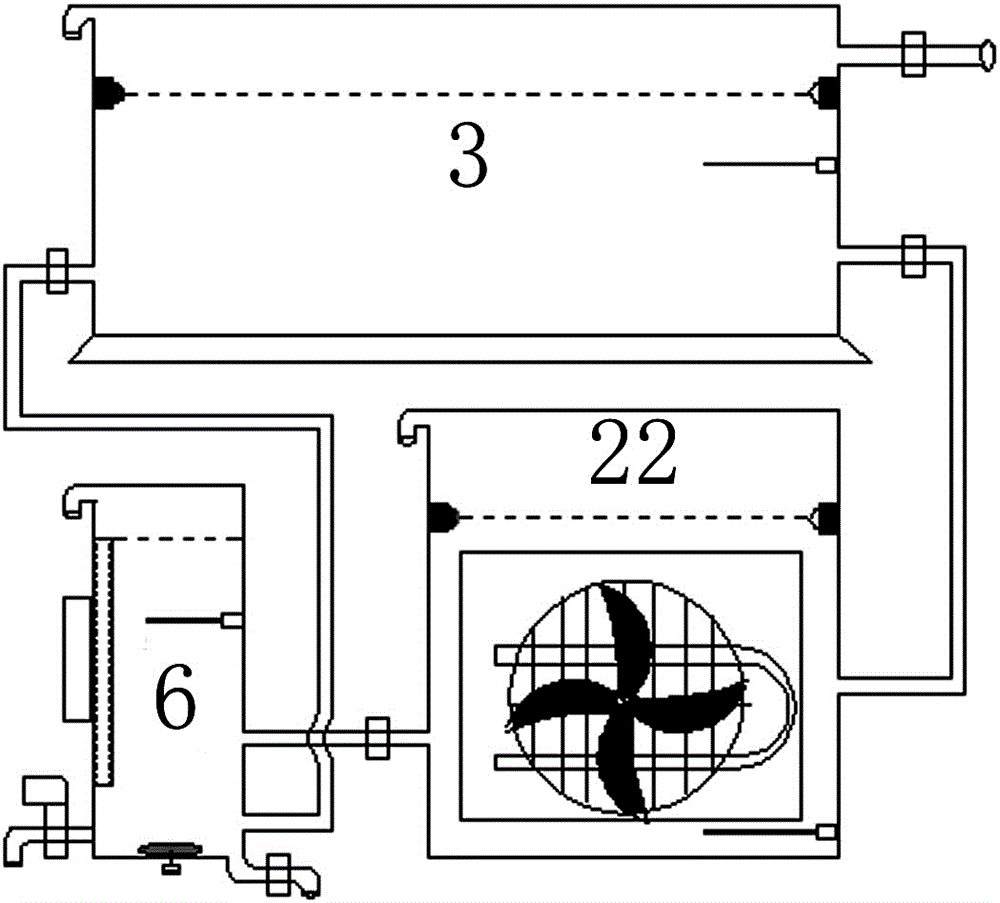

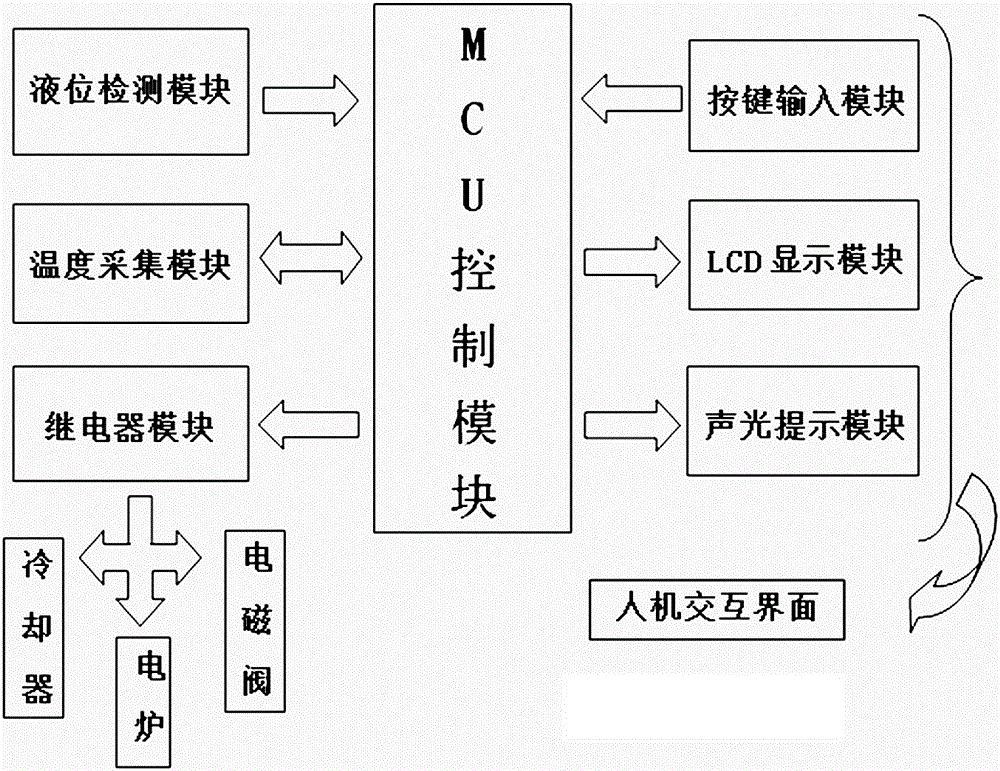

Small water temperature control system

ActiveCN105054797AMeet water temperature requirementsHigh speedBeverage vesselsControl systemWarm water

The invention provides a small water temperature control system. The small water temperature control system comprises a hot water tank, a cold water tank and a warm water tank. The hot water tank is provided with a heater, the cold water tank is provided with a cooler, the warm water tank is provided with a stirrer, and the hot water tank is provided with a water inflow pipe, connected with the cold water tank through a first water outflow pipe and connected with the warm water tank through a second water outflow pipe. A first temperature sensor and a first liquid level sensor are installed in the hot water tank. A second temperature sensor and a second liquid level sensor are installed in the cold water tank. The warm water tank is connected with a fourth water outflow pipe leading to a water receiving opening and connected with a water drainage pipe, and a third liquid level sensor and a third temperature sensor are installed in the warm water tank. According to the system, tap water is boiled and then mixed, warm water with the set temperature value can be quickly generated, the warm water volume can be monitored and prompted through liquid level detection, the volume of the drained warm water can be prompted, and therefore the concentration of made milk powder is proper.

Owner:CHINA THREE GORGES UNIV

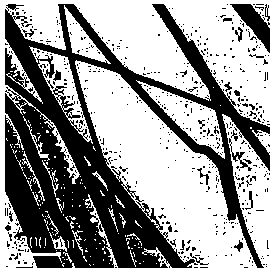

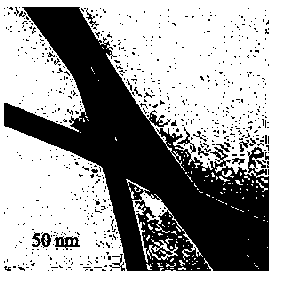

Preparation method of CIST nano wire

ActiveCN104064628AReductivePrevent oxidationMaterial nanotechnologyFinal product manufactureIndiumTrioctylphosphine

A preparation method of a CIST nano wire belongs to the technical field of new-generation thin-film solar cell materials. A toluene solution of Bi nanoparticles and a precursor solution of Se and Te are prepared separately. Then under the protection of nitrogen, trioctylphosphine is heated and added into the toluene solution of the Bi nanoparticles, and then the precursor solution containing indium acetate, copper acetate and Se is added into the mixture. After reactions, the precursor solution containing indium acetate, copper acetate and Se is added drop by drop. After reactions are completed, the mixture is cooled and toluene is added. Then the mixture is subjected to centrifugation. The solid phase is taken, is washed with toluene, and is subjected to centrifugation and vacuum drying. Then the CIST nano wire is obtained. The method uses the metal Bi nanoparticles as a catalyst. The toluene solution of the Bi nanoparticles is used, so that the concentration of the Bi nanoparticles can be effectively controlled, and the liquid form facilitates taking the catalyst. The method is simple in technique, can effectively control the stoichiometric ratio of multi-component materials, and obtains a large batch of high-purity CIST nano wires.

Owner:YANGZHOU UNIV

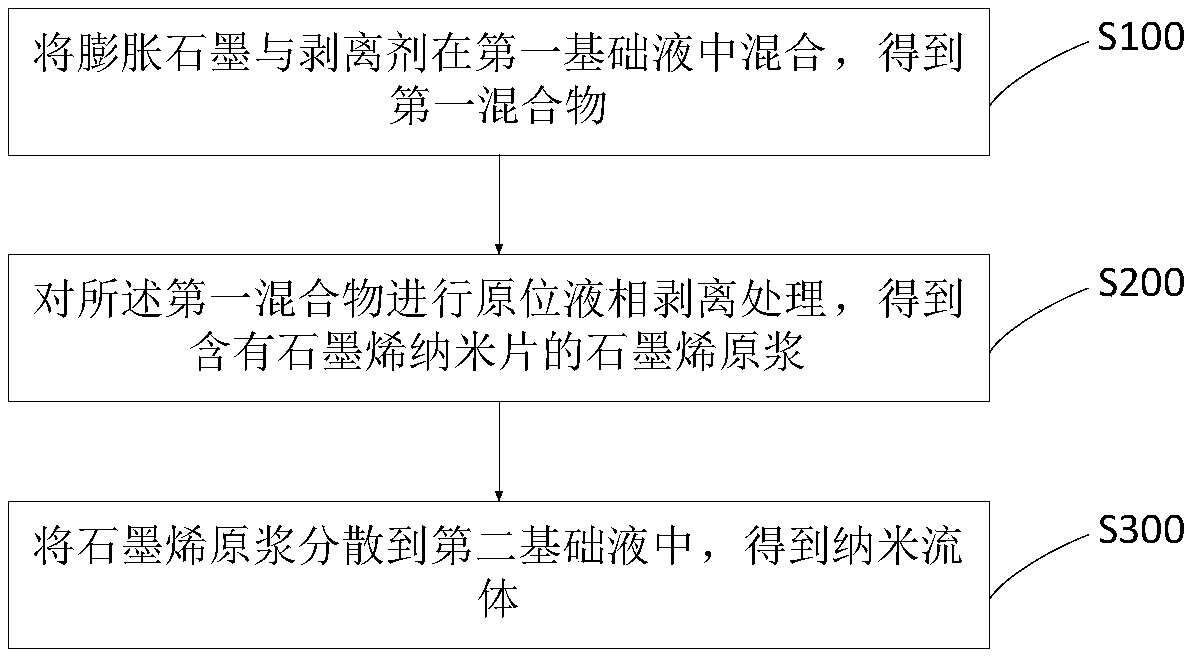

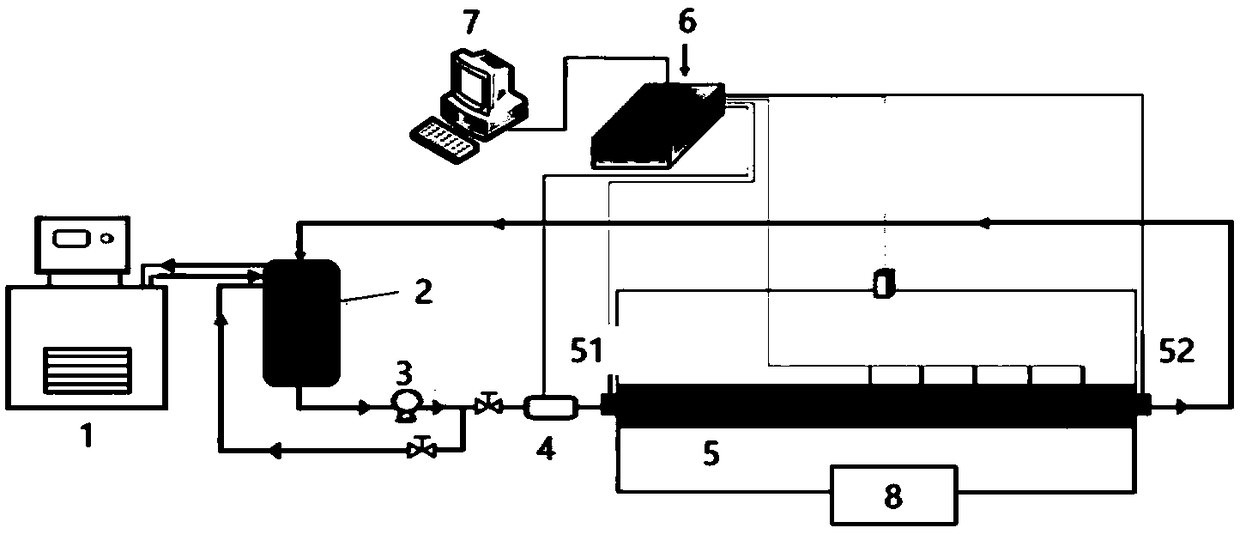

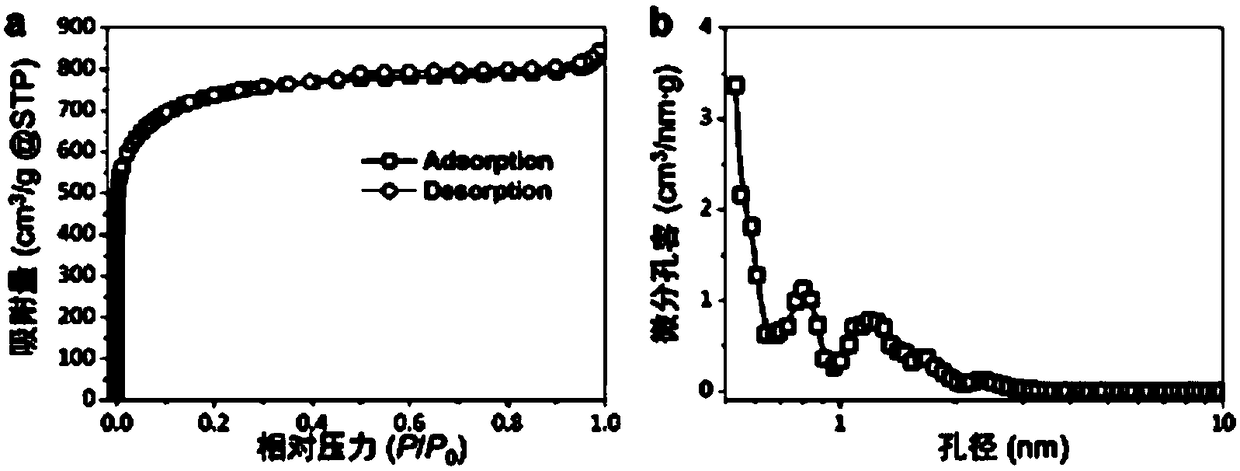

Nano-fluid for efficient heat transfer fluid, preparation method thereof and heat exchange device

The invention provides a nano-fluid, a preparation method thereof and a heat exchange device. The preparation method of the nano-fluid comprises the following steps: mixing expanded graphite with a stripping agent in a first base fluid to obtain a first mixture, and performing in-situ liquid phase stripping treatment on the first mixture to obtain a raw graphene stock containing graphene nano-sheets; and uniformly dispersing the raw graphene stock into a second base fluid to obtain the nano-fluid. The inventors have found that the method is simple and convenient to operate, facilitates large-scale production, is safe and environment-friendly, and can obtain the nano-fluid with high heat transfer coefficient, high thermal conductivity, low flow resistance and long-term stable dispersion.

Owner:ENN GRAPHENE TECH CO LTD

Preparation method of clove flavor cigar with auditory effect

The invention provides a preparation method of clove flavor cigar with an auditory effect. The preparation method concretely comprises the following steps of picking clove according to requirements; performing cleaning and dust removal on the picked dry clove buds; performing drying through drying equipment; taking out the buds for use after the water content is lower than 5 percent; putting 5 to6 processed clove buds into the center position of a single cigar core leaf; sequentially distributing the clove buds into a line to prepare a cigar core; then, taking one leaf roll for winding the cigar core; performing fixing and shaping; then, putting the materials into a wood cigar mold for 30 to 45 minutes; finally, taking one piece of a binder leaf for well covering a cigarette bundle; usingplant glue for bonding and winding the cigar; next, putting the cigar into a refrigerator; putting the refrigerator into a constant-temperature constant-humidity balance room; controlling the temperature to be 18 to 20 DEG C and the humidity to be 65 to 75 percent; performing placement for 25 to 35 days. The prepared cigar has the slight clove flavor; during the smoking, the uniform slight clacking sound is generated at a frequency of once per 2 to 3 seconds; the sound volume is proper; the auditory effect is added for the cigar smoking.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com