Production process for brewing apricot fruit vinegar from apricot peel pomace

A production process and apricot skin residue technology are applied in the field of production technology for brewing apricot fruit vinegar by using apricot skin residue, can solve the problems of rough production process arrangement, long brewing time and high production cost, and achieve smooth and reasonable production process and raw materials. The effect of high utilization rate and short processing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

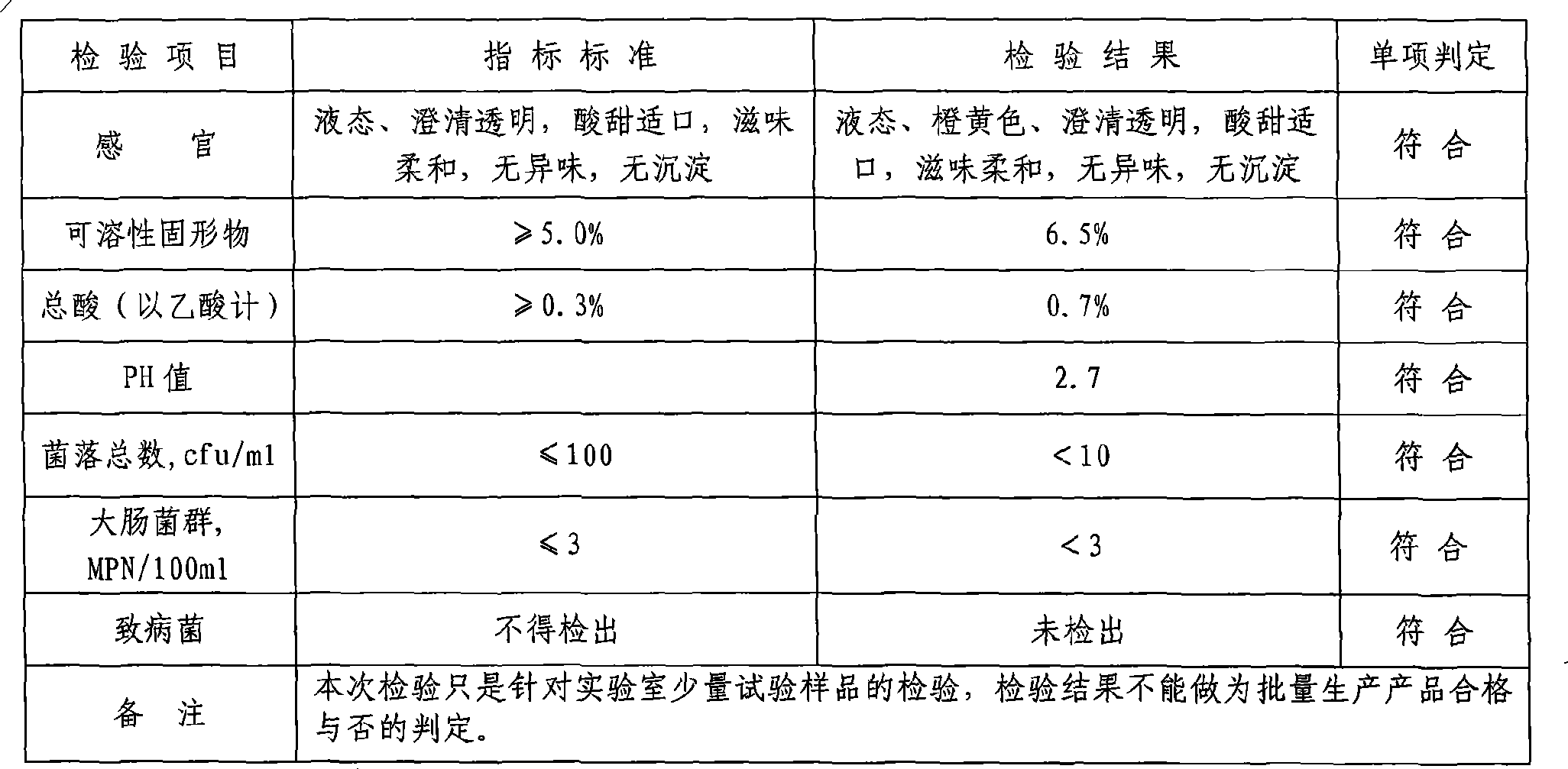

Image

Examples

Embodiment Construction

[0021] A kind of production technology that utilizes apricot pomace to brew apricot fruit vinegar comprises the following steps:

[0022] 1. Raw material dilution and mixing process: collect the apricot peel residue into a stainless steel tank, add drinking water accounting for 80% of the weight of the apricot peel residue and stir evenly, adjust the soluble solid content in the tank to 8°BX and adjust the product temperature to 42 -45°C, then transfer the adjusted apricot skin dregs mixed solution into the alcohol fermentation tank, and the feed amount of each fermentation tank should be less than or equal to 85% of the volume of the fermentation tank to prevent overflow.

[0023] 2. Enzymolysis and alcohol fermentation process: Add the activated active dry yeast into the fermenter and stir and mix it evenly with the apricot dregs mixture, the amount of active dry yeast is 10% of the apricot dregs mixture. 0.4‰ of the liquid weight, and at the same time, add the fruit pulp ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com