Patents

Literature

26715results about "Floor cleaners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

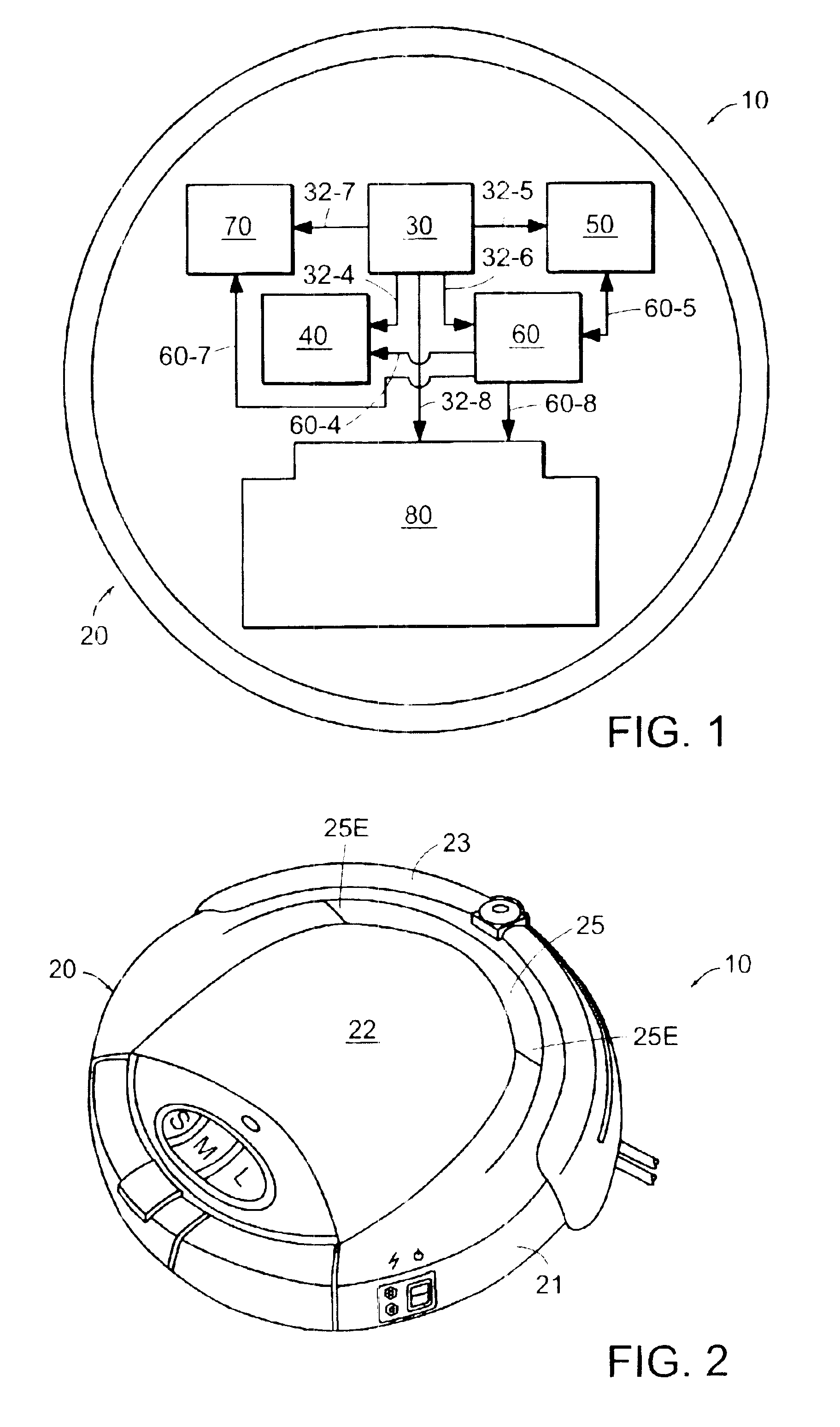

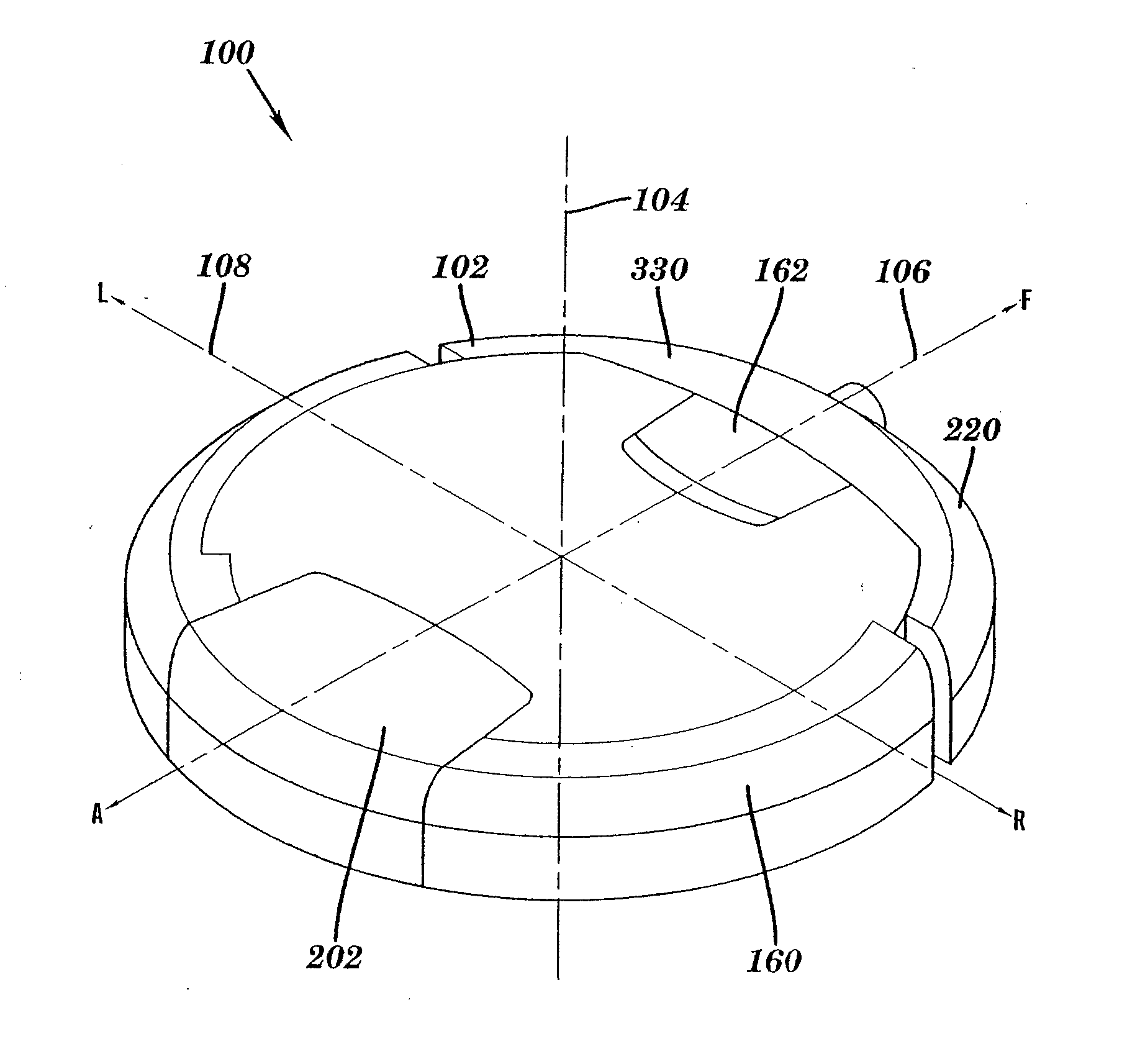

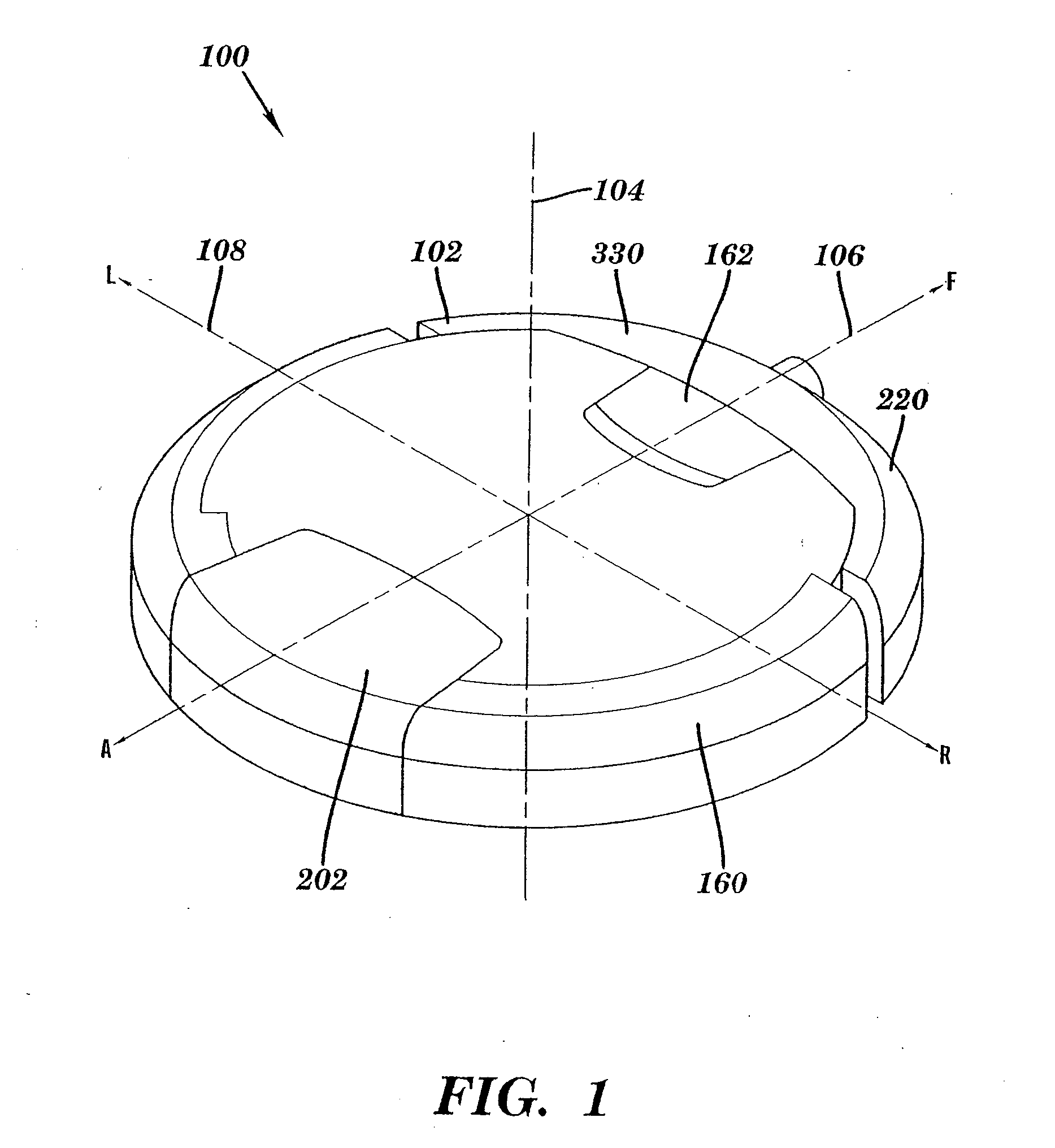

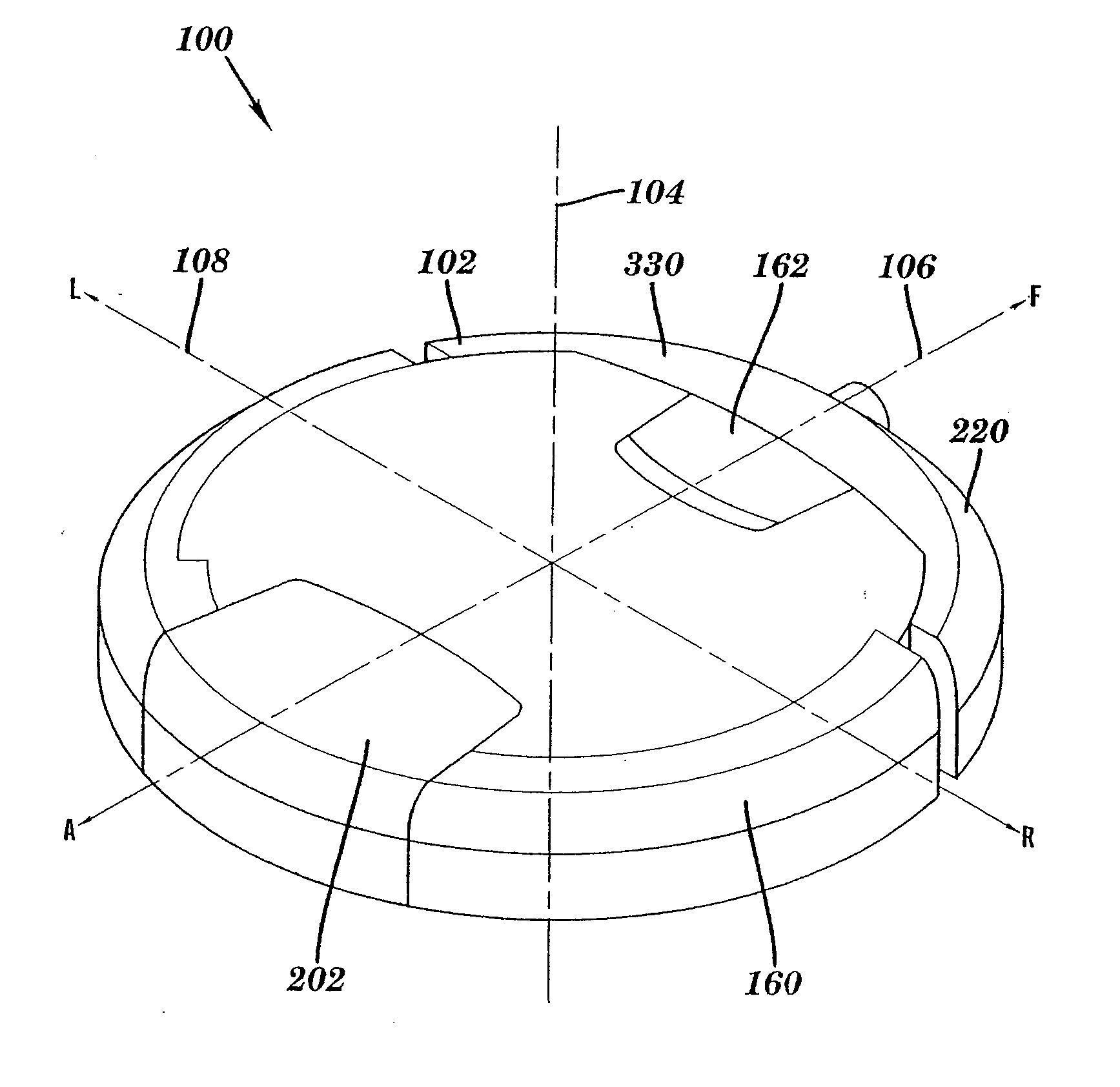

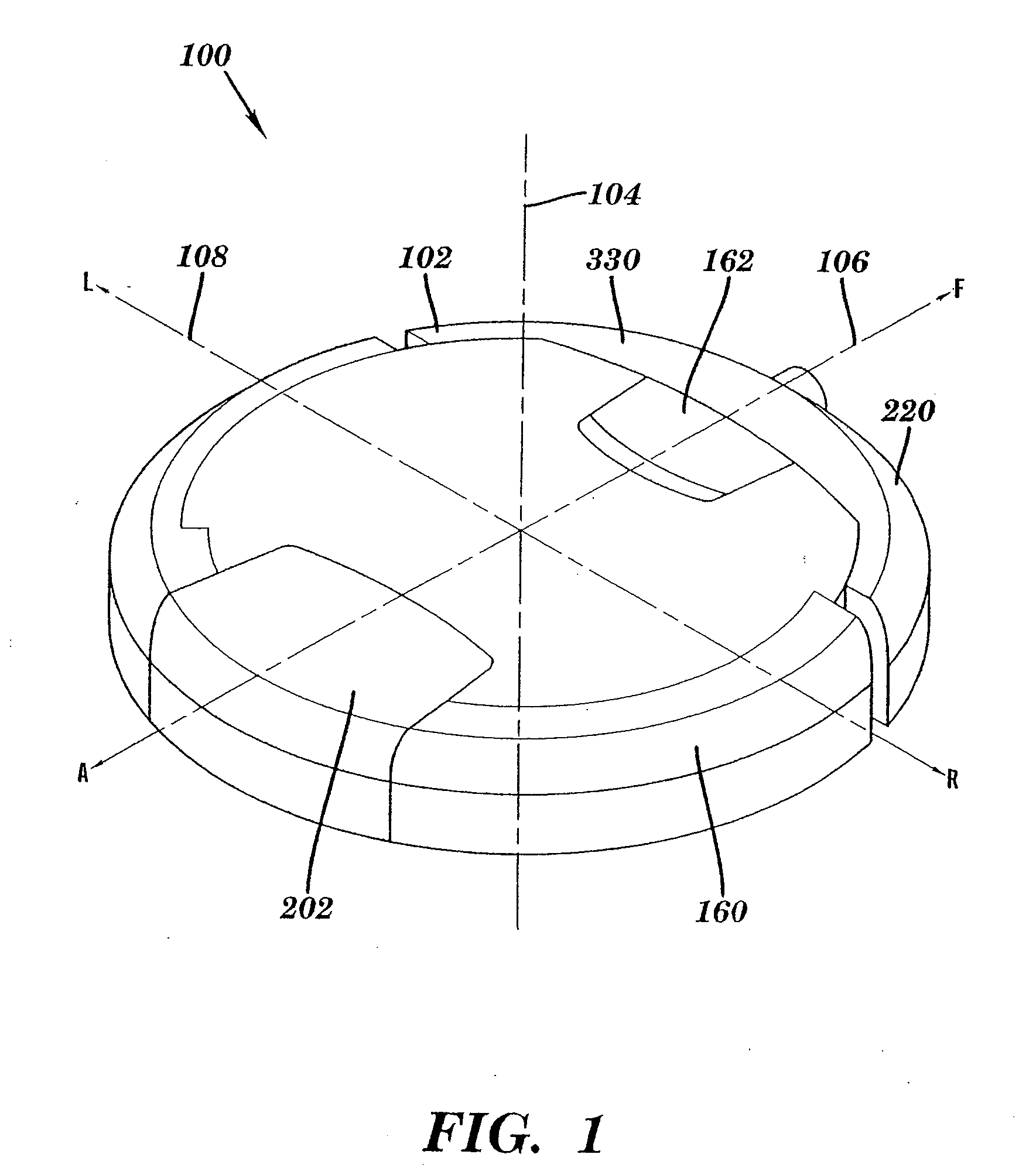

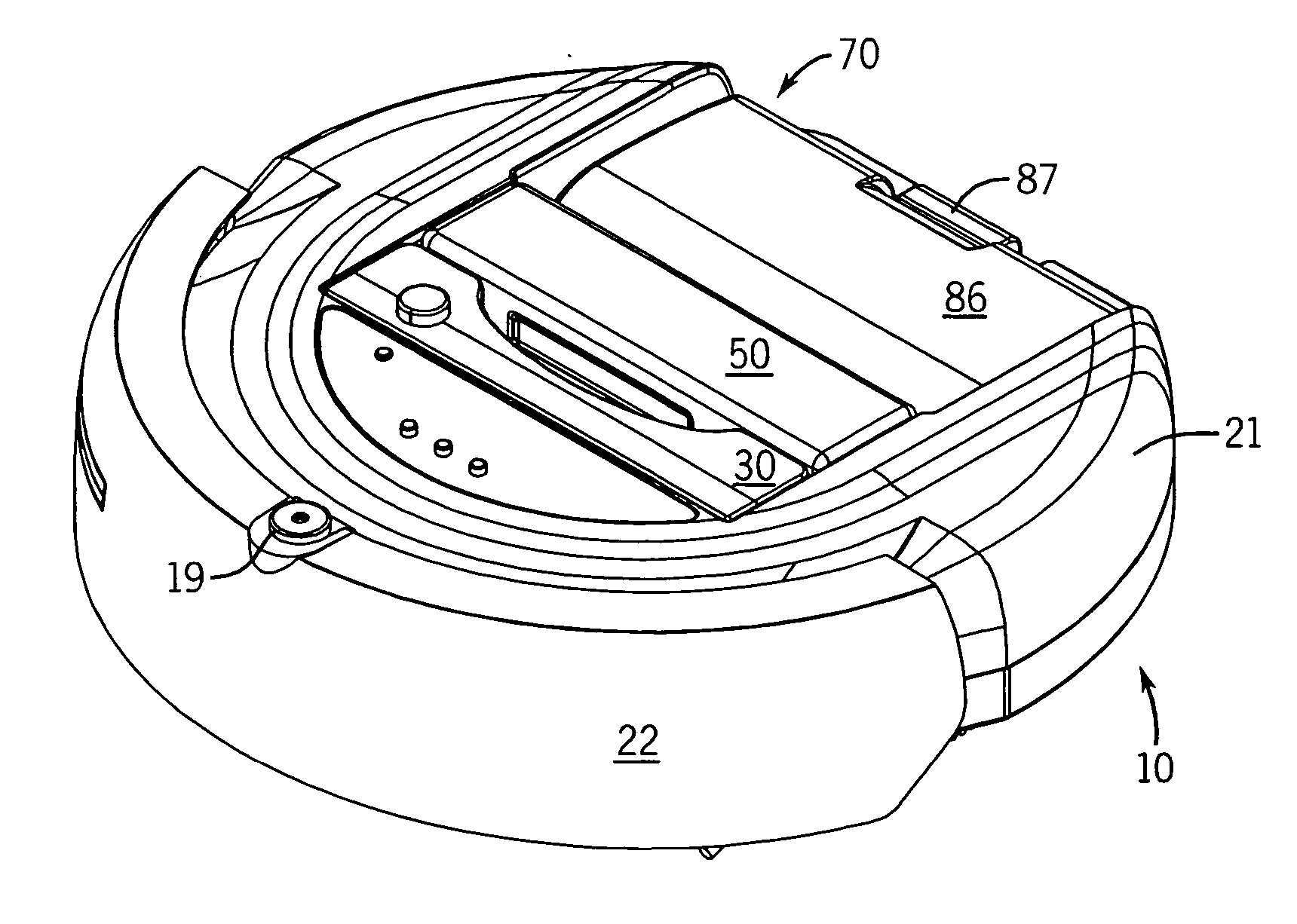

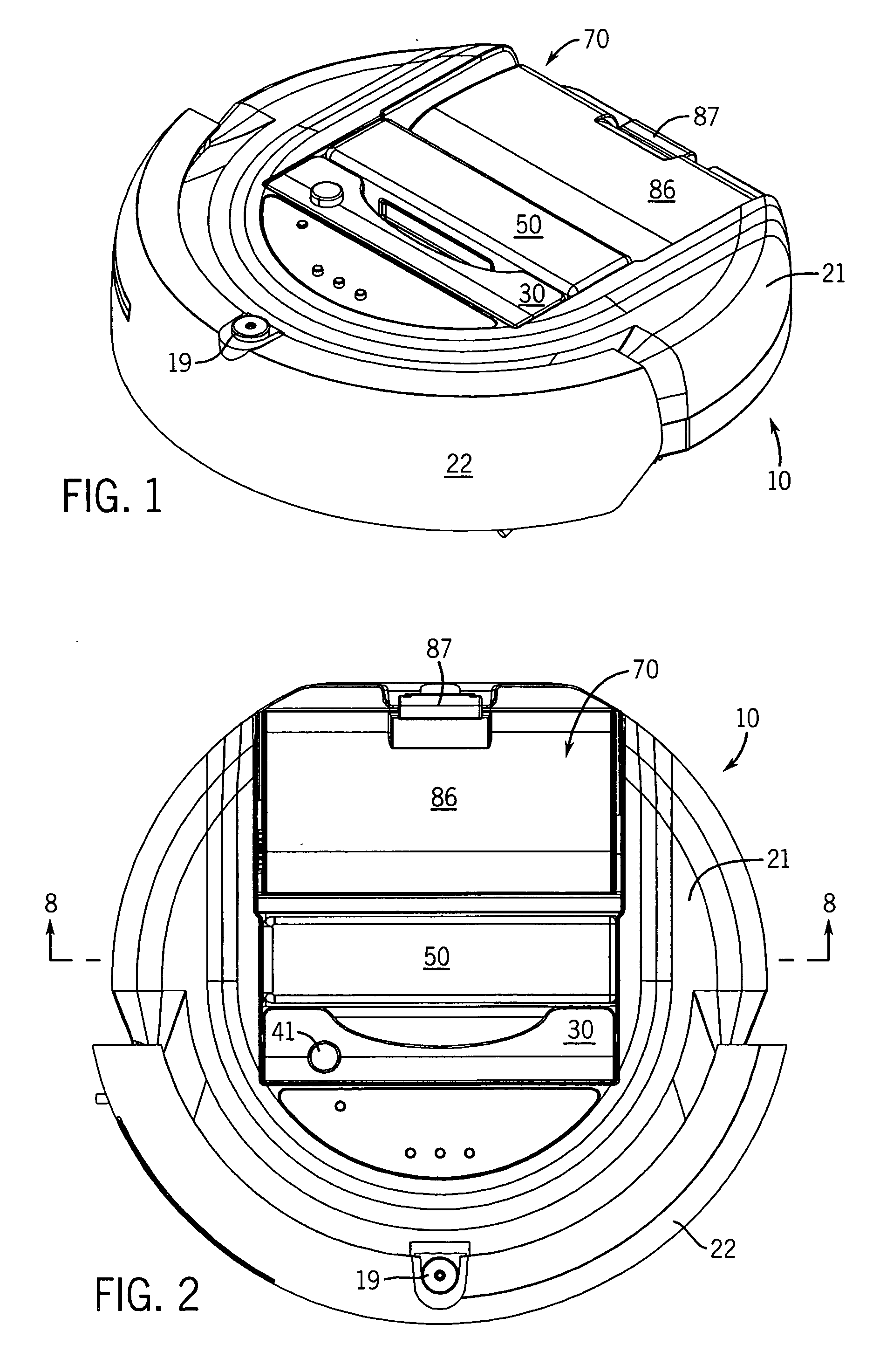

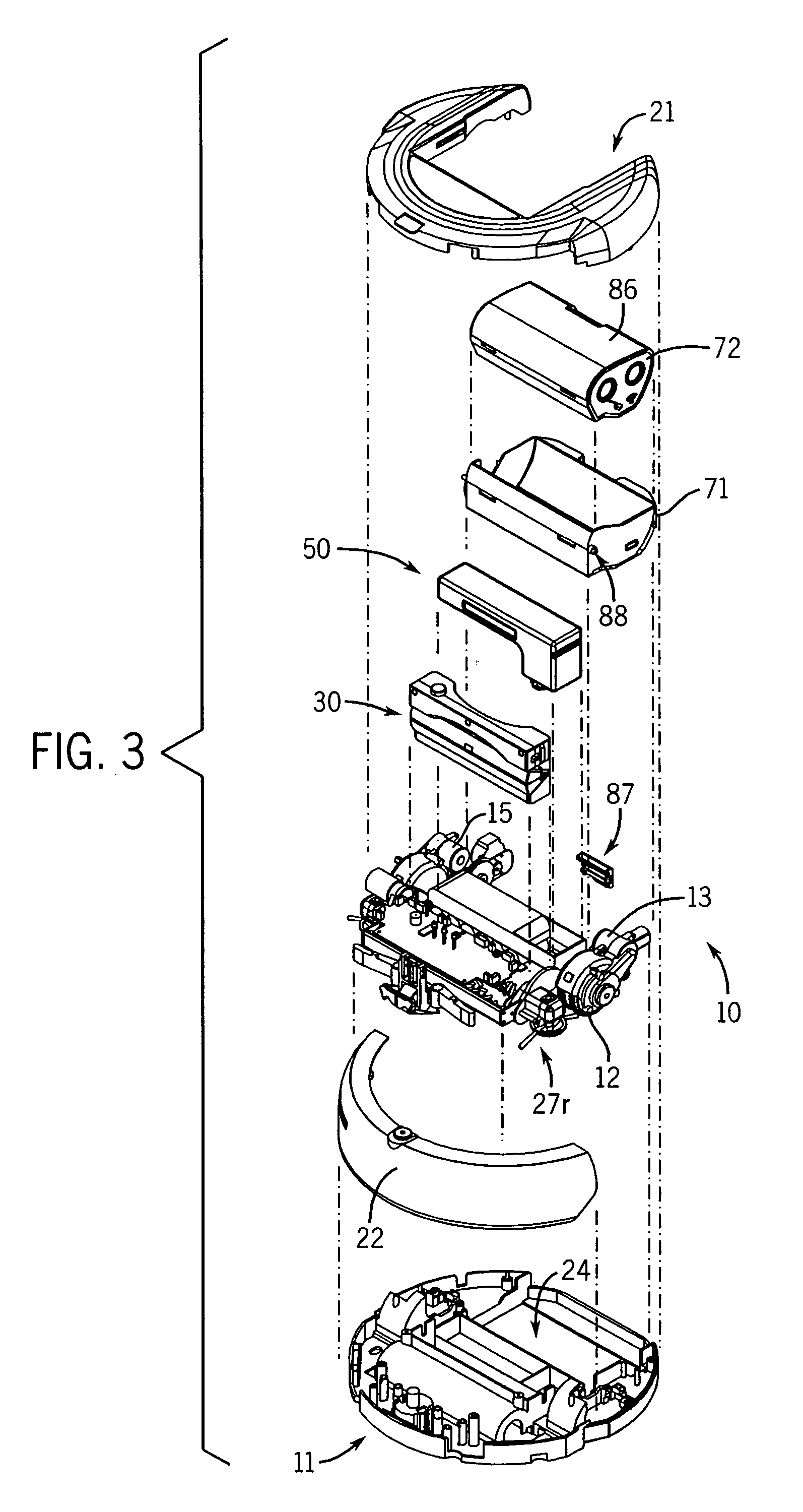

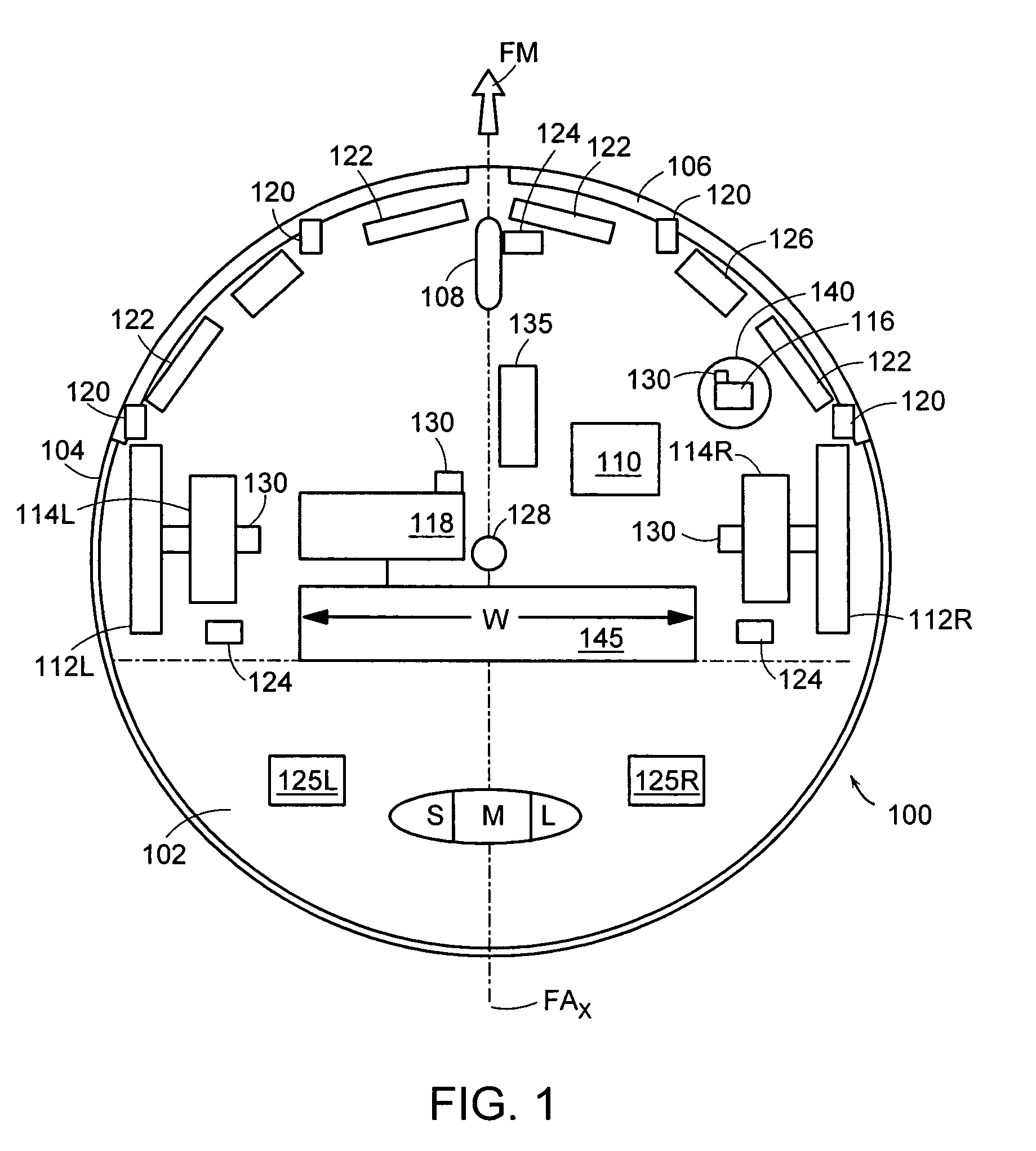

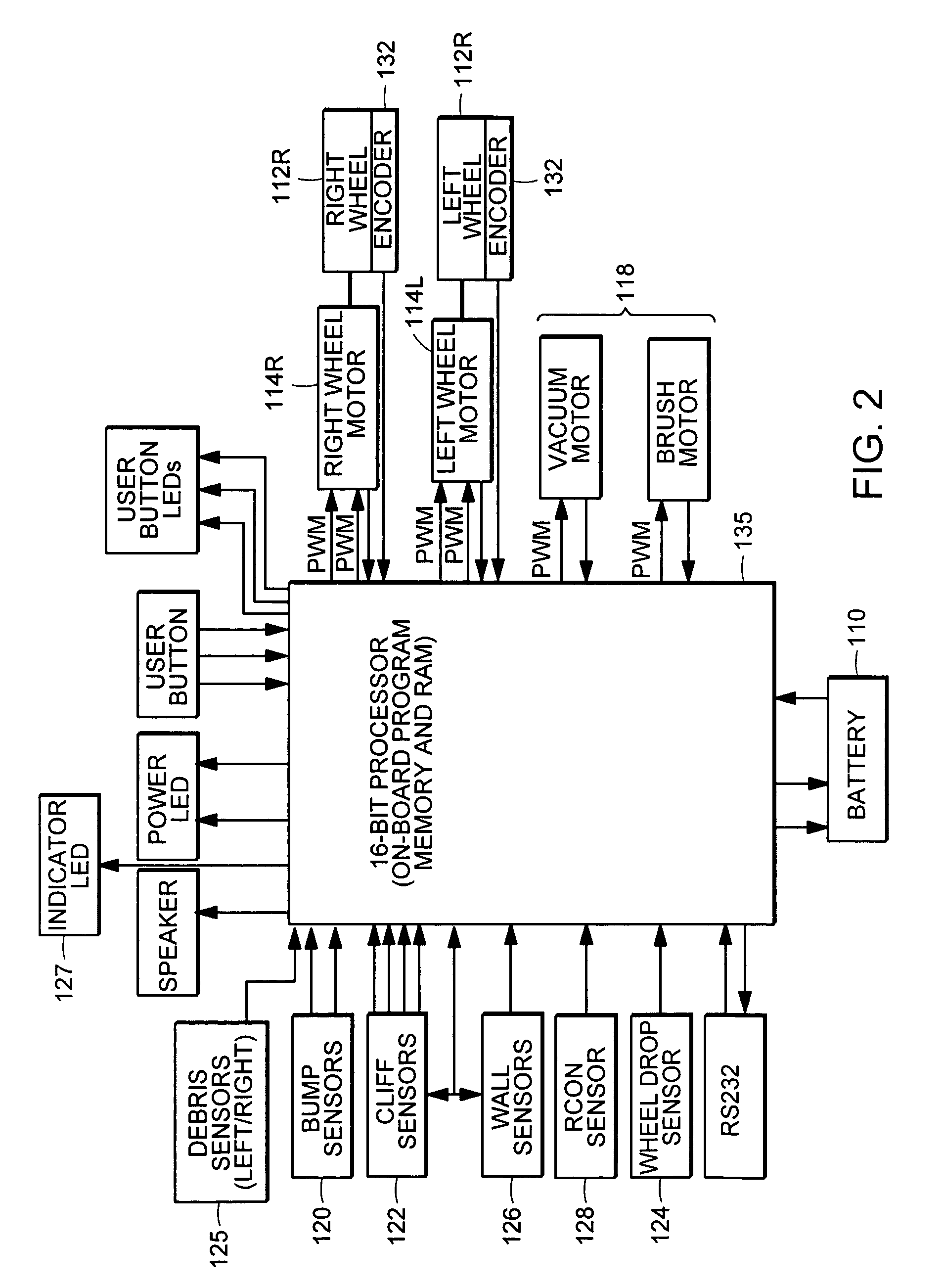

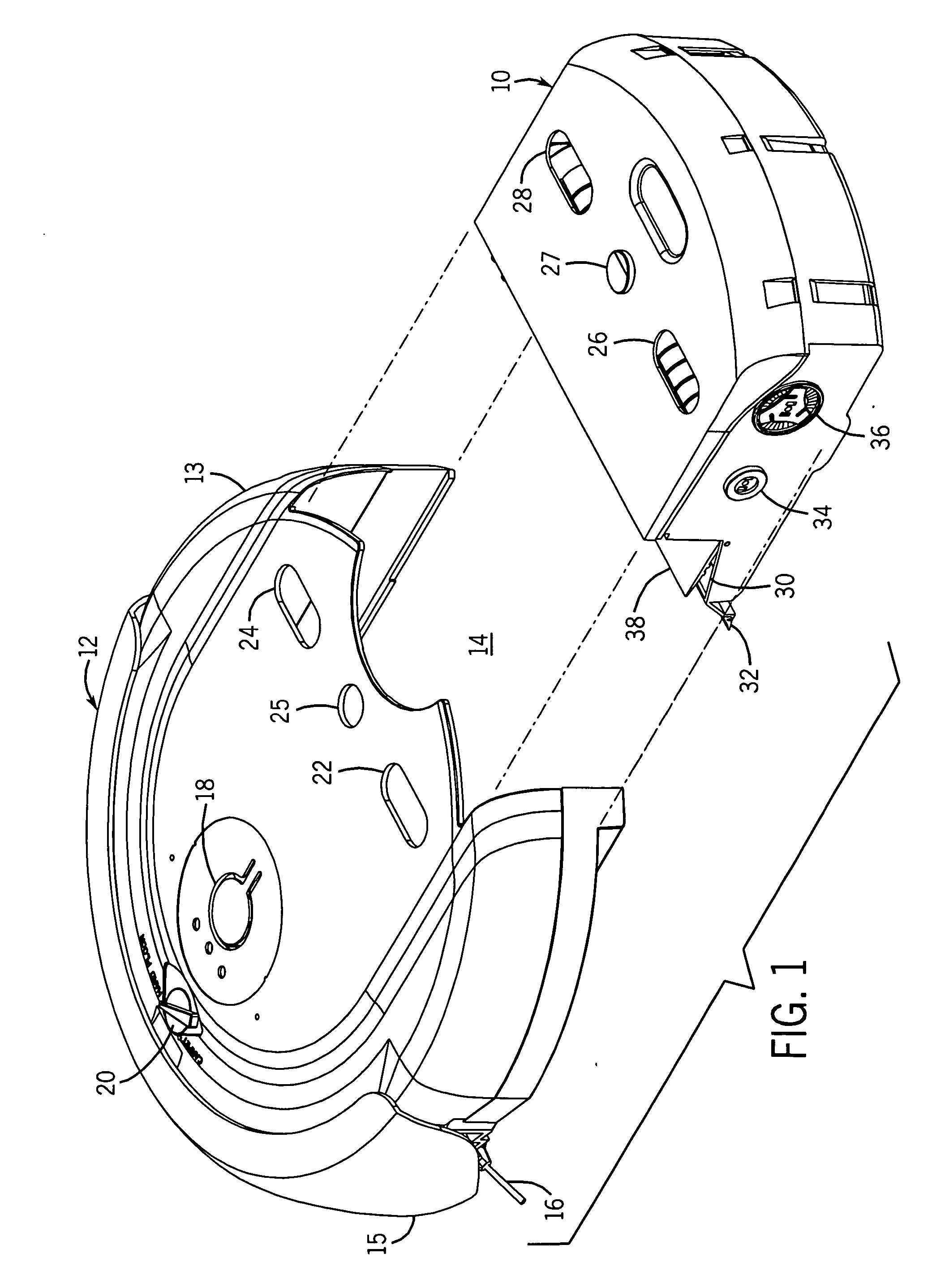

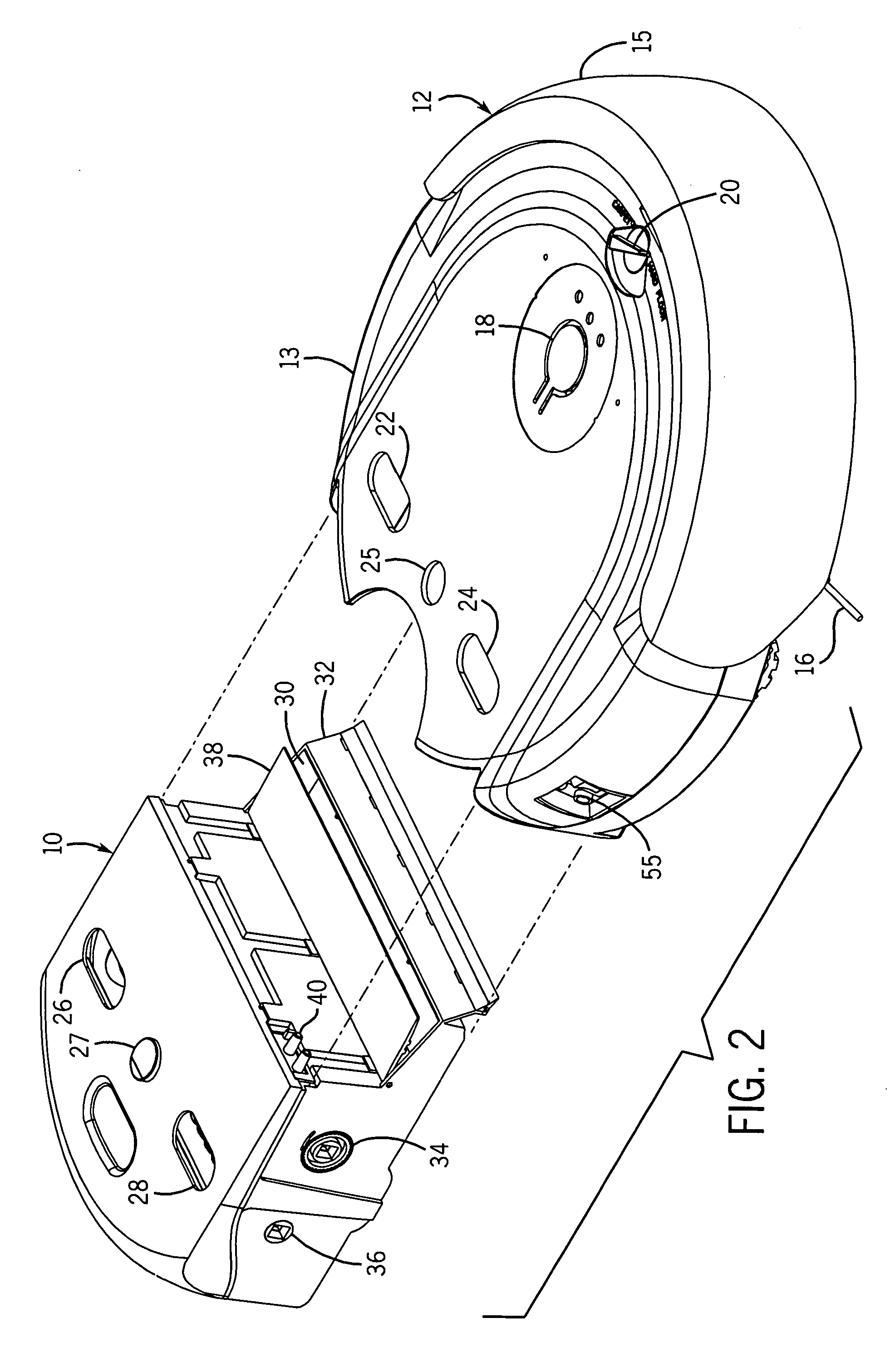

Autonomous floor-cleaning robot

InactiveUS6883201B2Improve rendering capabilitiesImprove efficiencyAutomatic obstacle detectionTravelling automatic controlDual stageEngineering

Owner:IROBOT CORP

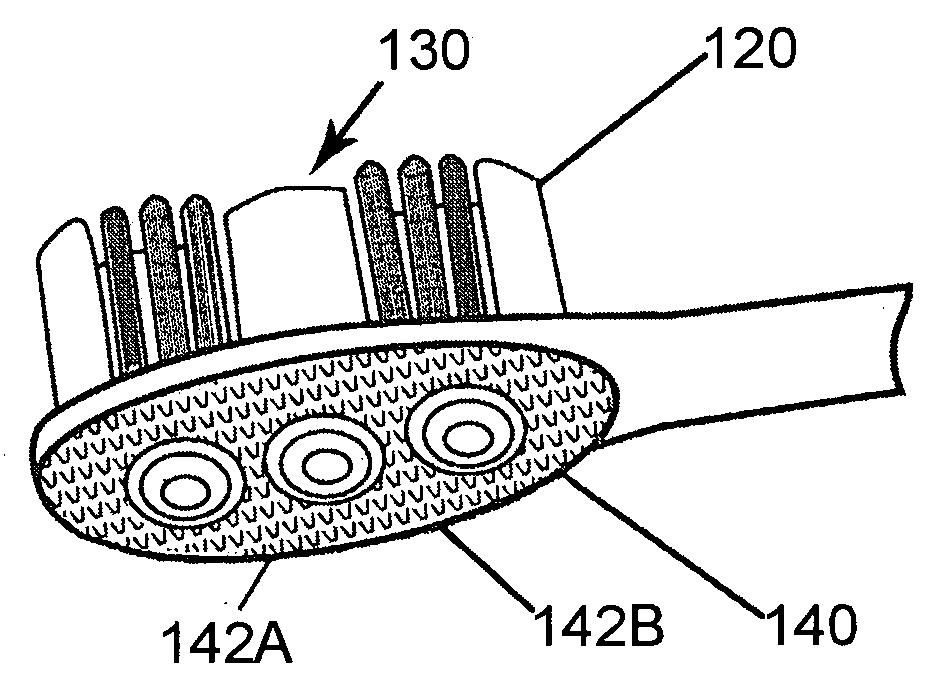

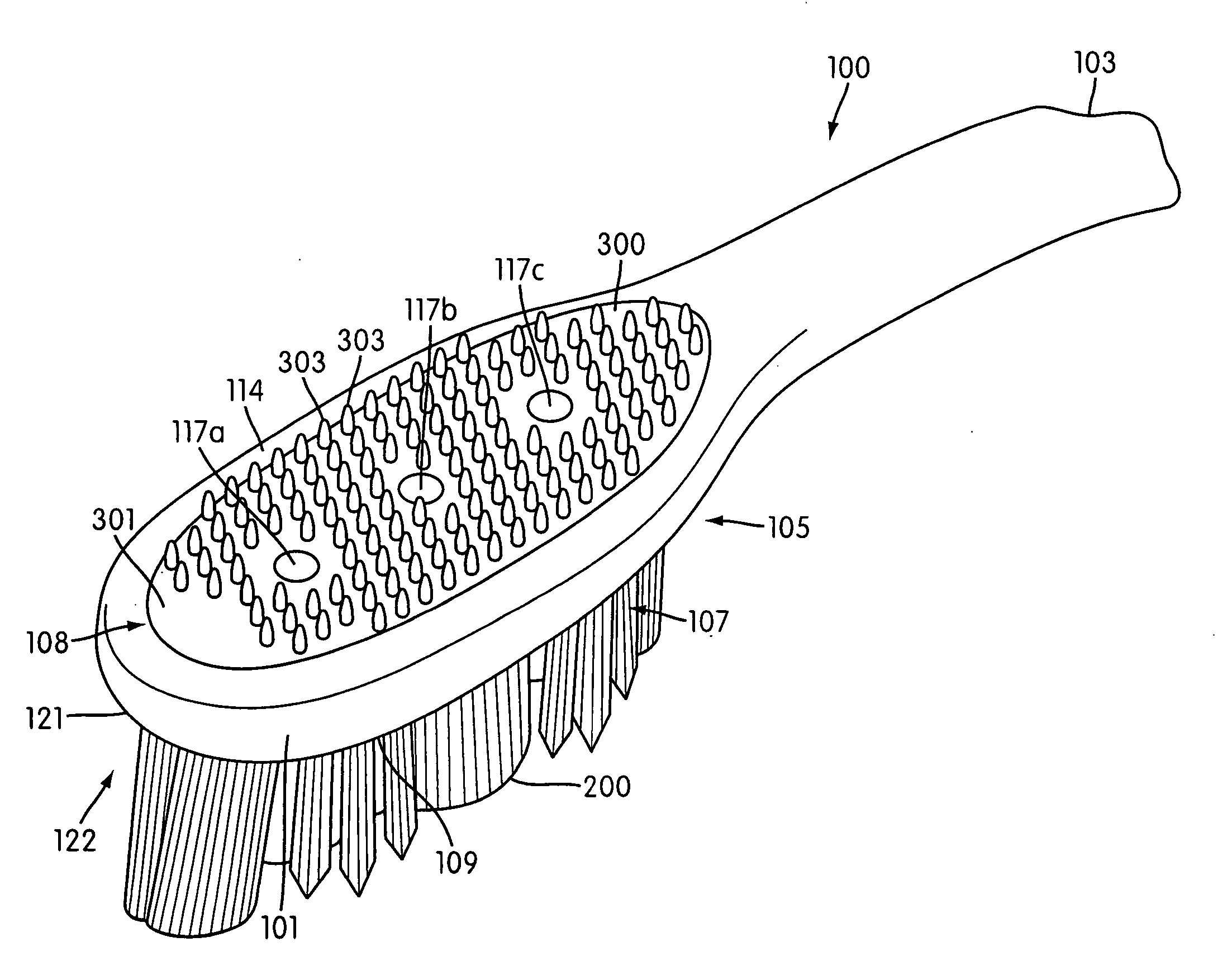

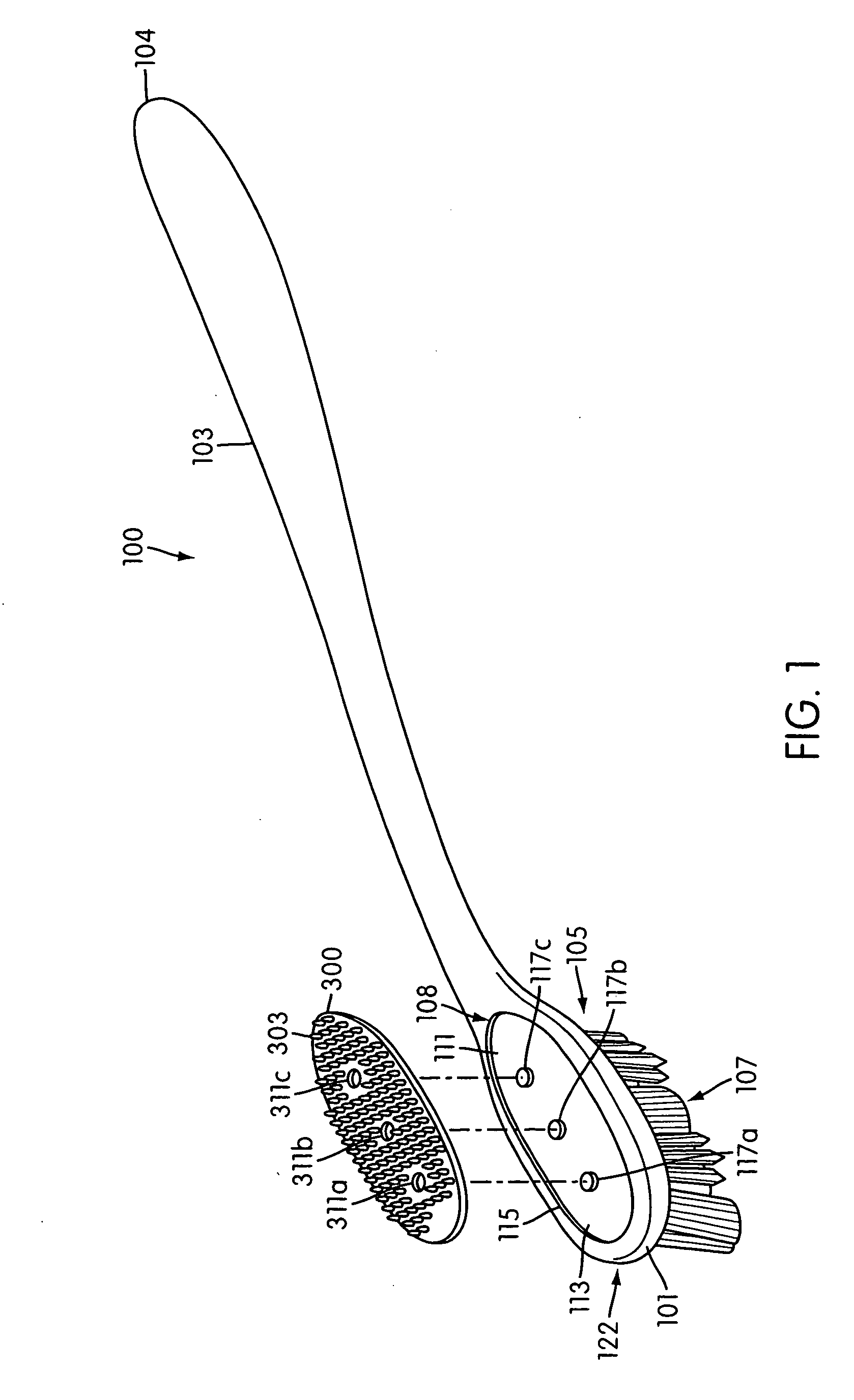

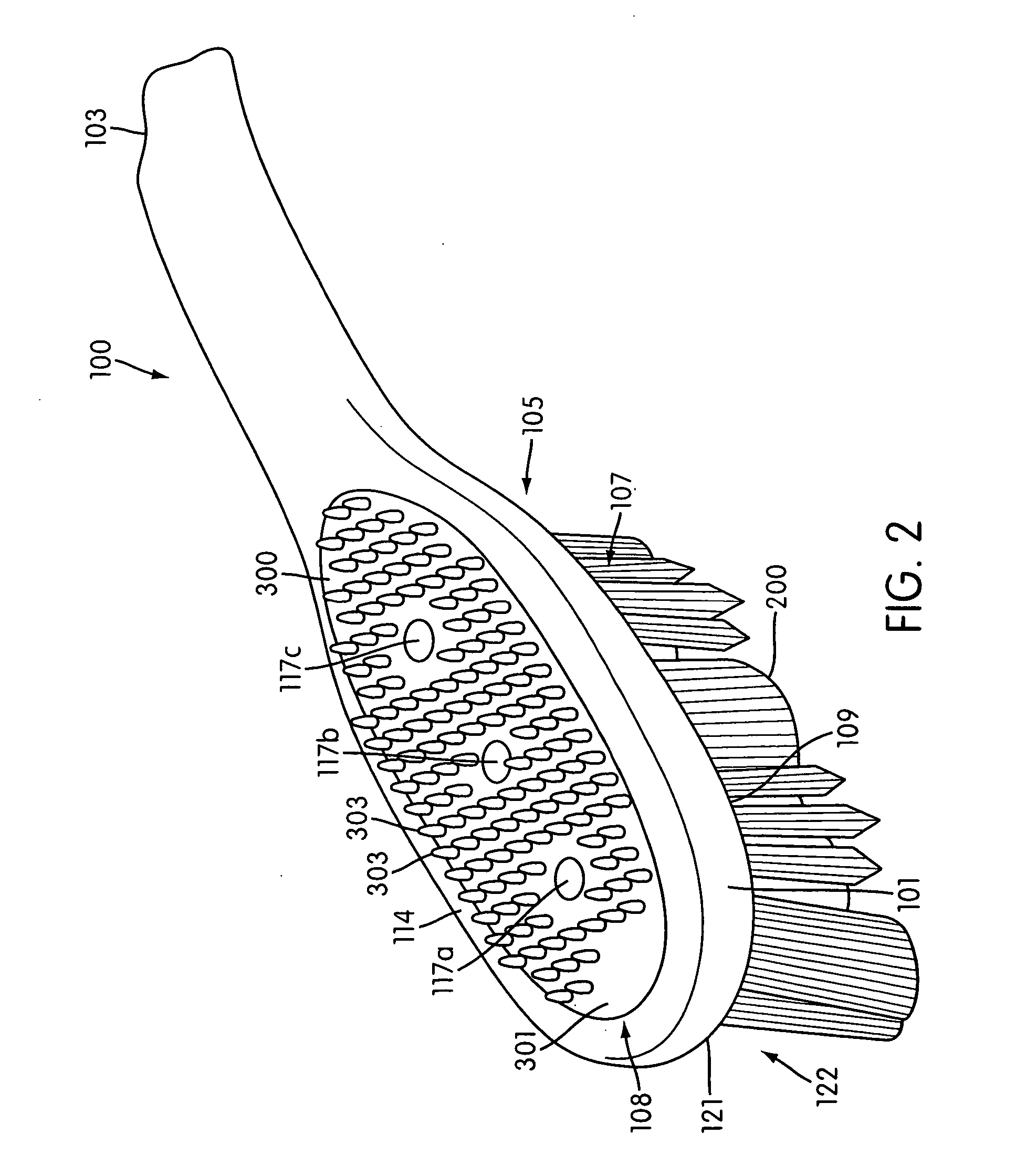

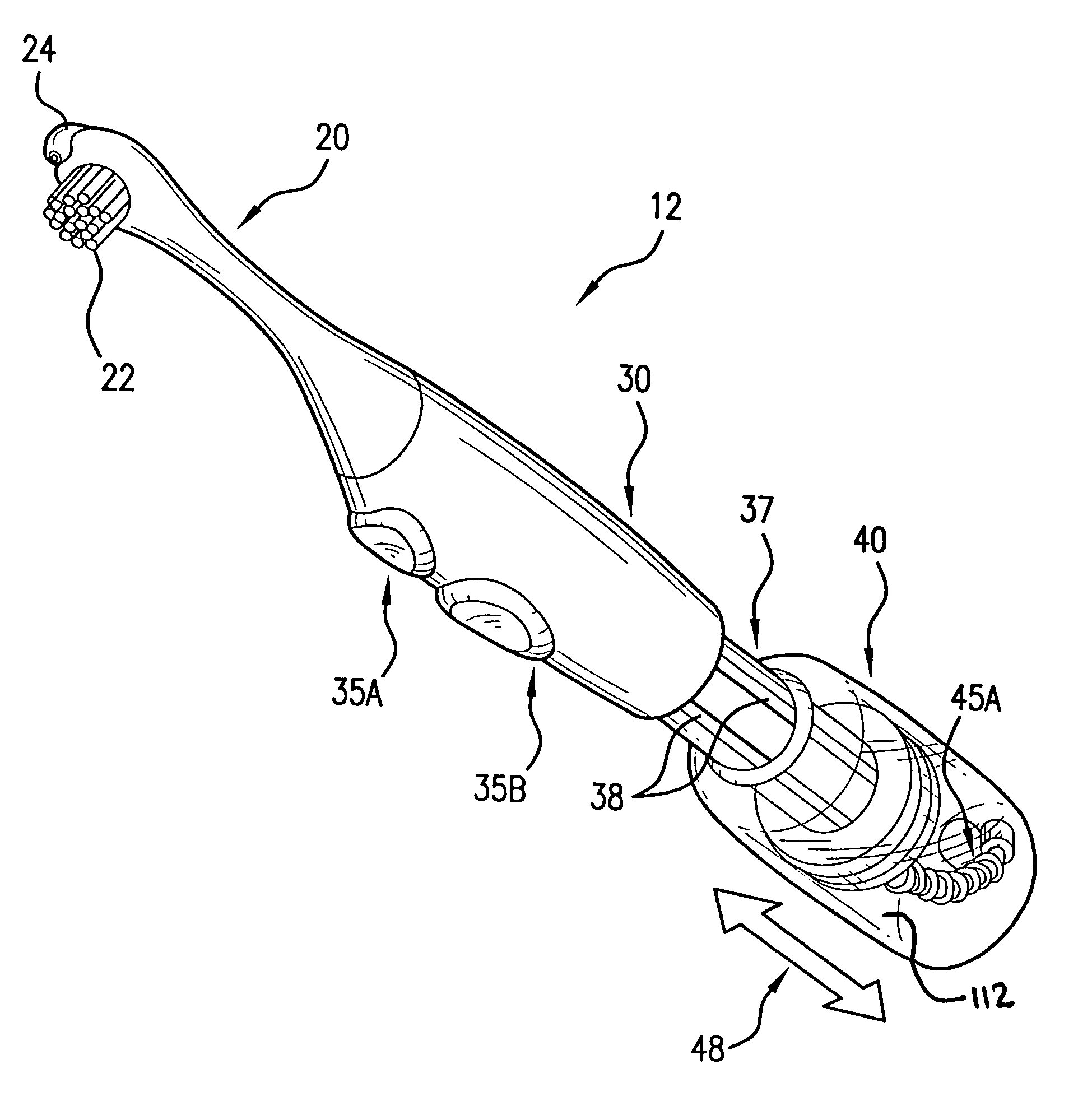

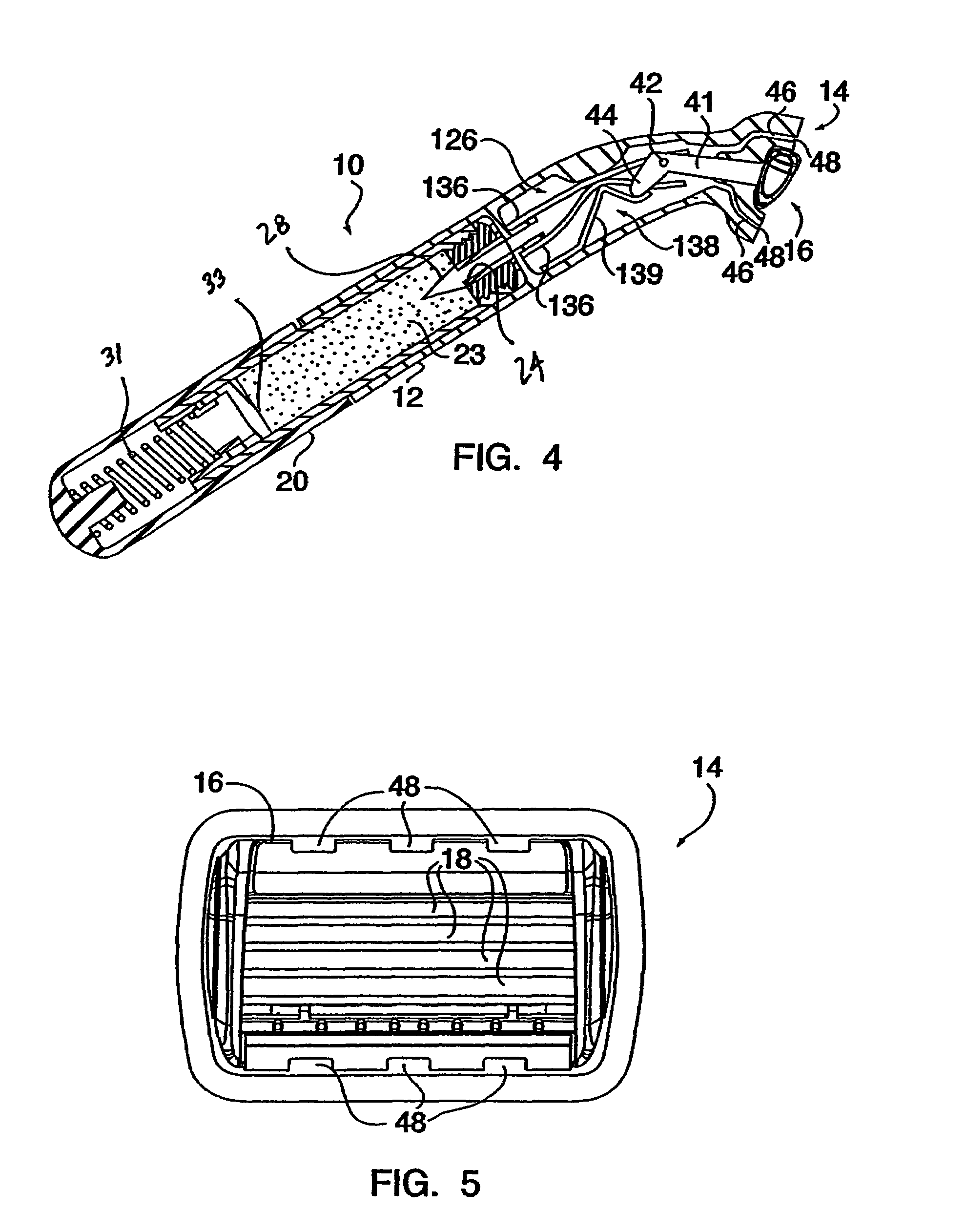

Oral care implement

An oral care implement with a handle includes a head with a tissue cleanser. The tissue cleanser may be a pad composed of an elastomeric material. The pad is disposed on the head on a surface opposite the tooth cleaning elements. The tissue cleanser may include a plurality of nubs extending for cleaning between the papillae of the tongue. The tissue cleanser may include a plurality of conically shaped nubs. A tissue cleanser can be used to reduce oral malodor problems and remove oral epithelial cells.

Owner:COLGATE PALMOLIVE CO

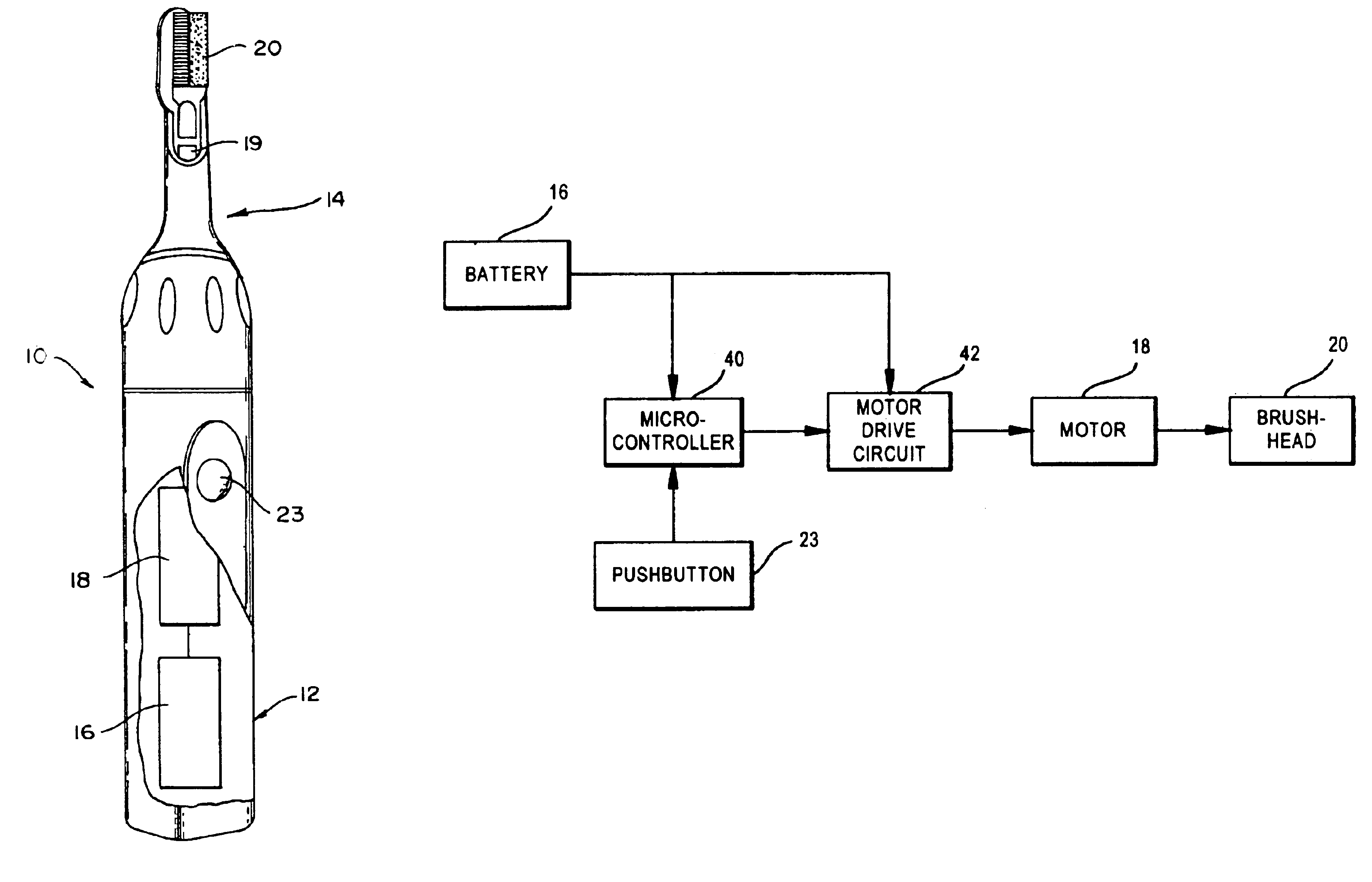

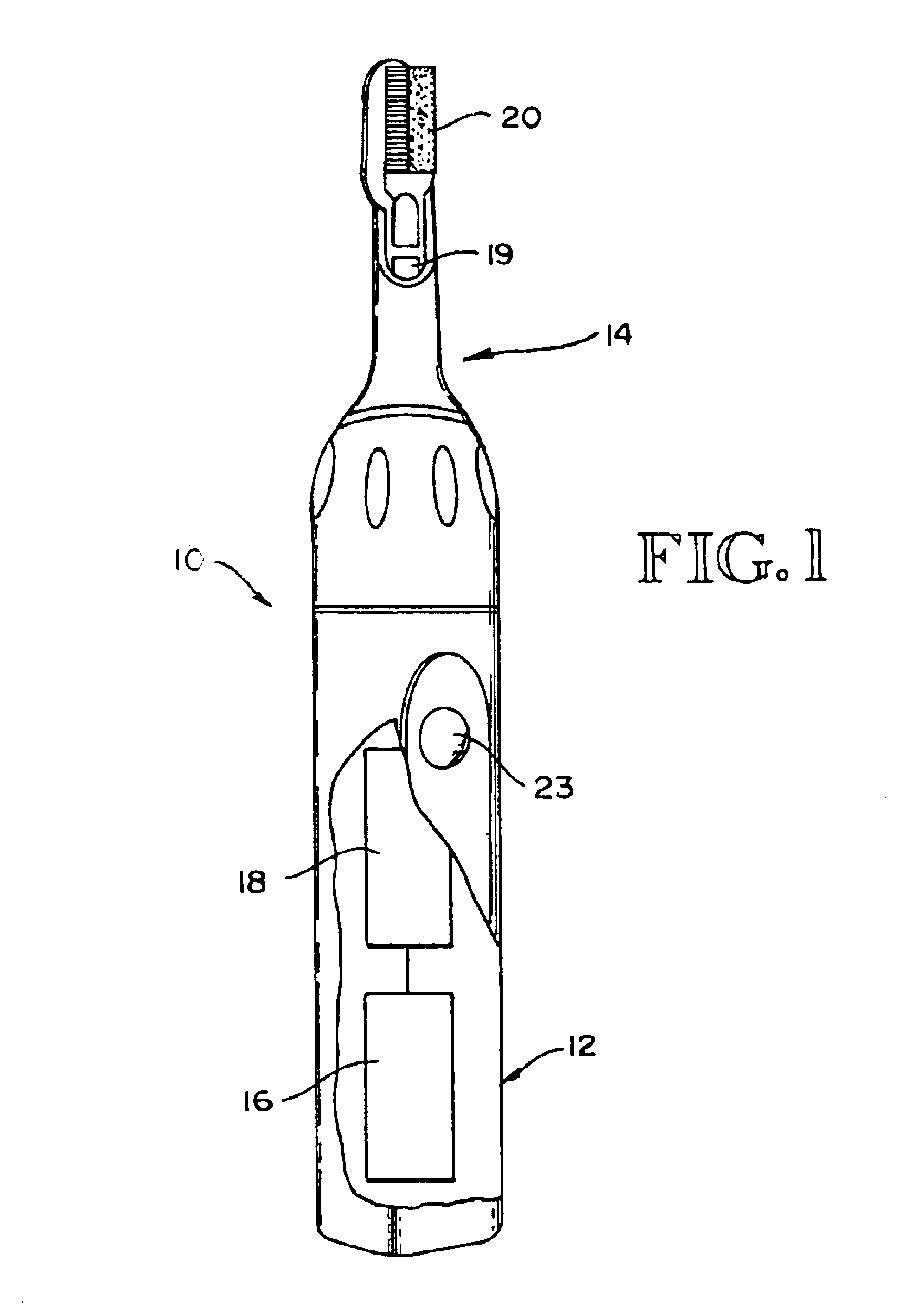

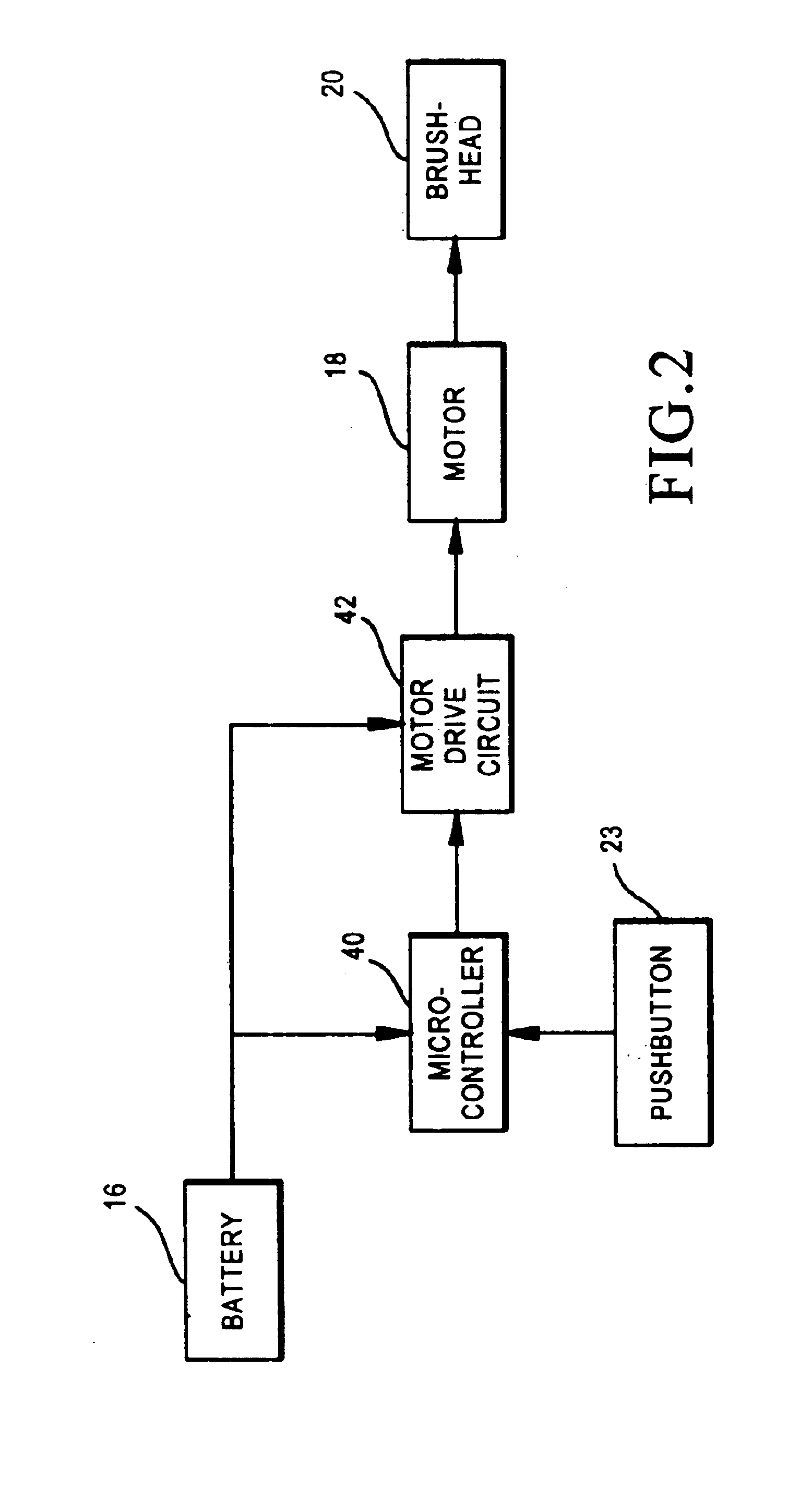

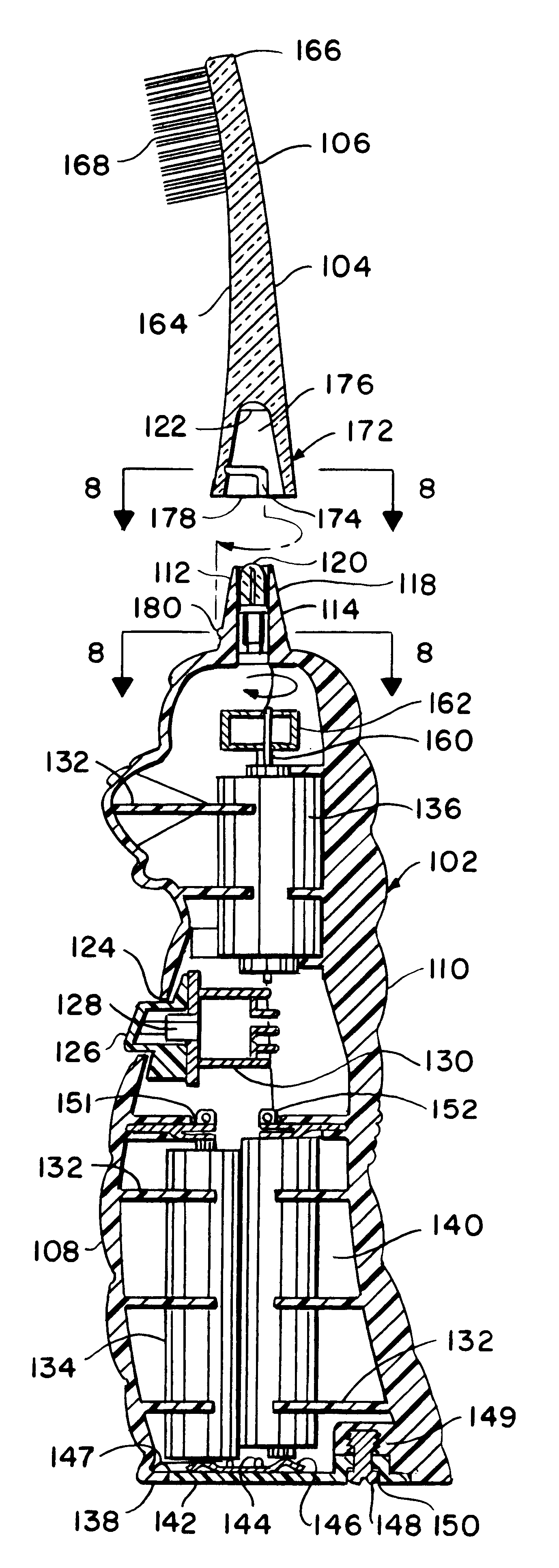

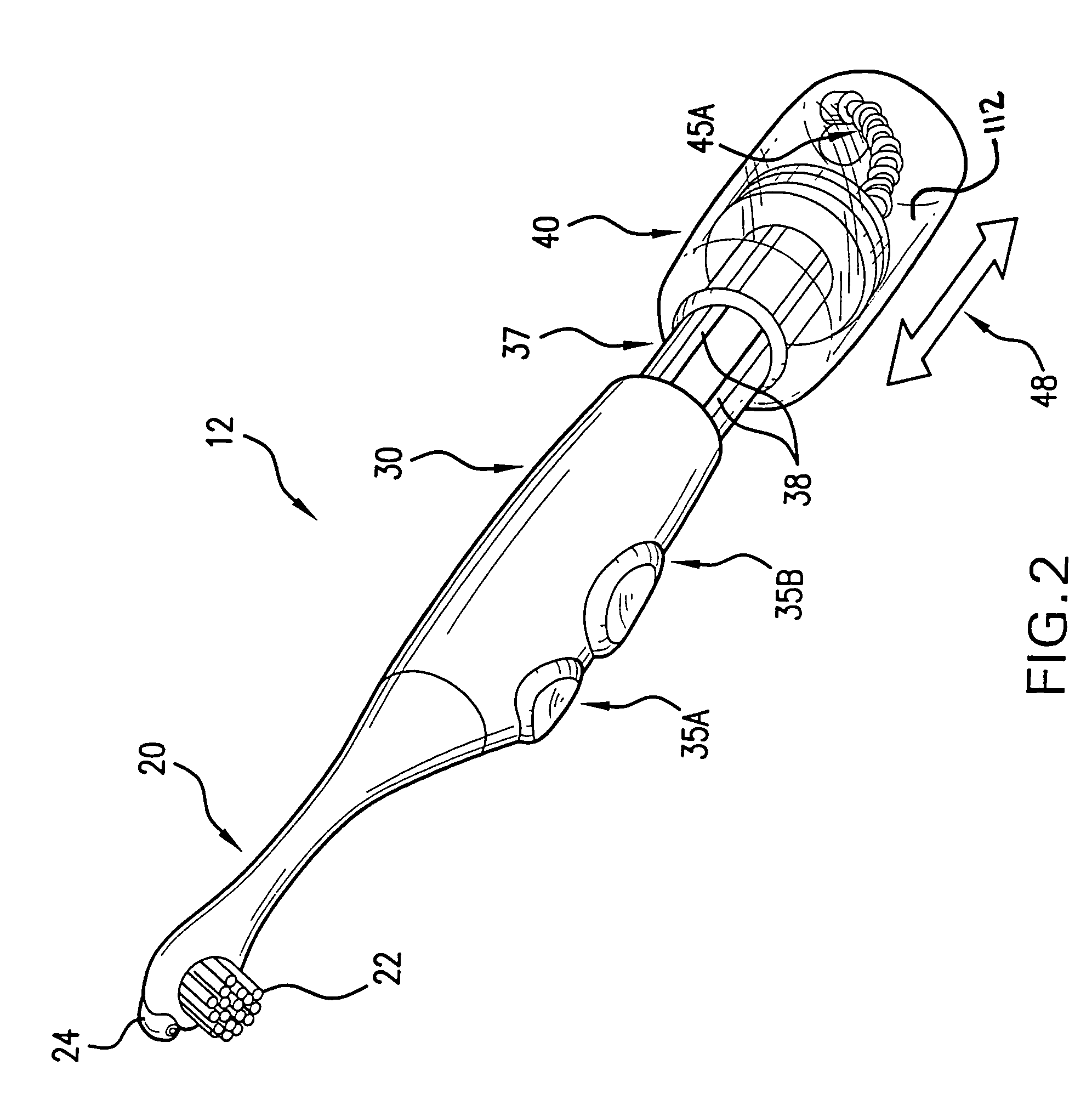

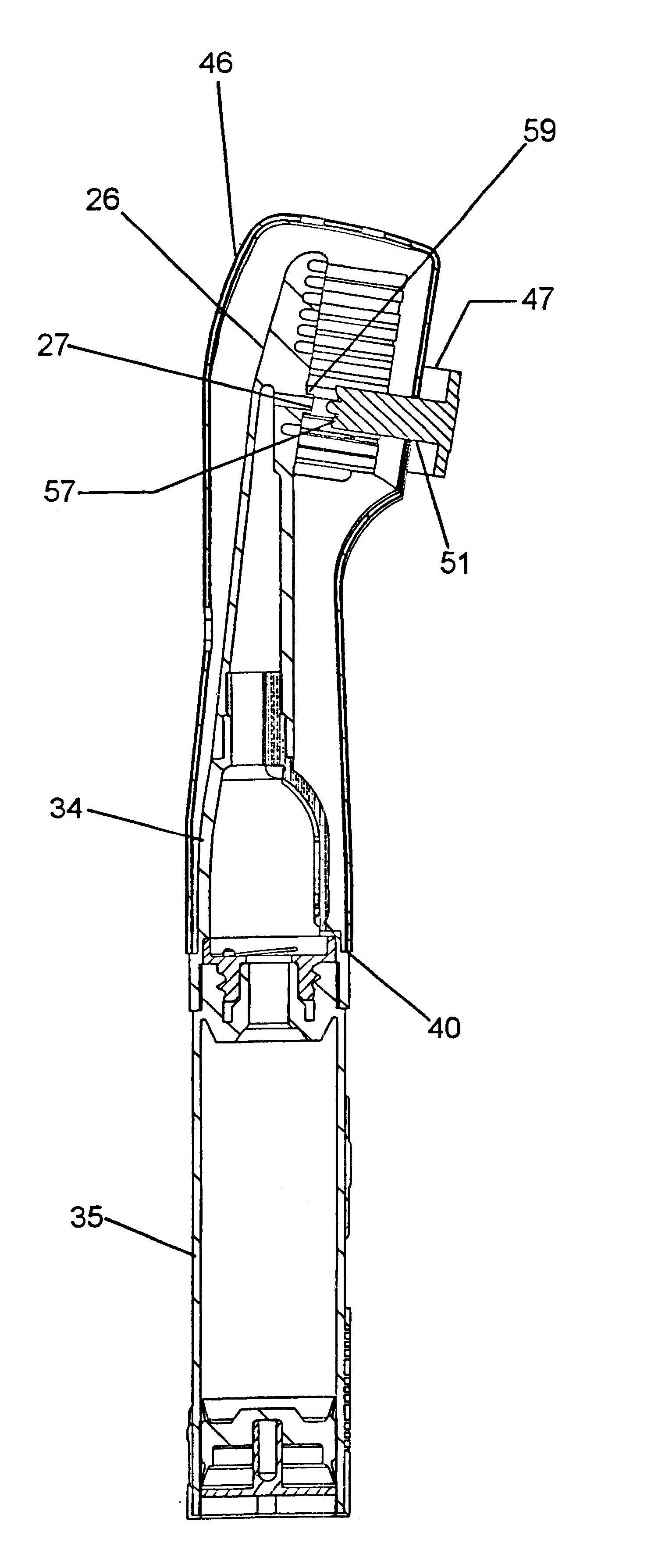

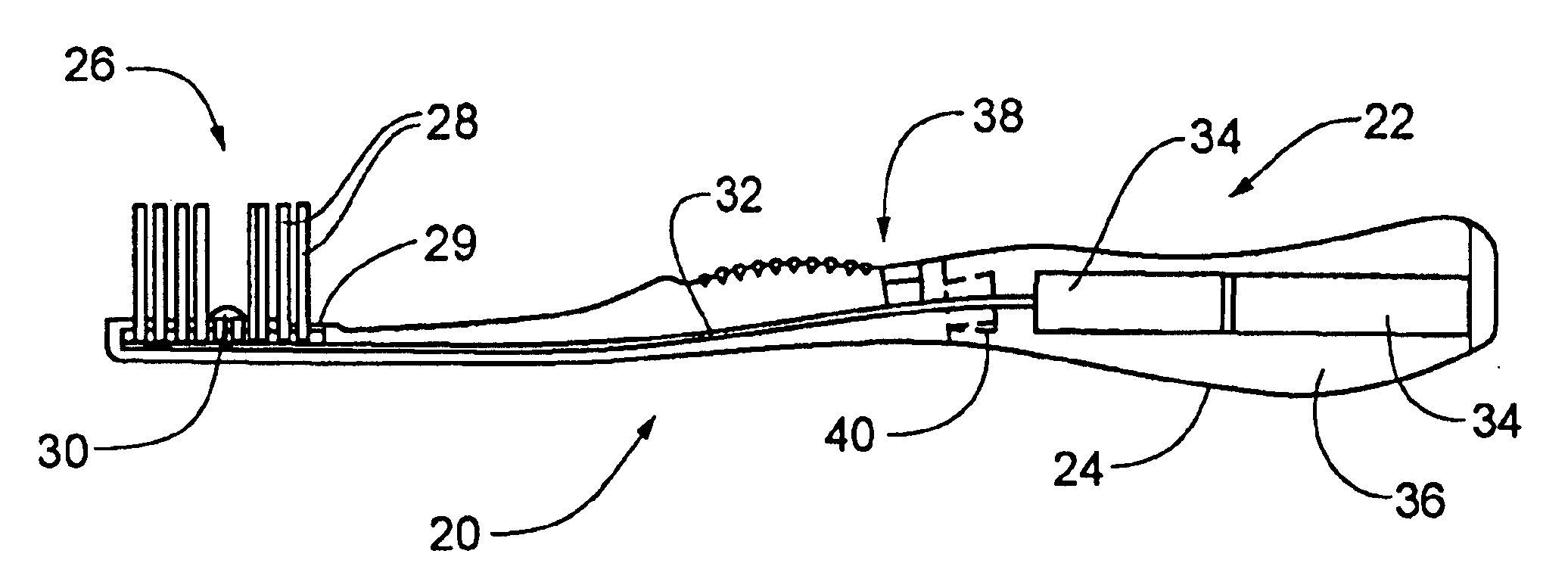

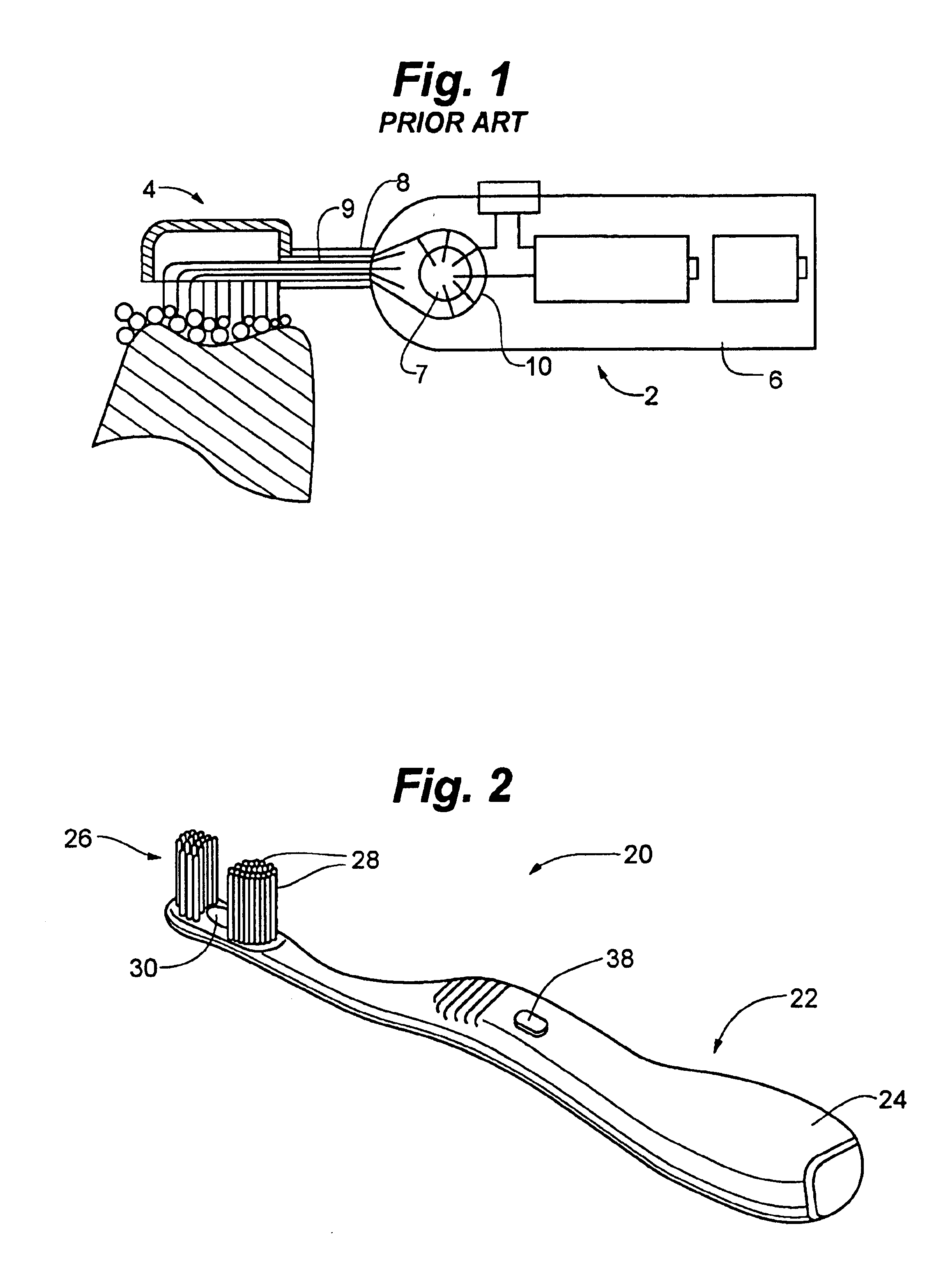

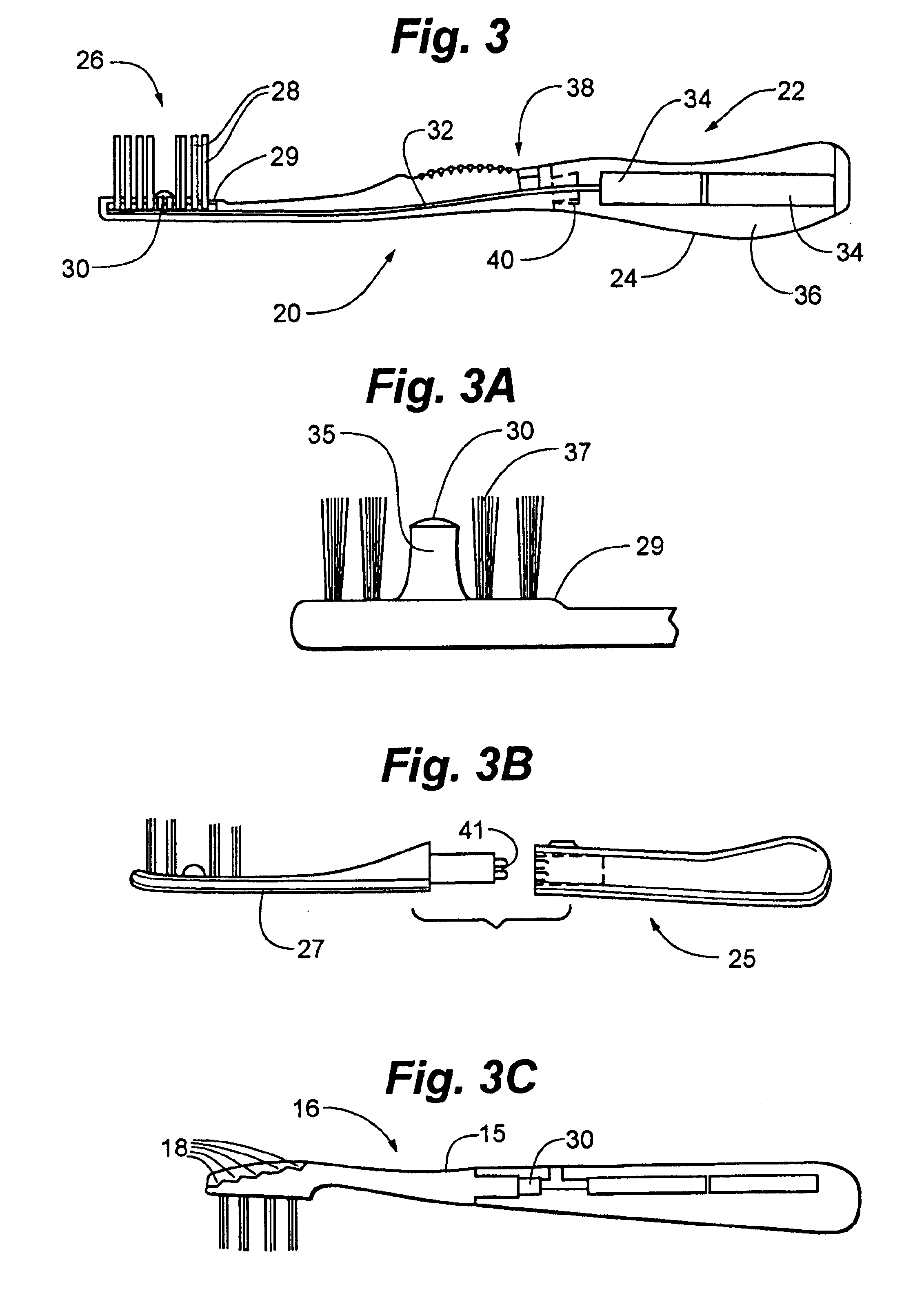

Short-life power toothbrush for trial use

A trial (test) power toothbrush designed to emulate the performance of a corresponding commercial toothbrush, powered by a non-rechargeable battery. The power to drive the toothbrush is controlled by a control circuit which is responsive to the battery to maintain the drive power at approximately the level of the commercial unit and a short “trial use” period, i.e. one month / 30 days, and then to terminate operation of the power toothbrush. The trial toothbrush may then be readily disposed of by the user, including the battery therein.

Owner:PHILIPS ORAL HEALTHCARE

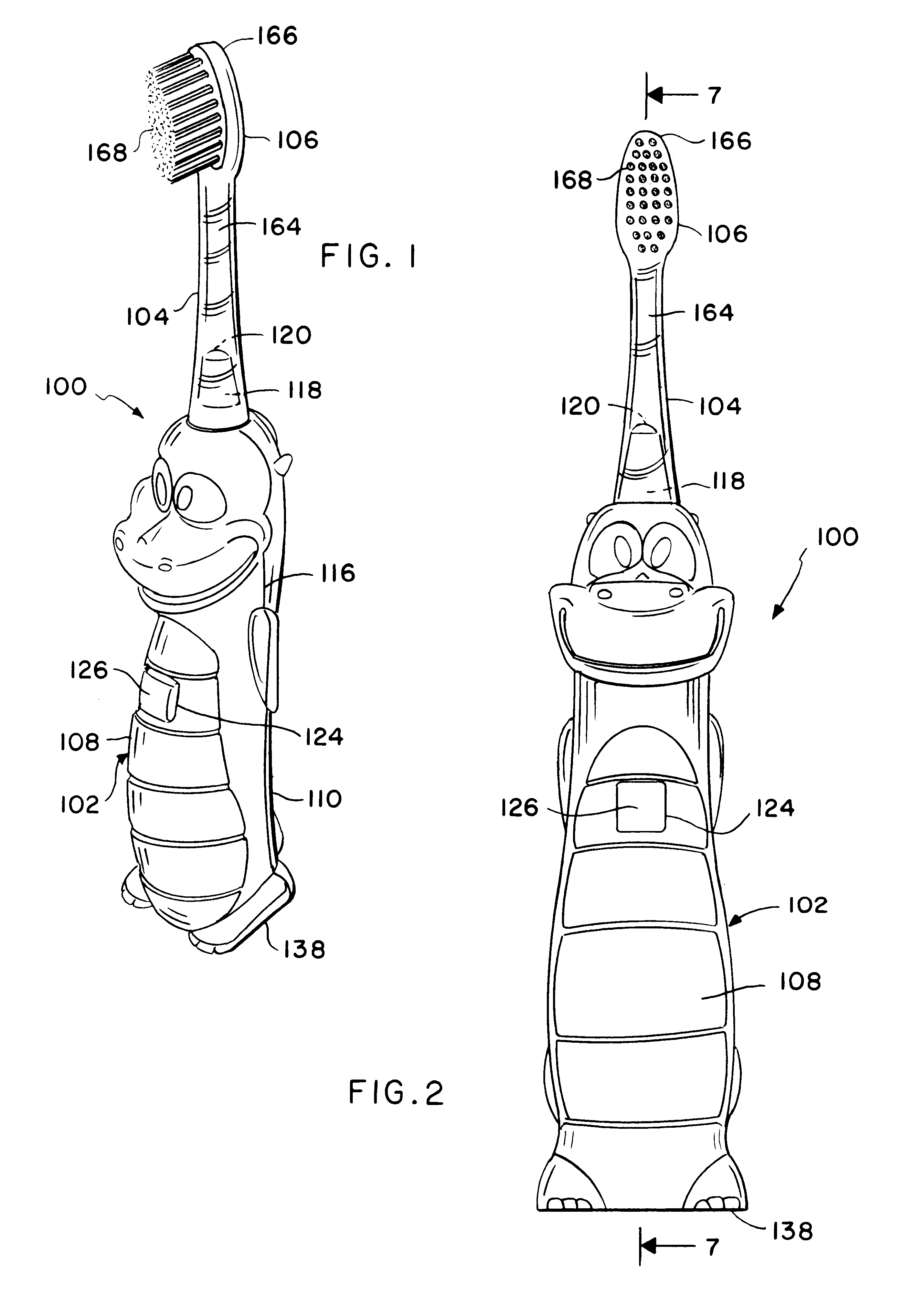

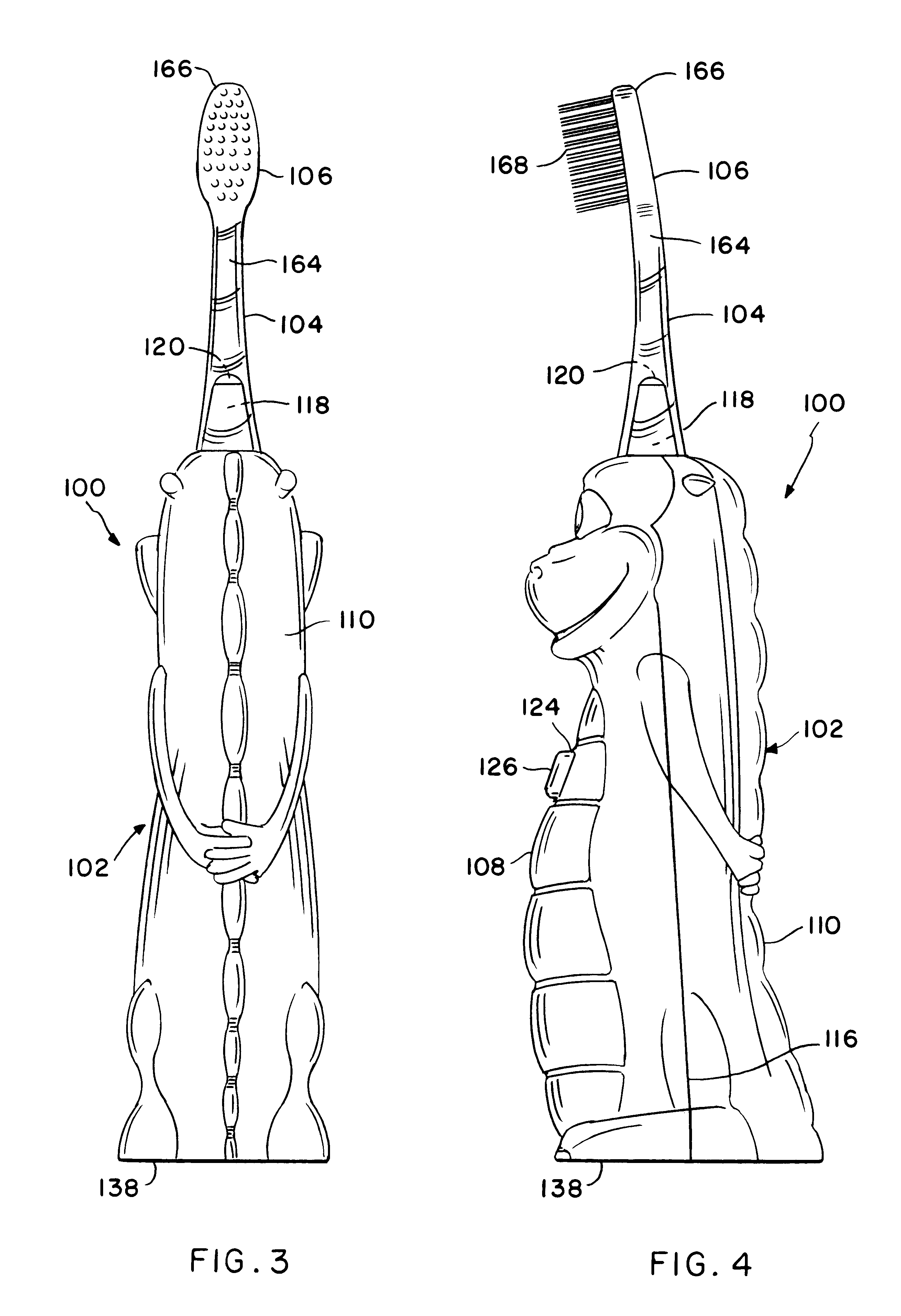

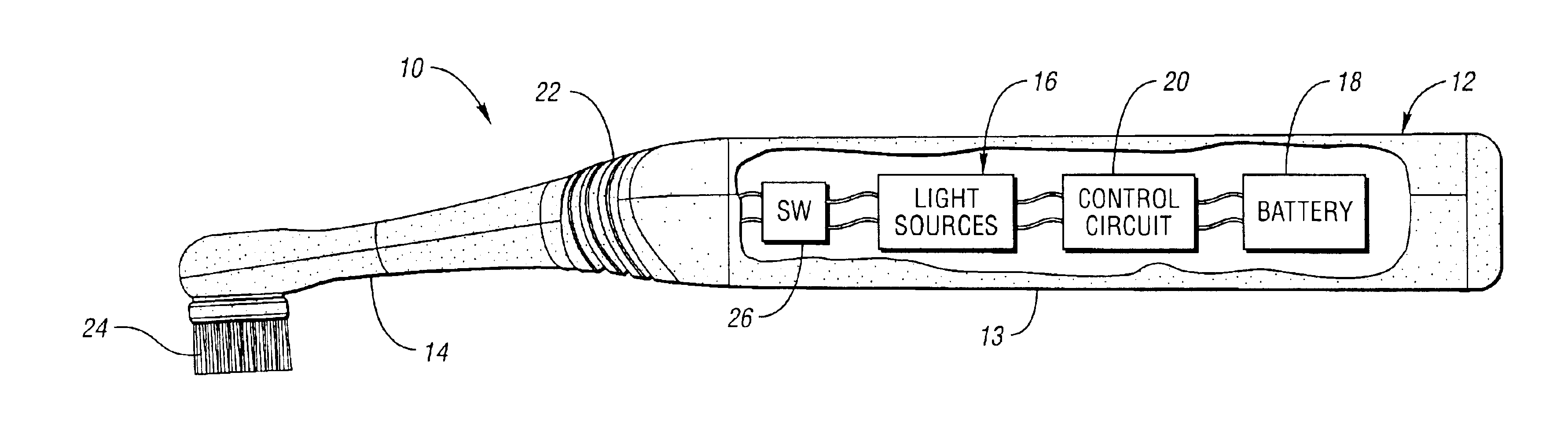

Light emitting electric toothbrush

A light emitting electric toothbrush and method therefore is disclosed which is intended for use by children, is comprised of a robust high-strength, plastic construction, and employs both light and vibration to assist in the development of suitable dental hygiene skills. In its most fundamental embodiment, the light emitting electric toothbrush comprises a construction including a handle having a bottom end and a top end and a toothbrush shaft mounted to the top end of the handle. The brush shaft is comprised of a plastic resin including a fluorescent colored light refractive additive for optimizing light transmission through the brush shaft. A high intensity light source is mounted within the top end of the handle for generating light and a domed-shaped optical lens is positioned over the high intensity light source for directing the generated light into the brush shaft. Finally, a switched electrical source is included for energizing the light source and the generated light therefrom creates a glowing illumination in the brush shaft for illuminating a dental cavity of a person during brushing of the teeth. In a preferred embodiment, the toothbrush also includes a vibrating motor mounted within the handle for causing the brush shaft to vibrate. The vibrating motor is also energized by the switched electrical source simultaneously with the light source.

Owner:ZEPHYR DESIGN

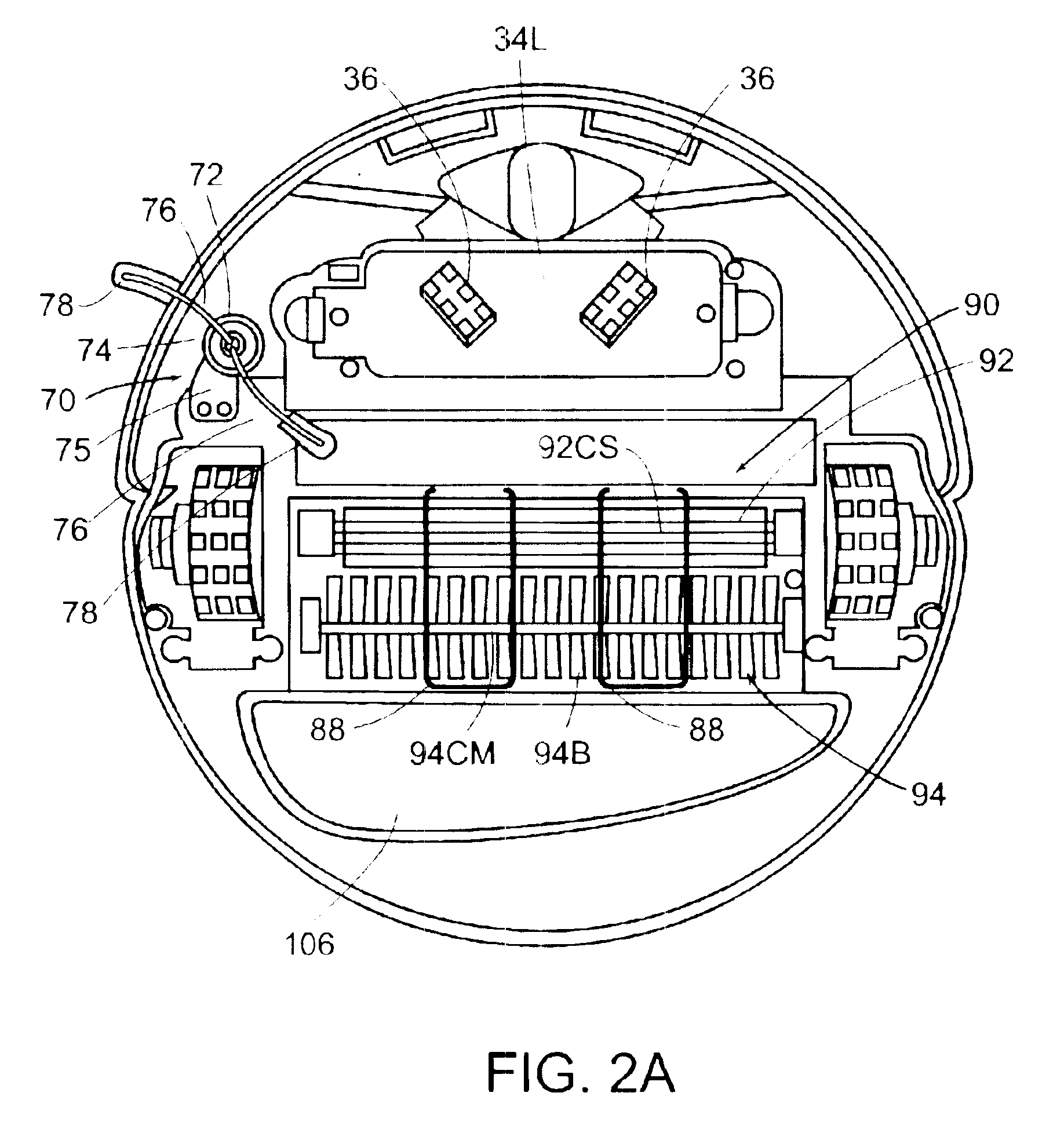

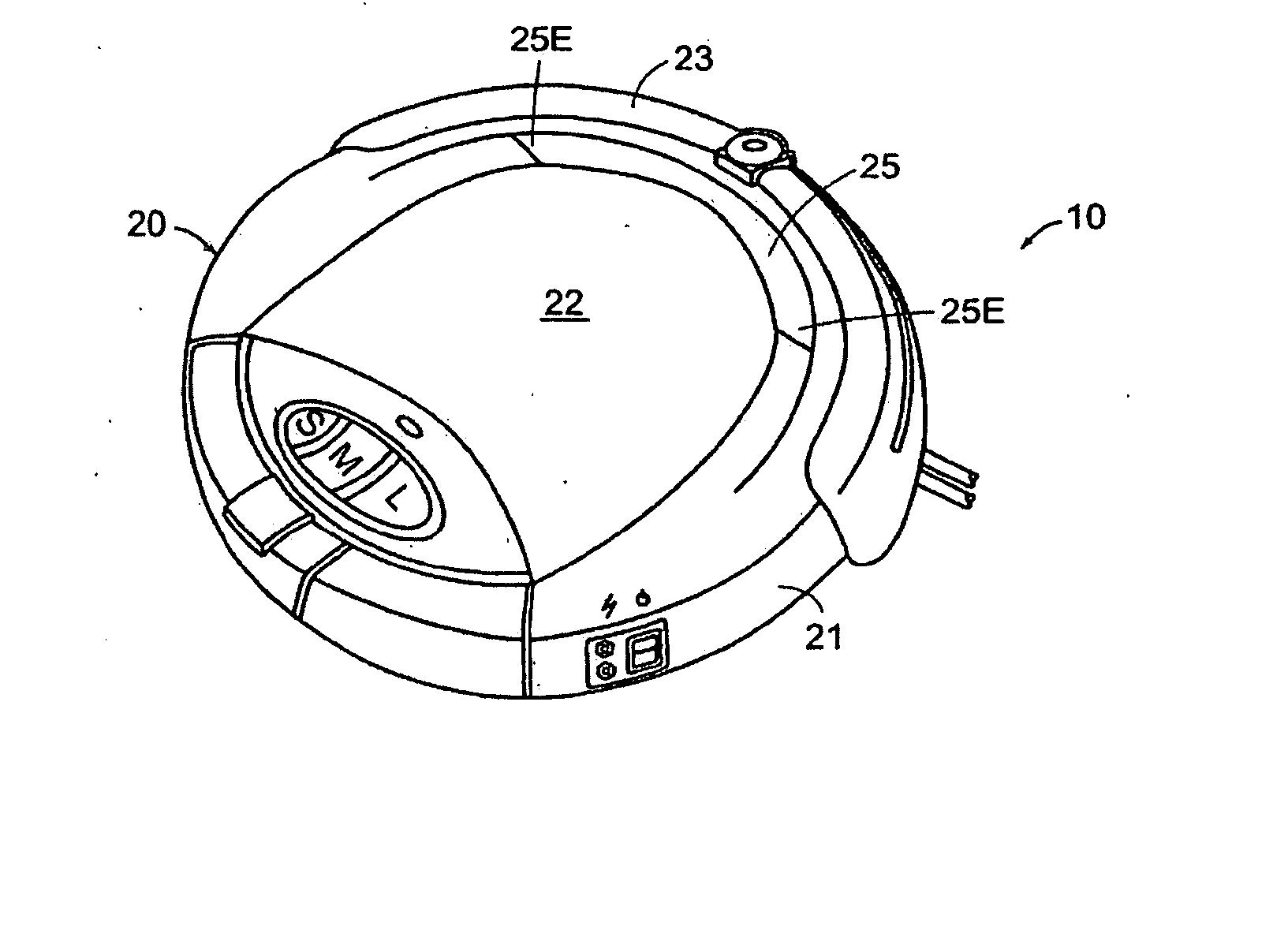

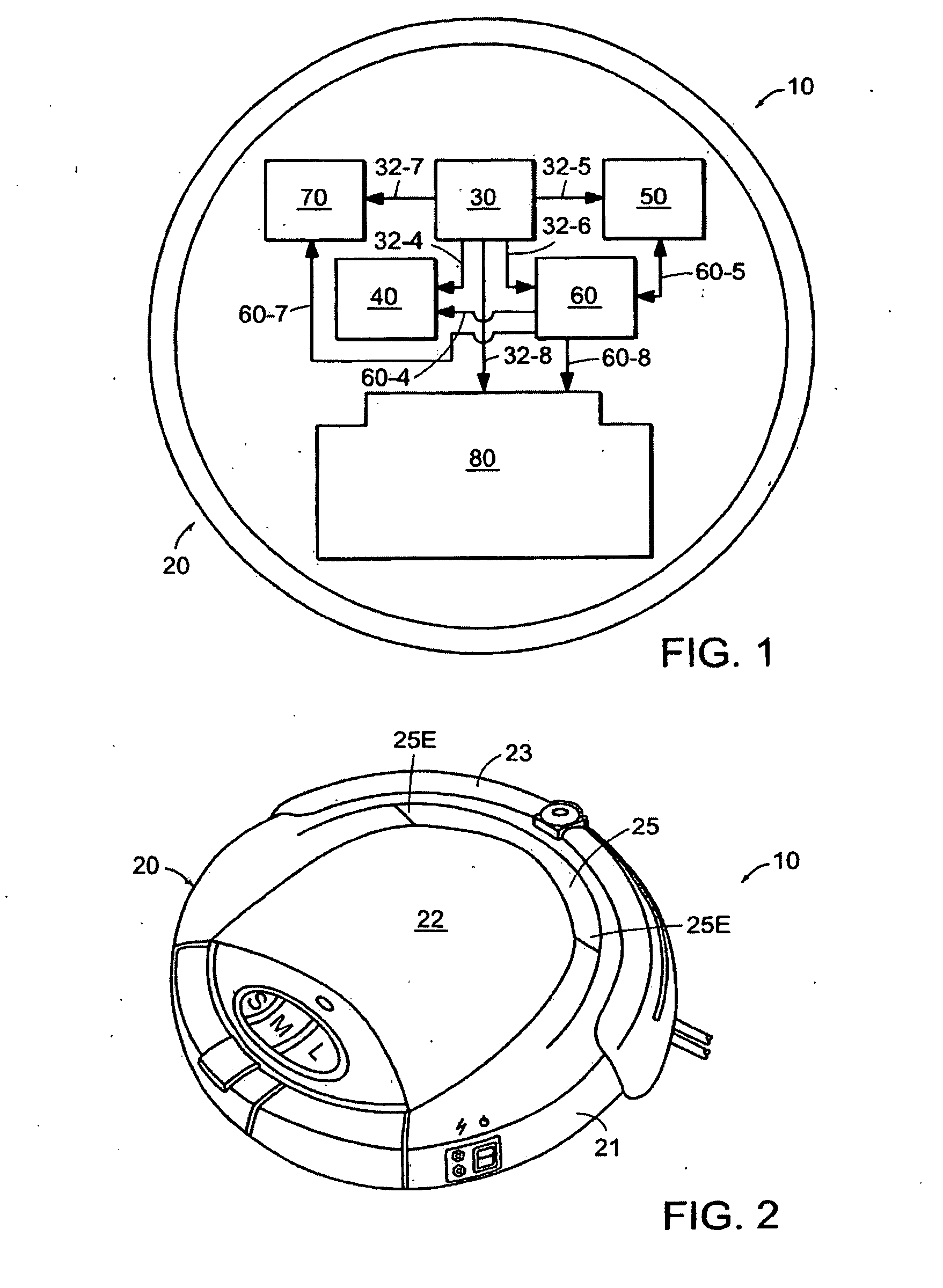

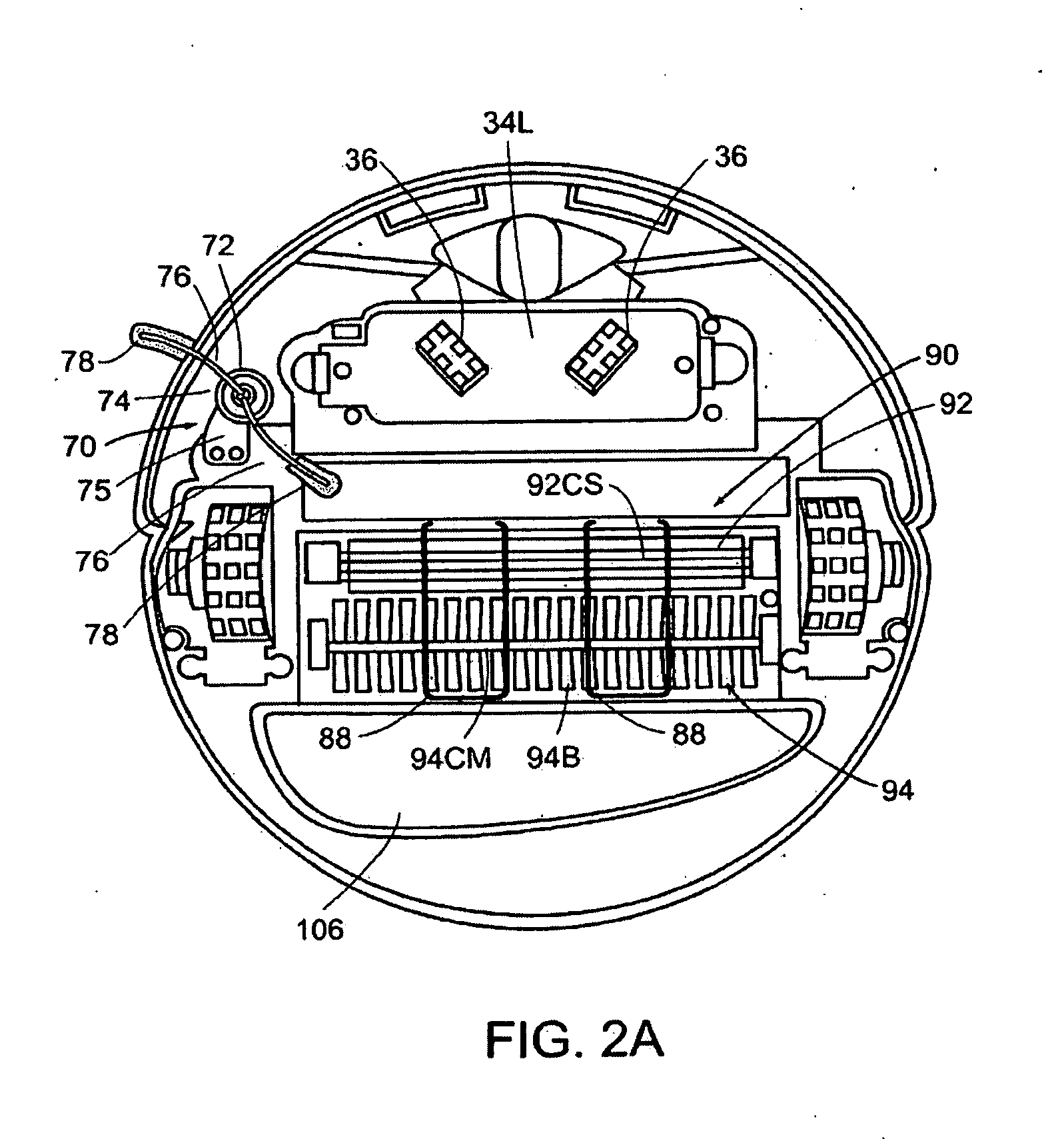

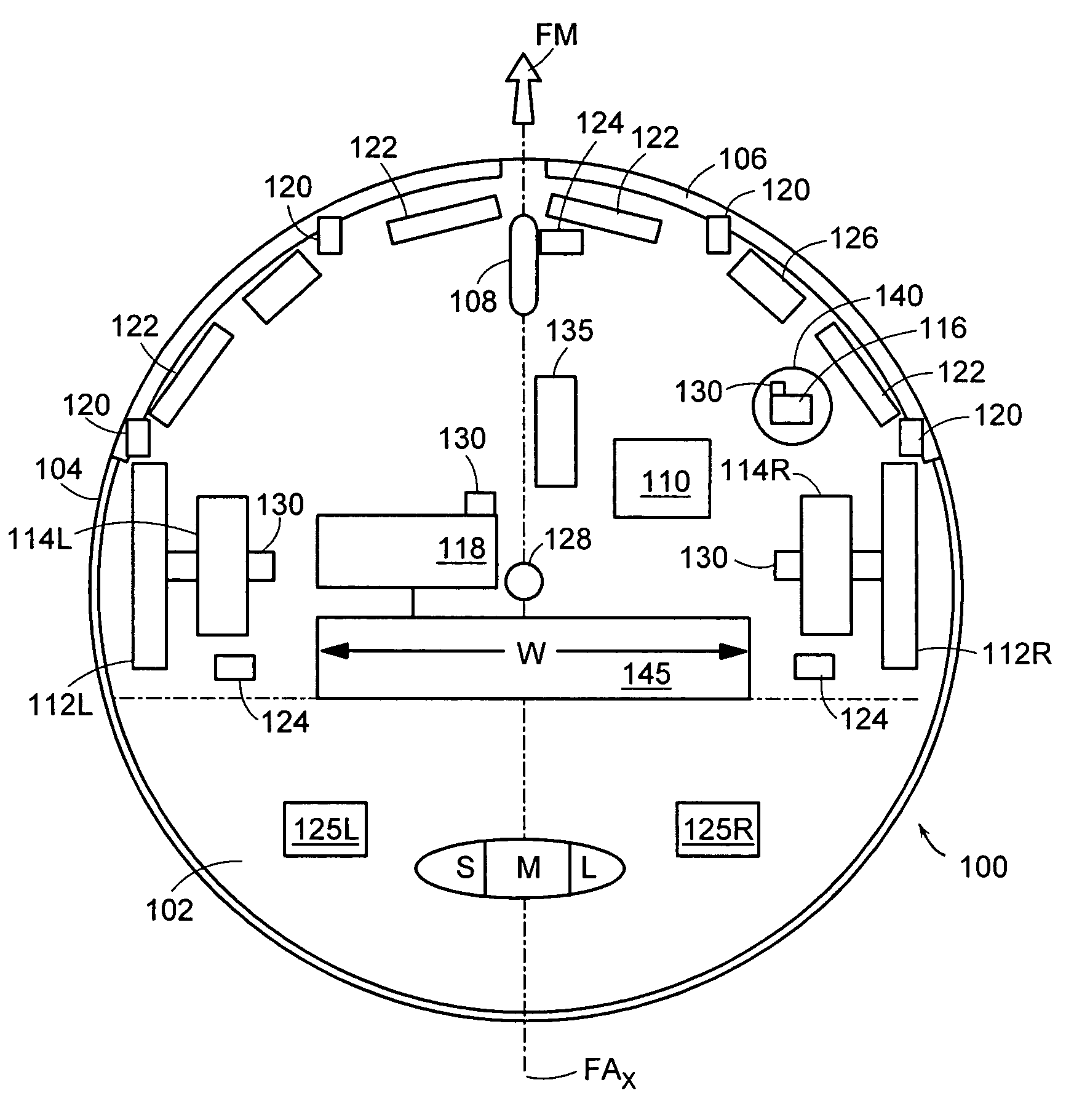

Autonomous surface cleaning robot for wet and dry cleaning

ActiveUS20070016328A1Improve balanceLow costAutomatic obstacle detectionTravelling automatic controlParticulatesSurface cleaning

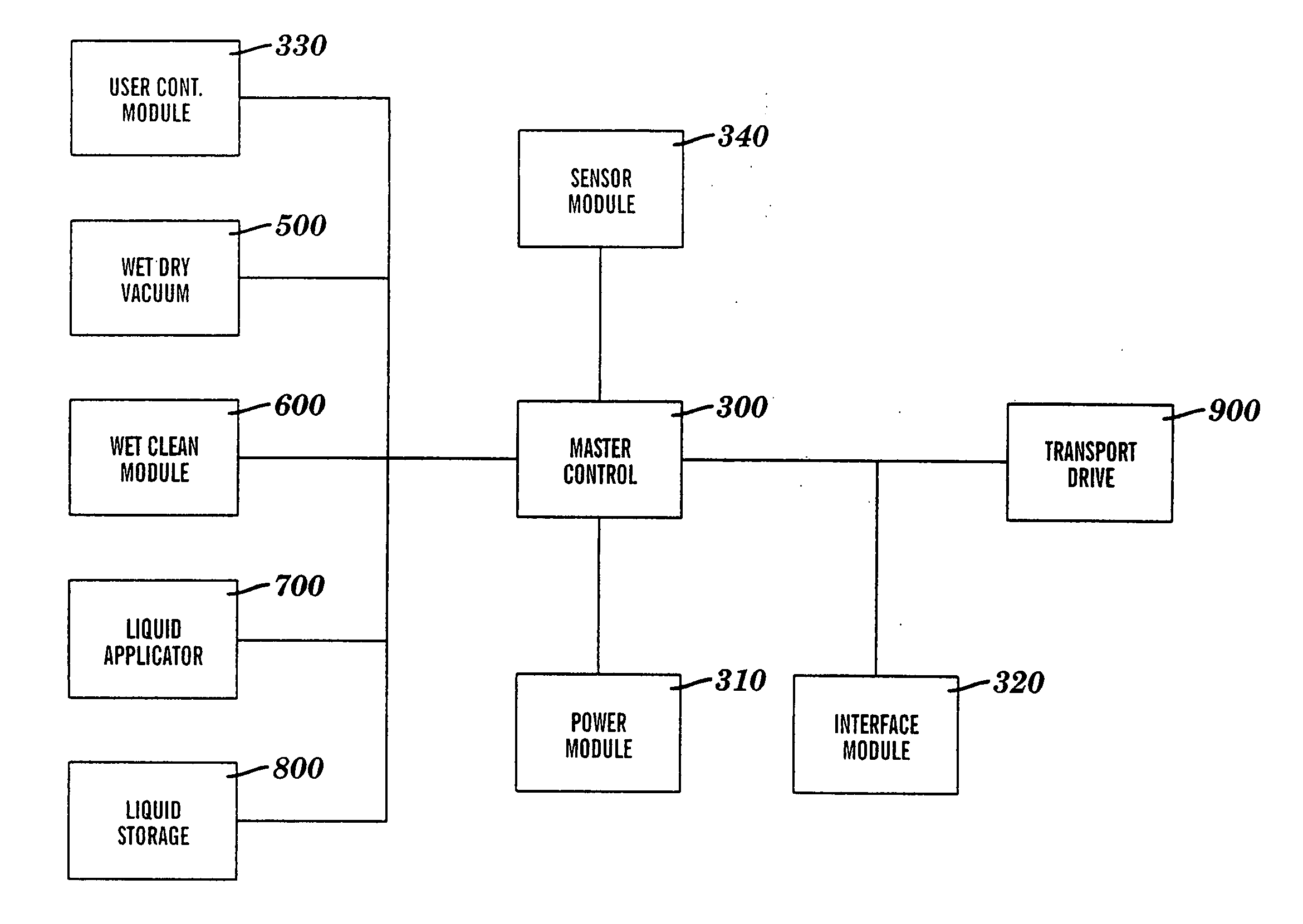

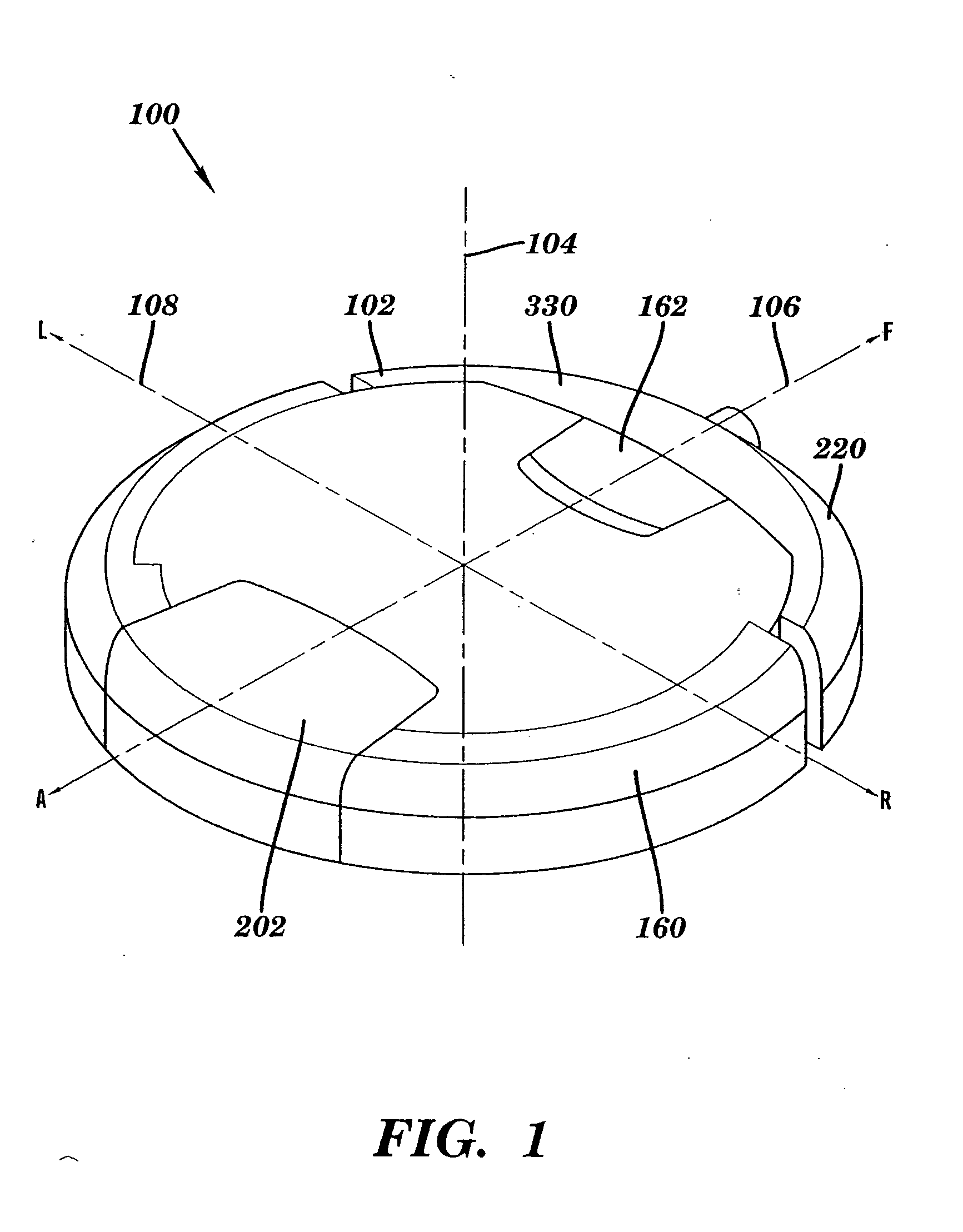

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

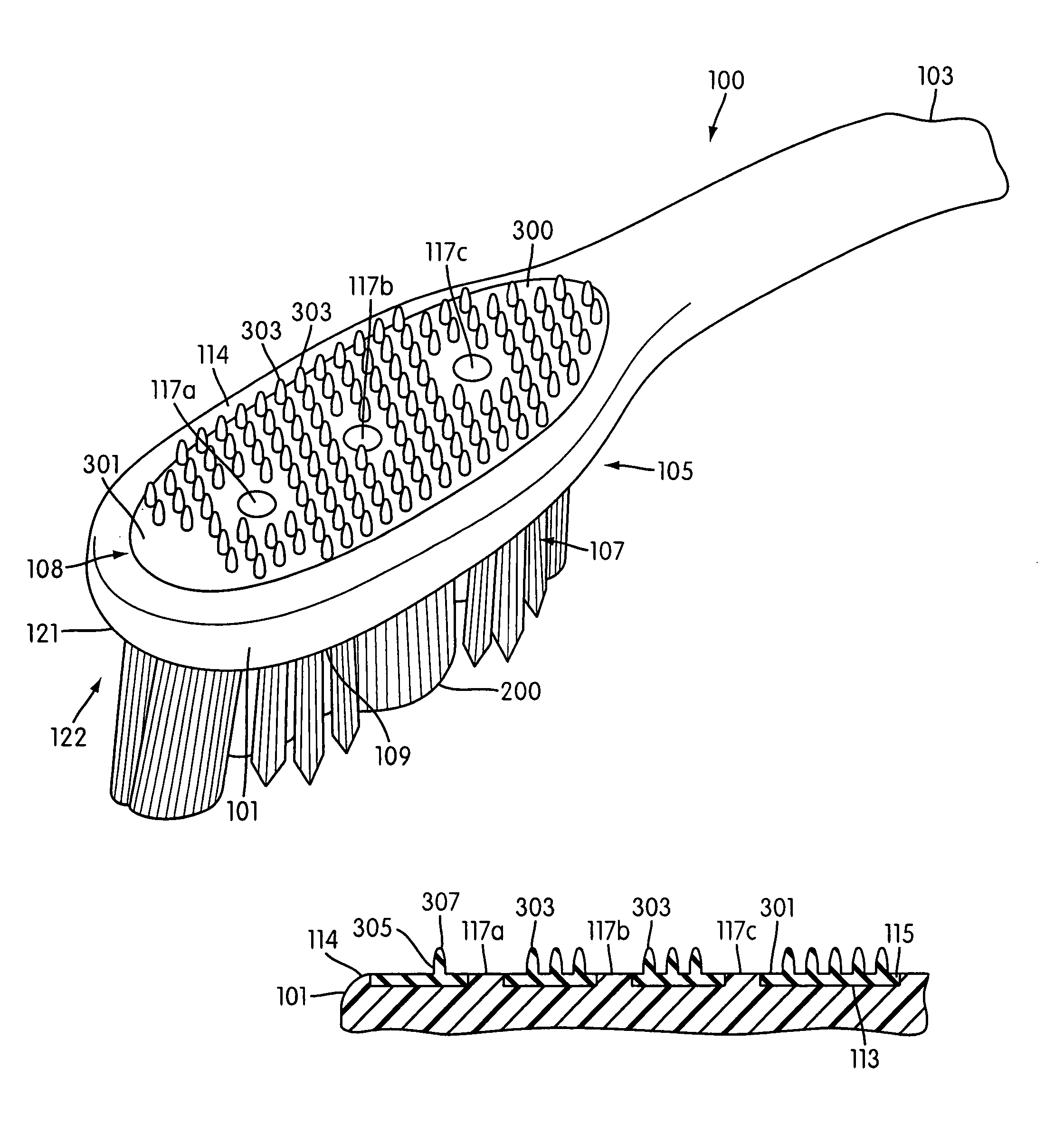

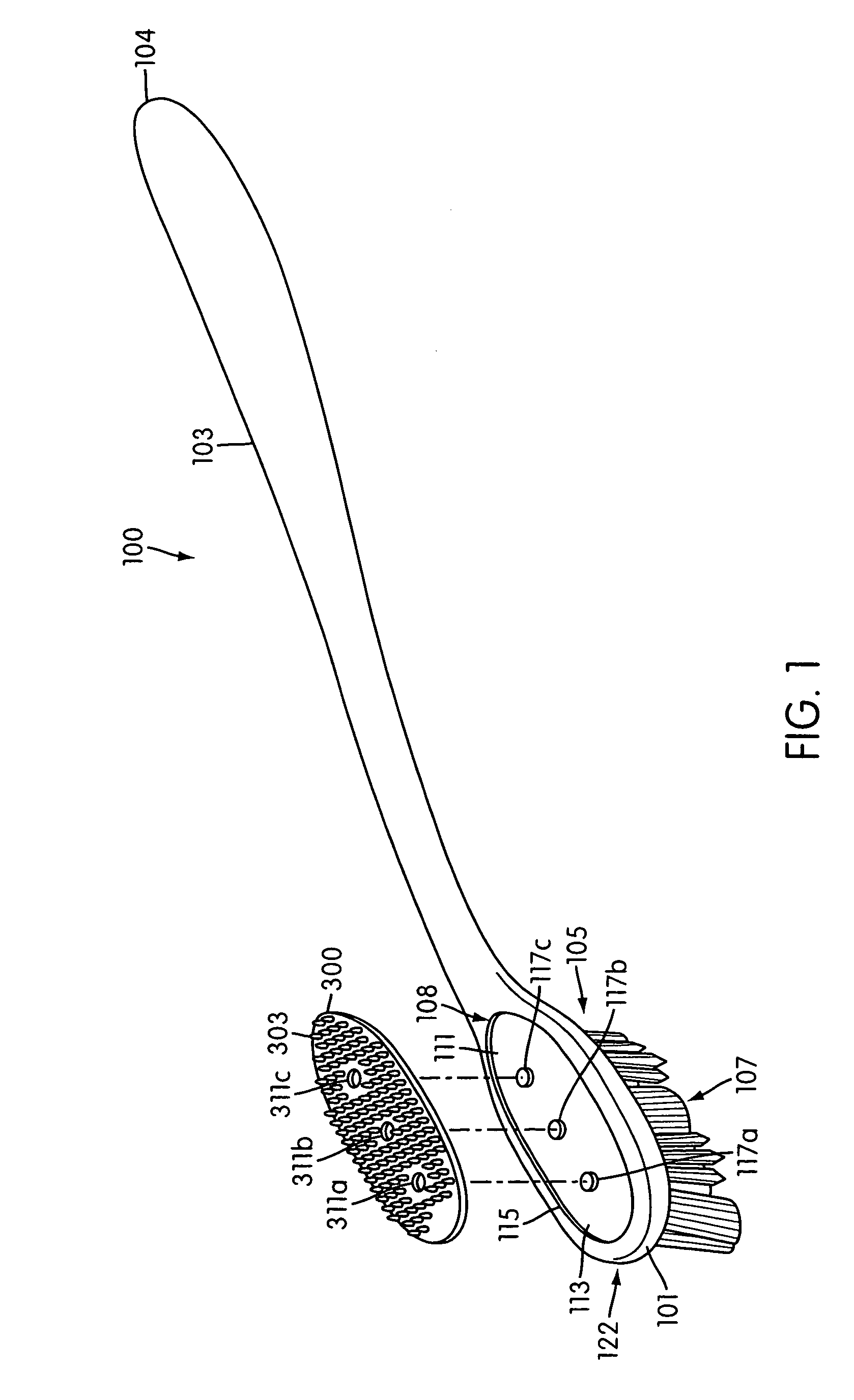

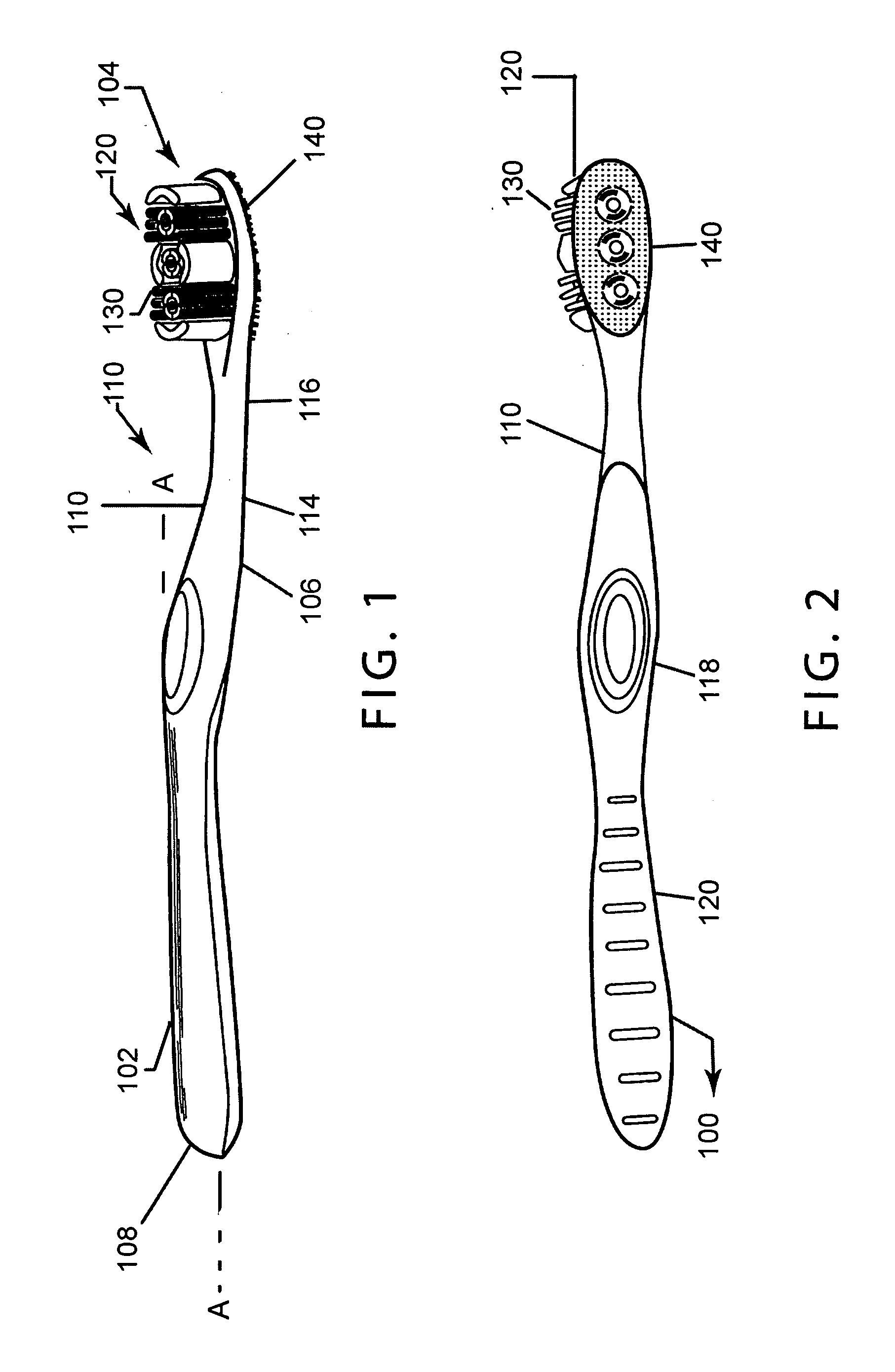

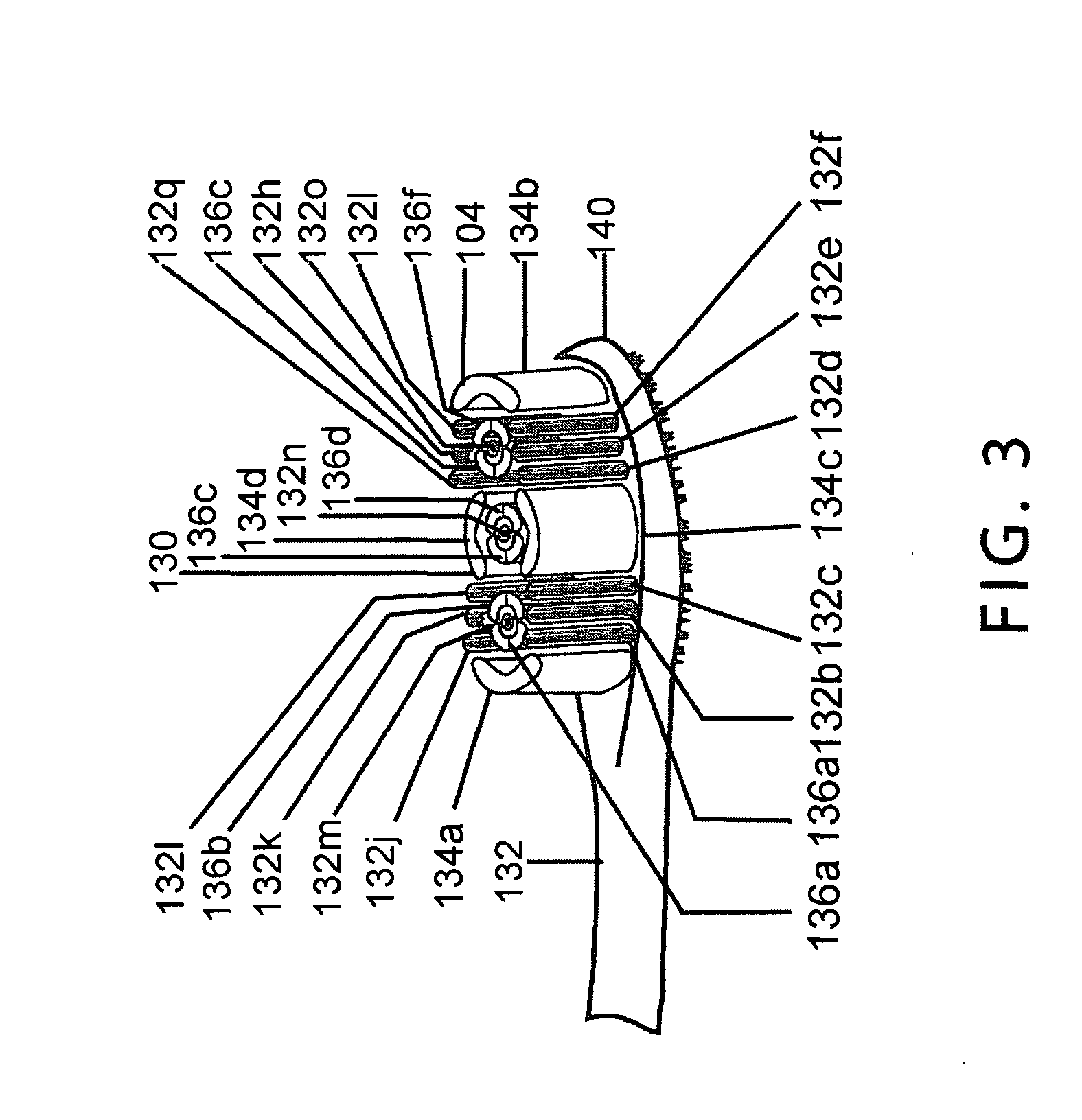

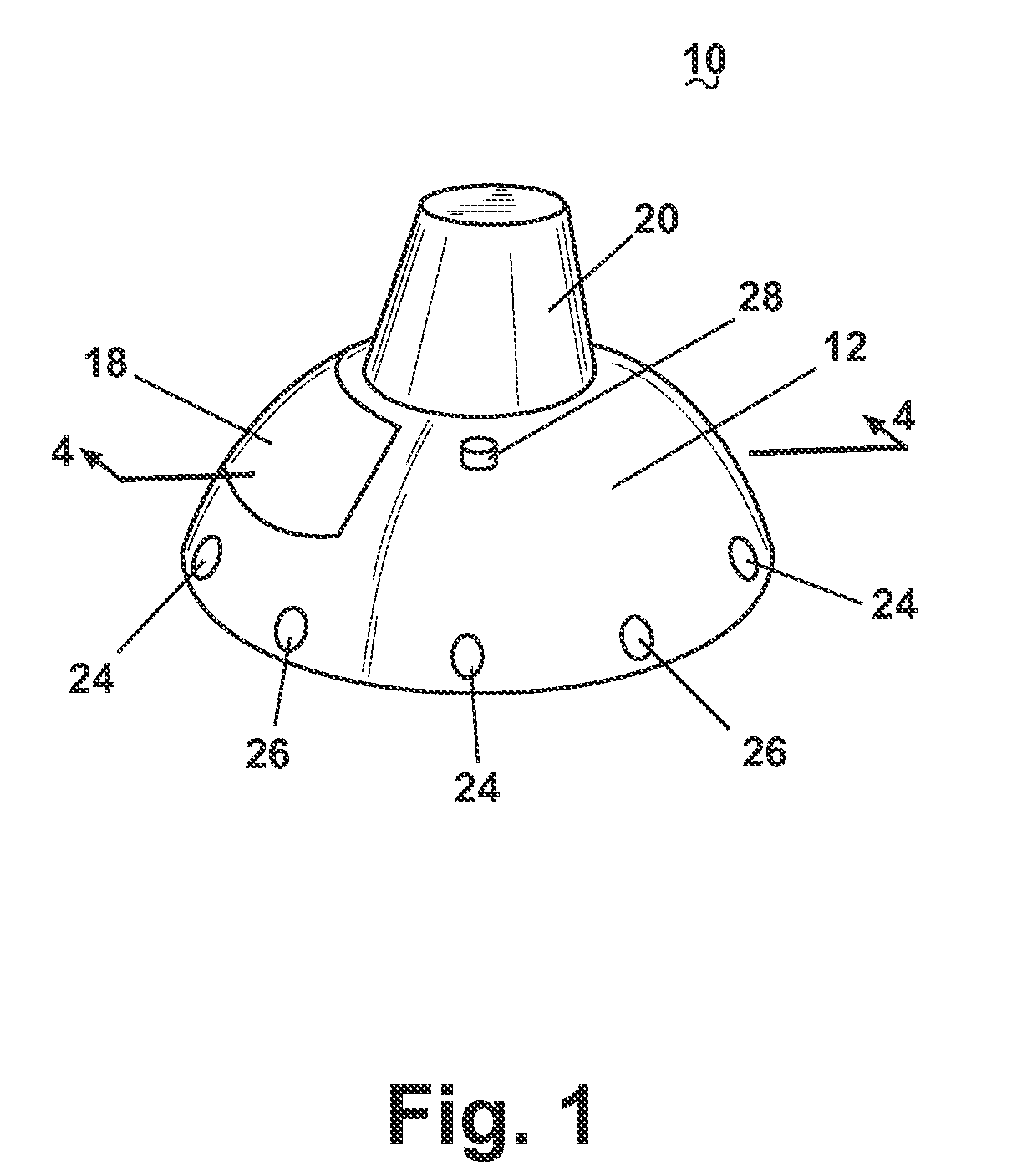

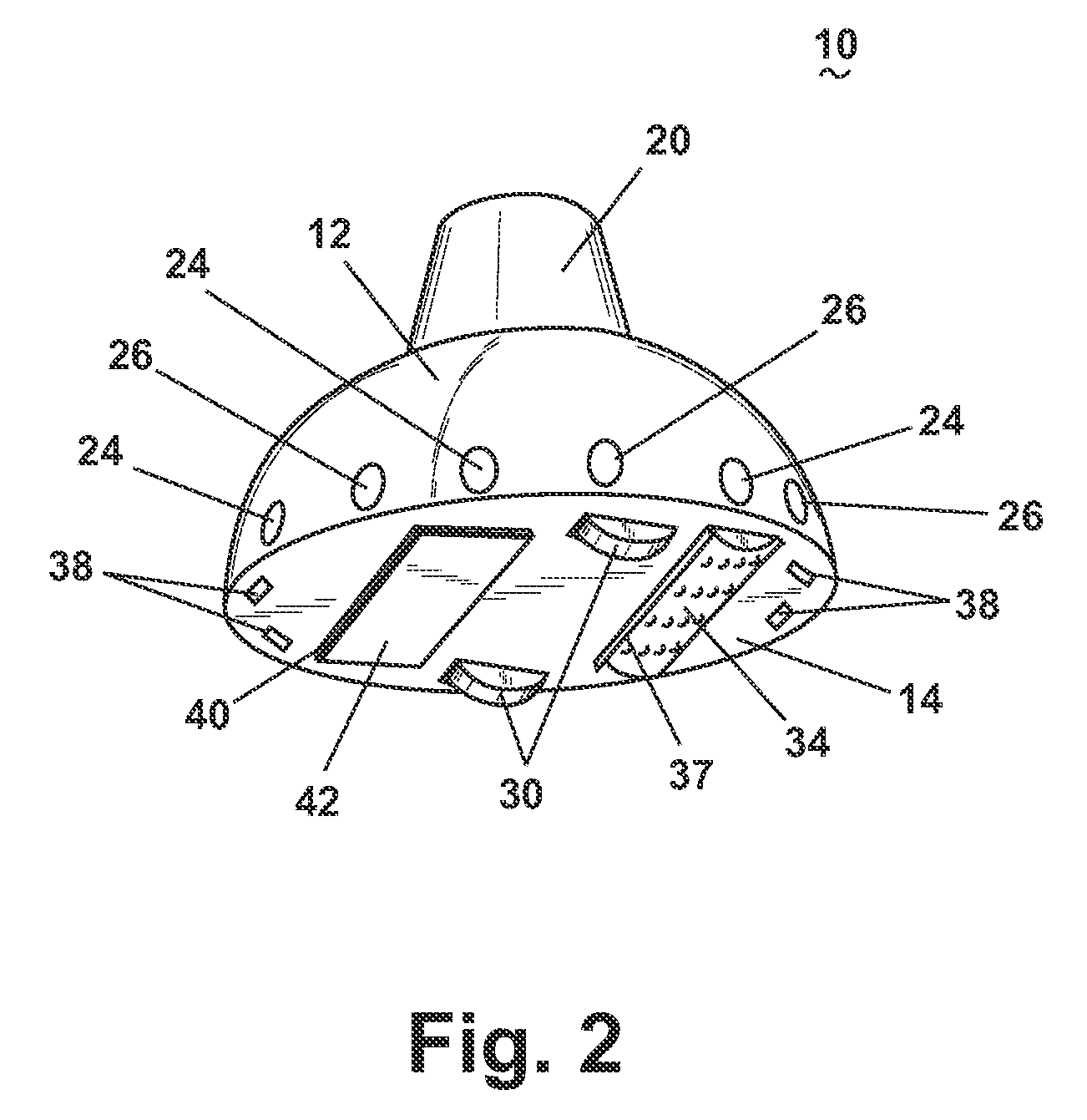

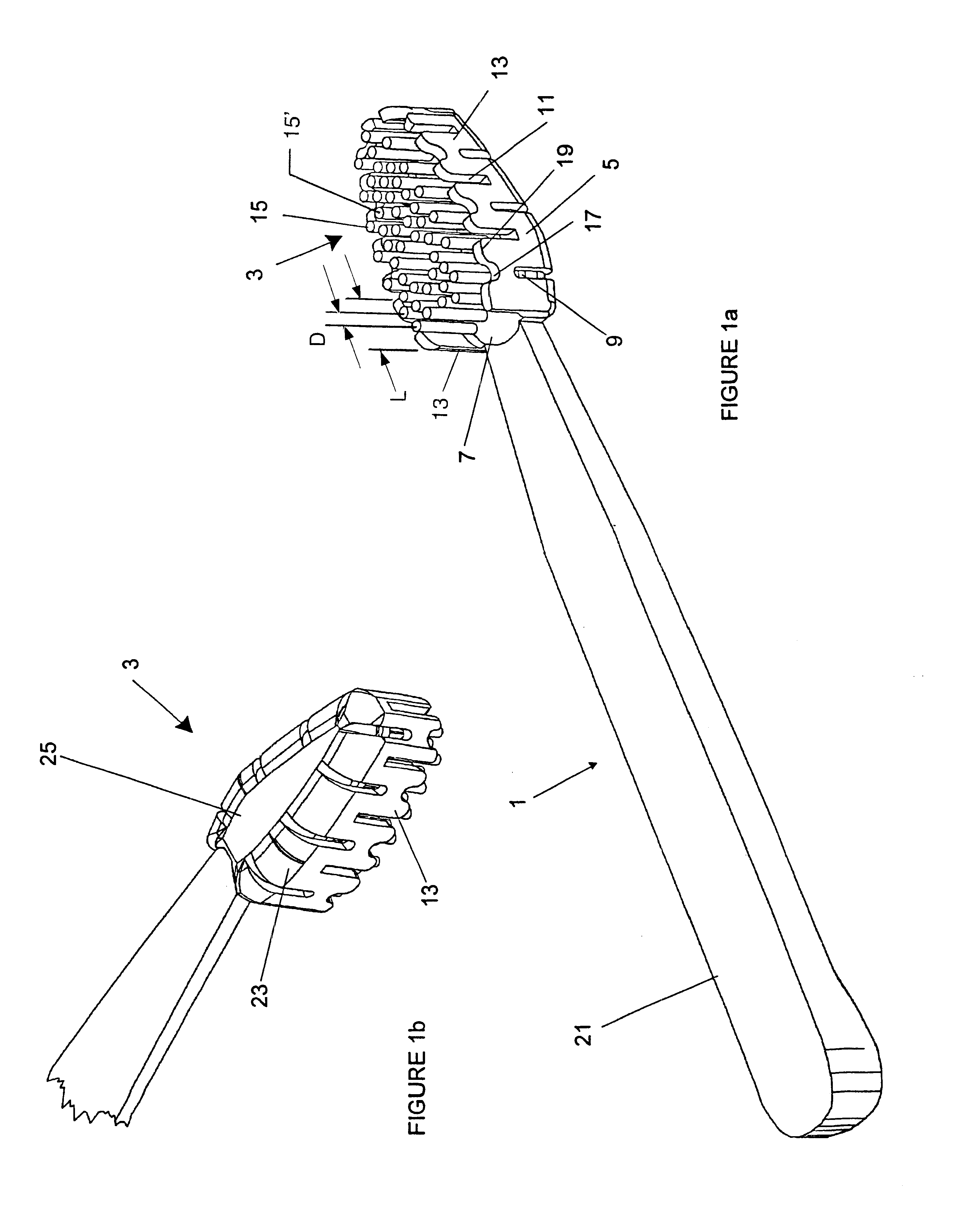

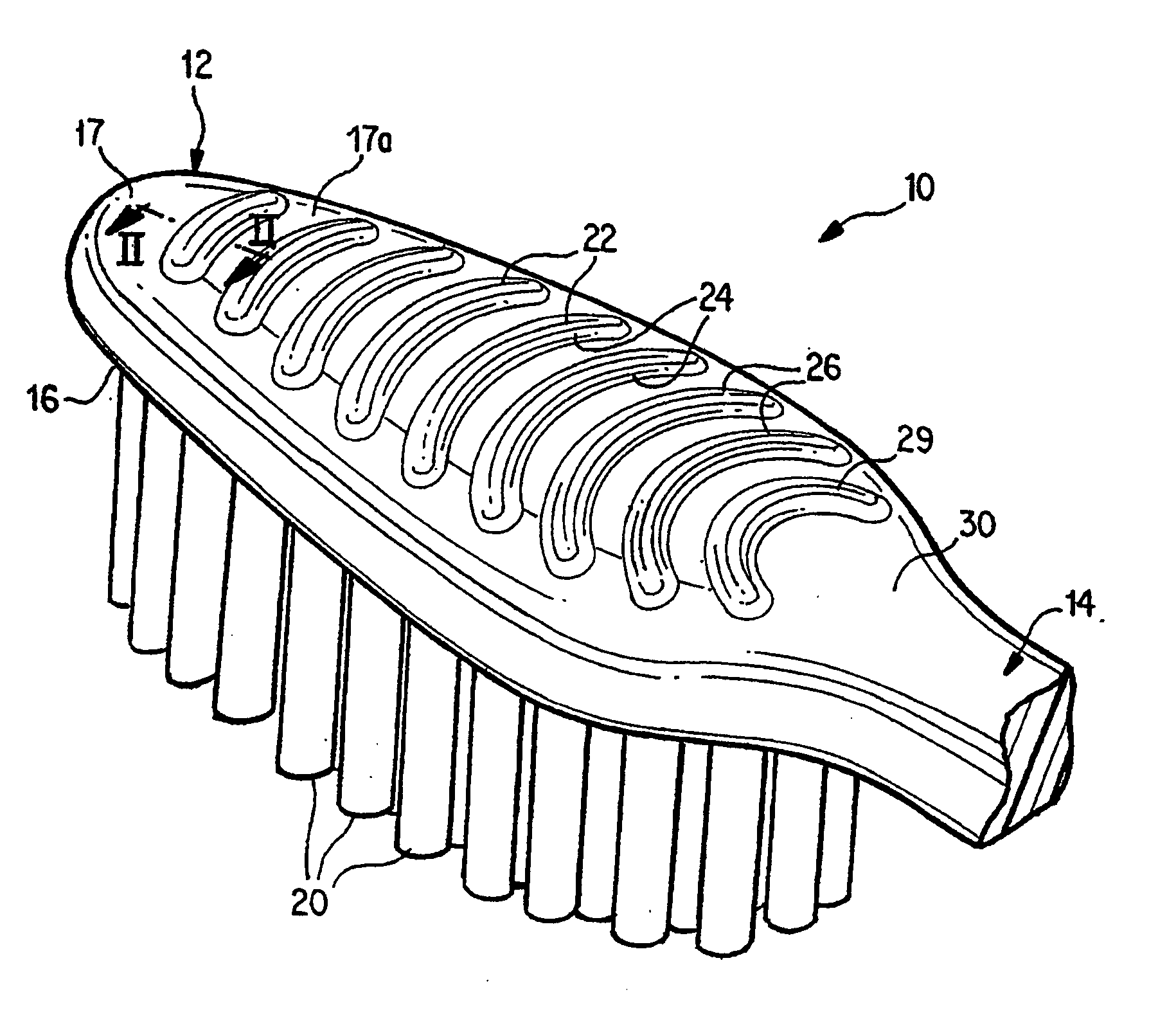

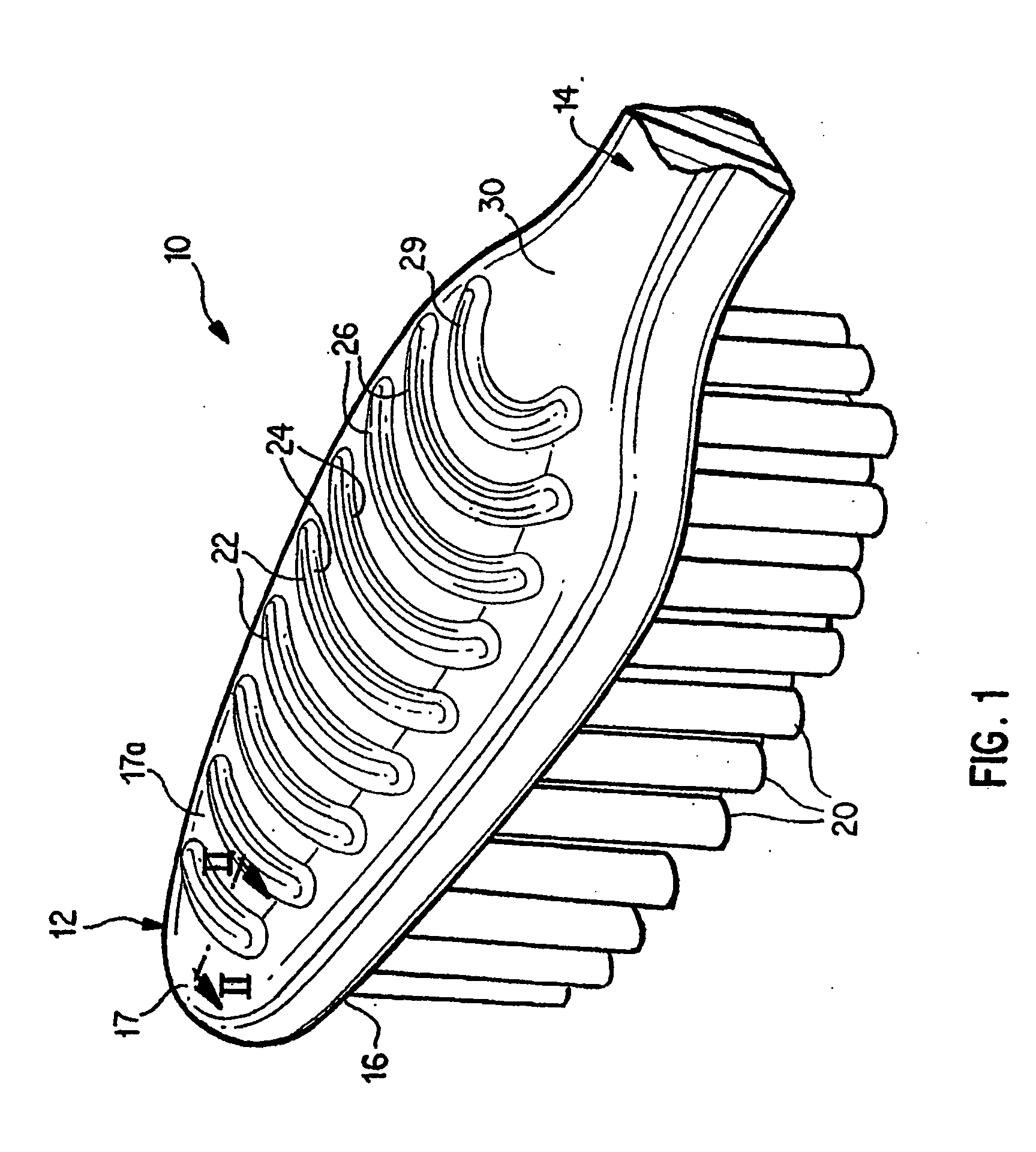

Toothbrush with tongue cleaning member

InactiveUS20040255416A1Large penetrationMinimal heightEar treatmentCarpet cleanersTongue cleaningEngineering

A toothbrush having a handle portion formed with a neck at one end thereof and extending along a first longitudinal axis. A head section is coupled to the neck. The head section includes a plurality of first cleaning members provided on a first head side thereof which extends outwardly from the first head side generally perpendicular to the first longitudinal axis. The head section further includes a second cleaning member provided on a second head side thereof opposite to the first head side. In order to reliably clean the tongue surface, the second cleaning member includes a plurality of flat-tipped conical-shaped cleaning elements which extend outwardly from the second head side of the head section generally perpendicular to the first longitudinal axis. Alternately, the second cleaning member can include a plurality of grated cleaning elements which extend outwardly from the second head side of the head section generally perpendicular to the first longitudinal axis.

Owner:COLGATE PALMOLIVE CO

Autonomous surface cleaning robot for wet and dry cleaning

ActiveUS20080155768A1Low costWet cleaningAutomatic obstacle detectionTravelling automatic controlSurface cleaningControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

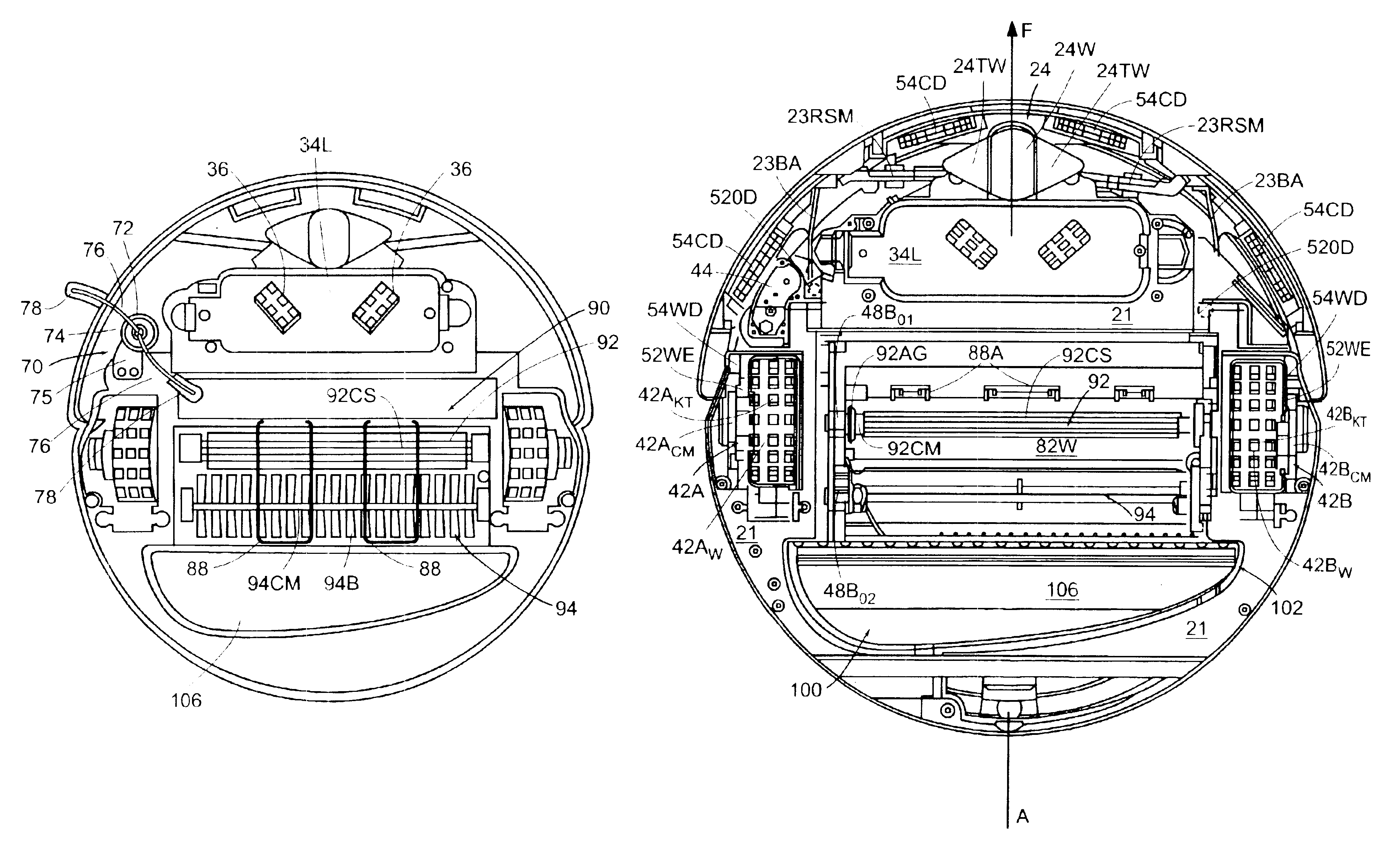

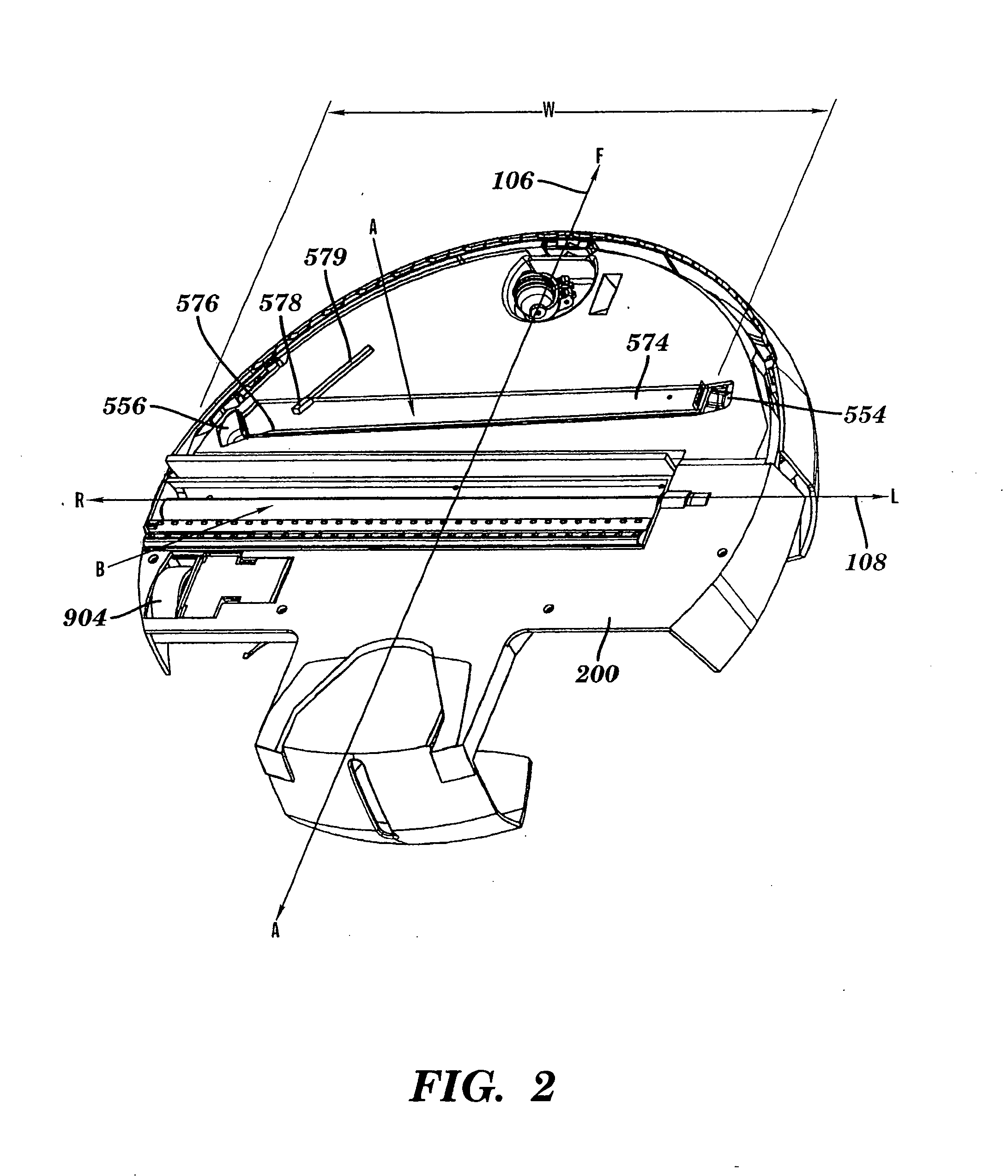

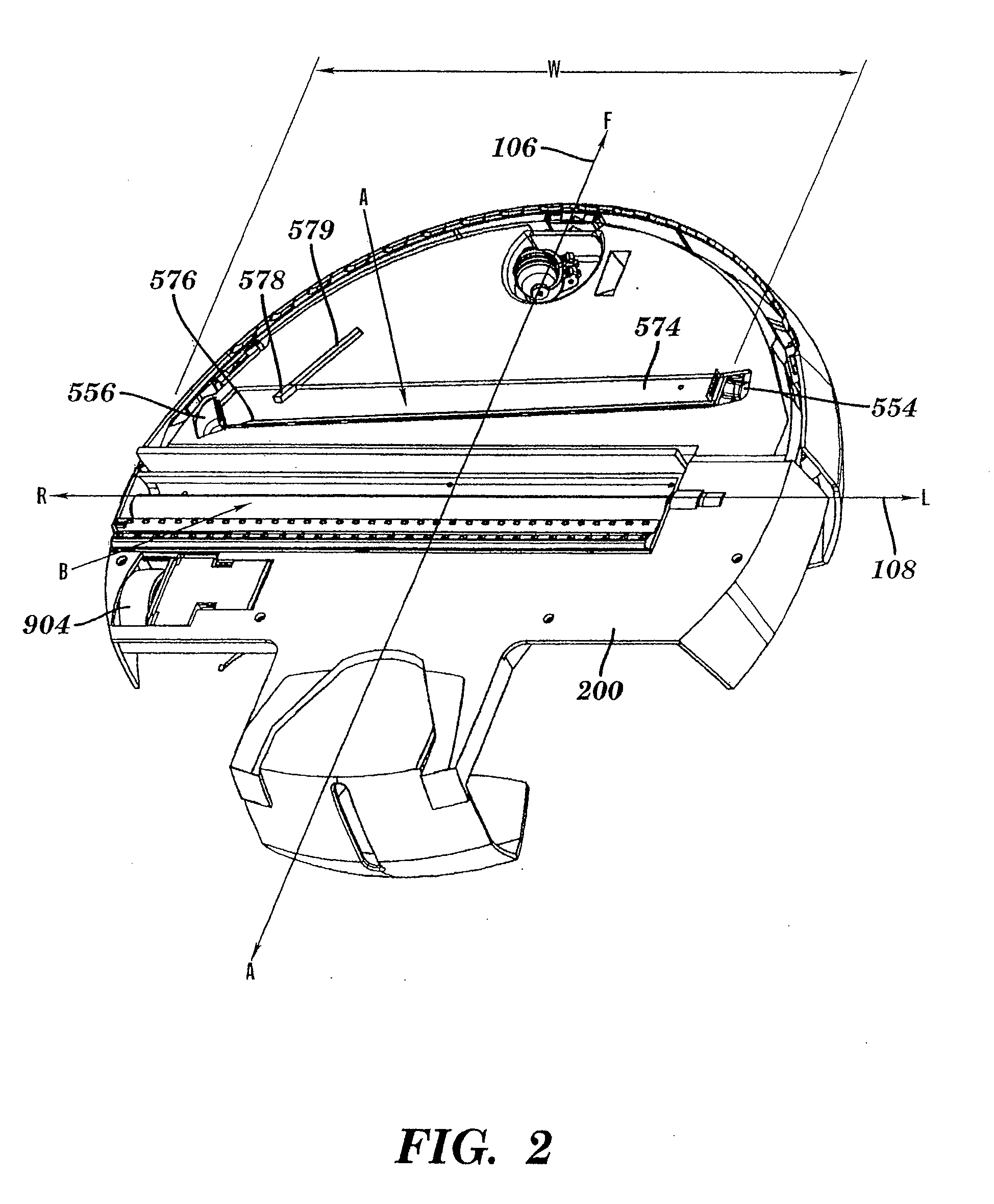

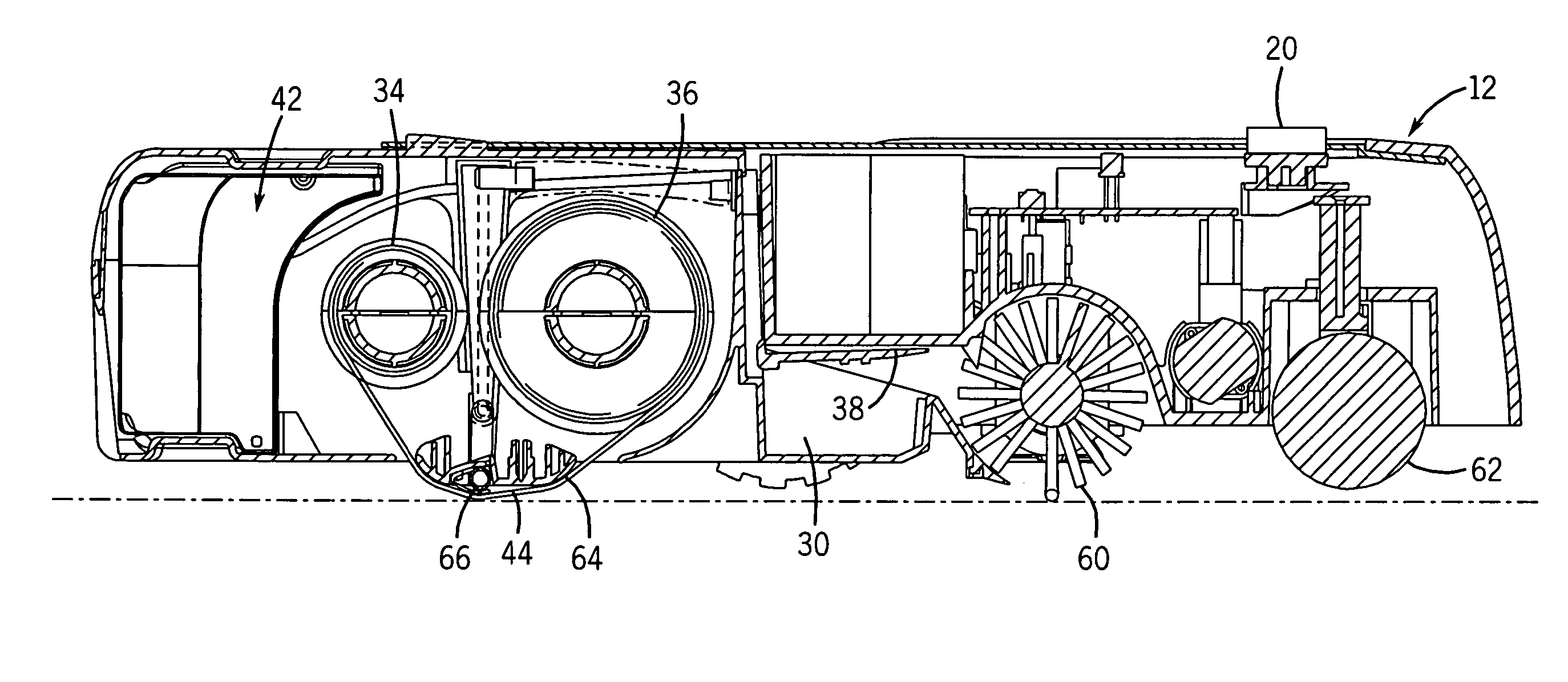

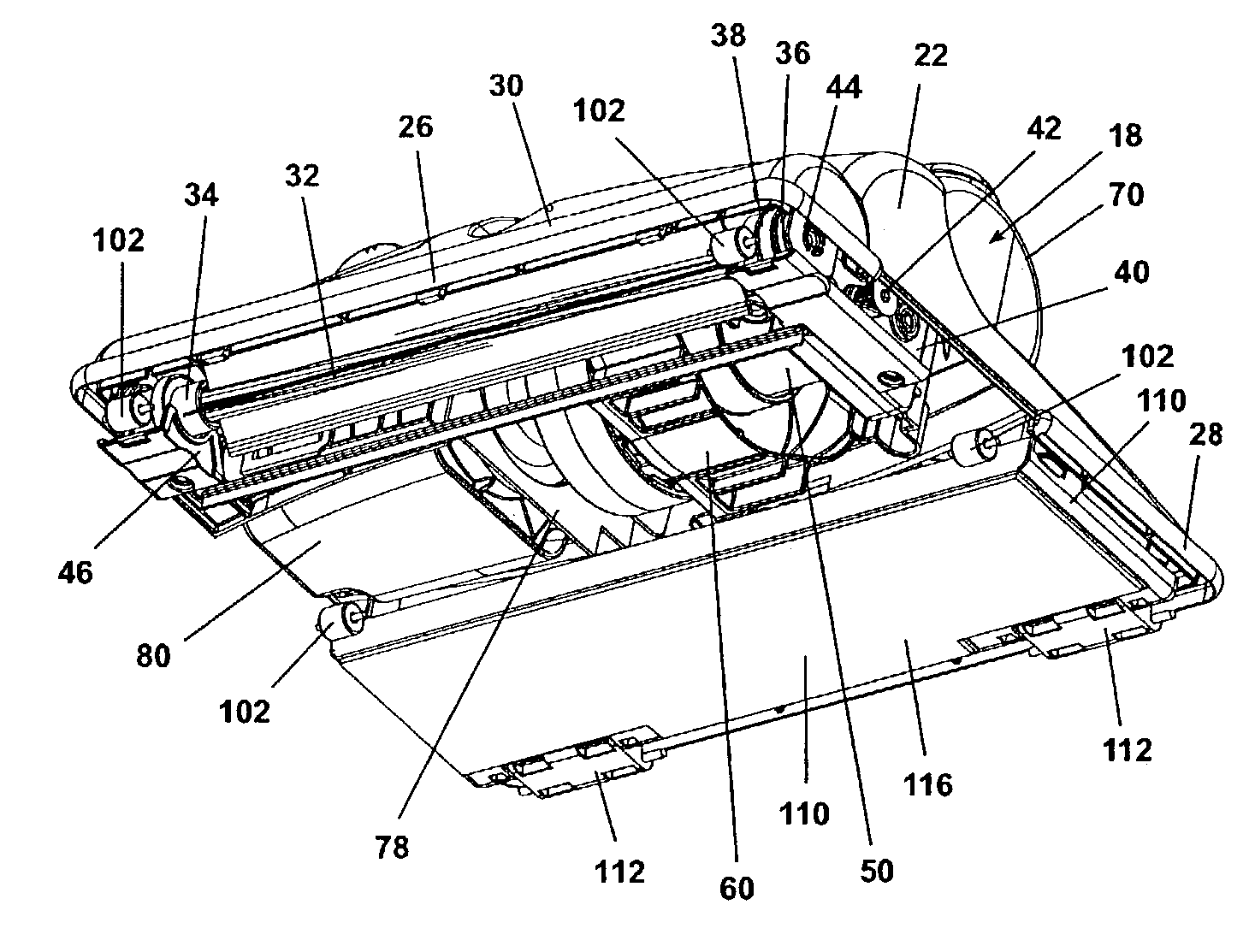

Autonomous Floor Cleaning Robot

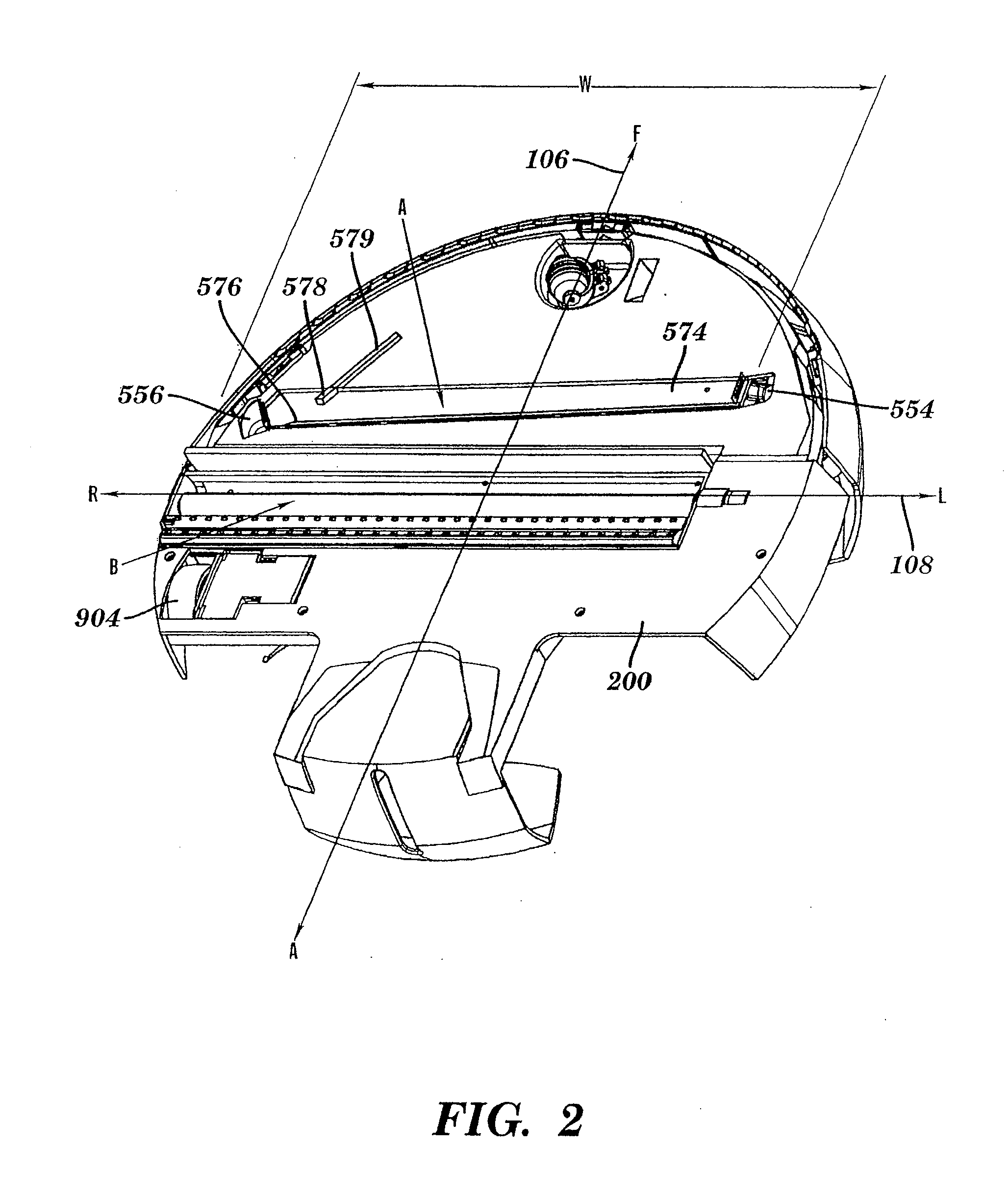

InactiveUS20070266508A1Improve rendering capabilitiesImprove efficiencyCleaning filter meansAutomatic obstacle detectionCommand and controlMarine engineering

An autonomous floor-cleaning robot comprising a housing infrastructure including a chassis, a power subsystem; for providing the energy to power the autonomous floor-cleaning robot, a motive subsystem operative to propel the autonomous floor-cleaning robot for cleaning operations, a command and control subsystem operative to control the autonomous floor-cleaning robot to effect cleaning operations, and a self-adjusting cleaning head subsystem that includes a deck mounted in pivotal combination with the chassis, a brush assembly mounted in combination with the deck and powered by the motive subsystem to sweep up particulates during cleaning operations, a vacuum assembly disposed in combination with the deck and powered by the motive subsystem to ingest particulates during cleaning operations, and a deck adjusting subassembly mounted in combination with the motive subsystem for the brush assembly, the deck, and the chassis that is automatically operative in response to an increase in brush torque in said brush assembly to pivot the deck with respect to said chassis. The autonomous floor-cleaning robot also includes a side brush assembly mounted in combination with the chassis and powered by the motive subsystem to entrain particulates outside the periphery of the housing infrastructure and to direct such particulates towards the self-adjusting cleaning head subsystem.

Owner:IROBOT CORP

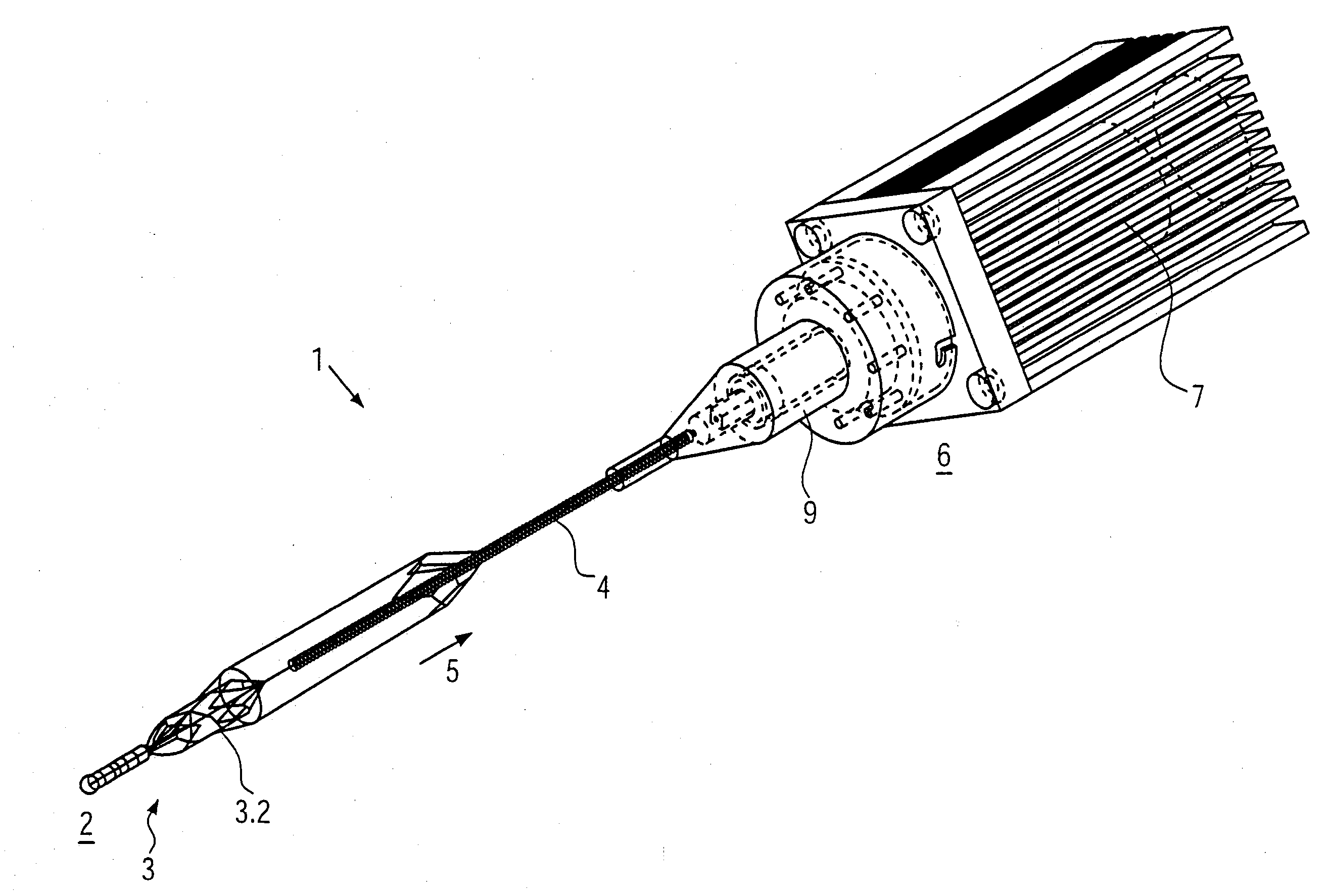

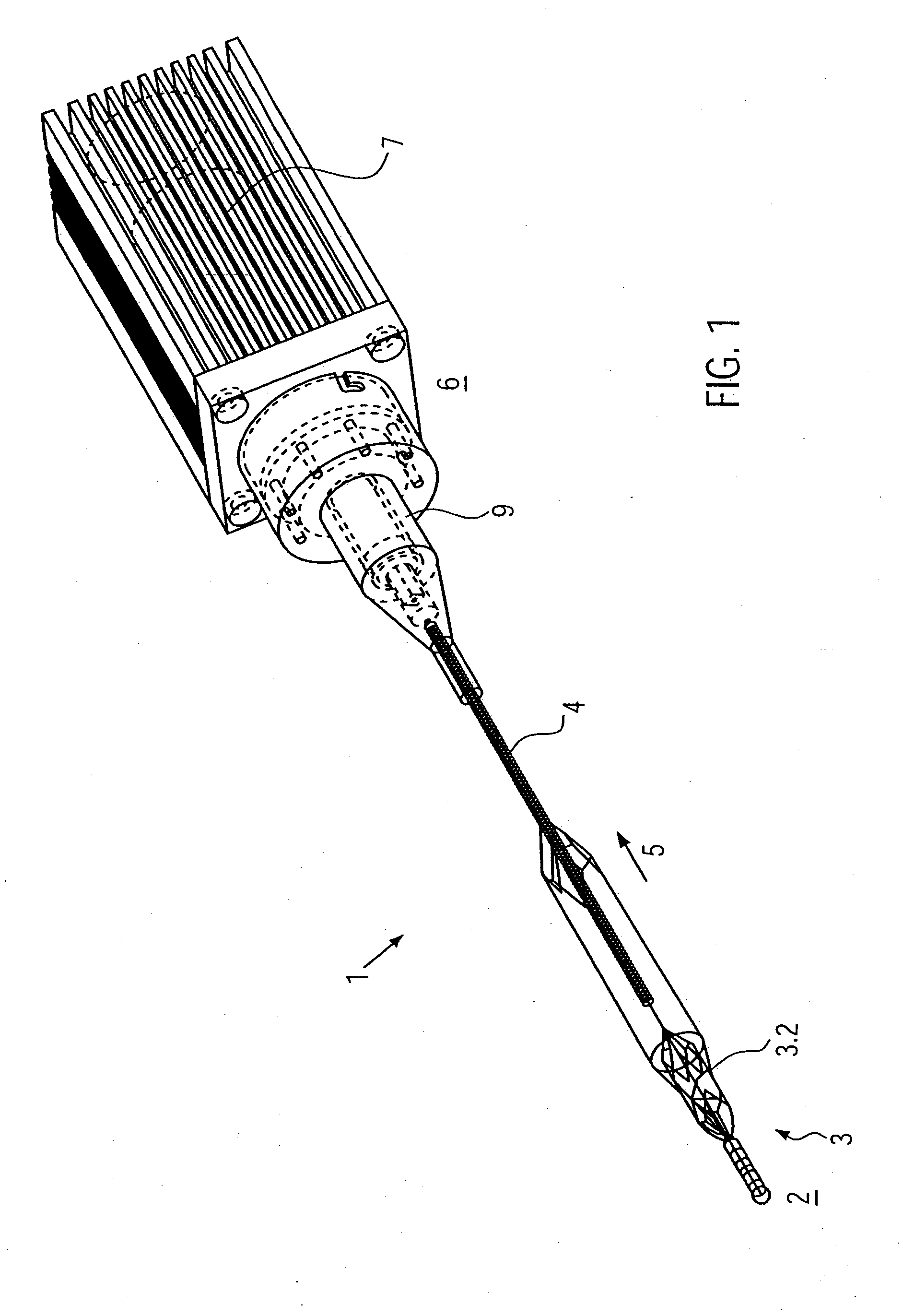

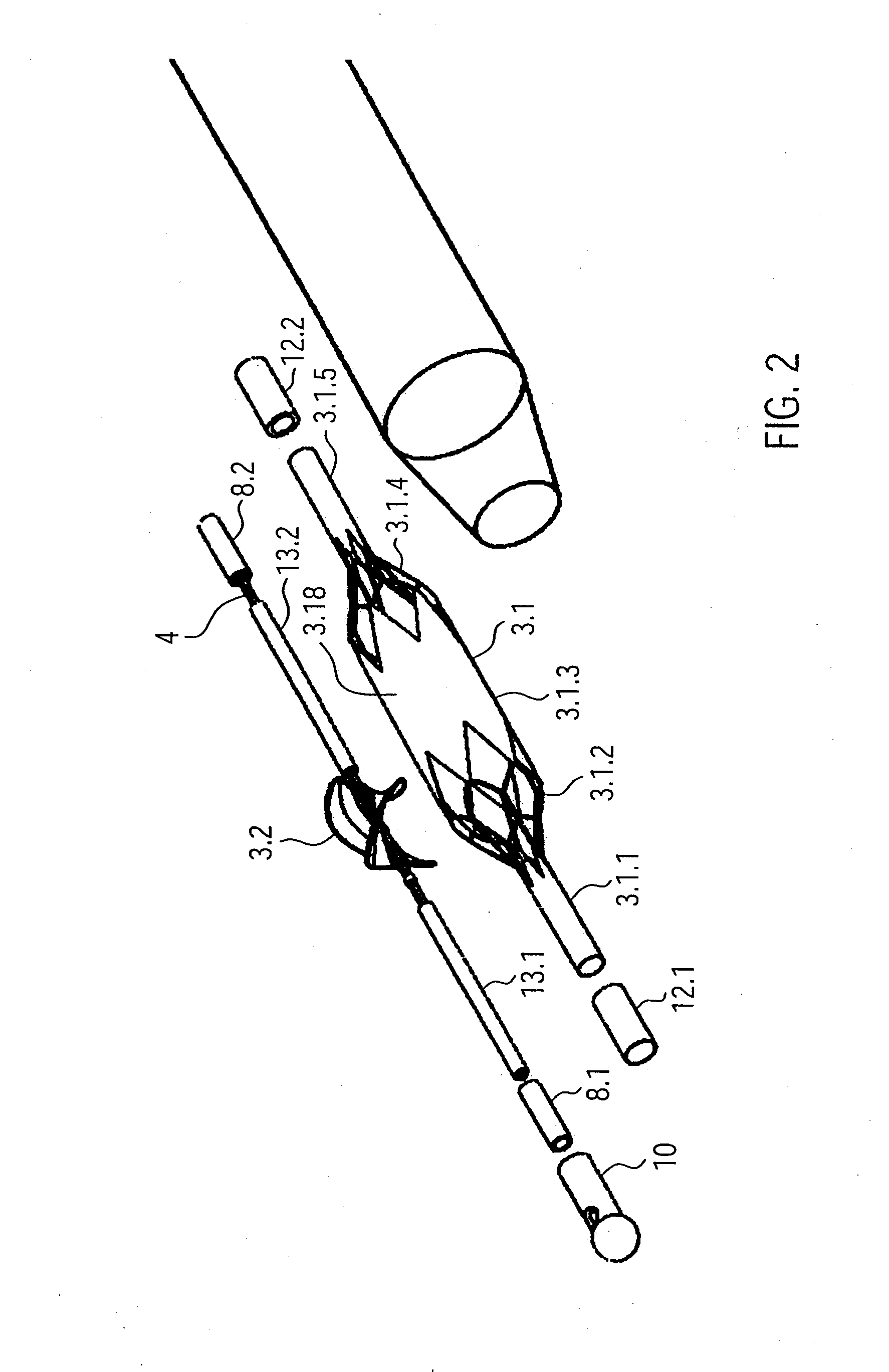

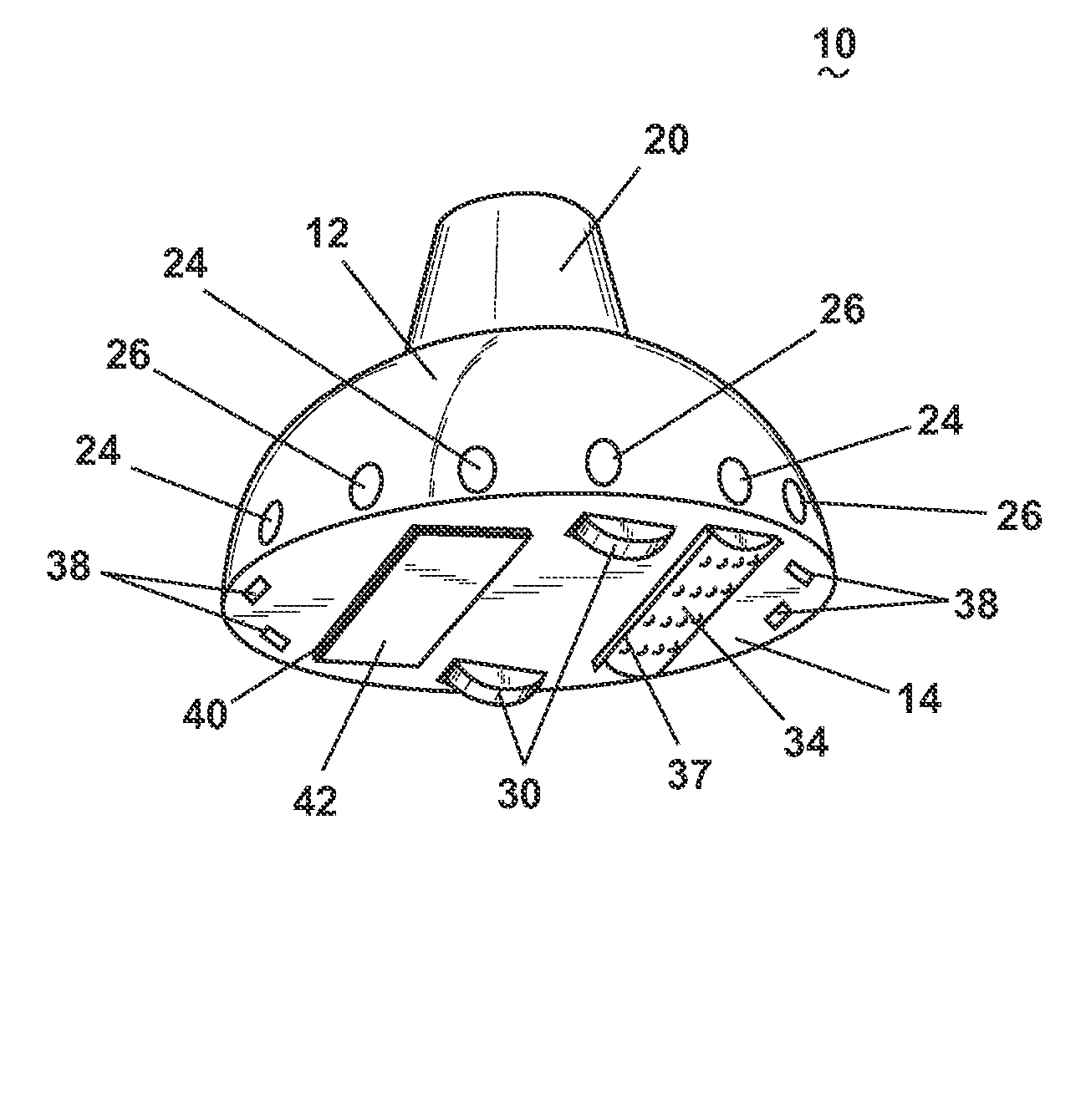

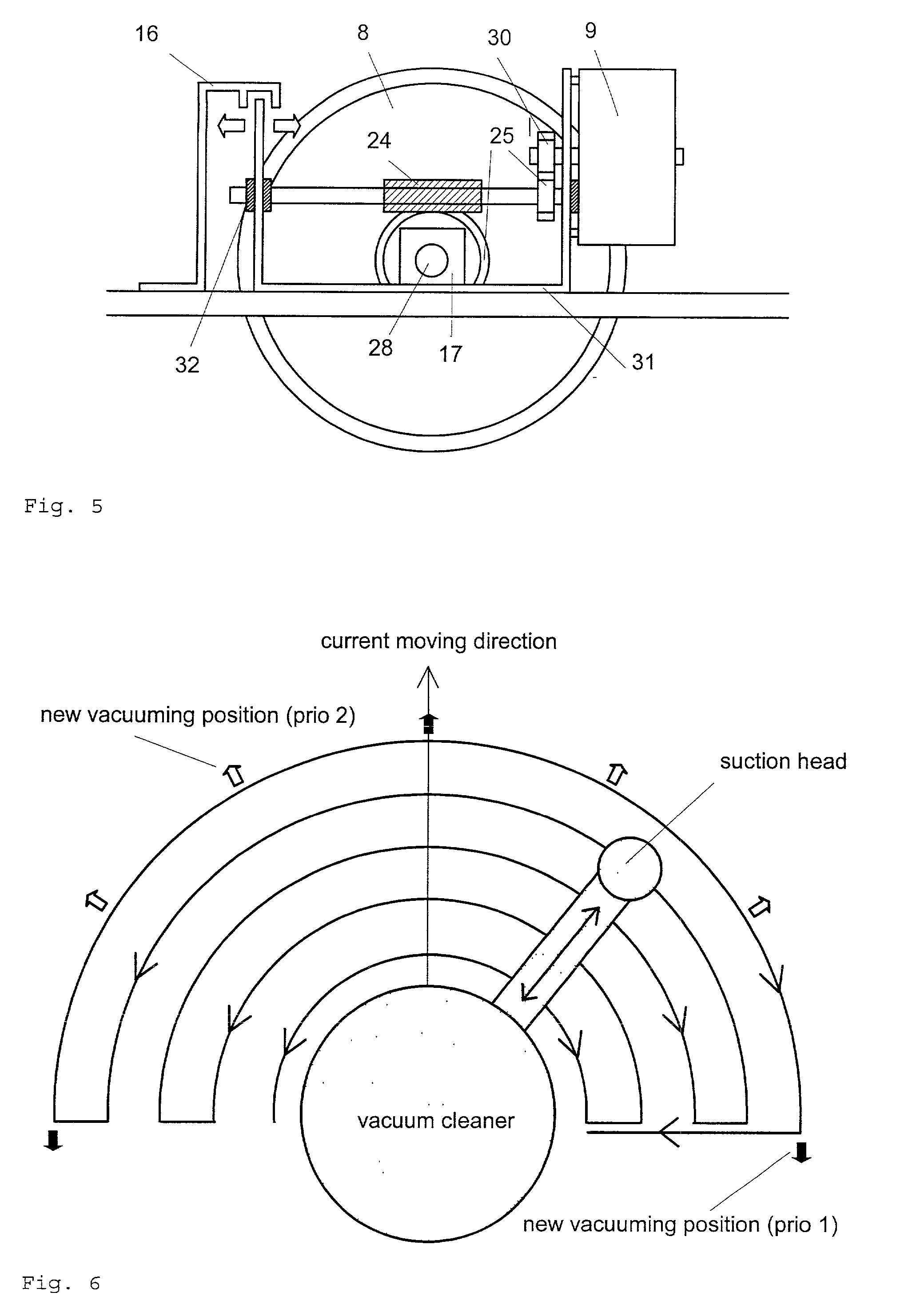

Catheter device

ActiveUS20090093764A1Impairing rotatabilityAccurate settingElectrotherapyCarpet cleanersDrive shaftClutch

The catheter device comprises a motor located at the proximal end of the catheter device and a drive shaft, extending from the proximal end section to the distal end section of the catheter device, for driving a rotating element located at the distal end of the catheter device. The catheter device also comprises a hose-like catheter body which encompasses the drive shaft and extends from the proximal end section to the distal end section of the catheter device. At the proximal end of the catheter device, the drive shaft is connected to a motor by a clutch. The clutch is a magnetic clutch with a proximal and a distal magnet unit. The proximal magnet unit is connected to the motor and the distal magnet unit to the drive shaft. The distal magnet unit is mounted fluid-tight in a clutch housing. The proximal end of the catheter body makes a fluid-tight connection with the clutch housing.

Owner:AIS AACHEN INNOVATIVE SOLUTIONS

Robotic extraction cleaner with dusting pad

An vacuum cleaning robot has a drive system adapted to autonomously move a base housing along a horizontal surface and is controlled by a computer processing unit. A dusting assembly is mounted to the base housing and is adapted to selectively rest on a surface to be cleaned. A suction source draws dirt and debris through a suction nozzle and deposits the same in the recovery tank. A power source is connected to the drive system and to the computer processing unit. The computer processing unit is adapted to direct horizontal movement of the base housing within boundaries of the surface to be cleaned based upon input data defining said boundaries.

Owner:BISSELL INC

Autonomous surface cleaning robot for wet and dry cleaning

InactiveUS20080140255A1Low costWet cleaningAutomatic obstacle detectionTravelling automatic controlSurface cleaningControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

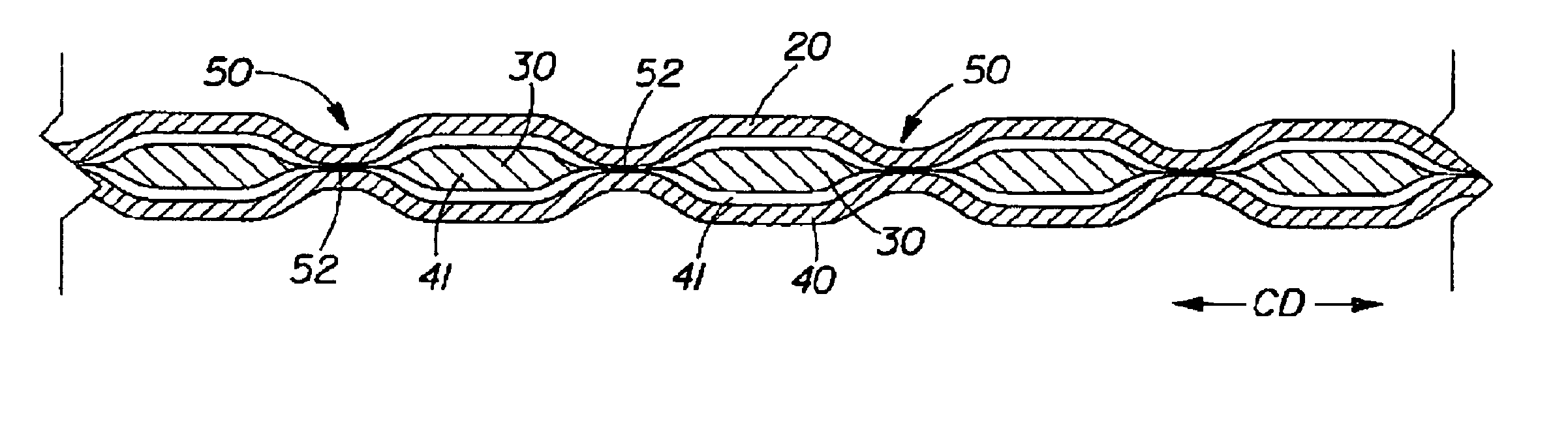

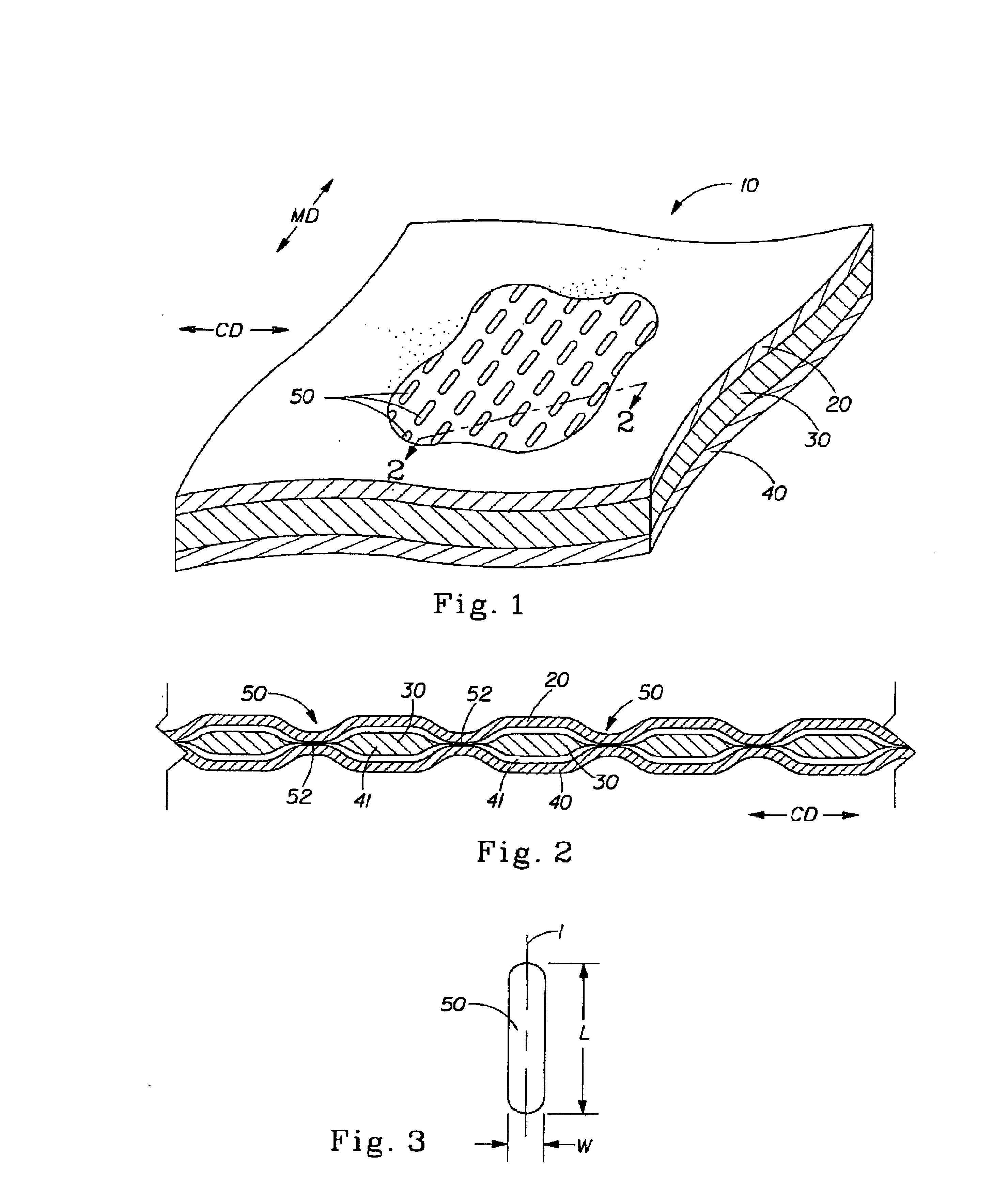

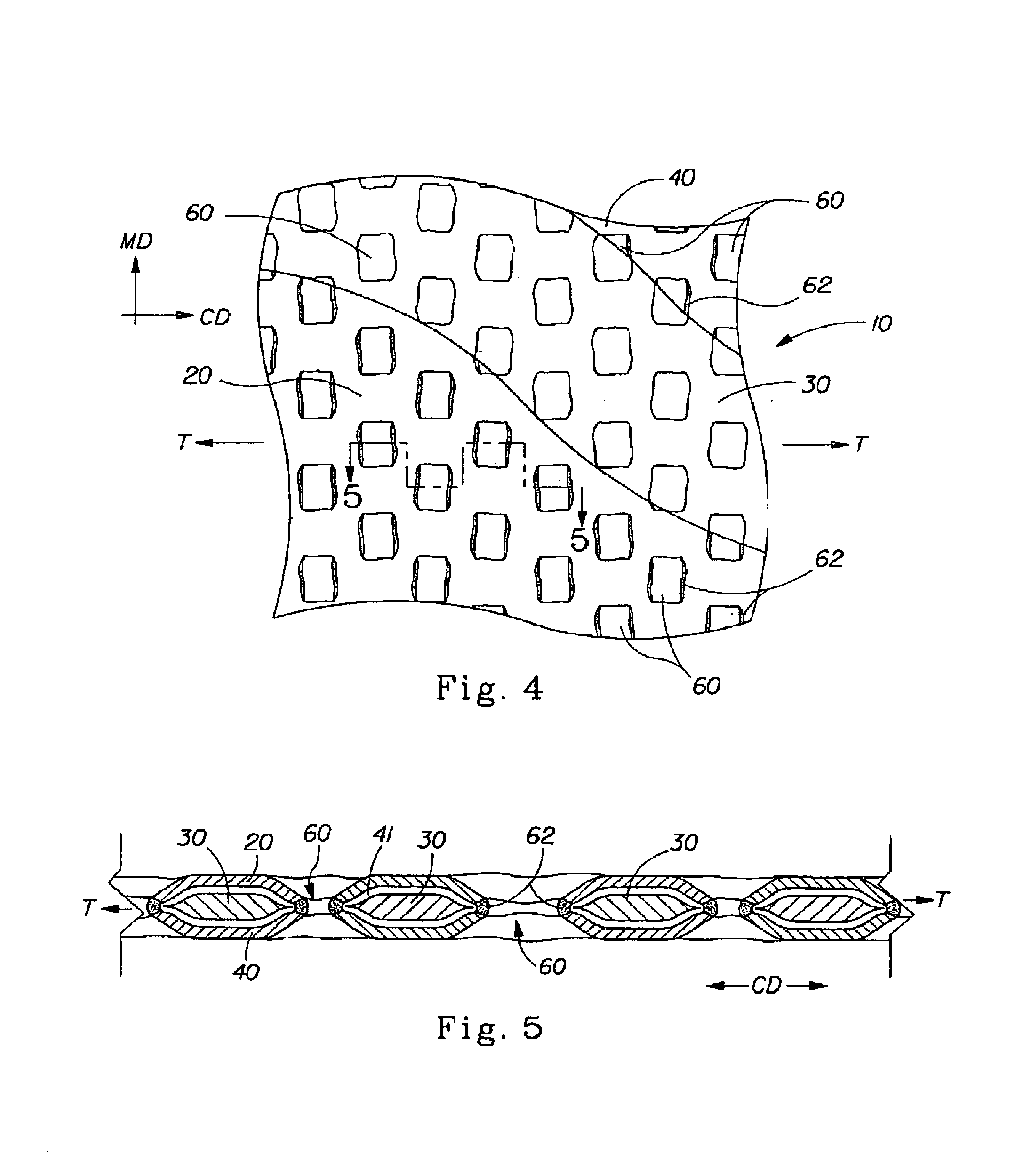

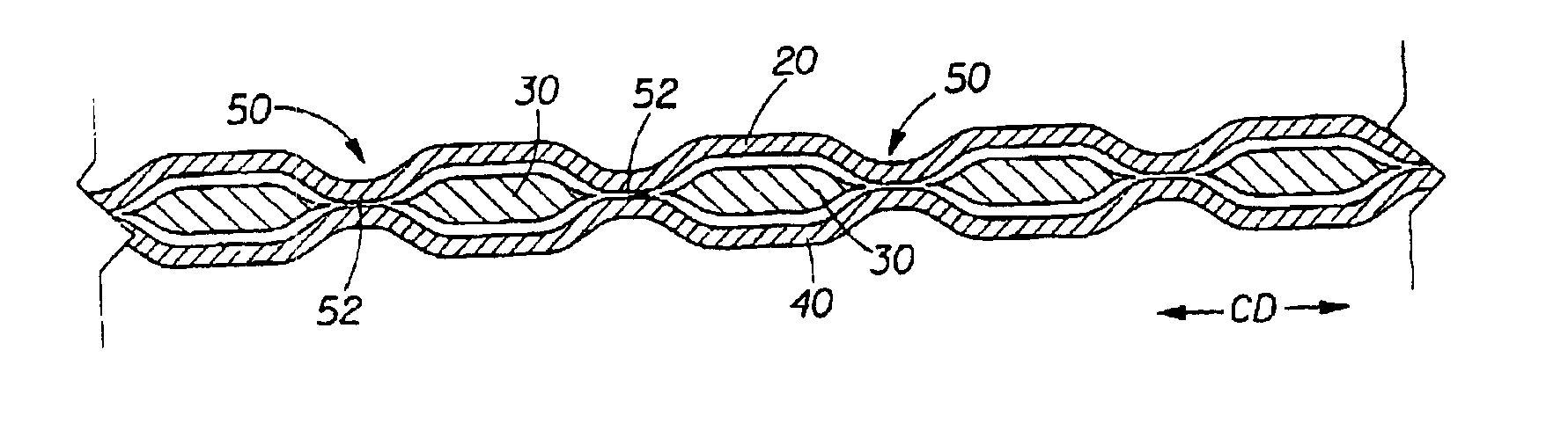

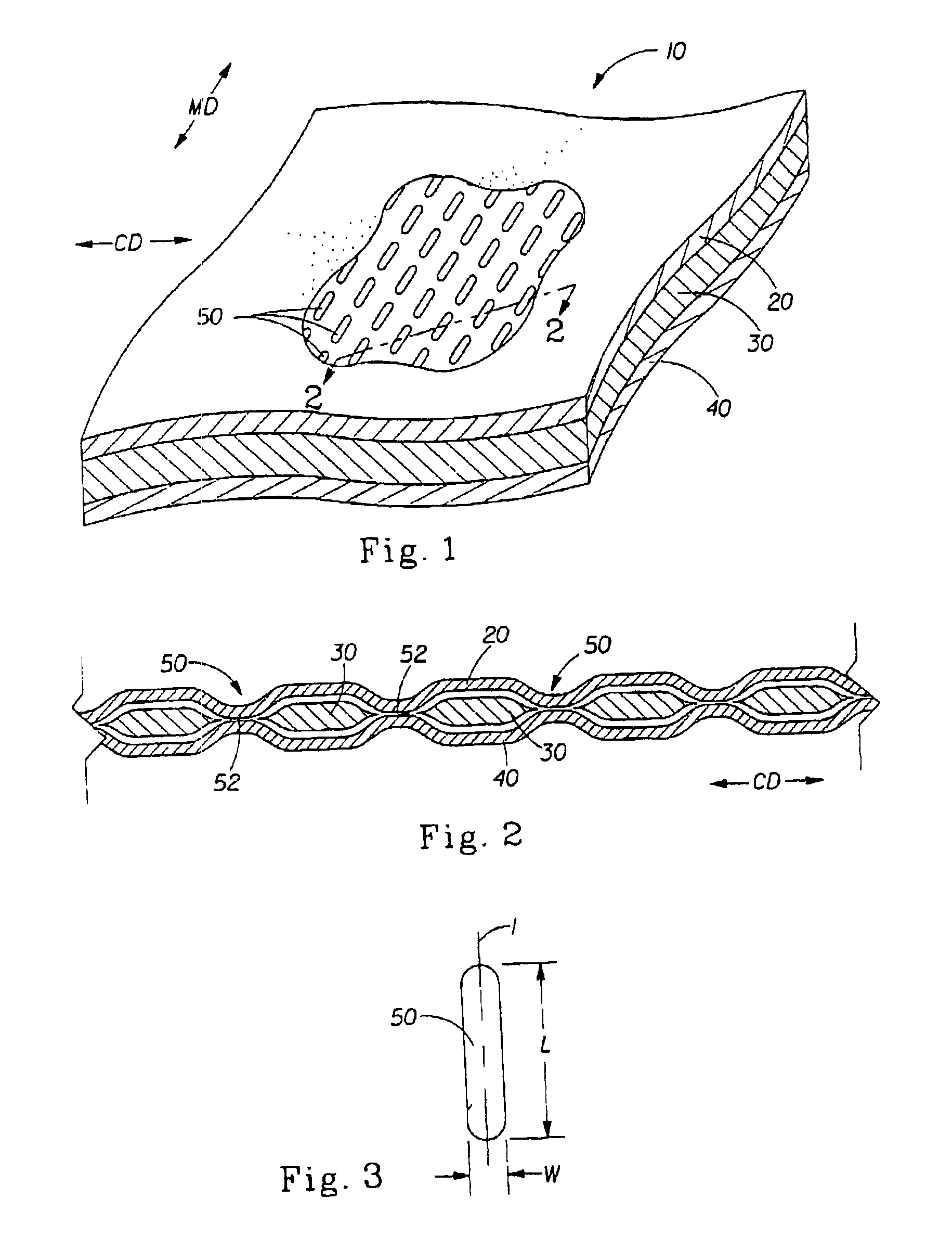

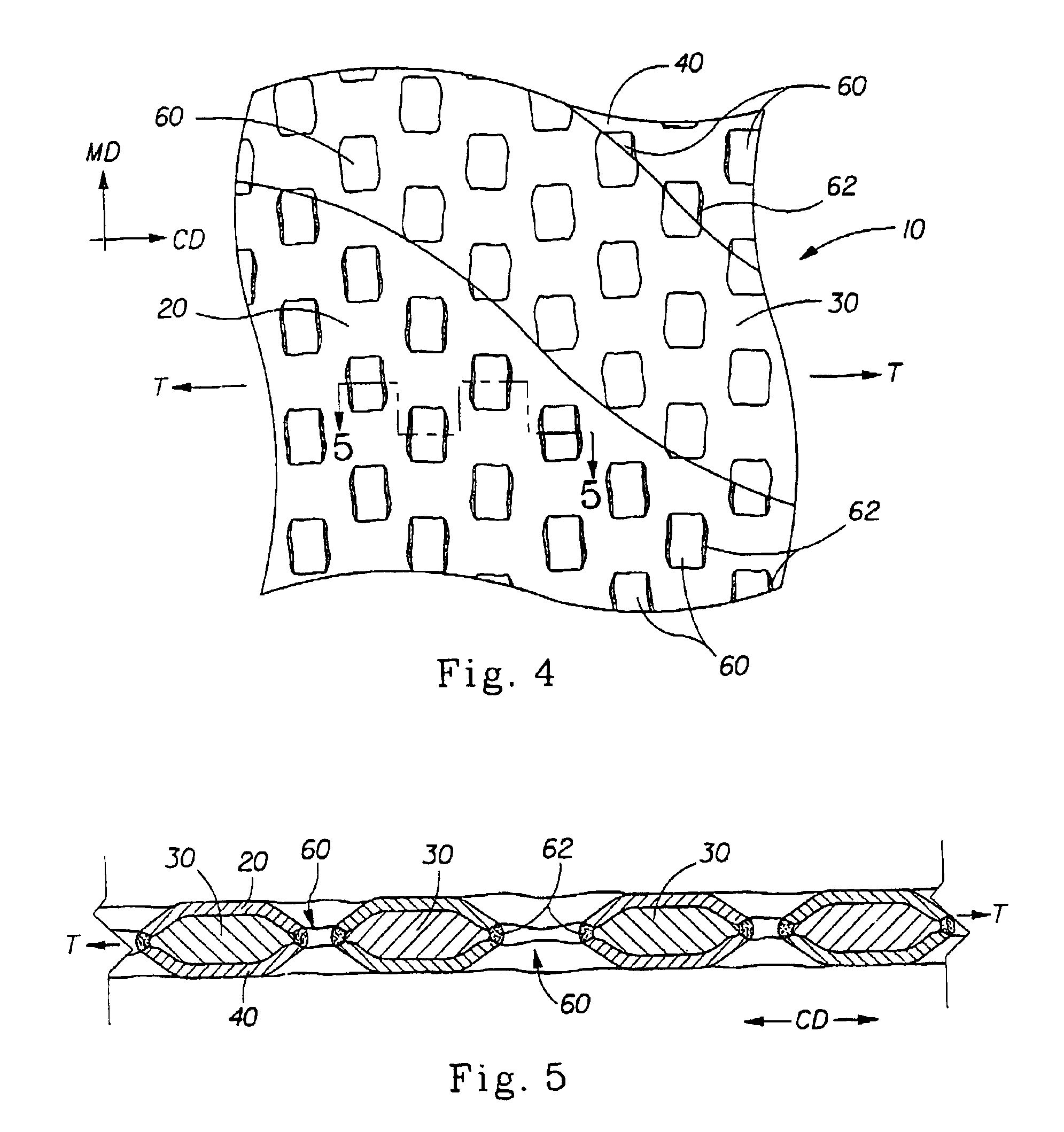

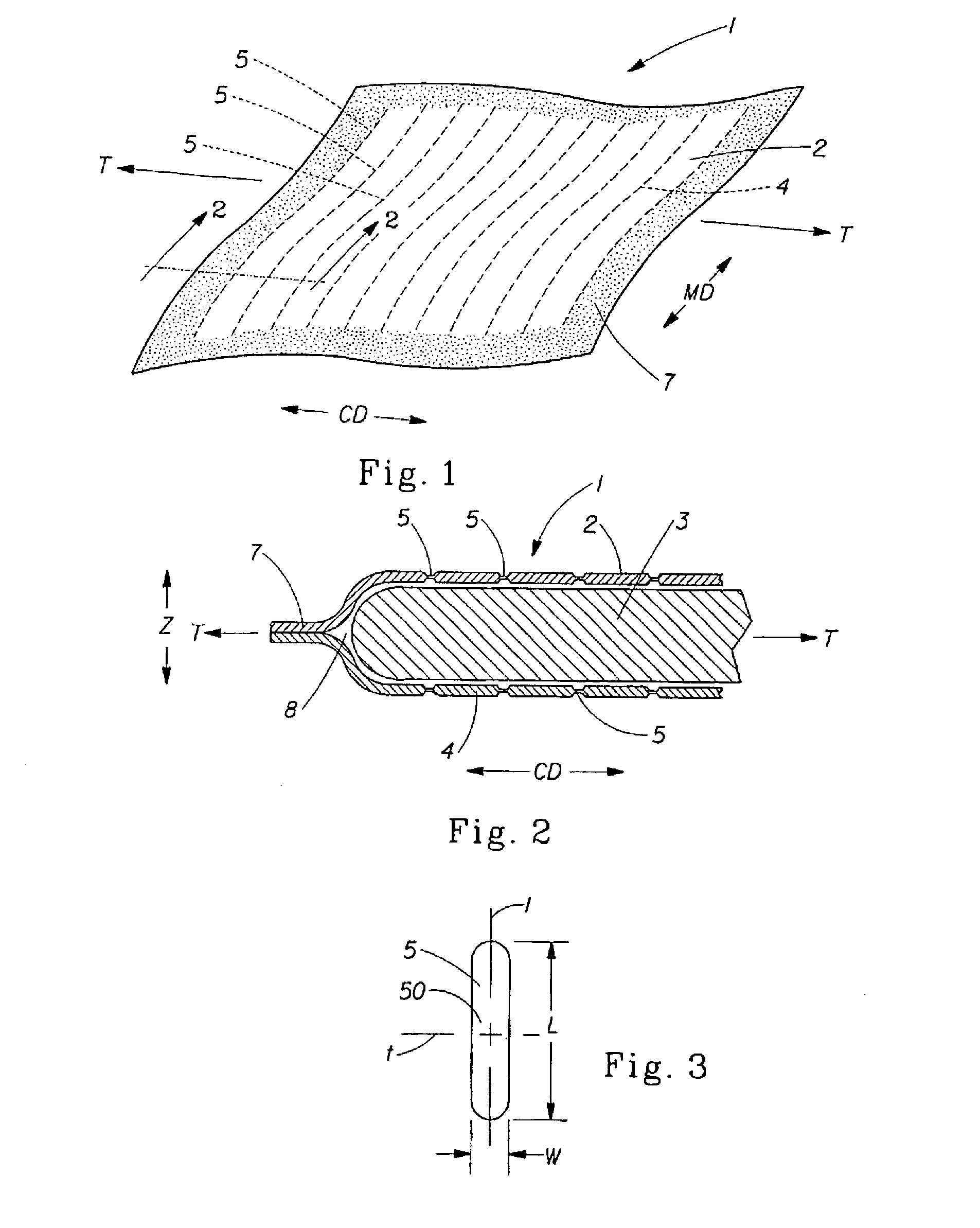

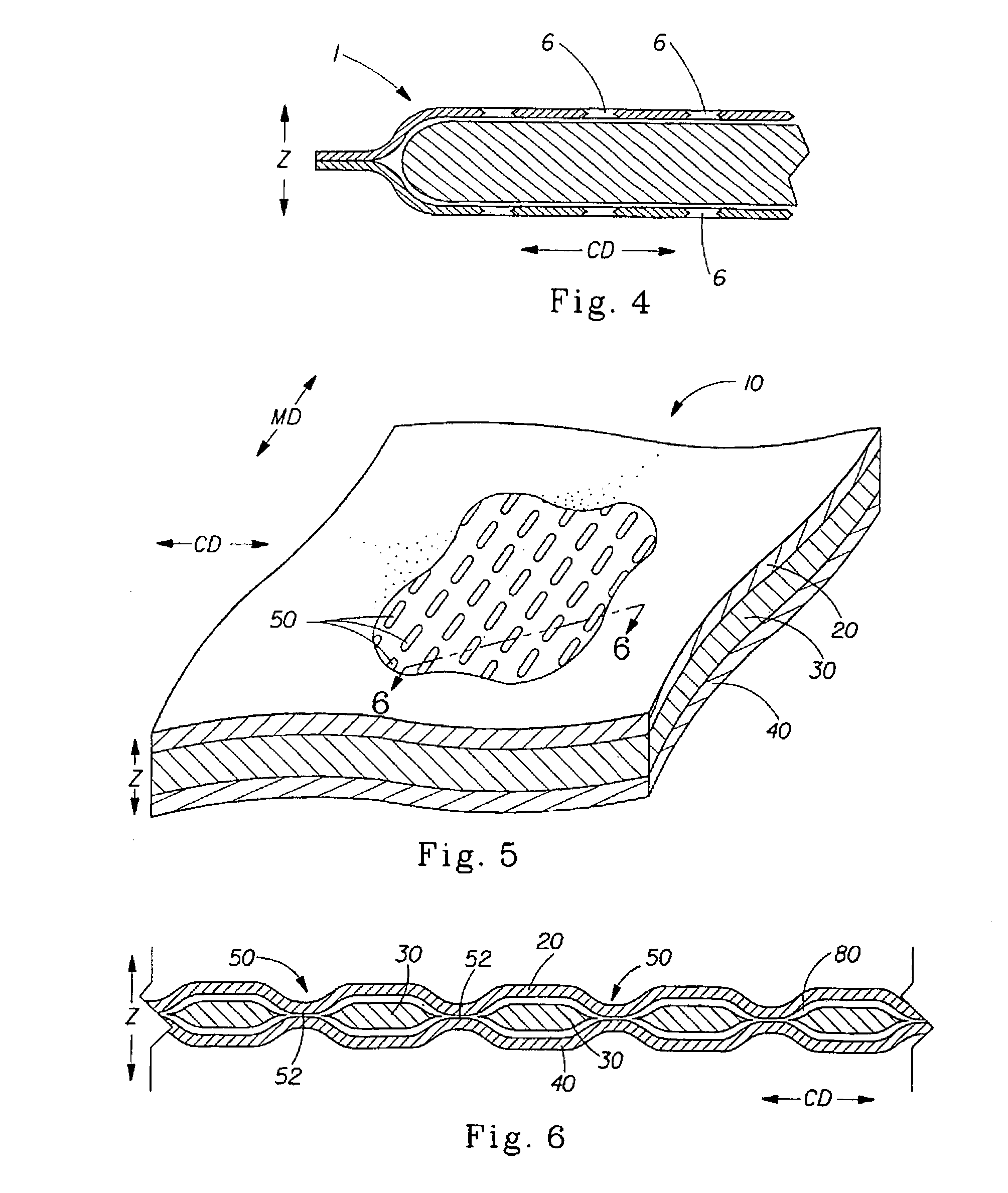

Laminate web

A laminate web is disclose, the laminate web comprising a first web, a second web joined to the first web at a plurality of discrete bond sites; and a third material disposed between at least a portion of the first and second nonwovens. The third material is apertured in regions adjacent the bond sites, such that the first and second nonwoven webs are joined through the apertures. In one embodiment an apertured laminate web is disclosed, having a first extensible web having a first elongation to break, and a second extensible web joined to the first extensible web at a plurality of bond sites, the second extensible web having a second elongation to break A third web material is disposed between the first and second nonwovens, the third web material having a third elongation to break which is less than both of the first or second elongations to break. In a further embodiment, an apertured laminate web is disclose, having first and second extensible webs being joined at a plurality of discrete bond sites and a third material disposed between the first and second nonwoven webs. The first and second nonwoven webs are in fluid communication via the apertures and have distinct regions being differentiated by at least one property selected from the group consisting of basis weight, fiber orientation, thickness, and density.

Owner:THE PROCTER & GAMBLE COMPANY

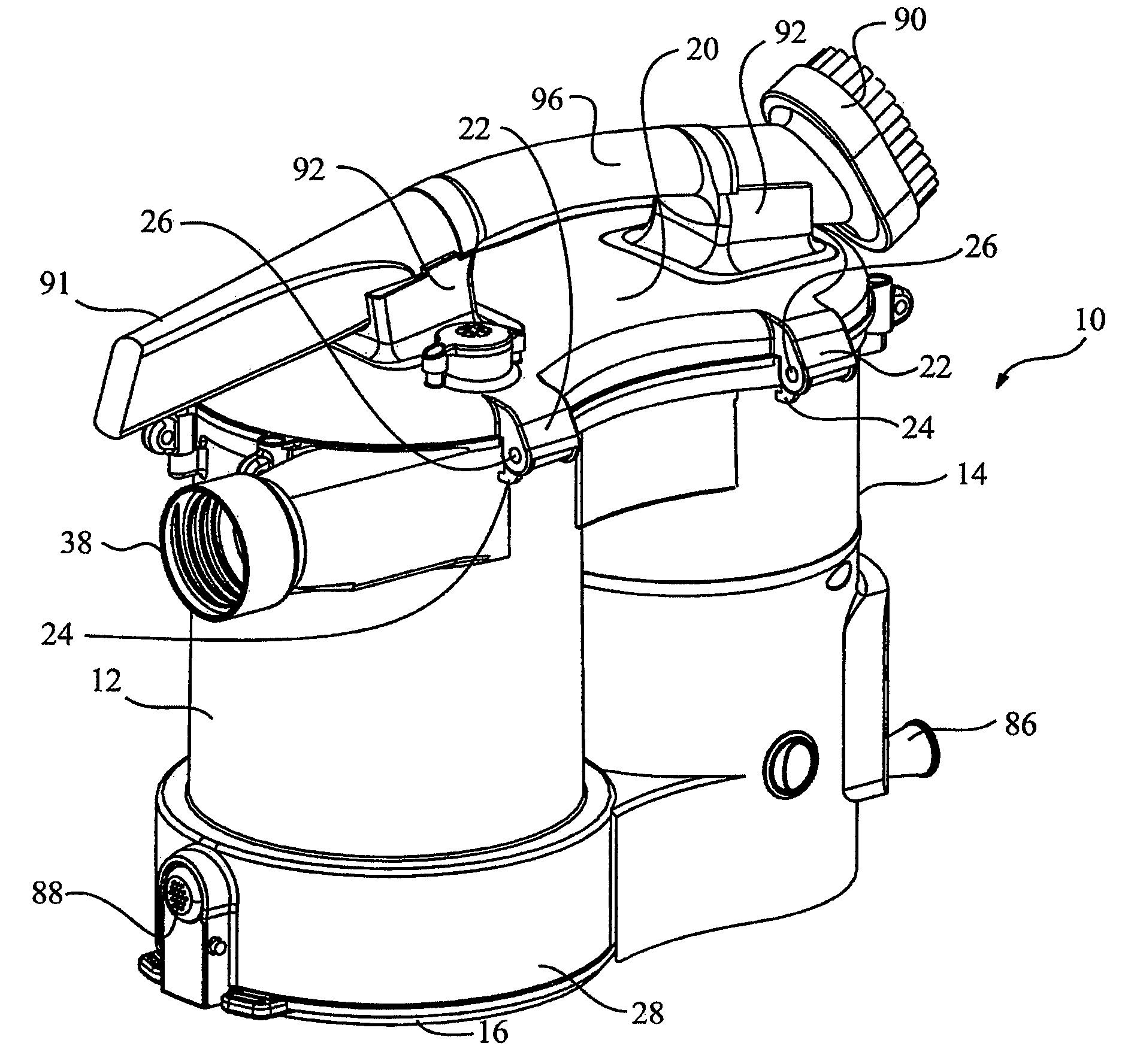

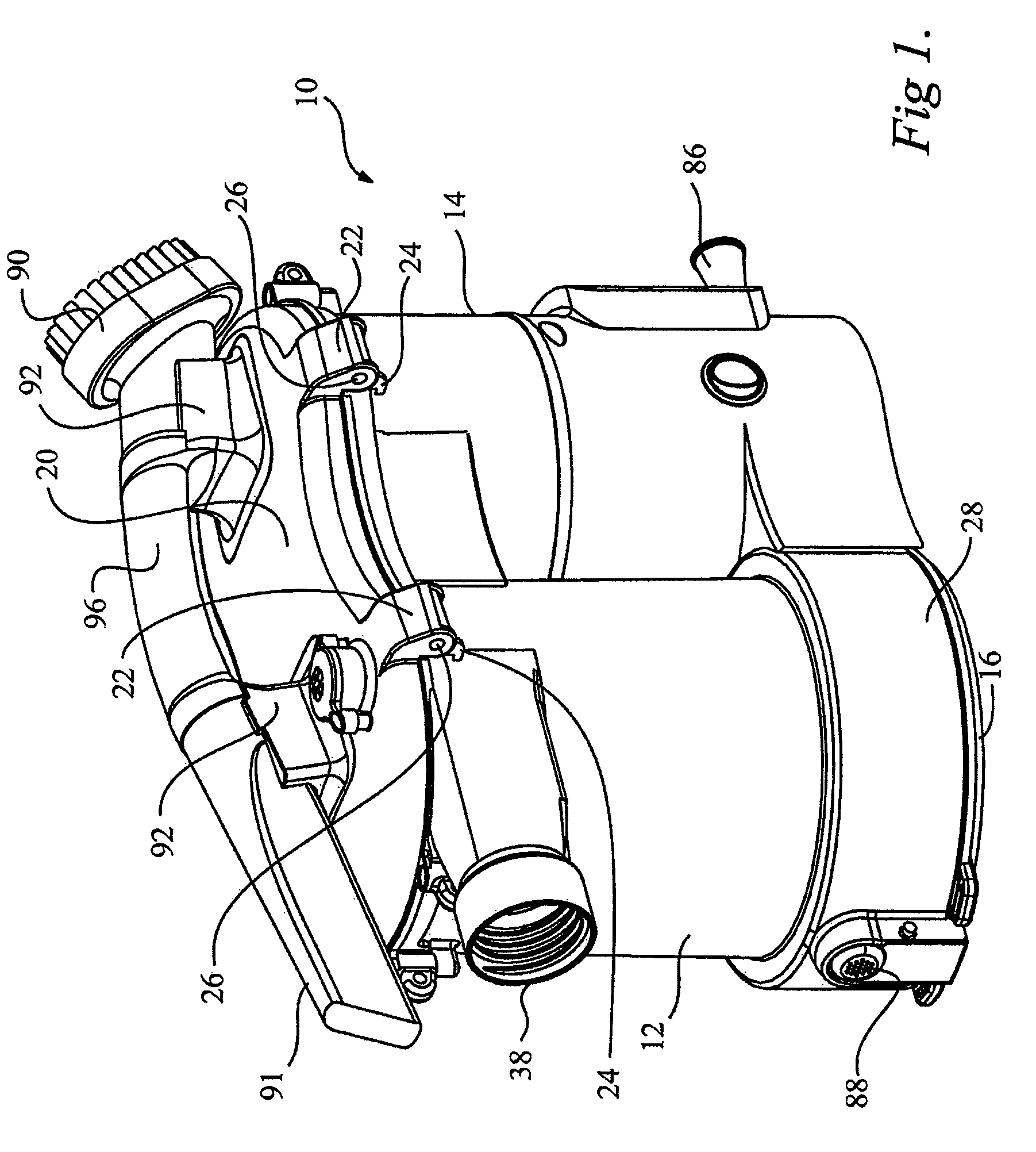

Surface treating device with top load cartridge-based cleaning systsem

ActiveUS20060288519A1Easy loadingFluid delivery is preventedLiquid processingCarpet cleanersBiomedical engineeringDelivery system

A robotic surface treating device that can perform carpet sweeping, hard-surface dry sweeping / wiping, and hard-surface sweeping / mopping is disclosed. The robotic surface treating device includes a sweeper brush, a dust bin for collecting debris from the brush, a reel-to-reel sheet of cleaning material, and a fluid delivery system for delivering fluid from a fluid reservoir onto the sheet of cleaning material and / or onto the surface to be treated. The dust bin, reel-to-reel sheet of cleaning material, and the fluid reservoir are separately installed from the top of the device, and may be separately removed for replacement.

Owner:SC JOHNSON & SON INC

Debris sensor for cleaning apparatus

InactiveUS6956348B2Reduce movement speedEasy to cleanAutomatic obstacle detectionTravelling automatic controlMultiple sensorMechanical engineering

A piezoelectric debris sensor and associated signal processor responsive to debris strikes enable an autonomous or non-autonomous cleaning device to detect the presence of debris and in response, to select a behavioral mode, operational condition or pattern of movement, such as spot coverage or the like. Multiple sensor channels (e.g., left and right) can be used to enable the detection or generation of differential left / right debris signals and thereby enable an autonomous device to steer in the direction of debris.

Owner:IROBOT CORP

Laminate web comprising an apertured layer and method for manufacturing thereof

A laminate web comprising a first web, a second web joined to the first web at a plurality of discrete bond sites; and a third material disposed between at least a portion of the first and second nonwovens. The third material is apertured in regions adjacent the bond sites, such that the first and second nonwoven webs are joined through the apertures. In one embodiment an apertured laminate web is disclosed, having a first extensible web having a first elongation to break, and a second extensible web joined to the first extensible web at a plurality of bond sites, the second extensible web having elongation to break. A third web material is disposed between the first and second nonwovens, the third web material having a third elongation to break which is less than both of the first or second elongations to break. In a further embodiment, an apertured laminate web is disclosed, having first and second extensible webs being joined at a plurality of discrete bond sites and a third material disposed between the first and second nonwoven webs. The first and second nonwoven webs are in fluid communication via the apertures and have distinct regions being differentiated by at least one property selected from the group consisting of basis weight, fiber orientation, thickness, and density.

Owner:THE PROCTER & GAMBLE COMPANY

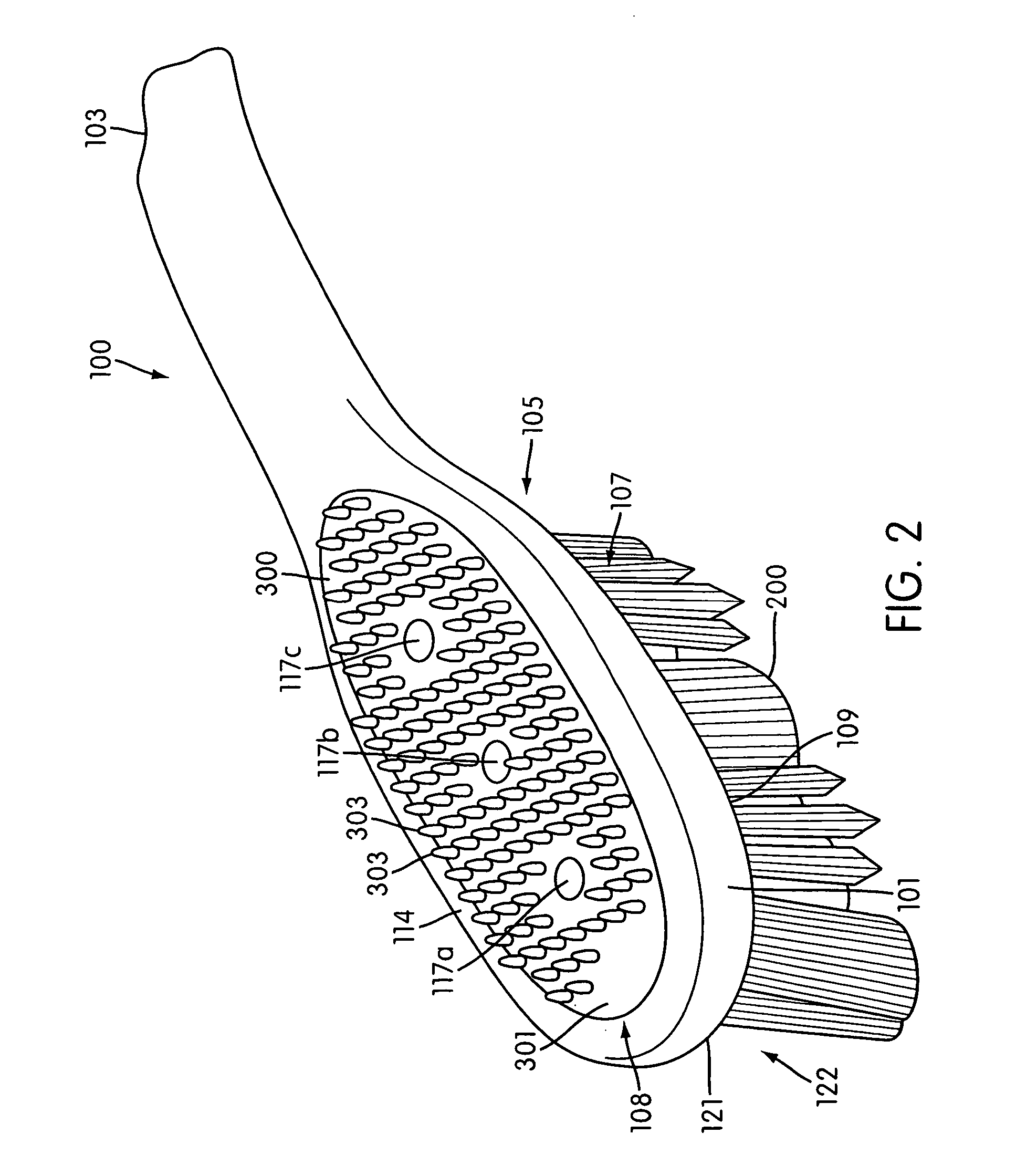

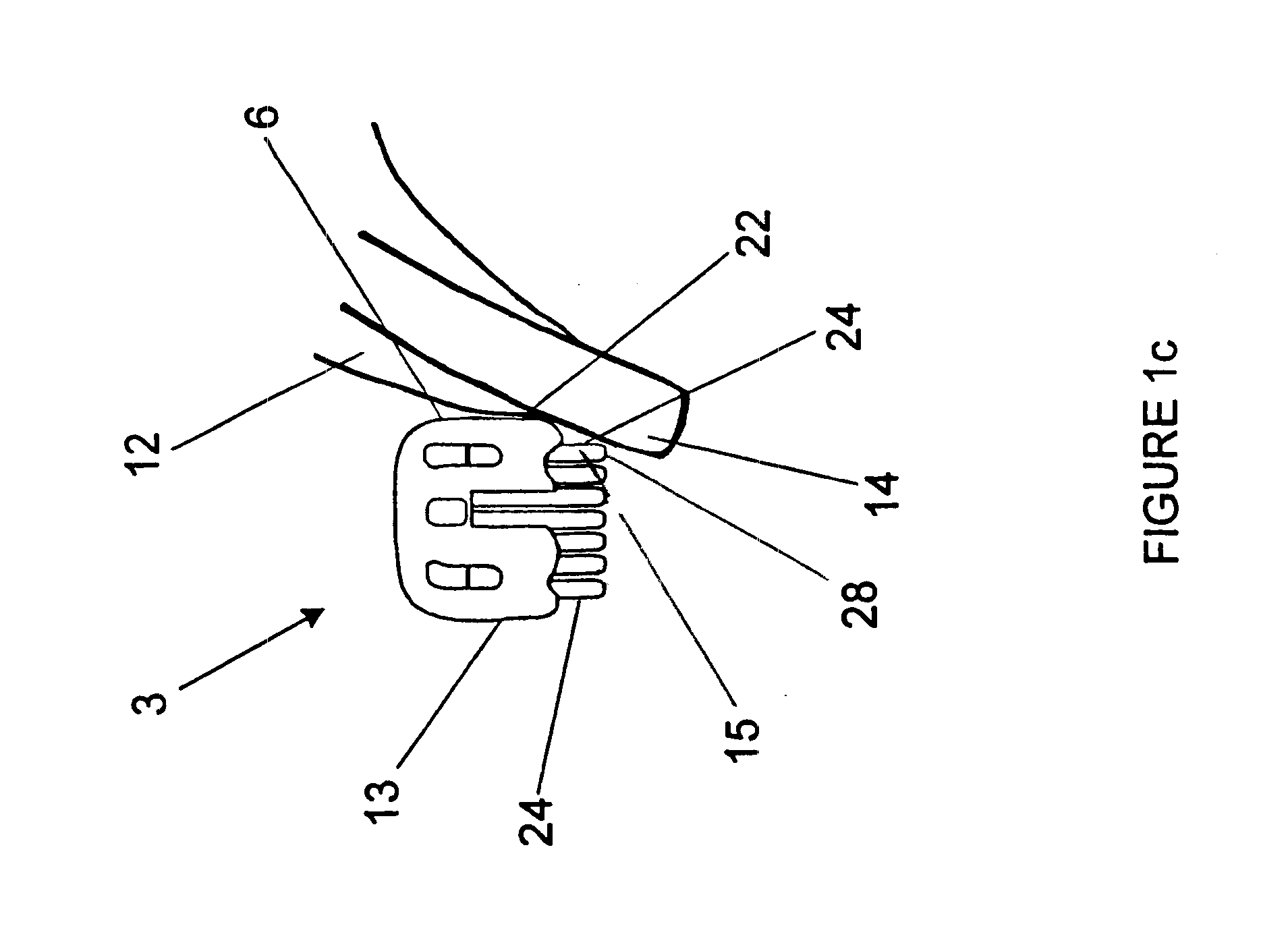

Oral care implement

InactiveUS20050000049A1Easy to cleanEfficient removalGum massageEar treatmentCleansers skinMouth care

An oral care implement with a handle includes a head with a tissue cleanser. The tissue cleanser may be a pad composed of an elastomeric material. The pad is disposed on the head on a surface opposite the tooth cleaning elements. The tissue cleanser may include a plurality of nubs extending for cleaning between the papillae of the tongue. The tissue cleanser may include a plurality of conically shaped nubs. A tissue cleanser can be used to reduce oral malodor problems and remove oral epithelial cells.

Owner:COLGATE PALMOLIVE CO

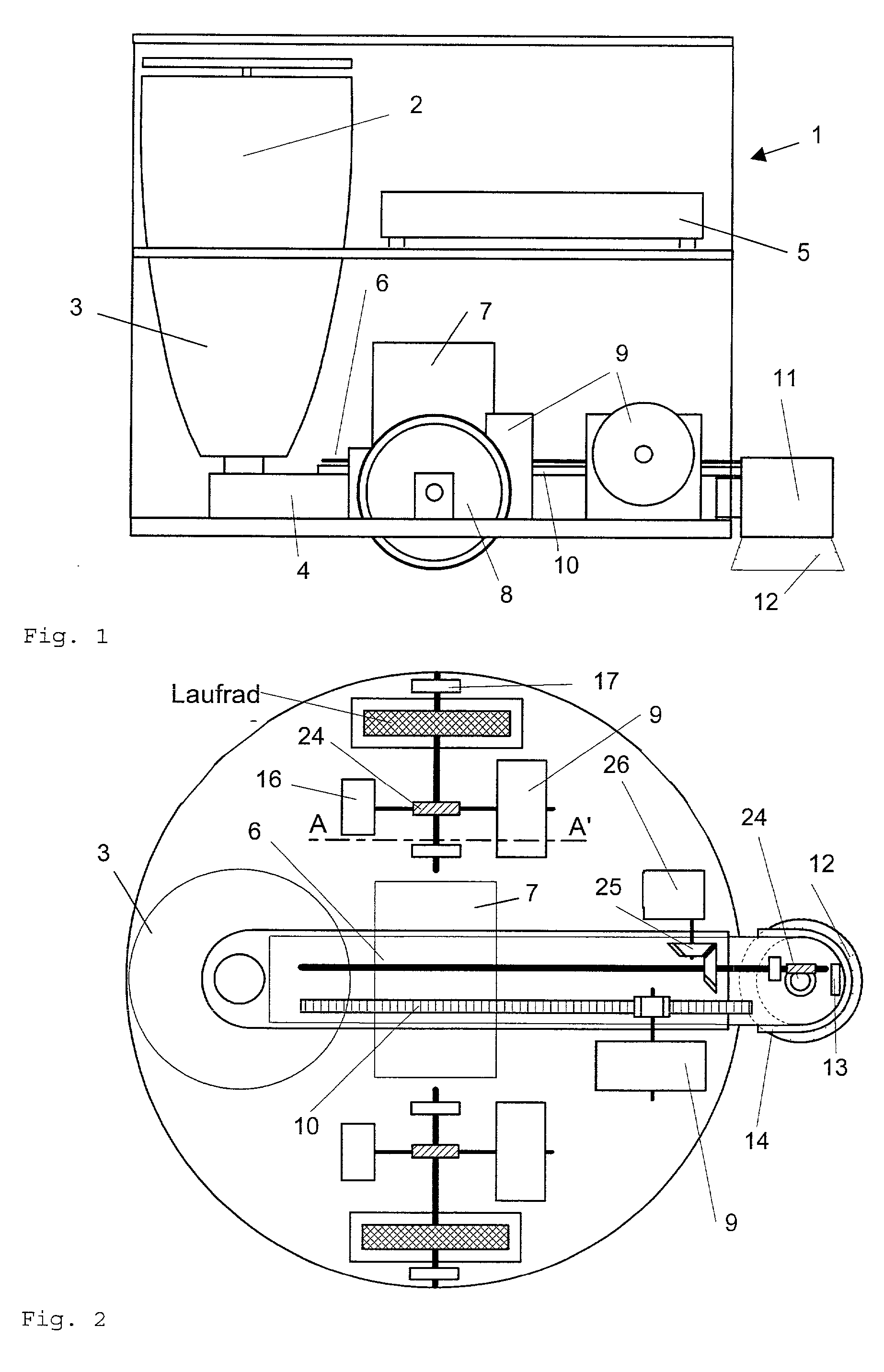

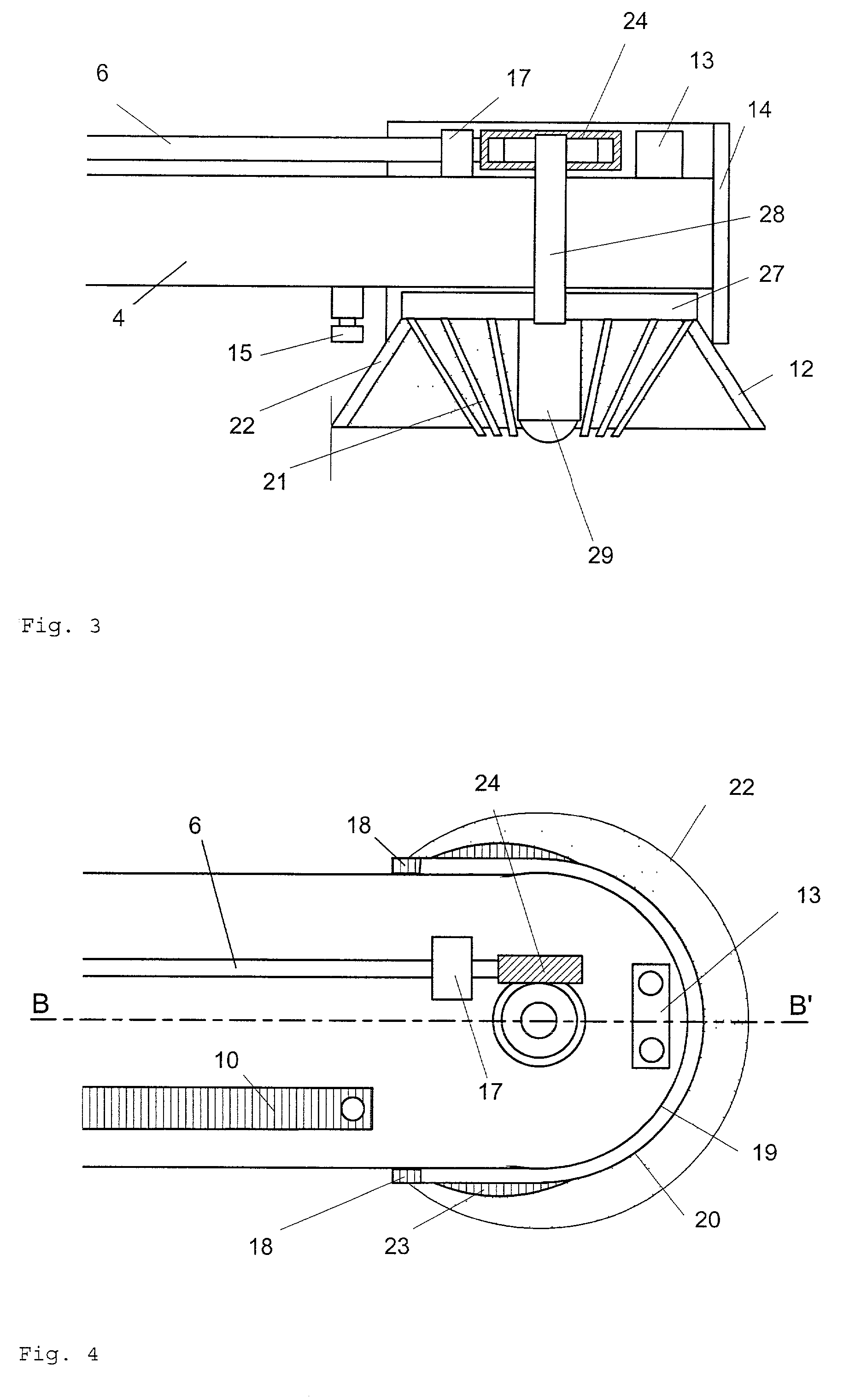

Service robot for the automatic suction of dust from floor surfaces

InactiveUS20010004719A1Automatic obstacle detectionTravelling automatic controlData fieldEngineering

The present invention is used for the complete and fully automatic examination of floor surfaces of all kind as well as for a particularly efficient suction of dust therefrom since the lower areas, the edges and the recessed can be detected. In each case, the robot is controlled so as to explore the adjacent area and to detect the potential obstacles using special sensors before storing them in a data field. The displacement towards a new location is then carried out using the stored data until the whole accessible surface has been covered. One of the main constituent members of the robot consists of an extensible arm that rests on the robot and on which contact and range sensors are arranged. When the robot is used as an automatic vacuum cleaner, an air flow is forced into the robot arm and the -cleaning effect can further be enhanced by providing one or more Circular rotary brushes at the front end of the arm. This invention can essentially be used for domestic or industrial Cleaning purposed with a view to replace traditional vacuum cleaners.

Owner:TECHN FACHHOCHSCHULE BERLIN

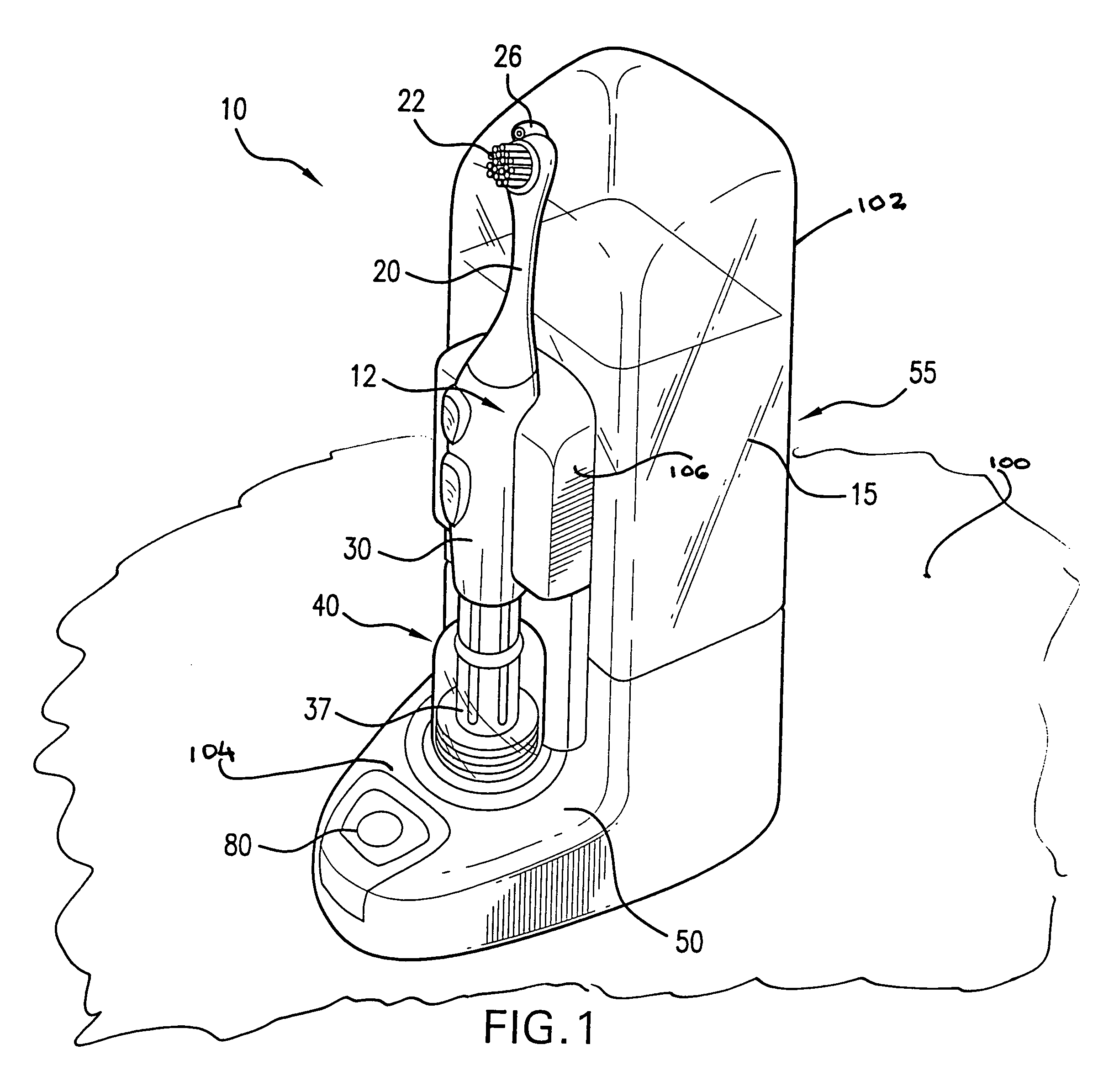

Dental hygiene device

InactiveUS7080980B2Minimal amount of maintenanceGum massageKitchenware cleanersDocking stationMotor drive

A dental hygiene system provided with interchangeable dental heads permits power-enhanced brushing and concurrent fluid irrigation to optimize a user's personal dental hygiene efforts. The system has a handle assembly with an irrigation nozzle in close proximity to displaceable bristles driven by a battery-operated handle motor. Pumping of irrigation fluid such as an antiseptic solution into the oral cavity is also motor driven. A telescoping chamber with irrigation fluid fits on the piston-like base end of the handle and is refilled by docking the handle assembly on a complementary docking station that includes a detachable fluid reservoir, microswitch controls and a base fluid pump. Docking of the handle assembly triggers the microswitches and opens a check valve in the bottom of the handle chamber, which activates the flow of fluid from the reservoir into the chamber. An optional fiberoptic subassembly illuminates the oral cavity.

Owner:KLUPT MICHAEL

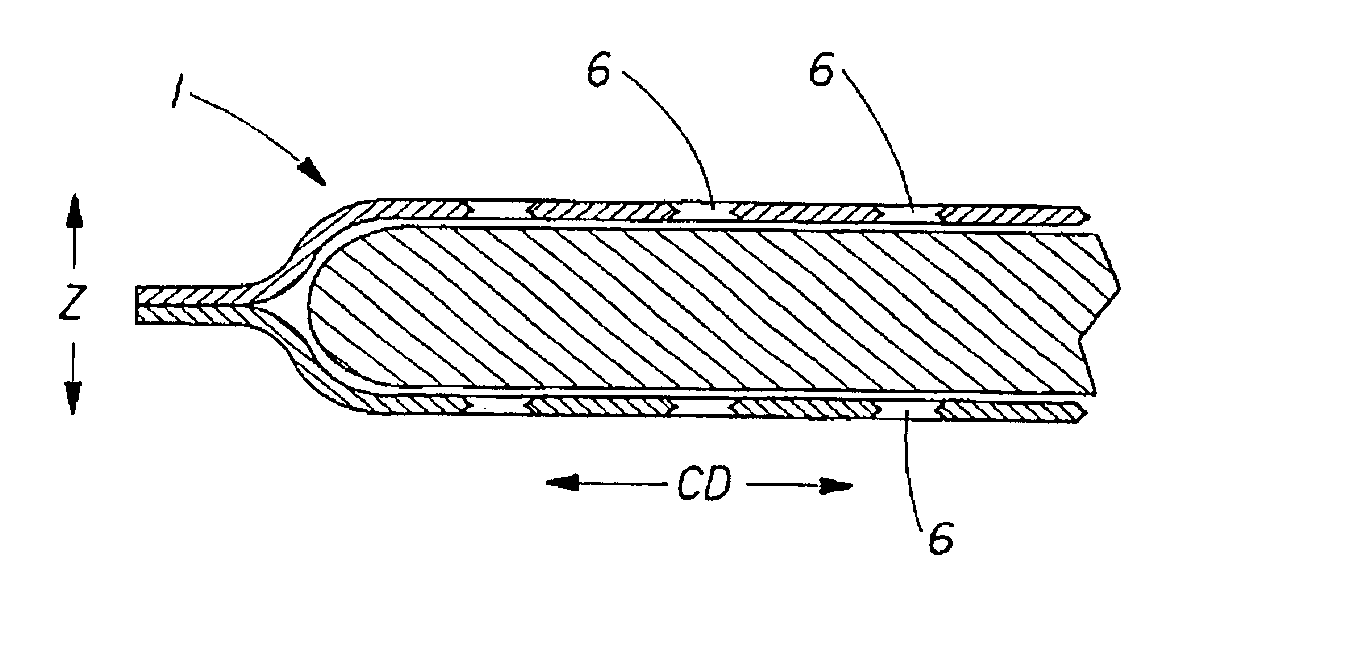

User-activatible substance delivery system

InactiveUS6863960B2Facilitate exposure and deliveryCosmetic preparationsToilet preparationsFiberTransverse axis

A user-activatible substance delivery system of the present invention comprises a first web and a second web, the first and second webs having a periphery and being enclosed about their respective peripheries and defining a void space therein. A substance for delivery upon user activation is disposed in the void space. At least one of the first or second webs has at least one bond site. The bond site(s) define(s) a melt weakened region such that upon application of a force having a vector component parallel to the transverse axis, the bond site(s) fracture(s) to form a corresponding aperture in the respective web. The apertures provide a fluid communication path to facilitate delivery of the substance from the void space.

Owner:THE PROCTER & GAMBLE COMPANY

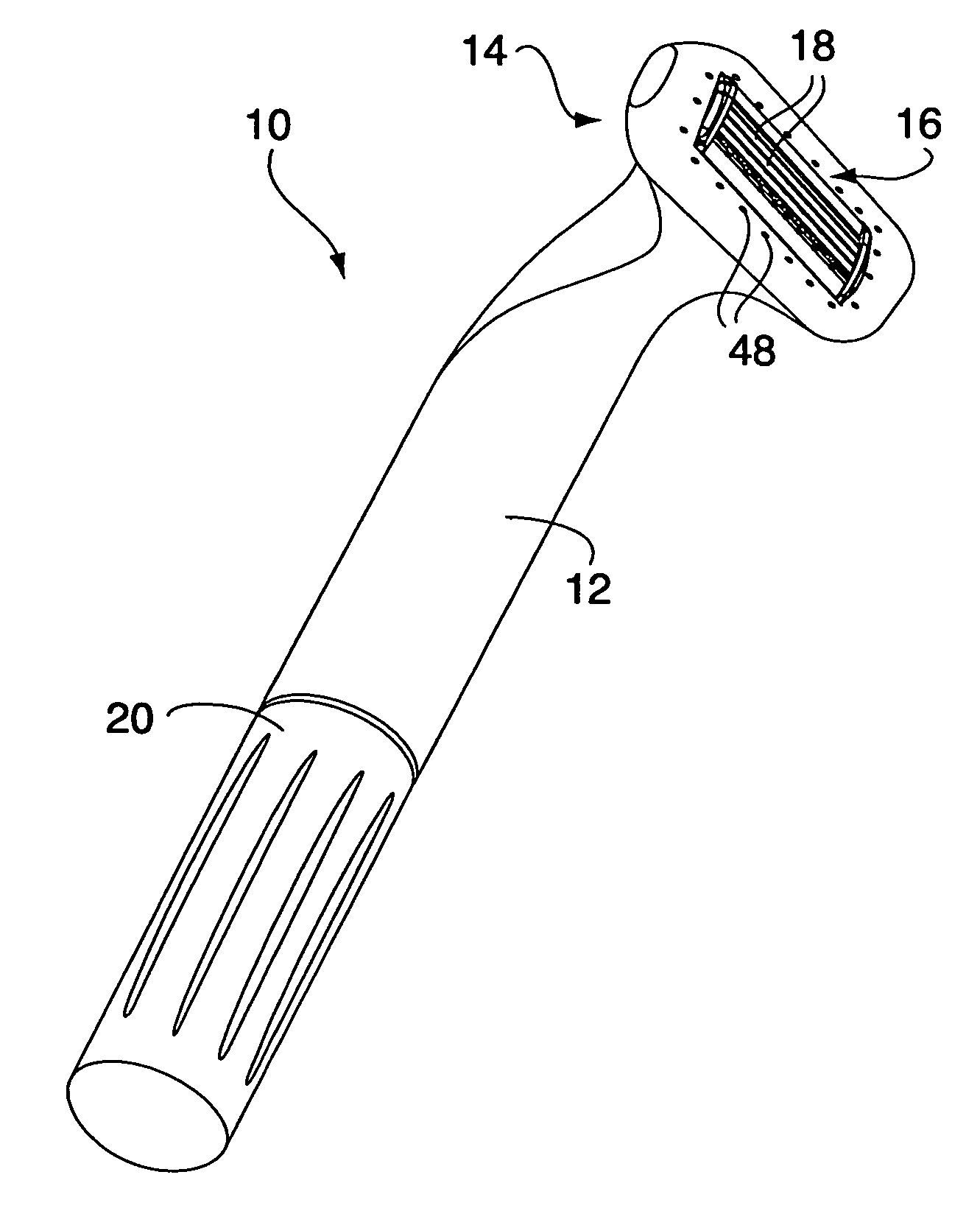

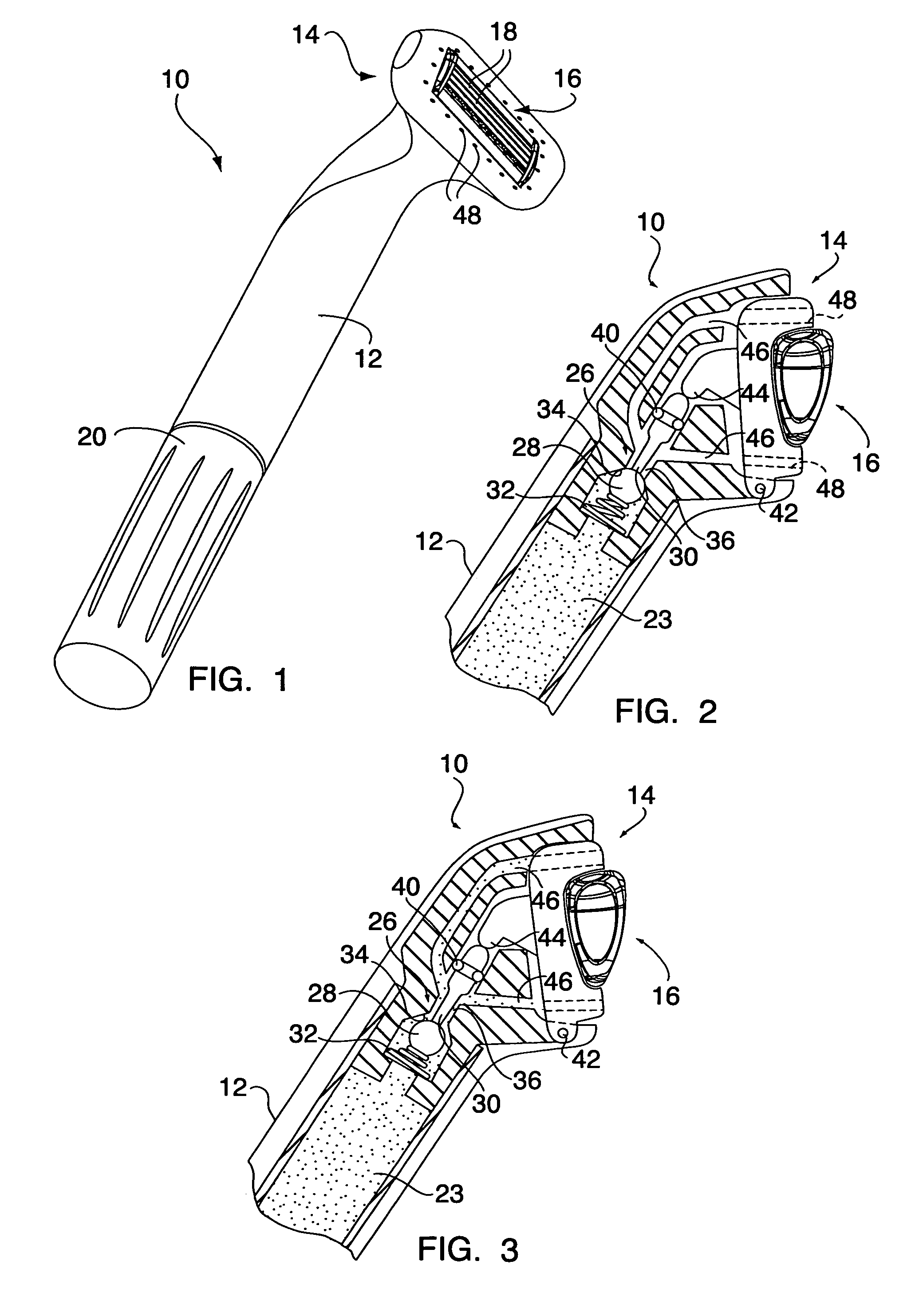

Shaving apparatus with pivot-actuated valve for delivery of shaving aid material

InactiveUS7121754B2Prevent materialObstruct passageCarpet cleanersFloor cleanersEngineeringRazor Blade

A shaving apparatus includes a reservoir for storing a shaving aid material, a razor cartridge having at least one razor blade, and a valve selectively actuatable by movement of the razor cartridge between a first position and a second position. In the first position the valve permits passage of a shaving aid material from the reservoir, and in the second position the valve substantially prevents the passage of the shaving aid material from the reservoir.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

Toothbrush for massaging and protecting gums

InactiveUS6599048B2Control deflectionControl pressureCarpet cleanersFloor cleanersBristleMechanical engineering

A toothbrush that utilizes a replaceable brush head having rubber gum guard on its top surface and a triangular shaped rubber pad on its bottom surface. The rubber gum guard is shorter than the height of the bristles and is positioned on the peripheral edge of a brush head for functioning as a sensor for providing feedback to prevent brushing at excessive pressures and improper angles as well as for massaging the gumlines without the risk of gum damages. The triangular shaped rubber pad is for conforming to and massaging gumlines at the back of teeth. The replaceable brush head having the rubber gum guard and massaging pad features is economically used in conjunction with a permanent handle that dispenses dentifrice material to the top of bristles. The handle has a resilient contractible connector for secure mounting of the replaceable brush head.

Owner:KUO YOUTI

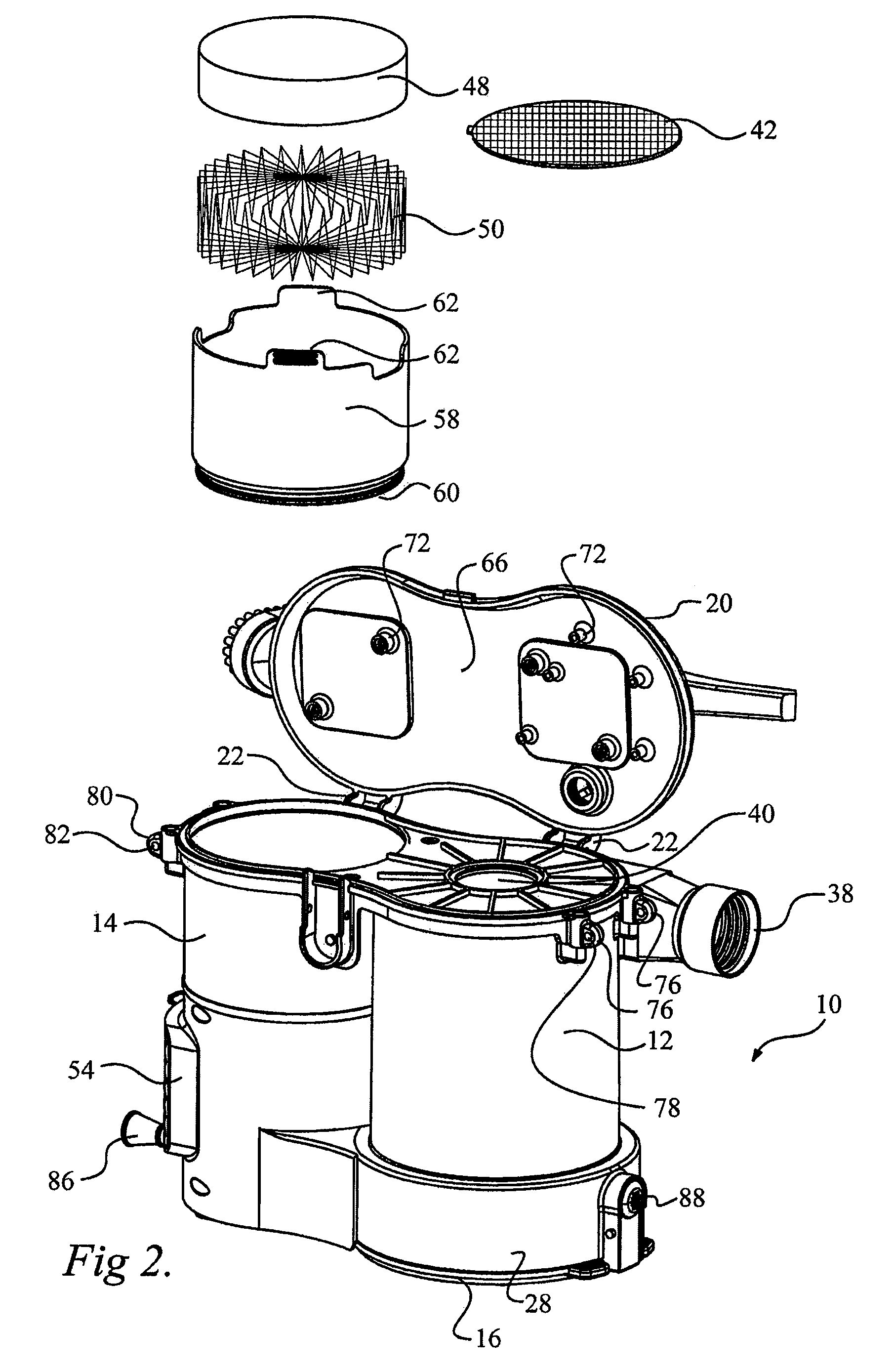

Surface cleaning apparatus

ActiveUS8146201B2Increasing overall height and linear extentMore compactCleaning filter meansBowling gamesSurface cleaningFiltration

A vacuum cleaner comprises adjacent housings, which contain the filtration and suction fan motor assembly of the vacuum cleaner.

Owner:OMACHRON INTPROP

Surface treating device with cartridge-based cleaning system

A cartridge is disclosed comprising a reel-to-reel roll of cleaning material, for use in a hand-held or robotic cleaning device. The cartridge provides either an electrostatic dust cloth or wet mop, and includes a fluid reservoir for maintaining the wet mop cloth during use. A dust bin is also provided on the cartridge, and includes a hinged lid for providing selective access to the dust inside of the bin. A motor, optical sensor, and fluid pump inside of a cleaning apparatus control the operation of the reel-to-reel cloth, and control fluid delivery to the wet cloth.

Owner:SC JOHNSON & SON INC

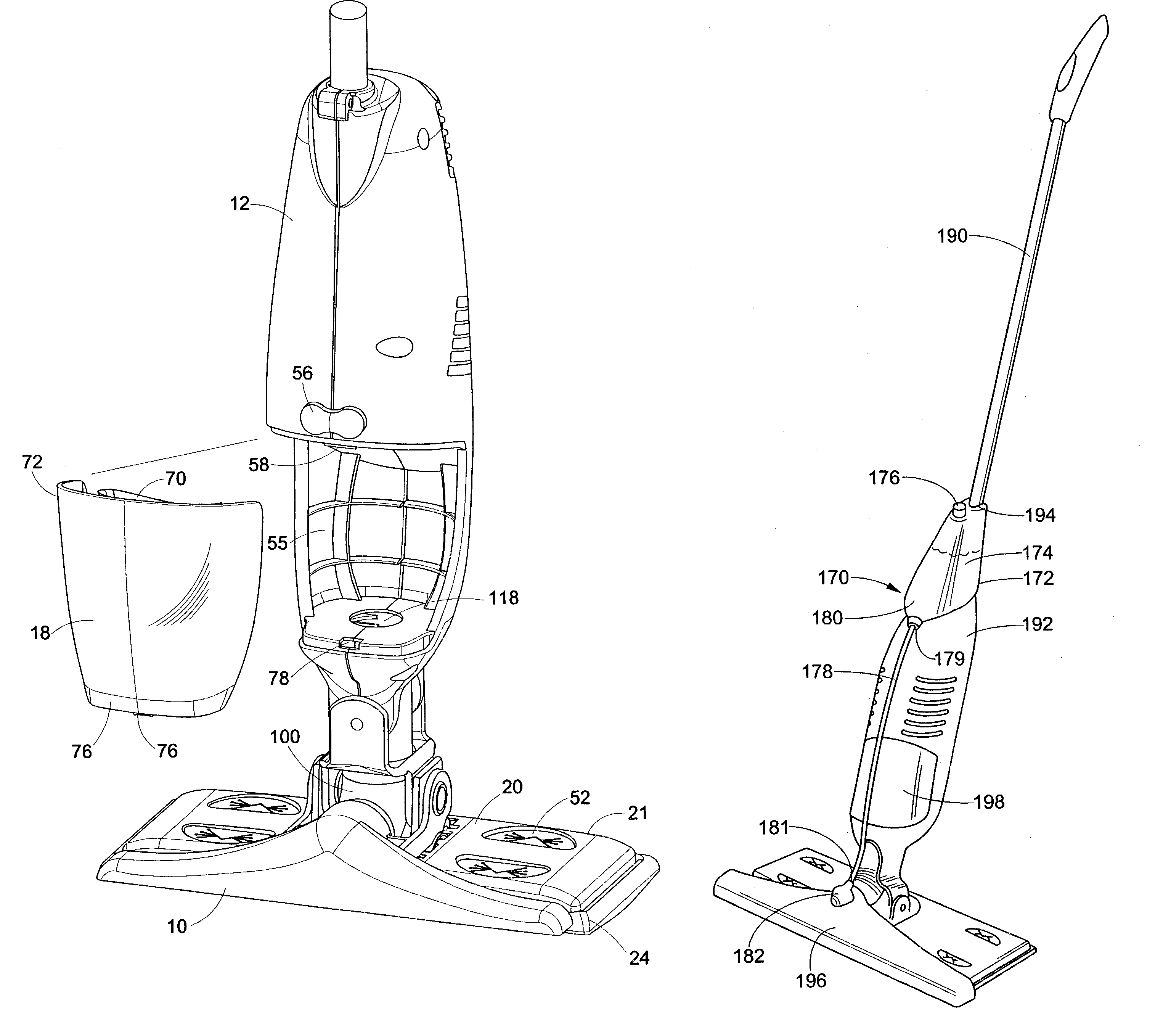

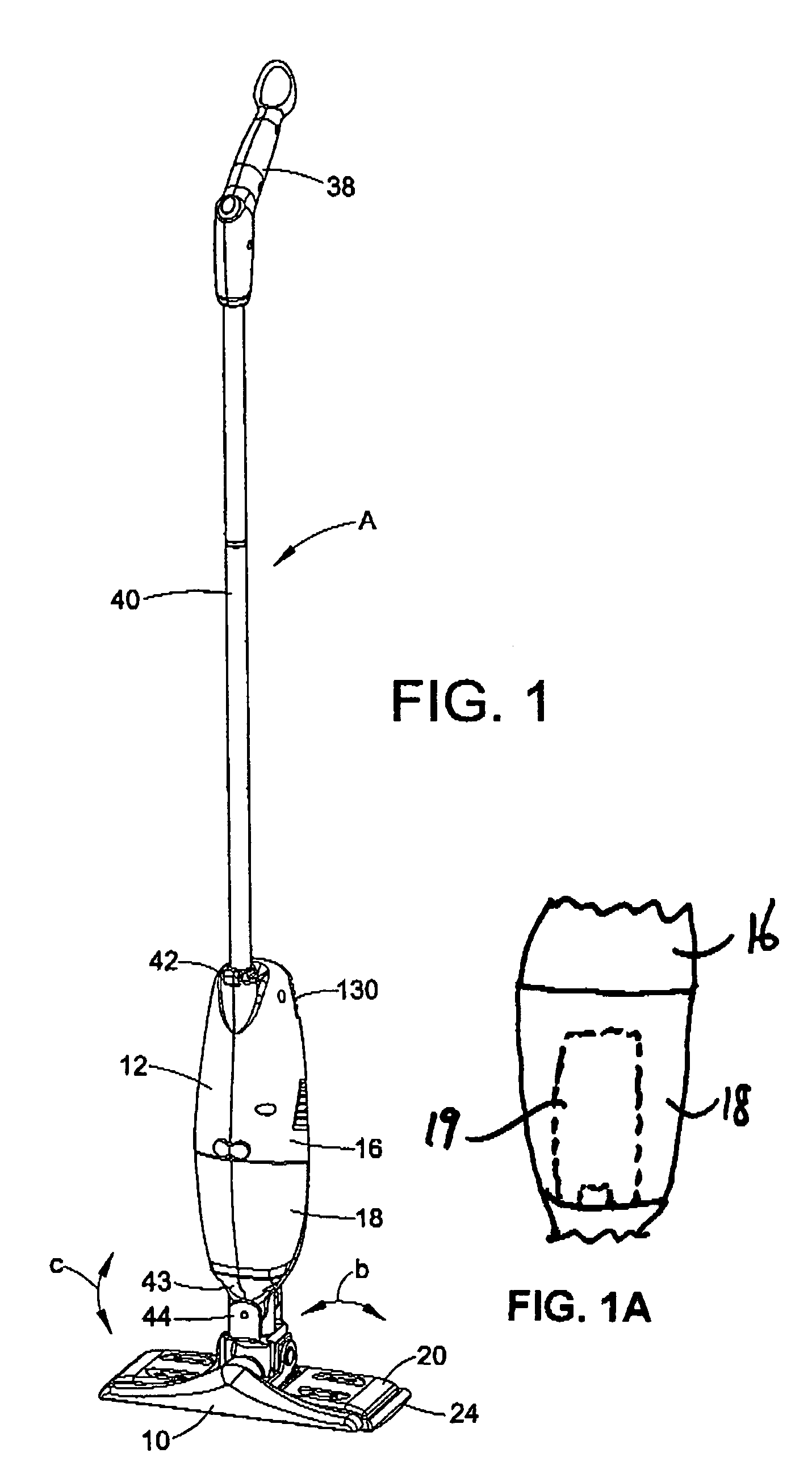

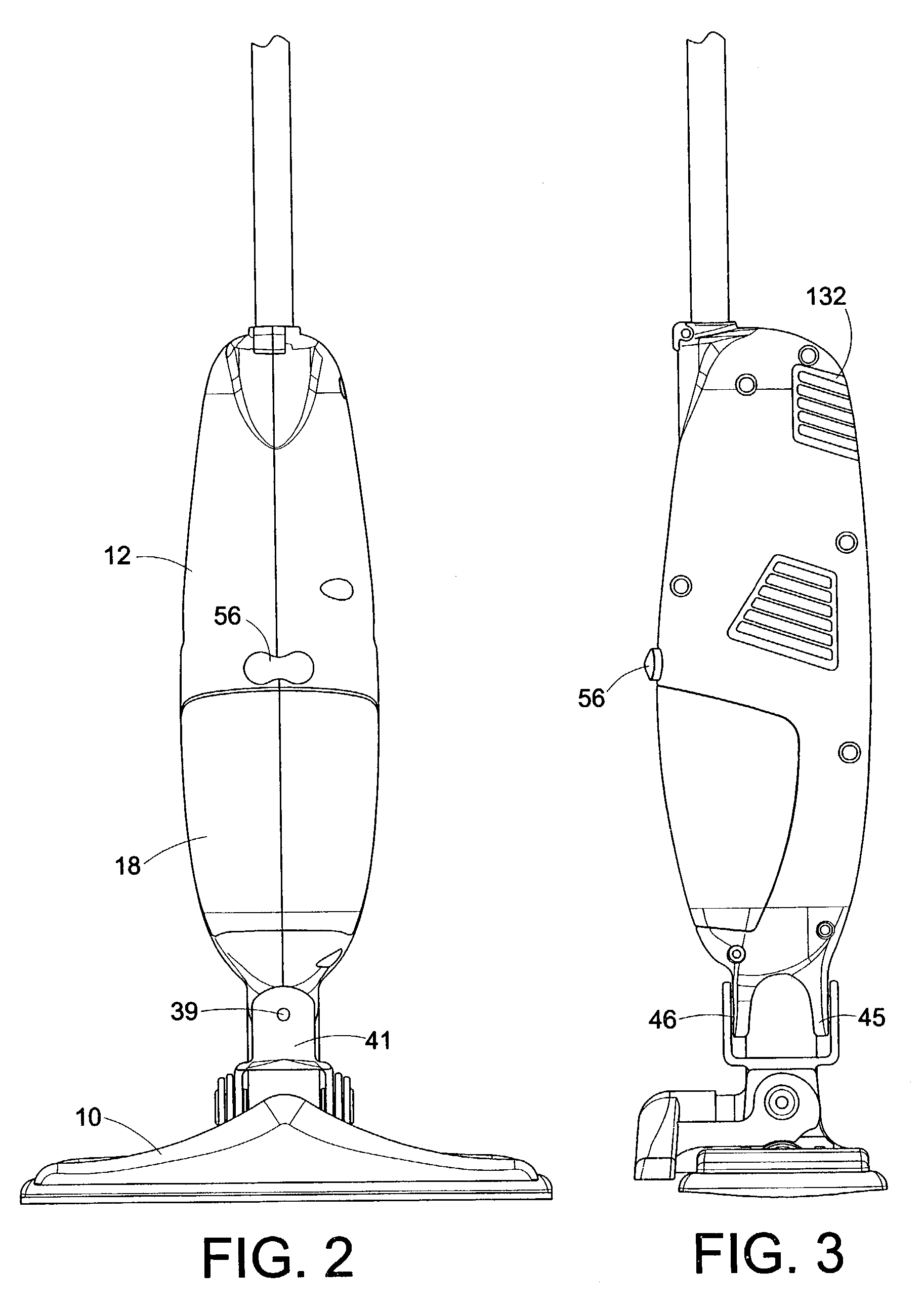

Vacuum cleaner with cleaning pad

A vacuum cleaner has a suction nozzle, a housing connected to the suction nozzle and a suction fan and motor assembly mounted to the housing. A dirt collecting receptacle is mounted to the housing and is in communication with the suction nozzle and suction fan and motor assembly. A support plate is pivotally mounted to the housing and selectively holds a cleaning sheet for collecting dust and debris from a surface to be cleaned.

Owner:ROYAL APPLIANCE MFG

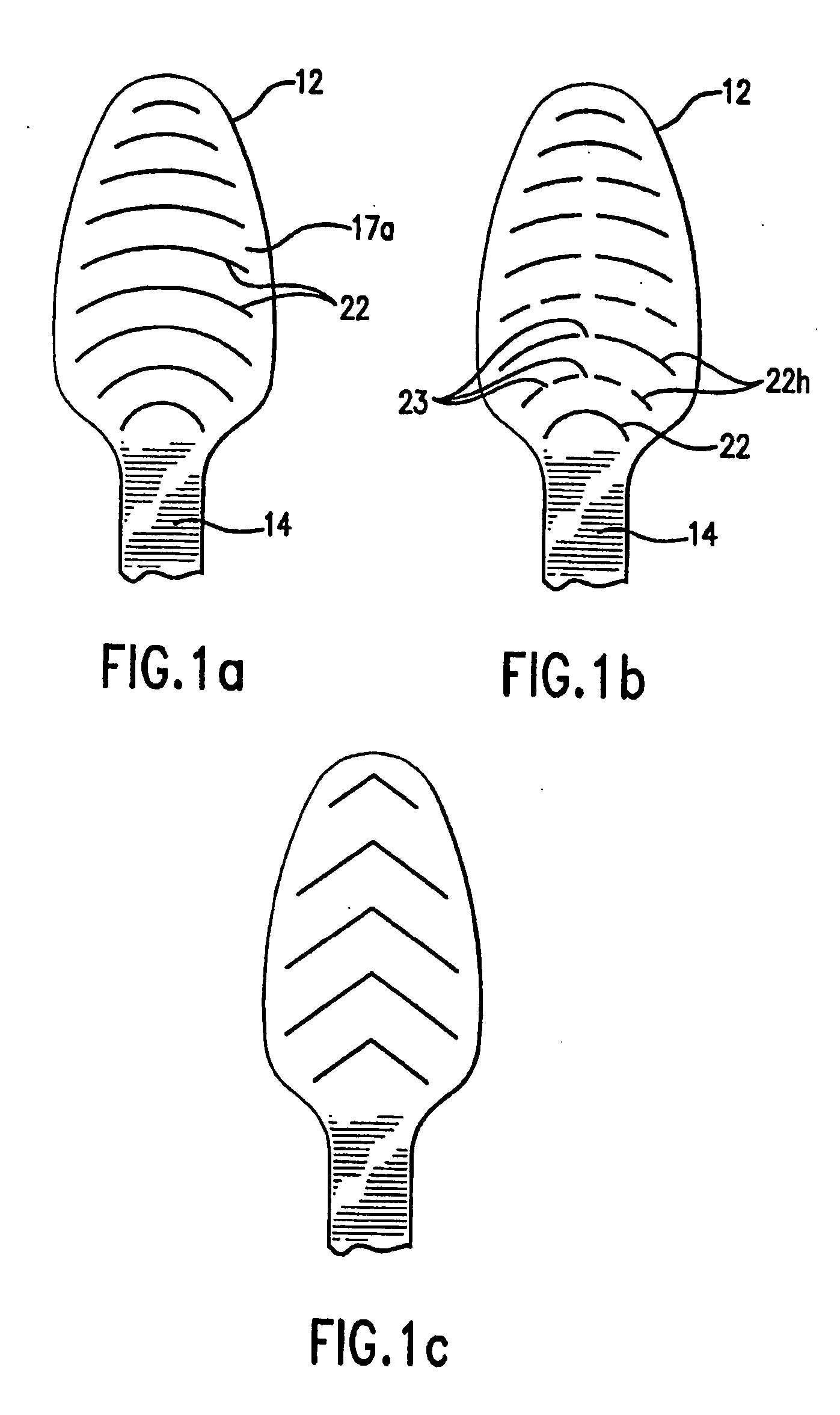

Oral care implement

ActiveUS20060010628A1Easy to cleanEfficient removalEar treatmentCarpet cleanersCleansers skinMouth care

An oral care implement including a handle and a head with a tongue cleanser. The tongue cleanser has at least one ridge which is at least as wide as it is high. In one preferred construction, the ridges are shaped so as to define a concave surface facing generally toward the handle. The ridges also preferably include aligned segments from front to back that are oriented at different angular positions.

Owner:COLGATE PALMOLIVE CO

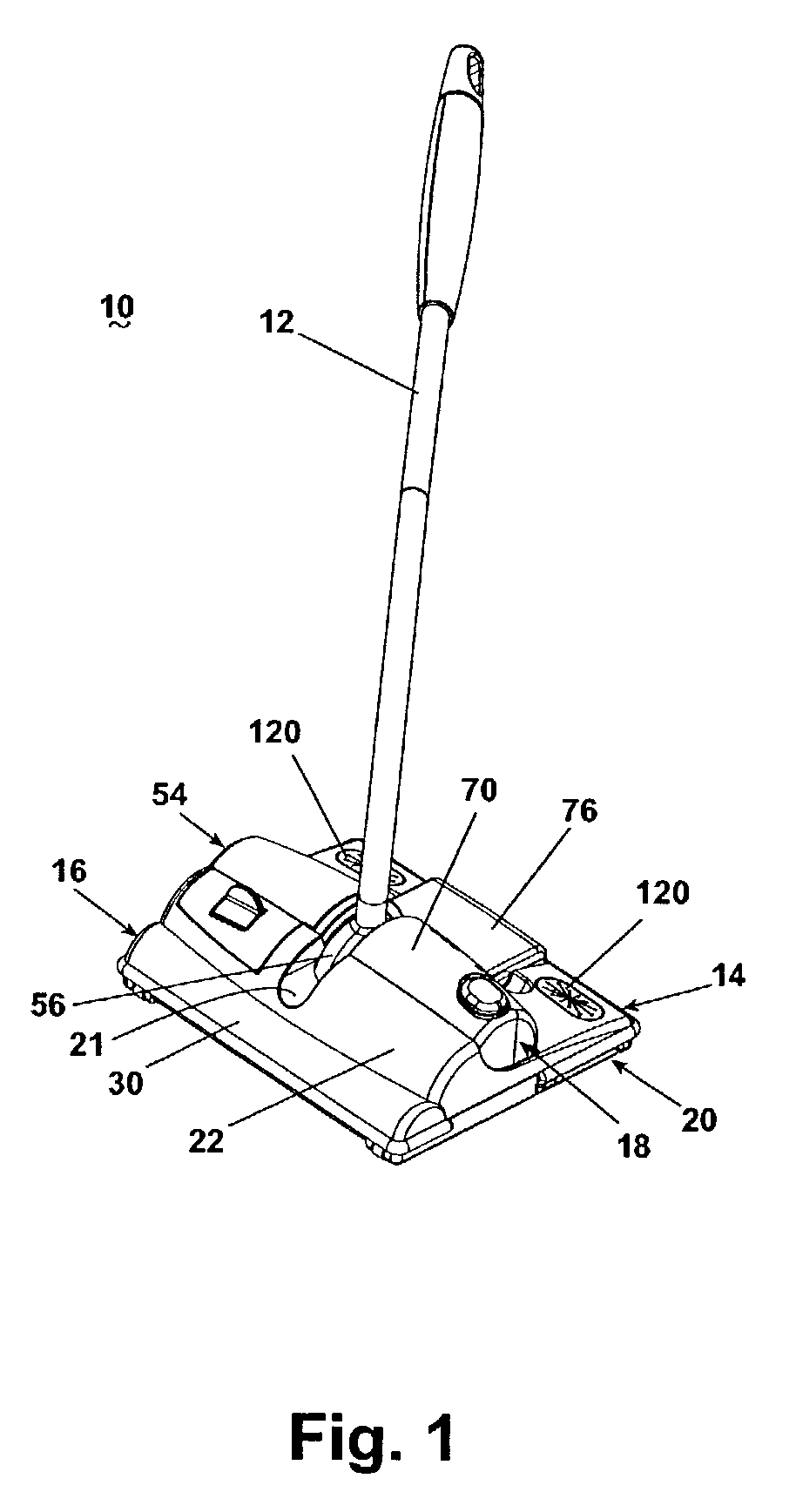

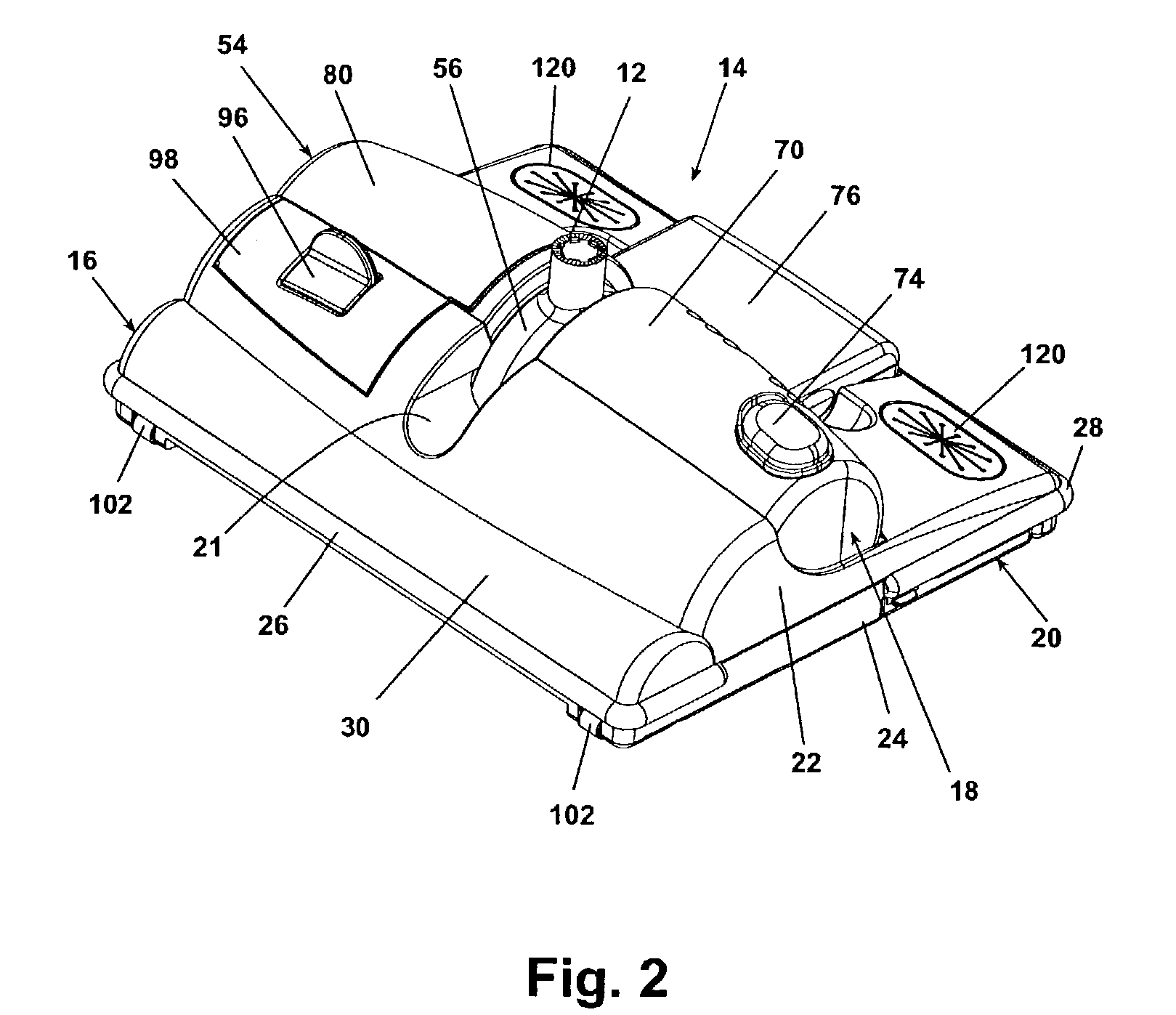

Floor cleaner with dusting

A battery-powered, upright vacuum sweeper comprises a base assembly and a handle pivotably attached thereto. The base assembly comprises a vacuum fan assembly fluidly communicating with an inlet for vacuuming dust and the debris particles from a surface into a removable reservoir. A rotating roller brush attached to the base assembly sweeps the particles into the inlet. A dust pad assembly comprises a disposable dust cloth extending over a portion of the base assembly in contact with the surface to be cleaned for removing dust particles which are not removed by vacuuming.

Owner:BISSELL INC

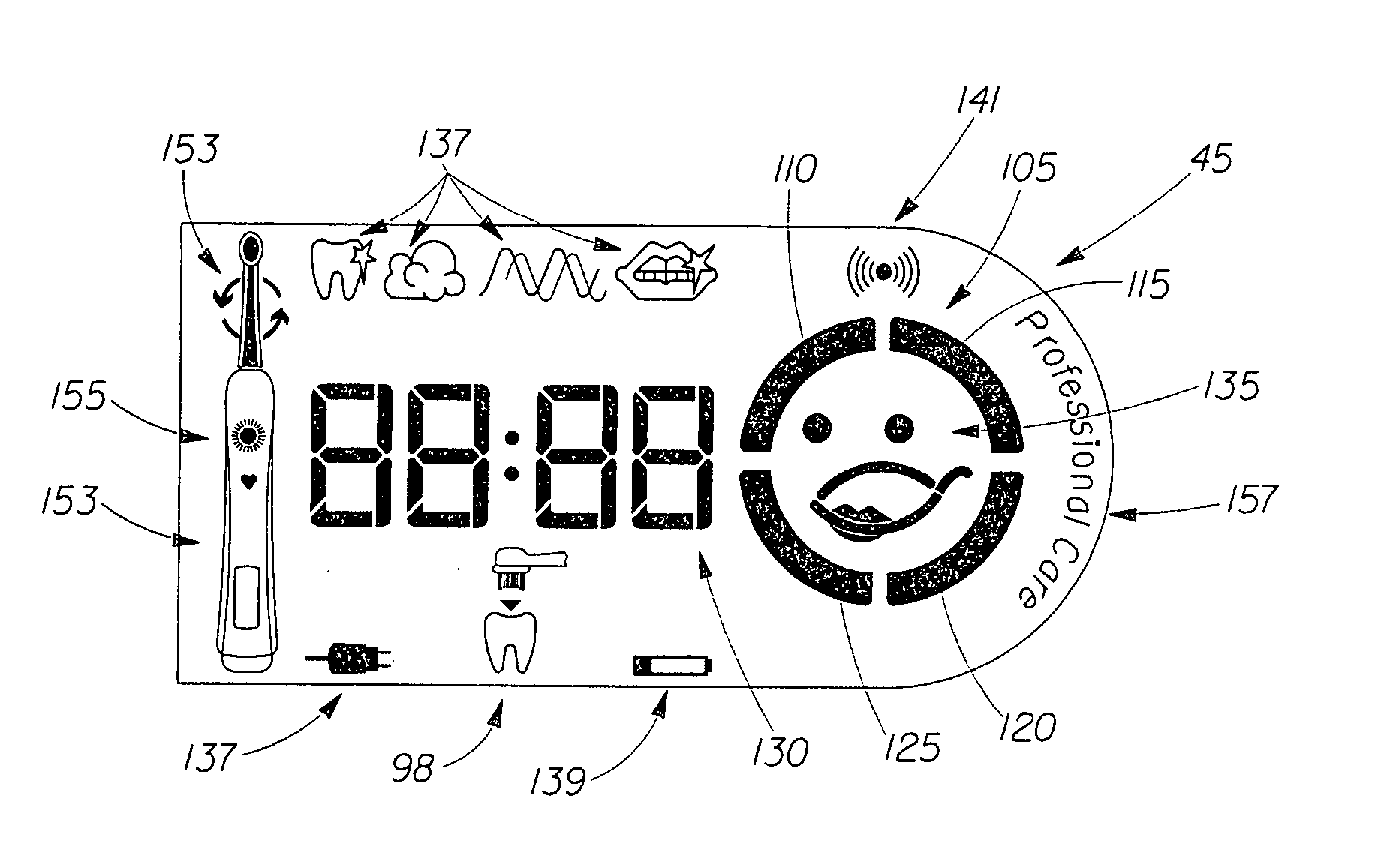

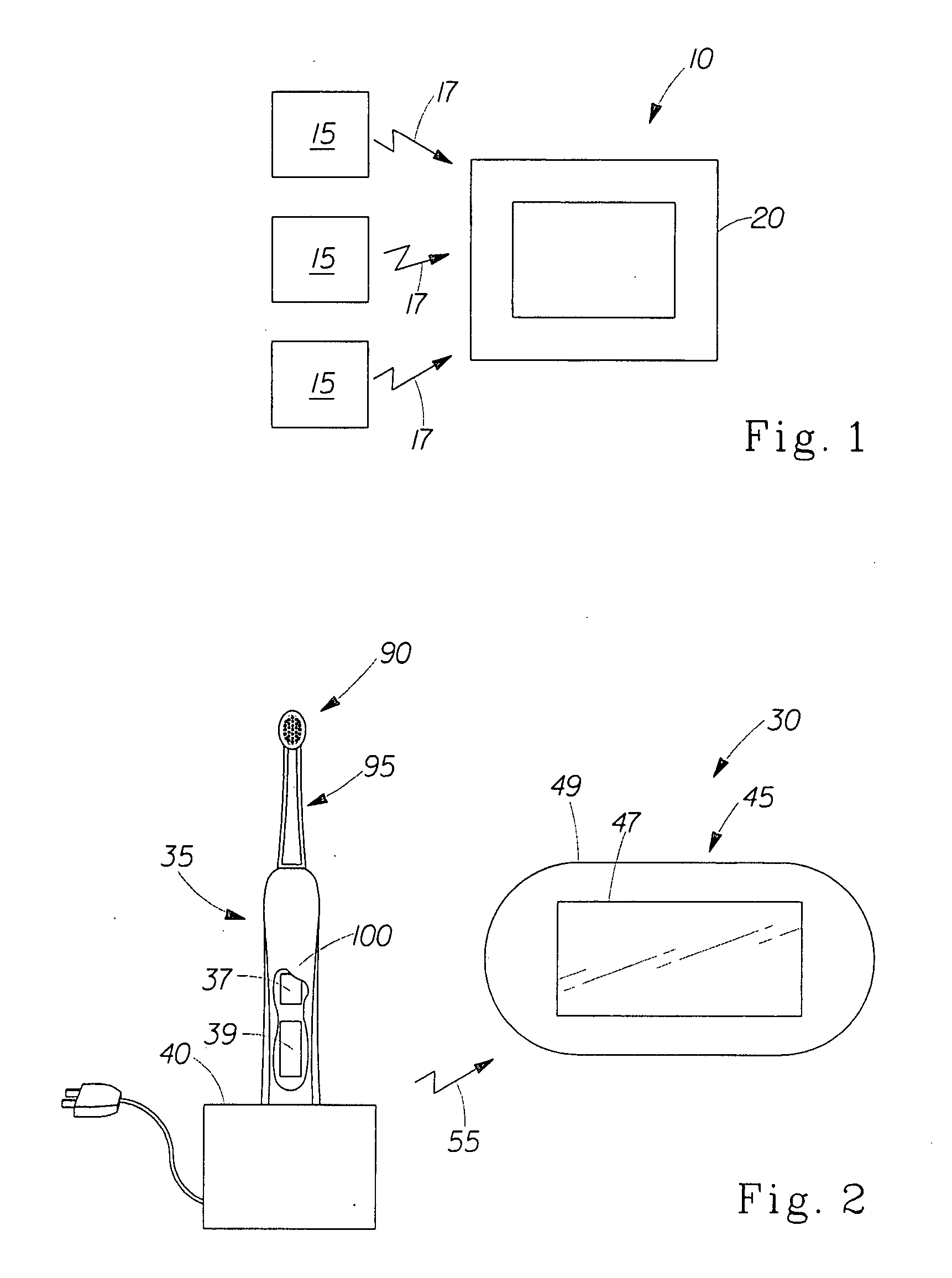

Personal care products and methods

In one embodiment, an oral-care system is provided. The oral-care system includes an electric toothbrush having a motor, a power source in electrical communication with the motor, and a bristle holder operatively connected to the motor. A display is in data communication with the electric toothbrush.

Owner:THE GILLETTE CO

Enhanced dental hygiene system with direct UVA photoexcitation

A device and a method for delivering UVA light to the mouth in which a photocatalytic agent is distributed in the mouth and a UVA light source is located contiguously to the head of the device so that the photocatalytic agent distributed in the mouth is efficiently activated by UVA light produced by the device. The UVA light delivery device of the invention may be, inter alia, a toothbrush, a tongue scraper, an interdental toothbrush, a denture brush, a flossing device, a dental hand tool, or a wand adapted exclusively to applying UVA light to photocatalyst coated surfaces.

Owner:SUSR AMERICAS

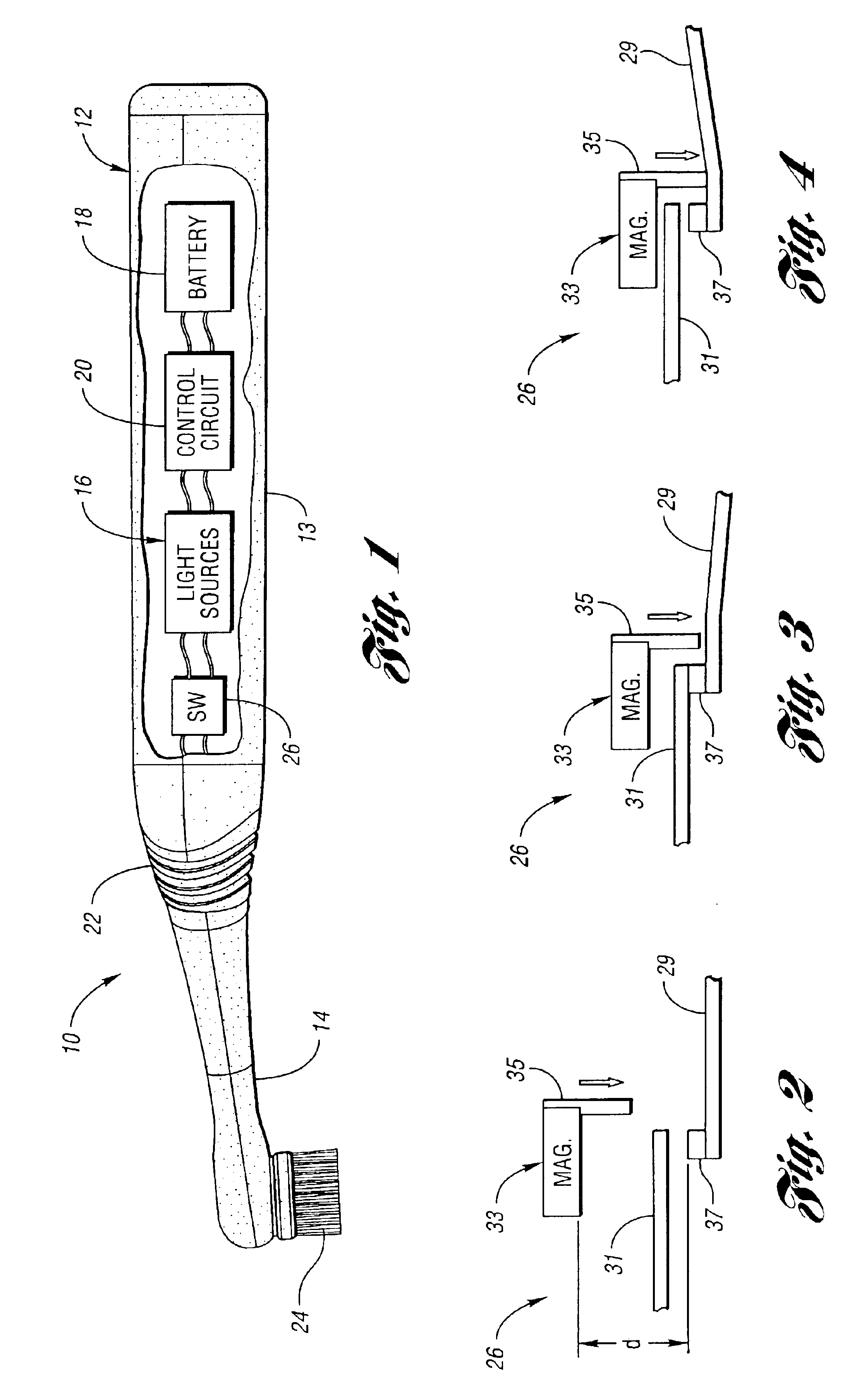

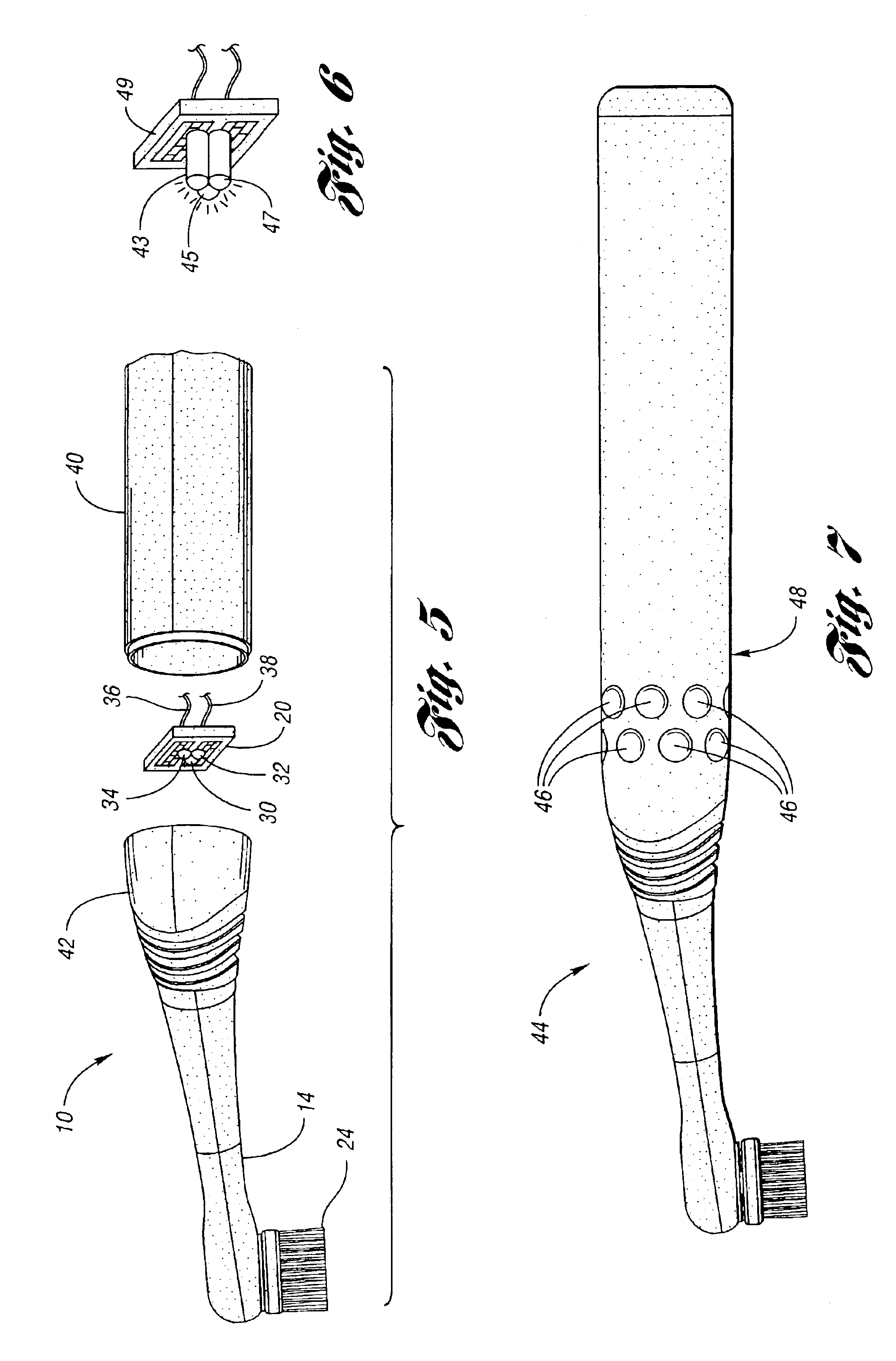

Light emitting toothbrush

InactiveUS6954961B2Inhibition of activationPromote activationKitchenware cleanersDispensing apparatusElectrical batteryEngineering

A light emitting toothbrush is provided that includes three light emitting diodes, each having a different primary color. A battery is provided as a power source, and a control circuit is used to control the diodes. The control circuit is configured to sequentially or simultaneously power some or all of the diodes, and it can be configured to vary the power to each diode, thereby providing an almost infinite spectrum of colors of light. A switch is actuated when the brush head contacts an operator's teeth, thereby activating the diodes. A package is provided that allows a potential purchaser to apply a force to the brush head and activate the lights while the toothbrush is still in the package. The control circuit can be configured to control the diodes to provide signals to the operator and / or provide aesthetically pleasing light.

Owner:FKA DISTRIBUTING CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com