Patents

Literature

160 results about "Debris particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Floor cleaner with dusting

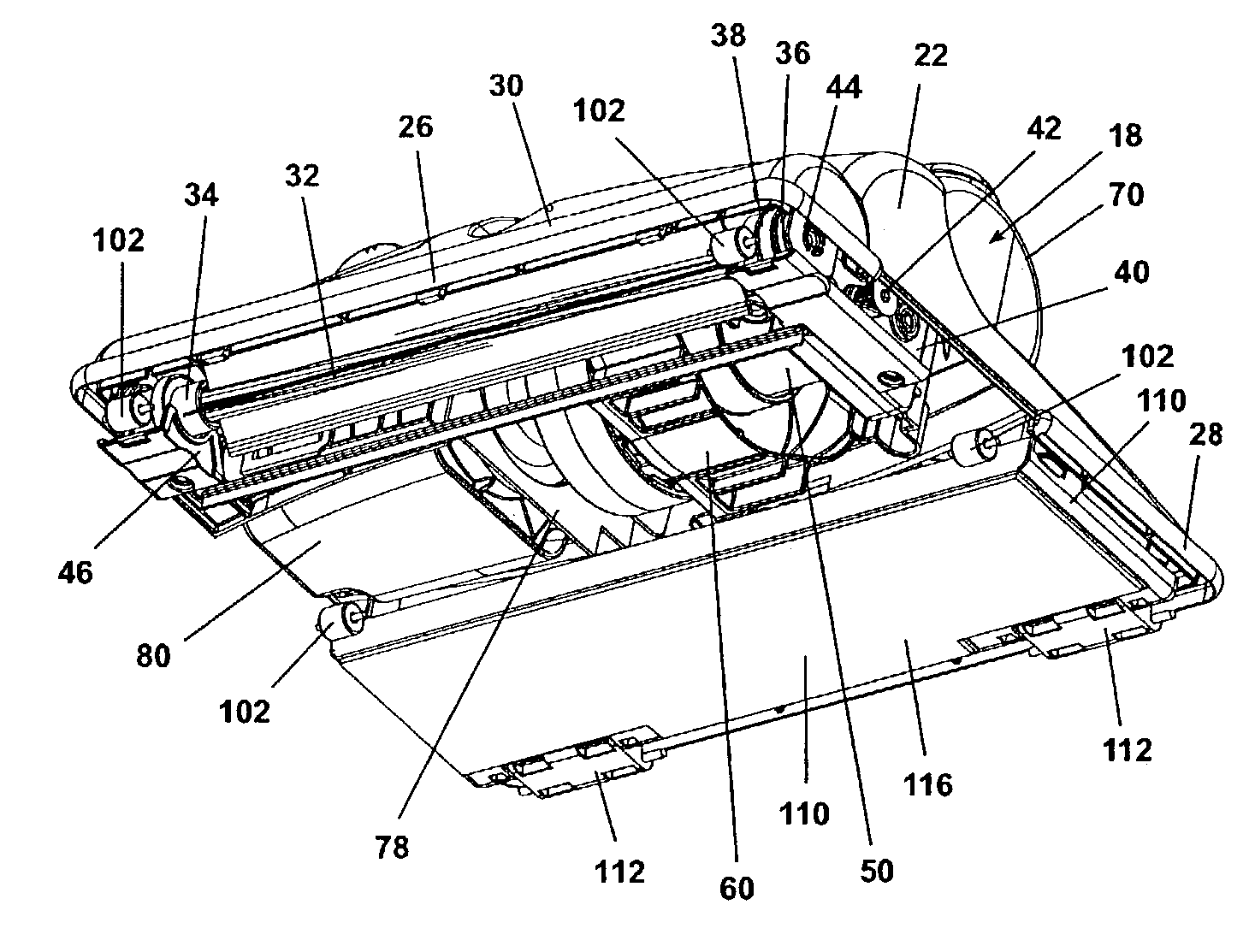

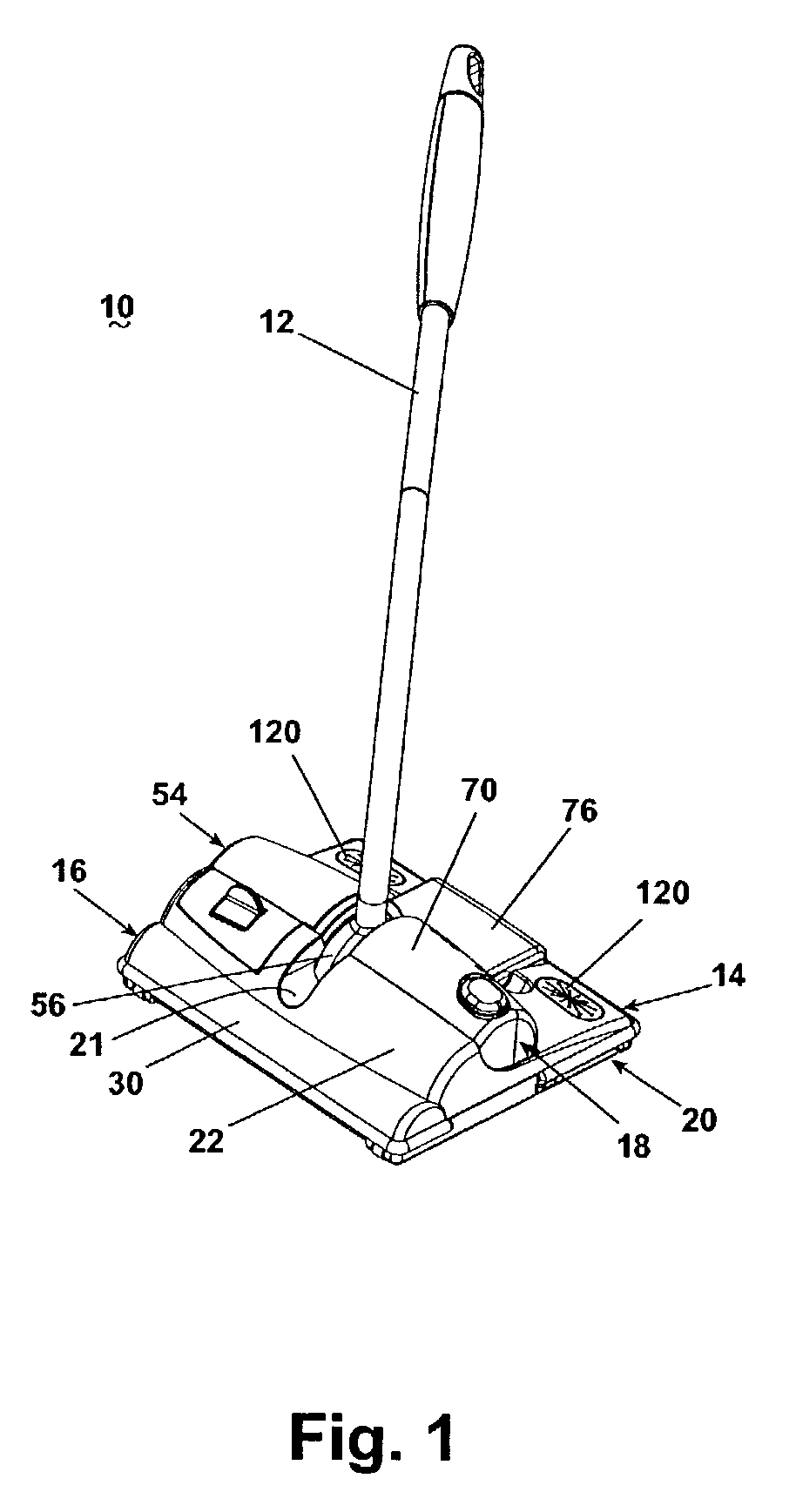

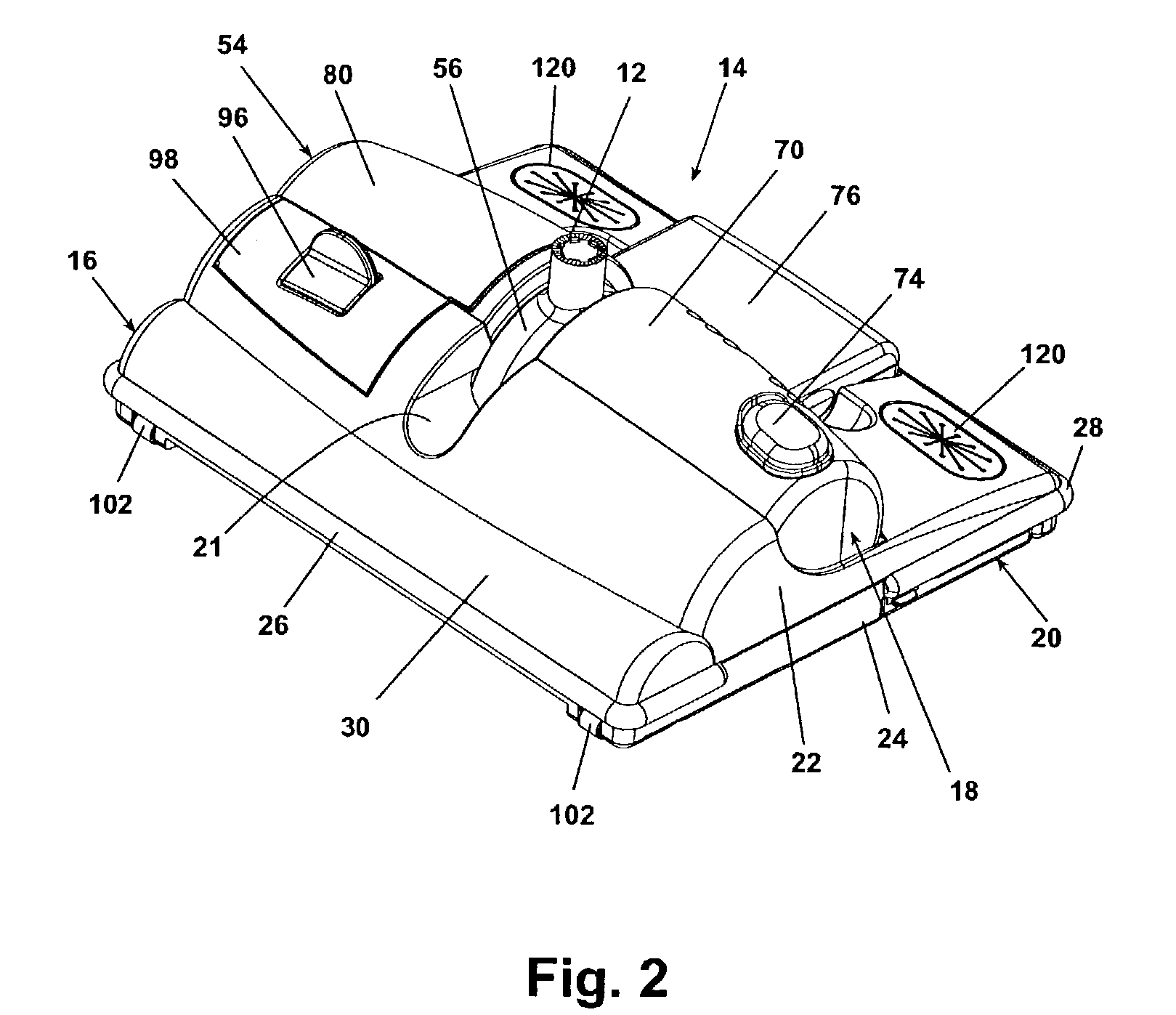

A battery-powered, upright vacuum sweeper comprises a base assembly and a handle pivotably attached thereto. The base assembly comprises a vacuum fan assembly fluidly communicating with an inlet for vacuuming dust and the debris particles from a surface into a removable reservoir. A rotating roller brush attached to the base assembly sweeps the particles into the inlet. A dust pad assembly comprises a disposable dust cloth extending over a portion of the base assembly in contact with the surface to be cleaned for removing dust particles which are not removed by vacuuming.

Owner:BISSELL INC

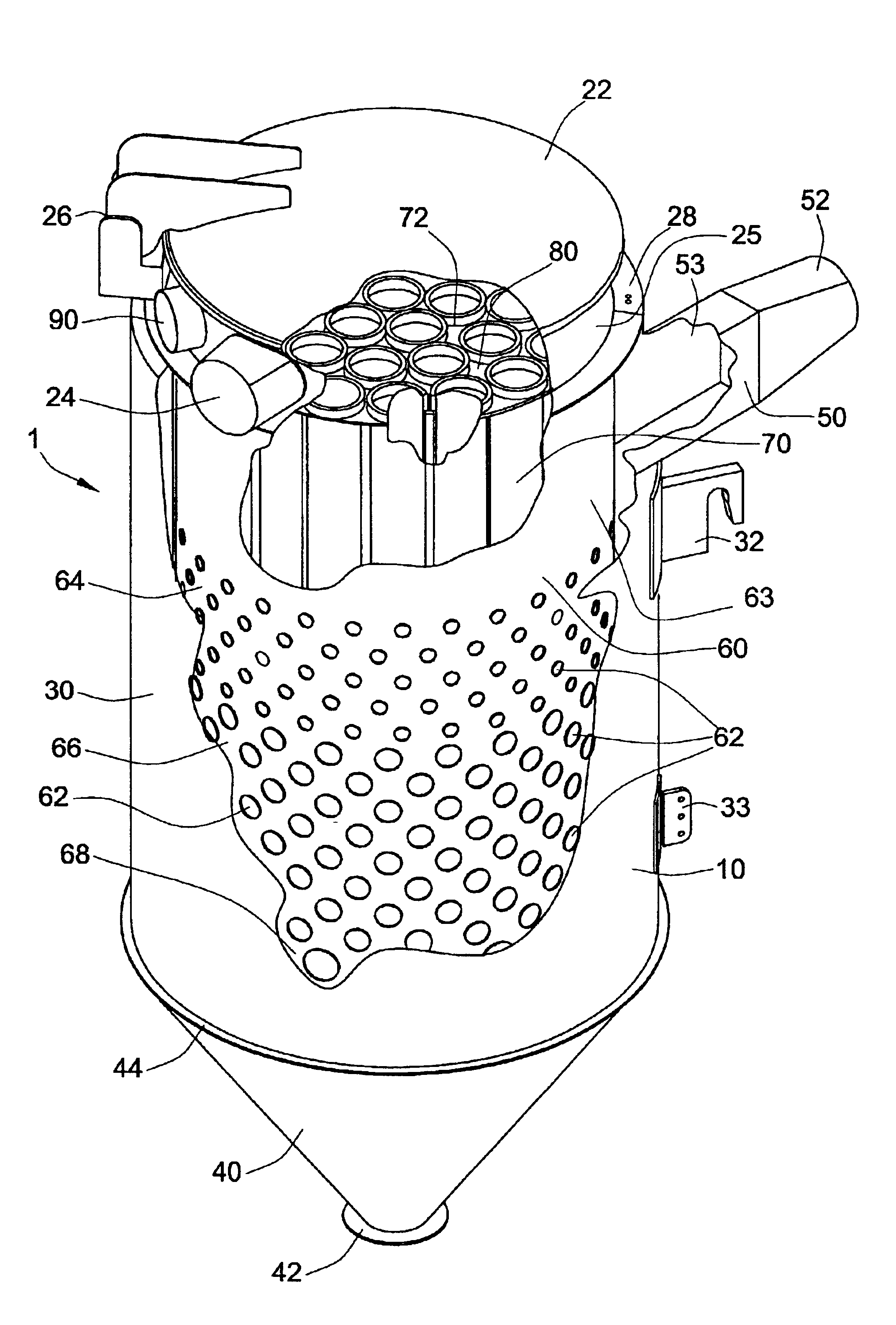

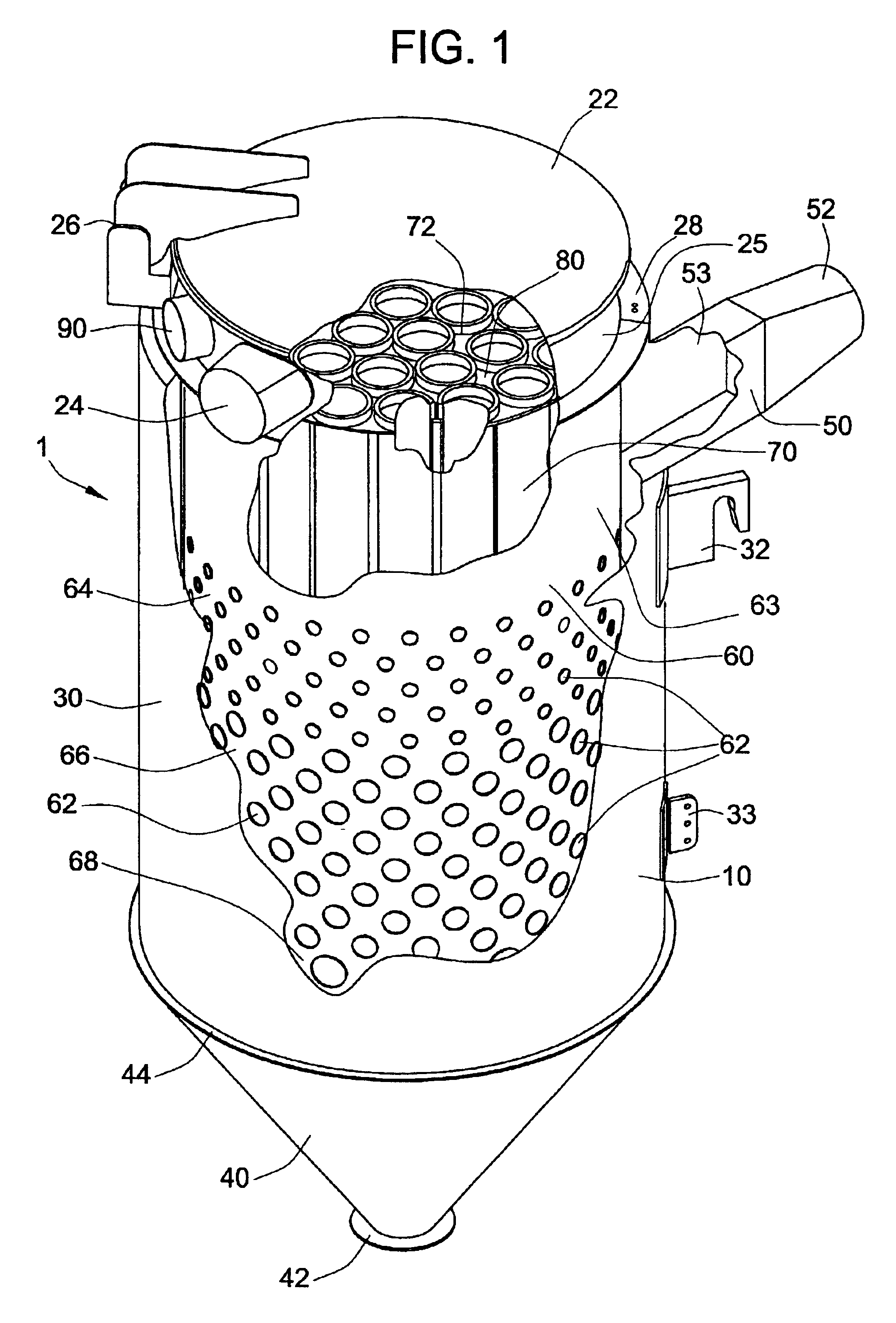

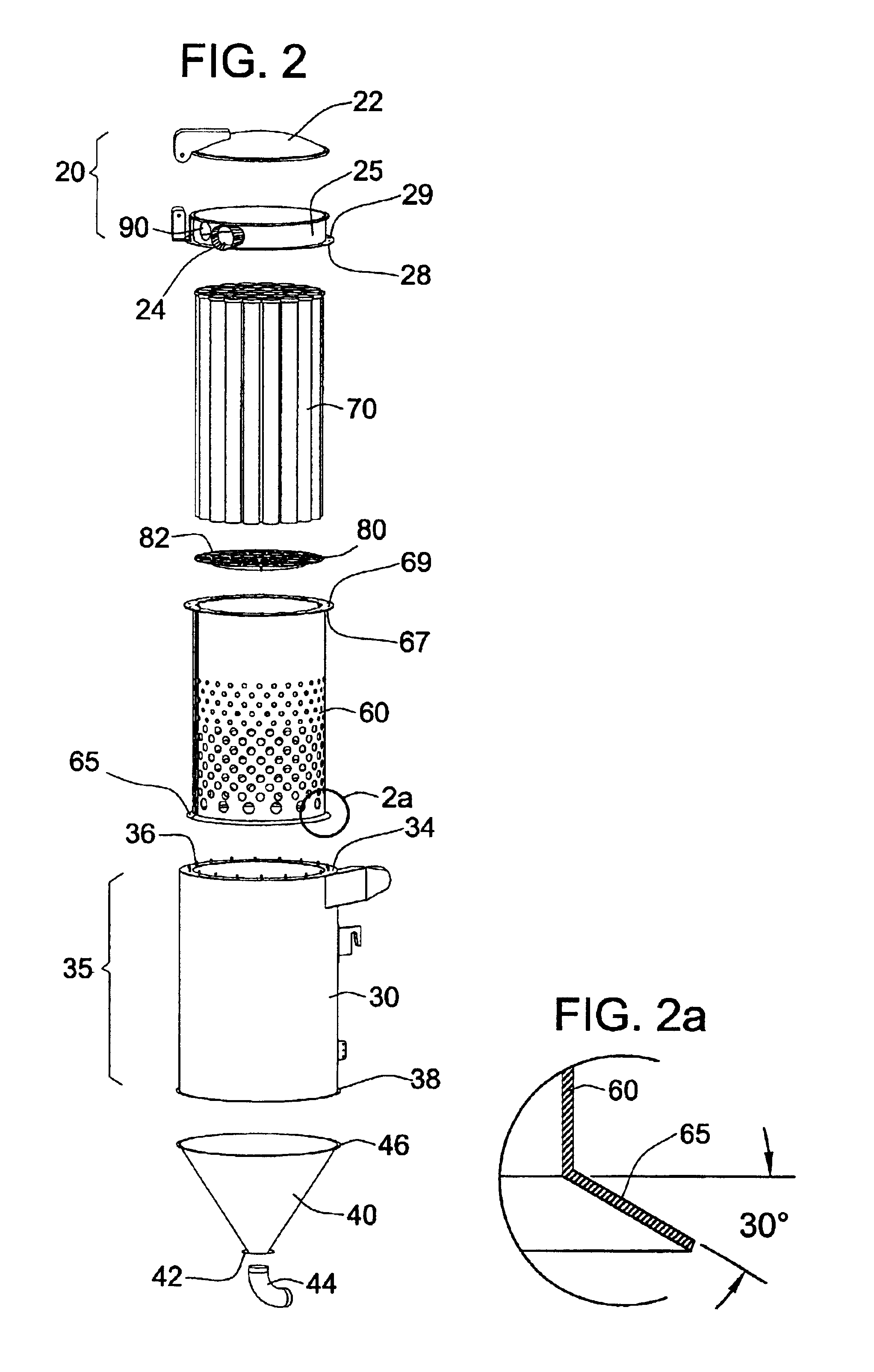

Debris separation and filtration systems

The invention provides a debris separation-filtration unit comprising a housing; an inlet that receives debris-laden air delivers the air in a tangential, centrifugal airflow-forming manner to the interior of housing; an inner shell that includes a number of airflow passageways; and a debris-capturing filter, the sides of which filter are at least substantially surrounded by the inner shell. Due to the formation of the centrifugal airflow and presence of the inner shell in the housing, only a portion of the debris particles entering the unit come in contact with the filter. The invention also provides debris collection, separation, and filtration systems comprising one or more of the separation-filtration units of the invention; debris collection vehicles comprising one or more of such units or systems; and related methods of collecting, separating, and filtering debris.

Owner:FEDERAL SIGNAL CORPORATION

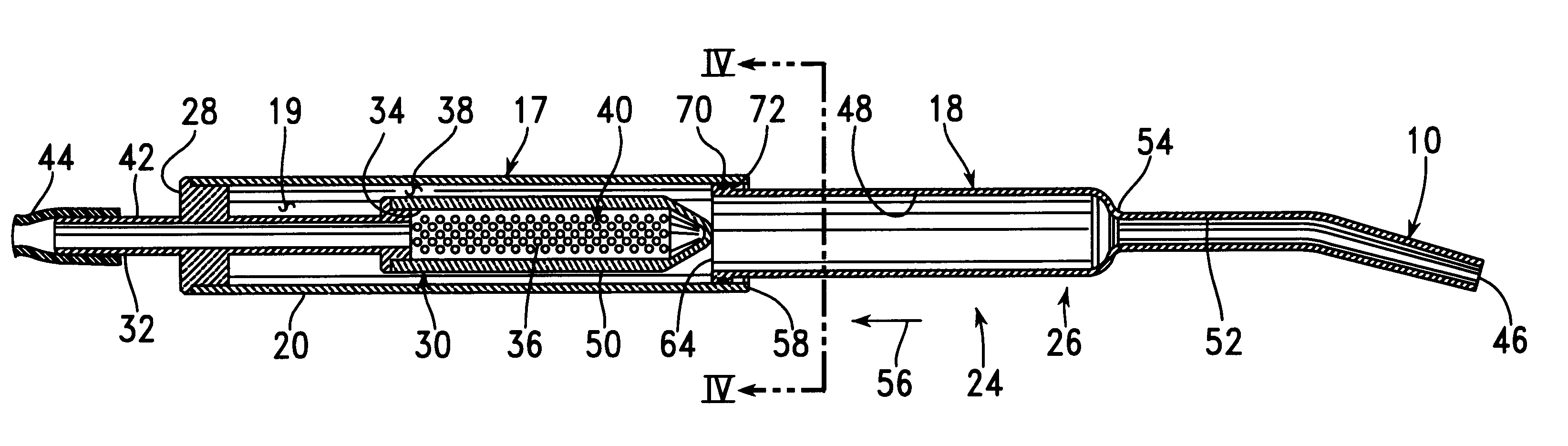

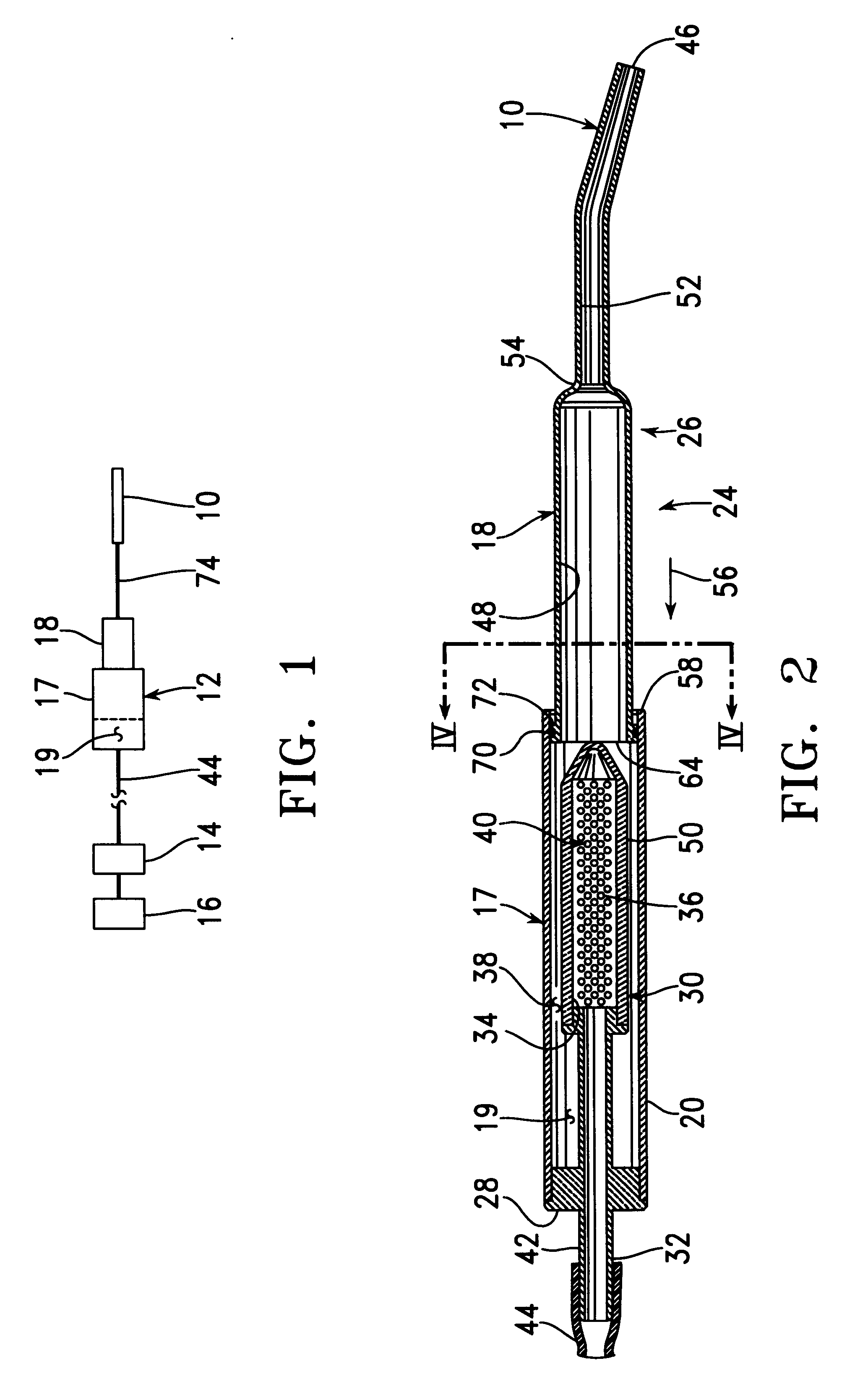

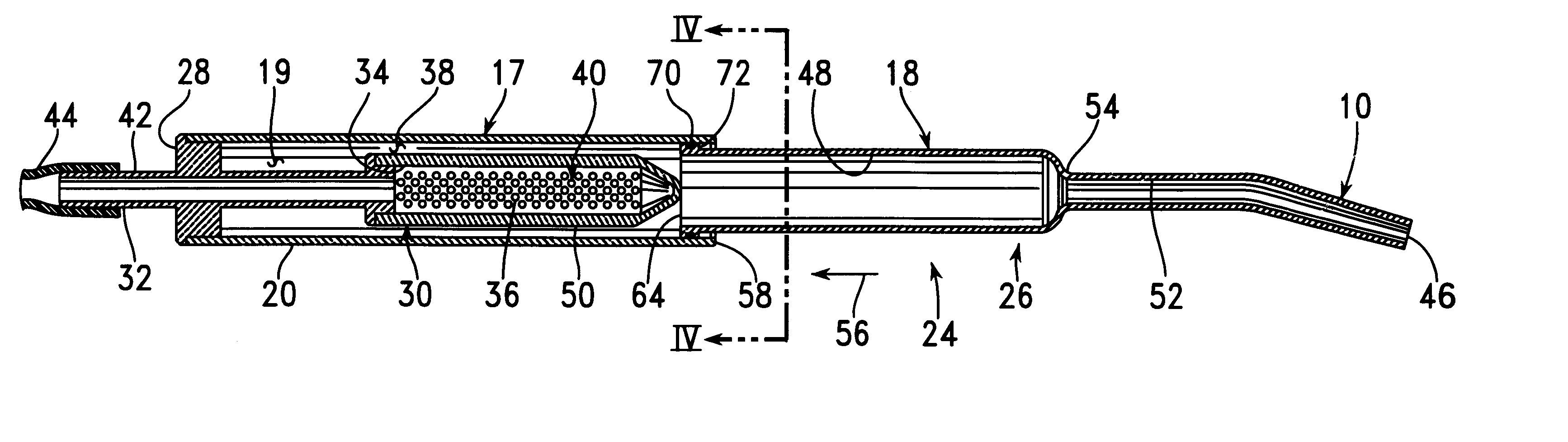

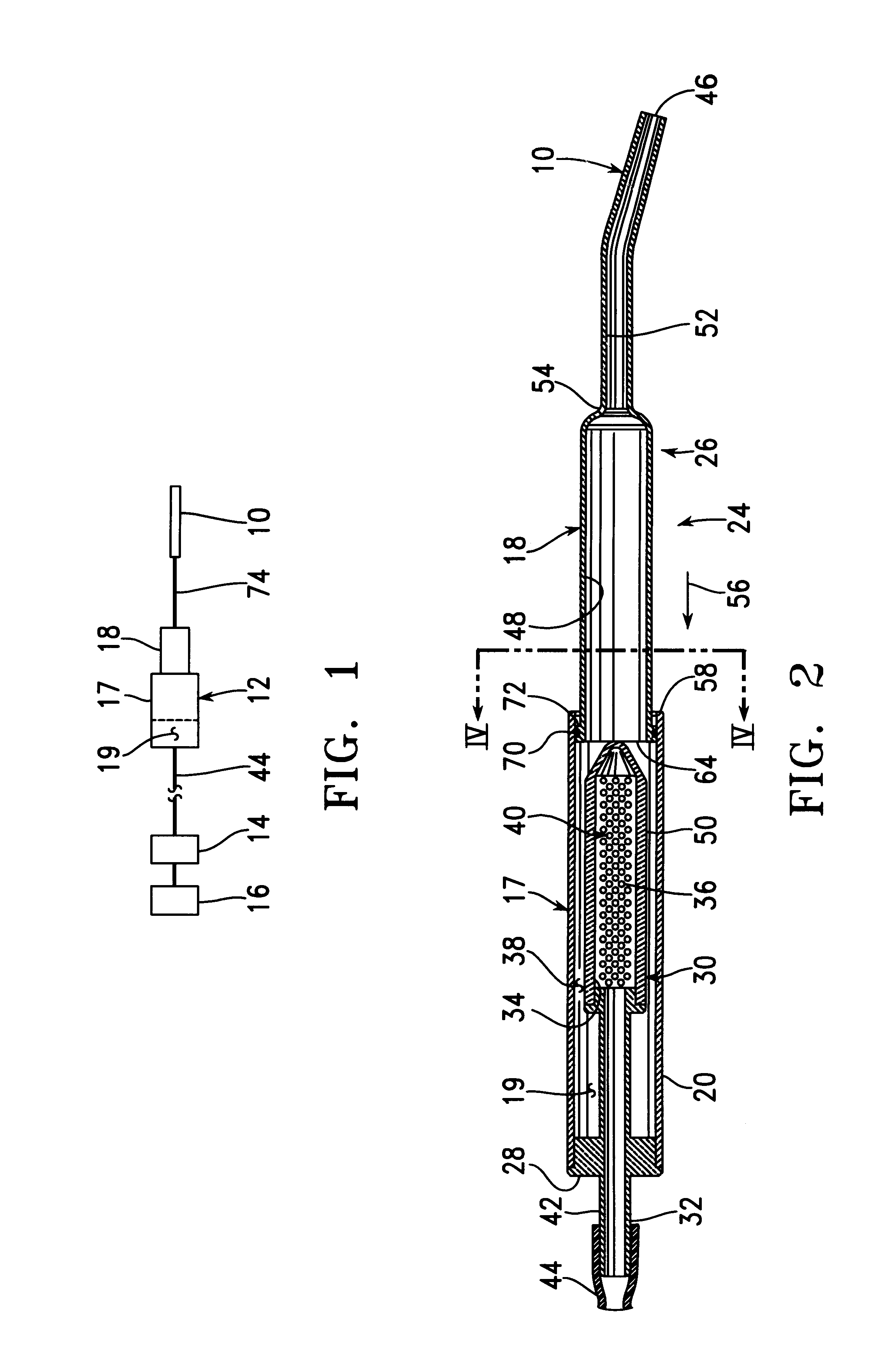

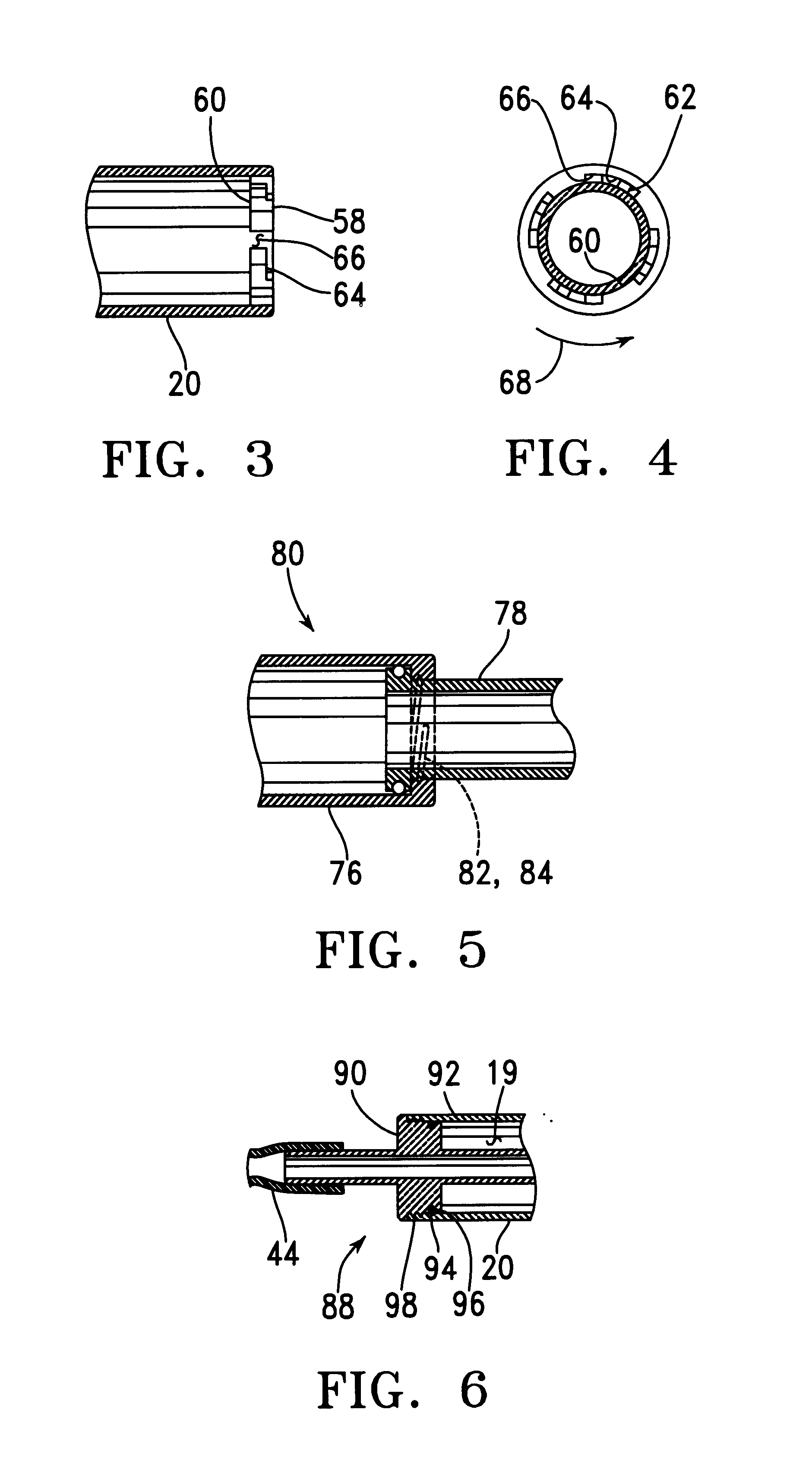

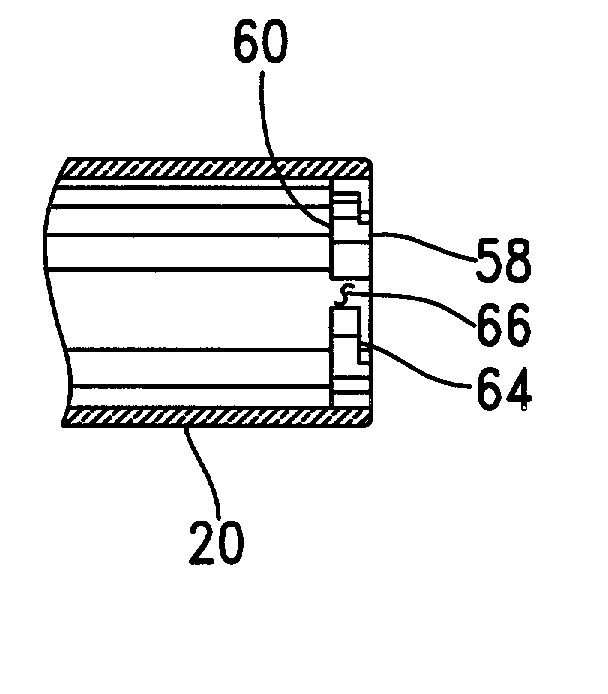

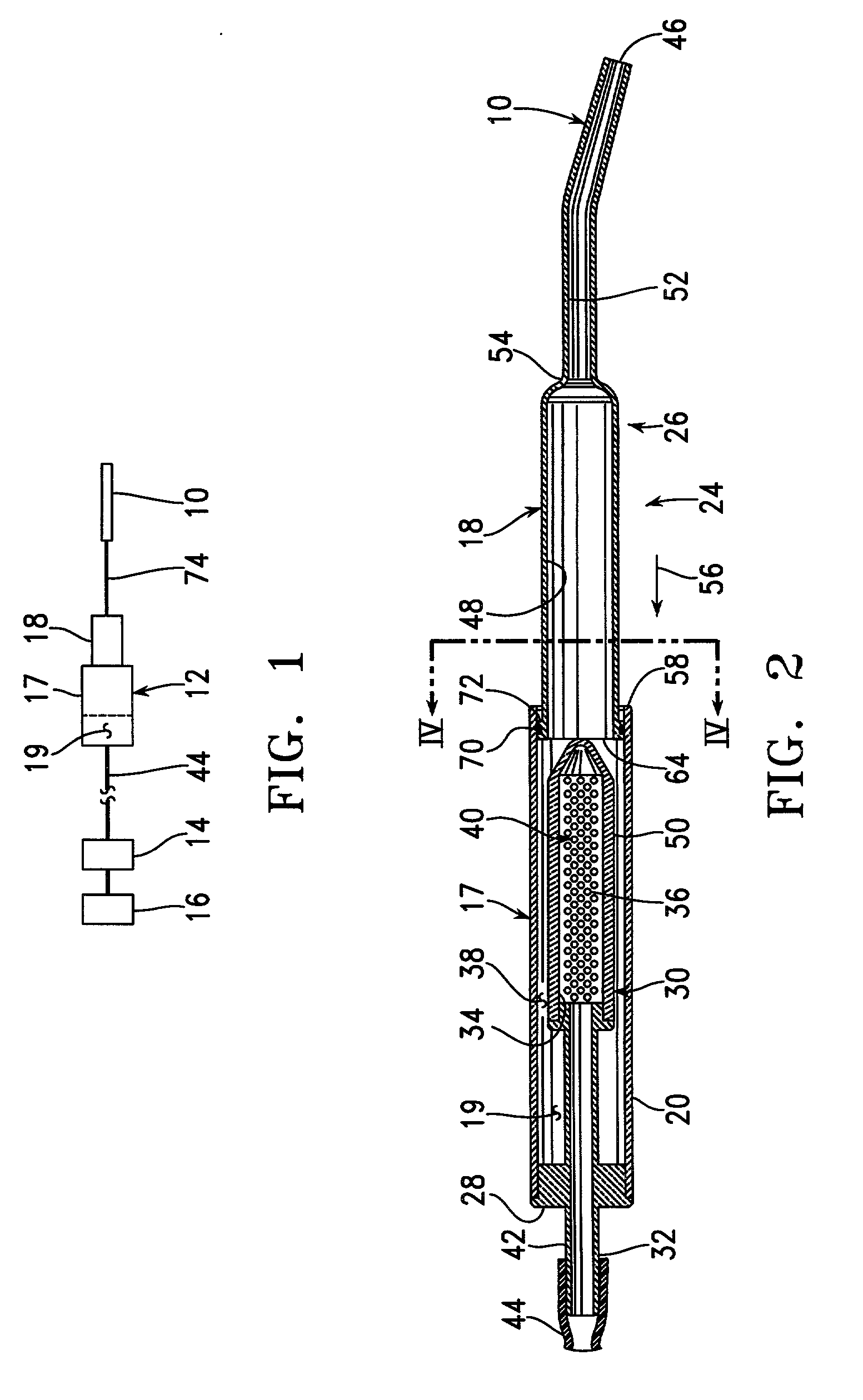

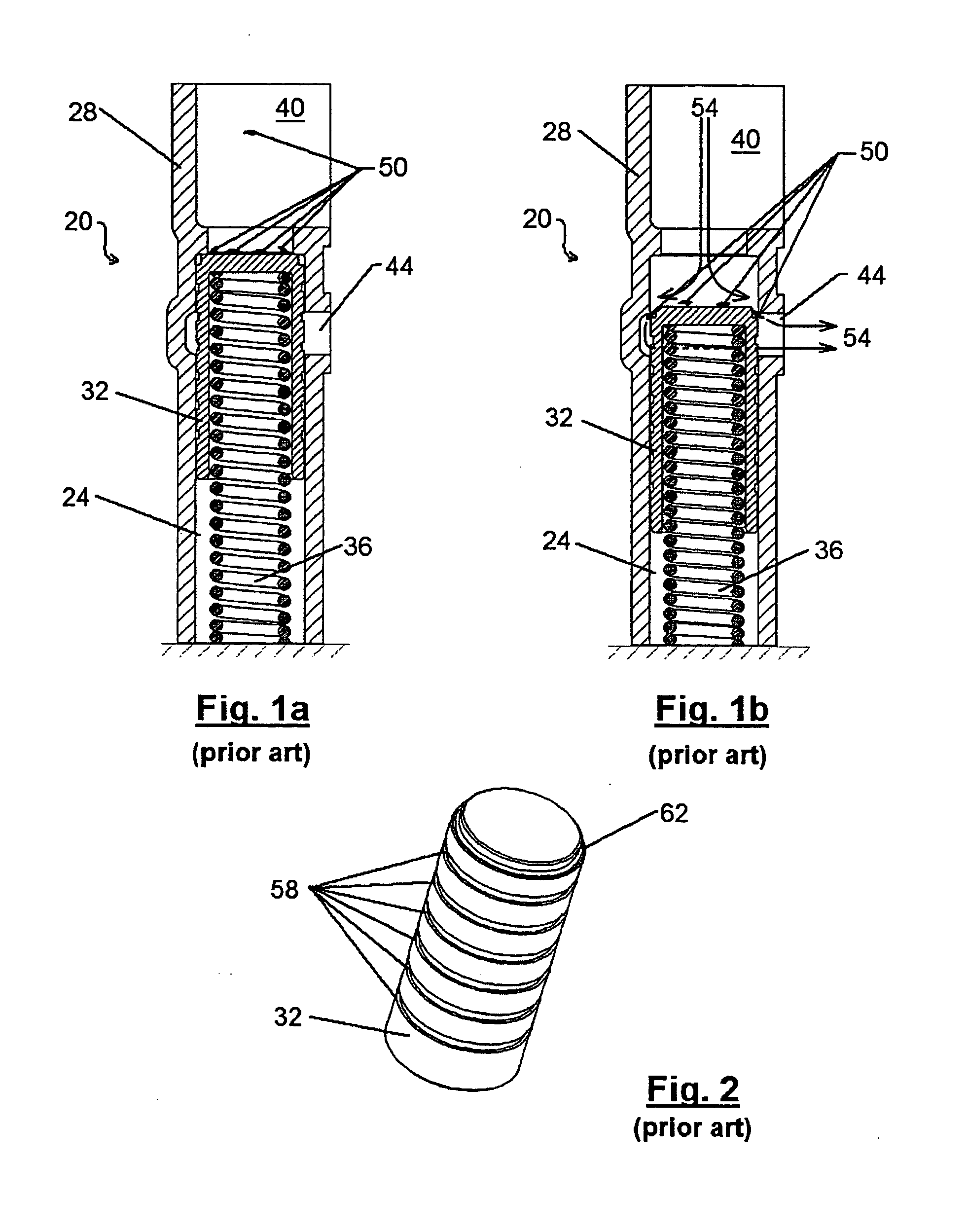

Surgical suction probe system with an easily cleaned internal filter

A suction probe system for cleaning debris from a surgical site includes a probe tip, a filter unit in fluid communication with the probe tip, and a suction source in fluid communication with the filter unit. The filter unit includes a cylindrical filter having an inner chamber attached to the suction source and an outer surface which accumulates debris particles too large to pass through holes within the cylindrical filter. The filter unit also includes a slider having an open-ended cylinder which is slid along the outside of the cylindrical filter to remove accumulated debris particles and to push these debris particles into a reservoir within the filter unit. The slider and the probe tip can be made integral parts of a single sliding member.

Owner:MEDECON

Turbine shroud hanger with debris filter

A turbine shroud hanger apparatus for a gas turbine engine includes: an arcuate shroud hanger having at least one cooling hole passing therethrough, the cooling hole having an inlet and an outlet; and a filter carried by the shroud hanger positioned upstream of the inlet of the cooling hole, the filter having a plurality of openings formed therethrough which are sized to permit air flow through the cooling hole while preventing the entry of debris particles larger than a preselected size into the cooling hole.

Owner:GENERAL ELECTRIC CO

Self-cleaning strainer

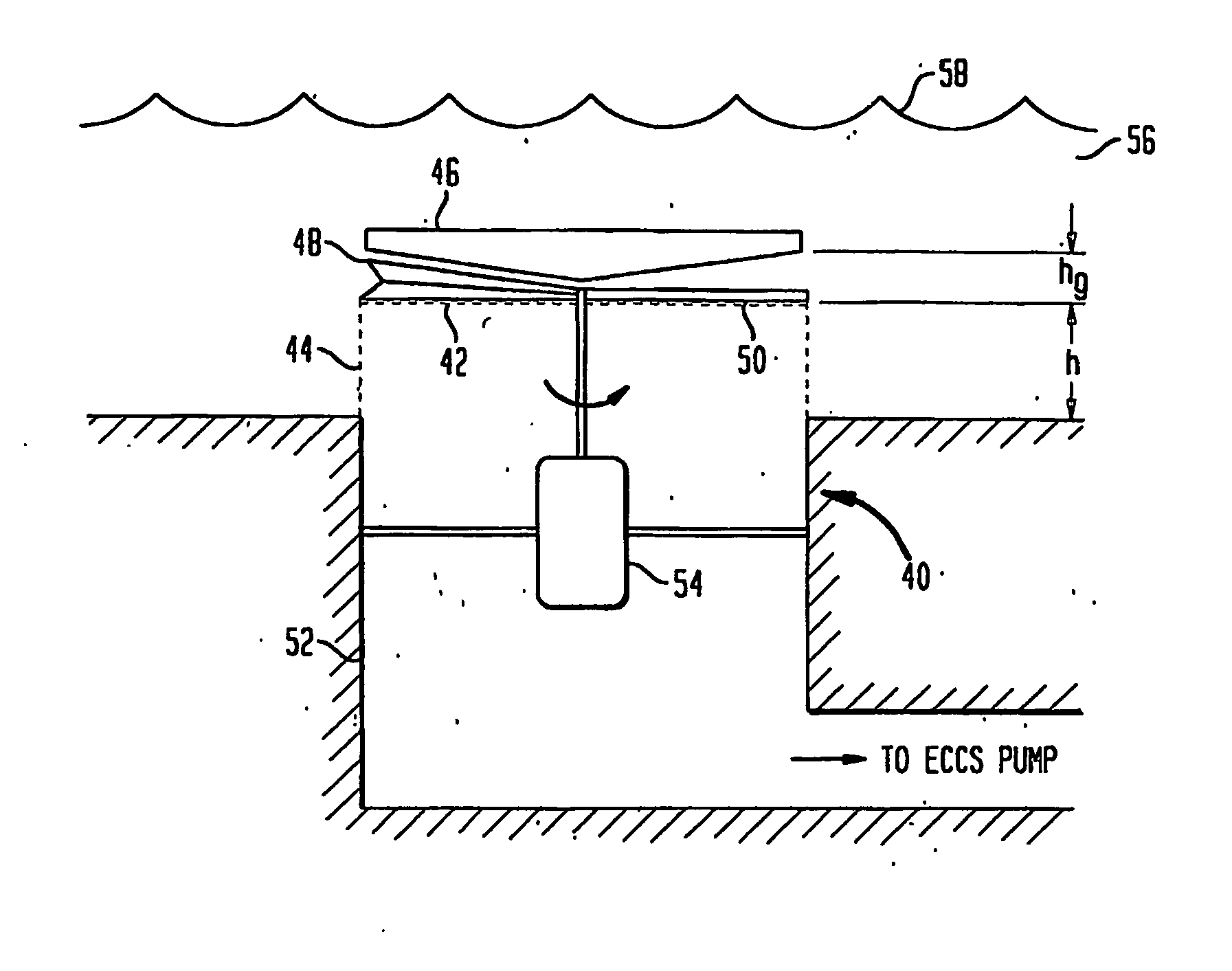

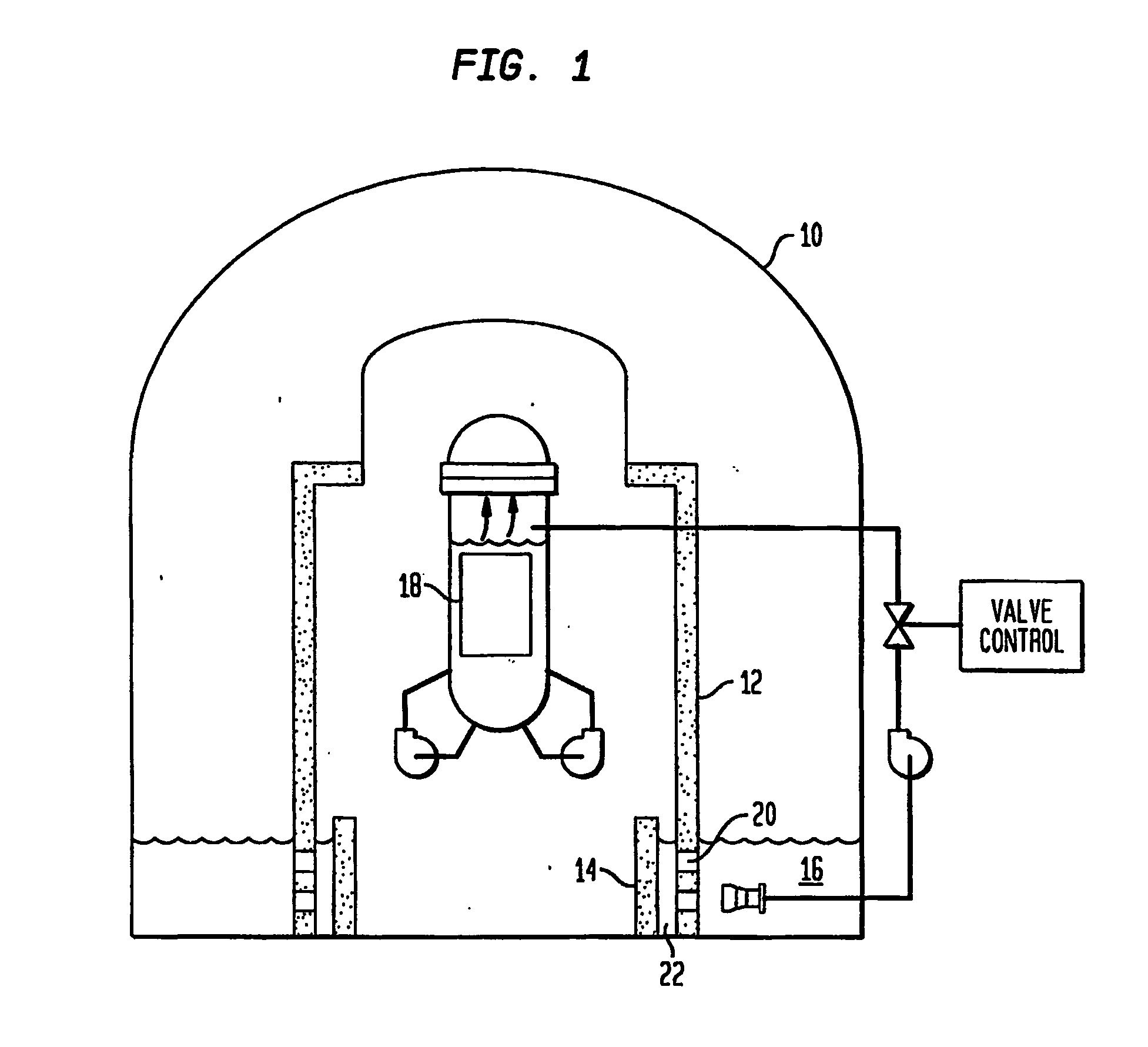

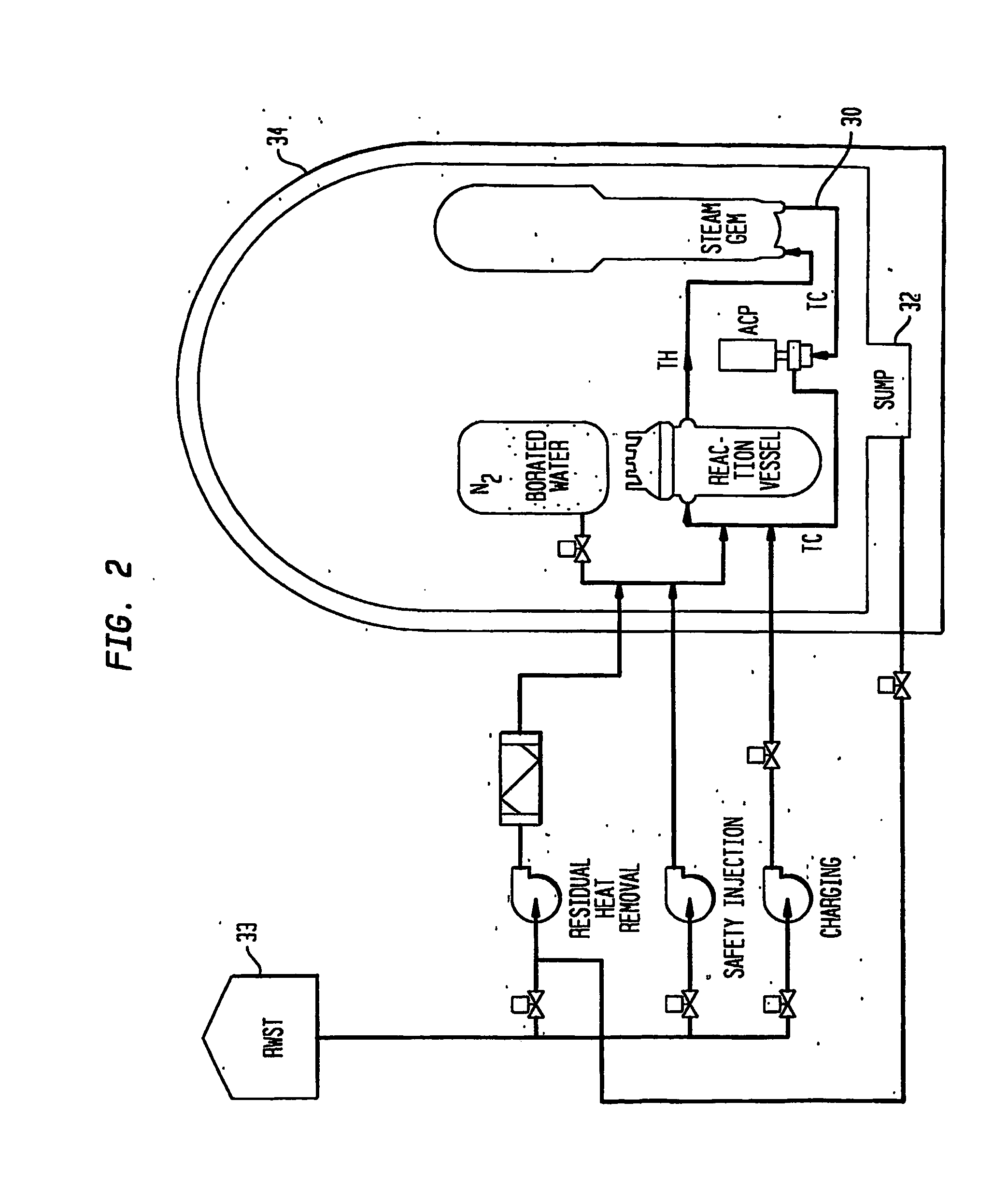

InactiveUS20060219645A1Improve performanceAvoids additional head-lossNuclear energy generationNuclear elementsImpellerMotor drive

An externally powered, self cleaning strainer incorporating a projectile shield, which is capable of operating for an extended period of time. A suitably shaped, motor driven, impeller creates a localized, radially outward flow of fluid in the vicinity of the strainer inlet. The projectile shield has a lower surface shaped to deflect fluid to the strainer at a constant velocity, enabling the impeller to eject debris more efficiently. Maintaining a constant flow through the strainer also avoids additional head loss associated with accelerating flow. The self cleaning strainer may also include a brush attached diametrically opposite to the impeller to aid in removing debris from the inlet side of the strainer. The impeller may also be shaped so that when it is swept past the inlet side of the strainer, it causes a localized, reverse flow through the strainer, thereby removing debris particles from within the strainer.

Owner:CONTINUUM DYNAMICS

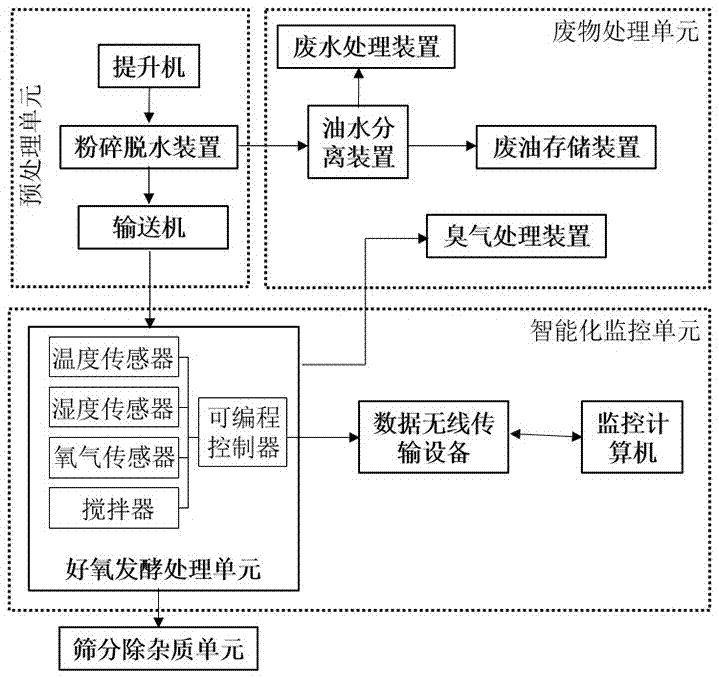

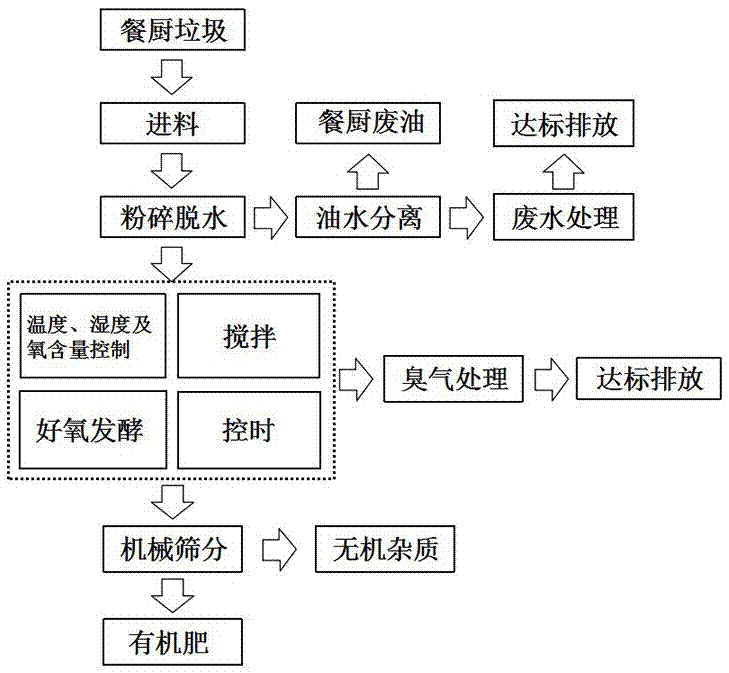

Novel kitchen waste treatment system and technology based on intelligent monitoring

InactiveCN106975645AImprove work efficiencyImprove biological activitySolid waste disposalIntelligent lightingOxygen

The invention discloses a novel food waste treatment system based on intelligent monitoring and a process thereof. The food waste treatment system based on intelligent monitoring of the present invention is characterized in that: the system comprises a pretreatment unit, an aerobic Fermentation processing unit, screening and removing impurities unit, waste processing unit and intelligent monitoring unit. The present invention also provides a kitchen waste treatment process, which is characterized by comprising the following steps: firstly, the collected kitchen waste is pulverized and dehydrated to obtain oil-water mixed liquid and residue particles; then the residue particles enter the aerobic state through a conveyor. The fermentation tank is mixed and stirred with fermentation strains, and aerobic fermentation is carried out at the same time to generate odor and organic materials; finally, the organic materials are mechanically screened by the screening and removal unit to separate organic materials and inorganic impurities to obtain high-quality organic materials. The fertilizer is used for recycling; the waste water obtained from dehydration and the odor generated during the aerobic fermentation process will be properly treated and disposed of by the waste treatment unit and then discharged up to the standard.

Owner:杭州科瑞特环境技术有限公司

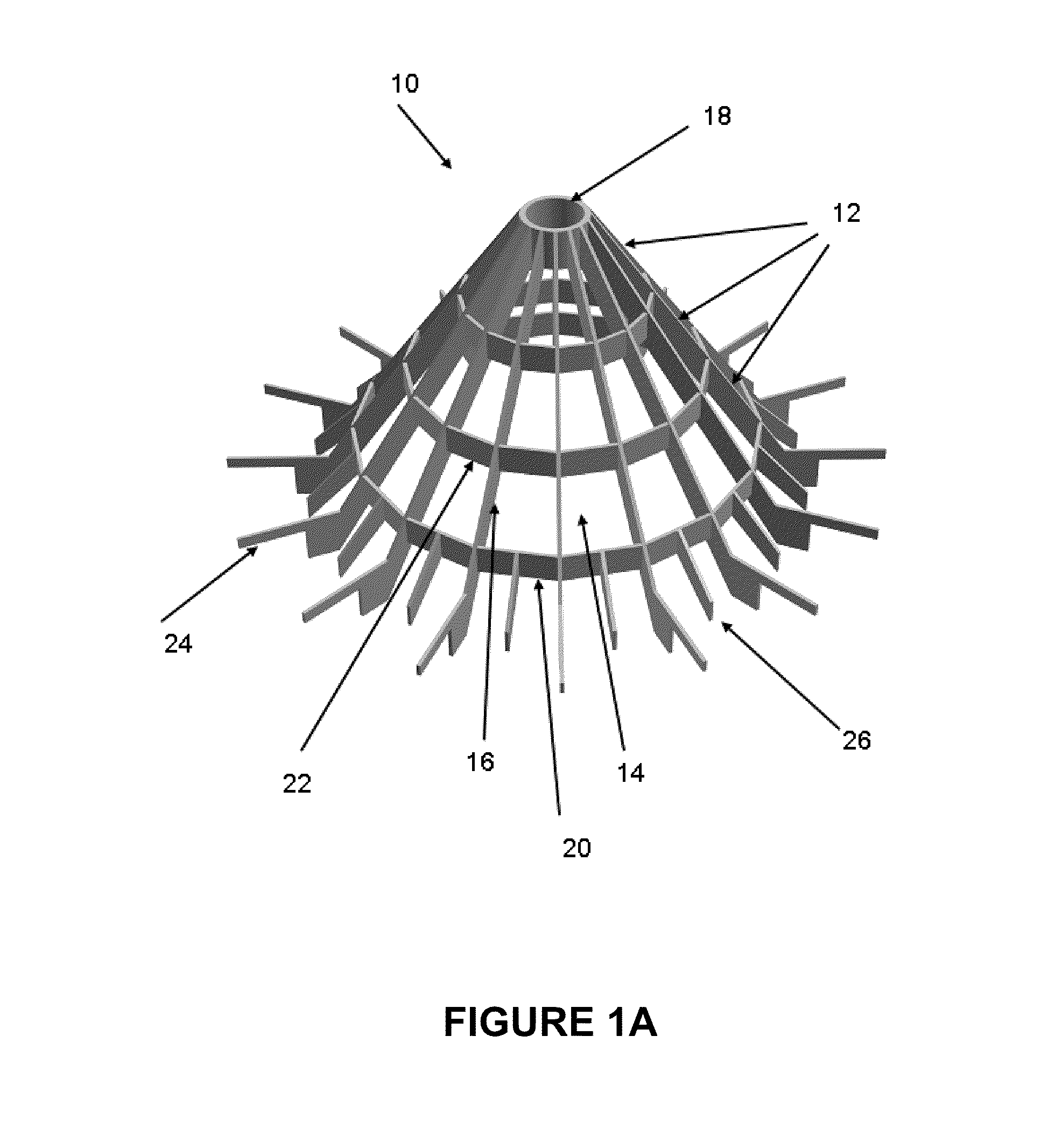

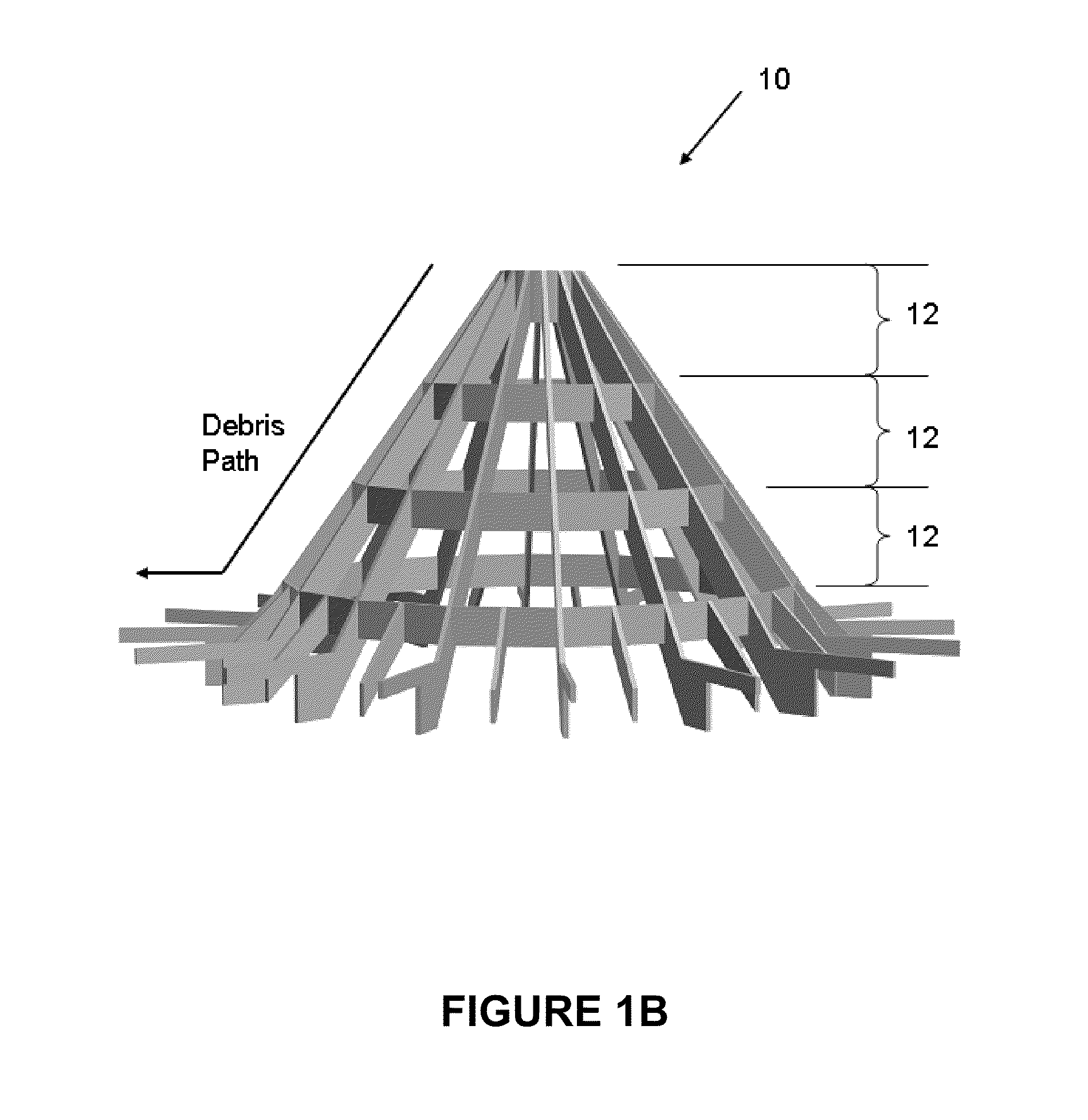

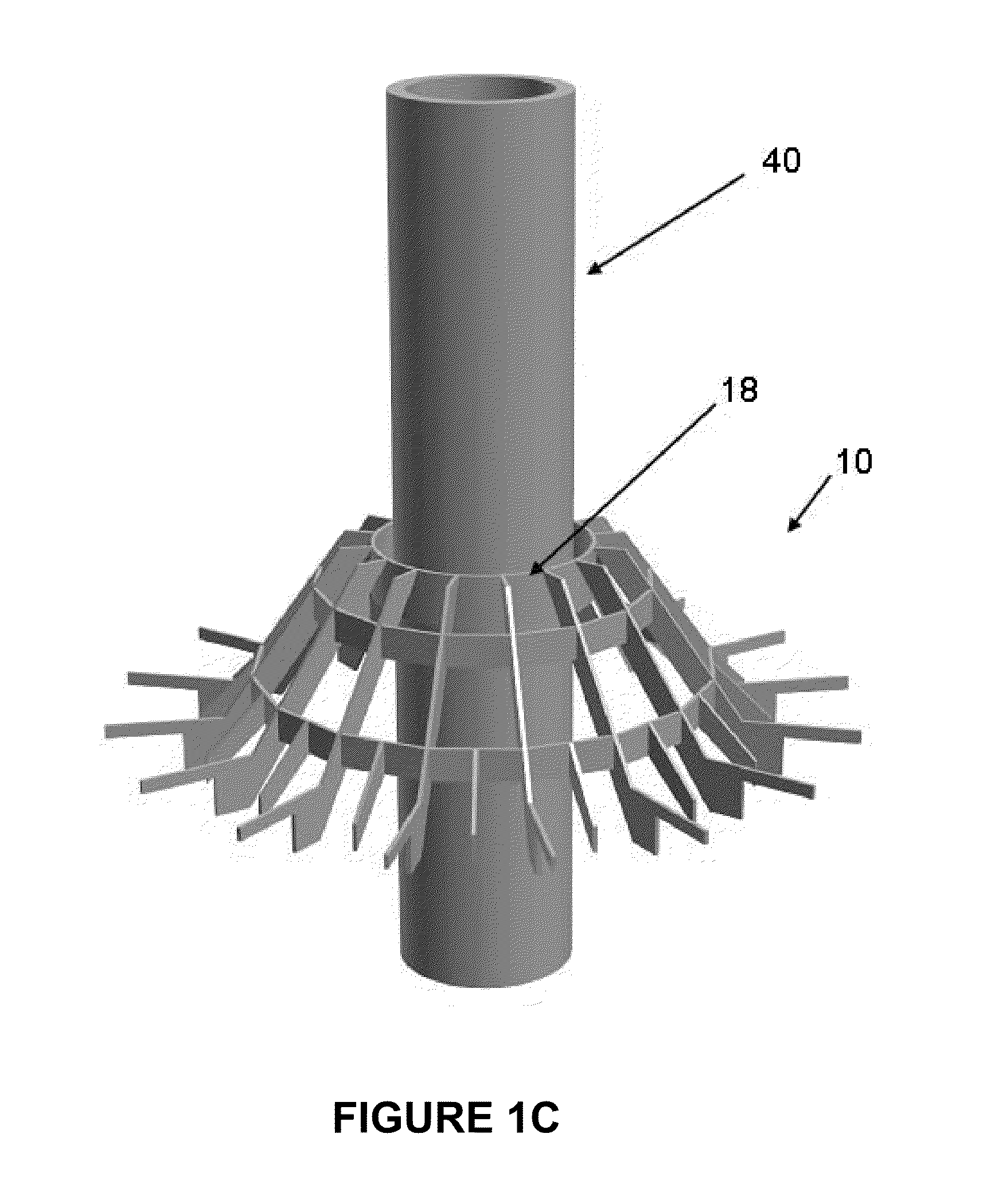

Debris Separation Device and Method of Use

InactiveUS20110240526A1Efficient screeningCatalytic crackingRefining by dialysisVertical planeEngineering

A device for use in separating debris from a flowing stream which comprises a substantially hollow, substantially conical shaped structure comprising a top end member and a plurality of adjacently positioned side members angularly extending from a top end member to a substantially circular bottom end. The top end member has a smaller diameter than the circular bottom end. The adjacently positioned side members are configured to provide multiple tiers in a vertical plane in the conically shaped structure. The multiple tiers comprise a plurality of apertures in a horizontal plane in the conically shaped structure. The plurality of apertures are configured for separating large debris particles, generally formed from coke and spent catalyst, from a flowing fluidized catalytic cracking stream, and directing the captured debris toward the circular bottom end of the device. A method of separating debris from a flowing stream is also provided. In particular, the device and method are useful for separating coke deposits in a fluidized catalytic cracking (FCC) process.

Owner:EXXON RES & ENG CO

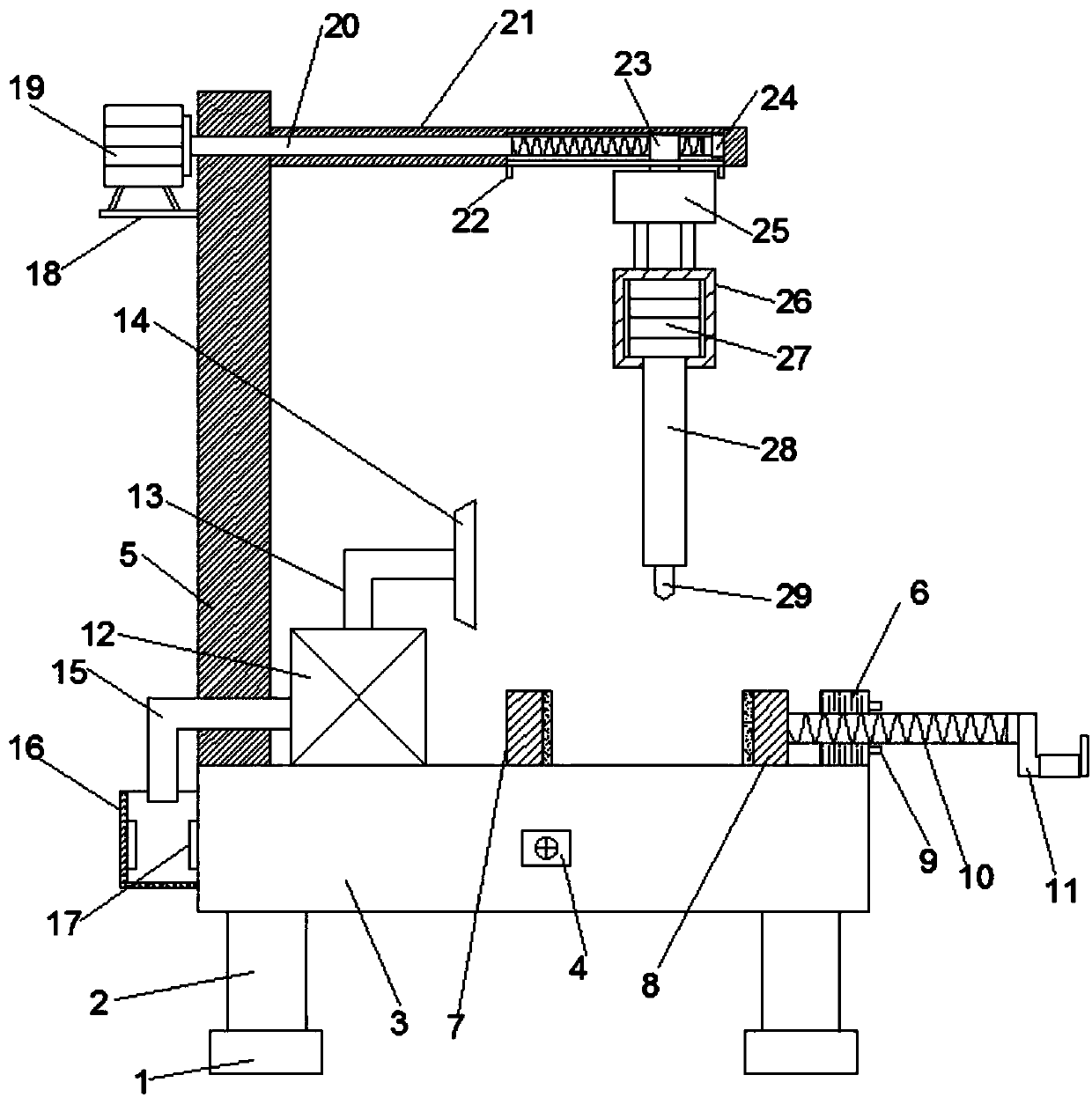

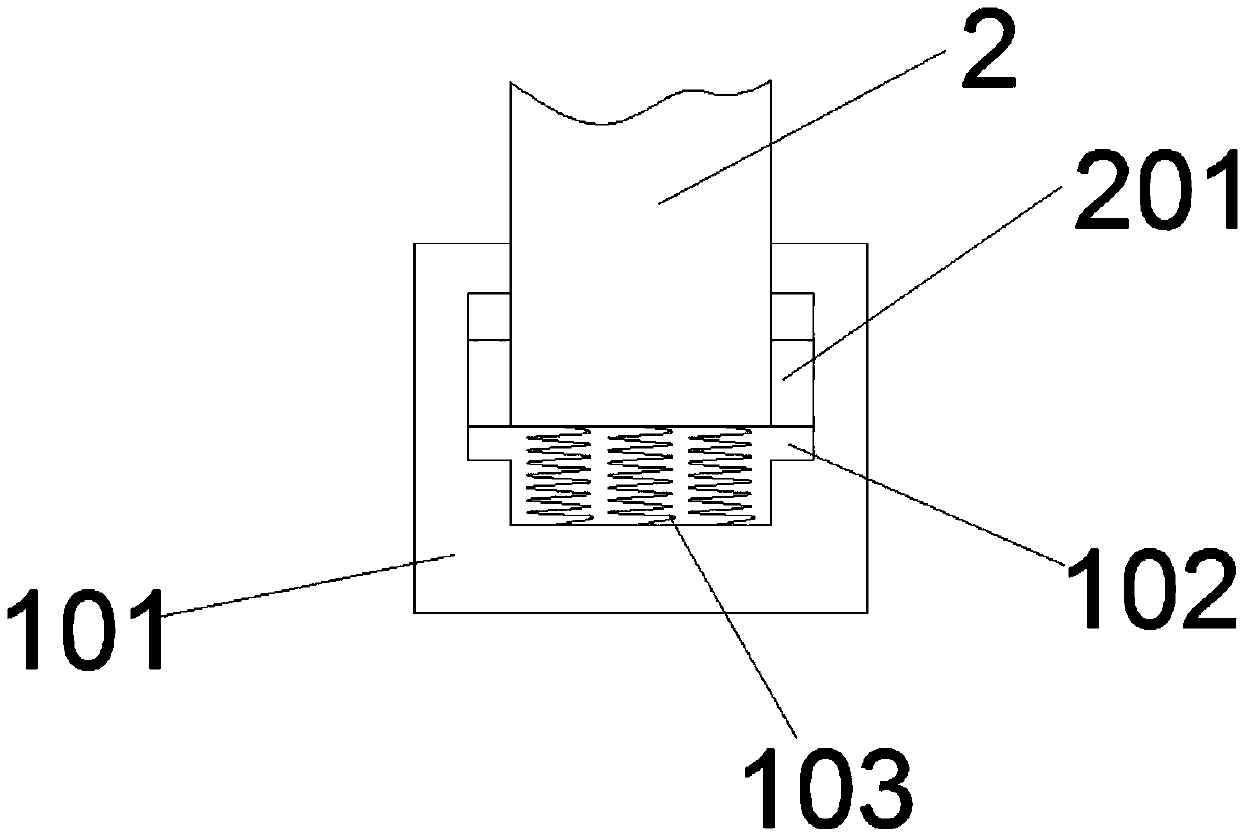

Drilling machine for machining hardware fittings

InactiveCN107824835AEasy to adjust the widthEasy to collectNon-rotating vibration suppressionDirt cleaningShock mountEngineering

The invention discloses a drilling machine for machining hardware fittings. The drilling machine comprises damping seats, wherein the damping seats comprise shells; sliding grooves are formed in the left sides and the right sides of the interiors of the shells; springs are arranged at the bottom ends of the interiors of the shells; supporting columns are arranged at the upper ends of the springs;and first sliding blocks are arranged at the left sides of the bottoms of the supporting columns and the right sides of the bottoms of the supporting columns. According to the drilling machine, the structure is simple, and the operation is easy; a movable clamping plate is moved by shaking a handle so as to clamp a machined workpiece, so that the operation is more convenient and labor-saving, andthe widths of the clamping plates can be conveniently adjusted for machining machined workpieces with different sizes; meanwhile, anti-slip mats are arranged on one sides of the outer walls of the clamping plates respectively, so that the surface friction force between the contact surfaces of the clamping plates and the machined workpiece is increased; after a fan works, the influence of debris particles on normal operation is avoided, the working efficiency is improved, and potential safety hazards caused by the debris particles to physical health of workers are eliminated; and the damping seats are arranged at the bottom of the drilling machine, so that the effects of damping and noise reduction are achieved when the drilling machine works.

Owner:WUXI WEI KELAI TECH CO LTD

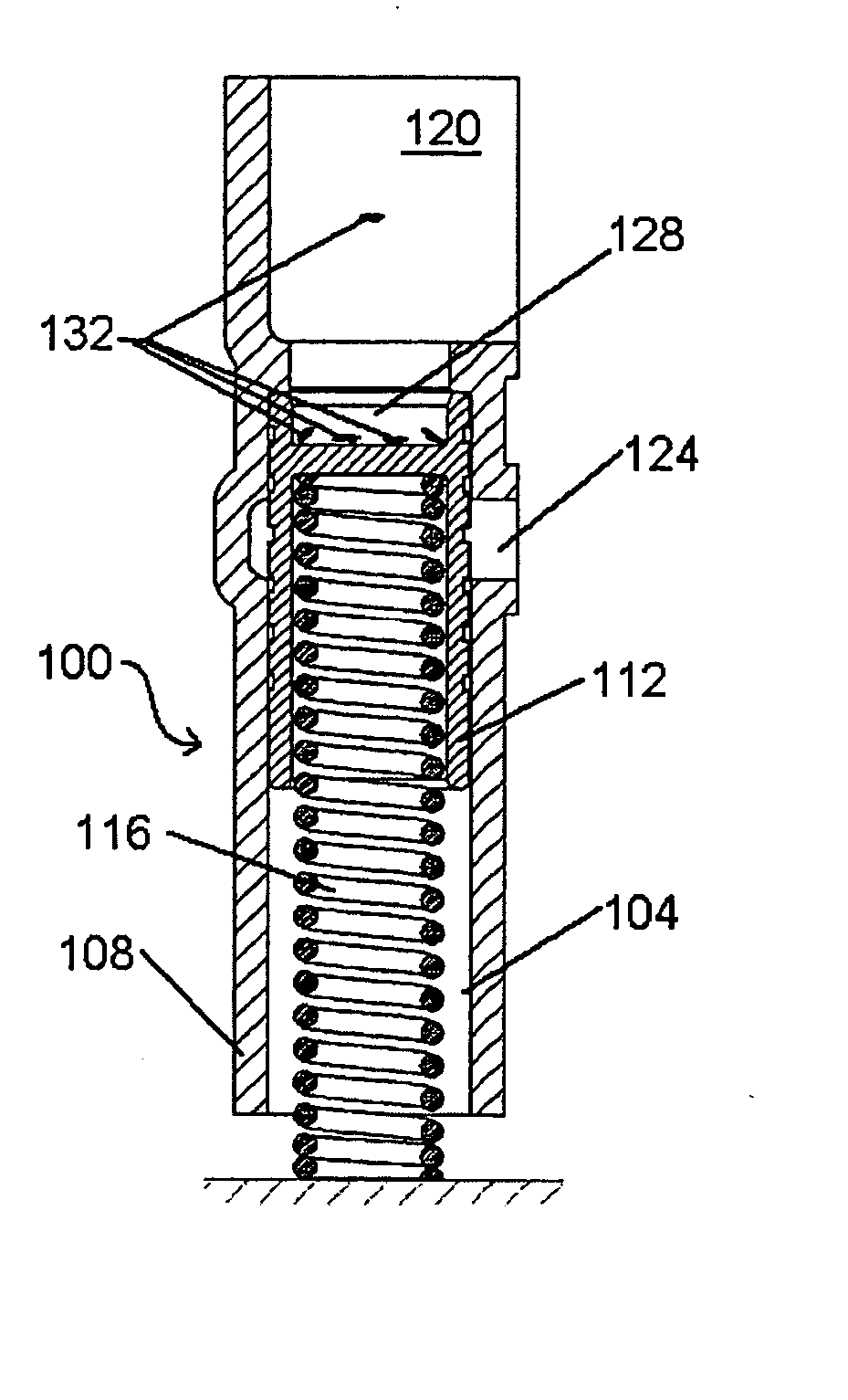

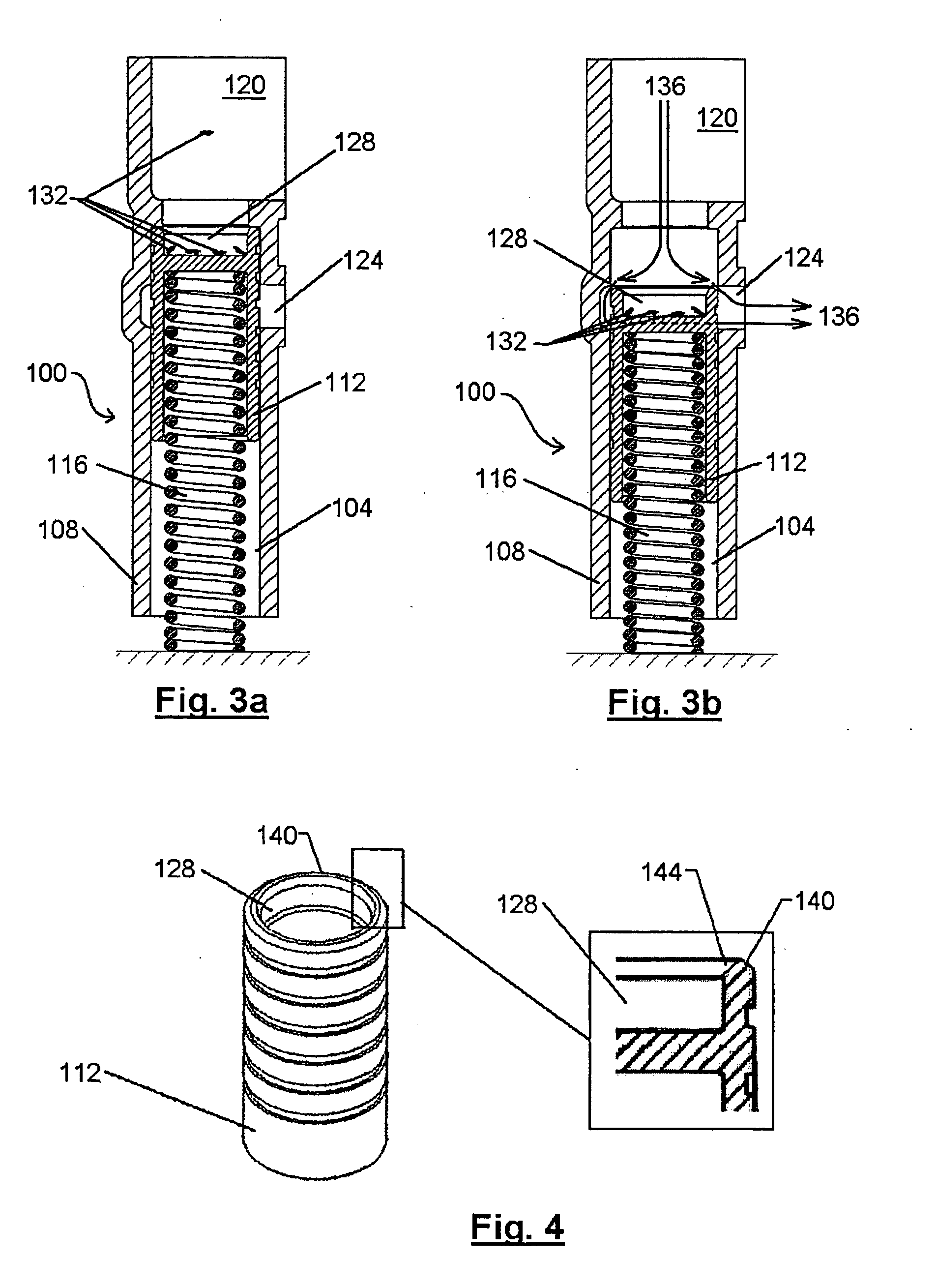

Surgical suction probe system with an easily cleaned internal filter

A suction probe system for cleaning debris from a surgical site includes a probe tip, a cylindrical filter with inner and outer chambers in fluid communication with the probe tip, and a suction source in fluid communication with the filter unit. In a first version, the inner chamber is attached to the suction source, and an outer surface of the filter accumulates debris particles, which are removed by a cleaning cylinder sliding along the outer surface of the filter as a distal portion of the probe system is slid along a proximal portion thereof. In a second version, the outer chamber is attached to the suction source, and a inner surface of the filter accumulates debris particles, which are removed by rotation of a paddle within the filter as the distal portion of the probe system is rotated on the proximal portion thereof.

Owner:MEDECON

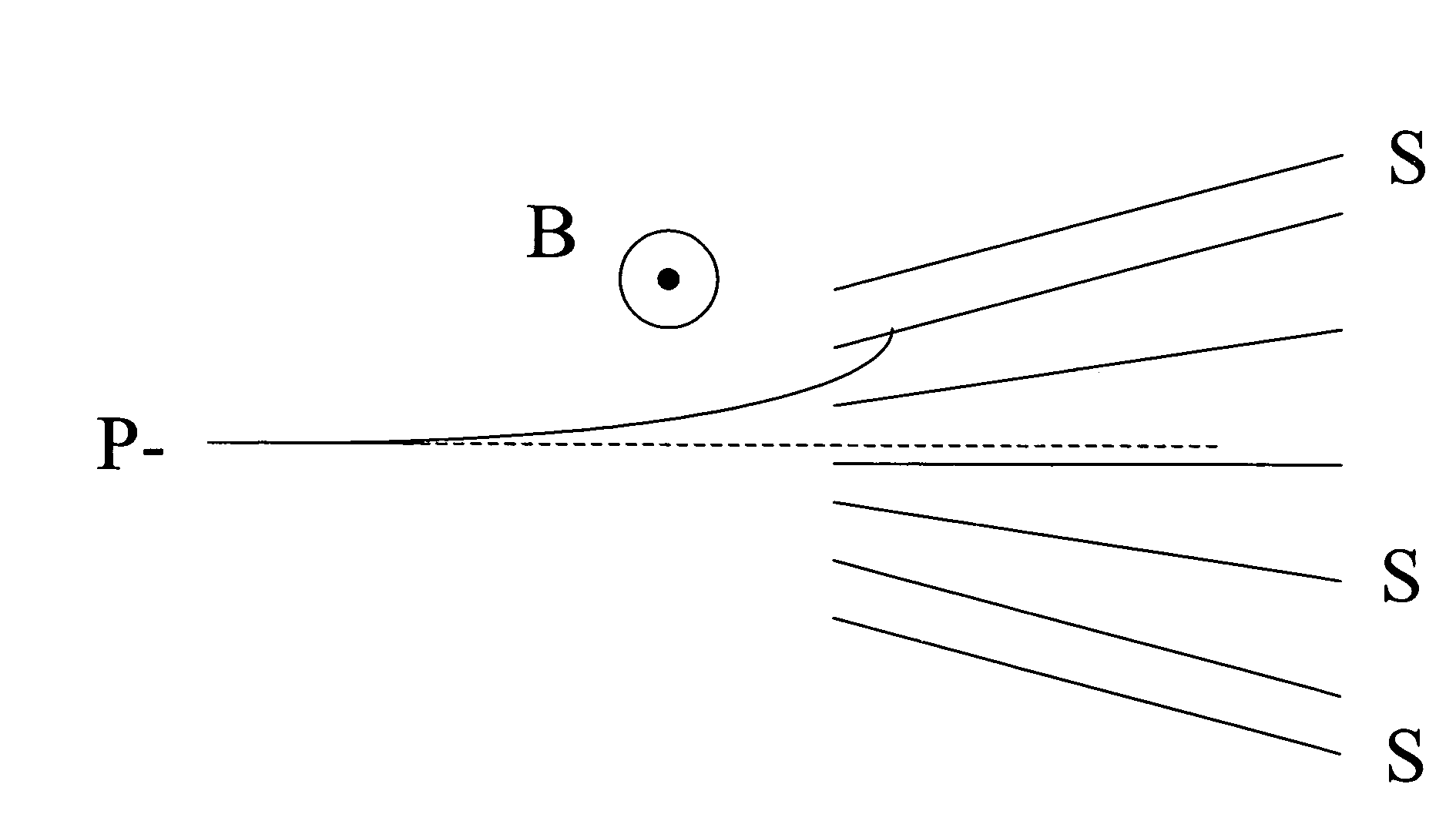

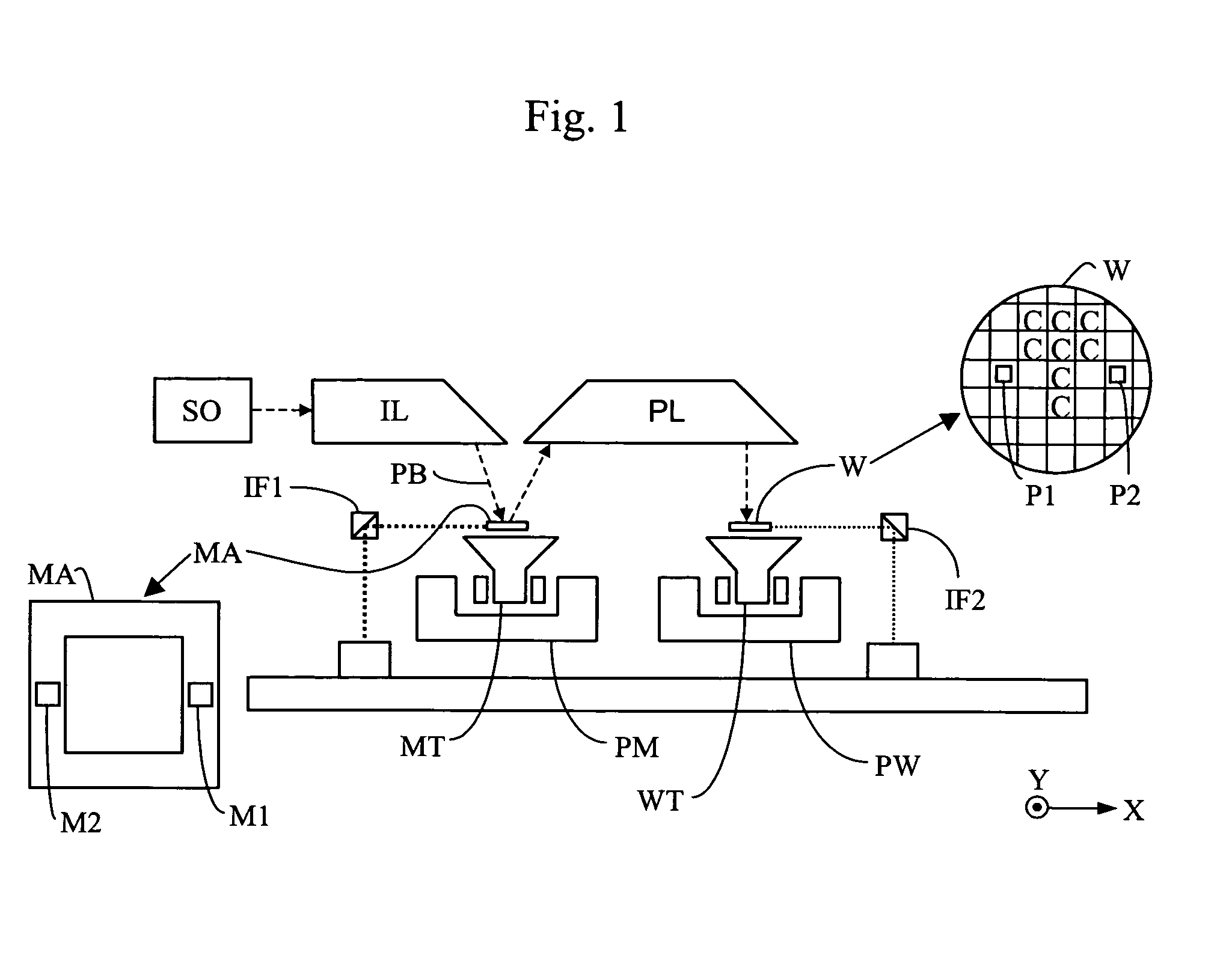

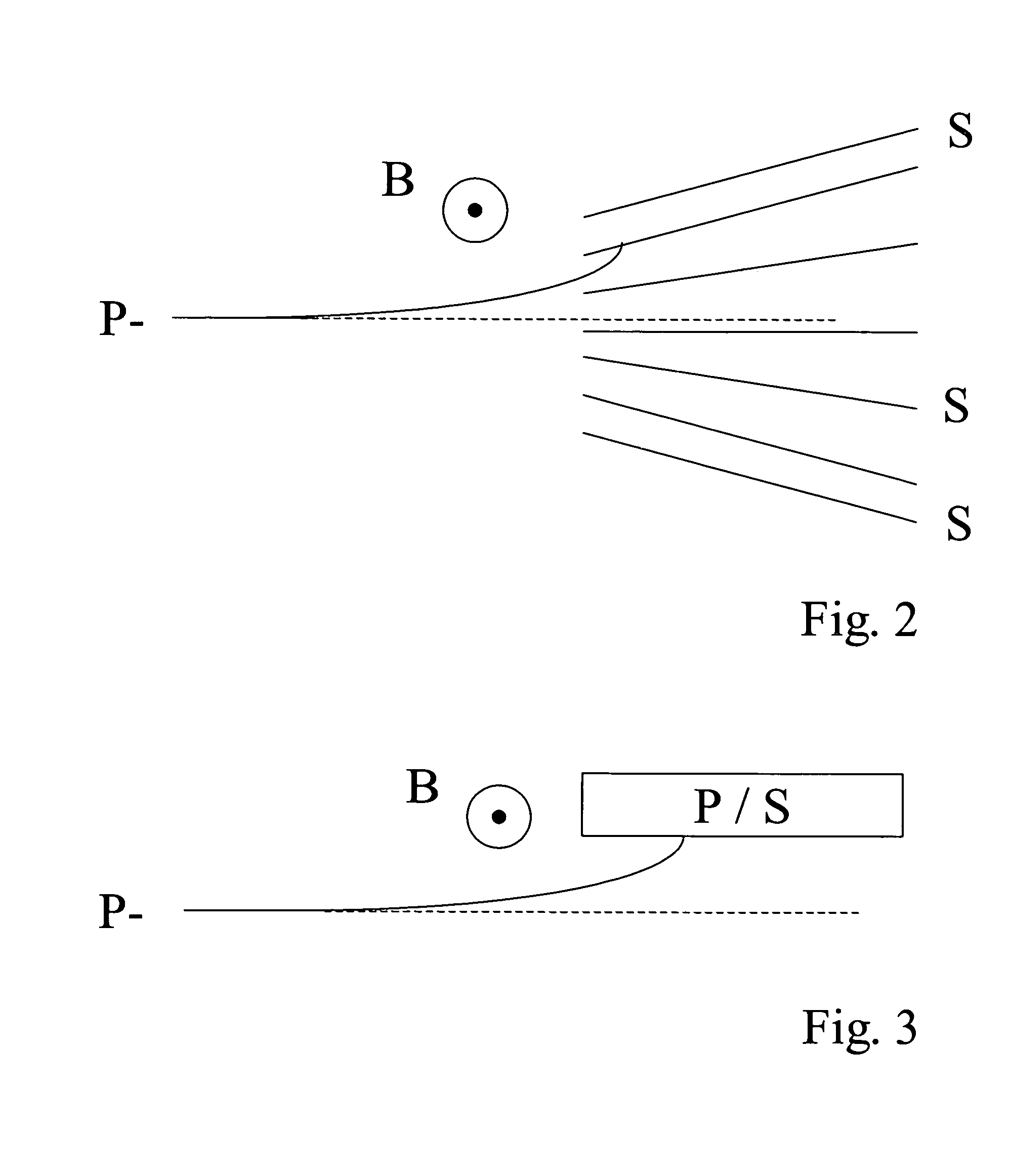

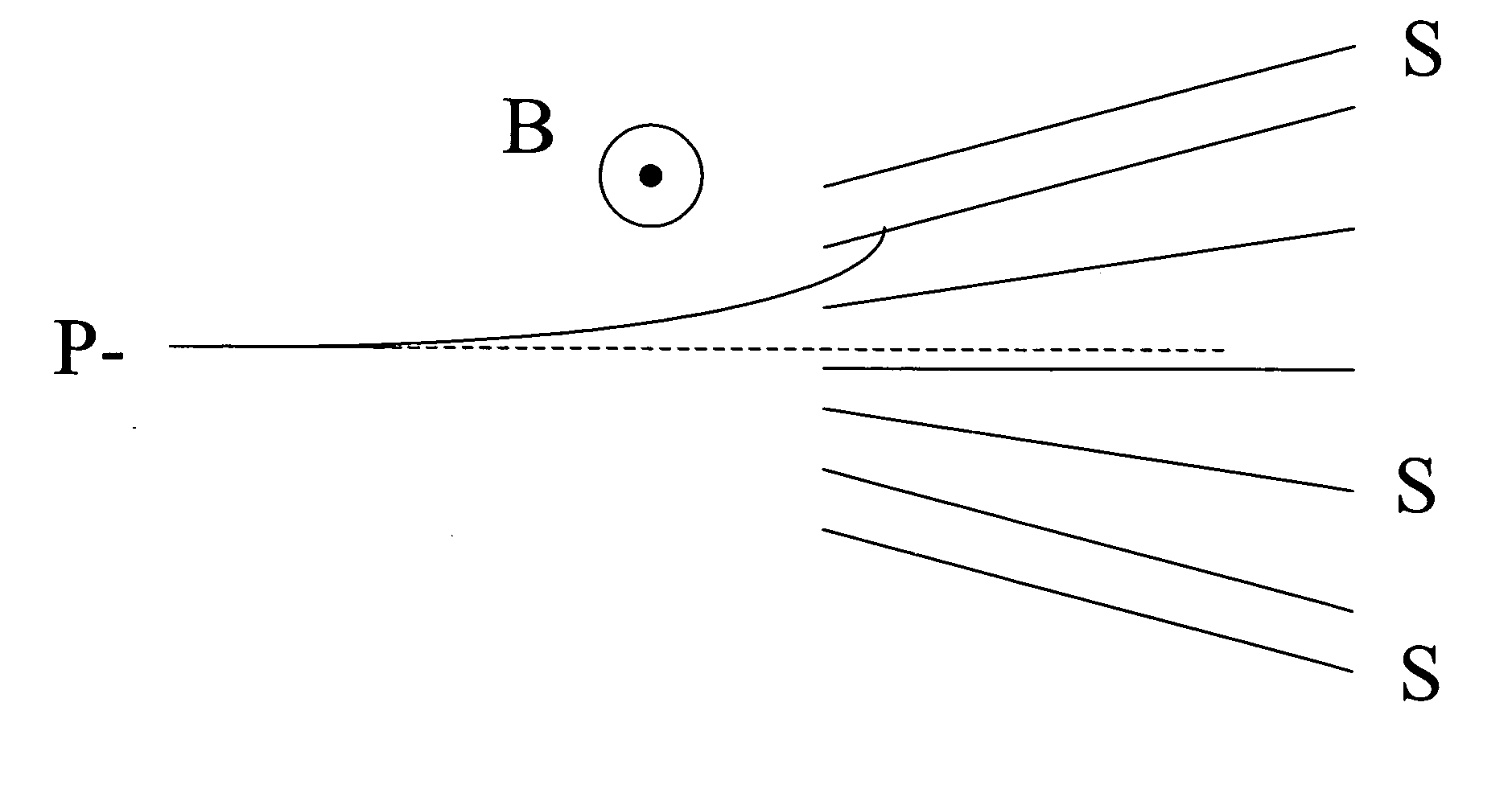

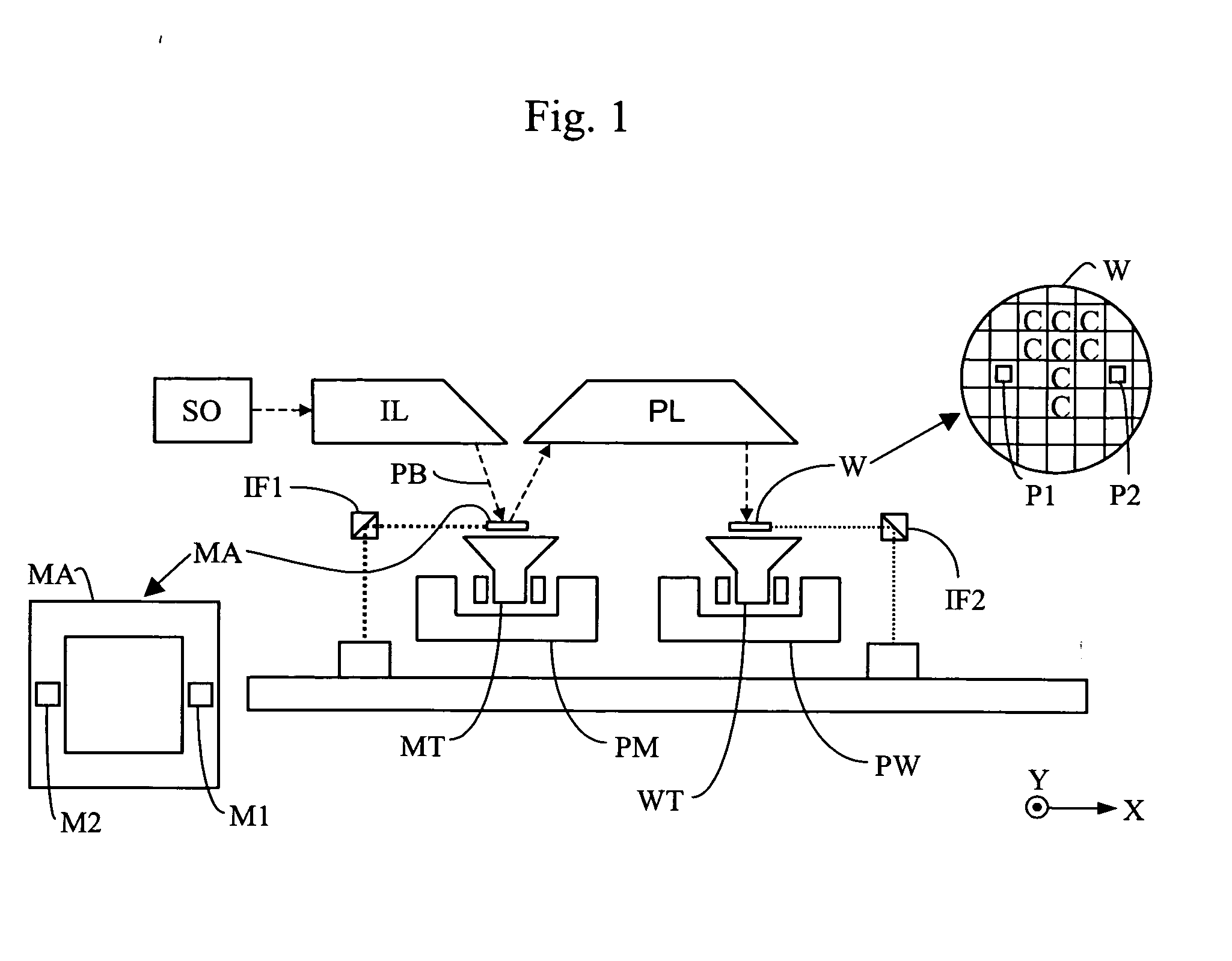

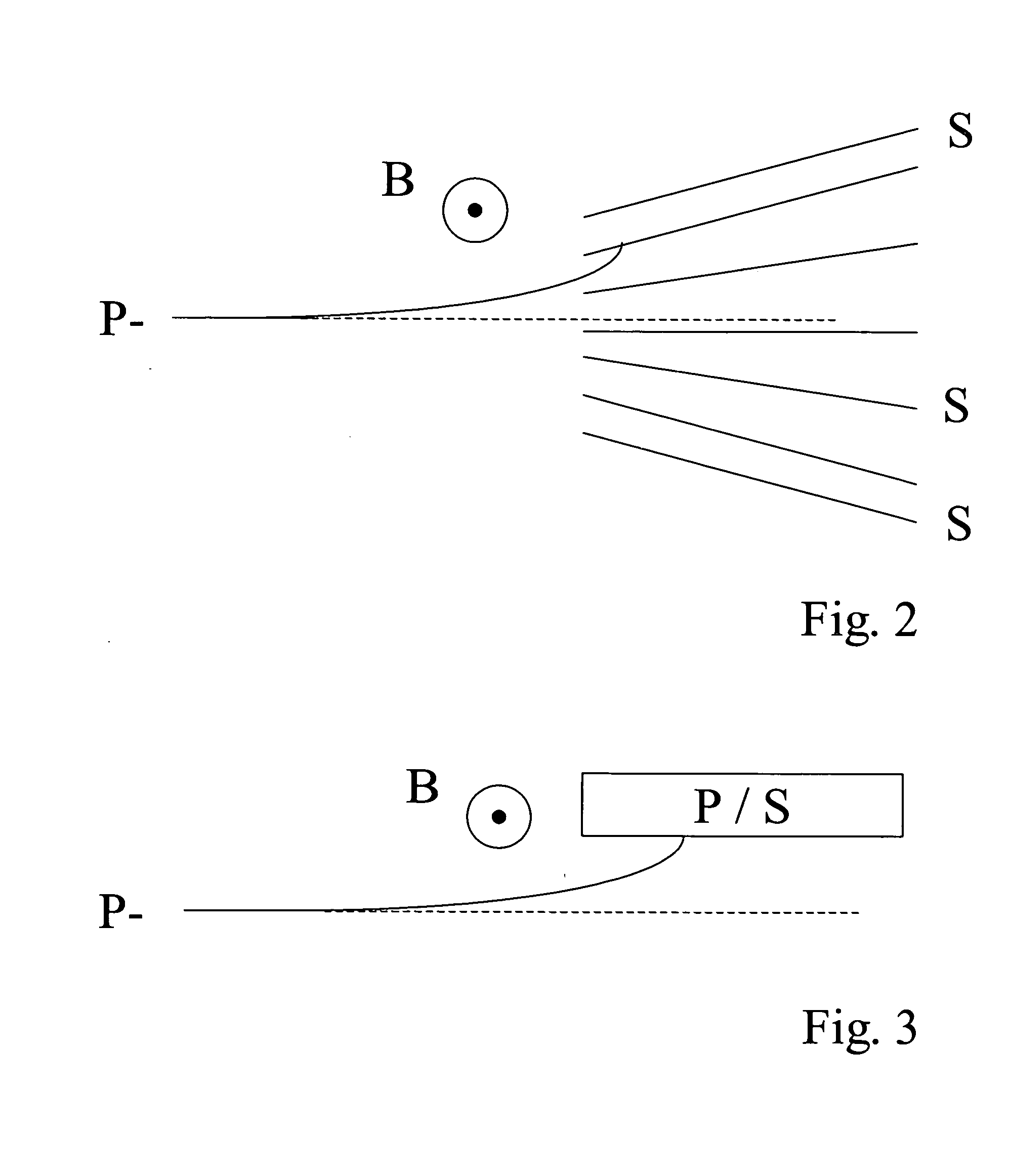

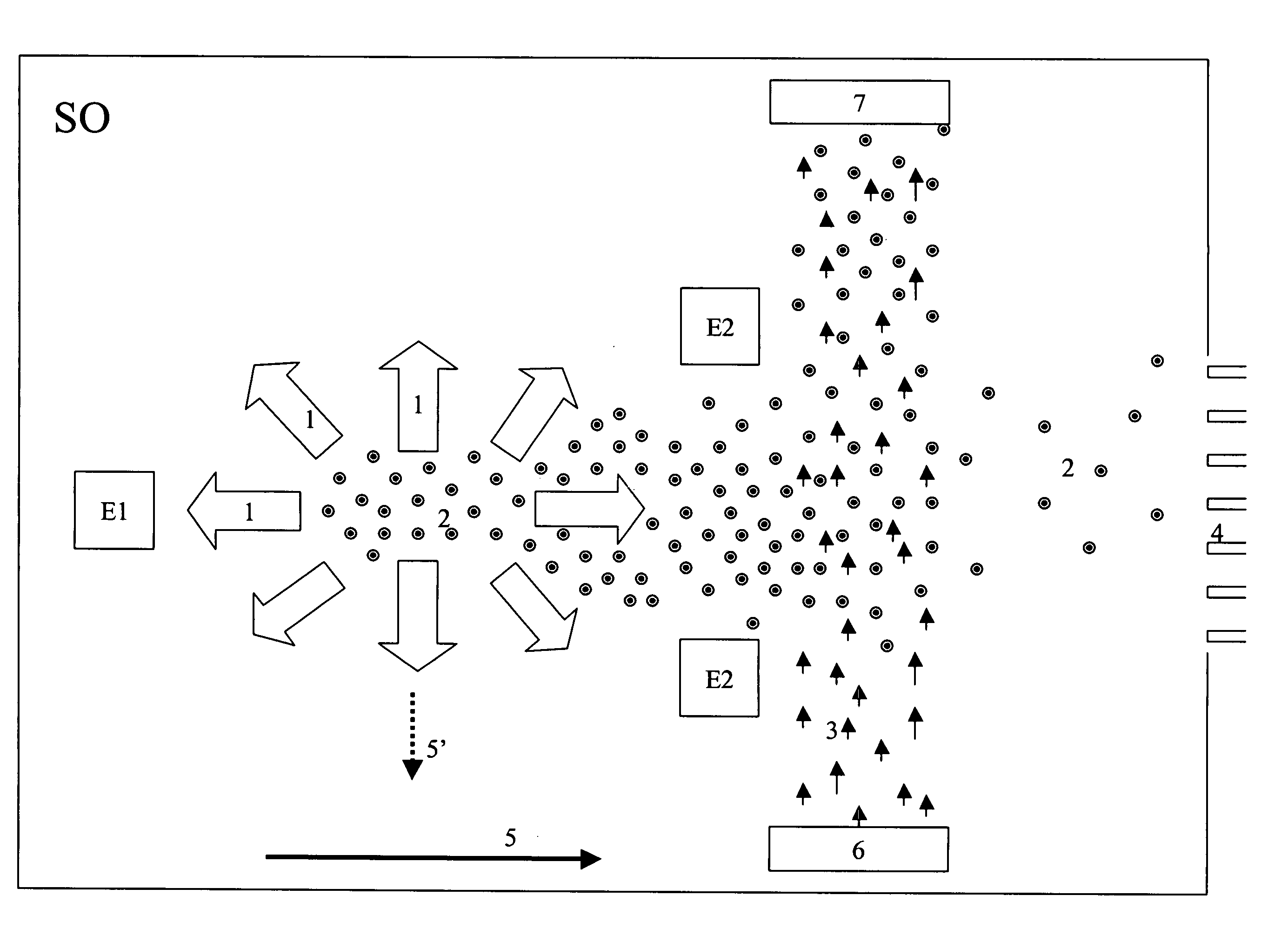

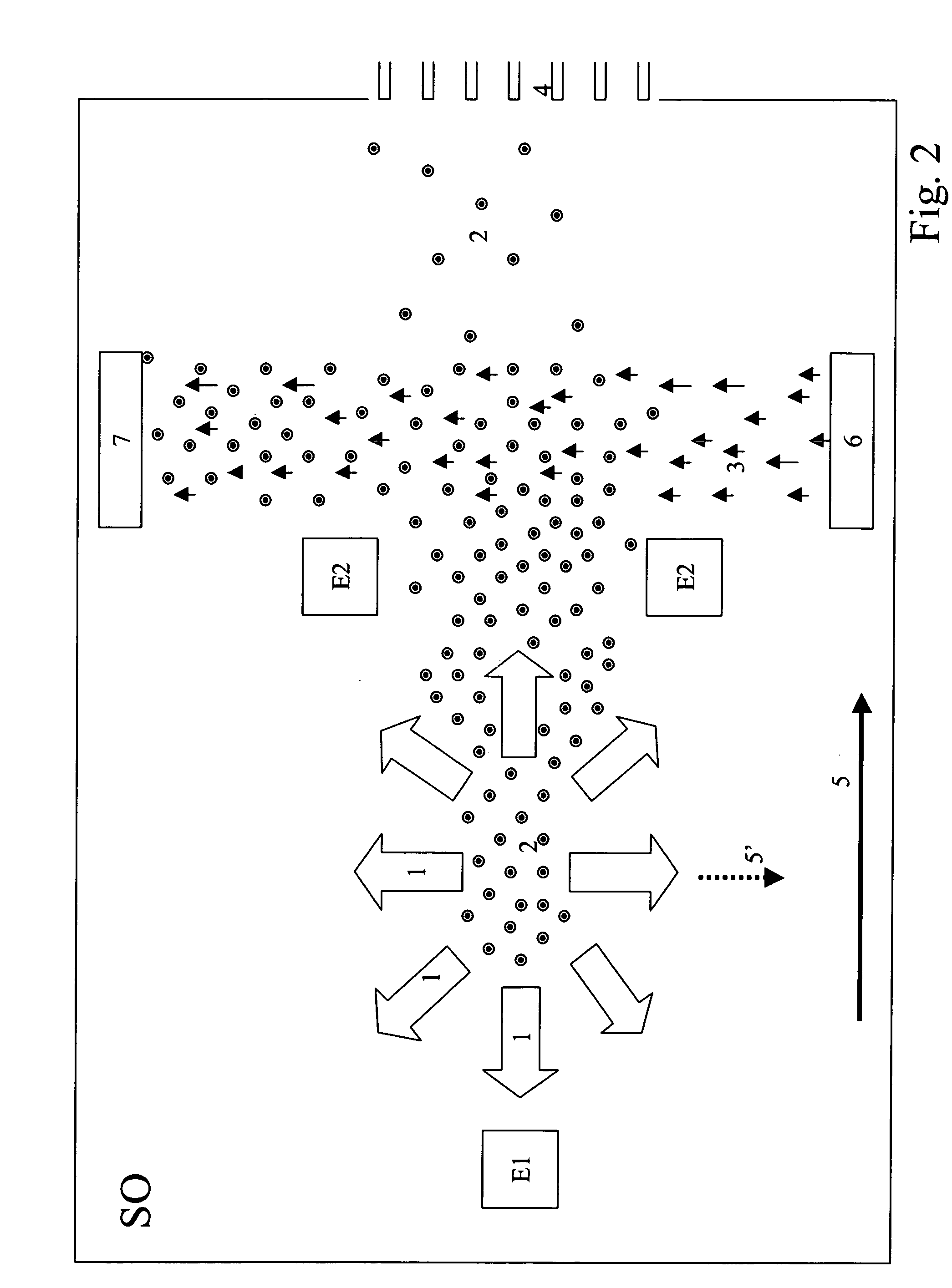

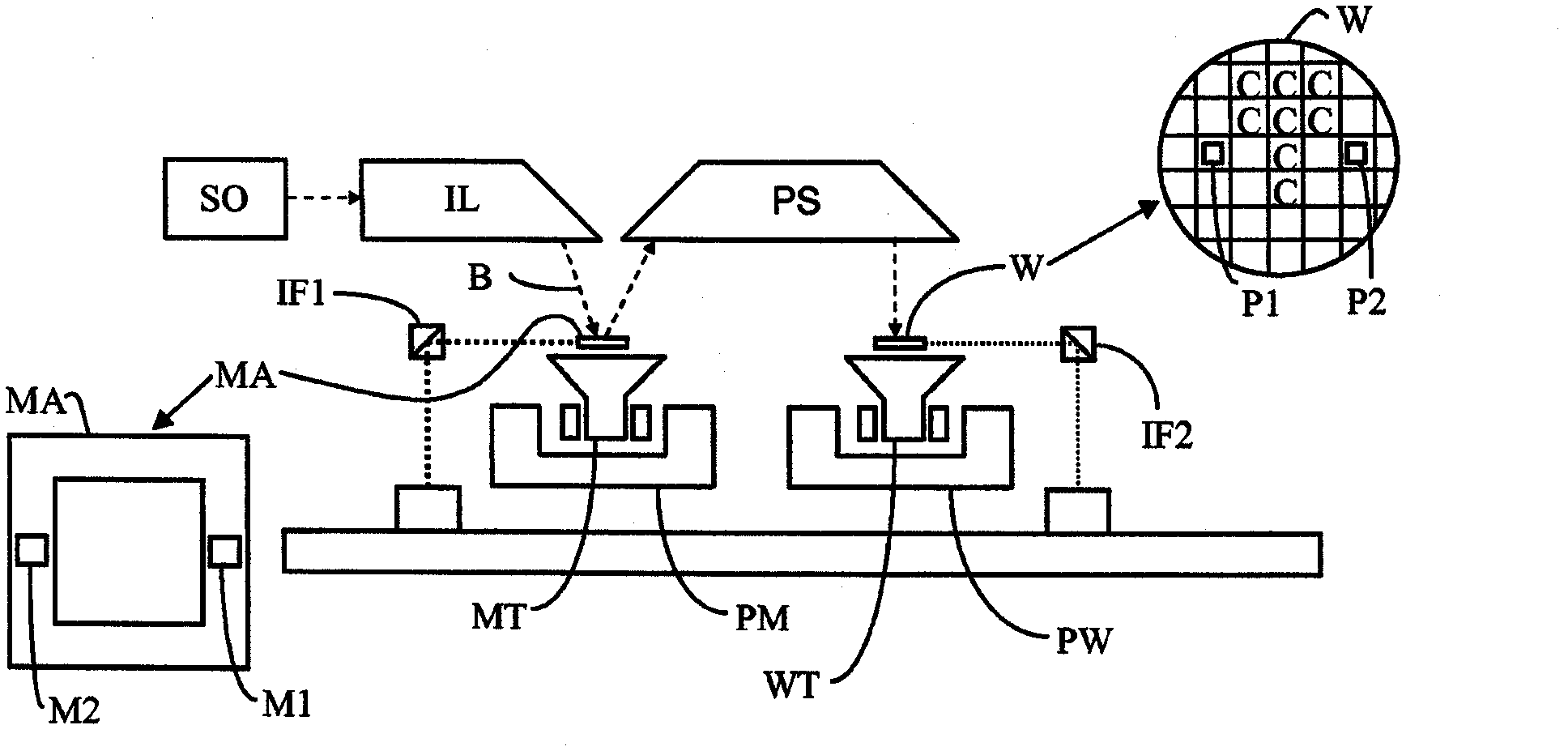

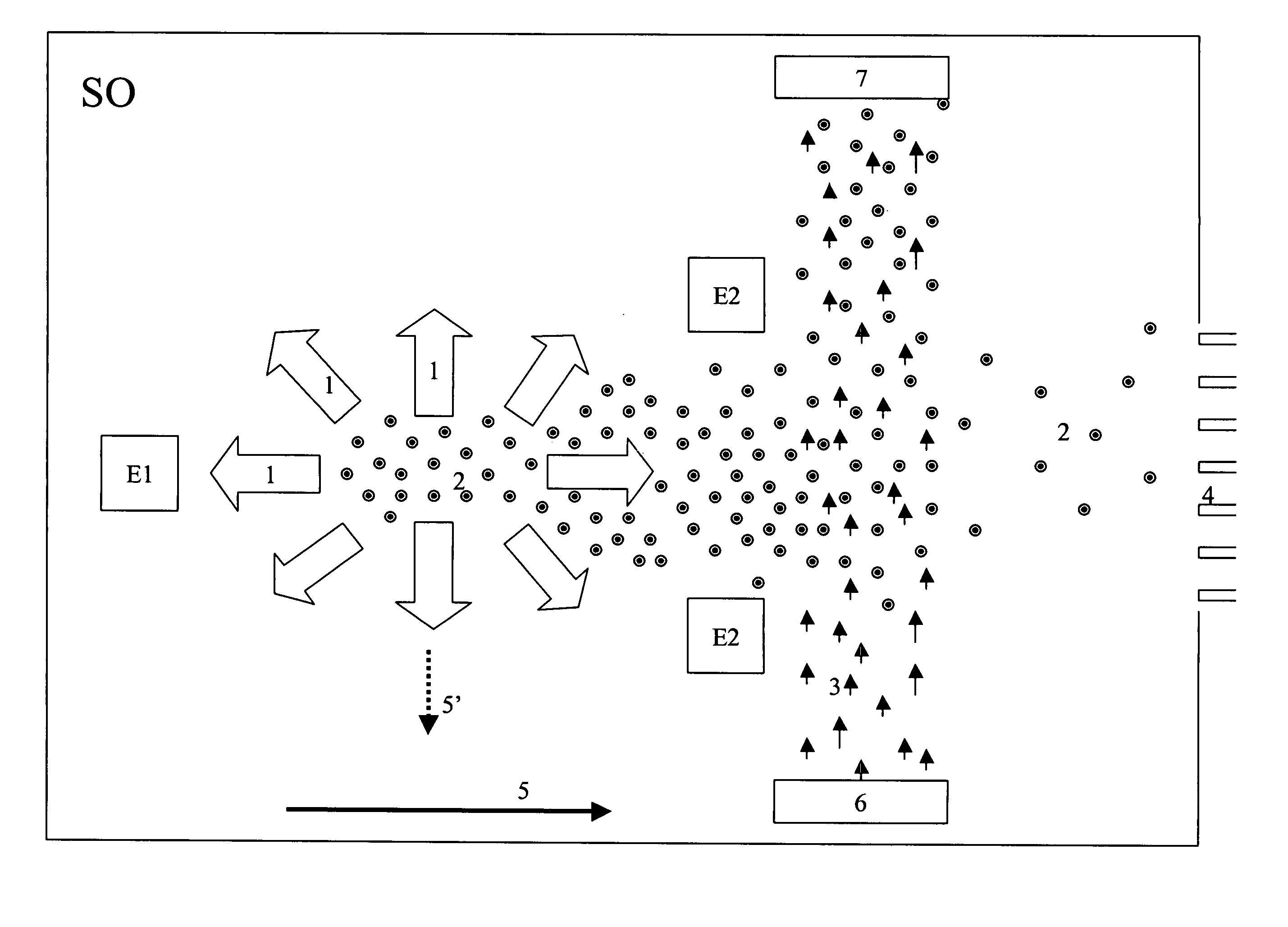

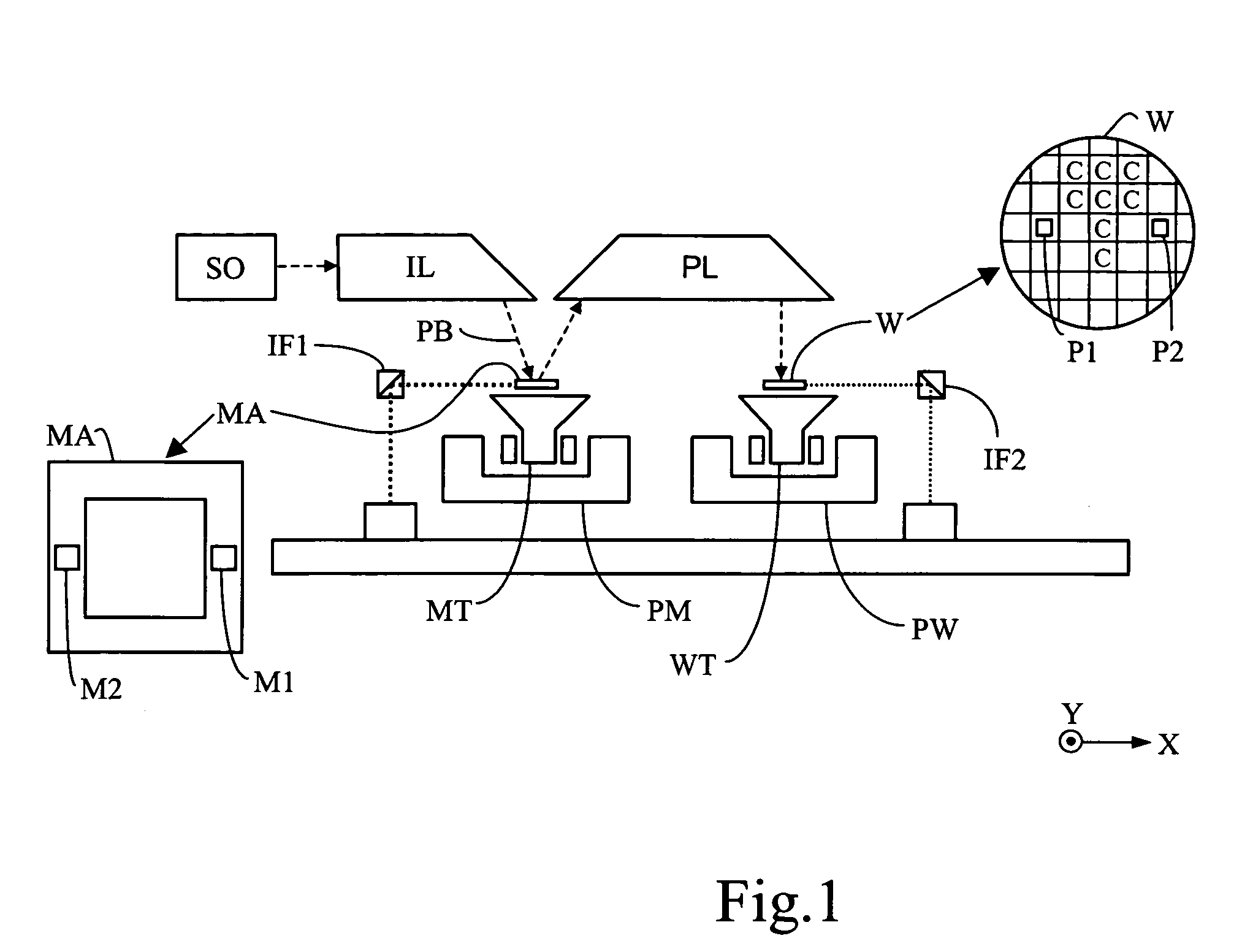

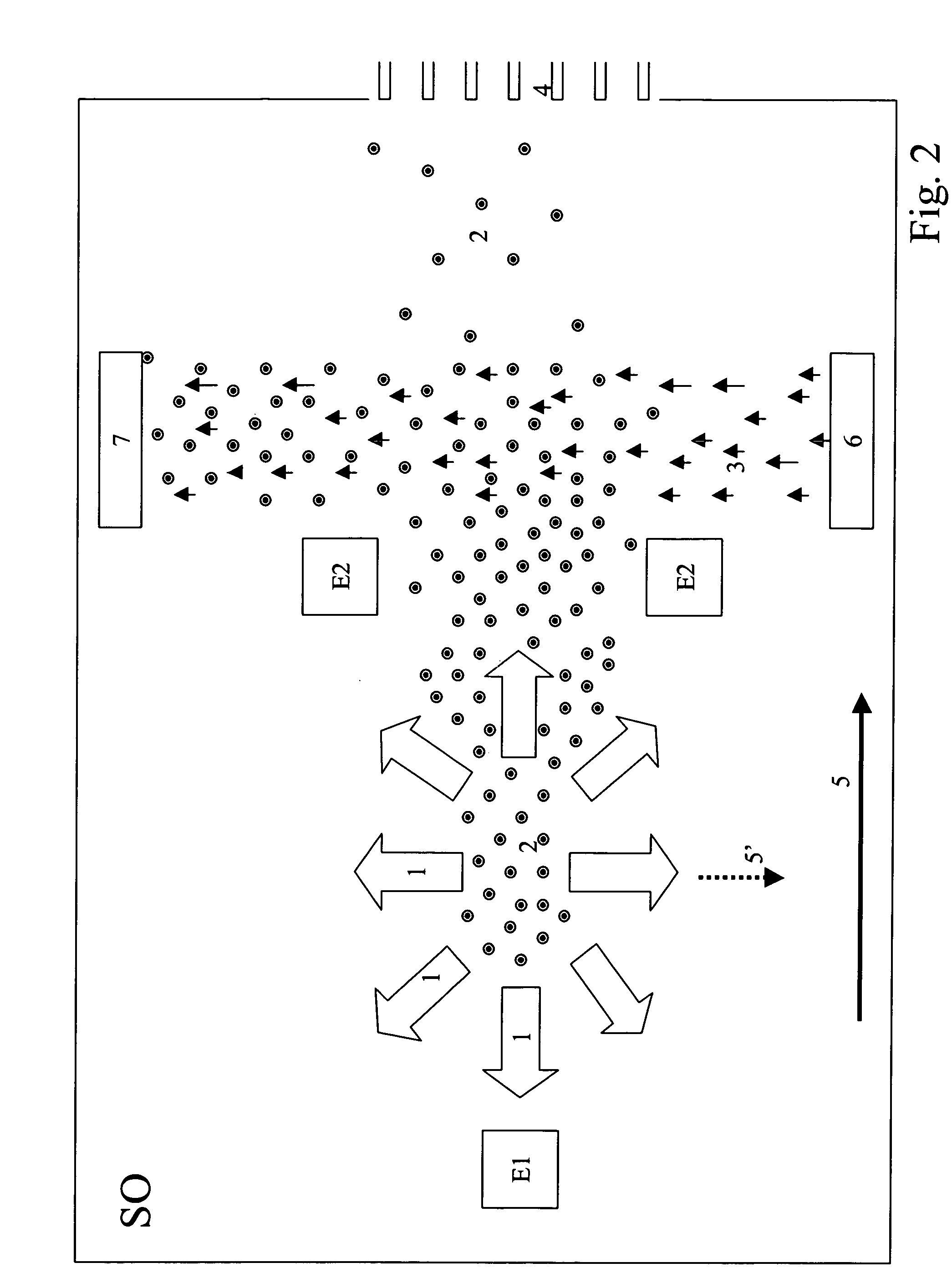

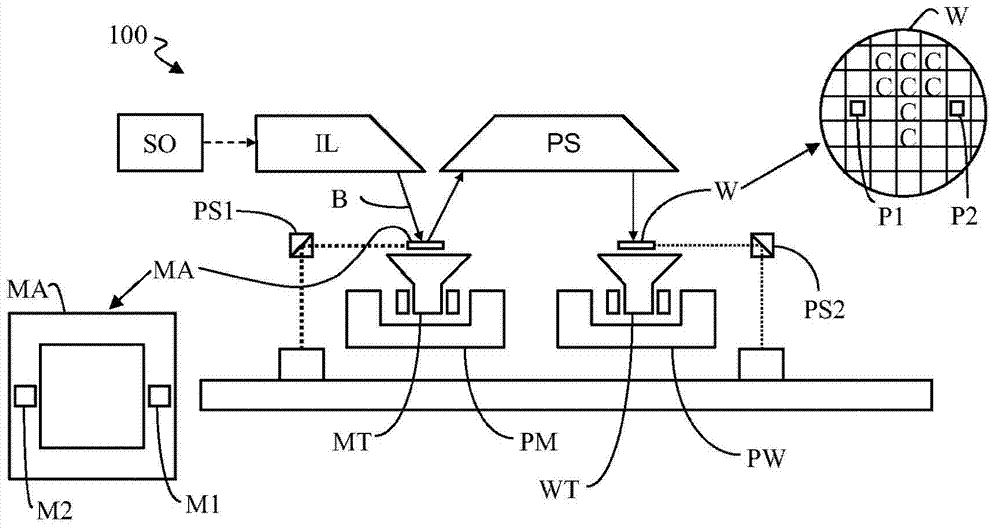

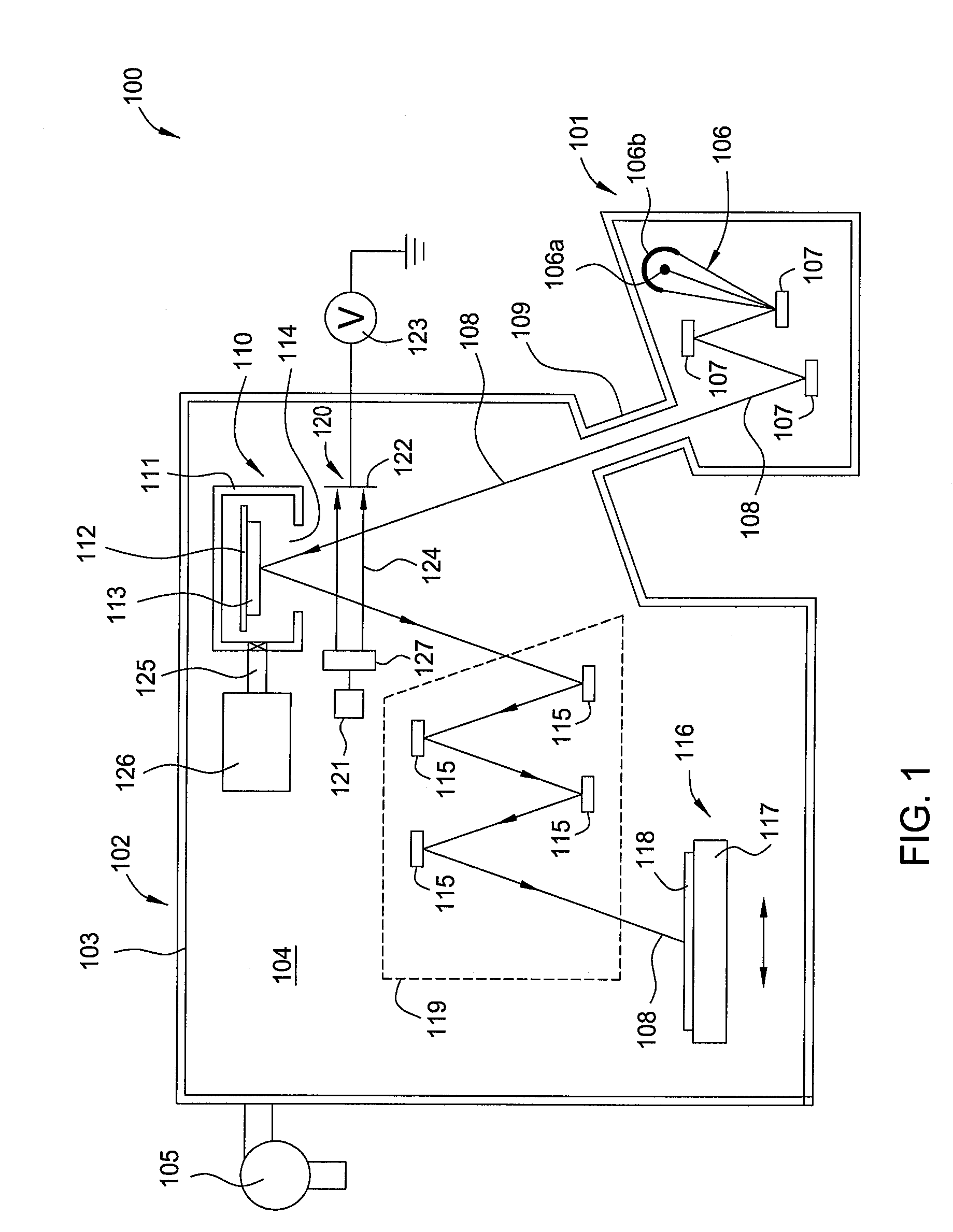

Lithographic apparatus having a debris-mitigation system, a source for producing EUV radiation having a debris mitigation system and a method for mitigating debris

A lithographic apparatus is disclosed. The apparatus includes an illumination system that provides a beam of radiation, and a support structure that supports a patterning structure. The patterning structure is configured to impart the beam of radiation with a pattern in its cross-section. The apparatus also includes a substrate support that supports a substrate, a projection system that projects the patterned beam onto a target portion of the substrate, and a debris-mitigation system that mitigates debris particles which are formed during use of at least a part of the lithographic apparatus. The debris-mitigation system is arranged to apply a magnetic field so that at least charged debris particles are mitigated.

Owner:ASML NETHERLANDS BV

Lithographic apparatus having a debris-mitigation system, a source for producing EUV radiation having a debris mitigation system and a method for mitigating debris

ActiveUS20050140945A1Harm reductionEffective redirectingInvestigating moving sheetsPhotomechanical exposure apparatusLight beamParticle physics

A lithographic apparatus is disclosed. The apparatus includes an illumination system that provides a beam of radiation, and a support structure that supports a patterning structure. The patterning structure is configured to impart the beam of radiation with a pattern in its cross-section. The apparatus also includes a substrate support that supports a substrate, a projection system that projects the patterned beam onto a target portion of the substrate, and a debris-mitigation system that mitigates debris particles which are formed during use of at least a part of the lithographic apparatus. The debris-mitigation system is arranged to apply a magnetic field so that at least charged debris particles are mitigated.

Owner:ASML NETHERLANDS BV

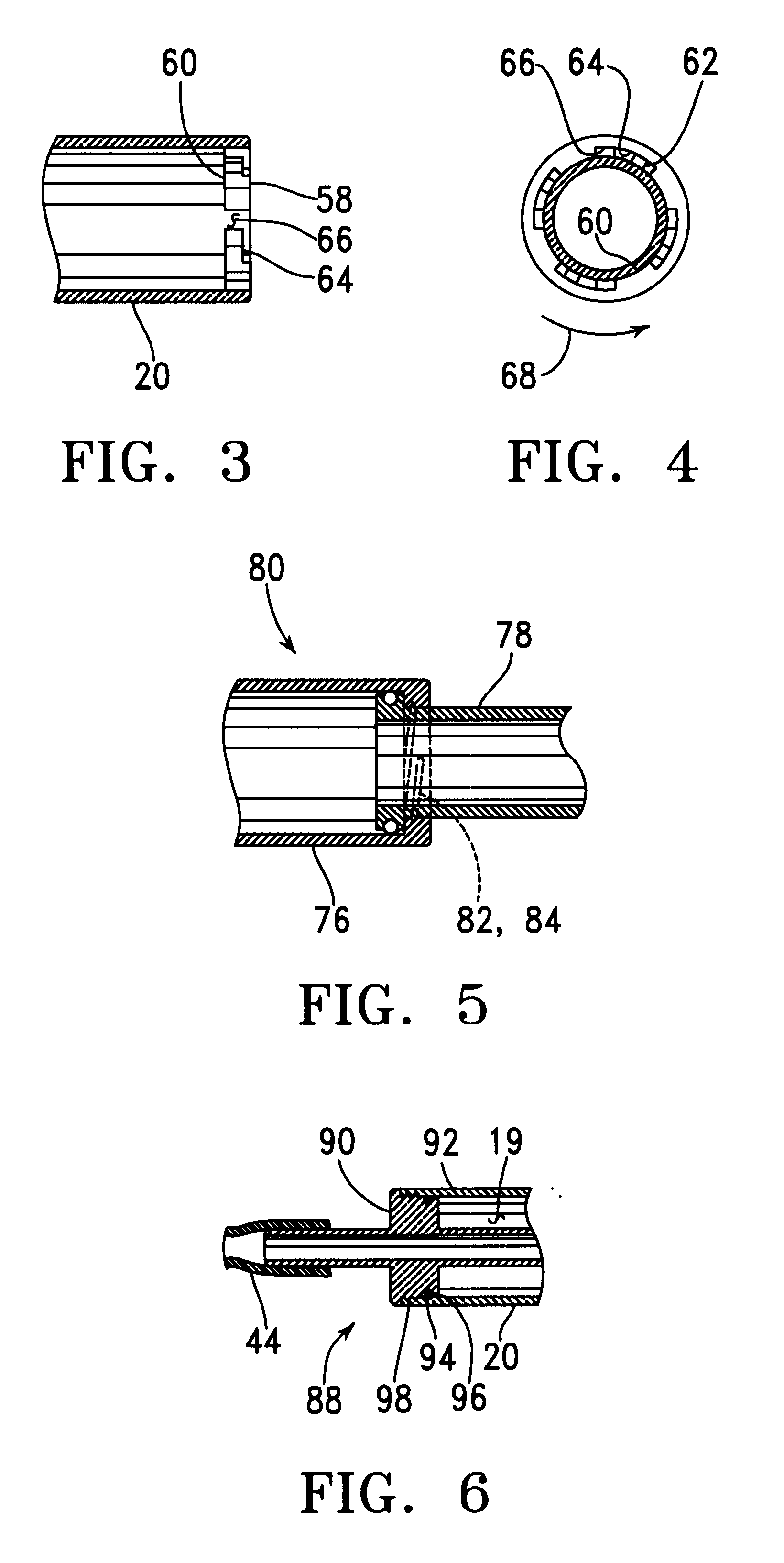

Surgical suction probe system with an easily cleaned internal filter

A suction probe system for cleaning debris from a surgical site includes a probe tip, a cylindrical filter with inner and outer chambers in fluid communication with the probe tip, and a suction source in fluid communication with the filter unit. In a first version, the inner chamber is attached to the suction source, and an outer surface of the filter accumulates debris particles, which are removed by a cleaning cylinder sliding along the outer surface of the filter as a distal portion of the probe system is slid along a proximal portion thereof. In a second version, the outer chamber is attached to the suction source, and a inner surface of the filter accumulates debris particles, which are removed by rotation of a paddle within the filter as the distal portion of the probe system is rotated on the proximal portion thereof.

Owner:MEDECON

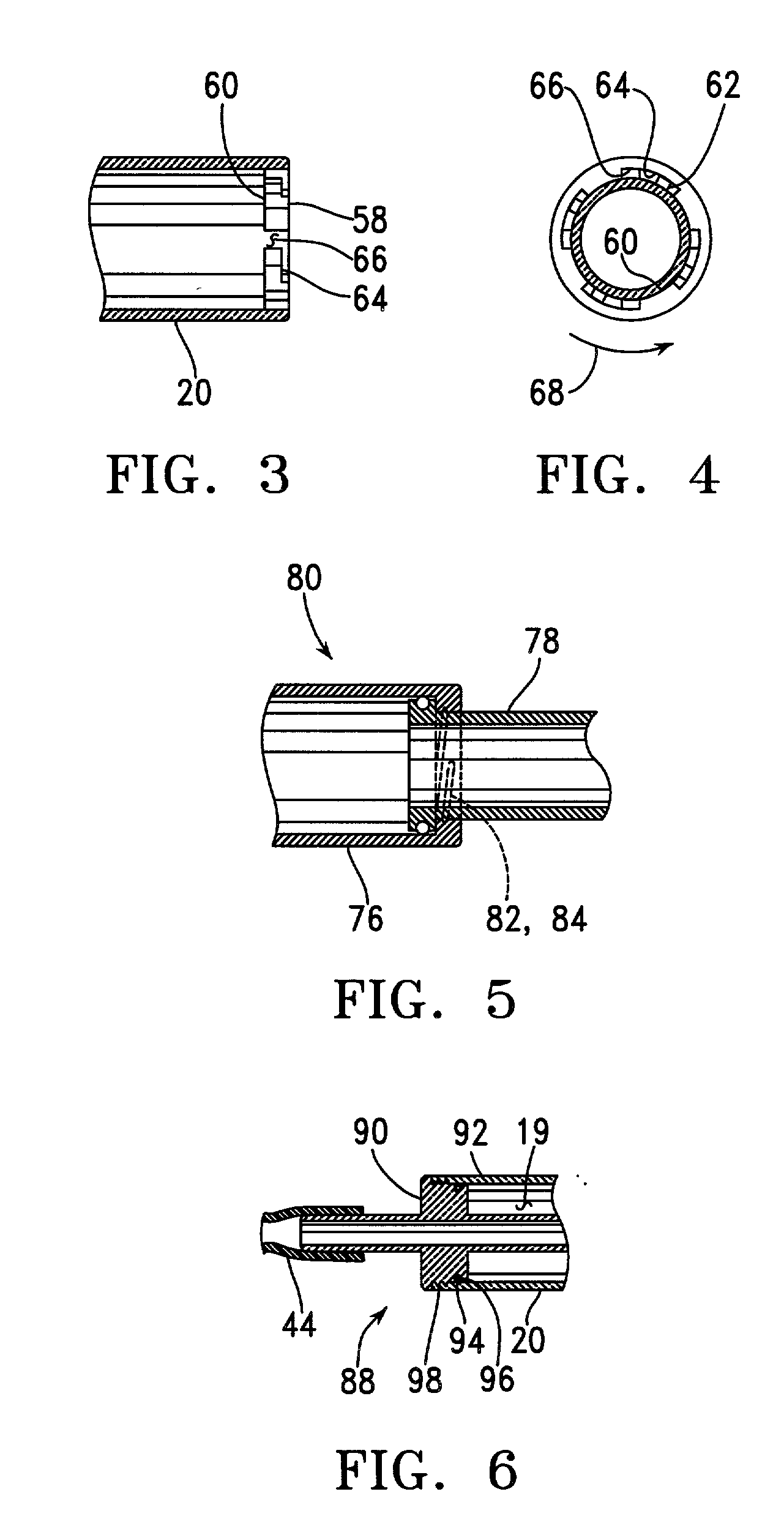

Lithographic apparatus and radiation source comprising a debris-mitigation system and method for mitigating debris particles in a lithographic apparatus

InactiveUS20050139785A1Raise the possibilityEffectively mitigatedRadiation pyrometryPhotomechanical exposure apparatusLight beamParticle physics

A lithographic apparatus is disclosed. The lithographic apparatus includes a radiation source that produces EUV radiation, an illumination system that provides a beam of the EUV radiation produced by the radiation source, and a support structure that supports a patterning structure. The patterning structure is configured to impart the beam of radiation with a pattern in its cross-section. The apparatus also includes a substrate support that supports a substrate, and a projection system that projects the patterned beam onto a target portion of the substrate. The radiation source includes a debris-mitigation system that mitigates debris particles which are formed during production of EUV radiation. The debris-mitigation system is configured to provide additional particles for interacting with the debris particles.

Owner:ASML NETHERLANDS BV

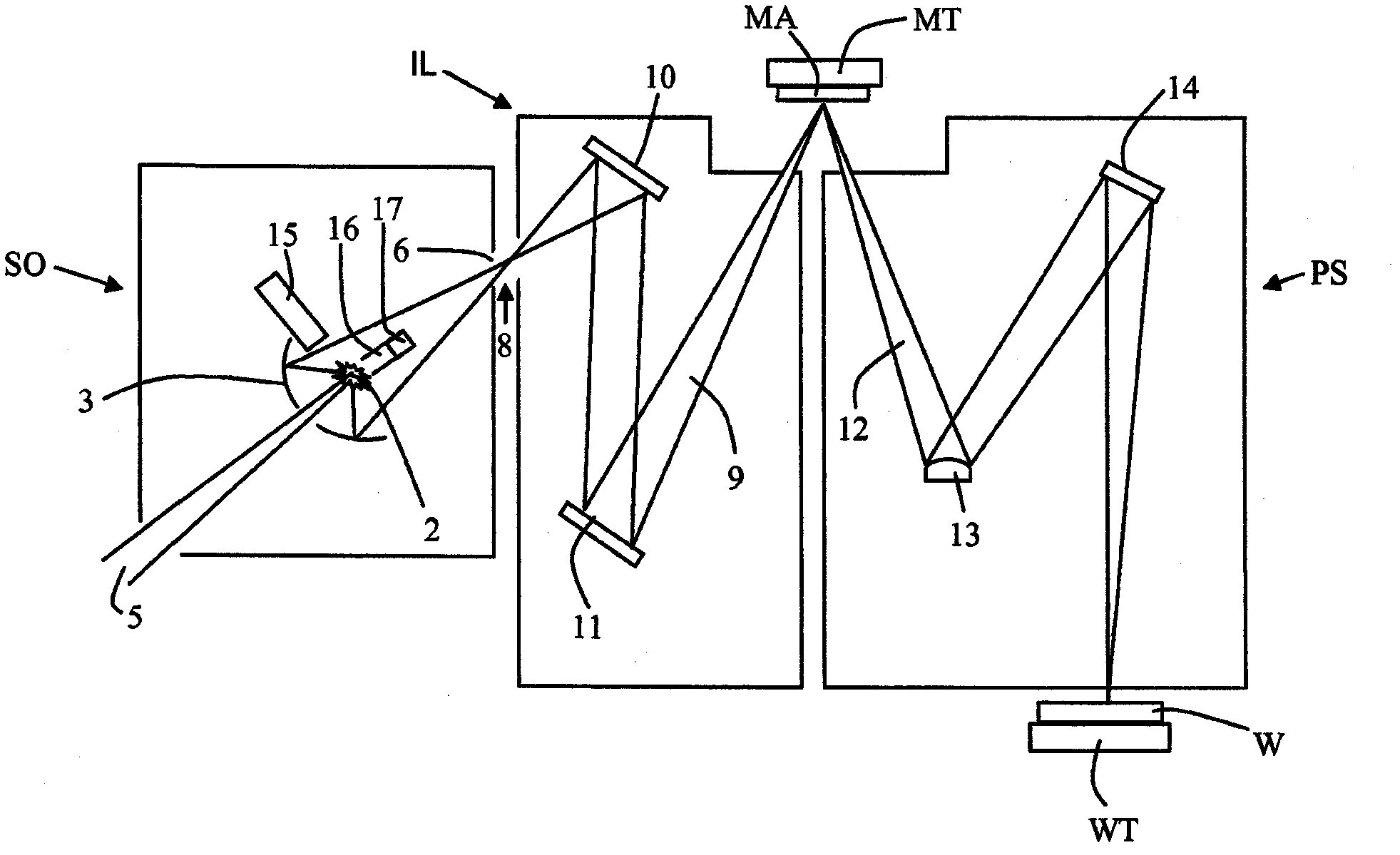

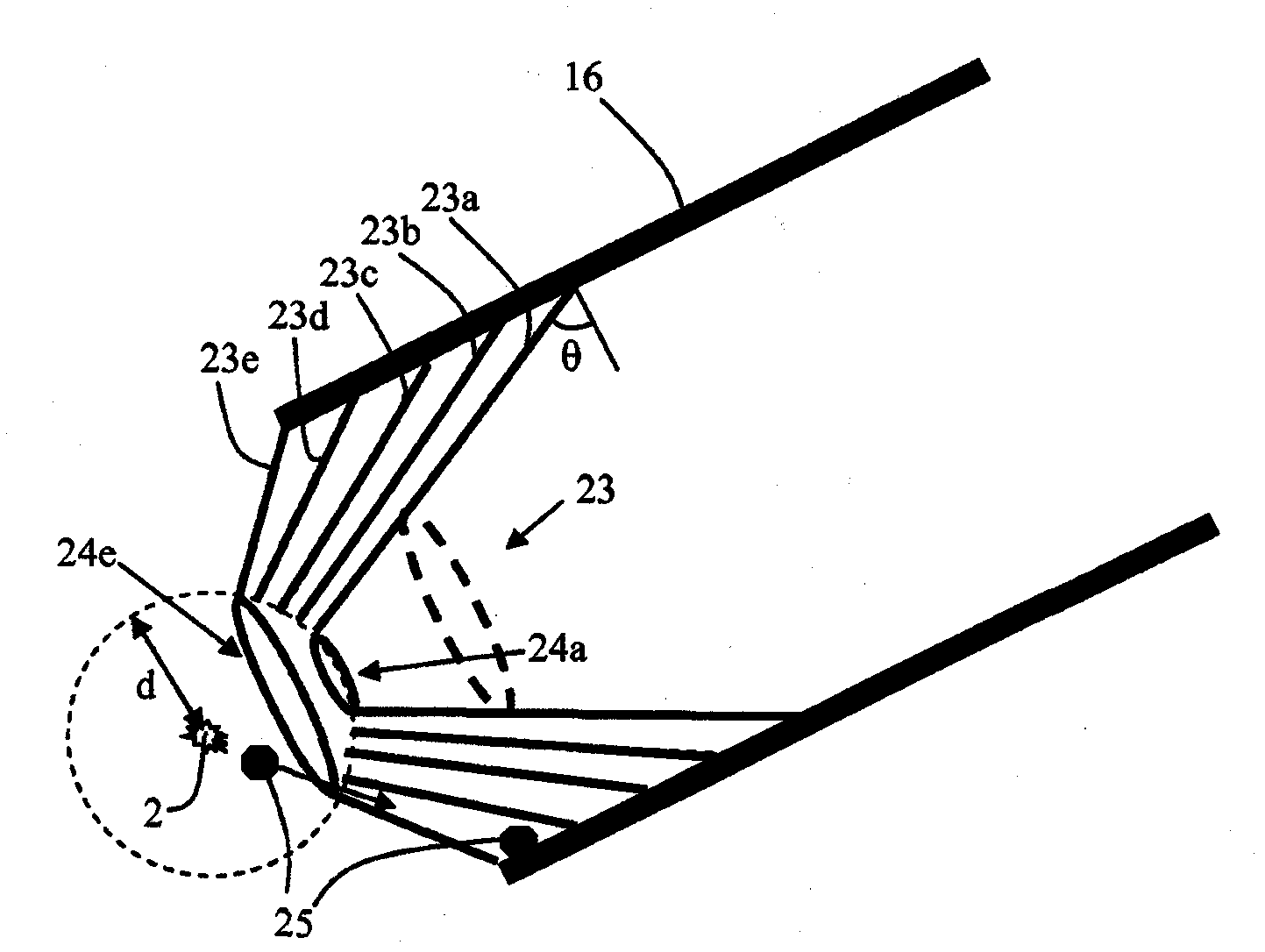

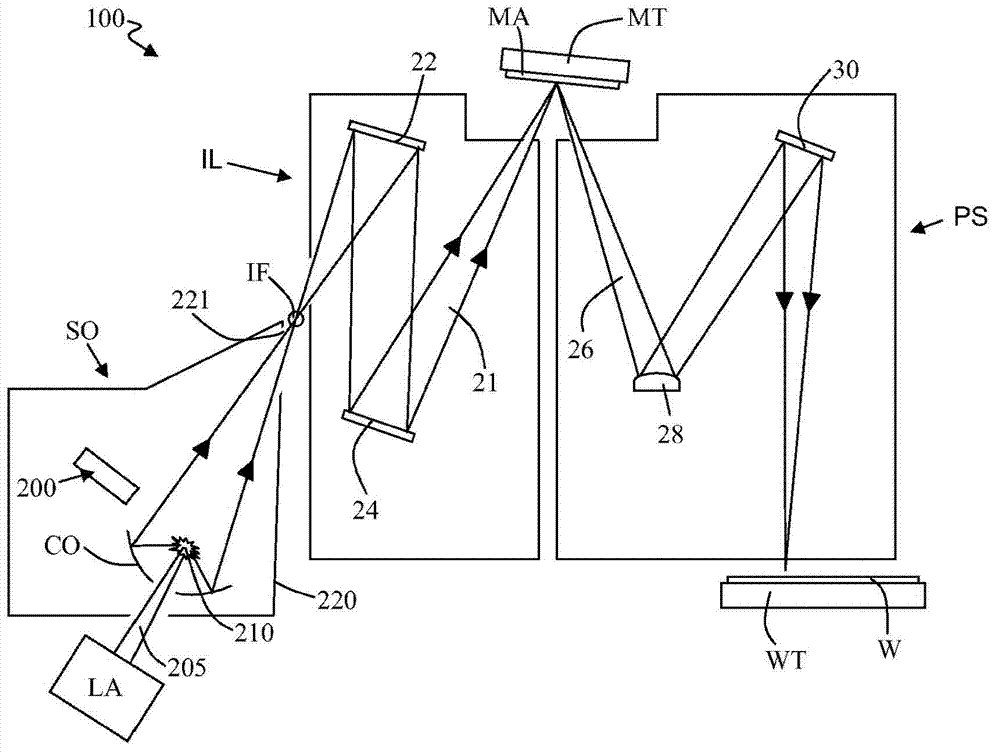

Radiation source and lithographic apparatus

ActiveCN102144191AReduce scatterReduce sputteringSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusUltraviolet radiationExtreme ultraviolet

A radiation source (SO) is configured to generate extreme ultraviolet radiation. The radiation source (SO) includes a plasma formation site (2) located at a position in which a fuel will be contacted by a beam of radiation (5) to form a plasma, an outlet (16) configured to allow gas to exit the radiation source (SO), and a contamination trap (23) at least partially- located inside the outlet (16). The contamination trap is configured to trap (23) debris particles that are generated with the formation of the plasma.

Owner:ASML NETHERLANDS BV

Lithographic apparatus and radiation source comprising a debris-mitigation system and method for mitigating debris particles in a lithographic apparatus

InactiveUS7167232B2Reduce adverse effectsPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamParticle physics

A lithographic apparatus is disclosed. The lithographic apparatus includes a radiation source that produces EUV radiation, an illumination system that provides a beam of the EUV radiation produced by the radiation source, and a support structure that supports a patterning structure. The patterning structure is configured to impart the beam of radiation with a pattern in its cross-section. The apparatus also includes a substrate support that supports a substrate, and a projection system that projects the patterned beam onto a target portion of the substrate. The radiation source includes a debris-mitigation system that mitigates debris particles which are formed during production of EUV radiation. The debris-mitigation system is configured to provide additional particles for interacting with the debris particles.

Owner:ASML NETHERLANDS BV

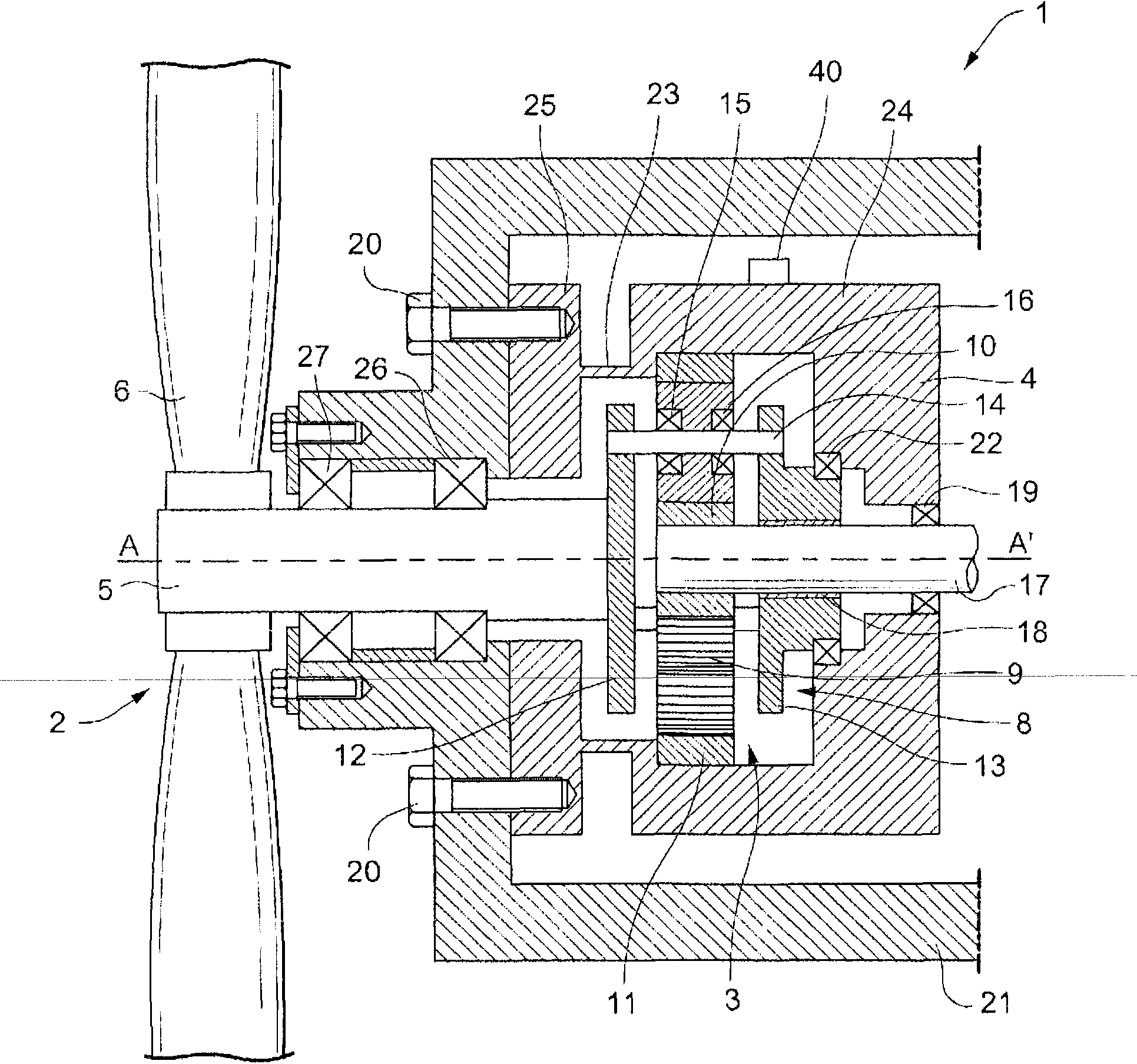

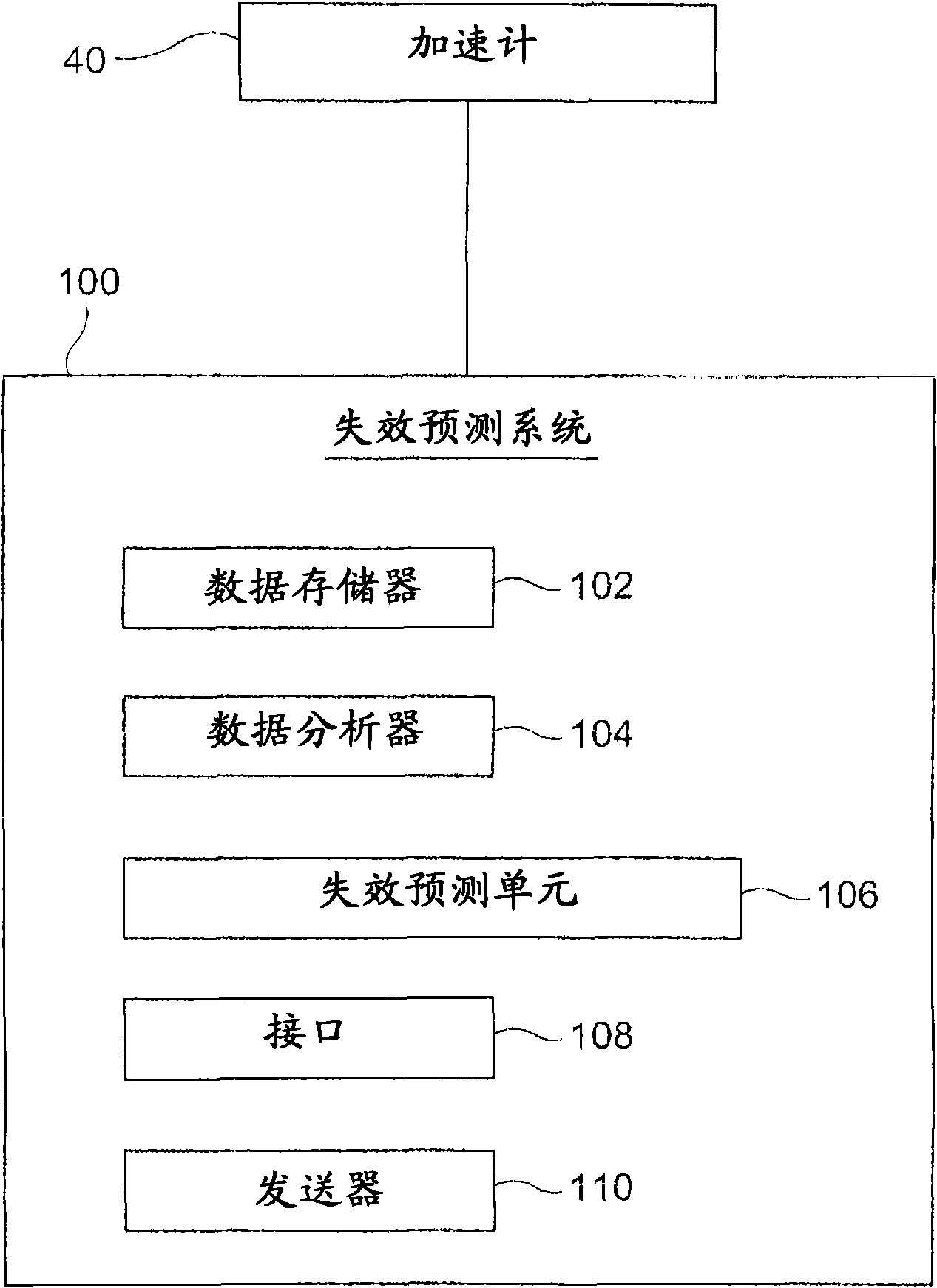

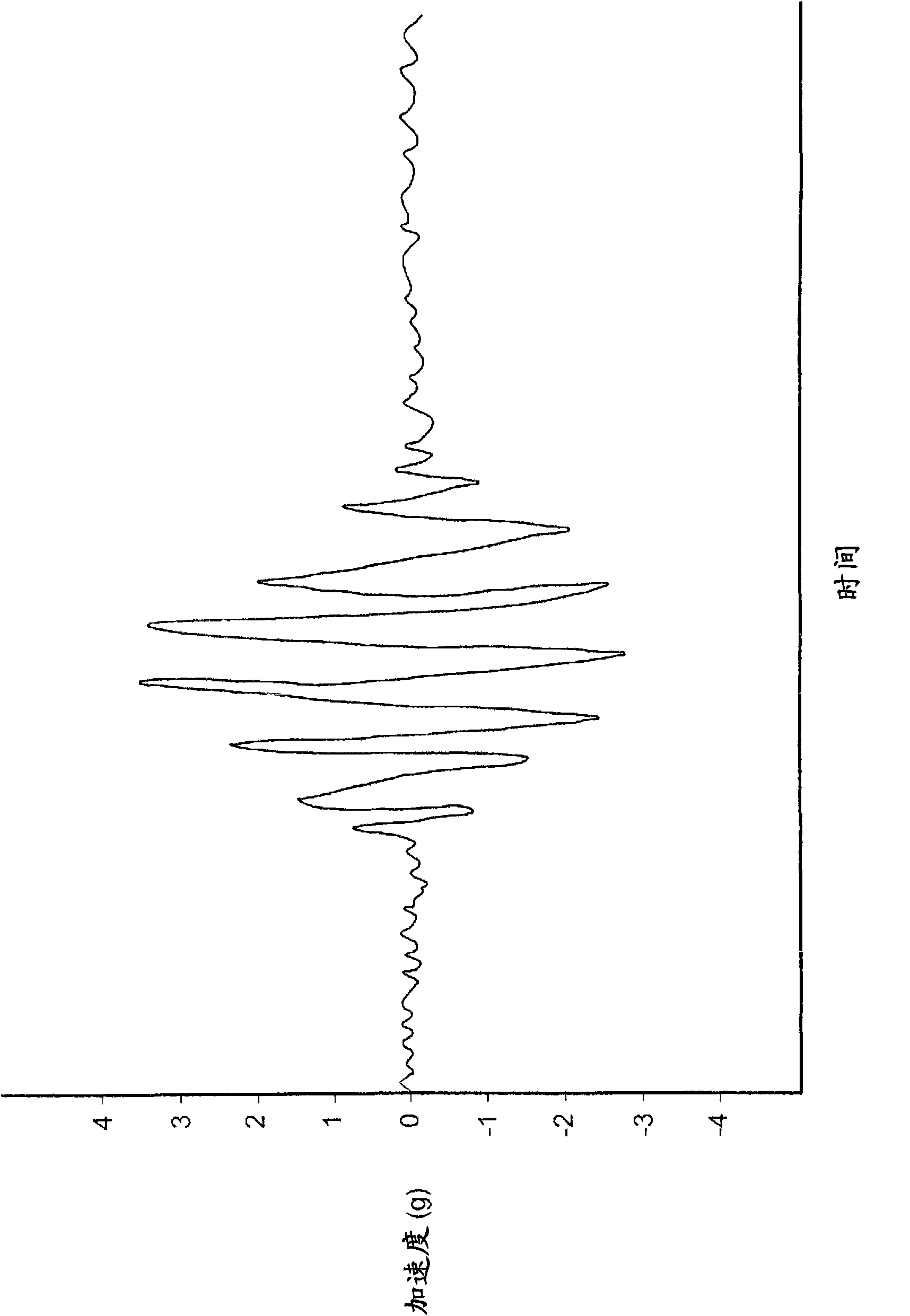

System and method for monitoring the condition of a gear assembly

InactiveCN101819090AVibration measurement in solidsMachine gearing/transmission testingEngineeringDebris particle

A system and method for monitoring the condition of a gear assembly analyzes a signal output by a vibration detector that is attached to the gear assembly. Each time that an amplitude of the signal output from the vibration detector exceeds a threshold value, the system assumes that a debris particle has passed between meshing parts of the gear assembly. The number of times that this occurs, and possibly the amplitude of the vibrations are analyzed to determine a condition of the gear assembly, and possibly a damage index. This system and method are particularly applicable to planetary gear arrangements where the vibration detector can be mounted on a fixed ring gear of the gear assembly, or a structure upon which the fixed ring gear is mounted.

Owner:GENERAL ELECTRIC CO

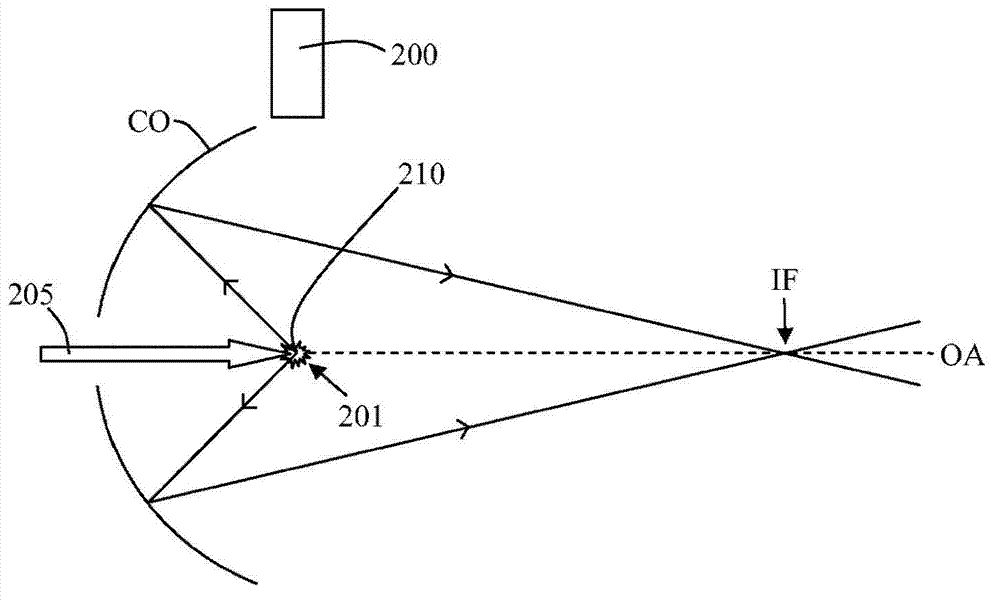

EUV radiation source and EUV radiation generation method

InactiveCN102823330APhotomechanical exposure apparatusX-ray tube with very high currentVaporizationDebris particle

An EUV radiation source comprises a fuel supply (200) configured to deliver a droplet of fuel to a plasma generation location (201), a first laser beam source configured to provide a first beam of laser radiation (205) incident upon the fuel droplet at the plasma generation location and thereby vaporizes the fuel droplet, and a second laser beam source configured to subsequently provide a second beam of laser radiation (205) at the plasma generation location, the second beam of laser radiation being configured to vaporize debris particles (252) arising from incomplete vaporization of the fuel droplet.

Owner:ASML NETHERLANDS BV

Pressure relief valve with debris trap

InactiveUS20060185737A1Easy to captureHigh retention rateCheck valvesEqualizing valvesWorking fluidEngineering

A pressure relief valve for a pump includes a recess in its surface adjacent the high pressure side of the pump. The recess acts as a trap to capture and retain debris particles in the working fluid. By capturing and retaining the debris particles in the recess, jamming of the pressure relief valve in an open position can be avoided. Preferably, the upper edge of the recess includes a chamfered edge which enhances the likelihood of the debris particles entering the recess. Also preferably, the recess can be magnetized, or a magnetic member can be inserted into the recess, to enhance the capture and retention of magnetic debris particles in the recess.

Owner:MAGNA POWERTAIN

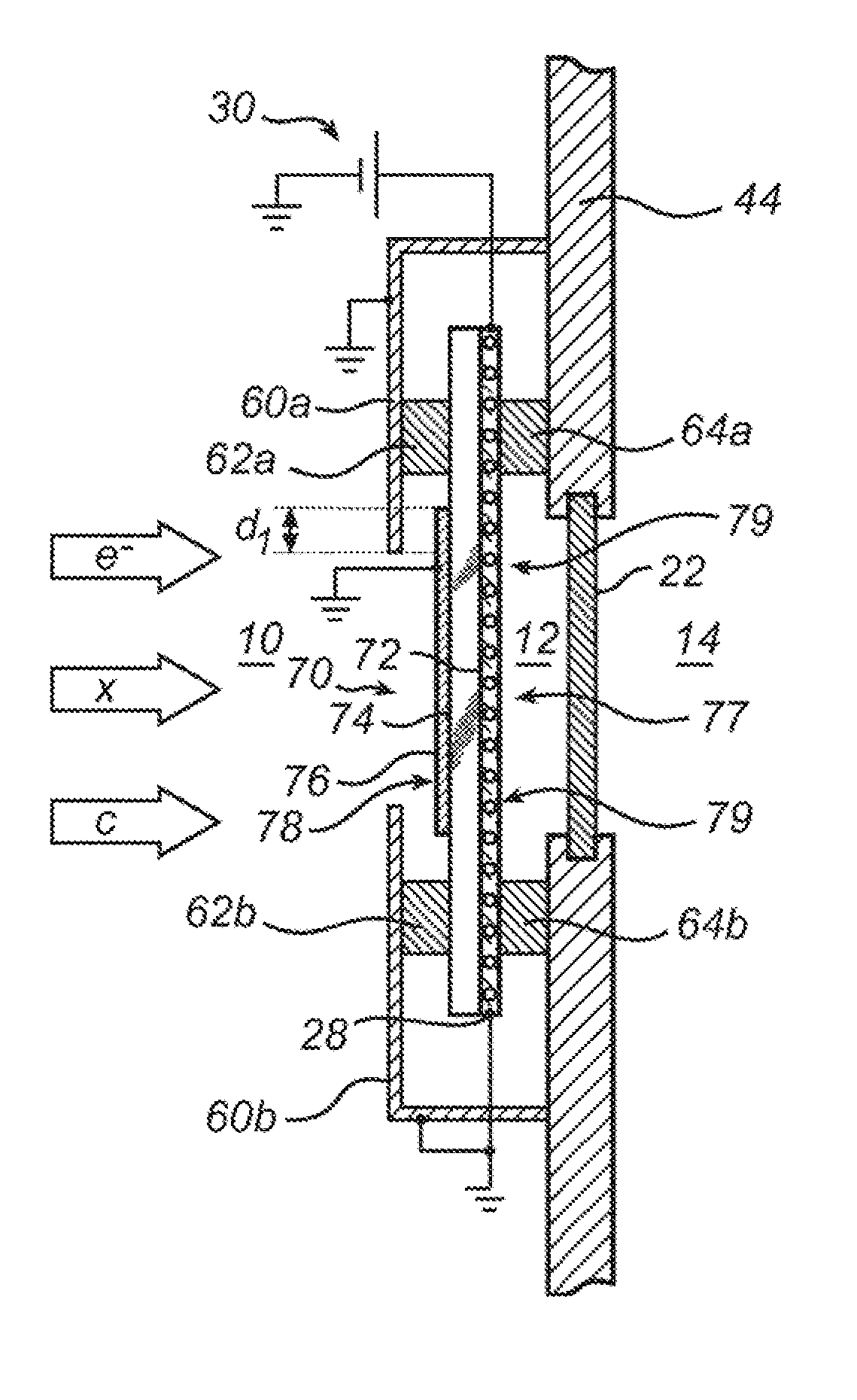

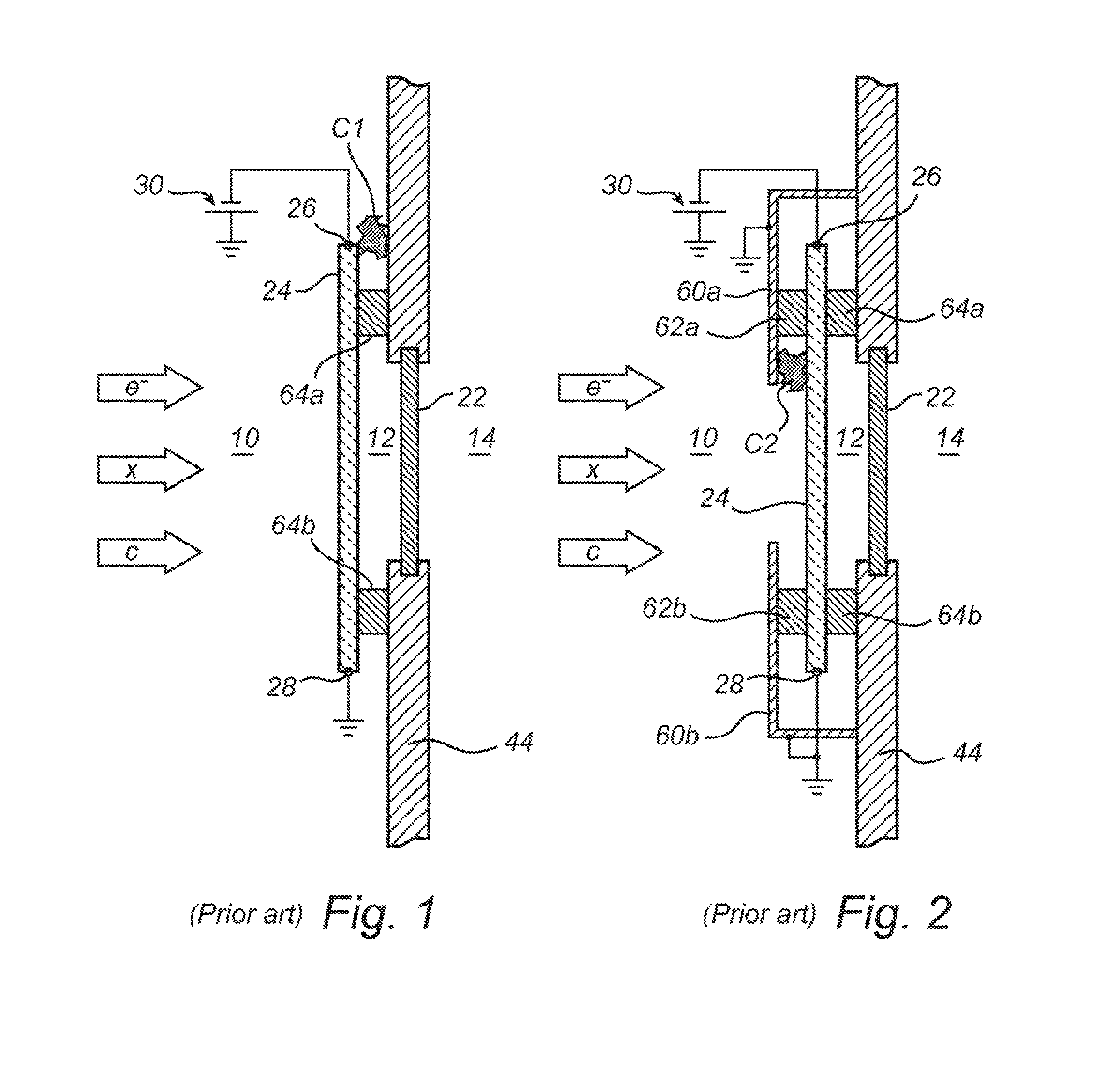

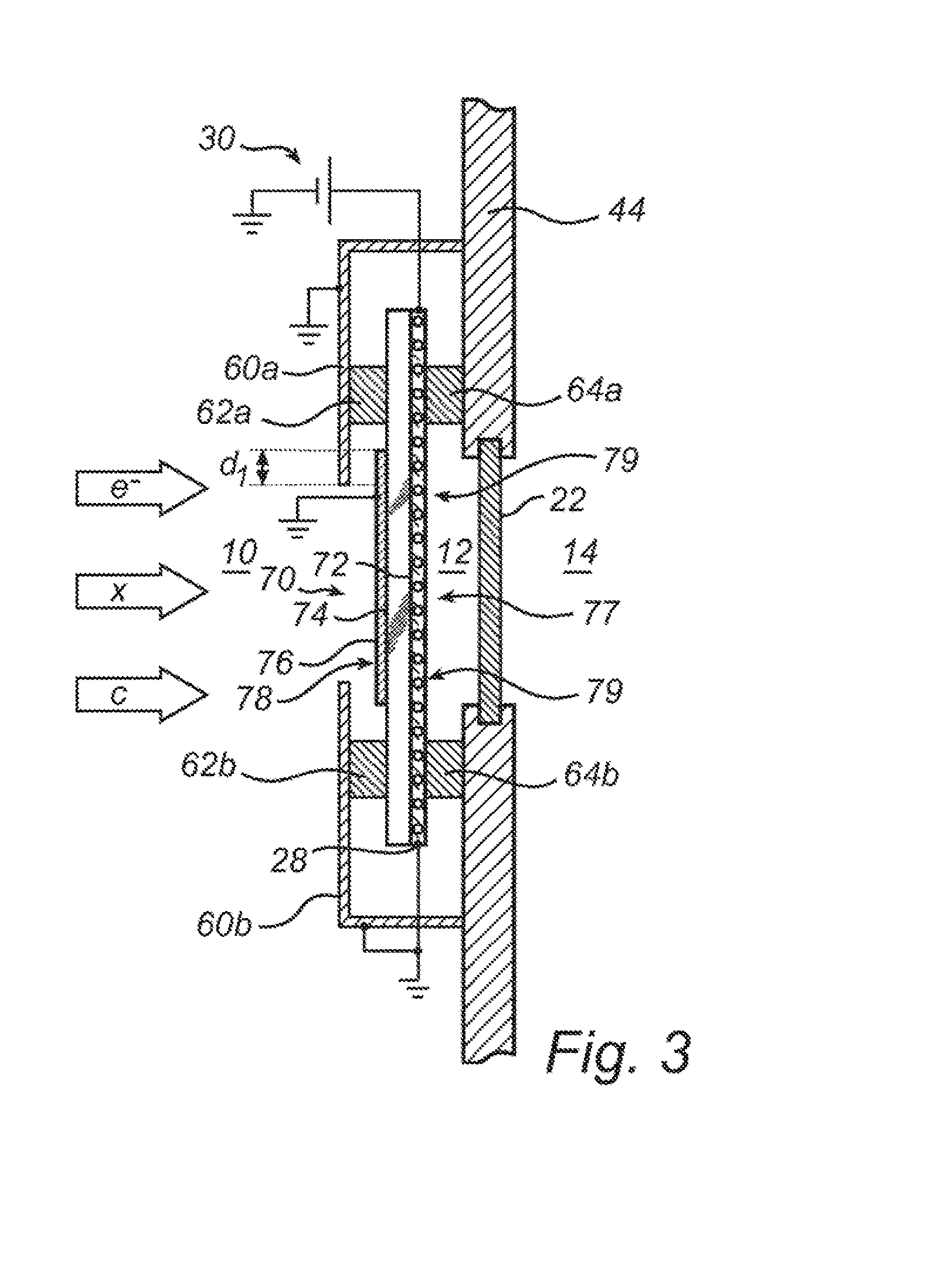

Coated x-ray window

ActiveUS20150146866A1Improve anti-pollution performanceRobust self-heating functionalityX-ray tube structural circuit elementsRadiation/particle handlingPower flowX-ray

An X-ray window includes a primary and a secondary window element. In order to evaporate debris by ohmic heating, current flows through the secondary (upstream) window element. Meanwhile, electric charge originating from electron irradiation and / or depositing charged particles is to be drained off the secondary window element via a charge-drain layer. To prevent large debris particles from short-circuiting the secondary window element, the current for heating the window element flows through heating circuitry which is electrically insulated from the charge-drain layer.

Owner:EXCILLUM

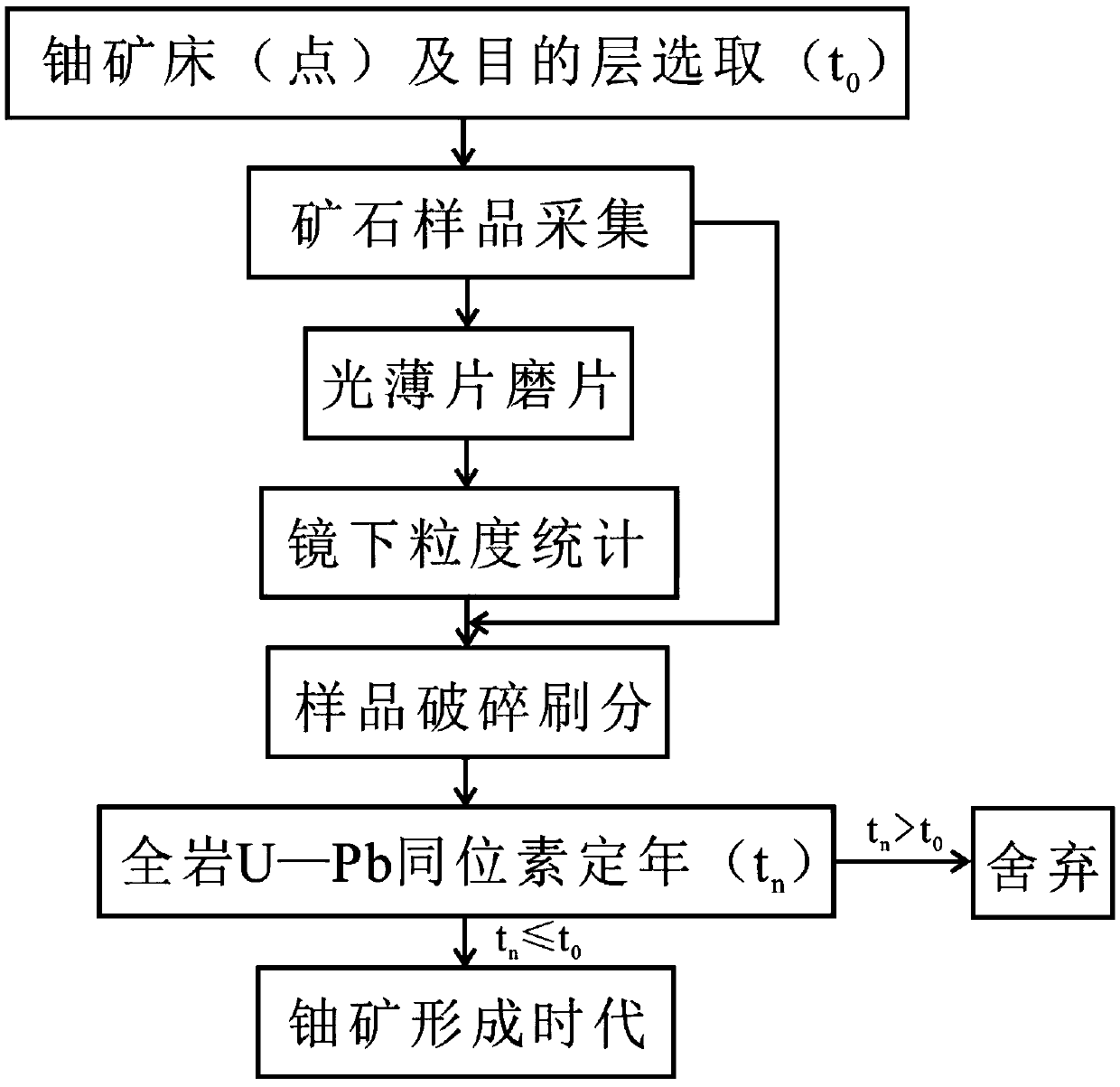

Method for determining mineralization age of sandstone-type uranium ore in basin

ActiveCN109540929ATruly reflect the multi-stage formation processAvoid influenceMaterial analysis using wave/particle radiationUranium mineralizationDebris particle

The invention discloses a method for determining a mineralization age of a sandstone-type uranium ore in a basin, belonging to the technical field of sandstone-type uranium ore in the basin. The method for determining the mineralization age of the sandstone-type uranium ore in the basin comprises the following steps: step (1), selecting a deposit and a target layer to determine a stratigraphic aget0 of an ore-bearing construction; step (2), collecting an ore sample; step (3), performing polished thin section grinding on the ore samples; step (4), performing particle size statistics on the polished thin section; step (5), breaking the samples according to the particle size level classification result, and dividing the samples according to the particle levels; step (6), performing total rock U-Pb isotopic dating on the classified samples with different particle size levels, and performing isochron age calculation meanwhile; and step (7), determining the uranium mineralization age according to the isochron age and the stratigraphic age t0. The method for determining the mineralization age of the sandstone-type uranium ore in the basin disclosed by the invention can accurately determine the formation age of the basin sandstone-type uranium ore, and eliminate the influence of the uranium-containing debris particles in the sandstone to the greatest extent, thereby maximally approaching the true formation age of the uranium ore.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

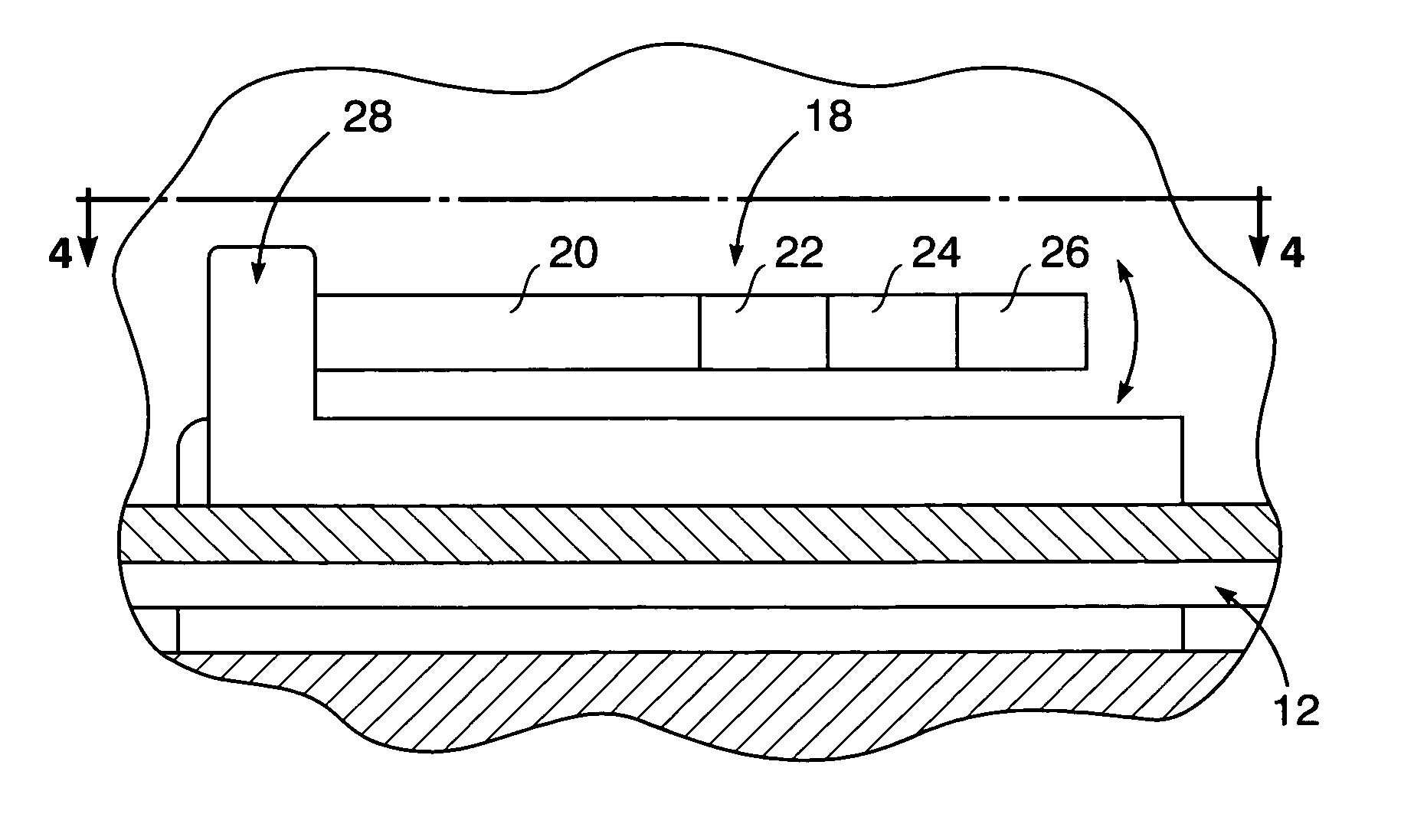

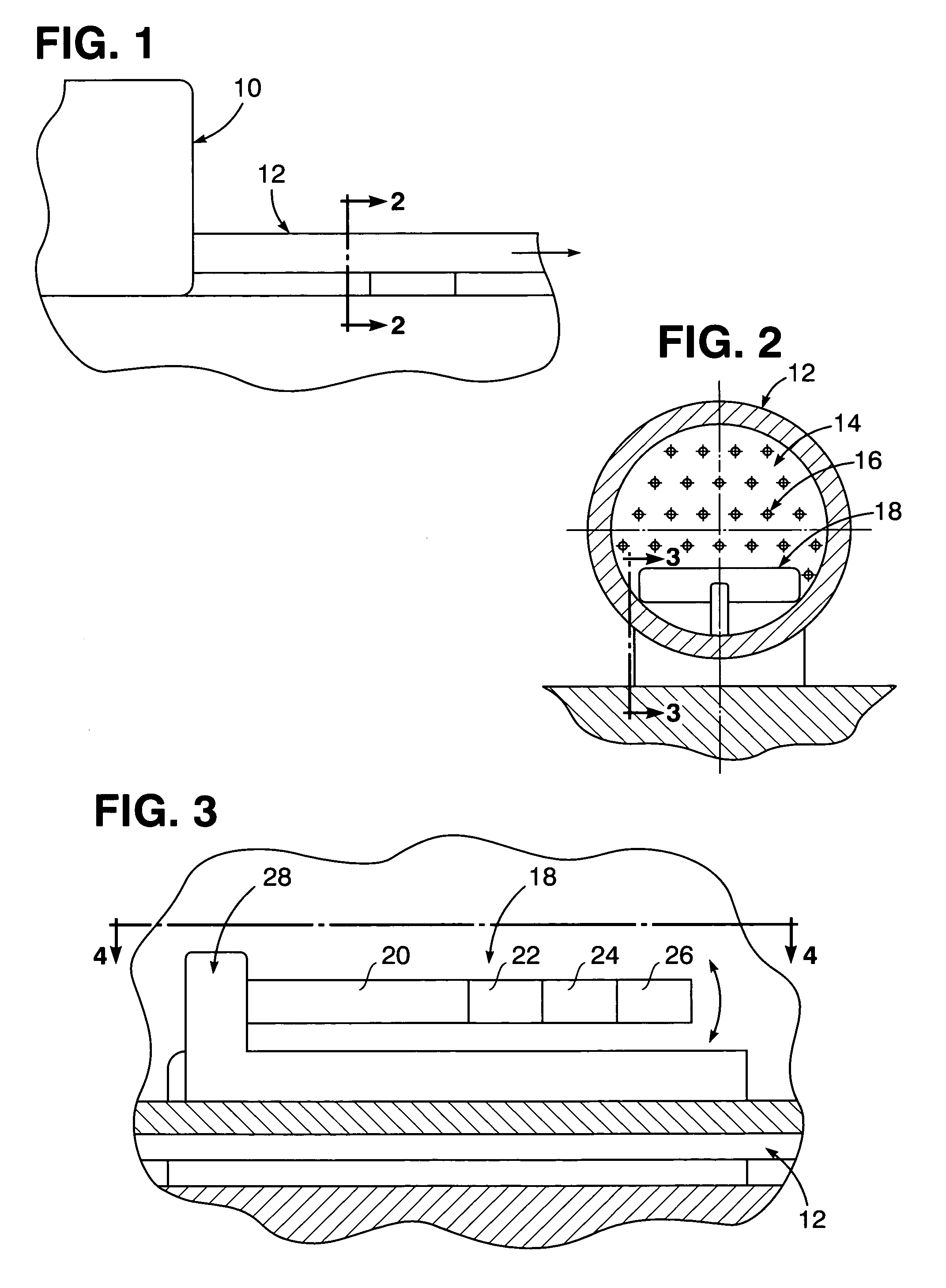

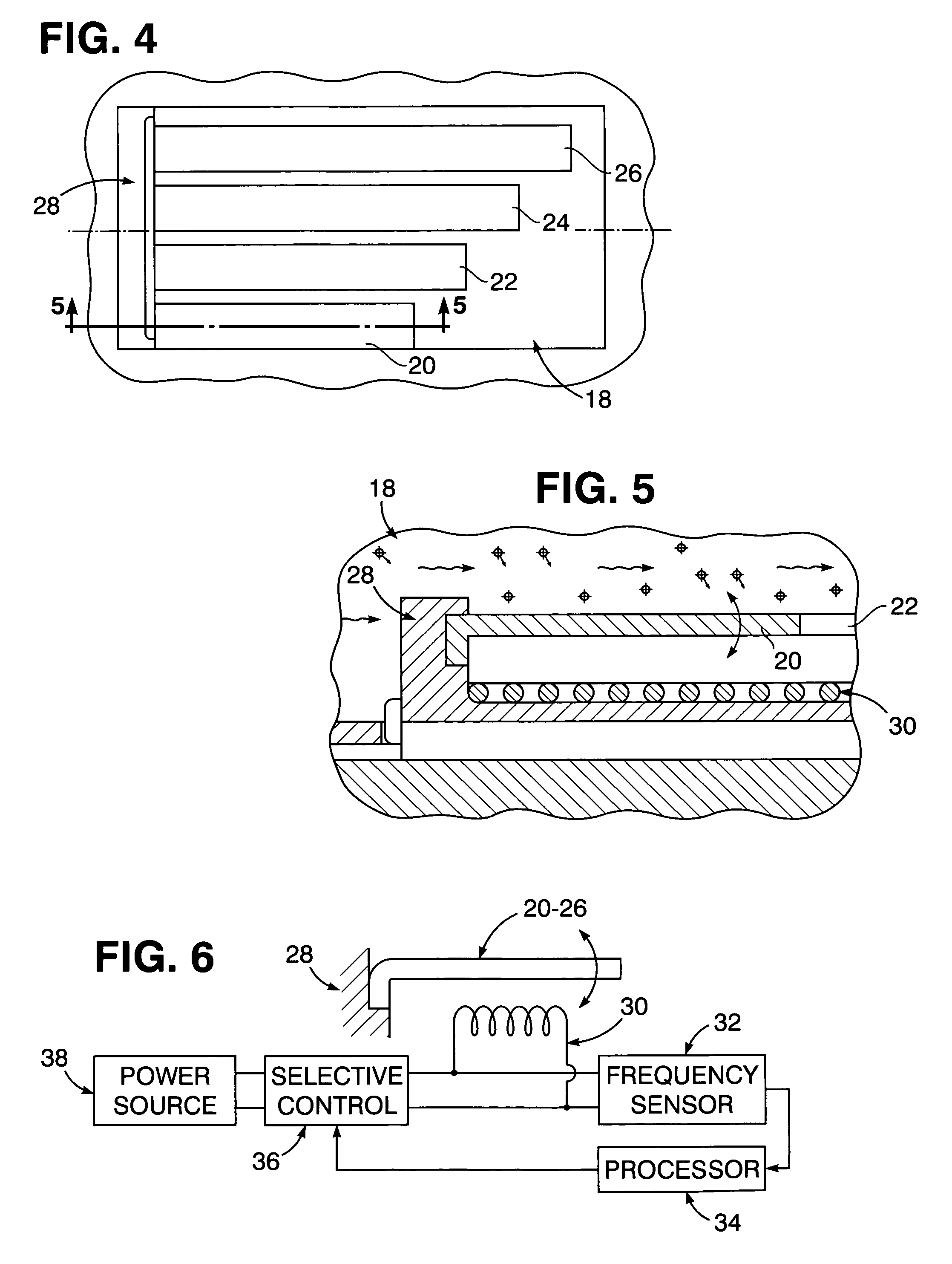

System for measurement of metallic debris in fluid

InactiveUS7068027B1Magnetic property measurementsMaterial magnetic variablesResonanceParticle physics

A debris sensor arrangement is positioned within an enclosed body of fluid for detecting the presence of metallic debris particles therein. Debris detection involves exposure of cantilever beams to the fluid when magnetized within an electromagnetic field to attract the metallic debris particles thereon and induce vibratory motion thereof at a resonant frequency varied by changes in the density of the debris particles magnetically held thereon. Measurement of the resonance frequency reflecting the density of the debris particles within the fluid being tested thereby monitors the corresponding wear of machinery reflected by the debris density.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

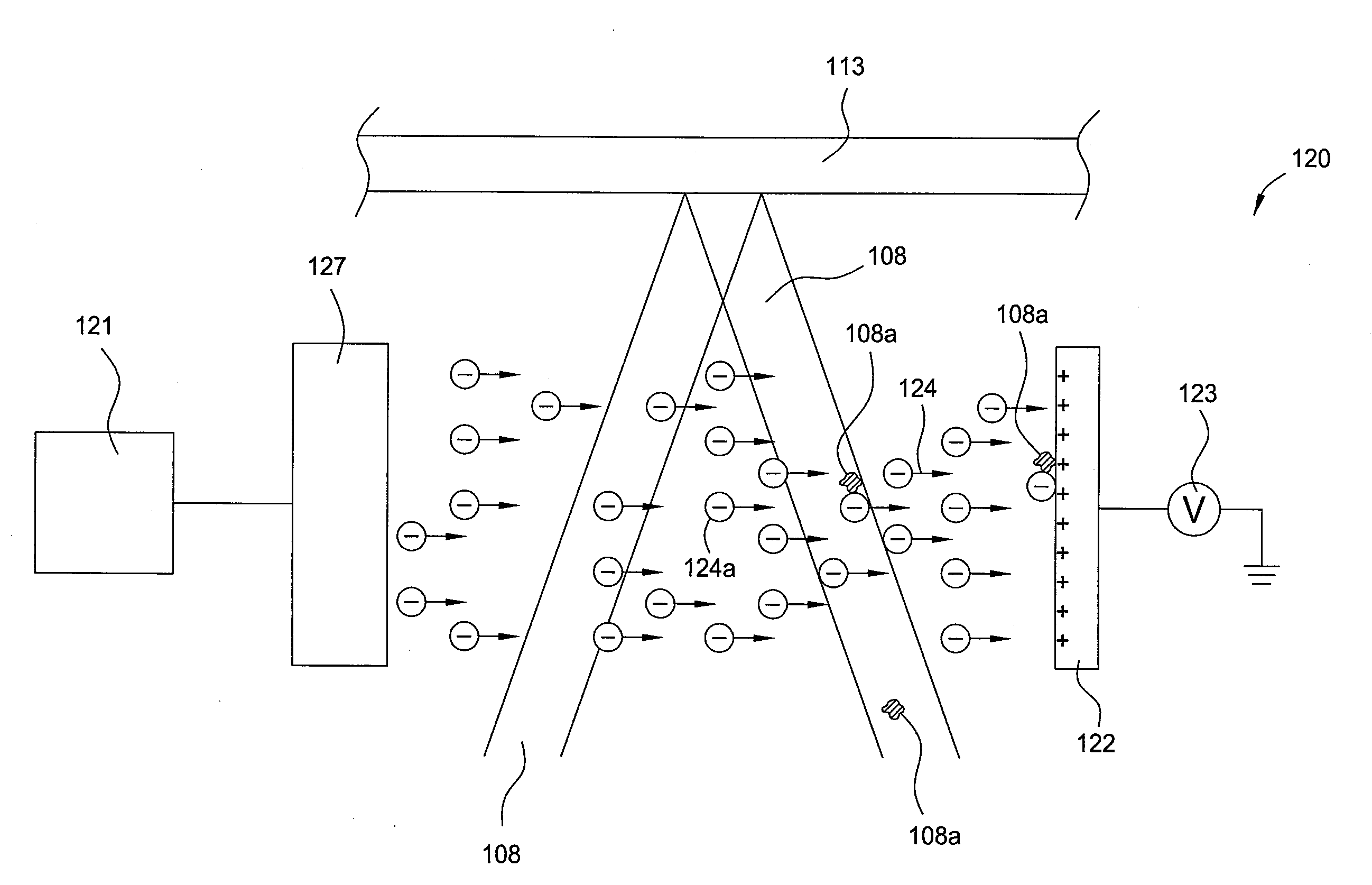

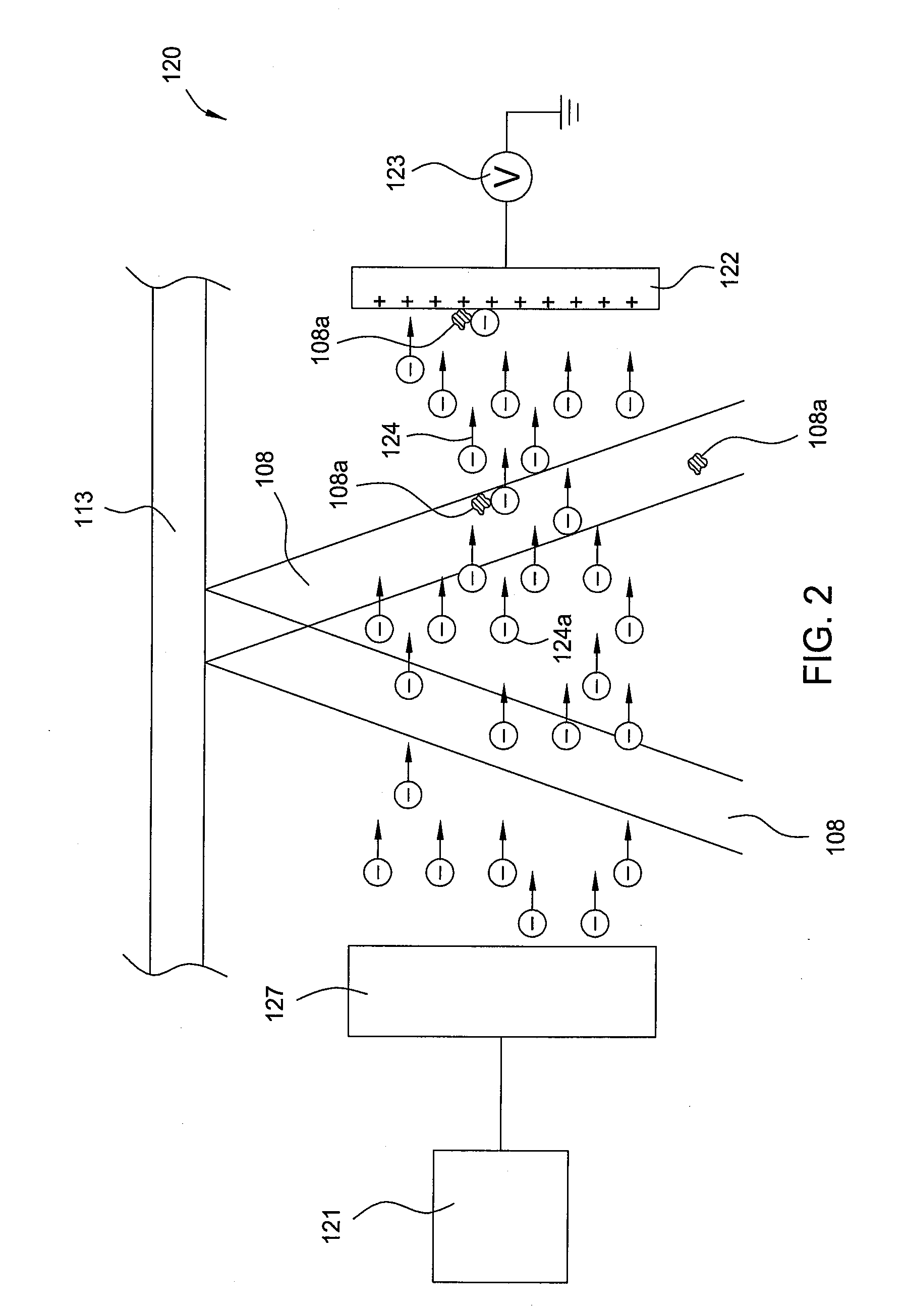

Contamination prevention in extreme ultraviolet lithography

Embodiments of the present invention provide methods and apparatus for removing debris particles using a stream of charged species. One embodiment of the present invention provides an apparatus for removing debris particles from a beam of radiation comprising a charged species source configured to dispense electrically charged species, and a collecting plate biased electrically opposite to the charged species from the charged species source, wherein the collecting plate and the charged species source are disposed on opposite sides of the beam of radiation, a stream of charged species from the charged species source to the collecting plate intersects the beam of radiation, the stream of charged species is configured to attach and remove debris particles from the beam of radiation by electrostatic force, and the collecting plate is configured to receive the charged species and the debris particles removed from the beam of radiation.

Owner:APPLIED MATERIALS INC

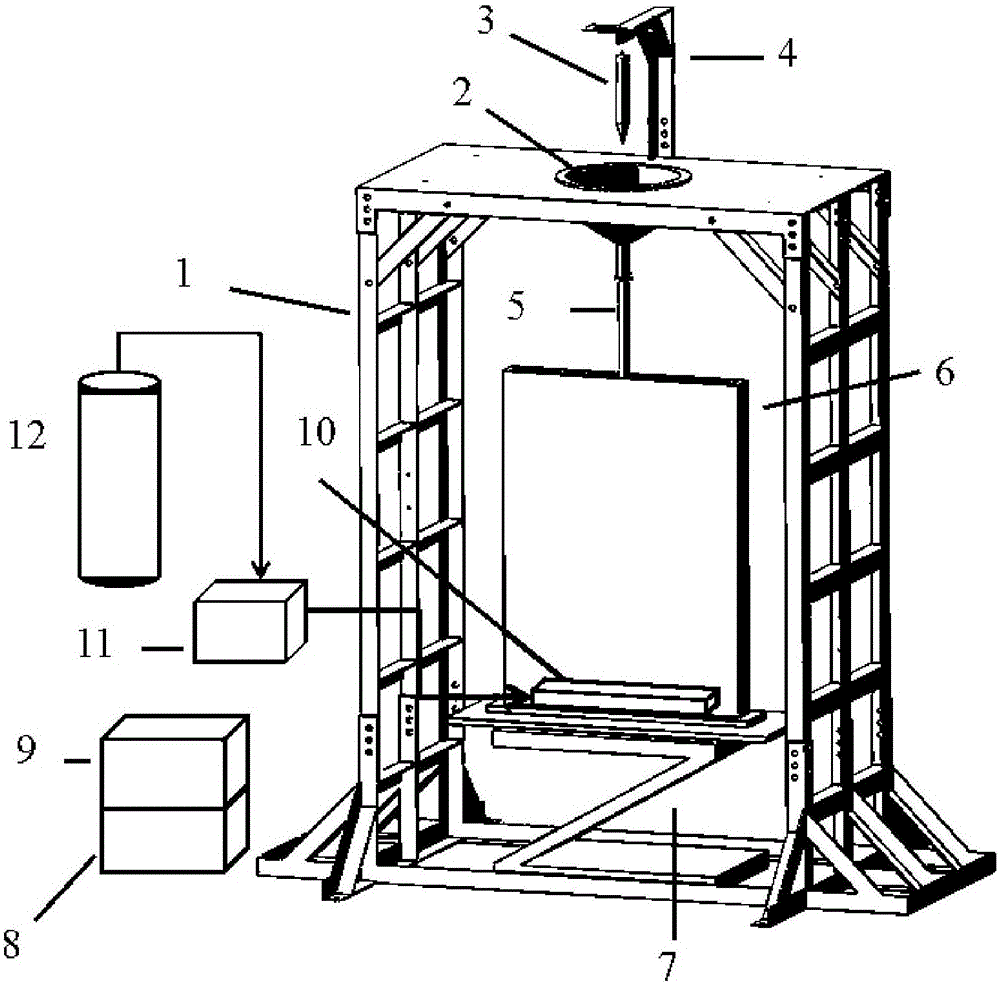

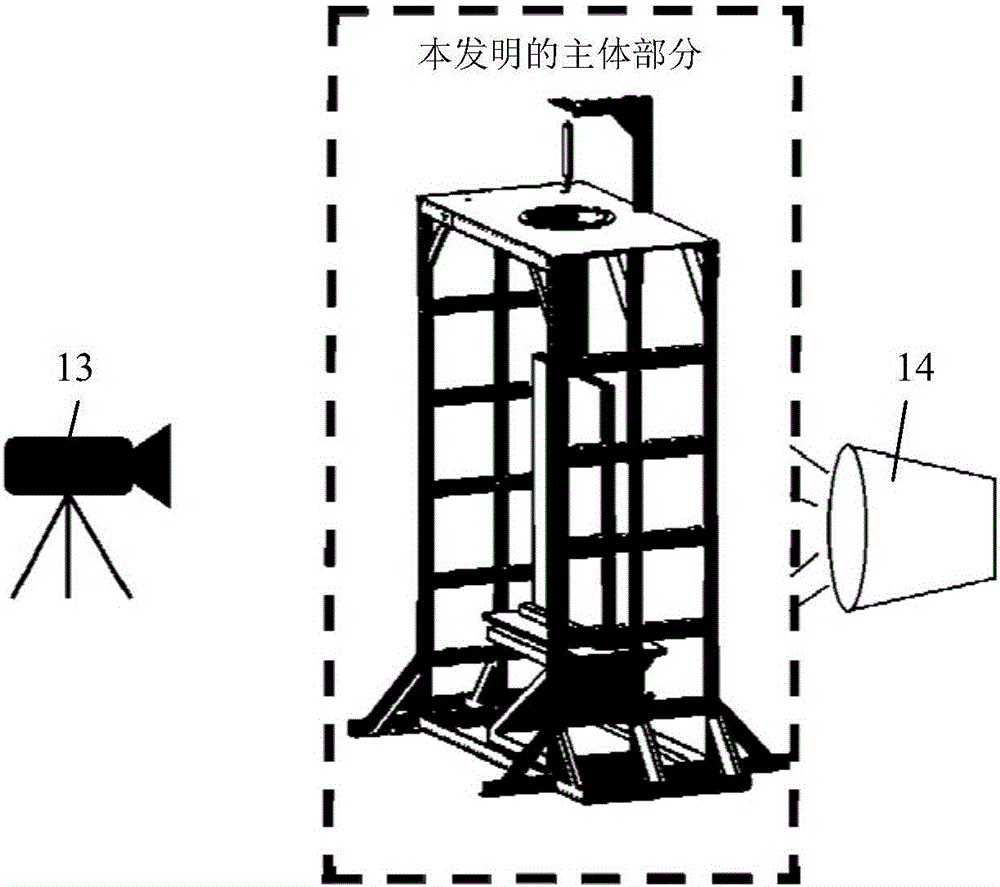

Experimental system for forming characteristic of sodium-cooled fast reactor debris bed

ActiveCN106409349AApplicable to a wide range of researchThe results of the study are comprehensiveNuclear energy generationEmergency protection arrangementsData acquisitionSodium-cooled fast reactor

The invention provides an experimental system for the forming characteristic of a sodium-cooled fast reactor debris bed. The experimental system comprises an experimental support, a particle container, a particle conduit, a visual experiment container, a particle release controller, a visual data acquisition module, an environmental parameter detection module and a decay heat simulating generator, wherein the particle container and the particle conduit support multiple release apertures and release heights, an experimental particle system comprises various debris particles with different materials, shapes and sizes, visual experimental containers with different sizes are designed for two-dimensional and three-dimensional experiments, and the particle release controller and the visual data acquisition module can acquire and store images synchronously in the whole experimental process. The experimental system can be applied to researching and analyzing the forming mechanism of the fuel particle debris bed in the sodium-cooled fast reactor core disassembly accident process. The experimental system has the advantages that the experimental process is visual, qualitative analysis is combined with quantitative analysis, multiple controllable experimental variables exist, the operation principle is simple, the system is easy to expand, stable and safe and the like.

Owner:SUN YAT SEN UNIV

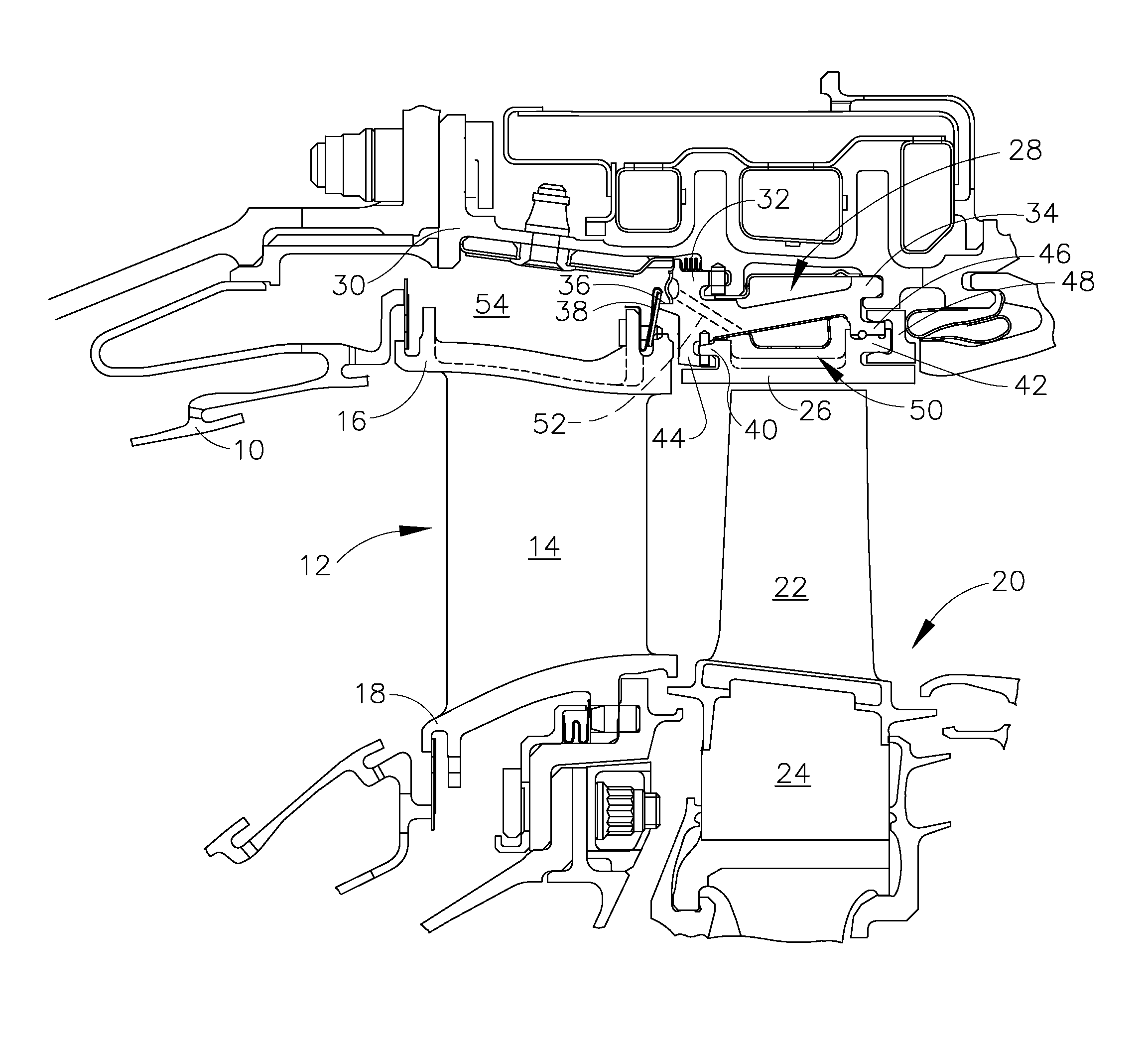

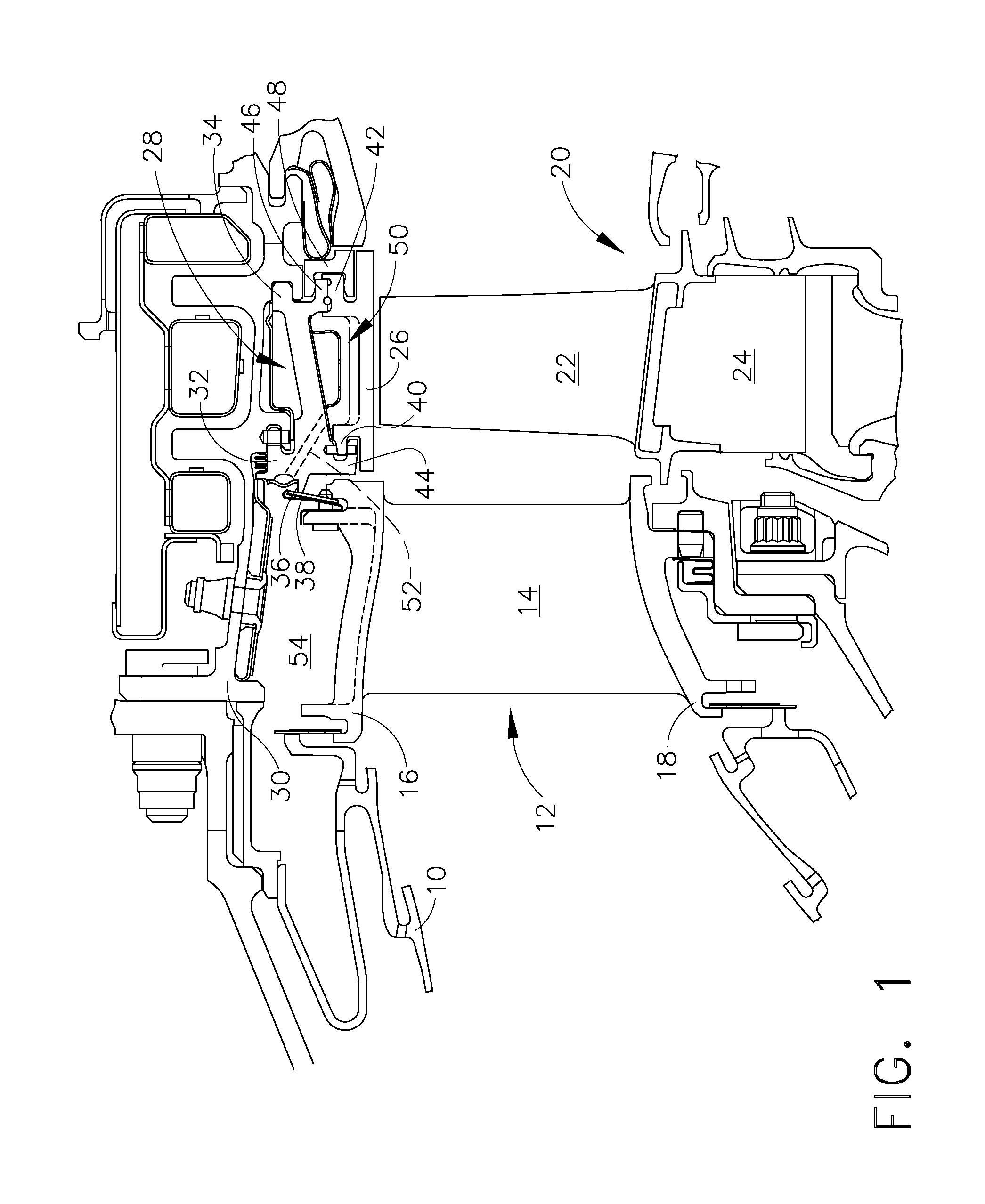

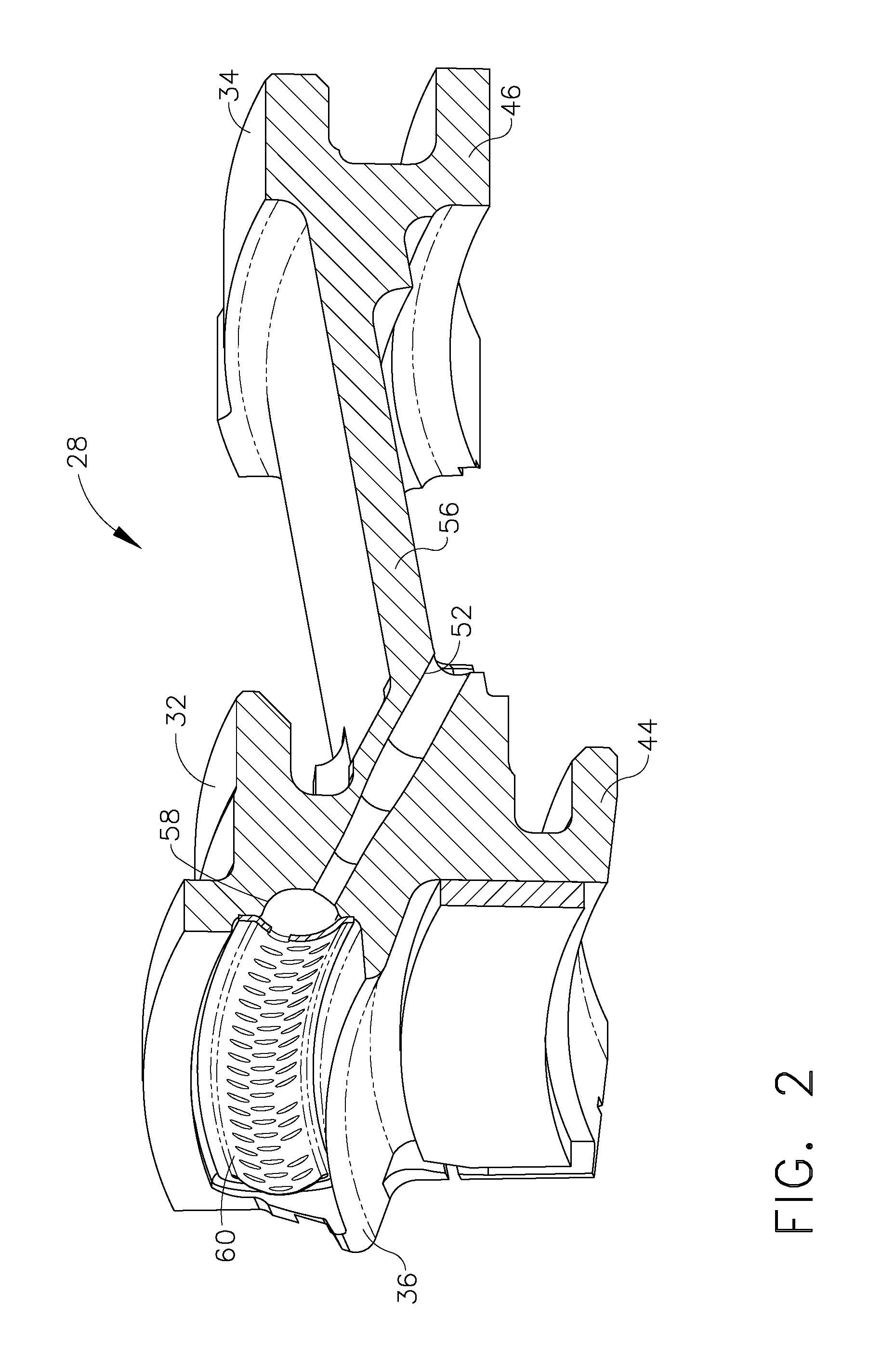

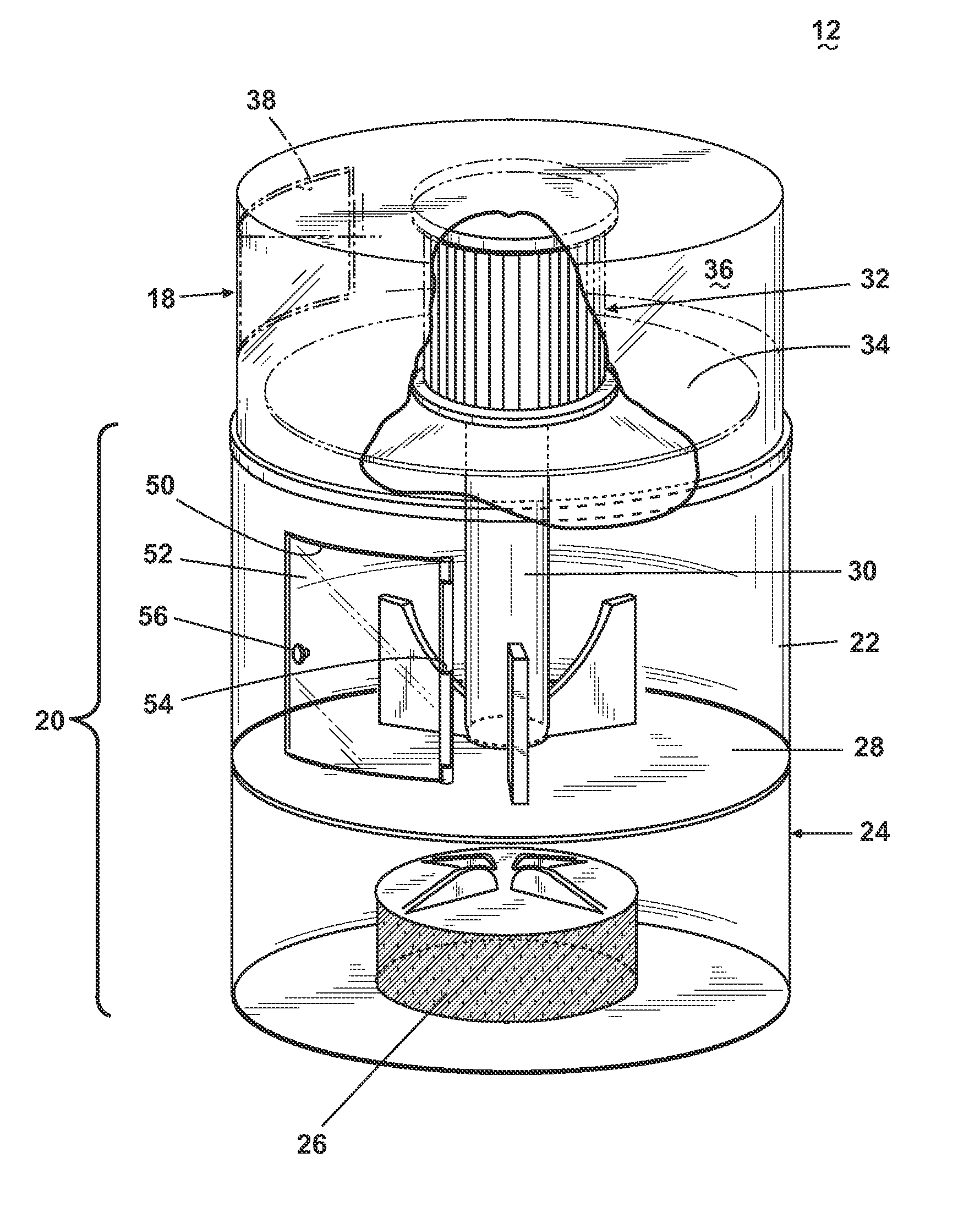

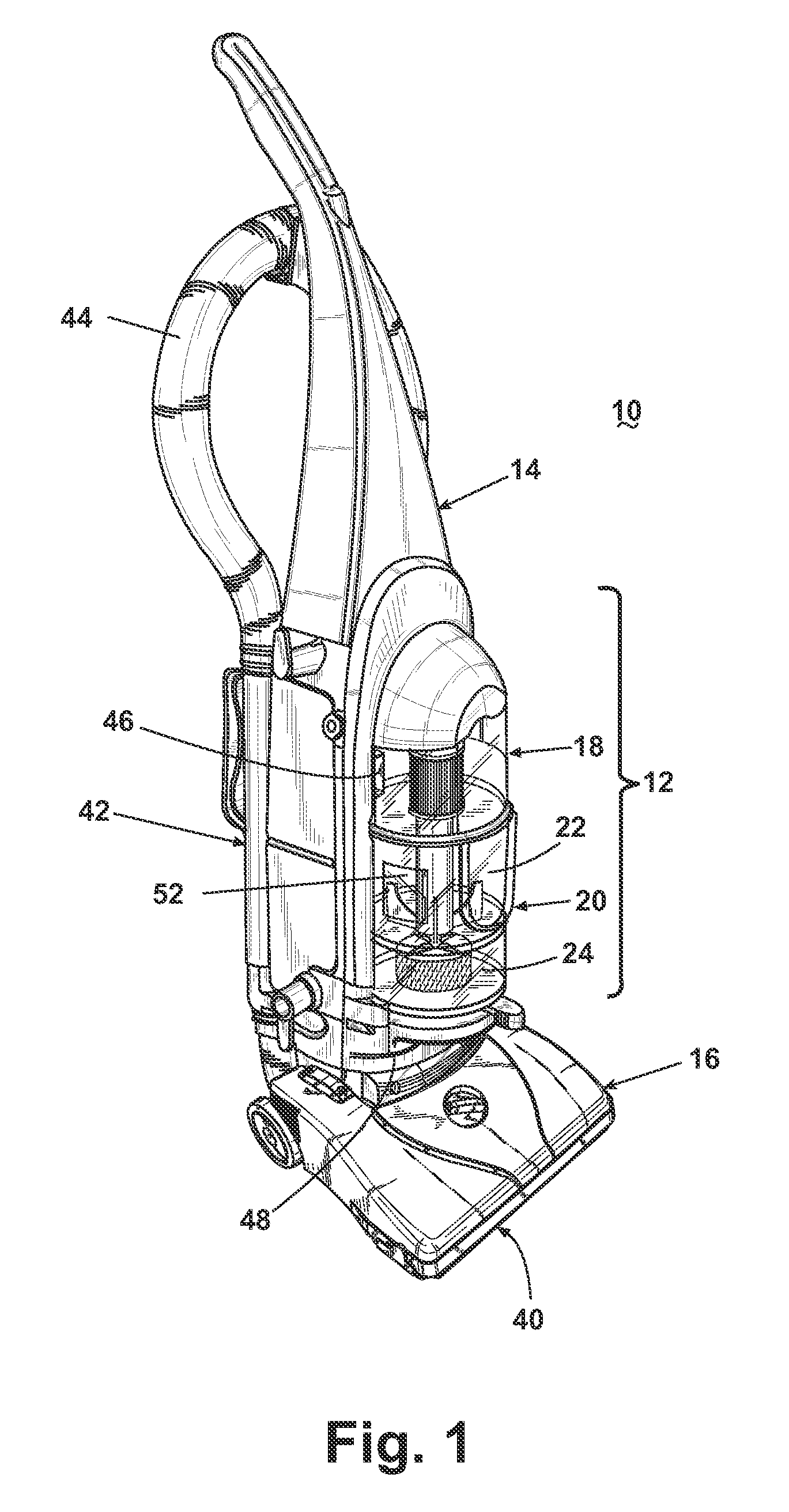

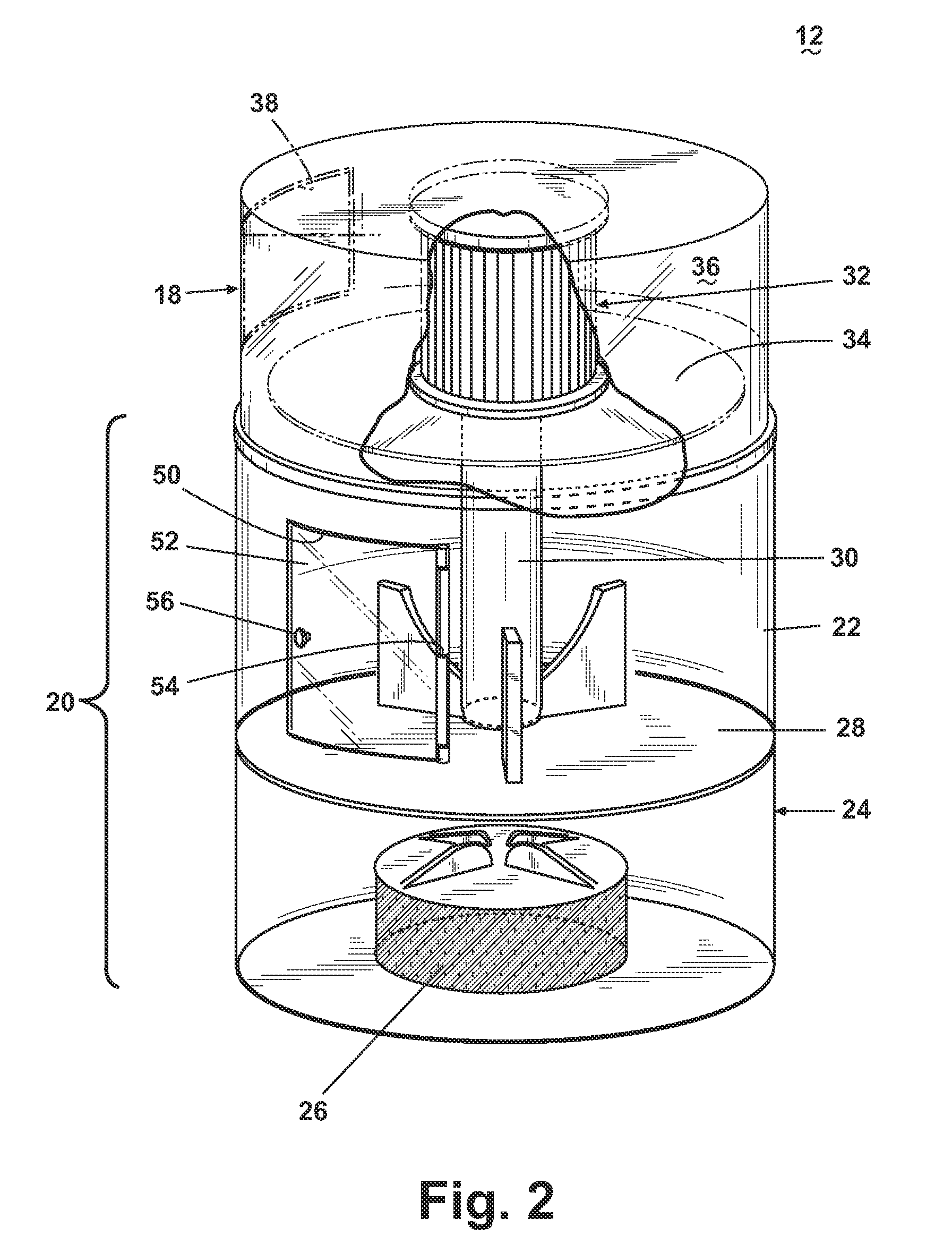

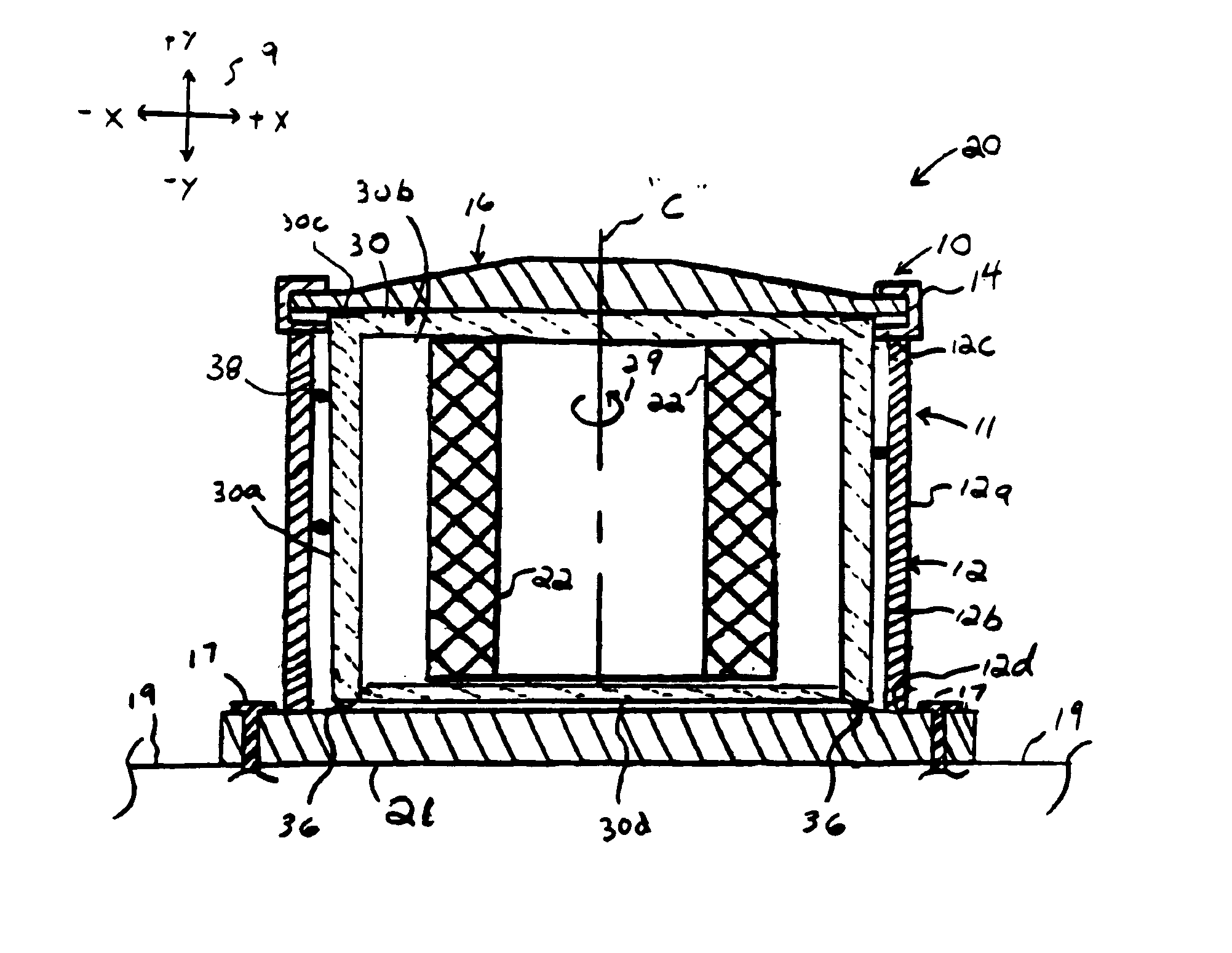

Vacuum cleaner with large debris receptacle

Owner:BISSELL INC

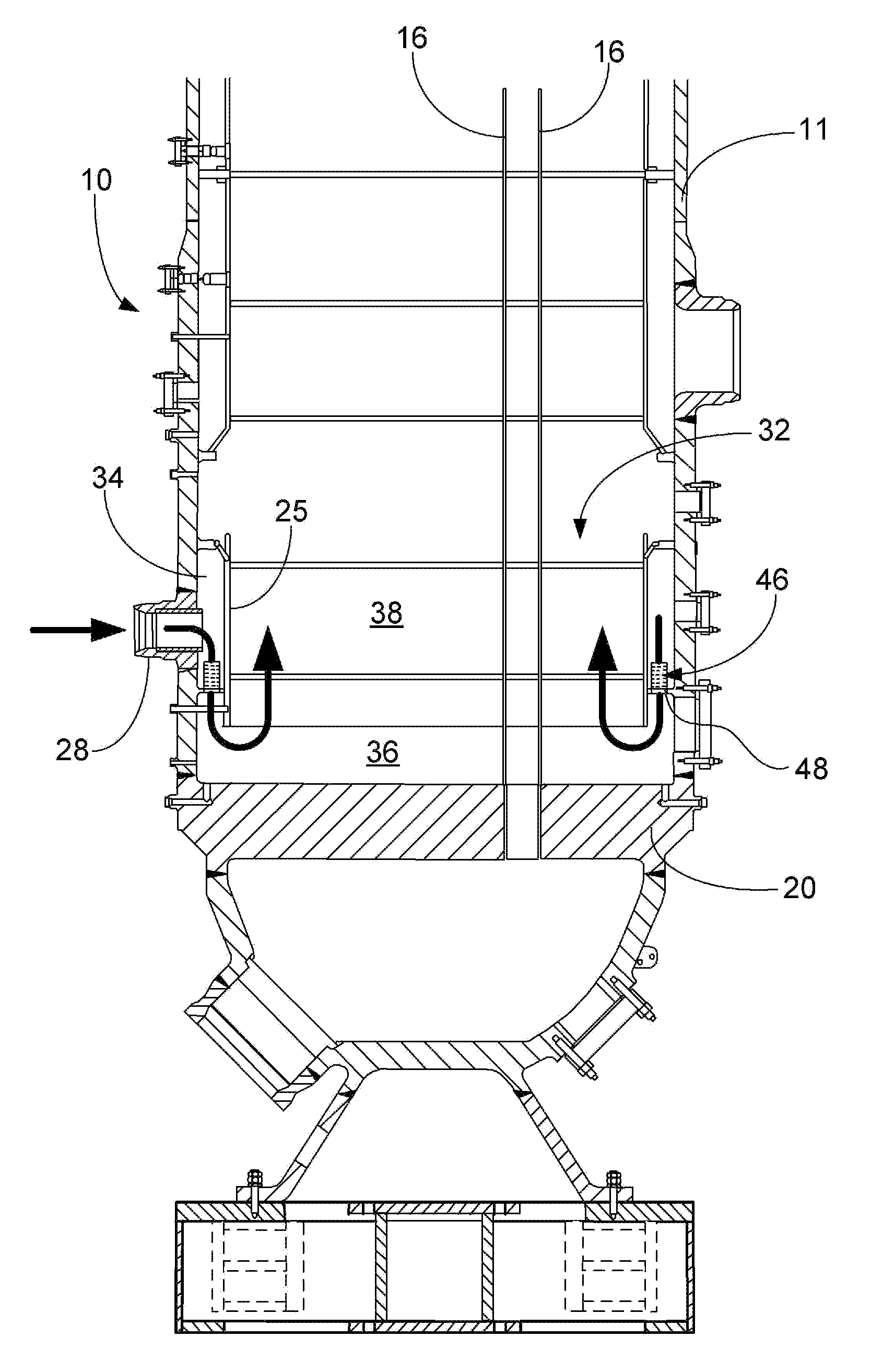

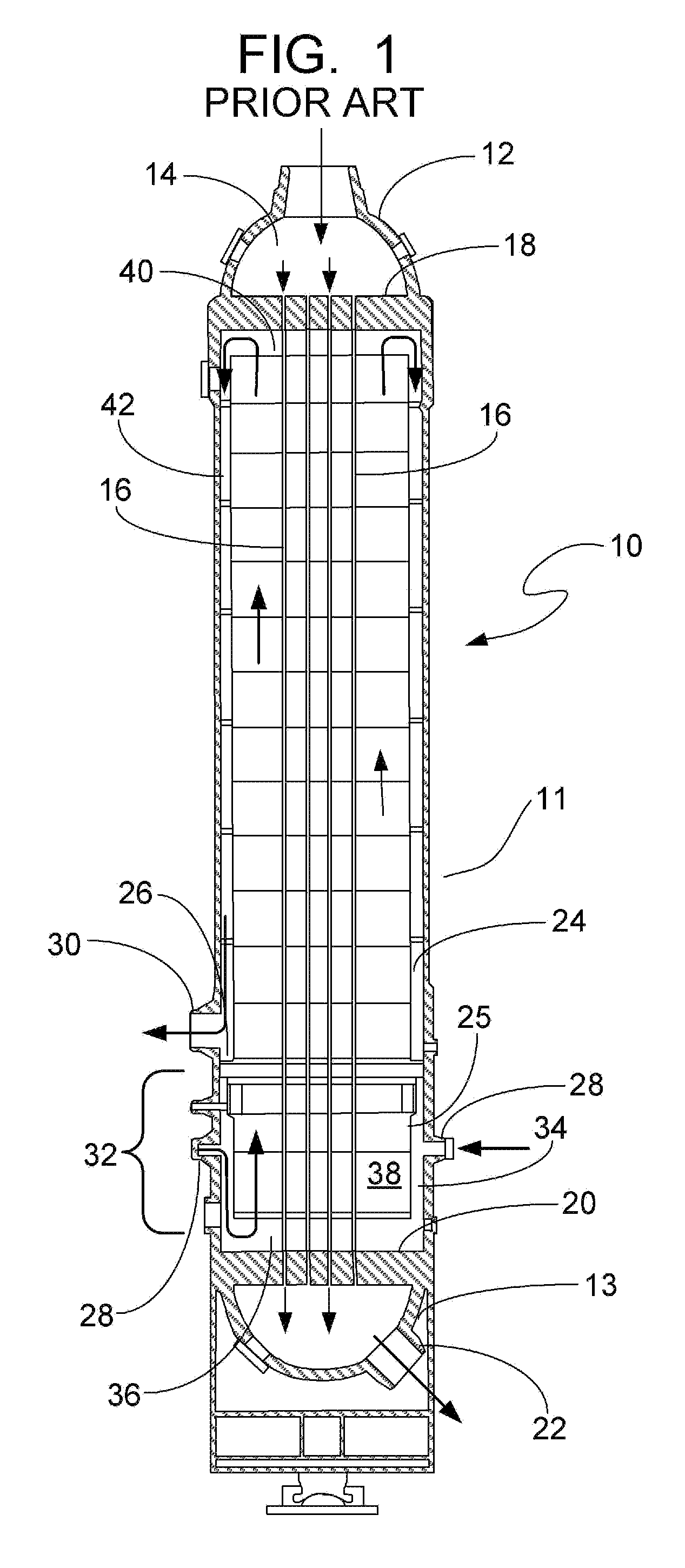

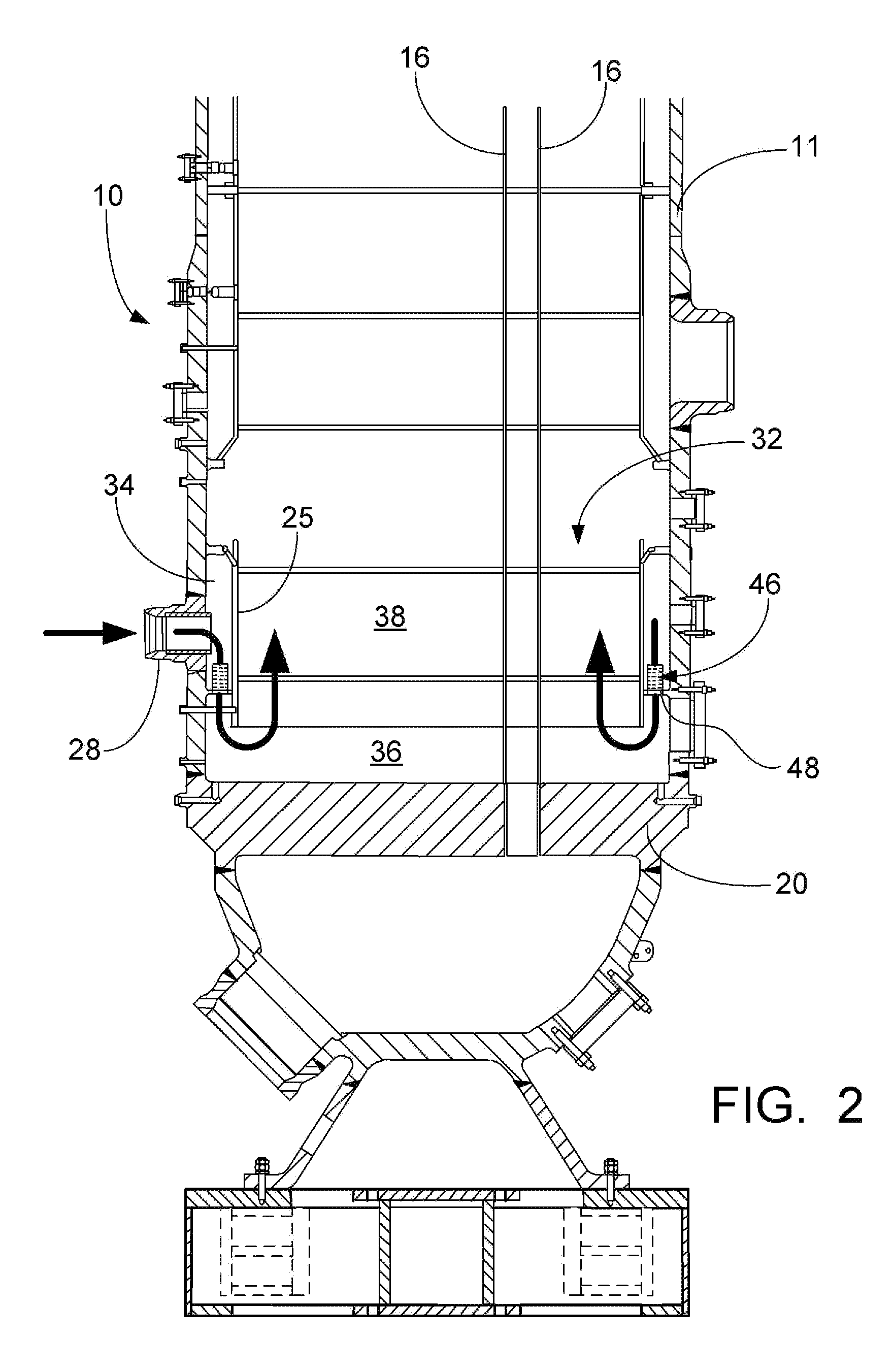

Feedwater debris trap

ActiveUS20100276124A1Avoid enteringCombustion enginesSteam/vapor condensersForeign matterNuclear engineering

A debris filter trap to prevent potentially damaging debris carried by the feedwater entering the pressure vessel of a once through steam generator from entering into the section of tubes which are positioned within the confines of an integrally contained economizer of the once through steam generator. The trap will remove foreign material, from the feedwater flow, that is larger than the space between the tubes, and thus prevent debris particles that are large enough to get lodged in the tube spacing from entering the economizer.

Owner:BABCOCK & WILCOX CANADA LIMITED

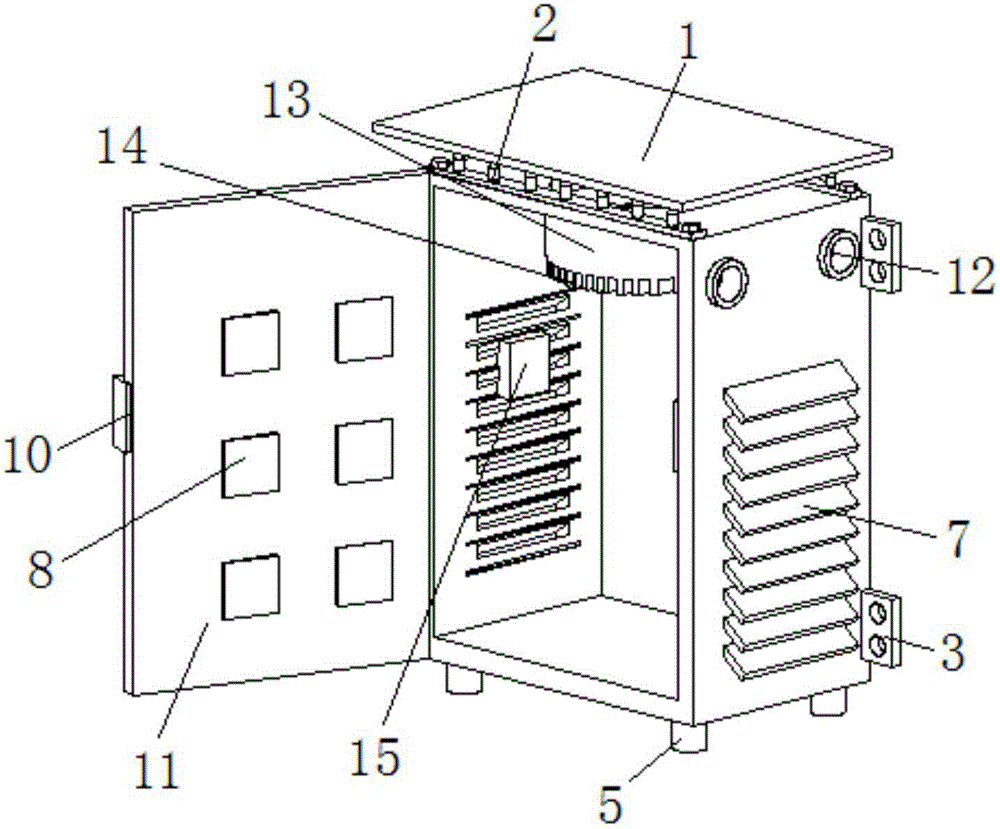

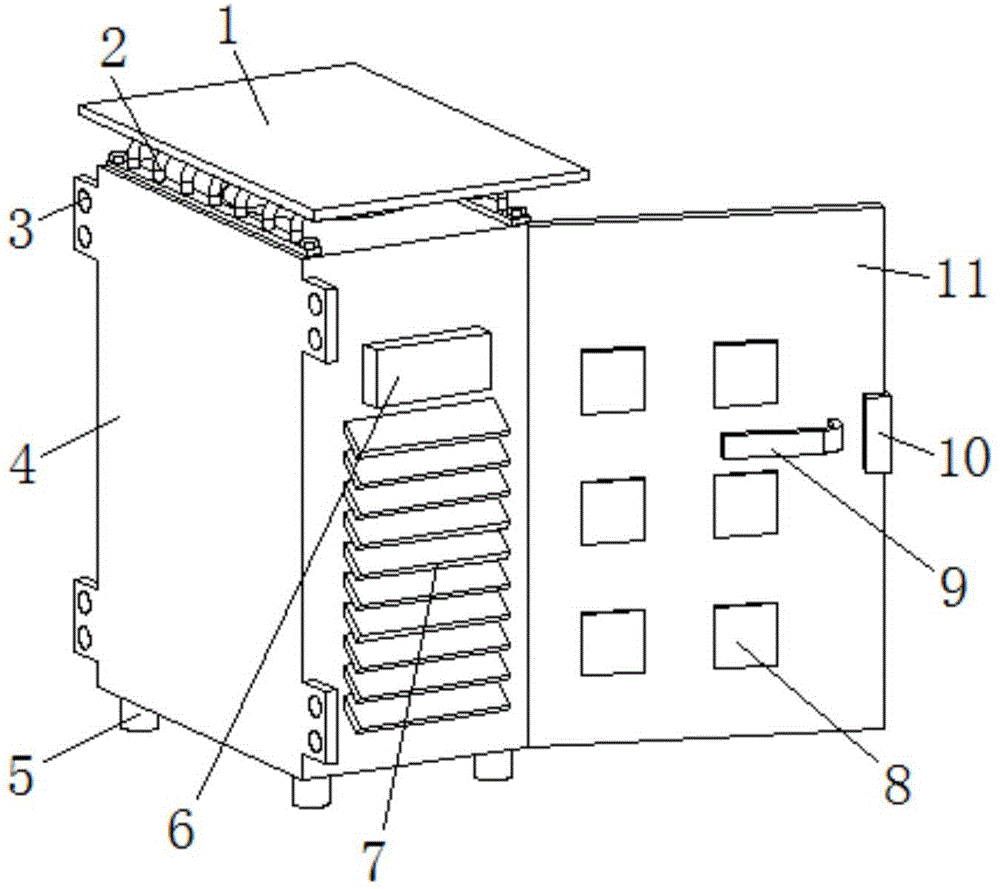

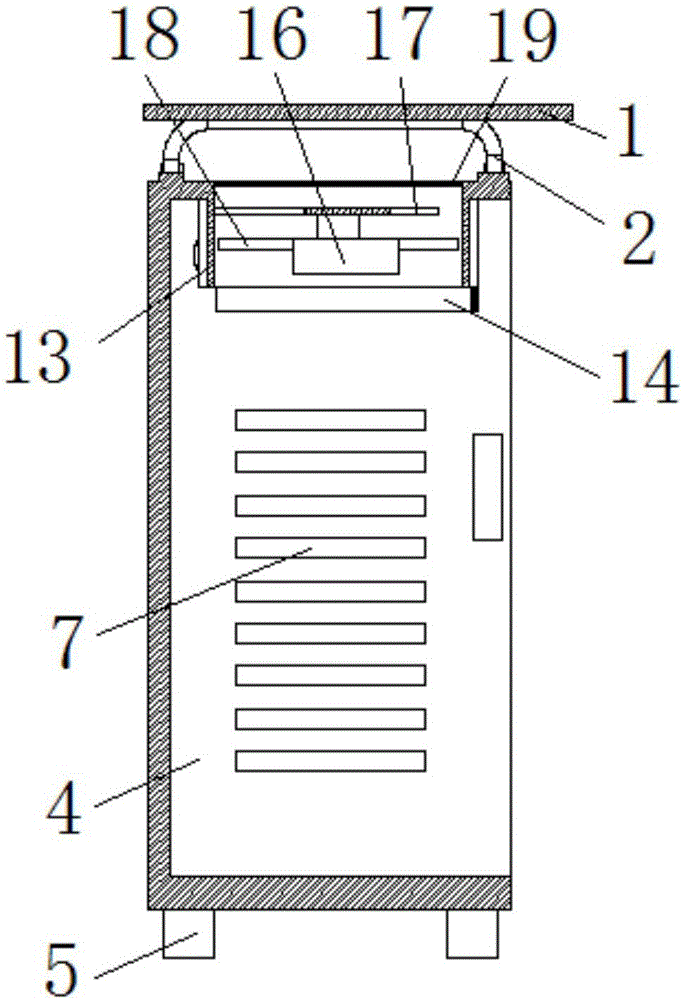

Electrical control cabinet with heat dissipation protective device at top part

InactiveCN106255366AImprove cooling effectSimple structureCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsElectrical controlEngineering

The invention discloses an electrical control cabinet provided with a heat dissipation protective device at the top part. The electrical control cabinet comprises a control cabinet body, wherein an opening is formed in the front surface of the control cabinet body, one side of the opening is provided with a cabinet door, the cabinet door is connected with the control cabinet body through a hinge, one side of the cabinet door is provided with a lock catch, fan blades are driven to rotate by power, the heat of the electrical control cabinet is dissipated through the rotation of the fan blade, so that the electrical control cabinet has better heat dissipation effect, the lower end of a ventilation pipe is provided with a heat dissipation frame, the heat of the electrical control cabinet is dissipated more quickly by means of the heat dissipation frame, and the control cabinet body is protected by a protective plate and a protective frame, so that the control cabinet body is more solid. The electrical control cabinet provided with the heat dissipation protective device at the top part is simple in structure, can dissipate the heat inside the electrical control cabinet quickly, and can prevent tiny debris particles and a lot of dust from falling into the cabinet from the top part, thereby protecting the electrical appliance elements inside the electrical control cabinet and prolonging the service life of the electrical appliance elements.

Owner:江苏明强电气有限公司

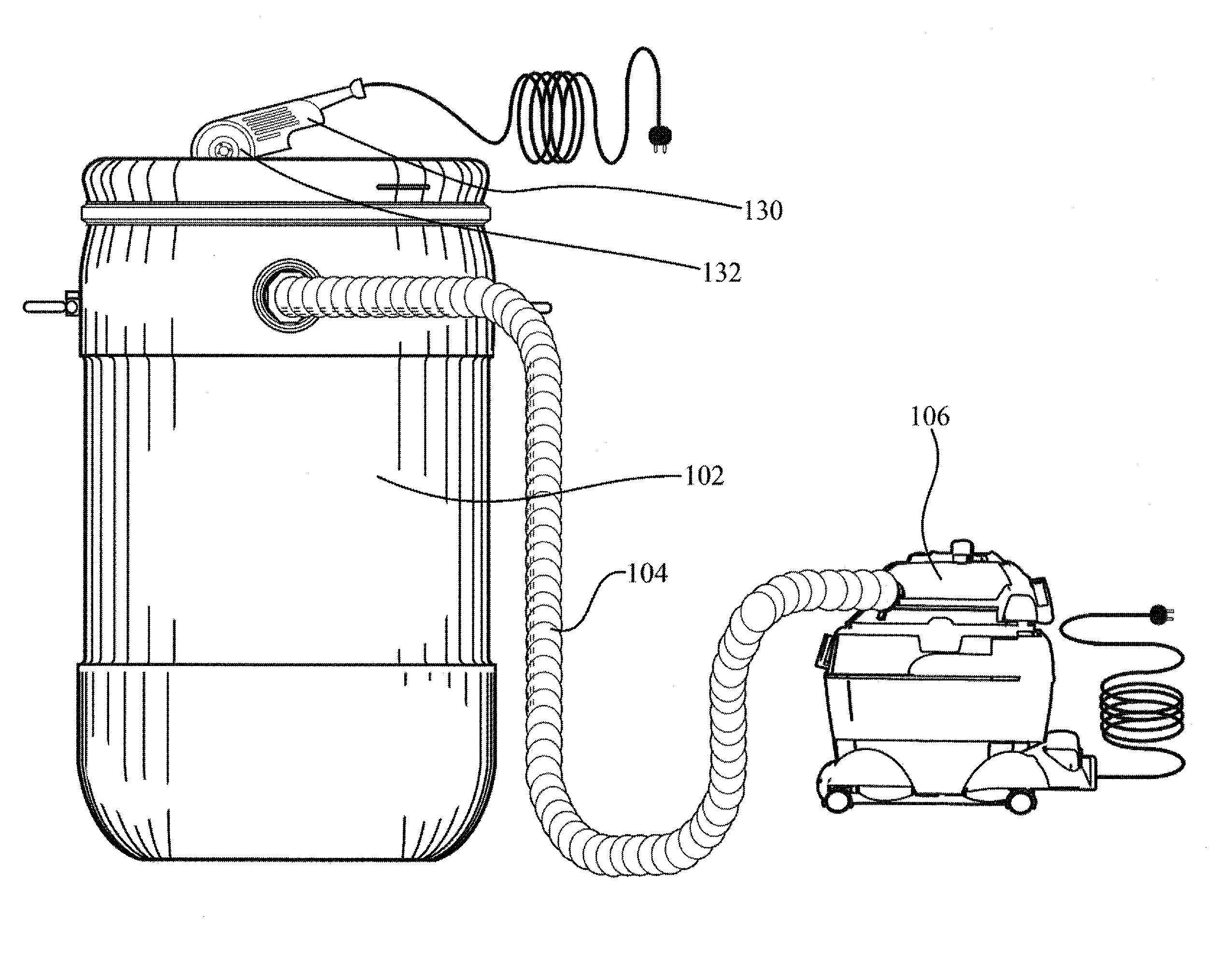

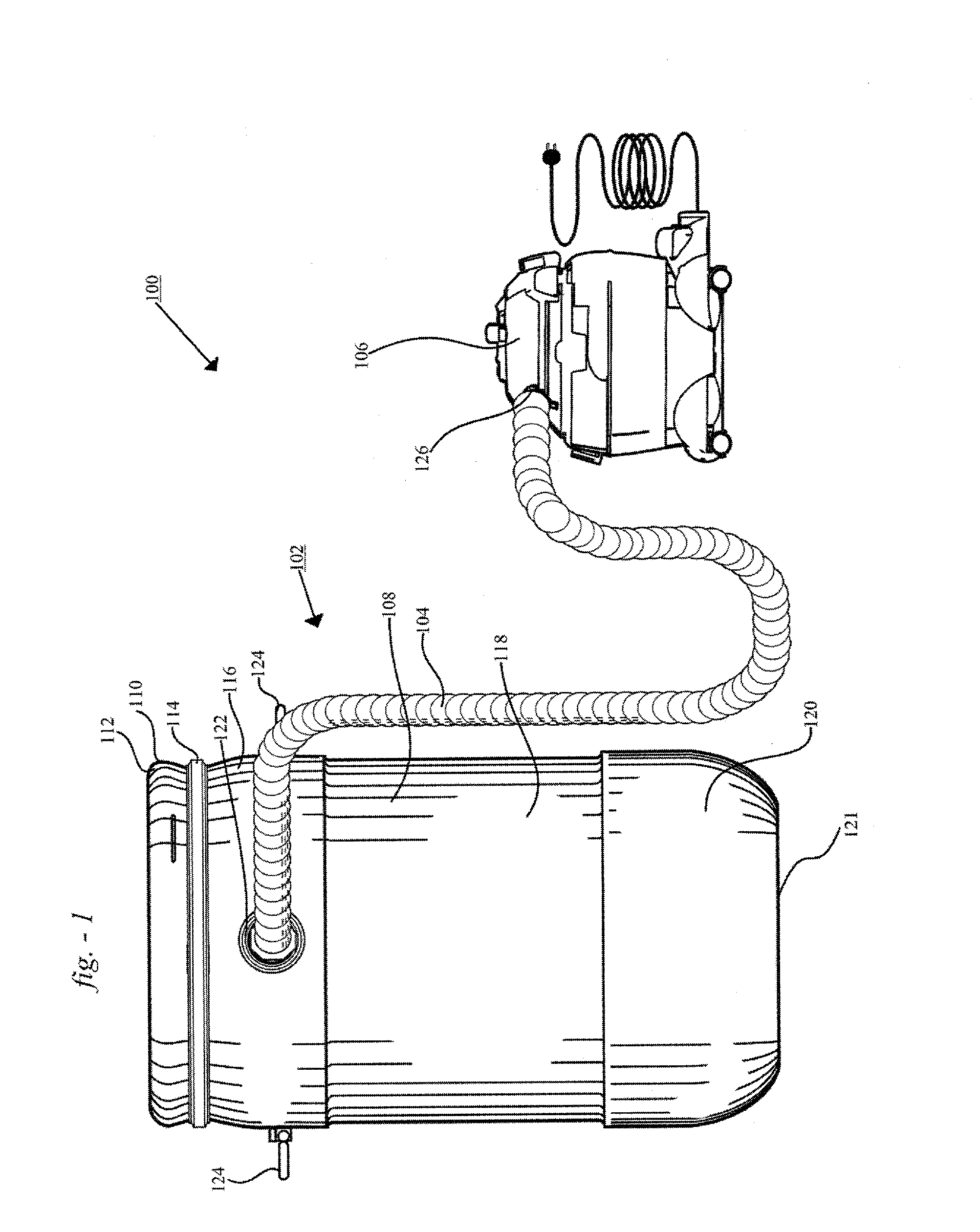

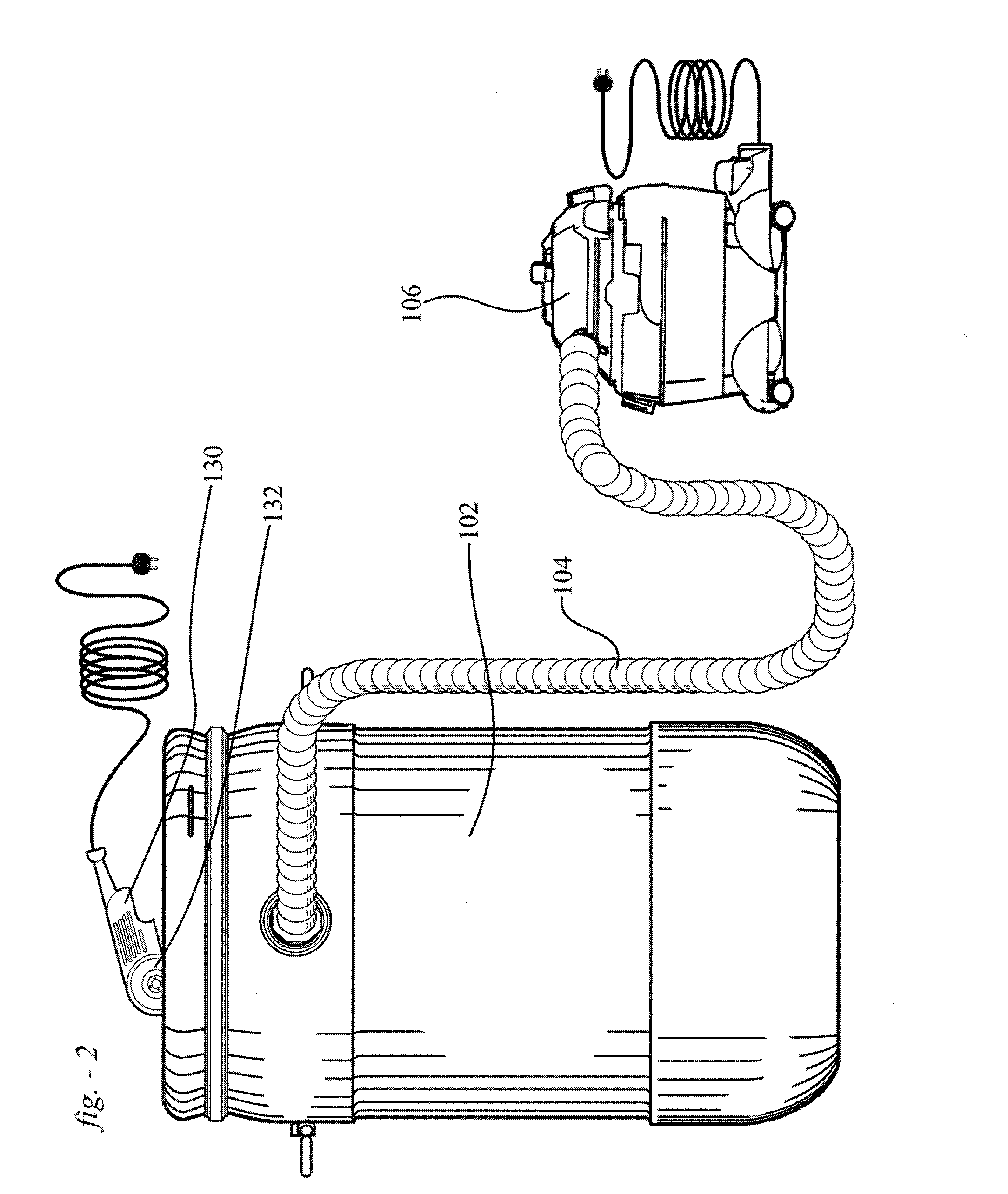

Tile cutting and dust collection system

The present concept is a cutting surface and debris container in combination with a vacuum cleaner. The cutting surface and debris container includes a hollow container with a debris storage compartment, and a cutting surface for supporting a workpiece to be cut. The cutting surface has an opening to allow fresh air to be drawn into the container. The top section of the container has an outlet that can connect to a hose which couples the container to a vacuum cleaner. Debris generated from cutting the workpiece is drawn into the container. Large debris particles drop in the debris storage compartment while small particles are extracted by the vacuum cleaner.

Owner:WOLOSZCZUK LUKE

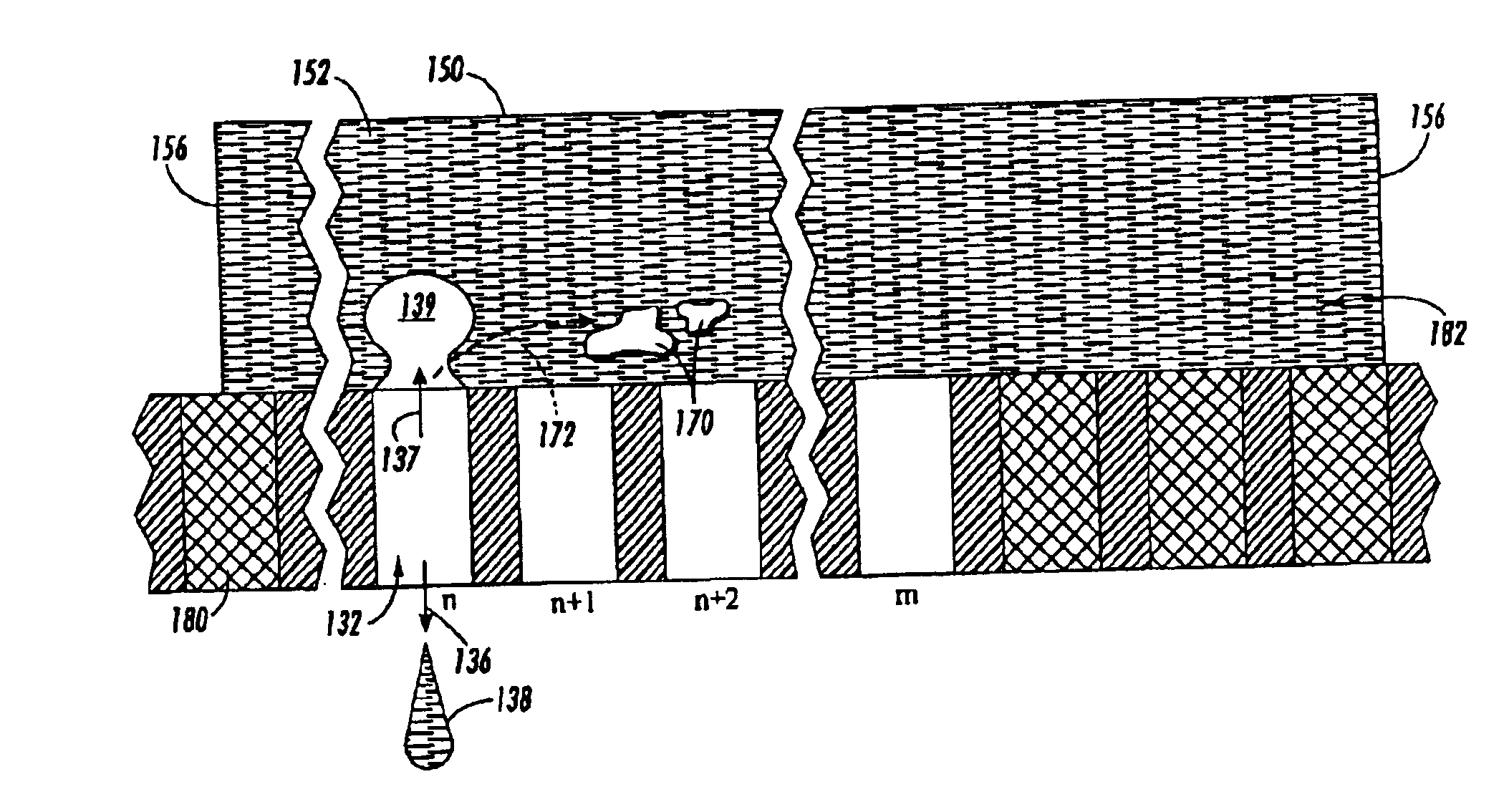

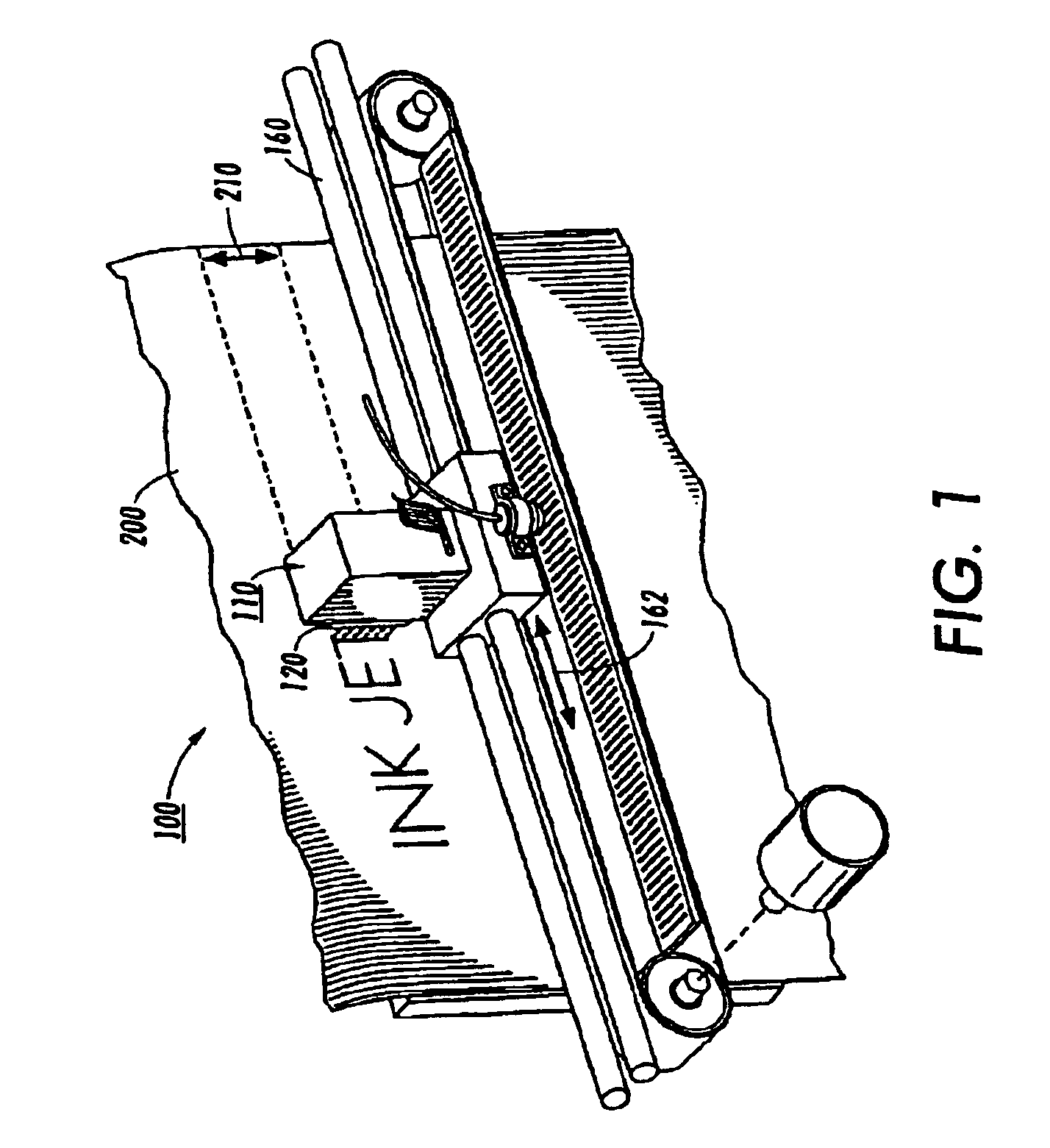

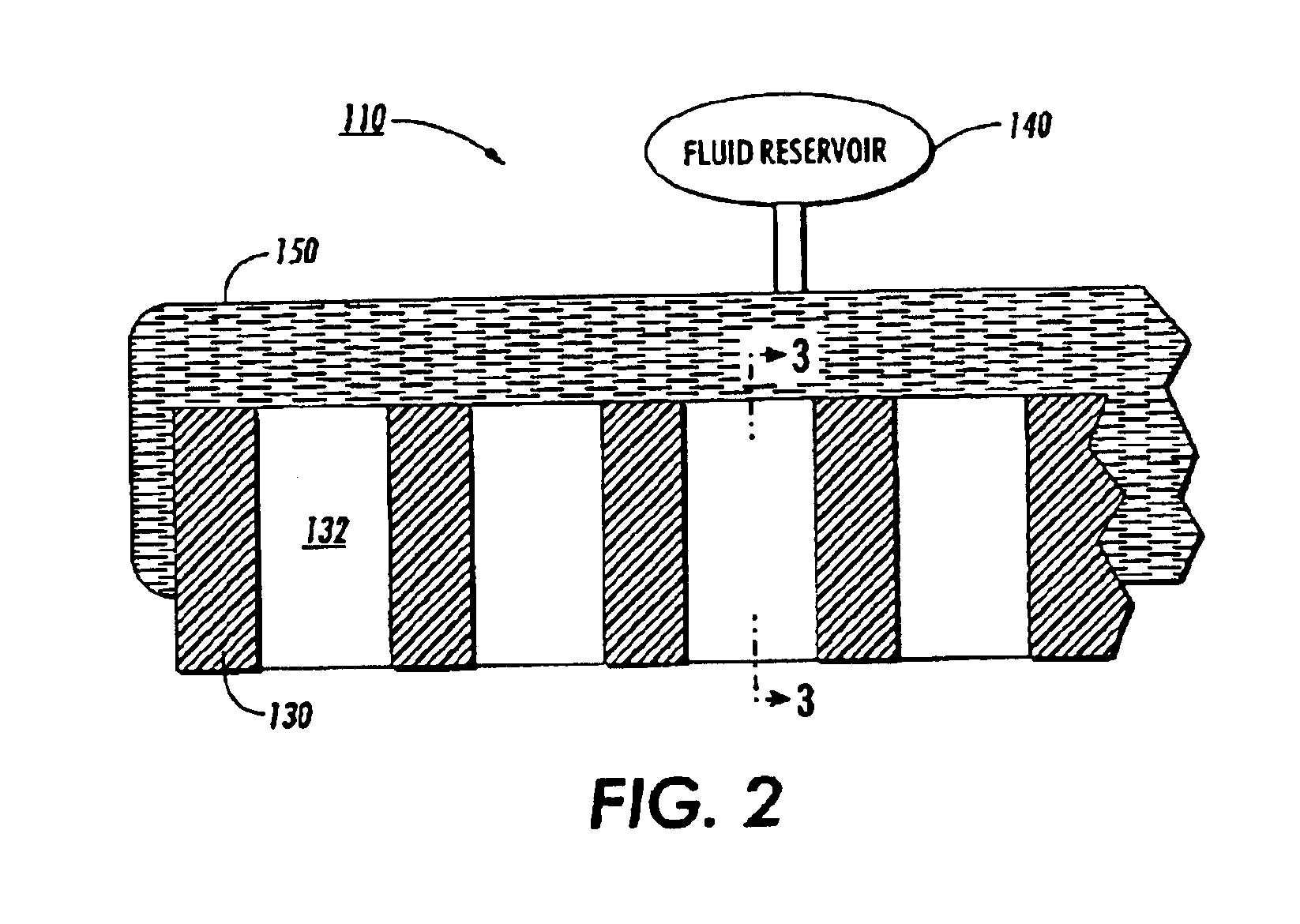

Systems and methods for operating fluid ejection systems using a print head preparatory firing sequence

Current fluid ejector maintenance techniques do not adequately deal with moveable debris particles present in the fluid supply manifold. Such moveable particles within the fluid supply manifold of a fluid ejector head can cause random ejection defects by clogging, restricting and / or blocking the channel inlets and / or filters present in the channel inlets, causing missed or misfired and / of misdirected drops. At least some of a plurality of fluid ejectors can be fired in a sequential pattern. Sequentially firing the fluid ejectors can move movable particles in the direction of the firing sequence. The moved movable particles can be deposited into non-operative areas within the fluid supply manifold, such as, for example, non-firing fluid ejection locations. The fluid ejectors can be fired in a sequential pattern within blocks of the fluid ejectors. For example, a fluid ejector head with 120 fluid ejectors can fire 1 out of every 20 fluid ejectors.

Owner:XEROX CORP

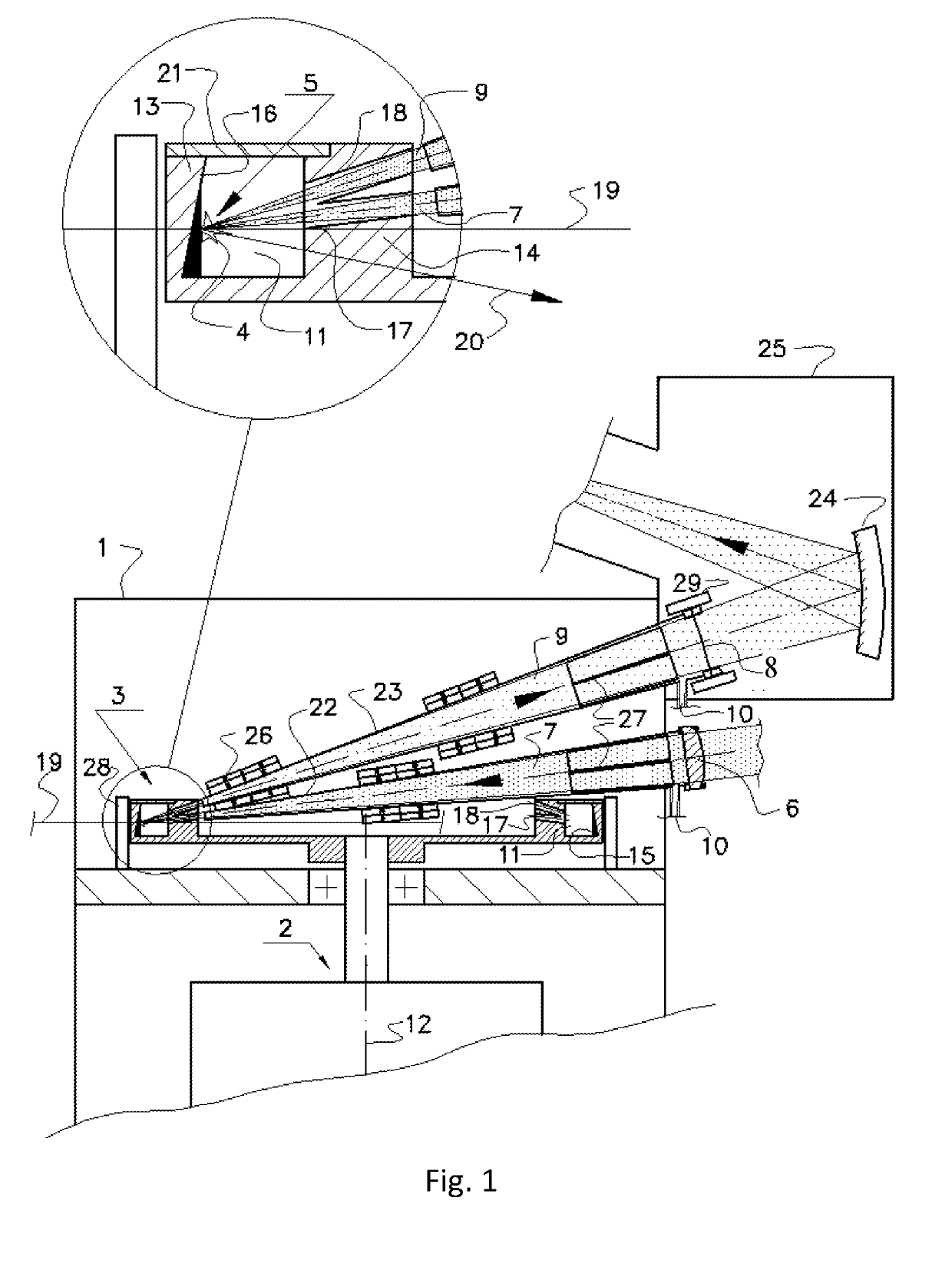

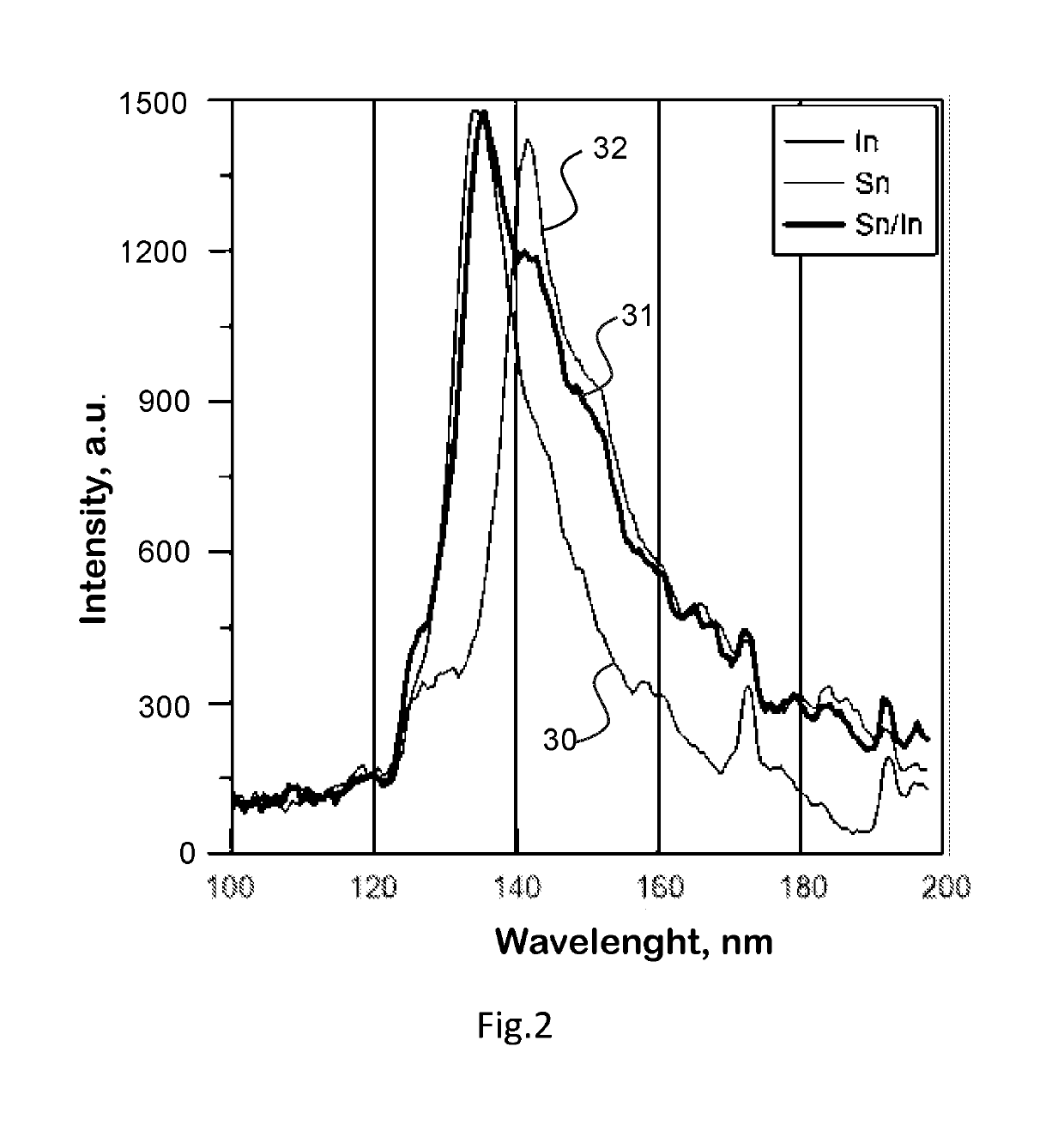

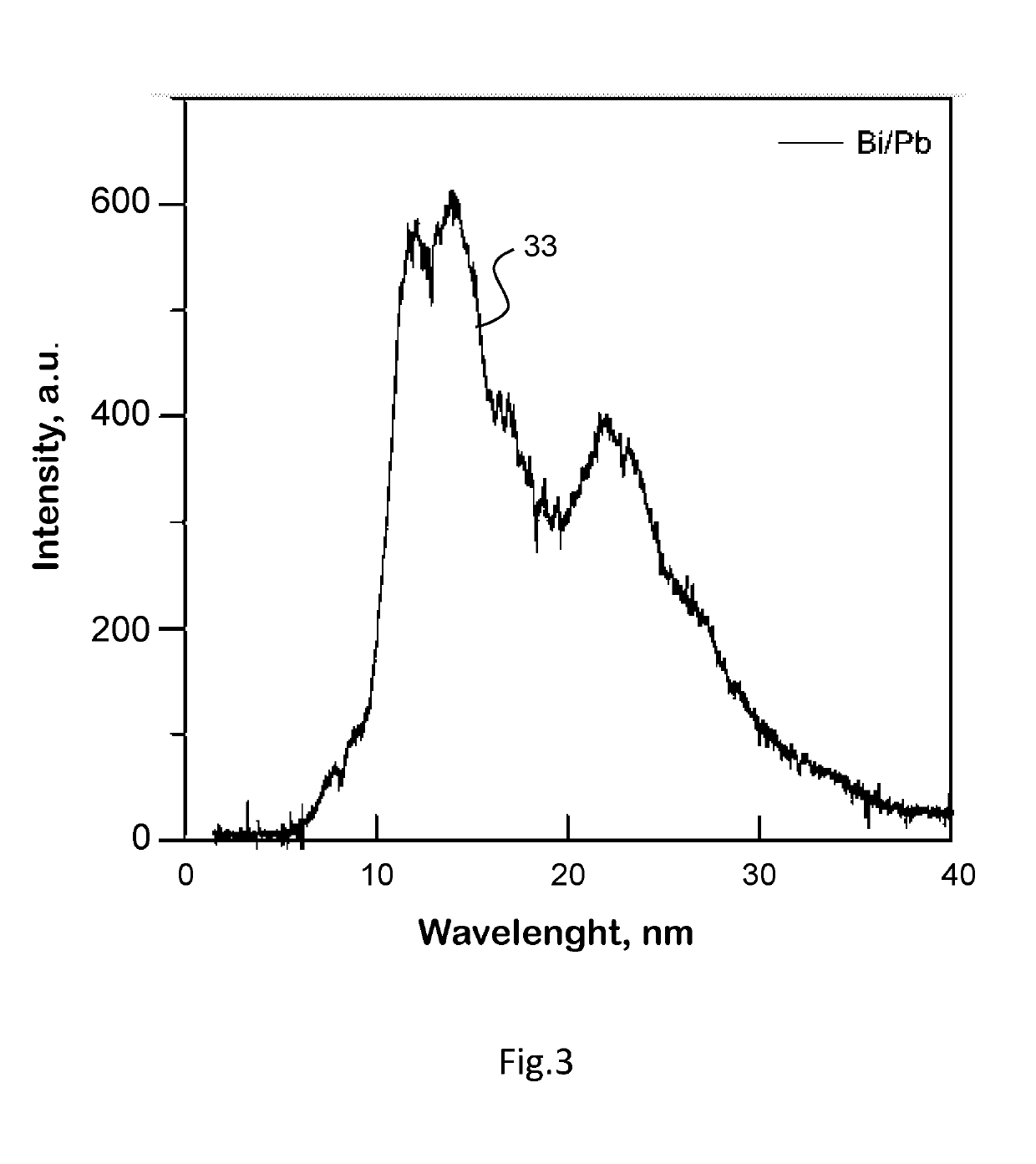

High-brightness laser produced plasma source and methods for generating radiation and mitigating debris

ActiveUS20190166679A1Reduce decreaseExtended service lifeX-ray tube with very high currentX-ray apparatusDropletonLight beam

High-brightness LPP source and method for generating short-wavelength radiation which include a vacuum chamber (1) with an input window (6) for a laser beam (7) focused into the interaction zone (5), an output window (8) for the exit of the short-wavelength radiation beam (9); the rotating target assembly (3), having an annular groove (11); the target (4) as a layer of a molten metal formed by centrifugal force on the surface of the distal wall (13) of the annular groove (11) while the proximal wall (14) of the annular groove is designed to provide a line of sight between the interaction zone and both the input and output windows particularly during laser pulses. A method for mitigating debris particles comprises using an target orbital velocity high enough for the droplet fractions of the debris particles exiting the rotating target assembly not to be directed towards the input and output windows.

Owner:ISTEQ BV

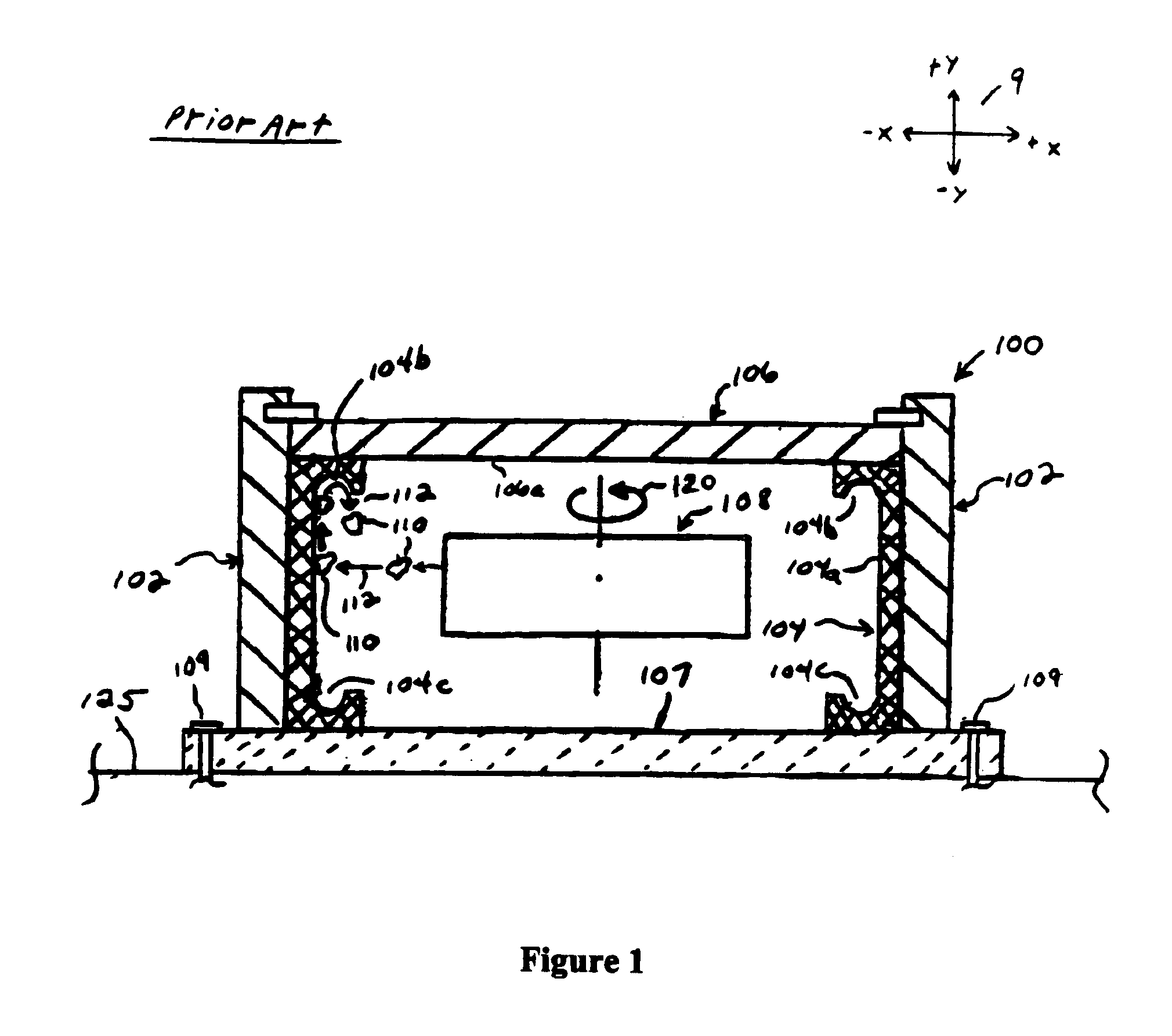

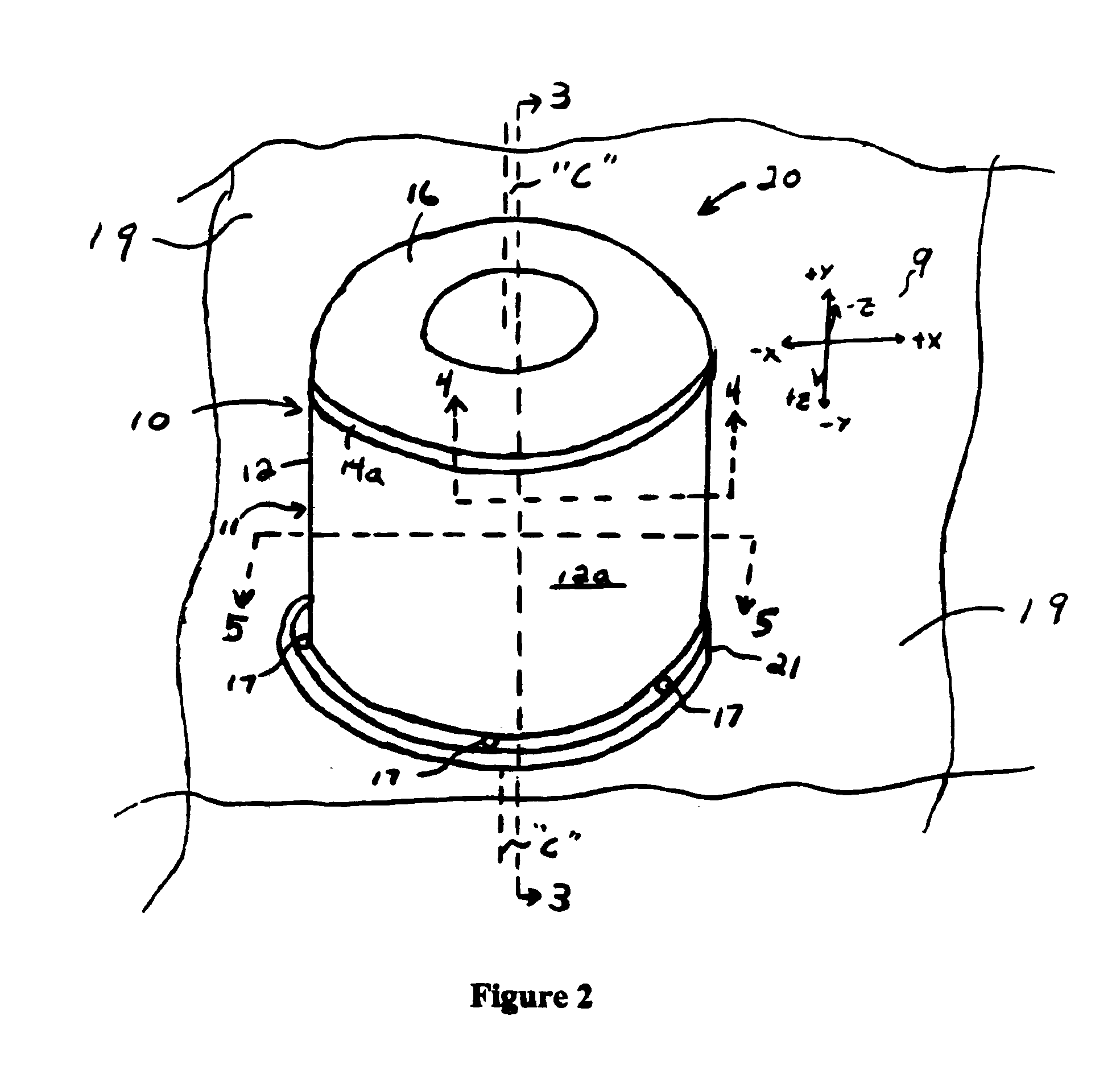

Energy-absorbing housing for high-speed flywheels

The invention provides a flywheel system with energy-absorbing housing. The system provides a novel liner and restraint ribs which serve to de-energize debris particles resulting from the catastrophic failure of a flywheel. Also provided are energy-absorbing housing systems comprising a rotatable liner, one or more restraint ribs, and a fluid film bearing to control and dissipate the energy from the failure of a rotating mass.

Owner:AFS TRINITY POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com