Surgical suction probe system with an easily cleaned internal filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

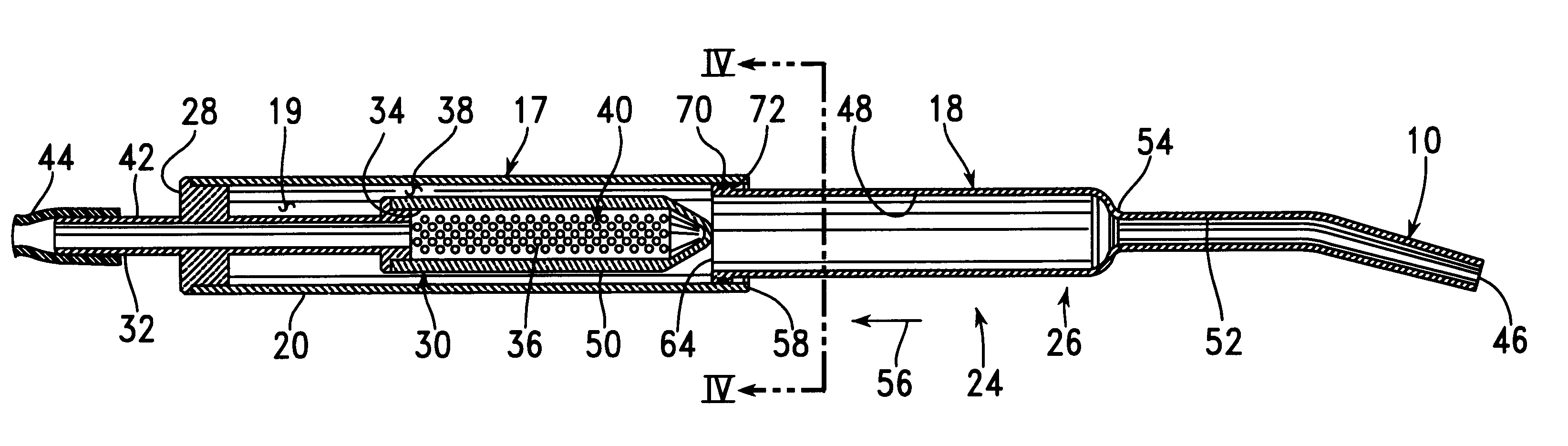

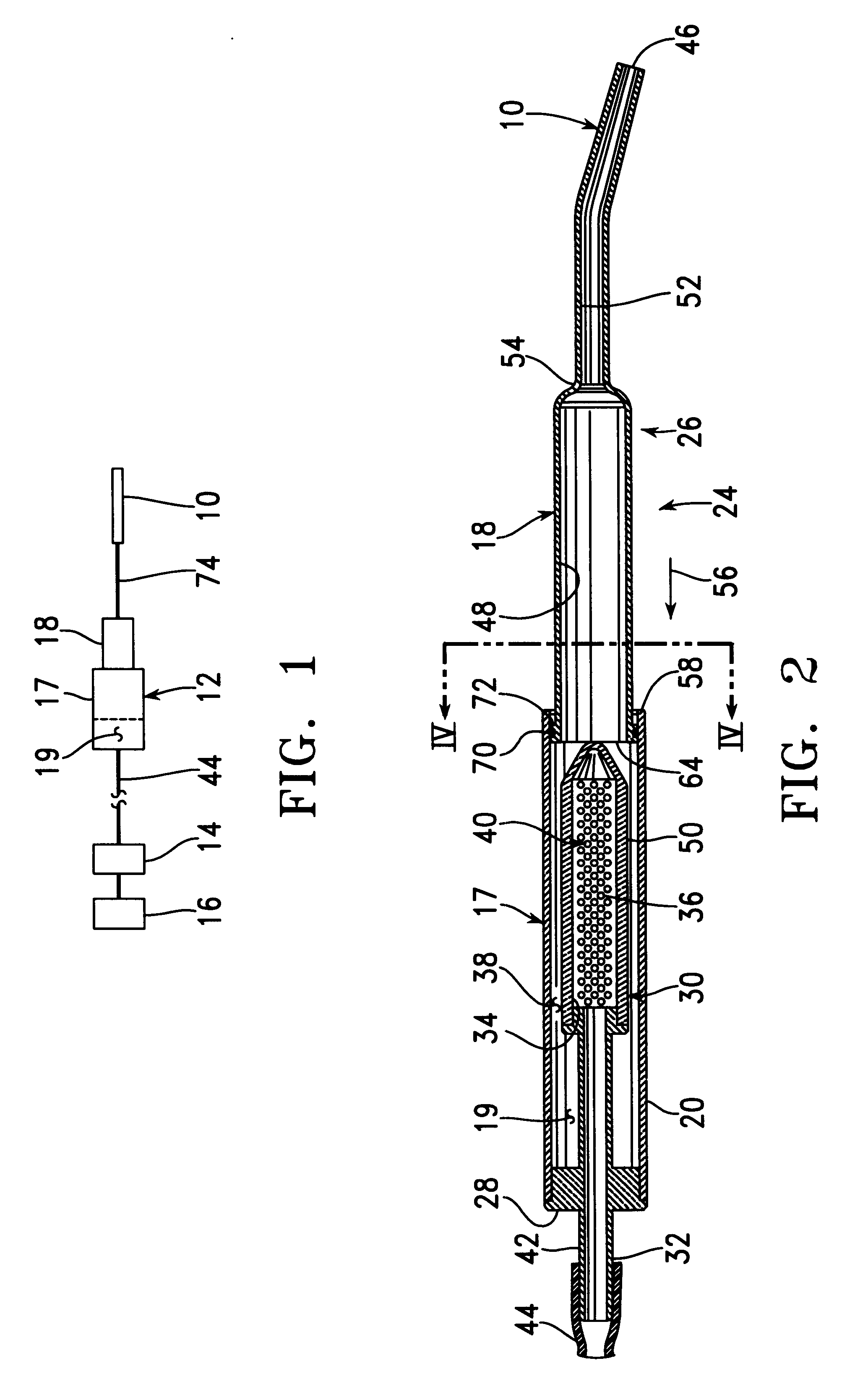

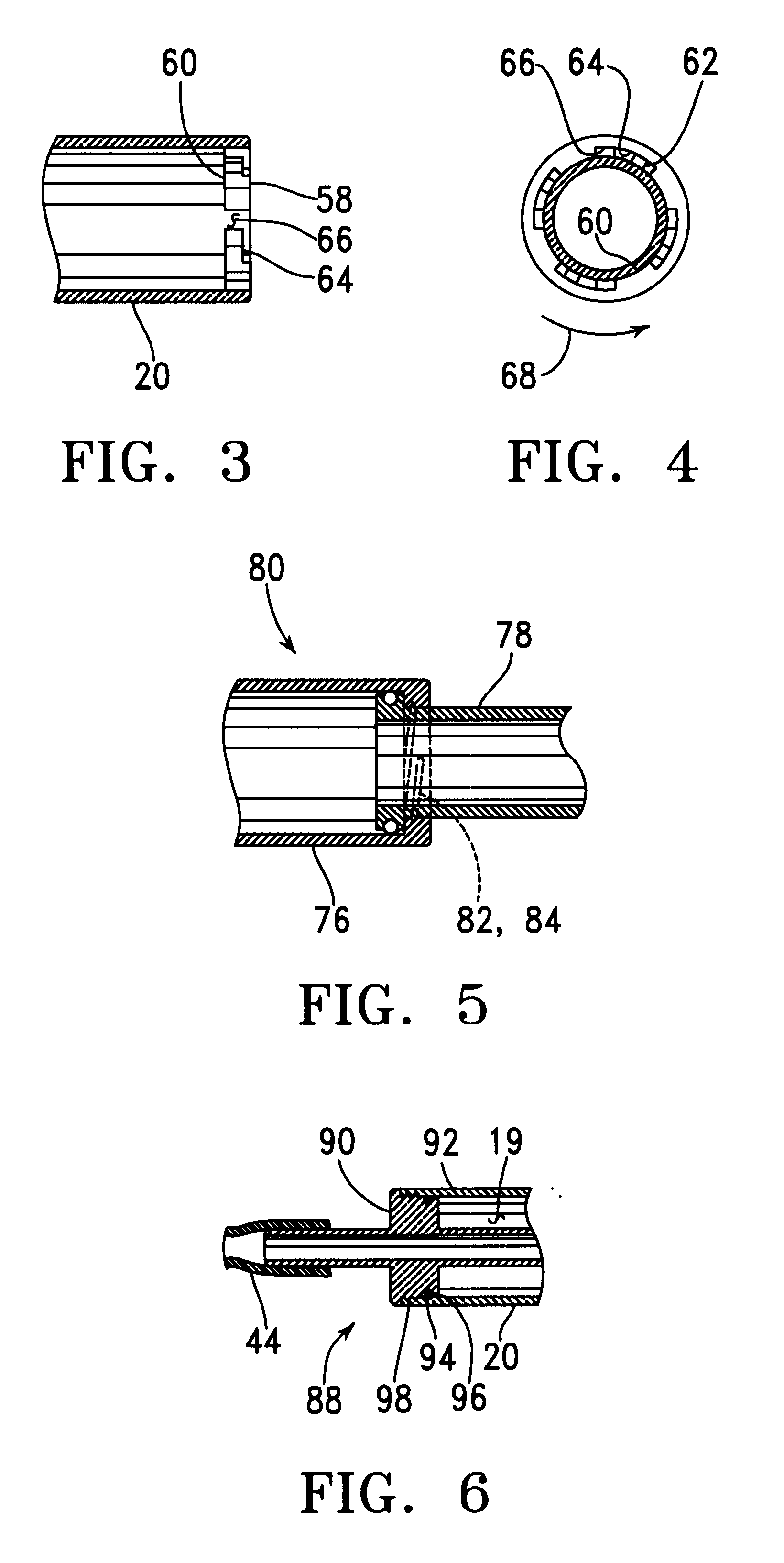

FIG. 1 is a schematic view of a surgical suction system built in accordance with the present invention for removing debris from a surgical site, including a probe tip 10, a first filter 12, a second filter 14, and a vacuum source 16. The surgical suction system may be partly composed of a central vacuum system within the hospital, with the probe tip 10 and the first filter 12 being disposed within an operating room, and with the second filter 14 and the vacuum source 16 being disposed in another part of the hospital in the form of a central vacuum system. In accordance with the present invention, the first filter 12 includes a filter section 17, a slider 18, and a reservoir 19. When the slider 18 is moved into the filter section 16, debris held on a surface of a filter surface (not shown) within the filter section 17 is scraped off the filter surface and deposited within the reservoir 19.

FIG. 2 is a longitudinal cross-sectional view of a surgical suction probe 24 built in accordance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com