System and method for monitoring the condition of a gear assembly

A technology of gears and components used in machine gear/transmission testing, measuring devices, measuring vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

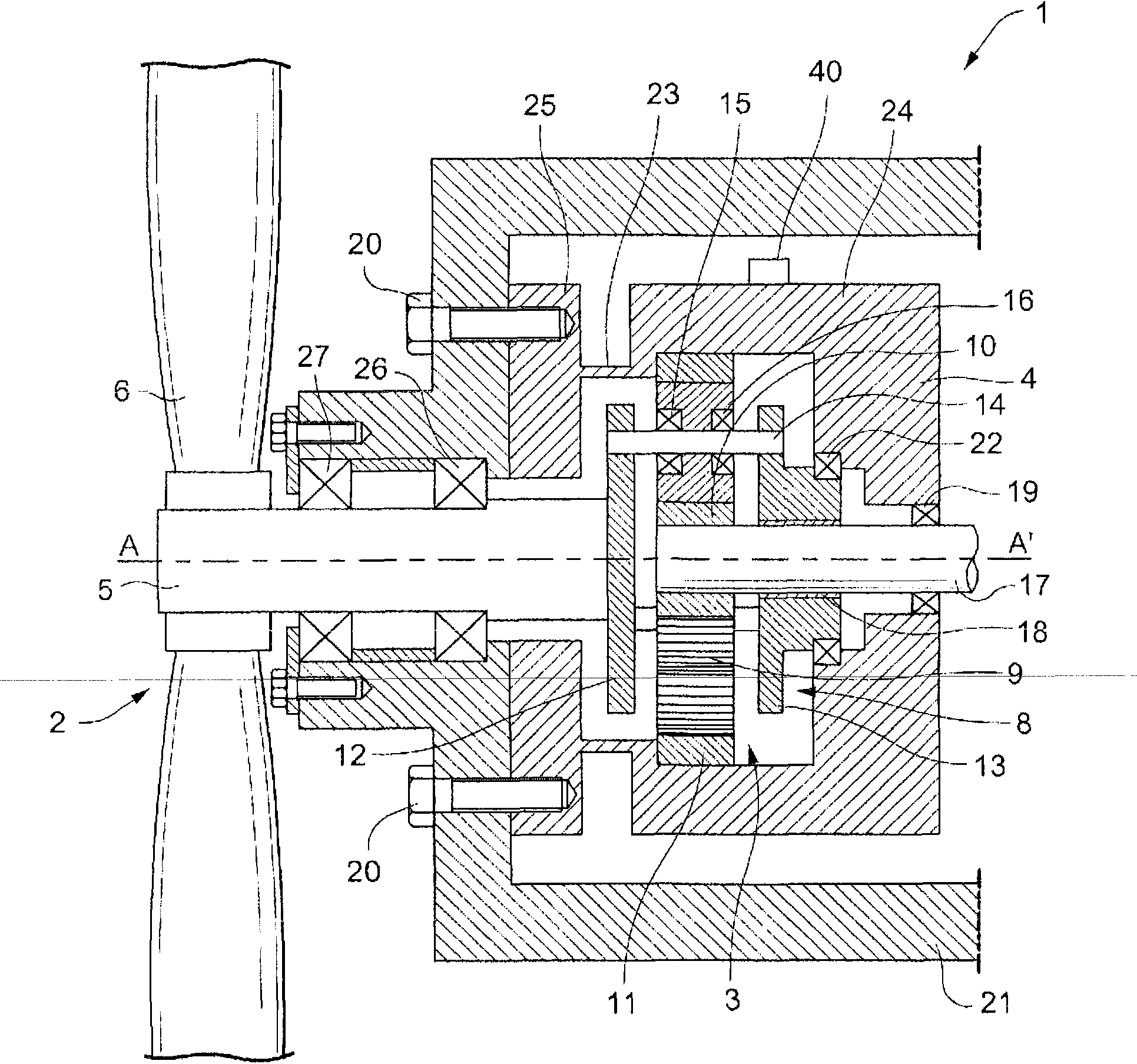

[0010] figure 1 Shown is part of a planetary gear assembly for connecting the rotating blades of a wind turbine to an electrical generator. Such as figure 1 As shown in , a plurality of blades 6 of a wind turbine are connected to a blade shaft 5 . The blade shaft 5 is mounted on the wind turbine via bearings 26,27.

[0011] At the other end of the assembly, the rotating shaft 17 is attached to a generator (not shown). The sun gear 10 is mounted on one end of a rotary shaft 17 . A plurality of planetary gears 9 are positioned between the sun gear 10 and the ring gear 11 . The ring gear 11 is fixed to the housing 24 of the gear assembly.

[0012] The planetary gears 9 are rotatably mounted on a planetary gear shaft 14 mounted on a front planetary gear plate 12 and a rear planetary gear plate 13 . Typically, the planet gears 9 are rotatably mounted on bearings 15 and 16 fixed to the planet gears 9 and the planet gear shafts 14 . This allows the planet gears 9 to rotate fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com