Experimental system for forming characteristic of sodium-cooled fast reactor debris bed

A sodium-cooled fast reactor and experimental system technology, applied in the fields of reactors, climate sustainability, nuclear reaction control, etc., can solve the problem of not involving the fuel particle debris bed, not paying attention to the formation law of the particle bed shape, and the difference in the formation scene of the debris bed and other problems, to achieve the effect of a wide range of research, convenient two-dimensional and three-dimensional experiments, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

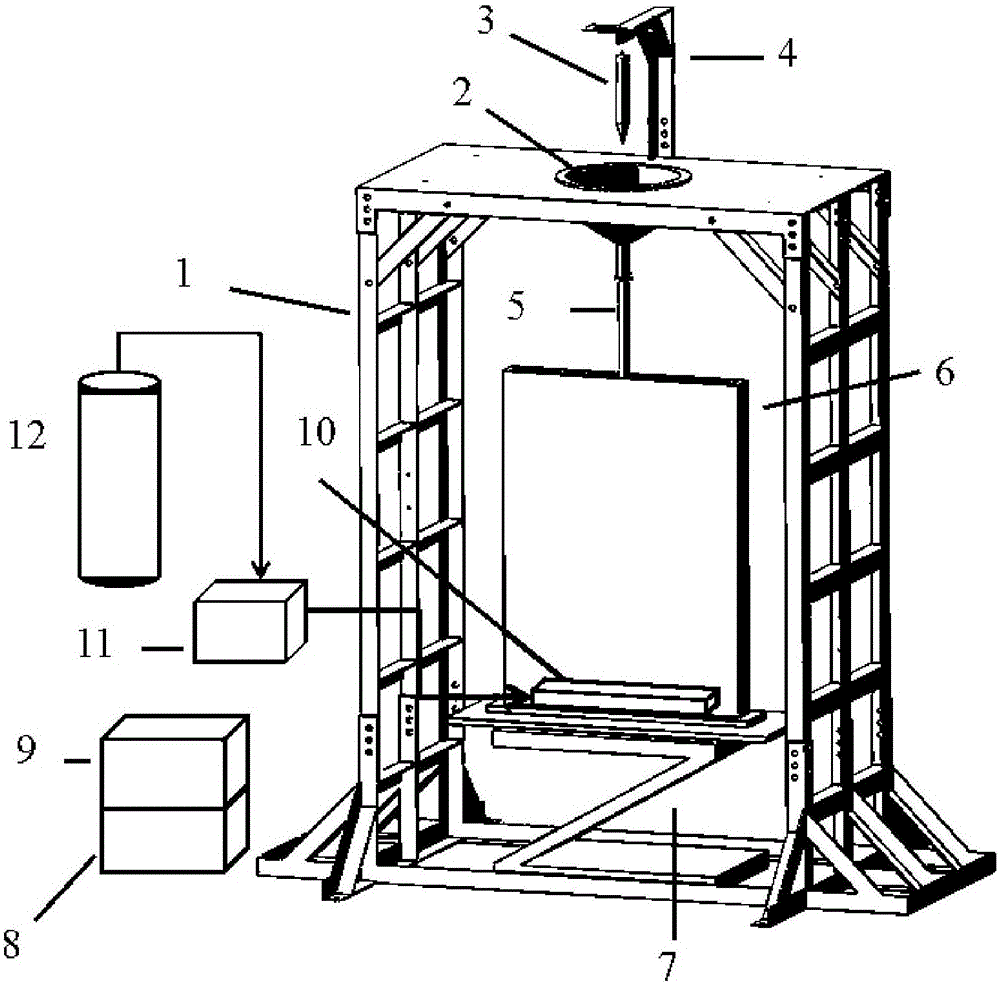

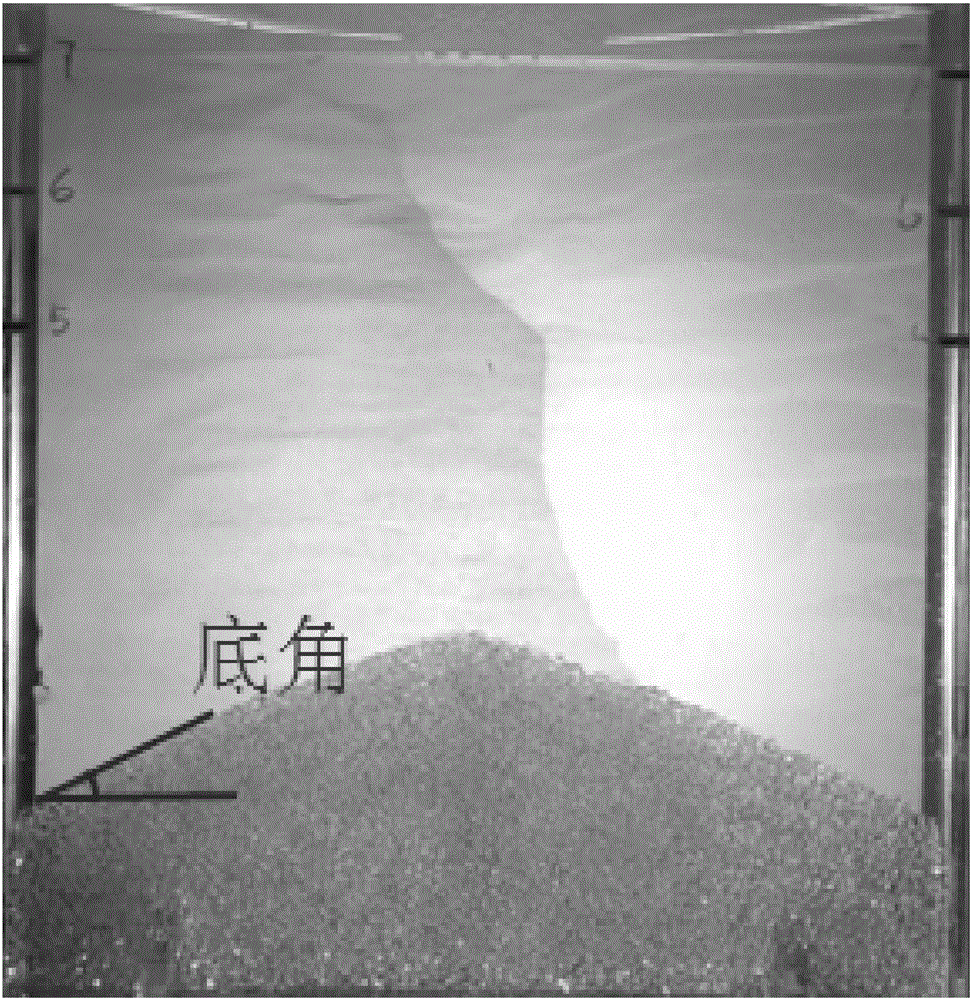

[0049] Example 1: Measuring the bottom angle of the granular bed and analyzing the effect of particle size on the bottom angle of the granular bed

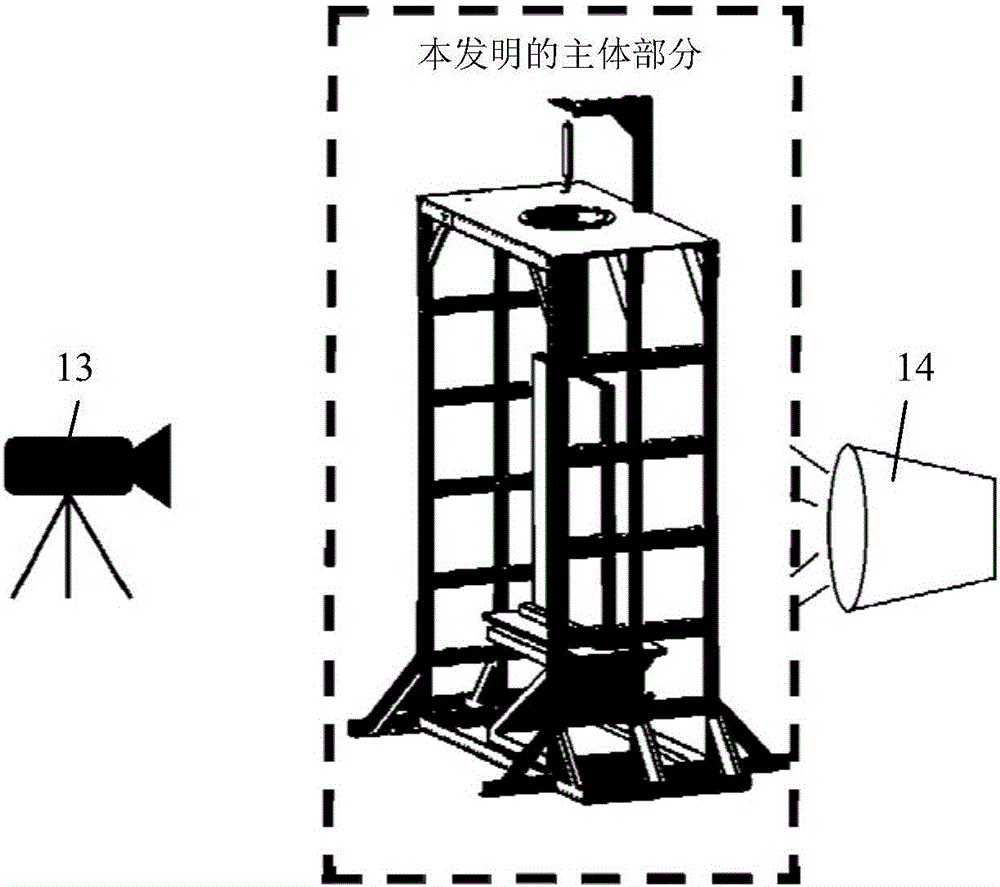

[0050] The particles to be tested are loaded in the particle container 2, and at this time, the particle release control rod 3 fits with the particle container 2 to prevent the release of the particles; according to the experimental needs, select a suitable particle conduit 5 and install it on the bottom of the particle container 2; according to the needs of the experimental parameters, select And replace the visualization experiment container 6 with a suitable width and dimension, and add a certain depth of coolant (water) into it. Fix the thin wire to the top of the particle release control rod 3, pass through the inverted L-shaped pulley bracket 4, and connect to the particle release controller 8. Turn on the backlight 14, place the high-speed camera 13, and connect the camera trigger line to the particle release controller 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com