Patents

Literature

922results about "Material strength using steady torsional forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Motion analysis device and motion analysis method

ActiveUS20120179418A1Accurate calculationImprove accuracyGymnastic exercisingDigital computer detailsObject basedData acquisition

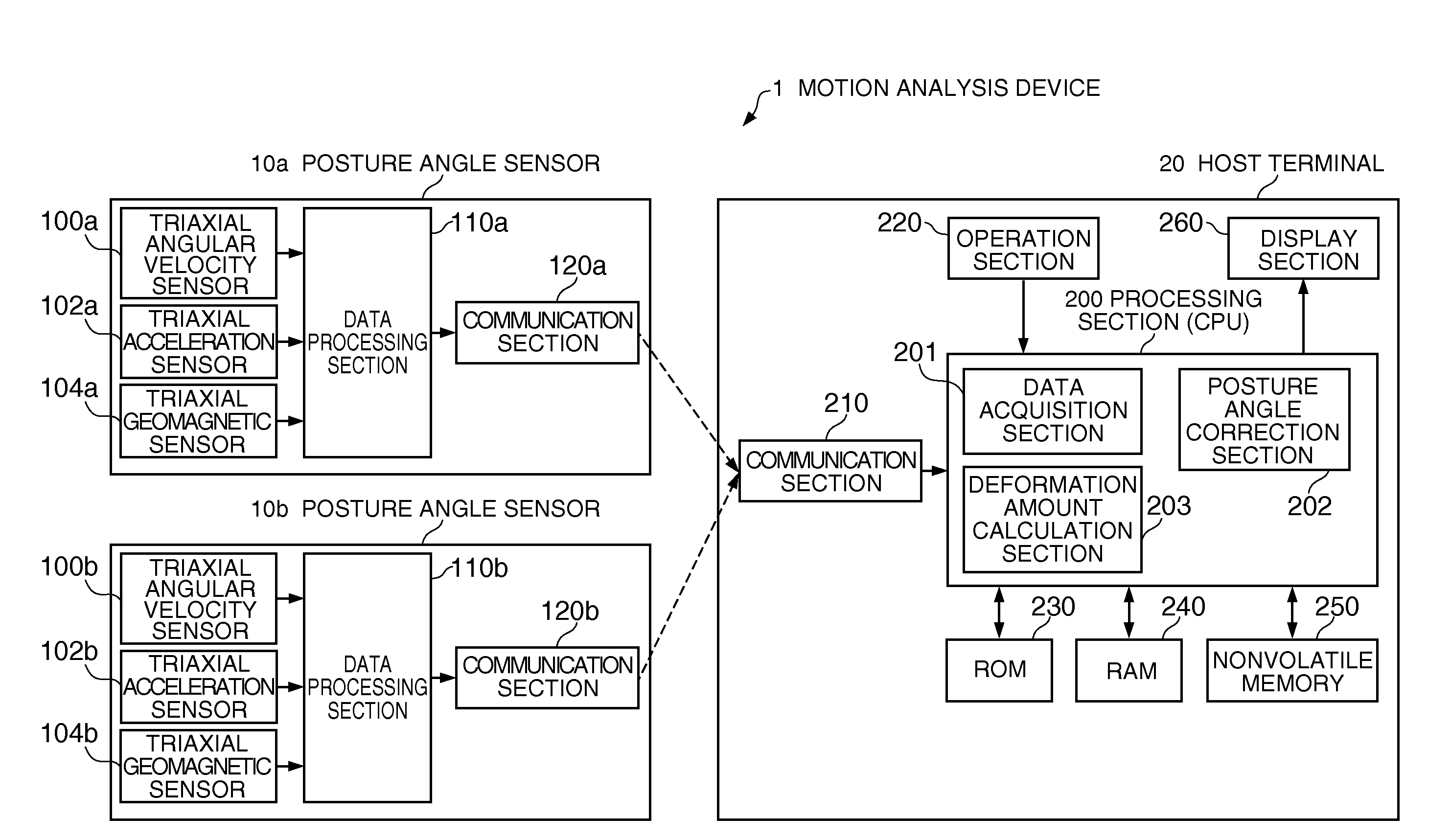

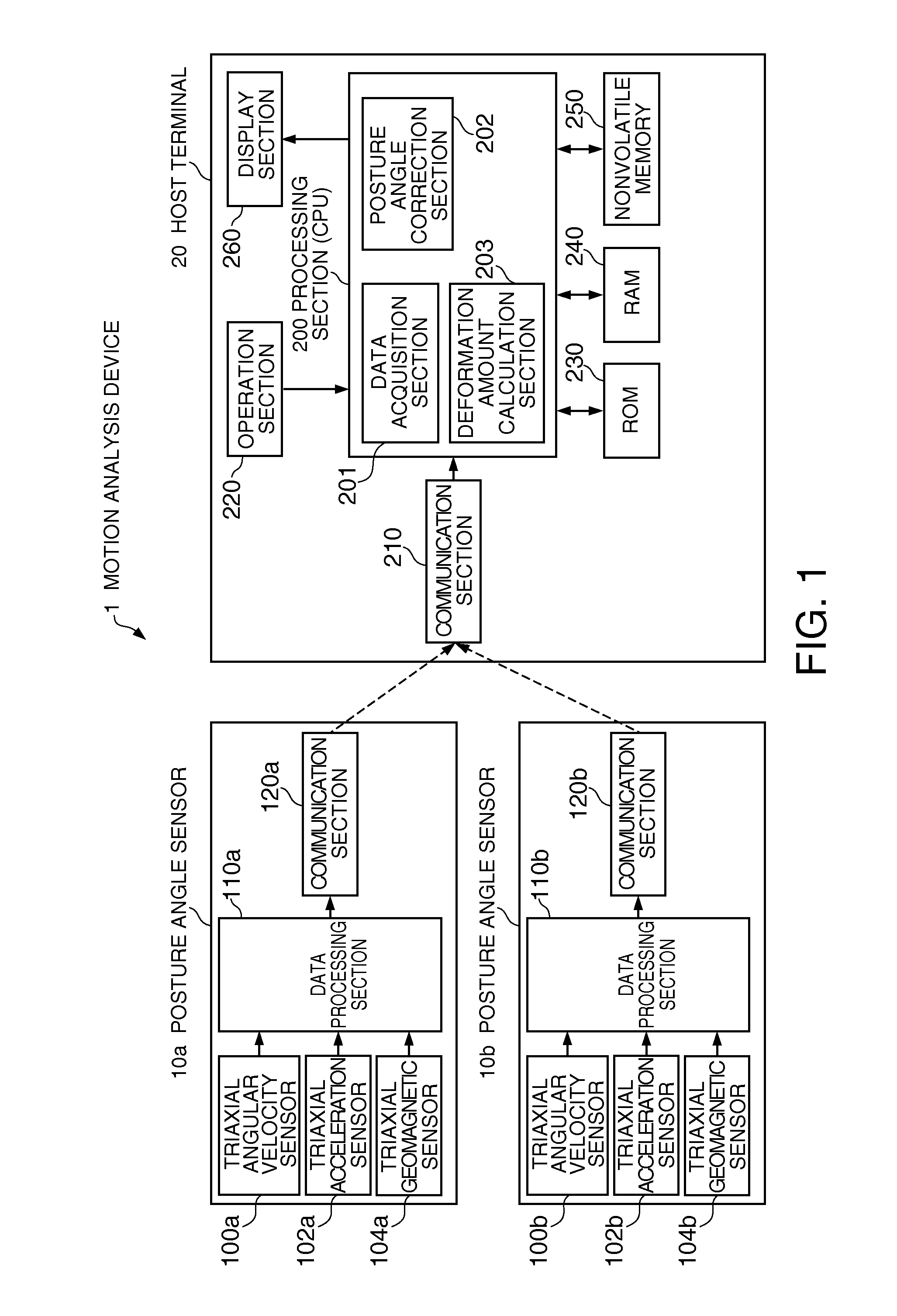

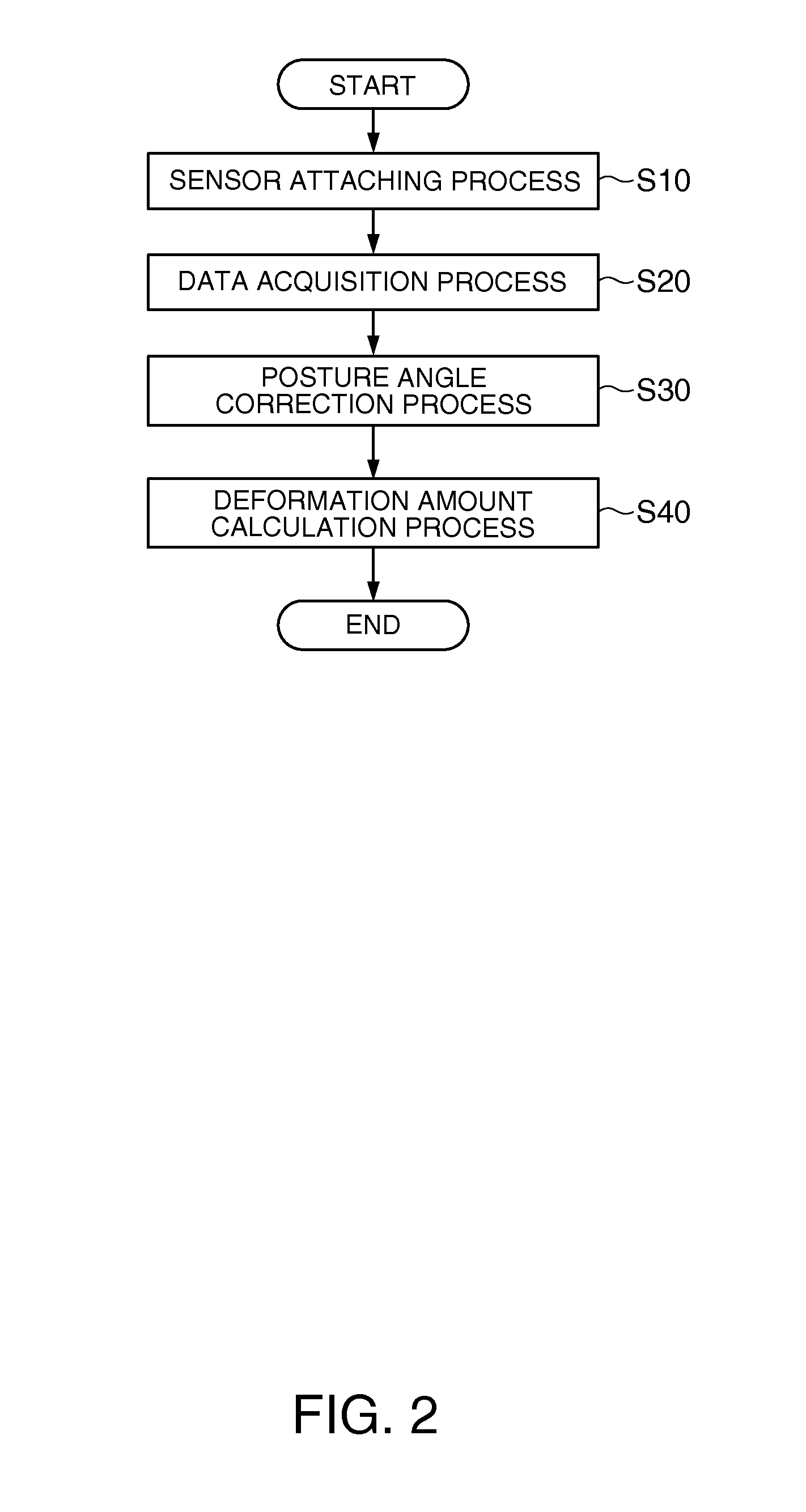

A motion analysis device includes two posture angle sensors attached to a measurement object at locations distant from each other, a data acquisition section, a posture angle correction section, and a deformation amount calculation section. The data acquisition section acquires data of a first posture angle and a second posture angle respectively detected by the posture angle sensors. The posture angle correction section corrects a difference between the first posture angle and the second posture angle after starting a motion of the measurement object in accordance with a difference between the first posture angle and the second posture angle before starting the motion of the measurement object. The deformation amount calculation section calculates a deformation amount of the measurement object based on a difference between the first posture angle and the second posture angle corrected by the posture angle correction section.

Owner:SEIKO EPSON CORP

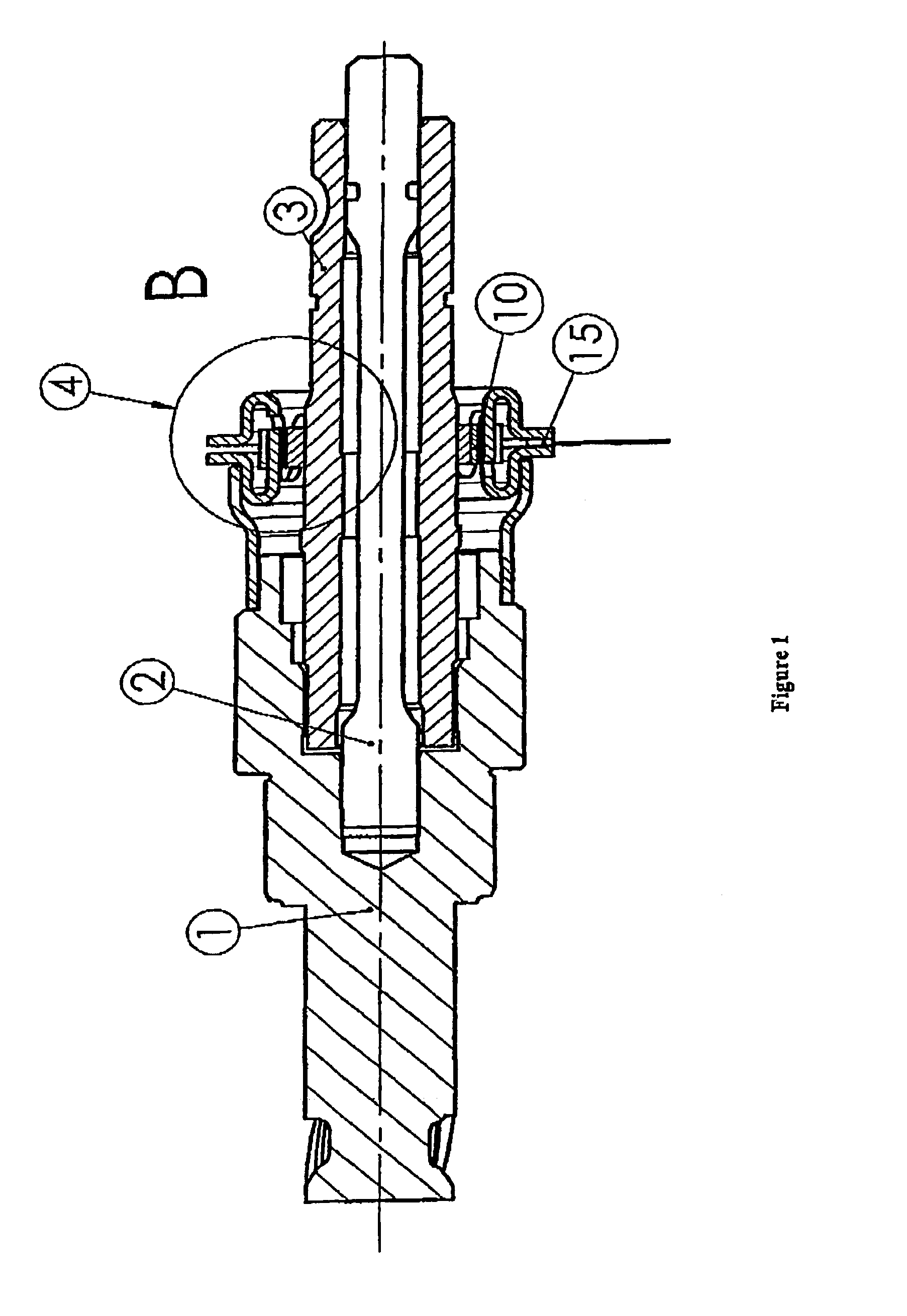

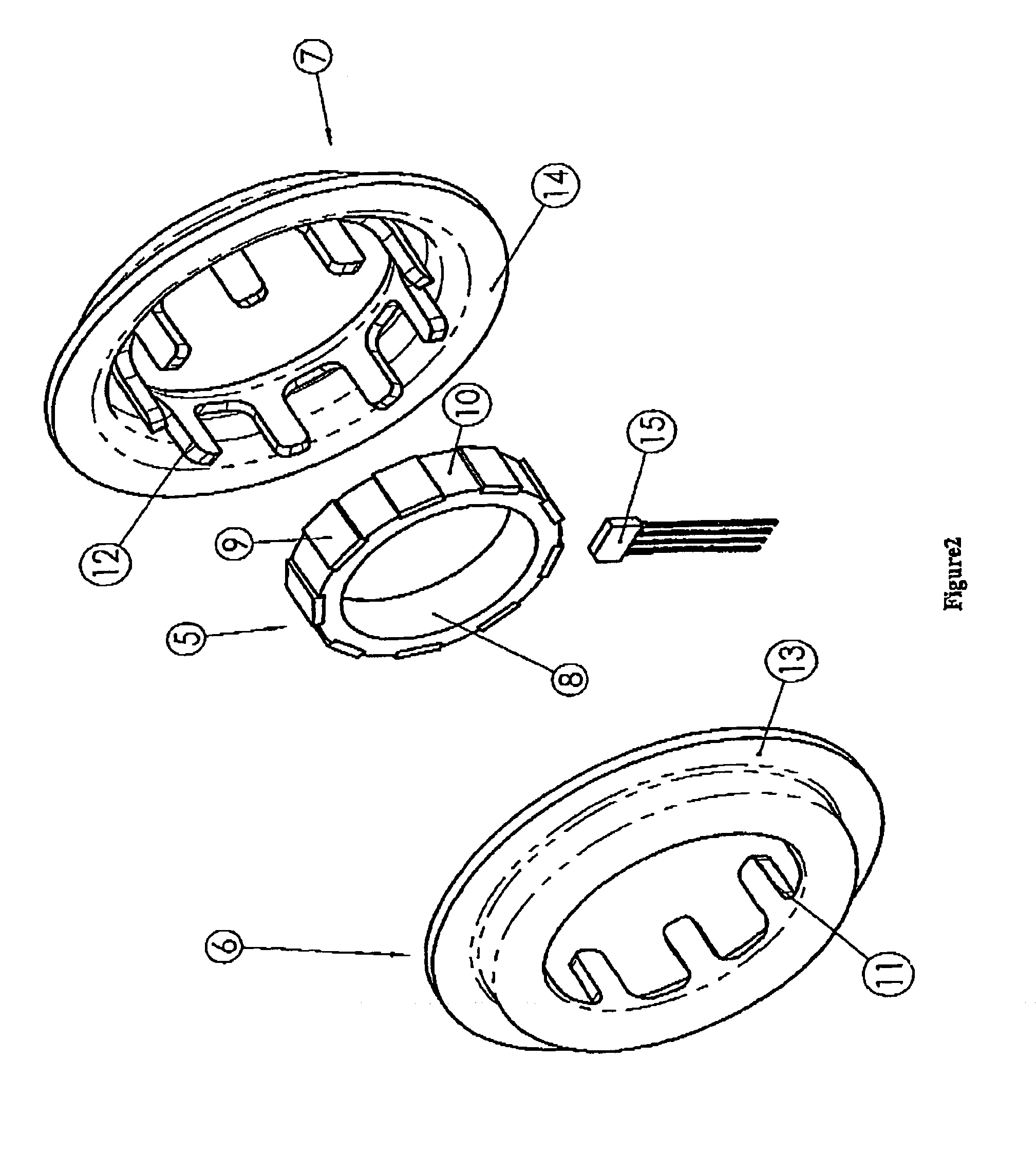

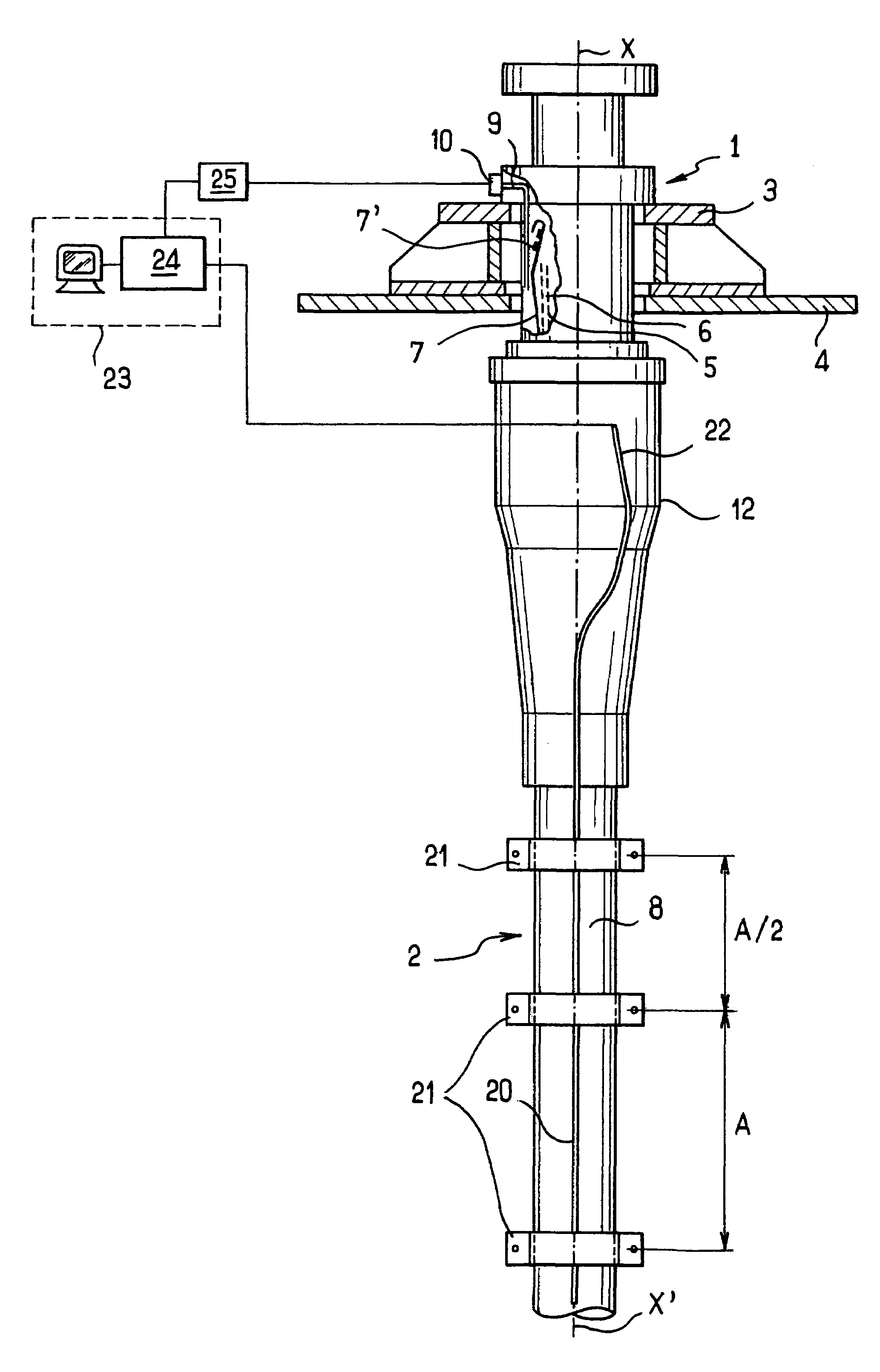

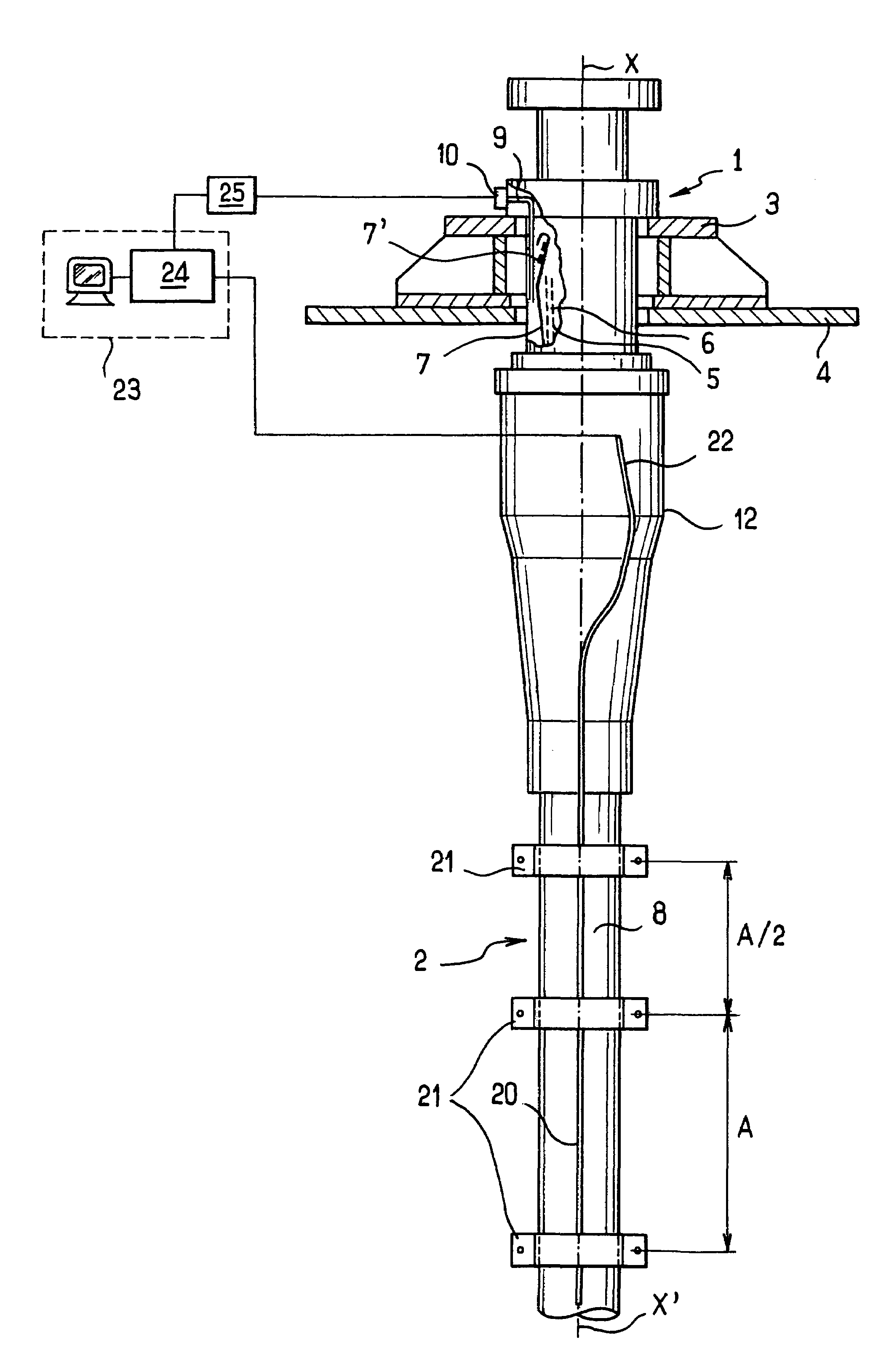

Position sensor, designed in particular for detecting a steering column torsion

InactiveUS7028545B2Better signal to noise ratioRaise the ratioWork measurementUsing electrical meansSteering columnEngineering

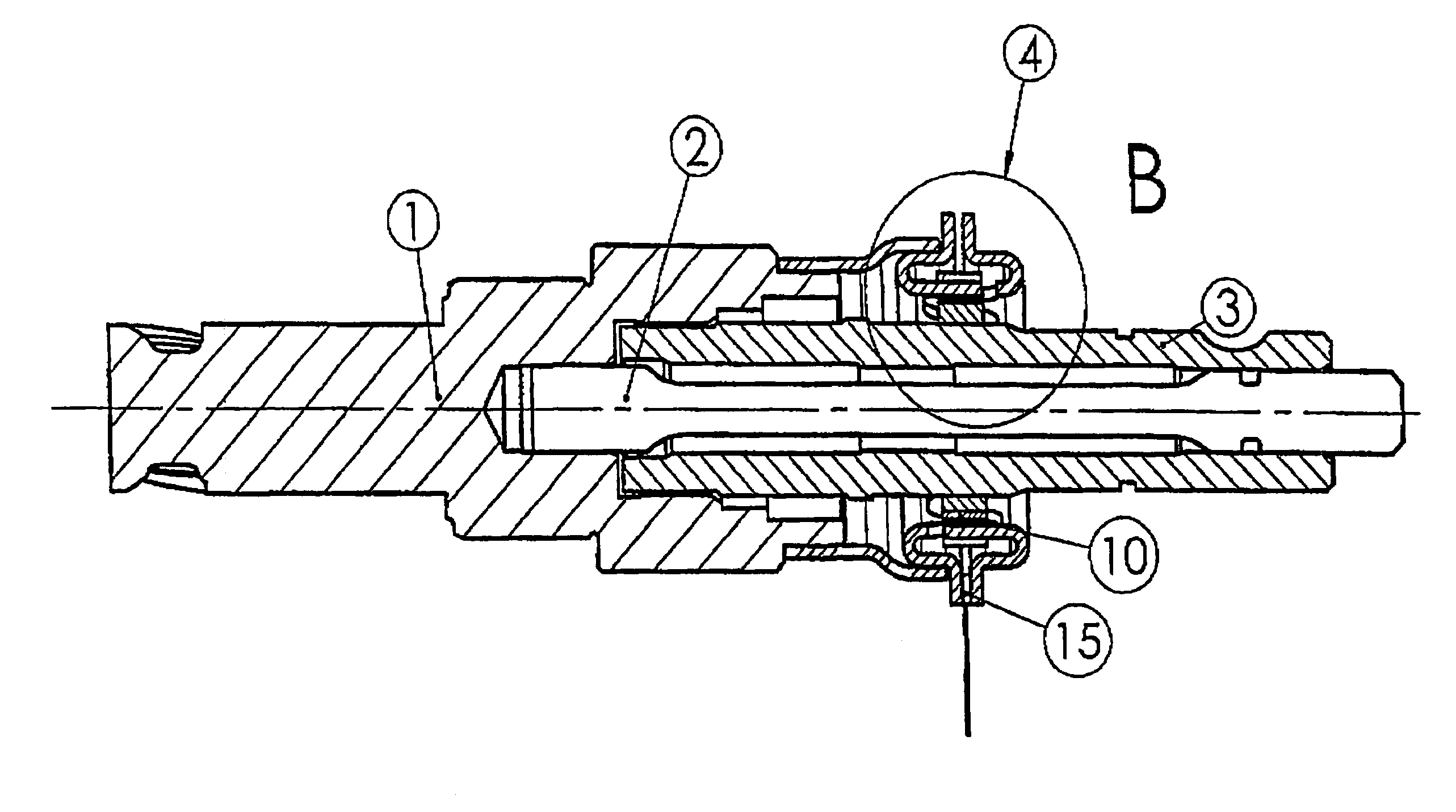

The invention concerns a position sensor, designed in particular for detecting a steering column torsion, consisting of a first magnetic structure including a plurality of magnets and a second magnetic structure including two ferromagnetic rings (6, 7) having a plurality of teeth (11, 12) and defining an air gap wherein is placed at least a magneto-sensitive element (15), the two magnetic structures being respectively integral with two parts in relative rotation. The invention is characterised in that the two ferromagnetic rings (6, 7) are nested and have each a substantially tubular part forming axially oriented teeth (11, 123) connected by a flux-closing zone (13, 14), the detecting air gap being delimited by said flux-closing zones.

Owner:MOVING MAGNET TECH

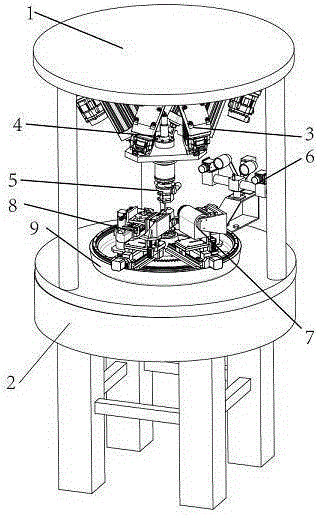

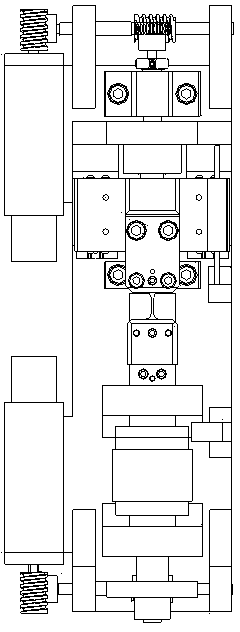

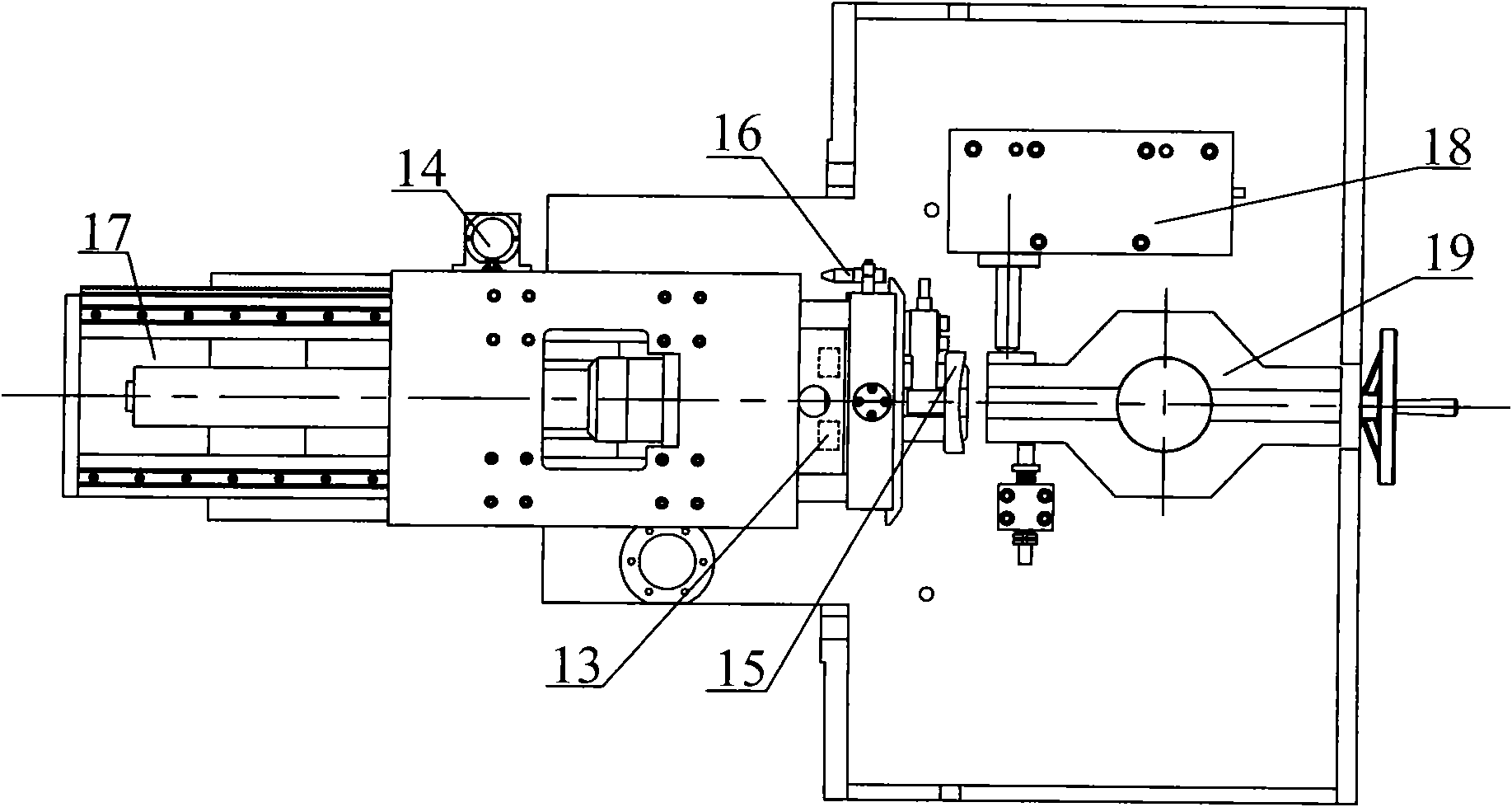

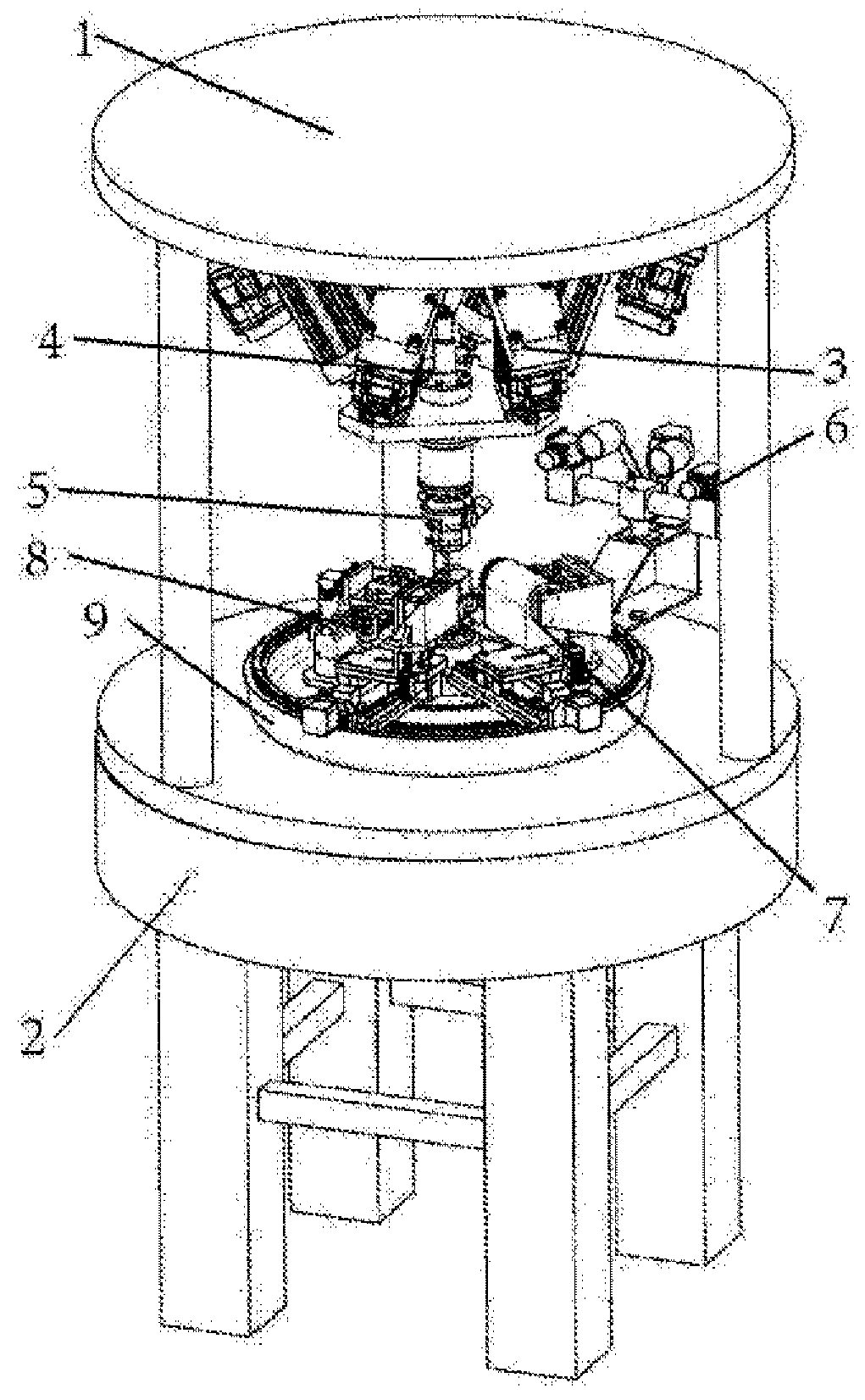

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

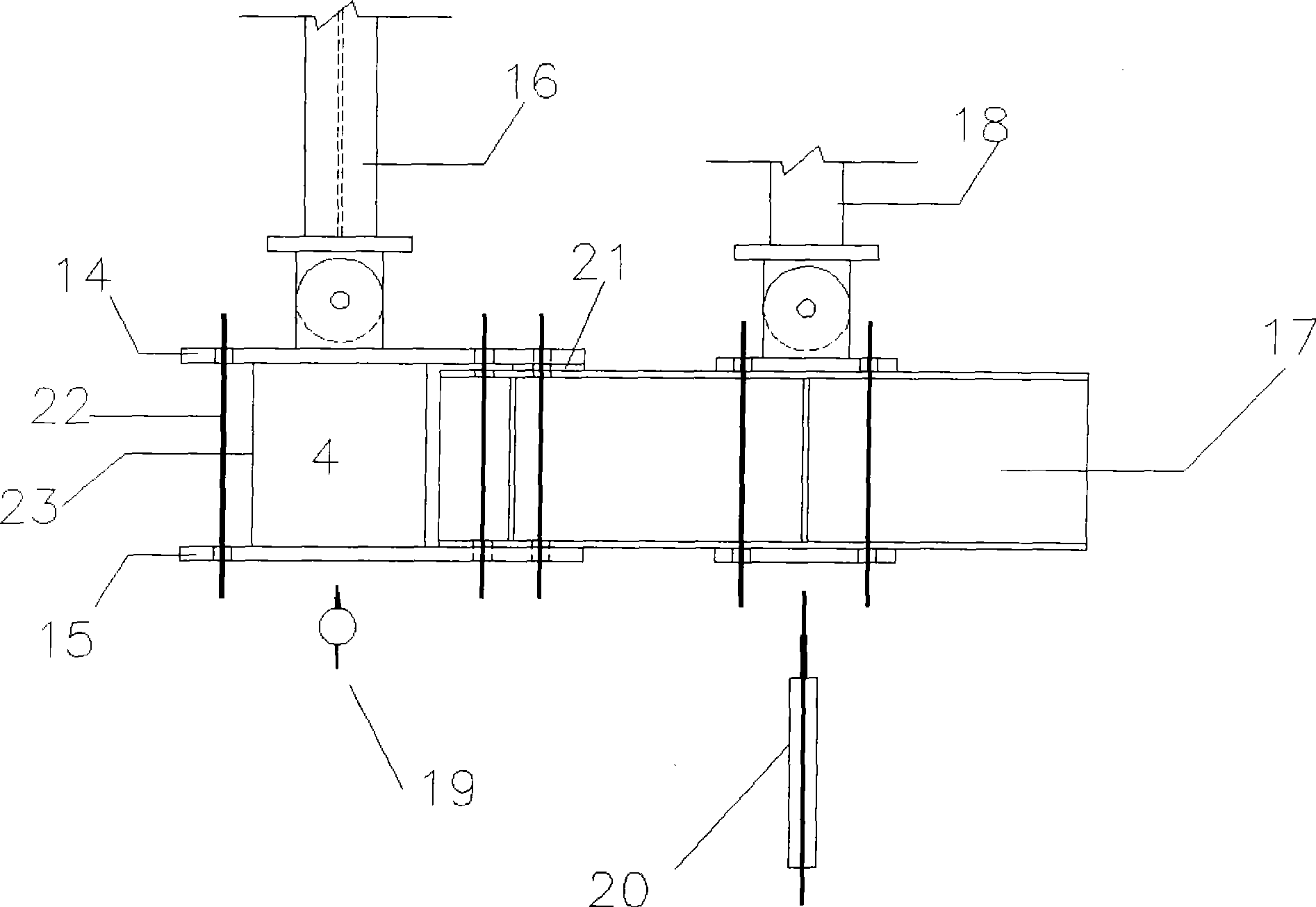

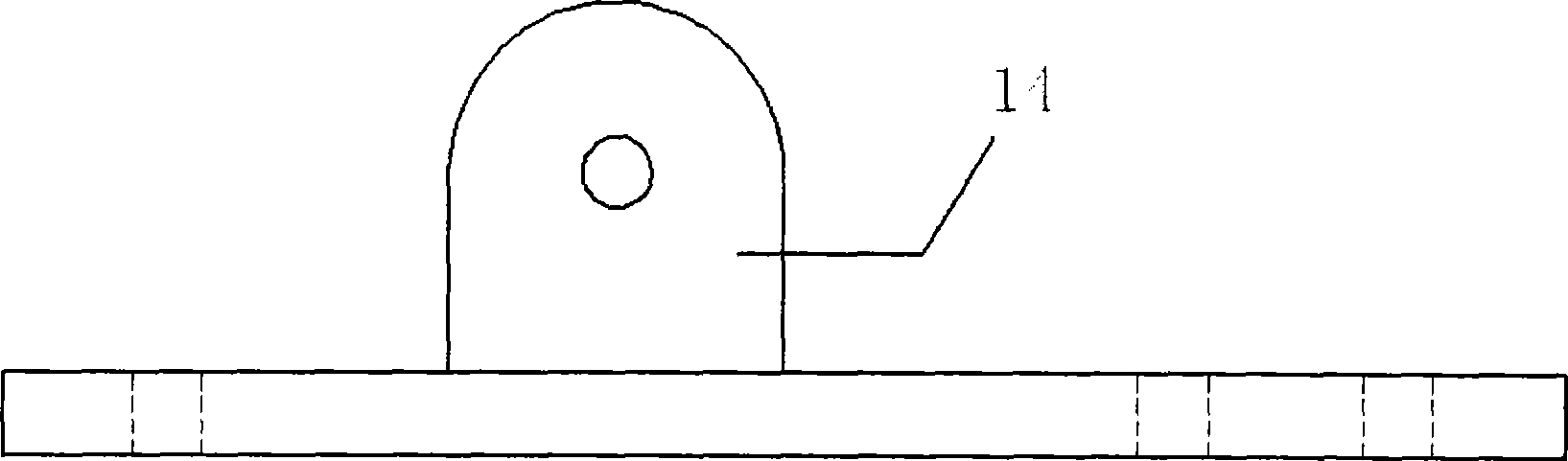

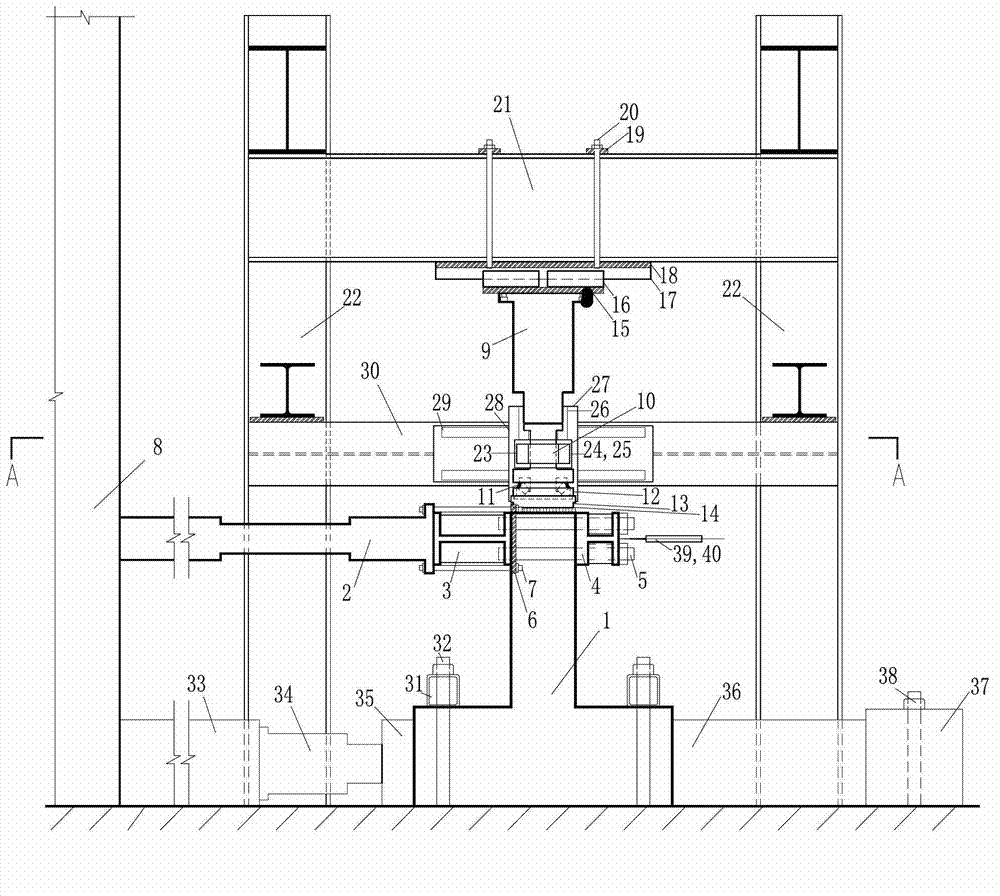

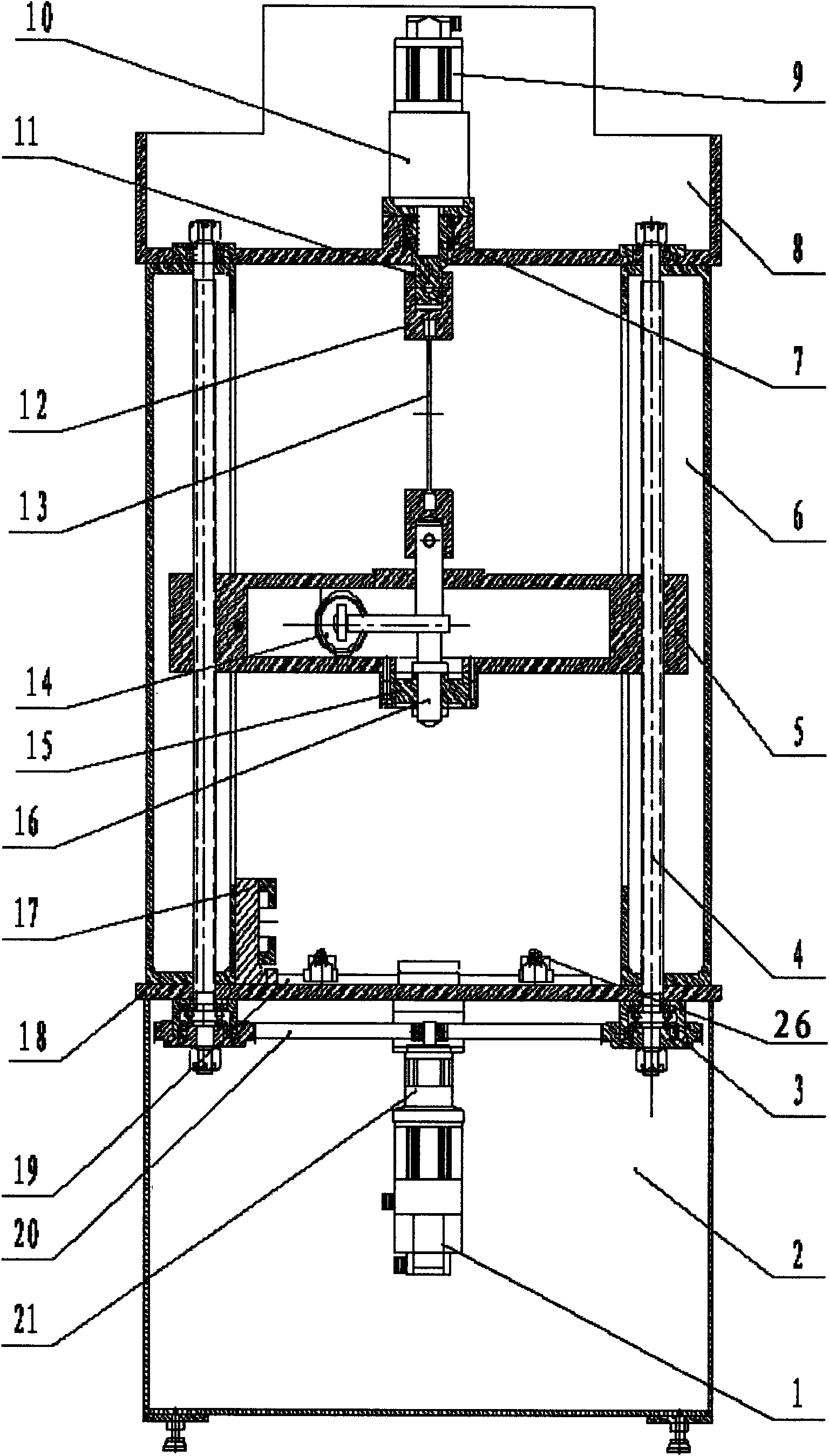

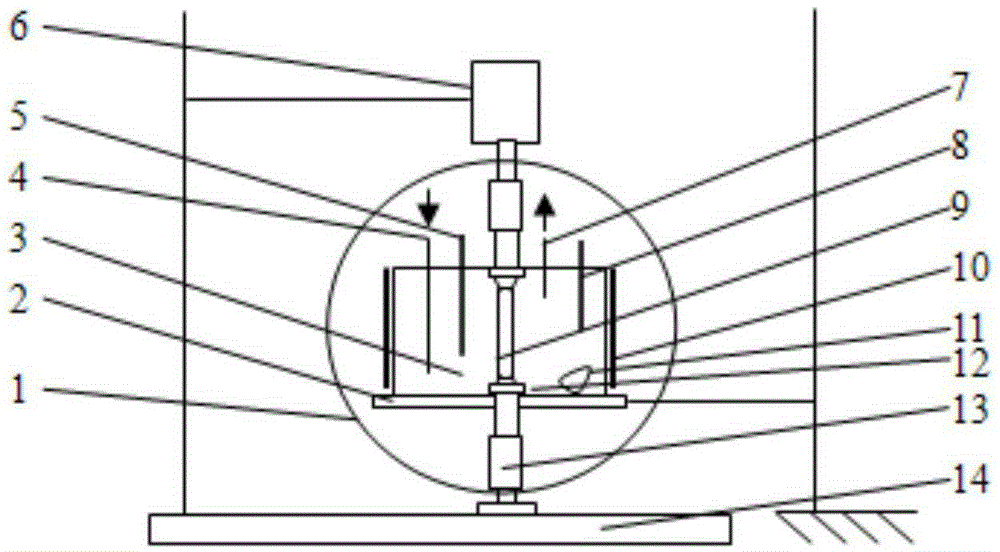

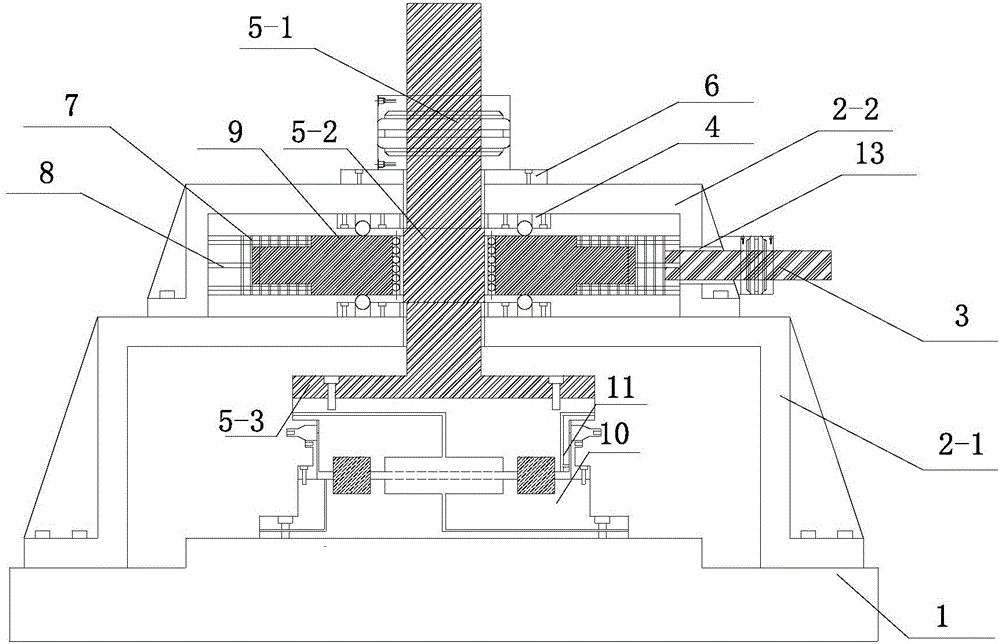

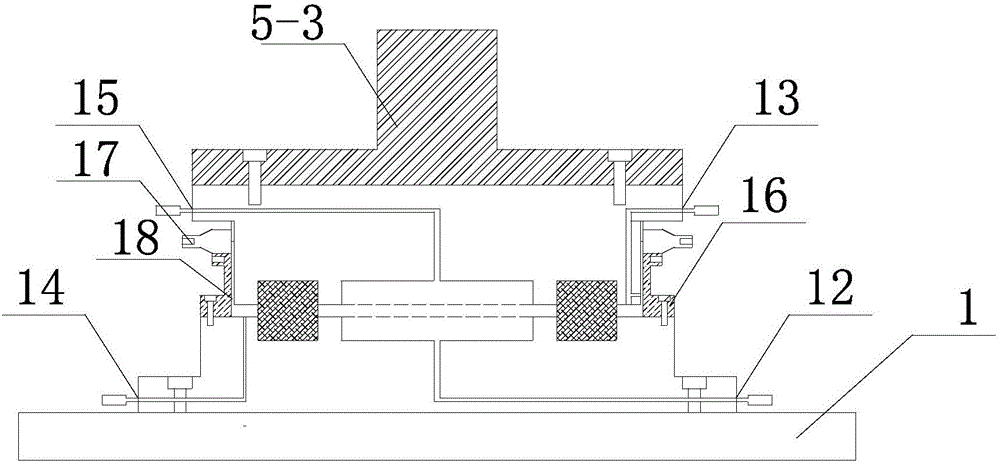

Component pressing and twisting experimental device and method thereof

InactiveCN101498625AObservation forceEasy to measureStructural/machines measurementMaterial strength using steady torsional forcesHorizontal forceAxial pressure

The invention relates to a device and a method for component compression-torsion testing, belonging to the technical field of architecture structure test. The device comprises a pedestal, a reaction beam, a reaction wall, a vertical force jack, a front clamp plate, a back clamp plate, a pure torsion loading beam, a loading beam and a horizontal force jack, wherein a component is fixed on the pedestal; the vertical force jack is connected at the lower surface of the reaction beam and corresponds to the component in position; the top of the component is tightly clamped between the front clamp plate and the back clamp plate; the loading beam is fixedly connected with the front clamp plate and the back clamp plate; one end of the pure torsion loading beam is articulated with the front clamp plate and the other end is fixedly connected with the reaction wall; one end of the horizontal force jack is articulated with the loading beam by a force sensor and the other end is fixedly connected with the reaction wall. In a test, the vertical force jack applies axial pressure to the component and the horizontal force jack applies horizontal force to the component to form the torque to the component. The device for component compression-torsion testing has simple structure and convenient assembly, can be used instantly after the assembly and can be used repeatedly.

Owner:BEIJING UNIV OF TECH

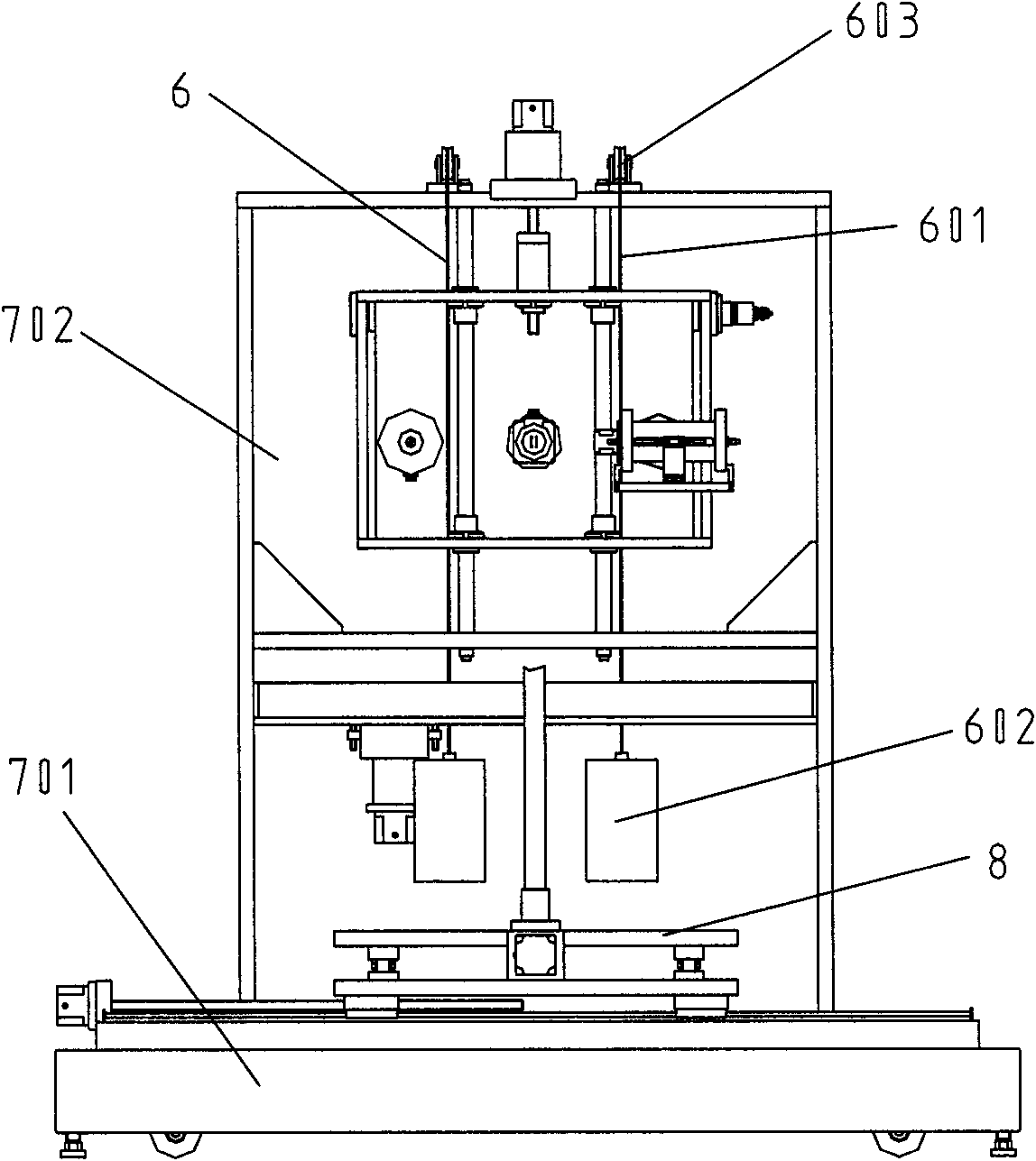

Pressing-twisting multi-shaft loading testing machine

ActiveCN101949800AGreat effortUniform and controllable dynamic and staticMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesControl systemAxial pressure

The invention discloses a pressing-twisting multi-shaft loading testing machine. The pressing-twisting multi-shaft loading testing machine comprises a machine frame, a sample pressure chamber, an axial pressure controller, a confining pressure controller and an oil source system, wherein the sample pressure chamber is arranged on the machine frame and is used for accommodating samples therein; the axial pressure controller is used for applying axial loads to the samples in the sample pressure chamber; the confining pressure controller is used for applying confining pressure loads to the samples in the sample pressure chamber; the oil source control system is used for controlling the axial pressure controller and the confining pressure controller respectively to apply different paths of loads; and the axial pressure controller and the confining pressure controller are configured in a mode that the axial force is coupled with the confining force when the loading of the samples in the sample pressure chamber is buffered. The pressing-twisting multi-shaft loading testing machine can integrate complicated loading such as pressing-twisting combination, plane strain, true triaxiality and the like and is suitable for the tests of static power units of the common coarse-grained soil and ideal soil simulation materials during engineering construction.

Owner:TSINGHUA UNIV

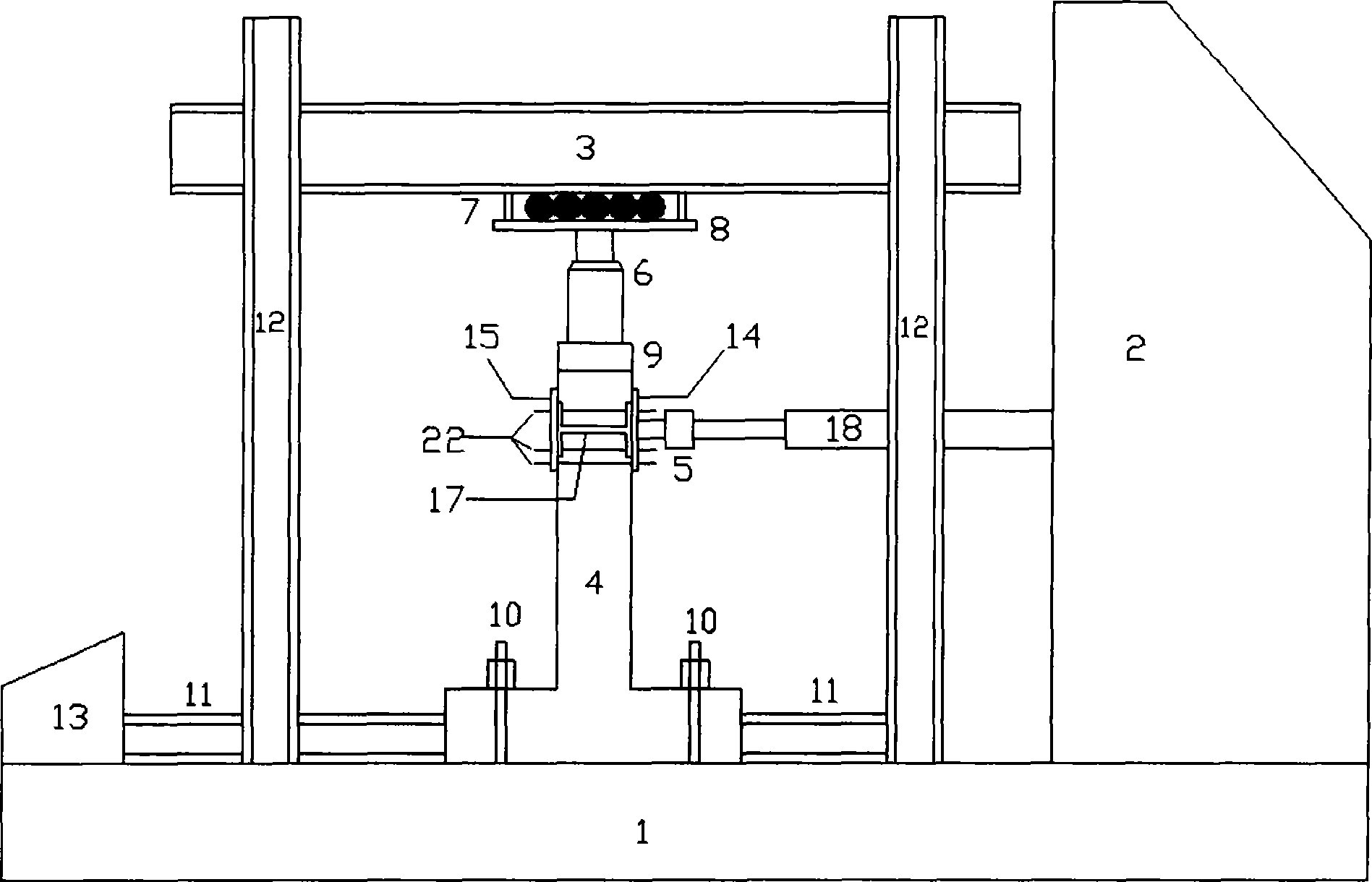

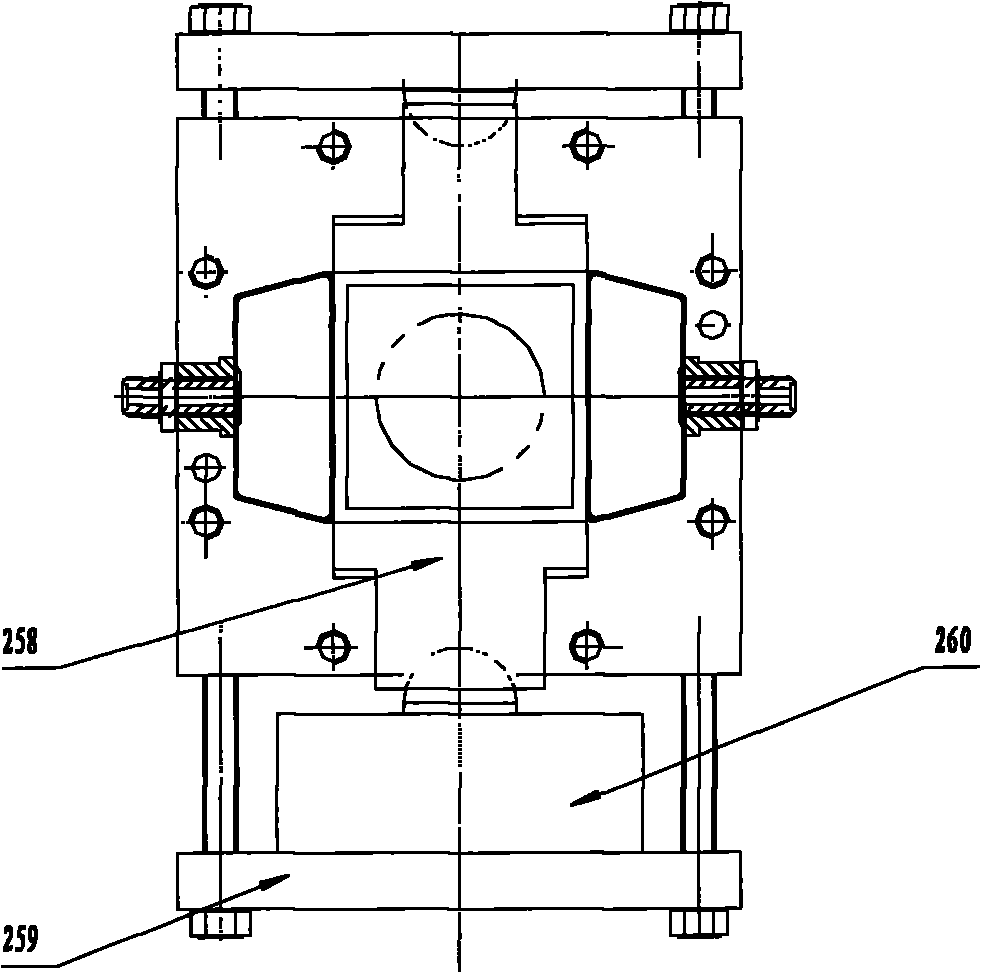

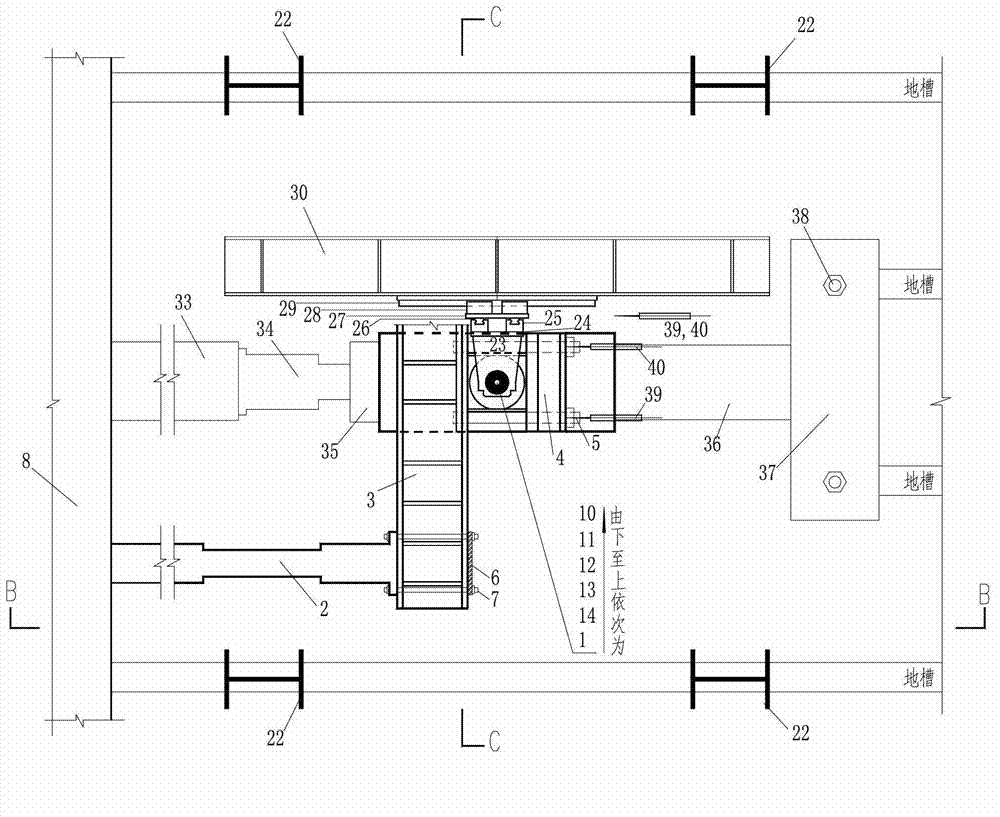

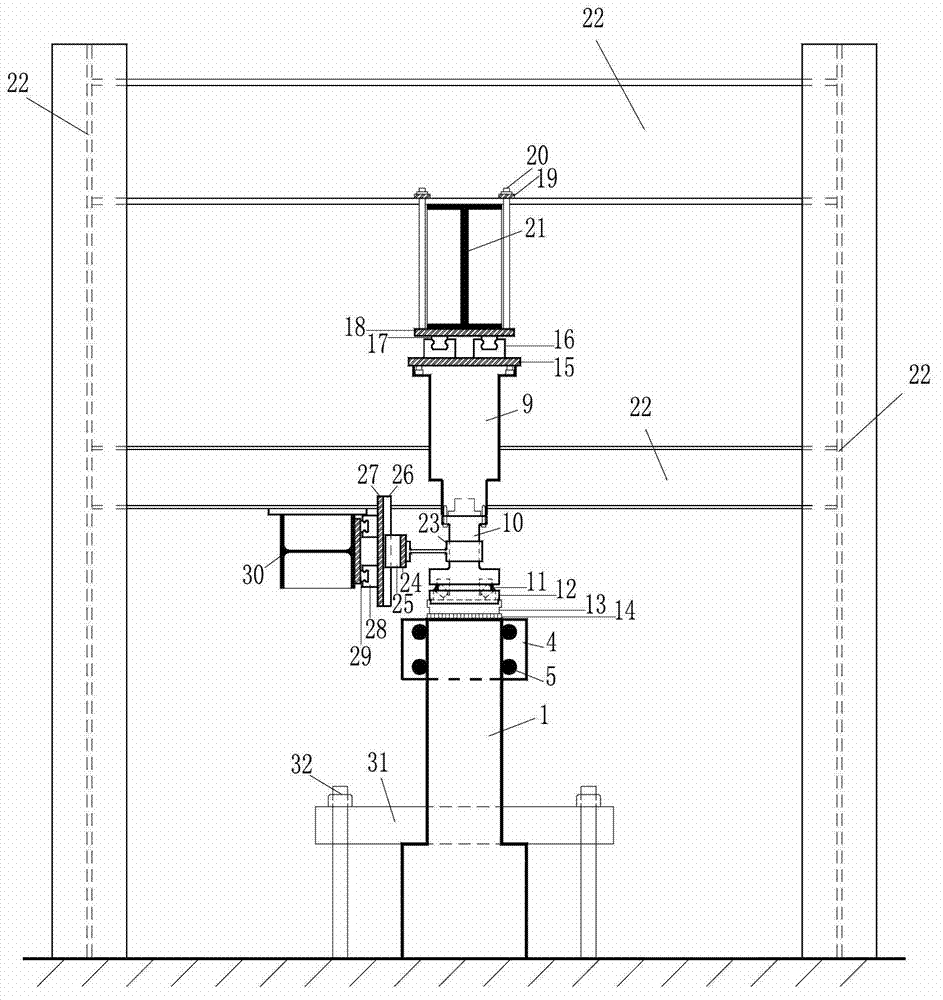

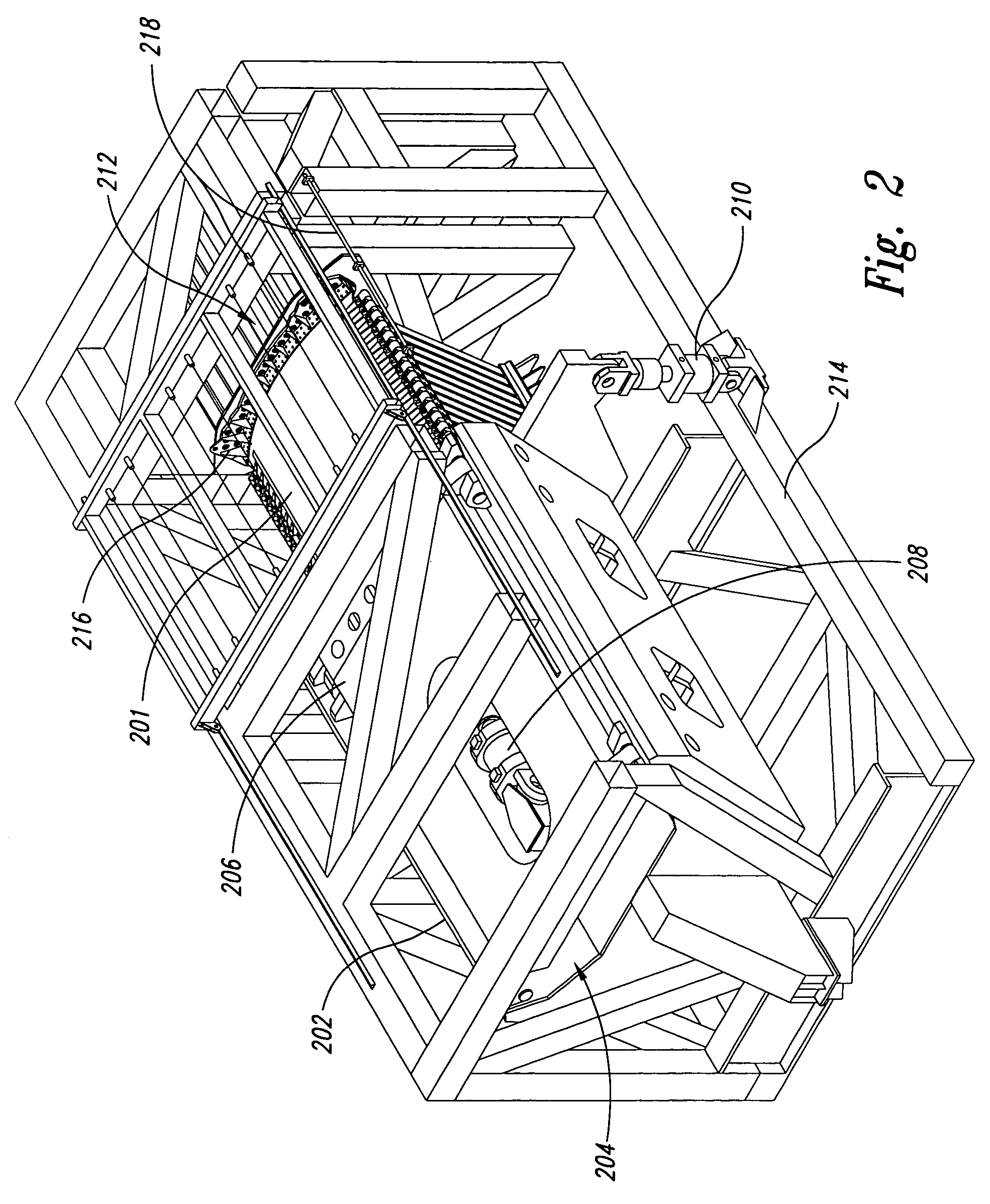

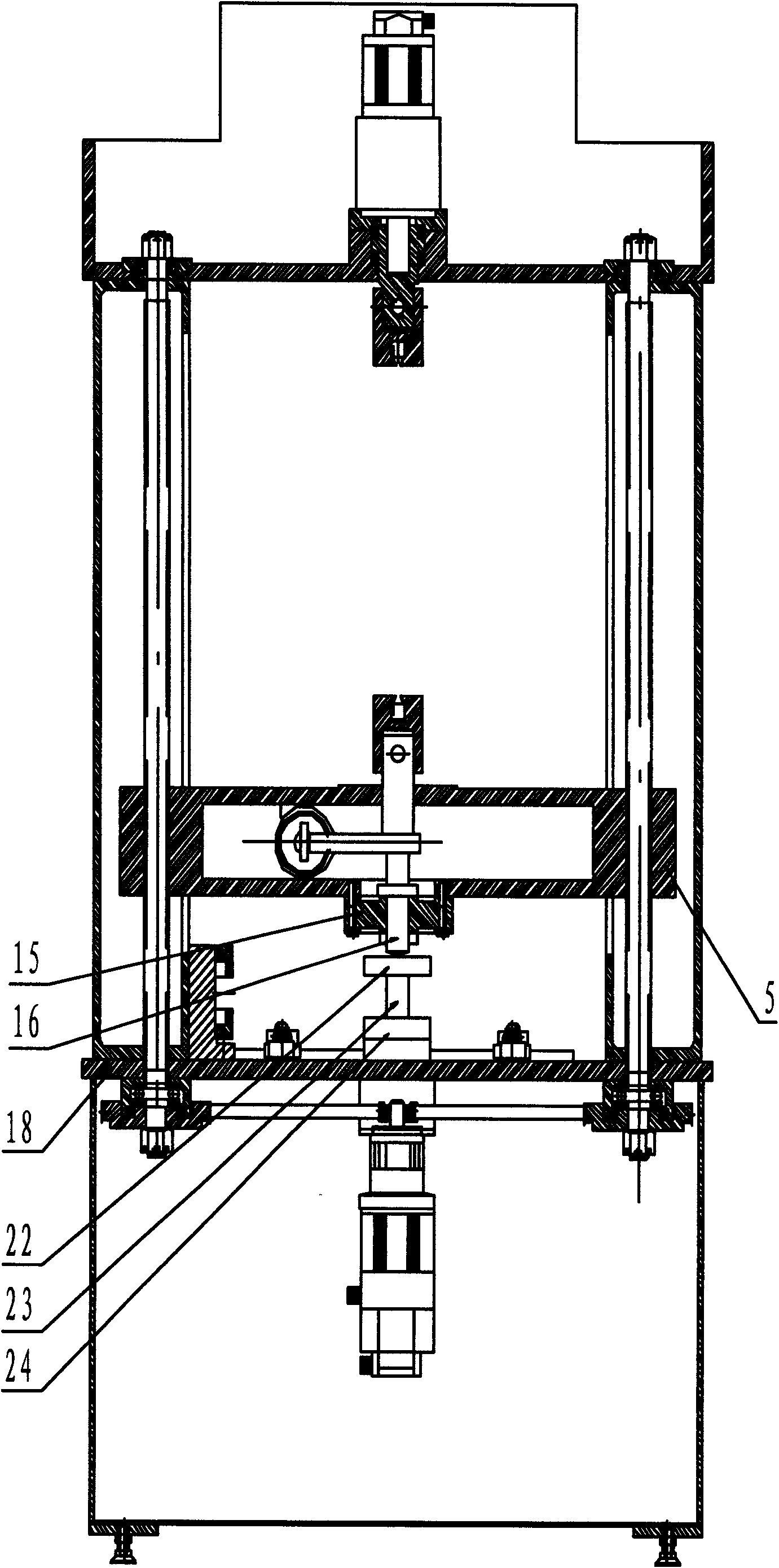

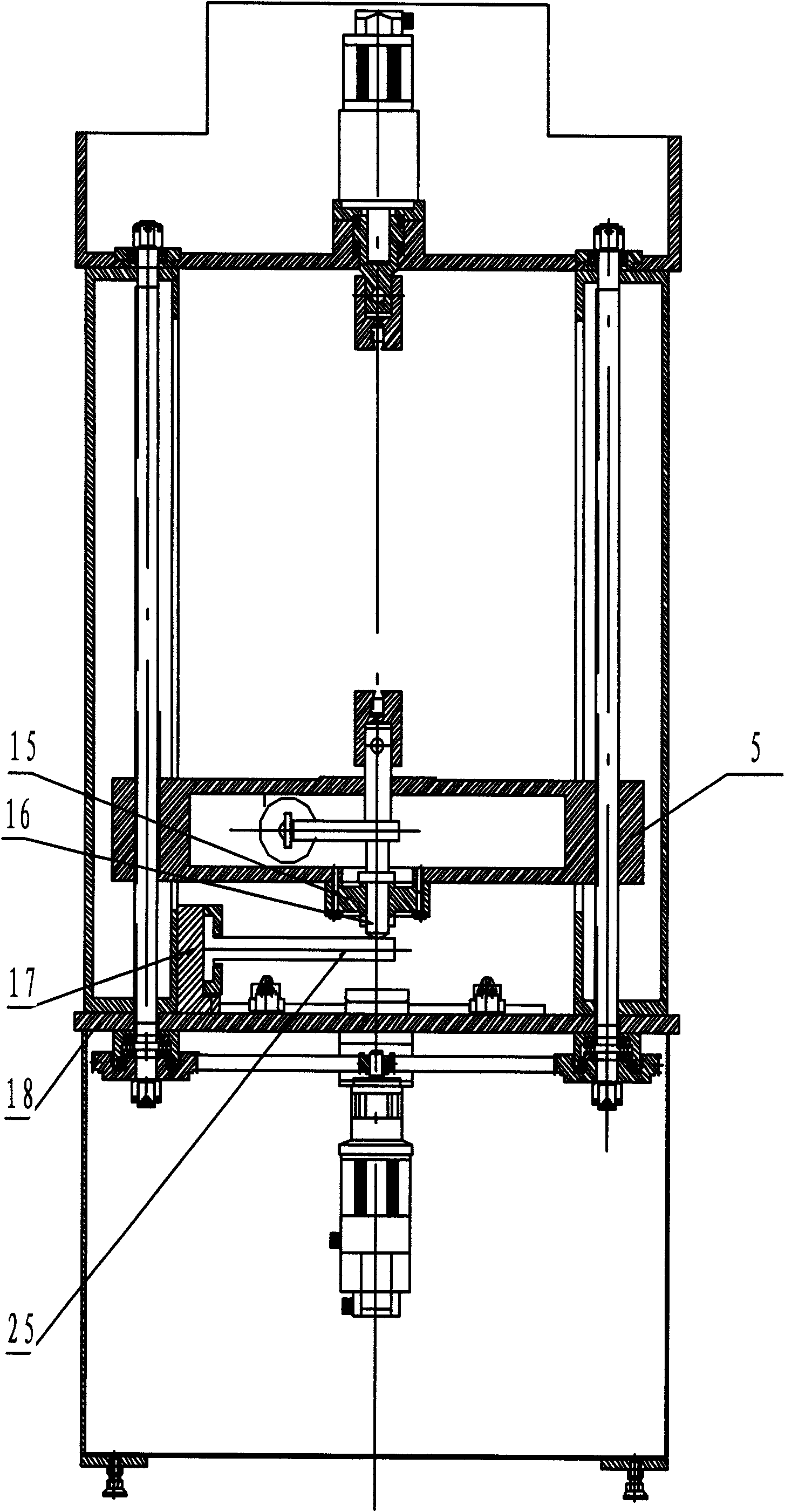

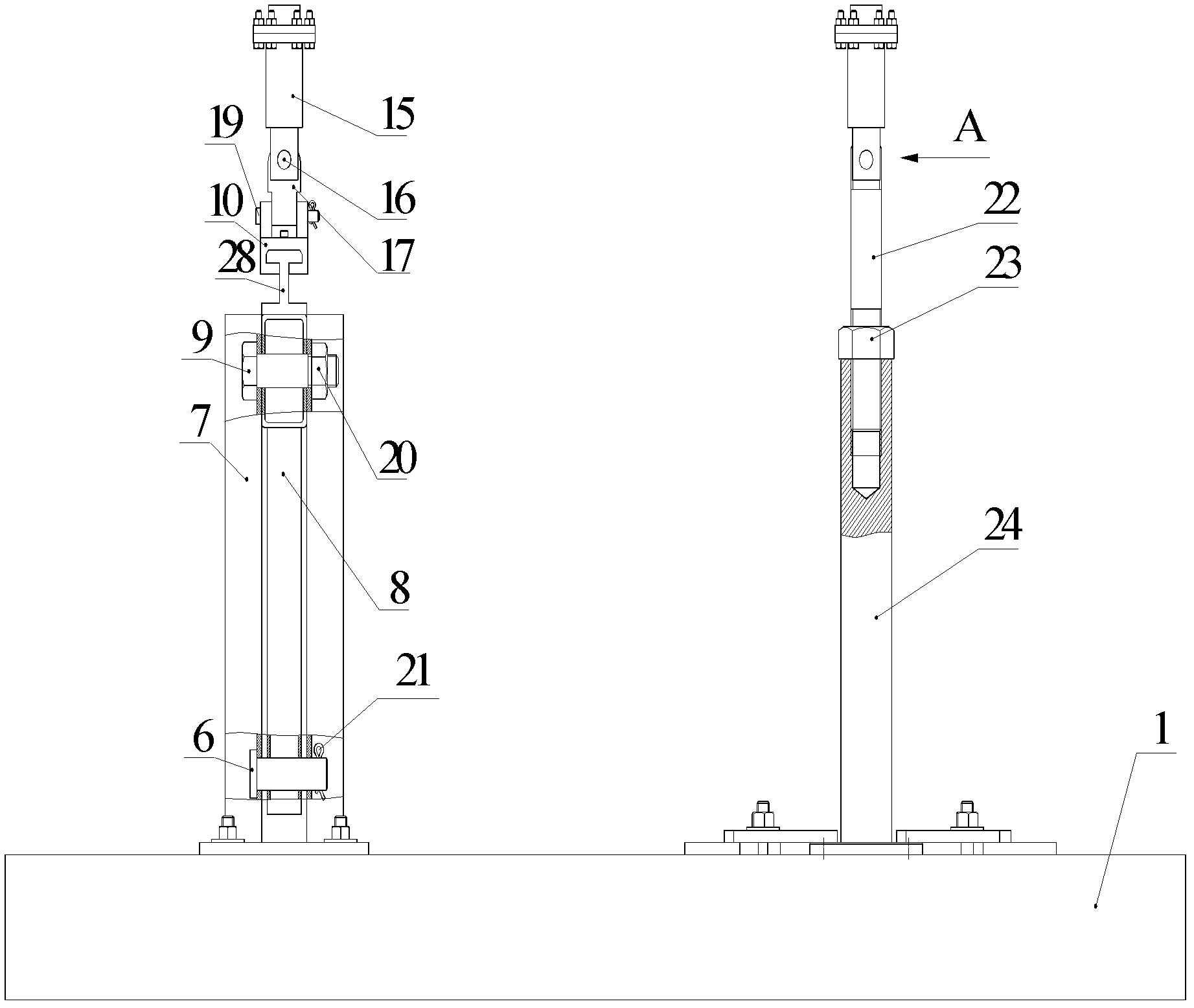

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

E-fixture

InactiveUS20060101921A1Material strength using tensile/compressive forcesMaterial strength using steady torsional forcesInternal pressureDegrees of freedom

A device and a method are disclosed for testing a curved panel assembly, which simulates a segment of an aircraft fuselage barrel section, subjected to combined loading. The device includes an axial load head assembly attached to the test panel assembly via one axial load fitting and configured to apply an axial load to the test panel assembly, and an axial-torsion reaction box connected to the axial load head assembly via linear journal bearing assemblies, where the axial-torsion reaction box is configured to be rotated by a pair of torsional loading systems to apply a torsional load to the test panel assembly. The device also includes a gore section attached to hoop load fittings of the test panel assembly, configured to provide degrees of freedom that constrain the test panel assembly to load and deflect as it would naturally in an actual fuselage barrel, form a plenum box to apply an internal pressure load, and provide hoop loading systems that complete the full hoop load application to the test panel assembly. A fixed reaction box attached to the test panel assembly via another axial load fitting rigidly attaches the test panel to the self-reacting frame, completing the internal load path of the overall system.

Owner:THE BOEING CO

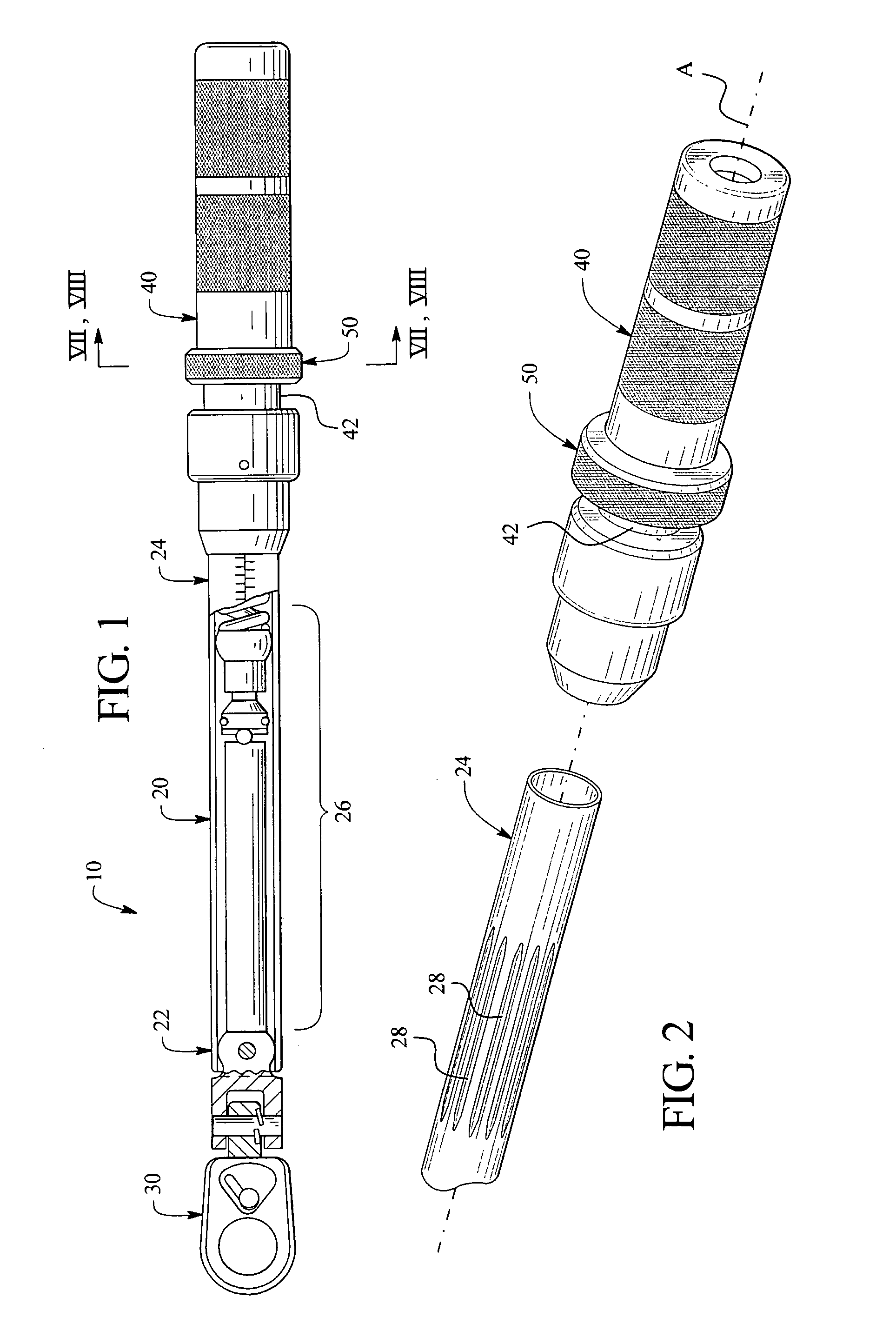

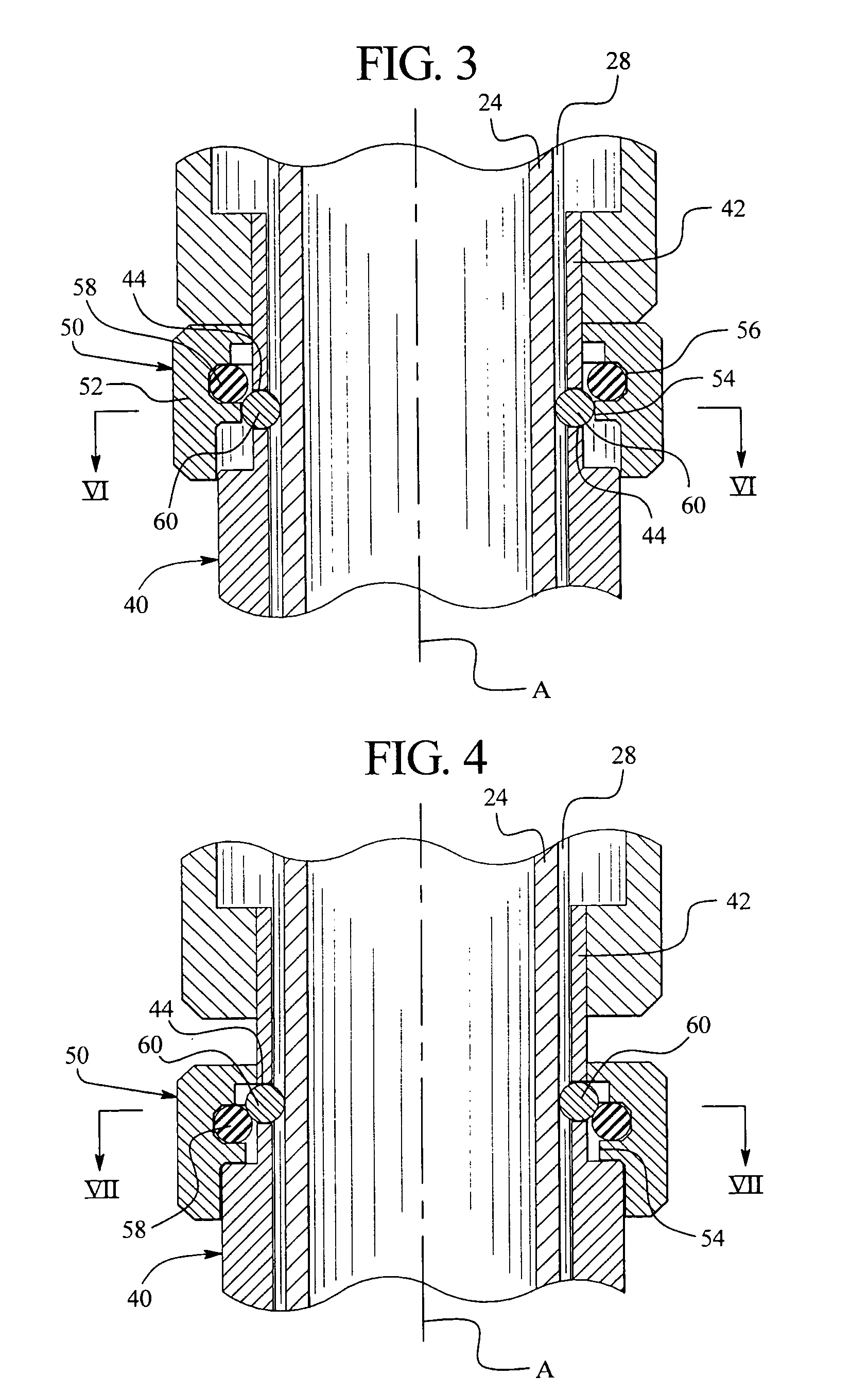

Torque wrench with sleeve for locking rotatable handle

InactiveUS6948410B1Improved locking mechanismReduce decreaseFurniture joining partsMeasurement arrangements for variableDetentTorque wrench

A torque wrench is provided having body and a handle that is rotatably mounted to the body for adjusting the torque setting, and an axially movable sleeve operable to selectively lock the handle. The sleeve includes a rigid member and an elastomeric member, such as an O-ring, and the sleeve is configured to act against a locking ball held in a bore of the handle. The sleeve is selectively movable between two positions: (a) a locked position wherein the rigid member firmly retains the locking ball seated in one of several detents in the body, thereby preventing rotation of the handle; and (b) an unlocked position wherein the elastomeric member biases the locking ball inwardly, deflecting when the locking ball unseats from the detent to permit handle rotation. When the sleeve is in the unlocked position, the locking ball can incrementally “click” over the detents during handle rotation.

Owner:PRECISION INSTR

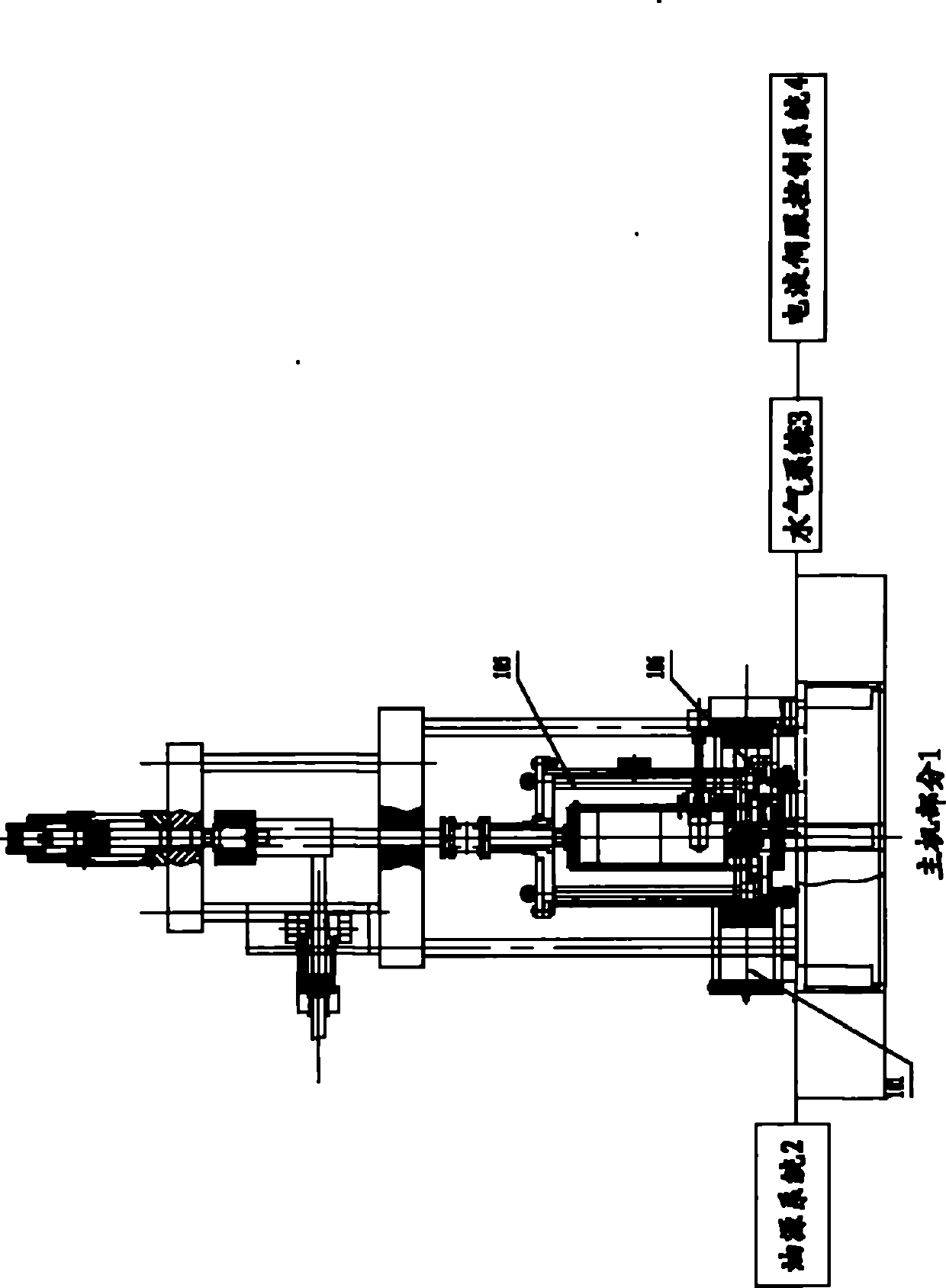

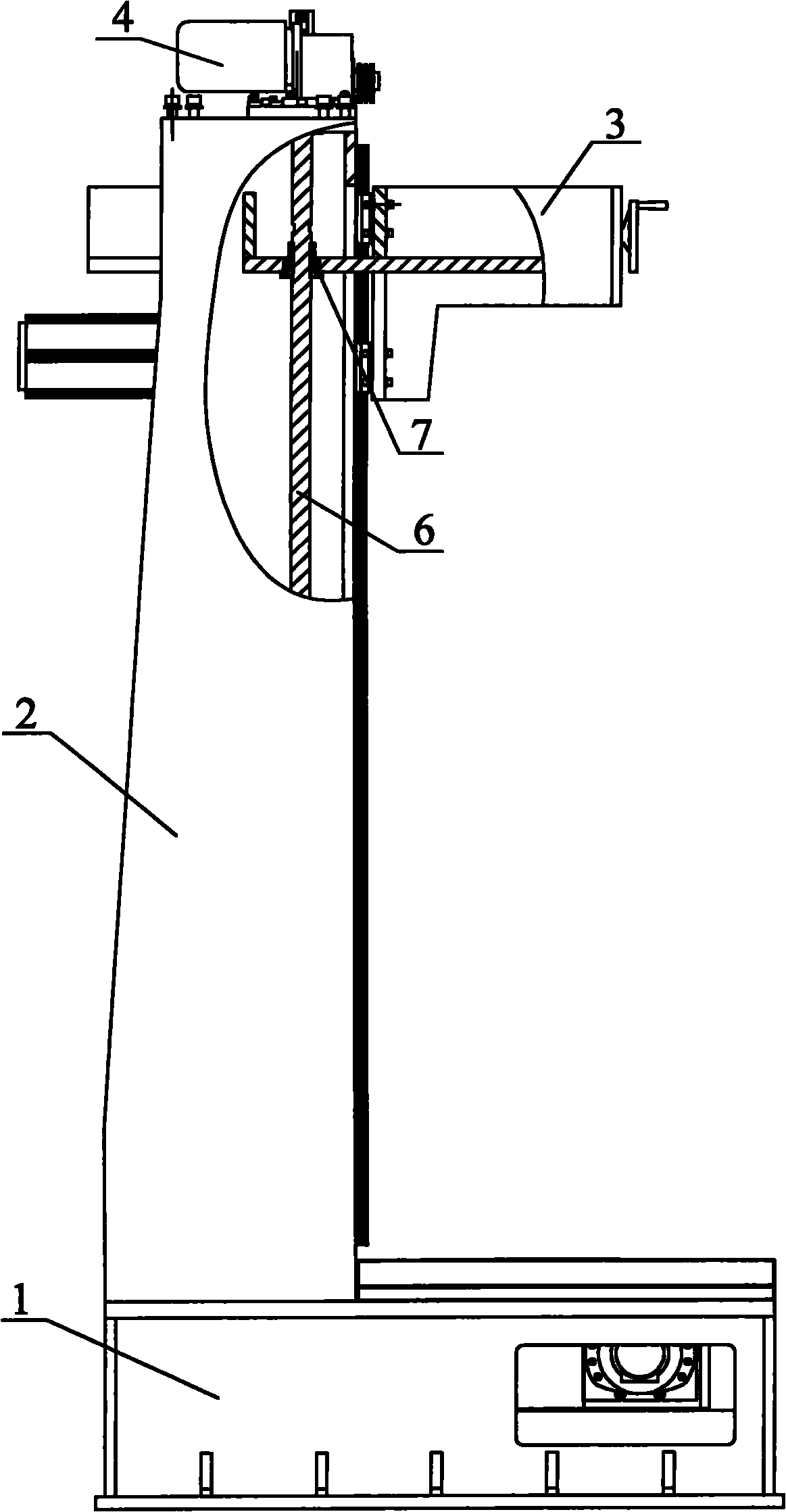

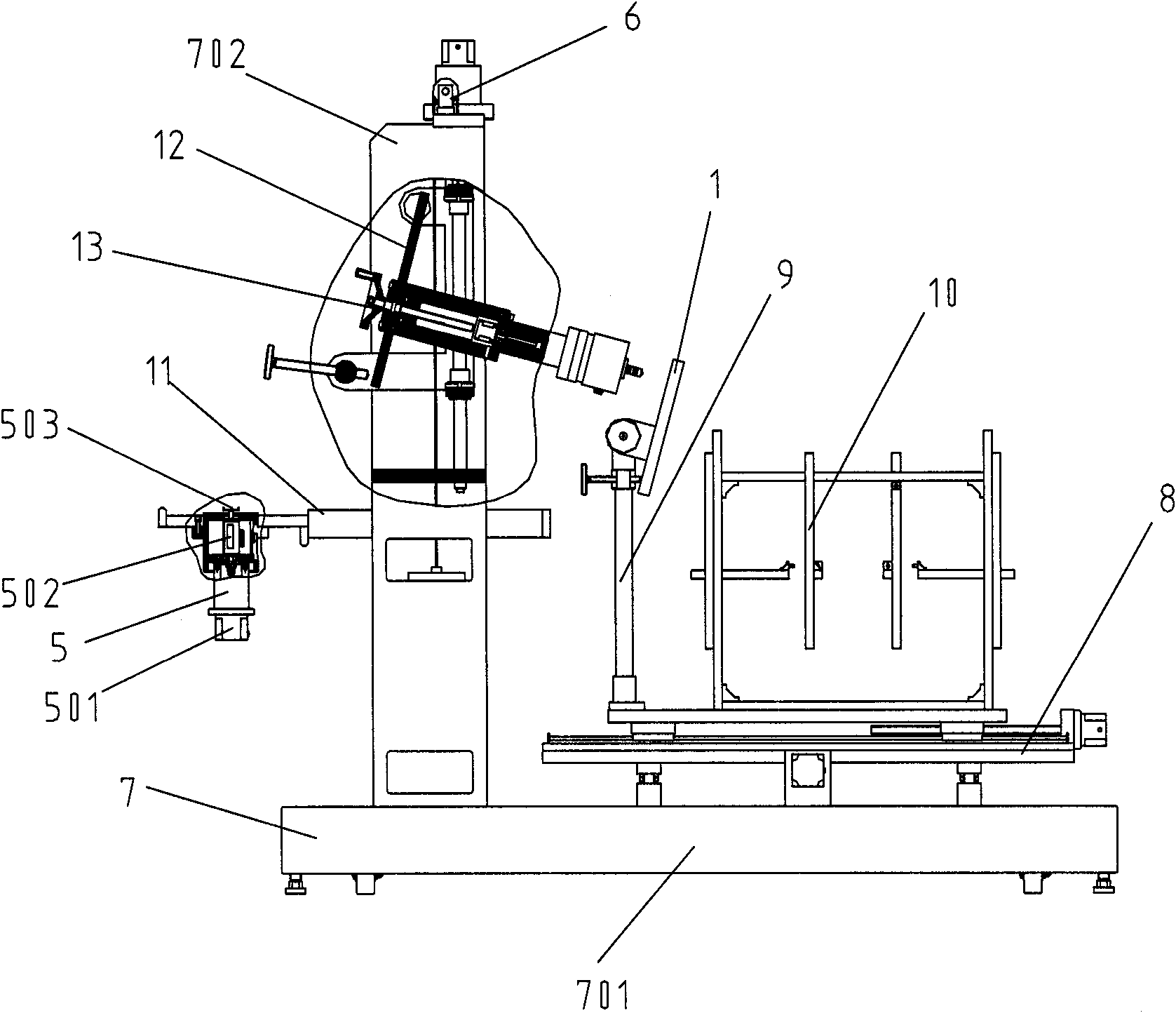

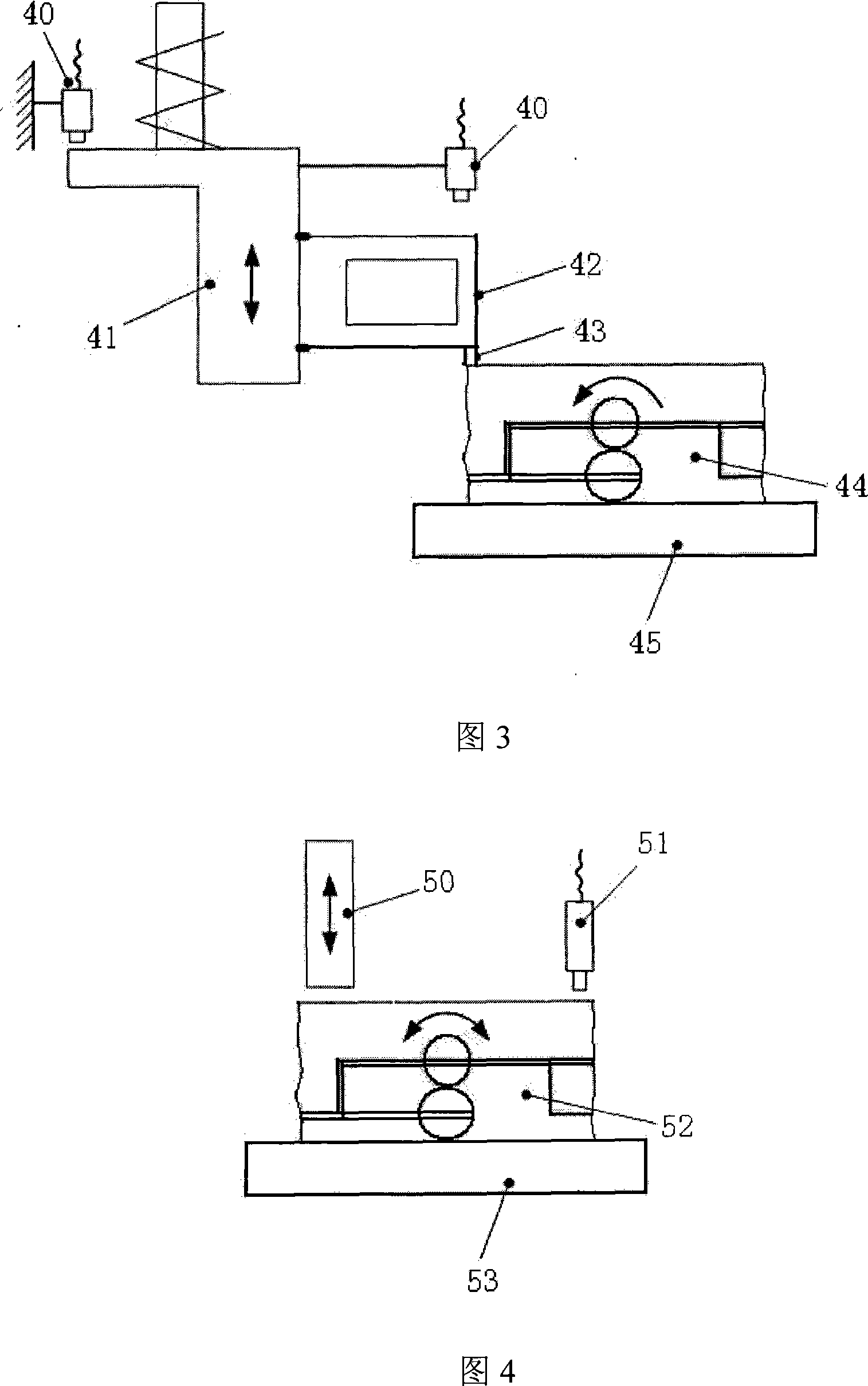

Multifunctional material mechanics testing machine with functions of tension torsion and pressure torsion

InactiveCN101625296ARealize pull torsionRealize functionMaterial strength using steady torsional forcesTorsion testTension compression

The invention relates to a material mechanics testing machine, belonging to the technical field of the material mechanics testing machine. The material mechanics testing machine is characterized in that the upper end and the lower end of the stander are provided with a lift motor and a torsion motor; the two motors form into one set of dynamic loading system and are controlled as well as coordinated to realize a tension torsion test and a pressure torsion test by an external electrical control system; a guide screw is arranged between the work table and an upper beam, wherein the upper end of the guide screw is fixed at the upper bean, and the lower end of the guide screw is driven by a synchronous belt wheel in a connection way; a middle beam is arranged between the work table and the upper beam; the middle beam is respectively provided with a tension compression rod and a tension compression sensor as well as a torsion sensor, wherein the tension compression sensor and the torsion sensor are communicated with a computer; the upper part of the wok table is provided with a slide way with a slide pillow; one side of the work table, near the vertical rod, is provided with a support seat; and the lower part of a torsion reduction machine is fixedly provided with a hanging rod, wherein the lower part of the hanging rod is provided with a clamp head. The two motors in the one set of dynamic loading system are simultaneously coordinated and controlled by the electrical control system to realize the functions of tension torsion and pressure torsion, and the rotate speeds of the two motors are adjusted by the electrical control system to meet the requirement of different experiments, digitally process the collection and the transmission of a parameter to be tested, and truly and exactly display the parameter on a screen.

Owner:孙仙山 +1

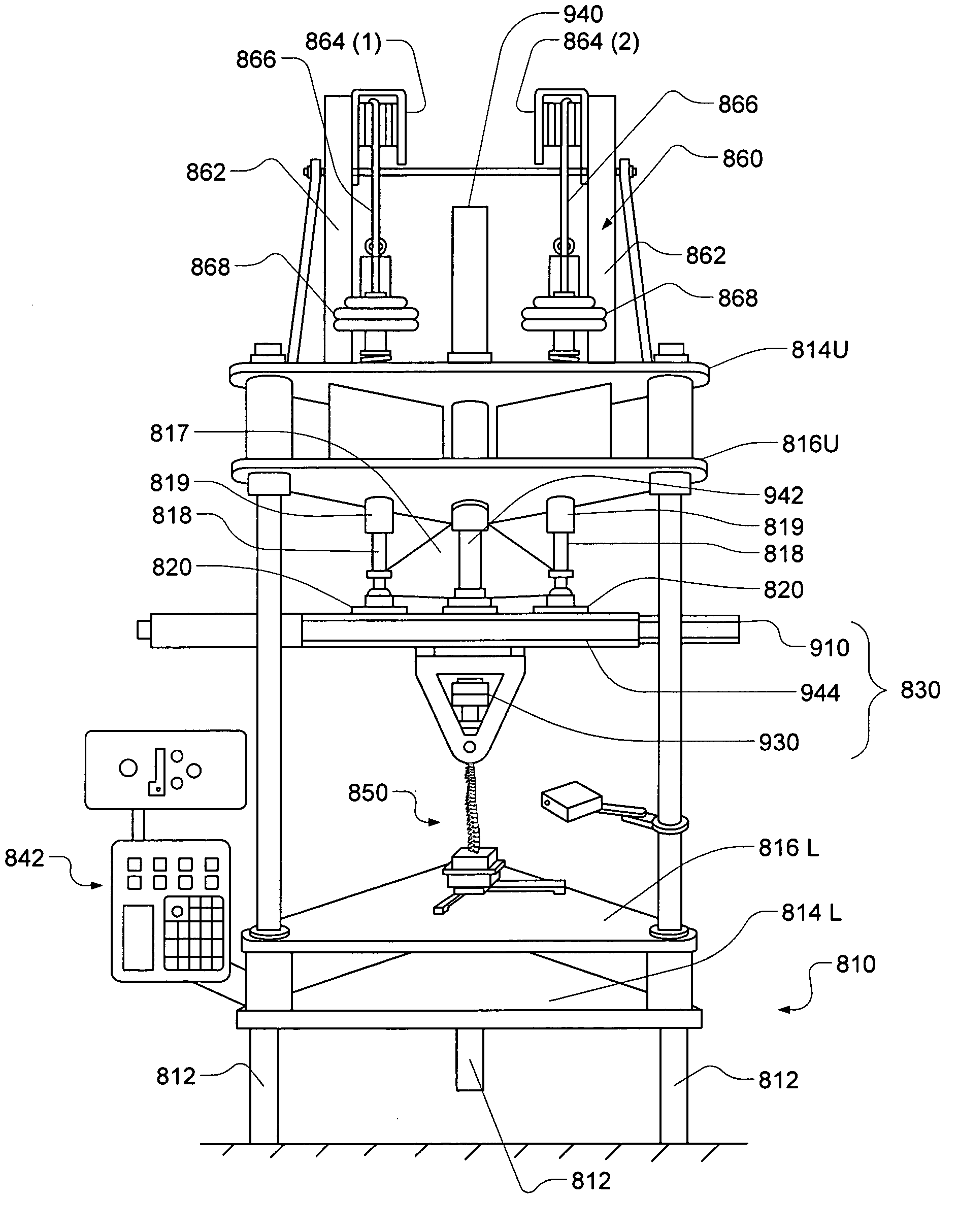

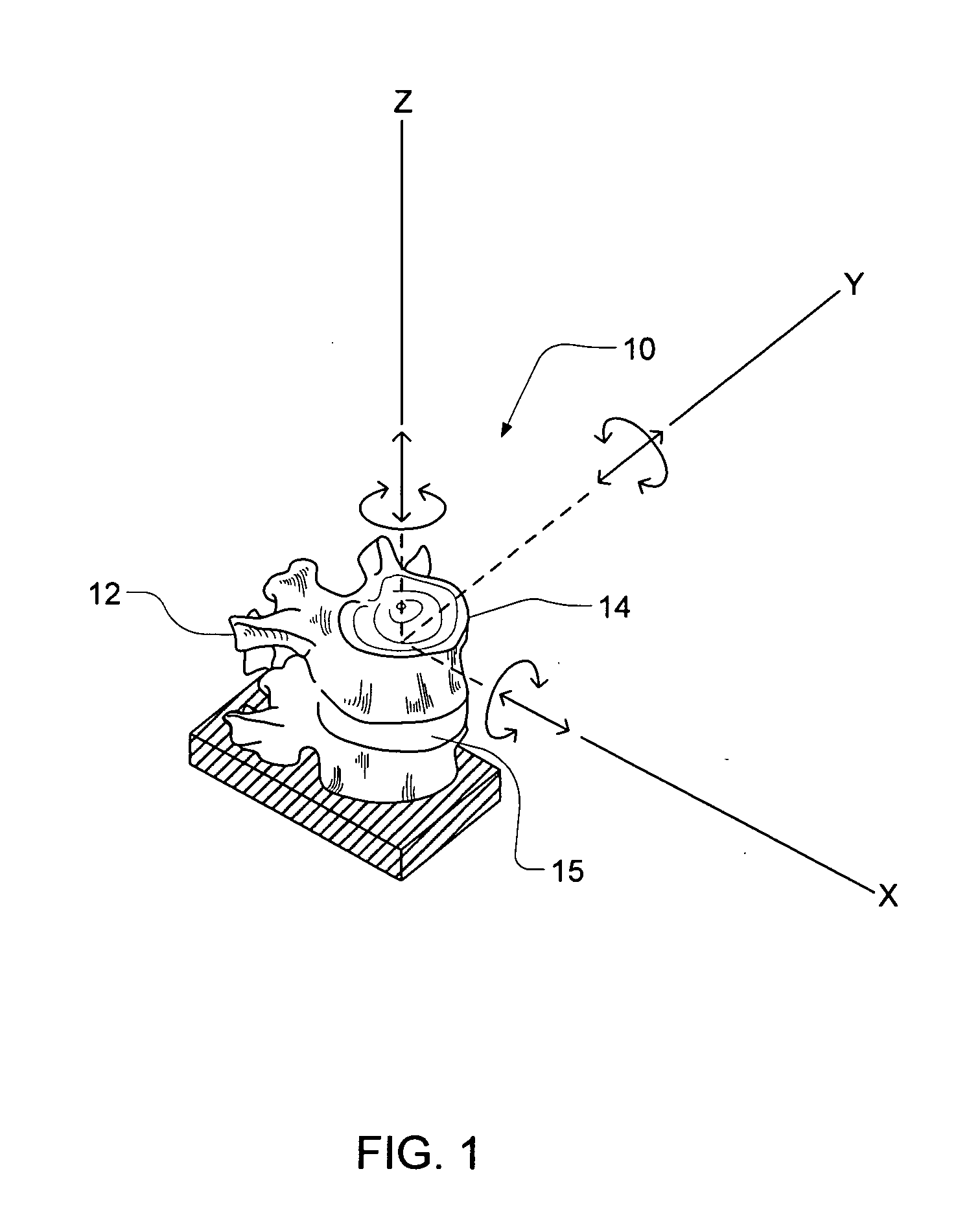

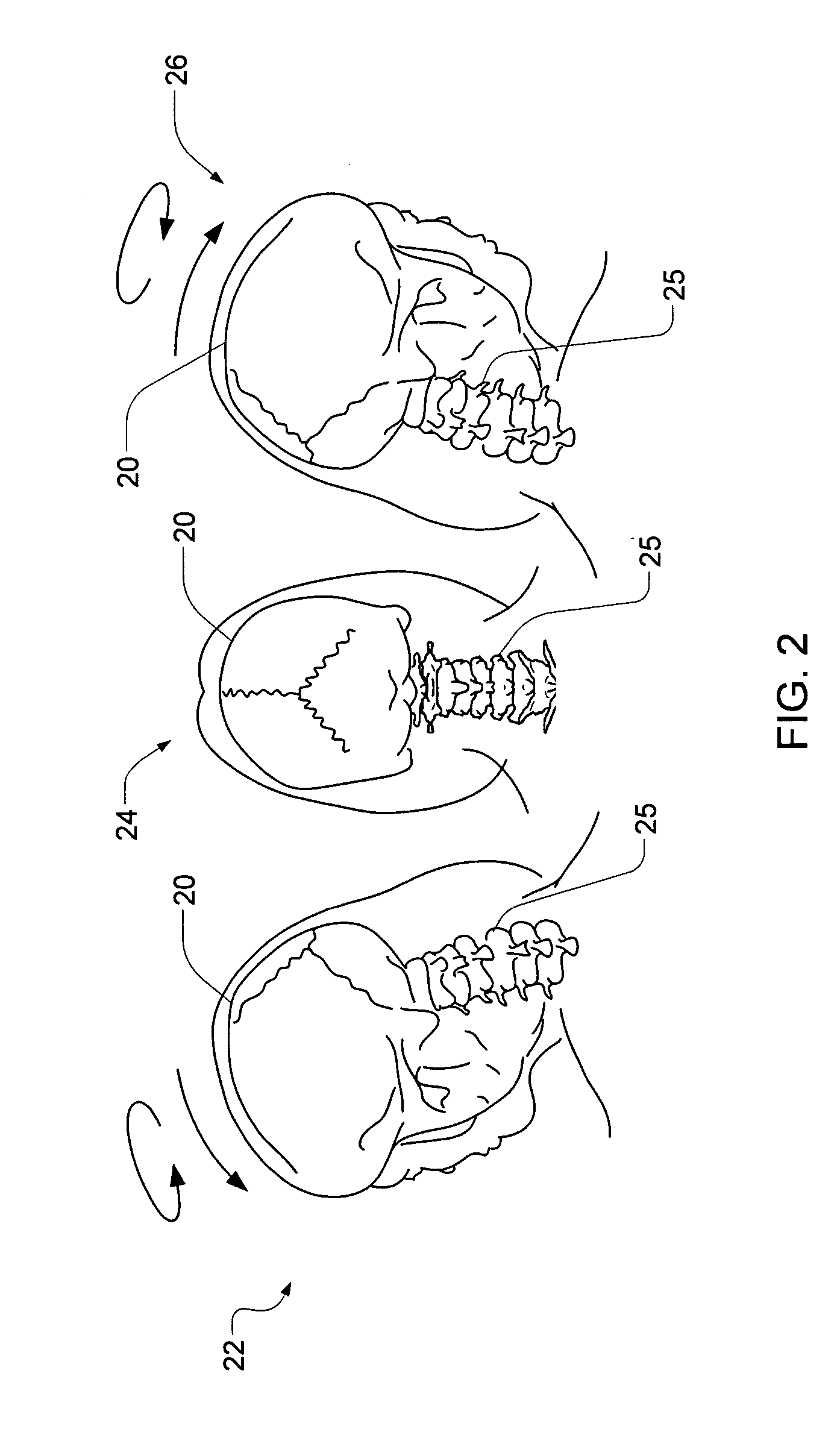

Multi-axis, programmable spine testing system

A biomechanical system for testing a coupled joint is provided. The coupled joint has a fixed first end and a moving second end within the testing system. The testing system includes a servo actuation system operatively connected to the moving end. The system is able to impart at least four degrees of freedom to the moving end of the coupled joint. The testing system also includes a first force sensor disposed between the servo actuation system and the moving end of the coupled joint for sensing applied load, and a second force sensor disposed at the fixed end of the coupled joint for sensing transmitted load. The system also includes a controller for selectively directing input signals to the servo actuation system in order to apply selected forces and / or motions to the moving end of the coupled joint. The coupled joint may be a cervical spine specimen.

Owner:UNIV OF TENNESSEE RES FOUND

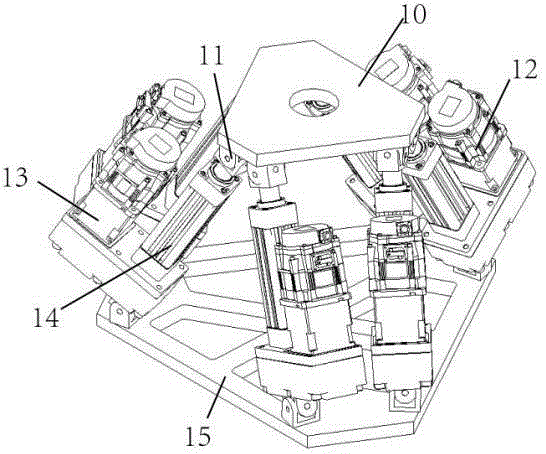

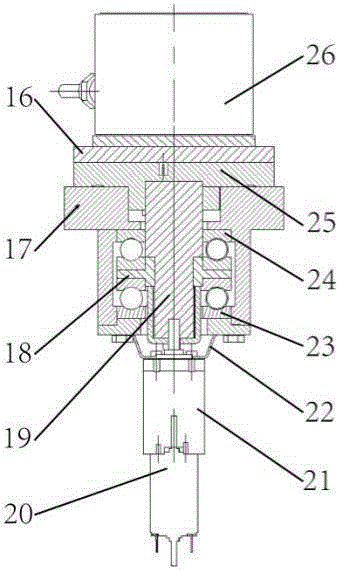

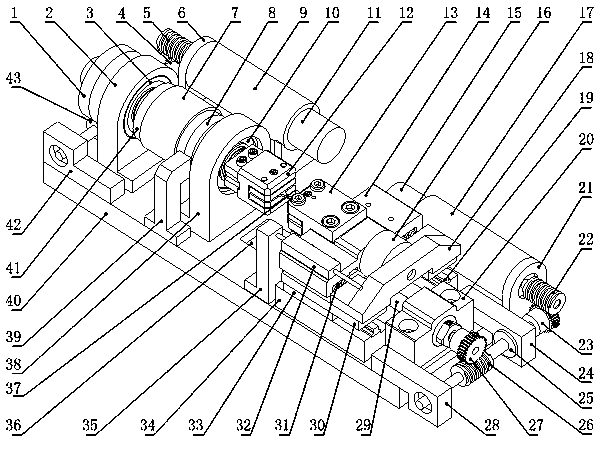

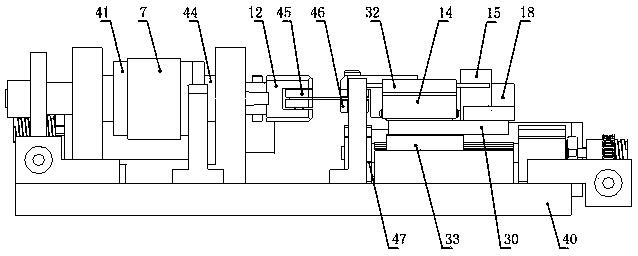

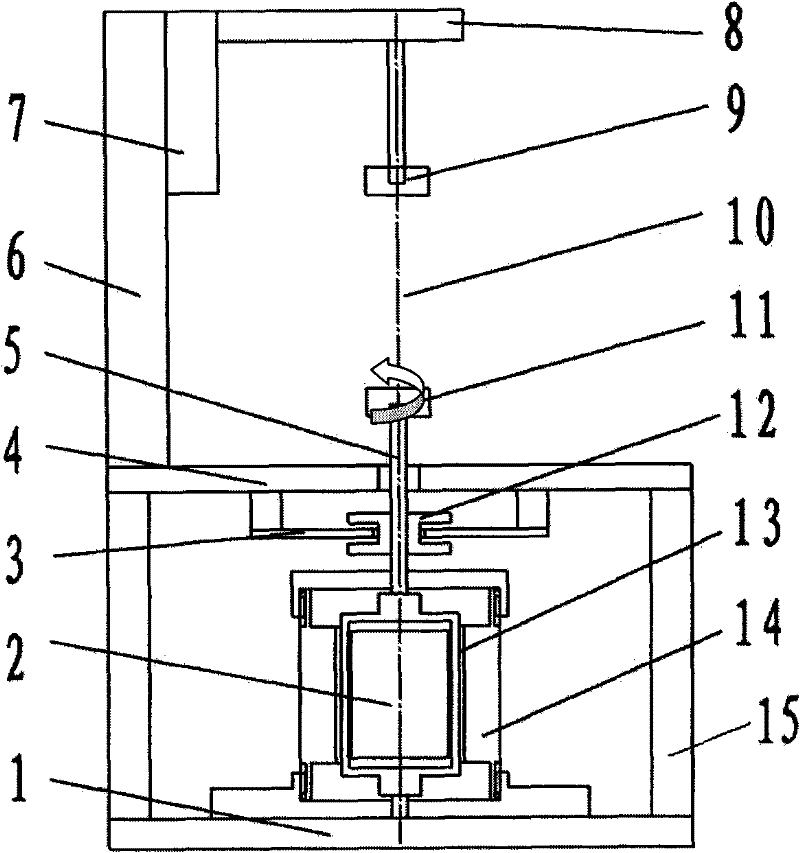

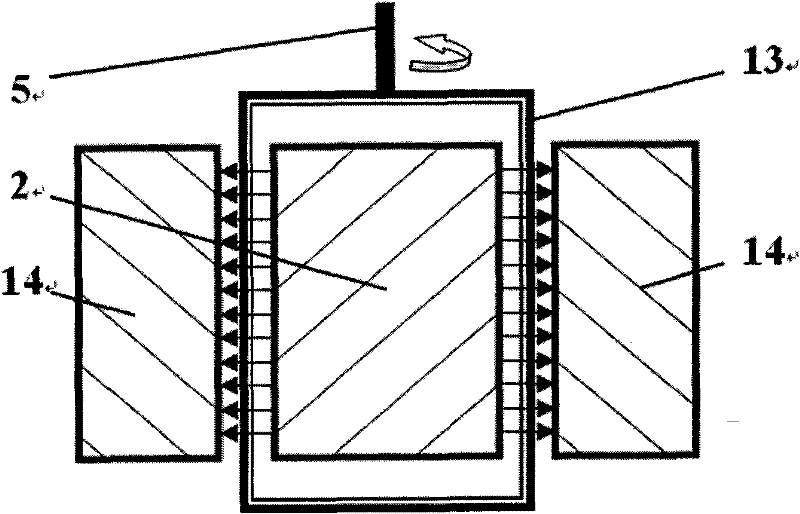

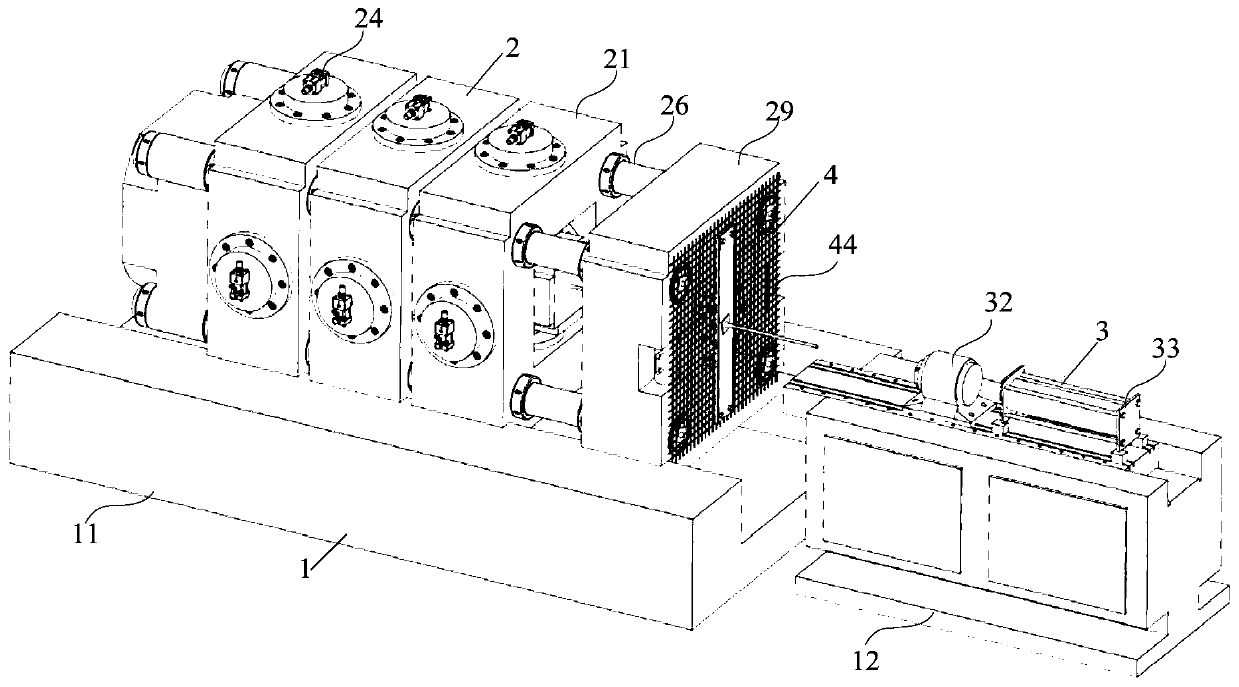

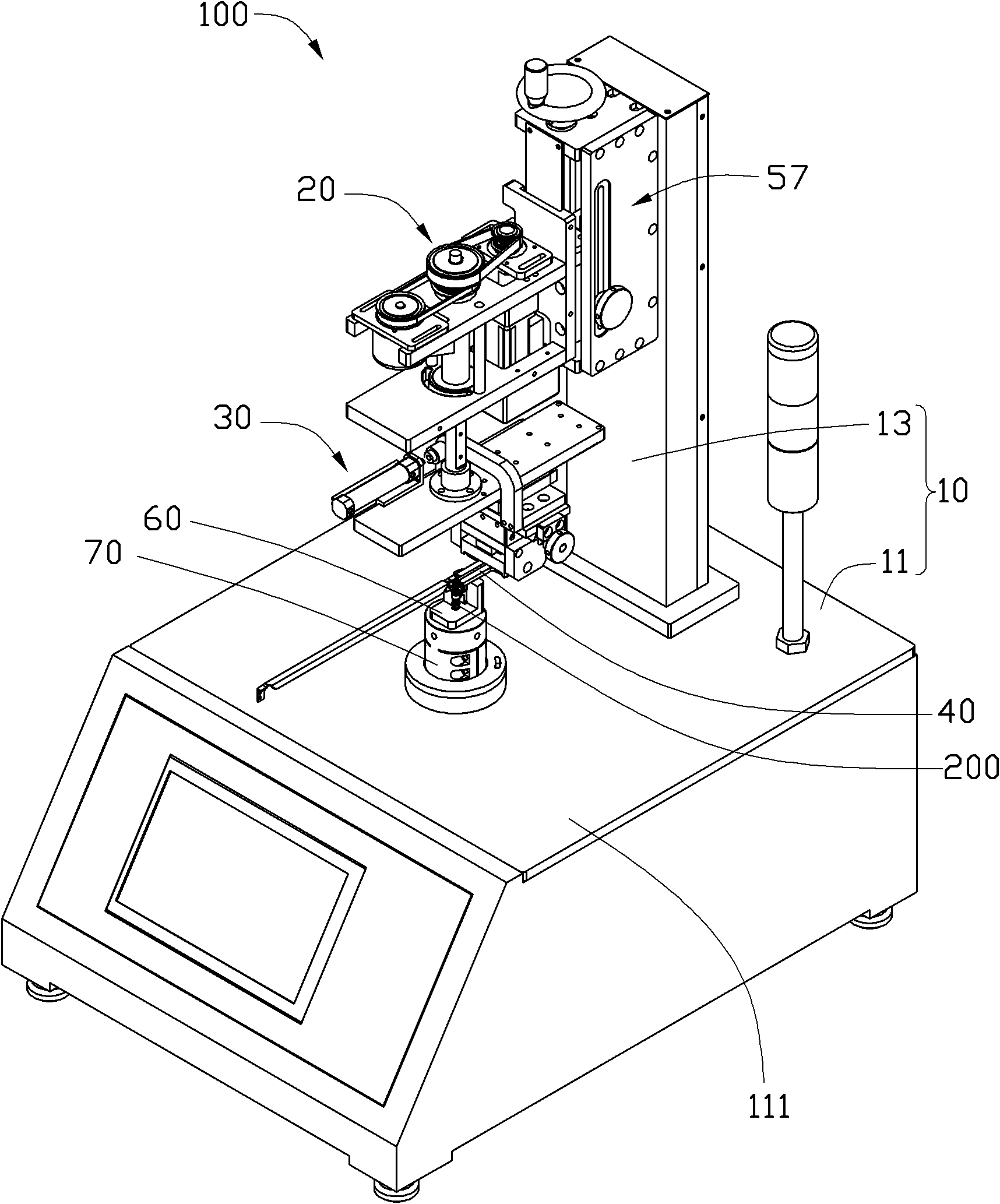

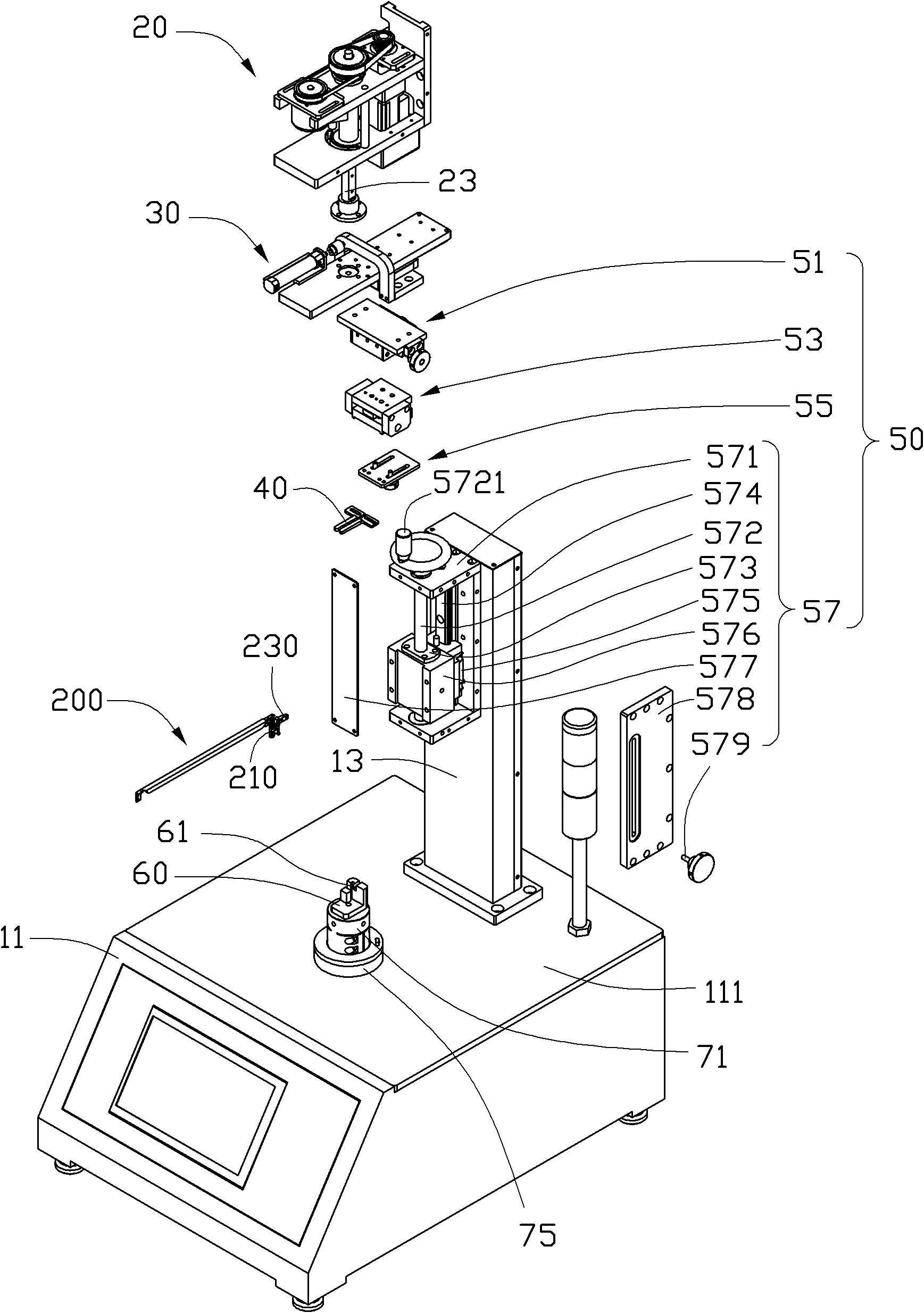

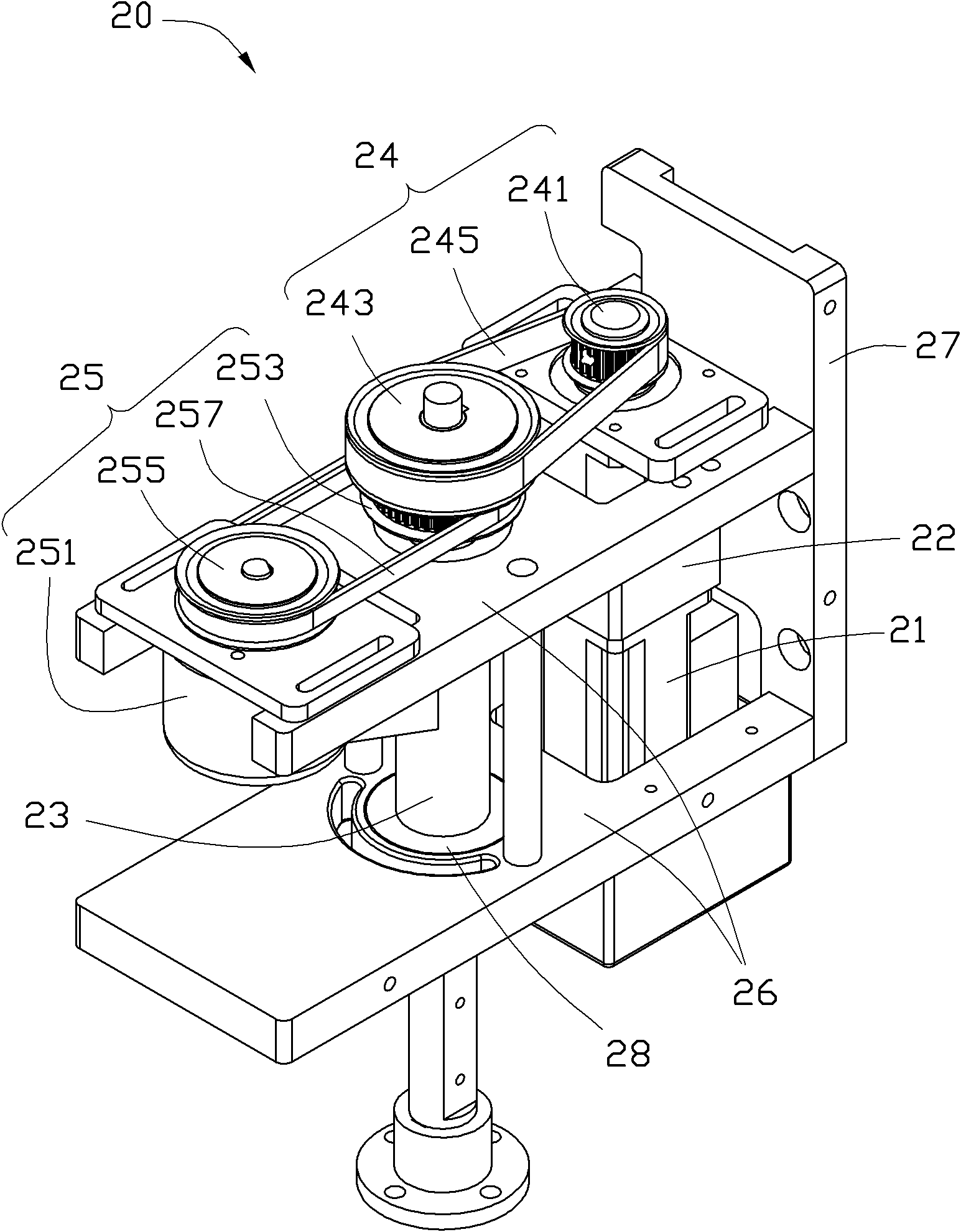

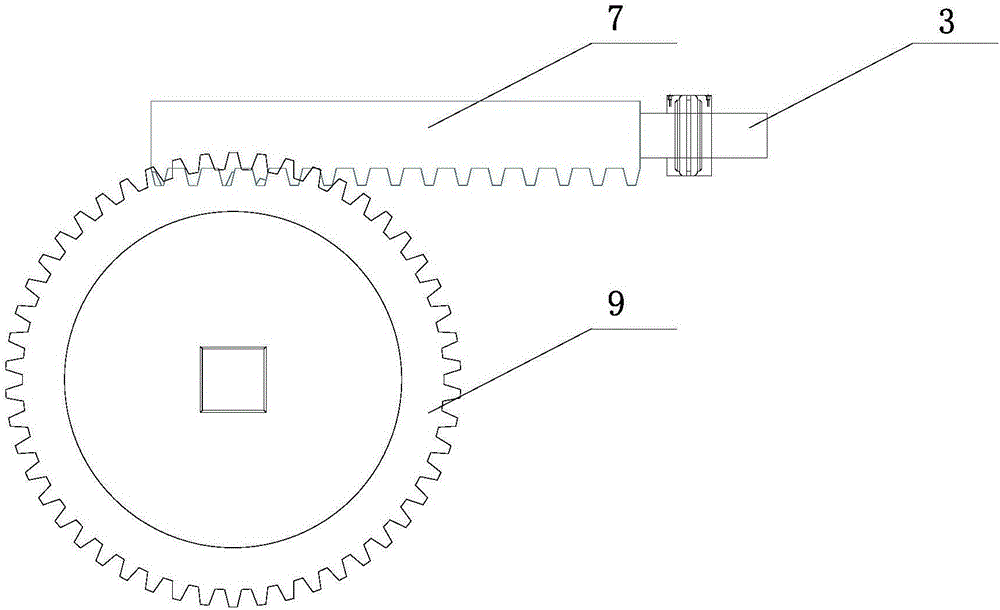

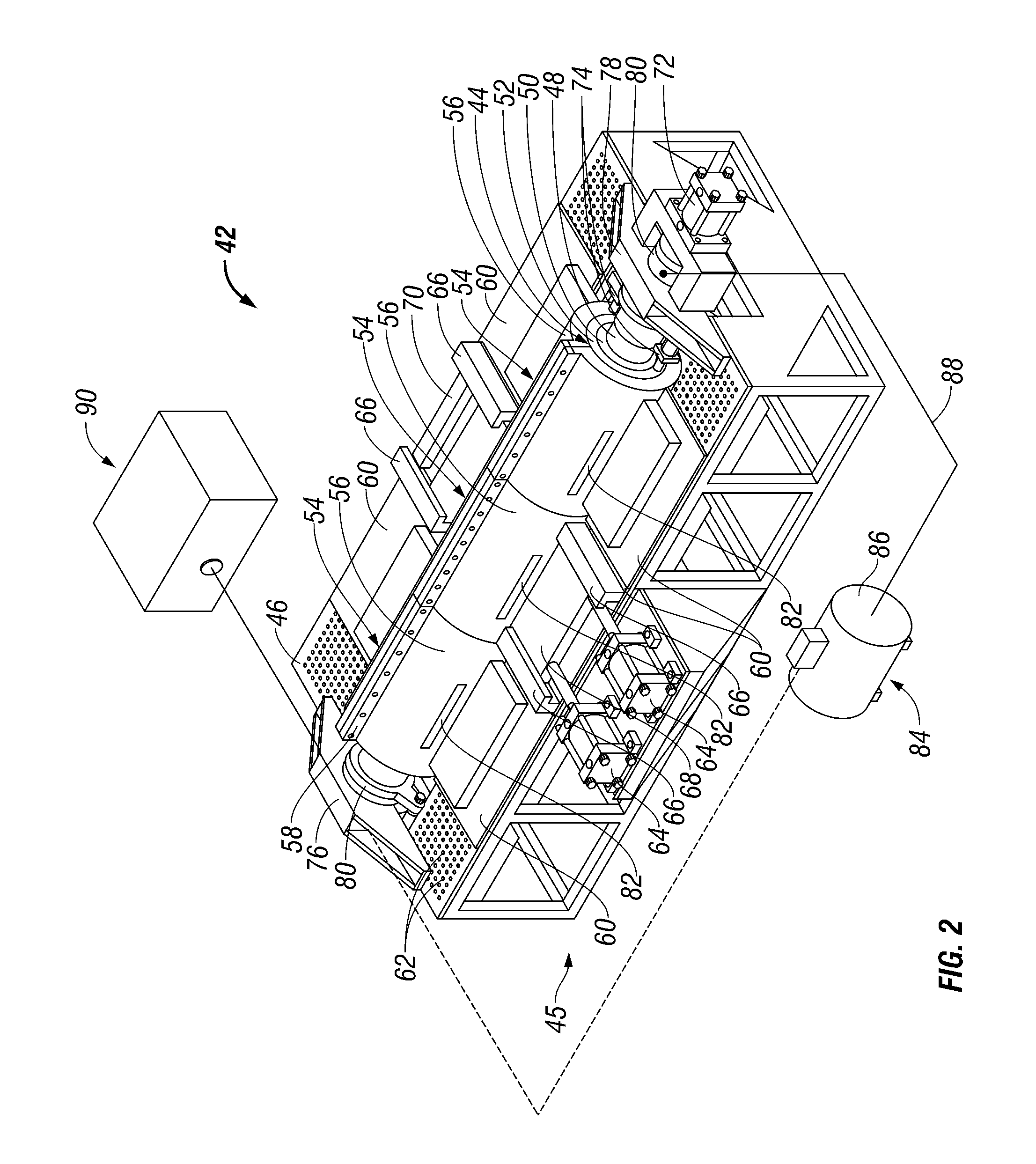

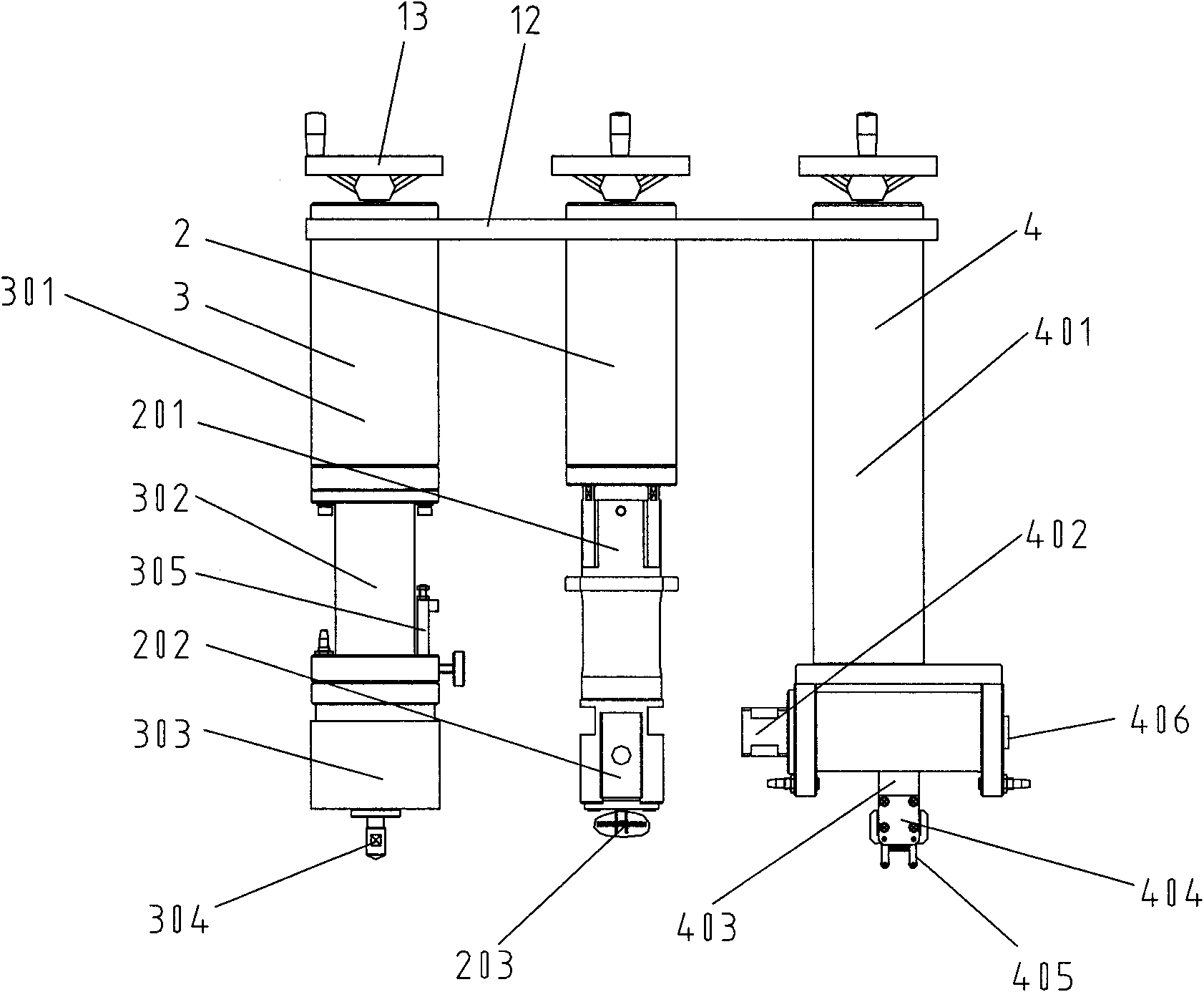

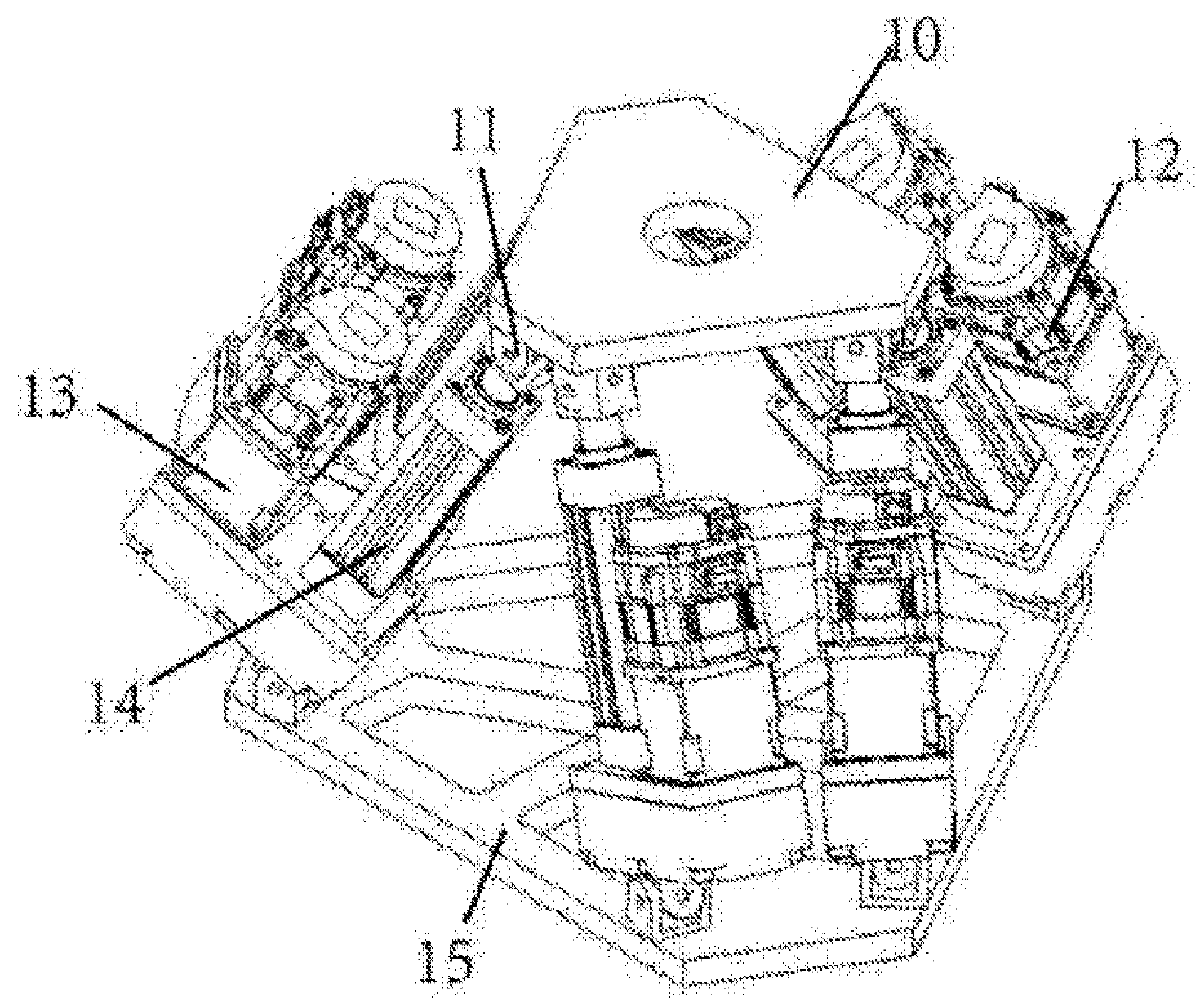

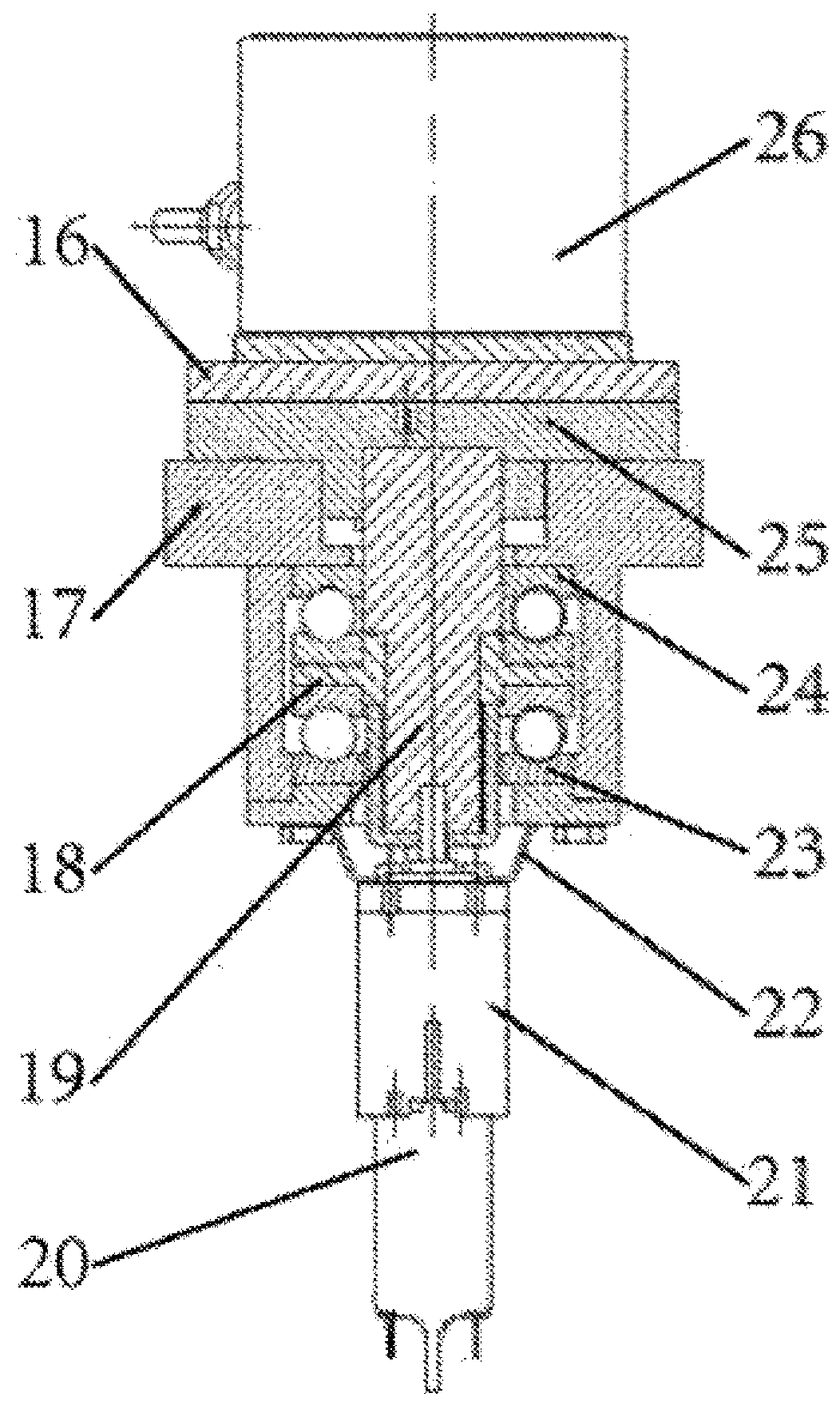

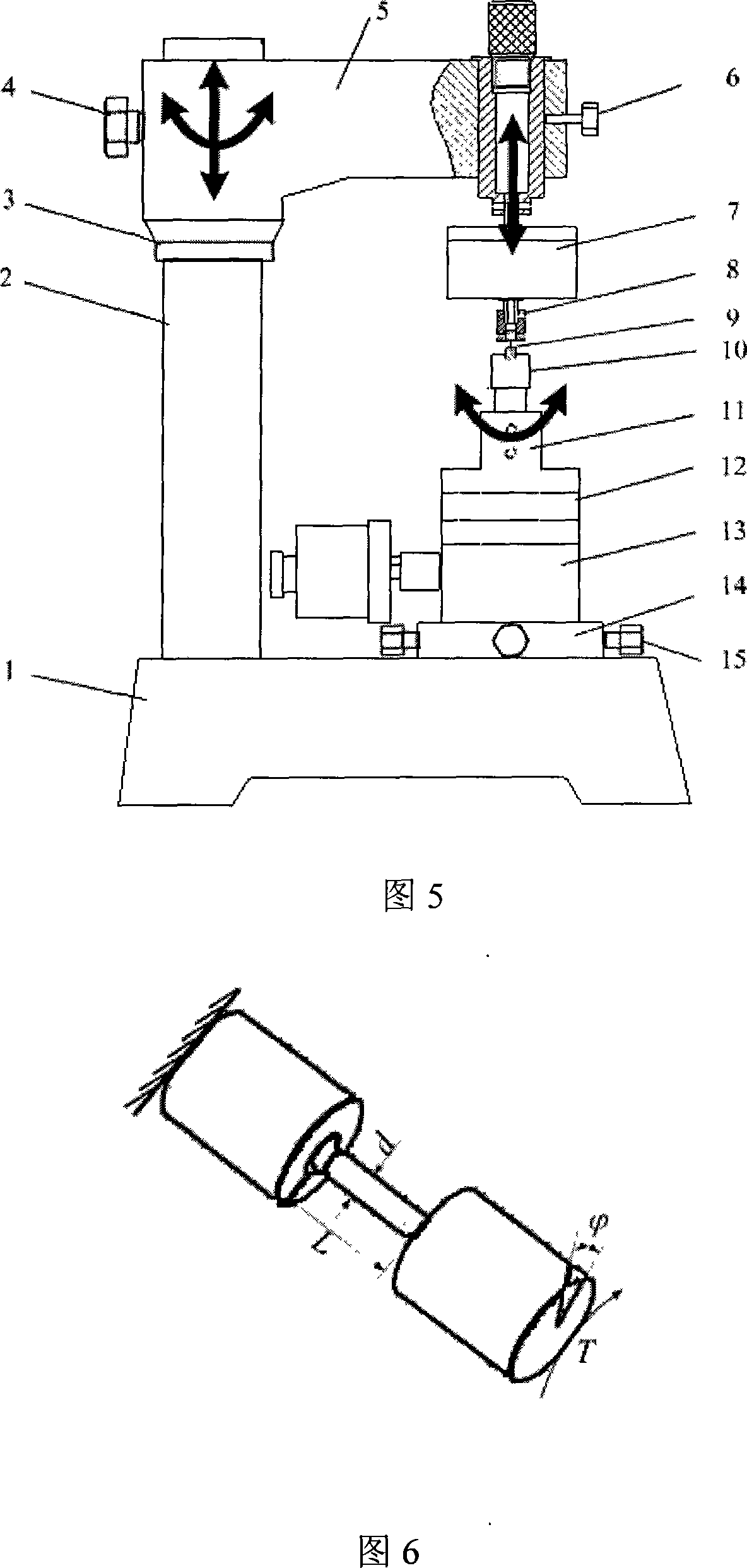

In-situ pull/press-torque combined load material micromechanics test platform

ActiveCN103528887AReduce volumeCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesMicro nanoGrating

The invention relates to an in-situ pull / press-torque combined load material micromechanics test platform and belongs to the field of material mechanics tests. The in-situ pull / press-torque combined load material micromechanics test platform consists of a base, a precise loading unit, a detection control unit and a clamping and connecting unit, wherein the precise loading unit comprises a torque loading unit and a pull-press loading unit and can be used for realizing the independent and combined loading of pull-press loads and torque loads; aiming at the pull-press loads and the torque loads, the detection control unit respectively uses a pull pressure sensor and a torque sensor to perform load detection and is combined with a contact-type capacitance displacement sensor, a circular grating ruler and a photoelectric encoder so as to monitor and control a loading mechanism. The in-situ pull / press-torque combined load material micromechanics test platform is compact in structure, small in size and controllable in strain rate, and can be used for performing in-situ monitoring on microtexture structural changes, deformation damage mechanisms and performance evolution laws of a material under the action of the combined load, so that an effective test method for revealing the nanoscale mechanics characteristics and damage mechanisms of the material under an approximate service condition is provided.

Owner:JILIN UNIV

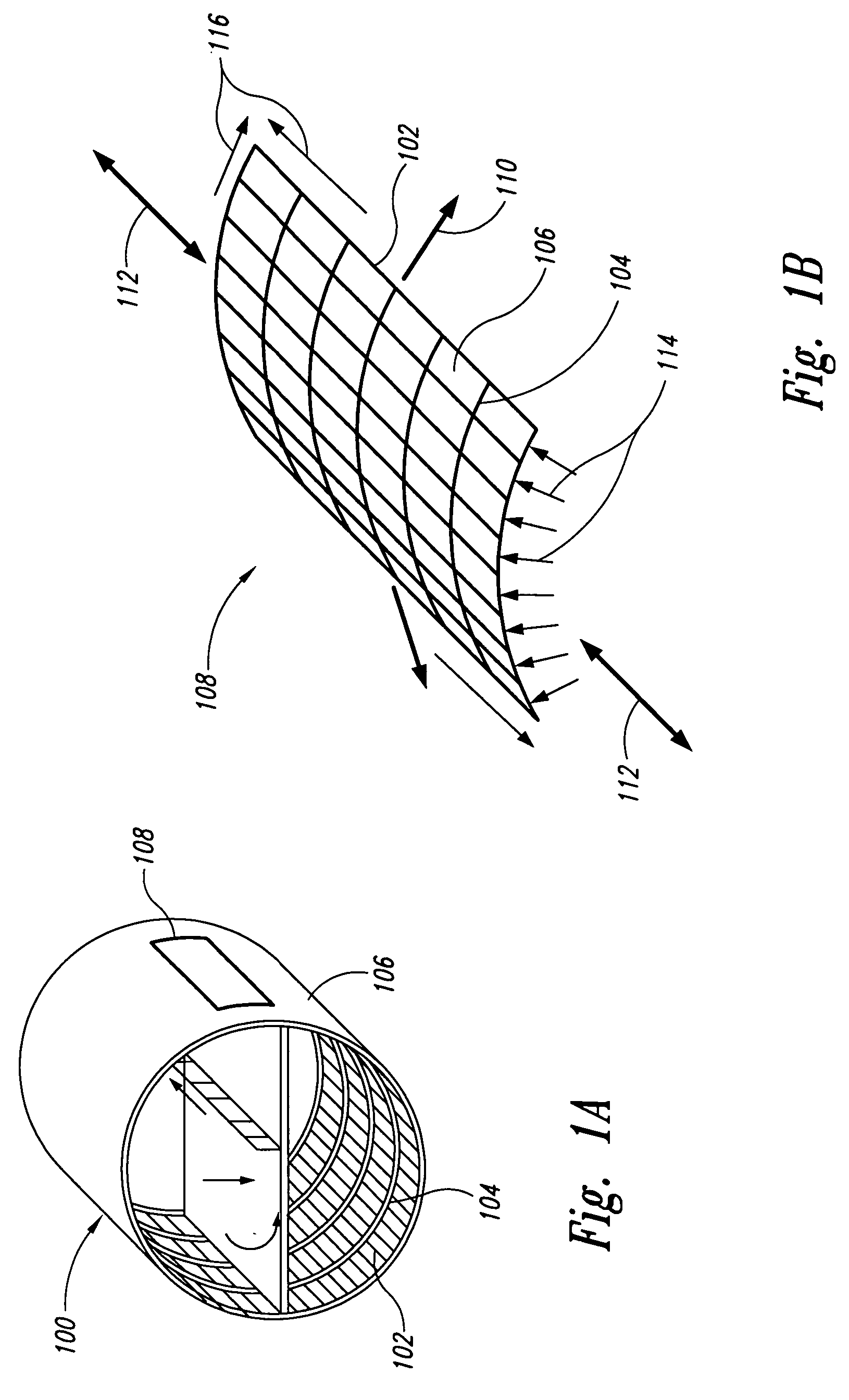

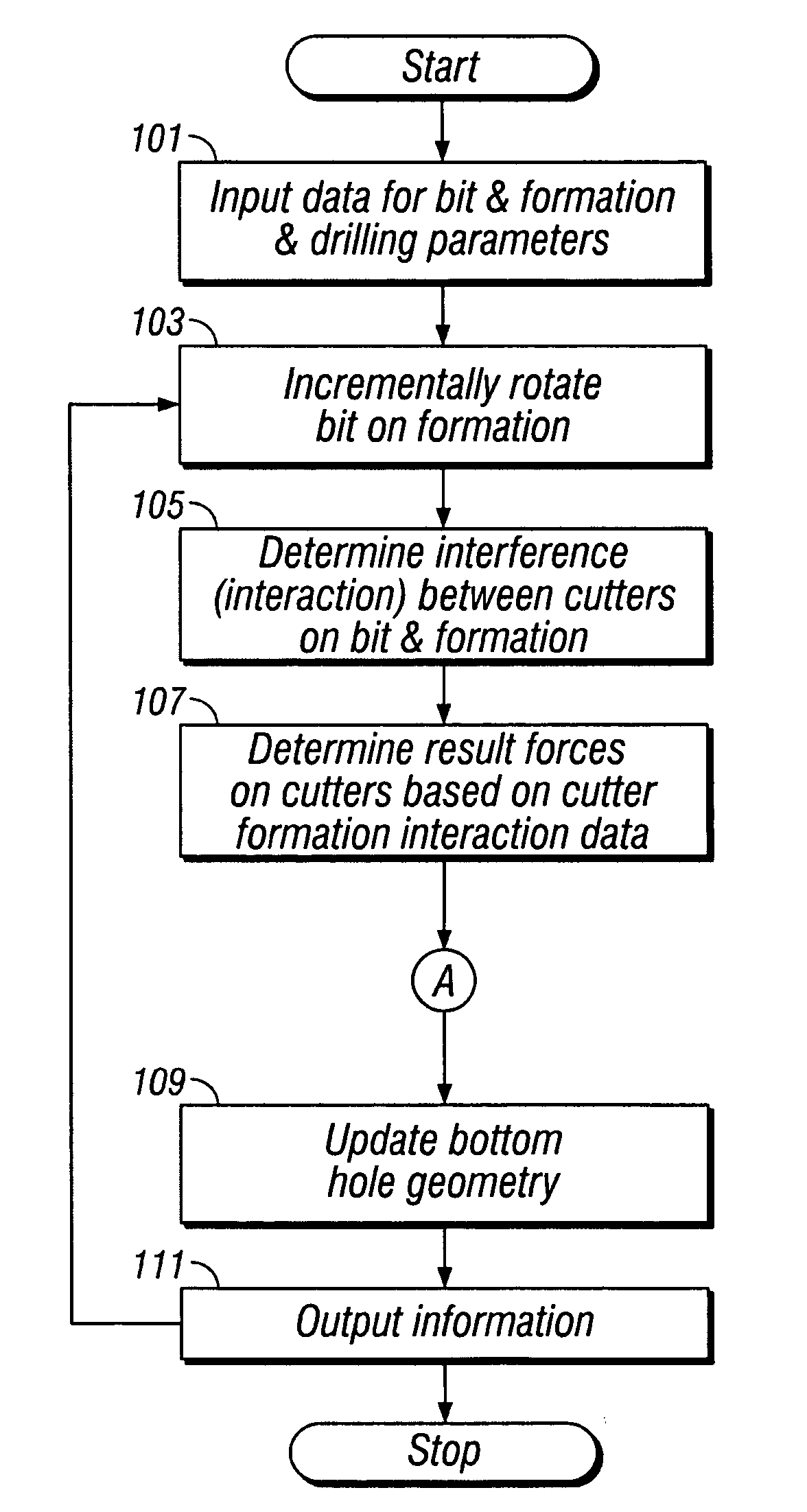

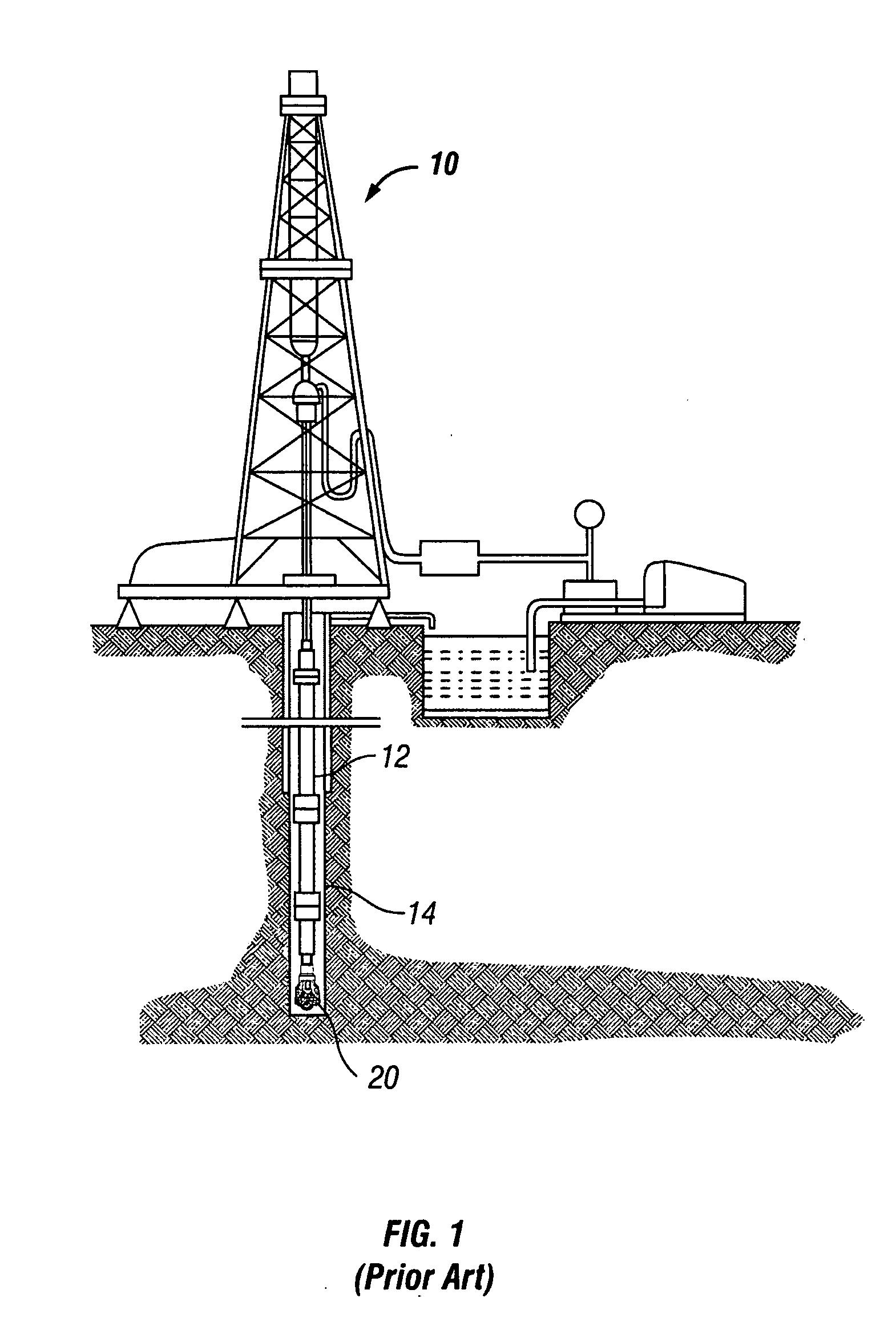

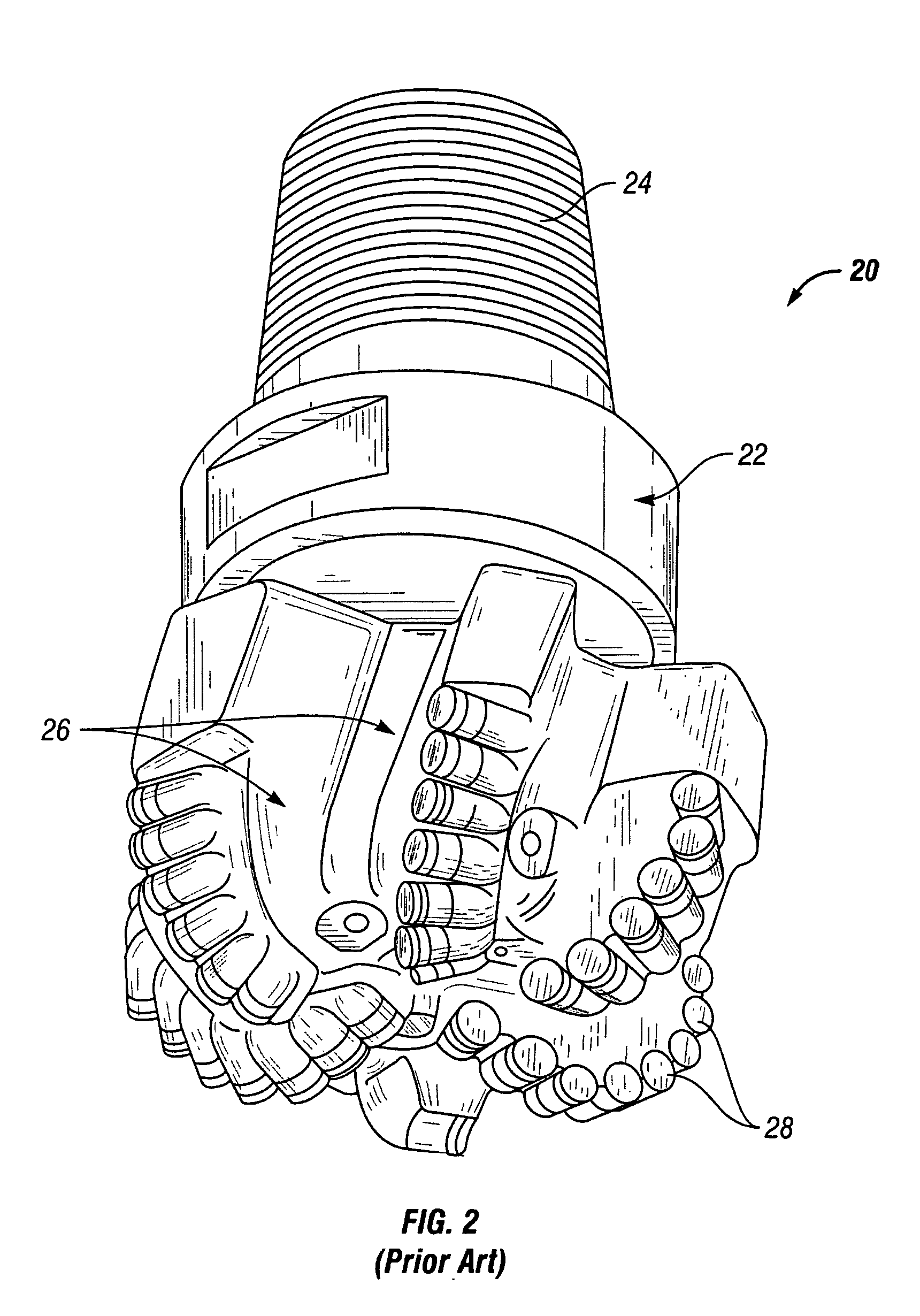

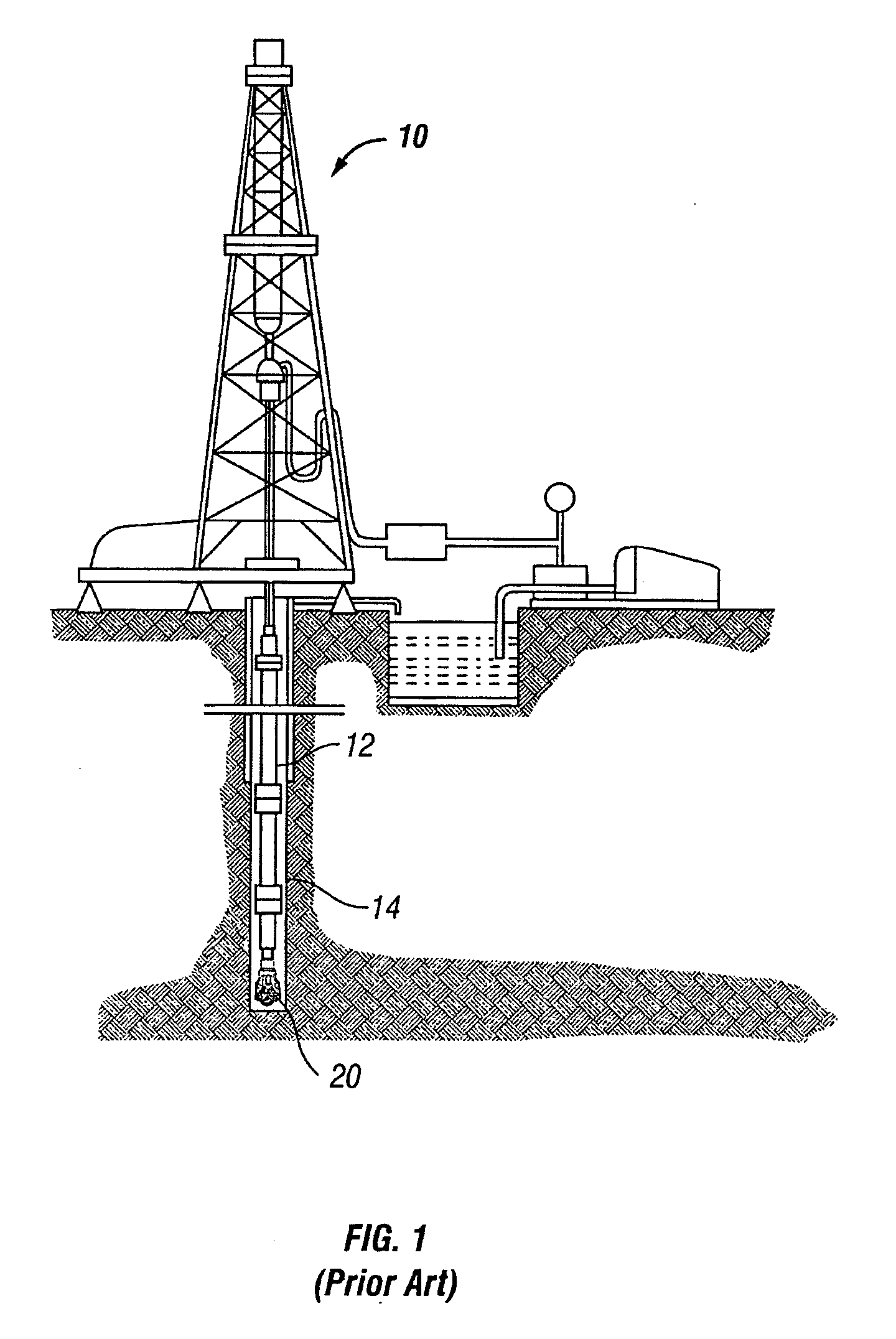

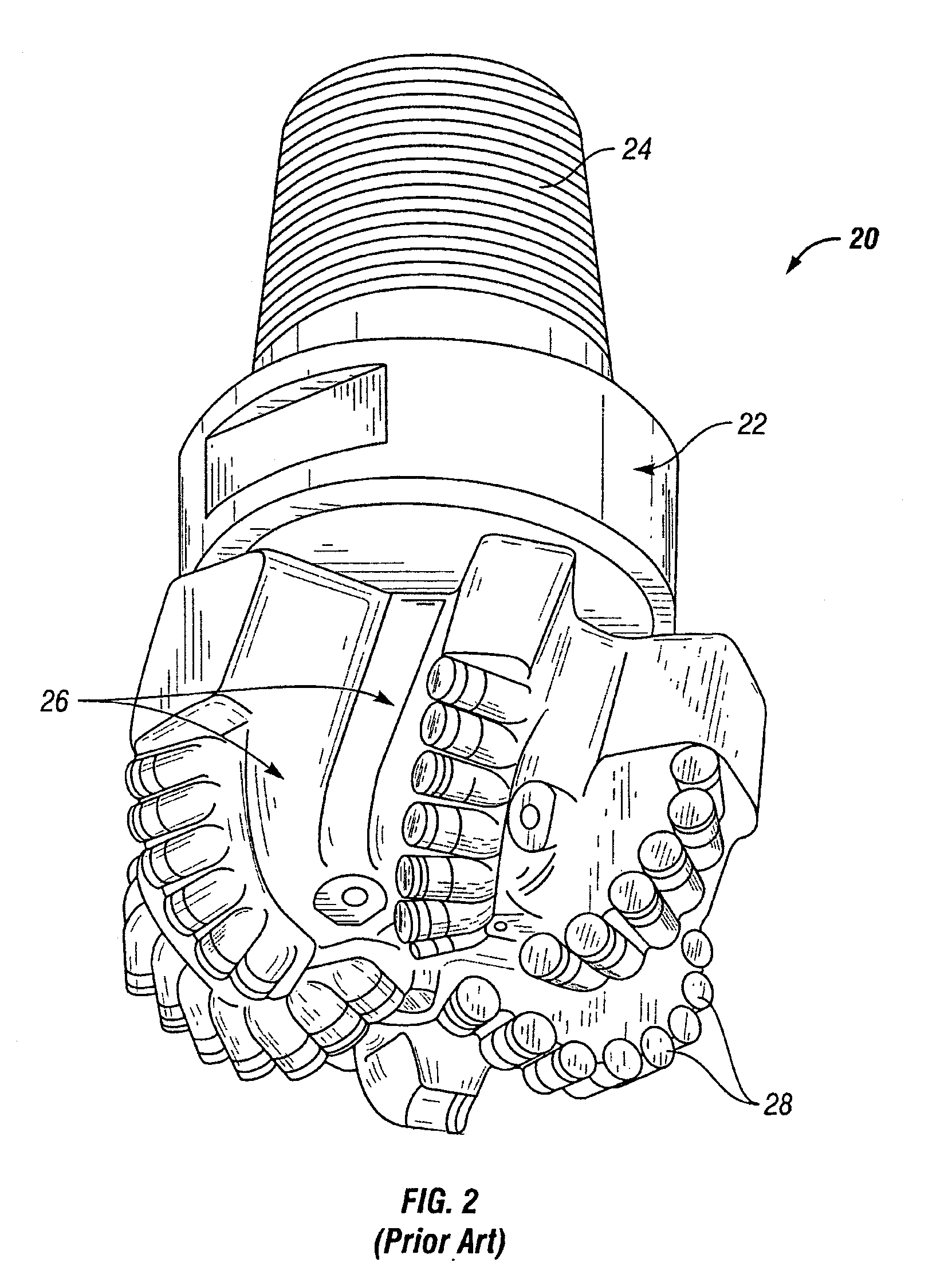

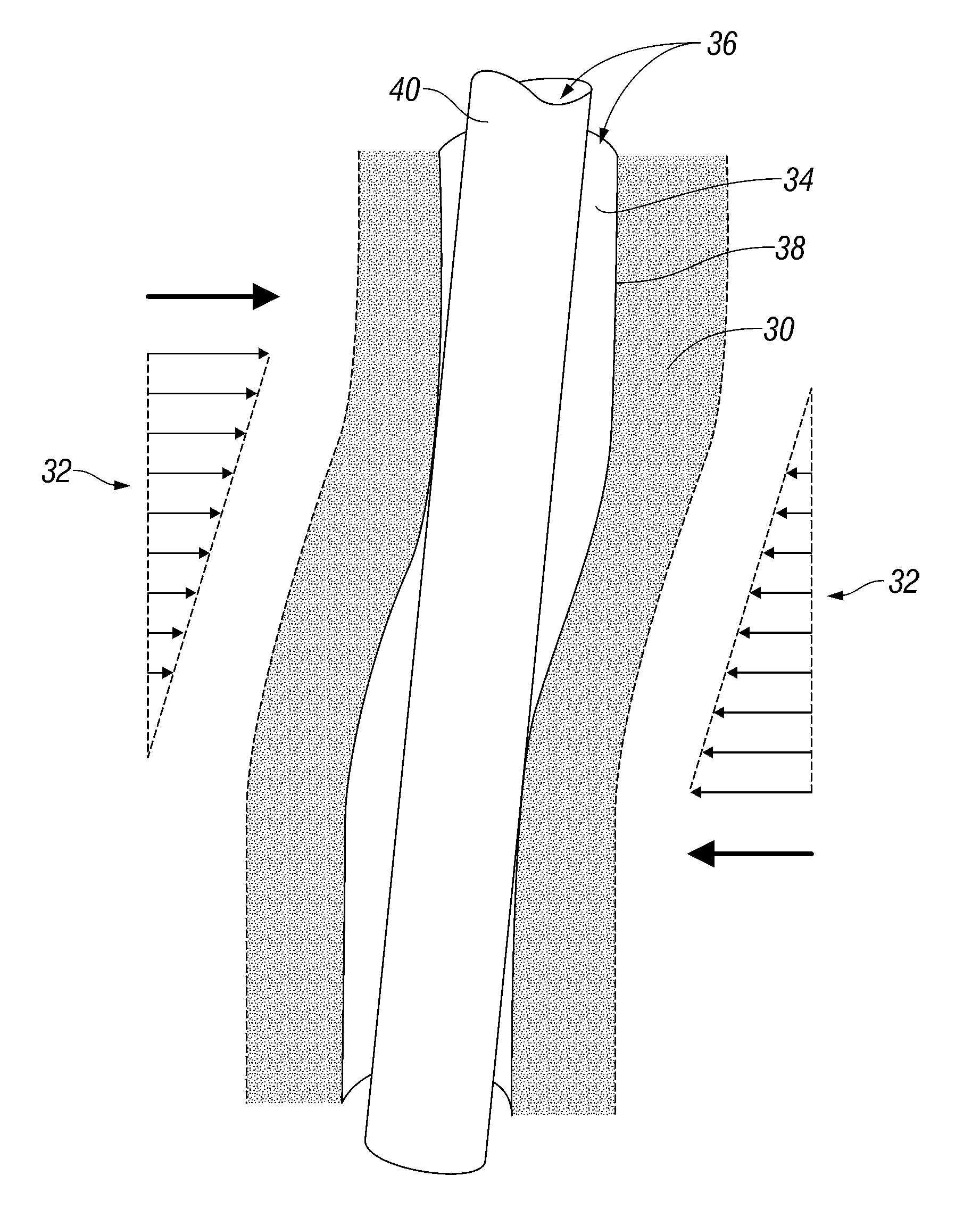

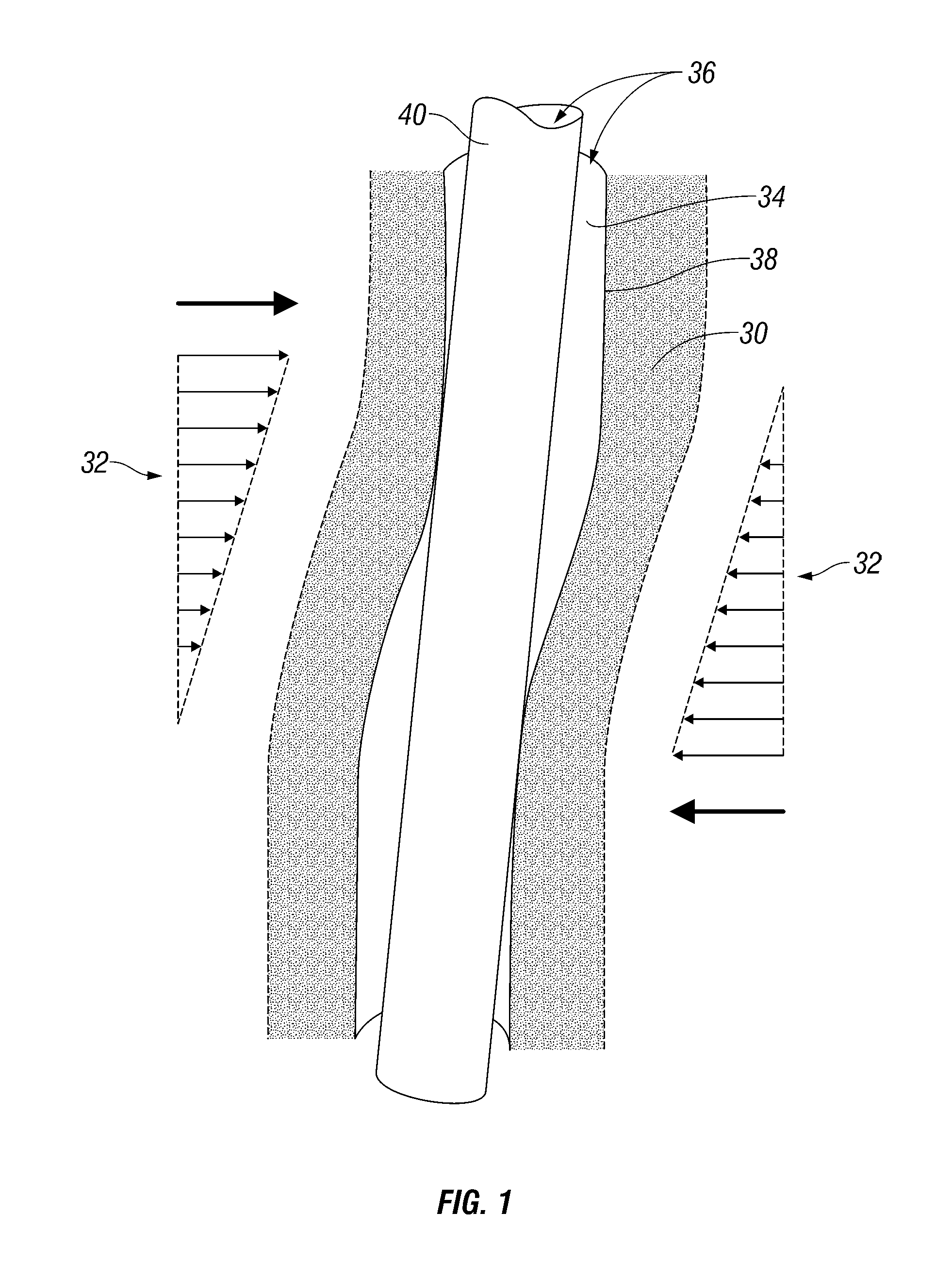

Methods for designing fixed cutter bits and bits made using such methods

In one aspect, the invention provides a method for modeling the dynamic performance of a fixed cutter bit drilling earth formations. In one embodiment, the method includes selecting a drill bit and an earth formation to be represented as drilled, simulating the bit drilling the earth formation. The simulation includes at least numerically rotating the bit, calculating bit interaction with the earth formation during the rotating, and determining the forces on the cutters during the rotation based on the calculated interaction with earth formation and empirical data.

Owner:SMITH INT INC

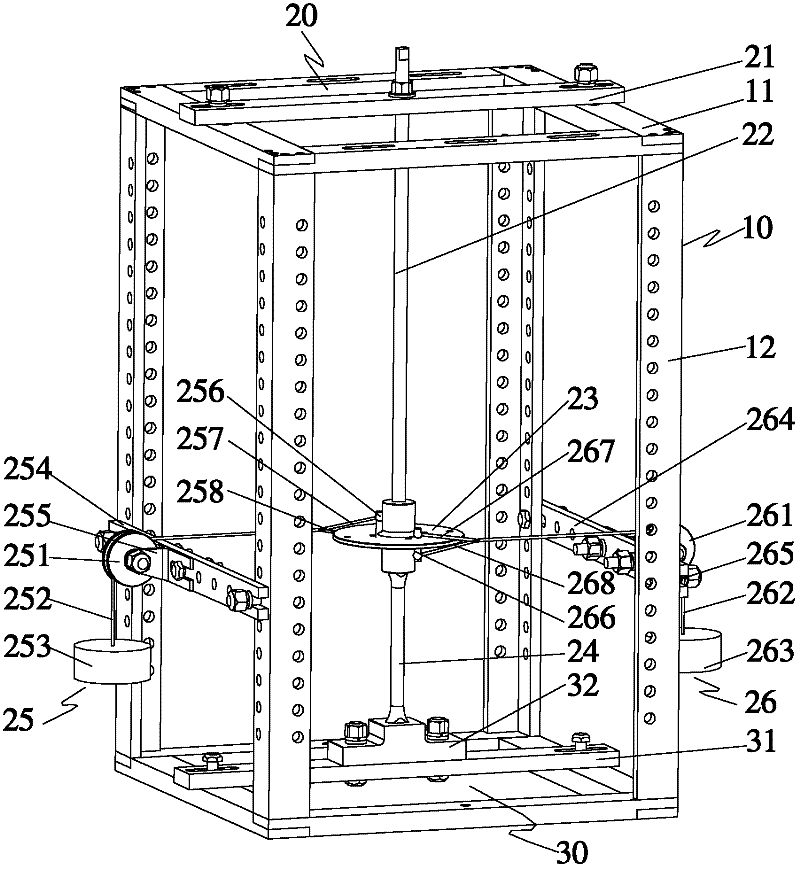

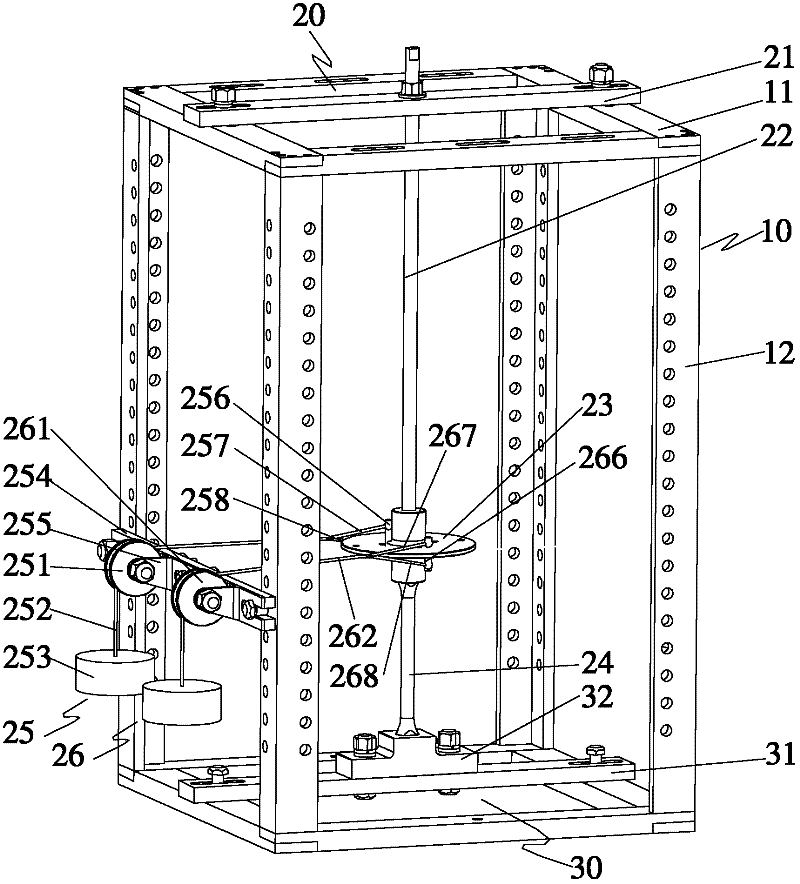

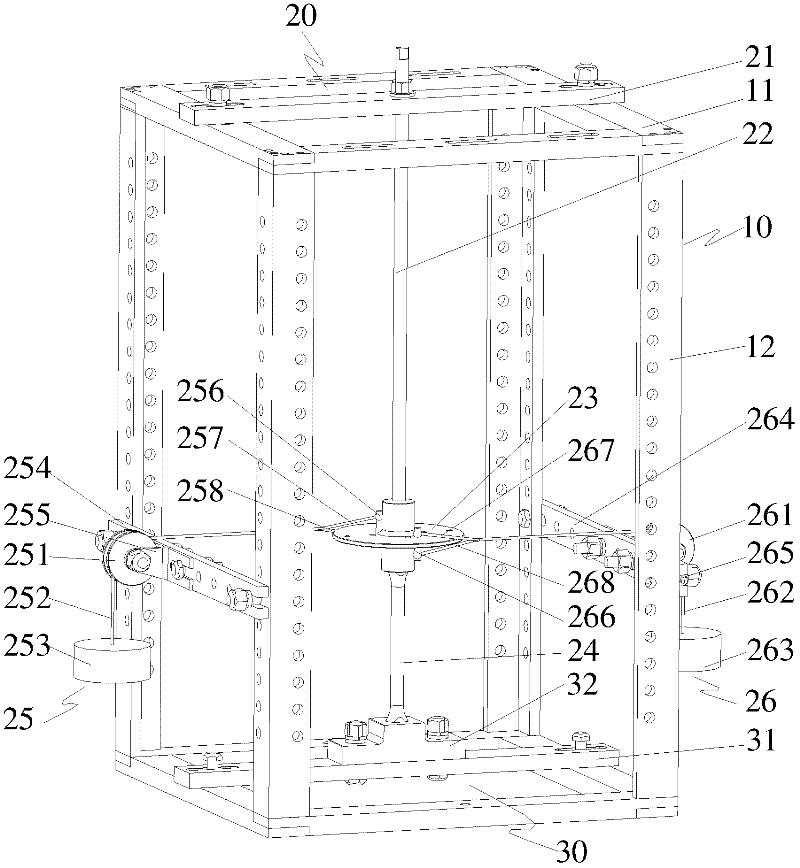

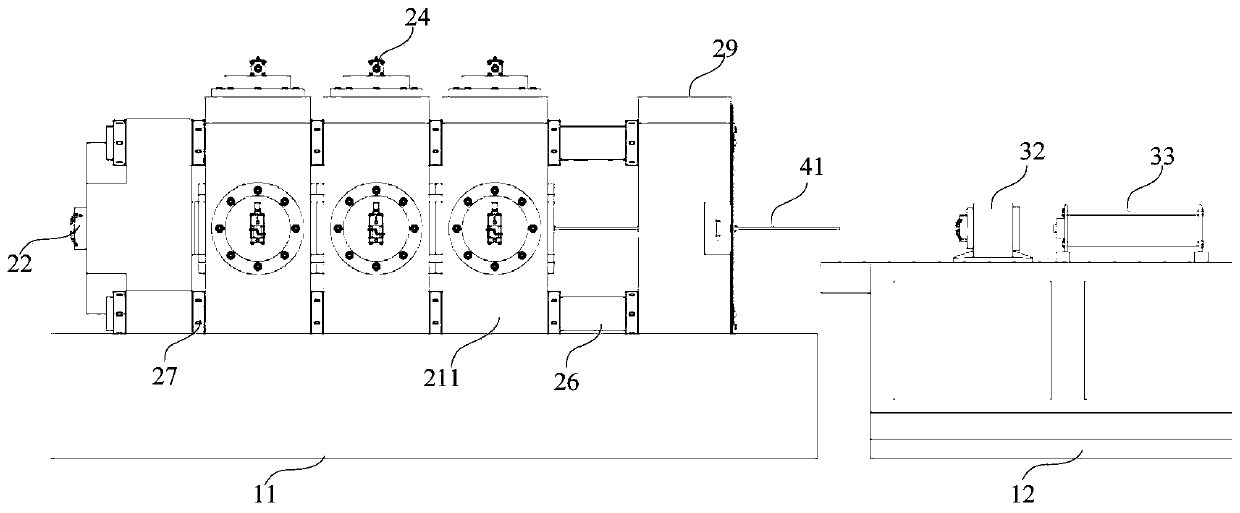

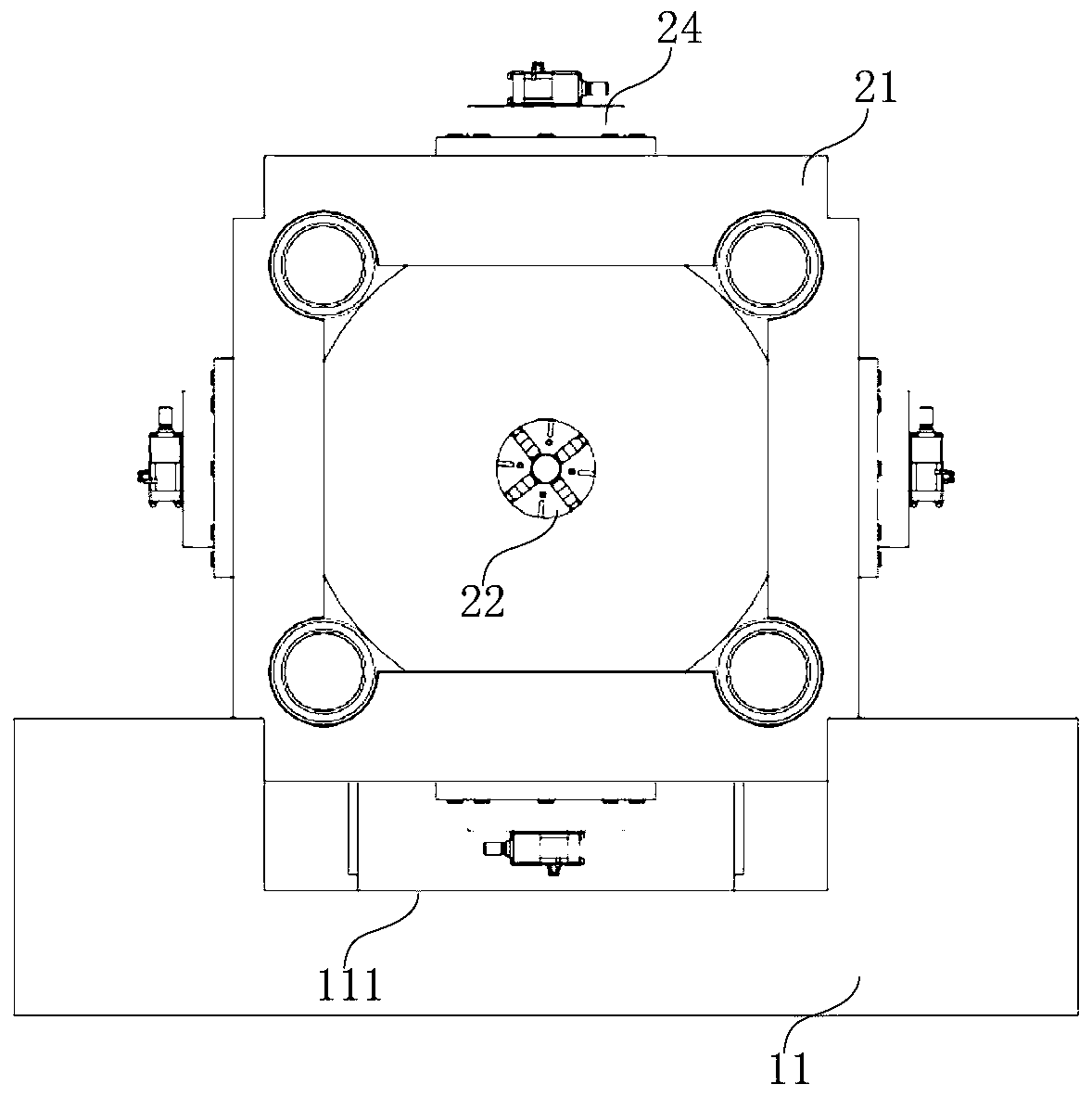

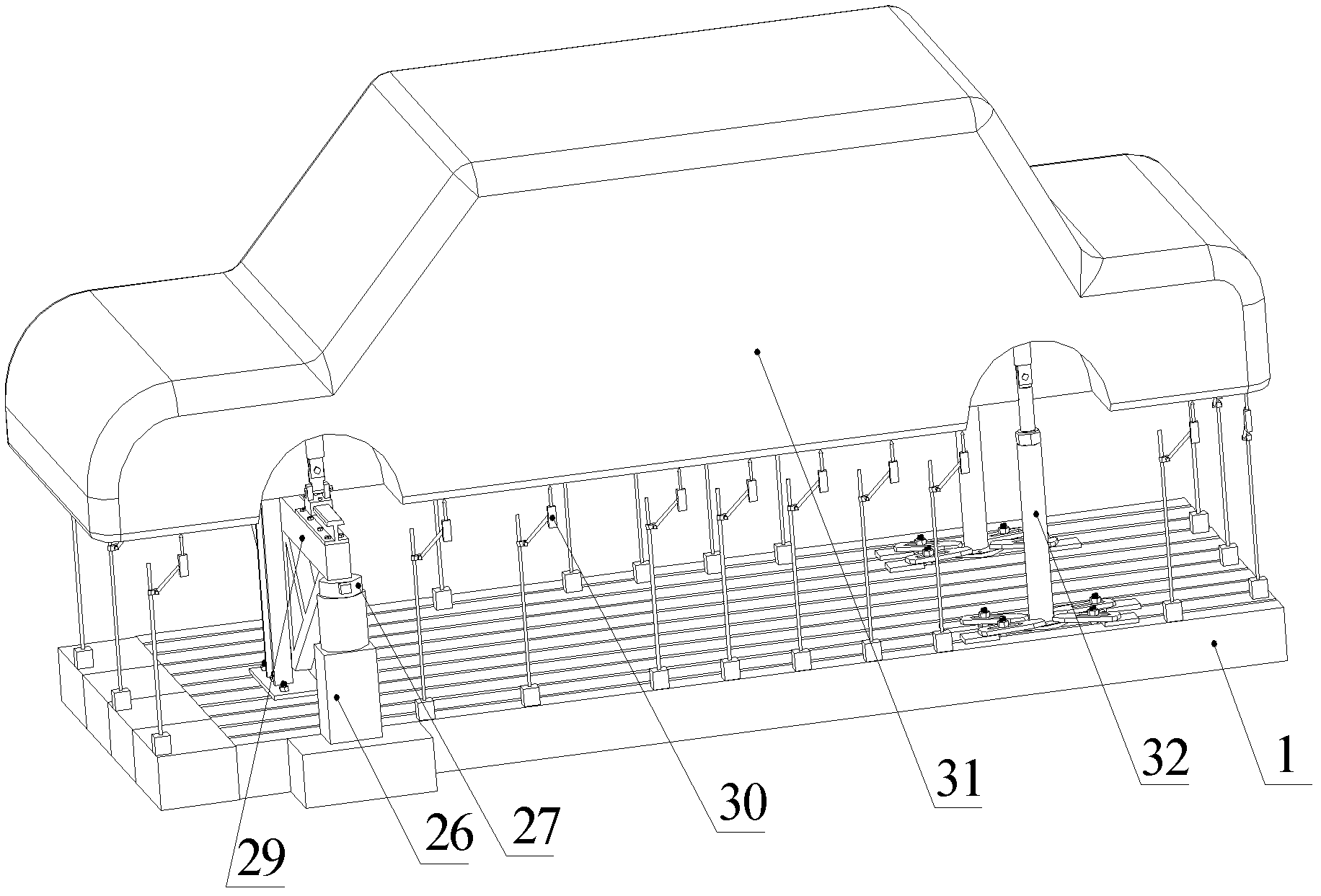

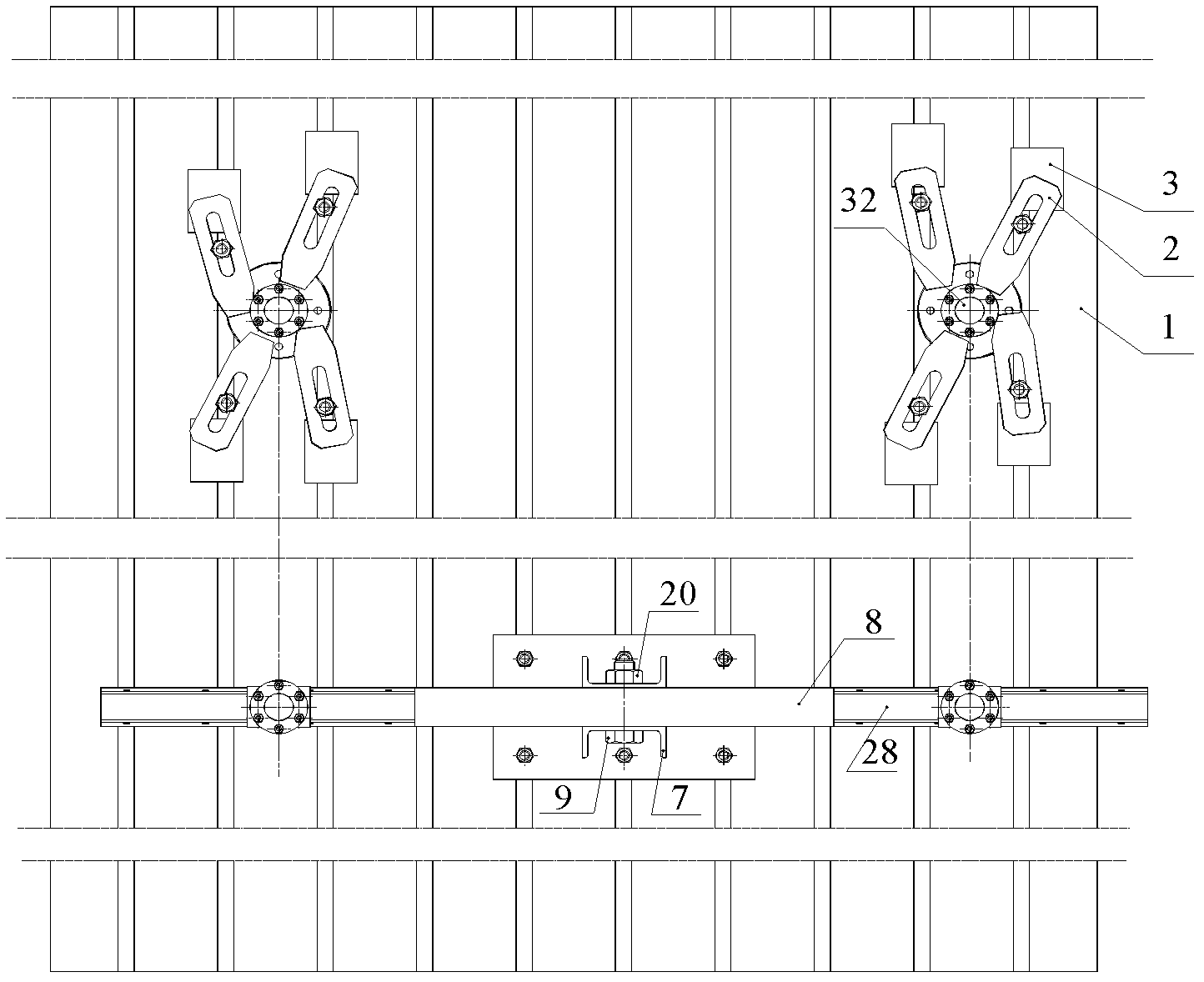

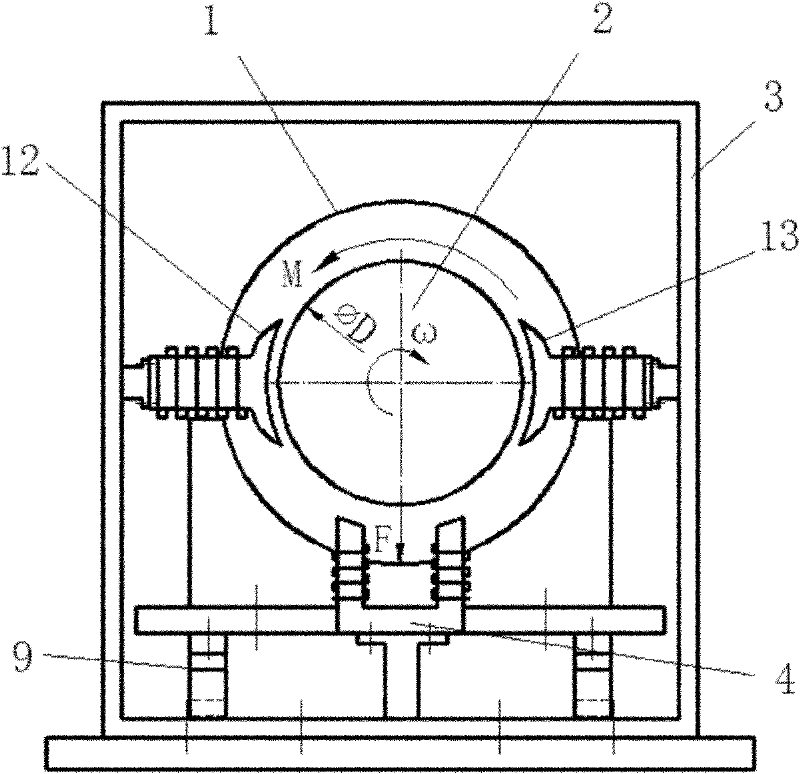

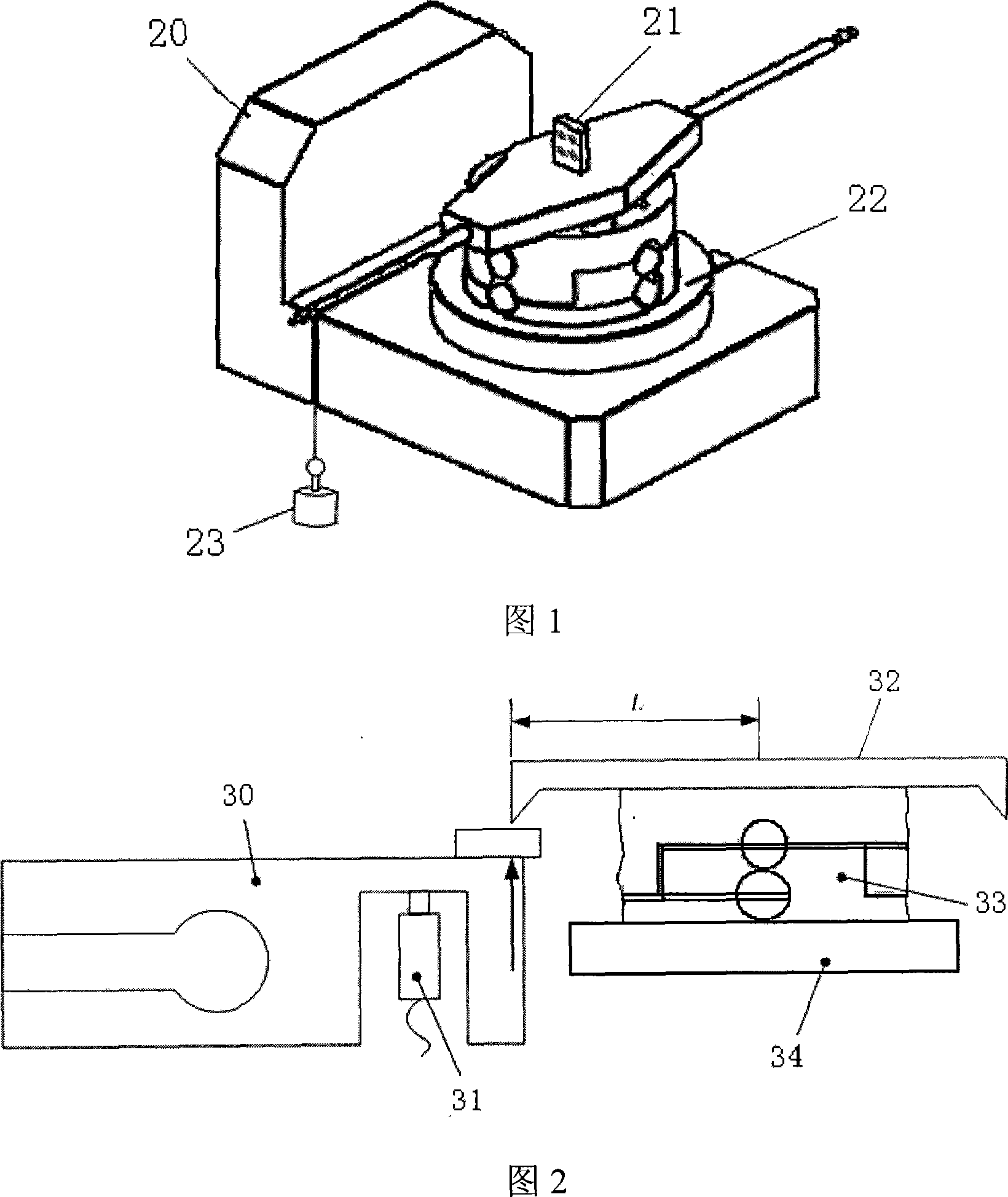

Model loading device

ActiveCN102401764ASave moneyLow costMaterial strength using steady torsional forcesEngineeringTest element

The invention provides a load loading device which comprises an installing frame (10), a load applying device (20) and an element positioning device (30), wherein the load applying device (2) comprises a positioning rod installing plate (21), a positioning rod (22), a torsion disk (23), a test element (24) rotatably connected to the second end of the positioning rod (22), a first load generating mechanism (25) connected to the torsion disk (23) and used for applying a pull force to the torsion disk (23), and a second load generating mechanism (26) connected to the torsion disk (23) and used for applying a pull force to the torsion disk (23), wherein the pull force applied to the torsion disk by the second load generating mechanism and the pull force applied to the torsion disk by the first load generating mechanism (25) form a couple or an equidirectional action force. According to the model loading device provided by the invention, the advantages of small occupation space, simple structure, convenience for use, lower cost and capability of realizing loading of multiple kinds of loads through the same device are obtained.

Owner:CHINA AVIATION POWER MACHINE INST

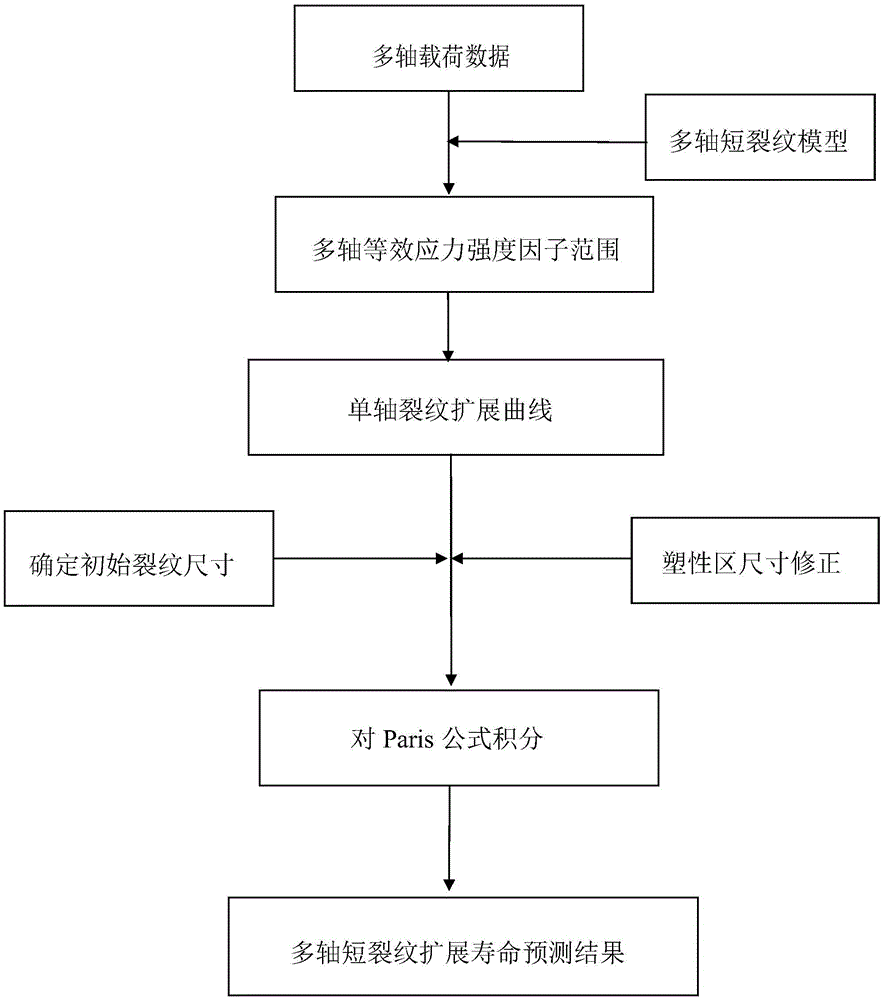

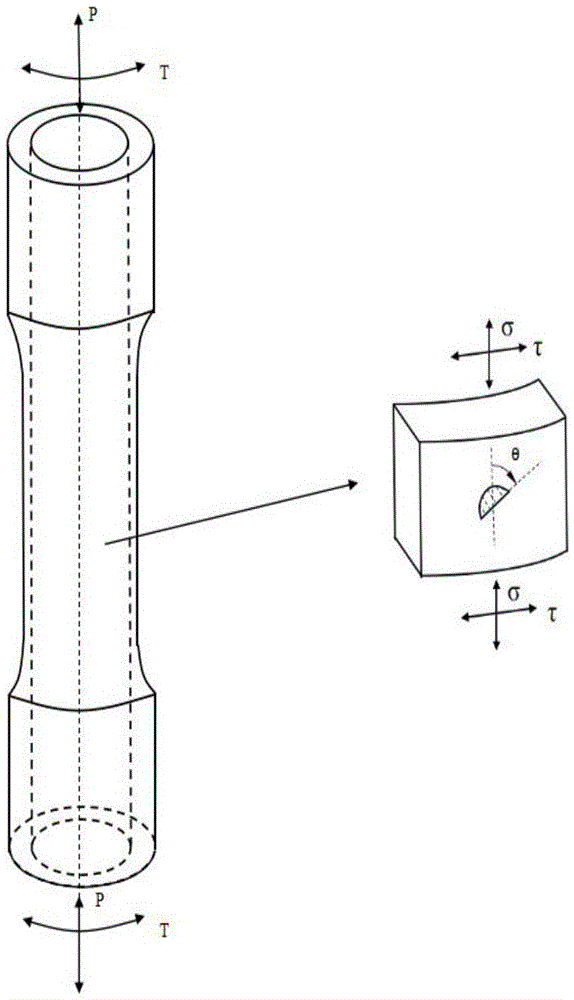

Multiaxial short crack propagation life prediction method based on critical surface method

ActiveCN105466772APromote engineering applicationMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesFatigue damageEngineering

The present invention provides a multiaxial short crack propagation life prediction method based on a critical surface method, and relates to the field of multiaxial fatigue strength theory. The algorithm comprises the steps of: (1) selecting a plane, which contains the maximum shearing strain range, as a critical surface, and using the damage parameters on the critical surface to characterize a short crack propagation driving force; (2) based on the shear-type multiaxial fatigue damage parameters, establishing an equivalent crack stress intensity factor applicable to the multiaxial stress state; (3) fitting the short crack propagation rate data under uniaxial loading to obtain an uniaxial short crack propagation curve; and (4) carrying out plastic zone size correction on the crack tip, and calculating the short crack propagation life by a fracture mechanics method. The method can well descript the influence of non-proportional loading on crack propagation. The results show that the method can well predict the short crack propagation life under multiaxial proportional and non-proportional loading.

Owner:BEIJING UNIV OF TECH

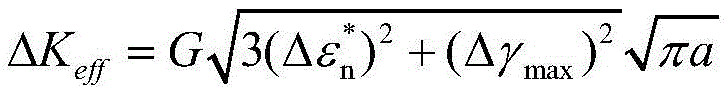

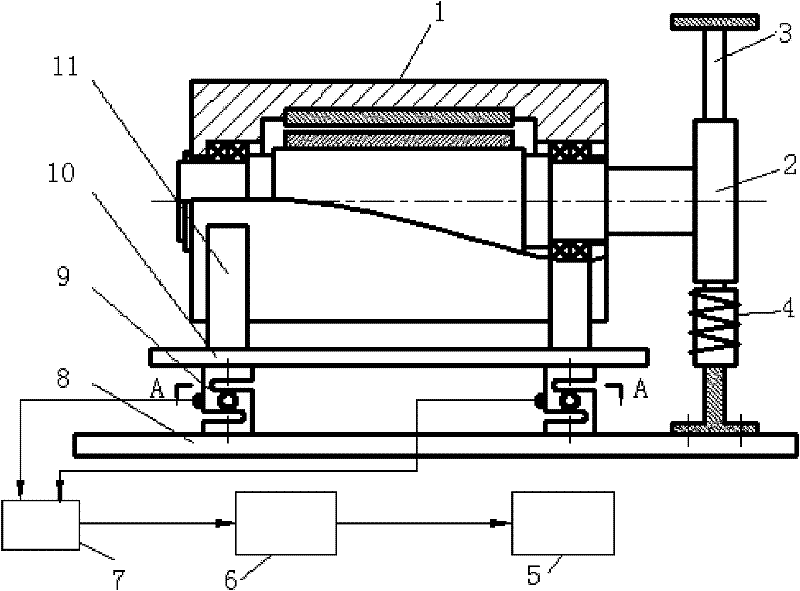

Equipment for testing bending and torsion resisting performances of electrical insulator

ActiveCN101788429AAchieve storageRealize printingMaterial strength using steady bending forcesMaterial strength using steady torsional forcesReducerEngineering

The invention relates to equipment for testing the bending and torsion resisting performances of an electrical insulator. The equipment is characterized in that: the equipment comprises a slewing worktable, an upright post, a cross beam assembly and a lifting driving mechanism; the upright post is vertically fixed above the slewing worktable; the lifting driving mechanism arranged at the top end of the upright post comprises a screw rod, a speed reducer and a lifting coder; the screw rod is connected with a screw rod nut in the upright post, the top part of the screw rod is connected with the speed reducer, a linear guide rail is arranged on the side wall of the upright post, and the cross beam assembly is connected with the upright post by the linear guide rail in a sliding manner; a bending pressure head, a bending load sensor, a bending displacement coder and a torsion block are arranged on the cross beam assembly; a bending oil cylinder is connected at the rear of the bending pressure head, the bending displacement coder is arranged on the bending oil cylinder, a torsion load sensor is arranged on the torsion block, and the position of a groove of the torsion block is corresponding to that of a test piece fixing seat on the slewing worktable. With the characteristics of saving space and being convenient for use, the equipment can accurately detect the bending and torsion resisting performances of the electrical insulator.

Owner:SHANDONG LIANMEI SPRINGS TECH CORP

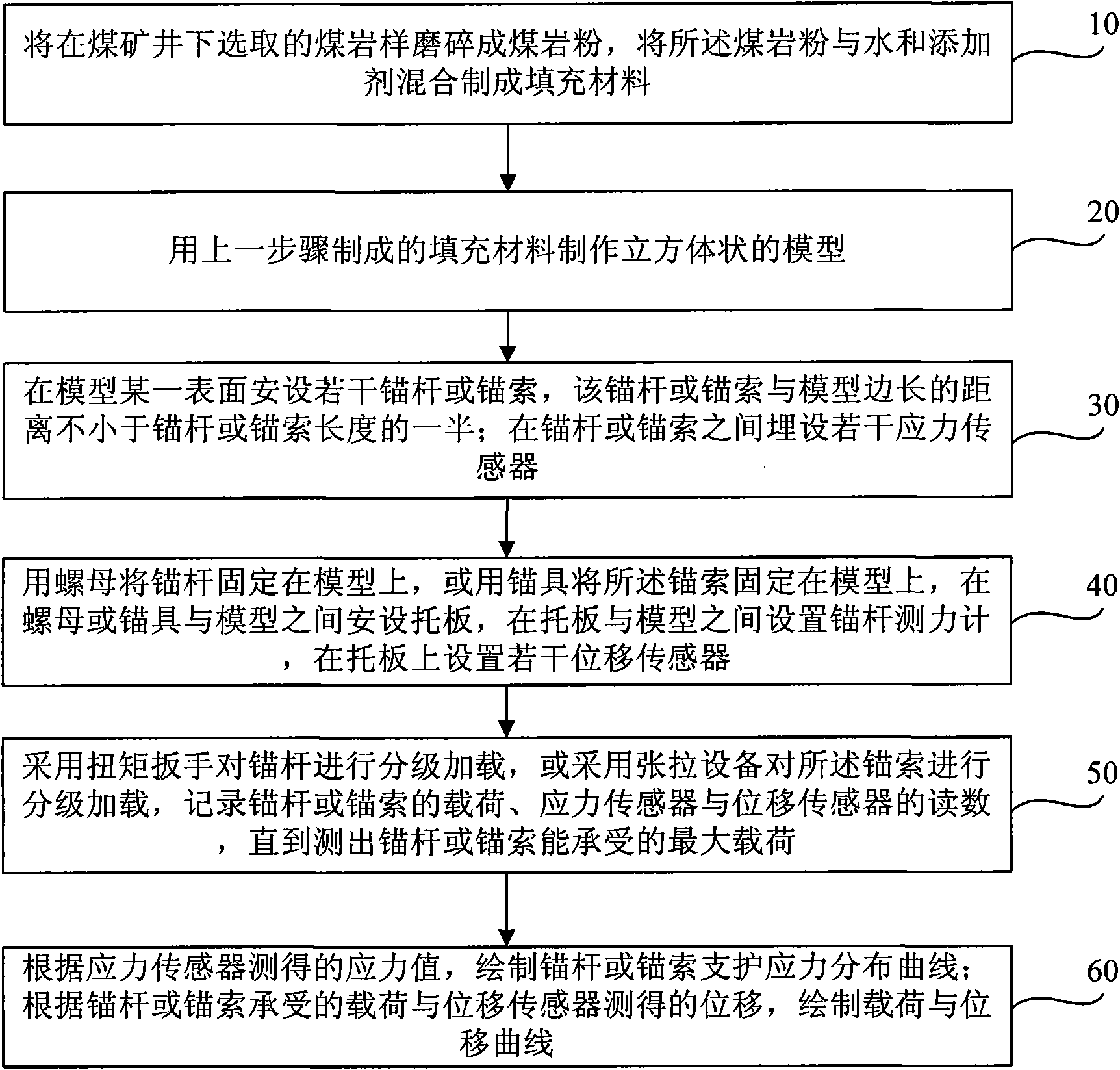

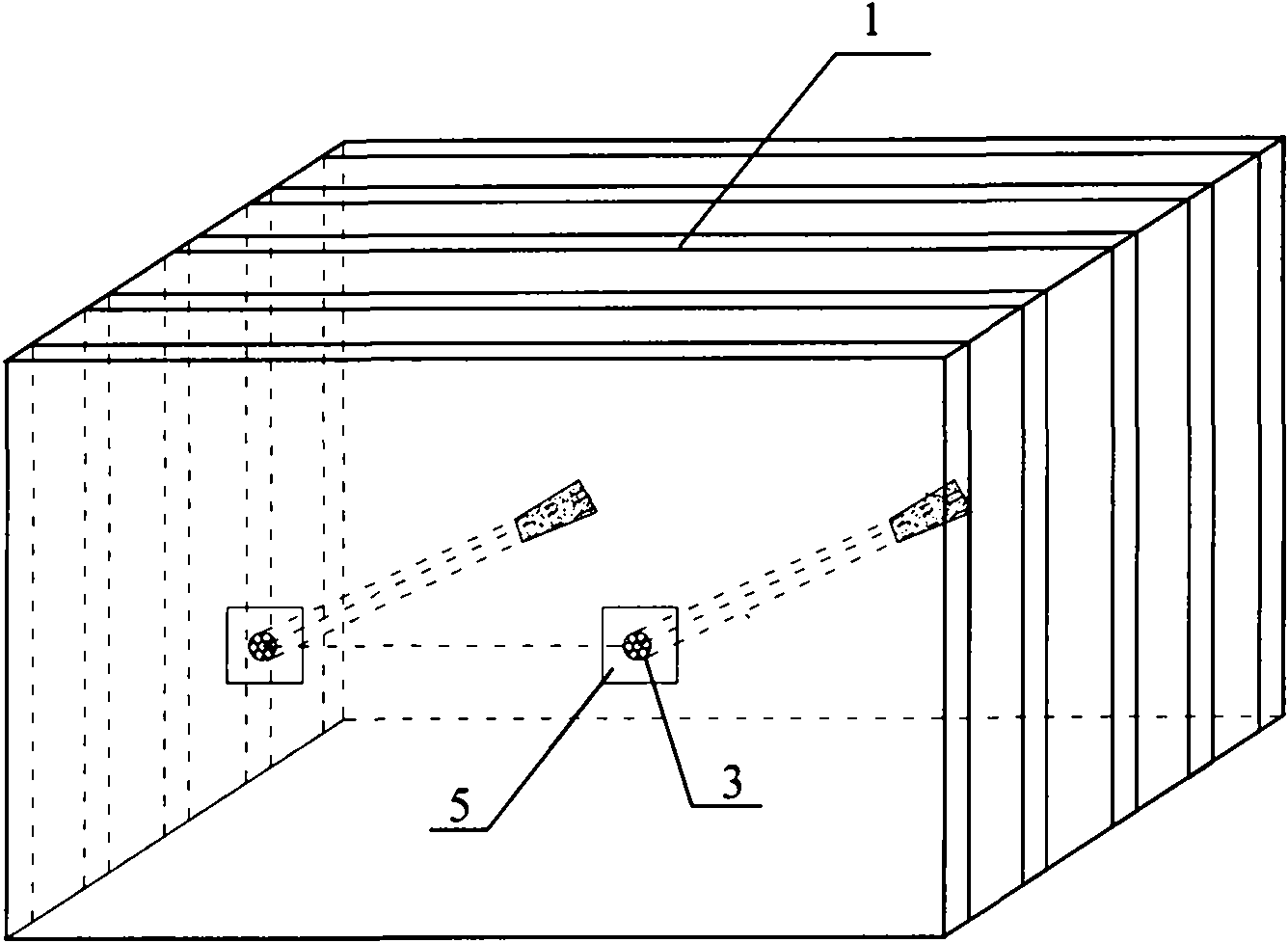

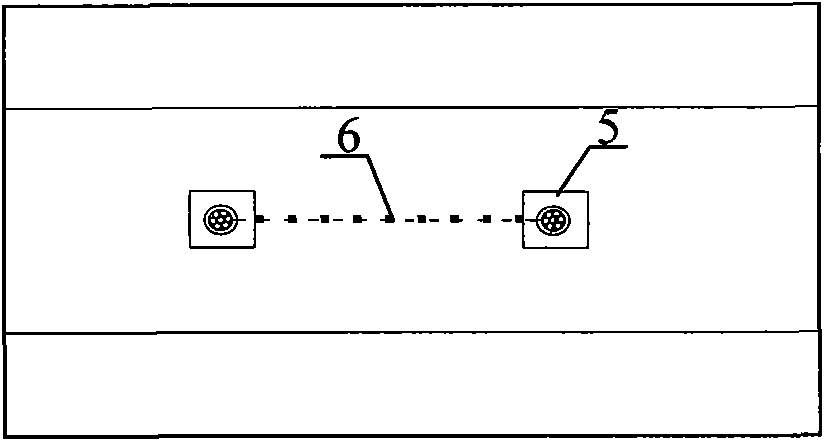

Anchor rod or anchor rope support stress test method and device

InactiveCN101963555AScientific and reasonable designMaster the mechanism of supportForce measurementMaterial strength using tensile/compressive forcesFilling materialsEngineering

The invention discloses an anchor rod or anchor rope support stress test method and device. The method comprises the following steps: preparing coal powder through the coal selected from a coal well, mixing the coal powder, water and additive to obtain filling material; preparing solid model through the filling material; installing a plurality of anchor rods or anchor ropes on one surface of the model; embedding a stress sensor between the anchor rods or anchor ropes; fixing the anchor rods on the model through screws, or fixing the anchor ropes on the model through anchoring members; installing a support plate between the screws or anchoring members and model, installing an anchor rod or anchor rope force tester between the support plate and the model, installing a plurality of displacement sensors on the support plate; using a torque spanner to perform hierarchical load to the anchor rods or using expansion device to perform hierarchical load to the anchor ropes, and recording the load and indications of the stress sensor and displacement sensor until reaching the maximal load of the anchor rods or anchor ropes. The invention can effectively test the support stress of anchor rods or anchor ropes and is easy to implement.

Owner:TIANDI SCI & TECH CO LTD

Combined-loading stress corrosion testing apparatus and method

ActiveCN105388101AAvoid influenceImprove accuracyWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesStress conditionsEngineering

The invention provides a combined-loading stress corrosion testing apparatus. The apparatus comprises a tension ring; a hermetically arranged environmental container; a gas inlet pipe, a gas outlet pipe, a thermocouple and a pressure sensor which extend into the environmental container from above; upper and lower clamps respectively arranged at the upper and lower ends of the environmental container; a loading bolt in threaded connection with the free end of the lower clamp; a rotary motor connected with the free end of the upper clamp; an electromagnetic stirrer arranged in the lower part of the environmental container; and a magneton arranged in the container. The radial end of the tension ring is fixedly connected with the upper clamp, and the other end of the tension ring is connected with the end, far away from the lower clamp, of the loading bolt; and the tension ring applies tension on the upper and lower clamps through rotation of the loading bolt. A testing method based on the apparatus is used for research on corrosion resistance of a drilling rod, an oil sleeve material and the like in an oil and gas well with high temperature, high pressure and a multiphase flow corrosive medium under complex stress conditions including drawing, torsion and liquid flow impact.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

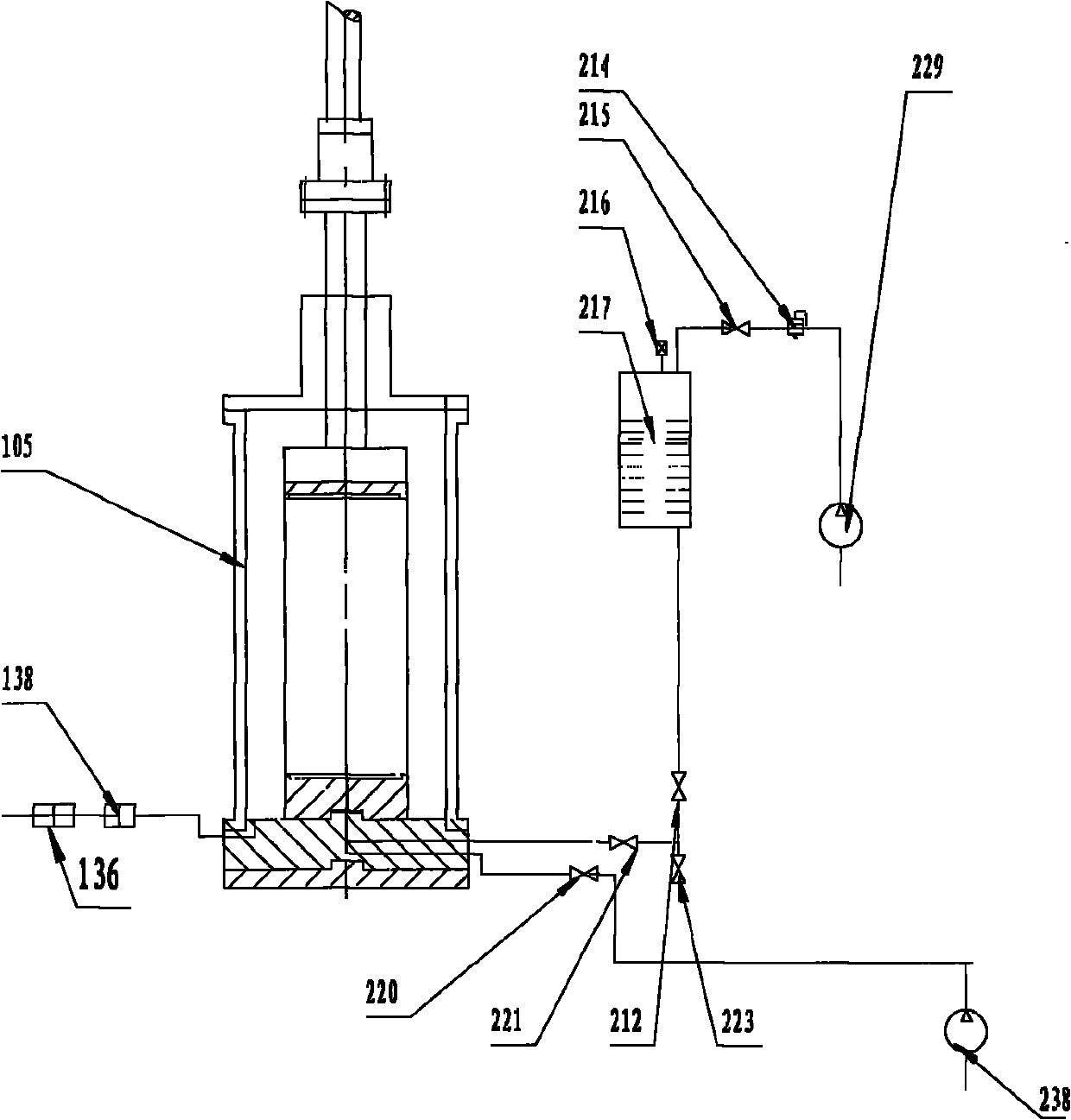

Micro-torque mechanical testing machine and method

InactiveCN102128752AImproved torque resolutionMeet the needs of micro torque testingWork measurementMaterial strength using steady torsional forcesShear modulusShear stress

The invention relates to a micro-torque mechanical testing machine and method. The testing machine comprises a control device and a testing machine host, wherein the control device is used for setting a testing method, sending a command to the testing machine host and analyzing and processing test data obtained from the testing machine host; and the testing machine host is used for loading a test sample. The testing method comprises the following steps of: controlling a signal generating module to generate a voltage signal through customized testing software, and driving the testing machine host to work after conditioning and amplifying; acquiring an angle signal and a coil driving signal by a signal acquisition module; converting the acquired angle signal into a rotation angle, and converting the acquired coil driving signal into a torque; and carrying out data processing according to a mechanical model to obtain a shear stress-shear strain curve of the test sample, thereby further calculating shear modulus and shear strength. By adopting electromagnetic driving and torque measuring ways, the torque resolution of the torque testing machine is greatly improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

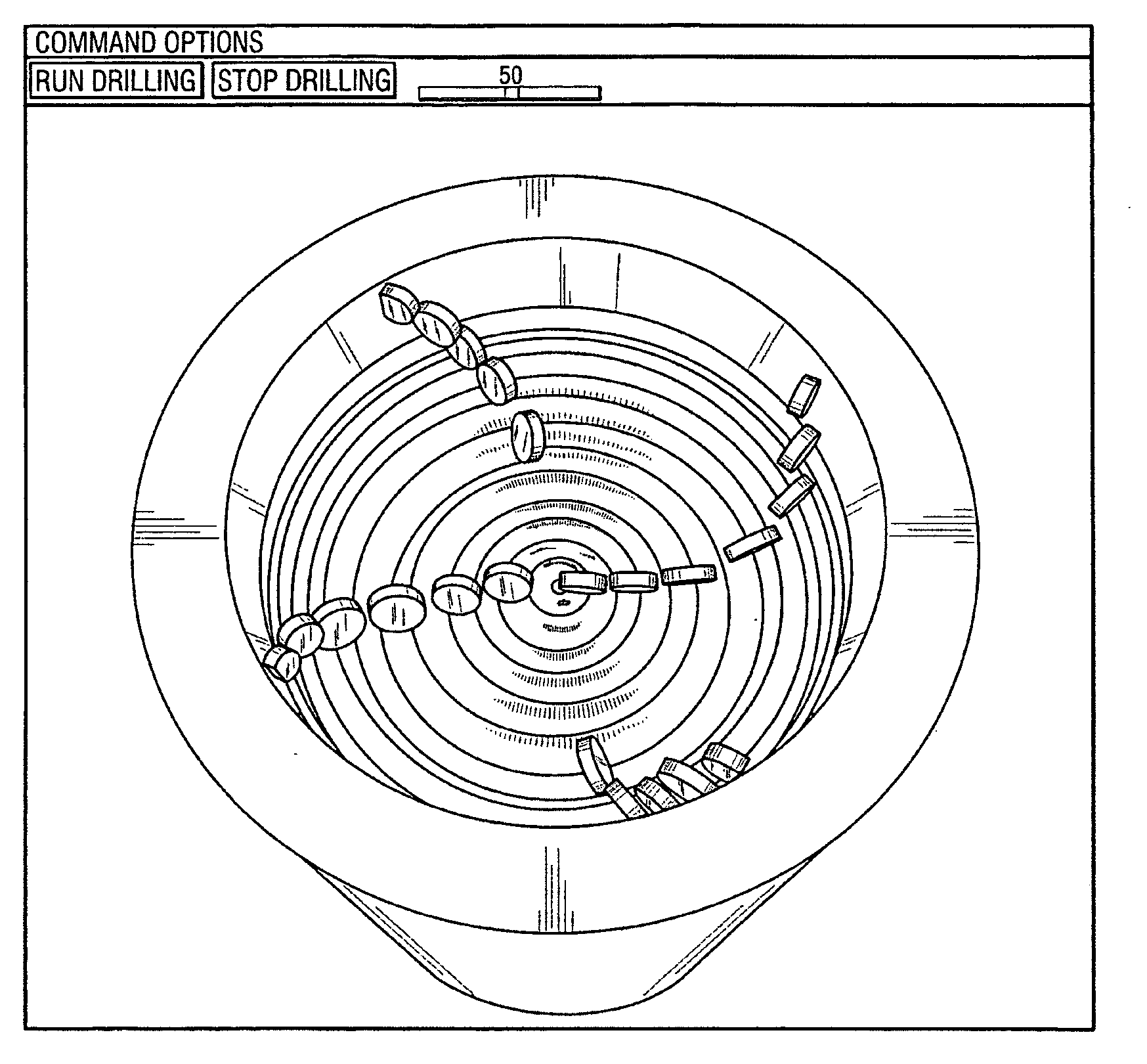

Methods for modeling, displaying, designing, and optimizing fixed cutter bits

ActiveUS20100211362A1Electric/magnetic detection for well-loggingEarth drilling toolsEngineeringDesign methods

In one aspect, the invention provides a method for modeling the performance of a fixed cutter bit drilling an earth formation. In one embodiment, the method includes selecting a drill bit and an earth formation to be represented as drilled, simulating the bit drilling the earth formation, displaying the simulating, and adjusting at least one parameter affecting the performance. The method of design is used to make a fixed cutter drill bit. In another embodiment the method includes numerically rotating the bit, calculating bit interaction with the earth formation during the rotating, and determining the forces on the cutters during the rotation based on the calculated interaction with earth formation and empirical data.

Owner:SMITH INT INC

Anchor rod (cable) supporting structure test and anchoring system performance integration test device and method

ActiveCN110274831AHigh simulationImplement torsion testMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesIntegration testingAcoustic emission

The invention provides an anchor rod (cable) supporting structure test and anchoring system performance integration test device and method and relates to the anchoring test technology field. The device comprises a frame, a loading mechanism, a test mechanism and a test piece. The frame comprises a pedestal and an operation bench. The loading mechanism includes a loading frame, a chuck, a surrounding rock stress loading oil cylinder, and a drawing hollow oil cylinder. The test mechanism includes monitoring mechanisms of a load, displacement, acoustic emission and the like. The test piece includes a rock test piece, an anchor rod (cable), an anchor net and the like. The loading mechanism and the drawing hollow oil cylinder are arranged above the pedestal, and a torsion motor and an anchor rod drilling machine are arranged on the operation bench. The rock test piece is placed between bearing plates, and one end of the anchor rod (cable) is fixed or anchored in the rock test piece through the chuck, and the other end passes through the drawing hollow oil cylinder. The device can test mechanical performance of the anchor rod (cable) and an anchoring component, can realize stress environment simulation of ''five-sided loading and one side empty'', and can carry out surrounding rock drilling response or anchoring system performance integration testing.

Owner:SHANDONG UNIV OF SCI & TECH

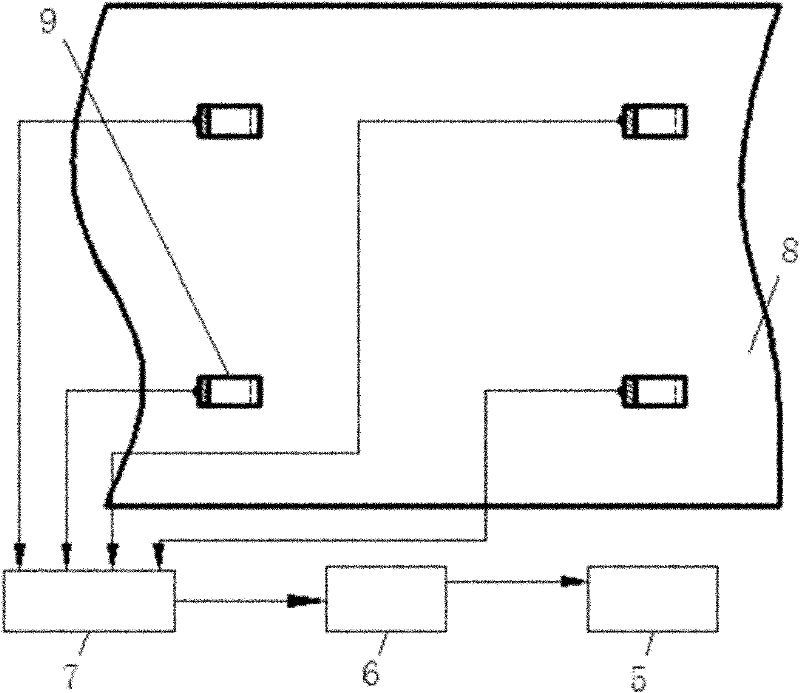

White car body static stiffness restriction device and static stiffness detection method

InactiveCN102435508AImprove structural performanceImprove test efficiencyMaterial strength using steady torsional forcesSplit pinStructural engineering

The invention discloses a white car body static stiffness restriction device of a passenger car and a static stiffness detection method. The device is characterized in that: one side of a front bearing support is provided with a pressure transducer and a hydraulic jack, a plurality of displacement sensors are arranged at the periphery of the white car body bottom surface; the front bearing support comprises a front rack, a T-shaped rack, and a I-shaped guide rail, wherein, the end portion of the front rack is connected with the very center of a crossbeam of the T-shaped rack through bolts and nuts, the crossbeam of the T-shaped rack is arranged at the left and right side of the white car body, and the lower side of the crossbeam is provided with the hydraulic jack; the bottom of the T-shaped rack is connected with the bottom of the front rack through a pin roll and a split pin; the upper surface of the crossbeam of the T-shaped rack is symmetrically provided with I-shaped guide rails; a torque value of the applied load is divided by a twisting angle to calculate a twisting stiffness, and the actual value of the load is divided by a car body deformation displacement to obtain a bending stiffness. According to the invention, the efficiency of various vehicle tests is increased, and the device cost is obviously reduced on the premise that the test accuracy is guaranteed.

Owner:JIANGSU UNIV OF SCI & TECH

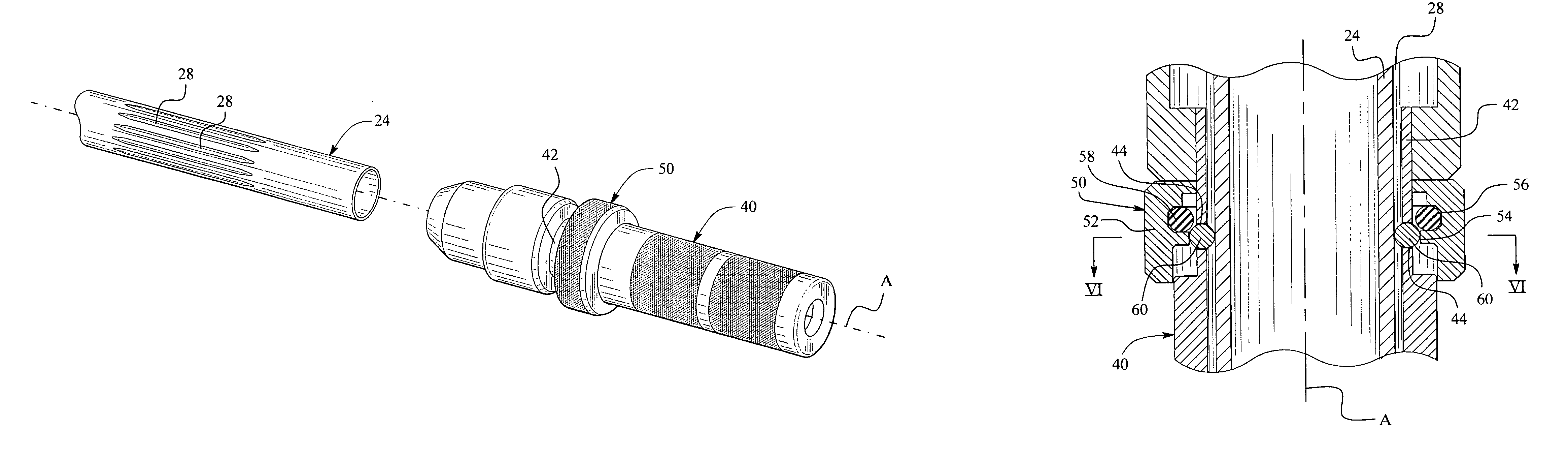

Method and device for monitoring a flexible pipe

ActiveUS7296480B2Improve certaintyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateInternal pressureDevice Monitor

A device for monitoring the integrity of a flexible pipe used for transporting a pressurized fluid in a terminal end-fitting. The pipe includes an internal pressure sheath, plies of tensile armor wires and an outer sheath fastened to the end-fitting. A device monitors the change in a phenomenon associated with a failure of the armor plies as a result of a fracture of several tensile armor wires inside the end-fitting. The device detects an increase in the twist in the pipe near the end-fitting, which twist is a phenomenon of a fracture of tensile armor wires inside the end-fitting.

Owner:TECH FRANCE SA

Torque testing device

InactiveCN102650580AAvoid measurement errorsImprove test accuracyMeasurement of torque/twisting force while tighteningMaterial strength using steady torsional forcesControl theoryTraining set

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shear and seepage flow coupling rheological test instrument with tension and compression rings for rock

ActiveCN106248557AThe deformation is continuous and smoothAchieving force controlClimate change adaptationMaterial strength using tensile/compressive forcesClassical mechanicsSystem pressure

The invention belongs to the technical field of mechanical test devices for rock, and discloses a shear and seepage flow coupling rheological test instrument with tension and compression rings for rock. The shear and seepage flow coupling rheological test instrument comprises a base, an upper shear box, a lower shear box, a first frame, a second frame, an axial loading system, a torque loading system, pressure control structures and deformation detecting structures. The first frame is fixed onto the base, and the second frame is fixed onto the first frame; the lower shear box is fixed onto the base; the upper shear box and the lower shear box are opposite to each other, and annular upper test specimen grooves and annular lower test specimen grooves are respectively formed in the upper shear box and the lower shear box; the torque loading system is connected with an output end of the axial loading system; the pressure control structures are respectively connected with the axial loading system and the torque loading system, and feedback control can be carried out on applied axial force and torque by the pressure control structures; the deformation detecting structures are arranged in the shear boxes and are used for detecting deformation of rock test specimens. The shear and seepage flow coupling rheological test instrument with the tension and compression rings for the rock has the advantage of multiple stress paths.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

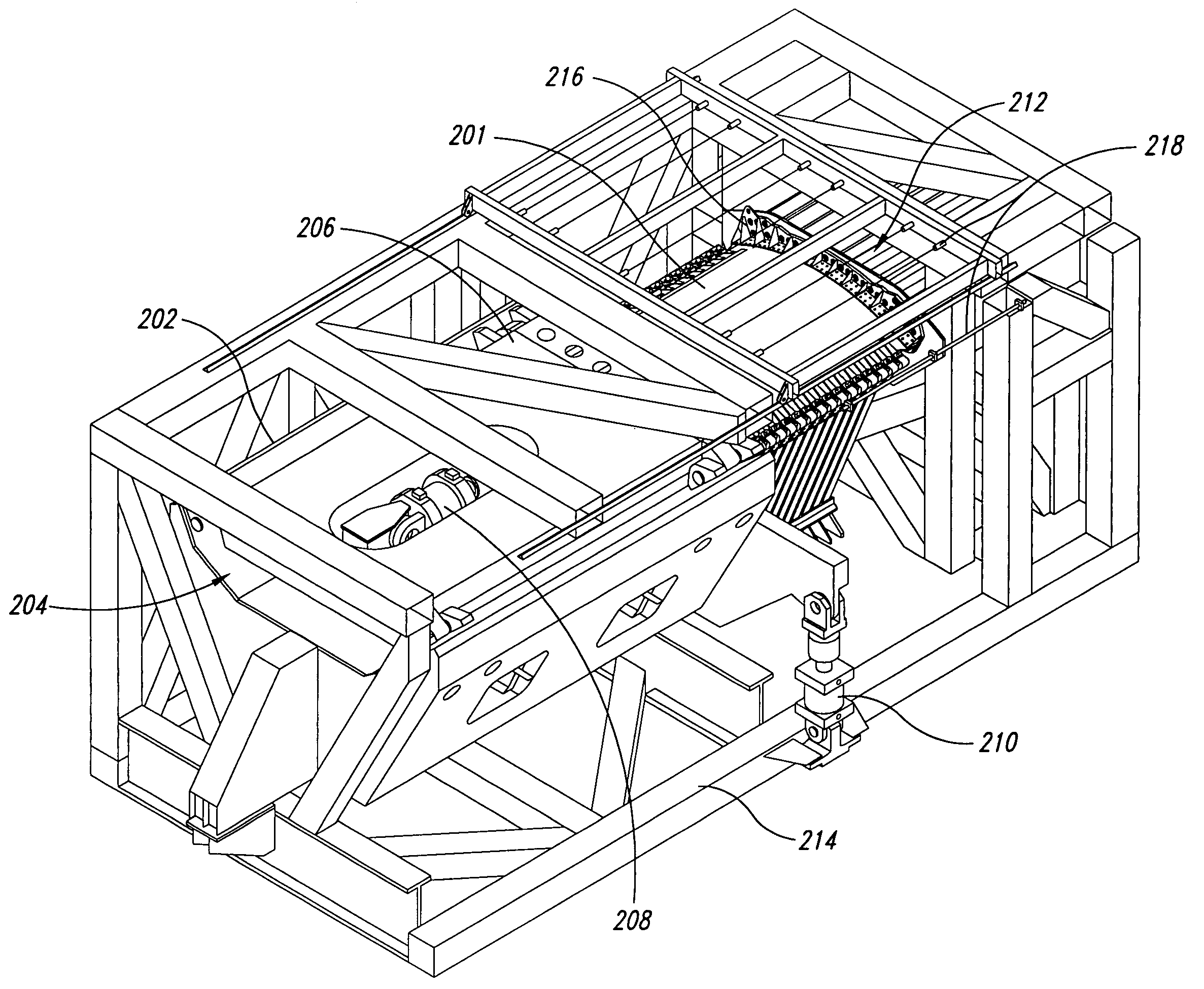

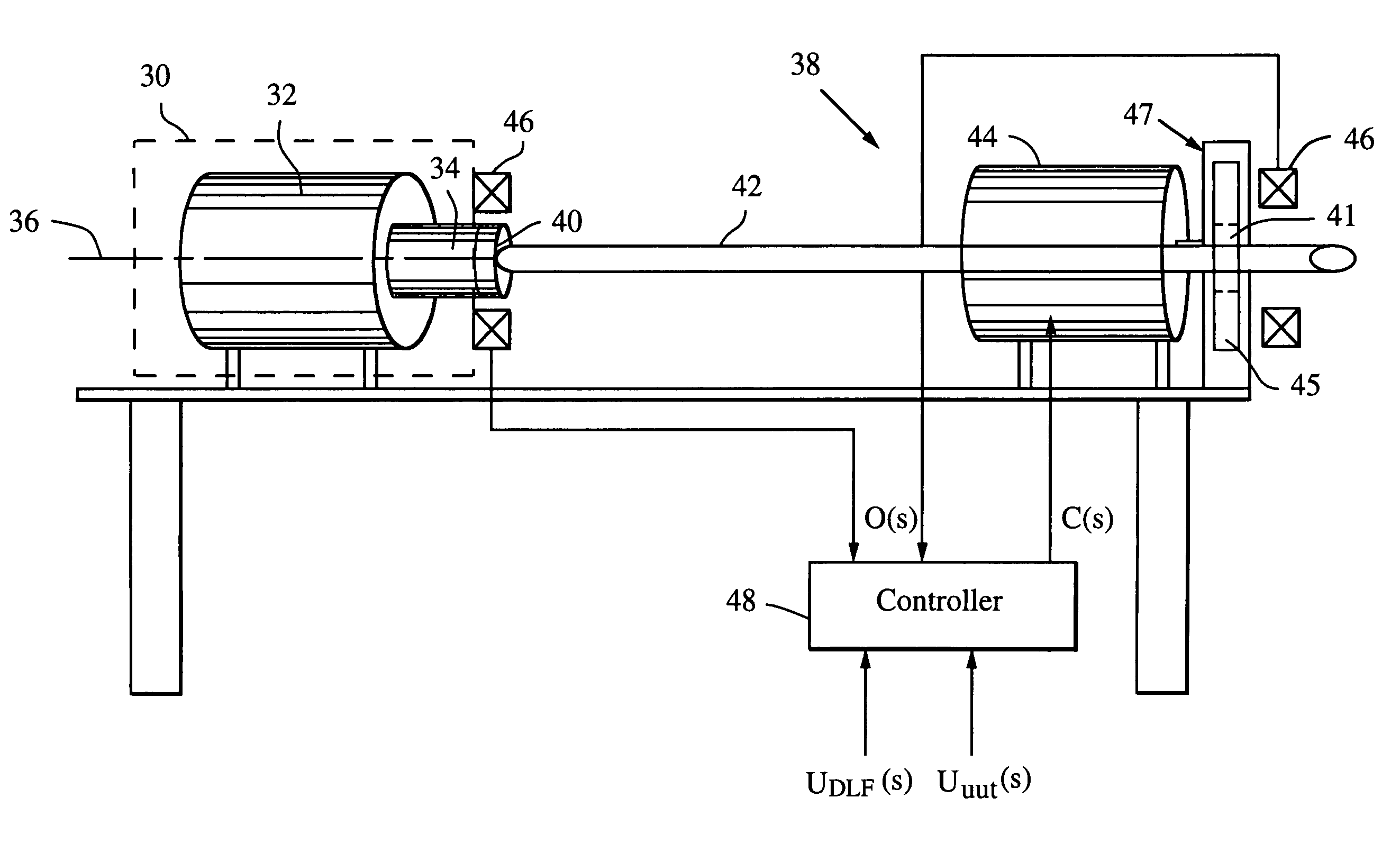

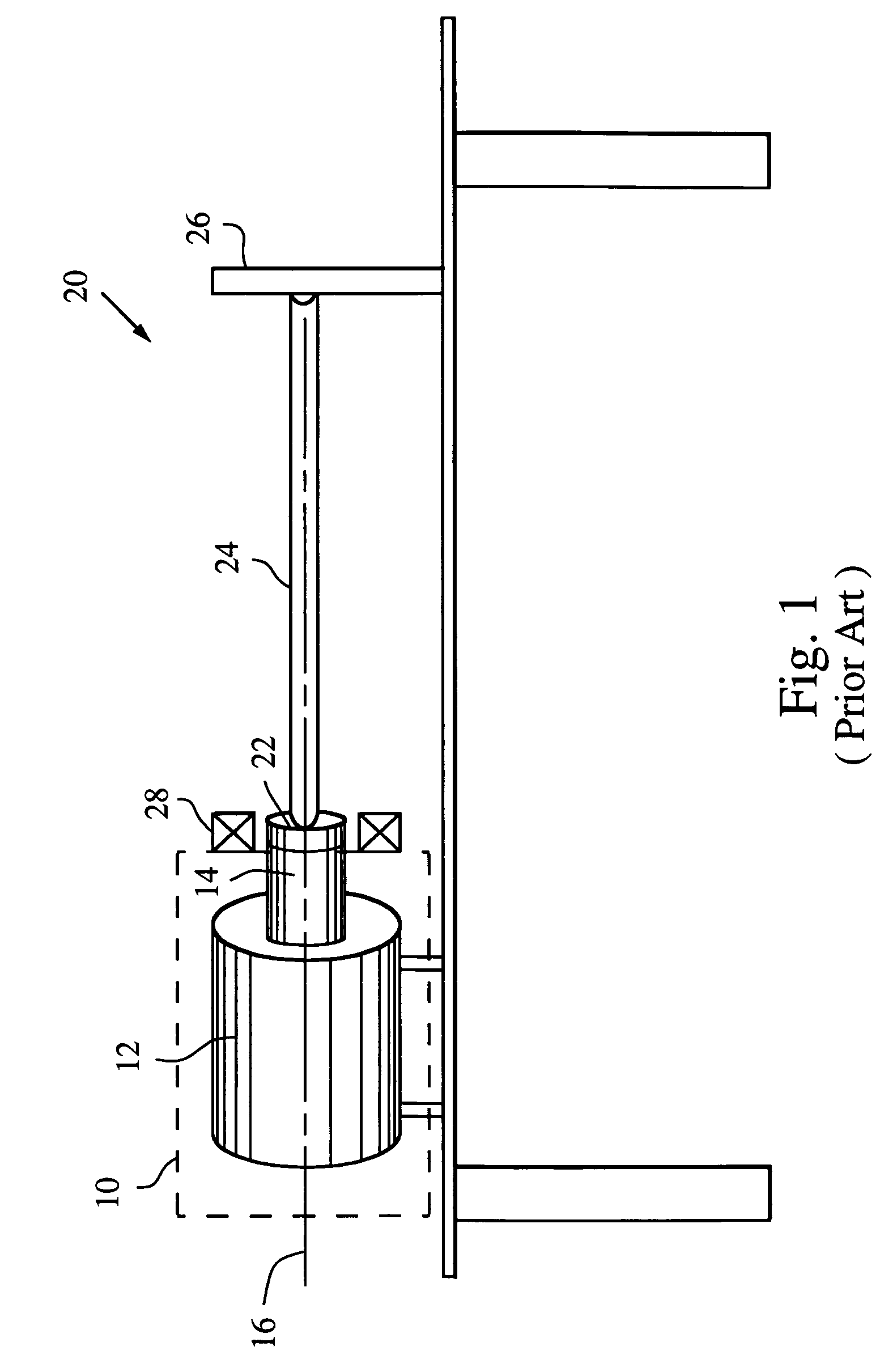

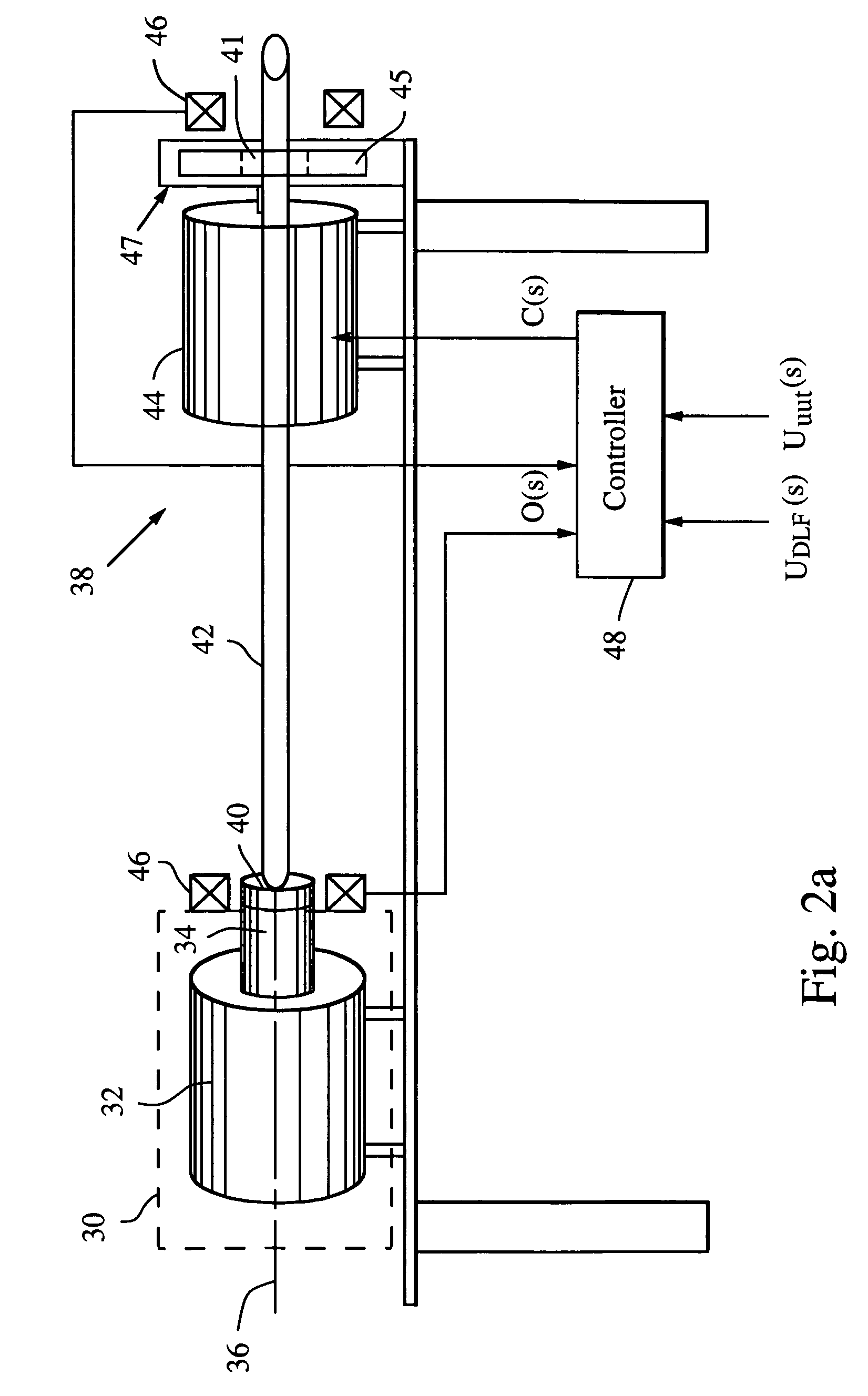

Dynamic load fixture for application of torsion loads for rotary mechanical systems

ActiveUS7165465B2Efficient reproductionImprove response bandwidthMachine part testingWork measurementNegative feedbackAerodynamic load

A dynamic load fixture (DLF) applies a torsion load to a unit under test (UUT) to achieve the demanding aerodynamic load exposures encountered by a control actuation system (CAS) in flight. Instead of fixing the end of the torsion bar, the DLF controls the application of torque to the torsion bar, hence the UUT via a DLF motor. The dynamic load can be independent of the angular rotation of the UUT, which allows the DLF to more effectively reproduce desired acceptance tests such as torque-at-rate and nonlinear loads. Furthermore, application of the loads through a torsion bar allows the system the compliance needed to generate precise loads while allowing for the flexibility of changing torsion bars to test a wide variety of UUT on one test platform. To achieve the demanding aerodynamic load exposures encountered by a CAS in flight, the controller must be able to respond both very fast and very precisely. Control is enhanced by the thorough characterization of the DLF and application of either “classic” negative feedback control or “modern” state-space control methods of linear observers and quadratic optimum control.

Owner:RAYTHEON CO

System and method for testing tubular well products

A technique enables testing of a wellbore tubular under simulated well conditions. The wellbore tubular is mounted in a fixture for testing. Controllable systems are used to subject the wellbore tubular to a variety of predetermined conditions simulating potential downhole environments. The controllable systems include manipulators able to place the wellbore tubular under predetermined load, displacement, temperature, and pressure conditions.

Owner:SCHLUMBERGER TECH CORP

Test bed for detecting control panel of vehicle air conditioner

InactiveCN101832864AEasy to storeConvenient researchVehicle testingMaterial strength using tensile/compressive forcesPull forceAutomobile air conditioning

The invention relates to a test bed for detecting a control panel of a vehicle air conditioner. The test bed is characterized by comprising a stand, which is provided with a panel positioning device, an angle torque testing device, a pressing force testing device and a push-pull force testing device, wherein the angle torque testing device comprises a first torque sensor; the press force testing device comprises a press force sensor and a first displacement sensor; the push-pull force testing device comprises a pressure sensor and a second displacement sensor; and the output signal of the sensors are input into a computer. The test bed can carry out test on the torque, the press force, the push-pull force and the like of control keys on the control panel of the vehicle air conditioner.

Owner:WUHAN UNIV OF TECH

High-speed motorized spindle non-contact loading force and torque testing device and method

InactiveCN102128697ASolve complexitySolve the costForce measurementWork measurementElectricityCircular disc

The invention discloses a high-speed motorized spindle non-contact loading force and torque testing device. A fixed seat and an entire support are arranged on a working platform, the fixed seat is installed on the working platform through four pull pressure sensors which are distributed at the four corners of the lower surface of the fixed seat, a support seat is fixed on the upper surface of the fixed seat and is provided with a motorized spindle, and one axial end of the motorized spindle is sleeved with a loading disk; and the four pull pressure sensors are simultaneously connected with an amplified filter circuit, the amplified filter circuit is connected with a data acquisition card, the data acquisition card is connected with an industrial personal computer, and the industrial personal computer is connected with a displaying, printing and keyboard input device. The invention also discloses a radial loading force and loading torque testing method by utilizing the device. The problem of difficult testing of loading capacity in a high-speed motorized spindle characteristic analysis test is solved by using the device and method disclosed by the invention.

Owner:XIAN UNIV OF TECH

Material in-situ detection device and method under multi-load and multi-physical field coupled service conditions

ActiveUS20180180521A1Easy maintenanceReduce impactMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldMicroscopic observation

Provided are a material in-situ test device and method under multi-load and multi-physical field coupled service conditions. The device is composed of a precise six-degree-of-freedom composite load applying module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load and multi-physical field coupled experiment, and is integrated with a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module, so as to carry out in-situ observation and quantitative characterization on material deformation behaviours and damage mechanism phenomena in a composite-load and multi-physical field loading process. For example, loading methods of “cantilever type pure bending, cantilever type tension / compression-torsion, and cantilever type bending-torsion”, etc. can realize the loading of composite load. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of multiple physical fields such as cold / hot-electricity fields.

Owner:JILIN UNIV

Adjustable clamping device of minisize torsional rod rigidity test

InactiveCN101101248AImprove efficiencyHigh stiffness testMaterial strength using steady torsional forcesCouplingTransducer

The invention relates to a zoom type institution of testing mini type twisted bar rigidity, it includes test desk base, column, cross arm, the characteristic is that the cross arm cover the outer of column, the inferior extremity face touch the rise fall nut on the column, and setting the locknut on the lateral surface; setting the motion joint sleeve on the front cross arm, and locking the location by locknut, removing the suspension torque detector under the joint sleeve, the transducer gaging spindle of the torque detector connect with tested torsion lever by coupling, locking and fixing the inferior extremity of tested torsion lever by self centering collet; fixing and connecting self centering collet with coupling flange,shear lever and electric control gear table, the electric control gear table is on the adjustable base of self centering collet, the adjustable base laying on the test desk base, fixing the adjusting screw of side face of adjustable base. It can solve the low efficiency and stability of the in existence static testing equipment, the technology problem of loading difficulty, the structure of institution is simple,convenience operation, it can realize high performance,high accuracy testing of torsion lever rigidity.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com