In-situ pull/press-torque combined load material micromechanics test platform

A test platform and composite load technology, applied in the direction of testing material strength by applying stable tension/pressure, testing material strength by applying stable torsion, etc., can solve problems that do not involve in-situ observation and nanoscale mechanical properties of materials and other problems, to achieve the effect of good application development prospects, compact structure, and controllable angular strain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

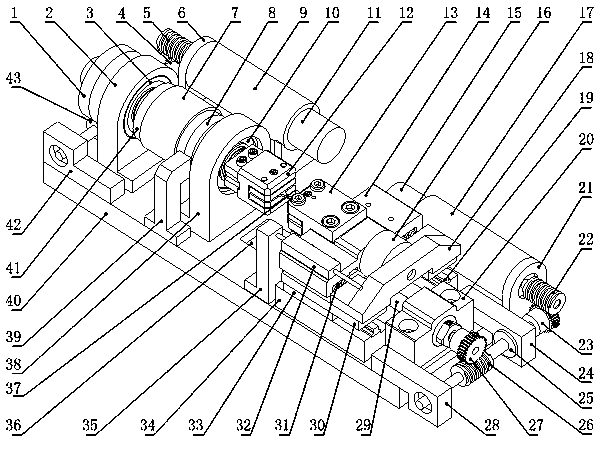

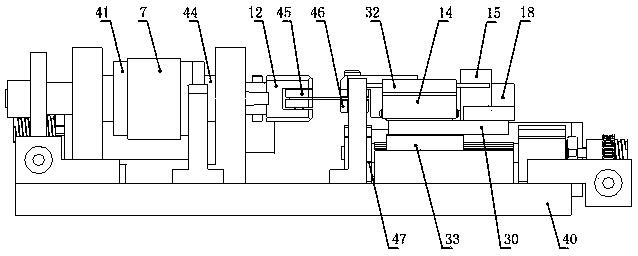

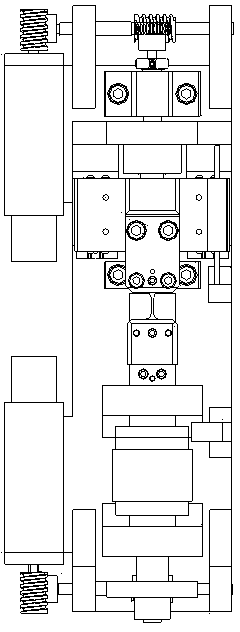

[0026] see Figure 1 to Figure 5 As shown, the in-situ tensile / compression-torsion composite load material micromechanics test platform of the present invention includes a test platform base 40, a precision loading unit, a detection control unit, a clamping and a connection unit, and the precision loading unit includes a torque loading unit. The unit and the tension-compression loading unit are composed of precision DC servo motors Ⅰ, Ⅱ9, 17, secondary enveloping worm gear pairs Ⅰ, Ⅱ, precision ball screw pairs, and precision ball linear guides, among which precision DC servo motors Ⅰ, Ⅱ9 , 17 can provide high-resolution torque and angular displacement output, and the secondary enveloping worm gear pair Ⅰ can provide a large reduction ratio of 2500:1, which can greatly increase the output power of precision DC ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com