Patents

Literature

251 results about "Shear testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

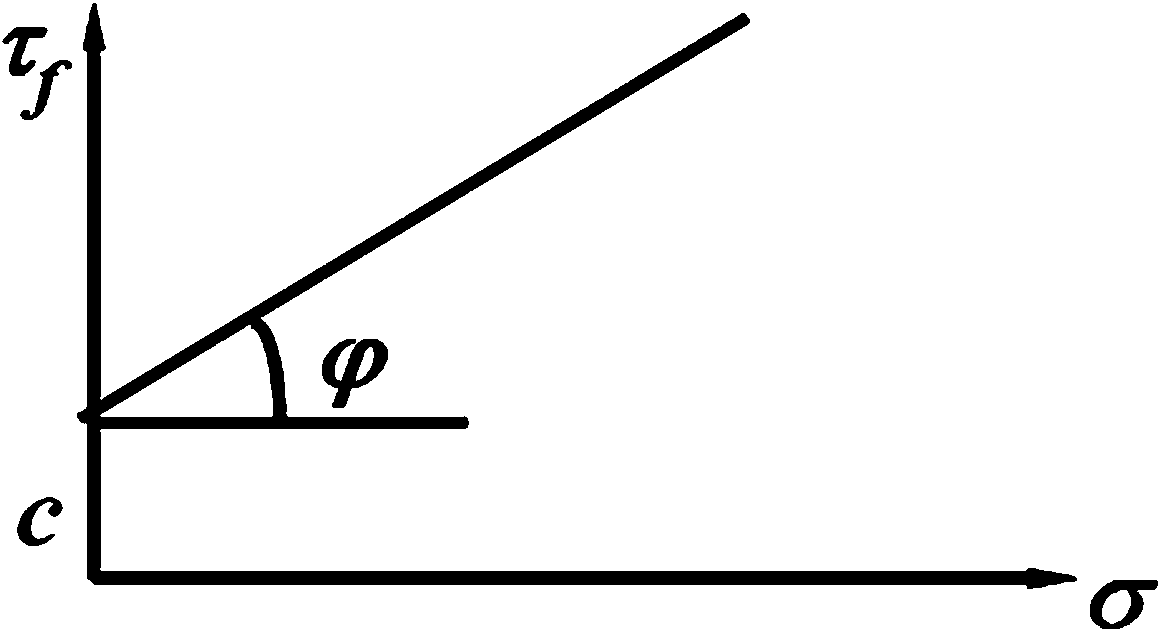

A shear test is designed to apply stress to a test sample so that it experiences a sliding failure along a plane that is parallel to the forces applied. Generally, shear forces cause one surface of a material to move in one direction and the other surface to move in the opposite direction so that the material is stressed in a sliding motion.

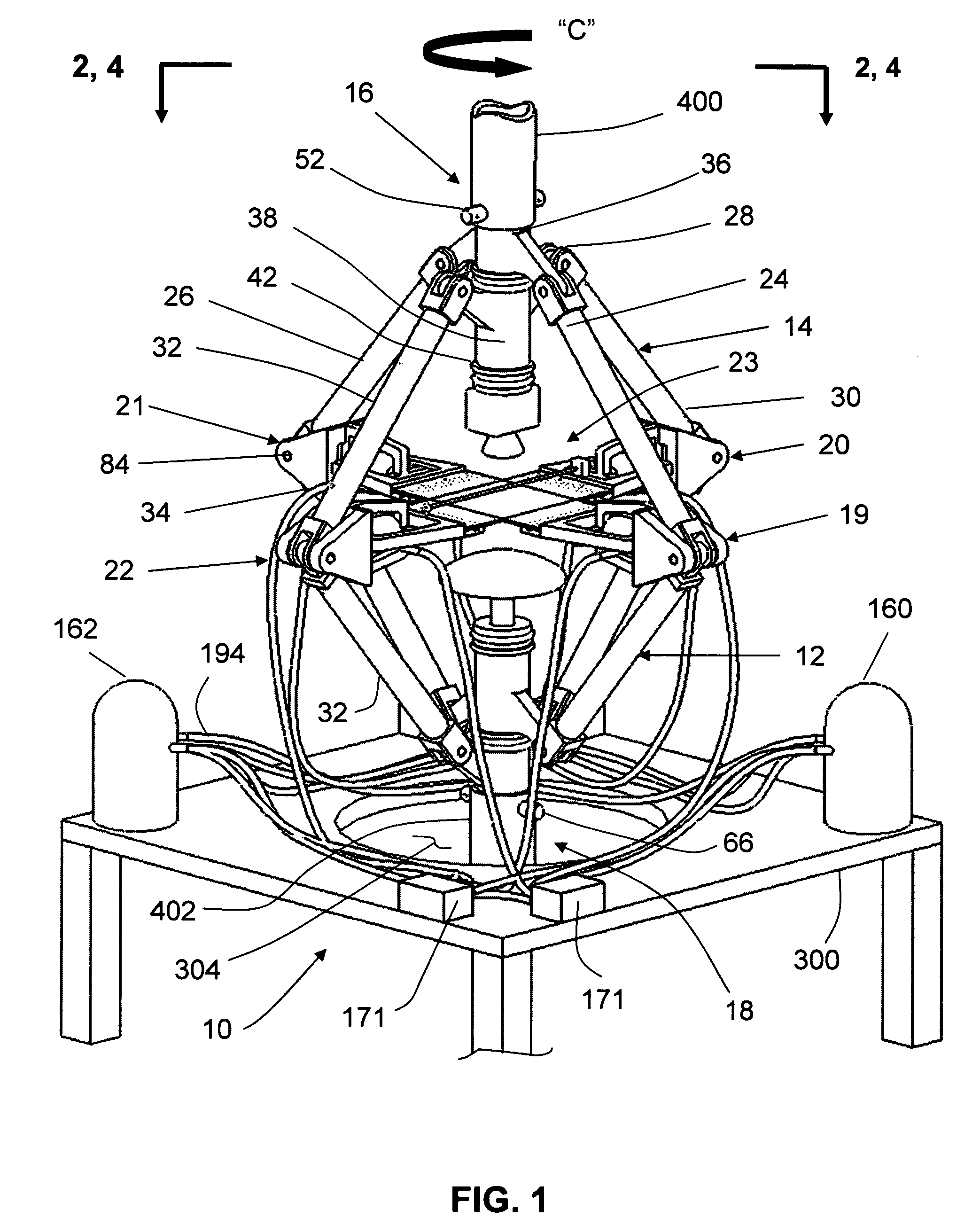

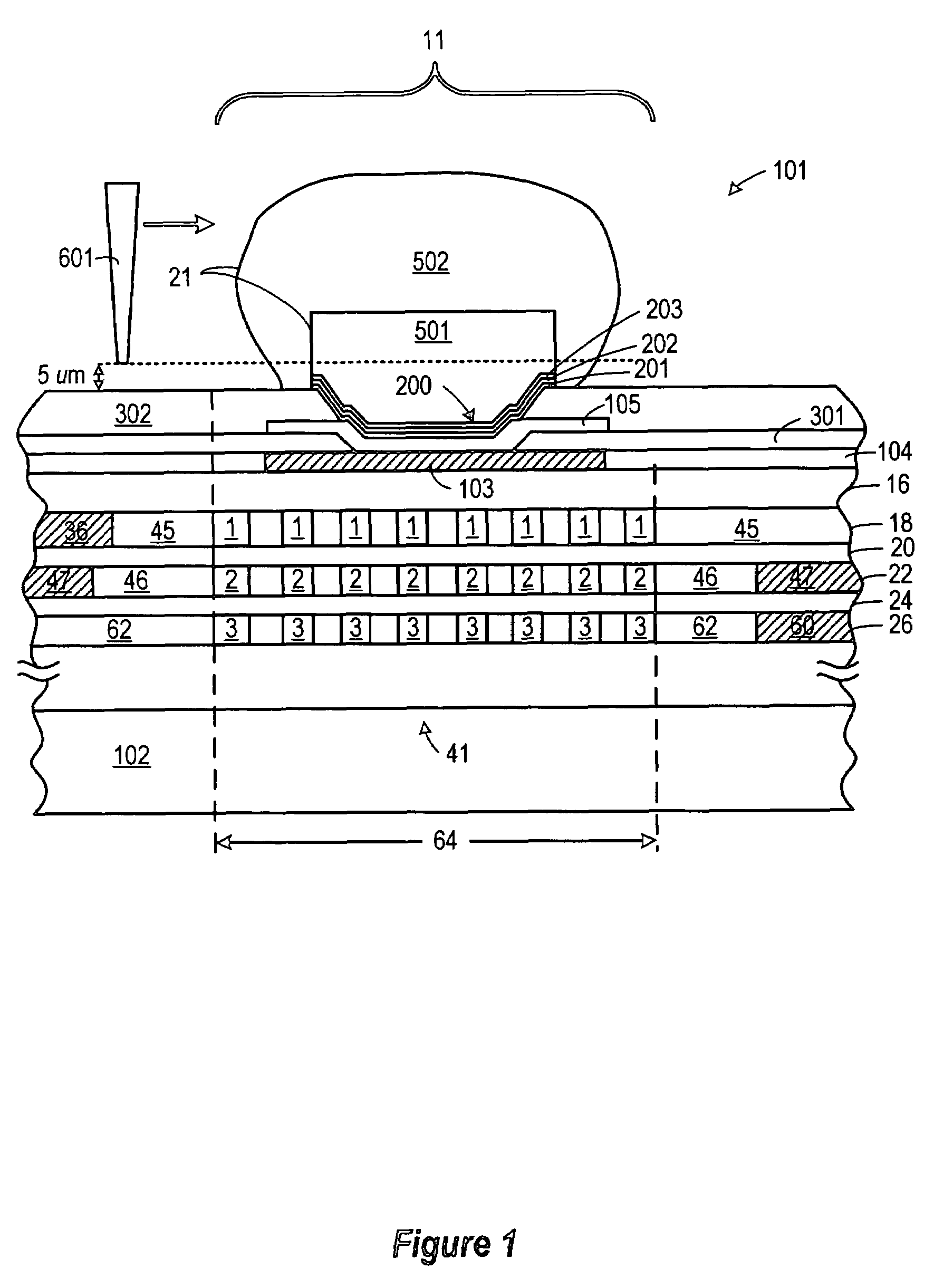

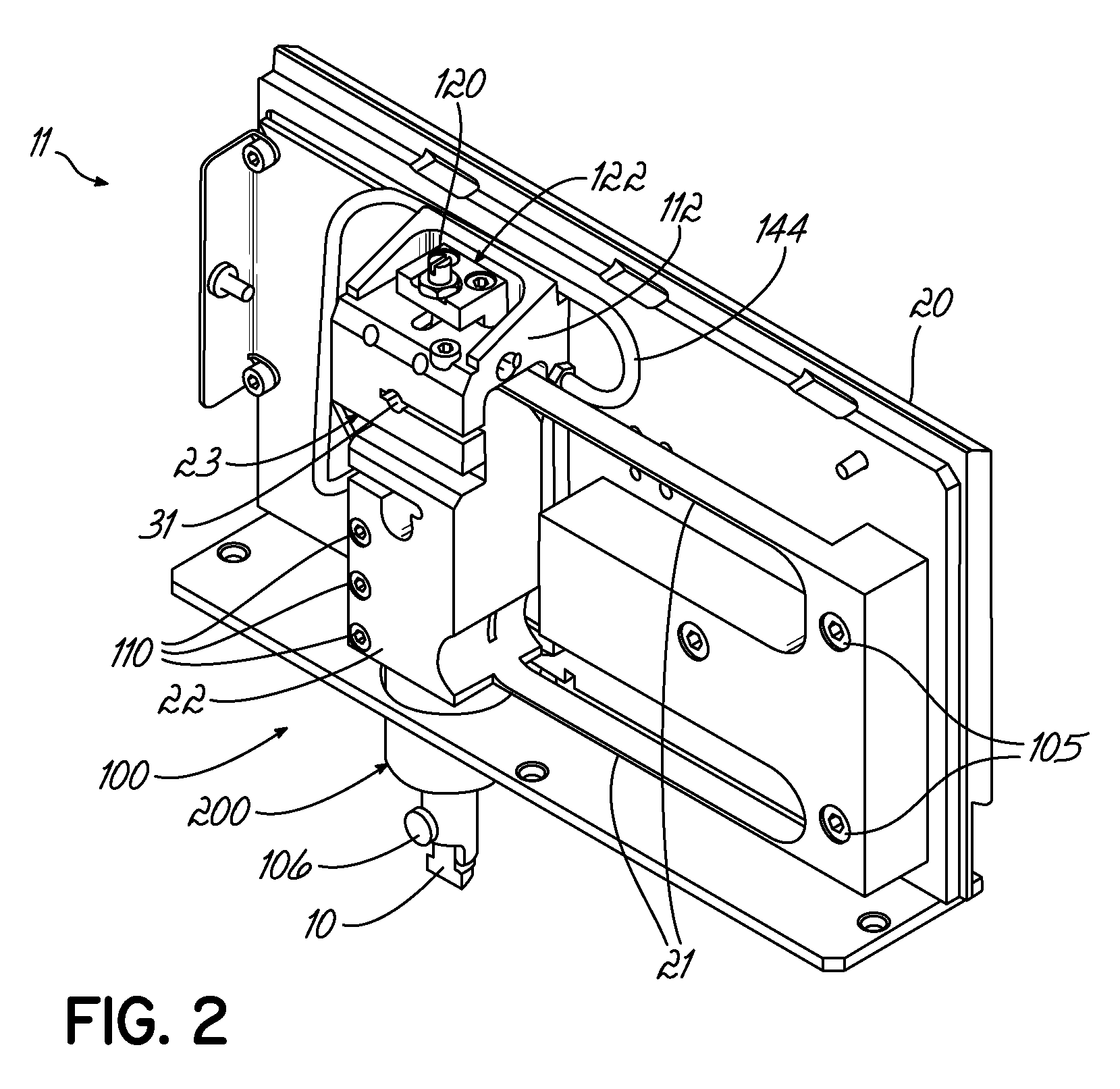

Combined in-plane shear and multi-axial tension or compression testing apparatus

ActiveUS6860156B1Provide flexibilityIncrease distanceMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringTorsional load

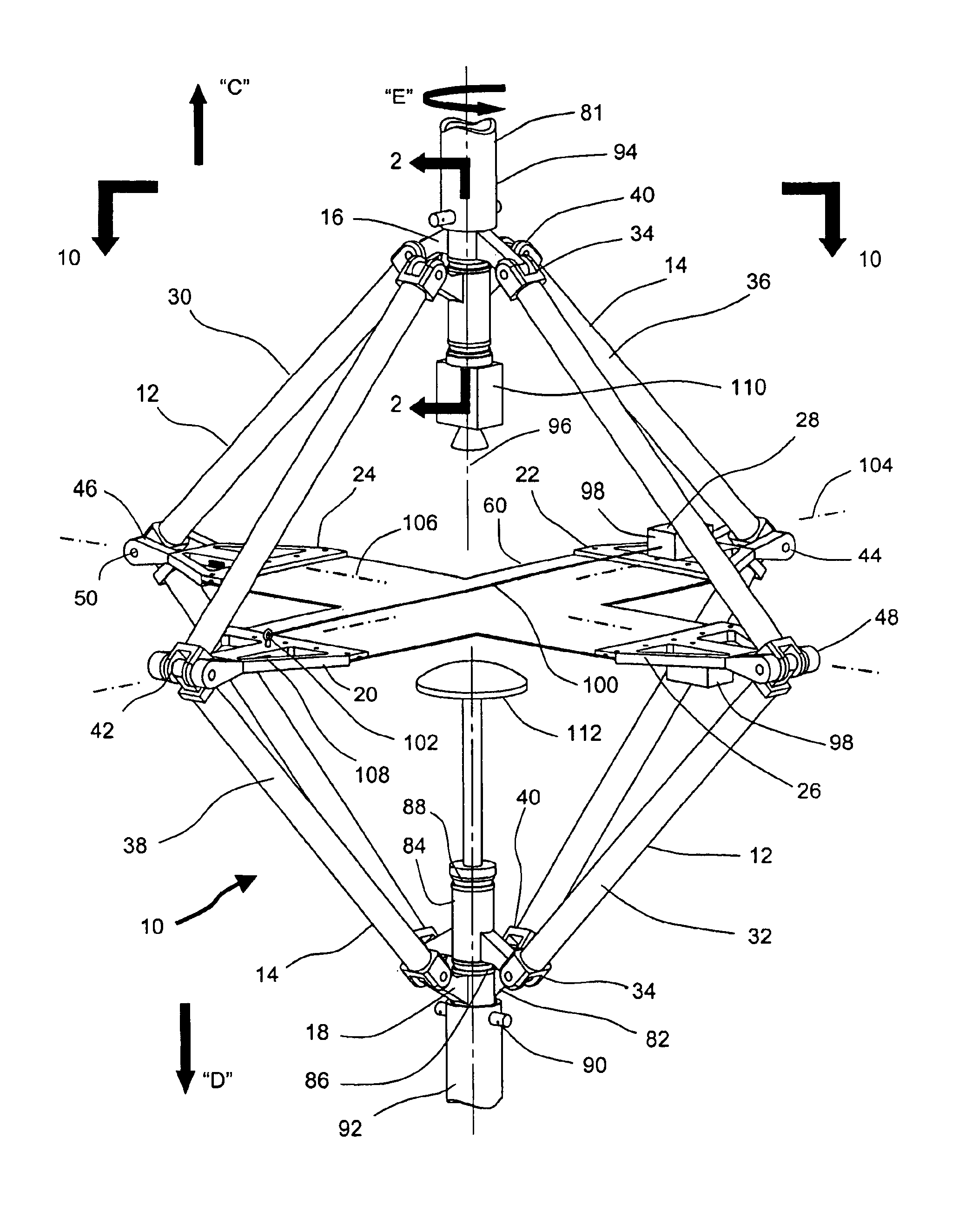

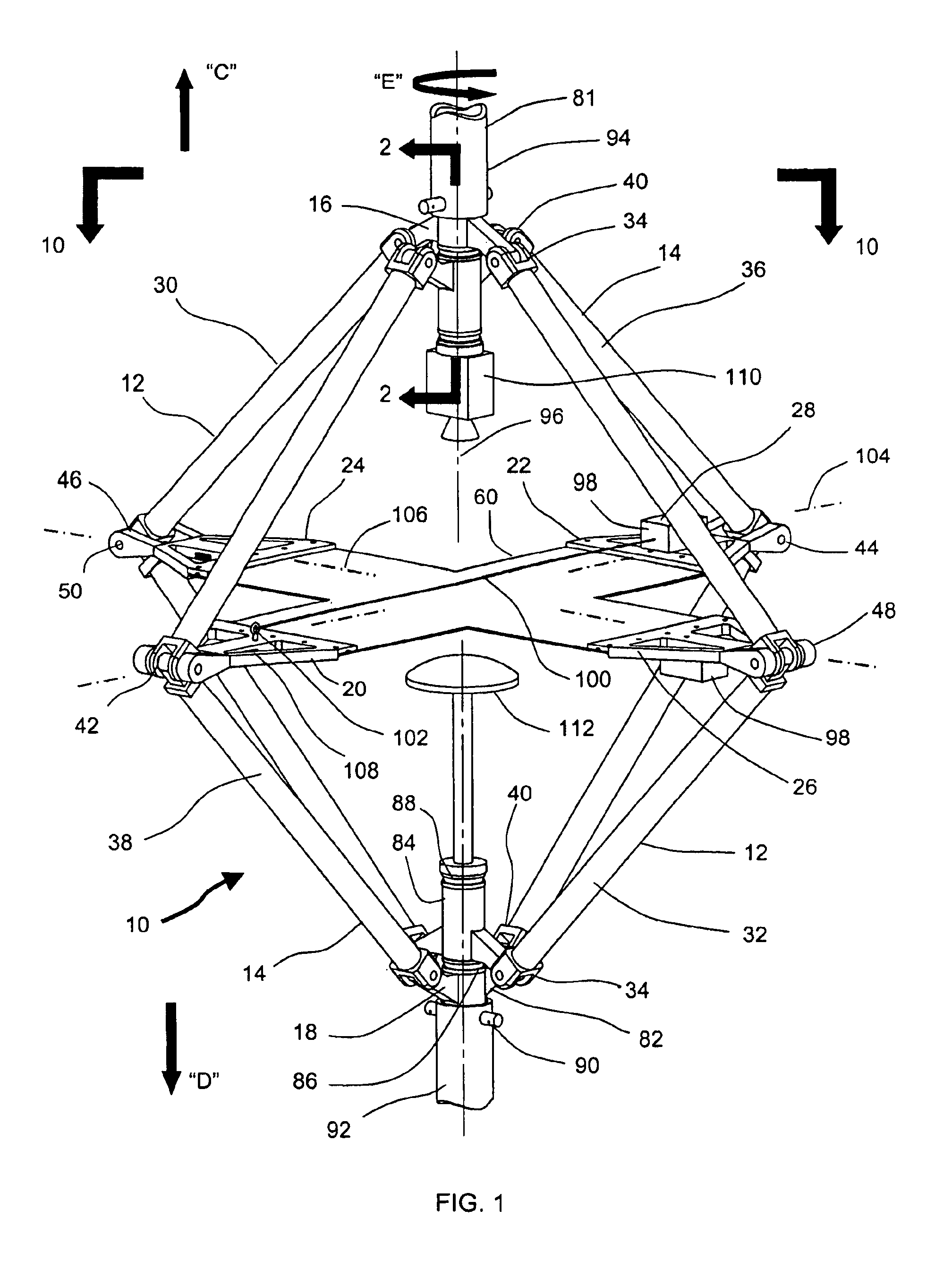

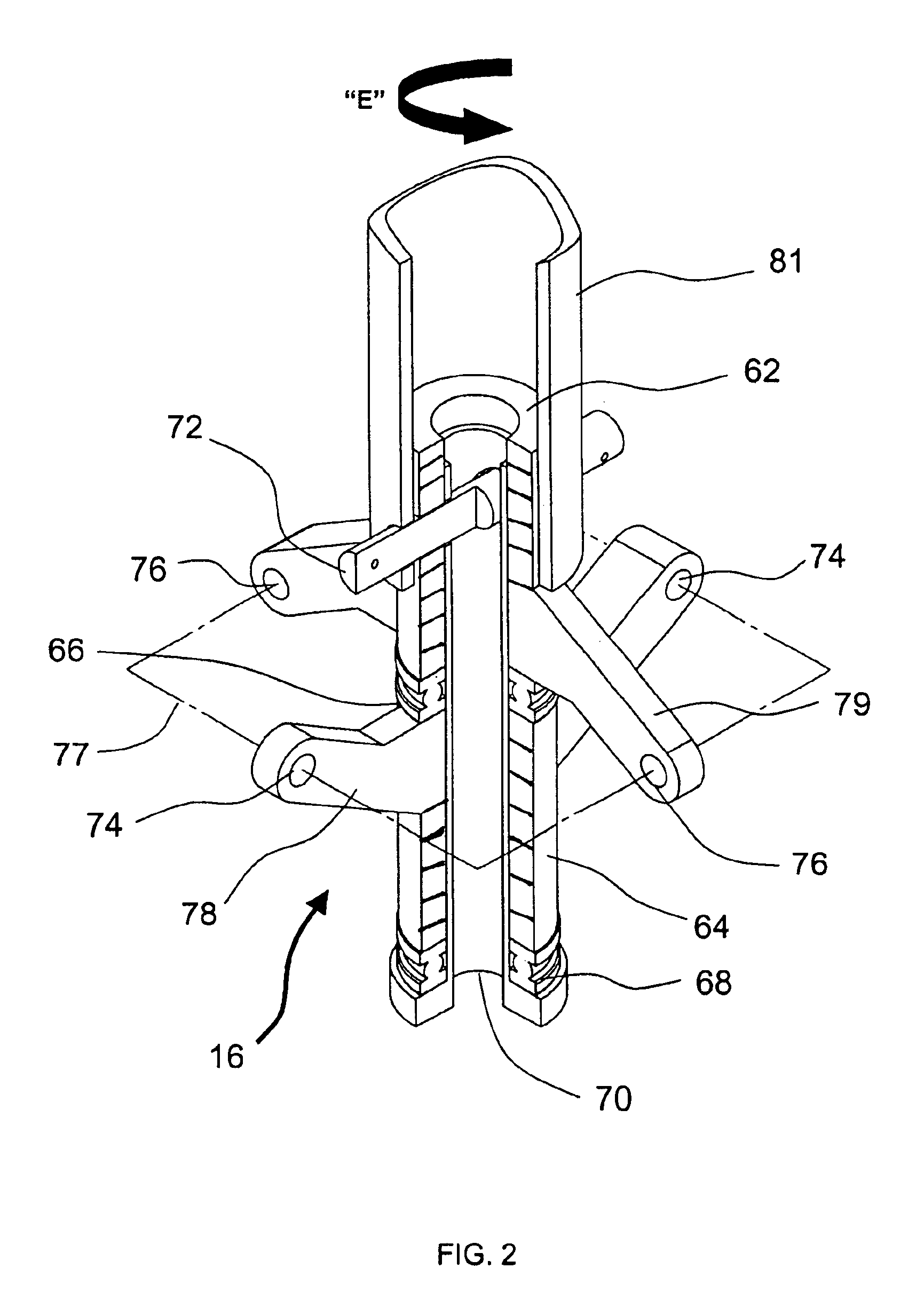

An in-plane shear and multi-axial tension or compression testing apparatus having four-bar linkages pivotable to two sleeves on an opposite vertices with the sleeves of each vertex rotationally attached to each other. Lateral links of each linkage are pivotally attached to load transfer plates in which the plates secure a test specimen. Each linkage is rotatable to the other linkages while the vertices are subjected to a compression or tensile load. The vertices are also capable of rotation by a testing machine for shear testing. During compression or tension of the vertices of the apparatus, the plates respectfully move toward or away from each other thereby applying compression or tension to the specimen. The bars of one linkage can be rotated with respect to the other, thereby applying torsional loading to the specimen.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

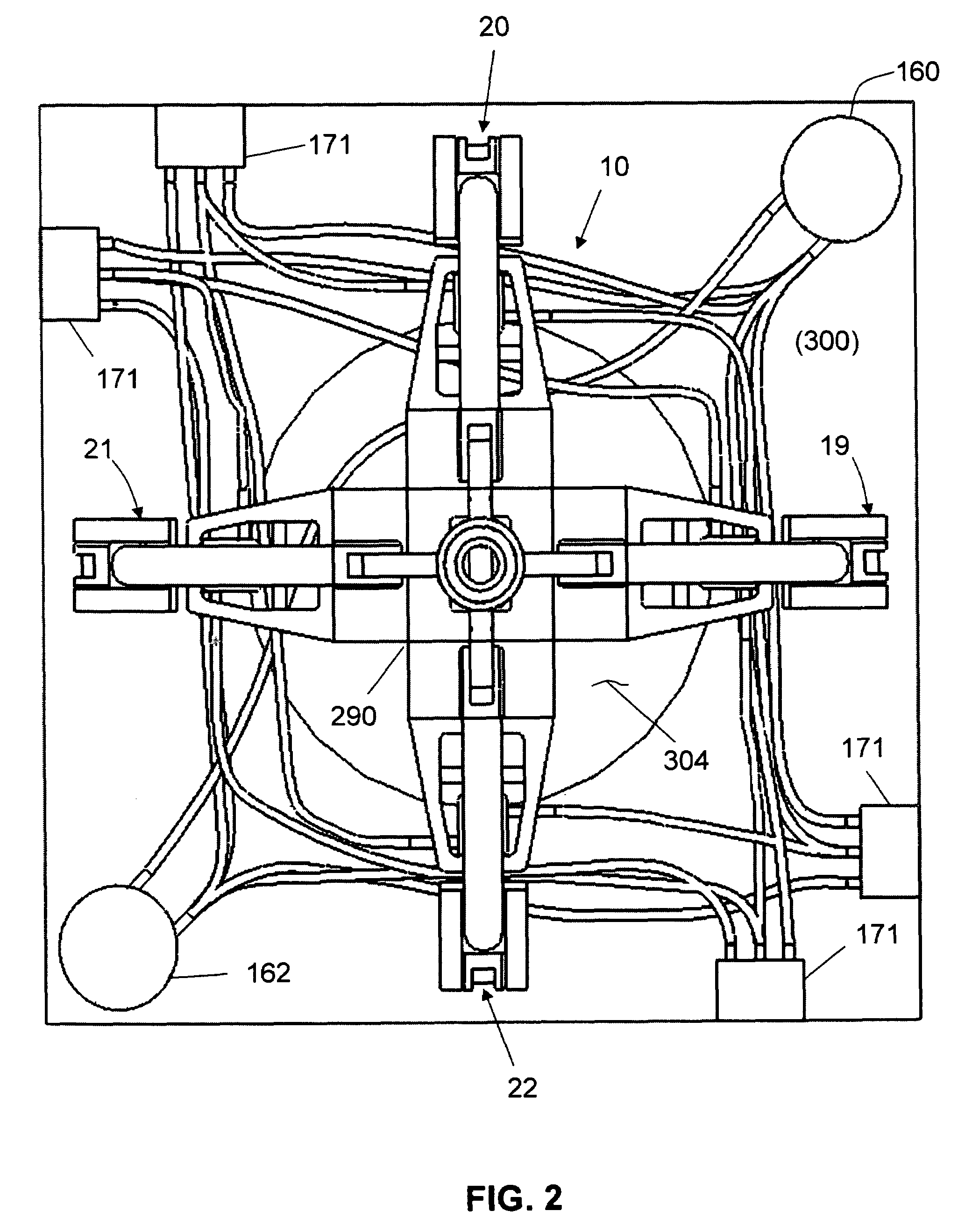

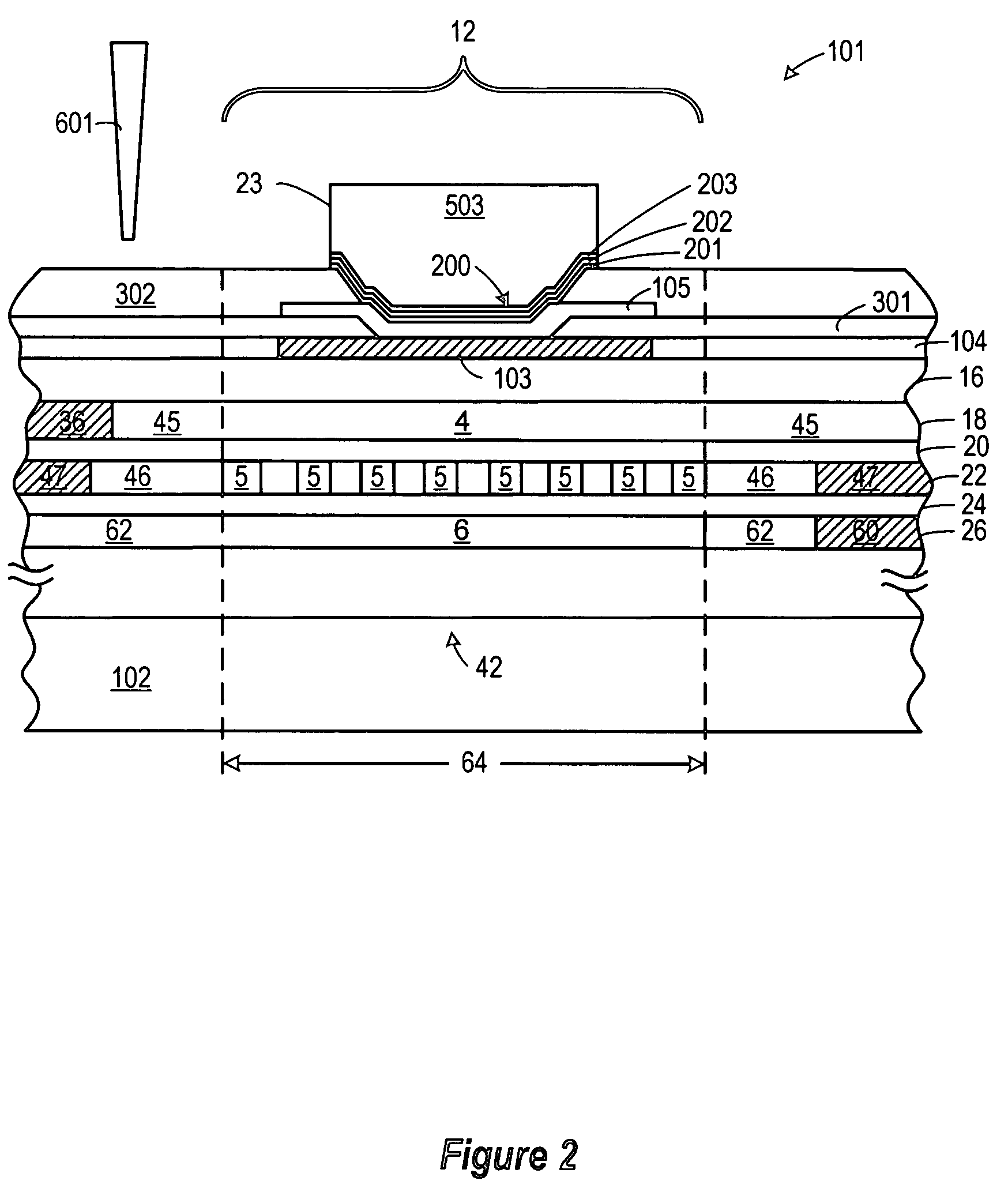

Biaxial and shear testing apparatus with force controls

InactiveUS7204160B1Apparatus is enlargedForce measurementMaterial strength using tensile/compressive forcesPressure systemEngineering

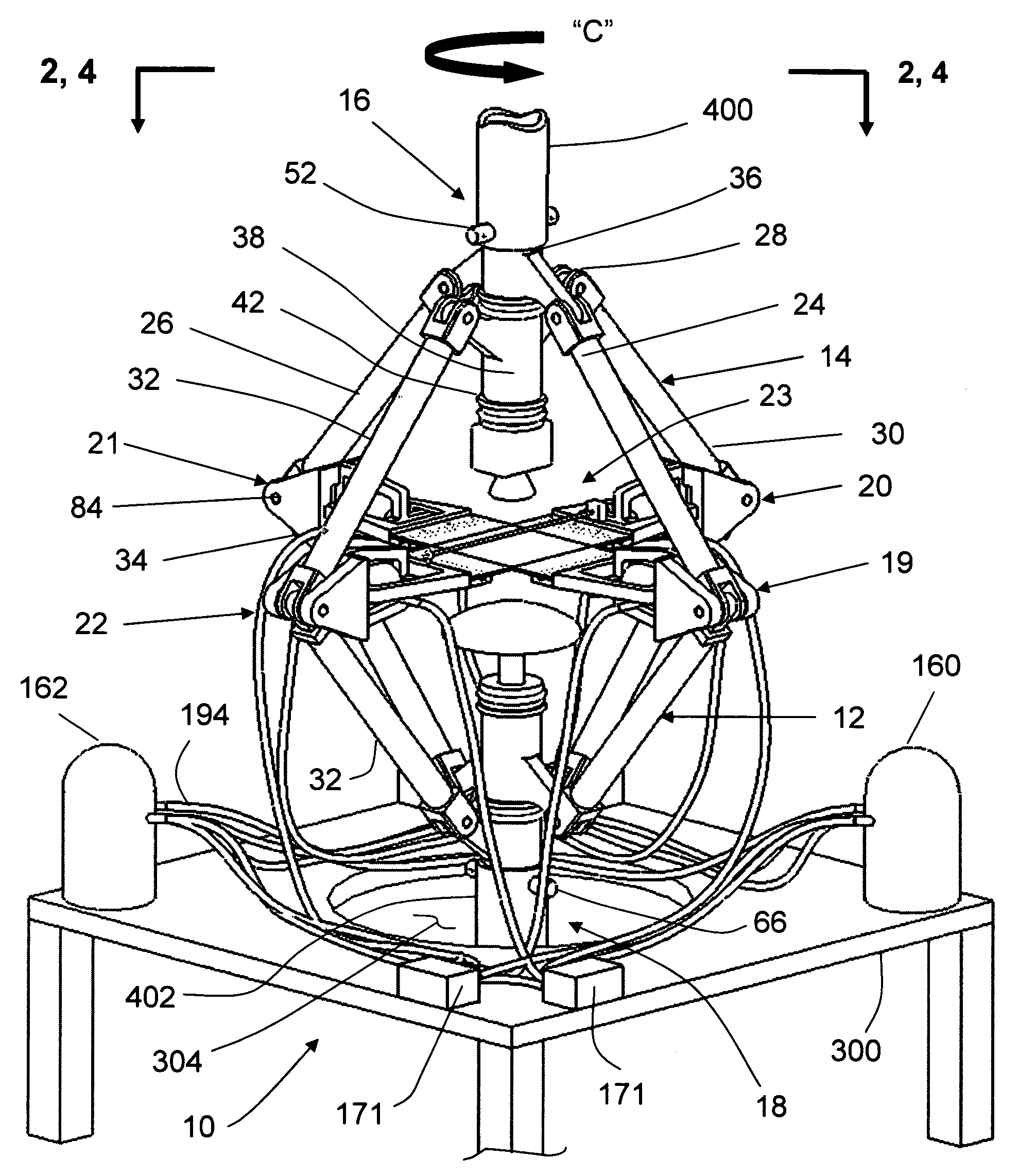

A testing apparatus having four-bar linkages pivotable to sleeves on opposite vertices with the sleeves of each vertex rotationally attached to each other. Links of each linkage are pivotally attached to loading plate assemblies securing a test specimen. During loading, the assemblies move toward or away from each other; thereby, applying compression or tension to the specimen. A pressure system fluidly impacts opposite faces of a piston of the assembly such that one of the faces is pressurized and impacts arms of the assembly for a sliding motion to move toward or away from the longitudinal axis of the apparatus thereby, applying a compression or tensile load on the specimen or augmenting the loads applied by the movement of the loading plate assemblies. The pressure system includes a controller connected to a reservoir, a pressurized source, a plurality of shutoff valves and pressure-adjustable check valves.

Owner:NAVY UNITED STATES OF AMERICA

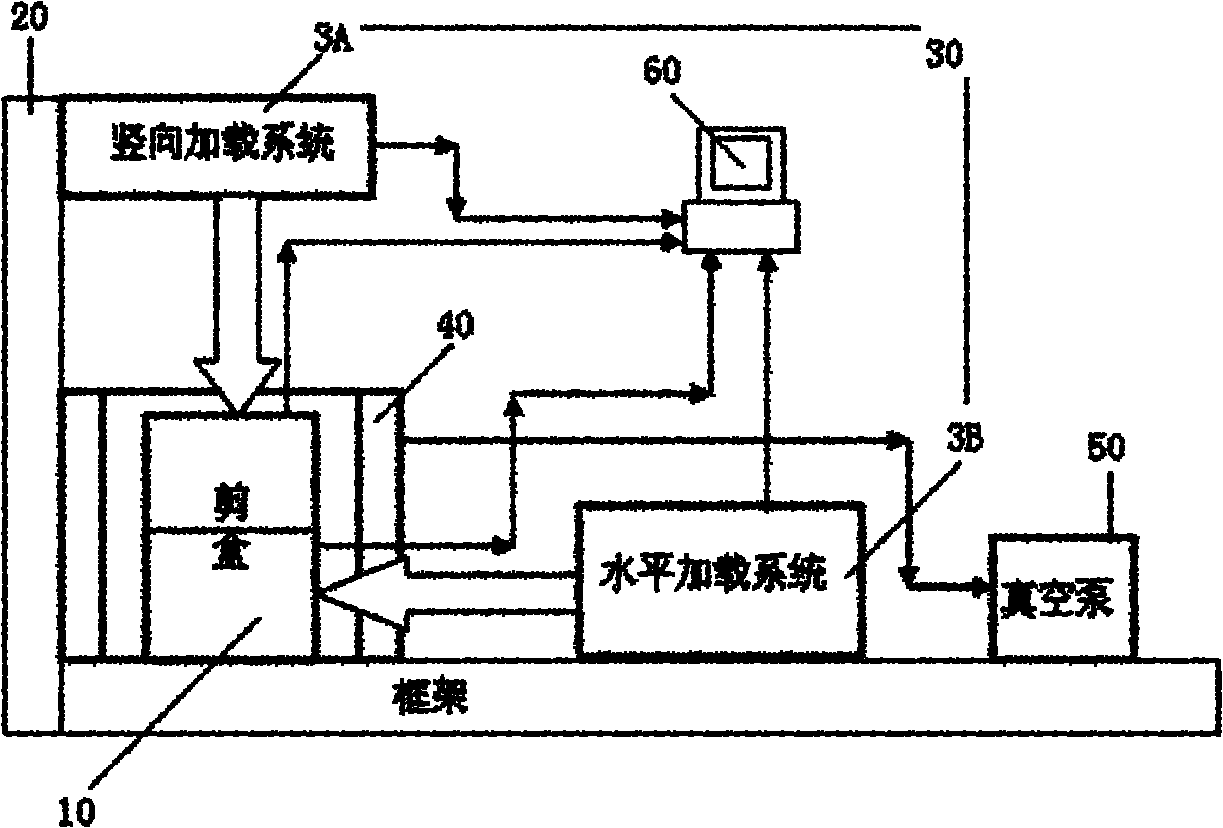

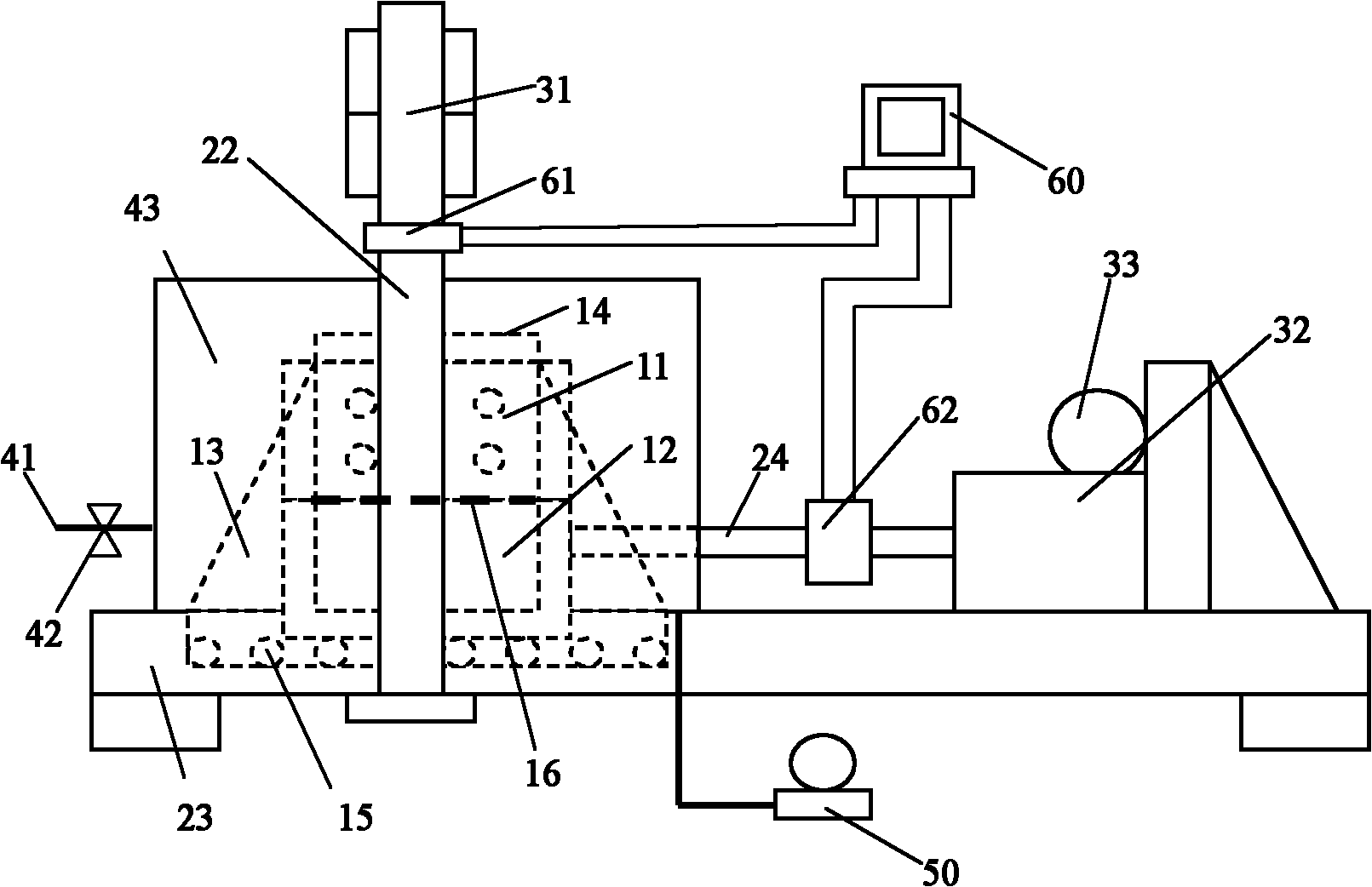

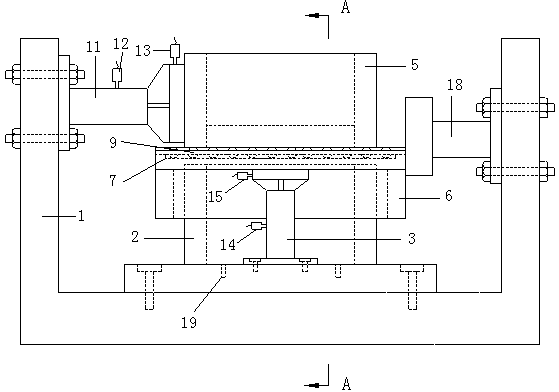

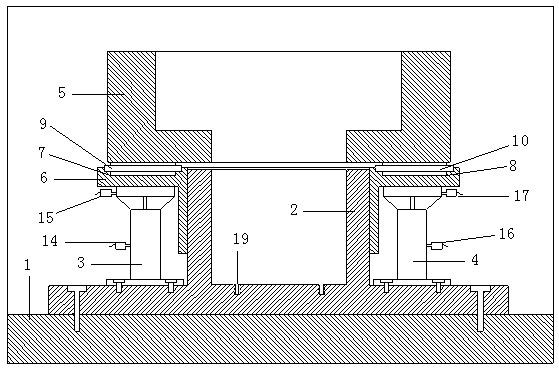

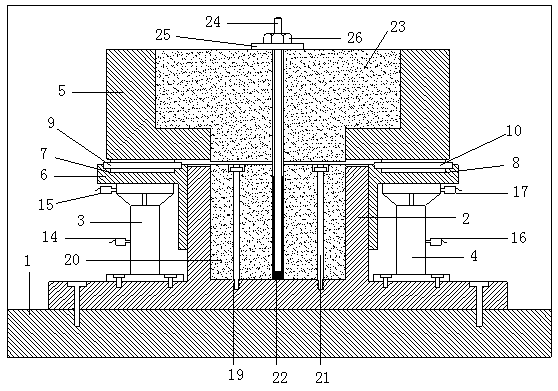

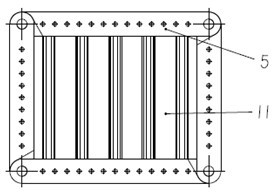

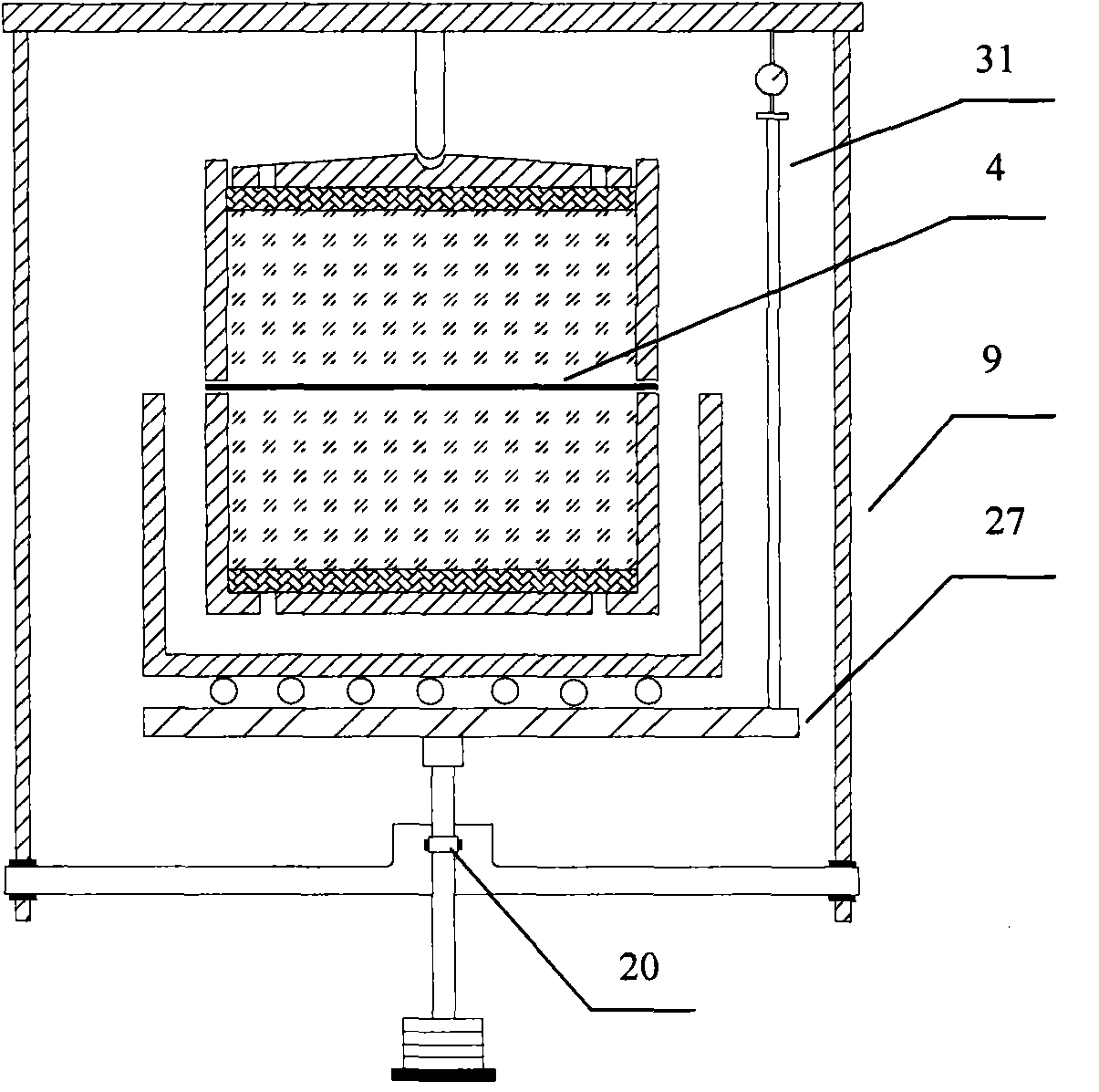

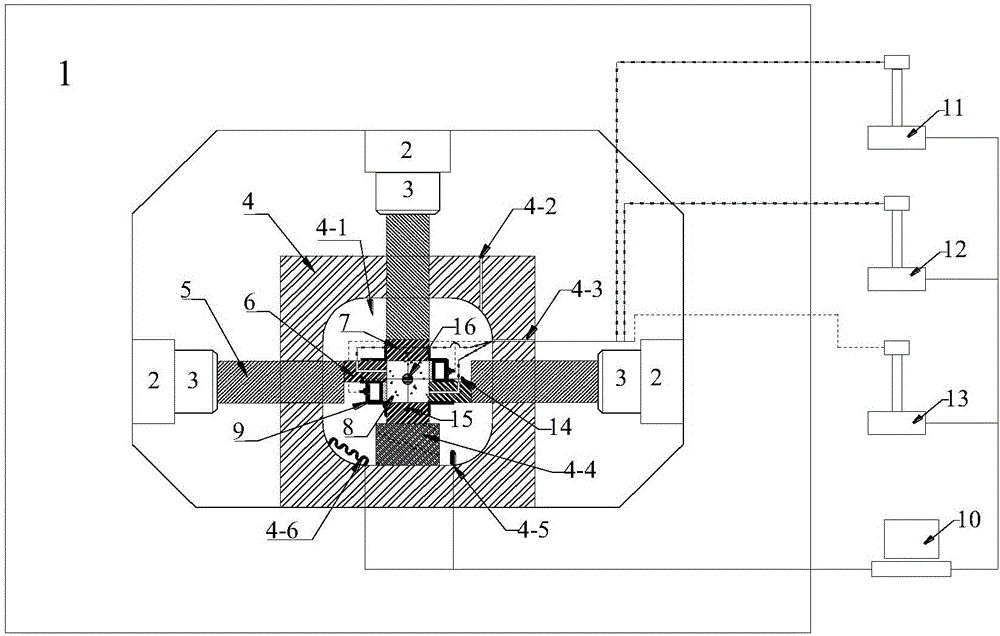

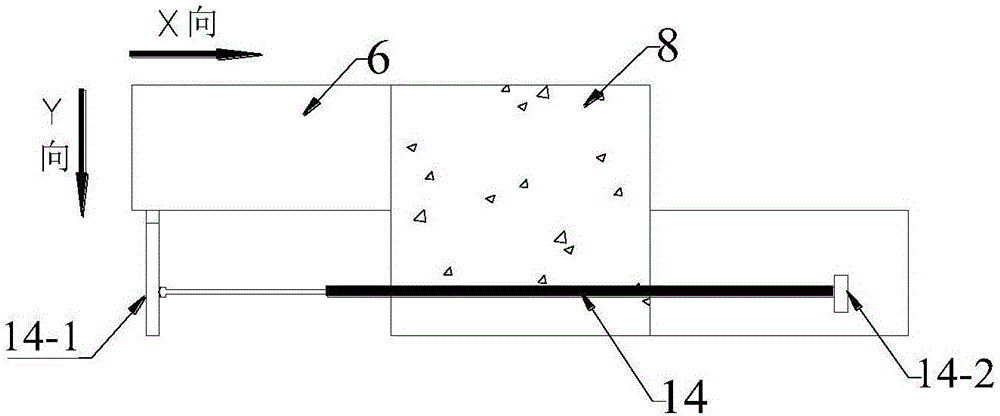

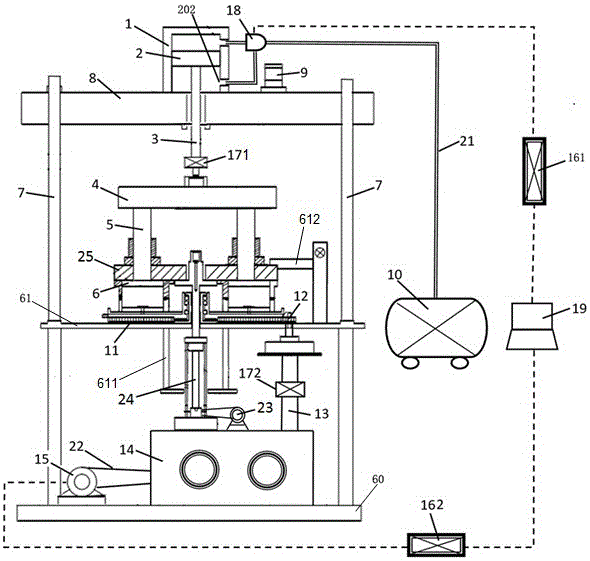

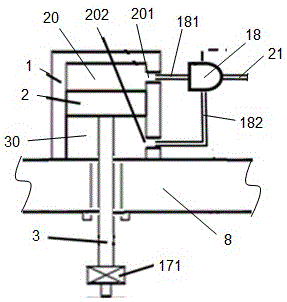

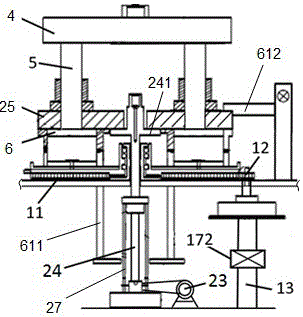

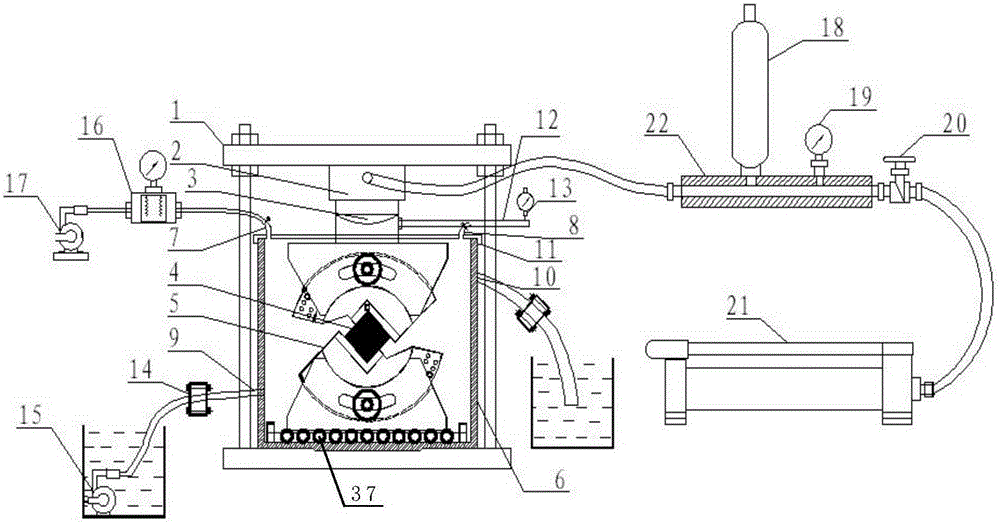

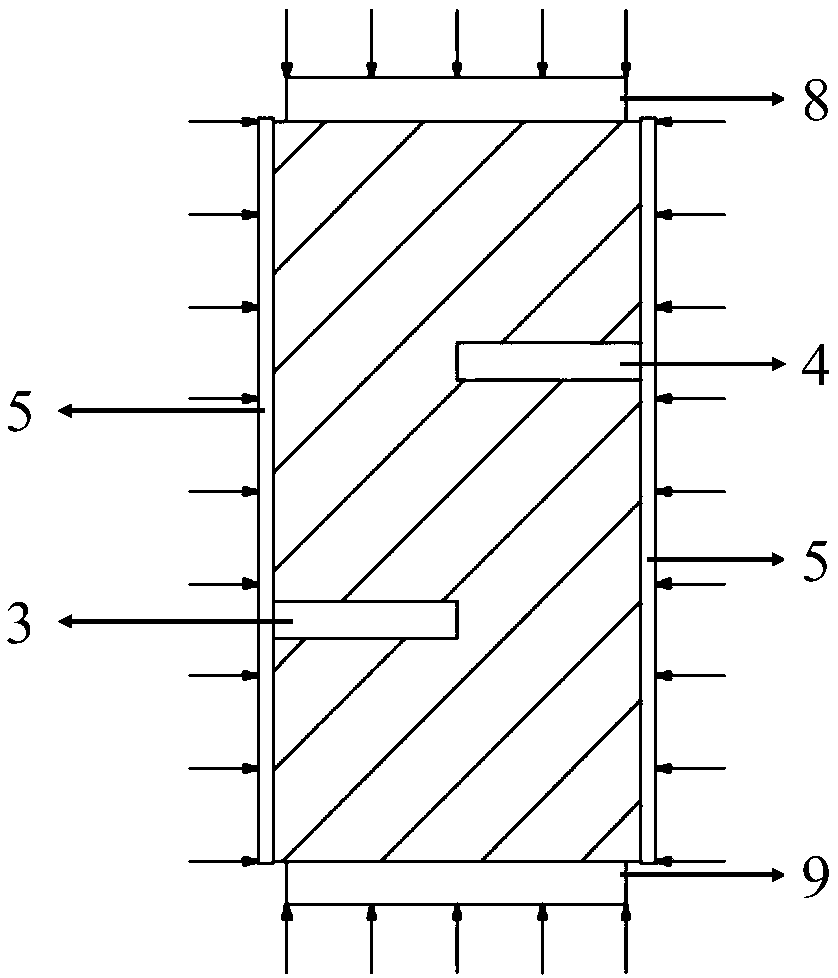

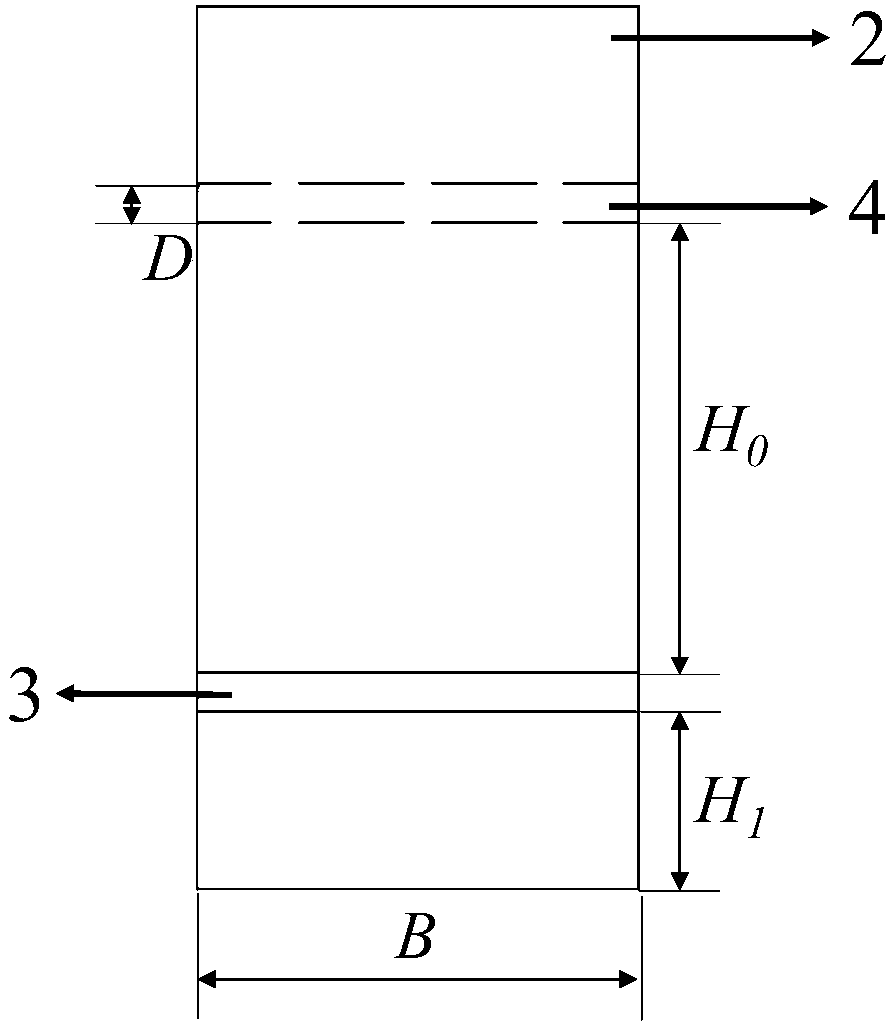

Direct shear testing device of saturated rock soil samples

InactiveCN102095649ARealize the direct shear test testRealize reciprocating direct shear testMaterial strength using steady shearing forcesMaterial strength using repeated/pulsating forcesWhole bodyWater channel

The invention discloses a direct shear testing device of saturated rock soil samples, which relates to the technology of mechanical strength test of rock soil. The structure of the direct shear testing device comprises a sample shear box, a loading system, a saturation system, a vacuum pump and a data acquisition system which are fixed on a frame to form a whole body, wherein the shear box is arranged in a water channel of the saturation system and guarantees the sample to be saturated completely, the loading system comprises a vertical loading system and a transverse loading system, the vertical loading system and the transverse loading system are respectively connected with the shear box and realize vertical loading and transverse loading of the shear box, the vacuum pump is connected with the saturation system and used for vacuumizing the closed water channel, and the data acquisition system is connected with the shear box and the loading system respectively and used for monitoring and recording the force and the displacement of the shear box. The direct shear testing device realizes direct shear tests of small-size and medium-size gravel soil, crack soil and soft rocks, and particularly can realize site tests of samples on the construction site and reciprocating direct shear tests of saturated rock soil.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

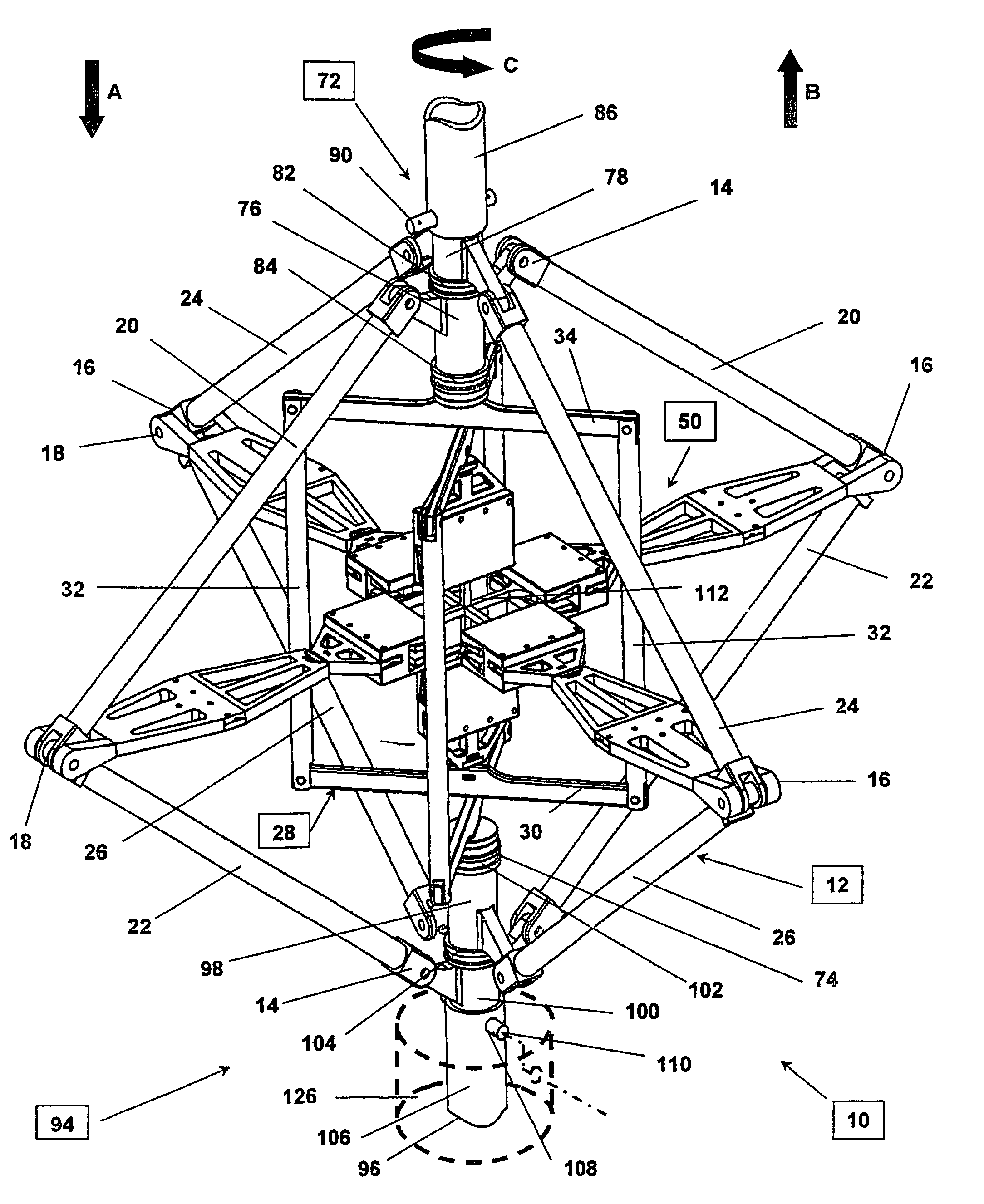

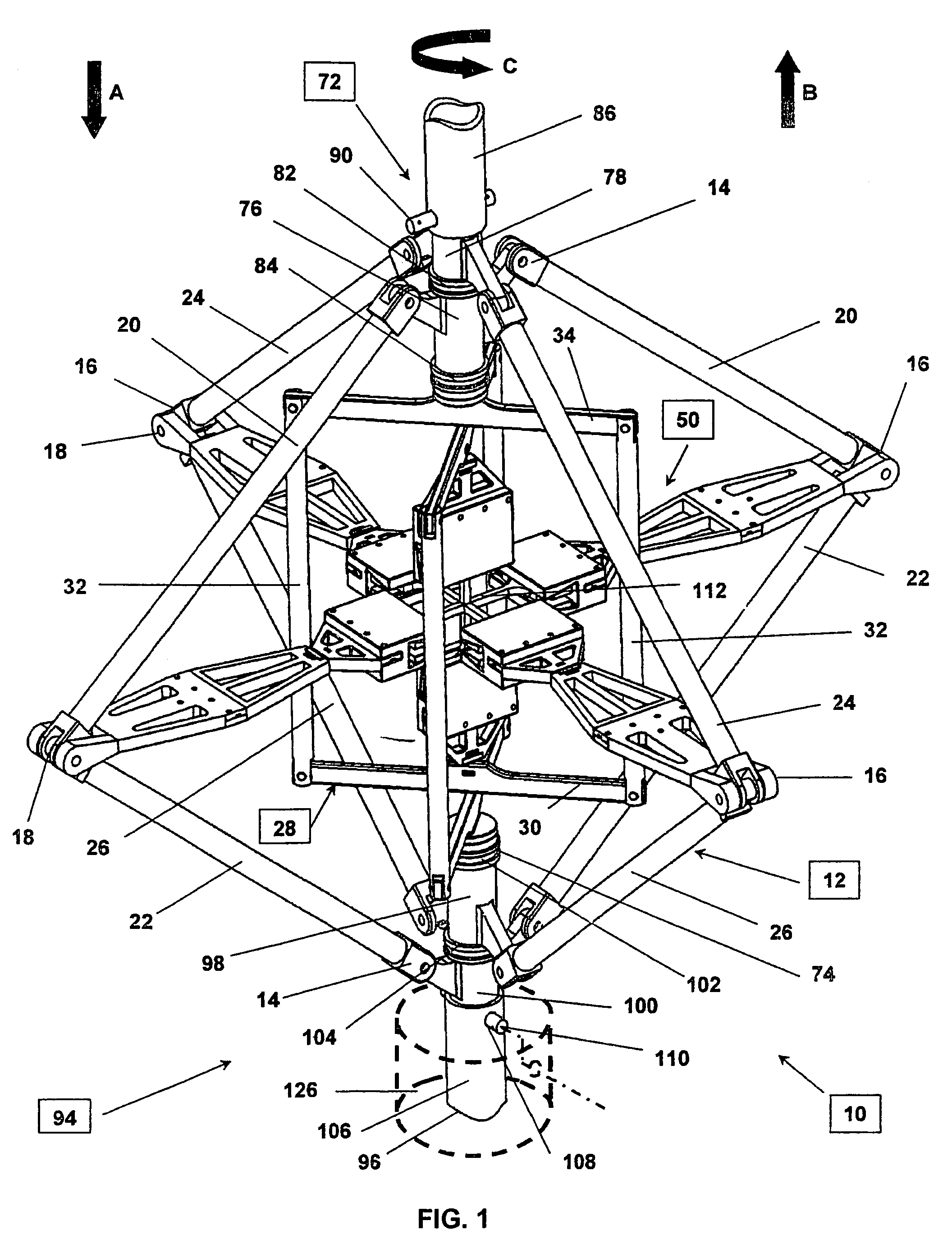

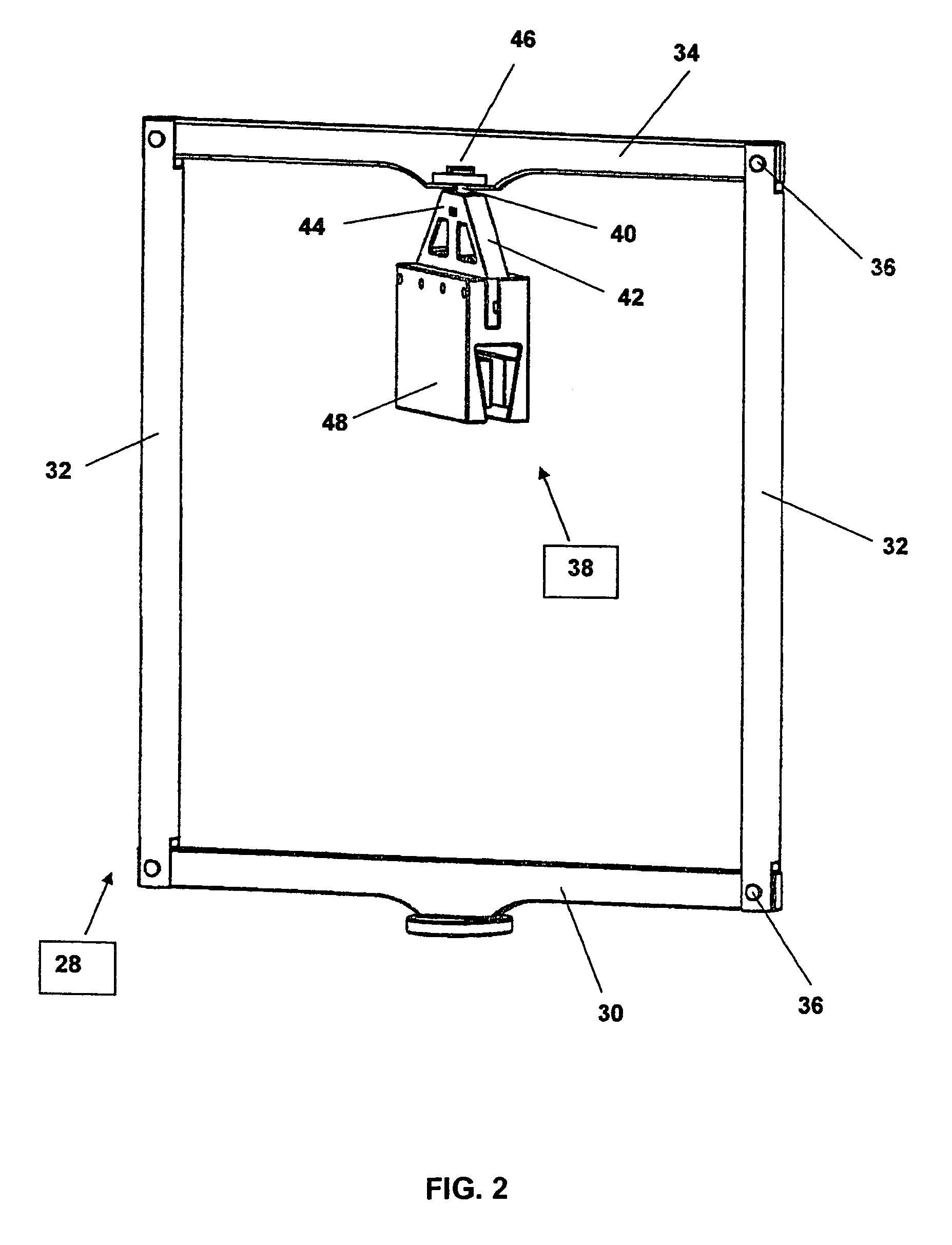

Triaxial tension compression, shear testing apparatus

InactiveUS7051600B1Facilitate triaxial testingCost-effectiveForce measurementMaterial strength using tensile/compressive forcesIn planeTension compression

A triaxial testing system of material properties having top and bottom joint assemblies that rotate about and move along a longitudinal axis in response to forces imparted by a testing machine. The joint assemblies are connected together by horizontal and vertical linkage assemblies. The horizontal and vertical linkage assemblies are connected to horizontal and vertical loading and clamping assemblies to thereby transfer in-plane and multi-axial loads from the testing machine and the joint assemblies to a material test specimen. The test specimen is rigidly clamped to the horizontal and vertical clamping assemblies. The bases and ends of the test specimen are shaped for clamping and axial loading. Rigid plates may be disposed over ends of composite test specimens for spatially stabilizing such specimens during testing. The test specimens may include devices to measure and record the axial and shear loads, displacement and strains imparted to the specimens during testing.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

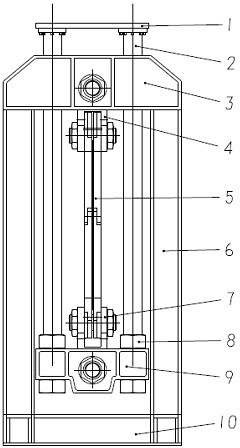

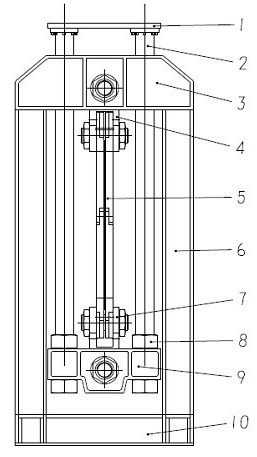

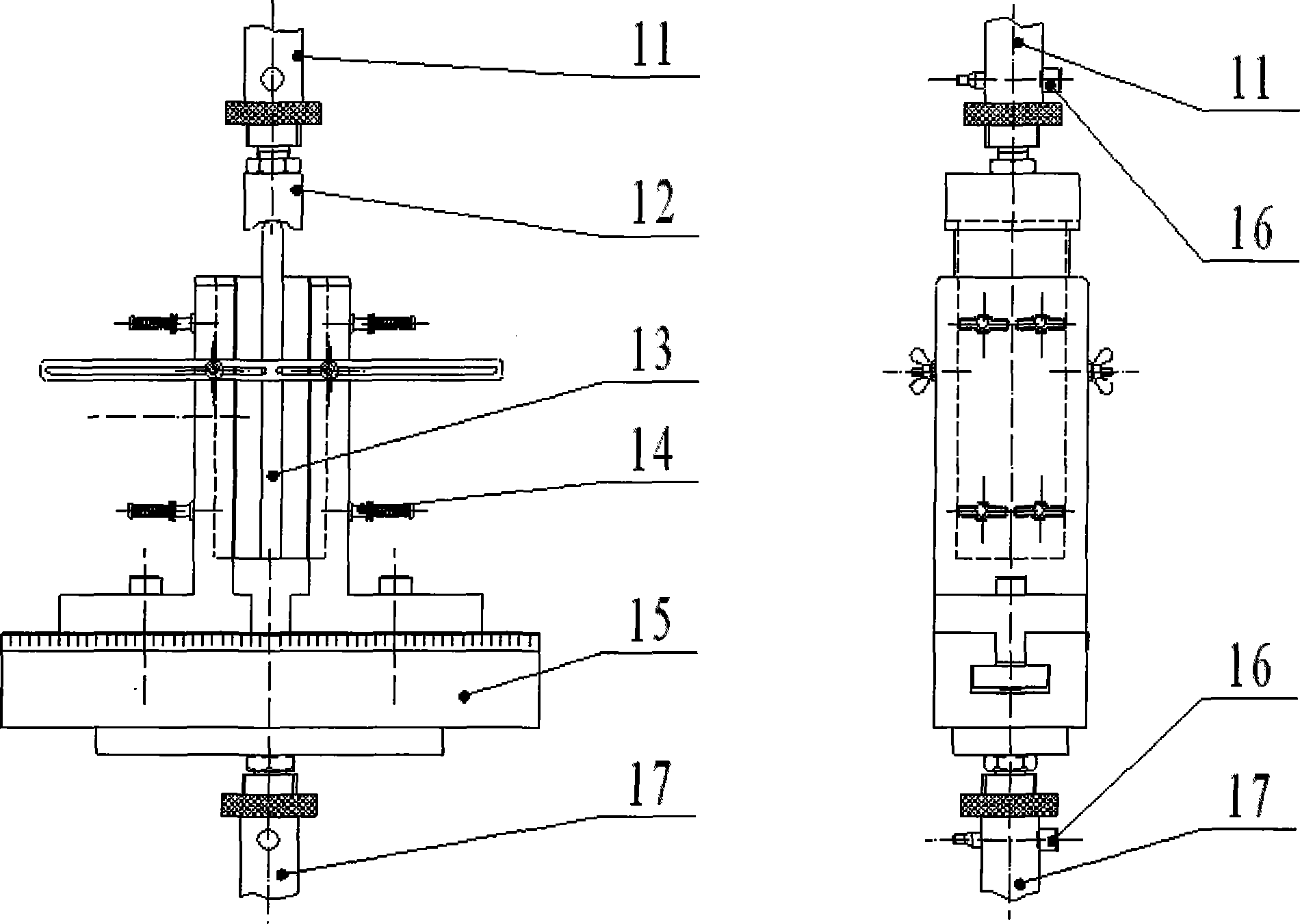

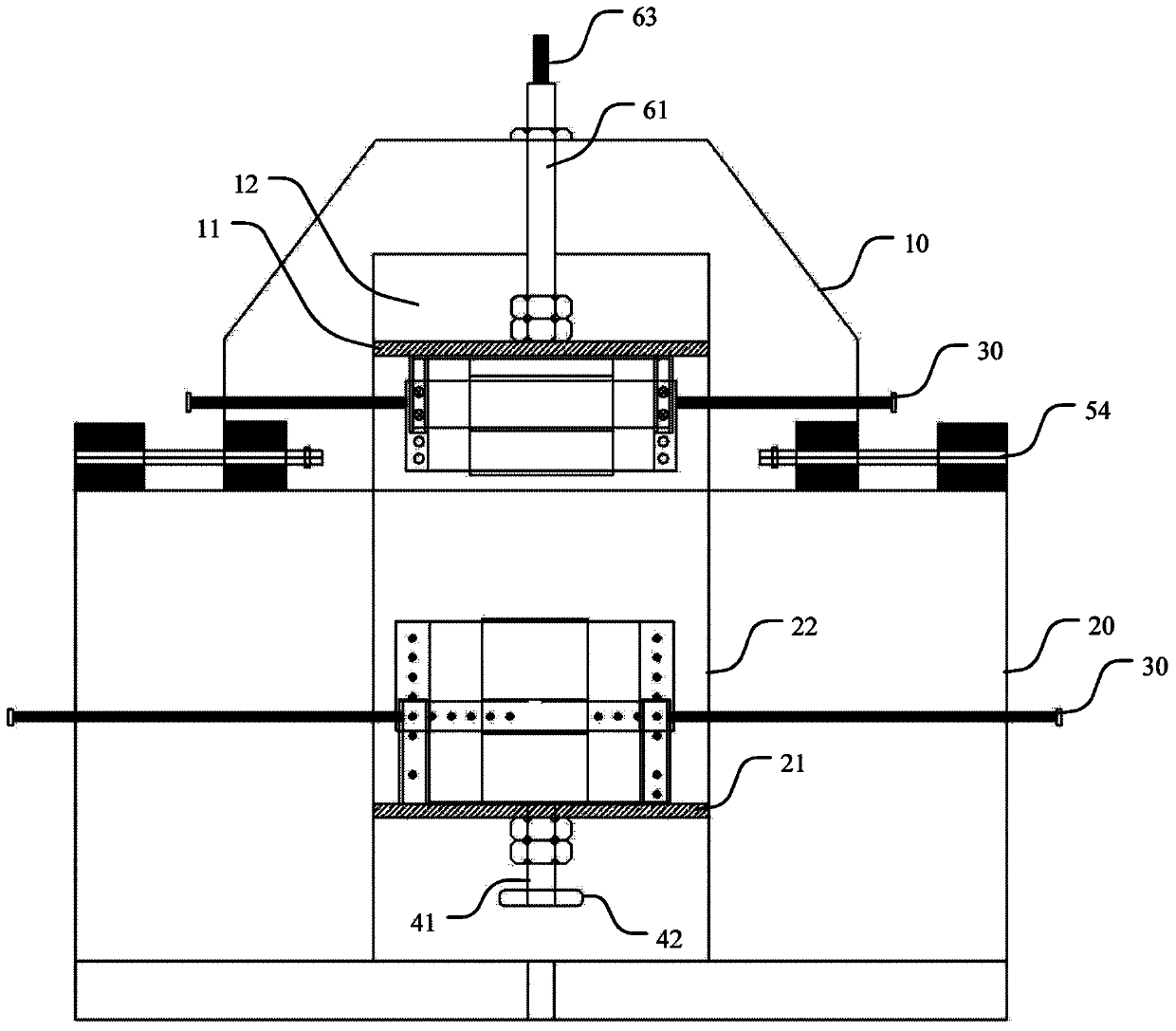

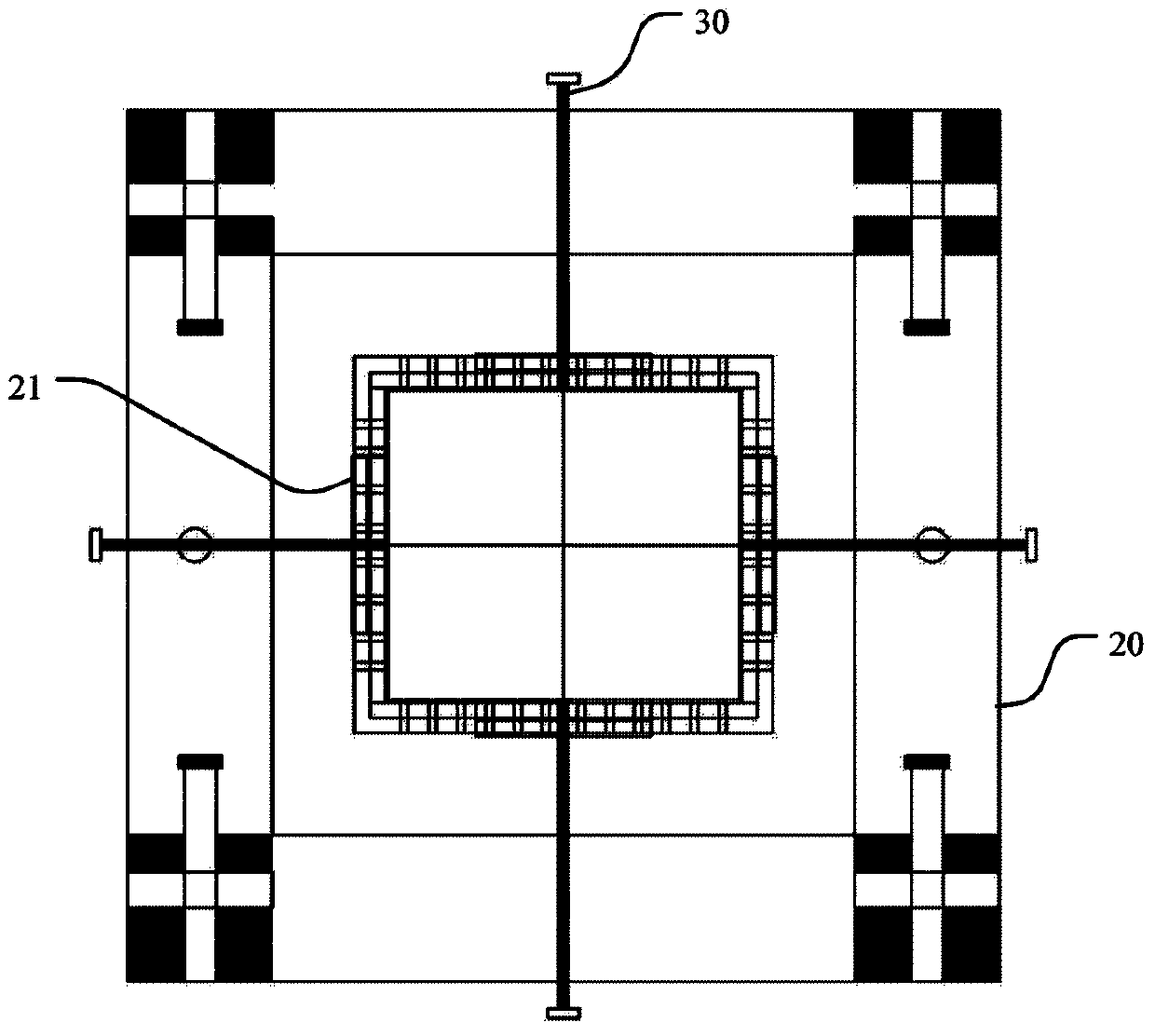

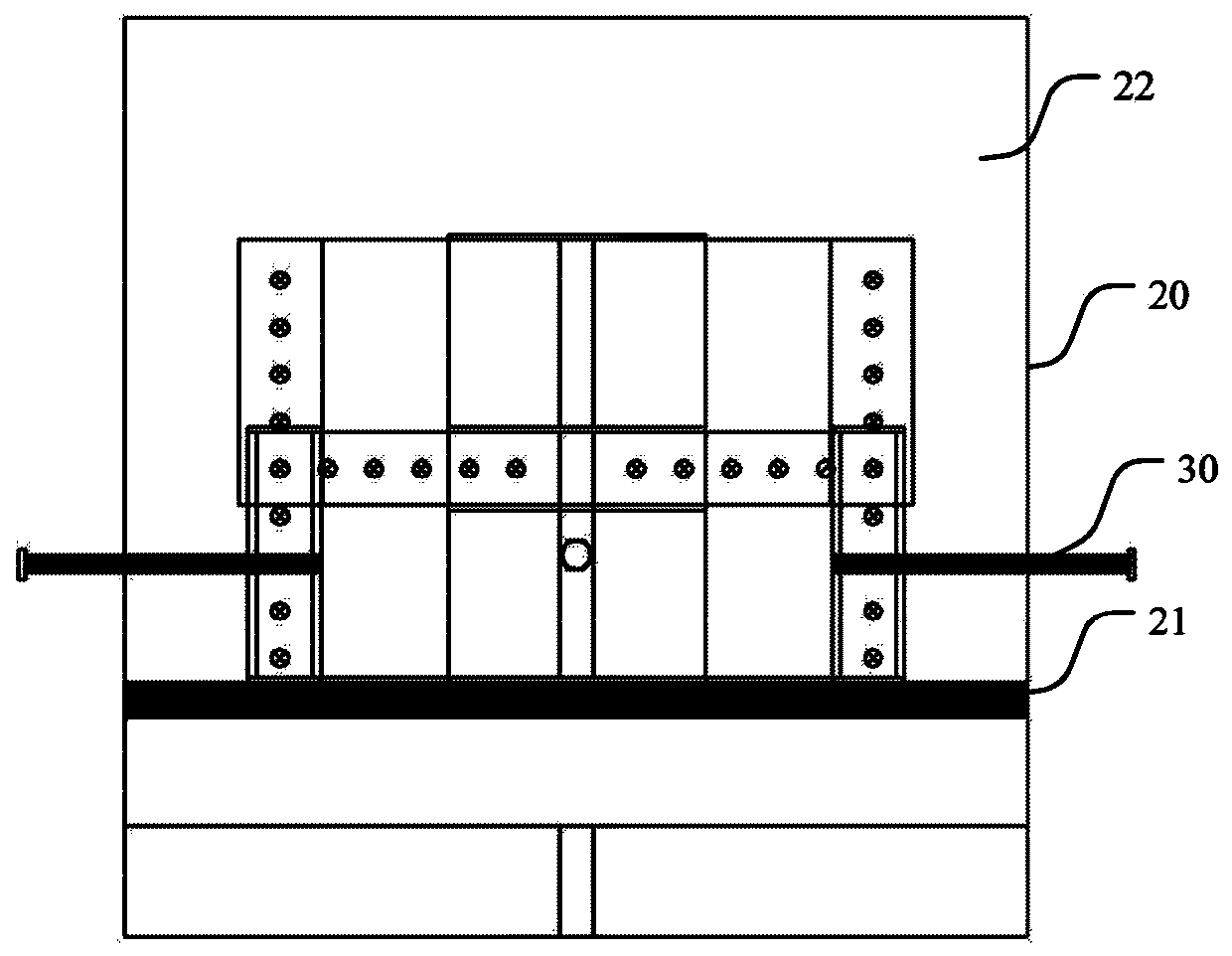

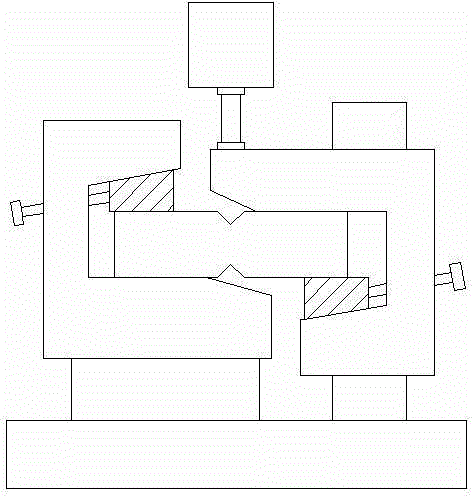

Indoor stretching-shearing testing device for anchor rod

InactiveCN103543069AImplement vertical loadingAchieve axial stretching effectMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesJackscrewCounterforce

The invention relates to an indoor stretching-shearing testing device for an anchor rod, belonging to the technical field of geotechnical engineering. The device comprises a counterforce frame, a horizontal loading system, a lower shearing box, a vertical loading system, a horizontal guide rail system, an upper shearing box and a limit device. Due to the structure design of the horizontal guide rail system, the shearing movement of the upper shearing box along the horizontal loading direction is realized and a friction resistance in a shearing process can be effectively reduced. A first vertical loading jack and a second vertical loading jack in the vertical loading system are connected with the same hydraulic control system, thus a test anchor rod can always bear a vertically upward axial stretching force in the vertical loading process. By the indoor stretching-shearing testing device for an anchor rod, a shearing damage test of the anchor rod under different axial drawing forces can be realized and the defect that a conventional indoor stretching-shearing testing device for an anchor rod is only capable of performing a pure-stretching test is overcome; and the indoor stretching-shearing testing device for an anchor rod is of great importance in acquiring stretching-shearing damage test data of the anchor rod and understanding a damage mechanism of the anchor rod under a stretching and shearing comprehensive function.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

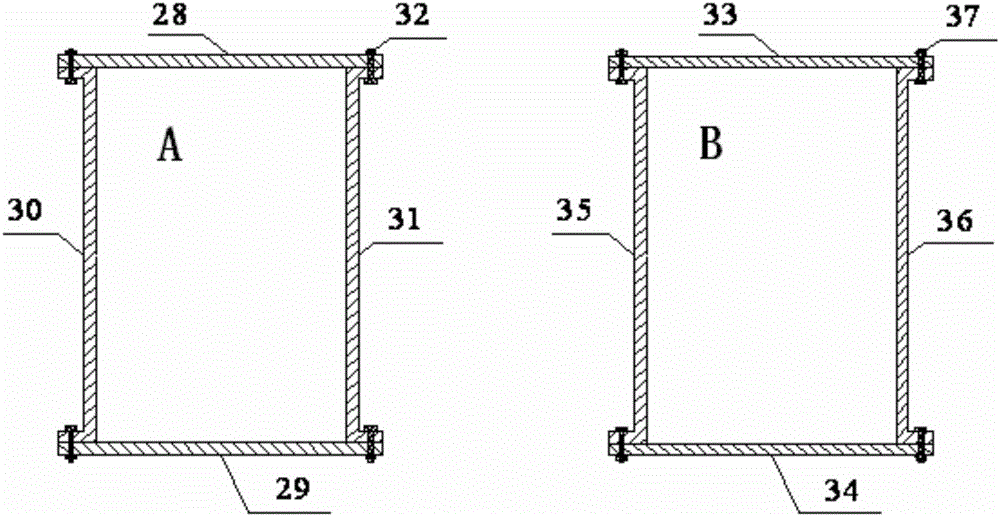

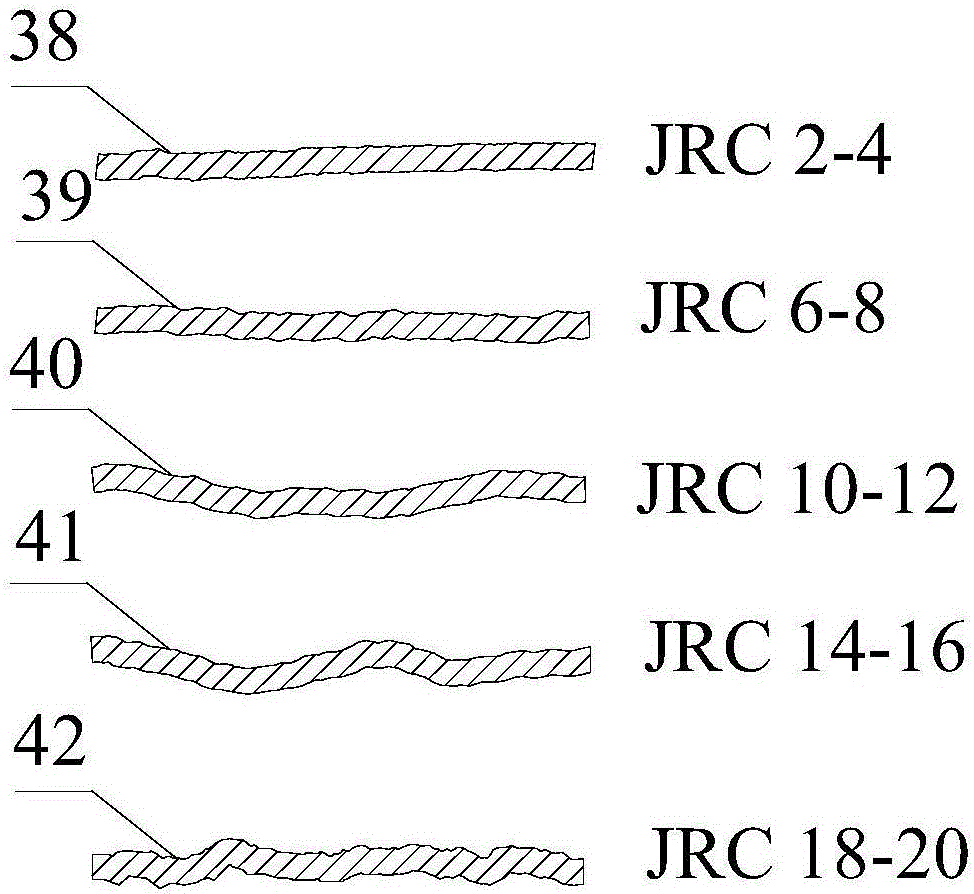

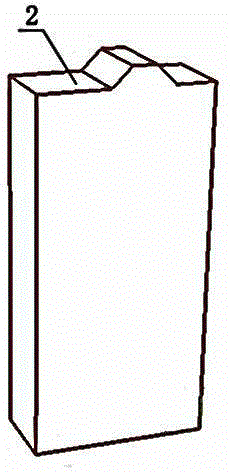

Device and method for preparing rock-like material structural plane and utilizing rock-like material structural plane to shearing test

ActiveCN106092695ASimple installation and disassemblyWon't scatterPreparing sample for investigationMaterial strength using steady shearing forcesStructure of the EarthData acquisition

The invention relates to a device and method for preparing a rock-like material structural plane and utilizing the rock-like material structural plane to a shearing test. The device comprises a test part manufacturing system, a test part system, a loading system and a data acquisition system. The device provided by the invention can realize preparation of the rock-like material structural plane and a weak intercalated layer structural plane containing different fillers, and researches on shearing properties of the structural plane can be realized.

Owner:HUNAN UNIV OF SCI & TECH

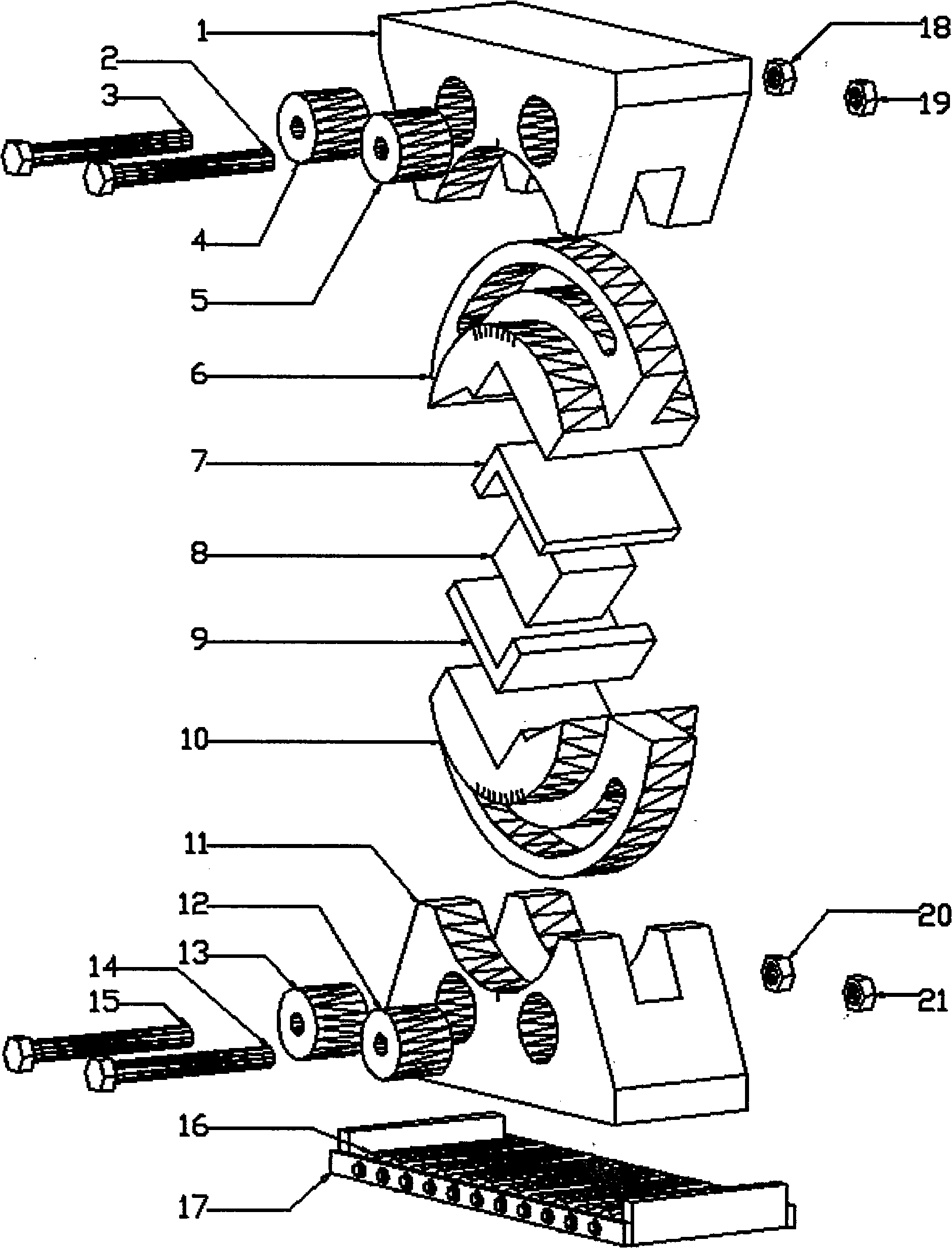

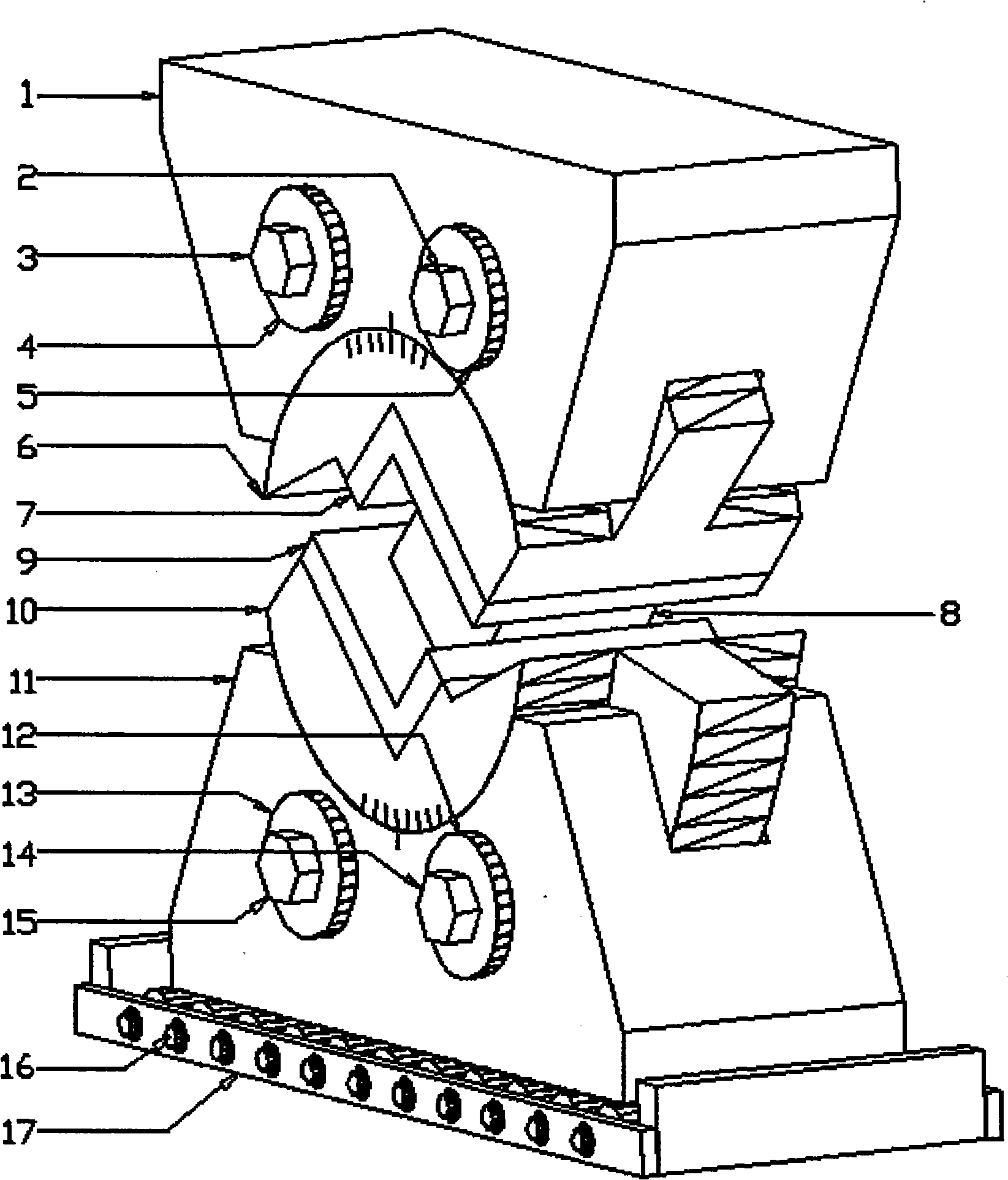

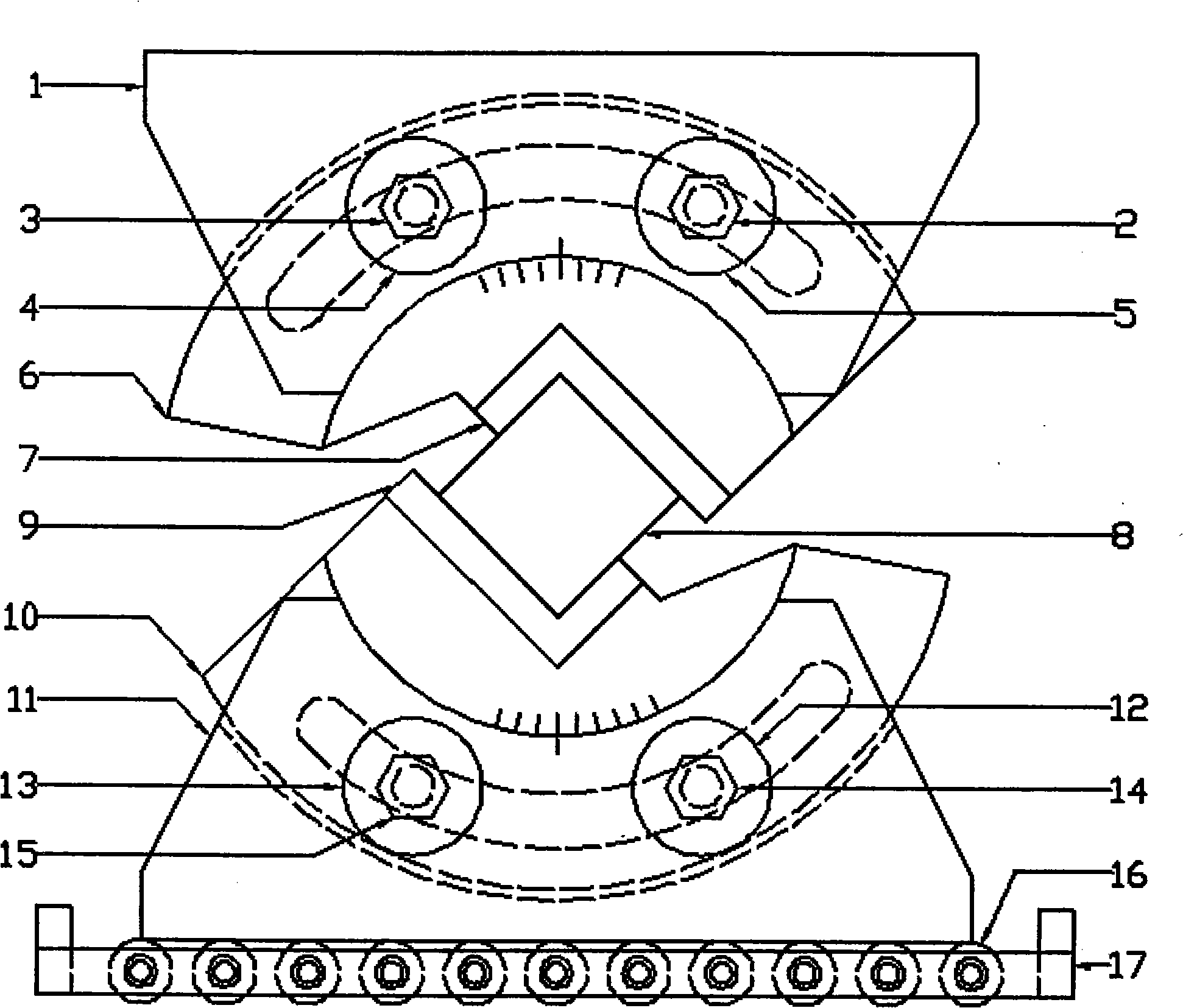

Compression shear test device

InactiveCN101315320AImprove integritySimple structureMaterial strength using steady shearing forcesEngineeringRock sample

The invention discloses a compression-shear testing device, which comprises a clamping plate, a cylindrical cushion block, an angle-varied plate, a right angle base plate, a roller, a roller frame, a bolt and a nut. The device is characterized in that the angle-varied plate has an arc-shaped edge; the dimensions of the arc-shaped borderline of the angle-varied plate are matched with the dimensions of the arc-shaped borderline of the clamping plate; the edge part of the angle-varied plate, which is provided with annular holes, is inserted into a groove of the clamping plate; the cylindrical cushion block, the bolt and the nut fix the angle-varied plate on the clamping plate; the right angle base plate on the inner side of the angle-varied plate is in direct contact with a rock sample; the roller is arranged on the roller frame; the roller is in the shape of a cylindrical bar; and the diameter of the middle part of the bar is larger than that of the two ends thereof. The device can flexibly adjust the angle of a shearing surface of a sample. Furthermore, the device has the advantages of good autostability, good wholeness and high durability.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

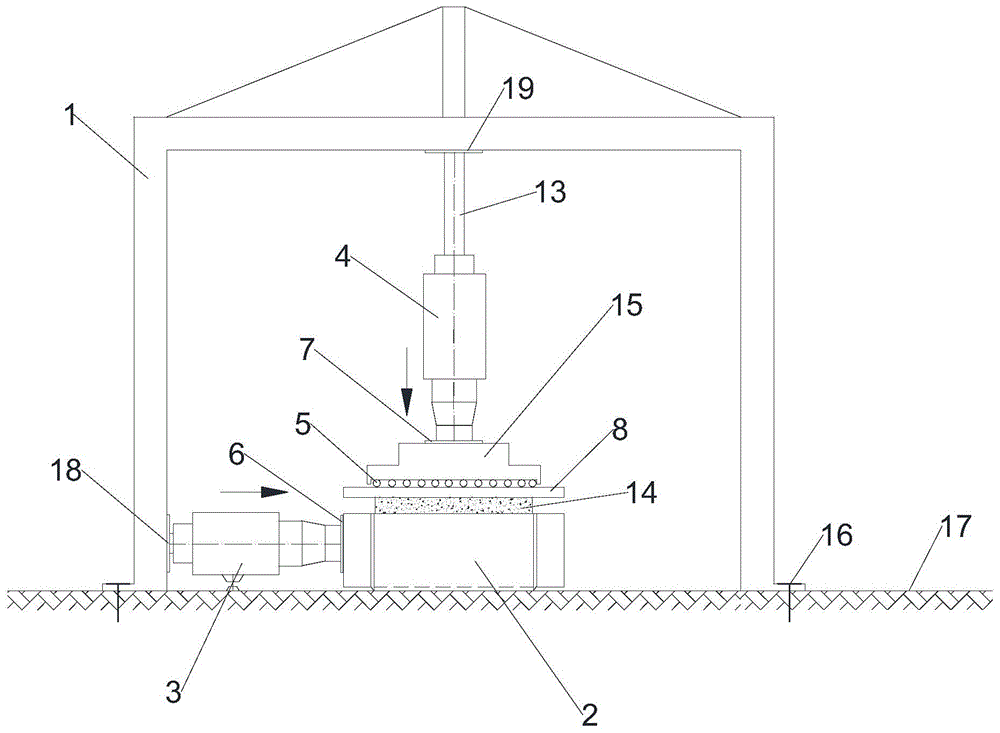

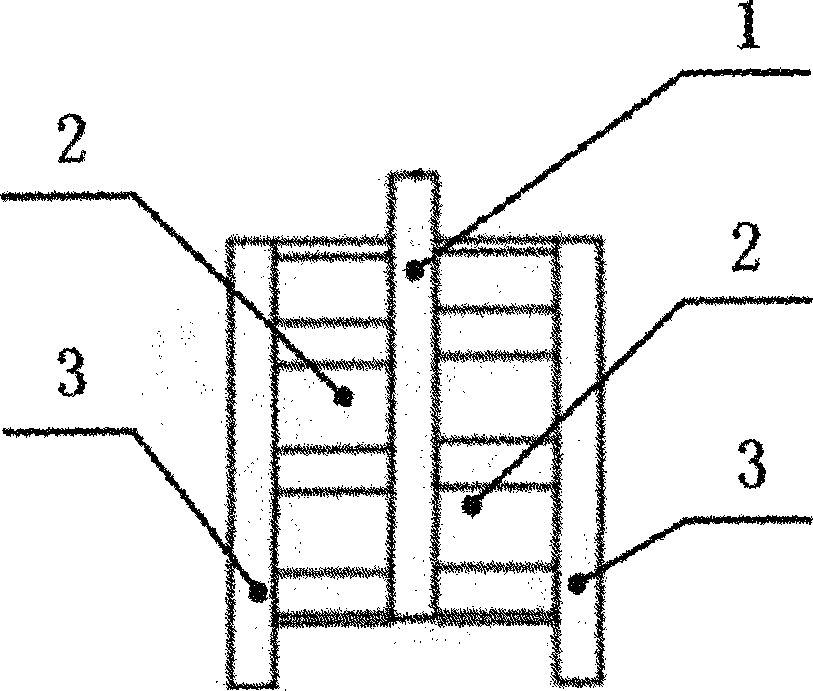

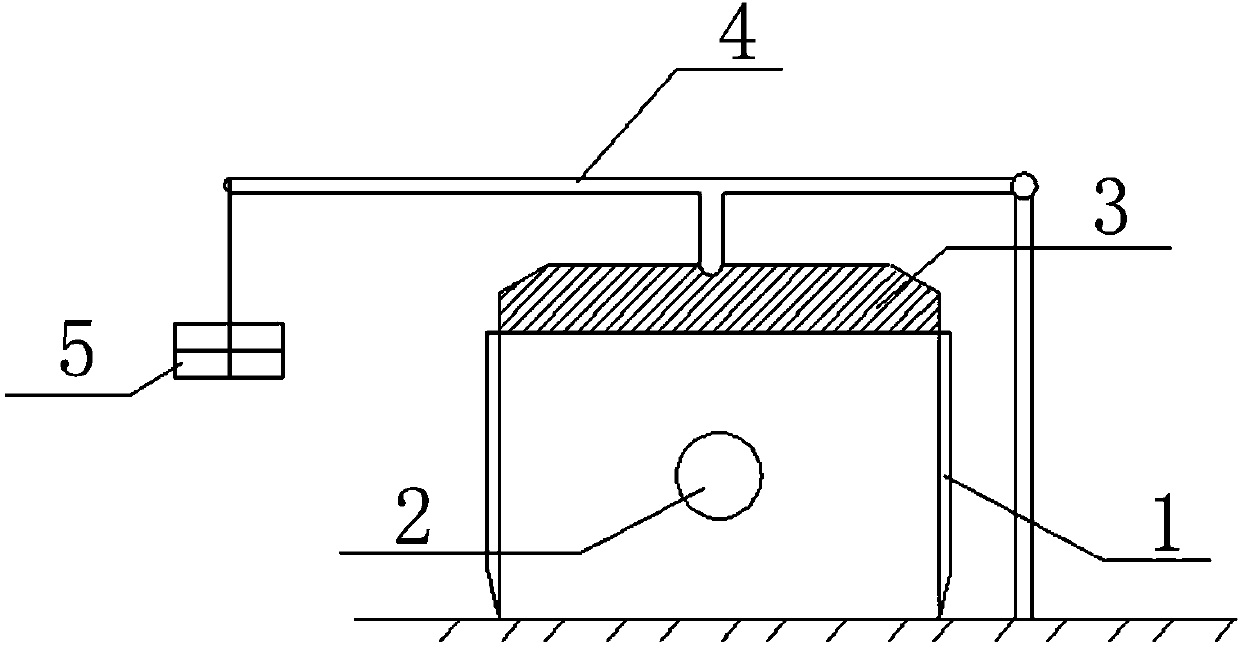

Portable weak-layer in-situ direct-shear tester and testing method thereof

InactiveCN104807706AThe result is accurateReliable resultsMaterial strength using steady shearing forcesSteel frameEngineering

The invention provides a portable weak-layer in-situ direct-shear tester and a testing method thereof. The portable weak-layer in-situ direct-shear tester comprises a counter-force steel frame, a shear box, a horizontal loading system and a vertical loading system, wherein a test space is formed in the counter-force steel frame; the shear box is mounted in the test space; one end of the horizontal loading system acts on the counter-force steel frame, and the other end of the horizontal loading system acts on the vertical lateral wall of the shear box; the vertical loading system comprises a row of balls, one end of the vertical loading system acts on the top cover of the counter-force steel frame, and the other end of the vertical loading system acts on the upper surface of the shear box through the balls. Through the adoption of the portable weak-layer in-situ direct-shear tester disclosed by the invention, the shear parameters of unperturbed weak layers in situ can be quickly obtained on site, so that the tested result is more accurate and reliable, and the tester is convenient to test the shear strength parameters of weak layers in situ; in addition, the portable weak-layer in-situ direct-shear tester disclosed by the invention also has the characteristics of being simple in structure, easy to operate and portable.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI +1

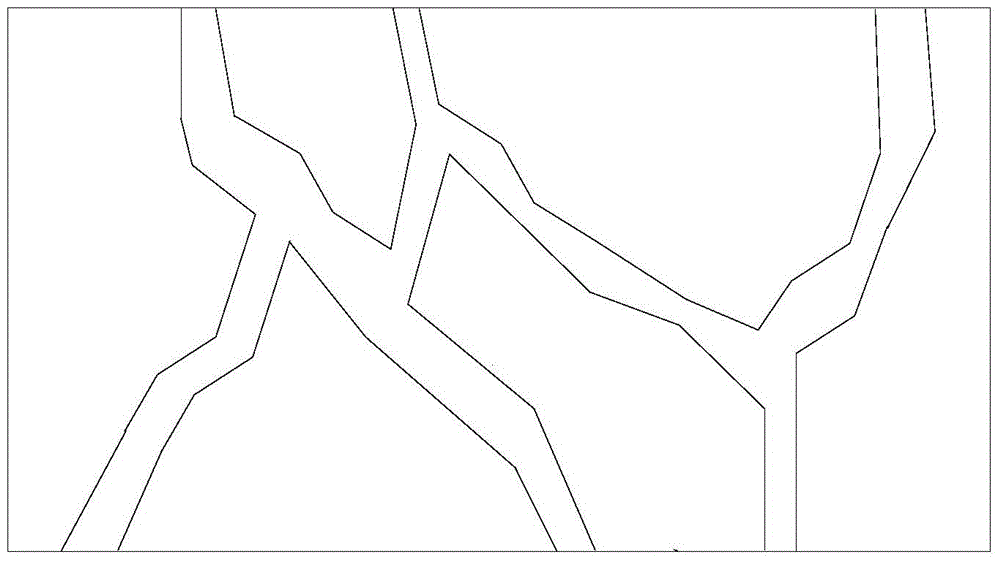

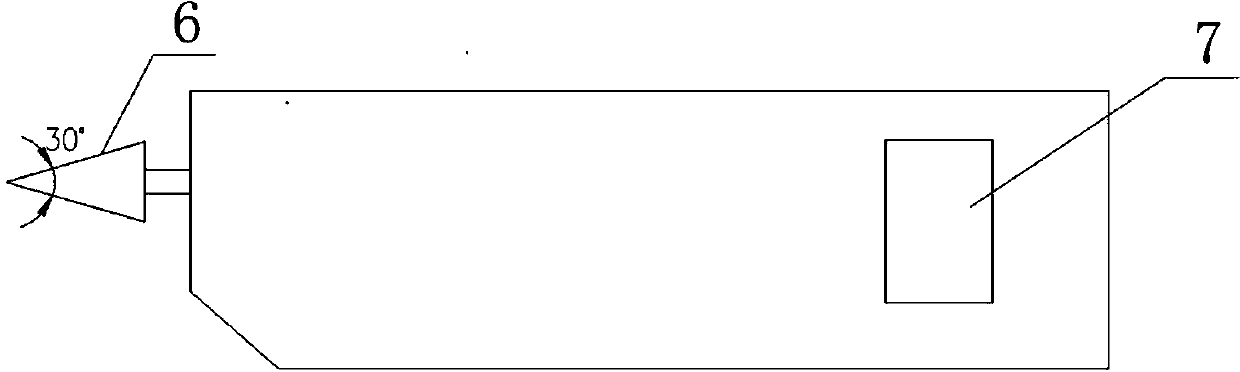

Shearing-seepage coupling experiment method of fracture network rock

InactiveCN103954511AImage and detailed researchLow costMaterial strength using steady shearing forcesNumerical controlDigital video

A coupling experiment device and method for engraving of a fracture network rock test piece and its fracture seepage belong to the fields of hydromechanics and rock mechanics. The method of the invention comprises the following steps: 1. preparing a rock test piece with a certain size required by the experiment; 2. engraving a fracture network by using a full-automatic engraving machine according to real fractures; 3. performing the experiment by using a numerical control direct shearing testing machine with an electro-hydraulic servo microcomputer control system; 4. measuring the pressure of the fracture network, and deriving a flow velocity based on a formula; 5. measuring the change and development state of water or oil in the rock fractures; 6. recording the flowing process and state of colored water in the fractures by a digital video camera; 7. establishing a model with combination of the experiment. The experiment method changes the state in the past that a shearing seepage experiment of a test piece is carried out in a manner that a single fracture is obtained by manual cleavage, and reflects the real state of fractures inside the rock. Experiment materials are low in cost and convenient for manual engraving by onself. The engraving speed is high, the determination device is small in land occupation, and the operation is simple.

Owner:BEIJING UNIV OF TECH

Tensile-shear test loading device with flight structure

InactiveCN102607940AAchieve shearMaterial strength using tensile/compressive forcesAviationEngineering

The invention relates to a test loading device, in particular to a tensile-shear test loading device with a flight structure. Compression bars are arranged between stand columns, the upper ends of the compression bars are extended to form an upper beam, a compression plate is arranged on the top ends of the stand columns, a lower beam is arranged on the bottom ends of the stand columns, an upper cross type joint is arranged between the compression bars on the bottom end of the upper beam, a lower cross type joint is arranged on the upper end of the lower beam between the compression bars; and a fixture is arranged between the upper cross type joint and the lower cross type joint. The test loading device provided by the invention can be used for converting pressure of a compression tester into tensile of a test piece or realizing shear force of the test piece through the action of the fixture, and can be used for a tensile or shear test of stiffened wall plates and similar structures without being provided with a special large loading tensile testing machine independently.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

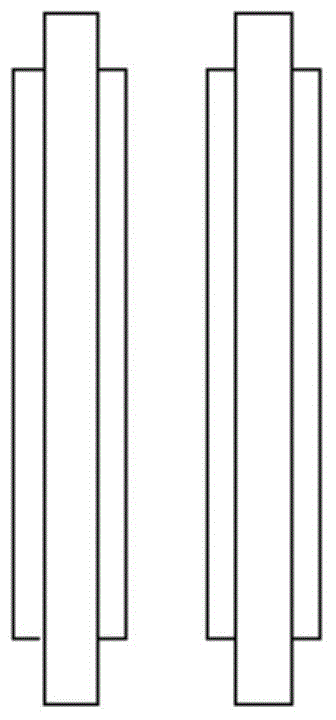

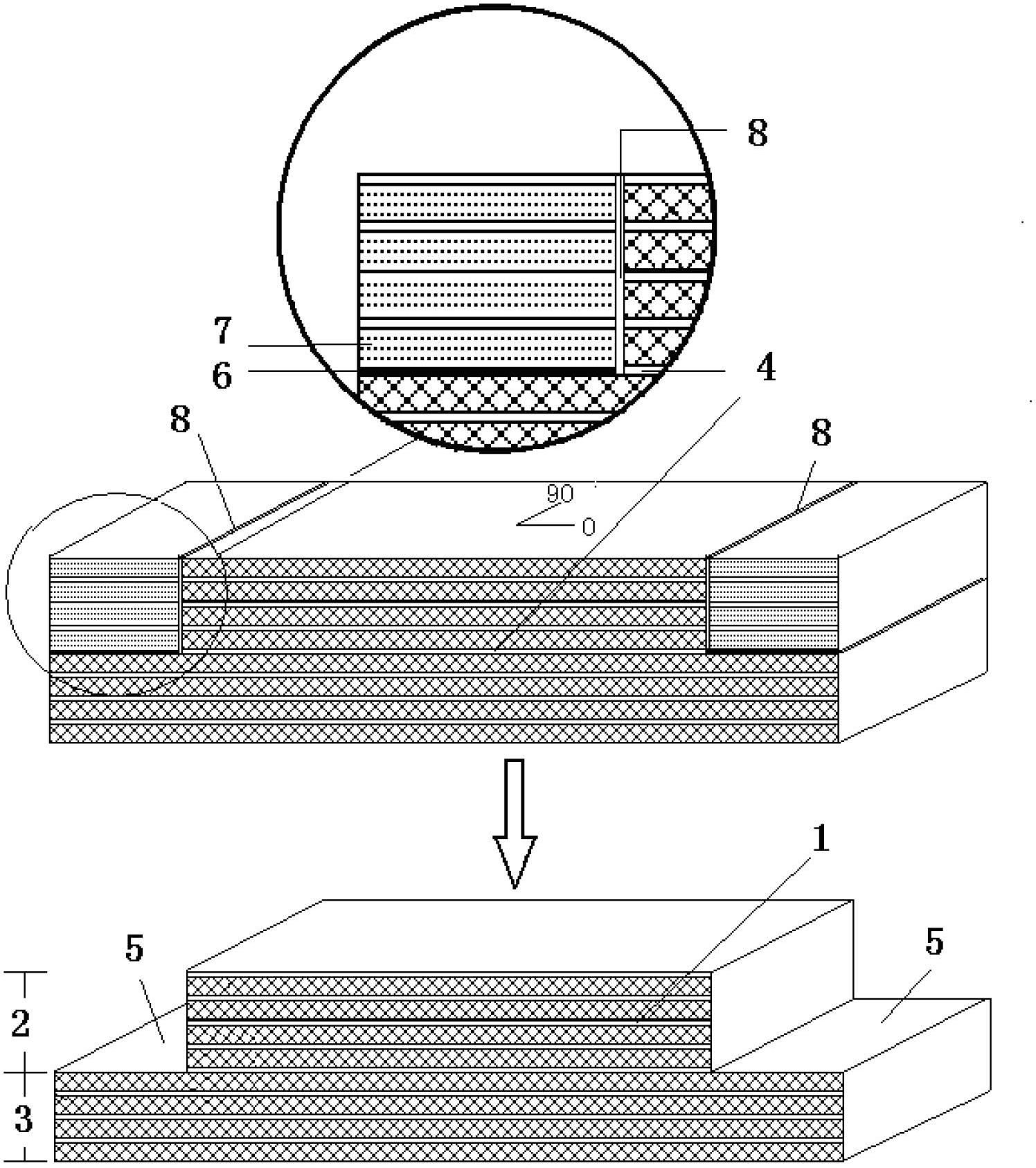

Test fixture for compression shear of symmetric sandwich structure

The invention provides a test fixture for compression shear of a symmetric sandwich structure, which belongs to the field of sandwich structure material test fixtures and aims to solve the problems of asynchronous manual indication of a deformation gauge and compression shear force value data and to-be-converted testing machine values in current standards and patents as well as poor stability and inconvenient alignment of a simple symmetric fixture. The test fixture disclosed by the invention is mainly composed of a compression shear pressure head component, a testing sample component, a connecting and locking device and a base component; the testing sample component is formed in a method that a pair of testing samples are symmetrically bonded to a sample group middle bonding board and a pair of sample sticking boards; the connecting and locking device is used for connecting the testing sample component with the base component; a locking head can be moved horizontally in a compression shear test process; the position of a base fixing sample component device of the base component can be regulated through an inner hexagon bolt; stability of the base fixing sample component device is ensured; and the testfixture is suitably used for compression shear tests of the sandwich structure materials such as honeycomb paperboards and aluminum honeycomb boards.

Owner:邳州市城洁保洁有限公司

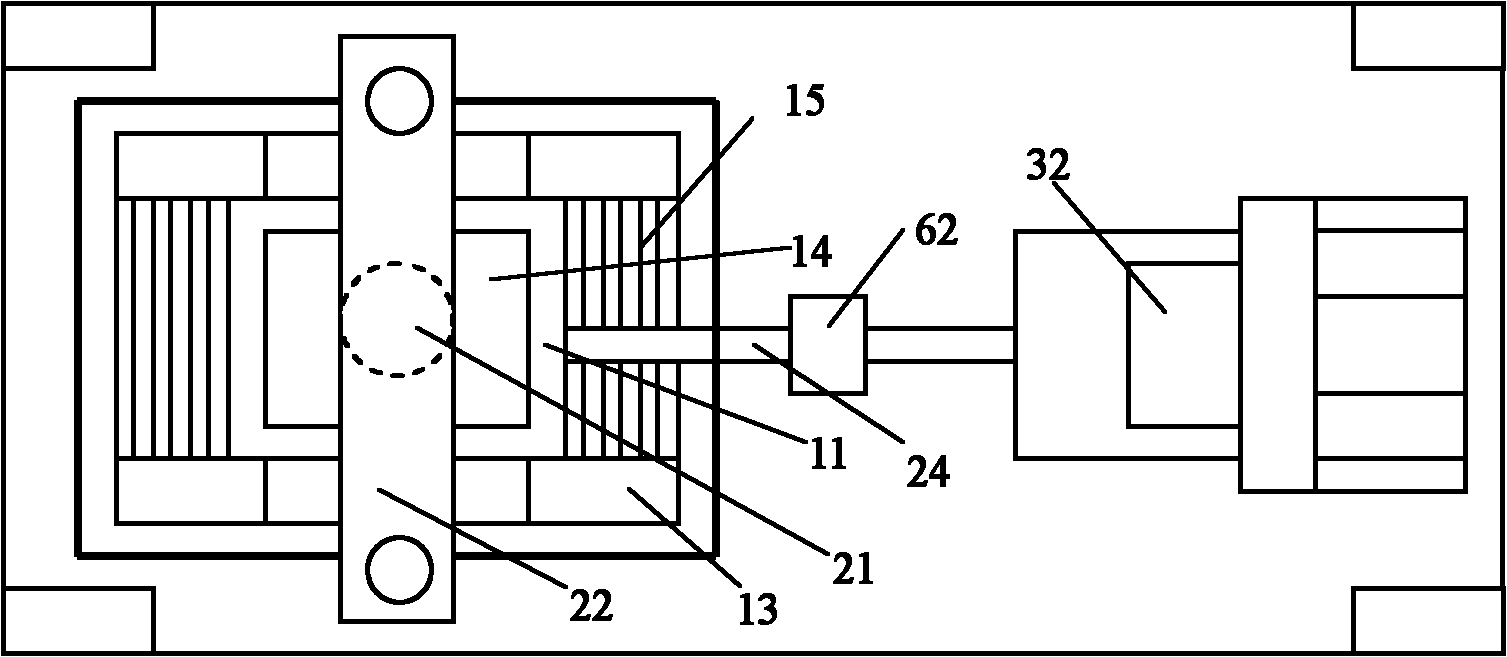

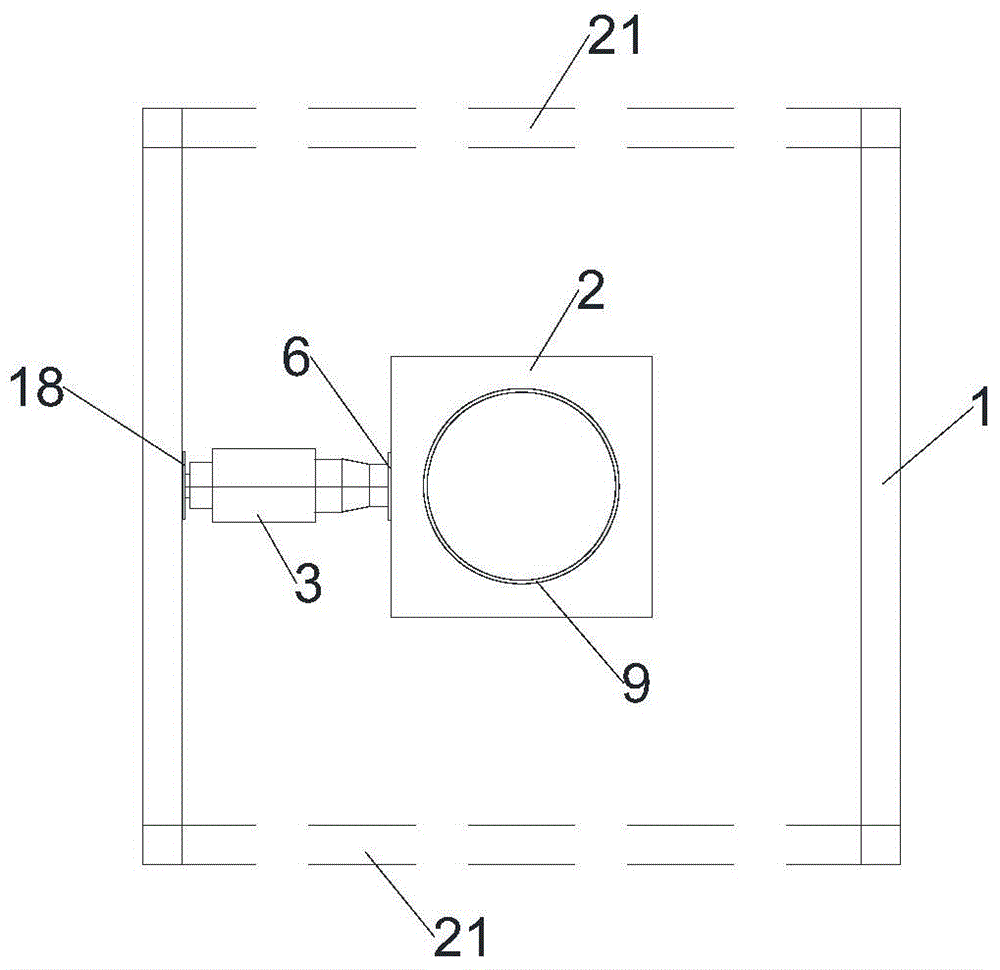

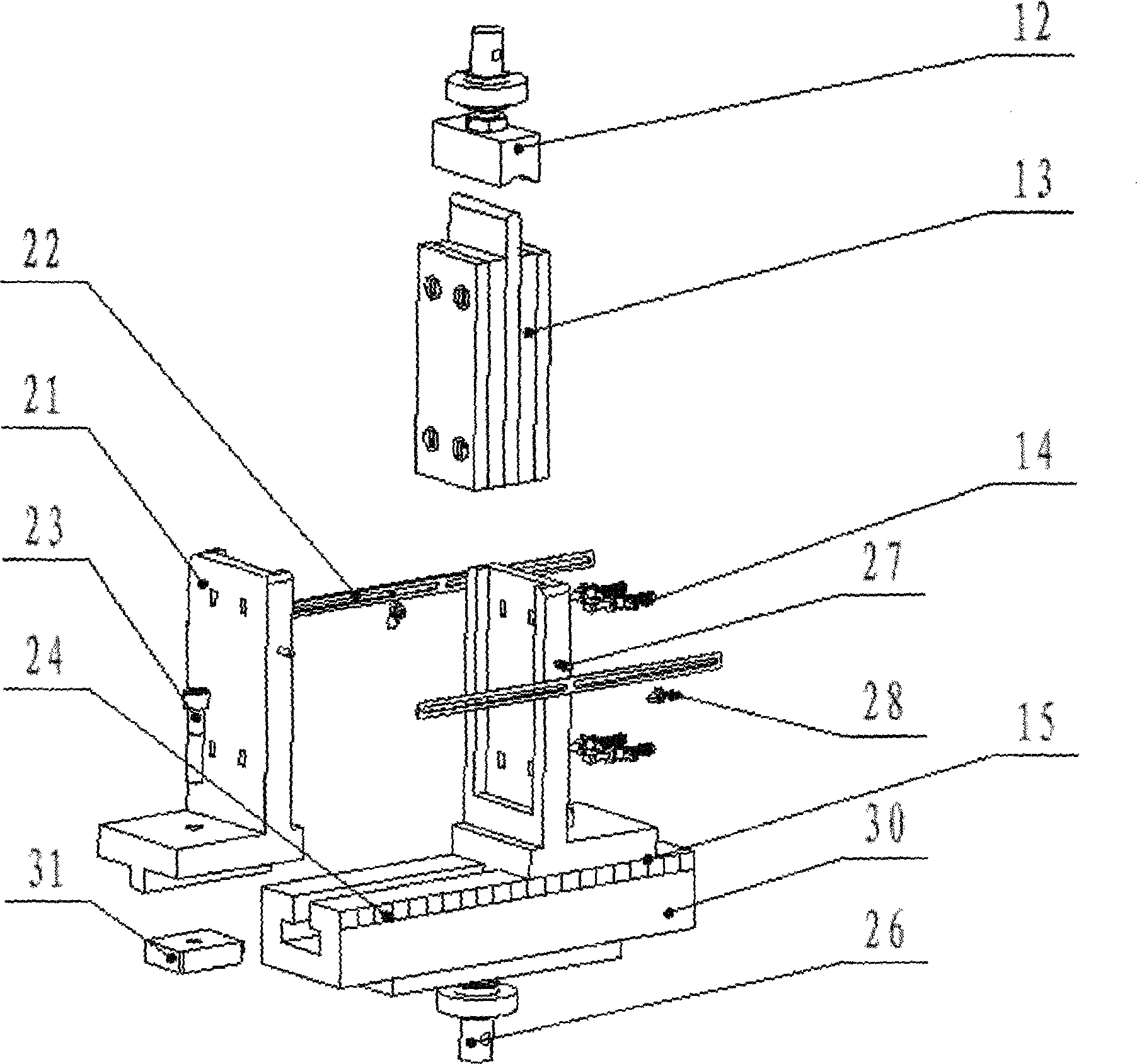

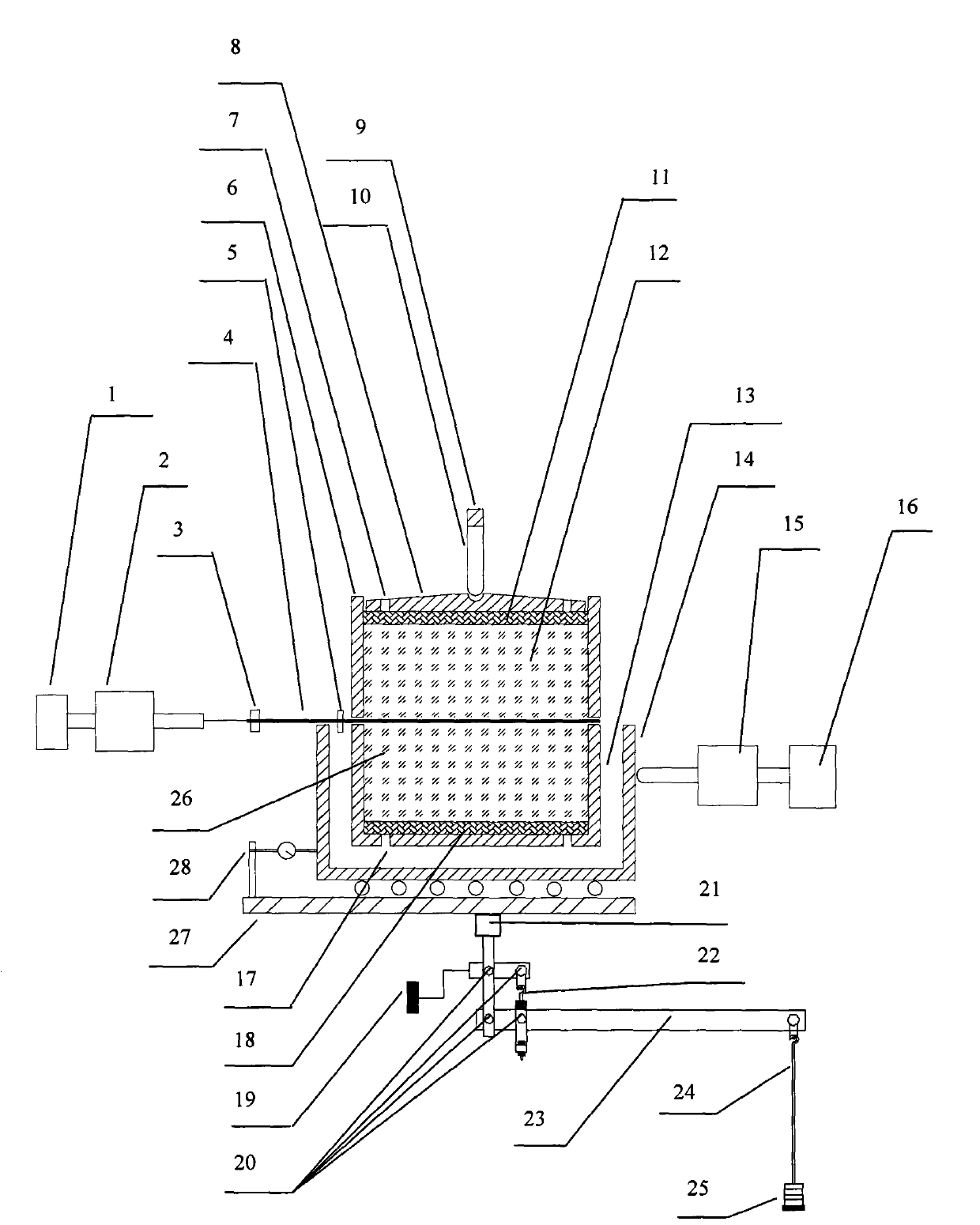

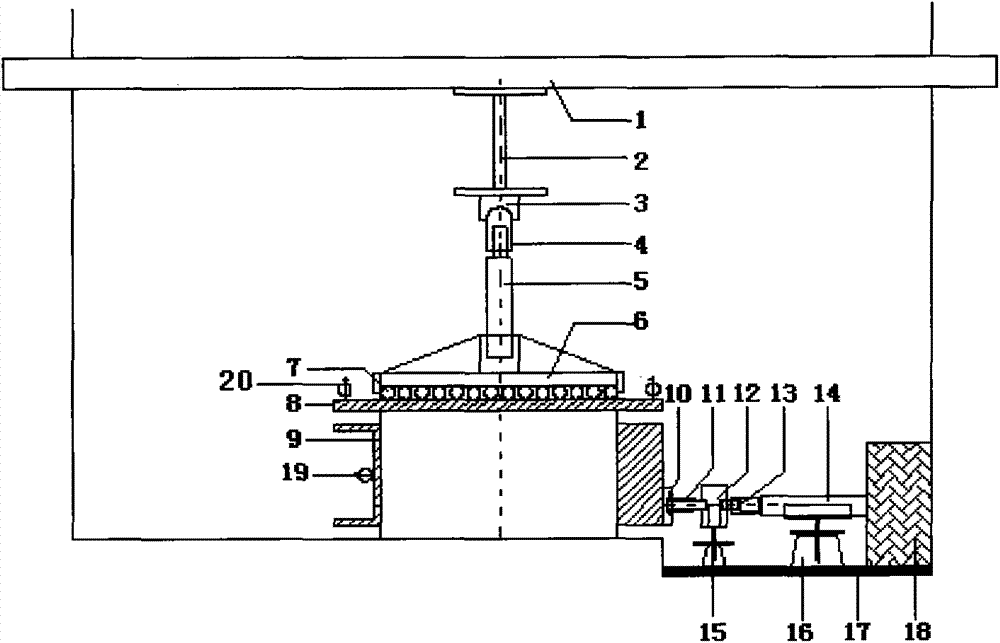

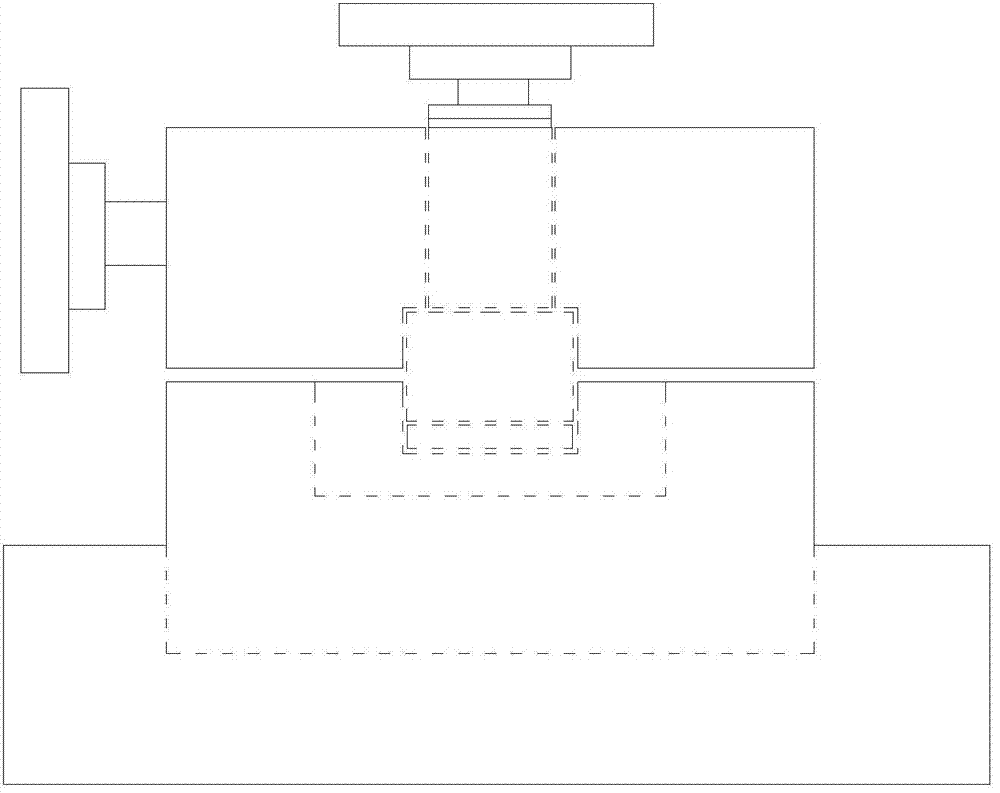

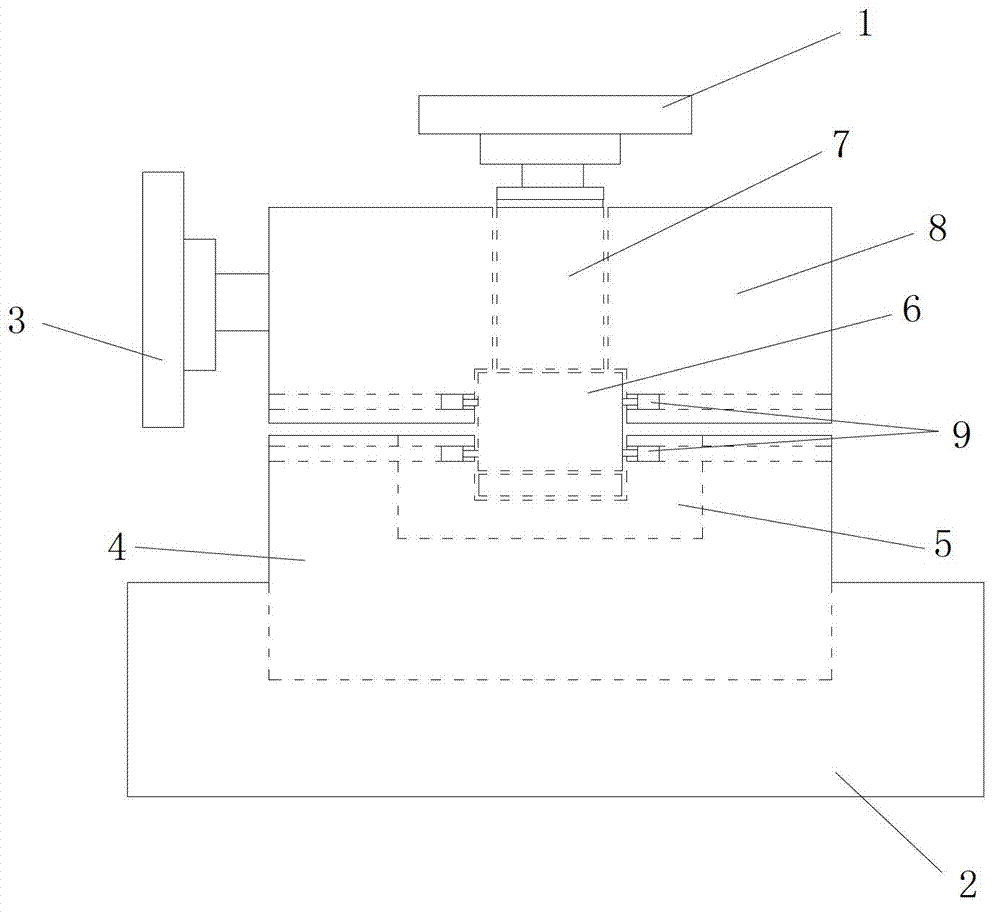

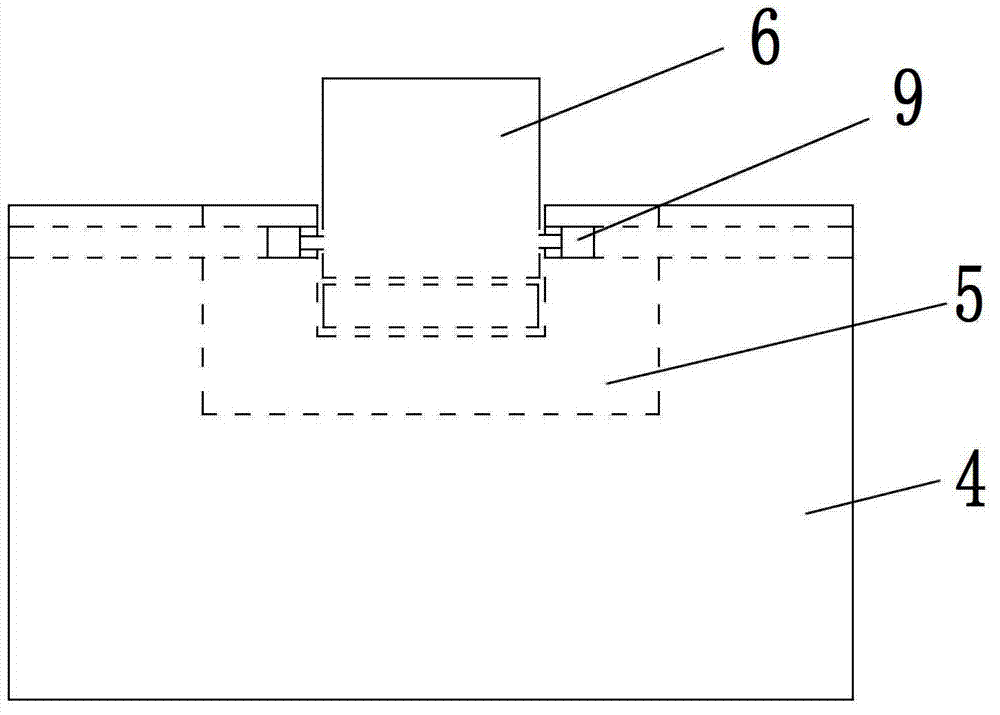

Drawing and shear testing device for geosynthetics

InactiveCN103776696AMeet the tensile strengthFulfil requirementsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesPorous mediumEngineering

The invention discloses a drawing and shear testing device for geosynthetics. The drawing and shear testing device is characterized by comprising a drawing stepping motor (1), a drawing force measuring ring (2), an upper sample box (6), a pressurizing frame (9), a lower sample box (13), a lower base (14), a shear force measuring ring (15), a shear stepping motor (16), a pressurizing lever (23) and a weight (25), wherein the drawing stepping motor (1) is connected with the drawing force measuring ring (2); the lower sample box (13) is mounted on the lower base (14); a lower sample (26) is arranged on a piece of filter paper; geosynthetics (4) are laid between the lower sample (26) and an upper sample (12); the geosynthetics (4) are fixed through a clamp (3) and a deformable clamp (5); a top cover (8) is arranged on upper water permeating stones (11); upper drain holes (7) are formed in the top cover (8); a cushion block is arranged between the upper sample box (6) and the lower sample box (13); the top cover (8) has contact with a pressurizing shaft (10), and the shear stepping motor (16) is used for providing a shear force by means of pushing the lower base (14). The drawing and shear testing device is simple to manufacture, high in measurement accuracy, convenient to use and capable of being used for measuring the tensile strength and shear strength properties of various geosynthetics in a porous medium in civil engineering or geological engineering.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Interlayer direct shear testing device and testing method

ActiveCN104198299AAvoid destructionImprove accuracyMaterial strength using steady shearing forcesRoad surfaceEngineering

The invention relates to an interlayer direct shear testing device and a testing method and provides an interlayer direct shear testing device applied to pavement structure double-layer type samples. The interlayer direct shear testing device comprises an upper shear box, a lower shear box, a vertical loading device and a transverse loading device, wherein the upper shear box is capable of changing holding volume so as to be adapted with the structure of the upper layer of each tested pavement structure double-layer type sample; the lower shear box is capable of changing the holding volume so as to be adapted with the structure of a lower structure of each tested pavement structure double-layer type sample; the vertical loading device is used for directly or indirectly applying predetermined vertical load to the tested pavement structure double-layer type samples; the transverse loading device is used for directly or indirectly applying predetermined shear force to an interlayer interface among components of the upper layer and the lower layer of each tested pavement structure double-layer type sample. In addition, the invention also provides a testing method applied to the interlayer direct shear testing device. The interlayer direct shear testing device can be applied to pavement structure double-layer type samples with different plane sizes and heights.

Owner:CHINA ROAD & BRIDGE +1

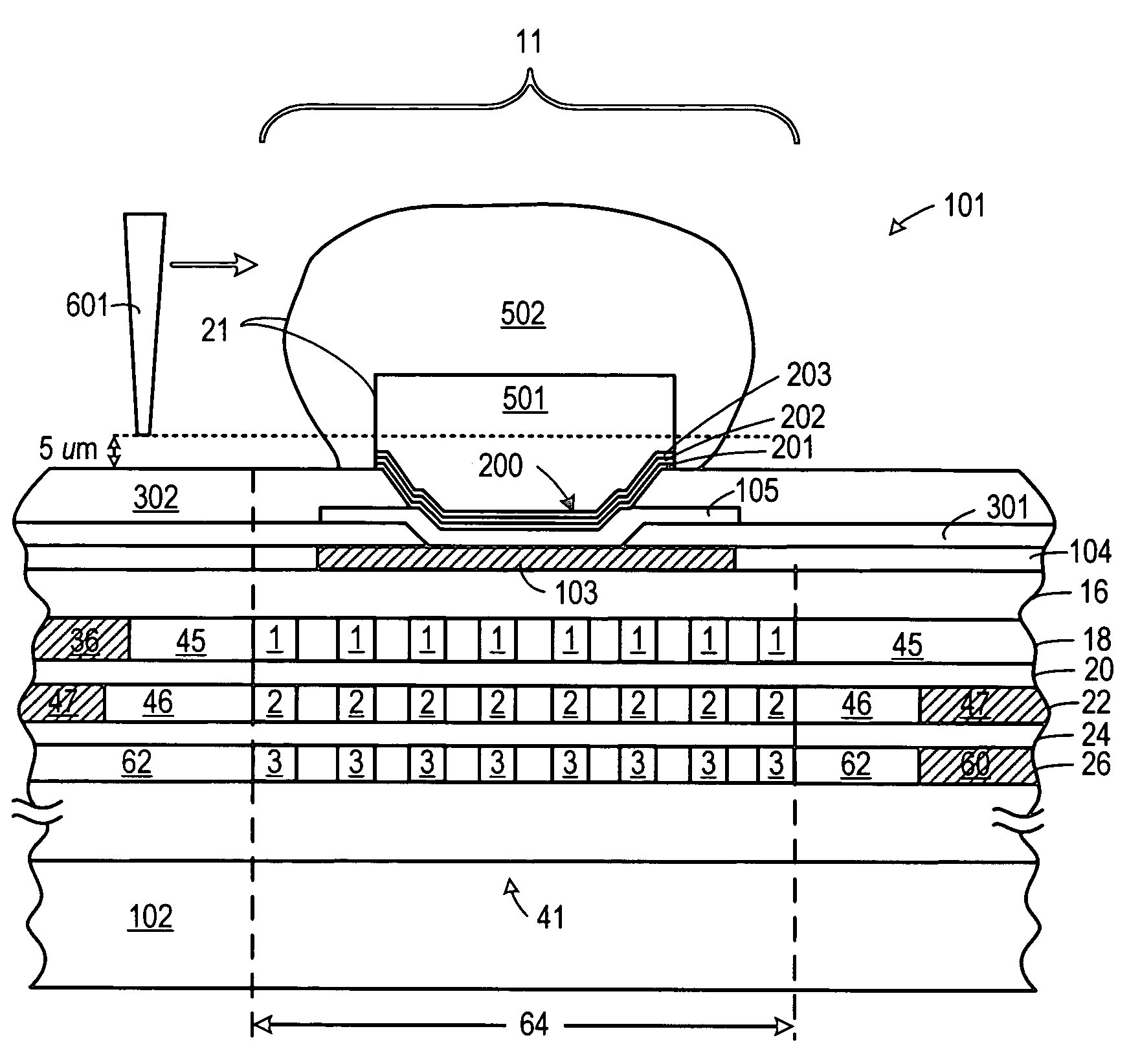

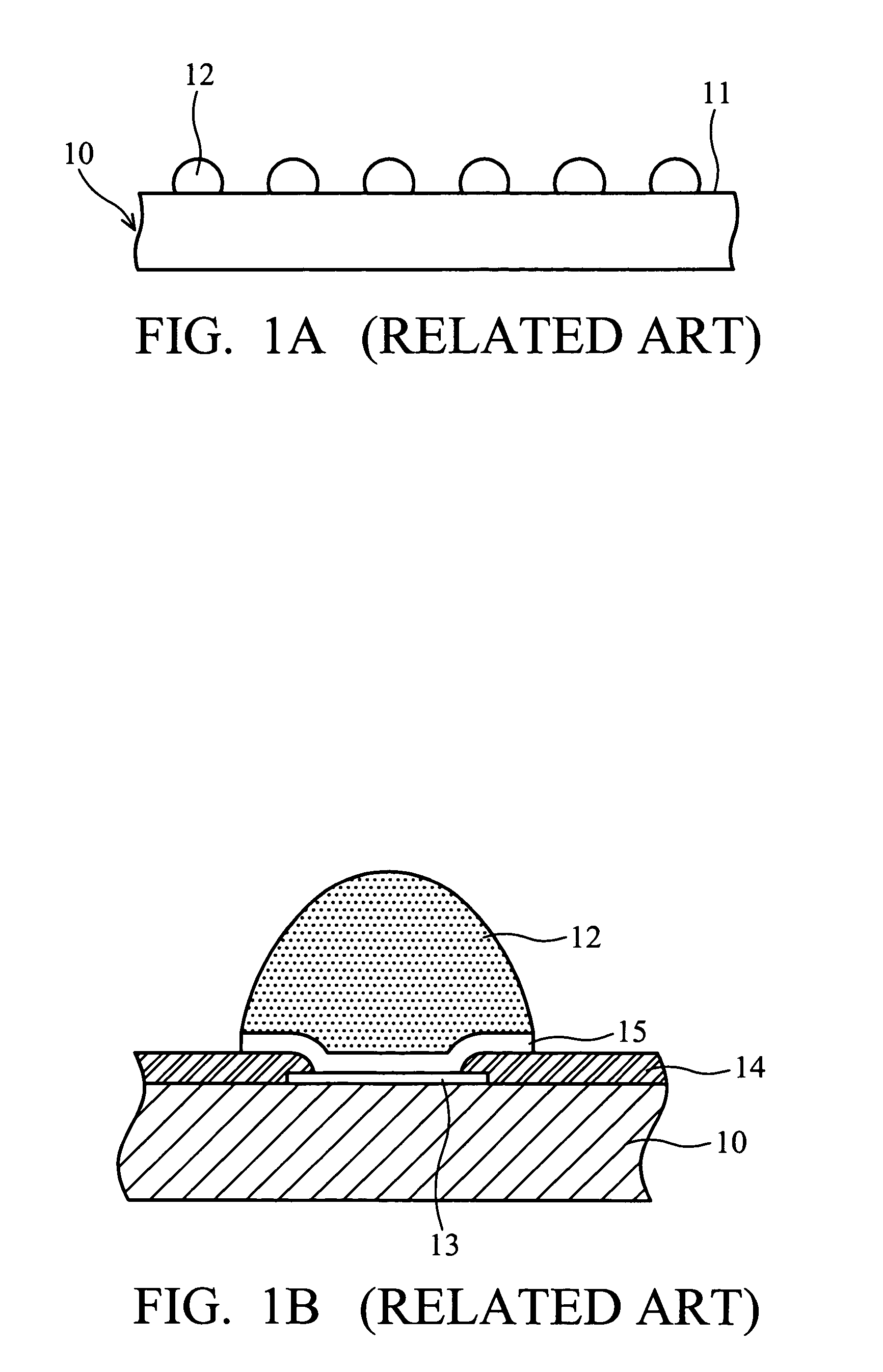

Mechanical integrity evaluation of low-k devices with bump shear

InactiveUS7622309B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMechanical integrityEngineering

Owner:TAIWAN SEMICON MFG CO LTD

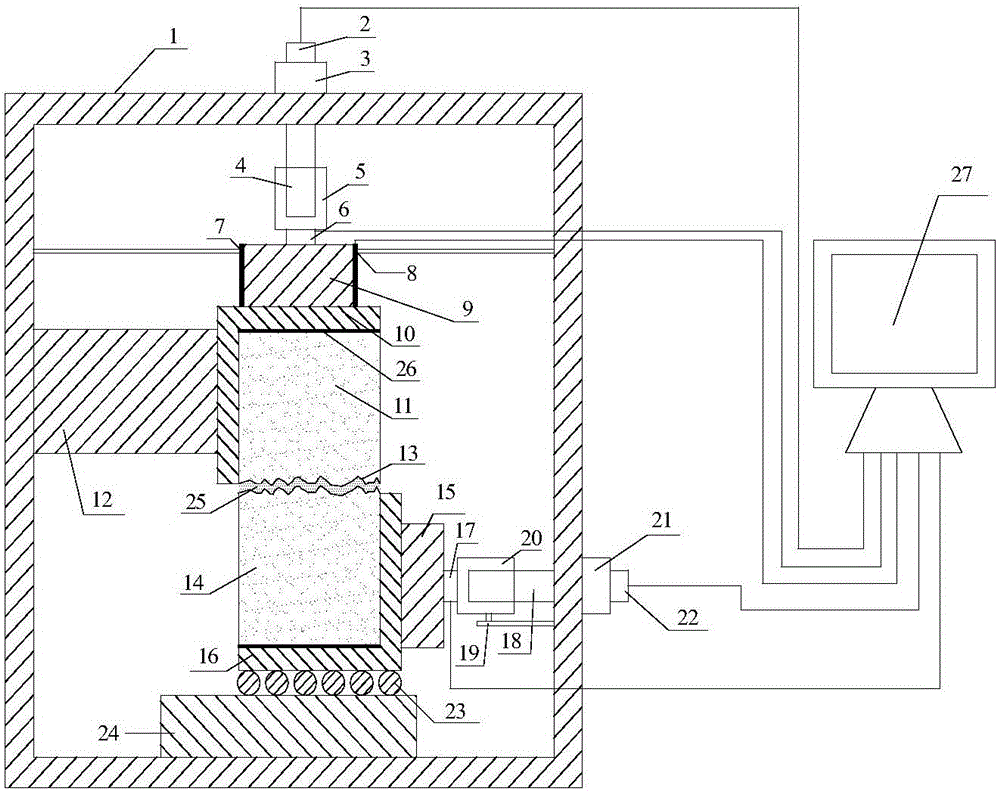

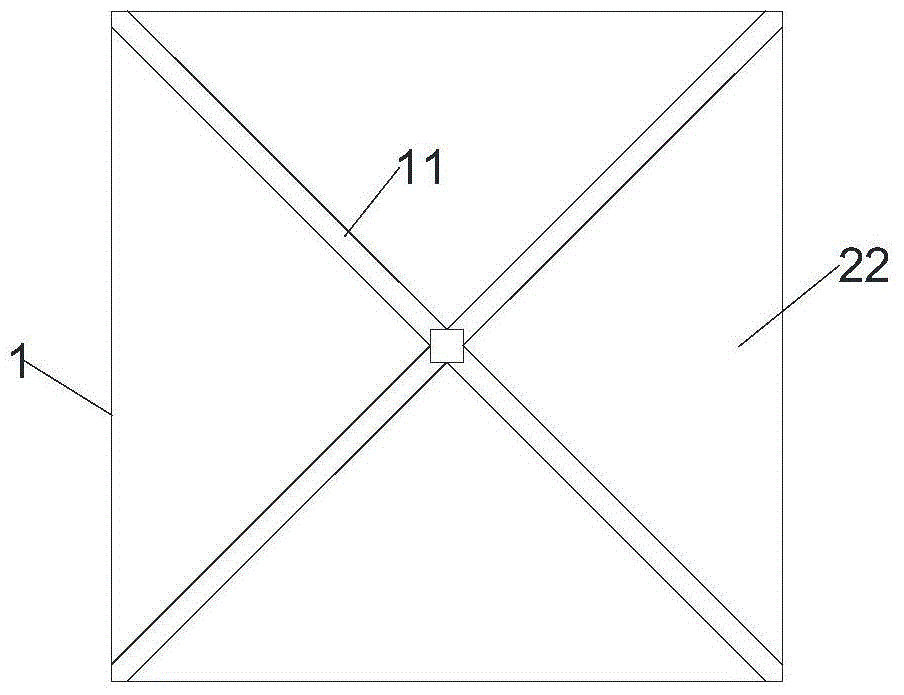

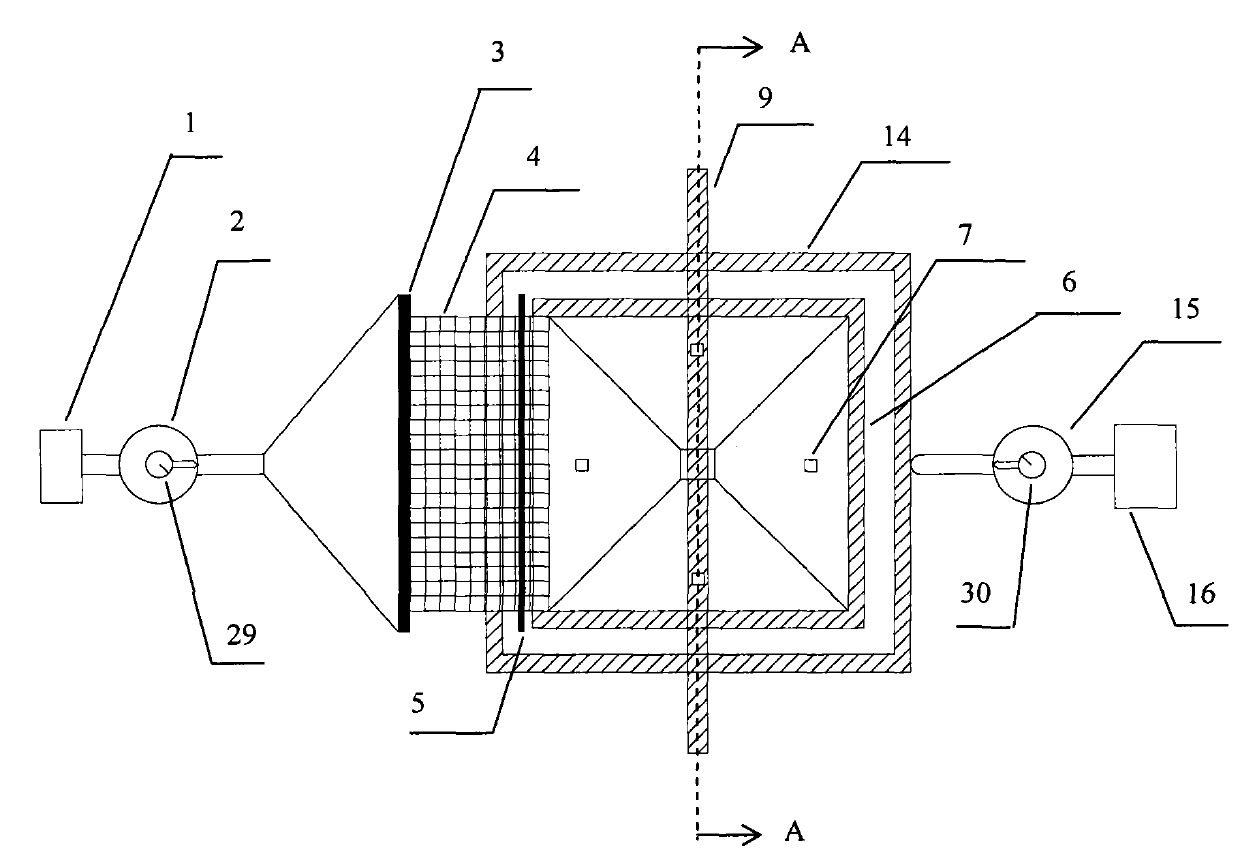

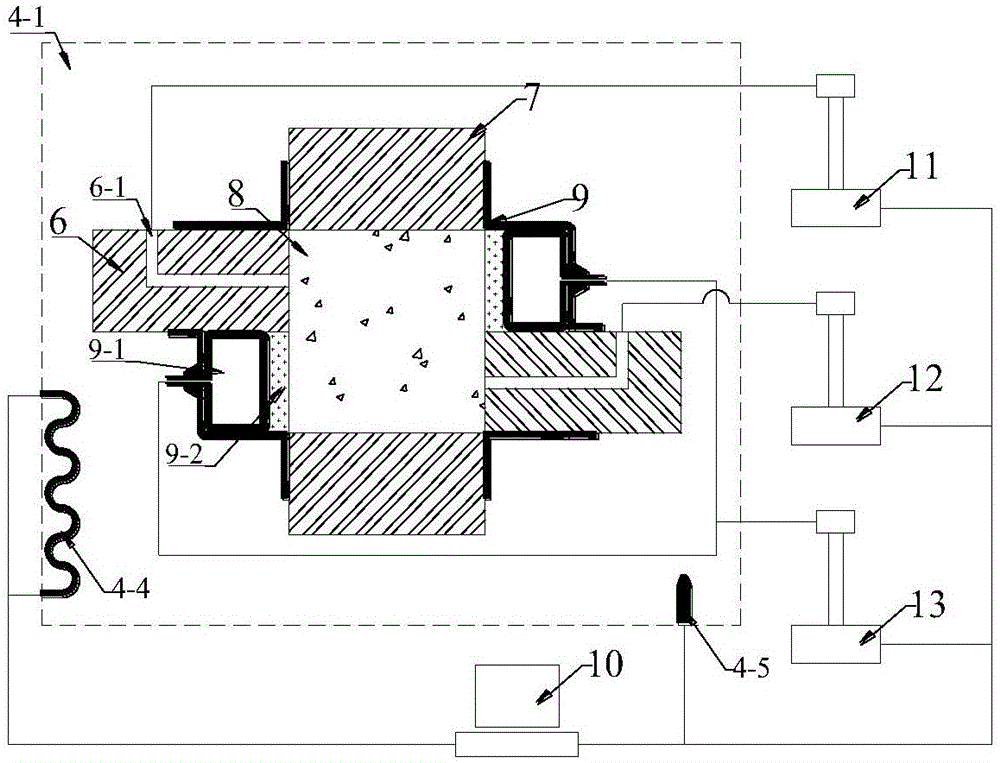

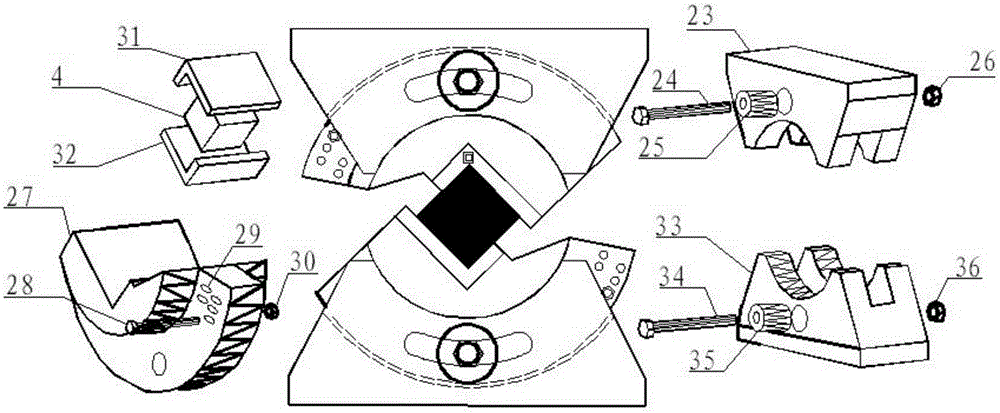

True triaxial shear rock mass shearing seepage test device suitable for high seepage pressure, and test method of test device

PendingCN106370581AImprove sealingRealize volume deformationPermeability/surface area analysisLine tubingHigh pressure

The invention discloses a true triaxial shear rock mass shearing seepage test device suitable for high seepage pressure, and a test method of the test device, and relates to a rack mechanics test technology. The device comprises a rigid frame, an oil cylinder, a pressure sensor, a high pressure cavity, a compression column, a shear plate, a normal pressure plate, a rock sample, a plastic sleeve, a computer, a fluid injection metering pump, a fluid return metering pump, a confining pressure tracking pump, an X-direction displacement sensor, a Y-direction displacement sensor and a Z-direction displacement sensor. The method comprises the steps of preparing a rock sample; assembling a composite member; placing the composite member; connecting pipelines; loading stress; checking airtightness; adjusting the stress and temperature; injecting fluid; carrying out a shearing test; unloading the stress; cleaning the device. After the device and the method are adopted, a true triaxial shear rock mass shearing seepage test can be realized under the complicated conditions of high temperature, high stress and high seepage pressure, and the sealing problem of high permeability fluid is solved during shearing; the highest seepage pressure reaches 50MPa, and the volume and pressure of seepage fluid can be accurately controlled and measured.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

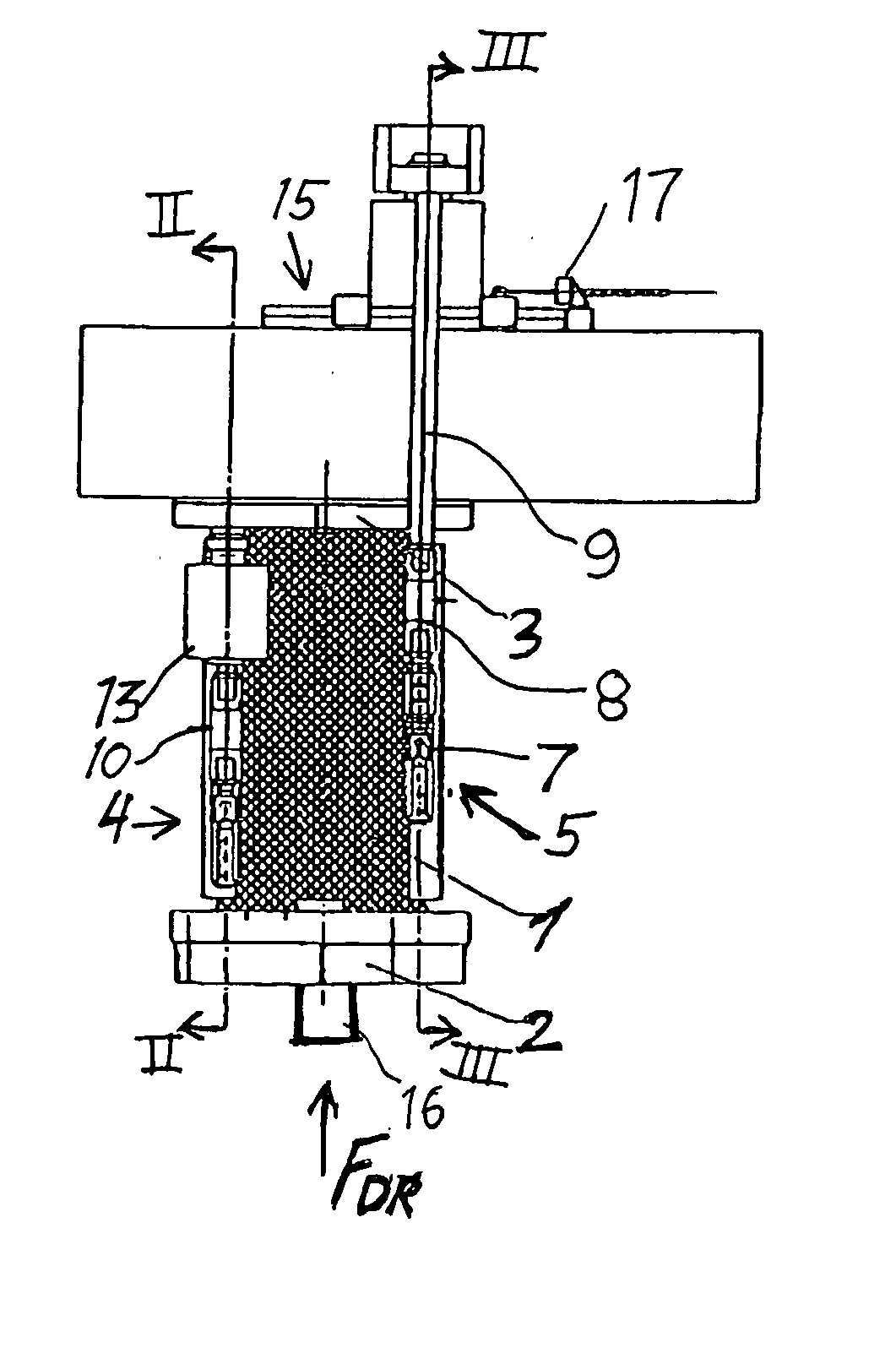

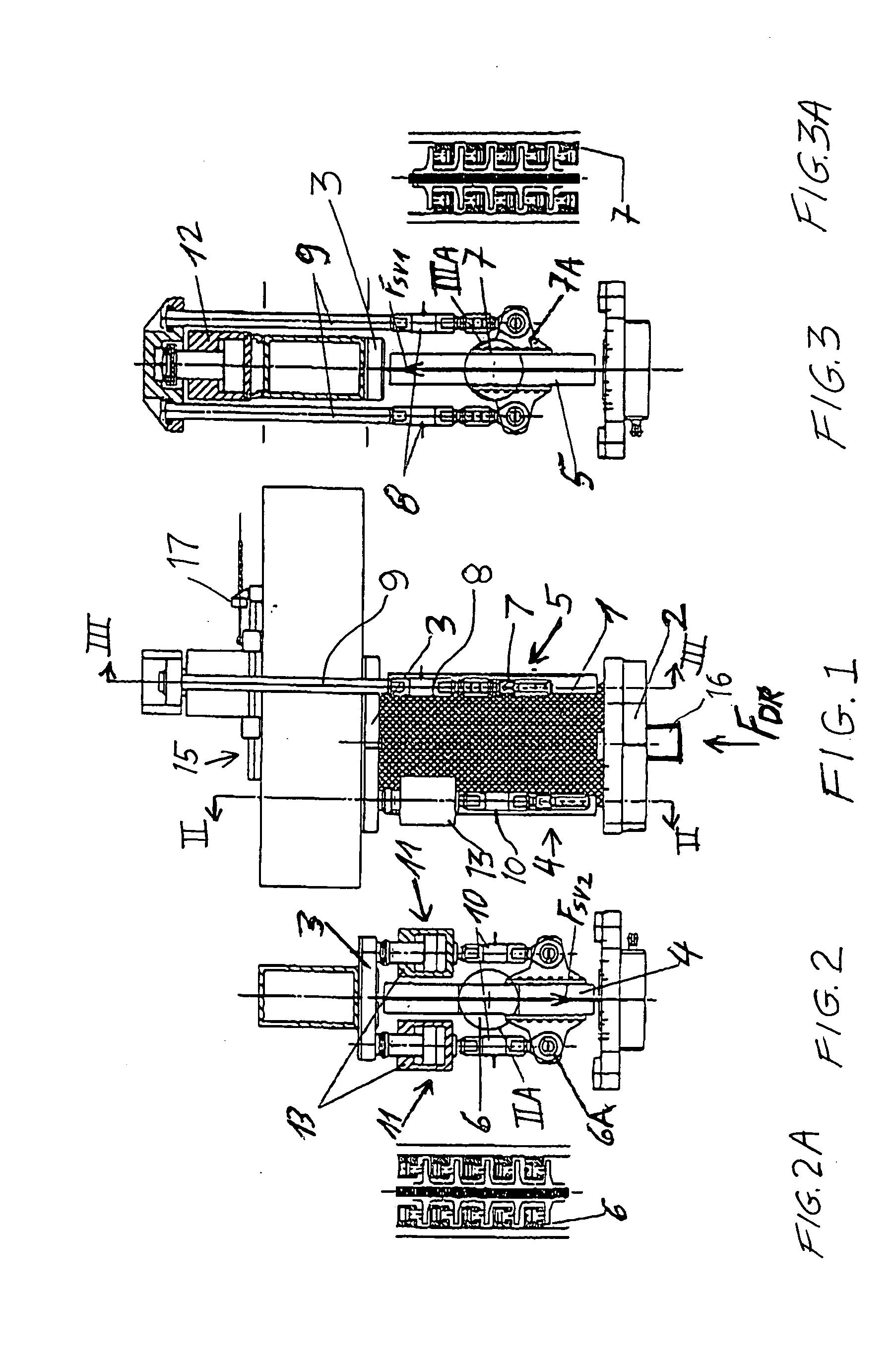

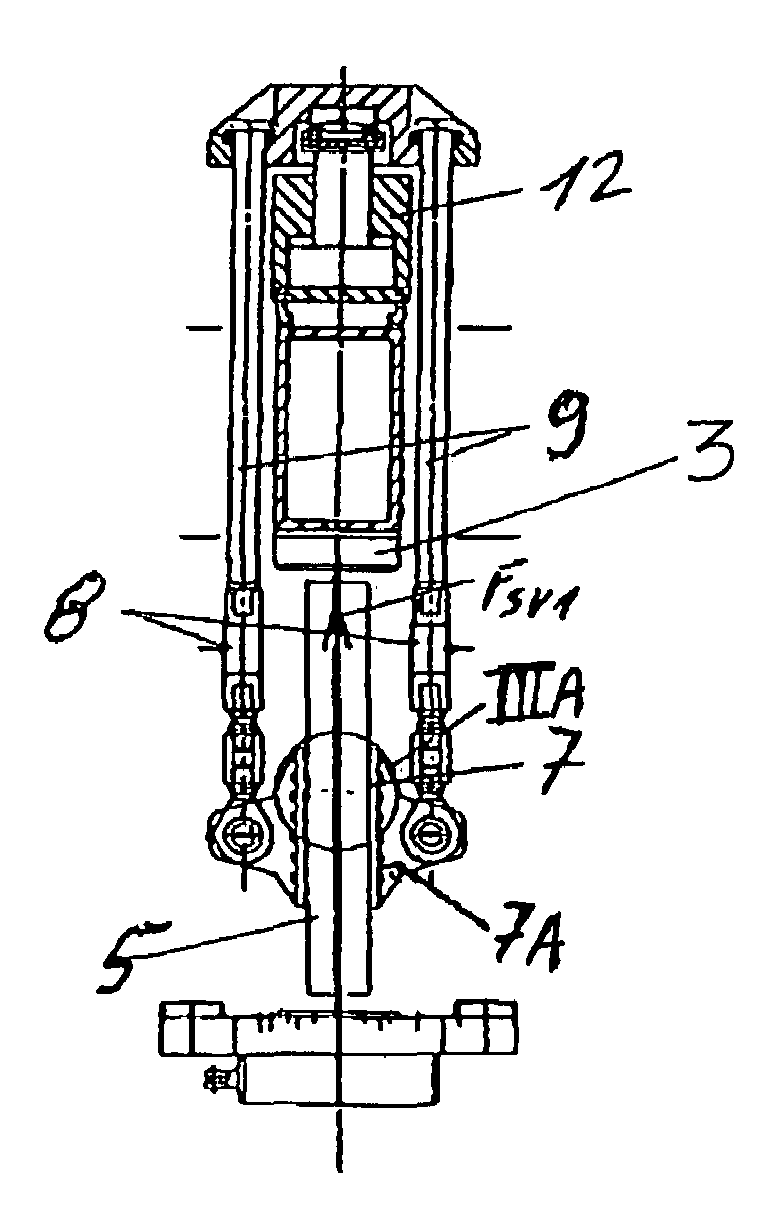

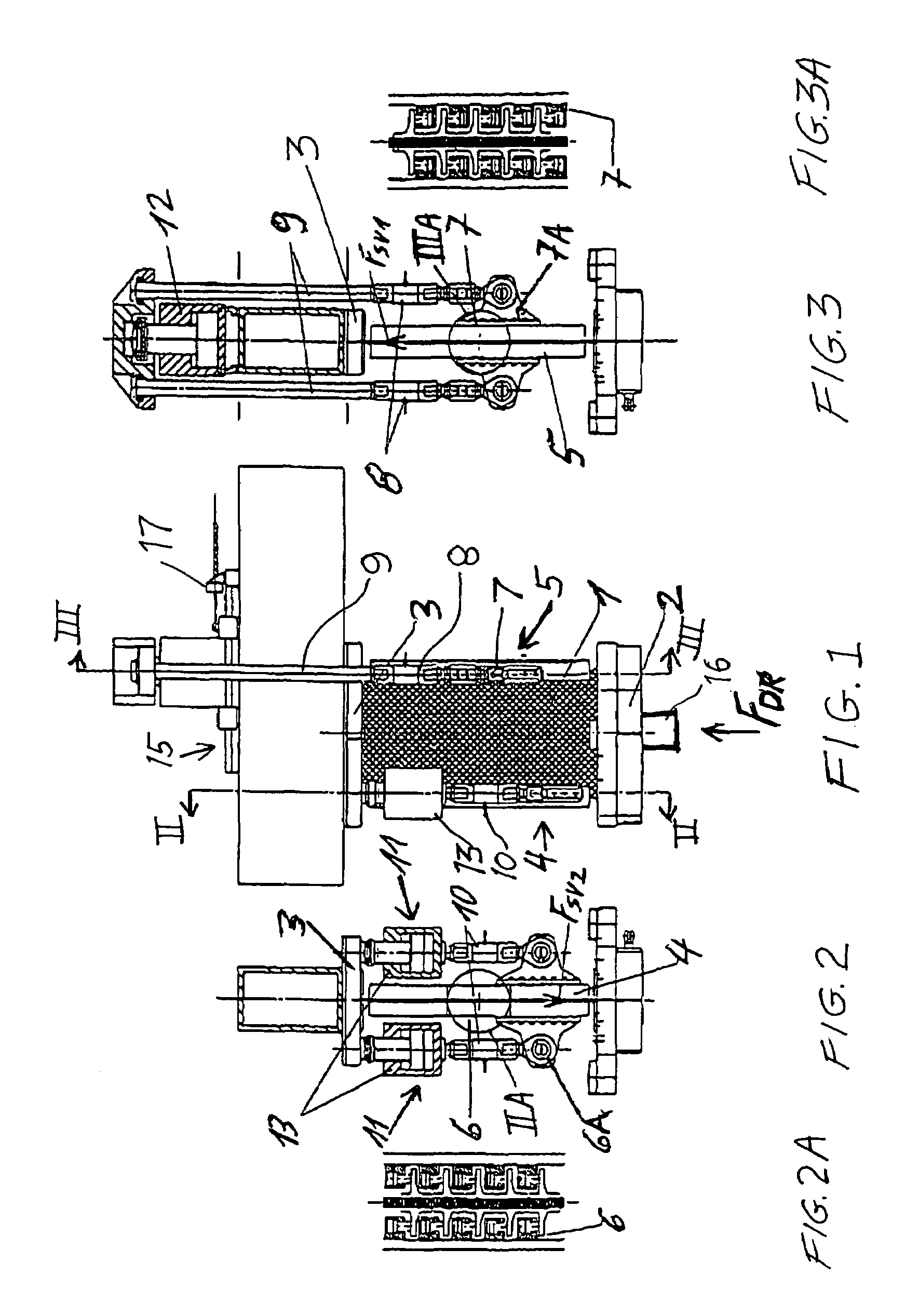

Testing apparatus for compression and shear testing of a test component such as a curved aircraft component

InactiveUS20050109118A1Convenient ArrangementMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesVertical planeEngineering

A testing apparatus receives a test component between a force introduction table and a pressure plate, which apply a compressive load to the component therebetween. First and second shear beams are secured to opposite vertical edges of the component to respectively introduce upwardly and downwardly directed shear forces into the component. The upwardly directed shear force is generated by a first hydraulic cylinder that is arranged above the pressure plate in a horizontally adjustable manner on a head frame, and that is connected to the first shear beam through two tension rod assemblies including tensile force measuring transducers. The downwardly directed shear force is generated by two second hydraulic cylinders that are arranged under the pressure plate and that are connected to the second shear beam by strut assemblies including compressive force measuring transducers. High shear loads can be applied in the same vertical plane as the compressive load.

Owner:AIRBUS OPERATIONS GMBH

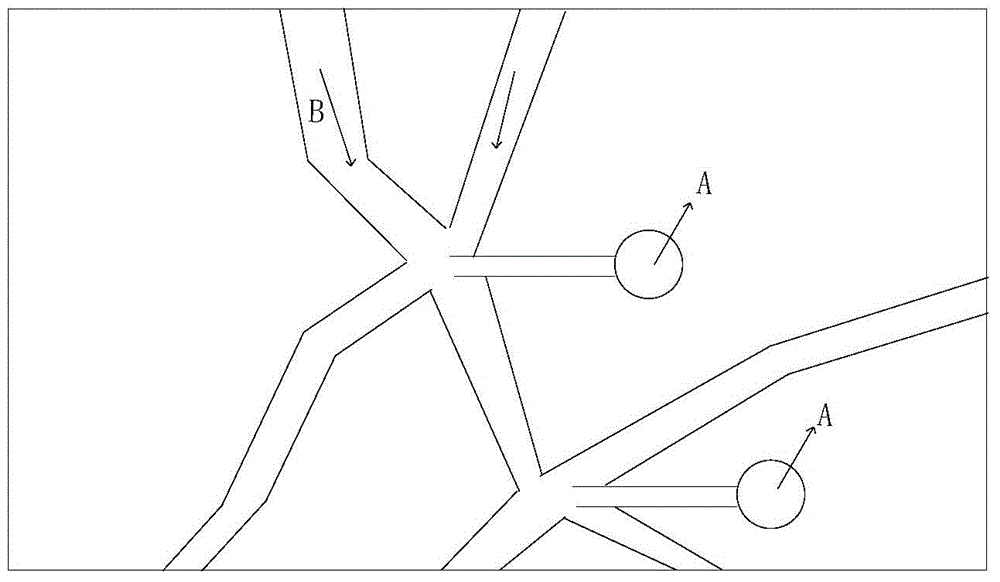

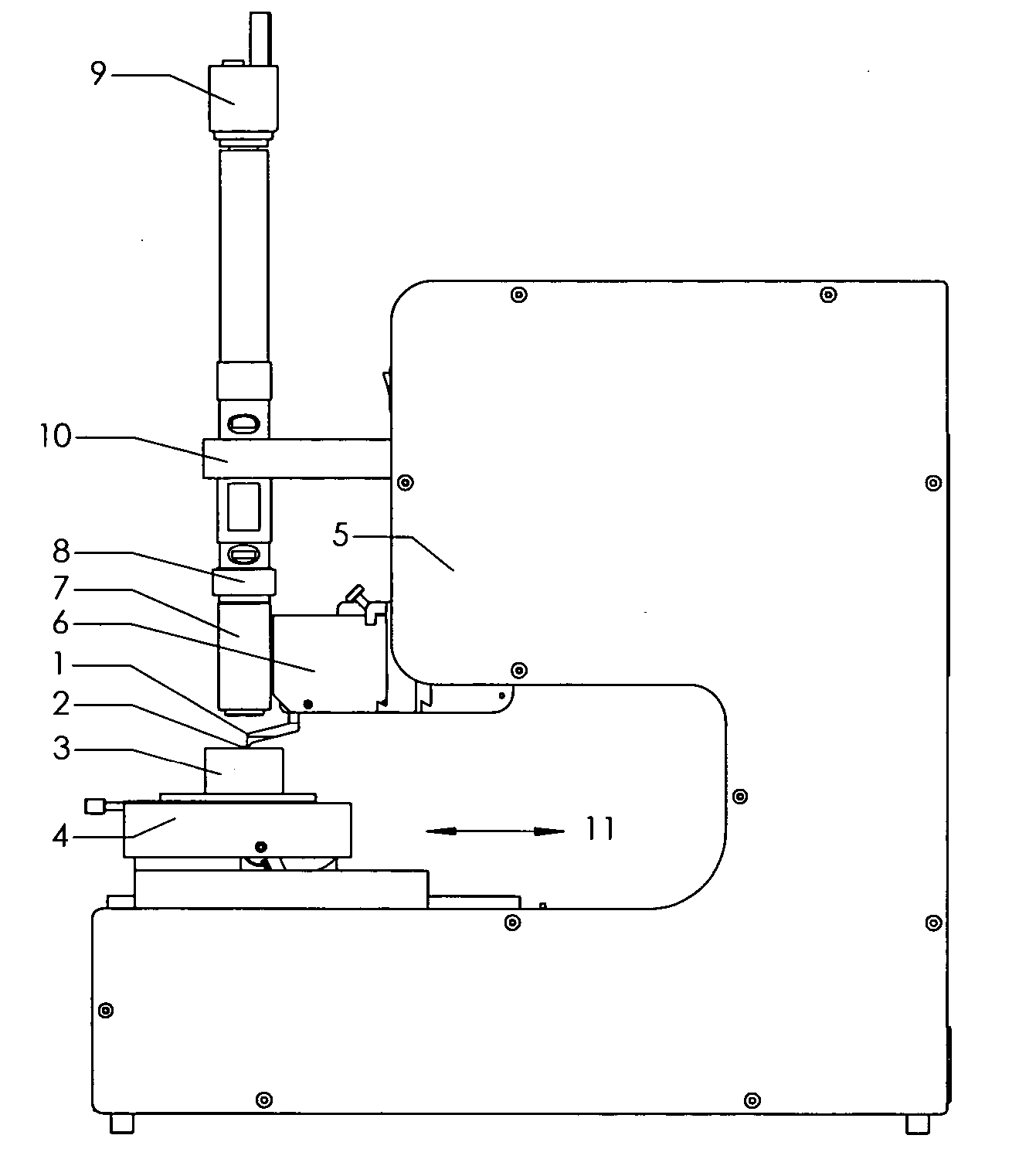

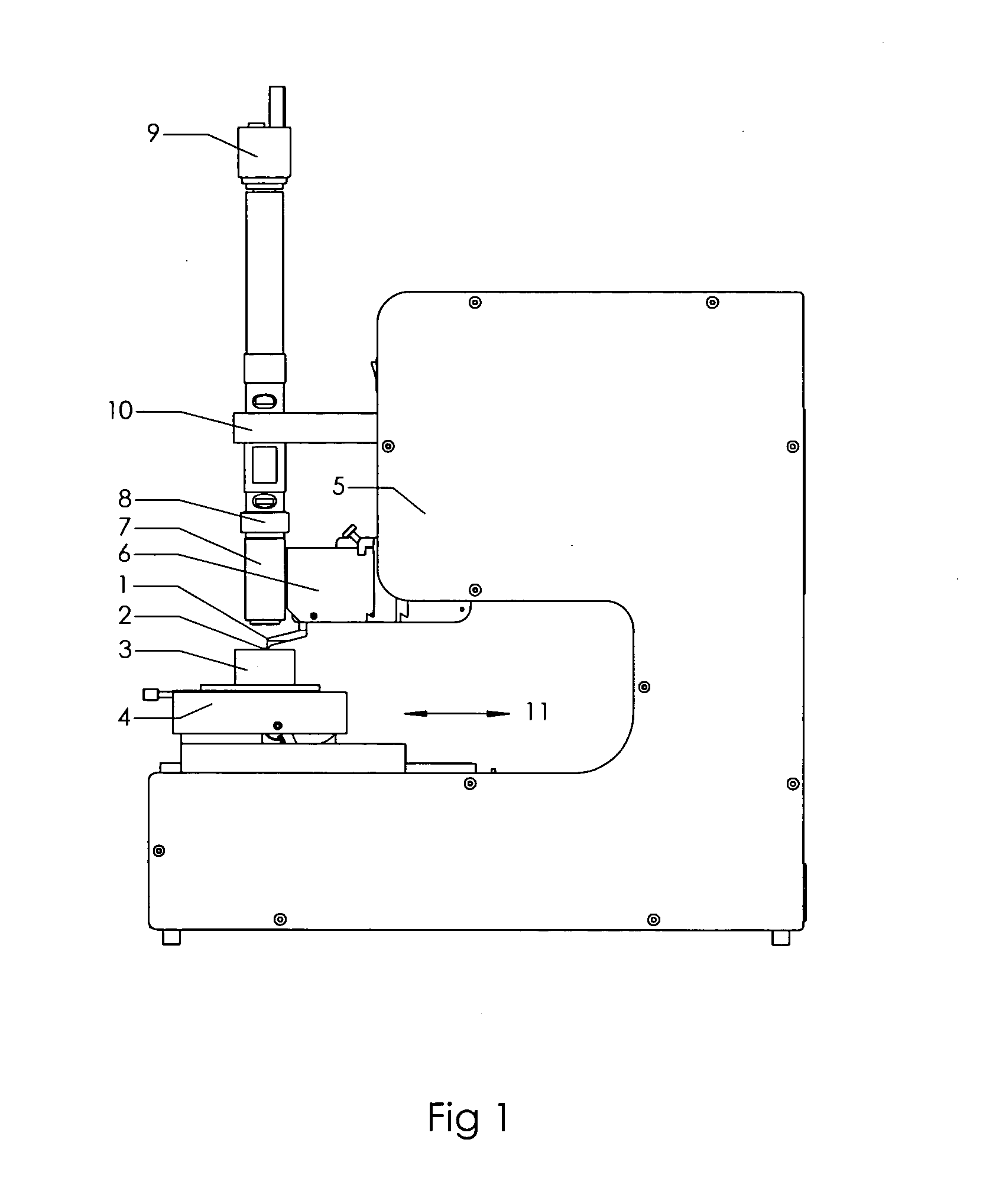

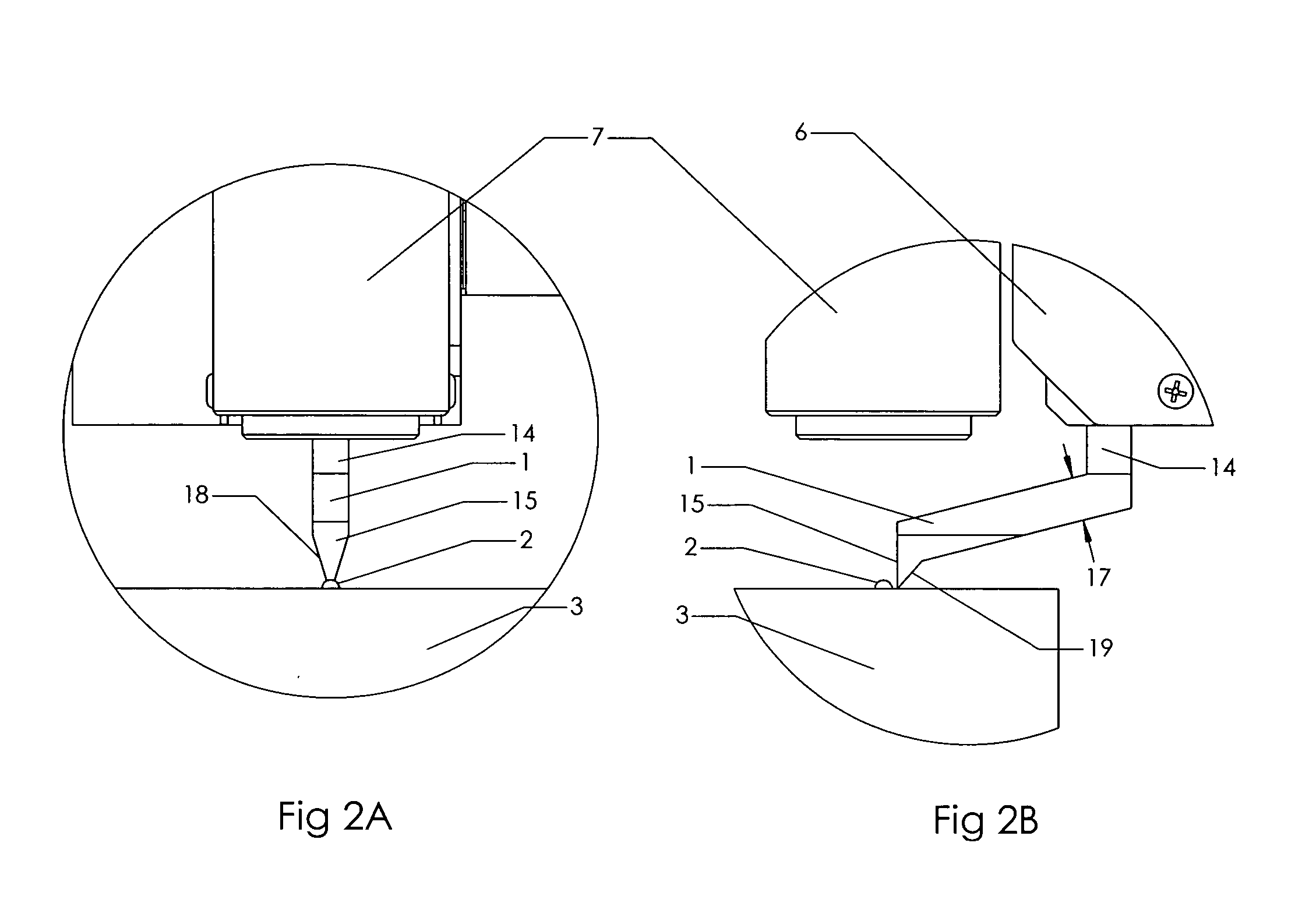

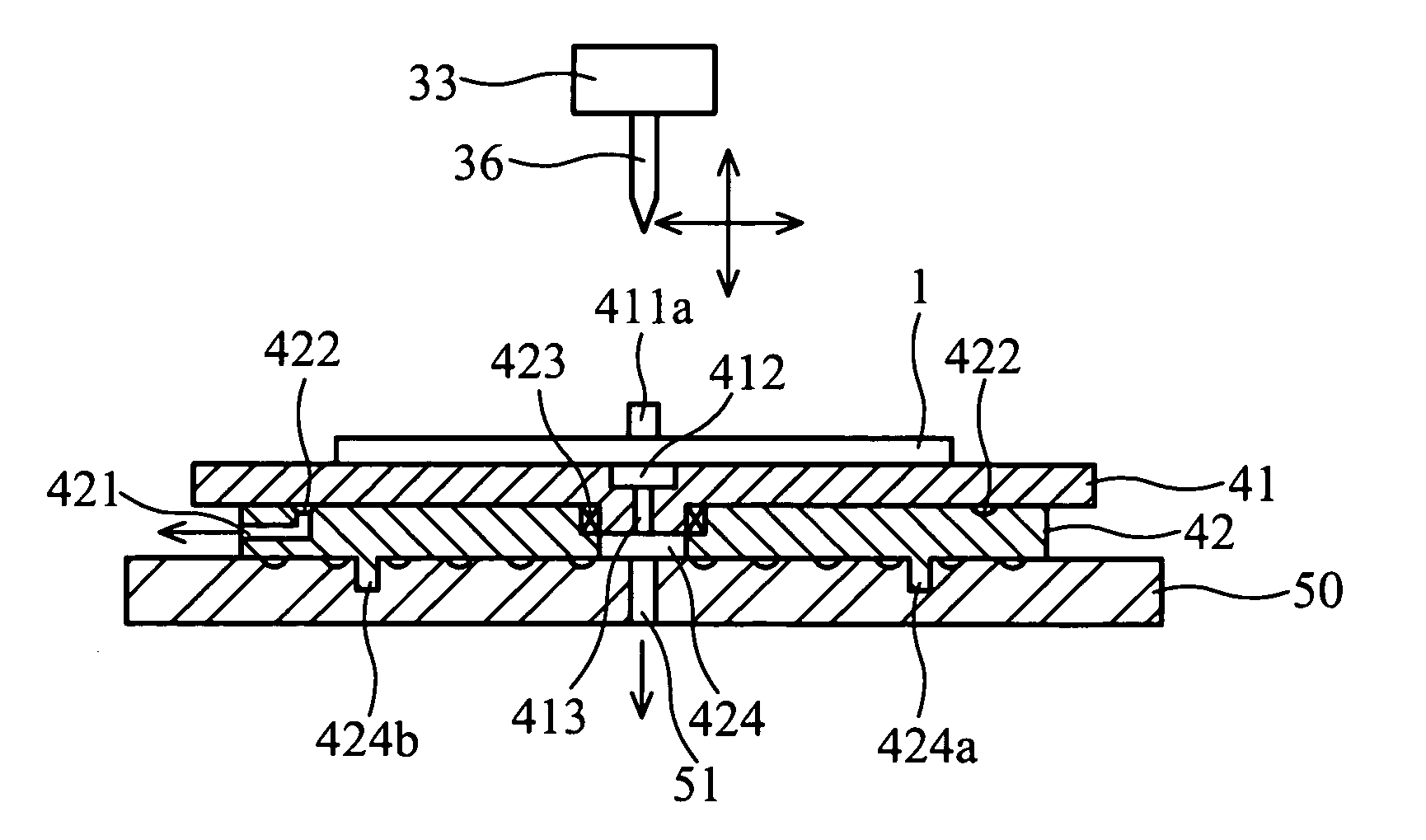

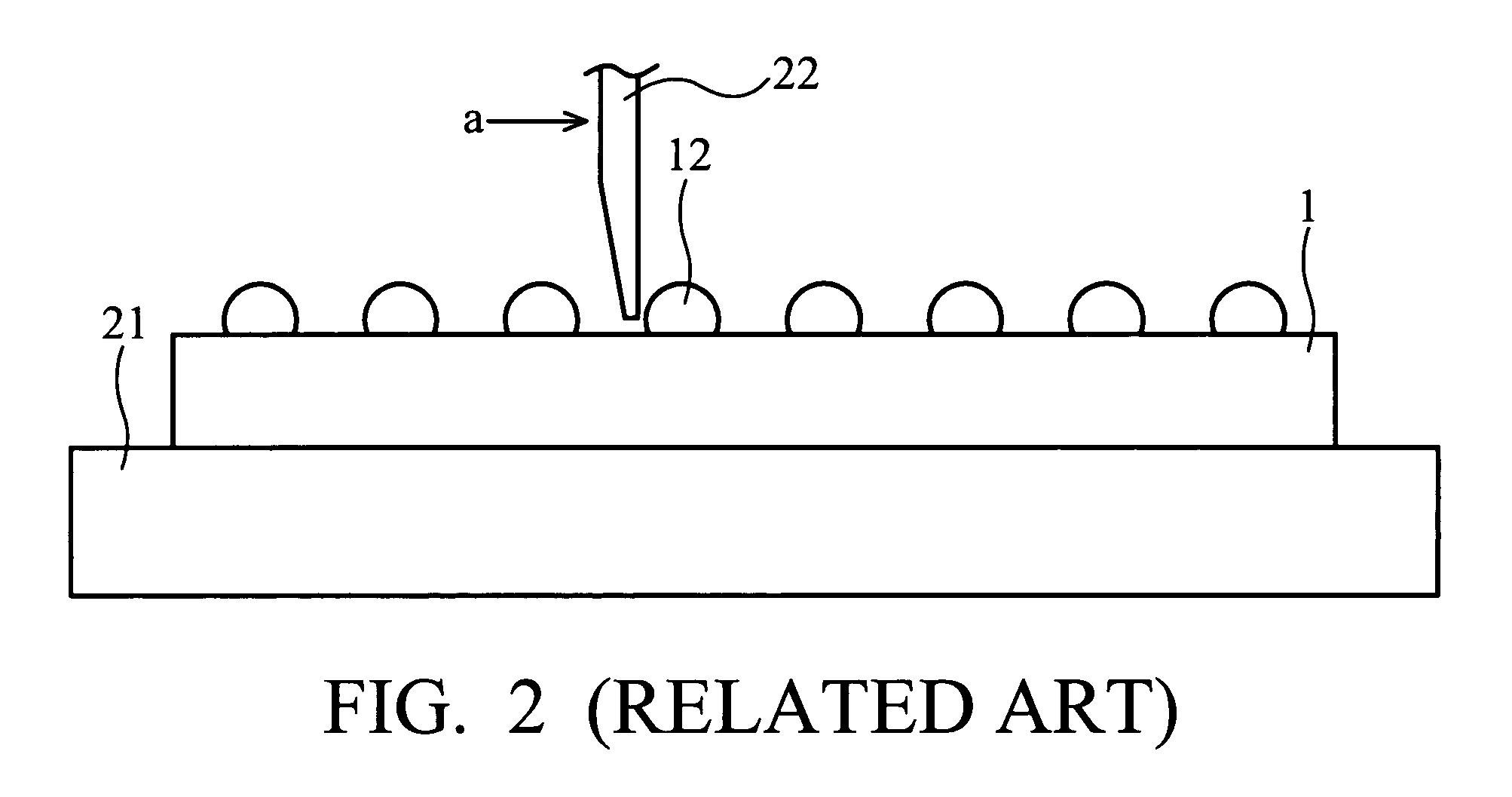

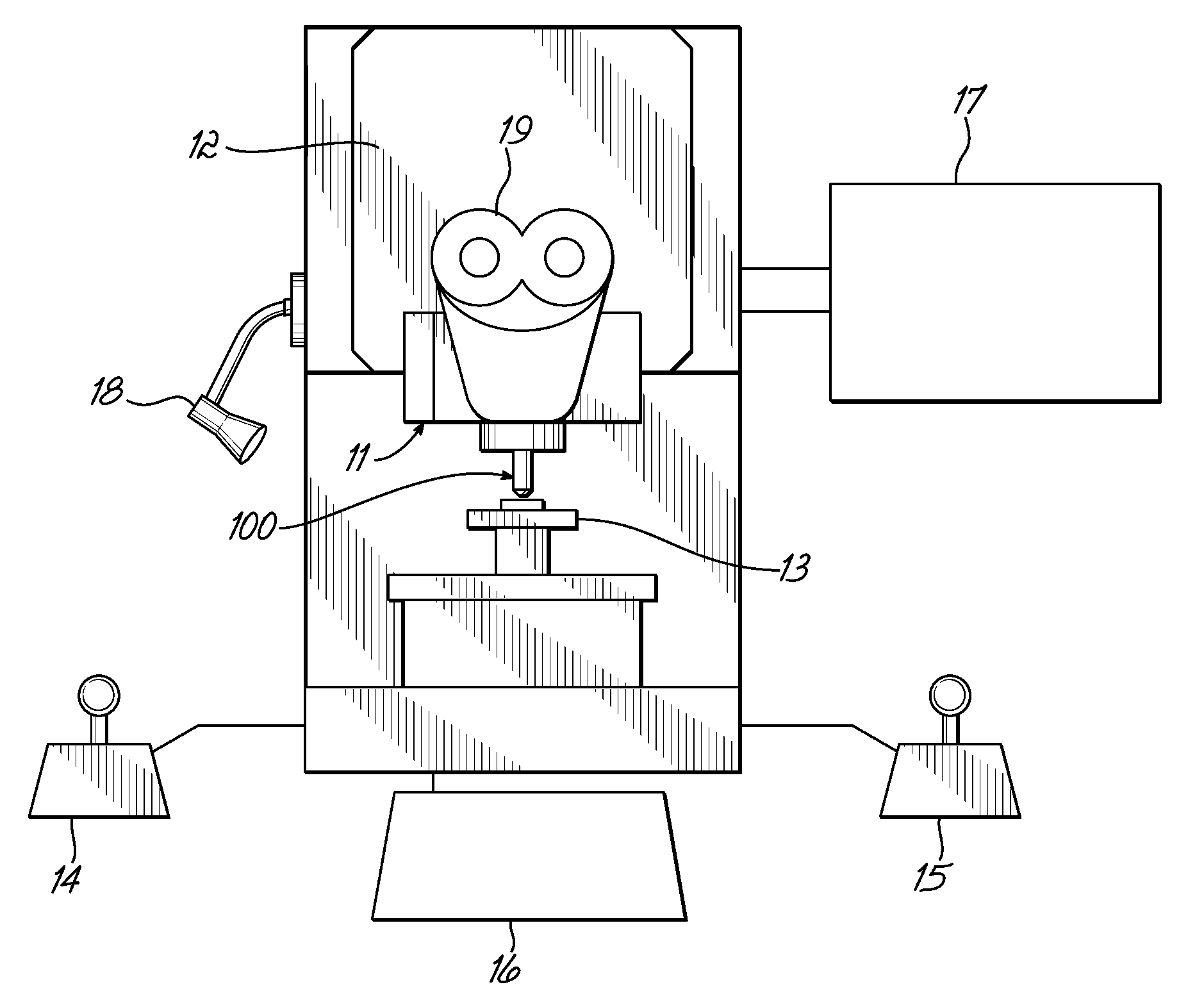

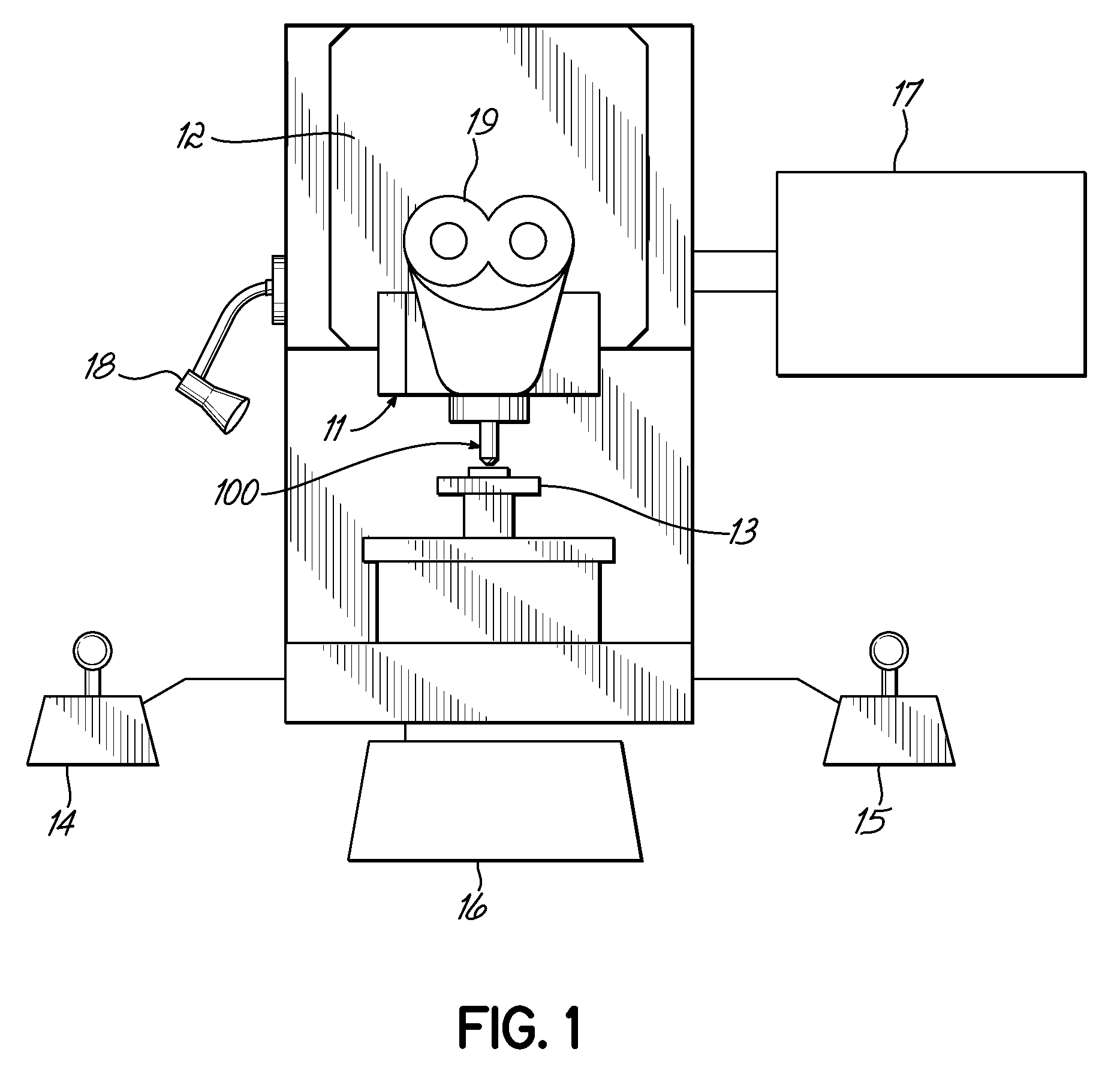

Bond test systems with offset shear tool

A tool 1 to be installed into a test module 6 of a Bond Test System 5 to provide the capability to directly view a bond shear test. This capability enables a vision system camera 9 coupled to magnifying optics 8 to provide real time viewing, image capture, and vision guided automation for more effective analysis, additional analytic capability and improved ergonomics. This greatly enhances the utility of the shear test function of the Bond Test System 5.

Owner:COX MALCOLM

Annular shearing experiment equipment and testing method

InactiveCN105699189AGood for studying the influence of strength parametersGood for research impactMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesVertical vibrationPore water pressure

The invention provides an annular shearing experiment equipment and a testing method, the annular shearing experiment equipment includes a support seat, a shear box assembly located on the support seat, and a load applied to soil samples in the shear box assembly The loading device, the loading device includes a vertical vibration loading device and a horizontal shear vibration loading device, and the annular shear experimental equipment further includes a load control device for controlling the loading of the vertical vibration loading device and / or the horizontal shear vibration loading device. device. The vertical vibration loading device and / or the horizontal shear vibration loading device can apply vibration loads of different frequencies and amplitudes, which is beneficial to study the influence of dynamic loads on soil strength parameters, more conducive to simulating the actual stress situation, and conducive to revealing The stress changes, pore water pressure changes, local soil damage and liquefaction phenomena occurred during the shear test of the soil under the action of vibration loads, and then reveal the occurrence and movement mechanism of geological disasters such as landslides from the mechanical properties.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Shearing testing device and operation method thereof

ActiveCN104677750ANeutral goodSimple structureMaterial strength using steady shearing forcesEngineeringTest element

The invention discloses a shearing testing device and an operation method thereof. The shearing testing device comprises a fixture base, guide rails, a movable fixture, a fixed fixture, a center-aligning block, a first aligning plate, a second aligning plate, a wedge-shaped block, a first compressing block, a second compressing block and a fixture leveling plate, wherein the two guide rails are longitudinally fixed on the fixture base side by side; symmetrical bosses are arranged at two sides of the movable fixture, and are provided with through holes; the movable fixture sleeves the guide rails via the through holes; the top of the center-aligning block is provided with a bulge matched with a V-shaped notch of a test element; the first aligning block and the second aligning block are both hexahedron square blocks with bulged steps; the first compressing block is positioned below the upper clamping surface of the fixed fixture and is connected with the upper clamping surface; the second compression block is positioned below the upper clamping surface of the movable fixture and is connected with the upper clamping surface. According to the invention, the precise alignment of the shearing test element at the thickness direction and length direction can be ensured, and the clamping operation is very convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Compression-shear testing apparatus for rock in dry-wet cyclic process

ActiveCN105181483ASimple structureEasy to operateMaterial strength using steady shearing forcesCyclic processEngineering

The invention belongs to the field of geotechnical engineering, and in particular relates to a compression-shear testing apparatus for a rock in a dry-wet cyclic process. The apparatus comprises an angle-variable compression-shear unit, and a compression machine for vertically applying load onto the angle-variable compression-shear unit; the apparatus also comprises a reservoir, water injection equipment for carrying out moisture saturation treatment on a rock sample in the angle-variable compression-shear unit, and heating equipment for carrying out hot-gas drying treatment on the rock sample in the angle-variable compression-shear unit. The angle-variable compression-shear unit is located in the reservoir, and the reservoir is communicated with the water injection equipment and the heating equipment. By adopting the compression-shear testing apparatus, the integration of rock sample dry-wet cyclic treatment and a shear test is realized, and the apparatus has the advantages of simple structure, convenient operation, low cost, wide application range and long service life; the rock samples in different states after different dry-wet cyclic times can be accurately simulated, shear test research is carried out on the rock samples, and moreover, failure load and displacement of the rock samples in the vertical direction in the shear test process can be recorded in real time.

Owner:ANHUI INST OF BUILDING RES & DESIGN

On-site large-scale coarse-grained soil direct shear testing equipment

InactiveCN103884607AEasy to carryMaterial strength using steady shearing forcesEngineeringUltimate tensile strength

The invention discloses on-site large-scale coarse-grained soil direct shear testing equipment. The on-site large-scale coarse-grained soil direct shear testing equipment comprises a counter-force device, a vertical loading system, a horizontal loading system, a testing system and a shear box; machine excavation and hand excavation are combined with trimming to prepare a wedge-shaped undisturbed soil weir (or stereobate) with required size, counter force is provided through bearing strength of a surrounding rock, and a bulb flat-pushing method is adopted to perform a stress type quick shear test on on-site coarse-grained soil under a natural moisture-containing status. The on-site large-scale coarse-grained soil direct shear testing equipment is reasonable in design, simple in structure and convenient to operate, can completely obtain real and reliable shearing strength resisting parameters of the undisturbed coarse-grained soil. The on-site large-scale coarse-grained soil direct shear testing equipment has the beneficial effects that the equipment is suitable for testing on the undisturbed coarse-grained soil to obtain the real and reliable shearing strength resisting parameters, the testing result can reflect the on-site soil status, and the equipment has the characteristics of integral detachability, convenience in carrying and wide using range.

Owner:黄斌

Soil body shearing testing device and soil body shearing method

InactiveCN103616301AAccuracy is easy to guaranteeEasy to operateMaterial strength using steady shearing forcesSoil scienceTest sample

The invention discloses a soil body shearing testing device. The soil body shearing testing device comprises a special cutting ring, a pressurizing system and a mini-type injection instrument. The shearing testing device is characterized in that a plurality of side holes are formed in the periphery of the special cutting ring; the pressurizing system is composed of a pressurizing top cover, a lever and a weight; the mini-type injection instrument is provided with a conical probe, a reading window and the like. The invention discloses a soil body shearing testing method. According to the brand-new shearing testing device and shearing testing method for determining the shearing strength index of the soil body, the device is simple and convenient to operate; the shearing strength index of the soil body can be determined by only using one test sample and the uniformity of the test sample is guaranteed; the time for injecting the soil body by virtue of the mini-type injection instrument is short and the test sample can be controlled well to discharge water; all the characteristics are good for the accuracy of testing results; the soil body shearing testing device and the soil body shearing testing method are suitable for various civil engineering construction fields.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

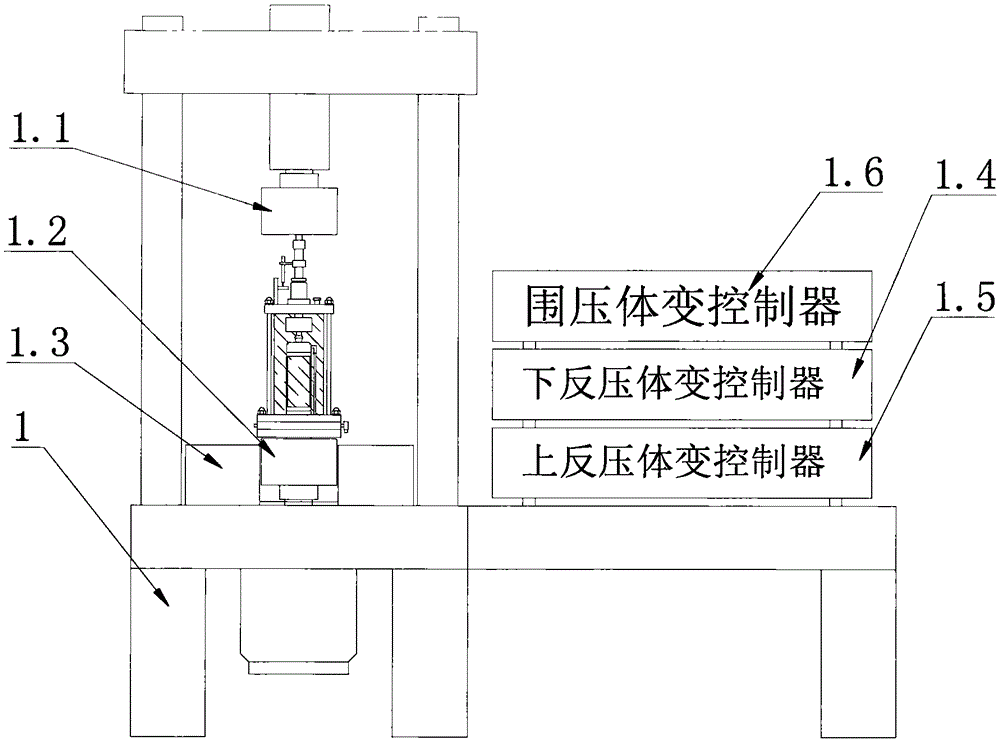

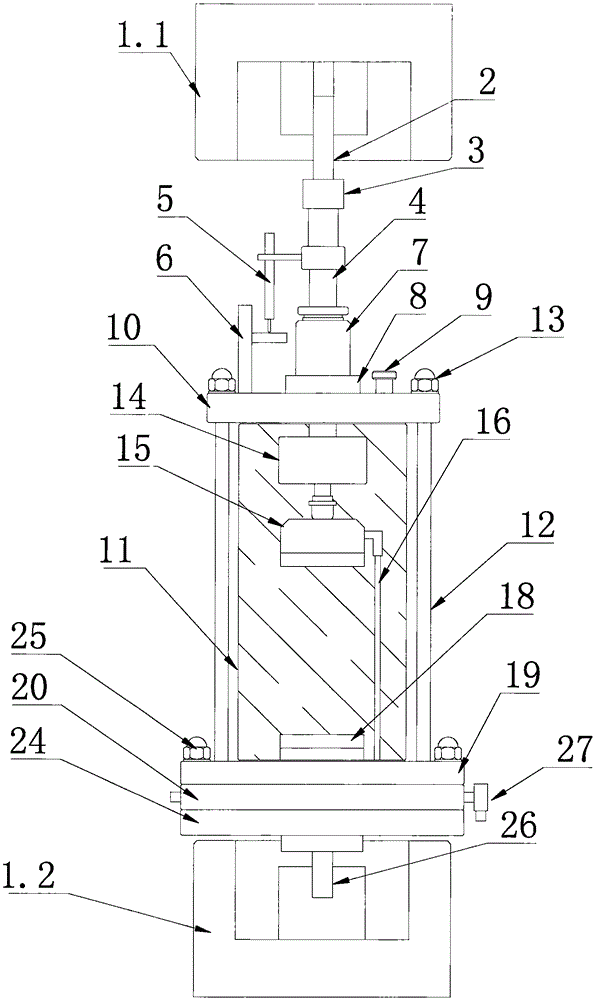

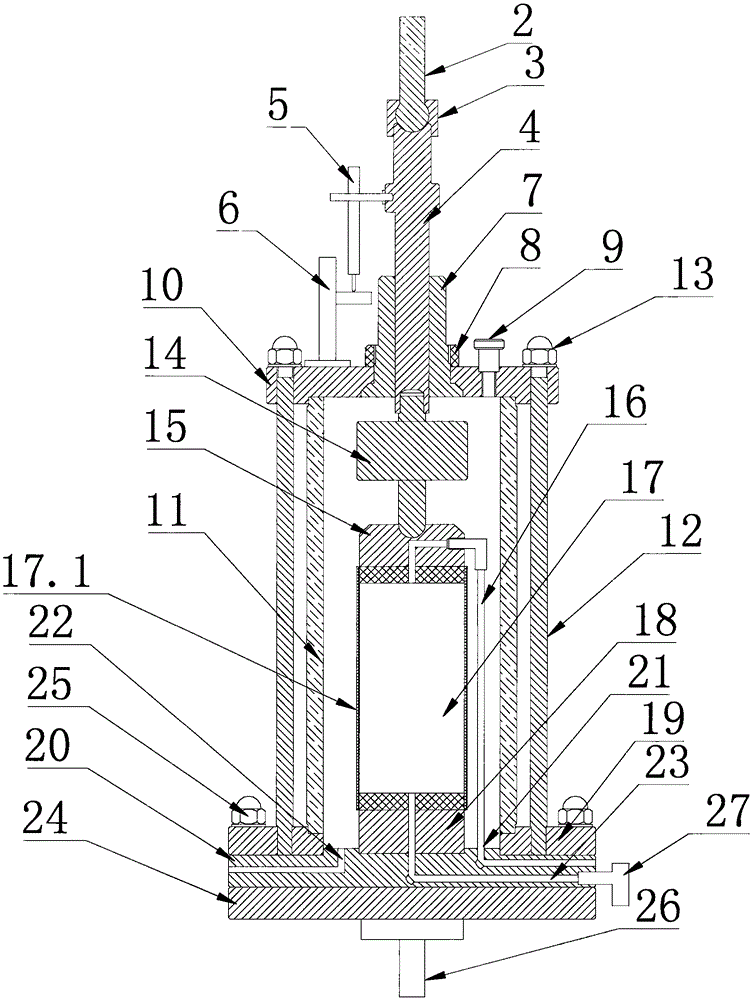

Soil engineering triaxial shear test equipment based on MTS electro-hydraulic servo tester

InactiveCN105527175ASimple and fast operationHigh degree of automationMaterial strength using steady shearing forcesTriaxial shear testElectro hydraulic

The invention discloses soil engineering triaxial shear test equipment based on an MTS electro-hydraulic servo tester. The soil engineering triaxial shear test equipment comprises the MTS electro-hydraulic servo tester, wherein a soil engineering triaxial shear testing device is mounted on an MTS electro-hydraulic servo tester upper chuck and an MTS electro-hydraulic servo tester lower chuck of the MTS electro-hydraulic servo tester. The soil engineering triaxial shear test equipment has the following technical effects as follows: an accurate and stable force source is provided through sufficient utilization of the MTS electro-hydraulic servo tester, perpendicular pressurization on a sample is realized through an upper fixing rod and an axial drive rod, increasing and stabilizing of the confining pressure and the back pressure of the sample are realized through matching of a fed liquid of a liquid feeding port and a pressure volume controller, finally, back pressure saturation, isotropy and anisotropy of consolidation loading and unloading circulation, K0 solidification, creep solidification and dynamic and static triaxial shear test of the sample can be performed on the sample through close matching of components, the test process is controlled through software, the operation is simple and convenient, the automation degree is high, and the soil engineering triaxial shear test equipment is suitable for research, popularization and application; the equipment is simple and compact in structure, convenient to assemble, low in cost, high in measurement accuracy and good in stability and occupies small space.

Owner:XIANGTAN UNIV

Apparatus for shear testing bonds on silicon substrate

InactiveUS6912915B2Eliminate needSemiconductor/solid-state device testing/measurementForce measurementPull forceComputer module

Owner:TAIWAN SEMICON MFG CO LTD

Testing apparatus for compression and shear testing of a test component such as a curved aircraft component

InactiveUS7155982B2Convenient ArrangementMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesHydraulic cylinderVertical plane

A testing apparatus receives a test component between a force introduction table and a pressure plate, which apply a compressive load to the component therebetween. First and second shear beams are secured to opposite vertical edges of the component to respectively introduce upwardly and downwardly directed shear forces into the component. The upwardly directed shear force is generated by a first hydraulic cylinder that is arranged above the pressure plate in a horizontally adjustable manner on a head frame, and that is connected to the first shear beam through two tension rod assemblies including tensile force measuring transducers. The downwardly directed shear force is generated by two second hydraulic cylinders that are arranged under the pressure plate and that are connected to the second shear beam by strut assemblies including compressive force measuring transducers. High shear loads can be applied in the same vertical plane as the compressive load.

Owner:AIRBUS OPERATIONS GMBH

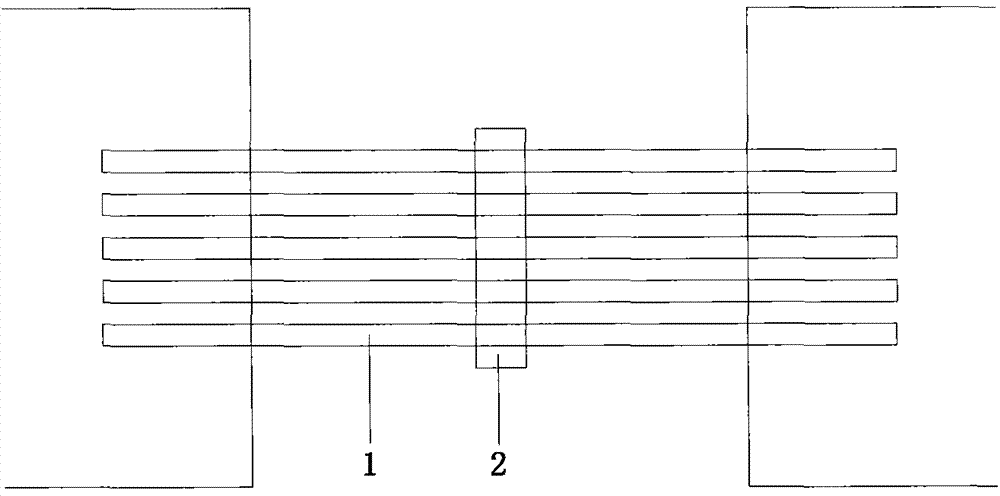

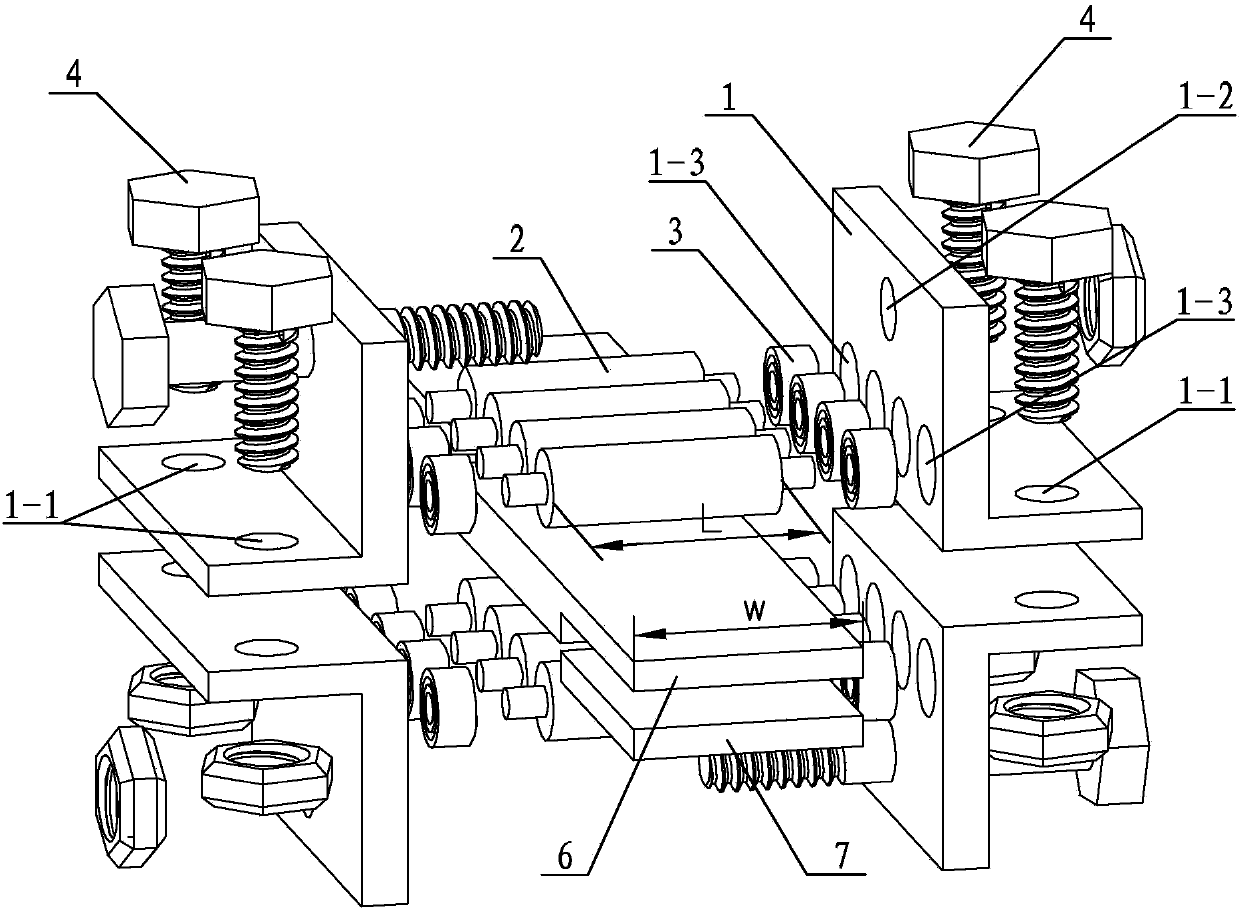

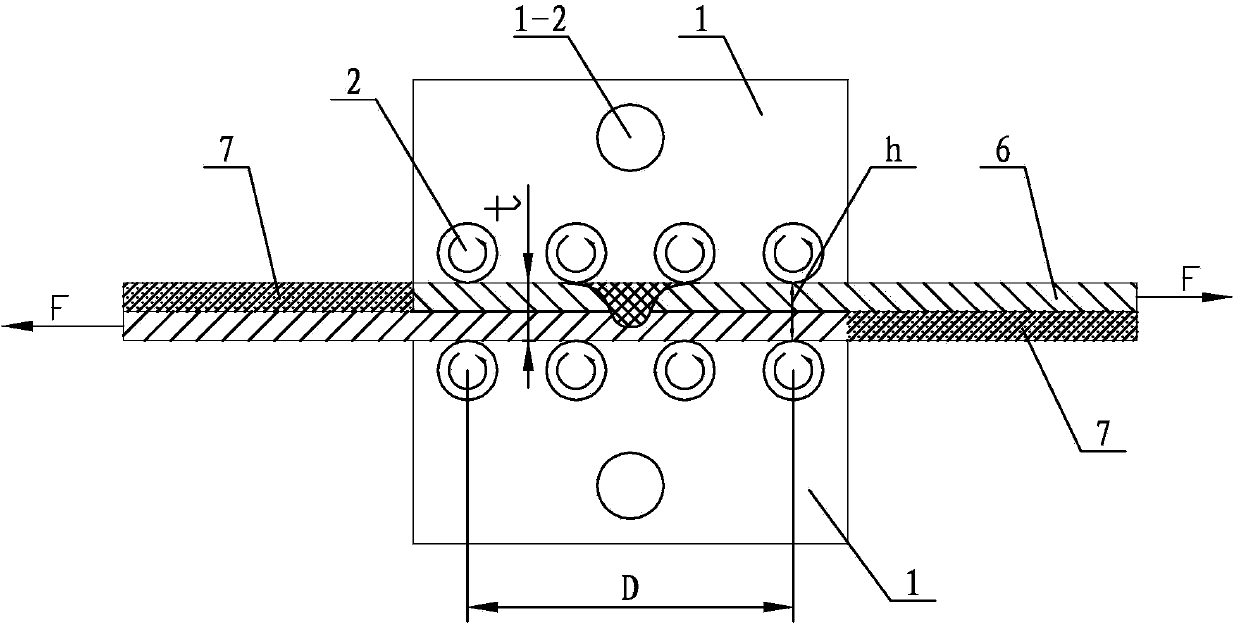

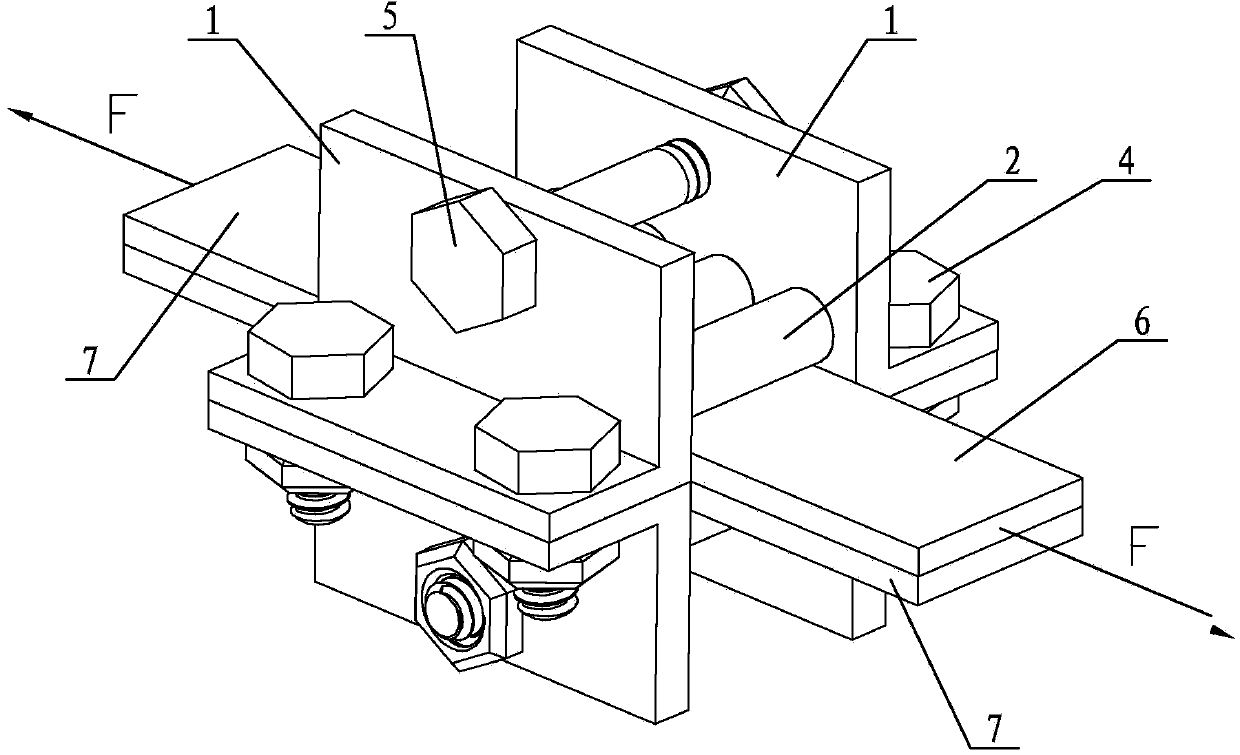

Fixture and method for measuring maximum tensile and shearing force of lap joint of friction stir welding

ActiveCN103592181AGuaranteed pure tensile shear failureEliminate additional bending momentsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFriction weldingLap joint

The invention provides a fixture and a method for measuring the maximum tensile and shearing force of a lap joint of friction stir welding to overcome the problem that additional bending moment influences measurement results of the maximum tensile and shearing force of a lap joint of friction stir welding in a traditional tensile and shearing test. According to the fixture, four bearing installing holes are arranged along a same horizontal line; eight rollers are arranged in two layers, each layer consisting of four parallely arranged rollers; the end parts of each roller is mounted in a corresponding bearing installing hole through a positioning bearing. The method comprises the following steps: 1, allowing the distance between axle centers of two rollers located at two outermost sides of each layer of rollers to be 10 to 20 times thickness of the lap part of a test piece for tensile and shearing testing; 2, placing the test piece for tensile and shearing testing between the upper layer of rollers and the lower layer of rollers; and 3, clamping the assembled test piece for tensile and shearing testing, the fixture and cushion blocks on a tensile and shearing testing machine, carrying out tensile and shearing testing on the test piece for tensile and shearing testing at a loading speed of 0.5 to 1.5 mm / min and recording a maximum tensile and shearing test load F. The fixture and the method provided by the invention are used for measuring the maximum tensile and shearing force of the lap joint of friction stir welding.

Owner:HARBIN INST OF TECH

Composite interlaminar shear performance testing method

ActiveCN102680330AReduce finishing linksEasy to operatePreparing sample for investigationMaterial strength using steady shearing forcesInterlaminar shearComposite laminates

The invention belongs to the technical field of composites and relates to a composite interlaminar shear performance testing method. The testing method comprises two steps, namely the preparation of a test piece and the preparation of a testing device. In the step of preparing the test piece in the testing method disclosed by the invention, a common ply splicing and laying technology of a composite laminated plate is utilized, thus the operation is convenient, and the precision is high. When the manufacturing of the composite laminated plate is completed, the manufacturing of the test piece is completed, thus a fine processing link of the test piece is reduced, and the cost can be reduced by above 70%. The interlaminar shear testing method is simple to operate; and by adopting the interlaminar shear testing method, the damages of the test piece between designated tested layers can be ensured, the generation of pure shear damages between the tested layers can be ensured, the composite interlaminar shear performance can be precisely tested, and the testing method is suitable for composite laminated structures in various thicknesses.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

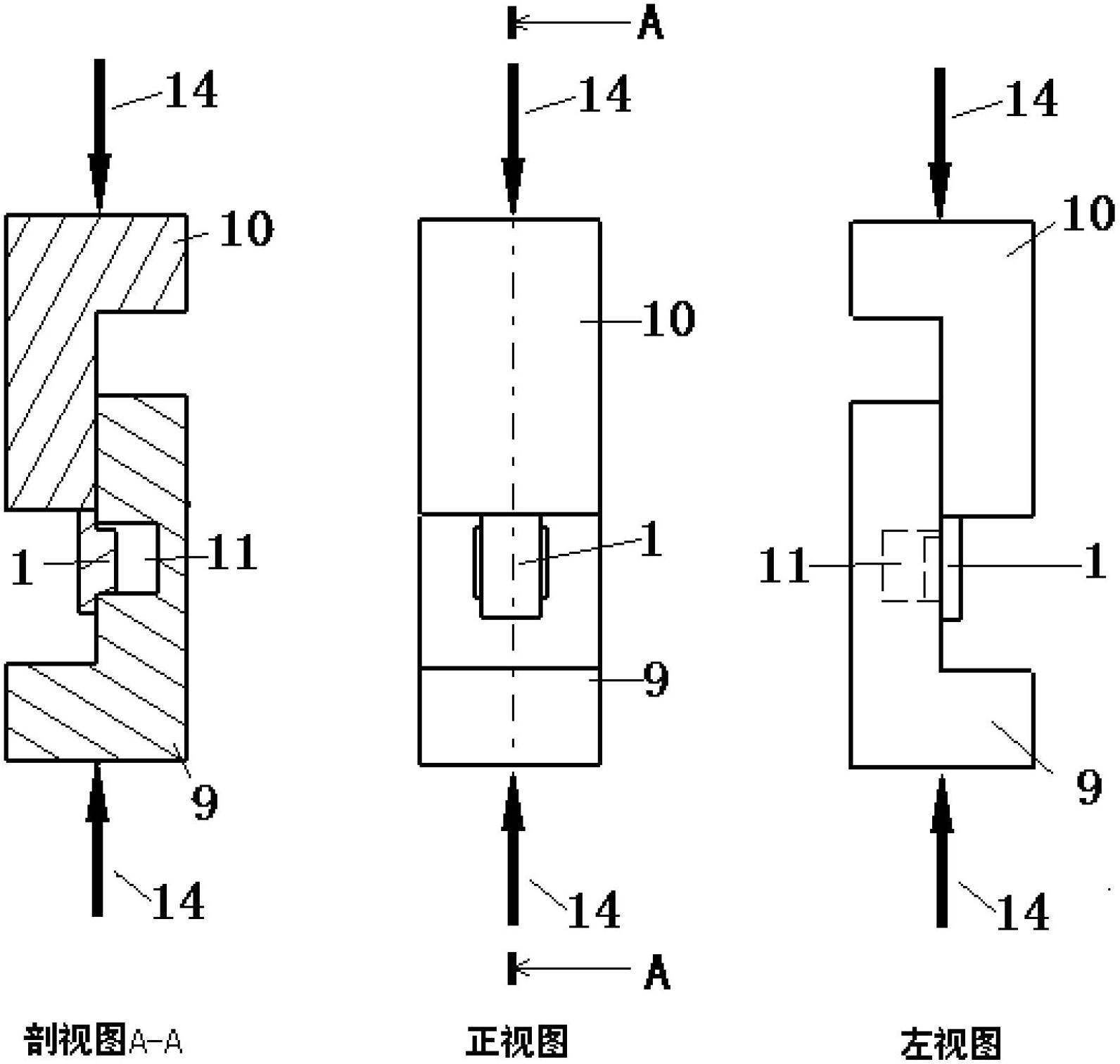

Clamping mechanism for shear testing apparatus

ActiveUS20110214510A1Using mechanical meansMaterial strength using steady shearing forcesEngineeringAbutment

A shear test device for testing the strength of attachment between a bond and an electronic substrate. The device incorporates a clamping mechanism and a shear test tool that are mounted on a baseplate. During a set-up procedure, the shear test tool is movable relative to the baseplate. During a test procedure, the shear test tool is clamped by the clamping mechanism in a fixed position relative to the baseplate. At least one abutment is provided that is fixed in position relative to the baseplate. During the test procedure, a drive mechanism provides relative movement between the shear test tool and the bond to cause the shear test tool to shear the bond off the substrate. The at least one abutment provides an additional clamping force on the test tool while the test tool is shearing the bond off of the substrate. Strain gauges associated with the shear test tool provide signals to an electric circuit indicating the strength of attachment between the bond and the substrate.

Owner:NORDSON CORP

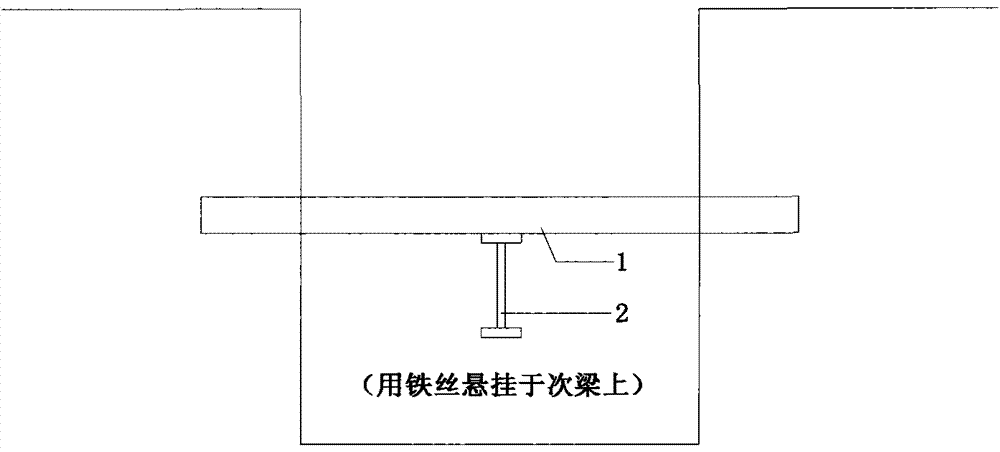

Acoustic emission test device for rock mechanics direct shear process

InactiveCN103207113AEasy to installReal-time monitoring of time-varying relationshipsStrength propertiesHorizontal forceAcoustic emission

The invention relates to a device for rock mechanics direct shear test, in particular to an acoustic emission test device for the rock mechanics direct shear process, in order to solve the problem that damaged microstructure and energy loss of rock cannot be analyzed as an existing rock mechanics direct shear tester does not perform acoustic emission test. The acoustic emission test device mainly comprises an upper pressure head, a base, a horizontal pressure head, a lower shear box, a shear ring, a test piece, a force transmission iron briquette, an upper shear box, sensors and the like, and is characterized in that the upper pressure head and the horizontal pressure head load normal and horizontal force respectively, the lower shear box is placed on the base, the test piece can be placed in the shear ring inside the lower shear box, the force transmission iron briquette is arranged in the upper shear box, and the sensors contact with the test piece through slots inside the upper shear box, the lower shear box and the shear ring. Thus, when a tester performs shear test according to structural features thereof, a time-varying correlation diagram about impact number, shear force, energy accumulation and the like is created via the acoustic emission test device, and strength and property of the test piece can be known from microstructure.

Owner:ANHUI UNIV OF SCI & TECH

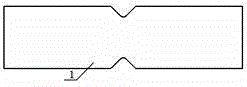

Rock direct shear experiment test piece, test piece clamp and shear testing method thereof

PendingCN108426788ARich test usesSimple structureMaterial strength using steady shearing forcesClimate change adaptationStress distributionTriaxial shear test

The invention relates to a rock direct shear experiment test piece, a test piece clamp and a shear testing method thereof, and belongs to the technical field of rock mechanical testing. The test piececan be directly applied to a triaxial testing machine and comprises a cuboid body; a first cutting groove is formed in the left part of the lower side of the cuboid body; the first cutting groove extends from the side to the internal part of the body in a horizontal direction; the test piece also comprises a second cutting groove; the first cutting groove and the second cutting groove are distributed in a centrally symmetrical mode by taking the center of the body as a center; the length of each cutting groove is equal to the length of the side of the cuboid body; and the width of the cuttinggroove is not more than half of the side length of the bottom surface. The structure is simple and portable; the rock direct shear experiment can be conducted on a triaxial mechanical testing machinewhich only can perform compression; the test purposes of the triaxial mechanical testing machine are enriched; the surface pressure stress of the test piece is provided through confining pressure loading provided by a confining pressure oil source; the pressure stress distribution is more uniformly compared with the axial centralized load loading selected by the traditional direct shear test; thestress distribution uniformity is improved; the high-temperature rock direct shear test can be conducted subsequently; and the test piece is suitable for carrying out the rock direct shear test research.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com