Device and method for preparing rock-like material structural plane and utilizing rock-like material structural plane to shearing test

A technology of rock materials and structural surfaces, applied in the direction of measuring devices, preparation of test samples, and analysis of materials, etc., can solve problems affecting the normal progress of tests and filling materials scattered, and achieve automatic data collection, simple installation and disassembly, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

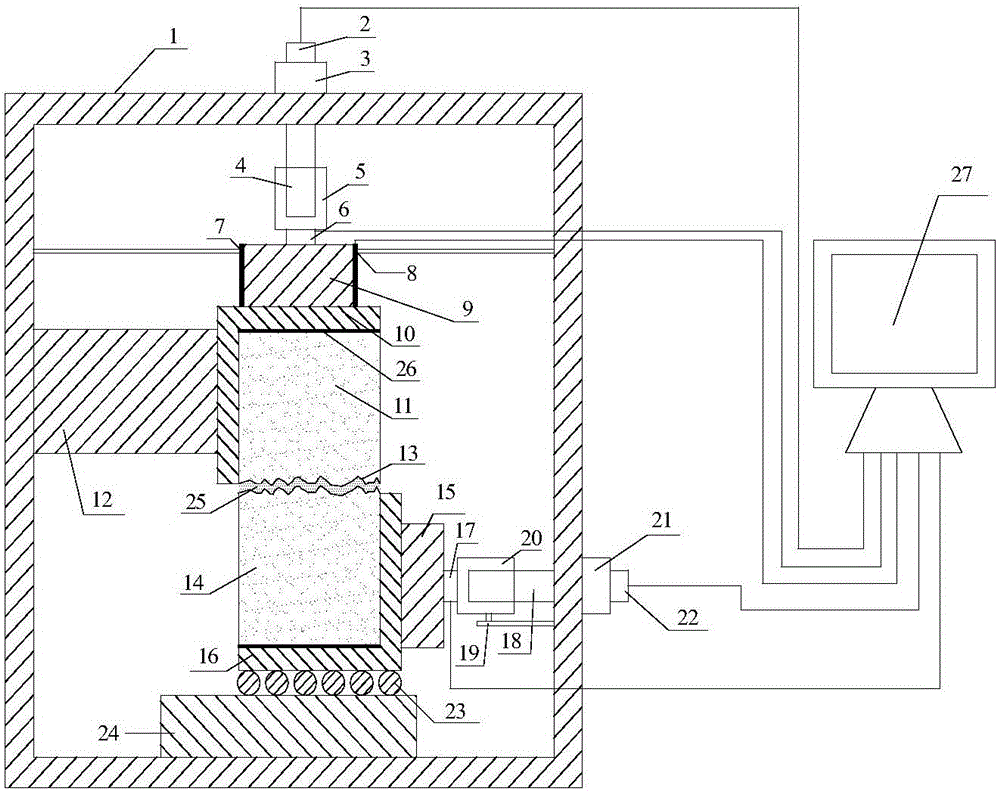

[0037] The method for preparing and shearing a rock-like material structure surface of the present invention includes the following steps:

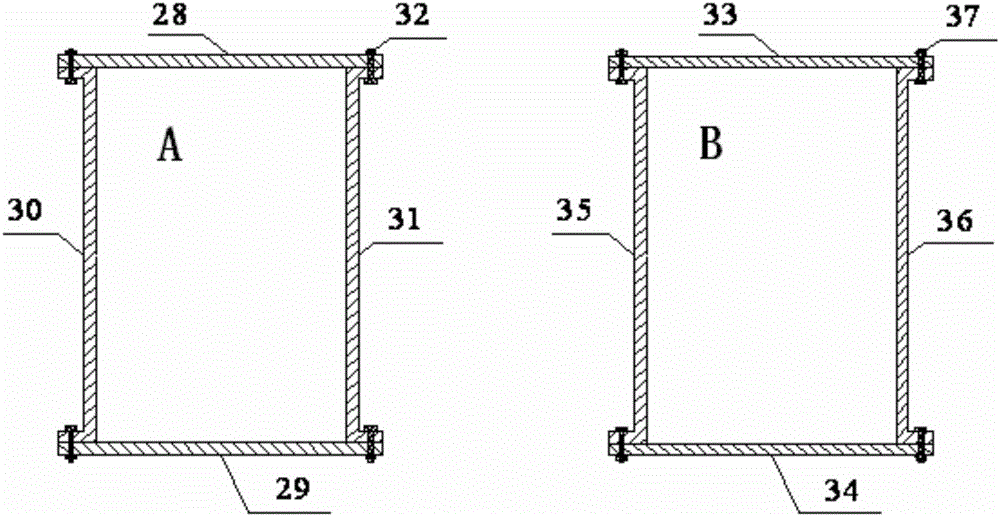

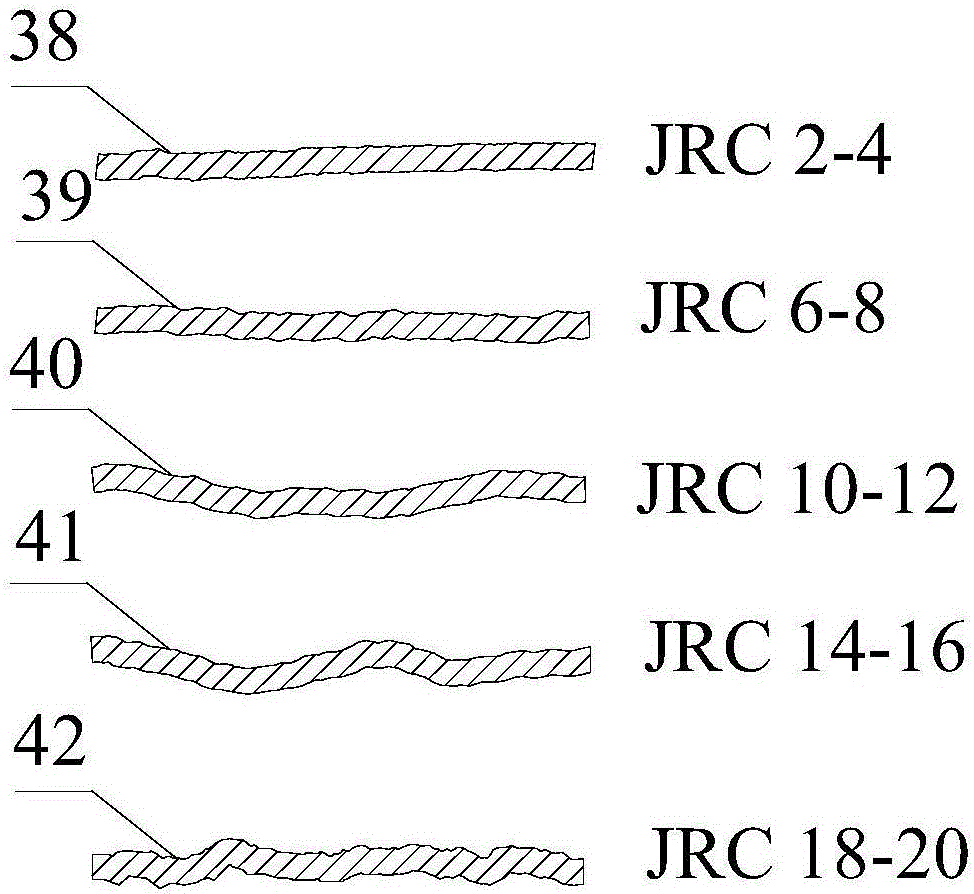

[0038] (1) Test piece production: Assemble the front template I28, the left template I30, the right template I31, the rear template I29, and the bolts 32 (8 in total) into a rectangular mold of length×width×height=100mm×160mm×100mm, and the front template Ⅱ33, left formwork Ⅱ35, right formwork Ⅱ36, rear formwork Ⅱ34, bolts Ⅱ37 (total 8 pieces) assemble a rectangular mold of length×width×height=100mm×160mm×100mm, and then take P32.5 cement, screen sand (screen type) 20 mesh, pore size 0.85mm), and water according to its mass ratio of 26:25:10 to mix and stir. After stirring, pour into the first mold, length×width×height=110mm×170mm×5mm The thin steel plate is aligned with the mold and pressed on the upper surface, the second mold is aligned and placed on the first mold, the uniformly stirred model material is injected into the second mold, af...

Embodiment 2

[0045] This embodiment adopts the same implementation method as that of embodiment 1, the difference is: in the steps (1) and (2) of the embodiment, a step is added to prepare the interview piece containing the yellow mud structure: take step 1 and test the rock Lay the piece flat on the ground, then put the prepared yellow mud with a water content of 50% in a container to a semi-condensed state and smear it on the cracked surface with a thickness of about 5mm. Finally, cover the hanging rock sample on it until Completely condensed. After complete condensing, take a PVC pipe 26 with a length of 100mm to wrap the hanging rock block 11, filling 25, and bottom rock block 14 along the direction of the vertical structural plane, and use a high-power electric hair dryer to heat the PVC pipe to shrink it Completely adhere to the surface of the test piece, and complete the preparation of the yellow mud with 50% moisture content.

[0046] The above-mentioned treatment conditions yielded a...

Embodiment 3

[0048] This embodiment adopts the same implementation method as that of embodiment 1, the difference is: in the steps (1) and (2) of the embodiment, a step is added to prepare the gravel-containing sand layer structure interview piece: take step 1 bottom plate type rock Place the test piece flat on the ground, and then spread the selected gravel and sand evenly on the crack surface with a thickness of about 5mm. Finally, cover the hanging rock test piece on it, and take a PVC pipe 26 with a length of 100mm along the vertical structure surface. Wrap the hanging rock block 11, the filling 25, and the bottom rock block 14 in the direction of travel, and use a high-power electric hair dryer to heat the PVC pipe to shrink and fully fit the surface of the test piece to complete the preparation of the structure with gravel sand.

[0049] The above treatment conditions yielded a peak shear strength of 3.01 MPa and a peak dilatancy displacement of 0.46 mm on the structure surface of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com