Multipurpose vegetable cutting mechanism and multifunctional vegetable cutting machine

A multi-purpose, vegetable cutting machine technology, applied in metal processing and other directions, can solve the problems of vegetable water loss, vegetable body extrusion, fiber damage, etc., to achieve the effect of reducing vegetable cutting failure, convenient processing and molding, and low transmission noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

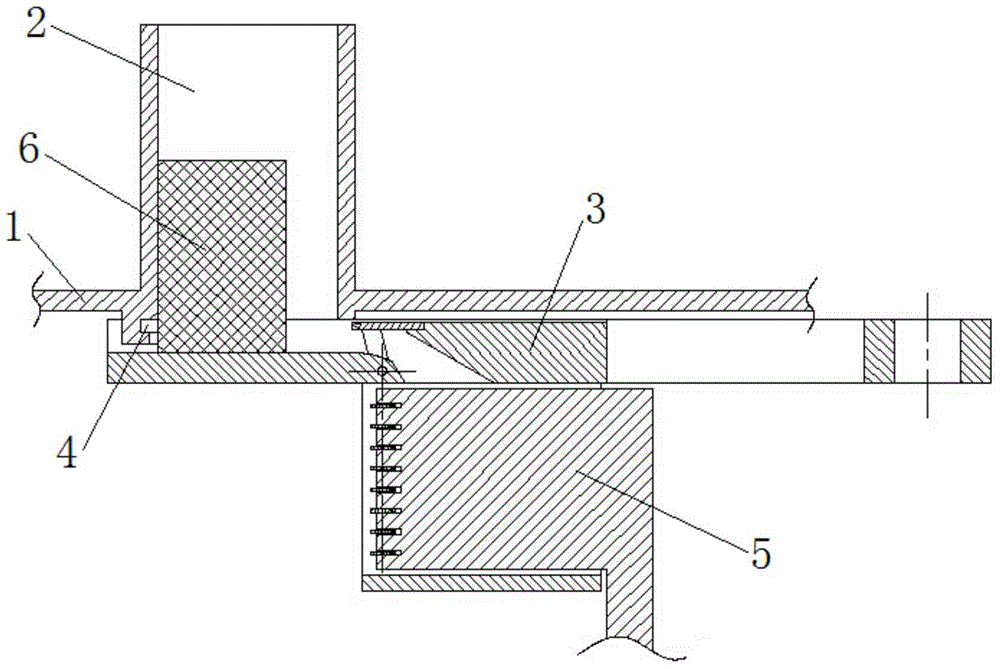

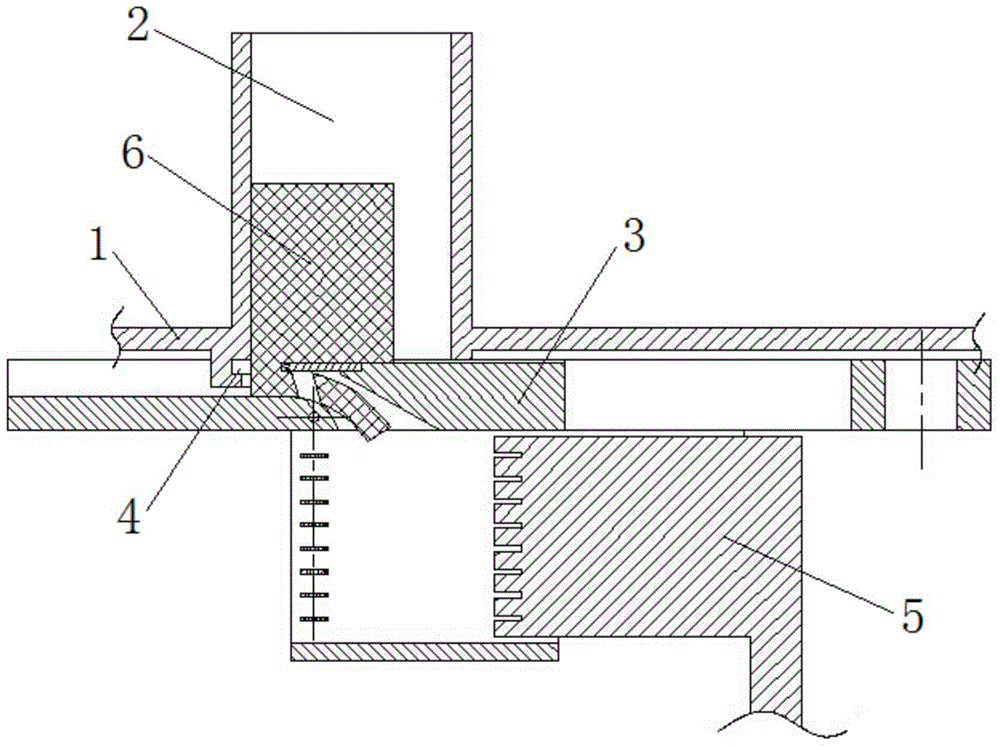

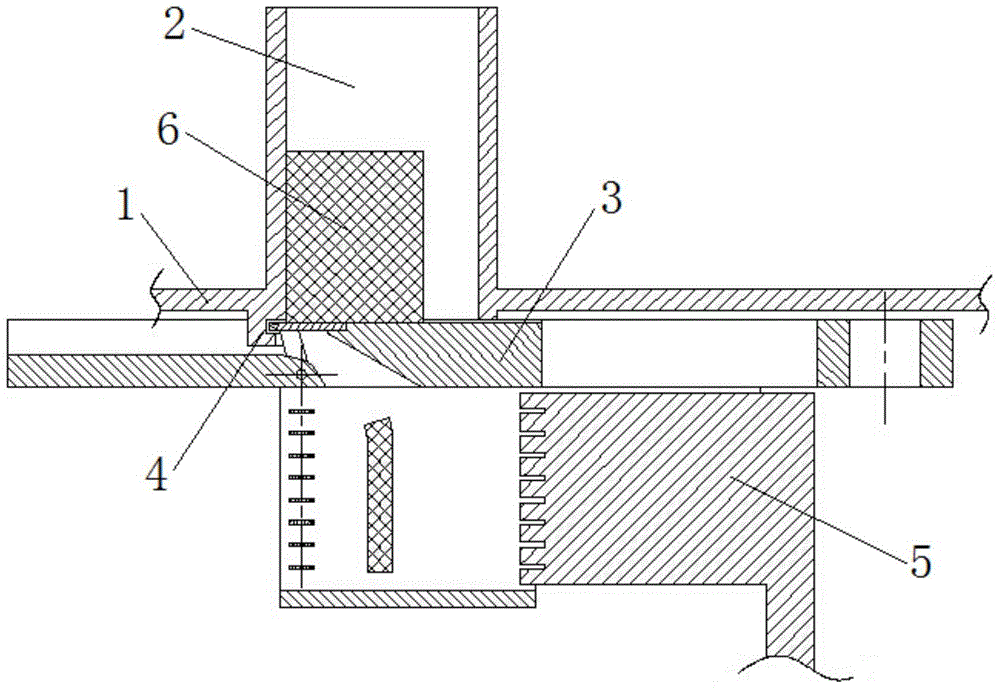

[0047] combine Figure 1 to Figure 4 , a multi-purpose vegetable cutting mechanism of the present embodiment, including a vegetable bucket 2, a blade assembly 3 and a cutting board 5, wherein, as Figure 5 As shown, the blade assembly 3 includes a slicing knife fixing part 31, a vegetable retaining plate 33 and a secondary vegetable cutting cavity 36, and an inclined vegetable guide opening 35 is provided between the vegetable retaining plate 33 and the slicing knife fixing part 31. 35 connects the vegetable bucket 2 with the secondary vegetable cutting cavity 36, so that the once-cut vegetable body 6 smoothly enters the secondary vegetable cutting cavity 36 to realize secondary vegetable cutting; The slicing knife 32 at the entrance of the mouth 35, the gap between the slicing knife 32 and the dish blocking plate 33 is the thickness of the dish body 6 cut off by the slicing knife 32; The bottom of the mouth; the blade assembly 3 is installed below the vegetable bucket 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com