Patents

Literature

77results about How to "Cut off smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

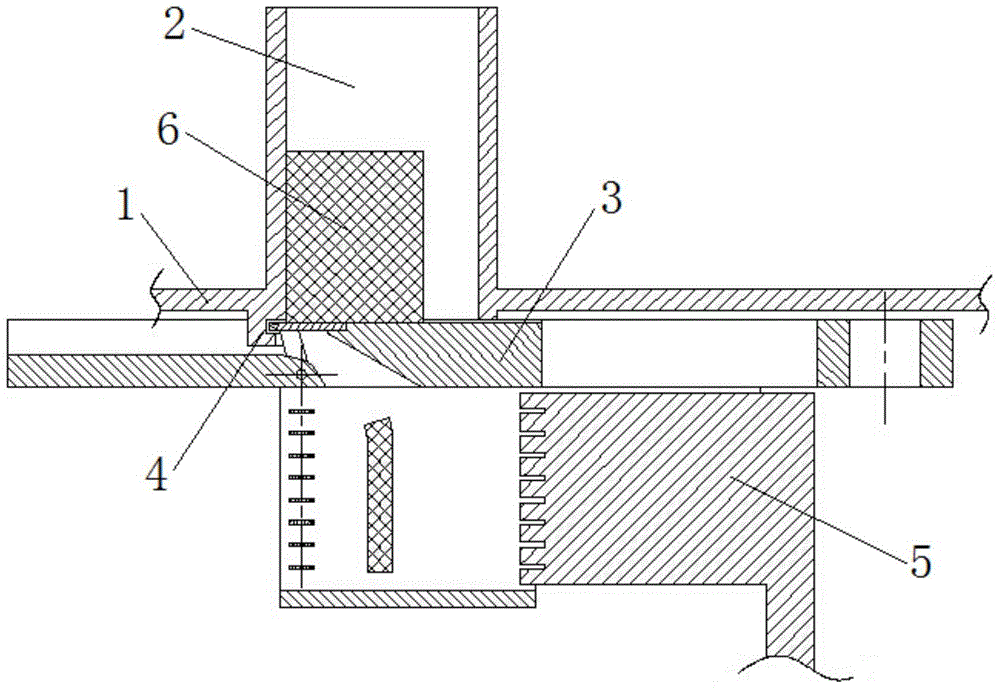

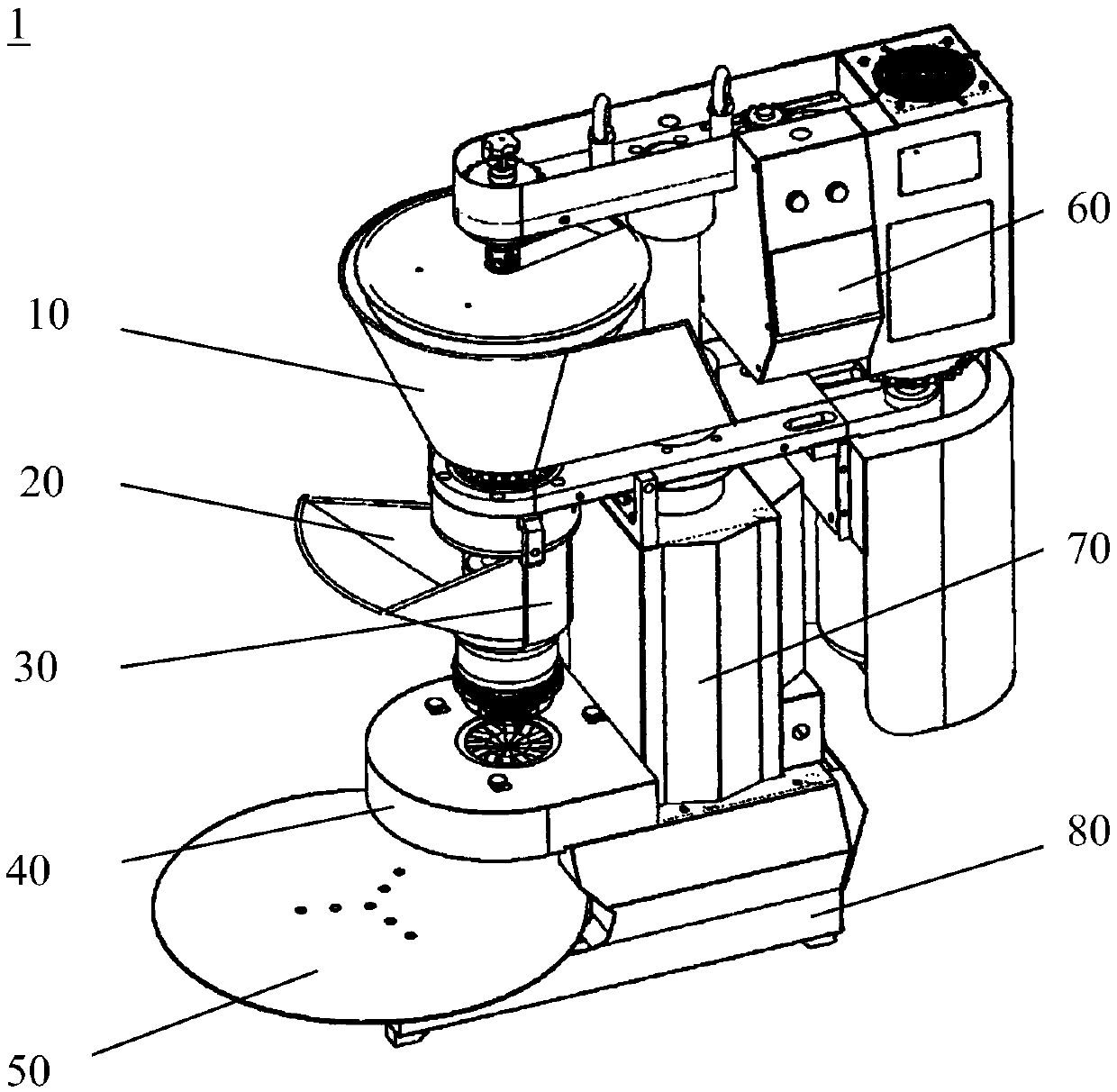

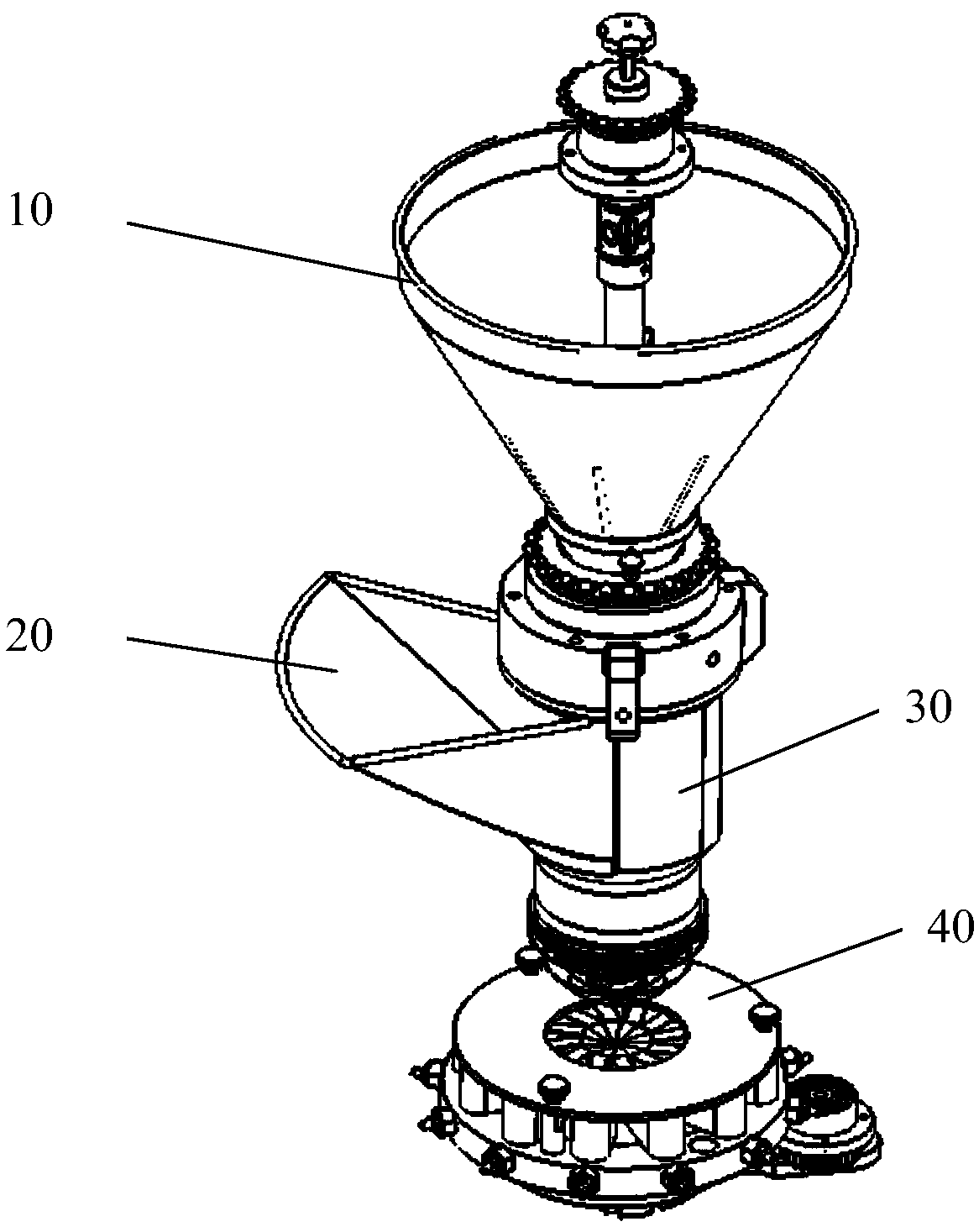

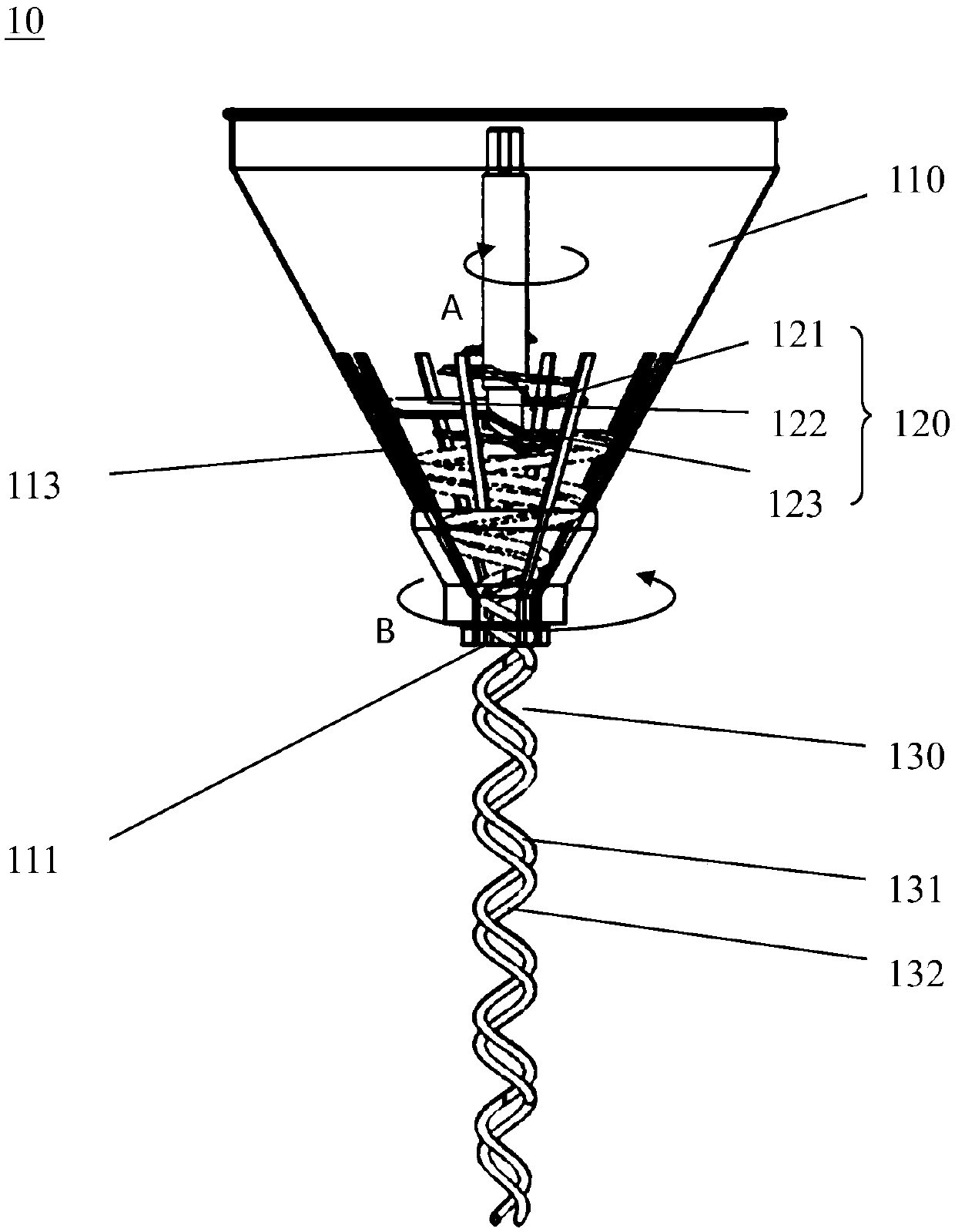

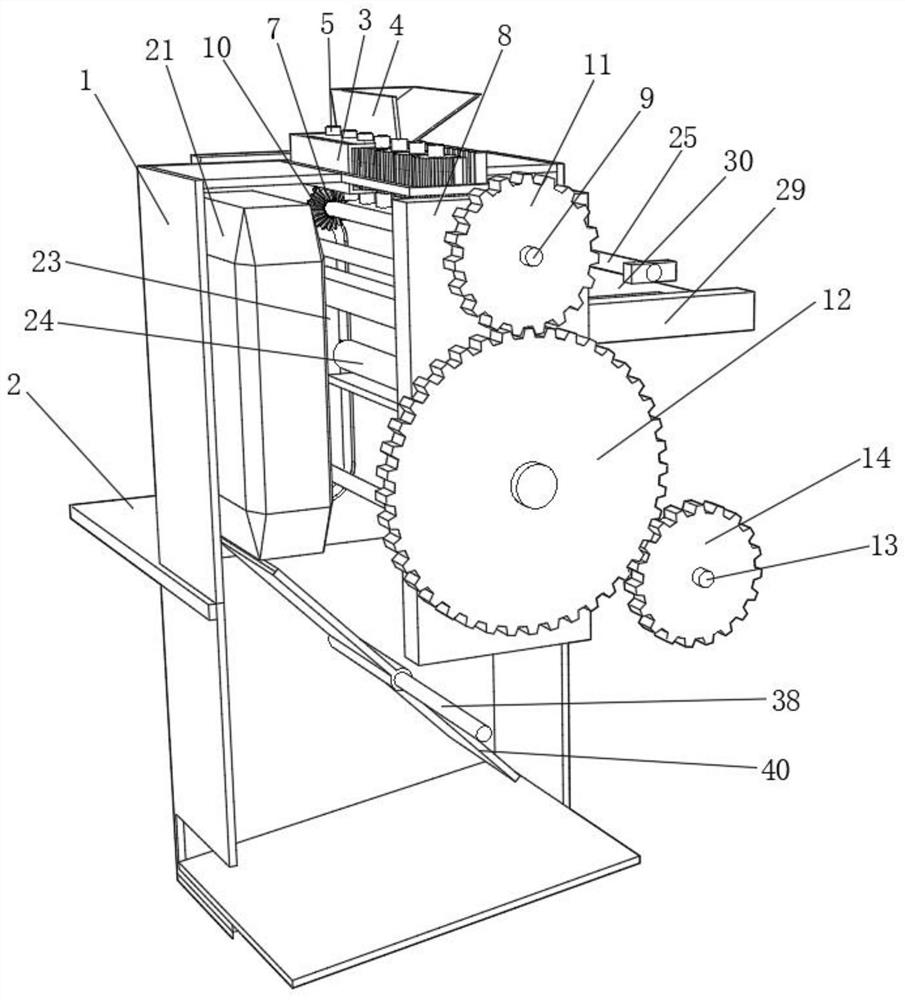

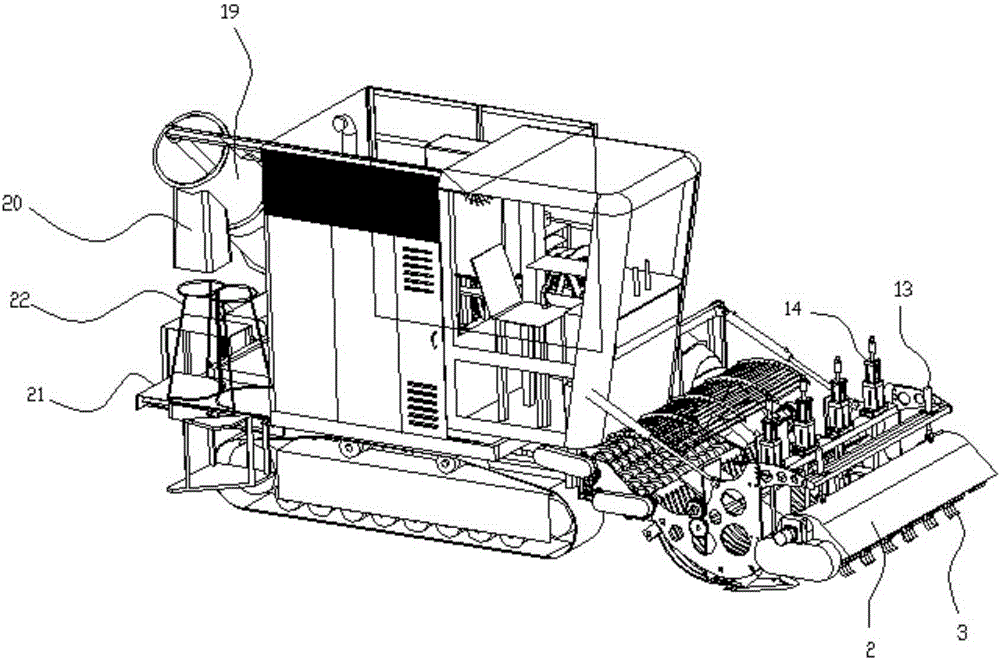

Full-automatic stalk removing machine

ActiveCN103689760ACut off smoothlyReduce processing costsFood treatmentAgricultural engineeringEconomic benefits

Owner:QINGDAO LULU AGRI EQUIP CO LTD

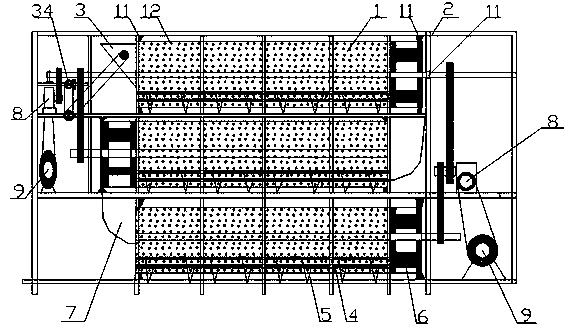

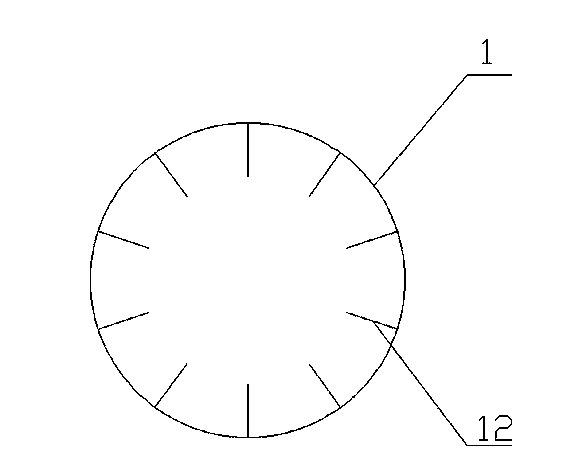

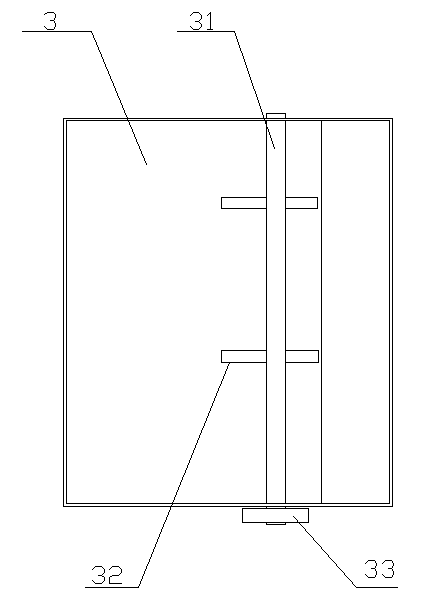

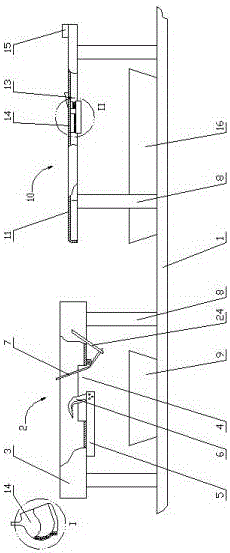

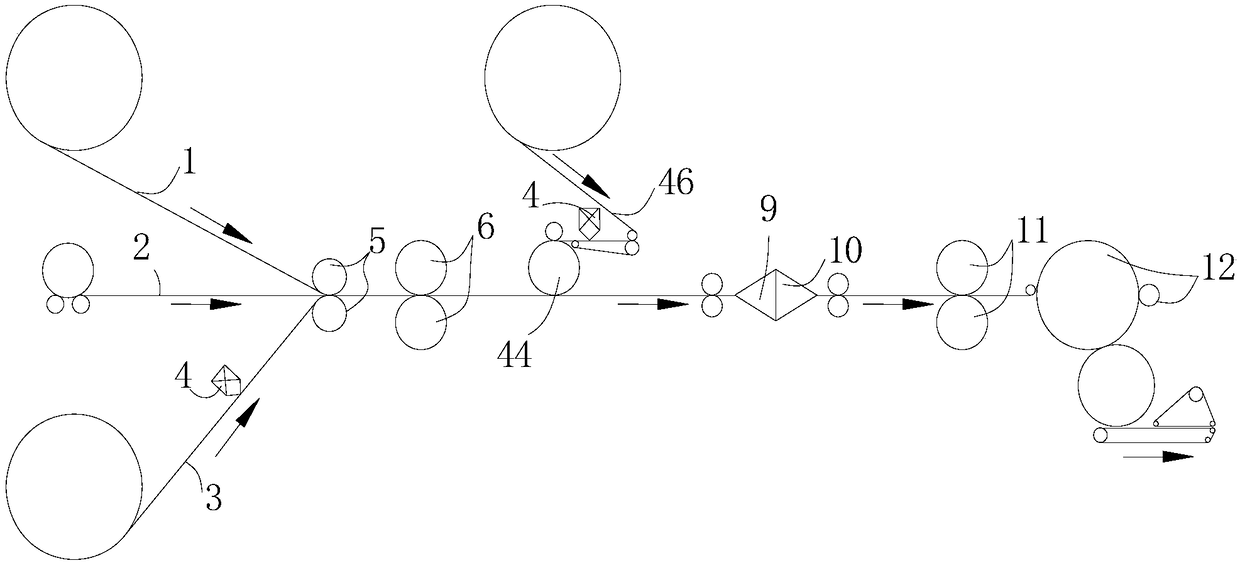

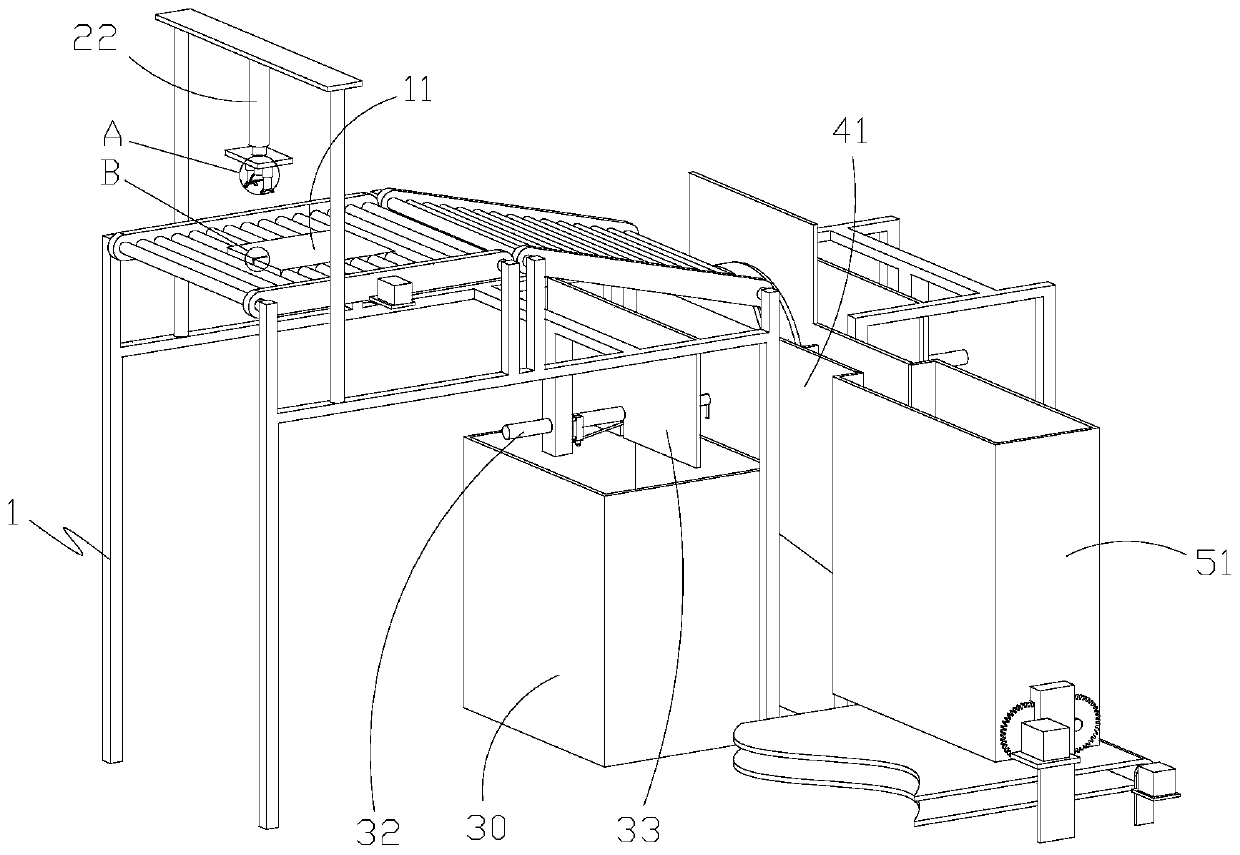

Production assembly line for woven bags

ActiveCN110552076AAvoid stickingAvoid tilting your headPaper article packagingCircular loomsAssembly lineAutomation

The invention relates to the field of production of woven bags, in particular to a production assembly line for woven bags. The production assembly line comprises a ribbonfil production device, a circular weaving device, a roll printing device, a cutting sewing device and a packaging device. Raw materials are heated, melted, extruded and formed into ribbonfil through the ribbonfil production device, the circular weaving device weaves the continuous cylindrical woven bags through the ribbonfil, the woven bags are printed with patterns and characters through the roll printing device, and the printed woven bags are cut off and sewn through the cutting sewing device, then discharged from the cutting sewing device and automatically packaged through the packaging device finally. The production assembly line for the woven bags has the advantages that the production assembly line for the woven bags can achieve production of the woven bags, the overall production efficiency and automation degree are high, the product quality is good, and the production assembly line is suitable for large-scale popularization.

Owner:泗县鸿盛塑业股份有限公司

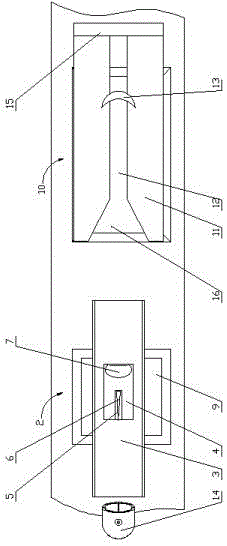

Multipurpose vegetable cutting mechanism and multifunctional vegetable cutting machine

InactiveCN104440984AQuality improvementCut off smoothlyMetal working apparatusAgricultural engineeringVegetable fibers

The invention discloses a multipurpose vegetable cutting mechanism and a multifunctional vegetable cutting machine and belongs to the technical field of vegetable cutting machines. According to the multipurpose vegetable cutting mechanism, an inclined vegetable guiding opening is formed between a vegetable baffle and a slicing knife fixing part which is horizontally provided with a slicing knife located on a vegetable inlet of the vegetable guiding opening, and a secondary vegetable cutting cavity is formed below a vegetable outlet of the vegetable guiding opening; a blade assembly is installed below a vegetable hopper, and a horizontal movement starting point and an end point of the slicing knife are located on the two sides of a vegetable entrance of the vegetable hopper respectively; longitudinal shredding knifes which are vertically arranged and located on the vegetable inlet of the vegetable guiding opening are selectively installed on the vegetable baffle; transverse shredding knifes which are horizontally arranged and used in cooperation with a cutting-off chopping board are selectively installed in the secondary vegetable cutting cavity. The invention further discloses the multifunctional vegetable cutting machine. On the basis that the principle of the cutting mechanism and the cutting machine is similar to that of manual vegetable cutting, vegetables are fast cut off, vegetable fiber texture is kept intact, the cut vegetables taste good, and the problem that vegetables are seriously extruded when the vegetables are shredded and cut into blocks through single procedures is solved in the aspect of the principle.

Owner:吴守林

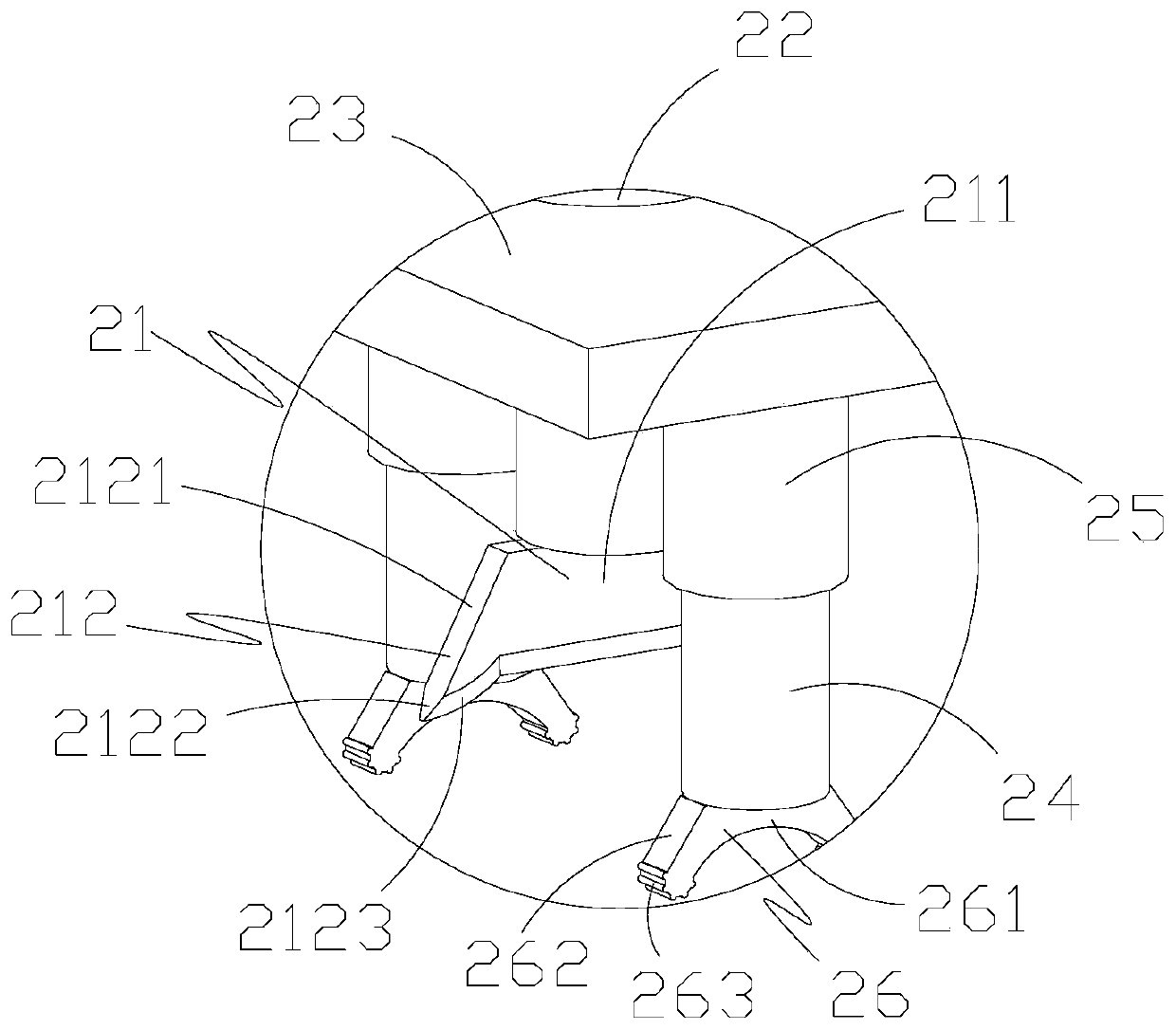

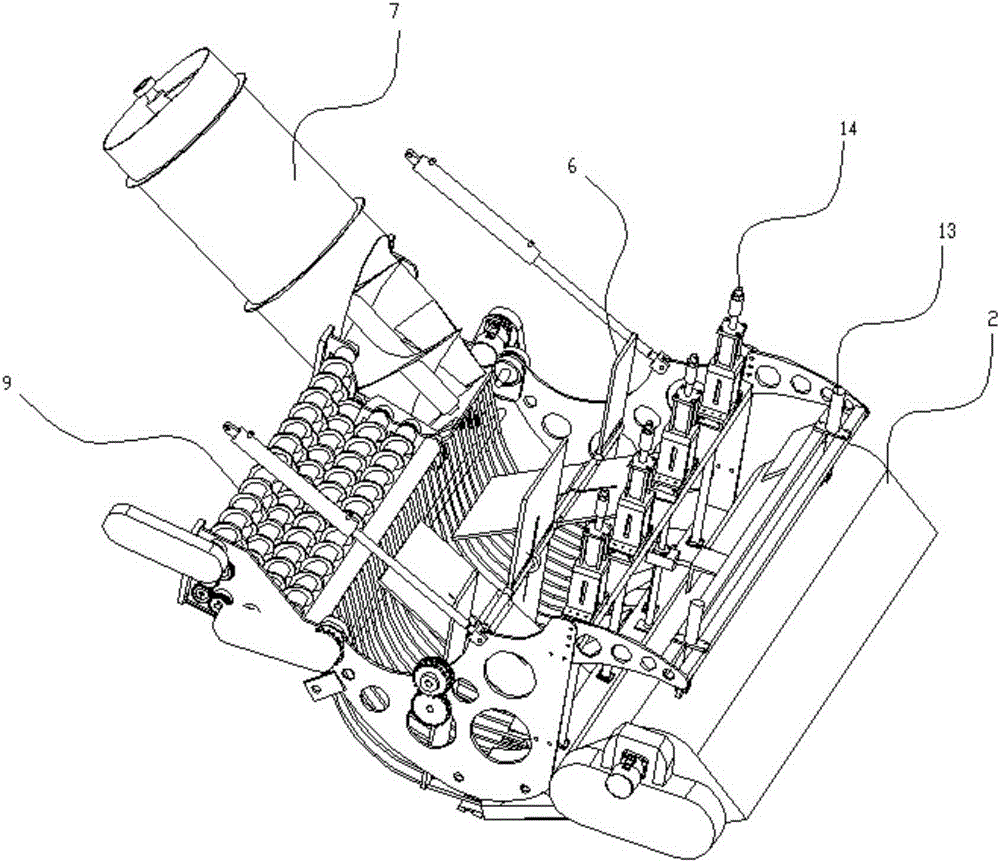

Automatic duck gizzard and duck glandular gastro-esophagus separation device

ActiveCN106720154AReliable split operationImprove permeabilityPoultry processingGizzardOesophageal tube

The invention discloses an automatic duck gizzard and duck glandular gastro-esophagus separation device. The automatic duck gizzard and duck glandular gastro-esophagus separation device comprises a duck gizzard bag driven by a chain, and a duck glandular gastro-esophagus and content separation mechanism and a duck gizzard and duck glandular gastro-esophagus separation mechanism, which are arranged on a working table and are connected end to end, wherein the duck glandular gastro-esophagus and content separation mechanism is provided with a blade I with a sharp end part and a food removing pulling sheet with the diameter more than a duck glandular gastro-esophagus, and the blade I is close to the food removing pulling sheet; the duck glandular gastro-esophagus can be cut apart very well, and contents in the duck glandular gastro-esophagus are scraped very well; the duck gizzard and duck glandular gastro-esophagus separation mechanism is provided with a guide platform for forming a gap and the gap is provided with a blade II; after the contents is separated from the duck glandular gastro-esophagus, the a duck gizzard can be separated from the duck glandular gastro-esophagus, without changing a container. The automatic duck gizzard and duck glandular gastro-esophagus separation device has the beneficial effects that according to the description, the automatic duck gizzard and duck glandular gastro-esophagus separation device is simple in structure and reasonable in design; the labor is released, the working efficiency is improved and the production quality is also improved.

Owner:单县六和饲料有限公司 +1

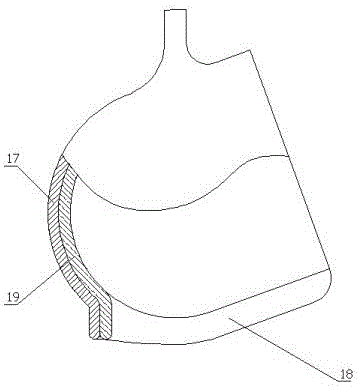

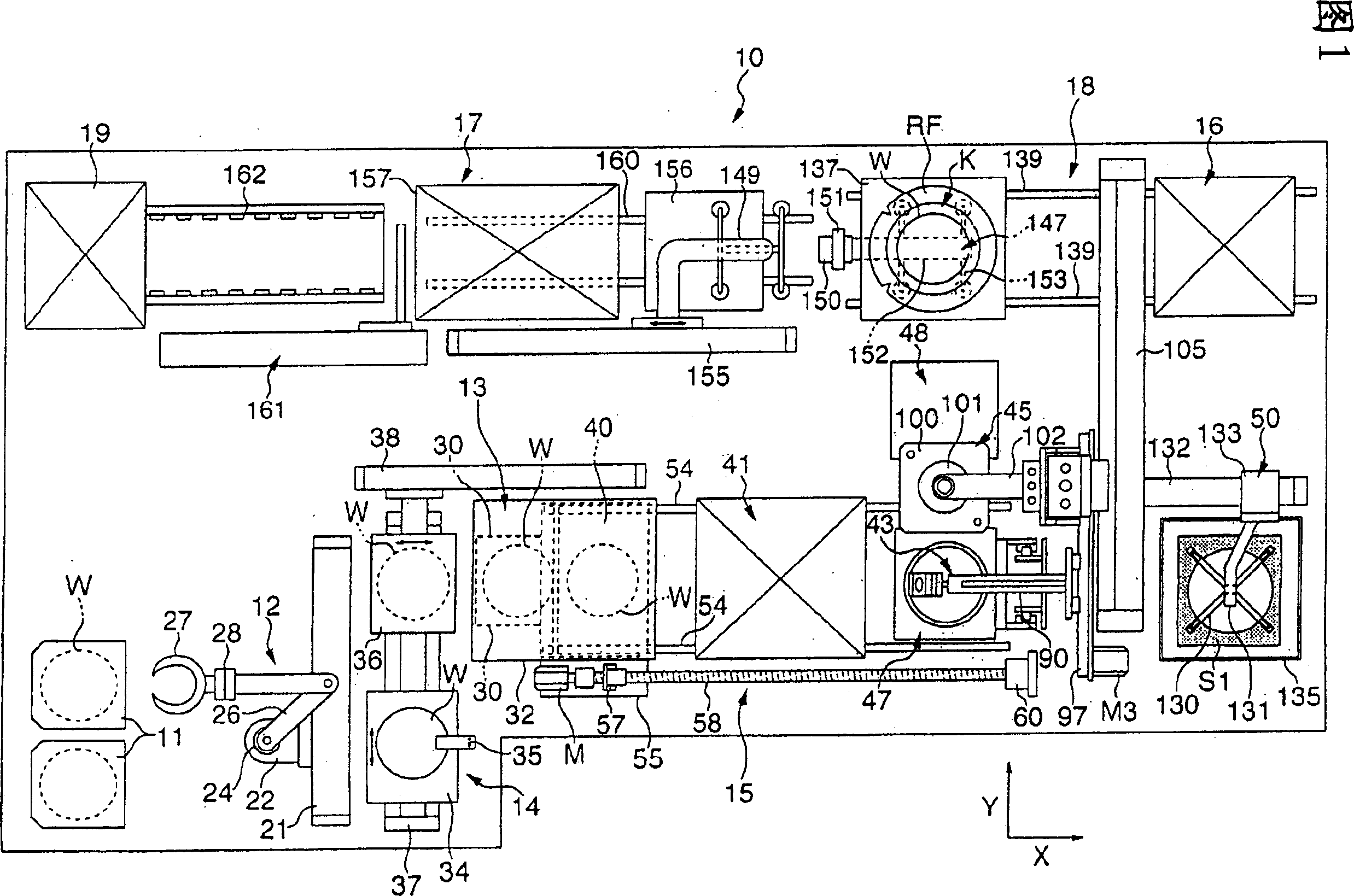

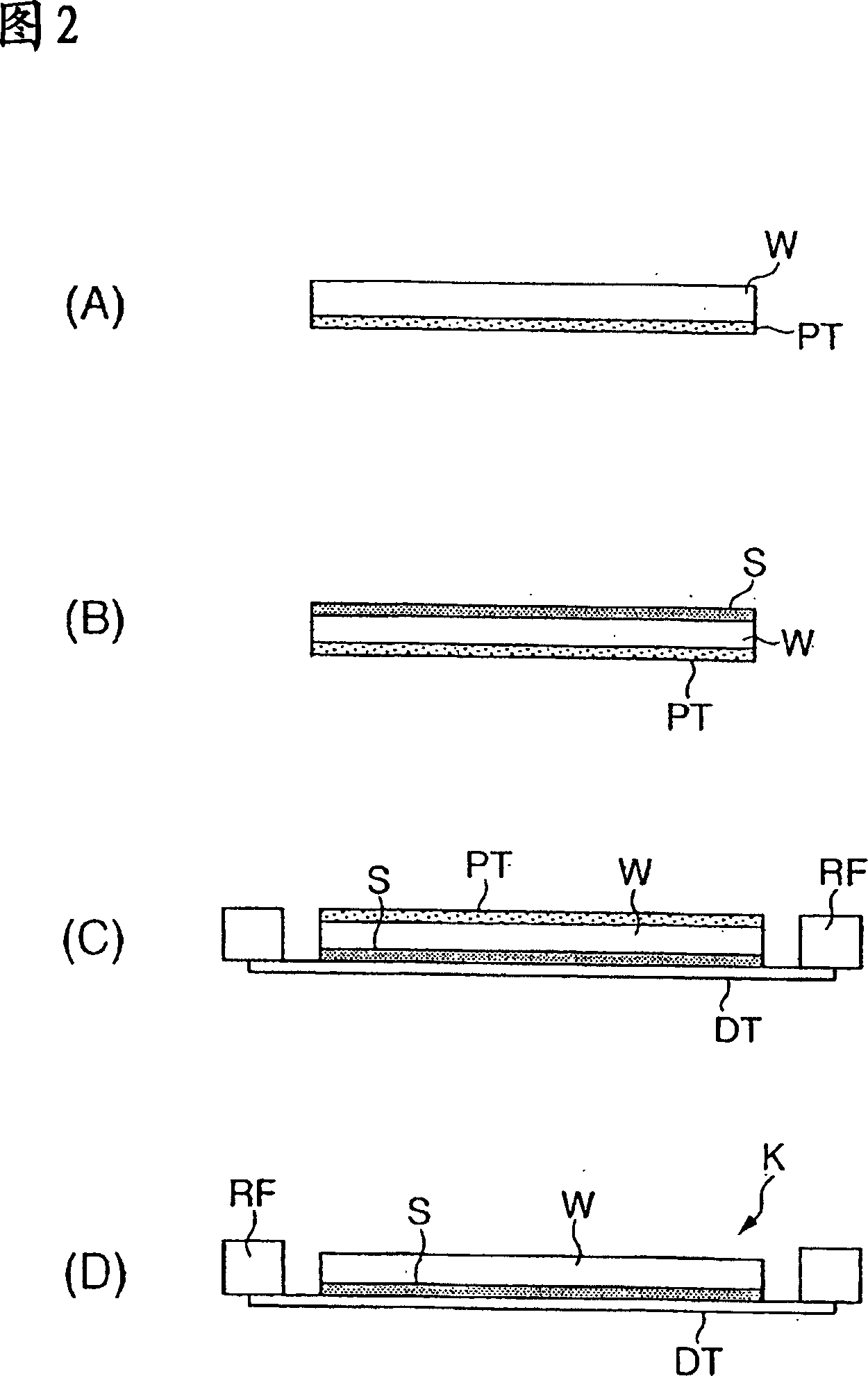

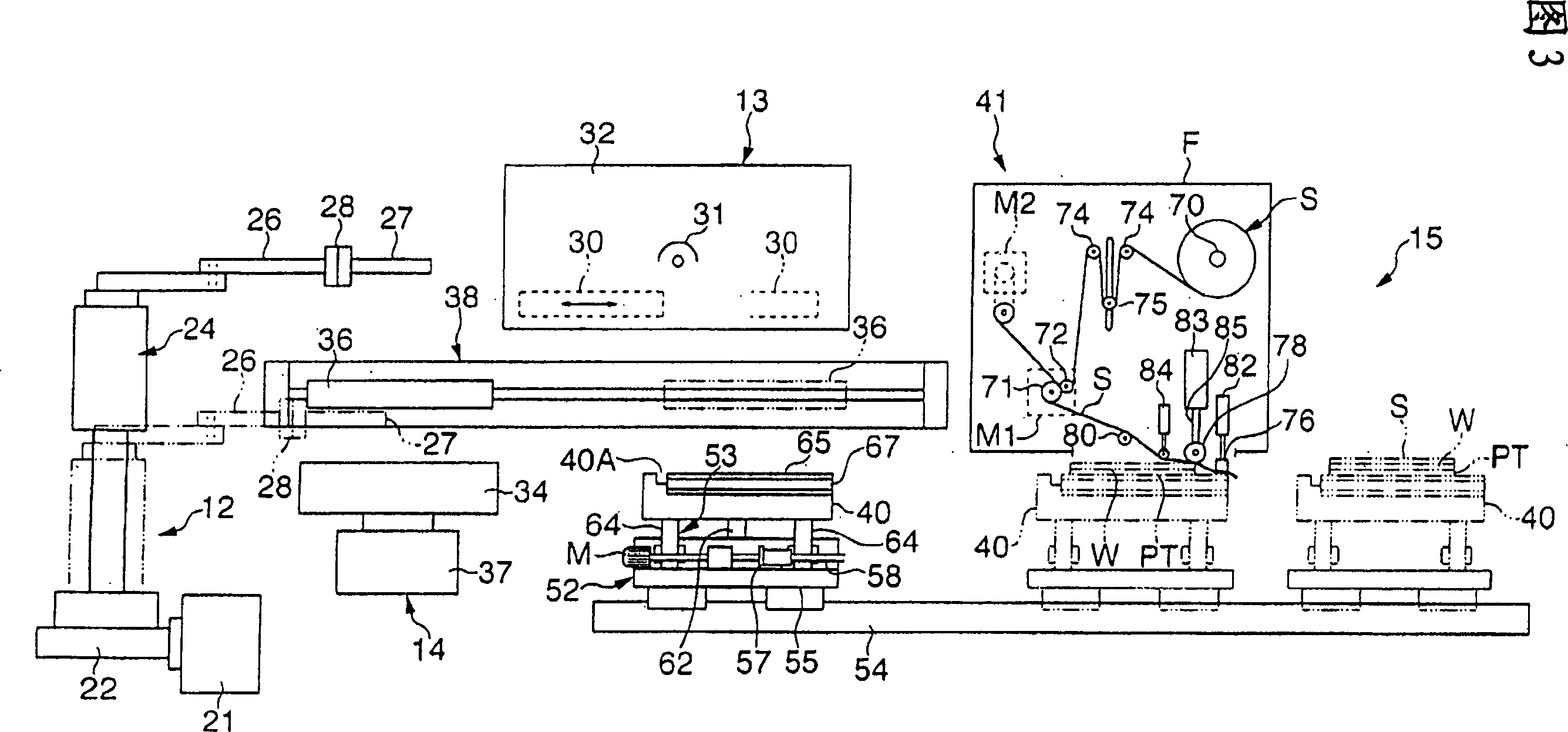

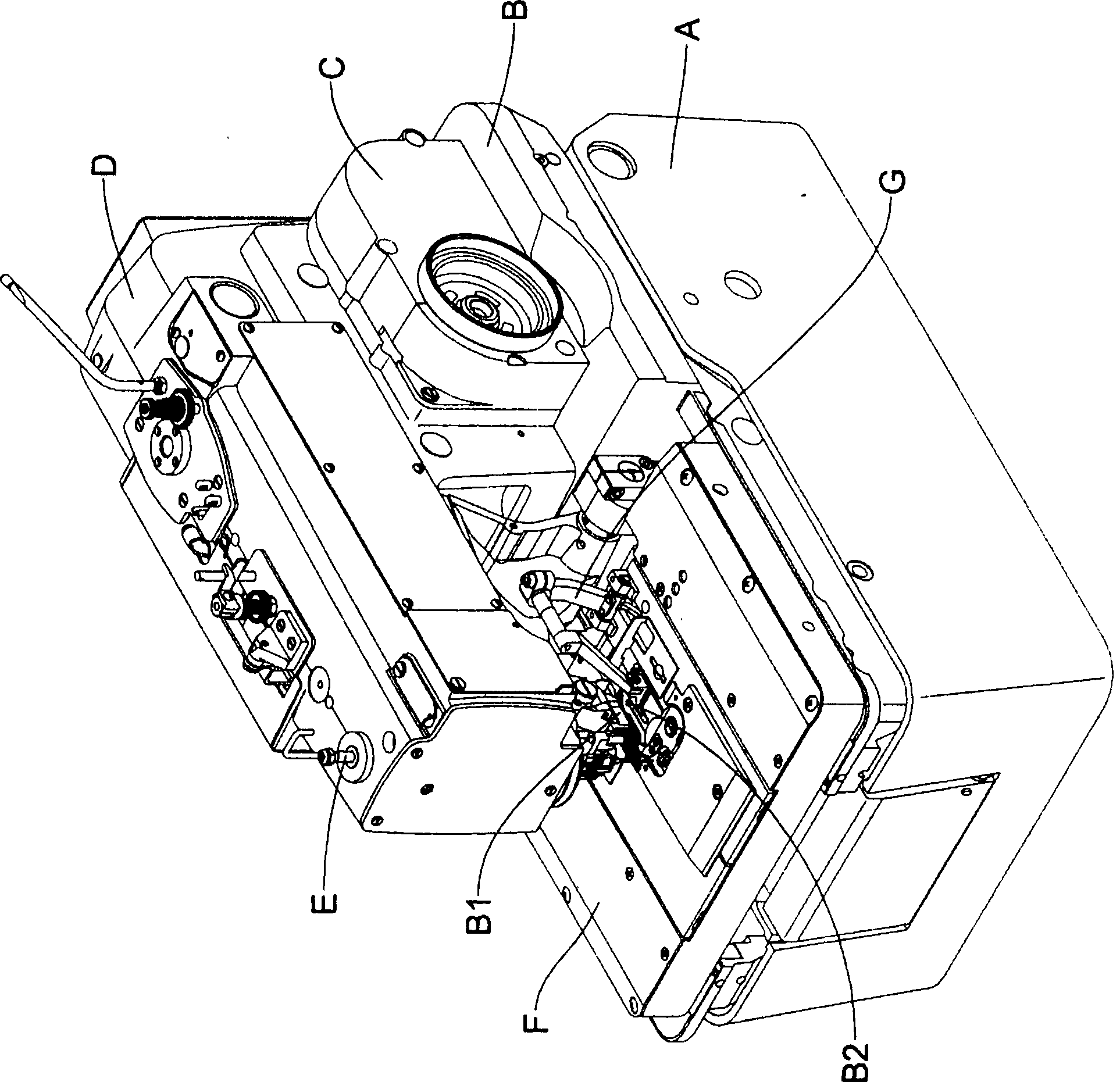

Wafer processing device and wafer processing method

InactiveCN1943025AEasy temperature controlAvoid lagSemiconductor/solid-state device manufacturingDomestic articlesHeat sensitiveEngineering

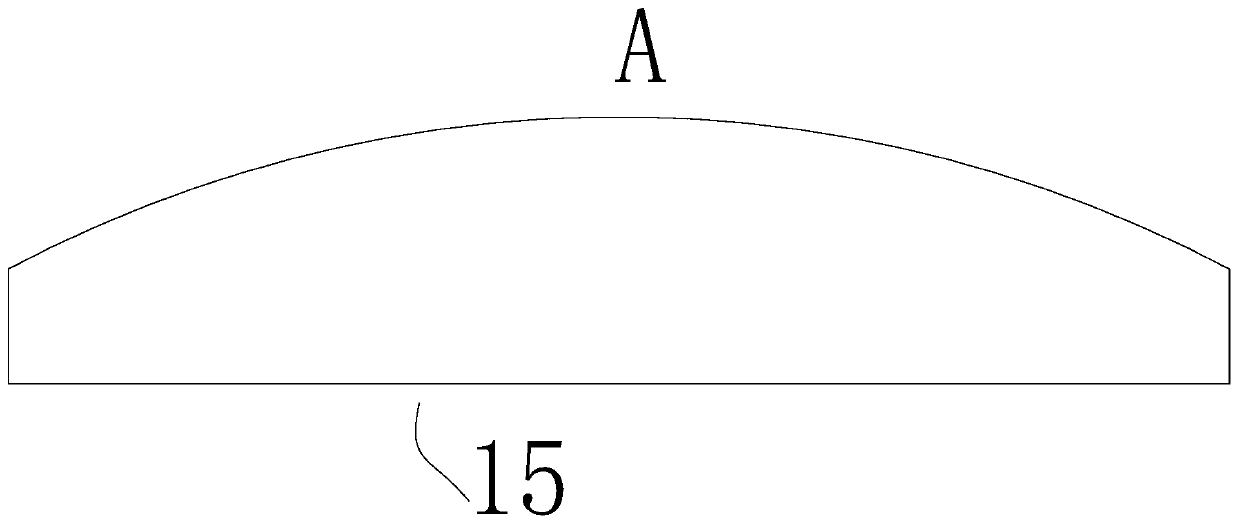

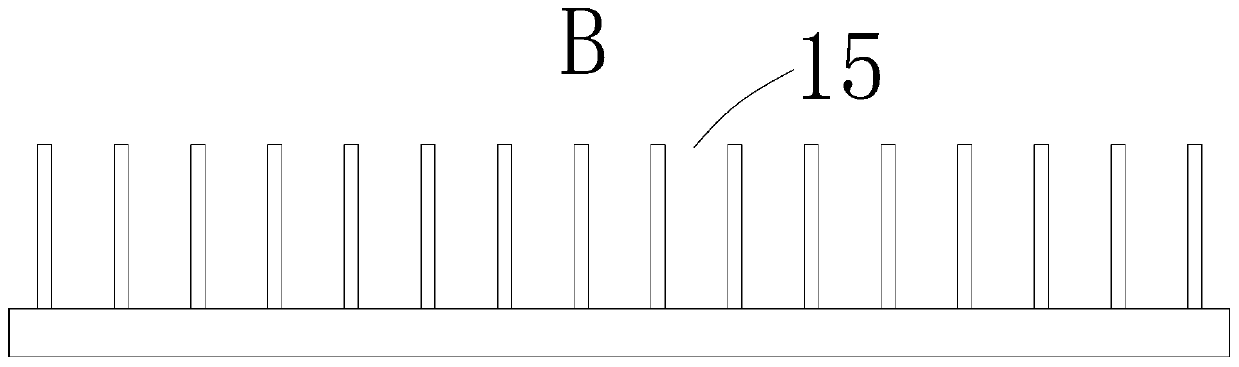

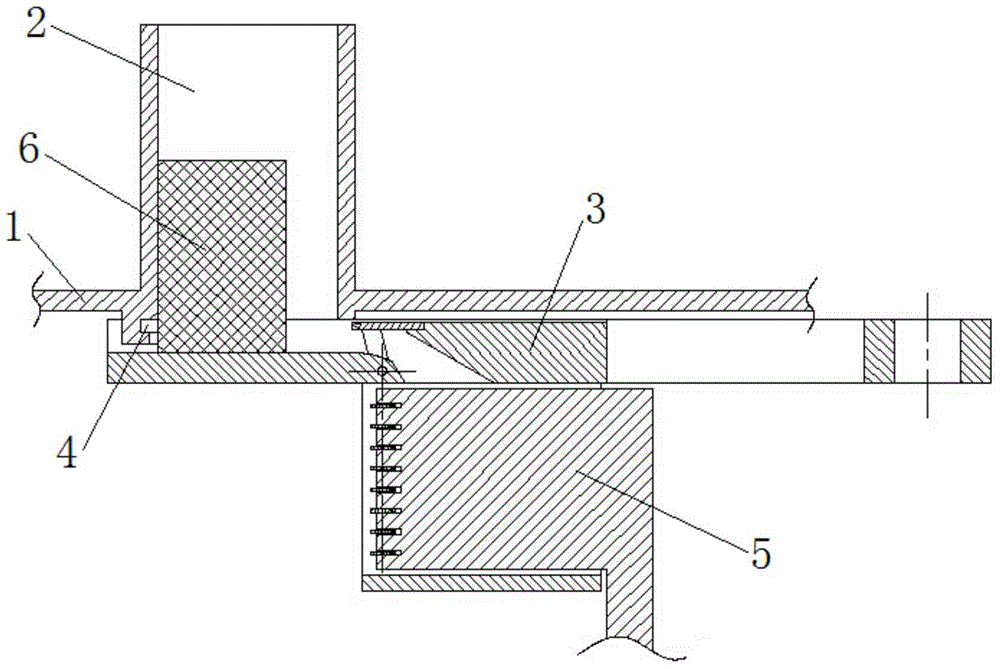

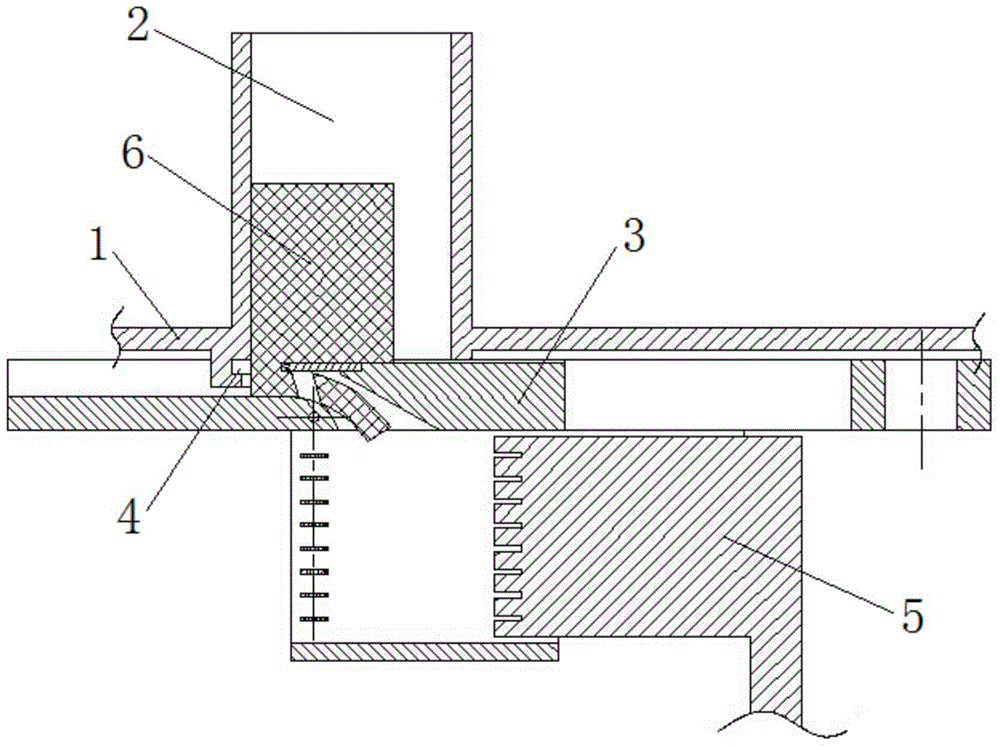

A sticking device (15) is constructed from a sticking table (40) supporting a semiconductor wafer (W), a sticking unit (41) for sticking a heat-sensitive adhesive sheet (S), and a cutter (96) for cutting the adhesive sheet crosswise and peripherally for each semiconductor wafer. The table comprises the first sticking table (40) controlled to a first temperature for temporarily sticking the adhesive sheet (S) to the wafer (W), an outer periphery cutting table (47) controlled to a second temperature which lowers the stickiness of the adhesive sheet for cutting the latter, and a connecting table (48) controlled to a third temperature for completely sticking the adhesive sheet (S) to the wafer (W).

Owner:LINTEC CORP

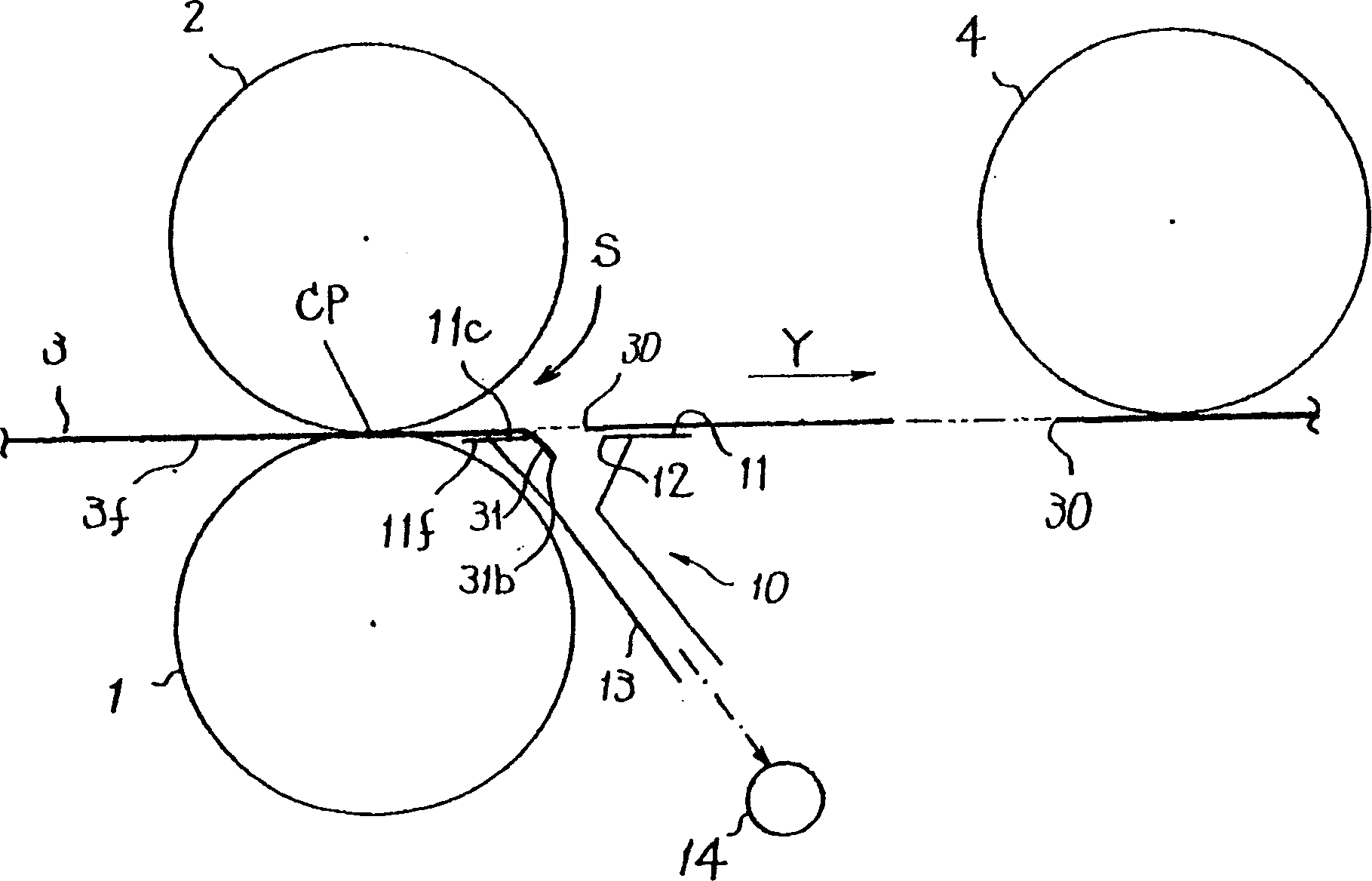

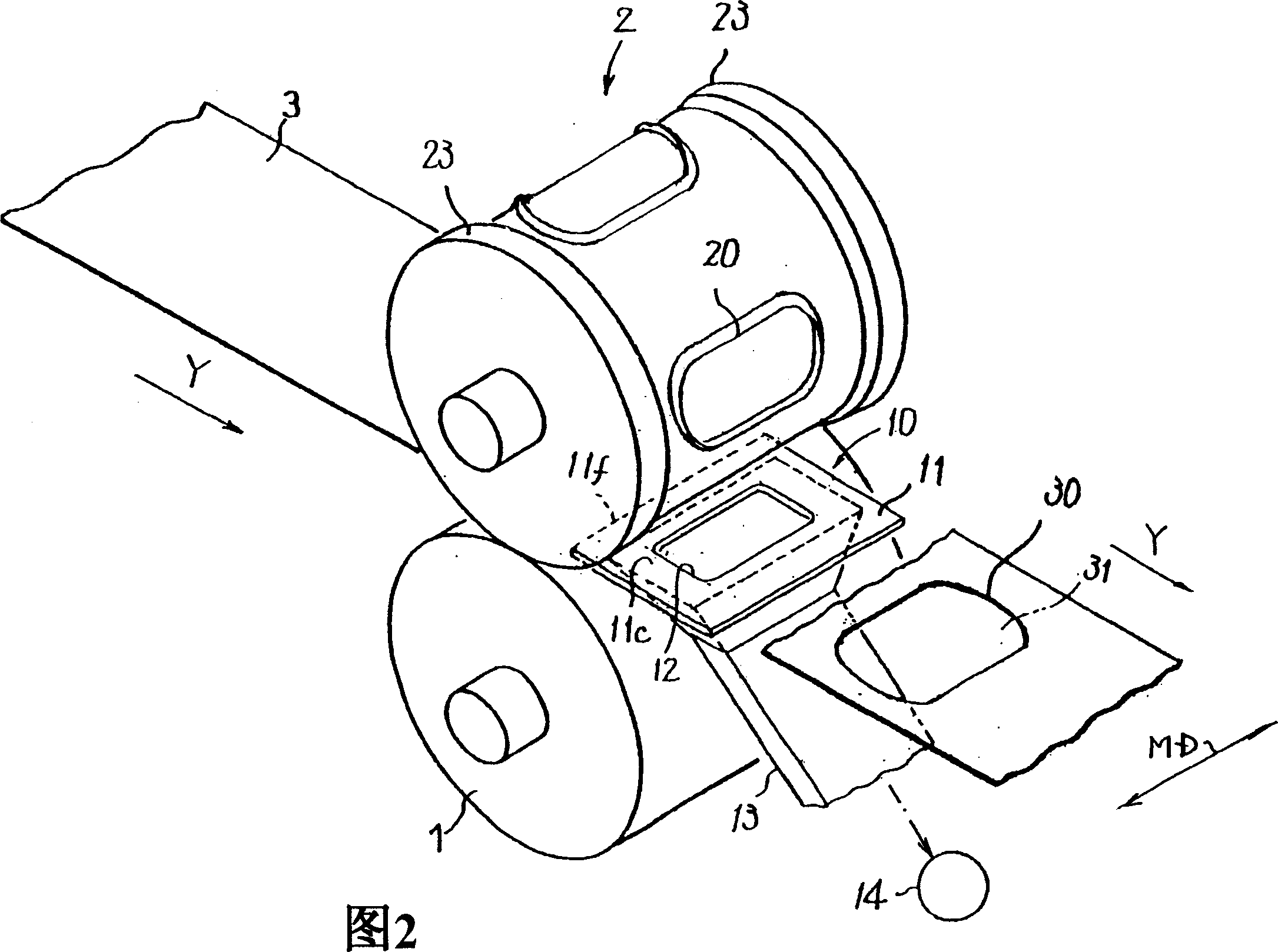

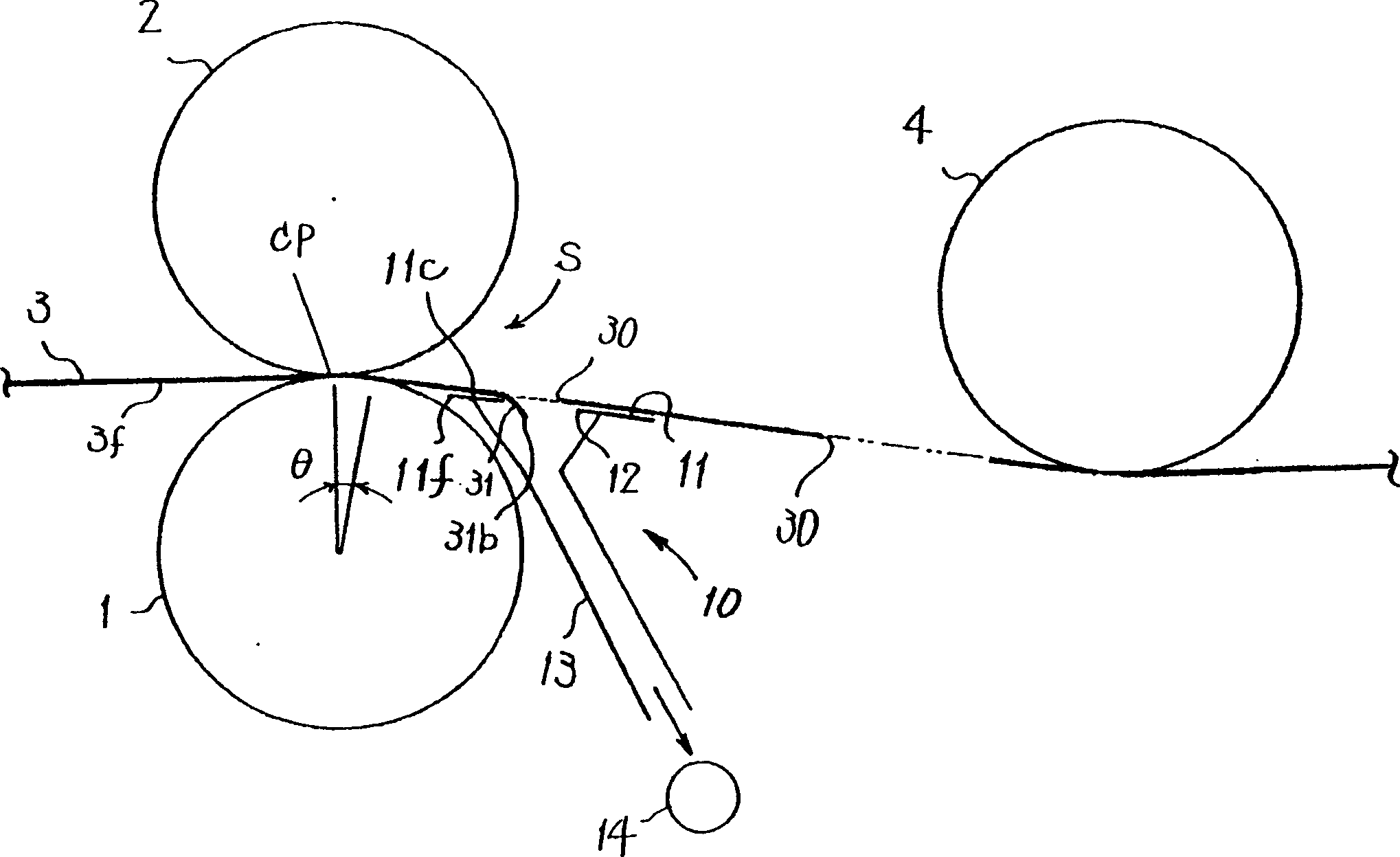

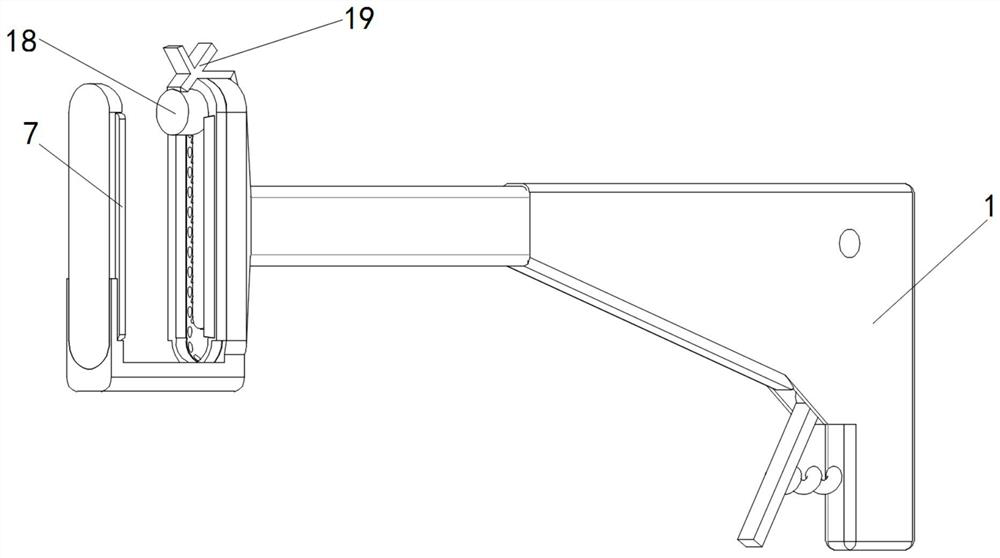

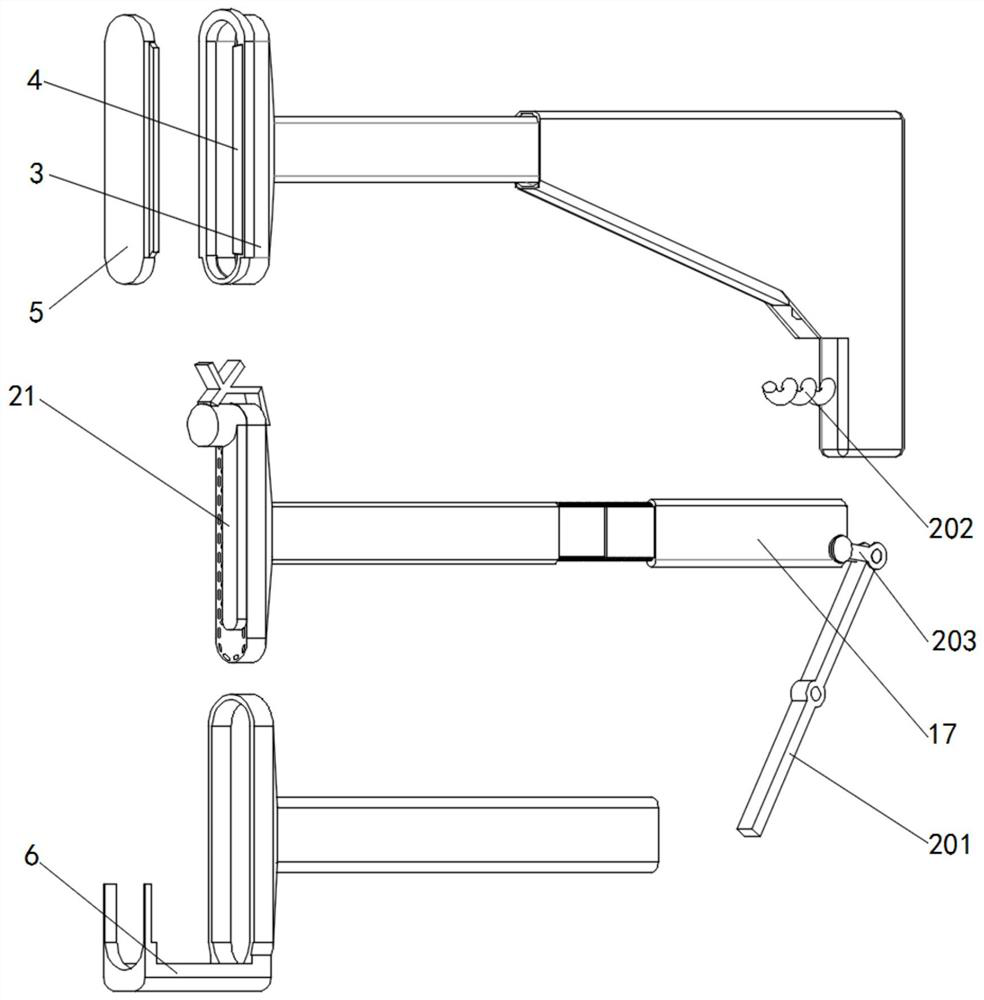

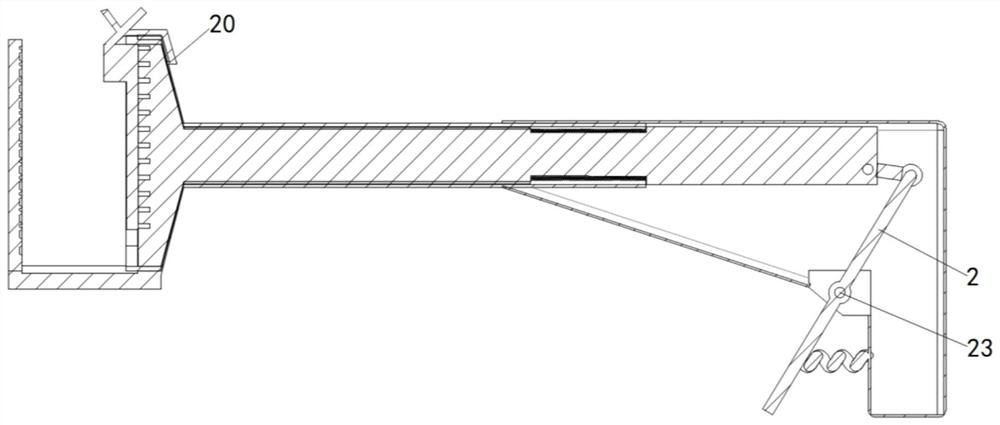

Cut-off removed device

Provided is a cutting and removing device with a high availability factor, which smoothly cuts a sheet-like product and performs high speed operation. The cutting and removing device is provided with an anvil roll 1, a cutter roll 2, a blade 20 provided to the cutter roll 2, a suction unit 10, and forms a through-hole 30 at a prescribed part of the sheet-like product 3. The suction unit 10 is provided downstream of a cutting position of the both rolls 1, 2, and has a guide face 11c along a flow direction Y of the sheet-like product 3, a guide member 11 guiding the face of the sheet-like product 3 on the guide face 11c, and a opening 12 opened on a part of the guide face 11c of the guide member 11 for sucking in a cut and removed part 31 of the sheet-like product 3.

Owner:ZUIKO CORP

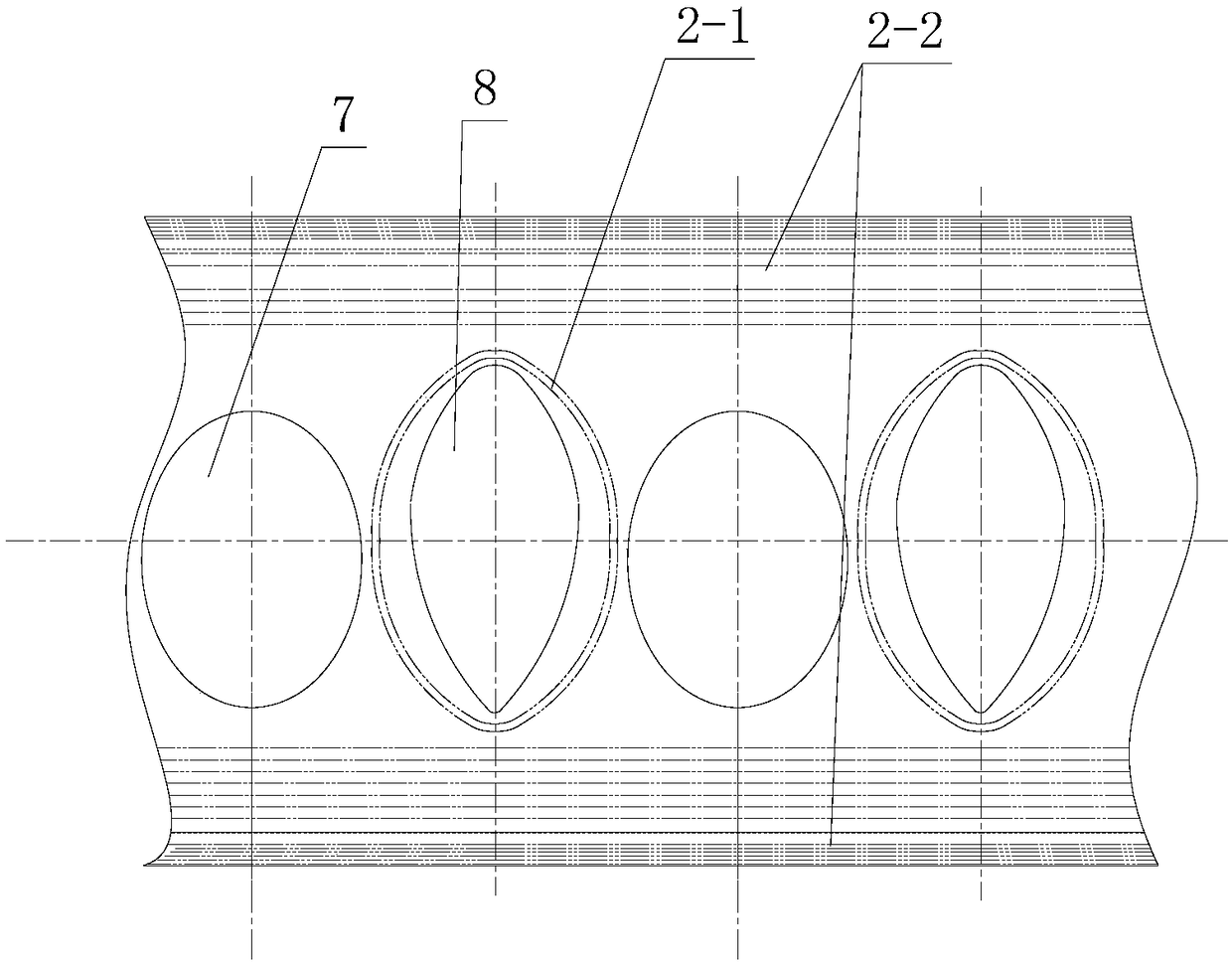

Super-wide linen fabric and production process thereof

InactiveCN106435934AExcellent fabric performanceWith thermoregulationMercerising of indefinite length fabricsSingeingYarnUltraviolet

The invention provides a production process of a super-wide linen fabric. The process includes the specific steps of firstly, conducting softening processing on linen rough yarn through an organosilicon softening finishing agent; secondly, conducting high-frequency drying processing on softened linen raw yarn; thirdly, conducting spooling and waxing processing on the linen raw yarn obtained after high-frequency drying; fourthly, conducting yarn steaming processing on the linen obtained after waxing and sealing; fifthly, weaving the linen raw yarn obtained after yarn steaming processing on a machine to obtain a gray fabric; sixthly, conducting double-side singeing processing on the obtained gray fabric; seventhly, conducting liquid ammonia mercerization processing on the gray fabric obtained after double-side singeing processing; eighthly, calendering the mercerized gray fabric, conducting sizing through a hydrophilic softener, and conducting preshrinking to obtain the linen knitted fabric. The prepared linen fabric is excellent in fabric performance, has temperature adjusting, allergy resisting, electrostatic preventing, ultraviolet preventing and bacteria resisting functions, is smooth in surface, stiff and smooth, breathable and strong in woolen-type feeling and has soft texture.

Owner:WUHAN ZHIFU ENTERPRISE MANAGEMENT CONSULTING CO LTD

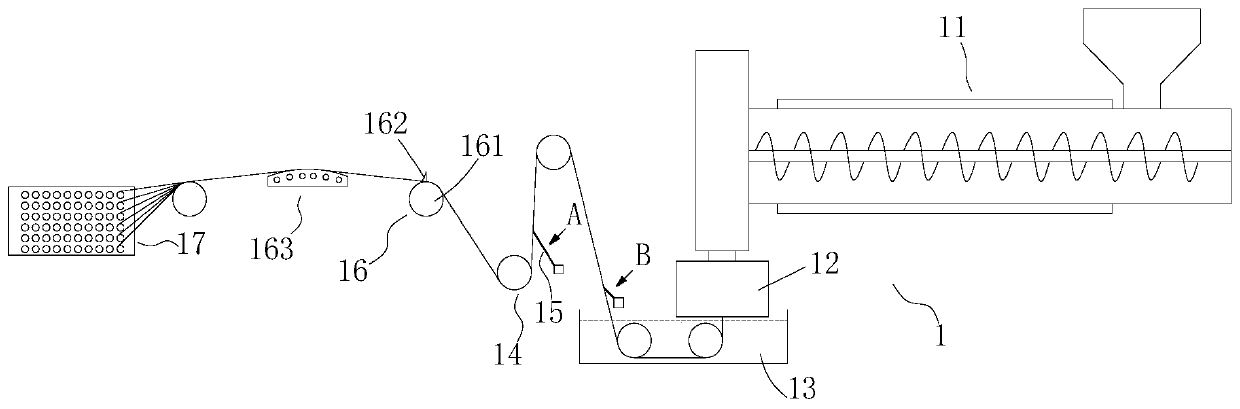

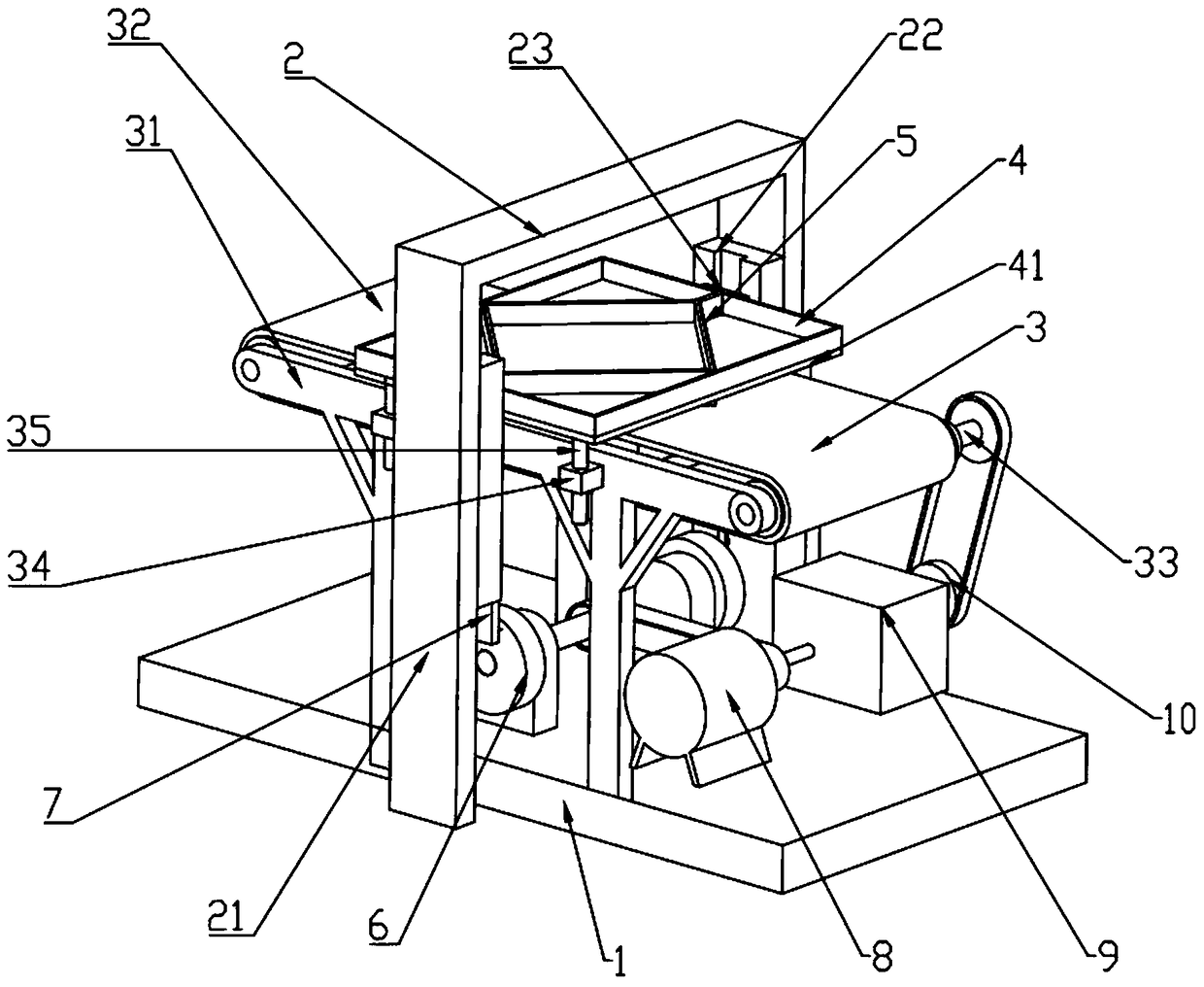

Manufacturing method and equipment of disposable anti-galactorrhea bra

PendingCN108078023AIncrease productivityLow manufacturing costBrassieresClothes making applicancesGalactorrheaWoven fabric

The invention discloses a manufacturing method and equipment of a disposable anti-galactorrhea bra. The method is characterized in that an inner layer non-woven fabric, a rubber band and an outer layer non-woven fabric are sequentially subjected to material compounding, cutting shaping, pocket compounding, folding turning, side edge sealing pressing and cutting shaping for finally forming the disposable anti-galactorrhea bra. In the material conveying direction, the equipment comprises a material unreeling mechanism, a composite roller group, a cutter shaping device, a cutter compounding device, a folding mechanism, a turning mechanism, a sealing pressing device and a cutting transferring device in sequential connection; a pocket opening non-woven unreeling roller is arranged at one side of the cutter compounding device; an inner layer non-woven unreeling roller, a rubber band unreeling roller and an outer layer non-woven fabric unreeling roller are arranged in the material unreeling mechanism. The method and the equipment can adapt to the high-speed operation of sanitary product production and package equipment; the production efficiency is high; the manufacturing cost is low; theprepared disposable anti-galactorrhea bra has stretching performance; the disposable anti-galactorrhea bra can be tightly attached to the breasts of the human body; phenomena of wearing looseness, rolling and the like can be avoided.

Owner:GUANGZHOU XINGSHI EQUIPS

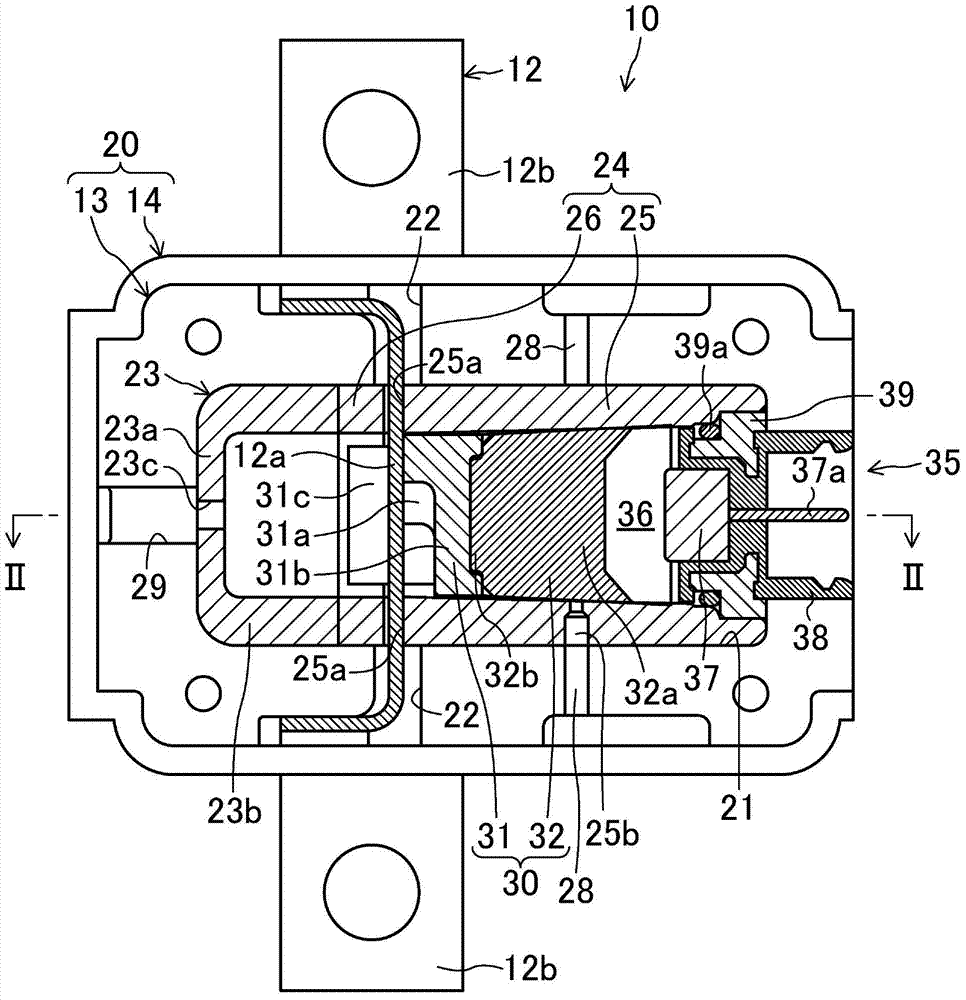

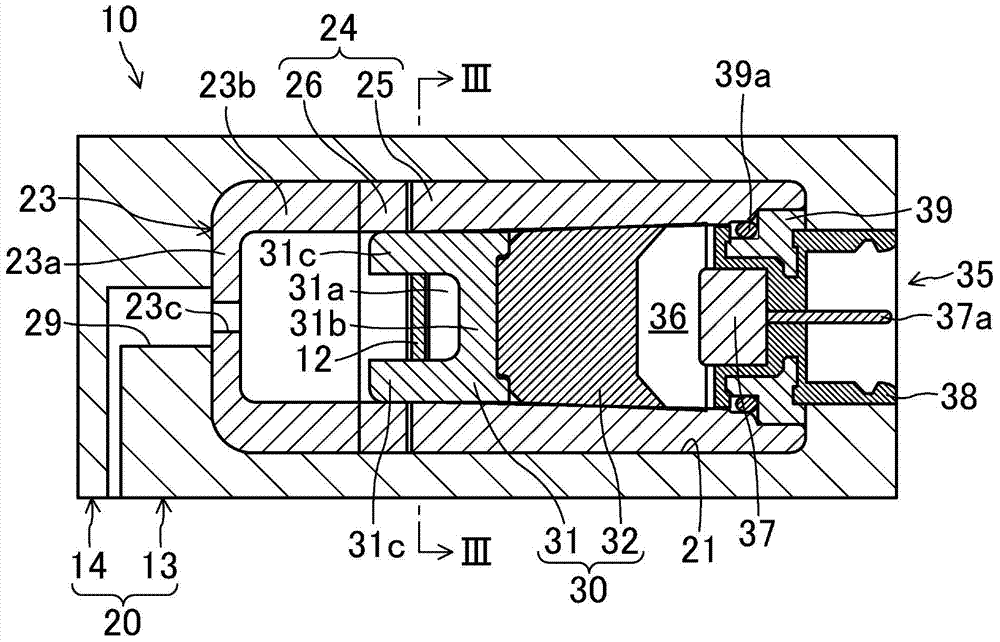

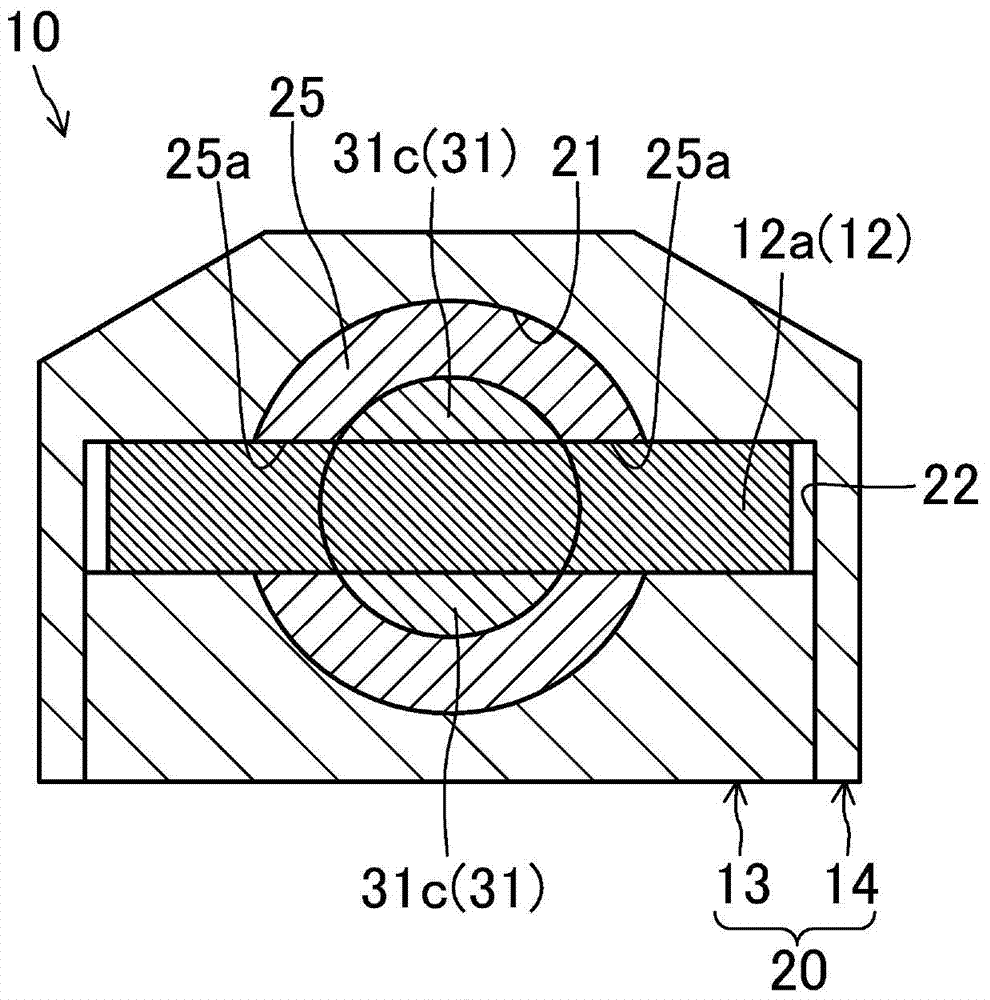

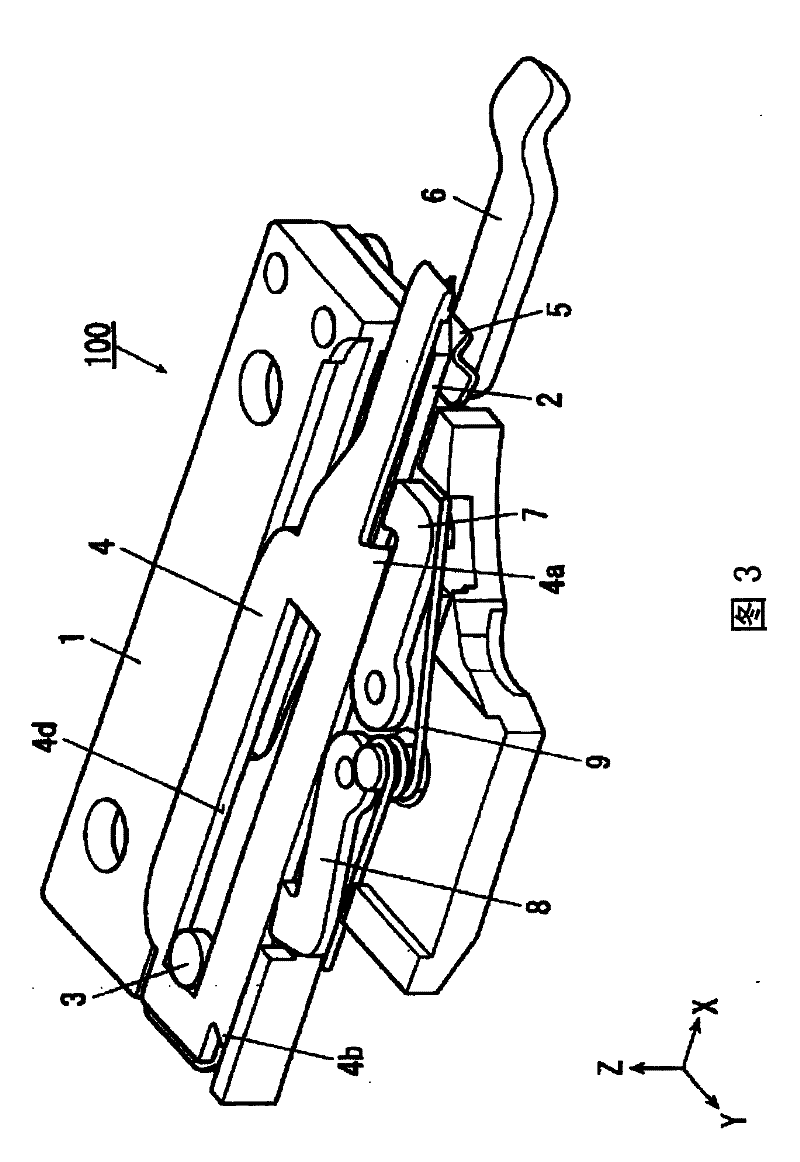

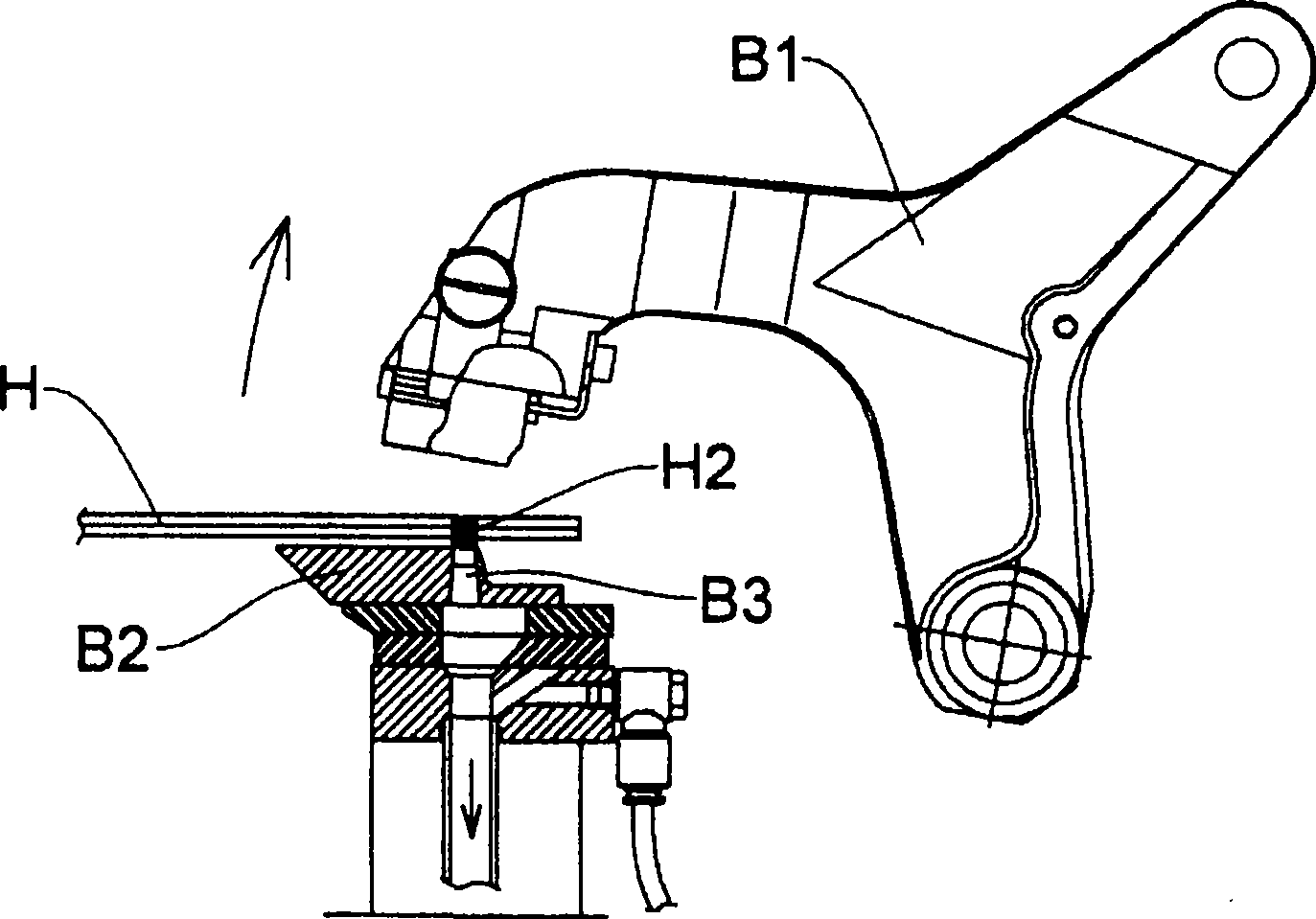

Cutting device

InactiveCN103946947APrevent movementCut off smoothlyConductor severing switchesShearing machinesMechanical engineeringEngineering

A cutting device (10) prevents movement of a harness during cutting. The cutting device (10) is provided with: a first tubular member (25) and a second tubular member facing each other with a specified interval between the axial-direction end face (25c, 26c) of each, said tubular members having a harness (12) inserted therebetween in the axial direction; and a blade (30) stored in the first tubular member (25) so as to slide freely in the axial direction, and having a front-side cutting portion (31) and a rear-side pusher (32). In the first tubular member (25), a rear-side tapering portion (25d) and a front-side tapering portion (25e) are formed, in which the inner circumference gradually narrows from rear to front in the plane in which the pusher (32) slides.

Owner:DAIKIN IND LTD

Waste tire recovery processing equipment

ActiveCN109834870APrevent movementGuaranteed cut offPlastic recyclingGrain treatmentsEngineeringWaste tires

The invention discloses waste tire recovery processing equipment. The waste tire recovery processing equipment includes a rack, a cutting device arranged on the rack, a wire drawing device matched with the cutting device and a crushing device matched with the wire drawing device, and the cutting device includes a cutting part which can move back and forth, a first driving part for driving the cutting part to move back and forth, a synchronous plate for connecting the cutting part and the first driving part and a compression structure for fixing tires; and a cutting table matched with the cutting part is arranged on the rack. According to the waste tire recovery processing equipment, by arranging the cutting device, steel wires are easier to pull out, the degree of deformation is low, winding is difficult, removing is easier even when the steel wires are winded, production is more time-saving and labor-saving, and the efficiency of the wiredrawing work is improved.

Owner:湖南启恒环保科技有限公司

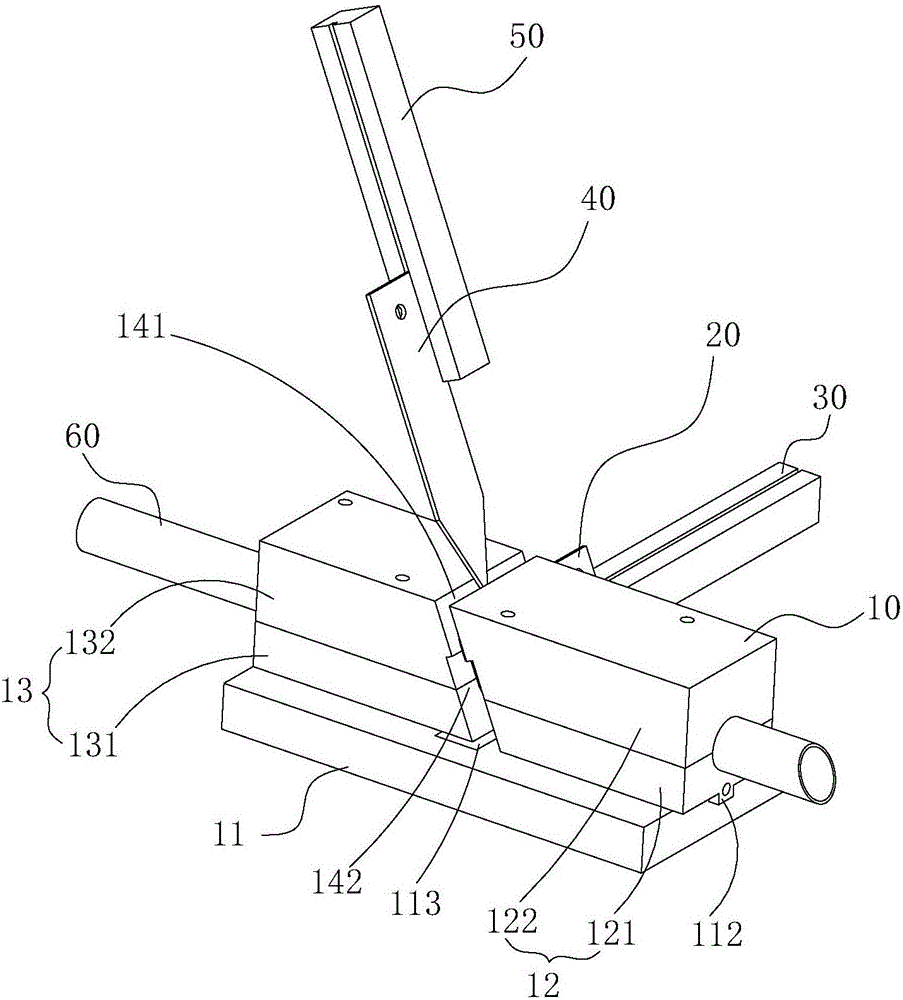

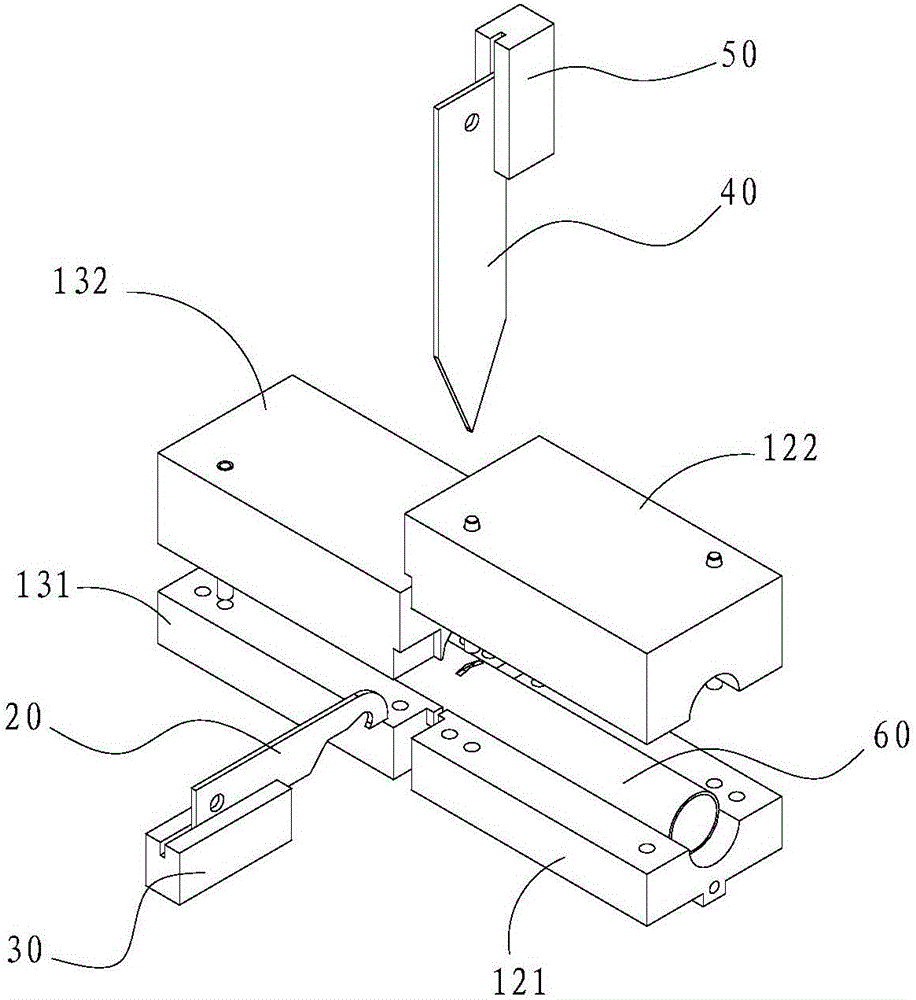

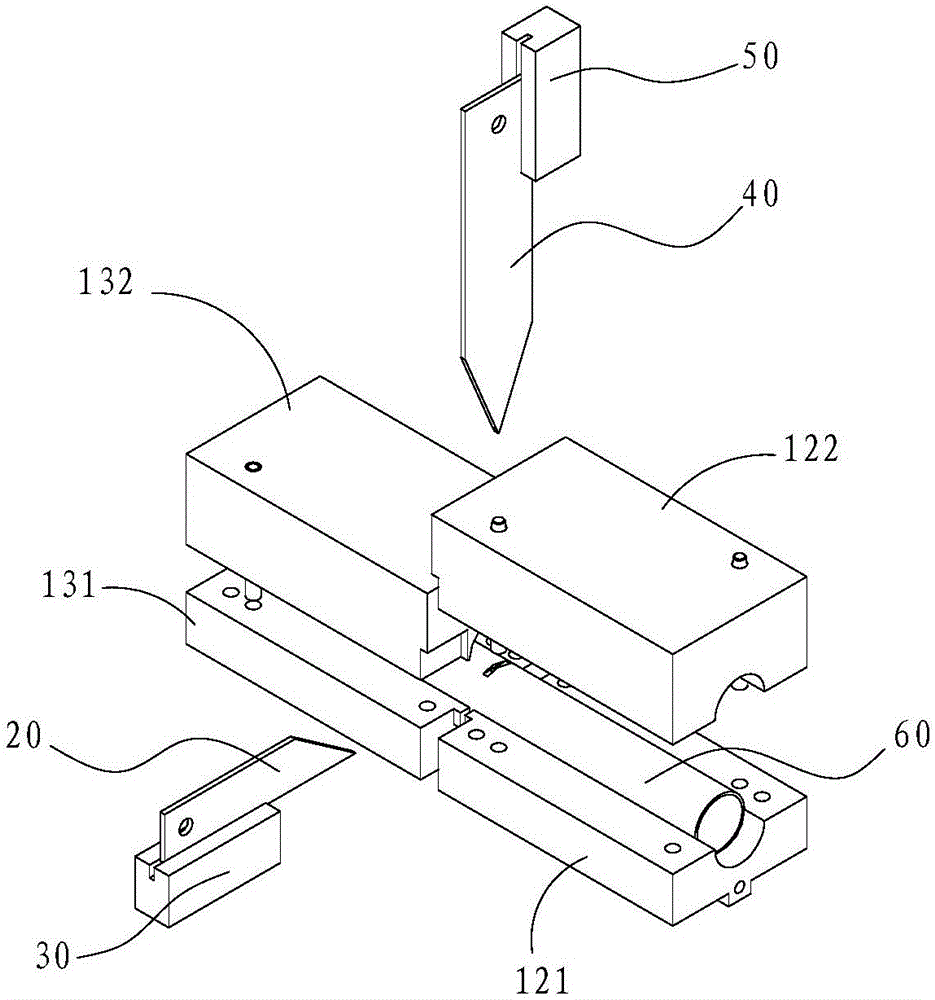

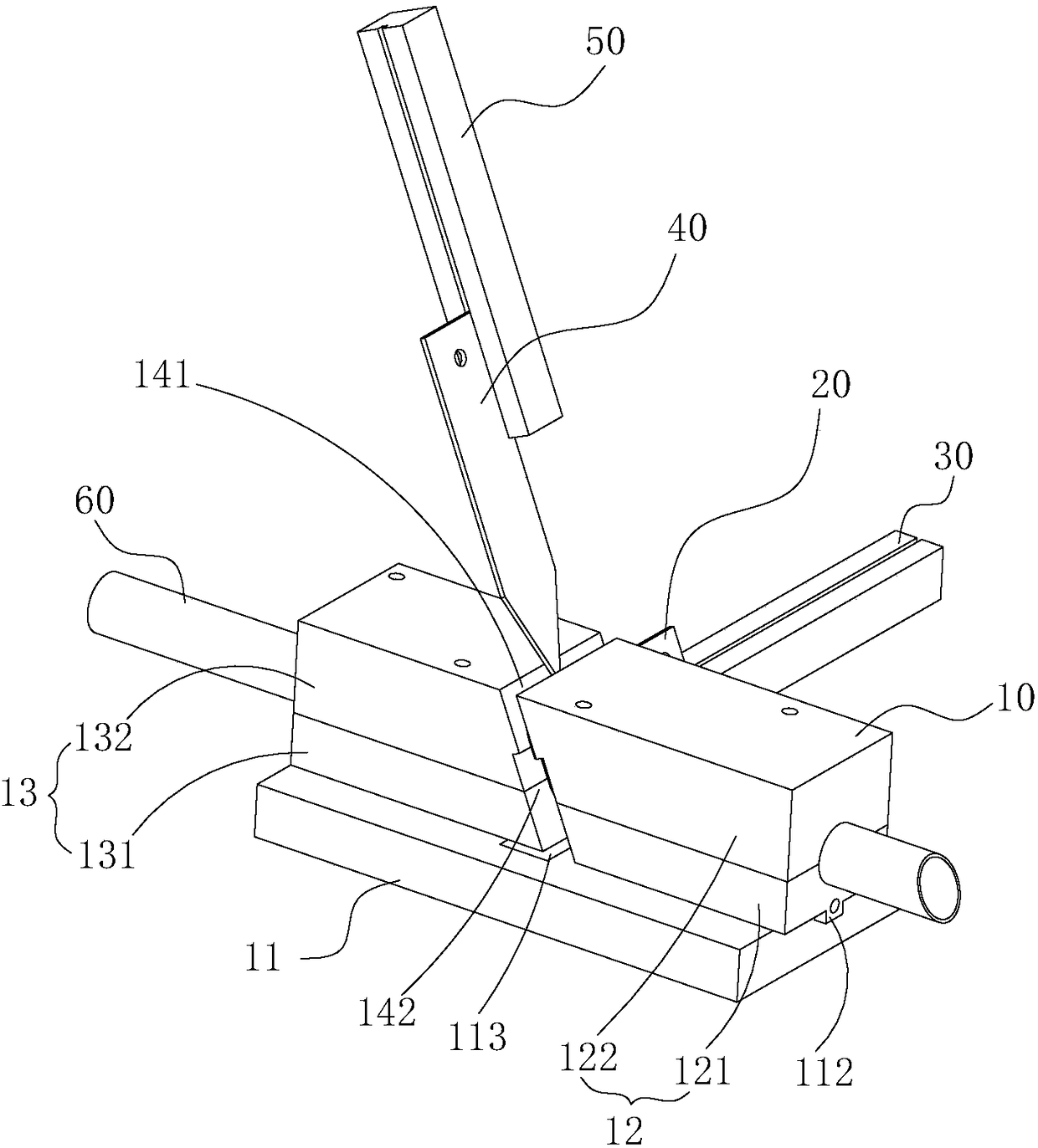

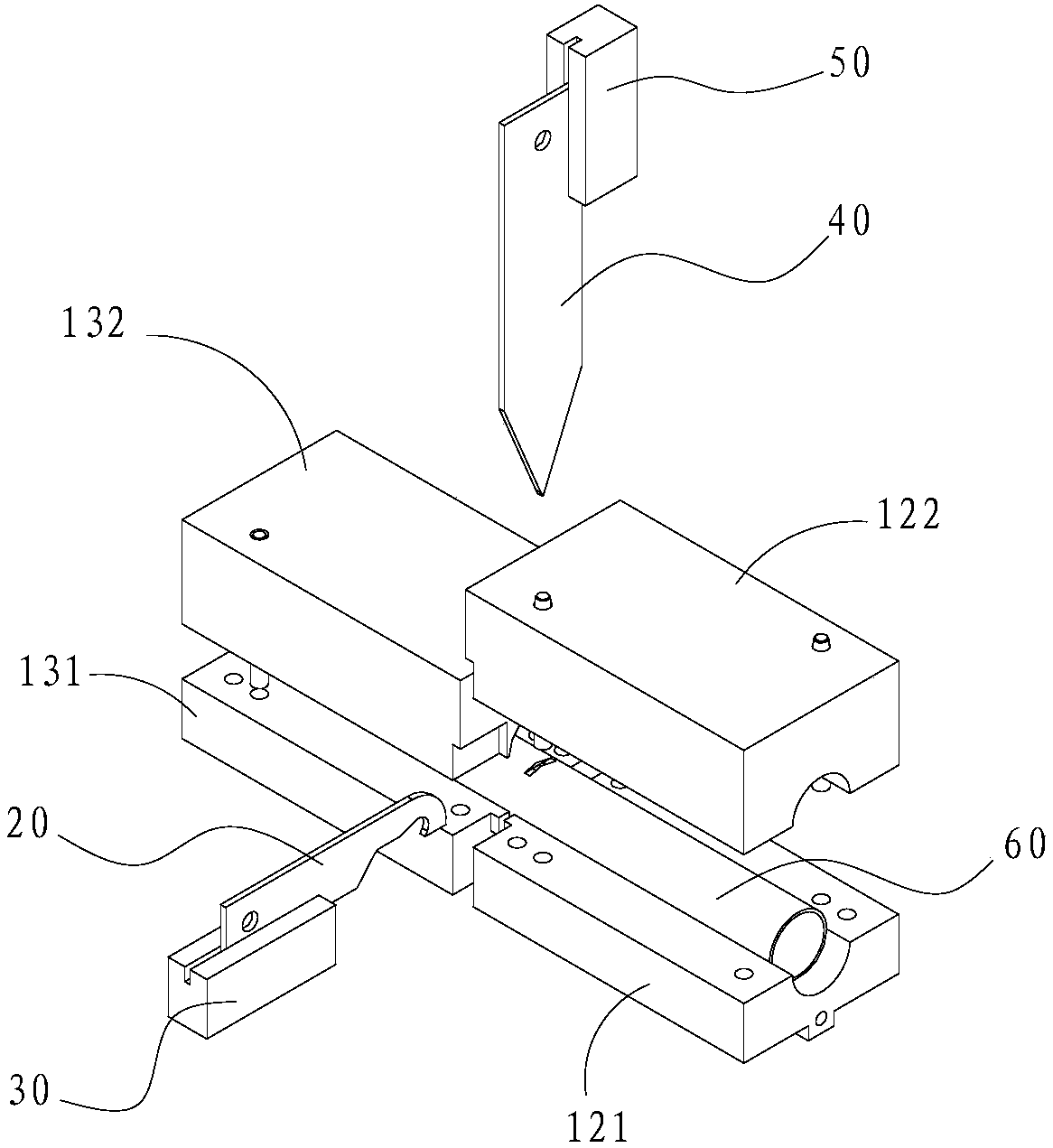

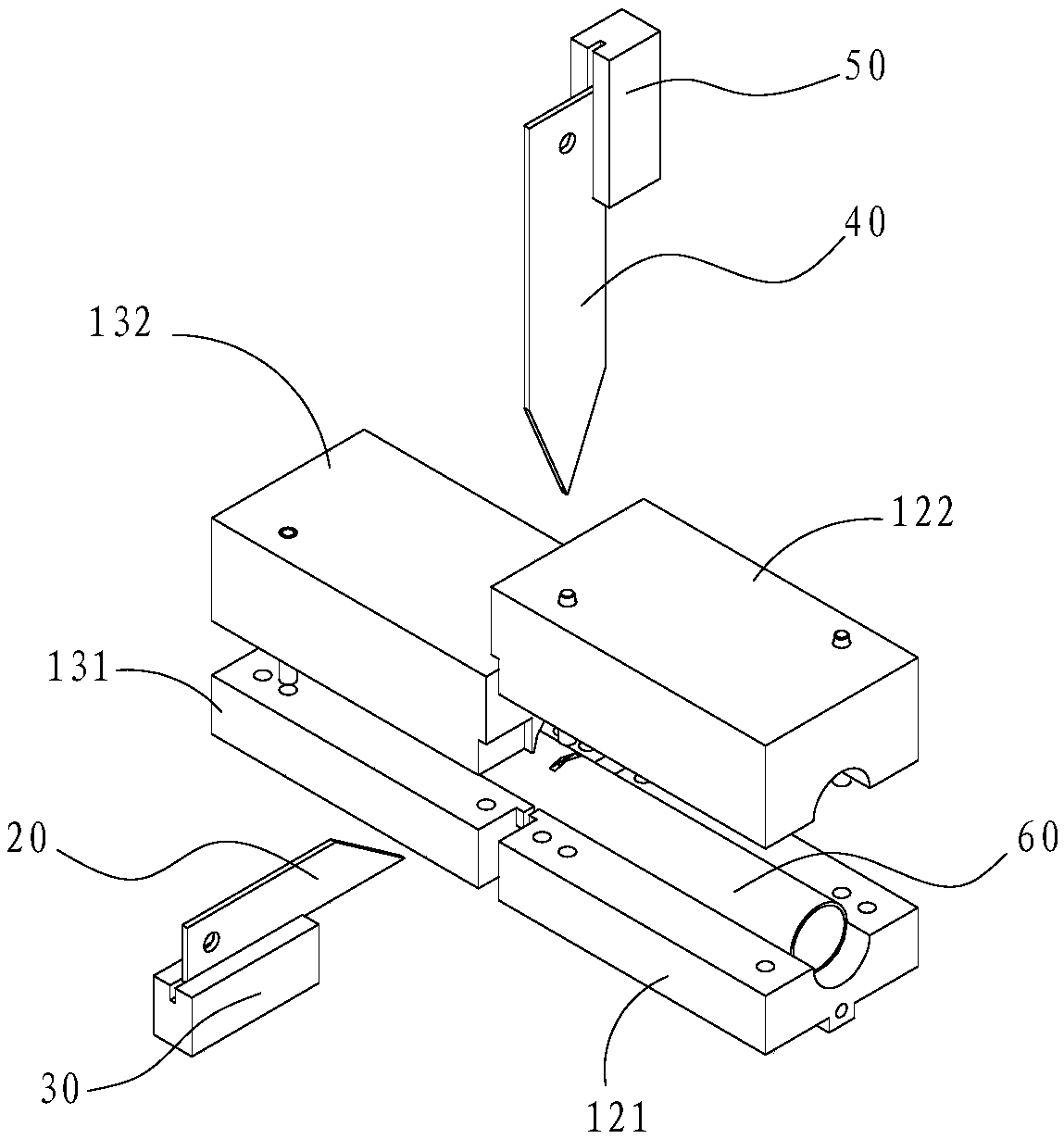

Cutting device and cutting method of pipes

ActiveCN106216758ACut off smoothlyLess dustPlaning/slotting toolsTube shearing machinesEngineeringScrap

The invention discloses a cutting device and cutting method of pipes. The cutting device comprises a clamping mechanism, a first cutting part, a first driving part, a second cutting part and a second driving part; the clamping mechanism is used for clamping the pipes; the first cutting part is arranged in an inclined mode relative to the pipes; the first driving part is in drive connection with the first cutting part; the second cutting part is arranged in an inclined mode relative to the pipes, and the inclination direction of the second cutting part is the same as the inclination direction of the first cutting part; and the second driving part is in drive connection with the second cutting part, is used for driving the second cutting part to move back and forth in a second direction and enables the head of the second cutting part to be inserted into the pipes through notches. According to the cutting device, powdered scraps generated in the cutting process are reduced, and burrs on inclined cutting surfaces of the pipes are reduced.

Owner:OMS MASCH CO LTD

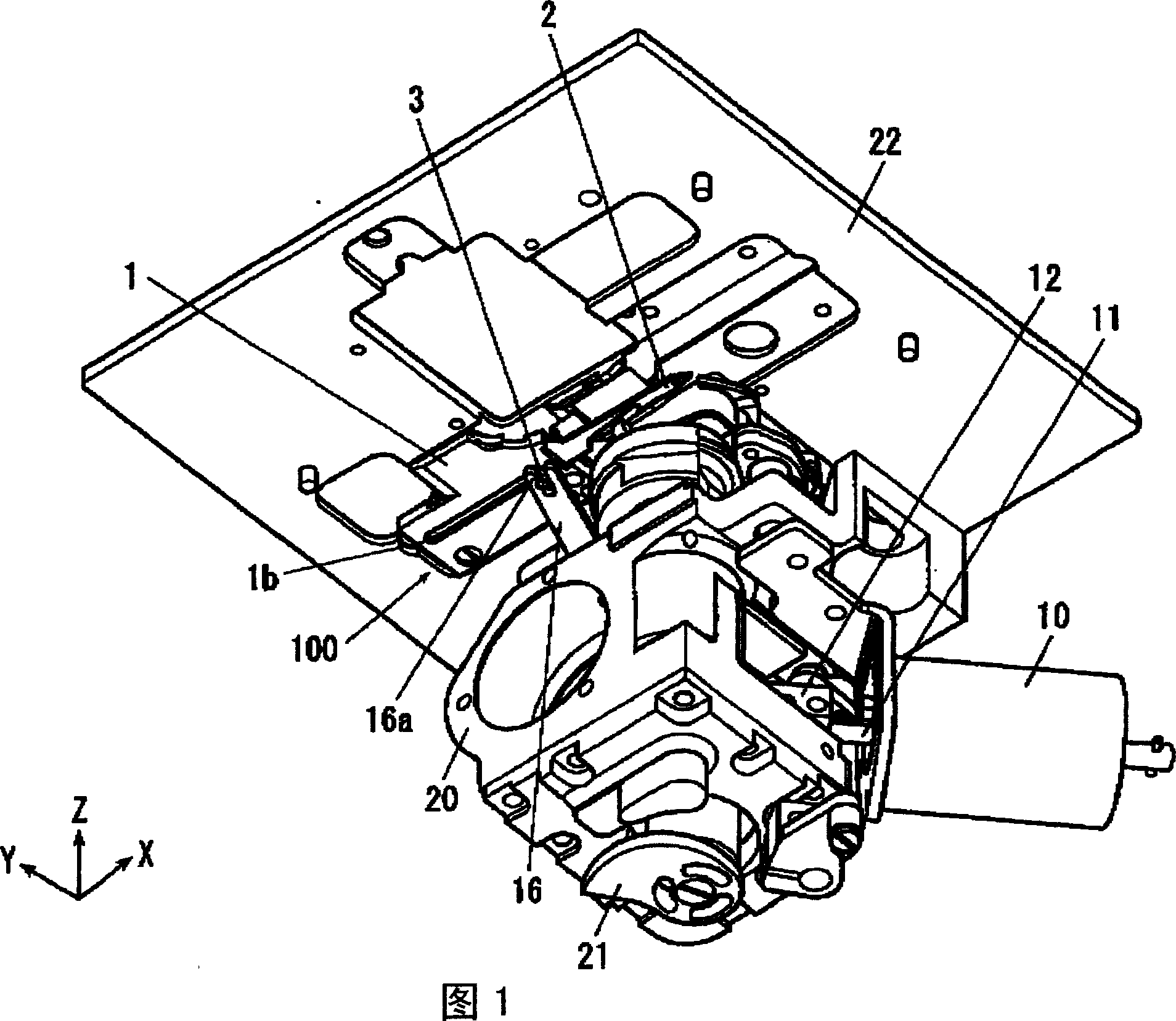

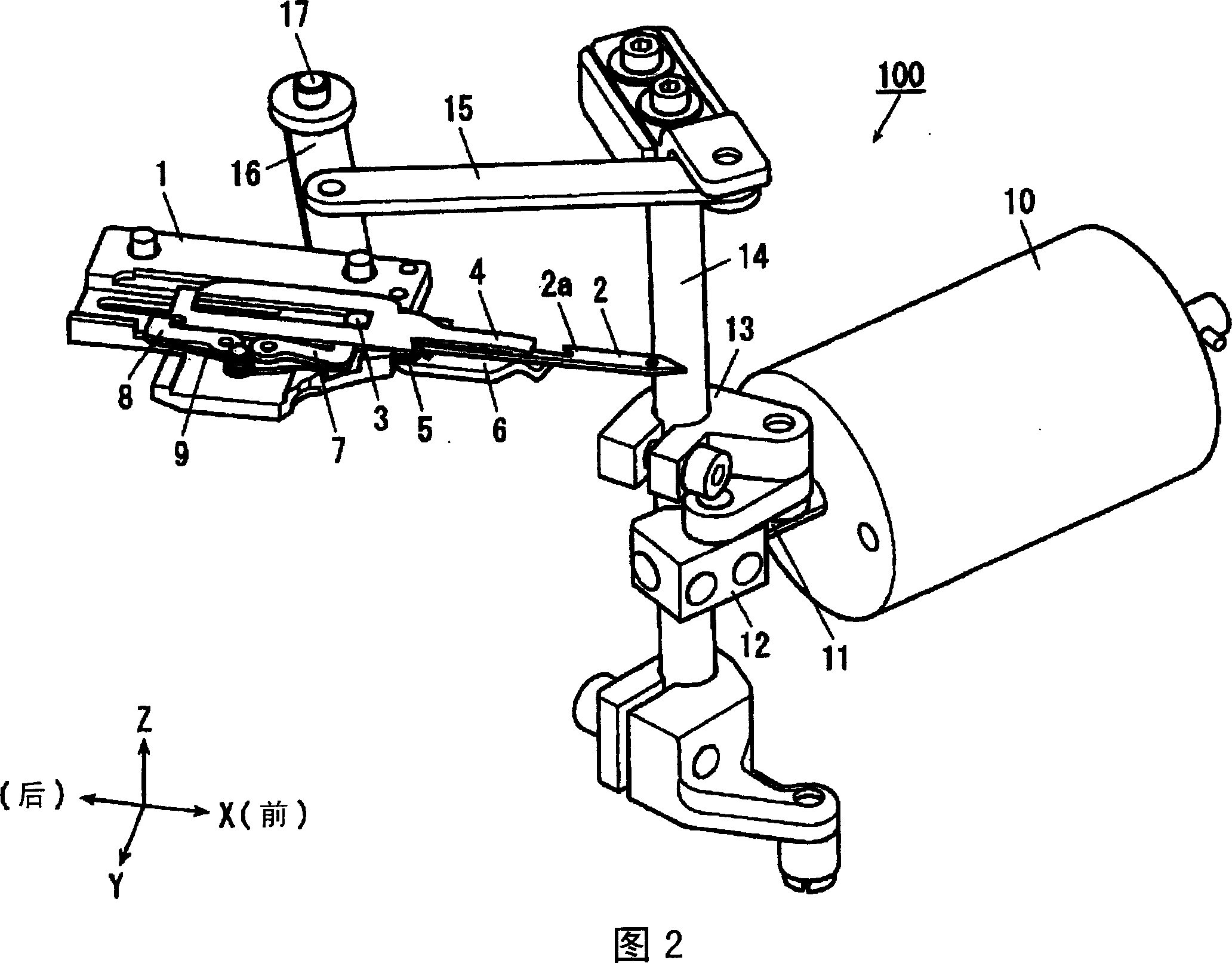

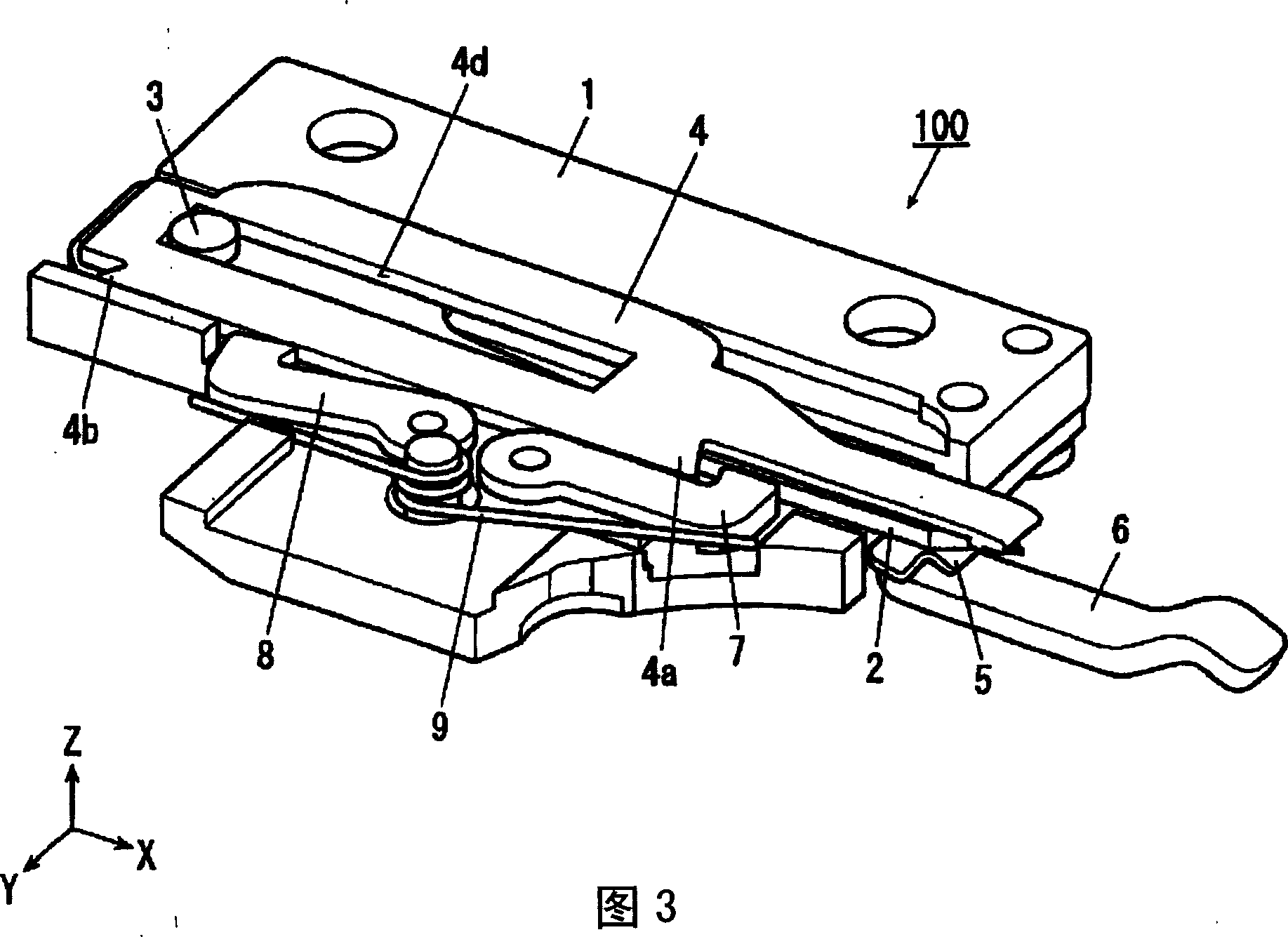

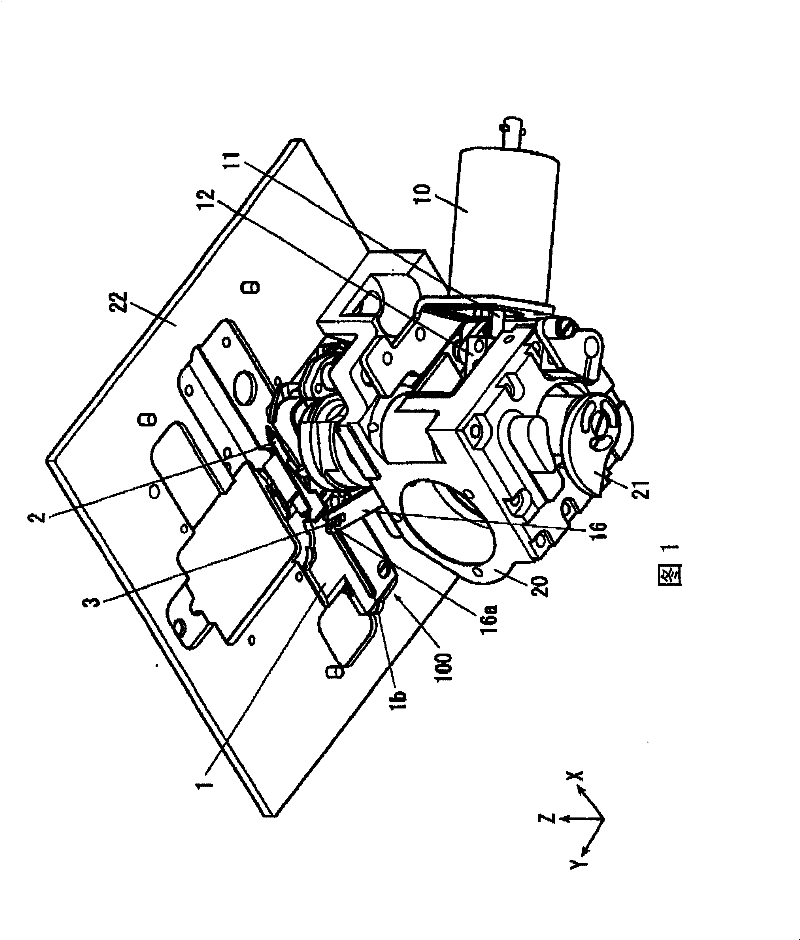

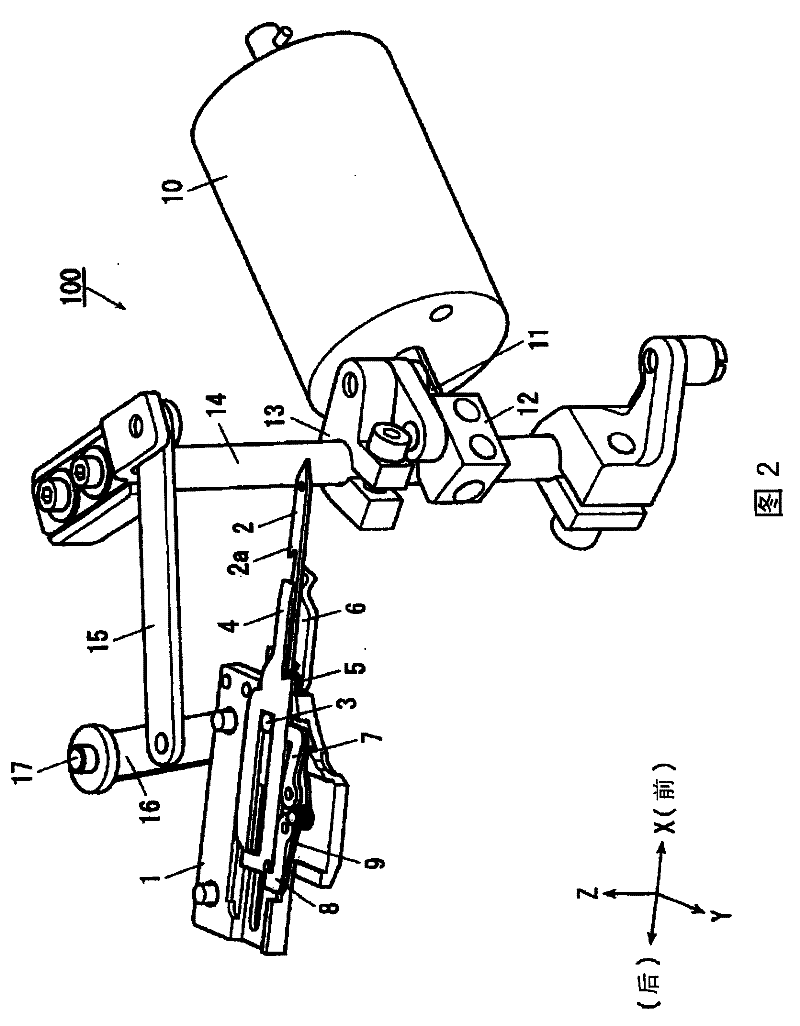

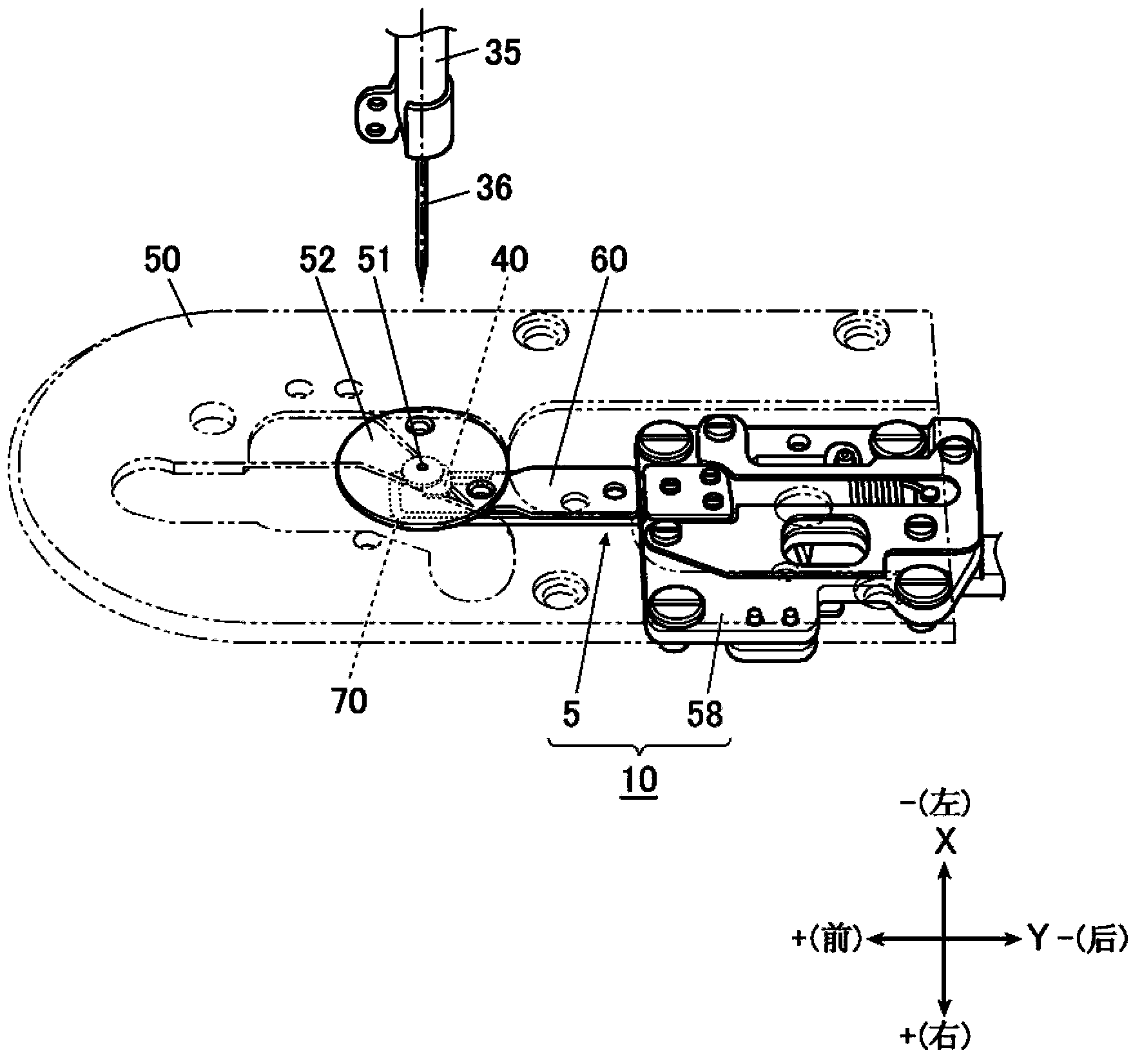

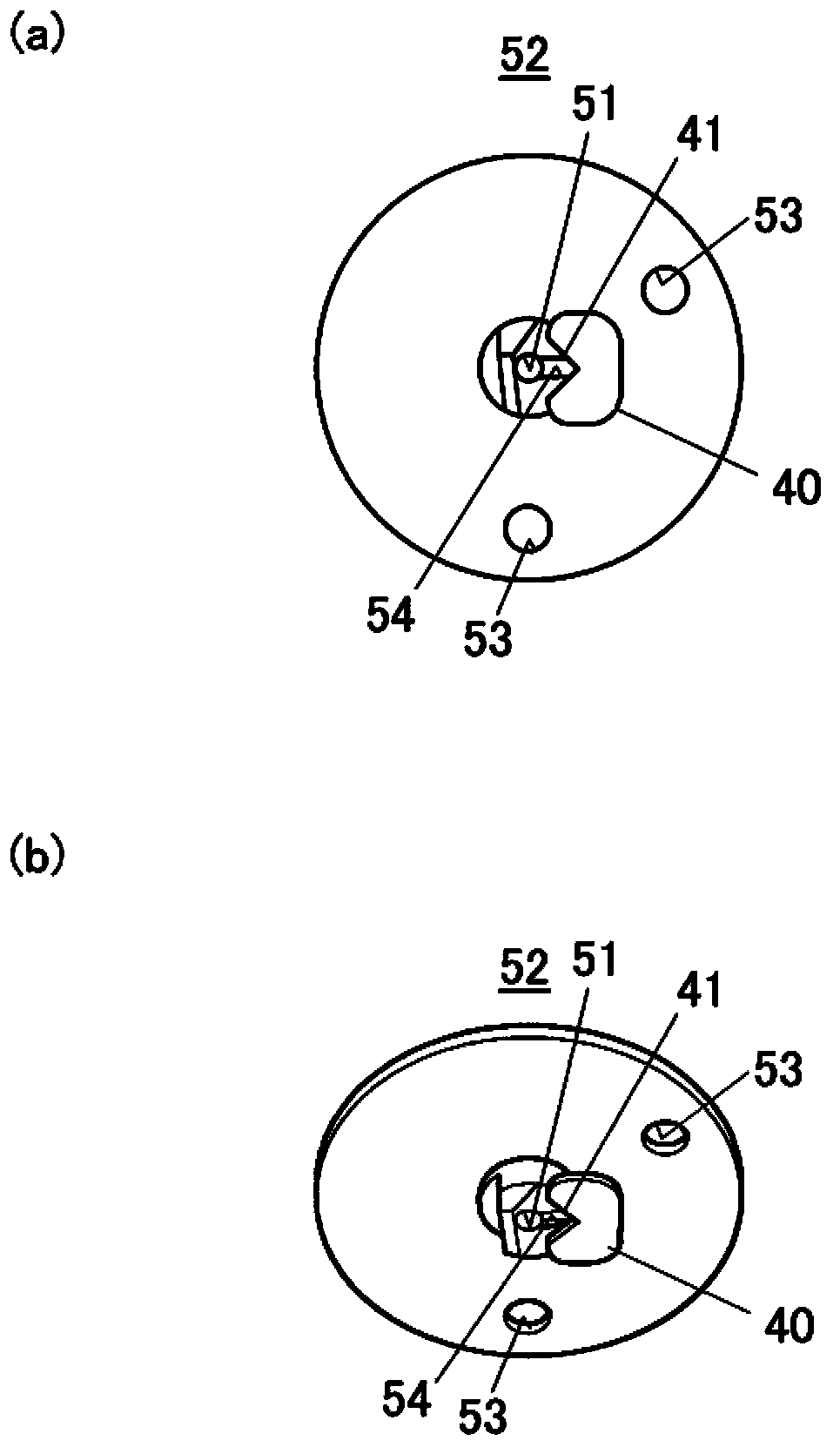

Wire cutting device for swwing machine

InactiveCN1982525AFull cutting forceSmooth tangent actionNeedle severing devicesWire cuttingEngineering

Owner:JUKI CORP

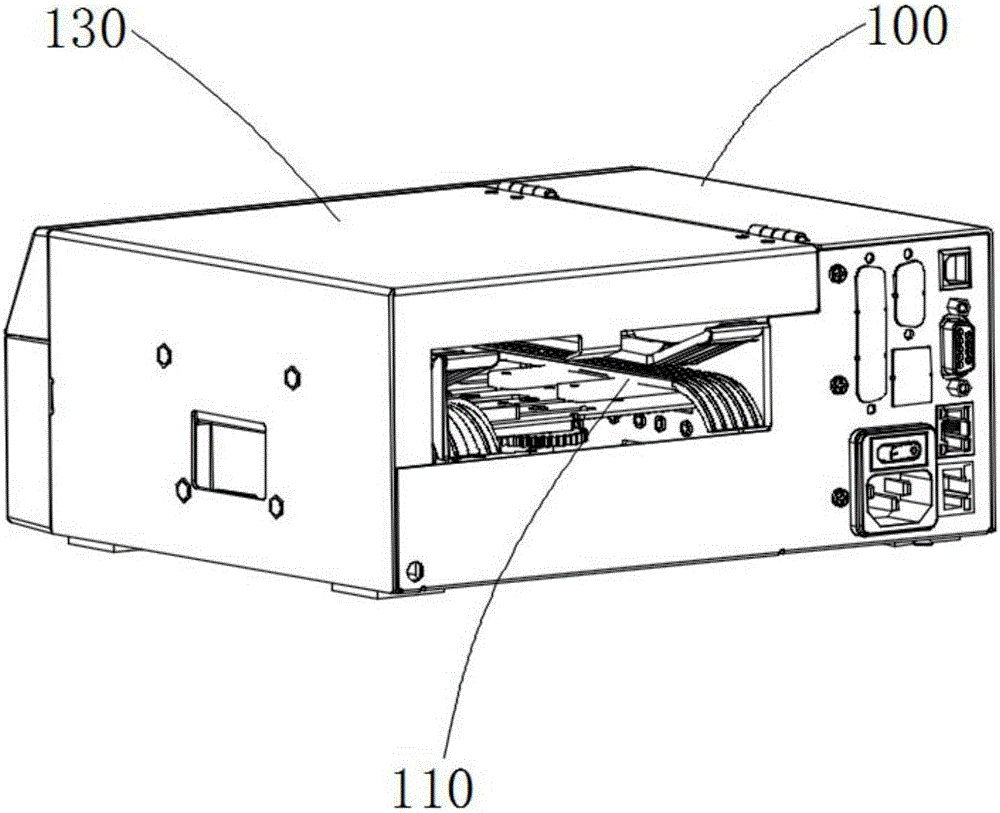

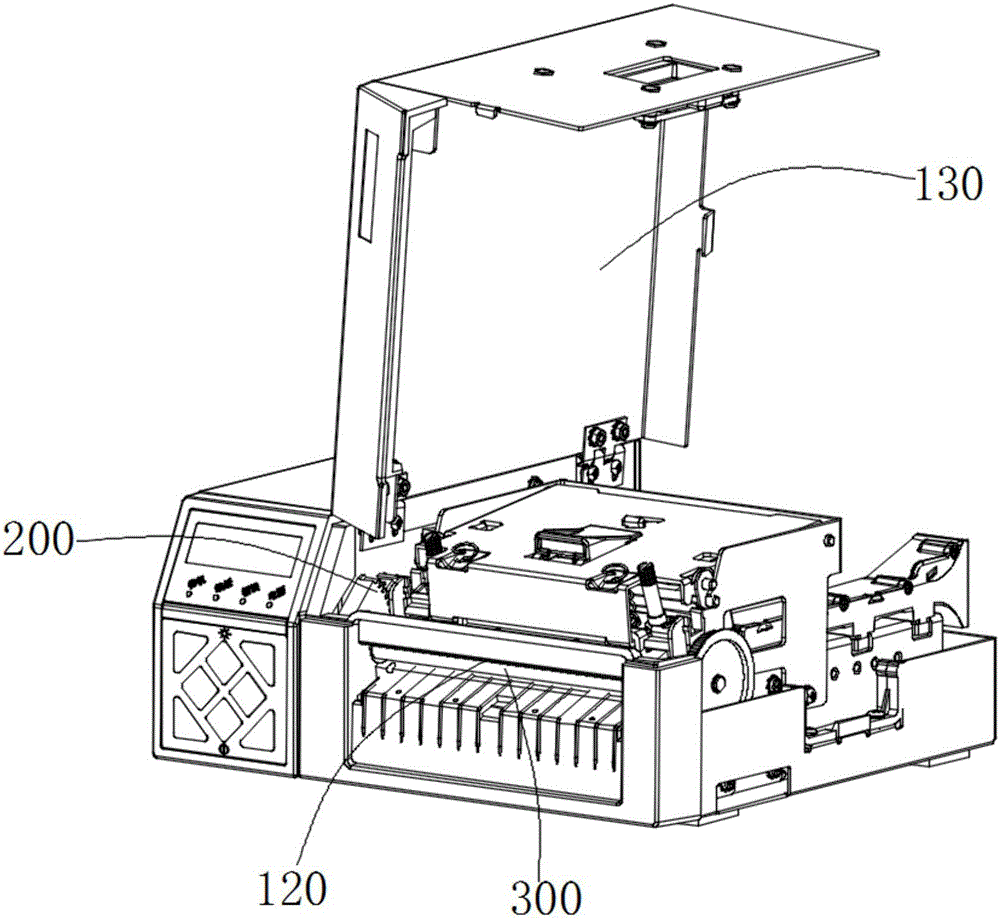

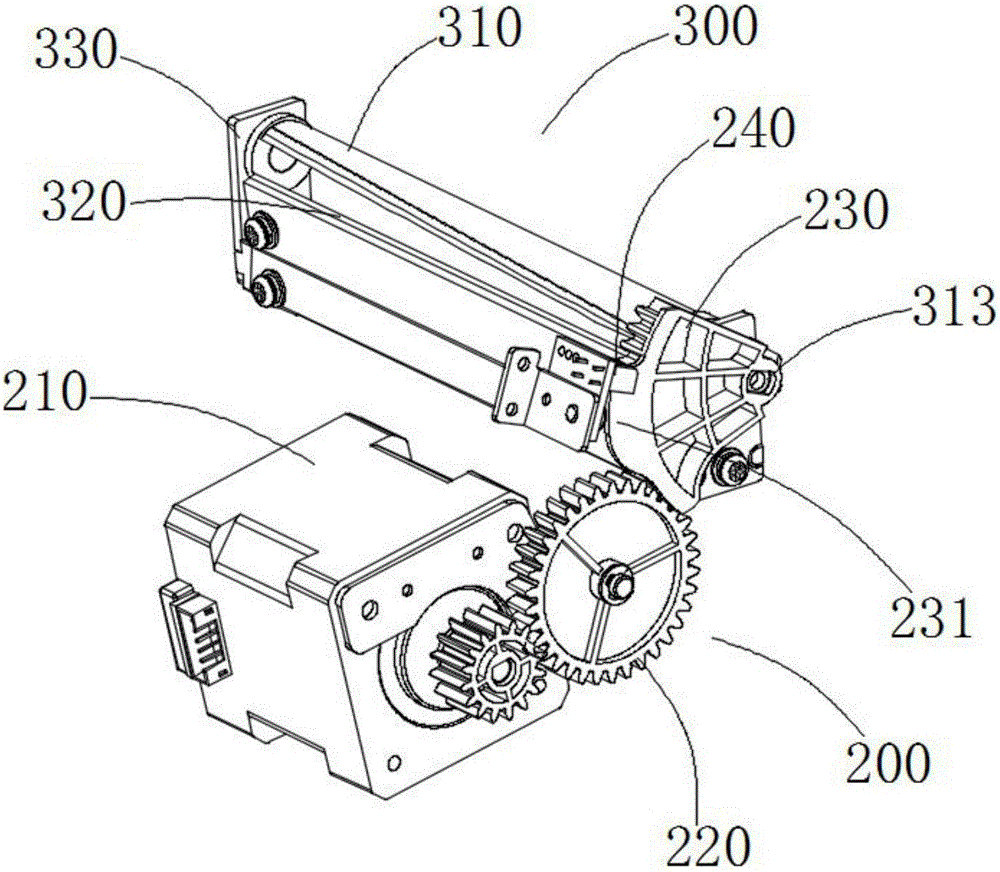

Efficient cutter device used for printer and printer

The invention provides an efficient cutter device used for a printer and the printer. The cutter device comprises a fixing frame, a fixed cutter and a movable cutter. The fixed cutter is arranged on the fixing frame and provided with a fixed blade, and a cutting edge of the fixed blade is formed by two intersecting planes. The movable cutter is located above the fixed cutter and rotatably arranged on the fixing frame. The movable cutter comprises a movable blade and a support, wherein the movable blade is arranged in the support, and a cutting edge of the movable blade is formed by intersecting a curved surface and a plane and arranged obliquely relative to the cutting edge of the fixed blade, and protrudes outwards relative to the support. A scrap discharging space is formed between the top surface of the movable blade and the support. According to the cutter device, the cutting edge of the movable blade protrudes outwards relative to the support, and the scrap discharging space is formed between the top surface of the movable blade and the support. Paper scraps generated in the cutting process are removed out smoothly along the scrap discharging space, so that smooth cutting is ensured.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

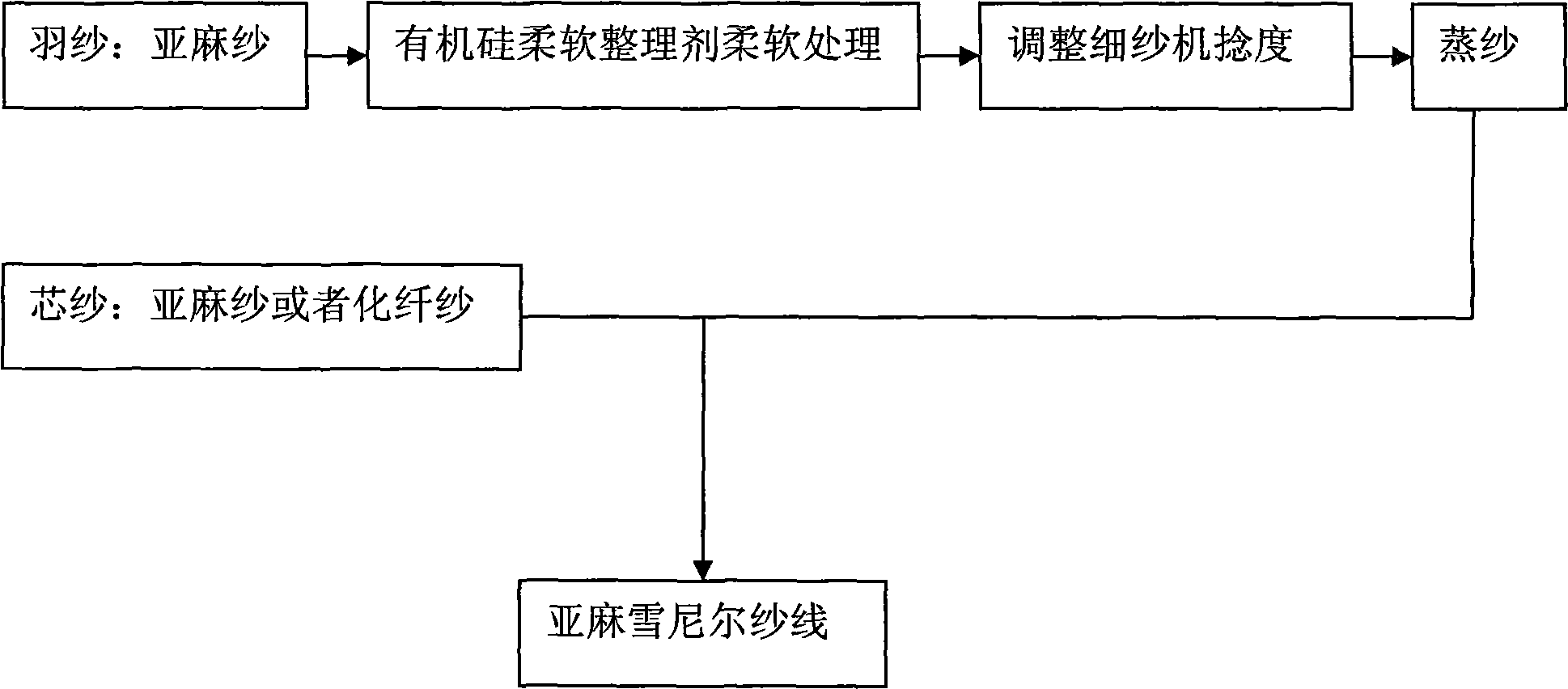

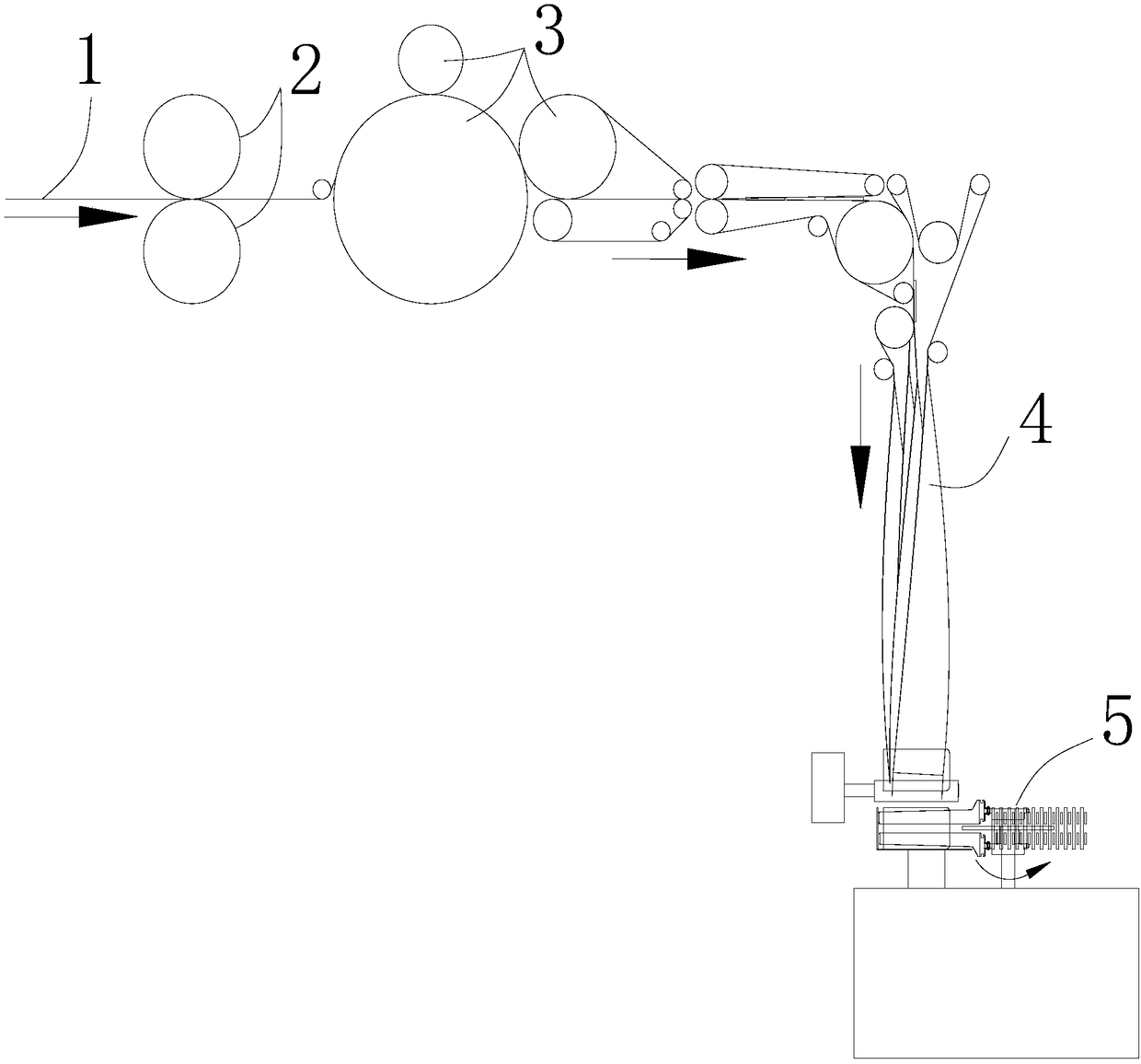

Process for manufacturing linen-chenille yarn

The invention discloses a process for manufacturing linen-chenille yarn used on knitwear and home textile fabric. The linen-chenille yarn comprises center yarn and camblet, wherein the camblet is linen yarn; the center yarn can adopt linen yarn or chemical fiber yarn; the center yarn is two folded yarns; and the linen-chenille yarn is spun from the linen camblet which is cut off and then twisted so as to be clamped between the two folded yarns. The process is characterized in that the treatment for the linen camblet comprises the steps of adopting an organosilicon softening-finishing agent MEGASOFT LUX to soften rough linen yarn which is boiled and bleached, regulating the twist degree of a linen-yarn spinning machine and steaming the spun linen yarn which is wound. The linen-chenille yarn produced by the process for manufacturing linen-chenille yarn has the advantages of even yarn levelness, good spinnability and soft hand feel.

Owner:ZHEJIANG JINYUAN FLAX

Linear anastomat with secondary nail discharging function

ActiveCN113057701APrevent fallingPrevent falling outIncision instrumentsSurgical staplesAnastomosis couplerStructural engineering

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

Food cutting processing machine and steamed stuffed bun making machine

PendingCN109511701AImprove cutting efficiencyCut off smoothlyDough shaping and cutting apparatusDough processingEngineeringMechanical equipment

The invention relates to a food cutting processing machine and a steamed stuffed bun making machine. The food cutting processing machine is characterized in that a plurality of shaping cutters in uniform distribution in the peripheral direction are used; the cutting edge end of each shaping cutter points to the axis center and is gathered in the axis center position to form a closed state; each shaping cutter can realize the synchronous swinging by using the opposite end of the cutting edge end as the axis, so that the cutting edge end of each shaping cutter leaves away from the axis center position, so that the axis center positions becomes an open state. The food cutting processing machine has the effects that the strip-shaped food can be cut in a peripheral shrinkage way; the contact between the food and a transmission mechanism of the mechanical equipment is avoided; safety and sanitation are realized; the cutting efficiency is high.

Owner:王晓杰

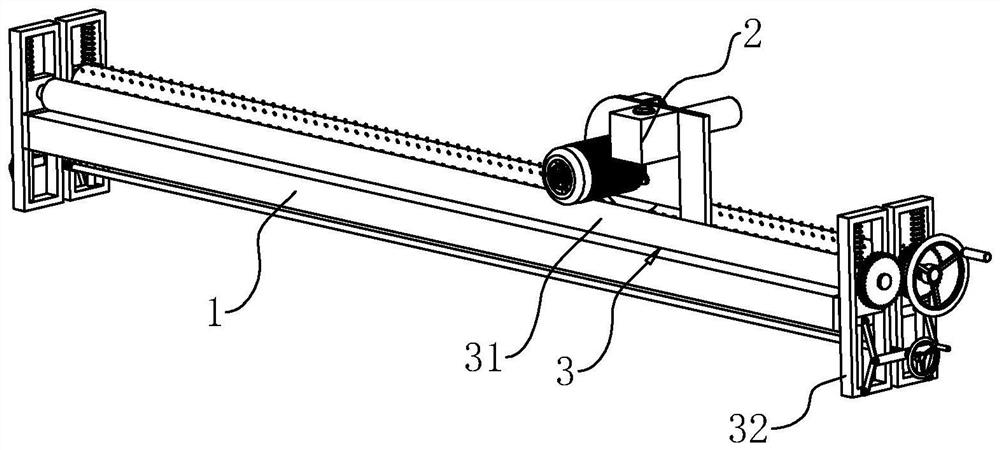

Novel cloth cutting machine

ActiveCN111945411ASituations that limit gatheringCut off smoothlySevering textilesEngineeringMechanical engineering

The invention relates to a novel cloth cutting machine which comprises a sliding rail used for being fixed to a workbench. An electric shear is slidably connected to the sliding rail in the length direction of the sliding rail, and a pressing assembly used for extruding cloth is arranged on the sliding rail; the pressing assembly comprises two pressing rollers arranged at the left side and the right side of the electric shear respectively, the pressing rollers are arranged in the length direction of the sliding rail, frames fixedly connected to the ends of the sliding rail are arranged at thetwo ends of each pressing roller, sliding blocks are slidably connected into the frames in the vertical direction, and rotating shafts are fixedly connected to the two ends of each pressing roller, penetrate through the sliding blocks and are rotationally connected with the sliding blocks; and pressure springs for driving the sliding blocks to move downwards are arranged above the sliding blocks.The novel cloth cutting machine has the effect that the situation that when the electric shear cuts the cloth, the cloth is gathered and wrinkles are generated is reduced.

Owner:北京阿尔法针织有限公司

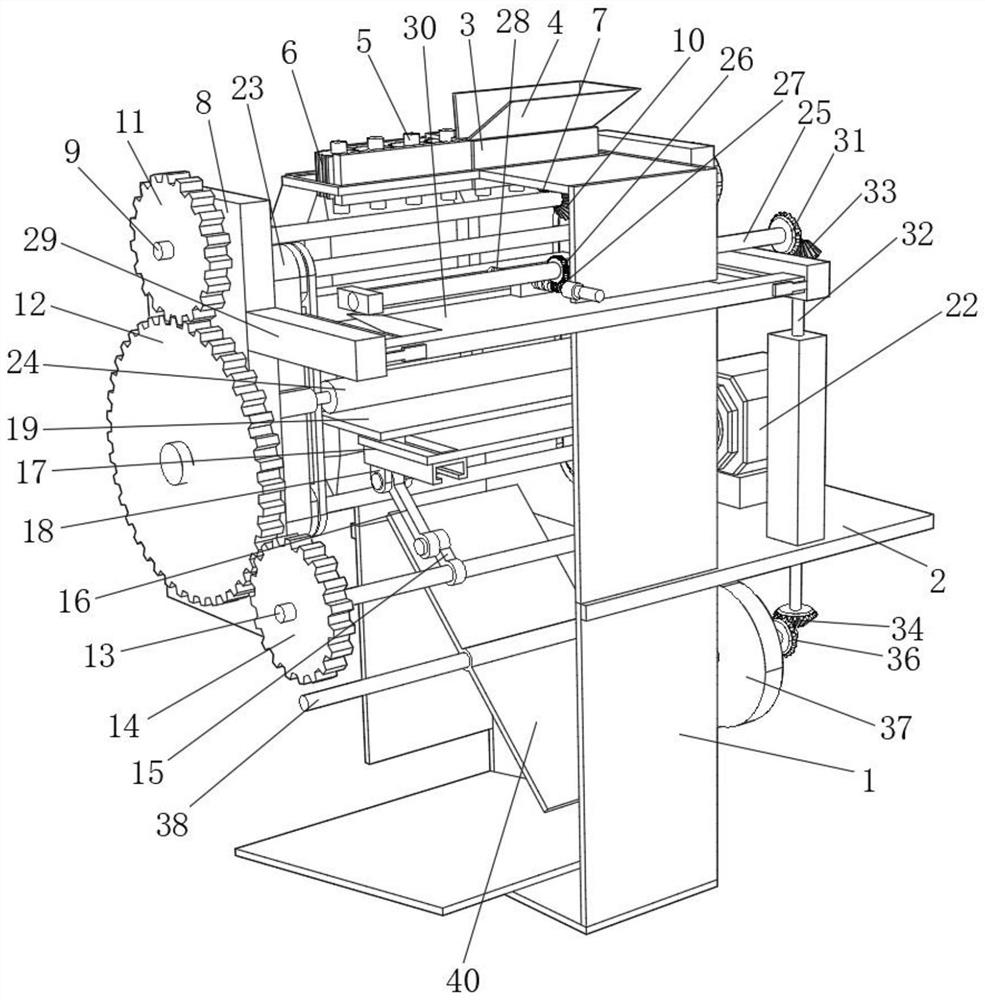

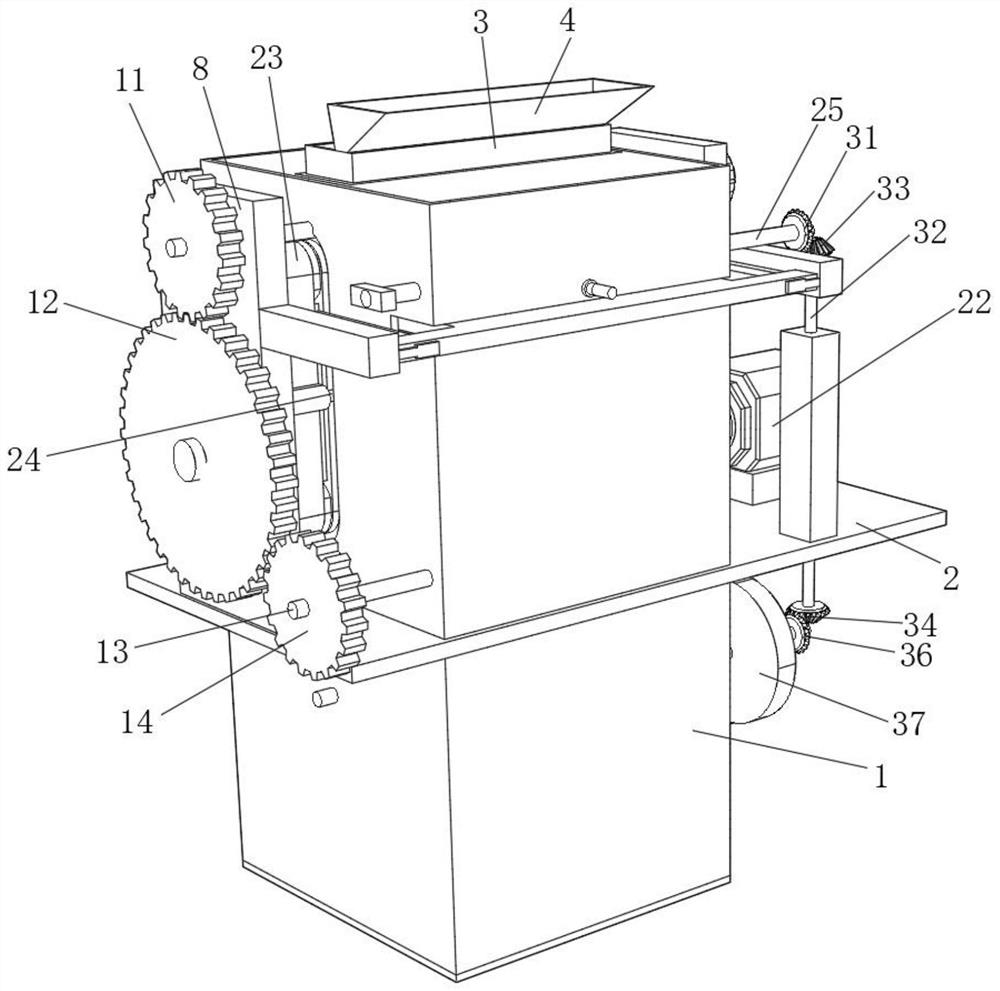

Improved food cross-cutting device

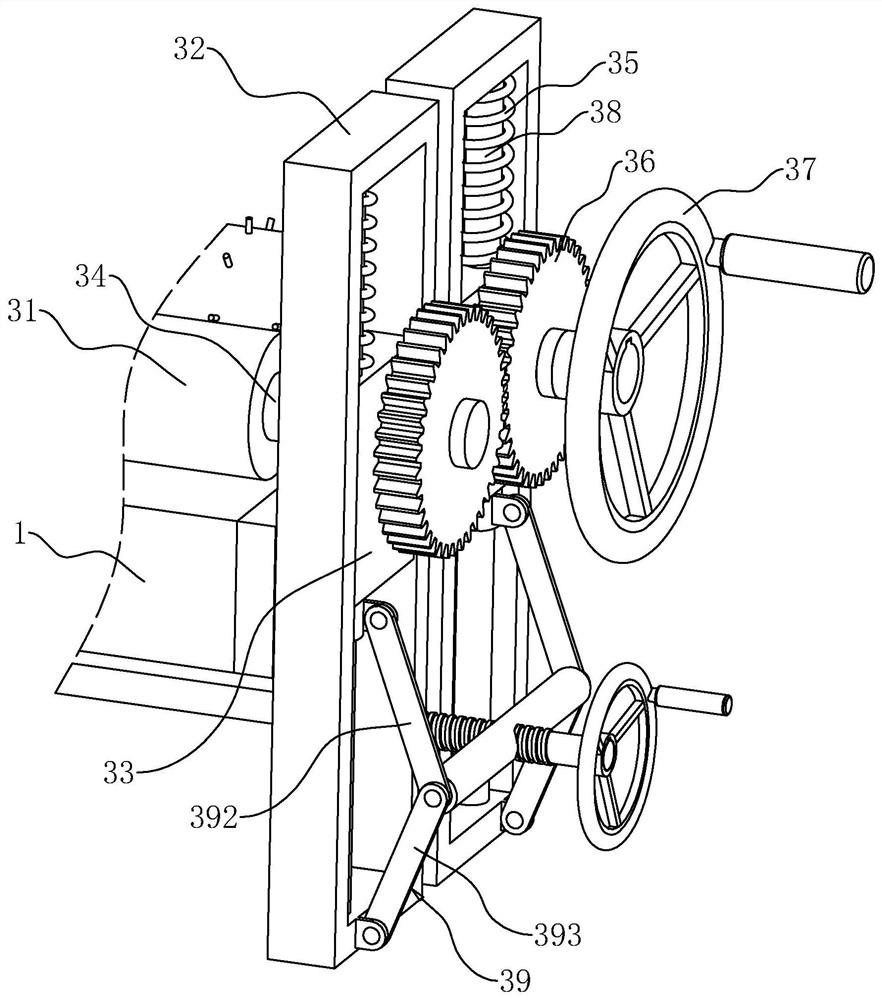

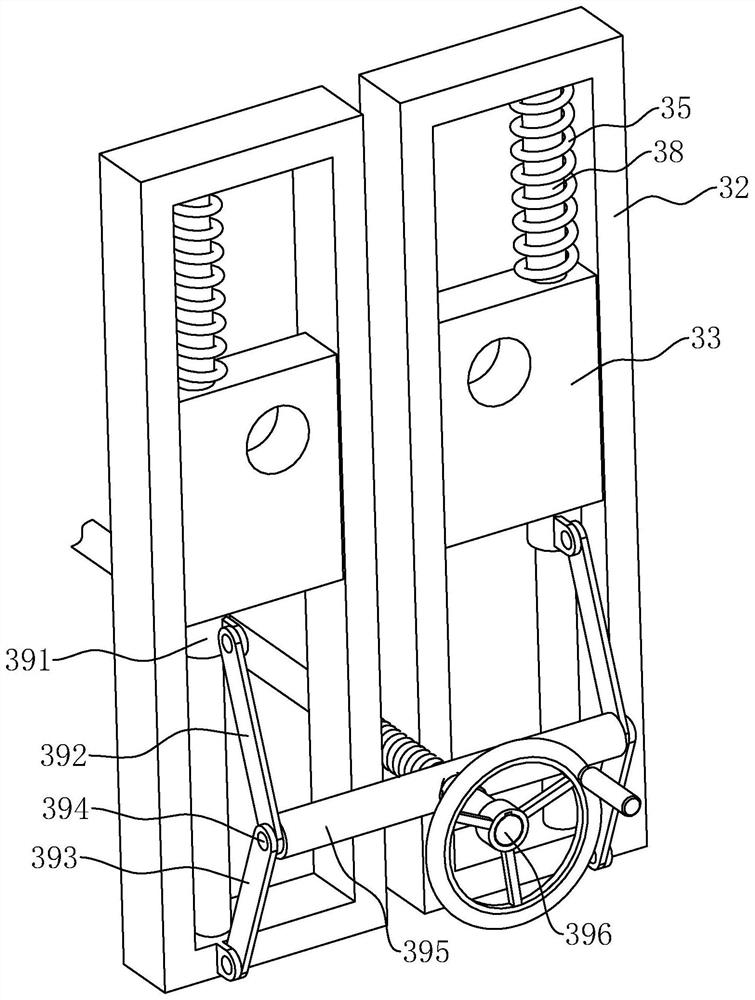

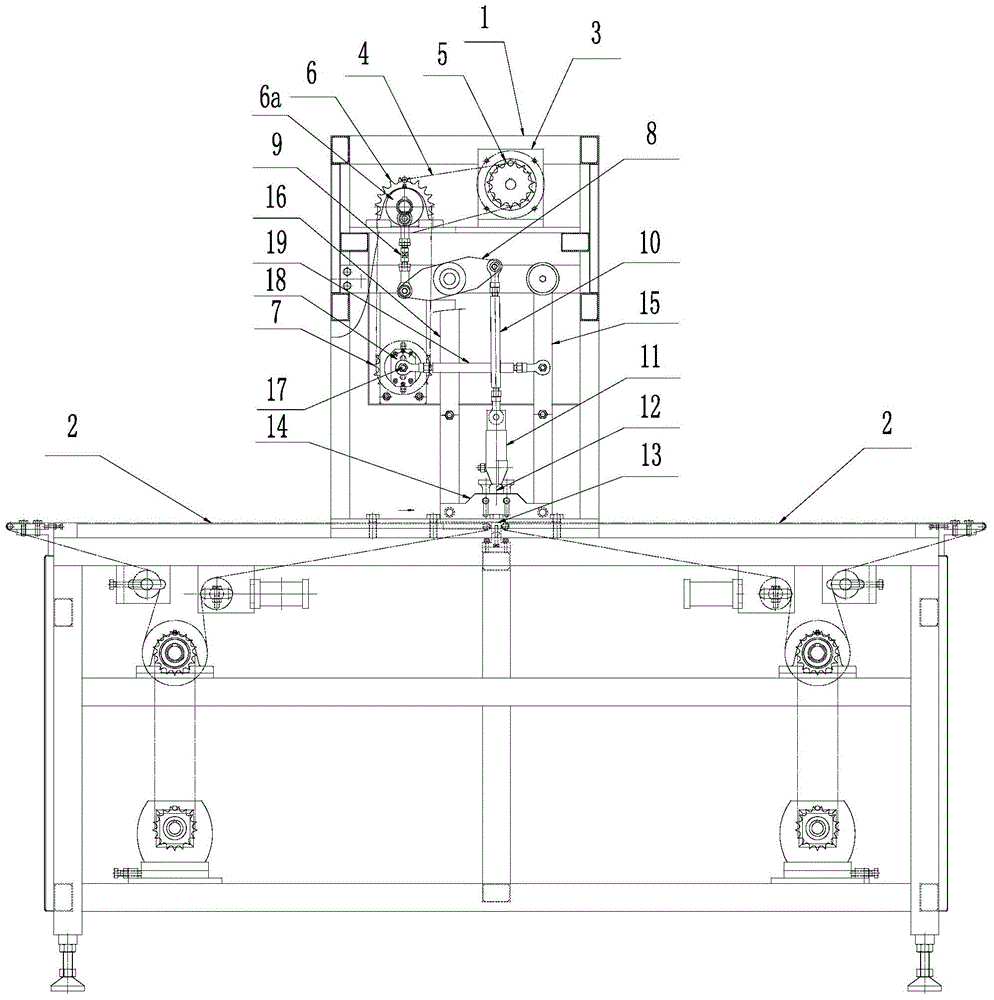

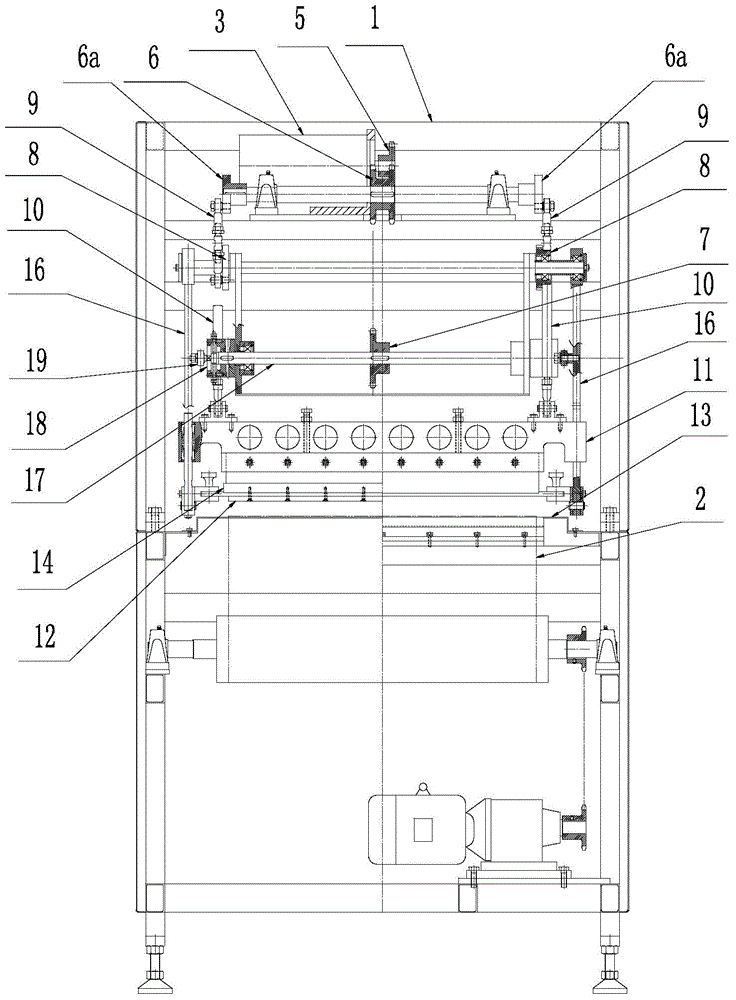

ActiveCN104890028APrevent contact deformationIncreased cutting stability and reliabilityCocoaMetal working apparatusSprocketCam

The invention discloses an improved food cross-cutting device. An original material conveying mechanism and an original cutter driving mechanism are both improved, and a fixed support block is arranged in a gap between two groups of driving belts to replace an original roller, so that a cutter is effectively prevented from being in contact with the roller leading to deformation, stability and reliability of cutting of the cutter are improved greatly, and materials are ensured to be cut smoothly; the cutter driving mechanism is replaced, an original cam and tension spring combination is omitted, a two-stage sprocket drive mechanism taking an eccentric wheel as the main component respectively drives a vertical cutter movement mechanism and a cutter swing mechanism to act respectively, noise of operation is lowered greatly, a complete set of mechanism is compact in structure and high in operation reliability, and working efficiency of the cross-cutting device is improved greatly.

Owner:苏州姑苏食品机械有限公司

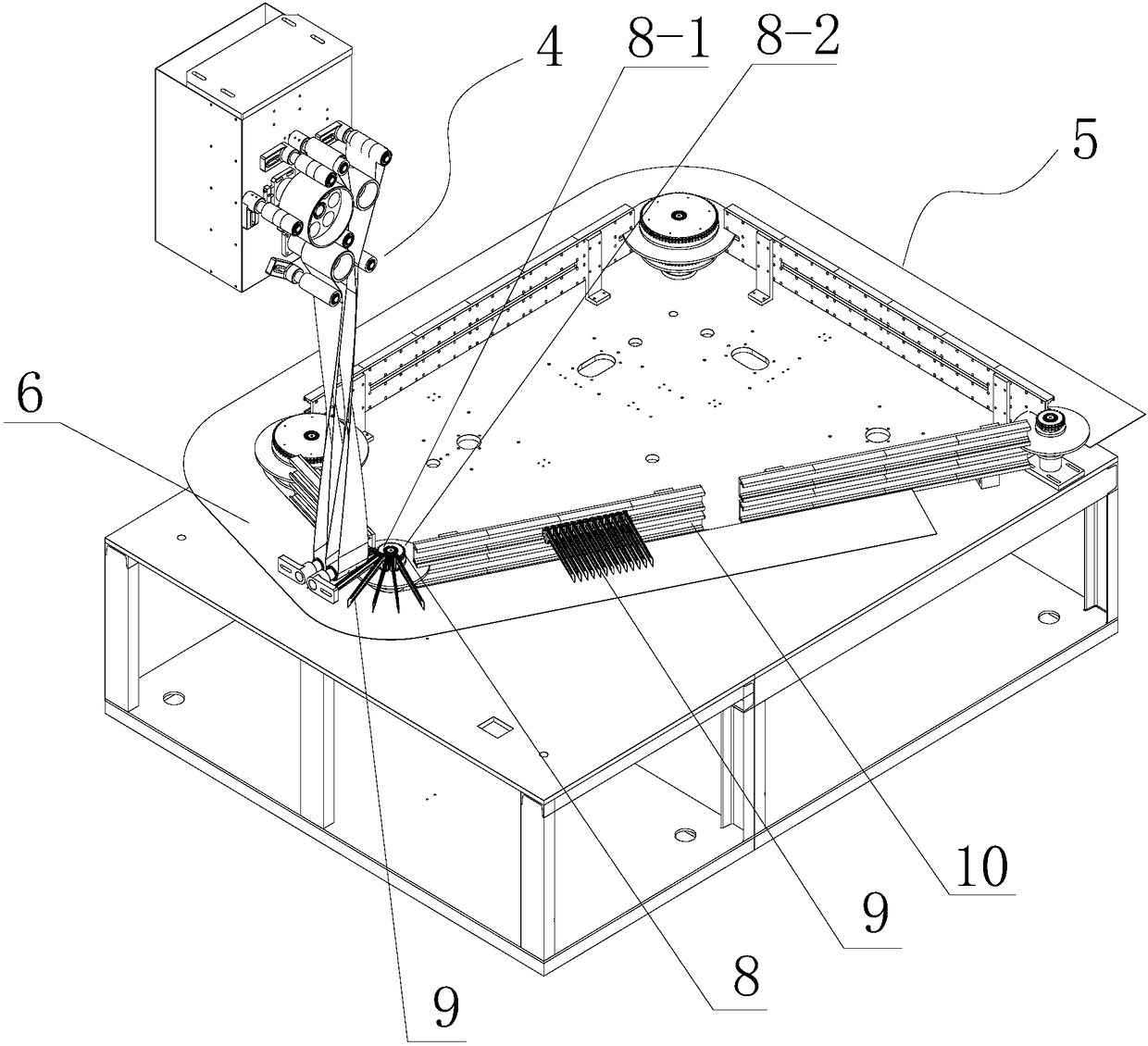

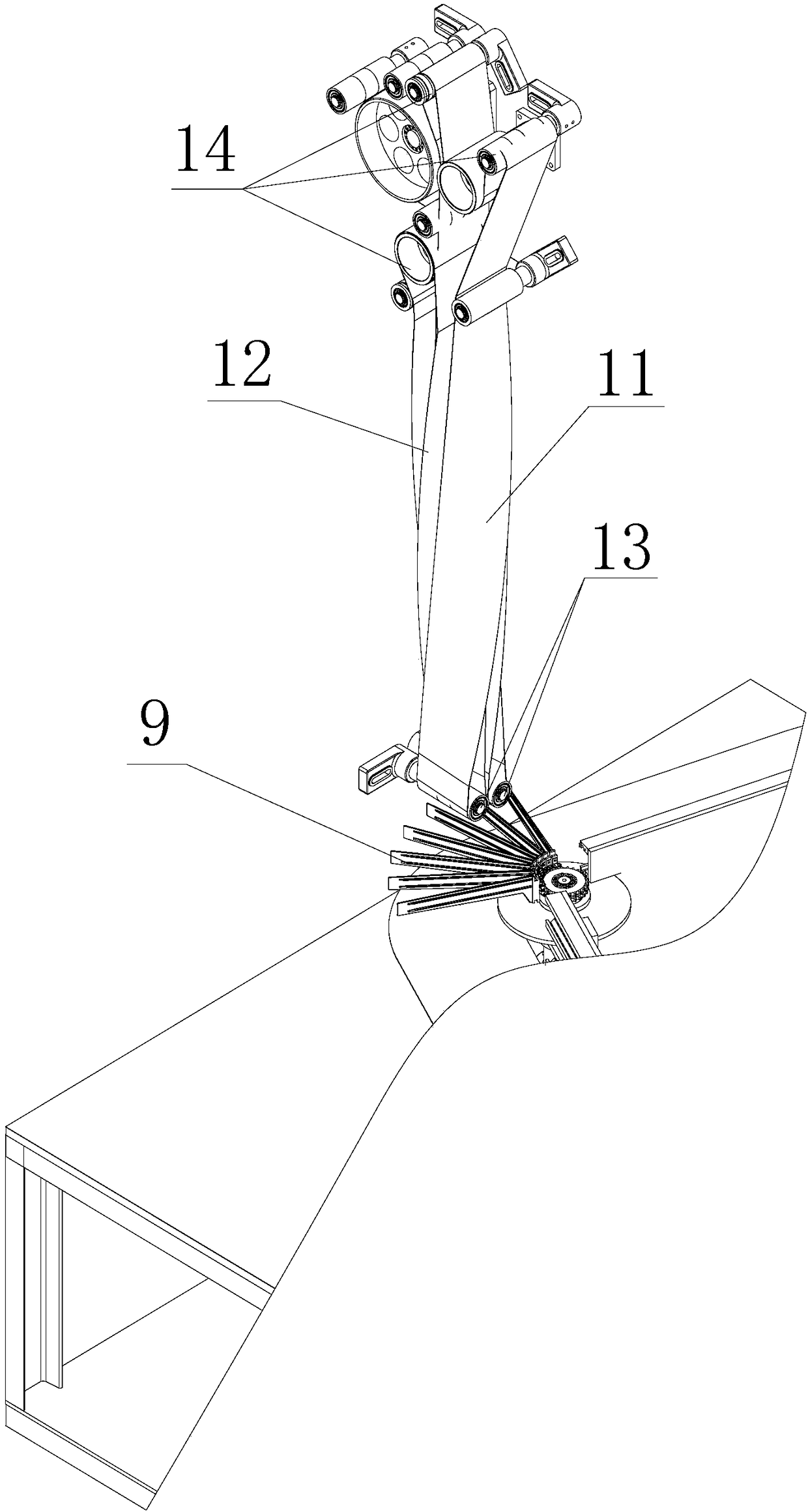

Forming conveying method and equipment for disposable briefs-type sanitary products

PendingCN108455239ASmooth transitionImprove running stabilityConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a forming conveying method and equipment for disposable briefs-type sanitary products. The method comprises the steps that after being formed, the products are conveyed to theposition above a stacking device through a twisting and conveying mechanism; and then, the products are delivered onto a collection station of the stacking device one by one in the width direction ofthe products and collected and delivered out to be stacked through the stacking device. The equipment comprises a sealing and pressing mechanism, a cutting-off and transferring mechanism, the twistingand conveying mechanism and the stacking device, wherein the sealing and pressing mechanism, the cutting-off and transferring mechanism, the twisting and conveying mechanism and the stacking device are connected in sequence. The twisting and conveying mechanism is arranged above the stacking device. The stacking device is provided with the collection station. A product outlet of the twisting andconveying mechanism is vertically formed above the collection station. According to the forming conveying method and equipment for the disposable briefs-type sanitary products, the mode that the products are delivered into the stacking device is changed from the horizontal conveying mode into the vertical conveying mode, the products are inserted into the stacking device in the width direction, and the integral time during which the products are inserted into the stacking device can be effectively shortened; the circumstance that the products are stuck when vanes of the stacking device rotateis prevented; the accidental shutdown rate is lowered; operation stability of the stacking device is improved; and production efficiency is also improved.

Owner:GUANGZHOU XINGSHI EQUIPS

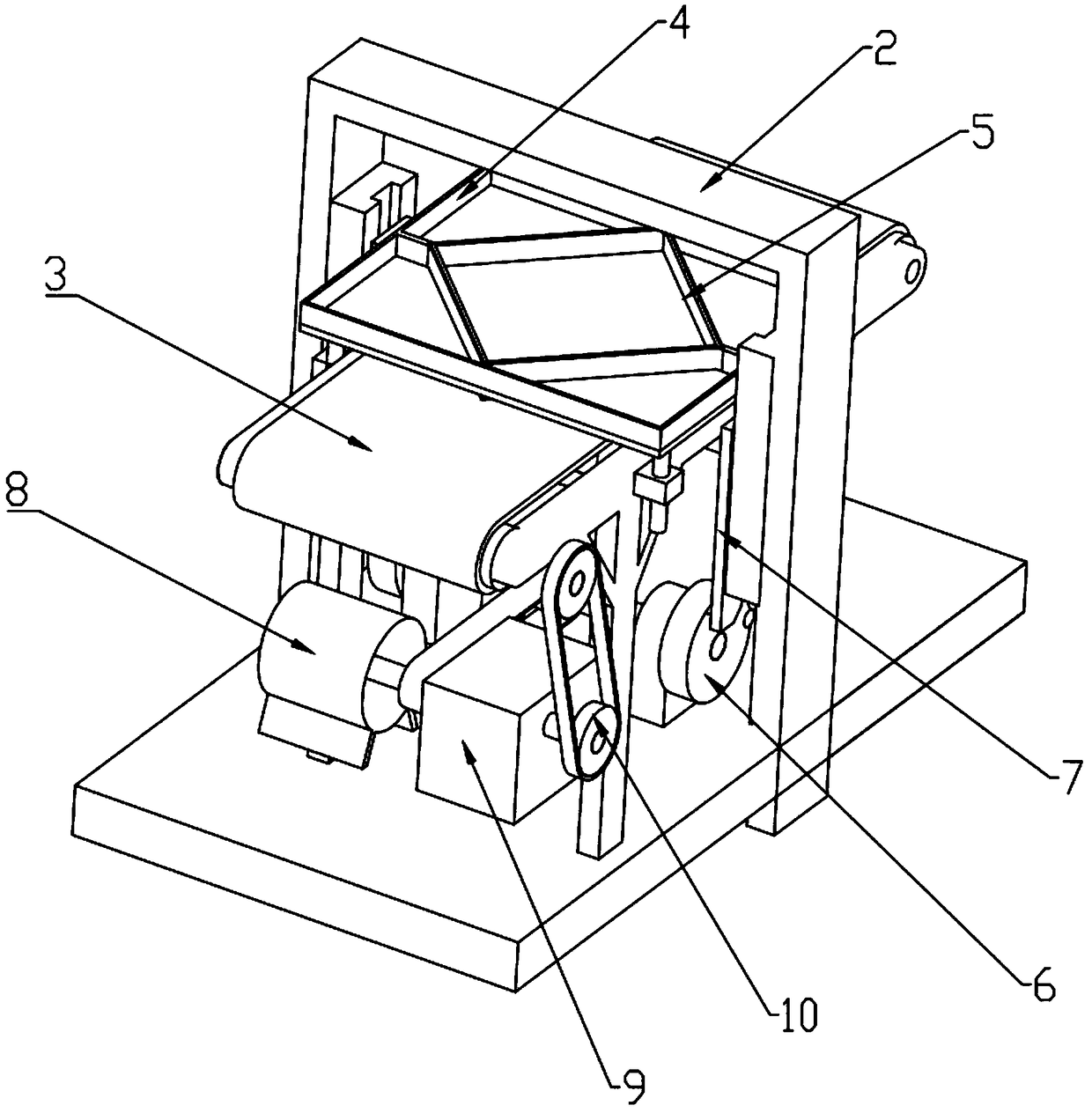

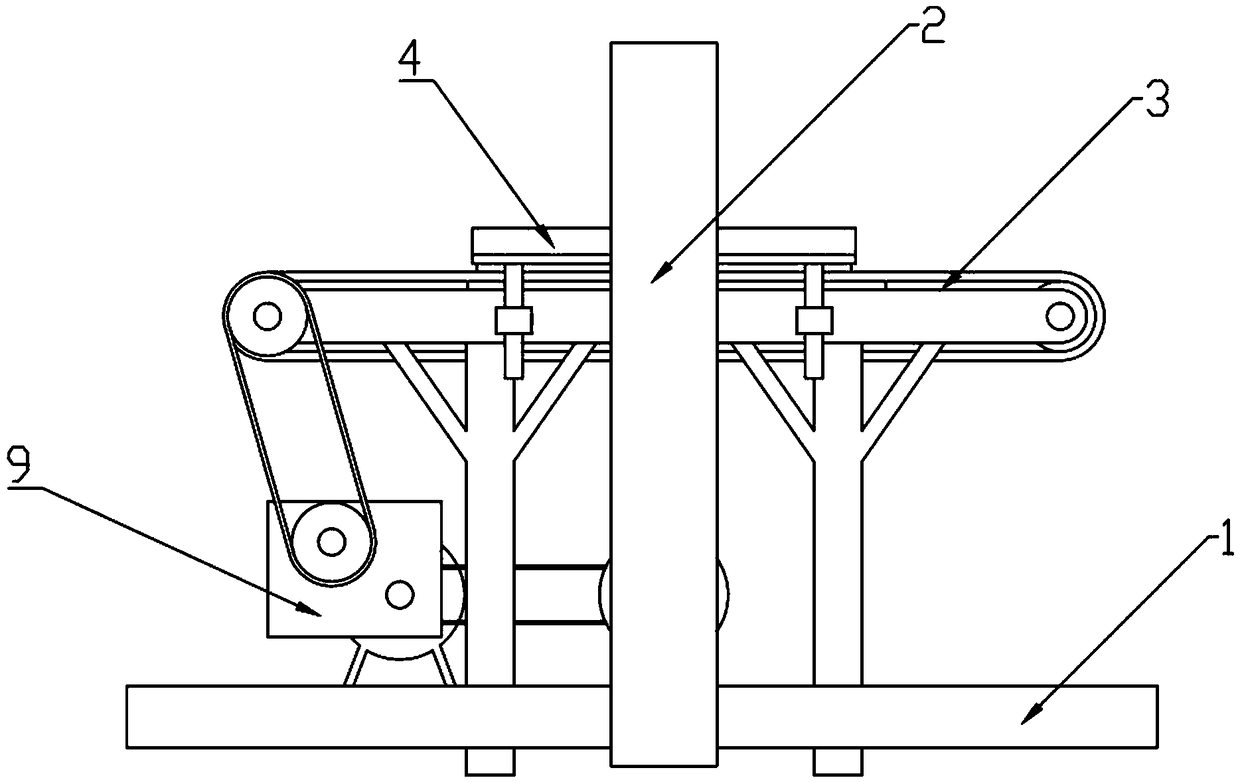

Diced meat cutting machine

The invention provides a diced meat cutting machine which comprises a machine base. The diced meat cutting machine is characterized in that a portal frame is installed on the machine base, a conveyingbelt mechanism is arranged in the portal frame and installed on the machine base, a cutter frame is connected in the portal frame in a sliding manner in the vertical direction, the cutter frame is located above the conveying belt mechanism, a rhombus blade is fixed in the cutter frame, a pressing plate is further fixed to the lower portion of the cutter frame, the pressing plate is provided witha hole for the blade to penetrate through, and the machine further comprises a reciprocating mechanism which is connected to the cutter frame and controls the cuter frame to move up and down. According to the diced meat cutting machine, the rhombus blade is adopted for cutting, and cut diced meat is uniform in shape; the blade is fixed through the cutter frame, the cutter frame moves up and down in the vertical direction, and thus sliced meat can be cut off smoothly; and a motor is adopted for driving moving of a conveying belt and lifting of the cutter frame, the number of the motor is saved,the meat cutting efficiency is high, the structure is simple, the blade is easy to clean, and the equipment is easy to maintain.

Owner:FOSHAN YOUQIANG HARDWARE MACHINERY CO LTD

Drying device for sweet potato vermicelli processing

InactiveCN112146425AEasy to controlEasy to take outDrying solid materialsMetal working apparatusMechanical engineeringSweet Potatos

The invention relates to the technical field of vermicelli processing, and discloses a drying device for sweet potato vermicelli processing. The drying device comprises a cylinder body, wherein a supporting plate sleeves the outer side of the circumference of the cylinder body, a dryer is fixedly connected to one side of the inner wall of the cylinder body, fixing plates are fixedly connected to the two sides of the upper surface of the supporting plate, and a mounting opening is formed in the upper surface of the cylinder body; and a supporting cylinder is fixedly connected into the mountingopening, a feeding pipe is fixedly connected to the upper surface of the supporting cylinder, a powder scattering mechanism is arranged in the supporting cylinder, movable openings are formed in one side of the outer wall of the cylinder body, a movable rod is movably connected into the movable openings and penetrates through the fixing plates, and a driving gear and an adjusting knob are fixedlyconnected to the two ends of the movable rod respectively. According to the drying device, the powder scattering mechanism and an auxiliary mechanism can be directly operated, the control over a vermicelli drying procedure is improved, the operation of operators is facilitated, a vermicelli cutting mechanism and a tilting mechanism can synchronously run, dried vermicelli can be conveniently takenout, and the operation time for processing vermicelli is saved.

Owner:湖南新食康农业发展有限公司

Wire cutting device for swwing machine

InactiveCN1982525BFull cutting forceSmooth tangent actionNeedle severing devicesWire cuttingEngineering

Owner:JUKI CORP

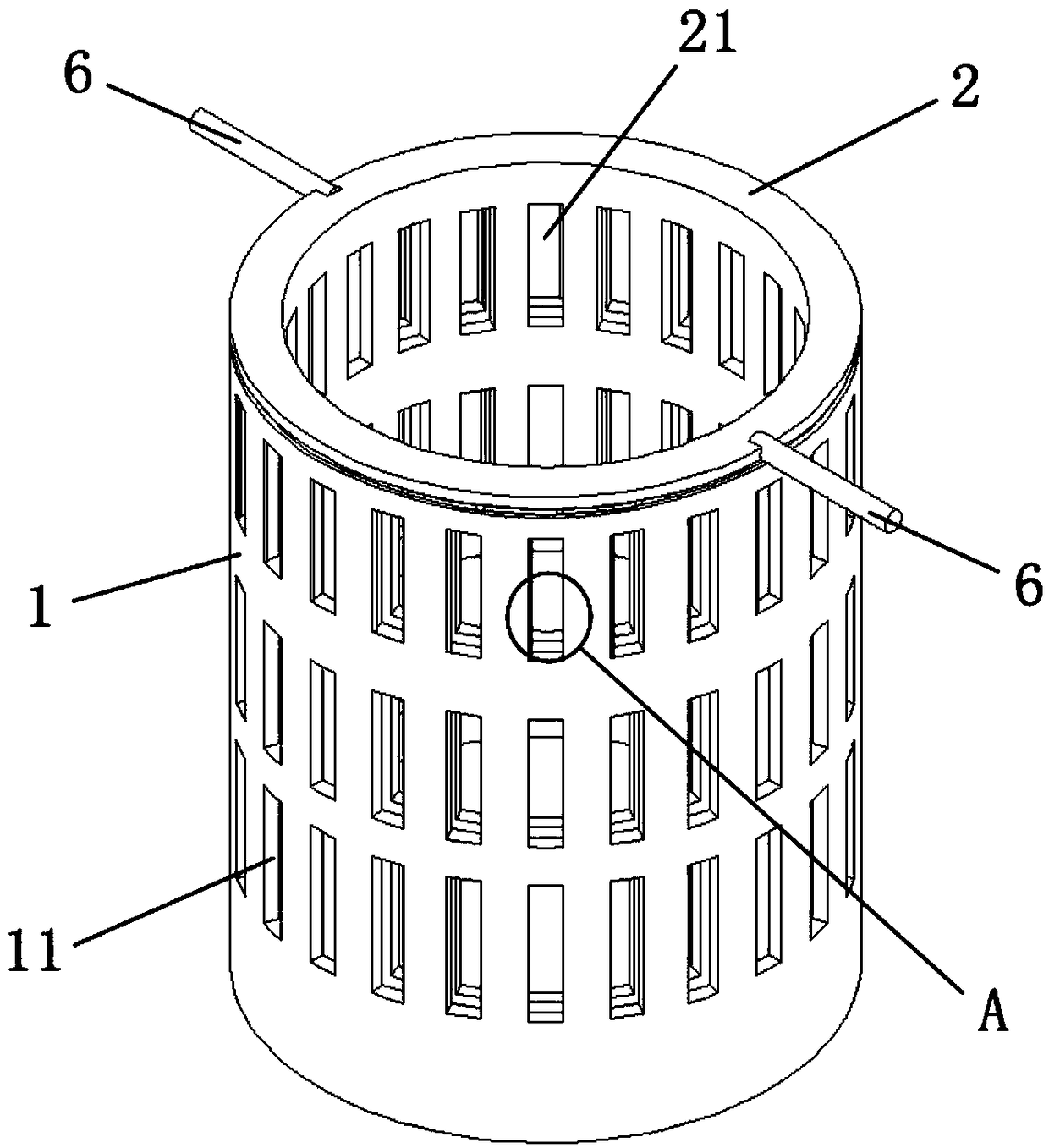

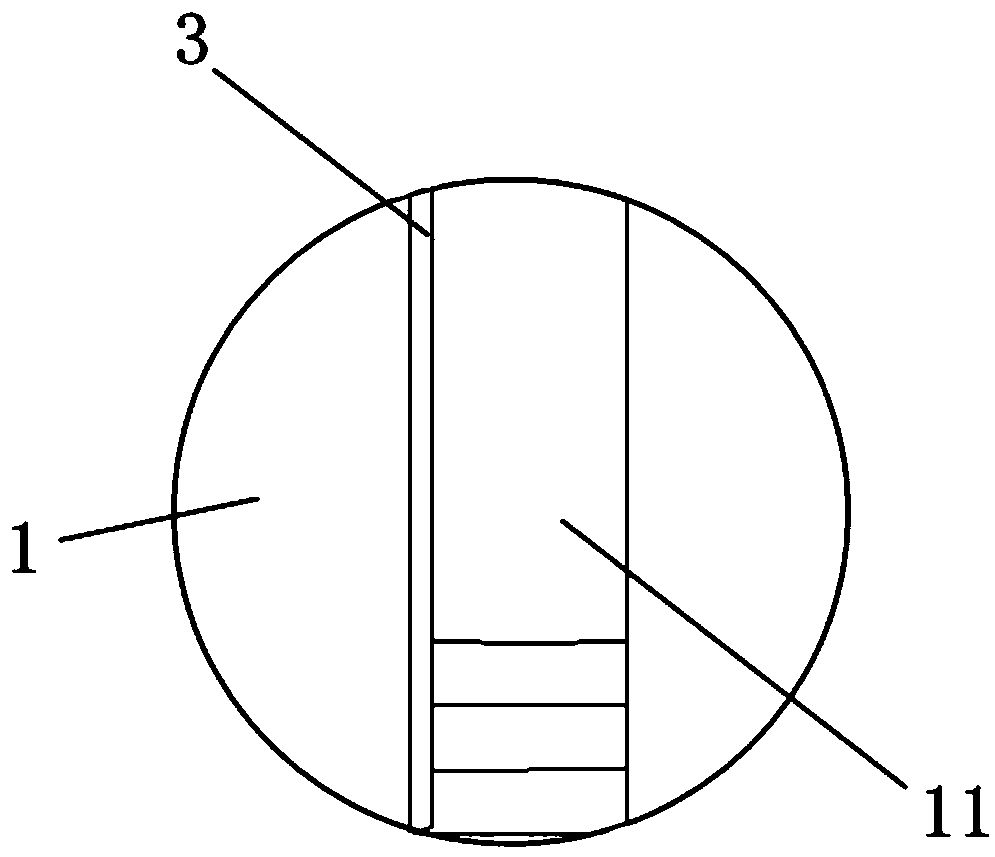

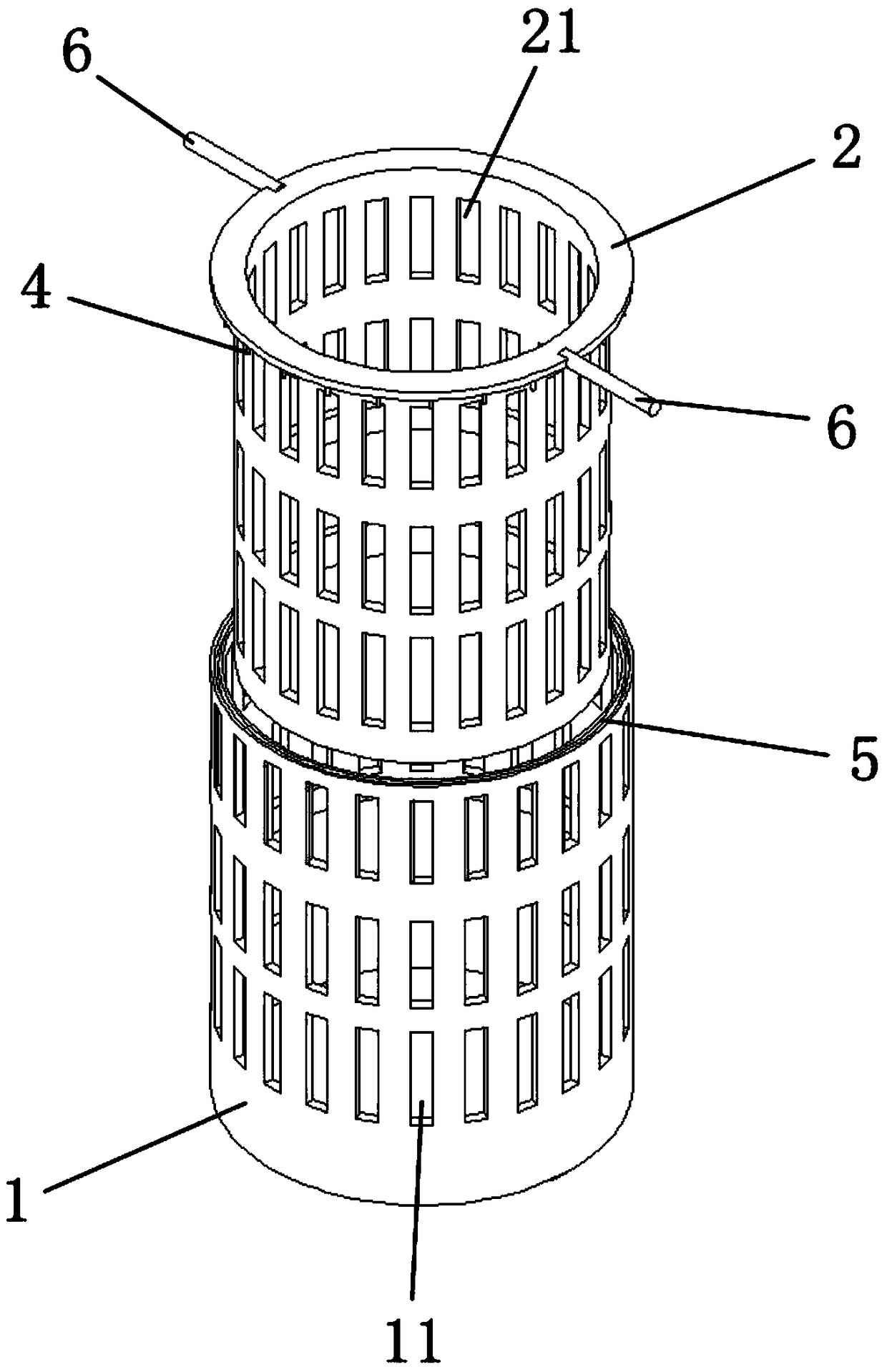

Convenient-to-take out double-layer root fixator

InactiveCN109169236AEasy to fixGuaranteed growth effectAgriculture gas emission reductionCultivating equipmentsMedicineUltimate tensile strength

The invention discloses a convenient-to-take out double-layer root fixator, which comprises an outer root fixator and an inner root fixator, wherein the surface of the outer root fixator is provided with a plurality of outer passing holes; the surface of the inner root fixator is provided with a plurality of inner passing holes; the inner root fixator can rotate relative to the outer root fixator;the inner root fixator is connected with the outer root fixator through a positioning mechanism; and the outer passing hole is internally provided with a cutting edge. According to the convenient-to-take out double-layer root fixator provided in the invention, after soilless culture is carried out on vegetables, the vegetables in the root fixator can be quickly taken out, and the labor intensityof an operator is reduced.

Owner:FOSHAN BAOYUEMEI SCI & TECH CO LTD

Chip discharging device of button hole of button

InactiveCN101519832ADo isolateAvoid sewing backWorkpiece carriersClothes making applicancesEngineeringElectrical and Electronics engineering

The invention relates to a chip discharging device of a button hole of a button. The chip discharging device is characterized in that a pressing-cutting block in a pressing-cutting device is provided with a movable extruding rod; when the pressing-cutting block declines and is jointed with a cutting tool at the lower part to cut off the cloth, the movable extruding rod applies local extrusion to the cloth to lead the cloth to be in tight state so as to be beneficial to cutting off; and the buttonhole-shaped cloth chips generated after being cut off are extruded into a through hole of the cutting tool and are discharged downwards, thus separating the cloth chips from the cloth assuredly and avoiding the cloth chips from being sewn into the cloth so as to improve the sewing quality.

Owner:CHEESIANG SEWING MACHINE S H

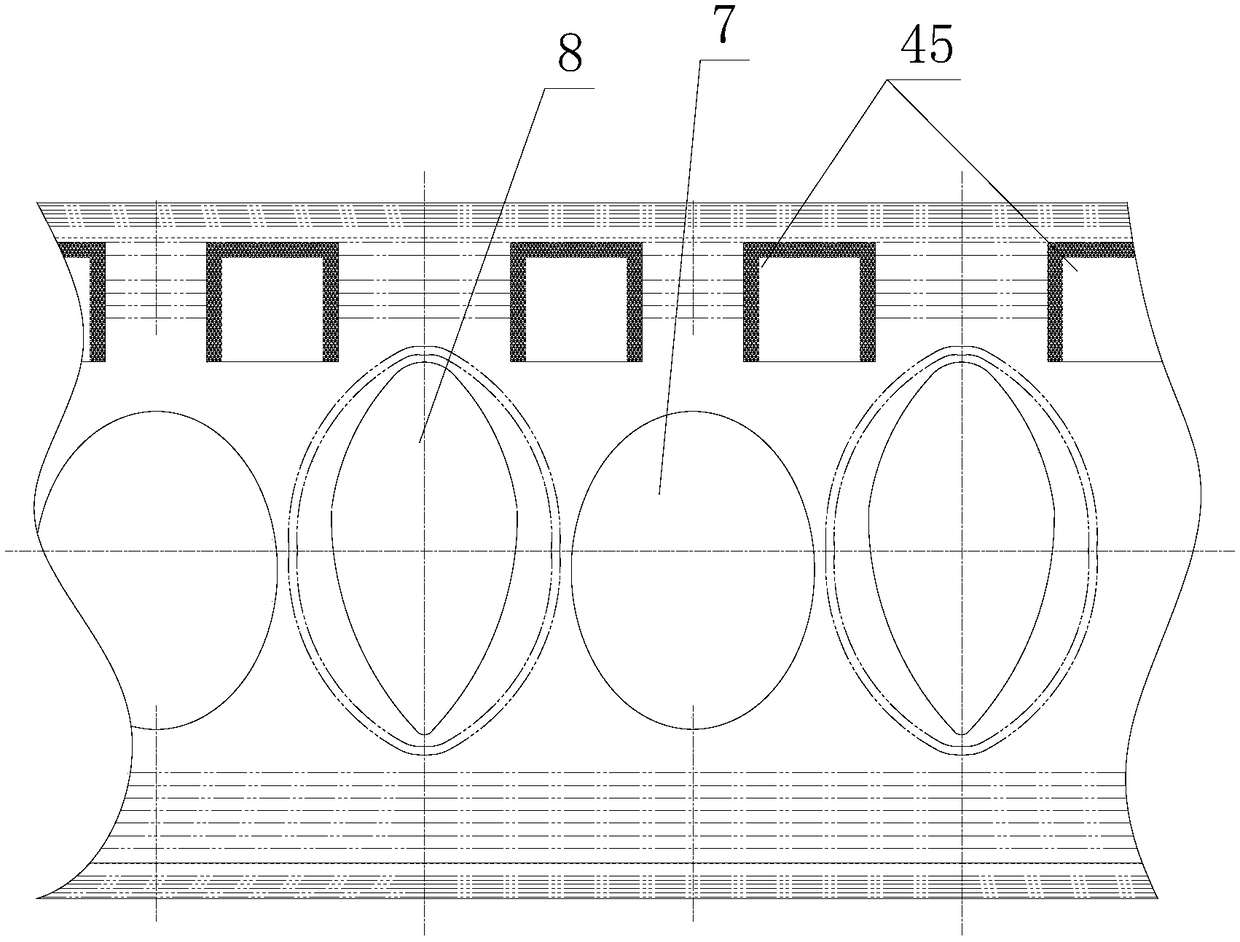

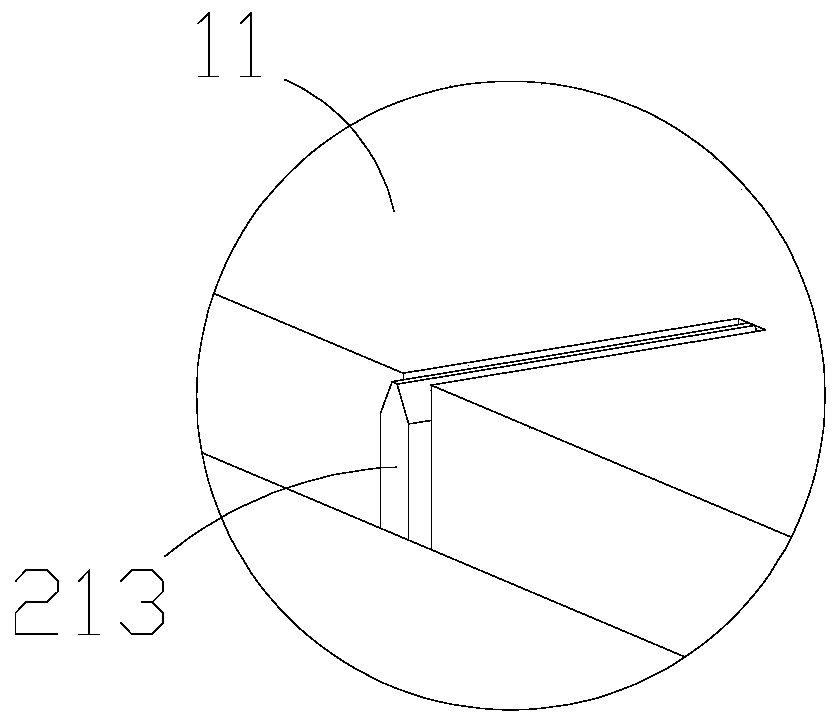

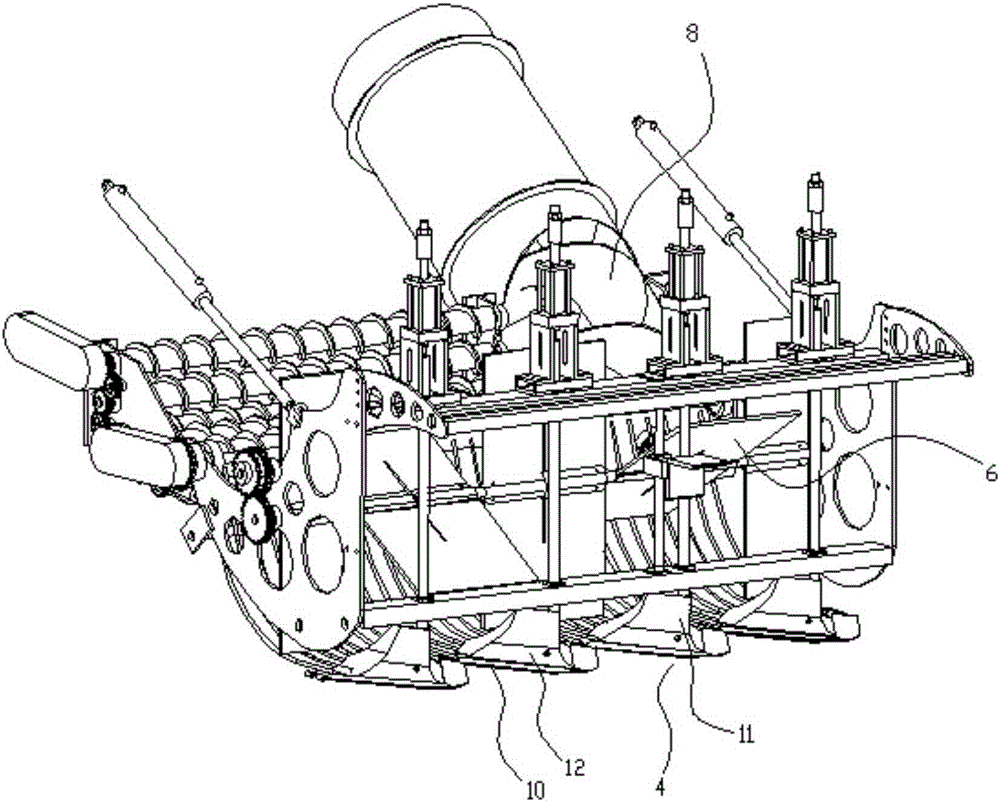

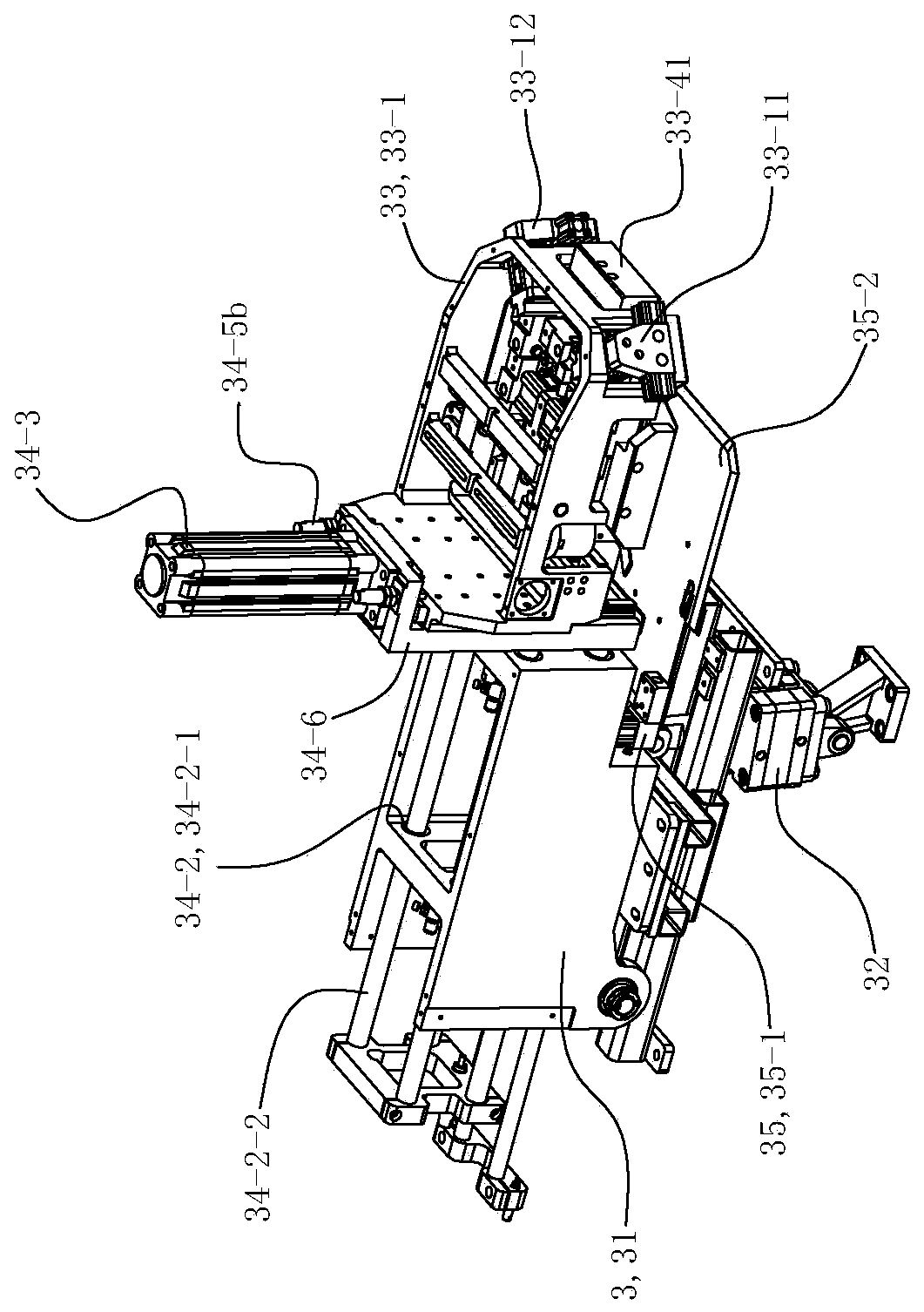

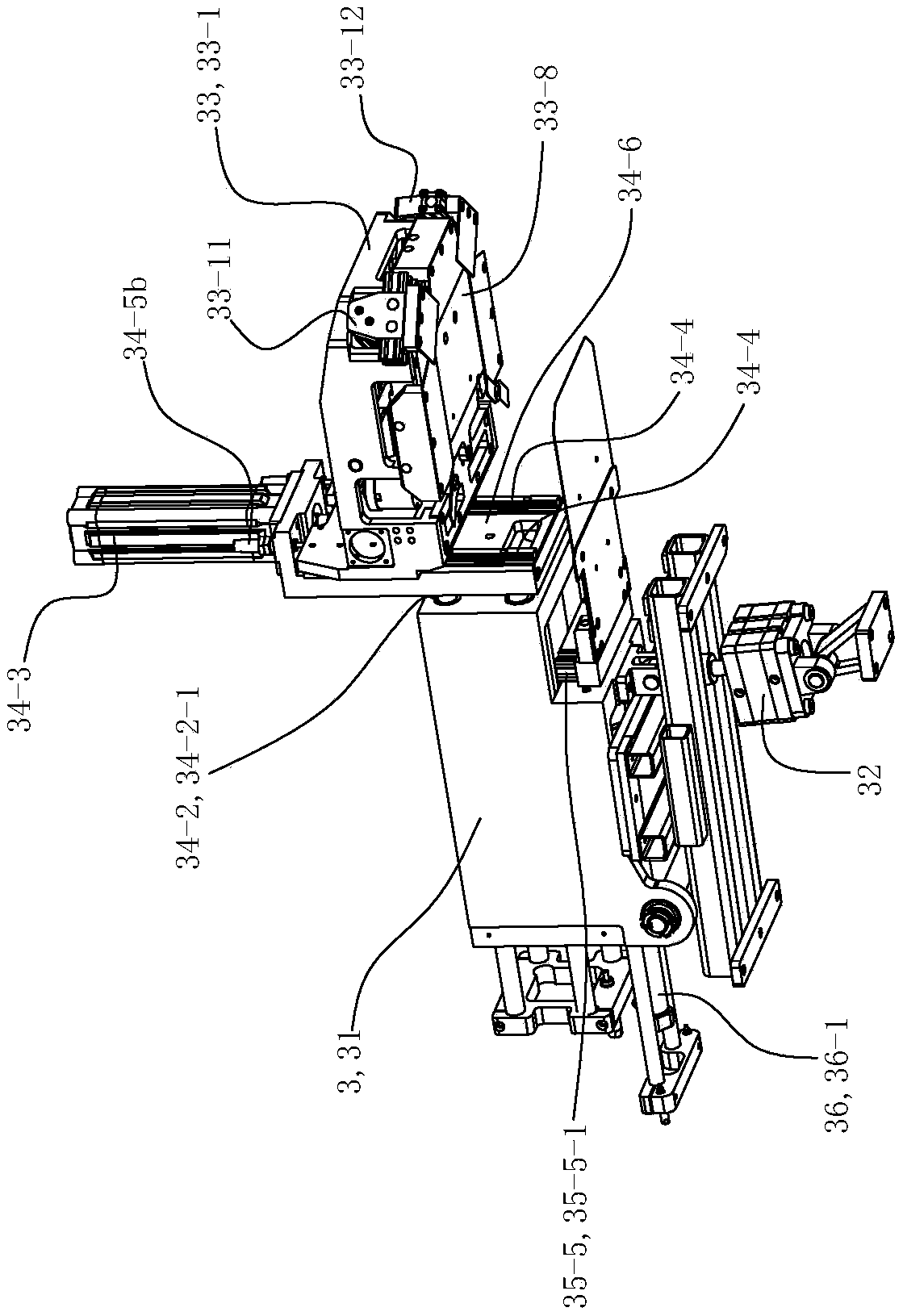

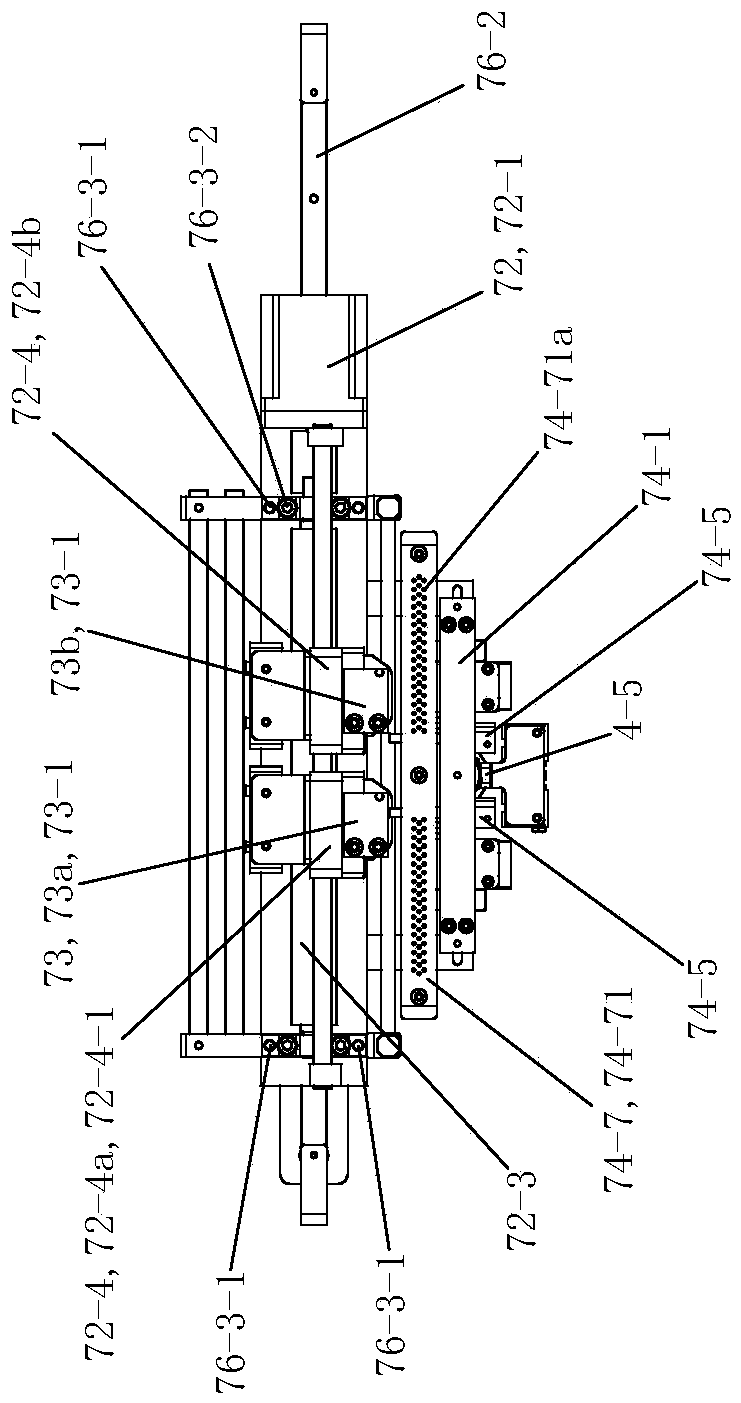

Harvester head structure and mustard tuber harvester comprising same

The invention discloses a harvester head structure and aims to provide the harvester head structure capable of effectively removing mustard tuber leaves and cutting off mustard tuber roots and effectively cleaning mustard tuber stems when being conveyed. The harvester head structure comprises a head rack, a leaf beating mechanism and a stem shoveling mechanism, wherein a plurality of leaf beating cutter wheels are arranged on a leaf beating shaft; the stem shoveling mechanism comprises a plurality of steam shoveling cutters; a bottom material fence arc plate is arranged on the head rack, a plurality of material stirring wheels are arranged above the bottom material fence arc plate, a transverse conveying mechanism and an oblique conveying barrel are arranged behind the bottom material fence arc plate, an oblique conveying auger is arranged in the oblique conveying barrel, and the transverse conveying mechanism comprises a plurality of transverse conveying augers. The harvester head structure disclosed by the invention has the benefits that mustard tuber leaves are rapidly removed and mustard tuber stems are smoothly cutoff; through medium conveyance of structures such as the oblique conveying barrel, a medium conveying mesh barrel, a raising barrel and the like, the collecting process of mustard tubers is stable; in the whole process, sludge and impurities are continuously removed, so that the harvester head structure is convenient and efficient; after the raising barrel discharges materials, the materials are directly bagged, so that the harvester head structure is time-saving and labor-saving.

Owner:XINGGUANG AGRI MACHINERY

Full-automatic cold-folding bagging machine

PendingCN110306301AEasy to install and replaceAdaptableWork-feeding meansPressersEngineeringSewing machine

The invention discloses a full-automatic cold-folding bagging machine. The full-automatic cold-folding bagging machine comprises a workbench assembly, a sewing assembly, an edge folding device, a feeding device and a feeding and sewing driving device. The workbench assembly comprises a frame and a workbench plate. The sewing assembly comprises a sewing machine. The sewing machine is fixedly arranged on the frame of the workbench assembly in the left-right direction. The full-automatic cold-folding bagging machine is characterized in that each folding knife of a folding knife assembly is fixedly arranged on the corresponding driving device on the bottom plate of an edge folder base in a quick-assembling manner, and is driven to act by the corresponding driving device. The distance between aleft rear corner folding knife and a right rear corner folding knife of a corner edge folding assembly in the left-right direction is adjustable. A feeding large-body presser foot is fixedly arrangedon a large-body presser foot driving device in a quick assembling mode, and the feeding large-body presser foot is driven by the large-body presser foot driving device to move up and down. A feedingpocket presser foot is fixedly arranged on a pocket presser foot driving device in a quick mounting mode, and the pocket presser foot driving device drives the feeding pocket presser foot to move up and down.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

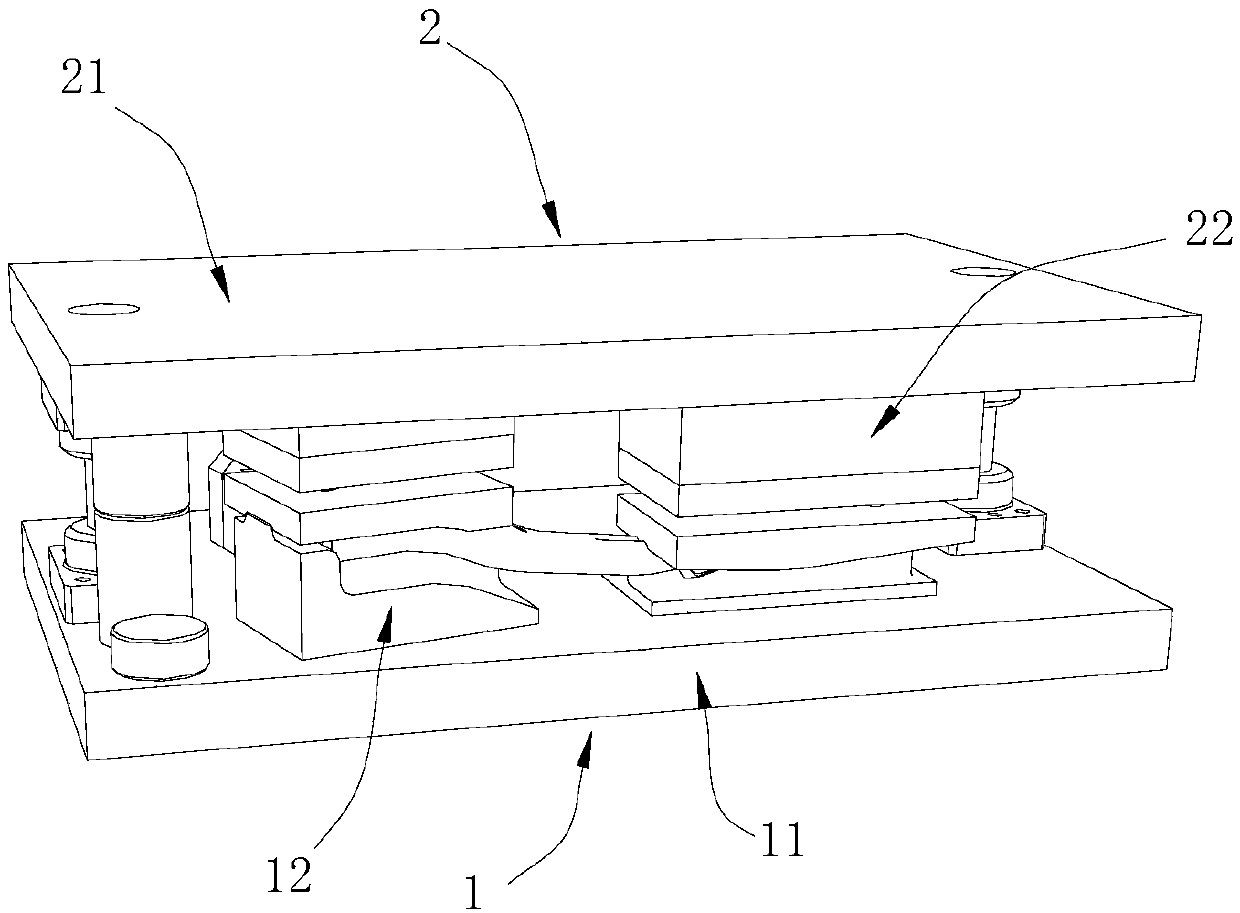

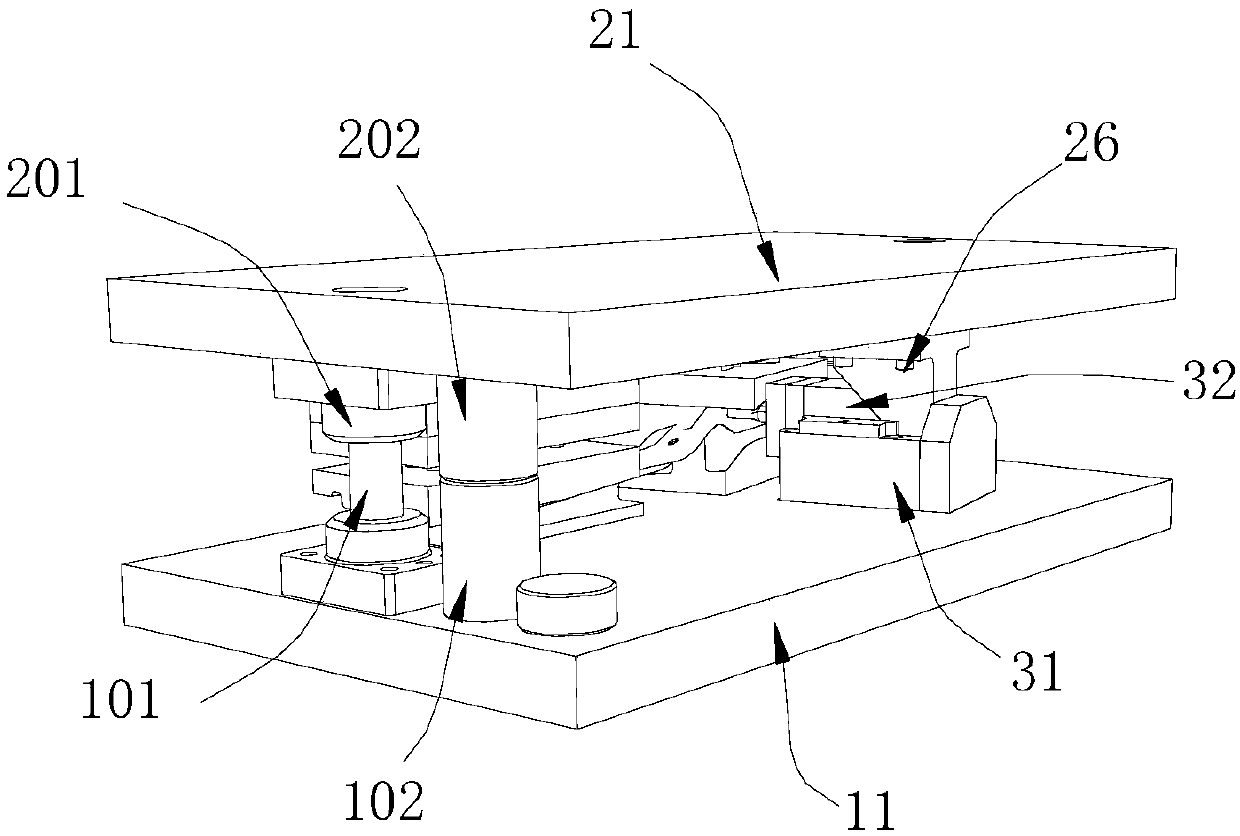

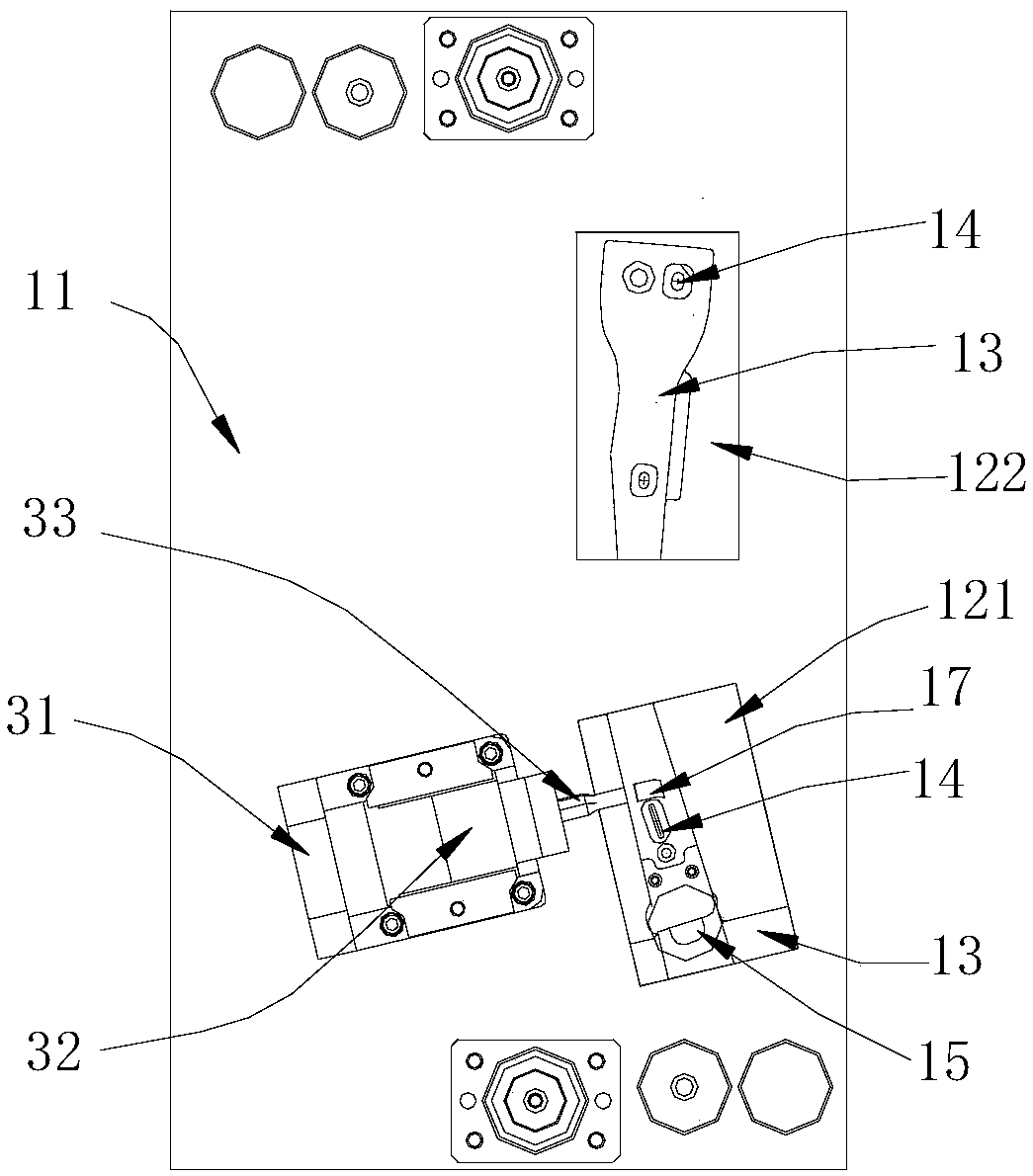

Metal sheet stamping die

PendingCN107584016AAvoid deformationCut off smoothlyShaping toolsPerforating toolsPunchingEngineering

The invention relates to the field of stamping dies. A metal sheet stamping die comprises a lower die and an upper die paired with the lower die. The lower die comprises a lower die base plate and a lower die table fixed to the lower die base plate. The upper die comprises an upper die base plate and an upper die table fixed to the upper die base plate. The upper die table is correspondingly matched with the lower die table. A lower die boss for positioning a metal sheet is arranged at the upper end of the lower die table, and the lower die table is internally provided with a longitudinal punching cavity and a longitudinal die cutting cavity. The upper die table comprises an upper die seat plate fixed to the upper die base plate, a longitudinal punching column, a longitudinal die cutting column and an upper die compression plate movably arranged on the longitudinal punching column and the longitudinal die cutting column, wherein the longitudinal punching column and the longitudinal diecutting column are fixed to the upper die seat plate. The longitudinal punching column and the longitudinal die cutting column correspond to the longitudinal punching cavity and the longitudinal diecutting cavity respectively. The stamping die can conduct trimming and punching processes on the metal sheet simultaneously, the machining efficiency is improved, and the machining cost is reduced.

Owner:浙江博鑫涵汽车零部件有限公司

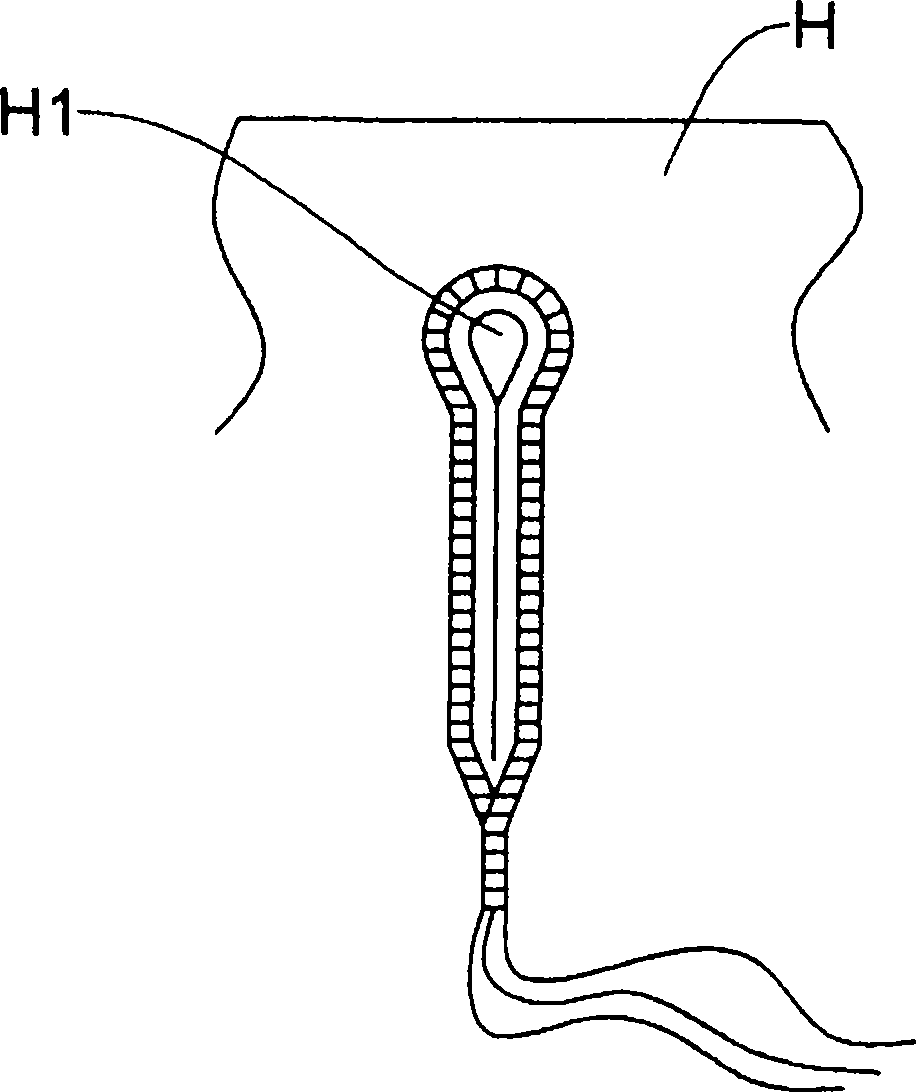

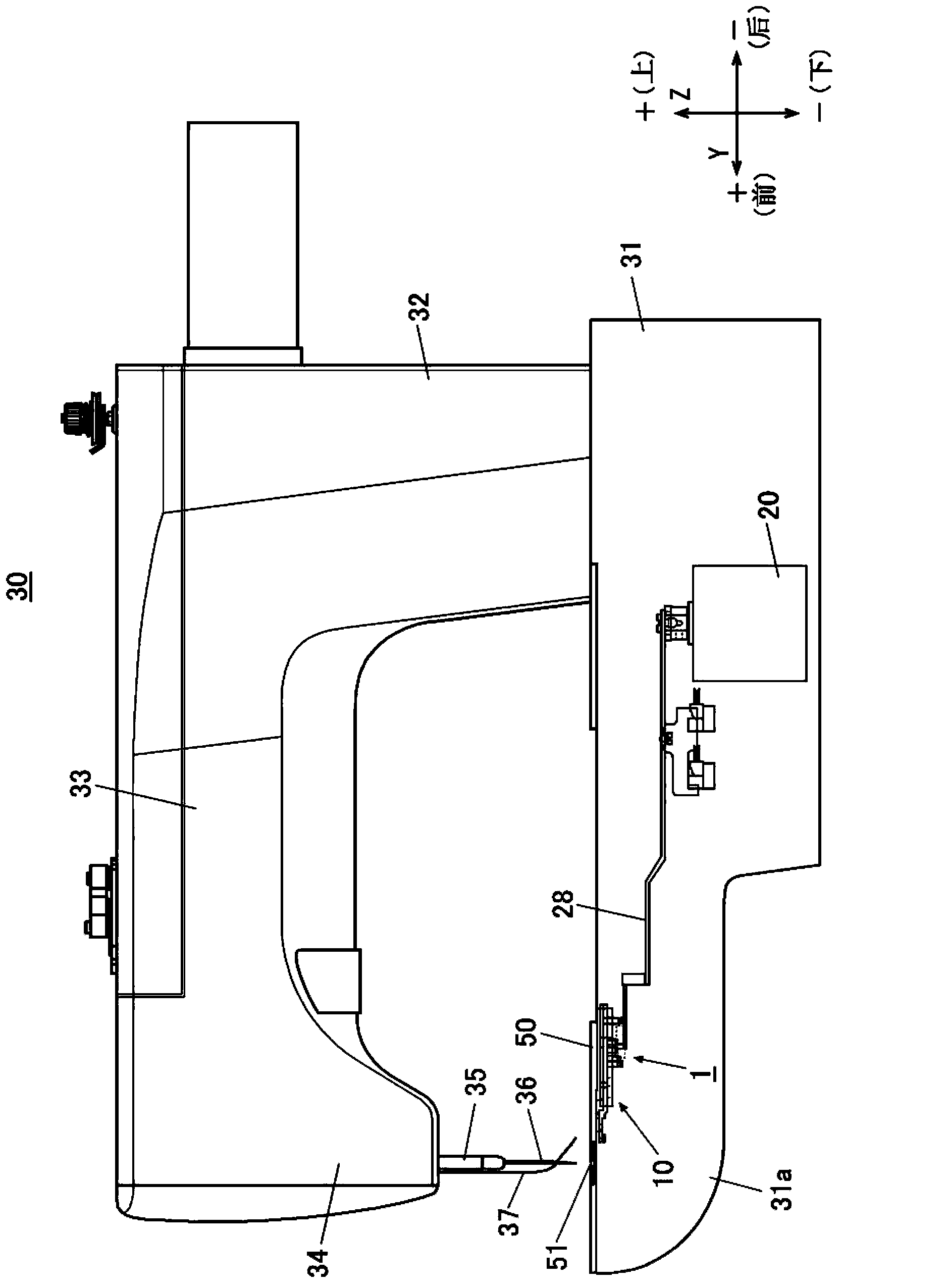

Top thread keeping device of sewing machine

ActiveCN103510291AShorten the lengthSuppresses getting caught in stitchesNeedle severing devicesThread-break detectorsEngineeringSewing machine

The invention provides a top thread keeping device of a sewing machine, the device can prevent the top thread from involving into a stitch trace, thereby improving the beauty of the thread trace. The top thread keeping device of the sewing machine comprises the following structures: a cutter portion cutting the top thread and configured close to the needle hole; a top thread keeping portion keeping the top thread passing the needle hole; a control portion controlling the driving mechanism of the top thread keeping portion. The top thread keeping portion comprises the following structures; a first keeping portion with a front end portion capable of freely moving back and forth along a Y direction; a second keeping portion capable of freely contacting with / separating from the front end portion of the first keeping portion in the Y direction, and the first and second keeping portions commonly keeps the top thread. The control portion employs the first and second keeping portions to clamp the top thread, and configures the top thread to be close to the cutter, and when the sewing machine finishes a set needle number, the first and second keeping portion are kept away from the needle hole under the condition that the top thread is firmly clamped, thereby enabling the cutter portion to cut off the top thread.

Owner:JUKI CORP

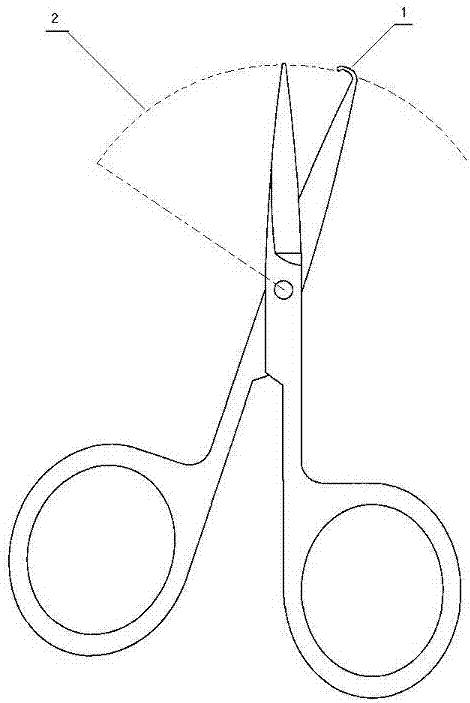

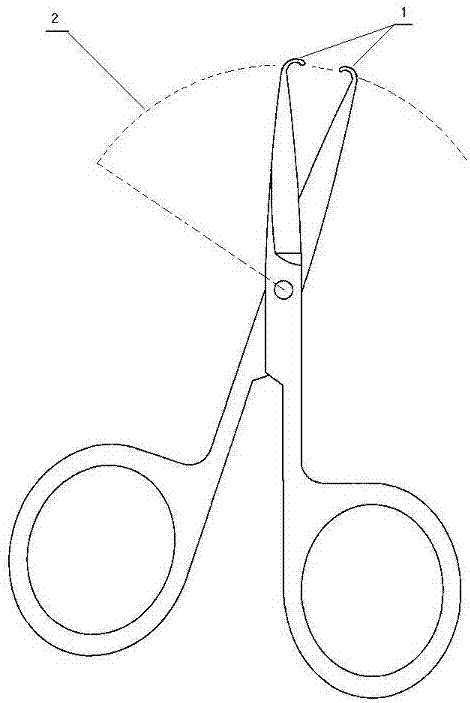

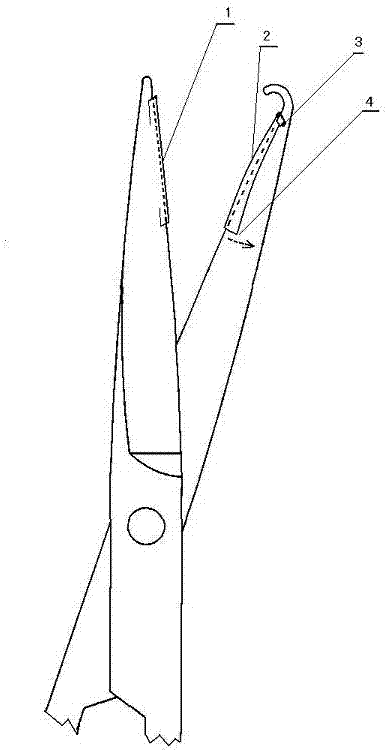

White hair scissors

The present invention is a kind of white hair scissors, which is characterized in that at least one cutting point of the scissors is provided with an inner curved hook and the inner curved hook can be closed with another cutting point or a similar inner curved hook provided on another cutting point to form a hole. The scissors can conveniently realize several consecutive actions of cutting white hair: "pick", pick out the white hair on the head from the black hair; Re-mixing; "pressing", sending the cutting edge of the scissors to the root of the selected white hair; "cutting", that is, cutting the selected white hair; "taking", holding or clamping the cut hair, leaving the head ; "throw", to throw away or collect the cut hair. The present invention is not only a kind of white hair scissors, but also a kind of nose hair scissors.

Owner:梁平原

Pipe cutting device and cutting method

ActiveCN106216758BCut off smoothlyLess dustPlaning/slotting toolsTube shearing machinesEngineeringMechanical engineering

The invention discloses a pipe material cutting device and a cutting method. The cutting device includes a clamping mechanism, a first cutting part, a first driving part, a second cutting part and a second driving part. The clamping mechanism is used to clamp the pipe. The first cutting part is arranged obliquely relative to the pipe. The first driving member is in transmission connection with the first cutting member. The second cutting part is arranged obliquely relative to the pipe, and the direction in which the second cutting part is arranged obliquely is the same as the direction in which the first cutting part is arranged obliquely. The second driving member is in transmission connection with the second cutting member, and the second driving member is used to drive the second cutting member to move back and forth in the second direction, so that the head of the second cutting member is inserted into the pipe through the incision. In the present invention, less dust is produced during the cutting process of the pipe material, and the burrs on the oblique cut surface of the pipe material are less.

Owner:OMS MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com