Novel cloth cutting machine

A cloth cutting machine, a new type of technology, is applied in the direction of textiles, papermaking, and textile material cutting. It can solve problems such as uneven edges, difficulty in cutting with electric scissors, fabric wrinkles, and bulges, etc., to achieve smooth cutting surfaces, smooth cutting, and smooth cutting. The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

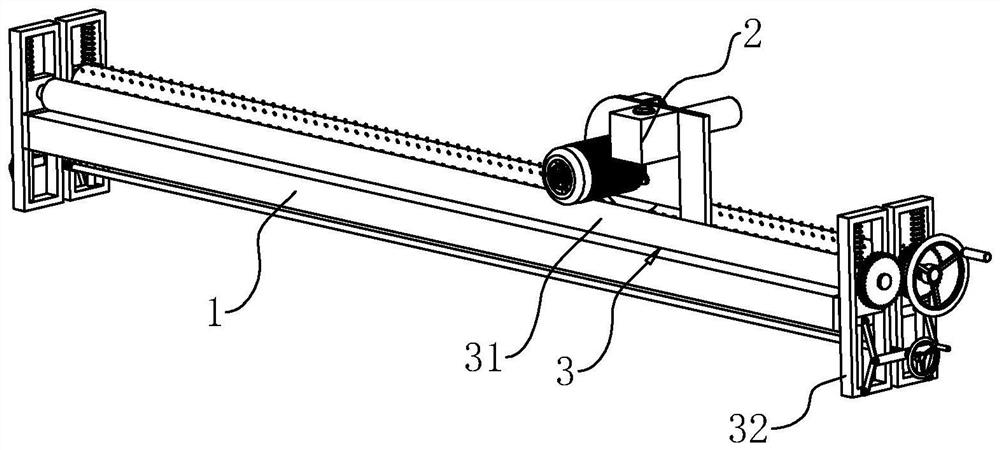

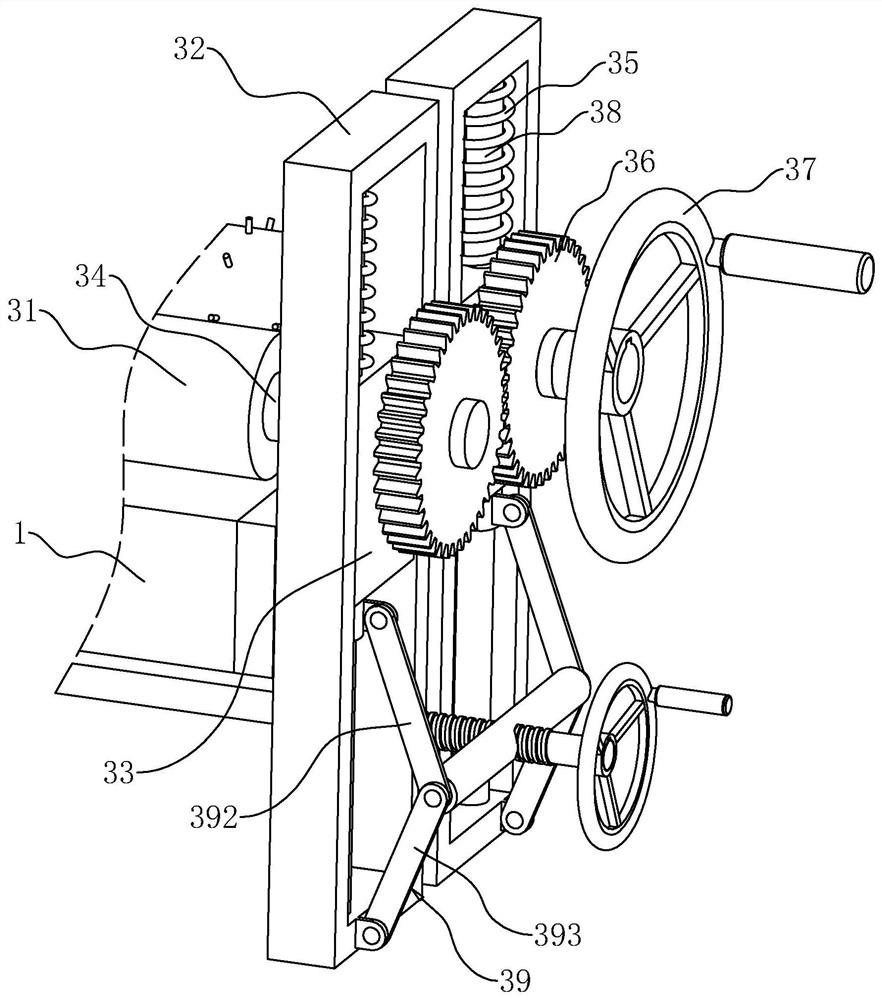

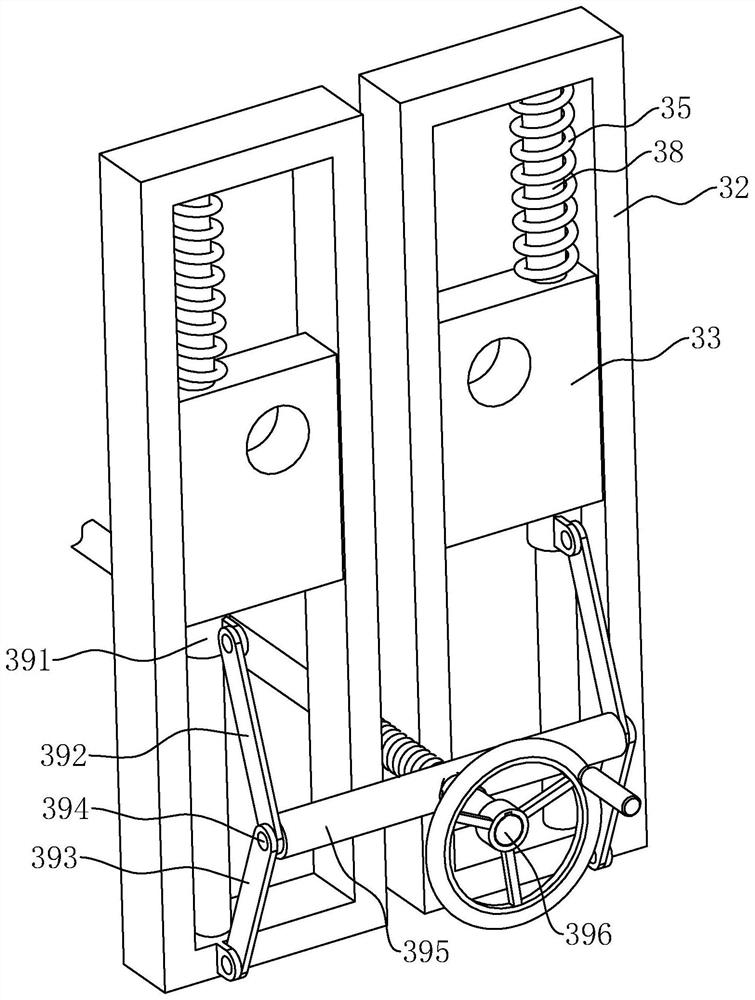

[0031] The embodiment of the present application discloses a new type of cloth cutting machine. refer to figure 1 and figure 2 , the cloth cutting machine includes a slide rail 1 for fixing on the workbench, and electric scissors 2 are slidably connected to the slide rail 1 along its length direction, and the upper surface of the slide rail 1 is provided with a pressing device for squeezing the cloth. Assembly 3, the compression assembly 3 includes two compression rollers 31 arranged above the slide rail 1 along the length direction of the slide rail 1, and the two compression rollers 31 are respectively placed on the left and right sides of the electric scissors 2, each compression Both ends of the roller 31 are vertically provided with a strip-shaped frame 32, the frame 32 is fixed on the end face of the slide rail 1, and a slide block 33 is connected to slide along the vertical direction in the frame 32, and the pressing roller 31 faces the frame 32 A rotating shaft 34 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com