Patents

Literature

6333results about "Severing textiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

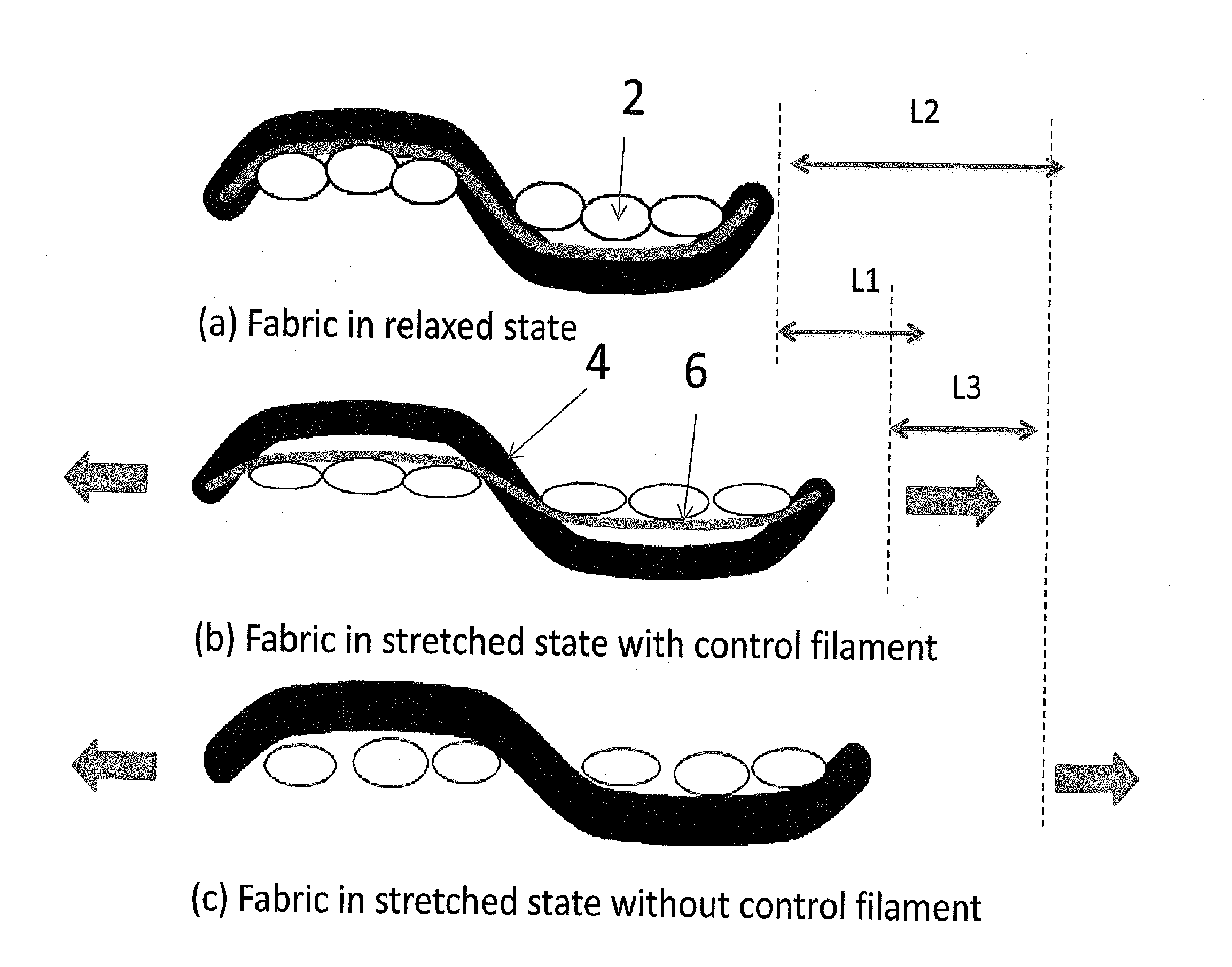

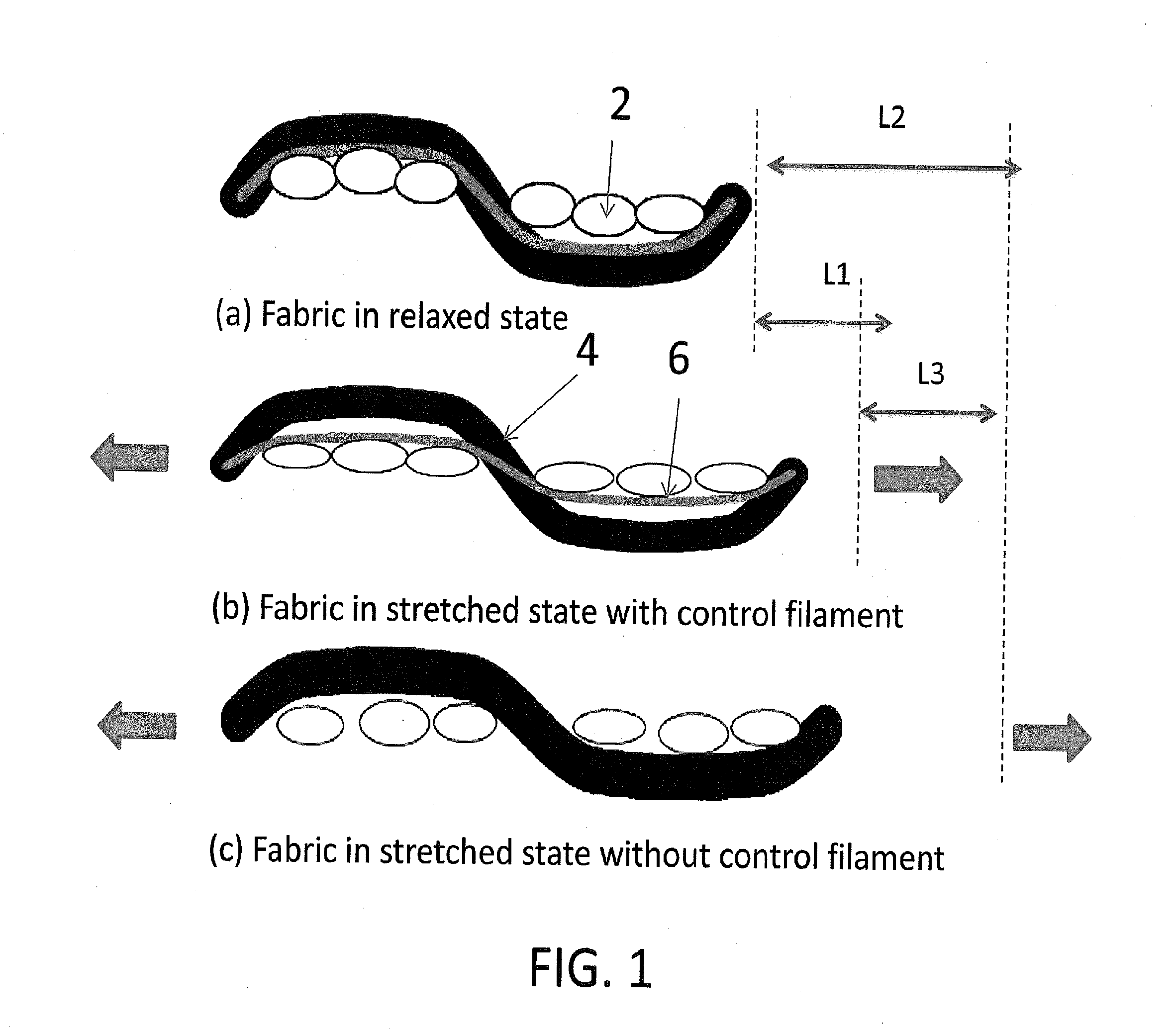

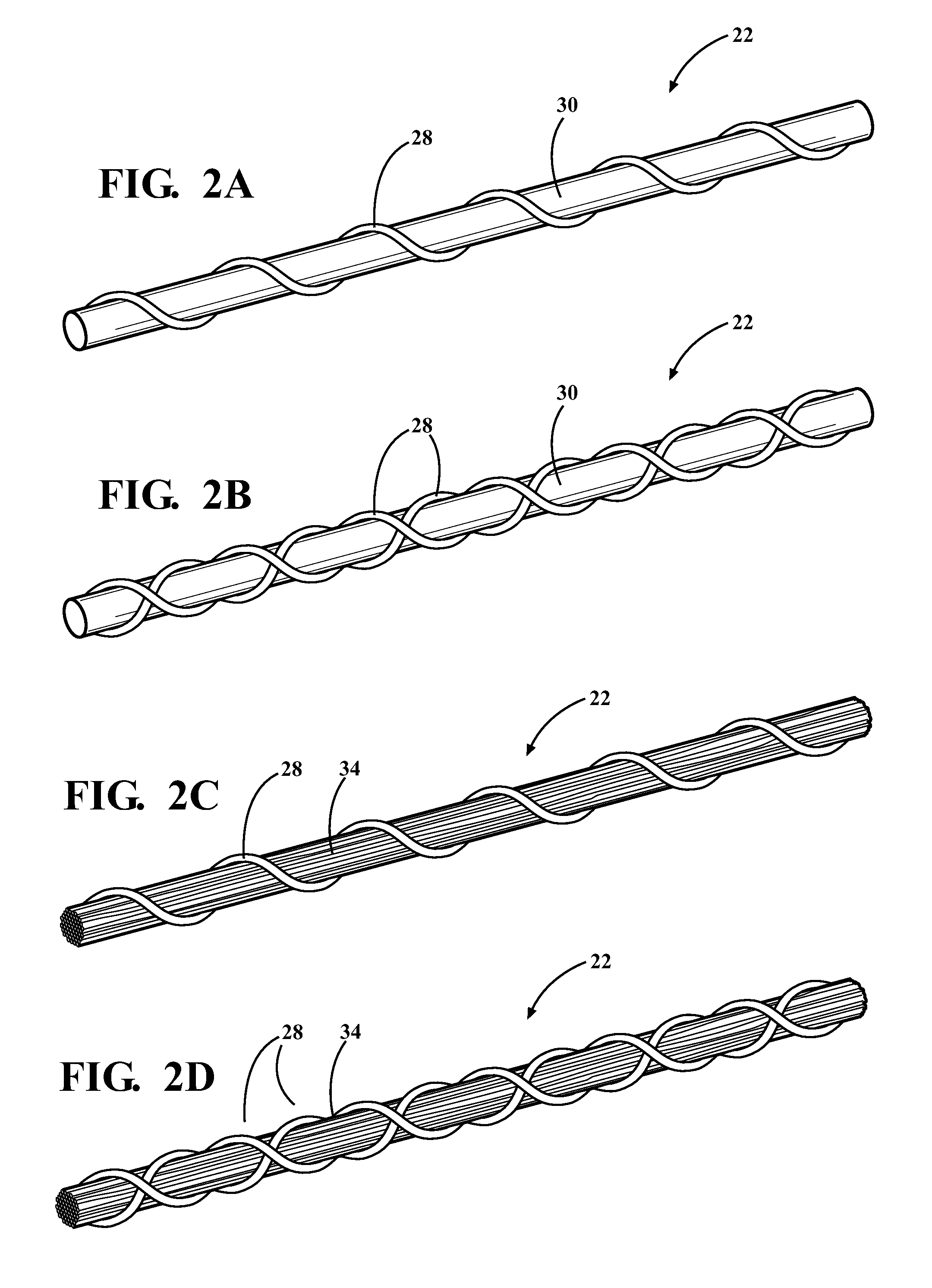

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

Terylene coral fleece blanket fabrics and processing method thereof

The invention relates to terylene coral fleece blanket fabrics and a processing method thereof, which belongs to the technical field of terylene fiber products and comprises voile weave and ground weave, the raw material used by the voile weave is DTY terylene filament in 133dtex / 192f, 111dtex / 192f or 111dtex / 144f, and the raw material used by the ground weave is FDY terylene filament of 75dtex / 24f, wherein the mass percentage of the DTY terylene filament occupied in the fabrics is 60-70 percent, and the mass percentage of the FDY terylene filament occupied in the fabrics is 30-40 percent. The invention can lead villus of the fabrics to be straight so as to have excellent lodging resistance and warmth retention property, and can obtain 150-250g / m<2> of gram weight of thread count and be suitable to fabricate household wares such as bathrobe, sleepwear, sheet, and the like. The method can ensure the advantages of the terylene coral fleece blanket fabrics, and can lead the terylene coral fleece blanket fabrics to have better sterilizing, antistatic and anti-allergic effects so as to meet the serviceability.

Owner:CHANGSHU XINXIN WARP & KNITTING

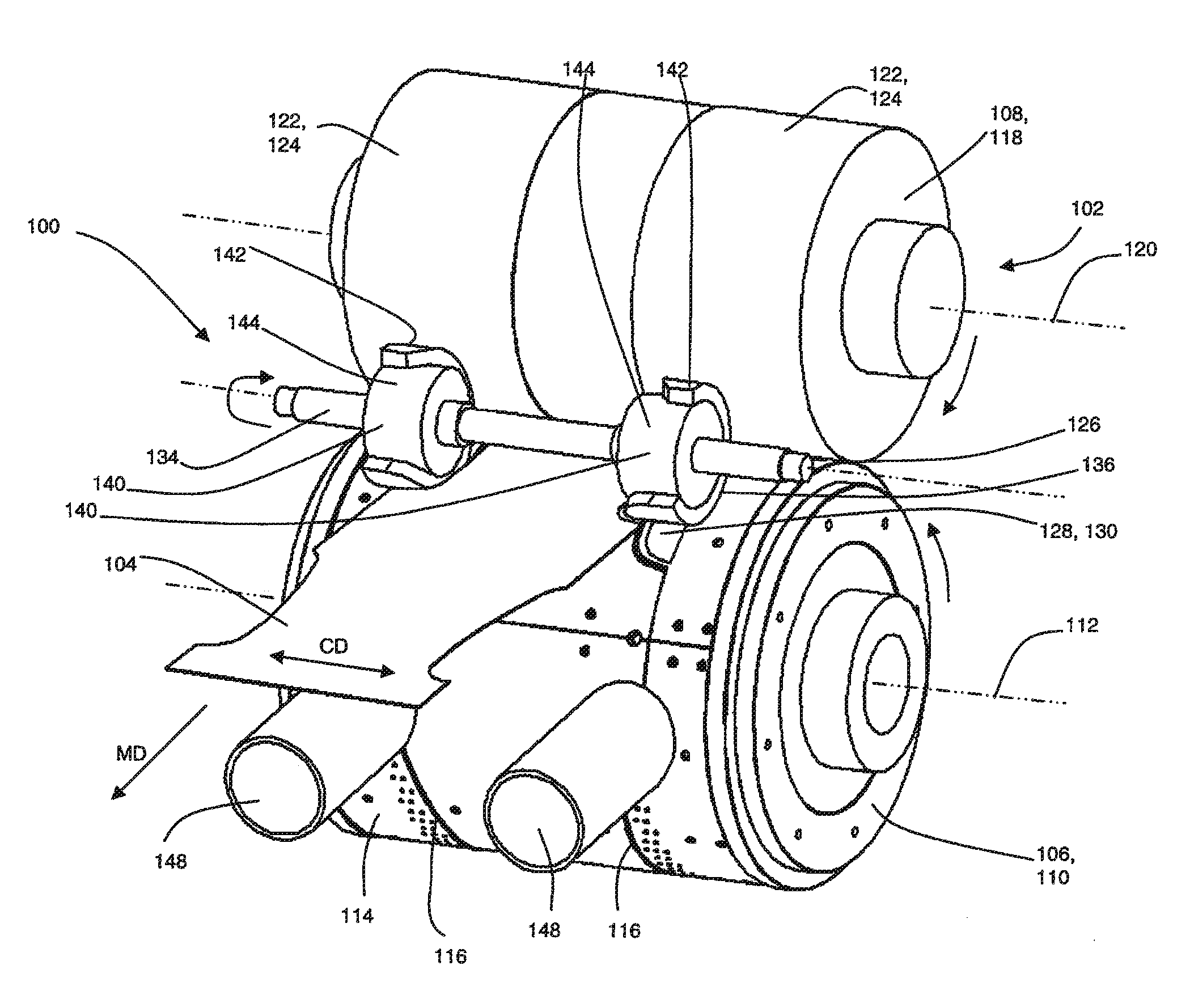

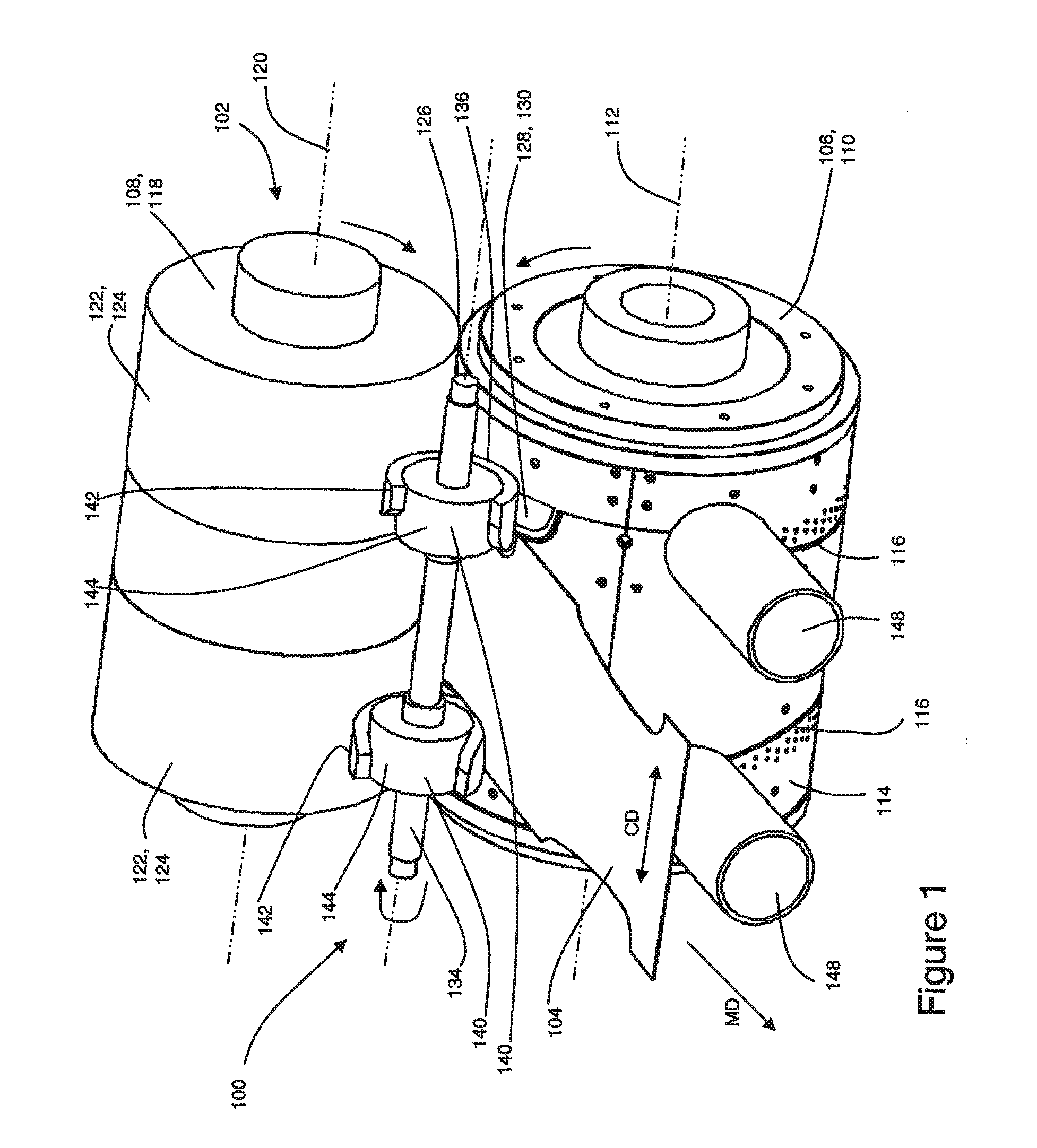

Absorbent Article Substrate Trim Material Removal Process and Apparatus

Aspects of the present disclosure involve methods and apparatuses for cutting and removing trim from an advancing substrate. Particular embodiments of the apparatuses and methods disclosed herein provide for removal of continuous lengths of trim, and in some embodiments, discrete pieces of trim from an advancing substrate.

Owner:THE PROCTER & GAMBLE COMPANY

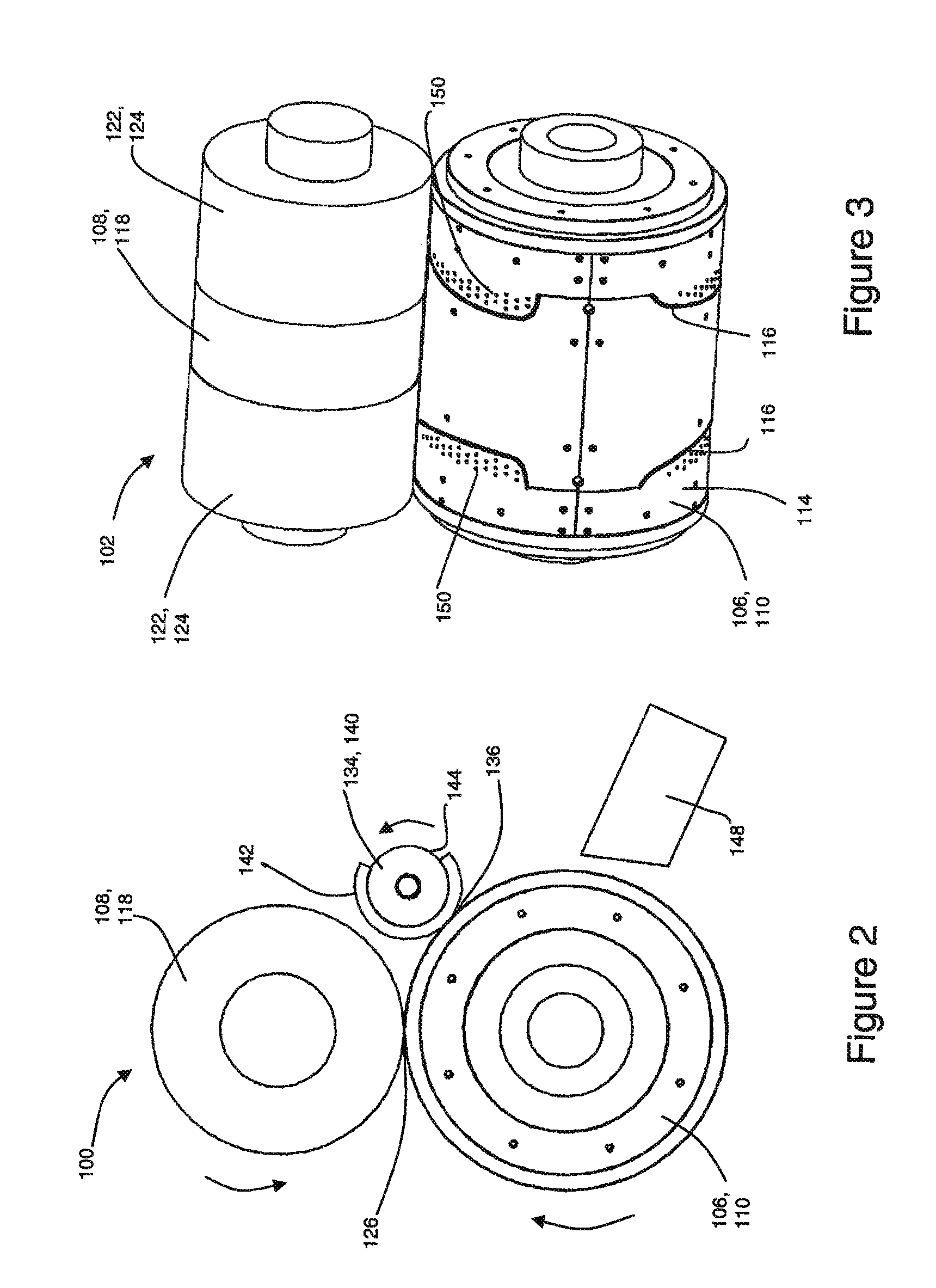

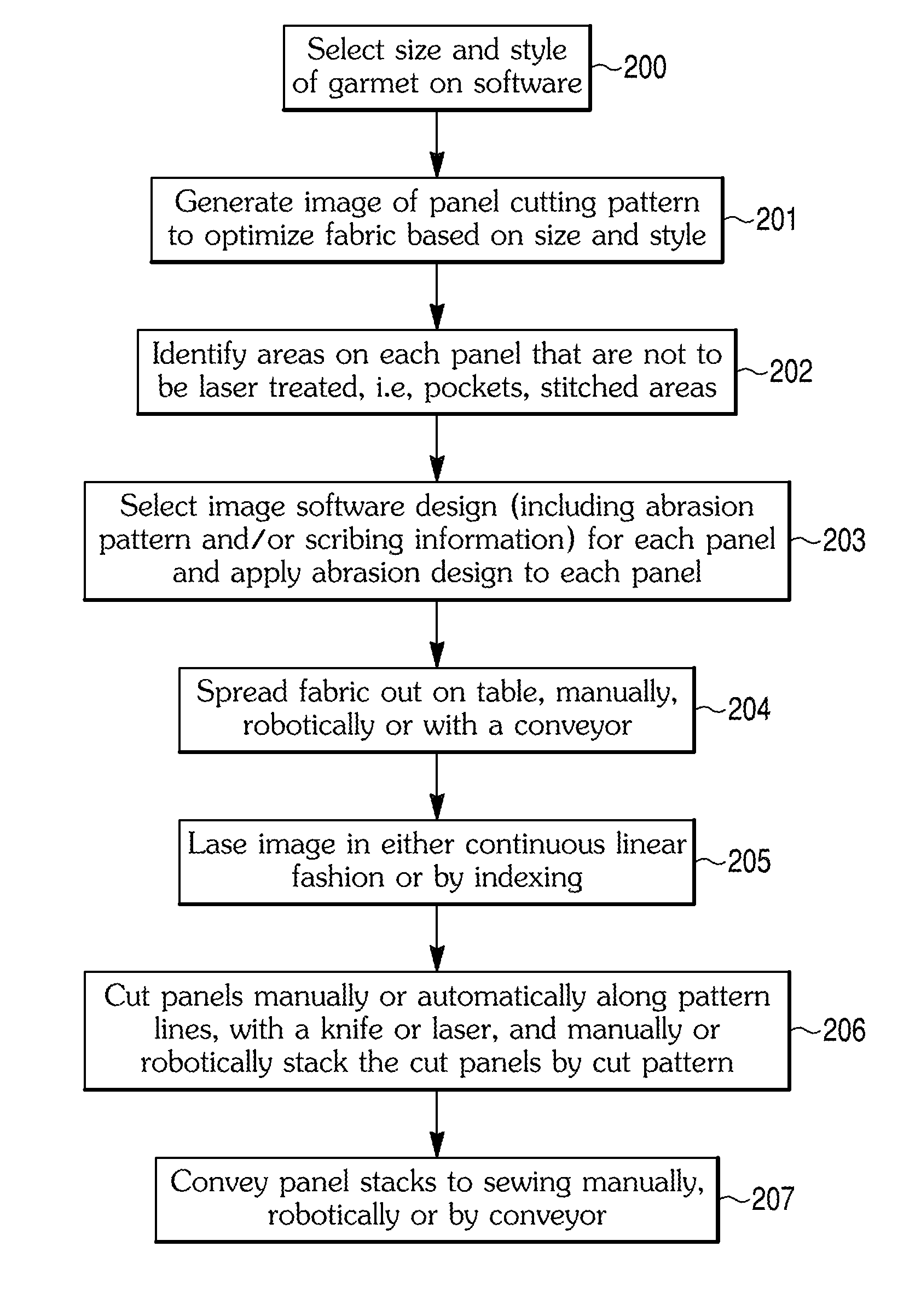

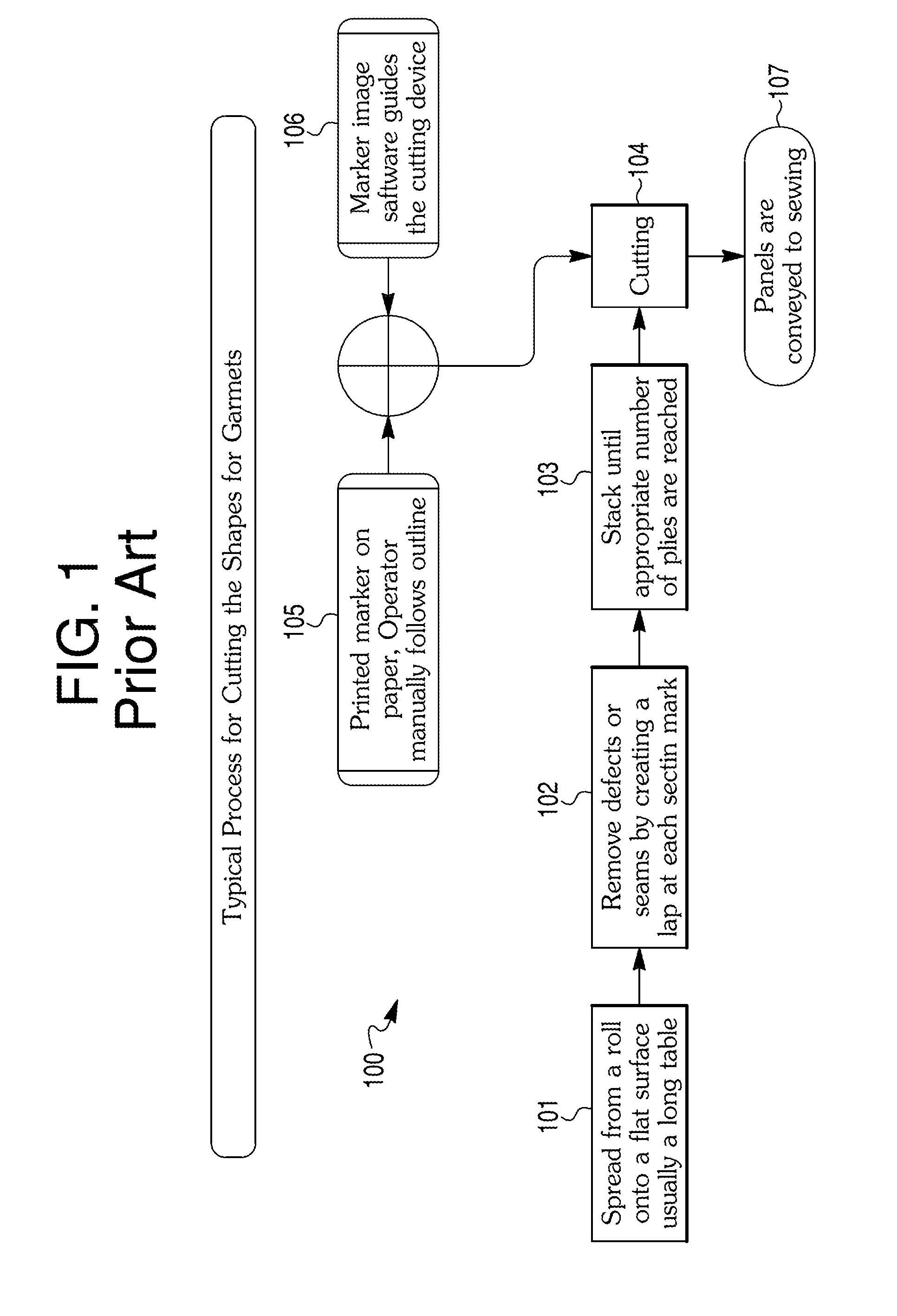

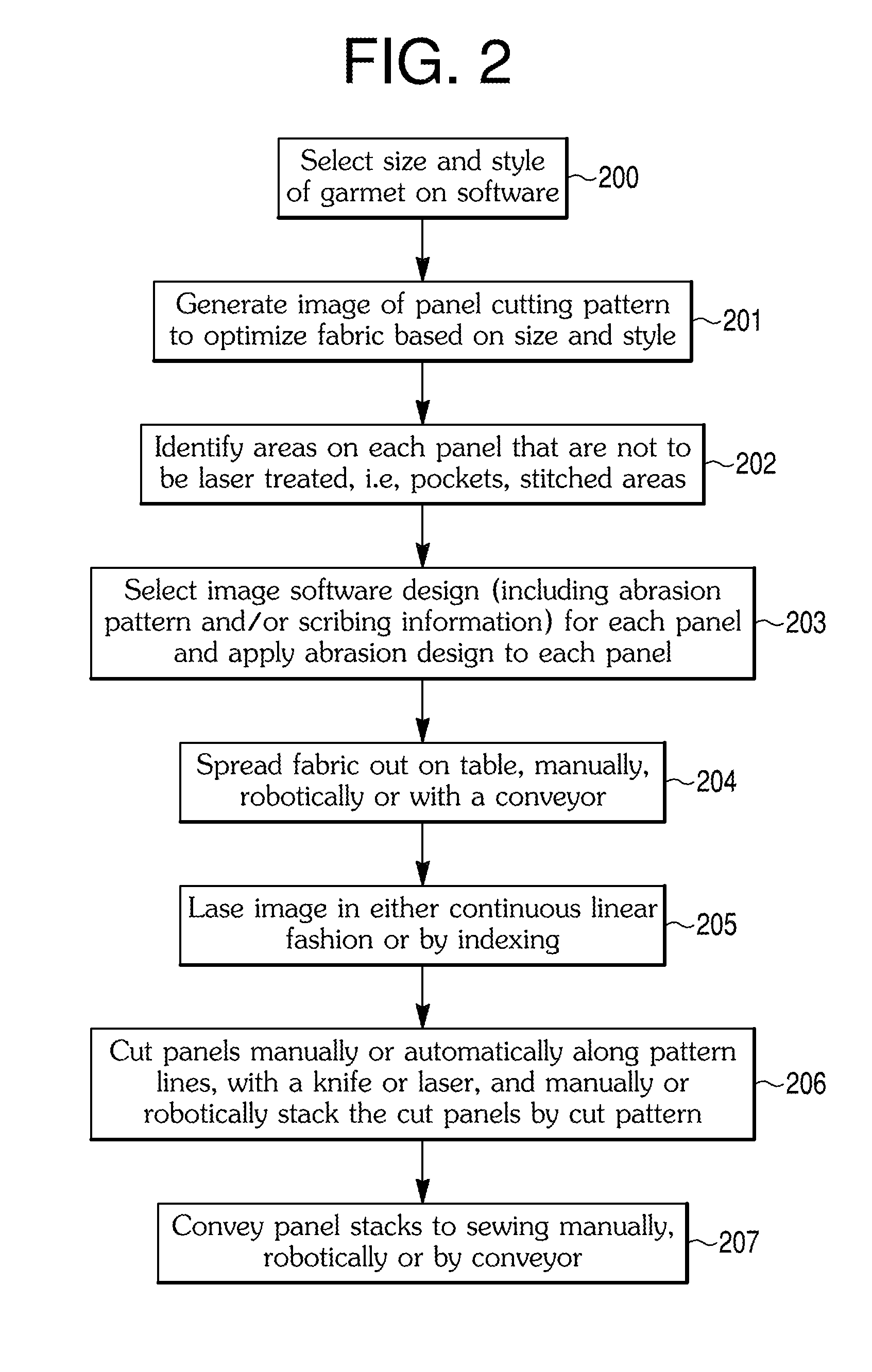

System and method of generating a pattern or image on fabric with linear laser irradiation, fabric made by said method, and products made with said fabric

A method of scribing abrasion aesthetics, patterns, images, serial numbers, ply markings and / or other information, such as sizing or care information, on fabric such as denim, before or during the fabric cutting process is provided. The method comprises loading the panel abrasion software, pattern marker software, and fabric scribing software; placing the fabric on a flat surface under at least one laser; laser scribing ply numbers, serial labels, fabric markers, and panel abrasions on the fabric; cutting the fabric into fabric lengths; spreading the pre-abraded and pre-marked fabric lengths on top of each other to create multiple plies in precise alignment; cutting shaped panels along the lines of the pattern marker with a conventional knife, laser, or other appropriate cutting tool; and stacking the abraded, labeled and shaped panels robotically or manually for sewing.

Owner:REVOLAZE LLC

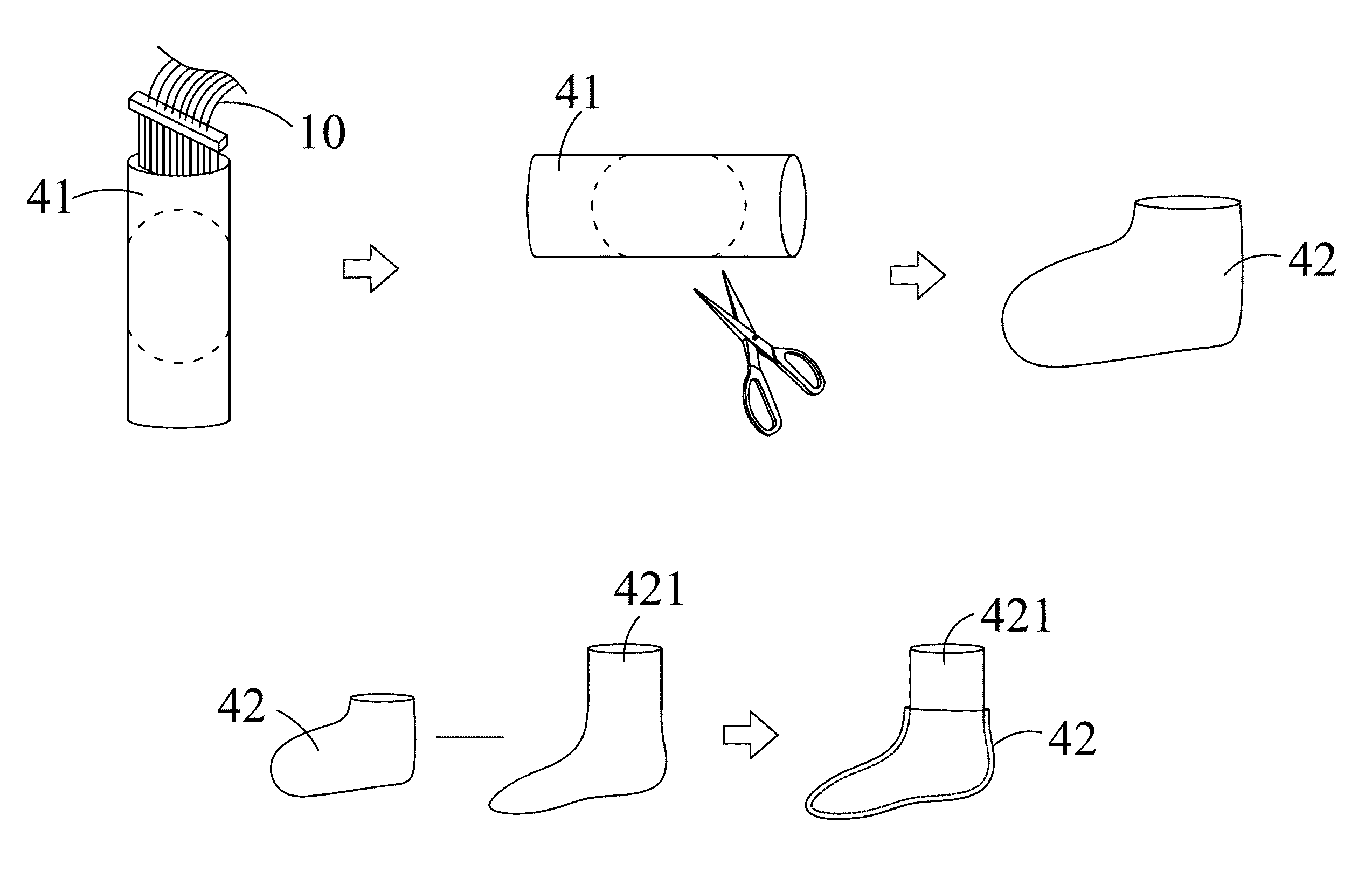

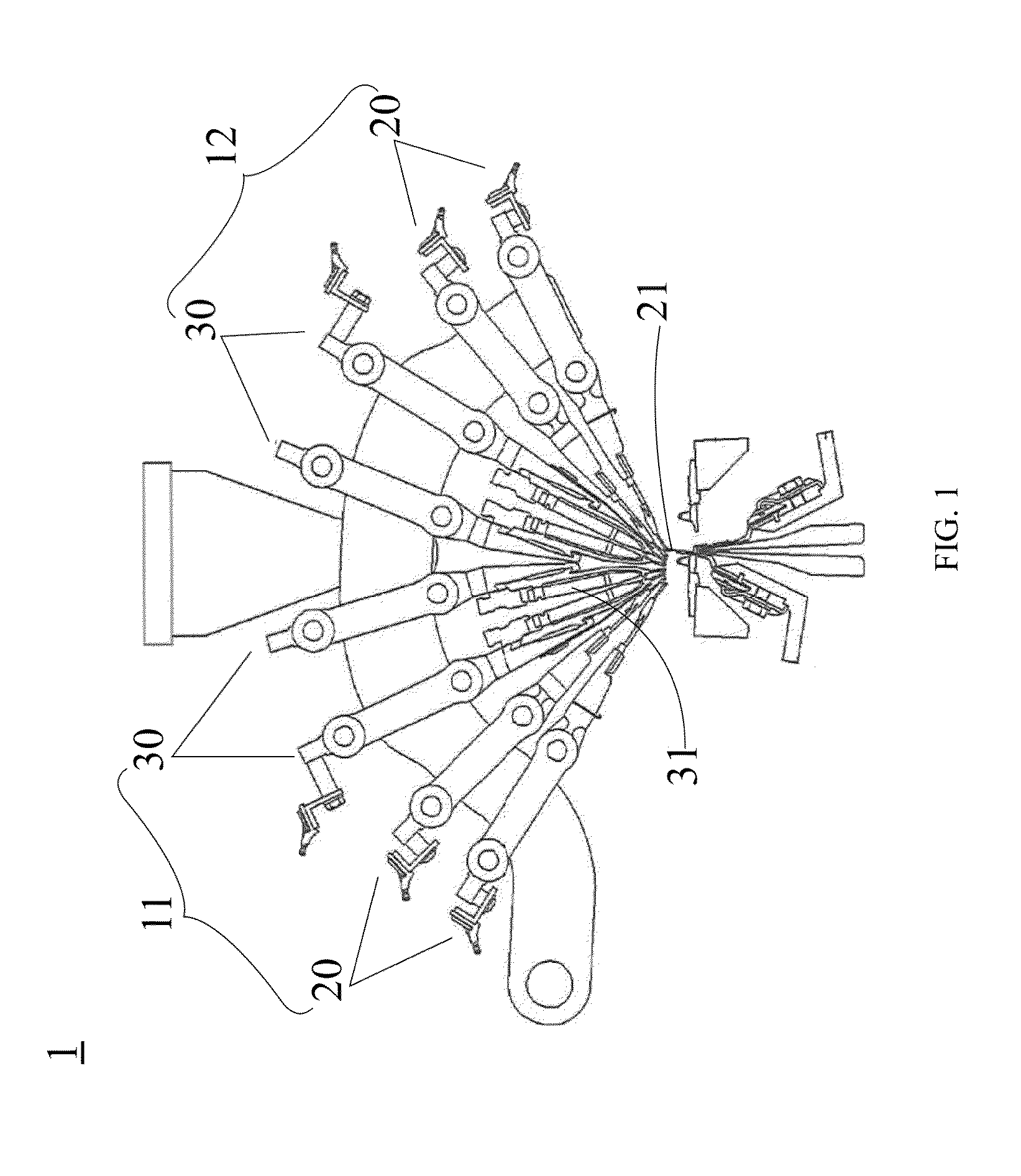

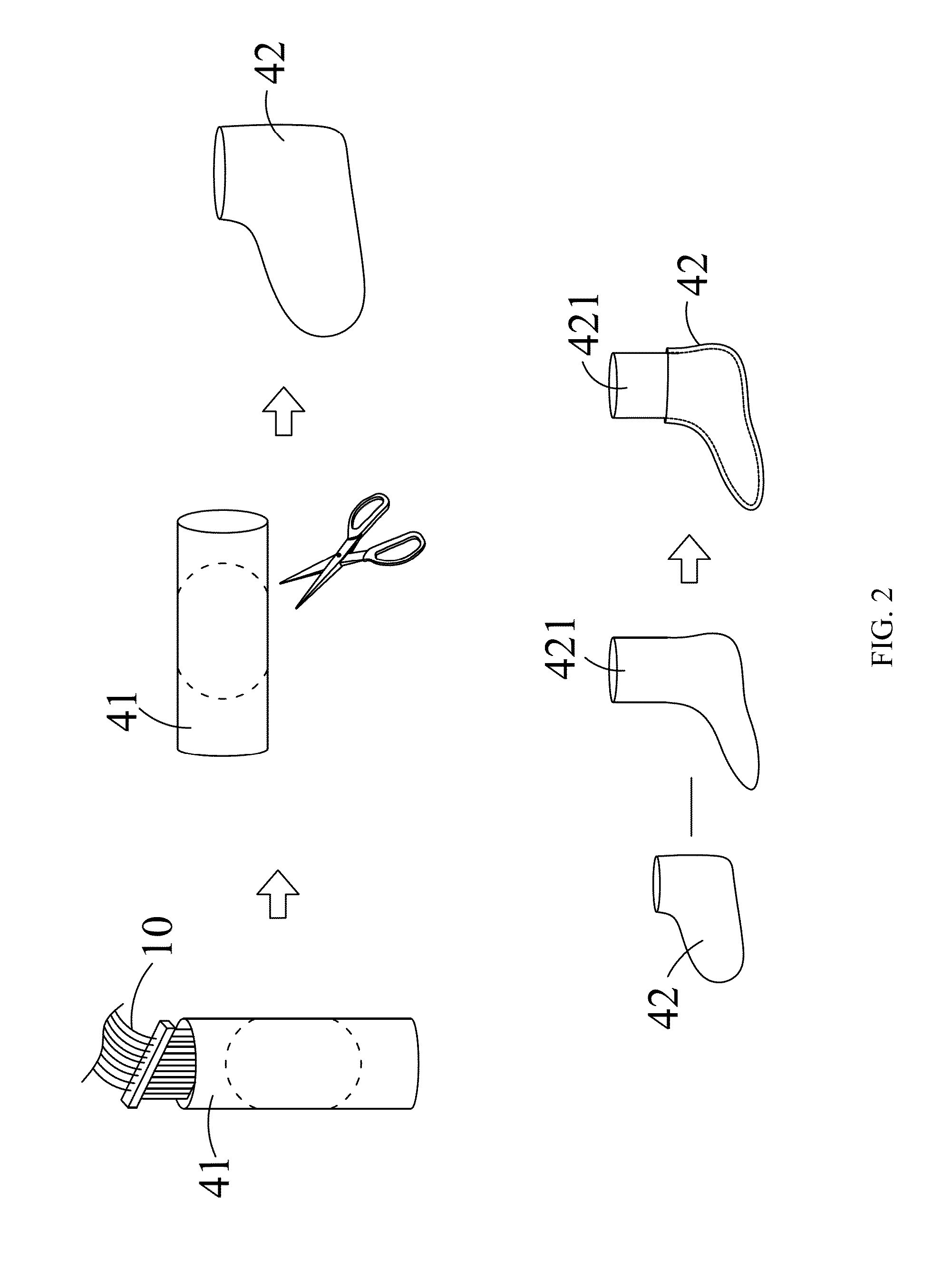

Weaving Method of Three-Dimensional Vamp

ActiveUS20140082905A1Increase labor costEliminate needMechanical cleaningPressure cleaningEngineeringHot melt

A weaving method of a three-dimensional vamp includes the steps of: weaving yarn by a warp-knitting machine to form a top vamp by a first part needle bar of the warp-knitting machine which is interactively woven with a bottom vamp formed by a second part needle bar of the warp-knitting machine so as to form a tube-shaped fabric; cutting the tube-shaped fabric to form a sock-shaped fabric; disposing the sock-shaped fabric on a shoe last; and heating the sock-shaped fabric to tighten the sock-shaped fabric in order to seal the shoe last and consequently obtain the three-dimensional vamp. The heat shrinkable and irreversible properties of a high shrinkage yarn or hot melt yarn are used to seal the sock-shaped fabric with the shoe last, thereby achieving the substantial physical properties. The turner cost and the fabric flotsam can be reduced by the process of manufacturing the integrally formed vamp.

Owner:LONG JOHN TSUNG RIGHT IND

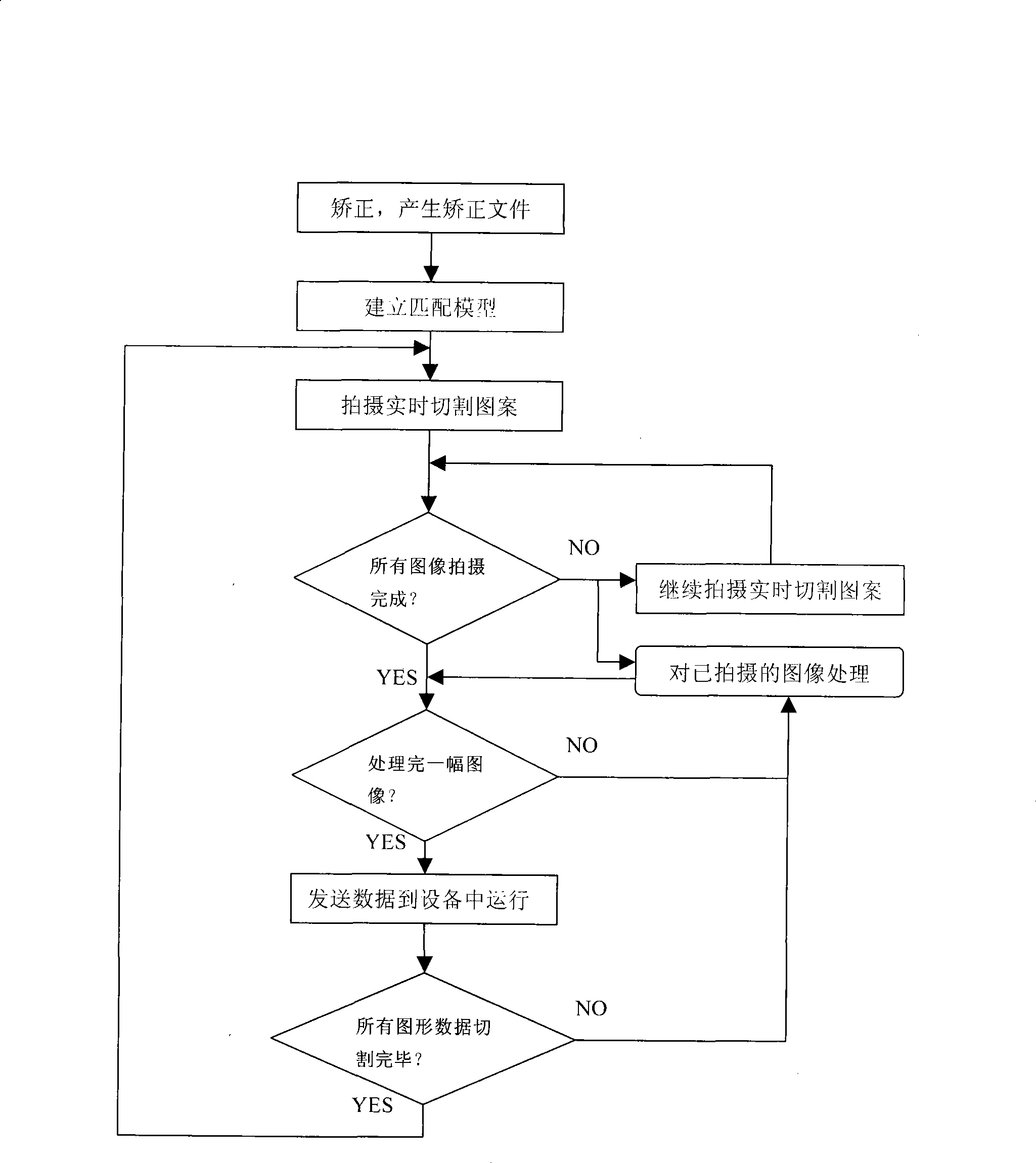

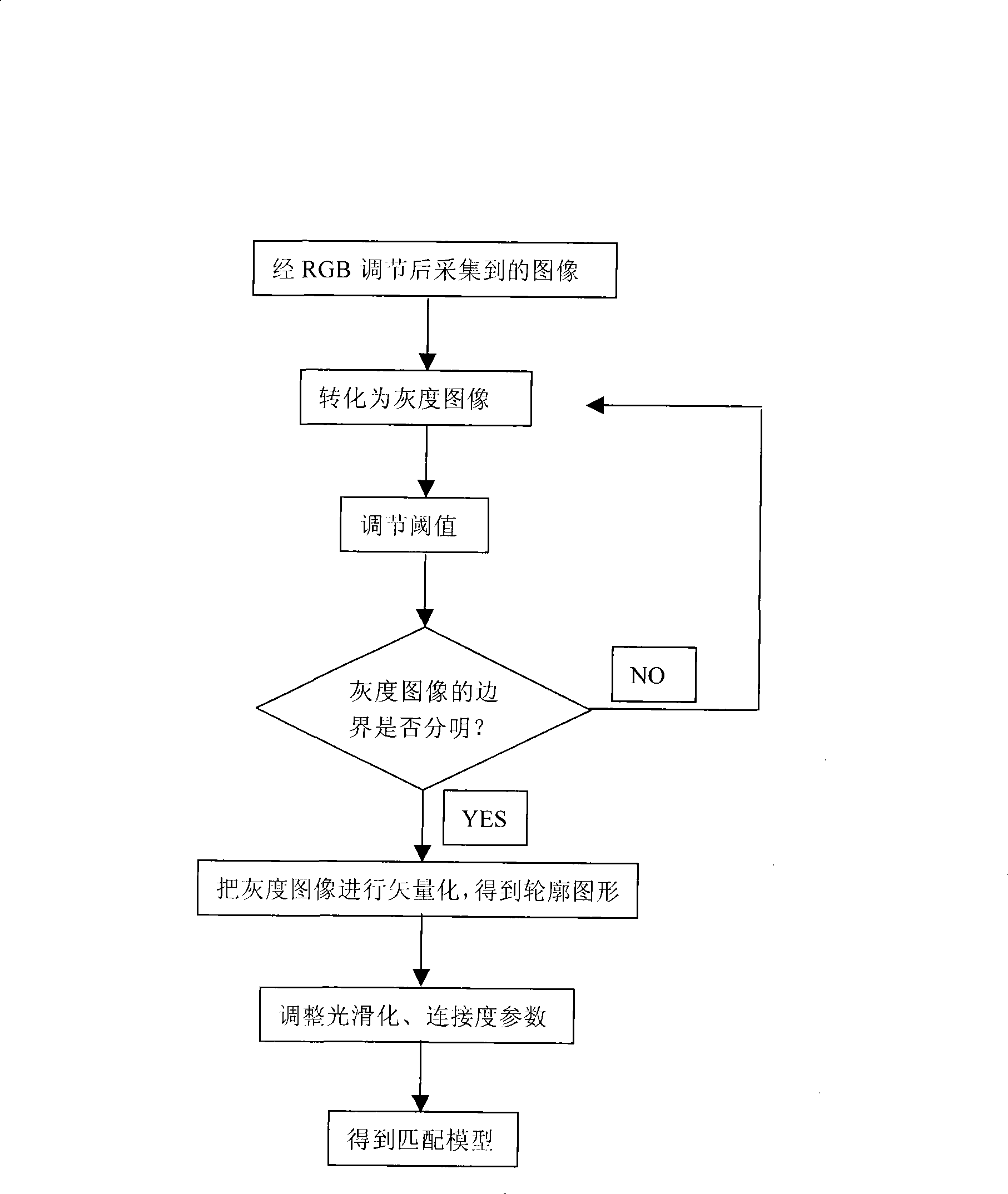

Cutting method along boundary of laser cutting equipment

InactiveCN101363188AAchieve precise cuttingReduce waiting timeSevering textilesLaser beam welding apparatusGraphicsPattern recognition

The invention discloses an edge finding cutting method of a laser cutting device which is characterized in that images of an object needing to be cut are collected through a camera. A correcting document is used for the correction to generate a contour graph. Then, based on the contour graph, a matching model is constructed. Then, the patterns cut in real time are collected through the camera according to set parameters. The vectorization treatment is implemented on the collected images to generate graphs. The graphs are compared with the matching model according to the set similarity. An image satisfying the set similarity is the successful matching image. To the successful matching image, cutting data are generated according to the contour graph of the actually paragraphed image. Finally, the cutting data are sent to the laser cutting device to be cut. The cutting method is characterized by automatically adapting to the cut image differences within certain similarity scope and realizing the precise cutting of images.

Owner:瑞安市博业激光应用技术有限公司

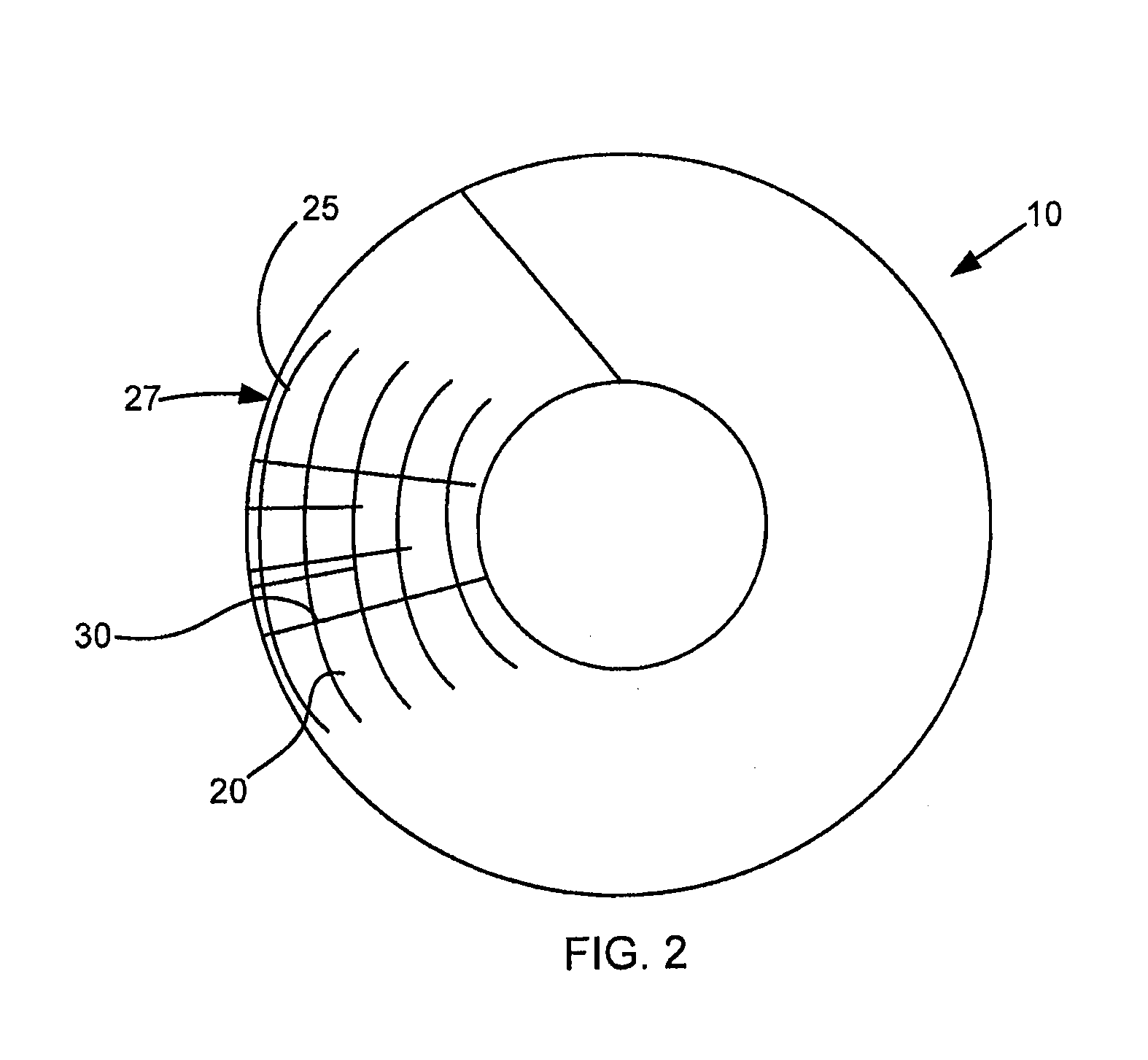

System and method for textile positioning

InactiveUS20110275266A1High fiber volumeEasy to createLayered productsLoomsEngineeringMechanical engineering

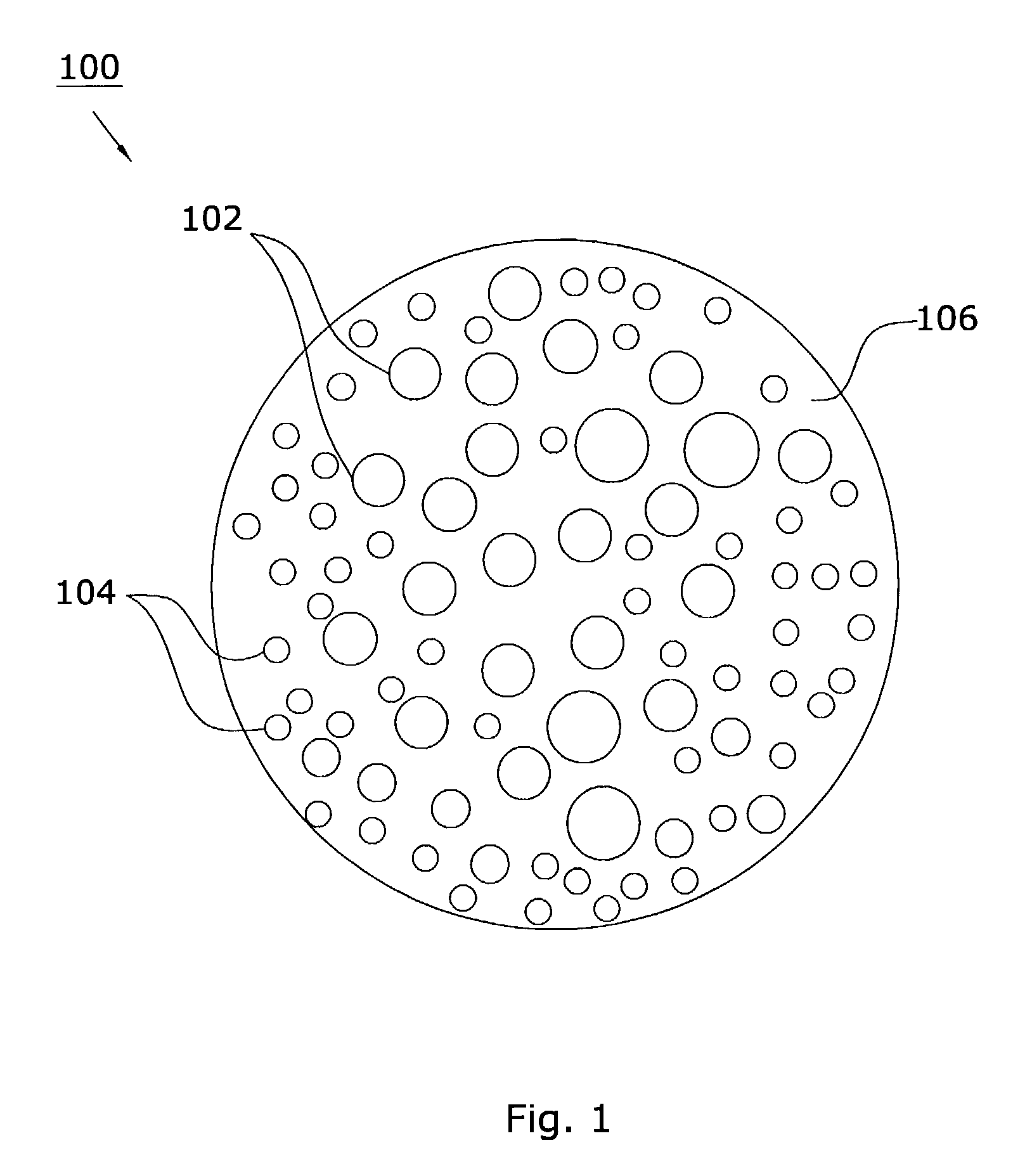

A circular needle loom comprises a stationary bed plate for receiving a spiral textile. Engagement members may be disposed next to the stationary bed plate, such that the engagement members interface with a positional structure of the spiral textile that is used to position and rotate the spiral textile around the stationary bed plate. A conical roller deploys the spiral textile on the stationary bed plate. The engagement members rotate the spiral textile around the stationary bed plate until a predetermined number of layers are deposited on the stationary bed plate.A spiral textile comprises a weft tow that extends from an inside diameter to an outside diameter, and a positional structure, such as a sacrificial edge and / or loop, is located next to and / or is attached to the weft tow. The positional structure facilitates positioning the spiral textile in a desired manner with respect to the circular needle loom in order to create a needled preform.

Owner:THE BF GOODRICH CO

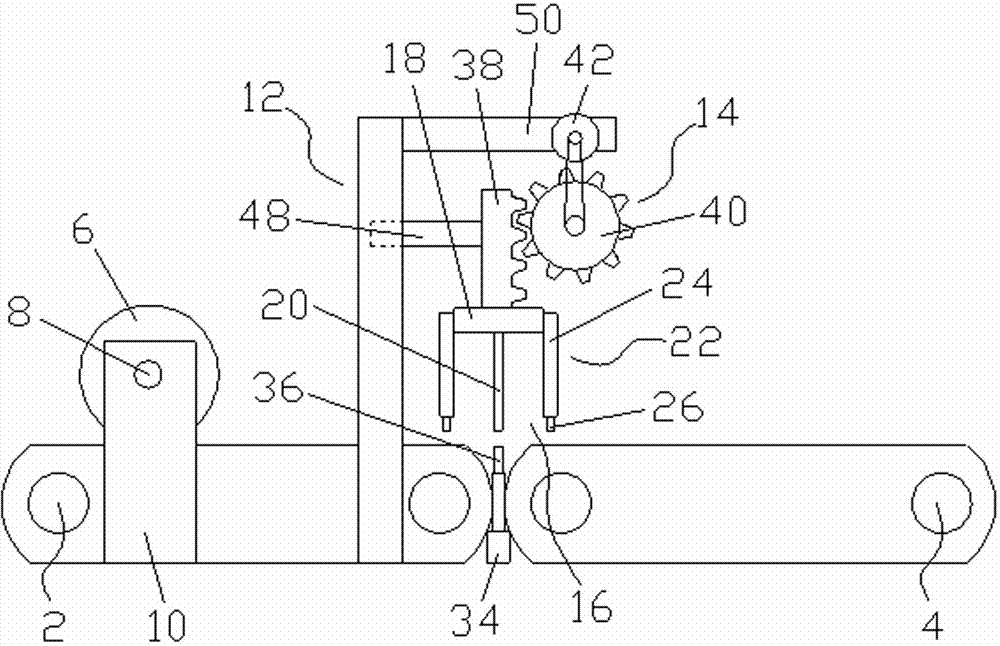

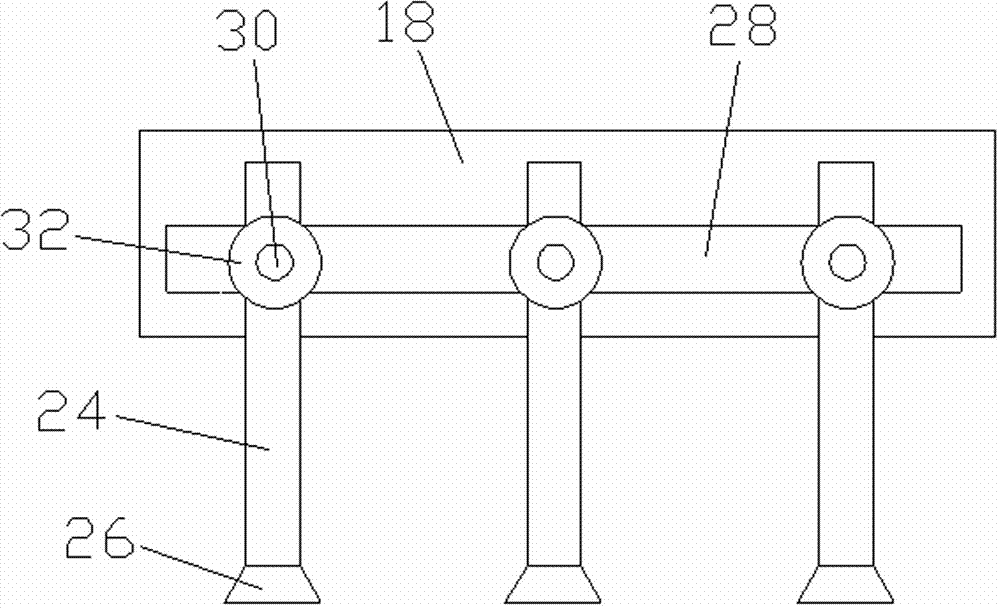

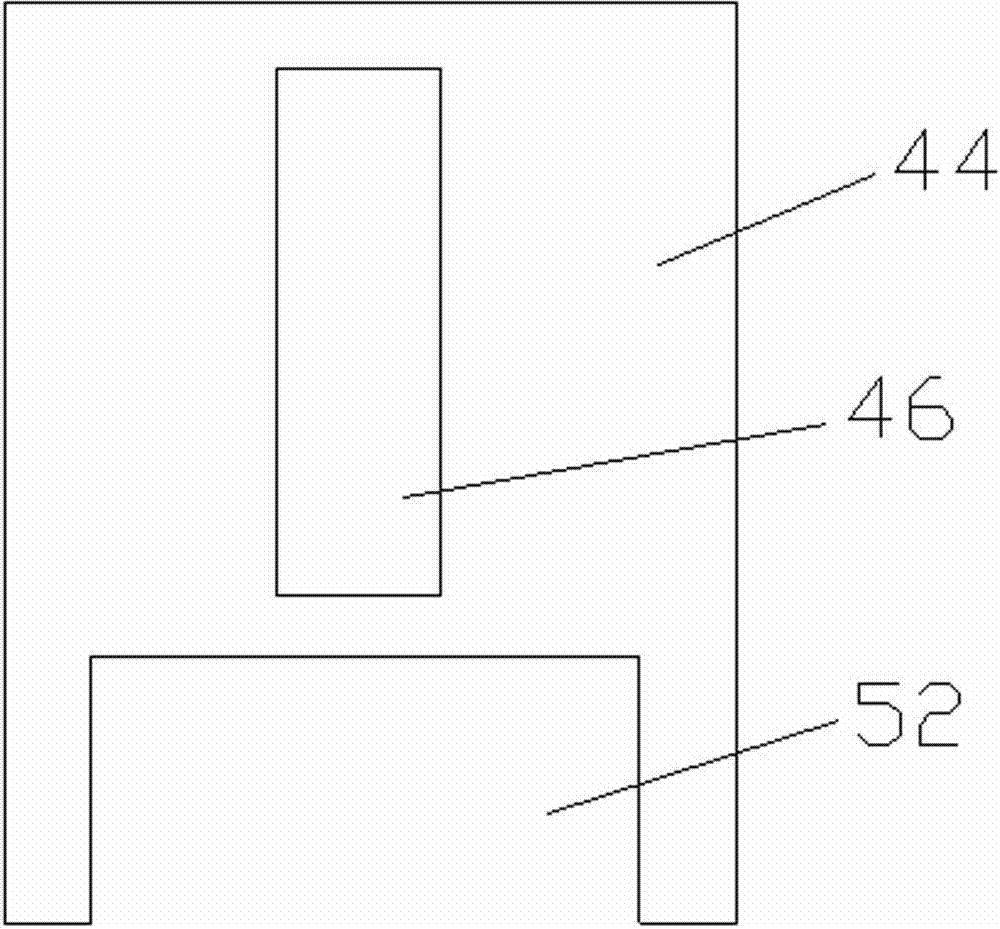

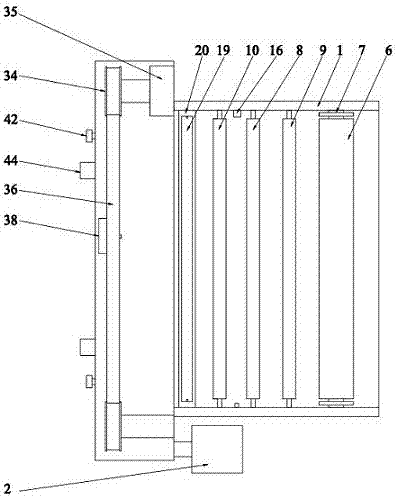

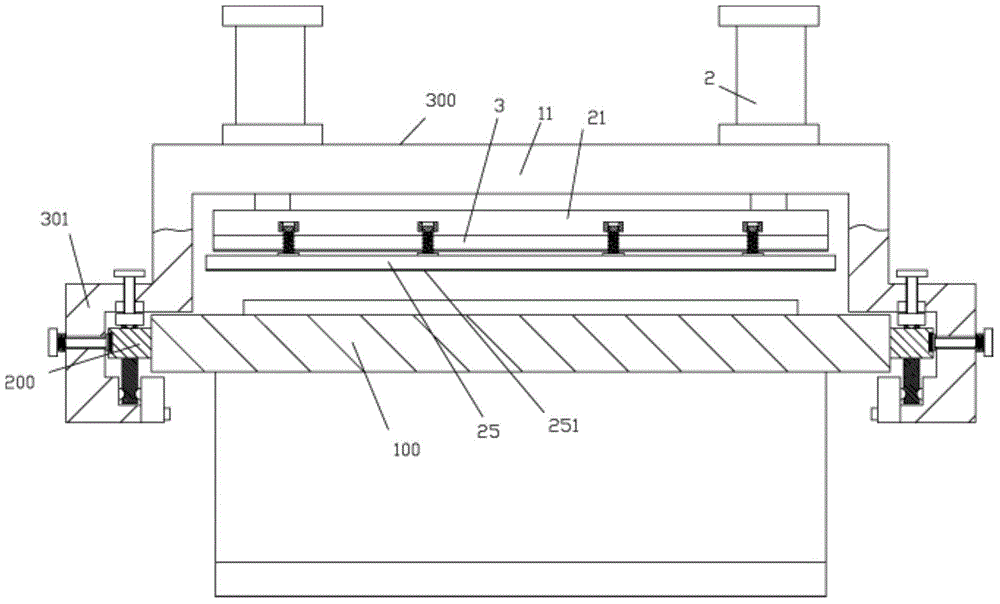

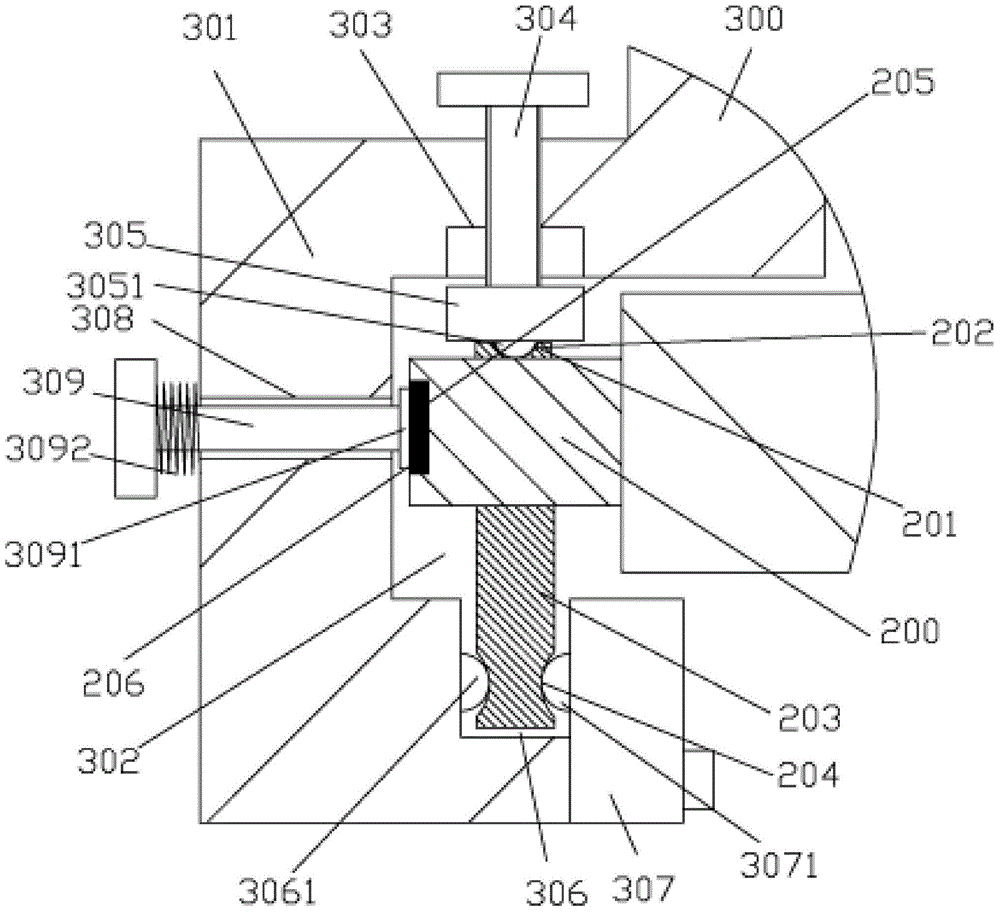

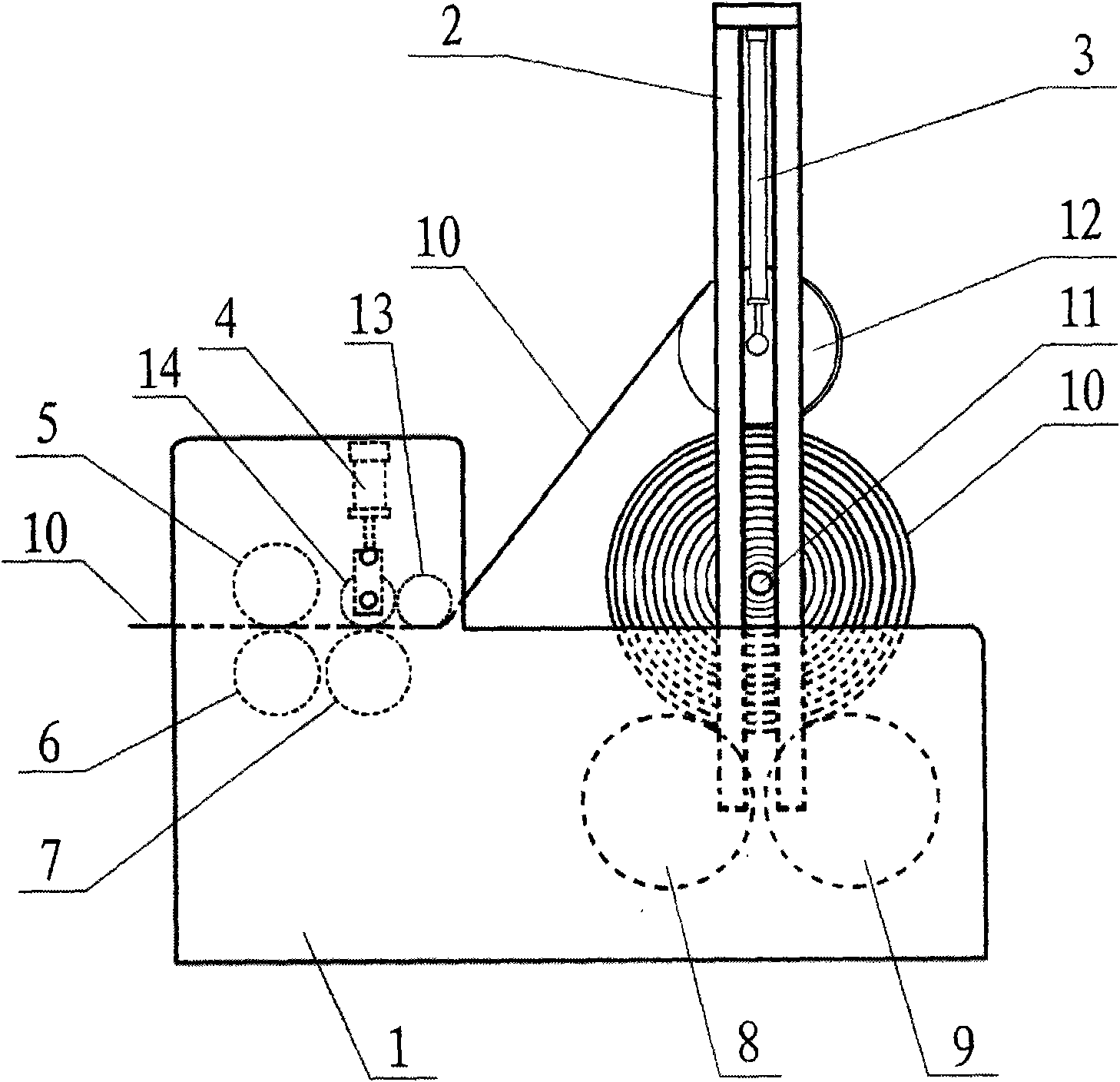

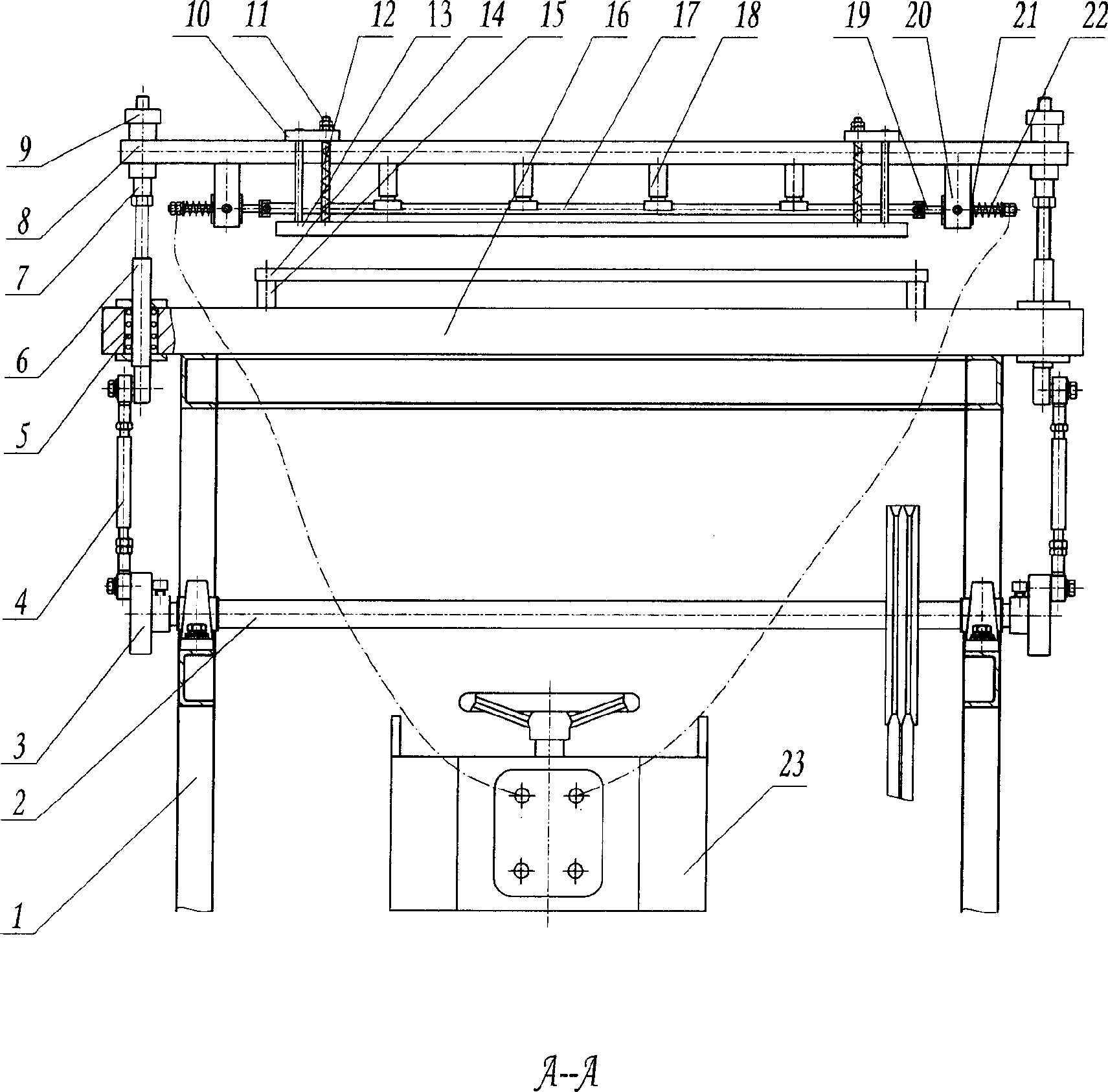

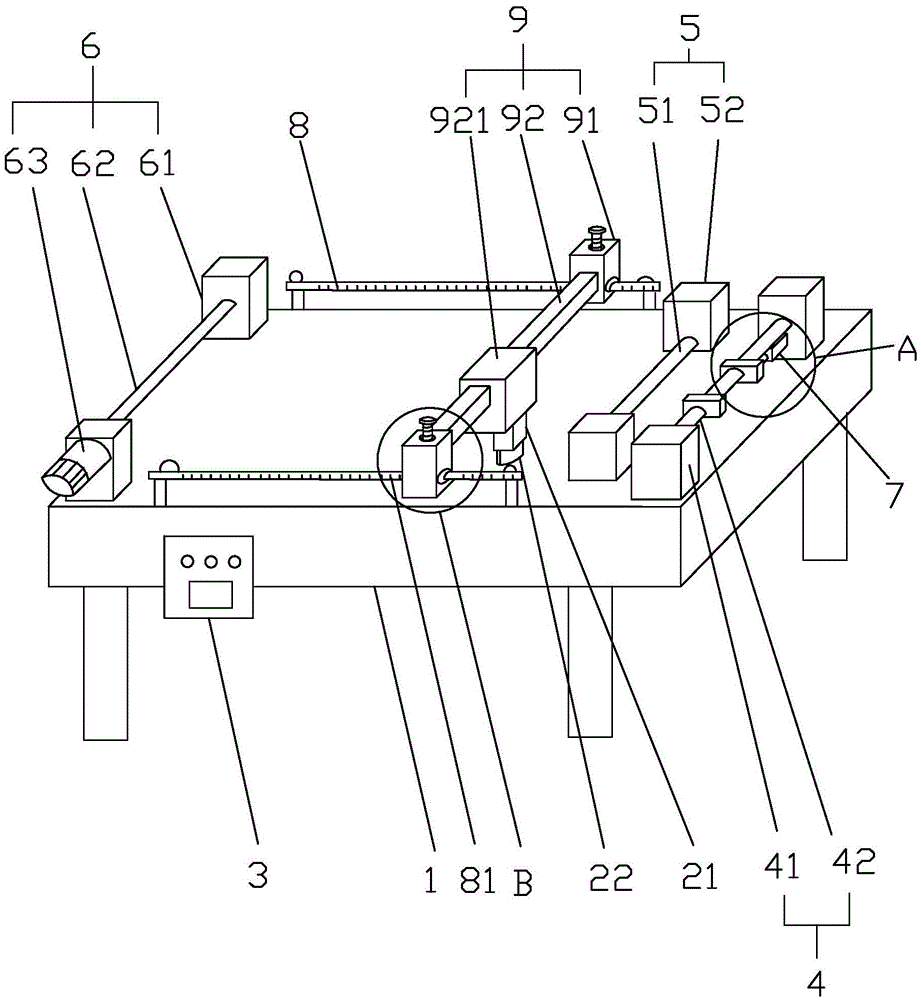

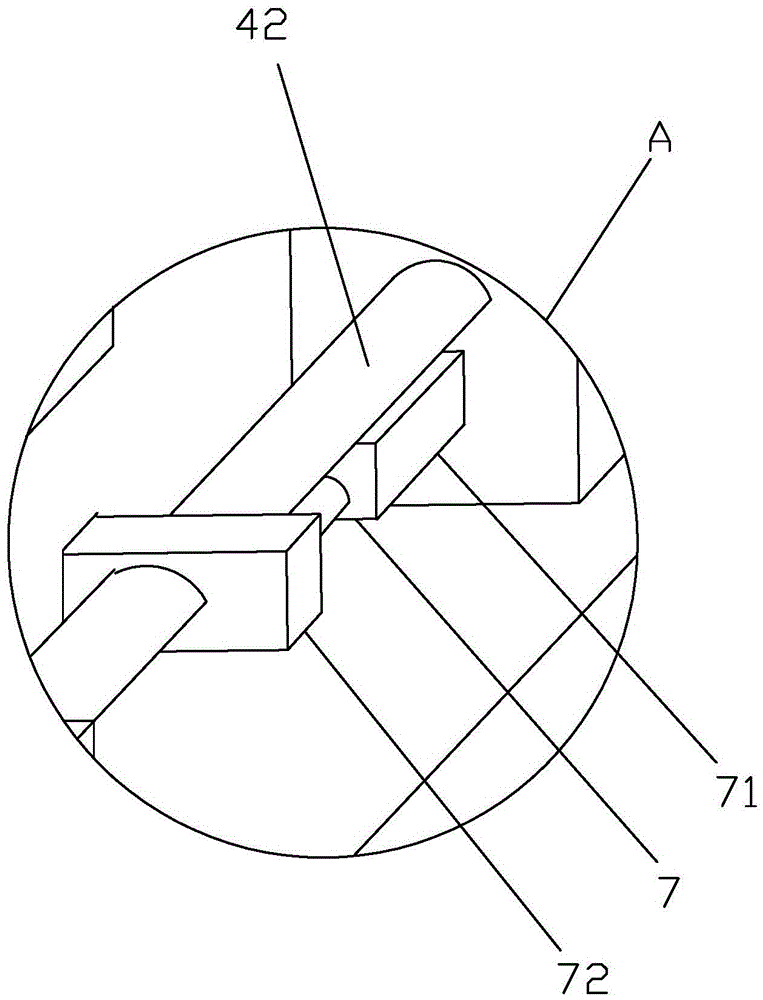

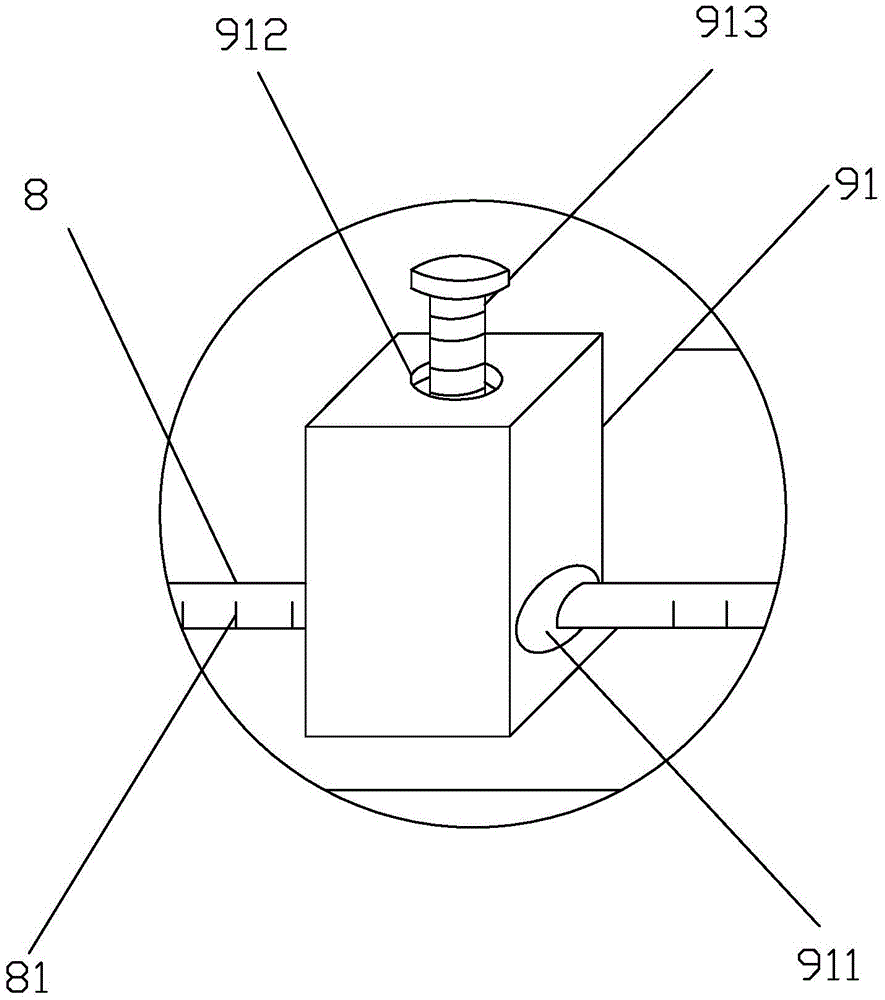

Cloth cutting device

The invention relates to a cloth cutting device. The cloth cutting device comprises a first delivery mechanism and a second delivery mechanism which are arranged in sequence. A gap is formed between the first delivery mechanism and the second delivery mechanism. A cloth feeding roller is arranged above the first delivery mechanism. The two ends of the cloth feeding roller are arranged on supports located on the two sides of the first delivery mechanism through supporting shafts respectively. A lifting mechanism is further arranged and comprises a sliding assembly, a driving assembly connected with the sliding assembly and a cutting assembly which is driven by the driving assembly to move vertically. The cutting assembly comprises a cutter holder, a cutter connected to the middle of the lower end of the cutter holder and pressing rods connected to the two sides of the cutter holder respectively. According to the cloth cutting device, a gear drives a rack to move vertically, and then the cutter is driven to cut cloth; in the cutting process, press rod heads press the cloth, so that the cloth does not shift; meanwhile, an air cylinder pushes a top plate to be matched with the cutter, so that cutting is conducted smoothly, and work efficiency is improved.

Owner:WUJIANG MINGJIA WEAVING

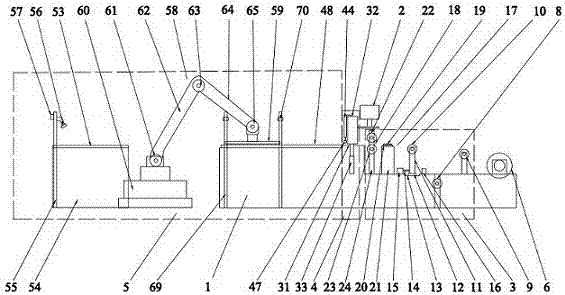

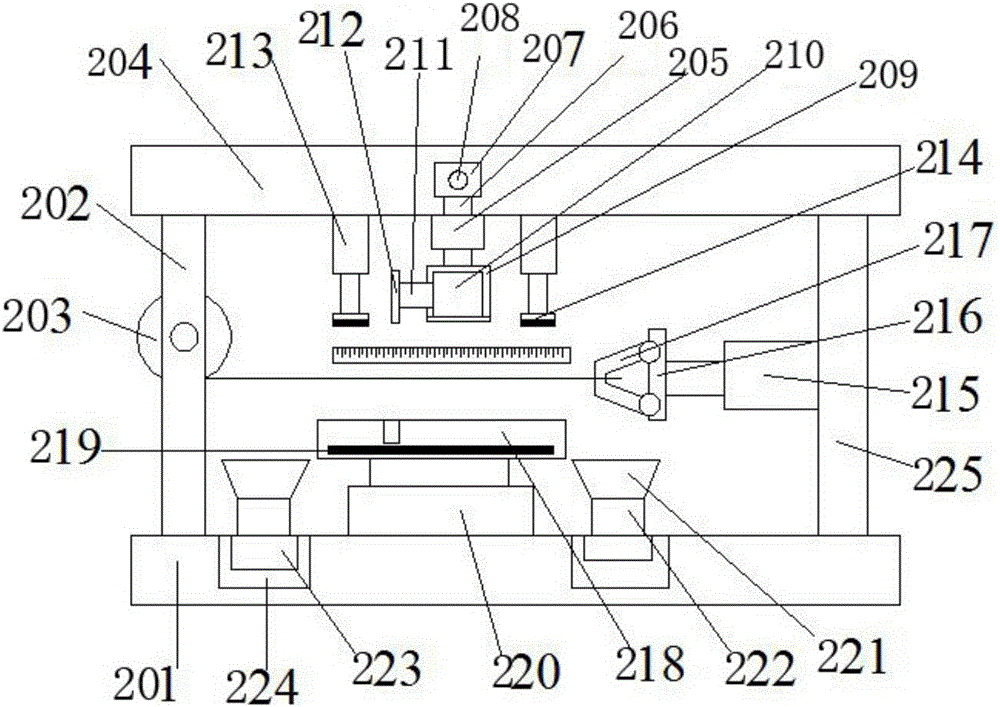

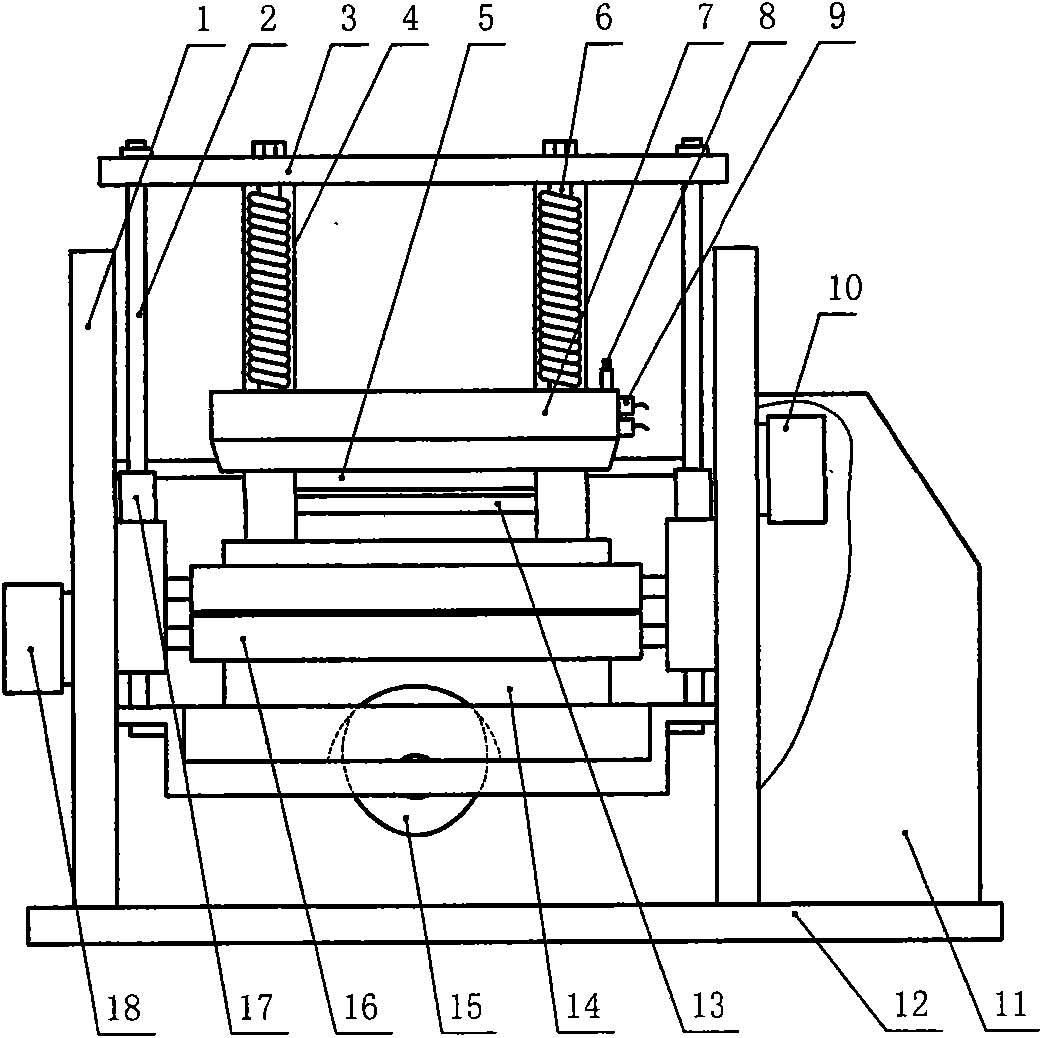

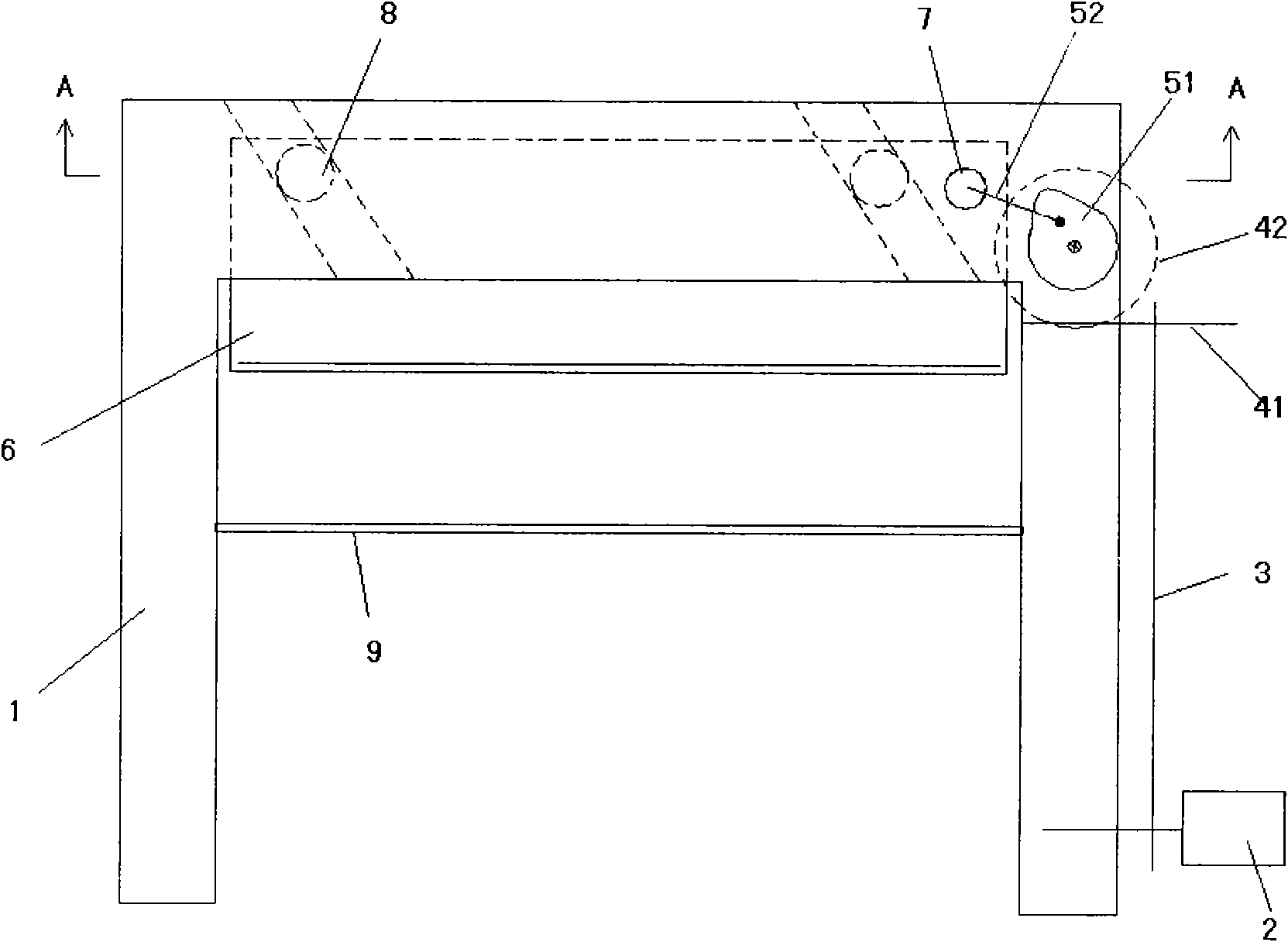

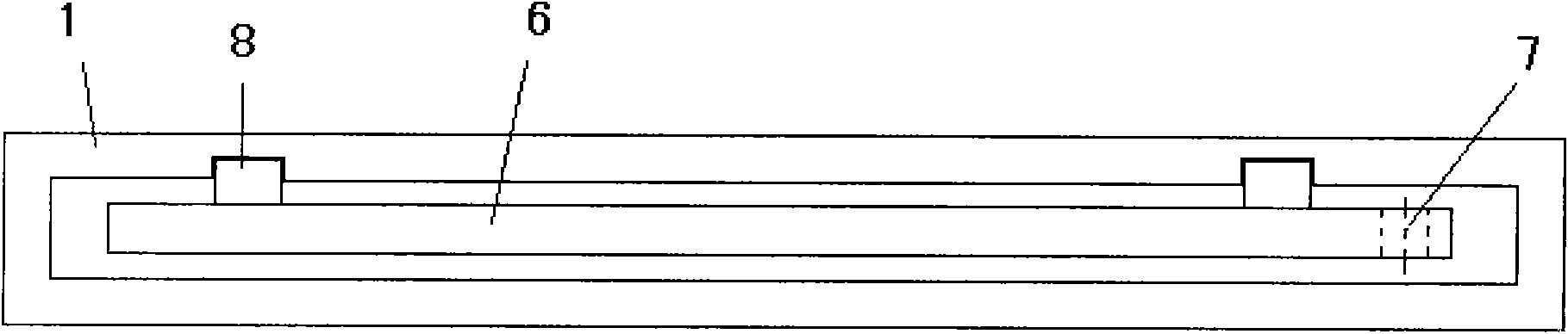

Full-automatic cloth cutting device

ActiveCN107354708AImprove cutting yieldReduce intensitySevering textilesMetal working apparatusHydraulic cylinderControl system

The invention relates to the field of cloth processing equipment, in particular to a full-automatic cloth cutting device which comprises a machine frame and a power distribution console. The machine frame is provided with a cloth feeding device, a cloth cutting device and a cloth collecting device. The front end of the cloth feeding device is provided with a raw material roller. The full-automatic cloth cutting device is characterized in that the cloth feeding device comprises a first cloth supporting roller, a tension roller, a second mop roller, a cloth pressing mechanism and a driving mechanism. The cloth cutting device comprises a cutting platform and a cutting lifting table which are connected through a cutting hydraulic cylinder. The cutting lifting table is provided with a linear guideway, a synchronizing wheel, a synchronous belt, a cutting knife, a limiting switch and a cloth pressing roller. The cloth collecting device comprises a belt conveying platform, an image collector, an automatic cloth detection platform, an industrial camera and a robot cloth collecting mechanism. The robot cloth collecting mechanism comprises a mechanical hand, a sucker mechanism and a control system. The sucker mechanism comprises a sucker support and a vacuum sucker. The full-automatic cloth cutting device can implement automatic calibration, automatic cloth cutting, automatic cloth collection and cloth detection, and the cutting yield and working efficiency are greatly improved.

Owner:WEIHAI BAOWEI NEW MATERIAL TECH CO LTD

Preparation method of regenerated cotton

InactiveCN104593910AReduce pollutionReduce defective rateMechanical cleaningPressure cleaningYarnFiber

The invention discloses a preparation method of regenerated cotton. The method comprises the following steps: a, sorting: firstly performing vibratory screening treatment on leftover, scrap, waste silk and yarn ends to obtain various cotton textile scraps; b, pretreating: performing alkaline cleaning, primary washing, hydrogen peroxide bleaching and secondary washing treatment on the obtained various cotton textile scraps respectively to obtain a pure white fabric stock with moisture content of being smaller than 1 percent; c, reprocessing: cutting the pure white fabric stock into fabrics with a physical character of being smaller than 1,200 mm, then reducing the fabrics into wool cotton, next loosening the wool cotton, and finally fluffing the wool cotton to form the regenerated cotton; d, packing: collecting fibers with length of 26-28 mm in the regenerated cotton, and packing the collected fibers to obtain the qualified regenerated cotton. According to the method, the waste textiles such as the leftover, the cloth scrap, the waste silk and the yarn ends are recovered and recycled.

Owner:YIBIN WEILUO TEXTILE

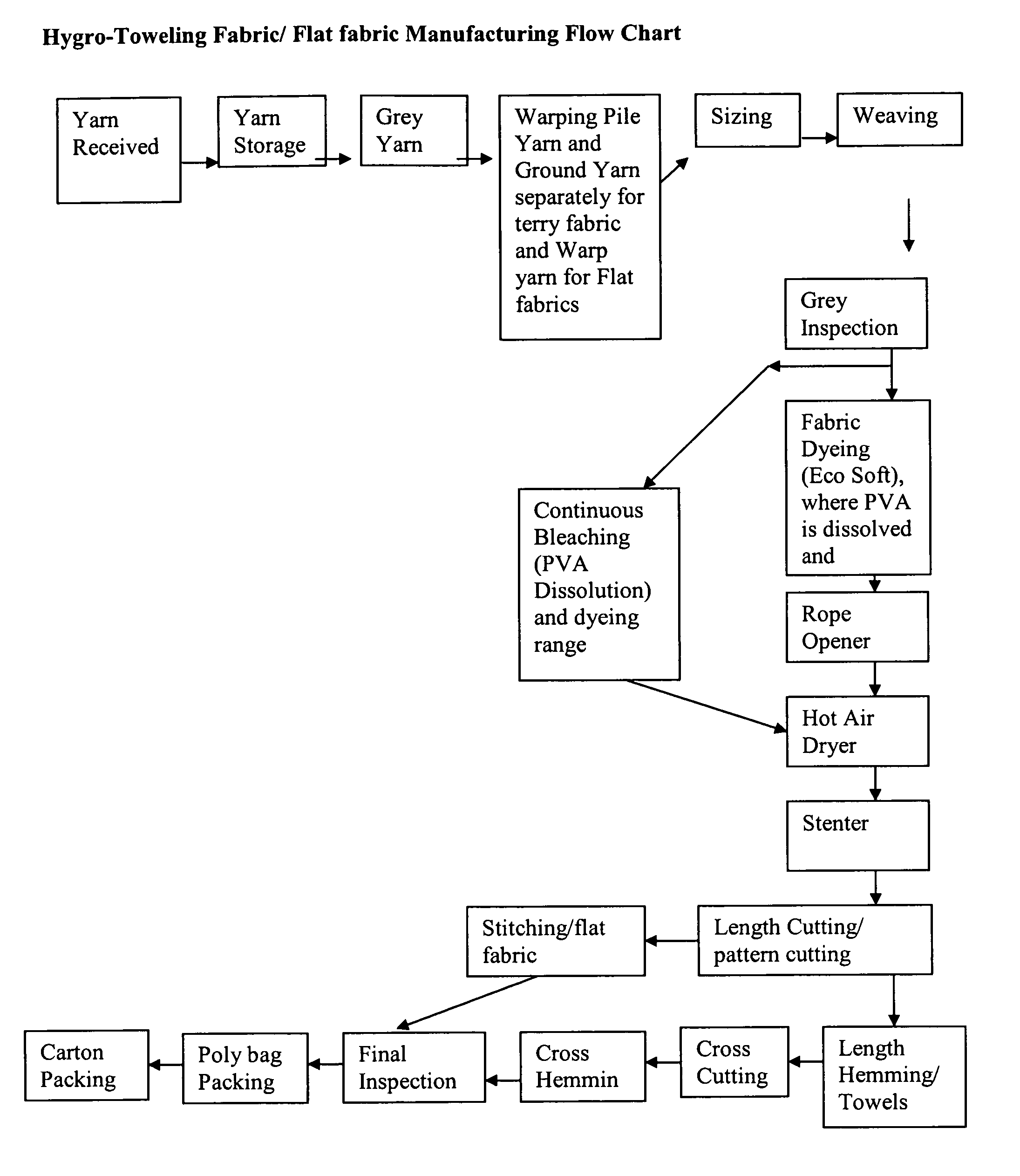

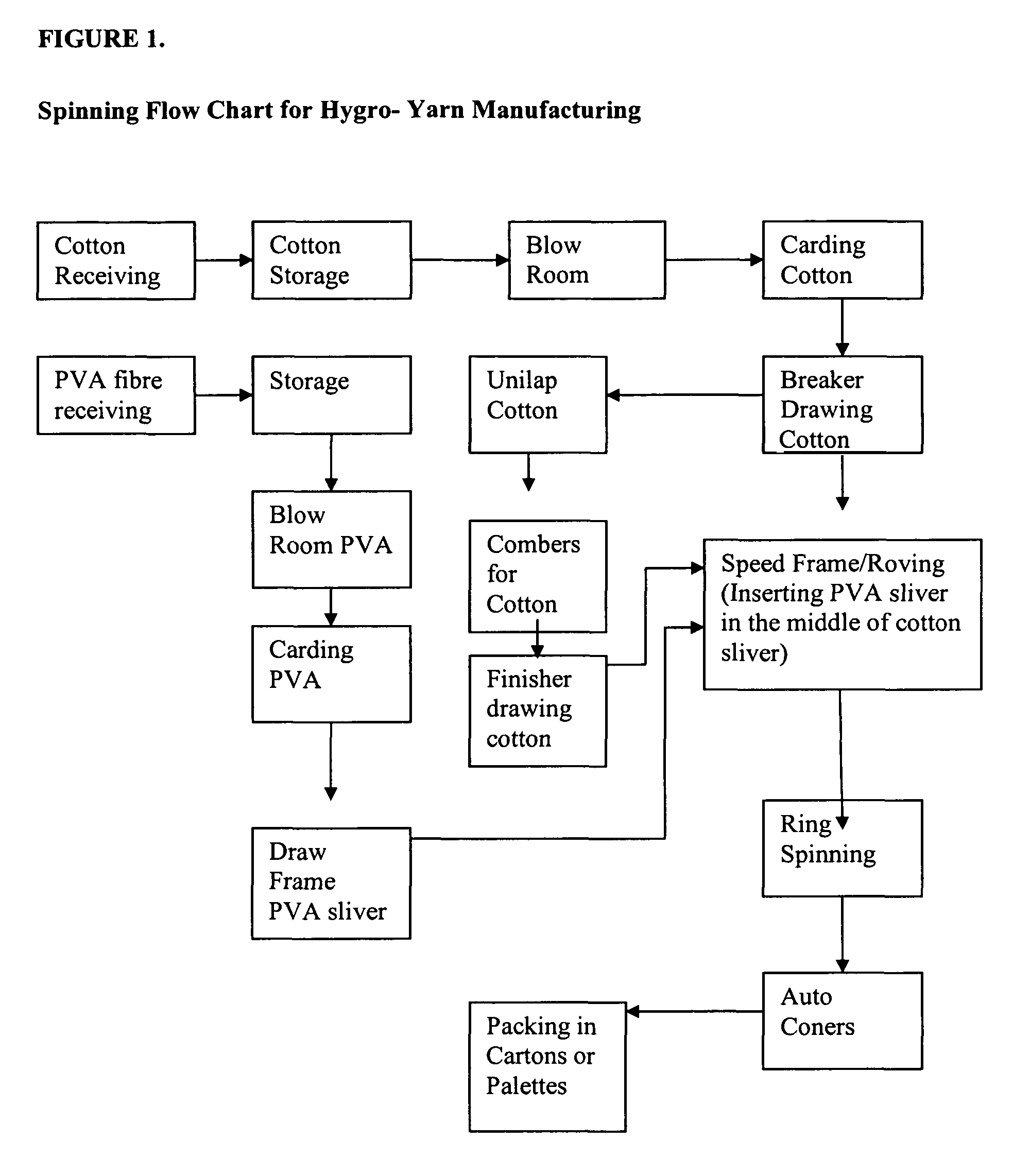

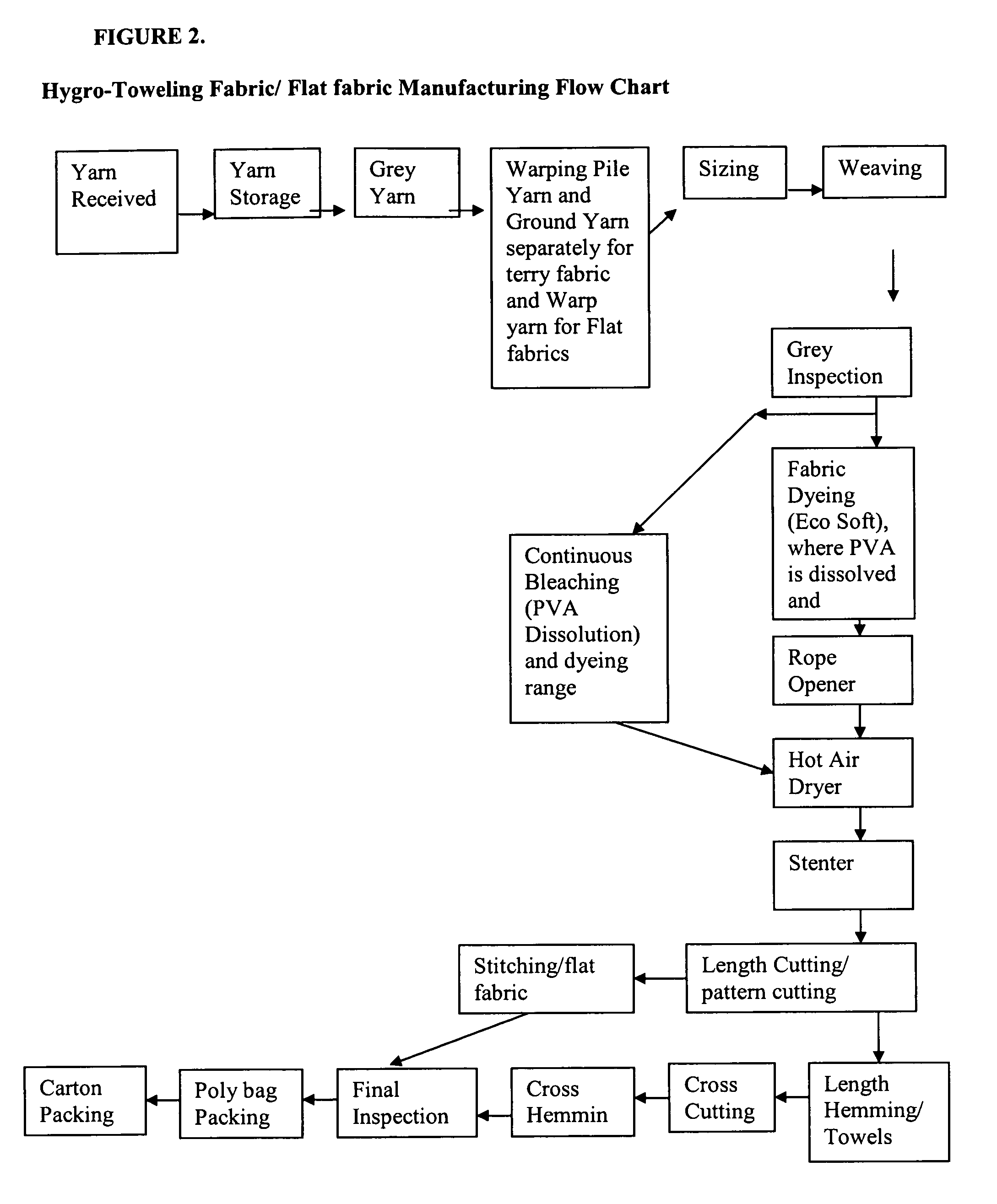

Hygro materials for use in making yarns and fabrics

ActiveUS8733075B2Fast dryingIncrease in sizeFabric breaking/softeningLayered productsFiberWarm water

A process is described wherein pile yarn is woven with cotton weft and warp yarns to produce terry fabrics, such as towels. The fabric is then washed in warm water to dissolve the PVA fibers. The amount of fibers dissolved, depends upon the count of the yarn or yarns used. By dissolving the PVA fibers, a hollow air space is produced throughout the pile yarn, corresponding to an increase in the air space in the pile yarn. By increasing the air space in the pile yarn, the resulting towels are softer and bulkier than standard cotton towels. The present invention further relates to pile yarn in terry woven fabric (warp yarn), or weft yarn, in the case of flat fabrics.

Owner:WELSPUN INDIA LTD

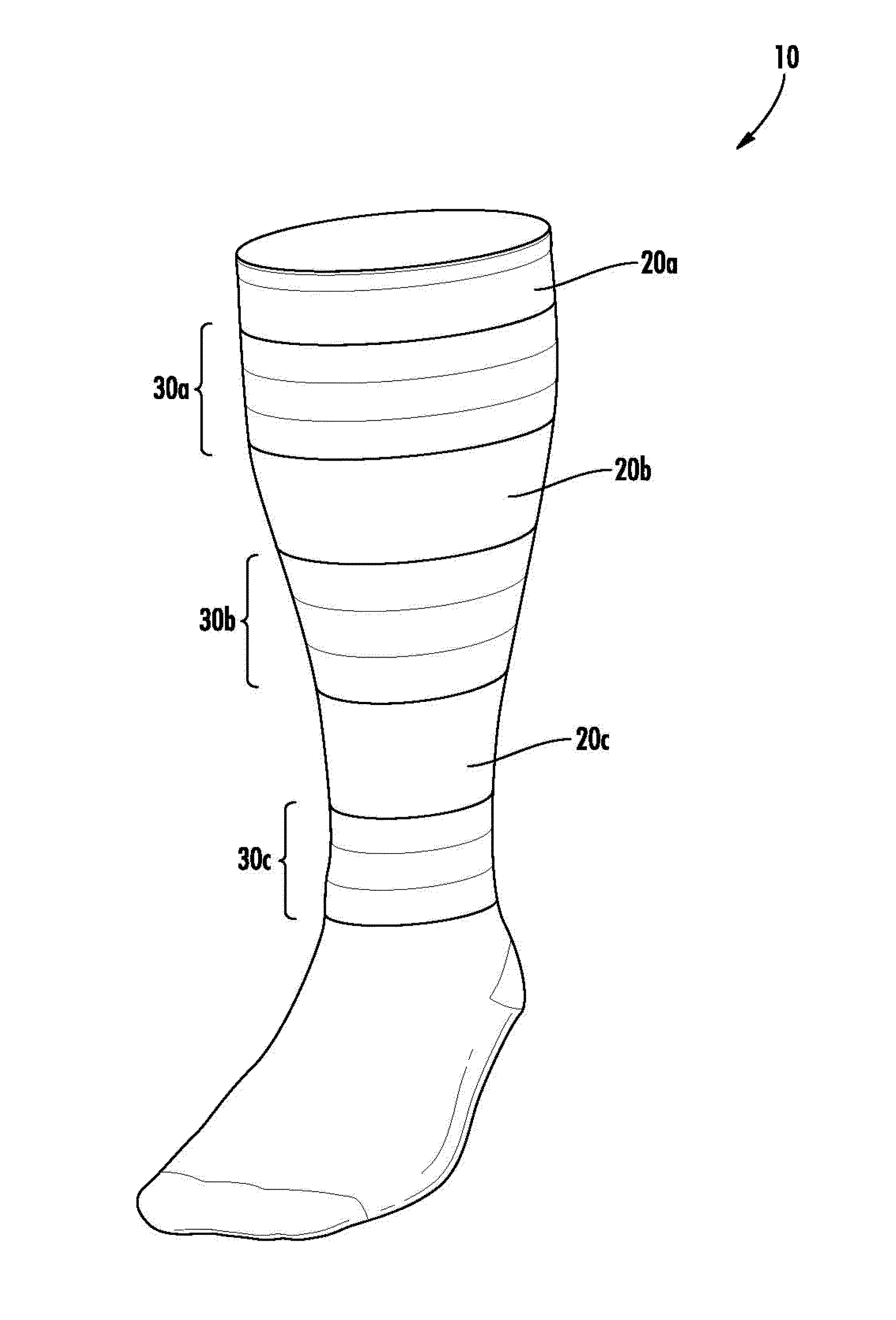

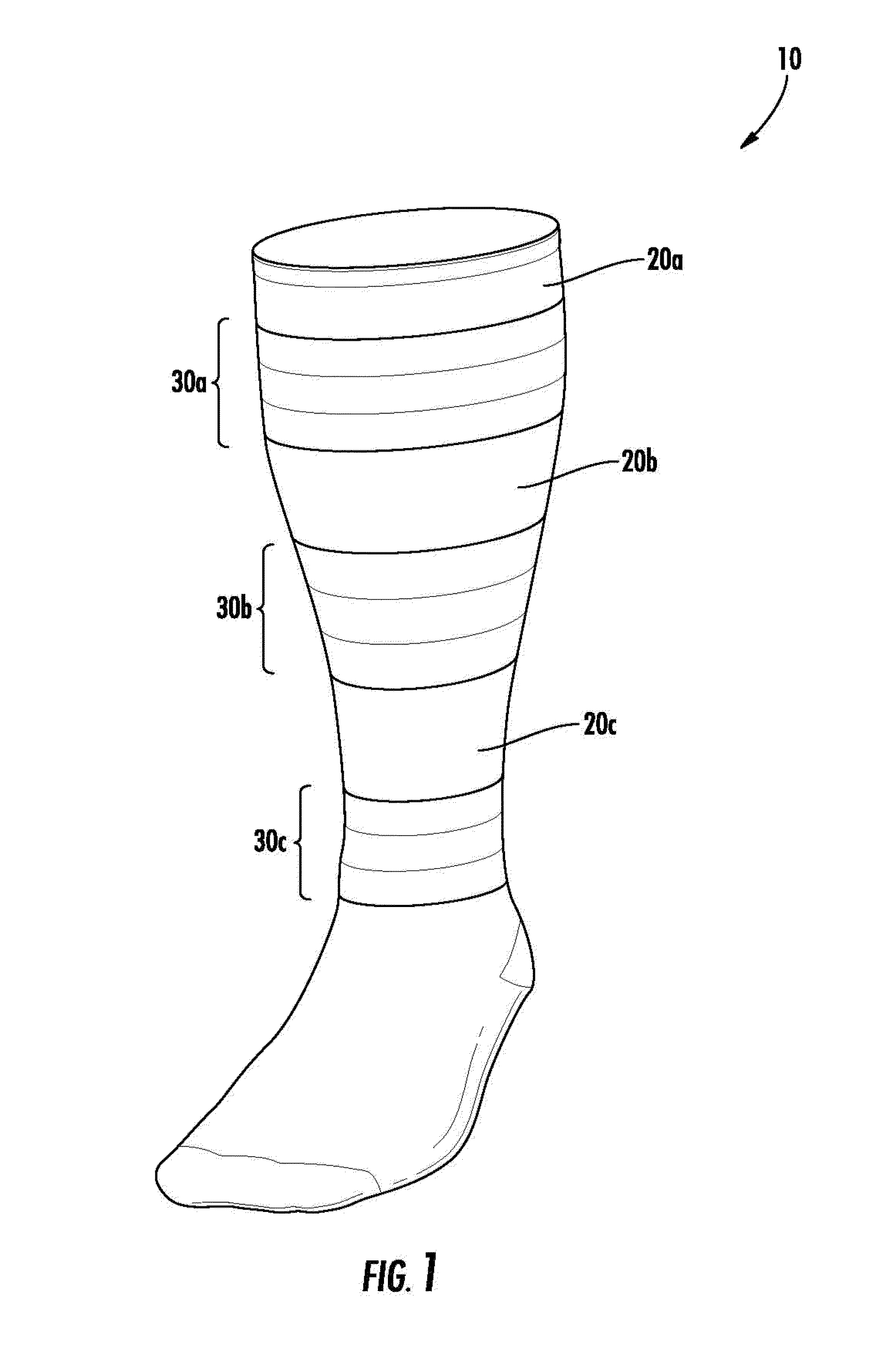

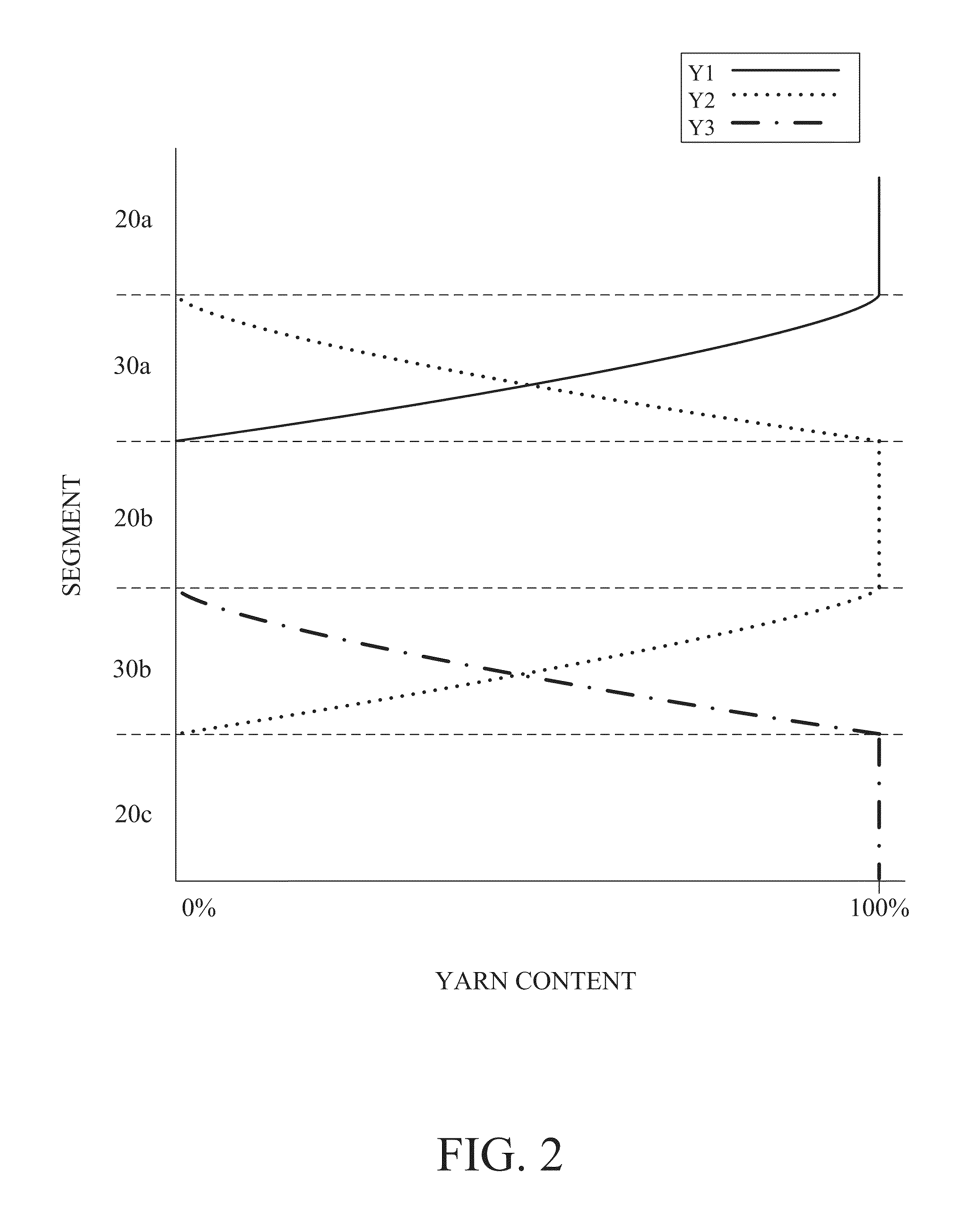

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

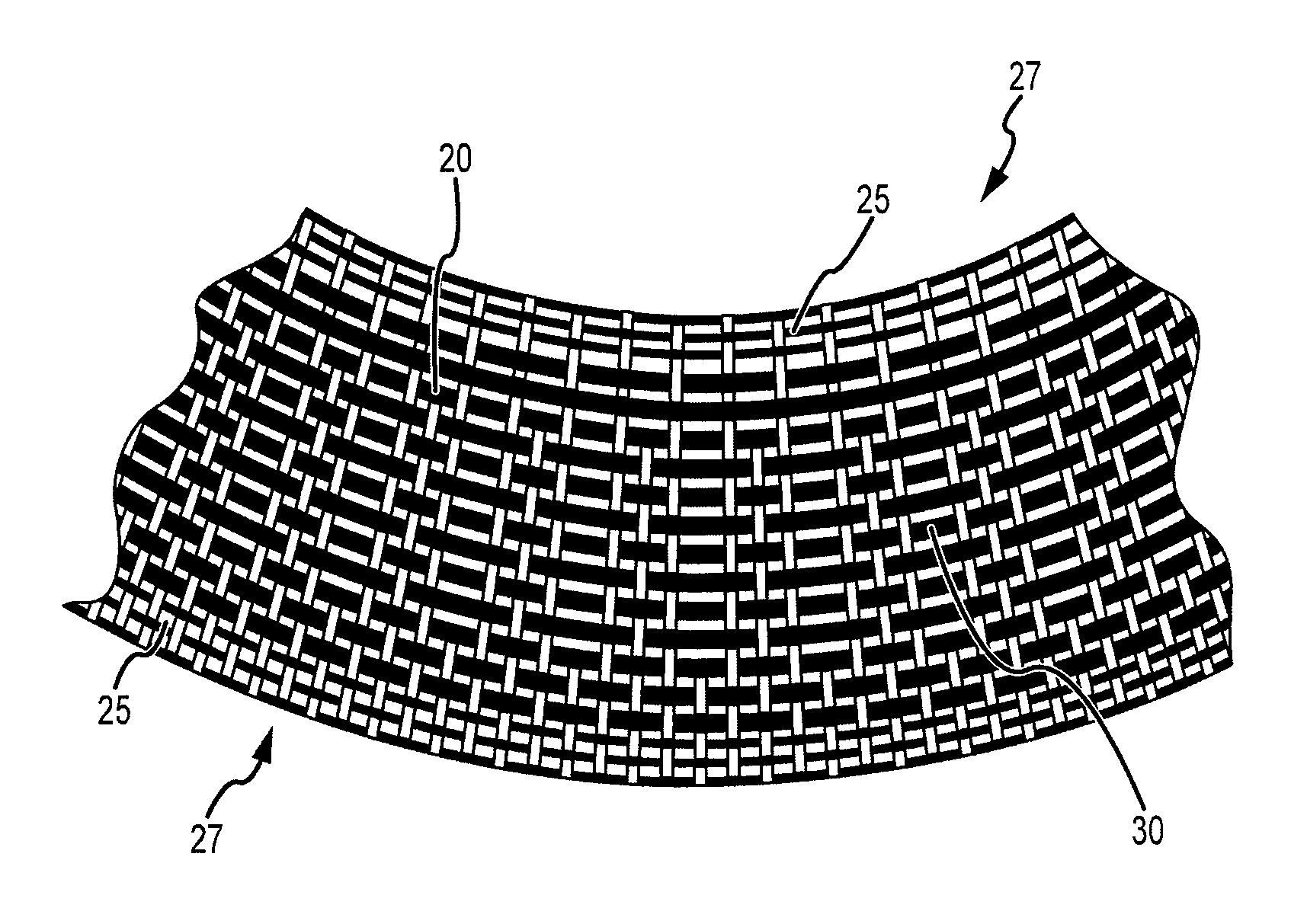

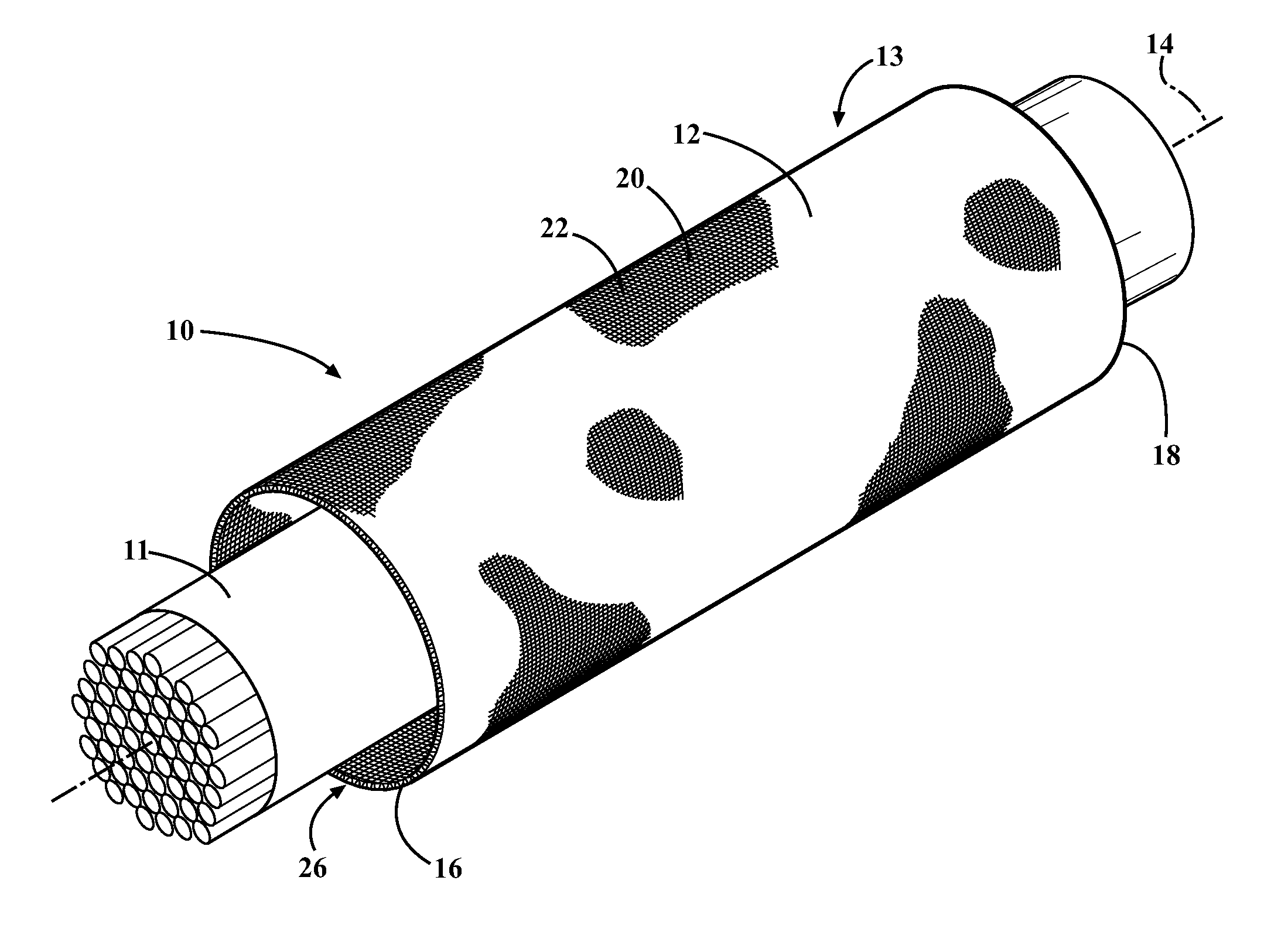

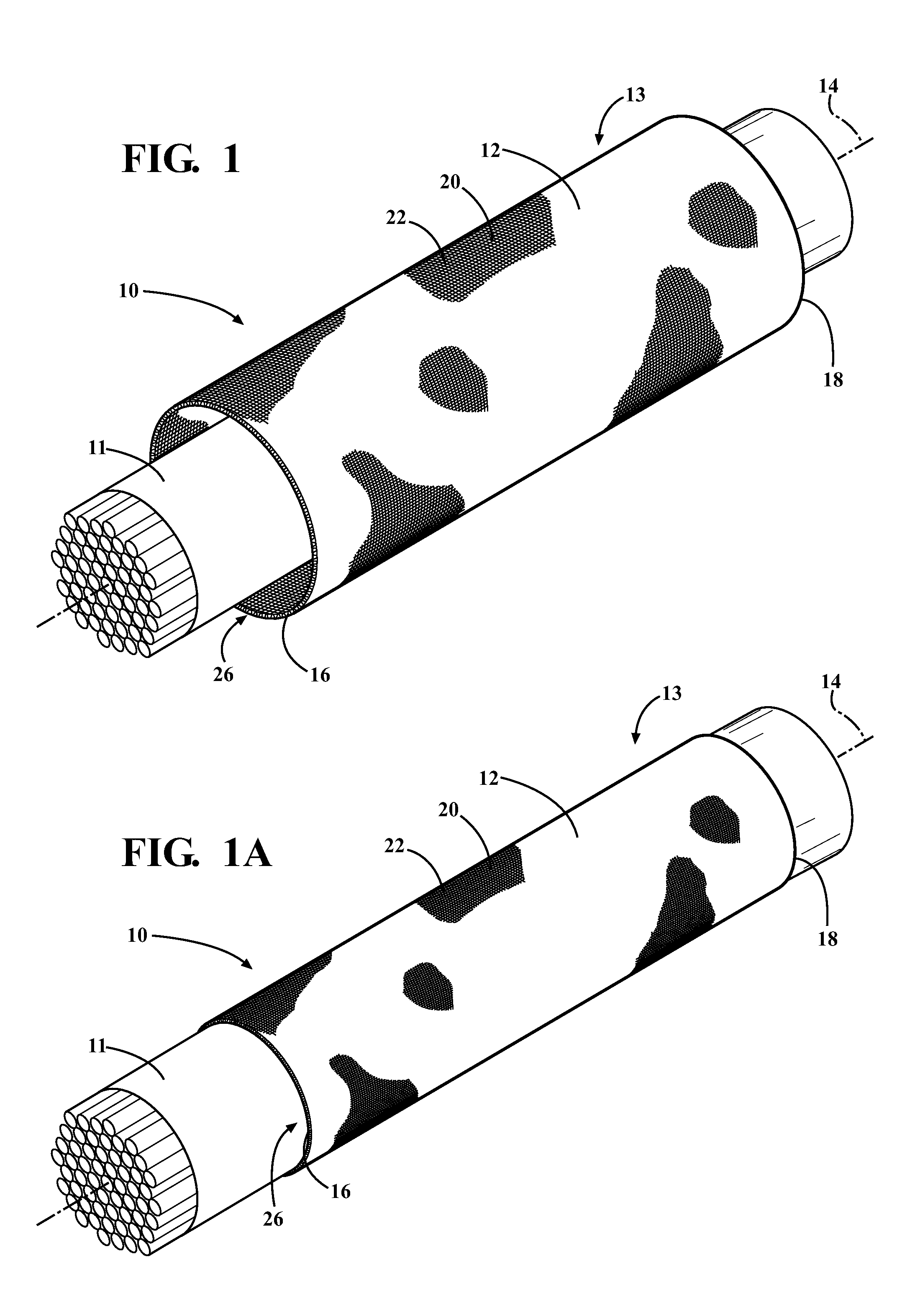

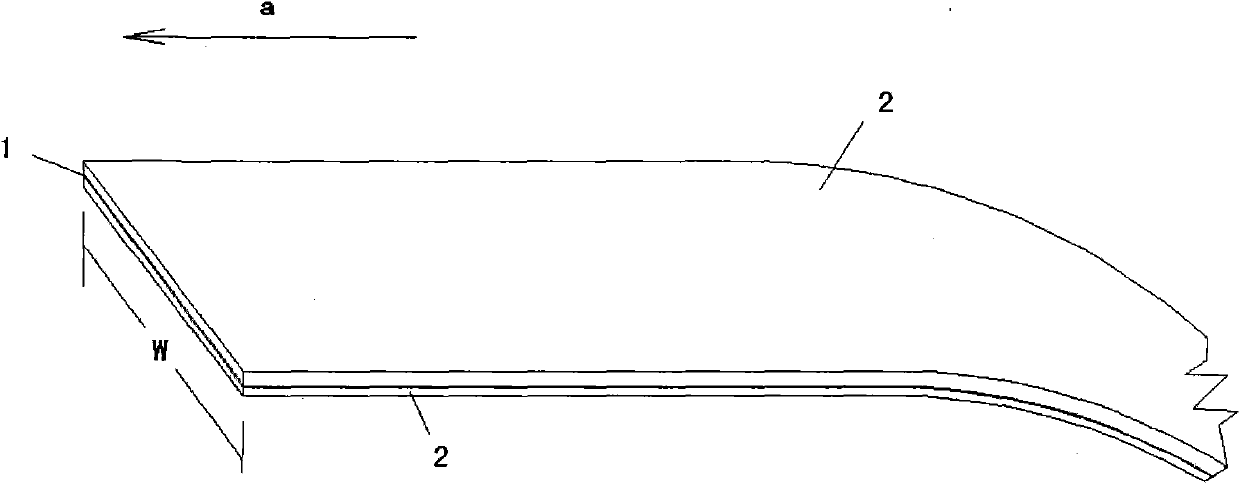

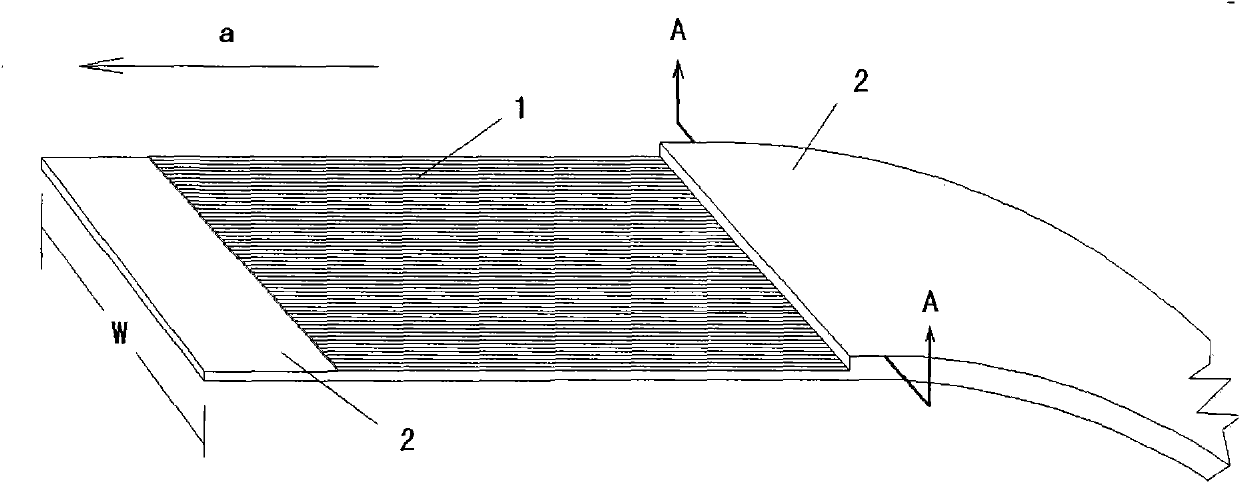

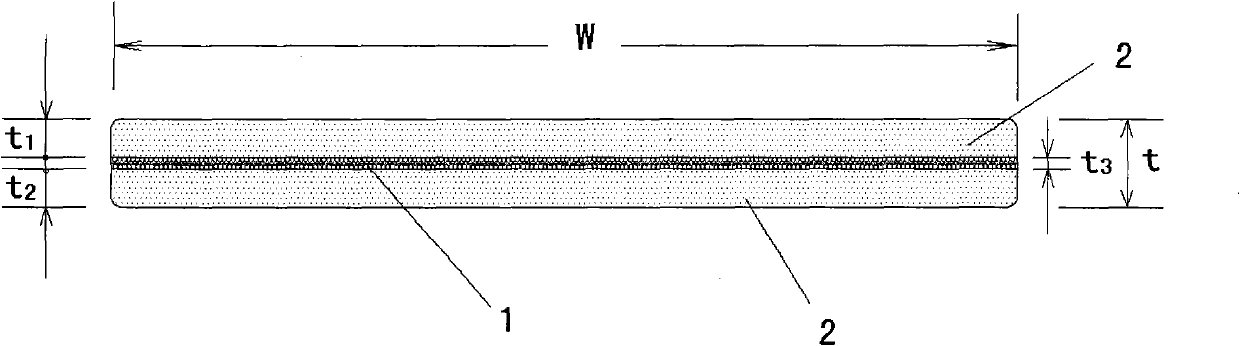

End-Fray Resistant Heat-Shrinkable Woven Sleeve, Assembly Therewith and Methods of Construction Thereof

ActiveUS20140272218A1Excellent abrasion resistanceIncreased crush strengthWrappers shrinkageProtective fabricsPliabilityArchitectural engineering

A woven sleeve, sleeve assembly and methods of construction thereof are provided. The sleeve has a flexible, abrasion resistant, circumferentially closed and continuous elongate wall extending lengthwise along a central axis between opposite ends. The wall is woven with warp yarns extending generally parallel to the central axis and at least one heat-shrinkable weft yarn extending generally transversely to the warp yarns. The warp yarns provide the sleeve with coverage, abrasion resistance and flexibility and the weft yarn provides the ability to shrink the wall about an elongate member being protected within a cavity of the sleeve, as well as providing enhanced crush strength and abrasion resistance. At least one of the warp yarns and / or weft yarn includes at least one low melt, heat-fusible yarn served therewith to enhance resistance to end-fray during a cutting operation.

Owner:FEDERAL MOGUL POWERTAIN LLC

Low bfs composite and process of making the same

InactiveUS20130059496A1Improve adhesionProtective equipmentLayered productsBallistic resistanceFibrous composites

Methods for producing composites useful for the formation of both soft and hard armor. More particularly, methods for the production of ballistic resistant fibrous composites having improved ballistic resistance properties, including low backface signature. The methods employ fiber surface treatments to improve the anchorage of substances applied onto fiber surfaces, achieving a low delamination tendency and corresponding benefits.

Owner:HONEYWELL INT INC

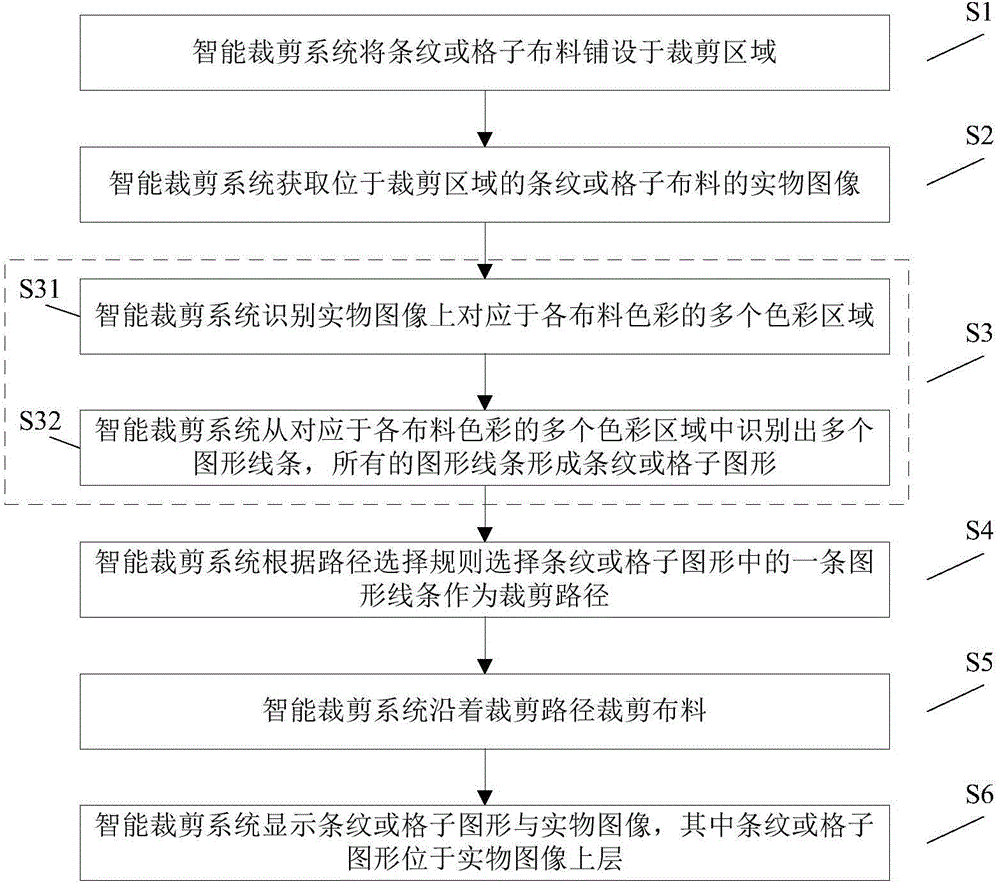

Intelligent cutting method and system

InactiveCN104818603AAvoid misalignmentGuaranteed aestheticsSevering textilesManufacturing engineering

The invention relates to the technology of automatic cutting, and discloses an intelligent cutting method and system. The method is used for cutting stripe or quadrille cloth, and is used for the intelligent cutting system with a cutting region. The method comprises the following steps: the intelligent cutting system enables the stripe or quadrille cloth to be laid in the cutting region; the intelligent cutting system obtains an object image of the stripe or quadrille cloth located in the cutting region; the intelligent cutting system recognizes the stripe or quadrille pattern from the object image; and the intelligent cutting system selects one line from the stripe or quadrille pattern according to a path stored in the intelligent cutting system, and enables the line to serve as a cutting path. The method and system prevents the stripe or quadrille pattern of cut cloth from being staggered, and guarantee the appearance beauty of a product made of the cloth.

Owner:长园和鹰科技(河南)有限公司

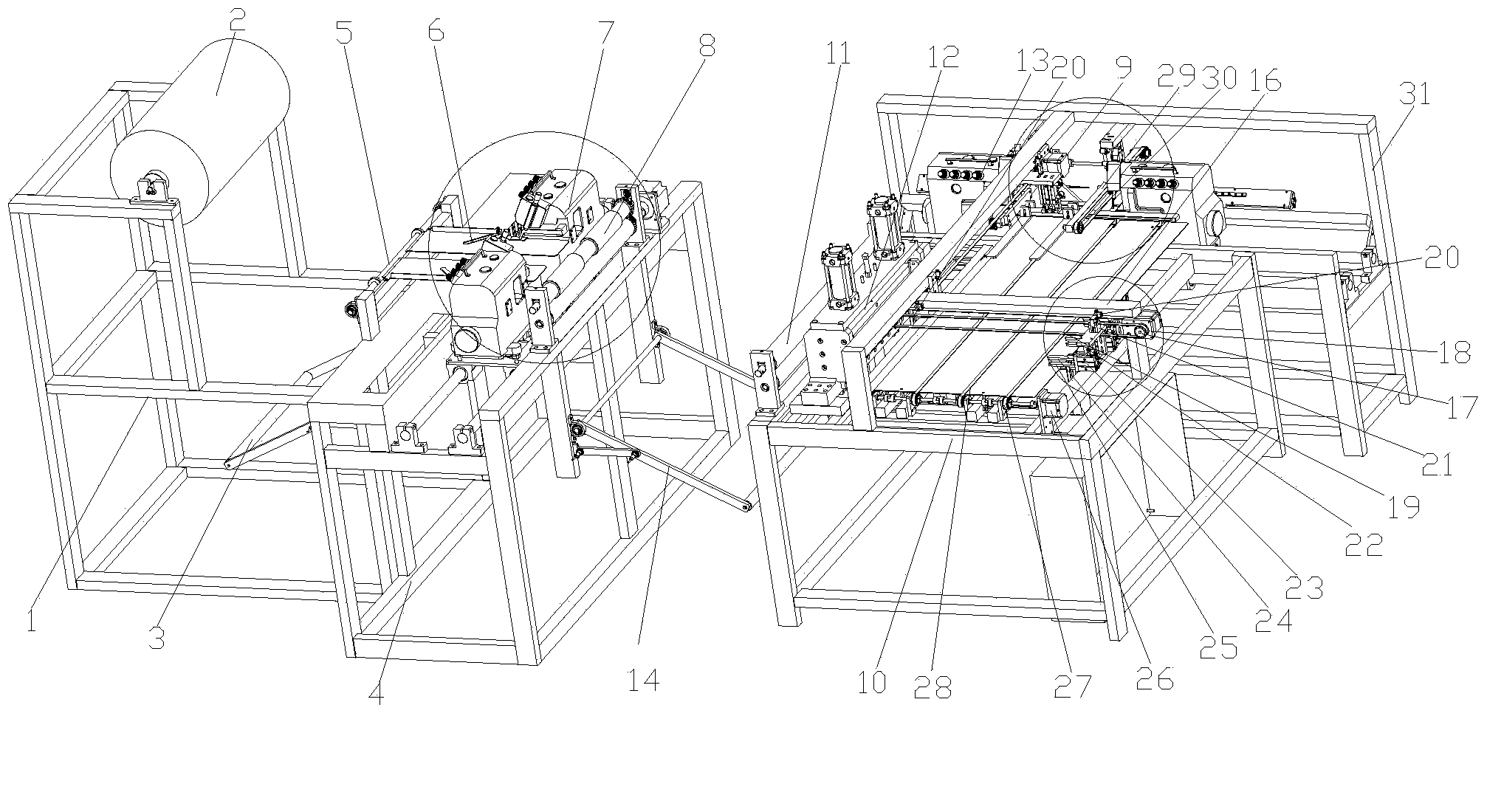

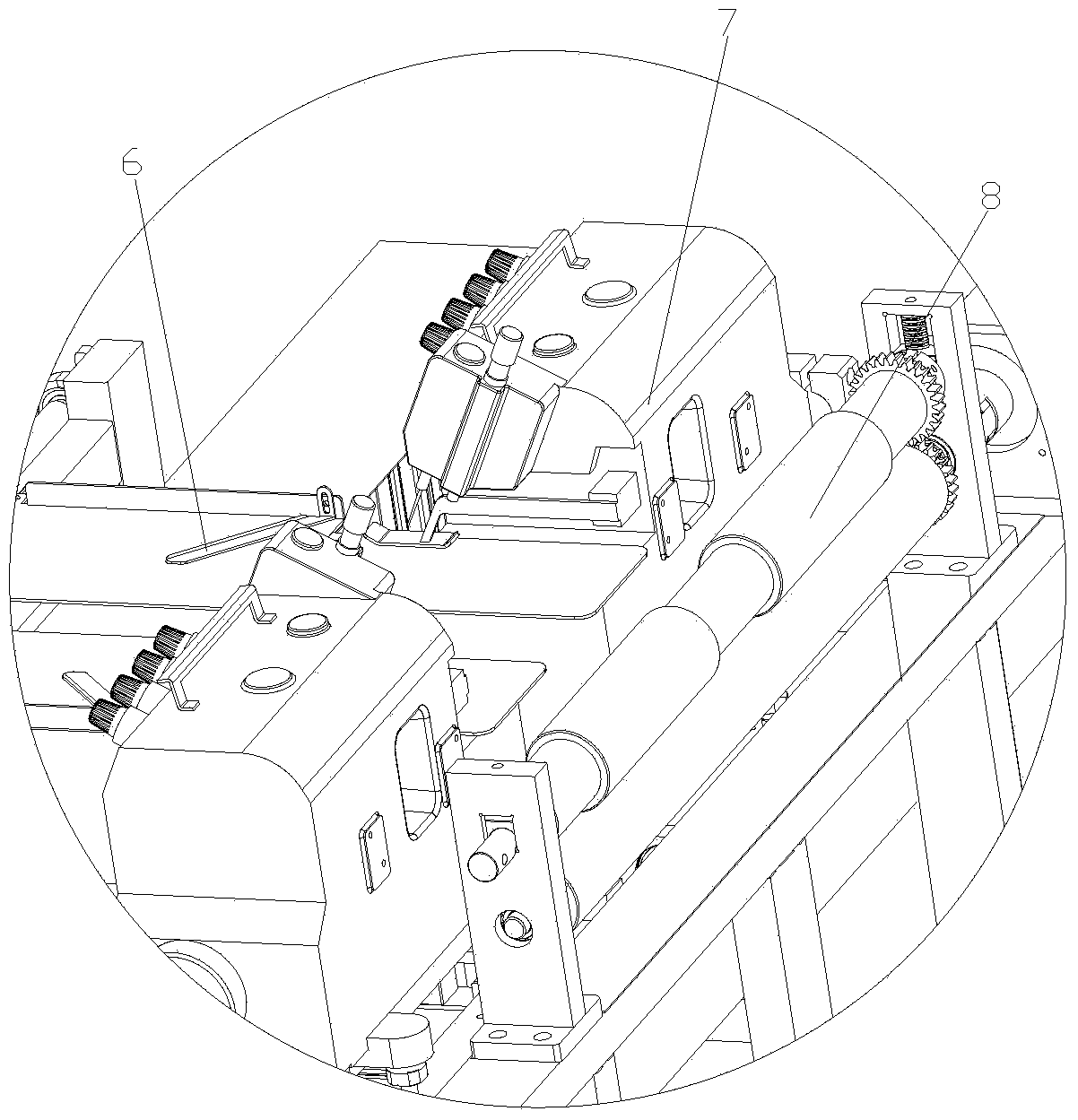

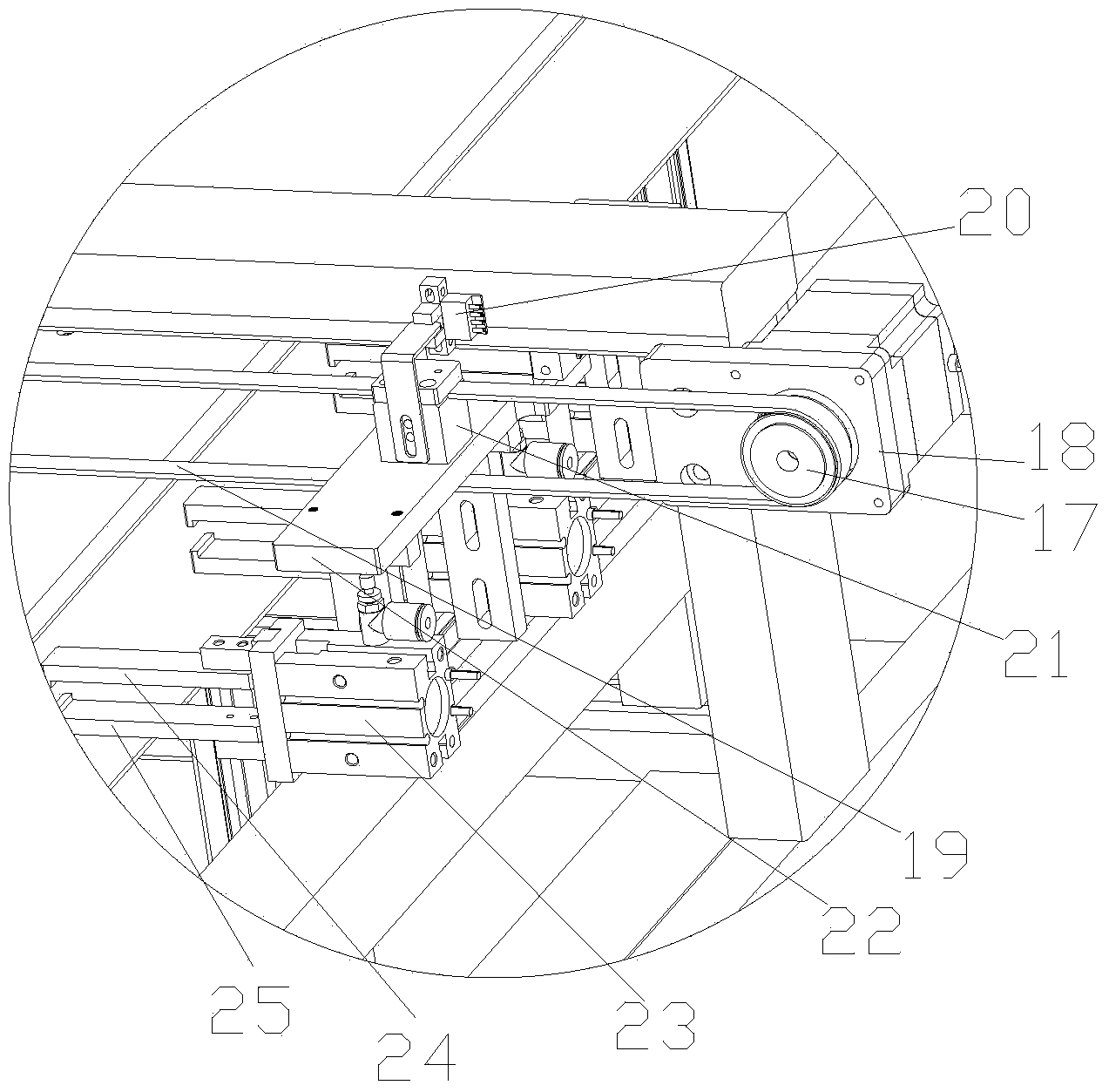

Towel machine with high product quality

ActiveCN103757827AReduce labor intensityReduce manufacturing costWork-feeding meansPressersUltimate tensile strengthAutomation

The invention discloses a towel machine with high product quality. The towel machine comprises a feeding device, a serging device, a manufacturing device and a hot melting device. The feeding device is fixedly connected with the serging device. The manufacturing device and the serging device are arranged in a relatively fixed mode. The hot melting device is arranged on the side face of the manufacturing device. Cloth is fed into the serging device by the feeding device. Primary double-side serging is carried out on the cloth fed by the feeding device by the serging device. Secondary double-side serging is carried out on the cloth by the manufacturing device after the cloth discharged out of the serging device is cut off. The hot melting device carries out hot melting on the cloth discharged out of the manufacturing device. According to the towel machine with the high product quality, mechanical automation replaces the original manual operation to produce towels, the labor intensity of workers is lowered, product production efficiency is stably improved, production cost is lowered, production can be effectively managed, and practical high production requirements are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Method for producing ultrafine fiber and artificial leather

InactiveUS7025915B2Fastness of wet abrasionExcellent silk-like glossPattern makingLayered productsSolubilityPolymer dissolution

A method for producing an artificial leather includes mixed spinning an island polymer and a sea polymer having a different dissolving property from that of the island polymer at a predetermined temperature, producing a non-woven substrate from the fiber obtained, immersing the non-woven substrate into a polymer, dissolving and removing the sea polymer in the non-woven substrate to obtain an artificial leather as a semi-finished product, and polishing the surface of the artificial leather to obtain an artificial leather having excellent dyeability and advanced fluff-like property. The ratio of melt flow index of the sea polymer to relative viscosity of the island polymer is about 20 to about 55, in which the relative viscosity of the island polymer is about 2.7 to about 3.5 and the weight percentage of the sea polymer relative to the sum of the sea polymer and the island polymer is about 30% to about 70%.

Owner:SAN FANG CHEM IND

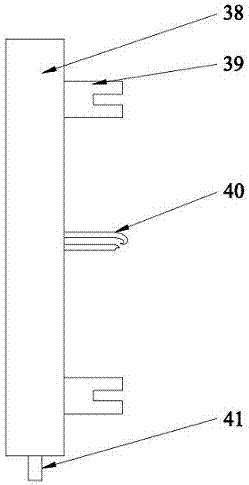

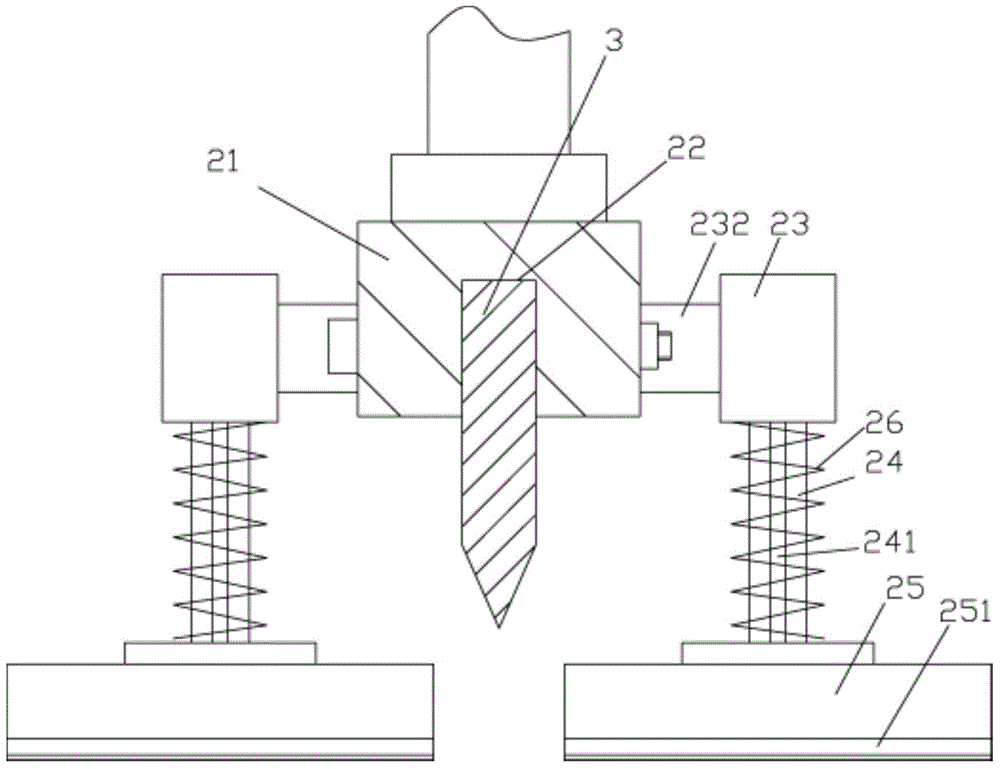

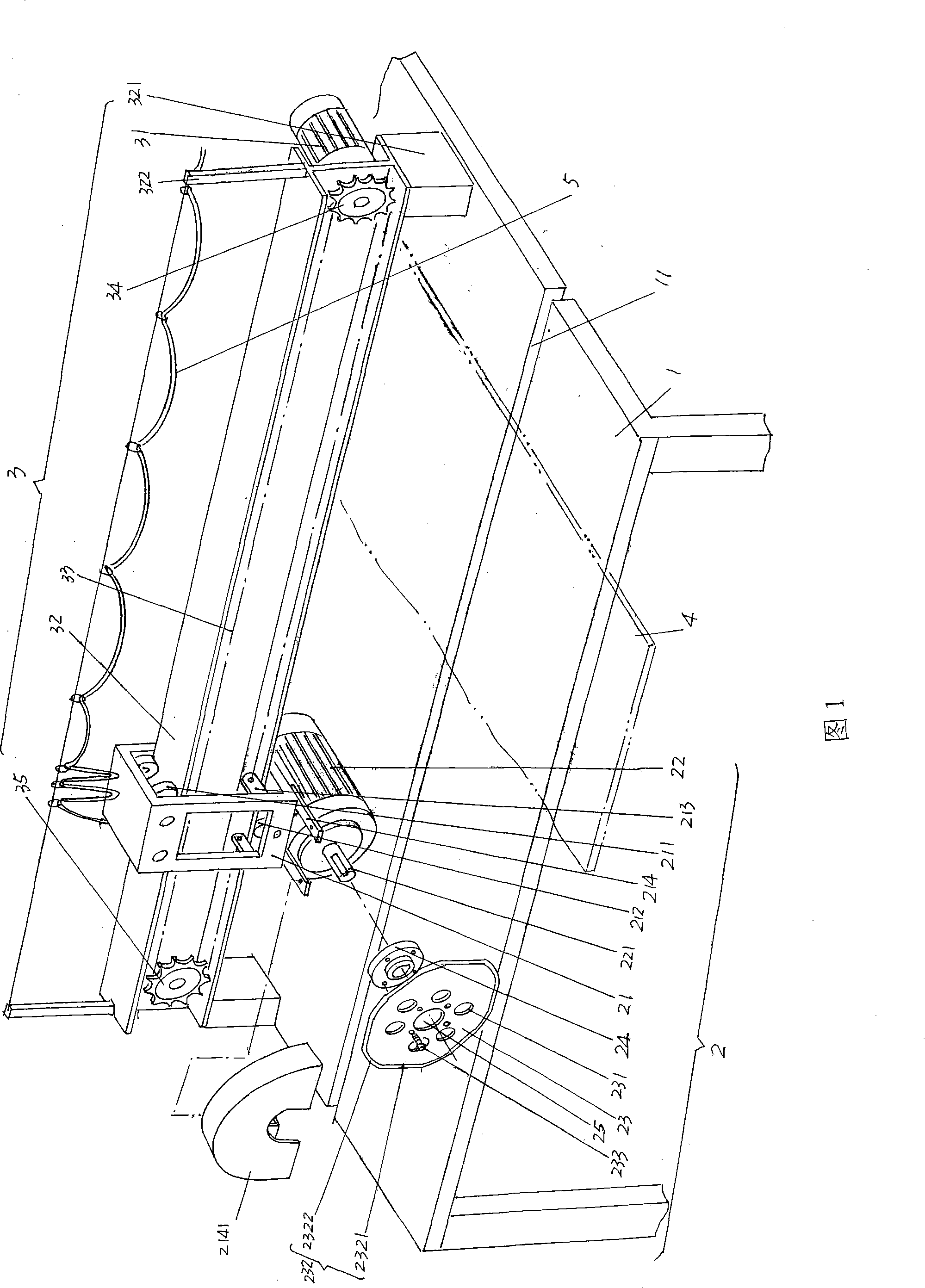

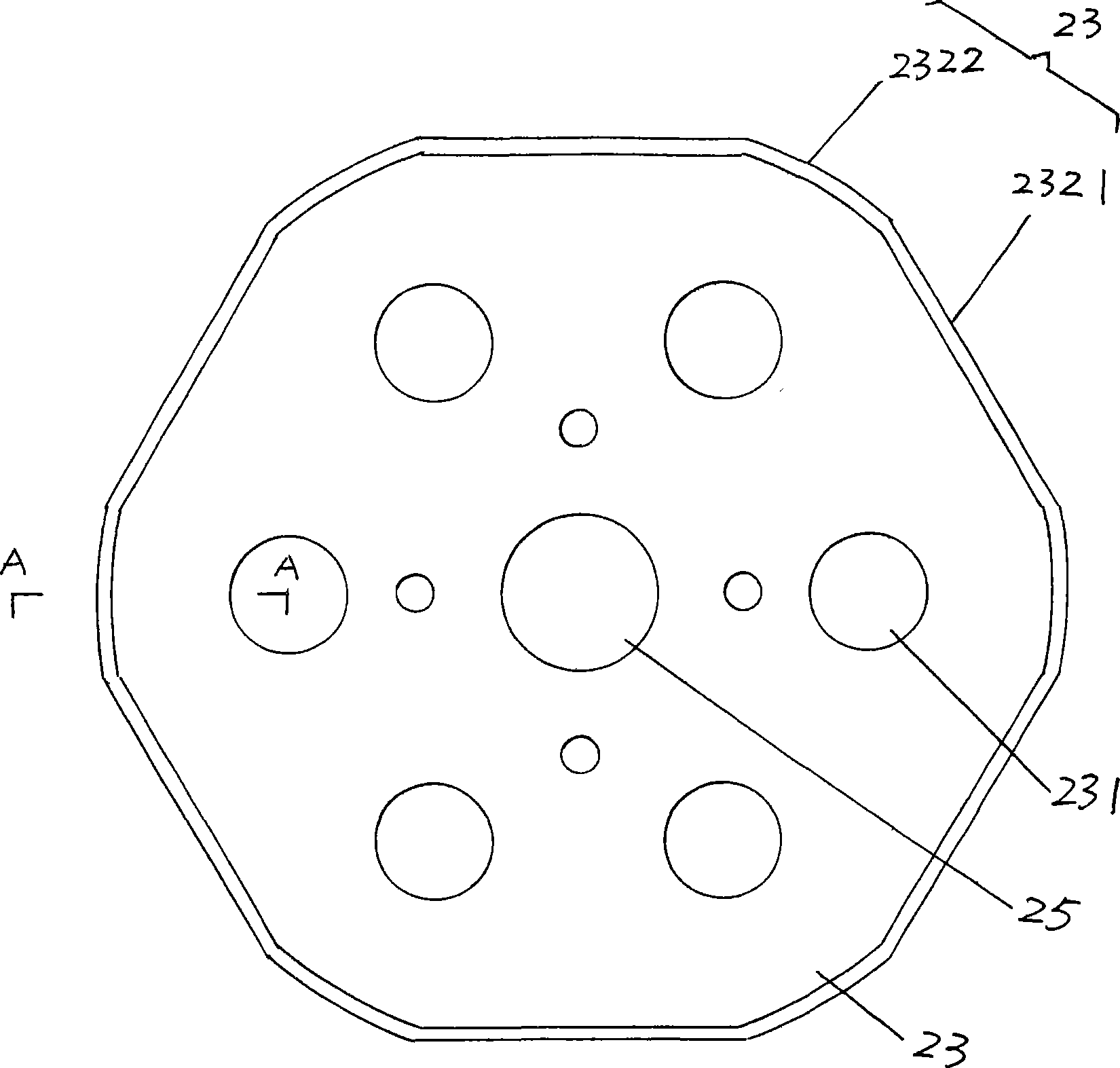

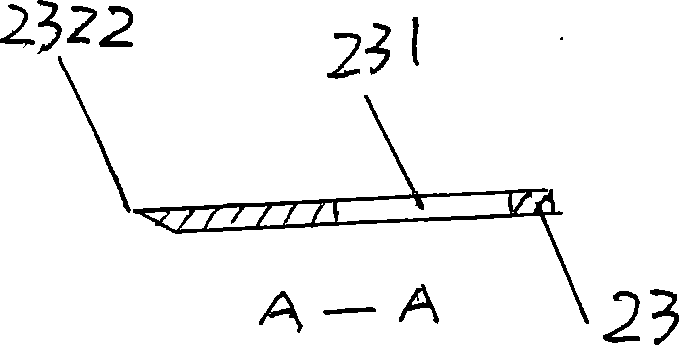

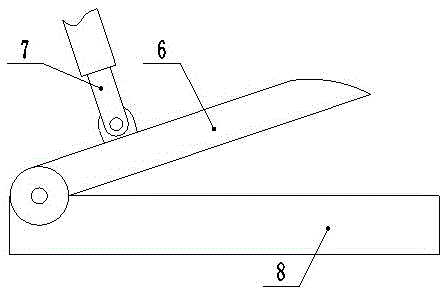

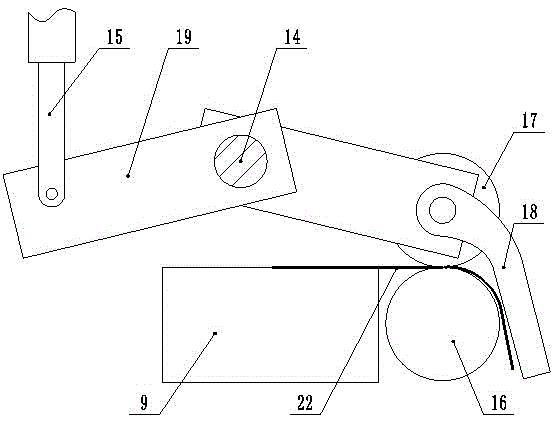

Movable shearing cutter rest for cloth cutting machine

ActiveCN104786271AIncrease flexibilityImprove cutting effectSevering textilesMetal working apparatusEngineeringMagnet

The invention discloses a movable shearing cutter rest for a cloth cutting machine. The movable shearing cutter rest comprises a rack platen. Sliding strips are fixed to the left side wall and the right side wall of the rack platen. Limiting blocks are fixed to the top faces of the sliding strips. Long grooves with arc-shaped sections are formed in the top faces of the limiting blocks. Bottom sliding blocks are fixed to the bottom faces of the sliding strips. Long main grooves with arc-shaped sections are formed in the left side and the right side of each bottom sliding block. Permanent magnet strips are embedded in the long grooves in the left side walls or the right side walls of the sliding strips. A cutter moving rest is inserted in the rack platen. Sliding parts shaped like a left square bracket are arranged on the left side and the right side of the cutter moving rest. Push cylinders are fixed to a top transverse board of the cutter moving rest. Push rods of the push cylinders penetrate through the top transverse board downwards and a strip-shaped board is fixed to the push rods. The cutter moving rest can move along the rack platen so as to be move to the position needing to be sheared. The movable shearing cutter rest is good in flexibility, cloth can be fixed and pushed by the push cylinders so as to be sheared, notches are tidy, and efficiency is high.

Owner:刘骏

Dart carded felt guillotine

ActiveCN101250806AExtended service lifeReduce usageSevering textilesMetal working apparatusEngineeringMechanical engineering

Disclosed is a needled felt cutting machine belonging to the technical field of non-woven machineries, which comprises a cutting table which is provided with a hob cutter groove, a cutting mechanism which comprises a hob cutter motor, a hob cutter motor seat and a hob cutter and a traction mechanism which is fixed on the cutting table, wherein the hob cutter motor is fixed on the hob cutter motor seat which is glidingly matched on the traction mechanism, the hob cutter is fixed on a power take-off shaft of the hob cutter motor and is corresponded with the hob cutter groove, and cutting edges of the hob cutter are made of a plurality of straight flange cutting edges and a plurality of circular cutting edges in alternate spreading with each other. The needled felt cutting machine has the advantages of representing intermittent suspension process when the hob cutter cuts the needled felt, thereby being unable to arose heating and insuring that a cut is not deformed and charred, not only saving numerous operations for exchanging the hob cutter every day and the numbers of usage of the hob cutters, but also guaranteeing productive efficiency, and being capable of increasing operating life of the hob cutter and improving the cut quality of the needled felt.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

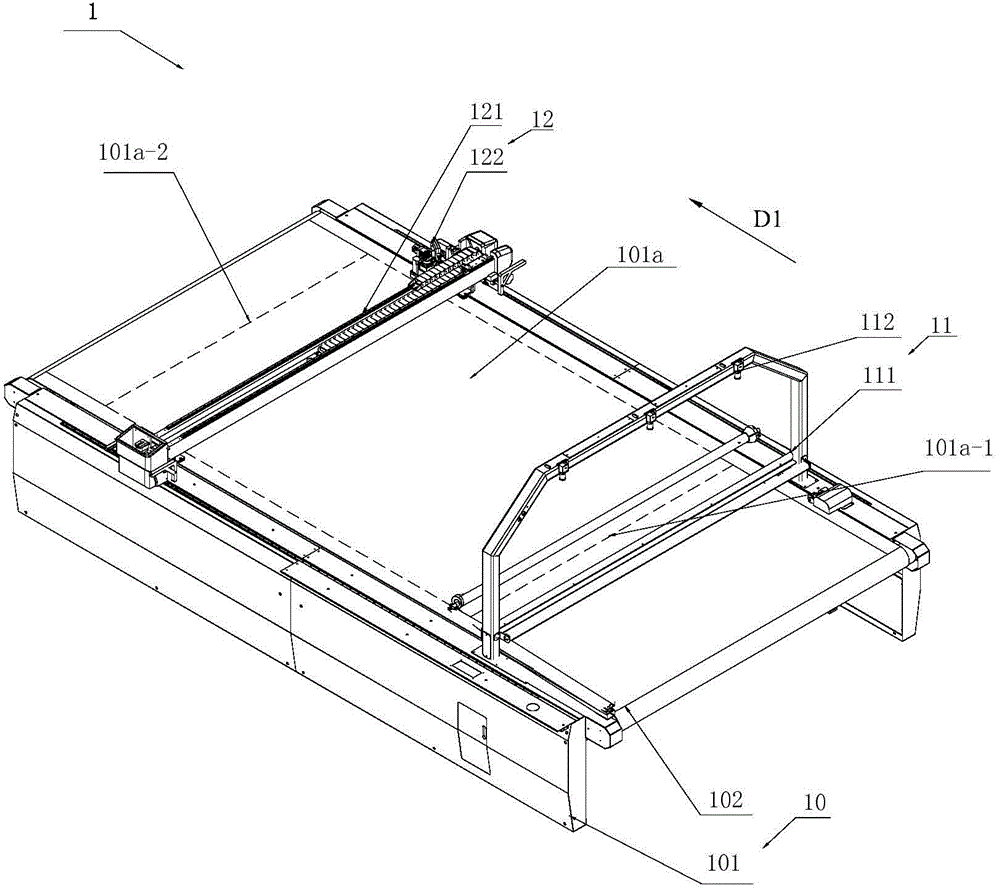

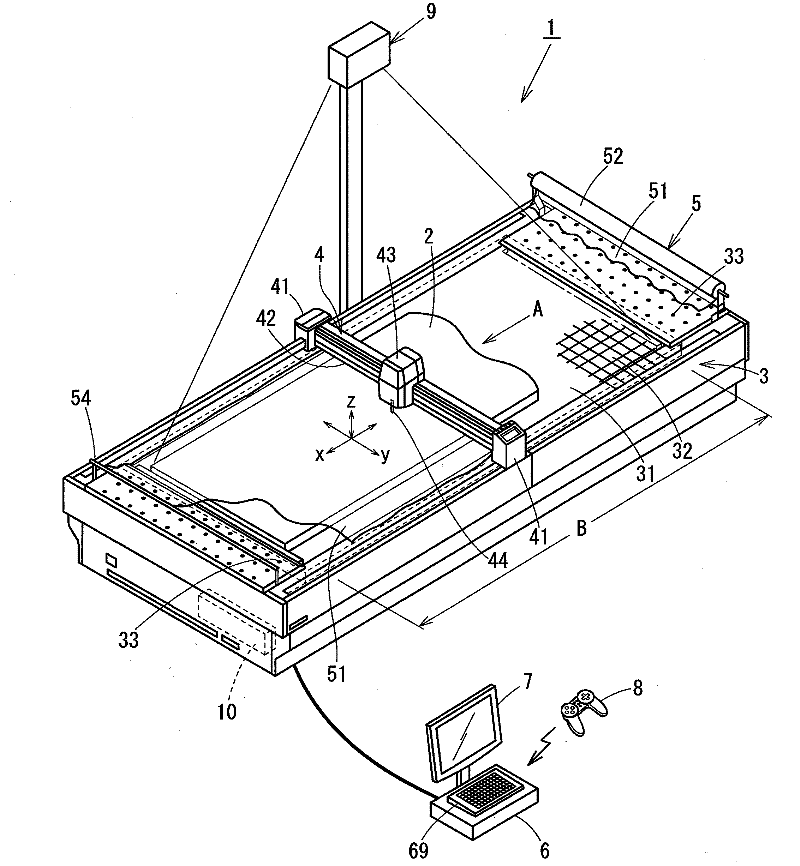

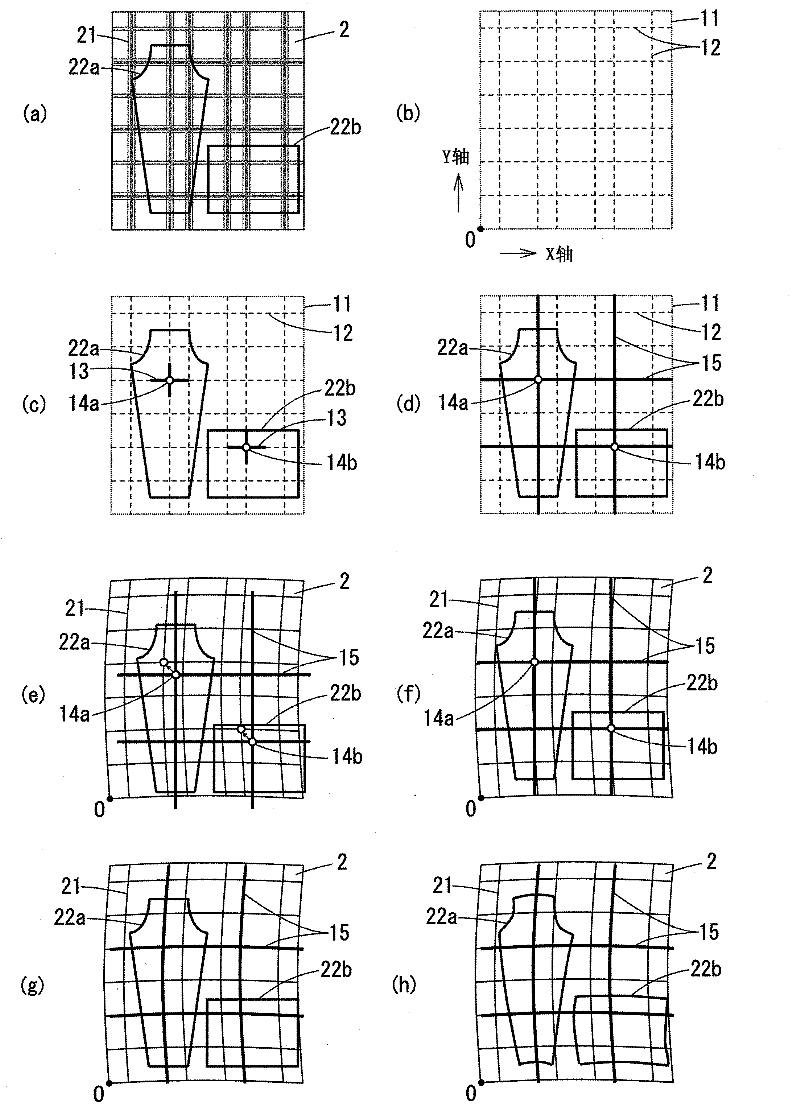

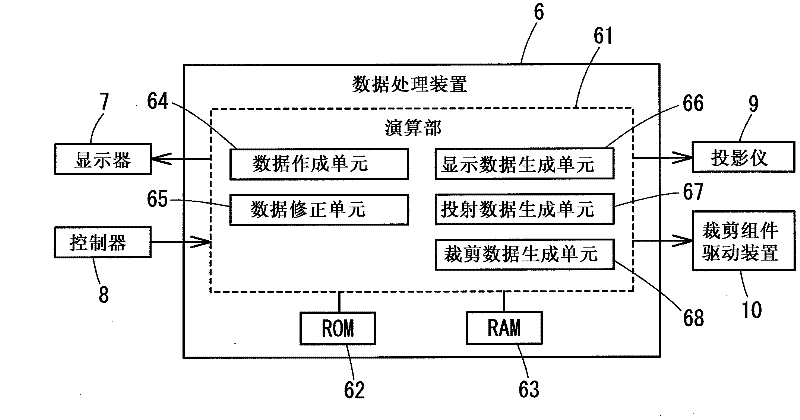

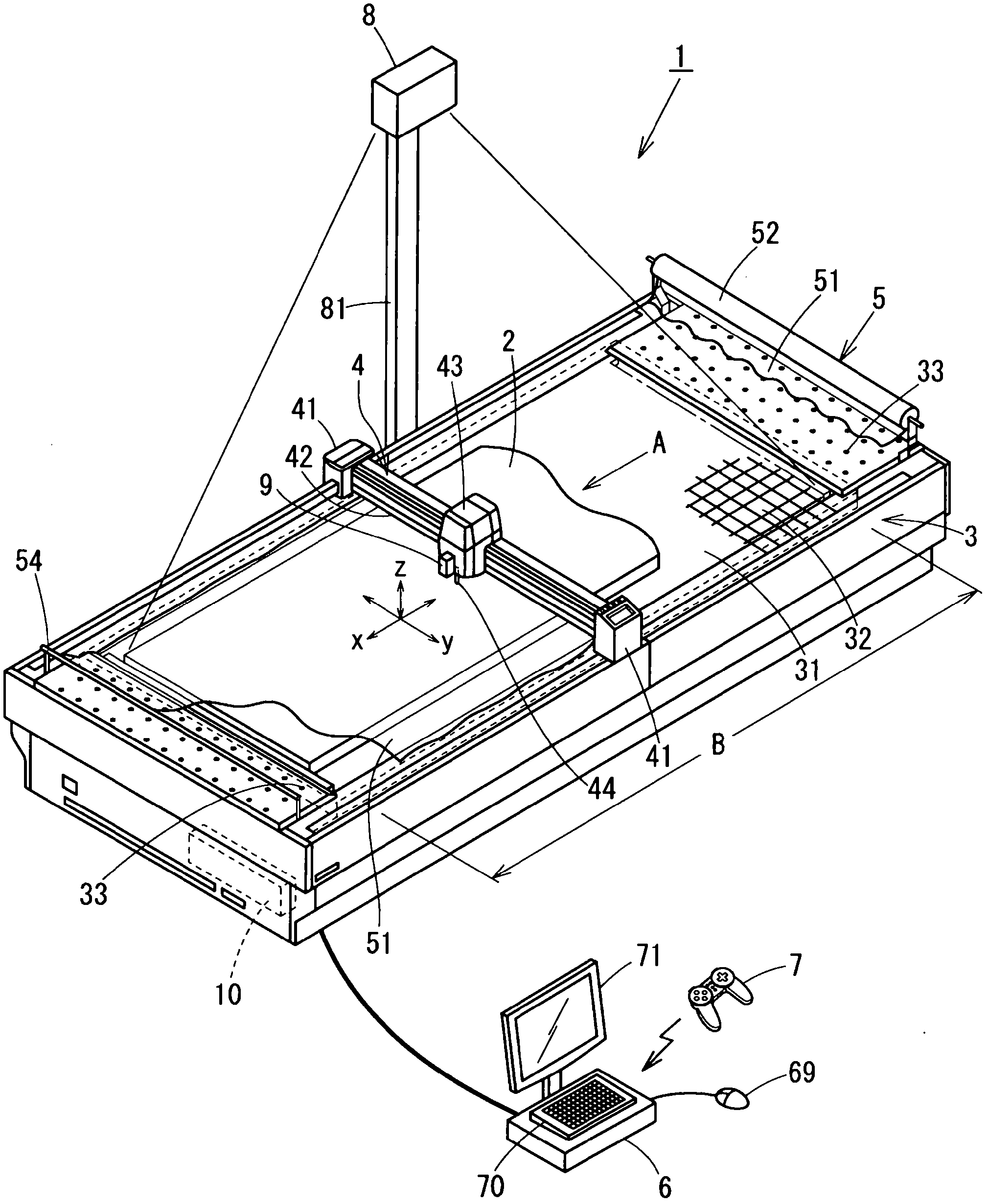

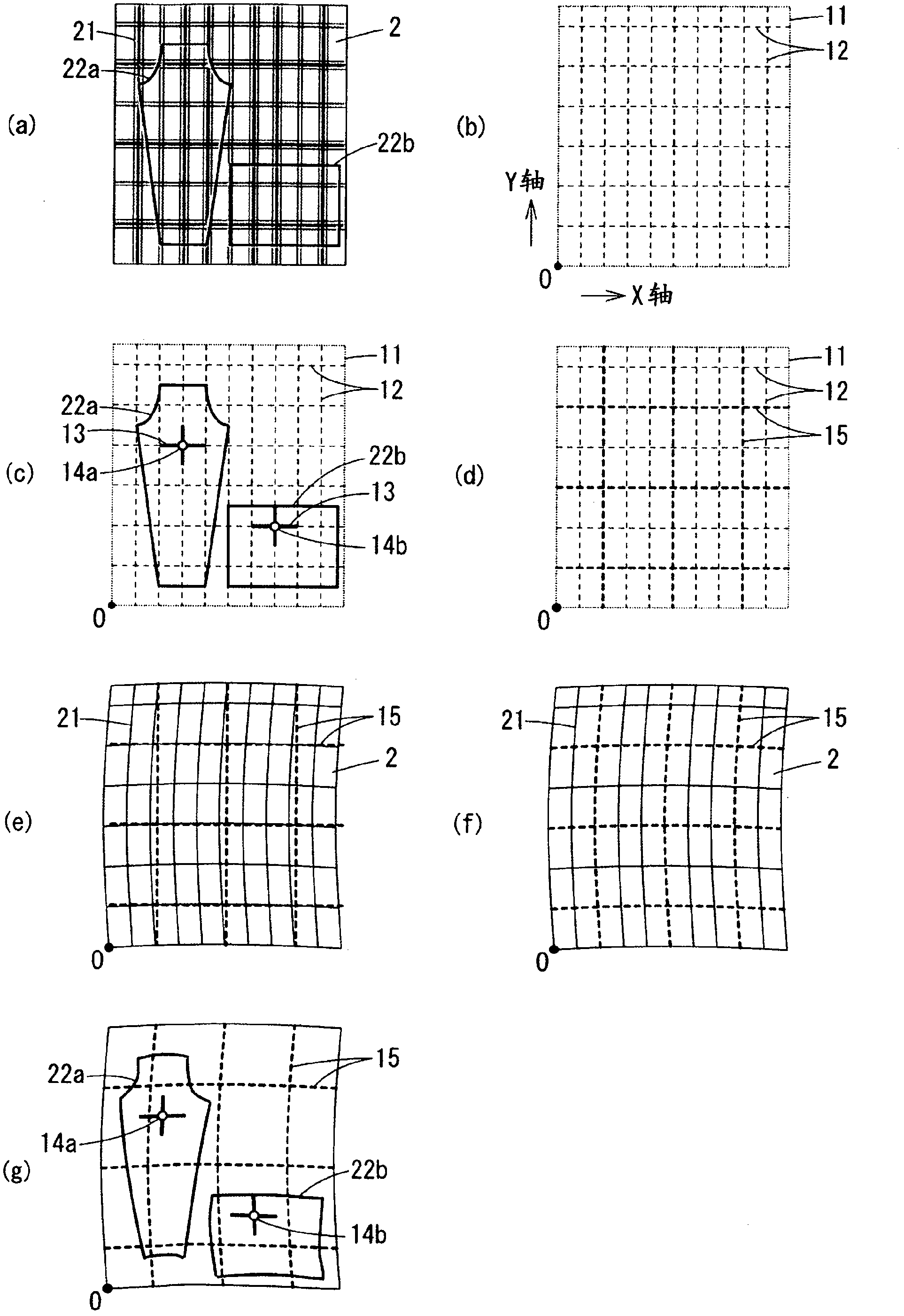

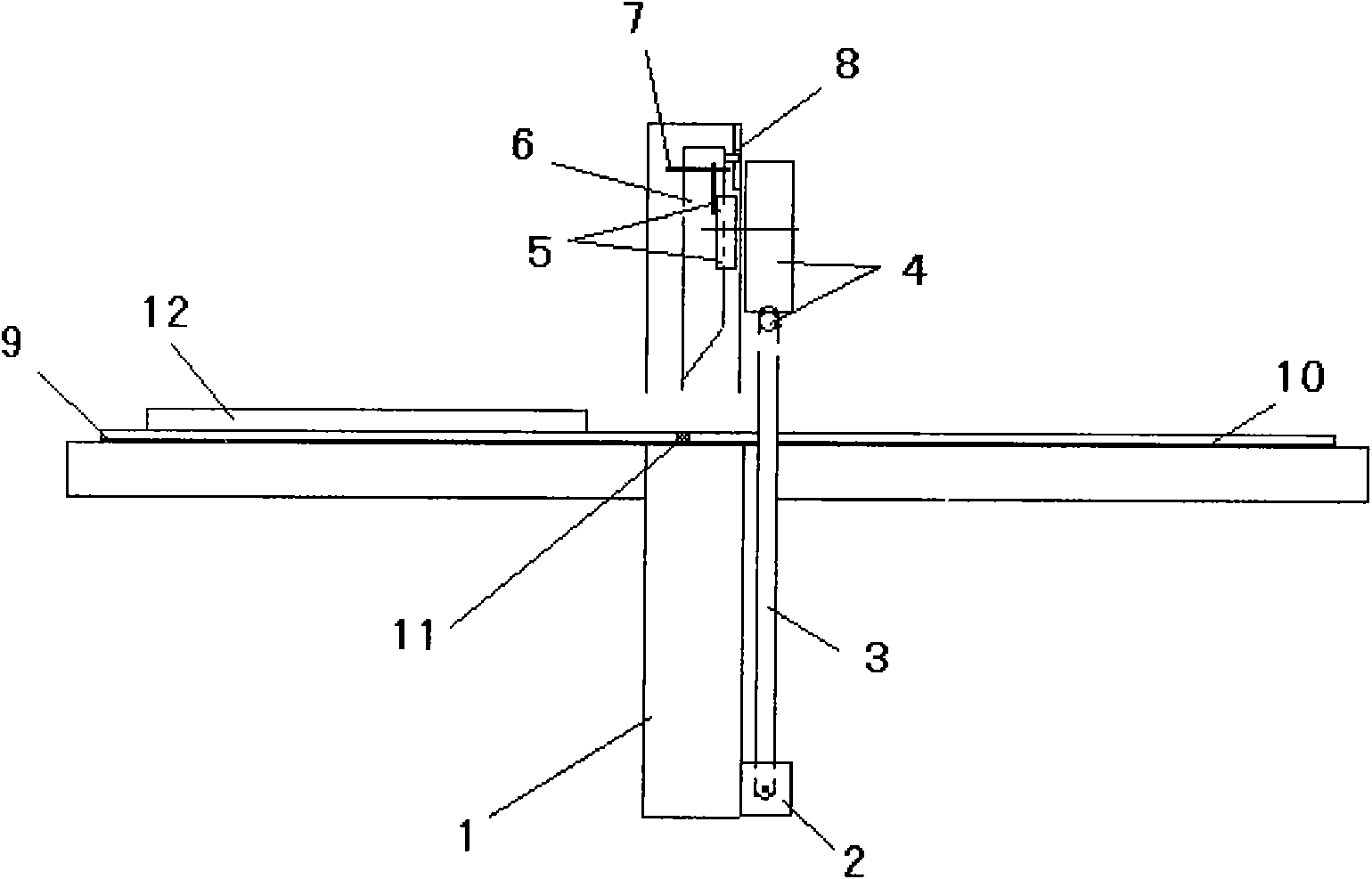

Sheet material cutting method and automatic cutting machine

The present invention provides a sheet material cutting method and an automatic cutting machine. The method is used for cutting the sheet which is carried on a worktable and is provided with patterns along the pattern of garment piece, wherein the data for cutting are corrected according to the garment piece deformation. A garment piece pattern (22) is configured on a theoretical pattern (12) of the sheet material which is formed on an imaginary plane (11) that corresponds with the sheet material (2), and pattern matching points (14) are set according to each garment piece. Afterwards, a reference pattern (15) which comprises the pattern matching points (14) are formed on the imaginary plane (11). Afterwards, a projector is used for projecting the matching points (14) and the reference pattern (15) with an actual dimension. Furthermore the shape of the reference pattern (15) deforms for matching with the shape of the pattern of the sheet material (2), thereby correcting coordinate data of the reference pattern (15). The coordinate data of the pattern (22) of the garment piece are corrected corresponding to the corrected reference pattern (15), and the sheet material is cut based on the coordinate data.

Owner:SHIMA SEIKI MFG LTD

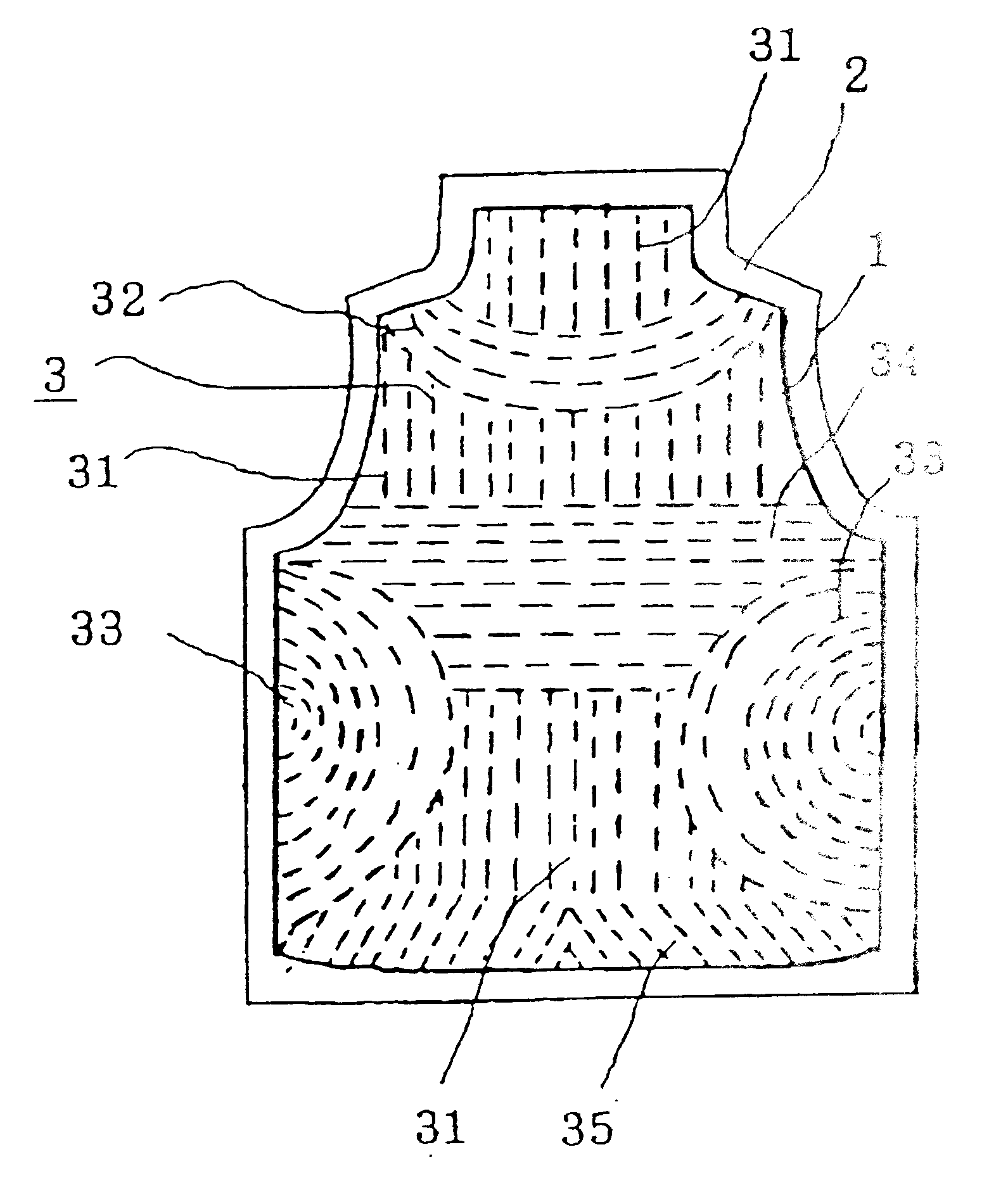

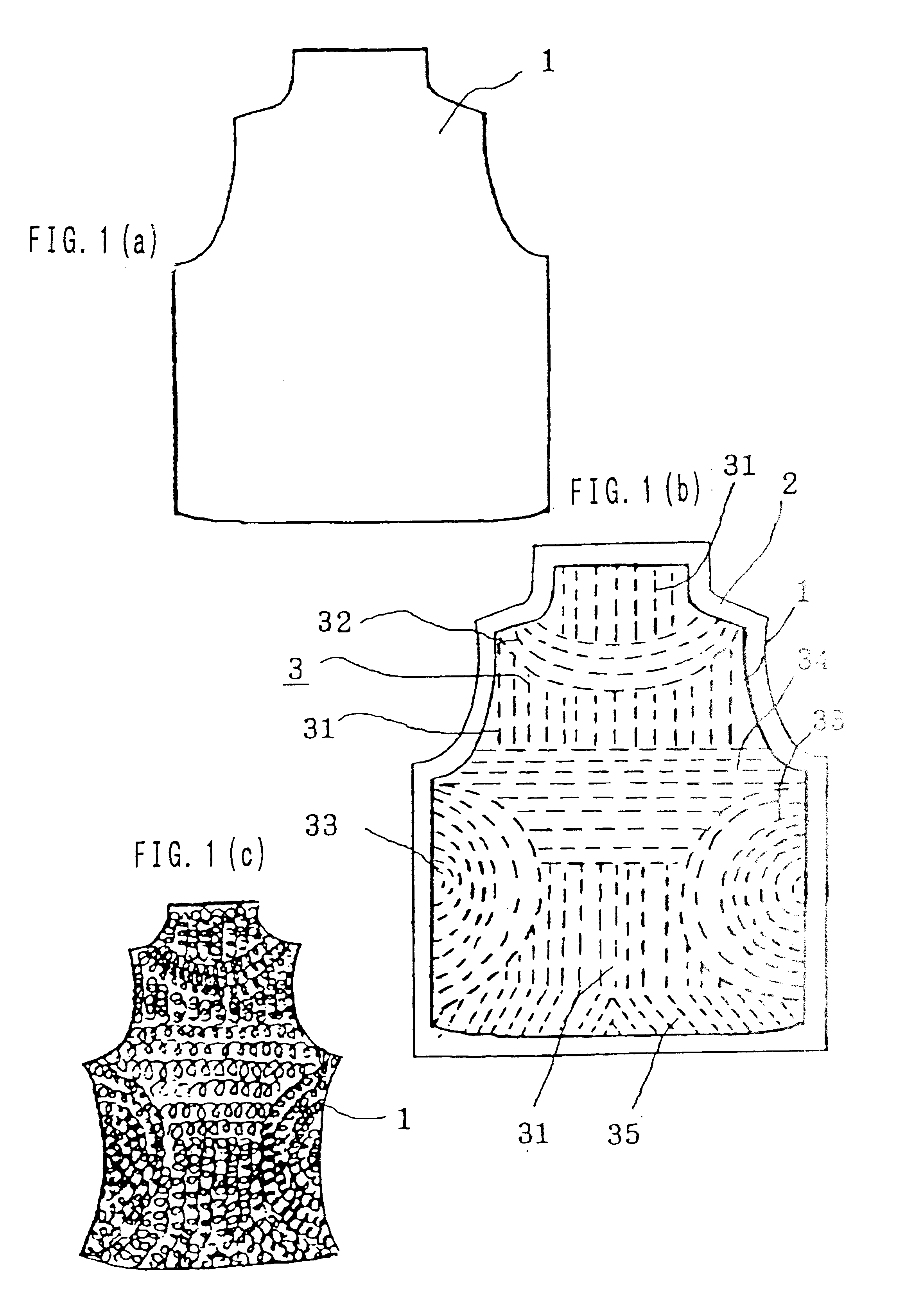

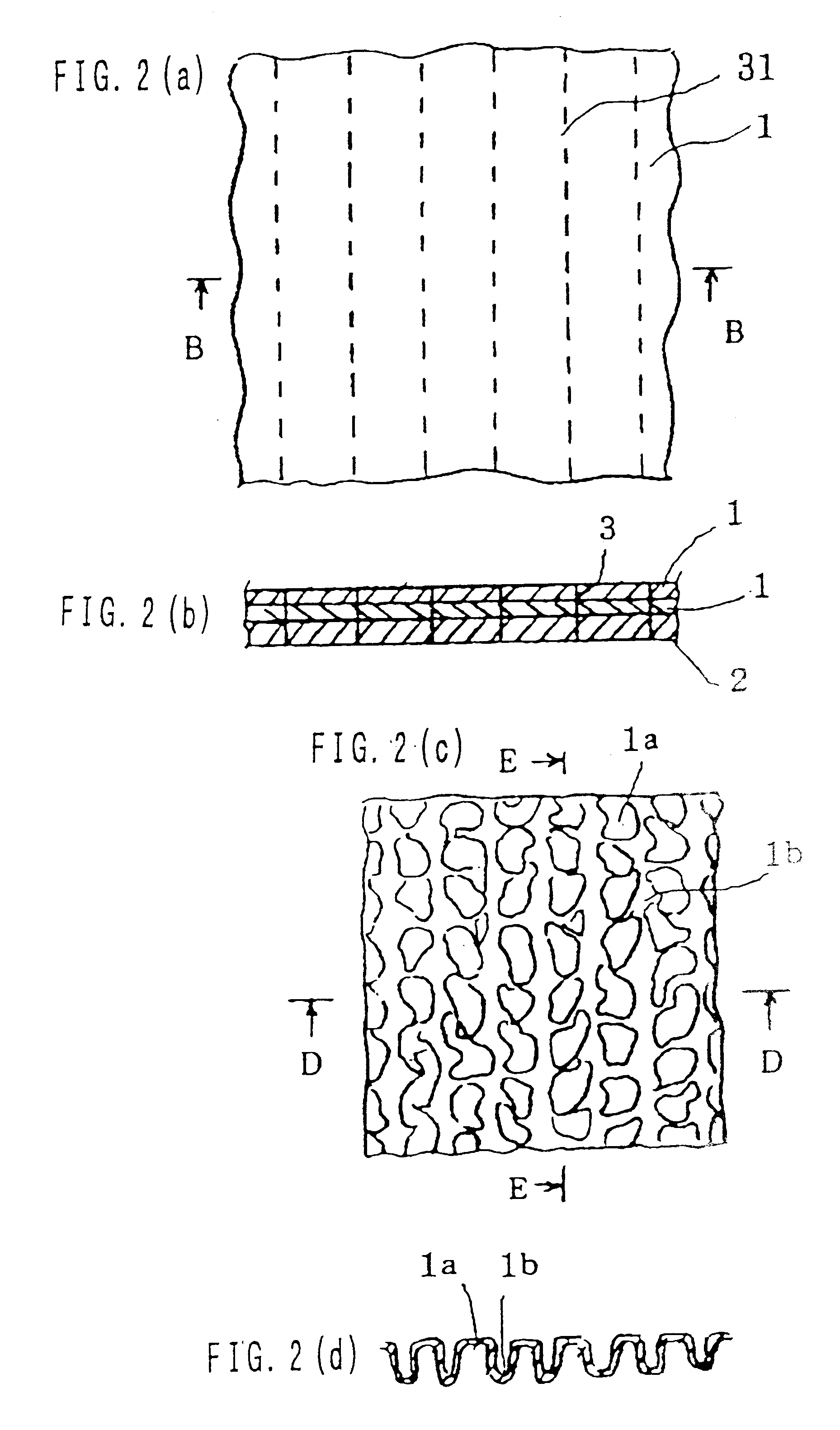

Method of making convexities and/or concavities on cloths of a garment

A method for forming convexities and / or concavities on cloths for a garment at almost entire portions of the garment or any desired portion of the garment without any substantial limitation from a design point of view. The method for forming a garment having convexities and / or concavities which can expand and contract in both the weft and wrap directions like a knitted fabric. Cloths including thermoplastic fiber are cut into parts of the garment, the parts are sewn in a shape of the garment. The garment is overlaid on a thermo-shrinkable cloth. They are sewn together with stitches of water-soluble threads. The sewn cloths are heated under dry heat and without applying any pressure to the cloths so as to permit the thermo-shrinkable cloth to shrink and form convexities and / or concavities on the cloths of the garment. The water-soluble threads are solved and removed, and the cloths of the garment are separated from the thermo-shrinkable cloth.

Owner:YOSHIKI HISHINUMA CO LTD

Complete equipment for tailoring

ActiveCN106367938AEasy to storeKeep drySevering textilesWork-collecting devicesEngineeringDrying Agents

The invention discloses complete equipment for tailoring. The complete equipment comprises a fabric storage cabinet, a fabric cutting machine, a sewing machine, a button sewing machine and an ironing machine, wherein the fabric storage cabinet comprises a cabinet body; the cabinet body is divided into left and right fabric accommodating cavities by virtue of a drying agent separator which is arranged at the center of the cabinet body, and the length of each fabric accommodating cavity is equal to the diameter of the fabric; the top end of the cabinet body is connected with a cover plate through a rotary hinge; a base is arranged at the bottom end of the cabinet body; and bottom ends of left and right side walls of the cabinet body are respectively connected with an upward lifting door through the rotary hinge. The fabric storage cabinet can be used for greatly reducing the time for searching fabrics, the dryness of the environment in the cabinet body is effectively maintained, and long-term fabric storage is facilitated.

Owner:MEISHENG CULTURE INNOVATION HLDG

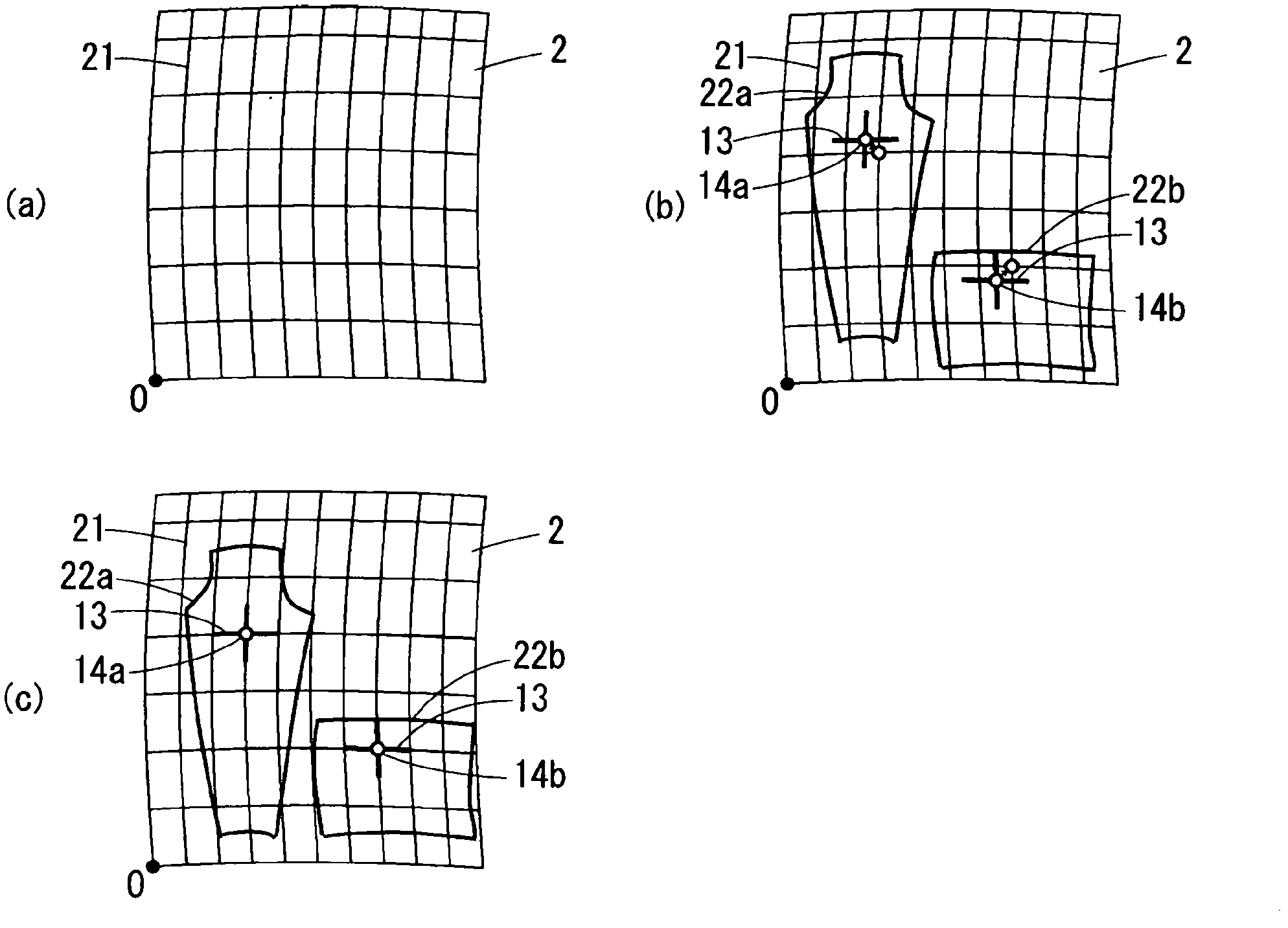

Method for cutting sheet and automatic cutting machine

A method for cutting a sheet comprises cutting the sheet which is placed on a working platform and with patterns along a pattern of a component, wherein, data used for the clipping is corrected corresponding to extension and deflection of the sheet. A pattern (22) of a component is configured on a pattern (12) which is theoretically provided by a sheet that is formed on an imaginary plane (11) corresponding to the sheet (2), each component is provided with pattern indentical points (14). Then, by taking the theoretic pattern (12) as a reference pattern (15), a projector is used to project the reference pattern (15) to the sheet (2) with an actual size, in addition, position and shape of the reference pattern (15) are made to move and deform consistently with position and shape of the pattern of the sheet (2), thereby correcting coordinate data. The corrected coordinate data of the pattern (22) of the component and a pattern of the sheet (2) which is taken by a camera are overlapped to perform display, positions of the indentical points (14) of the component which are corresponding to the pattern of the sheet (2) are interlapped, thereby correcting the coordinate data again.

Owner:SHIMA SEIKI MFG LTD

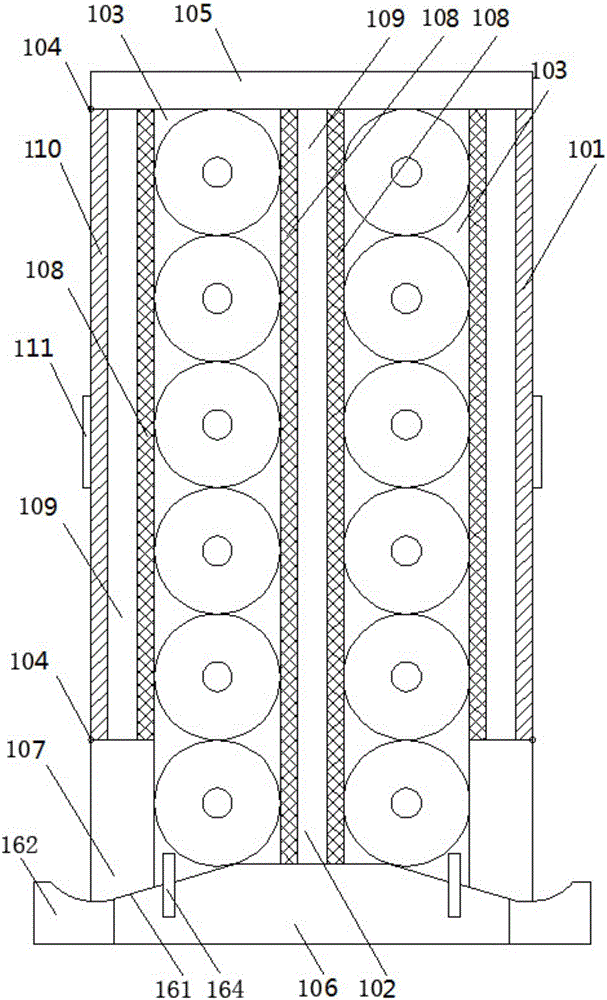

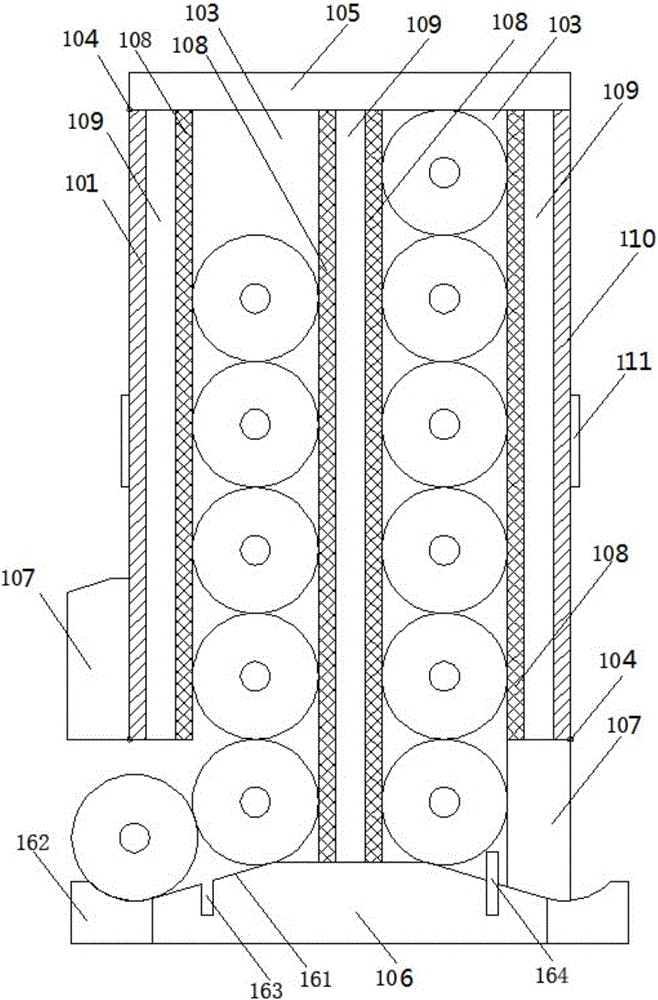

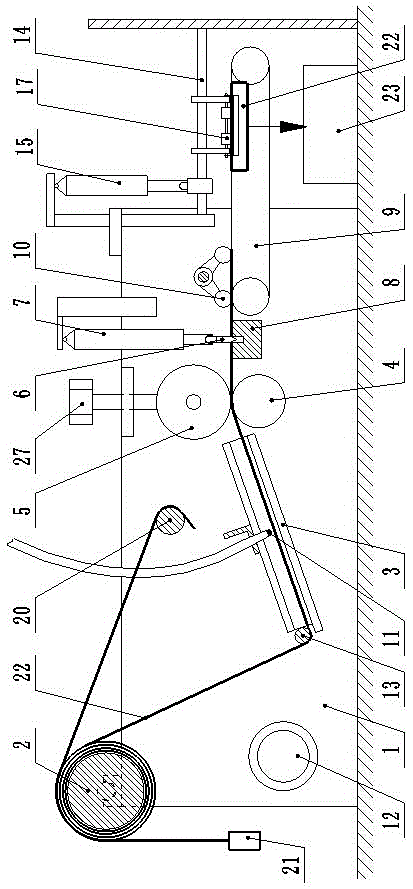

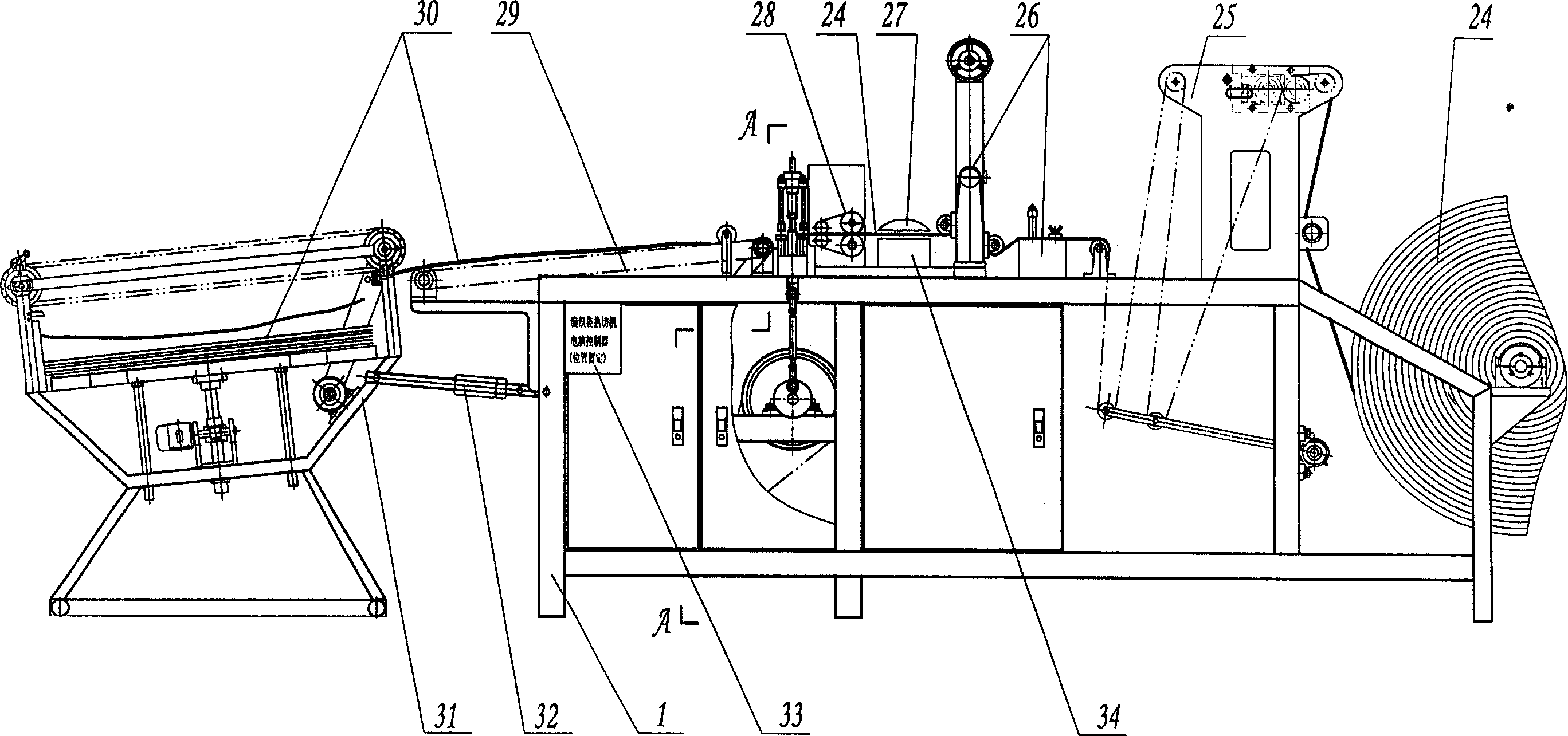

Lap former for producing non-woven fabrics

InactiveCN101597859AReduce volumeAvoid deformationSevering textilesArticle deliveryEngineeringNonwoven fabric

The invention provides a lap former for producing non-woven fabrics, which comprises an upper pinch roll and a lower pinch roll, wherein the upper pinch roll and the lower pinch roll pinch feed fabrics to the upper part of a cut-off knife supporting roll, change direction of the fabrics through the lower part of a rewind roll, and wind the fabrics on a cloth roller. The lap former is characterized in that the upper part of the cloth roller is provided with a compression roller; the compression roller applies downward and fabric compressing force by a pressure cylinder; and after bypassing a position on the external surface of the compression roller, the fabrics are wound on the cloth roller. To ensure that the fabrics can be wound on the cloth roller more tightly, two sides of the axle center of the compression roller are provided with the pressure cylinders, so that the compression roller can be automatically adjusted along with the thickness of the fabrics wound on the cloth roller. The batch wound by the lap former has small size, nice and tidy appearance, and difficult deformation, thereby saving space resource and reducing cost in the process of storage and transportation.

Owner:杨玉桥

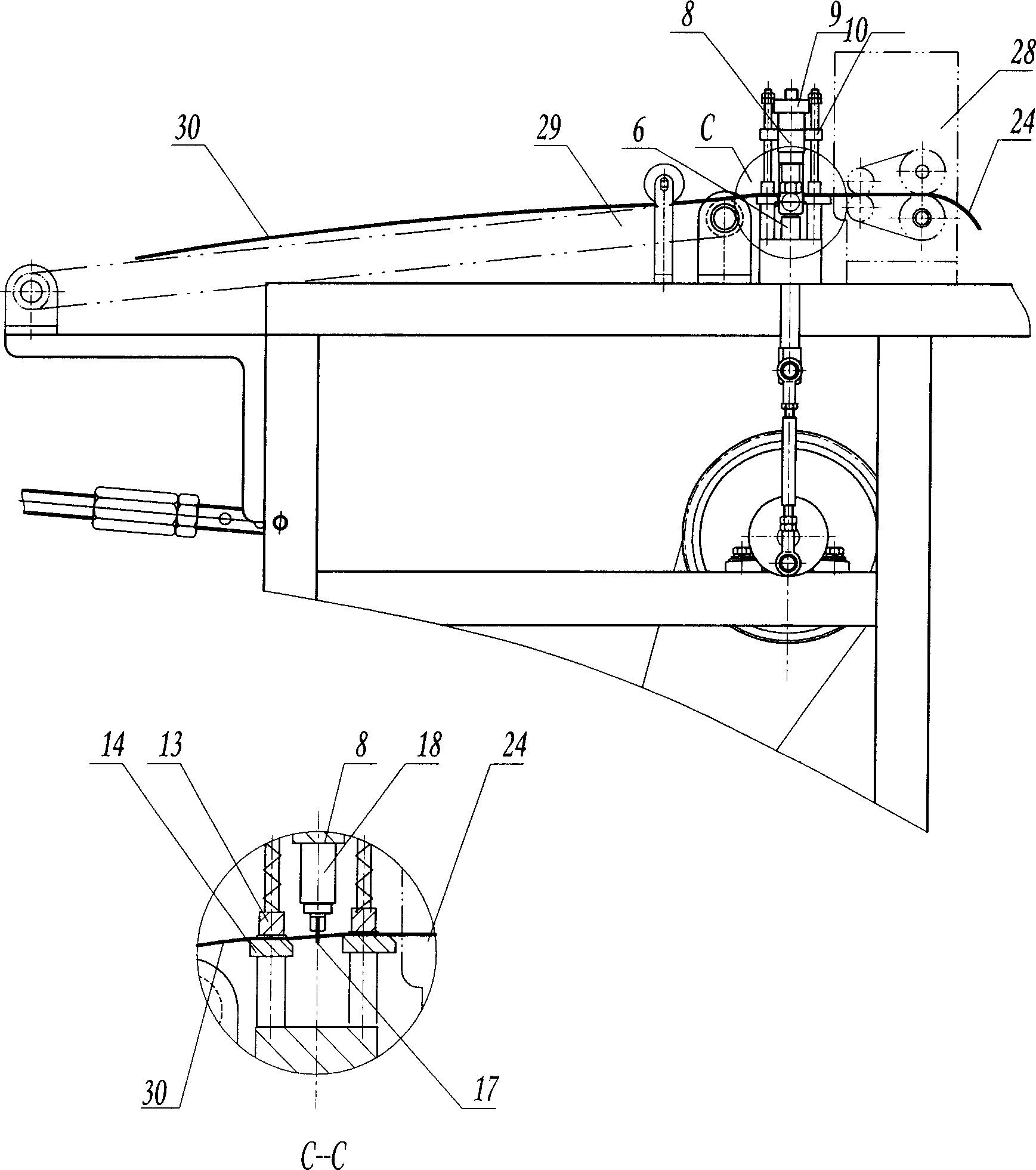

Automatic belt cutting machine

InactiveCN101643996AStable jobImprove securitySevering textilesMetal working apparatusAutomationEngineering

The invention relates to an automatic belt cutting machine, which consists of a cutting knife and a knife rest, wherein the knife rest is arranged on a base. The automatic belt cutting machine has thefollowing innovative points that: symmetrical vertical mounting plates are fixedly arranged on the base; a frame-shaped knife rest is movably arranged between the mounting plates in a vertical guiding mode; the top end of the knife rest is fixedly provided with the cutting knife horizontally; the knife rest achieves vertical ascending and descending by the driving of a cam mechanism driven by a first stepping motor through a bottom end of the knife rest; a horizontal belt cutting platform is fixedly arranged below the cutting knife; the upper surface of the belt cutting platform is provided with a feed roller driven by a second stepping motor; and the first stepping motor and the second stepping motor are connected with a controller arranged on the base through control wires. The automatic belt cutting machine has the advantages of compact structure, small space occupied by the entire machine and scientific and reasonable design, both the knife rest and the feed roller are controlledand driven by the controller through the stepping motors, and the entire machine has high automation degree, high processing efficiency, high accuracy and simple and convenient operation; therefore, the automatic belt cutting machine is the automatic belt cutting machine with high innovativeness.

Owner:TIANJIN CITY BAOJIA CLOTHING MACHINERY

Fiber-woven flexible composite traction belt for elevator and manufacturing method thereof

ActiveCN102002872AReasonable bearing structureReduce weightSevering textilesRope making machinesThermoplasticGlass fiber

The invention discloses a fiber-woven flexible composite traction belt for an elevator and a manufacturing method thereof. The manufacturing method comprises the weaving mode of a fiber woven belt, the manufacturing method of the fiber-woven flexible composite traction belt and the manufacturing method of plastic coating layers. The composite traction belt is formed by weaving steel wires or synthetic fibers; closely adhered plastic coating layers are arranged at the periphery and the internal part of the composite traction belt; and the plastic coating layers are made of elastic thermoplastic plastic. The fiber woven belt (1) is in synthetic fiber weaving, and comprises any one material of aromatic polyamide fibers, glass fibers, ceramic fibers or carbon fibers, or is formed by weaving an optional combination of the aromatic polyamide fibers, the glass fibers, the ceramic fibers and the carbon fibers. The plastic coating layers protect the fiber woven belt from being worn and maintain the woven belt in a tensioned state. The fiber woven belt is in the form of a tiled flat belt, and has the advantages of flat belt structure, higher fatigue resisting performance after long-time bending, longer service life, lighter weight and higher bearing strength.

Owner:浙江速捷电梯有限公司

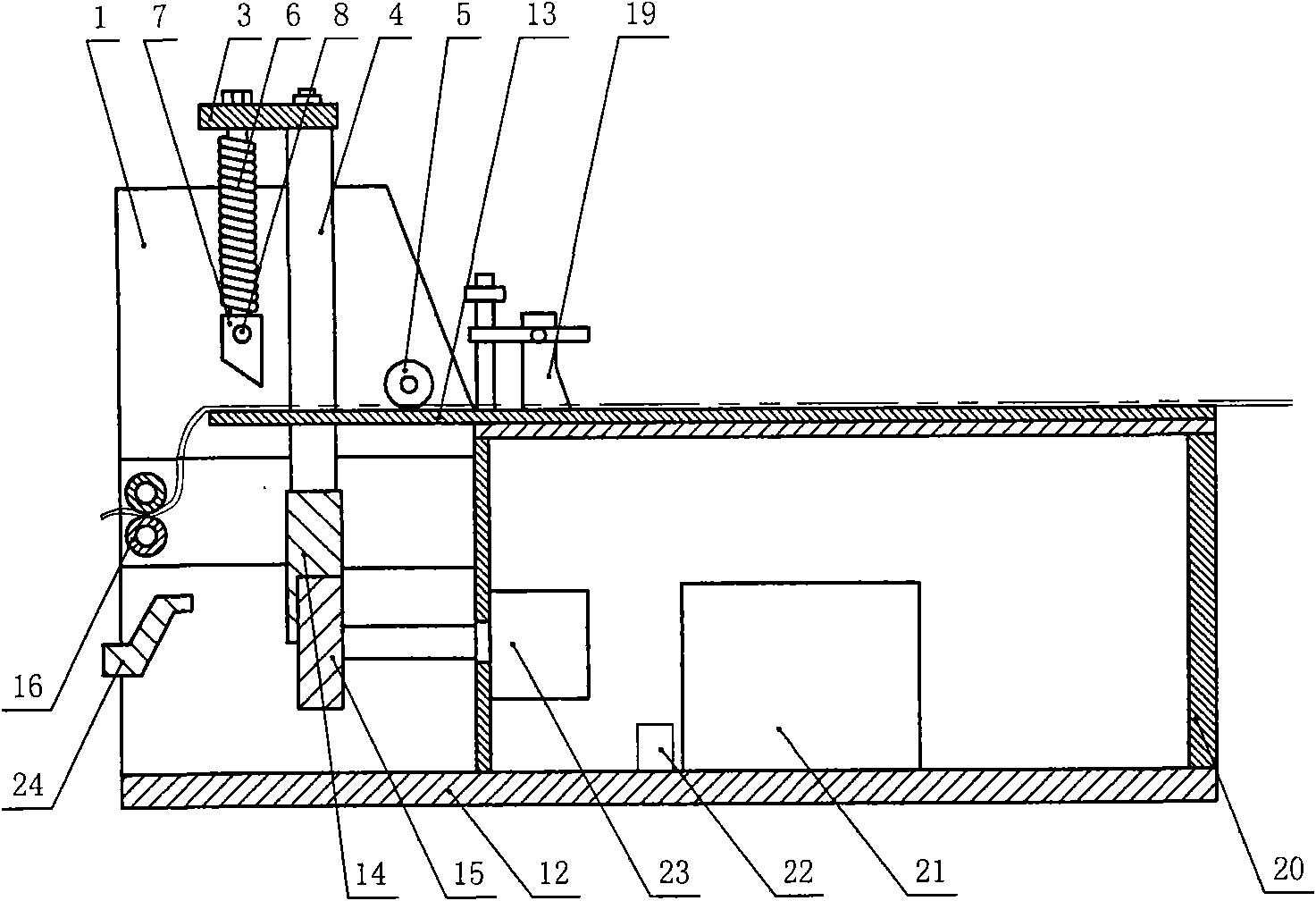

Cutting device of phloem fiber

The invention relates to a cutting device of phloem fiber, which is characterized in that the cutting device comprises a reverse U-shaped machine frame, one side of the machine frame is provided with a motor, the motor drives a group of worm and gear mechanisms through a transmission mechanism, worm wheels in the worm and gear mechanisms are coaxially connected with a crank disc of a crank connecting rod mechanism, a connecting rod is eccentricly connected on the crank disc, the other end of the connecting rod is connected with a cutter, the cutter spans between two vertical beams of the machine frame and is movably supported on the cross beam of the machine frame, the cutter is provided with a guide block and a guide groove in inclined movement correspondingly to the cross beams of the machine frame, both sides of the machine frame under the cutter are respectively provided with a material inlet support plate and a material outlet support plate, a cutter falling groove right aligned with the cutter is connected between the material inlet support plate and the material outlet support plate, and a hard pad block is arranged in the cutter falling groove. When the device provided by the invention is used for cutting the phloem fiber, the time and the labor can be saved, the cutting length required by the technology can be realized, the manual operation error can be reduced, and the production efficiency is high.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

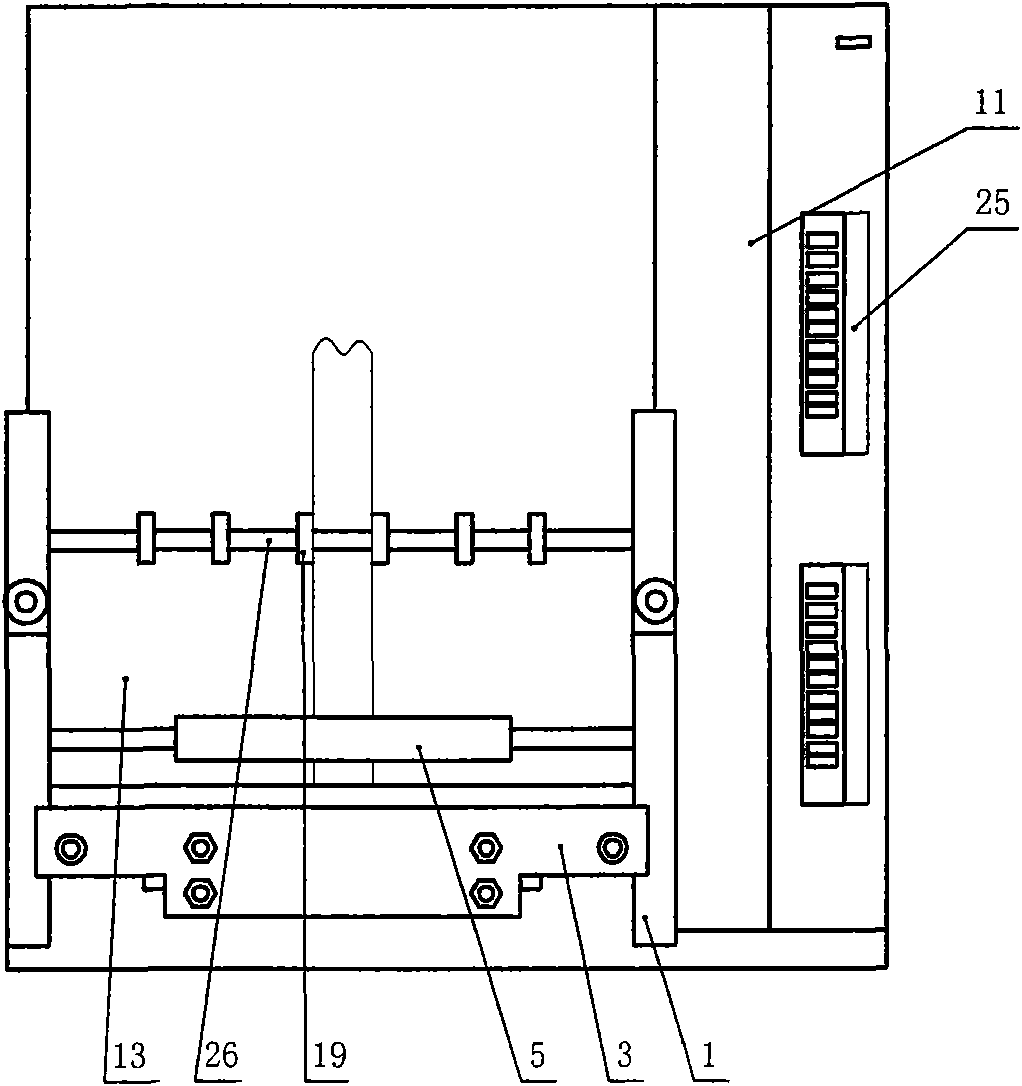

Automatic cutting and conveying device of trademark paper of woven bags or mesh bags

InactiveCN105538380ARealize automatic croppingRealize automatic one-shot moldingSevering textilesMetal working apparatusFixed frameTrademark

The invention discloses an automatic cutting and conveying device of trademark paper of woven bags or mesh bags and belongs to the technical field of automatic manufacture of the woven bags or the mesh bags. The technical problem to be solved is to provide an automatic cutting and conveying device of trademark paper of woven bags or mesh bags, achieve full automation of sewing of the trademark paper and save labor cost and time cost. The technical scheme adopted by the invention is as follows: a paper winding shaft is mounted at one end of a box body; a fixing frame is mounted inside the box body; a circular reversing rod is arranged on one side near the paper winding shaft; a driving conveying wheel, a cutting device, a conveying belt and an unloading device; the unloading device is mounted at the top of an outlet section of the conveying belt; a conveying device of a host for sewing the woven bags or the mesh bags is arranged at the lower part of the outlet section of the conveying belt; a plurality of mark points are uniformly arranged on trademark paper of the paper winding shaft; a trademark paper movable end passes through the fixing frame, the driving conveying wheel and the cutting device and is clamped between a second pressing wheel and the conveying belt; a probe is mounted on the fixing frame and corresponds to a mark point path of the trademark paper.

Owner:XINJIANG TIANLI PLASTIC CHEM CO LTD

Woven bag hot-cutting machine

InactiveCN1699678AOvercome three major problemsImprove production efficiencyInspecting textilesSevering textilesEngineeringMechanical engineering

The present invention relates to a kind of hot cutting machine for woven bags, consisting of a feeding and adjusting mechanism, inspection device, an output apparatus, a cutting-separation mechanism, a bag conveying and collecting mechanism. The invention has replaced the way of cutting bags by hand and overcome three difficult problems: using silicon electron inspection device to check pictures by silicon light so as to inspect the warp and weft of the bag surface materials in the course of weaving; using pressing bag cutting-separation mechanism to press a bag by a pressure bar and fix it and then cut it with hot knife, which is made of nickel chromium material, heated by adjusting voltage and cut by controlling the temperature and speed so as to achieve non-lose edge on the woven bags after cutting and separating; using chain belt ring caterpillar bag mouth binding mechanism to raise production efficiency by 4 times and save one man operation.

Owner:黄友总

Cloth cutting device

InactiveCN105459196AAvoid scratchesExtended service lifeSevering textilesMetal working apparatusEngineeringElectric control

The invention mainly discloses a cloth cutting device. According to the technical scheme, the cloth cutting device comprises a cutting table, a cutter and an electric control cabinet. A cloth releasing device and a cloth pressing device are arranged on the right side of the cutting table. A cloth collecting device is arranged on the left side of the cutting table. Sliding rods are arranged on both the front side and the rear side of the cutting table. A sliding frame is arranged on the sliding rods and comprises sliding bases and a rodless air cylinder. The sliding bases are movably connected with the sliding rods. The rodless air cylinder is installed between the sliding bases. A magnet ring sleeve is arranged outside the rodless air cylinder. The cutter is connected to the magnet ring sleeve and comprises a cutting base and a cutting knife. The cutting base is connected with the magnet ring sleeve. A containing cavity is formed in the cutting base. A miniature air cylinder is arranged on the inner wall of the containing cavity. The cutting knife is in telescopic fit in the containing cavity through the miniature air cylinder. The cloth cutting device has the advantages of being simple in structure, high in automation level and cutting efficiency and capable of cutting cloth to be in different widths, prolonging the service life of tools and improving the safety performance of the tools.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com