Cutting method along boundary of laser cutting equipment

A cutting method and laser cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of pattern difference, low cutting precision, and cutting waste, so as to improve the yield rate, improve work efficiency, The effect of reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

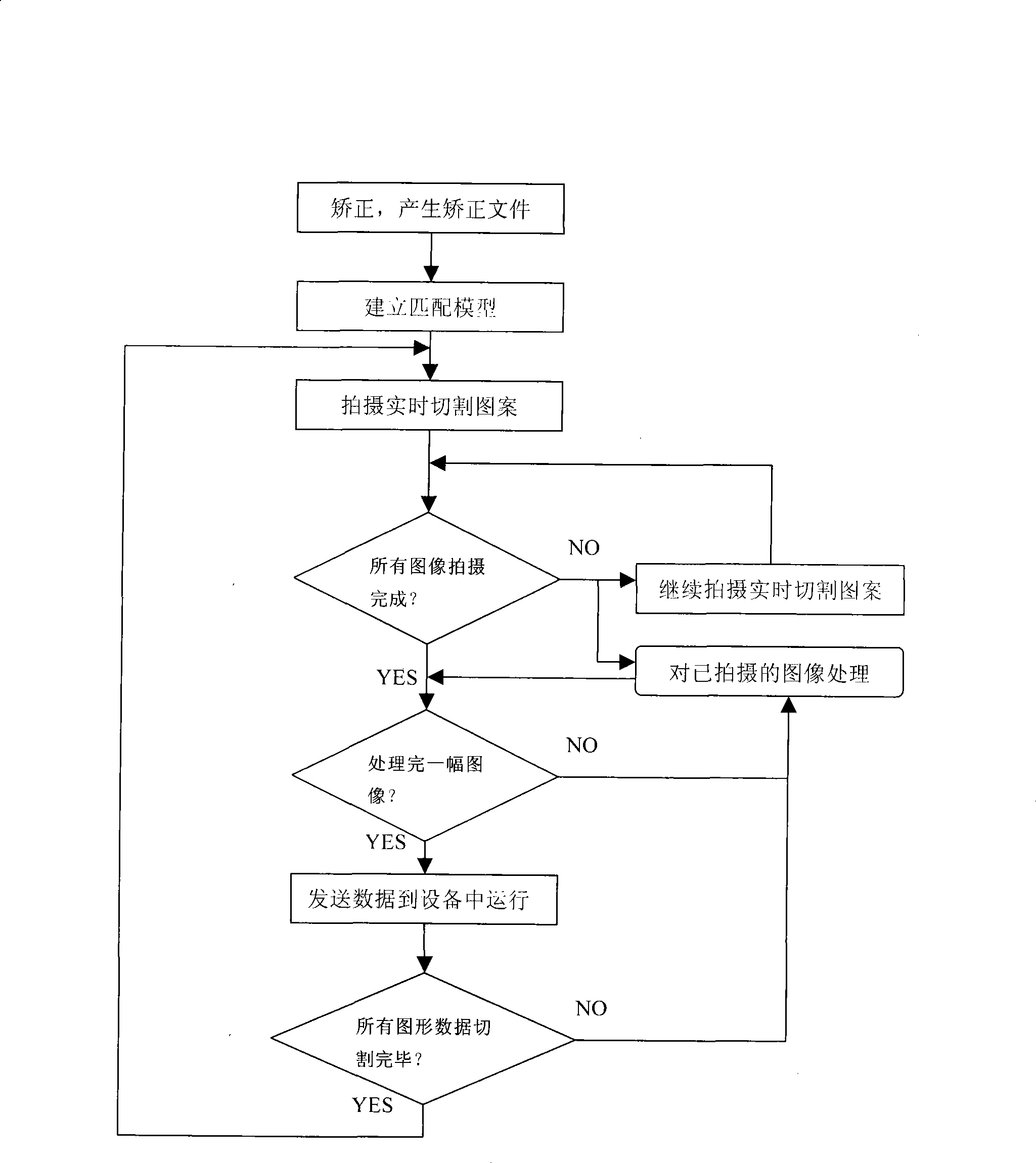

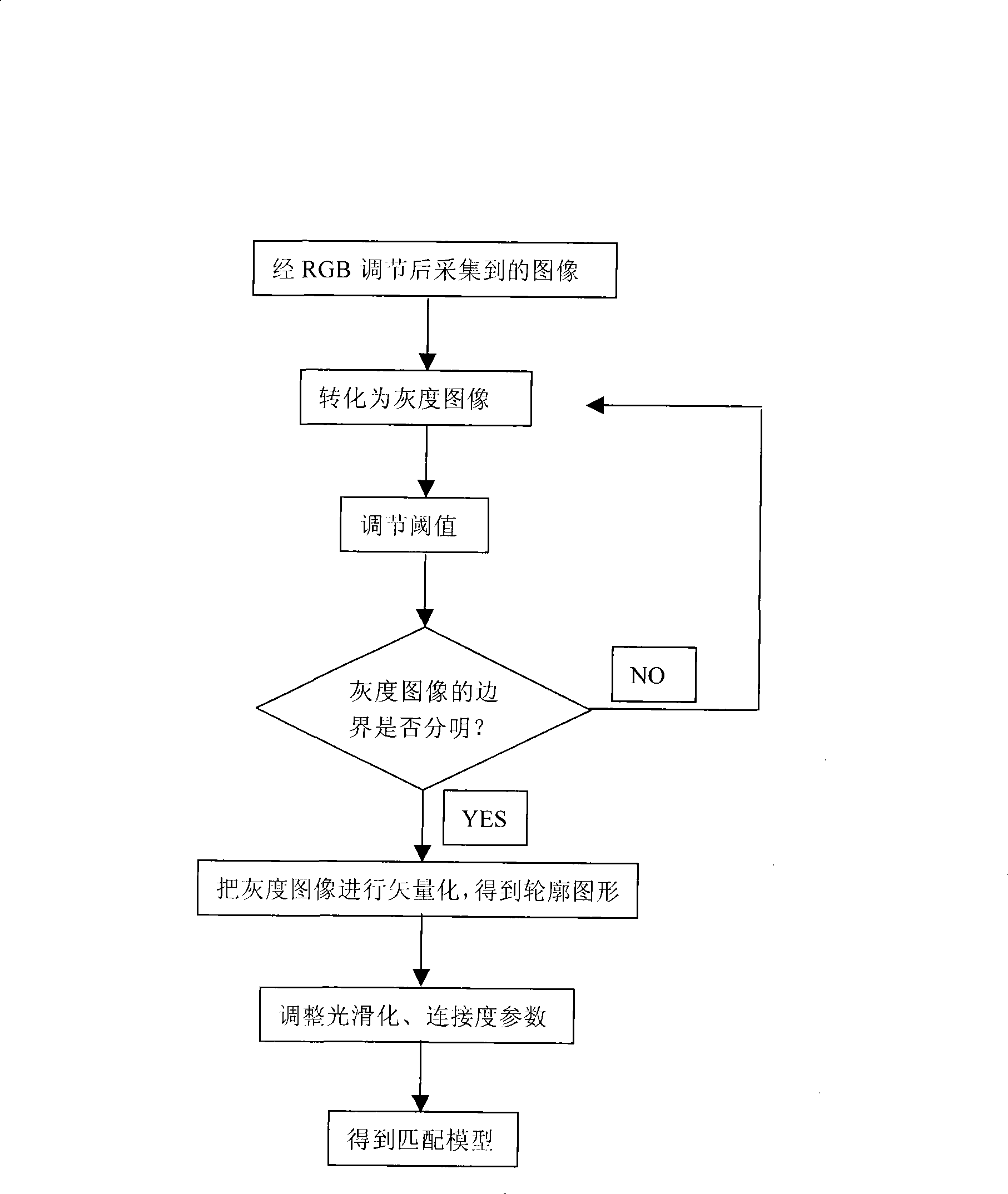

[0016] In the laser cutting machine of the present invention, when it is commissioned at the factory or is working for the first time, it is necessary to calibrate the camera on the laser cutting machine through the software of the computer to generate a correction file, which is stored in the computer; The camera on the laser cutting machine collects the pattern on the material to be cut, and sends it to the computer through the signal line, and the computer corrects the collected image with the correction file generated above; By adjusting the RGB of the real-time captured image, the boundary of the image is made clearer, and the sense of layering of colors with similar gray levels is more obvious. Replace the rectified image with a grayscale image, and then adjust its threshold to make the boundary of the image more distinct, convert the obtained grayscale image into a contour graphic through vectorization, and adjust the smoothing parameters and connectivity parameters to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com