Patents

Literature

647results about How to "Realize automatic cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

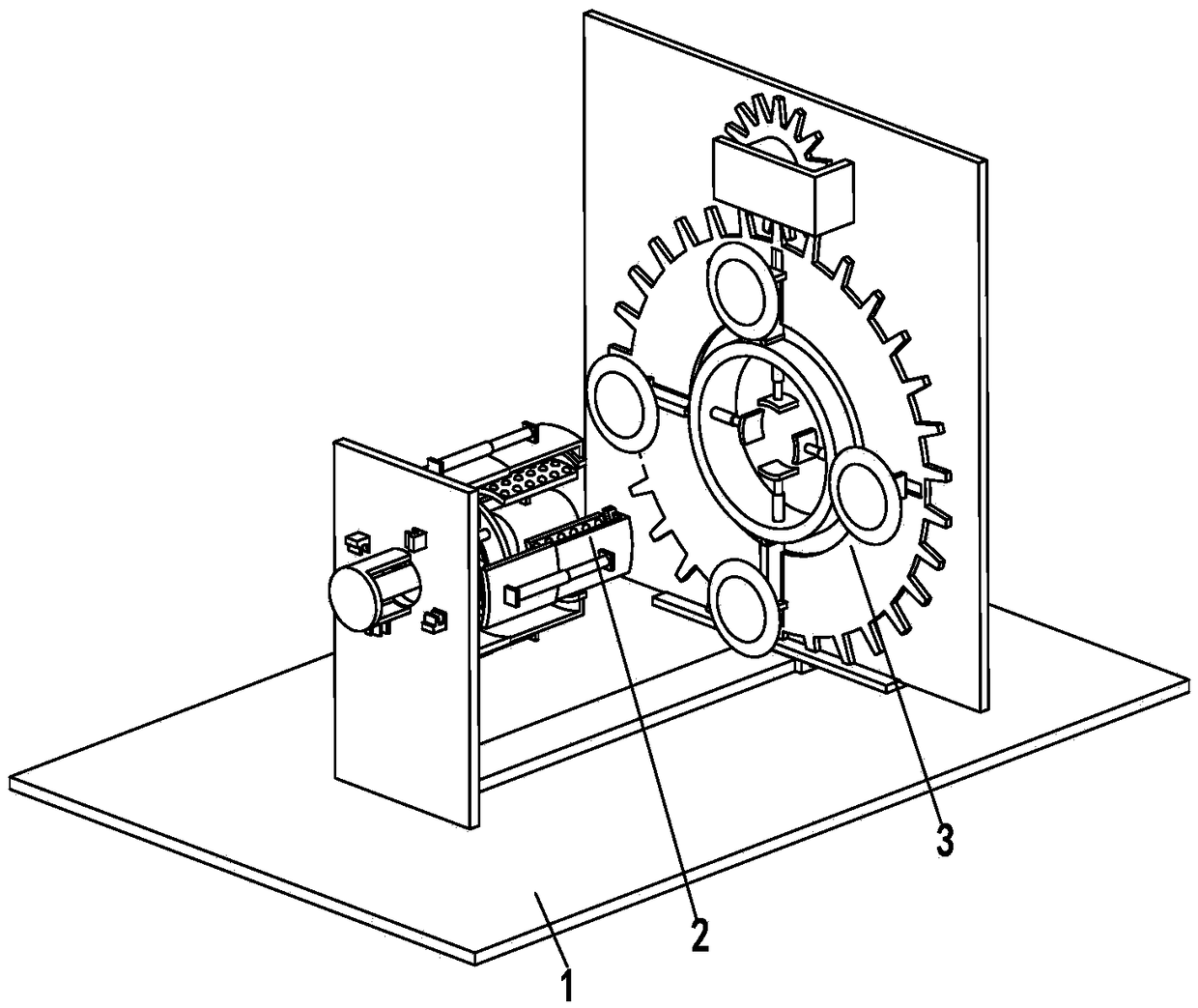

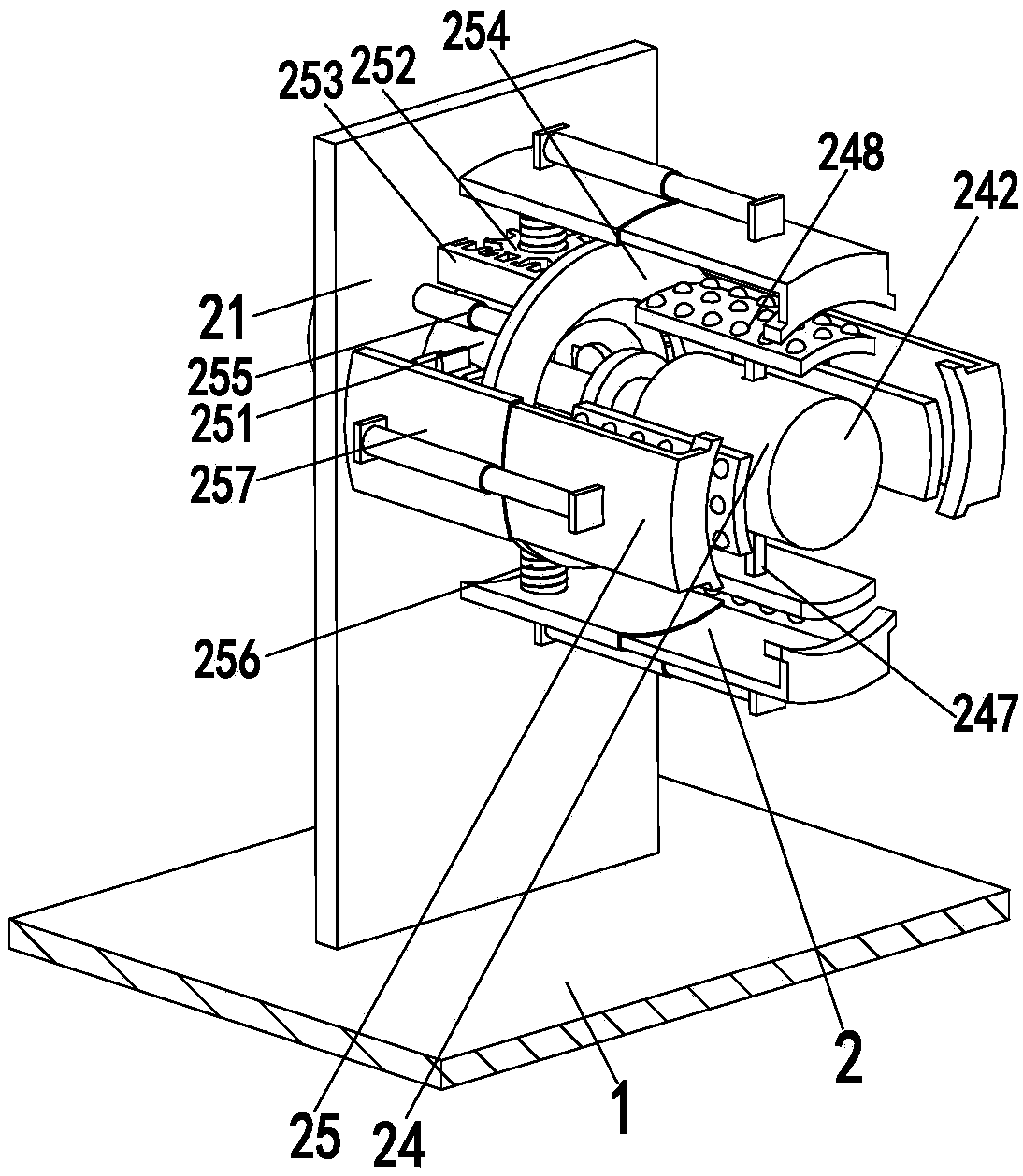

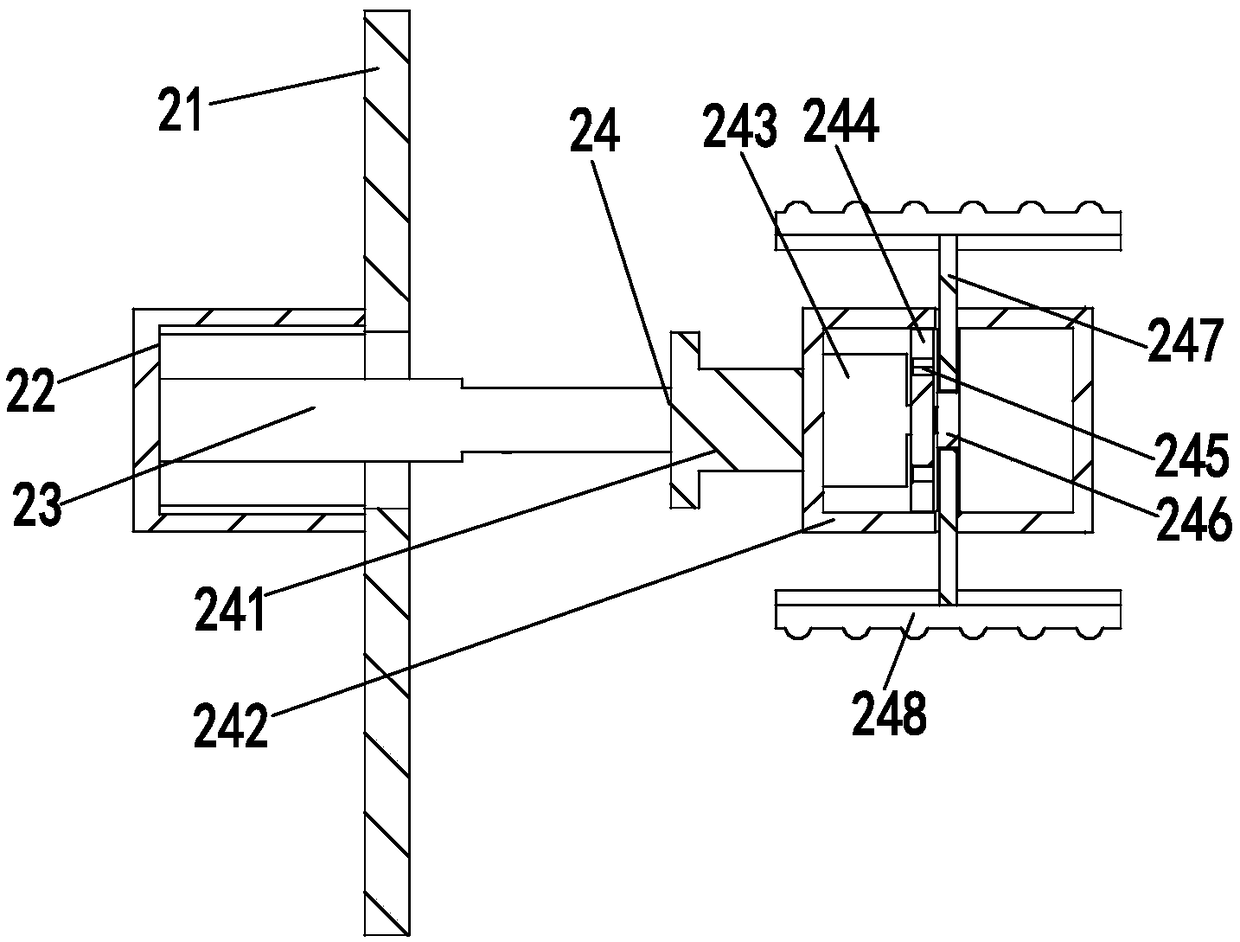

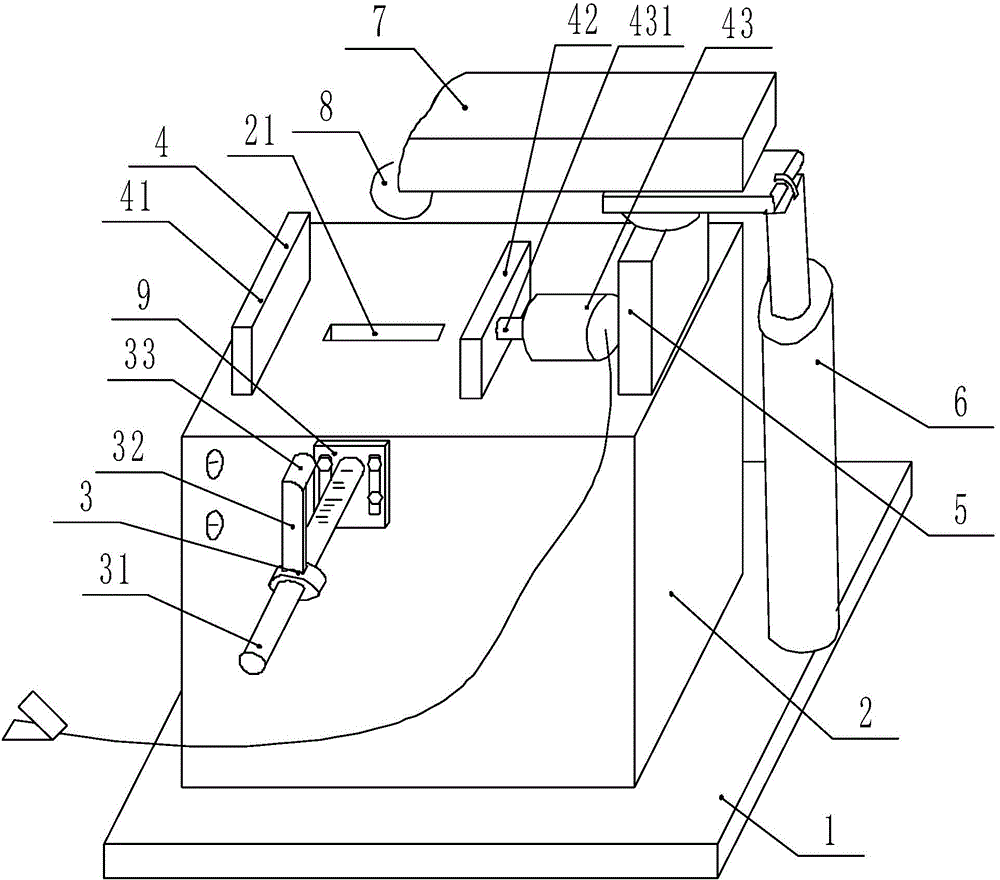

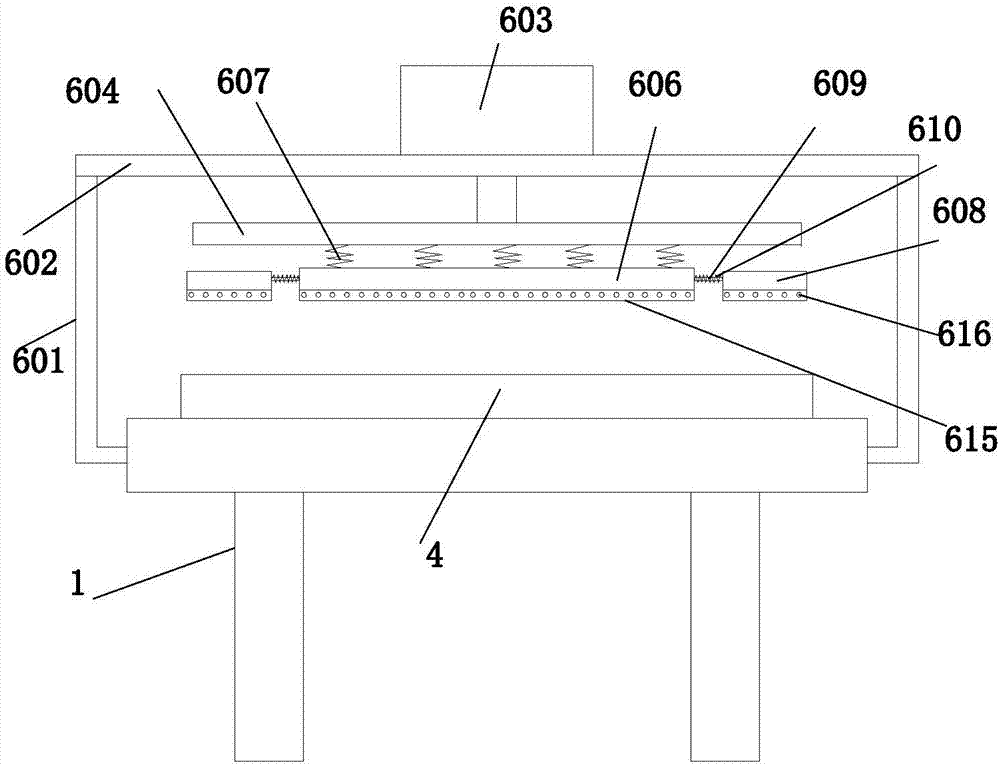

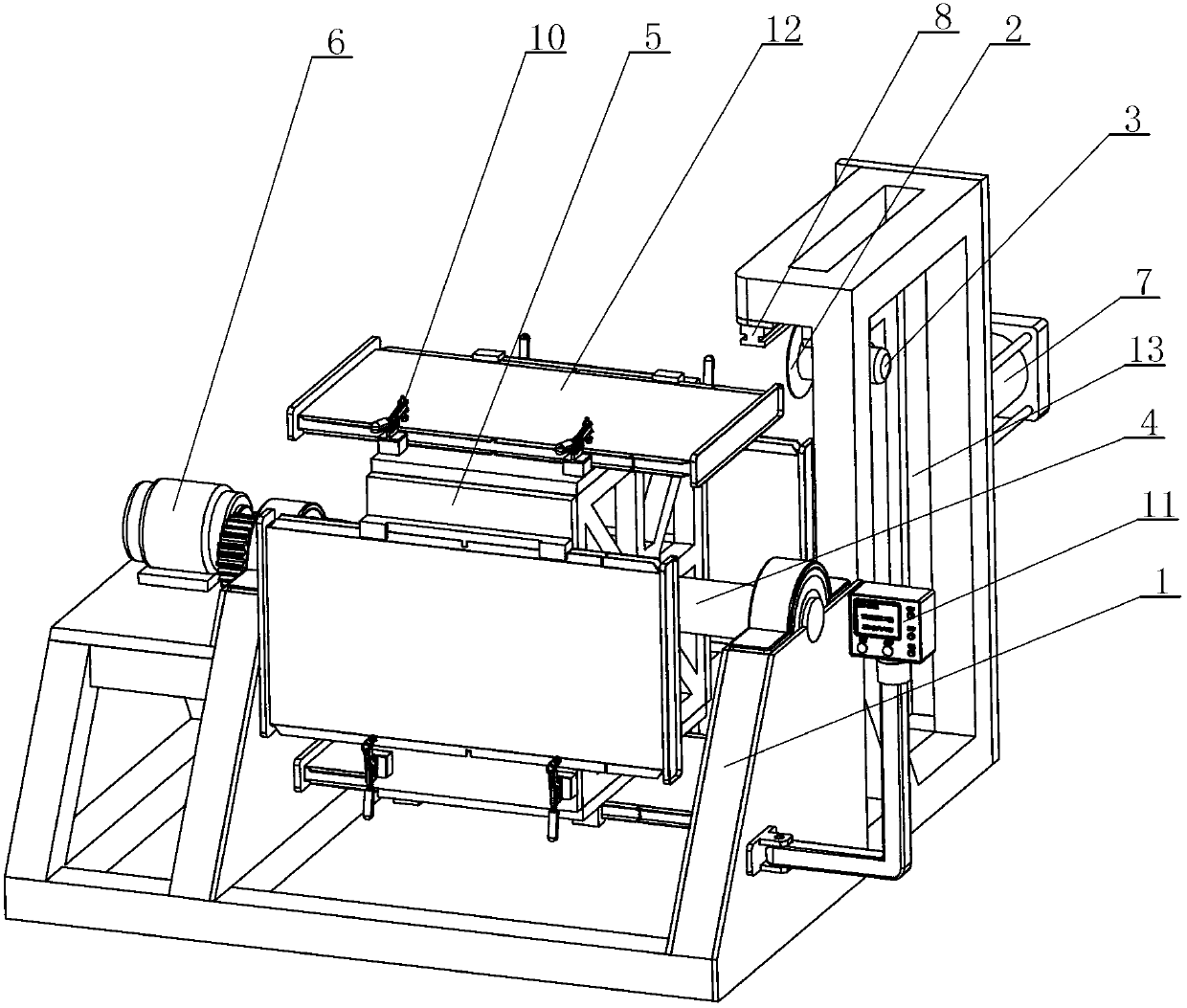

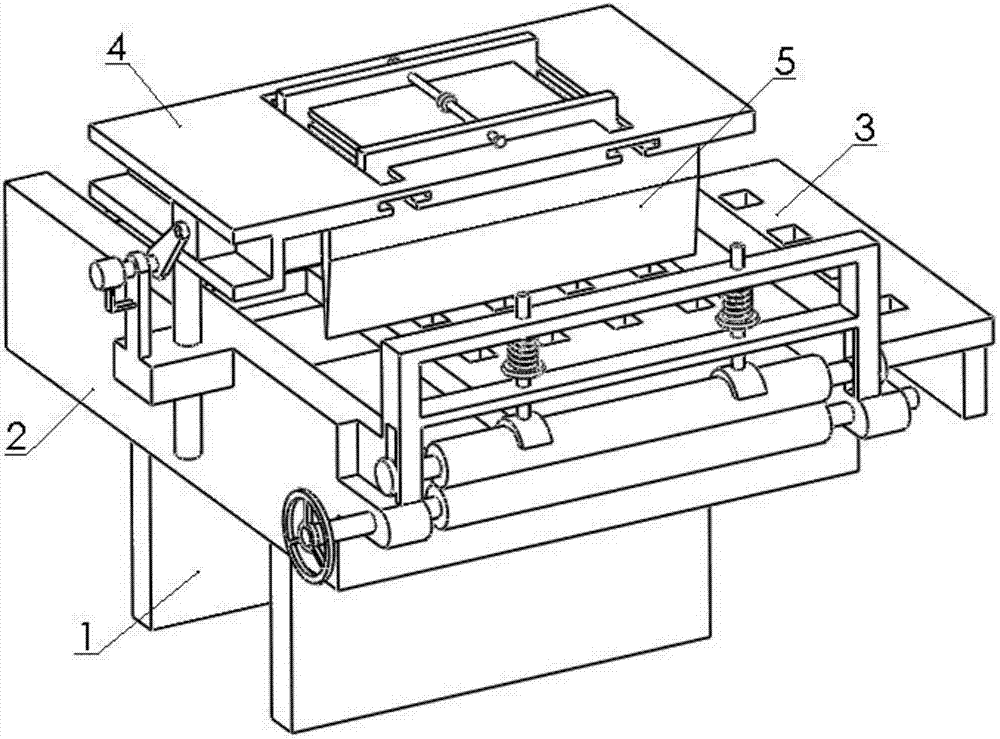

Automatic rubber hose cutting equipment and automatic rubber hose cutting technology

ActiveCN109227674ARealize automatic cuttingNot easy to scratchMetal working apparatusGear wheelFixed frame

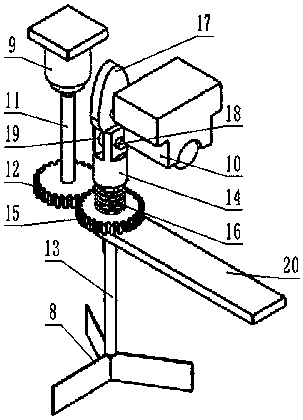

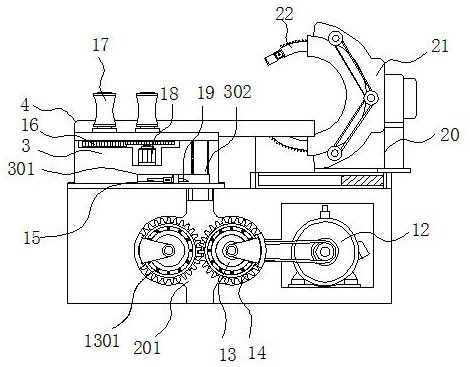

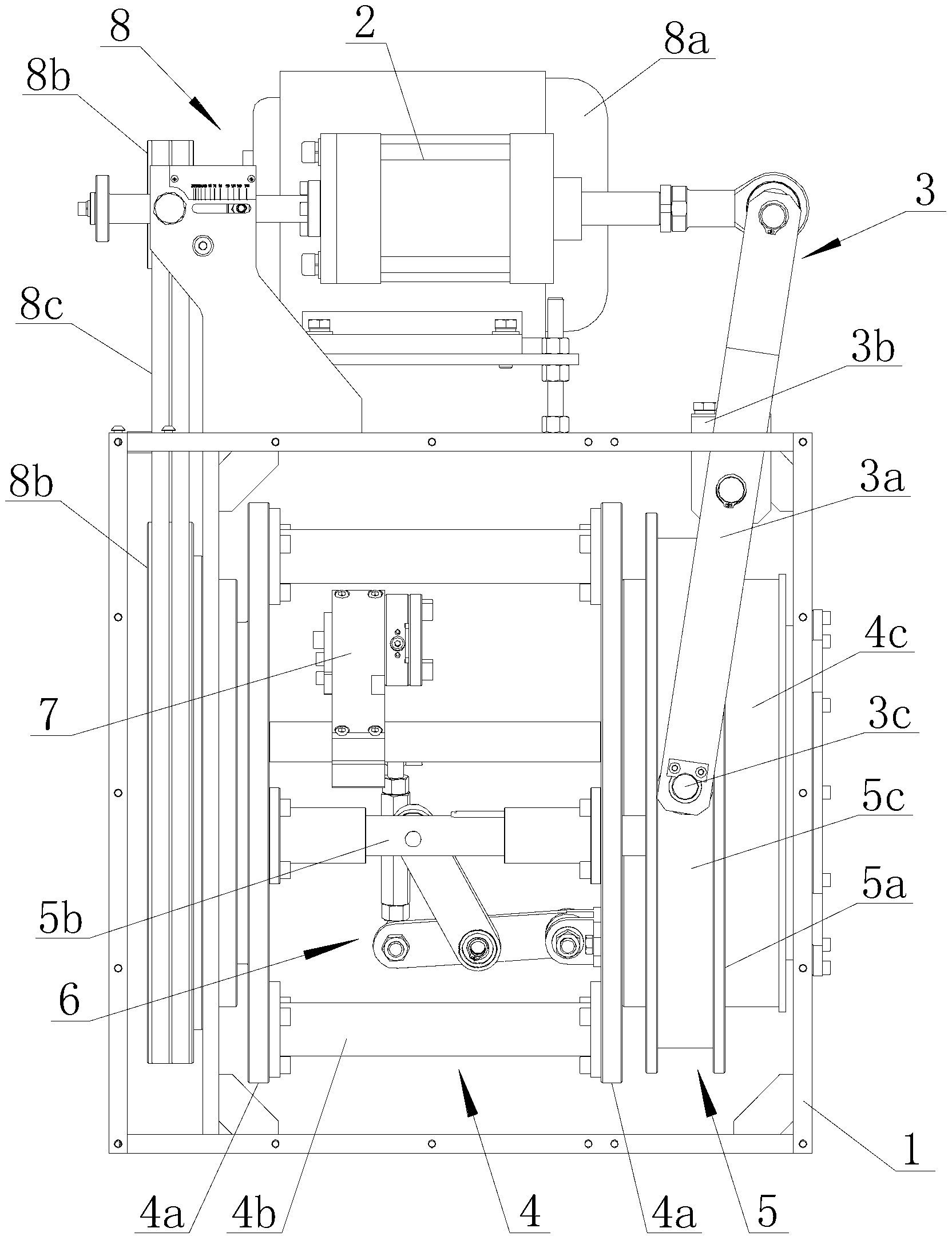

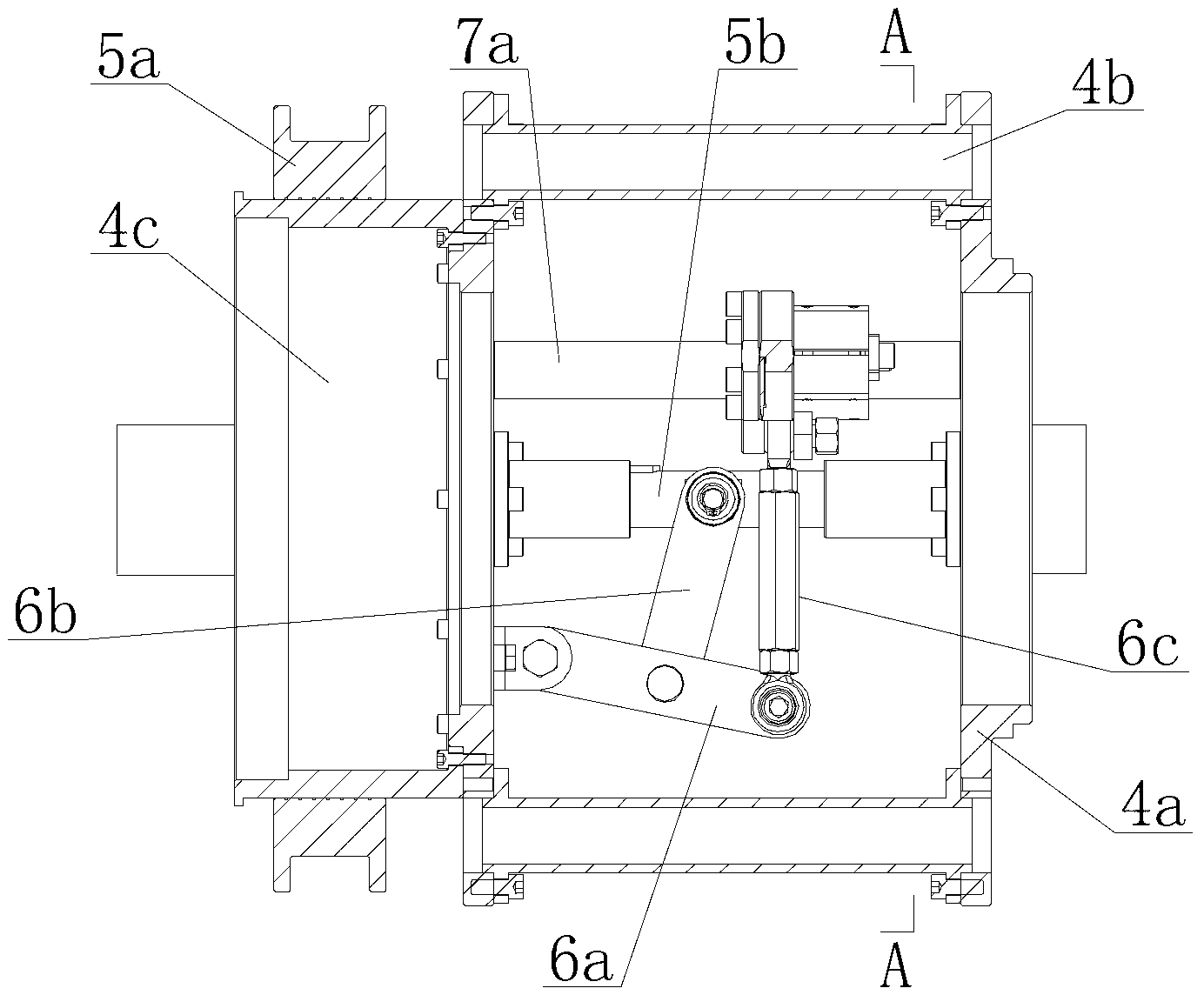

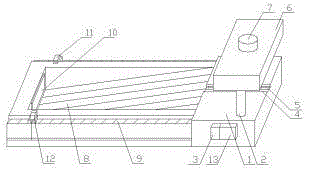

The invention relates to automatic rubber hose cutting equipment and an automatic rubber hose cutting technology. The automatic rubber hose cutting equipment comprises a bottom plate, a supporting device and a cutting device, and the supporting device and the cutting device are sequentially installed on the bottom plate from left to right; the supporting device comprises a fixing plate, a fixed frame, a movable air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the cutting device comprises a linear guide rail, an electric sliding block, a working plate, aworking gear, a driving gear, a driving motor, a rotating ring, a rotating gear, a rotating motor, a supporting air cylinder, a supporting plate, a rotating rod, a sliding frame, a mounting frame, a cutting motor and a cutting blade. The invention further provides a using method of the automatic rubber hose cutting equipment. The equipment and the technology can solve the problems that in an existing rubber hose cutting process, the labor cost is high, the working efficiency is low, the cutting surface is not smooth, safety hidden hazards exist and the surface of a rubber hose is easily scratched, and the function of automatically cutting the rubber hose can be achieved.

Owner:中金液压胶管股份有限公司

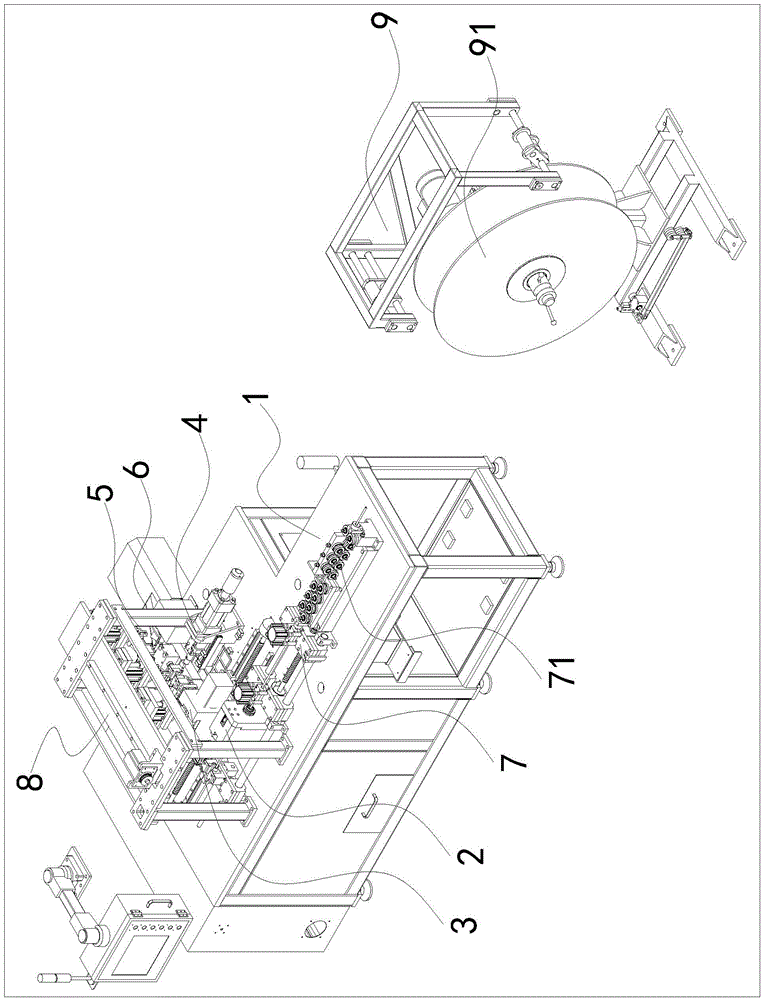

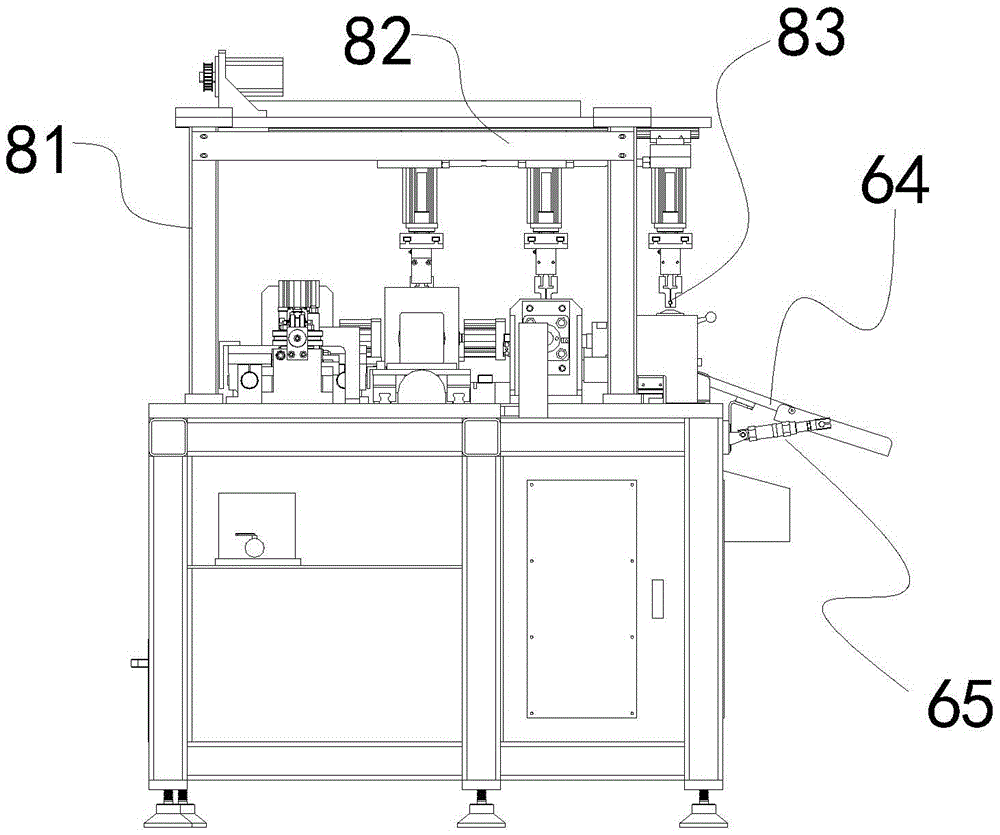

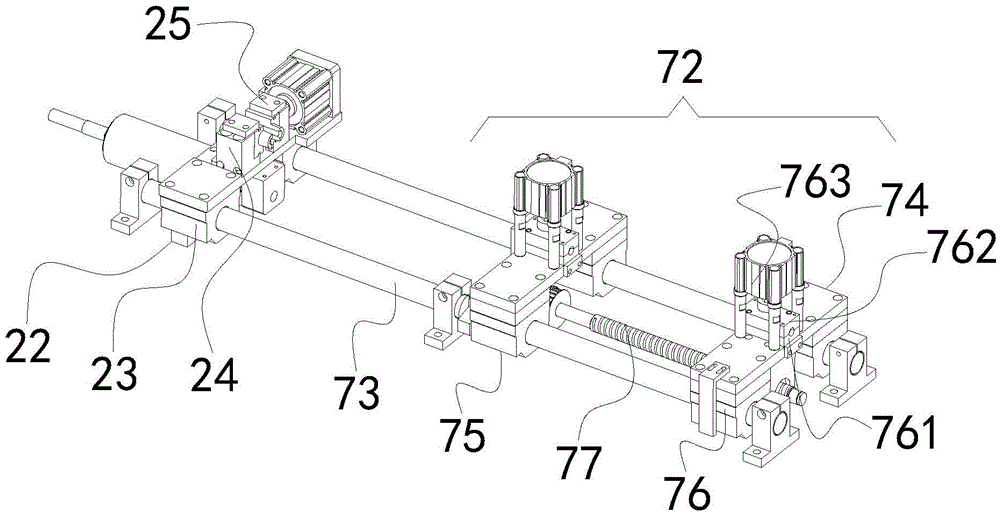

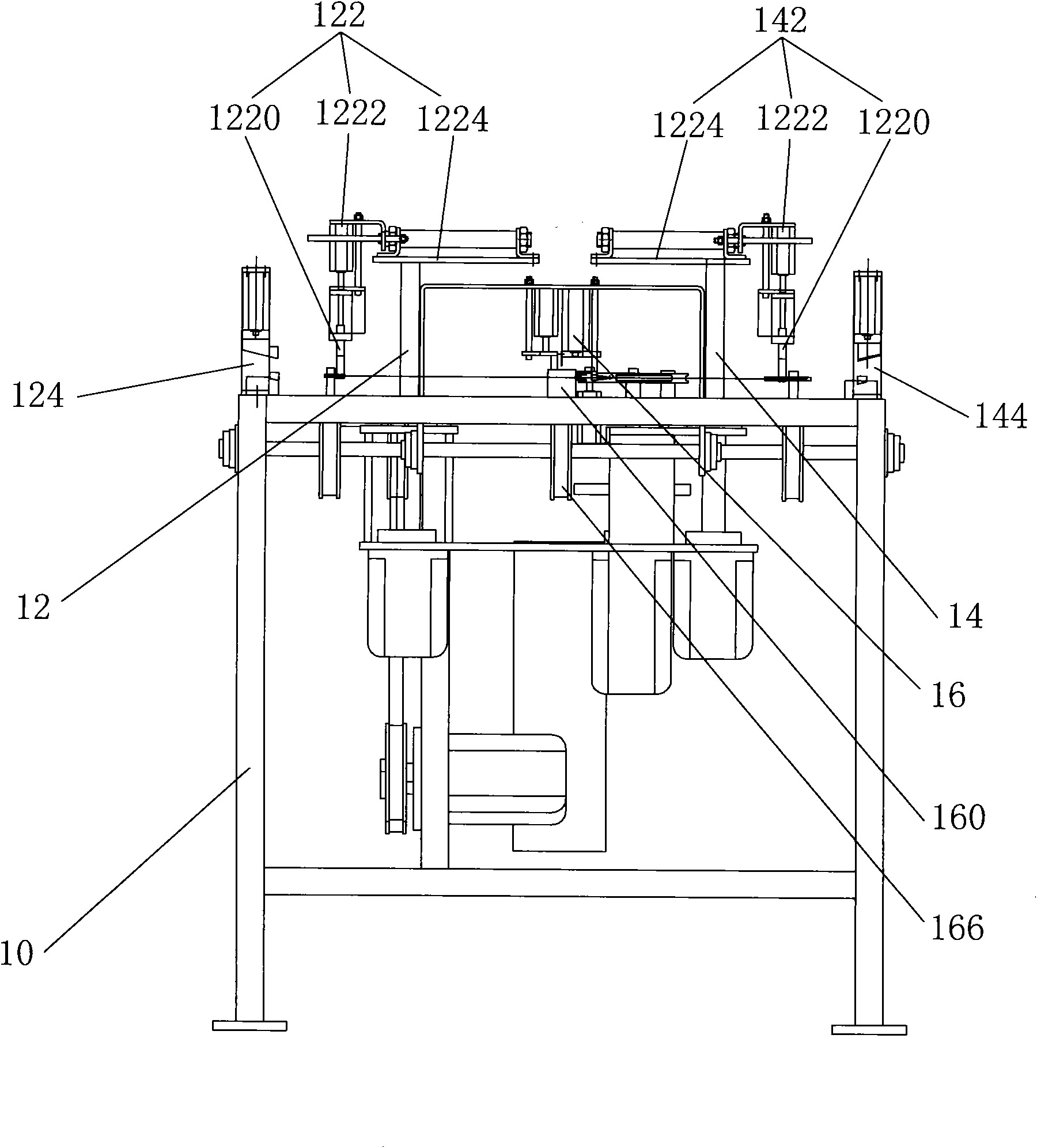

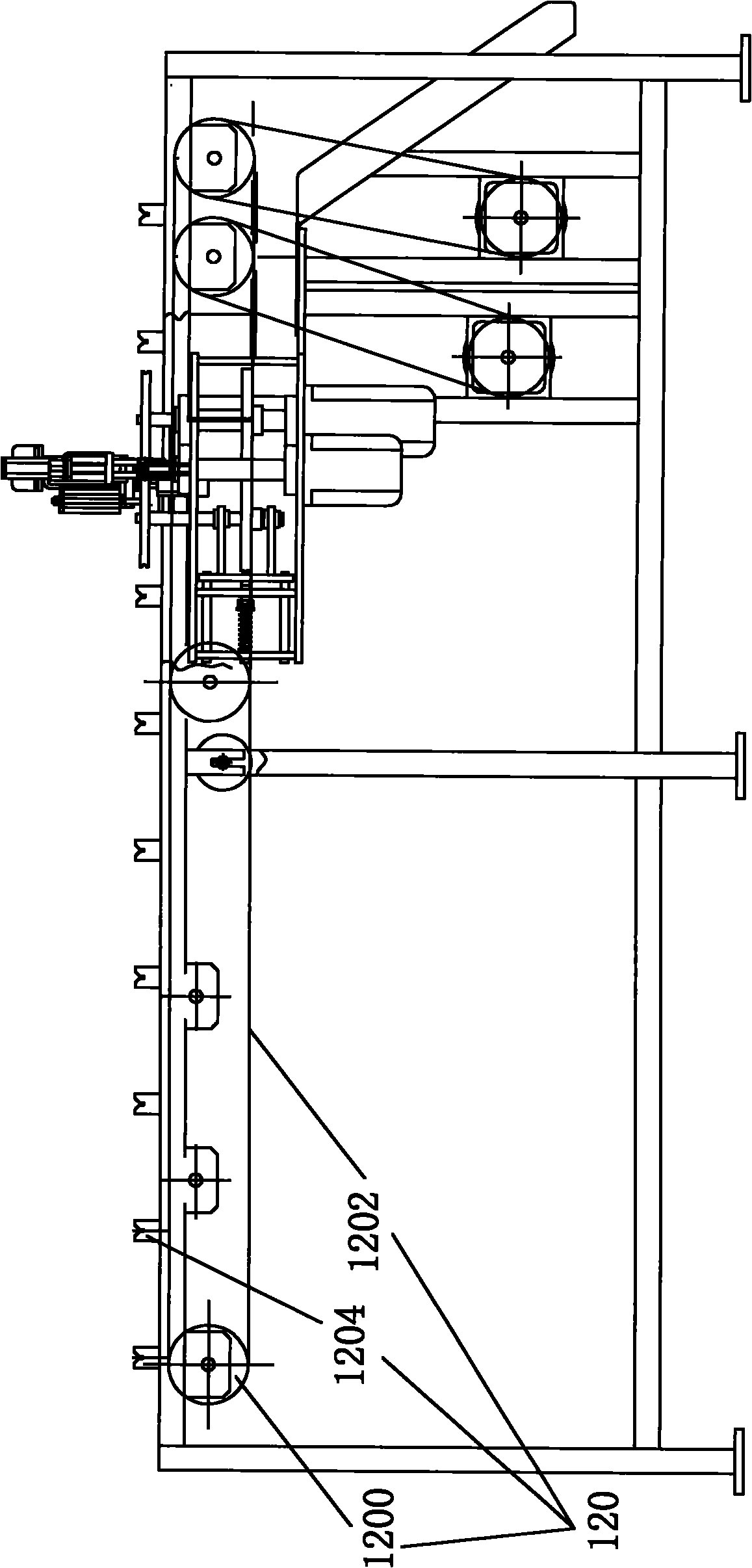

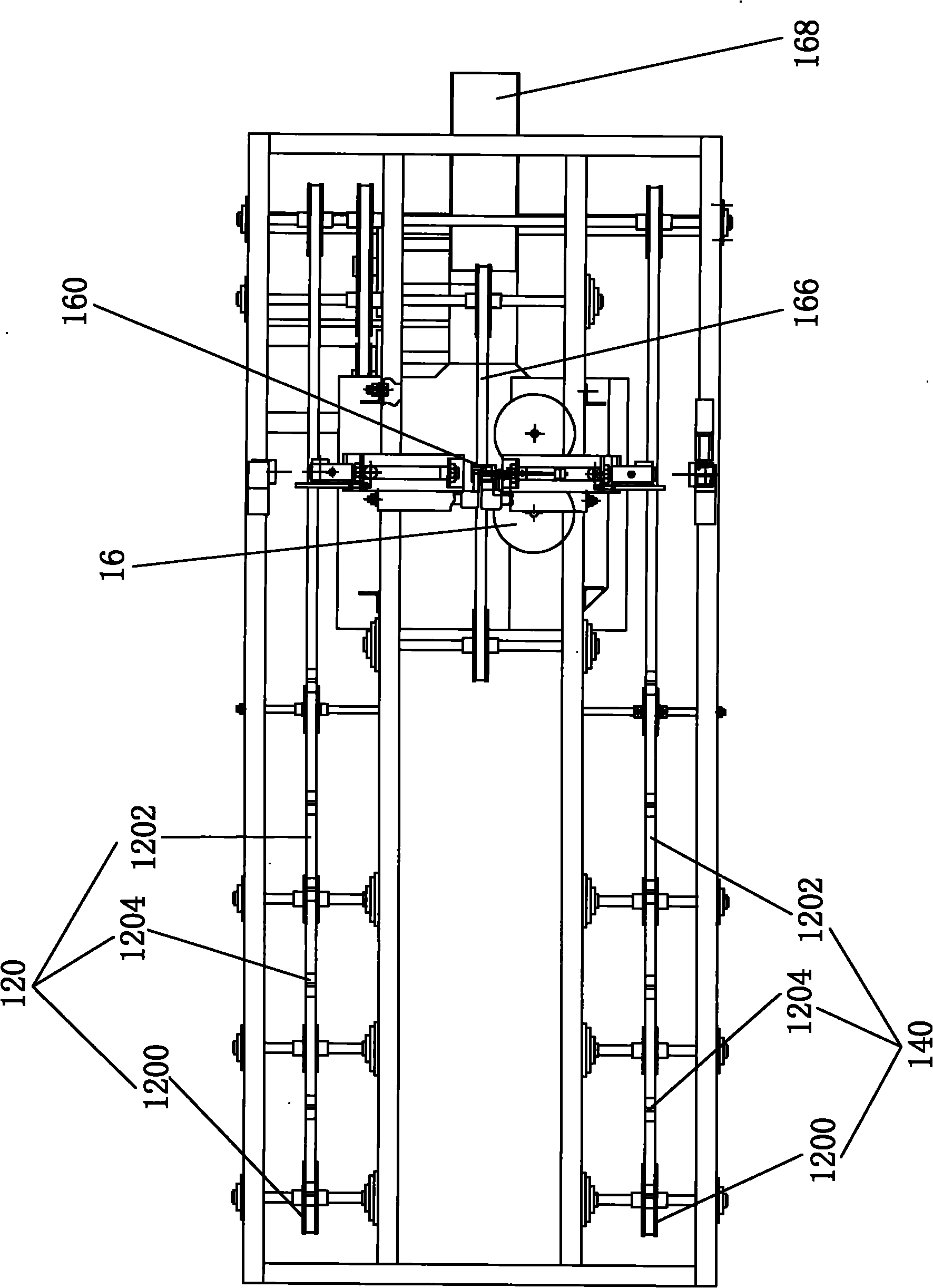

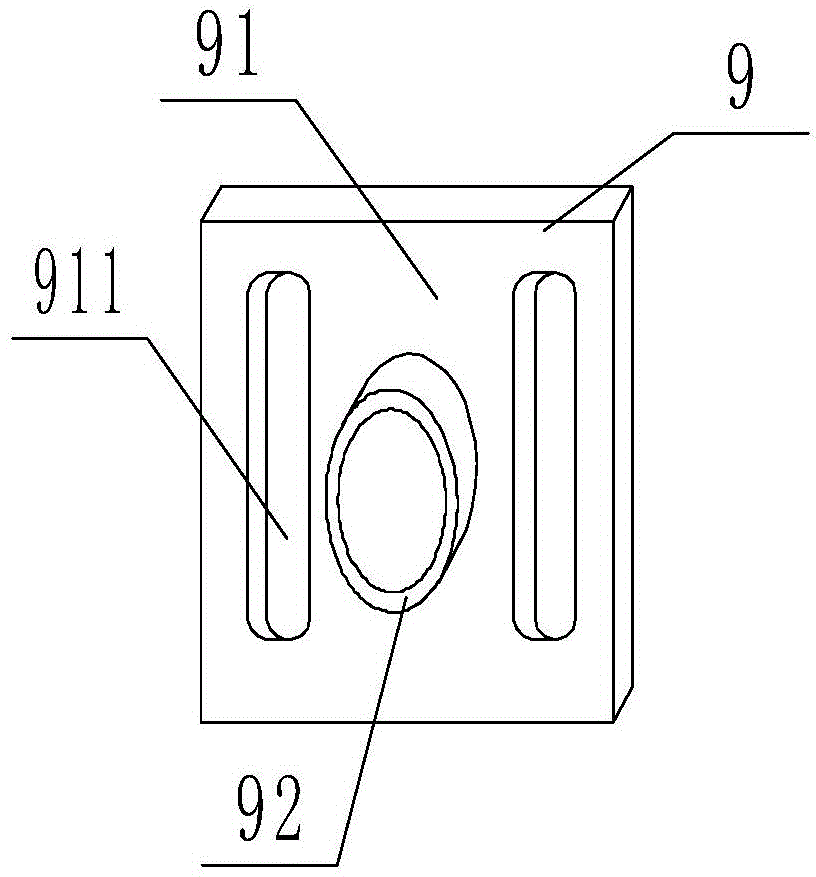

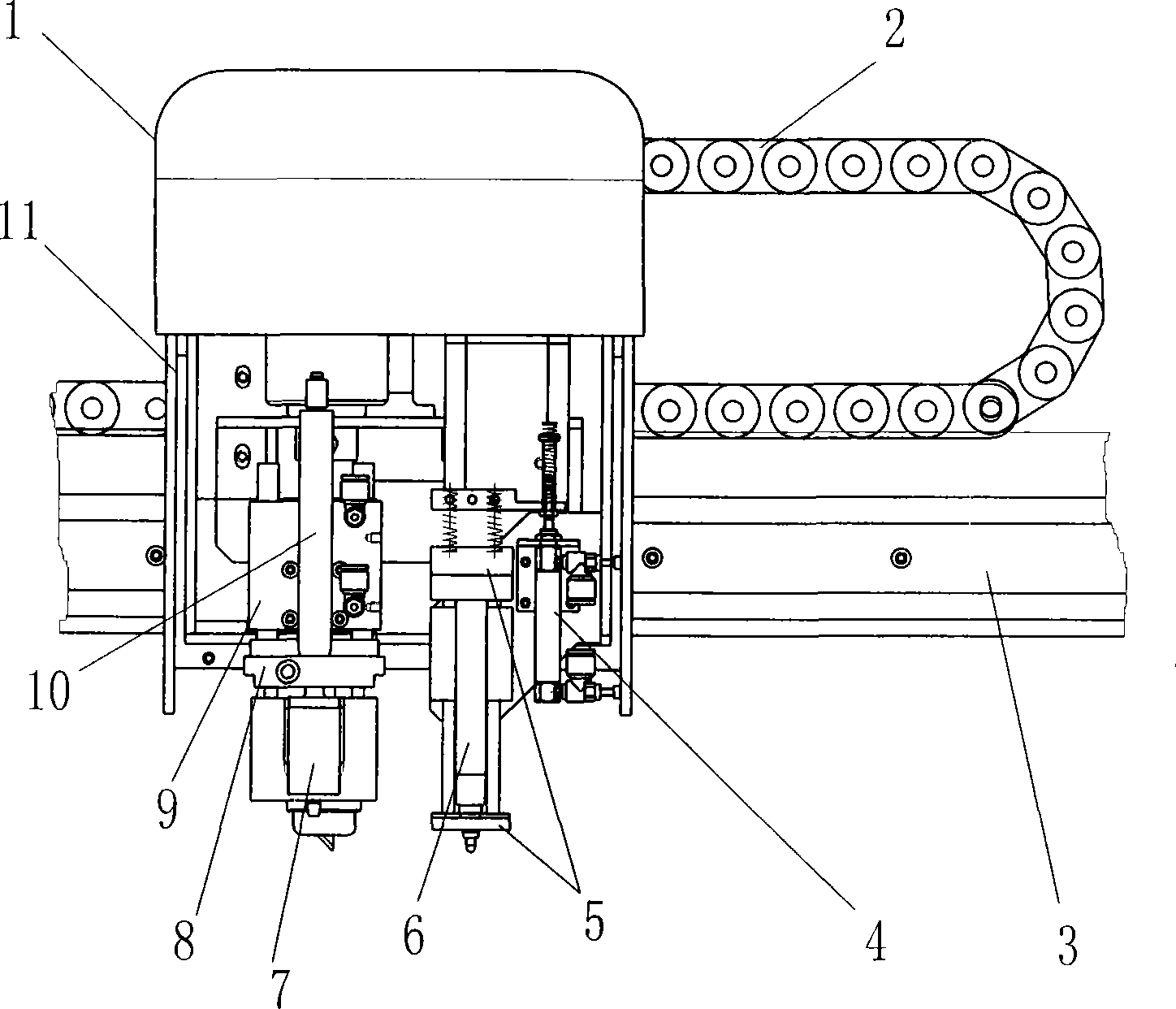

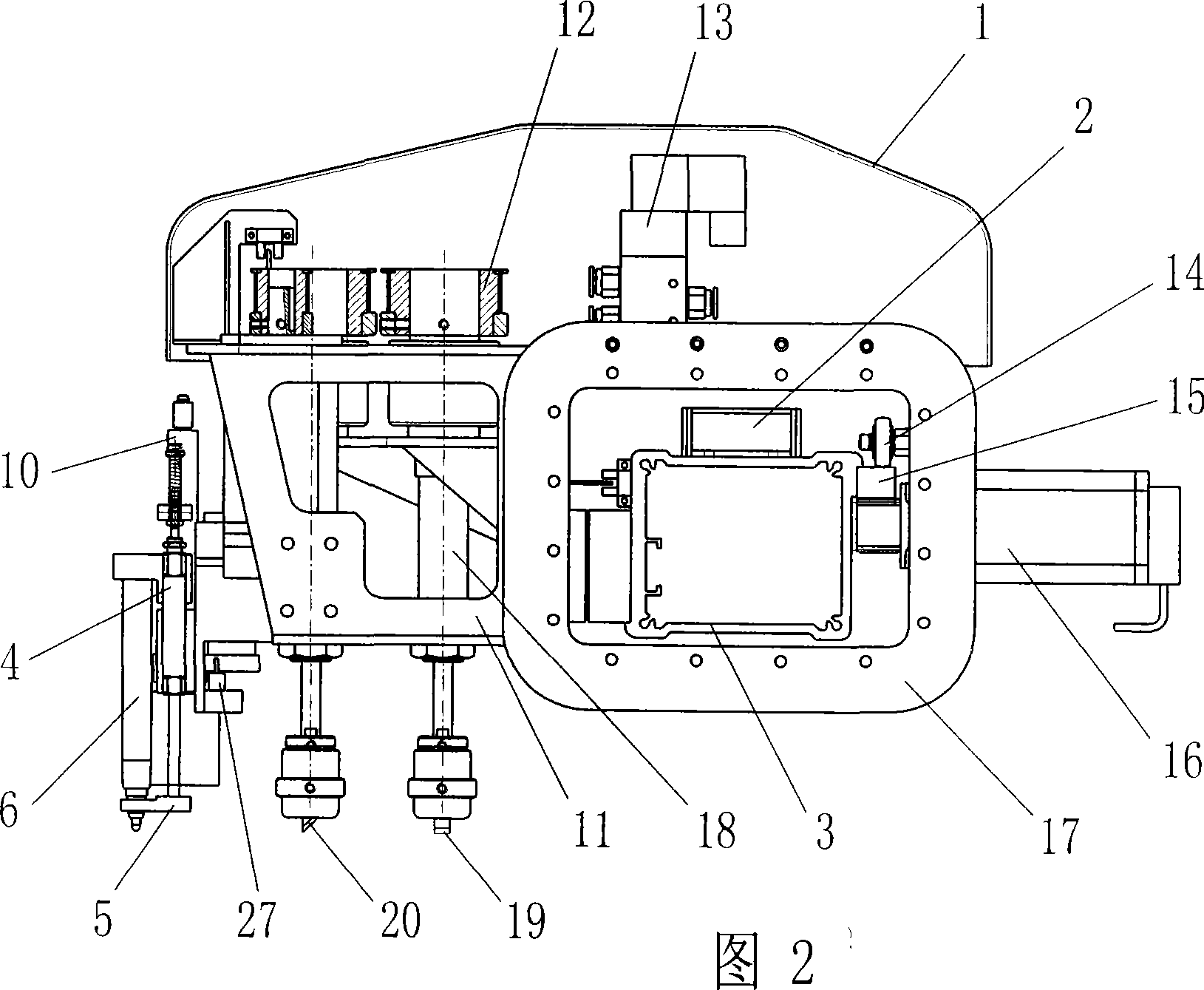

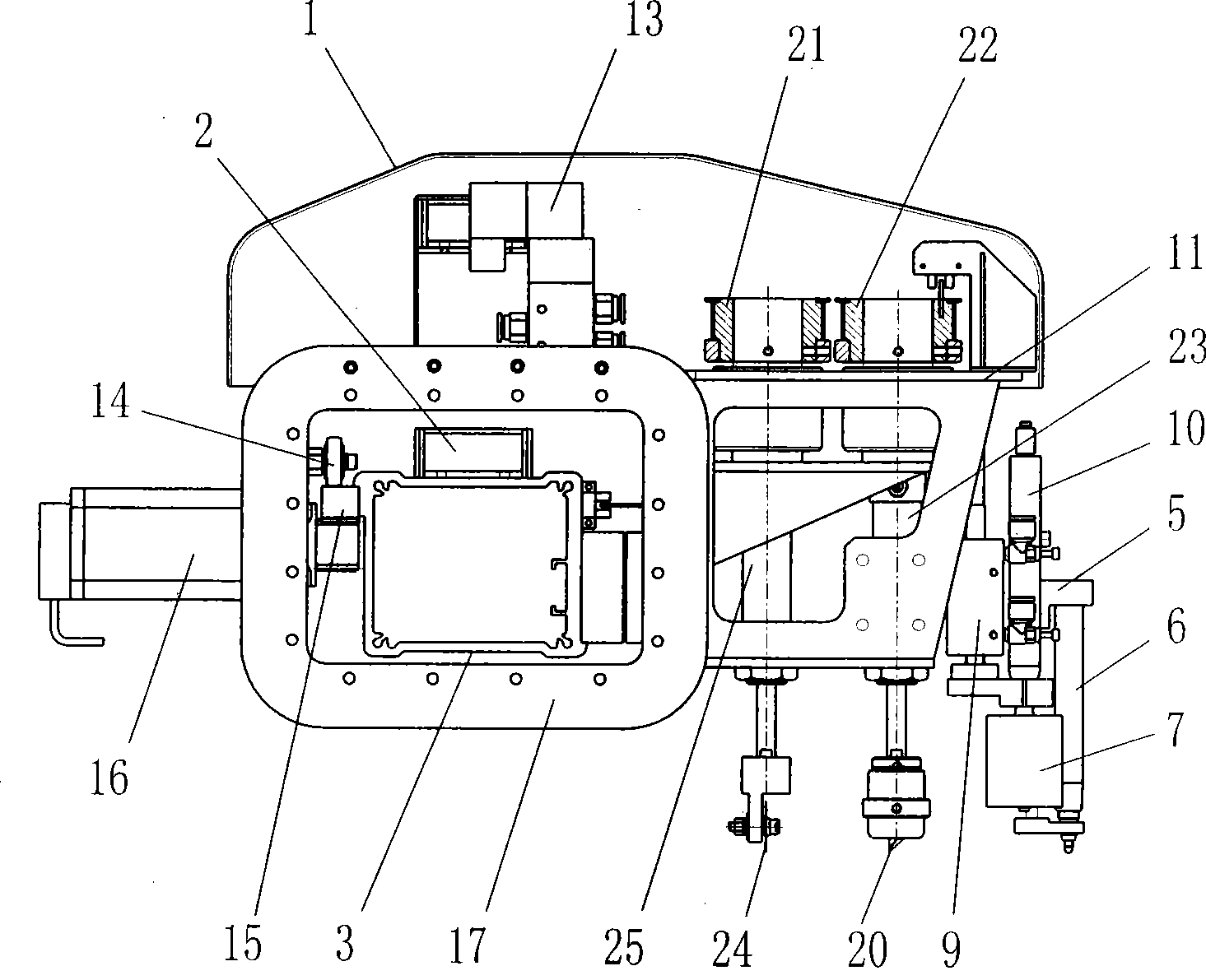

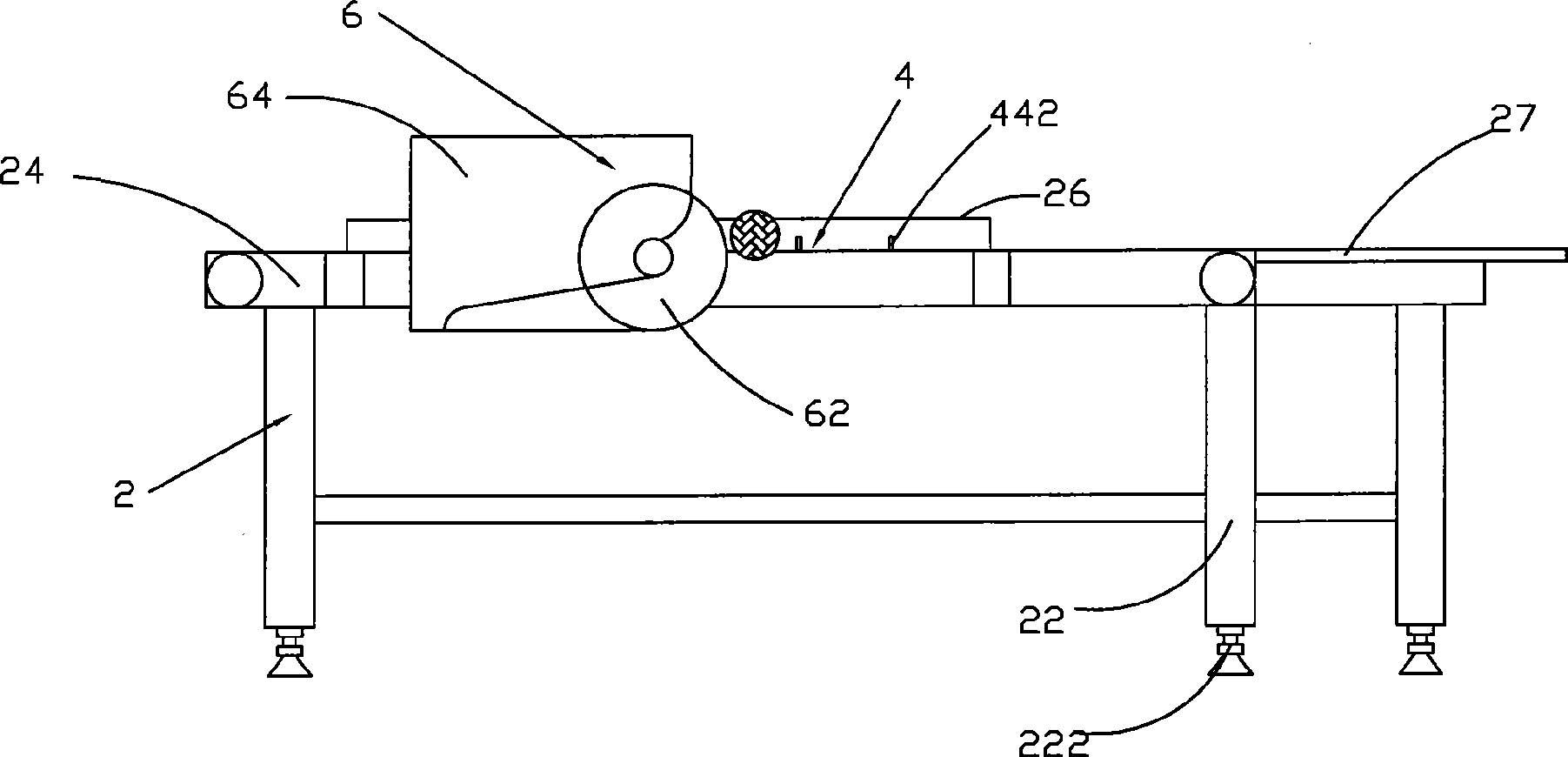

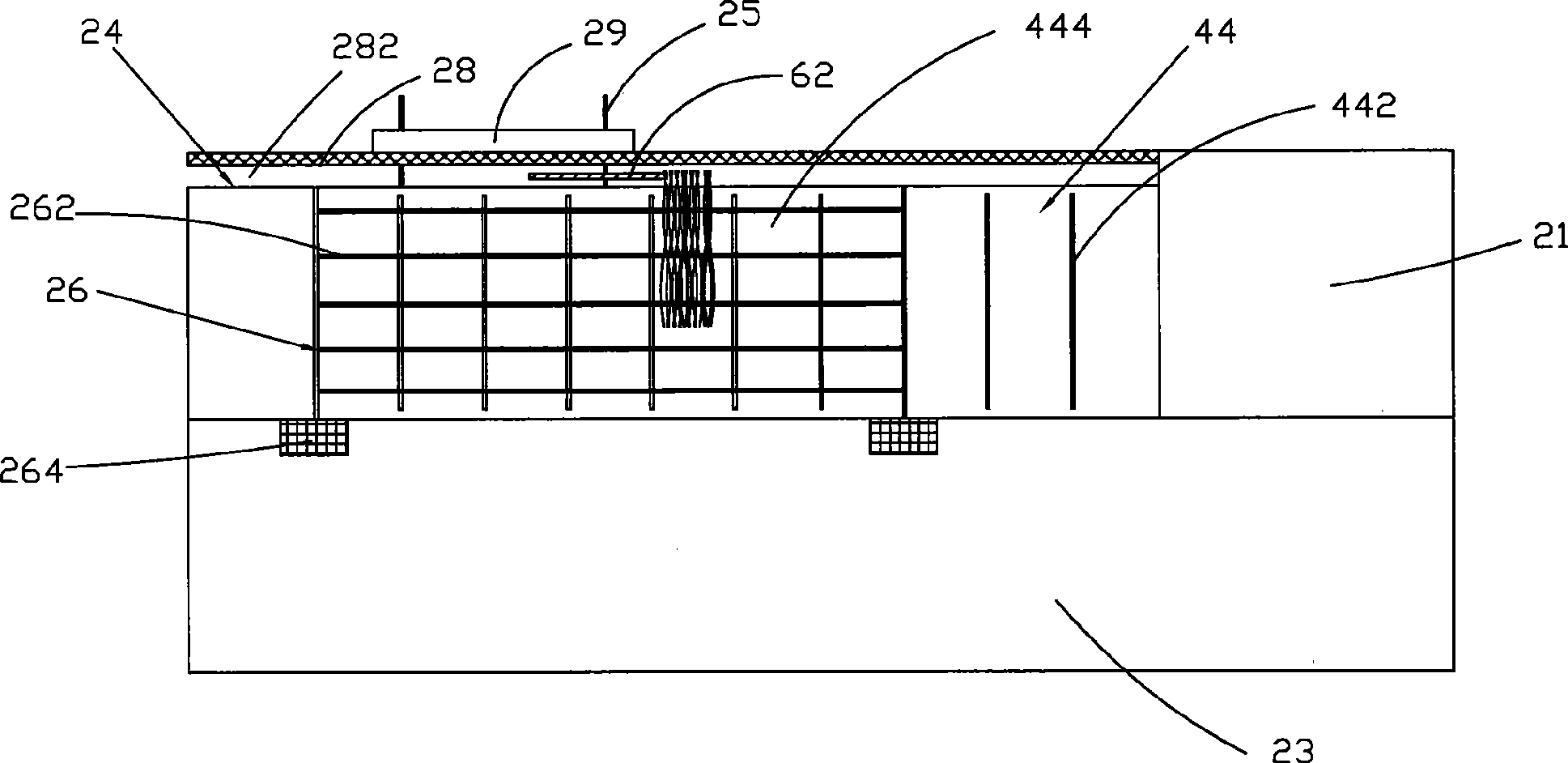

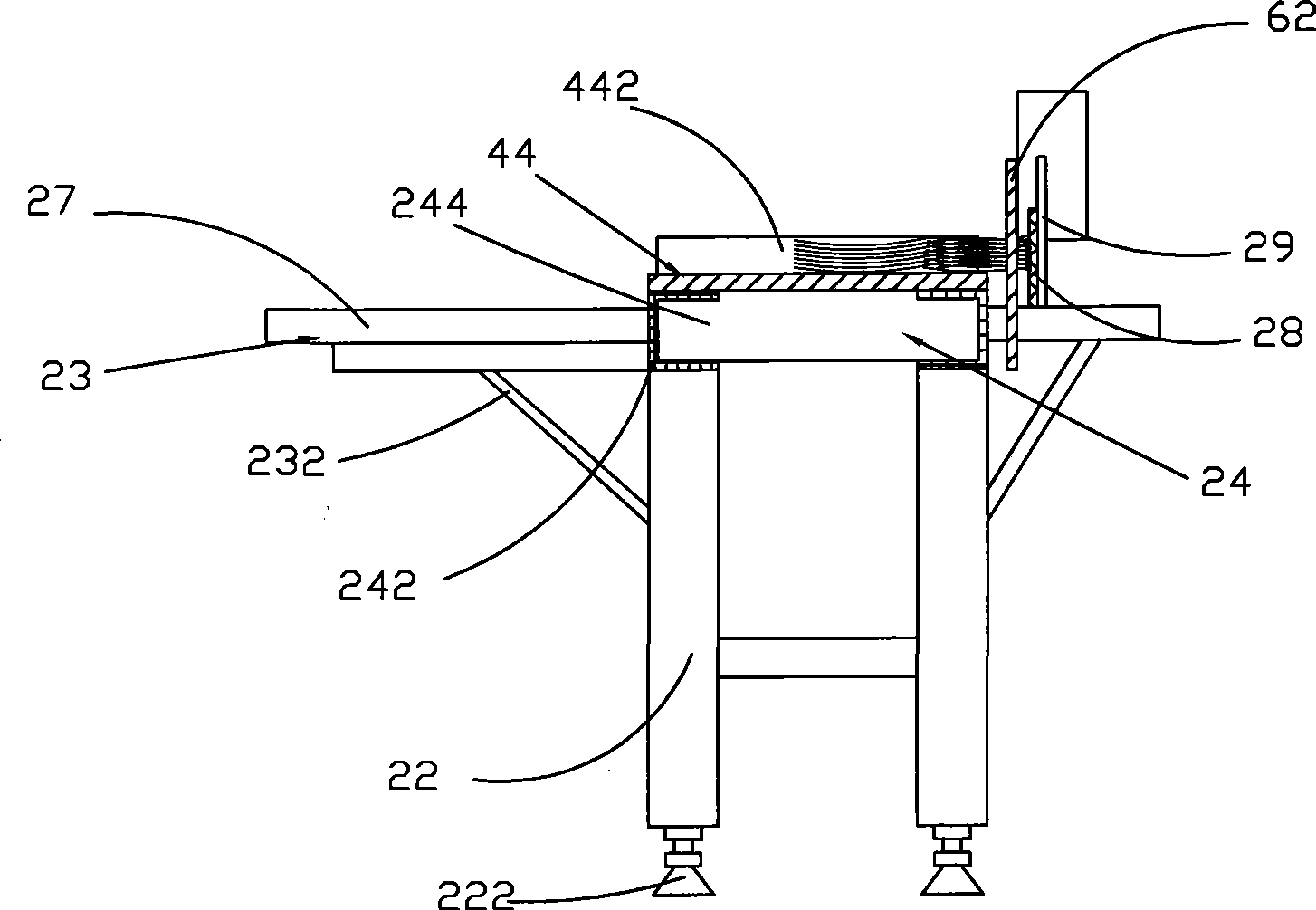

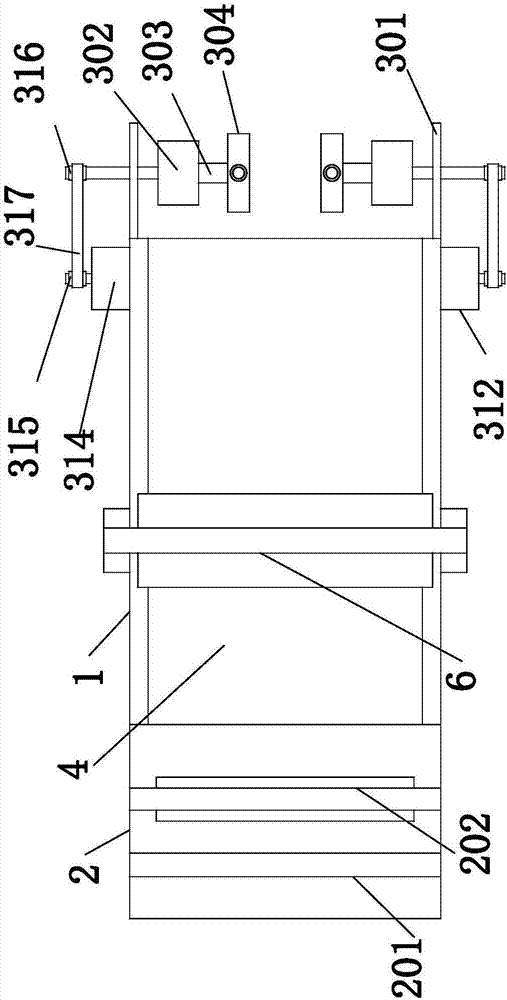

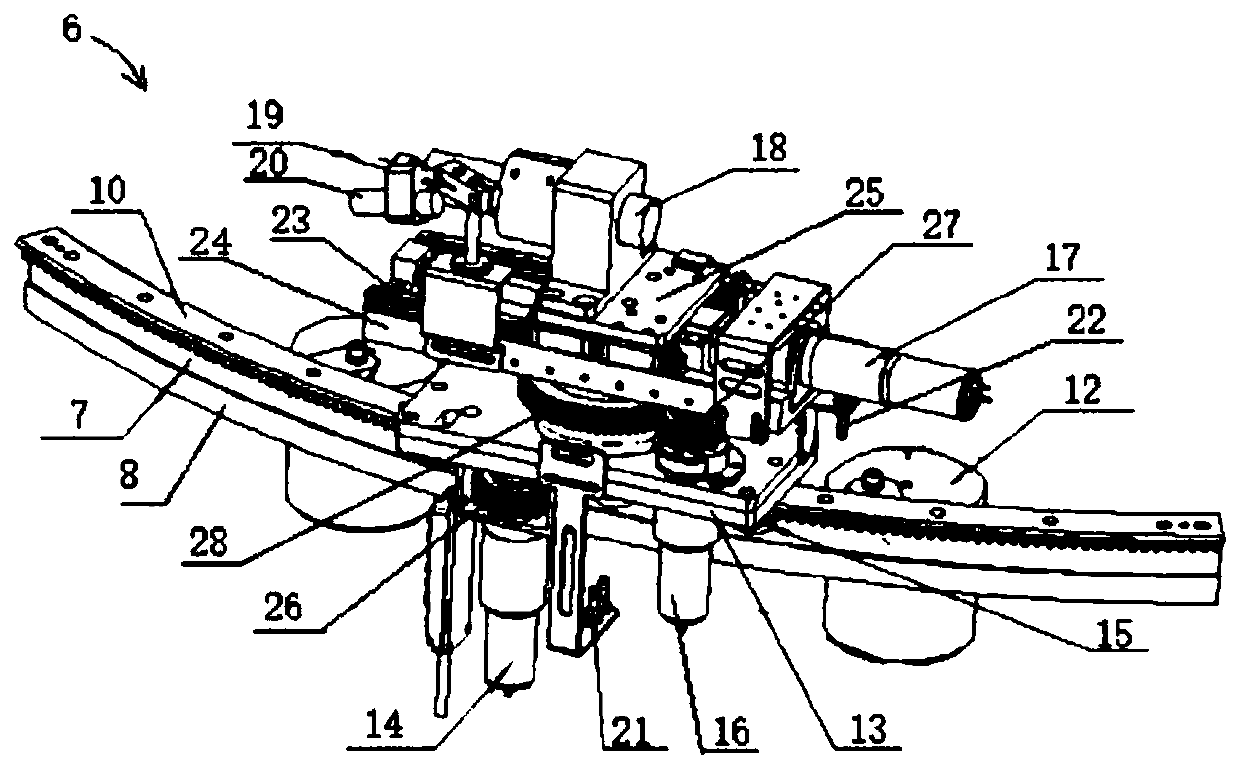

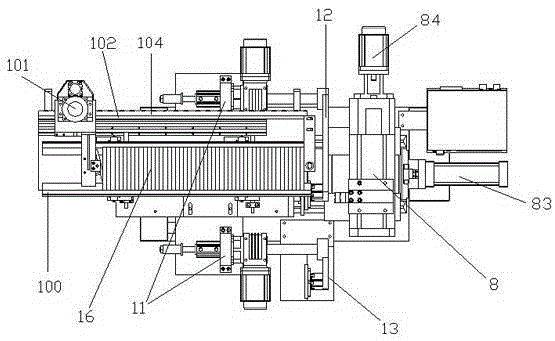

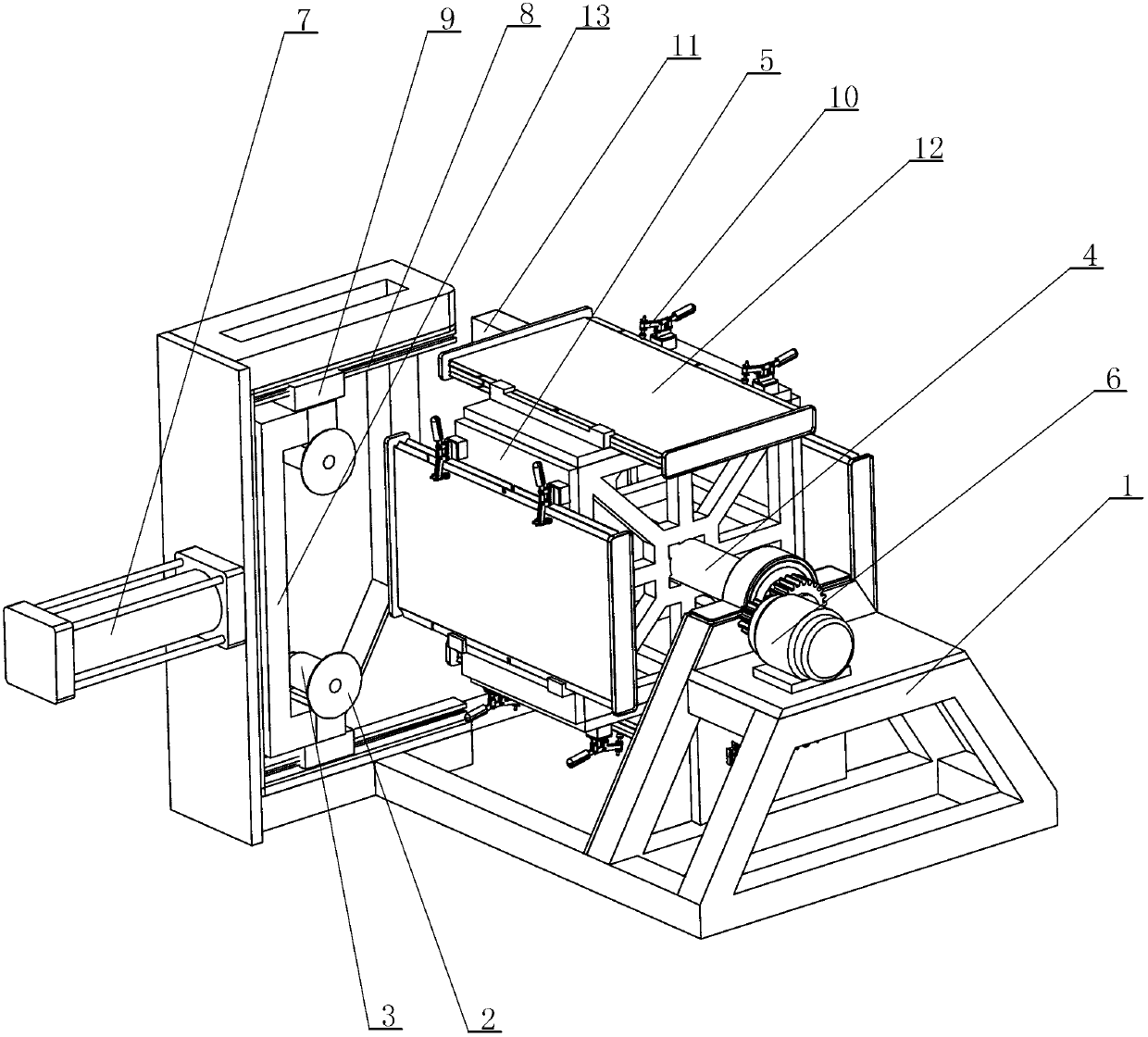

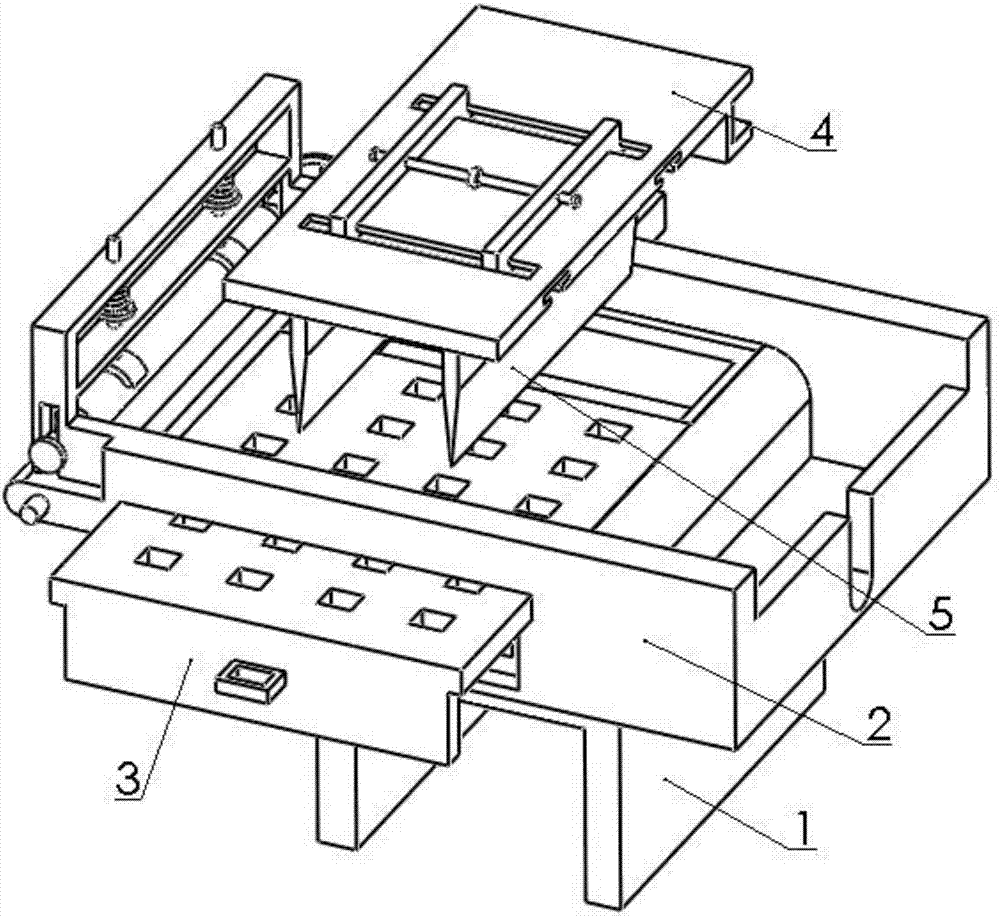

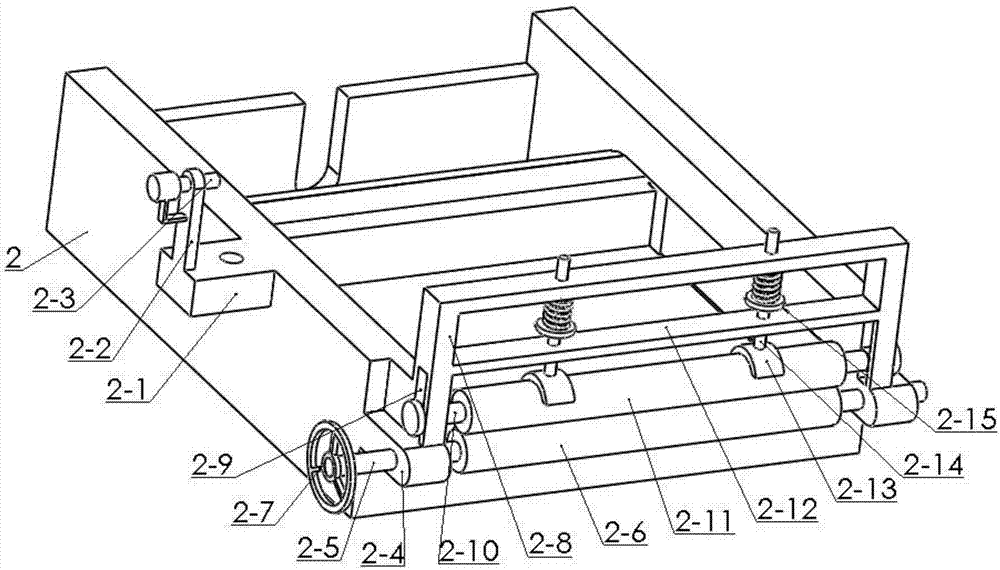

Pipe end cutting integrated machine

ActiveCN105537955ARealize automatic cuttingShorten the timeOther manufacturing equipments/toolsMetal working apparatusEngineeringMechanical engineering

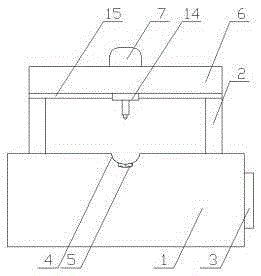

The invention discloses a pipe end cutting integrated machine. The integrated machine comprises a rack, a cutting mechanism, a chamfering mechanism, a pipe orifice machining mechanism and a detecting and discharging mechanism are sequentially arranged at one side of the rack, and a carrying mechanical hand mechanism is arranged on the rack and used for carrying a pipe from the cutting mechanism to the chamfering mechanism, then carrying the pipe from the chamfering mechanism to the pipe orifice machining mechanism, and then carrying the pipe from the pipe orifice machining mechanism to the detecting and discharging mechanism; a feeding mechanism used for conveying the pipe to the cutting mechanism is arranged at the other side of the rack, the pipe is fed by the feeding mechanism and cut by the cutting mechanism to the needed length, the cut pipe is chamfered by the chamfering mechanism, the chamfered pipe enters the pipe orifice machining mechanism so that a pipe orifice can be machined, and after pipe orifice machining is finished, the pipe is detected and discharged by the detecting and discharging mechanism. Cutting, chamfering, pipe orifice machining, detecting and discharging are automatically conducted on the pipe.

Owner:SUZHOU VEDETTE IND EQUIP CO LTD

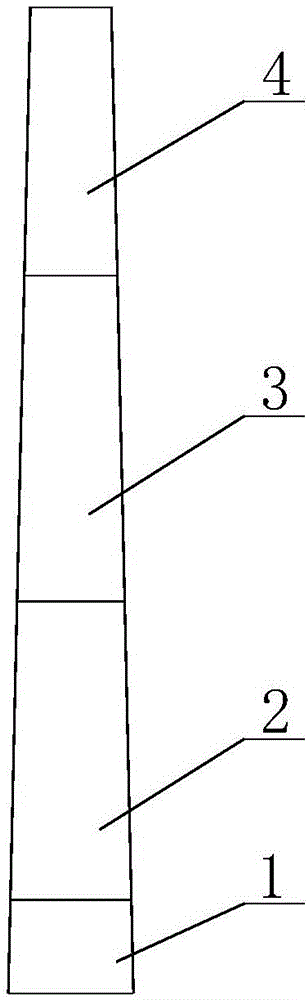

Method for manufacturing main body structure of wind turbine tower

InactiveCN106695252AImprove cutting efficiency and cutting qualityReduce labor intensityTowersWind energy generationManufacturing qualityQuality control

The invention relates to a method for manufacturing the main body structure of a wind turbine tower. The method comprises the steps: 1 cutting raw materials; 2 preparing grooves; 3 coiling shell rings; 4 welding longitudinal seams of the shell rings; 5 installing and welding the shell rings and flanges; 6 installing and welding circular seams of the shell rings of a shell; 7 inspecting a shell finished product. The method has the advantages of reasonable work procedure arrangement and strict quality control, can reduce labor intensity and improve the manufacture quality and efficiency.

Owner:CHINA THIRD METALLURGICAL GRP

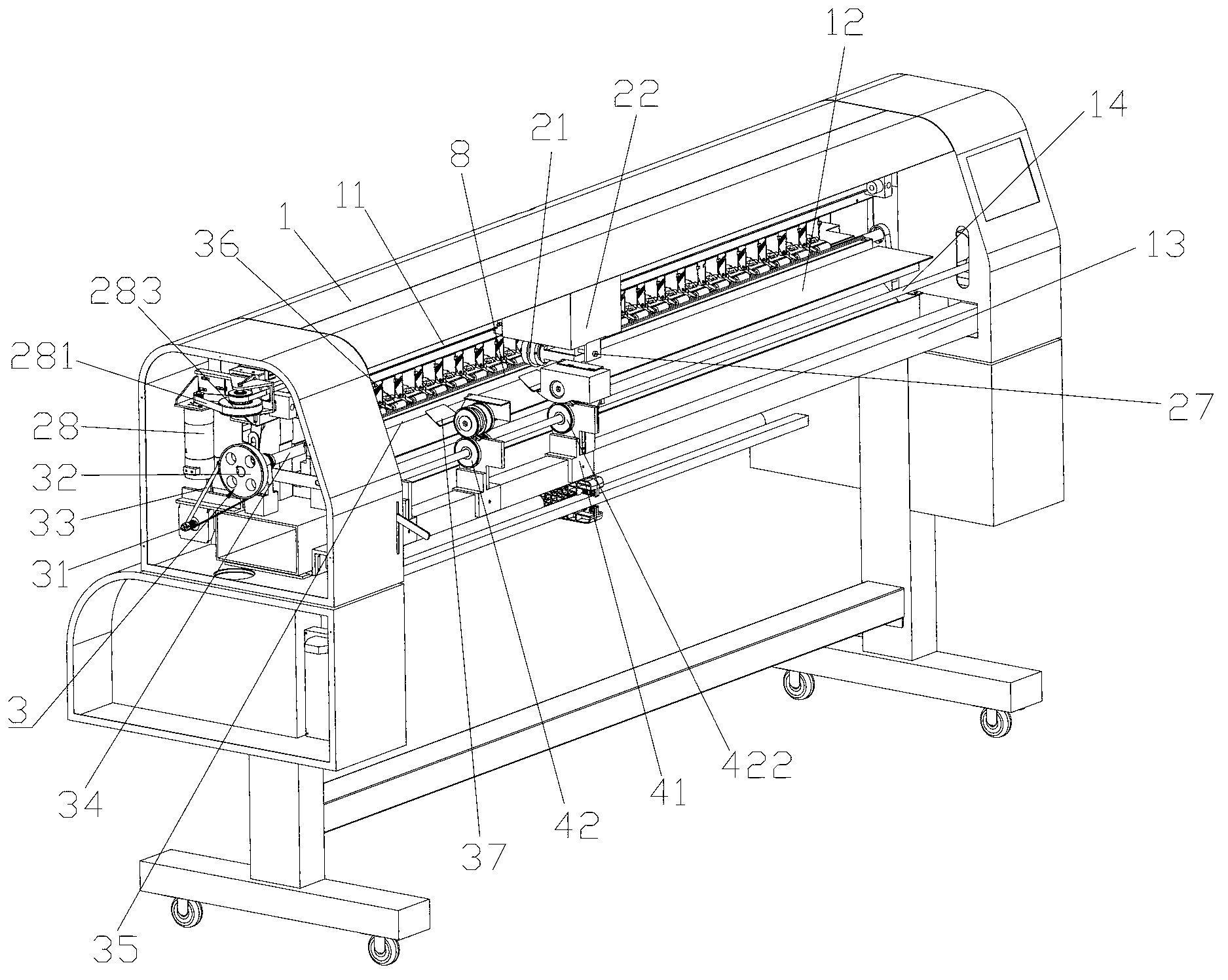

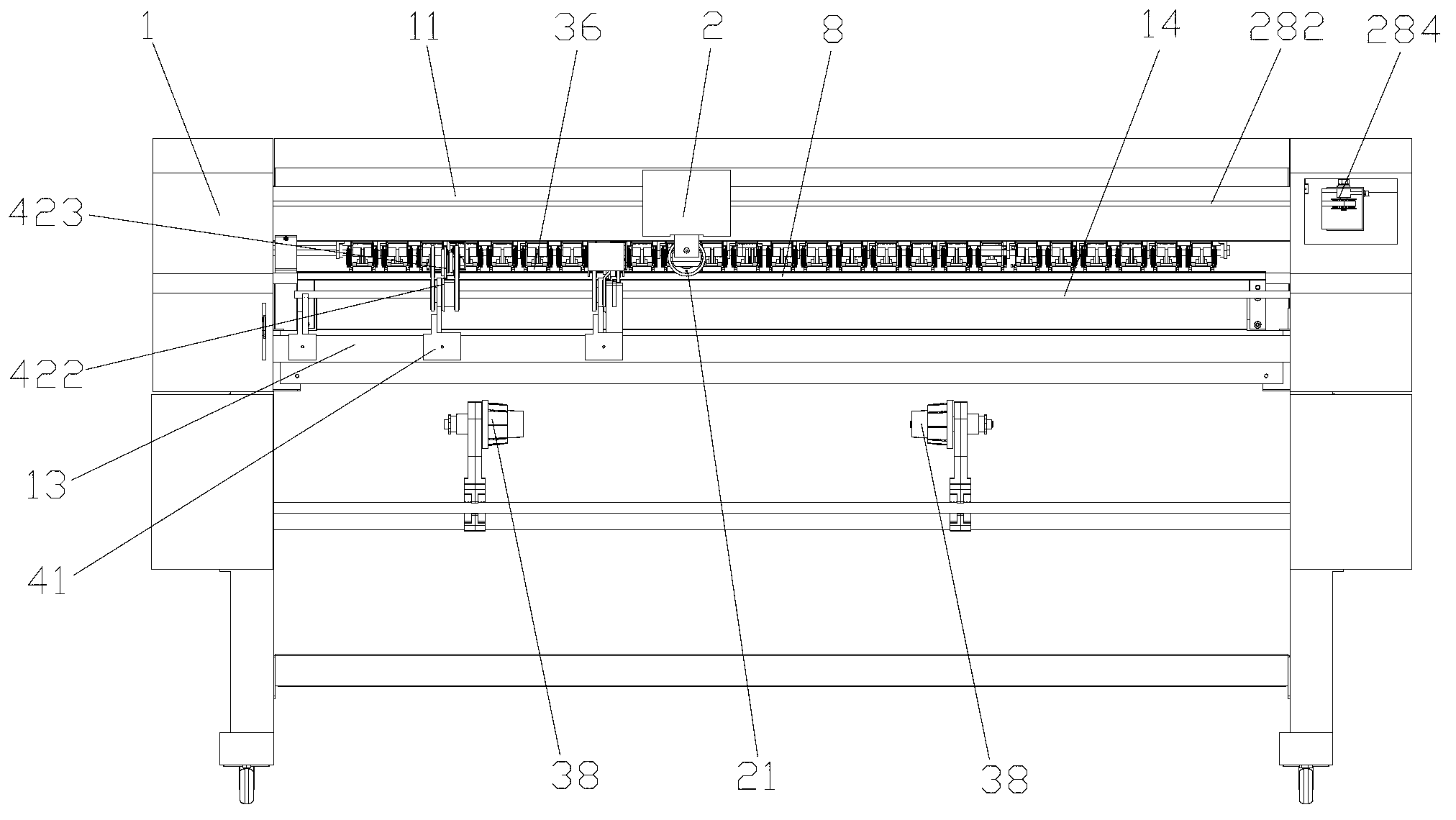

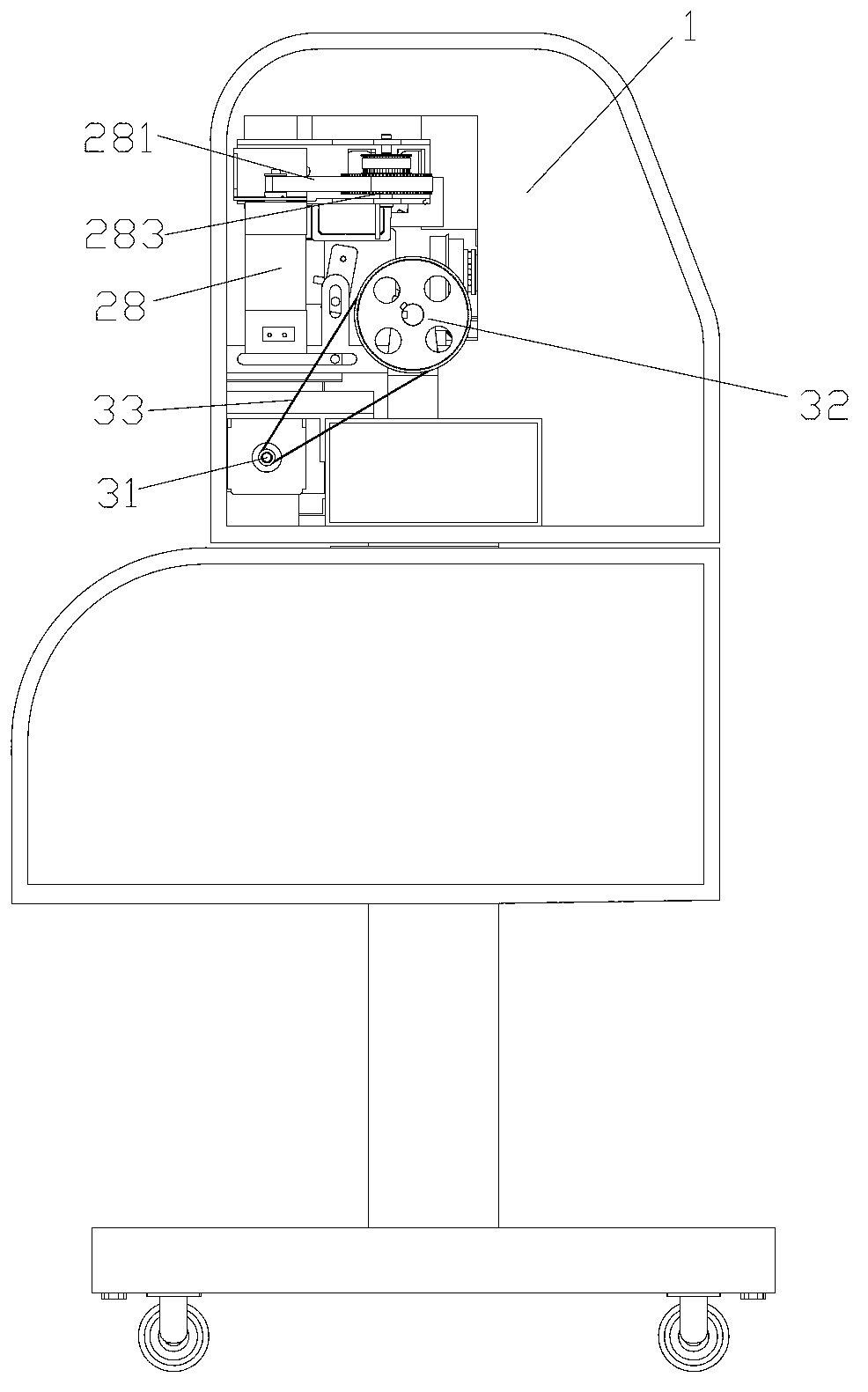

Cutting machine

InactiveCN103224160ARealize automatic cuttingMeet the needs of large-scale cuttingArticle deliveryMechanical engineeringEngineering

The invention discloses a cutting machine which is characterized by comprising a rack and a first cutting device, wherein the first cutting device comprises a first cutter; the first cutter can be mounted on the rack in a transversely reciprocating manner and cuts a medium when reciprocating transversely. According to the cutting machine, manual cutting for printed the medium in a conventional wide format print field is replaced, automatic cutting for the medium is realized, and large-scale cutting requirements can be met. Besides, the cutting machine can cut the medium transversely through the first cutting device, can also cut the medium longitudinally through a second cutting device, and can cut at least two perpendicular edges of the medium simultaneously in the same process.

Owner:广东欣宇机电自动化技术有限公司

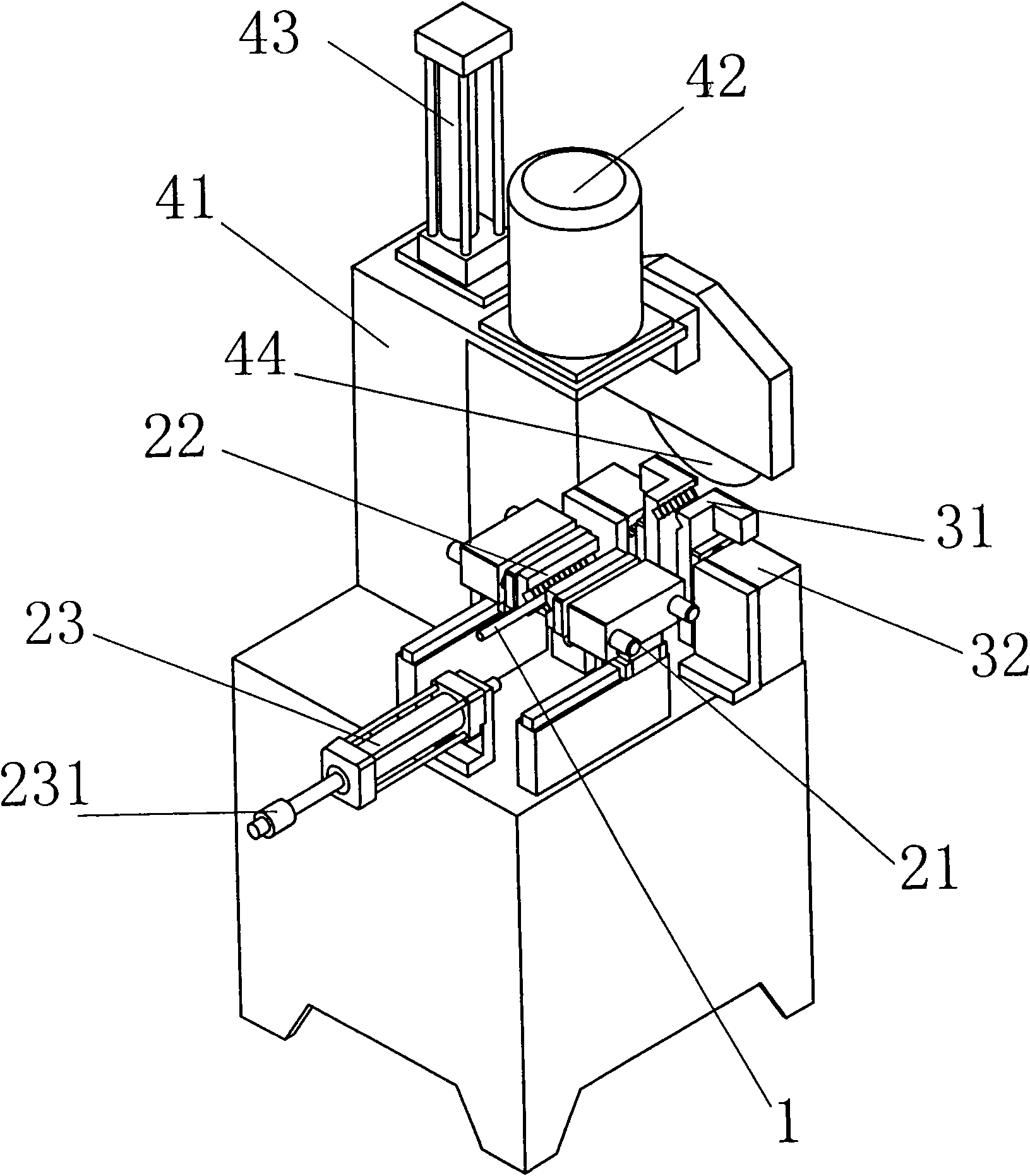

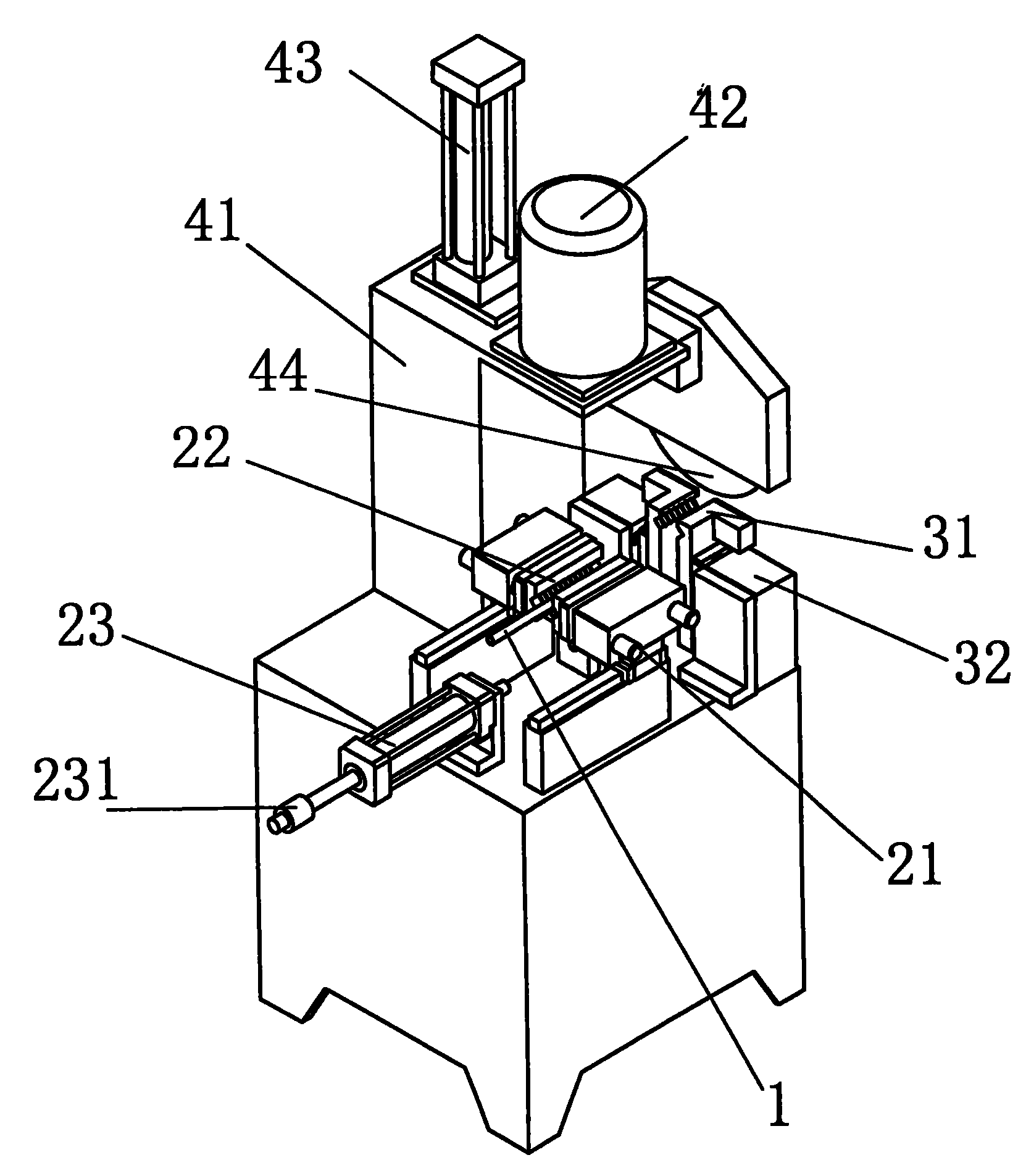

Device for automatically cutting pipe fitting

InactiveCN102009230ARealize automatic cuttingMetal sawing devicesMetal working apparatusPipe fittingEngineering

The invention relates to a device for automatically cutting a pipe fitting, which comprises a feeding mechanism, a clamping mechanism and a cutting mechanism, wherein the feeding mechanism comprises a sliding clamp die and a feeding cylinder, the sliding clamp die of a clamping pipe fitting is driven by a sliding clamping cylinder, and the feeding cylinder drives the sliding clamp die to slide; the clamping mechanism comprises a fixed clamp die and a fixed clamping cylinder, the fixed clamp die is capable of clamping the feeding mechanism to be fed to the pipe fitting, the fixed clamping cylinder drives the fixed clamp die to clamp the pipe fitting, and the fixed clamp die and the sliding clamp die are arranged in juxtaposition; and the cutting mechanism is located at the outer side of the fixed clamp die in juxtaposition and comprises an upright fixed seat, a main shaft head, a motor, a lifting oil cylinder and a saw blade, wherein the saw blade is fixed at the main shaft head and driven to rotate by the motor, the main shaft head is slidably fixed on the upright fixed seat through a sliding seat, and the sliding aiming at the pipe fitting is controlled by the lifting oil cylinder. In the invention, the operations, such as feeding, clamping, fixing, cutting, discharging, and the like of the pipe fitting can be automatically realized, and the processing efficiency of the pipe fitting is improved.

Owner:旭东机械(昆山)有限公司

Nursery stock grafting machine

The invention discloses a nursery stock grafting machine, comprising a rack, a caspica processing mechanism arranged at one side of the rack, a rootstock processing mechanism arranged at the other side of the rack and a grafting mechanism arranged in the middle of the rack. The nursery stock grafting machine of the invention can realize the operations of automatic cutting and automatic grafting and shaping of the caspica seedlings and the rootstock seedlings. On one hand, the production efficiency is improved, and on the other hand, the grafting survival rate is higher than that of the manual grafting.

Owner:HARBIN RES INST OF FORESTRY MACHINERY CHINA MIN OF FORESTRY

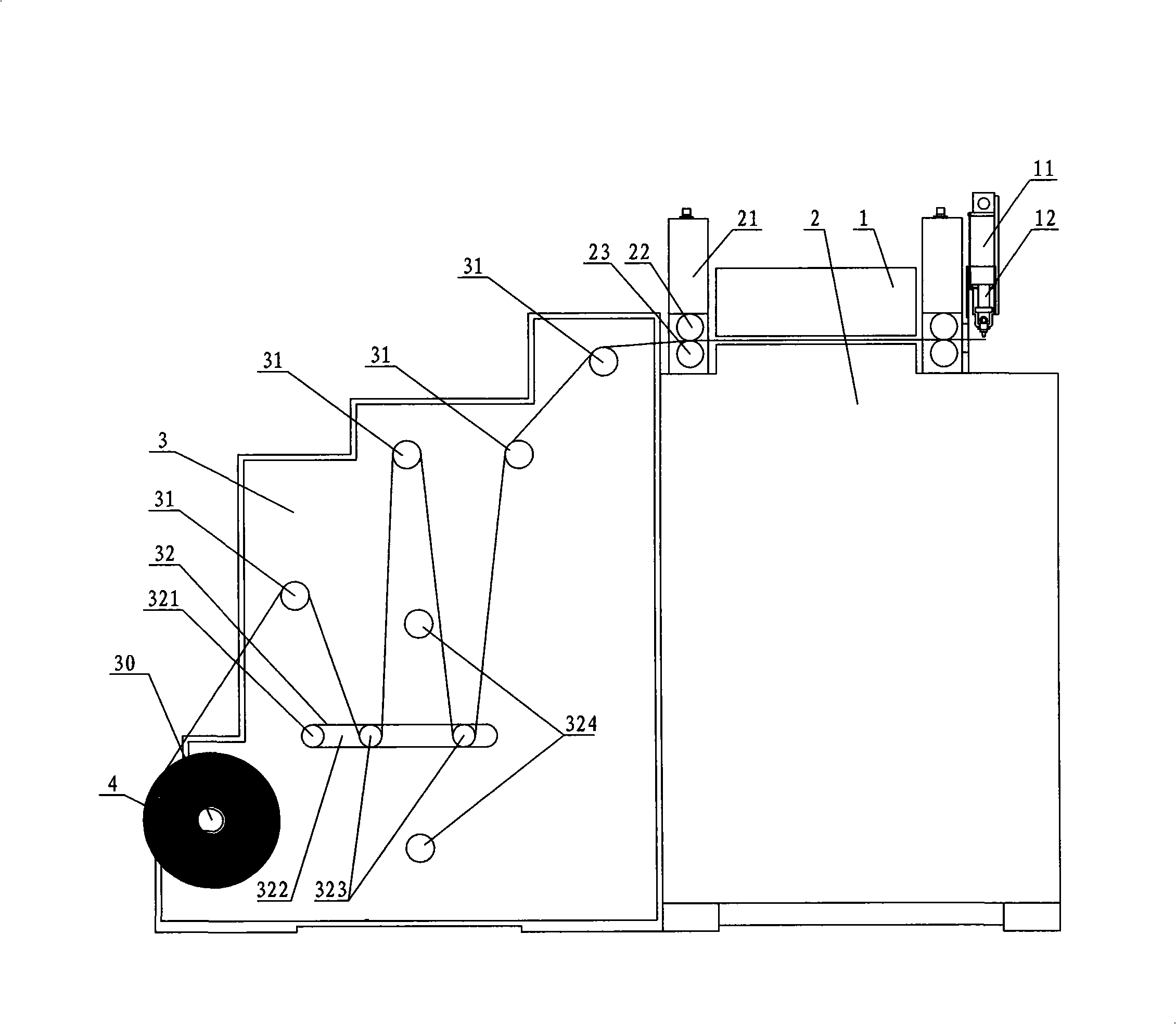

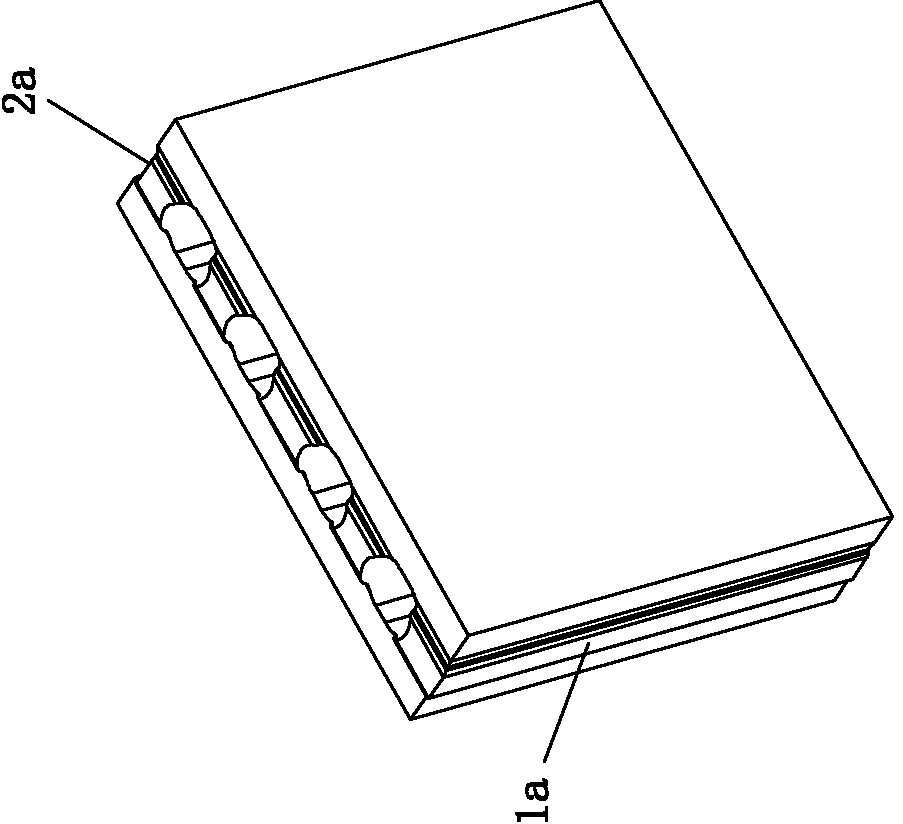

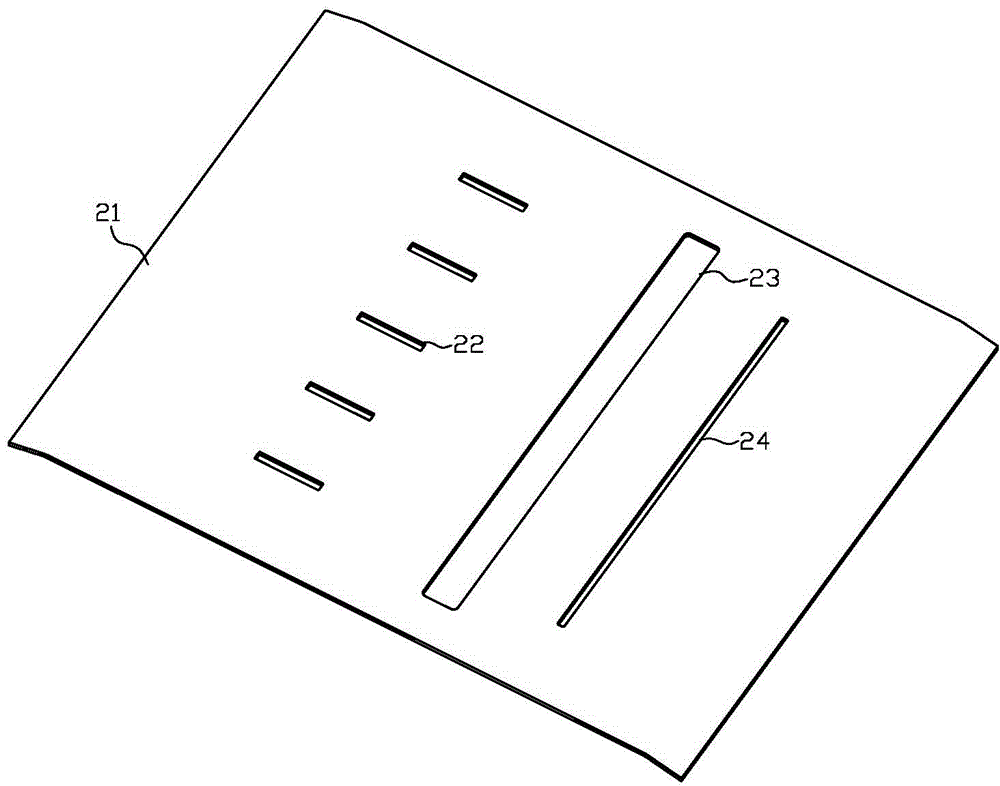

PP sheet cutting equipment and method thereof

ActiveCN101314194APrevent powderingRealize automatic cuttingWelding/soldering/cutting articlesLaser beam welding apparatusControl systemSheet film

The invention relates to PP film (prepreg film) cutting equipment and a method thereof. The cutting equipment comprises a main frame with a PP film transmission mechanism, a worktable arranged on the main frame, a feeding mechanism arranged on the upper stream of the worktable and a human-computer interaction interface control system. The worktable comprises a laser and a cutting head for receiving a laser beam output by the laser and forming a cutting light beam. Through the structure, the integral PP film laser cutting equipment is provided to avoid the phenomena of powder removal and silk removal in the cutting process, realize automatic cutting and reduce production cost.

Owner:HANS CNC SCI & TECH

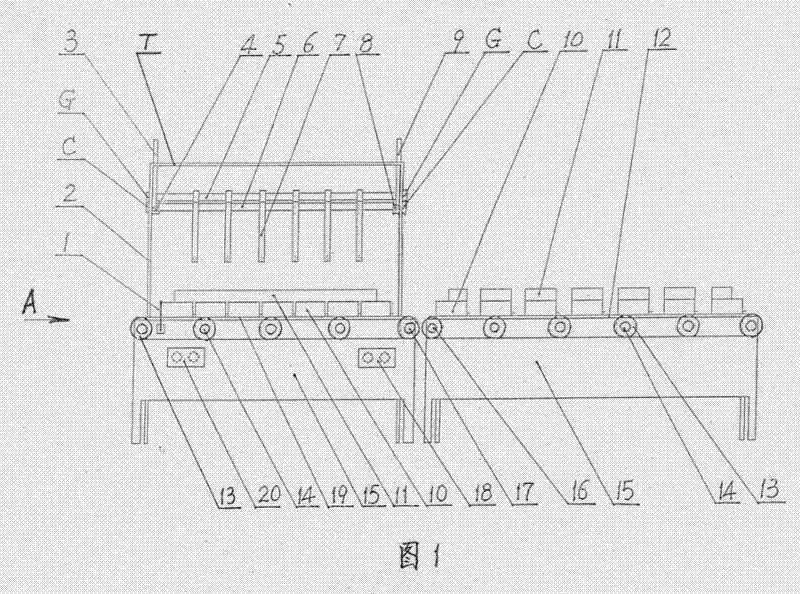

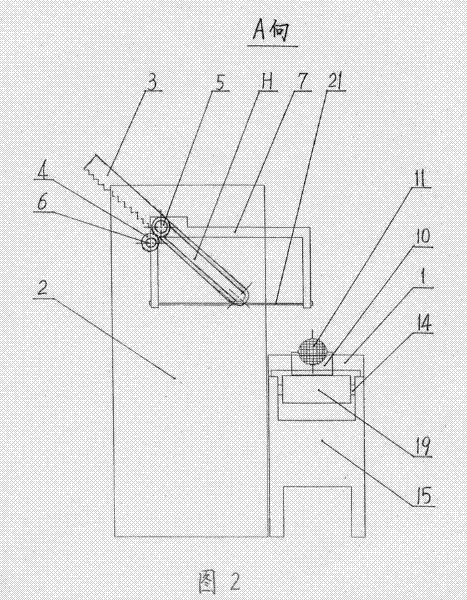

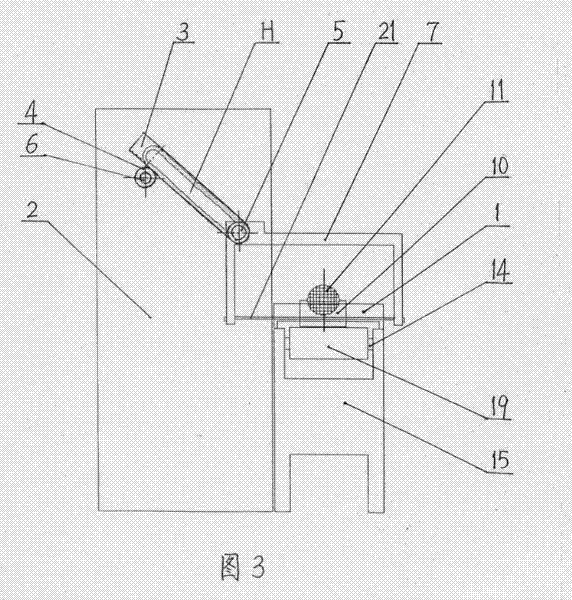

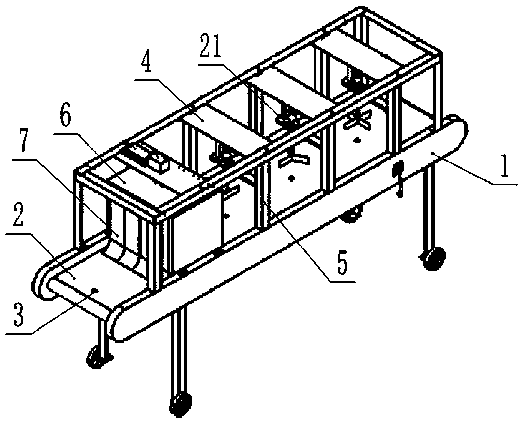

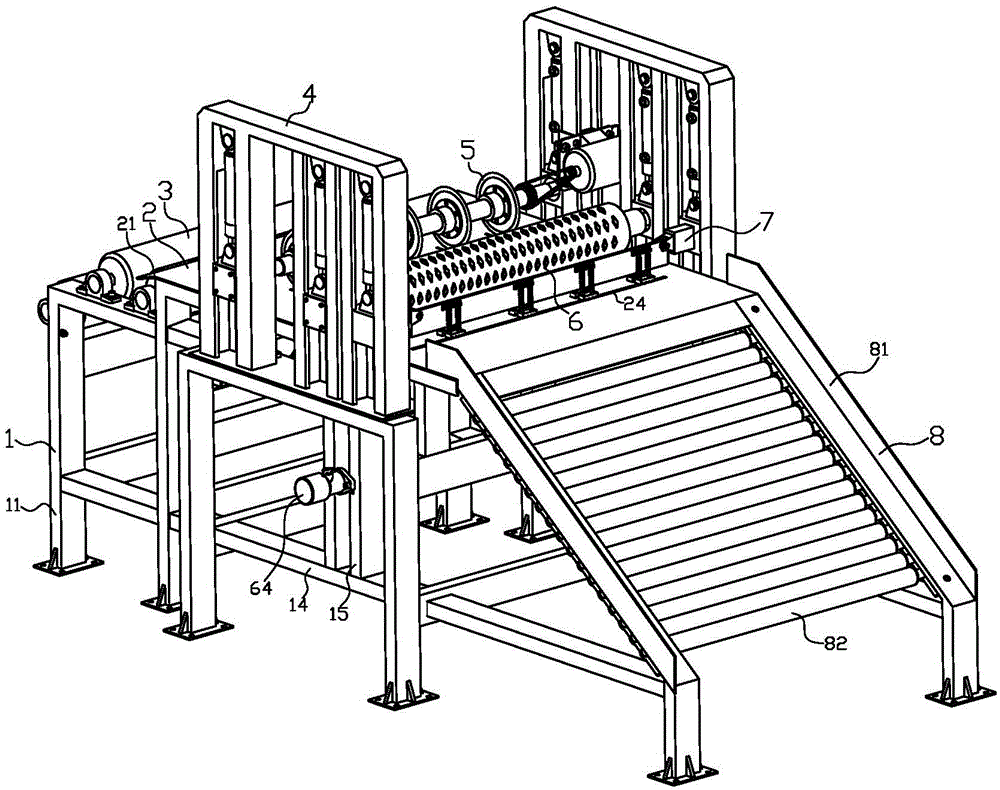

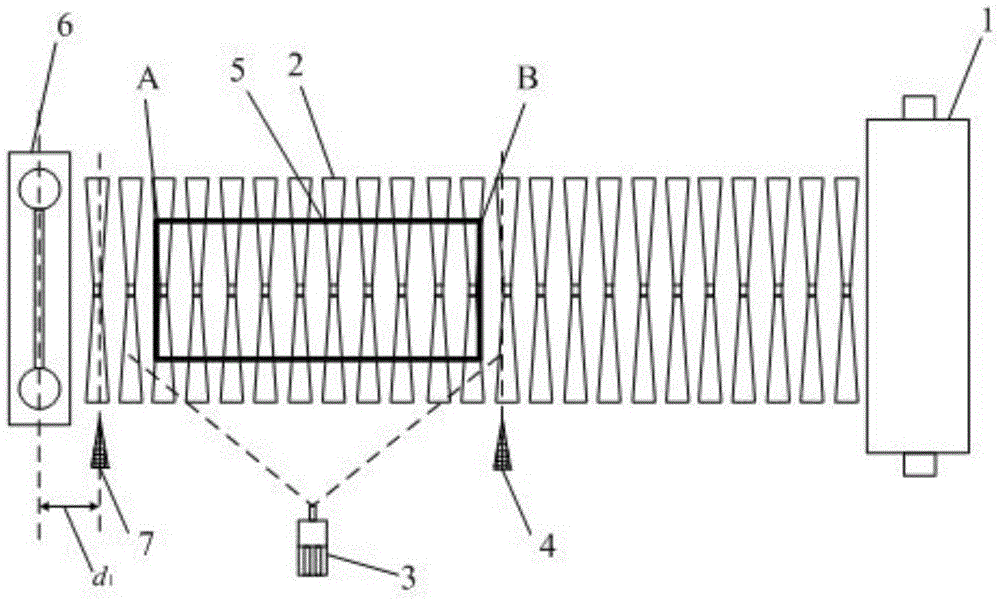

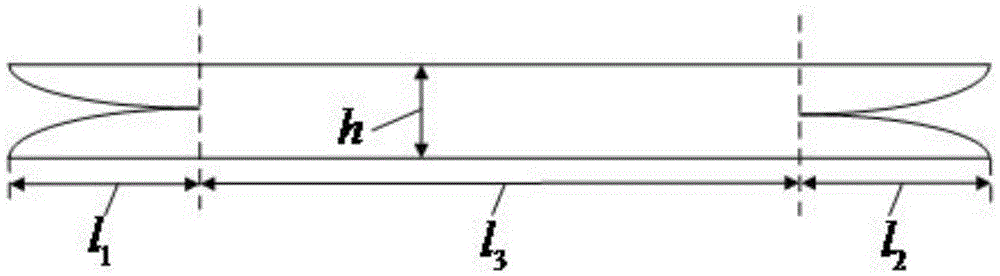

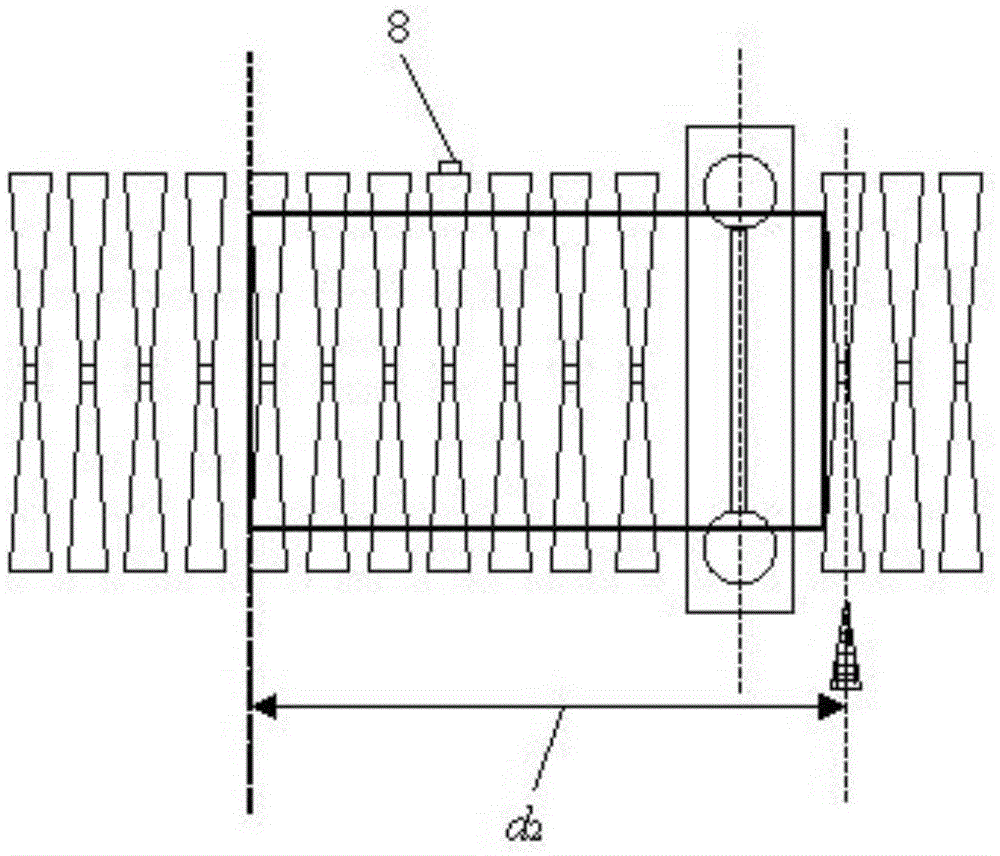

An automatic cutting and forming device for honeycomb ceramic wet blank

InactiveCN102267174ARealize automatic cuttingIncrease productionCeramic shaping apparatusConveyor beltMetal

An automatic honeycomb ceramic wet blank cutting and forming device is characterized in that a plurality of gantries (10) are arranged on a delivery working platform, a support (2) is arranged beside the delivery working platform, tool rests (7) are sheathed on a tool bar (5), two ends of the tool bar (5) are arranged in a slideway (H) of the support (2) at two ends, and a transmission rack (3) is arranged at the front end. A bearing (C) is sheathed at two ends of a drive rotation axle (6) and erected in shaft holes of the support (2) at two ends, a transmission gear (4) is sheathed at the front end and meshed with the transmission rack (3). A cutting motor (29) is started, the transmission gear (4) is driven by the drive rotation axle (6) to be meshed with the transmission rack (3), the tool bar (5) drives n tool rests (7) to slide down along the slideway (H), a metal wire blade (21) is embedded in gaps of the gantries (10), a cylindrical wet blank (11) is cut into n+1 sections, and the tool rests (7) return. A transmission motor (24) is started, and the gantries (10) are delivered to a fast conveyor belt (12) from a slow conveyor belt (19) and can be automatically separated off to take away the formed wet blank (11), thus being capable of cutting a plurality of wet blanks (11) at a time.

Owner:GAOTANGSHENG LIANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

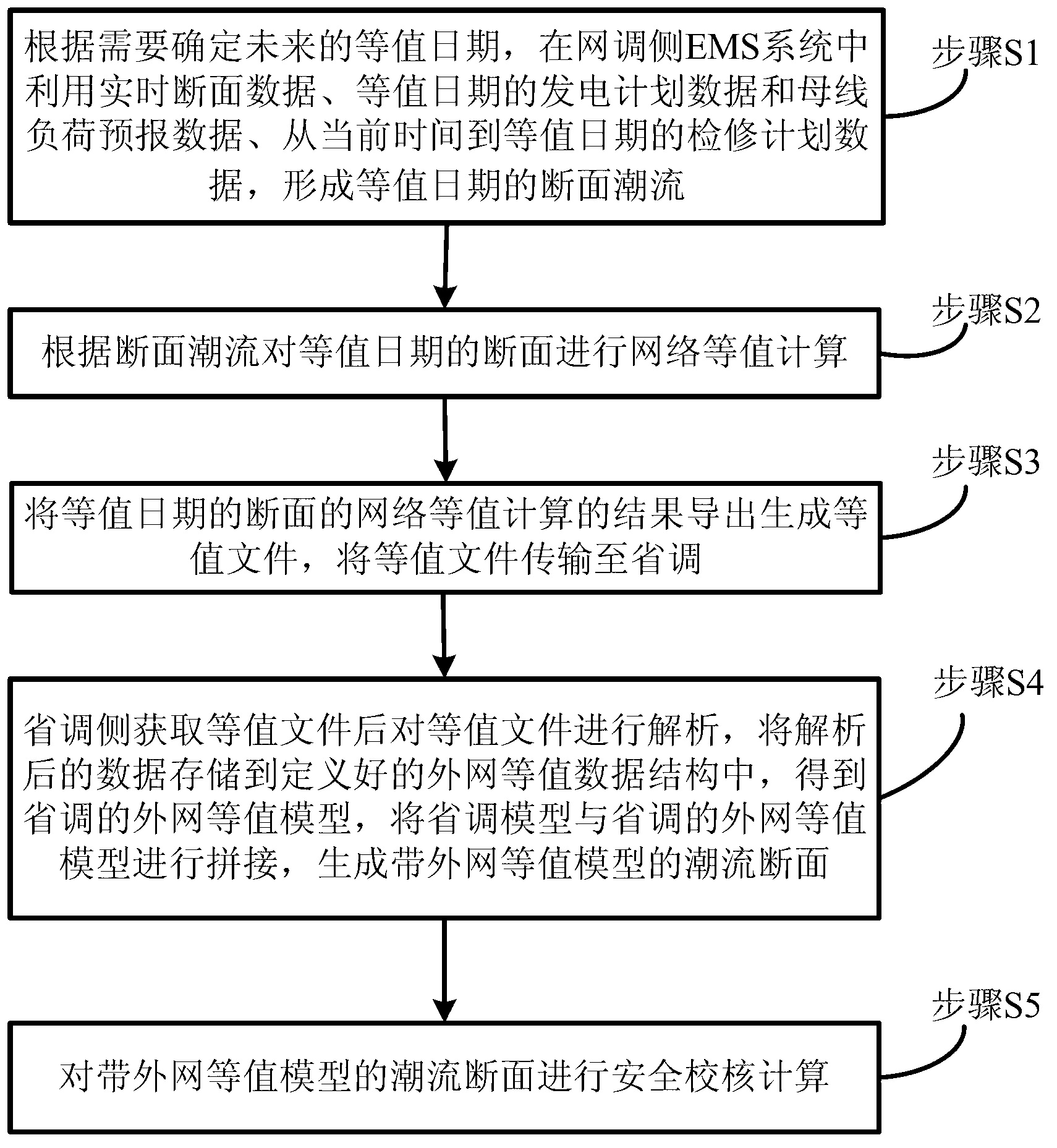

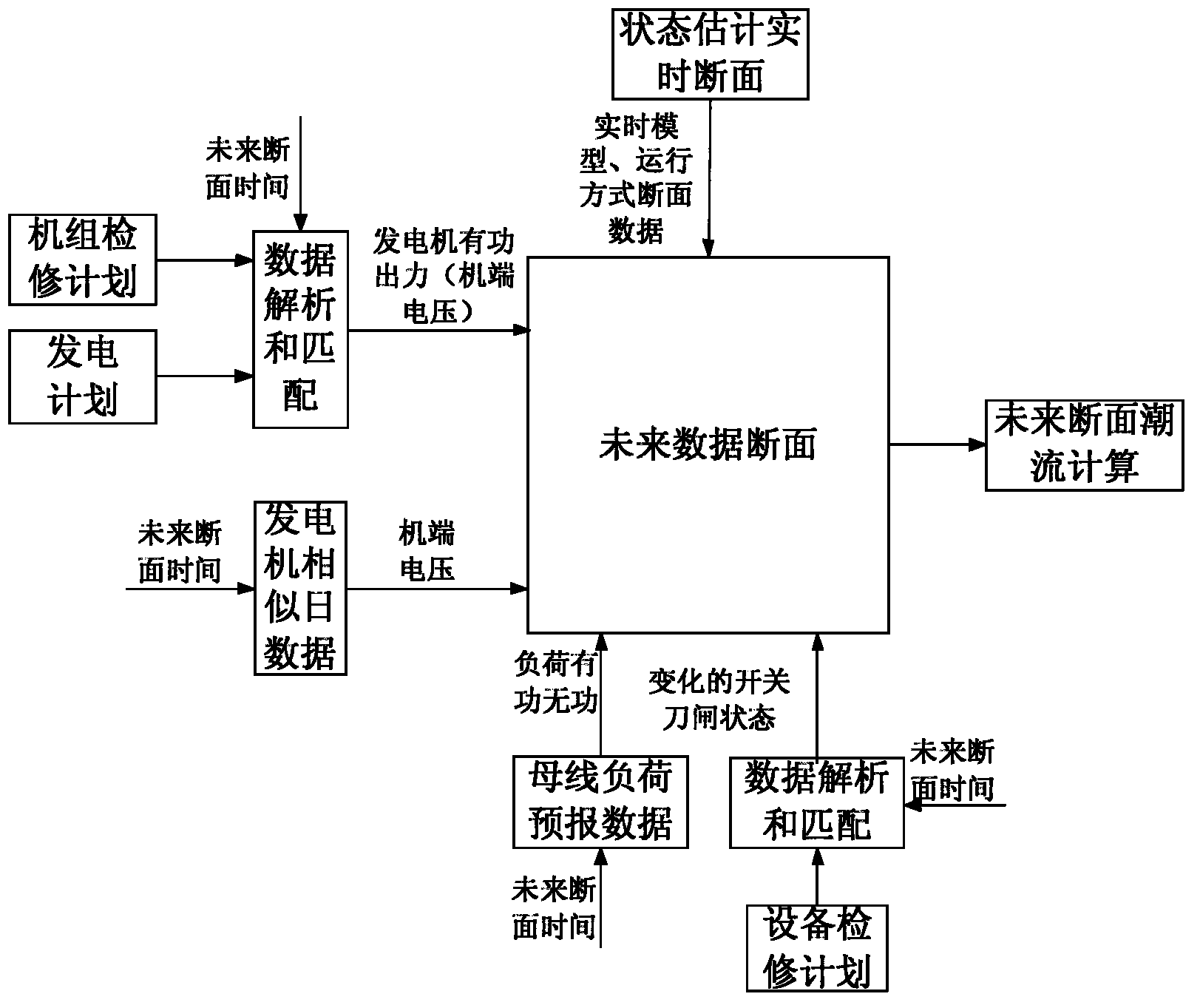

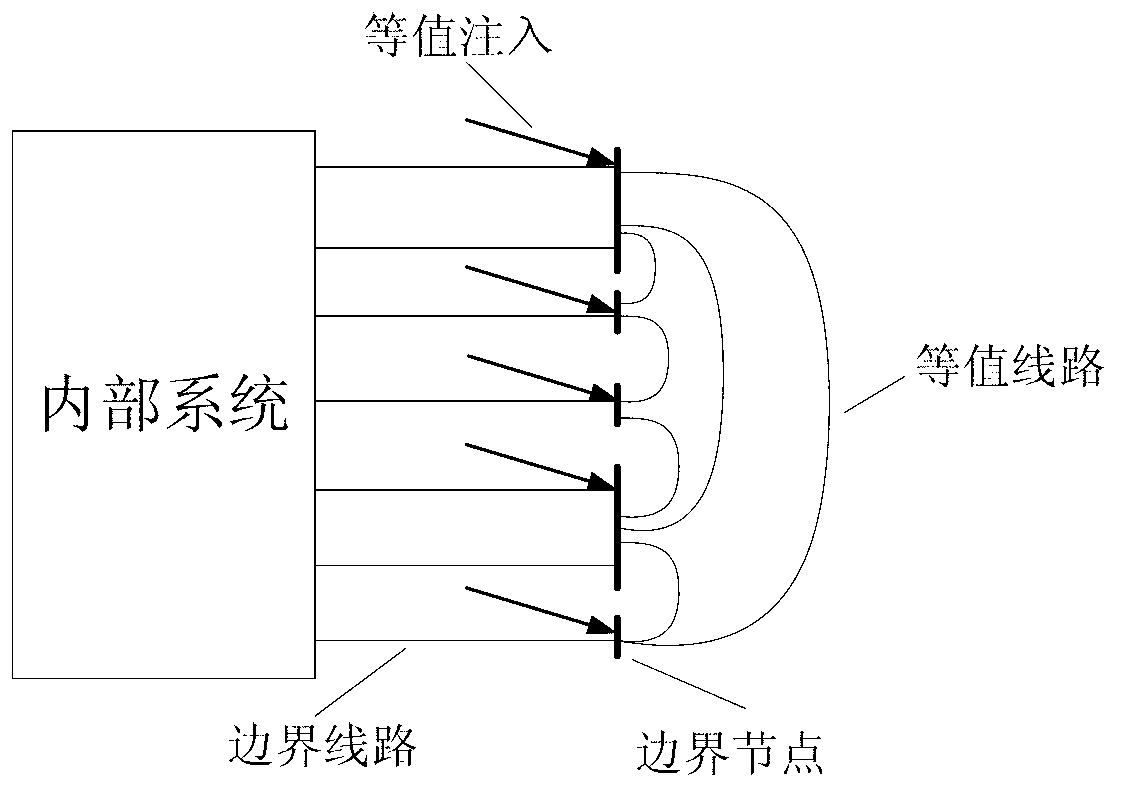

Safety checking method for power system

ActiveCN103077480AImprove accuracyImprove rationalityData processing applicationsPower flowParallel computing

The invention provides a safety checking method for a power system. The method comprises the following steps of: S1, determining a further equivalence date as required, and forming interface power flow of the equivalence date on a network scheduling side; S2, performing network equivalence calculation on the section of the equivalence date according to the interface power flow; S3, deriving the result of the network equivalence calculation on the section of the equivalence date to generate an equivalence file, and transmitting the equivalence file to provincial scheduling; S4, obtaining the equivalence file on a provincial scheduling side, resolving the equivalence file, storing resolved data into a defined outer net equivalence data structure to obtain an outer net equivalence model of the provincial scheduling, and splicing a provincial scheduling model with the outer net equivalence model of the provincial scheduling to generate a power flow section provided with the outer net equivalence model; and S5, performing safety checking calculation on the power flow section provided with the outer net equivalence model generated in the S4. Safety checking is performed in comparison to a use history and the current outer net equivalence model, so that the accuracy of an obtained result is increased greatly.

Owner:CHINA ELECTRIC POWER RES INST +1

Automatic abrasive wheel cutting machine

InactiveCN101797712AAchieve feedRealize automatic cuttingGrinding machinesGrinding/polishing safety devicesHydraulic cylinderEngineering

The invention discloses an automatic abrasive wheel cutting machine. In the technical scheme, one end of a beam is connected with a working table through a fixed hinge pair, the other end of the beam is provided with an abrasive wheel shaft assembly and an abrasive wheel, a motor is fixed on the end of the beam connected with the working table through the fixed hinge pair and drives the abrasive wheel to rotate, the middle part of the beam is connected with a hydraulic cylinder or a pneumatic cylinder through a fixed hinge, and a throttle valve used for regulating a feeding speed is arranged at the outlet of the hydraulic cylinder or the pneumatic cylinder through a hose. Since the hydraulic cylinder or the pneumatic cylinder is used as the kinetic damping of the abrasive wheel, the uniform and automatic cutting can be realized. A cooling pump is arranged on a water tank, and part cooling and dedusting can be realized through the cooling pump and spray of a water pipe. During cutting, the abrasive wheel can move downwards under the effect of gravity, and the cutting speed can be regulated through adjusting the opening of the throttle valve. After cutting, the beam can be lifted to reset the abrasive wheel, thereby completing the cutting. The invention has the advantages of simple structure, energy conservation, economical and practical use, low pollution and controllable cutting speed, and can realize the automatic cutting of different metal parts.

Owner:HEBEI AGRICULTURAL UNIV.

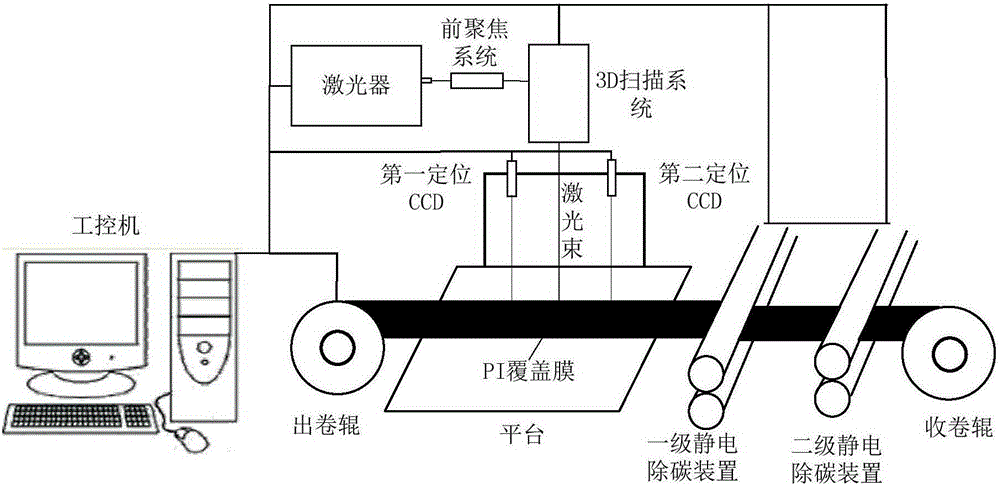

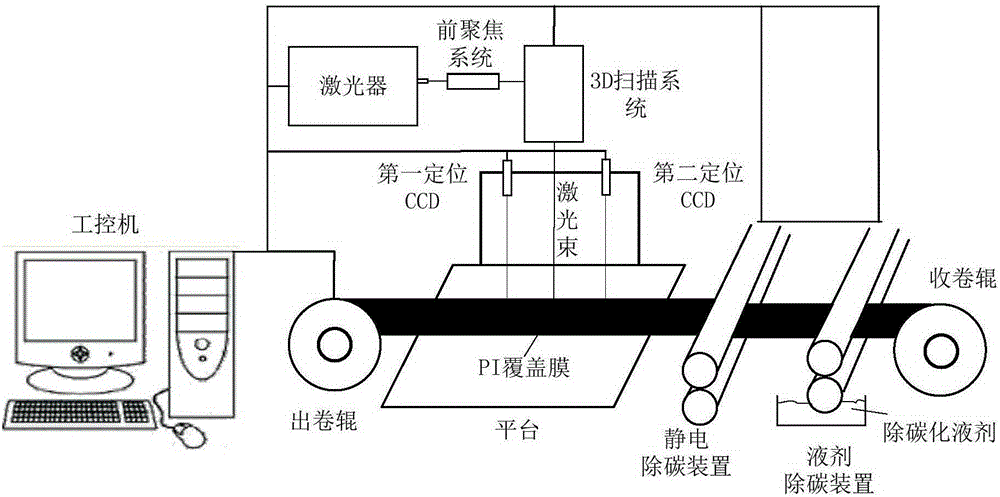

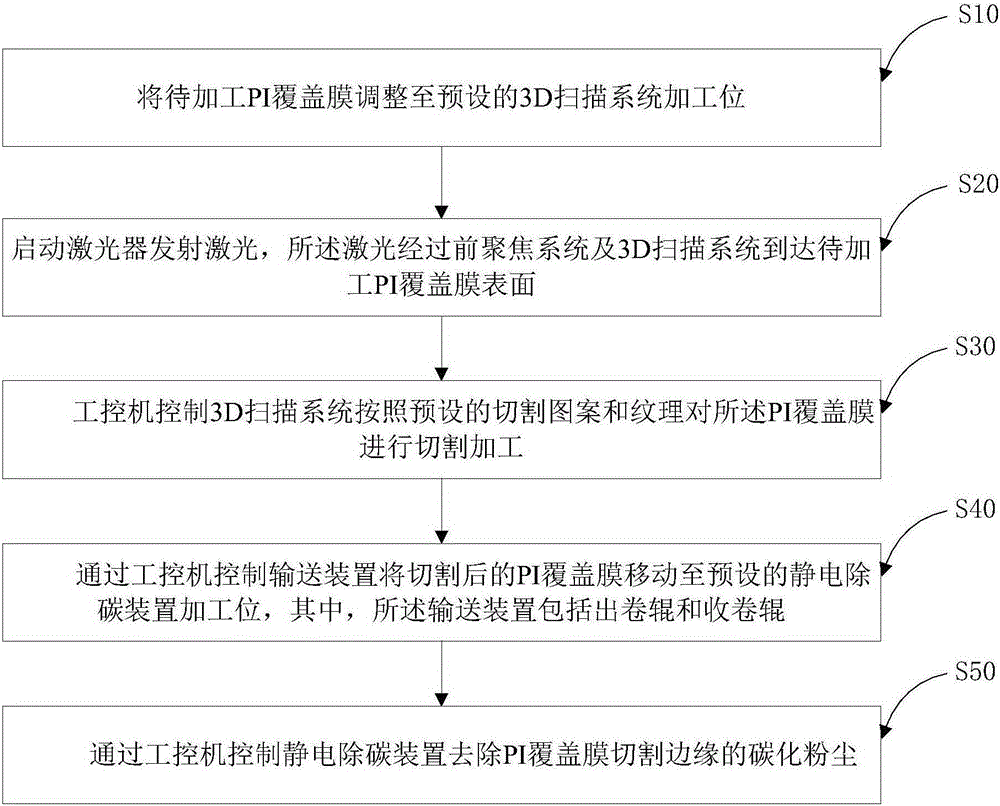

Automatic laser cutting static electricity decarbonizing system and method for PI cover film

ActiveCN105234561ARealize automatic cuttingRealize automatic decarbonizationLaser beam welding apparatusCleaning processes and apparatusAutomatic controlPersonal computer

The invention relates to the technical field of lasers, in particular to an automatic laser cutting static electricity decarbonizing system and method. The system comprises an industrial personal computer, a laser device, a 3D scanning system, positioning CCDs, a conveying device and a static electricity decarbonizing device. The laser device, the 3D scanning system, the positioning CCDs, the conveying device and the static electricity decarbonizing device are all connected with the industrial personal computer. The conveying device is provided with a platform for containing the PI cover film to be machined. When the PI cover film is machined, the platform is driven by the conveying device to move to a static electricity decarbonizing device machining station from a 3D scanning system machining station. The conveying device comprises an unrolling roller and a rolling roller. The positioning CCDs are used for monitoring and positioning the 3D scanning system machining station. Through automatic control over the laser device, the 3D scanning system, the positioning CCDs, the conveying device and the static electricity decarbonizing device by the industrial personal computer, large areas of the PI cover film can be cut automatically, and meanwhile automatic decarbonizing of the surface is achieved.

Owner:INNO LASER TECH CORP LTD +1

Pipe cutting equipment

InactiveCN105522213ASave human effortImprove securityTube shearing machinesPositioning apparatusEngineeringMechanical engineering

The invention provides pipe cutting equipment. The pipe cutting equipment comprises a base, a positioning device, a clamping device, a supporting frame, a feeding device, a cutting device and a worktable installed on the base, wherein the clamping device is arranged in the position, close to the obverse surface of the worktable, of the upper surface of the worktable, and the supporting frame is fixed to the position, far away from the obverse surface of the worktable, of the upper surface of the worktable; the positioning device corresponds to the clamping device and is arranged on the lateral surface of the worktable; the middle of the cutting device is rotationally connected to the supporting frame, a cutter is installed at the end, above the clamping device, of the cutting device, and the other end of the cutting device is hinged to the upper portion of the feeding device; the feeding device is installed on the base vertically upwards. According to the pipe cutting equipment, a pipe is fixed reliably and does not shift when cut, and the situation that too many burrs and oblique sections are generated is avoided. The feeding device realizes the feeding motions for cutting, labor is saved, and safety is improved. In addition, the cutting length can be accurately measured by means of scale marks on the positioning device, thereby being accurate.

Owner:天津鑫旭成科技有限公司

Cutting head for high-speed low-layer cutting lathe

InactiveCN101367215ARealize automatic cuttingAvoid wastingSevering textilesMetal working apparatusEngineeringPneumatic motor

The invention discloses a cutting head for a high-speed low-level cutting bed. The cutting head comprises a cutting head support, a pen, a plain knife, a sharp knife, a circular knife and a piercing drill, wherein the pencil is arranged on a pen stand which is connected to the upright moving end of a pen down cylinder; the fixed end of the pen down cylinder is connected to the cutting head support; the plain knife is arranged on the lower end of a piston rod of a plain knife cylinder; the plain knife cylinder is arranged on the cutting head support; the upper end of the piston rod of the plain knife cylinder is connected with a spline of a belt pulley of the plain knife, and the spline is rotationally arranged on the cutting head support; the sharp knife and the circular knife are arranged like the plain knife; the piercing drill is arranged on an output shaft of a piercing pneumatic motor; the piercing pneumatic motor is arranged on a piercing drill seat which is fixedly connected tothe upright moving end of a piercing cylinder; the fixed end of the piercing cylinder is connected with the cutting head support, wherein cylinders are all connected with an electromagnetic valve; belt pulleys are all in transmission connection with a servo motor of a rotary cutter; and the electromagnetic valve and the servo motor of the rotary cutter are arranged on the cutting head support andconnected with a control circuit. The technical proposal can realize multifunction large-scale cutting of various fabrics.

Owner:杭州柯瑞自动化技术有限公司

Gold needle mushroom cutting machine

A golden mushroom cutting machine comprises a stander, a conveying device and a cutting device; the stander comprises a conveying bench, a fixed mount arranged above the conveying bench, a positioning baffle and a knife rest arranged at one side of the conveying bench; the conveying device comprises a conveying belt arranged on the conveying bench and an electric control device driving the conveying belt to move along the conveying bench; the cutting device comprises a cutter fixed on the knife rest and a power plant driving the cutter to rotate; the positioning baffle and the conveying bench are arranged in parallel and keep an interval in between, the cutter is arranged in the interval between the positioning baffle and the conveying bench, the fixed mount comprises a plurality of fixed baffles which are arranged above the conveying belt. The golden mushroom cutting machine has simple structure, convenient operation, and can realize automatic cutting of the golden mushroom with high efficiency. The cut golden mushroom has tidy cutting parts, which facilitates package and saves time and cost to a big extent.

Owner:韶关市星河生物科技有限公司 +2

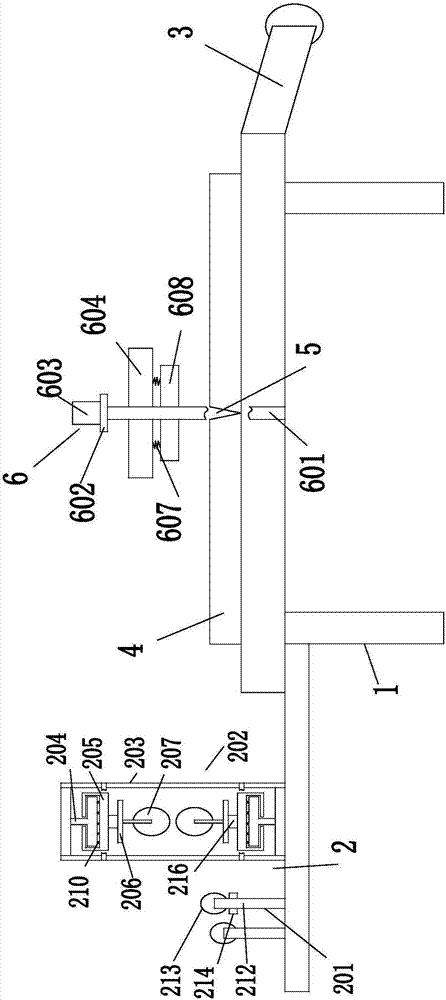

Equipment for rapidly cutting silk

InactiveCN107364756AImprove crop qualityImprove cutting uniformitySevering textilesArticle deliveryEngineeringMechanical engineering

The invention discloses a silk rapid cutting device, which comprises a frame (1), the feed end of the frame (1) is provided with a pressing roller group (2), and the discharge end of the frame (1) is provided with a cloth rolling device (3), a cutting platform (4) fixed on the top of the frame (1) is provided between the pressing roller group (2) and the cloth rolling device (3), and the cutting platform (4) is provided with a cutting groove ( 5), the top of the cutting groove (5) is provided with a cutting device (6) fixed on the frame (1); the cutting device (6) is connected with a controller (7), and the controller (7) is connected with the pressing The roller group (2) is connected with the cloth rolling device (3). The invention has the characteristics of being able to improve the cutting quality of the silk fabric, increase the cutting efficiency and reduce the waste of the silk fabric.

Owner:HUZHOU JINTELAI SILK WEAVING

Automatic cutting machine for potato seed potatoes

PendingCN108437044AImprove the utilization rate of seed potatoesImprove cutting efficiencyMetal working apparatusPotato seed cluttersCell buddingBud

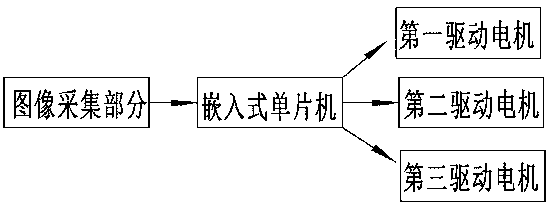

The invention relates to an automatic cutting machine for potato seed potatoes. The machine comprises a machine frame and a conveying mechanism, and the conveying mechanism comprises a driving roller,a driven roller and a conveying belt connected between the driving roller and the driven roller; one end of the driving roller is connected with a first driving motor; the machine further comprises acontrol mechanism, a potato seed identifying mechanism and a plurality of sets of cutter mechanisms, wherein the potato seed identifying mechanism and the plurality of sets of cutter mechanisms are located above the conveying mechanism and are sequentially arranged in the conveying direction; the potato seed identifying mechanism comprises a dark box, an illuminating part and an image collectingpart, wherein the illuminating part and the image collecting part are arranged in the dark box; each set of cutter mechanism comprises a cutter capable of rotating and changing the angle, a second driving motor capable of driving the cutter to rotate, and a third driving motor capable of driving the cutter to move up and down; and cutter blades of the groups of cutter mechanisms are different in shape. According to the automatic cutting machine for potato seed potatoes, the size of the potato seed potatoes can be automatically judged, the potato seed potatoes can be cut into blocks in an equaldivision mode, the position of the bud eyes of the potato seed potatoes is automatically identified, the bud eyes in the process of the potato seed potatoes are prevented from being cut, and the utilization rate of the potato is greatly improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Tapping robot

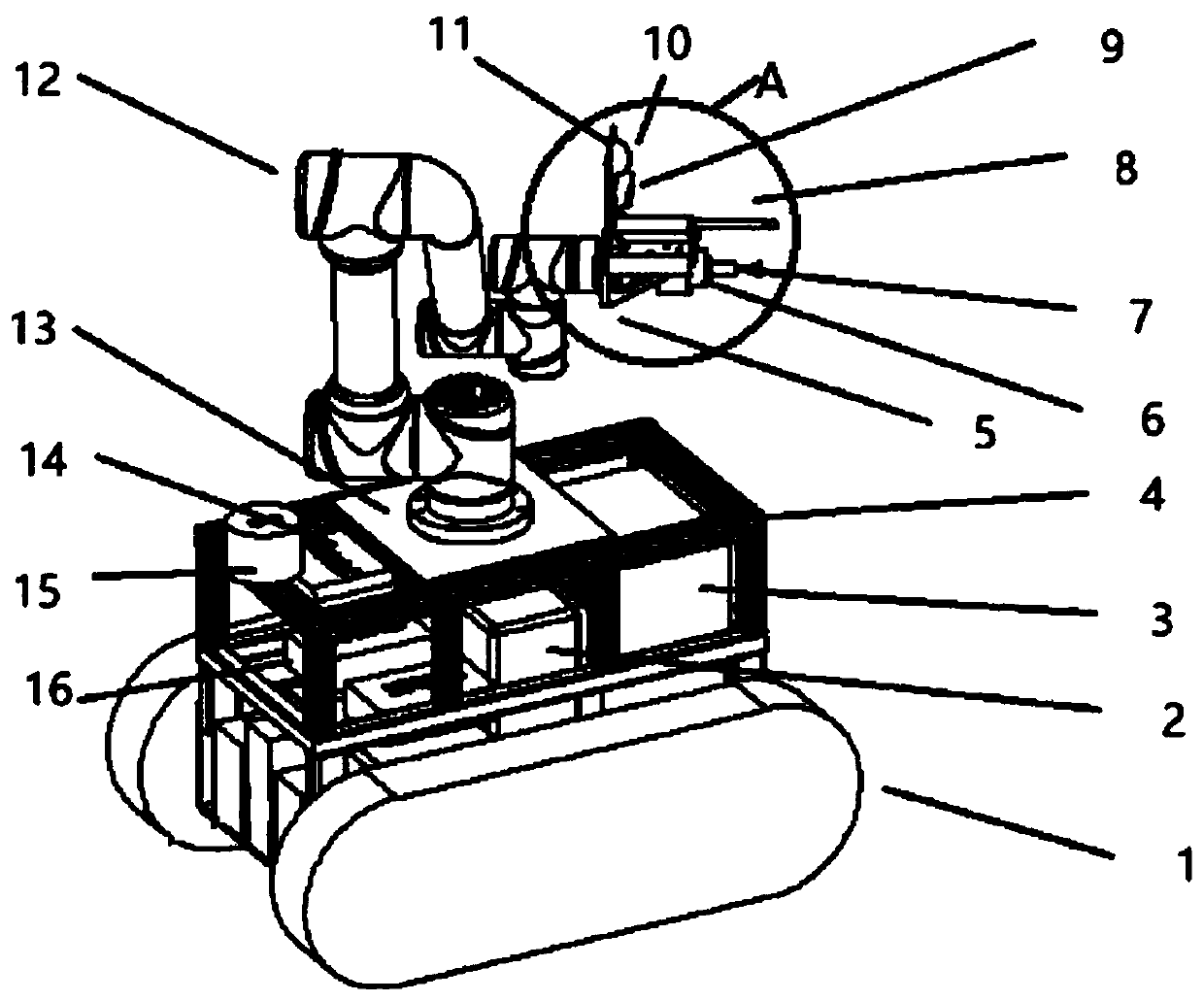

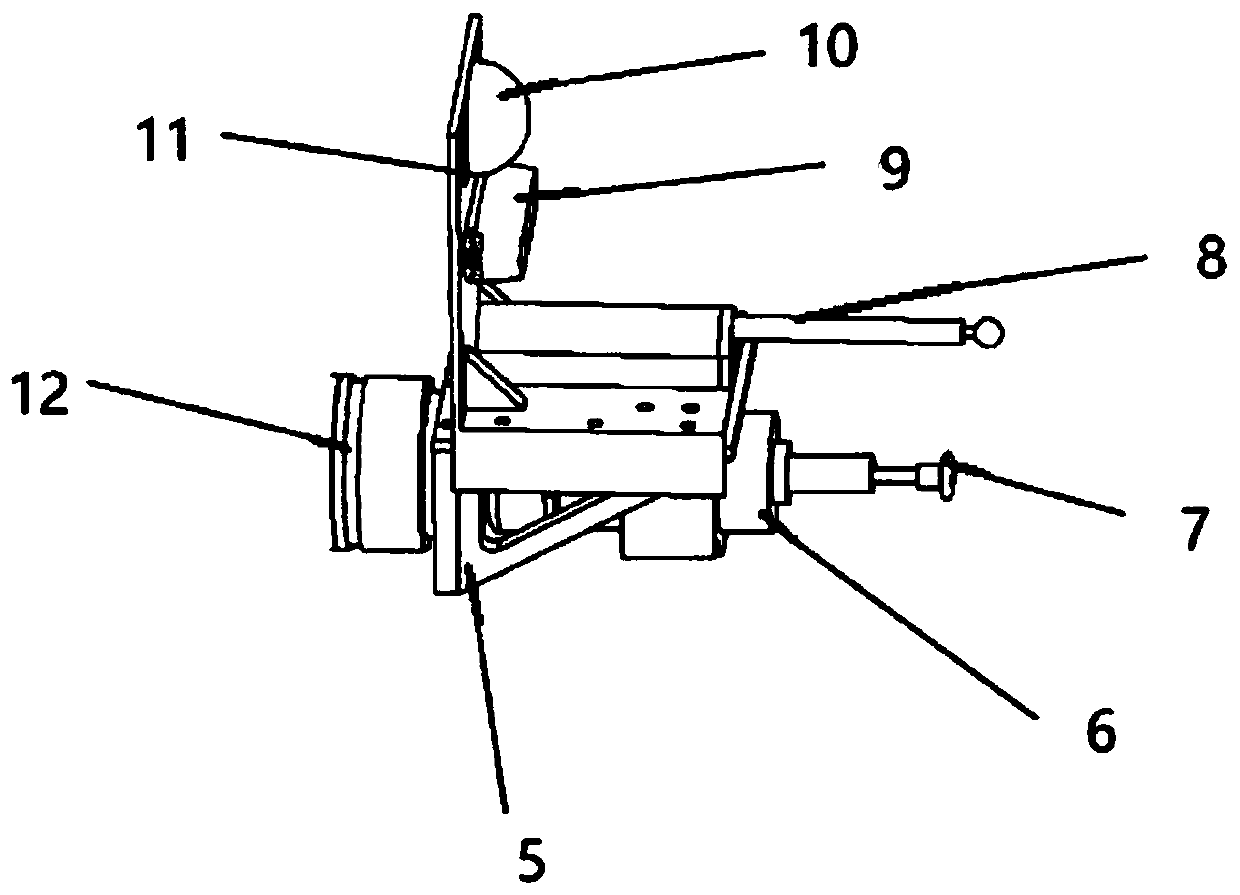

InactiveCN110558196ARealize automatic cuttingReduce labor intensityForestryManipulatorElectricityRadar

The invention discloses a tapping robot and relates to the technical field of tapping tools. The tapping robot comprises a mobile chassis, a three-dimensional laser radar, a power supply, a controllerand a cutting mechanism, wherein the power supply, the controller and the cutting mechanism are arranged on the mobile chassis, a fixed part of the three-dimensional laser radar is fixedly arranged on the mobile chassis, a movable part of the three-dimensional laser radar is fixedly arranged on the cutting mechanism, the fixed part is electrically connected with the movable part, the movable chassis moves for adjusting the cutting position of the cutting mechanism, the cutting mechanism is used for tapping, the movable chassis, the three-dimensional laser radar and the cutting mechanism are electrically connected with the controller, and the movable chassis, the three-dimensional laser radar and the cutting mechanism are electrically connected with the power supply to realize automatic tapping of the tapping robot, thus the defects of high labor intensity and shortage of tapping staff of existing manual tapping are overcome, not only can the labor intensity of tapping be reduced, butalso the tapping efficiency can be improved.

Owner:北京理工华汇智能科技有限公司

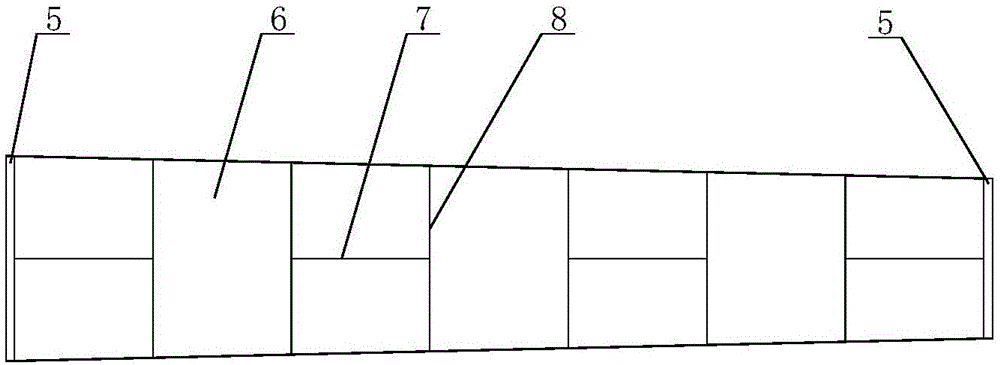

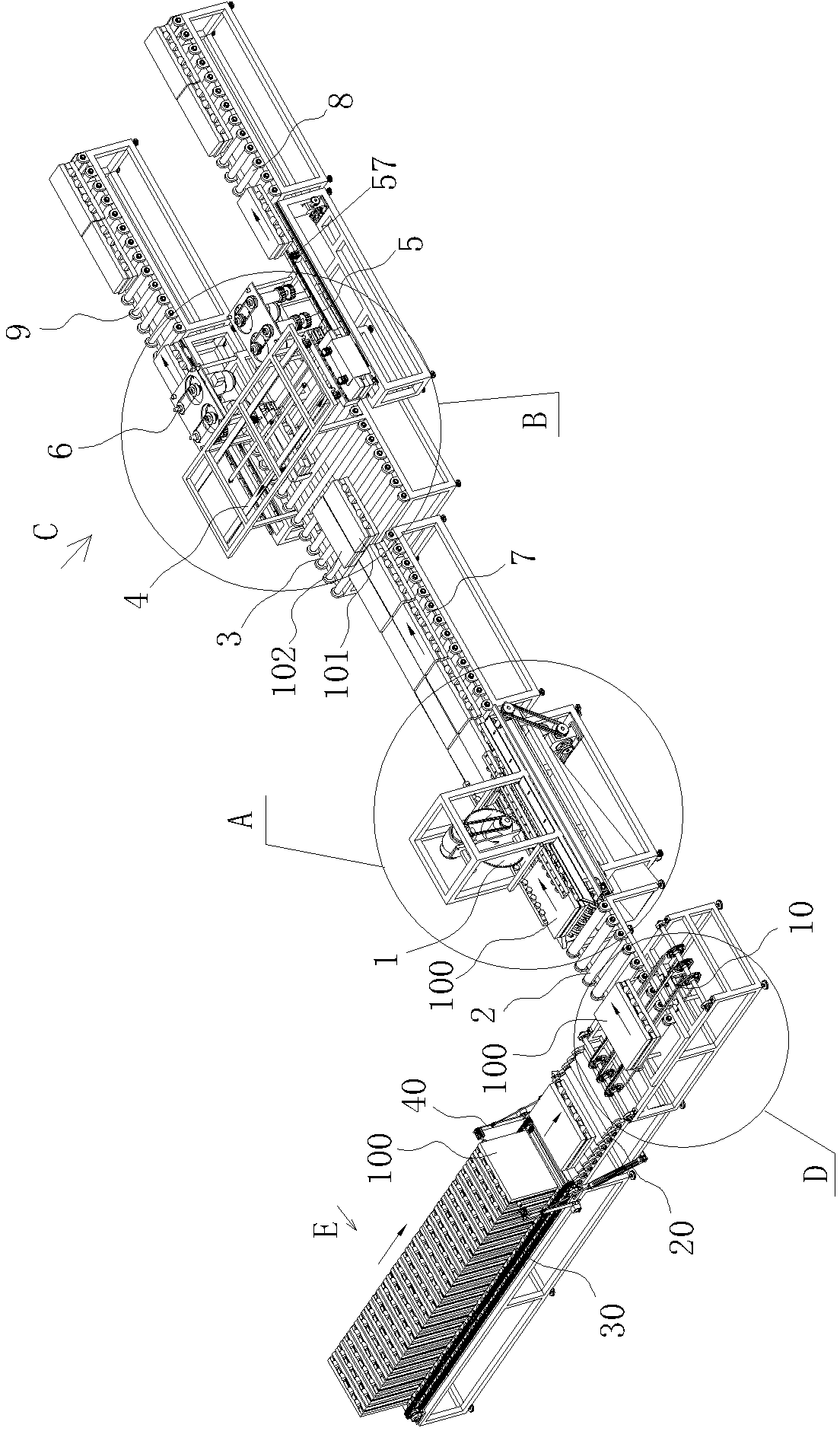

Production line of cut milling groove of gypsum block

ActiveCN102700007ARealize automatic cuttingReduce reprocessing costsWorking accessoriesStone-like material working toolsProduction lineControl system

The invention discloses a production line of a cut milling groove of a gypsum block. The production line comprises a cutting mechanism, a first conveying mechanism, a second conveying mechanism, a shunt conveying mechanism, a block tenon milling mechanism, a block mortise milling mechanism and a PLC (programmable logic controller) control system, wherein the first conveying mechanism is joined in the front of the cutting mechanism; the first conveying mechanism horizontally conveys blocks to the cutting mechanism; the second conveying mechanism is joined behind the cutting mechanism; the shunt conveying mechanism is arranged on the rear part of the second conveying mechanism; the block tenon milling mechanism and the block mortise milling mechanism are arranged on two sides of the shunt conveying mechanism; the PLC system coordinates each mechanism to act; and the second conveying mechanism conveys the blocks cut by the cutting mechanism below the shunt conveying mechanism, and the shunt conveying mechanism respectively transmits two cut blocks to the block tenon milling mechanism and the block mortise milling mechanism to respectively process tenons and mortises on the sides of the blocks. According to the production line, automatic cutting of the gypsum block and automatic processing of the tenons and mortises on the sides of the blocks are achieved, the production efficiency is high, and the reprocessing cost of the gypsum block is effectively reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

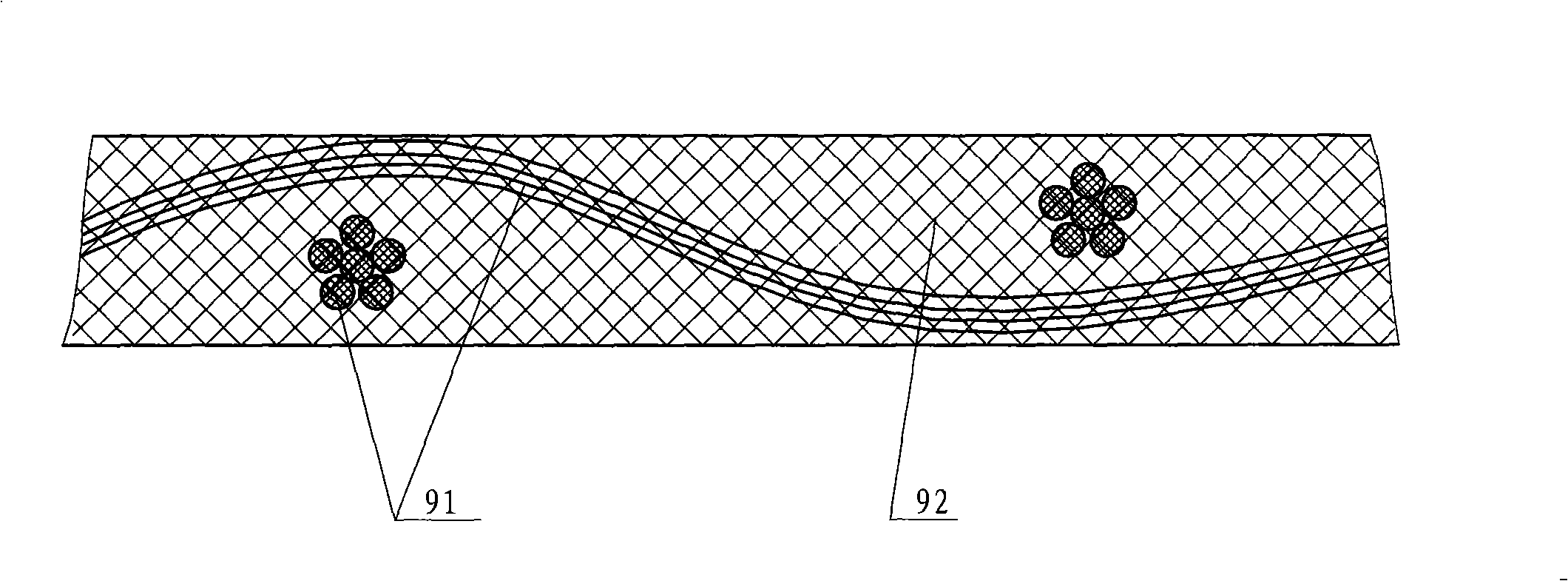

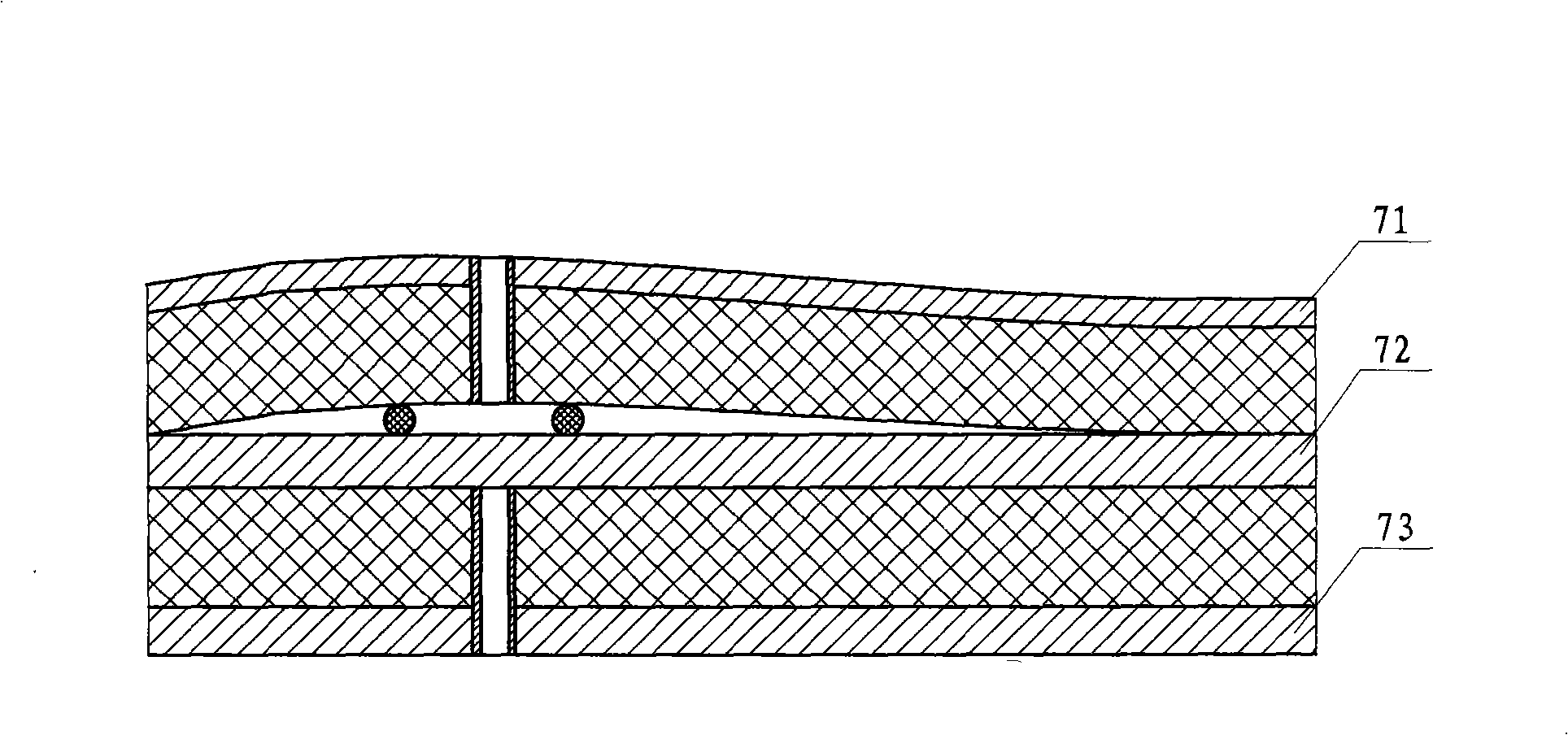

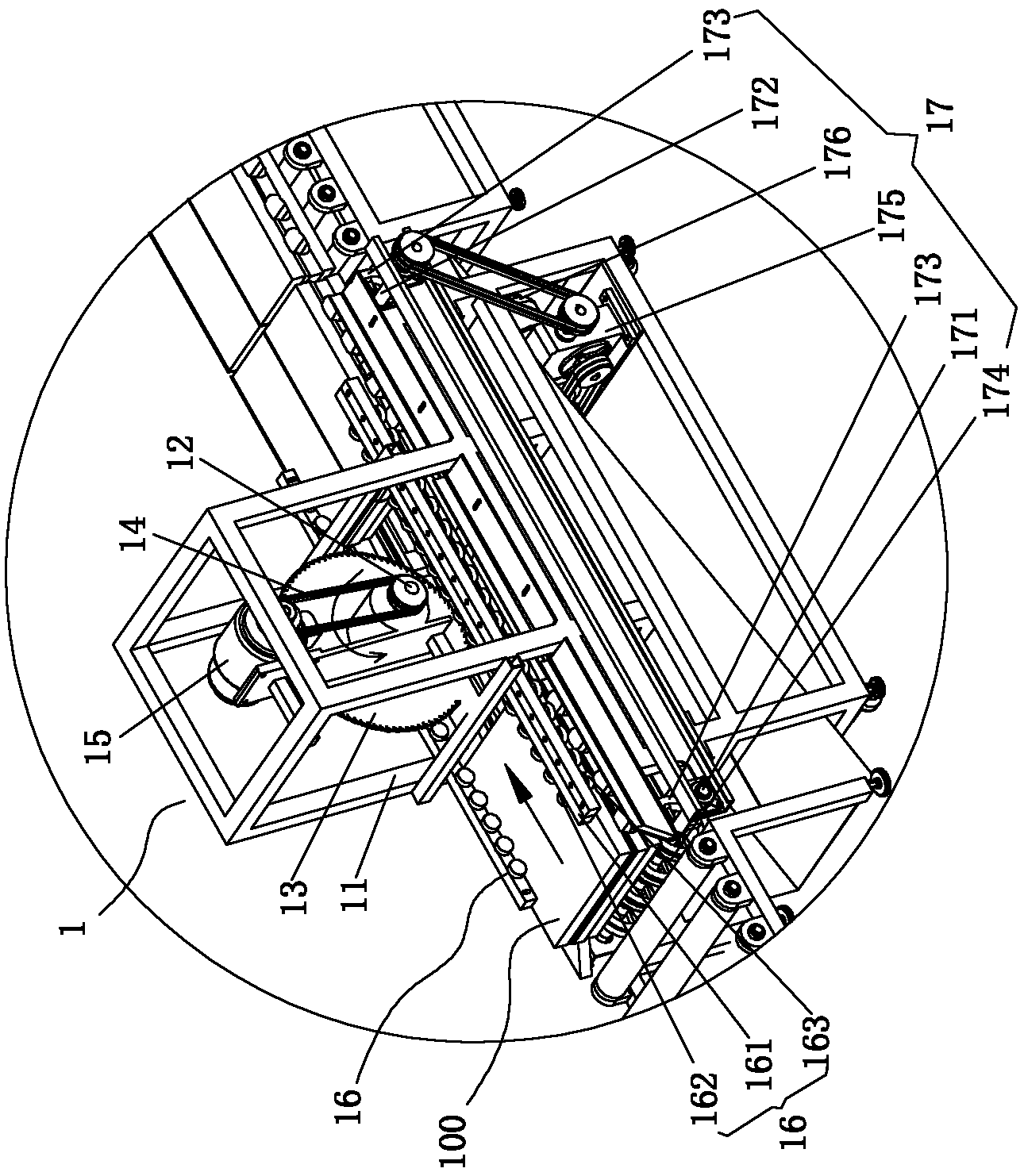

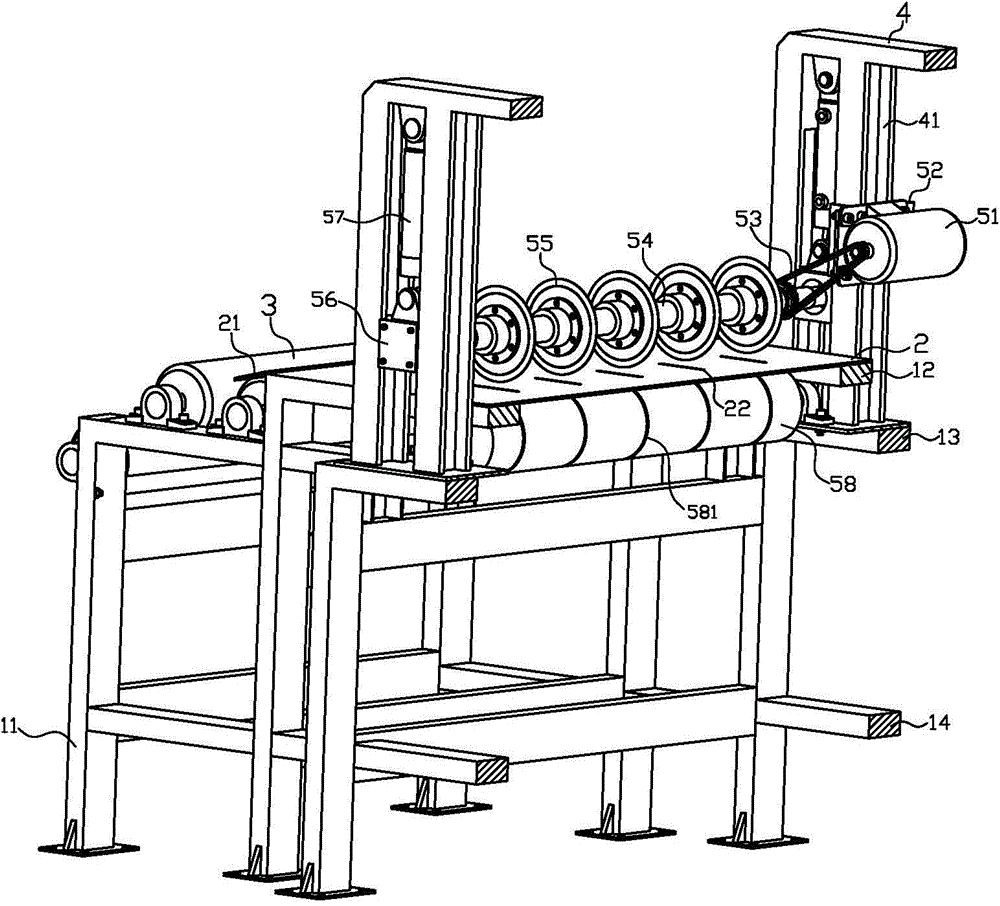

Cutting device utilizing waste conveying belt for manufacturing mining support stripe

ActiveCN104972510AImprove processing efficiencySave material costMetal working apparatusWebs handlingEnvironmentally friendlyEngineering

The invention discloses a cutting device utilizing a waste conveying belt for manufacturing a mining support stripe. The cutting device comprises a rack, a work table board, guide-in carrier rollers, guide supports, a longitudinal cutting device, a traction conveying device, a transverse cutting device and a discharging device. The waste conveying belt to be machined passes through the guide-in carrier rollers to enter work space formed by the work table board, the longitudinal cutting device and the transverse cutting device under traction of the traction conveying device, the waste conveying belt is cut into narrow stripes by the longitudinal cutting device, fixed-length blanking of the support stripe is completed through the transverse cutting device, the standard support stripe is obtained, and finally the discharging device is used for discharging. The support stripe meeting the underground support requirement can be obtained, the width and length of the support stripe can be adjusted according to needs, waste is turned into wealth, material costs are saved, and support and transport cost is greatly lowered. The cutting device has the advantages of being compact in structure, long in service life, high in efficiency, low in equipment cost and environmentally friendly, saving energy and the like.

Owner:ANHUI UNIV OF SCI & TECH

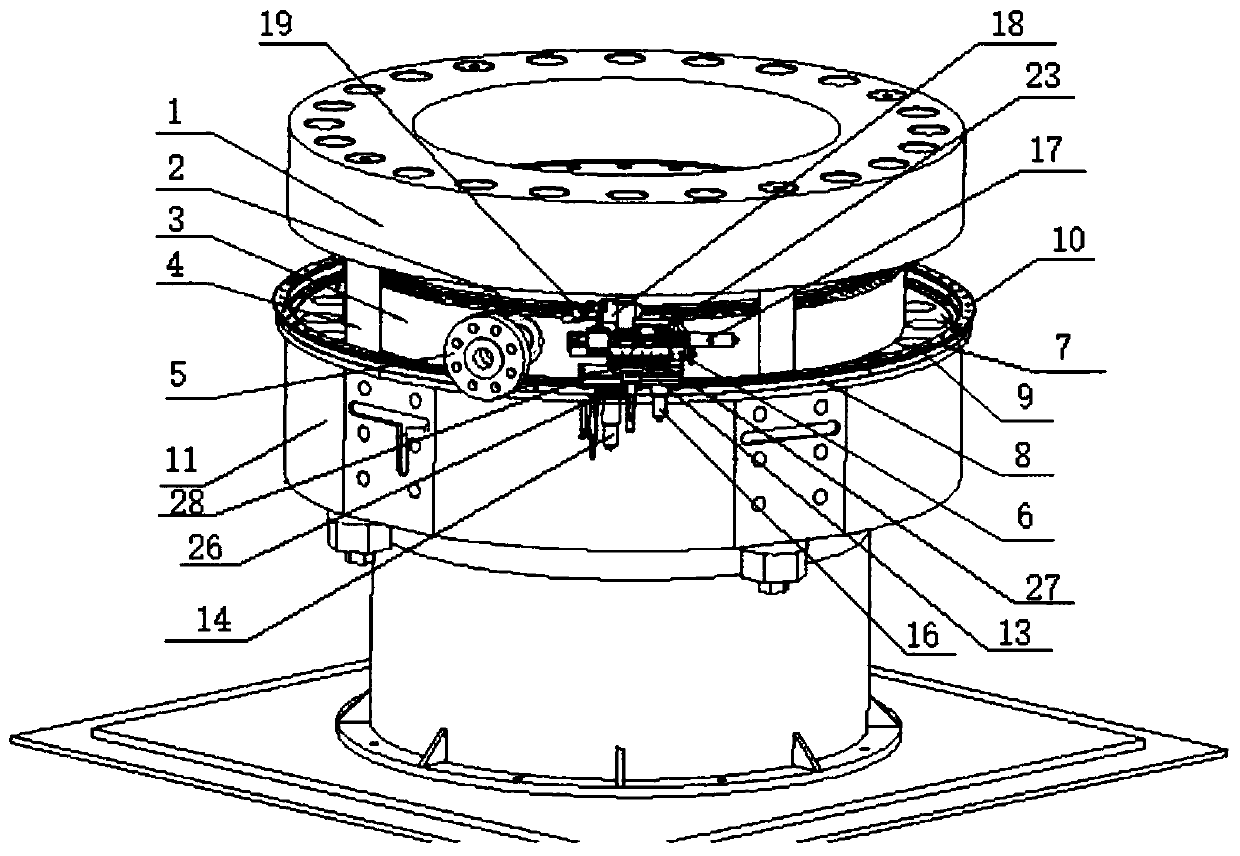

Sealing ring cutting device and cutting method thereof

ActiveCN110587030ARealize automatic cuttingSmall doseMeasurement/indication equipmentsManufacturing technologyEngineering

The invention discloses a sealing ring cutting device and a cutting method thereof, and relates to the technical field of equipment manufacturing. The sealing ring cutting device comprises an annularrail mounted on the outer side of a sealing ring, a cutting machine mounted on the annular rail, and a first motor connected with the cutting machine to drive the cutting machine to move along the annular rail. According to the sealing ring cutting device, the rail and the cutting machine are arranged on the outer side of the sealing ring, automatic cutting on the sealing ring is achieved, and theproblem that an operator receives a lot of irradiation dose in an existing sealing ring cutting process is solved.

Owner:STATE NUCLEAR POWER PLANT SERVICE

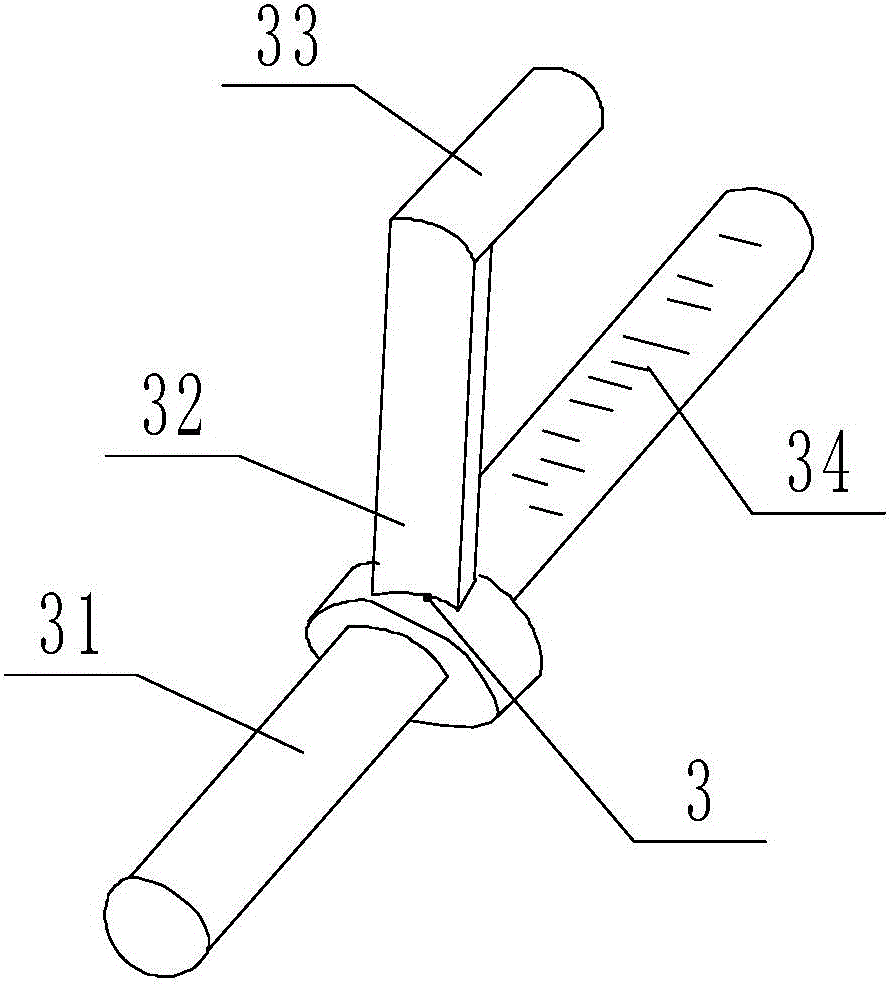

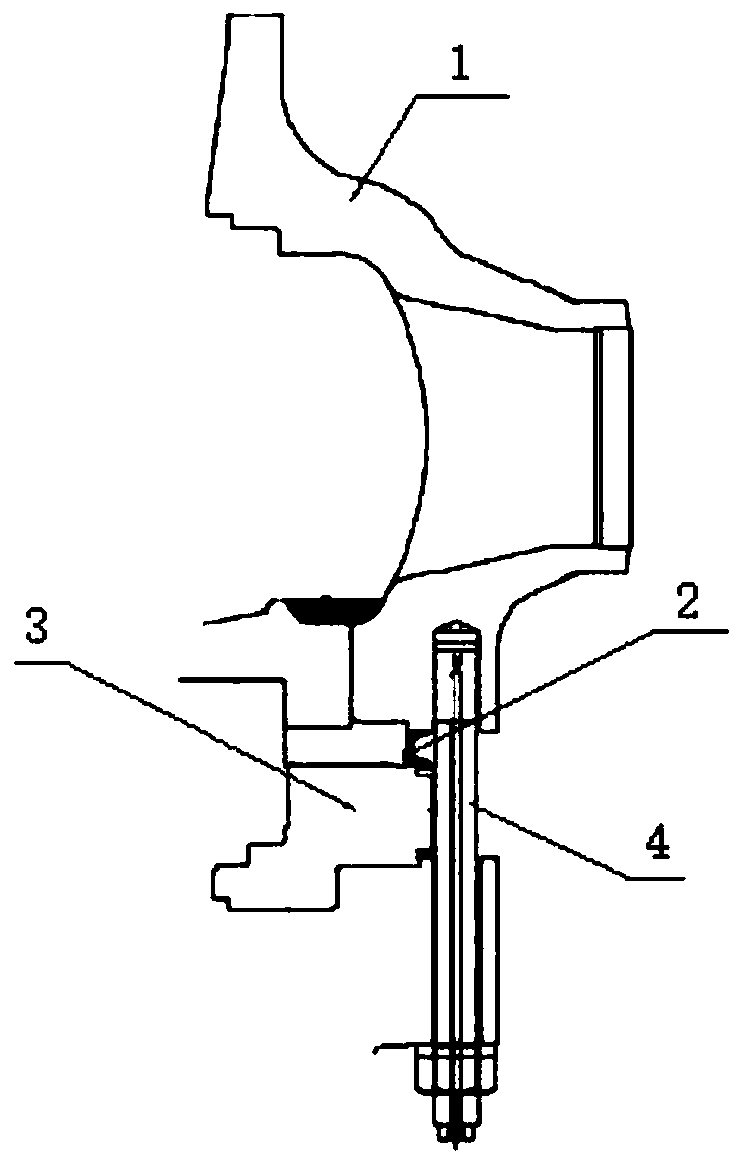

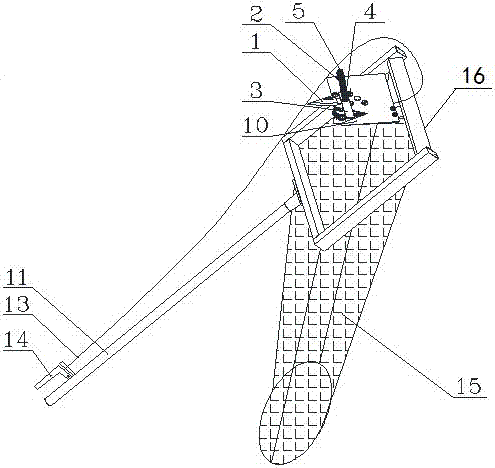

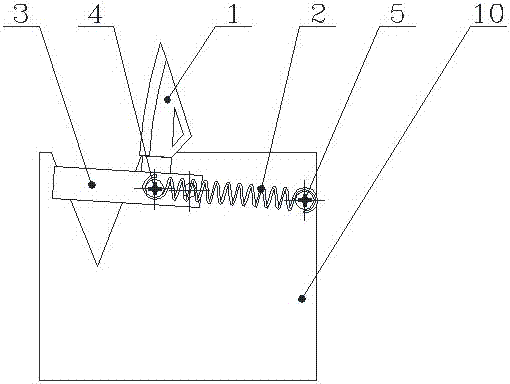

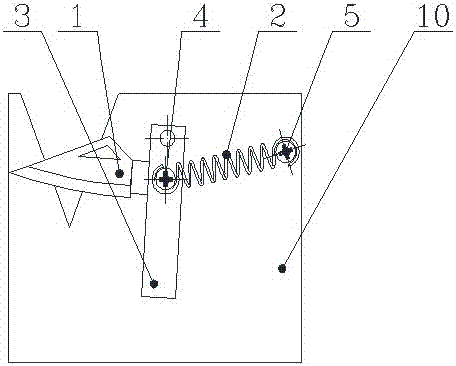

High-branch fruit picker and application method thereof

The invention relates to a high-branch fruit picker and an application method thereof. The picker comprises a cutter device, a reset device, a substrate plate (10), a frame (16), a net bag (15), a telescopic lever (11) and a cutter driving device, wherein the telescopic lever (11) is provided with the cutter driving device (14), the top of the telescopic lever (11) is provided with the frame (16), the bottom of which is provided with the net bag (11) while the middle of which is provided with the substrate plate (10), and the upper side of the substrate plate (10) is provided with the cutter device while the lower side is provided with the reset device. The application method thereof mainly includes the steps of resetting the cutter device, making a fruit stem contact with a trigger lever, enabling a cutter to cut the fruit stem, guiding fruit to the ground and the like. By means of the high-branch fruit picker, harmless and automatic picking of the fruit can be achieved, and continuous fruit picking can be conducted; the picking process is simple, labor-saving and efficient, and therefore the high-branch fruit picker has a wide application prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

End shearing method in middle-thickness plate rolling process

ActiveCN105537272ARealize automatic cuttingPrecise shear positioningMetal rolling arrangementsImage signalMechanical engineering

The invention discloses an end shearing method in a middle-thickness plate rolling process, and relates to the technical field of metal pressure processing. A shot rolled piece side face image signal is transmitted to a computer to be processed, rolled piece side face size data obtained through processing of the computer, a signal of a metal detector installed in front of a heavy shear and a signal of a rotary encoder installed at the shaft end of a conical roller arranged on a delivery roller way are transmitted to a PLC system, the rotary encoder turn number which is generated when the cocking portion at the head end of a rolled piece and the cocking portion at the tail end of the rolled piece are sheared and corresponds to the position of the roller piece is calculated through the PLC system, and then the rolled piece is delivered to the position which is calculated in advance though the roller way to be subjected to end shearing. The method comprises the following steps that 1, the length of the cracking portions of the ends of the rolled piece is detected and calculated; 2, locating calculation and control are performed on the rolled piece of which the back cracking portion is sheared; 3, locating calculation and control are performed on the rolled piece of which the front cracking portion is sheared. According to the method, the problem that in the rolling process of middle-thickness plates, the cracking portions of the ends of the rolled piece cannot be precisely located and sheared is solved.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

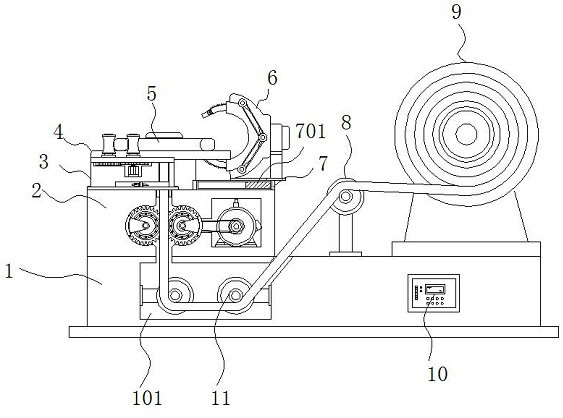

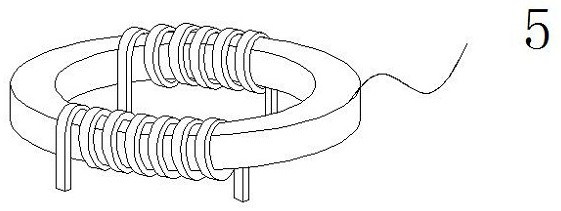

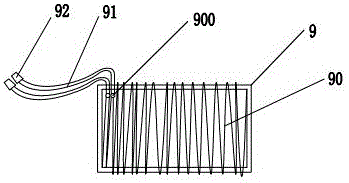

Automatic inductor winding device capable of controlling winding density

InactiveCN112259368AConsistent densityHigh precisionCoils manufactureWinding machineInductor windings

The invention discloses an automatic inductor winding device capable of controlling winding density. The automatic inductor winding device specifically comprises a base, a workbench, a coil placing frame, a winding mechanism and a rotating sleeve, wherein the workbench is mounted on one side of the top of the base, a winding wheel is fixed on the other side of the top of the base, a guide wheel ismounted on the base between the winding wheel and the workbench, and a positioning ring is fixed to the side, close to the guide wheel, in the winding wheel through a support. According to the automatic inductor winding device capable of controlling the winding density, the winding mechanism and a driving roller are arranged, the winding mechanism can drive an enameled wire to be wound on a coil,the driving roller clamps the coil and rotates relatively while winding is conducted so as to allow the coil to rotate at a constant speed, and therefore, uniform winding effect is obtained; comparedwith manual winding, the method has the advantages that efficiency is higher, the winding density can be controlled, it is guaranteed that the winding density is consistent, winding displacement is tidier, and winding precision is higher.

Owner:东莞市夯实科技有限公司

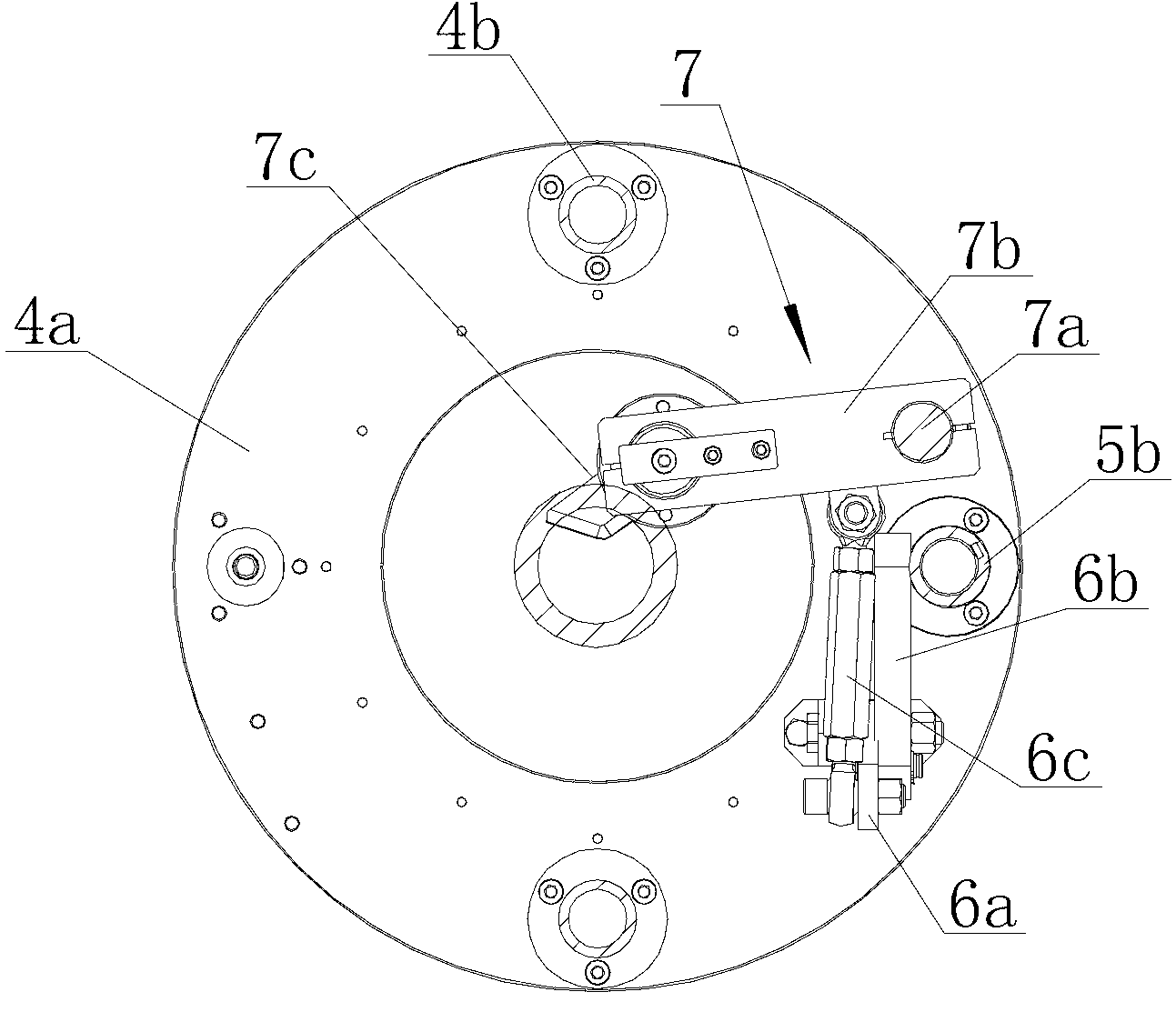

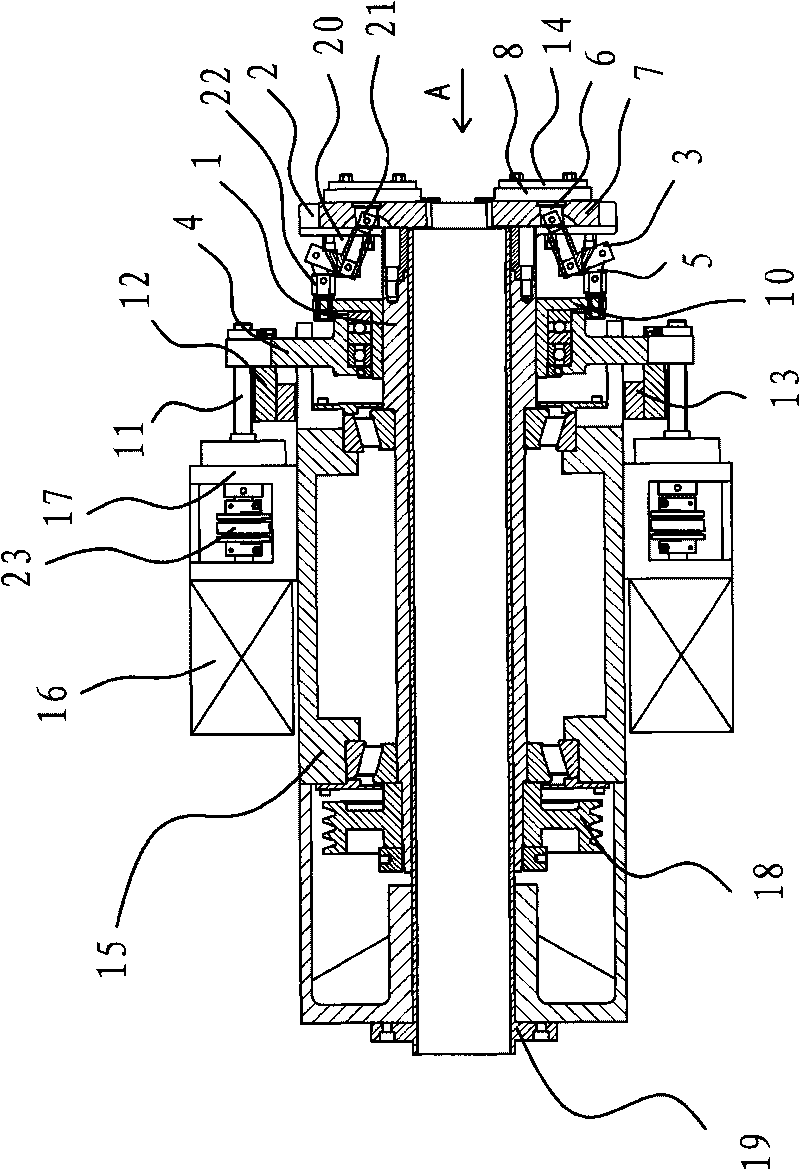

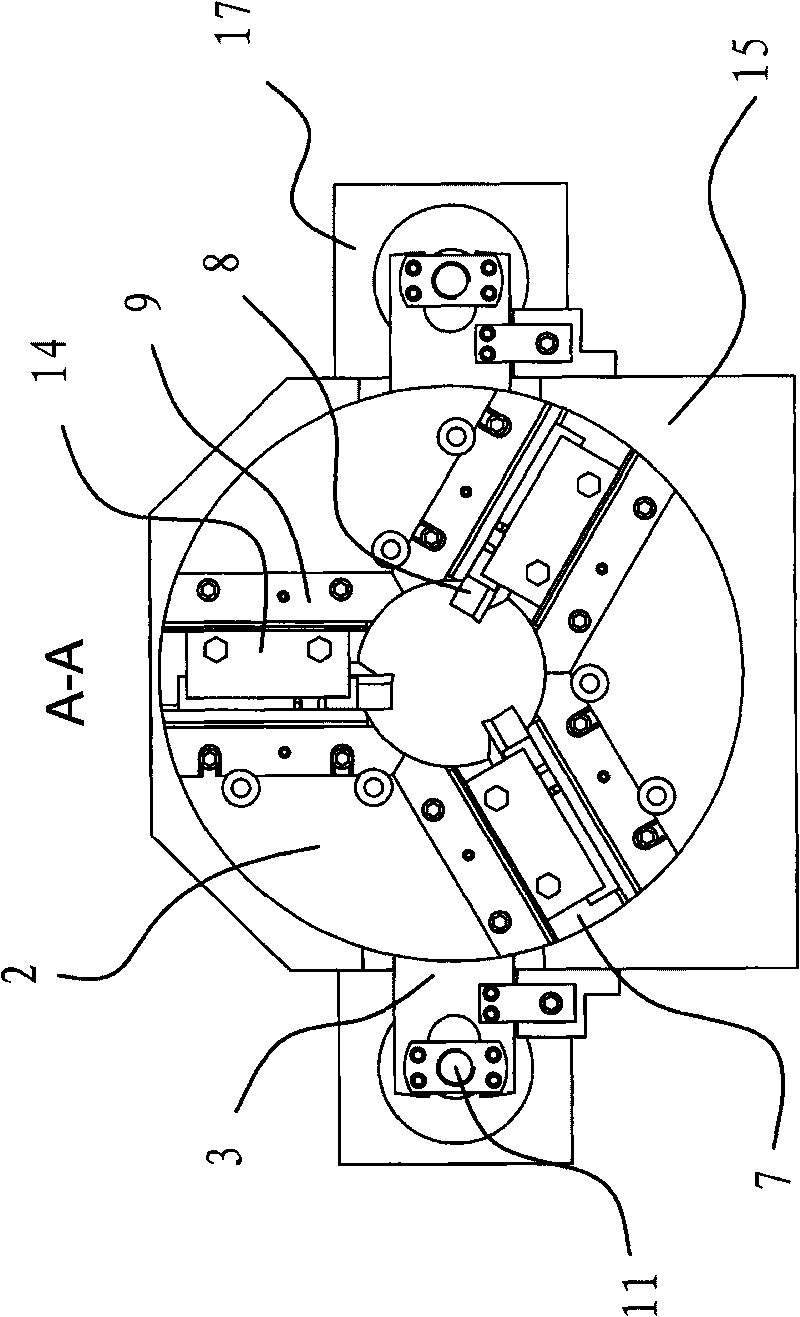

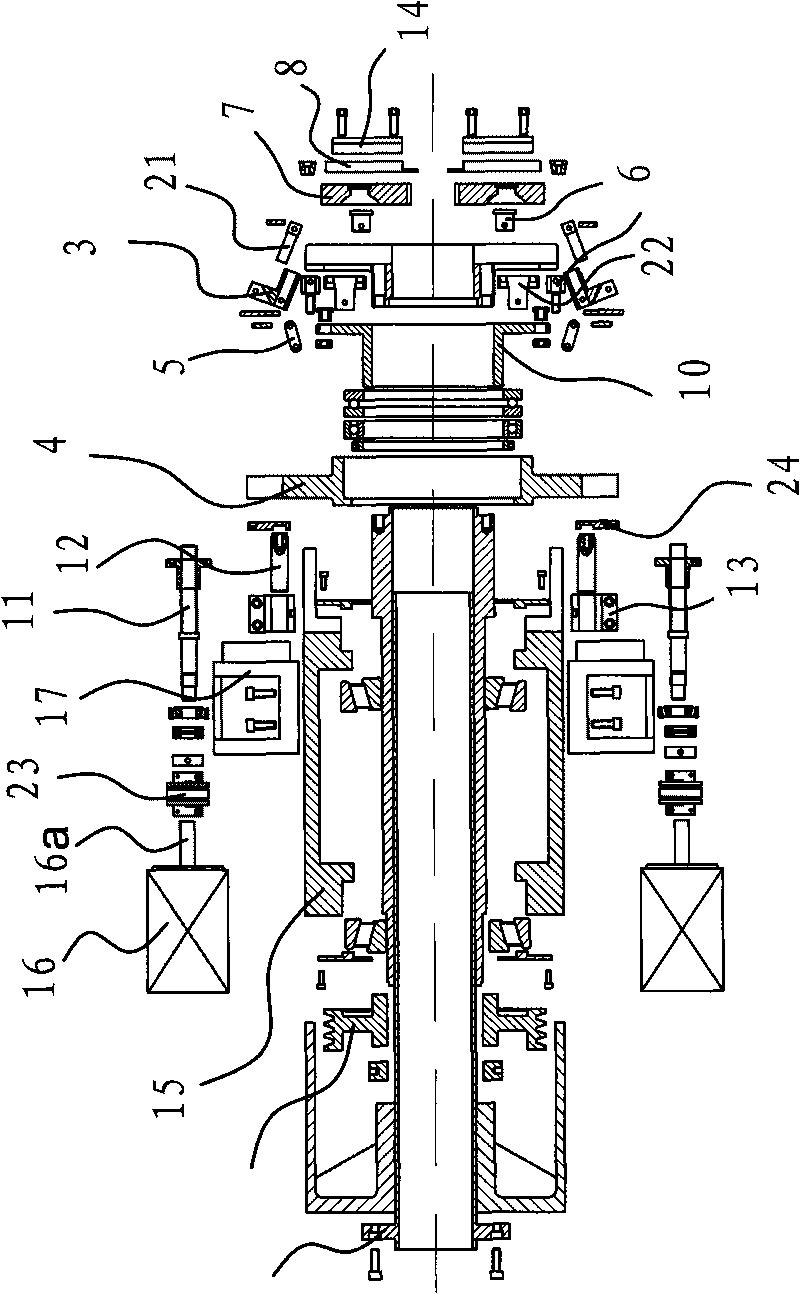

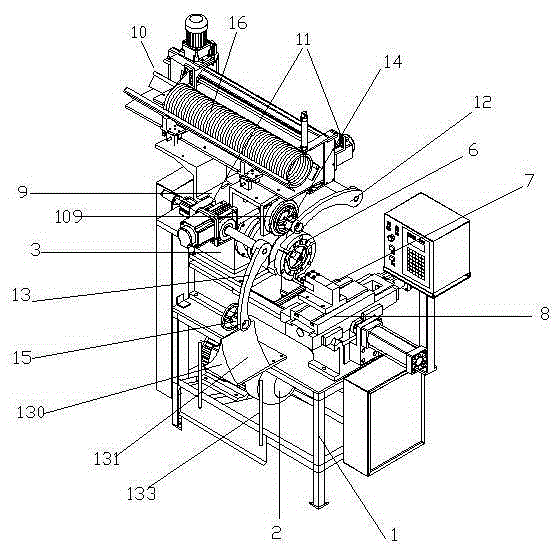

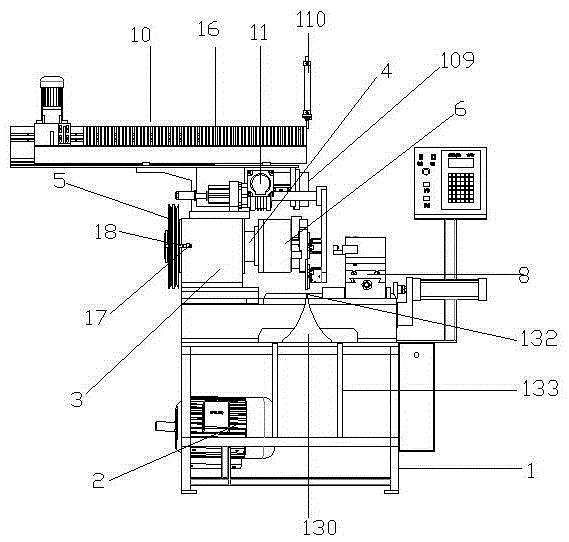

Rotary cutting type pipe cutting machine

ActiveCN103264189AImplement rotary cuttingNo pollution in the processFeeding apparatusTube shearing machinesEngineeringMechanical engineering

The invention discloses a rotary cutting type pipe cutting machine which belongs to the technical field of cutting machines. The rotary cutting type pipe cutting machine comprises a case, wherein a horizontal driving device is arranged on the case; a feeding and retracting mechanism is movably connected in the case, and the horizontal driving device is connected with the feeding and retracting mechanism through a shifting fork assembly; the feeding and retracting mechanism is mainly composed of a bracket, a sliding mechanism, a connecting rod driving mechanism and a cutter assembly, wherein the sliding mechanism is arranged on the bracket and movably connected with the shifting fork assembly, the connecting rod driving mechanism is respectively hinged to the bracket, the sliding mechanism and the cutter assembly which is hinged onto the bracket, and the cutter assembly is driven to rotate along the hinged part to feed and retract through the matching of the sliding mechanism and the movable connecting rod driving mechanism; and a rotary driving mechanism is arranged on the case and connected and linked with the bracket. The invention aims to provide the rotary cutting type pipe cutting machine which has the advantages of compact structure, no cutting chips in the cutting process and convenience in operation, and the rotary cutting type pipe cutting machine is used for cutting plastic pipes.

Owner:DEKEMO HUADA MECHANICAL DONGGUAN

Cutting device of pipe cutting machine tool

InactiveCN101758285ASave powerRealize automatic cuttingFeeding apparatusTube shearing machinesHigh rateMachine tool

The invention provides a cutting device of a pipe cutting machine tool, which belongs to the technical field of machinery. The invention solves the problems of low working efficiency, poor cutting effect, low rate of finished products and the like of the traditional pipe cutting machine tool. The cutting device of the pipe cutting machine tool is arranged on a rack of the machine tool and comprises a main shaft and a cutterhead, wherein the main shaft is connected with a main motor, the cutterhead is fixed on the main shaft, a plurality of sets of cutting elements which are evenly distributed on the outer end face of the cutterhead are installed on the cutterhead, a spindle gearing is fixedly connected on the rack, the main shaft is positioned in the spindle gearing, a motor is fixedly connected on the outer wall of the spindle gearing, a propulsion seat is arranged on the main shaft, a transmission mechanism which can enable the propulsion seat to axially move along the main shaft is arranged between the propulsion seat and the motor, and a feeding mechanism which can enable the cutting elements to radially move along the center of the cutterhead when the propulsion seat moves along the main shaft axially is arranged between the propulsion seat and the cutting elements. The cutting device of the pipe cutting machine tool has the advantages of high working efficiency, good cutting effect and high rate of finished products.

Owner:浙江申林智能设备有限公司

Fixed-length water jet cutting machine for metal pipe

InactiveCN105397174AAvoid changes in positionAvoid corrosionTube shearing machinesShearing machine accessoriesEngineeringWater jet cutter

A fixed-length water jet cutting machine for a metal pipe comprises a cutting table, a water jet cutter rack and the like. The fixed-length water jet cutting machine is characterized by further comprising supporting columns, a controller, a storage groove, a steel conveying belt, a blanking bin, clamping grooves, a drier, an infrared emitter, an infrared receiver, a counter and a sliding rail. The supporting columns are installed on the cutting table. The water jet cutter rack is installed on the supporting columns. The storage groove can fix the metal pipe to be cut, so that the position of the metal pipe is prevented from changing in the moving process. The metal pipe to be cut can be moved to a cutting position through the steel conveying belt, and a lot of time and labor are saved. The residual moisture content can be dried through the drier, and the metal pipe is prevented from being corroded by the residual moisture content on the surface of the metal pipe. When the infrared emitter and the infrared receiver are blocked by the metal pipe, a controller is triggered, the metal pipe is cut through the water jet cutter, automatic counting is achieved by the counter at the same time, and automatic cutting is achieved; in addition, the adjustable infrared emitter and the infrared receiver are located in the clamping grooves, and automatic fixed-length cutting is achieved.

Owner:TIANJIN XINDAYUAN METAL PROD

Fully-automatic cutting device for piston ring

ActiveCN105414564ARealize automatic cuttingImprove cutting accuracyPiston ringsAutomatic workpiece supply/removalEngineeringFully automatic

The invention relates to the technical field of piston ring cutting and discloses a fully-automatic cutting device for a piston ring. The fully-automatic cutting device comprises a frame, a main motor ad a lathe head box, wherein a spindle is arranged in the lathe head box; a belt pulley is arranged at one end of the spindle, and a piston ring positioning chuck is arranged at the other end of the spindle; a knife rest is arranged at the other end of the top of the frame; a connecting base is arranged at the upper side of the lathe head box; a feeding mechanism is arranged on the connecting base; a discharging end of the feeding mechanism is provided with a stopping cylinder; a positioning sleeve is arranged on the side surface of the connecting base; a rotating arm driving assembly is arranged on the connecting base and positioned on each of two sides of the feeding mechanism, wherein a feeding arm is connected to one rotating arm driving assembly, and a discharging arm is connected to the other rotating arm driving assembly; a feeding chunk is arranged at the outer end of the feeding arm; a discharging chuck is arranged at the outer end of the discharging arm; an automatic knife advance mechanism is arranged on the bottom of the knife rest; a distribution frame is arranged at a position, right below the discharging chuck, of the frame. The fully-automatic cutting device is high in cutting efficiency and high in cutting precision while used for cutting the piston ring.

Owner:上海谊奥汽配有限公司

Slugging machine for brass solder water radiator

ActiveCN103121133AHigh strengthRealize automatic cuttingFeeding apparatusLarge fixed membersReciprocating motionKnife holder

Provided is a slugging machine for a brass solder water radiator. The slugging machine for the brass solder water radiator mainly solves the problems that when a notch is machined in a lateral plate of the brass solder water radiator, the positioning accuracy is bad, the working efficiency is low and the labor intensity of an operator is high. The slugging machine for the brass solder water radiator is characterized in that a rotation shaft (4) is installed on a rack (1), a rotation positioning workbench (5) which can clamp the brass solder water radiator (12) is fixed on the rotation shaft(4) and the rotation shaft (4) is driven by a servo motor (6) to rotate by equal angles. A feeding knife rest (13) moving back and forth in a straight line is arranged on the lateral side of the rotation positioning workbench (5). A cutter motor (3) is fixed on the feeding knife rest (13). The feeding knife rest (13) is connected with a rectilinear actuating device (7). Two cutters (2) respectively correspond to two lateral plates on the brass solder water radiator (12). The slugging machine for the brass solder water radiator has the advantages of being simple in structure, convenient to operate, high in production efficiency, wide in application range and good in product quality.

Owner:纳百川新能源股份有限公司

Rapid paper cutting machine

InactiveCN107877563ARealize automatic cuttingAvoid damageMetal working apparatusArticle feedersPaper dustPulp and paper industry

The invention relates to the field of paper cutters, more specifically a quick paper cutter, comprising a bracket, a base, a cutting panel, a cutter seat and a cutter assembly, and the lower roller and the upper roller arranged inside the device can cut paper Whole sheet feeding, so that the paper can enter the cutting panel straight, and the paper is cut continuously through the first knife body and the second knife body, so as to realize the automatic cutting of the paper, which has a high degree of automation; the first knife The distance between the main body and the second knife can be adjusted to cut paper of different sizes; the arc-shaped pressing piece can realize the conveying and cutting of different sheets or different thickness of paper; the paper scraps generated by the paper cutter during work can be removed Fall into the waste paper dust collection tank to prevent the operator from inhaling paper waste for a long time to damage the lungs. The upper end of the bracket is provided with a base, the cutting panel is slidably connected to the right end of the base, the tool seat is slidably connected to the left end of the base, and the cutter assembly is slidably connected to the tool seat.

Owner:郑晓

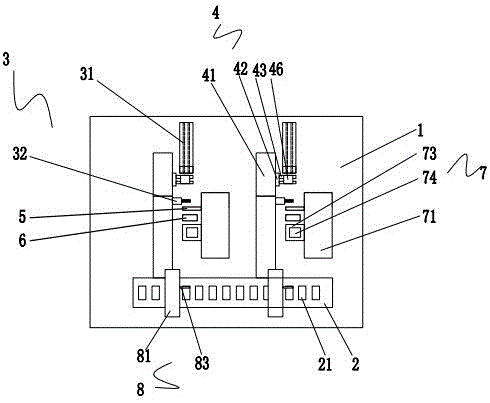

Automatic riveting and welding equipment for connection wires

ActiveCN106238854ARealize automatic cuttingReduce labor intensityOther manufacturing equipments/toolsMetal working apparatusHigh volume manufacturingEngineering

The invention relates to automatic riveting and welding equipment for connection wires. The automatic riveting and welding equipment comprises a rack and a worktable arranged on the rack, wherein a circular conveyer belt is arranged on the front side of the worktable; fixtures I for placing coils are arranged on the conveyer belt; welding mechanisms are arranged above the fixtures I in a spanning manner; connection wire material conveying mechanisms are arranged on the rear side of the worktable; and a wire stripping mechanism, a coating bag containing welding flux, a tin furnace and a riveting and pressing mechanism are sequentially arranged between each connection wire material conveying mechanism and the corresponding welding mechanism. The automatic riveting and welding equipment is reasonable in structure design; the connection wire material conveying mechanisms, the wire stripping mechanisms, the riveting and pressing mechanisms, the coating bags containing welding flux, the tin furnaces and the welding mechanism are arranged, so that automatic cutting, wire stripping, welding flux coating, tin soaking, riveting and welding of the connection wires are realized; the automation degree is high; the production efficiency is high; the automatic riveting and welding equipment is very suitable for large-scale production; the consistency of product quality is also high; worker labor intensity and enterprise production cost are also greatly lowered; and enterprise market competitiveness is enhanced.

Owner:江西百宏光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com